Method for measuring liquid-drop contact angle on solid surface and device thereof

A solid surface and measurement method technology, applied in the field of measurement, can solve the problems of not considering the influence of gravity, not considering the influence, and not being able to give the contact angle well, so as to improve the measurement accuracy and expand the measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

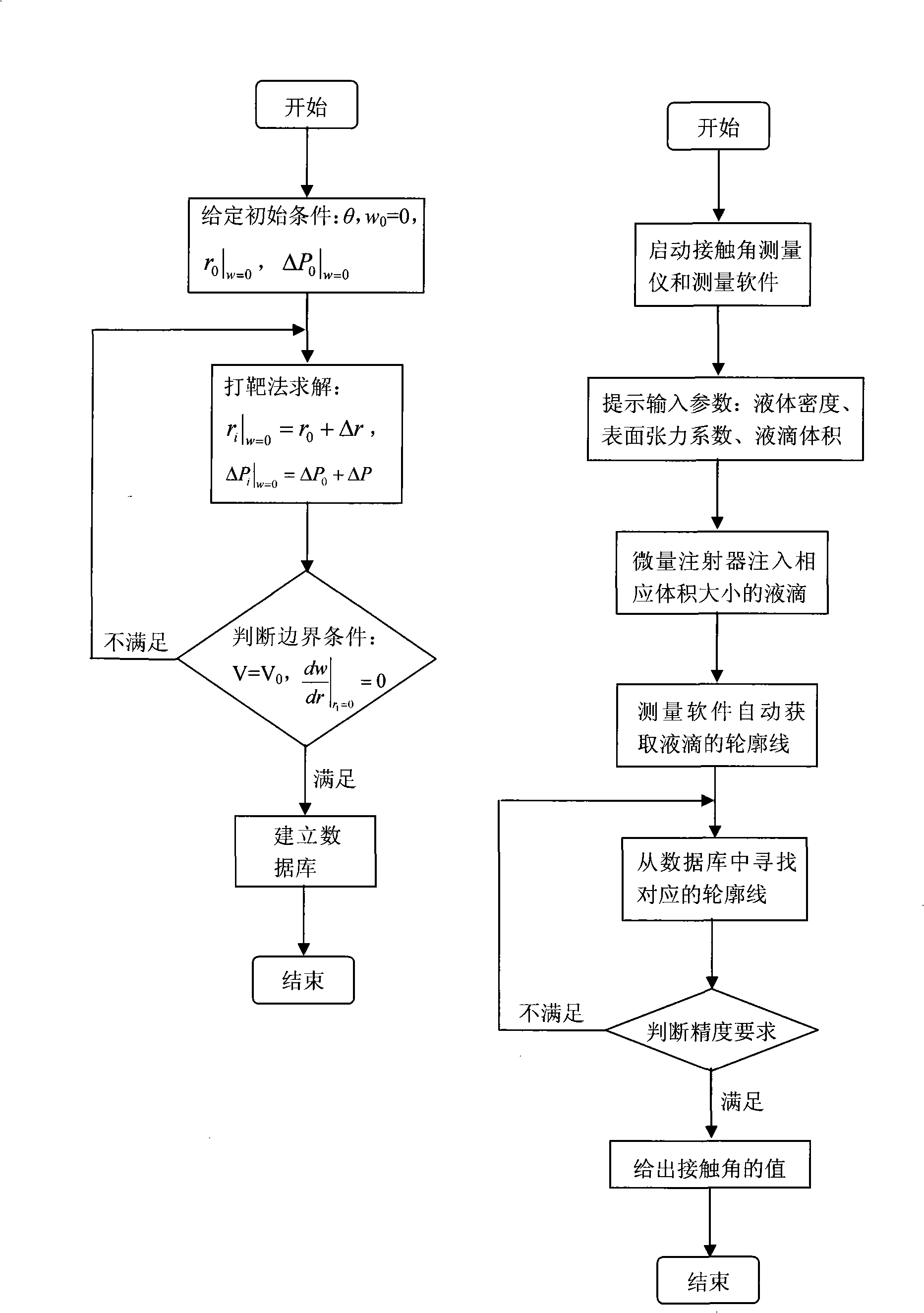

[0035] Such as image 3 As shown, the specific implementation is divided into two parts: 1) establishing a database; 2) calculating the contact angle in real time. The specific operation of creating the database is as follows:

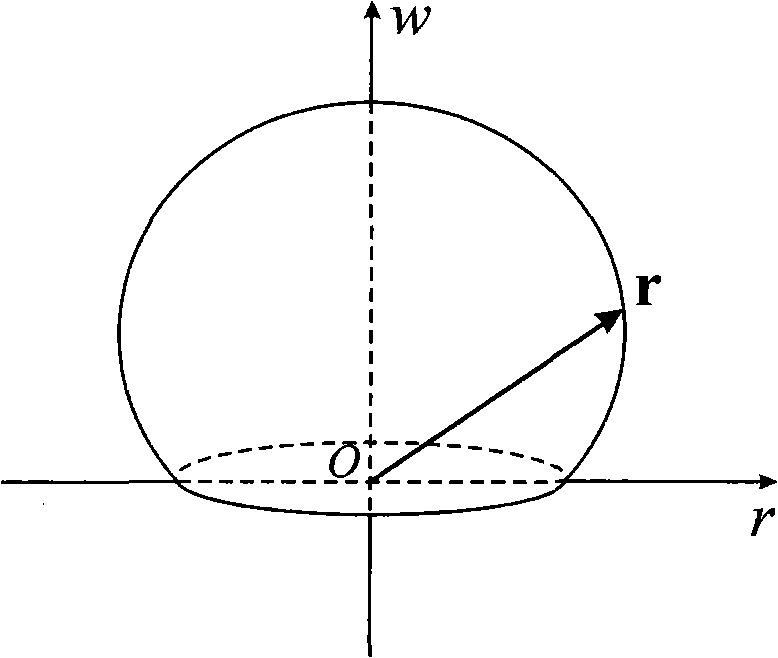

[0036] 1) The initial physical constants of the measured droplet are given: surface tension coefficient, density, volume. The initial boundary conditions are given in the process of numerical solution (the contact angle θ is given, in the specific calculation process w 0 = 0, the width r of any given adhesion area 0 | w=0 and the pressure difference ΔP between the inside and outside of the droplet exiting the substrate 0 | w=0 ).

[0037] 2) Solve by the shooting method (the formula of the shooting method is r i | w=0 = r 0 +Δr,ΔP i | w=0 =ΔP 0 +ΔP);

[0038] 3) Judging whether the final boundary condition is satisfied (that is, the condition of program termination V=V 0 , dw dr ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com