Patents

Literature

741results about How to "Realize automatic measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

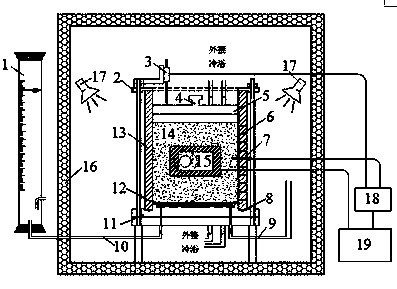

Testing system for deep soil freezing/thawing process

ActiveCN102590468AReduce distractionsMove up and down flexiblyEarth material testingGraduated cylinderCold formed

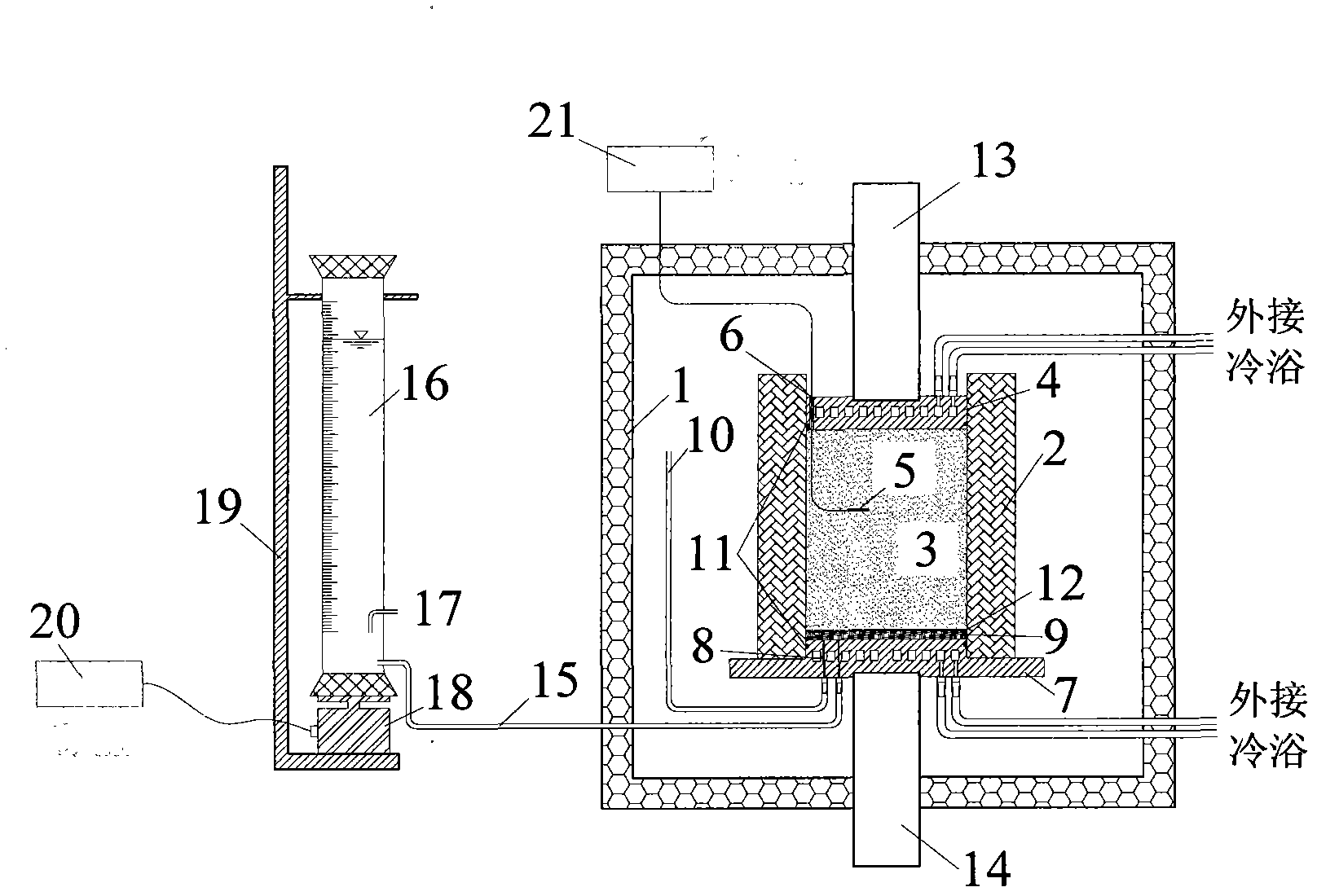

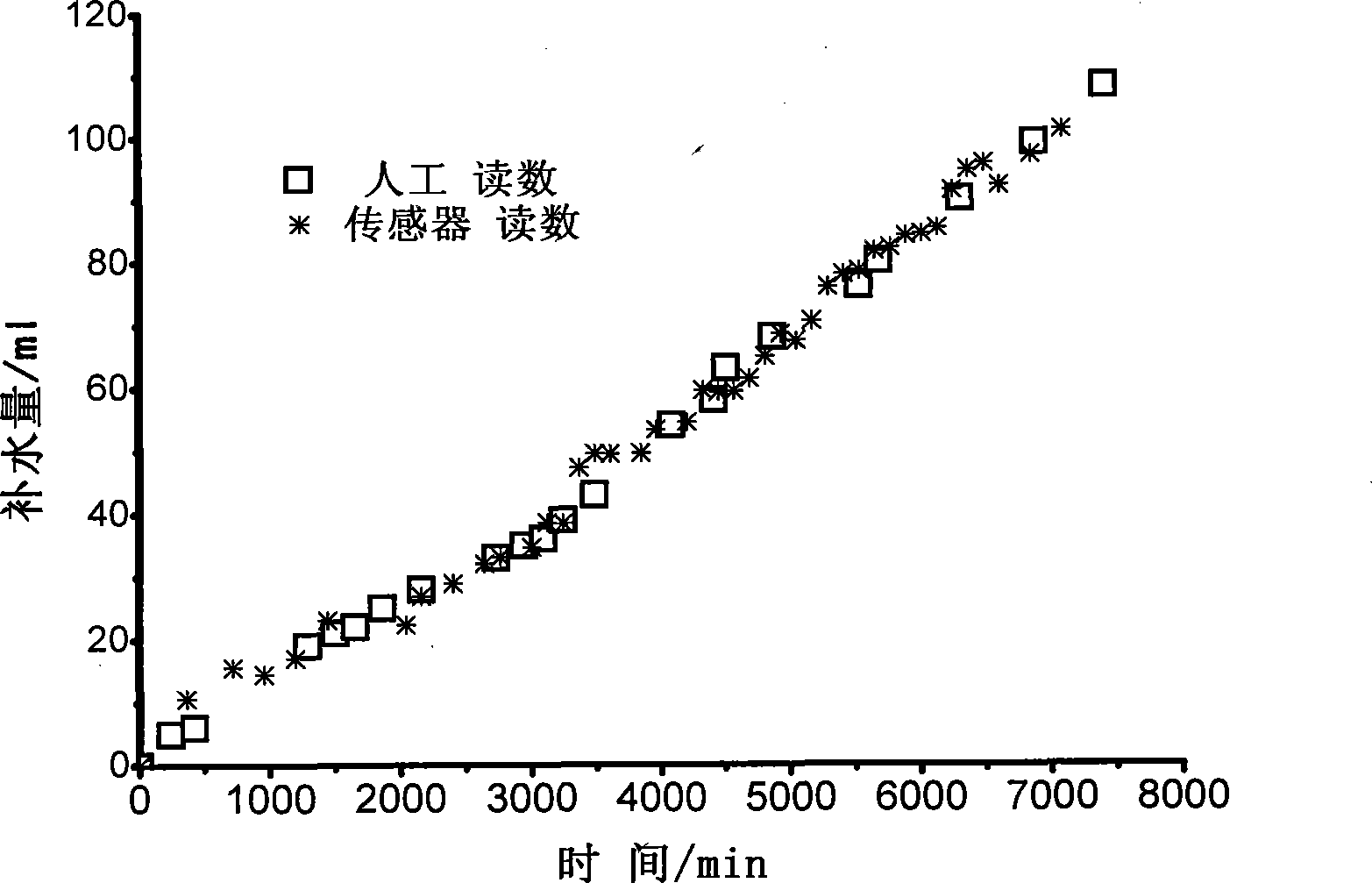

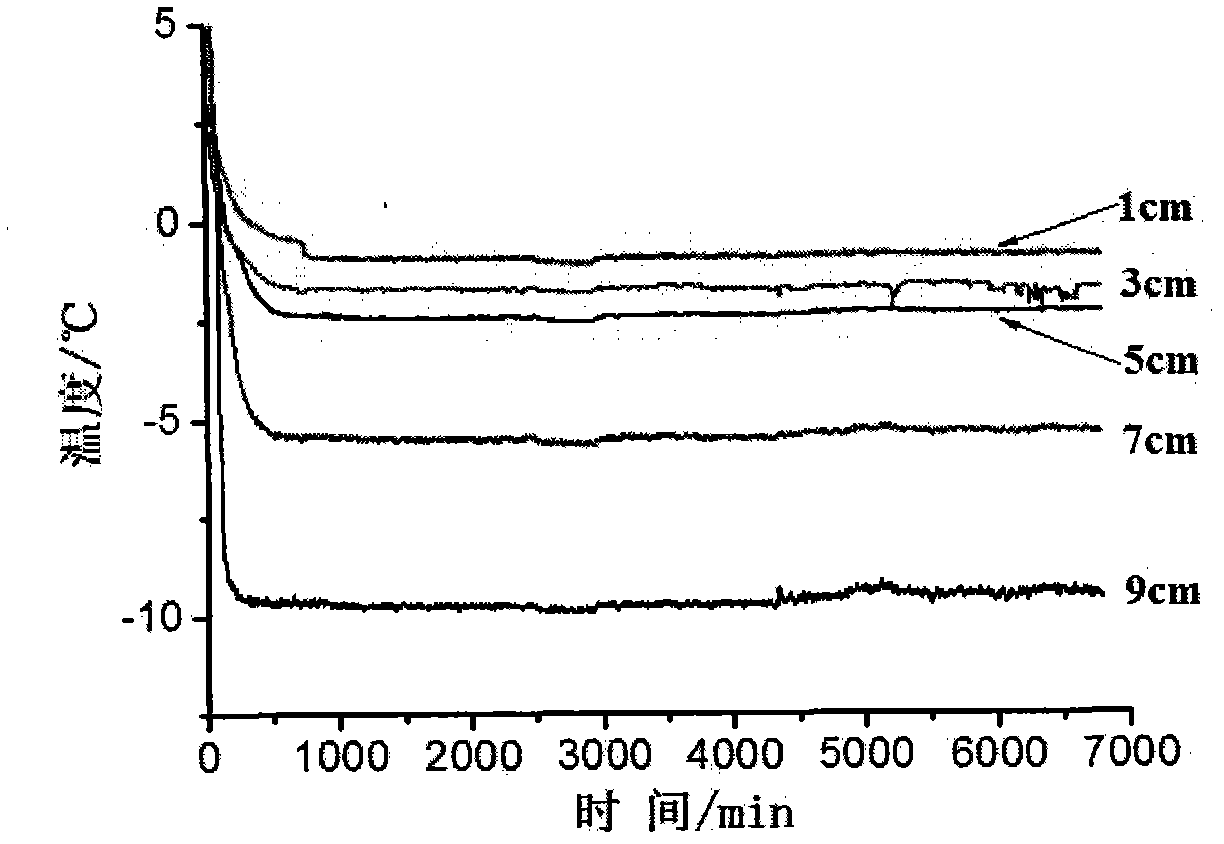

The invention relates to a testing system for deep soil freezing / thawing process, which is structurally characterized in that a temperature-controlled box is connected with an external cold bath; a high pressure-resistant organic glass cylinder is arranged on a temperature-controllable steel base; two small holes are formed in the base, one is connected with a water guide pipe, and the other is connected with a pressure adjusting pipe; a permeable stone, a piece of filter paper and a sample are sequentially arranged at the upper part of the lower base, and a temperature sensor is mounted in the sample; a temperature-controllable upper press head is arranged at the upper part of the sample; a line leading-out hole is formed in the upper press head, and is sealed through sealant after the line is lead out; the upper press head is connected with the transmission rod of a testing machine; a measuring cylinder is connected with the sample through the water guide pipe; and the measuring cylinder is arranged on a weighing sensor and fixed through a bracket. By adopting the testing system, the freezing / thawing process of the deep soil can be rather systematically researched, so as to obtain the frost heaving rate and the water absorbing / draining rate of the deep soil which is in different depths frozen under the different temperature gradients. The testing system provides the technical guarantee for the research in clarifying the action of the external load on the forming processes of the freezing soil and the frozen soil cold-formed structures, and the mutual action of the temperature, the moisture content and the pressure of the soil body in the process of freezing under the high-pressure action.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

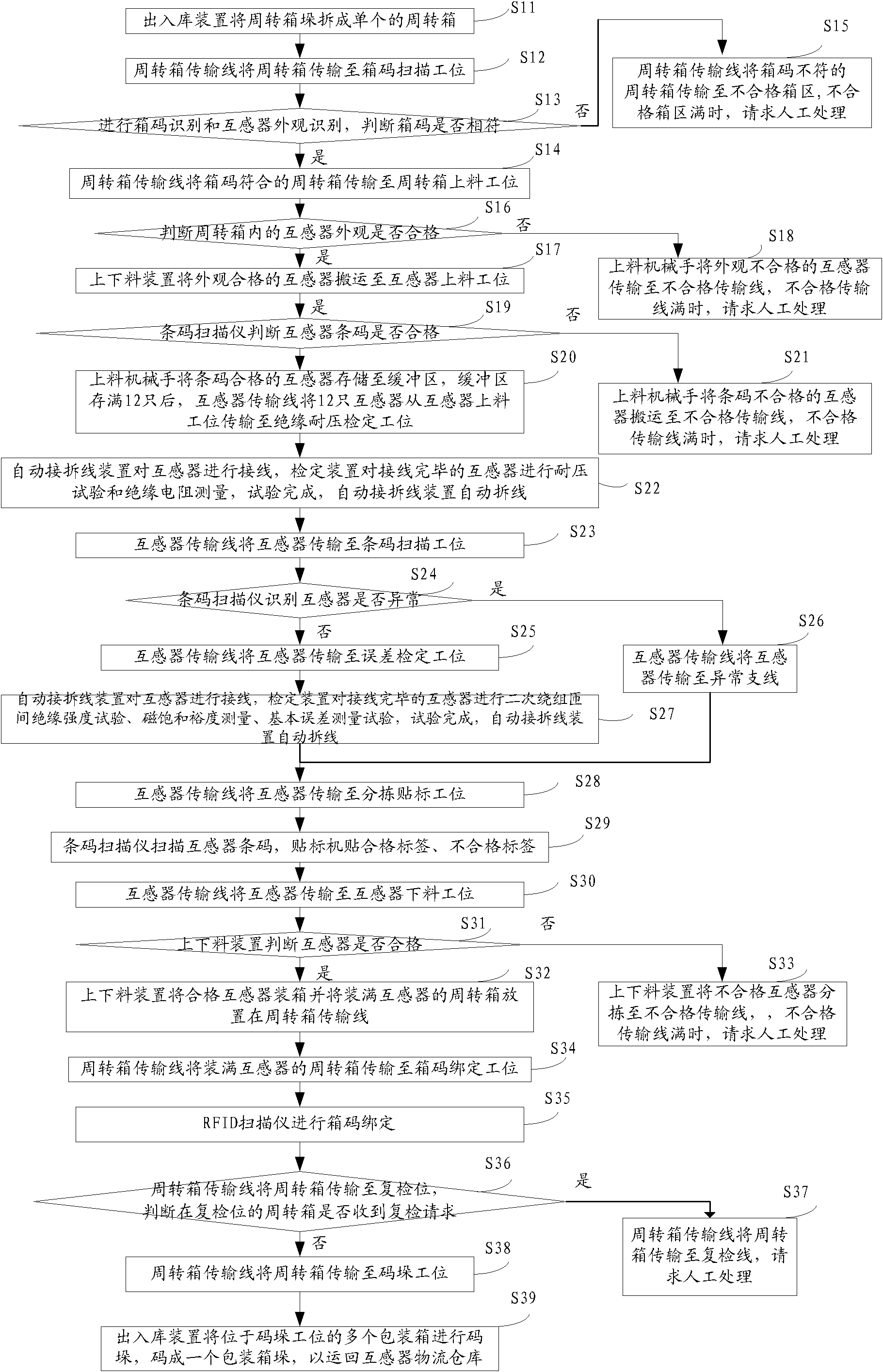

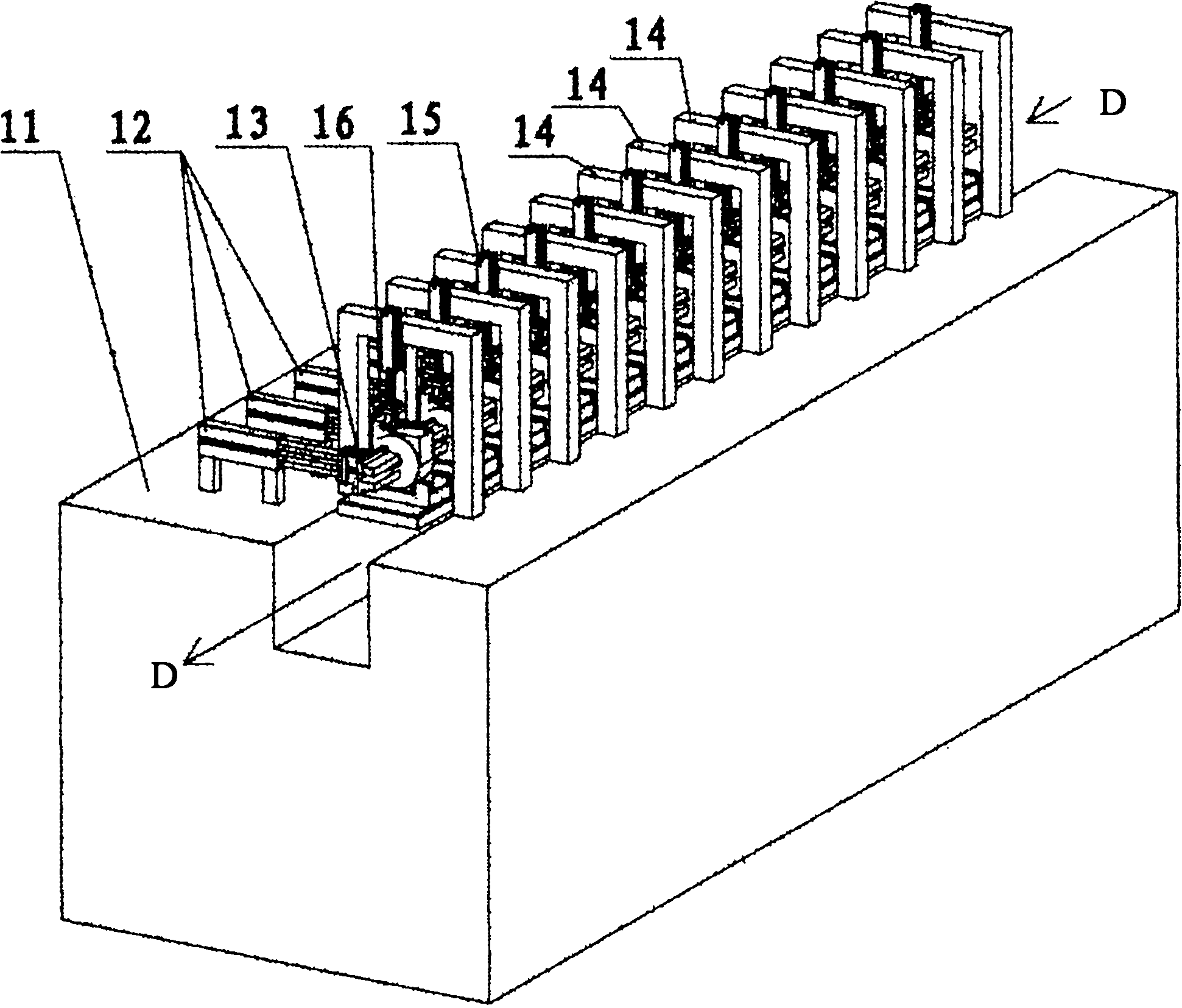

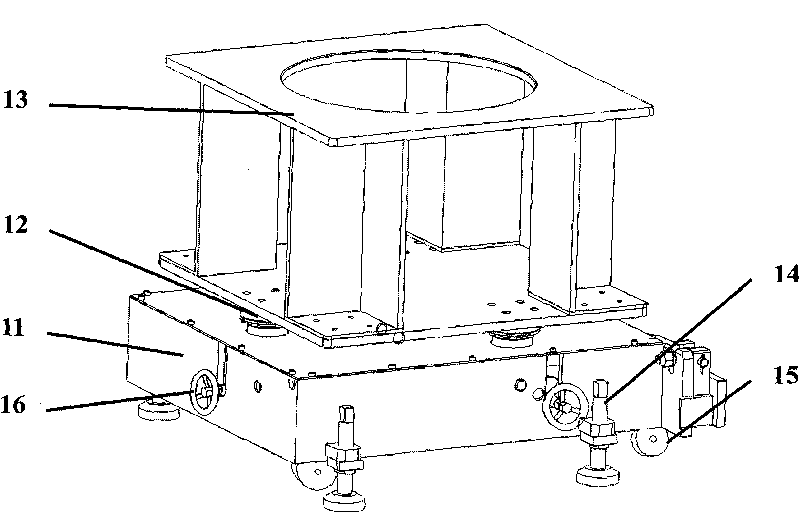

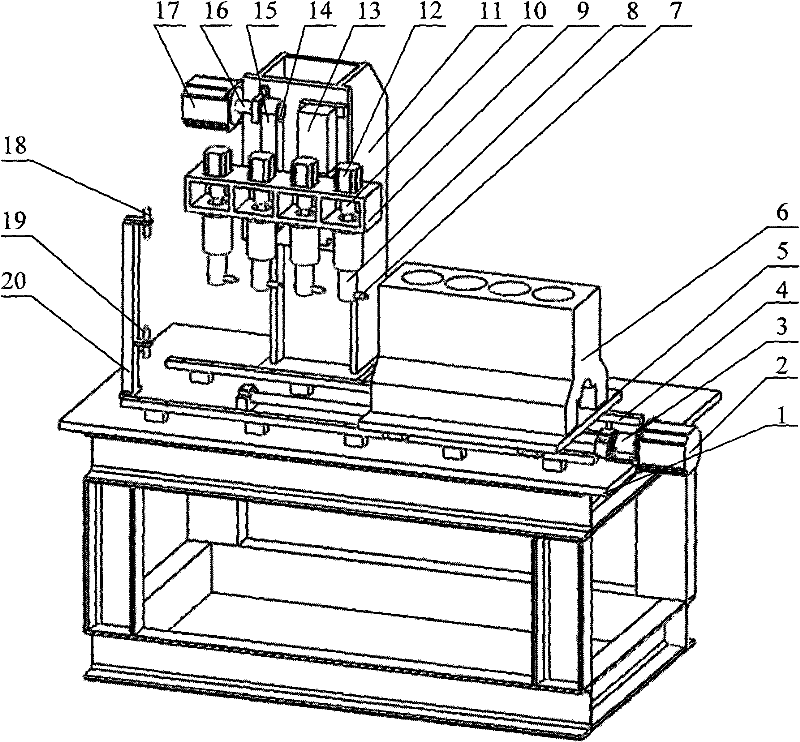

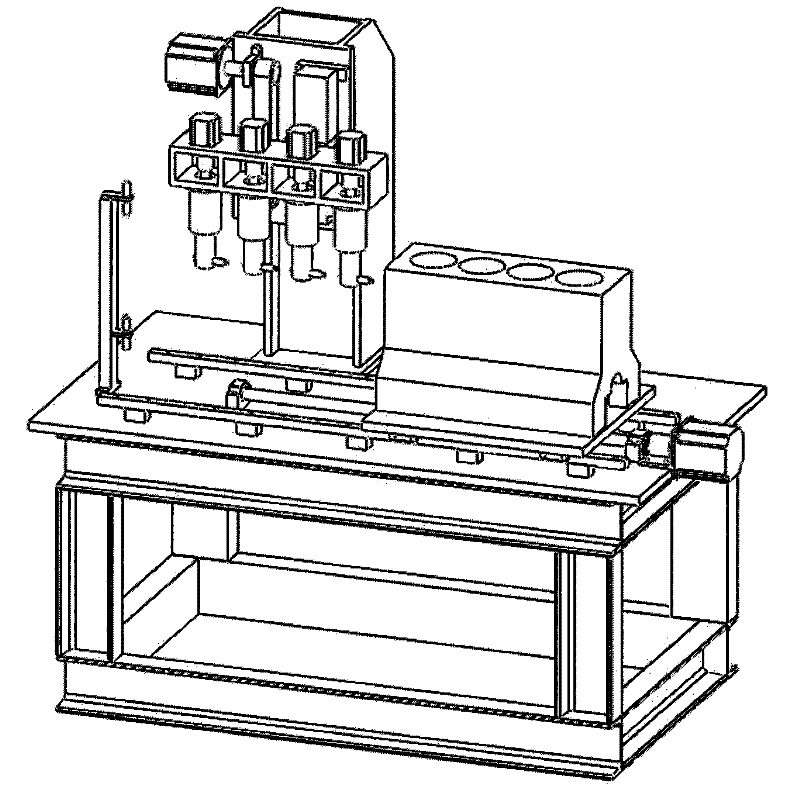

Automatic calibration line and method for intelligent type low-tension current transformers

ActiveCN102135607AImprove test efficiencyReduce human errorElectrical measurementsEngineeringIdentification device

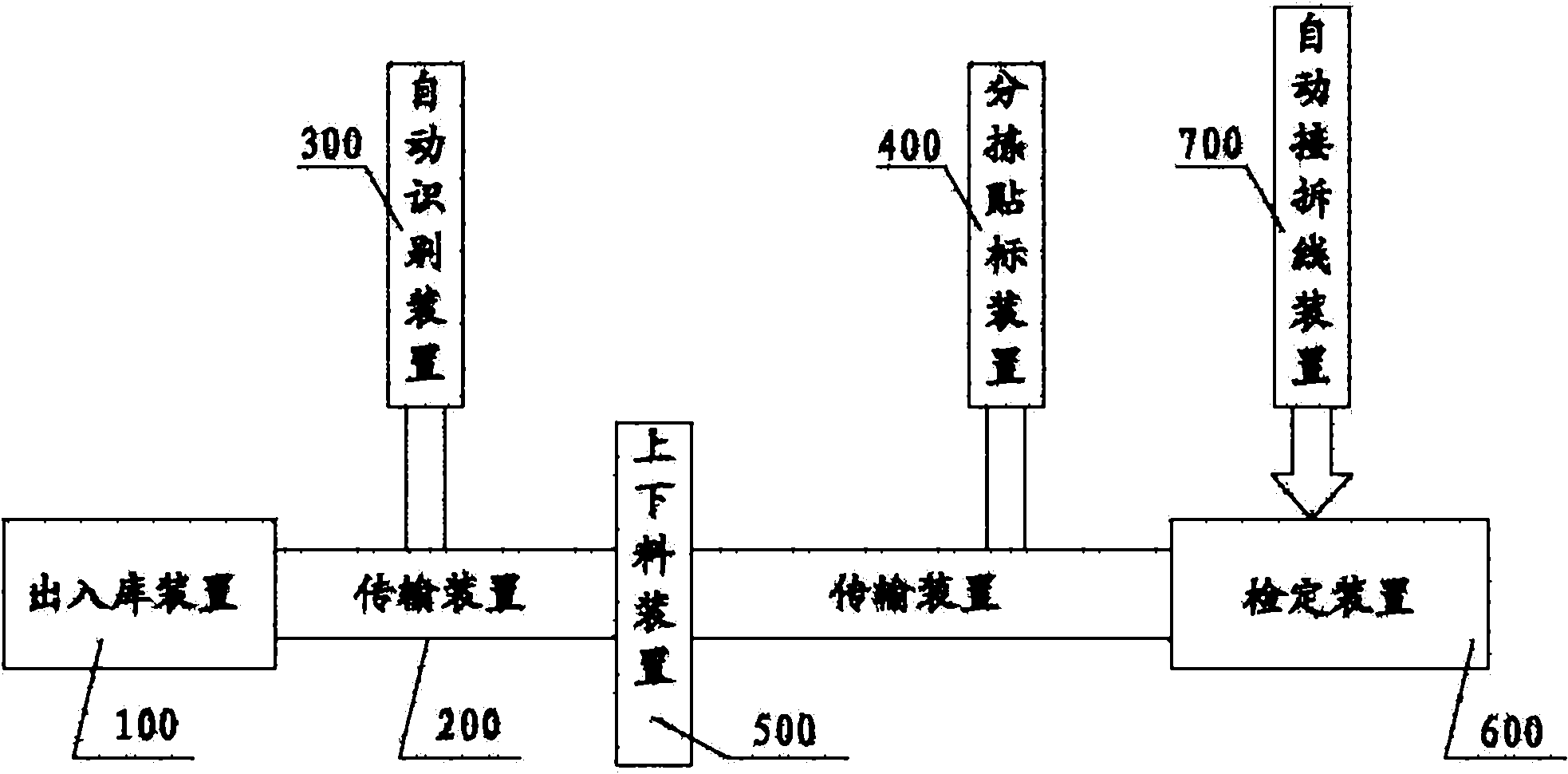

The invention discloses an automatic calibration line for intelligent type low-tension current transformers, comprising a warehouse in-out device, a loading and unloading device, an automatic identification device, a transmission device, an automatic line connecting and disconnecting device, a calibration device and a sorting and labeling device, wherein the warehouse in-out device realizes the automatic warehouse in-out of the intelligent type low-tension current transformers; the material loading and unloading device realizes the automatic loading and unloading of the intelligent type low-tension current transformers; the automatic identification device realizes the automatic identification of the intelligent type low-tension current transformers; the transmission device realizes the automatic transmission of the intelligent type low-tension current transformers; the automatic line connecting and disconnecting device realizes the automatic line connection of the intelligent type low-tension current transformers for the calibration by the calibration device and also realizes the automatic line disconnection of the intelligent type low-tension current transformers; and the sortingand labeling device realizes the automatic sorting of the intelligent type low-tension current transformers. The automatic calibration line is free from manually carrying out the warehouse in-out, the transmission, the identification, the sorting, the loading and unloading and the line connection and disconnection on the intelligent type low-tension current transformer when calibrating the intelligent type low-tension current transformer, and has the advantages of no personal error, high calibration efficiency, good automation degree and capability of automatically measuring multiple transformers. The invention also discloses an automatic calibration method of the intelligent type low-tension current transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +2

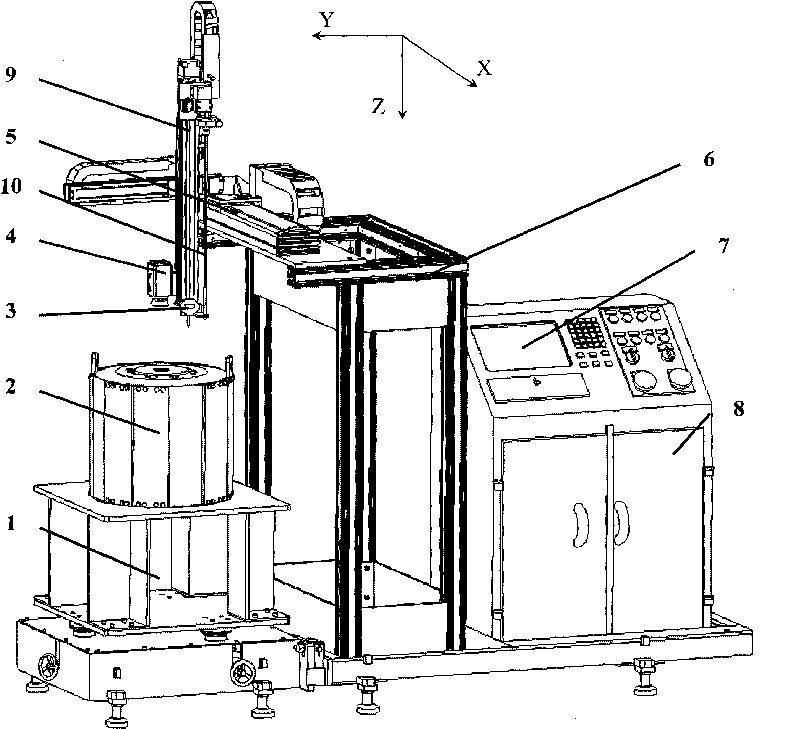

Magnetic field measuring device based on visual guiding robot

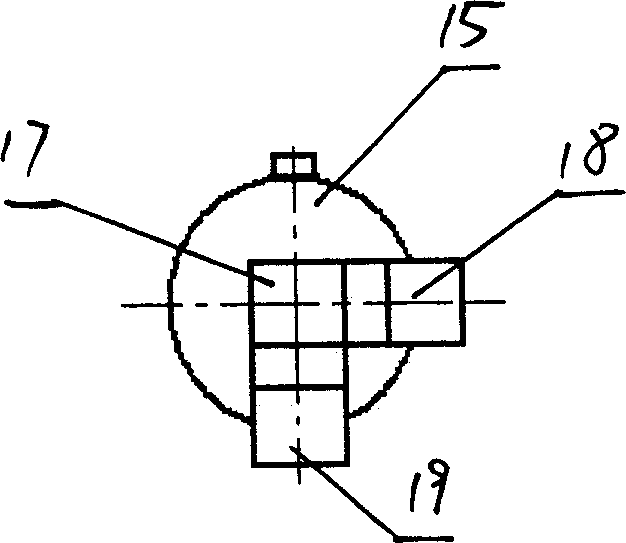

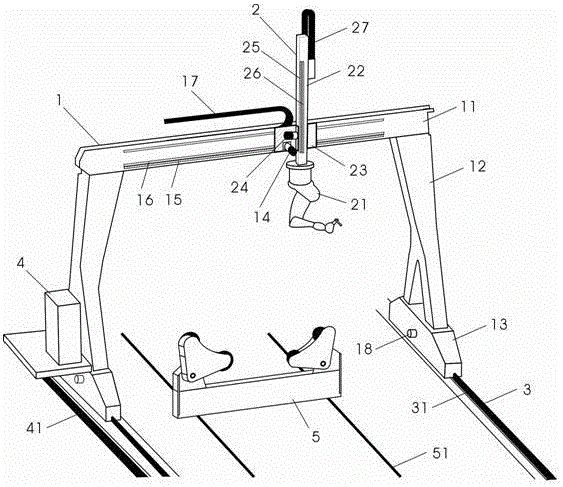

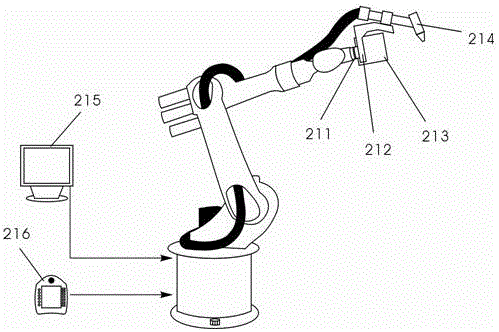

InactiveCN101702010AEasy to assembleEasy to carryMagnetic measurementsMeasurement deviceVision based

The invention relates to a magnetic field measuring device based on a visual guiding robot, which is characterized by comprising an adjustable workbench, a measuring system, a robot system and a control system which are matched with each other and have a modular design, wherein the adjustable workbench mainly consists of a base, there sets of adjusting mechanisms, a component placing table, foundation wheels and an adjustable support leg, and the gesture of the adjustable workbench can be adjusted by a hand wheel; the measuring system comprises a gesture measuring device of an object to be detected, a visual guiding positioning device and a magnetic field data collecting device; the gesture measuring device of the object to be detected mainly comprises a number dialgauge and a connecting rod; the visual guiding positioning device mainly comprises an integral camera and an image collecting card which are connected by cables; the magnetic data collecting device mainly comprises a multifunctional data collecting card, a teslameter and a Hall probe which are connected by cables; the robot system comprises a three-dimensional right angle coordinate robot; and the control system comprises an industrial personal computer and software.

Owner:HEBEI UNIV OF TECH

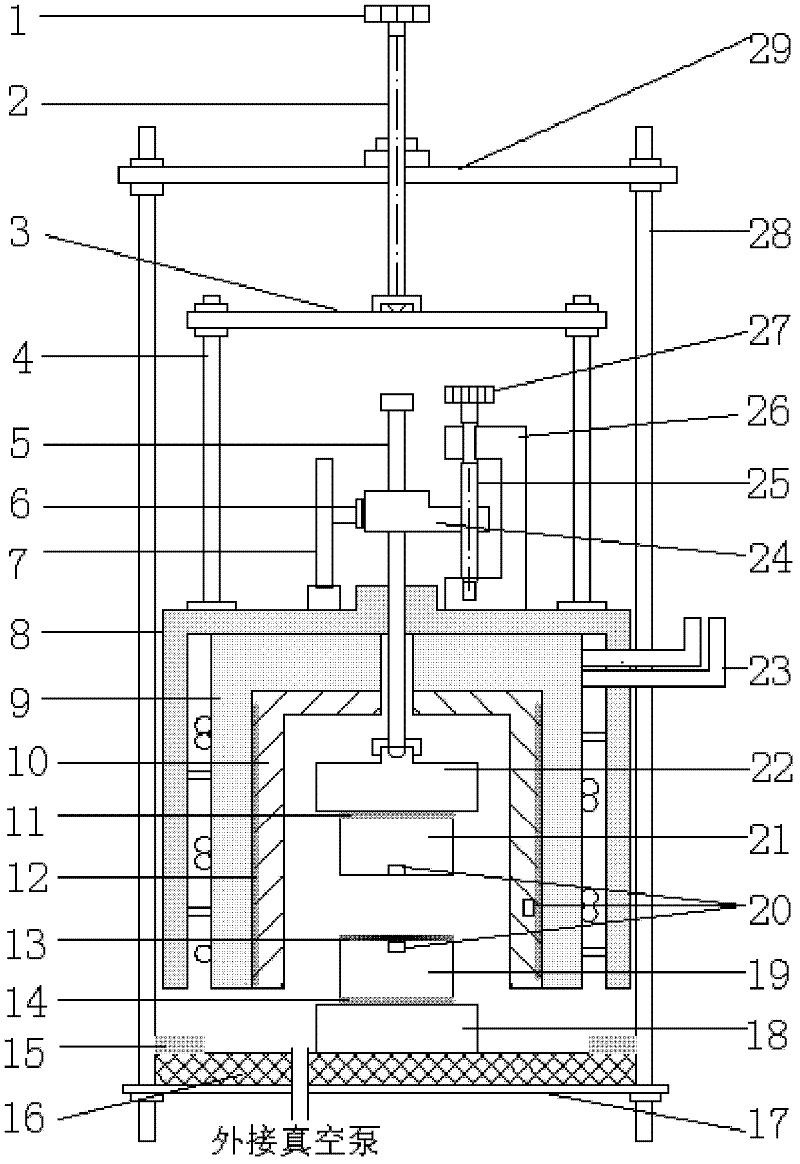

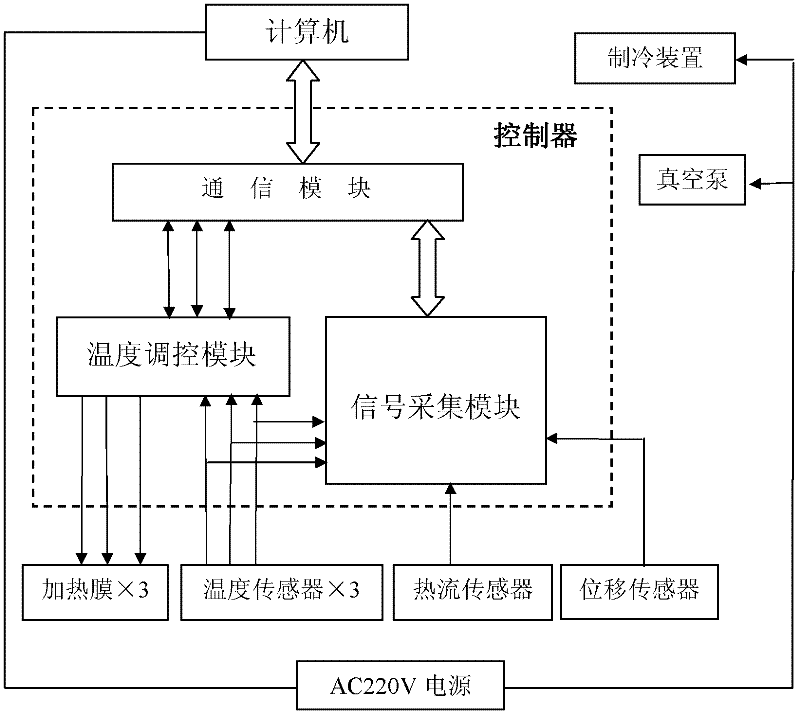

Protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing vacuum insulation and thickness measurement function

InactiveCN102645449AImprove measurement repeatabilityImprove accuracyMaterial heat developmentMeasuring instrumentEngineering

The invention provides a protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing the vacuum insulation and thickness measurement function. A test stack body of the measuring instrument comprises a hot plate and a cold plate, wherein a heating film is clamped between the hot plate and a hot plate fixed seat; and the cold plate is similar to the hot plate in structure. A vacuum system consists of a vacuum box, a vacuum pump, a sealing gasket and a sealing bottom plate; and the vacuum insulation function can be realized through the vacuum pump. A thickness measurement module consists of a displacement sensor capable of outputting an electric displacement signal; the displacement signal enters a controller and realizes the function of automatically measuring the thickness of a test piece; and the whole instrument is measured and controlled by a computer. The protective heat flow meter method thermal conductivity coefficient measuring instrument has the beneficial effects that the influence of environment on measurement stability is avoided through a vacuum chamber; meanwhile, the thickness of the test piece is automatically measured to avoid the personal error caused by manual measurement; and the measuring repeatability, the accuracy and the degree of automation of the instrument are improved. The protective heat flow meter method thermal conductivity coefficient measuring instrument can be widely applied to manufacturing enterprises of heat insulation and heat preservation materials, related quality inspection departments and units, institutes of higher learning, research institutes and other scientific research units.

Owner:TIANJIN UNIV

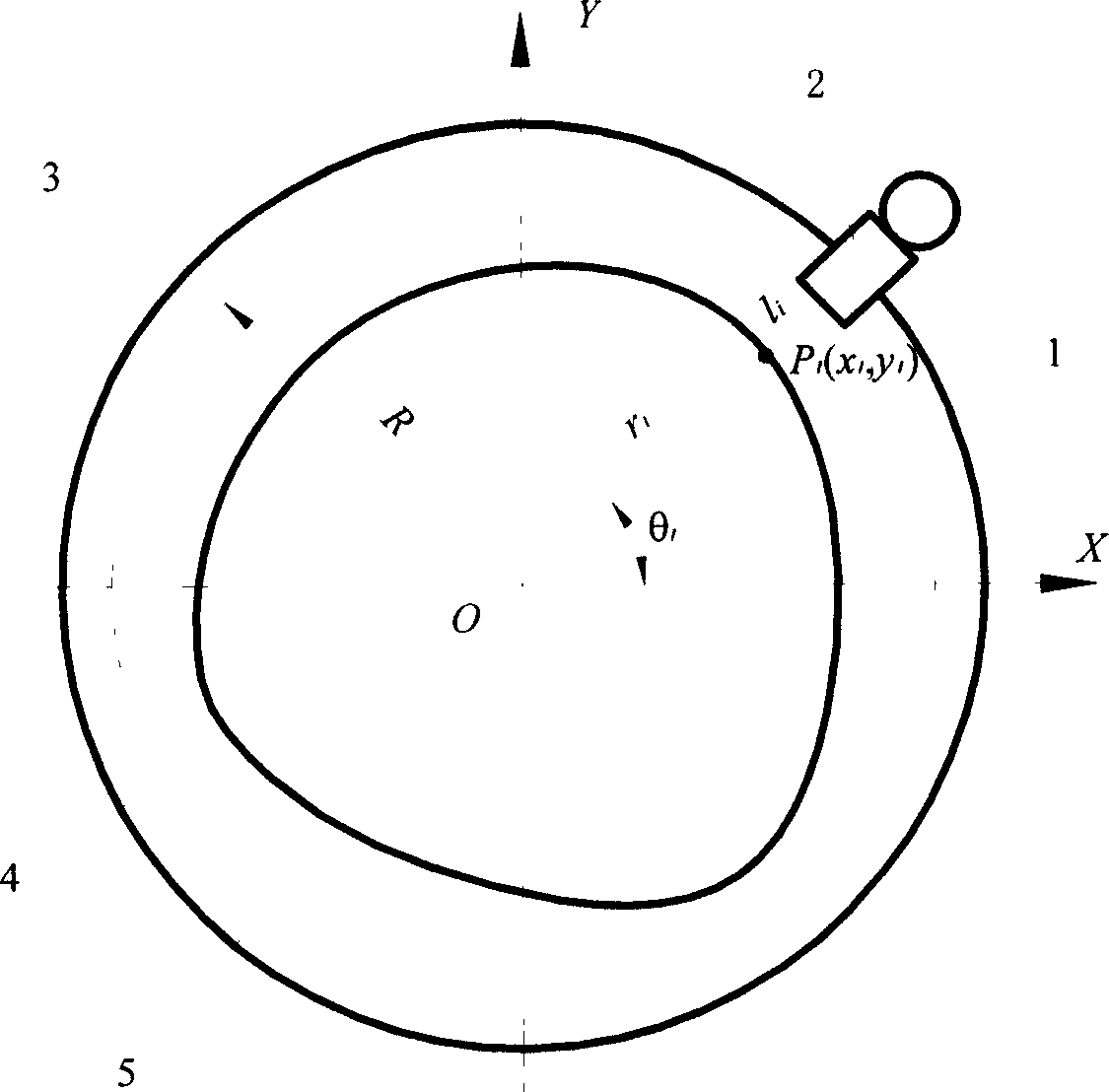

System and method for measuring section shape and size of heavy caliber steel pipe

InactiveCN1734233ATrue reflection of geometric featuresReflect geometric featuresMeasurement devicesInformation processingSize measurement

This invention discloses such a measurement and method of a large caliber steel tube cross-section shape, which belongs to the domain of geometric measurement technique. The measurement system of information processing mode and measurement mode is located in the small moving car, with the small car moving on the datum circular orbit. The input and output mode connect the information processing mode through the serial port. The measurement method is like this: testing a series of the steel tube surface and the radial distance of a certain known datum circular orbit radius in order to get a configuration point coordinates of the steel tube cross-section. When the amount of sampling points is abundant enough, we can get the accurate outline of steel tube. Then the information-processing mode counts the steel tube cross-section shape and dimension parameter.

Owner:TSINGHUA UNIV

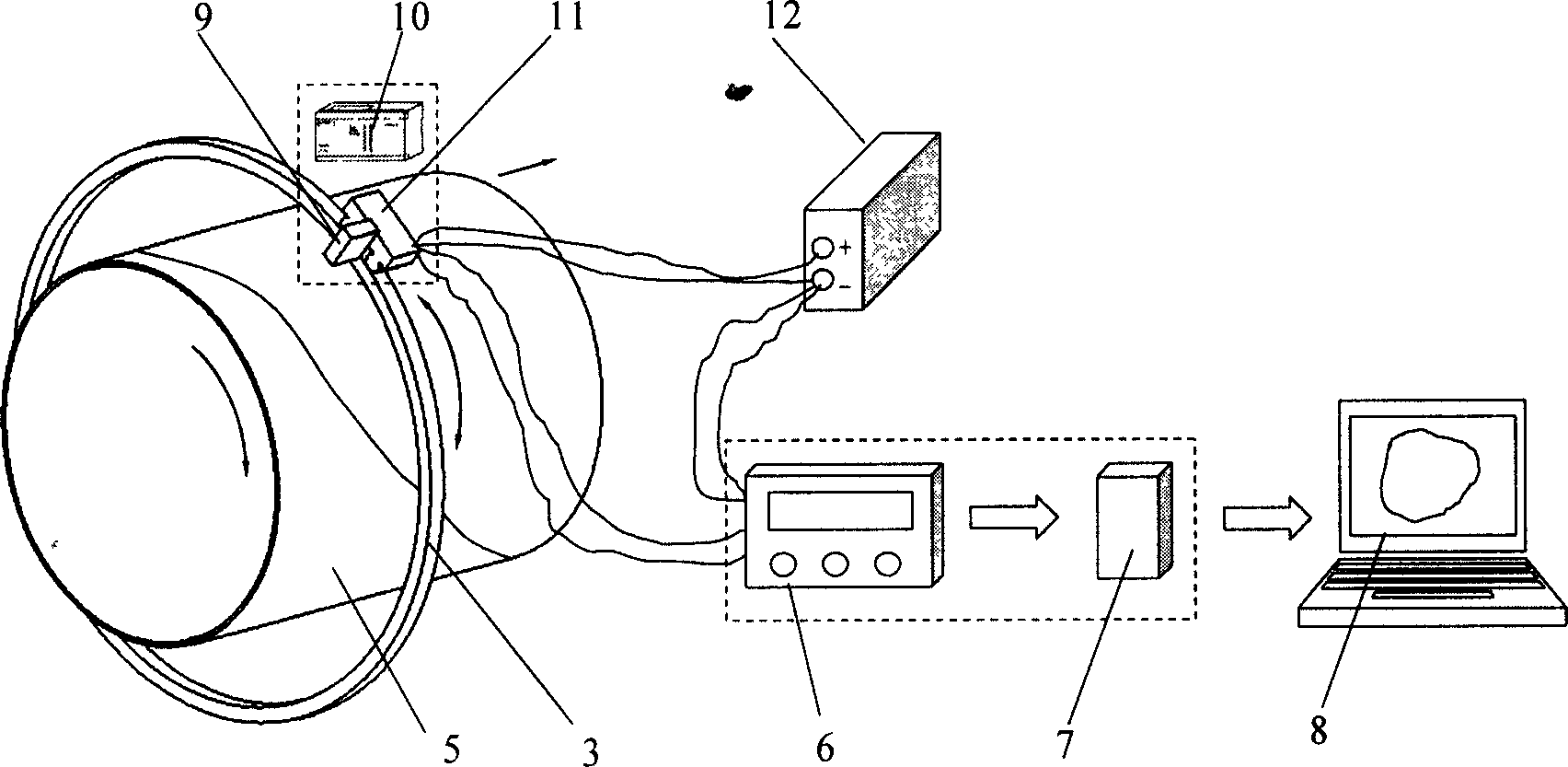

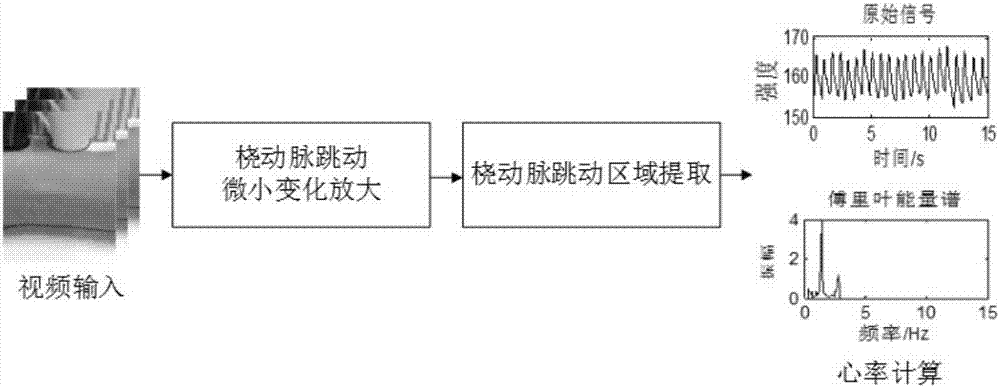

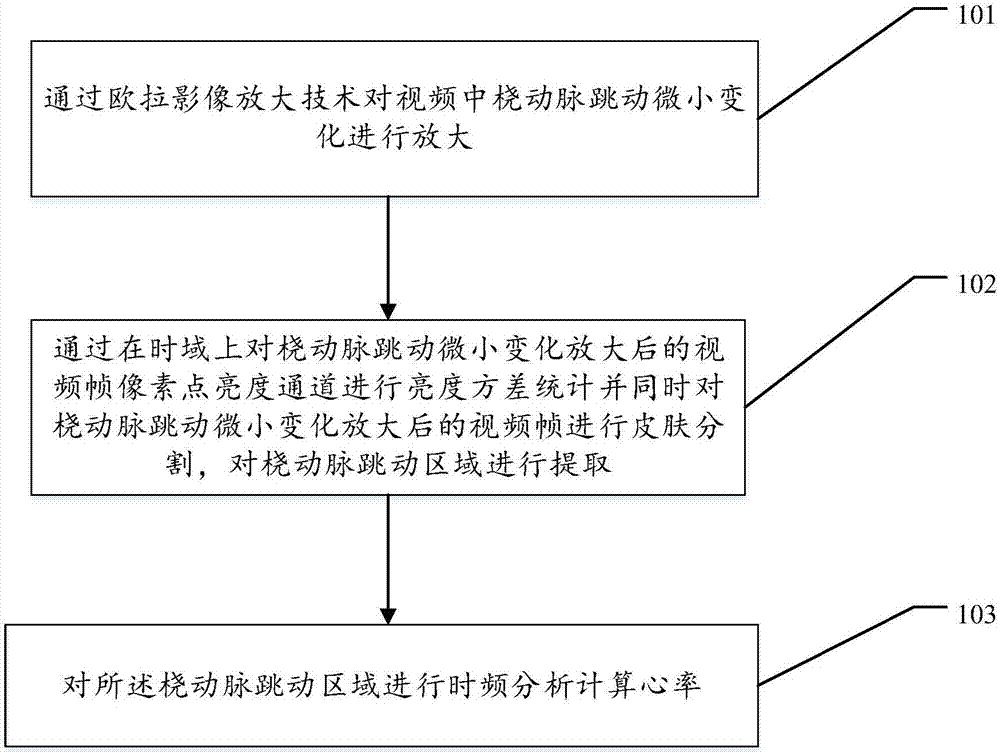

Non-contact heart rate measurement method and device based on Euler image magnification

ActiveCN107529646ARealize automatic measurementImage analysisCharacter and pattern recognitionTime domainHeart rate measurement

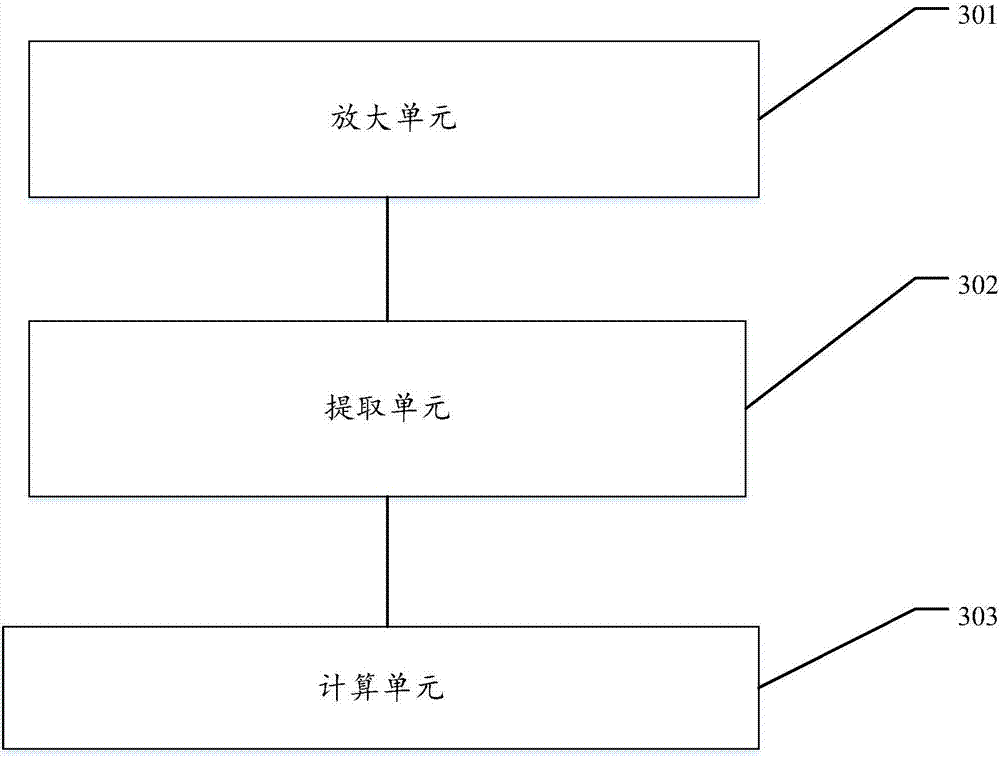

The embodiment of the invention discloses a non-contact heart rate measurement method and a device based on Euler image magnification, used for solving the technical problems existing in the existingnon-contact heart rate measurement method that the heart rate is great in same-frequency noise interference and is greatly influenced by an environment temperature, isolation signal authenticity lacksjudgment and the like. The non-contact heart rate measurement method and device based on Euler image magnification in the embodiment of the invention comprises the following steps: S1, magnifying tiny change of radial artery jump in a video through an Euler image magnification technology; S2, performing luminance variance statistics on a video frame pixel point luminance channel after magnifyingthe tiny change of radial artery jump in a time domain, performing skin segmentation on the video frame subjected to magnification of the tiny change of radial artery jump, and extracting a radial artery jump area; and S3, performing time-frequency analysis on the radial artery jump area so as to calculate the heart rate.

Owner:GUANGDONG UNIV OF TECH

Vision measuring apparatus of large size part

InactiveCN101349542AImprove image qualityReduce mistakesUsing optical meansMeasurement deviceEngineering

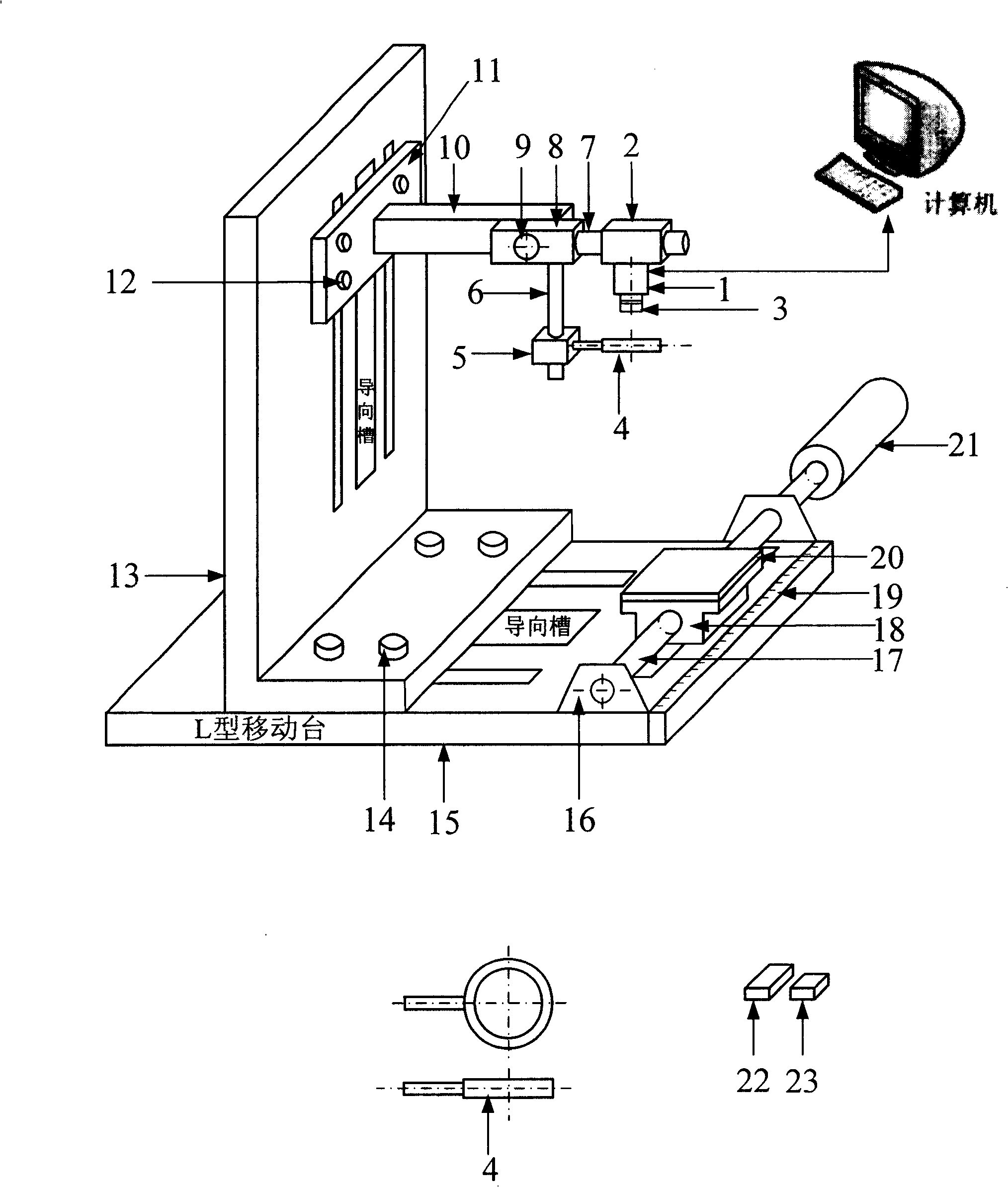

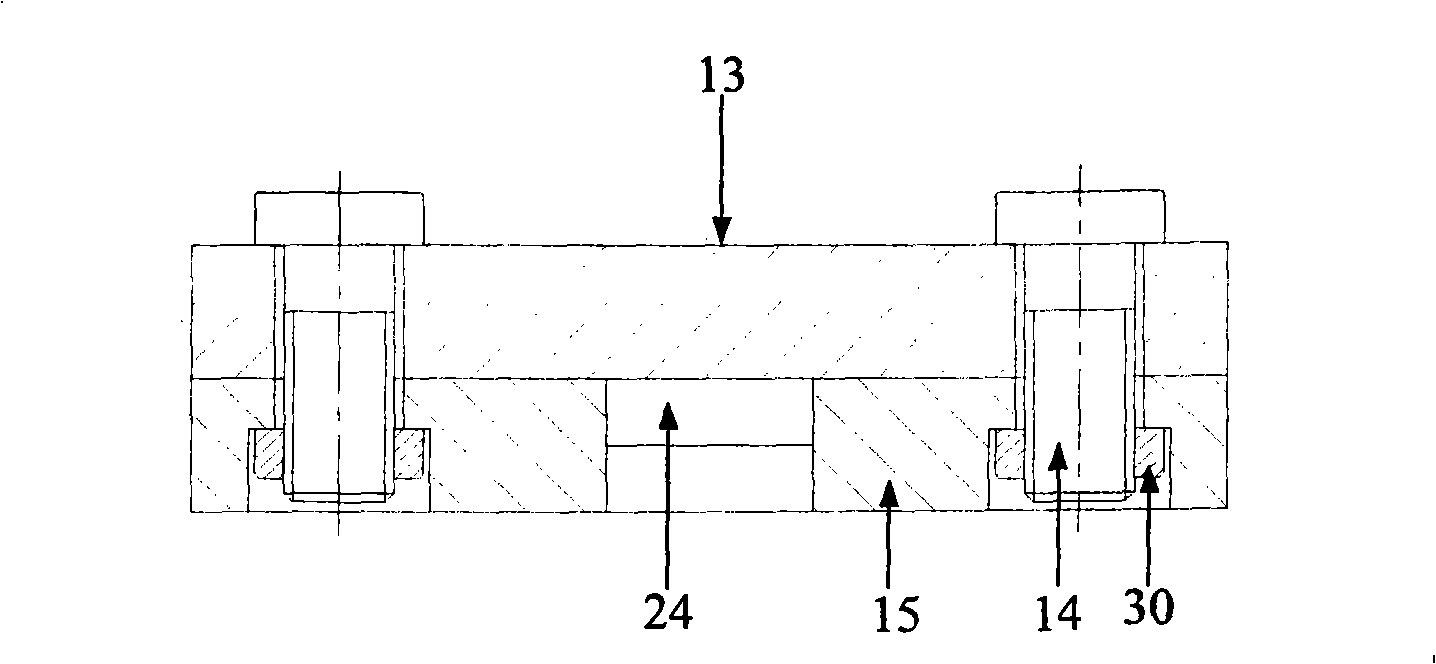

A large size element measuring device based on the machine vision comprises a chassis, a large calibration block and a small calibration block, wherein the length ratio of the large calibration block and the small calibration block is 3:2-2:1, an L-shaped mobile station is connected on the chassis in a sliding way, a support bar is connected on the vertical arm of the L-shaped mobile station in a sliding way, and the sliding direction of the L-shaped mobile station is perpendicular to the sliding direction of the support bar, a rotary block is rotatably connected on the support bar, and the rotational motion plane of the rotary block is perpendicular to a plane which is decided by the sliding direction of the L-shaped mobile station and the sliding direction of the support bar, a camera support plate is rotatably connected on the rotary block, and the rotational motion plane of the camera support plate is perpendicular to a plane which is decided by the sliding direction of the L-shaped mobile station and the sliding direction of the support bar, a camera is arranged on the camera support plate, a translation device is arranged on the chassis, a white background plate is arranged on the translation device, and is located under the camera, and a steel rule for observing the movement distance of a tray is arranged on the chassis.

Owner:SOUTHEAST UNIV

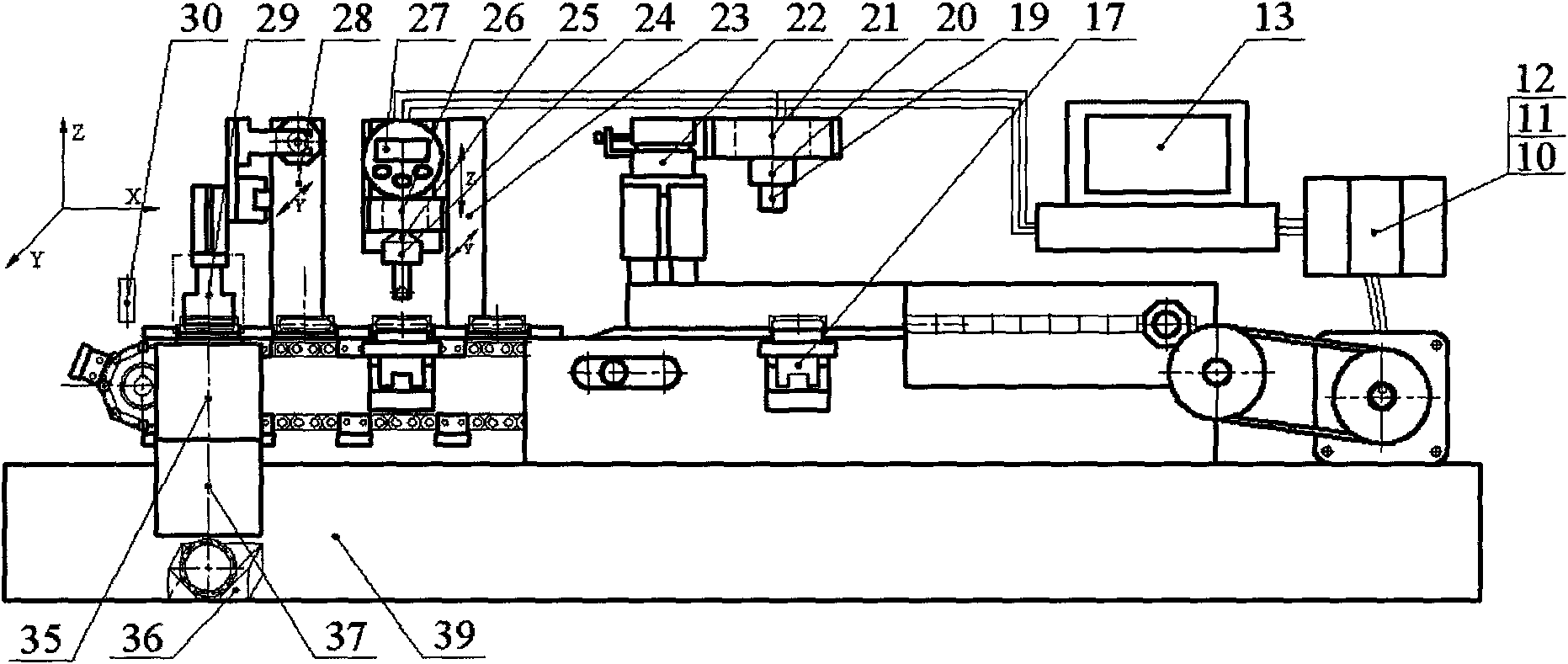

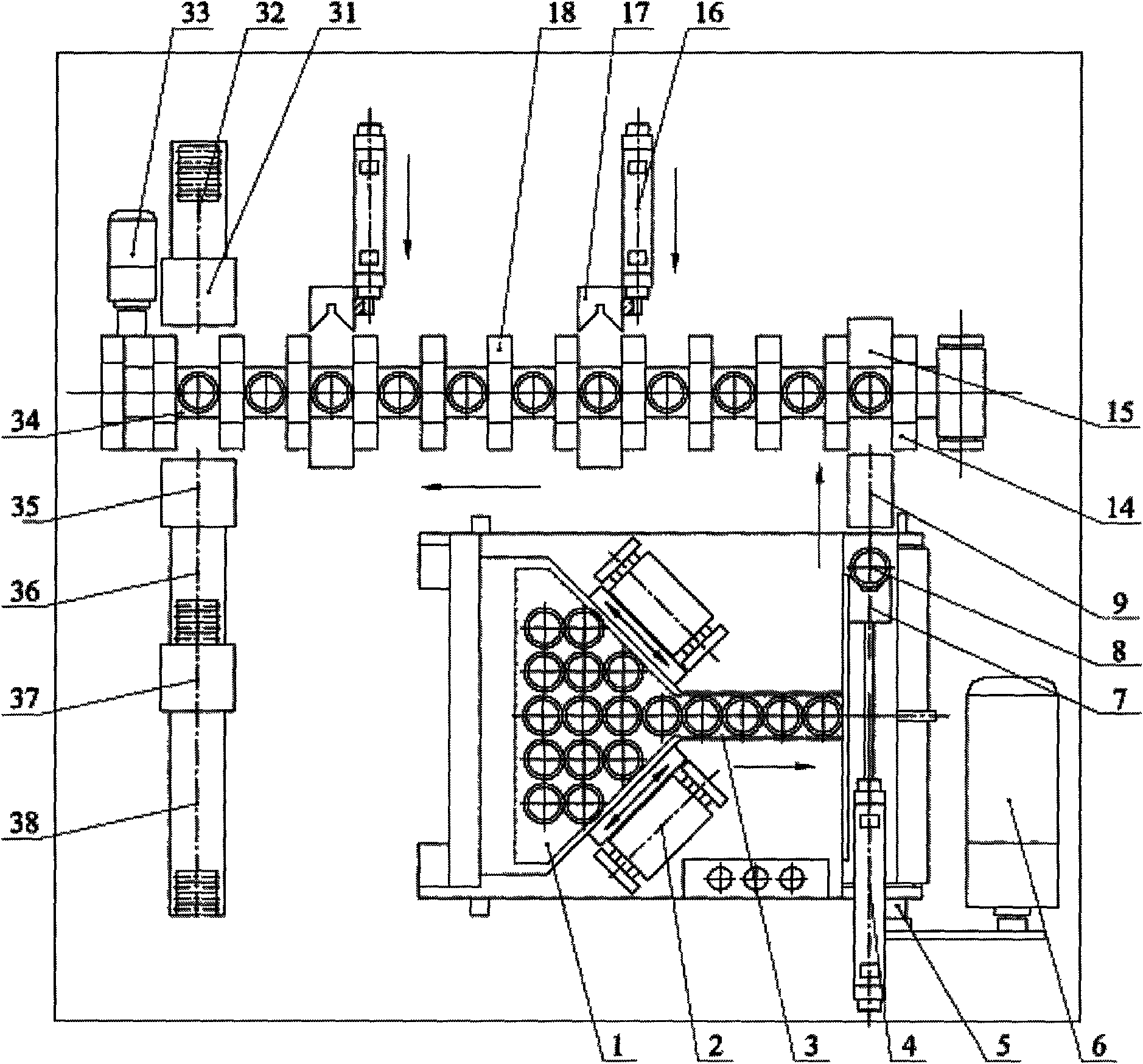

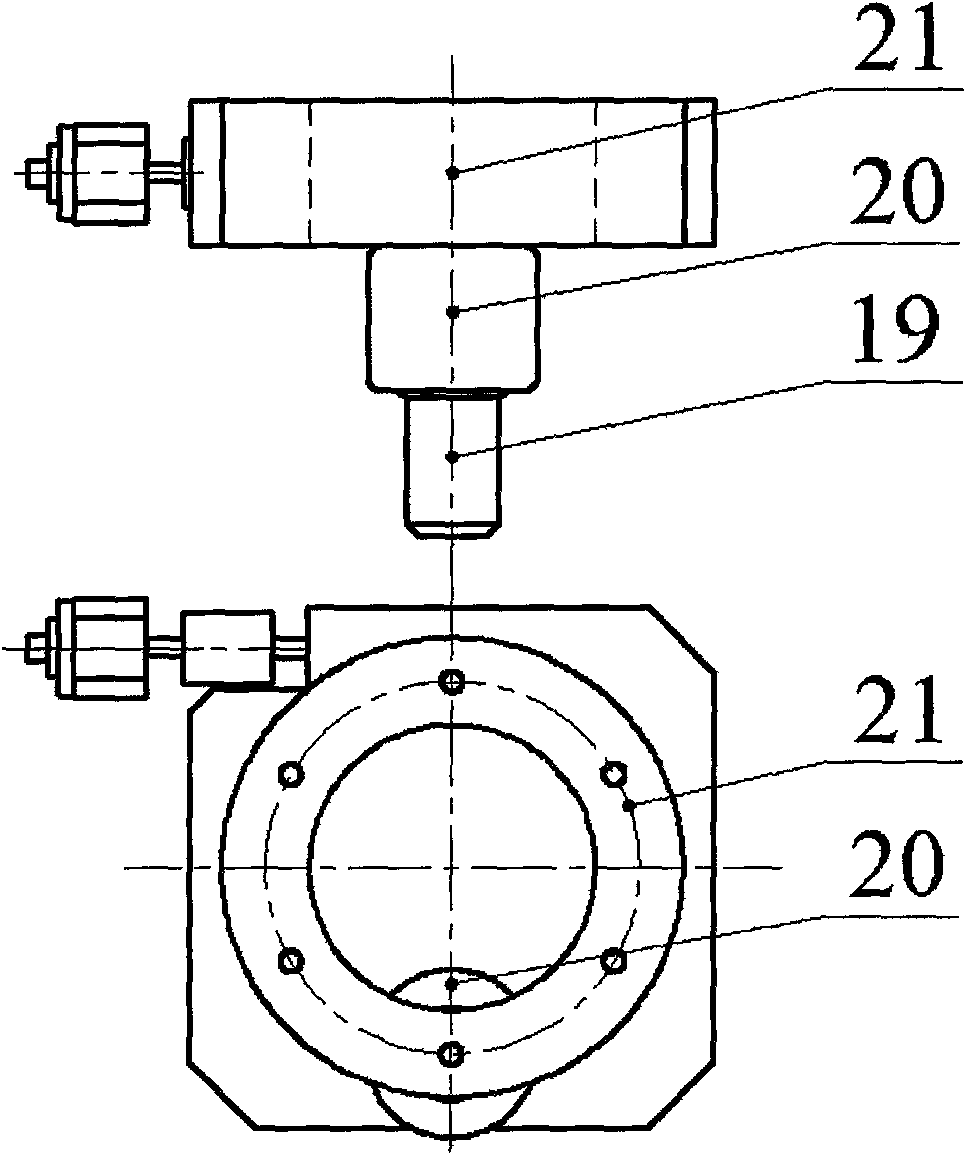

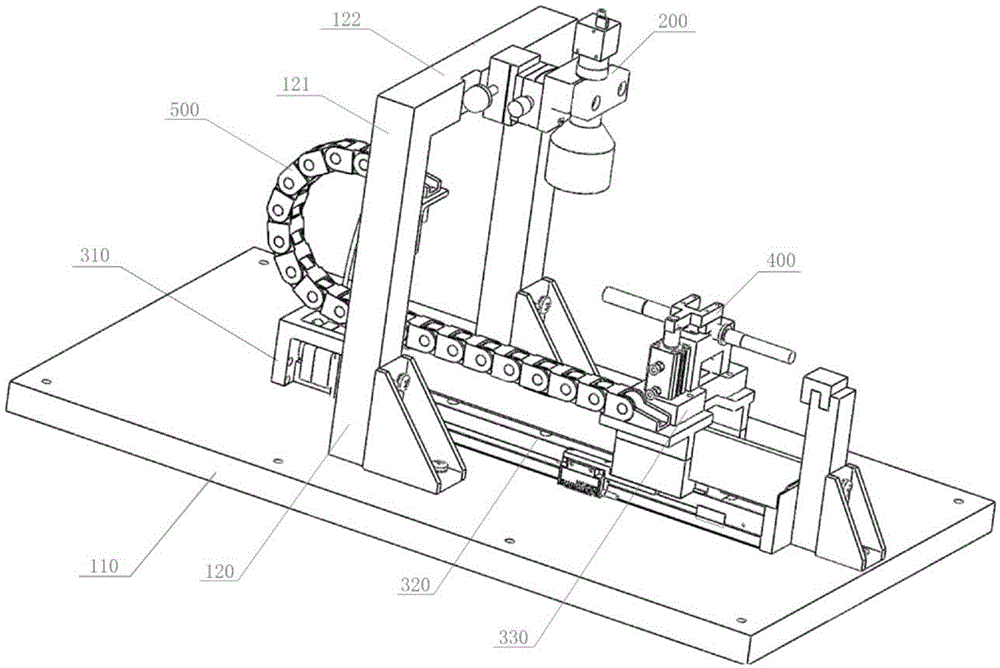

Comparative measurement method-based multi-parameter automatic measurement system of outer ring of rolling bearing

InactiveCN102735178AHigh measurement accuracyRealize high-precision measurementMechanical diameter measurementsUsing optical meansImage resolutionChain conveyor

The invention discloses a comparative measurement method-based multi-parameter automatic measurement system for an outer ring of a rolling bearing. The automatic measurement system comprises a feeding mechanism, a chained transmission mechanism, an axial parameter measurement apparatus, a radial parameter measurement apparatus, a separation mechanism, a PLC control module, an upper computer control module, and a man-machine interaction module. According to the measurement system, with utilization of a standard and high-precision inner ring of a bearing as a reference component as well as a camera and a digital dial gauge as comparative measurement instruments, a measured outer ring of the bearing is compared with the reference component so as to carry out separation of a qualified product, a reprocessed product and a scraped product. According to the invention, automatic comparative measurement of the outer diameter of an outer ring of a bearing and the variation thereof, an inner diameter and the variation thereof as well as the diameter of a groove and the variation thereof can be realized; and moreover, bottleneck problems that the system cost is too high due to a requirement of a high resolution ratio of a camera during the high precision detection and large-size detection of an outer ring of a bearing and the previous multi-parameter detection of an outer ring of a bearing needs to utilize special measurement instruments respectively to carry out measurement can be solved.

Owner:ZHEJIANG UNIV

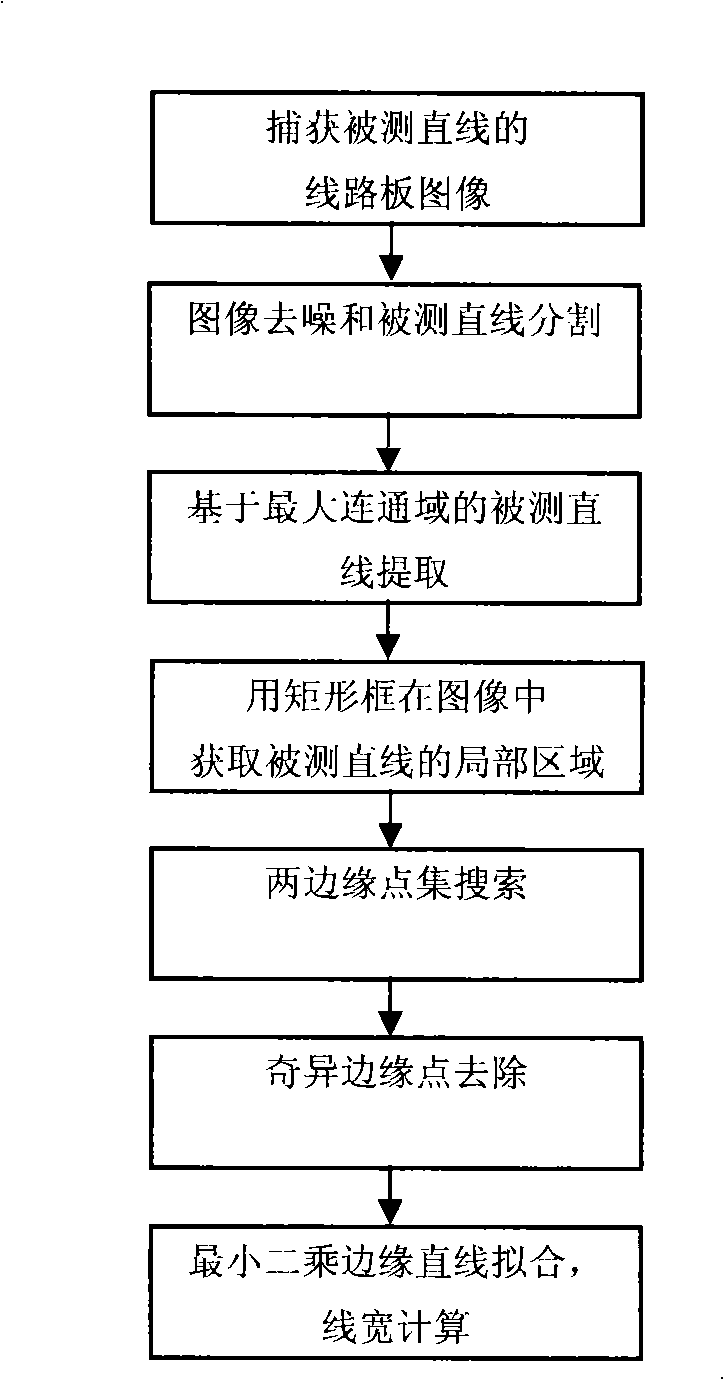

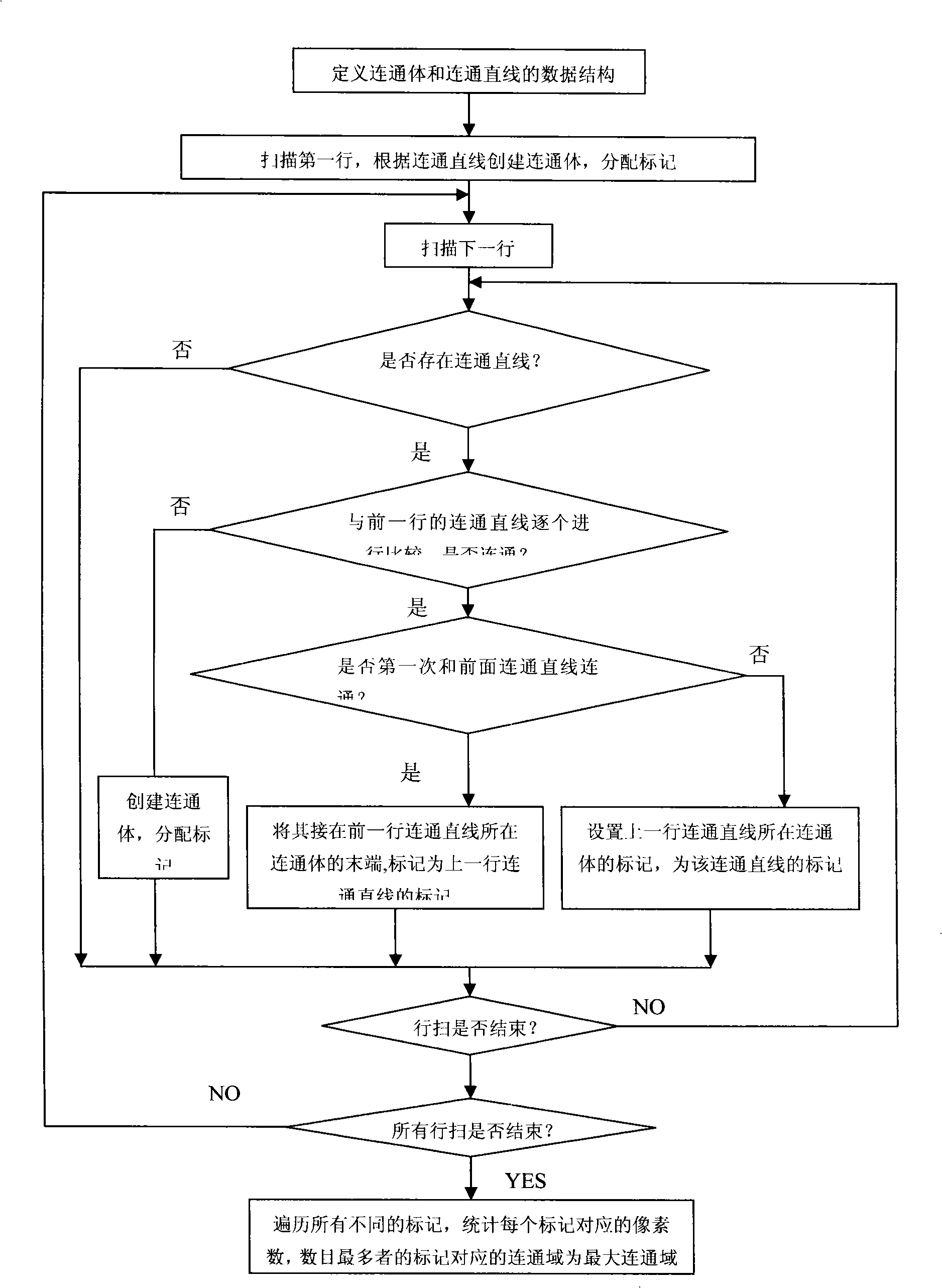

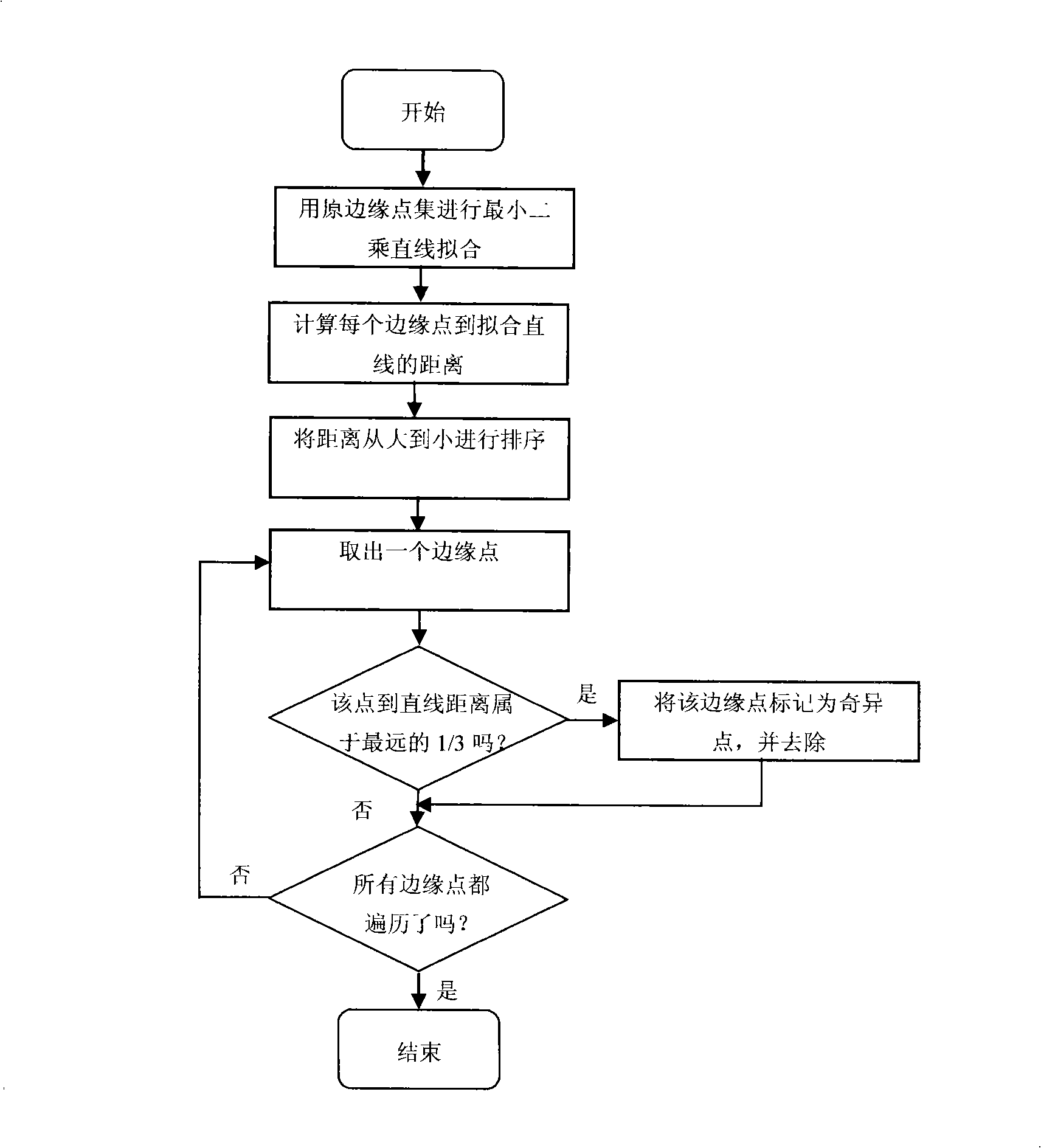

Method for measuring circuit board line width based on largest communication domain

InactiveCN101303226APrecise positioningRealize automatic measurementImage analysisUsing optical meansImage denoisingLine width

The invention relates to a method for measuring line width of a circuit board based on maximum connected domain, which comprises the steps of: 1) capturing the image of a target circuit board; 2) denoising the image and segmenting a target straight line; 3) extracting the straight line by using the maximum connected domain method within a rectangular frame; 4) determining the point sets of both edges of the target straight line by scanning; 5) removing singular edge points; and 6) fitting the two edges of the straight line and performing line width calculation by using the least square method. By introducing maximum connected domain search for acquiring target straight lines, the method of the invention is applicable to line width measurement for not only interior copper plates but also exterior copper plates with small contrast between circuit and substrate. And by employing image denoising and singular point removal, the method achieves accurate acquisition of edges of target straight lines, and as a result, improved precision and stability of line width measurement.

Owner:NANCHANG HANGKONG UNIVERSITY

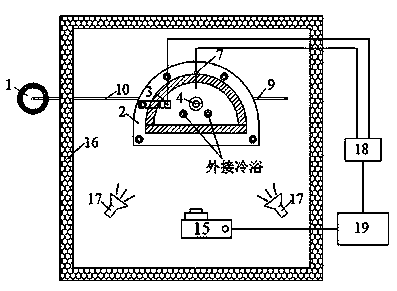

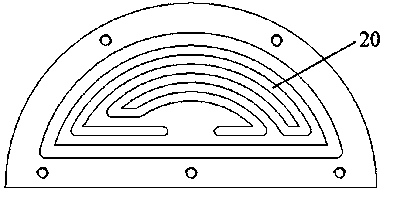

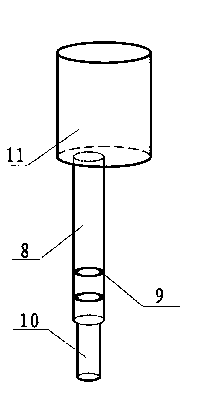

Visual soil freeze-thawing process test apparatus

ActiveCN104215566AEasy to observeGuaranteed uniformityWeather/light/corrosion resistanceElectronic computerLight source

The invention relates to a visual soil freeze-thawing process test apparatus. A temperature control box is connected with an external compressor, a semi-cylindrical sample tank is placed on a temperature control baseboard in the temperature control box, the temperature control baseboard is carved with a groove, the groove is provided with a sealing ring in contact with the semi-cylindrical sample tank, the temperature control baseboard is provided with holes, one of the holes is connected with a Mariotte bottle through a water guiding tube, the other of the holes is connected with a water head adjusting tube, the temperature control baseboard is provided with a filter paper and a soil sample, the top of the soil sample contacts with a temperature control top board, and the temperature control top board is provided with a handle; a displacement sensor is fixed on a bracket, and contacts with the top surface of the temperature control top board; a temperature sensor is inserted into the soil sample through a probe hole on the wall surface of the test tank, and the displacement sensor and the temperature sensor are respectively connected with a data acquisition instrument through a lead; and an adjustable light source is placed at both sides of a camera, the camera is placed at the right side of the semi-cylindrical sample tank, and the camera is connected with an electronic computer through a lead. The apparatus is used for researching the dynamic change process of the freezing rate, the moisture migration rate, the ice crystal speed, the segregated ice thickness and the frost heaving speed with time of soil in the soil freezing process, visually shows the movement of a frozen frontal surface in soil columns and the growth process of frozen fringe, and provides technical guarantee for the freezing and thawing mechanism of the soil.

Owner:NORTHWEST INST OF ECO-ENVIRONMENT & RESOURCES CAS

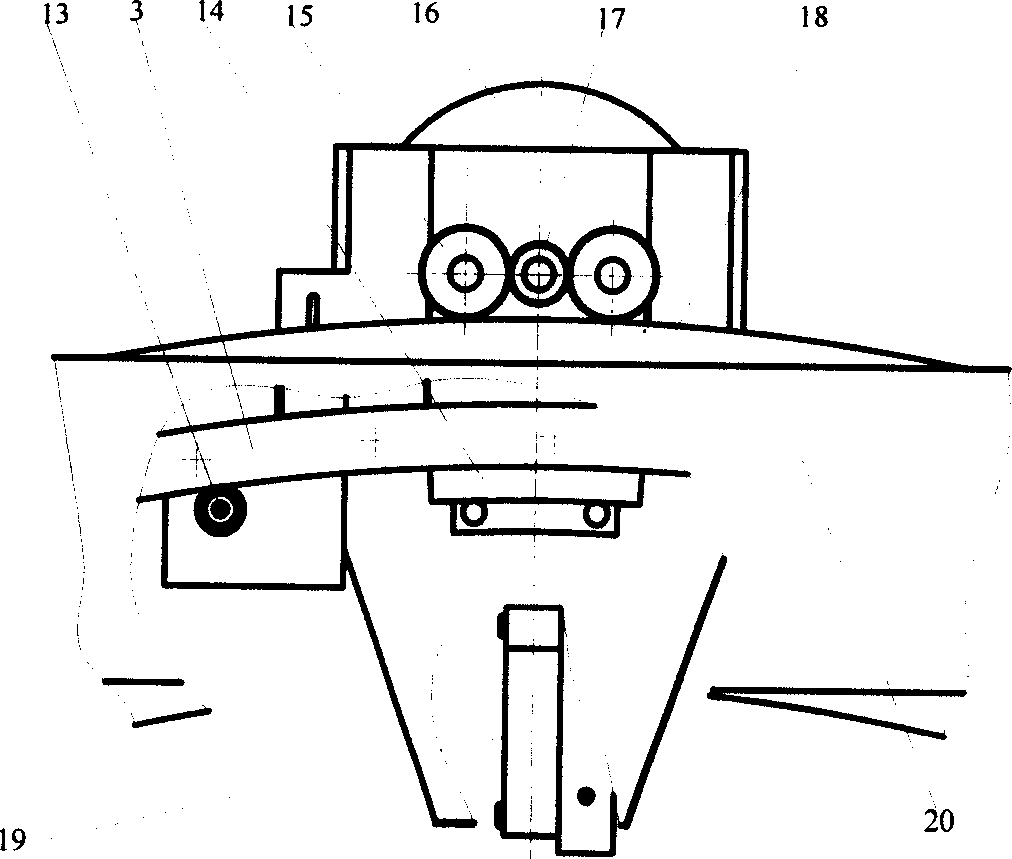

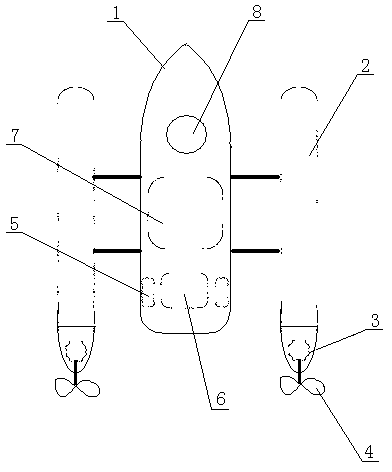

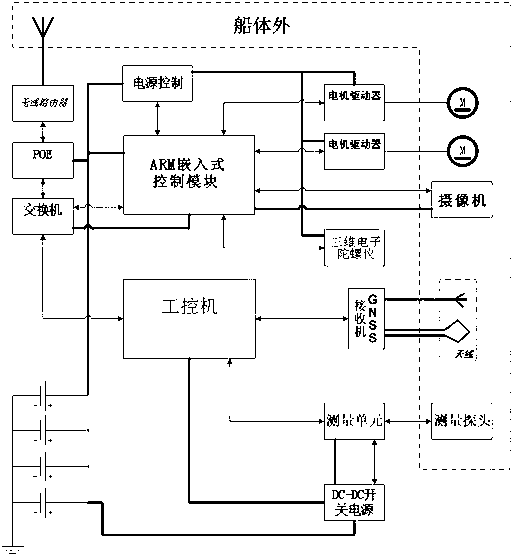

Rudderless unmanned ship capable of automatically sailing

ActiveCN103303452AReduce usageSimple structurePropulsion power plantsPropulsive elementsTerrainCommunication unit

The invention relates to the technical field of unmanned remote control measurement, and provides a rudderless unmanned ship capable of automatically sailing, which comprises a ship body, pontoons on the two sides, a communication unit, a navigation and positioning unit, a measuring unit, a power and driving unit, a ship body gesture measuring unit, an industrial personal computer, and a battery providing a working power supply for the other parts. According to the invention, the advancement, backing and turning of the unmanned ship can be realized through controlling the turning and speed difference of the power equipment mounted on the two sides of the ship body; the unmanned ship can complete planned sailing lines to perform measuring tasks such as underwater terrain plotting, flow velocity and flow rate measurement, and close-range photogrammetry; the automatic voyage of the unmanned ship at the rudderless state can be realized; the flexibility of the unmanned ship is improved; and the measuring working efficiency is greatly improved and the cost is reduced.

Owner:WUHAN CHUHANG SURVEYING SCI&TECH

On -line detection equipment for automobile engine cylinder body

InactiveCN102192721ARealize automatic measurementRealize measurementMeasurement devicesAir bearingCoupling

The invention relates to on-line detection equipment for an automobile engine cylinder body and belongs to the technical field of on-line precision measurement. The equipment comprises a substrate platform; a motor fixed on the upper part of the substrate platform is connected with a lead screw guide rail through a coupler; an engine cylinder body detection workbench is arranged above the guide rail; and an engine cylinder body is placed on the detection workbench. A cylindricity measurement substrate is arranged on the substrate platform; a high-precision guide rail is arranged on the cylindricity measurement substrate; a cylindricity measurement adapter plate is connected with a guide rail sleeve; motors, high-precision air bearings and displacement sensors form four groups of cylindricity measurement mechanisms which are arranged on the adapter plate; and a cylindricity measurement motor drives the air bearings to rotate to drive the displacement sensors to rotate to perform measurement. A stepping motor drives the cylindricity measurement adapter plate to move up and down along the guide rail through a synchronous belt to realize the measurement of a cylinder hole of an engine. The substrate platform is fixedly provided with a cylinder height measurement substrate and is provided with the displacement sensor to realize the measurement of the cylinder body height of the engine.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

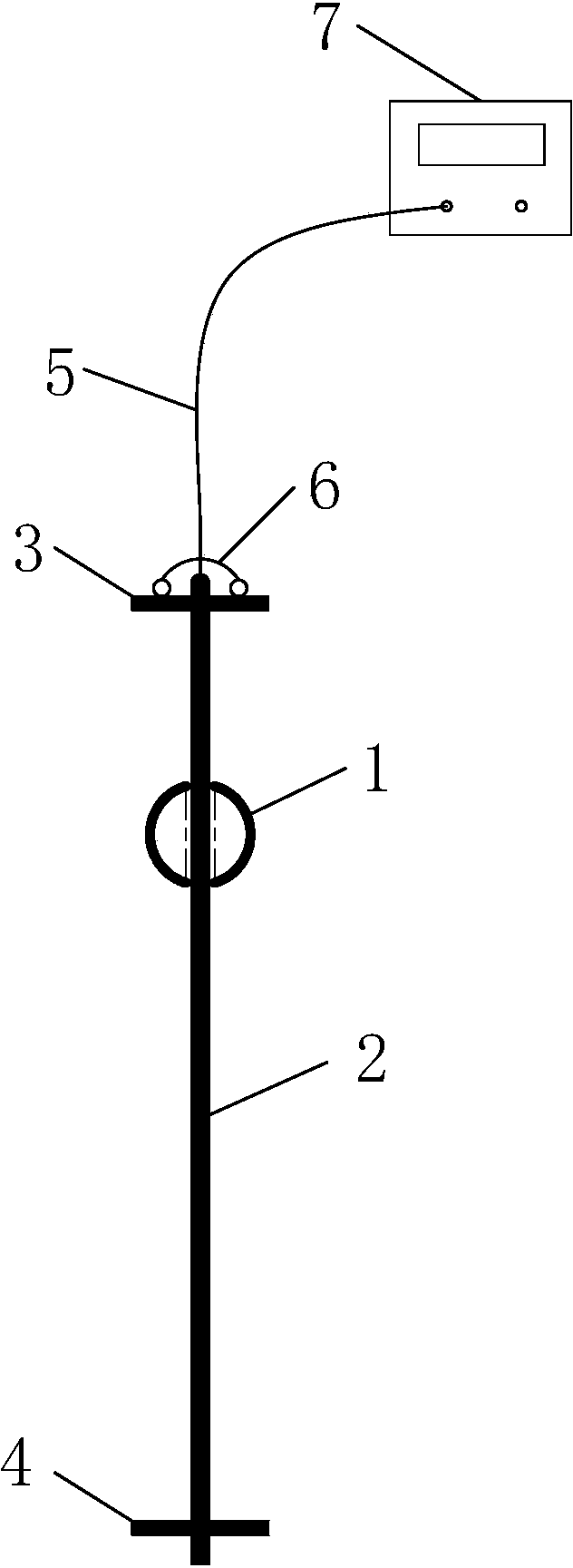

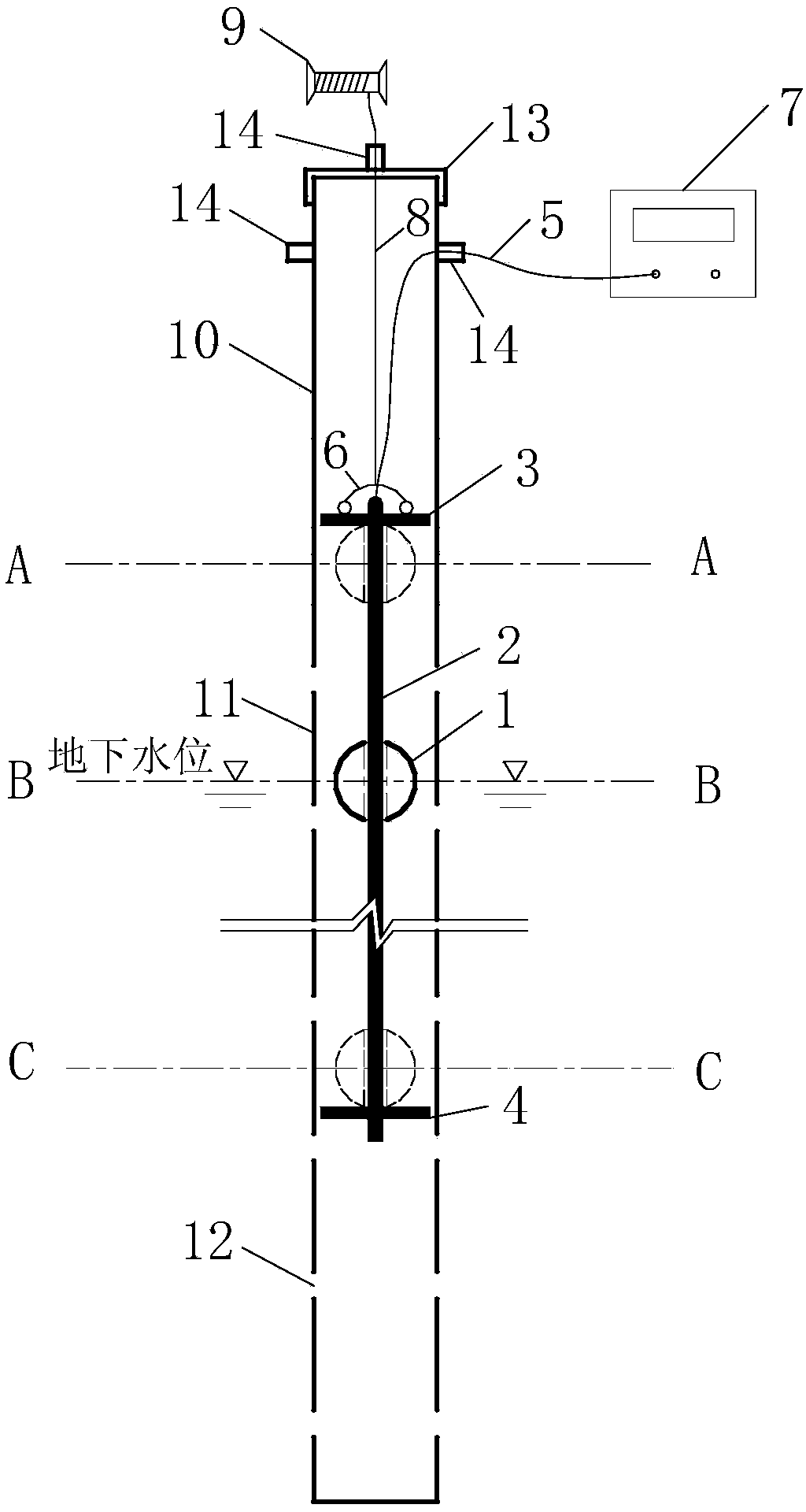

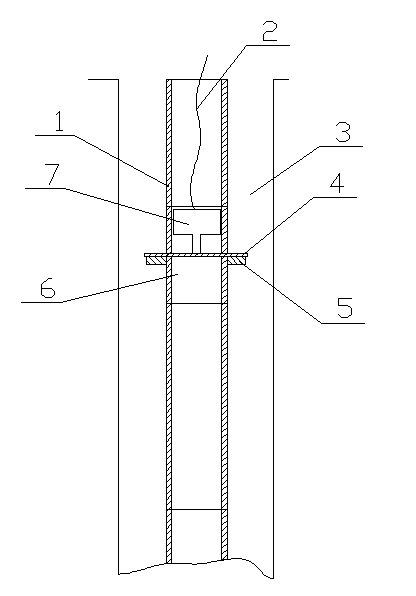

Device and setting method for measuring underground water level of vacuum drainage prepressing sealing membrane

InactiveCN103868569AEasy to measureRealize automatic measurementLevel indicators by floatsWater tableEngineering

The invention discloses a device and setting method for measuring the underground water level of a vacuum drainage prepressing sealing membrane. The device is composed of water level sighting tubes embedded in drill holes. A stainless steel guide rod for displacement of a magnetic floating ball is arranged in an airtight water level pipe, a reed pipe-resistance sensing component is arranged in an inner cavity of the stainless steel guide rod, a data line is led out through a sealing screw structure on the top of the stainless steel guide rod, a fixing and limiting flange is arranged at the top end of the stainless steel guide rod, and a lower end limiter is arranged at the lower end of the stainless steel guide rod. A sealing top cover and a line outgoing device are arranged at the top end of the airtight water level pipe. The data line is connected with a liquidometer electrical signal receiving and reading instrument through the line outgoing device. A liquidometer is fixed in the manner that a steel wire rope passes through a suspension point and penetrates through the sealing top cover, and the liquidometer is connected with a steel wire rope concentrator. The lower portion of the airtight water level pipe is sleeved with a perforated pipe with pores, and the airtight water level pipe is covered with non-woven geotechnical cloth. A vacuum meter is communicated with the interior of the airtight water level pipe through a vacuum meter plastic guide pipe. The device is easy to install and measure and capable of carrying out automatic measuring and measuring the actual underground water level in soft soil under the vacuum effect, and basic data can be more reliable.

Owner:NANJING HYDRAULIC RES INST

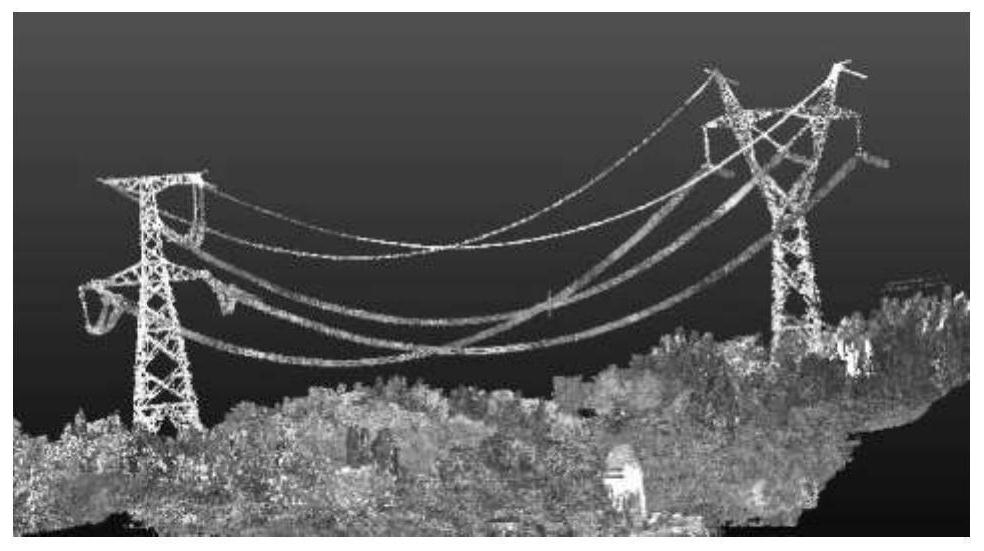

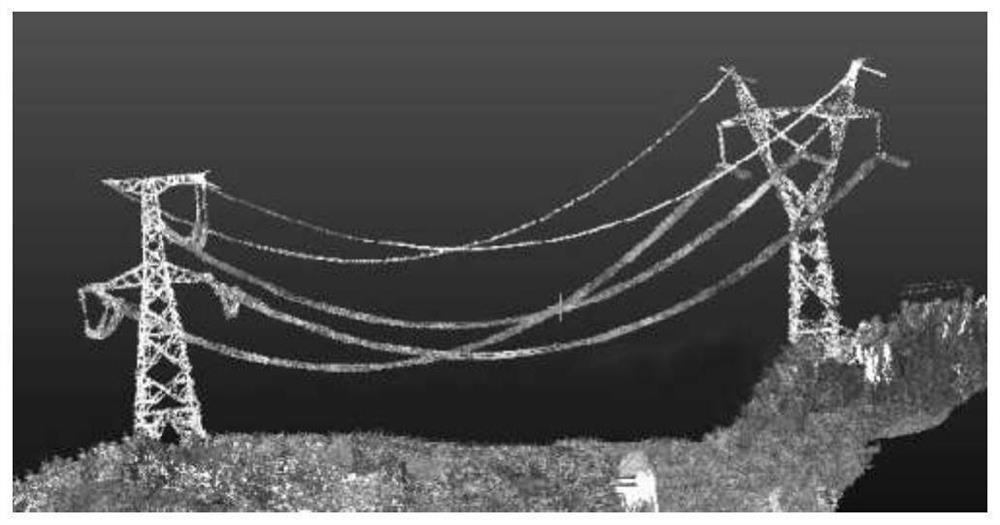

Laser-point-cloud-based tower characteristic point automatic identification and inclination parameter automatic measurement method

PendingCN111830528ARealize automatic identificationRealize automatic measurementImage enhancementImage analysisPoint cloudDigital surface

The invention discloses a laser-point-cloud-based tower characteristic point automatic identification and inclination parameter automatic measurement method. The method comprises the following steps:preprocessing acquired original point cloud data; then, extracting towers from the processed point cloud data by adopting a normalized digital surface model, a maximum between-cluster variance method,connected domain segmentation and point cloud density segmentation, and finally, obtaining the inclination angle of the towers through a horizontal section method, thereby realizing laser point cloud-based tower feature point automatic identification and inclination parameter automatic measurement. According to the invention, automatic identification and inclination measurement can be carried outon the towers, so that manpower and material resources are greatly saved; and the method has important research significance for stable operation of a power system.

Owner:XI AN JIAOTONG UNIV

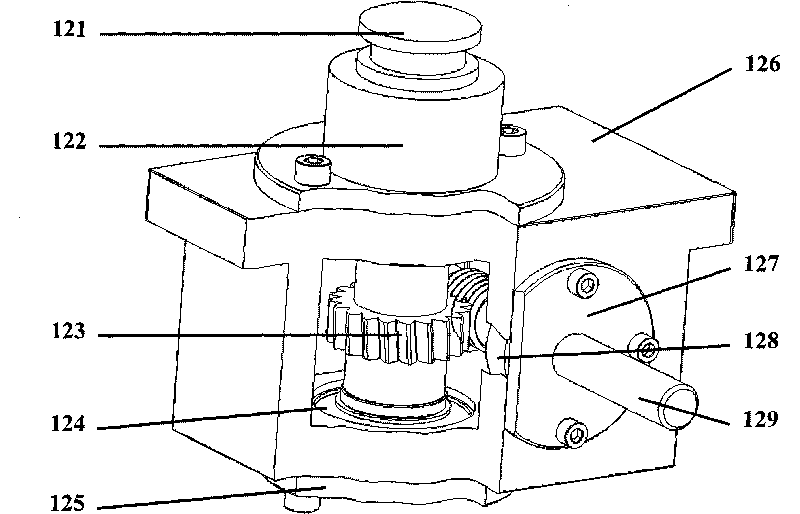

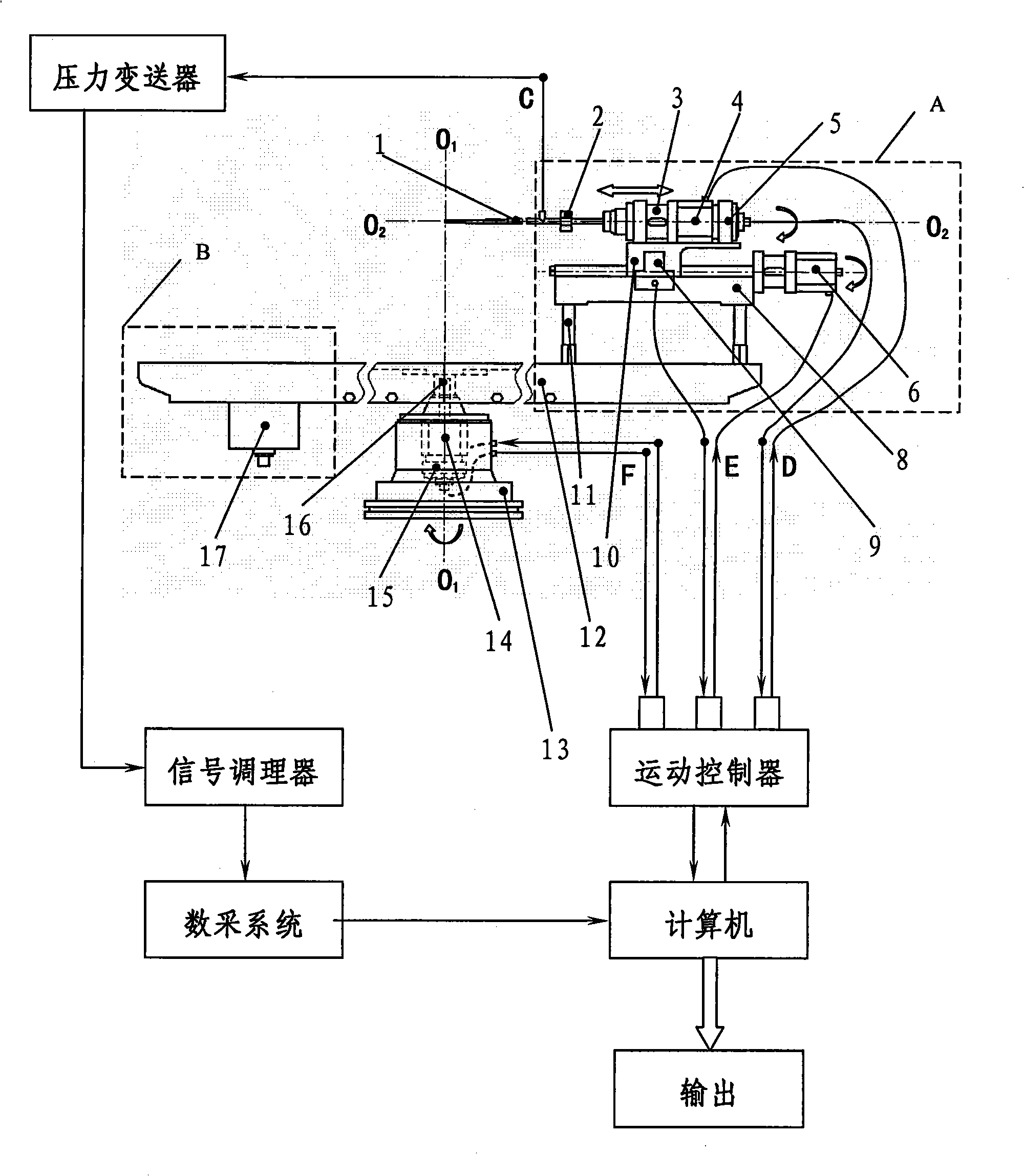

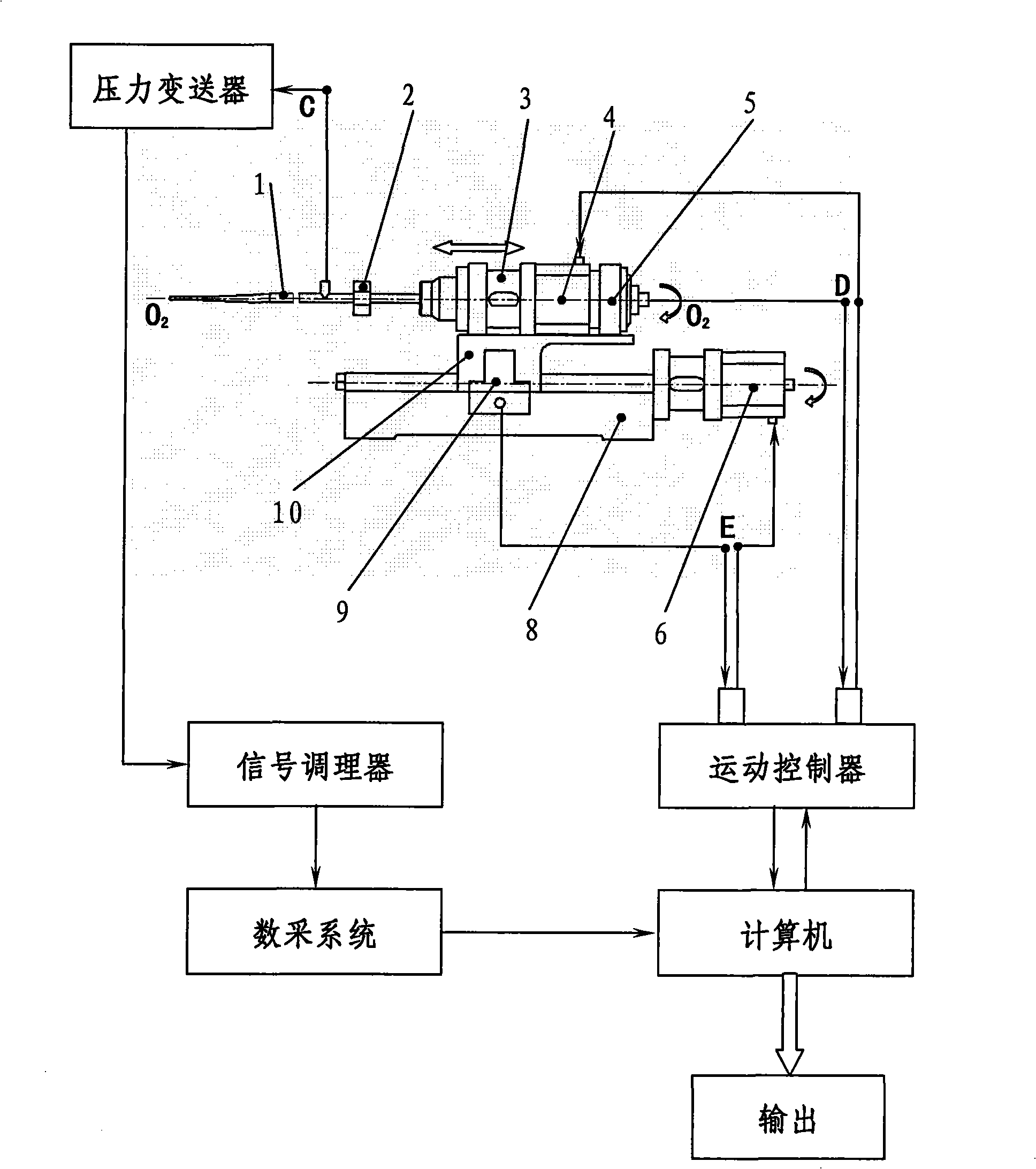

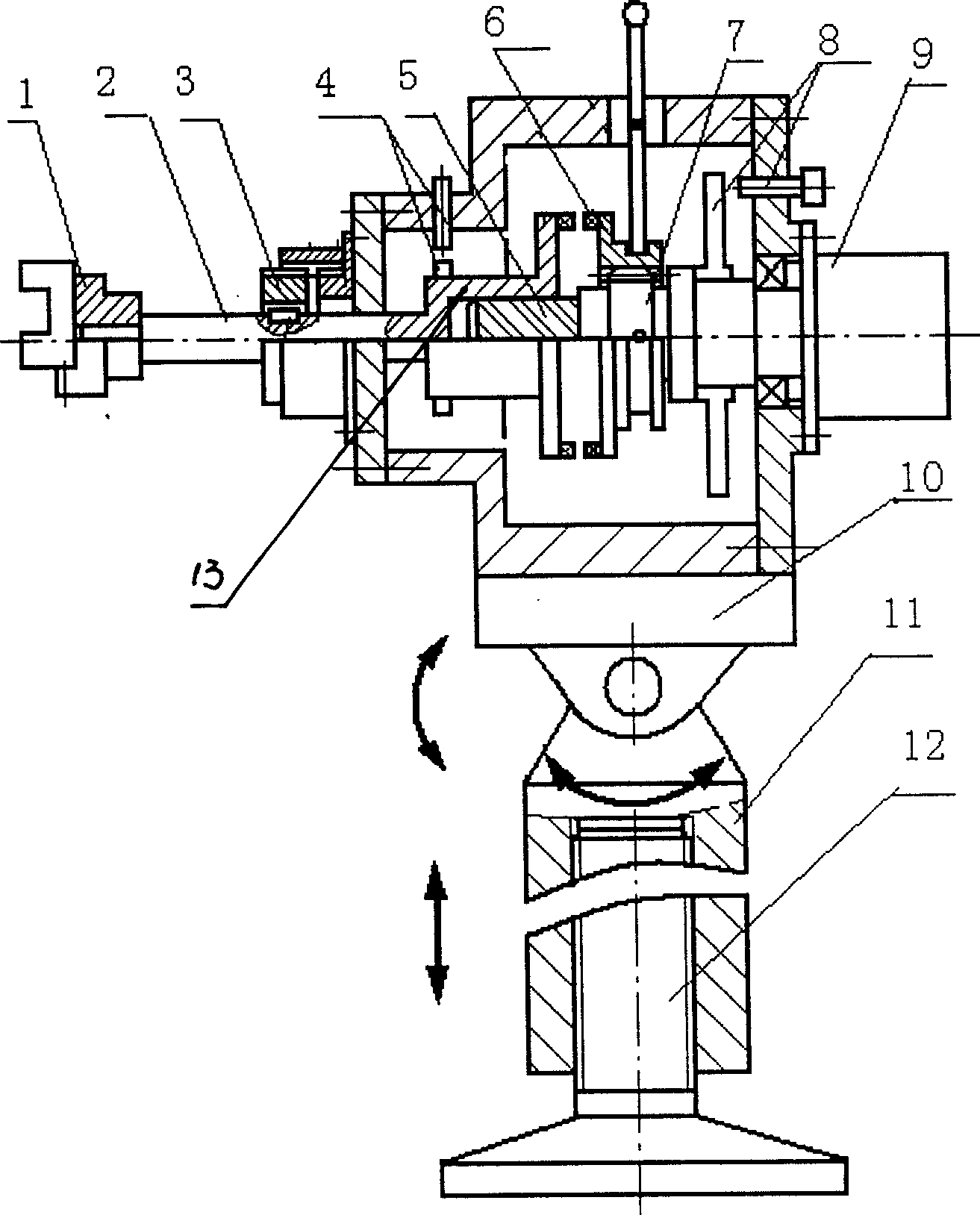

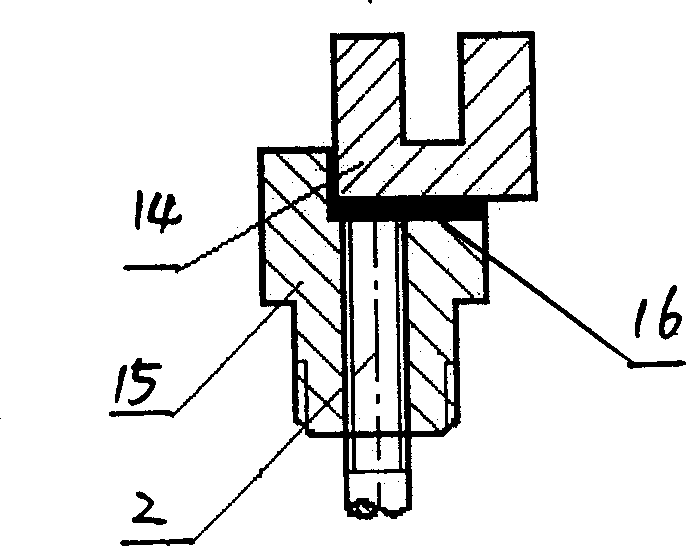

Automatic calibration and automatic measurement device of fluid flow test probe

InactiveCN101329218AAccelerateSave manpower and timeHydrodynamic testingElectric machineryElectrical control

The invention discloses an automatic calibration and measuring device of a fluid flowing test probe, which comprises a mechanical part and an electric control part, and can finish the following three actions that control the motion of the probe: the probe can realize topping rotation around a horizontal shaft O2-O2 by a probe topping angle adjusting mechanism with a first numerical control electric motor; the probe can realize translation motion along the horizontal shaft O2-O2 by a probe translation motion adjusting mechanism with a second numerical control electric motor; the probe can realize skew rotation around a vertical shaft O1-O1 by a probe skew angle adjusting mechanism with a third numerical control electric motor. According to a motion feedback signal, three numerical control electric motors are coordinated under control of a computer, and a data collecting system is combined so as to automatically finish the calibration and measurement jobs of the fluid test probe. Compared with the tests with manual operation, the automatic calibration and measuring device of the fluid flowing test probe improves testing precision and saves time and labor power.

Owner:XI AN JIAOTONG UNIV

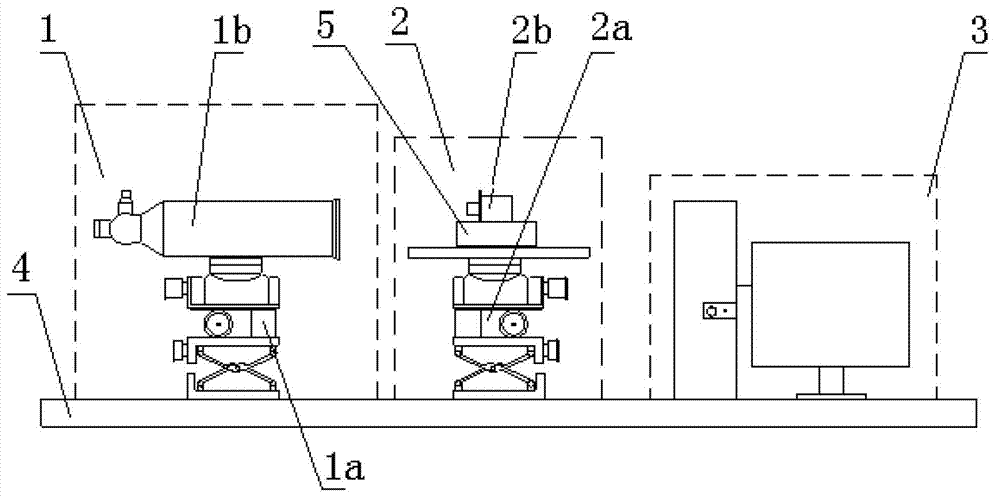

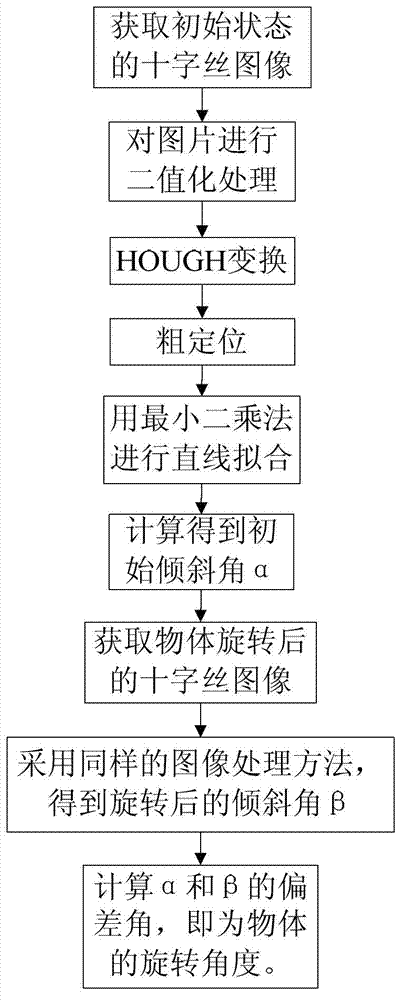

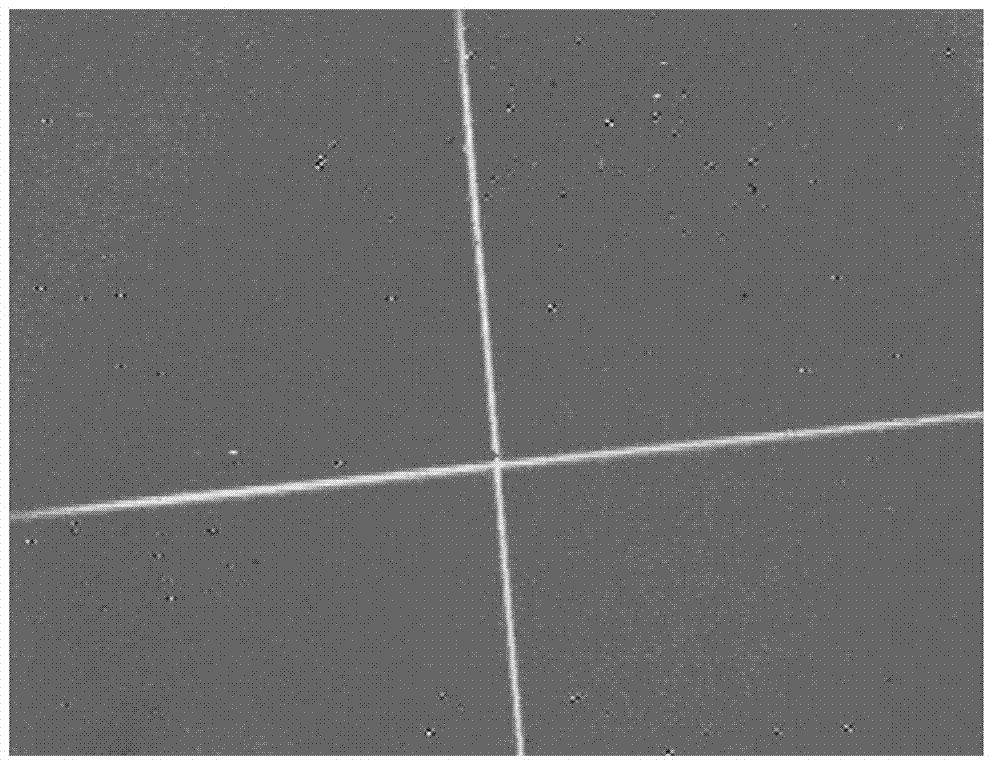

Object rotating angle measurement system and measurement method

ActiveCN103206927ARealize automatic measurementEasy to operateUsing optical meansInformation processingImaging processing

The invention provides an object rotating angle measurement system and an object rotating angle measurement method. The system comprises an angle datum instrument, a rotating angle measurement instrument and an angle information processing device, wherein the angle datum instrument comprises an adjustable base and parallel light tubes arranged on the adjustable base, and the parallel light tubes can emit bright cross wires in a parallel light form; the rotating angle measurement instrument comprises an adjustable measurement platform and a visible light digital camera; and the angle information processing device comprises a data acquisition module, an image processing module and an image display module. The measurement method comprises the following steps of: installing the visible light digital camera on a measured object, putting the measured object on the adjustable measurement platform, picking up an initial angle image by the visible light digital camera, and receiving and processing the initial angle image by an angle information processing system to obtain a cross wire inclination angle alpha in an initial state; likewise, obtaining a rotated cross wire inclination angle beta; and calculating the difference of the previous and later inclination angles by the angle information processing system, thus obtaining the rotating angle value of the measured object.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

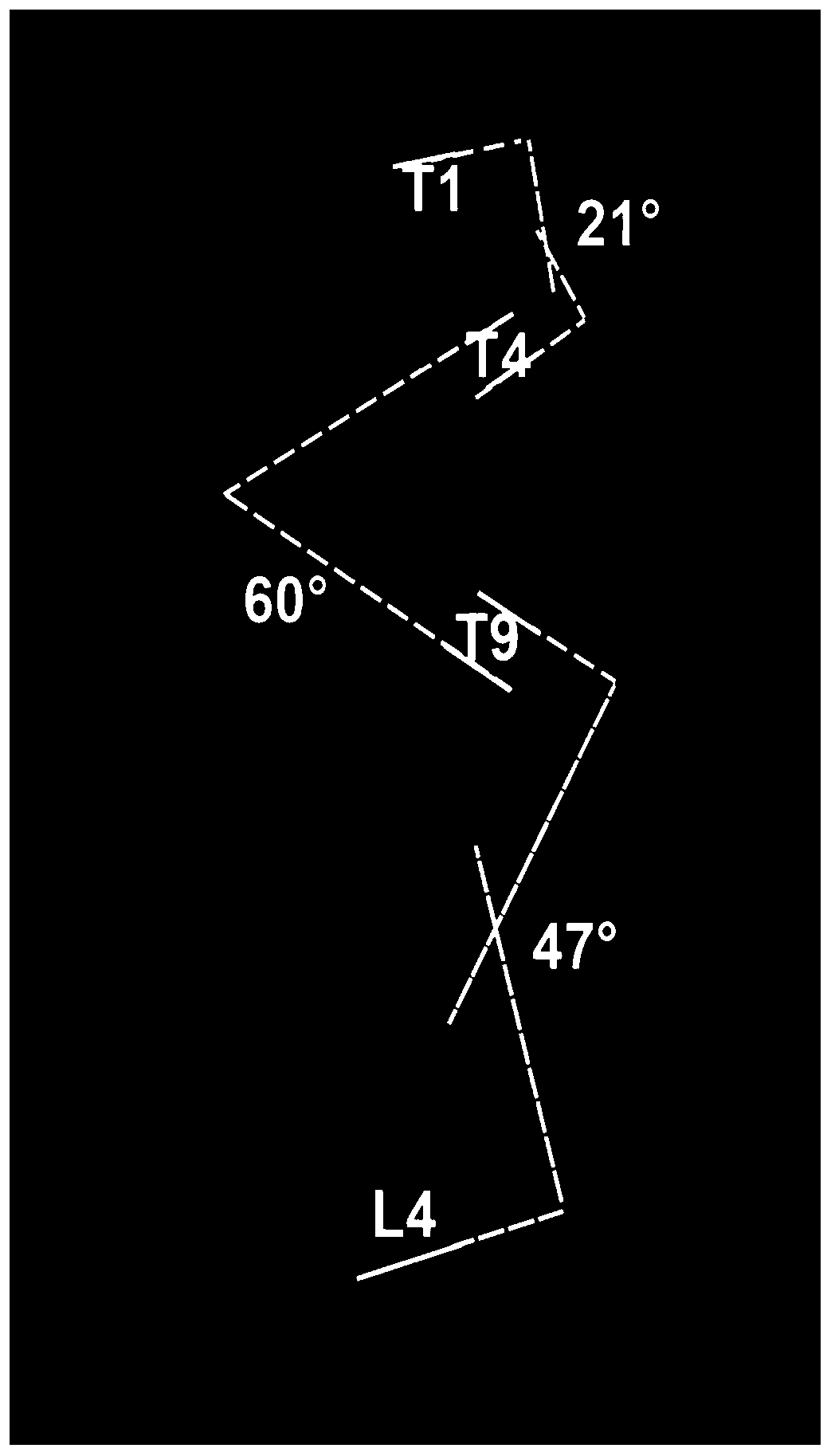

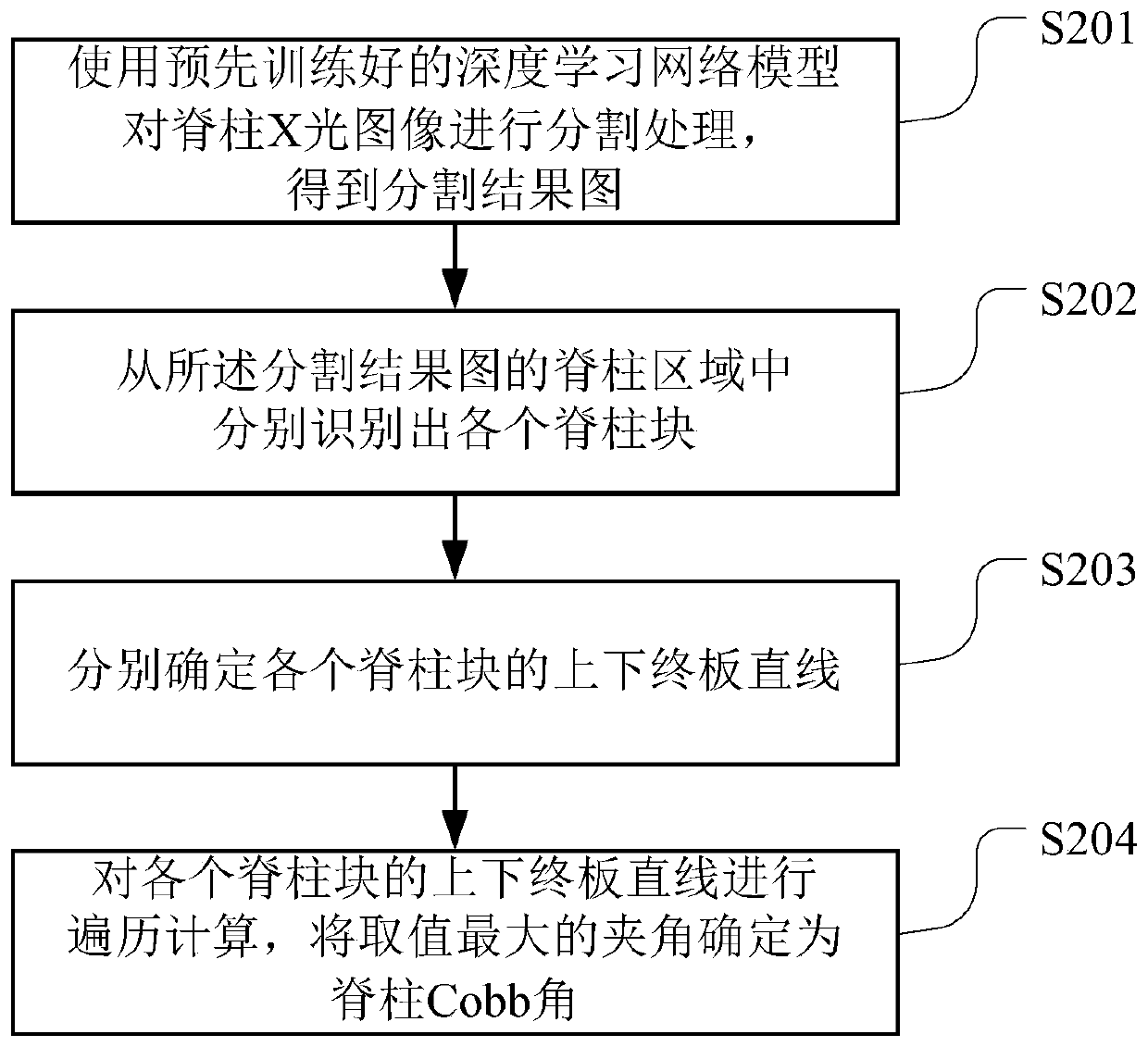

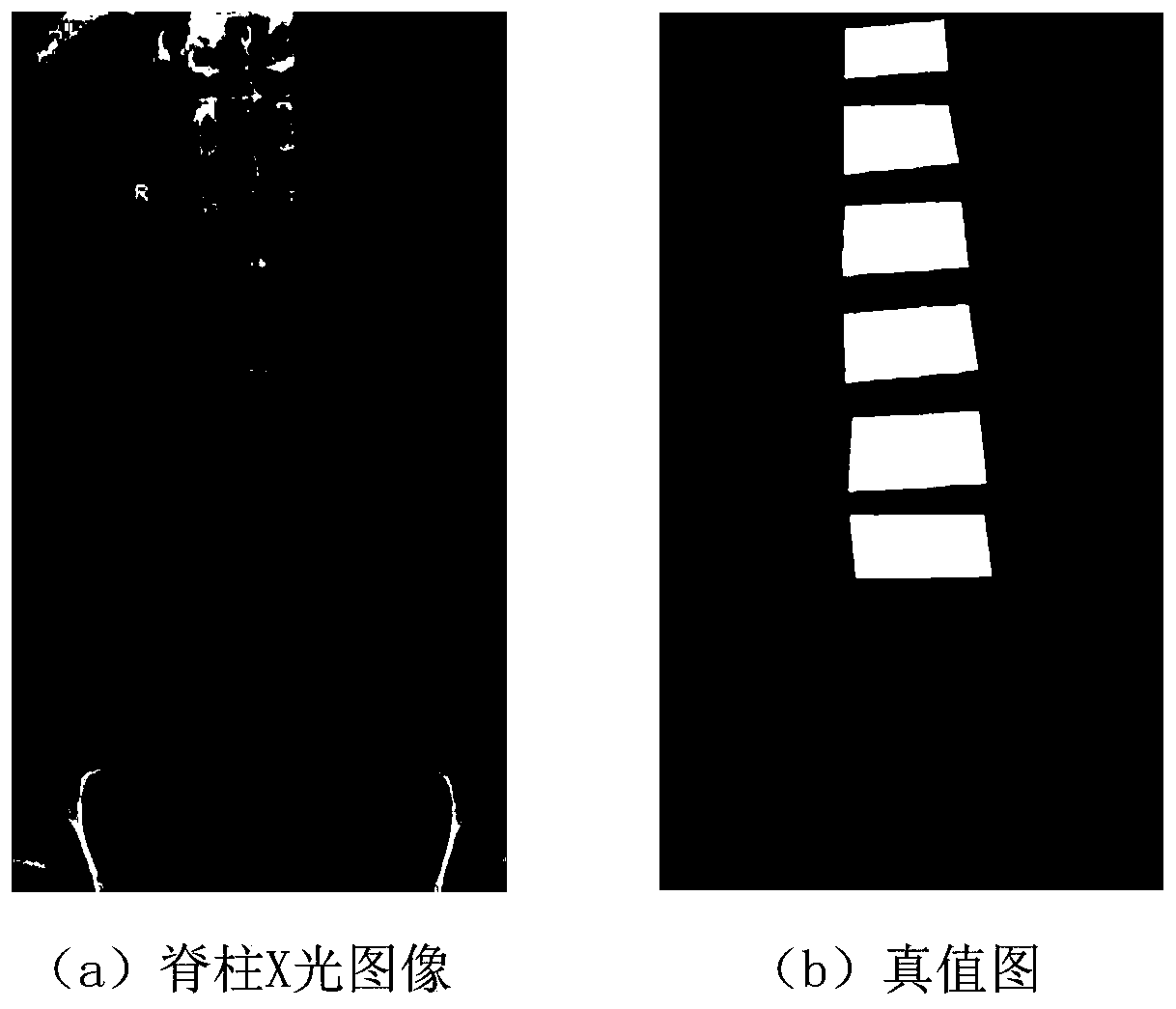

Spine Cobb angle measurement method and device, readable storage medium and terminal equipment

InactiveCN110175502AImprove reliabilityRealize automatic measurementAngles/taper measurementsImage analysisImaging analysisTerminal equipment

The invention belongs to the technical field of image analysis, and particularly relates to a spine Cobb angle measurement method and device, a computer readable storage medium and terminal equipment.The method comprises the steps of using a pre-trained deep learning network model for carrying out segmentation processing on a spine X-ray image to acquire a segmentation result image, wherein the segmentation result image is a binary image of a spine area and a non-spine area; respectively identifying each spine block from the spine area of the segmentation result map; determining upper and lower end plate straight lines of each spine block; traversing calculation is conducted on the upper end plate straight line and the lower end plate straight line of each spine block, wherein the included angle with the maximum value is determined as the spine Cobb angle. According to the embodiment of the invention, automatic measurement of the spine Cobb angle is truly realized, the required spineCobb angle can be obtained without additional operation of a worker, errors caused by manual or semi-manual measurement of the spine Cobb angle are avoided, and better reliability is achieved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Measuring method for monitoring soil mass layered settlement

ActiveCN103362114AEasy to measureImprove monitoring accuracyIn situ soil foundationPhysicsFiber Bragg grating

The invention provides a measuring method for monitoring soil mass layered settlement. A measuring hole is drilled in a foundation; then, the bottom of the measuring hole is backfilled with cement mortar; a settling pipe is placed in the middle of the measuring hole, and the bottom end of the settling pipe is inserted in the cement mortar; the distance between an outer circle of a settling ring and the wall of the measuring hole is larger than 2cm; then, a fiber bragg grating optical cable is used for connecting a fiber bragg grating displacement meter with a fiber bragg grating demodulation instrument; a gap between the measuring hole and the settling pipe is backfilled slowly, and the soil mass layered settlement can be measured after the gap is filled up; in the process of soil mass settlement, the settling ring on a settlement measuring pipe settles along with soil mass and pulls a pull rod on the lower portion of the fiber bragg grating displacement meter through a cross bar, therefore, a settlement signal is transmitted to the fiber bragg grating demodulation instrument through the fiber bragg grating optical cable, and the accurate value of the soil mass settlement is measured through the fiber bragg grating demodulation instrument.

Owner:深圳市城安物联科技有限公司

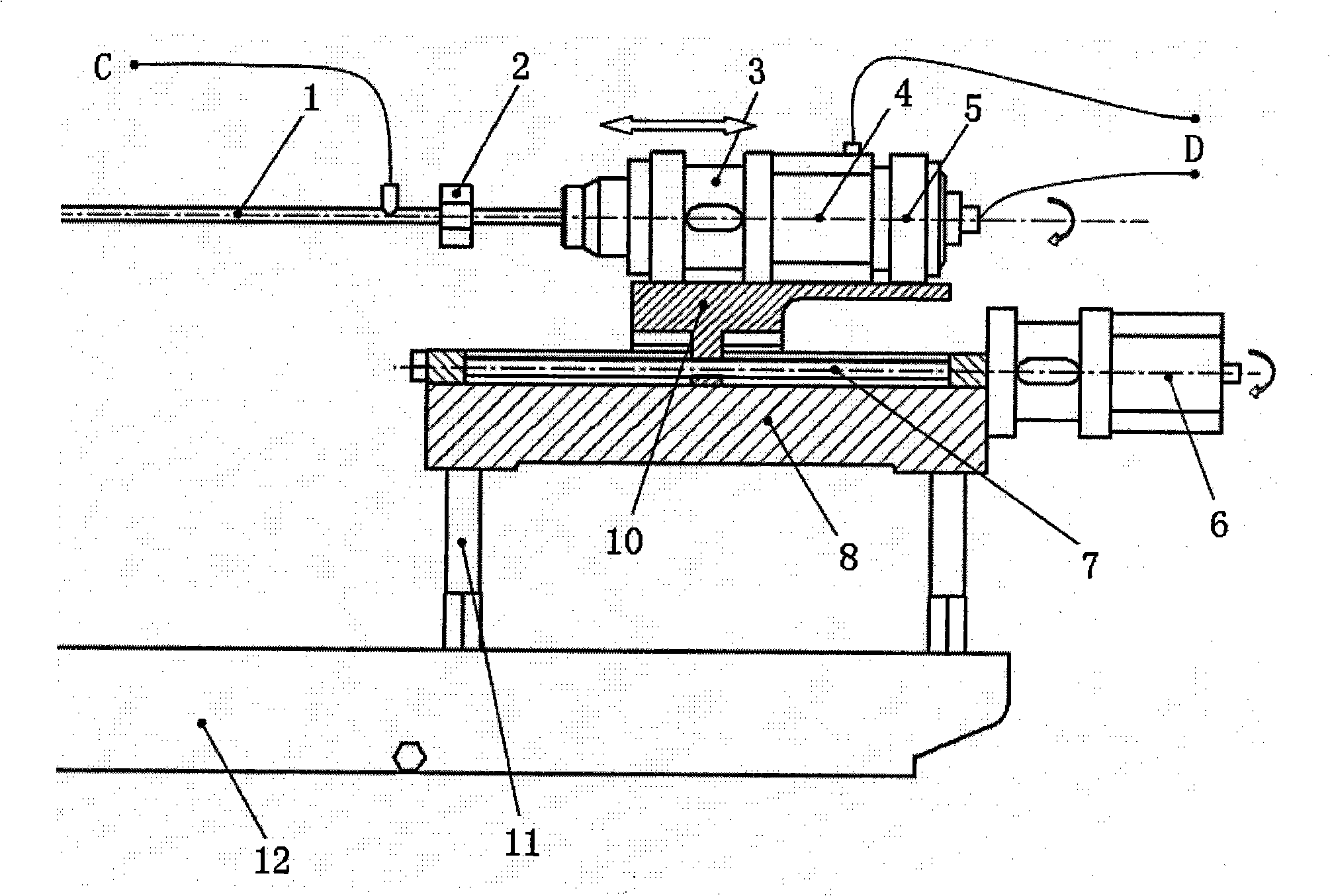

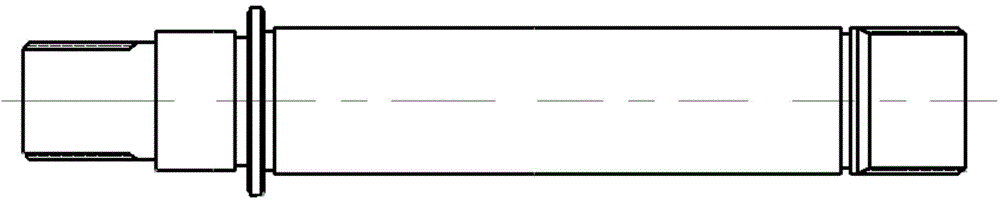

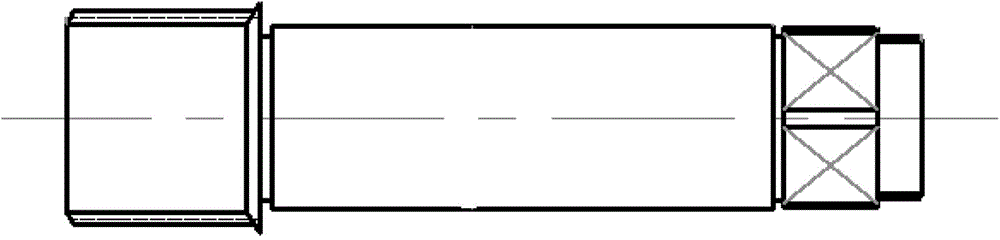

Transmission measuring device for dimension measurement of shaft parts

InactiveCN104165593AHigh precisionReduce manual labor intensityUsing optical meansMachine visionMeasurement device

Owner:HUAZHONG UNIV OF SCI & TECH

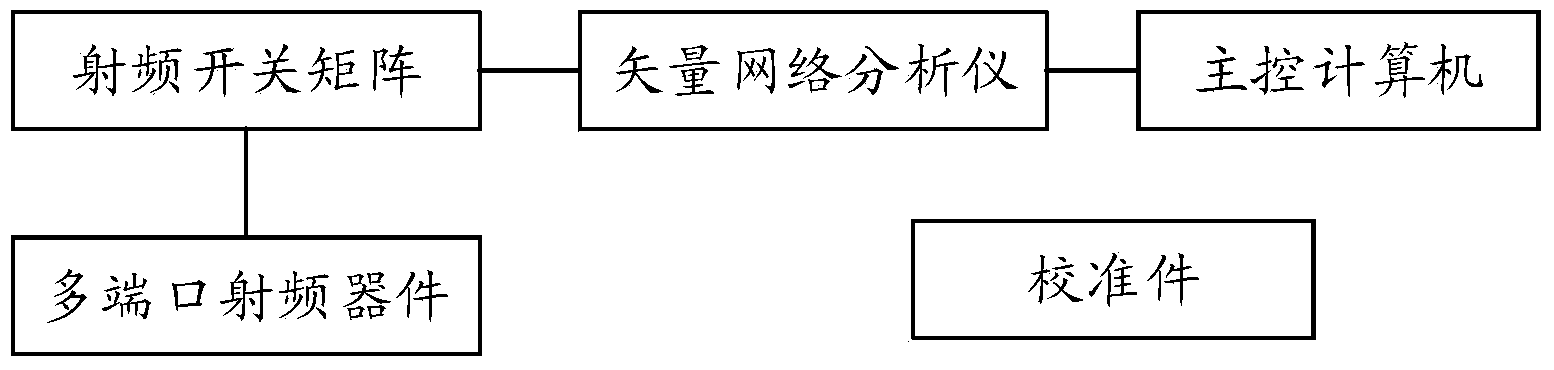

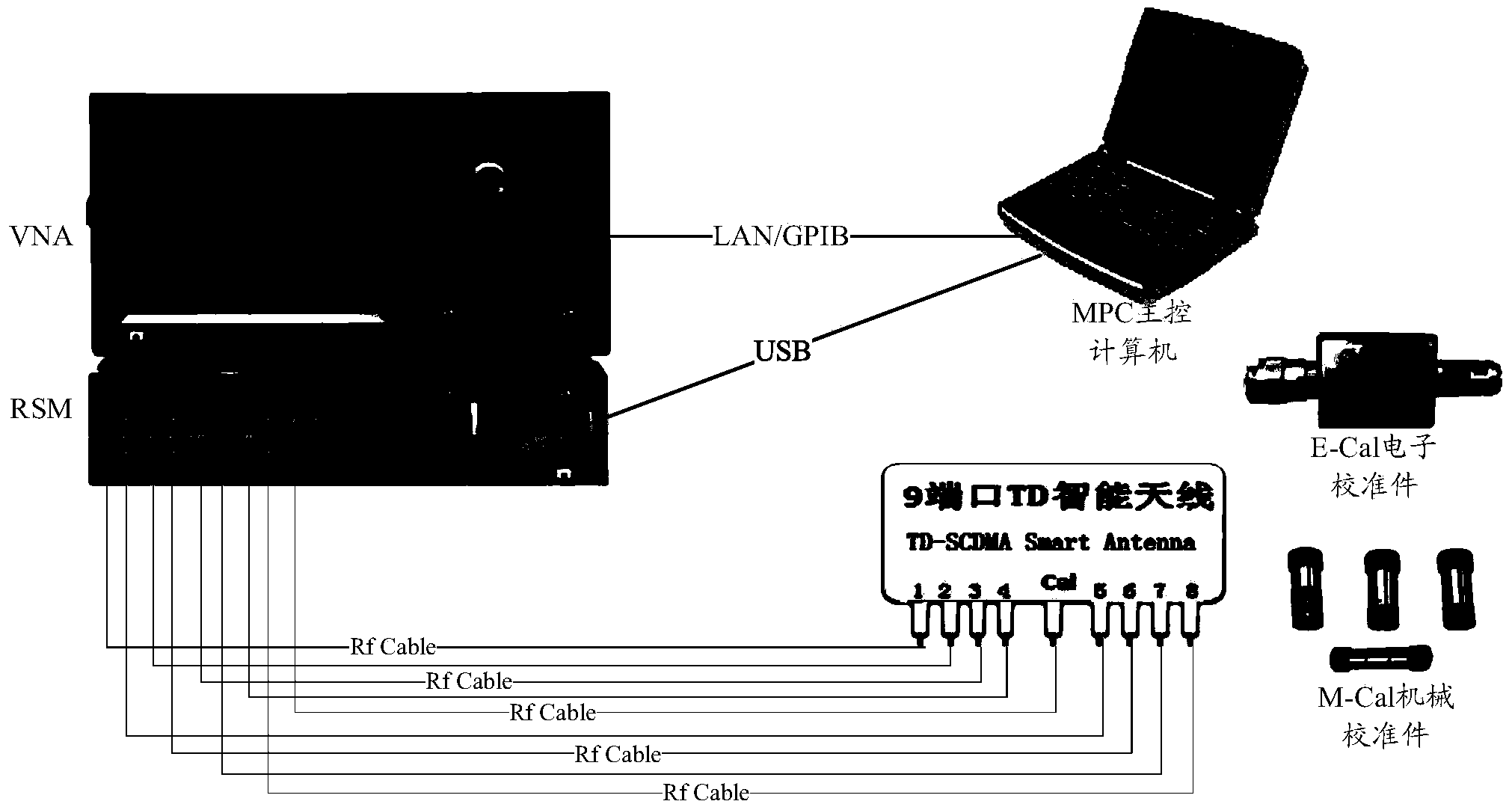

System and method for achieving multi-port radio frequency device measuring based on radio frequency switch matrix

InactiveCN103716104AReduce labor costsShorten test timeTransmitters monitoringReceivers monitoringMulti portRadio frequency

The invention relates to a system and method for achieving multi-port radio frequency device measuring based on a radio frequency switch matrix. The system comprises vector network analyzers, the radio frequency switch matrix and a main control computer. The vector network analyzers are used for measuring a multi-port radio frequency device. The radio frequency switch matrix is used for being connected with the vector network analyzers and the multi-port radio frequency device. The main control computer is used for controlling the vector network analyzers to measure the multi-port radio frequency device automatically. According to the system and method for achieving multi-port radio frequency device measuring based on the radio frequency switch matrix, automatic measuring of the multi-port radio frequency device is achieved based on the radio frequency switch matrix and the two port vector network analyzers, a measured piece is connected at one time, measuring of all S-parameter port indexes of the measured piece is automatically completed, no technical requirements for testing personnel exist, labor cost is lowered, testing time is shortened manifold, labor intensity is lowered, production efficiency is improved, and the wide application range is achieved.

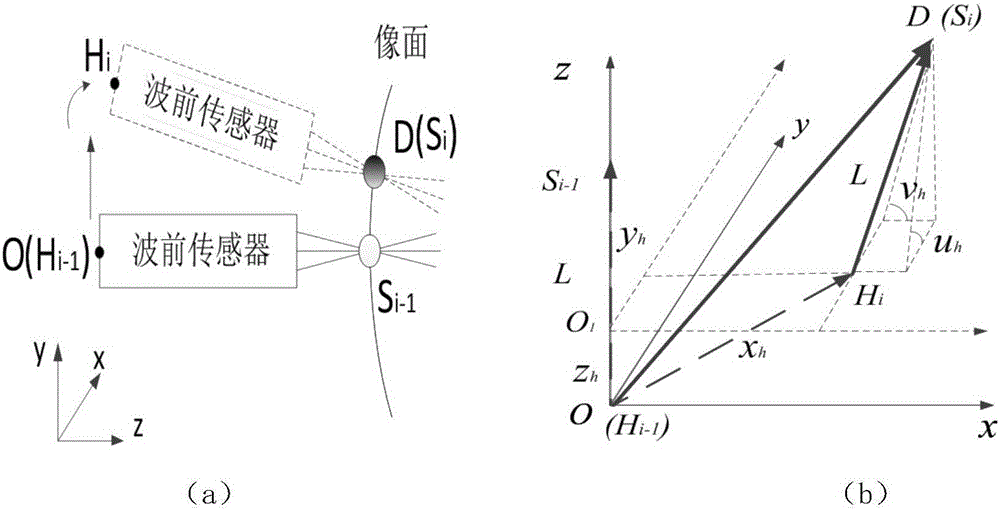

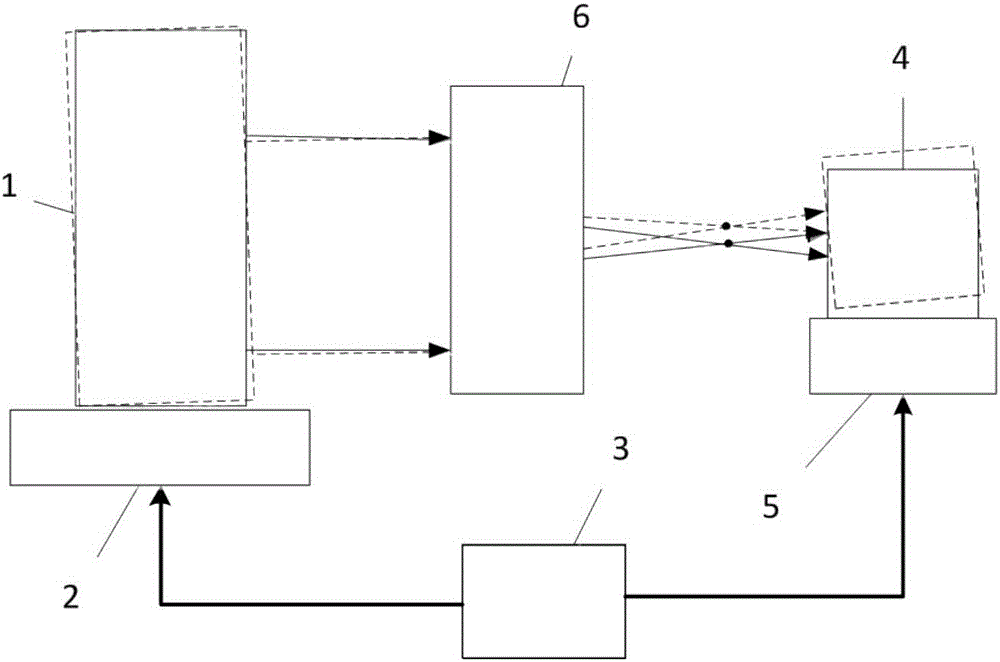

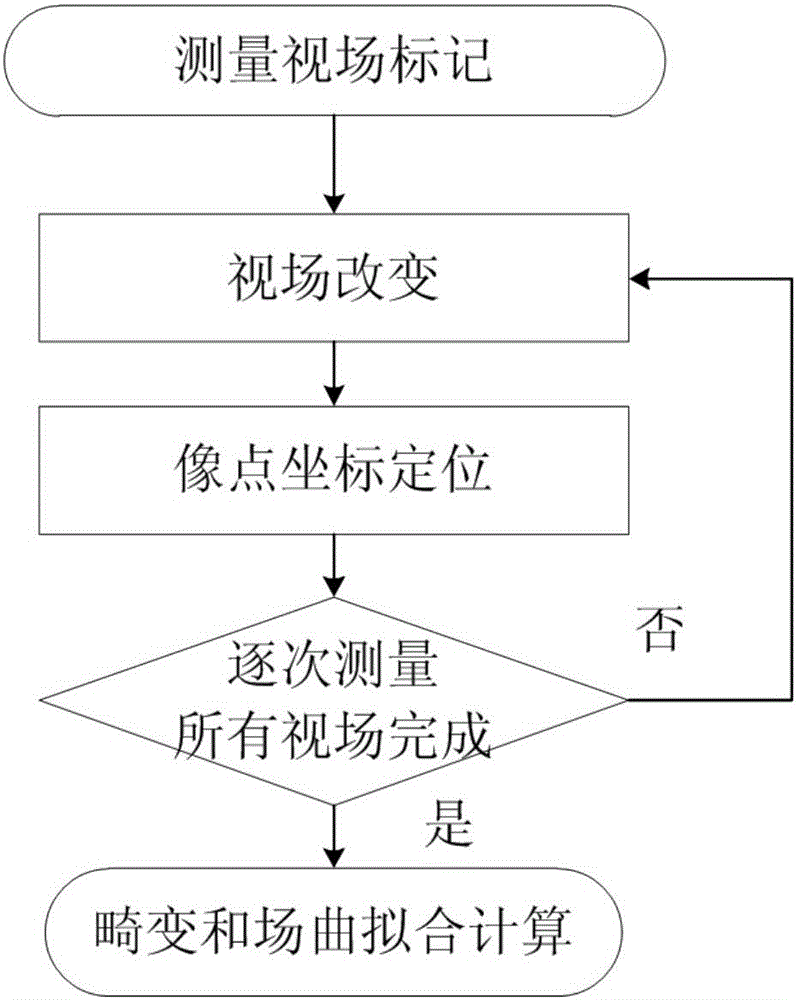

Method for measuring large field-of-view telescope optical system distortion and field curvature

ActiveCN106404352AOvercome operabilityOvercome precisionGeometric properties/aberration measurementWavefrontClosed loop

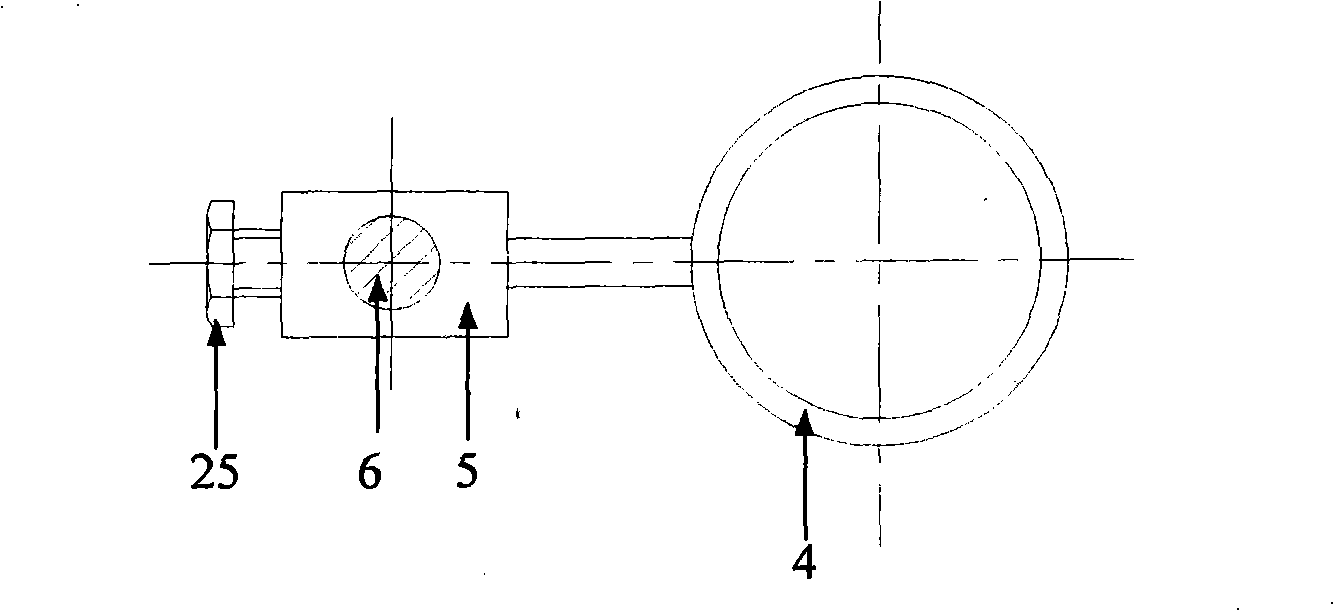

The invention relates to a method for measuring large field-of-view telescope optical system distortion and field curvature. According to the invention, parallel light sources (1) come directly into a to-be-detected large field-of-view telescope (6). The field of view can be changed through the adjustment of the inclination and the pitching attitude of the parallel light sources (1). In the process of full field of view measurement, the to-be-detected large field-of-view telescope (6) remains to be in a fixed state. A computer (3), a wavefront detector (4) and the motion platform (5) of the wavefront detector form a closed-loop positioning structure to precisely measure and position the spatial positions of the image points of the to-be-detected large field-of-view telescope. Through the comparison of the ideal positions of the image points, the distortion and field curvature of the to-be-detected large field-of-view telescope (6) optical system can be obtained through fitting. The measuring method of the invention can be operated simply and effectively and achieves high measurement efficiency. Further, the method can perform automatic checking and can provide reliable measurement data for large field-of-view telescope optical system to correct distortion and field curvature.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

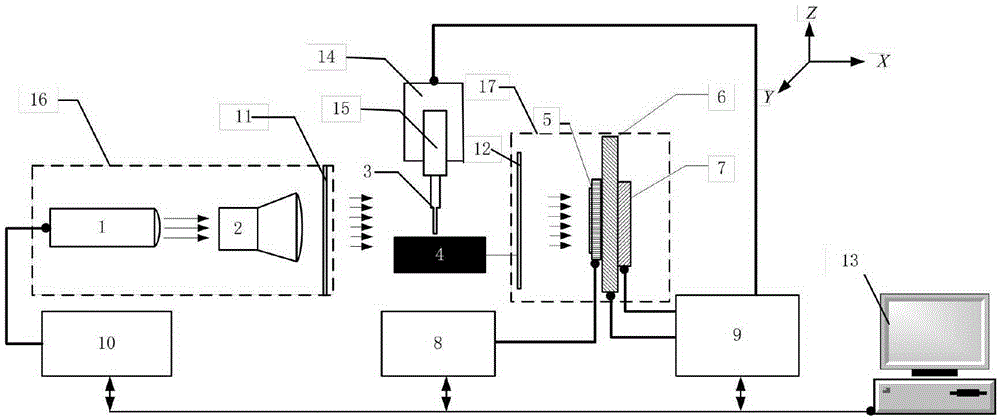

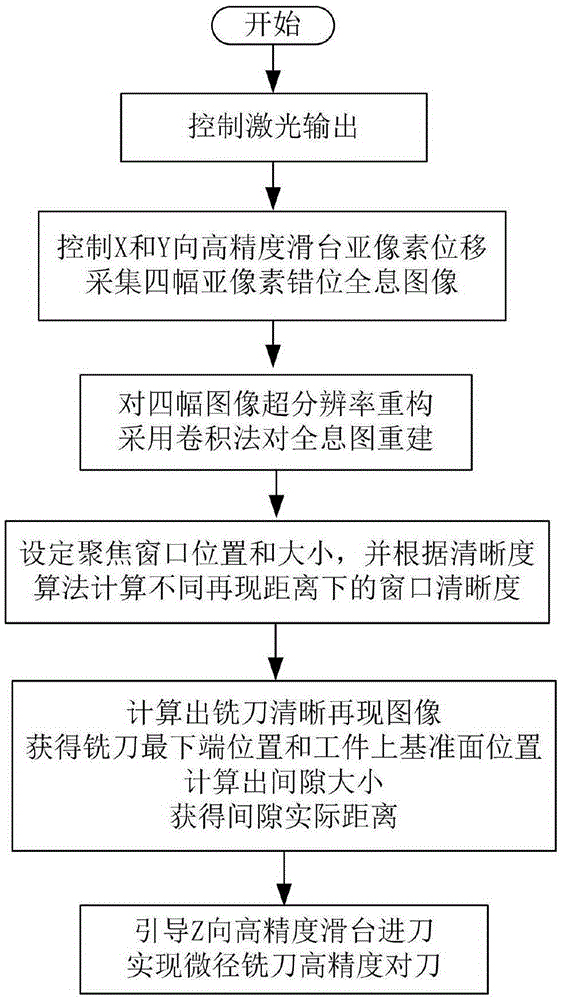

High-precision tool setting device and tool setting method of micro-diameter milling tool

ActiveCN105345595ARealize automatic measurementAvoid errorsAutomatic control devicesMeasurement/indication equipmentsNumerical controlMilling cutter

The invention discloses a high-precision tool setting device and tool setting method of a micro-diameter milling tool, and belongs to the technical field of mechanical automation. The device comprises a laser device, the micro-diameter milling tool, an electric spindle, a CCD chip, an X-direction high-precision sliding table, a Y-direction high-precision sliding table, a Z-direction high-precision sliding table, an image signal processing unit, a motor control unit, a laser device control unit and a computer master control unit. Z-direction high-precision tool setting of the micro-diameter milling tool at any position in the XY plane is achieved, and the laser coaxial holographic imaging technology and the super-resolution image reconstruction technology are utilized for achieving automatic measuring of a tool setting gap, so that the error caused by deformation generated by the contact between the milling tool and a workpiece during traditional try cutting is prevented, and meanwhile, the field depth error caused by the fact that the milling tool and the workpiece are not located in the same image imaging face is avoided. The device is low in cost, easy to operate, capable of being mounted in a distributed manner within the limited work space, and suitable for high-precision tool setting of a micro milling tool, a common milling tool and a numerical control milling tool.

Owner:CHANGCHUN UNIV OF SCI & TECH

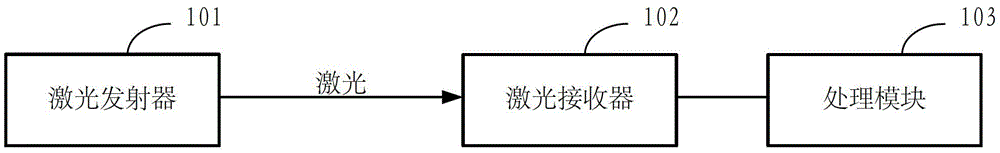

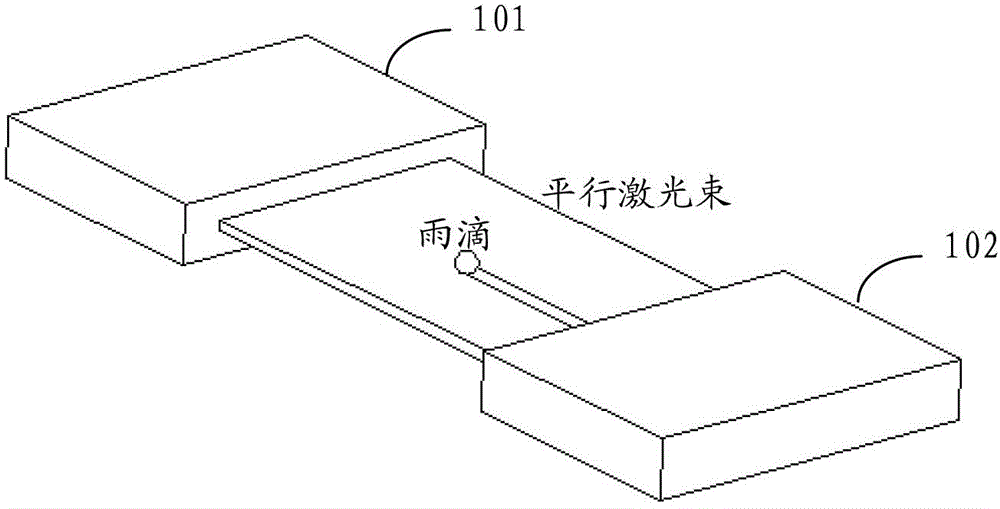

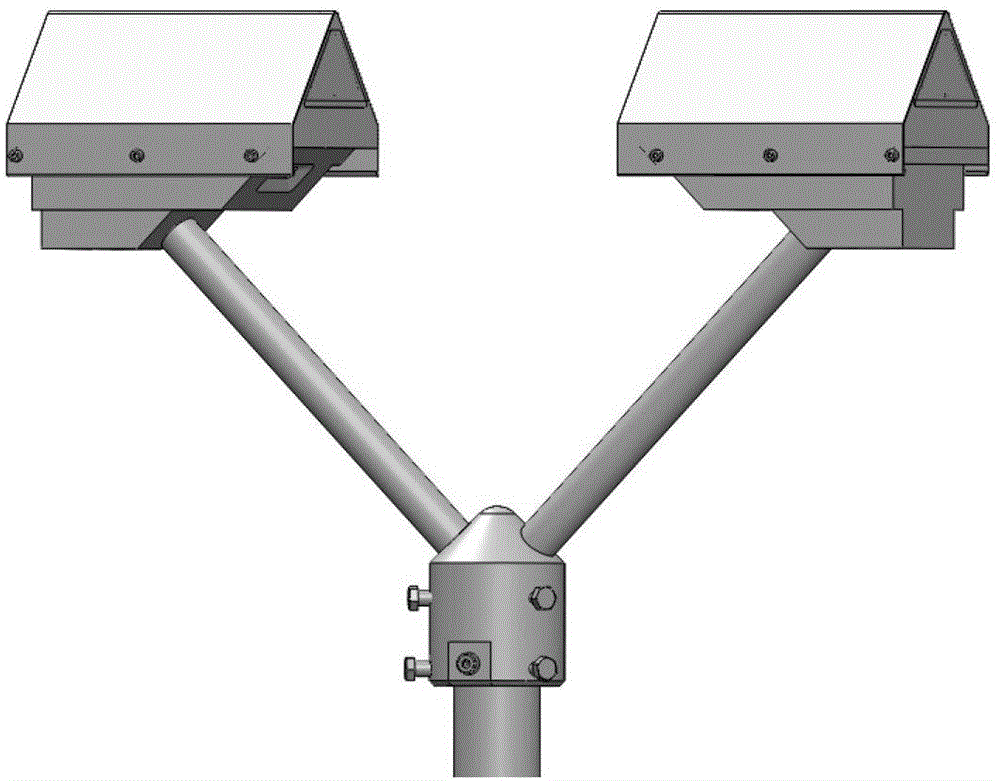

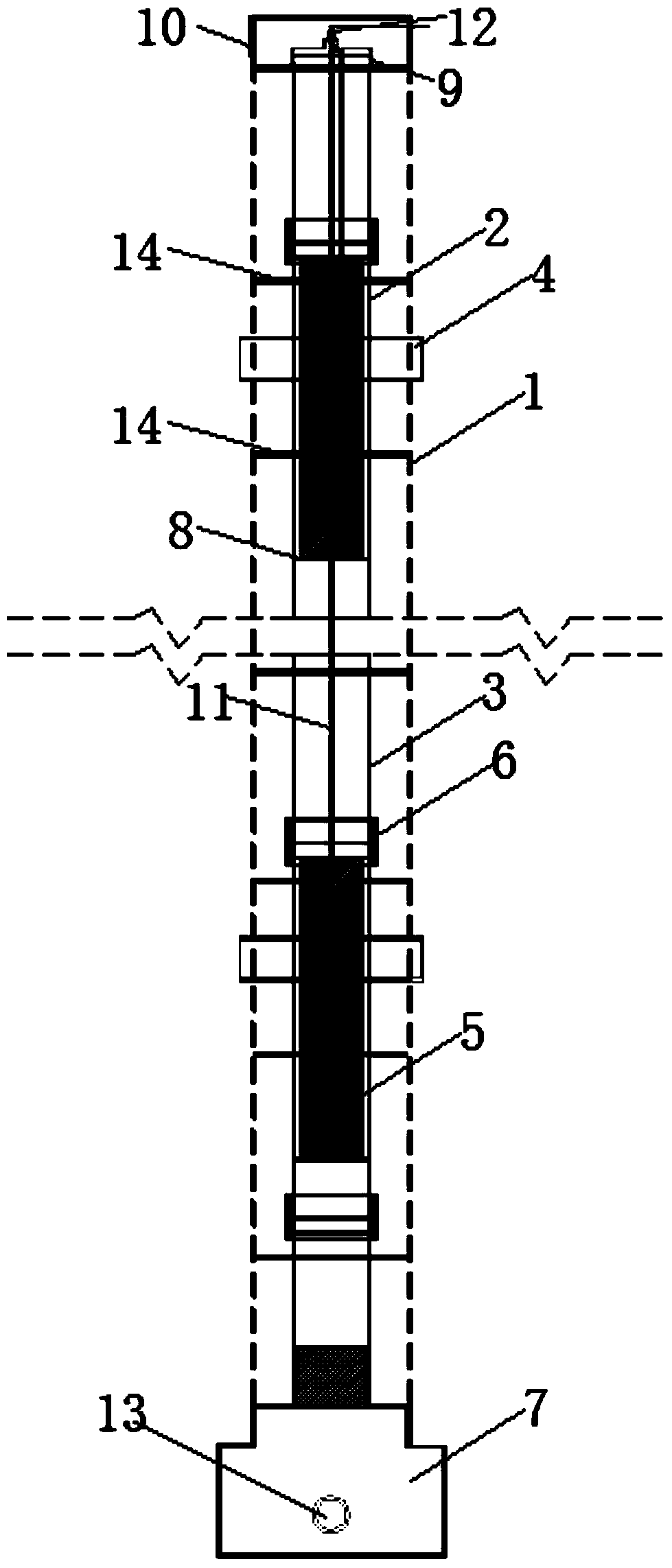

Laser raindrop spectrograph

ActiveCN103149605ARealize automatic measurementReduce manual involvementRainfall/precipitation gaugesLaser transmitterSpectrograph

The invention provides a laser raindrop spectrograph, which comprises a laser transmitter, a laser receiver and a processing module. A distance is preset between the laser transmitter and the laser receiver; the laser transmitter is used for emitting laser; and the laser receiver is used for receiving the laser which is emitted by the laser transmitter, performs photovoltaic conversion on the received laser, and then sends a converted electric signal to the processing module; the processing module is used for judging whether a descend range of the intensity of the laser received by the laser receiver, in comparison with standard intensity, is greater than a preset amplitude or not according to the received electric signal, if so, the diameter of raindrops is computed according to the received electric signal, the size of the laser which is received by the laser transmitter and the standard intensity; and the standard intensity is the intensity of the laser which is received by the laser receiver when a barrier does not exist between the laser transmitter and the laser receiver. The automatic measurement of a rain drop spectrum is realized by the laser, manual intervention is reduced and measuring efficiency is improved.

Owner:BEIJING METABTAR RADAR

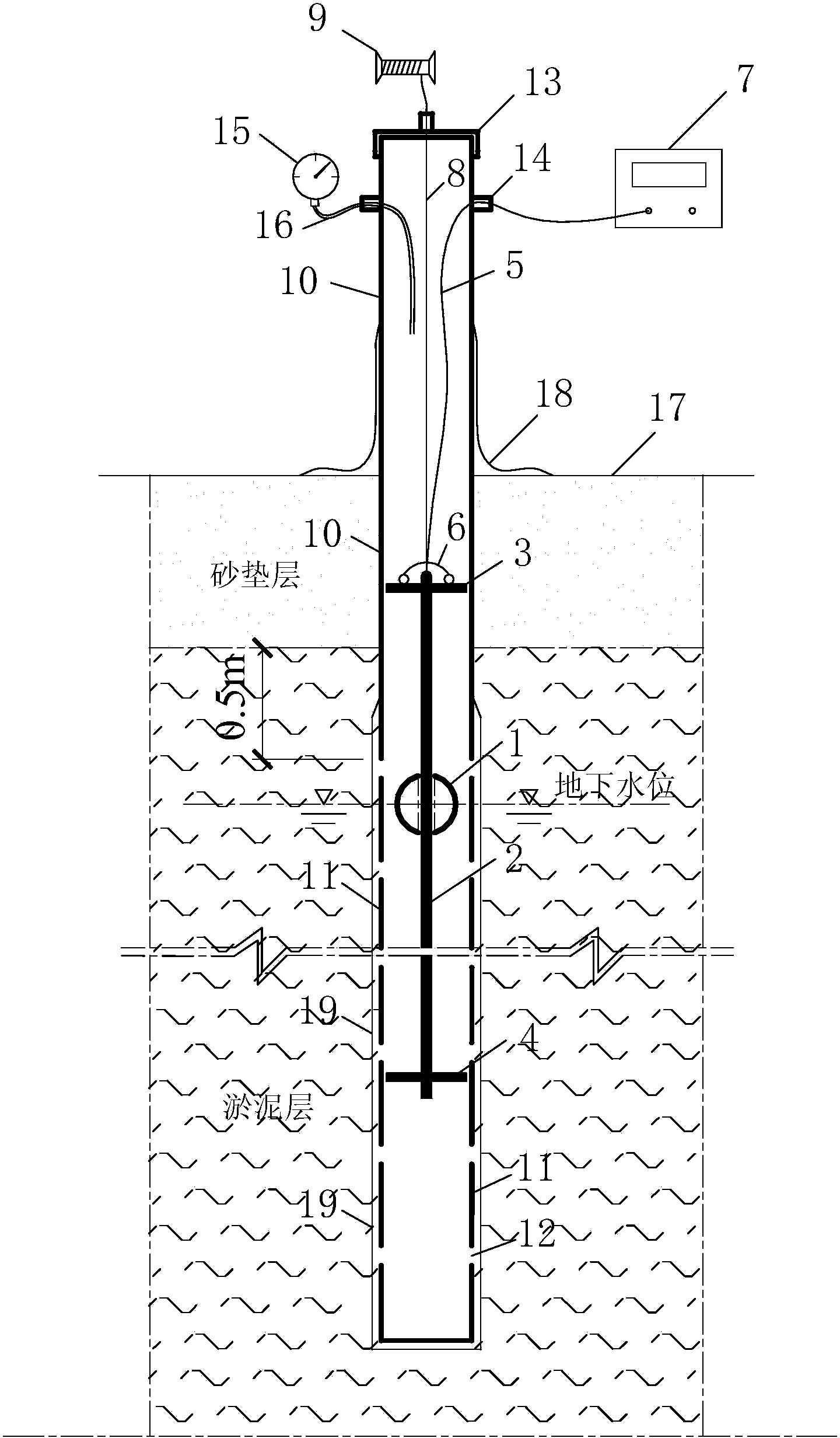

Equipment for measuring layered settlement of deep soft soil or blanket and setup method thereof

ActiveCN103953025ARealize automatic measurementEasy to installIn situ soil foundationElectrical resistance and conductanceEngineering

The invention discloses a kind of equipment for measuring layered settlement of deep soft soil or a blanket and a setup method thereof. A settlement observation pipe is embedded in a drill hole; a guide rod is arranged in the settlement observation pipe; the equipment is characterized in that the guide rod is formed by the connection of a plurality of common guide rods and a stainless steel guide rod, wherein the stainless steel guide rod is adopted at the place wherein the layered settlement is to be measured; an anchoring head is mounted at the bottom of the guide rod; the anchoring head is in sealing connection with the guide rod; in the meantime, a section of the anchoring head is tightly connected with the settlement observation pipe; a guide rod sealing cap is mounted at the top of the guide rod; a line outgoing device is arranged on the sealing cap; a reed switch-resistance sensing element is arranged inside the stainless steel guide rod; data lines of the reed switch-resistance sensing element are collected to form a data cable before the line outgoing device at the top of the guide rod, and connected with an external electric signal receiving reading device through the leading of the line outgoing device; a magnetic ring is mounted in a sleeving manner at the place where the layered settlement is required to be measured out of the settlement observation pipe. The equipment for measuring the layered settlement of the deep soft soil or the blanket is simple in installation and measurement, and can realize automatic measurement.

Owner:NANJING HYDRAULIC RES INST +1

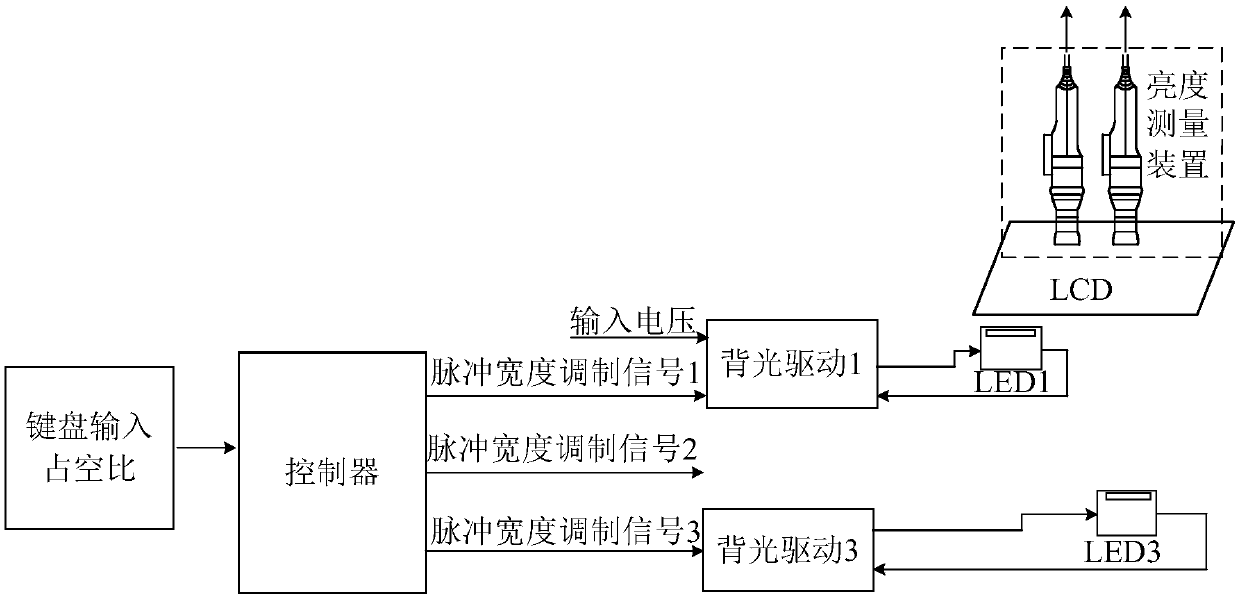

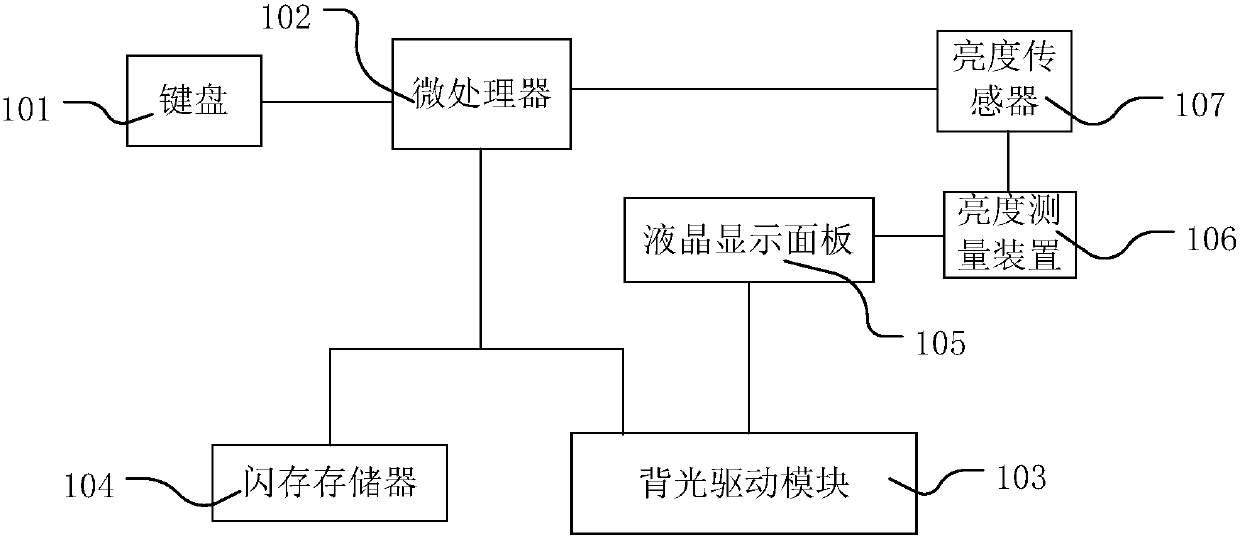

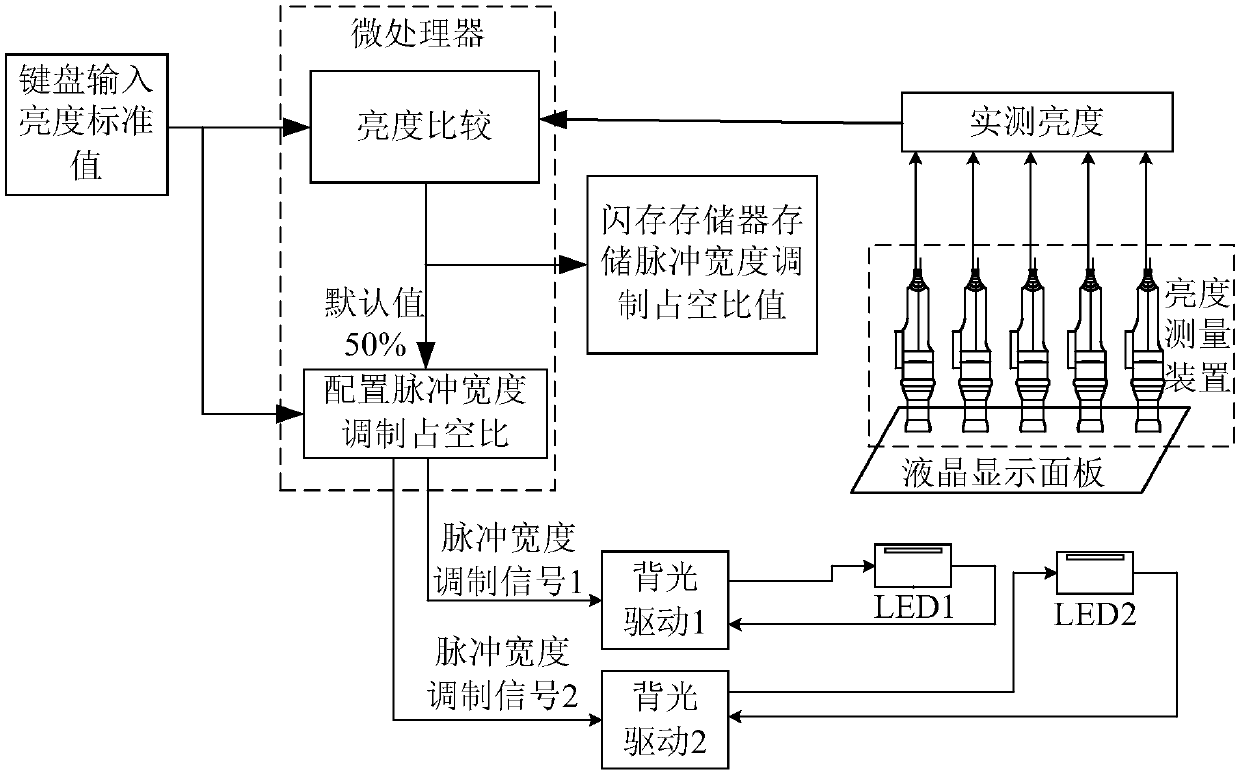

Backlight brightness adjustment method and device

InactiveCN107945745AFlexible disassemblyRealize automatic measurementStatic indicating devicesMeasurement deviceLiquid-crystal display

The application discloses a backlight brightness adjustment method including that a microprocessor calculates a PWM duty cycle initial value and outputs the PWM duty cycle initial value to a backlightdriving module; respective PWM duty cycle values are stored in a flash memory; a brightness measurement device measures the actual brightness of a liquid crystal display panel; the PWM duty cycle values are automatically increased step by step based on the initial value; the microprocessor reconfigures the backlight driving module; and the best brightness is displayed on the liquid crystal display panel. A backlight brightness adjustment device disclosed in the application includes a keyboard, a microprocessor that automatically increase the values of the duty cycles step by step based on theinitial value; a backlight driving module; a flash memory; a liquid crystal display panel; a brightness measurement device, and a brightness sensor. The backlight brightness adjustment method and device can automatically measure and adjust the brightness, select the optimal value of the PWM duty cycle, gradually form a brightness gradient from the middle to both sides of the liquid crystal display panel, and enhance a narrow viewing angle display effect.

Owner:KUSN INFOVISION OPTOELECTRONICS

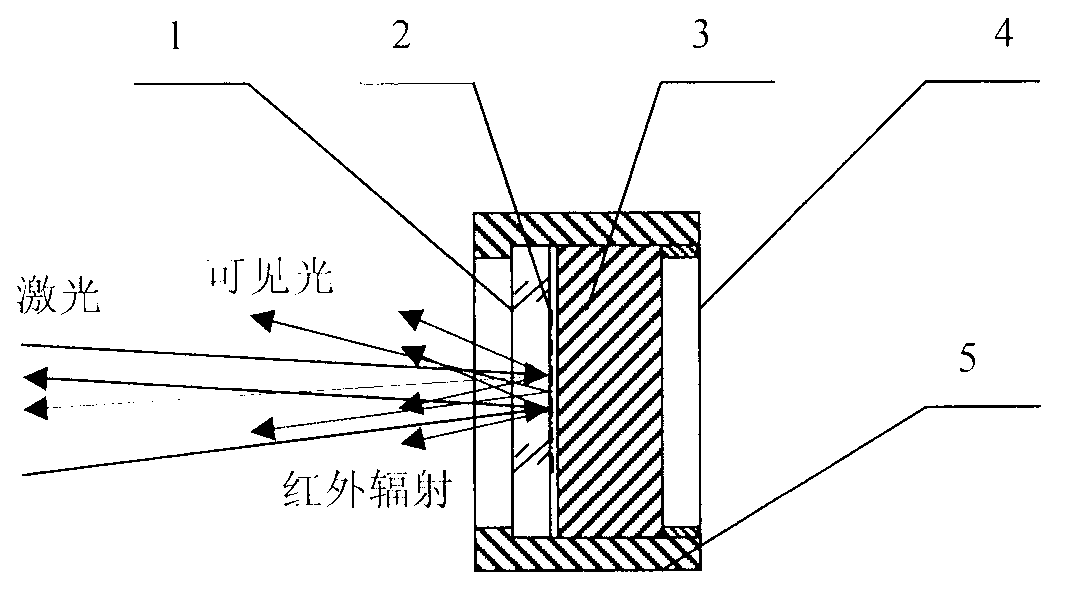

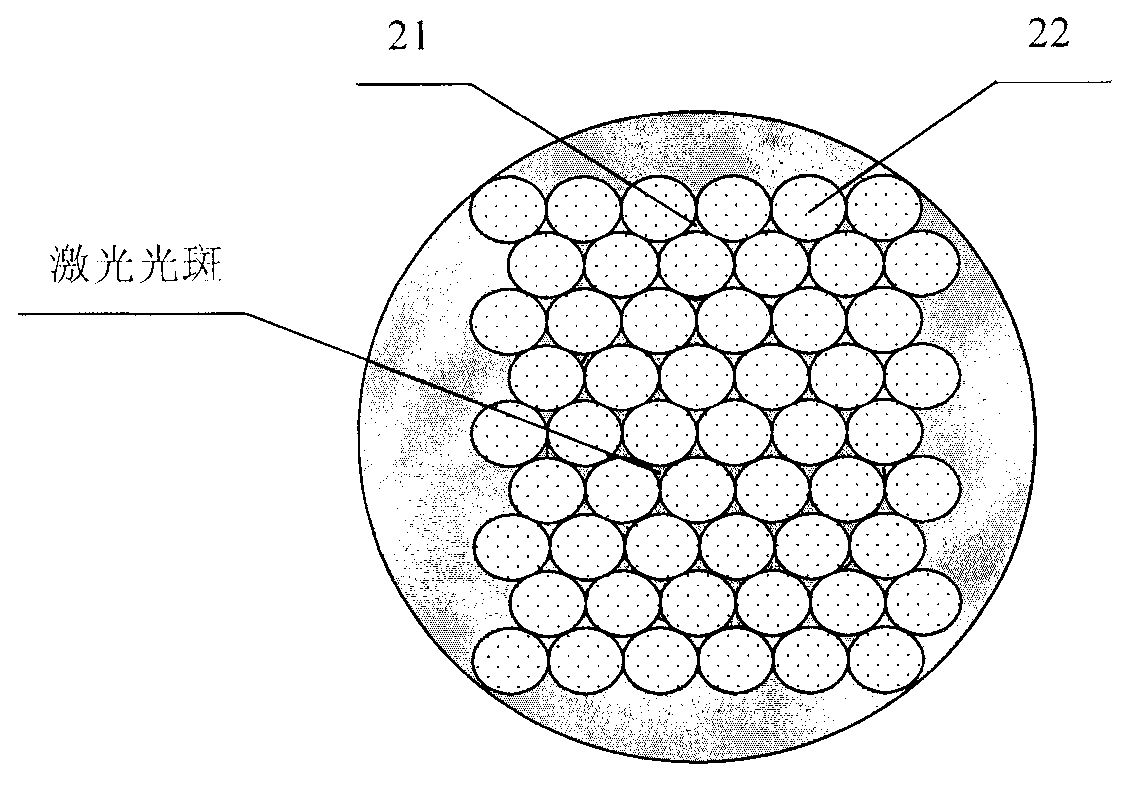

Standard comprehensive target board for rapid self-calibration of photoelectric system and measurement method for photoelectric system

ActiveCN103256862AFast conductionReduce dwell timeOptical apparatus testingTarget detectorsFar distanceMicro nano

The invention discloses a standard comprehensive target board for rapid self-calibration of a photoelectric system and a measurement method for the photoelectric system. The standard comprehensive target board is mainly technically characterized by comprising a base plate, a pattern, a substrate and a pressure ring. The base plate, the pattern, the substrate and the pressure ring are sequentially compressed and packaged in a housing. The pattern is formed by filling triangular through hole arrays which are etched a metal film and which are filled with micro-nano display powder. The standard comprehensive target board is placed in an optical system far field (a focal plane or far distance of a collimator) of the photoelectric system to be measured, the photoelectric system is aligned with the standard comprehensive target board to emit laser, the pattern of the standard comprehensive target board reflects a laser spot image and instantly radiate a visible-light and infrared laser spot image, the photoelectric system to be measured receives and stores the digital image, geometric center and linear length of a through hole and triangle complementary array in the digital image are calculated, and the geometric center and linear length are compared with theoretical values so that digital image correction function, resolution, radiation precision, tracking angular speed and tracking precision parameters of the photoelectric system are obtained.

Owner:中国兵器工业第二0五研究所

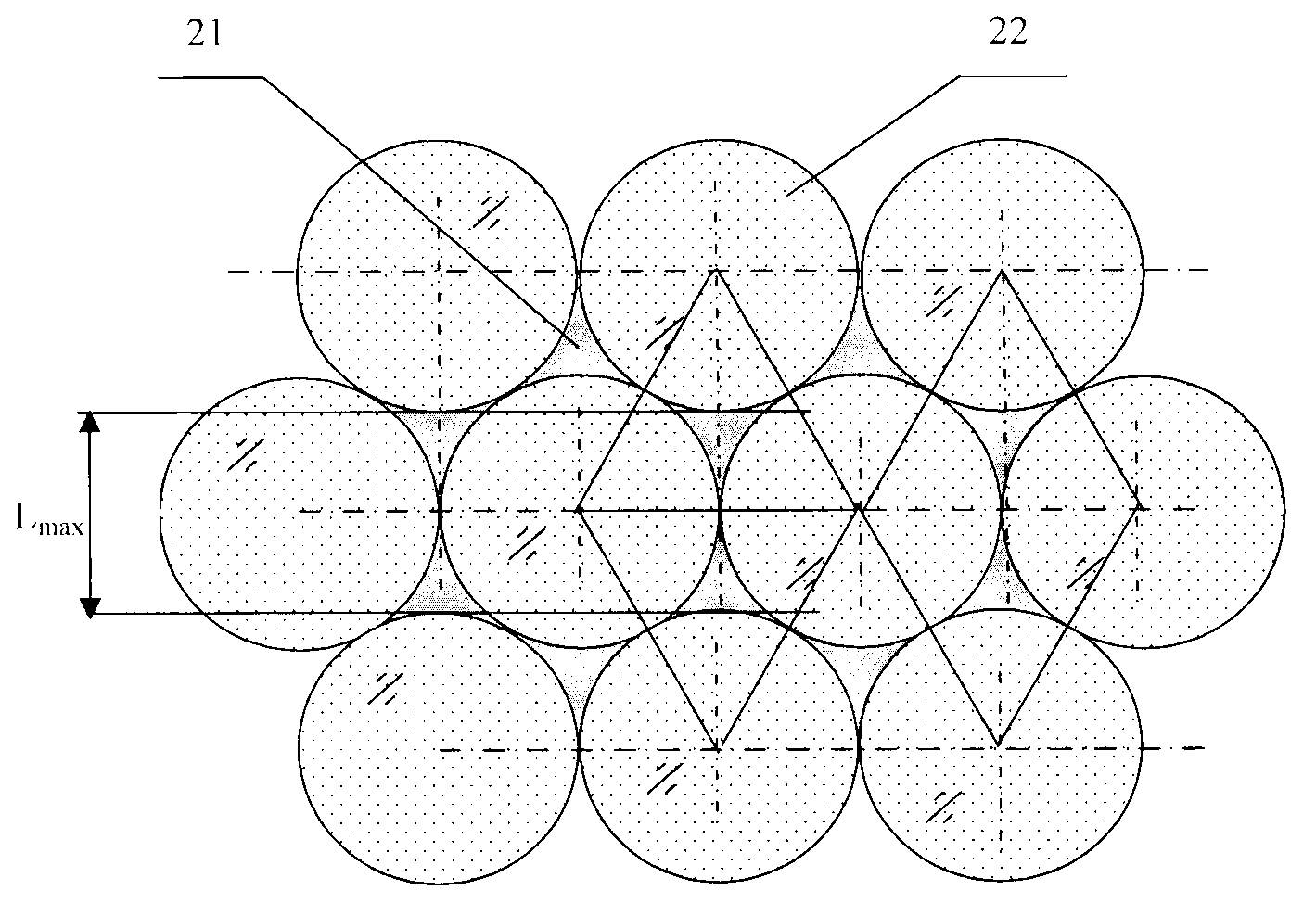

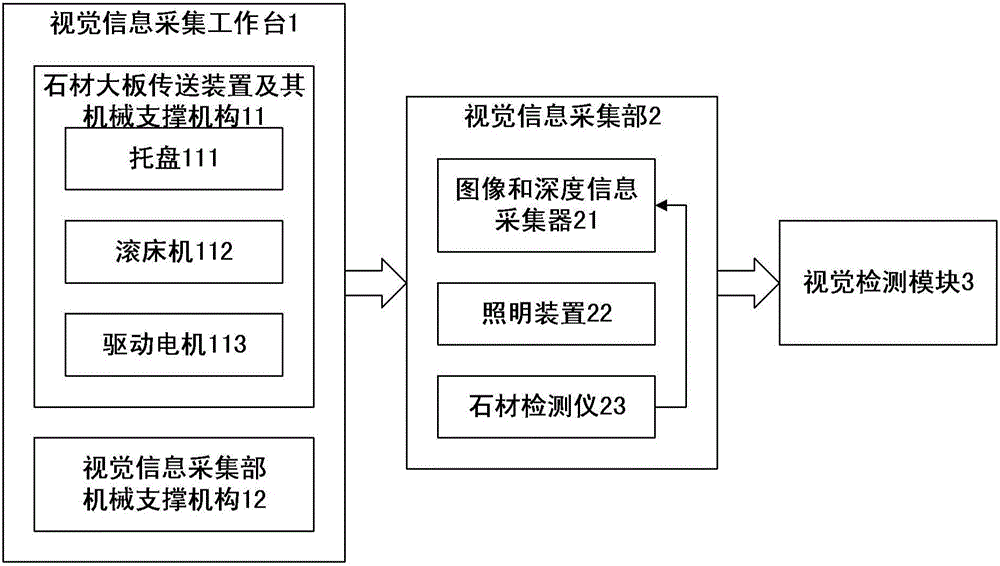

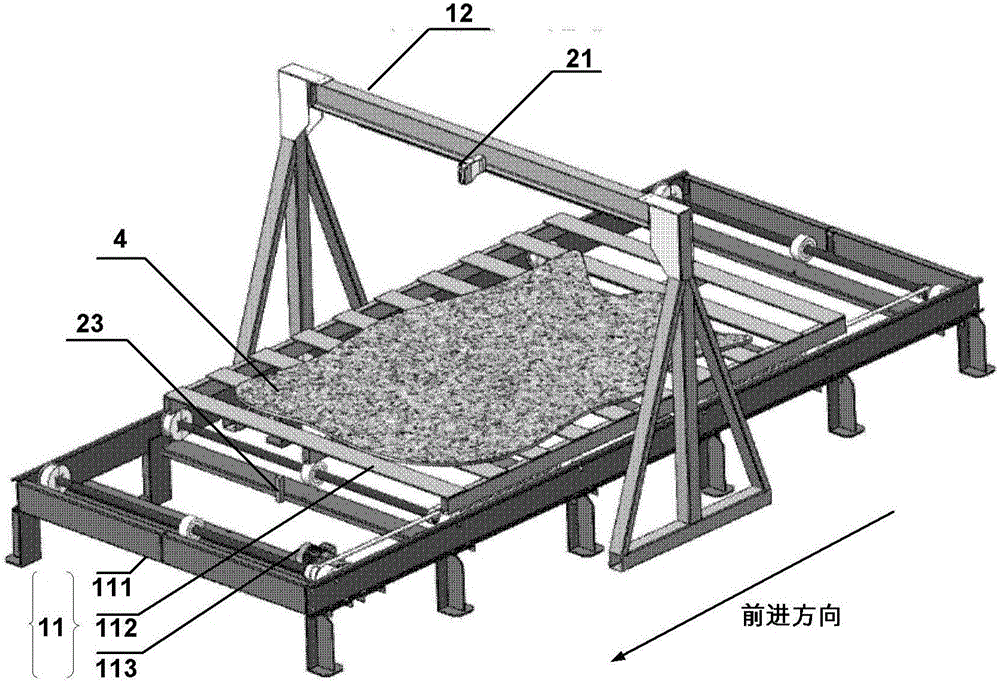

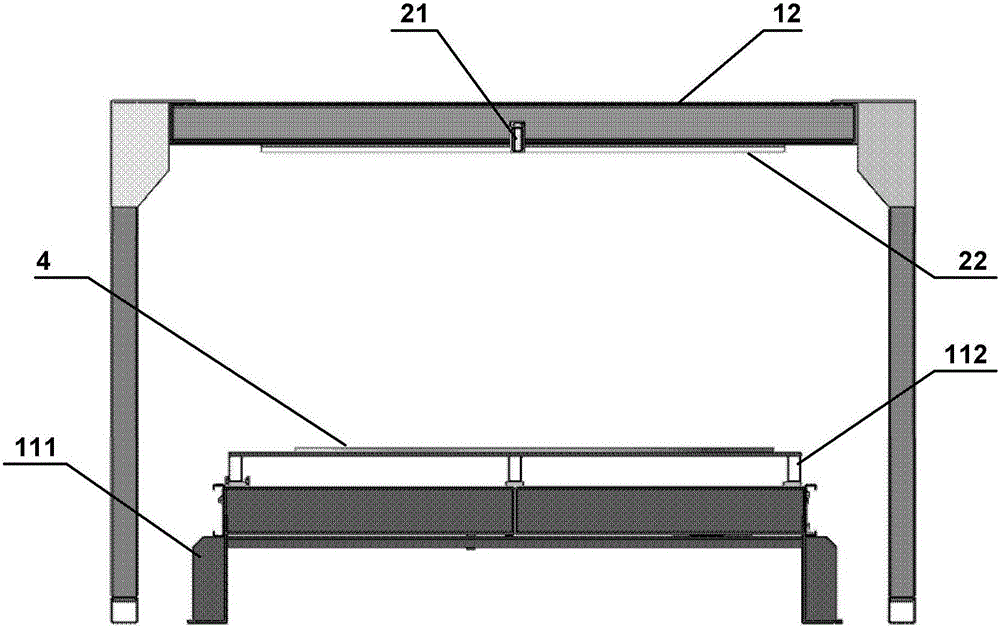

Stone big board surface contour dimension obtaining system and method based on machine vision

The present invention discloses a stone big board surface contour dimension obtaining system and method based on the machine vision. The system comprises a vision information collection work bench, a vision information collection portion and a vision detection module; the vision information collection work bench is provided with the vision information collection portion; the vision information collection portion collects the color images and the depth information of the stone big board in an online and non-contact mode; and the vision detection module is configured to perform feature analysis and target detection of the color images and depth information obtained by the vision information collection portion, identify the target area of the stone big board, extract the surface contour of the stone big board, and further combine imaging parameters to collect the length-width information of the maximum inscribing rectangular of the surface contour of the stone big board. The stone big board surface contour dimension obtaining system and method based on the machine vision can automatically extract the surface contour and the size of the stone big board through comprehensive adoption of the collected images and the depth information of the stone big board aiming at a stone block big board with the irregular shape.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

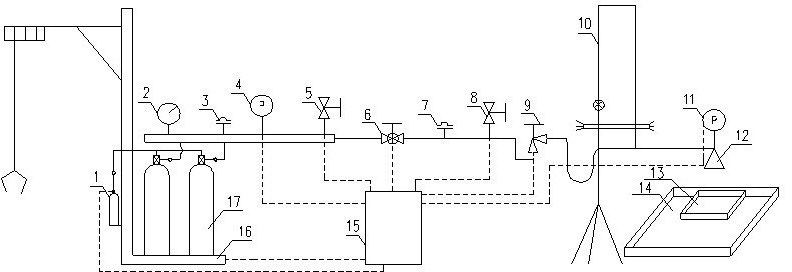

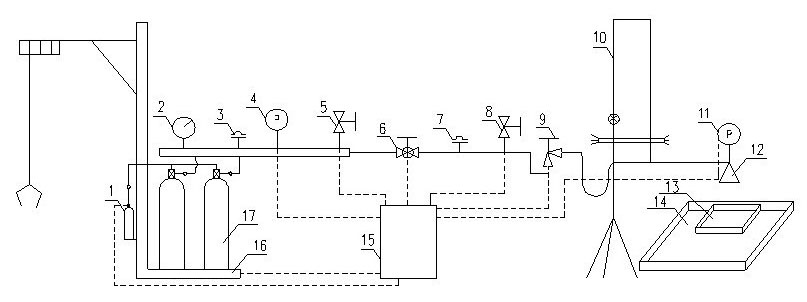

Test device for measuring spray characteristic of local application nozzle of carbon dioxide fire-extinguishing system

InactiveCN102305710ARealize automatic measurementAchieve recordMachine part testingSpecial purpose weighing apparatusVideo monitoringGas cylinder

The invention relates to a test device for measuring the spray characteristic of a local application nozzle of a carbon dioxide fire-extinguishing system. The test device comprises a hoisting weighing device, a driving gas cylinder group, a nozzle test interface, an adjustable oil tray, a video monitoring system, a data acquisition processing system and the like, wherein the hoisting weighing device is formed by combining an electric hoist and an electronic weighing platform scale effectively to measure and record the chemical weight of a carbon dioxide fire-extinguishing agent bottle group automatically; the installation height of the nozzle can be adjusted within the height range from 0.3 to 4 meters by an adjustable rack lifting frame, so the requirement of test height of an overhead type local application nozzle and a trough rim type local application nozzle which are specified by the standard is met; and the area of the oil tray can be adjusted within the range from 0.5 to 1 m<2>by the adjustable oil tray. The test device is convenient to operate, high in automaticity and high in measuring speed, improves work efficiency, reduces test cost and saves test space.

Owner:应急管理部天津消防研究所

Mechanical stress measuring apparatus

InactiveCN1865877ARealize automatic measurementSimple structureForce measurement by measuring magnetic property varationStress measuresAcoustics

The disclosed mechanical stress measuring device comprises: a sensor with an exciting electrode with coil D and two measuring electrodes with coils (E1, E2) connected by vertical equal-distance wires, a sensor driver arranged both a gear box driven by a step motor to connect the a probe frame by its output shaft and a control circuit with a displacement / angle sensor to send measured signal into a main computer, and a measuring circuit. This invention has high sensitivity for both static and dynamic measurement with simple structure.

Owner:HUAIHAI INST OF TECH

Robot intelligent pore-opening device

InactiveCN105965521ARealize automatic measurementGuaranteed to be exactly rightProgramme-controlled manipulatorWelding/cutting auxillary devicesSlide plateControl theory

The invention relates to a robot intelligent pore-opening device which comprises an outer rail, wherein a double-column portal frame is arranged on the outer rail; a control cabinet is mounted on the double-column portal frame; a base of the double-column portal frame is provided with a portal travelling drive device; the robot cutting device comprises a cutting robot; the cutting robot is mounted on a lifting supporting base in a suspended manner; the tail end of the cutting robot is provided with a laser detector; the lifting supporting base and a beam of the double-column portal frame are connected through a movable slide plate; a transverse drive device and a lifting drive device are arranged on the movable slide plate; and racks and guide rails are arranged on the beam and the lifting supporting base. The robot intelligent pore-opening device can open pores at different positions, in different directions and at different bevel angles in workpieces with different thicknesses and different radians; and the tail end of the cutting robot is provided with the laser detector, so that pore-opening positions, angles and radians can be guaranteed to be completely correct, and therefore, pore-opening operation saves both time and labor.

Owner:YONGSHENG MACHINERY IND KUNSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com