Patents

Literature

238results about How to "Reliable measurement data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

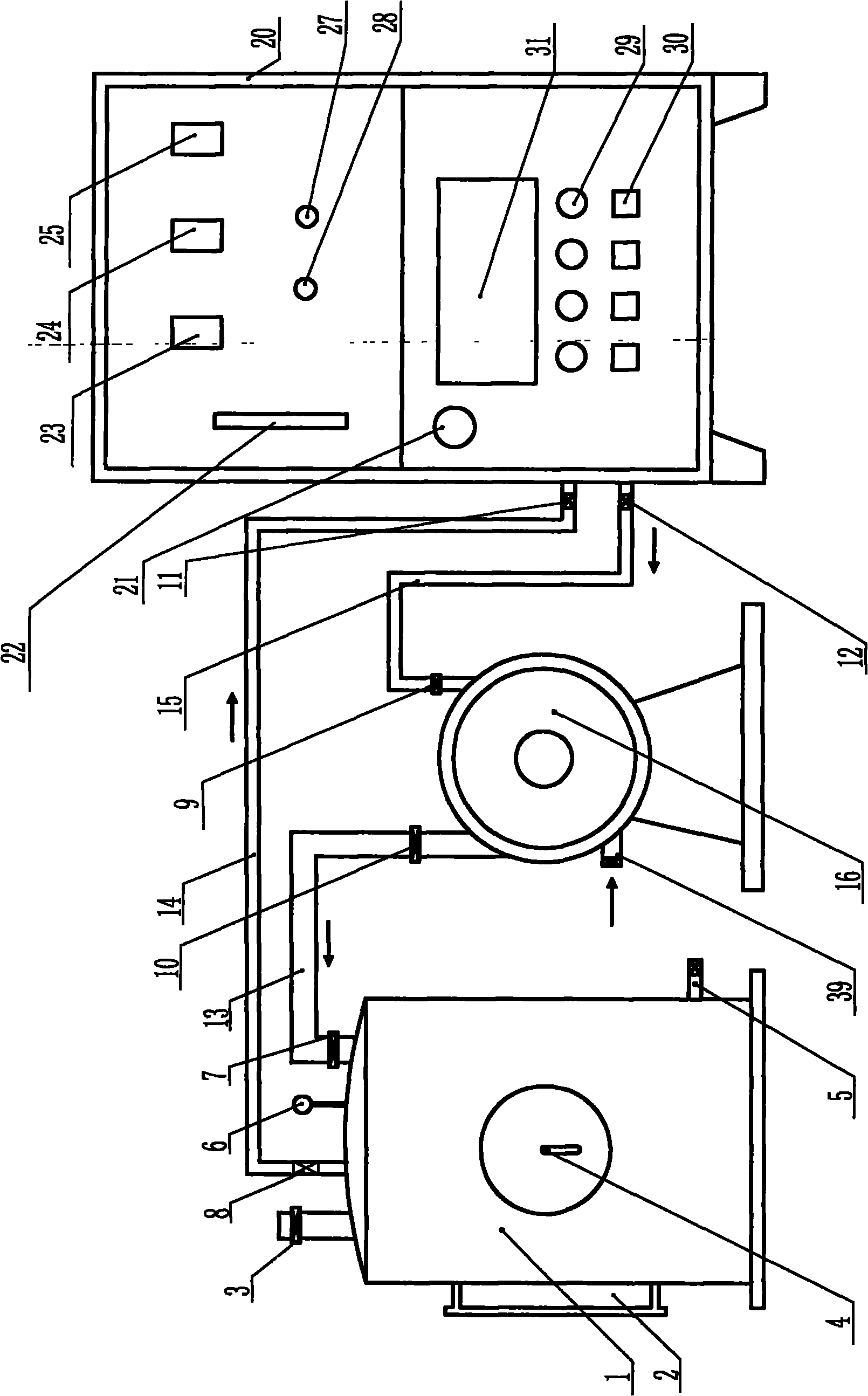

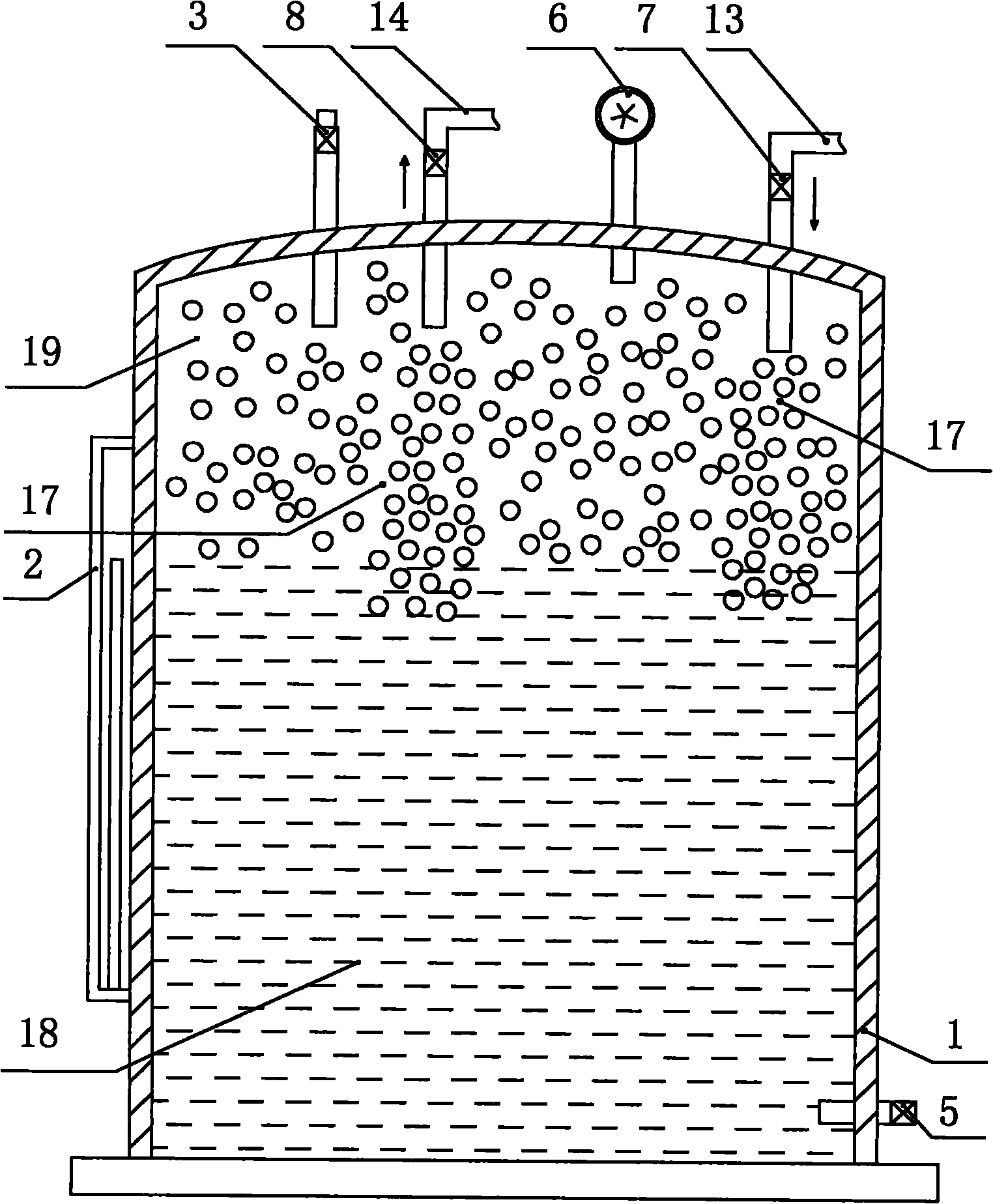

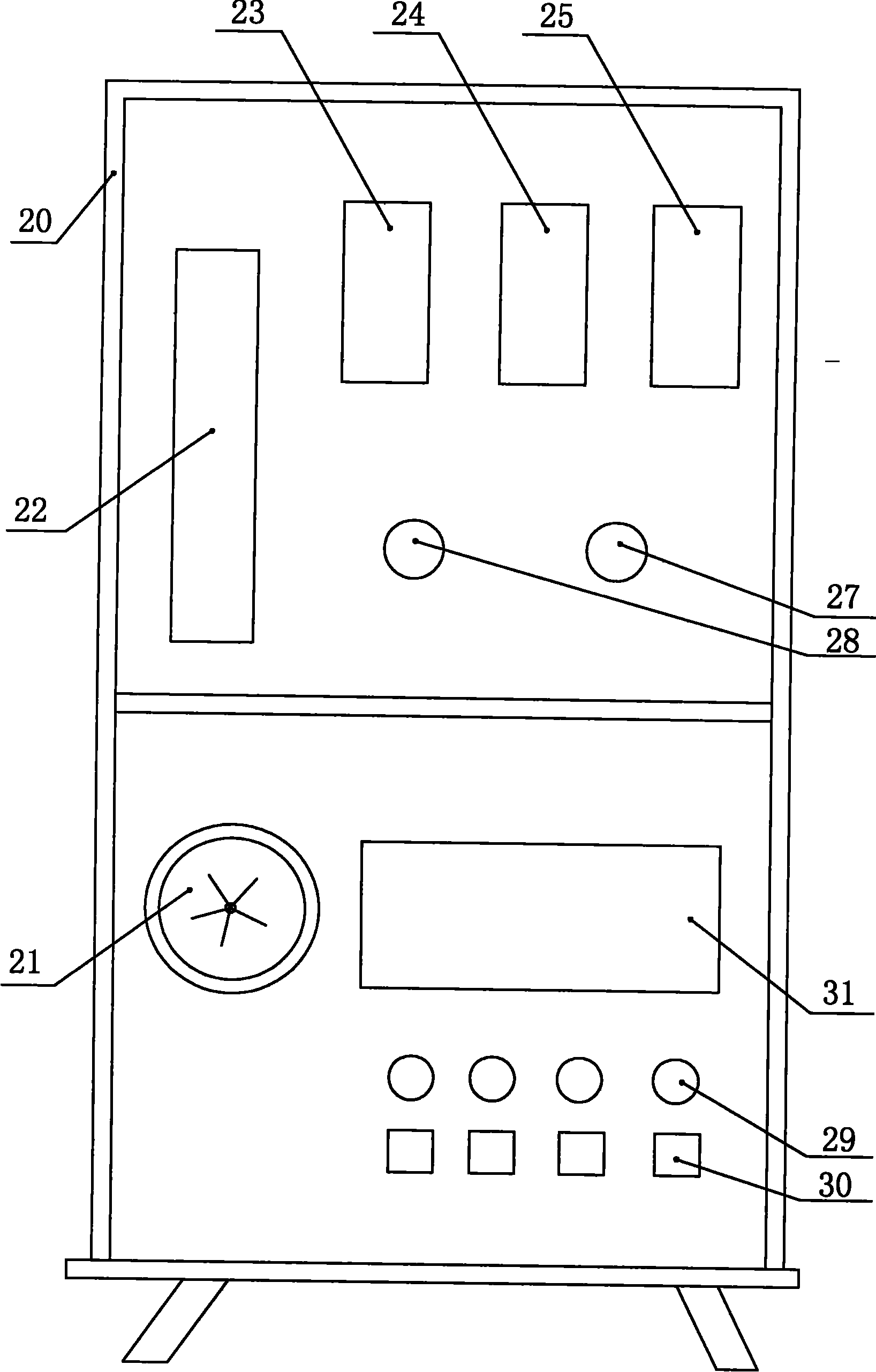

Coal mine underground mobile gas beam tube sampling and monitoring device

InactiveCN101788546AAdvanced and reasonable designCompact structureMining devicesMaterial analysisInformation processingBeam tube

The invention relates to a coal mine underground mobile gas beam tube sampling and monitoring device which mainly structurally comprises a gas-water separator, a vacuum pump, a gas sampling and monitoring control cabinet, an oxygen sensor, a methane sensor, a carbon monoxide sensor, a circuit board, a sampling beam tube, a dust precipitator, a dehumidifier, a gas control valve, a gas flow meter, a pressure gauge and a negative pressure gauge; beam tube sampling, dust precipitation and dehumidification, gas-water separation, flow control, sensor information capturing, control cabinet monitoring and control and micro-computer information processing are adopted for pre-warning, forecasting, analyzing and displaying fire gas concentration, and working out the gas change law; the device has the advantages of advanced and reasonable design, compact structure, easy operation and convenient operation, can move in a long distance in coal mine underground to acquire and monitor the fire gas in different coal bed gob areas or closed spaces, the monitoring distance can reach 5000m, the measurement data is accurate and reliable, and the accuracy can reach 96 percent; and the device can also be used on the ground or other ores.

Owner:邬剑明

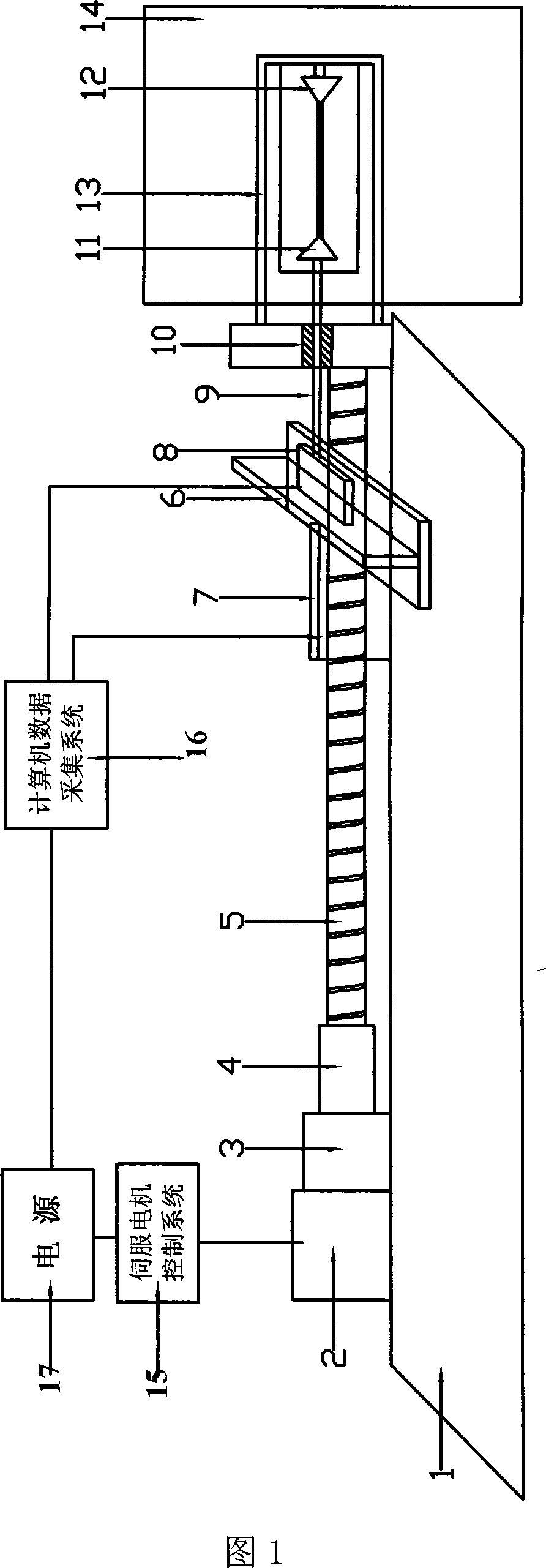

Metal wire material stretching mechanical property testing device

ActiveCN101196450ASimple structureEasy to operateInvestigating material ductilityTest fixtureMechanical property

The invention relates to a metal wire material drawing force performance testing device for testing the drawing force performance of metal wire material, which utilizes measuring the drawing deformation displacement of the metal wire material and the drawing force loaded on the metal wire material, according to the length and diameter of the metal wire material, counts the strain and stress of engineering, and obtains the drawing force performance of the metal wire material according to the gotten engineering stress-strain curve under different temperature. The invention also provides a device used for testing the drawing force of the metal wire material. The device has simple structure, small volume, light weight and low cost, which makes the combining testing accuracy of the method and the device in the invention high. The measured data is reliable and the operation is simple.

Owner:GRIMAT ENG INST CO LTD

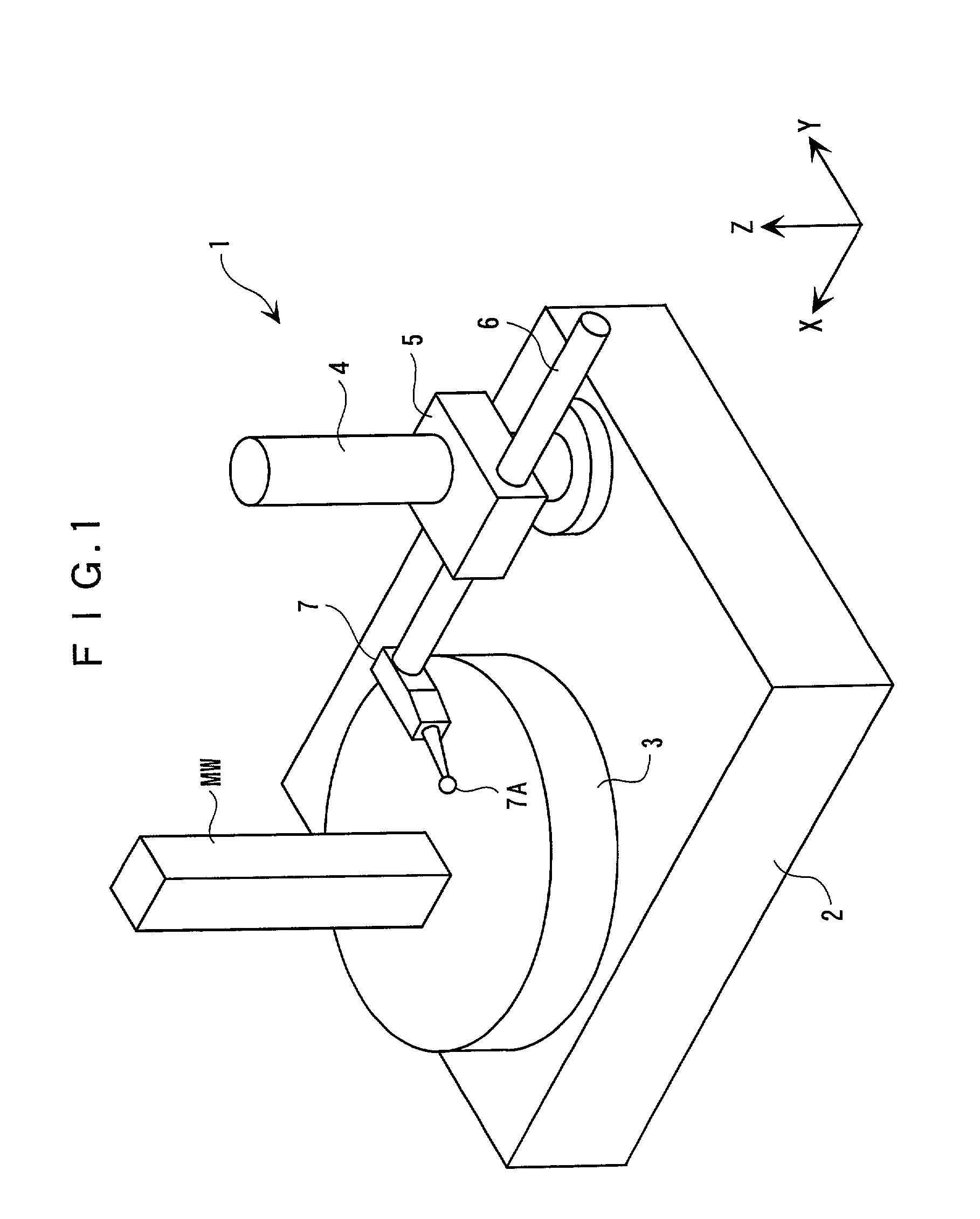

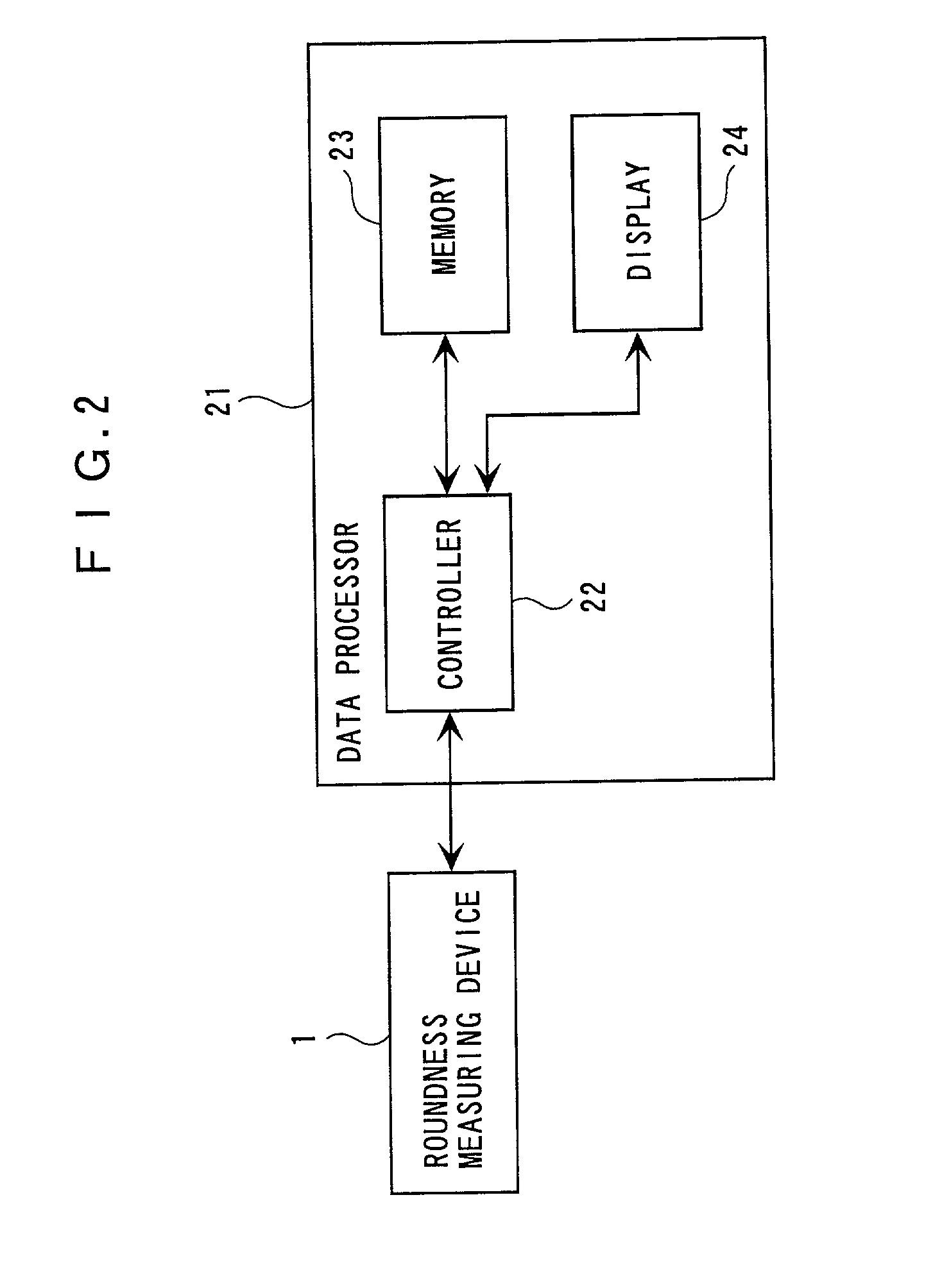

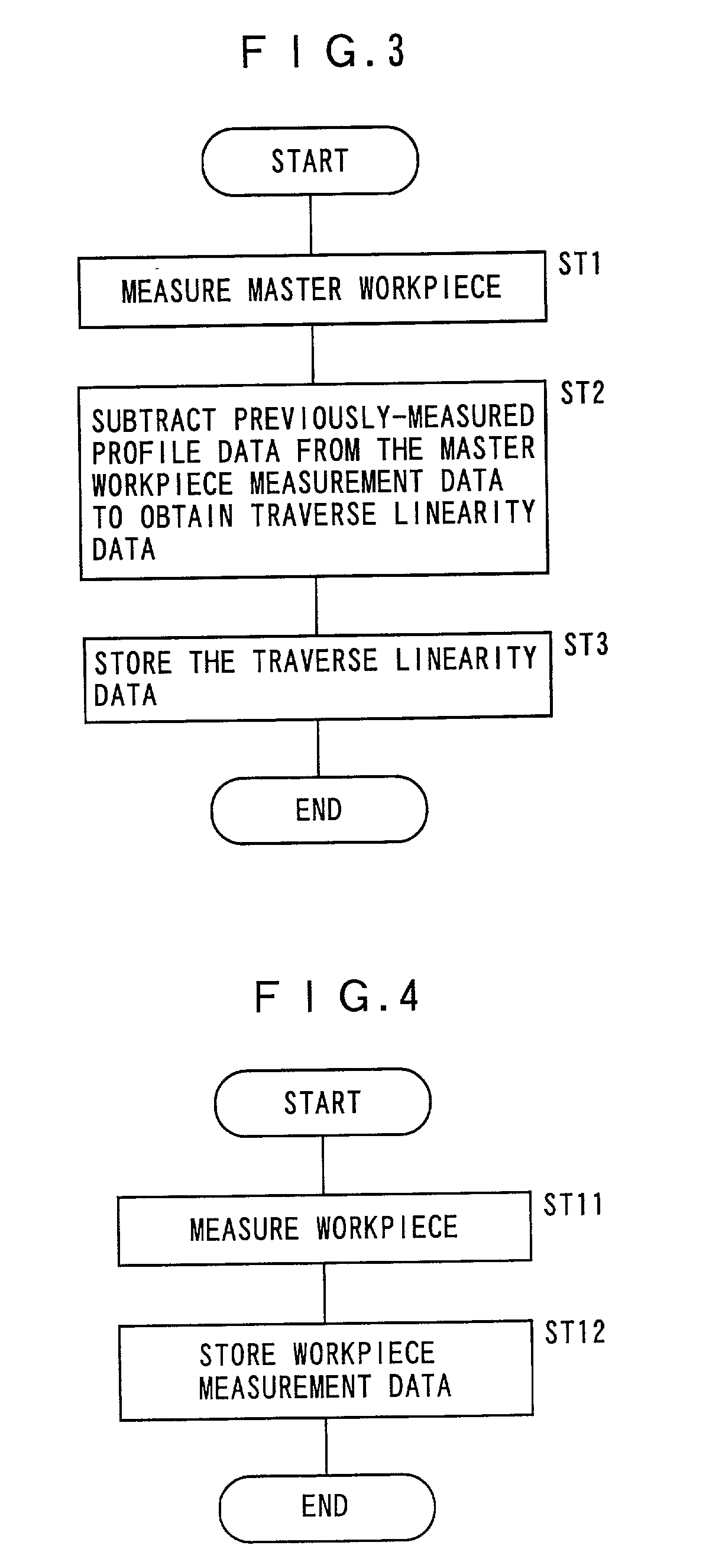

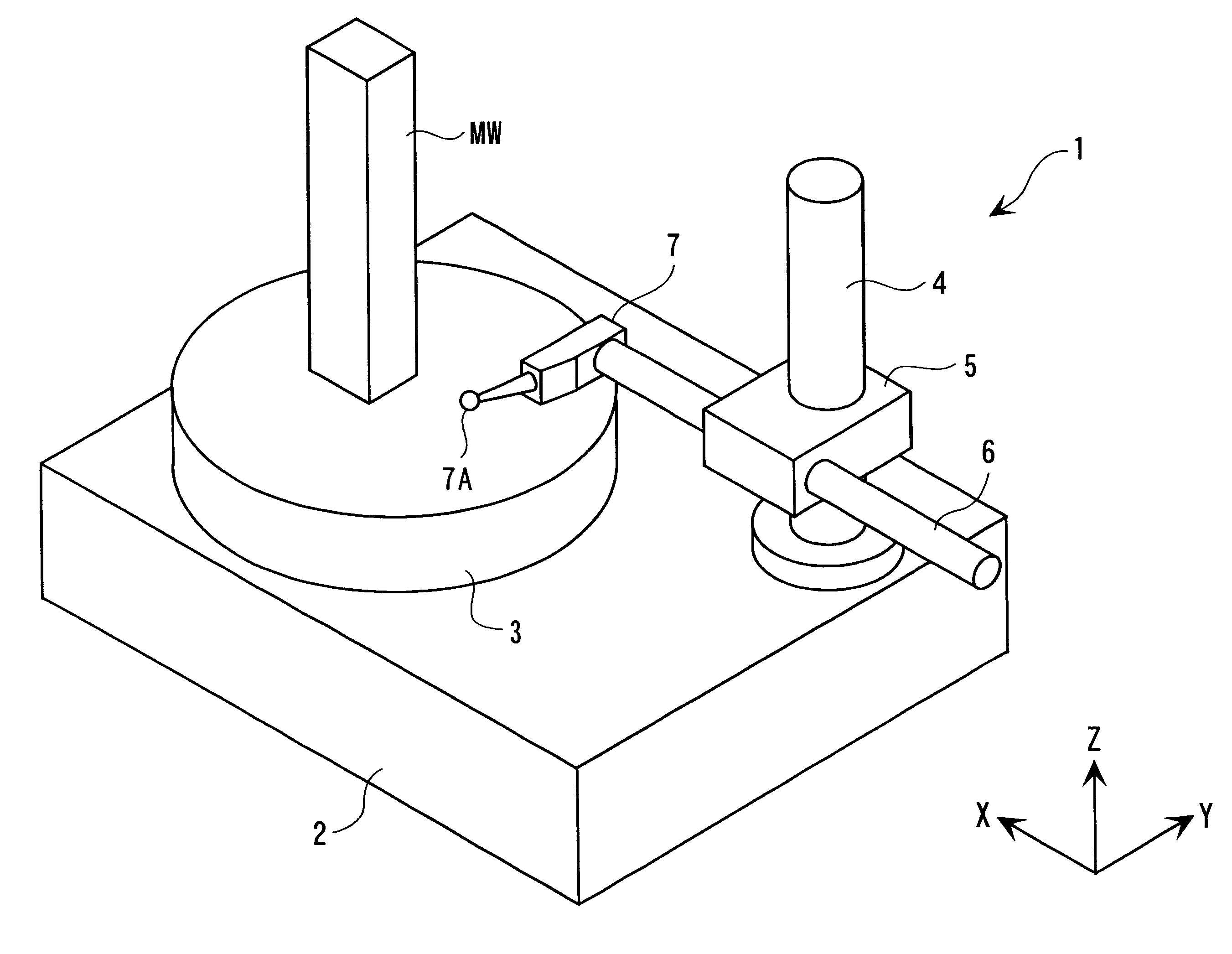

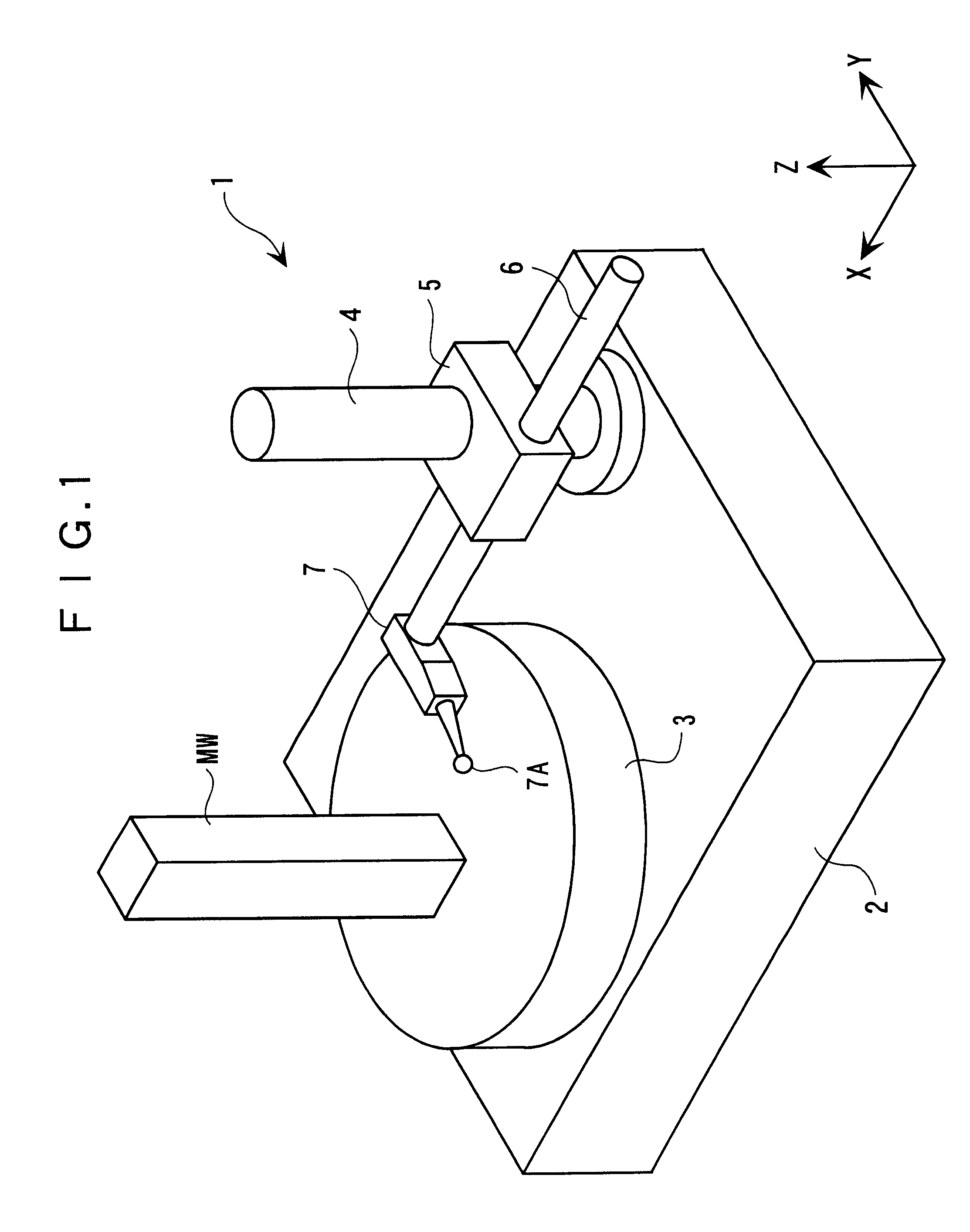

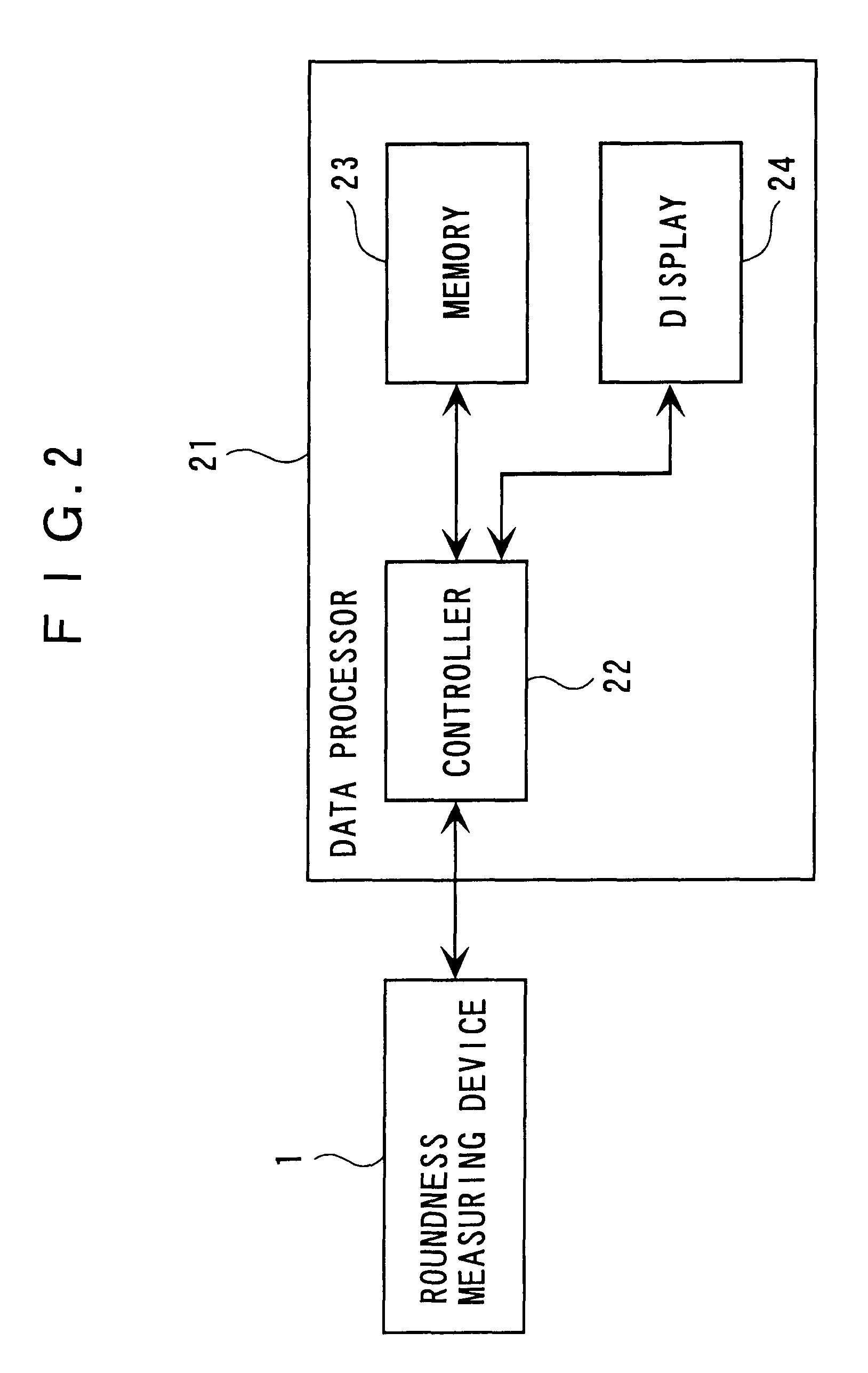

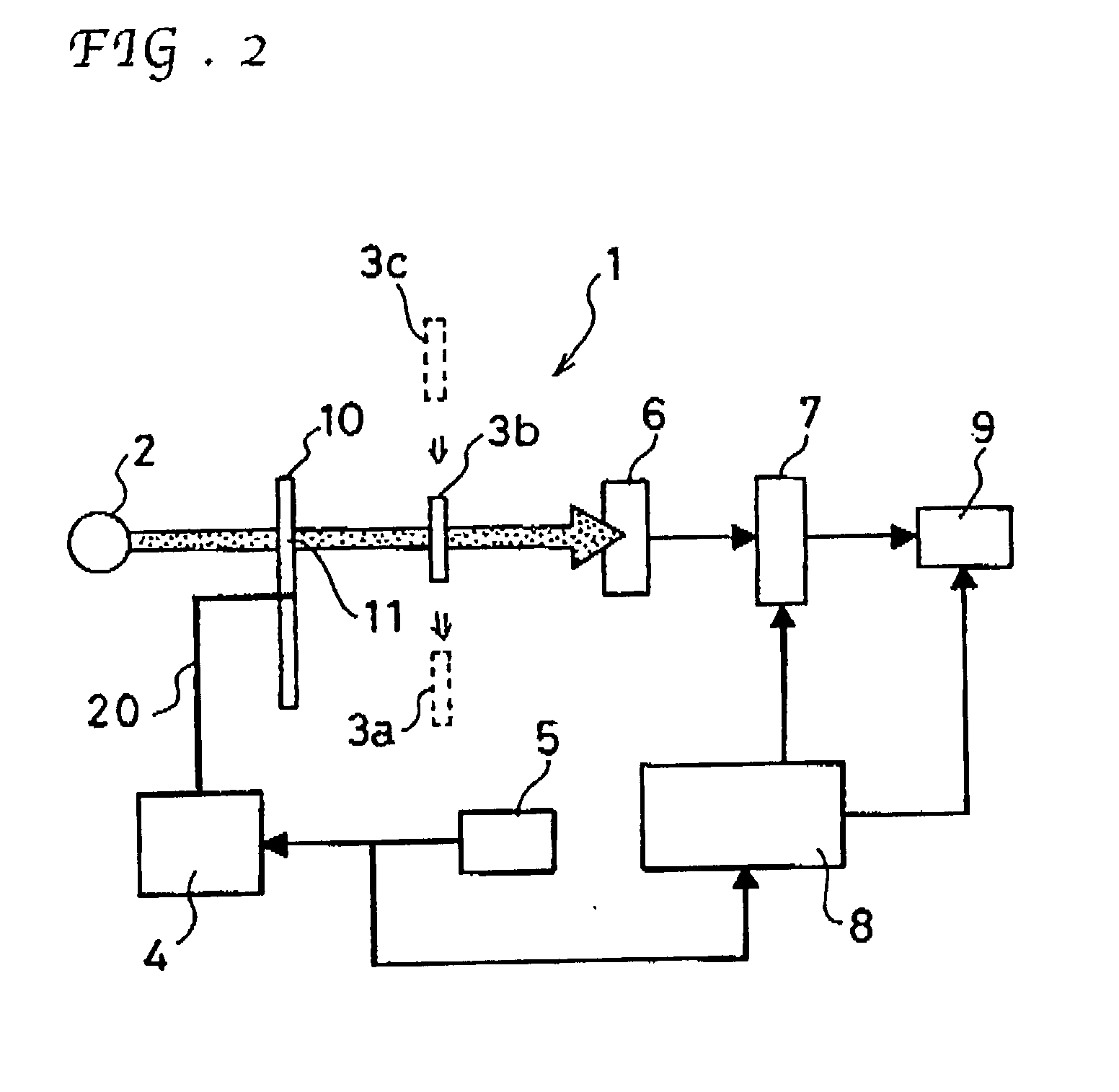

Traverse linearity compensation method and rotational accuracy compensation method of measuring device

InactiveUS20010008047A1Accurate compensationReduce dispersionWalking sticksTesting/calibration of speed/acceleration/shock measurement devicesMeasurement deviceLinearity

A compensation method according to the present invention includes: a traverse linearity data calculating step for measuring a master workpiece (MW) of which profile data is value-specified in advance while moving a sensor (7) using a linear movement mechanism (4, 5) of a measuring device (1) and for subtracting the previously value-specified profile data from the measurement data of the master workpiece to obtain a traverse linearity data of the linear movement mechanism; a workpiece measurement data calculating step for measuring the workpiece while moving the sensor by the linear movement mechanism of the measuring device to obtain a measurement data of the workpiece; and a workpiece profile calculating step for subtracting the traverse linearity data from the workpiece measurement data to obtain a true value data of the workpiece.

Owner:MITUTOYO CORP

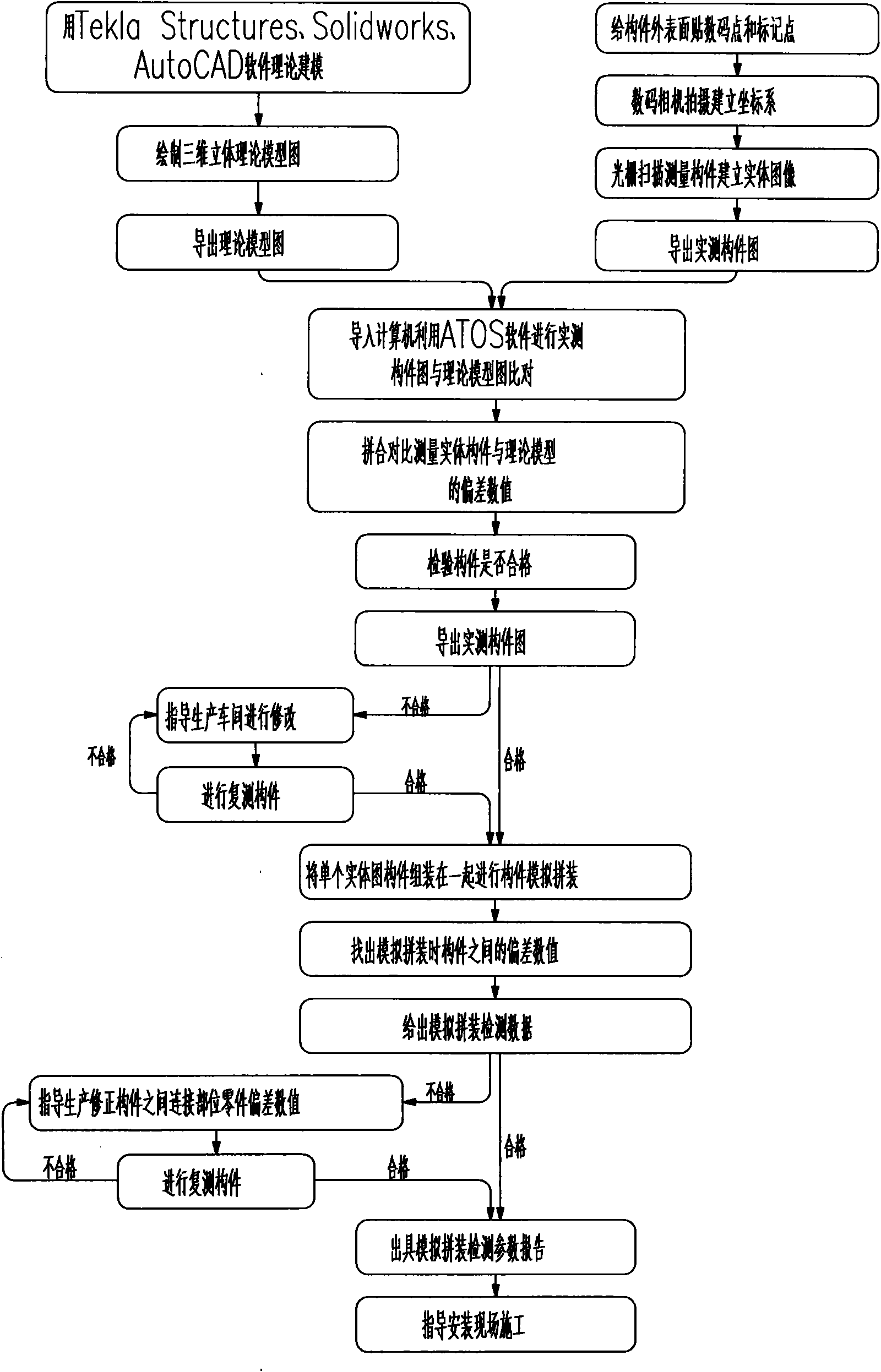

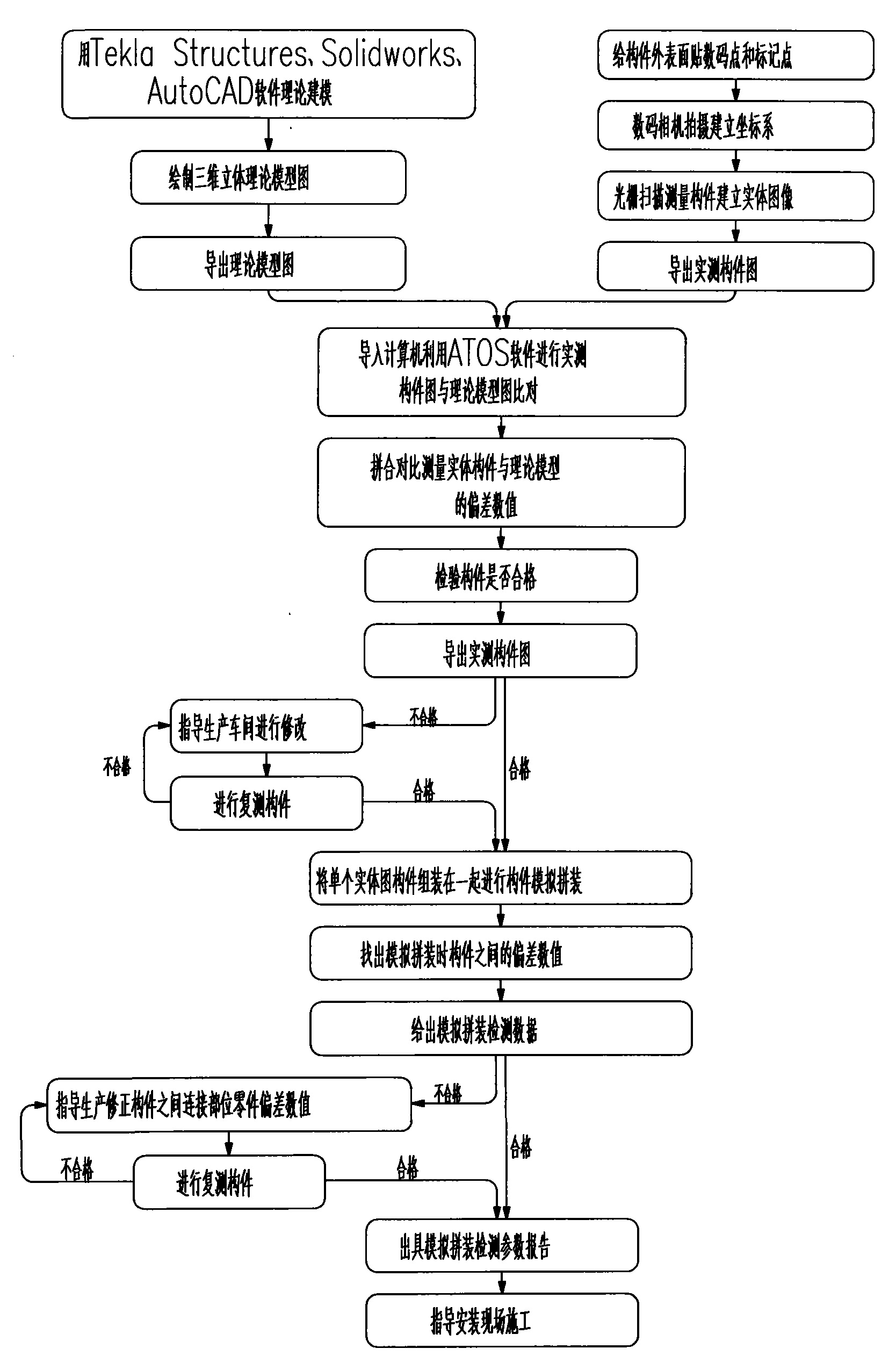

Computer simulation pre-assembly method of construction steel structure

InactiveCN101882180AEasy to operateShort timeSpecial data processing applications3D modellingGratingComputer software

The invention relates to a pre-assembly method of a construction steel structure, in particular to a computer simulation pre-assembly method of the construction steel structure. The method comprises the following steps: drawing out a three-dimensional standard map of all members of a construction structure according to a design drawing through computer software and establishing a three-dimensional model drawing and a standard map library; using a 3D optical scanning measuring system to carry out three-dimensional raster scanning on the members, measuring the entity members, and introducing into a computer for obtaining a three-dimensional stereo image; using the computer software to process the measured entity members, and being compared with the three-dimensional model drawing for inspecting whether the members are qualified or not; using the actually measured members to carry out simulation assembly on the whole construction structure; finding out amount of deflection of connecting parts between the actually measured members and the simulation assembly members; and providing a member simulation assembly detection parameter report after the simulation assembly of the actually measured members is qualified, and guiding the installation and the field construction. The method has simple operation, can cover the full process of the member overall part of the construction steel structure, and has representativeness and guidance; and one-time development can be utilized repeatedly, and the waste of resources can be further avoided.

Owner:CHINA 22MCC GROUP CORP

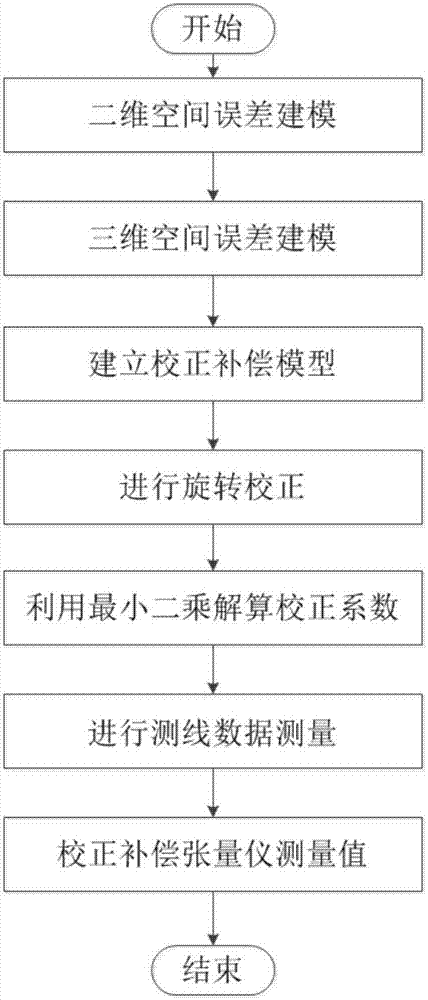

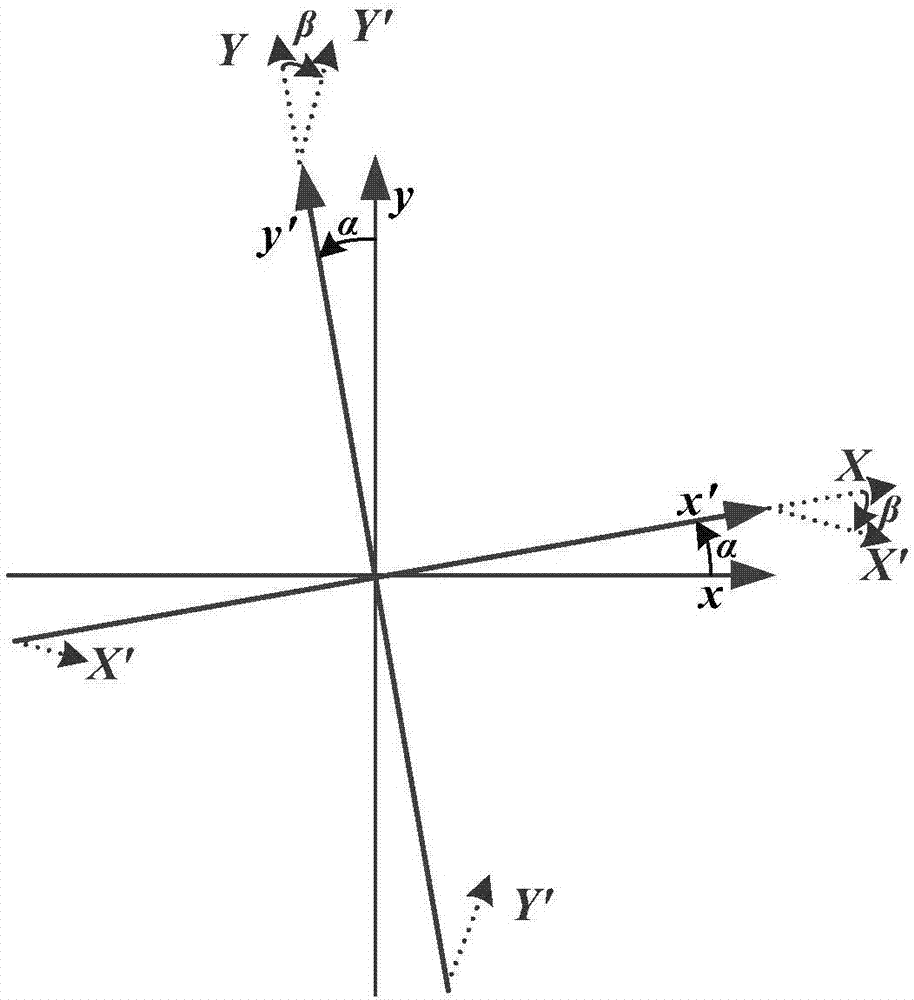

Magnetic gradiometer correction method based on magnetic gradient invariants

InactiveCN106997035AThe measured data is reliableOptimal Calibration ParametersElectrical measurementsCorrection methodMagnetic gradient

The invention relates to a magnetic gradiometer correction method based on magnetic gradient invariants. Modeling of scale factor errors, non-orthogonal errors, non-alignment errors, and zero offset errors existing during construction of tensor instrument is carried out. With help of a scaler constraint method during a magnetic vector instrument correction, two independent rotation invariants of the magnetic gradient tensor are used for the constraint, and then an optimal correction parameter is acquired. By starting from the integrated errors of the tensor instrument, the modeling of the errors of the tensor instrument is carried out, and the two independent rotation invariants of the magnetic gradient tensor are used for constraint, and then the optimal correction parameter is acquired. The errors of the tensor instrument are corrected more intensively, and measured data is more reliable. Compared with conventional tedious and complicated tensor instrument error correction methods, the magnetic gradiometer correction method is advantageous in that the result of the measured data is processed directly, and no other data is required, and use is more convenient; and in addition, the magnetic gradiometer correction method can be used in field environment provided with a geomagnetic field without being limited by various magnetic gradient measurement principles, and also can be used in magnetic shielding environment.

Owner:JILIN UNIV

Traverse linearity compensation method and rotational accuracy compensation method of measuring device

InactiveUS6546640B2Accurate compensationReduce dispersionWalking sticksTesting/calibration of speed/acceleration/shock measurement devicesMeasurement deviceLinearity

Owner:MITUTOYO CORP

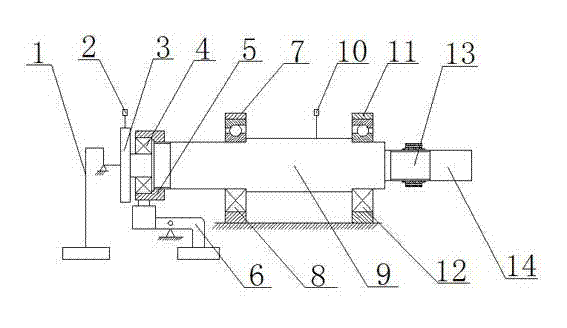

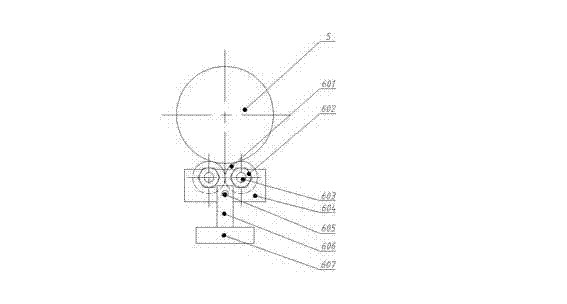

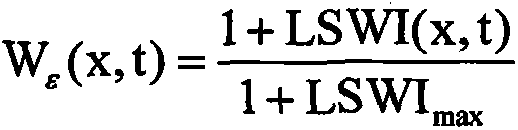

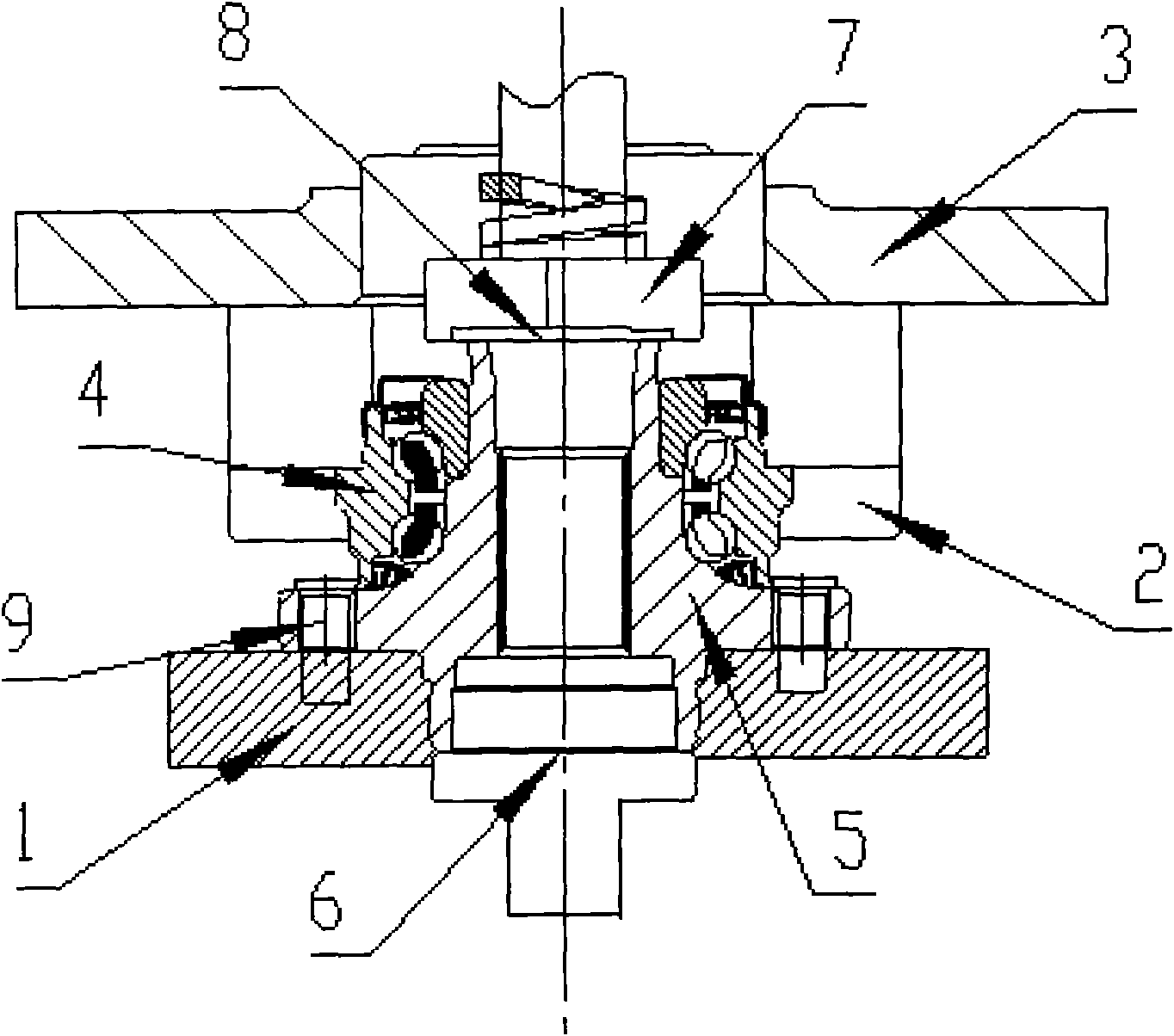

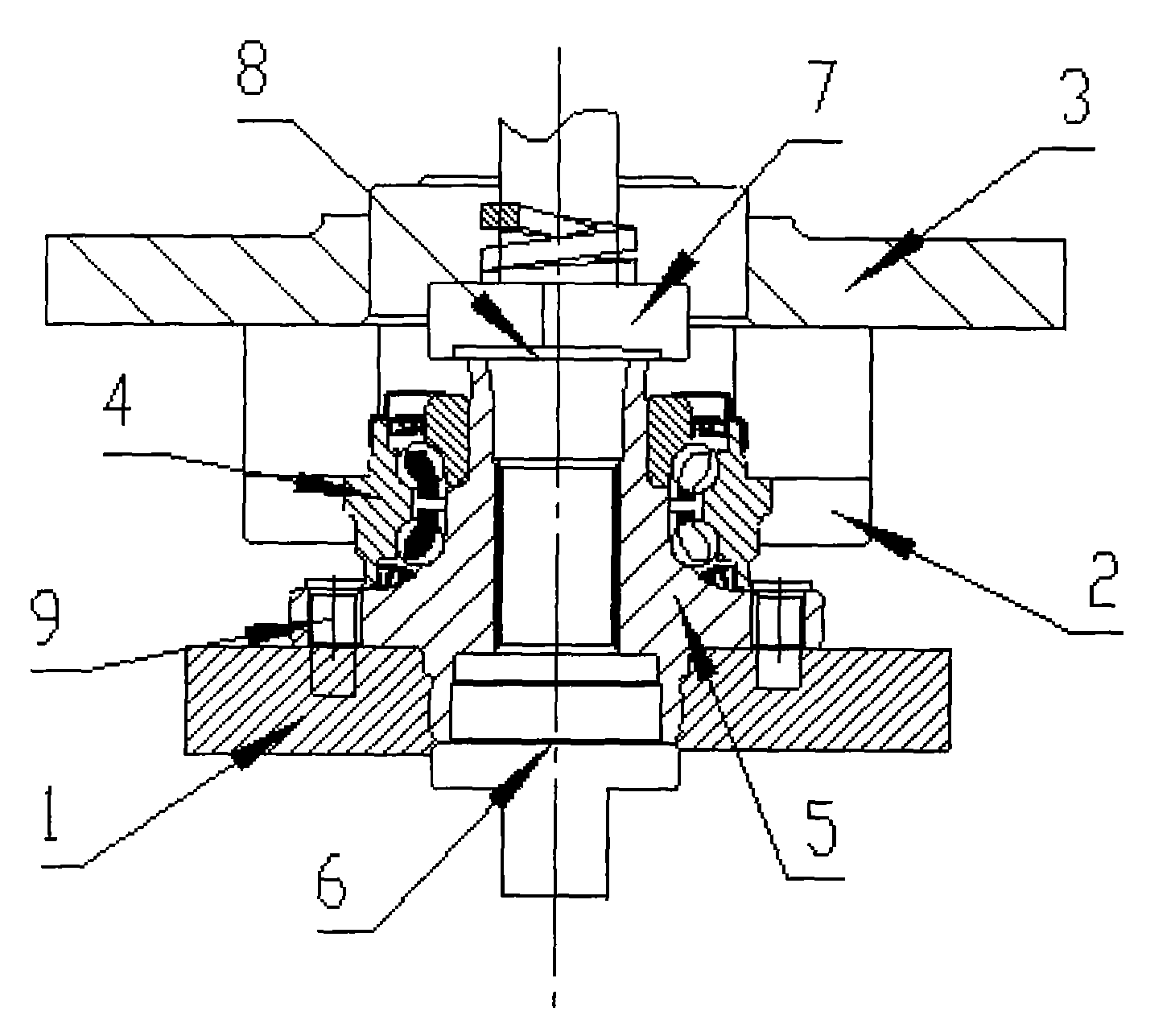

Friction torque measurement apparatus of horizontal bearing

InactiveCN102519639AAvoid eccentric load vibration problemsAppropriate to the actual working conditionsWork measurementTorque measurementFriction torqueElectric machine

The invention relates to a friction torque measurement apparatus of a horizontal bearing. A velocity sensor is arranged on a main shaft and a rotating speed is read by a digital indicator. An input terminal of a data collection card is connected with a force transducer by a strain gauge; the data collection card is installed in a main board of a PC machine; and the main board is connected with a display. The main shaft is arranged horizontally; one end of the main shaft is provided with a bearing replacing sleeve; and the other end of the main shaft is connected with a motor main shaft. A tested bearing is arranged in the bearing replacing sleeve; and an inner ring is provided with a force transmission rotary table that is connected with the force transducer by a dowel bar. A load output bulb of an axial loading apparatus is contacted with a vertical point of a table surface of the force transmission rotary table; and a load output terminal of a radial loading apparatus and an outer peripheral surface of the bearing replacing sleeve are mutually compacted and rolled. According to the invention, the apparatus employs a horizontal structure; and loading at two directions can be realized simultaneously. Therefore, an actual working condition of a bearing can be simulated approximately; and a problem of main shaft offset load vibration due to a belt drive mode of the main shaft can be solved. Besides, the apparatus has advantages of simple structure and strong practicality.

Owner:HENAN UNIV OF SCI & TECH

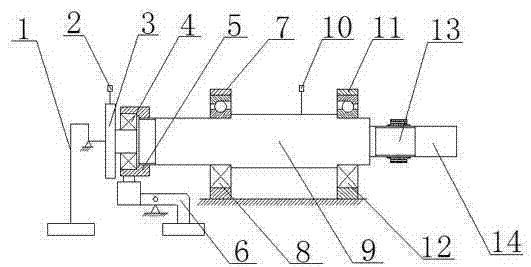

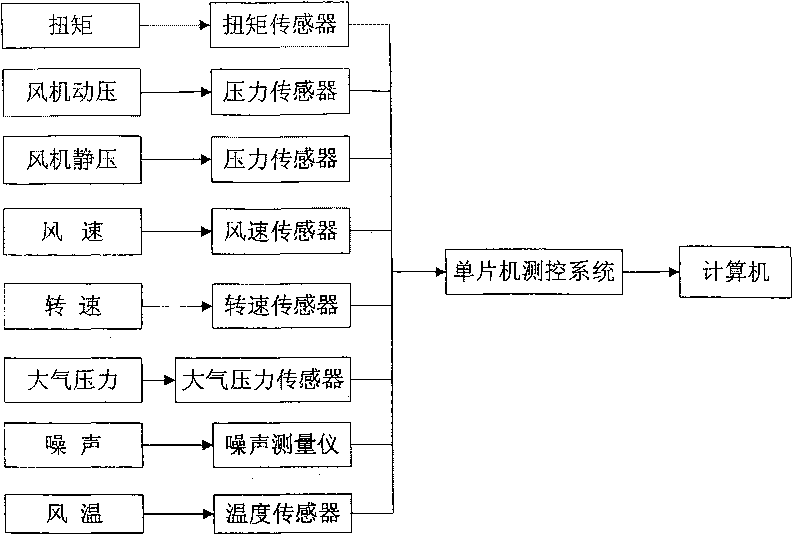

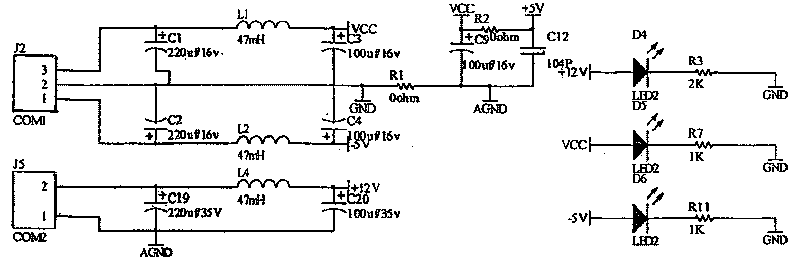

System and method for testing performance of cross flow fan

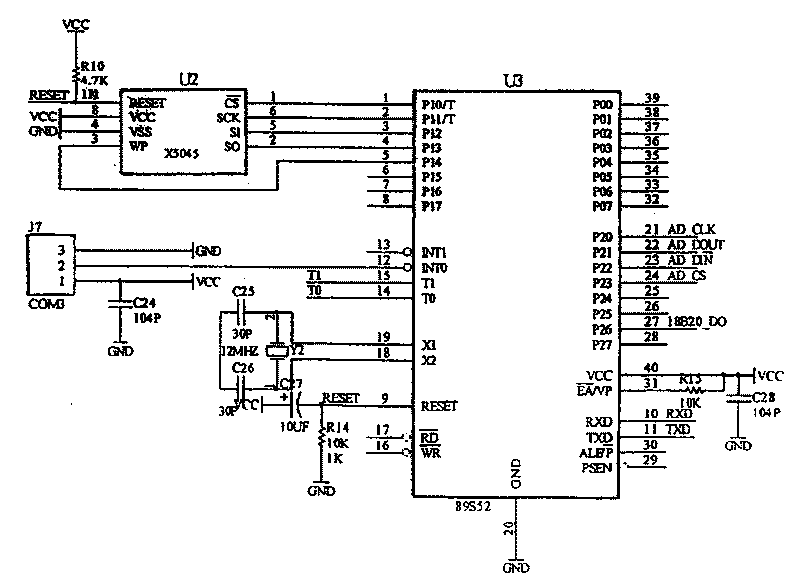

InactiveCN101710030AImprove efficiencyQuality assuranceFluid speed measurement using pressure differenceStructural/machines measurementMicrocontrollerTest performance

The invention discloses a system and a method for testing the performance of a cross flow fan. The system comprises a sensor system, a single chip testing and control system and a computer, wherein the sensor system comprises a fan rotating speed sensor, a fan air speed sensor, an air temperature sensor, an atmospheric pressure sensor, a fan dynamic pressure sensor, a fan static pressure sensor, a fan torque sensor and a noise measurer; the sensors and the measurer of the sensor system are used for outputting electric signals connected with the single chip testing and control system; the single chip testing and control system uses a single chip as a core for converting and processing data; and finally the data are transmitted into a host computer for processing and displaying by a serial port. The invention has the advantages of various automatic testing functions, strong adaptability, simple operation, convenient maintenance, higher reliability and higher accuracy.

Owner:CHANGSHA UNIVERSITY

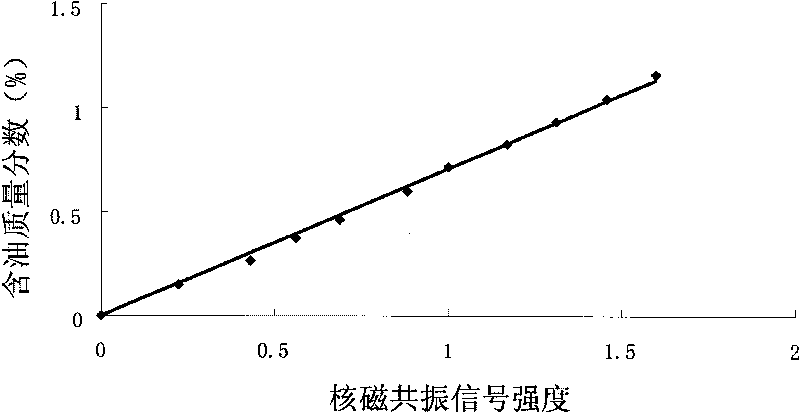

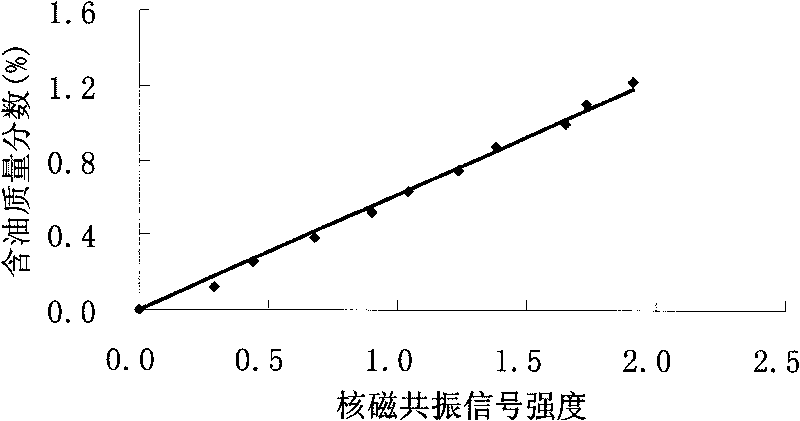

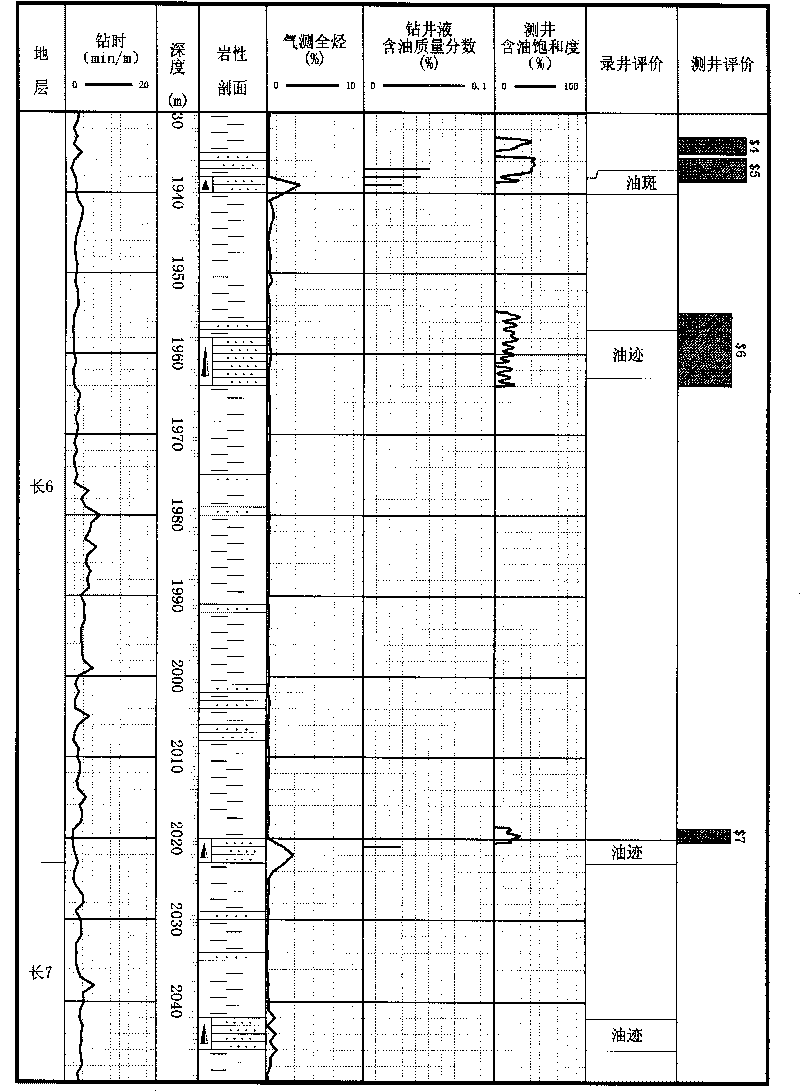

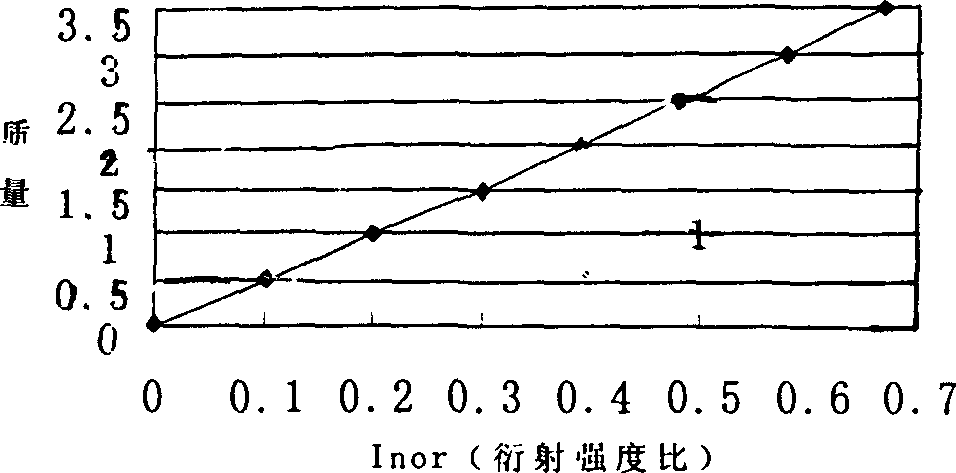

Method for analyzing oil mass fraction of drilling well fluid by nuclear magnetic resonance

InactiveCN101713754AAccurate detectionBreaking through the technical bottleneck of oily quantitative mud loggingAnalysis using nuclear magnetic resonanceContinuous analysisProton NMR

The invention relates to a method for analyzing the crude oil mass fraction in the drilling well fluid by a nuclear magnetic resonance technology. On the basis of the theory for measuring the oil content by nuclear magnetic resonance, the method realizes the quantitative analysis of the oil mass fraction of the drilling well fluid in a petroleum drilling well by a nuclear magnetic resonance analytical instrument through manufacturing a working curve of the oil mass fraction of the drilling well fluid in a target layer and carrying out the nuclear magnetic resonance continuous analysis of the drilling well fluid along the drilling. The method comprises the steps of calibrating by the nuclear magnetic resonance analytical instrument, manufacturing the working curve of the oil mass fraction of the drilling well fluid, collecting and processing a drilling well fluid sample, analyzing by nuclear magnetic resonance and solving the oil mass fraction in the drilling well fluid. After being applied, the invention can accurately detect the oil content of the drilling well fluid, analyze the drilling well fluid in the well drilling process in time at the well drilling scene, obtain the analytical data of the oil content of the drilling well fluid in time and achieve the quantitative evaluation on the oiliness of a storing and collecting layer, has real, accurate and reliable measured data and provides technology support for the exploration, development and production of petroleum in time.

Owner:中国石化集团华北石油局有限公司

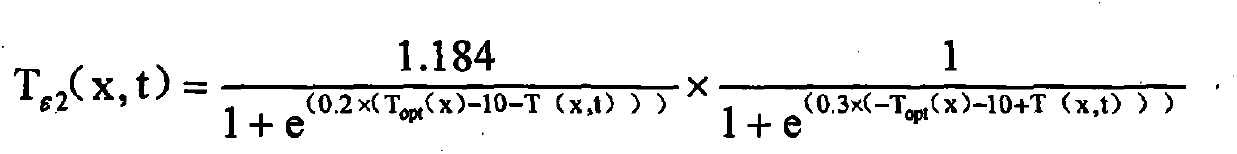

Method for measuring ecological compensation quantity based on remote-sensing images

InactiveCN103345567ASimple and fast operationReliable measurement dataSpecial data processing applicationsVegetationSensing data

The invention discloses a method for measuring ecological compensation quantity based on remote-sensing images. The method includes the steps that (1), in a target region, in combination with obtained data of the remote-sensing images and obtained temperature data of meteorological stations, a photosynthetic active radiation index and an actual solar energy utilization efficiency index for the target region are respectively investigated and inspected; (2), a NPP parameter estimating module is input, and a CASA model is established for estimating net primary productivity; (3), through a data extracting module, NPP parameters in the NPP parameter estimating module are extracted, a region landscape value estimating module is input, estimation is performed according to a region landscape value estimating model, and values of the ecological compensation quantity of types of vegetation in the measured region are obtained. The method for measuring the ecological compensation quantity based on the remote-sensing images has the advantage that through the finite remote-sensing data, the ecological compensation quantity of the different types of vegetation can be roughly measured.

Owner:QINGHAI NORMAL UNIV

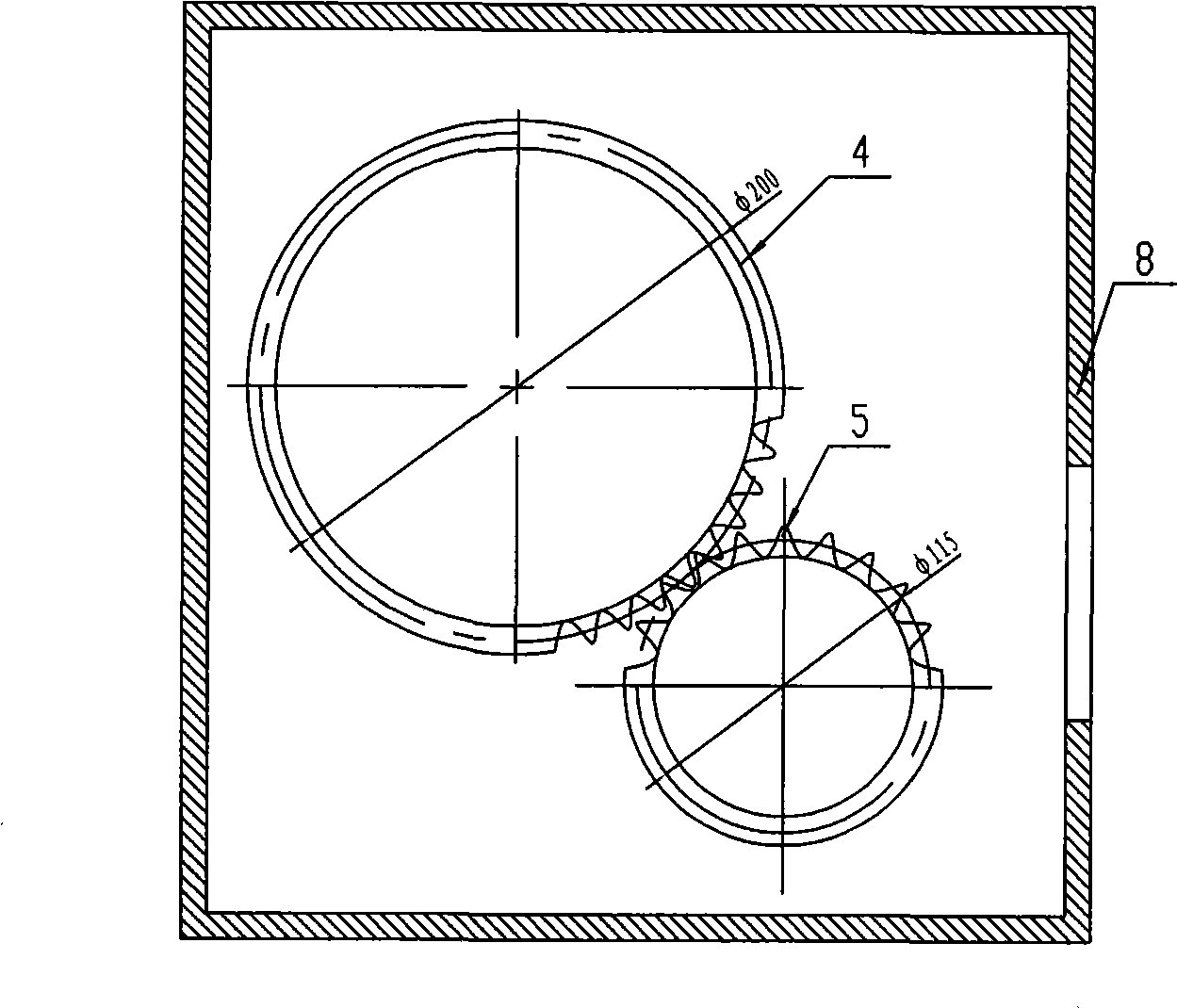

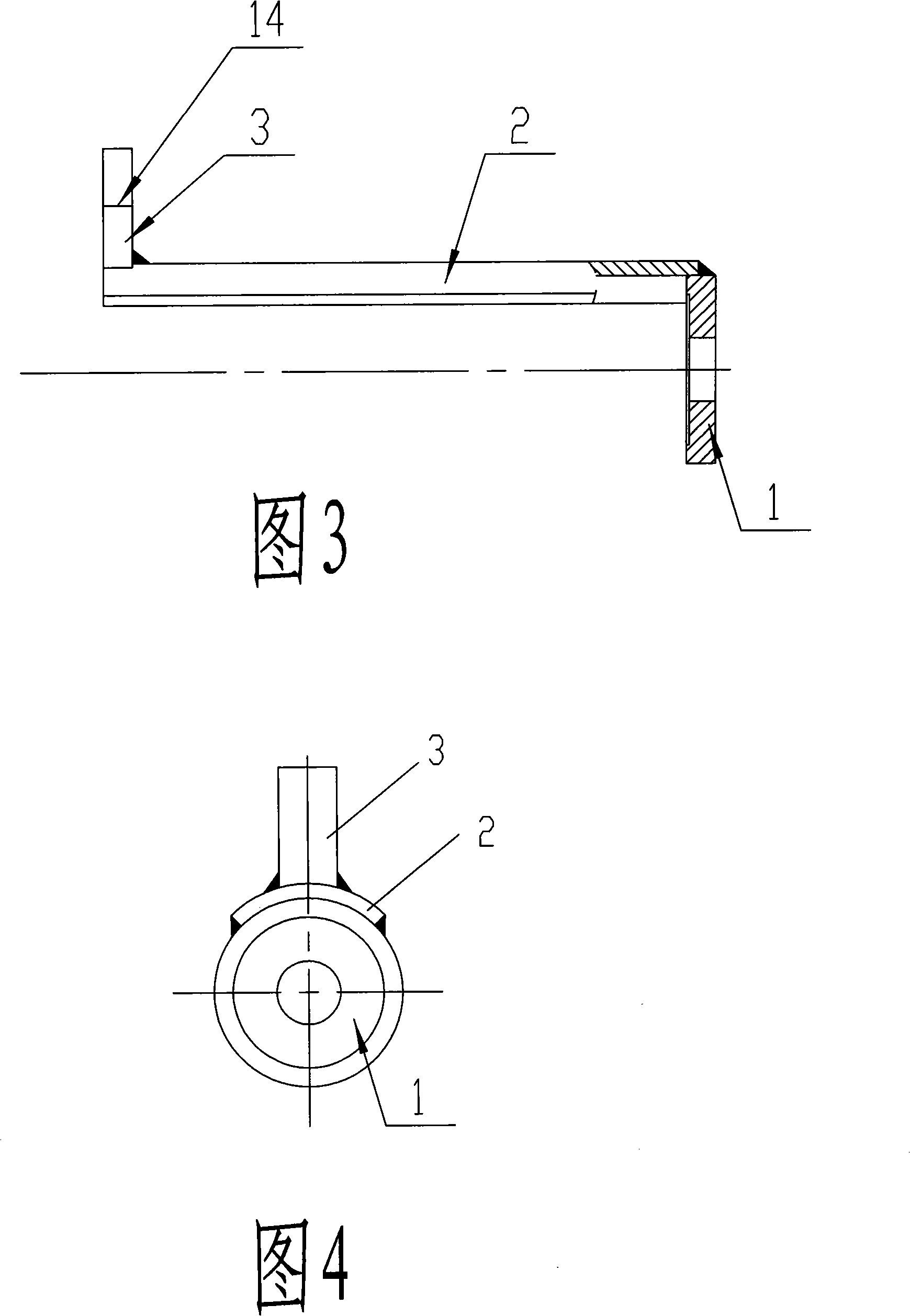

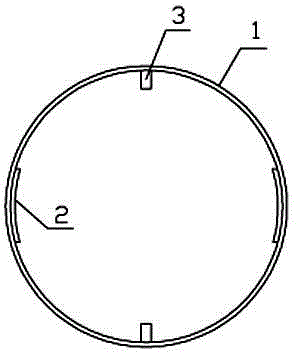

Apparatus and method for measuring meshing gear interspace in closed chamber

InactiveCN101256066AImprove efficiencySolve small spaceMechanical clearance measurementsClosed chamberEngineering

The invention relates to a device for measuring meshing gear clearance in a closed cavity, which is mainly composed of an integrated retaining plate, a long arc plate and a measure square plate, the long arc plate is an arc shaped tile plate, the retaining plate is a round plate, the center of the circle is equipped with a round hole, the measure square plate is a square plate, the retaining plate is fixed on the inner side of the arc on one end of the long arc plate, the measure square plate is fixed on the outer side of the arc on the other end of the long arc plate, the side wall of the measure square plate is carved with a horizontal line. The measurement of the meshing gear clearance can be done with the device and measure method according to the invention, which has the merits of simplicity and convenience, high practicability, and high labor efficiency.

Owner:HUDONG HEAVY MACHINERY

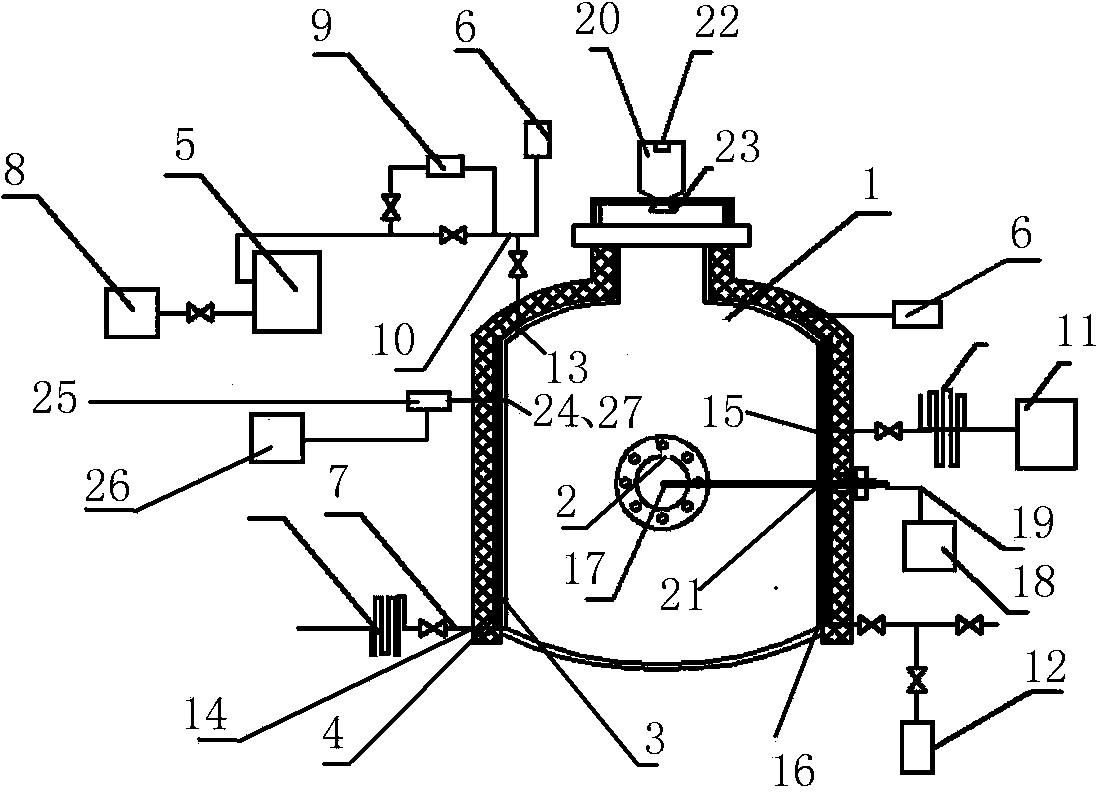

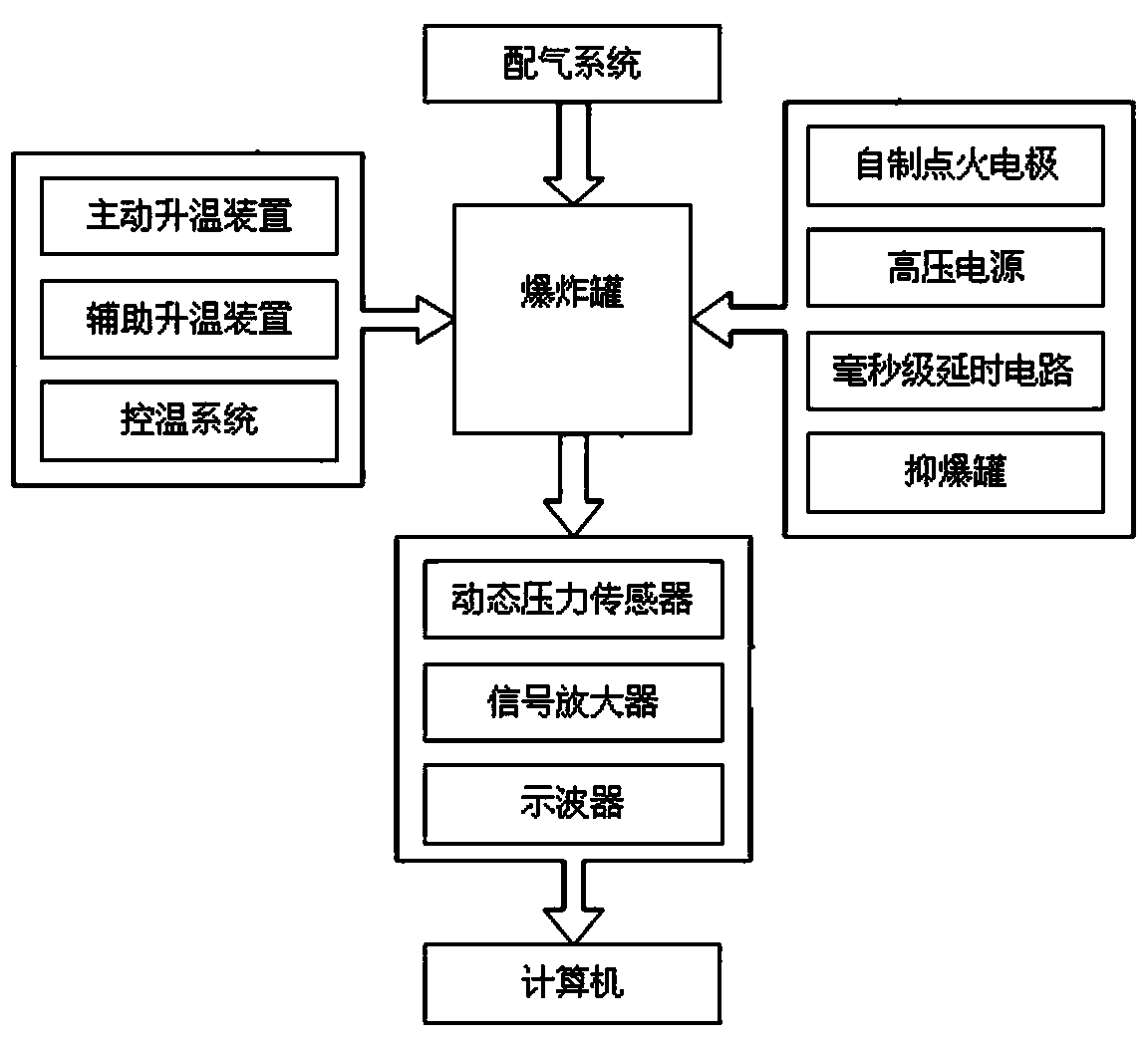

Combustible liquid vapor explosion and explosion suppression characteristic test system

InactiveCN103364531AFunctional DiversificationSimple processing capacityFuel testingIgnition delayEngineering

The invention discloses a combustible liquid vapor explosion and explosion suppression characteristic test system. The system comprises an explosion tank, a double heating temperature-control system, a gas distribution system, a double ignition delay explosion suppression system, and a data test and acquisition system. The explosion tank is provided with a window and six through holes. The explosion tank is covered by a heating sheet of the double heating temperature-control system on the explosion tank. An insulation material is covered on the heating sheet. The temperature-control system is connected with the heating sheet and an air heater. An air compressor of the gas distribution system communicates with a through hole I through the air heater, an ejector, and an ejector pipe. A gas discharge pipe communicates with a through hole II. A vacuum pump communicates with a through hole III. A static pressure sensor communicates with a through hole IV. An ignition electrode of the double ignition delay explosion suppression system is arranged in the explosion tank, and is connected with a delay circuit and a high-voltage power source through the through hole V. An explosion suppression tank is arranged on the top of the explosion tank. A gas generator is arranged in the explosion suppression tank. A nozzle is arranged on the bottom of the explosion suppression tank. A dynamic pressure sensor of the data test and acquisition system is arranged on the through hole VI, and is connected with an oscilloscope through a signal amplifier. The system provided by the invention has the advantages of simple application, multiple test functions, and high precision.

Owner:ZHONGBEI UNIV

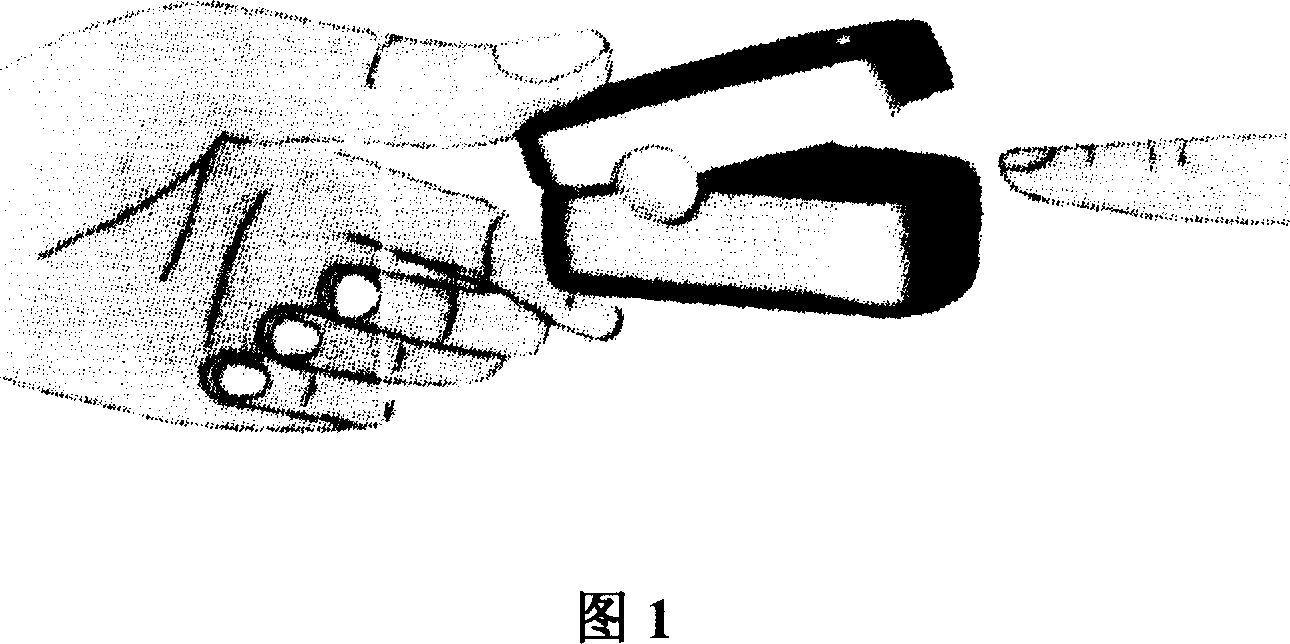

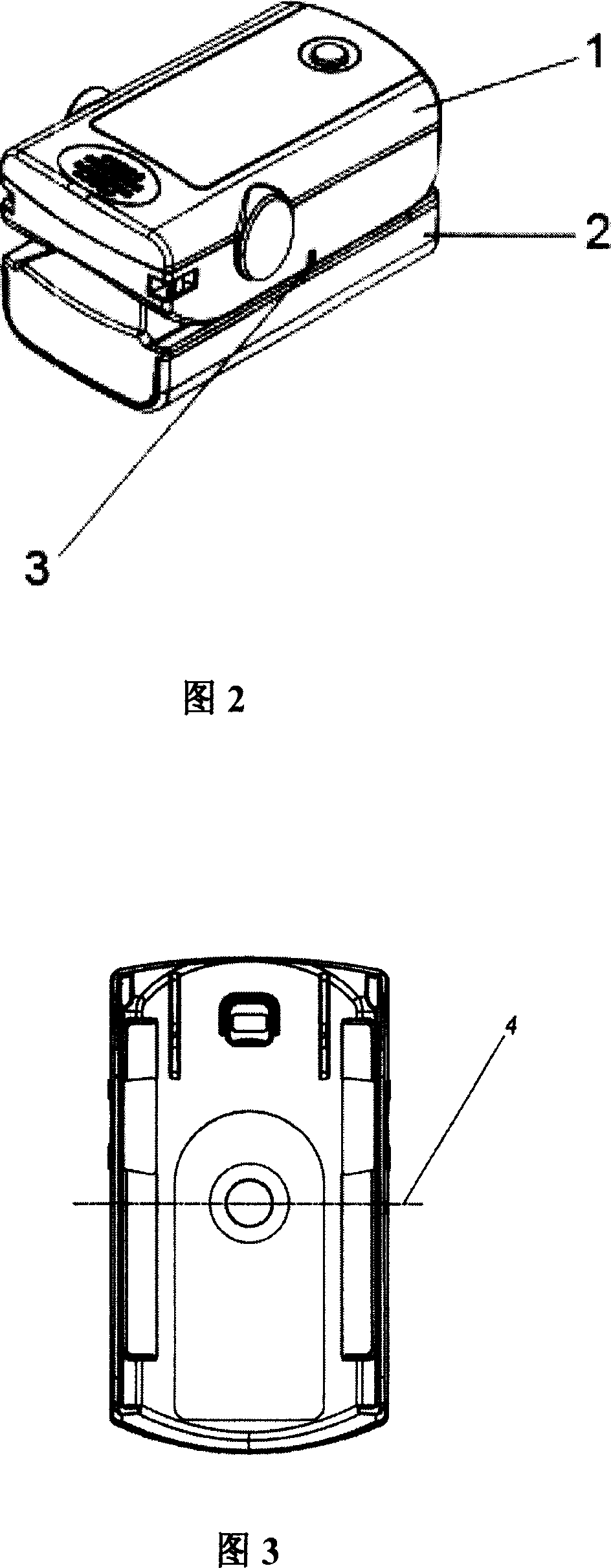

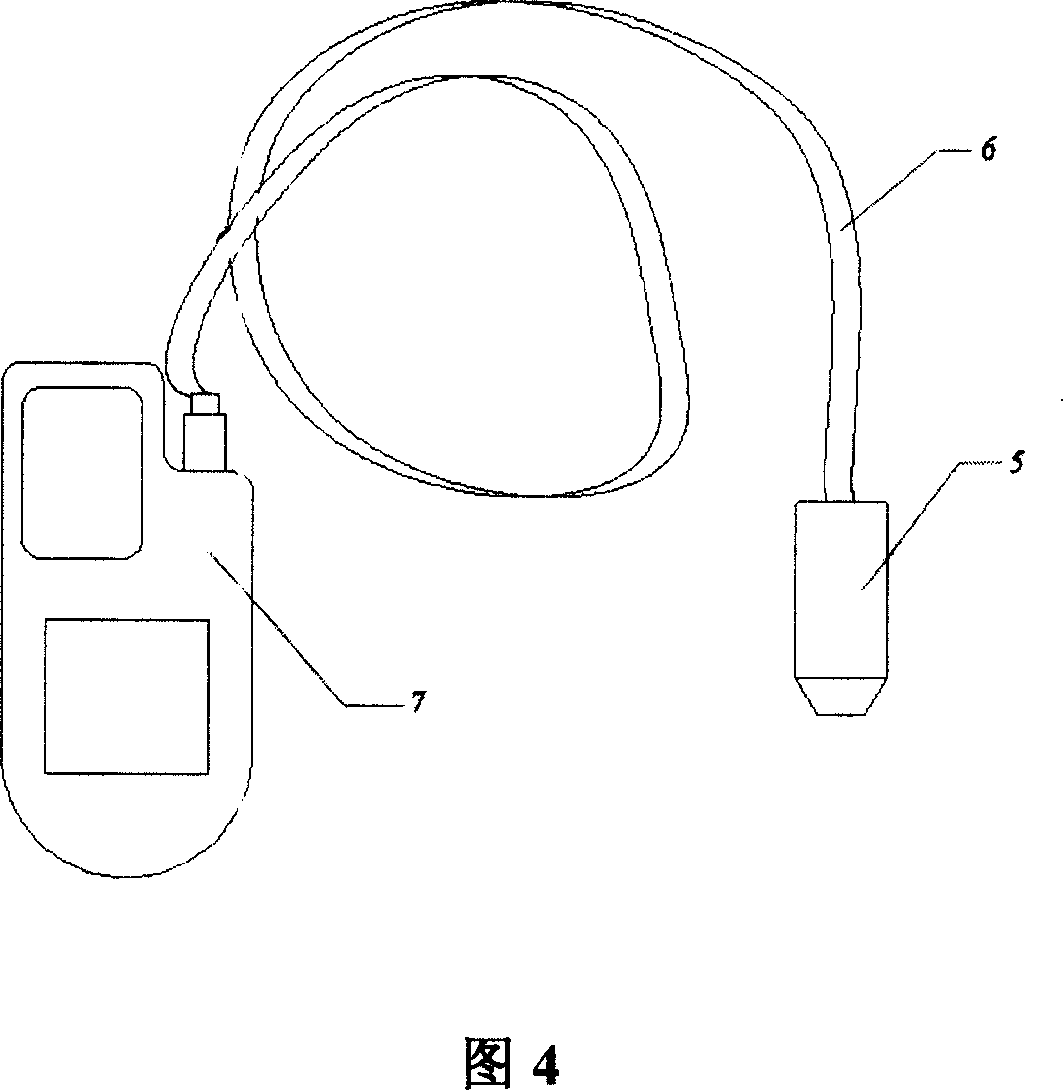

A finger-clipped saturation oxygen measuring apparatus

ActiveCN1961827AHumanizedAccurate measurement dataDiagnostic recording/measuringSensorsFluorescenceEngineering

The invention relates to a finger blood oxygen saturation tester, which comprises upper and lower frames, flexible composite structure, internal testing photoelectric tube, internal power, testing circuit, processing circuit, controlling circuit, and display, wherein the invention is characterized in that: the side of outer frame has a mark; the vertical line of said mark is superposition with the vertical line of internal testing photoelectric tube inside the frame; the mark can be protruded or concave on the side of frame, or marked with fluorescence. With said invention, the testing position can be watched simply.

Owner:BEIJING CHOICE ELECTRONICS TECH CO LTD

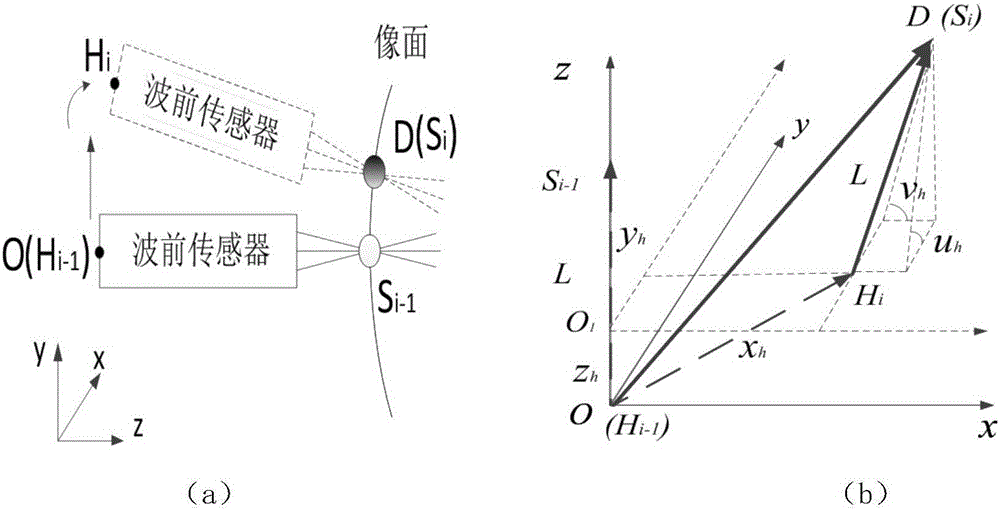

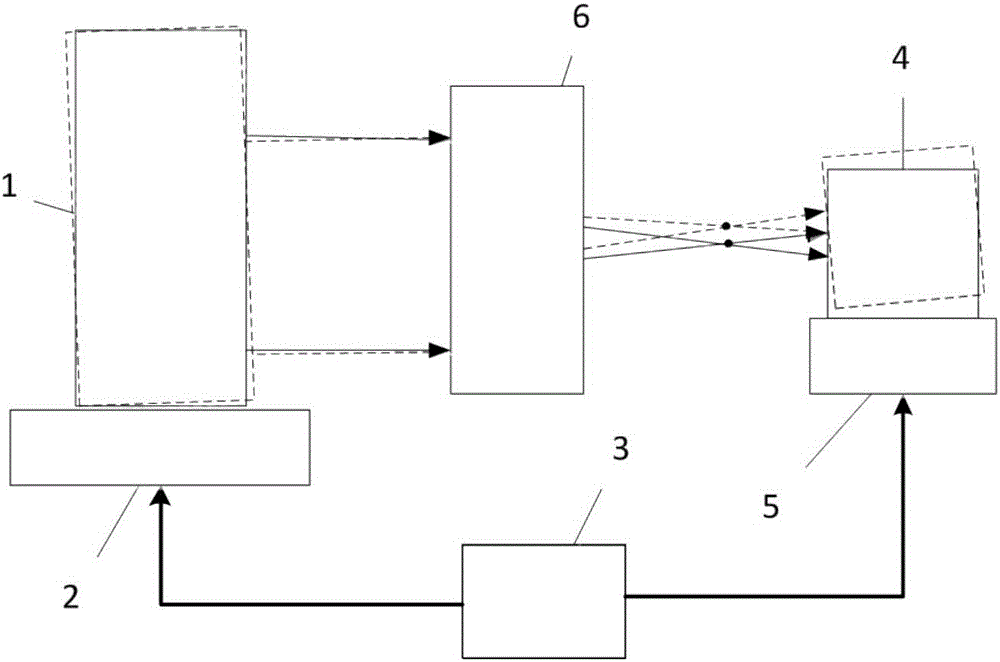

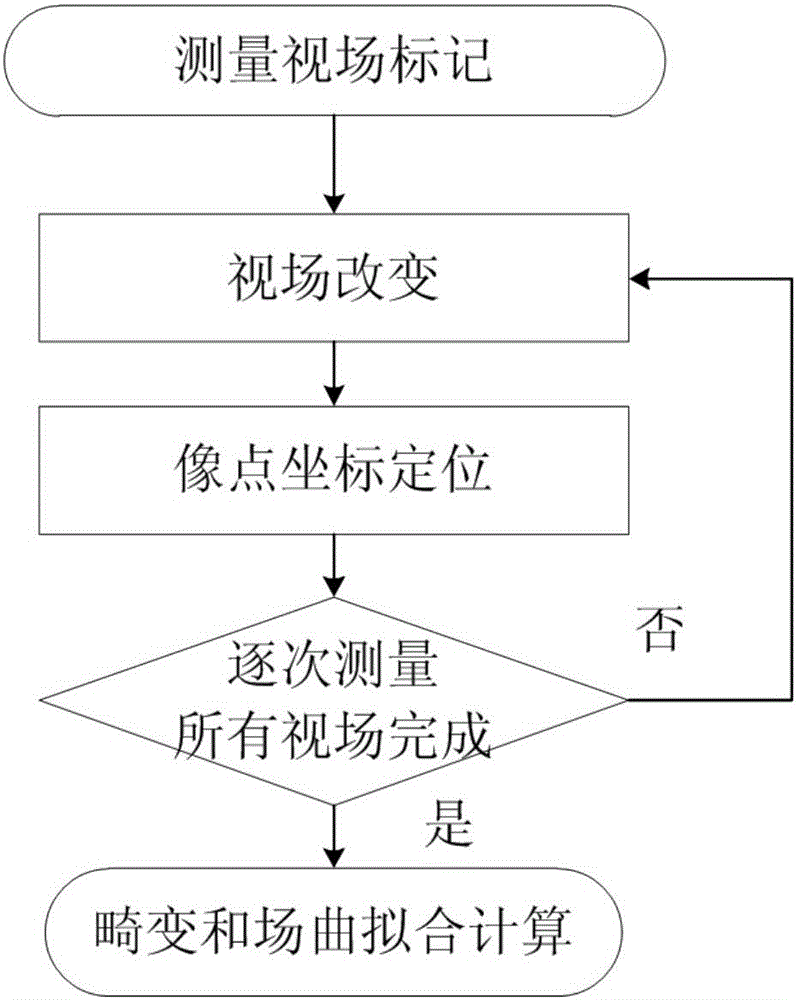

Method for measuring large field-of-view telescope optical system distortion and field curvature

ActiveCN106404352AOvercome operabilityOvercome precisionGeometric properties/aberration measurementWavefrontClosed loop

The invention relates to a method for measuring large field-of-view telescope optical system distortion and field curvature. According to the invention, parallel light sources (1) come directly into a to-be-detected large field-of-view telescope (6). The field of view can be changed through the adjustment of the inclination and the pitching attitude of the parallel light sources (1). In the process of full field of view measurement, the to-be-detected large field-of-view telescope (6) remains to be in a fixed state. A computer (3), a wavefront detector (4) and the motion platform (5) of the wavefront detector form a closed-loop positioning structure to precisely measure and position the spatial positions of the image points of the to-be-detected large field-of-view telescope. Through the comparison of the ideal positions of the image points, the distortion and field curvature of the to-be-detected large field-of-view telescope (6) optical system can be obtained through fitting. The measuring method of the invention can be operated simply and effectively and achieves high measurement efficiency. Further, the method can perform automatic checking and can provide reliable measurement data for large field-of-view telescope optical system to correct distortion and field curvature.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

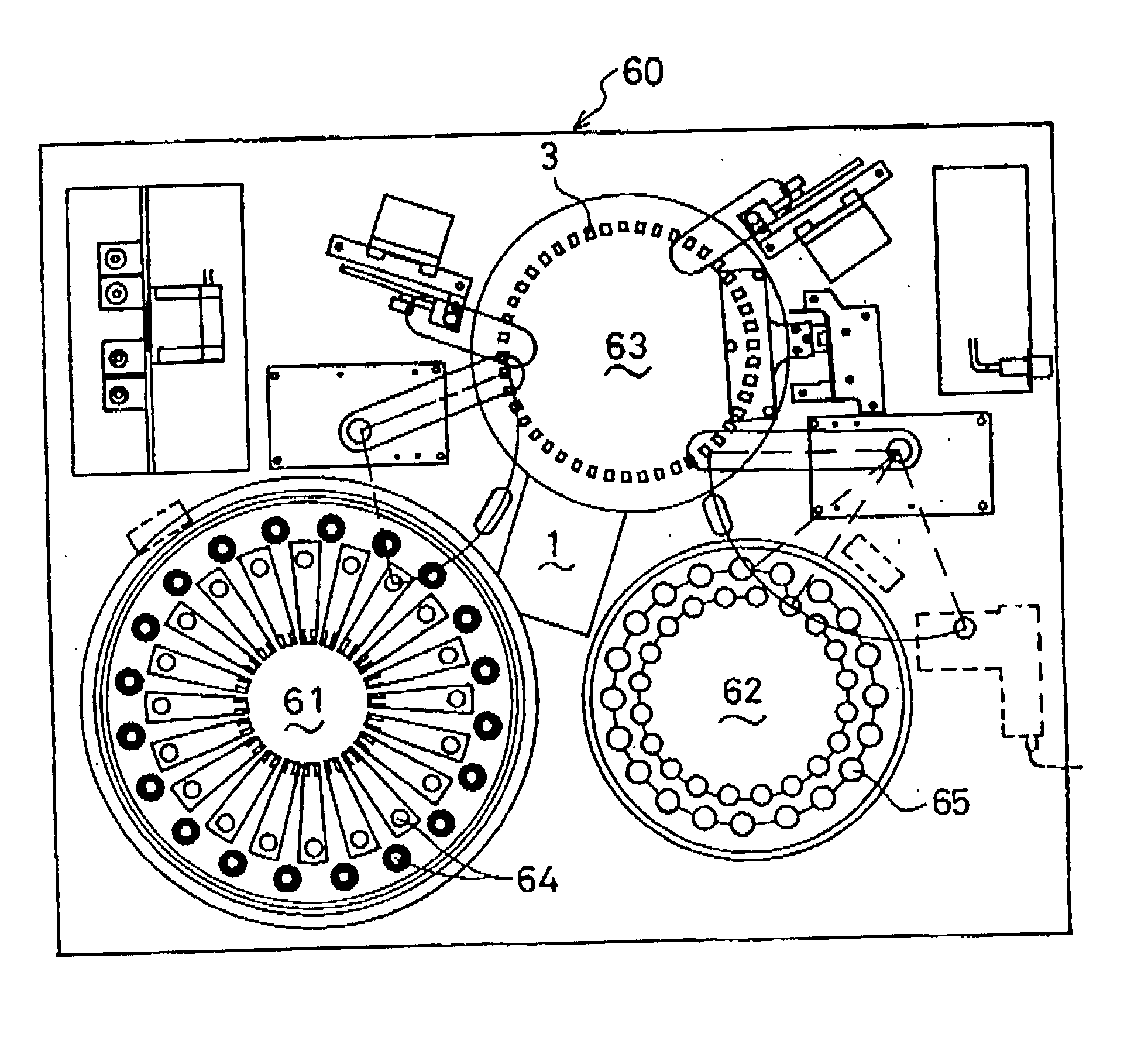

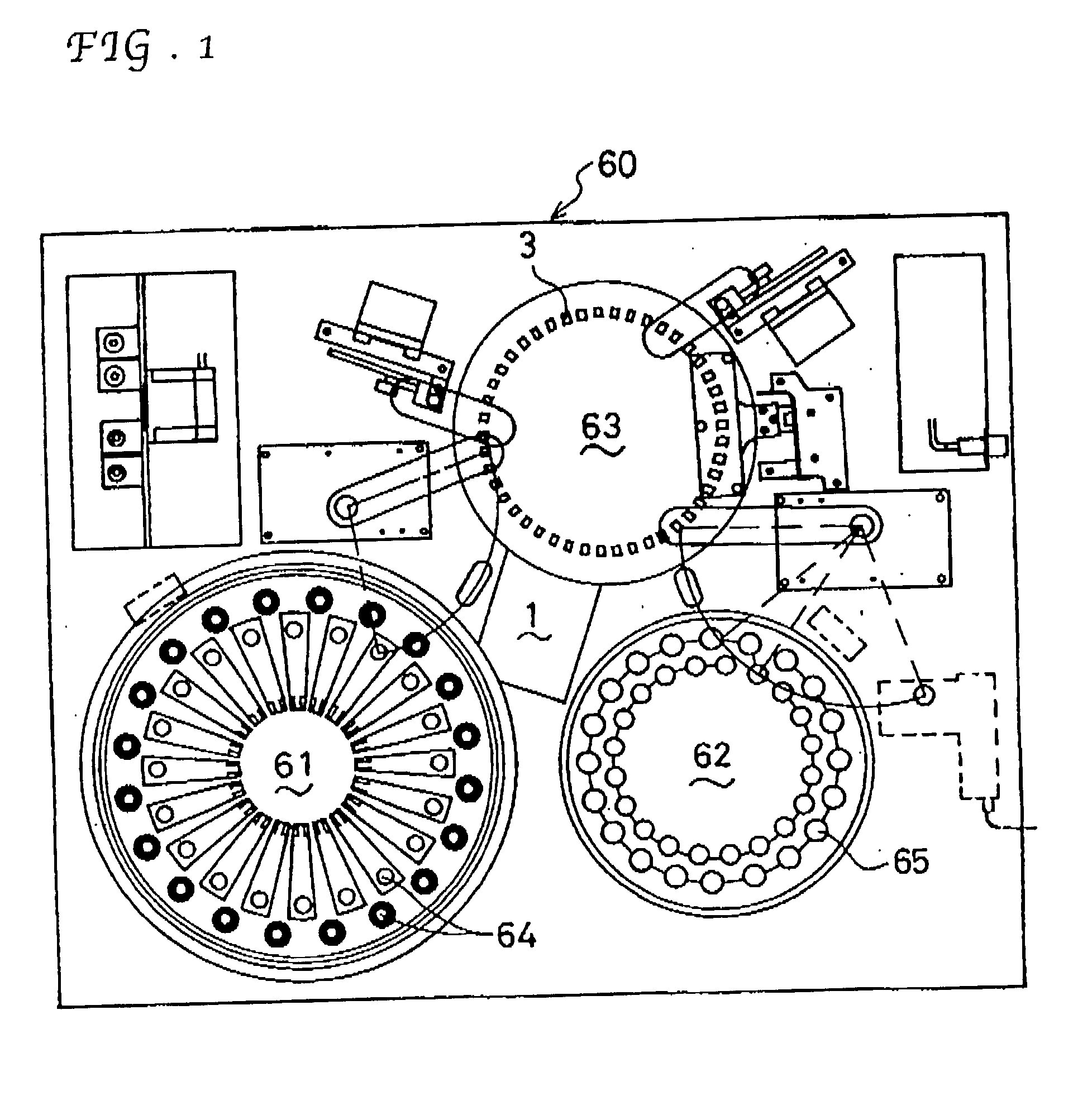

Colorimetric absorbance measurement apparatus

InactiveUS20030072680A1Increase the number ofHigh measurement efficiencySamplingTransmissivity measurementsTiming generatorMotor drive

In a colorimetric absorbance measurement apparatus, a filter assembly on which a plurality of filters are arranged in a circular pattern is continuously rotated by a motor at a regular speed based on a motor drive signal fed from a motor drive circuit, each of the filters being characterized by passing only such light components that have wavelengths falling within a range centering on a specific wavelength. The motor drive signal produced by the motor drive circuit is also fed into a timing generator circuit. The timing generator circuit supplies an A / D conversion start signal to an A / D converter in synchronism with the timing at which a selected one of the multiple filters is positioned on the optical axis of a measuring light beam.

Owner:FURUNO ELECTRIC CO LTD

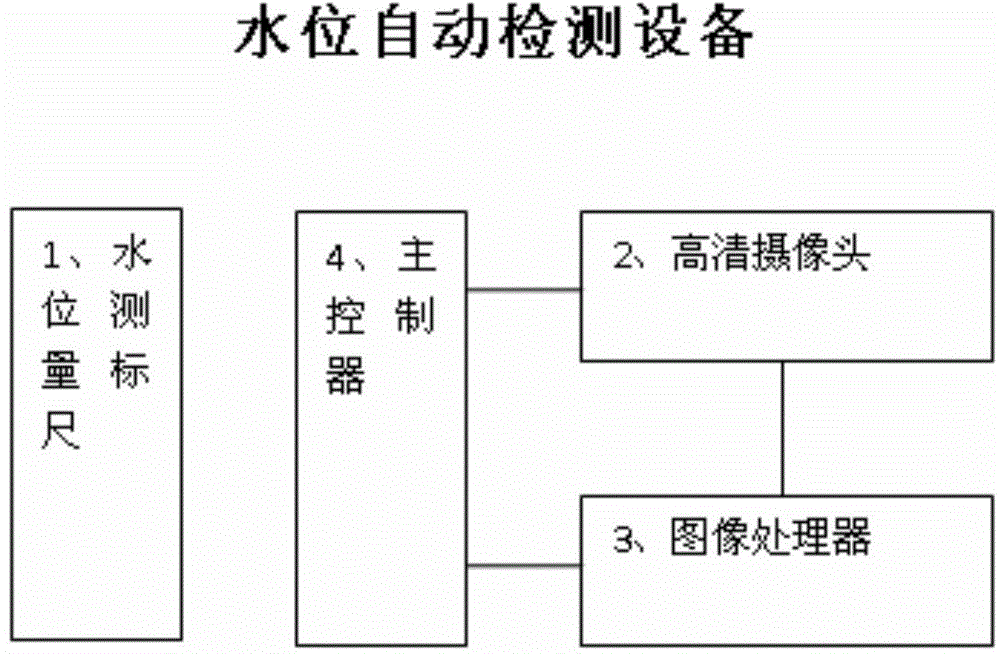

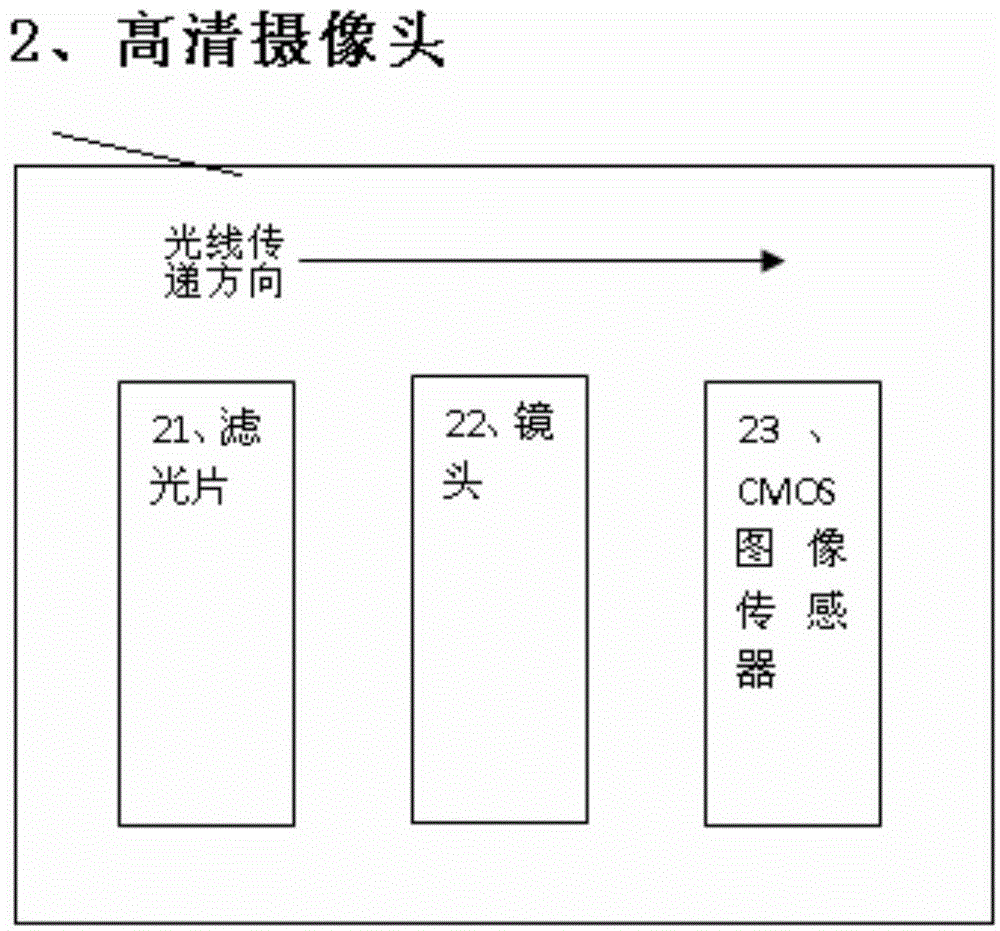

Automatic detection method for water level

InactiveCN104655233AAccurate detectionAccurate measurement dataLevel indicators by dip membersClosed circuit television systemsAutomatic test equipmentWater level

The invention relates to an automatic detection method for water level. The automatic detection method comprises the following steps: firstly, providing automatic detection equipment for the water level, wherein the detection equipment comprises a water level surveying rod, a high-definition camera, an image processor and a main controller; the water level surveying rod is vertically erected in water; the high-definition camera is used for shooting a part, above the water level, of the water level surveying rod, so an overwater staff image is obtained; the image processor is connected with the high-definition camera and is used for processing the overwater staff image, so the current water level is obtained; the main controller is connected with the image processor and is used for determining whether to alarm for the water level based on the current water level; secondly, using the equipment for detecting.

Owner:周俊彤 +2

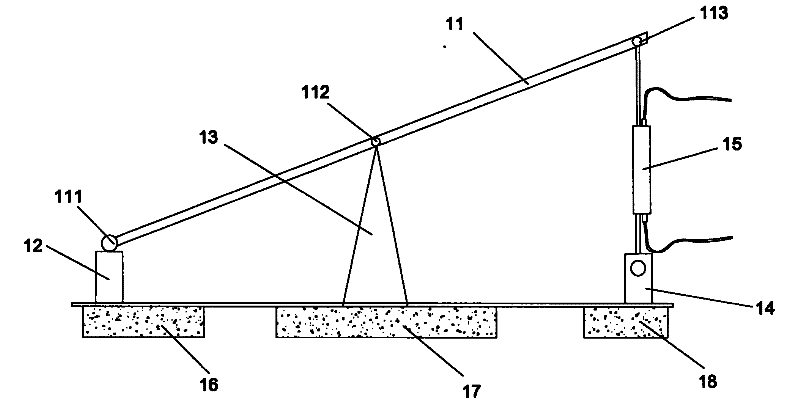

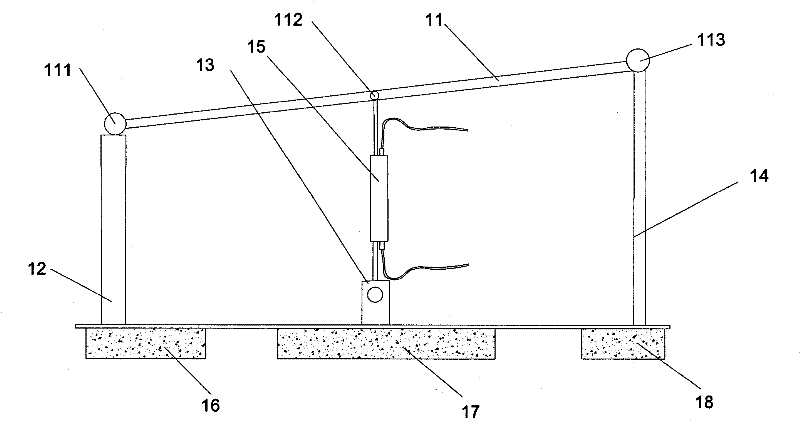

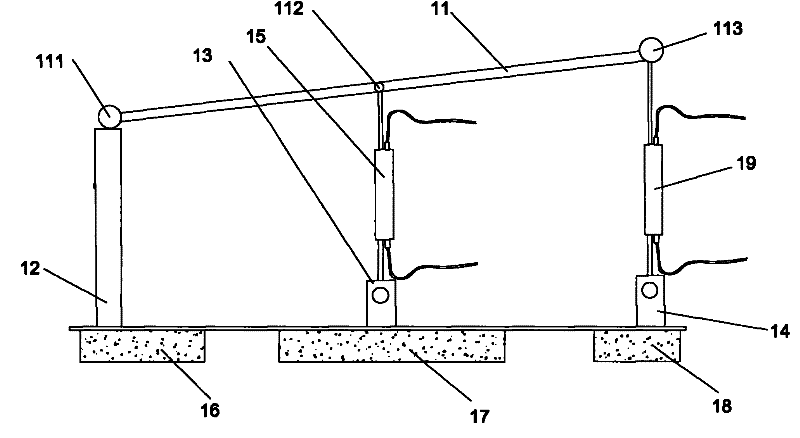

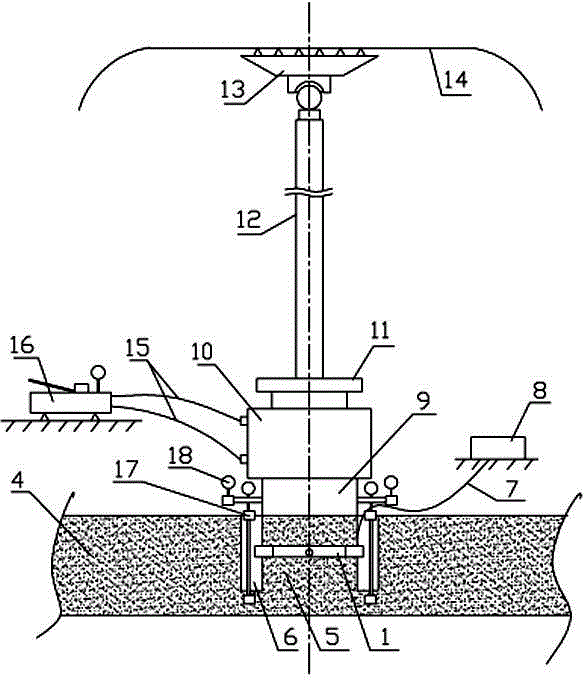

Device for measuring ground settlement

InactiveCN102235887ASimple structureAccurate measurementUsing optical meansConverting sensor output opticallyGround settlementGrating

The invention belongs to the technical field of engineering measurement, and relates to a device for measuring ground settlement, in particular to a device for measuring the settlement of a tunnel or a subway pipeline by combining an optical fiber grating sensor. The device for measuring the ground settlement comprises the optical fiber grating sensor, and is characterized by also comprising a lever and three supports which are positioned under any three positions of the lever respectively; the bottoms of the three supports are fixed on the ground; the tops of the supports are connected with the lever positioned over the supports or the optical fiber grating sensor; and when the tops of the supports are connected with one end of the optical fiber grating sensor, the other end of the optical fiber grating sensor is connected with the lever positioned over the optical fiber grating sensor. The device has the advantages of simple structure and measuring accuracy.

Owner:SHANGHAI KNP CHEM +1

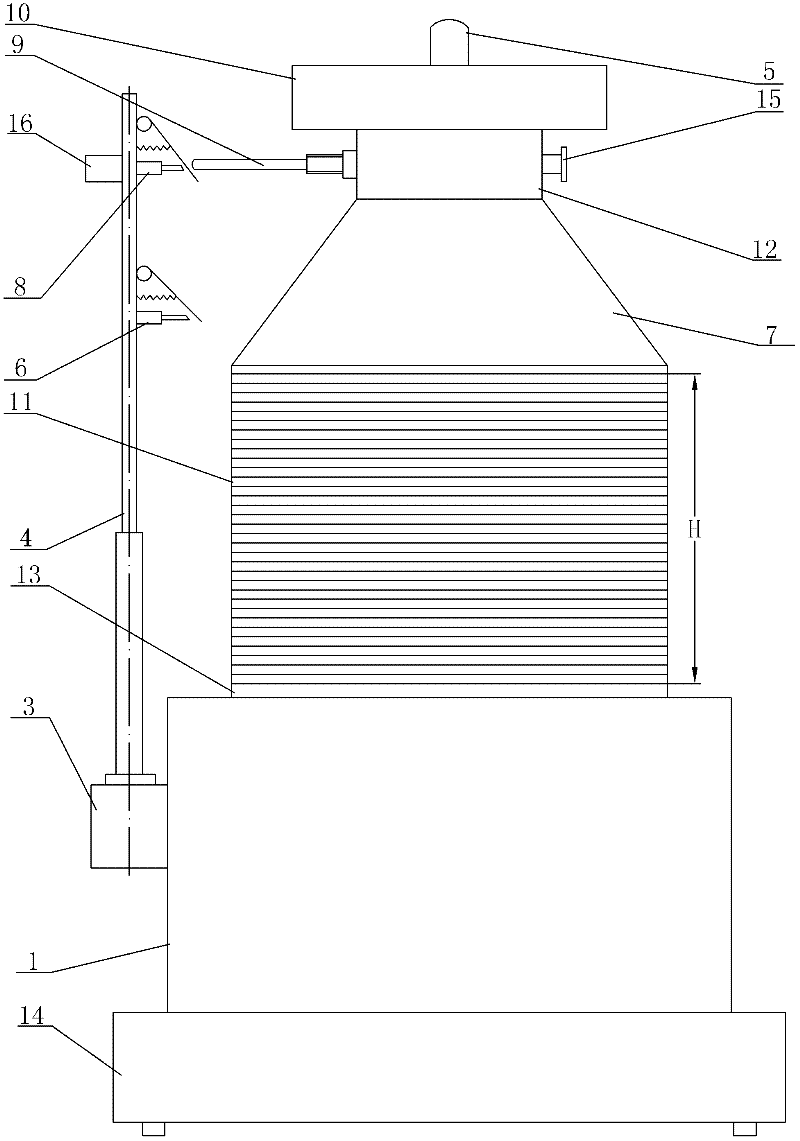

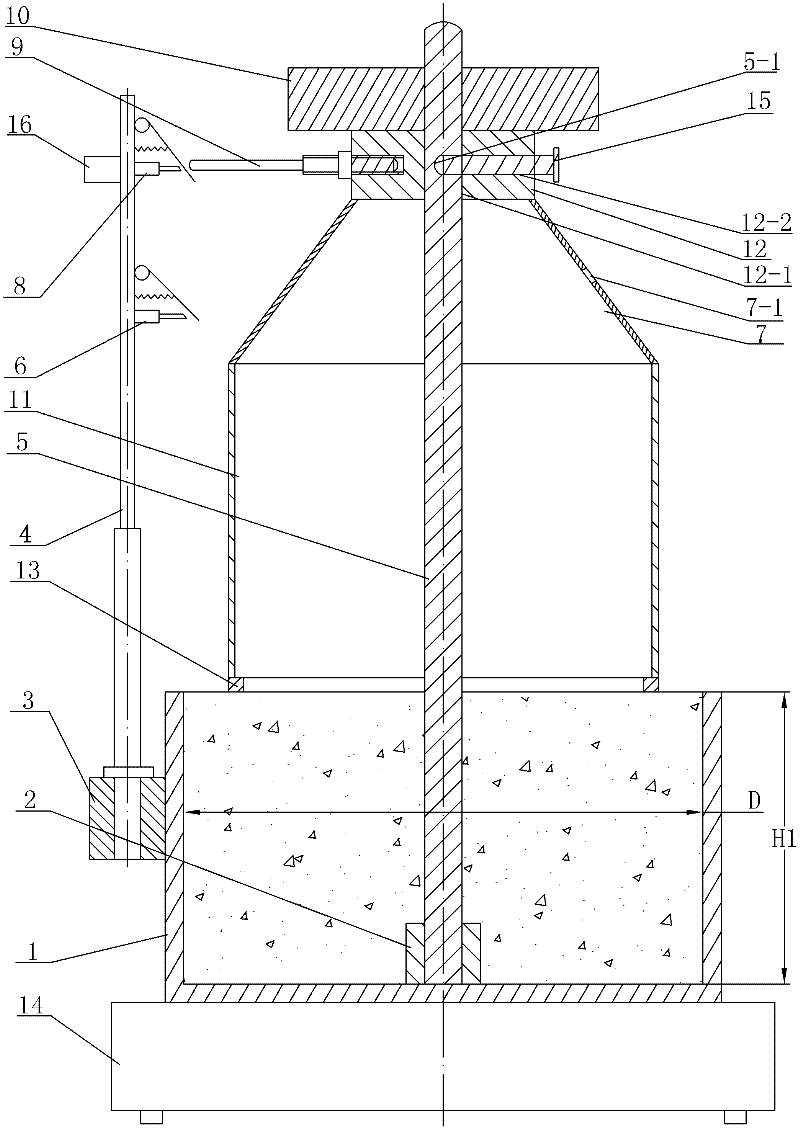

Device for measuring rheological parameters of fresh concrete

InactiveCN102590038ALarge measuring rangeWide measurement rangeFlow propertiesCircular discEngineering

The invention provides a device for measuring rheological parameters of concrete, and particularly relates to a device for measuring rheological parameters of fresh concrete, so as to solve the problem of inaccurate measuring result in the prior art for measuring the rheological parameters of the fresh concrete and the problem that the adaptability of the prior art is limited. The device comprises a cylindrical container, a first casing pipe, a second casing pipe, an upright rod, a shaft rod, a conical cylinder, a first time switch, a second time switch, a deflector rod, a weight, a cylinder,a disc, a ring, a concrete vibrating platform and a timer, wherein the end face of one end of the first casing pipe is fixedly arranged on the end face of the bottom in the cylindrical container; theend face of the other end of the cylinder is connected with the end face of one end of the ring; one end of the shaft rod is placed in the first casing pipe; the end face of one end of the shaft rod is propped against the end face of the bottom in the cylindrical container; the weight is arranged on the upper end face of the disc; and the cylindrical container is fixedly arranged on the surface of the concrete vibrating platform. The device is used for measuring the rheological parameters of the fresh concrete.

Owner:HARBIN INST OF TECH +1

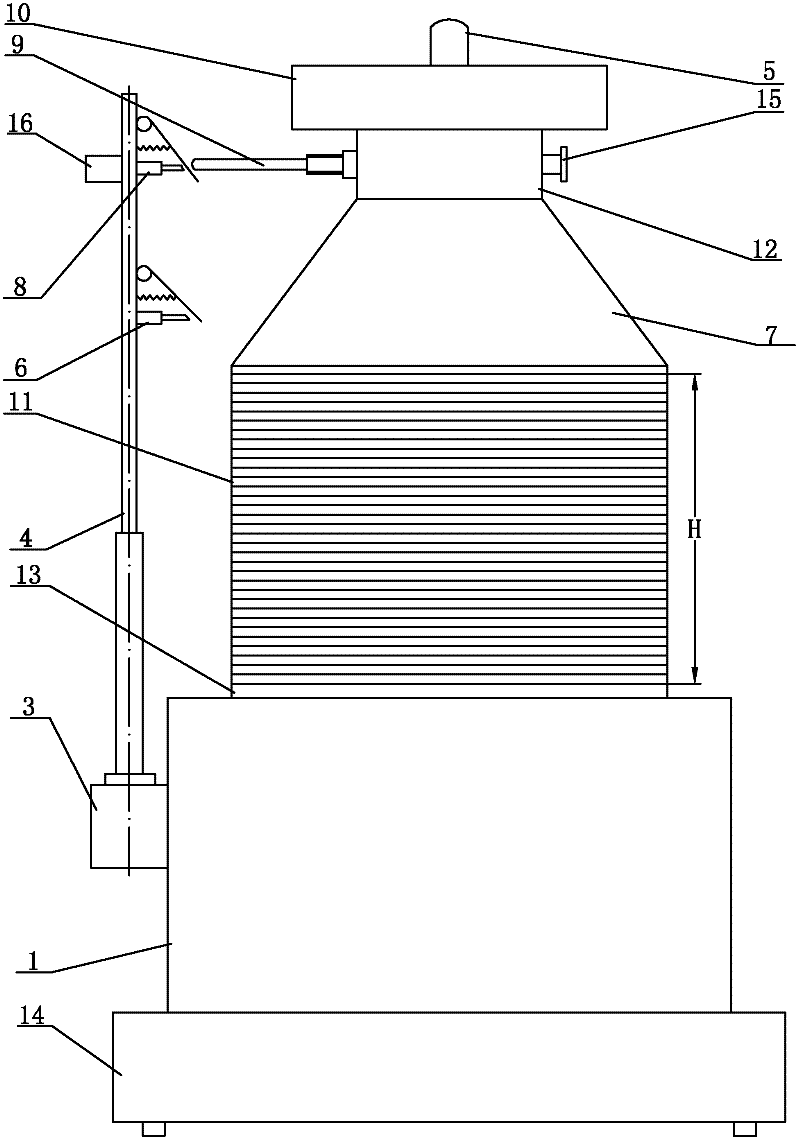

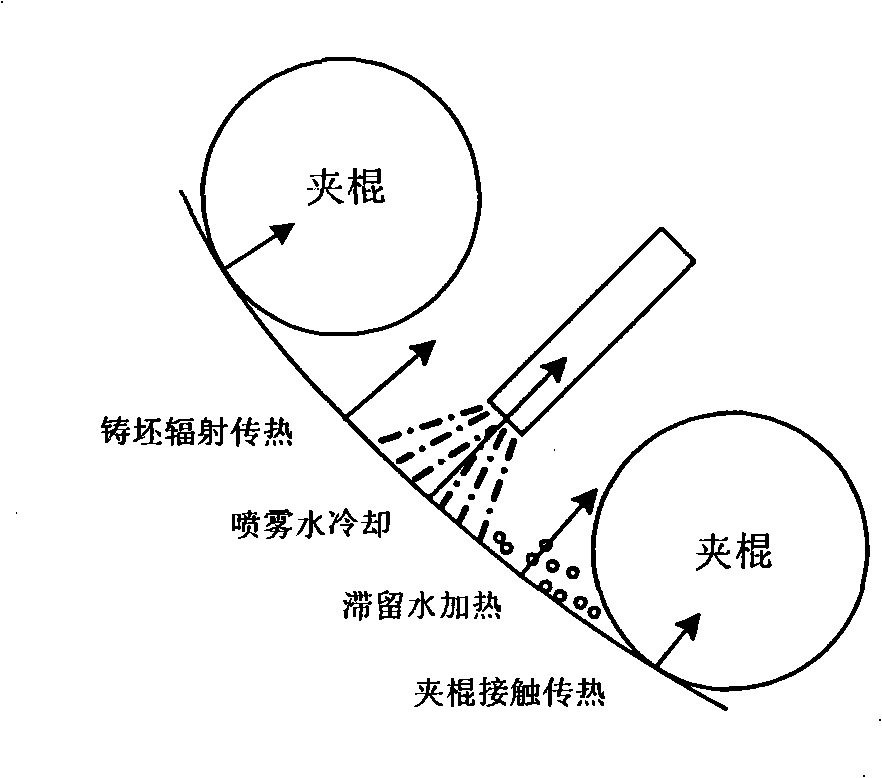

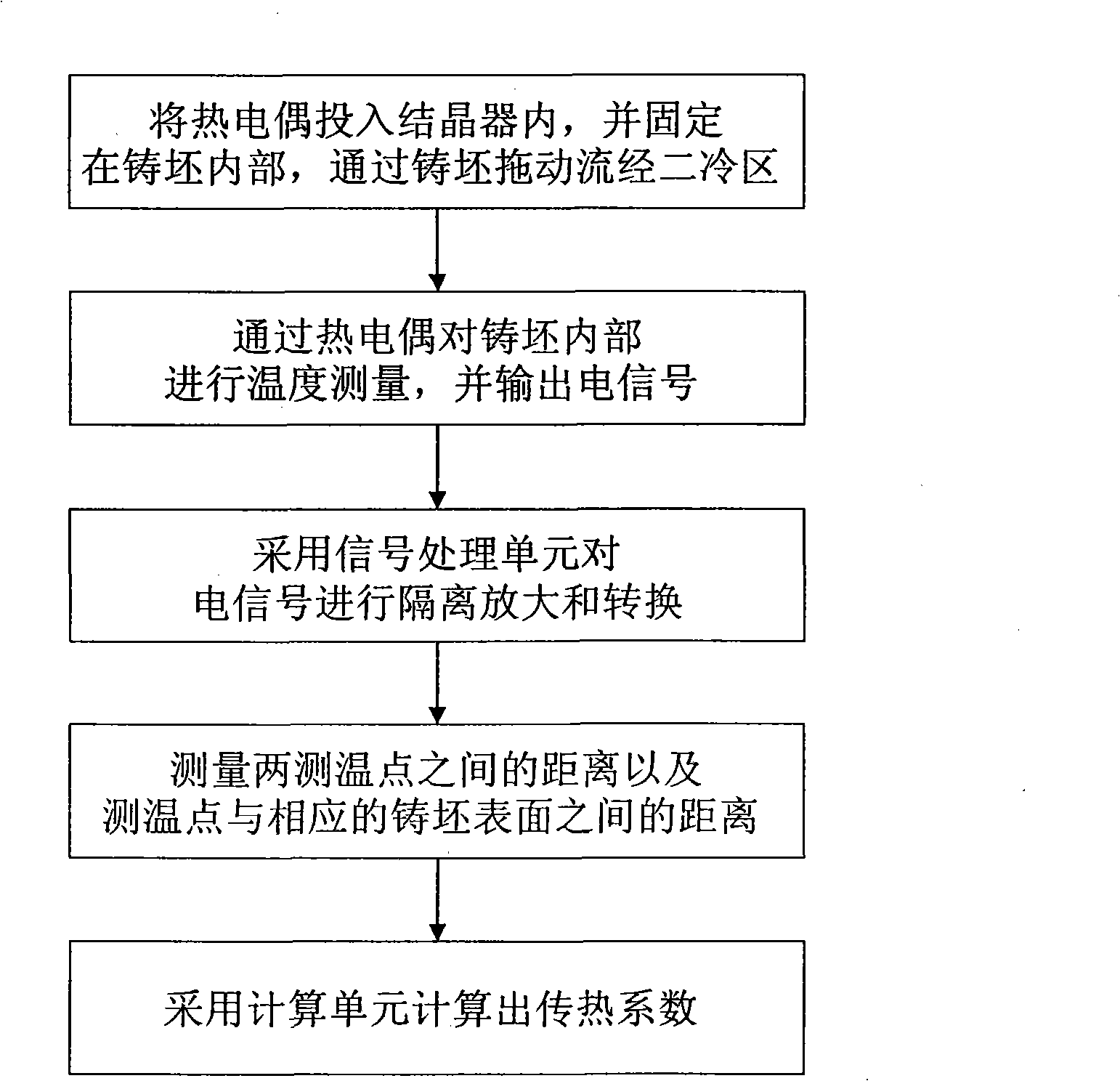

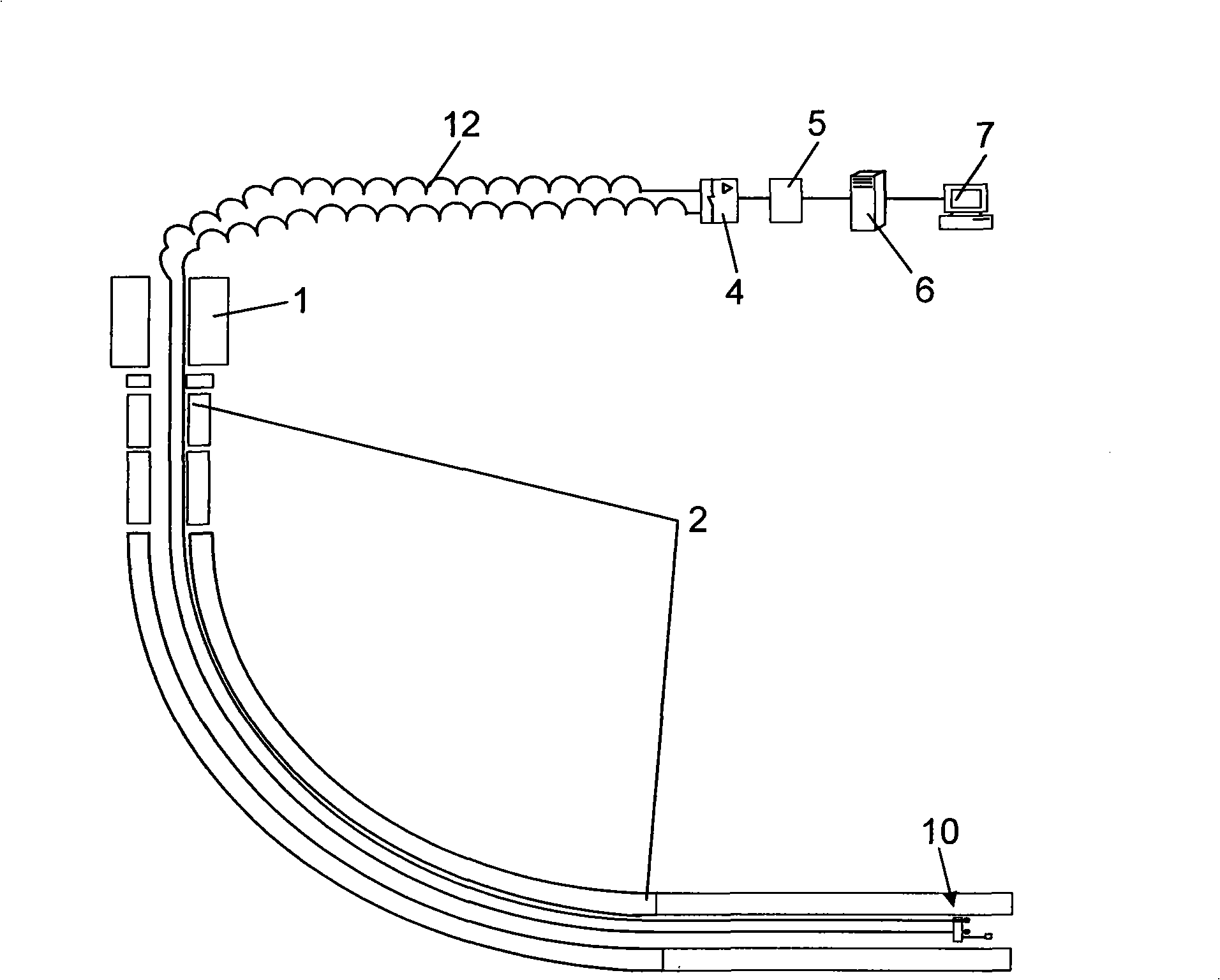

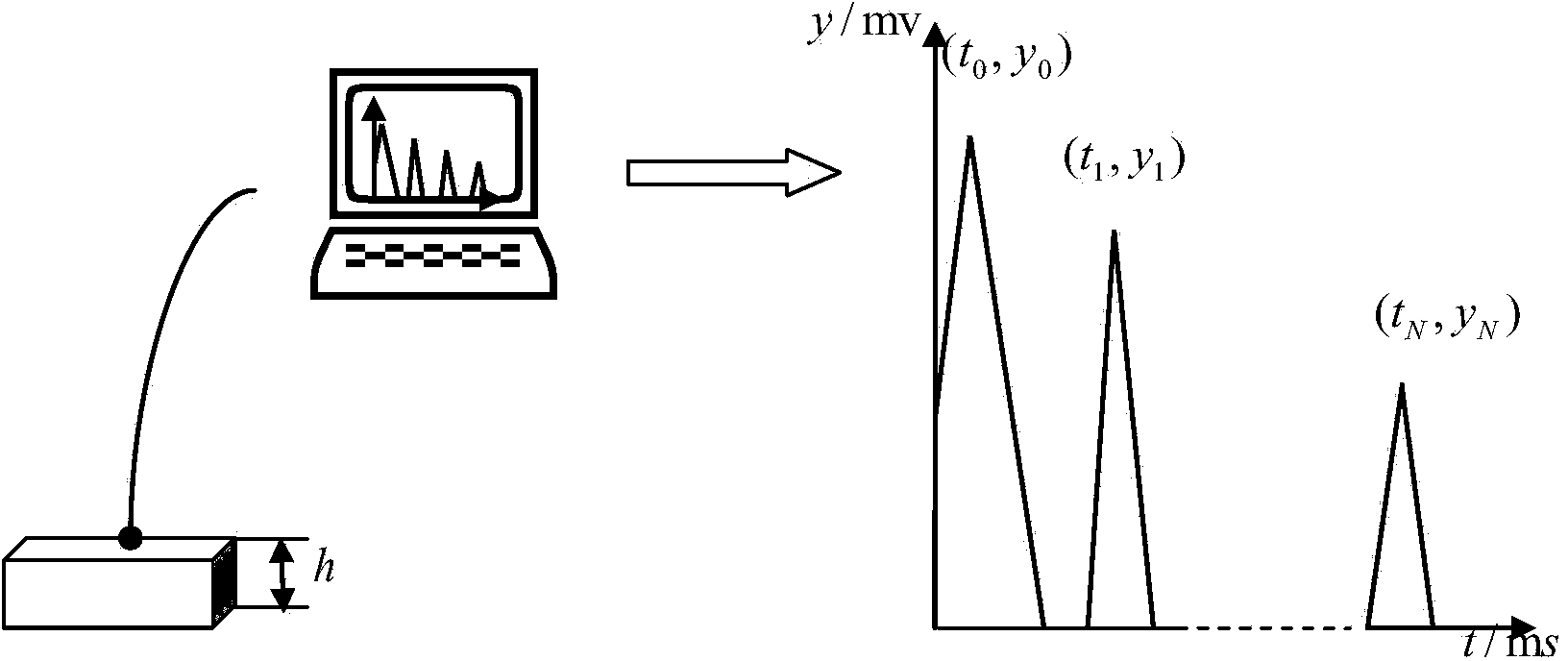

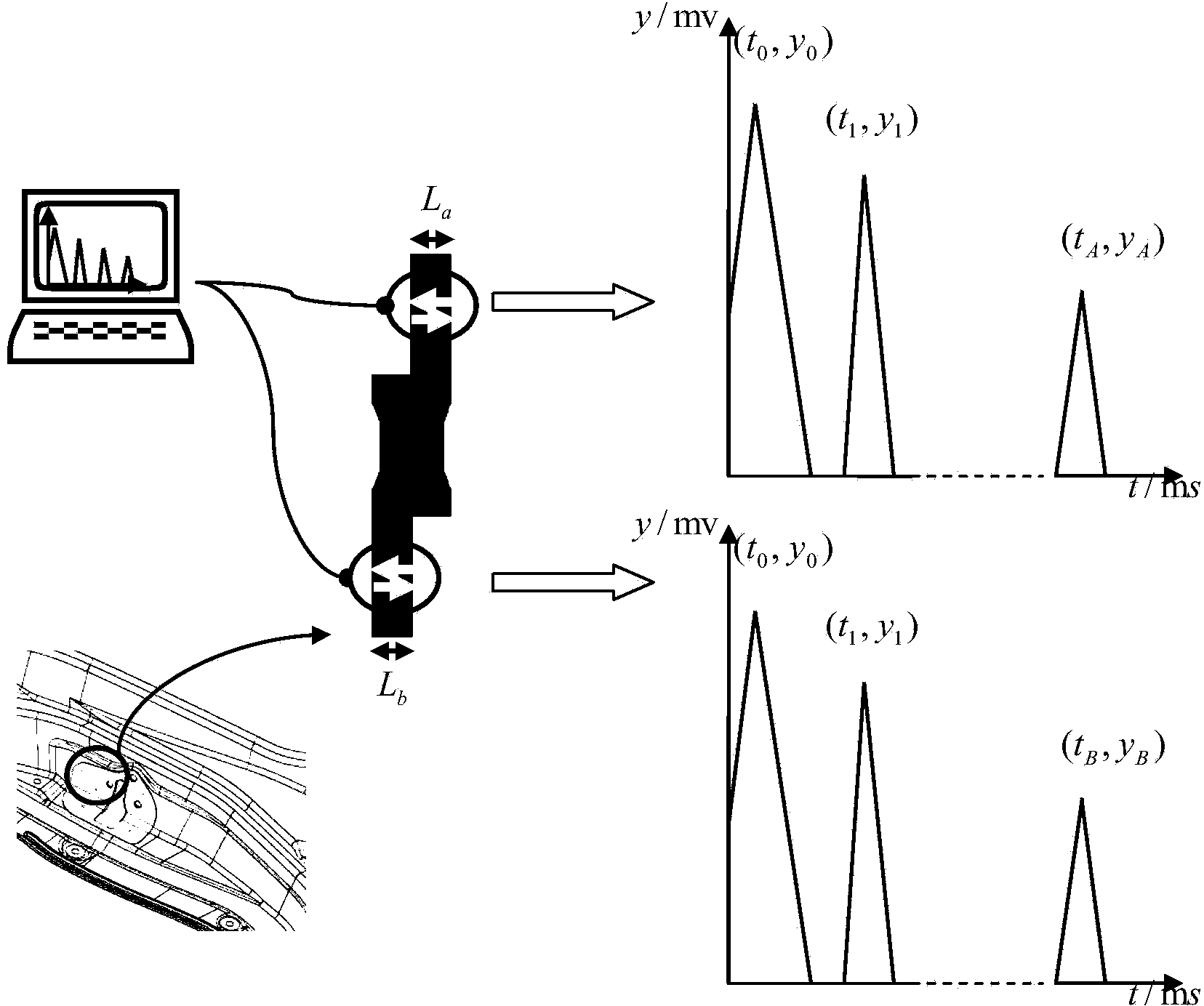

Method for measuring coefficient of secondary cooling area for continuous casting

ActiveCN101349663AAvoid wiggle phenomenonReliable measurement dataMaterial thermal conductivityMaterial heat developmentDiffusionMeasurement point

The invention discloses a method for testing the heat transfer coefficient in a continuous-casting secondary cooling area, which comprises casting a flame couple into a crystallizer, and fixing in a casting blank, dragging the flame couple through the casting blank to pass through the secondary cooling area, measuring the temperatures of two temperature measurement points in the casting blank through the flame couple, outputting electrical signals, adopting a signal processing unit to separate and magnify the electrical signals, and conversing into digital signals to be output, splitting the casting blank, measuring the distance between two temperature measurement points in the casting blank, adopting a calculation unit to record each measurement data, calculating and processing, and calculating the heat transfer coefficient. The testing method adopts a couple pulling method to directly measure temperatures in the casting blank of the secondary cooling area, and actually reflects the integral influences of various heat diffusion in the secondary cooling area through calculating to get the heat transfer coefficient, the measurement data are more accurate and reliable, and the actual production applicability is improved. The phenomenon that the flame couple is swung is avoided through adopting a supporting stand to fix the flame couple, and the accuracy of measurement is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Drive hub bearing unit assembly clearance measurement method

ActiveCN101825427AImprove detection efficiencyEliminate the effects of parallelismUsing electrical meansEngineeringExtreme position

The invention discloses a new measurement method for automobile drive hub bearing unit assembly clearance, which can carry out rotary multiple precise measurement to the automobile drive hub bearing unit assembly clearance to reach the upper extreme position and the lower extreme position of the inner ring flange raceway relative to the outer flange raceway of the drive hub bearing unit assembly and eliminate the interference error between the outer raceway and a retainer, so all rolling elements are fully contacted with the raceways, and the repeatability precision of the clearance of the automobile drive hub bearing unit assembly is assured.

Owner:HUBEI NEW TORCH SCIENCE & TECHNOLOGY CO LTD

Field rock mass poisson ratio test method

InactiveCN104483199AFully reflect the real stateLow costMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementElectrical resistance and conductanceBedrock

The invention discloses a field rock mass poisson ratio test method. The method comprises the steps of firstly digging a test flat hole in a mountain, drilling a cylindrical test piece on bedrock on the bottom surface of the test flat hole by utilizing a hollow drill bit, and symmetrically perforating test holes in the bottom of an annular groove at the periphery of the test piece; sleeving the test piece with an elastic steel lantern ring provided with a steel contact and a strain plate, connecting a strain plate test line and a resistance strain gauge, and calculating transverse deformation of the test piece by virtue of test; fixing the top surface of the test piece together with a test flat hole top plate sequentially through a pressure plate, a jack, a reducing connector steel plate, a combined force transfer rod and a hinge anchor, installing measuring points in bolt holes in two sides of the pressure plate and in the test holes in the bottom of the annular groove, and installing a dial indicator above the measuring point; calculating vertical deformation of the test piece after the load test; then calculating a corresponding transverse strain value and a vertical strain value, and calculating the poisson ratio of the test piece according to the transverse strain value and the vertical strain value. The field rock mass poisson ratio test method has advantages that the implementation method is simple and rapid, the measurement data is accurate and reliable, and the real condition of the rock mass can be comprehensively reflected.

Owner:YELLOW RIVER ENG CONSULTING

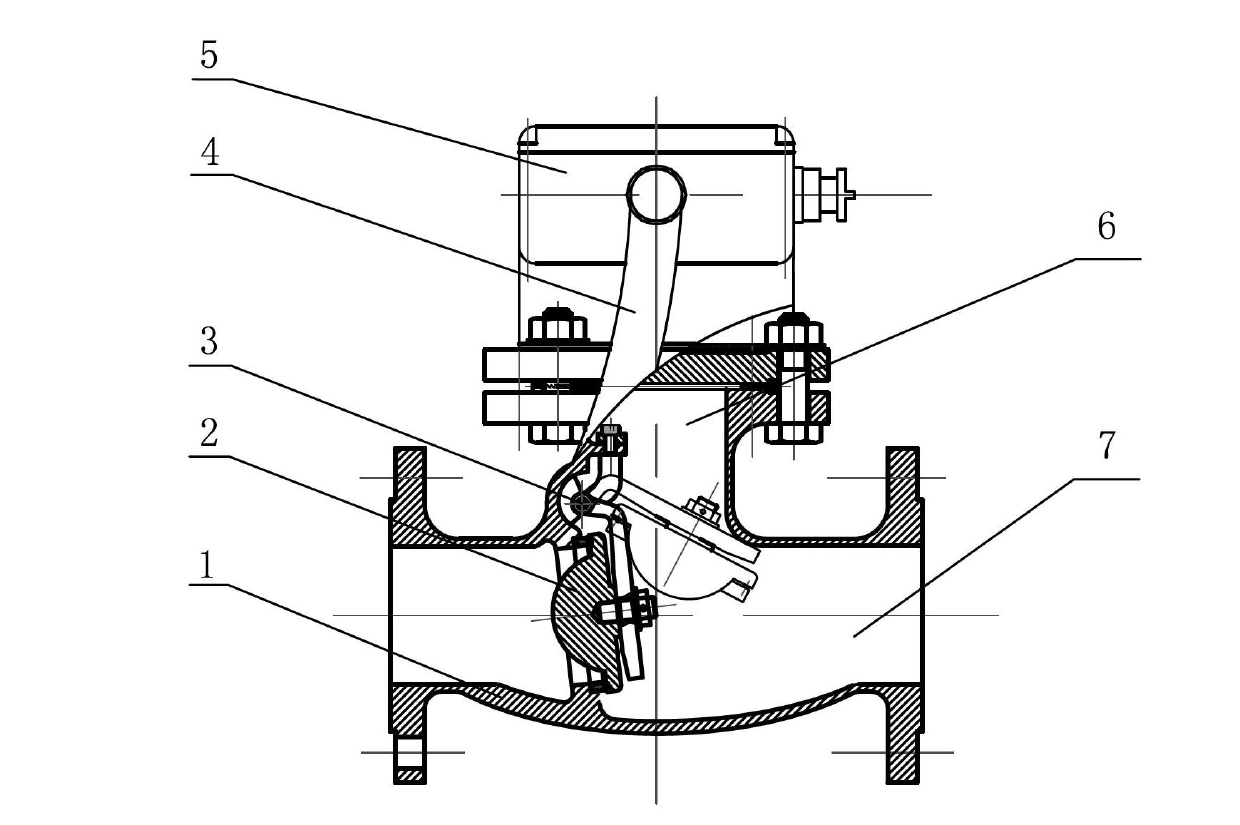

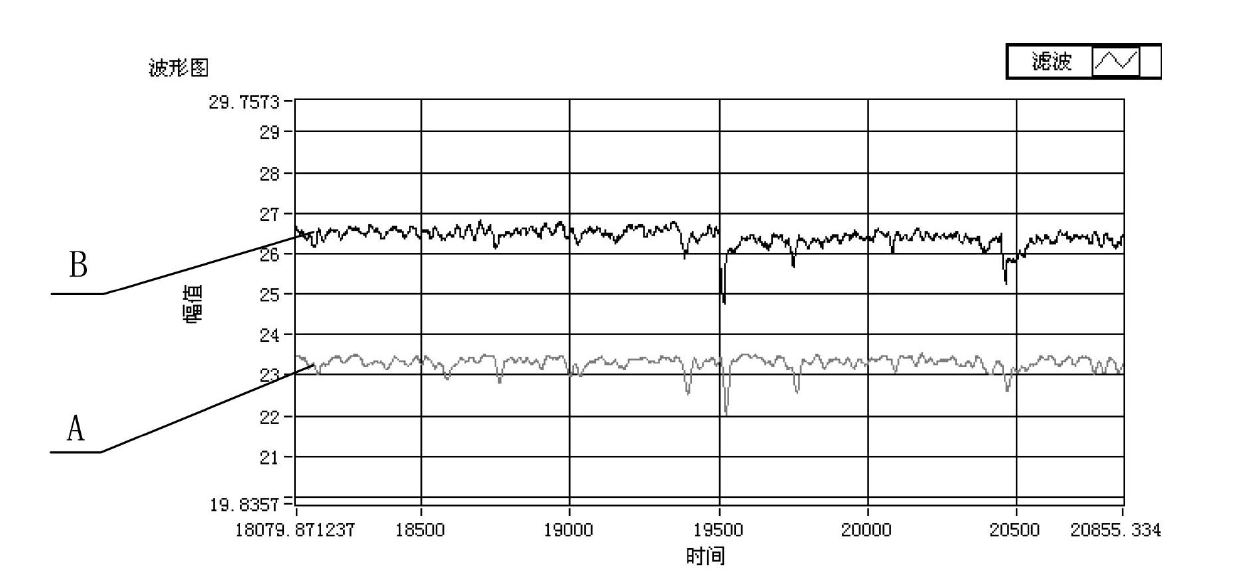

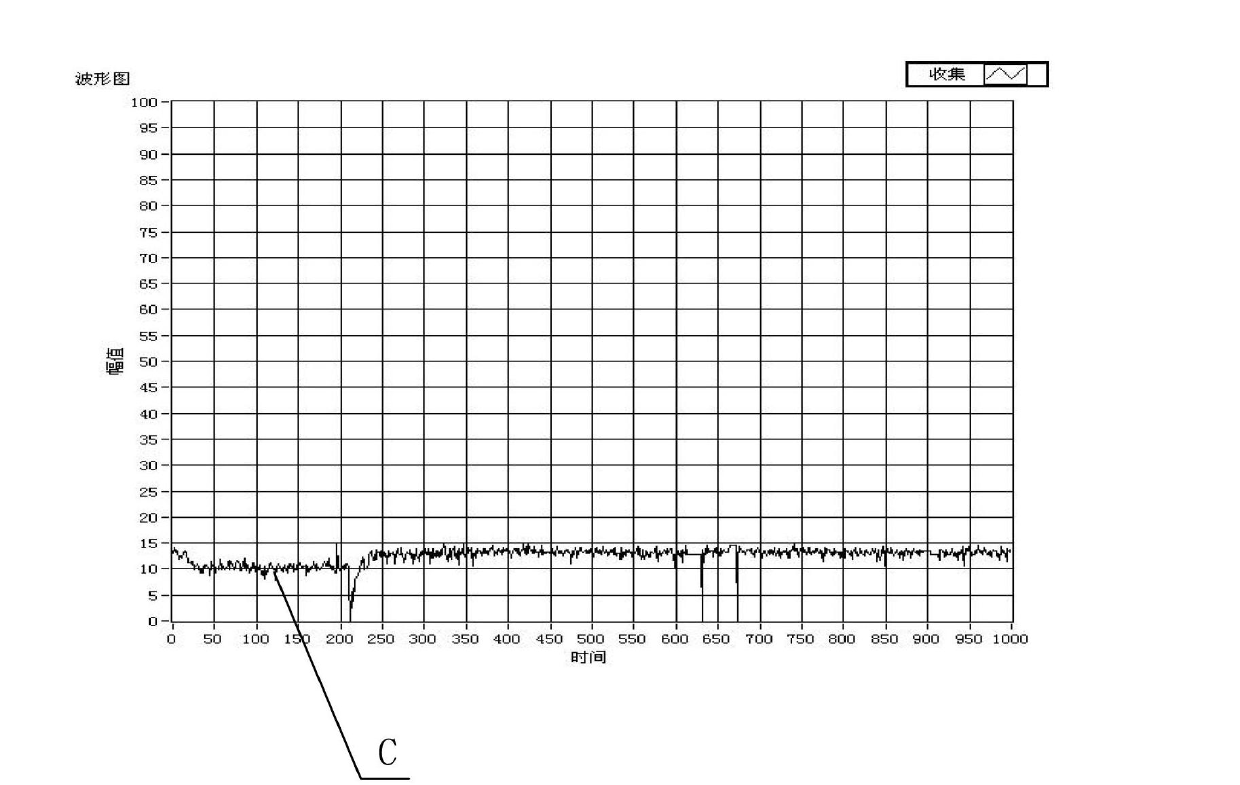

Intelligent swing type target flow meter

ActiveCN102636222ARealize measurementMeasurement fitVolume/mass flow by dynamic fluid flow effectTransducerEngineering

The invention relates to an intelligent swing type target flow meter, belonging to the field of liquid measuring devices. The intelligent swing type target flow meter is characterized in that a valve body (2) is provided with a detection hole (6), a target plate (2) is arranged at the detection hole and is hinged with the sidewall of the detection hole through an angle sensor (3) so as to form a swing type target structure, the target plate is adapted with a channel (7) in area, the flow variation of a measuring tube is converted into the swing angle variation of the swing type target, then the switch angle is converted into the angle variation of a magnetic line, and an intelligent transducer (5) is arranged and connected at the output end of the angle sensor (3). The target plate is stressed and rotated on a hinge point by a certain angle, the angle sensor sends out an electric signal and inputs the signal into the intelligent transducer, and the intelligent transducer processes the electric signal into a flow signal for display or output, thereby measuring the fluid flow. The intelligent swing type target flow meter has the characteristics of high sensitivity, high adaptive ability, better measuring effect of the flow of the liquid affected by high viscosity, gas and sand content and the like and is especially suitable for measuring the integrated flow of transmission media in a multiphase pipeline.

Owner:白泽检测(山东)有限公司

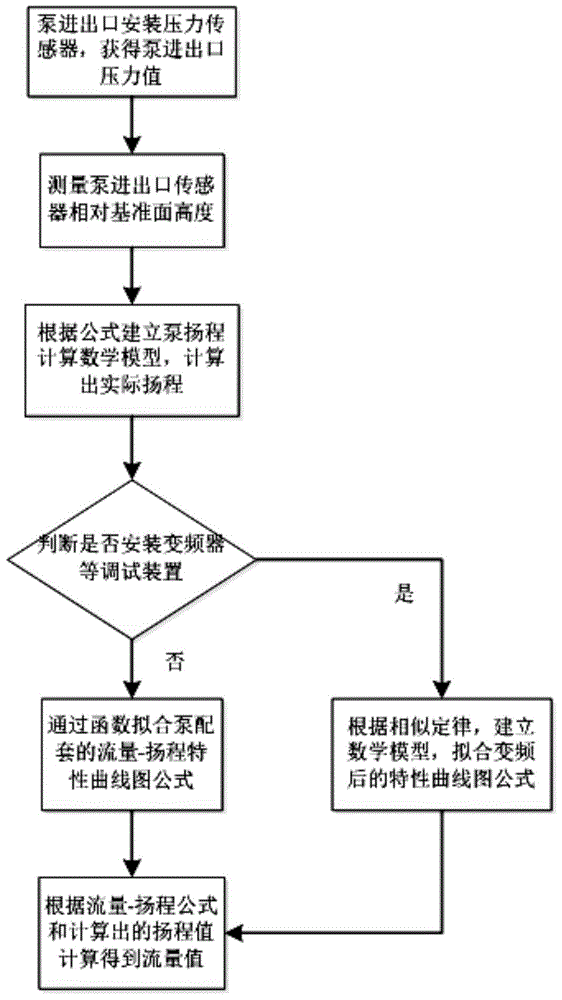

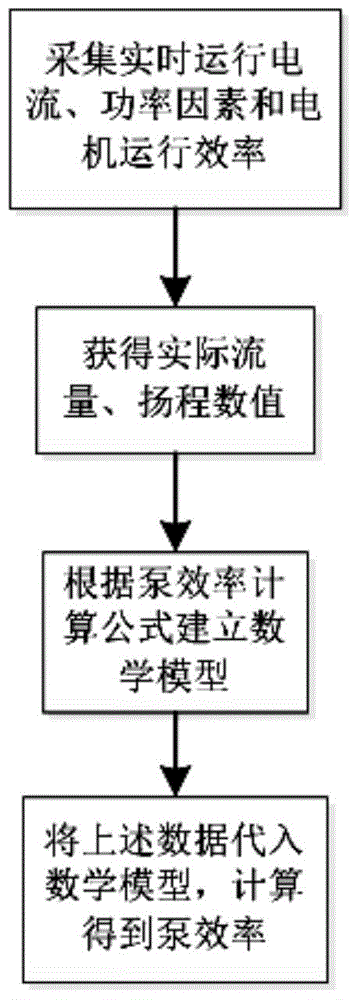

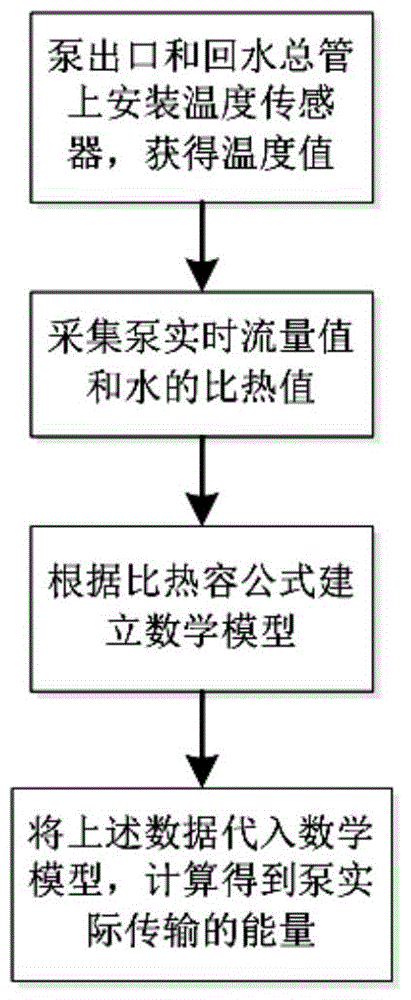

Integrated measuring method for operating parameters of general centrifugal pump

InactiveCN104405650AEasy to collectNo maintenancePump controlNon-positive displacement fluid enginesCalculation errorEngineering

The invention relates to the field of detection for related operating parameters of a centrifugal pump and aims to provide an integrated measuring method for the operating parameters of a general centrifugal pump. The integrated measuring method for the operating parameters of the general centrifugal pump comprises the step of using a pressure transmitter and a temperature sensor, specifically comprises measuring the pump flow, the operating efficiency of the pump and heat taken away by the pump. According to the invention, only the pump inlet and outlet pressure, pump outlet water temperature and total water temperature after heat exchange are detected, the data are easily collected, the accuracy is very high, the sensor equipment basically does not need to be maintained, and the cost of the equipment is ultralow. The invention designs the brand new method for detecting the centrifugal pump flow, the method is fit for all water conveying systems, the calculation errors of flow and efficiency are within 3%, and the non-measuring use demand is met.

Owner:HANGZHOU ZETA TECH

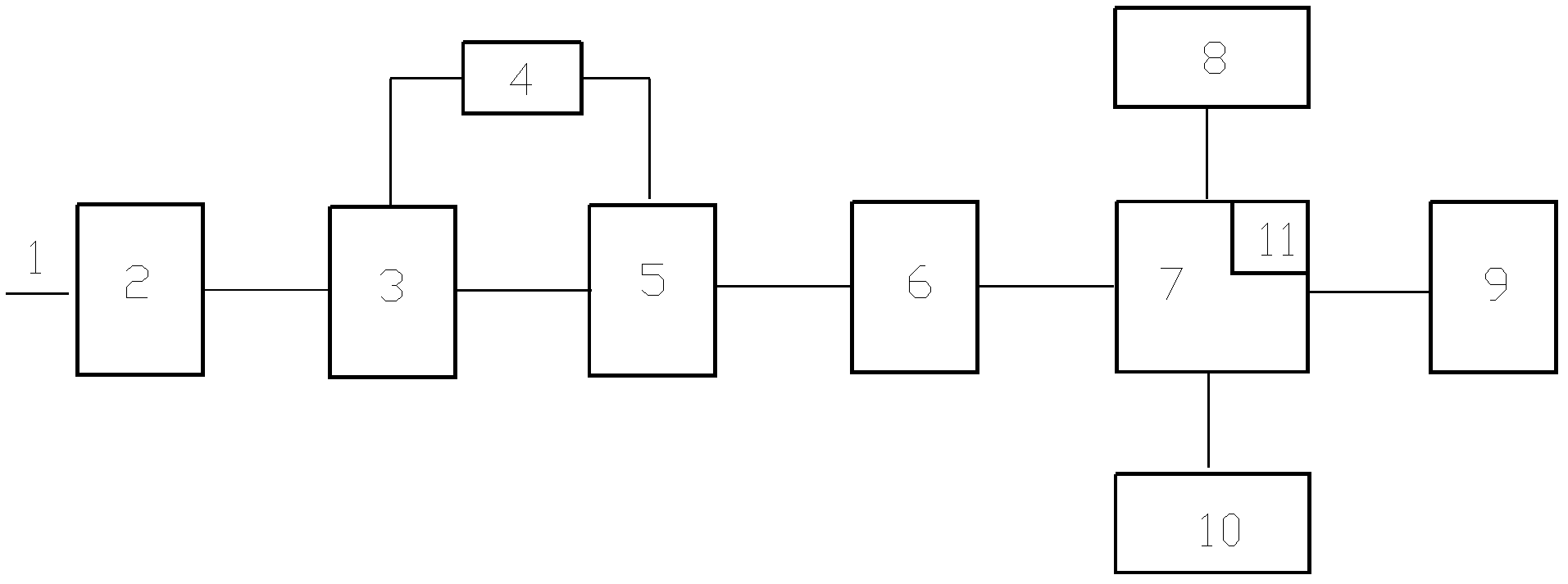

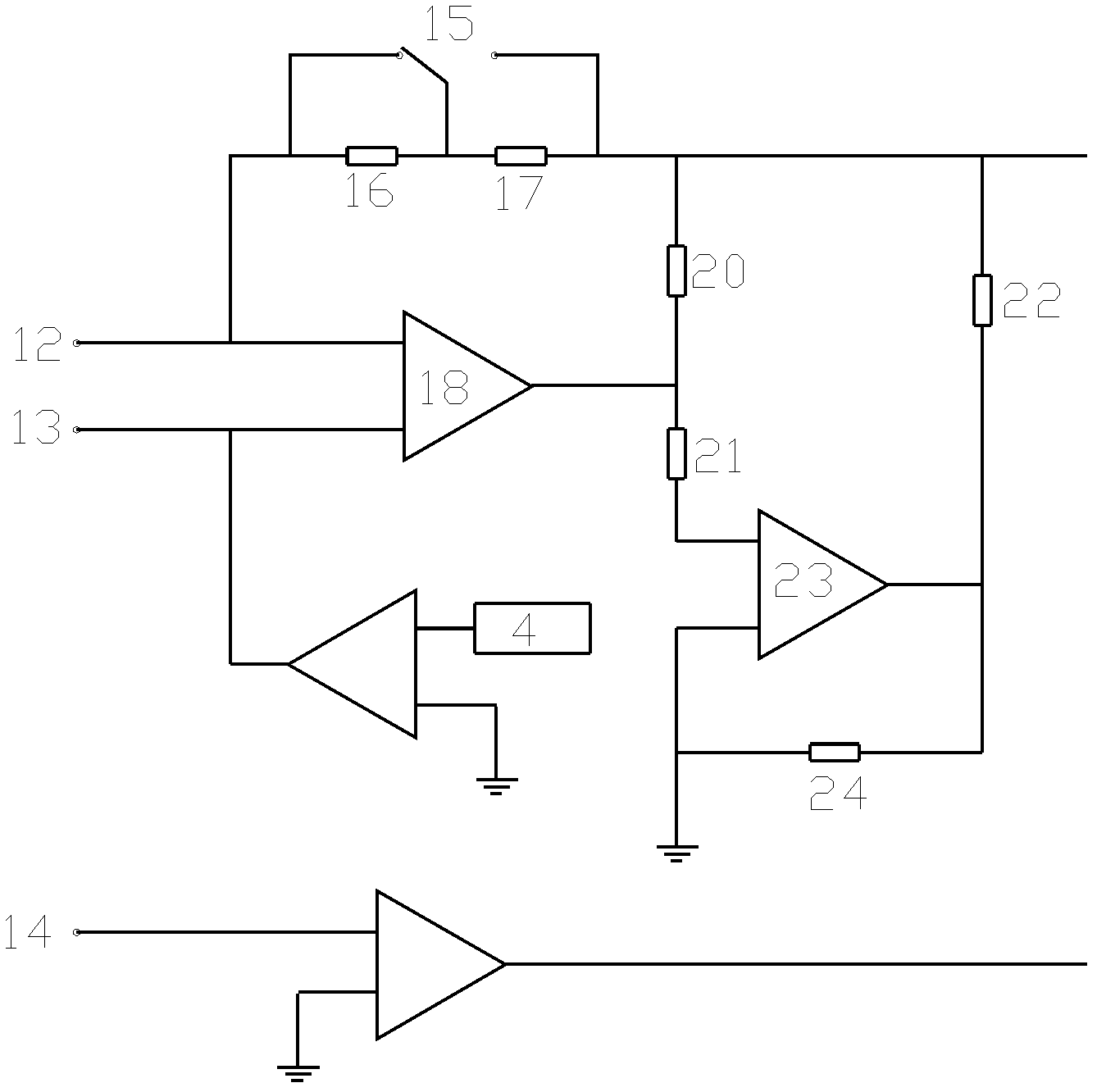

Multi-channel galvanic corrosion measurement device

ActiveCN102507431AEliminate mutual interferenceHigh linear precisionWeather/light/corrosion resistanceMeasurement deviceMetallic materials

The invention belongs to the technical field of galvanic corrosion measurement for metal materials, in particular relates to a multi-channel galvanic corrosion measurement device. According to the multi-channel galvanic corrosion measurement device, an SOC (System on a Chip) processor structural design is adopted; the front end of an electrode connection cable is connected with an electrode; the rear end of the electrode connection cable is connected into a voltage / current measurement switching unit; two ends of a front end signal conditioning circuit are bridged with a reference source afterbeing electrically communicated with an A / D (Analog-to-Digital) conversion circuit; the front end of the front end signal conditioning circuit is electrically connected with the voltage / current measurement switching unit; the output end of the A / D conversion circuit is electrically communicated with a main control module after being connected in series with a multi-channel electric isolation unit; an SOC processor is arranged in the main control module; the main control module is electrically connected with a display module, a storage module and a communication module respectively, so that electric information control is realized; and a signal input by a reference electrode is incorporated into the front end signal conditioning circuit after being amplified, so that a signal processing system is formed. The multi-channel galvanic corrosion measurement device has the characteristics of simple overall structure, reliable principle, convenience for use and operation, accuracy in measurement data, flexibility for control and wide application range.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

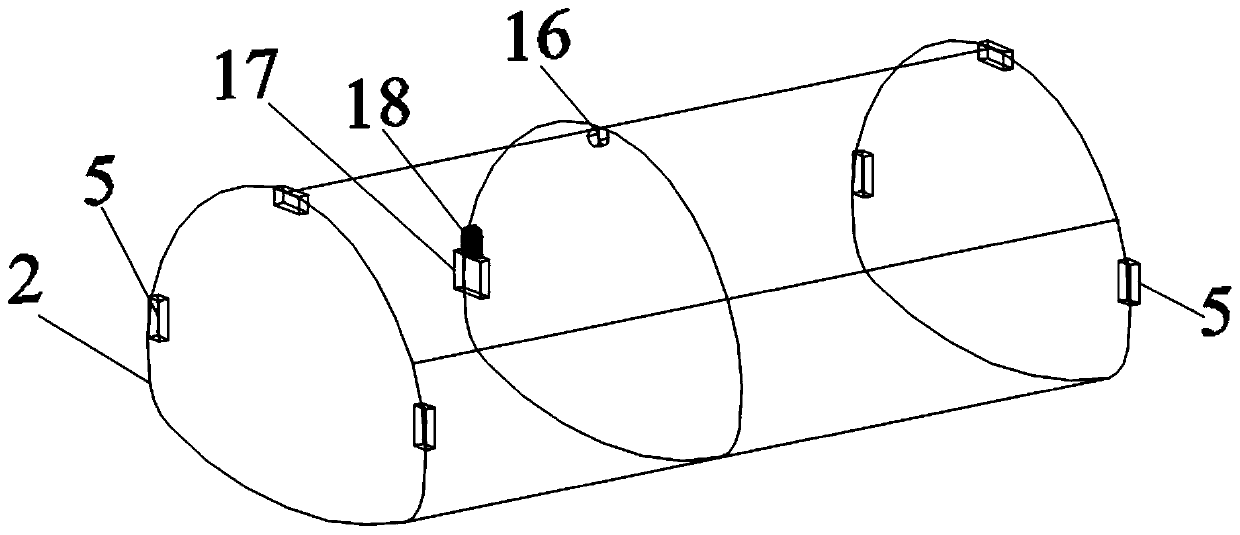

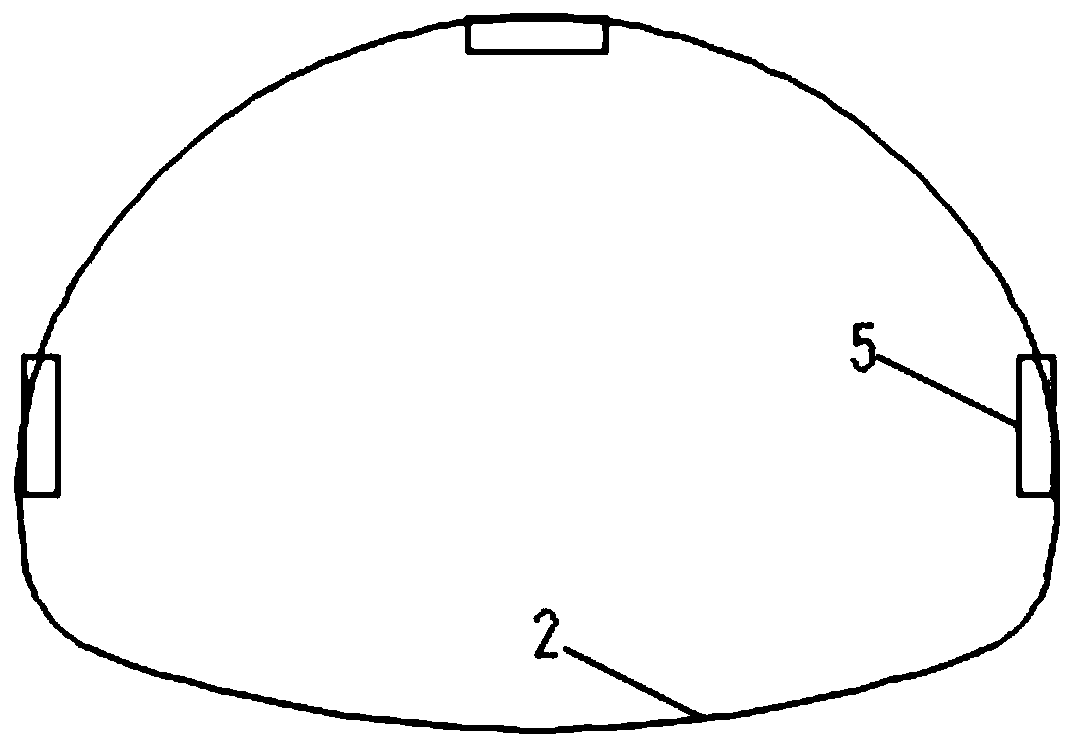

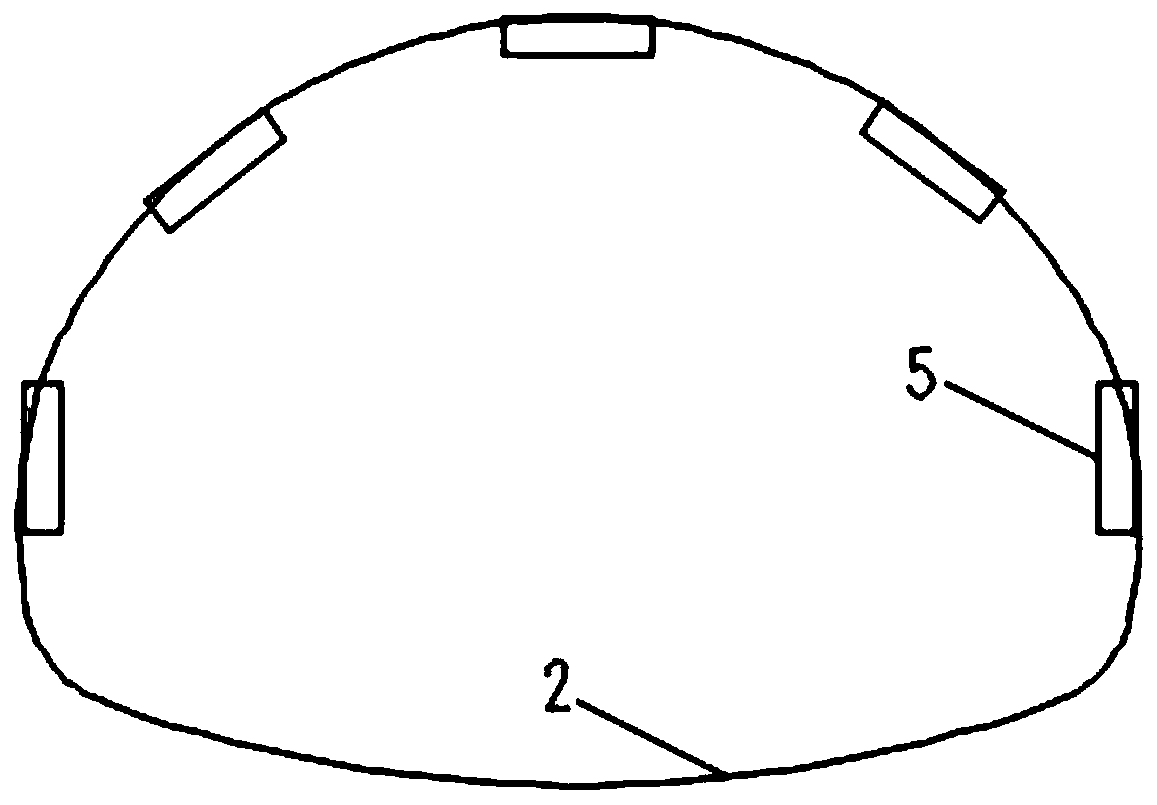

Tunnel construction surrounding rock loosing circle deformation automatic monitoring early-warning device and method

PendingCN110243335ALow priceSimple structureMining devicesMeasurement devicesGeomorphologyComputer terminal

The invention discloses a tunnel construction surrounding rock loosing circle deformation automatic monitoring early-warning device and method. The device comprises sensing systems and collection transmission systems fixedly connected to a tunnel lining surface; multiple detection fracture surfaces are arranged in a tunnel, and multiple sensing systems are arranged on each detection fracture surface; at least one collection transmission system connected with each sensing system is arranged between multiple adjacent detection fracture surfaces; the sensing systems are used for monitoring tunnel construction surrounding rock loosing circle deformation in real time and the monitoring data is sent to the collection transmission systems, and the data interaction is performed between the collection transmission systems and a remote terminal, and the early-warning in different levels is performed. The device disclosed by the invention is simple in structure, convenient to mount and use, low in cost, and capable of eliminating tunnel construction interference, high in monitoring precision, good in performance, and real and reliable in measurement; the automatic data collection and automatic alarming are performed, and the information is automatically pushed to a background, thereby facilitating a construction department to formulate a solution in time according to the corresponding monitoring information, the tunnel construction security and the construction efficiency are greatly improved.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

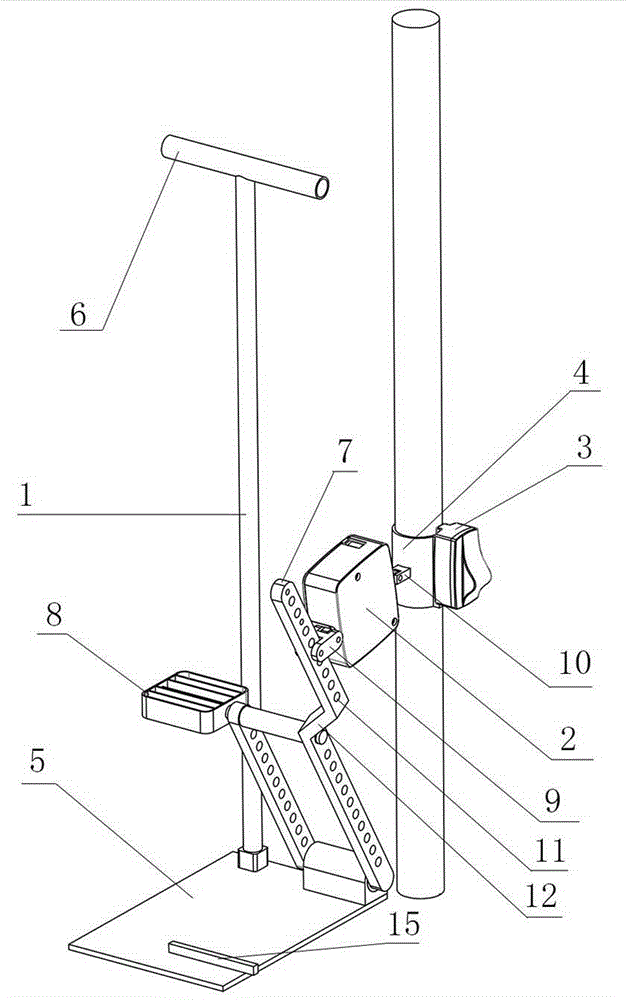

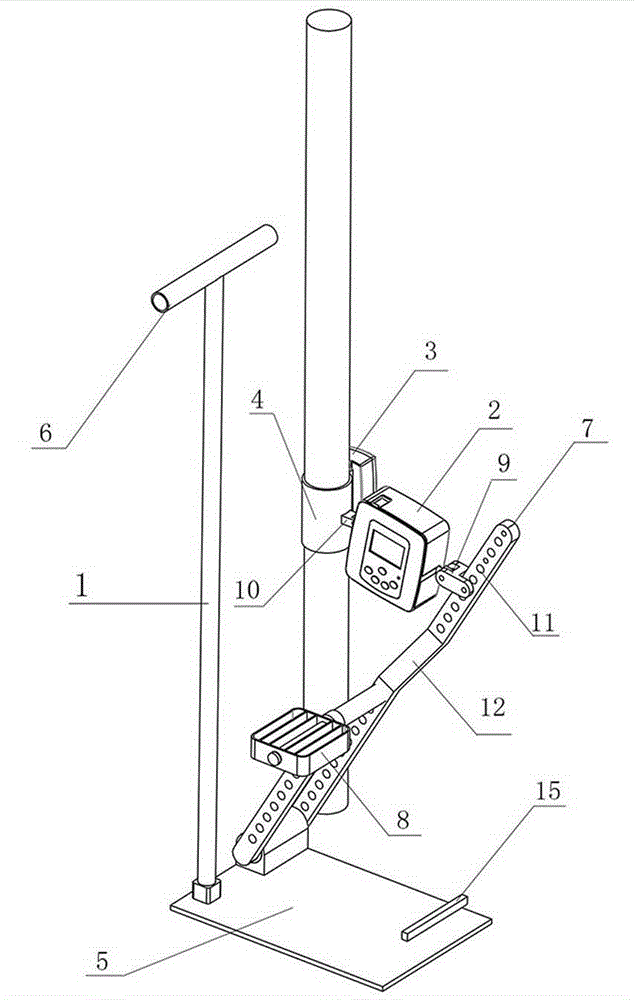

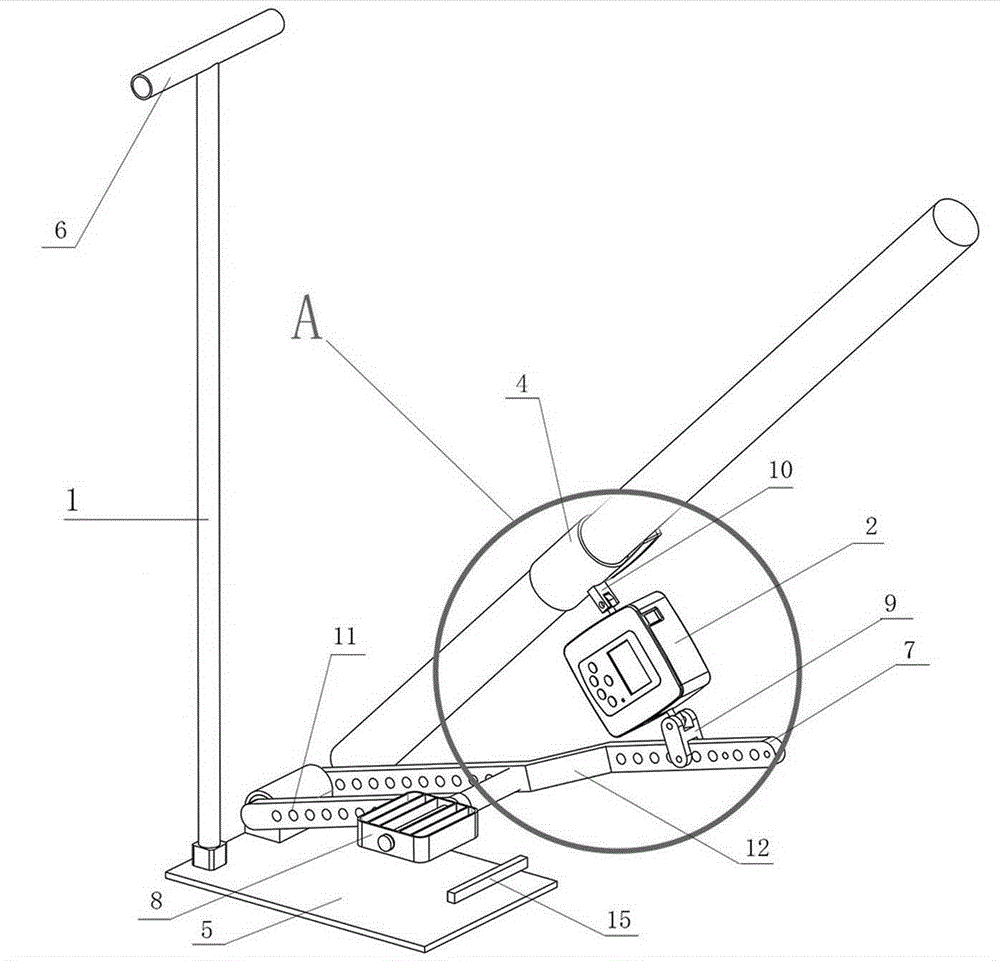

Device and method for measuring crop stem lodging resistance strength

InactiveCN105241756AAchieve outputMeasurement data is stableMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention discloses a device for measuring crop stem lodging resistance strength and a method for measuring stem lodging resistance strength by using the device. The device includes a force application mechanism, a tensile mechanism, a stem inclination collection mechanism and a stem fixture which is fixed on a crop stem. The force application mechanism comprises a base and a mobile tensile component installed on the base through a hinge; the mobile tensile component includes a tension rod, pedals and a mobile fastening part arranged on the tension rod; and a tension sensor is arranged on the tensile mechanism. The device for measuring crop stem lodging resistance strength can realize storage of a large amount of measured data in measurement of crop stem lodging resistance strength, and can realize the output of the measurement data; and repeated and convenient measurement can be carried out in the measurement of crop stem lodging resistance strength, and stable measurement data can be obtained. The method for measuring crop stem lodging resistance strength can obtain more accurate and reliable tensile strength measurement data in the measurement of crop lodging resistance.

Owner:HENAN AGRICULTURAL UNIVERSITY

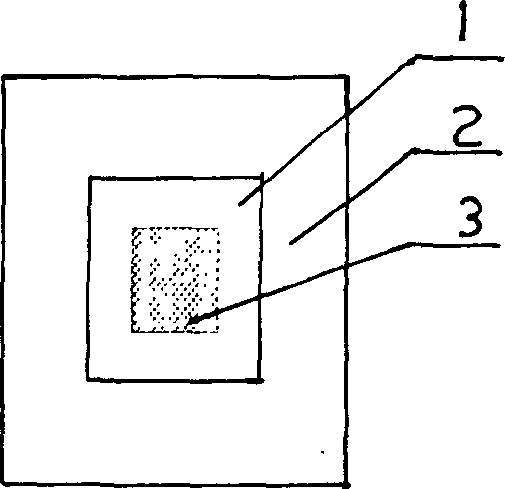

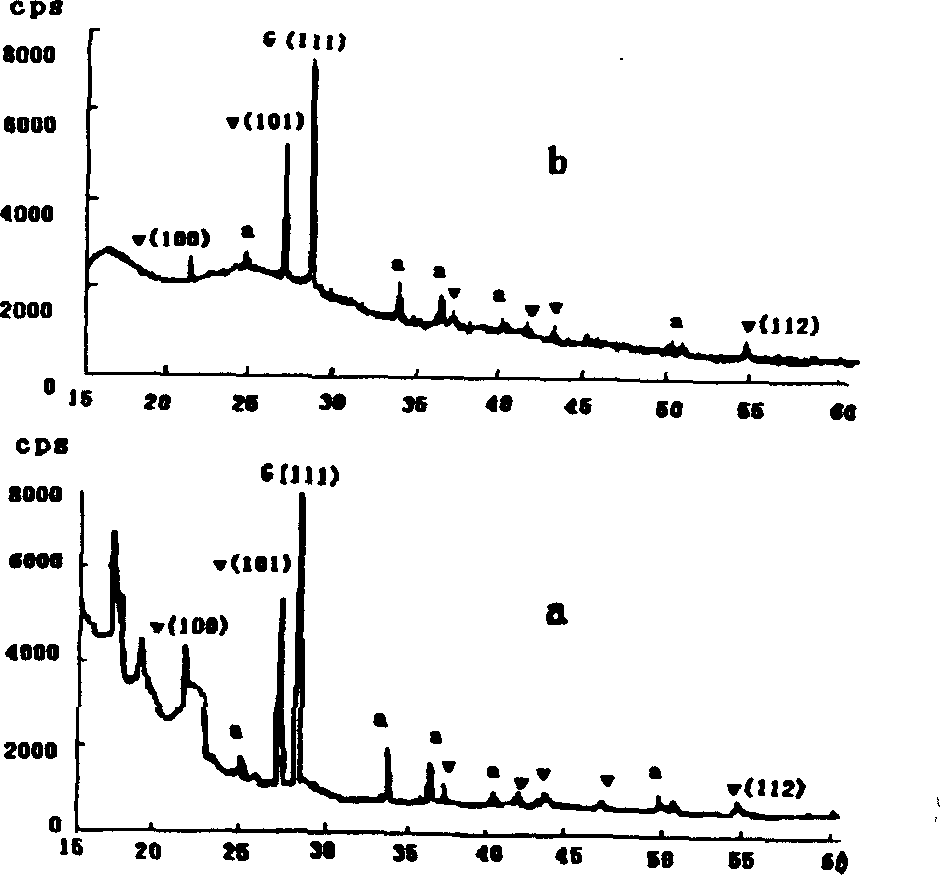

Sample rack for X-ray diffraction phase analysis and analysis method thereof

InactiveCN1800839AEliminate the effect of precisionInter-laboratory versatilityMaterial analysis using radiation diffractionSoft x rayQuantitative phase analysis

The invention relates to qualitative and quantitative analysis for X-ray diffraction mineral. Wherein, the X-ray diffraction phase analysis sample bracket comprises a silicon single-crystal piece in the following base frame, a base frame, and a dust-carry film stuck on said single-piece; the single-crystal piece is single diffraction peak, and is prepared by cutting into pieces along the crystal face 0-12Deg and grinding and polishing. This invention can eliminate the effect to measurement accuracy from device, time and parameter, simplifies operation, and cuts time to improve efficiency.

Owner:MAANSHAN IRON & STEEL CO LTD

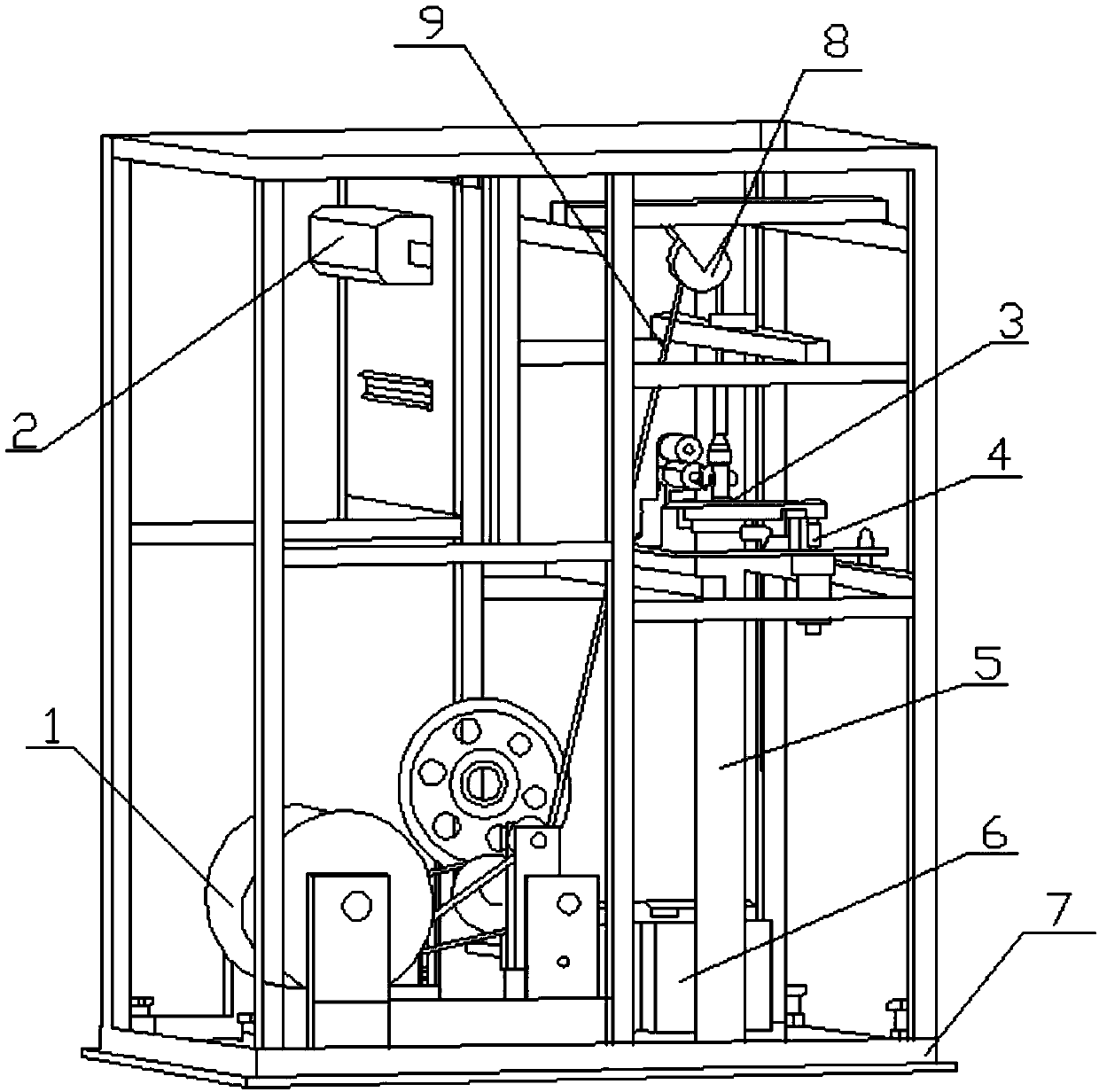

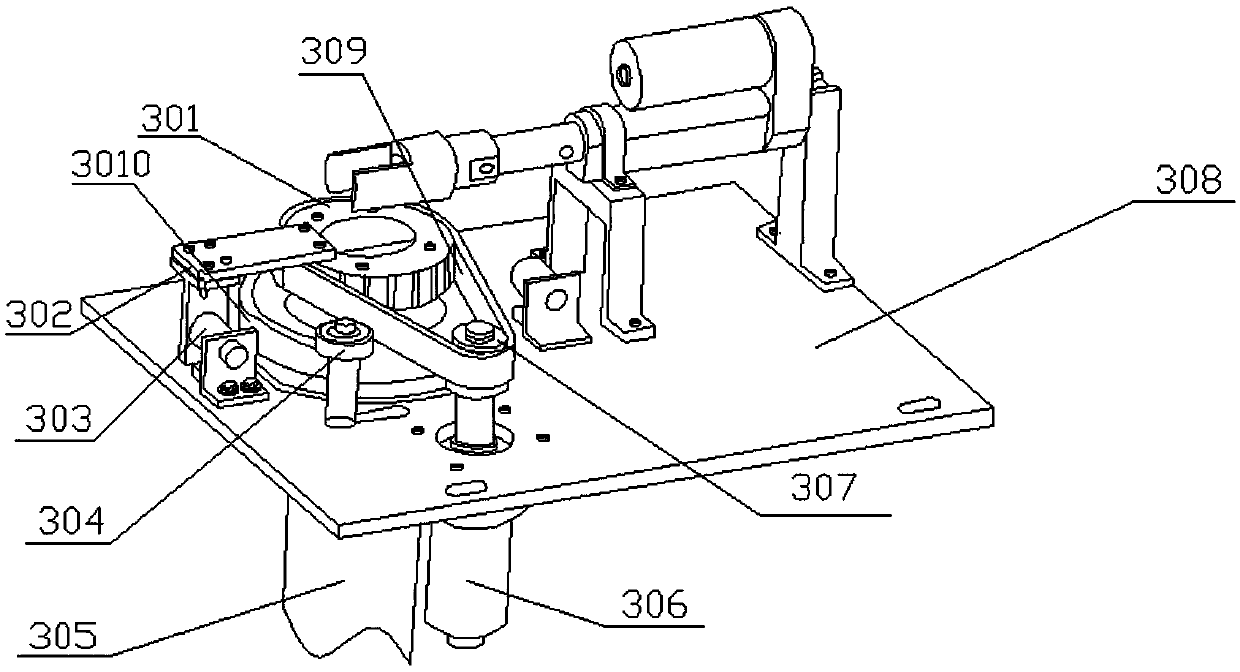

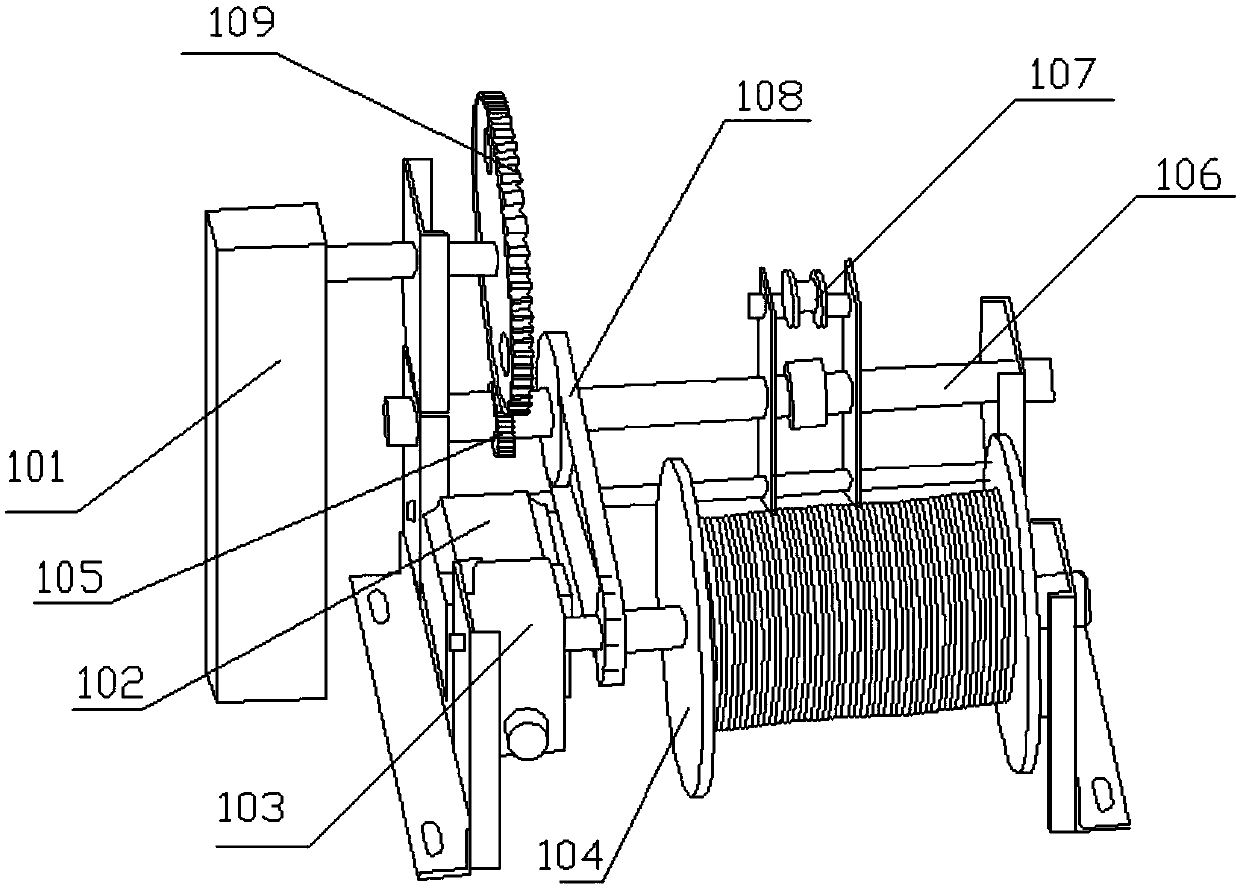

Integrated full-automatic declinator

ActiveCN109540085ANo human intervention requiredReliable measurement dataAngle measurementIncline measurementEngineeringRisk stroke

The invention relates to the field of engineering safety monitoring, and is mainly used for monitoring soil deformation around a high slope, an overhanging rock, a dam, a deep pit and a tunnel. The invention provides an integrated full-automatic declinator which can realize full-automatic, wireless and high-precision measurement. The integrated full-automatic declinator mainly settles the following technical problems of realizing full-automatic measurement for a pre-embedded inclinometer pipe inclination amount, changing a measurement mode of a traditional movable declinator, realizing full-process automatic measurement and all-weather continuous operation, and settling problems of high manpower labor strength and difficult operation in a special weather condition. The invention realizes an automatic cable paying and pay-off mechanism which has automatic cable paying and pay-off functions, and automatic cable winding. The integrated full-automatic declinator realizes function automaticfixing measurement of a measuring probe and a mechanical stroke automatic locking; an automatic probe overturning function, functions of remote measurement, measurement and wireless data transmission. The declinator integrally has an IP65-grade protecting function and can realize long-term reliable operation in an outdoor environment.

Owner:NARI TECH CO LTD +1

Checking fixture for measuring depth of bottom hole of valve retainer of engine cylinder cover

ActiveCN102564272AImprove versatilityExtended service lifeMechanical depth measurementsCircular discData display

The invention provides a checking fixture for measuring the depth of a bottom hole of a valve retainer of an engine cylinder cover, and the checking fixture is used for completing detection of the depth size of the bottom hole of the valve retainer of the engine cylinder cover. The checking fixture comprises a measurement execution mechanism, a displacement transmission mechanism, a support and control mechanism and a measurement data display mechanism, wherein the measurement execution mechanism comprises a guide measuring rod, a flange base and a flange cover; the guide measuring rod is located at the lower end of the checking fixture and consists of a measuring head and a connection base; the bottom face of the connection base is a test reference surface; the top end of the connection base is fixedly connected with the corresponding element of the support and control mechanism; the flange base is in an inverted disk structure; a large round hole is arranged on the top face of the flange base, and the bottom face of the flange base is provided with a measuring face; the flange cover is fixedly mounted on the top face of the flange base; and a disk-shaped groove is arranged at the center of the flange cover; and the disk-shaped groove is connected with a peripheral framework through three ribs. The checking fixture disclosed by the invention has the advantages of compact structure and simplicity in operation. The detection precision of a working piece to be measured can be ensured, and the service life of the checking fixture is prolonged.

Owner:HYCET ENGINE SYST JIANGSU CO LTD

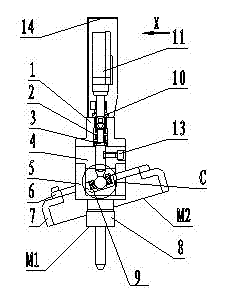

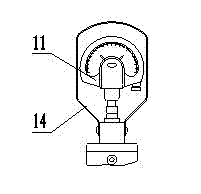

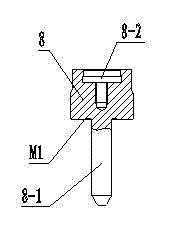

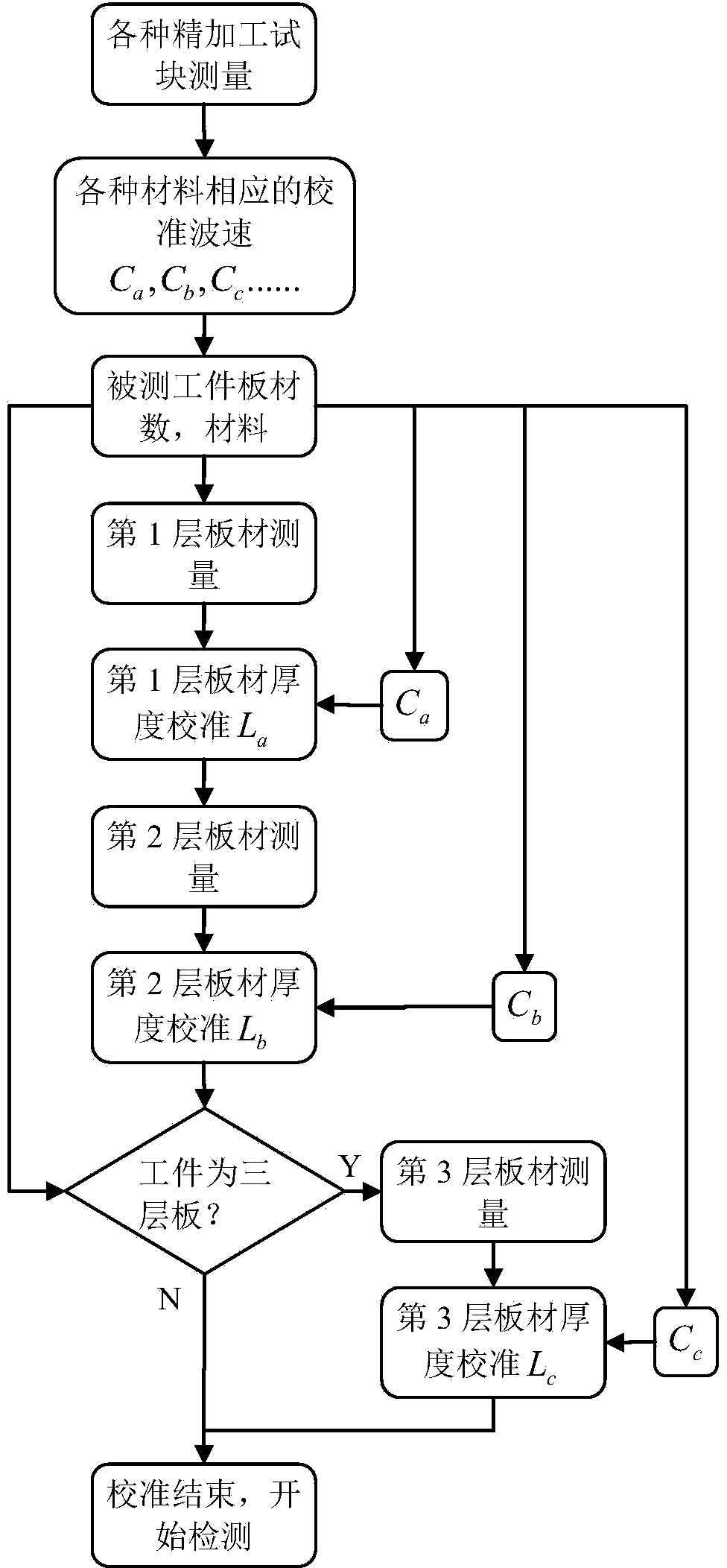

Wave velocity and thickness calibrating method for ultrasonic wave welding spot detection

ActiveCN104111286AHigh precisionReduce measurement errorMaterial analysis using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansObservational errorClassical mechanics

The invention relates to a wave velocity and thickness calibrating method for ultrasonic wave welding spot detection. A test block of a corresponding material is selected for to-be-tested workpieces of different materials, the wave velocity calibrating error caused by different materials is minimally reduced; meanwhile, the invention provides thickness calibration for the to-be-tested workpiece, and the defect of existing detection equipment is made up from the application point of view. By adopting the technical scheme provided by the invention, aiming at wave velocity calibration of different materials and thickness calibration of different workpieces, the measurement accuracy is greatly improved, the measurement error caused by inaccurate wave velocity and thickness is reduced, and thus the data measurement is more reliable.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com