Patents

Literature

2854results about How to "Reduce equipment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

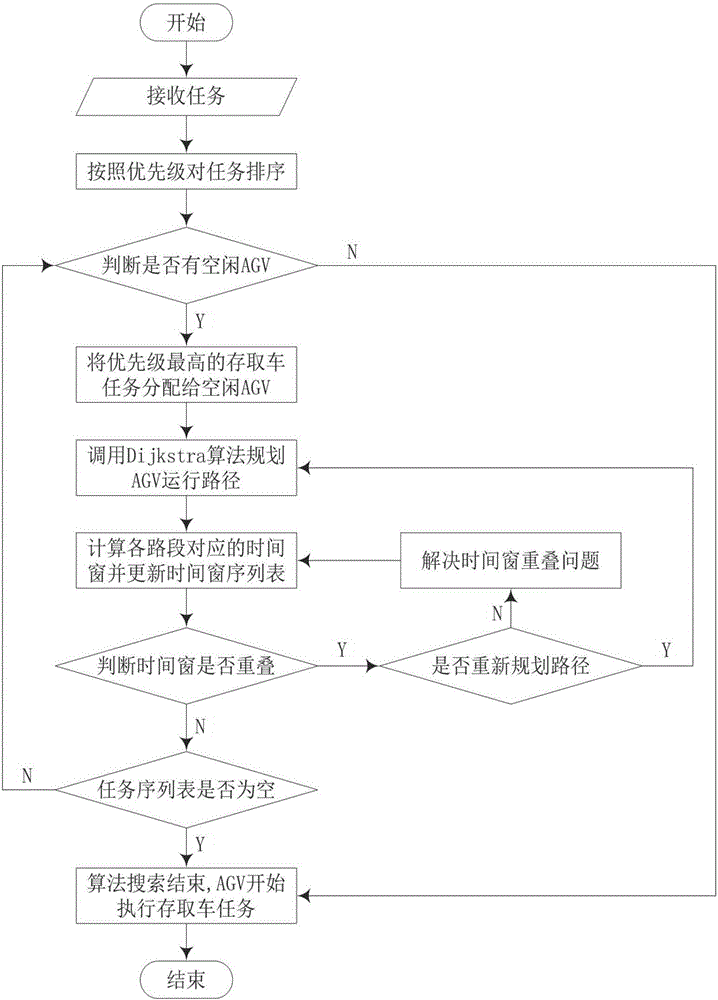

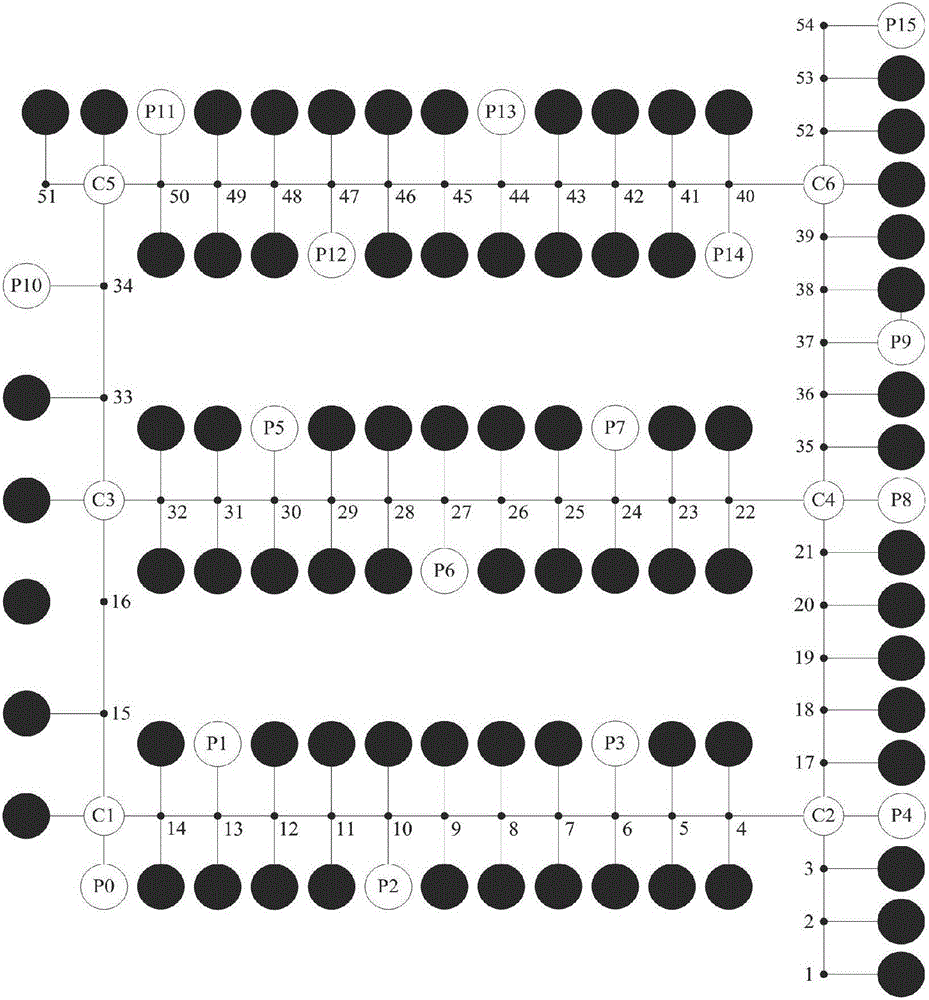

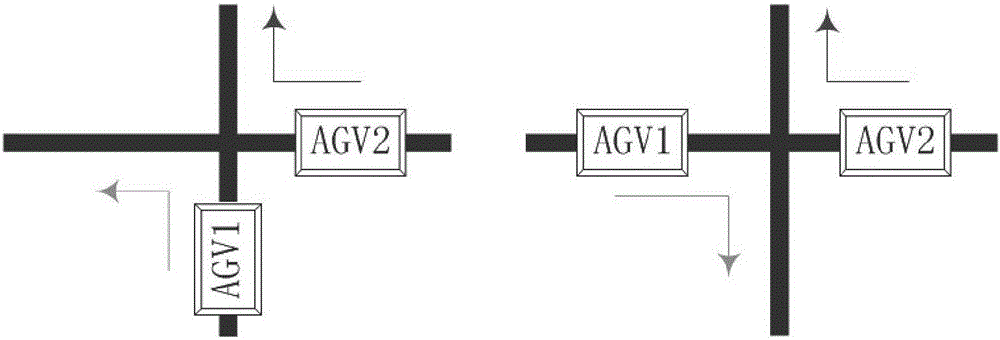

Parking system path planning method based on dynamic time windows

The invention discloses a parking system path planning method based on dynamic time windows, and belongs to the technical field of path planning. The method is characterized by comprising the following steps: S1, building a work environment model of AGVs in an intelligent garage in a topological method; S2, setting priority for each AGV and each car parking / picking task according to different evaluation criteria; S3, using a Dijkstra algorithm to plan a shortest possible path for an AGV accepting a task; S4, arranging feasible path time windows; S5, designing conflict resolution strategies according to different types of conflicts; and S6, planning a conflict-free optimal path for the AGV using a parking system path planning algorithm based on dynamic time windows. A time-sharing use strategy is used, and the Dijkstra algorithm and a time window method are combined effectively, so that the problem that the existing multi-AGV path planning is of poor flexibility and is prone to deadlock or collision conflict is solved effectively, and a shortest conflict-free optimal path can be planned for an AGV accepting a task. In addition, the overall operation efficiency of an intelligent three-dimensional parking system can be improved effectively, and the car parking / picking waiting time can be reduced for social members.

Owner:JIANGSU MARITIME INST

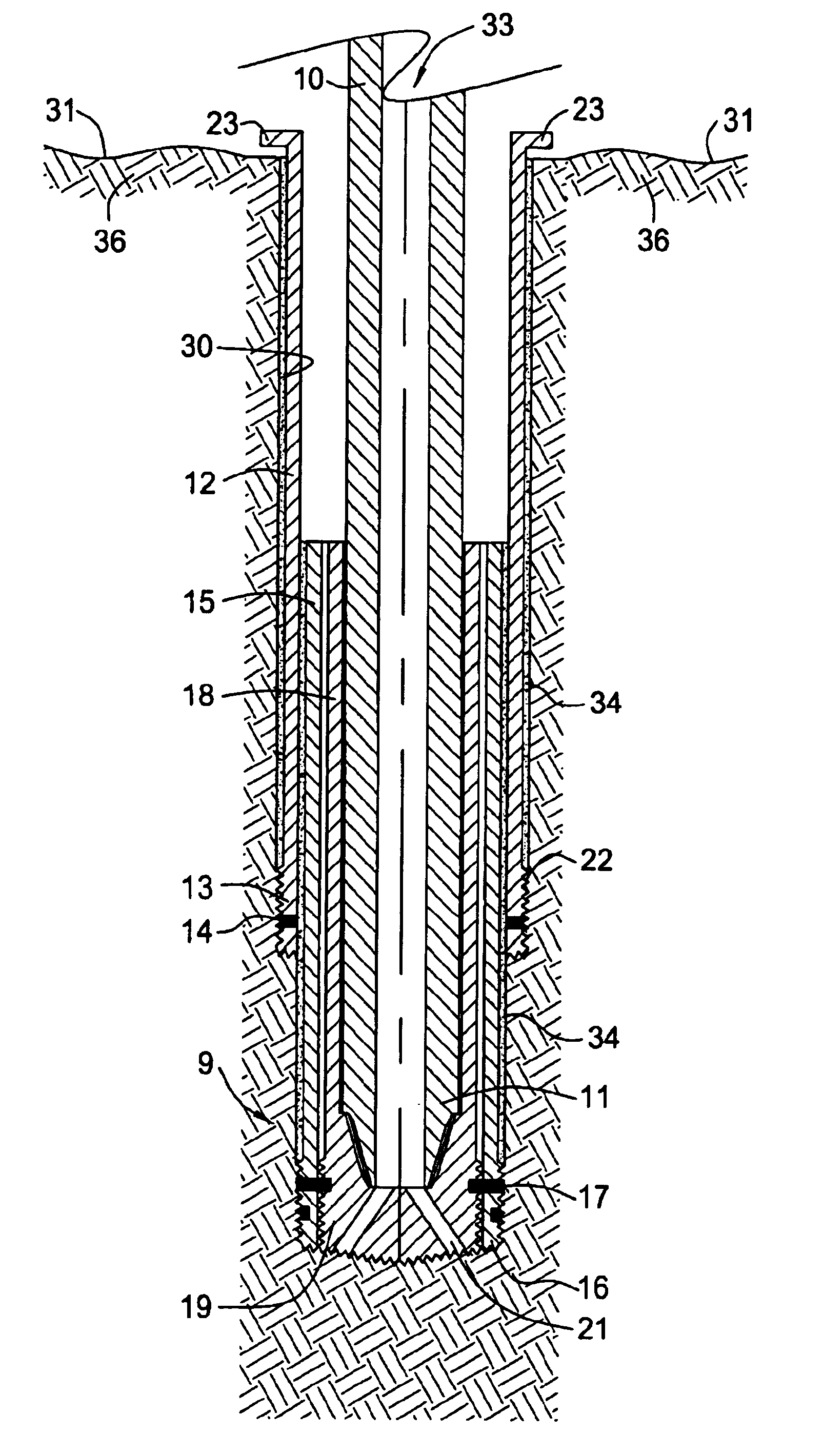

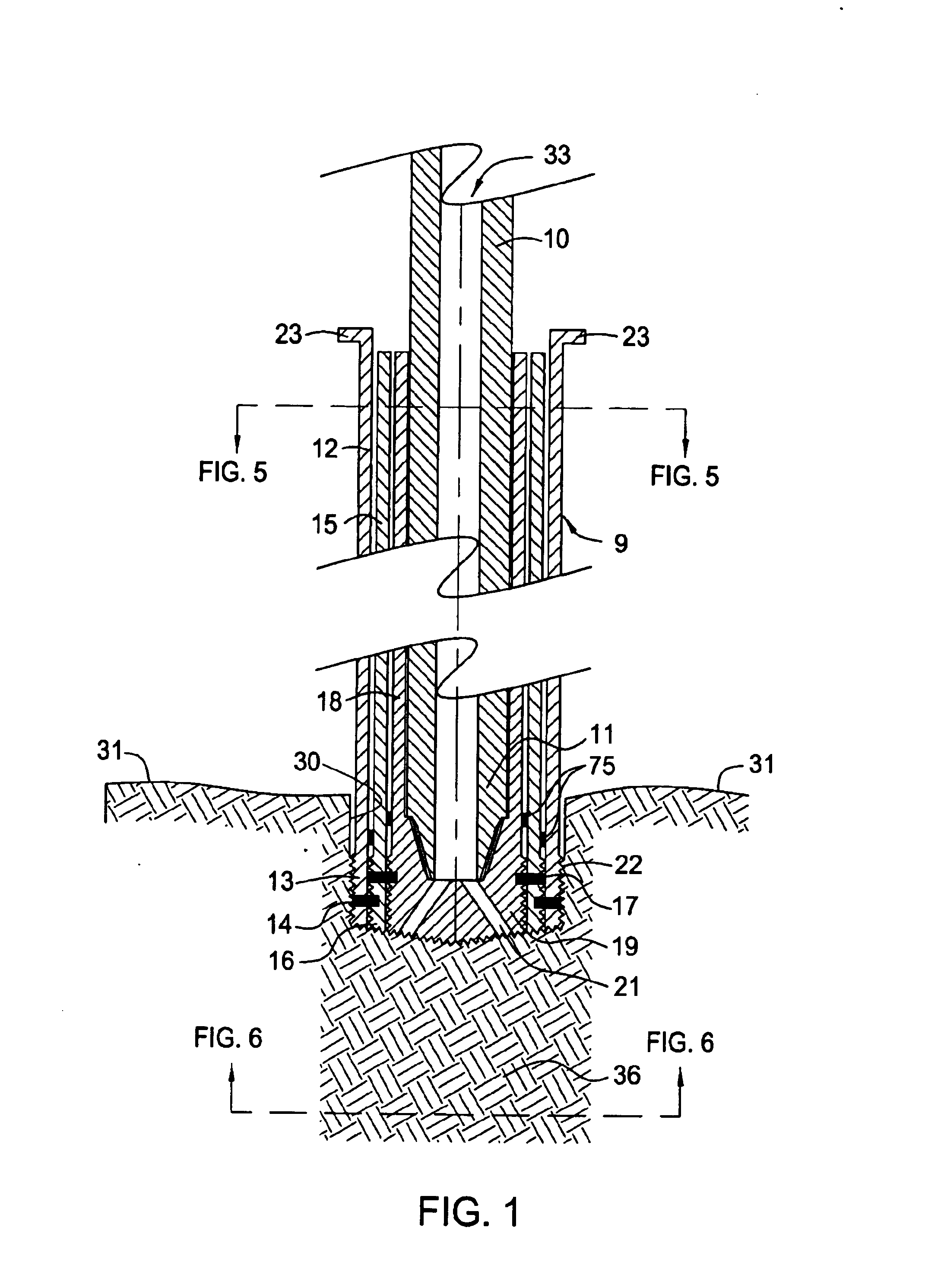

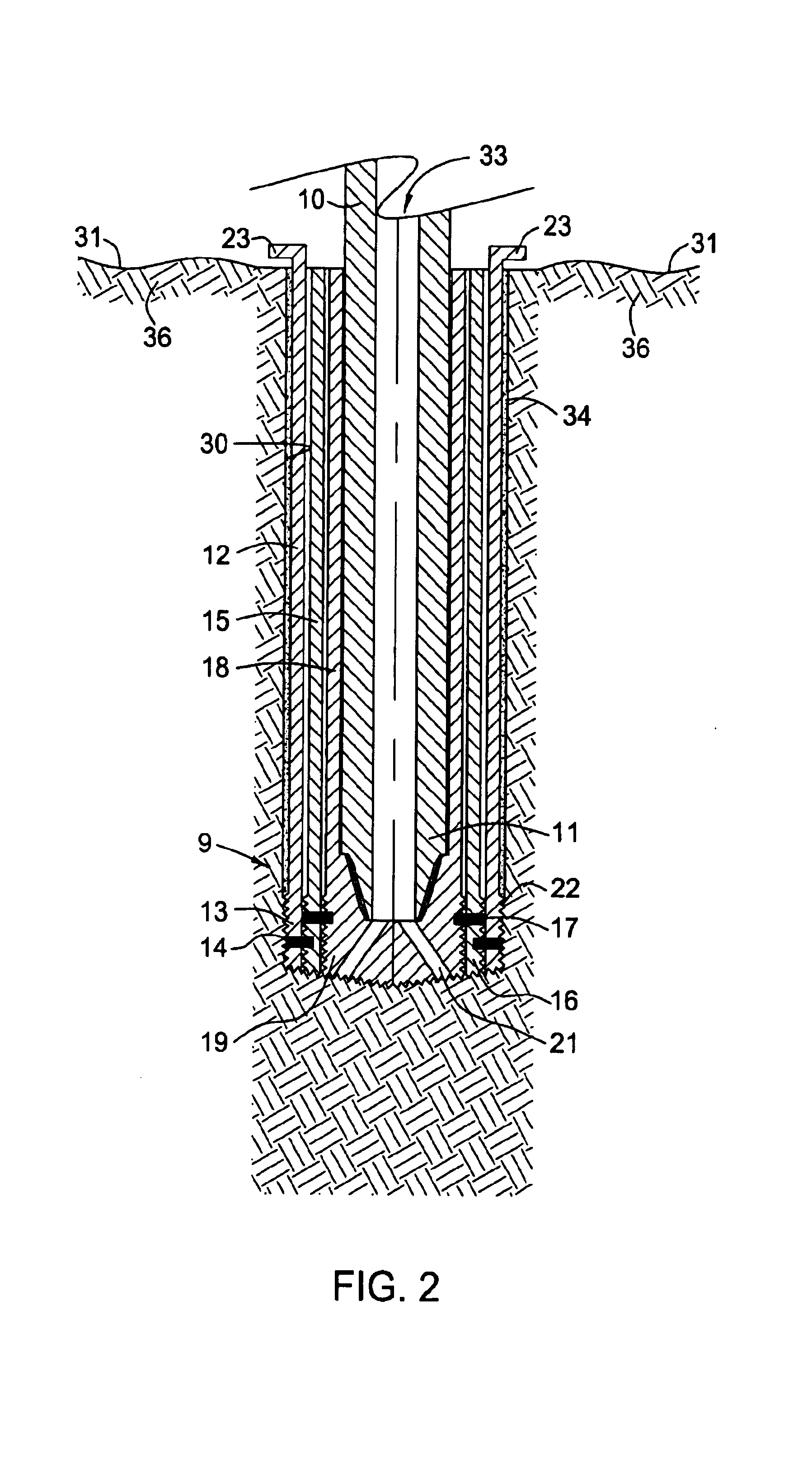

Drilling with concentric strings of casing

InactiveUS6857487B2Cost for assemblyReduce equipment costsEarth drilling toolsDrilling rodsWell drillingEngineering

The present invention provides a method and apparatus for setting concentric casing strings within a wellbore in one run-in of a casing working string. In one aspect of the invention, the apparatus comprises a drilling system comprising concentric casing strings, with each casing string having a drill bit piece disposed at the lower end thereof. The drill bit pieces of adjacent casing strings are releasably connected to one another. In another aspect of the invention, a method is provided for setting concentric casing strings within a wellbore with the drilling system. In another aspect of the invention, the releasably connected drill bit pieces comprise a drill bit assembly.

Owner:WEATHERFORD TECH HLDG LLC

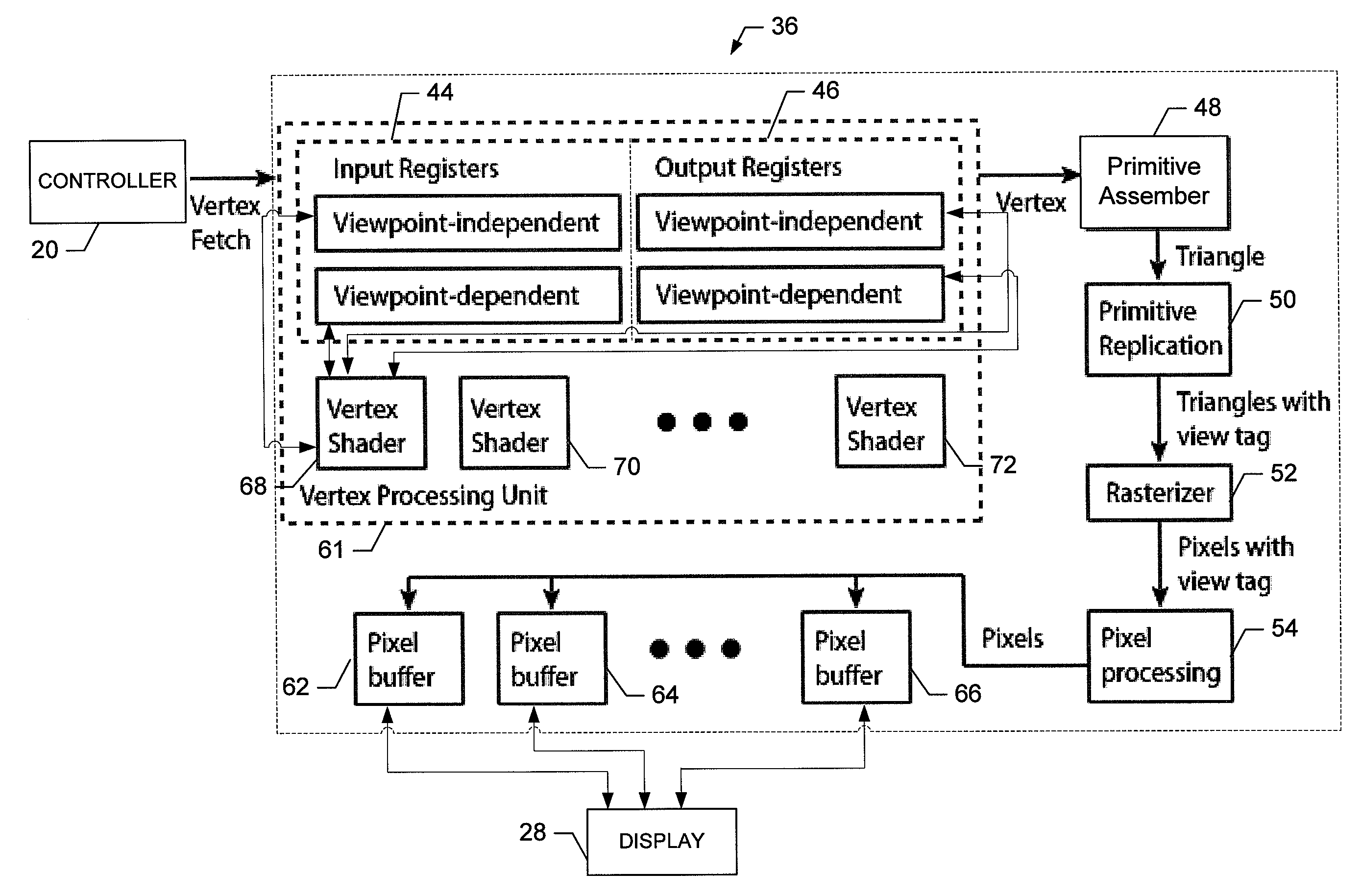

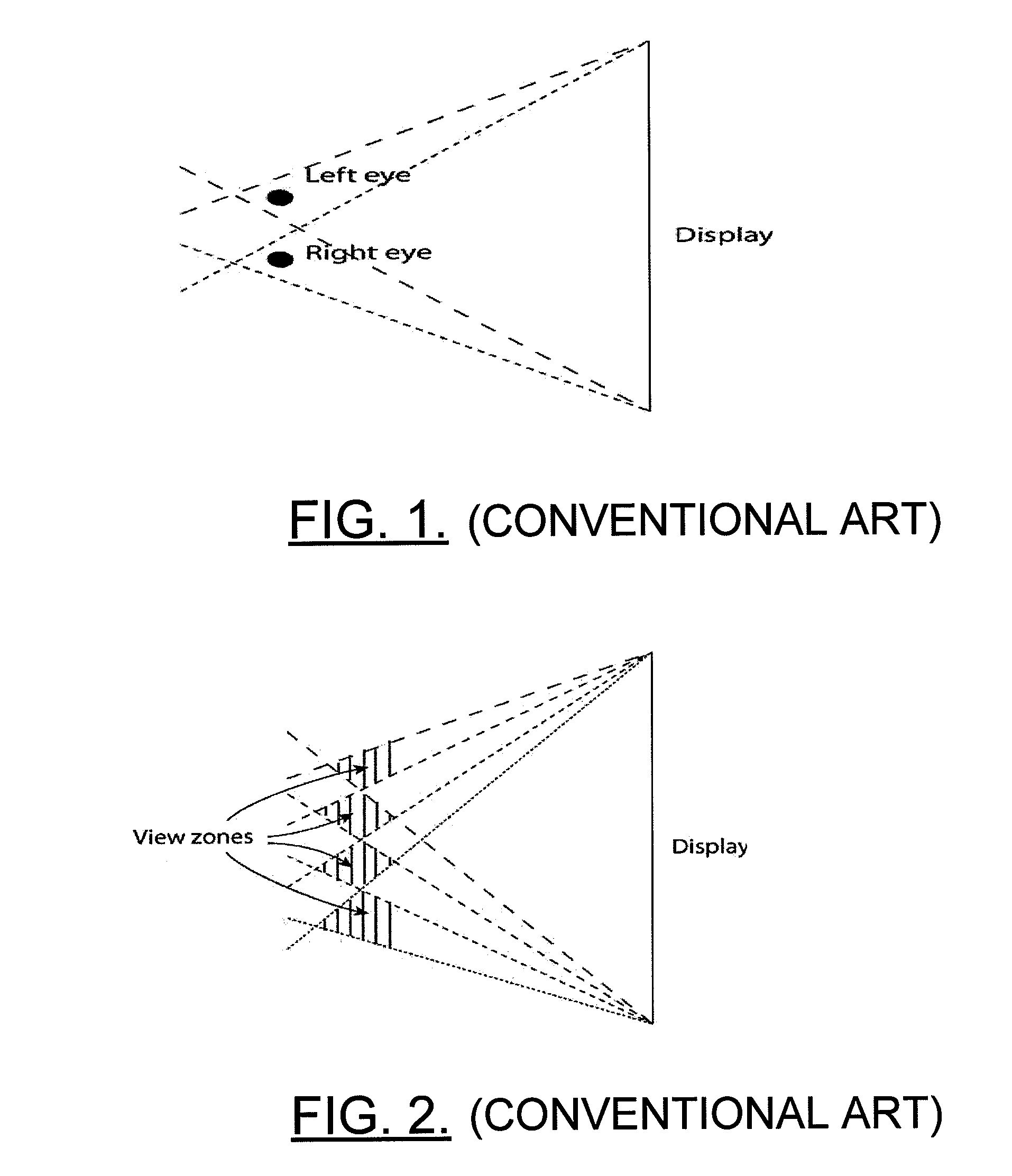

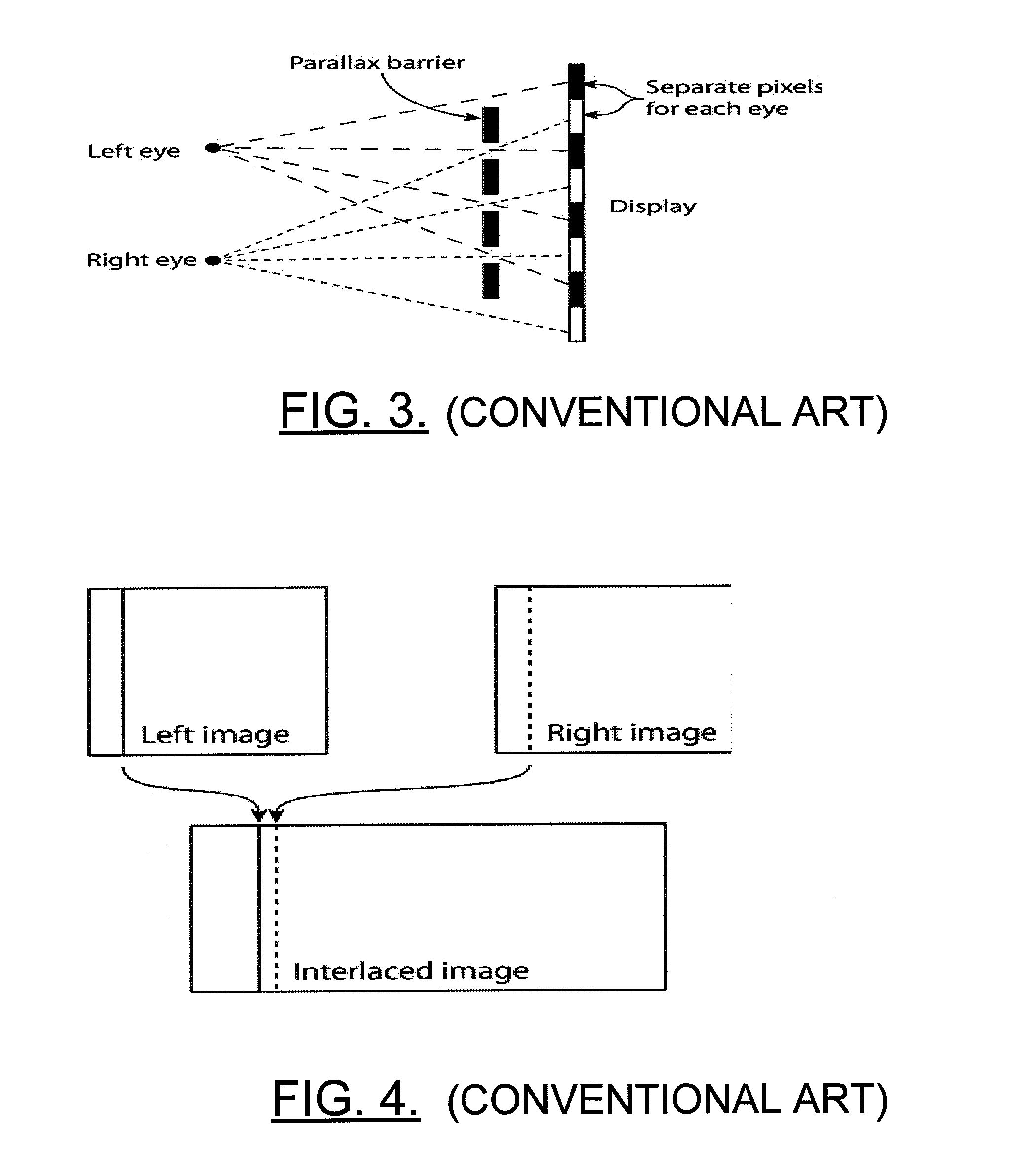

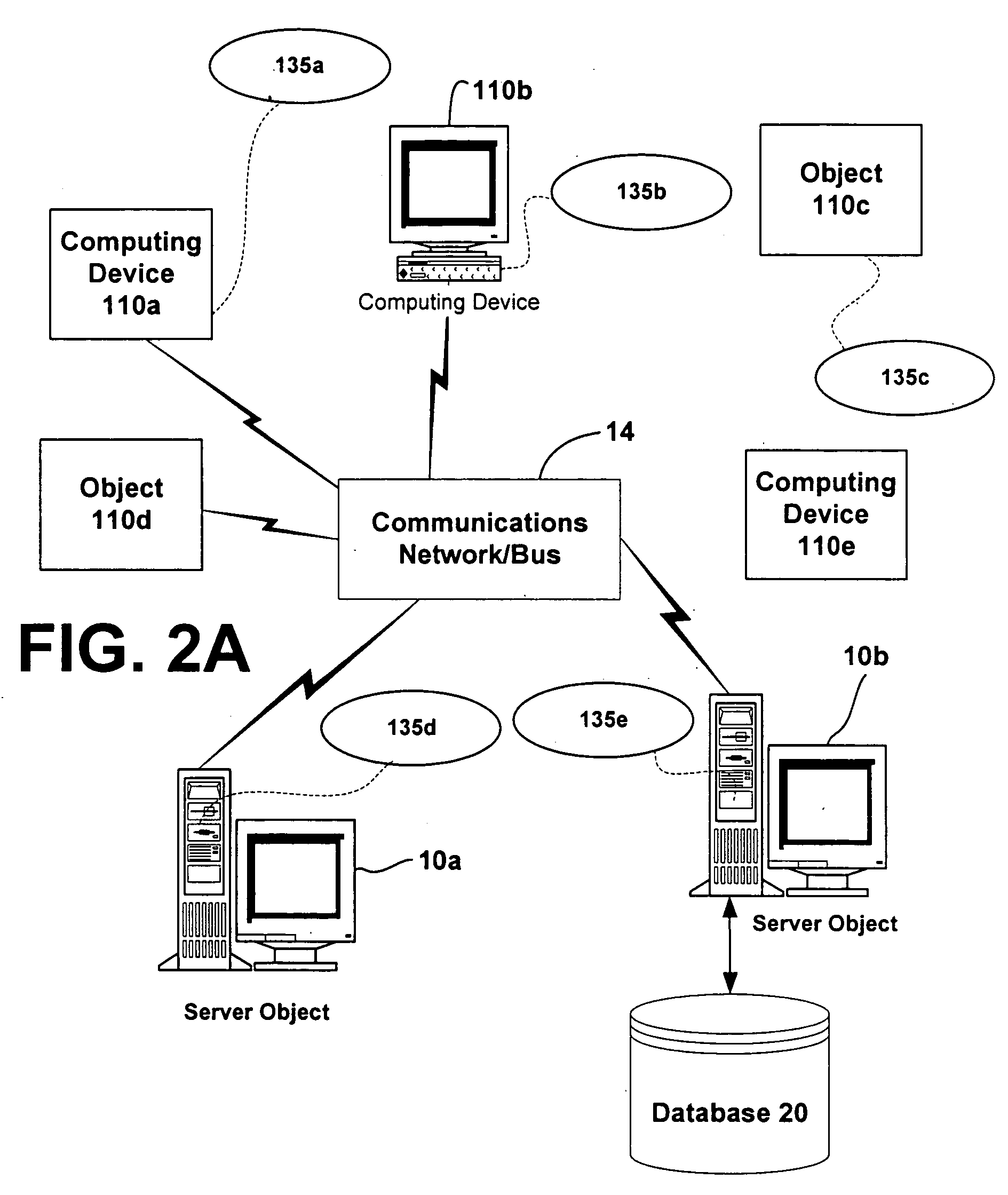

Apparatus, method and a computer program product for providing a unified graphics pipeline for stereoscopic rendering

InactiveUS20080007559A1Reduce computationReduce power consumptionDigital computer detailsImage data processing detailsDisplay deviceMultiple viewpoint

A device for rendering to multiple viewpoints of a stereoscopic display is provided. The device includes vertex shaders which receive vertices corresponding to primitives and process viewpoint dependent information. The device also includes a primitive replication unit which replicates primitives according to a number of viewpoints supported by the stereoscopic display. The primitive replication unit adds unique view tags to each of the primitives which identify the viewpoint that the respective primitive is destined for. Each replicated primitive is processed by a rasterizer and converted into pixels. The rasterizer adds a view tag to the rasterized pixels so that the pixels identify a respective primitive and identify a respective pixel buffer that the pixel is destined for. The pixels can then be processed by a pixel processing unit and written to a pixel buffer corresponding to a respective viewpoint. The pixels are subsequently output to the stereoscopic display.

Owner:WSOU INVESTMENTS LLC

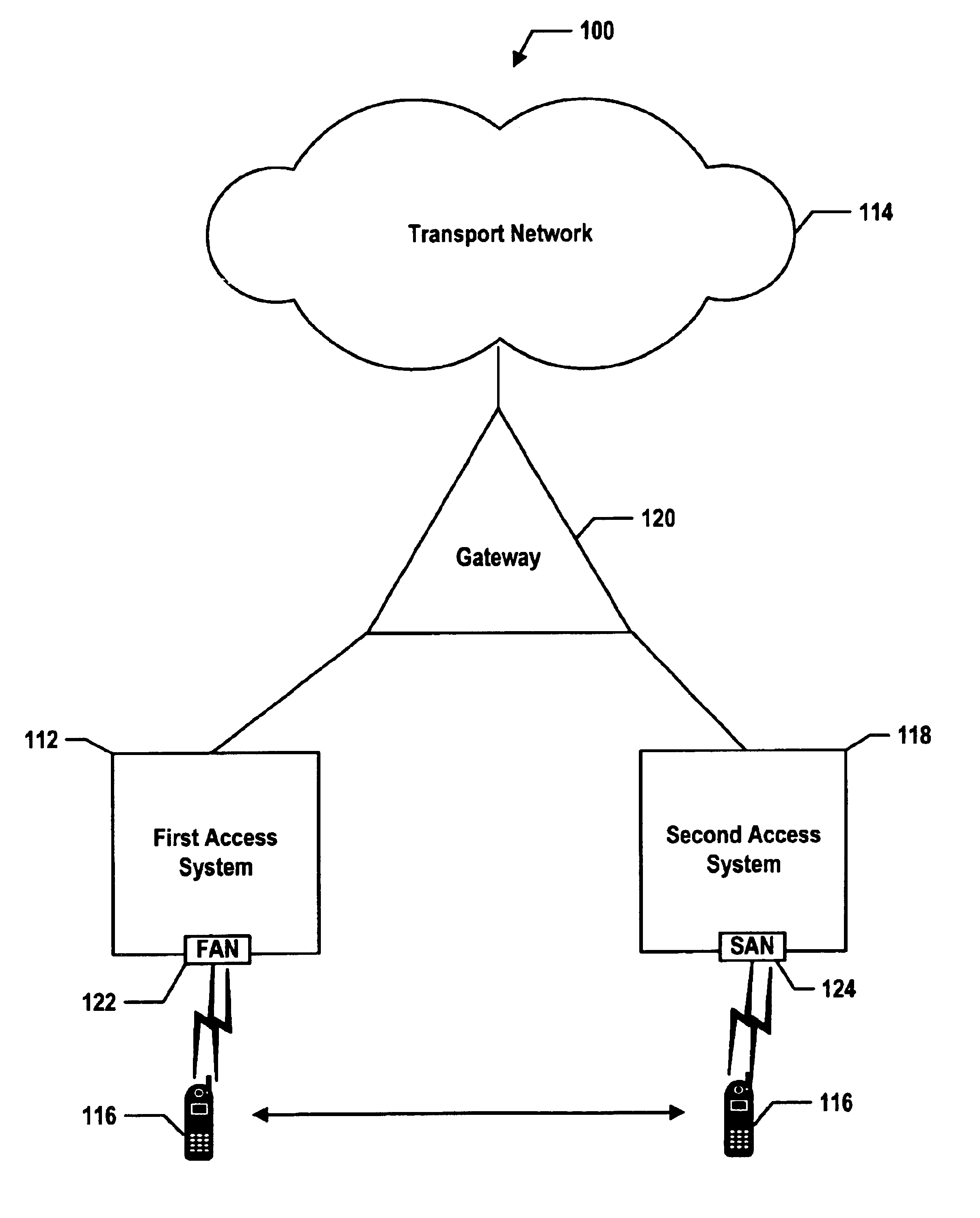

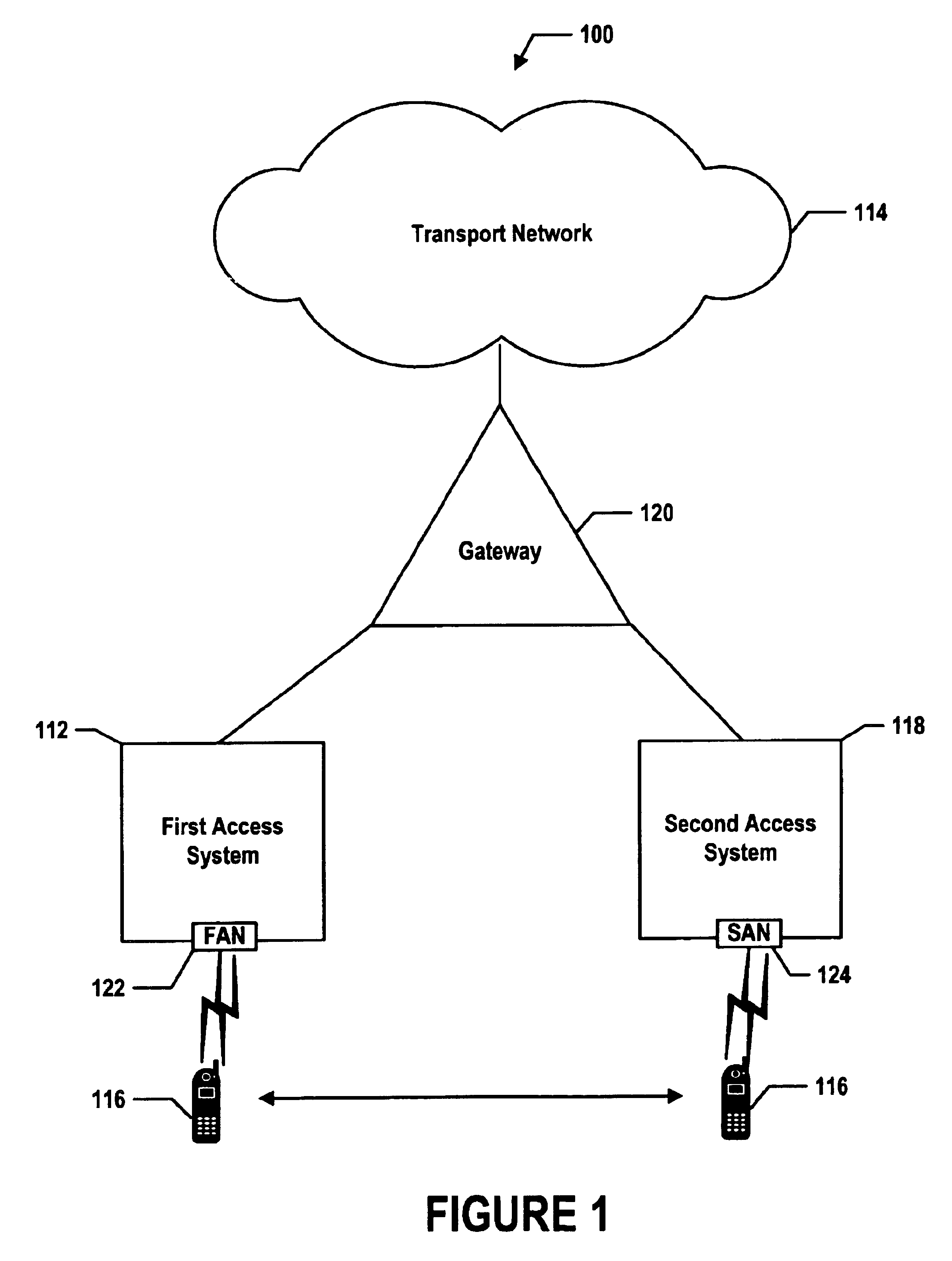

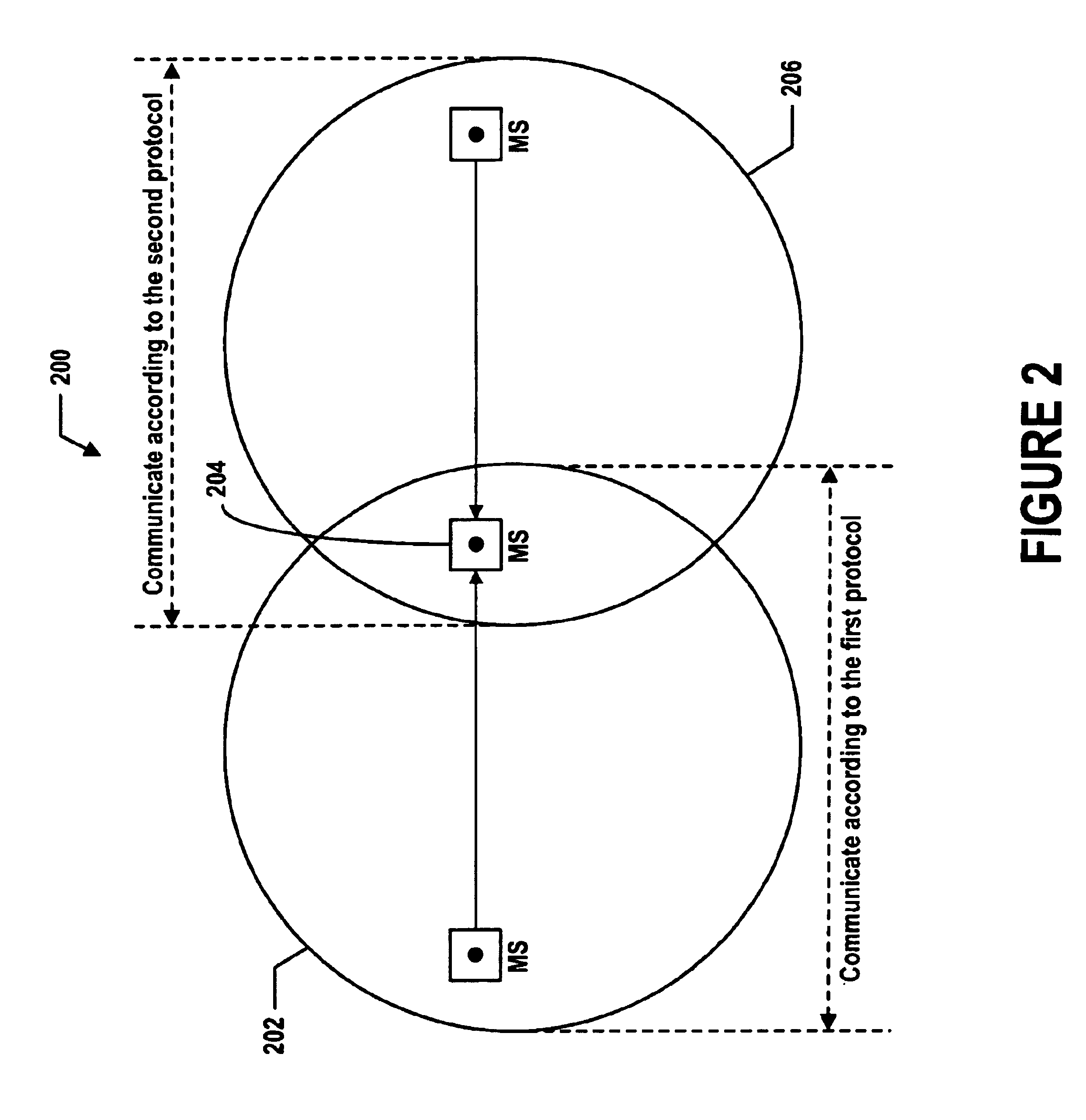

Method and system for intersystem wireless communication session arbitration

InactiveUS6879600B1Reduce complexityReduce complexity and number of componentTime-division multiplexRadio/inductive link selection arrangementsHand-offMobile station

A mobile station provides arbitration and hand-off between two or more differently formatted computer and / or telecommunication networks. To facilitate the mobile station arbitration and hand-off, the mobile station operates at a given location in which it can communicate according to a first protocol via a first-access system and at which it can communicate according to a second protocol via a second-access system. At the given location, the mobile station arbitrates between communicating real-time media according to the first protocol via the first-access system and communicating real-time media according to the second protocol over the first protocol via the second-access system.To carry out the arbitration, mobile station may be provisioned with one or more arbitration policies. Based on these arbitration policies, the mobile station commits resources to carry on a communication session via a selected access system. When the arbitration policies comprise a preferred-network attribute, such as a preferred-network threshold, the mobile station arbitration may be performed by a comparison function. This comparison function may include ascertaining a preferred-network metric and communicating voice content according to the first protocol via the first-access system when the preferred-network metric surpasses the preferred-network threshold or communicating voice content according to the second protocol over the first protocol via the second-access system when the preferred-network metric does not surpass the preferred-network threshold.

Owner:SPRINT SPECTRUM LLC

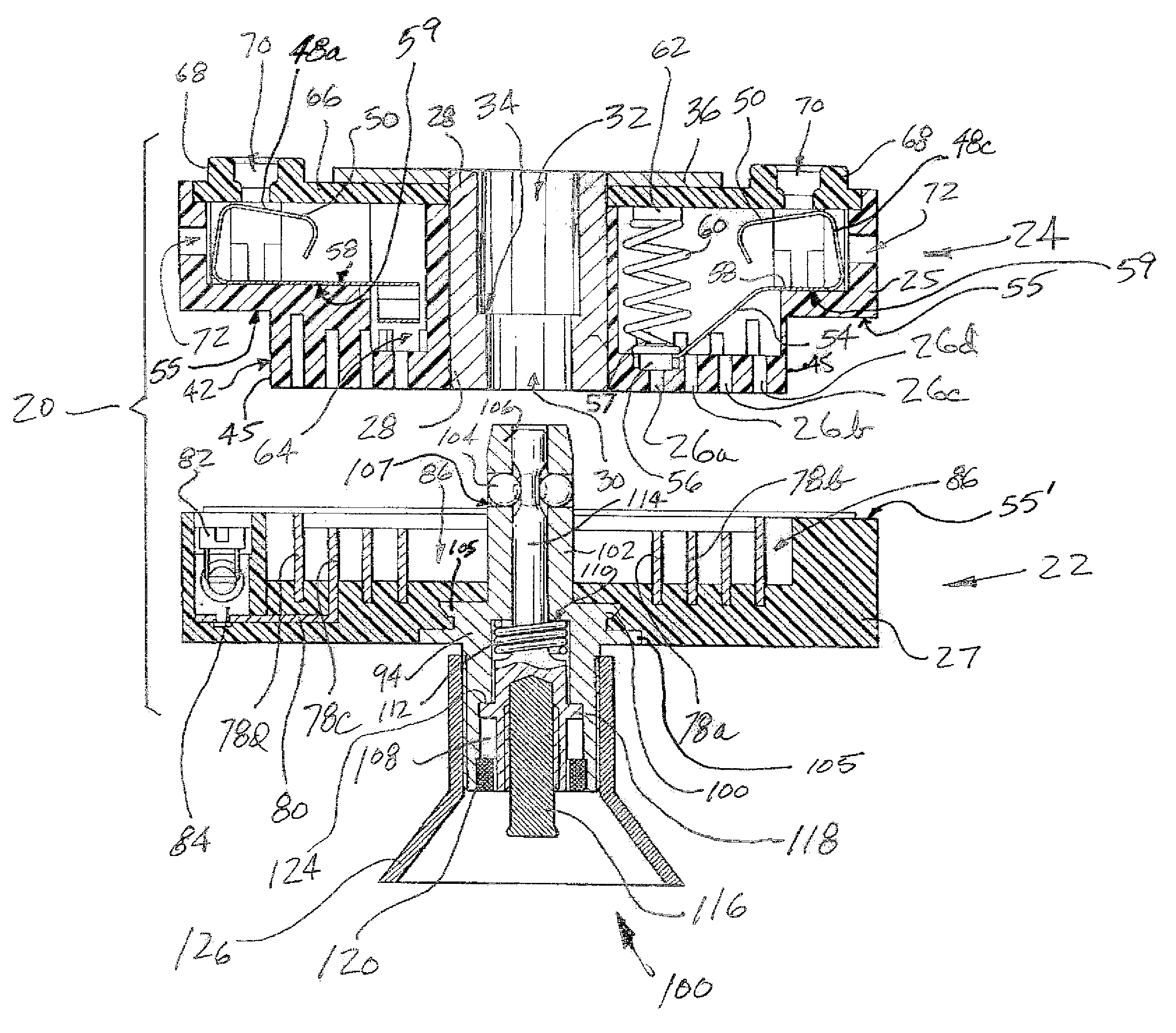

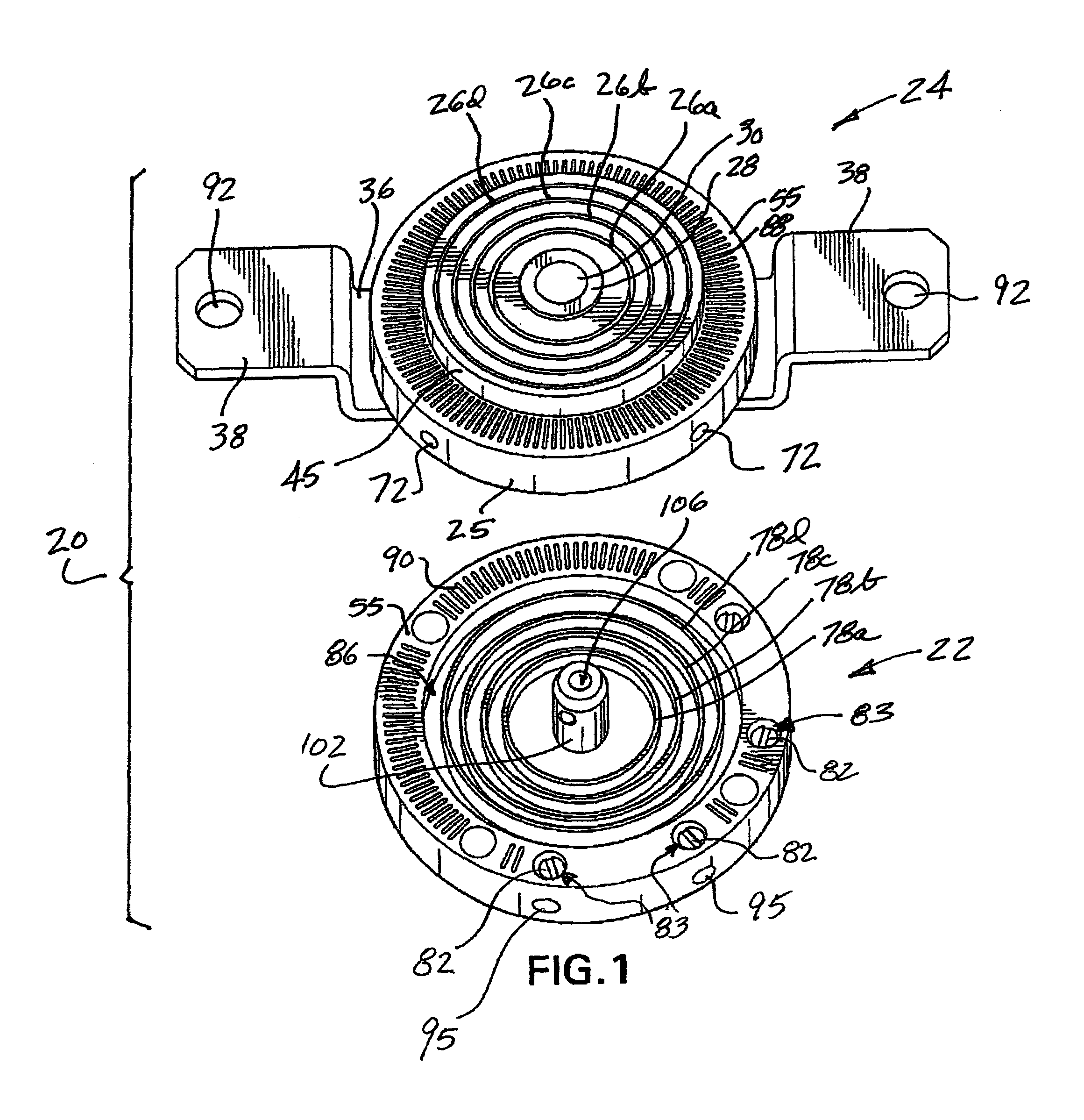

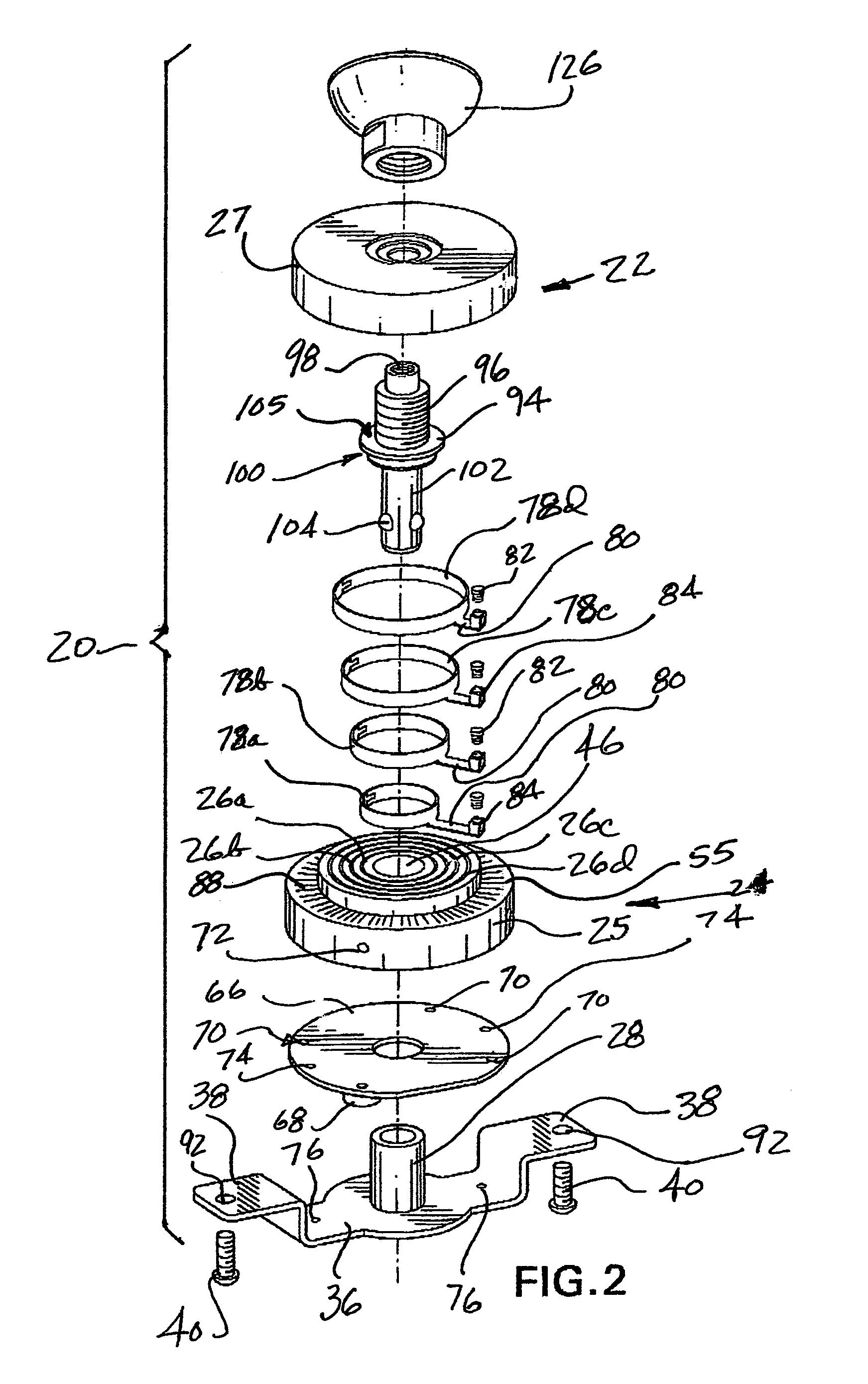

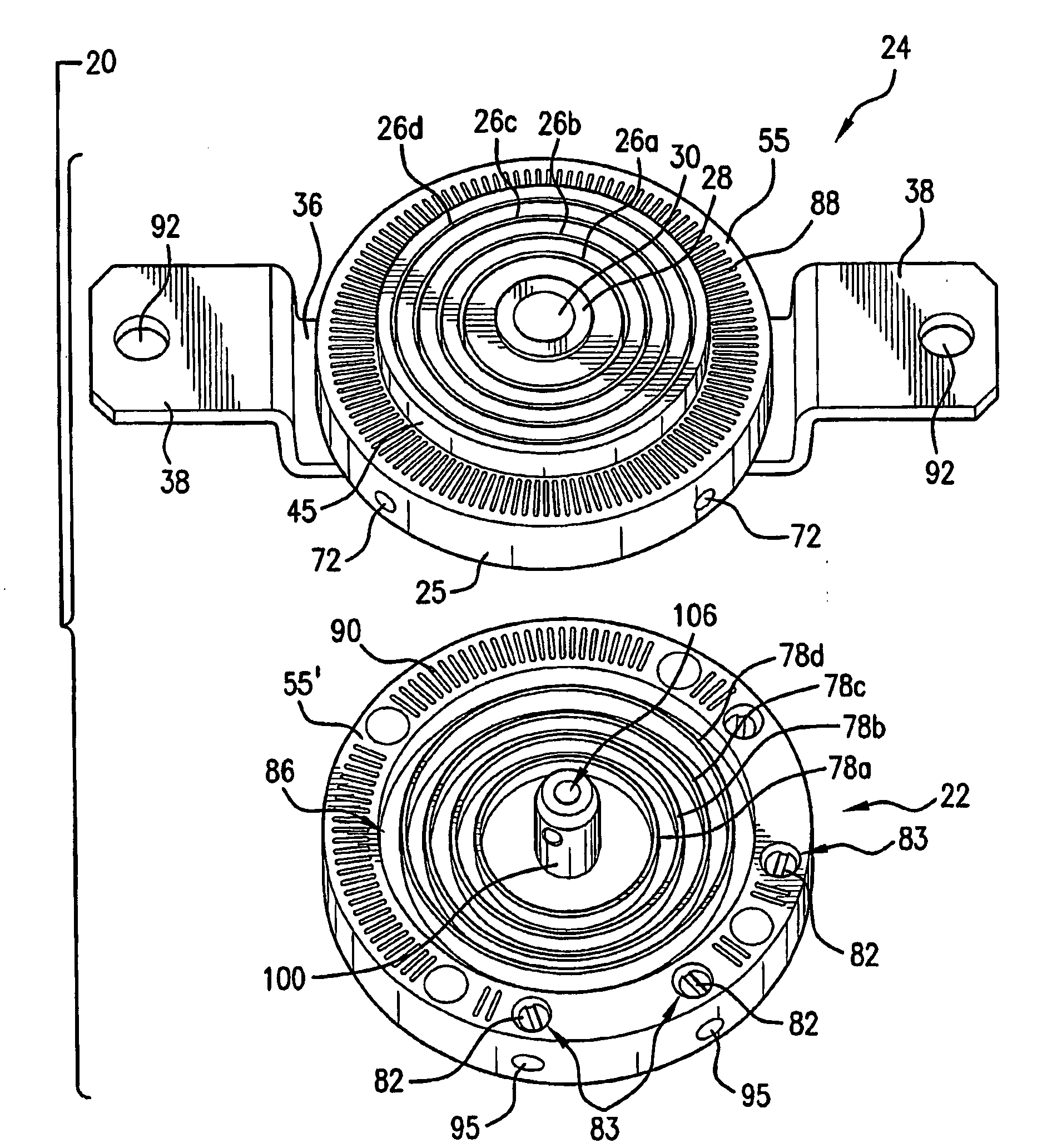

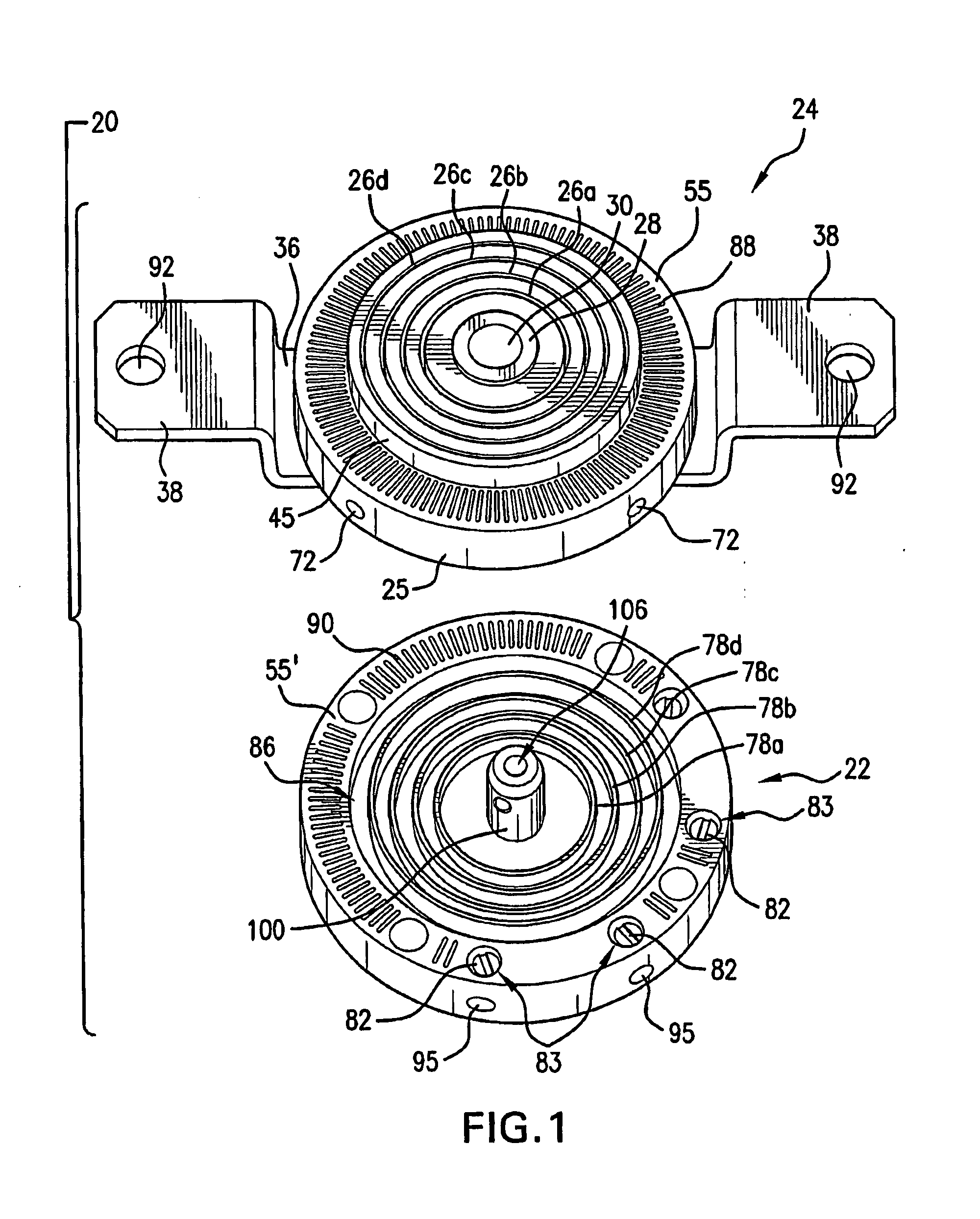

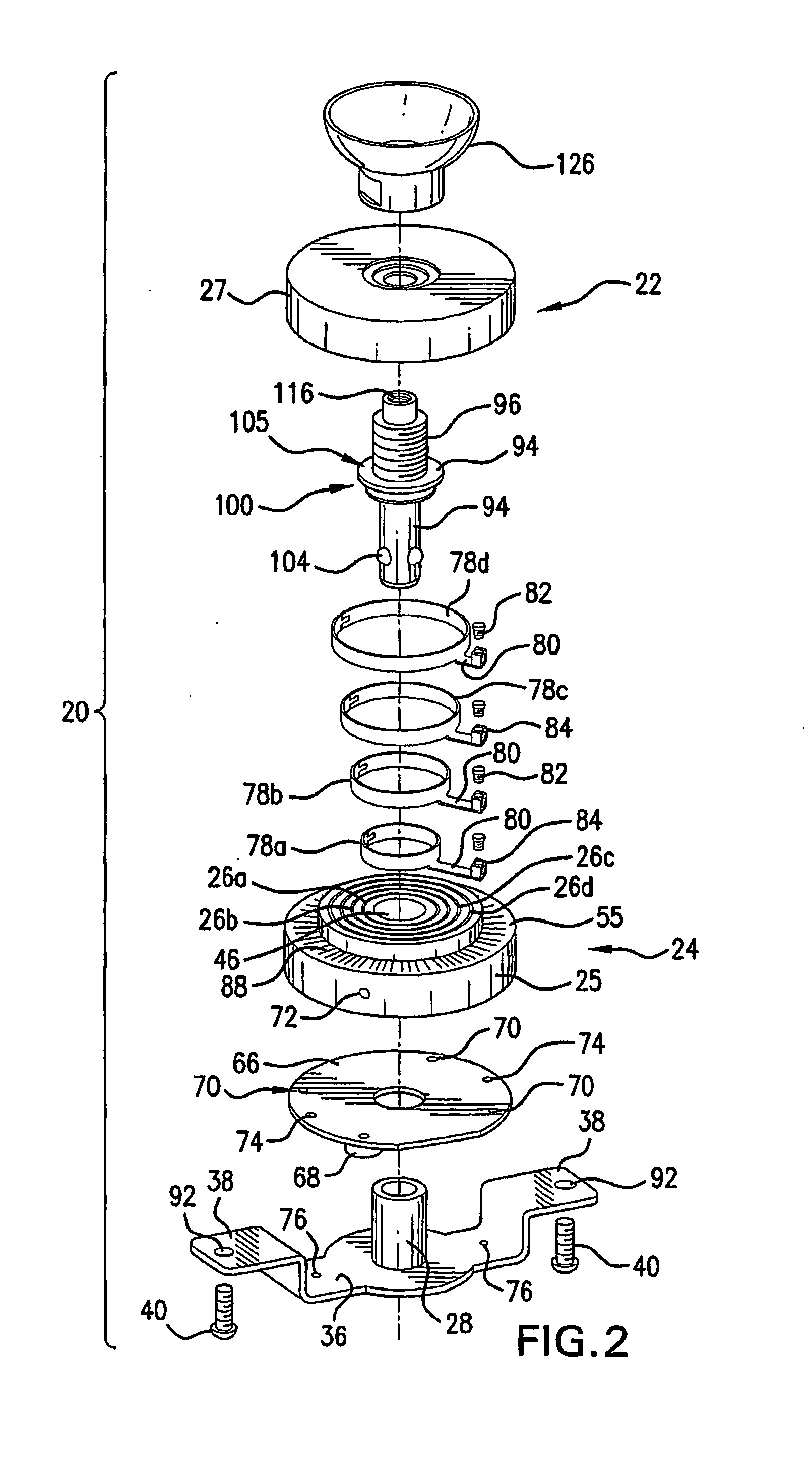

Quick connect device for electrical fixtures

InactiveUS7192303B2Quickly connectReduce cost of deviceRotary current collectorLighting support devicesFinger operationEngineering

A device for connecting and supporting electrical fixtures includes a male electrical plug, a mating female electrical socket and a releasable latch assembly for both holding the plug in the socket and mechanically mounting the fixture on a supporting surface or an electrical box. The plug is provided with concentric, ring shaped male connectors that are matingly received within similarly shaped female recesses in the socket to allow the fixture to be rotated to any of a plurality or mounting orientations. The releasable latch assembly is controlled by the stroke of a simple push rod operated by a user's thumb or finger. A cover may be used for covering the socket when a plug is not installed.

Owner:SKYX PLATFORMS CORP

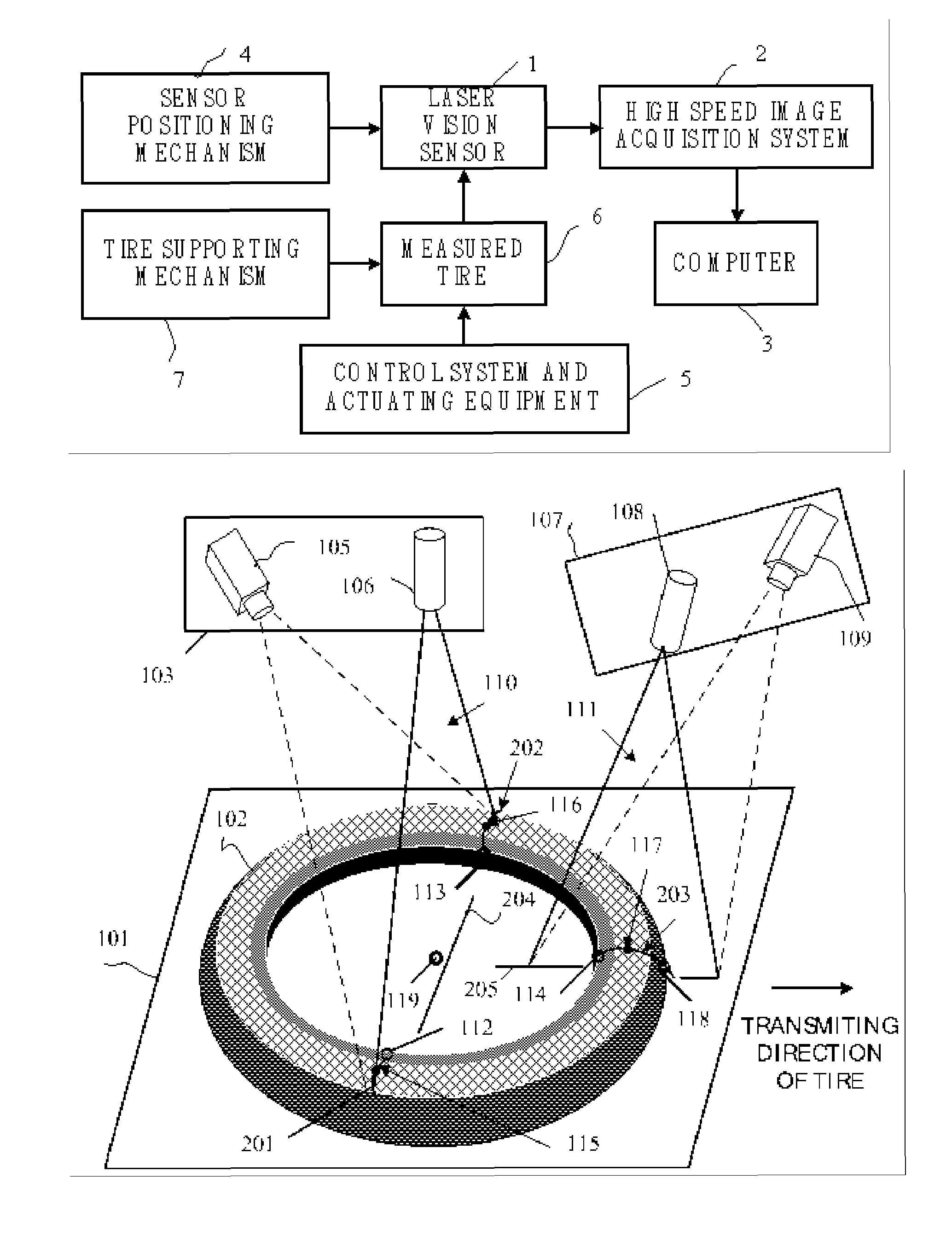

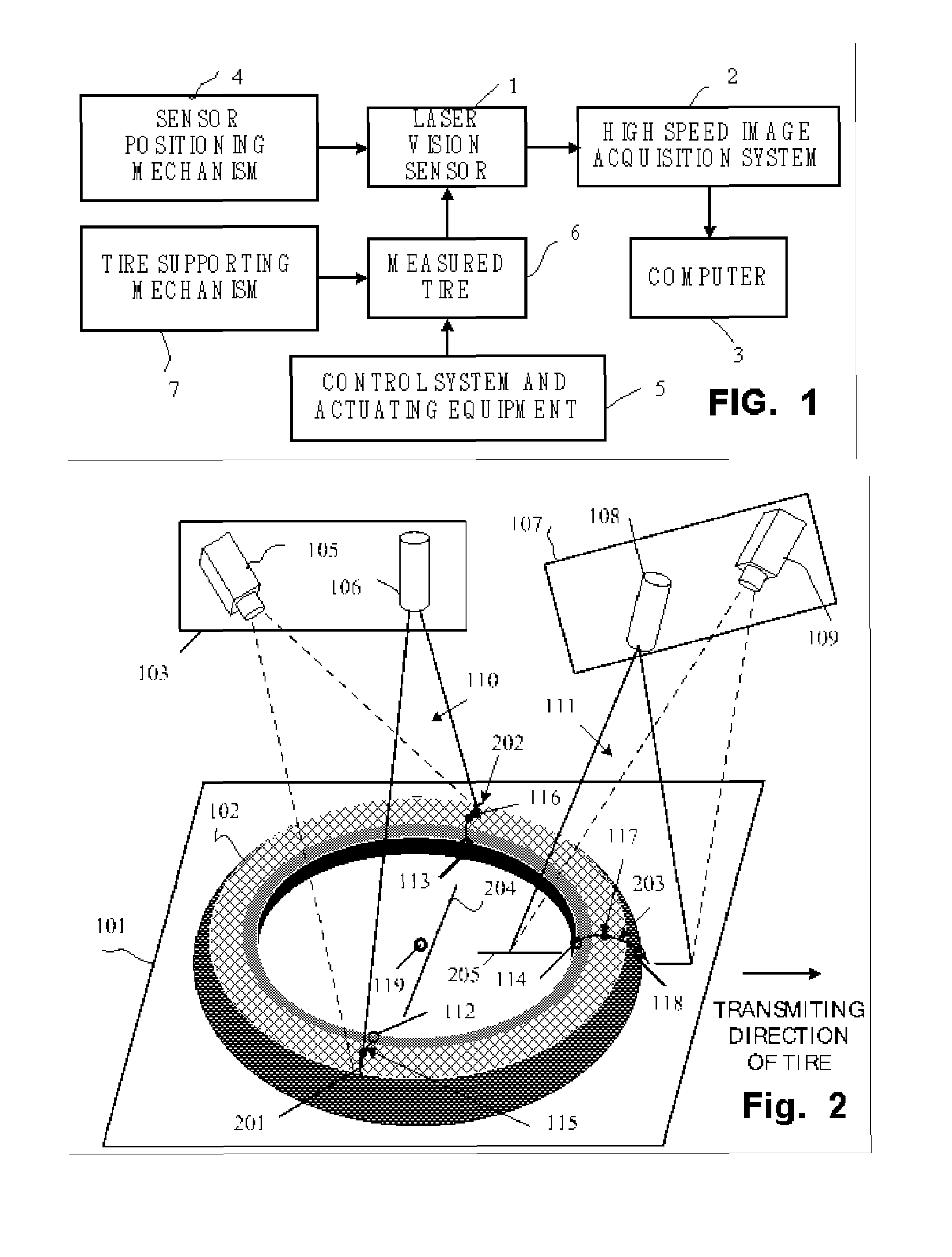

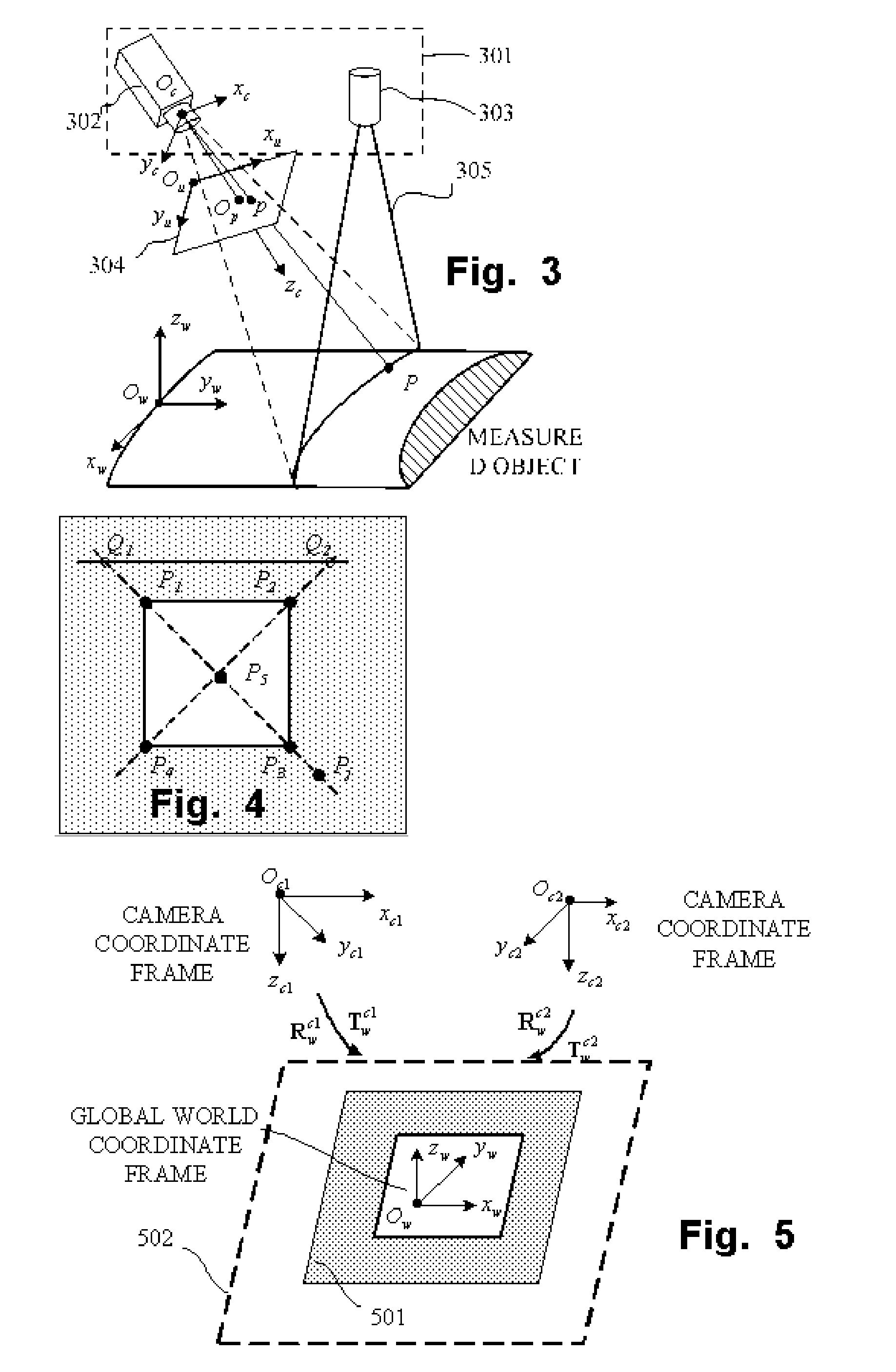

Method and apparatus for dynamic measuring three-dimensional parameters of tire with laser vision

ActiveUS7177740B1Reduce equipment costsHigh measurement accuracyVehicle testingRegistering/indicating working of vehiclesEngineeringVision sensor

Three-dimensional parameters of a tire are measured dynamically in a non-contact way using laser vision technology. Two laser vision sensors are used, which are calibrated and then used for practical measurement. The system offers a wide measuring range, high accuracy and high efficiency, even though the tire is moving, and it minimizes the size of the measuring apparatus, and reduces the cost of the apparatus.

Owner:BEIHANG UNIV

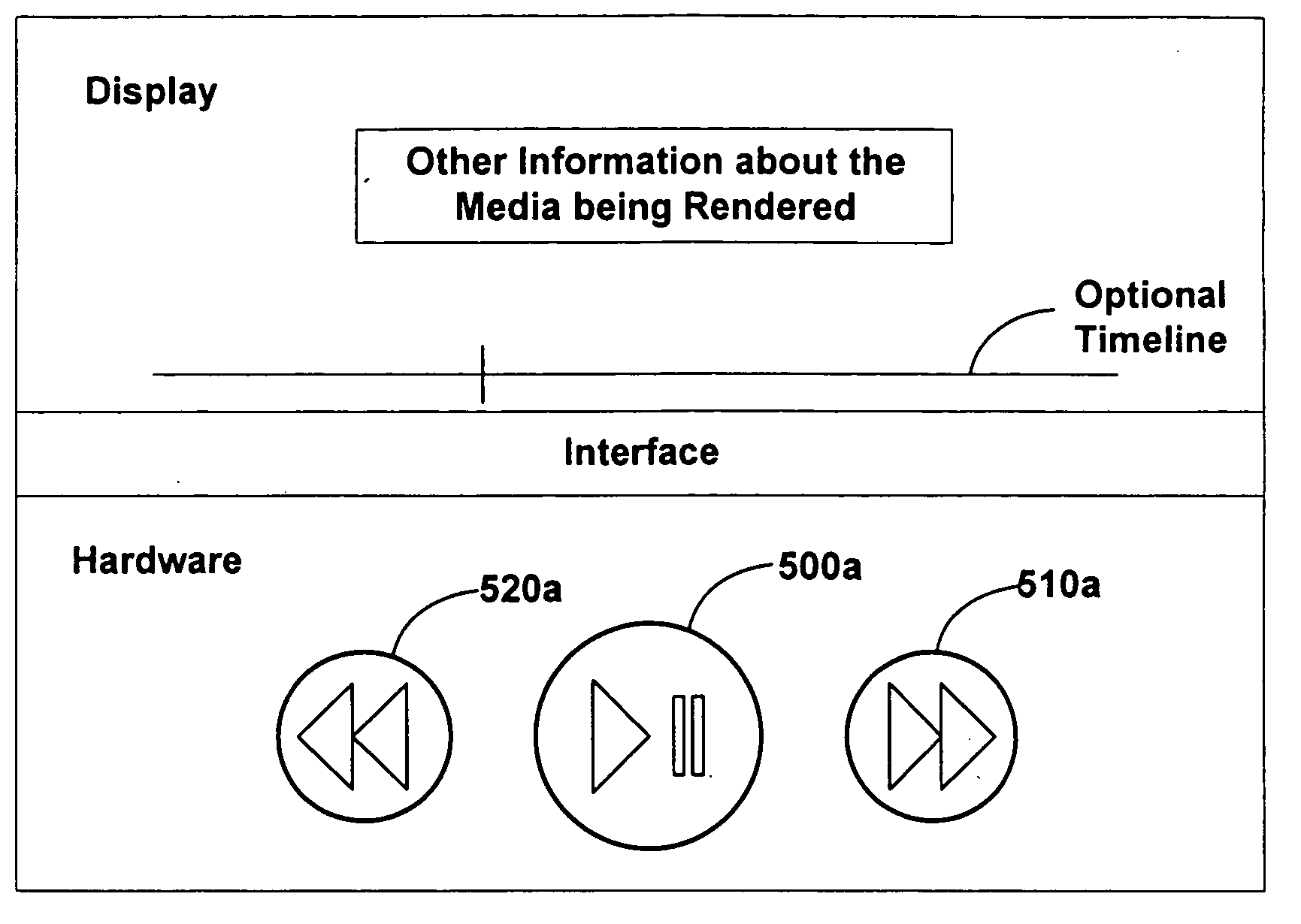

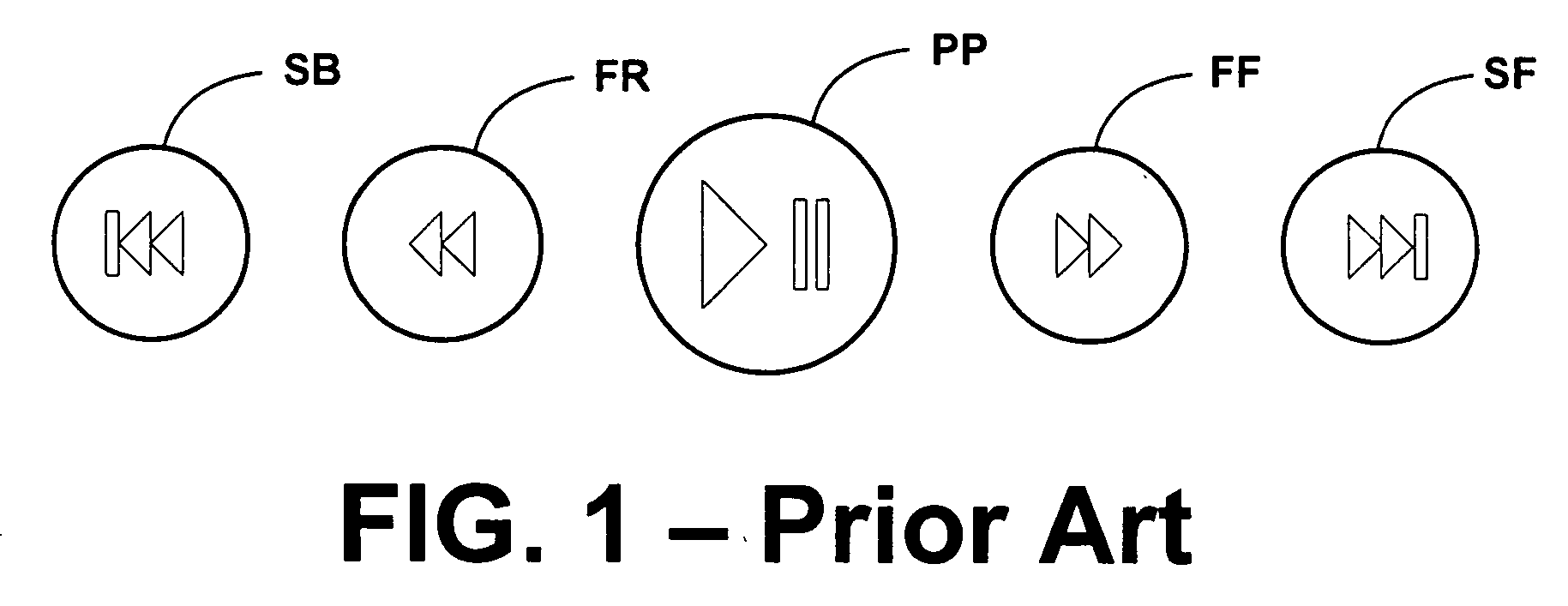

Systems and methods for interacting with a user interface of a media player

ActiveUS20050146534A1Reduce in quantityReduce equipment costsRecord information storageCathode-ray tube indicatorsComputer graphics (images)Computer science

Systems and methods for interfacing with playback of media by a media player are provided. By combining the functionality of fast forward and skip forward into a single button control, the invention reduces the numbers of control buttons that need be included on a device, reducing device costs and consumer “button overload.” In one embodiment, by pressing (and releasing) a forward button, media being rendered by a media player skips to a predetermined location in the media. By pressing and holding (and then releasing) the forward button, the media being rendered is fast forwarded according to algorithms for fast forwarding. A backward button covers skipping backward and fast reversing in a similar fashion. A device including a play / pause button and the described forward and backward buttons advantageously reduces the number of buttons required by two buttons.

Owner:MICROSOFT TECH LICENSING LLC

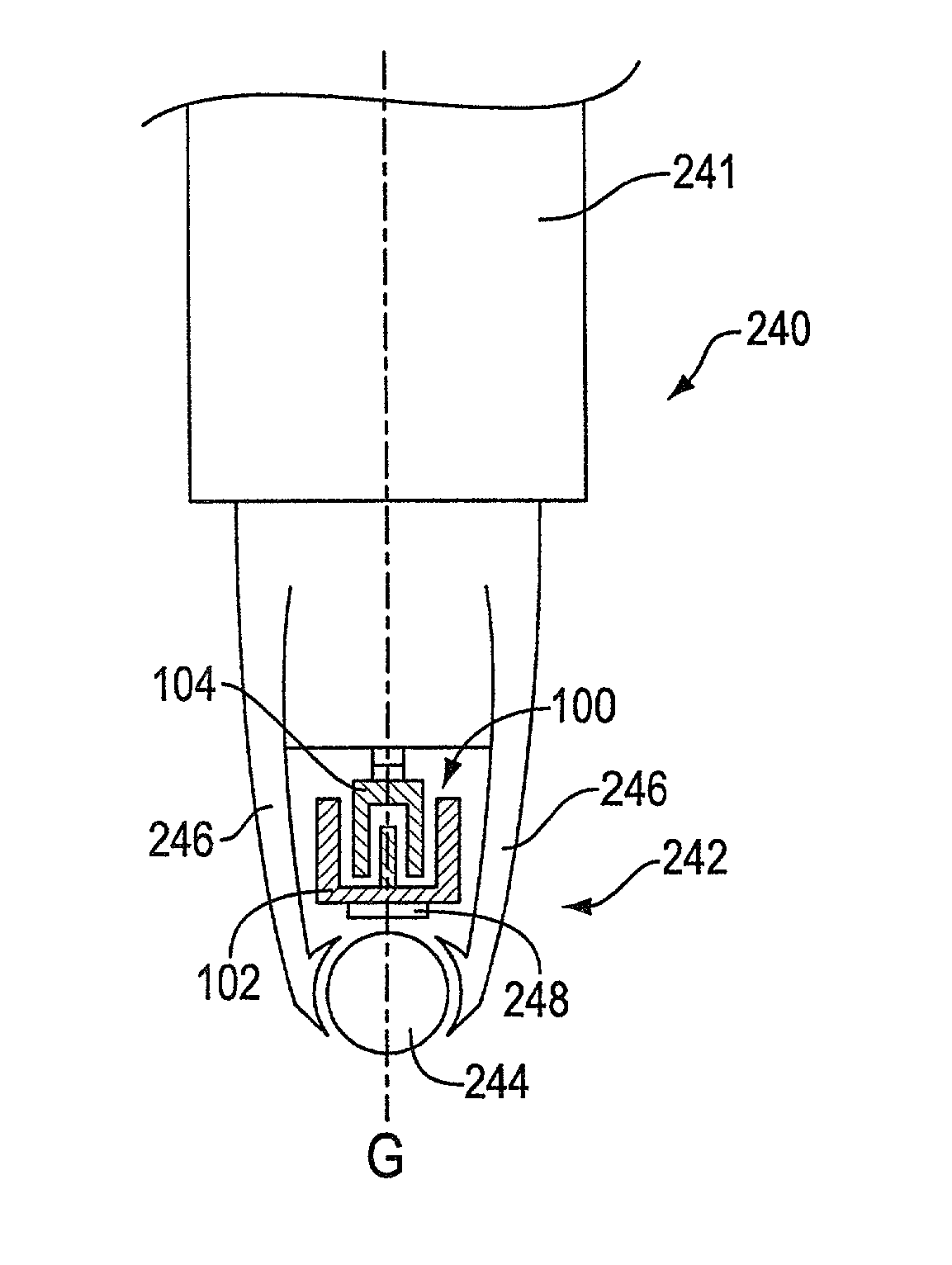

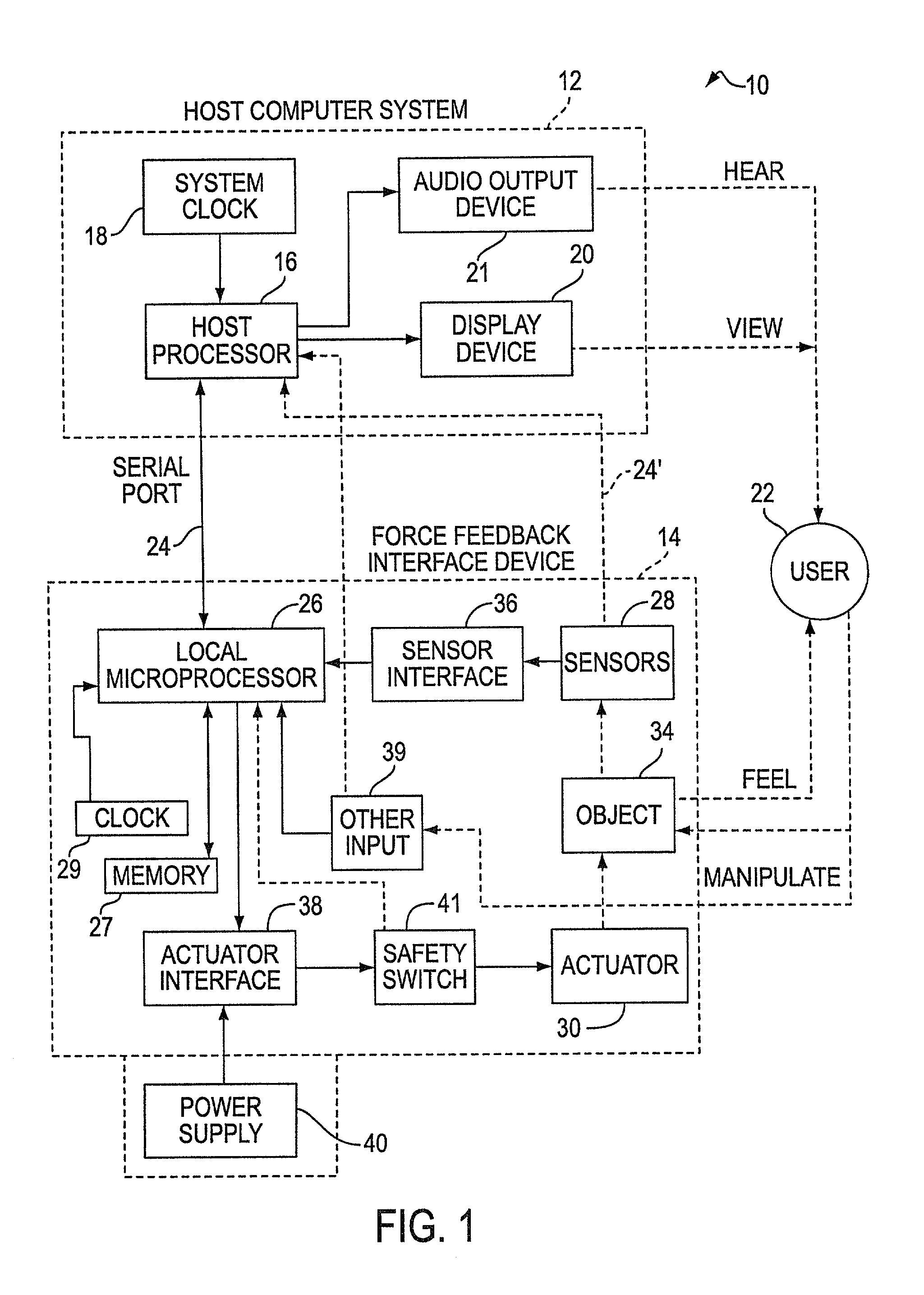

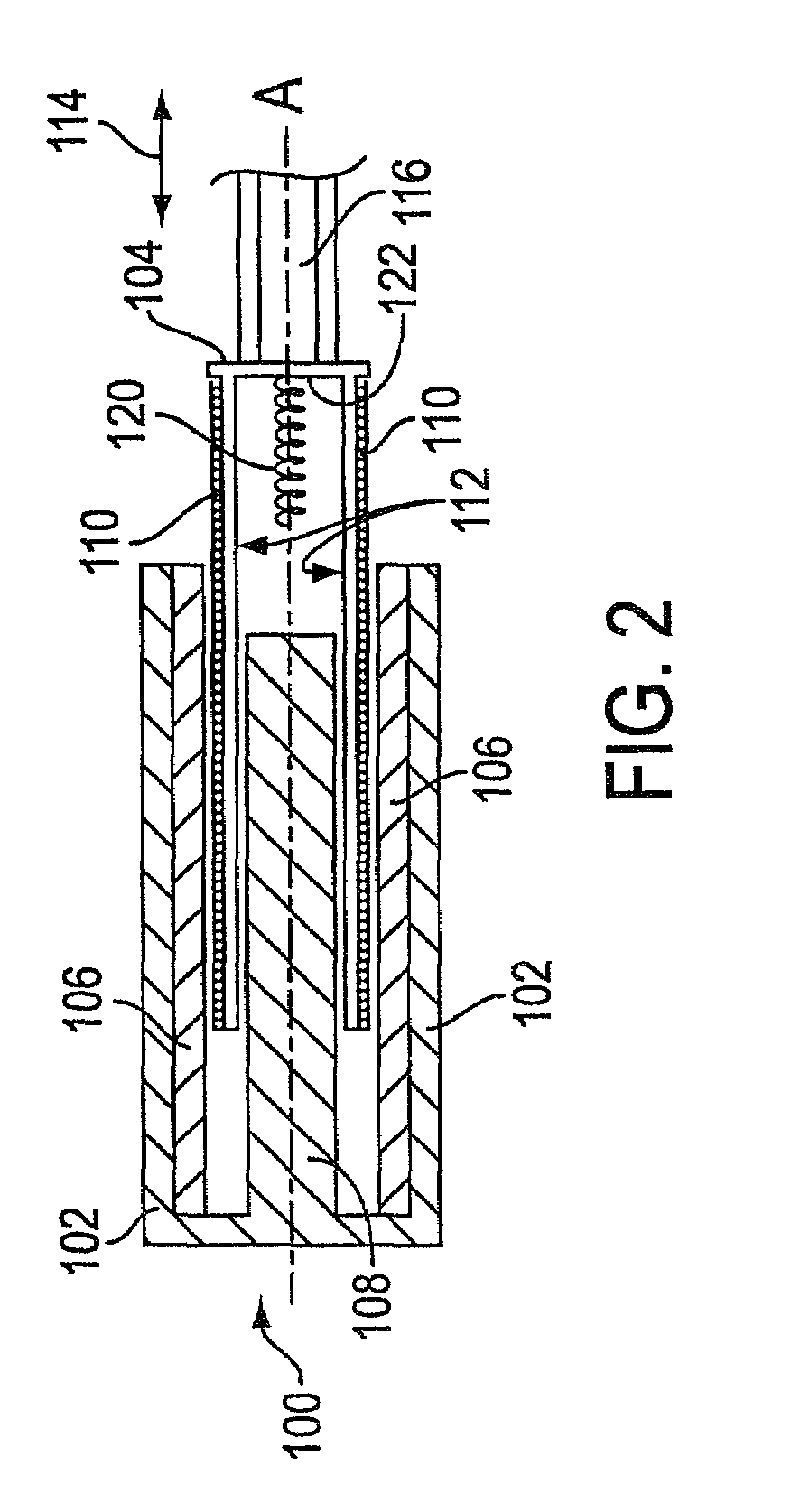

Haptic feedback stylus and other devices

InactiveUS7265750B2Low costSimpler and low force feedbackInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsTouch Perception

A force feedback interface and method including an actuator in a non-primary axis or degree of freedom. The force feedback interface device is connected to a host computer that implements a host application program or graphical environment. The interface device includes a user manipulatable object, a sensor for detecting movement of the user object, and an actuator to apply output forces to the user object. The actuator outputs a linear force on the user object in non-primary linear axis or degree of freedom that is not used to control a graphical object or entity implemented by the host computer, and movement in the non-primary degree of freedom is preferably not sensed by sensors. The axis extends through the user object, and there are preferably no other actuators in the device, thus allowing the force feedback device to be very cost effective. Force sensations such as a jolt, vibration, a constant force, and a texture force can be output on the user object with the actuator. The force sensations can be output in a direction perpendicular to a planar degree of freedom, radial to spherical degree of freedom, and / or along a lengthwise axis of the user object.

Owner:IMMERSION CORPORATION

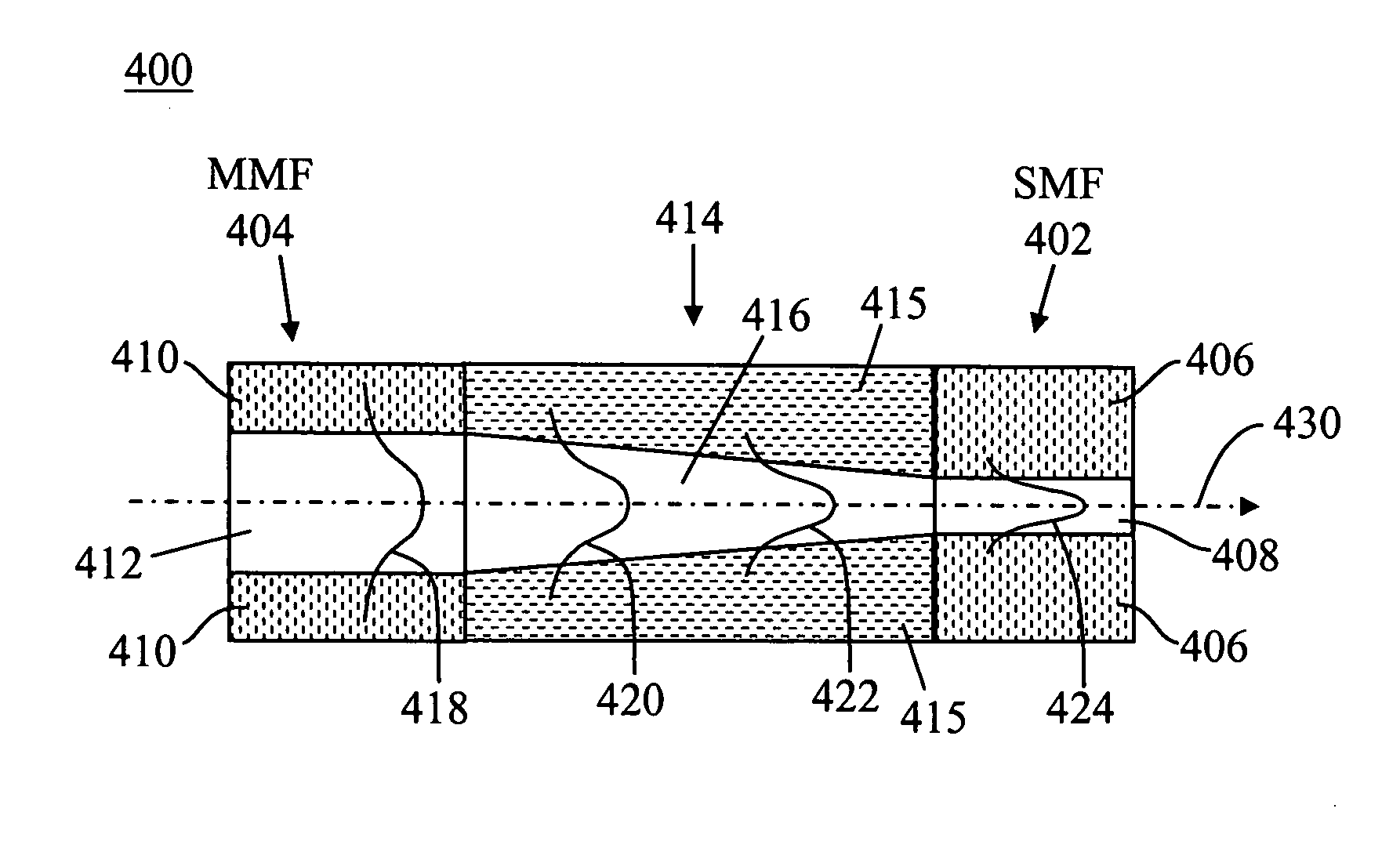

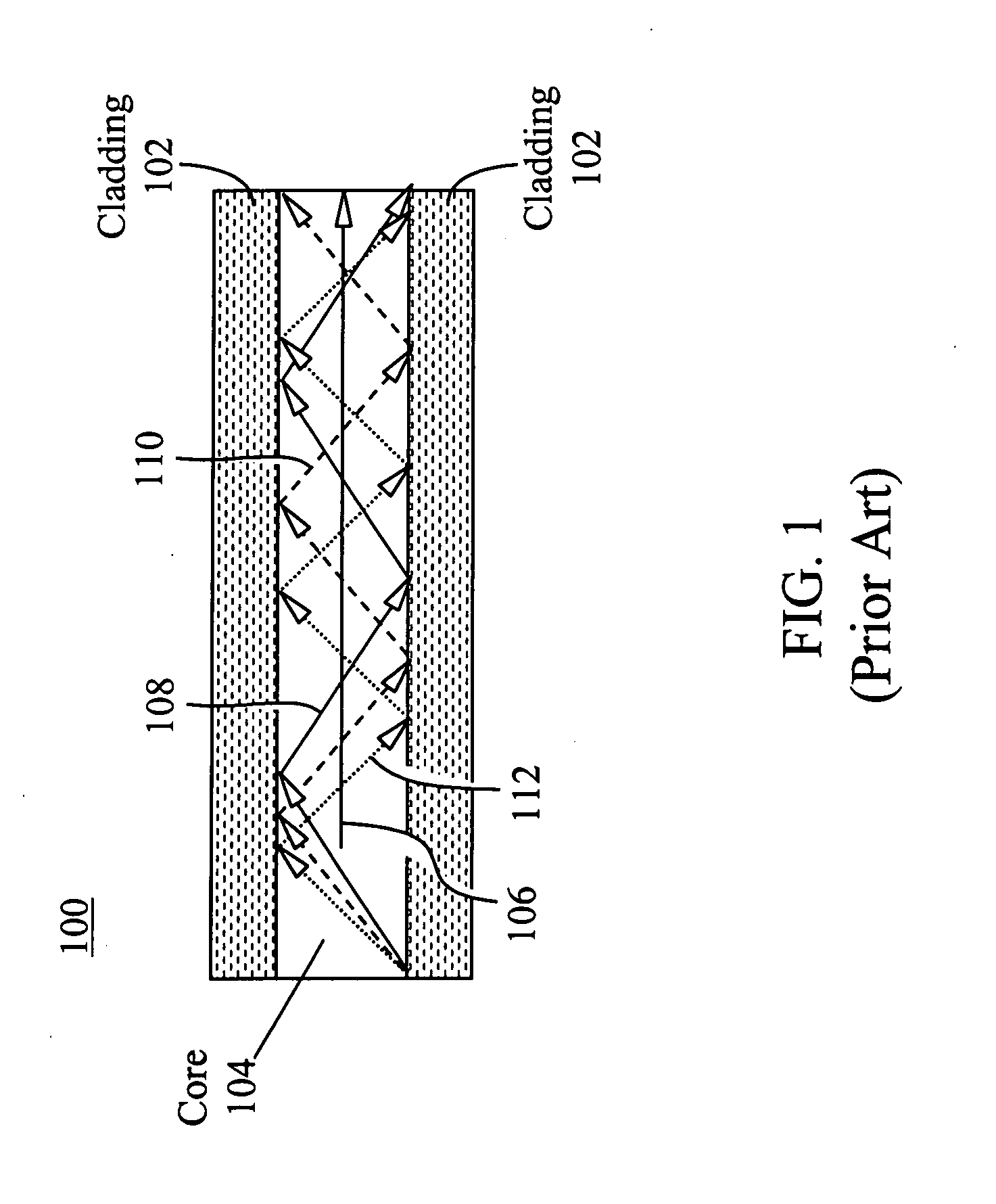

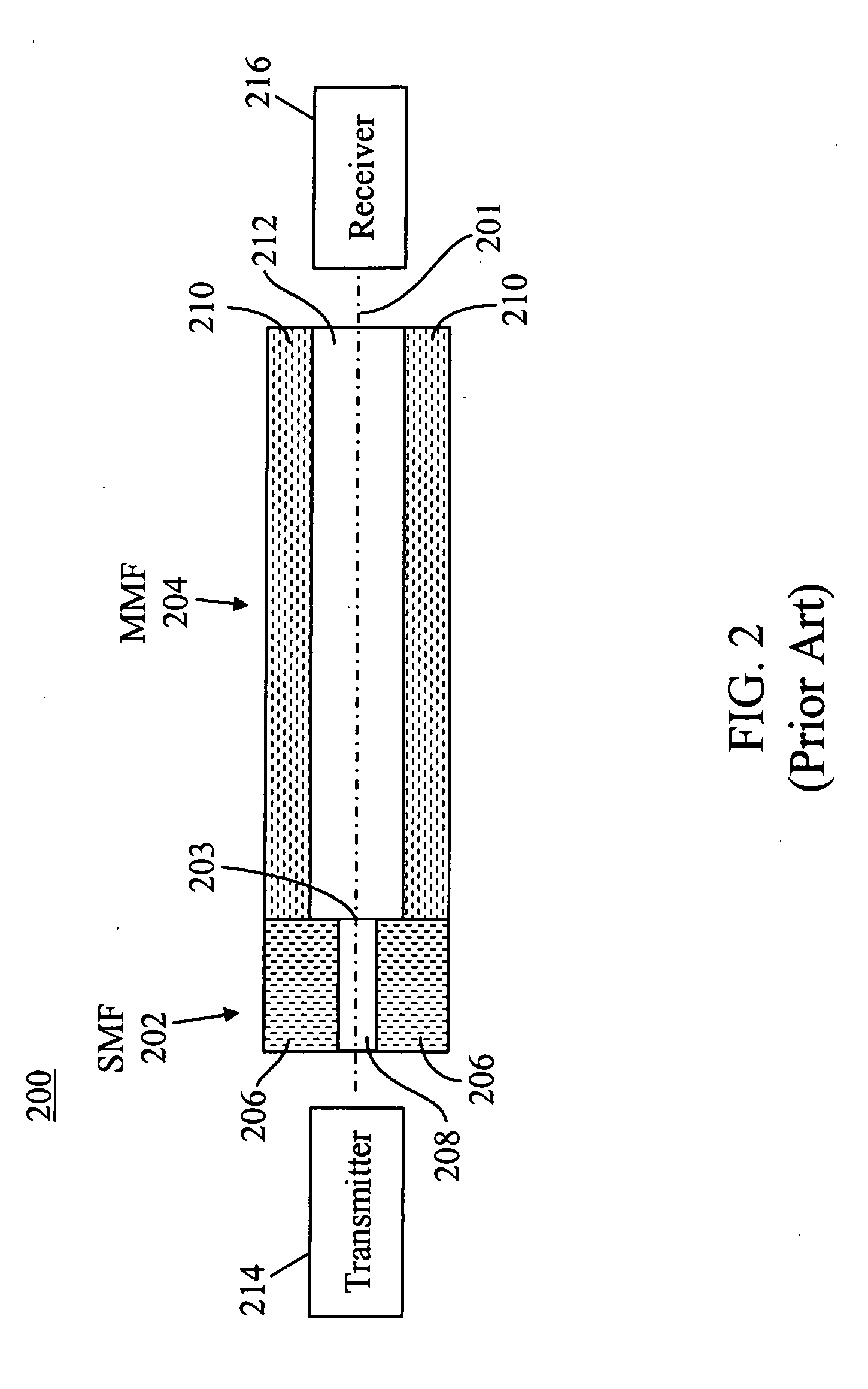

Apparatus, system and method for an adiabatic coupler for multi-mode fiber-optic transmission systems

InactiveUS20050265653A1Low insertion lossIncrease system bandwidthLaser detailsOptical fibre with graded refractive index core/claddingFiberRefractive index

An improved fiber-optic communications system comprises a multi-mode waveguide carrying an optical signal, a single-mode waveguide optically coupled to and receiving the optical signal from the multi-mode waveguide and an adiabatic coupler optically coupled between the multi-mode waveguide and the single-mode waveguide. The multi-mode and single-mode waveguides may be optical fibers. The adiabatic coupler may comprise a tapered core surrounded by a cladding. Alternatively, the adiabatic coupler may comprise a core surrounded by a cladding, wherein the refractive index of at least one of the core and the cladding varies over the length of the adiabatic coupler.

Owner:OCLARO NORTH AMERICA

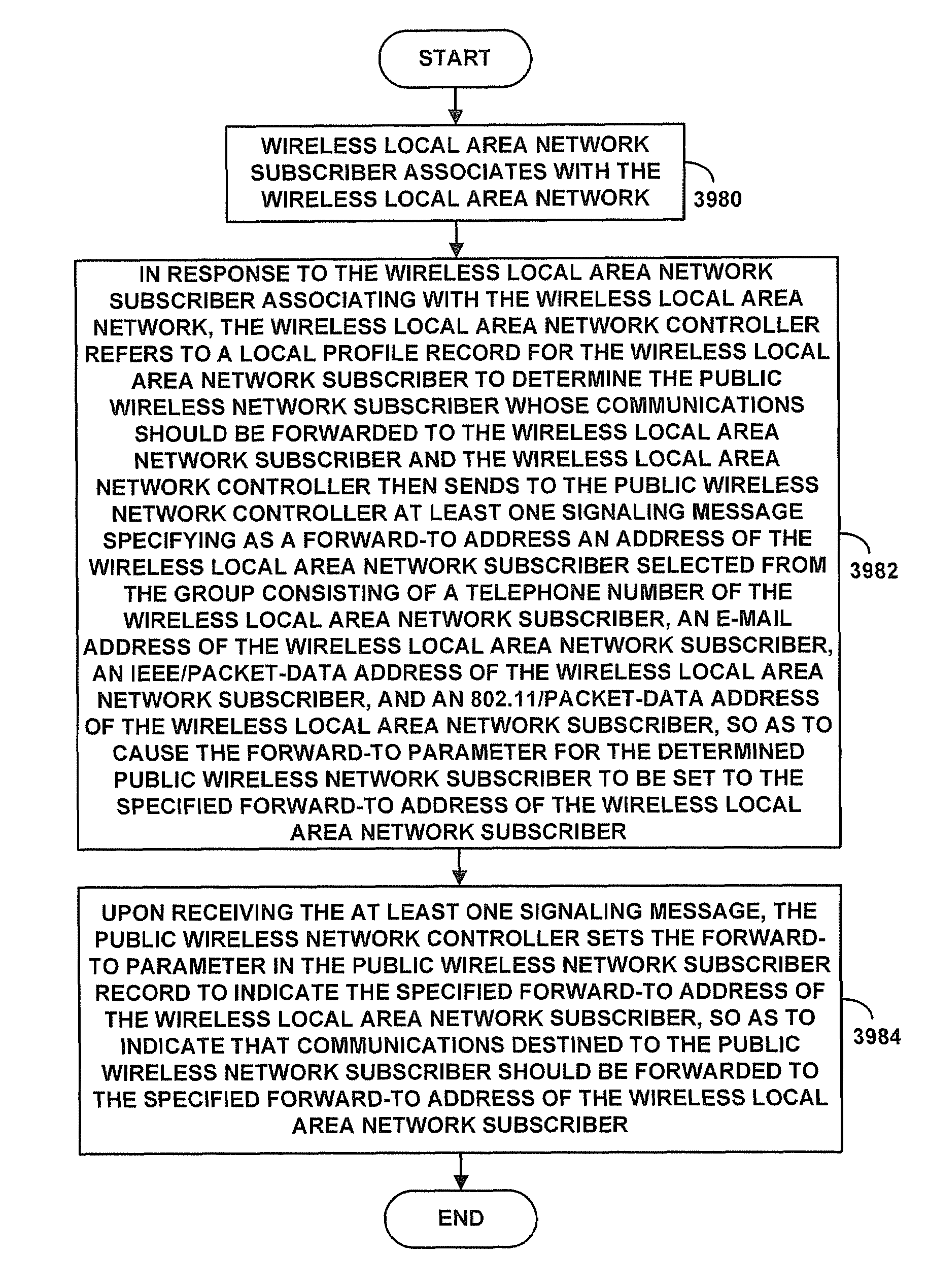

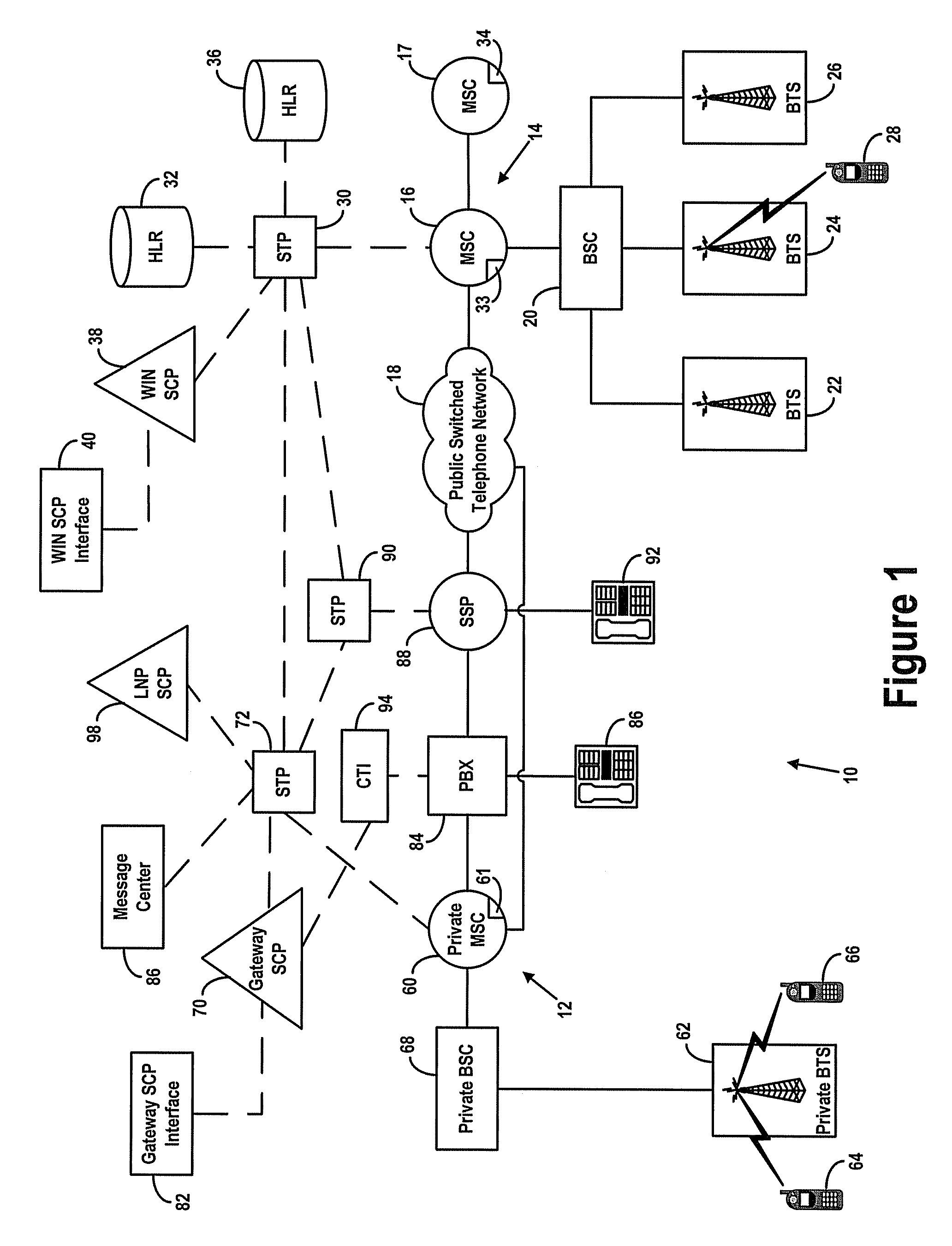

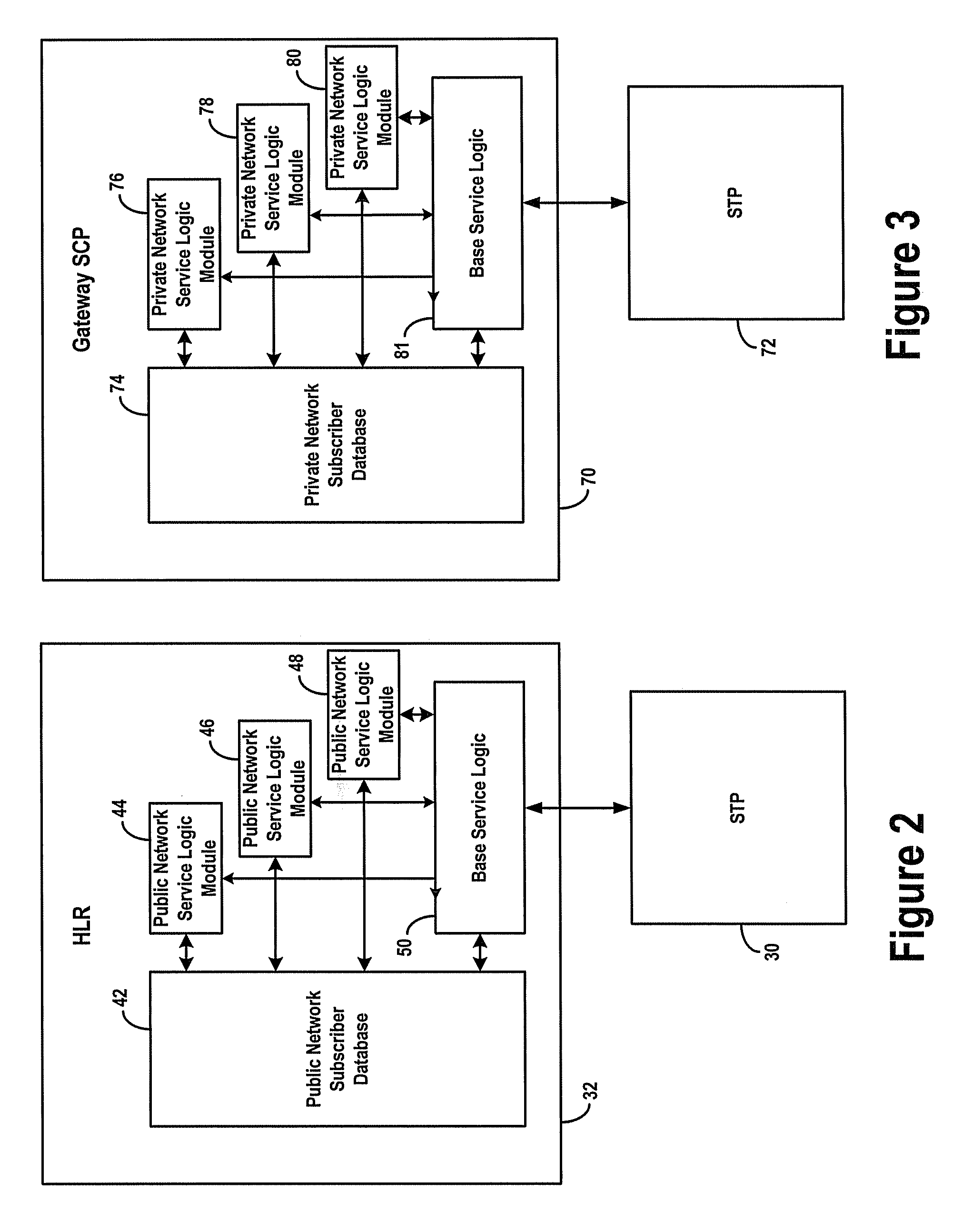

Method and system for diverting wireless network communications

InactiveUS7356001B1Increase data rateSuperior building coverageMultiplex system selection arrangementsNetwork topologiesService profilePrivate network

A private wireless network is able to provide wireless telecommunication services to subscriber mobile stations that also subscribe to a public wireless network. The private wireless network includes a private base transceiver station (BTS), a private mobile switching center (MSC), and a gateway service control point (SCP). The private BTS provides a private network wireless coverage area within which the mobile station can communicate with the base transceiver station over an air interface. The gateway SCP has a private network database containing private network data records for subscribing mobile stations. A private network data record includes a private network service profile and a private network locator address. The public wireless network has a home location register (HLR) with a public network database containing public network data records for subscribing mobile stations. A public network data record includes a public network service profile and a public network locator address. When a subscriber mobile station is active on the private wireless network, the private network locator address identifies the private MSC, and the public network locator address identifies the gateway SCP. By providing the private network wireless coverage area so that it overlaps the public network's wireless coverage area, the subscriber mobile station may be handed off between the private and public wireless networks.

Owner:SPRINT SPECTRUM LLC

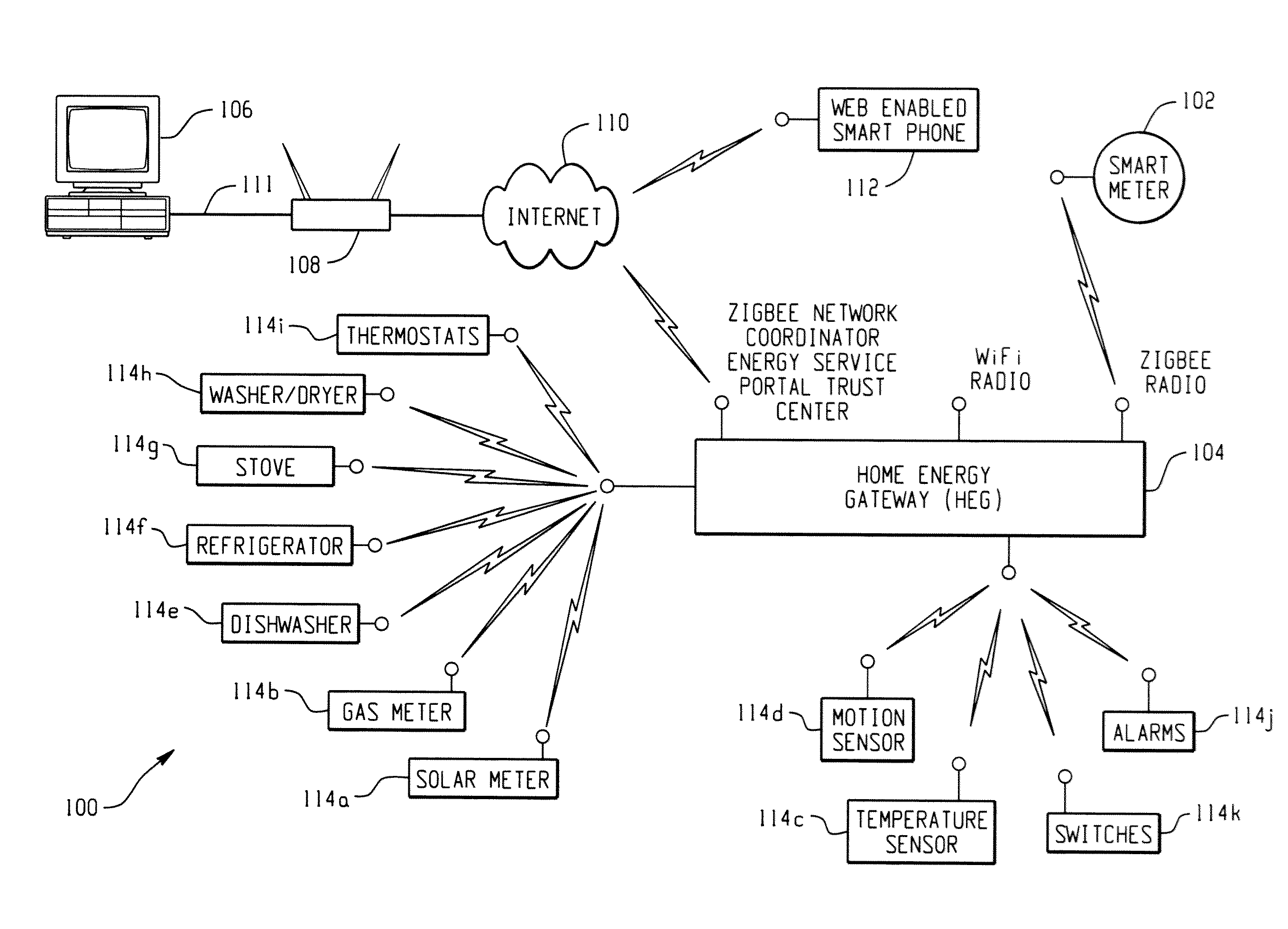

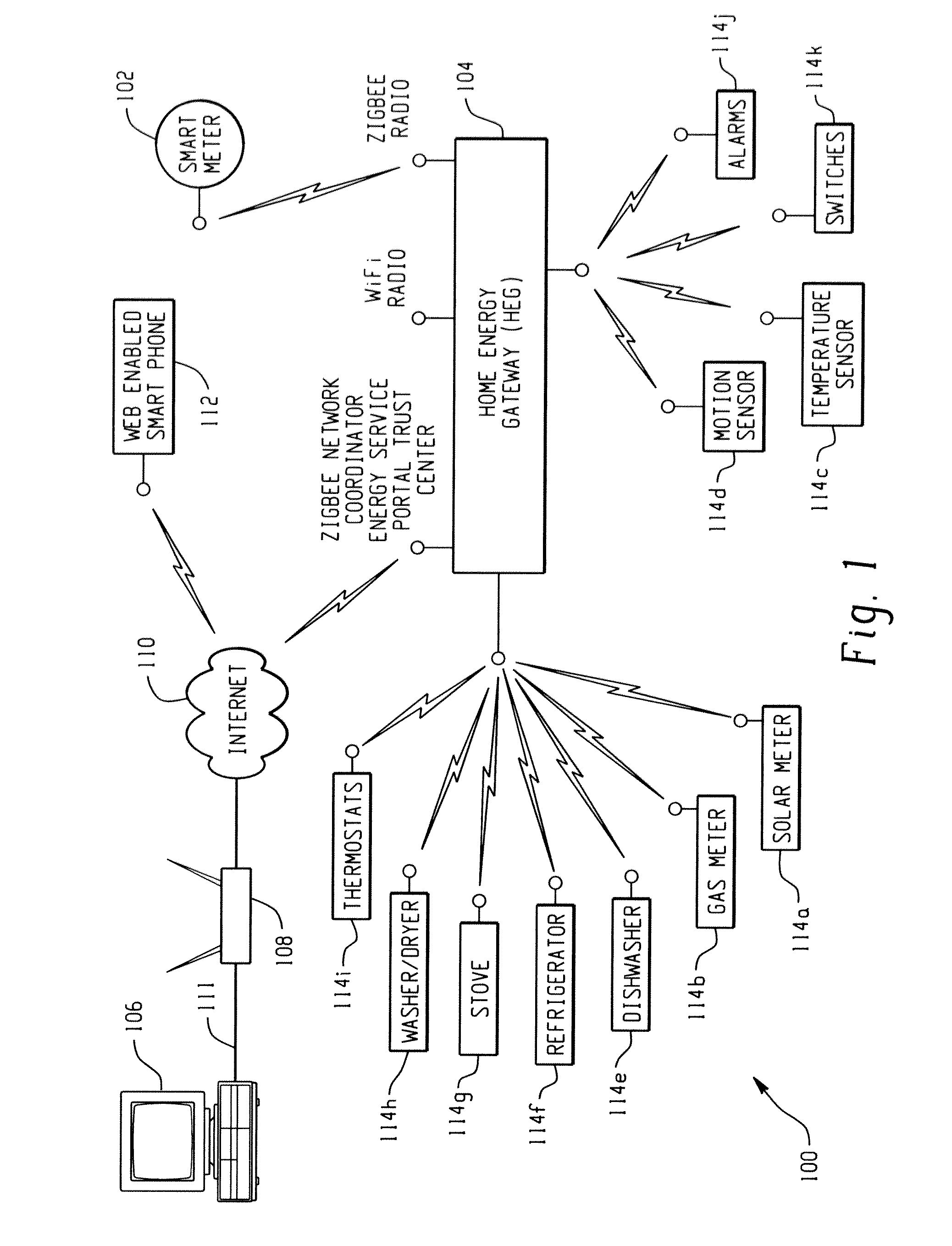

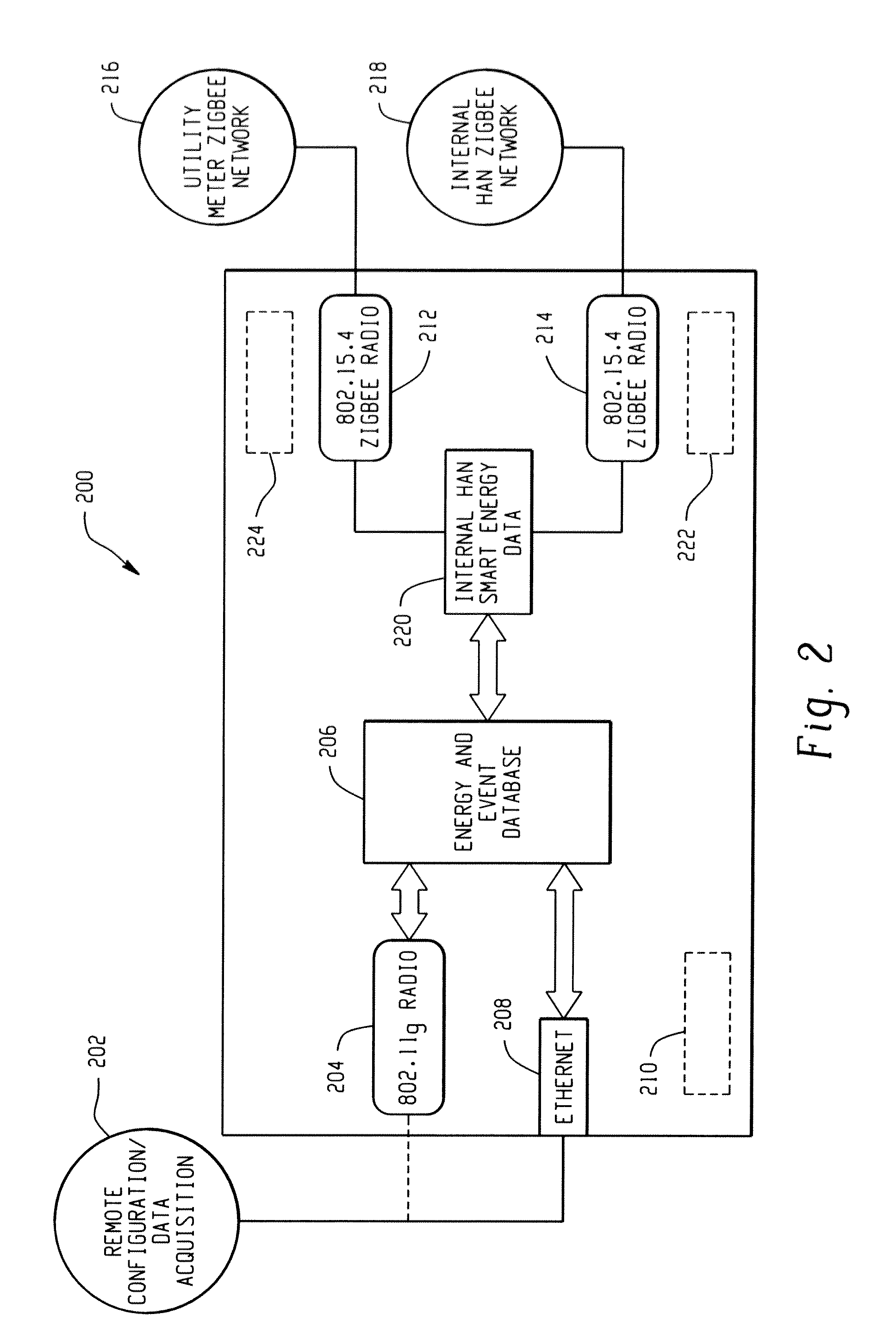

Low cost home energy manager adaptor

InactiveUS20110202195A1Low costMinimize the numberMechanical power/torque controlLevel controlComputer moduleEnergy depletion

A home energy management (HEM) device for use in a HEM system including a plurality of energy consuming devices and a HEM gateway adaptor module connectable to a host device. The home energy gateway (HEG) module is configured to utilize services / components of existing household electronics. Accordingly, a HEM device for controlling a plurality of energy consuming devices in a HEM network comprises a host device having hardware for performing at least one service, and a HEG adaptor module connectable to the host device, the HEG module including at least a home energy usage database for storing data related to usage of energy consuming devices in the home energy management network. The HEG module is configured to utilize at least one service of the host to carry out at least one function related to controlling the plurality of energy consuming devices.

Owner:HAIER US APPLIANCE SOLUTIONS INC

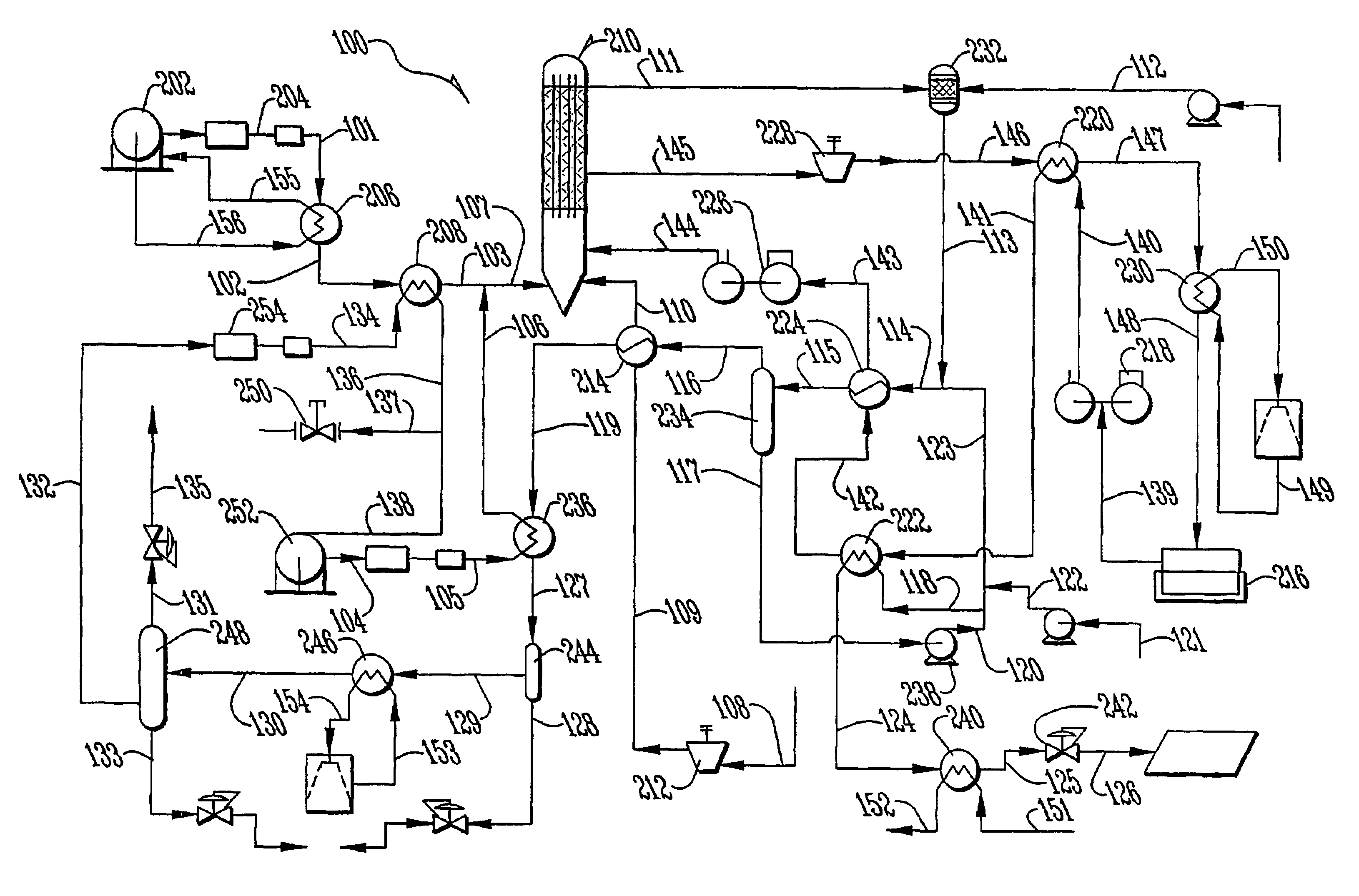

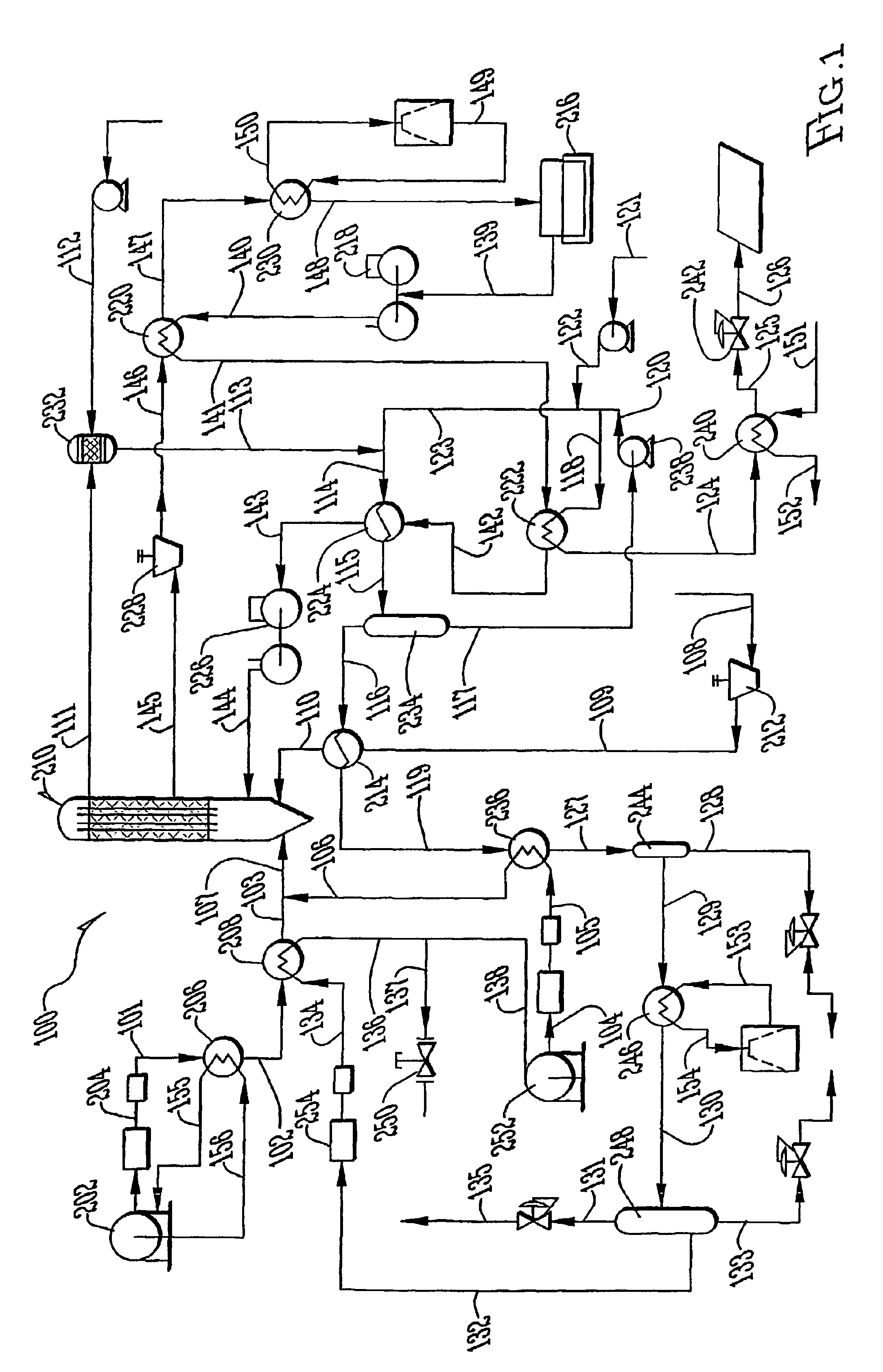

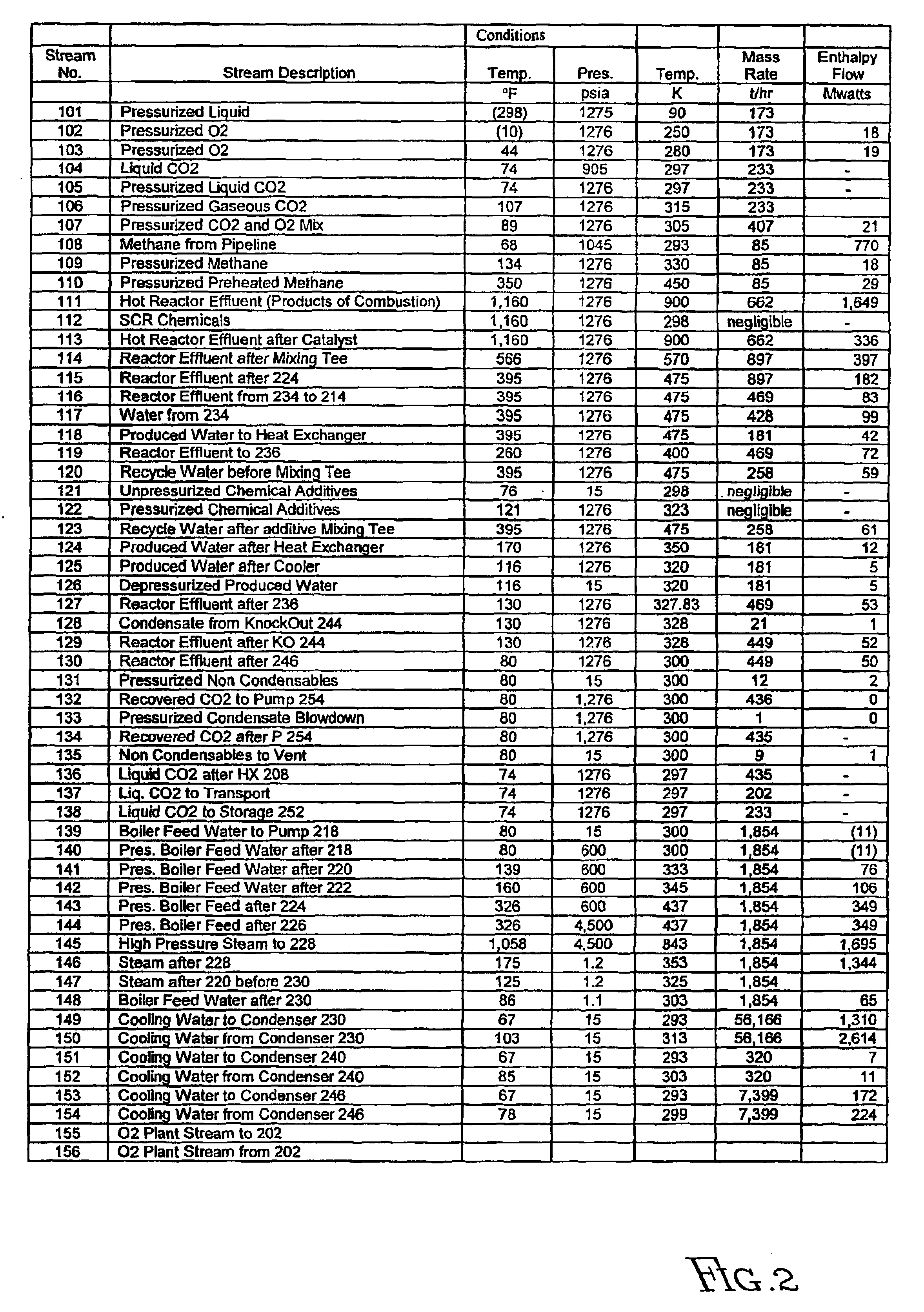

Power system with enhanced thermodynamic efficiency and pollution control

InactiveUS6918253B2Reduce equipment costsReduce wearSteam generation using pressureSteam useCondensed waterPressure range

An elevated pressure power plant (100) for cleanly and efficiently oxidizing, gasifying or combusting a fuel. The fuel is oxidized or gasified in a reaction chamber (210) at a pressure range from approximately 700 psia to 2000 psia, or from approximately 850 psia to 1276 psia. Products of combustion from the chamber may be passed to a heat exchanger (224). A portion of the condensed water may be recycled to the products of combustion upstream of the heat exchanger. Also, before being passed to the reaction chamber, the coolant may be routed through the heat exchanger in a two-step pressure fashion.

Owner:THERMOENERGY POWER SYST

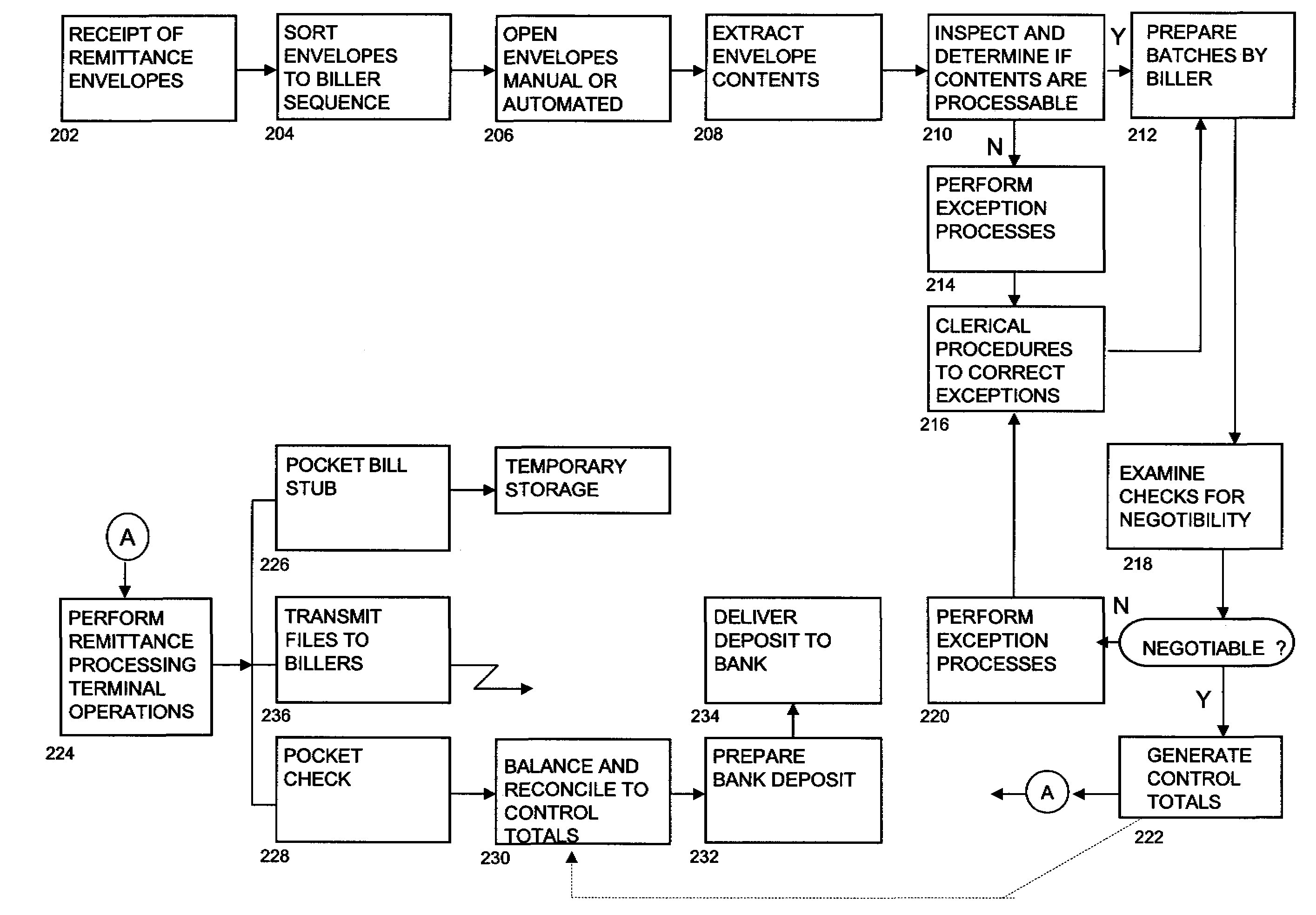

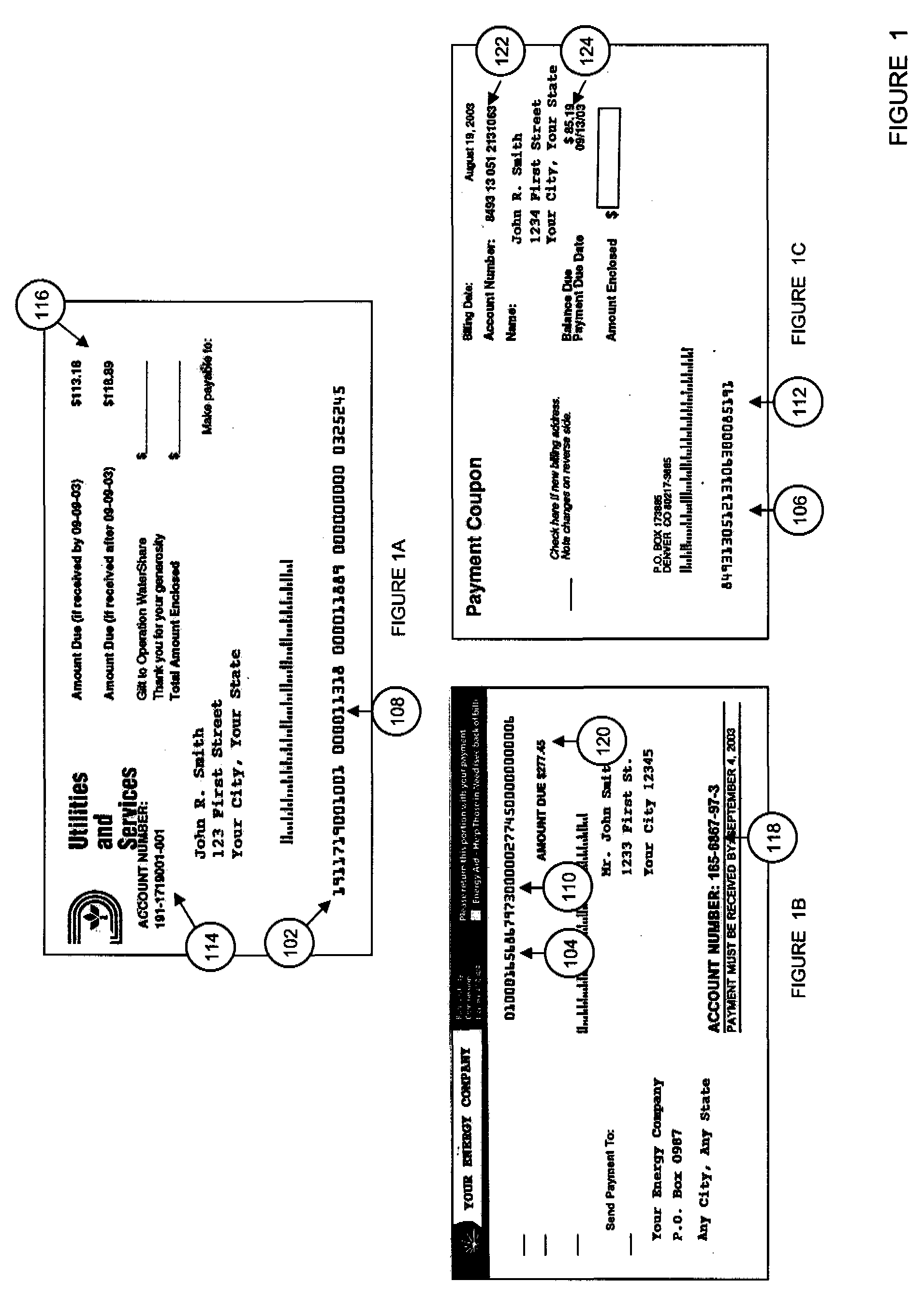

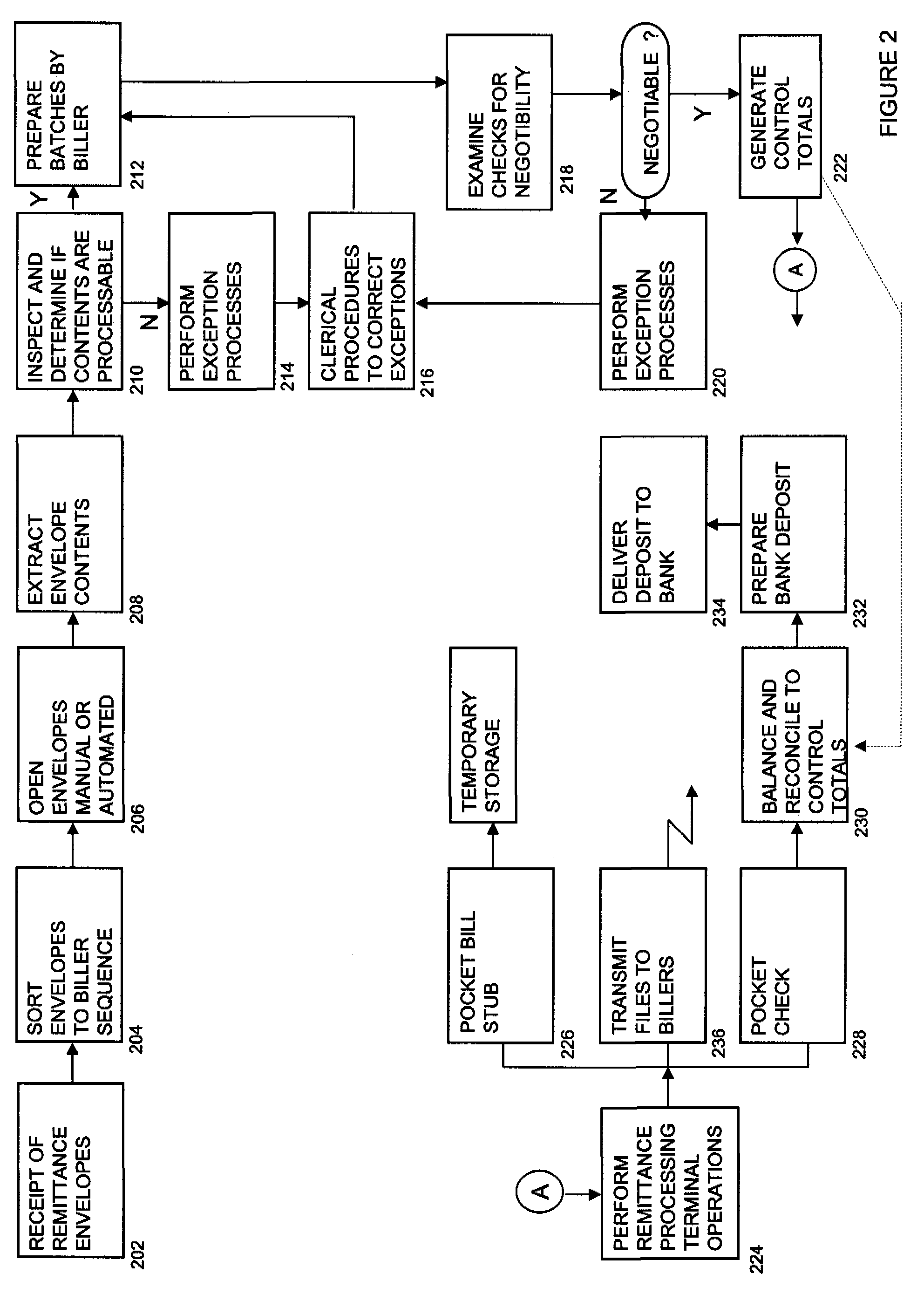

System and Method for Commingled Remittance Payment Processing

InactiveUS20050065893A1Improve productivityReduce equipment costsFinancePayment architectureDigital imageComputer science

A system and method for processing payment materials having at least one side with payment information, comprising providing a database having at least one electronic template having biller information specific to a biller, scanning the side of the payment materials to create a digital image, parsing the digital image for the payment information; and matching the payment information with the biller information.

Owner:THE ALLIANCE GROUP OF TEXAS

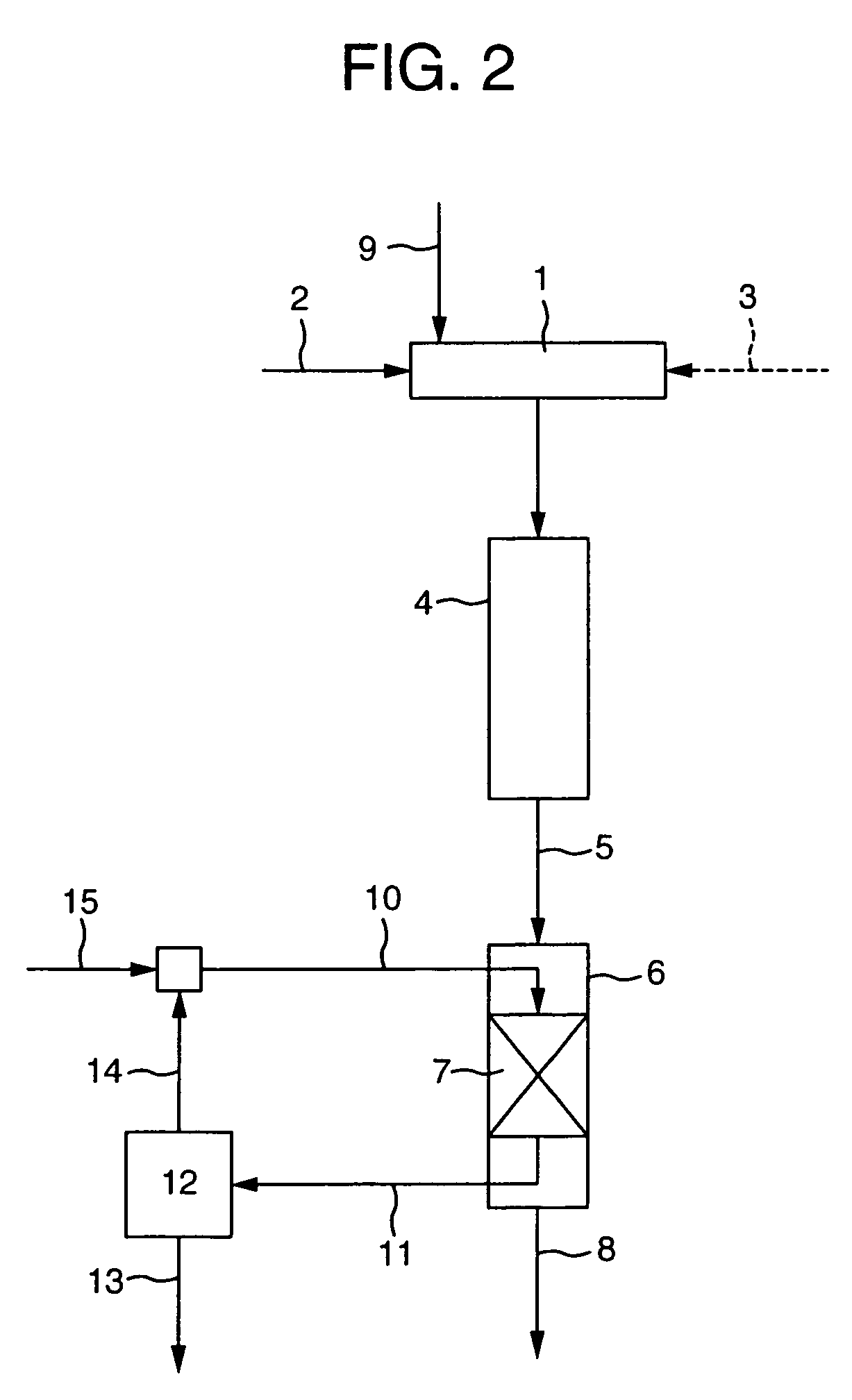

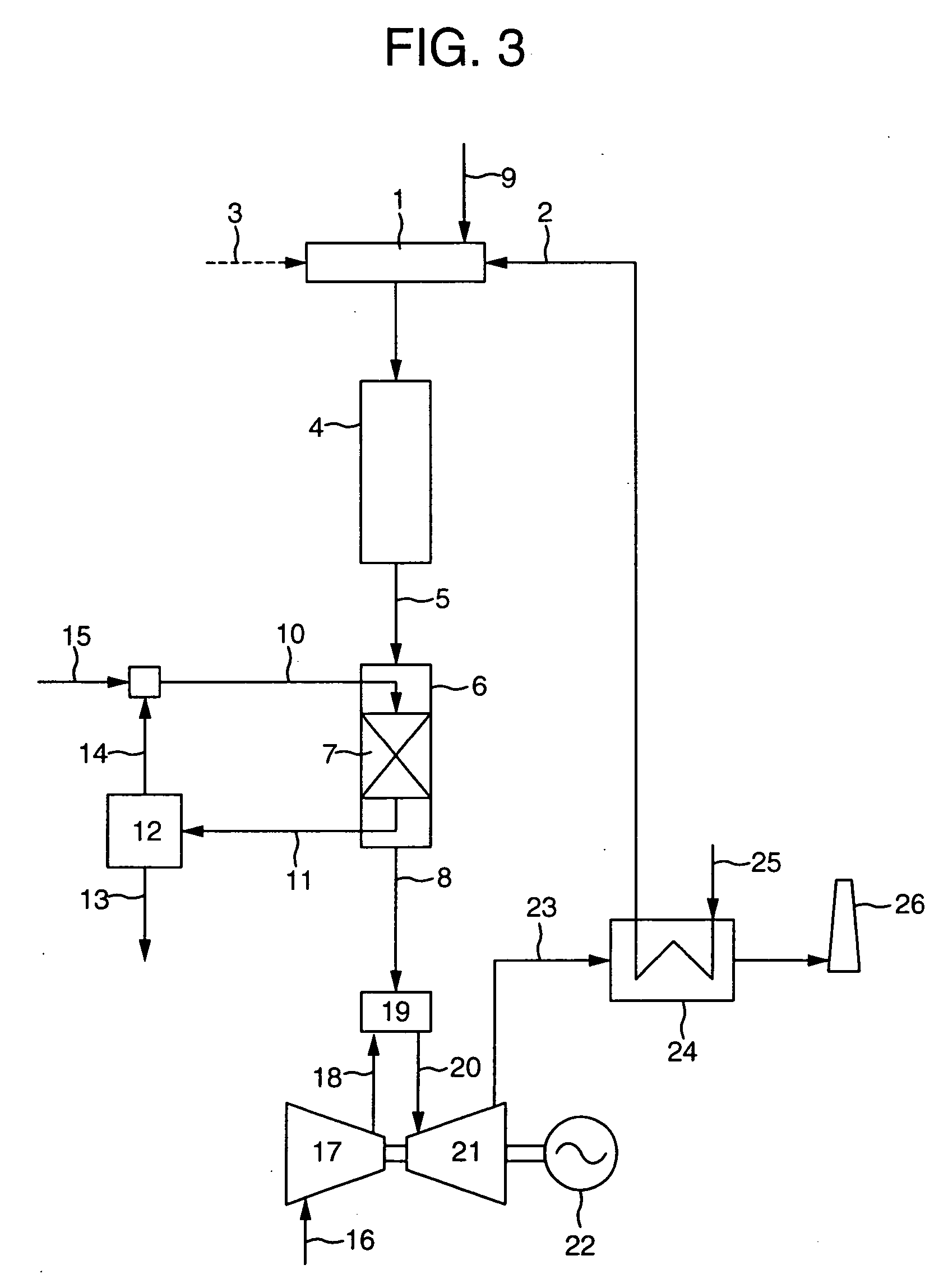

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

InactiveUS20060011511A1Reduce equipment costsReduce runningThermal non-catalytic crackingHydrogenScavengerCombustor

Owner:HOKARI NOBUYUKI +4

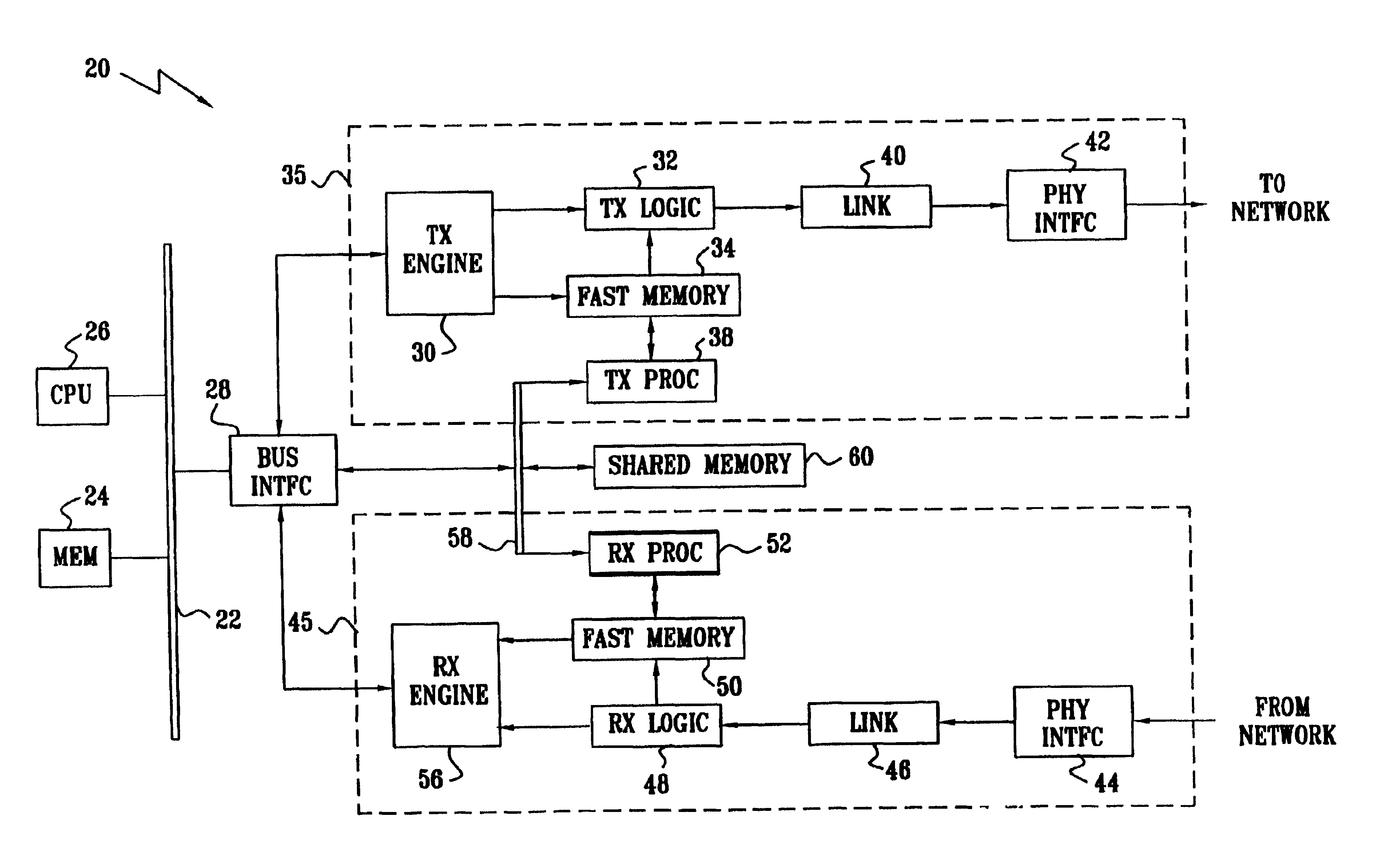

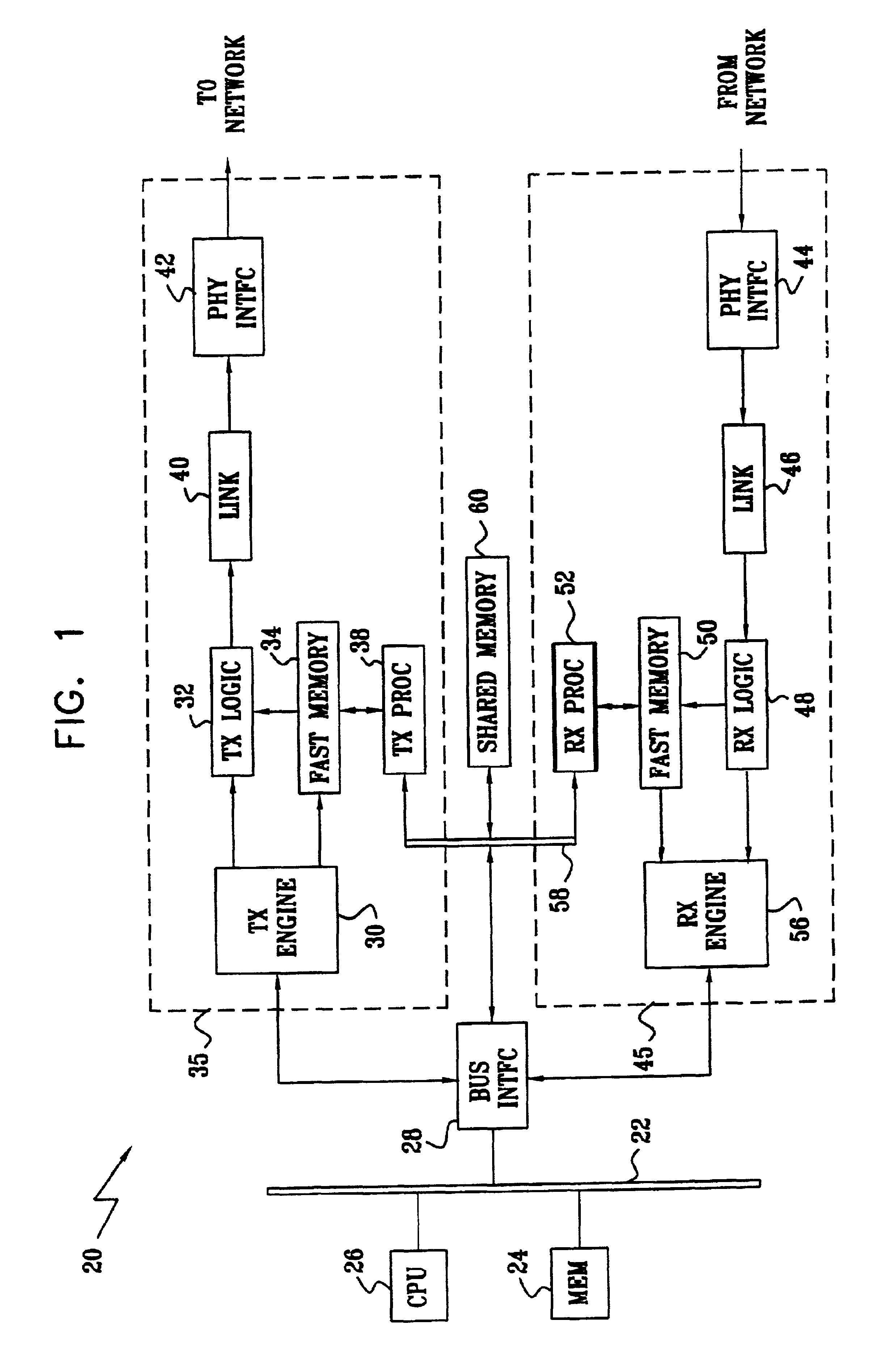

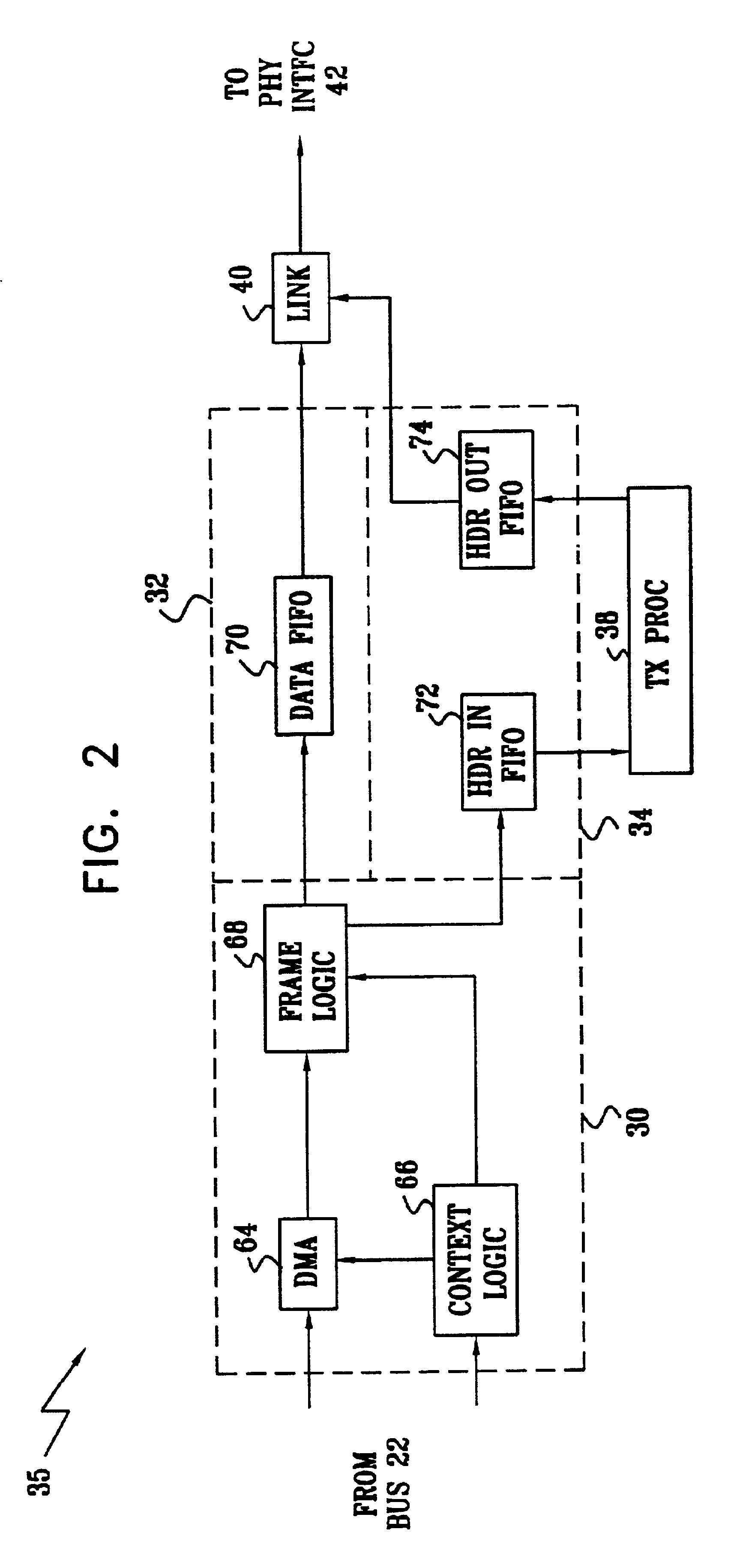

Network adapter with embedded deep packet processing

InactiveUS6947430B2Raise transfer toIncrease speedTime-division multiplexData switching by path configurationProtocol processingNetwork interface device

A network interface device includes host interface logic, arranged to receive from a host processor a frame of outgoing data that includes outgoing header information and outgoing payload data, and to separate the header information from the payload data. A transmit protocol processor is coupled to read and process the outgoing header information from the outgoing header memory so as to generate at least one outgoing packet header in accordance with a predetermined network protocol. Transmit logic is coupled to receive and associate the at least one outgoing packet header with the outgoing payload data from the outgoing data memory, so as to generate at least one outgoing data packet for transmission over a network in accordance with the protocol.

Owner:IBM CORP

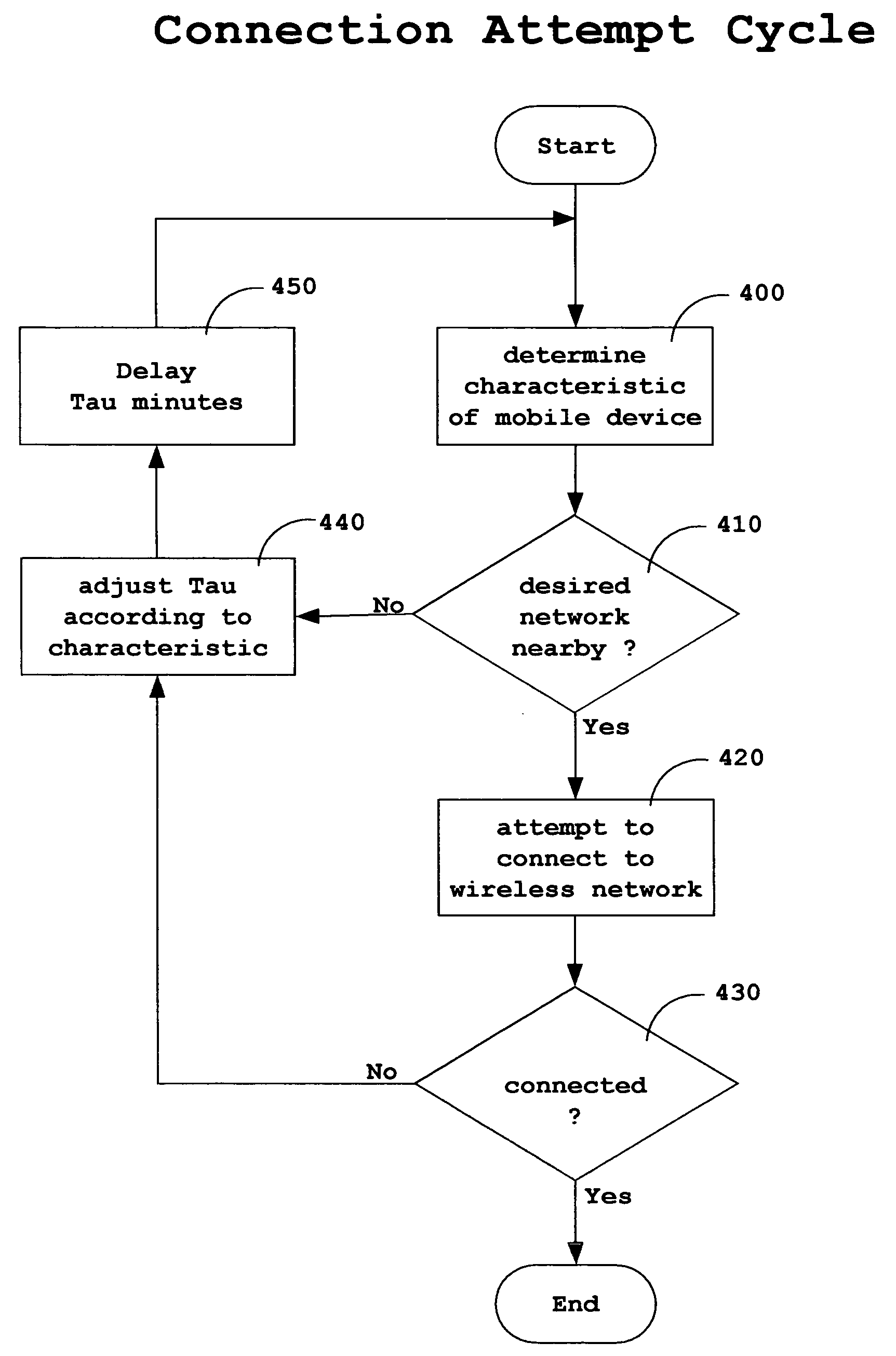

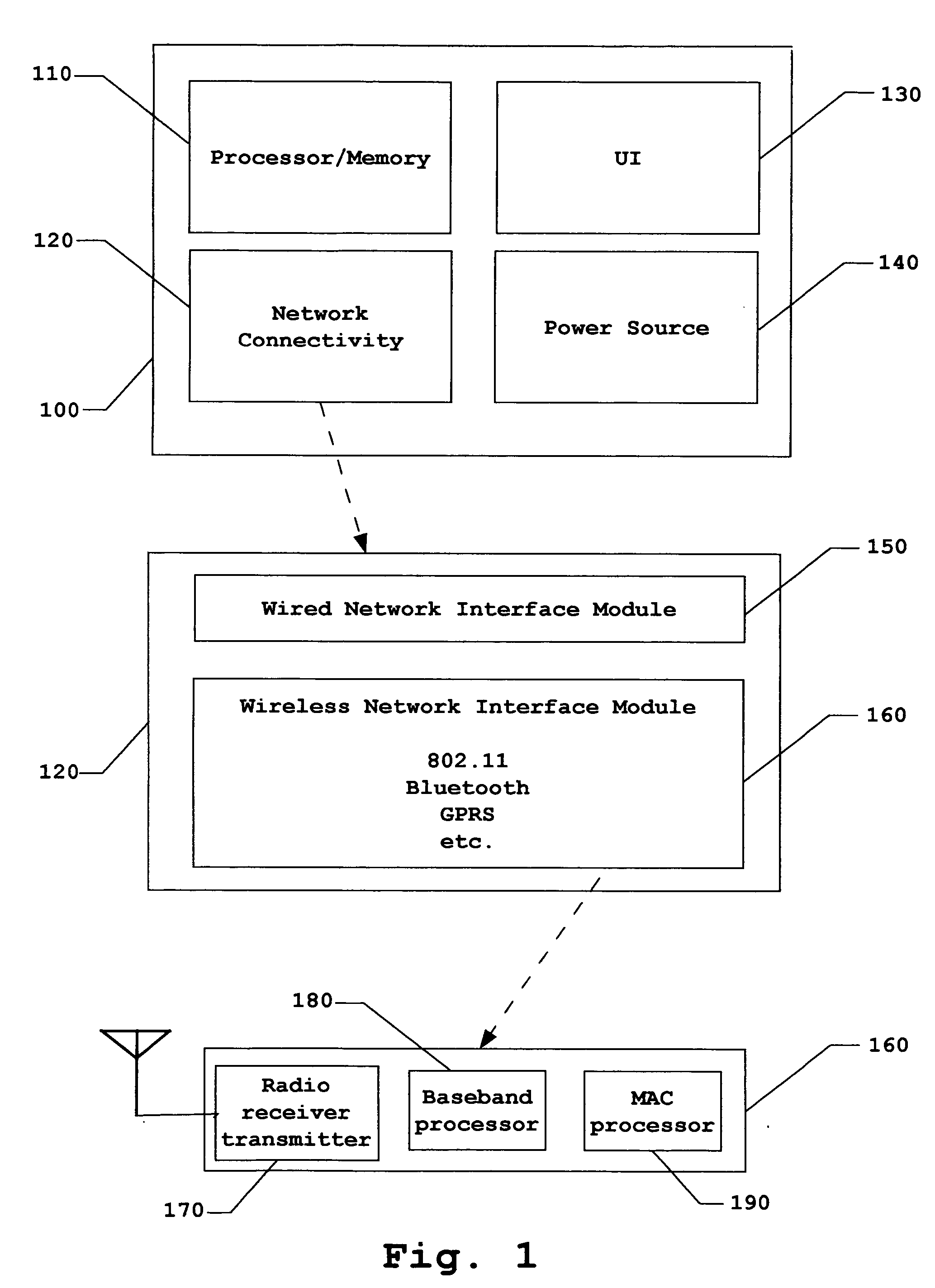

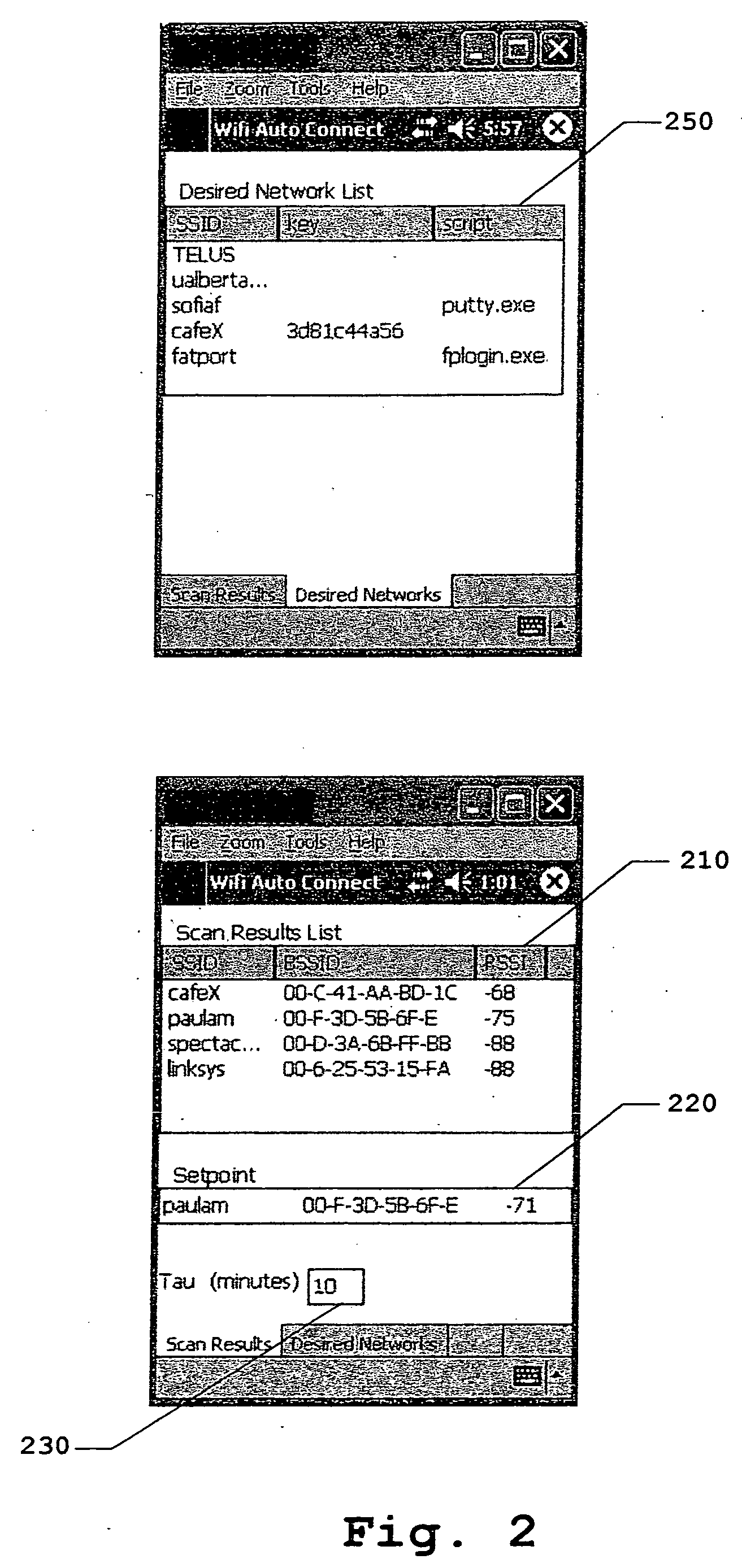

Automatic connection of a mobile device to a wireless network

InactiveUS20050181734A1Extension of timeReduce exposurePower managementAssess restrictionNetwork connectionMobile device

A novel method for automatically connecting a mobile device to a wireless network is presented. The goal of the automatic connection of a mobile device to a wireless network is to provide a rapid wireless network connection for a mobile device when it comes into range of a desired network while reducing rf emissions when the mobile device is not in range of a desired wireless network. The method focuses on adjusting the time between network connection attempts when the mobile device is not connected to a network. The method increases the time between network connection attempts when the mobile device is stationary and decreases the time between network connection attempts when the mobile device is moving.

Owner:KNIGHTSBRIDGE WIRELESS

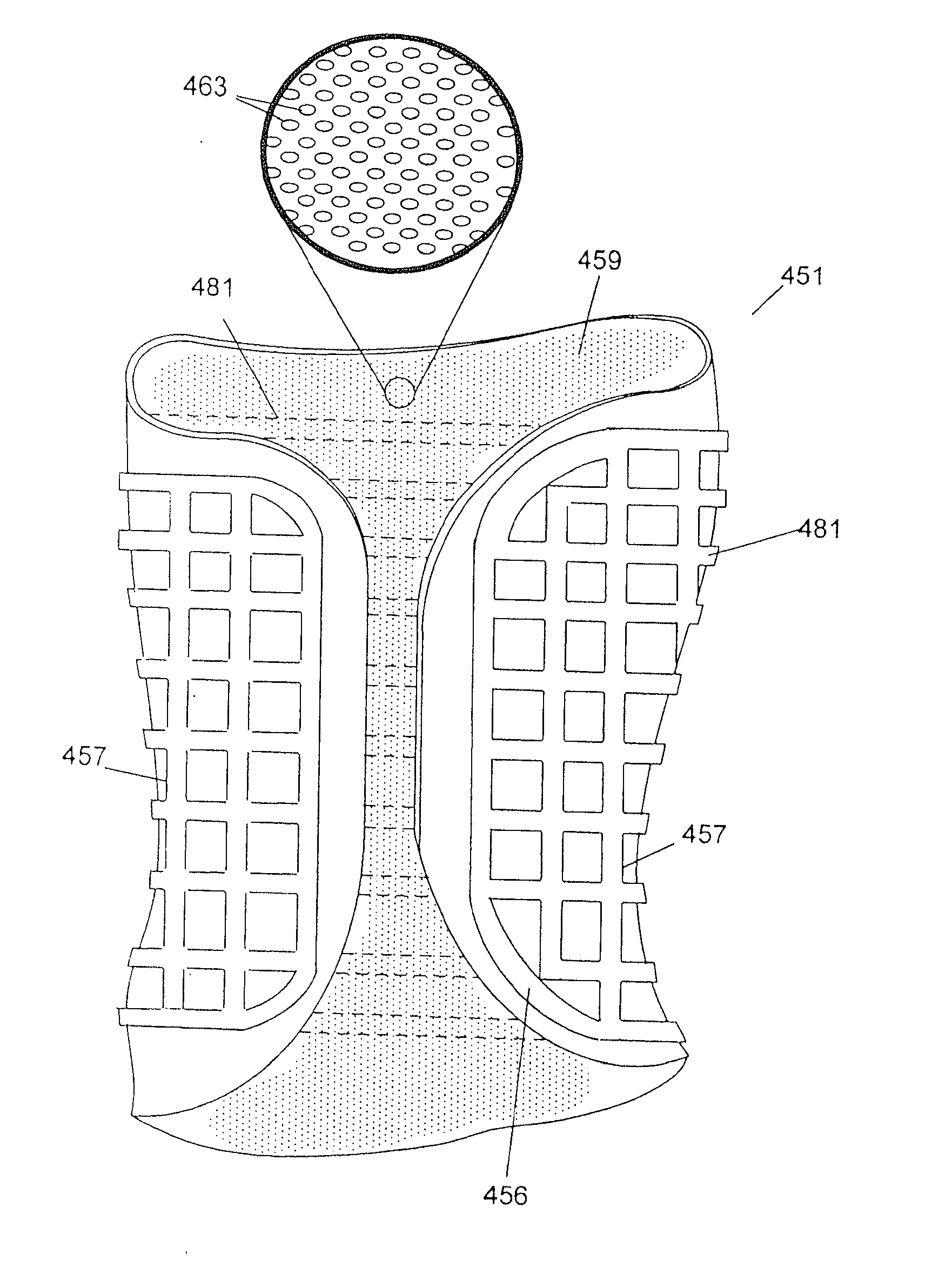

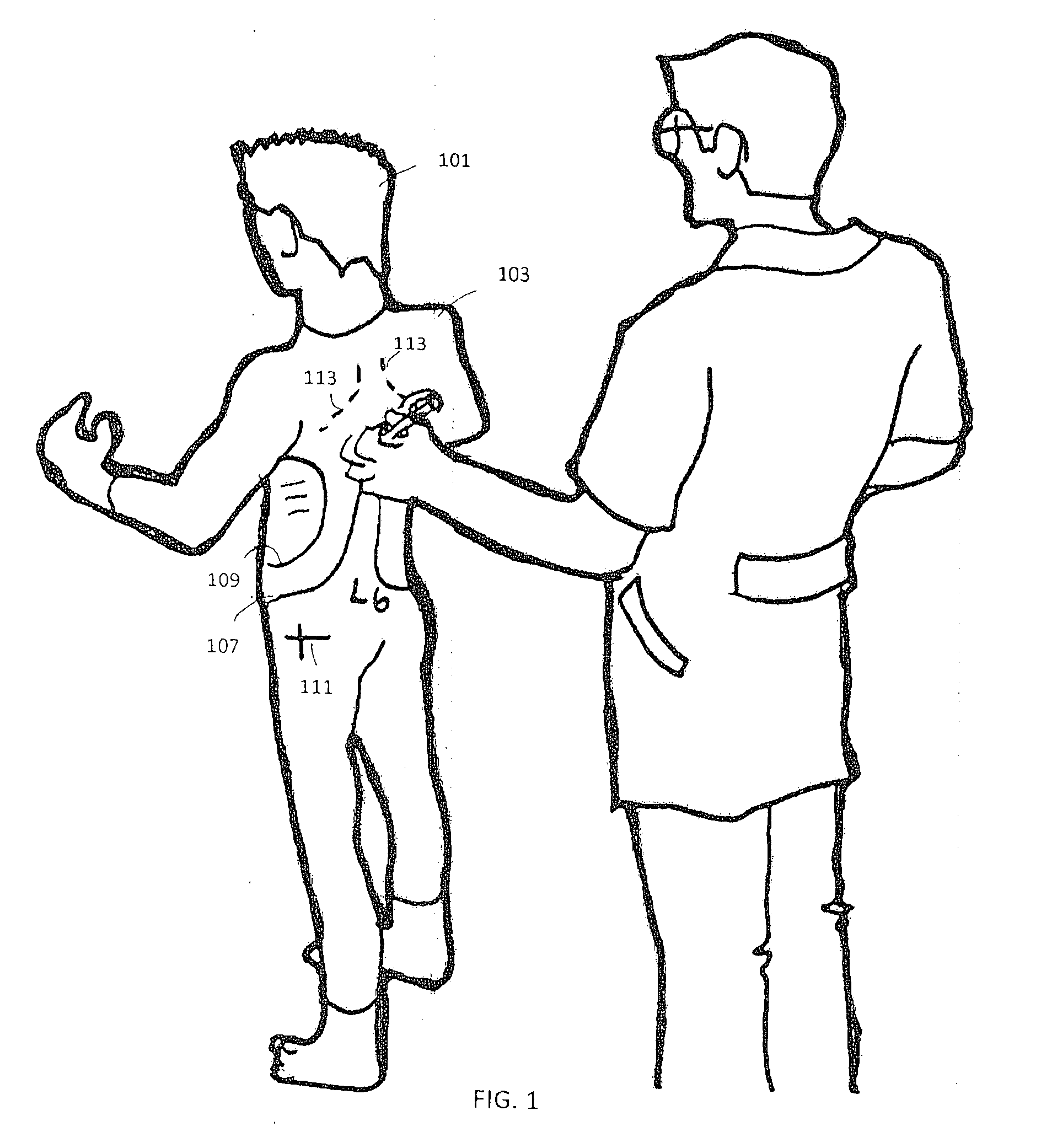

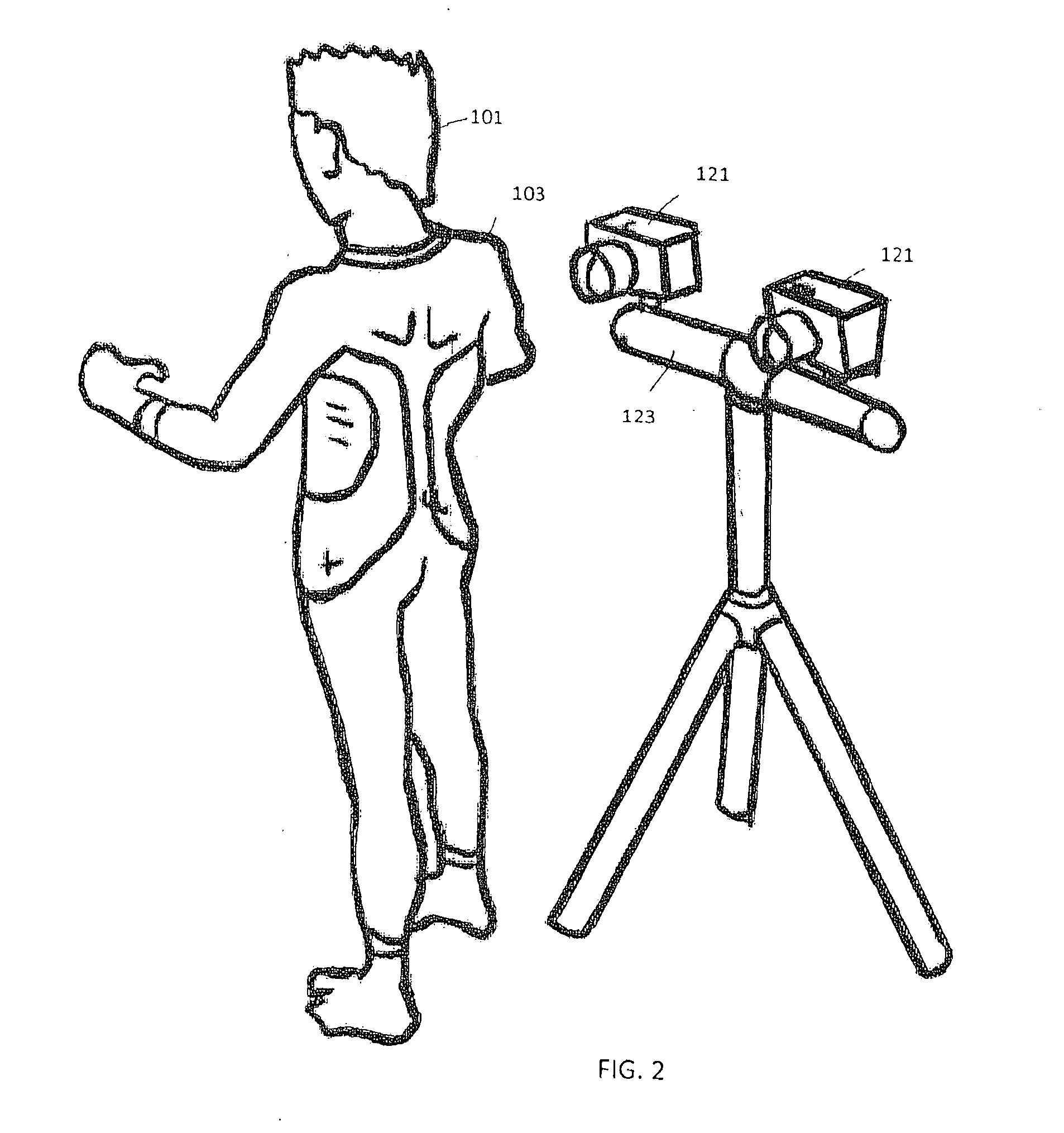

Custom braces, casts and devices having fenestrations and methods for designing and fabricating

ActiveUS20100262054A1Accurately measureEasy to transportNon-surgical orthopedic devicesComputer aided designBiomedical engineeringMultiple image

Owner:3D SYST INC

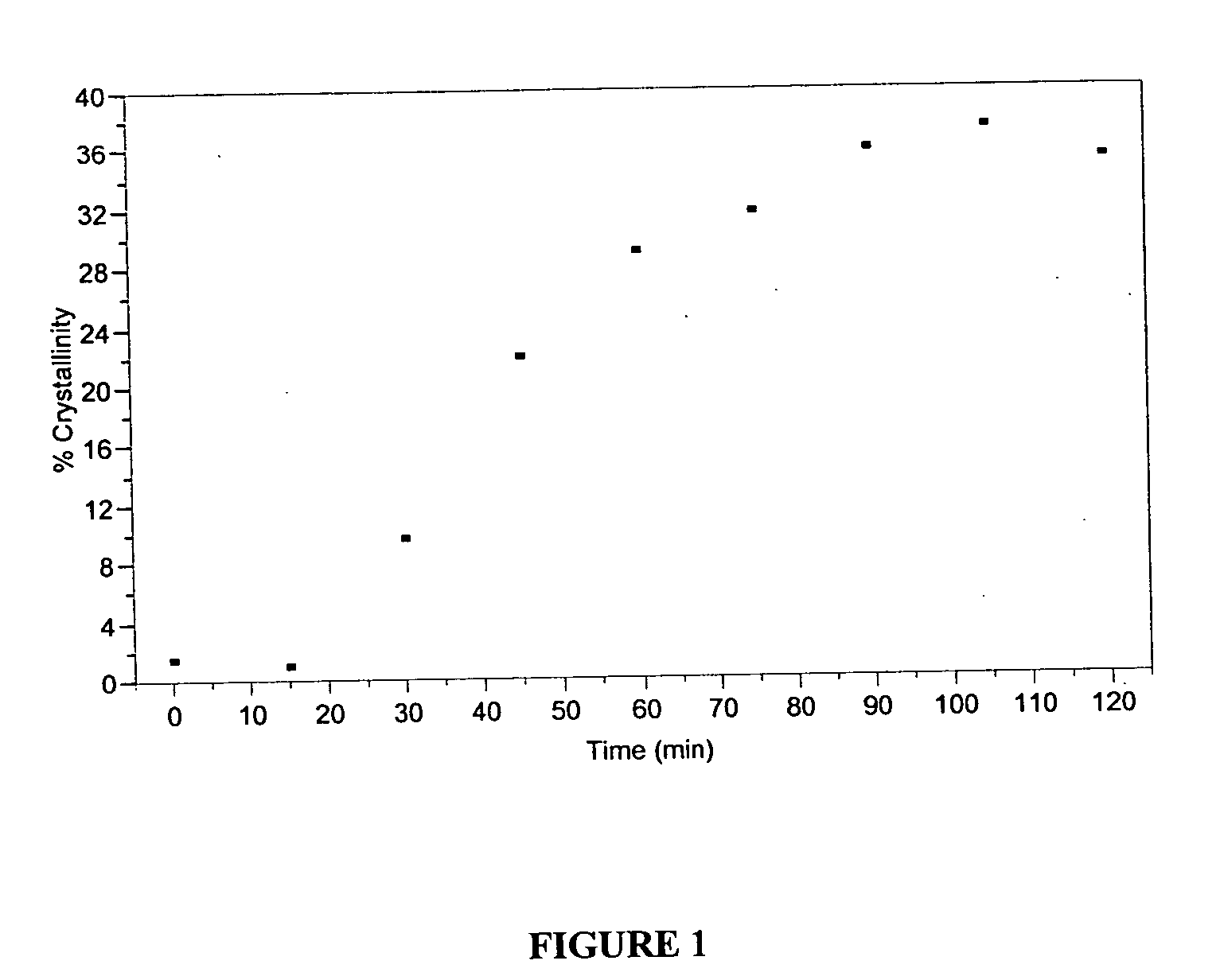

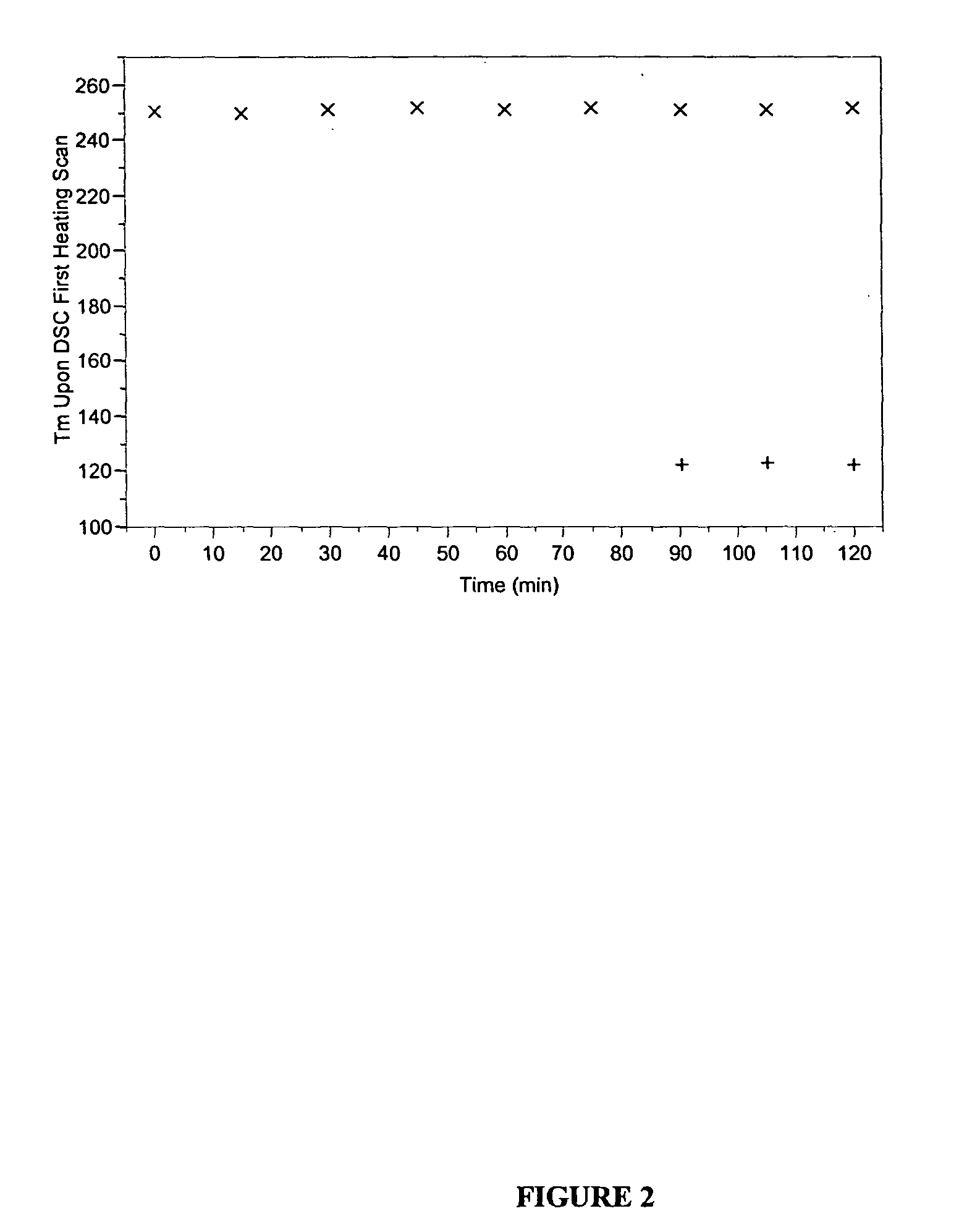

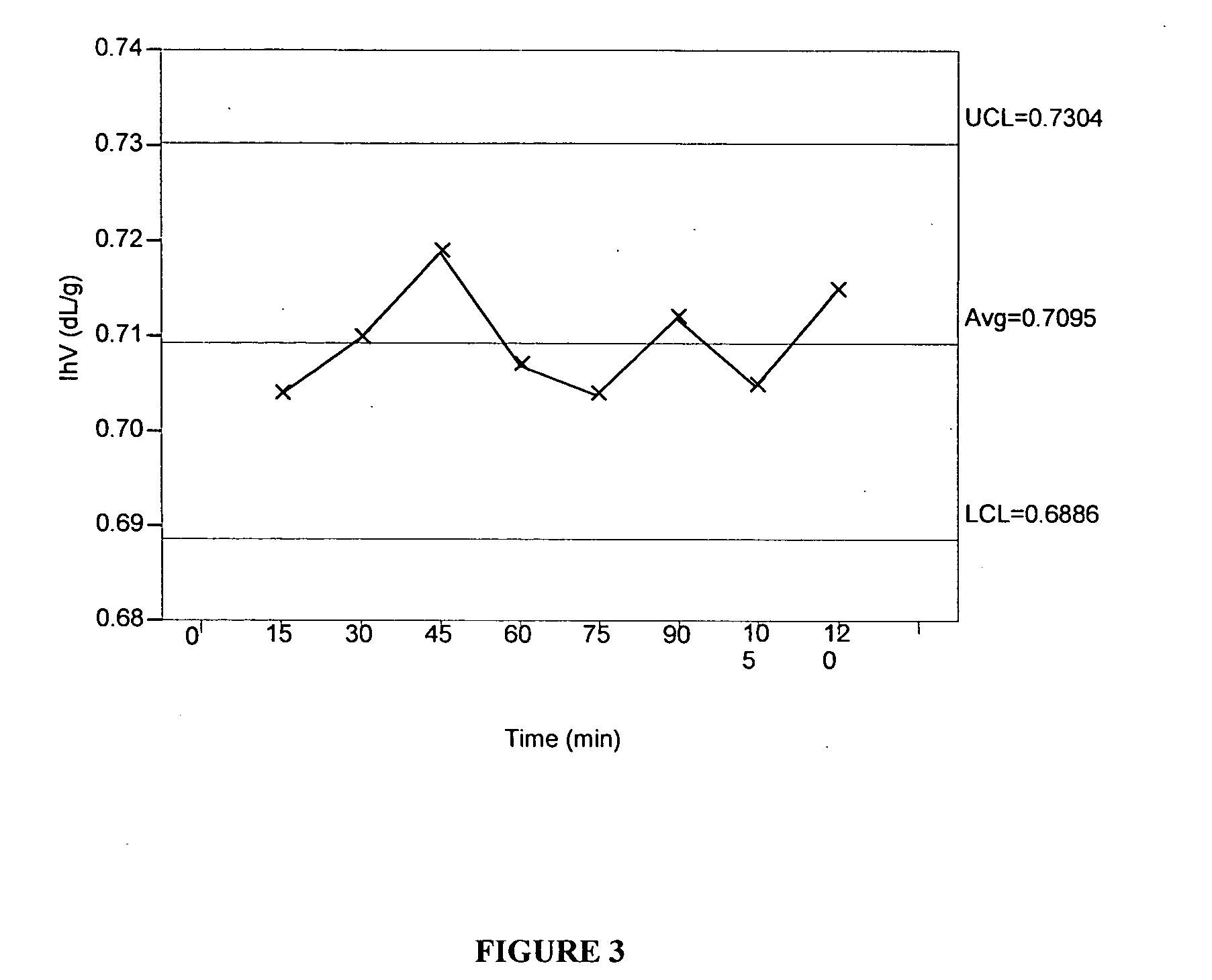

Thermal crystallization of polyester pellets in liquid

InactiveUS20050065318A1Improve heat transfer rateEnergy efficiencyCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

Semiconductor device and method for manufacturing the same

ActiveUS20100148341A1Bonding strengthImprove productivitySemiconductor/solid-state device detailsSolid-state devicesAlloyEngineering

A semiconductor device includes: a sensor including a sensor structure on a first side of the sensor and a periphery element surrounding the sensor structure; and a cap covering the sensor structure and having a second side bonded to the first side of the sensor. The cap includes a first wiring layer on the second side of the cap. The first wiring layer steps over the periphery element. The sensor further includes a sensor side connection portion, and the cap further includes a cap side connection portion. The sensor side connection portion is bonded to the cap side connection portion. At least one of the sensor side connection portion and the cap side connection portion provides an eutectic alloy so that the sensor side connection portion and the cap side connection portion are bonded to each other.

Owner:DENSO CORP

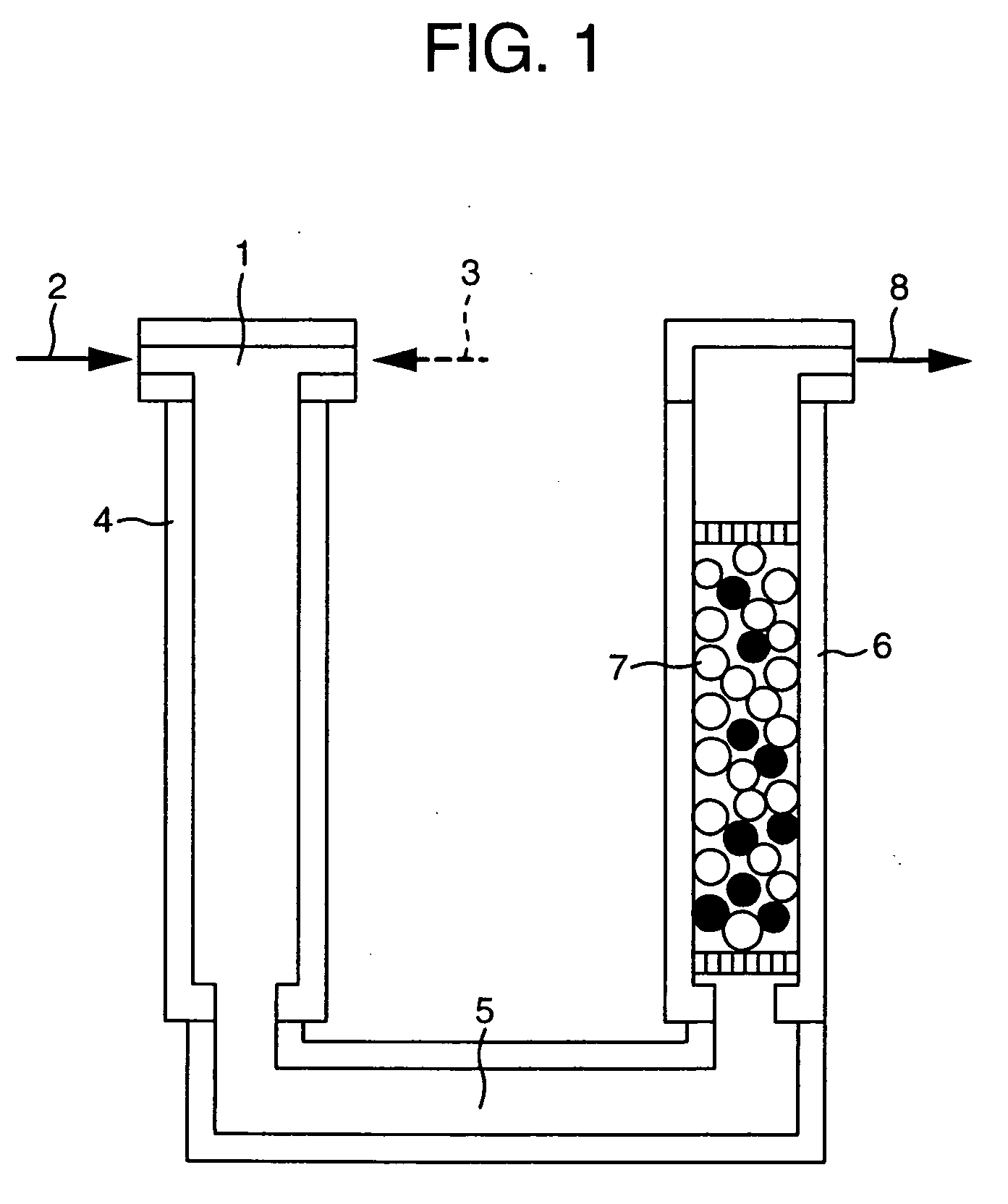

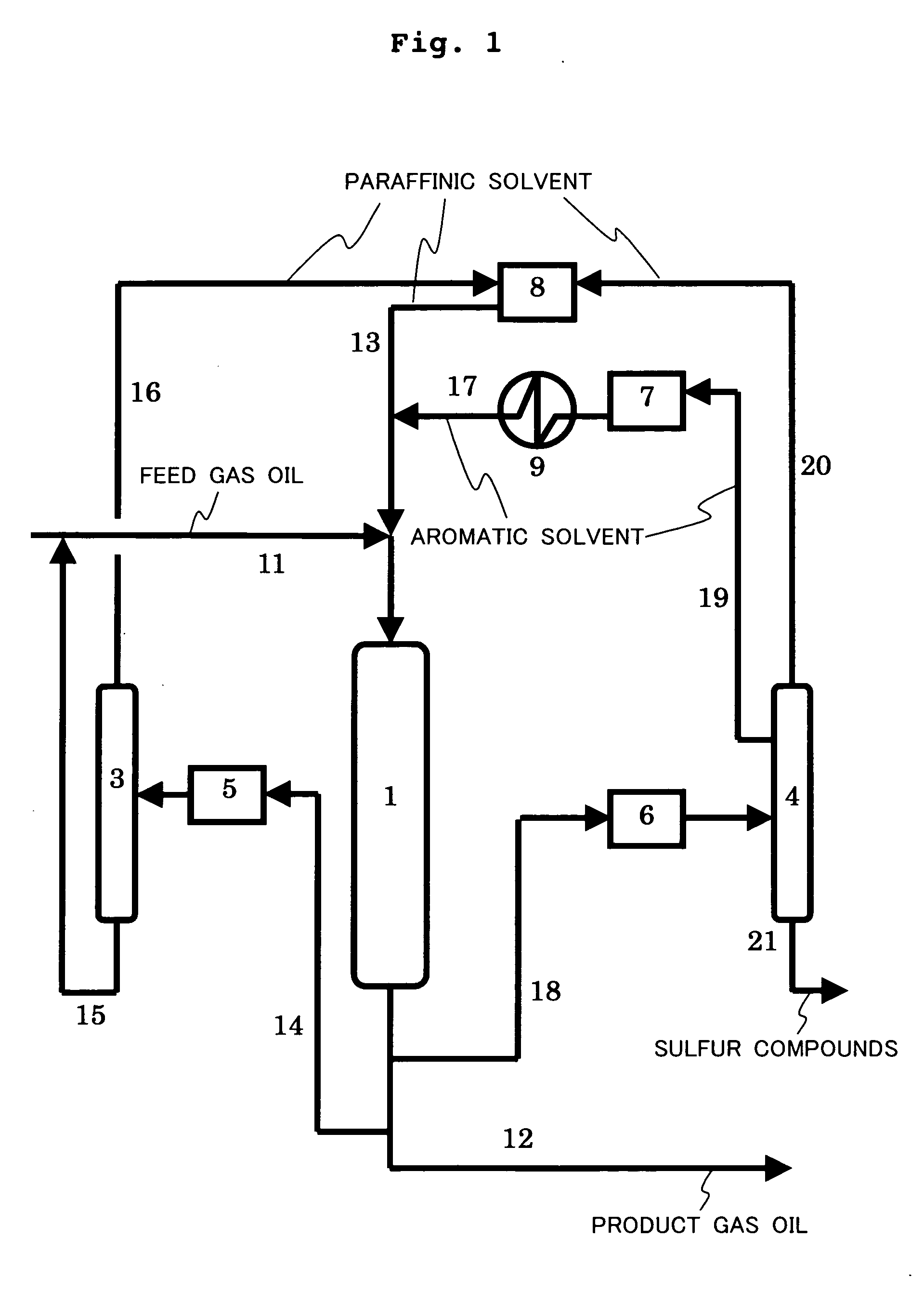

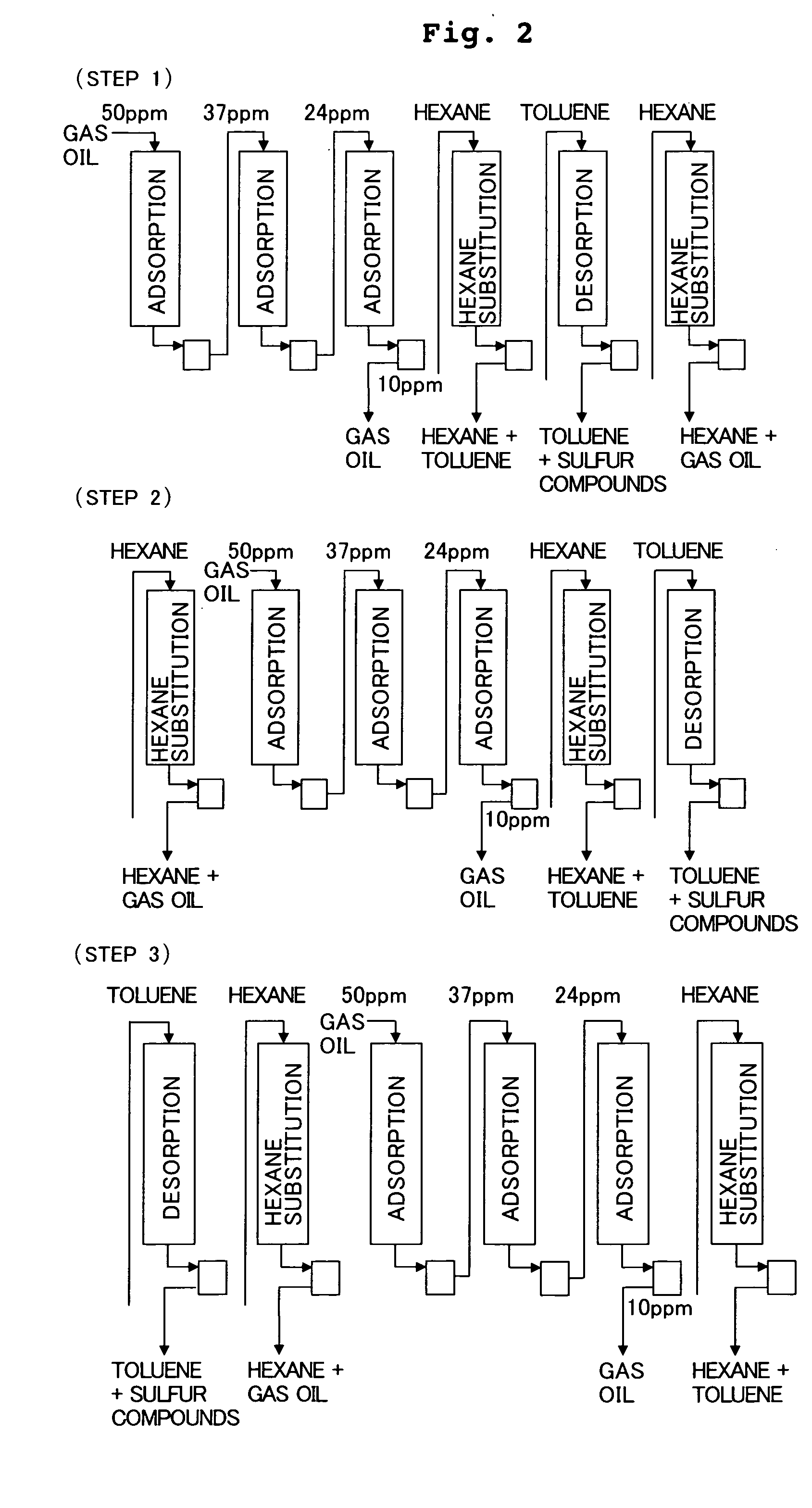

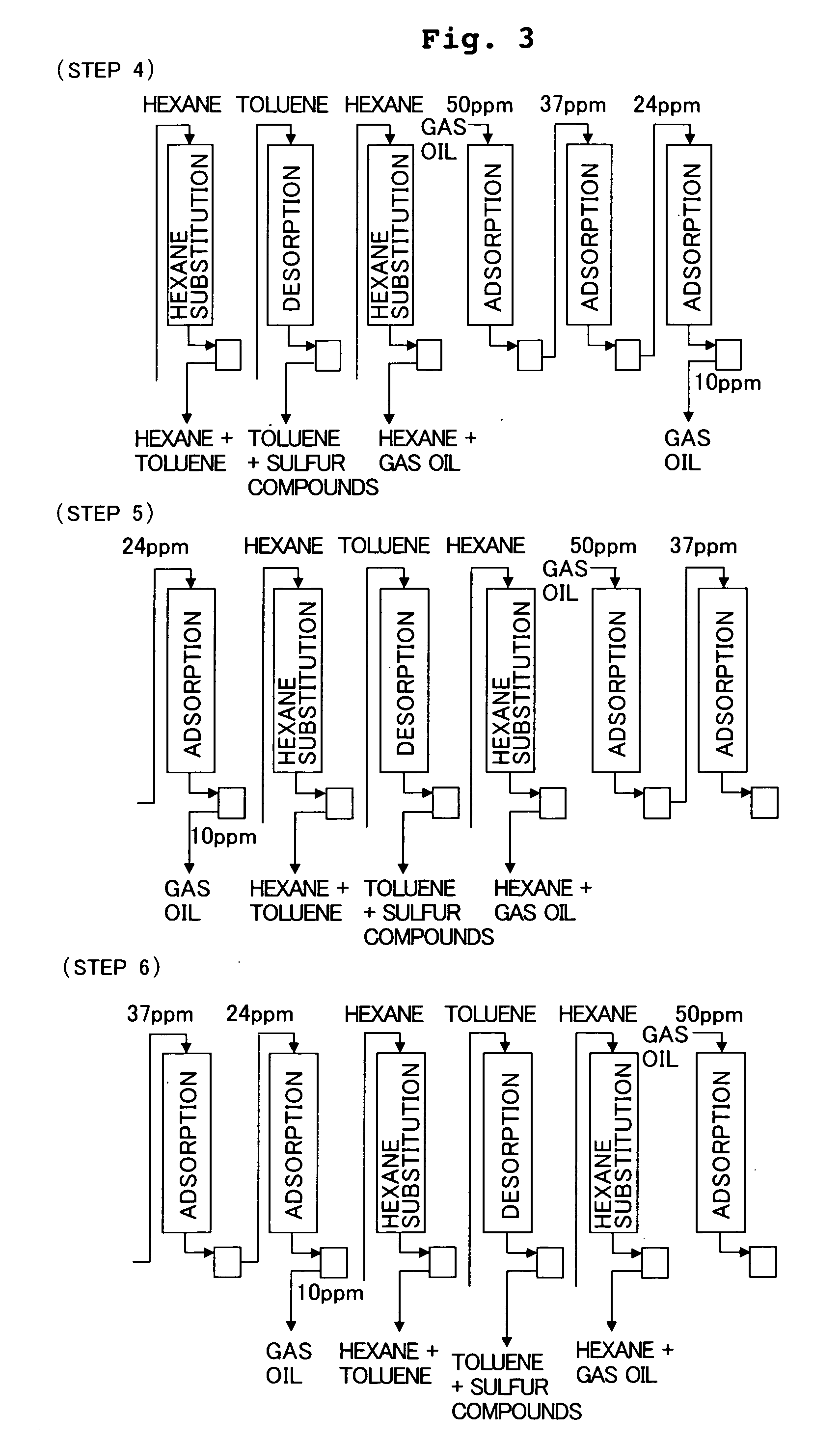

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

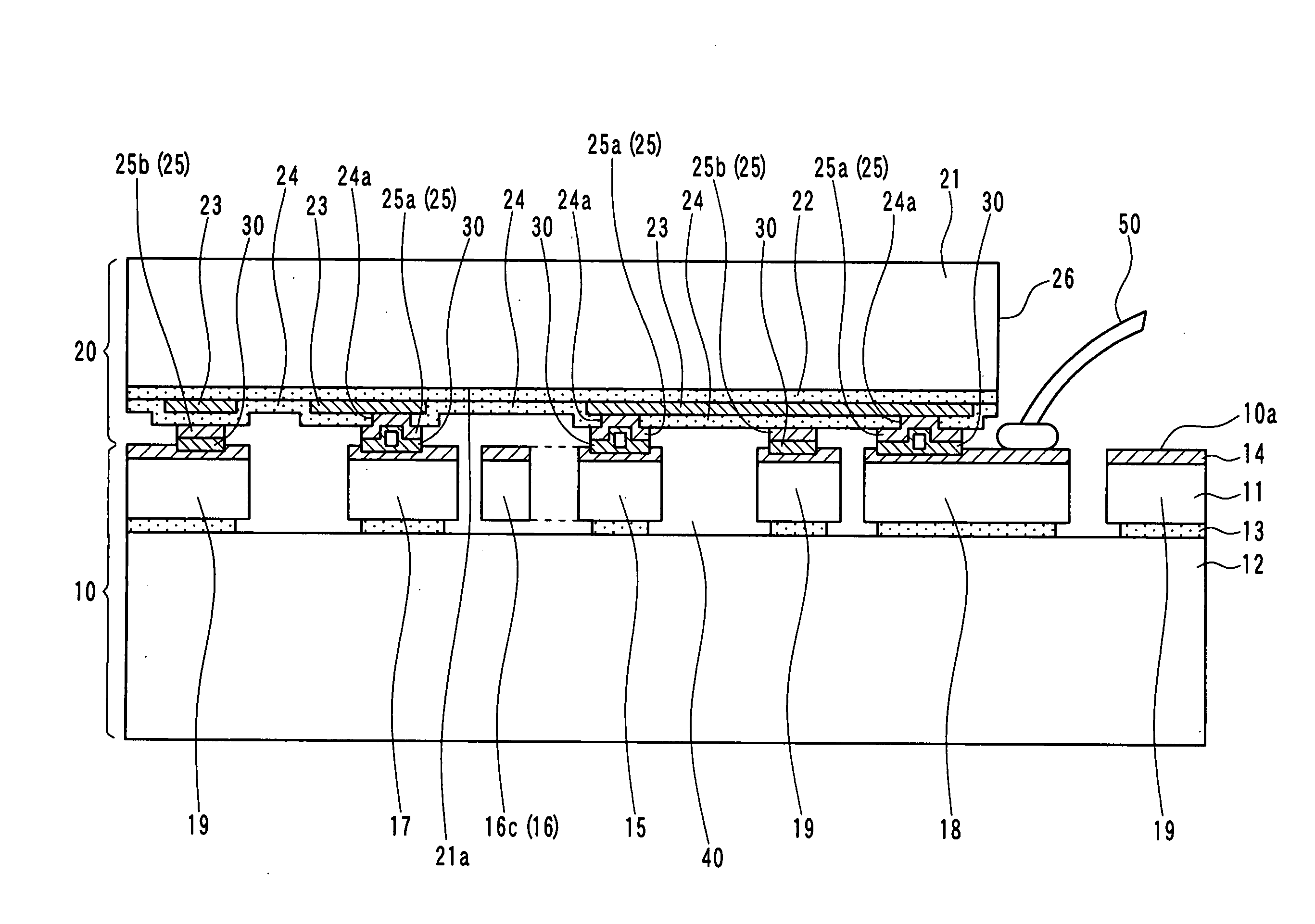

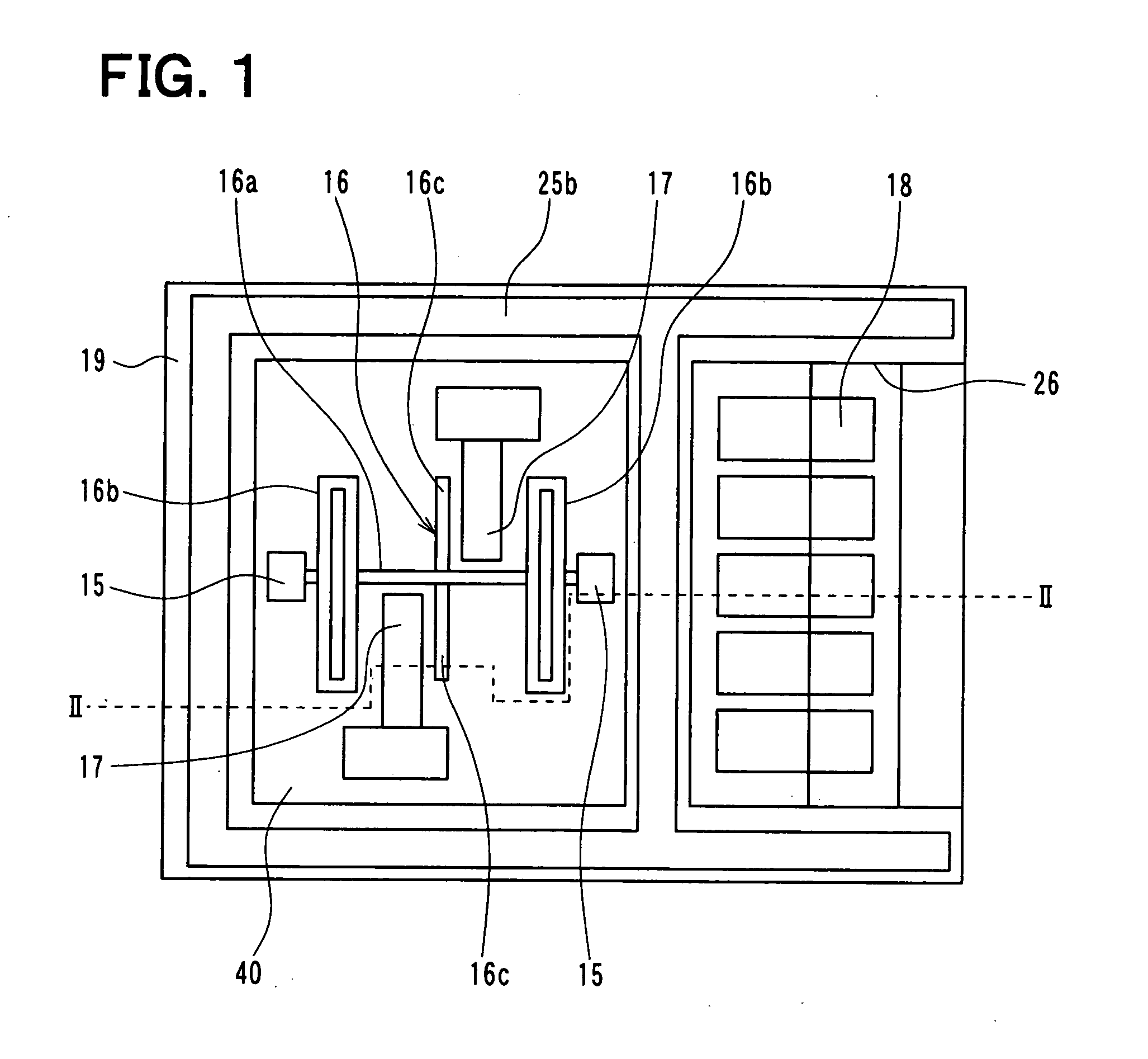

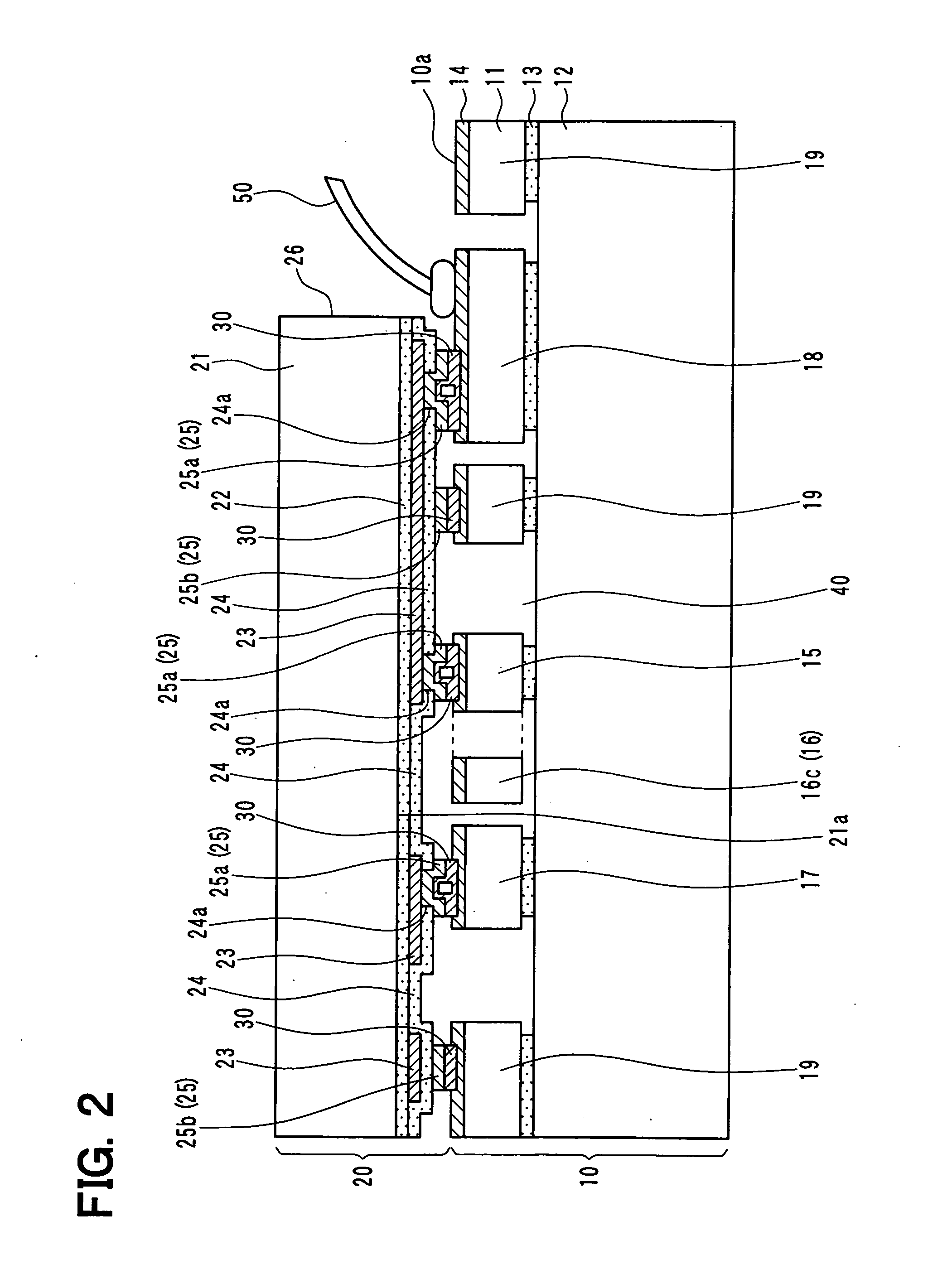

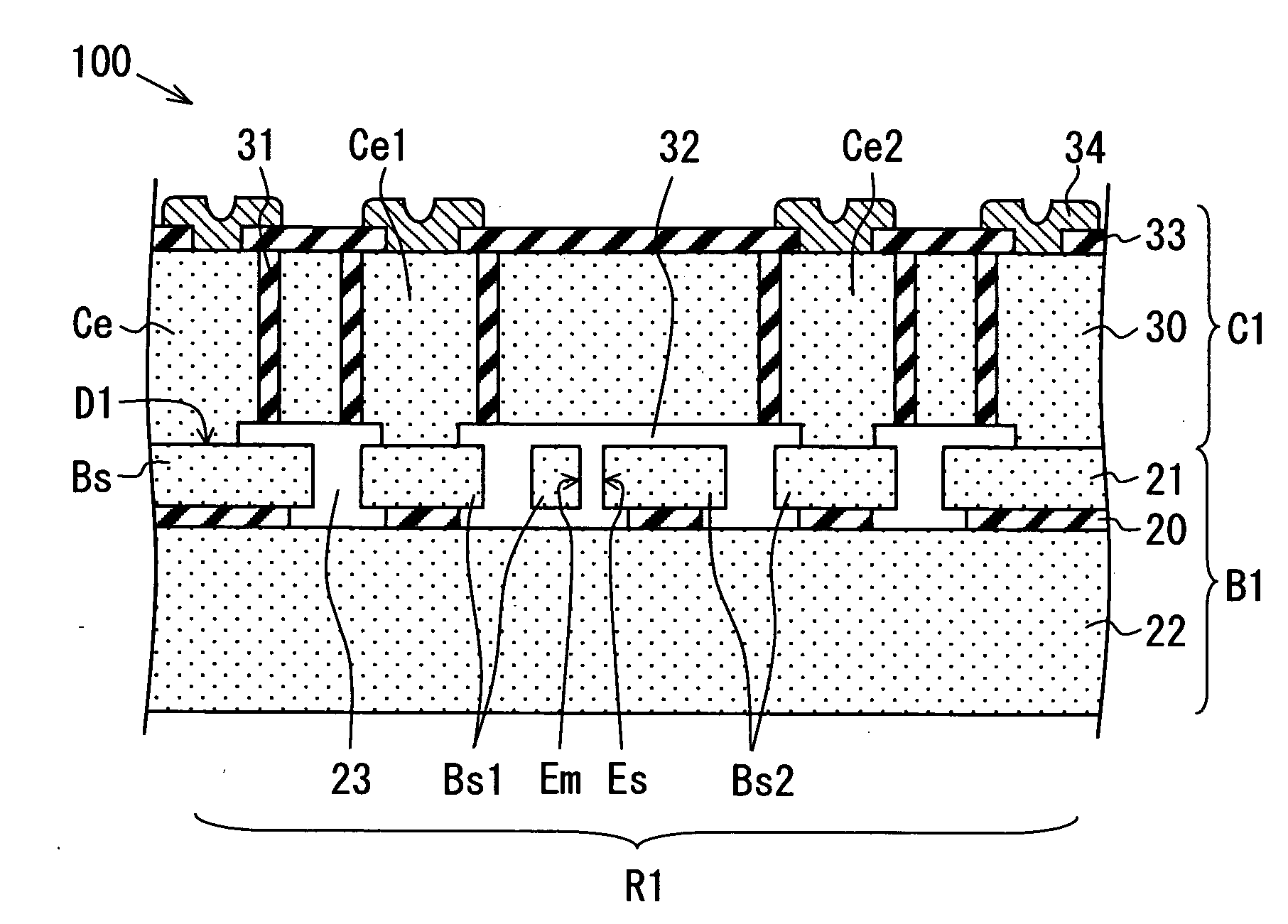

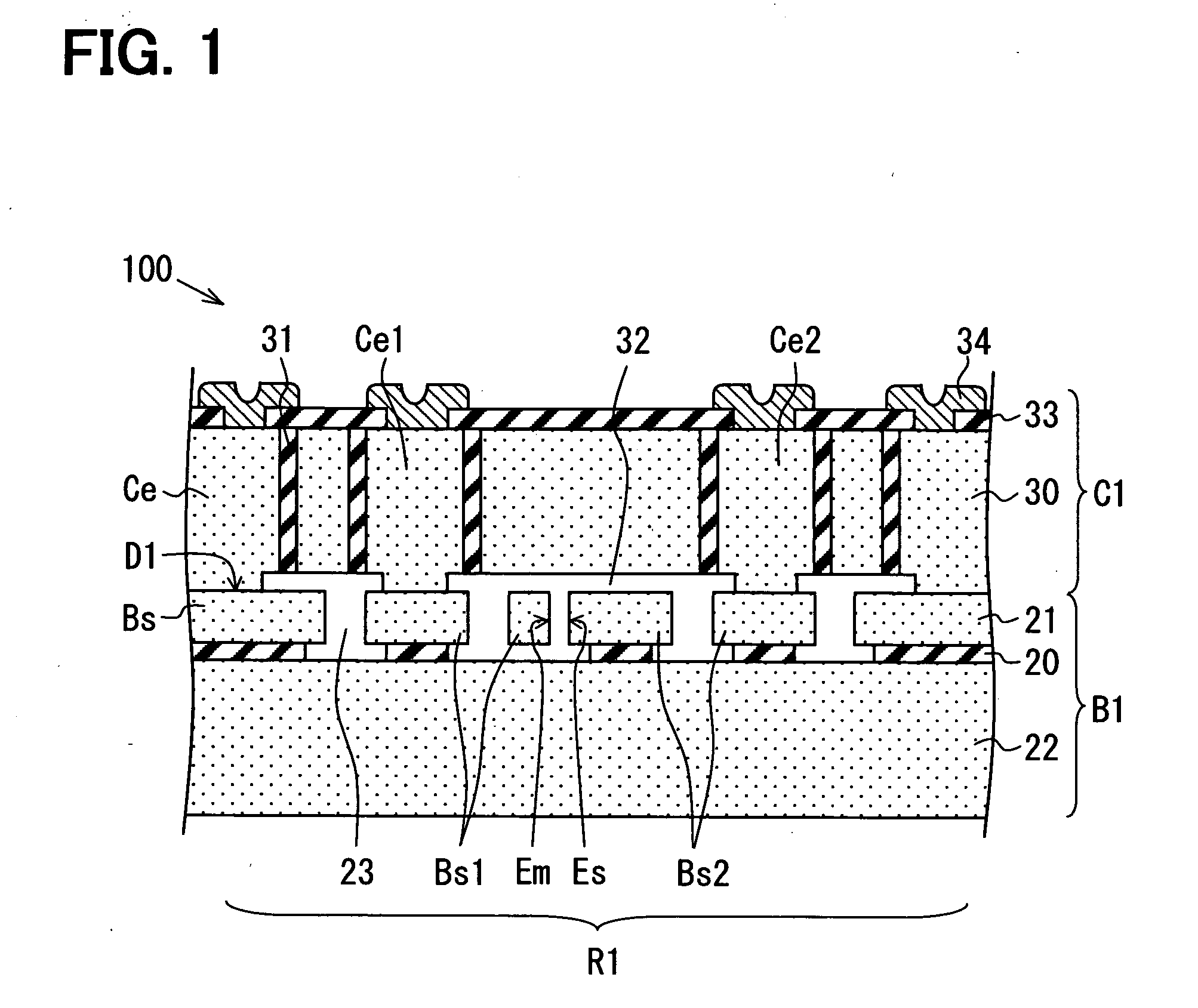

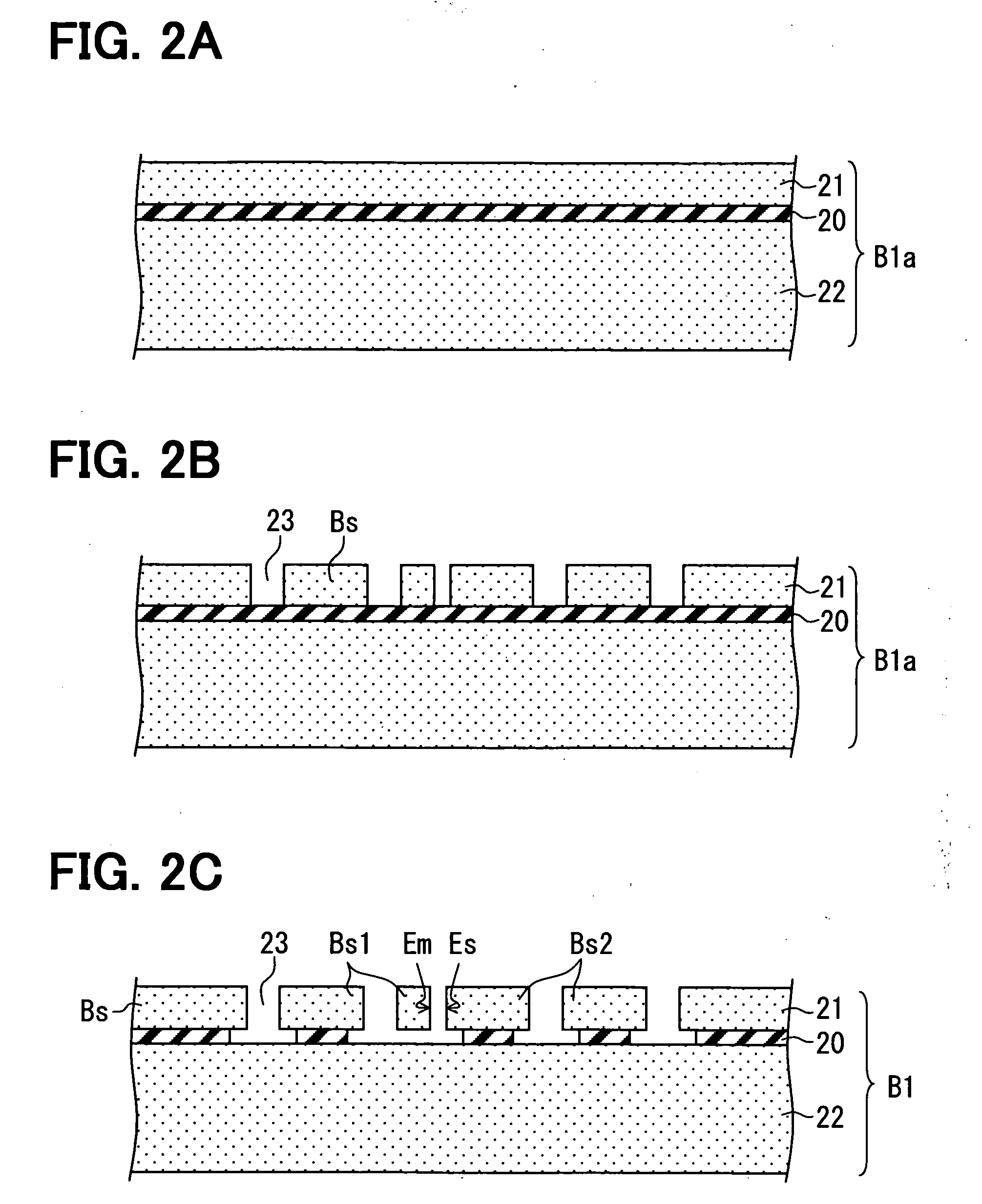

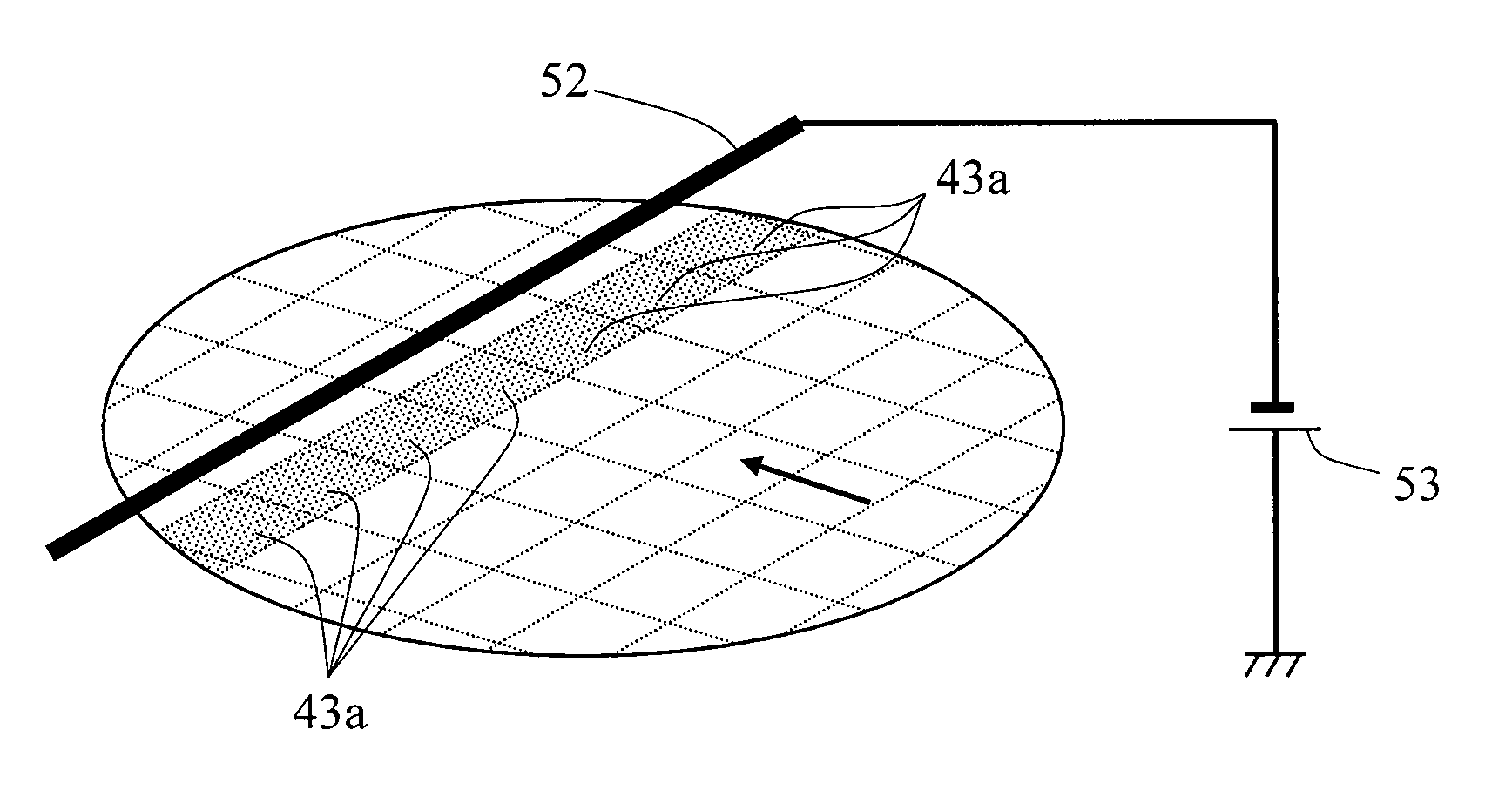

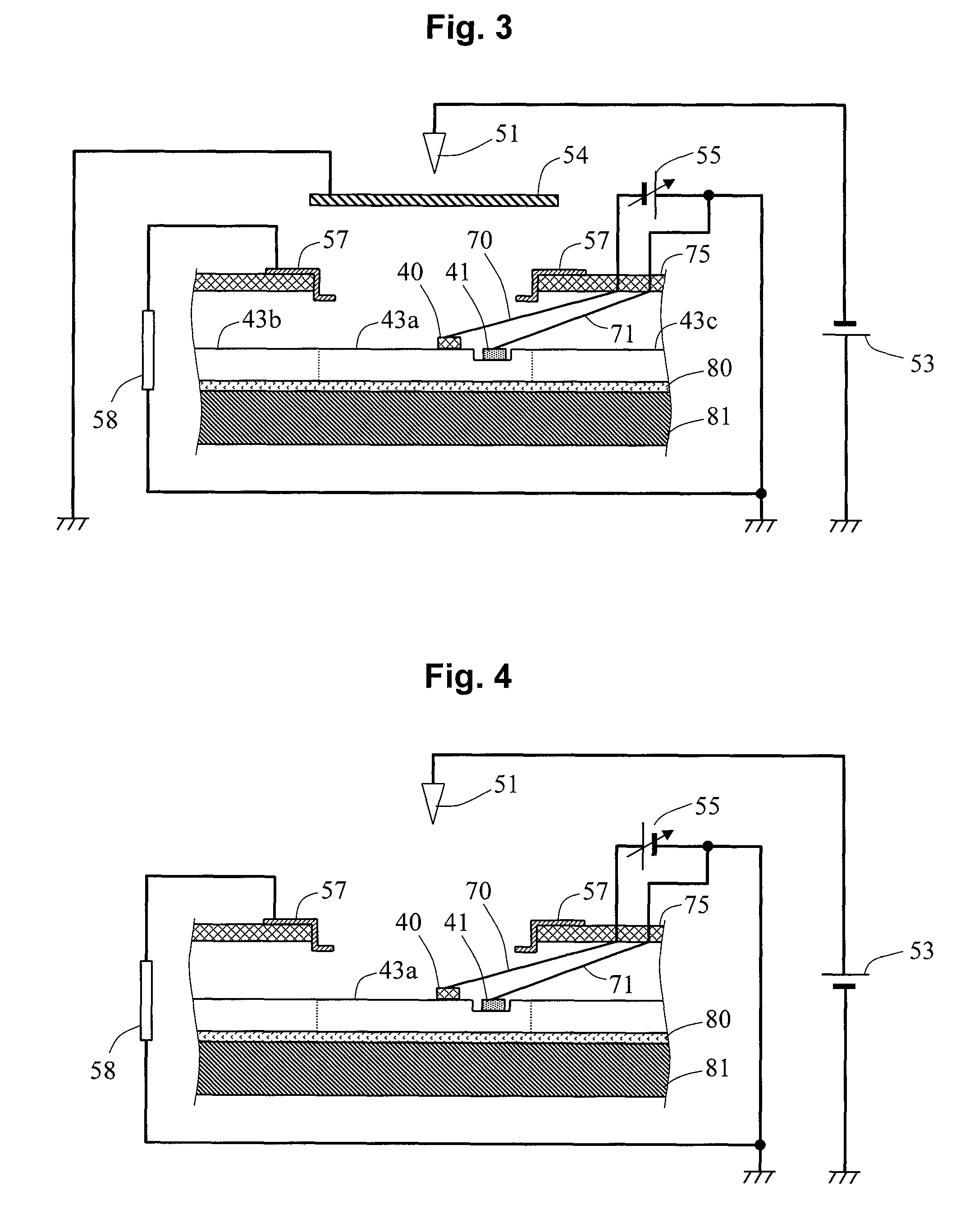

Semiconductor device and method for manufacturing the same

InactiveUS20080290490A1Reduce equipment costsSecure strengthPrecision positioning equipmentSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device includes: a first substrate made of semiconductor and having first regions, which are insulated from each other and disposed in the first substrate; and a second substrate having electric conductivity and having second regions and insulation trenches. Each insulation trench penetrates the second substrate so that the second regions are insulated from each other. The first substrate provides a base substrate, and the second substrate provides a cap substrate. The second substrate is bonded to the first substrate so that a sealed space is provided between a predetermined surface region of the first substrate and the second substrate. The second regions include an extraction conductive region, which is coupled with a corresponding first region.

Owner:DENSO CORP

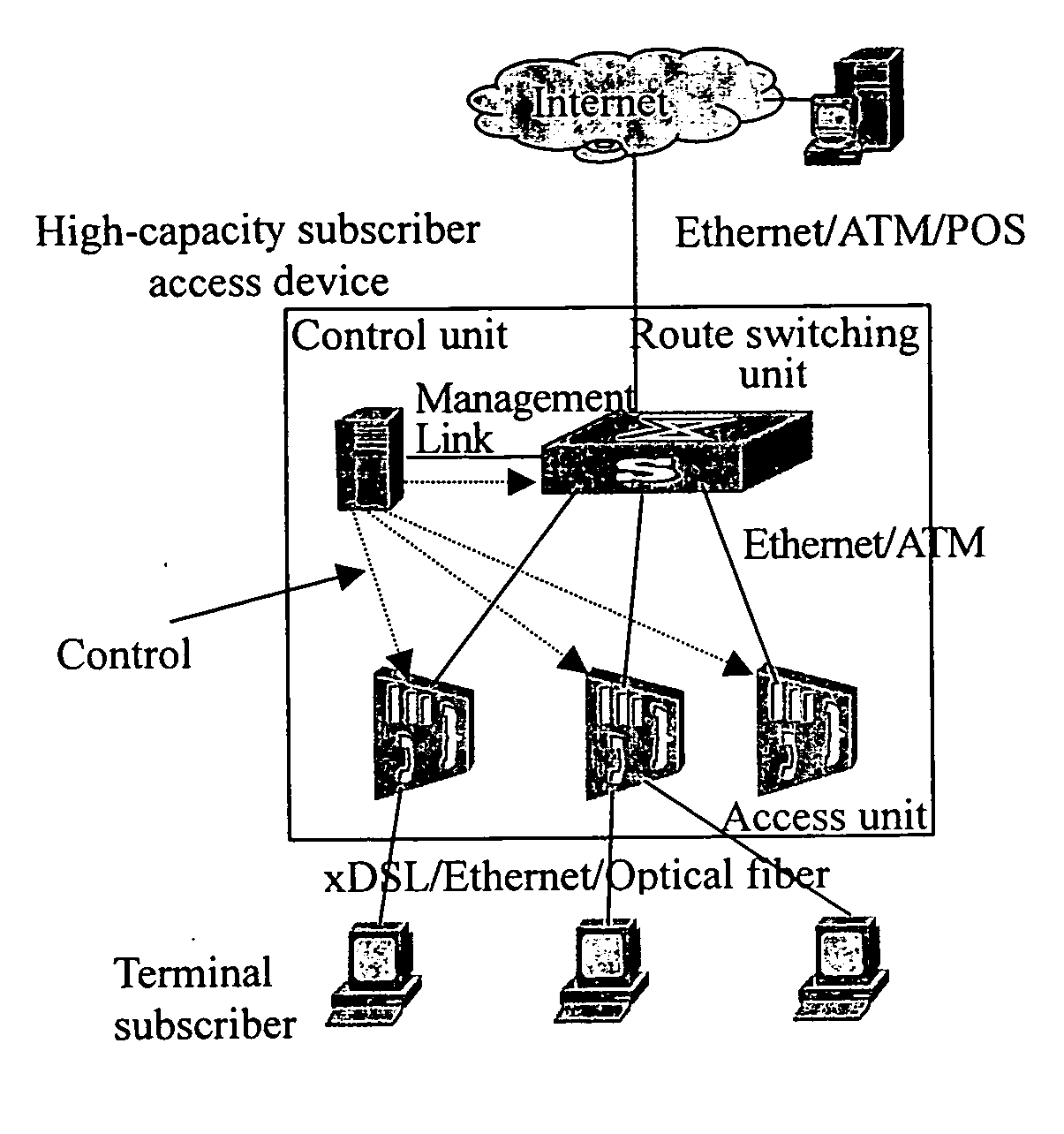

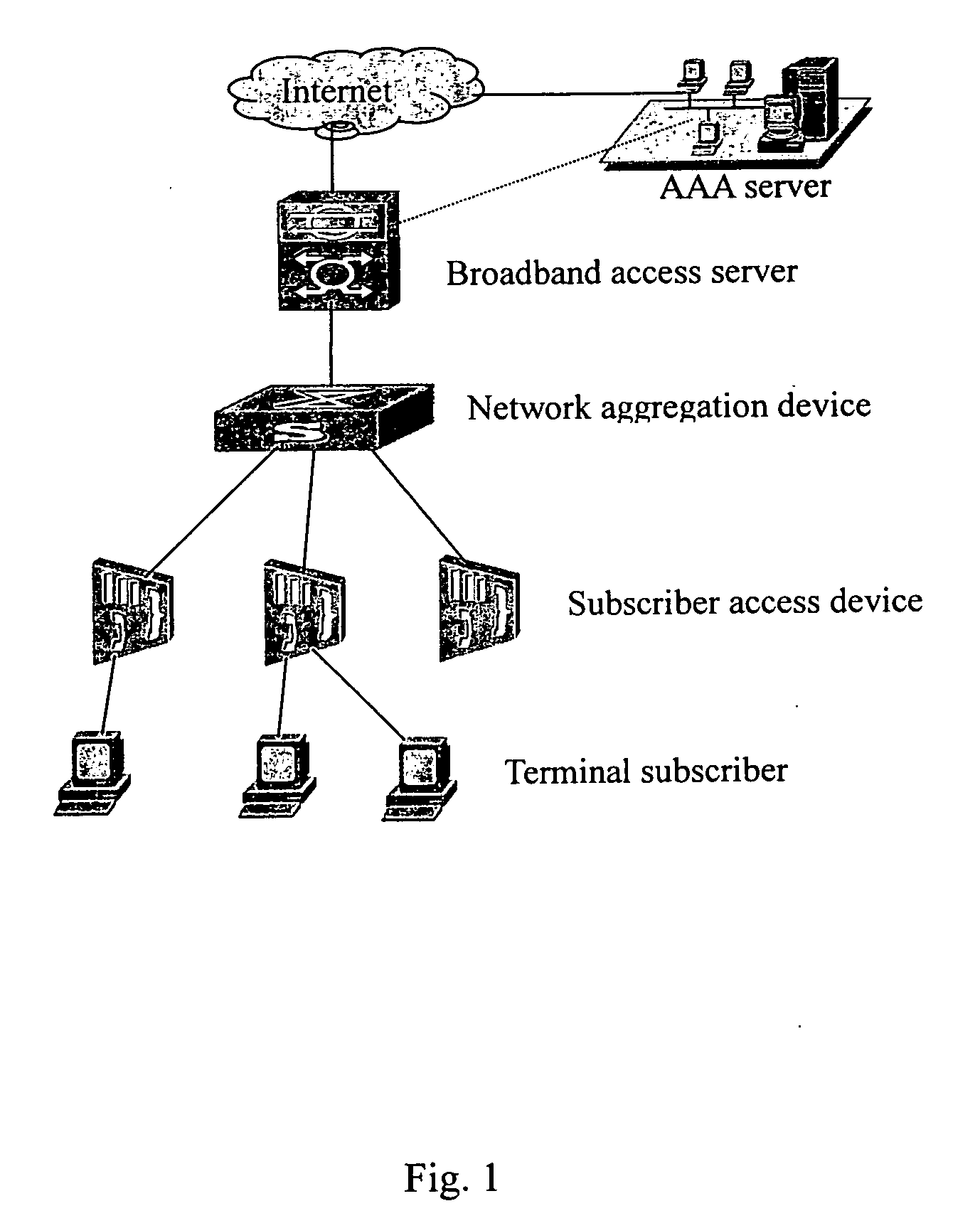

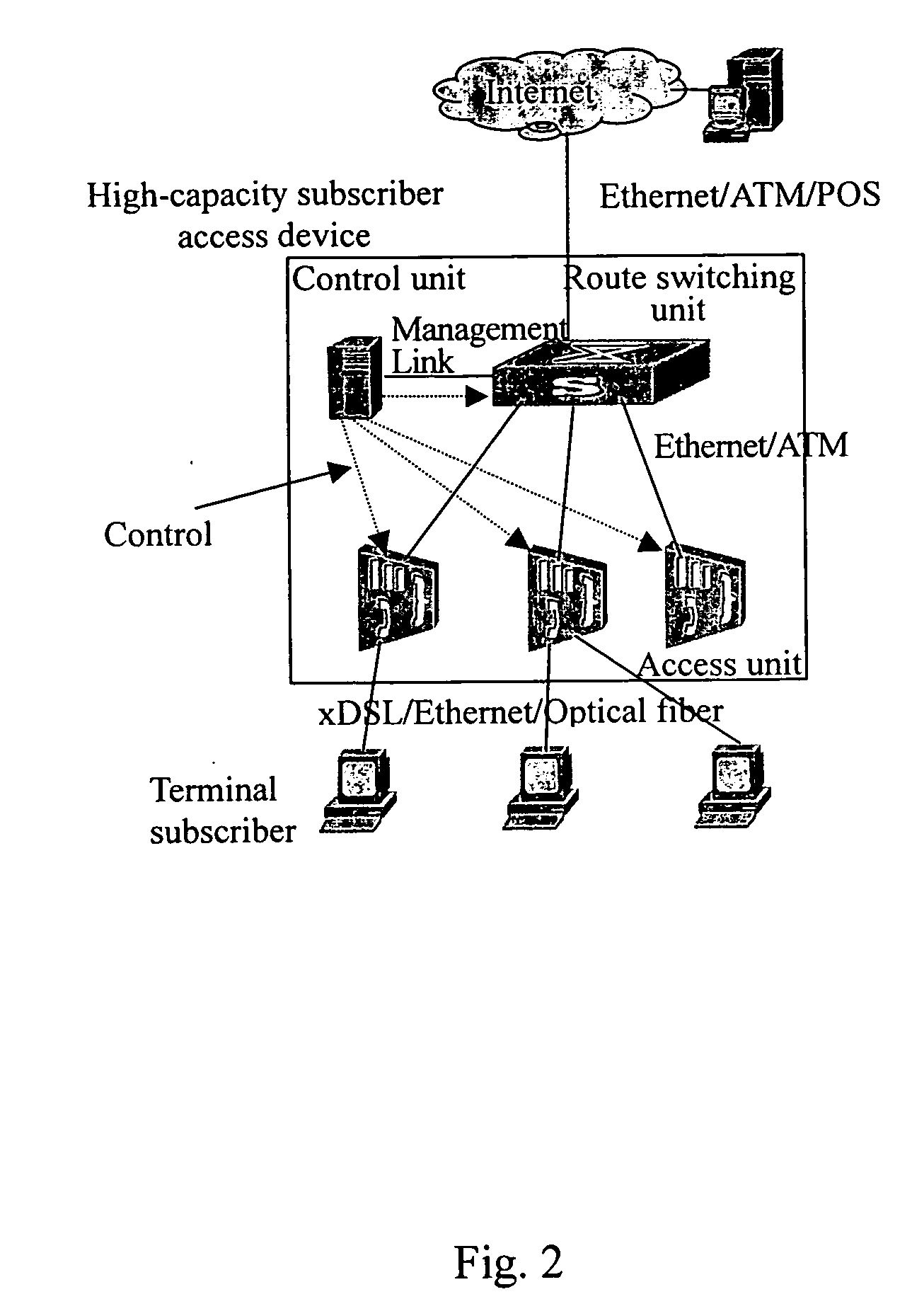

Broadband access method with great capacity and the system thereof

ActiveUS20070159971A1Low costReduce difficultyError preventionTransmission systemsAccess methodBroadband

The present invention discloses a high-capacity broadband access method, comprising: a broadband subscriber initiating an access request to an access unit; the access unit sending the subscriber authentication information to a control unit via a route switching unit; the control unit authenticating the subscriber with an internal or external authentication, authorization and accounting server, returning the authentication result to the access unit via the route switching unit, and sending the configuration information to the accessed subscriber; the route switching unit and the access unit accomplishing configuration of the subscriber information, allocating corresponding resource to the subscriber, and establishing a data channel for network access of the subscriber. The present invention also discloses a high-capacity broadband access device and a system thereof.

Owner:HUAWEI TECH CO LTD

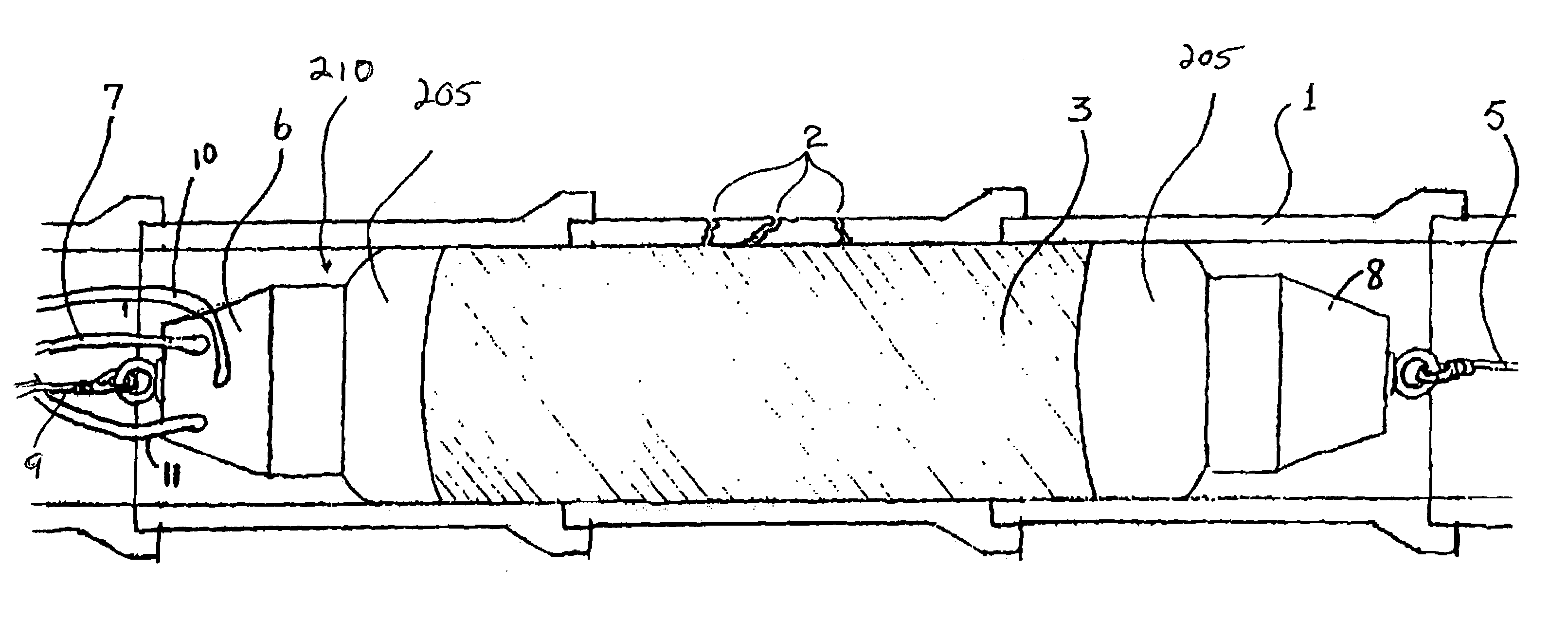

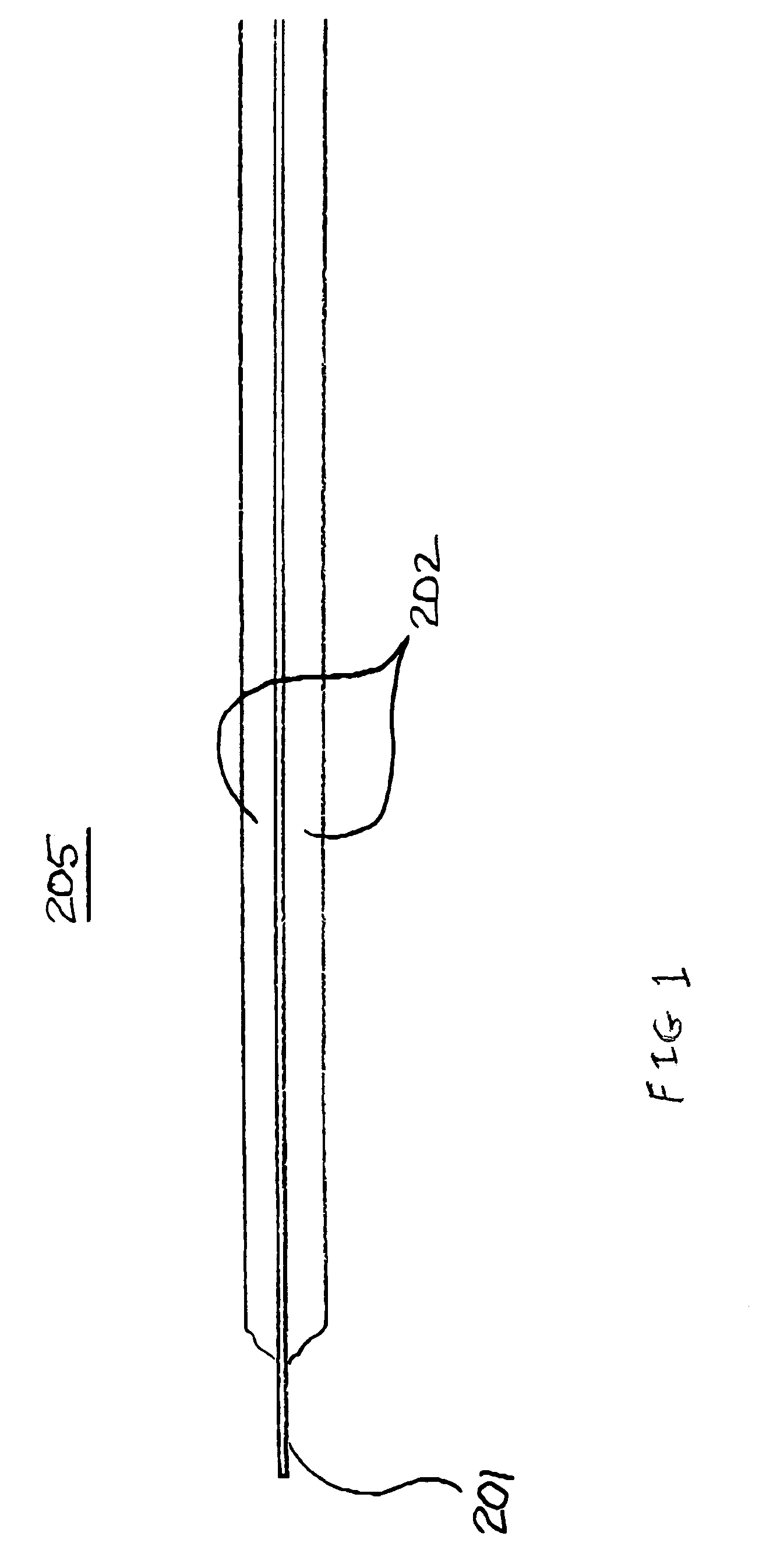

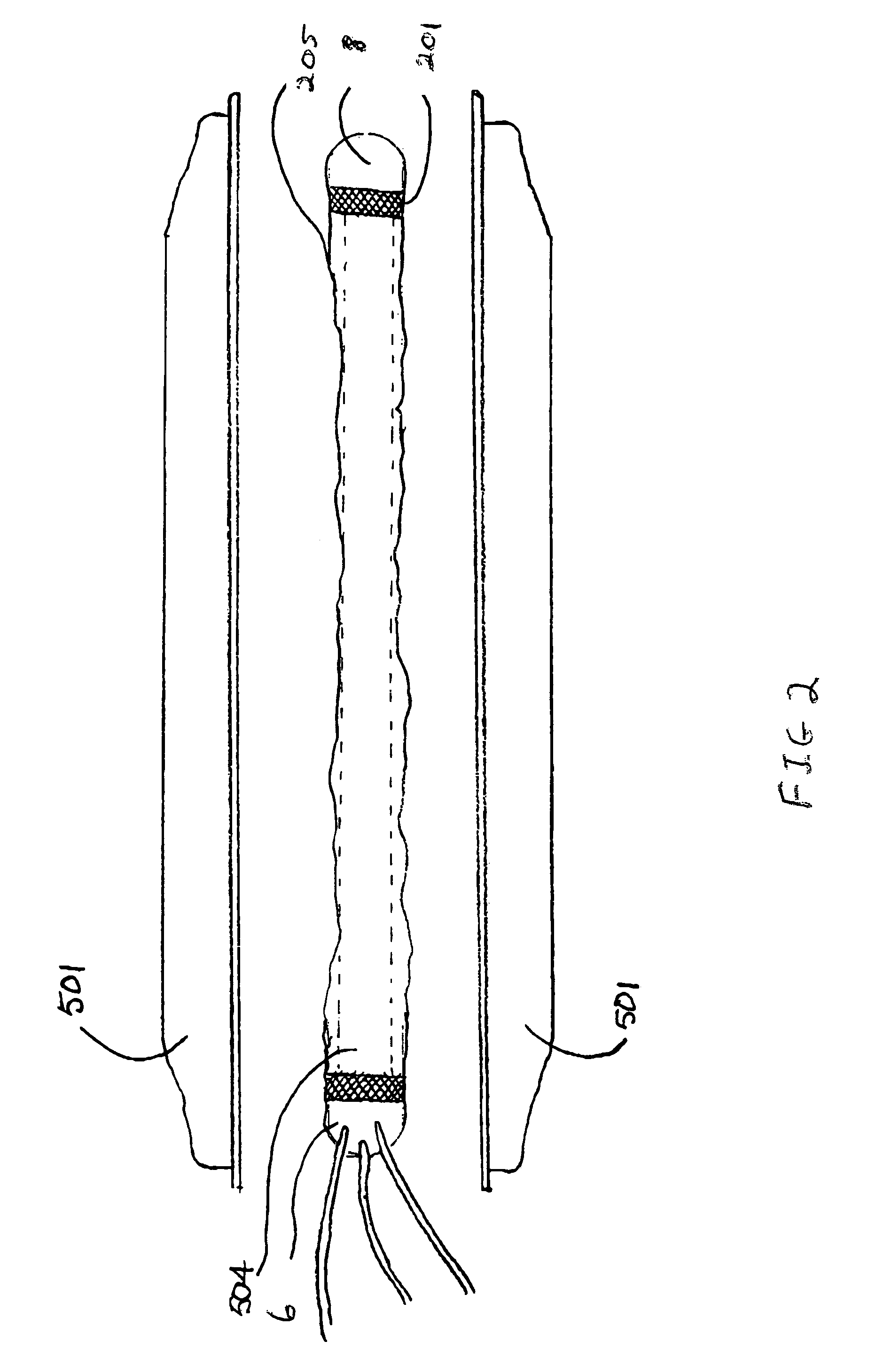

Inflatable heating device for in-situ repair of conduit and method for repairing conduit

InactiveUS7052567B1Extend the life cycleRobust and heatingConfectionerySweetmeatsElastomerResin matrix

The apparatus of the present invention is generally characterized by a heating / inflation module having pressurizable interior and an attached heat curable pre-preg. In particular, an elastomeric, seamless composite is provided that includes a heating element disposed within a thermoset resin matrix. The composite adapted to maintain a consistent temperature profile and an internal air pressure. A first end piece is attached to a first end of the composite and has an air port for communication with a compressed air source, a vacuum port for communication with a vacuum supply source and at least one electrical cable port for communication with a power supply source. A second end piece attached to a second end of the composite. The apparatus further includes a pre-preg removably attached to an outer surface of the composite. The pre-preg includes a structural fiber matrix supporting a heat curable resin. The composite is constructed by applying a liquid silicone matrix to at least one layer of braided or wound and / or tape fibers, wherein a portion of the fibers are electrically conductive. The layer of braided fibers is introduced into a mold, and a removable, expandable inner bladder is then loaded into the mold. The inner bladder is inflated to conform the layer of braided fibers to an interior surface of the mold. An electric current is caused to flow to the conductive fibers to cure the silicone matrix into a stable, elastomeric state. The composite is removed from the mold. A method for repairing a damaged section of a conduit is also disclosed.

Owner:EMS USA HLDG I +1

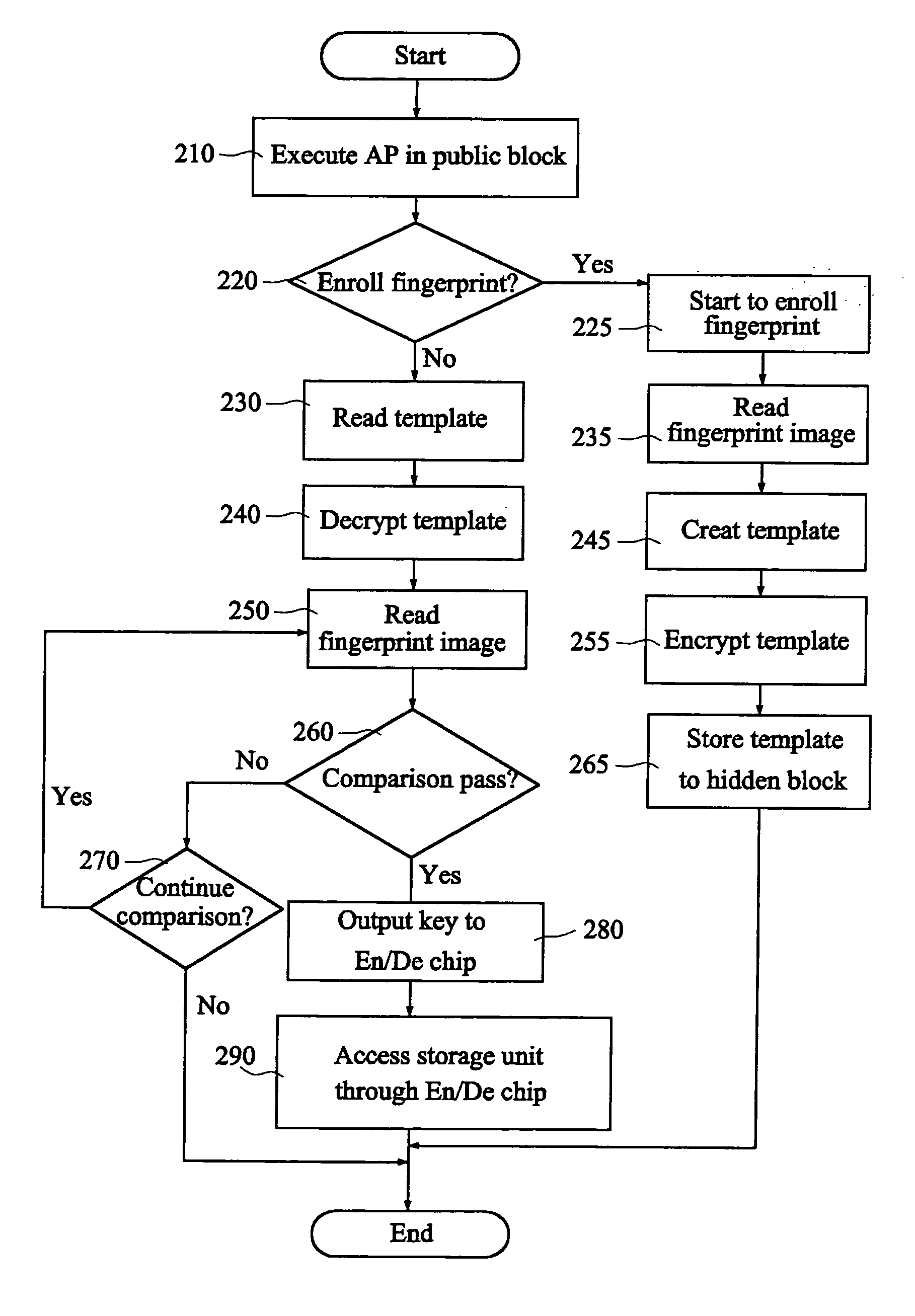

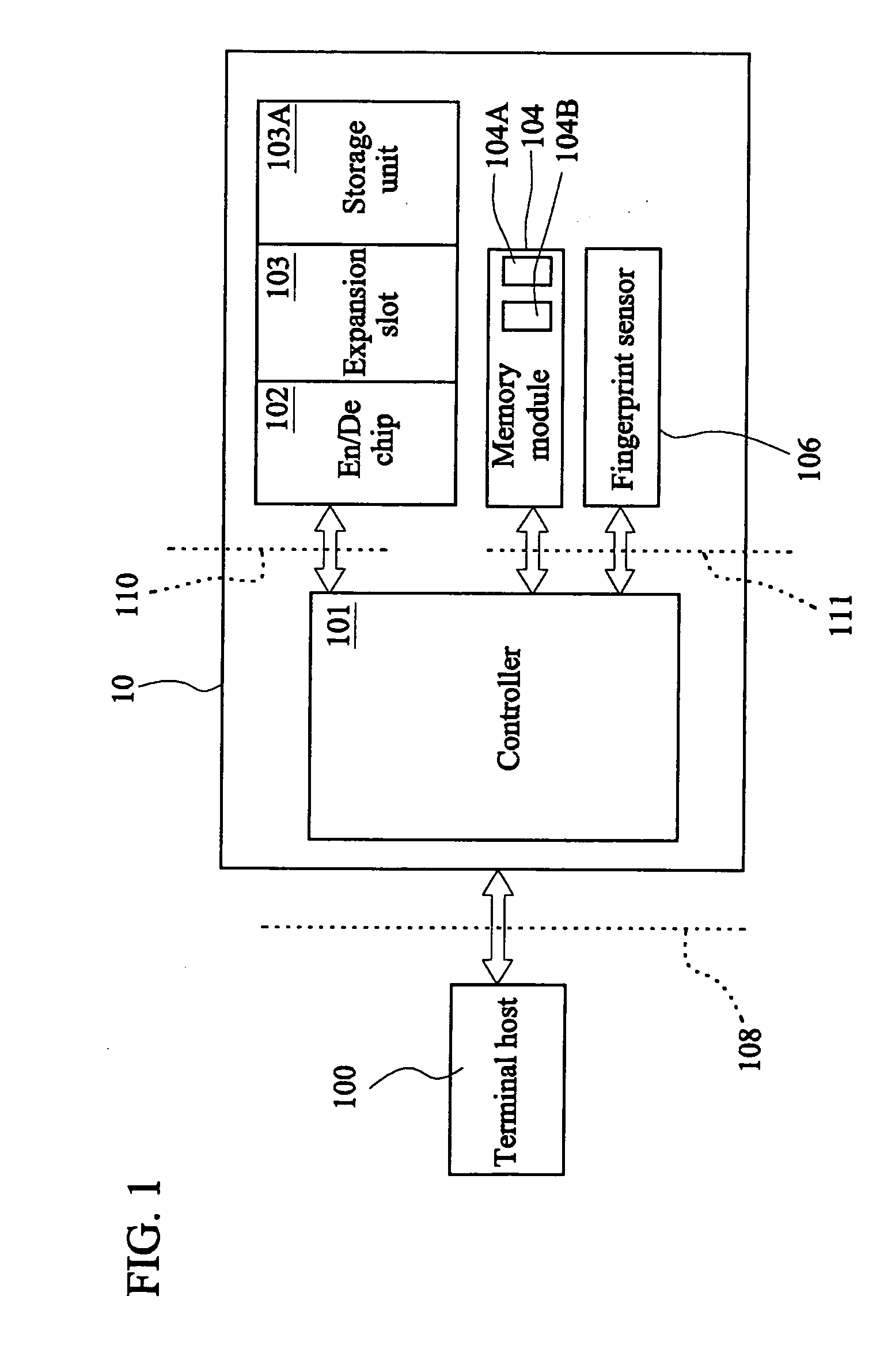

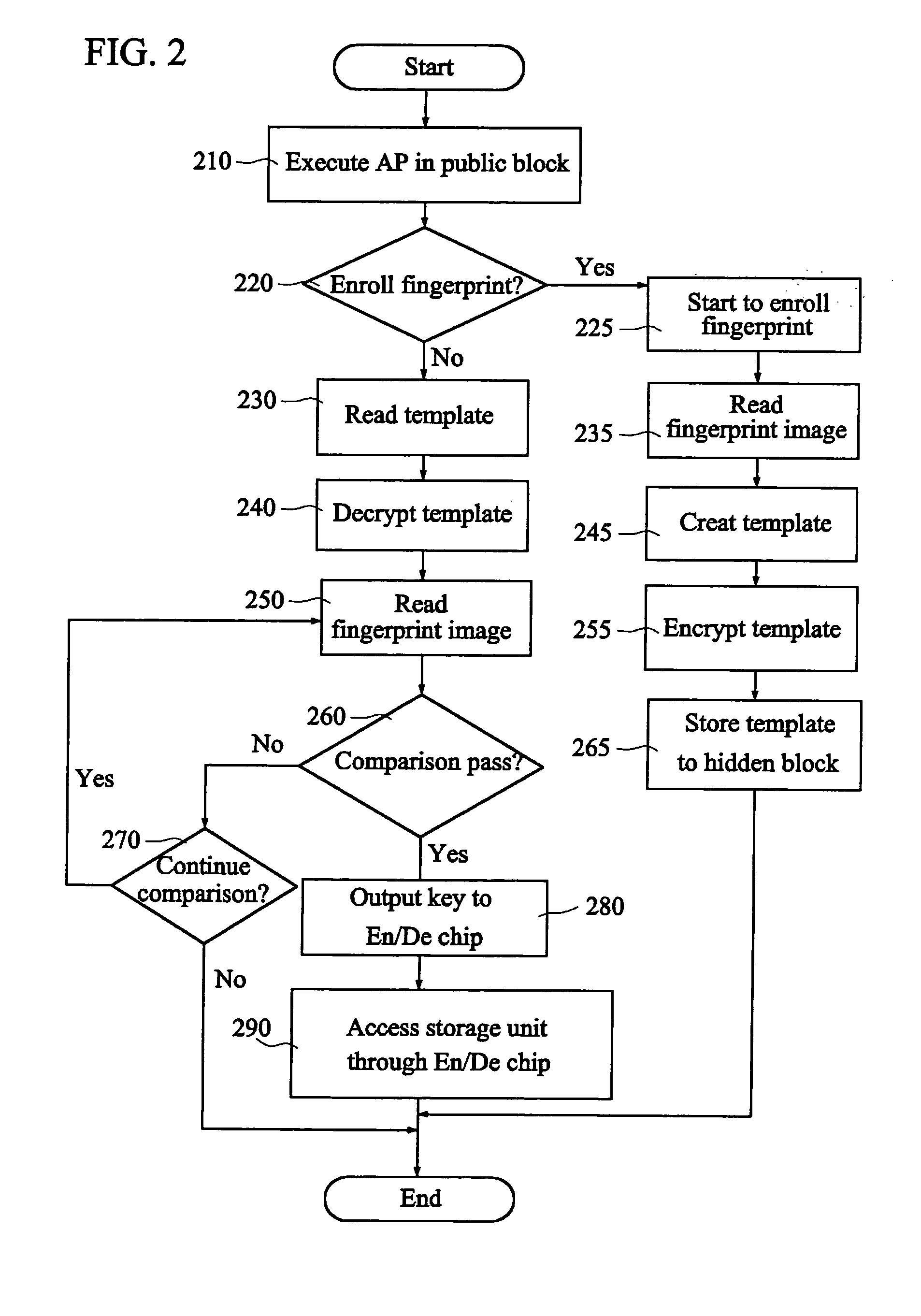

Portable encrypted storage device with biometric identification and method for protecting the data therein

InactiveUS20050244037A1Reduce equipment costsLow costUnauthorized memory use protectionHardware monitoringTerm memoryCell controller

A portable encrypted storage device with biometric identification includes a host interface connected to a terminal host, a controller connected to the host interface, a memory module, a fingerprint sensor, an encryption / decryption chip and a portable large-capacity storage unit connected to the controller. The controller communicates with the host by handshakes and enables the host to automatically run a fingerprint identification driver and application program from the memory module to the host. The host receives an instruction from the user through the driver and program, and informs the controller to control the fingerprint sensor to read to-be-recognized fingerprint data of the user. The host judges whether or not the to-be-recognized fingerprint data substantially matches with a fingerprint template stored in the memory module. If a match occurs, the host can recognize and access the hidden portable large-capacity storage unit through the encryption / decryption chip.

Owner:AIMGENE TECH +1

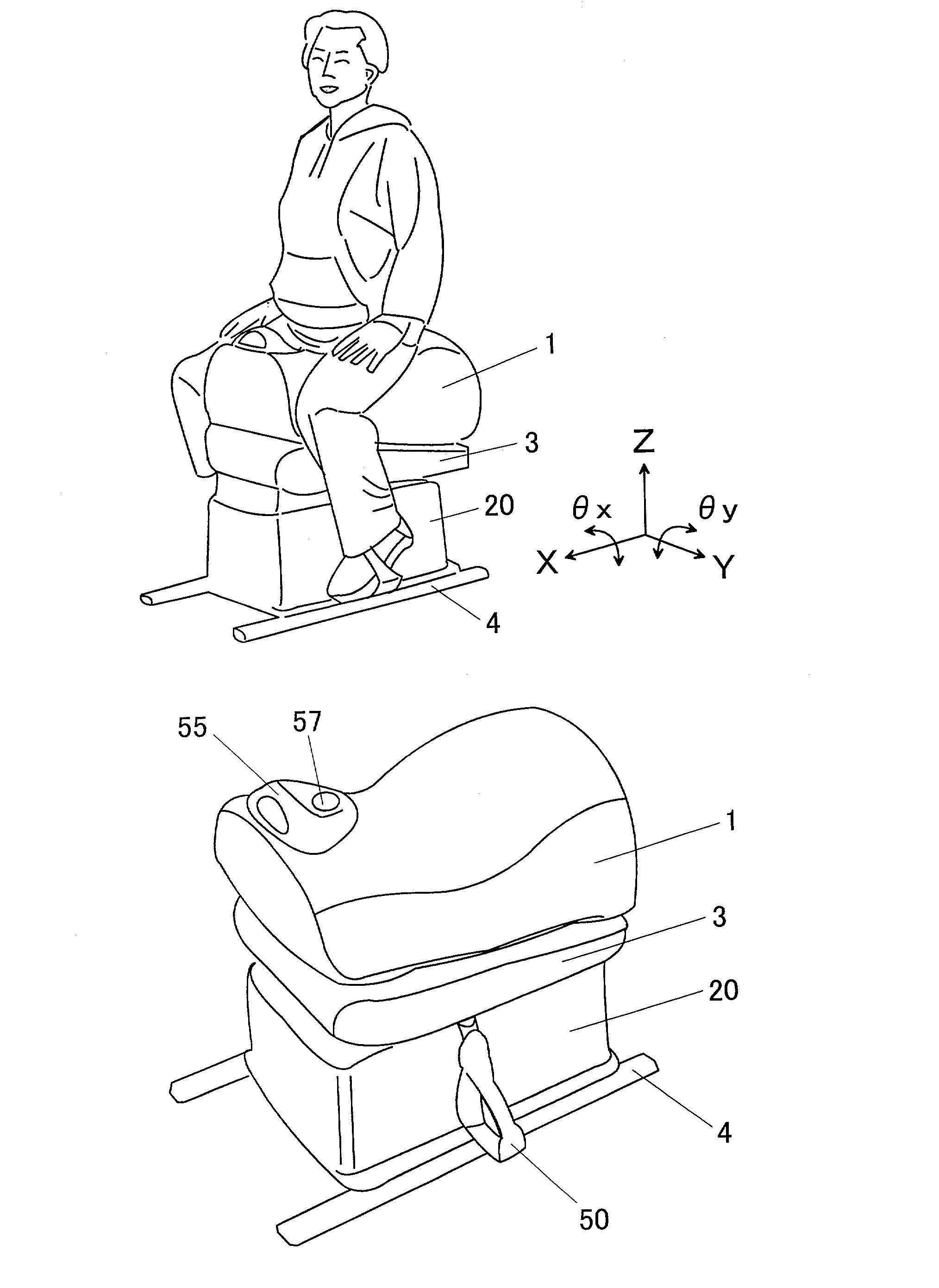

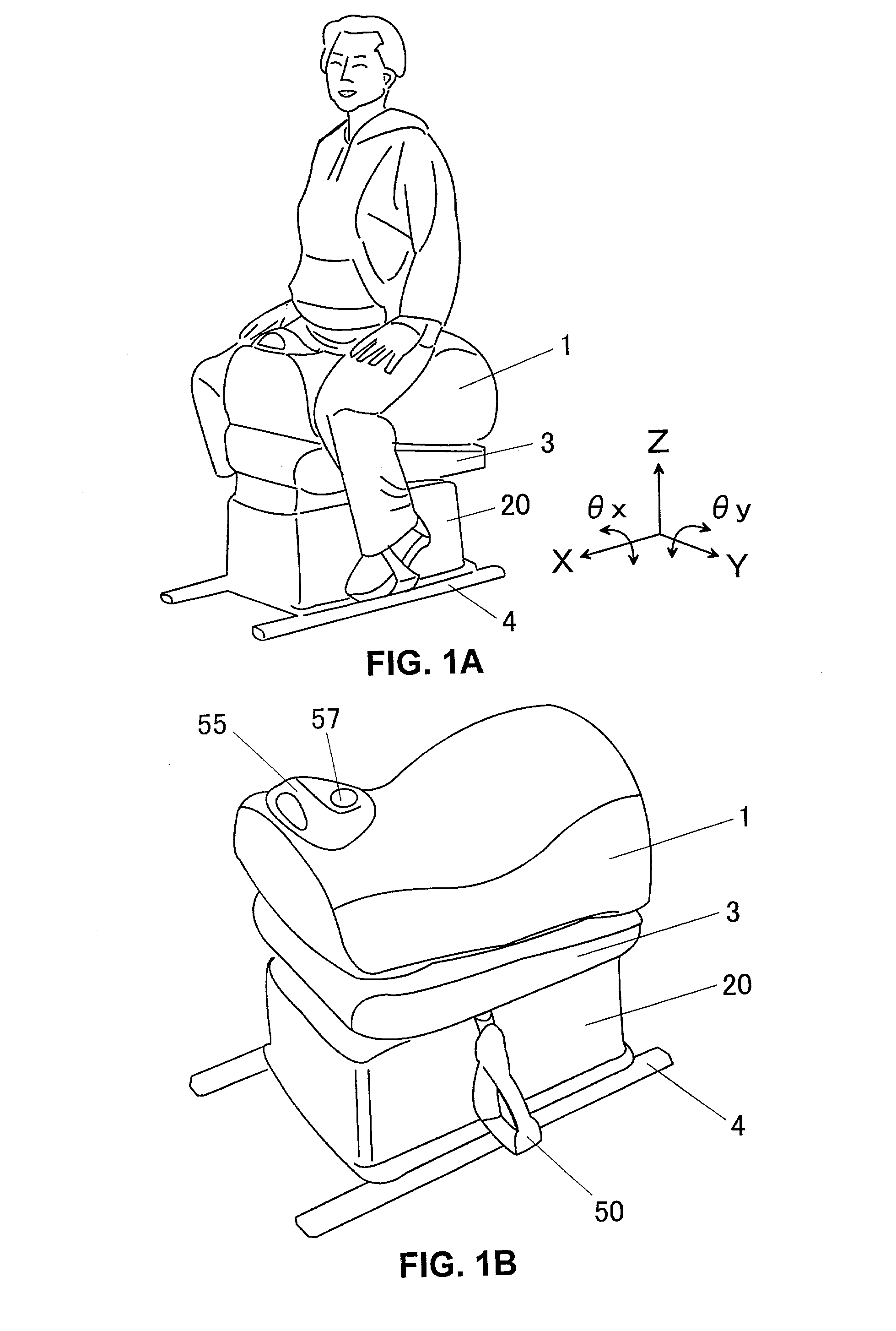

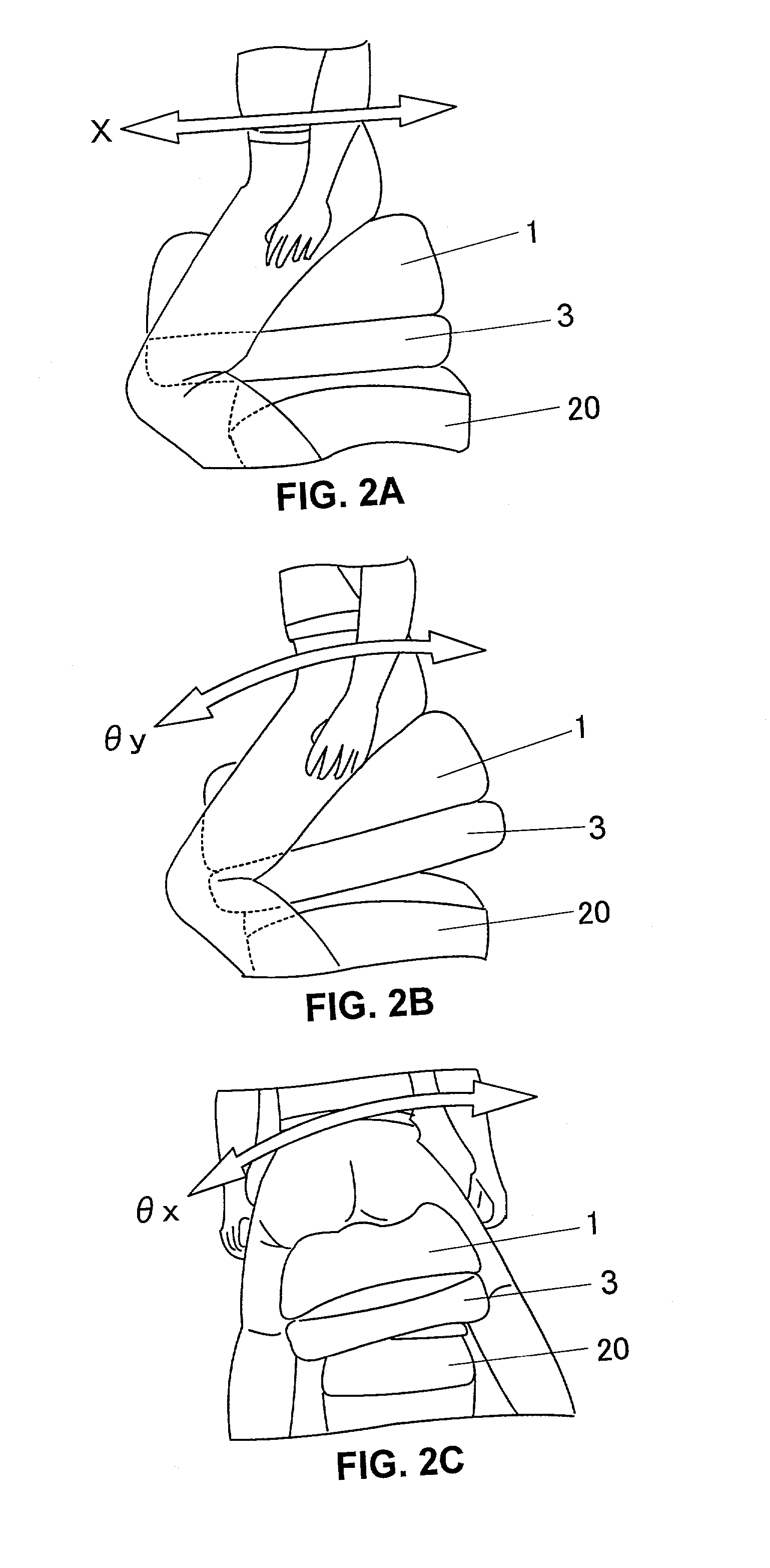

Balance training device

InactiveUS7070415B2Efficiently provideReduce equipment costsCosmonautic condition simulationsStage arrangementsBody balanceReciprocating motion

A balance training apparatus, which is preferably used for training a body balance function and a locomotive function of a user, and for rehabilitation for lumbago prevention, is provided. This apparatus has a seat for the user and a driving unit for driving the seat. The driving unit comprises a drive source and a power transmission unit for converting an output of the drive source into a horse-riding motion, which is a combination of a rectilinear reciprocating motion in a forward and backward direction (X) of the seat, a first pivotal reciprocating motion (θy) about an axis extending in a horizontal direction substantially perpendicular to the forward and backward direction, and a second pivotal reciprocating motion (θx) about an axis extending in the forward and backward direction, and transferring the horse-riding motion to the seat.

Owner:MATSUSHITA ELECTRIC WORKS LTD

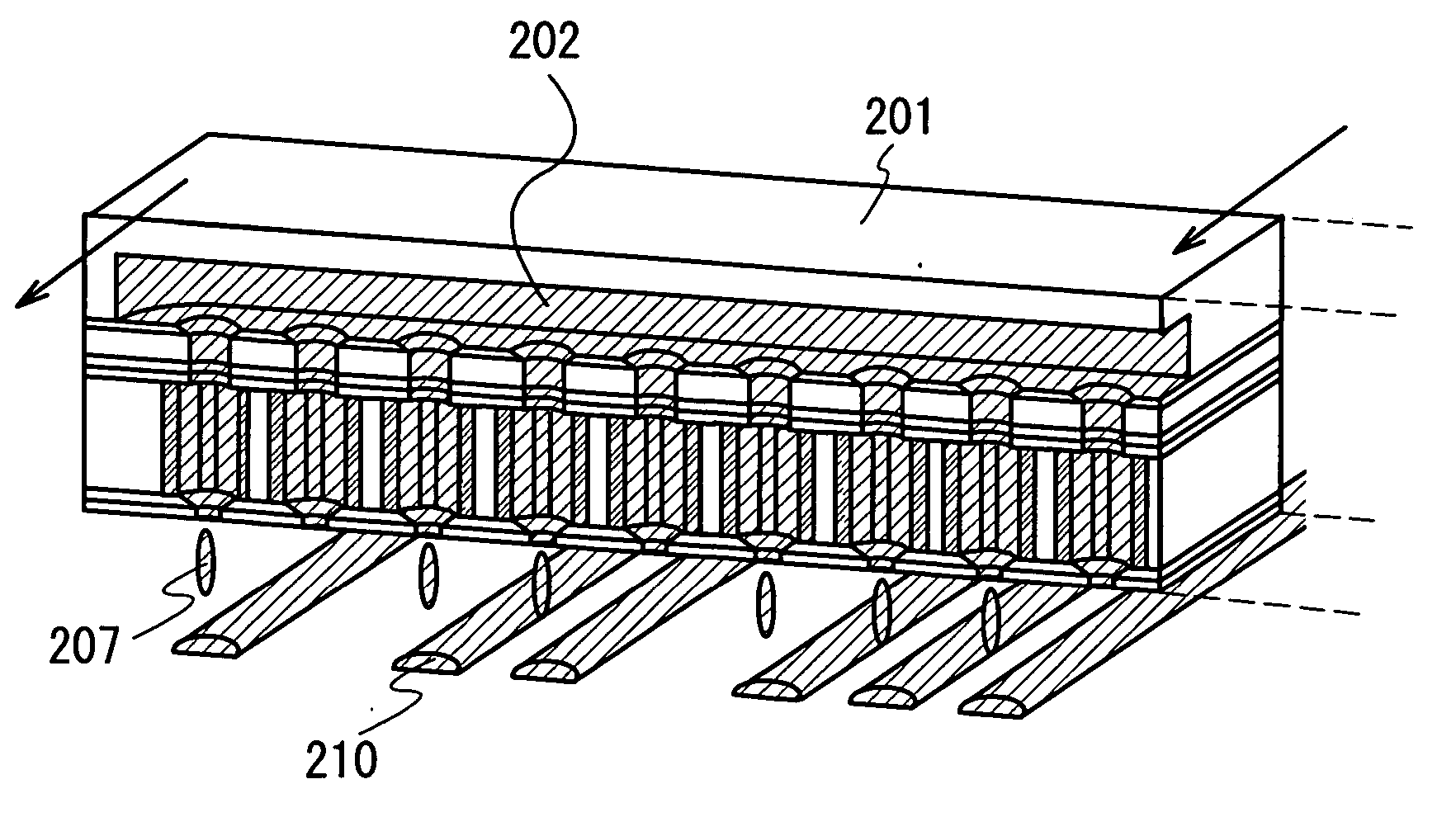

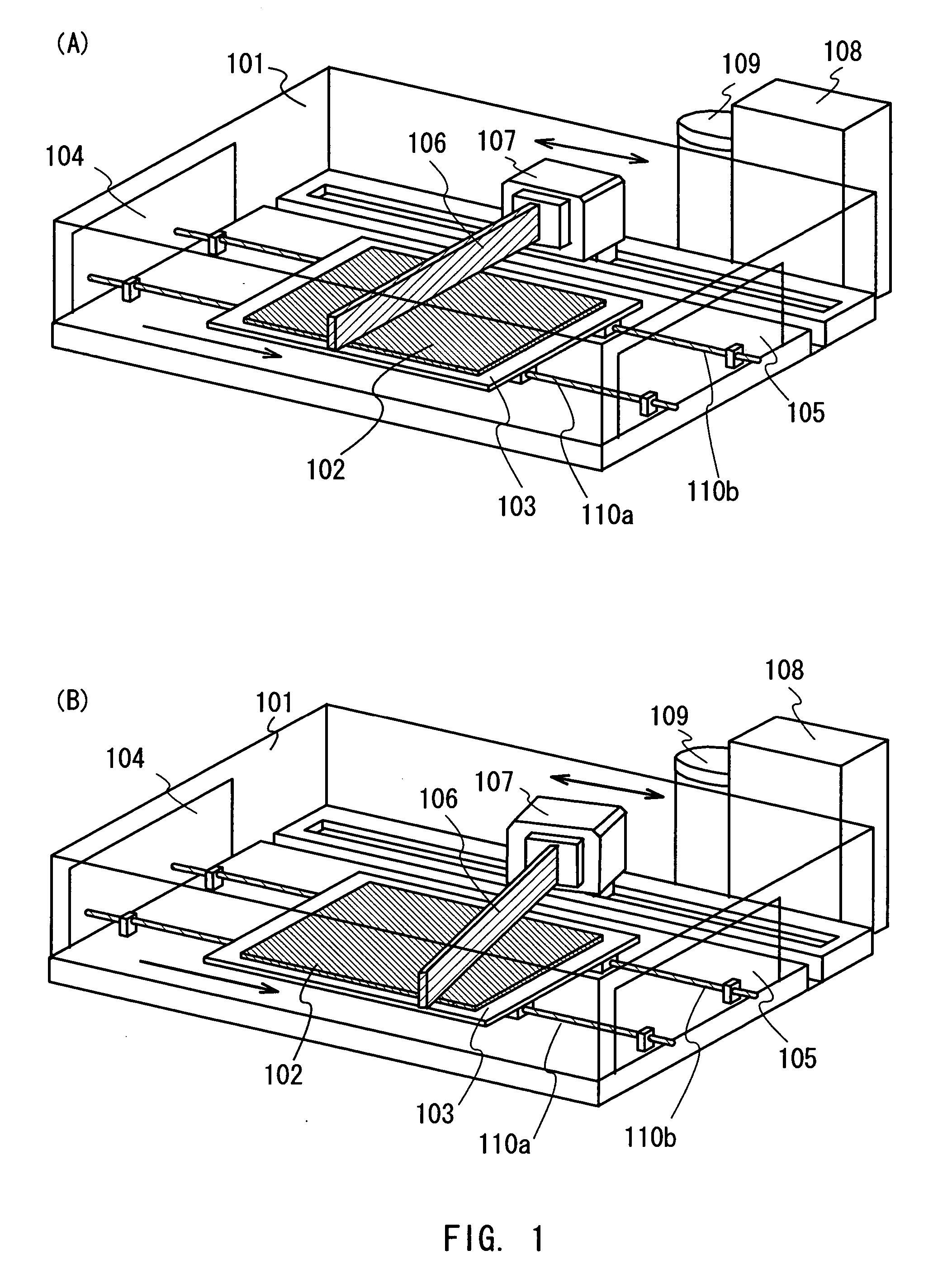

Method of manufacturing a display device

InactiveUS20050090029A1Simple processSuppress energySolid-state devicesPhotomechanical apparatusResistDisplay device

In a wiring manufacturing process which uses conventional photolithography, most of resist and wiring material, or process gas which is necessary at the time of plasma processing, etc. is wasted. Also, since air discharging means such as a vacuum equipment is necessary, an entire apparatus grows in size, and therefore, it has been a problem that production cost increases with growing in size of a processing substrate. In this invention, applied is such means that droplets are used for resist and wiring material, and they are emitted directly to a necessary place on the substrate in a line form or a dot form, to draw a pattern. Also, applied is means which carries out a gas reaction process such as ashing and etching, under atmospheric pressure or the vicinity of atmospheric pressure.

Owner:SEMICON ENERGY LAB CO LTD

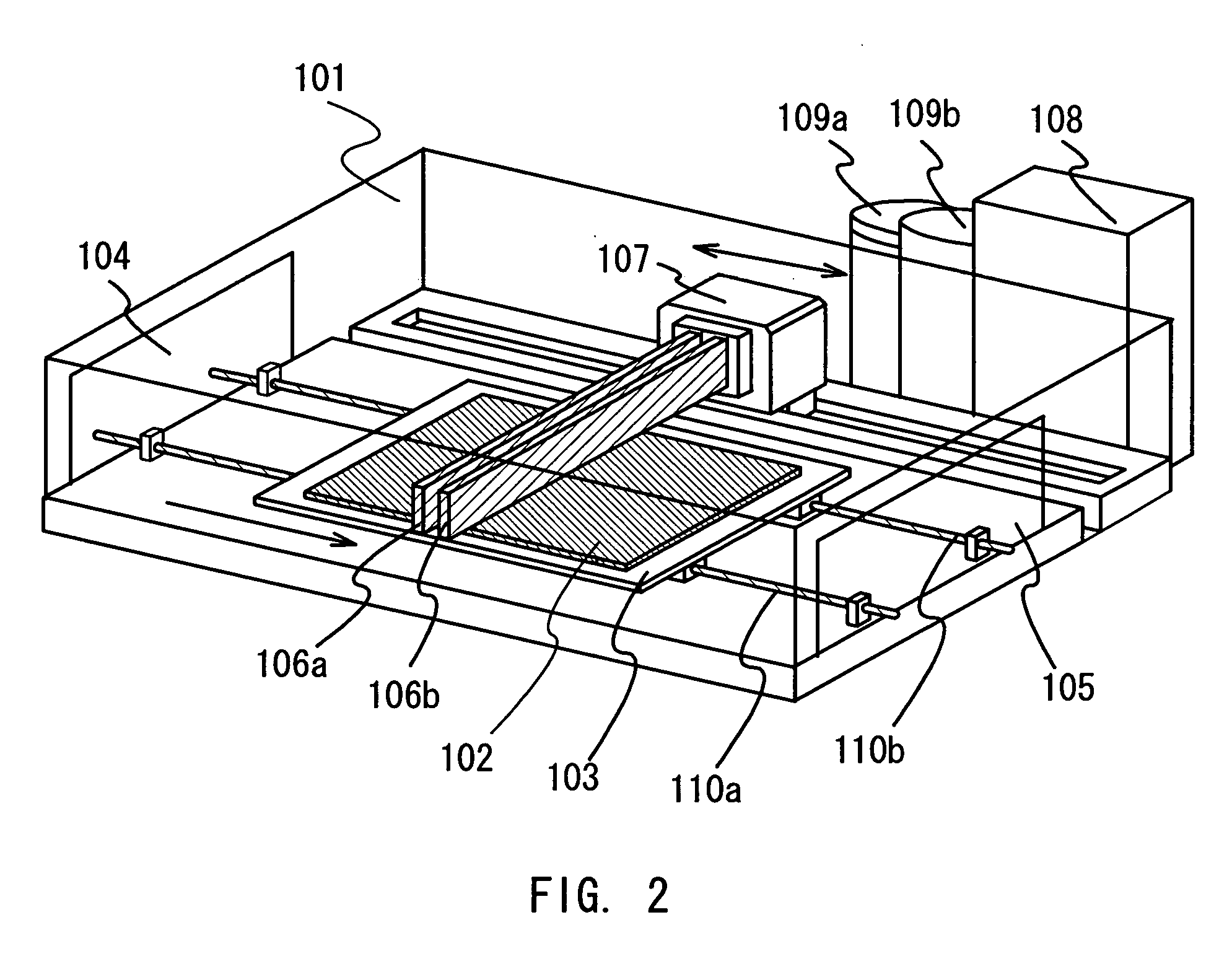

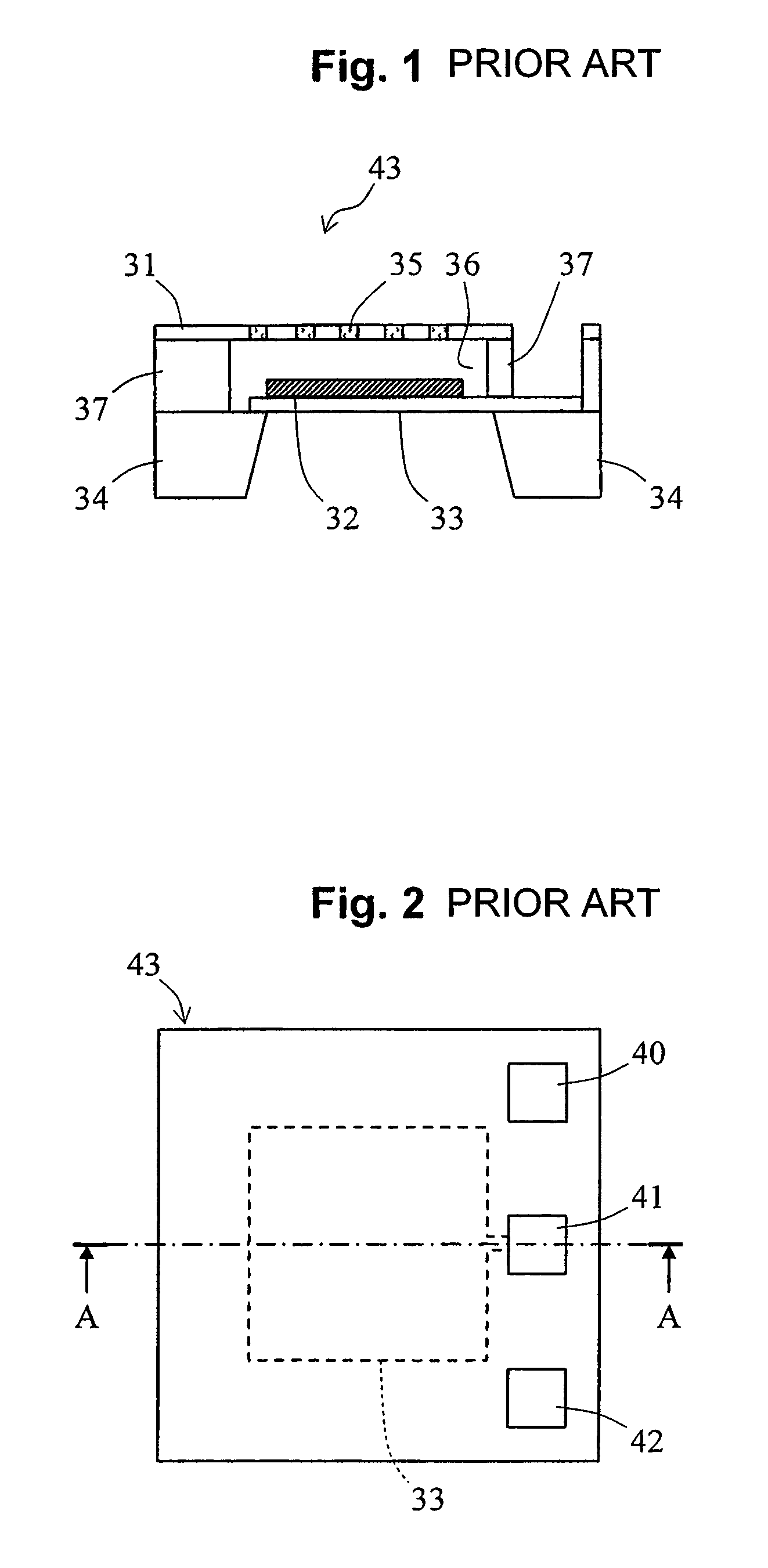

Method of fabricating an ultra-small condenser microphone

ActiveUS7855095B2Improve accuracyShort timeSemiconductor electrostatic transducersSemiconductor/solid-state device manufacturingProduction ratePotential difference

In the present invention, a semiconductor substrate wherein a plurality of MEMS microphones is formed is disposed opposed to a discharge electrode in a state of being stuck on a sheet. Electretization of a dielectric film provided in the MEMS microphone is performed by irradiating the dielectric film between a fixed electrode and a vibration film provided in the MEMS microphone with ions resulting from a corona discharge of the discharge electrode in a state that a predetermined potential difference is applied to the fixed electrode and the vibration film and fixing charges based on the ions to the dielectric film. The electretization is successively performed to each MEMS microphone on the semiconductor substrate by relatively moving the semiconductor substrate and the discharge electrode. Therefore, electretization of the dielectric film in the MEMS microphone chip is realized using a low-cost and simple fabricating equipment and productivity can be enhanced.

Owner:TDK CORPARATION

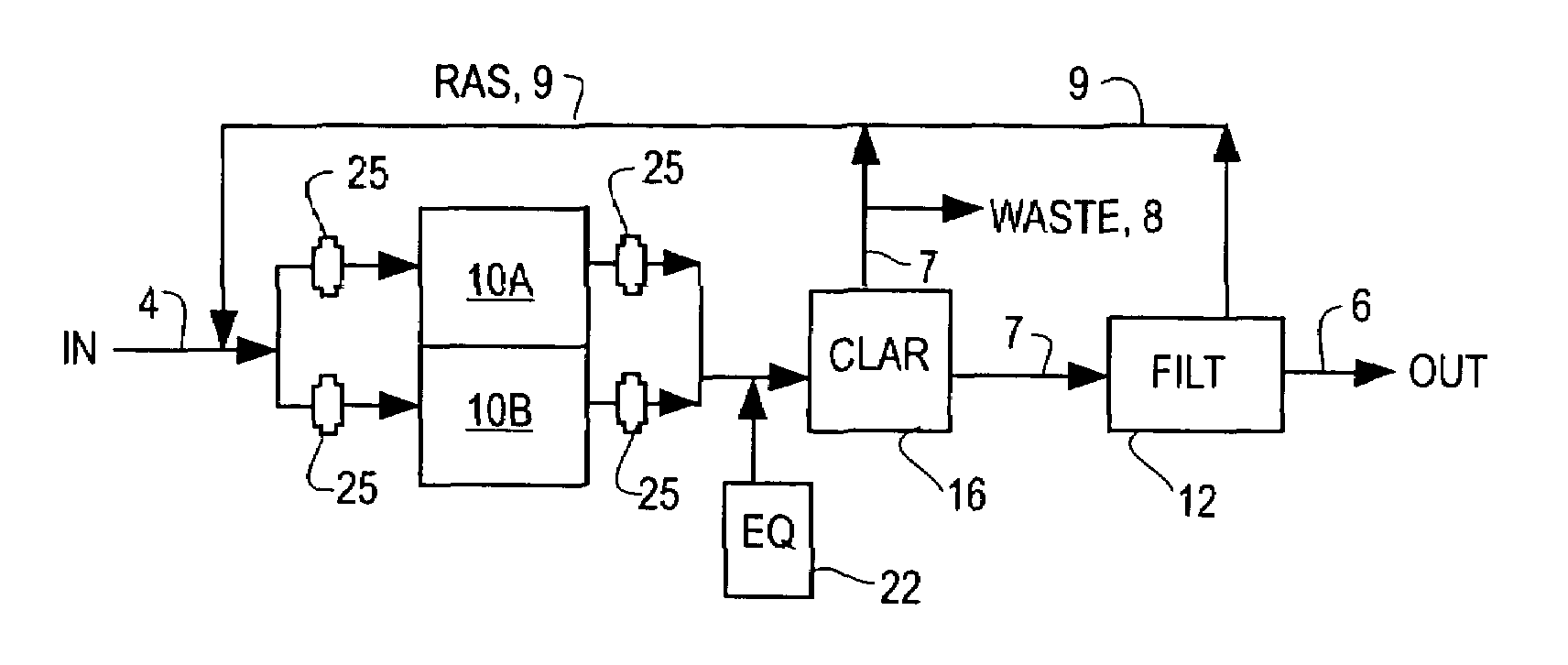

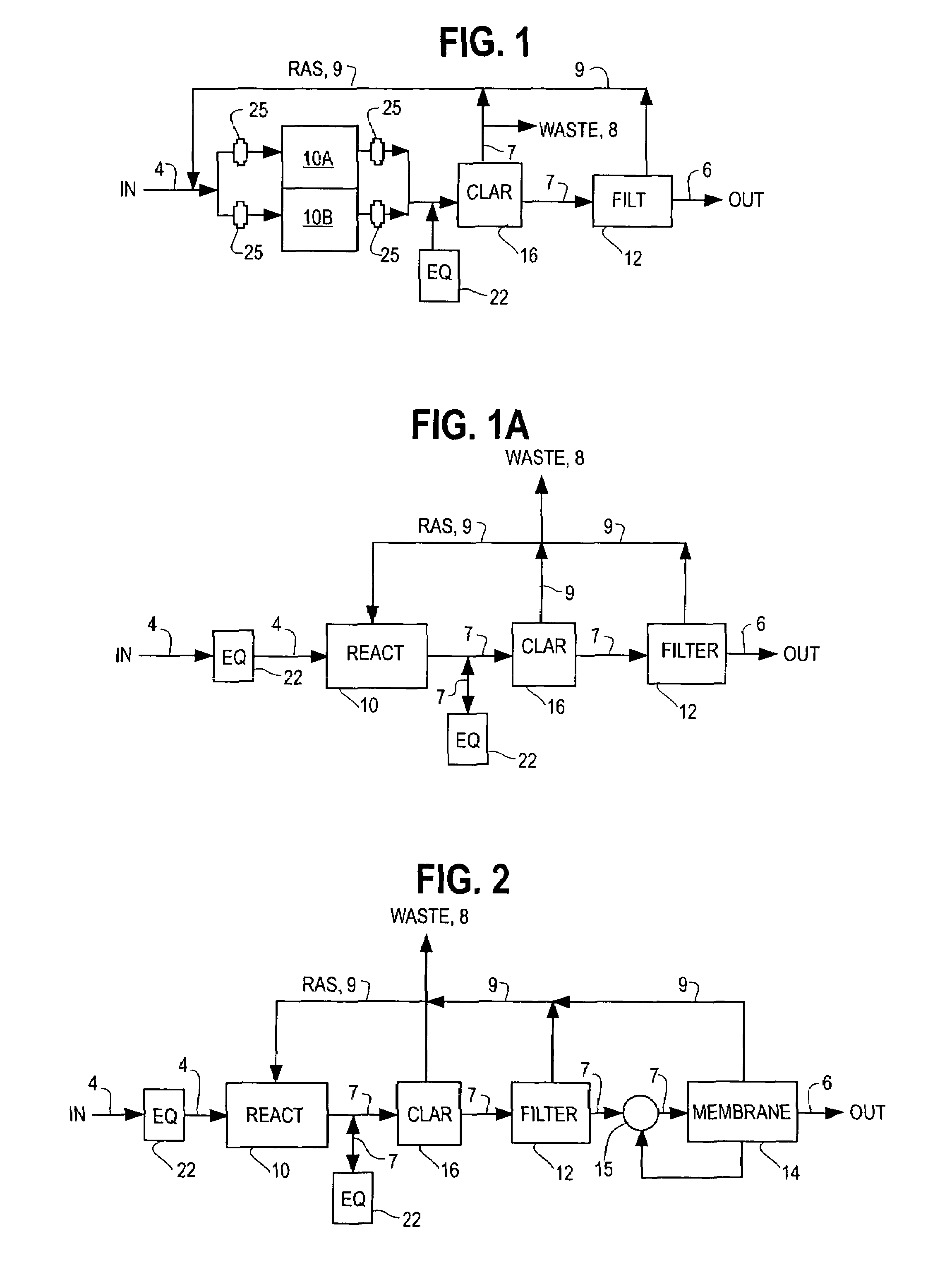

Multiple barrier biological treatment systems

InactiveUS7014763B2Small footprintReduce construction costsTreatment using aerobic processesMultistage water/sewage treatmentSequencing batch reactorSingle vessel

The inventions separate the activated sludge, biochemical reaction stages of the batch treatment process of a sequencing batch reactor from the clarification and sedimentation stages by separating the locations where each process takes place. The separation may be accomplished in a variety of ways including constructing separate basins for each process, installing baffles or other partitions in a single vessel to isolate the areas where each process takes place, or other methods of process separation as are known in the art. In each process, treatment occurs through the performance of a series of operations. The operations are repeated for each batch of wastewater processed by the SBR. In a conventional SBR process, the cycle of operations for clarification and sedimentation are dependent on a preceding biochemical reaction step. However, in the present invention the clarification and sedimentation operations are independent of the biochemical reaction operations. It remains possible to coordinate operations so that the process cycles are coincident, however the benefits of the invention are more readily realized by the practice of independent operation.

Owner:AQUA AEROBIC SYST

Quick connect assembly

InactiveUS20090280673A1Quick connectionReduce equipment costsEngagement/disengagement of coupling partsLighting support devicesElectrical connectionSupport surface

A device for connecting and supporting fixtures, such as electrical fixtures, includes a male plug, a mating female socket and a releasable spindle assembly for both holding the plug in the socket and mechanically mounting the fixture on a supporting surface or an electrical box. The plug is provided with concentric, ring shaped male connectors that are matingly received within similarly shaped female recesses in the socket to create electrical connections and also allow the fixture to be rotated to any of a plurality or mounting orientations. The releasable spindle assembly is controlled by the actuation of a push rod operated by a tool or user's finger.

Owner:KOHEN RAN

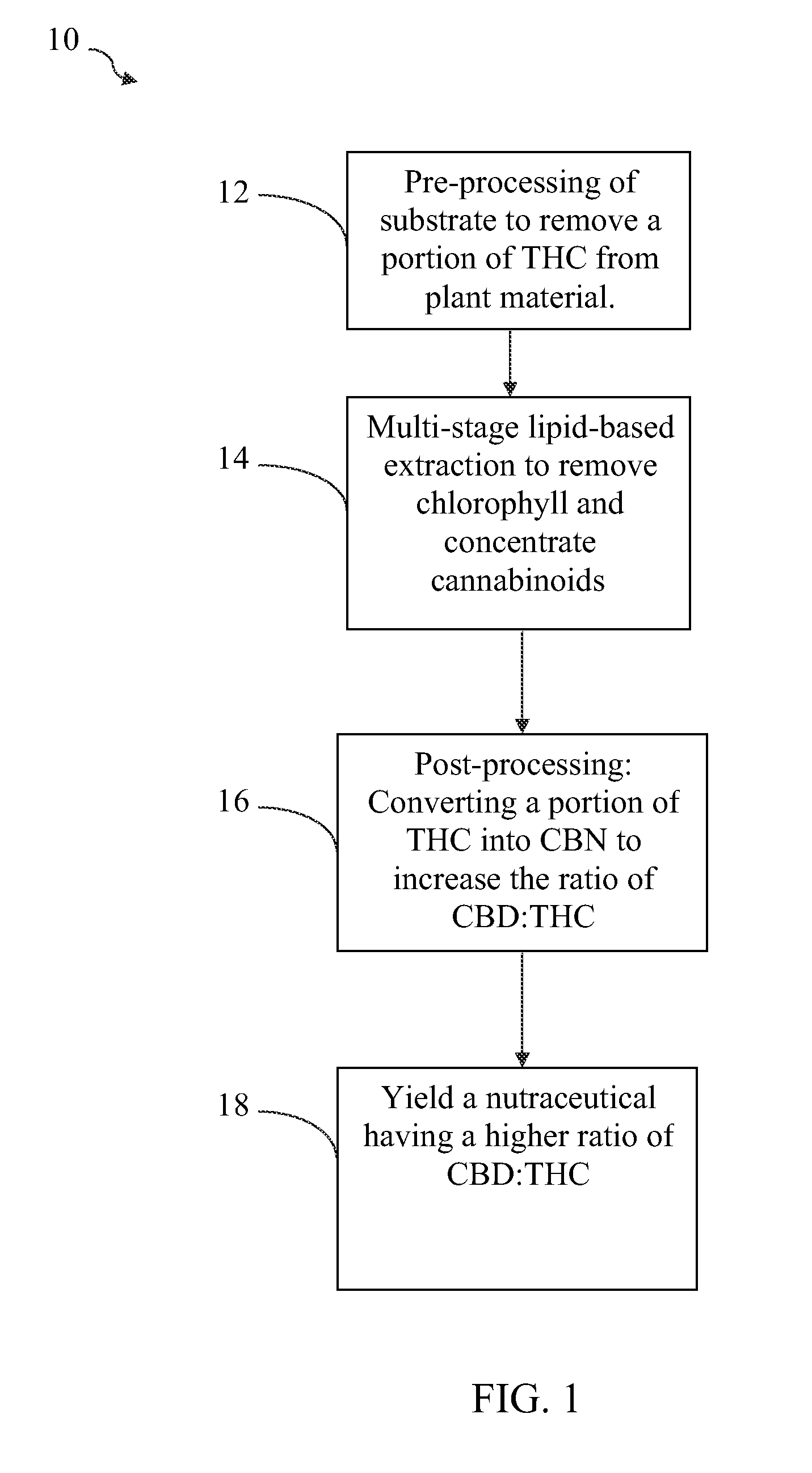

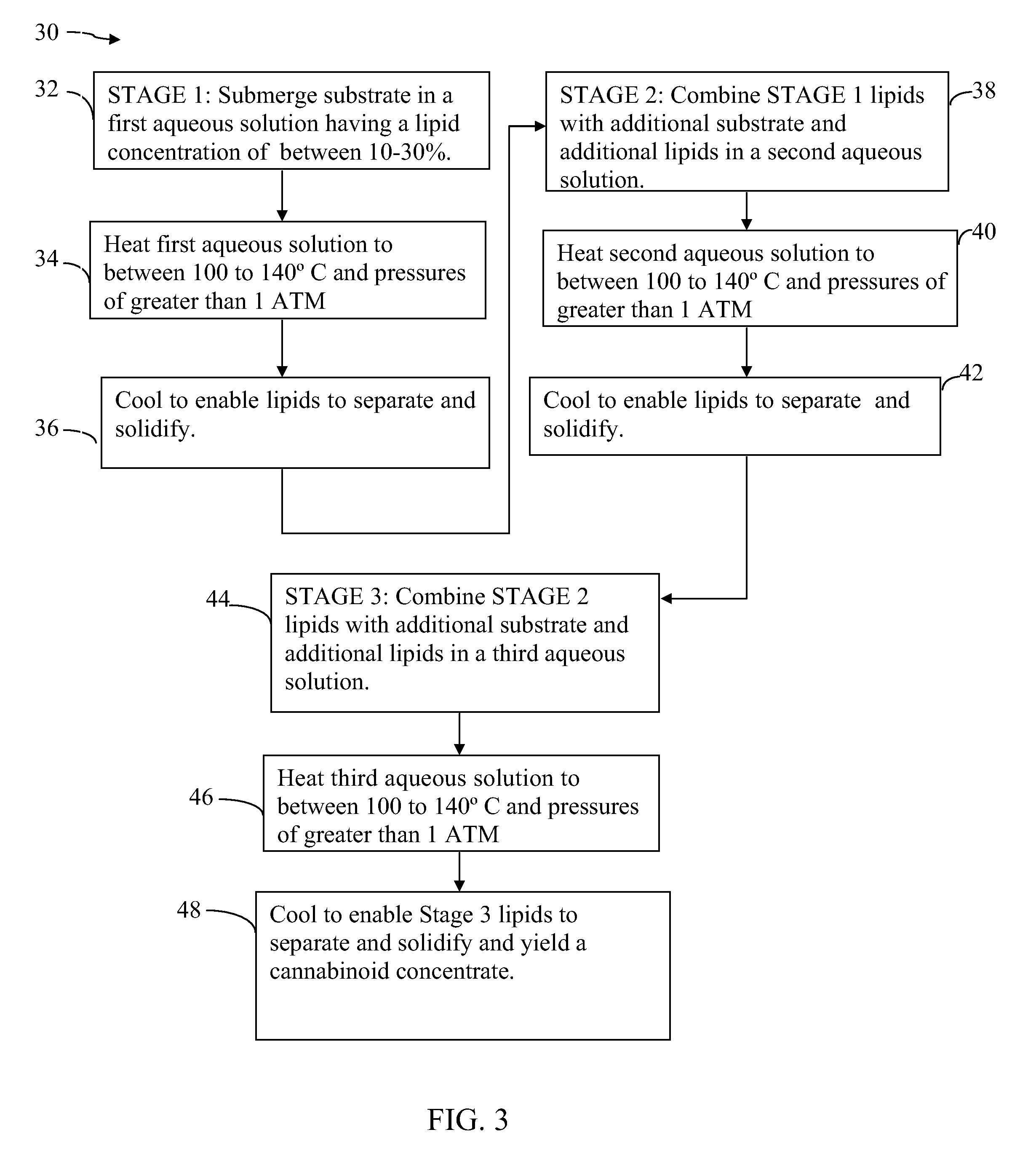

Method for modifying THC content in a lipid-based extract of cannabis

ActiveUS9259449B2Lower THCReduces psychoactivityBiocideHydroxy compound active ingredientsCannabisMedicine

Owner:RADERMAN HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com