Patents

Literature

2032results about How to "Large measuring range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

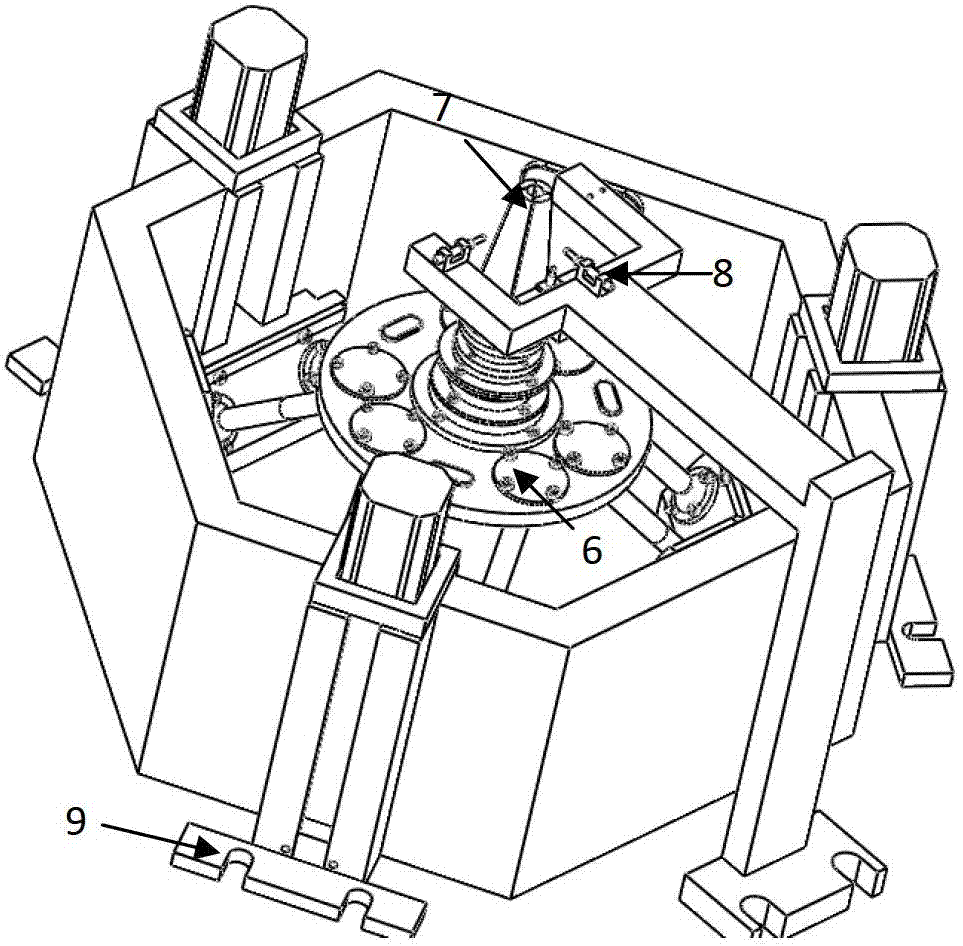

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

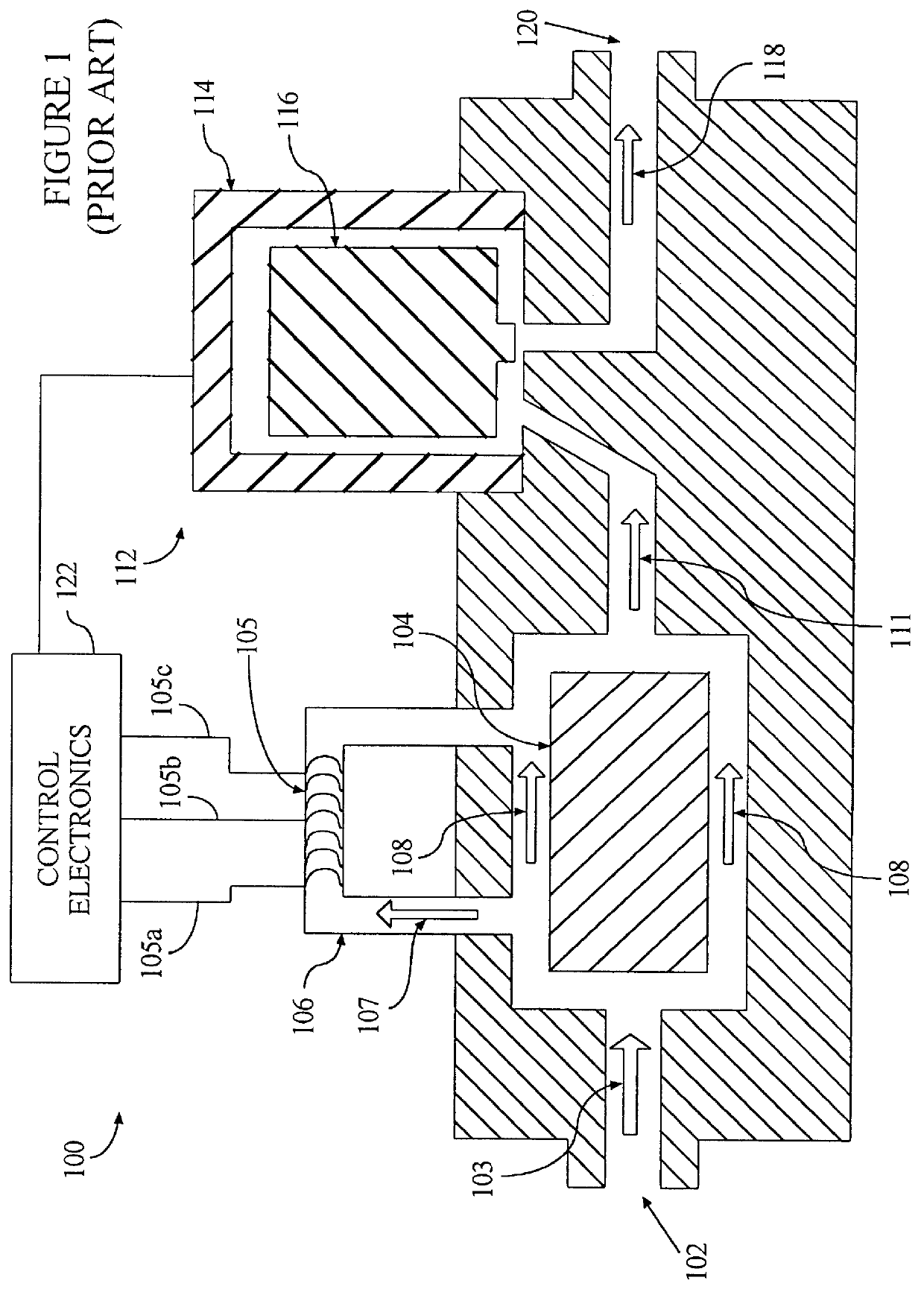

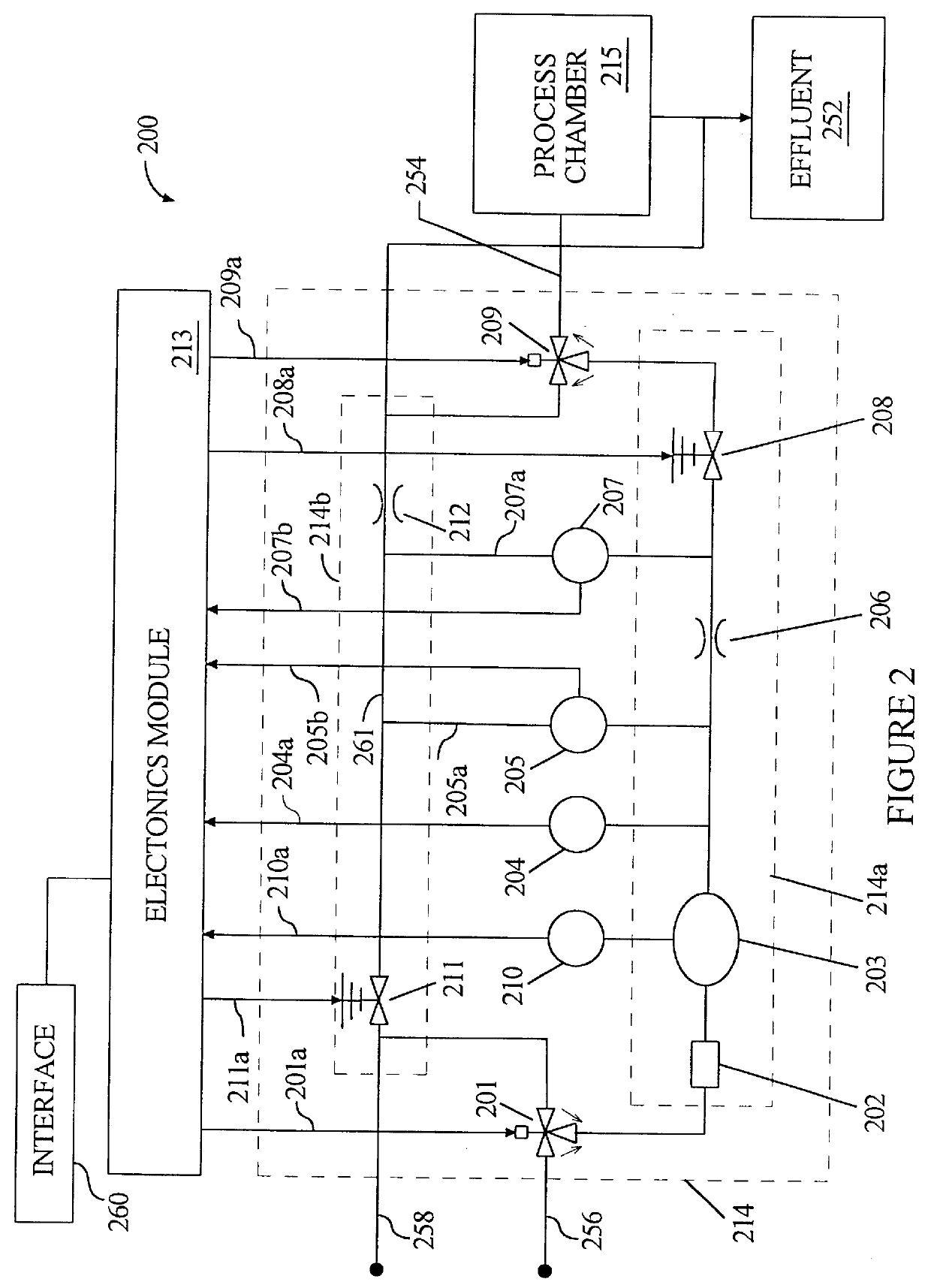

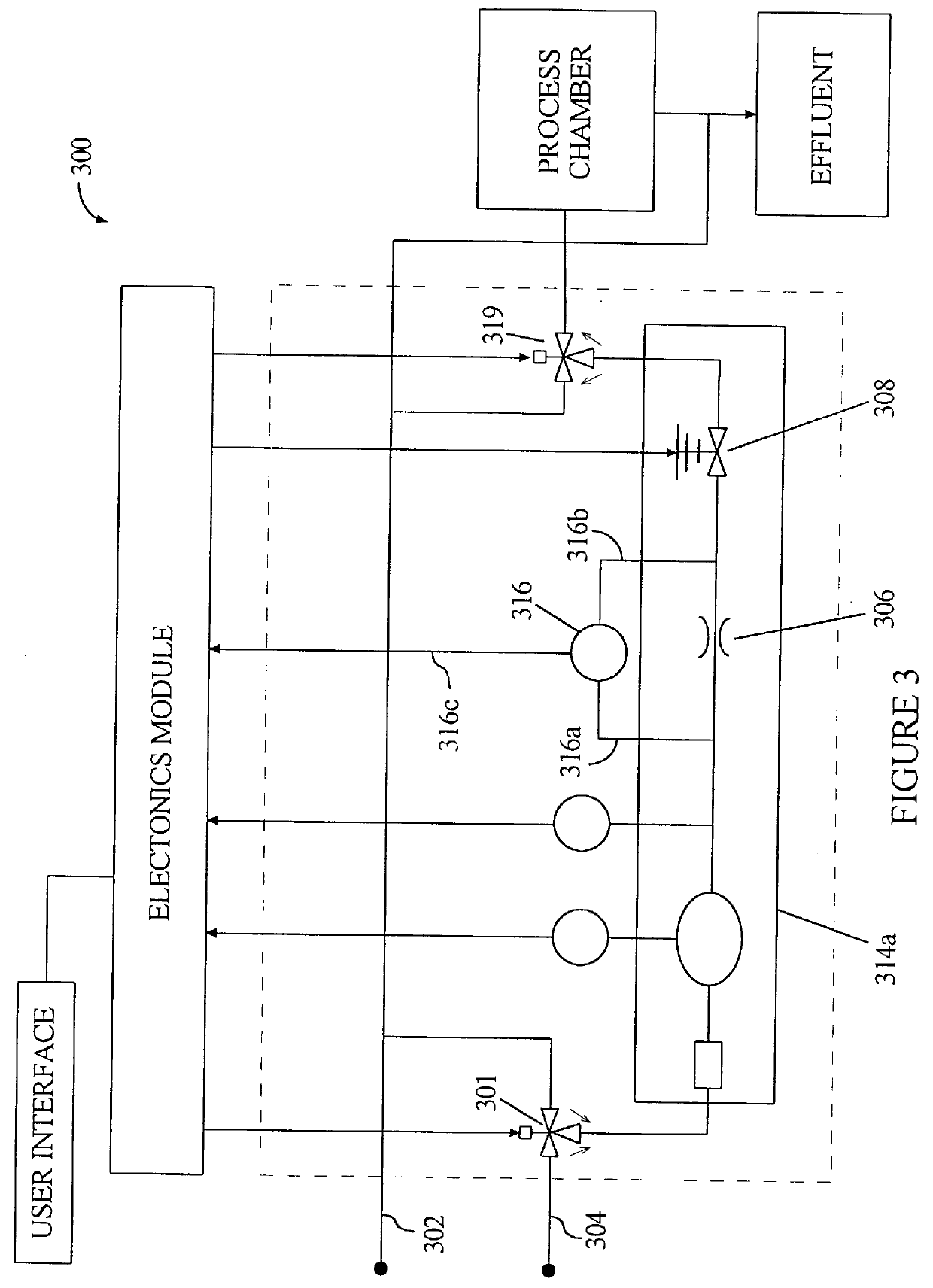

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

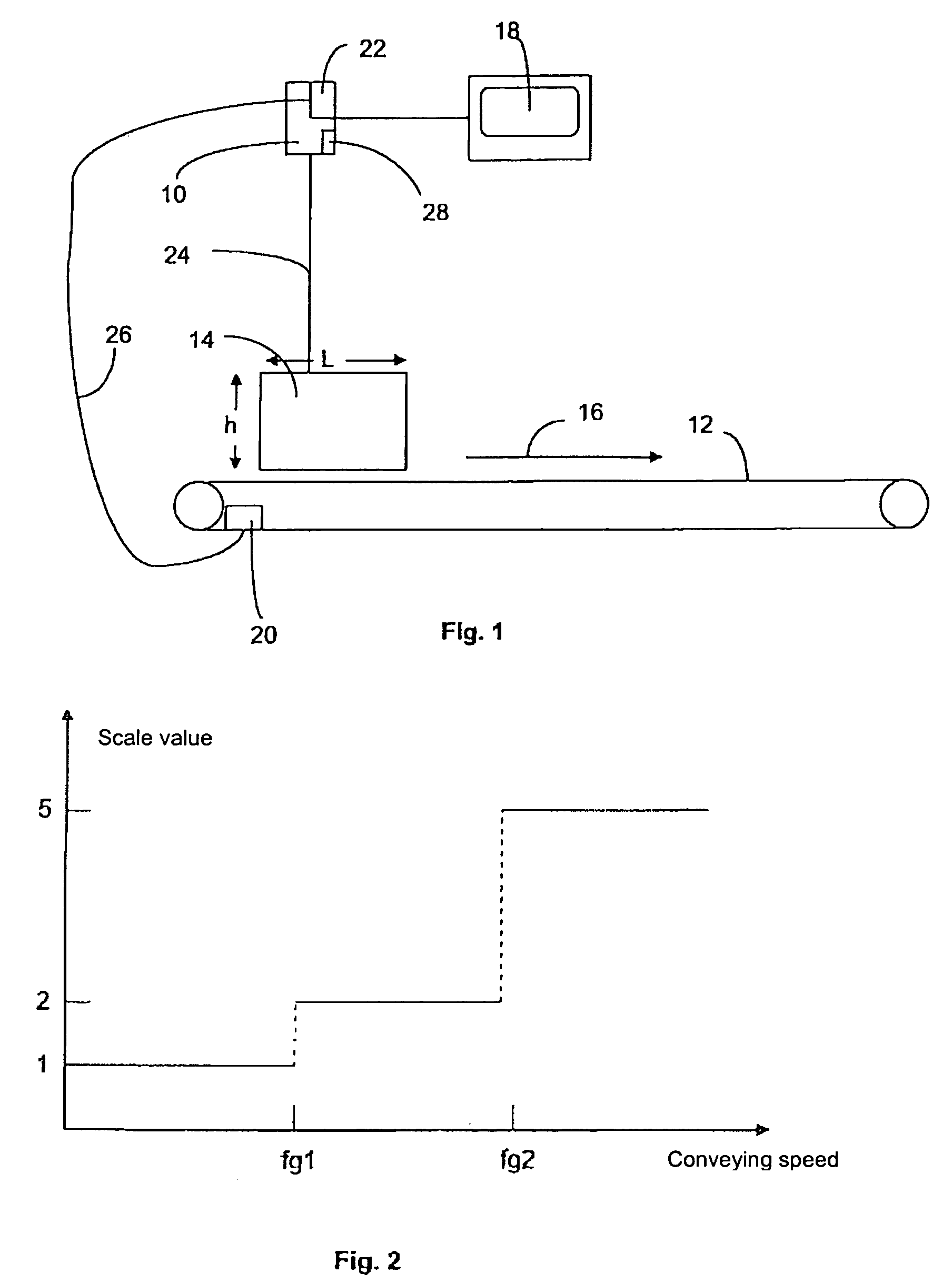

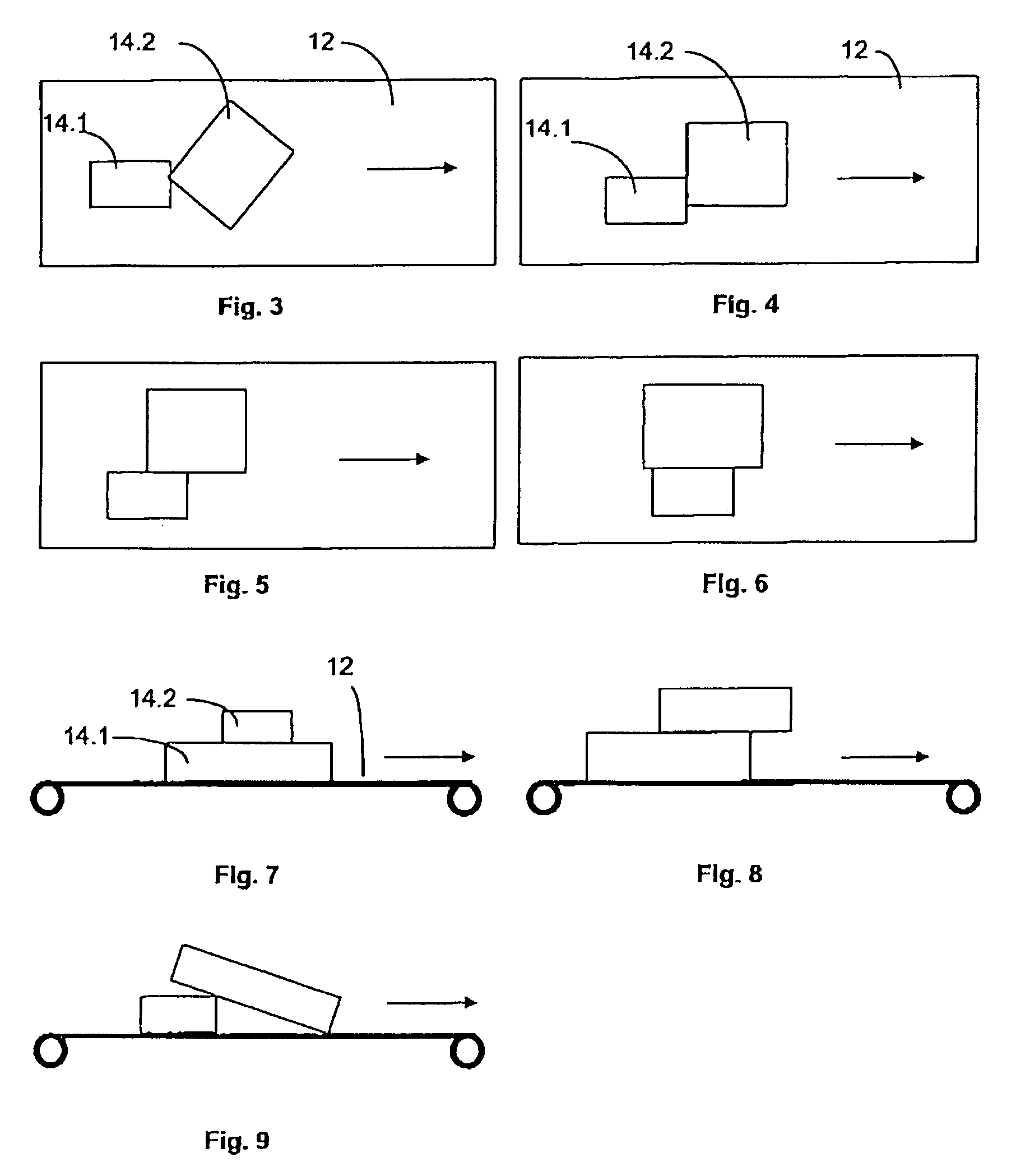

Method for operating optical sensors

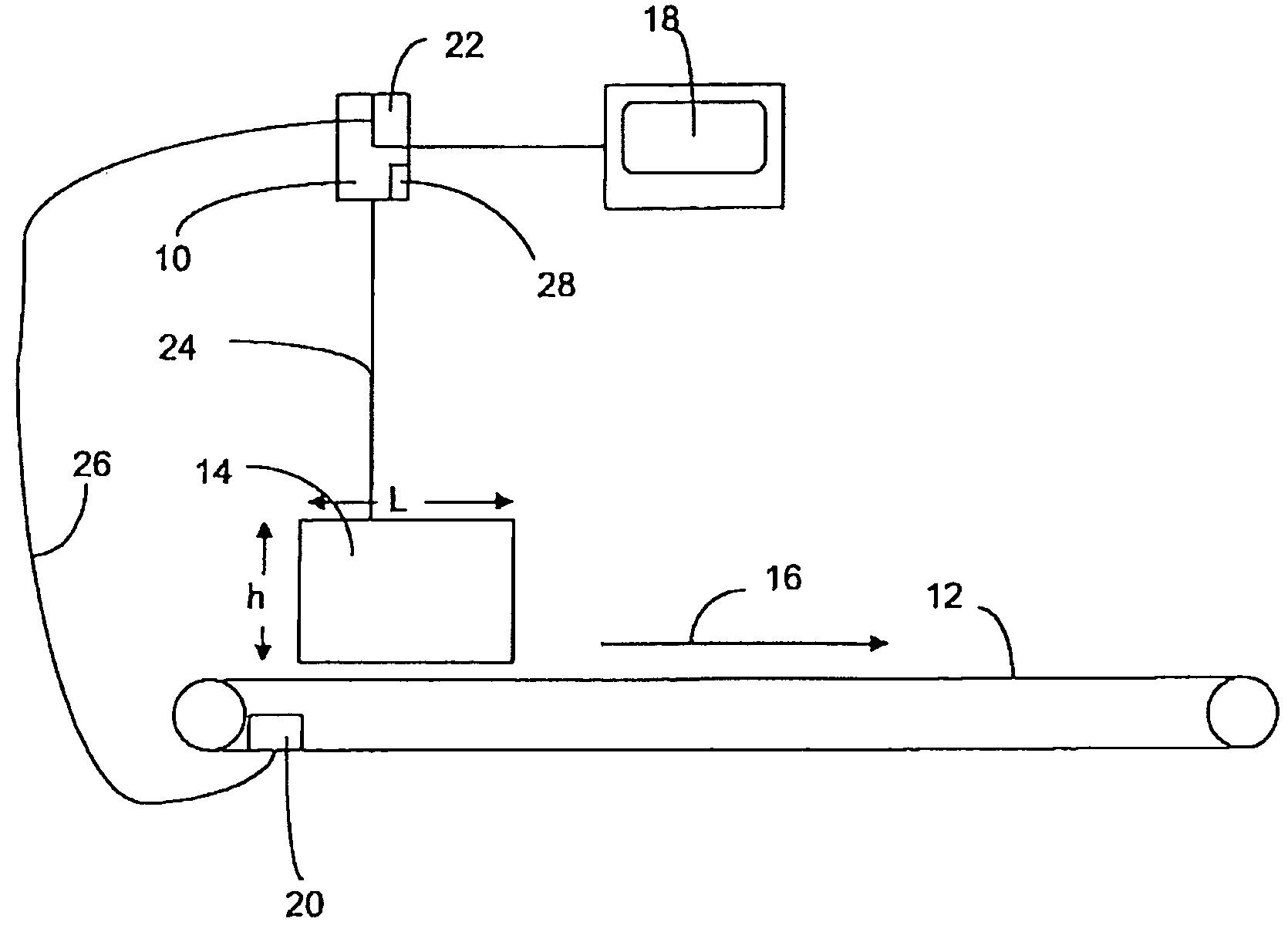

ActiveUS7214954B2Large measuring rangeInvestigating moving sheetsDigital computer detailsOpto electronicAuthorization

A method for operating an optical sensor for measuring a physical quantity with a defined scale value that is subject to a calibration certification. The measurement accuracy of the quantity being measured is dependent on at least one external condition, and a given scale value is used for the measurement according to the desired measurement accuracy. The scale value is appropriately changed when the measurement accuracy changes due to a change of external condition. An optoelectronic sensor has a switching arrangement for changing the scale value. The sensor is more diversified and can cover larger measurement ranges without requiring new certifications or authorizations for the different measurement ranges.

Owner:SICK AG

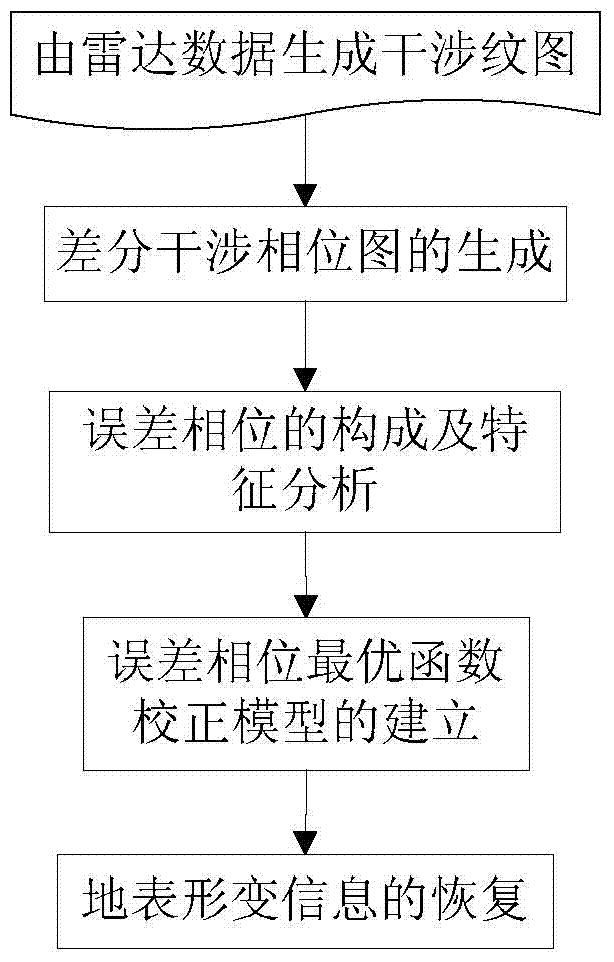

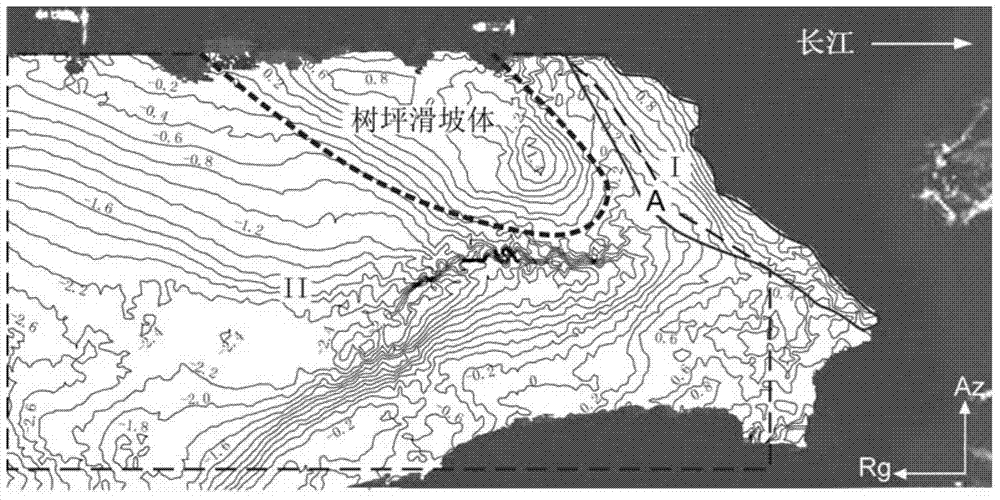

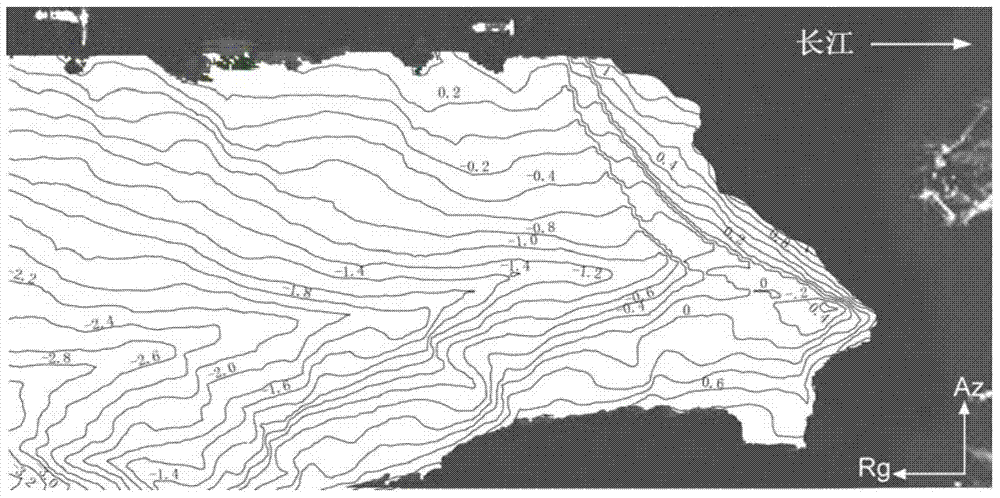

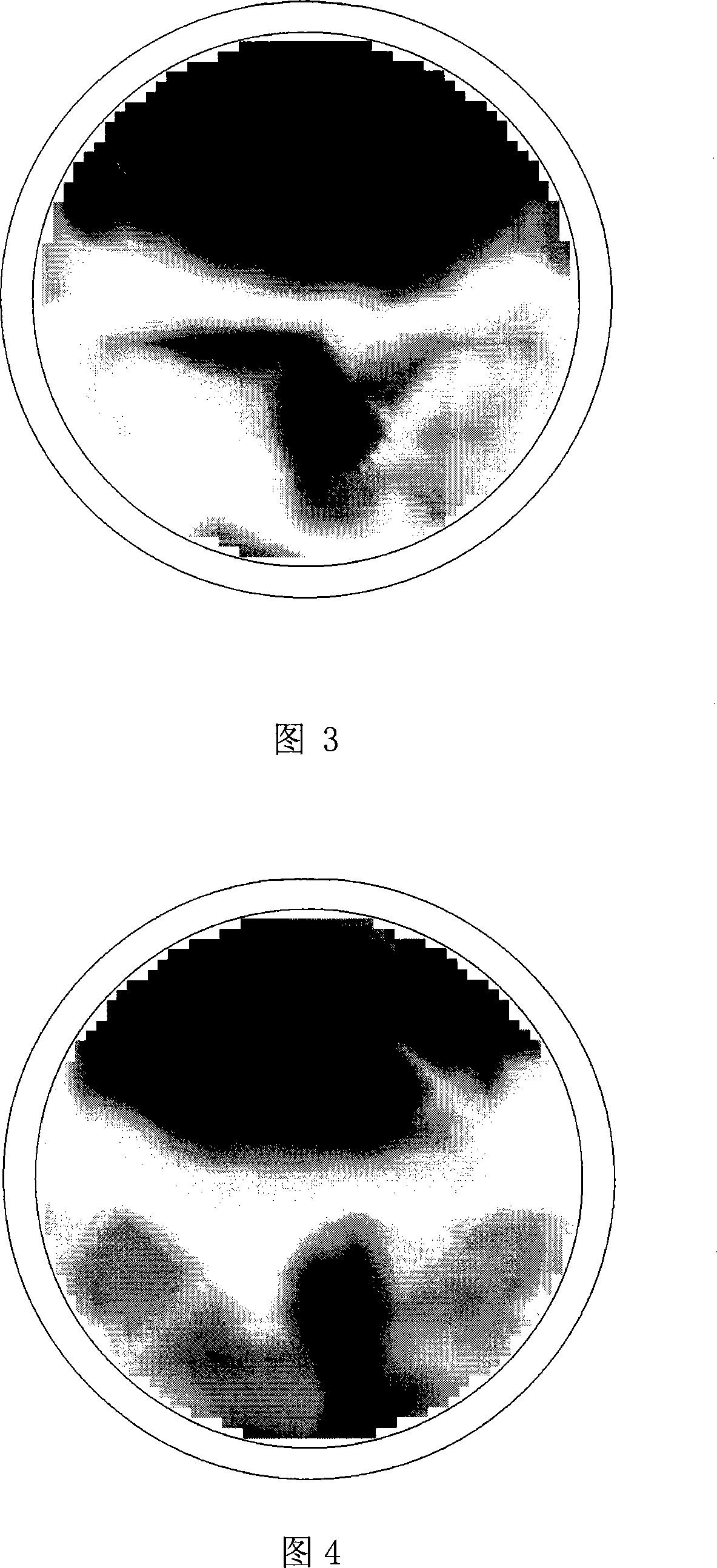

Method for improving earth surface shape change monitoring precision of InSAR (Interferometric Synthetic Aperture Radar) technology based on high-precision DEM (Digital Elevation Model)

InactiveCN103675790AError Phase CancellationHigh precisionRadio wave reradiation/reflectionShape changeInterferometric synthetic aperture radar

The invention discloses a method for improving earth surface shape change monitoring precision of an InSAR (Interferometric Synthetic Aperture Radar) technology based on a high-precision DEM (Digital Elevation Model). The method comprises five steps below: step 1, generating an interferogram by using radar data; step 2, generating a differential interference phase diagram; step 3, establishing error phases and performing feature analysis; step 4, establishing an error phase optimal function calibration model; step 5, recovering earth surface shape change information of a monitoring region based on results of steps 2 and 4. According to the invention, the error phases and elevation values or the error phases, the elevations and coordinate values along a distance / azimuth of different regions of a research region are extracted, the optimal function calibration models of the error phases of corresponding regions are established respectively based on a least square method, and a simulative error phase is finally removed from the differential interference phase diagram to further recover shape change information along a direction of a sight line of a radar in the monitoring region. The method for improving the earth surface shape change monitoring precision of the InSAR technology based on the high-precision DEM has practical value and wide application foreground in the application field of a satellite borne synthetic aperture radar monitoring technology for earth surface shape change.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

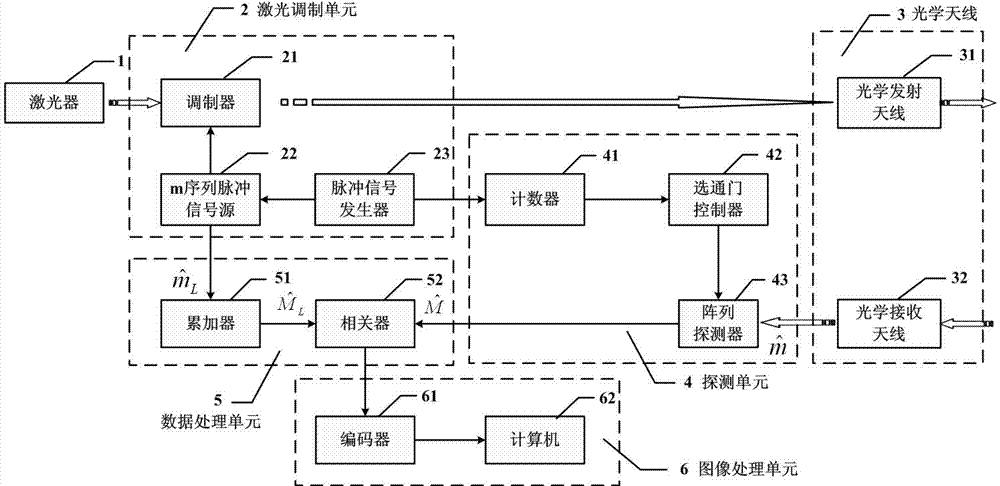

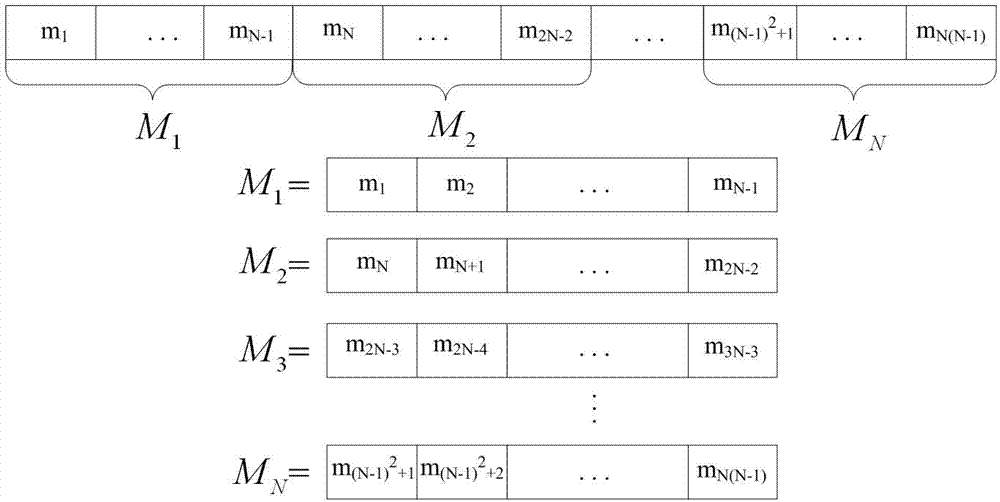

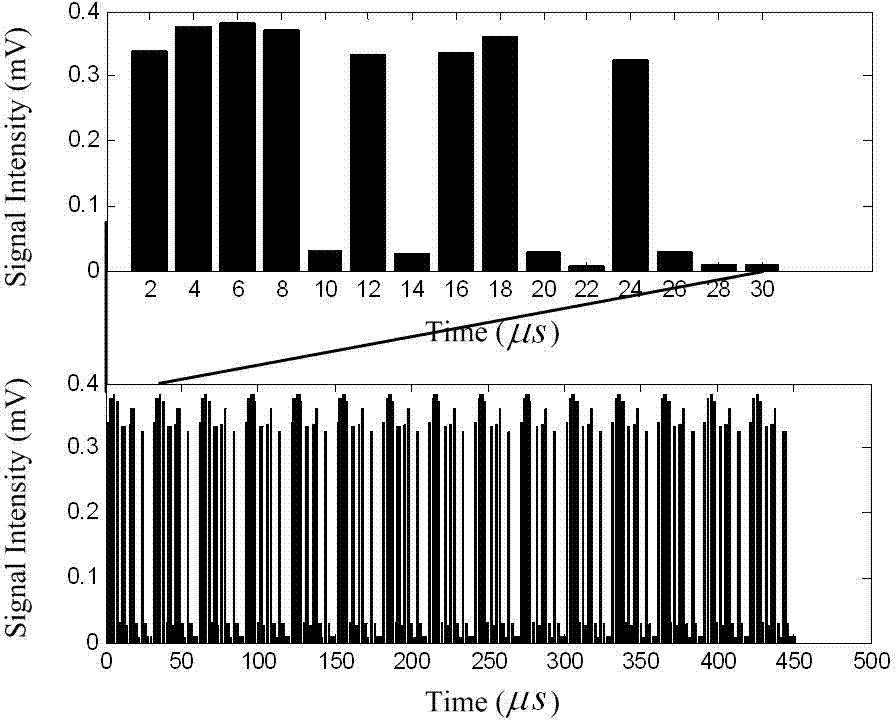

Laser imaging radar device and distance measurement method thereof

ActiveCN103616696AFast ranging speedProbe cycle shortenedElectromagnetic wave reradiationEngineeringRange gate

The invention provides a laser imaging radar device and a distance measurement method thereof. The laser imaging radar device and the distance measurement method thereof aims at the problem that an existing distance range gate laser imaging radar is low in distance resolution. The laser imaging radar device comprises a laser device, a laser modulation unit, an optical antenna unit, a detecting unit, a data processing unit and an image processing unit, wherein the detecting unit is composed of a counter, a gate controller and an array detector, and the data processing unit is composed of an accumulator and a correlator. According to the distance measurement method, an information loading process is carried out on laser signals with constant amplitude by using a phase code pulse amplitude modulation mode. The laser imaging radar device and the distance measurement method thereof have the advantages that the equipment and the method combine the advantages of long detecting distances of the distance ranging gate layer imaging radar and the advantage of high distance measurement resolution of the pulse phase coding mode, and meanwhile the detect of low distance measurement resolution of the distance ranging gate layer imaging radar and the detect of low imaging speed of the pulse phase coding mode are avoided.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

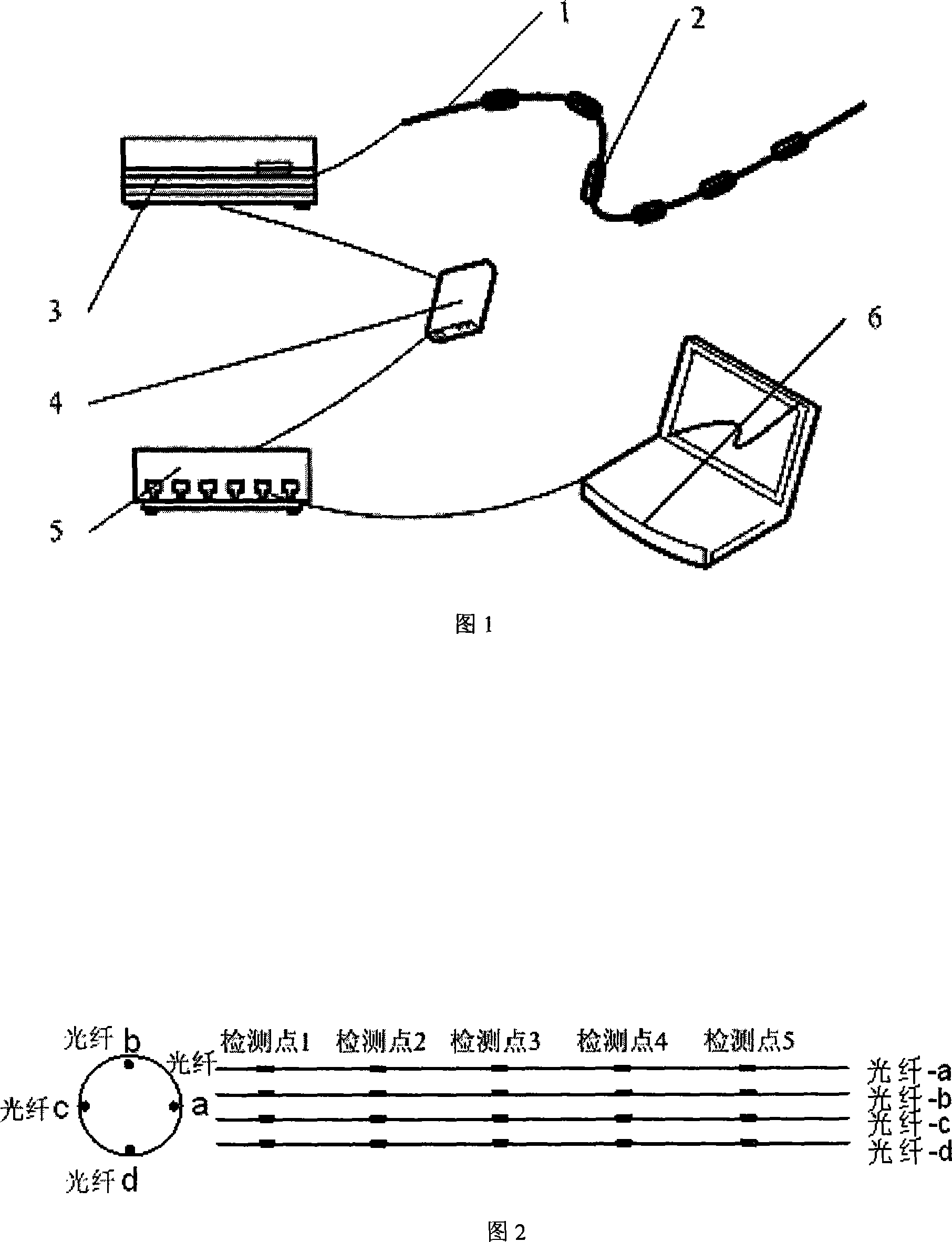

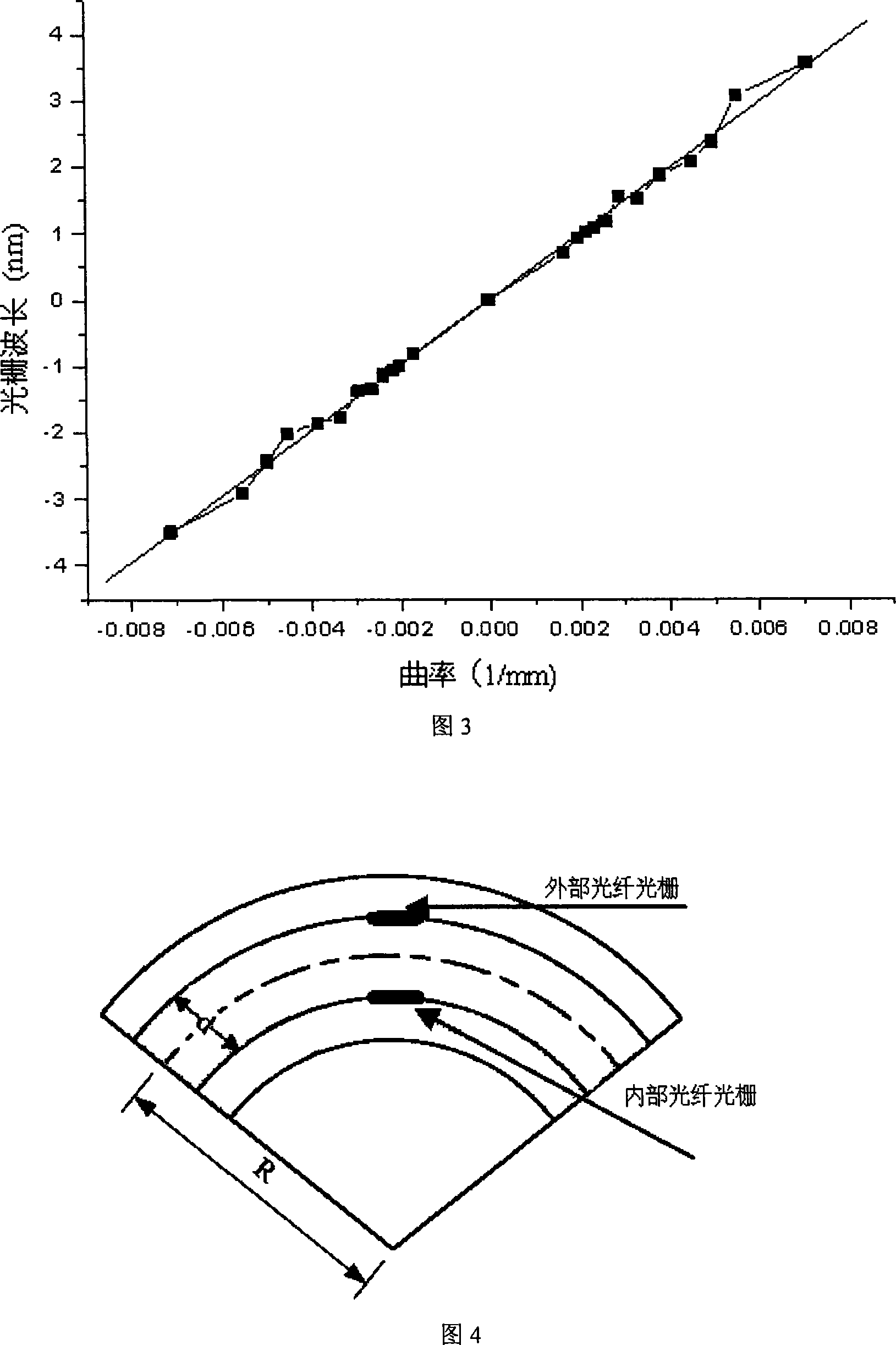

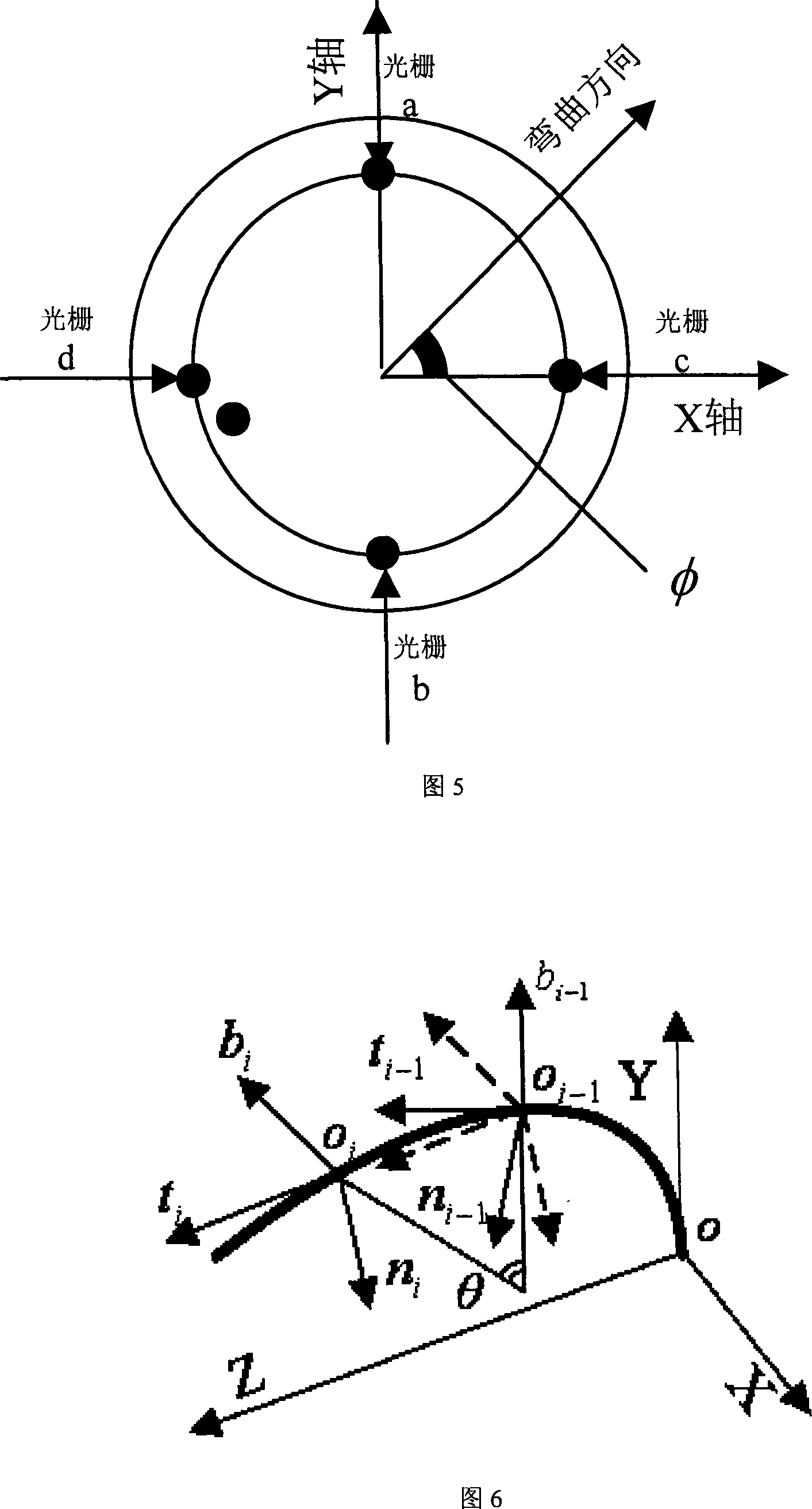

Thin long flexible rod spatial shape detecting device and method

InactiveCN101099657AImprove real-time response performanceSmall sizeSurgeryDiagnostic recording/measuringSensor arrayFiber

The present invention relates to a space form detection device of fine-long flexible bar and its detection method. Said device is composed of fine-long flexible bar, fiber-optic grating sensor array, fiber-optic grating modulator-demodulator, local area network router, data acquisition and data processing module and display equipment. The space form detection method of fine-long flexible bar includes the following steps: utilizing a group of grating array formed from four optical fibers arranged on the fine-long flexible bar, utilizing scale factor between the off-line labeled curvature and wavelength and utilizing fiber-optic grating modulator and demodulator to measure wavelengths of 20 raster points in five discrete points of fine-long flexible bar in the space so as to obtain the space curvature size and direction of discrete point position, then utilizing data processing module to reconstruct the form of said fine-long flexible bar in space. Said device can be used for making real-time tracking detection of human body cavity channel and fine-small vessel forms in the therapeutic process.

Owner:SHANGHAI UNIV

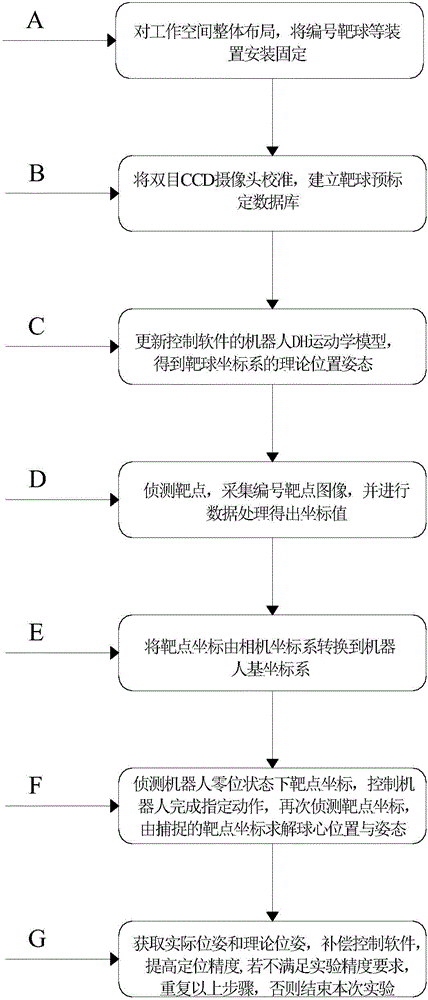

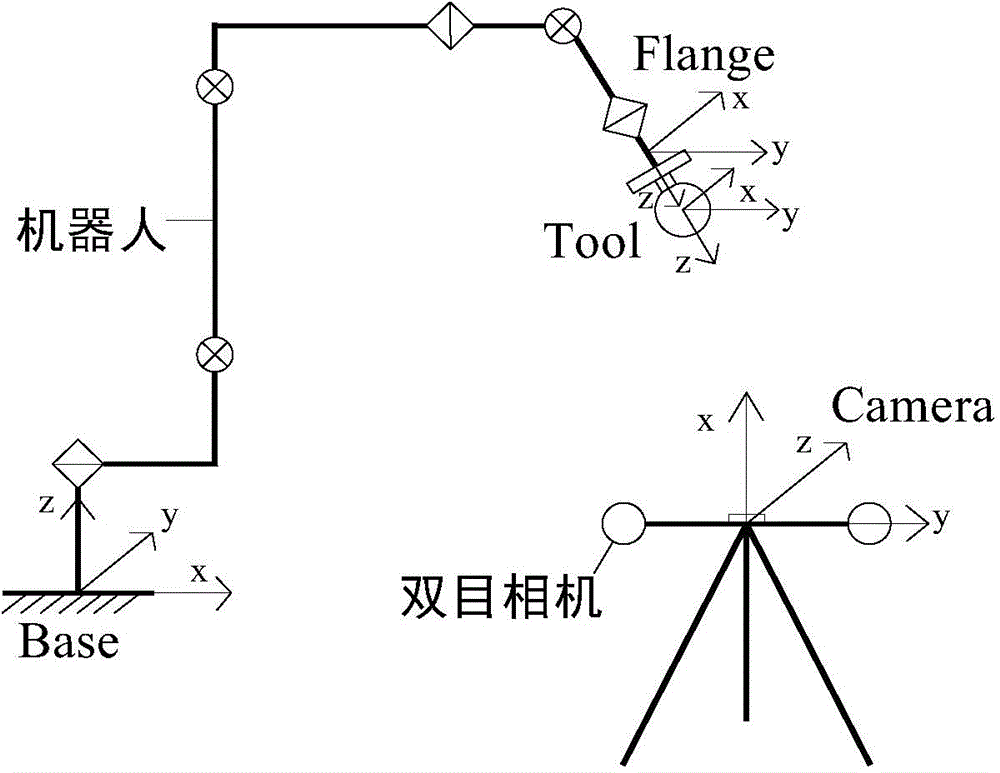

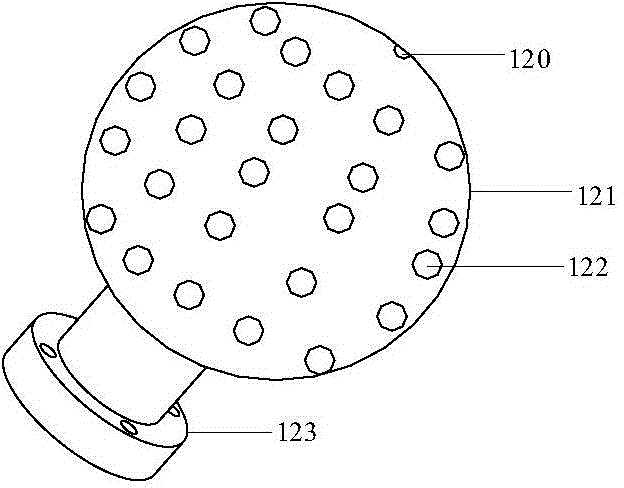

Industrial robot measurement method based on tail end numbered tool

InactiveCN104858870AHigh positioning accuracyLarge measuring rangeProgramme-controlled manipulatorCcd cameraData processing

The invention relates to an industrial robot measurement method based on a tail end numbered tool. The method specifically includes the following steps that the overall arrangement of a work space is conducted, and the number tool and other devices are installed and fixed; a binocular CCD camera is calibrated, and a tool pre-calibration database is established; a DH kinematic model is updated so that the theoretical pose of a tool frame can be obtained; the images of numbered points are collected, and data processing is performed so that coordinate values can be obtained; coordinates are converted into a robot base frame from a camera frame; the position of the tool center and the posture of the tool frame are obtained according to captured point coordinates; as is verified in an experiment, positioning precision is improved. The measurement method solves the problem that a traditional vision system is narrow in positioning and tracing view field, effectively improves the positioning precision of the behaviors of the robot, has the advantages of being simple, reliable and efficient and reduces the cost for measuring the tail end pose of the robot.

Owner:JIANGNAN UNIV

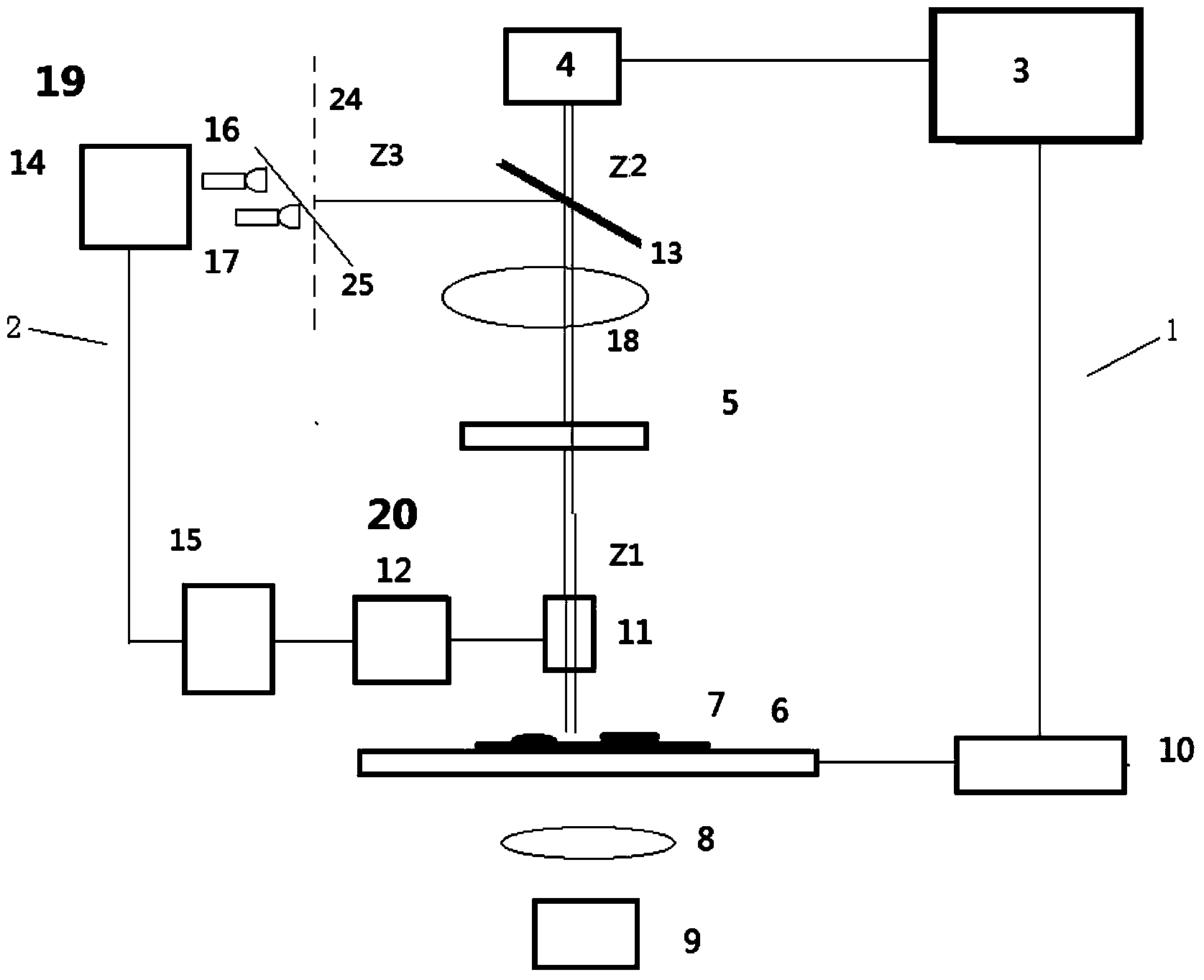

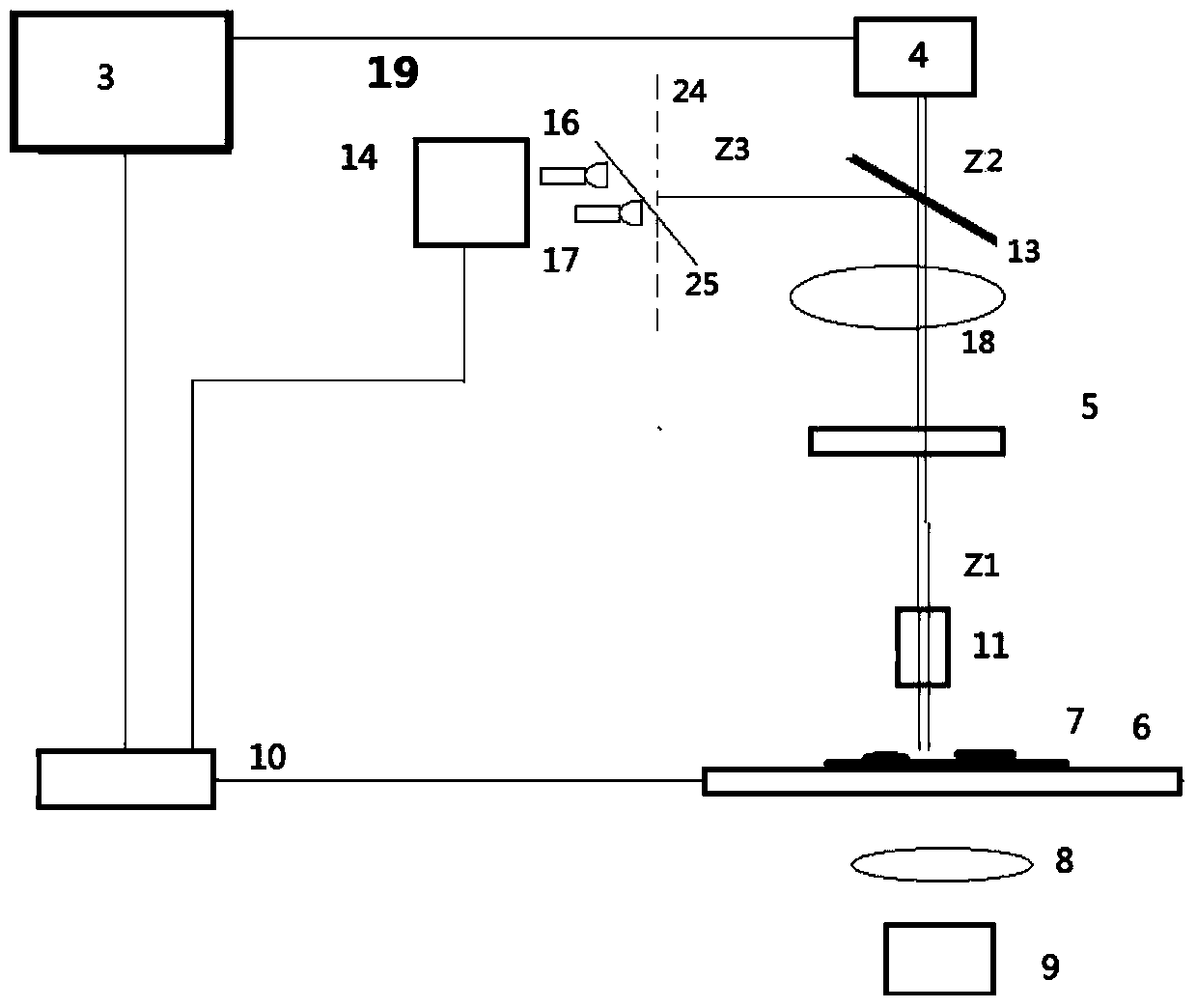

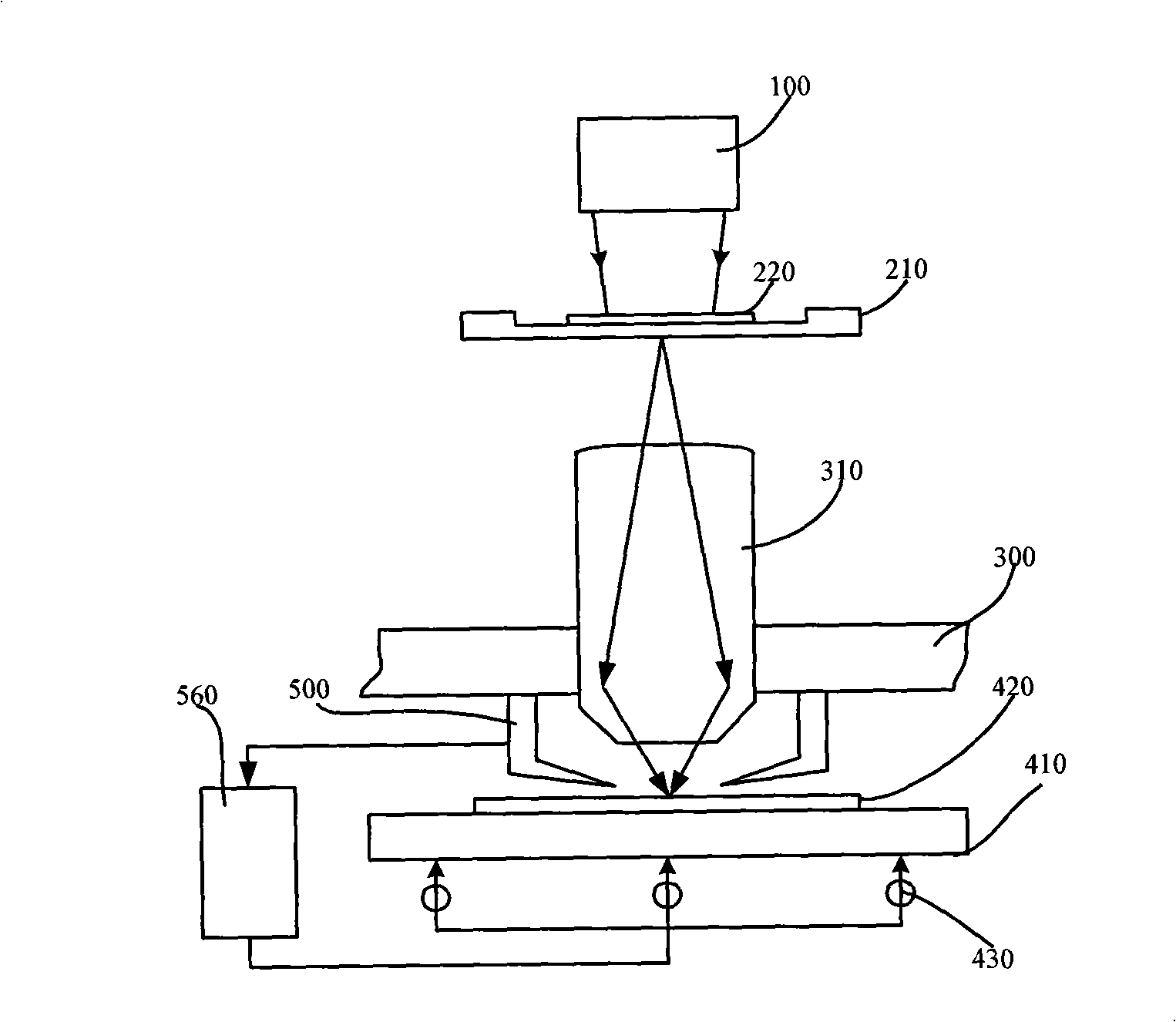

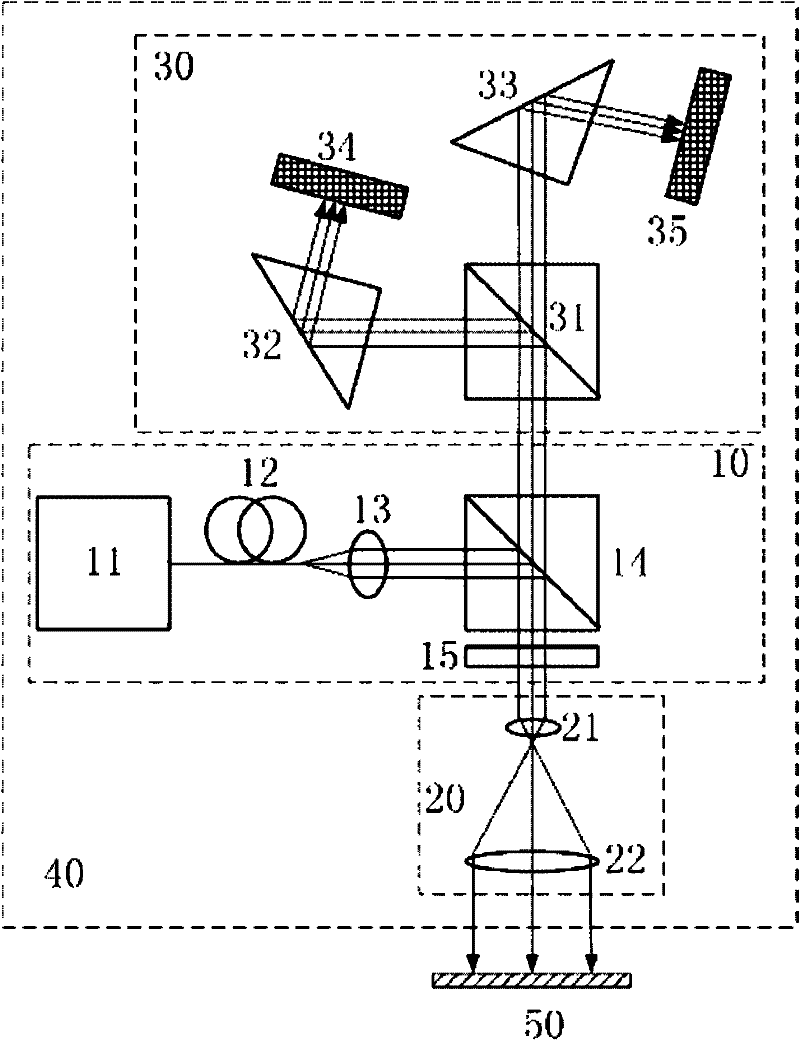

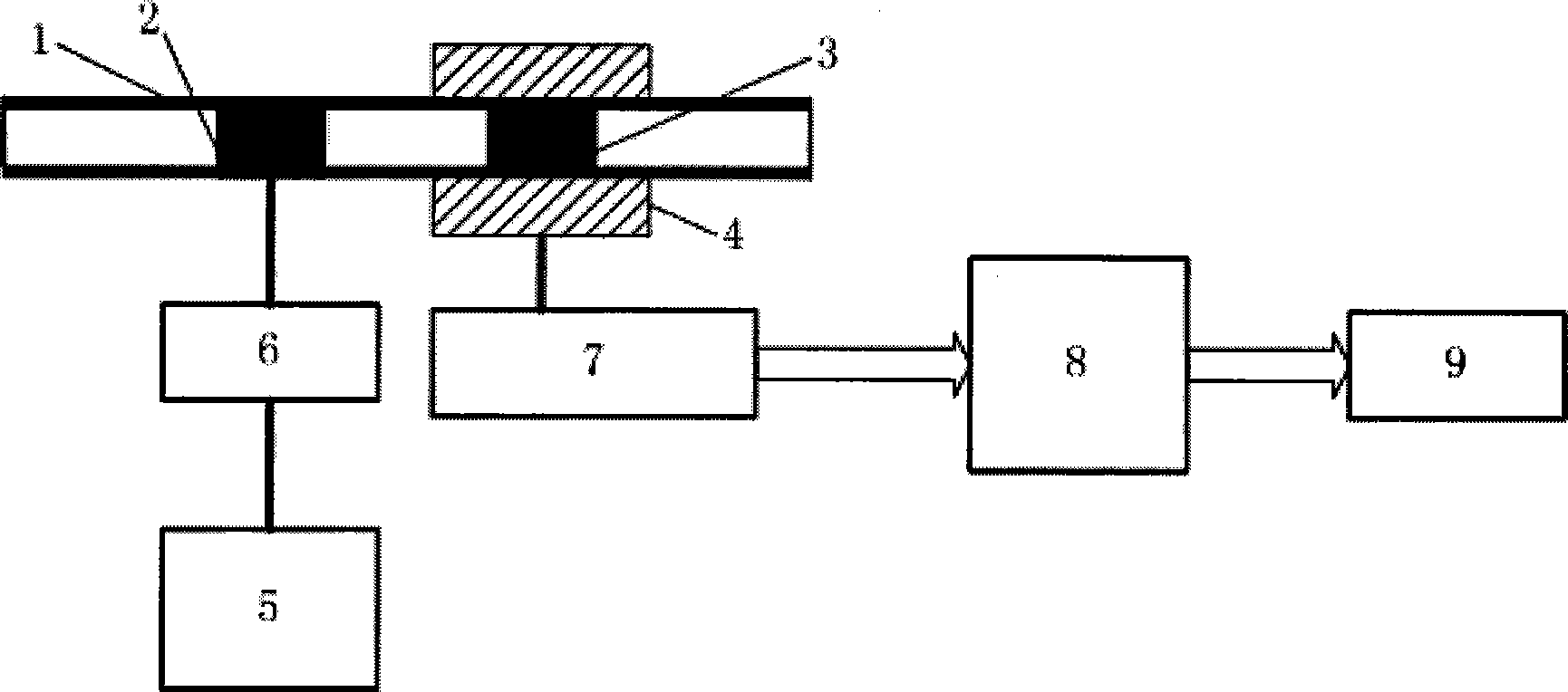

Microscopic section rapid digital scanning device and method with real-time focusing function

ActiveCN103852878AHigh frequency of data collectionLarge measuring rangeMicroscopesMicroscopeLight source

The invention discloses a microscopic section rapid digital scanning device and method with the real-time focusing function. The microscopic section rapid digital scanning device comprises a digital microscopic imaging system and a real-time focusing device combined with the digital microscopic imaging system in a matched mode. The digital microscopic imaging system comprises a computer, an image detecting device for achieving photovoltaic conversion, a microscopic optical imaging system, an automatic carrying table, a movement and control system corresponding to the automatic carrying table, a microscope lighting optical system, a lighting light source and the like. The real-time focusing device comprises a device for measuring the defocusing amount of a sample and a device for driving the sample or a lens to move and enabling the sample and the focal plane of the lens to be coincided. According to the microscopic section rapid digital scanning device and method, the distance between the sample and the focal plane of the imaging system in the section scanning process can be detected in real time, real-time focusing can be achieved, and therefore an excellent image is obtained; the time-consumed focal plane modeling process can be omitted through the real-time focusing technology; meanwhile, the large focusing range and the high focusing accuracy are both considered; in addition, the microscopic section rapid digital scanning method is high in efficiency and low in cost.

Owner:MOTIC CHINA GRP CO LTD

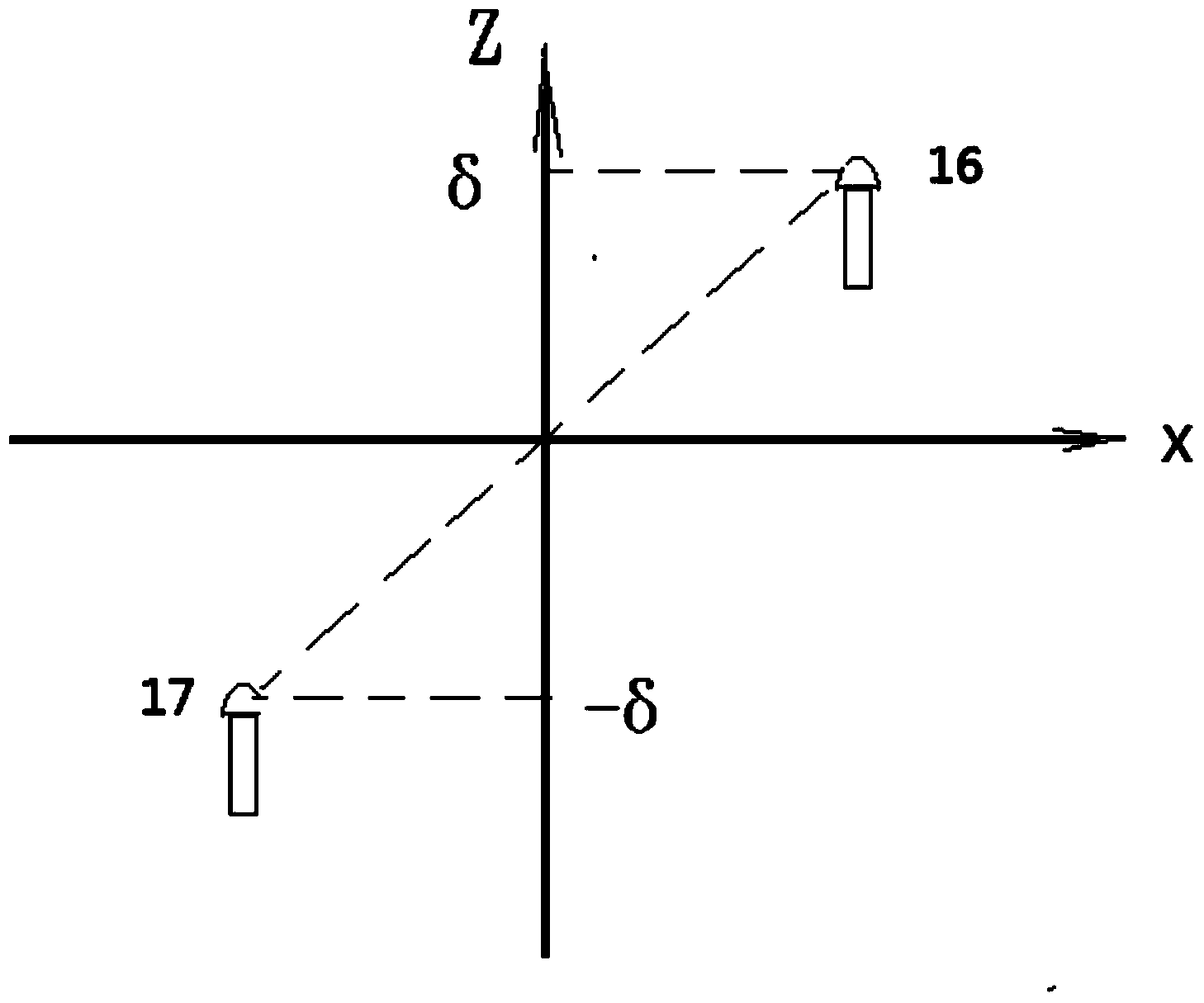

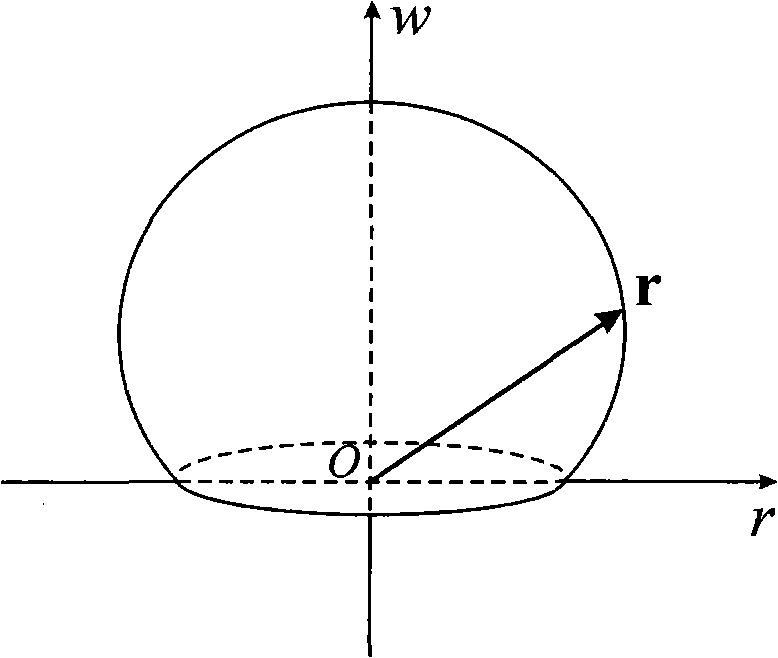

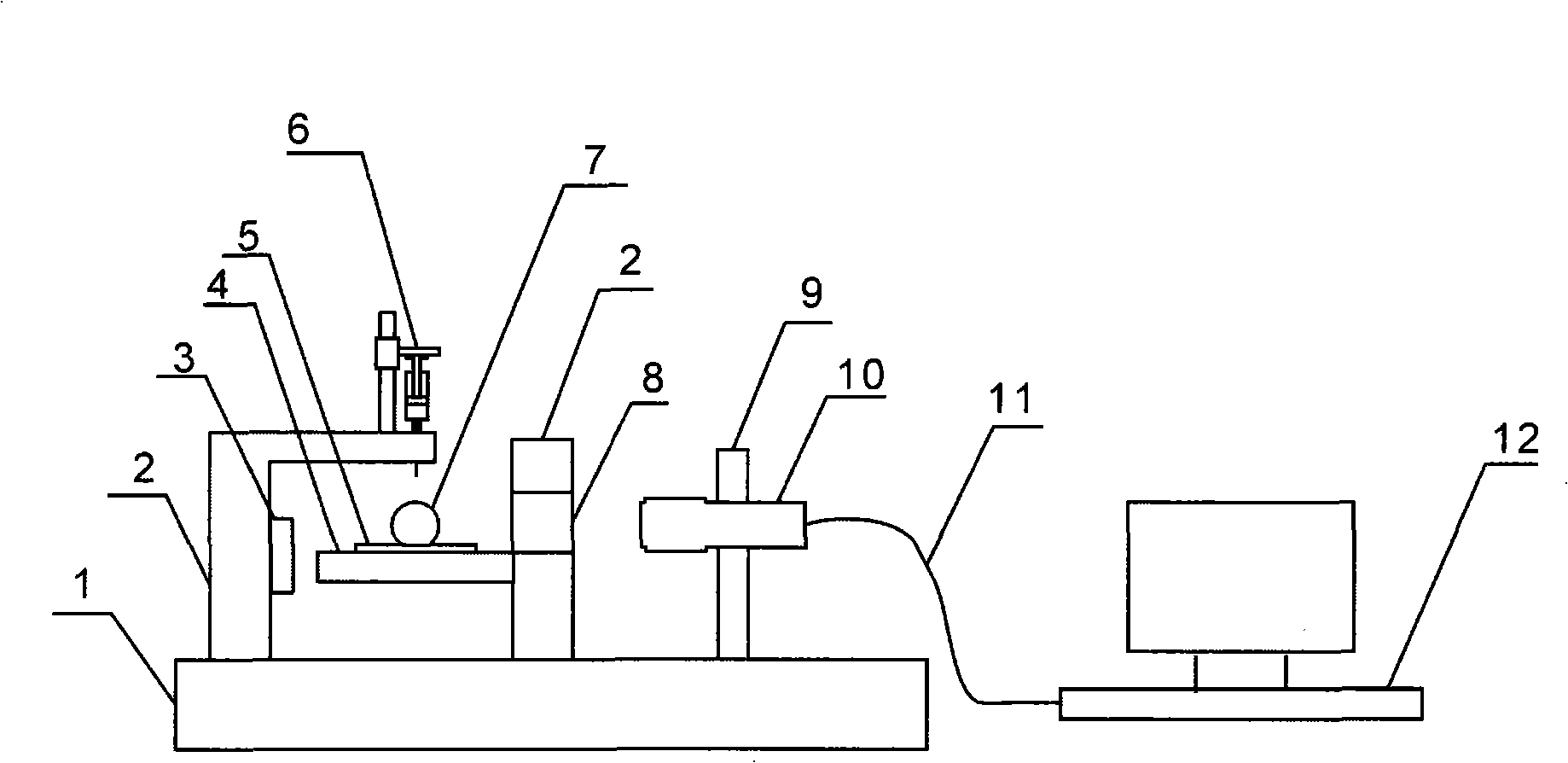

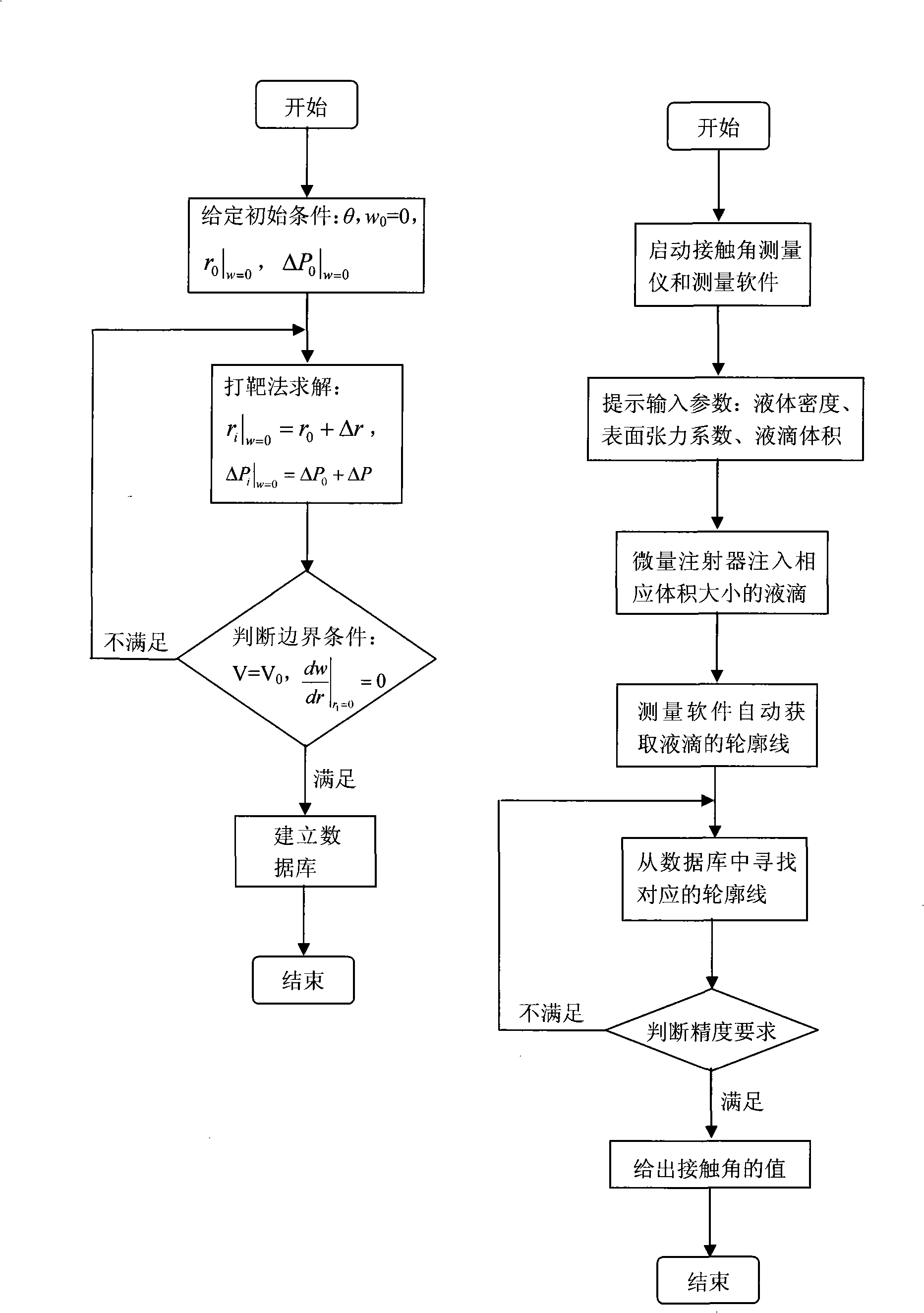

Method for measuring liquid-drop contact angle on solid surface and device thereof

ActiveCN101539502AHigh measurement accuracyLarge measuring rangeSurface/boundary effectInvestigating moving fluids/granular solidsCcd cameraInjector

The invention relates to a method for measuring a liquid-drop contact angle on a solid surface and a device thereof, which are used for measuring the contact angles of the liquid drops with different mediums and different sizes on the solid surface. The method comprises the following steps of: according to one-to-one correspondence between a liquid drop volume and a liquid drop contact angle, obtaining a plurality of liquid drop profiles which correspond to different contact angles, thus establishing a database used for storing different liquid drop profiles; when in measuring, fixing a sample on an earthquake isolation platform, and dropping the liquid with known volumes on the surface of the sample by utilizing a micro-injector; after the liquid drops achieve balance, acquiring a liquid drop image on the surface of the sample by utilizing an optical imaging system, a CCD camera and a computer; utilizing an image matching method to carry out processing and analyzing to the shapes of the liquid drops by computer software, and then carrying out calculation to obtain contact angles of the liquid drops; and matching the liquid drop profiles obtained by experimental measurements with the liquid drop profiles in the database so as to determine the corresponding contact angles. Compared with the existing method, the method takes the influence of volume and weight of the liquid drop in to consideration, thus improving the measuring precision.

Owner:TSINGHUA UNIV

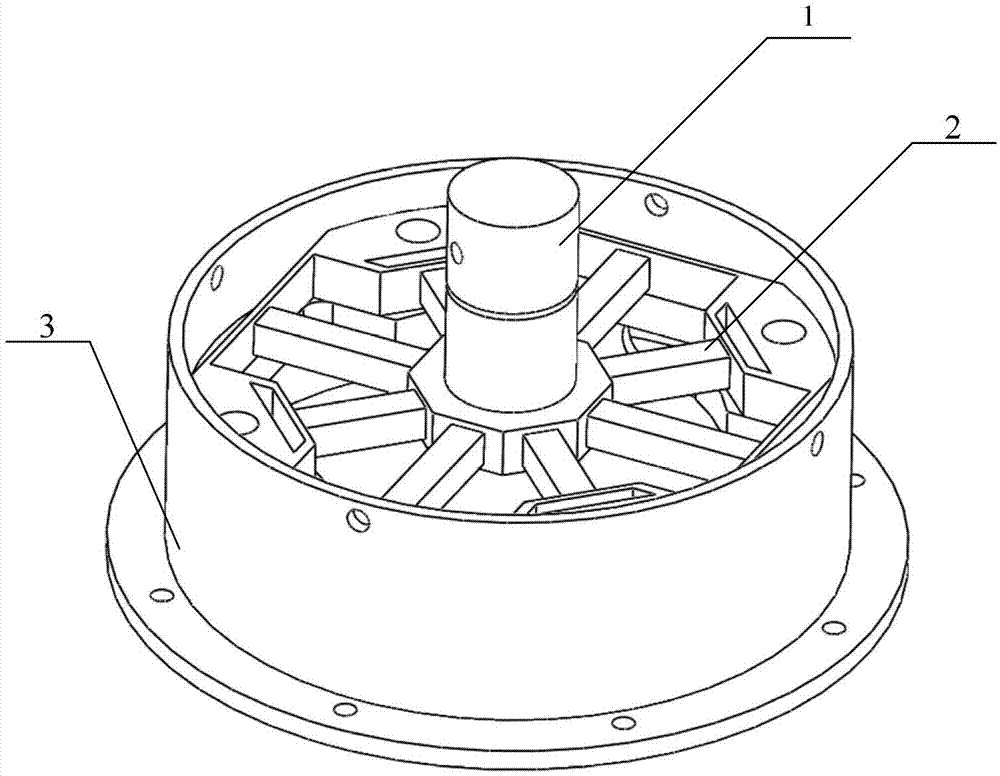

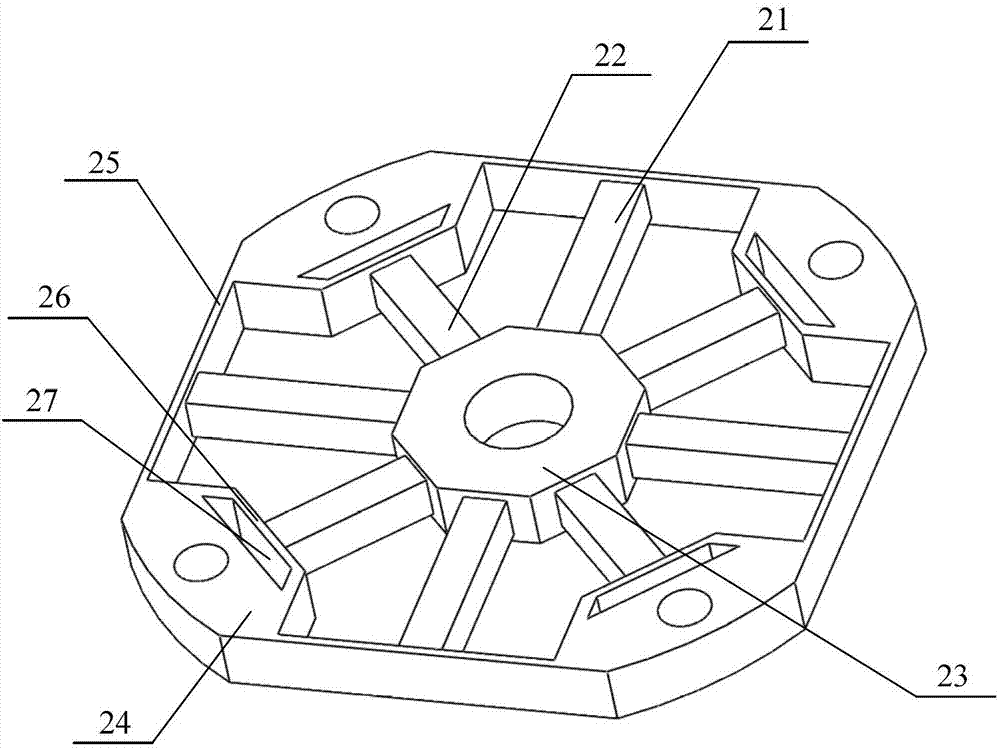

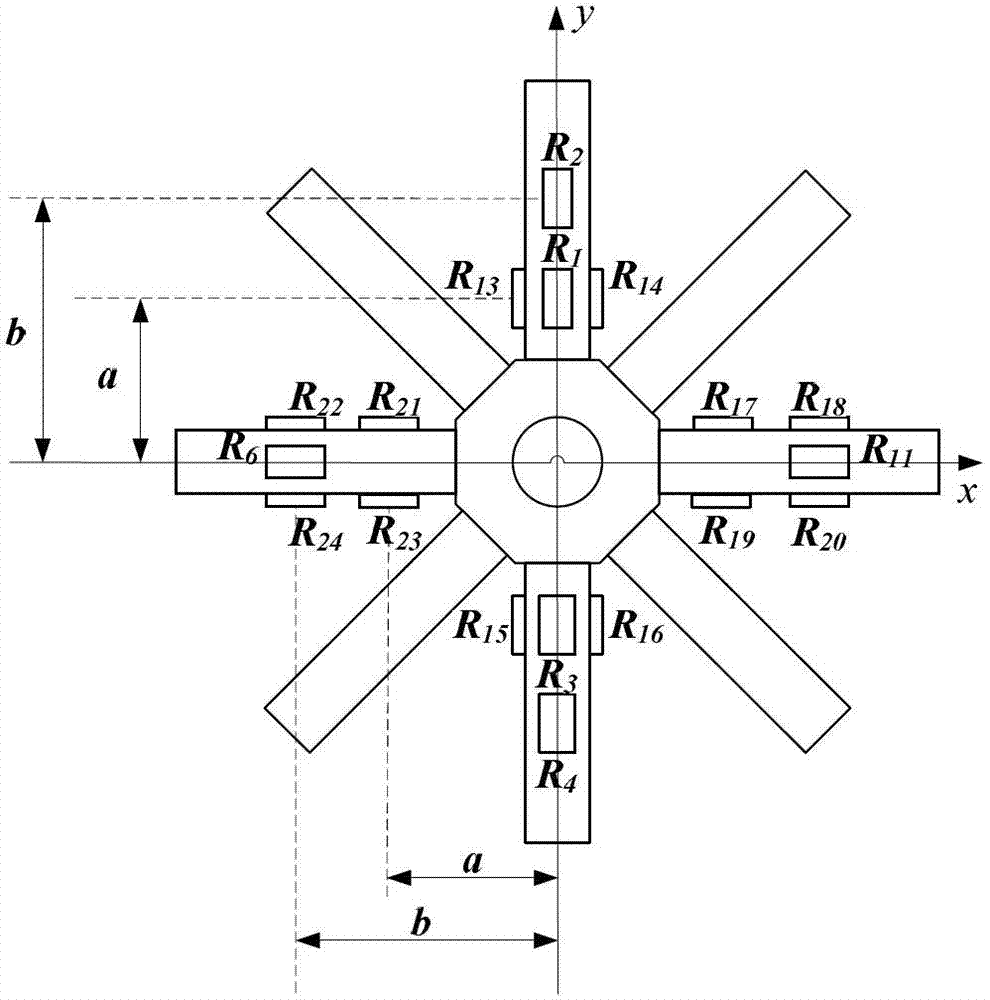

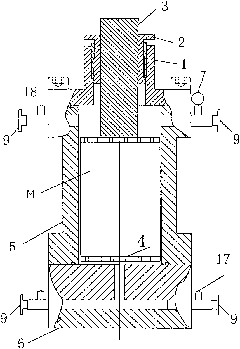

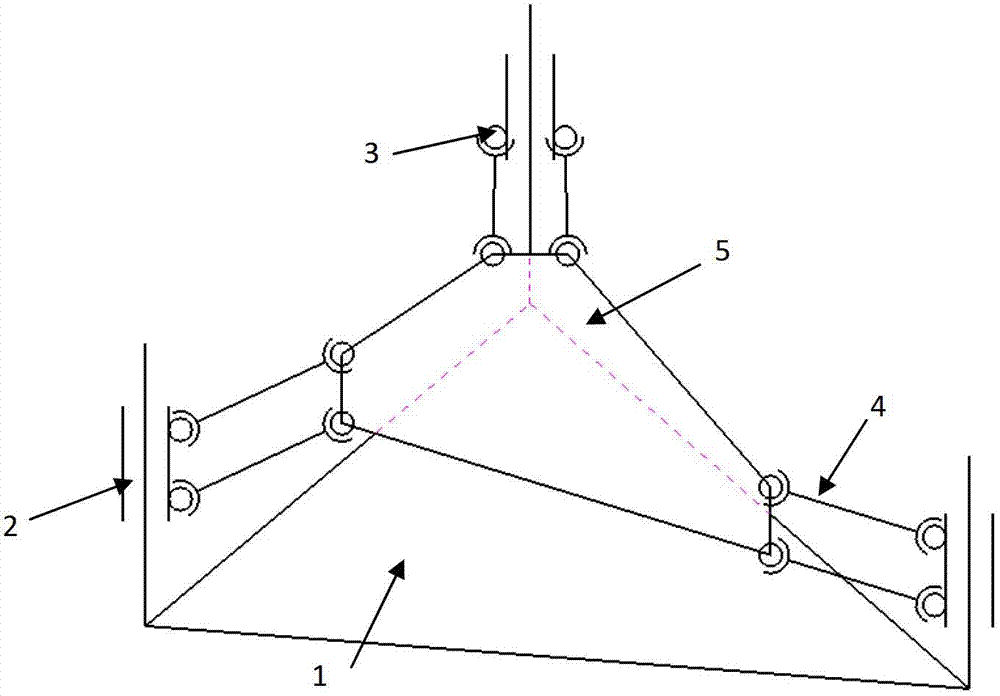

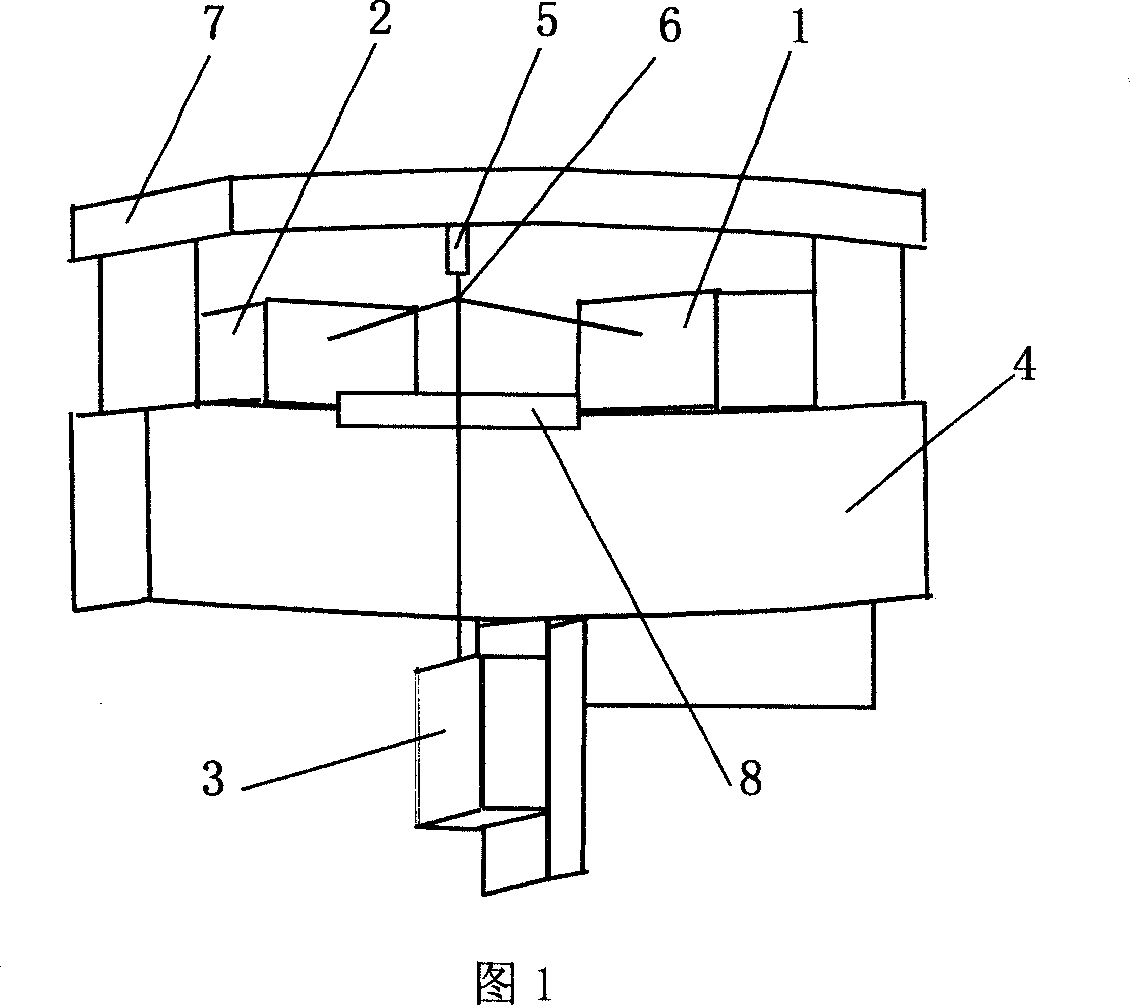

Six-dimensional force and torque sensor for measuring large force and small torque of large mechanical arm

ActiveCN103076131AIncrease rangeLarge measuring rangeWork measurementTorque measurementInterference fitEngineering

The invention discloses a six-dimensional force and torque sensor for measuring large force and small torque of a large mechanical arm. The six-dimensional force and torque sensor comprises a center shaft, a force sensitive element, a base and a strain gage component, wherein the force sensitive element is fixedly connected to the base; the center shaft penetrates through the force sensitive element and the base; the center shaft is in interference fit with the force sensitive element; the strain gage component is attached to the force sensitive element; the force sensitive element comprises four elastic main beams, four elastic auxiliary beams, a regularly octagonal center shaft platform, four fixing platforms, four main floating beams and four auxiliary floating beams; the strain gage component comprises a first strain gage group and a second strain gage group; two opposite elastic main beams in the four elastic main beams are respectively coated with the first strain gage group, and the other two elastic main beams are respectively coated with the second strain gage group; and the center shaft is in interference fit with a through hole of the center shaft platform. The six-dimensional force and torque sensor can improve the rigidity of measuring the force, and can also slightly improve the rigidity of measuring torque.

Owner:SOUTHEAST UNIV

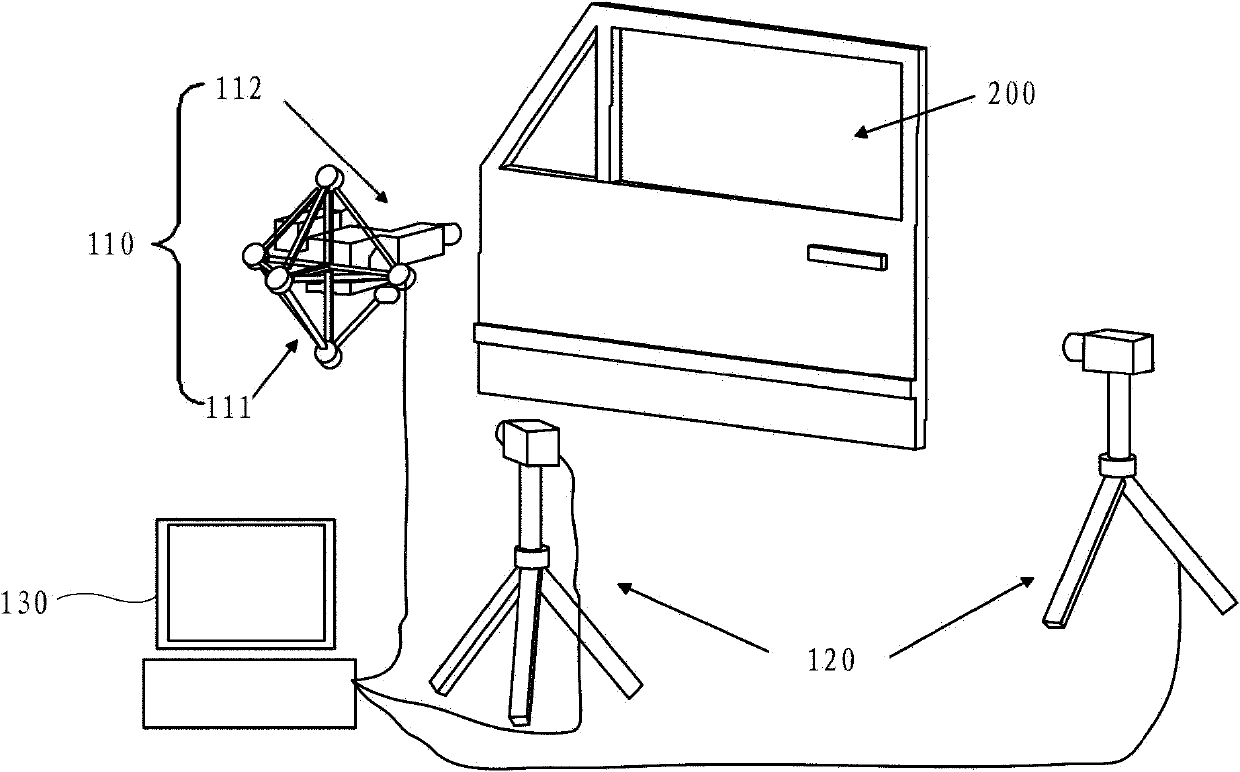

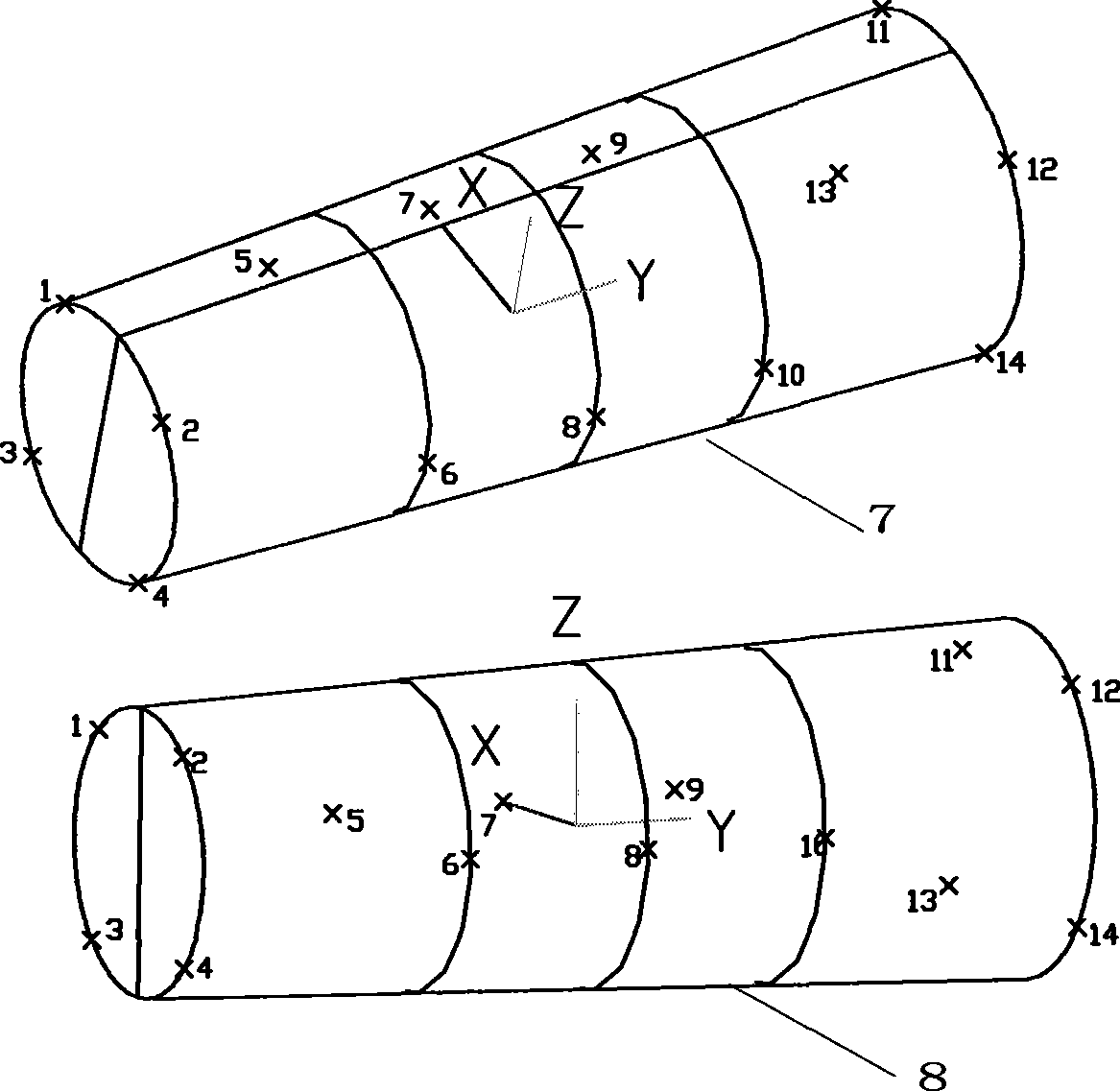

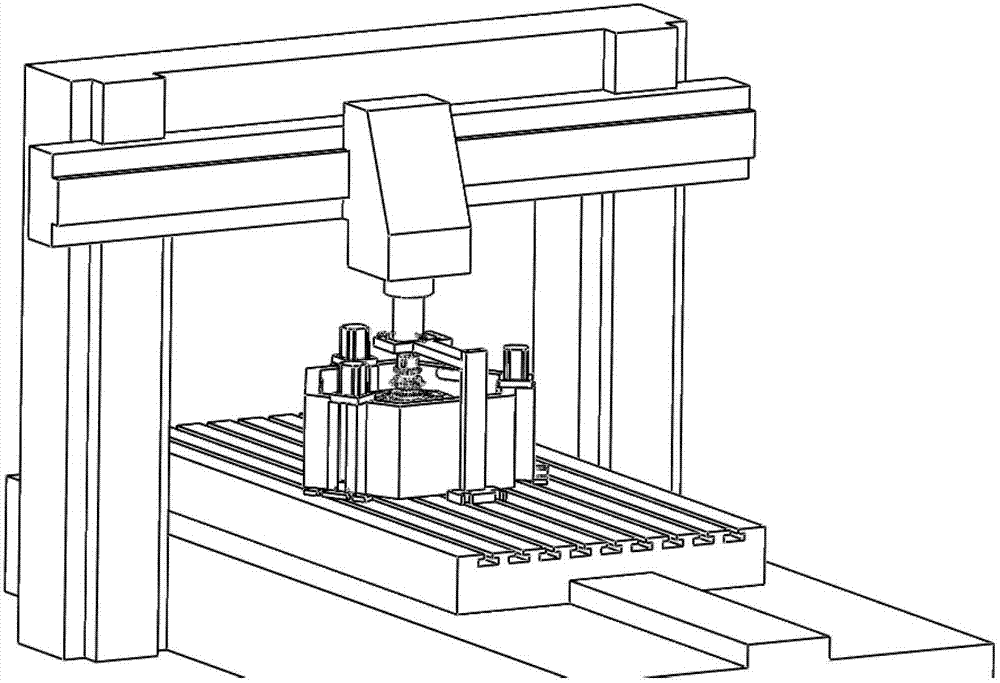

Splicing measuring method and system based on three-dimensional target

InactiveCN102155923ALarge measuring rangeEasy to operateMeasuring points markingUsing optical meansThree dimensional measurementVision sensor

The invention provides a splicing measuring method and system based on a three-dimensional target. The splicing measuring method comprises the following steps: (a) arranging two cameras in positions where a measured object can be observed, calibrating the parameters of the two cameras and setting a global coordinate system; (b) determining the coordinate value of a mark point on a three-dimensional target fixed on a vision sensor in a vision sensor coordinate system; (c) moving the vision sensor to the position where an area to be measured of the measured object can be measured, and carrying out three-dimensional measurement on the area to be measured of the measured object by using the vision sensor to obtain the three-dimensional data of the area to be measured of the measured object inthe vision sensor coordinate system; (d) determining the transformation relation between the vision sensor coordinate system in the current position and the global coordinate system; (e) transformingthe three-dimensional data obtained in the step (c) to the global coordinate system by using the transformation relation determined in the step (d); and (f) repeating the steps (c), (d) and (e) to complete the splicing of the three-dimensional measurement data of the measured object in the global coordinate system.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Device for testing axial loading/unloading gas permeability of coal

InactiveCN101825555ALow mechanical strength requirementSimple structurePermeability/surface area analysisInlet channelAxial pressure

The invention provides a device for testing the axial loading / unloading gas permeability of coal, comprising a gas pressurizer, a permeability test unit, an axial pressuring and unloading device and a gas collecting device, wherein the permeability test unit consists of a pressure chamber, a bleeder vent plate, a base, the base is provided with a gas inlet channel, a gas outlet channel is arranged at the top part of the pressure chamber and a piston pressure gauge is fixed on the top part; the permeability test device is arranged in the axial pressuring and unloading device which is composed of a lifting table, a triaxial shear instrument, a proving ring arranged at the upper part of the triaxial shear instrument, and the proving ring is provided with a strain dial gauge and a force-measurement dial gauge; the air tube of the gas pressuring device is connected with an air inlet of the base of the axial pressuring and unloading device; and the air header of the gas collecting device is connected with an air outlet at the upper part of the pressure chamber of the axial pressuring and unloading device. The device in the invention is suitable for permeability test for various coal body structures in particular to coal sample construction under the loading and unloading conditions, and has simple structure, convenient operation and good test repeatability.

Owner:CHINA UNIV OF MINING & TECH

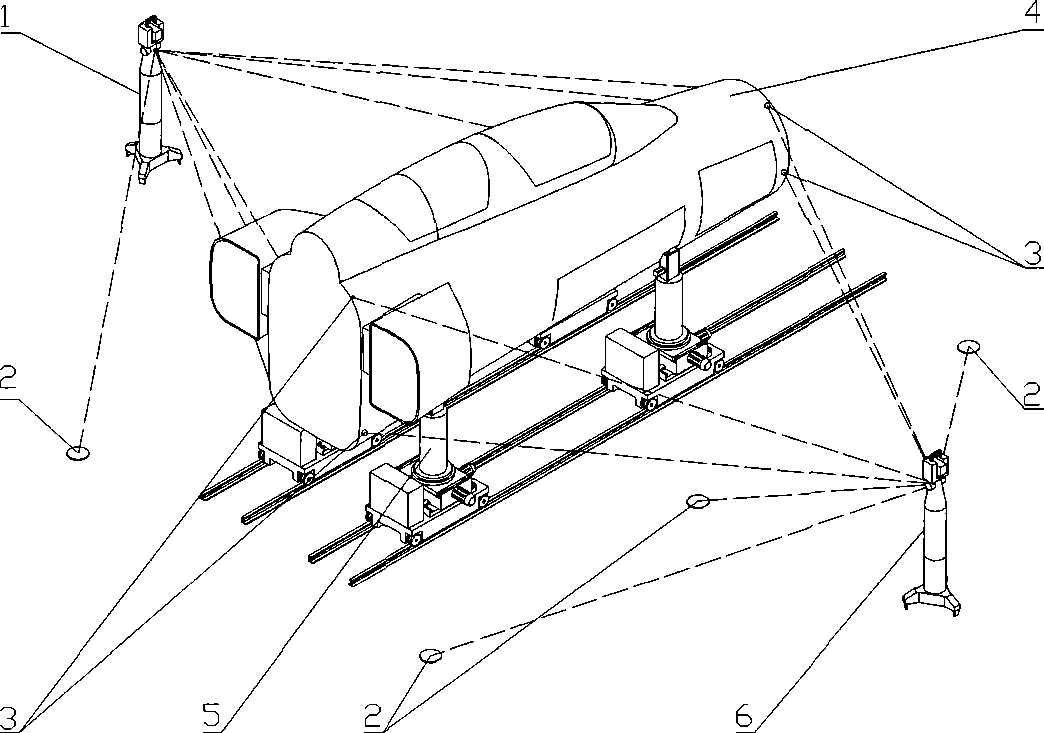

Computation method for attitude of aircraft fuselage based on laser tracking instrument

InactiveCN101363715AHigh precisionLarge measuring rangeUsing optical meansOptimization problemWeight value

The invention discloses an aircraft body attitude calculation method which is based on laser trackers. The attitude calculation method adopts a plurality of laser trackers to measure measurement points which are arranged on the measured aircraft body and used for expressing the aircraft attitude, and the current attitude of the aircraft part is calculated through the measurement values the theoretical values under the ideal designed attitude of the measurement points. The attitude calculation method takes into account the constraints to part of the measurement points, uses a least square error expression as a target function, utilizes a multi-target optimization model to combine the constraints and point matching, utilizes the Newton method to solve the optimization problem and obtains the aircraft body best attitude which is in line with the conditions of the constraints. The attitude calculation method adopts the advanced laser measurement technology to improve the precision of the measurement of the aircraft attitude; the attitude calculation method uses a plurality of points to carry out the attitude assessment and improves the accuracy of the attitude calculation by distributing errors to various points through the optimization function; and the attitude assessment takes into account the constraints of the measurement points and increases the flexibility of the attitude calculation by regulating the errors through the manual adjustment of weight value.

Owner:ZHEJIANG UNIV +1

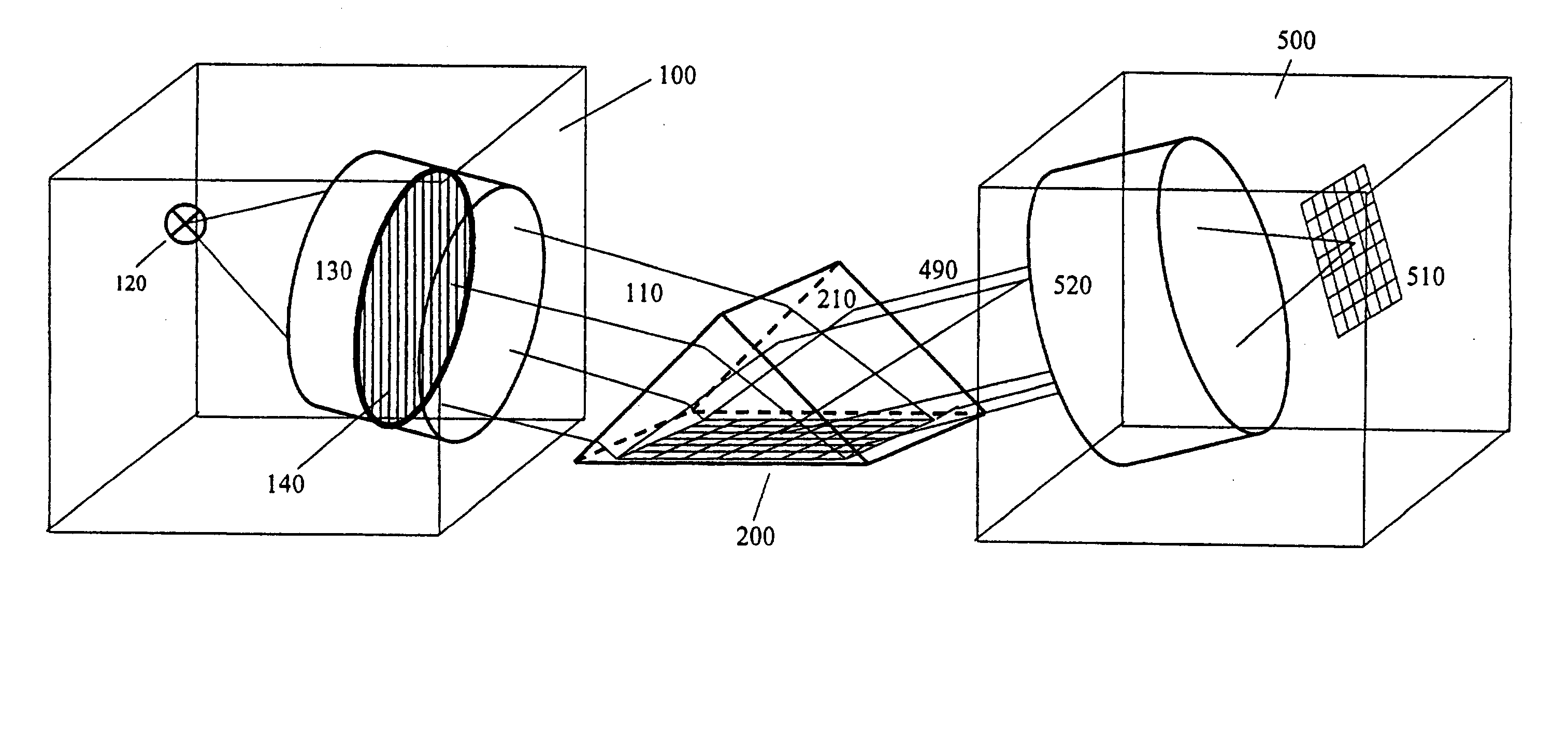

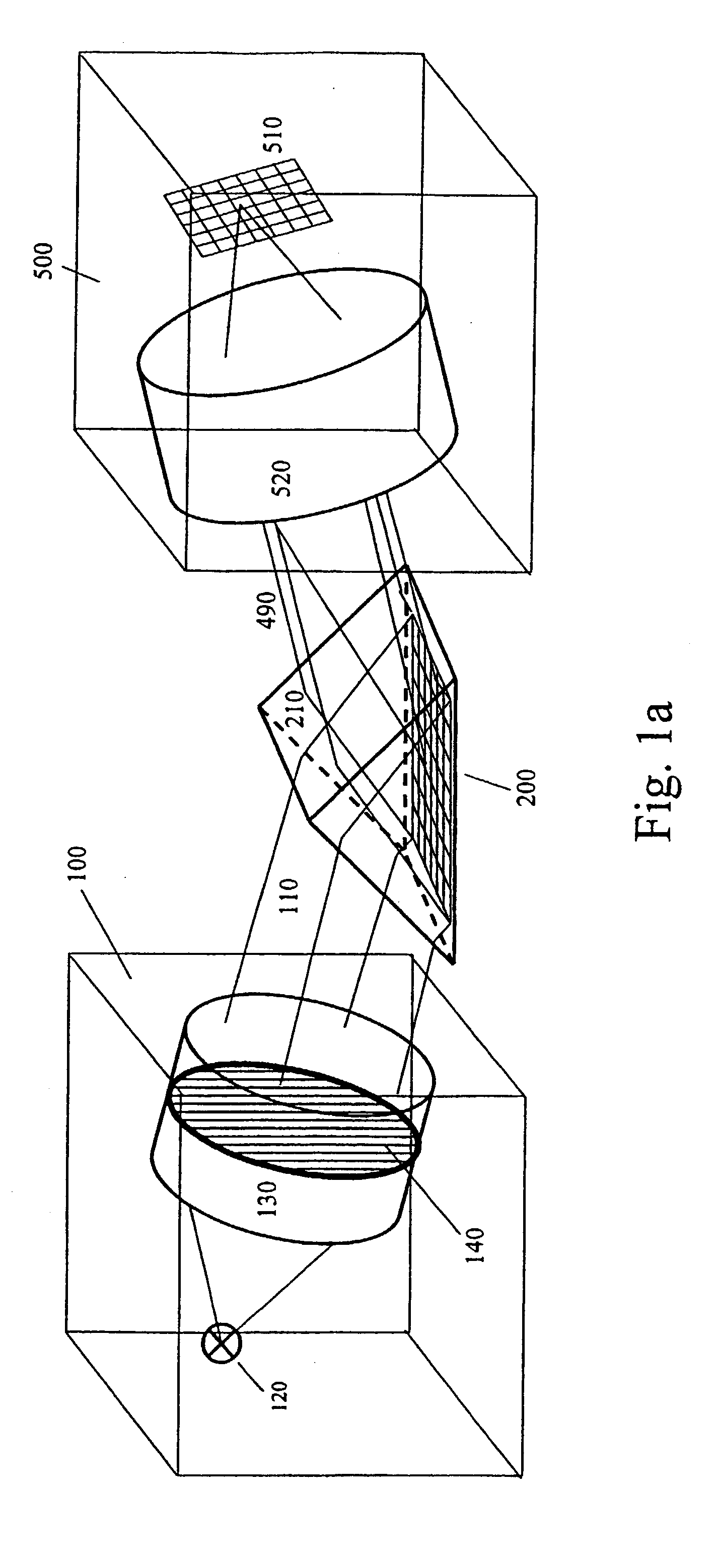

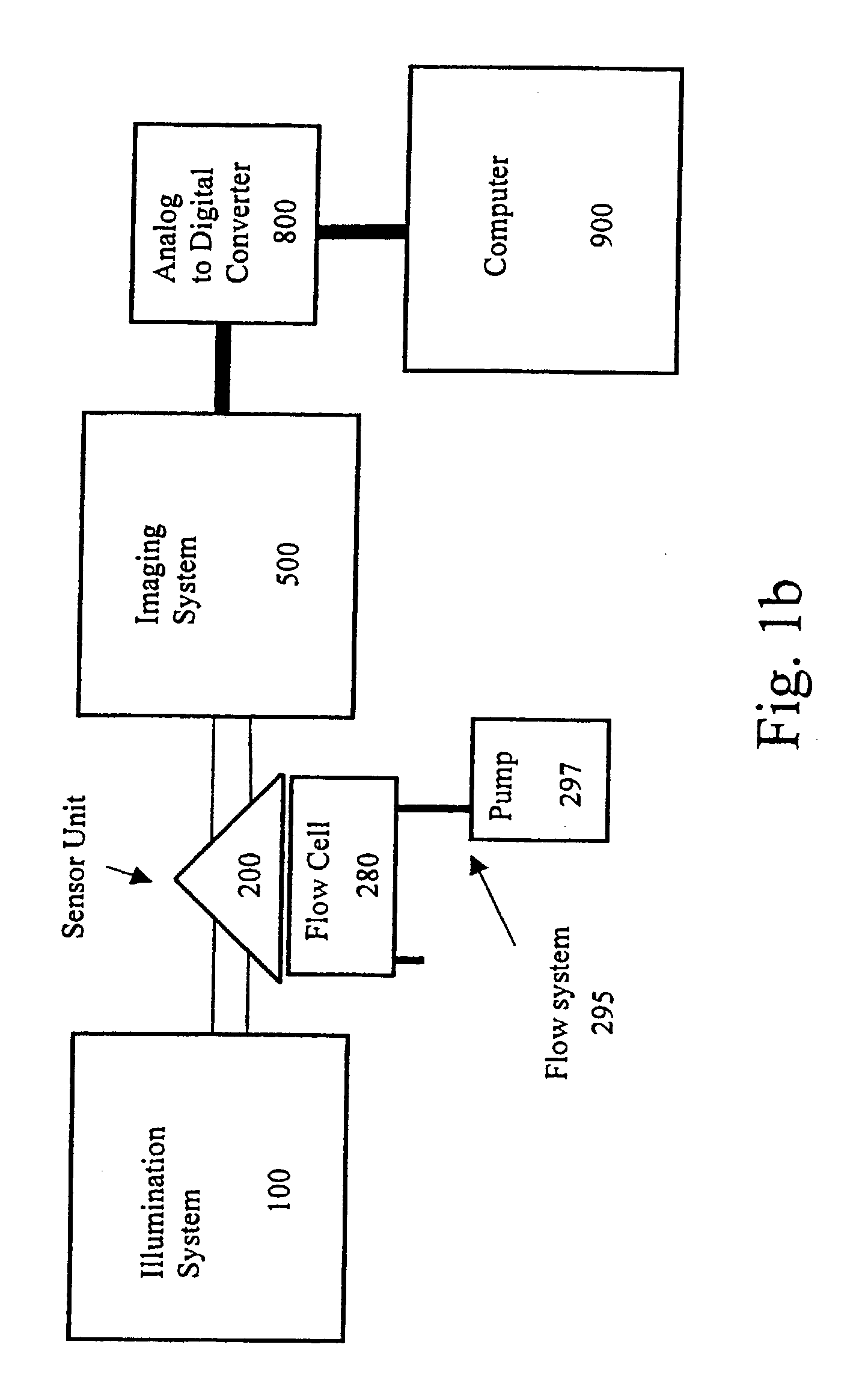

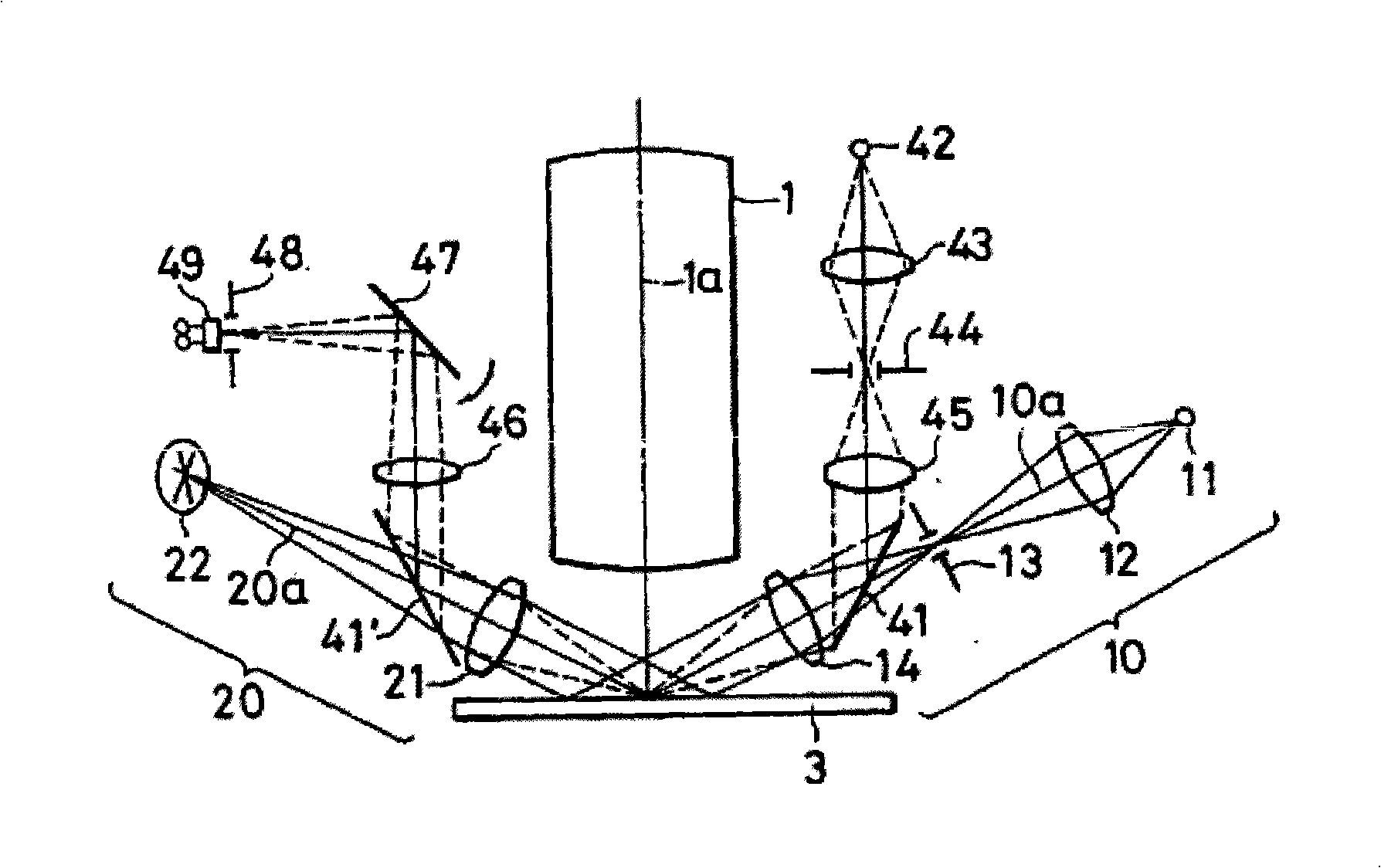

Imaging spr apparatus

InactiveUS20030048452A1Improve imaging effectImprove accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsColor imageConductive materials

A two-dimensional imaging surface plasmon resonance (SPR) apparatus for optical surface analysis of a sample area on a sensor surface is disclosed. The apparatus comprises a sensor surface layer of a conductive material that can support a surface plasmon, such as a free electron metal, e.g. gold, silver or aluminum, a source of electromagnetic beams of two or more wavelengths that illuminate a two-dimensional surface area from either the front or the backside of the sensor surface layer, and a detector for simultaneous, or pseudo simultaneous, detection of two or more wavelengths of reflected intensities from the two-dimensional surface area, providing two or more two-dimensional images of the surface area, the two-dimensional images being a function of the effective refractive index at each point on the surface area. The two-dimensional images put together result in a color image. The apparatus is suitable for use in biological, biochemical, chemical and physical testing.

Owner:SPRING SYST

Device and method for high-accuracy measurement of expansion coefficients of metal wire

InactiveCN101825590AEasy to handleHigh precisionMaterial thermal coefficient of expansionUsing optical meansPhase differenceFrequency modulation

The invention discloses a device and a method for high-accuracy measurement of expansion coefficients of a metal wire. The method uses a PZT oscillating mirror system to perform frequency modulation on incident light at different times, can not only modulate parameter information to be measured to a phase difference, but also modulate the parameter information to be measured to in a frequency difference for the convenience of later signal treatments; and the device consists of an interference system, a high-speed PZT oscillating mirror system, a heating system and a signal processing system. Comparing the method with other measuring methods, a multi-beam laser heterodyne measuring method for measuring the expansion coefficients of the metal wire has the advantages of high space and time resolutions, high measurement accuracy, high linearity, quick dynamic response, large measuring range and the like, and simultaneously the method has the advantages of simple structure for an experimental apparatus, low power consumption, convenient operation, high repeatability, small experimental result error, high accuracy and the like. Because experimental phenomena are obvious and experimental data is reliable, the method and the device can be widely applied in the fields of engineering designs and the like, and have very high practical values in the field of laser ultra-precision measurements.

Owner:HARBIN INST OF TECH

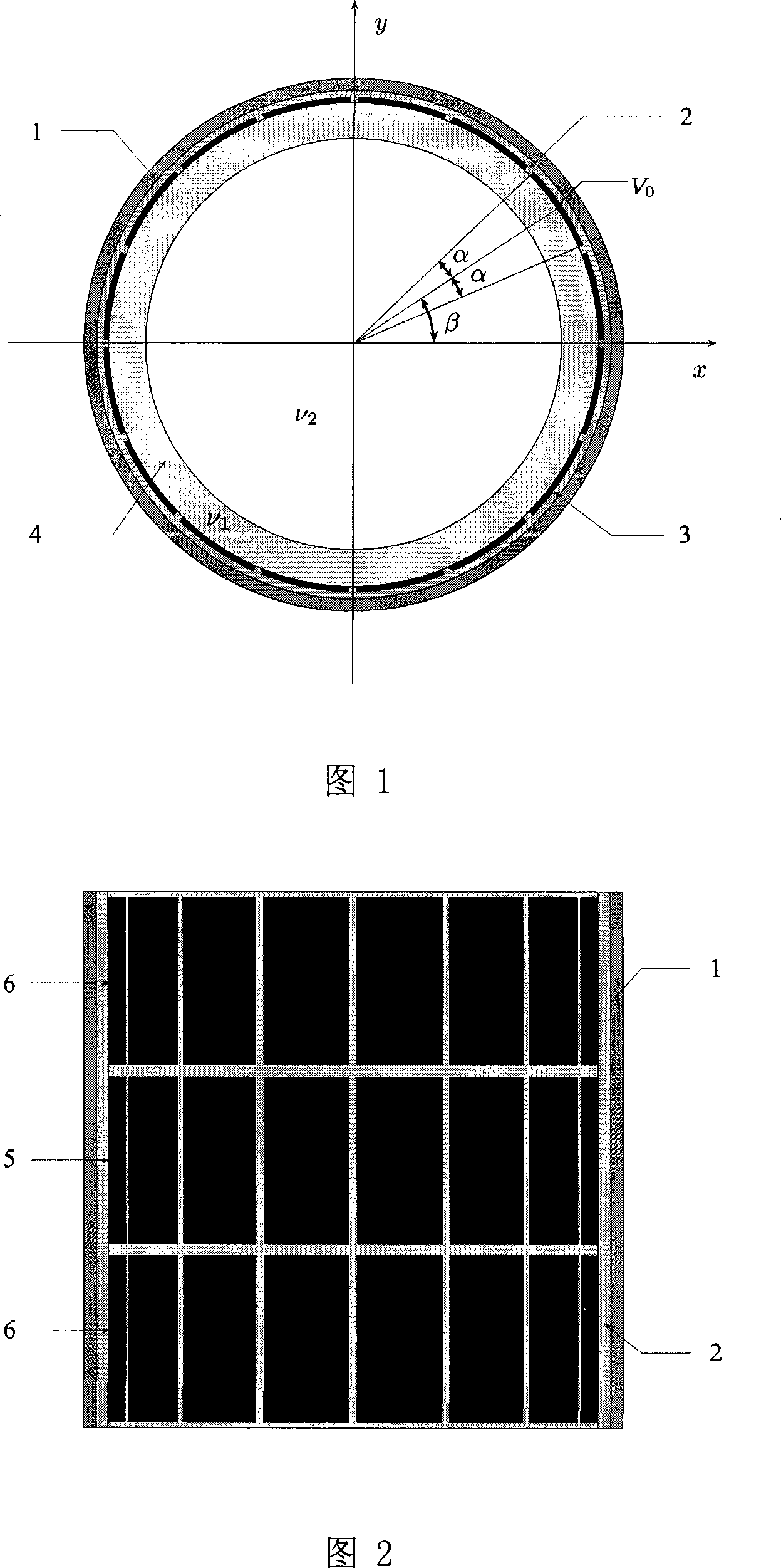

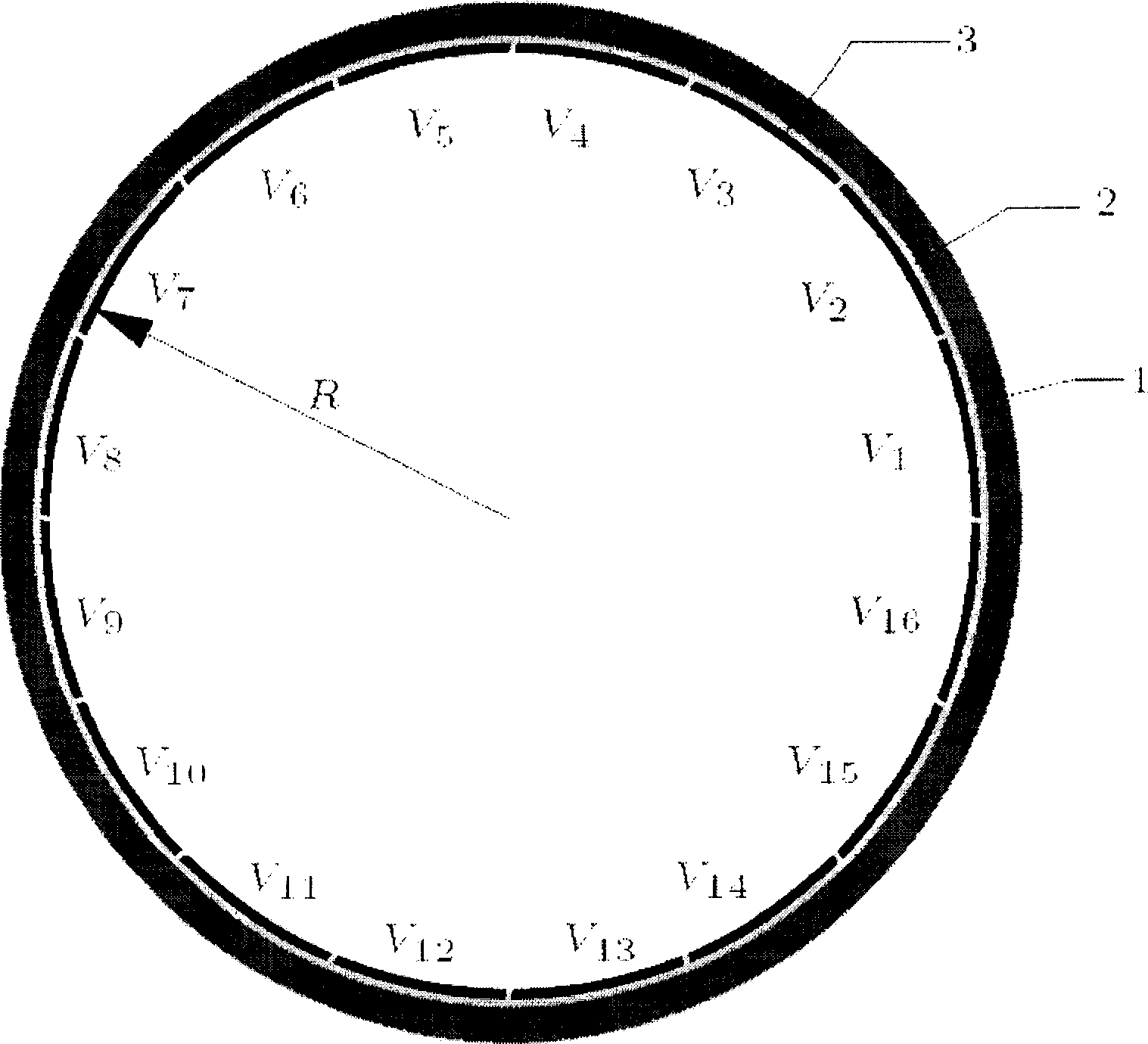

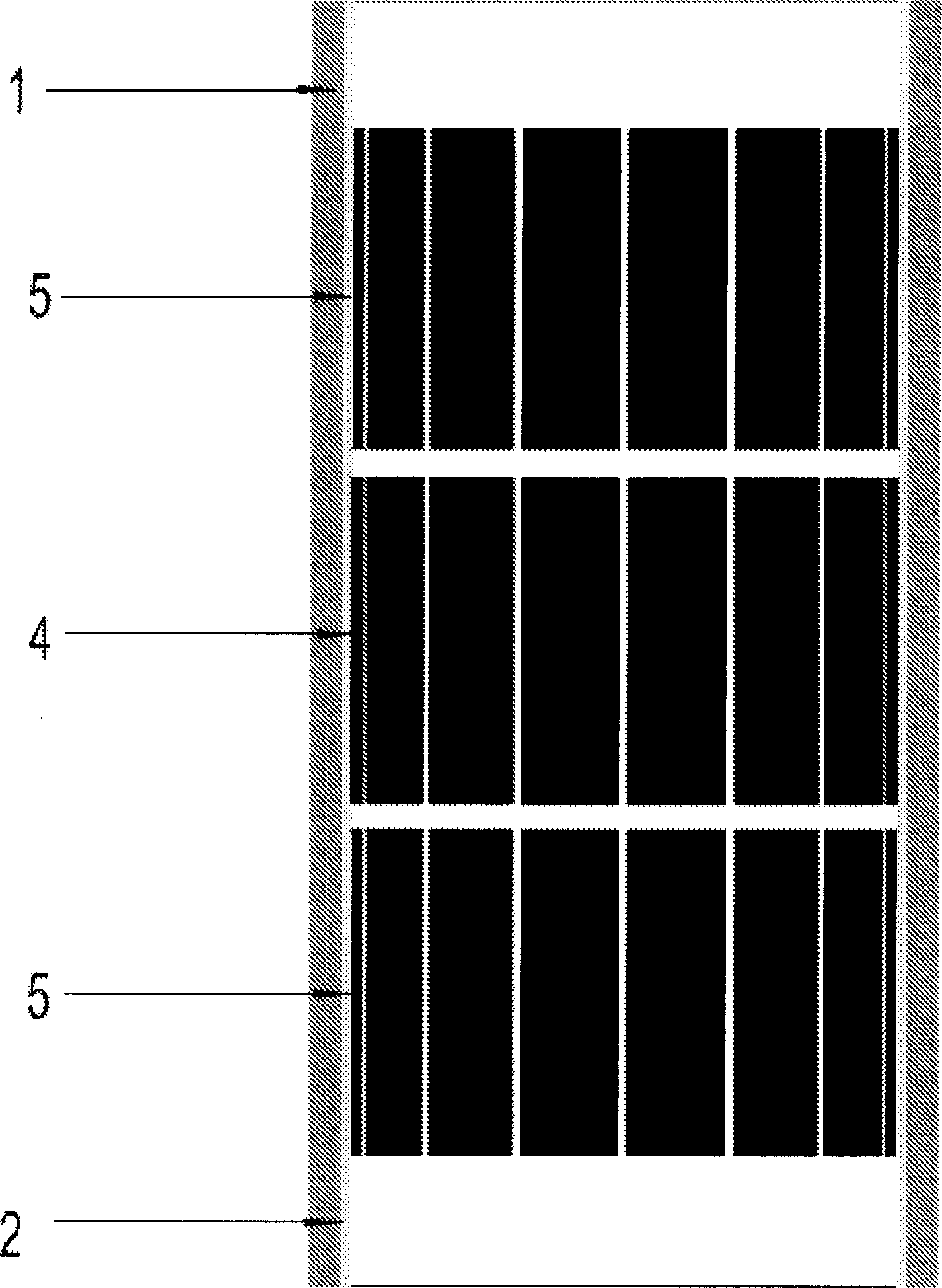

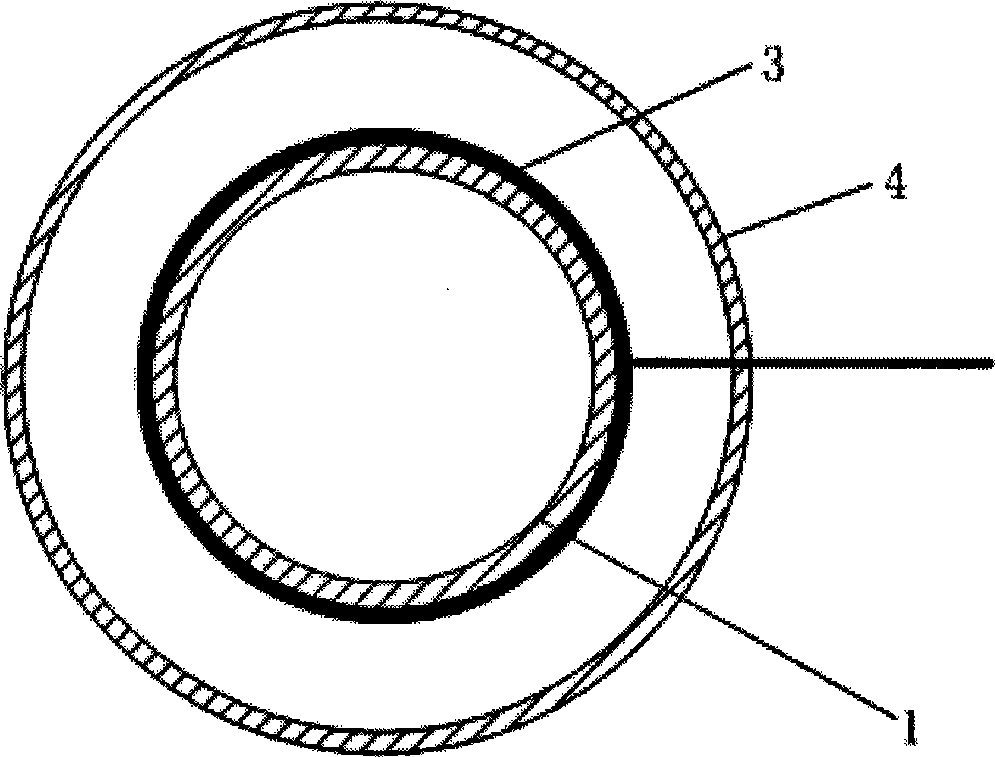

Non-contact type electric impedance sensor and image rebuilding method based on the sensor

InactiveCN101241094AQuick responseLow costDiagnostic recording/measuringSensorsRapid imagingBreakdown strength

The present invention provides a non-contact impedance sensor which is mounted on measuring region, the radial section structure of the sensor comprises of four layers, metal tube layer, insulation material layer, electrode array layer and insulation ring layer from outside to inside in turn. At least two electrodes are distributed in one circle on the insulation ring layer whose thickness is less than 1% of external diameter, and electric field intensity between electrode array and metal tube layer is less than breakdown strength of insulation layer. The electrode array is separated with measuring region by insulation ring layer. Two image reconstruction algorithms to realize electrical impedance tomography based on the said sensor are also provided. The present invention provides analytical medel, corresponding sensitivity distribution expression and two rapid imaging methods, the sensor can measuring synchronous same-positional dual-mode impedance, advance mutual fusion of real parts and imaginary part information of impedance distribution, predigest the design and implement of software and hardware of dual-mode measuring system.

Owner:TIANJIN UNIV

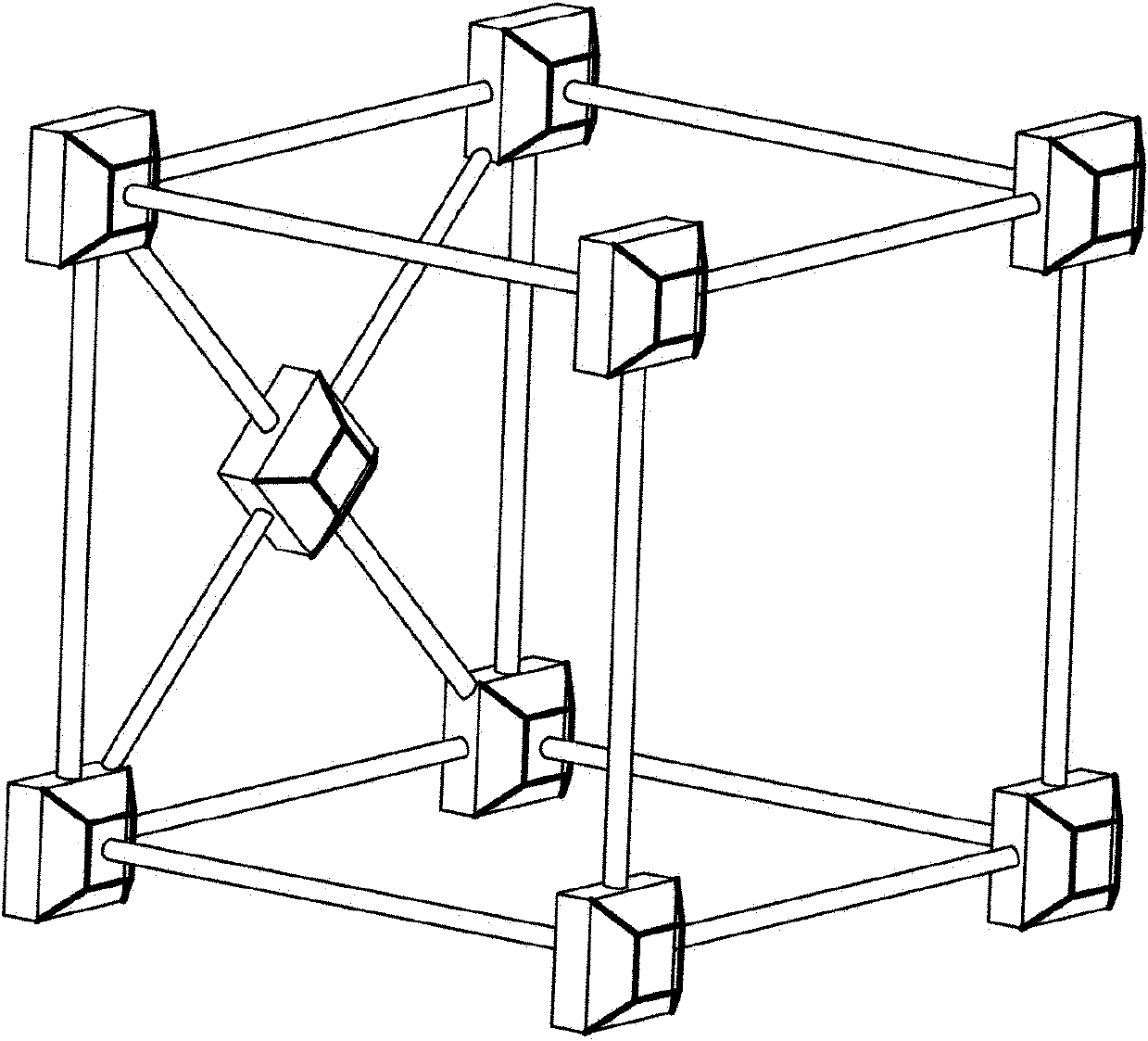

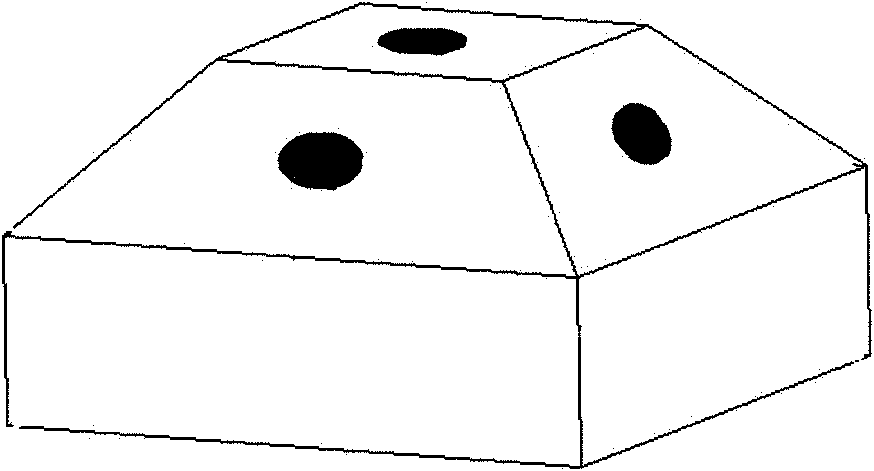

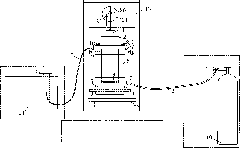

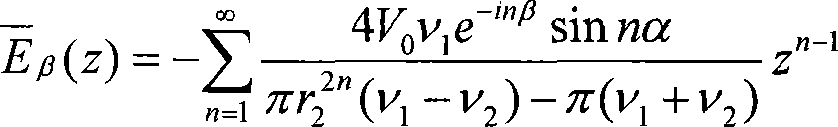

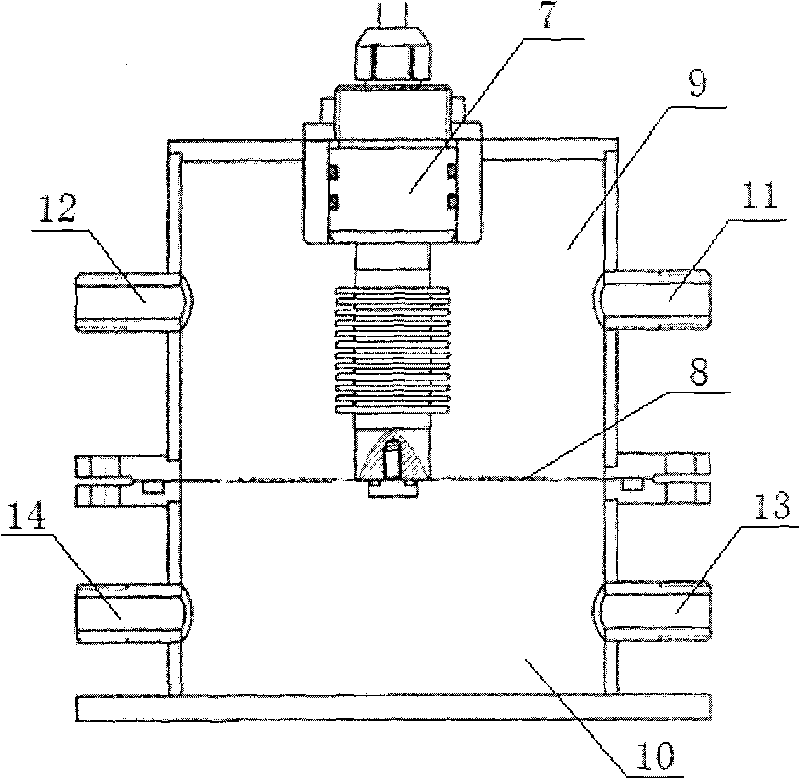

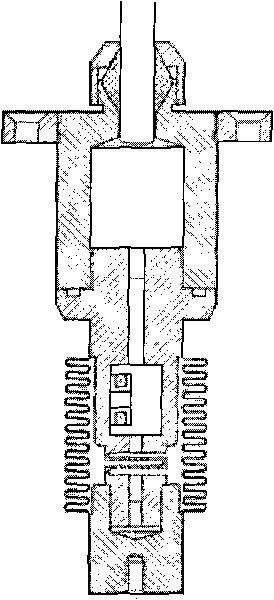

Testing device and method for three-dimensional static stiffness loading of machine tool

InactiveCN102853978AIncrease and decrease loadLarge measuring rangeElasticity measurementControl systemEngineering

A testing device for three-dimensional static stiffness loading of a machine tool comprises a parallel loading mechanism, a spindle interface, a force measuring module, a spindle deformation and displacement measuring device, a bench docking platform and a control system. The parallel loading mechanism is fixed on a bench of the machine tool through the bench docking platform, is connected with the spindle of the machine tool through the spindle interface and the force measuring module, and applies load to the spindle of the machine tool. In addition, the spindle deformation and displacement measuring device is also disposed on the bench of the machine tool. Deformation of the stressed spindle of the machine tool is measured by the aid of a high-precision displacement sensor disposed on the spindle deformation and displacement measuring device, and finally three-dimensional static stiffness of the machine tool is obtained. A testing method for three-dimensional static stiffness loading of the machine tool includes six steps. Three-dimensional static load can be applied to the machine tool for testing of three-directional static stiffness loading for the machine tool. The testing device and the testing method have practical value and promising application prospect in the technical field of machine tool performance testing.

Owner:BEIHANG UNIV

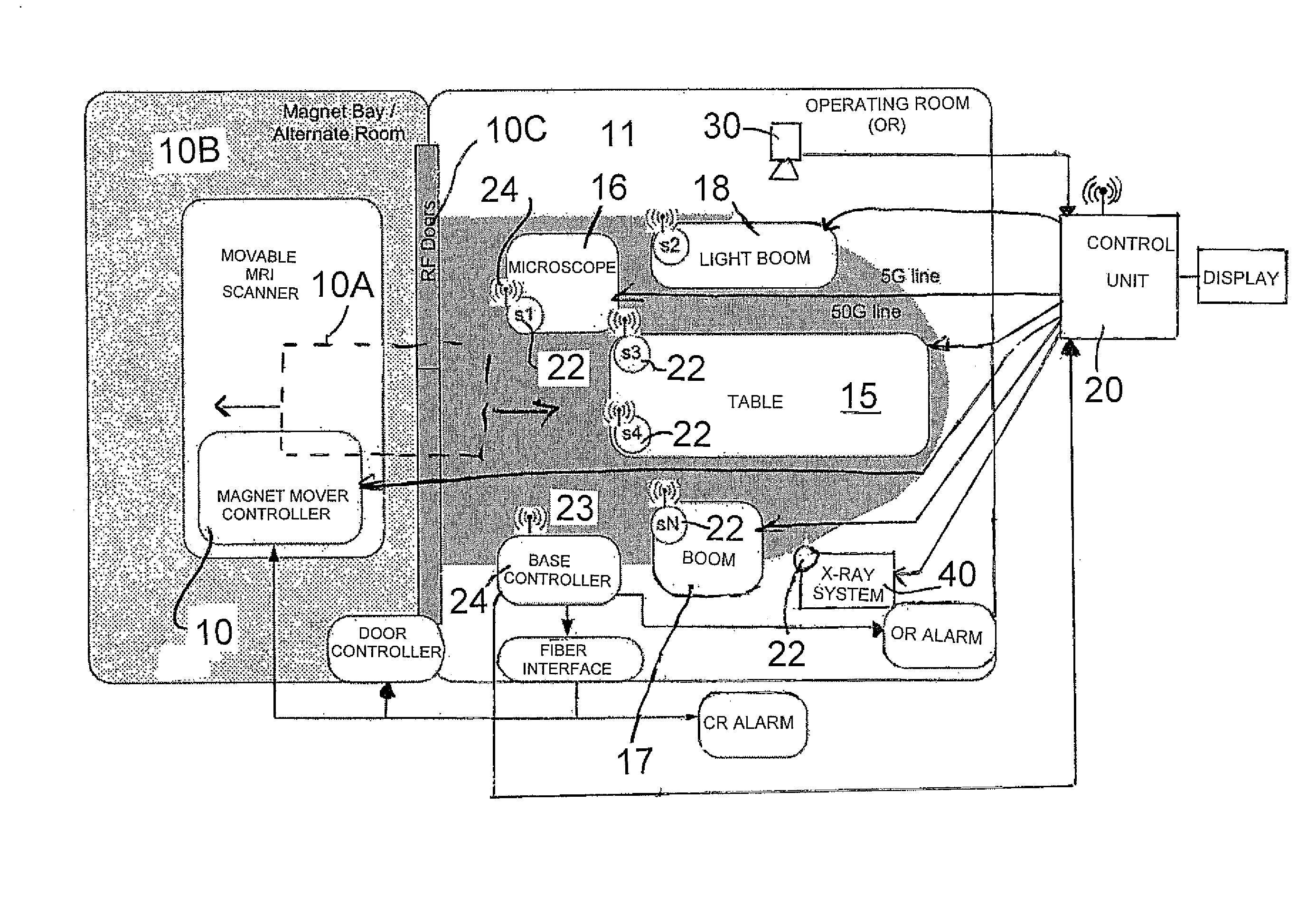

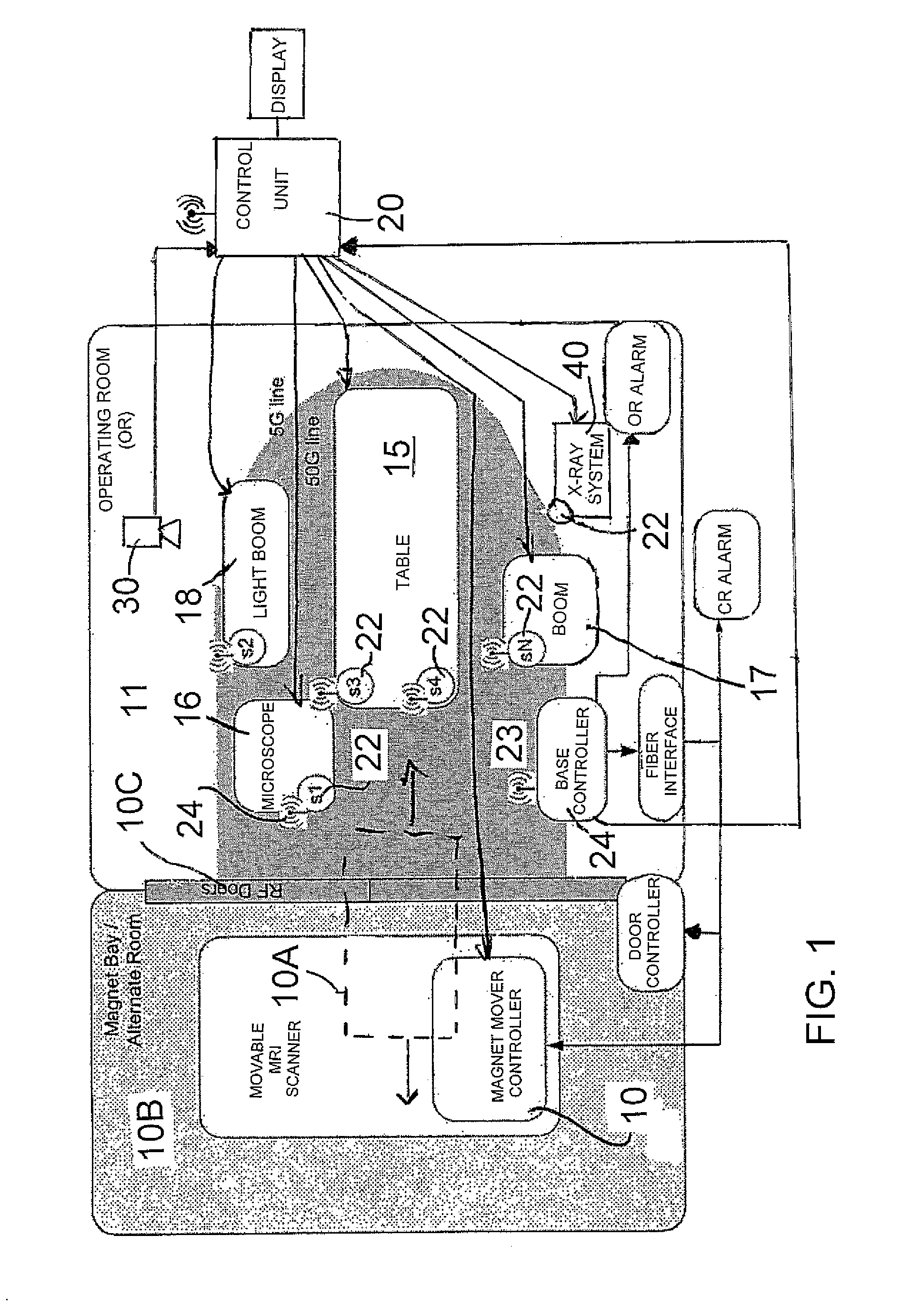

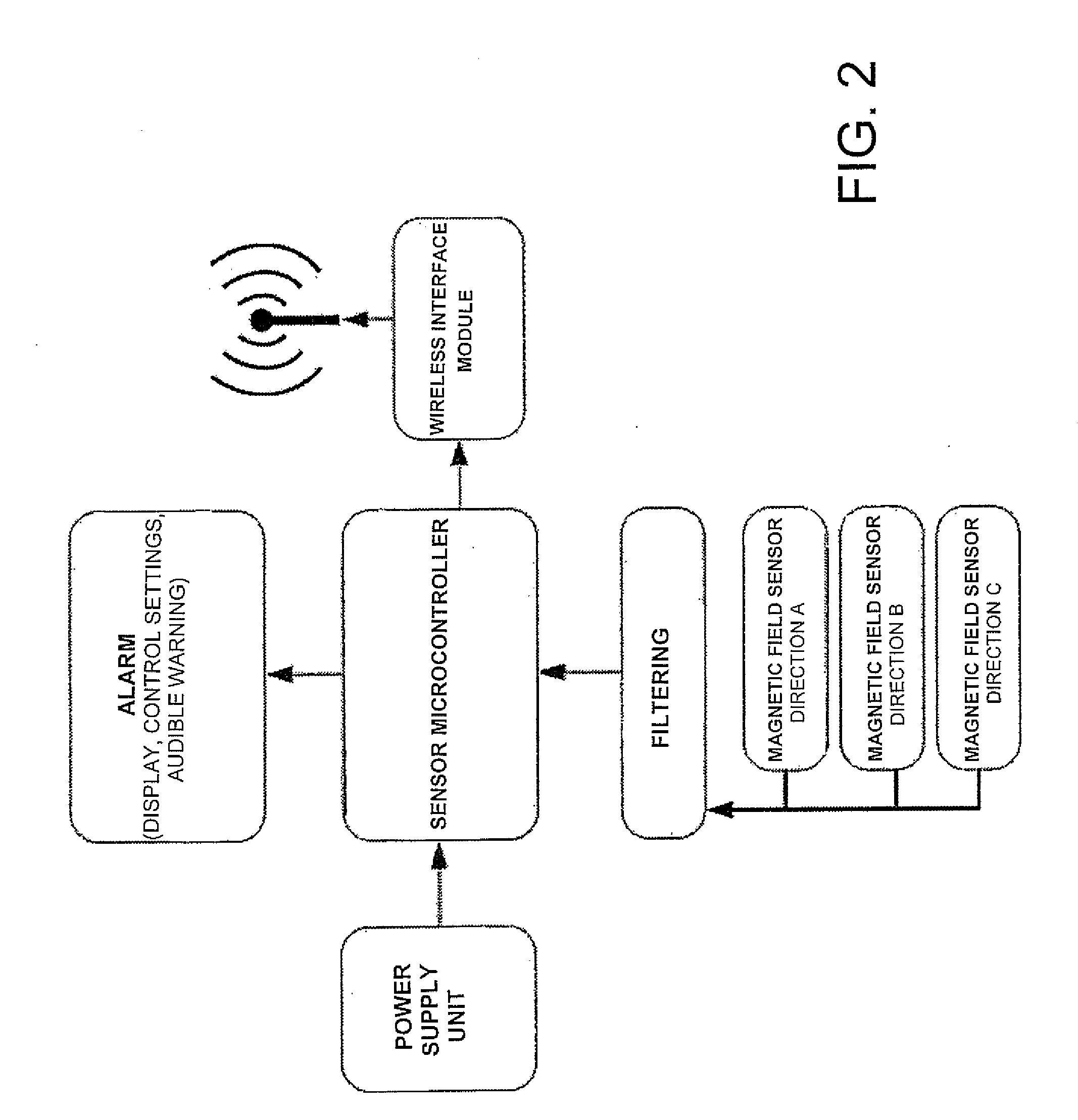

MRI Safety System

ActiveUS20120112747A1Avoid manual controlsIntroduce errorMeasurements using NMR imaging systemsElectric/magnetic detectionControl systemEngineering

In a MRI system housed within a room there is provided a movable magnet and additional components for other procedures on the patient, a control system is provided for the relative movement of the magnet and components. This includes a plurality of magnetic field sensors mounted on the components for measuring the magnetic field at the location of the component and an optional camera positioning system so that the control system can estimate relative positions of the components relative to the magnet from the sensed field strengths from the set of sensors to avoid collisions during the movements.

Owner:DEERFIELD IMAGING INC

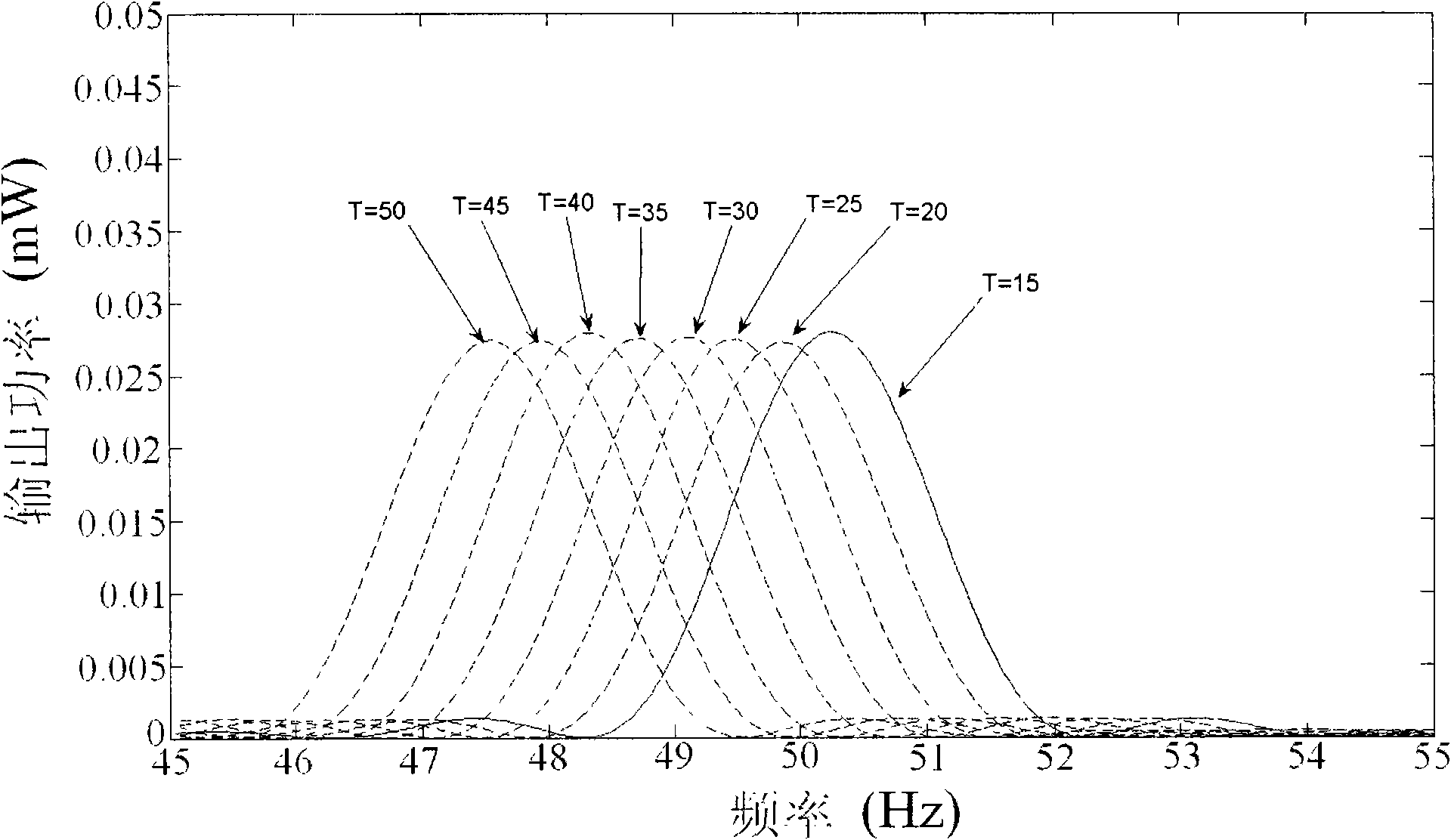

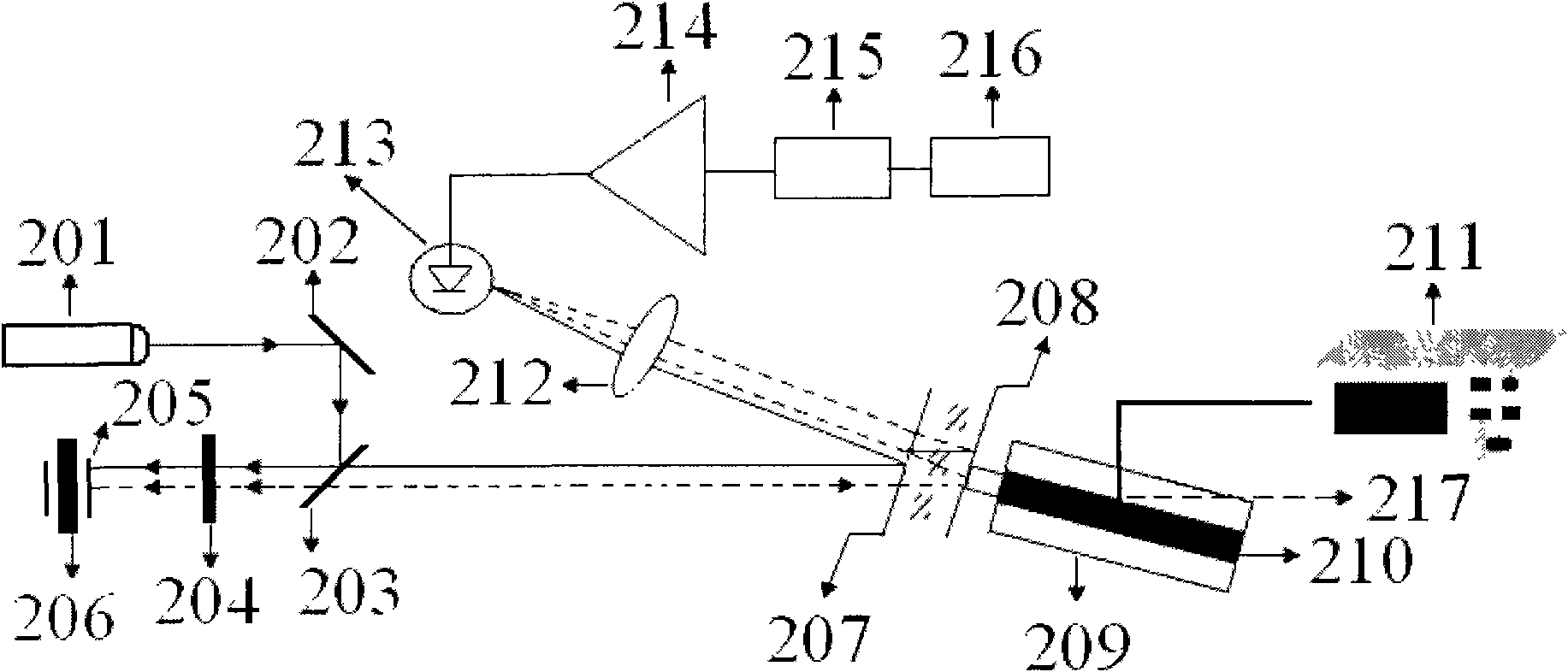

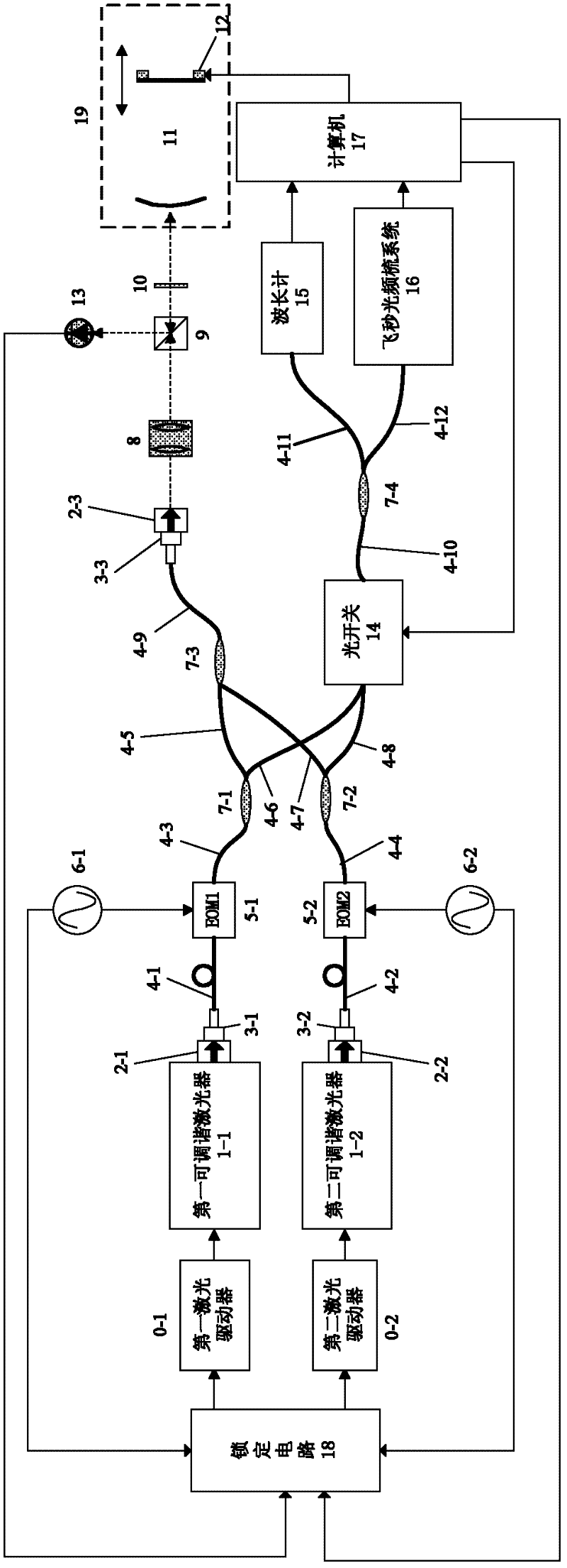

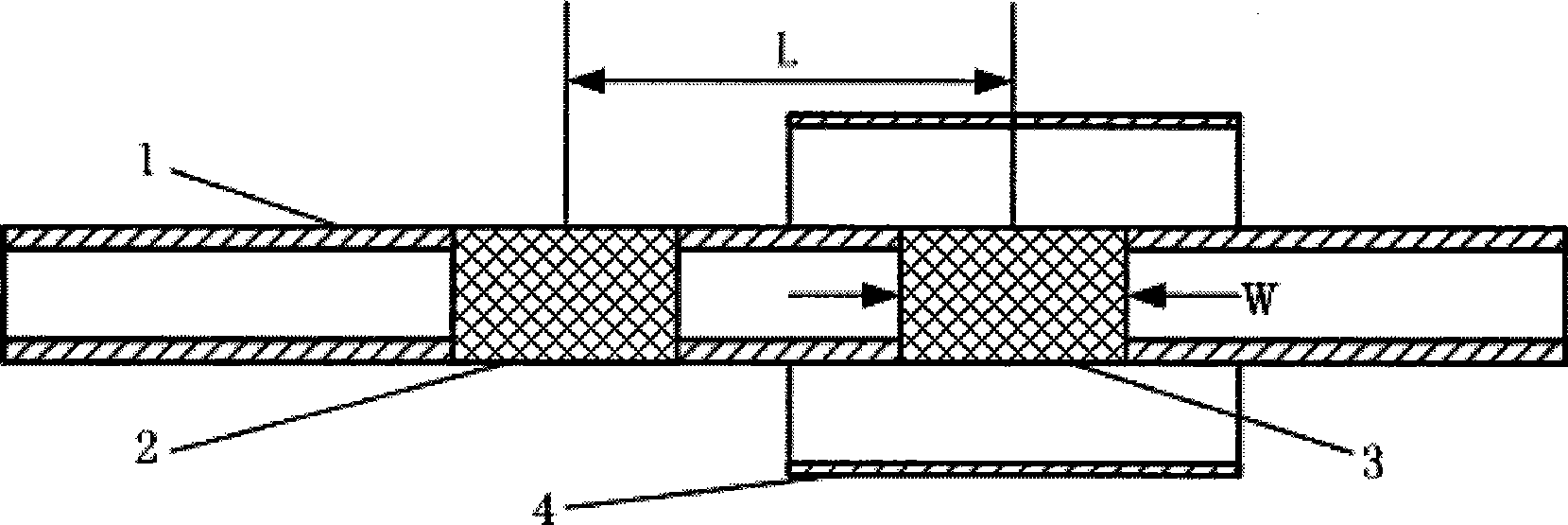

Fabry-Perot interference absolute distance measurement method based on femtosecond optical frequency comb and device thereof

InactiveCN102508231AImprove measurement speedHigh measurement accuracyUsing reradiationTunable laserAbsolute frequency

The invention relates to a Fabry-Perot interference absolute distance measurement method based on a femtosecond optical frequency comb and a device thereof. Two tunable lasers with frequency capable of being tuned within a large range and free of mode skip are simultaneously adopted, the optical wavelengths of the two lasers are respectively locked on two transmission peaks at a distance of N free spectral ranges of a to-be-detected Fabry-Perot cavity with the cavity length located in a vacuum vibration isolation cavity by utilizing the Pound-Drever-Hall (PDH) method, a wavemeter and an optical frequency comb system are used to respectively measure absolute frequency of two beams of laser, and then the free spectral ranges of the to-be-detected Fabry-Perot cavity are obtained. The cavity length of the to-be-detected Fabry-Perot cavity is obtained by means of the relationship between the to-be-detected cavity length and the free spectral ranges, frequency of the two tunable lasers can be tuned within a large range and free of mode skip, and measurement range is increased. Meanwhile, frequency of the two lasers is locked, and measurement speed can be increased. The optical frequencycomb system for measuring the frequency of the two lasers enables recurrence frequency and off-set frequency to be traced to the source of microwave frequency standard so that measurement results canhave traceability.

Owner:TSINGHUA UNIV

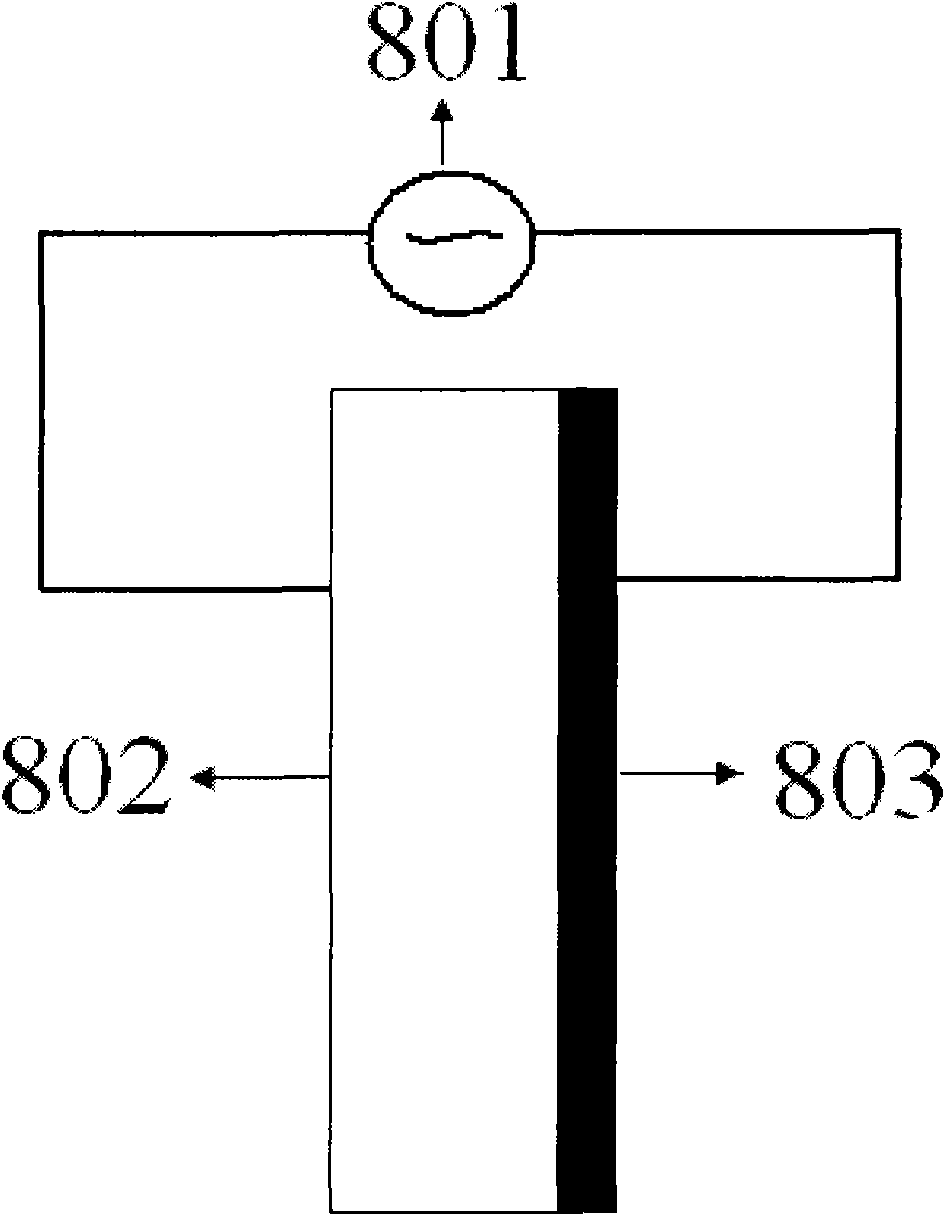

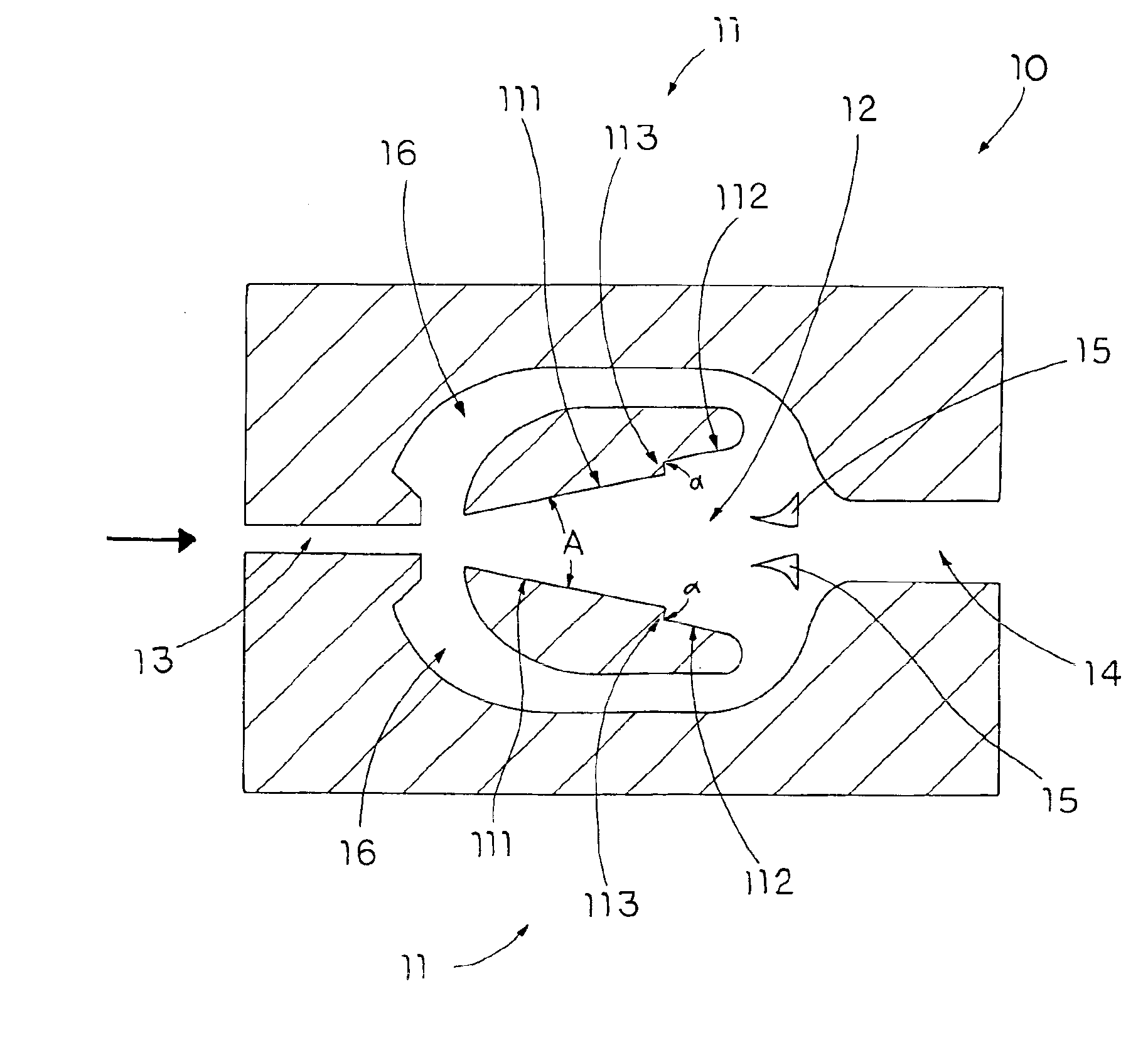

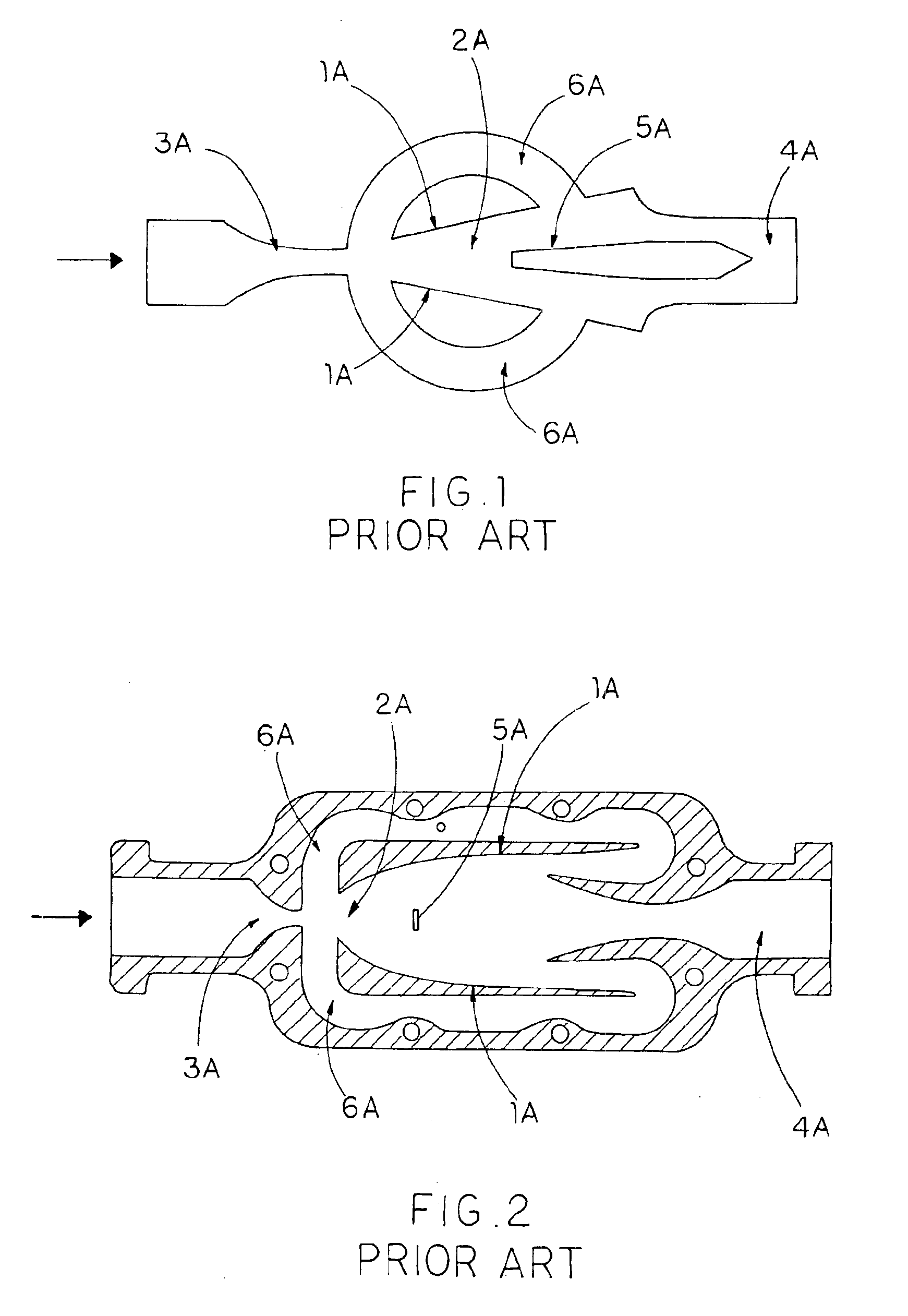

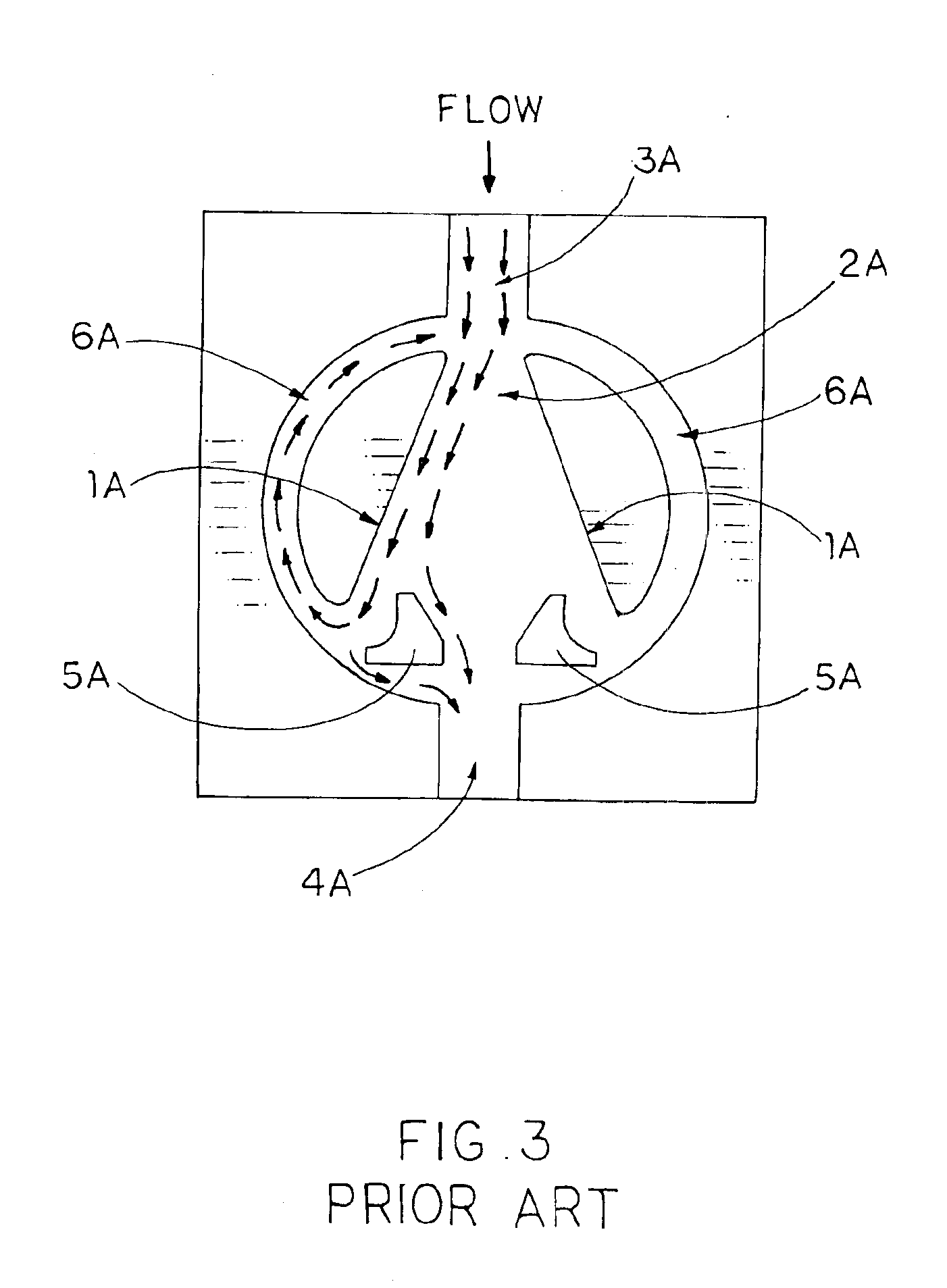

Fluidic oscillator

ActiveUS6860157B1Accurate measurementLarge measuring rangeCircuit elementsVolume/mass flow by dynamic fluid flow effect

A fluidic oscillator includes an oscillator body having two attachment walls defining an oscillating chamber therebetween, an inlet duct communicatively extended from the oscillating chamber for guiding a flow of fluid entering into the oscillating chamber, an outlet duct communicatively extended from the oscillating chamber for guiding the flow of fluid exiting from the oscillating chamber, a flow splitter provided at the outlet duct to communicate with the oscillating chamber, and two feedback channels communicating with the oscillating chamber. Each of the attachment walls has an upstream portion and a downstream portion integrally extended therefrom as a step shouldering manner to form a modulating shoulder for modulating an oscillation of the flow within the oscillation chamber so as to stabilize the flow of the fluid to pass through the oscillator body.

Owner:NATIONAL TSING HUA UNIVERSITY

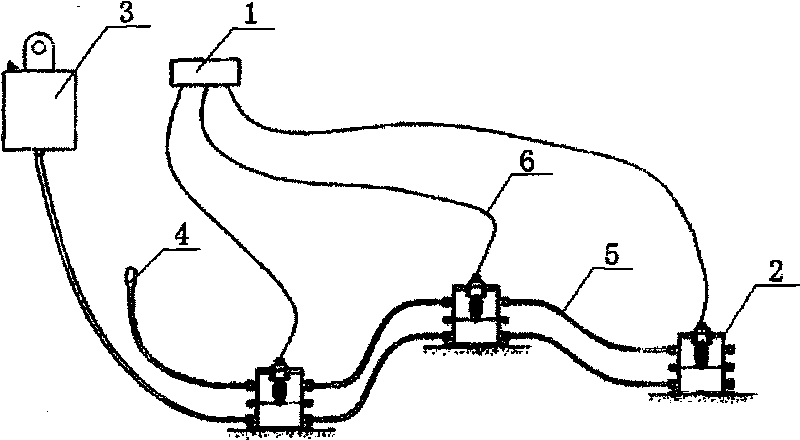

Static level monitoring system

InactiveCN101718544ATimely measurementLarge measuring rangeHydrostatic levellingMonitoring systemData acquisition

The invention provides a static level monitoring system, comprising a data acquisition system, a reference water tank, a static level gauge and a communicating pipe; at least one static level gauge is respectively connected with the reference water tank through the communicating pipe; and the data acquisition system is connected with the signal end of the static level gauge. The invention has the following advantages: the sedimentation or flotation of structures such as foundation fill is measured in time; the measuring range is large, the sensitivity is high, and the measuring efficiency is high; and the system is applied to round-the-clock remote monitoring and automatic data acquisition.

Owner:NANJING GEOT CIVIL ENG INSTR

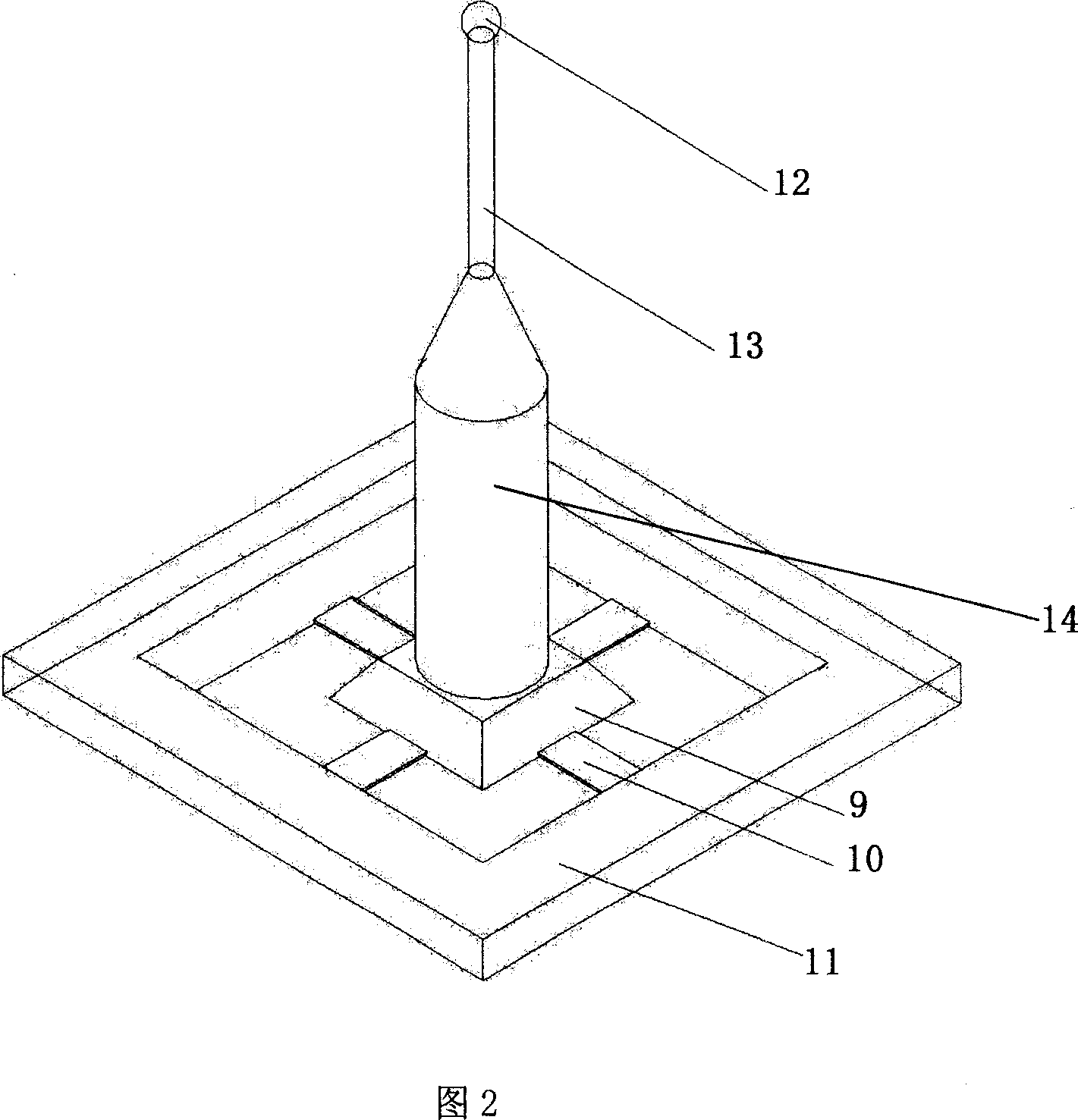

Micro-geometric sense measuring device based on nano-measuring machine and micro-tactometering head

InactiveCN1975322AOvercome limitationsLarge measuring rangeSurface/boundary effectForce measurement by measuring optical property variationOptical measurementsMicroscopic scale

This invention disclosed a measuring equipment which consists of a nanometer measuring machine and a tiny feeling gauge head. The feeling gauge head was fixed on the machine by a plank. The measuring range of scanning probe micro-technique was improved by this equipment, the range of object by other measuring means was widened; it could manage to measure some micro-geometric senses including dimension, displacement, etc. The measuring precision was improved by this equipment.

Owner:TIANJIN UNIV

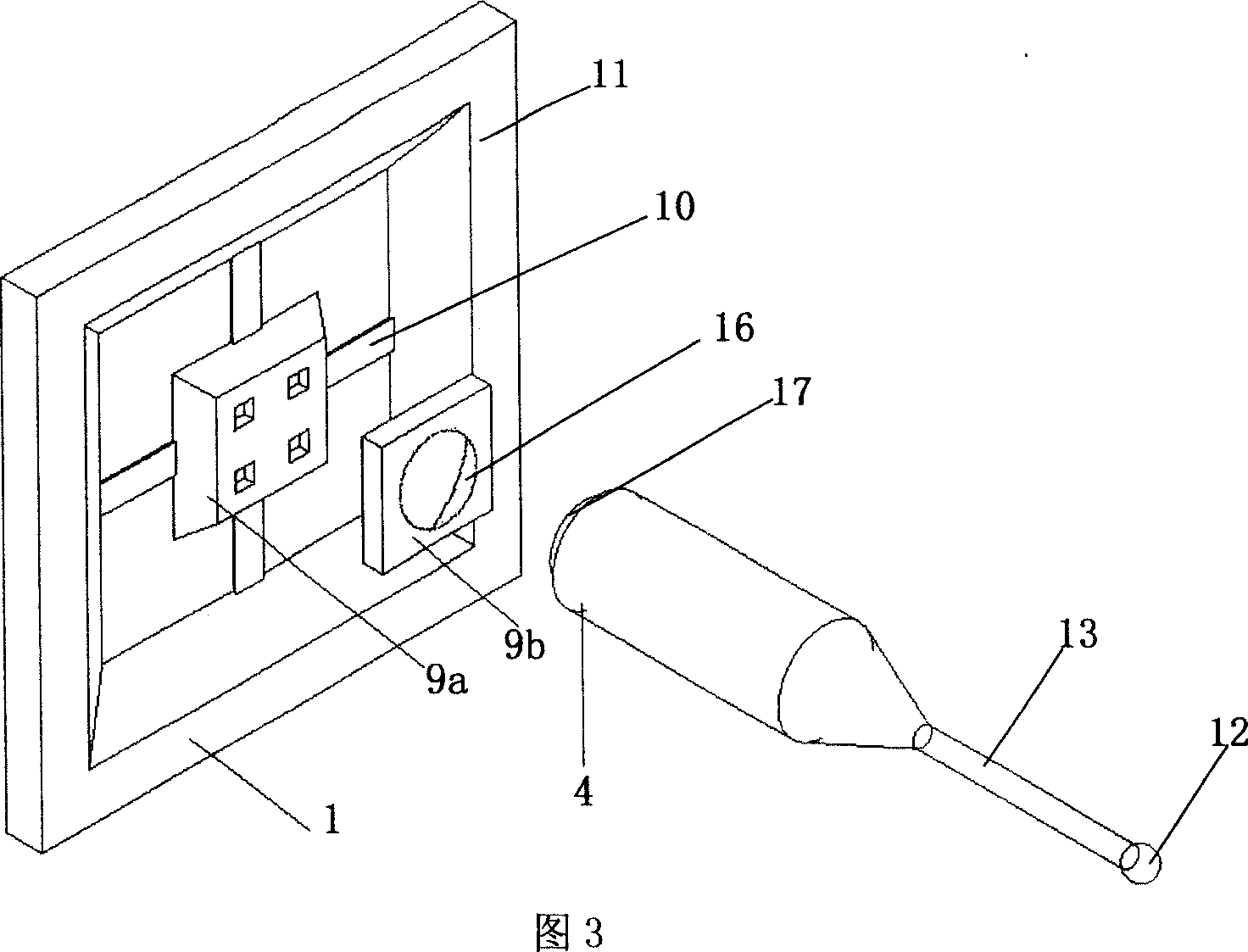

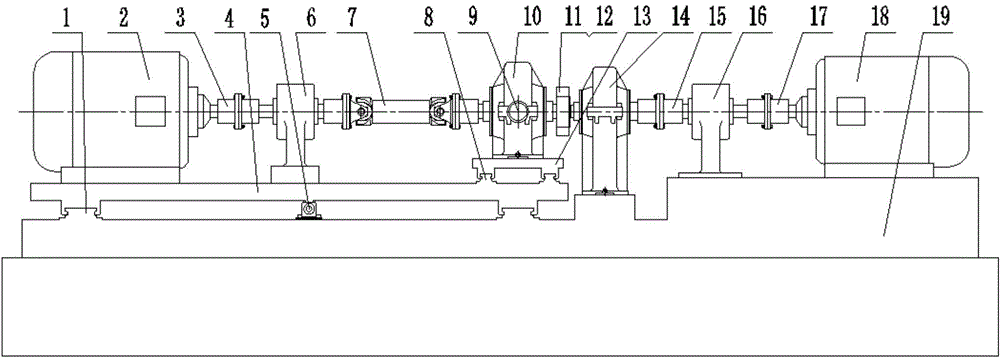

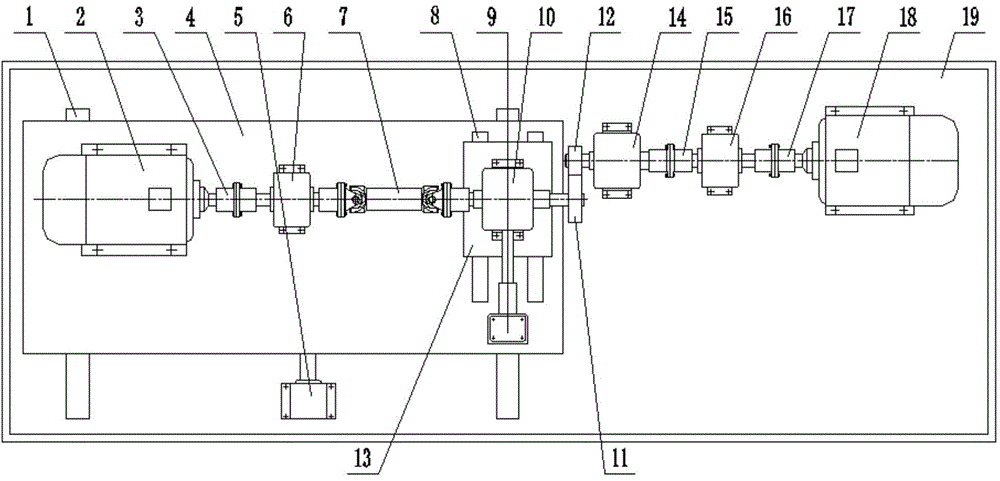

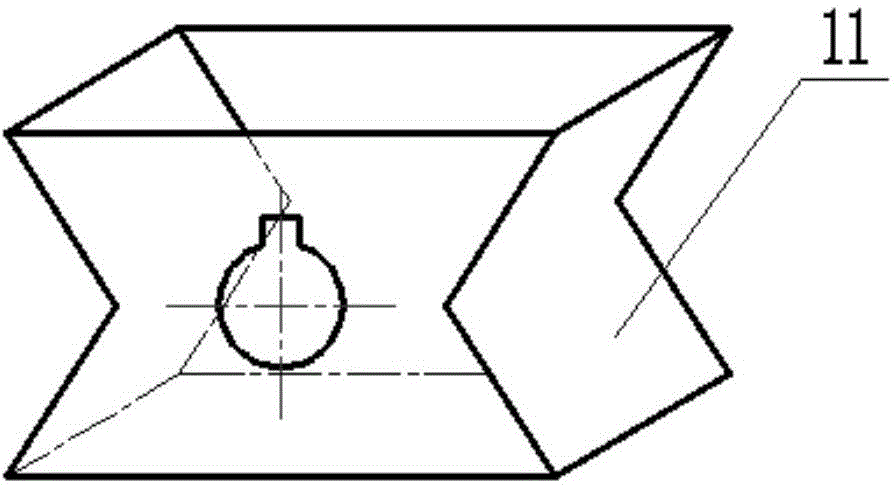

Transmission and friction experiment table for multifunctional mechanical part

InactiveCN104155102ARealize online detectionWide range of test objectsMachine gearing/transmission testingInvestigating abrasion/wear resistanceResearch ObjectVibration acceleration

The invention relates to a transmission and friction experiment table for a multifunctional mechanical part. The transmission and friction experiment table comprises a first guiding rail, a second guiding rail, a first driving motor, a second driving motor, a first supporting plate, a second supporting plate, a first main shaft box, a second main shaft box, a first test-piece, a second test-piece,a first torque sensor, a second torque sensor, a first rigid coupler, a second rigid coupler, a third rigid coupler, a first supporting plate sliding driving motor, an universal coupler, a loading electric cylinder, a bedplate, an acceleration vibration sensor, a temperature sensor, a displacement sensor, a pressure sensor, a lubricating system, a cooling system and a general controlling computer. According to the invention, various low and high friction pairs in a contact zone can be tested online for frictional wear, energy consumption, vibration and material behaviors under the different loads, rotating speeds and lubrication conditions, and transmission parts and systems can be conducted with friction and transmission process experiments; when testing data is gathered, parts and systems to be tested can be analyzed for the following situations such as frictional wear, power consumption, stress and the service behaviors of transmission pairs, so that the behavior features, variation rules and failure mechanisms of research objects in the operating process can be obtained.

Owner:CHONGQING UNIV

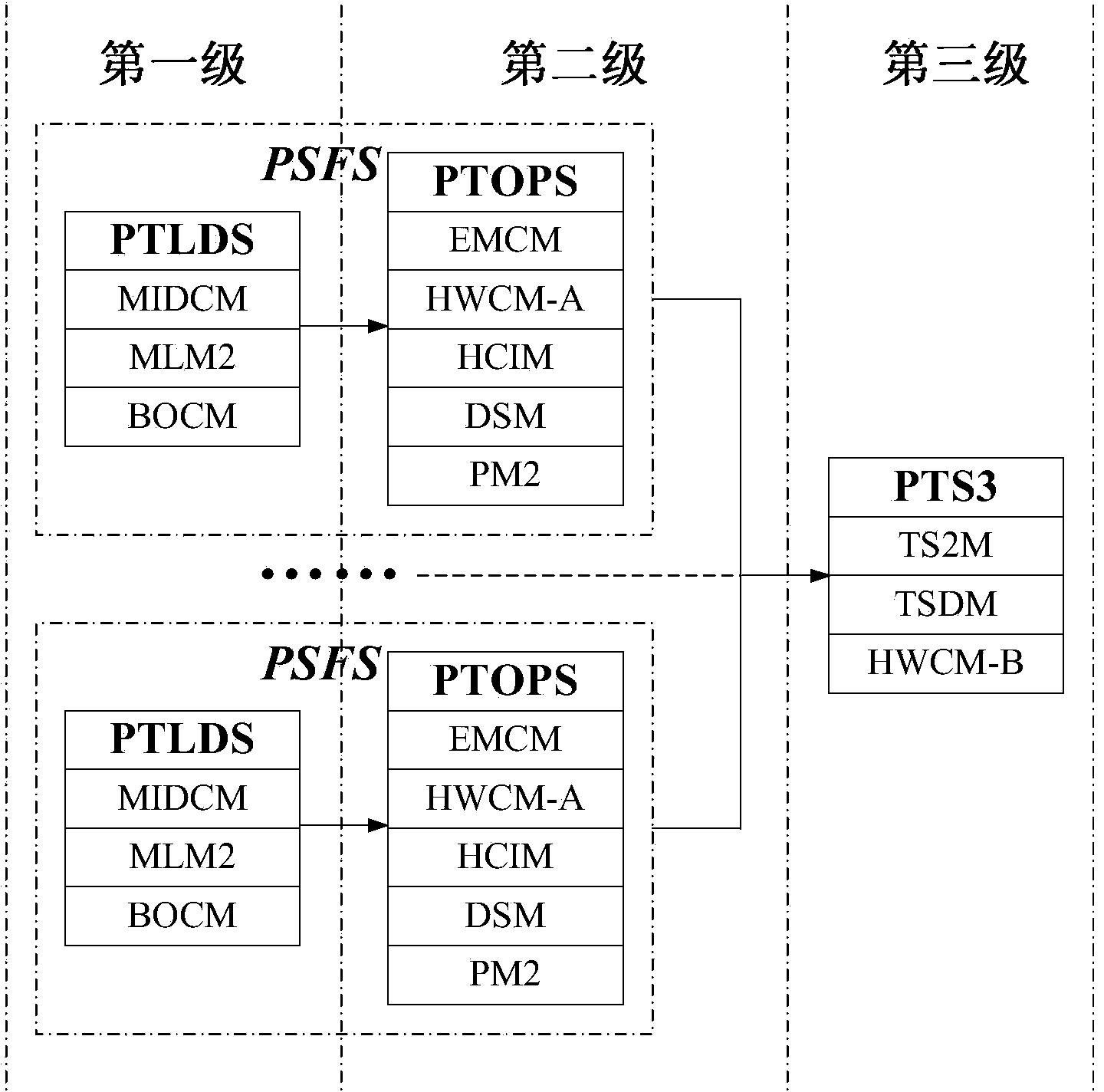

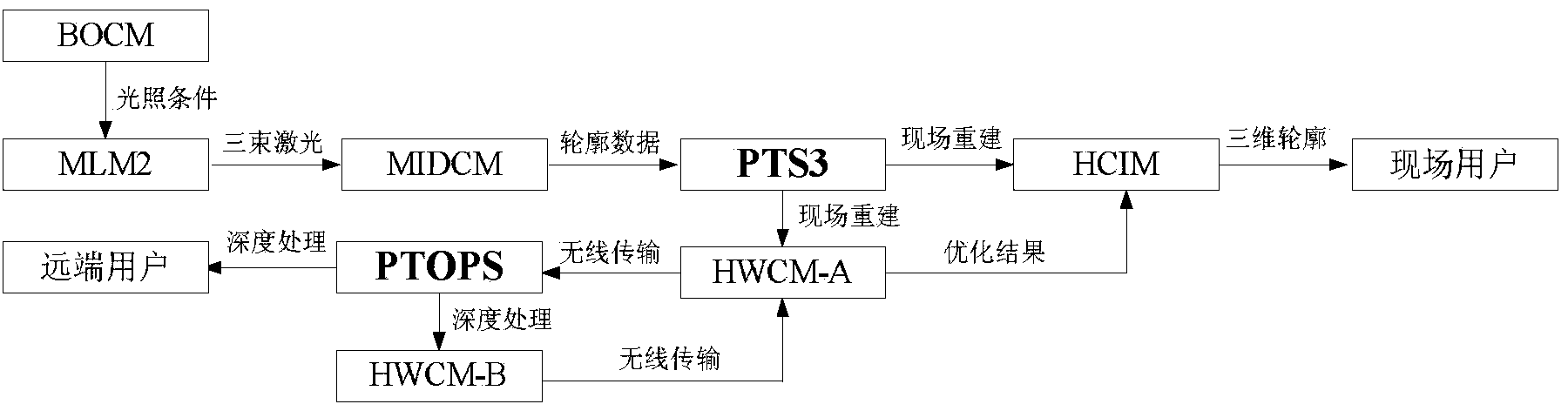

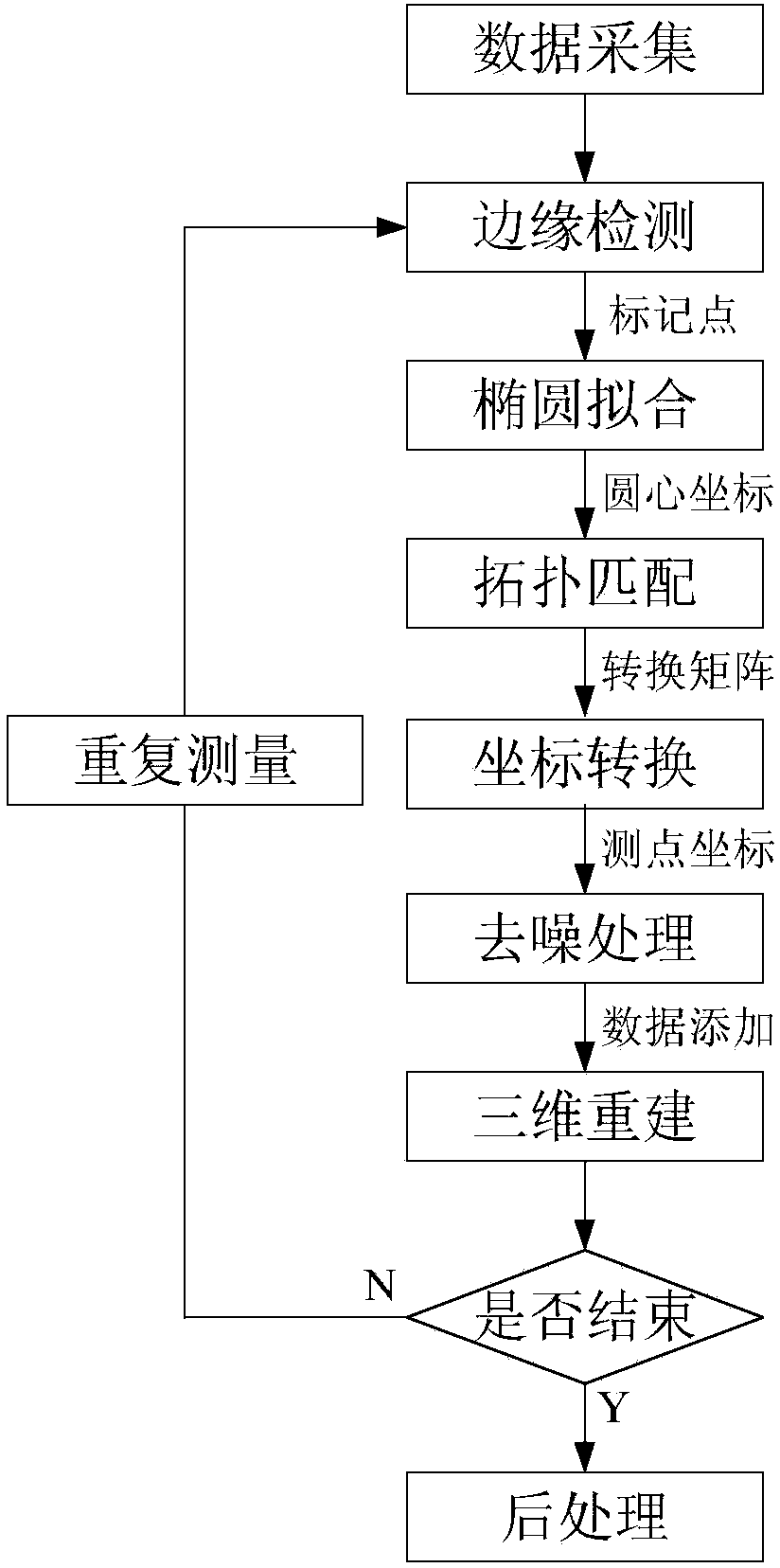

Wireless hand-held 3D laser scanning system

ActiveCN104165600AGuaranteed real-timeGuaranteed robustnessUsing optical meansLaser scanningHand held

The invention discloses a wireless hand-held 3D laser scanning system, comprising a hand-held 3D laser scanning data collection subsystem, a portable 3D data online processing display and control sub-system and a portable 3D data service terminal storage and analysis subsystem. The hand-held 3D laser scanning data collection subsystem is connected to the portable 3D data online processing display and control subsystem based on one-to-one correspondence, and the hand-held 3D laser scanning data collection subsystem and the portable 3D data online processing display and control subsystem are installed within a support frame to construct a portable subsystem which can independently perform 3D profile scanning. The portable 3D data online processing display and control subsystem is connected to the 3D data service terminal storage and analysis subsystem. The invention provides a wireless handheld 3D laser scanning system which is flexible, big in visual range and good in instantaneity.

Owner:SCANTECH (HANGZHOU) CO LTD

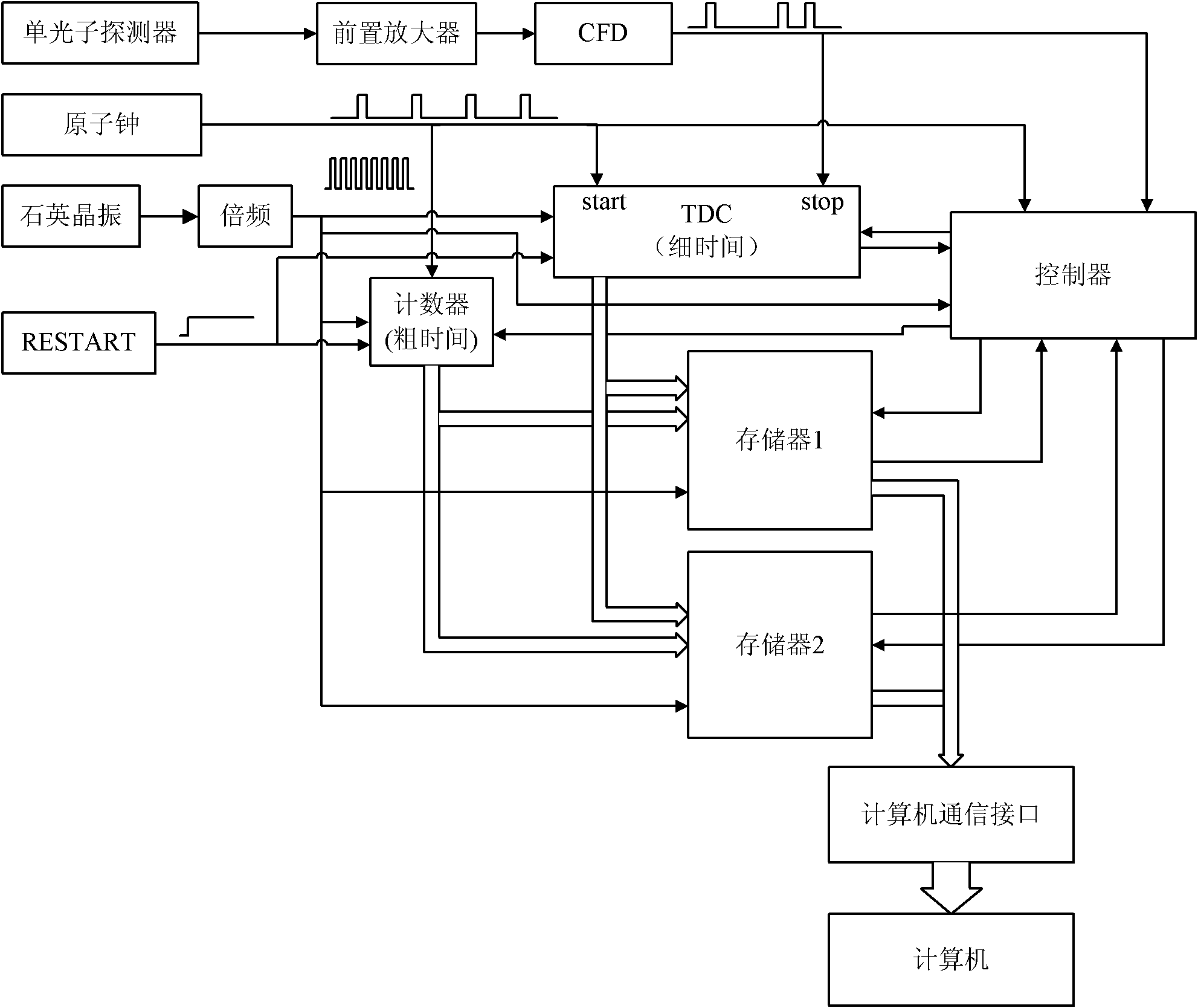

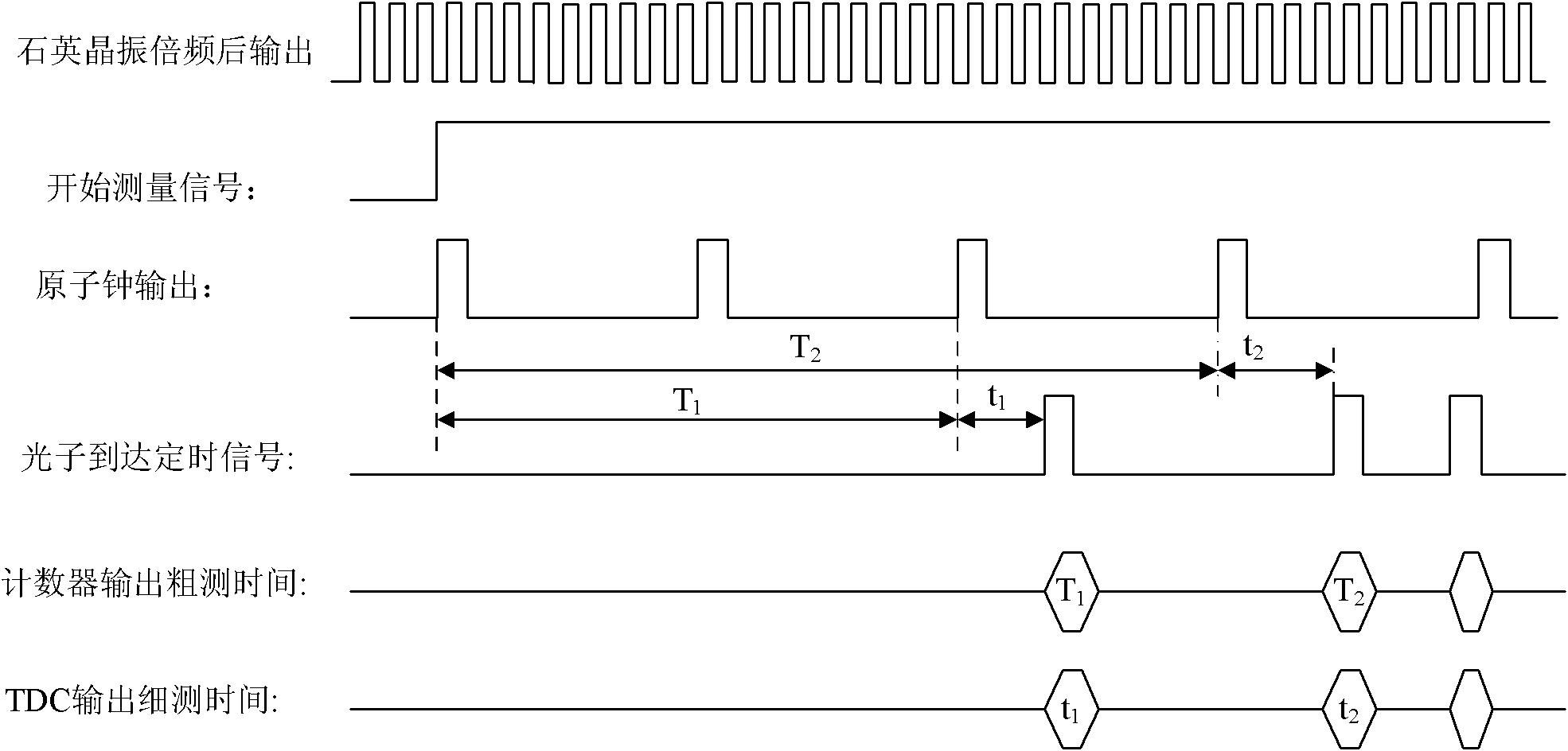

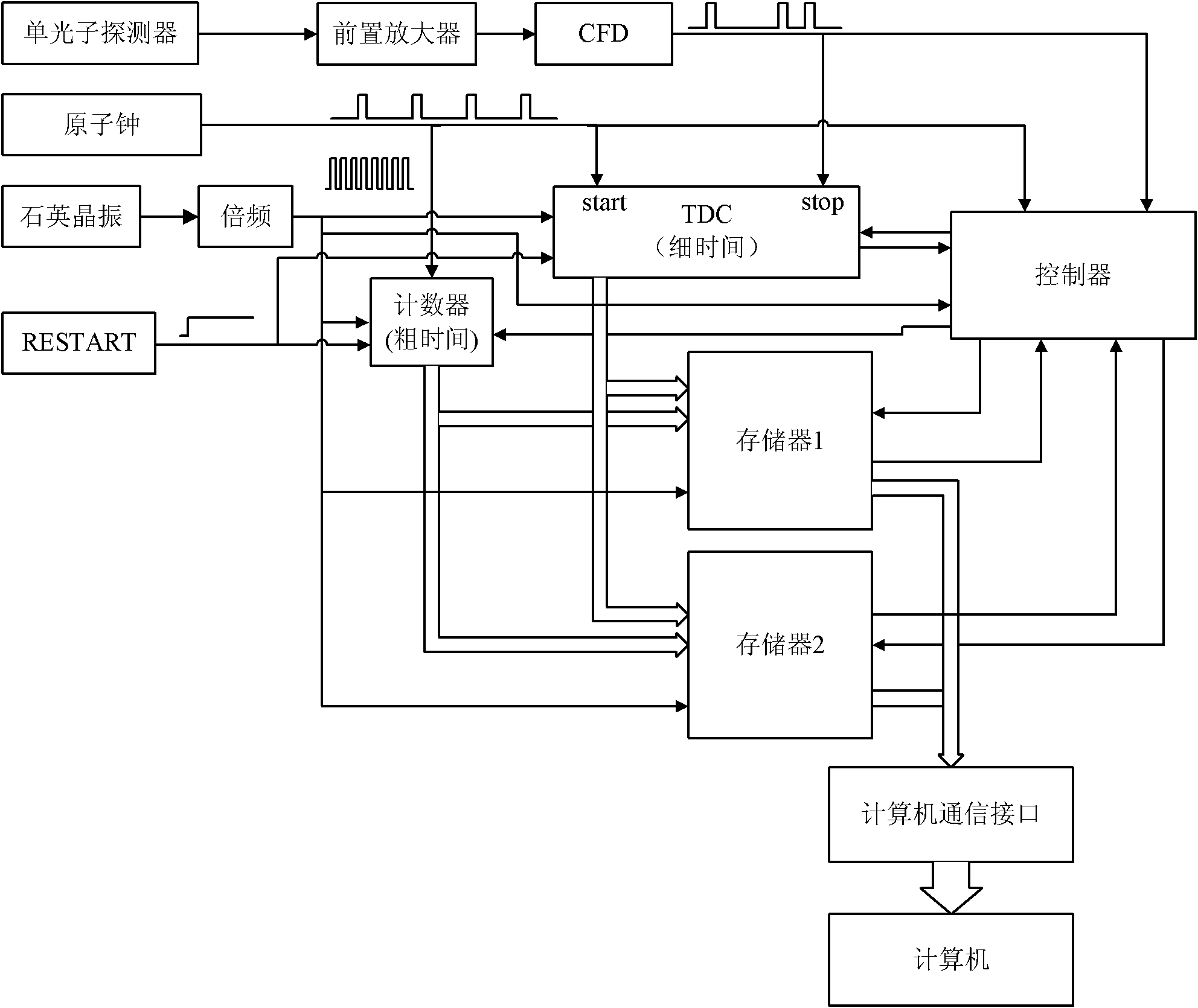

Device and method for continuously measuring arrival time of photon sequence

InactiveCN102141772ALarge measuring rangeImprove stabilityApparatus using atomic clocksContinuous measurementDiscriminator

The invention relates to a device and a method for continuously measuring the arrival time of a photon sequence. The device comprises a single photon detector, a preamplifier, a constant ratio discriminator, an atomic clock, a counter, a time-to-digital converter, a controller, a memory unit and a computer, wherein the output end of the constant ratio discriminator is connected with the controller; a square-wave pulse output by the atomic clock is used as a counting object of the counter and is transmitted into the time-to-digital converter; the rising edge of the square-wave pulse is used as a start signal of the time-to-digital converter, and the rising edge of a digital pulse signal is used as a stop signal of the time-to-digital converter; and the control end of the controller is respectively connected with the counter, a digit converter and the memory unit and used for controlling the synchronous storage of rough measuring time and fine measuring time into the memory unit. The invention solves the technical problems of continuous measurement incapability, narrow measurement range and limited application range of a traditional photon sequence arrival time measuring device, and the device has a wide measurement range and high accuracy in measuring the photon arrival time.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

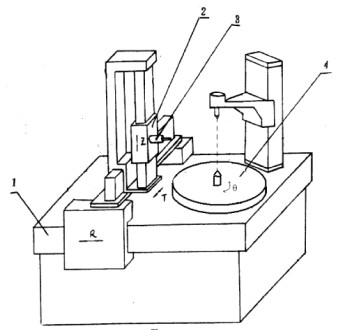

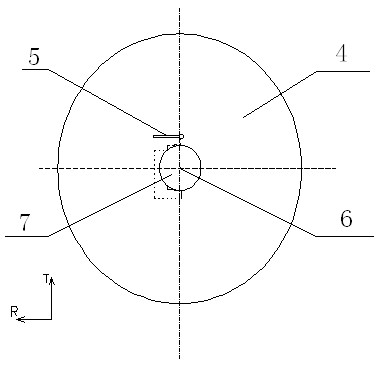

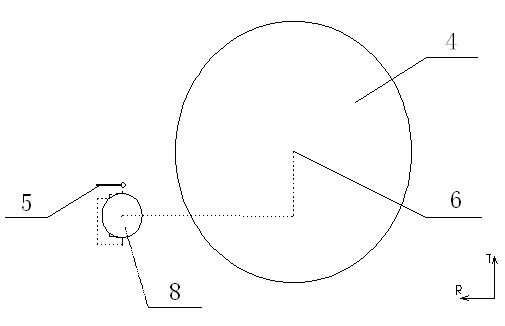

Measurement method and measurement accessory for zero point calibration of gear measuring center

InactiveCN101886921AEasy to measureTaking into account the problem of measurementMachine gearing/transmission testingGear wheelEngineering

The invention relates to a measurement method and a measurement assessor for the zero point calibration of a gear measurement center. In the prior art, the problem of incapability of meeting measuring requirements of large and small-size workpieces simultaneously due to inconvenient zero point calibration of the gear measuring center caused by a measuring stroke exists. The invention provides the measurement method and the measurement accessory of the zero point calibration of the gear measuring center. The method comprises the following steps of: arranging a standard sphere at the measuring position where any measuring heads can contact on the upper part of a rotary shaft table to obtain absolute coordinates (T1, R1 and q1) of the centre of sphere first; driving the rotary shaft table by a rotary shaft to rotate to allow the standard sphere to rotate to the other angle to obtain the other absolute coordinates (T2, R2 and q2) of the centre of sphere; and calculating the positions (T0 and R0) of a rotary center. The method provided by the invention has the advantages of simplicity, convenience and wide application range; and the accessory provided by the invention has the advantages of simple structure, reduction of the requirements on operators and low use cost.

Owner:XIAN TECHNOLOGICAL UNIV

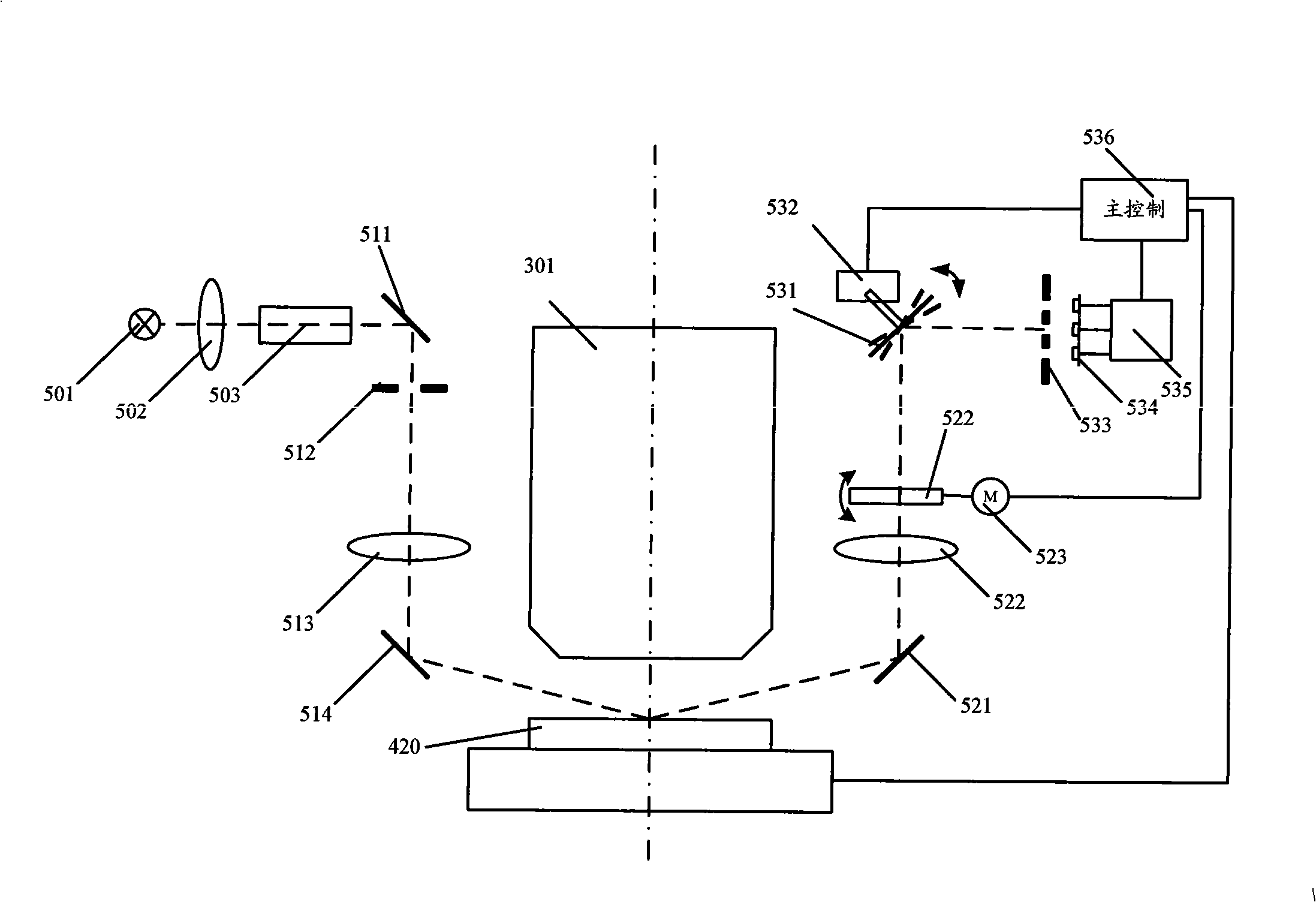

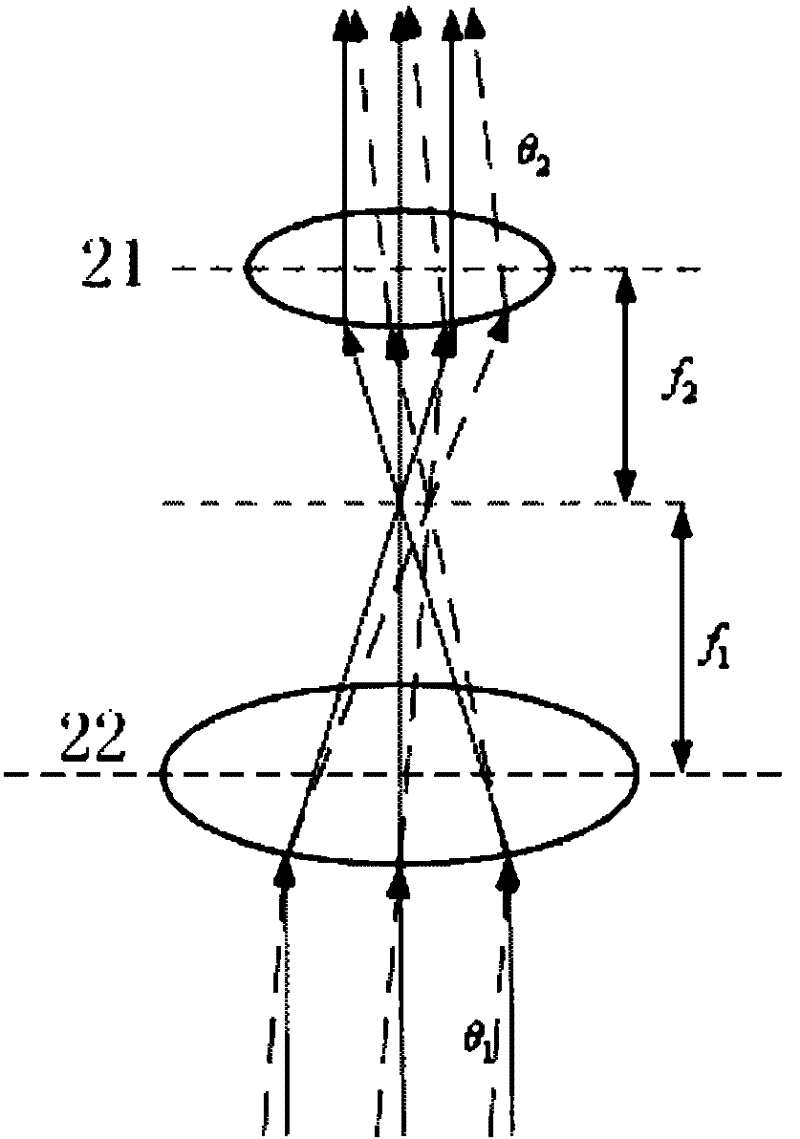

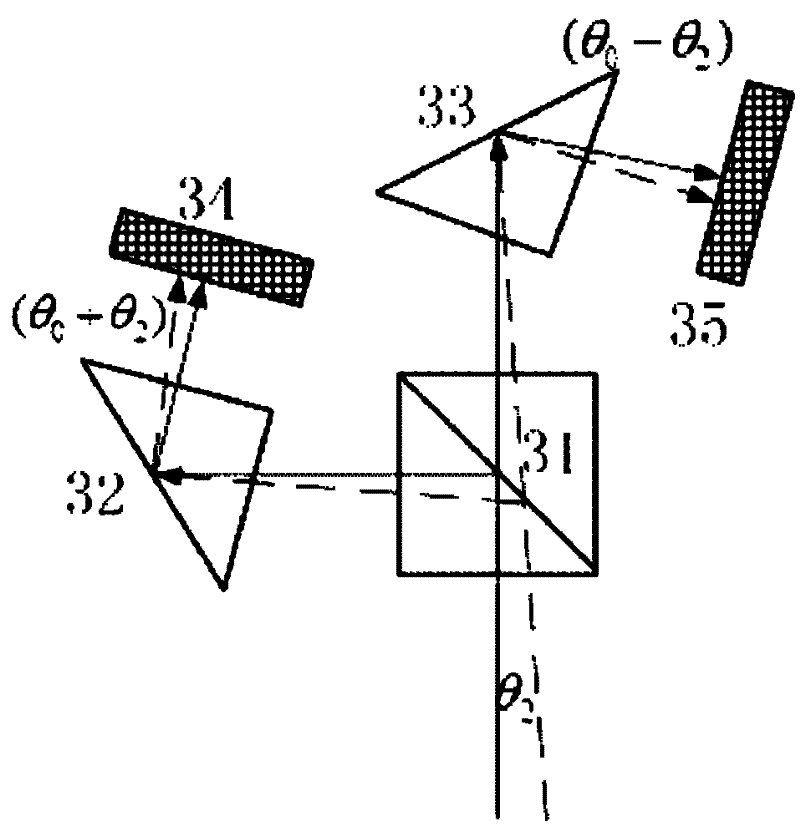

Focusing and leveling detection device and method

ActiveCN101344727ASimple structureEasy to operatePhotomechanical exposure apparatusMicrolithography exposure apparatusLight spotOptical axis

The invention discloses a focusing-leveling detection apparatus and a corresponding method. A measurement optical-path of the apparatus is respectively arranged on two sides of an optical axis of a projection lens; the apparatus consists of a lighting unit, a projection unit, an imaging unit and a detection unit and is characterized in that one of a plurality of detection slits in a detection slit array corresponding to a light spot is used for precision measurements and the other slits are used for rough measurements; a plurality of detection slits and detectors are adopted to detect the position of one light spot according to the one-to-one corresponding relation between the slits and detectors so as to realize the height and tilt measurements to a silicon plate surface with high accuracy in a wide range; characteristic elements are replaced and a plurality of detection slits are taken from the detection slit array and then are arranged into lines to realize the height and tilt measurements to the silicon plate surface with high accuracy in a wide range in virtue of redundant detection slits. The method is processed sequentially as follows: the processing to signals from detectors; the judgment by the detection slits and the output of measurement results. The invention has the advantages of simple structure and high measurement accuracy.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

Double mode electric imaging system sensor and image rebuilding method based on said sensor

InactiveCN1821762AAchieve simplicityHigh measurement accuracyDiagnostic recording/measuringSensorsElectrical imagingElectrode array

This invention provides a sensor with a double mode electric imaging system, in which, the radial section structure of the sensor is composes of three layers, the outside is a metal tube layer, the middle is an insulation substance layer and the inside structure layer is composed of multiple electrodes distributed on a same circle and adhered on the insulation substance layer and realizing the synchronous measurement of the actual and virtual parts of impedance, insulation substances are filled in slits between adjacent electrodes, the longitudinal sectional structure of the sensor is designed as an electrode array realizing synchronous measurement to the actual and virtual parts of the tube section impedance, besides, a method is provided for re-structuring two kinds of images based on the sensor to expand the sphere and accuracy of the measurement of the current ERT and ECT system.

Owner:TIANJIN UNIV

Method and device for high-accuracy and small-angle measurement

InactiveCN102226690AHigh resolutionLarge measuring rangeUsing optical meansLight beamOptoelectronics

The invention discloses a method and device for high-accuracy and small-angle measurement, wherein the method comprises the following steps: polarizing and splitting the reference light beam which is obtained after the collimation processing to obtain the first linearly polarized light; converting into the circularly polarized light and radiating to a measuring target mirror after the beam expansion; detecting the reverse return of the light beam which is reflected by the target mirror; carrying out the beam contraction and the secondary conversion to obtain the second linearly polarized light; polarizing and splitting the second linearly polarized light again and dividing the second linearly polarized light into the reflected light and the transmission light which have the light intensity ratio of 1 to 1; respectively radiating the two beams of light to two prisms to be reflected; and respectively receiving and processing the reflected light signals through two detectors. The device disclosed by the invention comprises a laser emitting unit, a beam expansion lens unit, a measuring target mirror unit and a differential detection unit, wherein the laser emitting unit comprises a light source, a single mode fiber, a collimation lens, a polarization splitter and a lambda / 4 wave plate; and the differential detection unit comprises the splitter, the two prisms and the two detectors. The method and device disclosed by the invention have the advantages of ultrahigh accuracy and large measuring range.

Owner:ZHEJIANG UNIV

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

ActiveCN101421483ALarge measuring rangeAccurate measurementSurveyConstructionsAc fieldSurvey instrument

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously 'listens' for, and recognizes, a 'start' signal that is initiated by the driller. After a 'start' signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronicpackages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

Capacity coupling non-contact conductance measuring device based on series resonance and method

InactiveCN101387613ALarge measuring rangeHigh-resolutionResistance/reactance/impedenceMaterial resistanceMeasurement deviceData acquisition

The invention discloses a measurer of capacity coupling type contactless conductivity, based on serial resonance and a method. The measurer comprises a signal generator, an inductor module, an insulated measurement tube, an exciting electrode, a detection electrode, a rectifying filtering circuit, a data acquisition module and a computer, wherein the output of the signal generator excites the exciting electrode via the inductor module, the detection electrode obtains the solution conductivity measurement information in the insulated measurement tube, the rectifying filtering circuit and the data acquisition module convert the information into voltage signals to be transmitted to the computer, and the computer utilizes the one-to-one relationship between voltage and conductivity to obtain the conductivity measurement value of the object liquid. The invention utilizes serial resonance method to effectively eliminate the effect of coupling capacitance and parasitic capacitance on the conductivity measurement and expands the conductivity measurement range. The relative measurer has the advantages of wide measurement range, high sensitivity, simple structure, contactless property and low cost, which provides an effective path for measuring the liquid conductivity in tube.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com