Patents

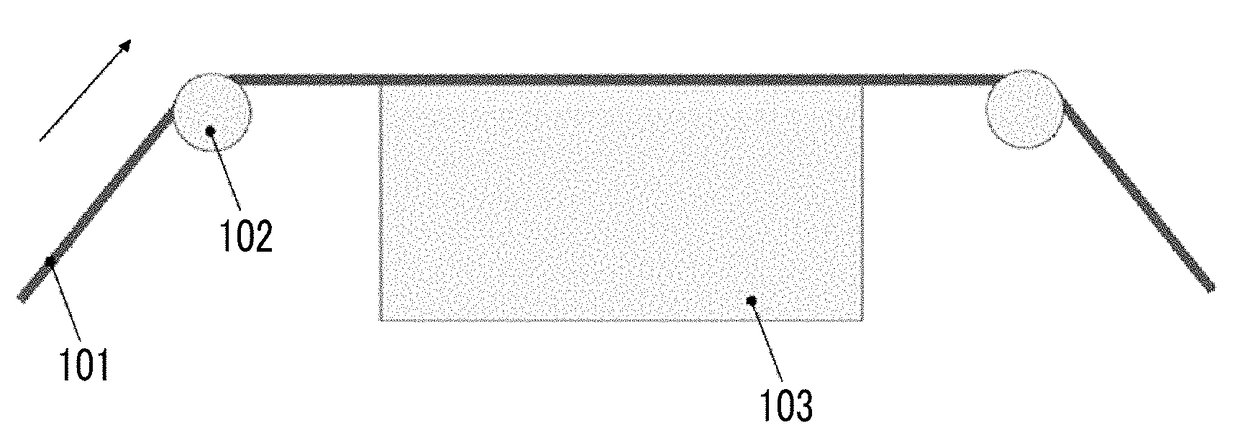

Literature

292results about How to "Reduce running" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

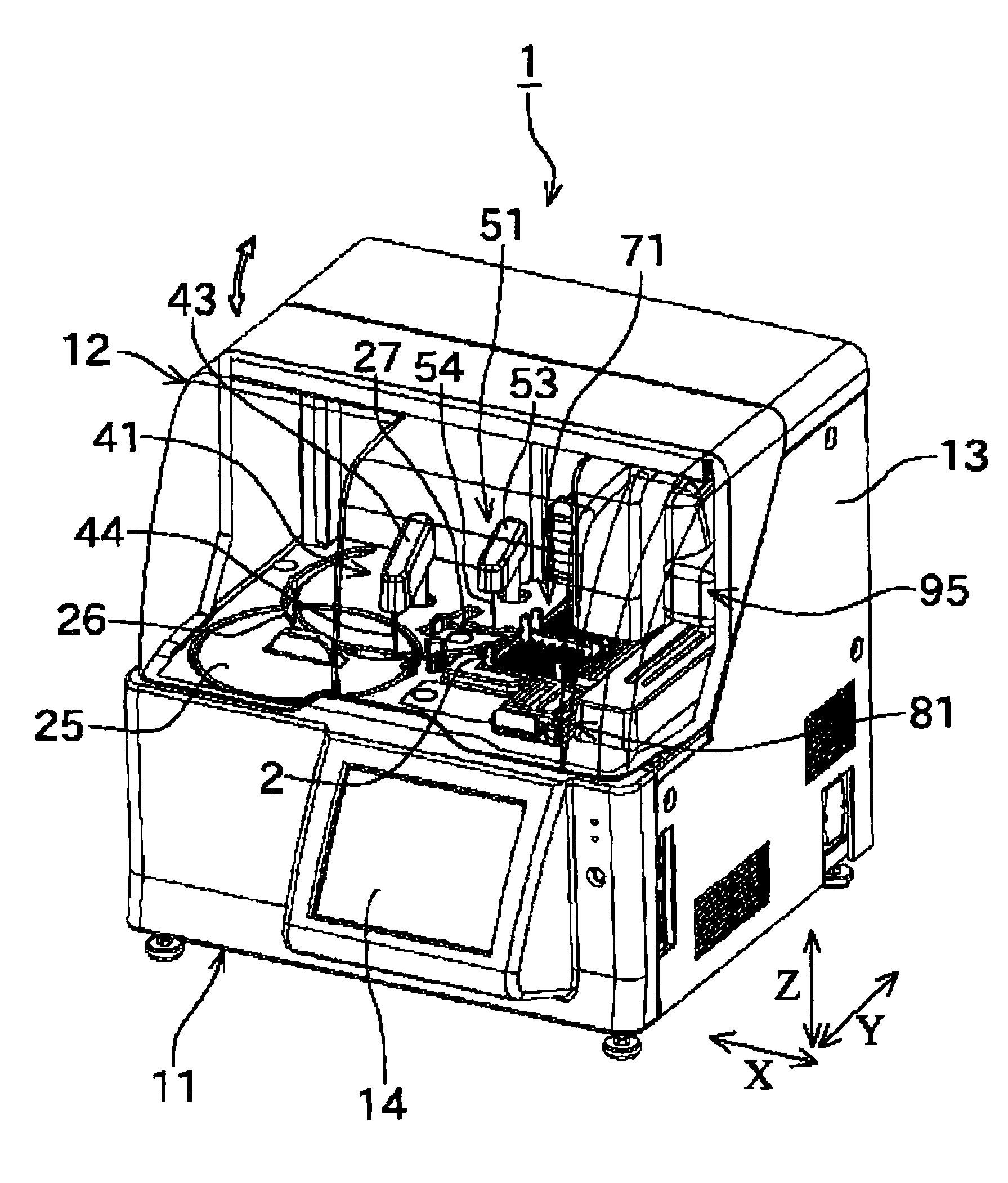

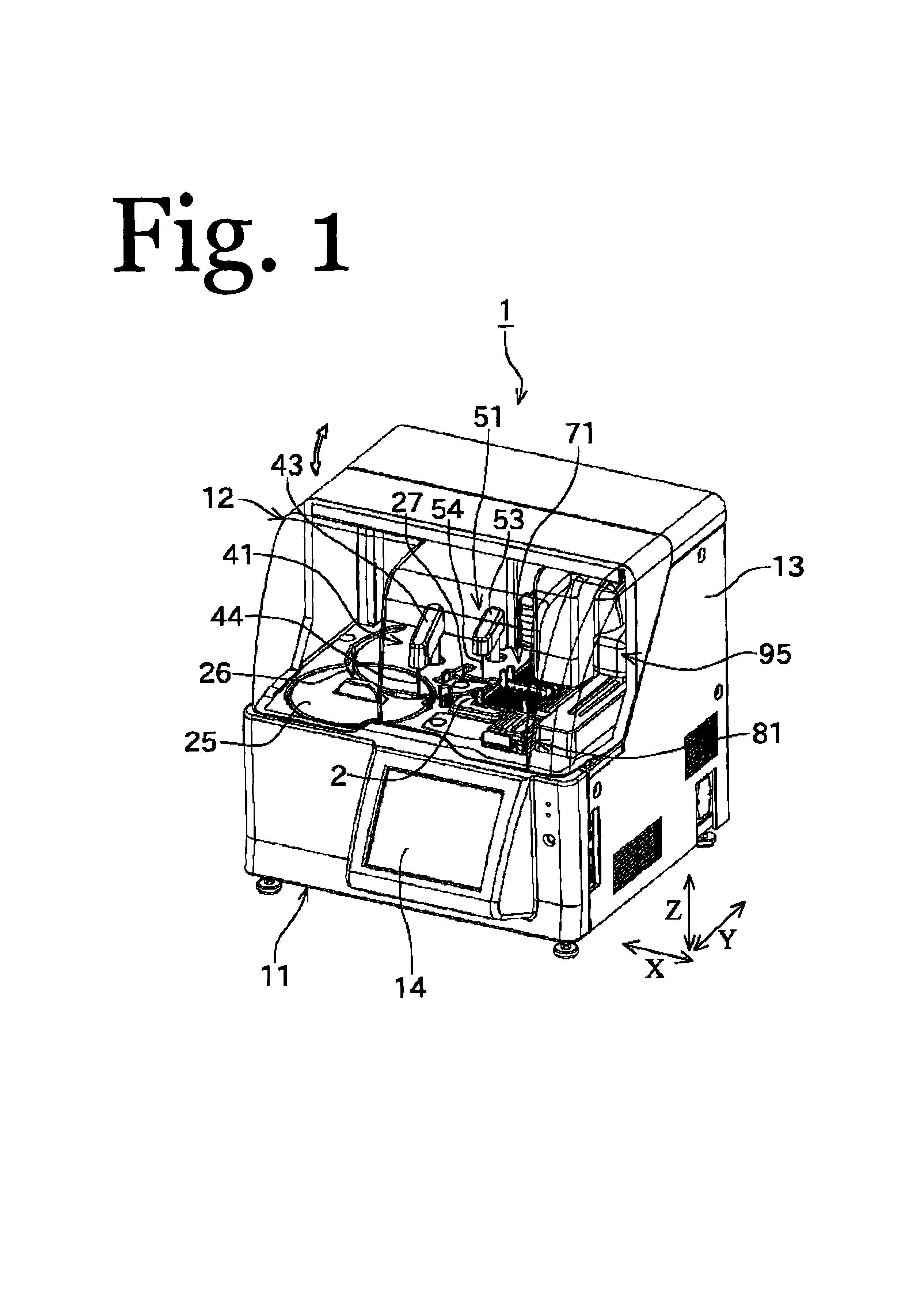

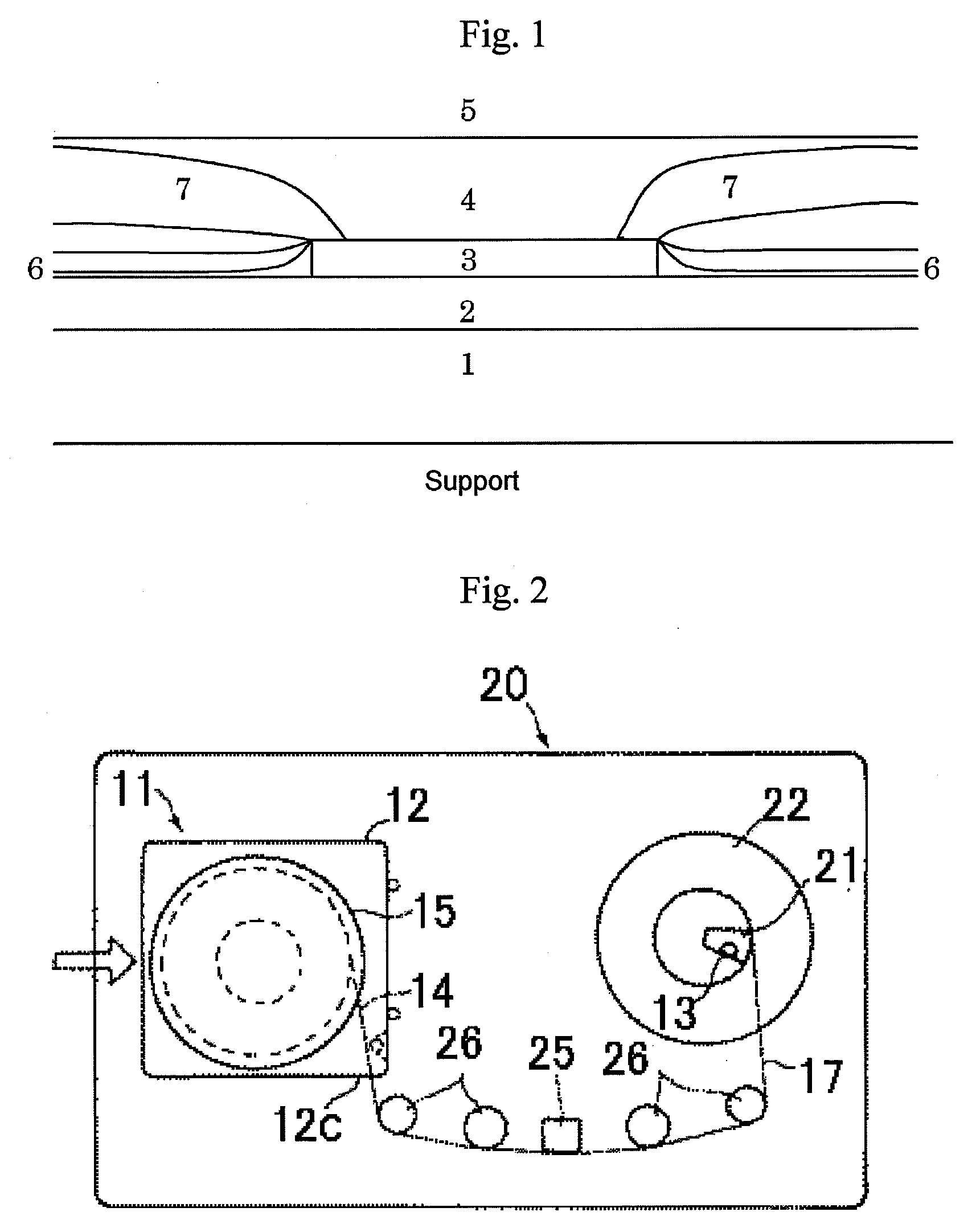

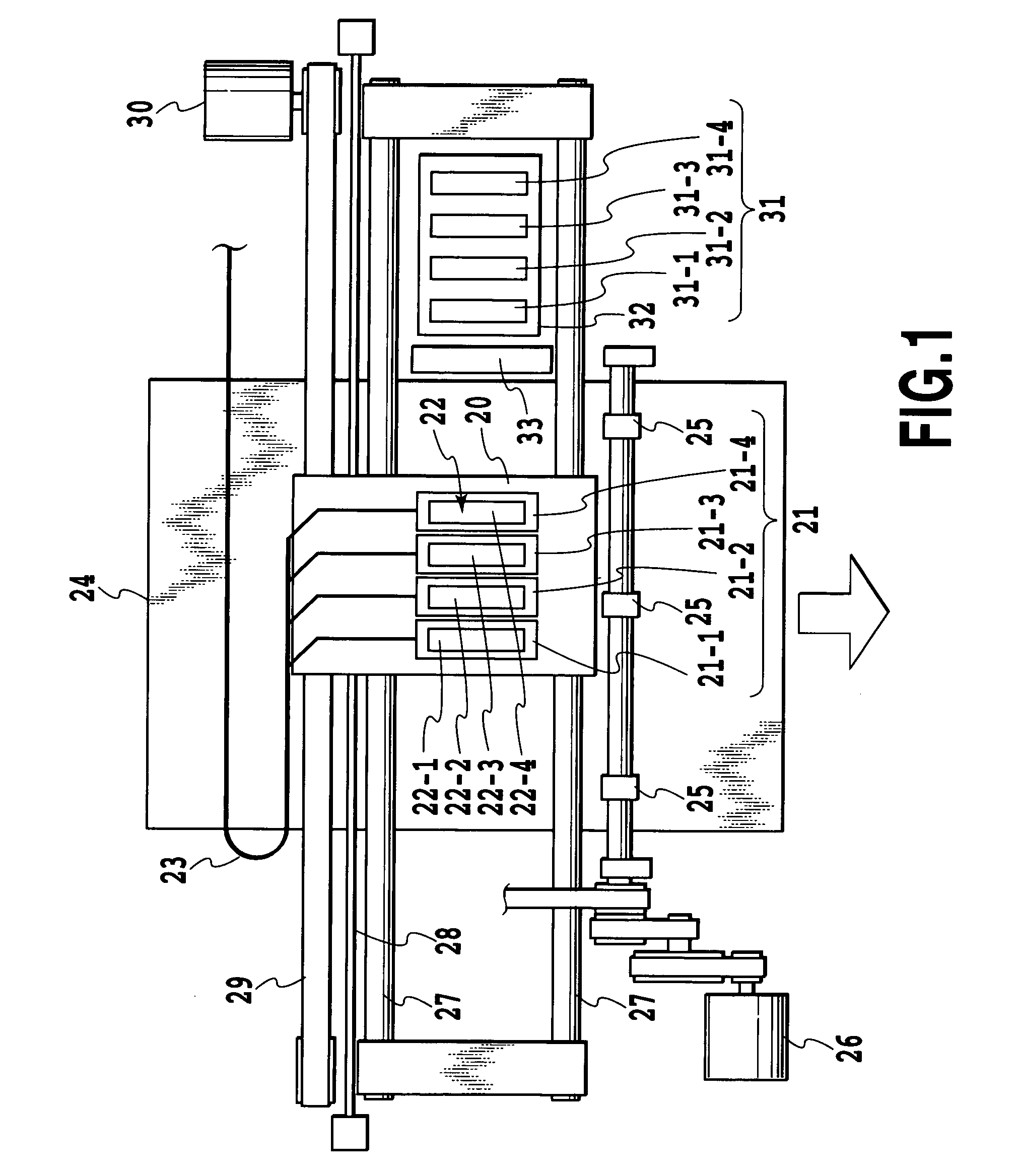

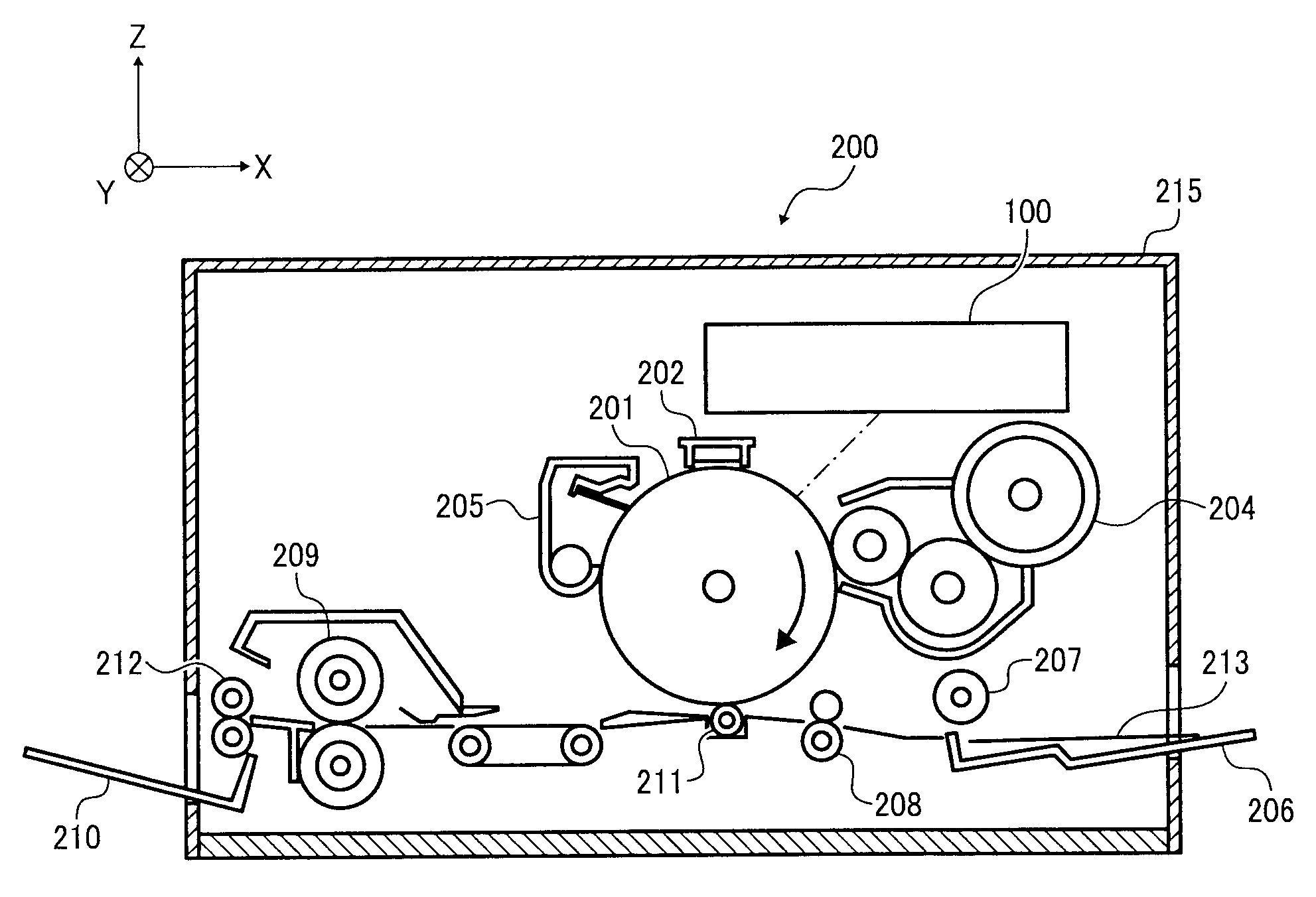

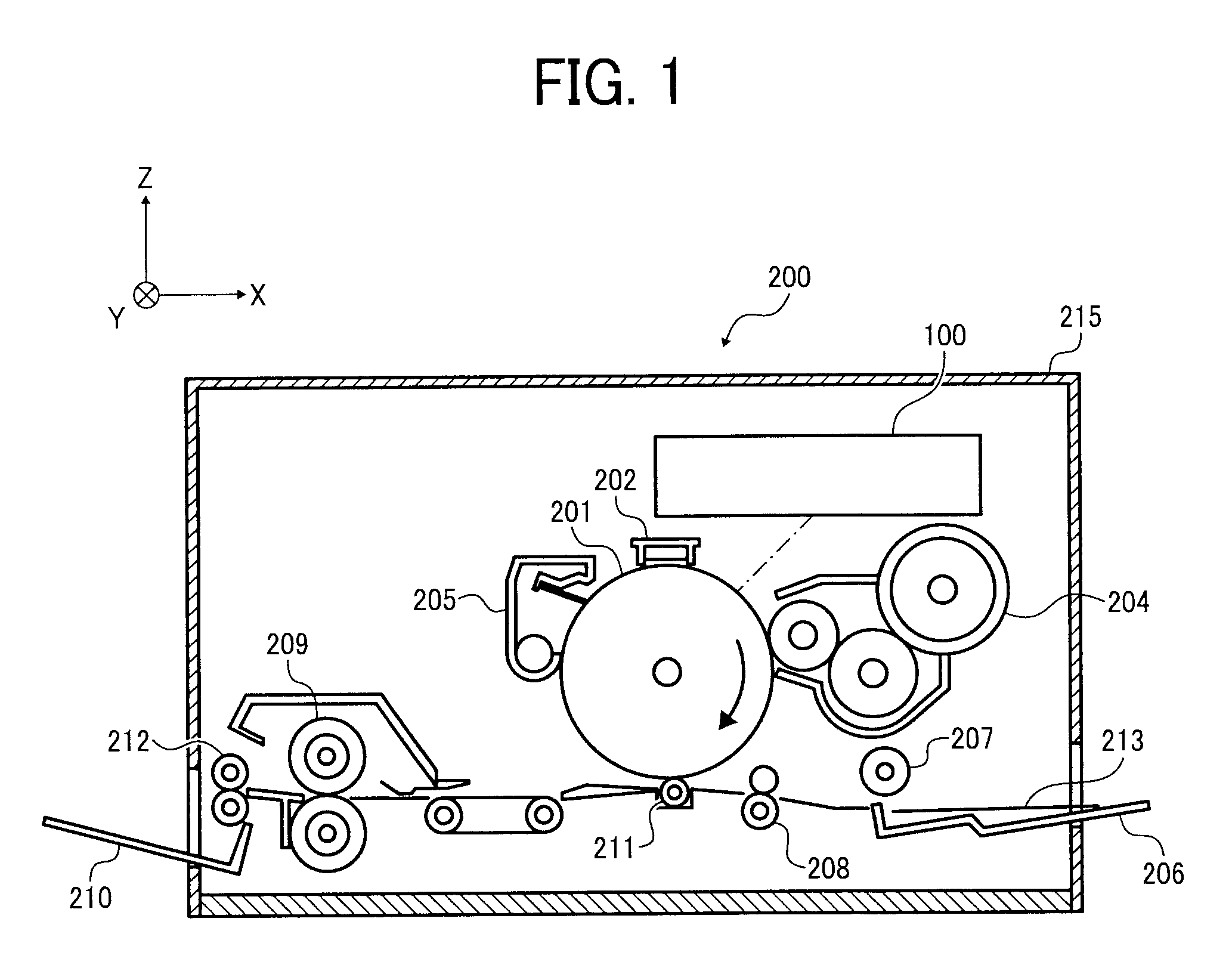

Automatic analyzer

ActiveUS8043560B2High measurement accuracyLittle changeAnalysis using chemical indicatorsMicrobiological testing/measurementCuvetteAutoanalysis

An automatic analyzer using a reaction vessels of disposable type is provided which is compact in construction and with high accuracy of measurement.The analyzer is comprised with a reaction container which is capable of having a plurality of cuvettes of disposable type set therein, an extracting and injecting unit for injecting a first reagent, a specimen and a second reagent into a disposable cuvette, a light measuring unit for emitting light to the cuvette, and for measuring absorbance thereof and a CPU for producing a calculated value based on outputs of the light measuring unit.The light measuring unit measures absorbance of the first reagent, specimen and second reagent injected into and reacted with each other in a disposable cuvette, and also measures an air blank value representing absorbance of an empty disposable cuvette and a first reagent blank value representing absorbance of a disposable cuvette having first reagent in the cuvette (S104, S106). The CPU compensates the absorbance based on at least one of the air blank value and the first reagent blank value (S112, S113).

Owner:FURUNO ELECTRIC CO LTD

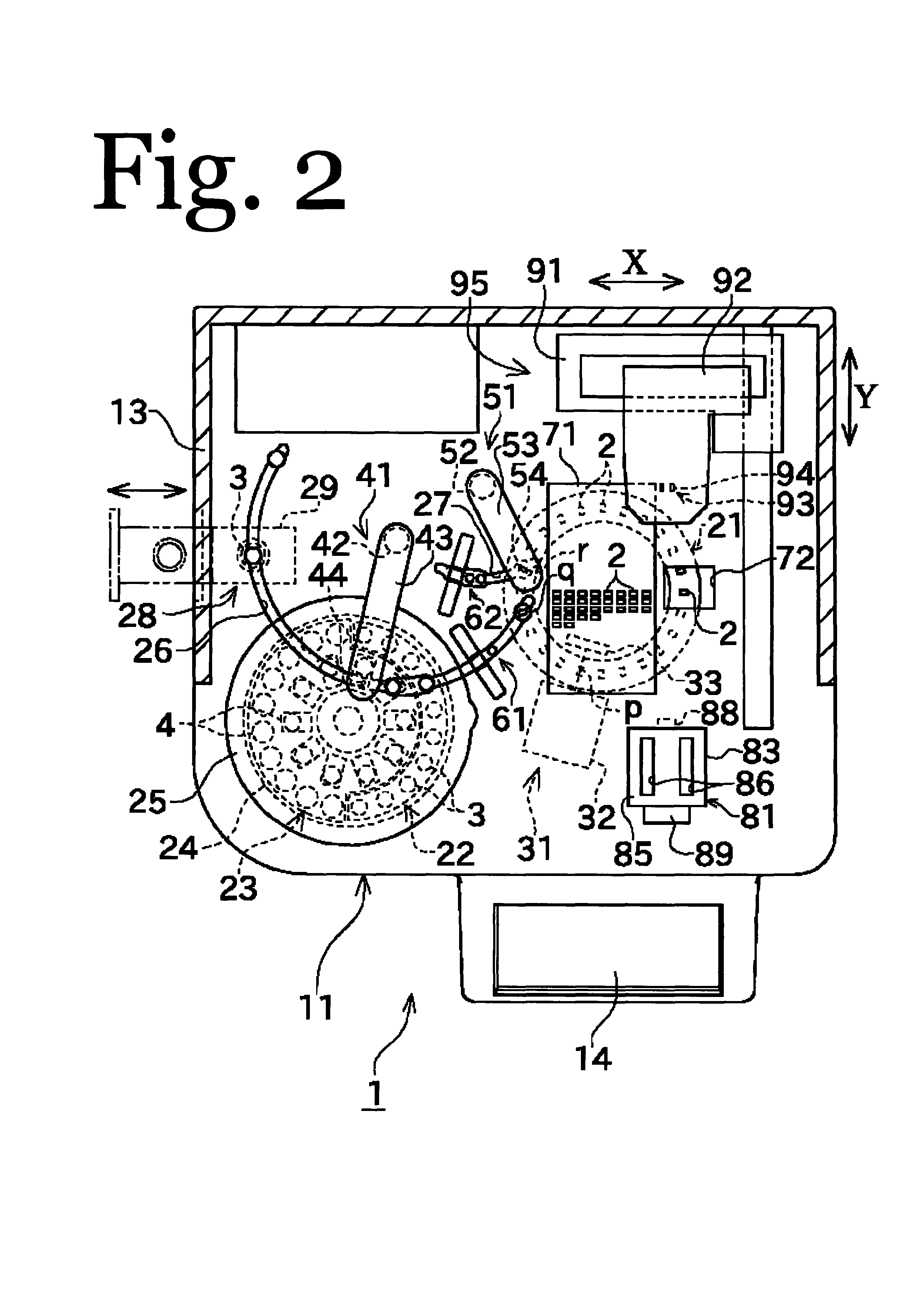

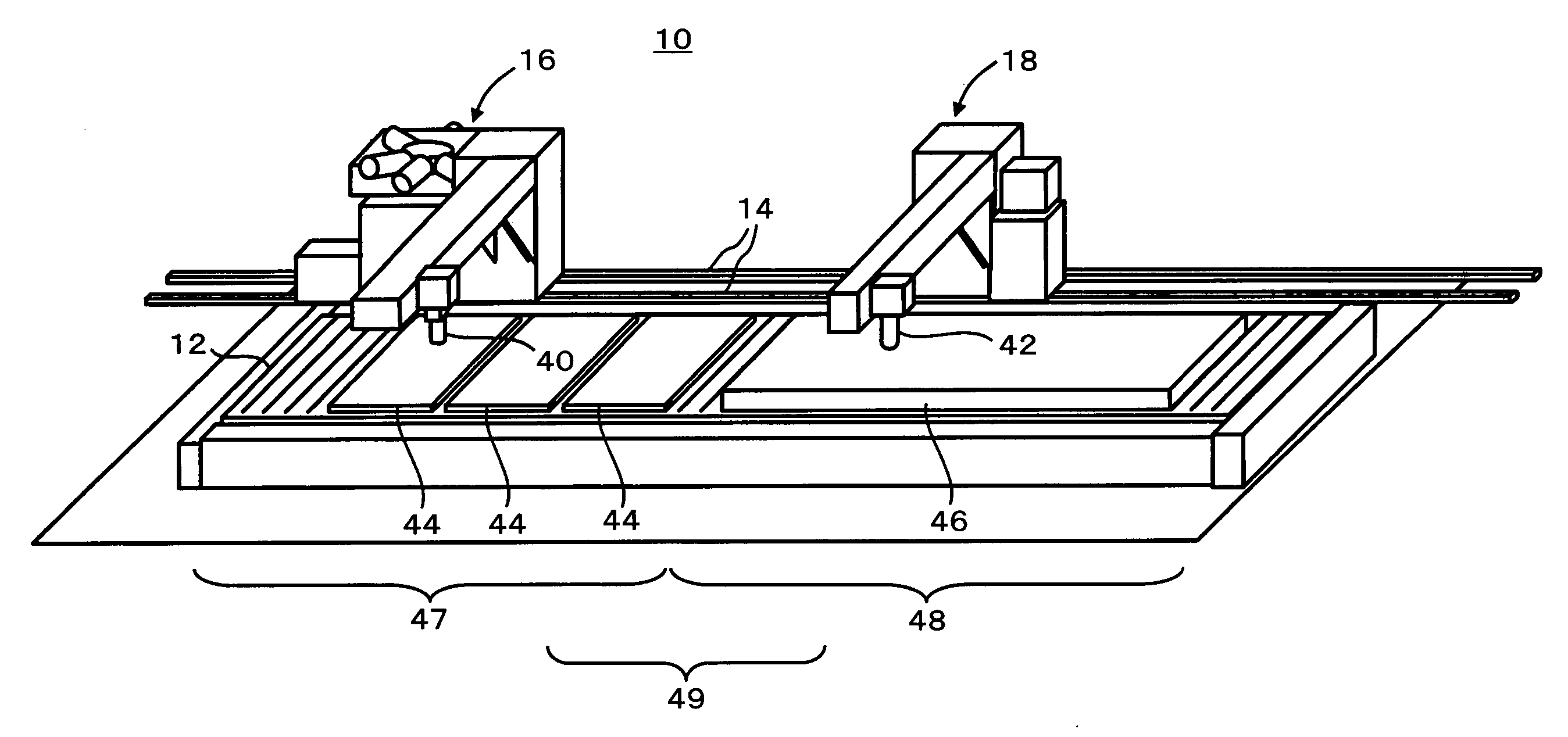

Determination of characteristics of material

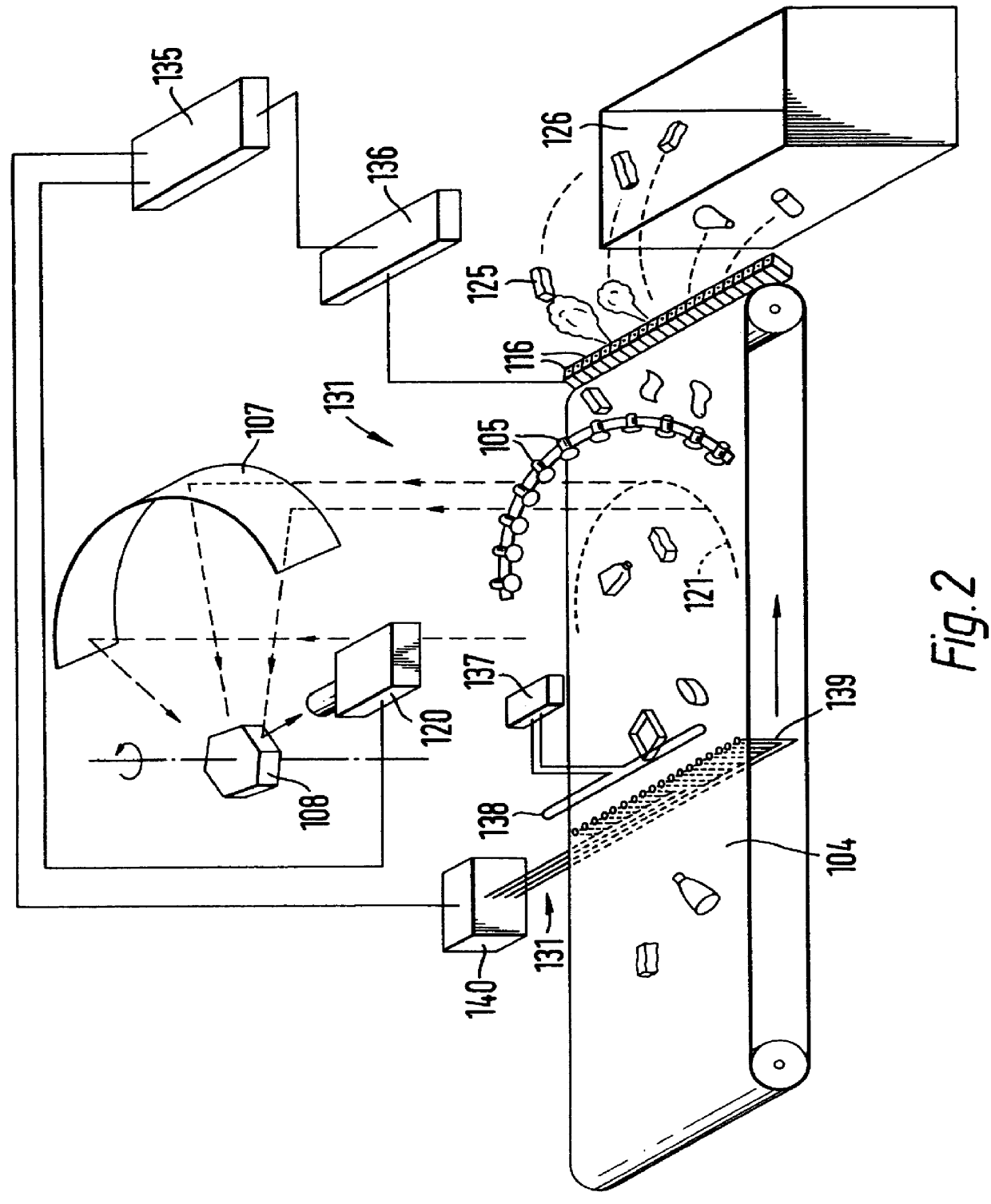

InactiveUS6060677ALow costReduce runningSolid waste disposalOptical detectionSolenoid valveLength wave

A system for automatically inspecting matter for varying composition comprises one or more detection stations through which one or more streams of matter are advanced and particular materials therein are detected through their diffusely reflected IR spectra, if any, and / or through their variation of an electromagnetic field by their metallic portions, if any. A row of light sources distributed across the overall width of one or more belt conveyors may cause desired portions of the stream to reflect light diffusely onto a part-toroidal mirror extending over that overall width, whence the light is reflected, by a rotating, polygonal mirror through optical filters dedicated to differing IR wavelengths, onto detectors the data output of which is utilized in controlling solenoid valves operating air jet nozzles which separate-out the desired portions. Alternatively or additionally, an oscillator and an antenna which extends over that overall width generate an electromagnetic field through the belt and sensing coils sense variations therein produced by metallic portions of the stream passing through the detection station and the detection data produced by the sensing coils is used to control the solenoid valves operating the nozzles to separate-out the metallic portions.

Owner:TITECH VISIONSORT +1

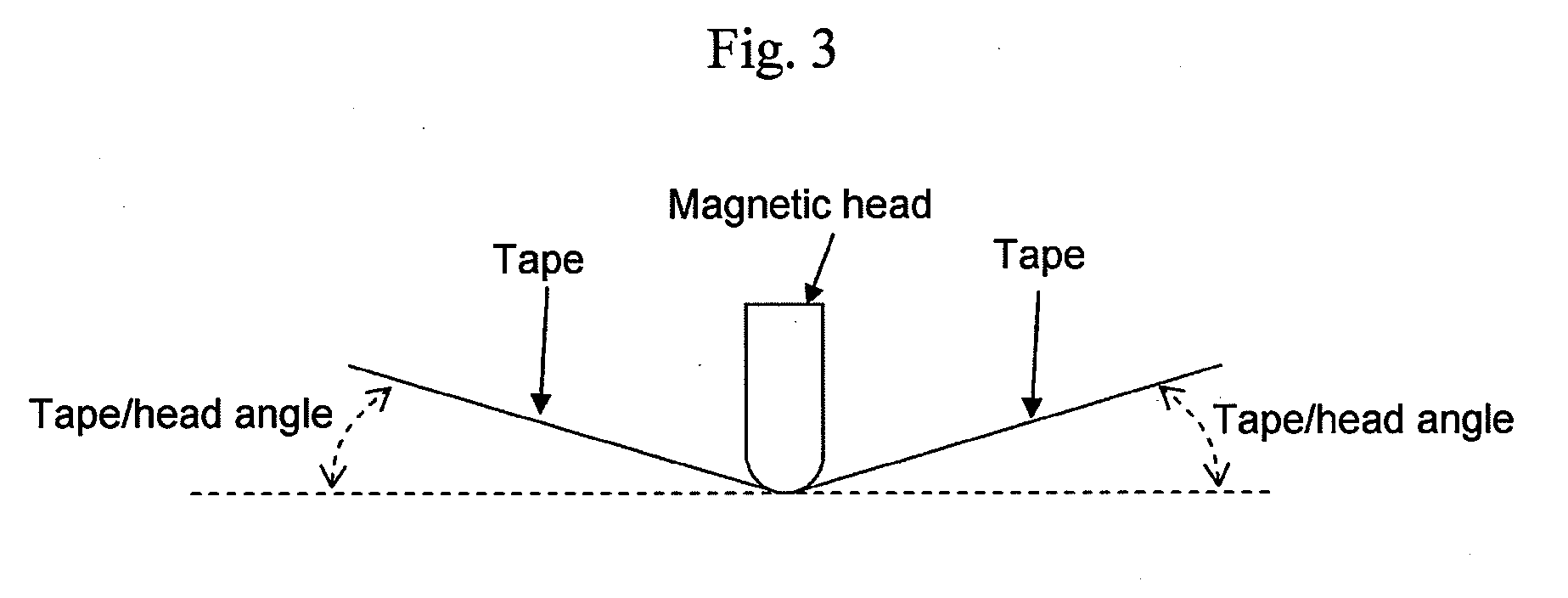

Magnetic signal reproduction system and magnetic signal reproduction method

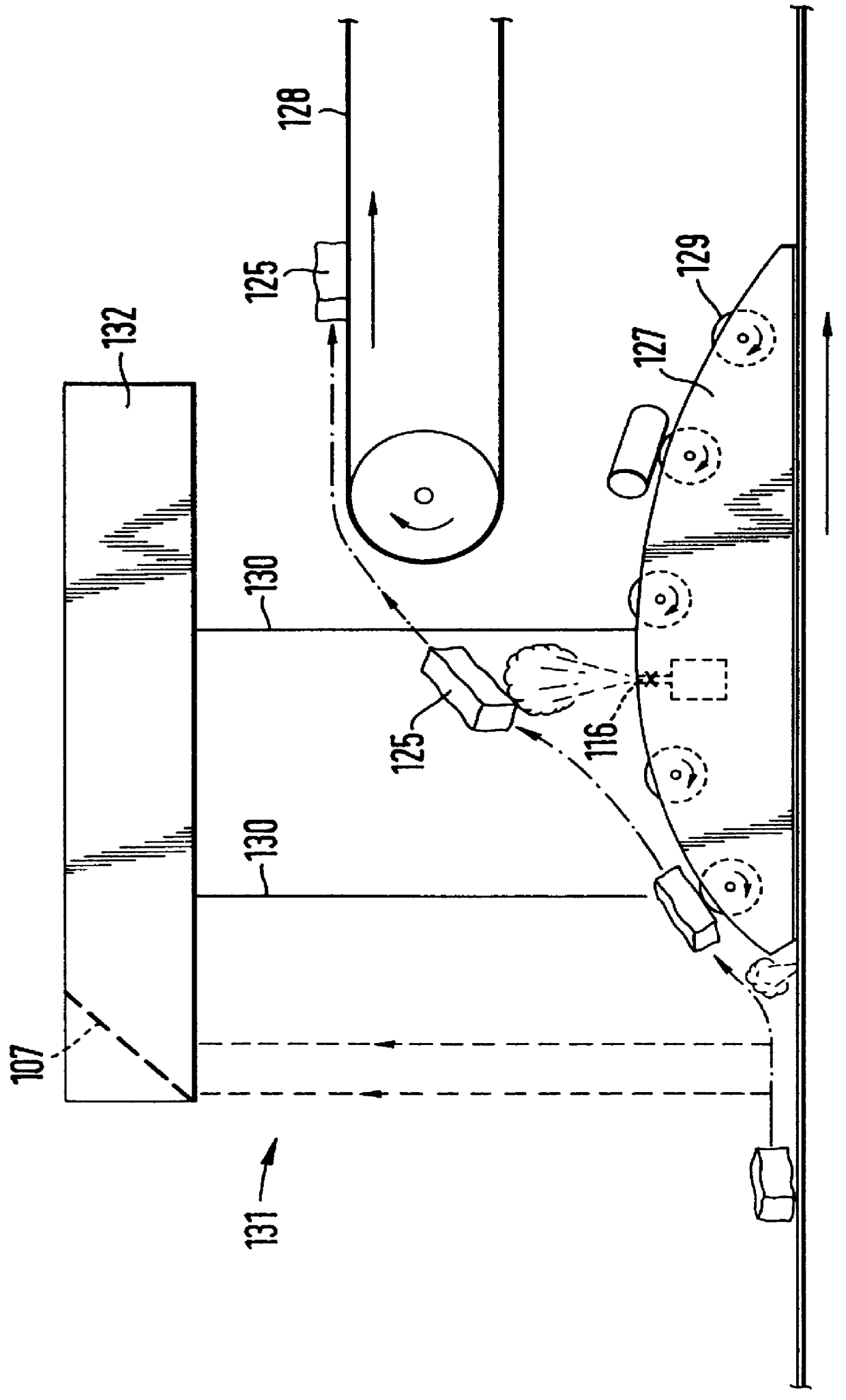

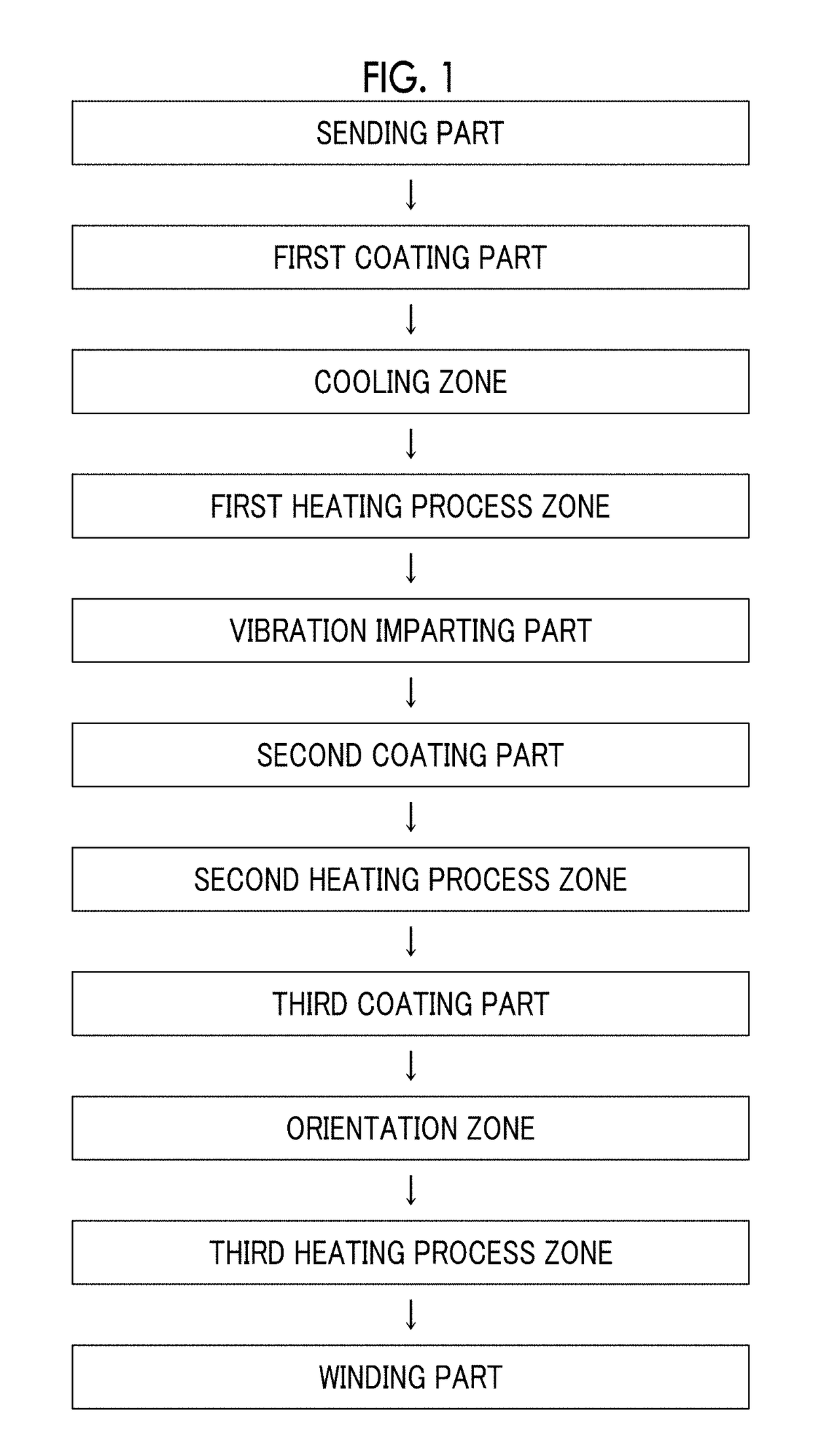

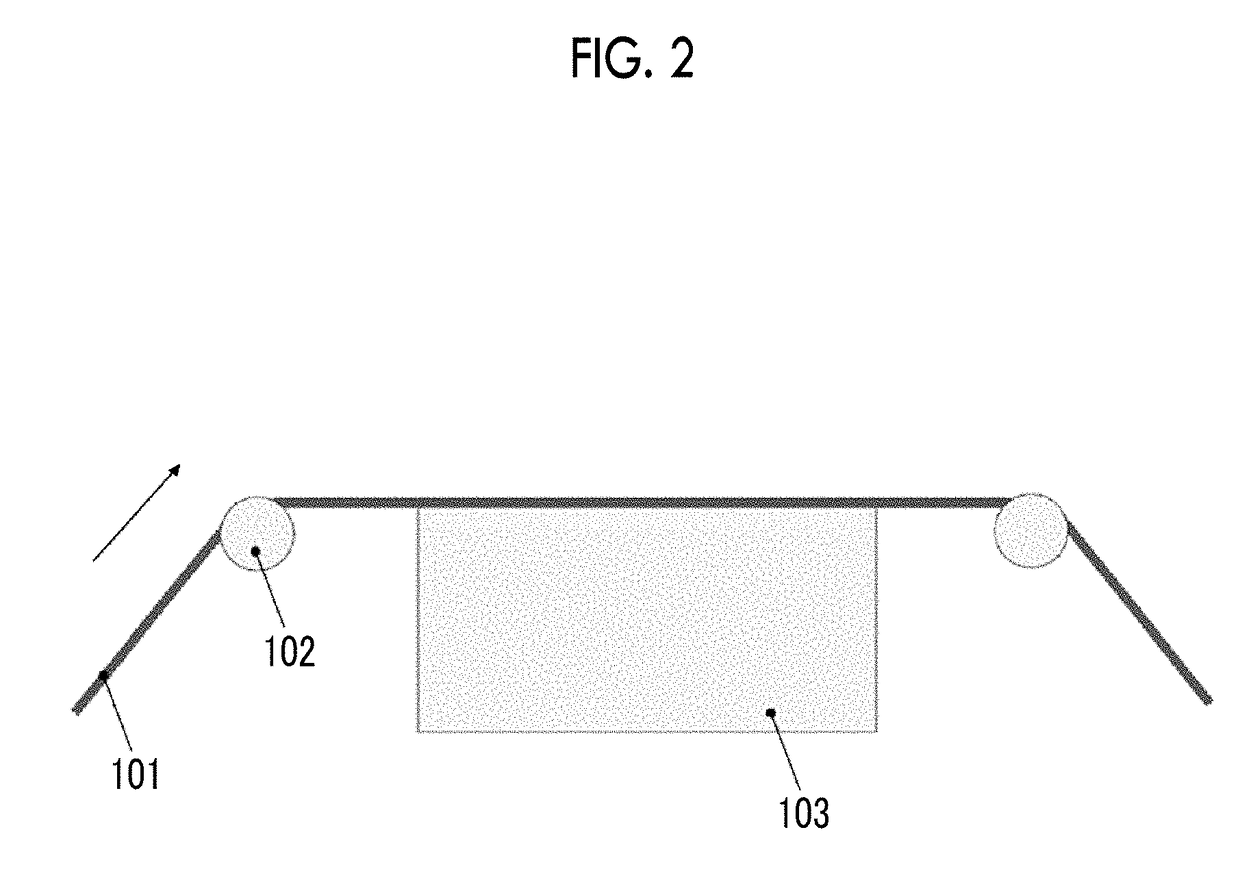

ActiveUS20080297950A1Good electromagnetic characteristicImprove running stabilityTape carriersRecord information storageNuclear magnetic resonanceMicroscope

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support; and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, and the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer.

Owner:FUJIFILM CORP

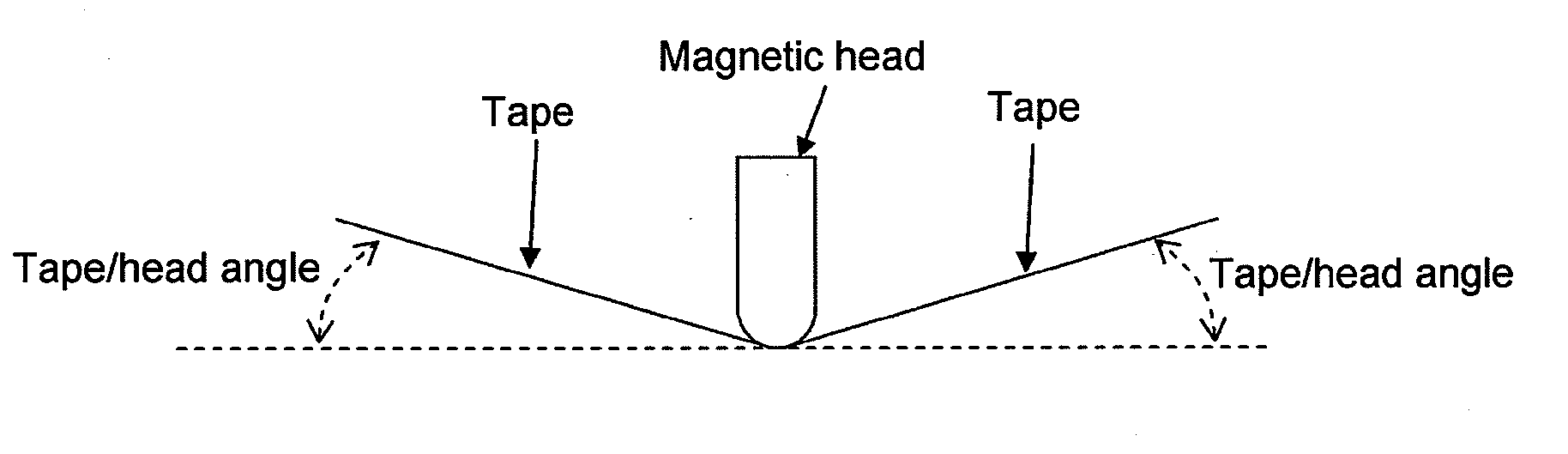

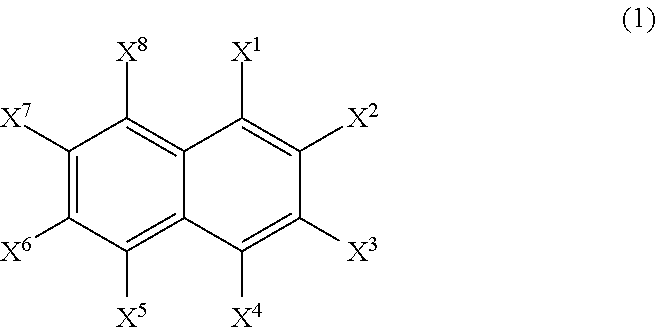

Magnetic recording medium

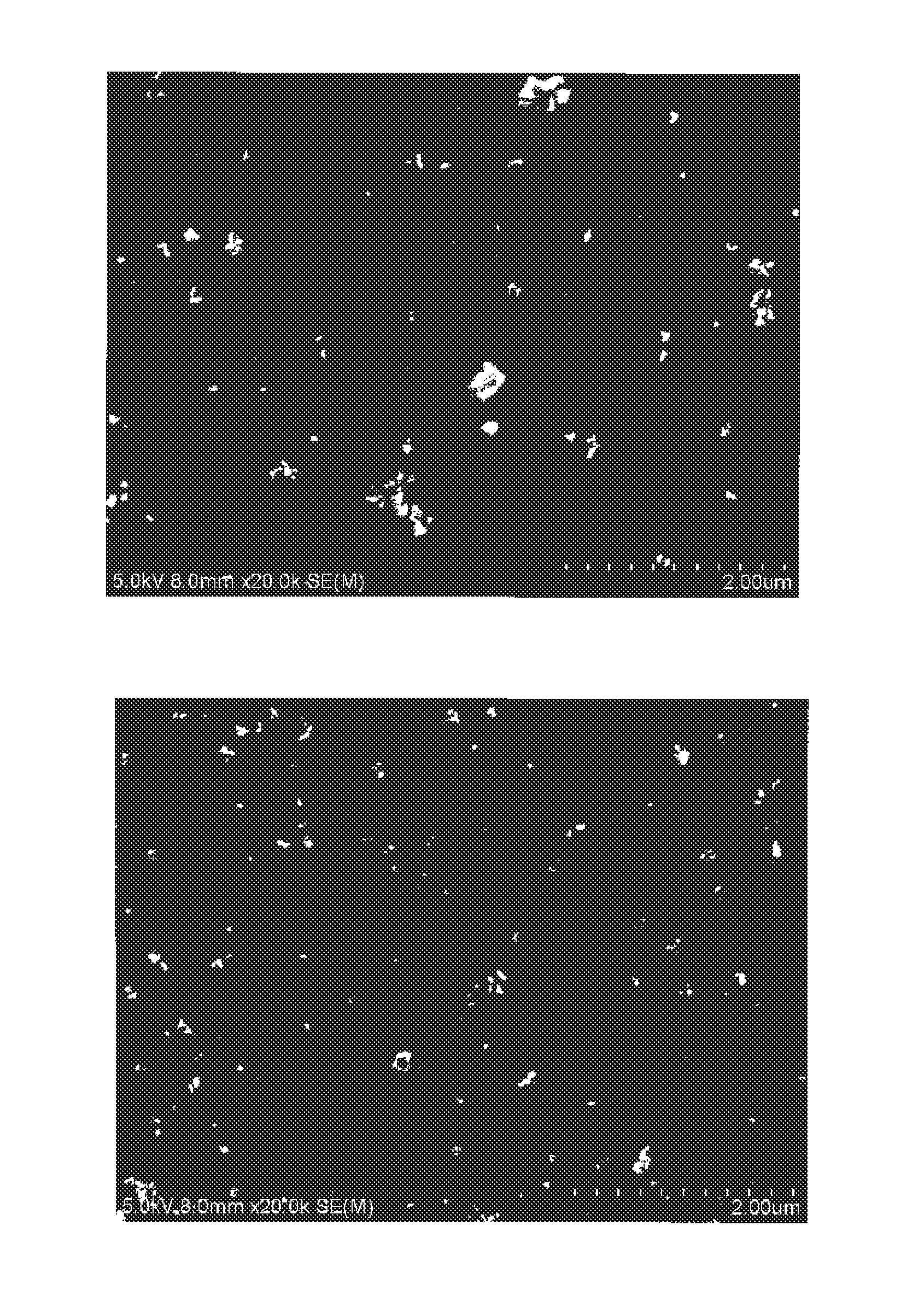

ActiveUS20140272474A1Increased durabilityReduce runningRecord information storageMaterials with non-metallic substancesScanning electron microscopeElectron microscope

An aspect of the present invention relates to a magnetic recording medium, which comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein the ferromagnetic powder is ferromagnetic hexagonal ferrite powder comprising 3 to 12 weight percent of Al, based on Al2O3 conversion, relative to 100 weight percent of a total weight of the powder, the magnetic layer further comprises abrasive, and a maximum plan view surface area of the abrasive as determined for a 4.3 μm×6.3 μm rectangular region of the magnetic layer by a scanning electron microscope is less than 0.06 percent relative to 100 percent of a total surface area of the region.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20170372741A1Improve running stabilitySuitable compatibilityProtective coatings for layersRecord information storageMagnetic tapeX-ray

Provided is a magnetic tape in which a thickness of a back coating layer is equal to or smaller than 0.20 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees, is equal to or greater than 35 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9530444B2Increased durabilityReduce runningMagnetic materials for record carriersRecord information storageScanning electron microscopeElectron microscope

Owner:FUJIFILM CORP

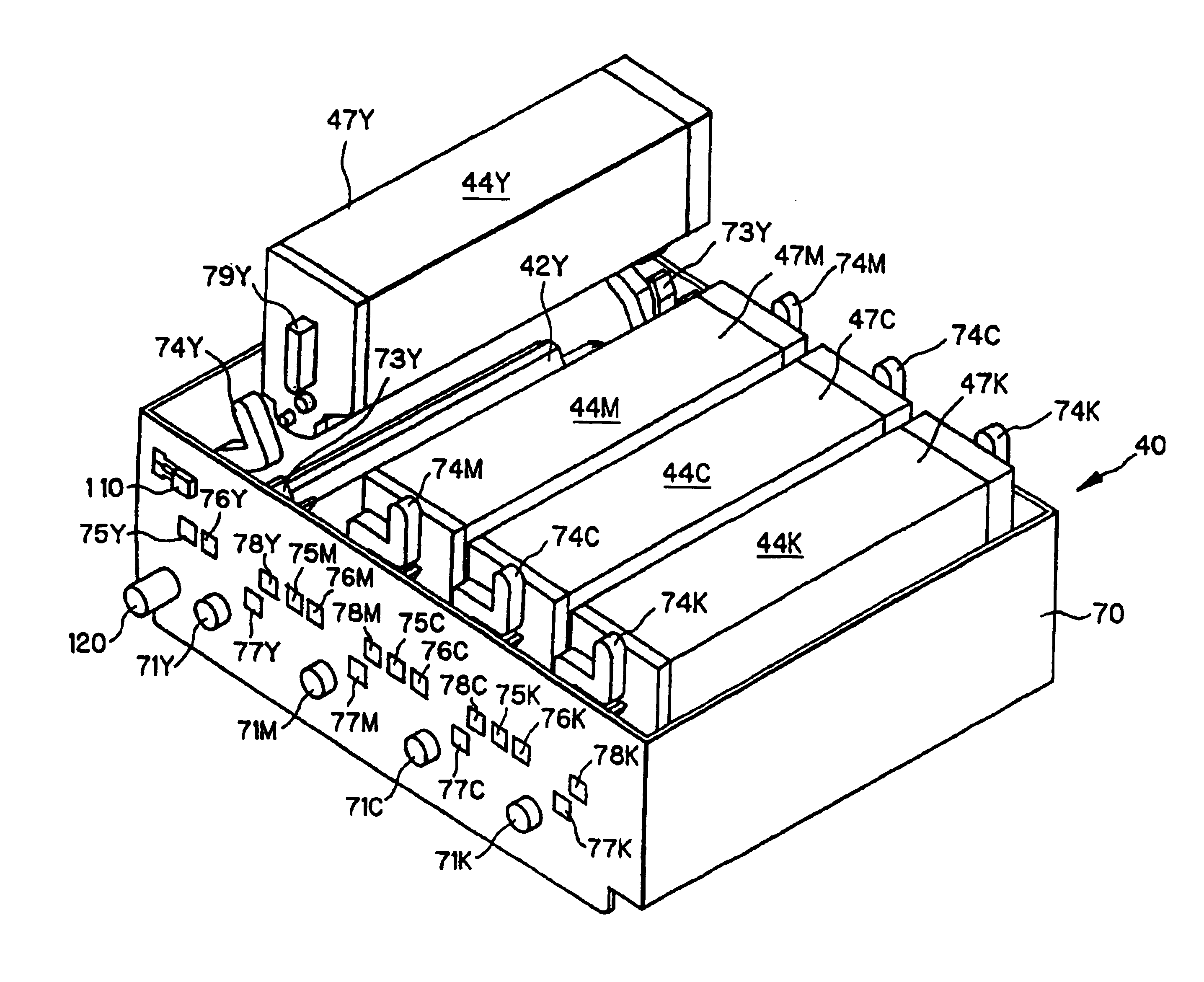

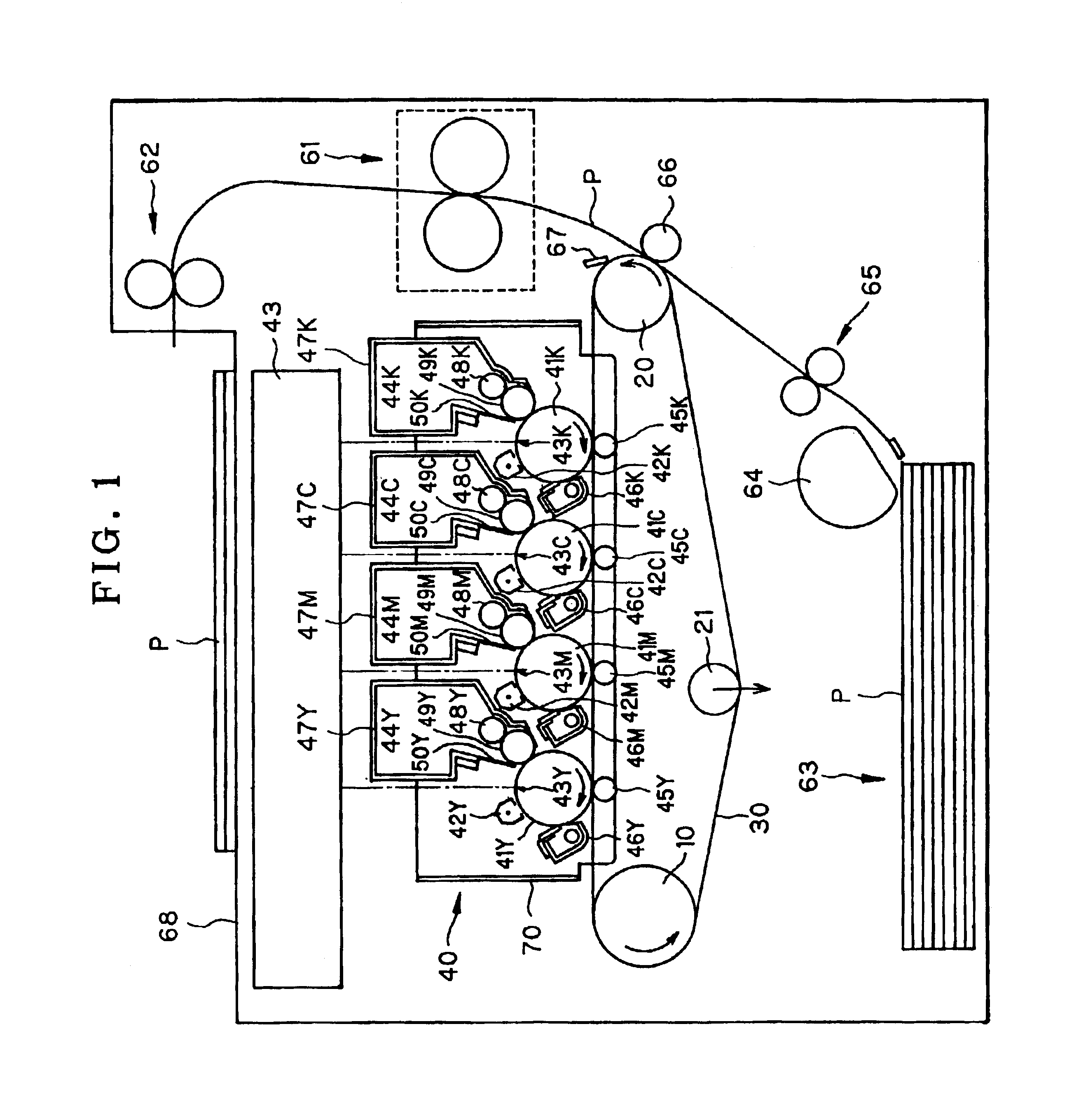

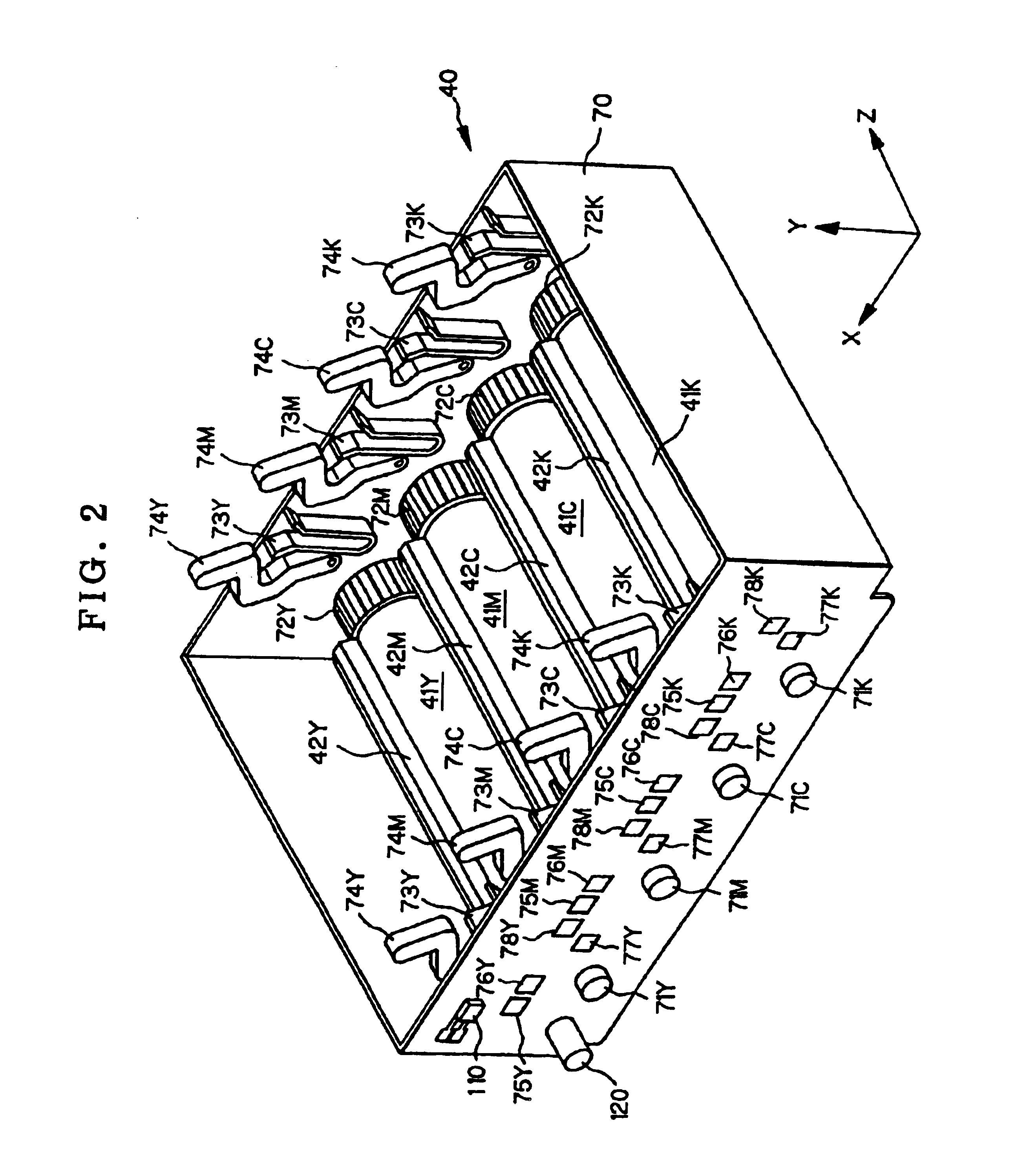

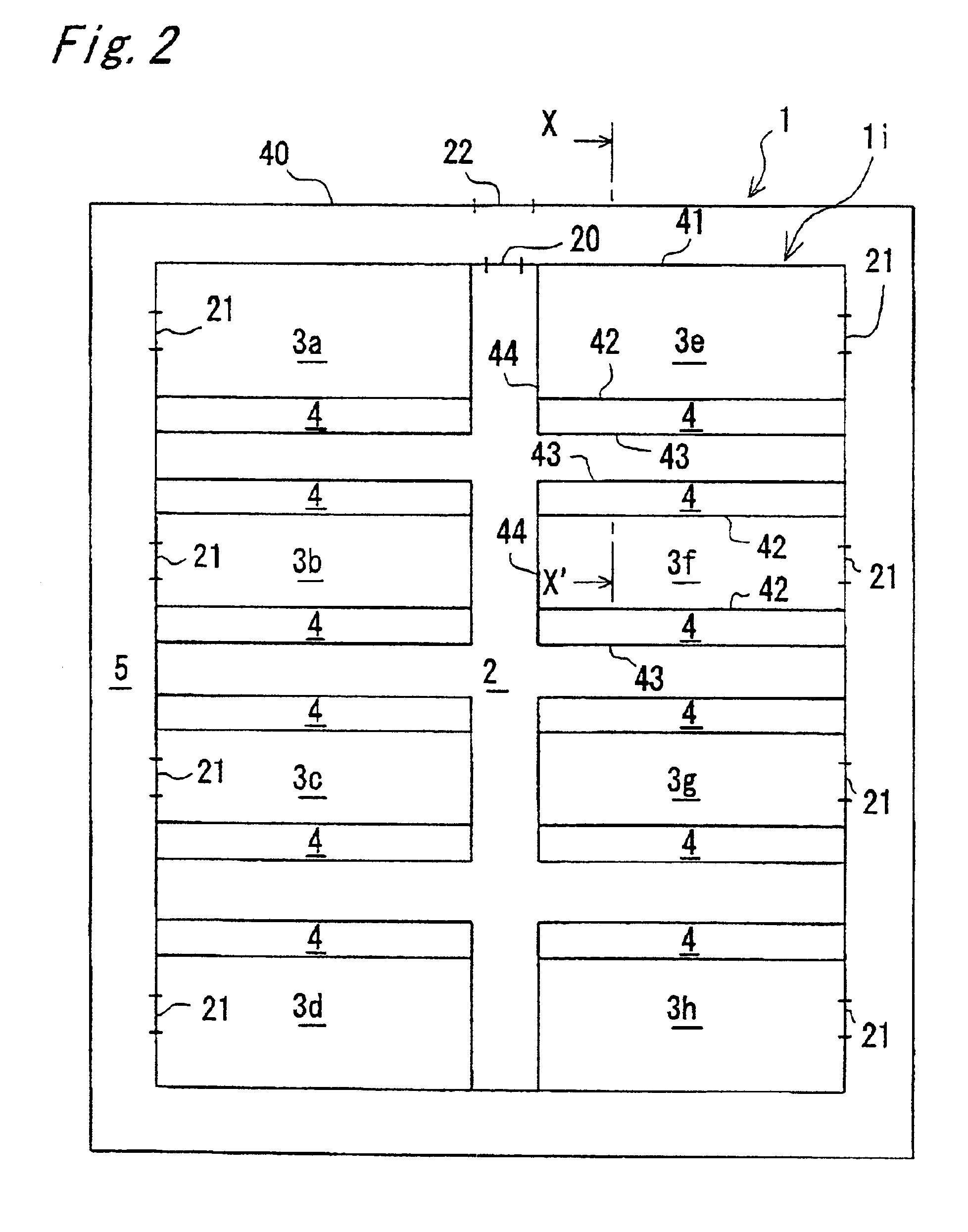

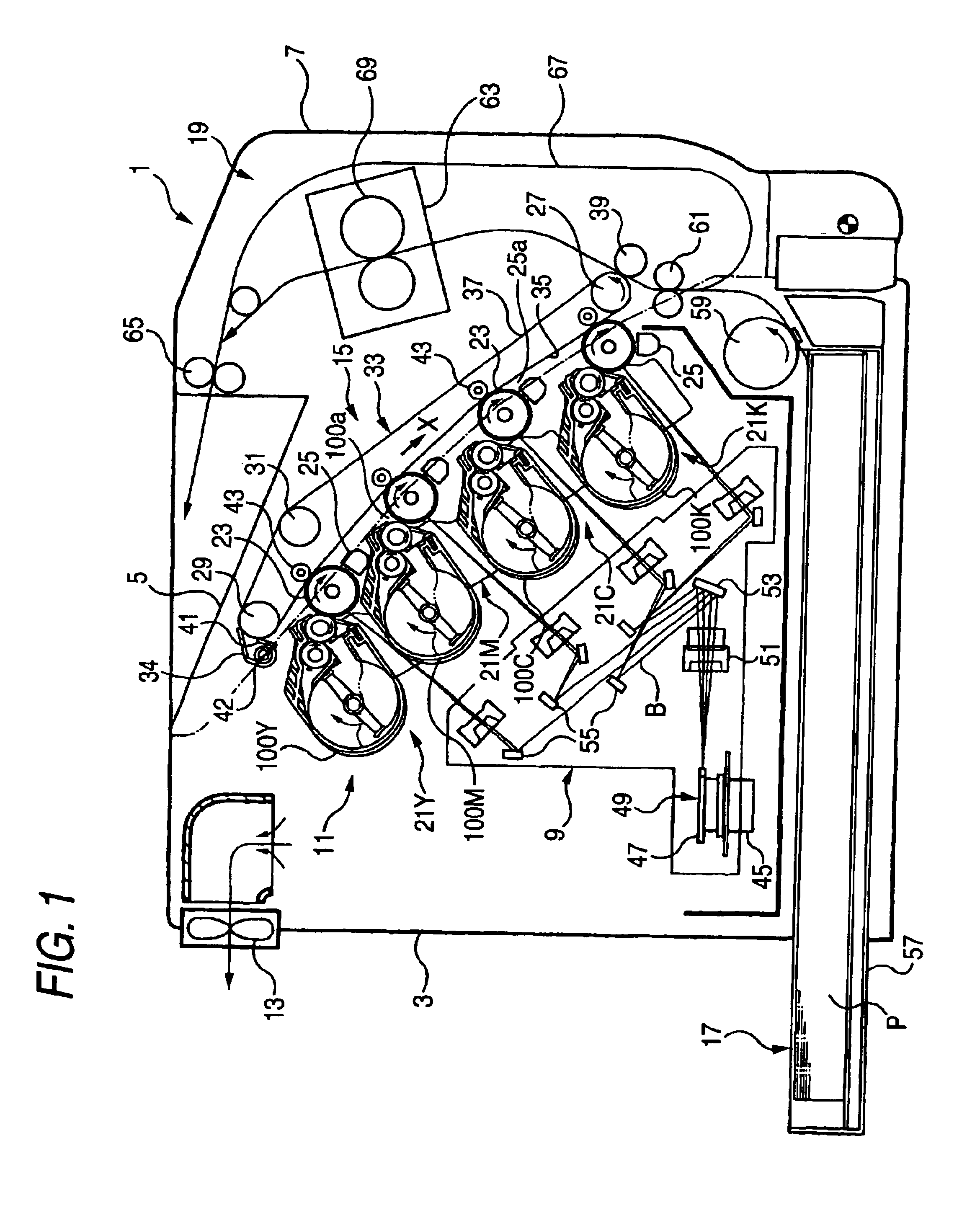

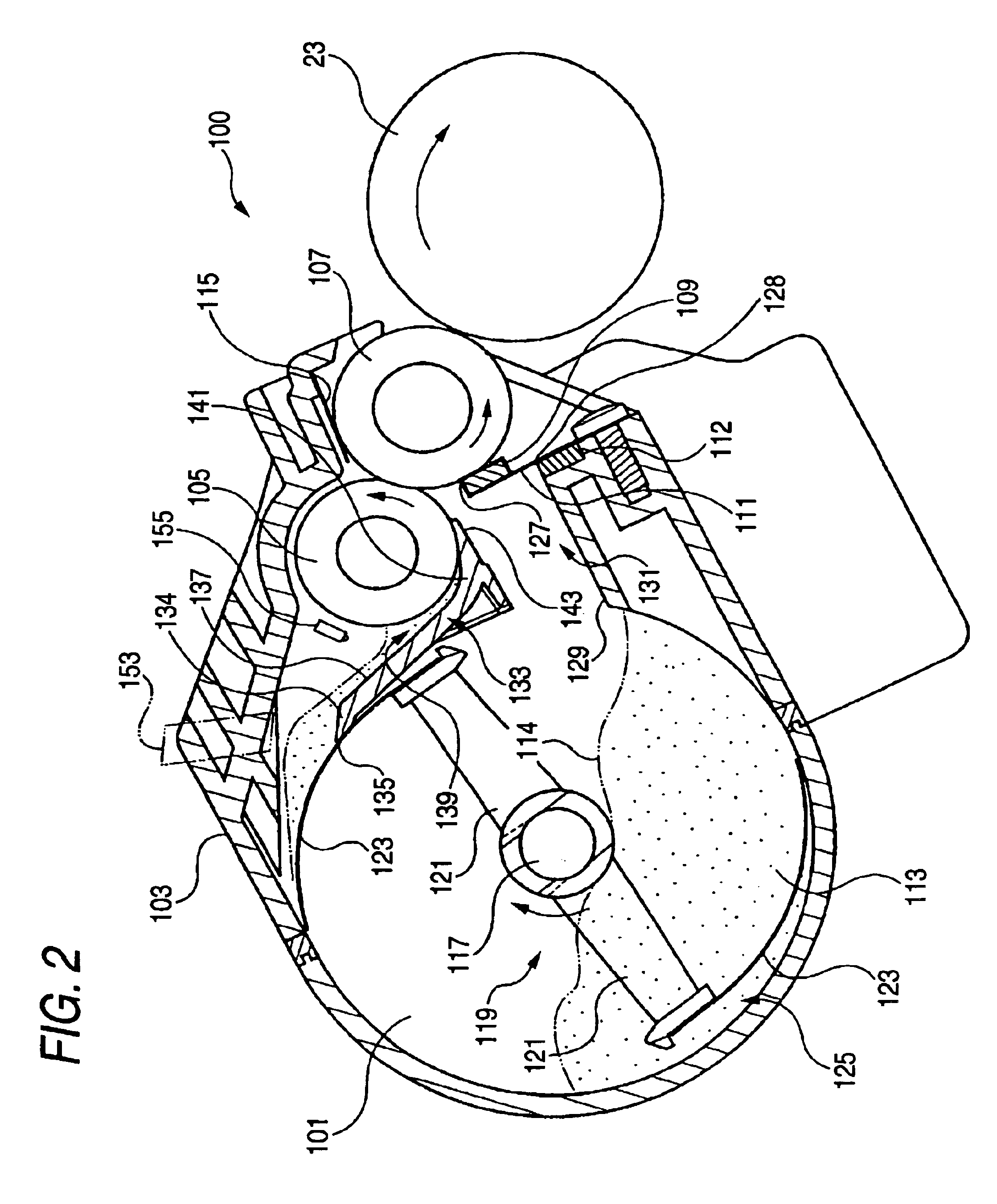

Image carrier cartridge having multiple image carriers

InactiveUS6944415B2Improve maintainabilityReduce runningElectrographic process apparatusCorona dischargeImage formationBiomedical engineering

In an image forming apparatus of a tandem type having at least two image forming stations each of which having an image carrier, and a charging device arranged around the image carrier and capable of forming an image. Additionally, a plurality of the image carriers are mounted at proper relative positions to an image carrier cartridge which is detachable relative to the apparatus body. Developing devices are designed to be detachable relative to the respective image carriers mounted to the image carrier cartridge. Writing devices and a transferring device are mounted at proper positions. The cartridge is provided with a storage device for storing information on color registration errors and color registration errors are corrected by a correcting device.

Owner:SEIKO EPSON CORP

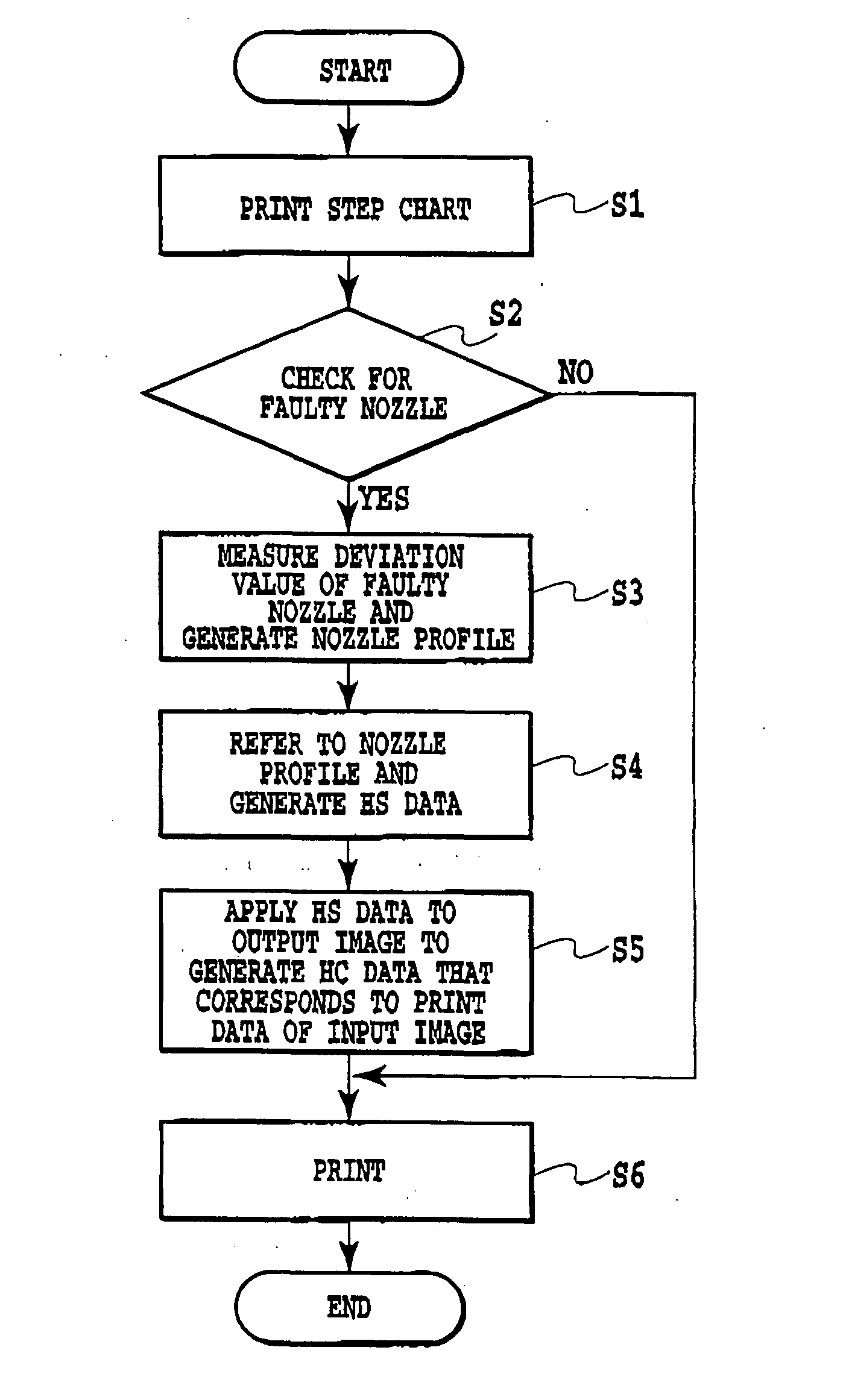

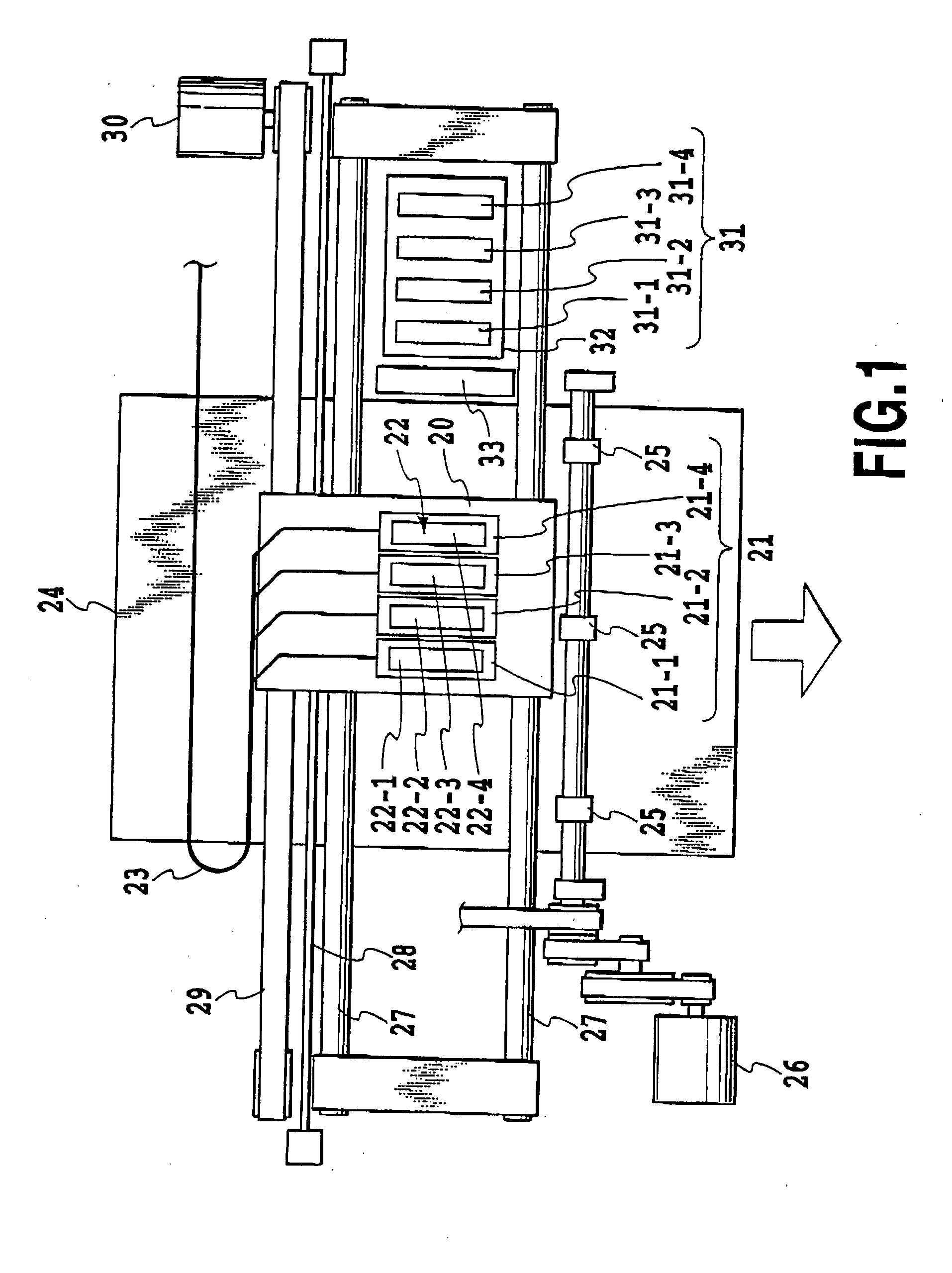

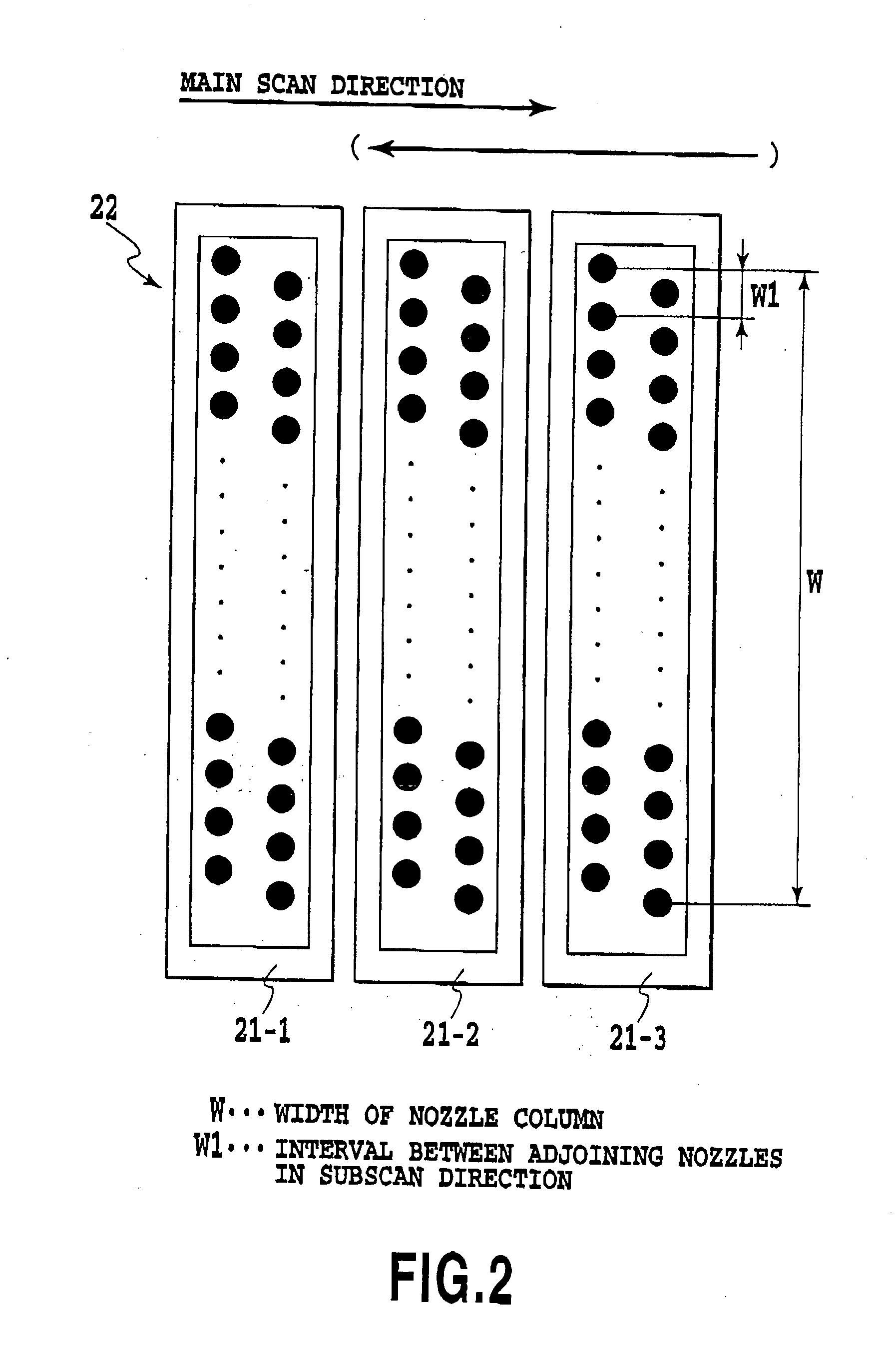

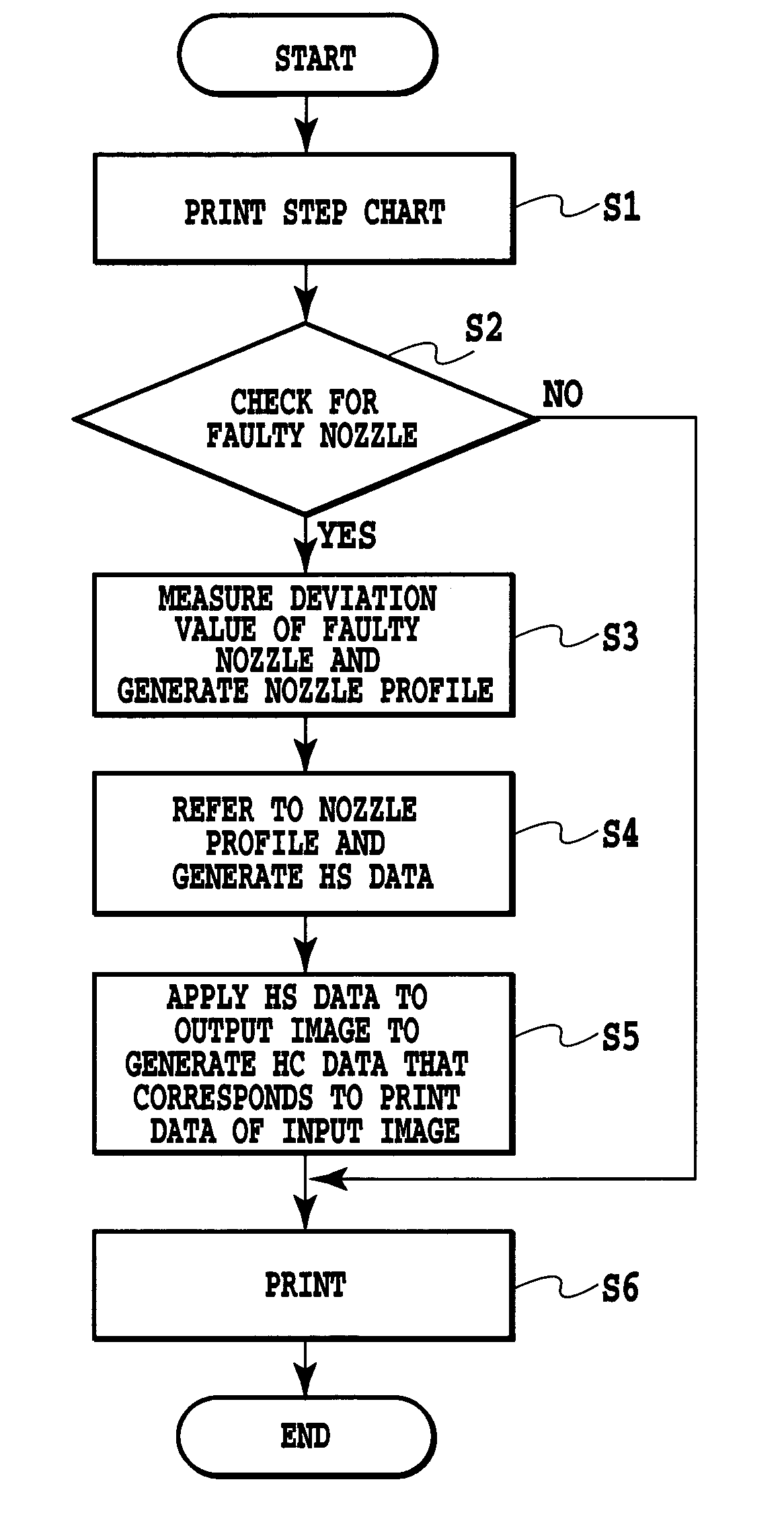

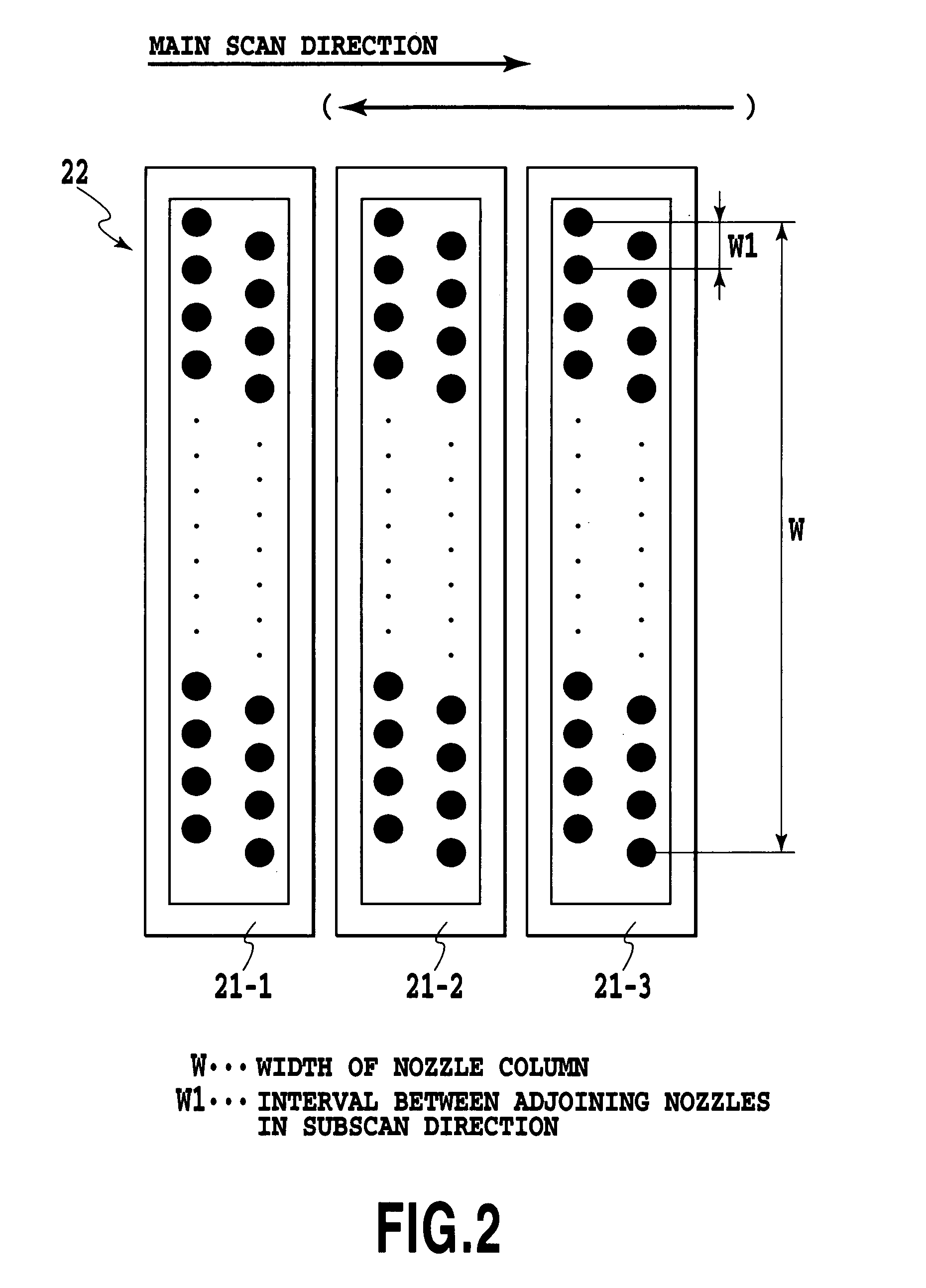

Ink jet printing apparatus and ink jet printing method

InactiveUS20040104951A1Reduce runningIncrease productionOther printing apparatusPictoral communicationVisible bandElectrical and Electronics engineering

The invention provides an ink jet printing apparatus which can prevent unwanted visible bands or stripes from appearing in a printed image. For this purpose, this invention performs a nozzle information generation step for generating nozzle information representing an ejection characteristic of each nozzle, according to a landing state on a print medium of an ink droplet ejected from each nozzle of the print head; an estimation step for estimating, based on the generated nozzle information and the print data, an effect that the ink droplet ejected from each nozzle has on the image to be formed; a correction information generation step for generating correction information to correct an ink ejection condition of each nozzle according to a result of estimation by the estimation step; and a control step for controlling a driving of the nozzles according to the correction information.

Owner:CANON KK

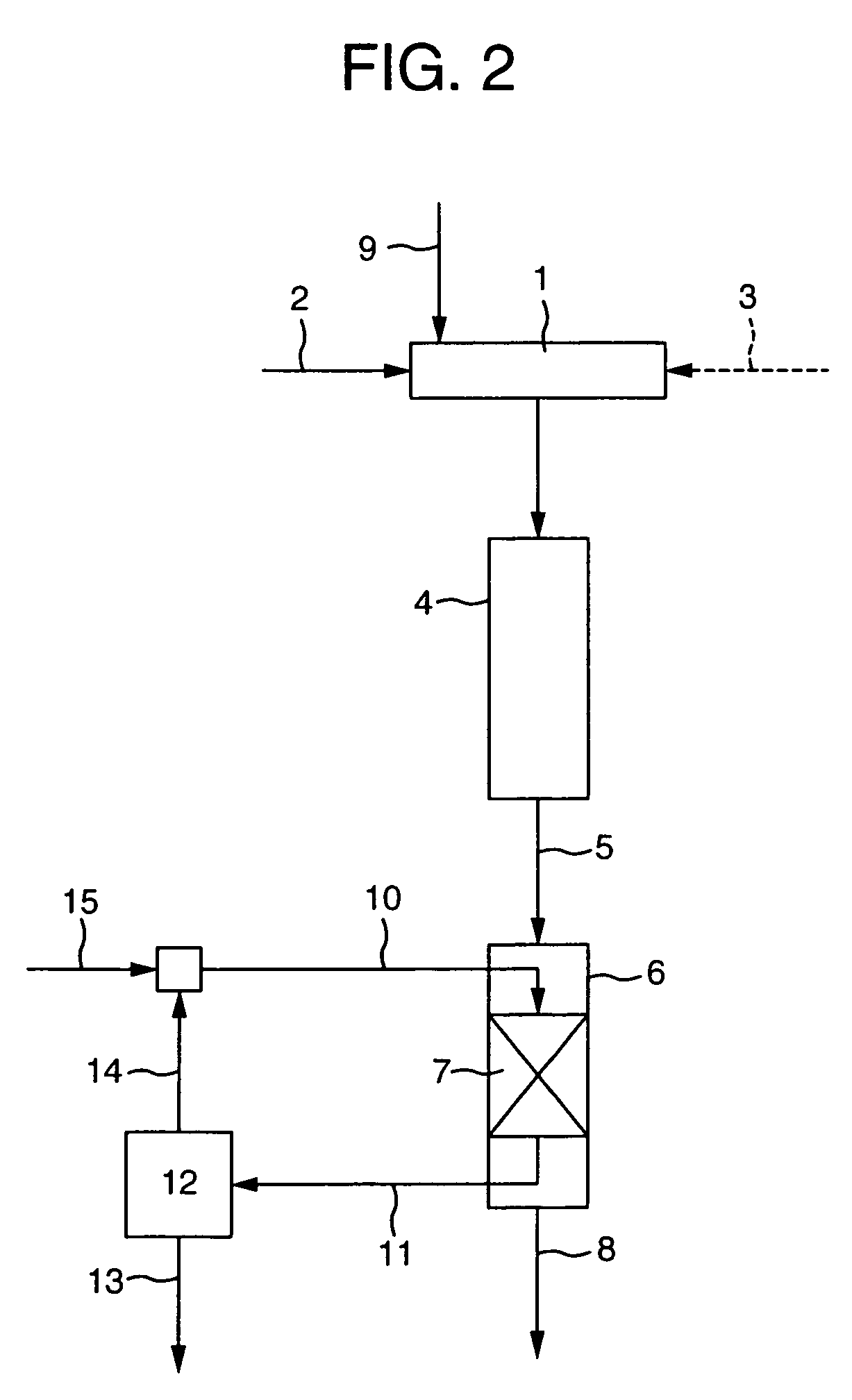

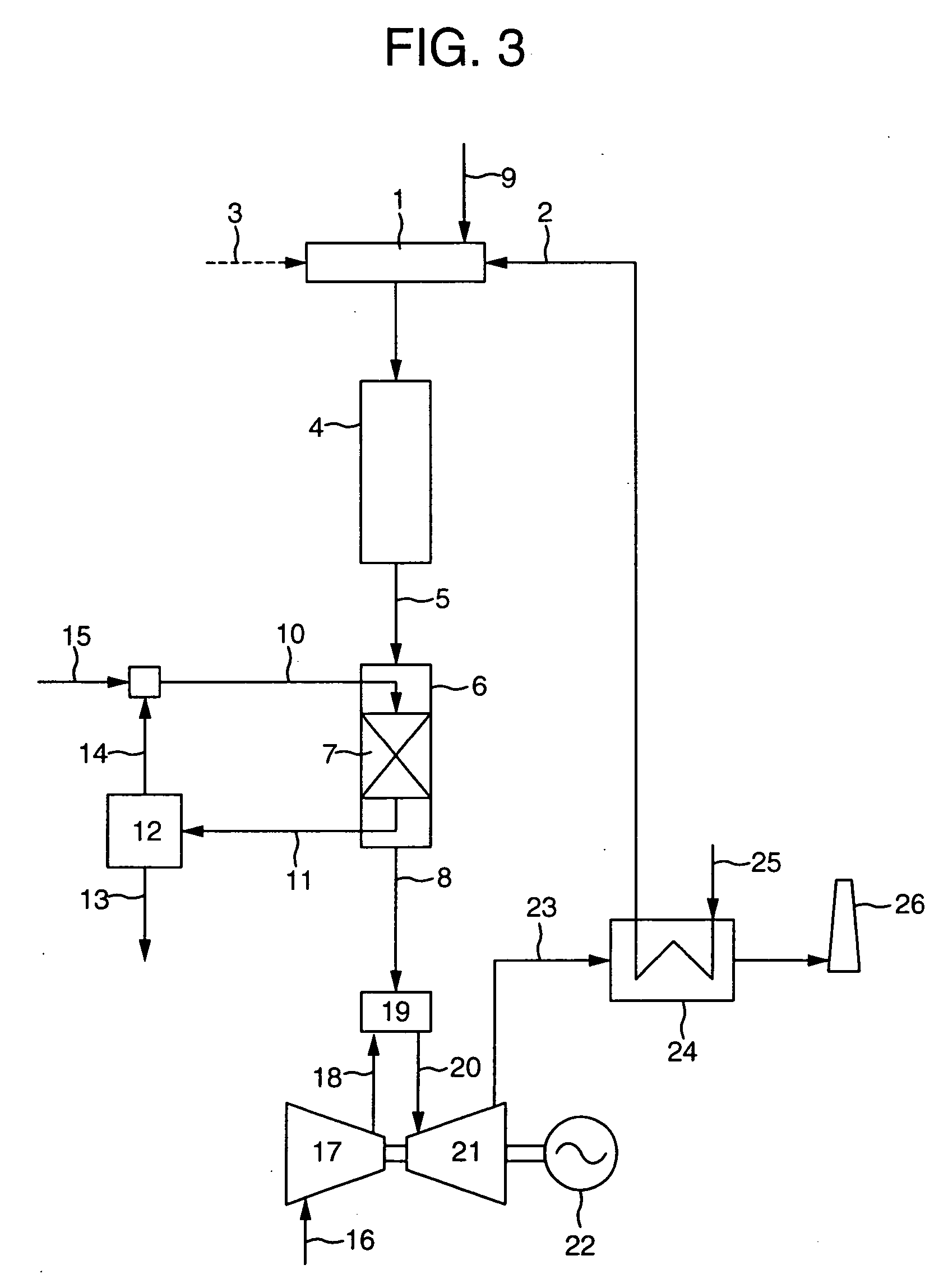

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

InactiveUS20060011511A1Reduce equipment costsReduce runningThermal non-catalytic crackingHydrogenScavengerCombustor

Owner:HOKARI NOBUYUKI +4

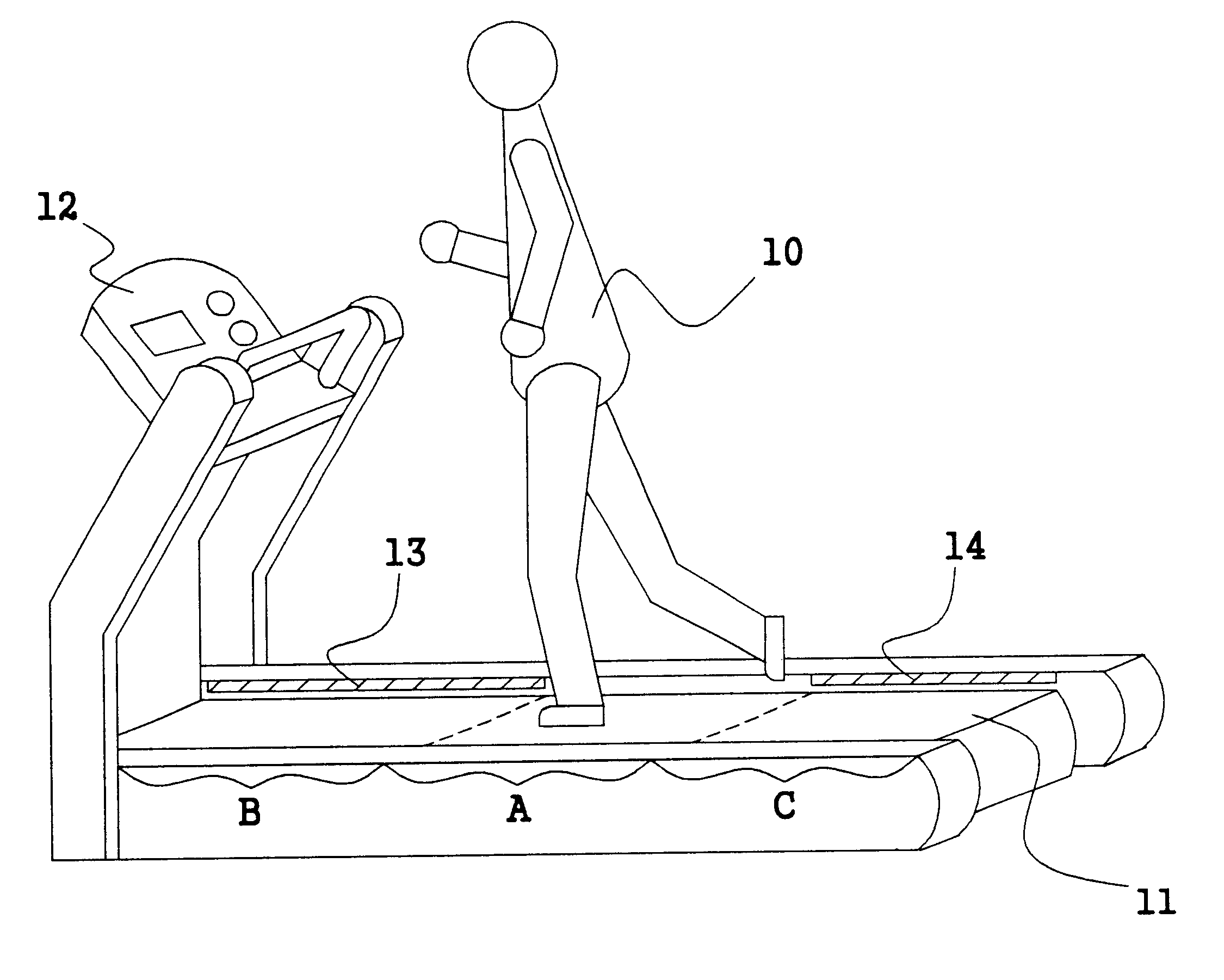

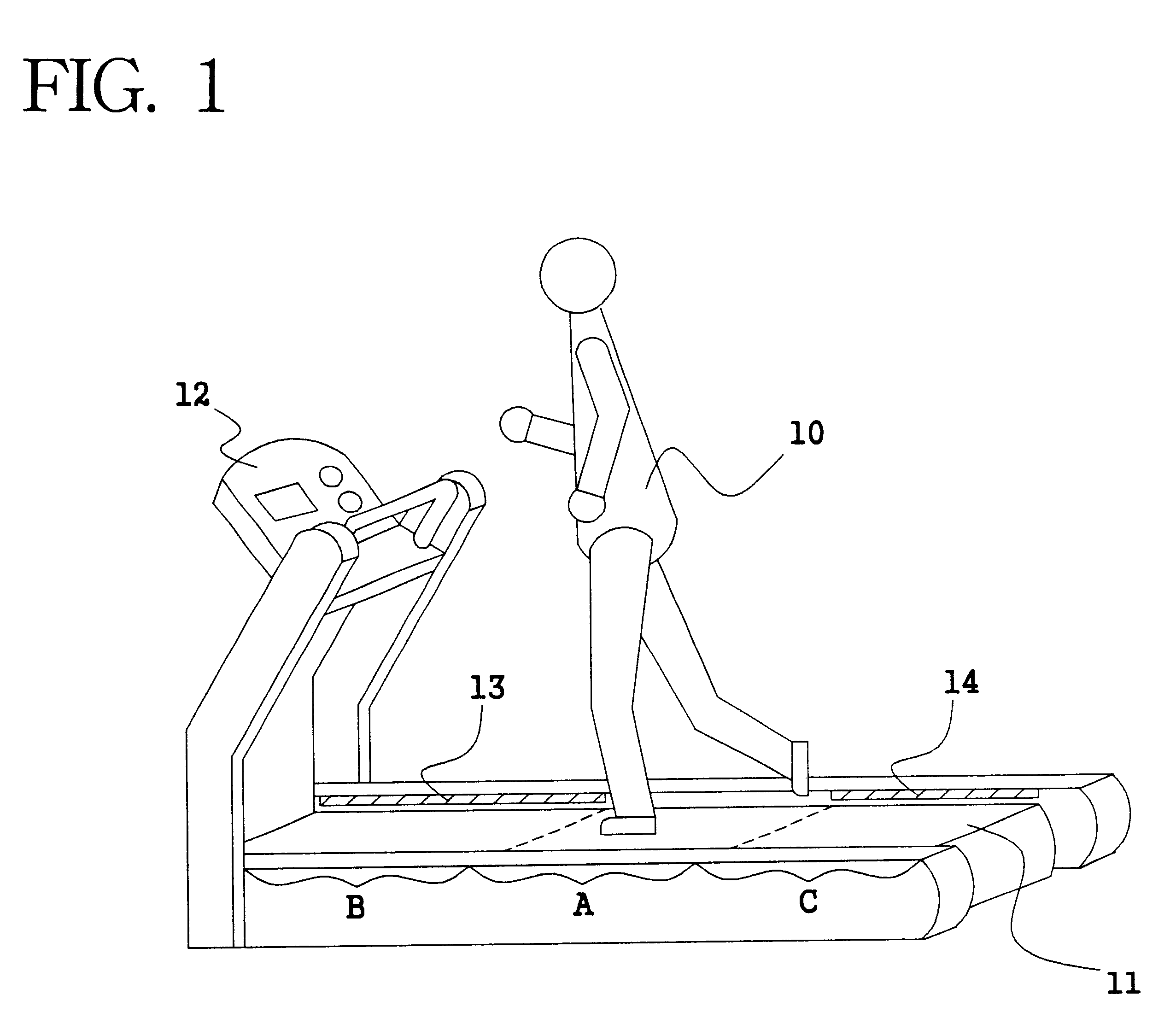

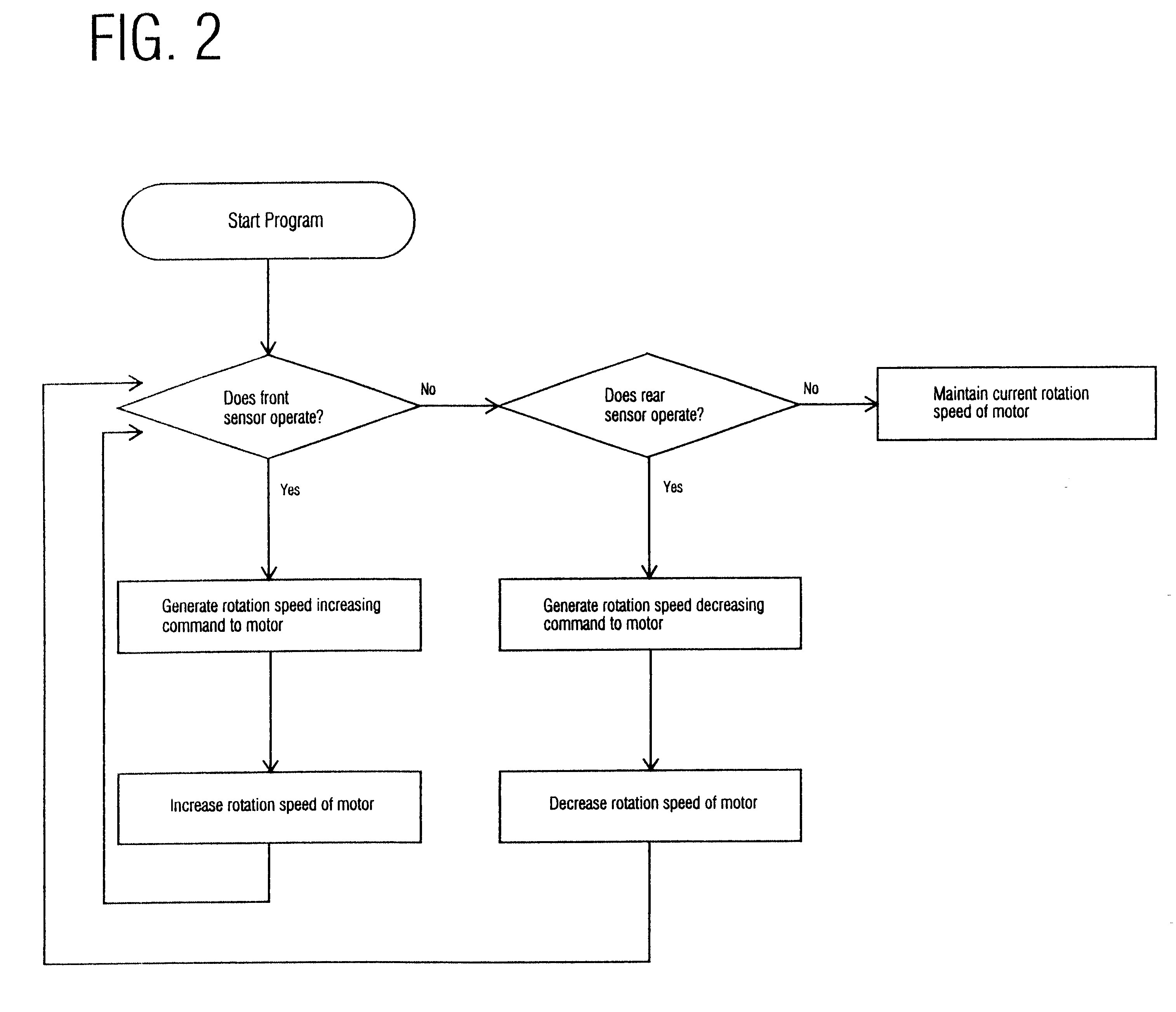

Treadmill having a walking belt whose running speed is automatically adjusted

InactiveUS6416444B1Increase and decrease rotation speedShort timeMovement coordination devicesCardiovascular exercising devicesBelt speedEngineering

A treadmill having a walking belt whose running speed is automatically adjusted in conformity with the walking or running speed of a user, without any manipulation of a walking belt speed control button, and a method for automatically adjusting the running speed of a walking belt in a treadmill. The treadmill of the present invention first checks and determines whether the rotation speed of the motor is deviated from an initial set range or the user is deviated from his original position and then if any one of the two deviations is checked, automatically increase or decrease the rotation speed of the motor.

Owner:SNS CARE

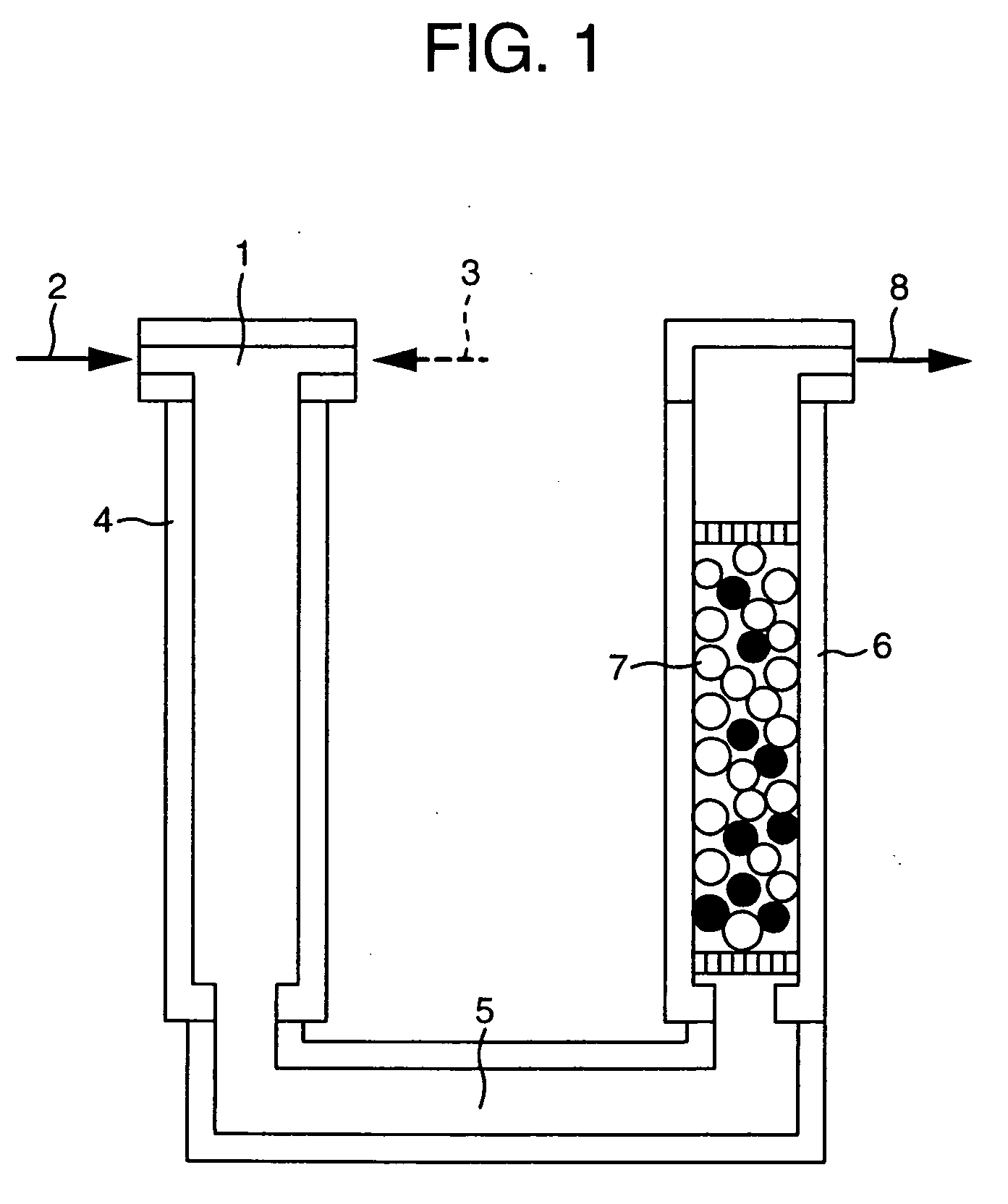

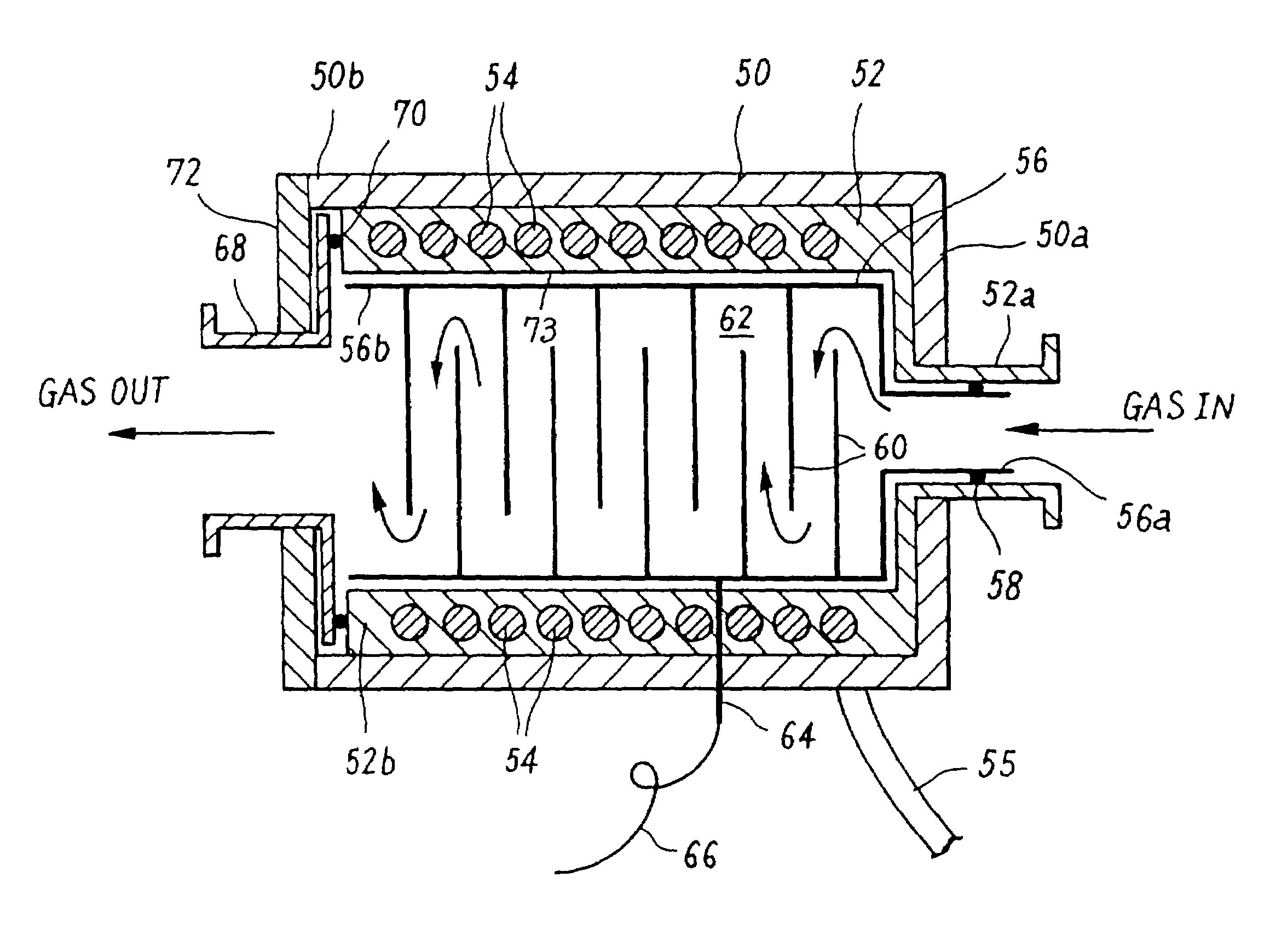

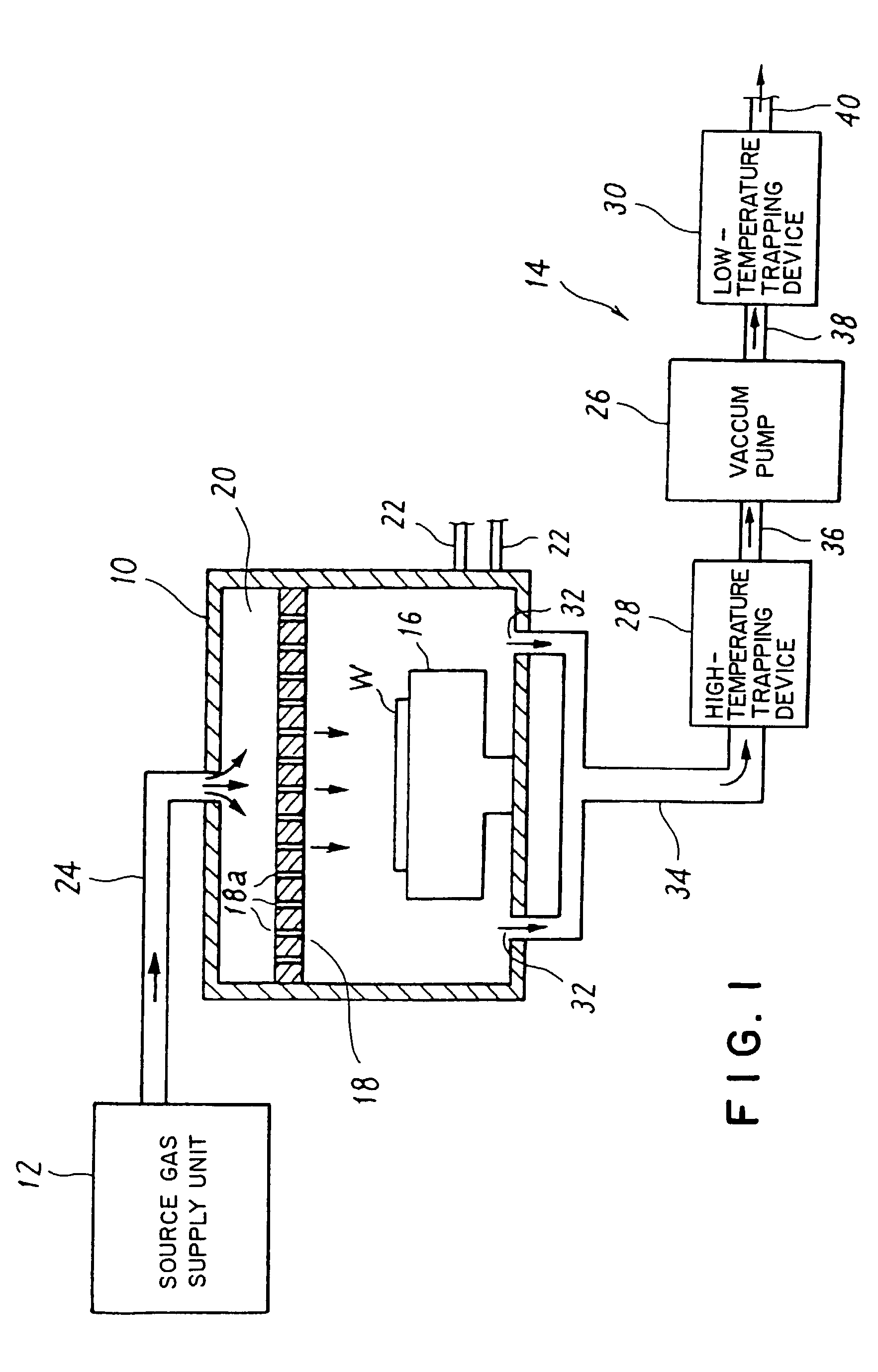

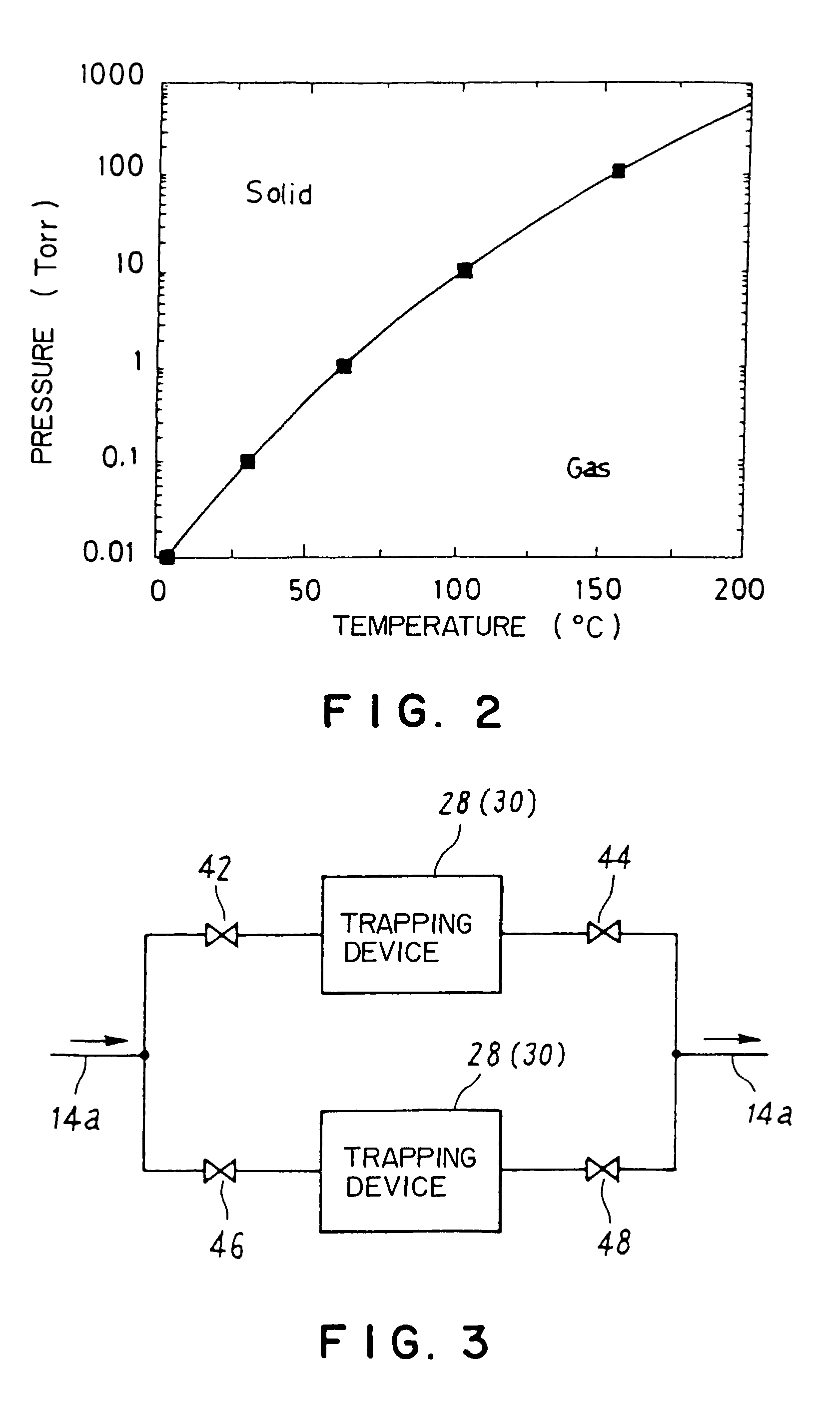

Processing system, evacuating system for processing system, low-pressure CVD system, and evacuating system and trapping device for low-pressure CVD system

InactiveUS6966936B2Run cost be reduceStable operationCombination devicesDispersed particle filtrationProduct gasEngineering

An object of the present invention is to ensure the stable operation of a vacuum pump for discharging an unused source gas and reaction byproduct gases from a low-pressure processing chamber, to recover the reaction byproducts efficiently for the effective utilization of resources and reduction of running costs. A low-pressure CVD system has a processing vessel (10) for carrying out a low-pressure CVD process for forming a copper film, a source gas supply unit (12) for supplying an organic copper compound as a source gas, such as Cu(I)hfacTMVS, into the processing vessel (10), and an evacuating system (14) for evacuating the processing vessel (10). The evacuating system (14) includes a vacuum pump (26), a high-temperature trapping device (28) disposed above the vacuum pump (26) with respect to the flowing direction of a gas, and a low-temperature trapping device (30) disposed below the vacuum pump with respect to the flowing direction of a gas. The high-temperature trapping device (28) decomposes the unused Cu(I)hfacTMVS contained in a gas sucked out of the processing vessel (10) to trap metallic copper. The low-temperature trapping device traps Cu(II)(hfac)2 produced as a reaction byproduct.

Owner:TOKYO ELECTRON LTD

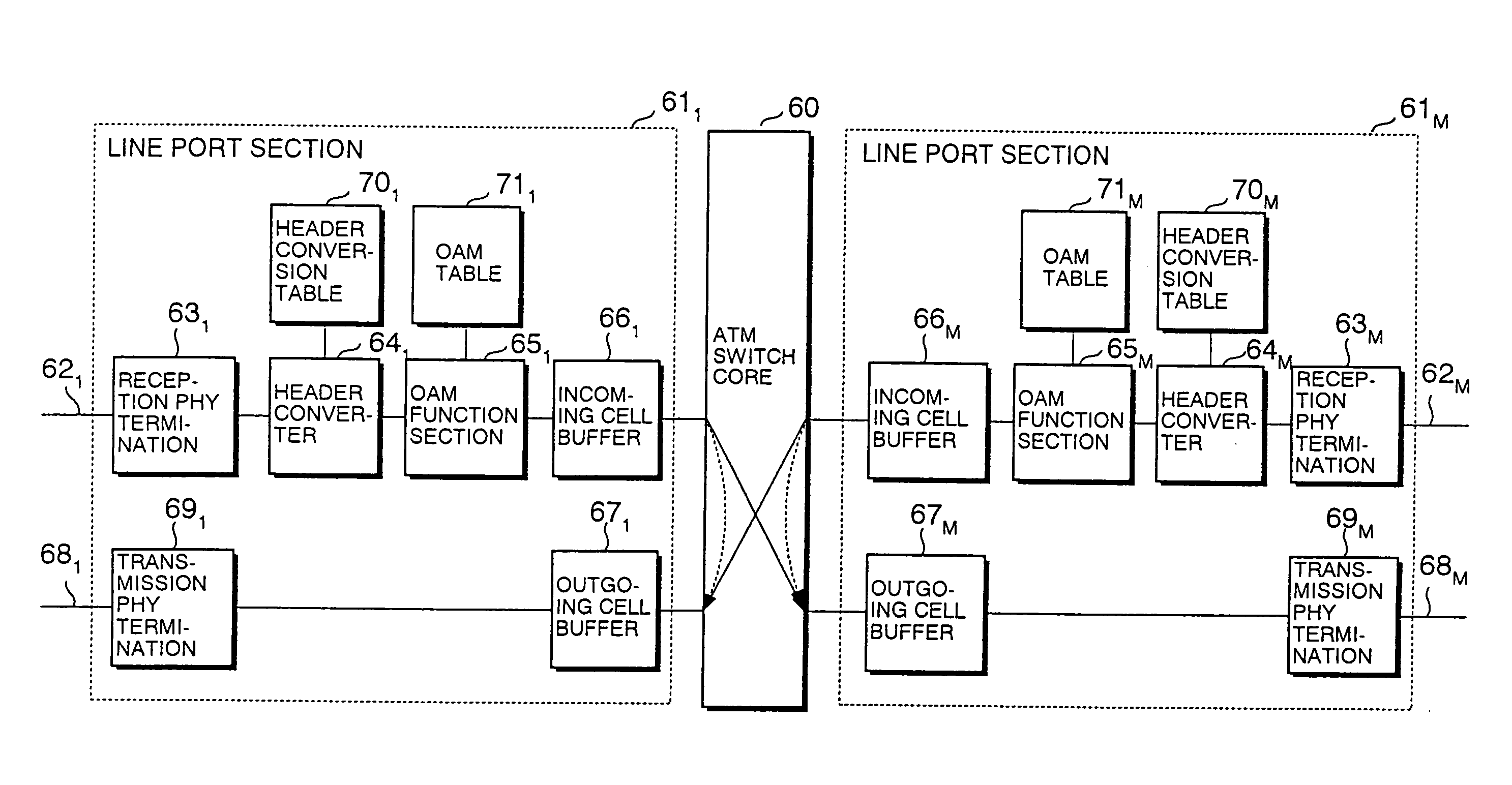

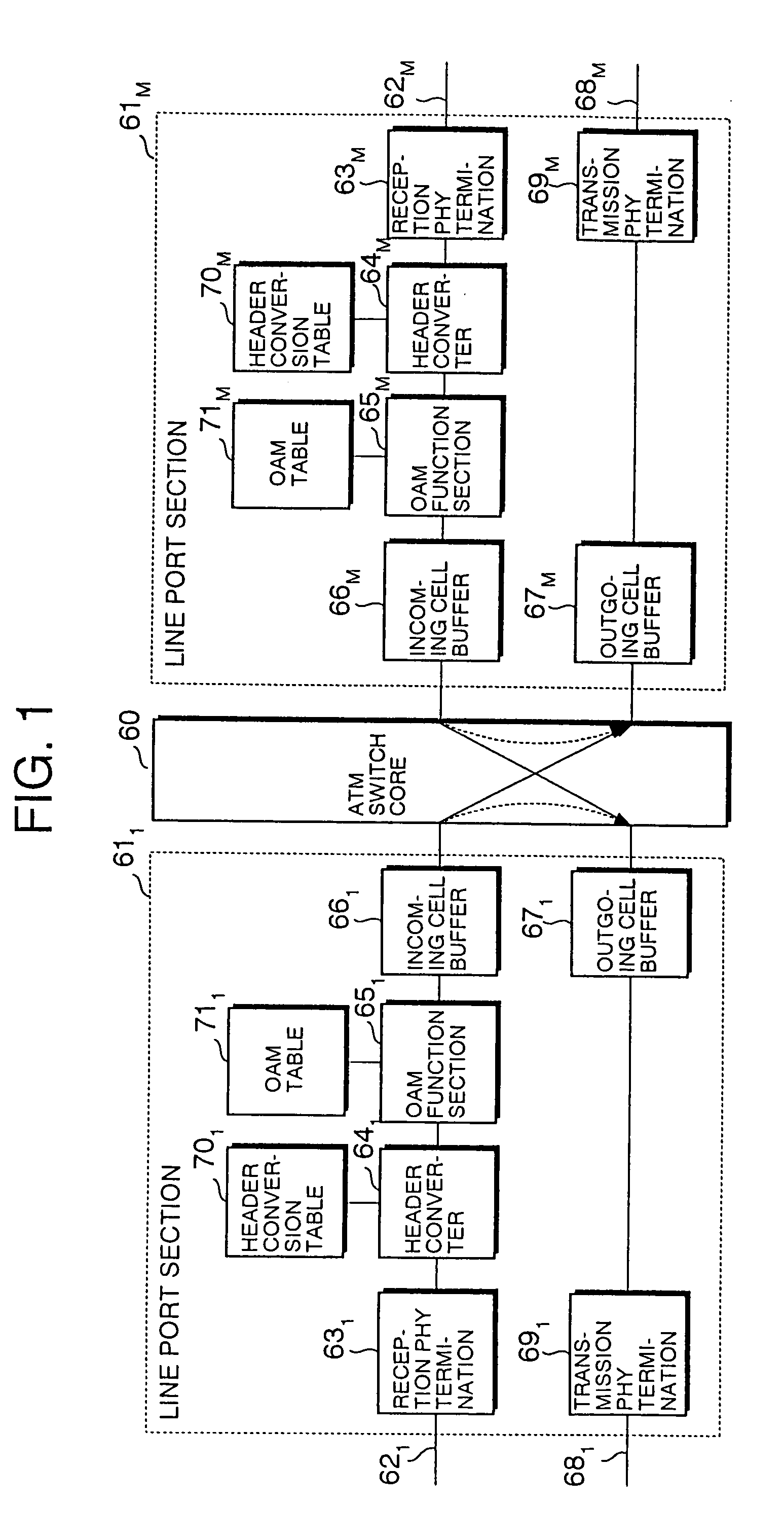

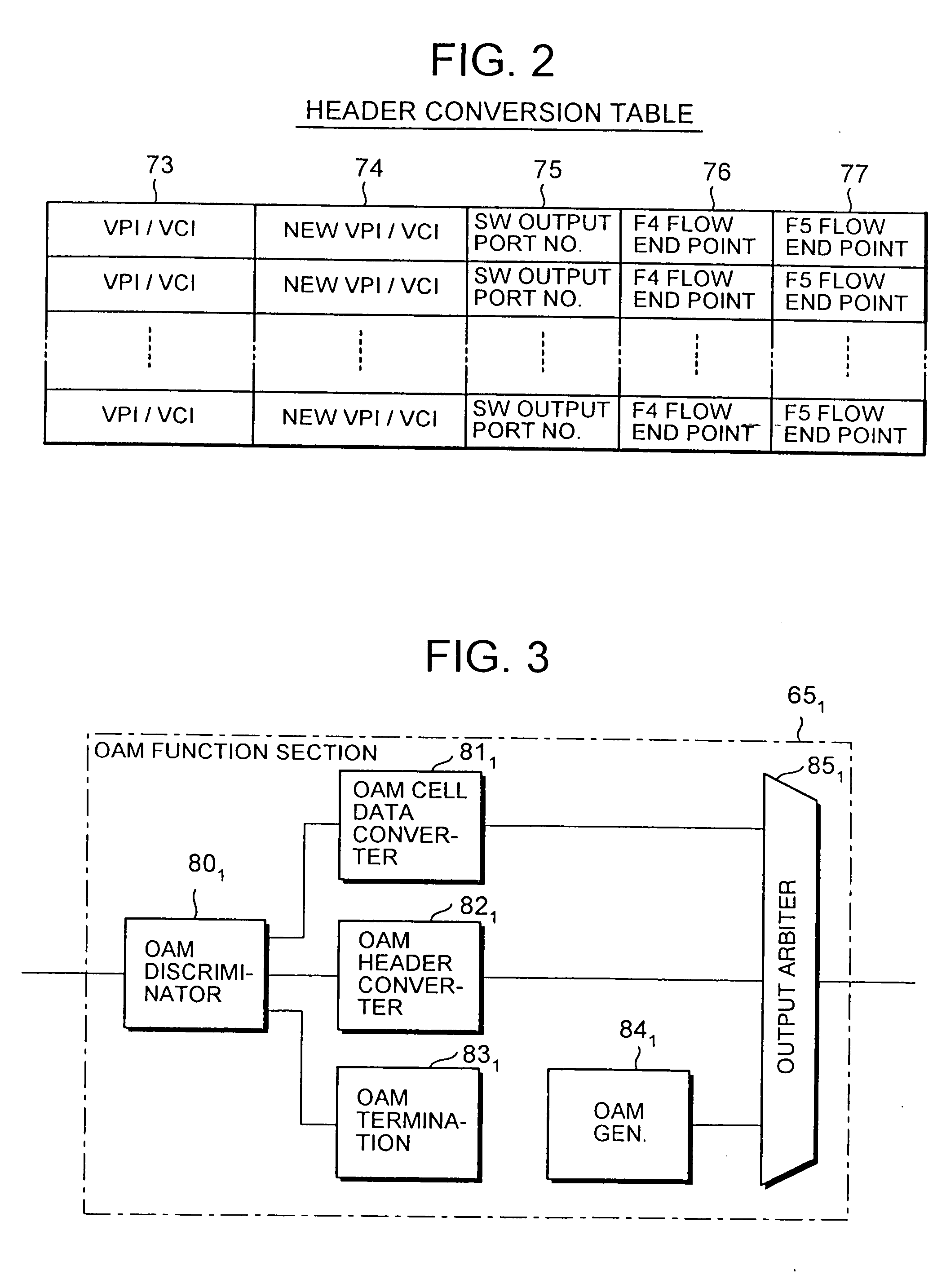

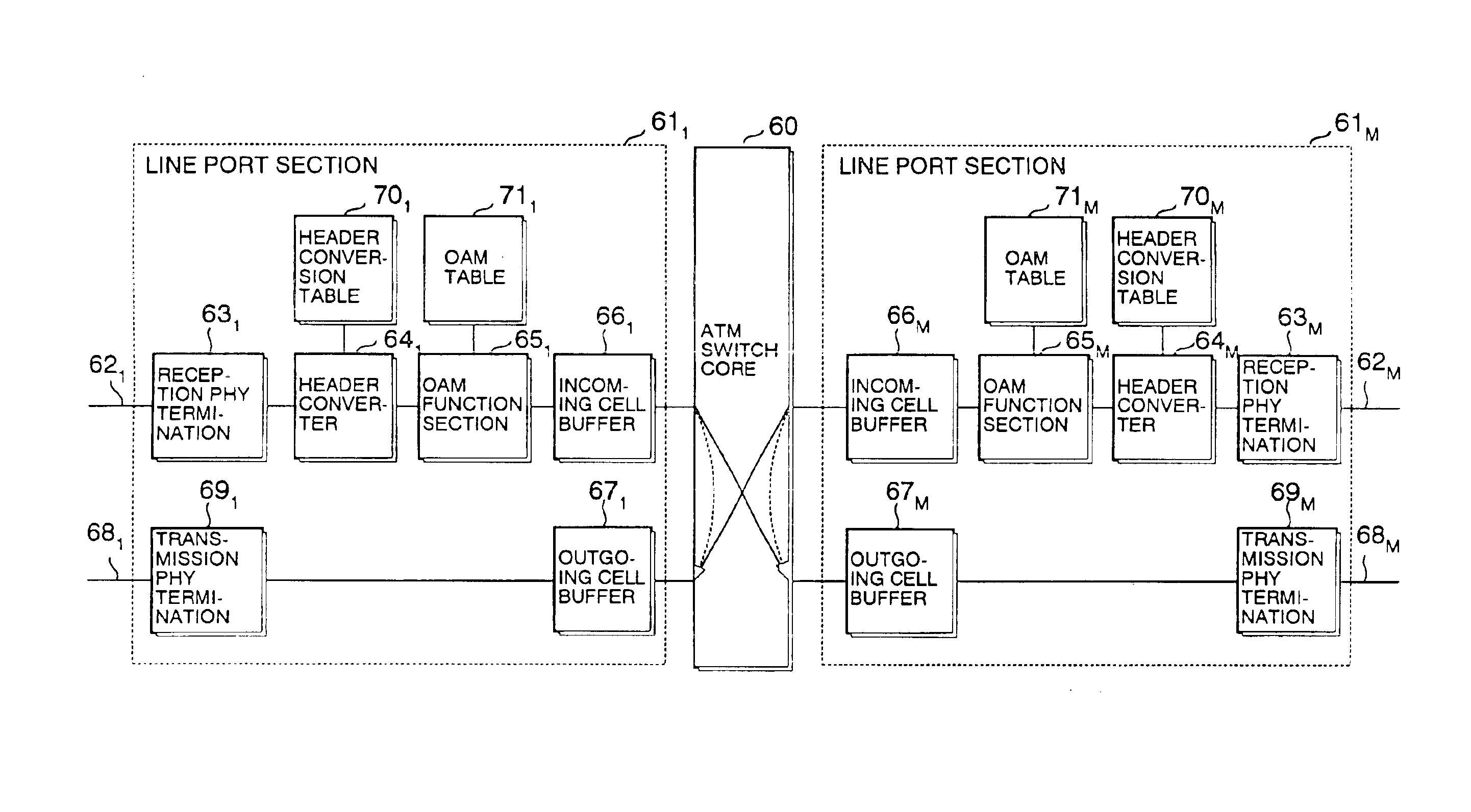

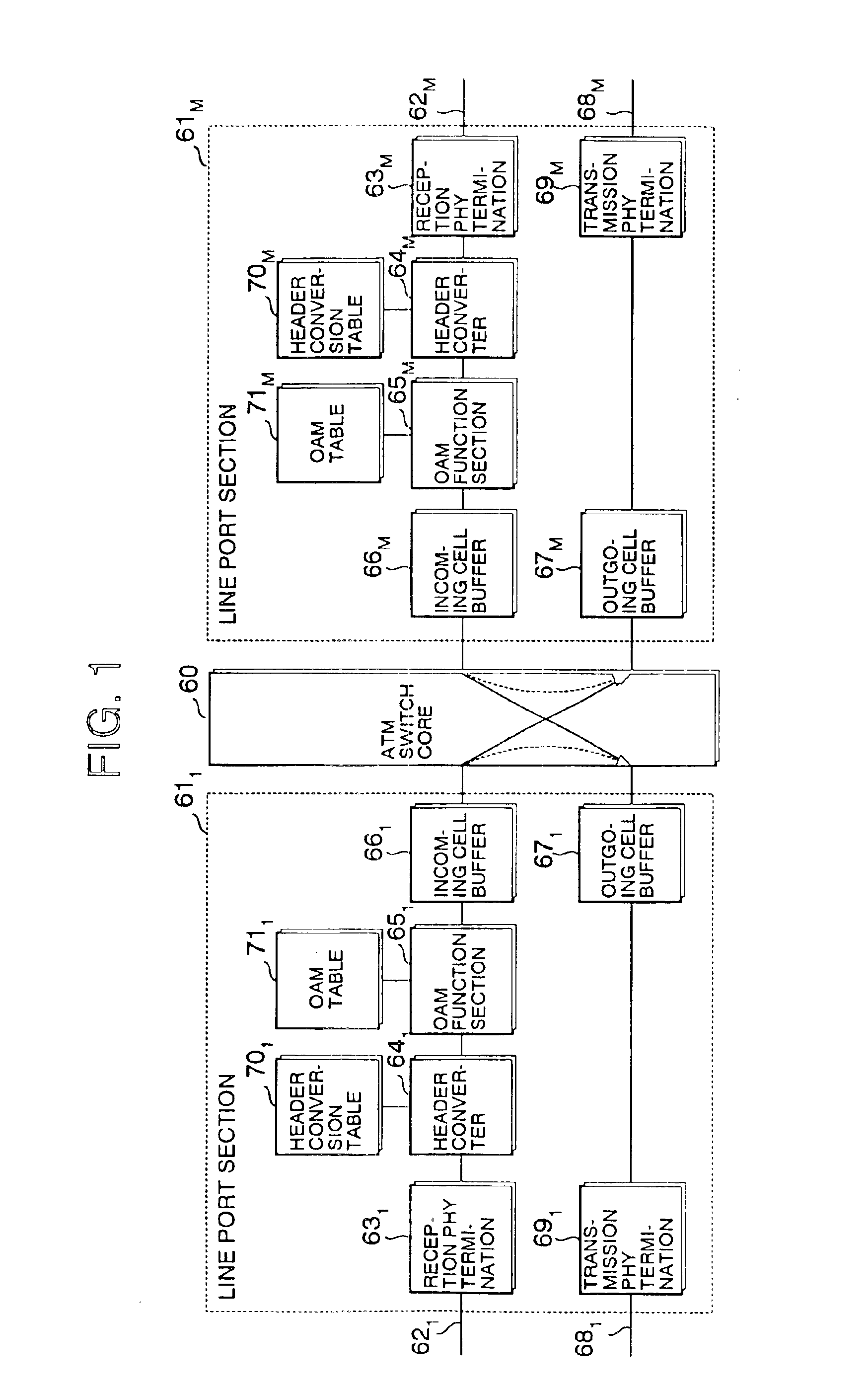

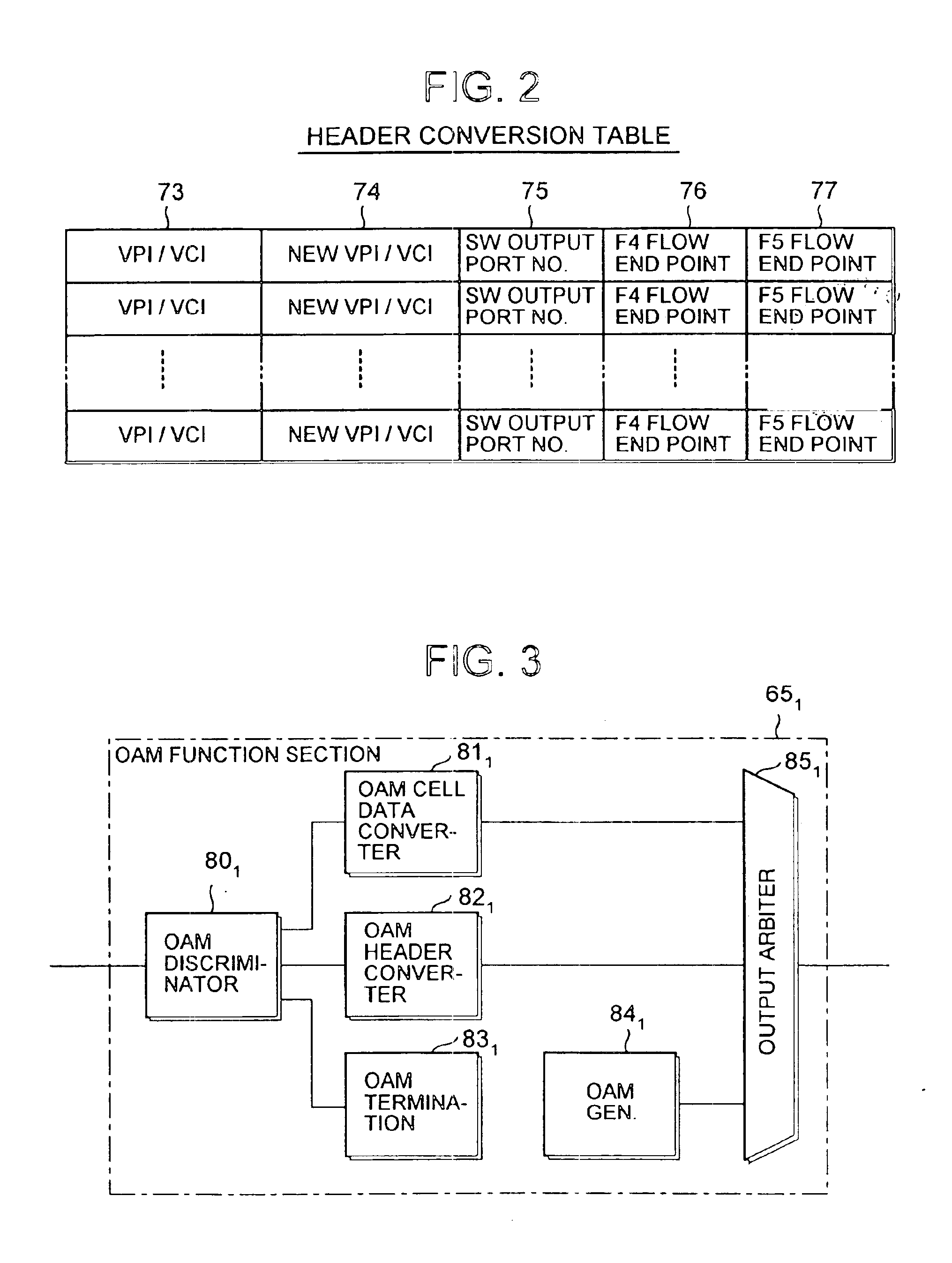

ATM switch with OAM functions

InactiveUS20050185652A1Low costReduce waiting timeError preventionTransmission systemsComputer scienceFunctional type

An ATM switch allowing simplified OAM processing only on the line incoming side is disclosed. An incoming line circuit has a header conversion table storing information indicating whether the system is an end point of an OAM processing flow for each connection and an OAM table storing an AIS flag and an RDI flag for each connection. As for an OAM cell found by referring to these tables to be forced to go back to its own port, an switch output port number is rewritten in the OAM function section. In addition, in the case of an AIS cell, the function type is rewritten so as to become an RDI cell. In the case of an LB cell, the LB indication is rewritten so as to become a return LB cell, and switching to its own port is conducted in the ATM switch core.

Owner:JUMIPER NETWORKS INC

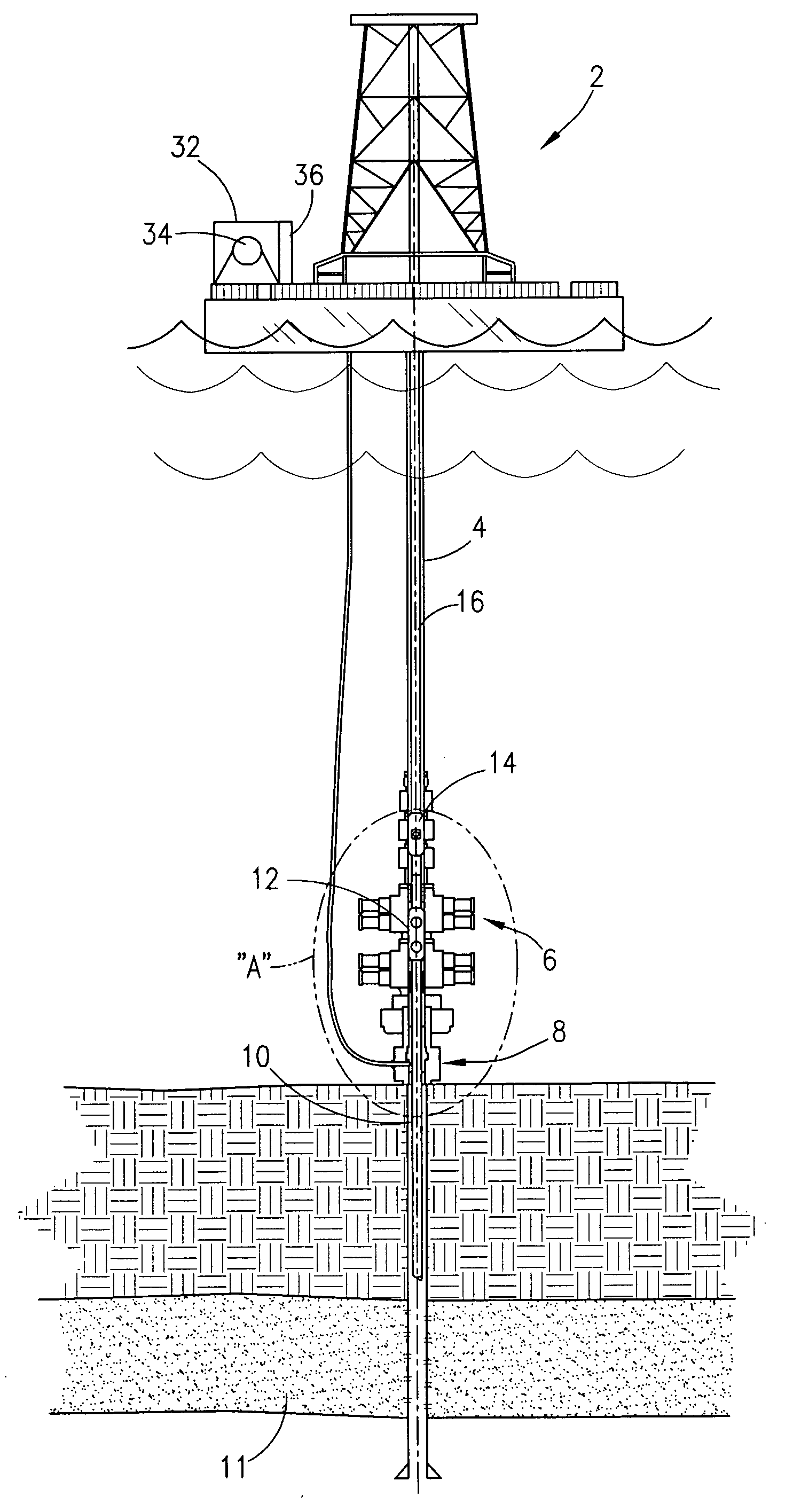

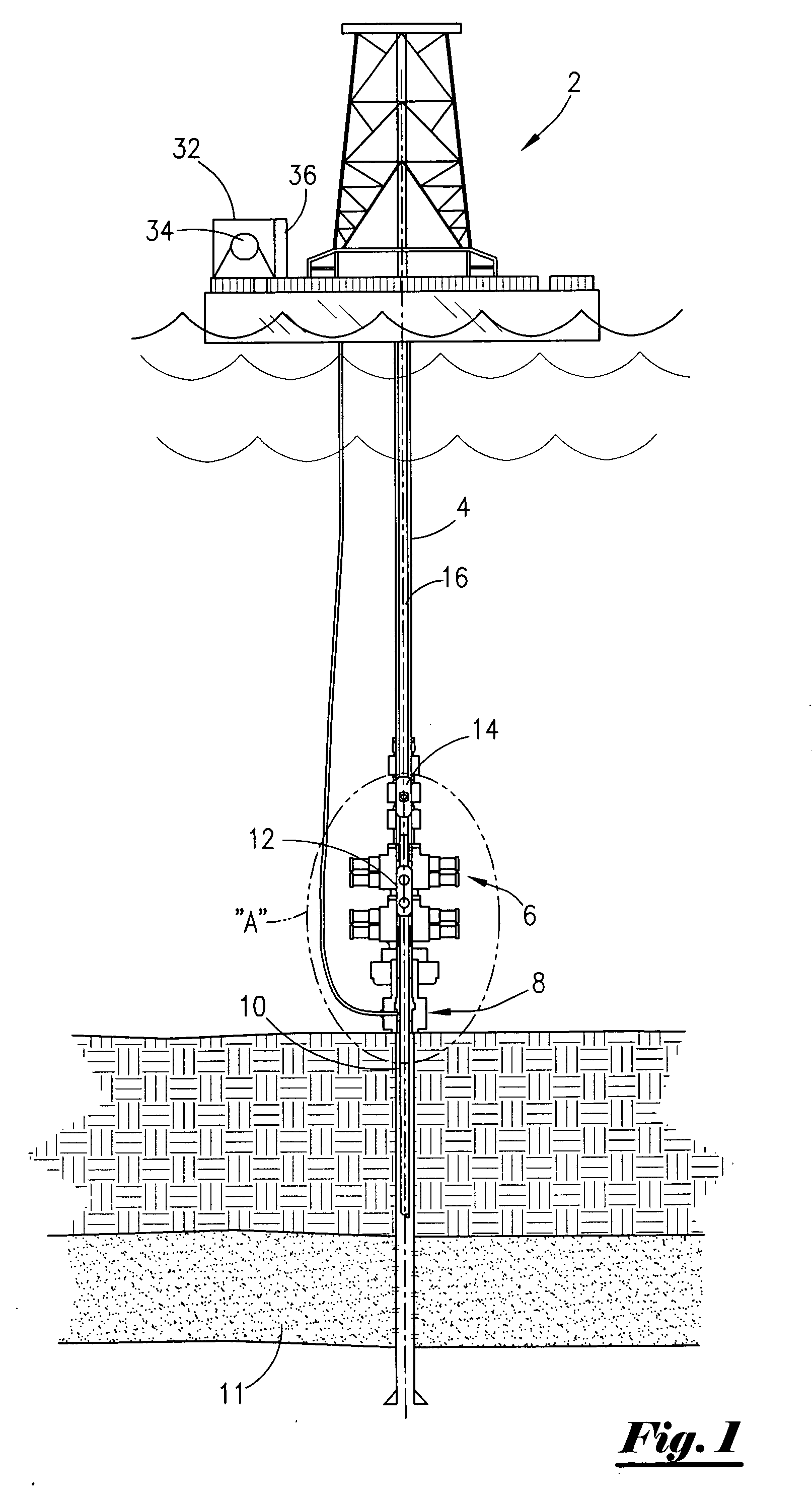

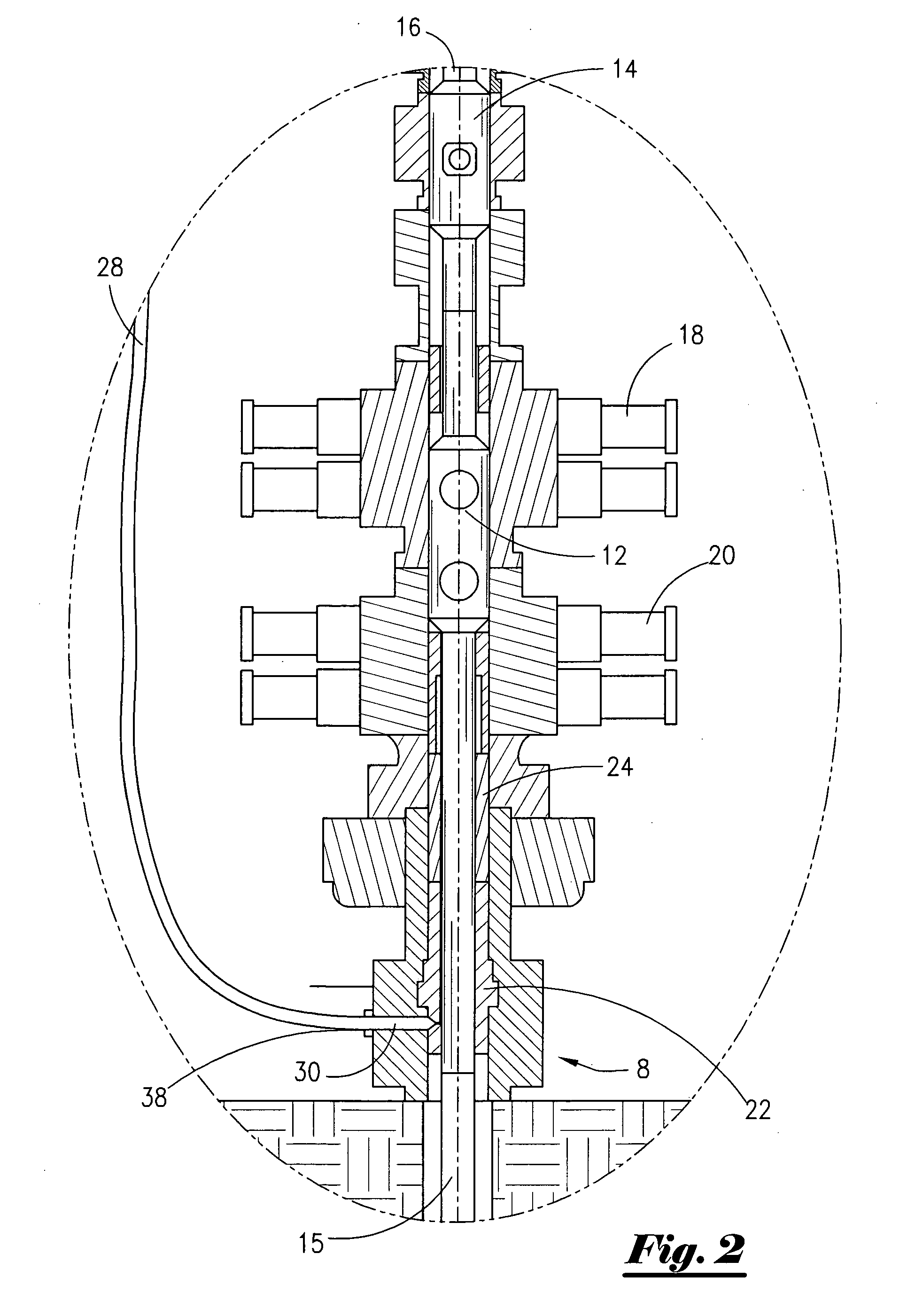

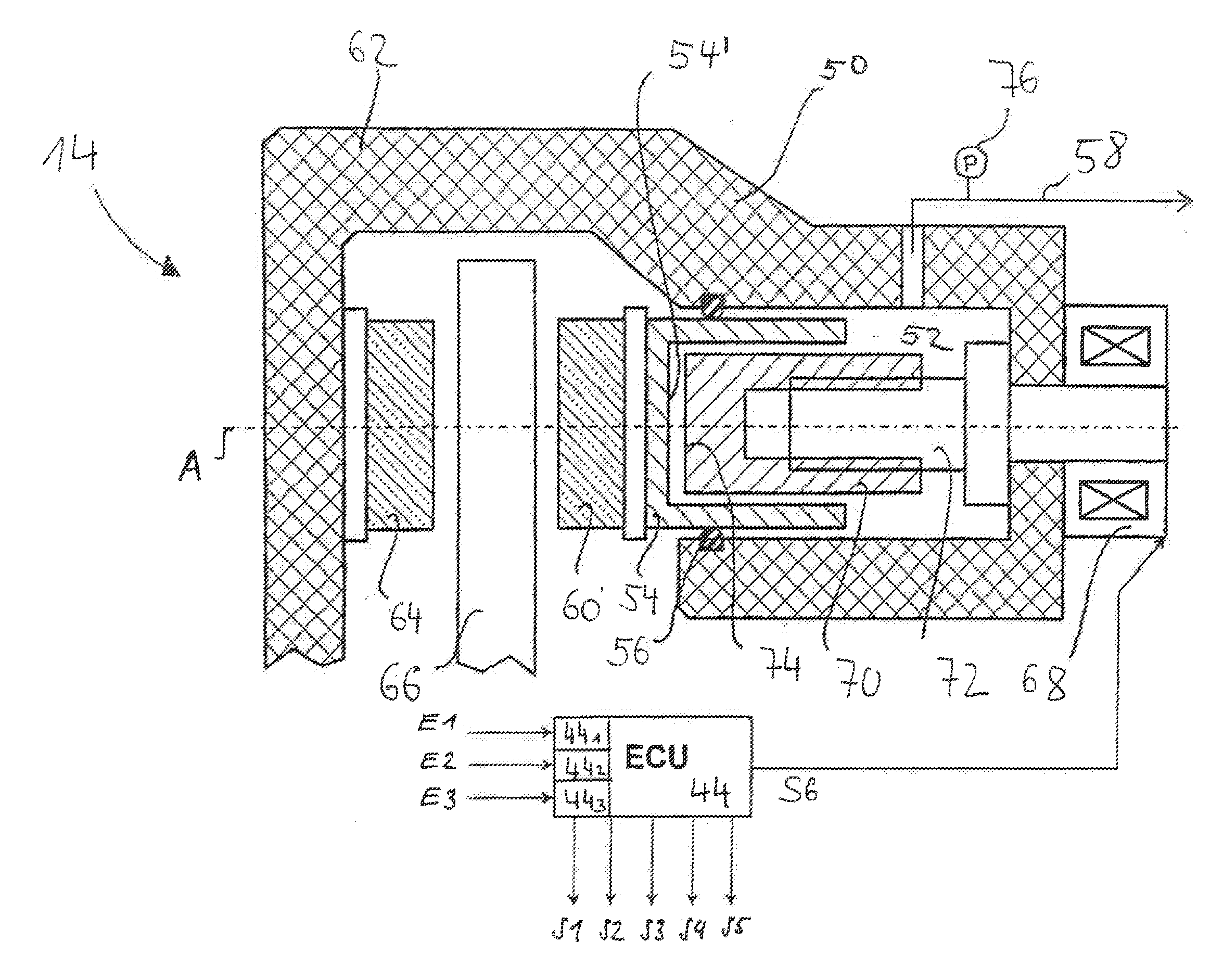

Method of controlling landing strings in offshore operations

InactiveUS20080110633A1Meet the regulationReduce riskFluid removalUnderwater drillingElectricityTubing hanger

A method and system of operating a landing string utilized on a floating platform. The landing string is disposed within a marine riser, with the marine riser being connected to a subsea production tree, and wherein the subsea production tree contains internal conduits communicating controls through a series of stab passageways. The method comprises providing a tubing hanger operatively connected to the landing string, delivering hydraulic or electrical controls from the floating platform through a control system umbilical to a junction plate operatively attached to the subsea production tree. The method further comprises landing the tubing hanger into the subsea production tree, establishing control of the tubing hanger by providing the hydraulic controls to the tubing hanger with the series of stab passageways through the subsea production tree, and establishing control of the completion bottom hole assembly with the stab passageways. In the preferred embodiment, the landing string has attached thereto a completion bottom hole assembly that will be placed in the well.

Owner:DEEPBLUE TECH L L C

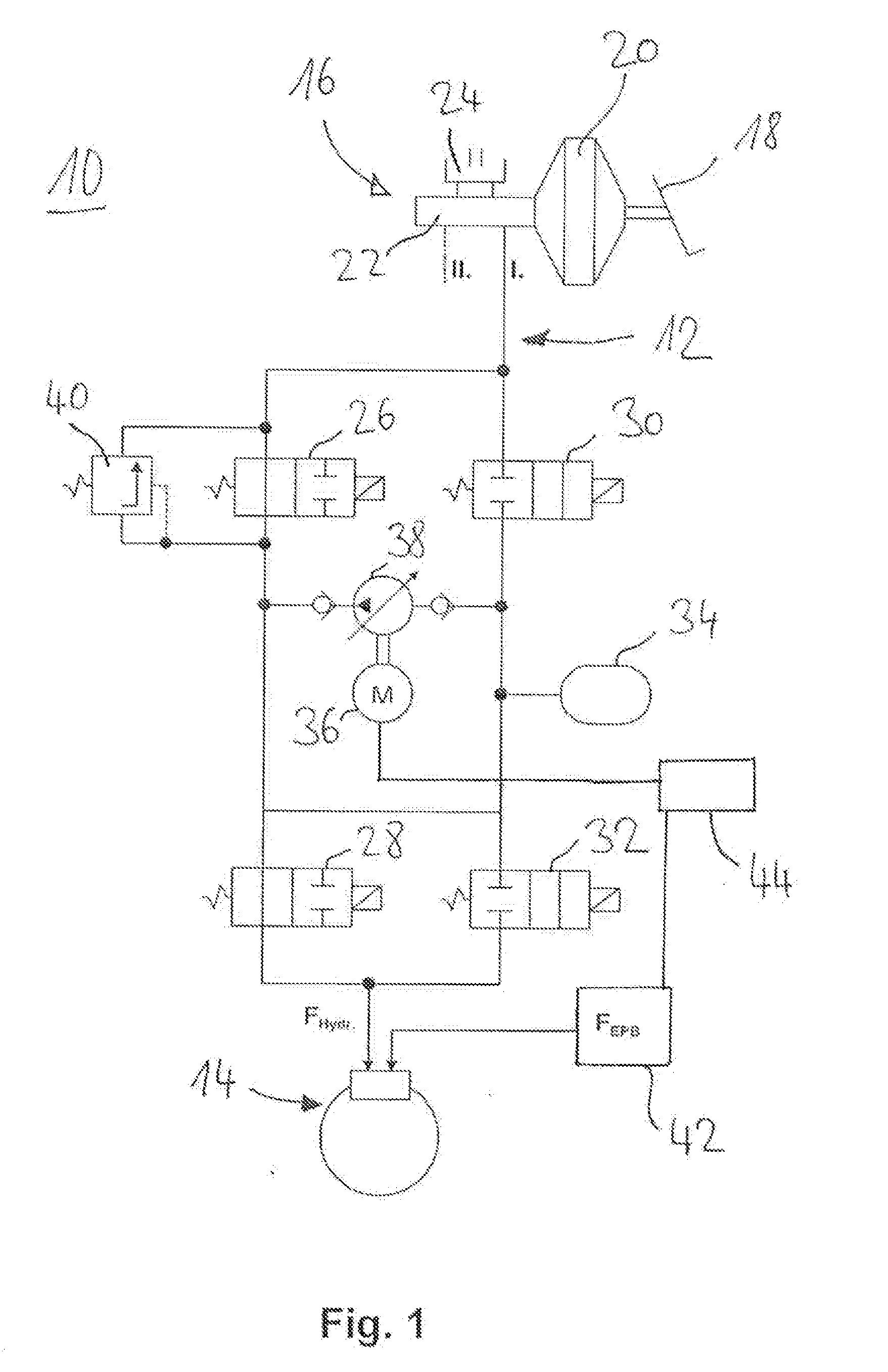

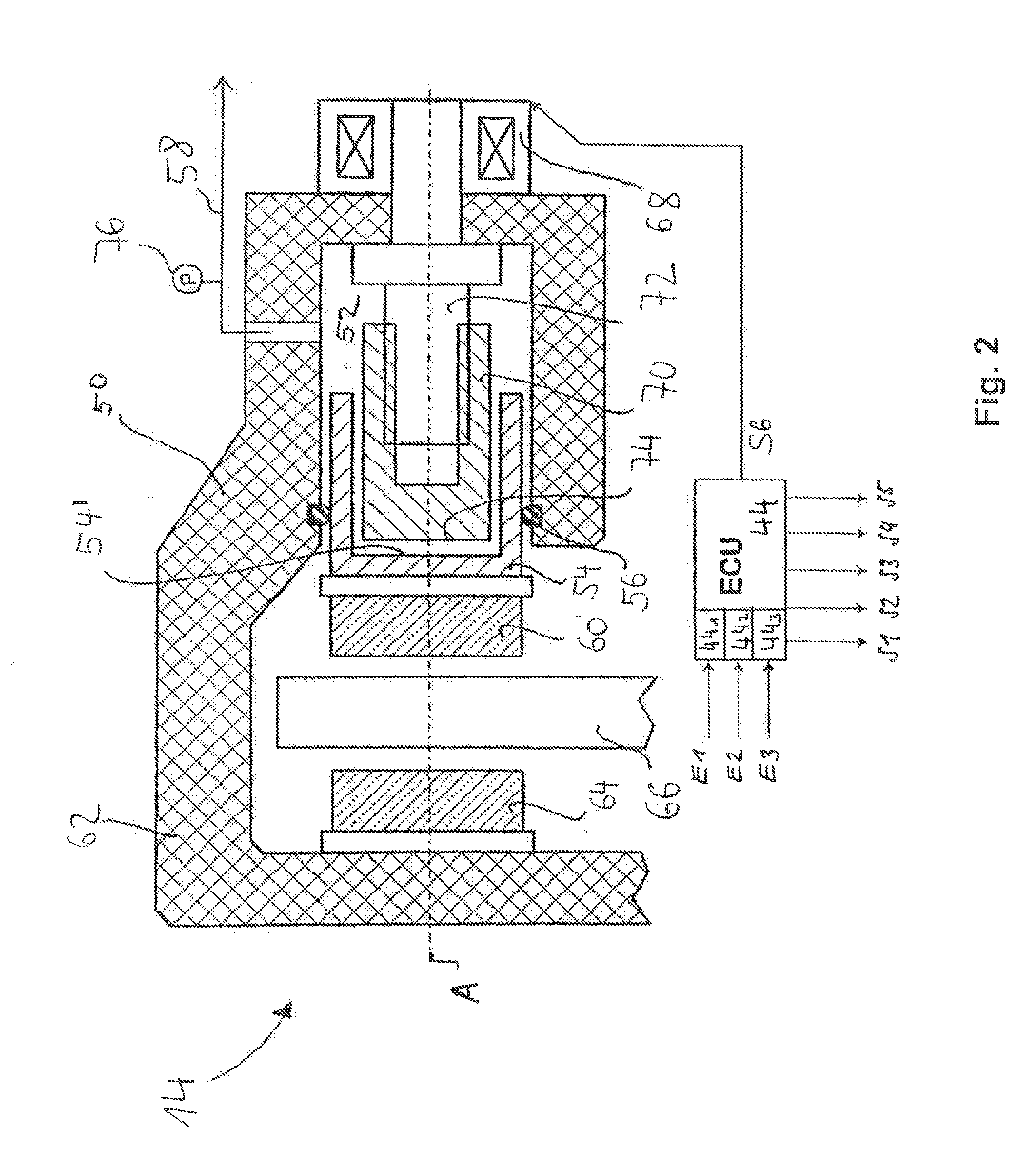

Procedure for Actuating a Hydraulic Parking Brake

ActiveUS20110042171A1Increase the amount of fluidReduce background noiseAnalogue computers for trafficMechanically actuated brakesEngineeringActuator

A procedure for actuating a parking brake is described, the parking brake comprising a brake piston which is received in a hydraulic chamber and is displaceable within the hydraulic chamber by means of a hydraulic actuator on the one hand and a mechanical actuator on the other. During operation of the parking brake the mechanical actuator is activated in a first step in order to displace the brake piston in the hydraulic chamber in such a way that a volume of a hydraulic fluid contained in the hydraulic chamber is increased. At a subsequent time the hydraulic actuator is activated in order to build up or increase a clamping force of the parking brake. The hydraulically generated or increased clamping force is then maintained by means of the mechanical actuator.

Owner:LUCAS AUTOMOTIVE GMBH

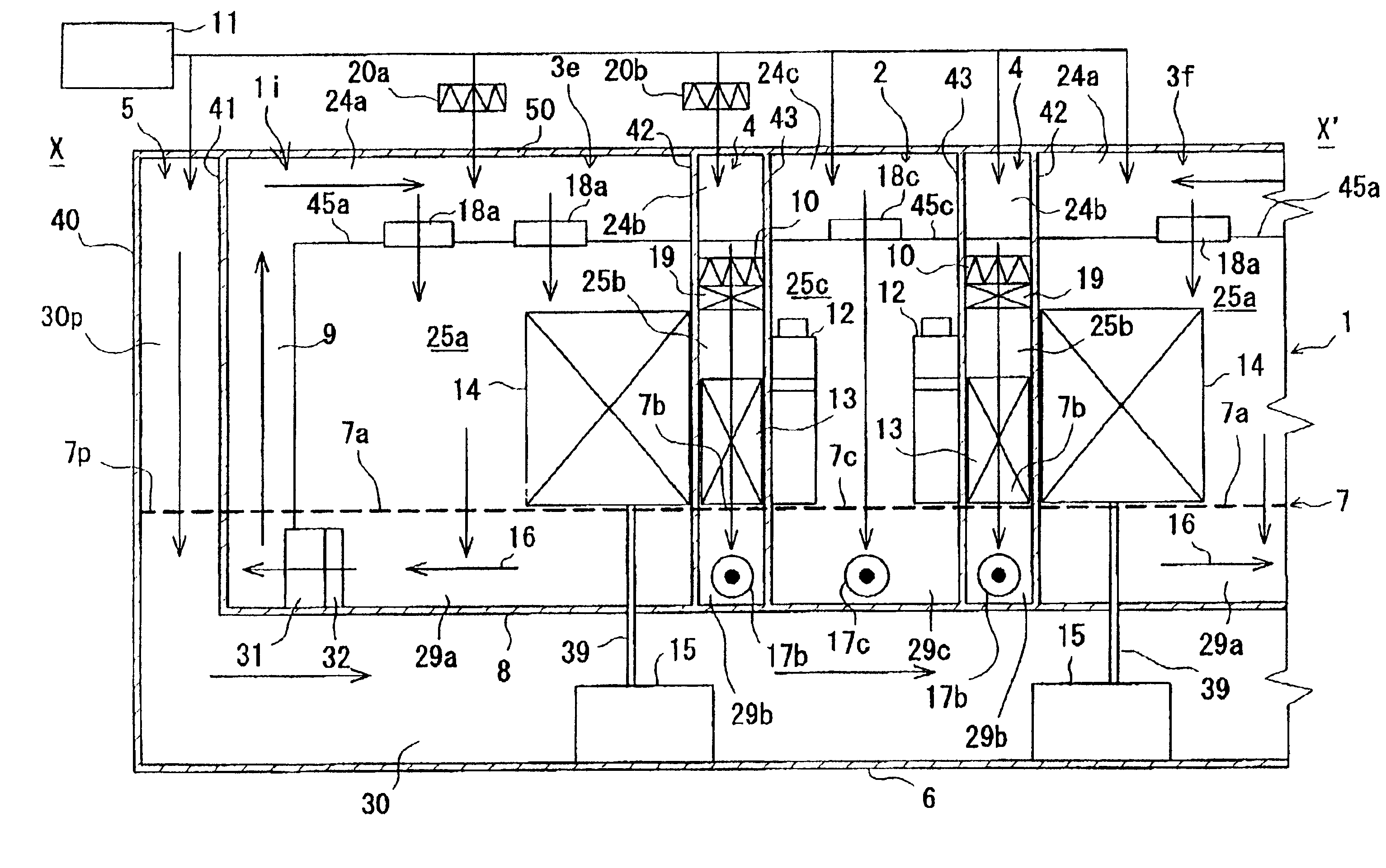

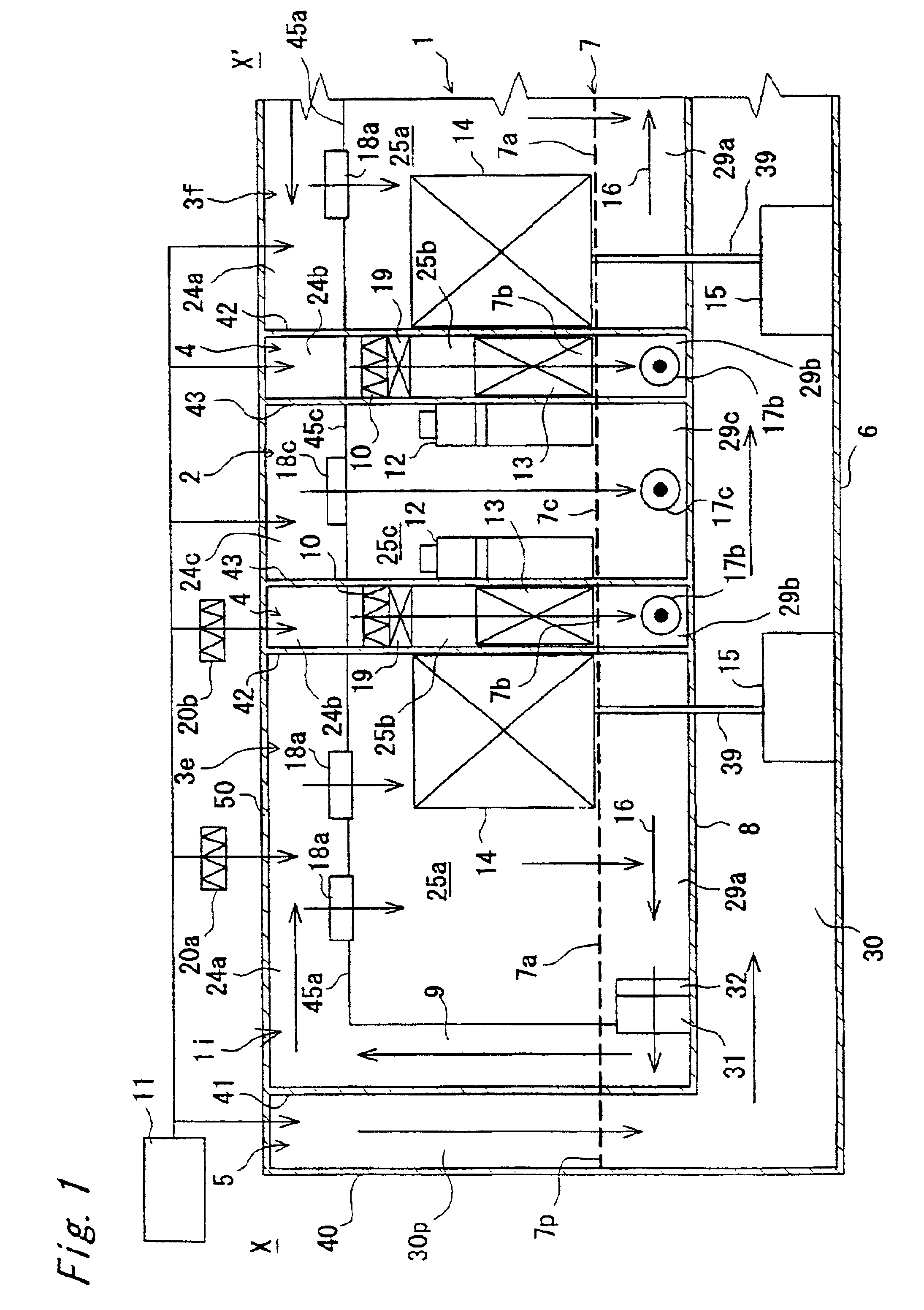

Clean room for semiconductor device

InactiveUS6869457B2Minimize turbulenceReduce runningCombination devicesMechanical apparatusProcess regionProcess engineering

A clean room has an equipment installation area where an apparatus for treating an object to be treated such as a semiconductor wafer is installed, a process area 4 where the object is loaded in or unloaded from the apparatus, and an operation area where operations of the apparatus are executed. The equipment installation area, the process area and the operation area are arranged horizontally in the above-stated order and separated by partitions. These areas are air-conditioned independently of one another. The clean room is thus capable of preventing contamination of the object and a running cost of chemical filters in the clean room is reduced.

Owner:SHARP KK

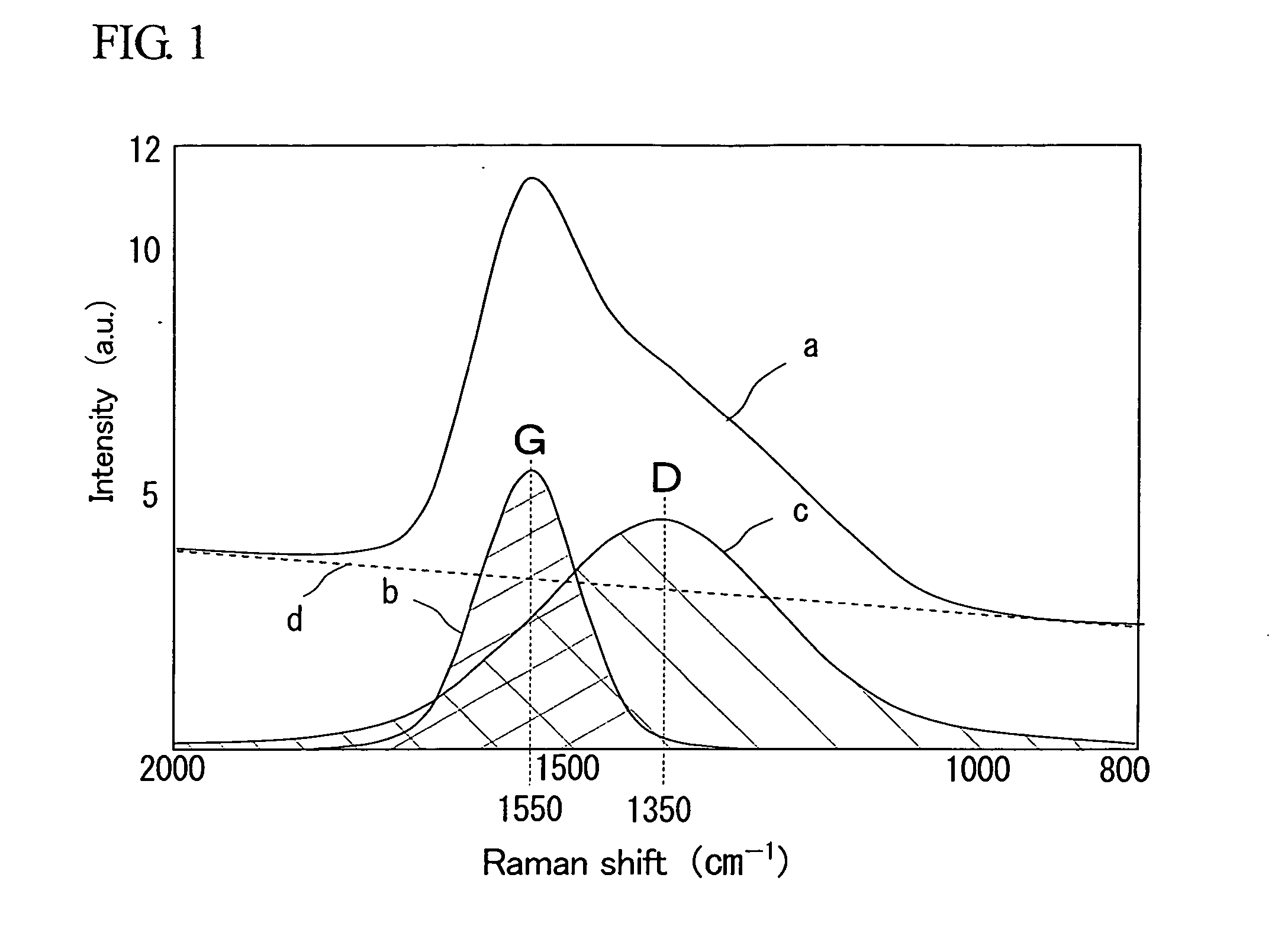

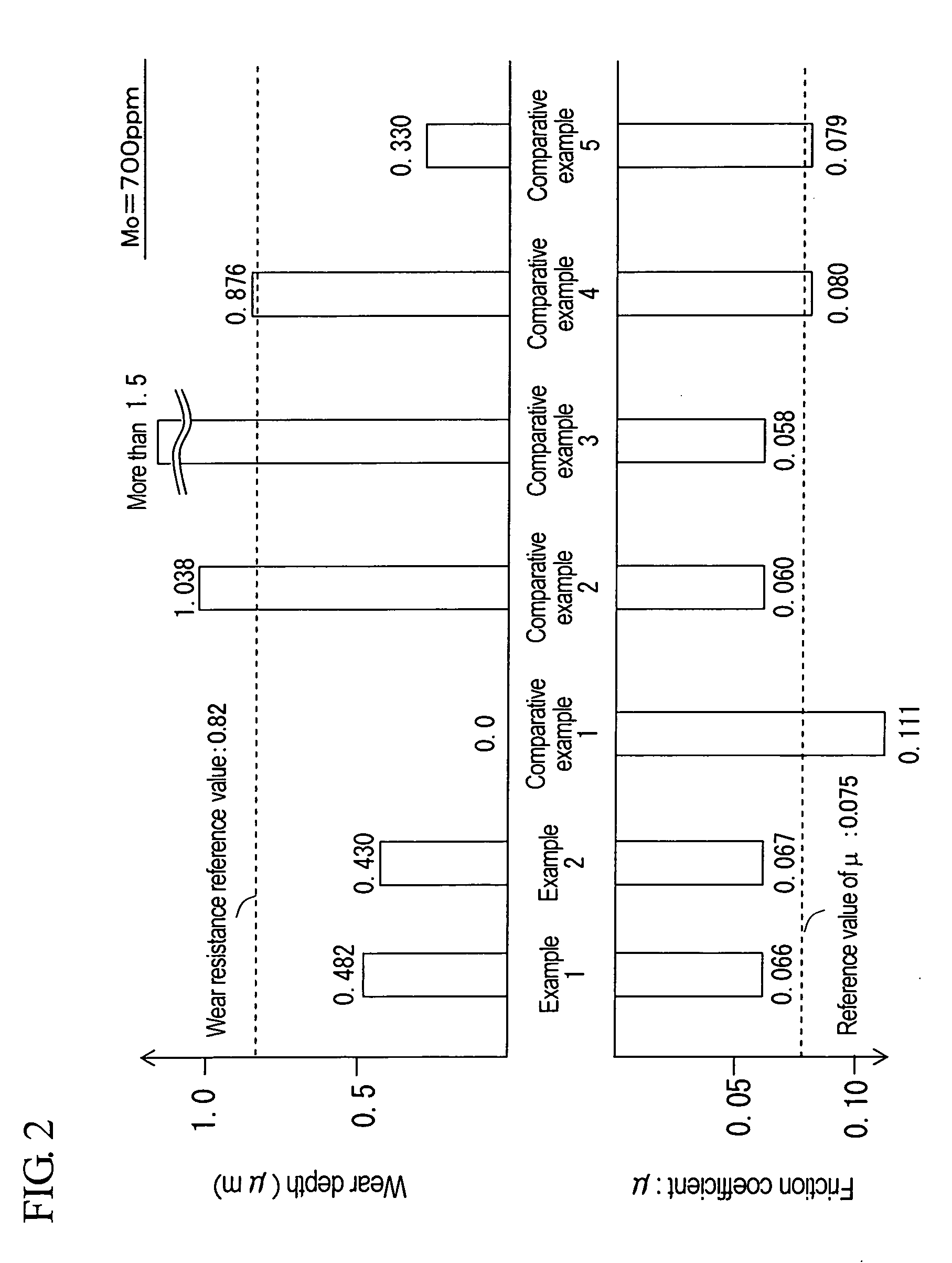

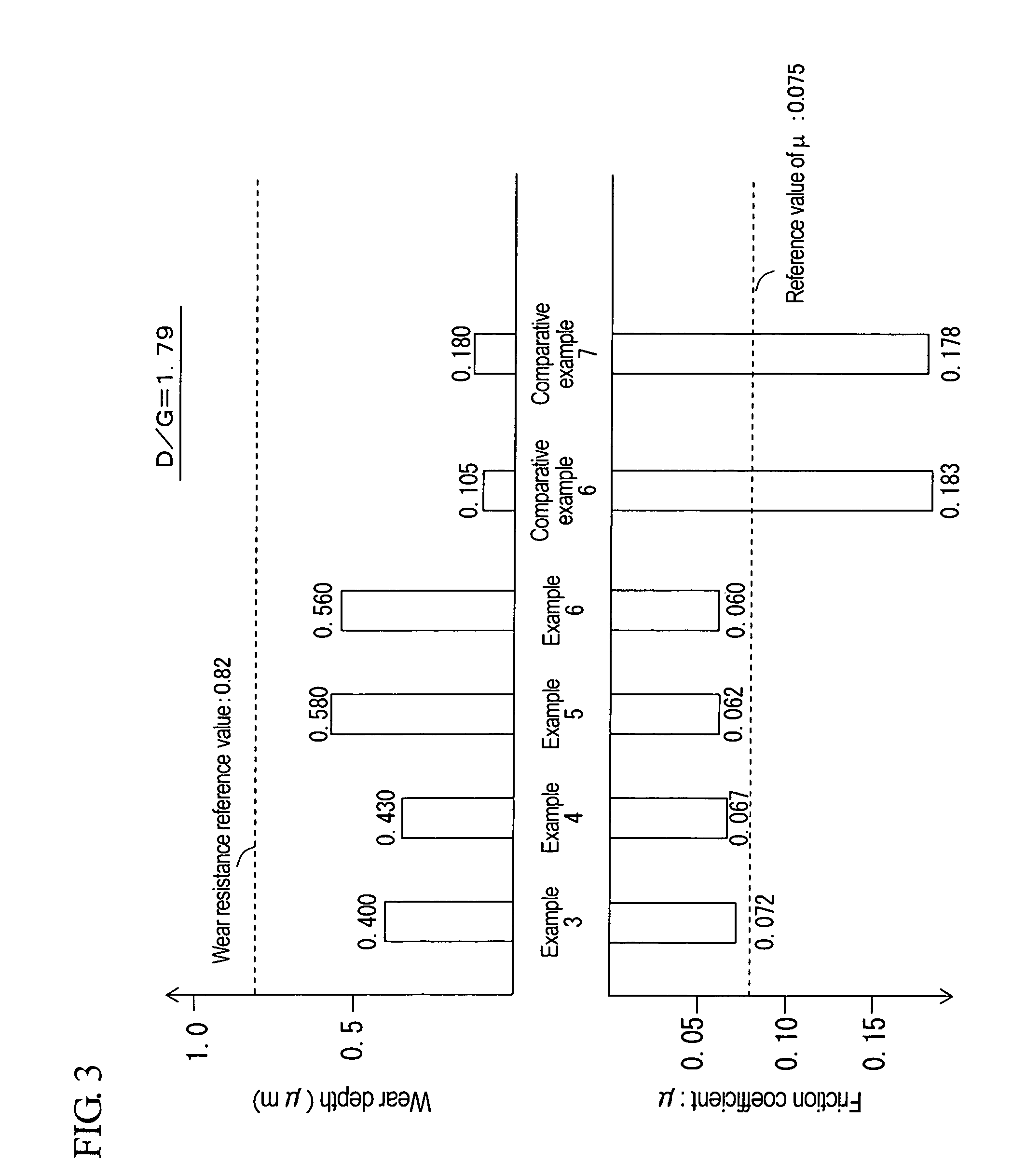

Sliding structure and sliding method

InactiveUS20070078067A1Running cost can be reducedCoefficient of frictionVacuum evaporation coatingSputtering coatingSulfurEngineering

According to the present invention, a sliding structure whereby wear resistance of a pair of sliding members that are able to slide relative to each other is improved and the friction coefficient can be reduced is provided. The sliding structure in which a lubricating oil is fed between sliding faces of a pair of sliding members that are able to slide relative to each other such that at least one of the members is allowed to slide is provided. The sliding structure is characterized in that: an amorphous carbon film is formed on the sliding face of at least one sliding member so as to result in a D to G band integrated intensity ratio in the Raman spectrum of between 1.5 and 2.0; and the lubricating oil existing between the sliding faces contains a compound comprising at least molybdenum and sulfur so as to result in a molybdenum content of not less than 400 ppm relative to the lubricating oil.

Owner:TOYOTA JIDOSHA KK

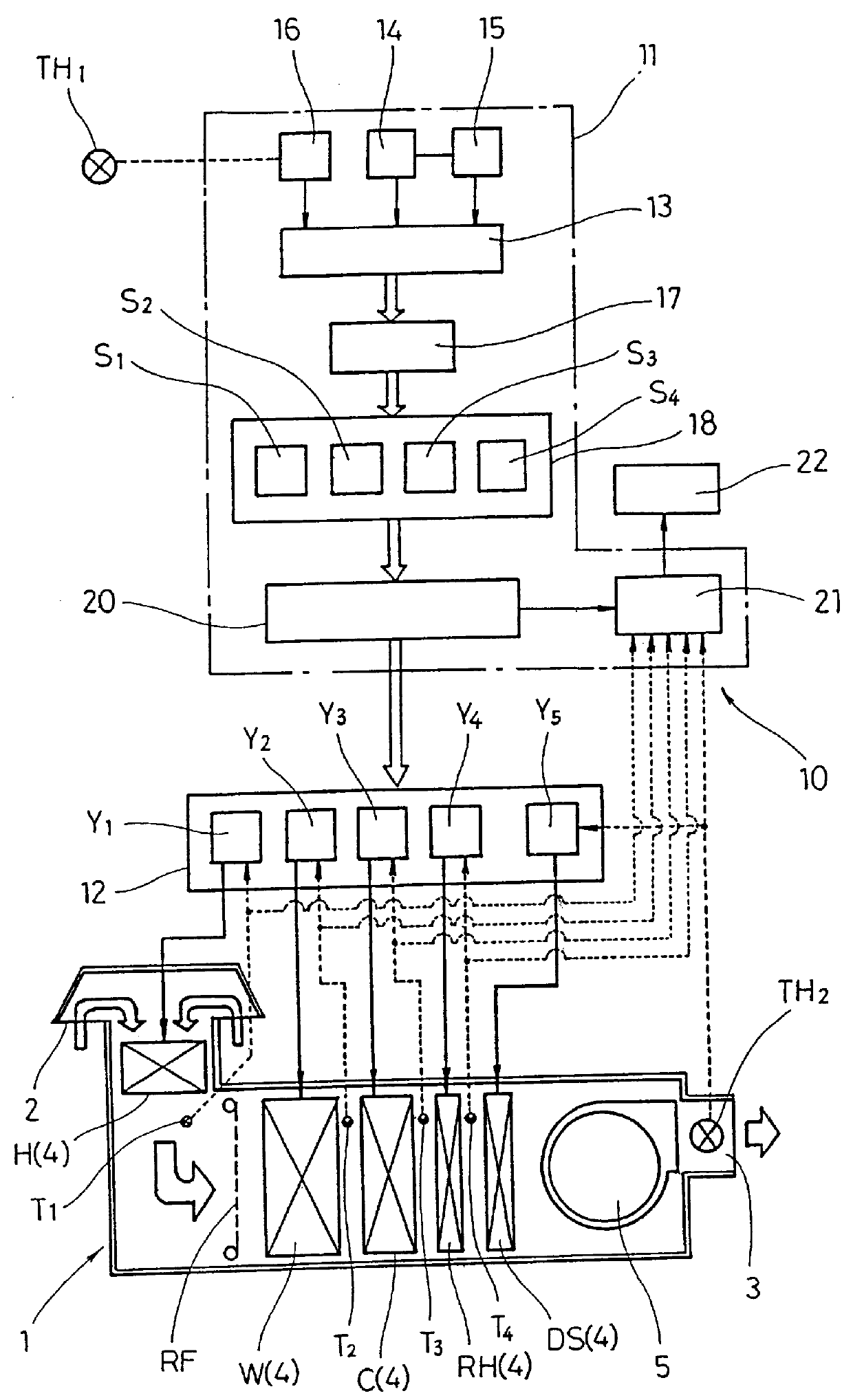

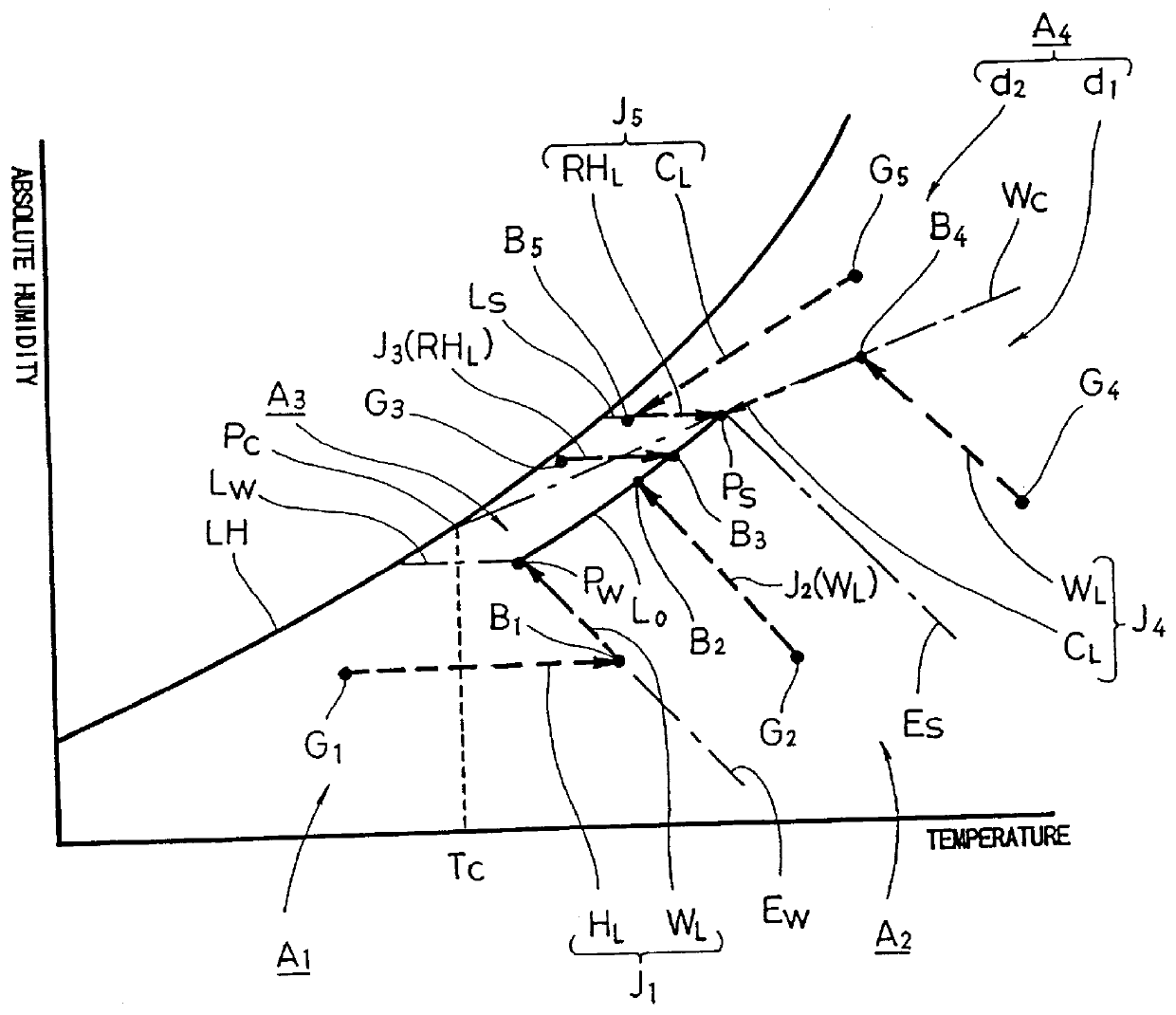

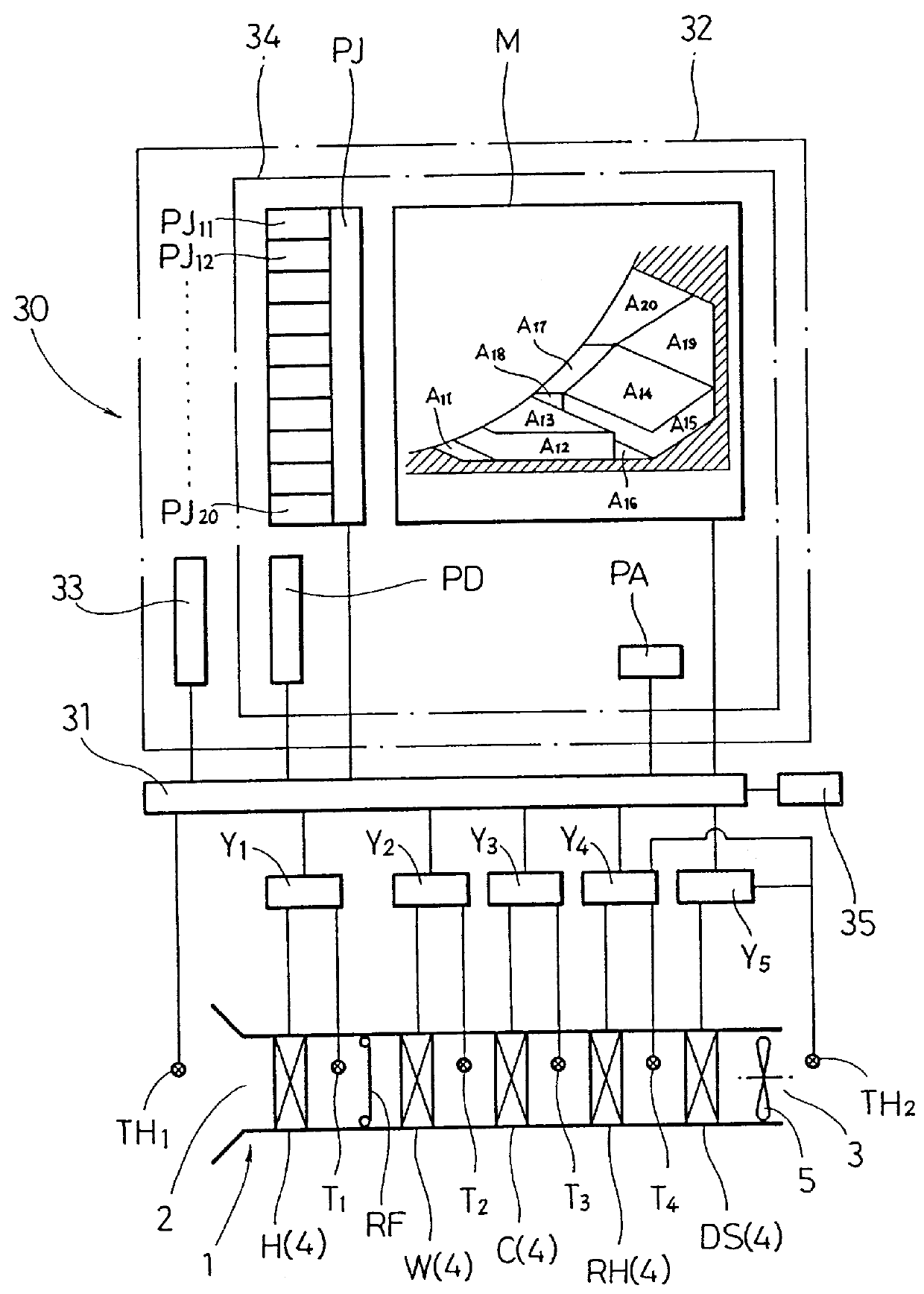

Temperature/humidity controller for use in an air conditioner and a recording medium storing temperature/humidity control programs used therefor

InactiveUS6079483AImprove responseLow running costAir-treating devicesSpace heating and ventilation safety systemsEngineeringFeedback control

In a main controller for use in an air conditioner for controlling temperature / humidity of an intaken outside air, a controlling line setter (18) sets each of control lines (J1-J5) on a psychrometric chart table (13), in which an aimed temperature / humidity line (Lo) is formed by connecting an upper limit state point (Ps) and a lower limit state point (Pw) of condition air from each of the outside air state points (G1-G5) to the aimed temperature / humidity line (Lo). The controlling line (J1-J5) is formed by connecting necessary lines selected from a main heating line (HL) showing the heating operation of a main heater (H), an adiabatic humidifying line (WL) showing the humidifying operation of an adiabatic humidifying device (W), a cooling line (CL) showing the cooling operation of a cooler (C) and an auxiliary heating line (RHL) showing the heating operation of the auxiliary heater (RH), and the end point temperature for each of the lines is set as the aimed exit temperature for each of the temperature / humidity adjusters (4, 4) and each of the temperature / humidity adjusters (4-4) is individually put to feedback control. Temperature / humidity control can be conducted accurately and at a good response, and energy can be saved and the running cost can be reduced.

Owner:TRINITY IND CORP

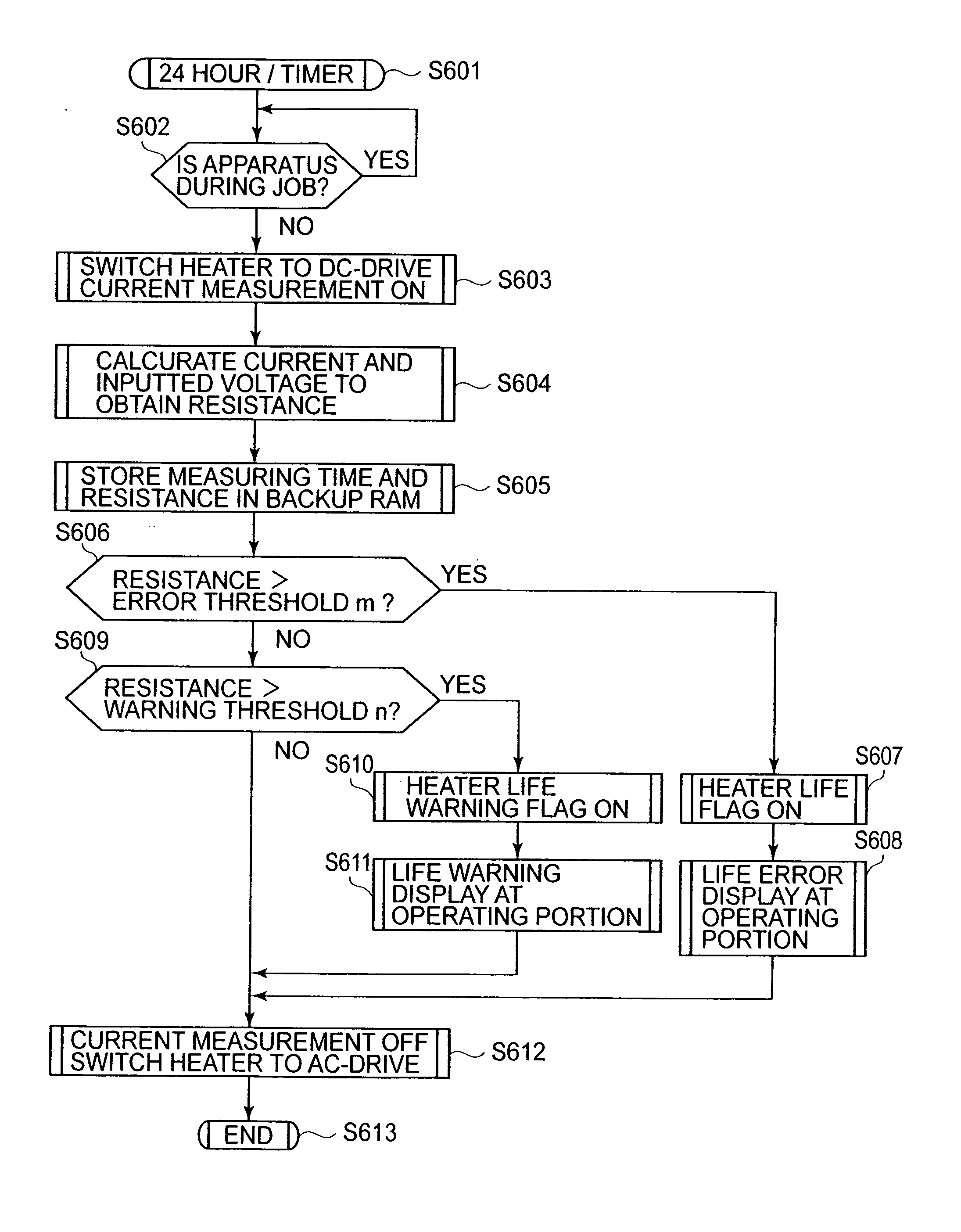

Image forming apparatus

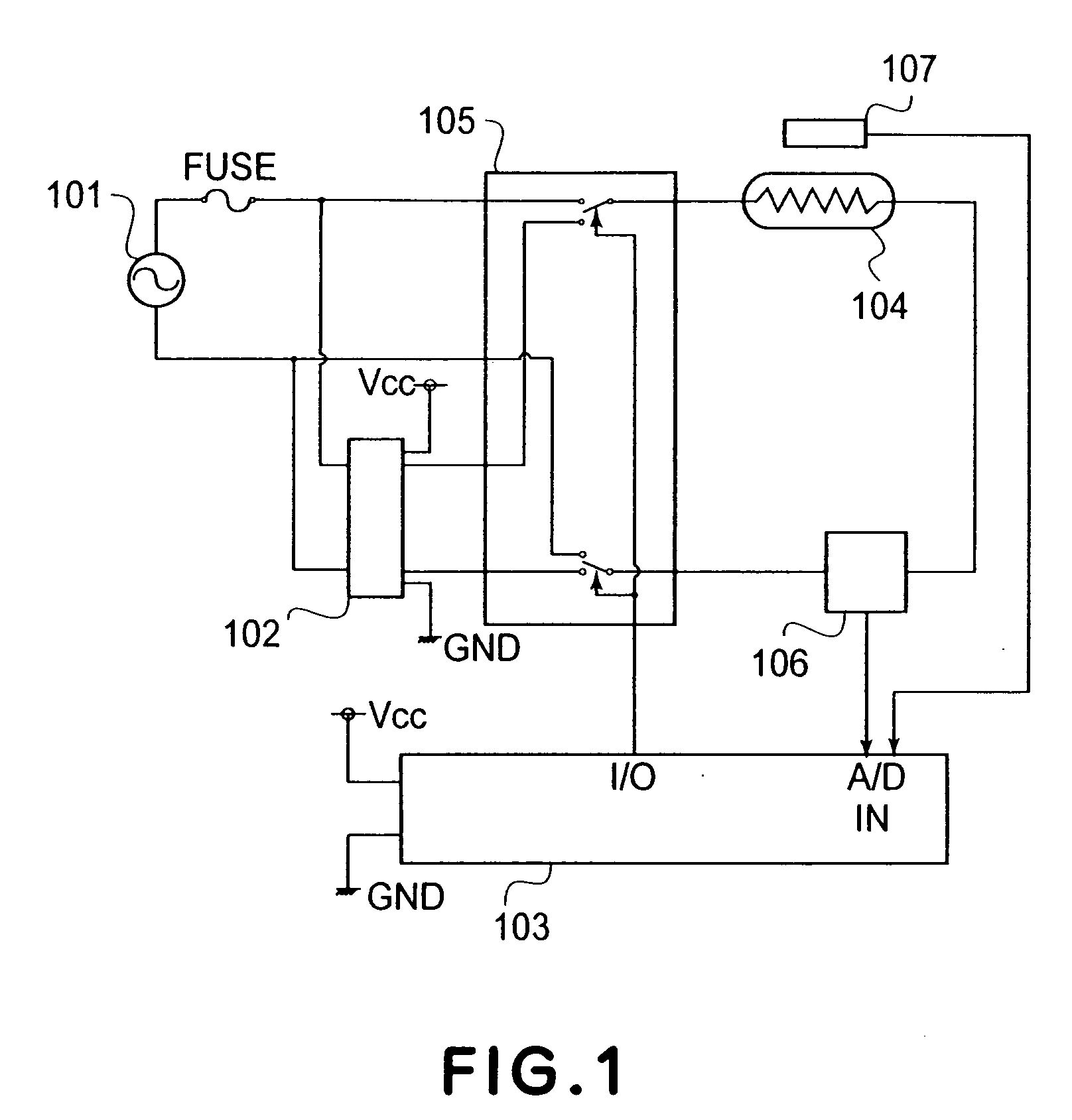

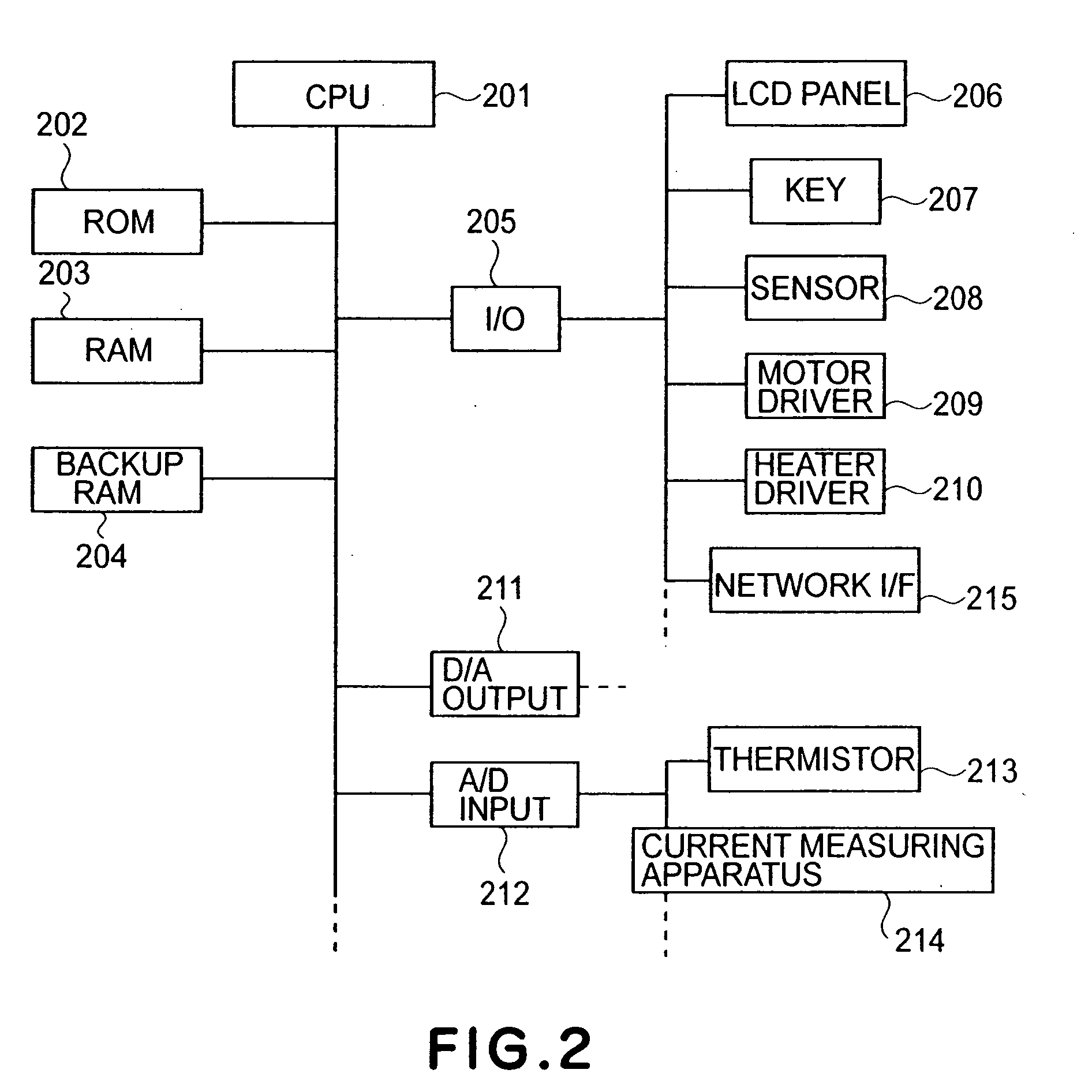

InactiveUS20060024072A1Running cost can be reducedImprove accuracyElectrographic process apparatusElectrical currentImage formation

Owner:CANON KK

ATM switch with OAM functions

InactiveUS6865158B2Easy to implementHighly reliable ATM networkError preventionFrequency-division multiplex detailsPointing systemsFunctional type

An ATM switch allowing simplified OAM processing only on the line incoming side is disclosed. An incoming line circuit has a header conversion table storing information indicating whether the system is an end point of an OAM processing flow for each connection and an OAM table storing an AIS flag and an RDI flag for each connection. As for an OAM cell found by referring to these tables to be forced to go back to its own port, an switch output port number is rewritten in the OAM function section. In addition, in the case of an AIS cell, the function type is rewritten so as to become an RDI cell. In the case of an LB cell, the LB indication is rewritten so as to become a return LB cell, and switching to its own port is conducted in the ATM switch core.

Owner:JUMIPER NETWORKS INC

Multiple Thermal Cutting Device and Multiple Thermal Cutting Method

ActiveUS20070241083A1Decrease processingLow running costWelding/cutting auxillary devicesArc welding apparatusPlasma torchManufactured Object

A hybrid thermal cutting apparatus has both a laser head and a plasma torch, both of which can be controlled independently, can perform both laser processing and plasma processing, thus reducing the running costs. A large number of cutting lines for cutting out various types of manufactured products from plate materials are classified into a laser cutting type and a plasma cutting type, according to the cutting length, whether they are the external periphery of manufactured products or apertures, the size of the manufactured products or the apertures, the required process accuracy, the plate thickness, or the like. The lines of the laser cutting type are cut by laser processing, while the lines of the plasma cutting type are cut by plasma processing.

Owner:KOMATSU IND CORP

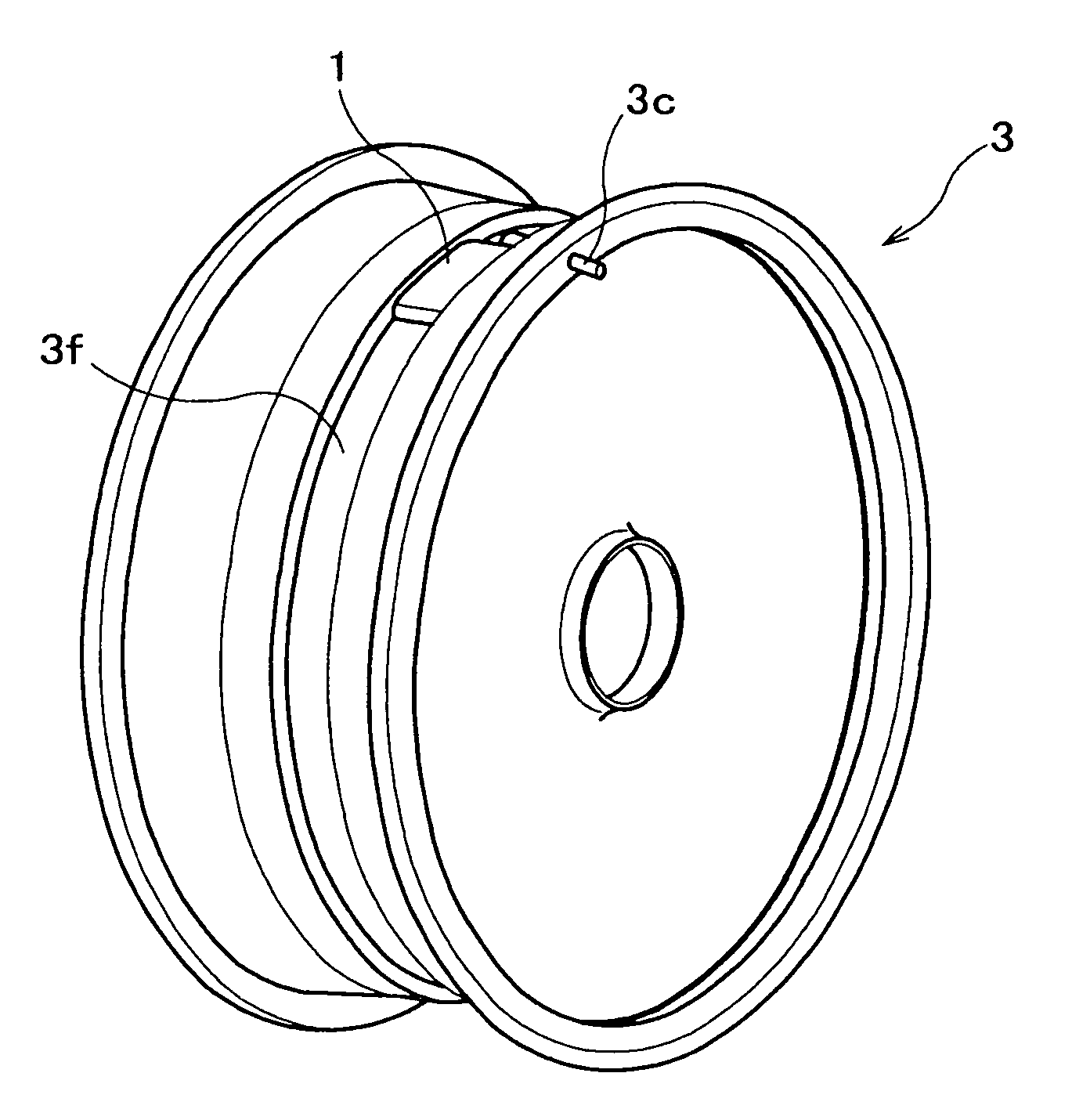

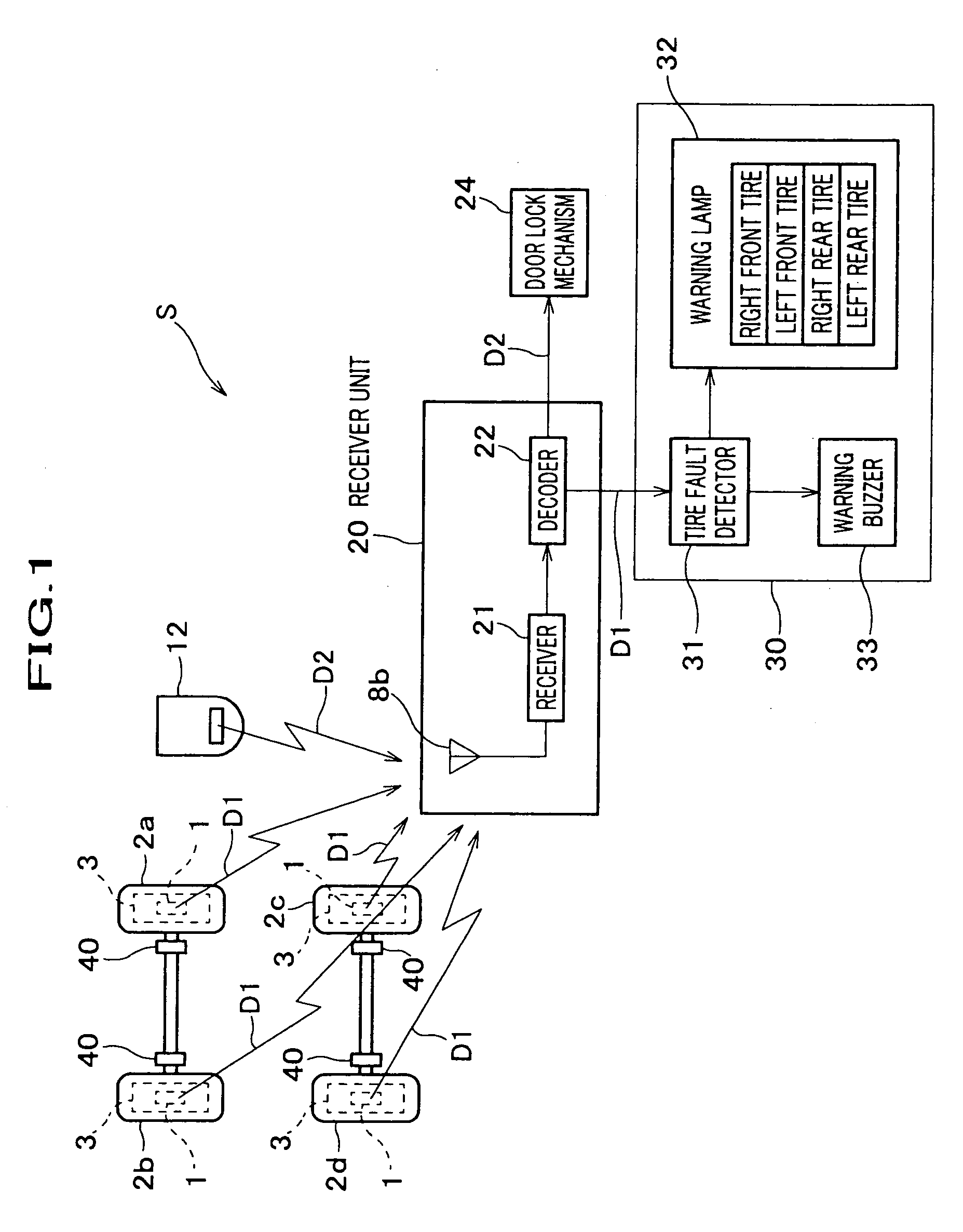

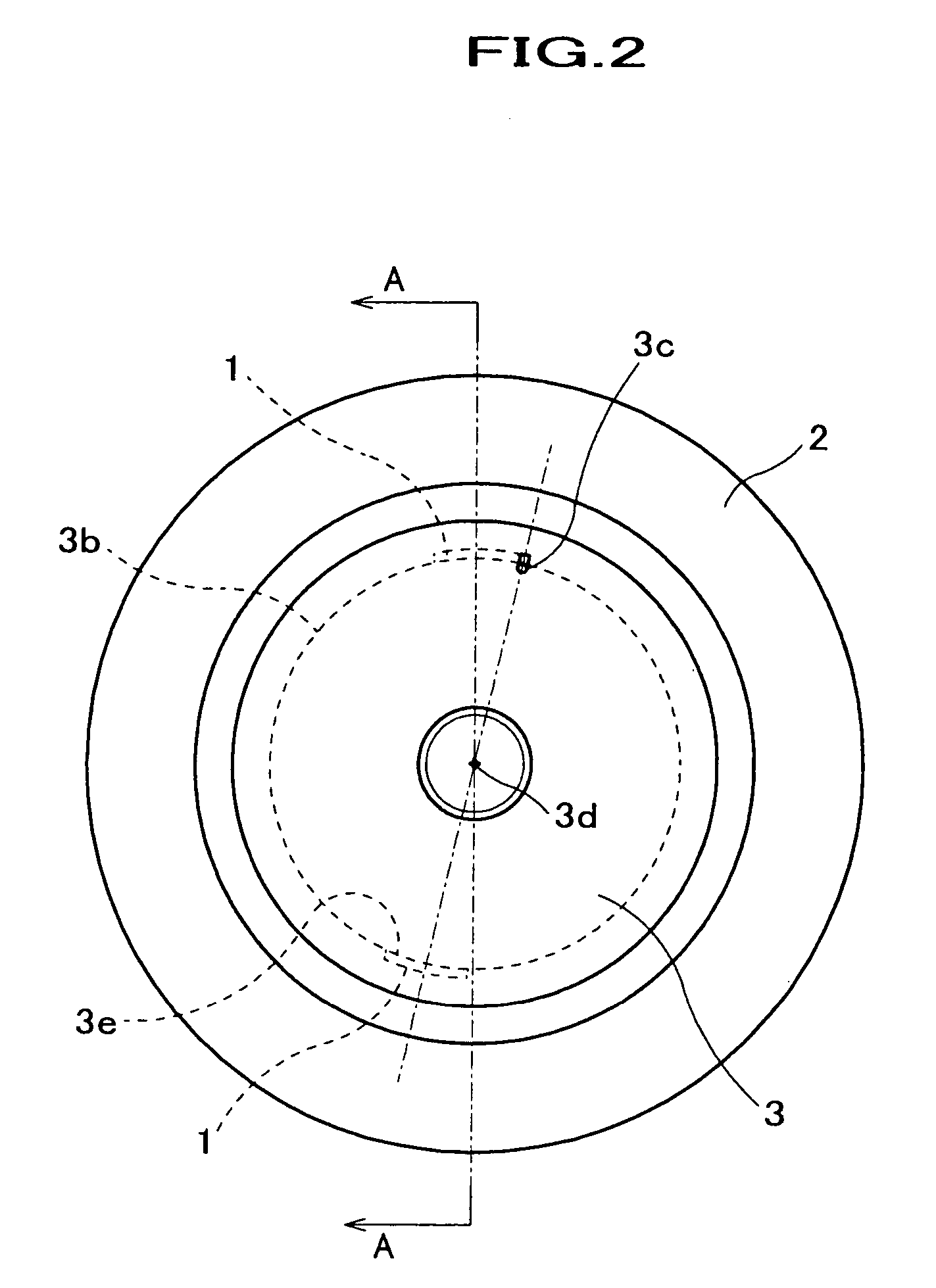

Tire pressure detection system and a wheel used therein

InactiveUS7091840B2Running cost can be reducedGuaranteed continuous useThermometer detailsInflated body pressure measurementLine sensorWireless

Owner:HONDA MOTOR CO LTD

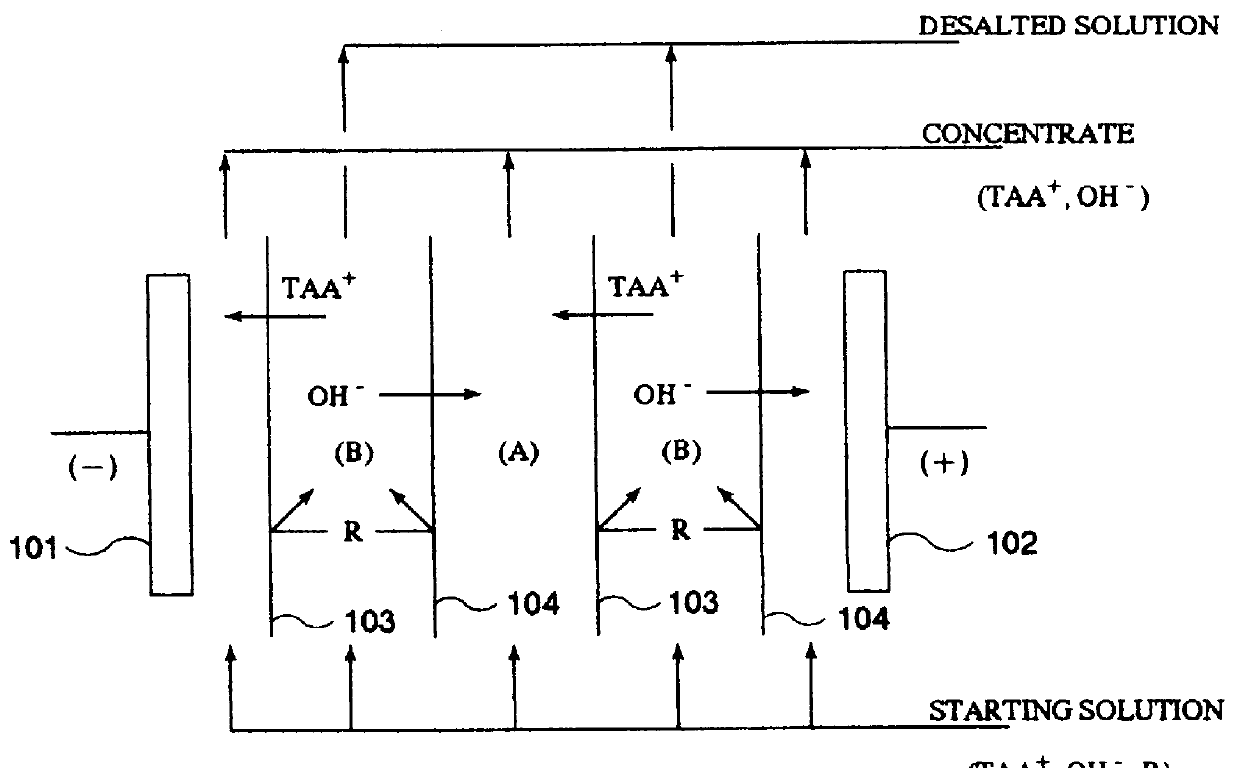

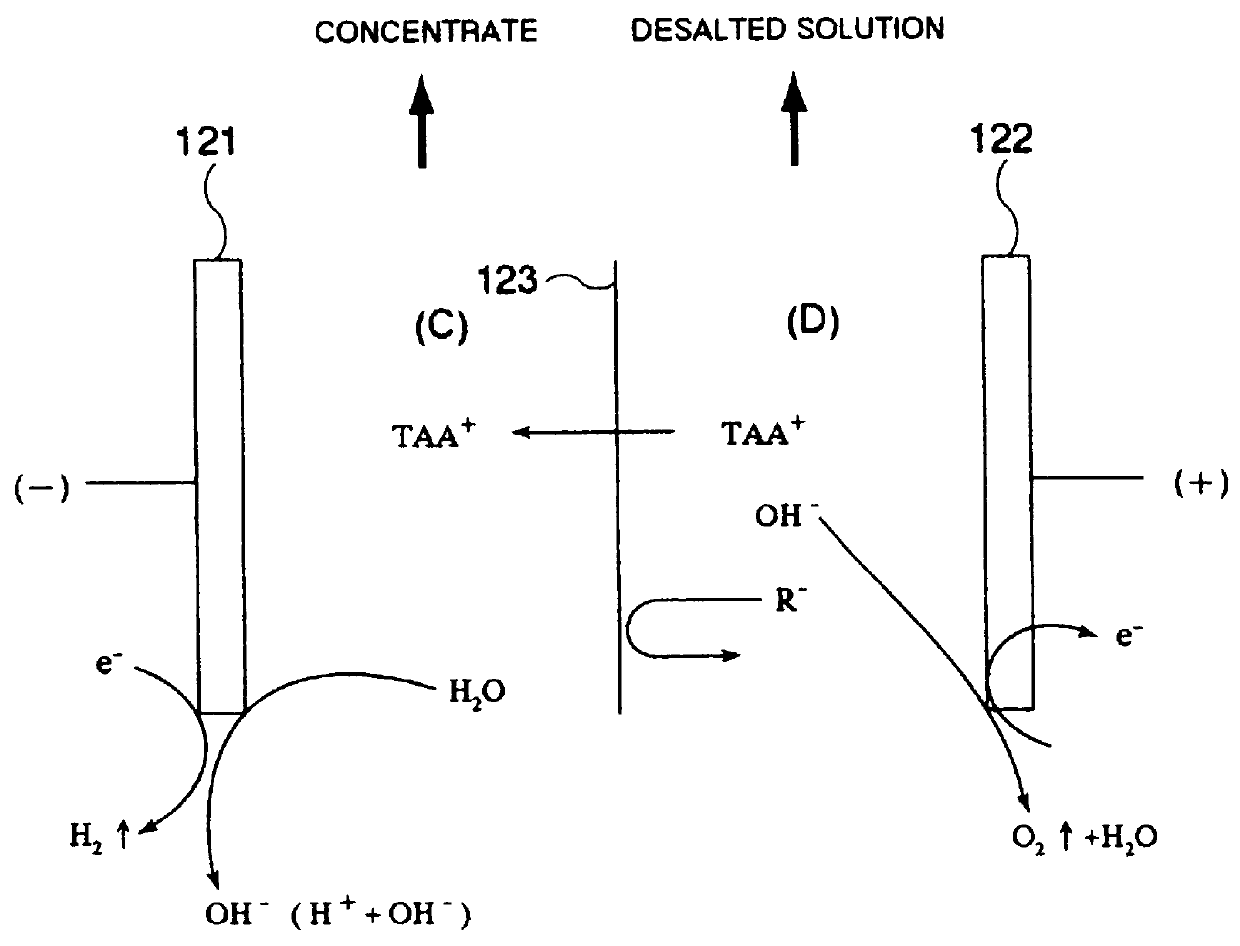

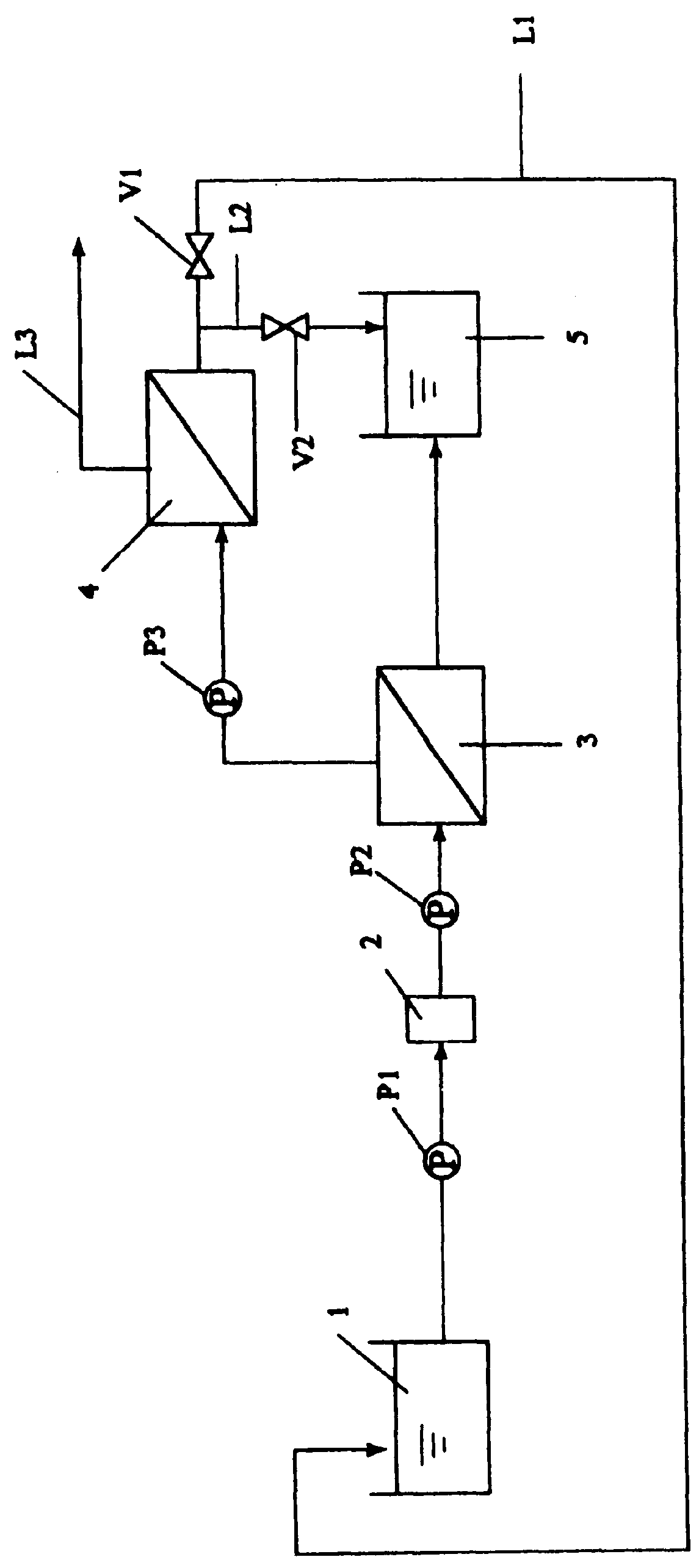

Process and equipment for rejuvenation treatment of photoresist development waste

InactiveUS6083670AIncreased rejectEfficient removalIon-exchanger regenerationOrganic anion exchangersElectrolysisWastewater

The disclosed process for rejuvenation treatment of a photoresist development waste mainly containing a photoresist and tetraalkylammonium (TAA) ions comprises at least a simple membrane separation step of treating the photoresist development waste or a treated solution derived from the photoresist development waste with a nanofiltration membrane (NF membrane) to obtain a concentrate (NF concentrate) mainly containing impurities such as the photoresist and a higher-purity permeate (NF permeate) mainly containing TAA ions. The NF concentrate and / or the NF permeate, preferably the NF permeate, is desirably subjected to a step of concentration and refining by electrodialysis or electrolysis and / or a step of refining by ion exchange treatment, for example, with an anion exchange resin and / or a cation exchange resin in one of the H form and the TAA form. The NF permeate may advantageously be passed through the concentrating cells of an electrodialysis unit while passing the NF concentrate through the desalting cells of the electrodialysis unit to further recover TAA ions remaining in the NF concentrate, whereby the amount of wastewater discharged as the desalted waste can be decreased. The NF membrane separation step is preferably effected in multiple stages.

Owner:ORGANO CORP

Ink jet printing apparatus and method for correcting ejection driving

InactiveUS7201462B2Avoid showingReduce runningOther printing apparatusPictoral communicationEngineeringVisible band

An ink jet printing apparatus, which can prevent unwanted visible bands or stripes from appearing in a printed image, performs a nozzle information generation step for generating nozzle information representing an ejection characteristic of each nozzle, according to a landing state on a print medium of an ink droplet ejected from each nozzle of the print head; an estimation step for estimating, based on the generated nozzle information and the print data, an effect that the ink droplet ejected from each nozzle has on the image to be formed; a correction information generation step for generating correction information to correct an ink ejection condition of each nozzle according to a result of estimation by the estimation step; and a control step for controlling a driving of the nozzles according to the correction information.

Owner:CANON KK

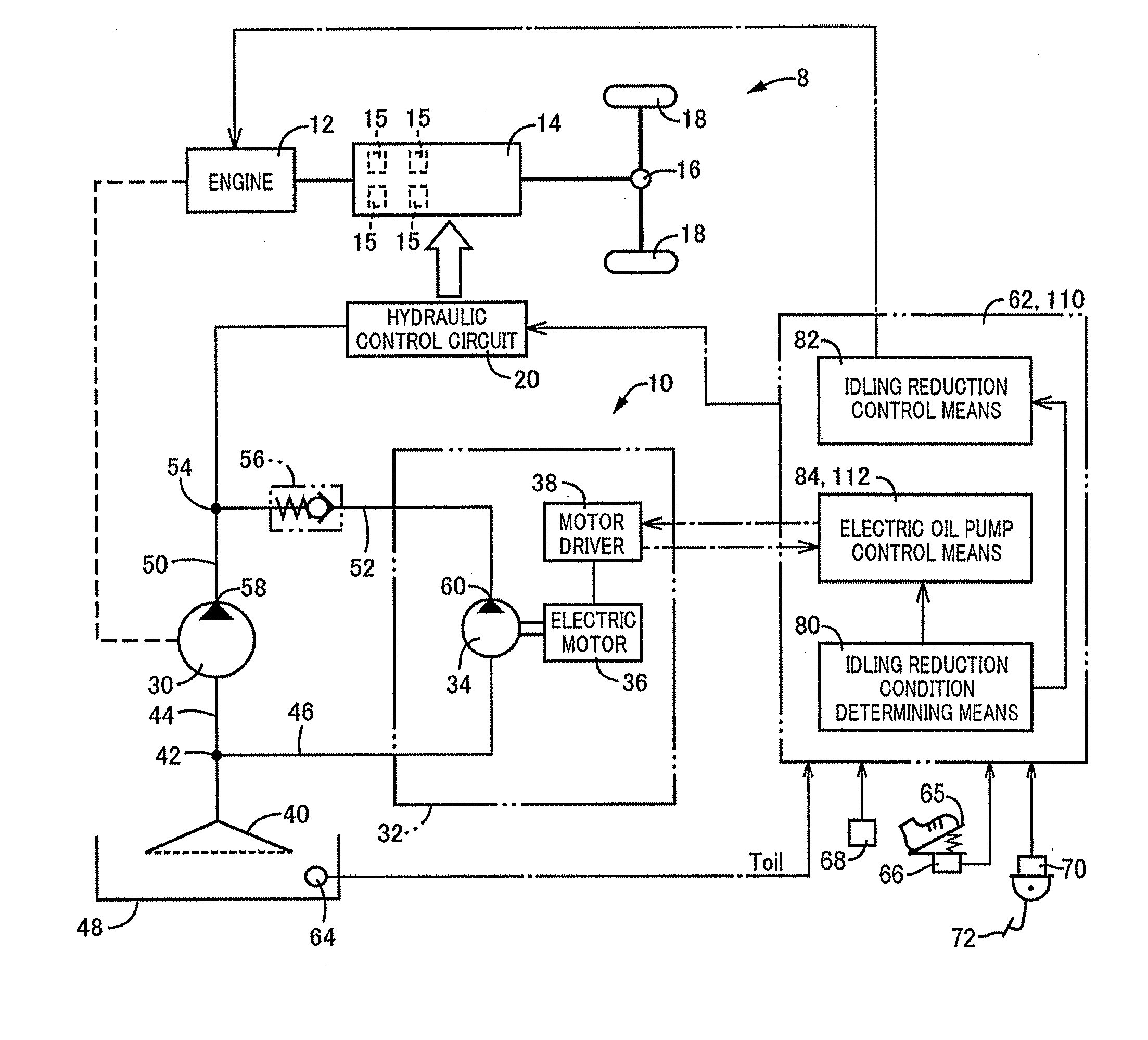

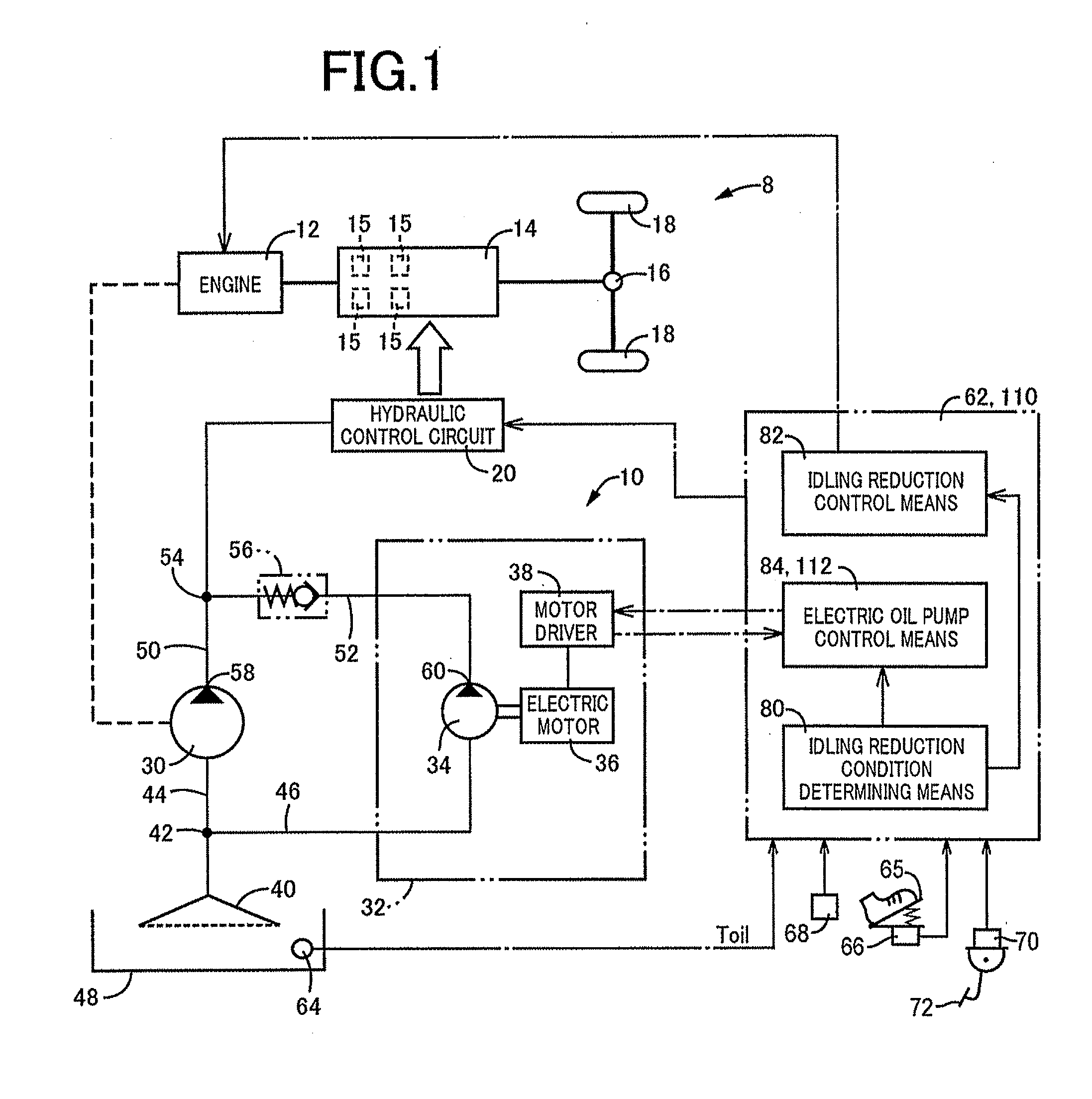

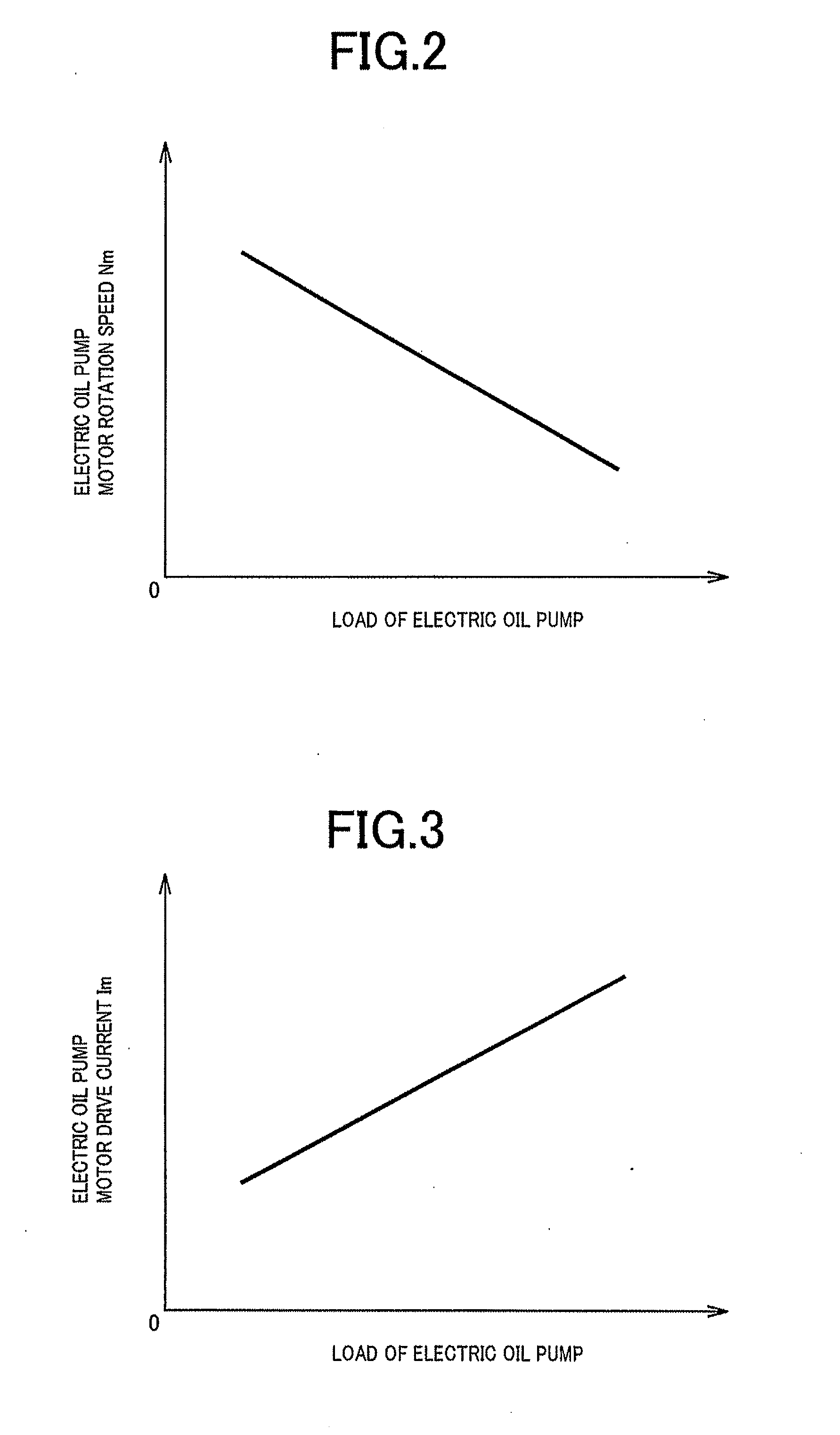

Control device of vehicle oil supply device

InactiveUS20130319366A1Improve fuel efficiencyWasteful operation of the electric oil pump is reducedLubrication of auxillariesGearing controlCheck valveOil pressure

A control device has a mechanical oil pump driven by an engine and an electric oil pump supplying oil via a check valve in an oil passage connecting the mechanical oil pump and the electric oil pump, the check valve allowing a flow of the oil from the electric oil pump side to the mechanical oil pump side while blocking a flow in an opposite direction, regardless of the pressure of the electric oil pump. When the check valve is closed under an oil pressure condition in which the electric oil pump outputs a maximum output oil pressure while the mechanical oil pump is driven by the engine at idle, the control device is configured to drive the electric oil pump during stop of the mechanical oil pump, and to stop the electric oil pump based on a load increase after start of the mechanical oil pump.

Owner:TOYOTA JIDOSHA KK

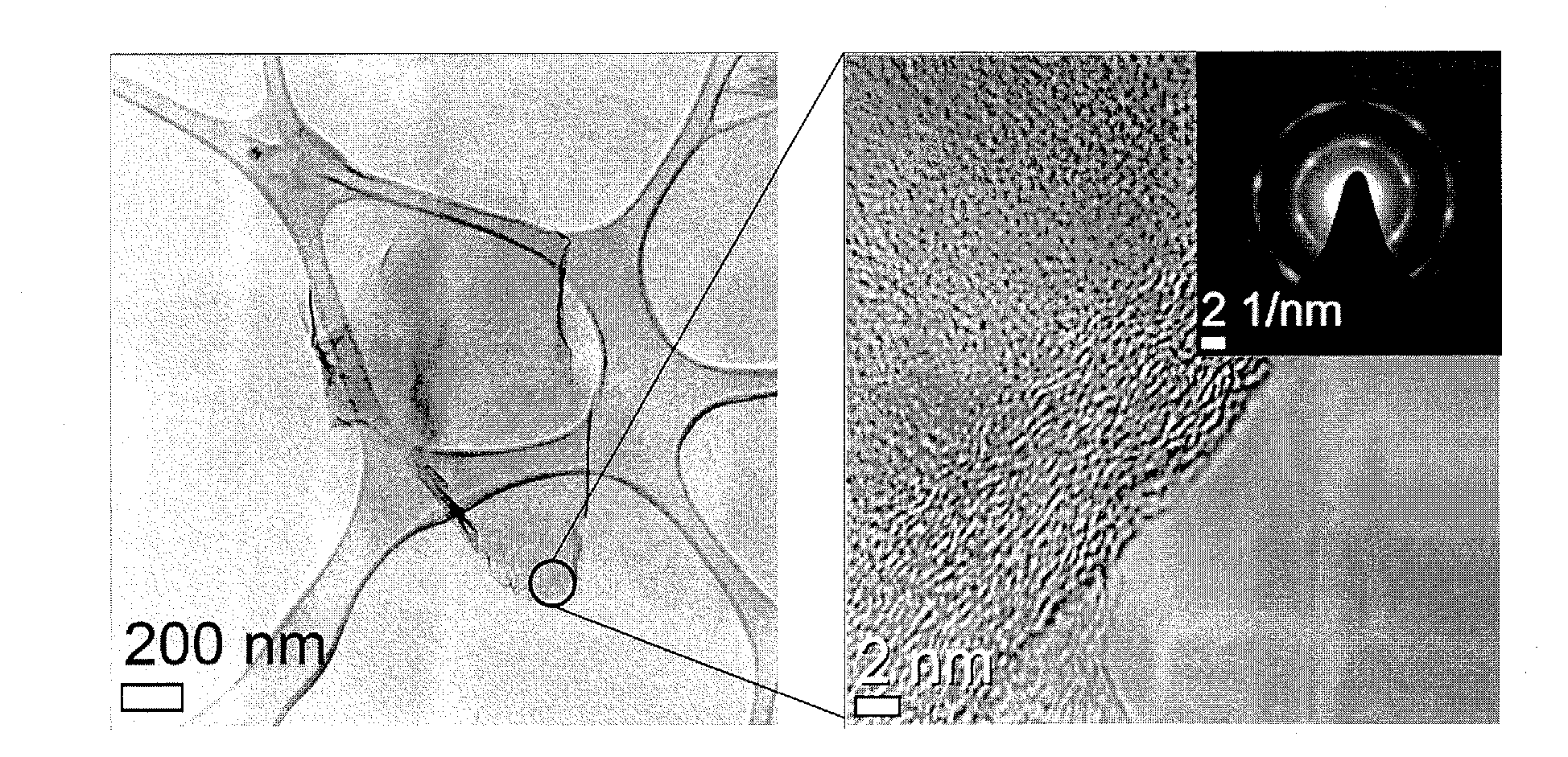

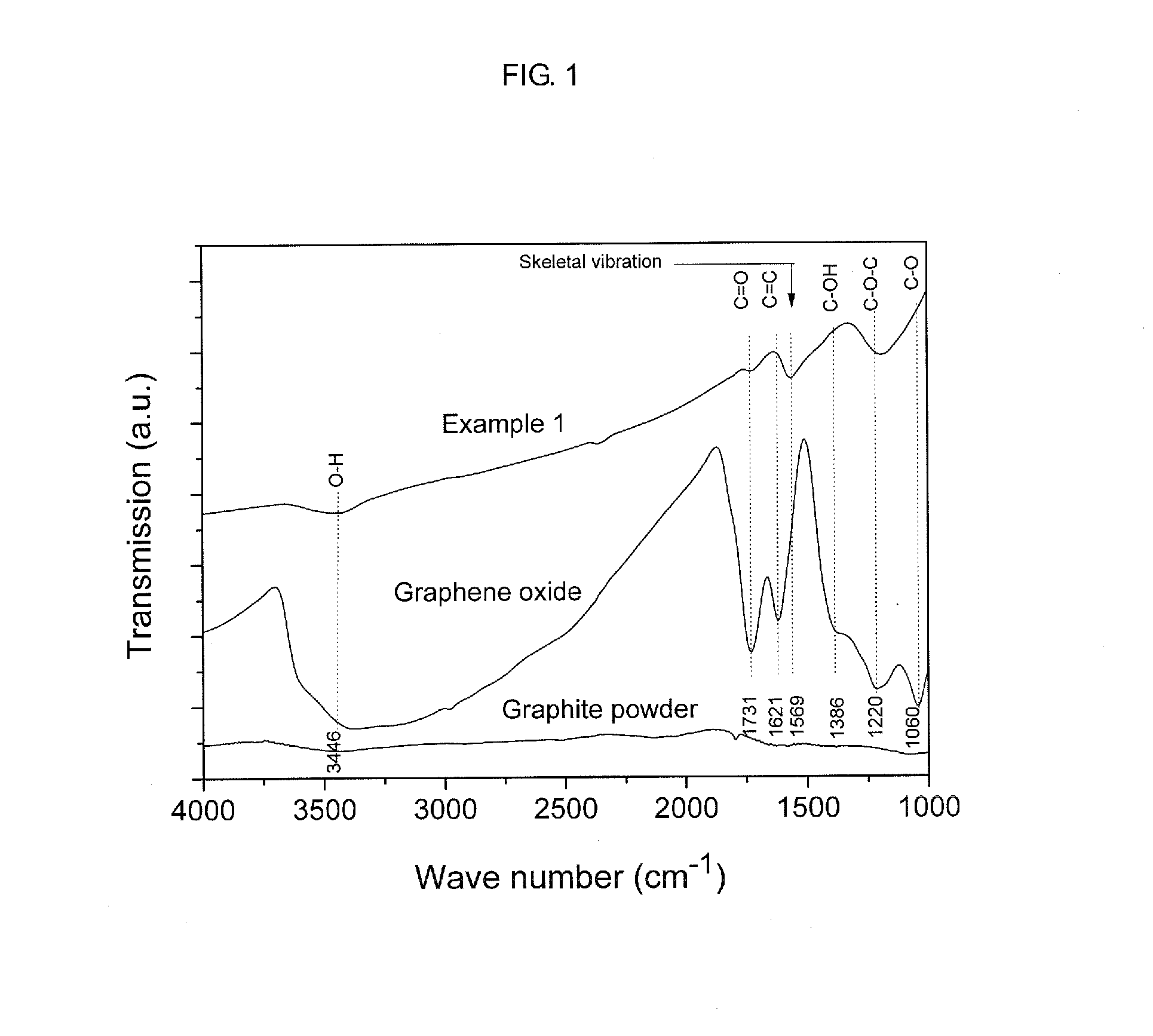

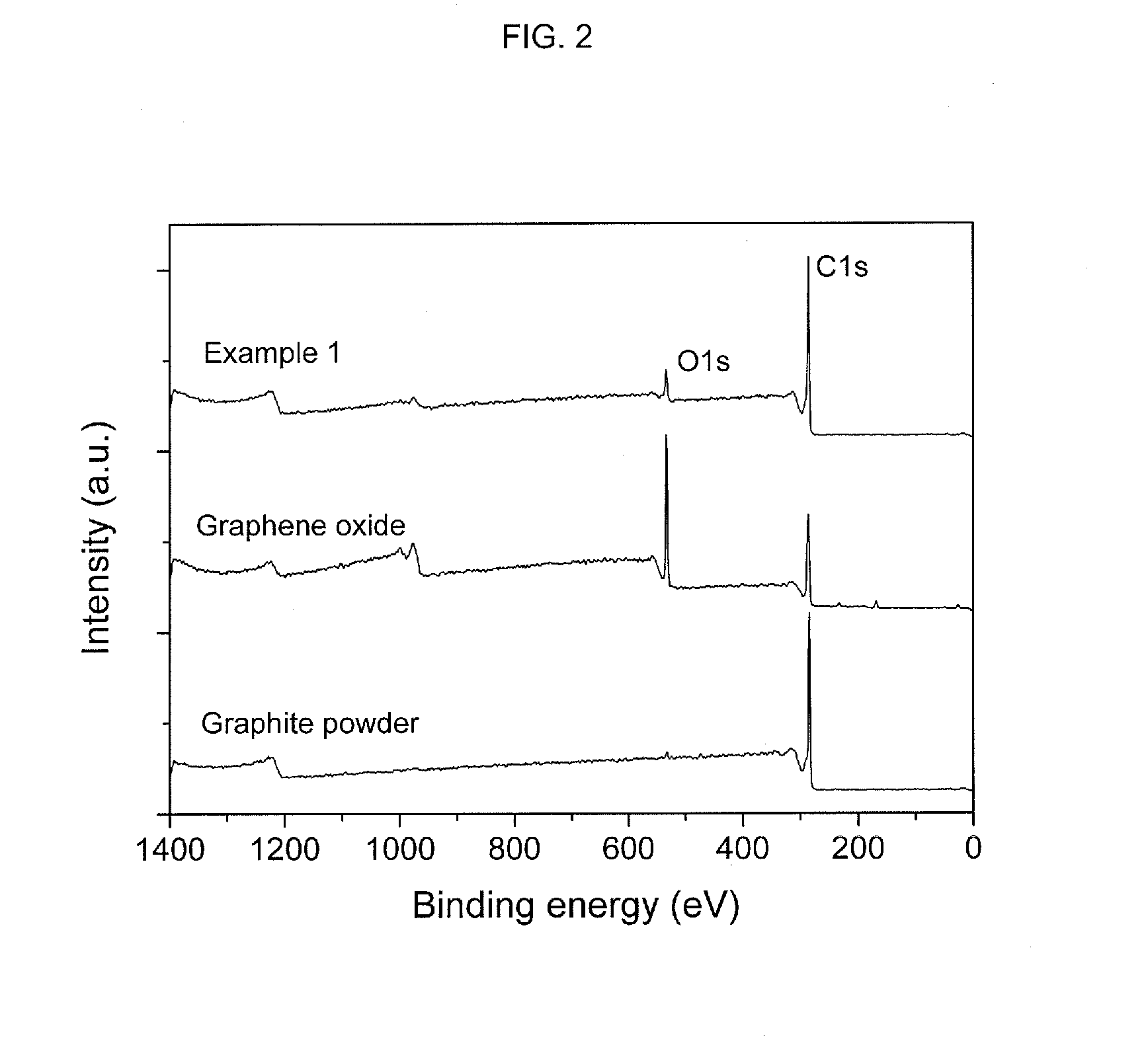

Method for fabricating graphene sheets or graphene particles using supercritical fluid

InactiveUS20120171108A1Increase production capacityUniform high qualityMaterial nanotechnologyCarbon compoundsCvd grapheneMaterials science

A method for fabricating graphene sheets or graphene particles includes (a) dispersing graphene oxide in an alcohol solution to prepare a graphene oxide dispersion solution, (b) reducing the graphene oxide dispersion solution under a supercritical condition to prepare graphene sheets or graphene particles, each of which is as a cluster of the graphene sheets, and (c) separating the graphene sheets or graphene particles, followed by washing and drying, and a method for fabricating a graphene film is configured to fabricate a graphene film in form of a thin film using the graphene sheets or graphene particles fabricated according to the method.

Owner:KOREA INST OF SCI & TECH

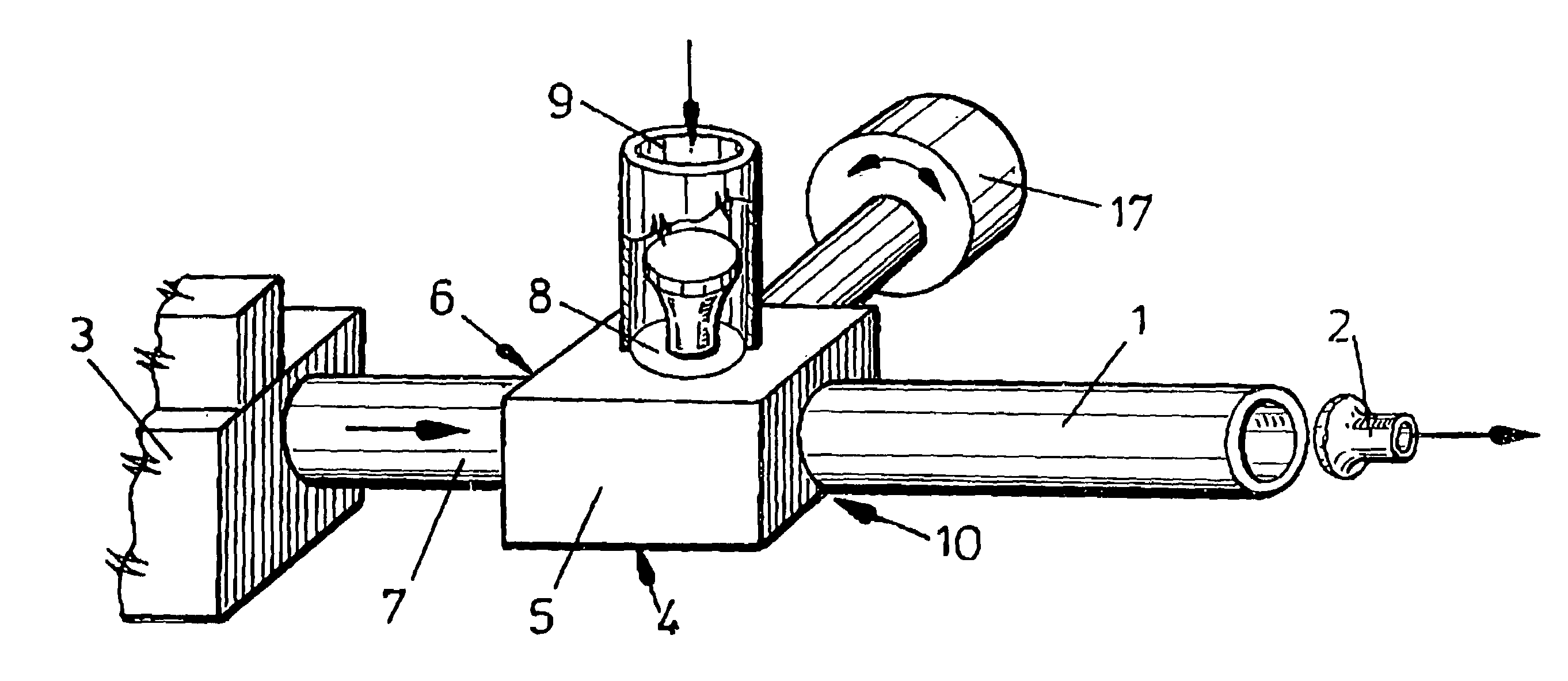

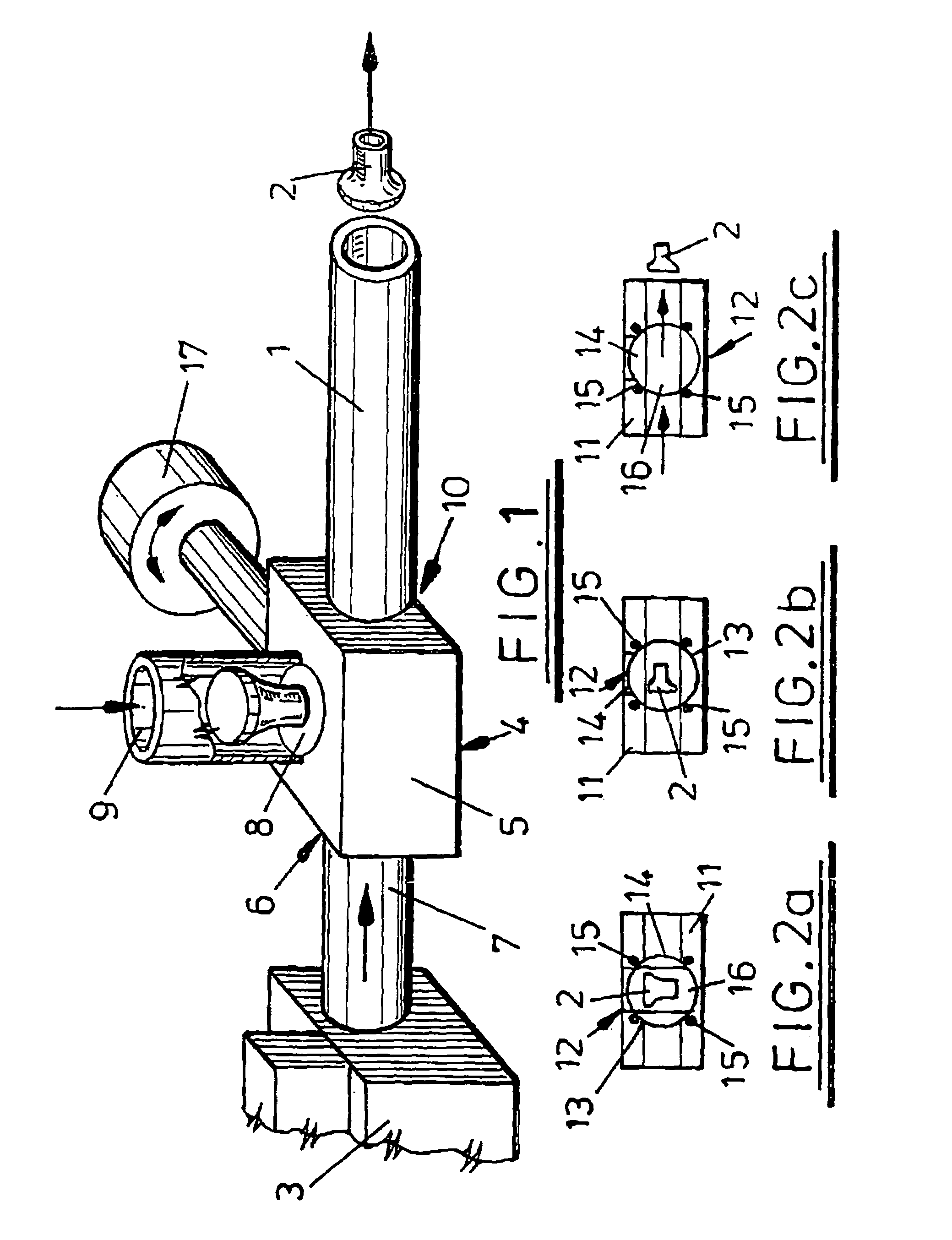

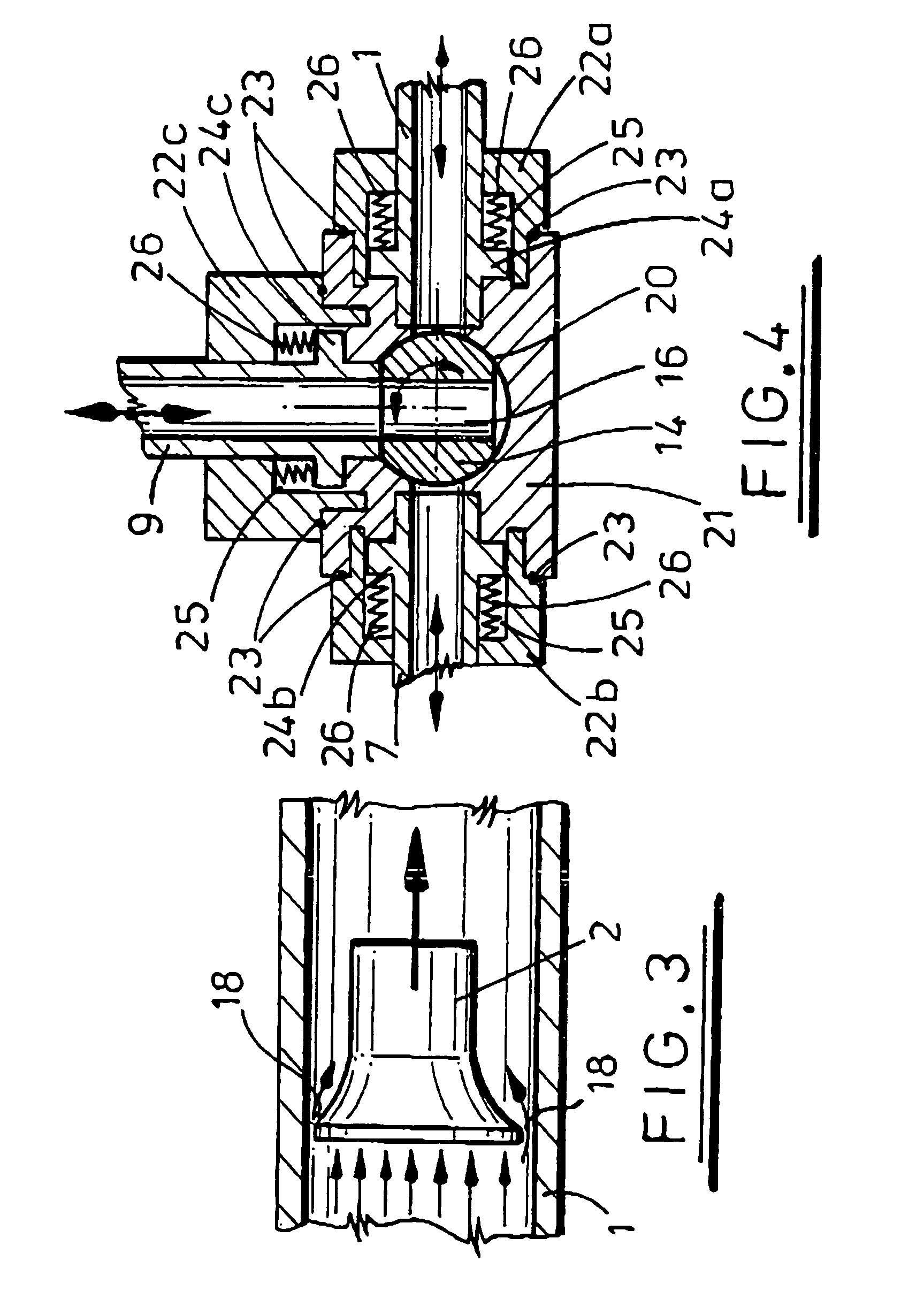

Fastener delivery apparatus

InactiveUS6951298B1Reduce frictionReduce the power requiredStapling toolsMetal working apparatusEngineeringRivet

A fastener delivery tube (1) is connected between a supply of fasteners, such as rivets (2), and the nose of a fastener setting machine. The delivery tube (1) is connected to an outlet tube (7) of a source of compressed air (3), the outlet tube (7) having an internal bore substantially equal in size to the internal bore of the delivery tube (1). The supply of fasteners is connected to the delivery tube via a feeder tube (9) and transfer gate (4). The transfer gate (4) is sealed so as to prevent leakage of air from the delivery tube (1). The arrangement reduces turbulence in the delivery tube (1) ensures that friction between the fastener (2) and the tube (1) is reduced and permits compressed air to be supplied at significantly lower pressure than has heretofore been possible.

Owner:ATLAS COPCO IAS UK LIMITED +1

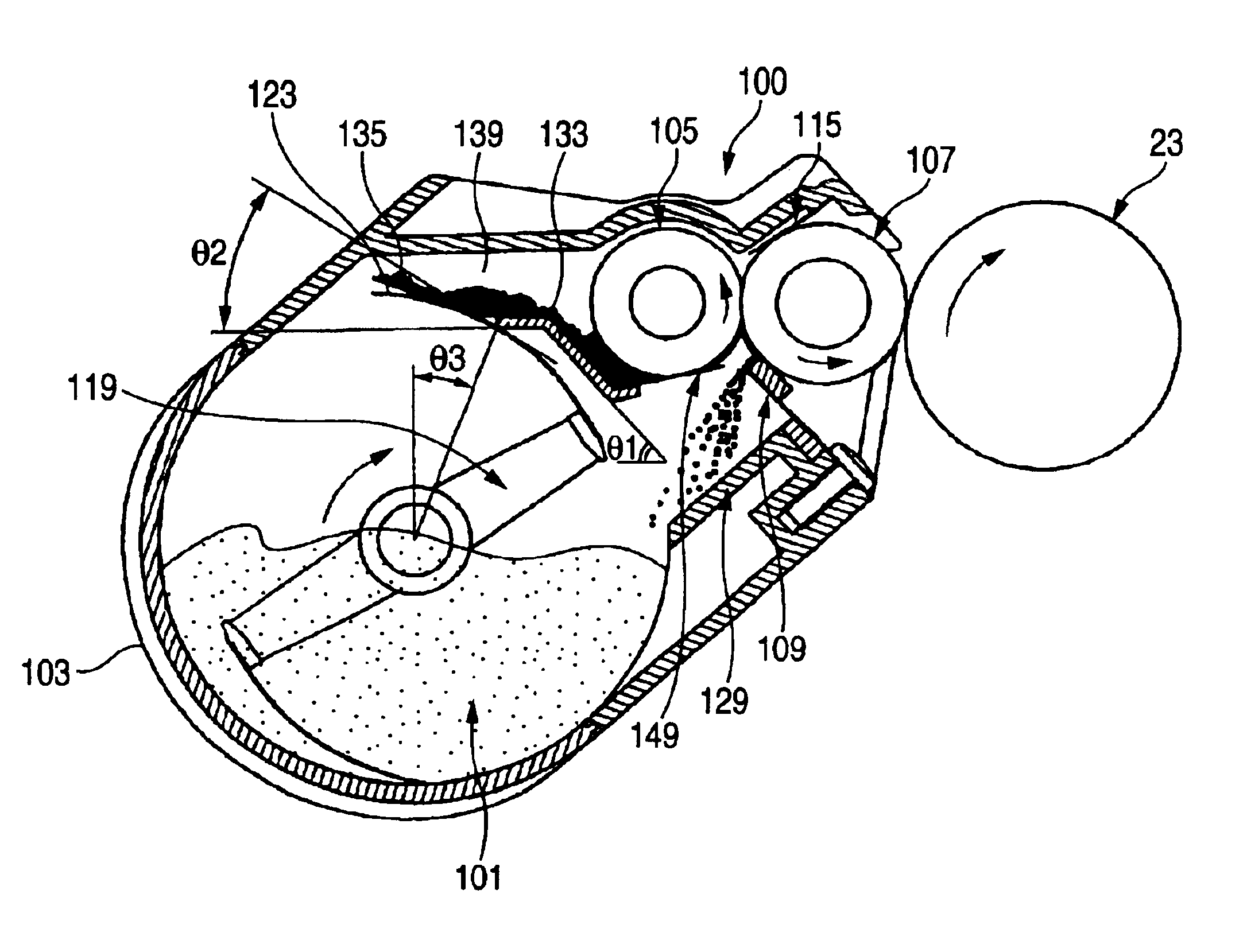

Developing device and image forming apparatus incorporating the same

InactiveUS6907215B2Improve image qualityReduce mechanical stressElectrographic process apparatusDevelopersImage formationEngineering

Owner:SEIKO EPSON CORP

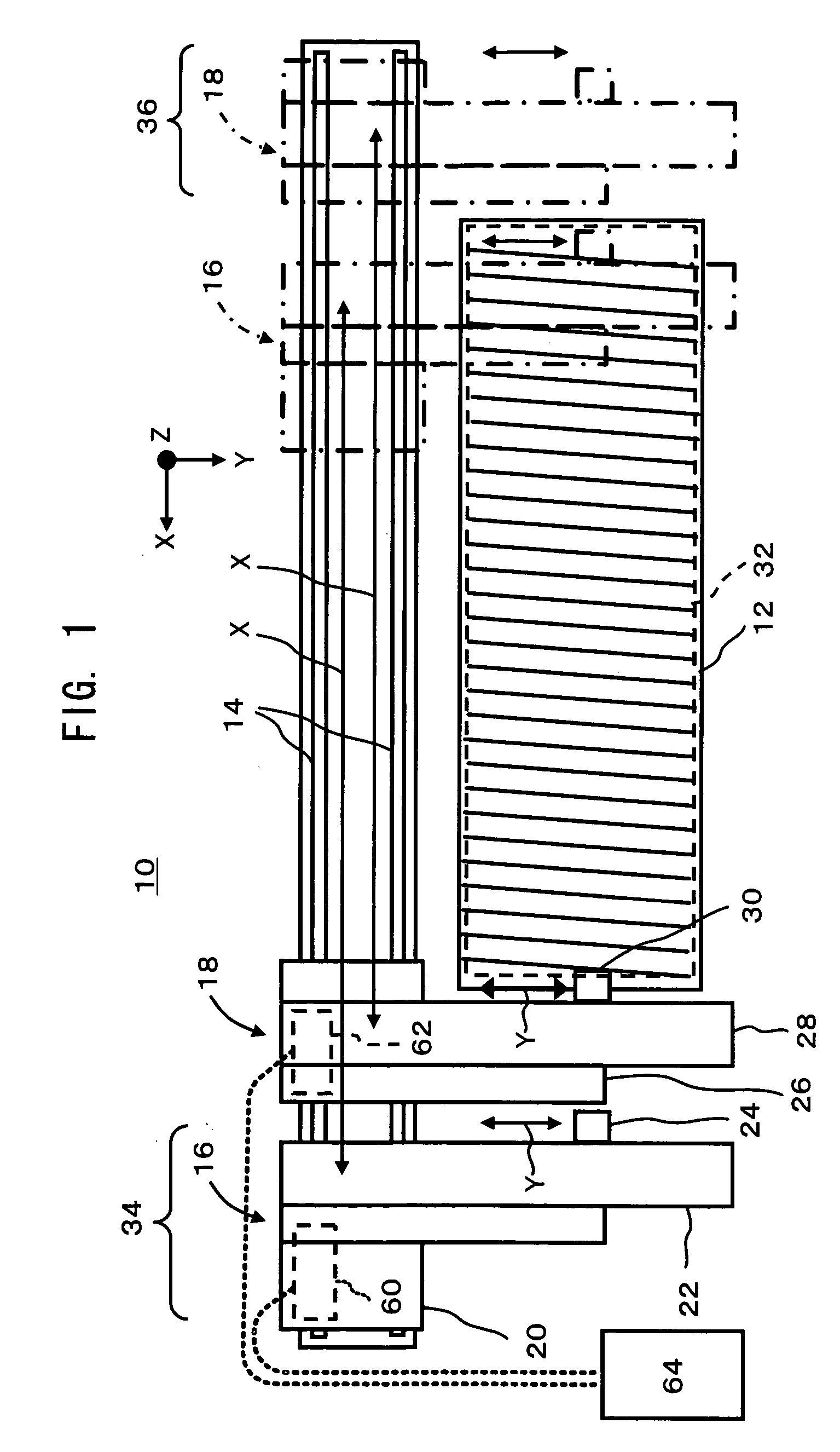

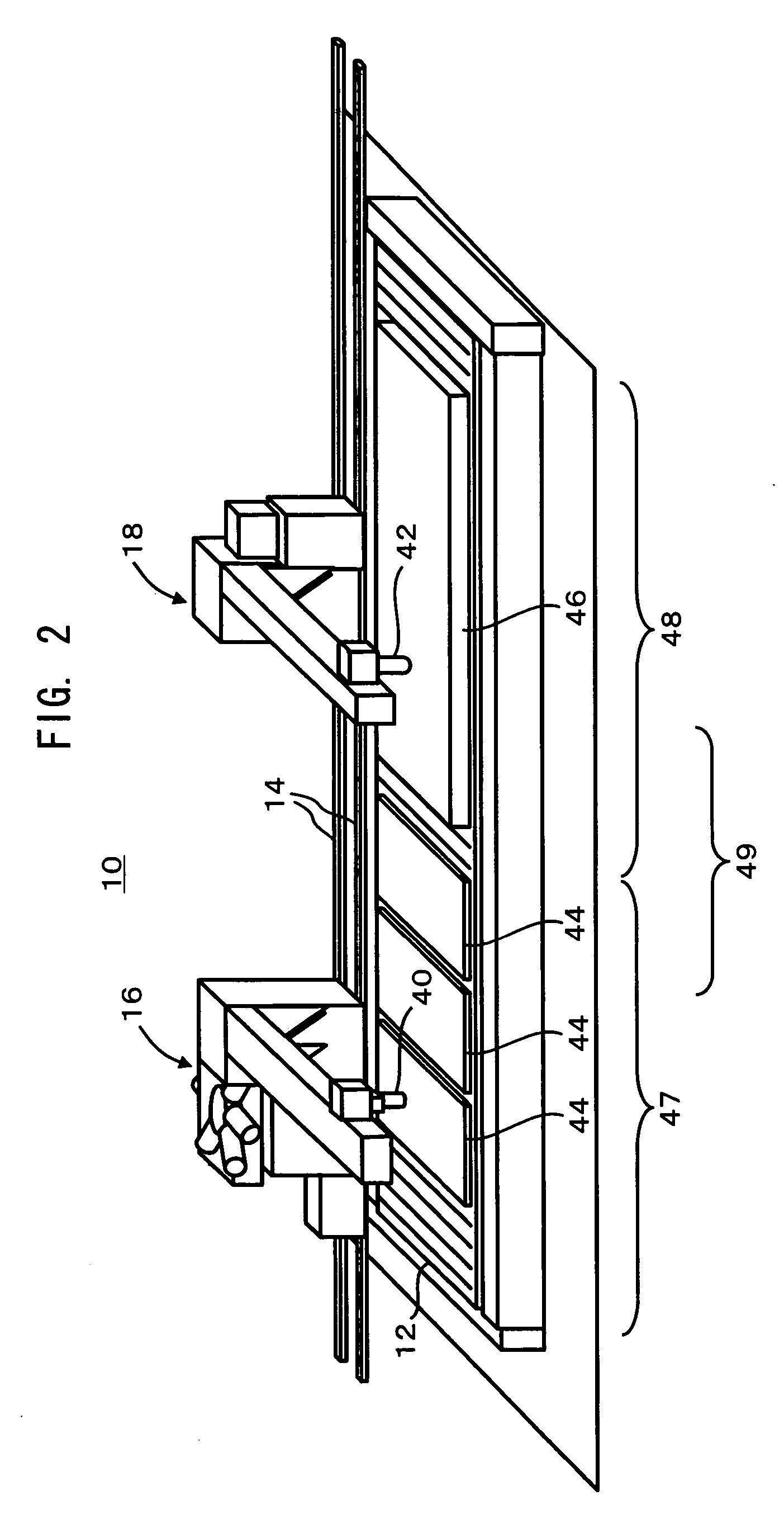

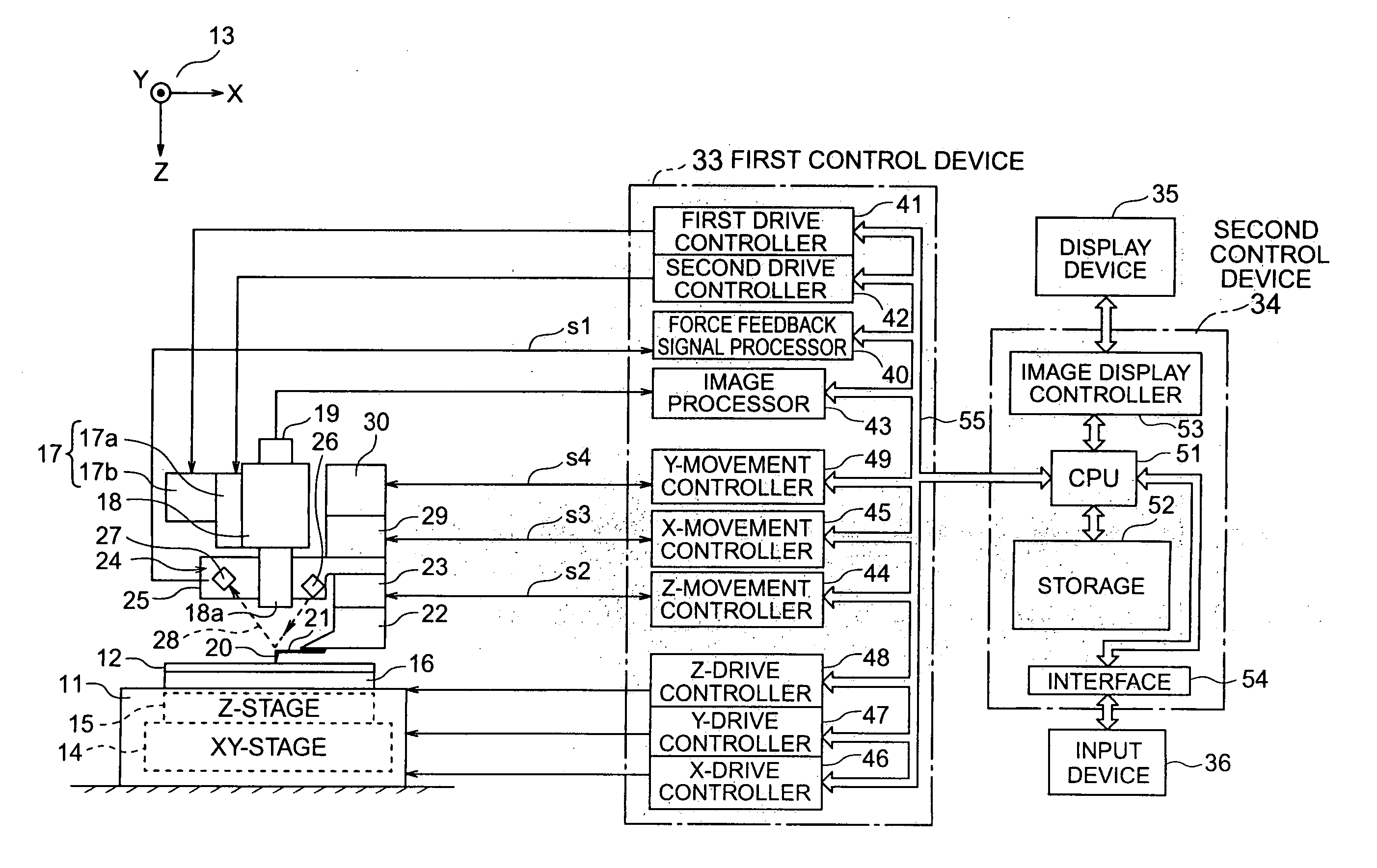

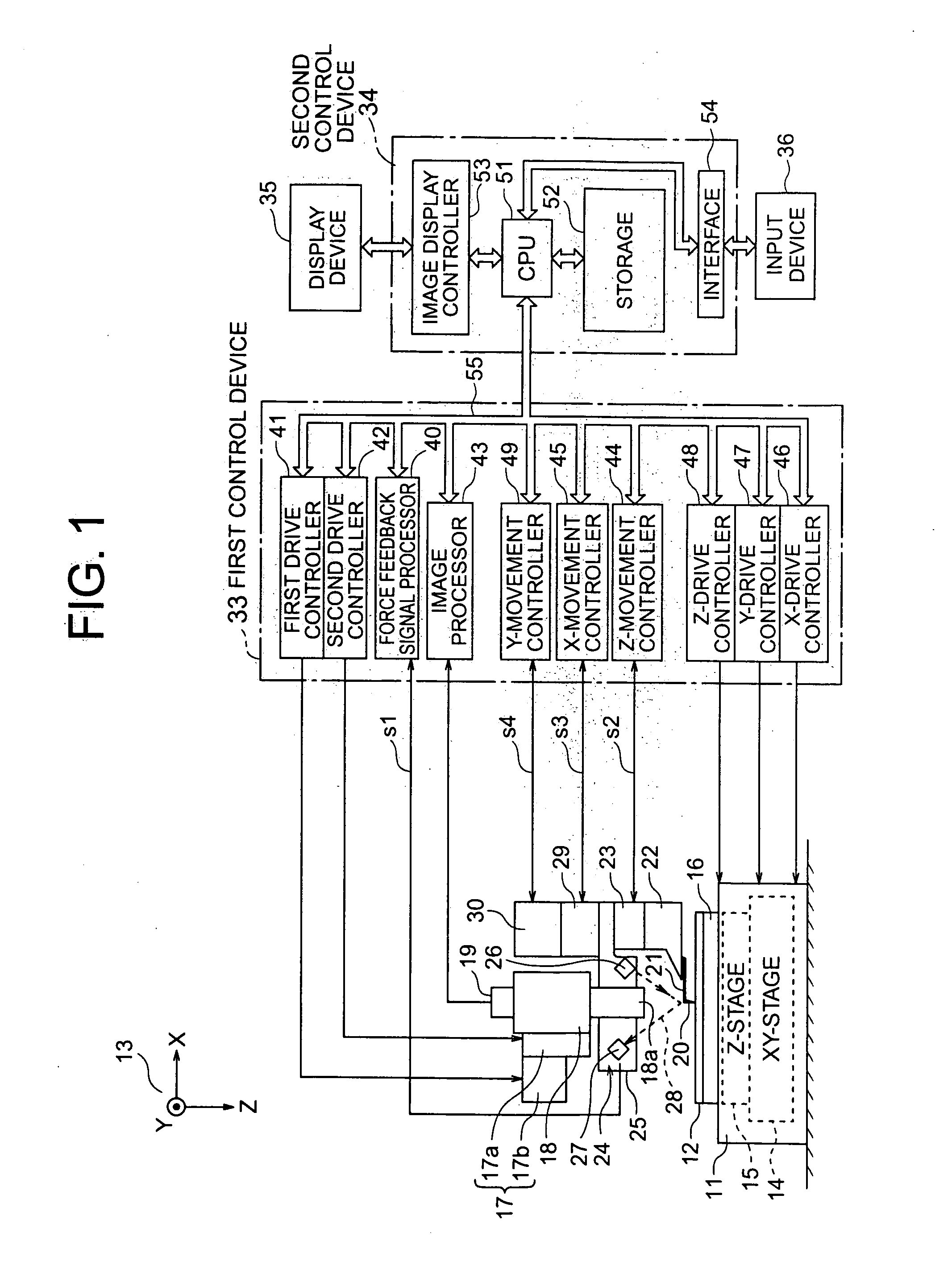

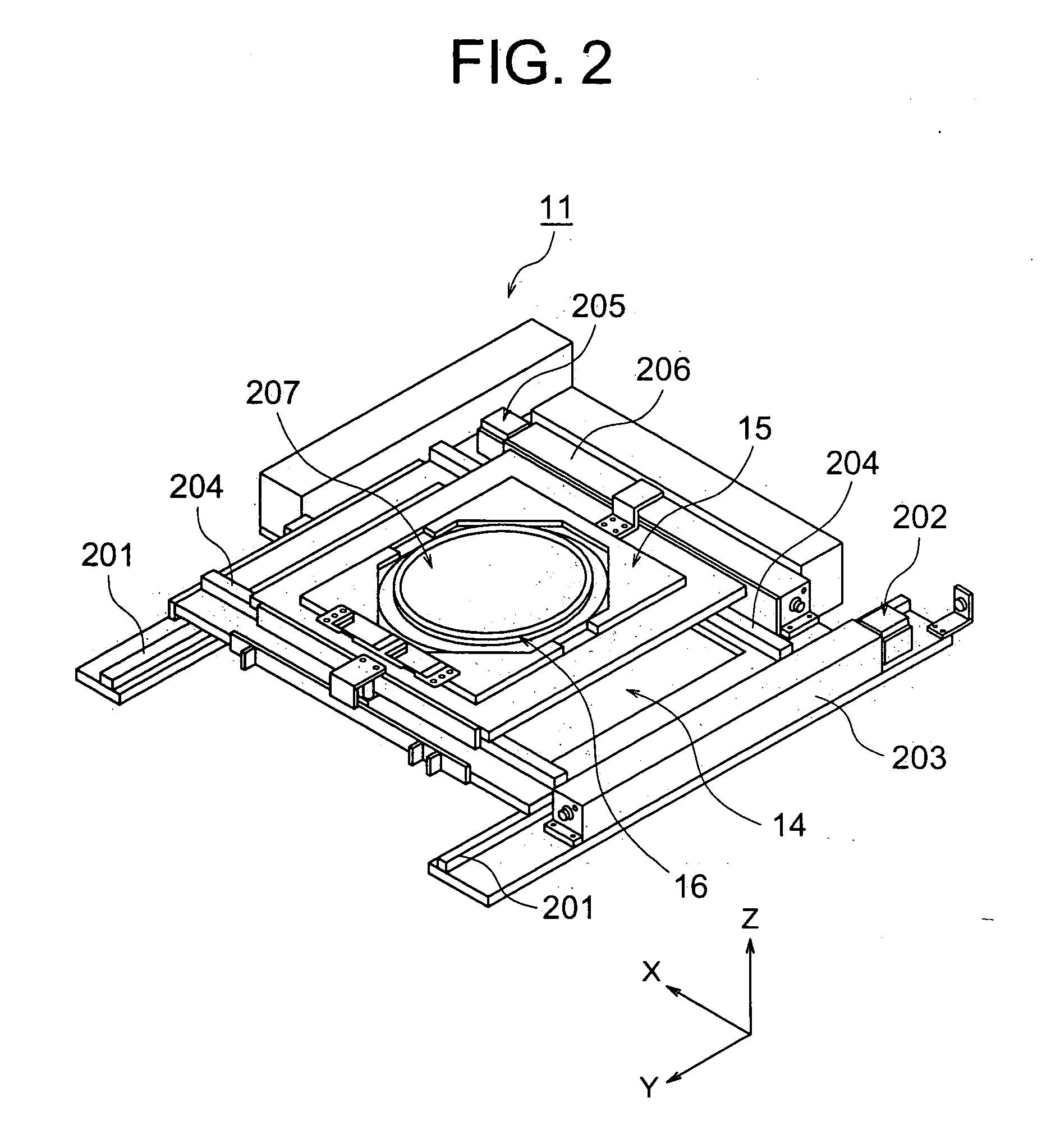

Scanning type probe microscope and probe moving control method therefor

InactiveUS20060284083A1Improve measurement accuracyLow frequencyMaterial analysis using wave/particle radiationMeasurement/indication equipmentsPhysicsMovement control

The probe tip movement control method of the scanning probe microscope is used for a scanning probe microscope provided with a cantilever 21 having a probe tip 20 facing a sample 12. The atomic force occurring between the probe tip and sample is measured when the probe tip scans the surface of the sample. X-, Y-, and Z-fine movement mechanisms 23, 29, and 30 are used to relatively change the positions of the probe tip and sample. It is possible to maintain a high measurement accuracy and enable scan movement of a probe tip on a sample surface by simple control when measuring a part having a gradient in measurement of an uneven shape on a sample surface.

Owner:HITACHI KENKI FINE TECH CO LTD

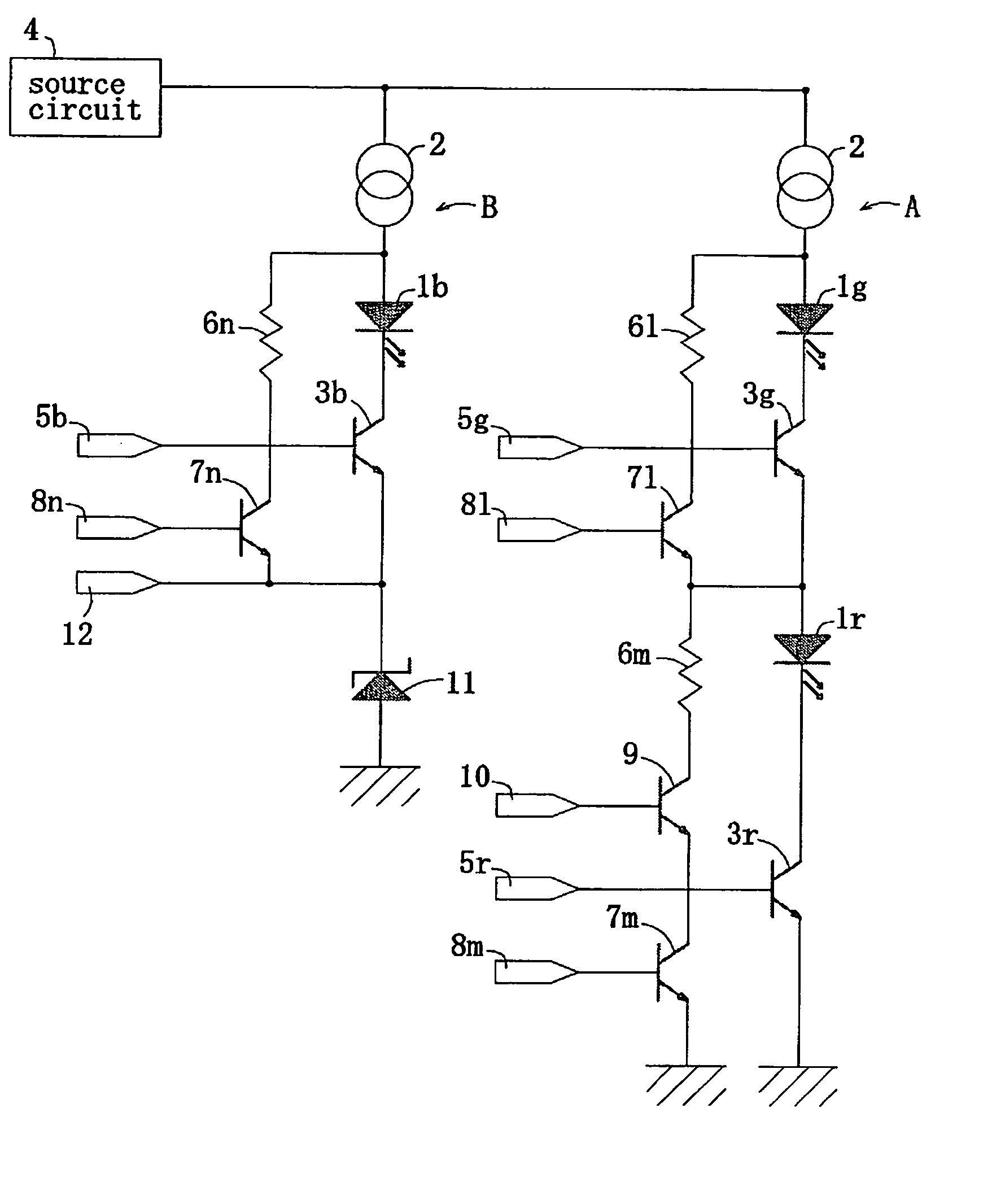

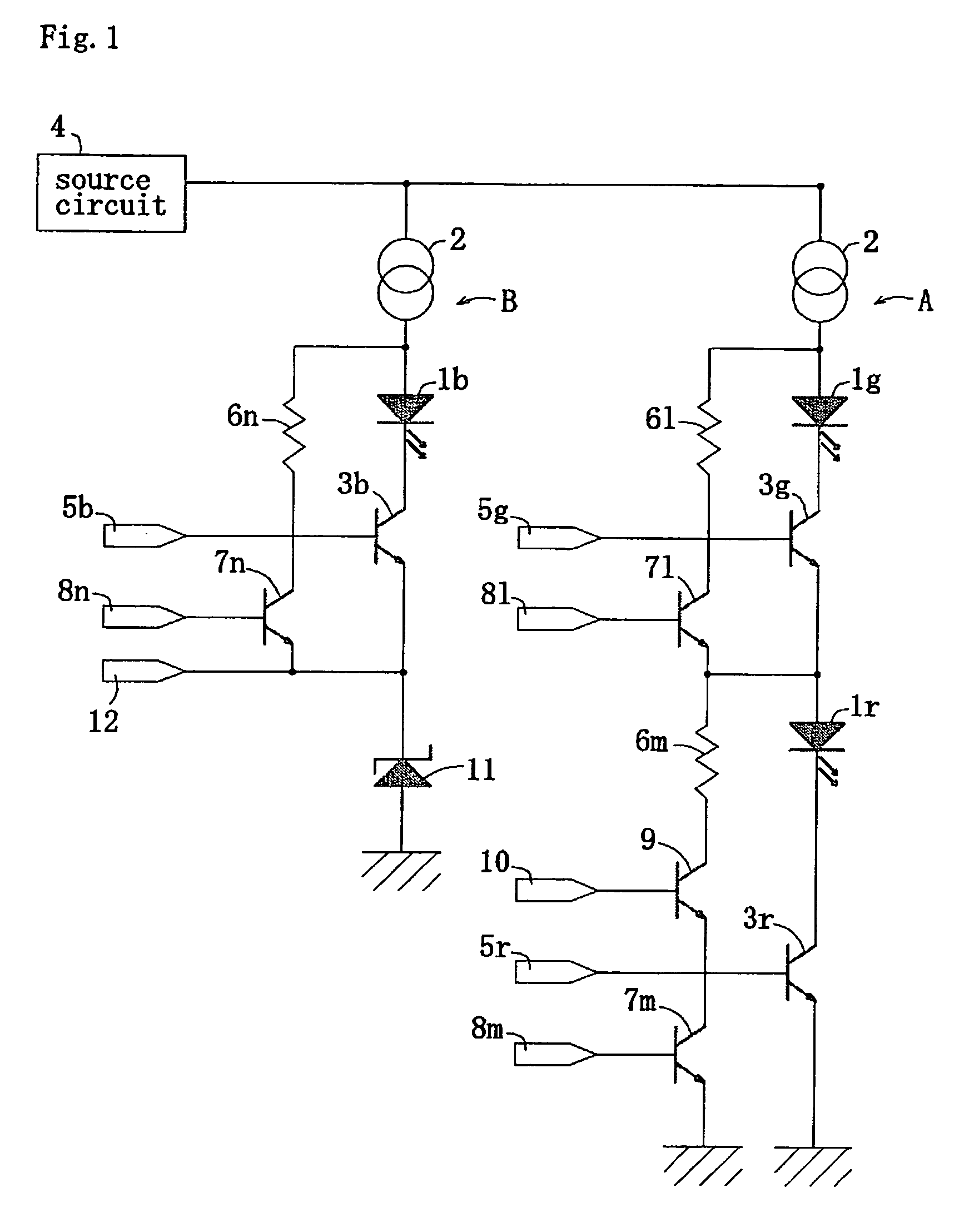

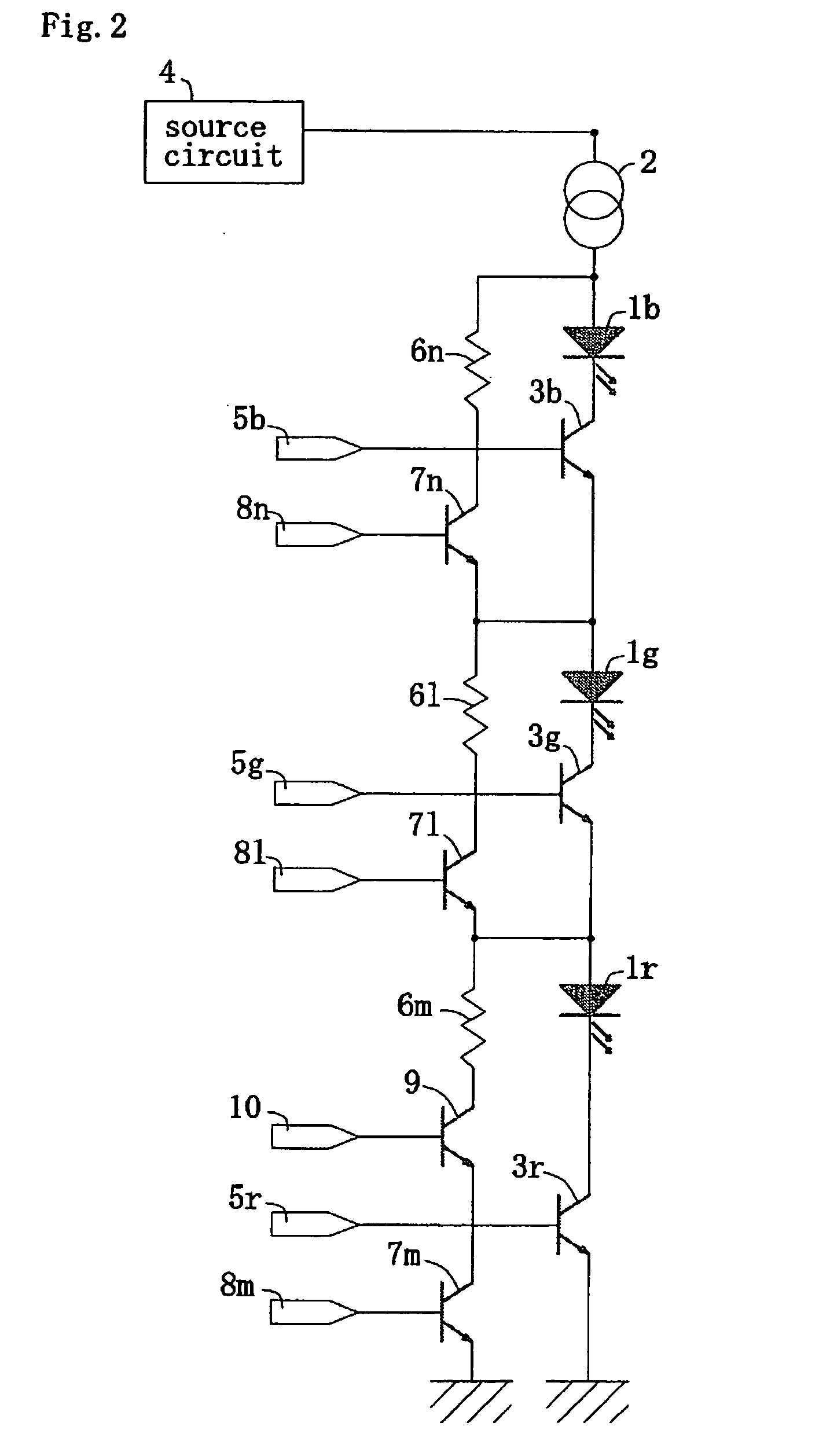

Display led drive circuit

ActiveUS20060197722A1Increase temperatureReduce in quantityStatic indicating devicesElectroluminescent light sourcesCapacitancePotential difference

A display LED drive circuit configured in such a manner that, for example, a constant current circuit, a green display LED circuit, and a red display LED circuit are connected in series and a resistor circuit having a resistor that generates a potential difference identical to the respective display LEDs is connected in parallel to the respective LED circuits, a corresponding switching element of the display LED circuit and a corresponding switching element of the resistor circuit connected in parallel are controlled to be opened and closed in opposite ways, another route connected to a source circuit in parallel is connected to the constant current circuit, a blue display LED circuit connected in parallel to the resistor circuit as described above, and a constant voltage diode in series, and a predetermined voltage is derived from an output terminal by the constant voltage diode and supplied to a control circuit. In this arrangement, the number of constant current circuits can be reduced, and hence reduction of current consumption and cost, and improvement of the power source usage efficiency are achieved.

Owner:KOMADEN CORP

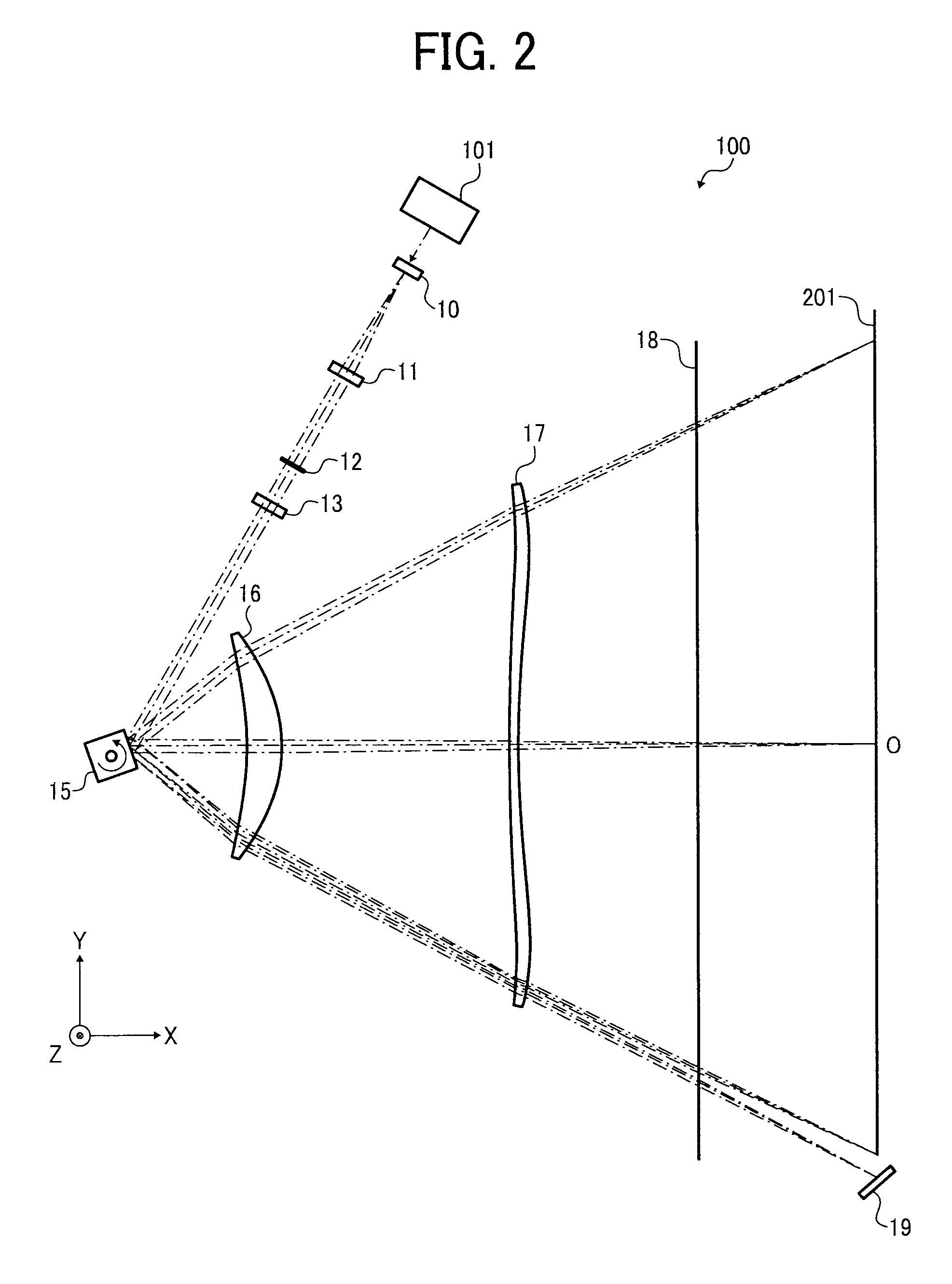

Optical scan apparatus and image formation apparatus

InactiveUS20080284838A1Low running costSuppress lightVisual presentationPrintingOptoelectronicsLight source

An optical scan apparatus which deflects a plurality of light beams to scan a write region on a scan surface in a main scan direction is configured to include a light source which has a plurality of emission portions emitting the plurality of light beams arranged two-dimensionally on a plane in parallel to the main scan direction and a sub scan direction perpendicular to the main scan direction; a deflector which deflects the plurality of light beams from the plurality of emission portions; a light receiving element which receives the light beams and outputs a synchronous detection signal in accordance with the received light beams; and a control unit which selectively controls any one of the emission portions to emit a light beam upon each scanning and allows the light beam from the selected emission portion to be incident on the light receiving element via the deflector.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com