Device and setting method for measuring underground water level of vacuum drainage prepressing sealing membrane

A groundwater level and vacuum drainage technology, applied in the direction of buoy liquid level indicators, etc., can solve the problems of accumulation error, affecting the effect of vacuum drainage preloading reinforcement, and being susceptible to disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

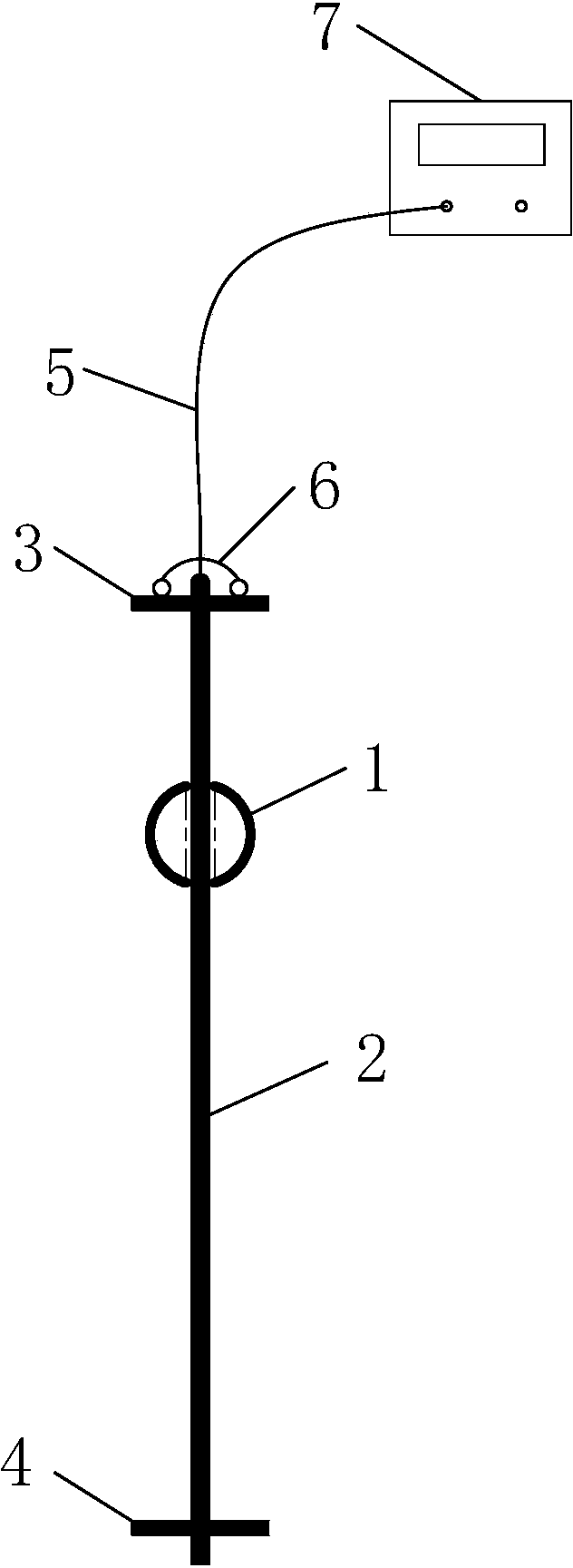

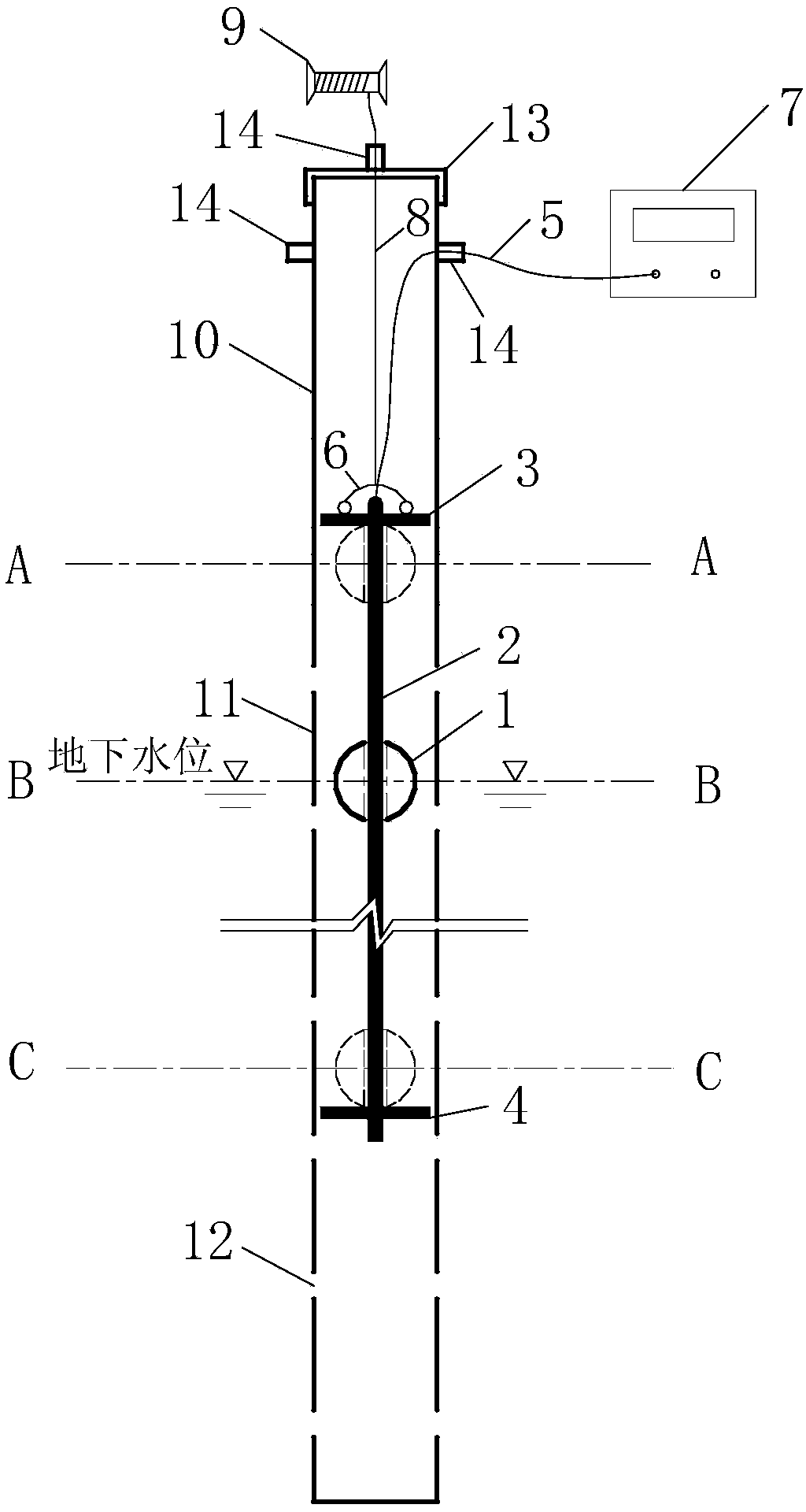

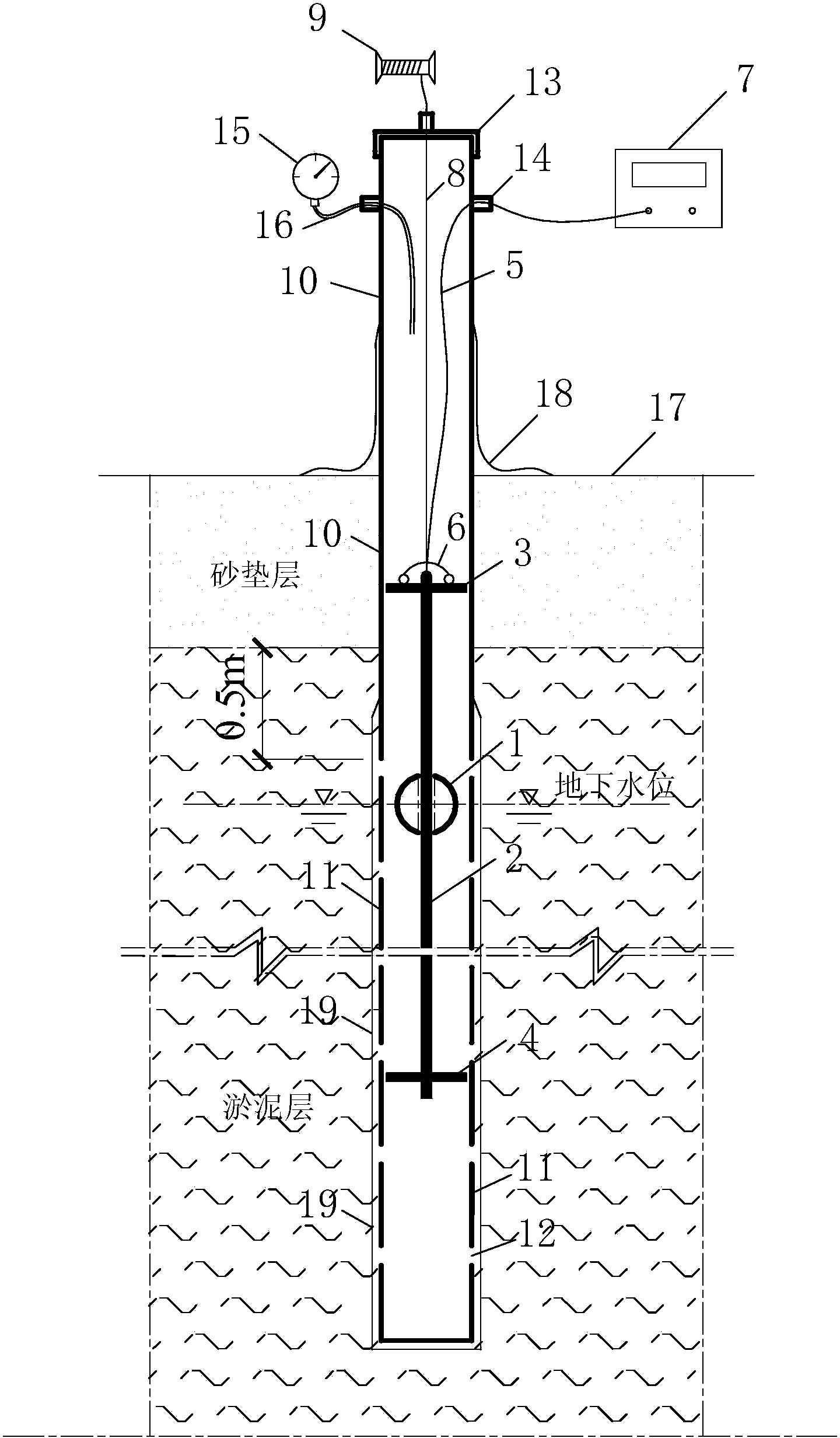

[0047] Embodiment 1, the equipment and method for measuring the groundwater level under the sealing membrane in the process of vacuum drainage preloading and strengthening the soft soil foundation.

[0048] Select the location where groundwater level monitoring needs to be carried out in the vacuum preloading area, and determine the buried depth of the groundwater level tube of the groundwater level measuring device in the reed switch-resistance vacuum preloading area according to the hydrogeological conditions on site;

[0049] Select the centroid position of the planar layout of the drainage board to drill and bury the water level pipe (including the airtight plastic water level pipe 10 and the water level pipe floral tube 11). Take the 0.5m below the bottom surface of the horizontal drainage sand cushion in vacuum preloading as the dividing line, the lower water level pipe section flower tube 11, and the upper water level pipe section is a closed water level pipe 10. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com