Method for measuring large field-of-view telescope optical system distortion and field curvature

An optical system and measurement method technology, applied in the direction of testing optical performance, geometric characteristics/aberration measurement, etc., can solve the problems of inability to meet the application requirements of large-diameter and large-field telescopes, cumbersome operation, low precision, etc. Influence of factors, simplified measurement device, effect of reliable measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

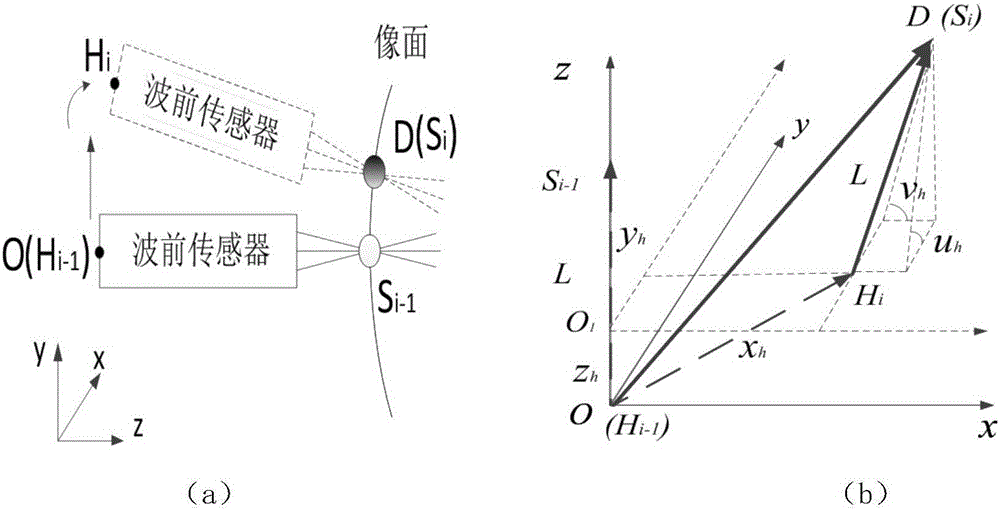

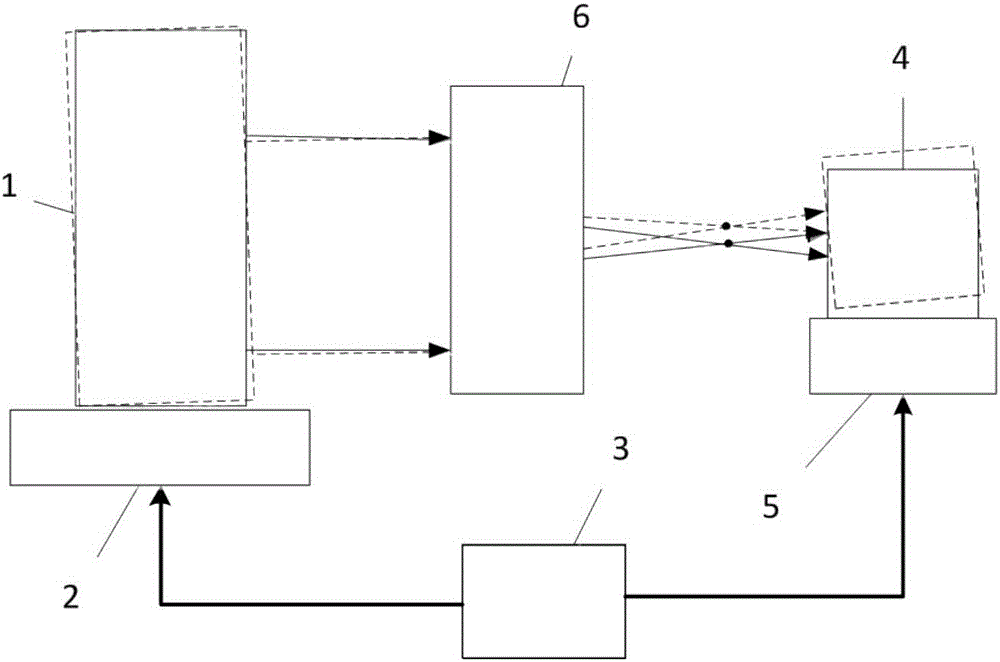

[0038] The detection device that the present invention relates to sees figure 1 , which mainly includes a parallel light source 1 and its adjustment platform 2, a wavefront detector 4 and its moving platform 5, a computer 3, a closed-loop positioning structure composed of a computer 3, a wavefront detector 4 and a moving platform 5, and is used to detect The image point position of field telescope 6.

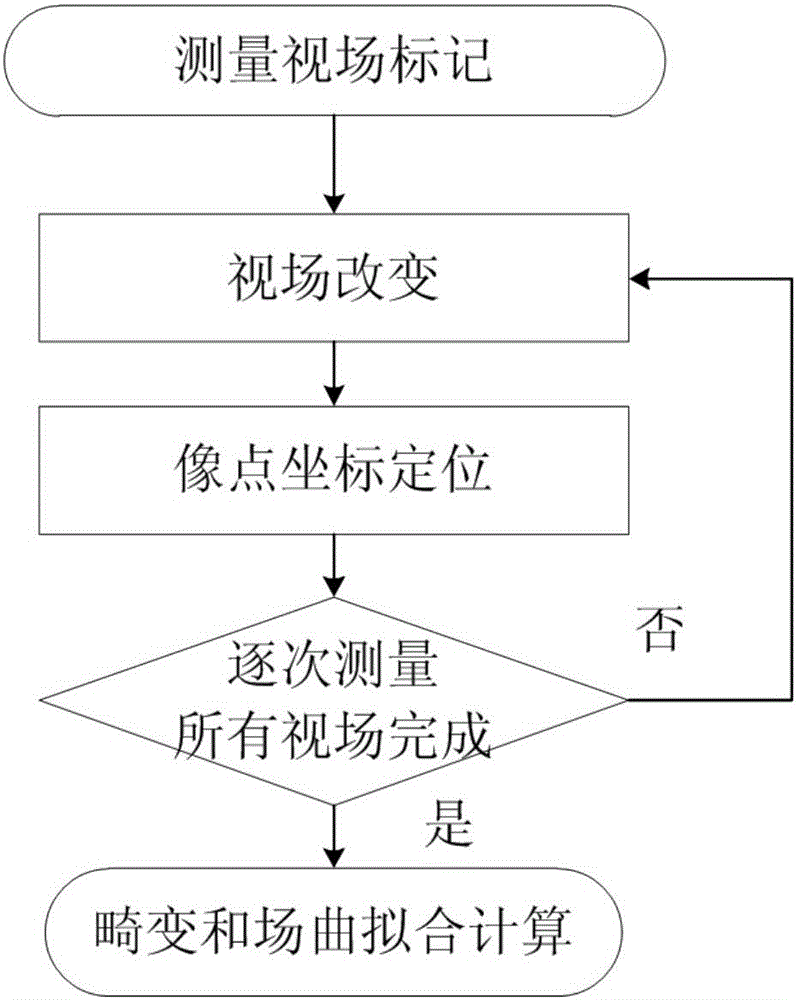

[0039] See figure 2 , the main detection steps are:

[0040] The first step: measure the field of view mark, select the measurement field of view according to the field of view range and measurement accuracy requirements, and mark the serial number FOV i ;

[0041] Step 2: Change the measurement field of view according to the selected measurement field of view FOV i , change the tilt and pitch attitude of the parallel light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com