Closed coring device for testing coal bed methane and rock formation gas contents in surface well drilling

A surface drilling and sealed coring technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, wellbore/well components, etc., can solve problems such as inaccurate measurement of coalbed methane content, gas loss, and inability to realize fixed-point collection of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

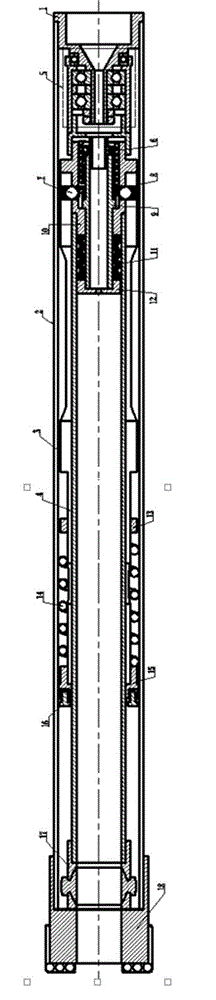

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] An embodiment of the present invention provides a closed coring device for testing the content of coalbed methane and rock formation gas in ground drilling, such as figure 1 As shown, the device includes: a coring inner cylinder 4, a coring bit 18, an outer cylinder 2, a power mechanism, and a starting mechanism. The outer cylinder 2 is sleeved with a coring inner cylinder 4, and one end of the outer cylinder 2 is set There is a drill pipe joint 1, the other end of the outer cylinder 2 is provided with a coring bit 18, the lower end of the drill pipe joint 1 is connected with the outer cylinder 2 through threads, and the lower end of the outer cylinder 2 is connected with the core bit 18 through threads, The drill joint 1, the outer cylinder 2, and the core bit 18 form a cylindrical shape suitable for drilling, and the outer cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com