Patents

Literature

132results about How to "Reduce the power required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

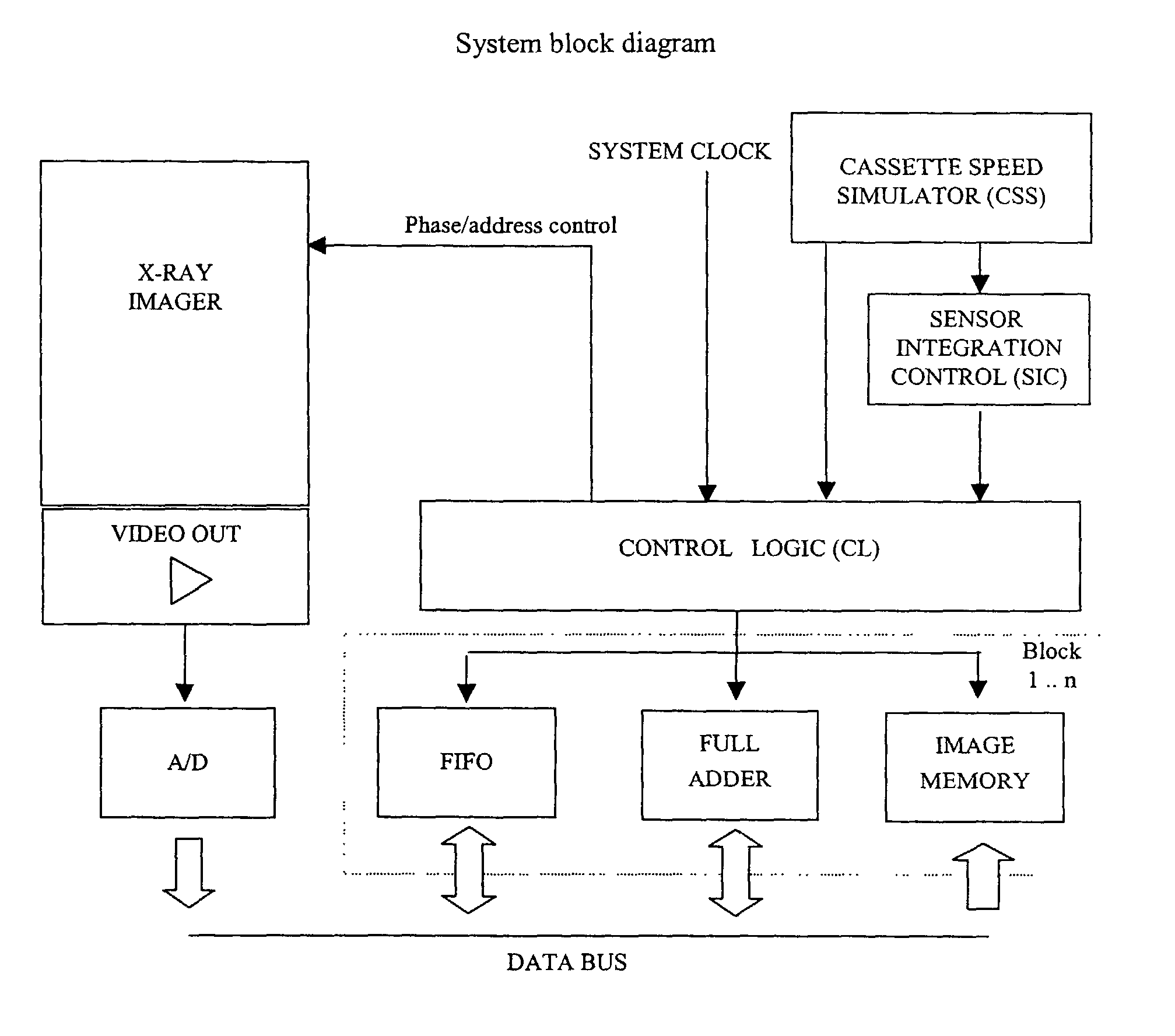

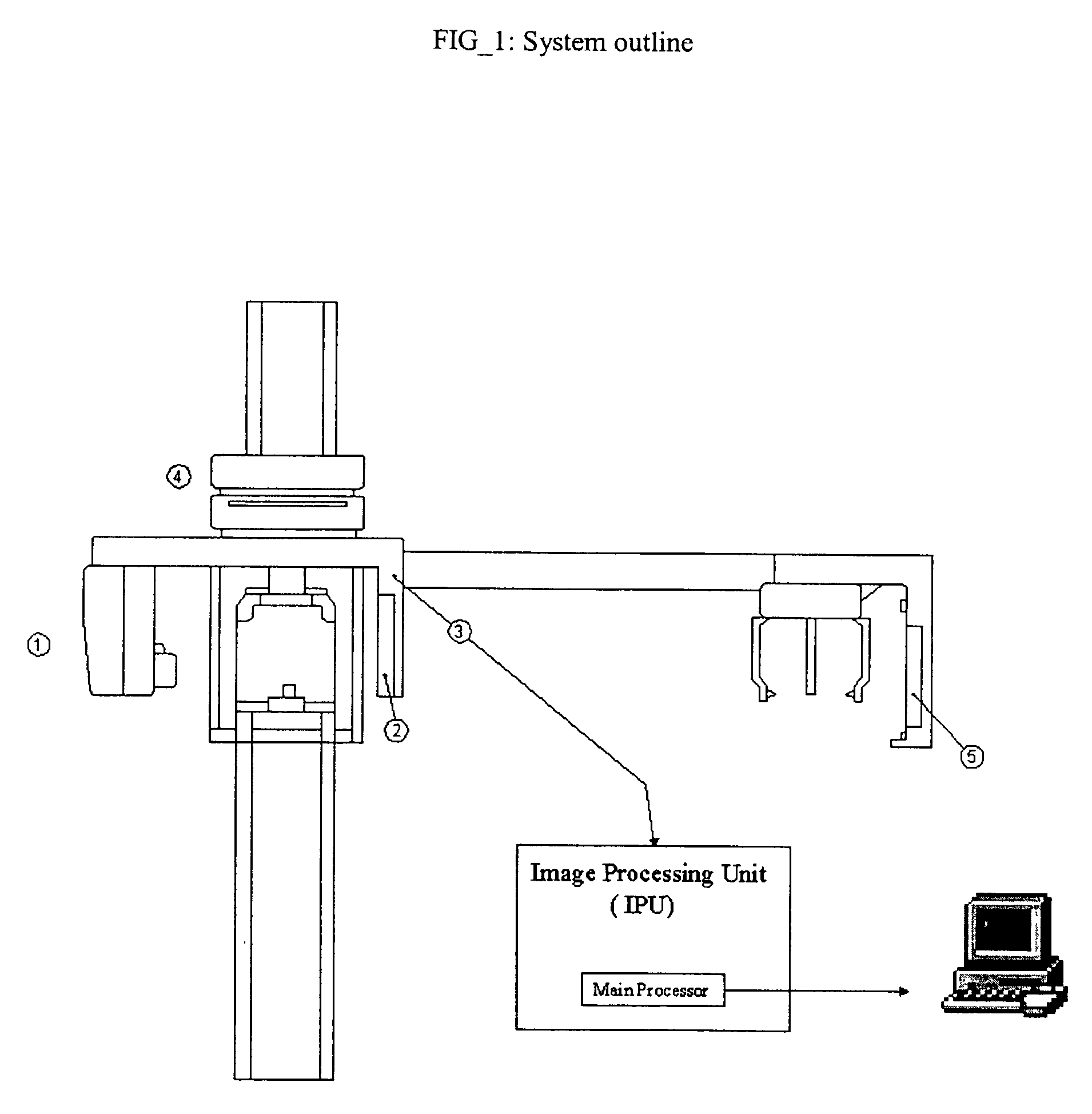

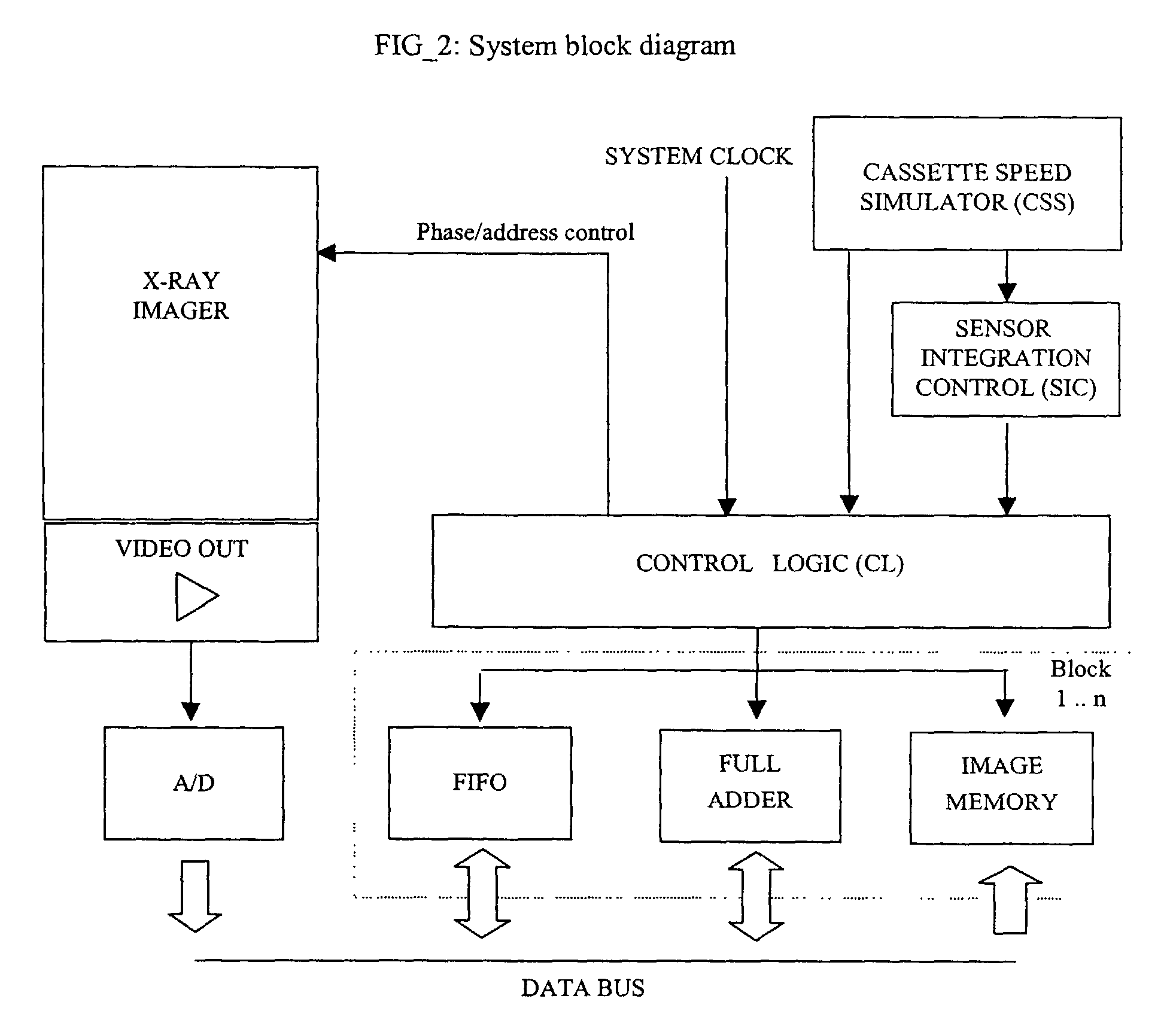

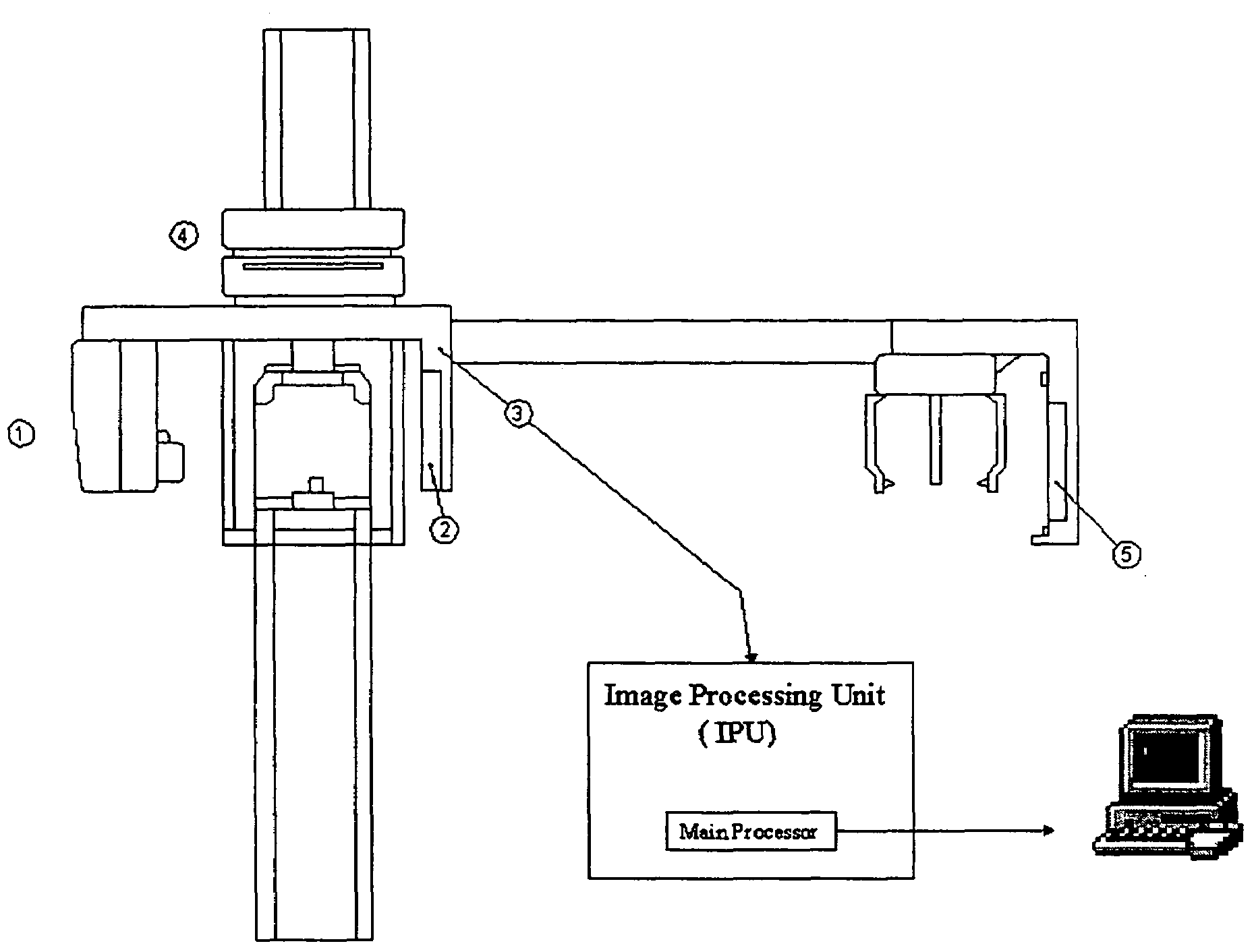

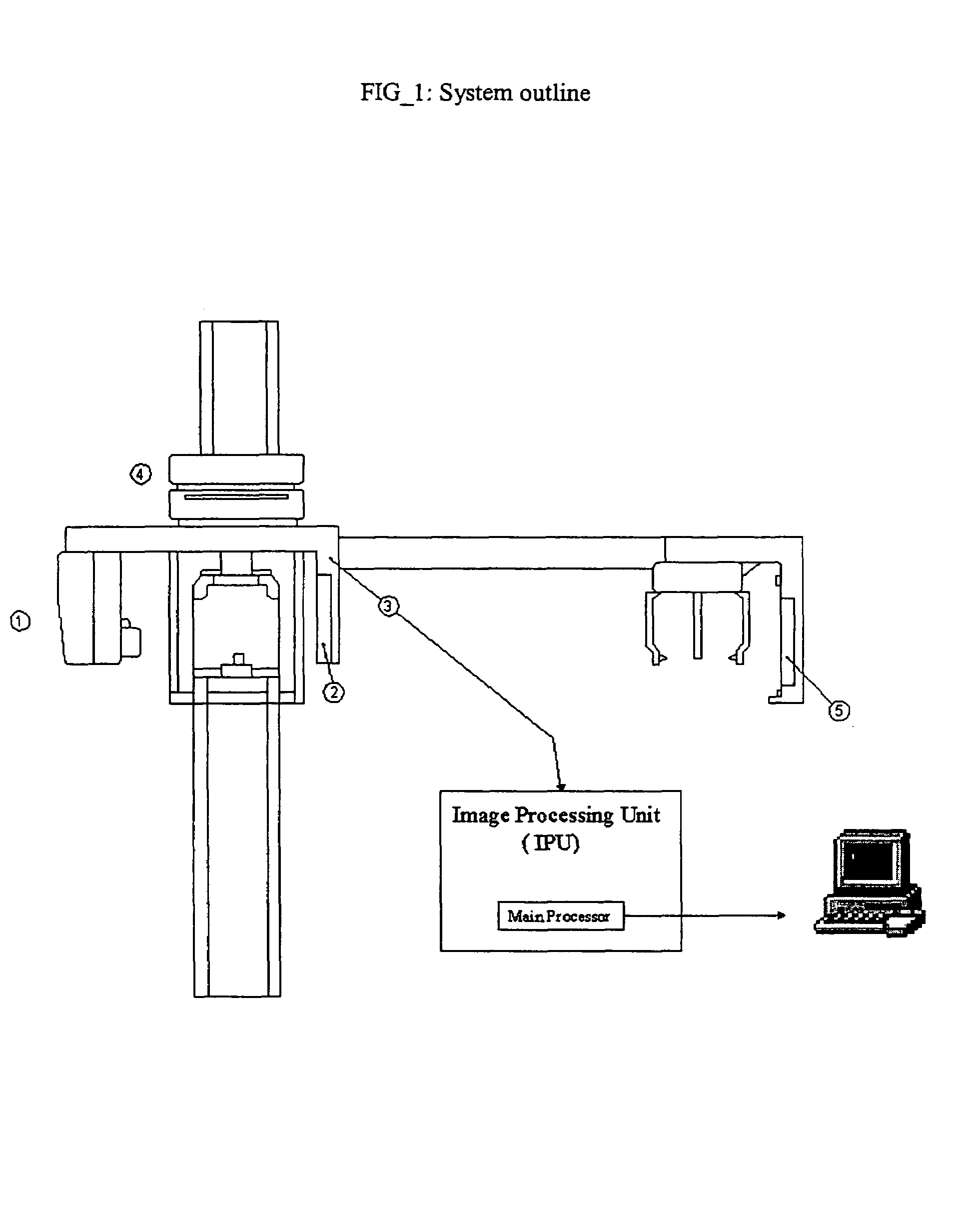

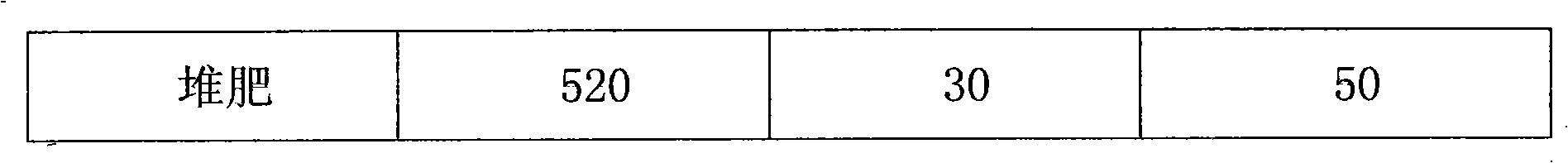

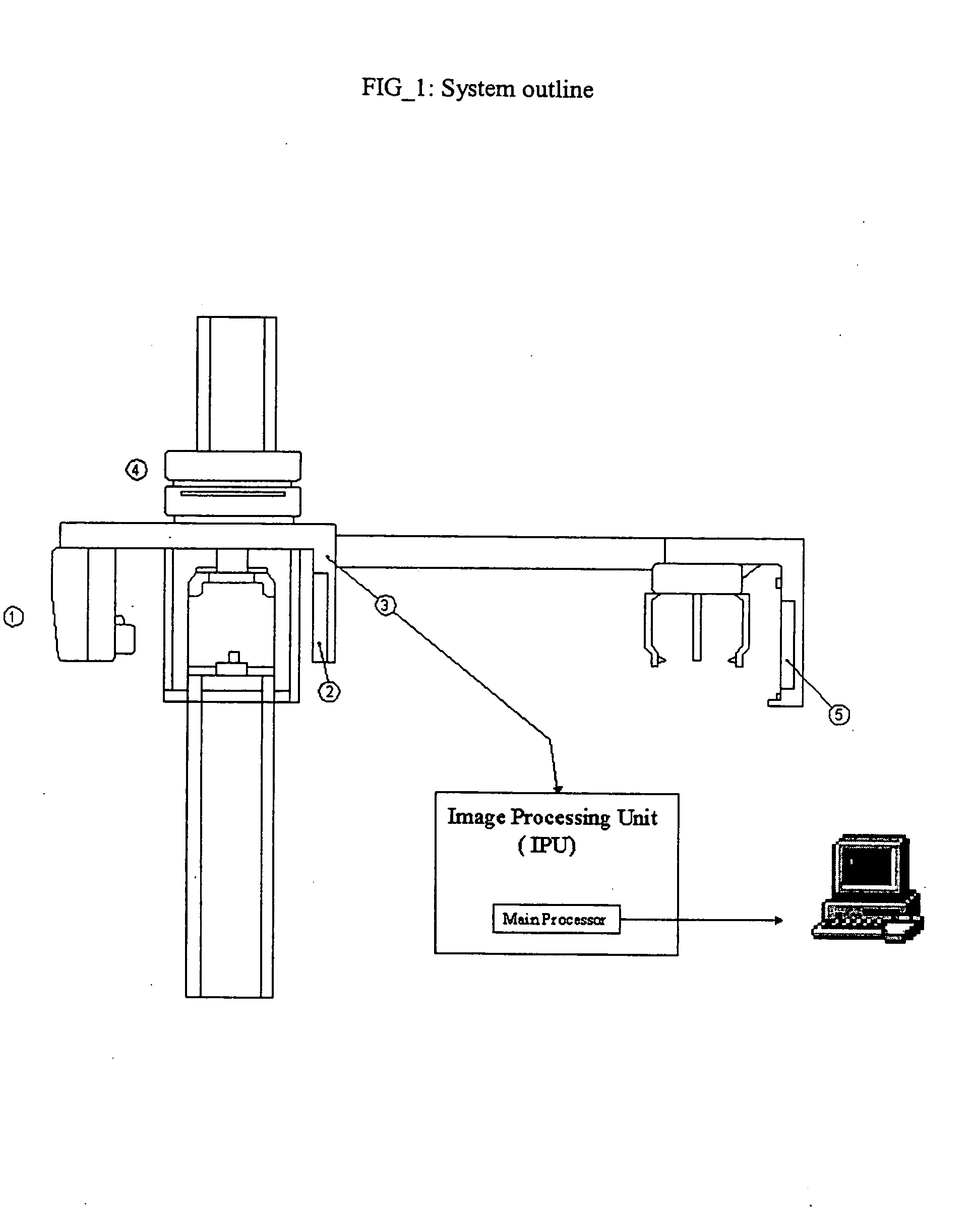

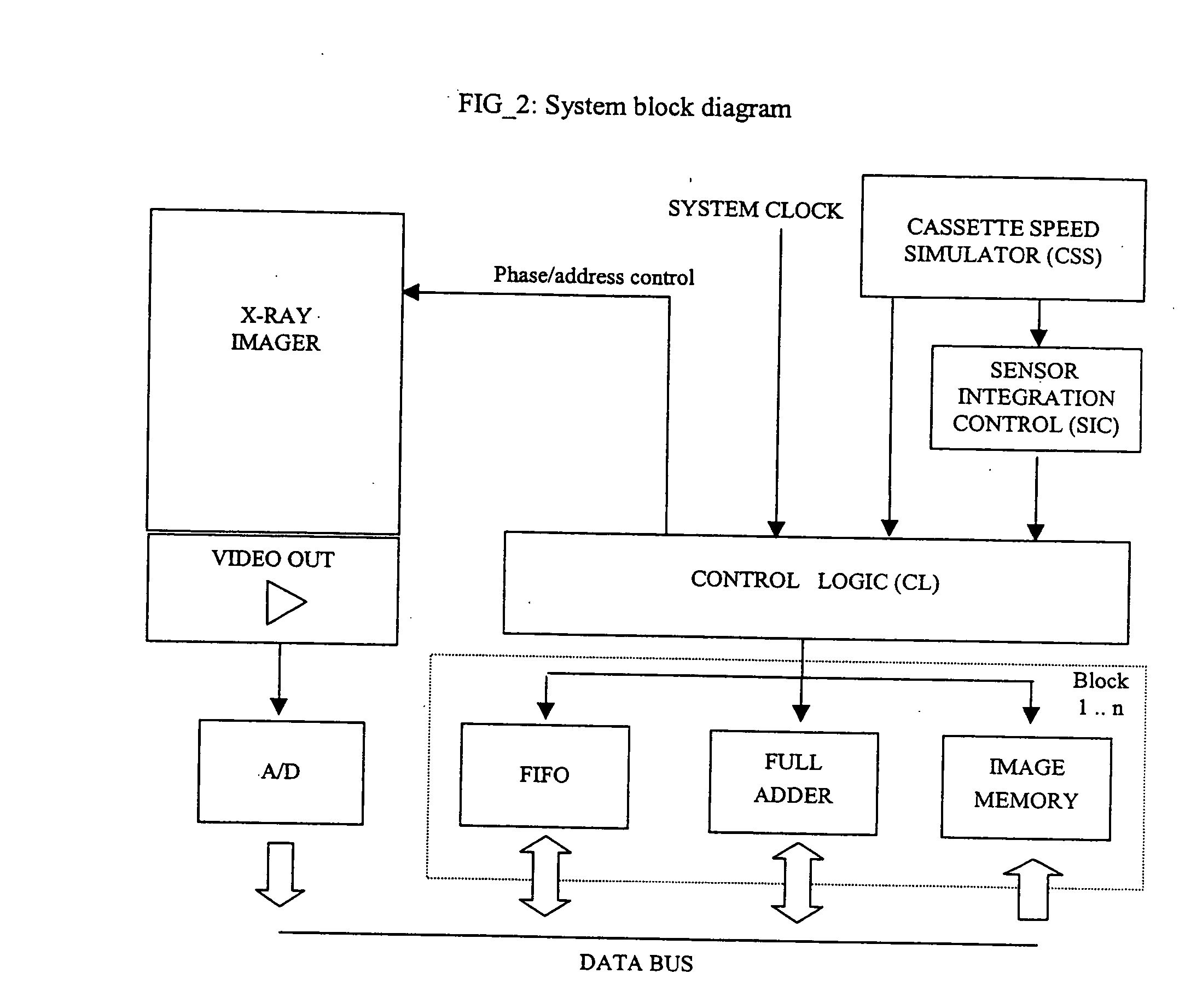

Real-time digital x-ray imaging apparatus

InactiveUS7016461B2Easy to optimizeReduce exposureTomosynthesisRadiation measurementAcquisition rateElectron

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality.In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface.The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal.It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

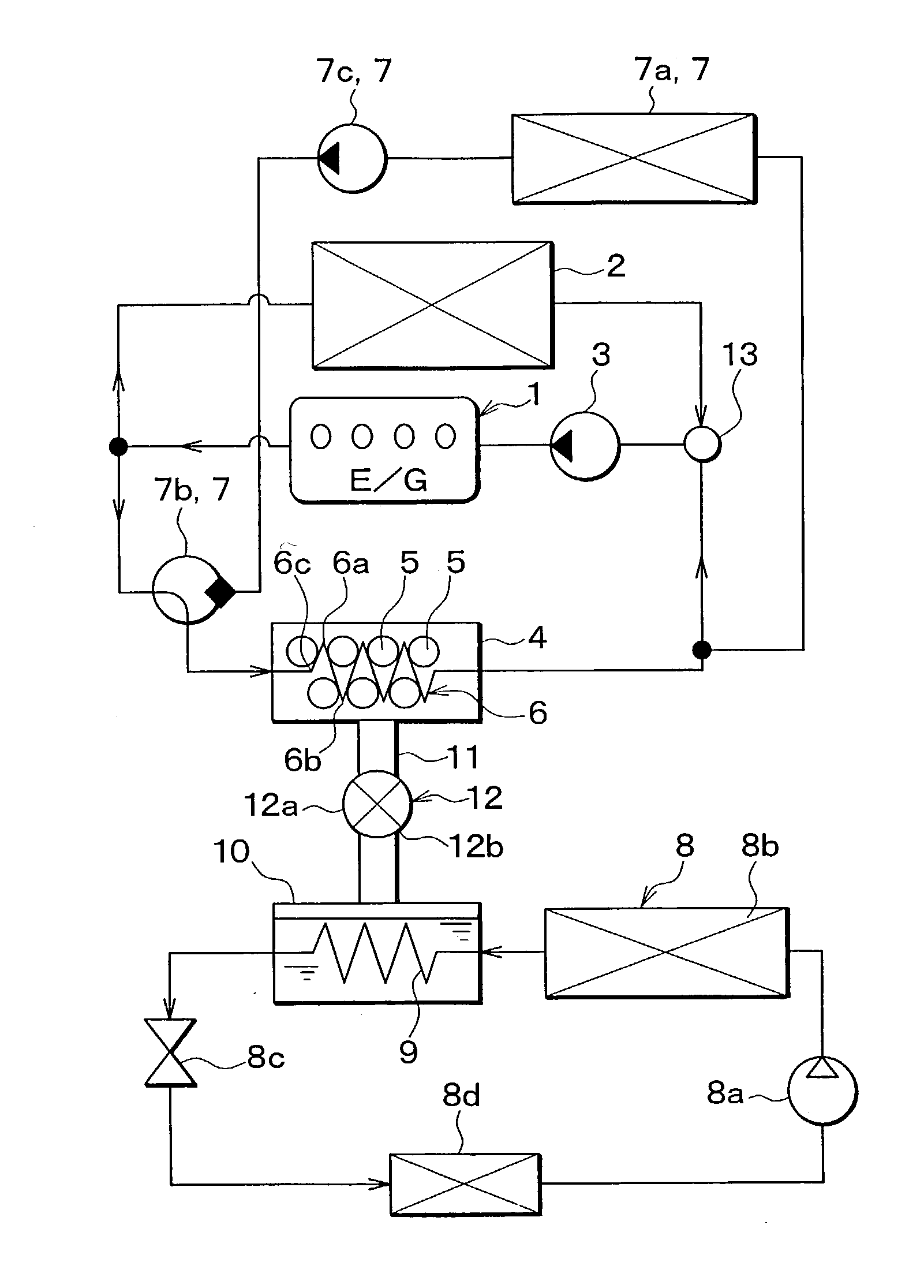

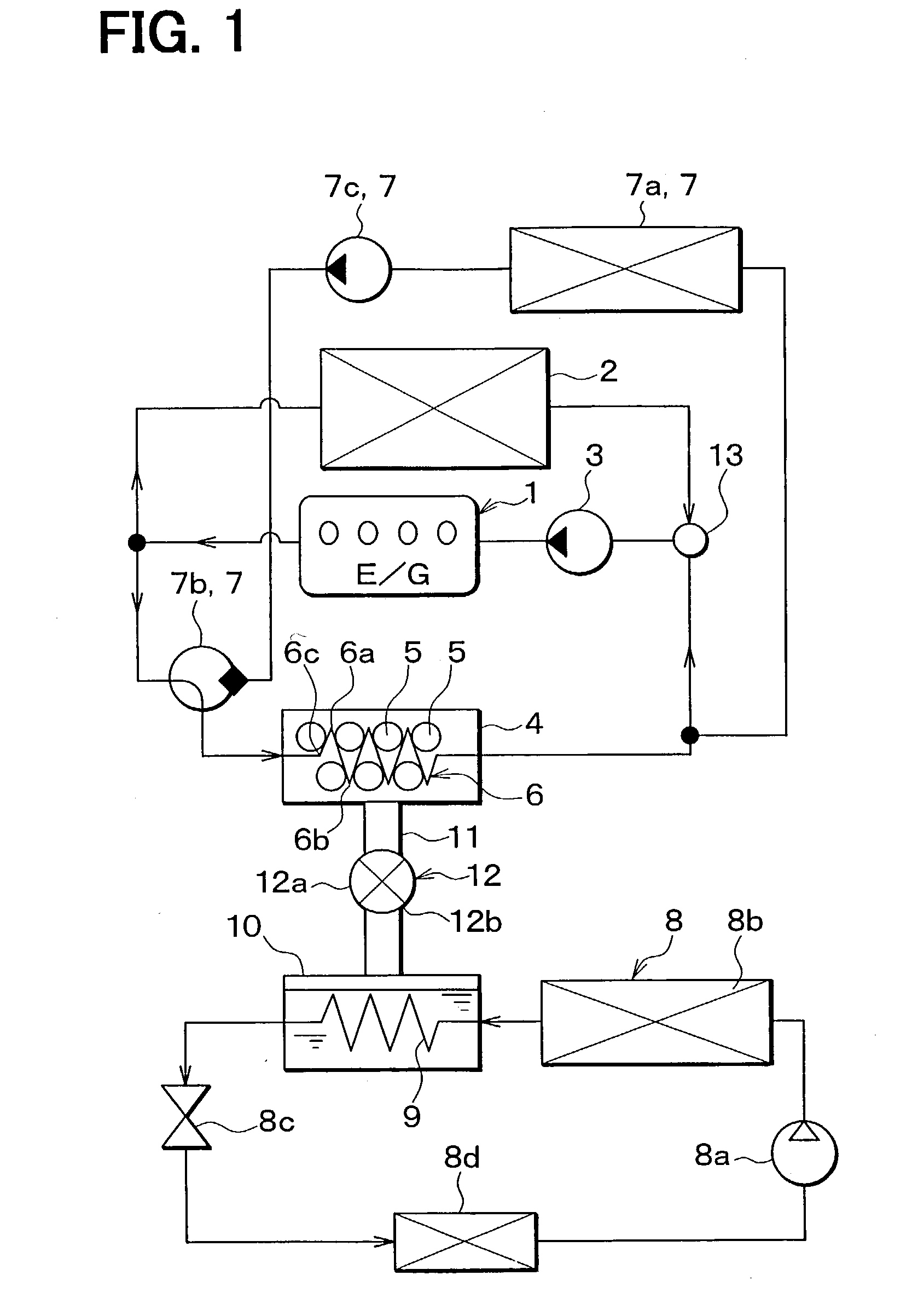

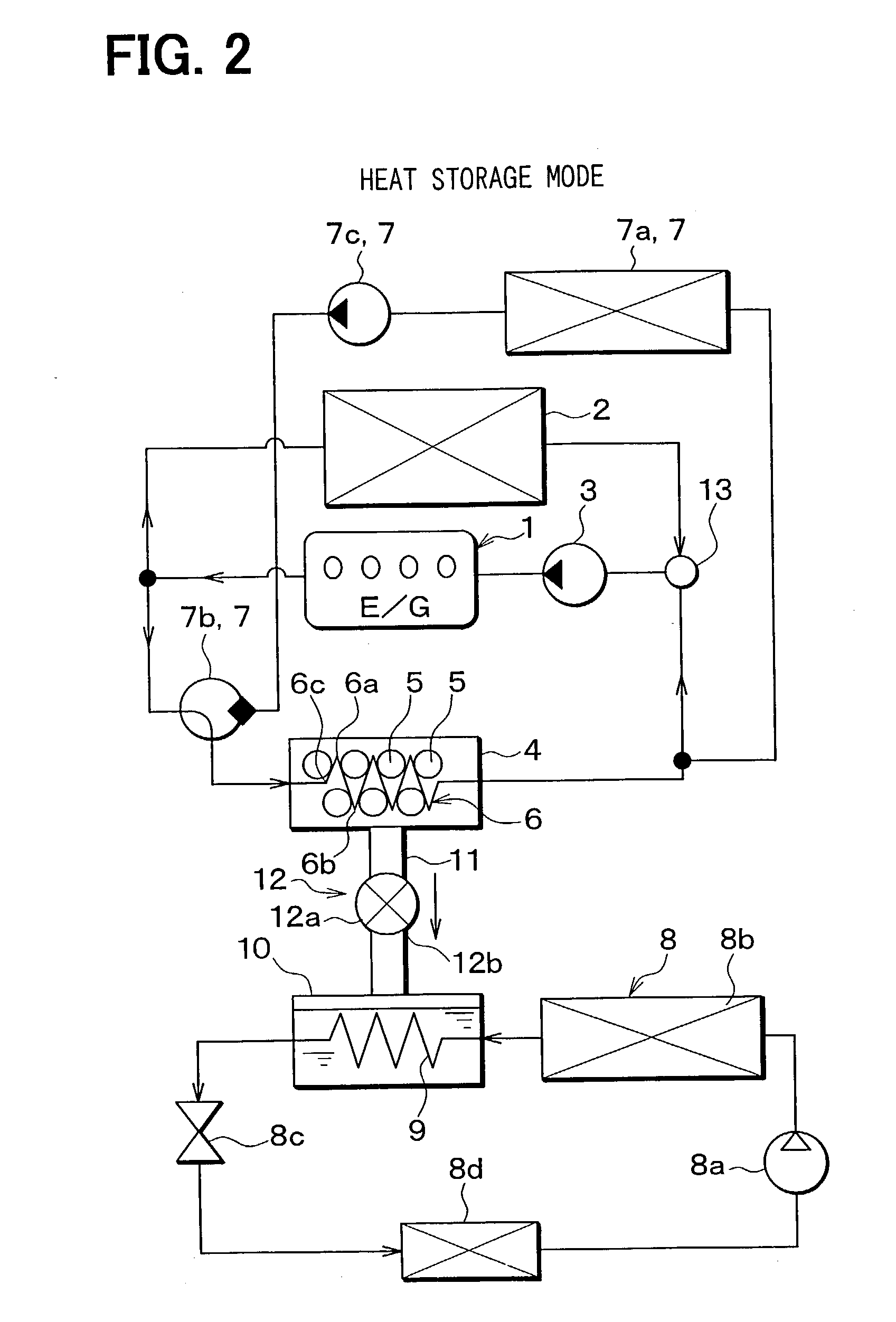

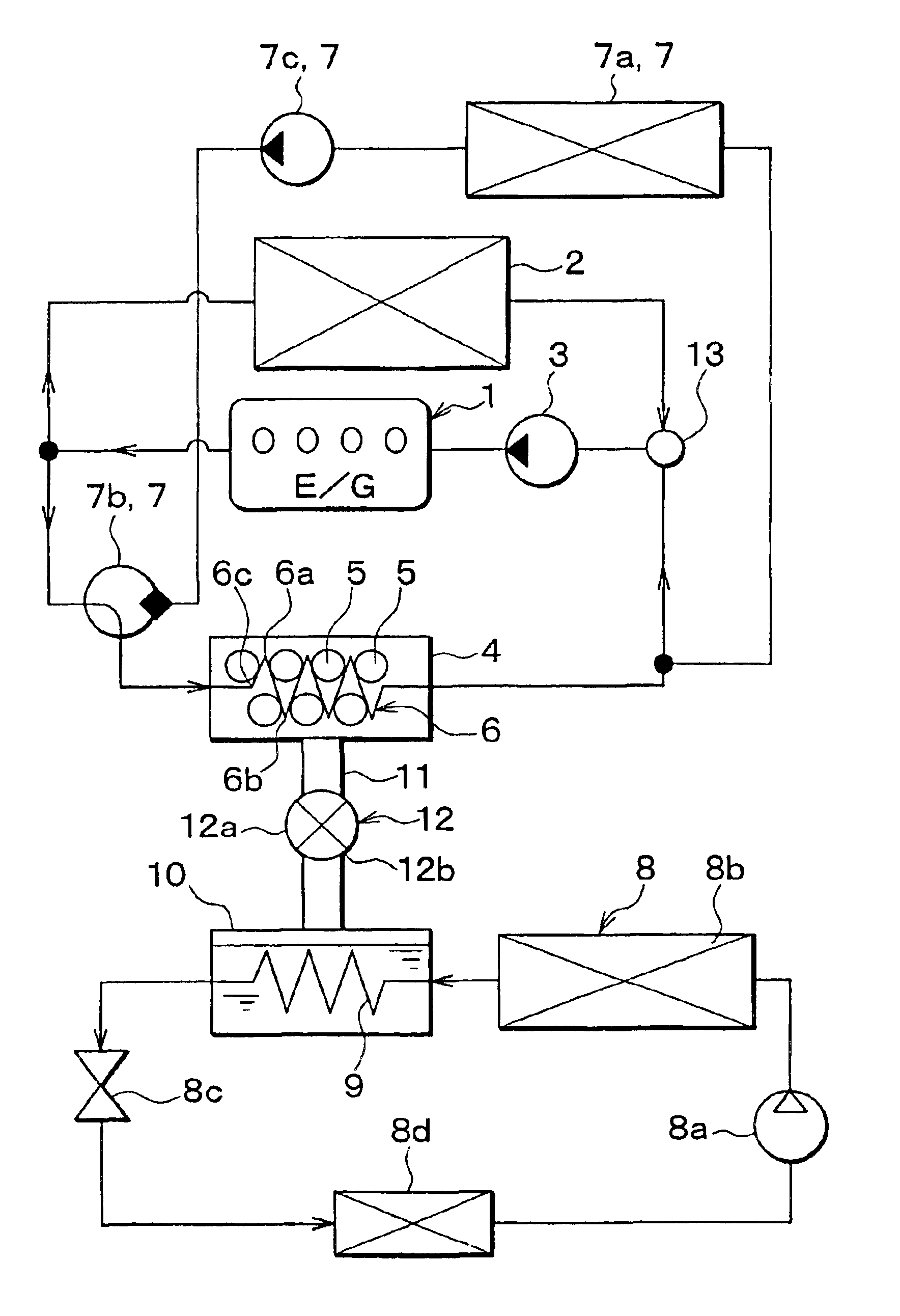

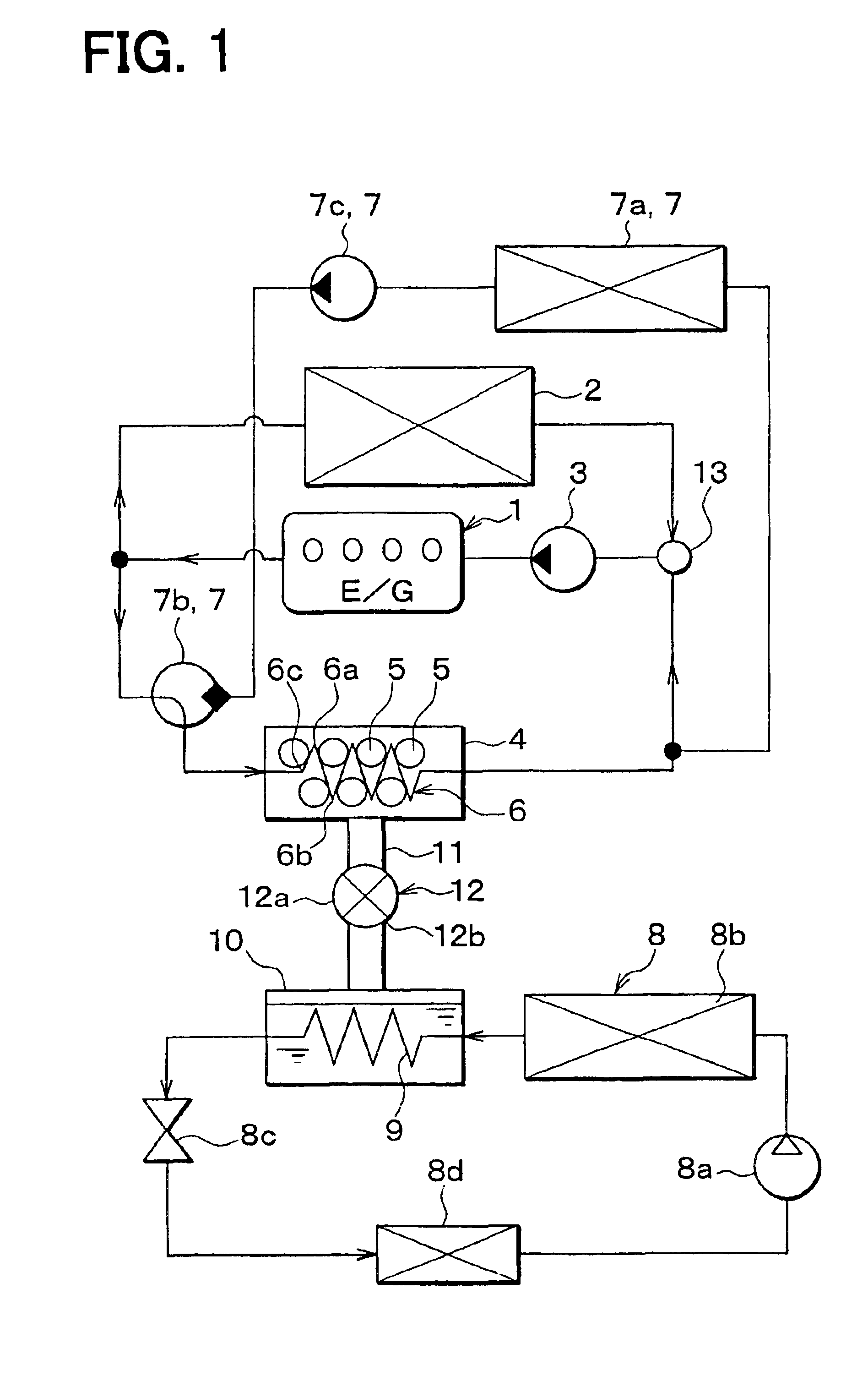

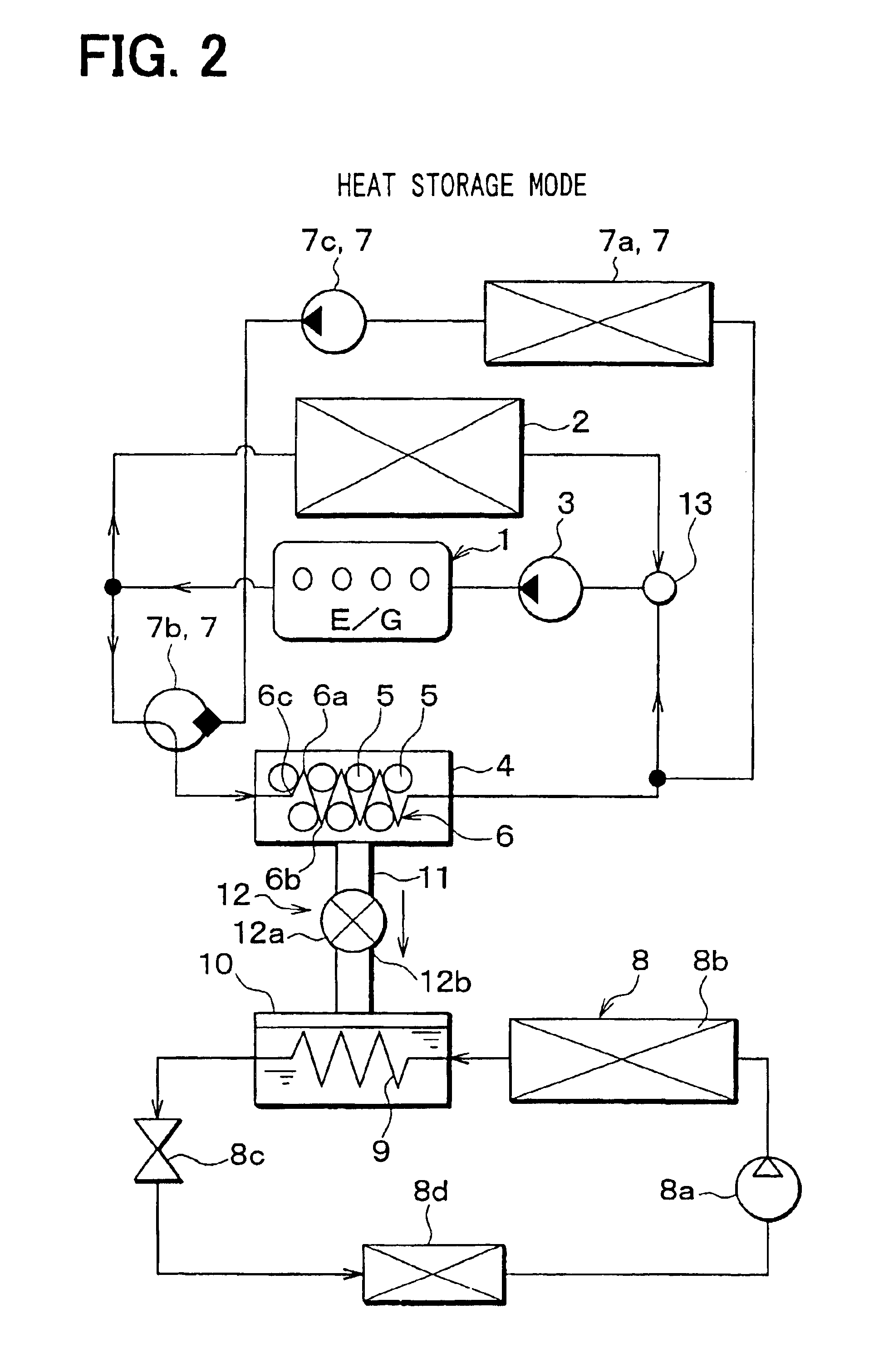

Heat storage system for vehicle, with adsorbent

InactiveUS20030167925A1Improve efficiencyReduce the power requiredCombination devicesAir-treating devicesEngineeringRefrigerant

In a heat storage system for a vehicle, when a temperature of cooling water from a vehicle engine is high, adsorbents are heated by the cooling water, so that moisture is desorbed from the adsorbents in order to store heat. When the temperature of cooling water is low, the moisture is adsorbed in the adsorbents to heat the cooling water, while refrigerant in a vapor compression refrigerator is cooled by evaporating water. Thus, adsorption heat is generated from the adsorbents, and the cooling water is heated by using the adsorption heat. Accordingly, warm-up operation of the vehicle engine is facilitated, while motive power consumed by the vapor compression refrigerator can be reduced.

Owner:DENSO CORP

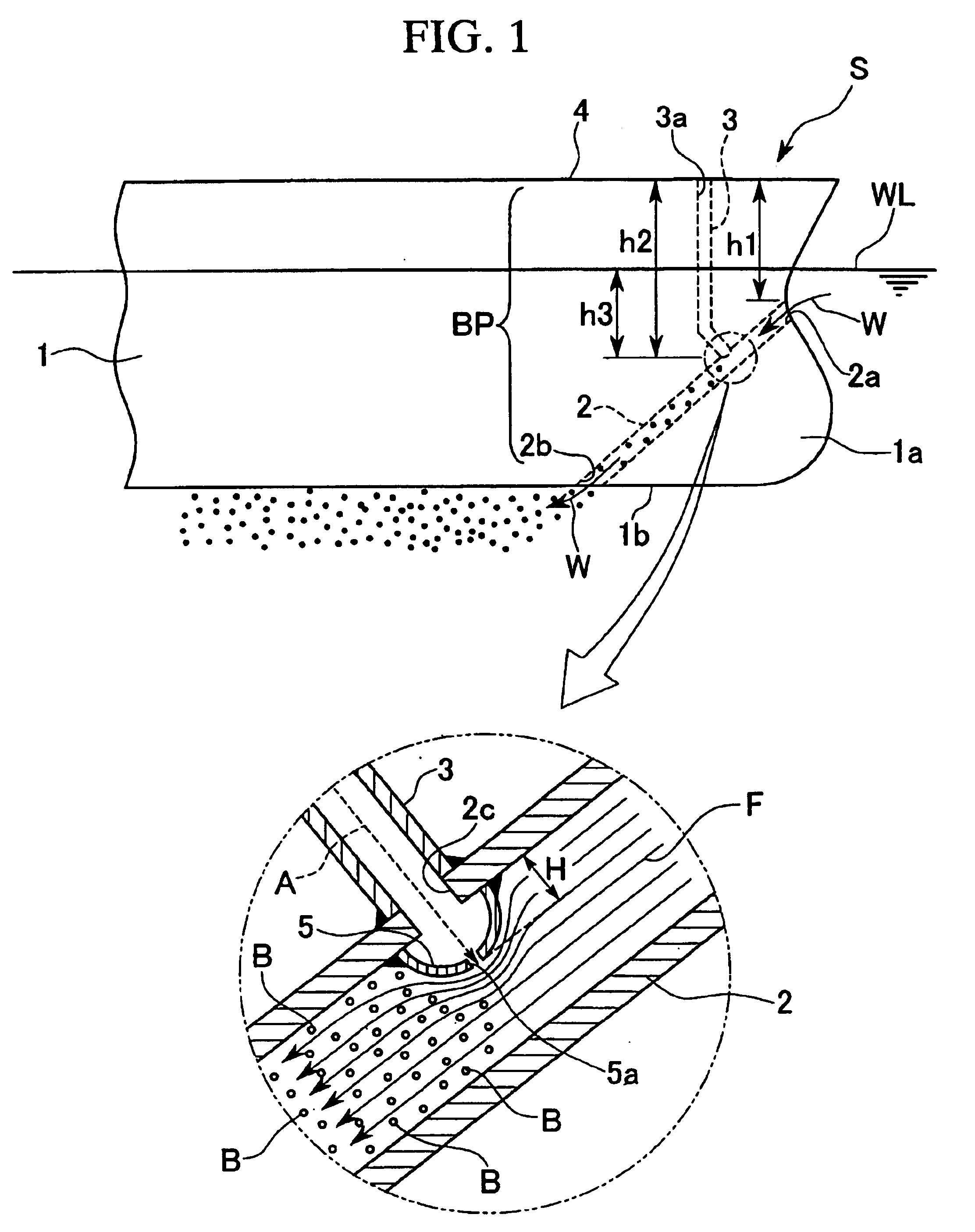

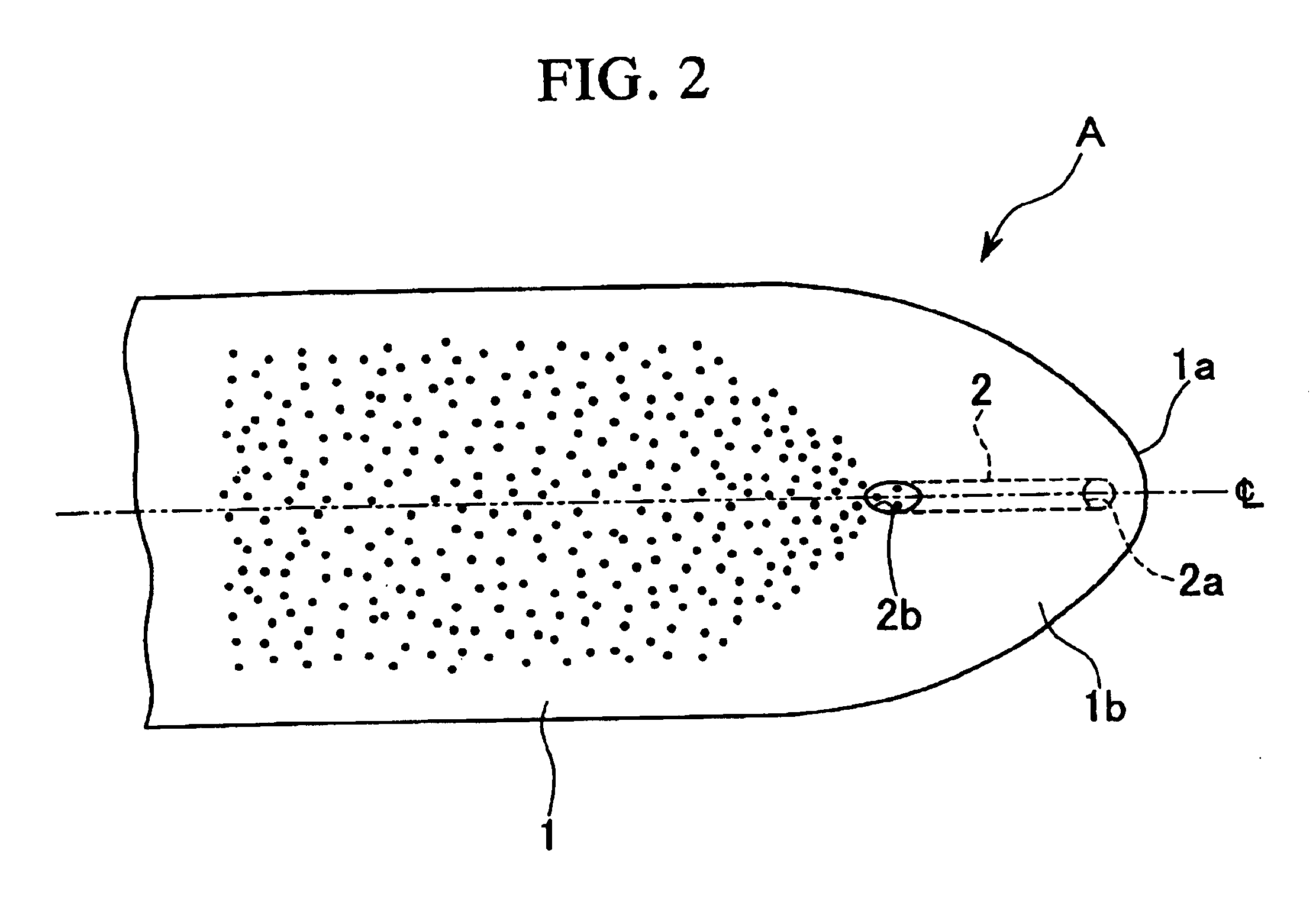

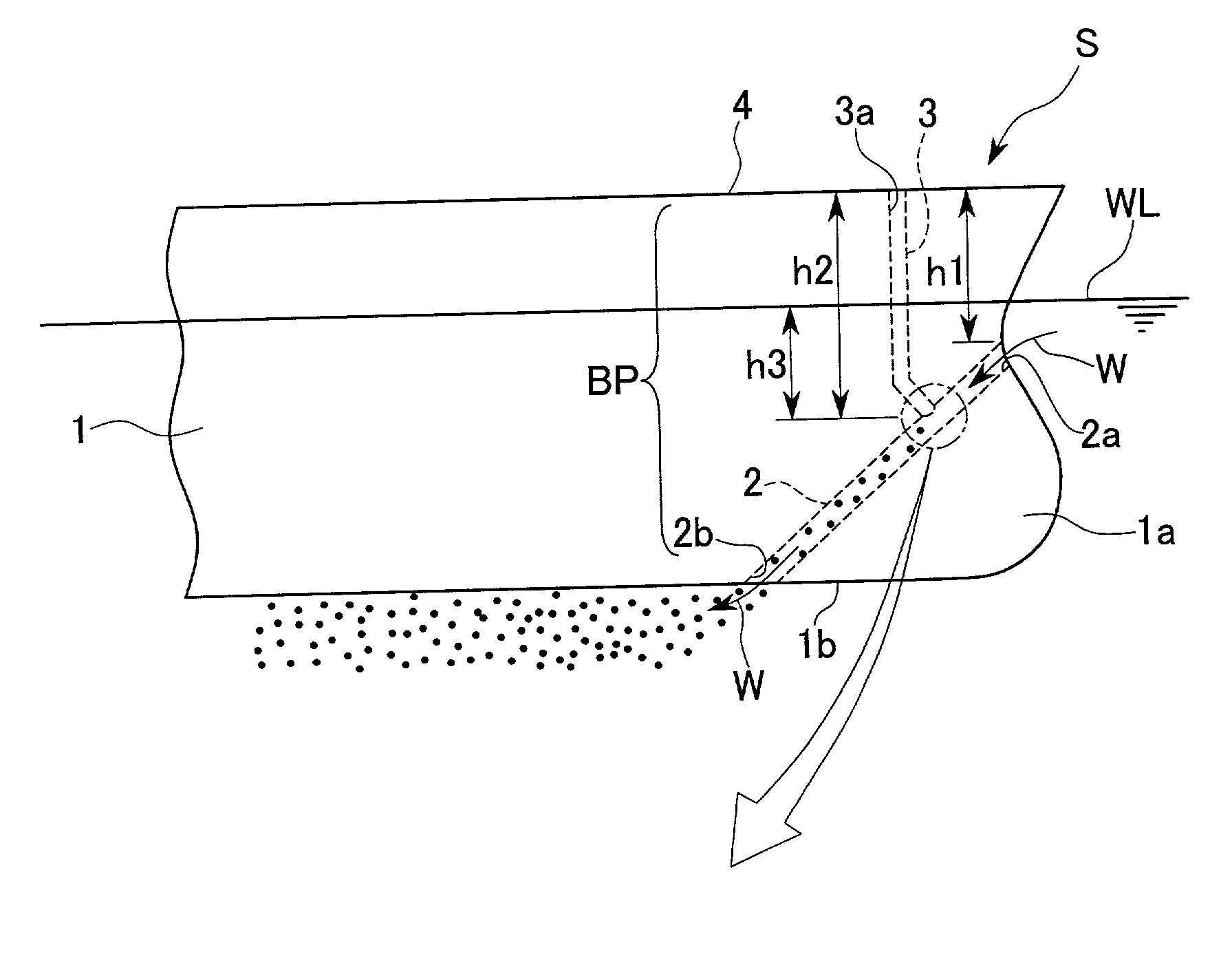

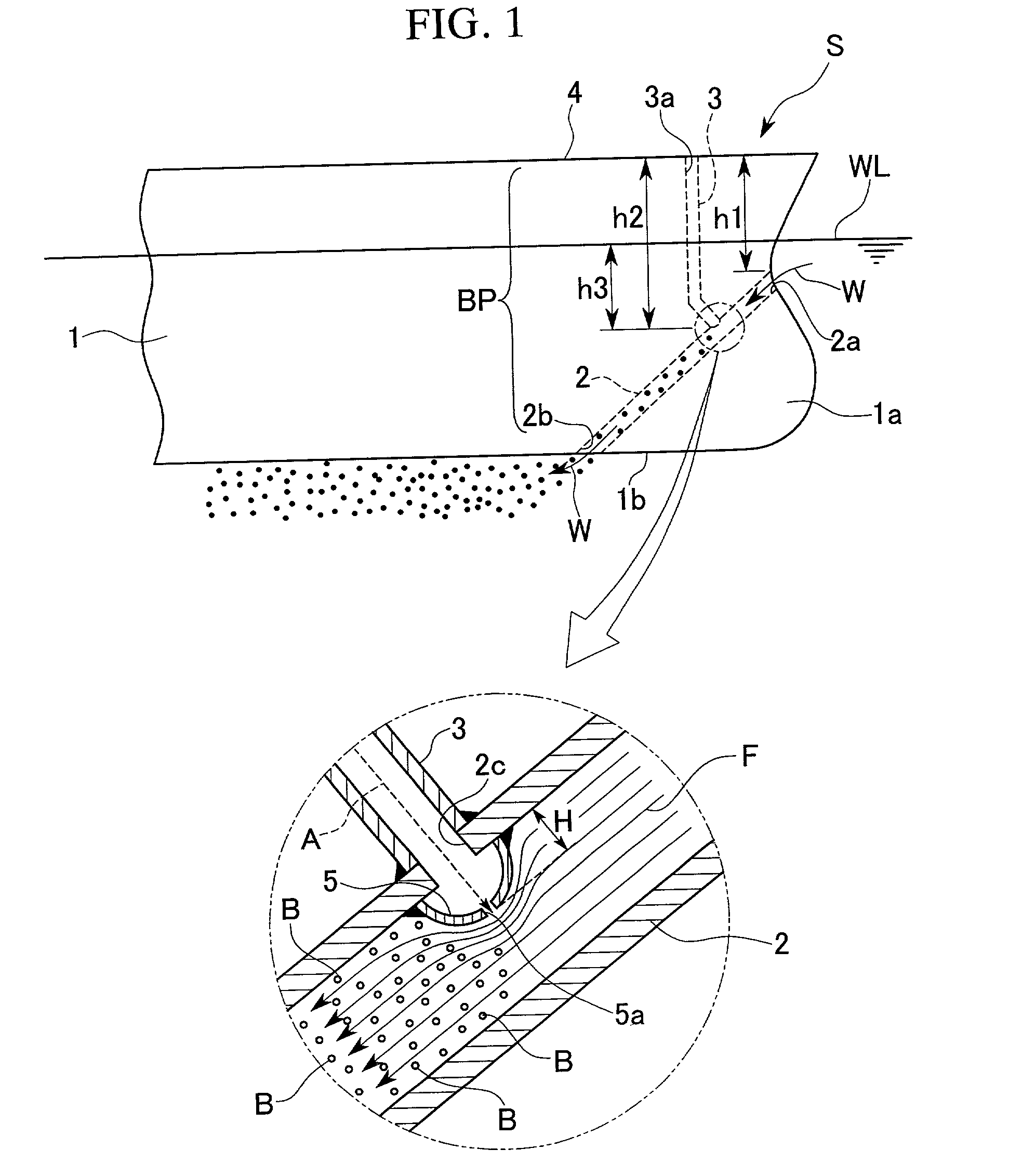

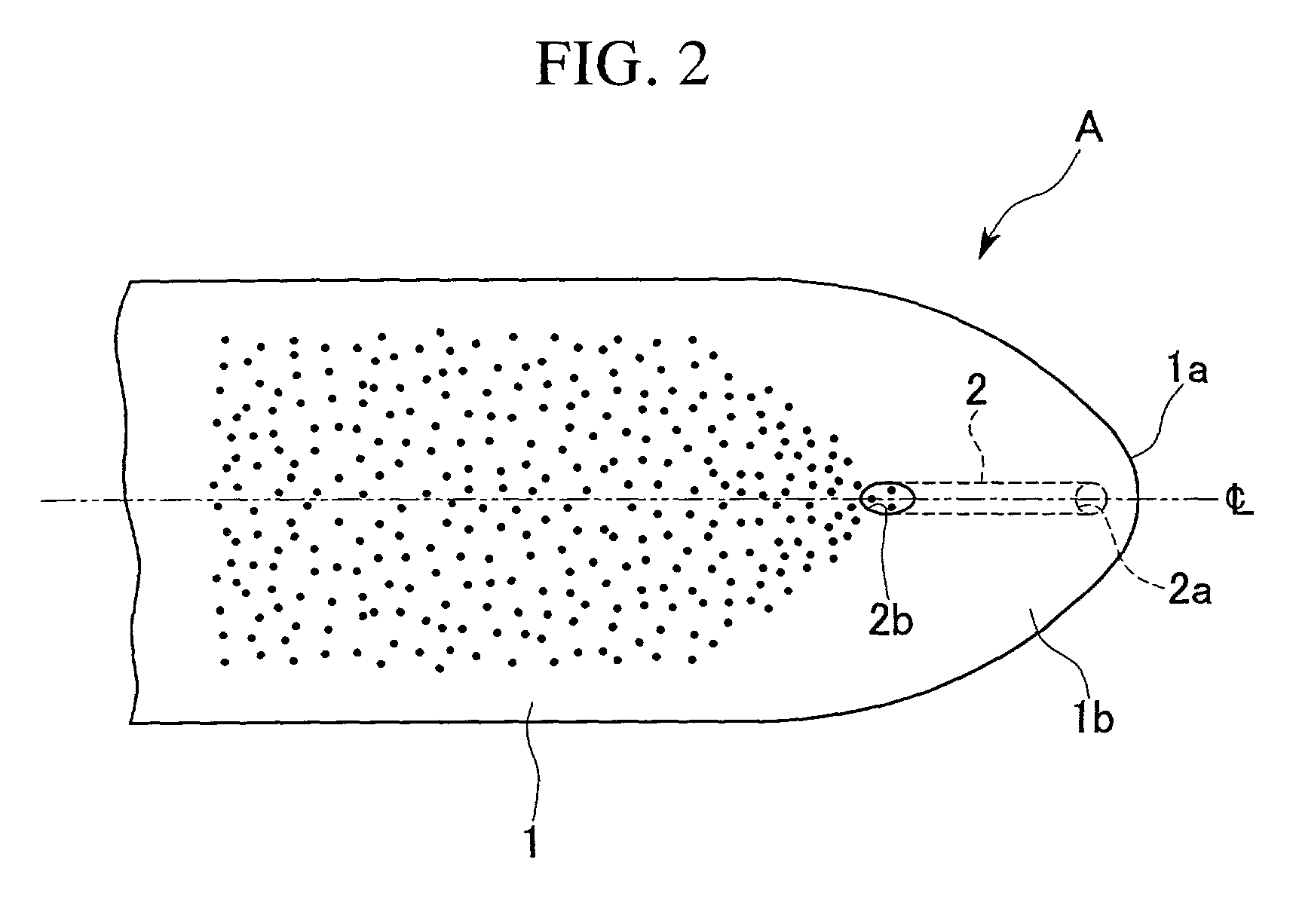

Friction reducing ship and method for reducing frictional resistance

InactiveUS6789491B2Reduce the power requiredReduce frictional resistanceWatercraft hull designJet pumpsWater dischargeAtmospheric air

A friction reducing ship reduces frictional resistance between the external hull plate 1 and water W by ejecting air A from the external hull plate 1 into water W to generate micro-bubbles B on the surface of the external hull plate 1. A structural feature of the ship is that micro-bubbles B are generated by creating a negative pressure region in the water W admitted in the water intake opening 2a, disposed below the waterline WL in the bow section 1a, so as to eject atmospheric air above the water into the water to generate micro-bubbles B, and discharging the micro-bubbles B together with water to the water discharge opening 2b provided in the bottom section 1b.

Owner:IHI MARINE UNITED INC

Friction reducing ship and method for reducing frictional resistance

InactiveUS20020014192A1Reduce the power requiredWatercraft hull designJet pumpsMarine engineeringAtmospheric air

A friction reducing ship reduces frictional resistance between the external hull plate 1 and water W by ejecting air A from the external hull plate 1 into water W to generate micro-bubbles B on the surface of the external hull plate 1. A structural feature of the ship is that micro-bubbles B are generated by creating a negative pressure region in the water W admitted in the water intake opening 2a, disposed below the waterline WL in the bow section 1a, so as to eject atmospheric air above the water into the water to generate micro-bubbles B, and discharging the micro-bubbles B together with water to the water discharge opening 2b provided in the bottom section 1b.

Owner:IHI MARINE UNITED INC

Heat storage system for vehicle, with adsorbent

InactiveUS6807820B2Improve efficiencyReduce the power requiredCombination devicesAir-treating devicesEngineeringRefrigerant

In a heat storage system for a vehicle, when a temperature of cooling water from a vehicle engine is high, adsorbents are heated by the cooling water, so that moisture is desorbed from the adsorbents in order to store heat. When the temperature of cooling water is low, the moisture is adsorbed in the adsorbents to heat the cooling water, while refrigerant in a vapor compression refrigerator is cooled by evaporating water. Thus, adsorption heat is generated from the adsorbents, and the cooling water is heated by using the adsorption heat. Accordingly, warm-up operation of the vehicle engine is facilitated, while motive power consumed by the vapor compression refrigerator can be reduced.

Owner:DENSO CORP

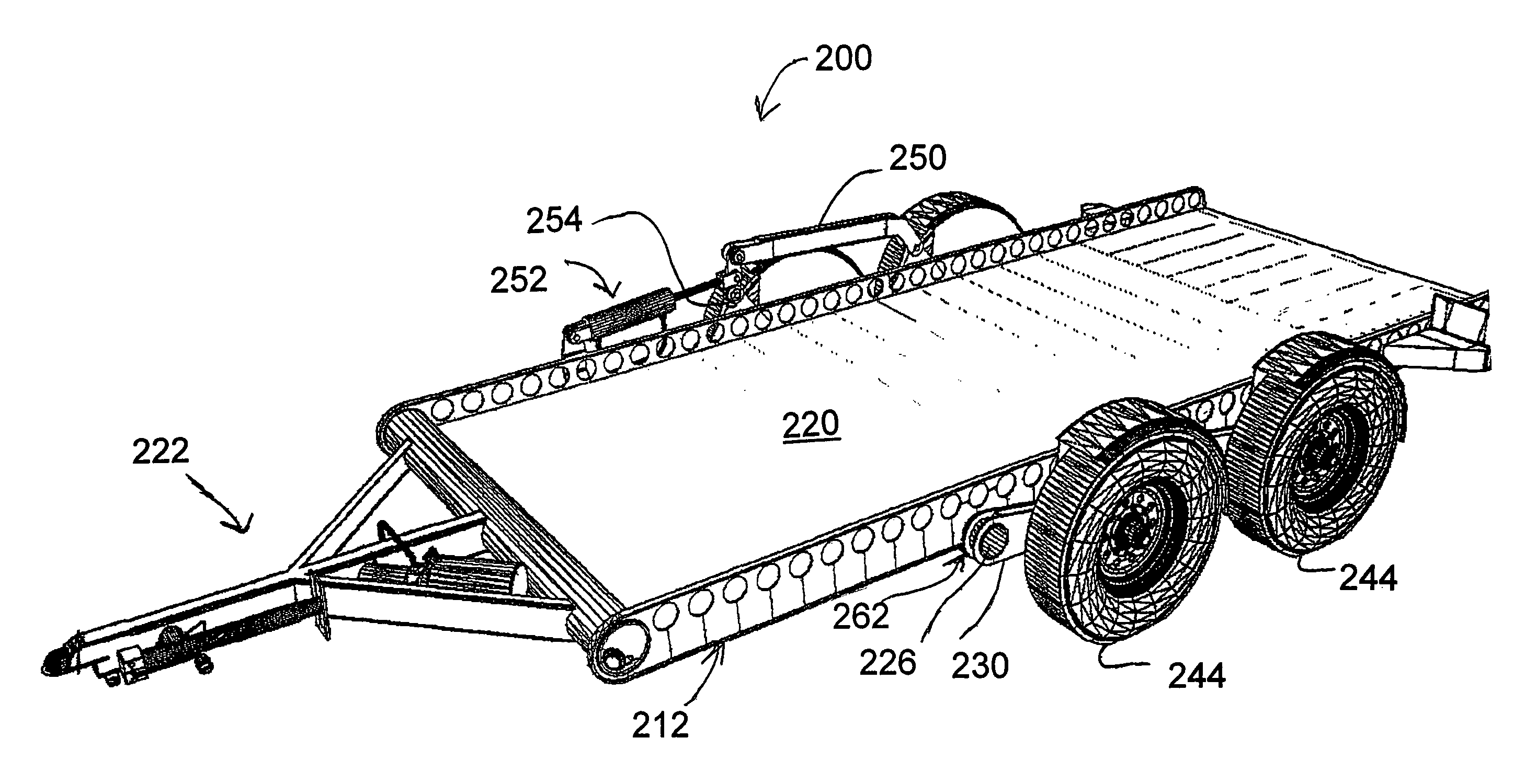

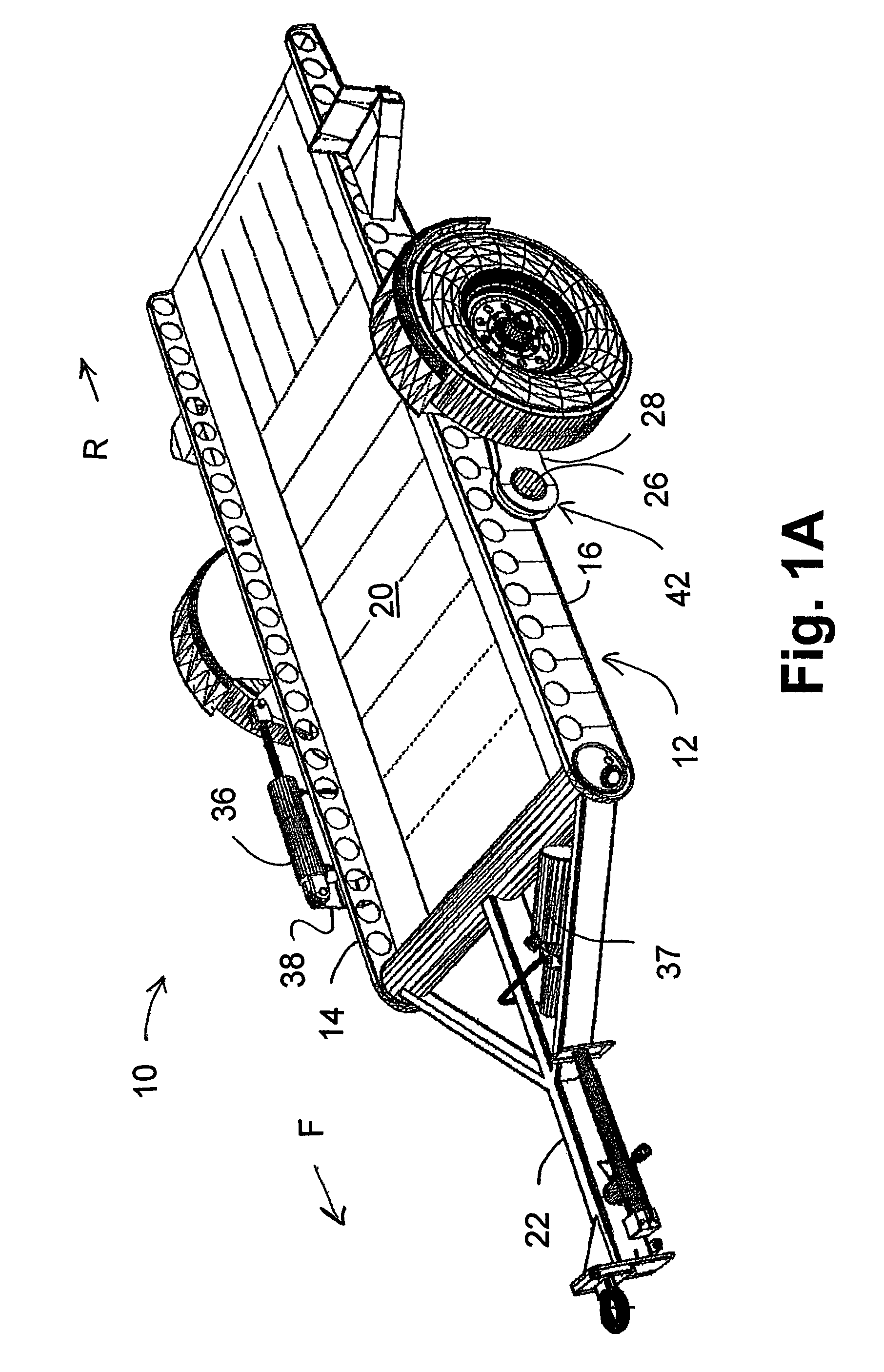

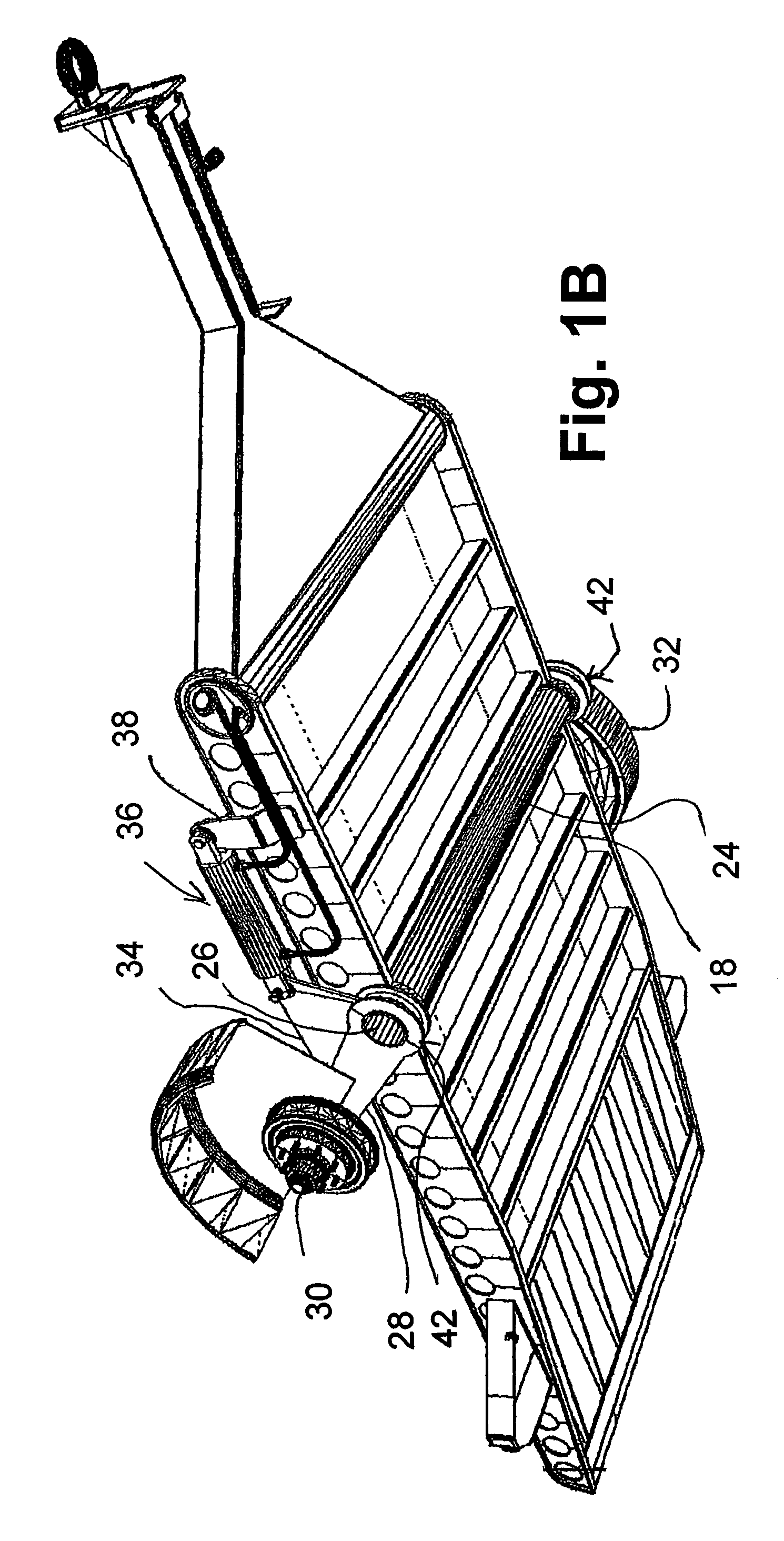

Method and apparatus for an adjustable trailer

ActiveUS7618227B2Reduce the power requiredVehicle cleaning apparatusUnderstructuresMechanical engineering

A trailer having a front and a rear. The trailer includes a frame constructed to receive a bed and a hitch attached to the frame at the front of the trailer. A tube is pivotally connected to the frame between the front and the rear of the trailer. First and second support arms are connected to the tube. Each wheel support arm has an axle and a wheel located at its distal end. The trailer further includes means for rotating the tube. In one embodiment, the trailer has an inclining feature and a shoe for ground engagement. The shoe is located vertically below a central axis of the tube and longitudinally between the wheels and the front of the trailer. In a second embodiment, the trailer has an inclining and elevating feature. In this second embodiment, the hitch is pivotally connected to the front of the trailer and there is provided means for rotating the tube and rotating the hitch relative to one another to elevate, incline, or decline the bed.

Owner:FOUR DEGREE TRAILER CO

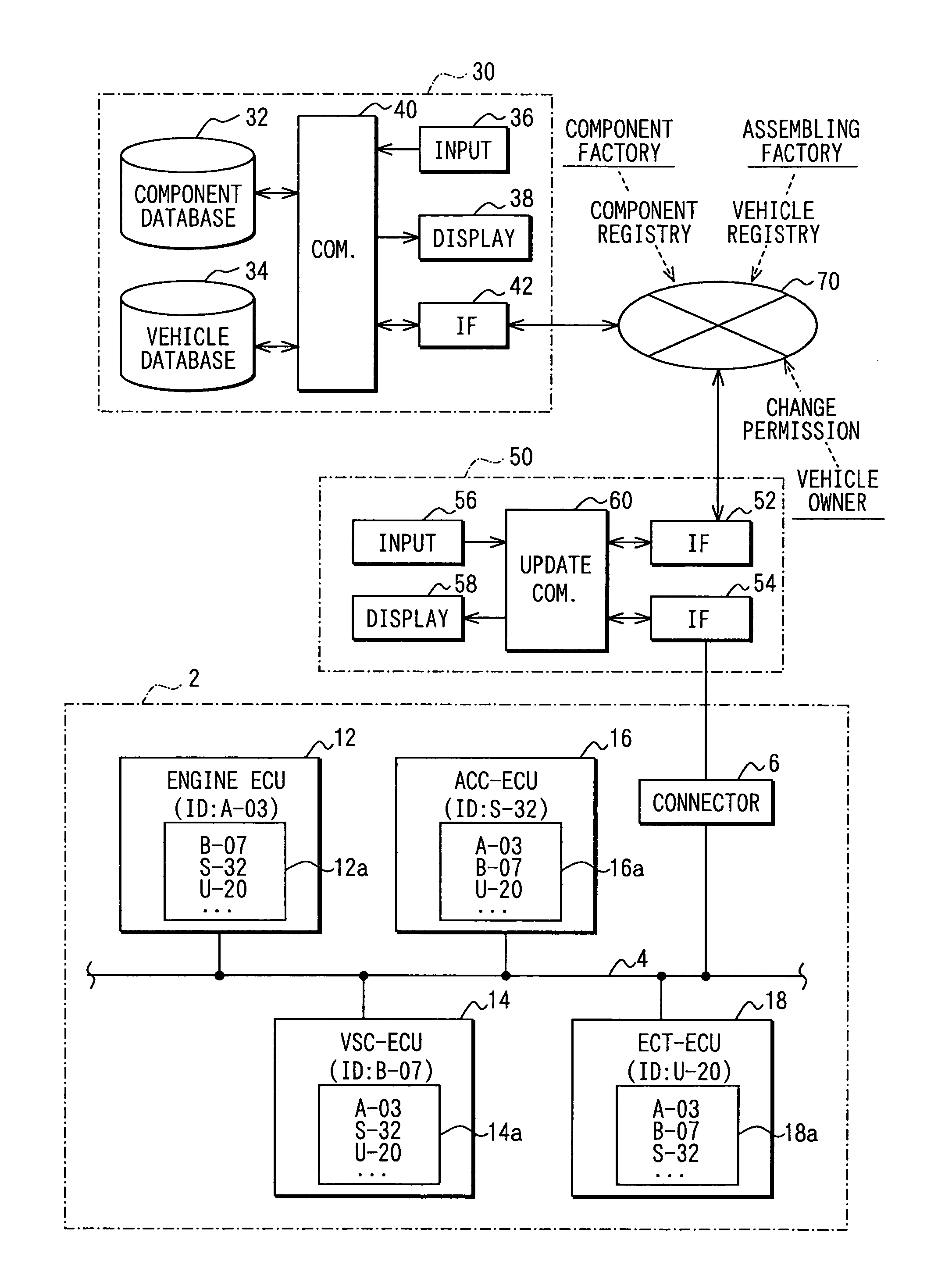

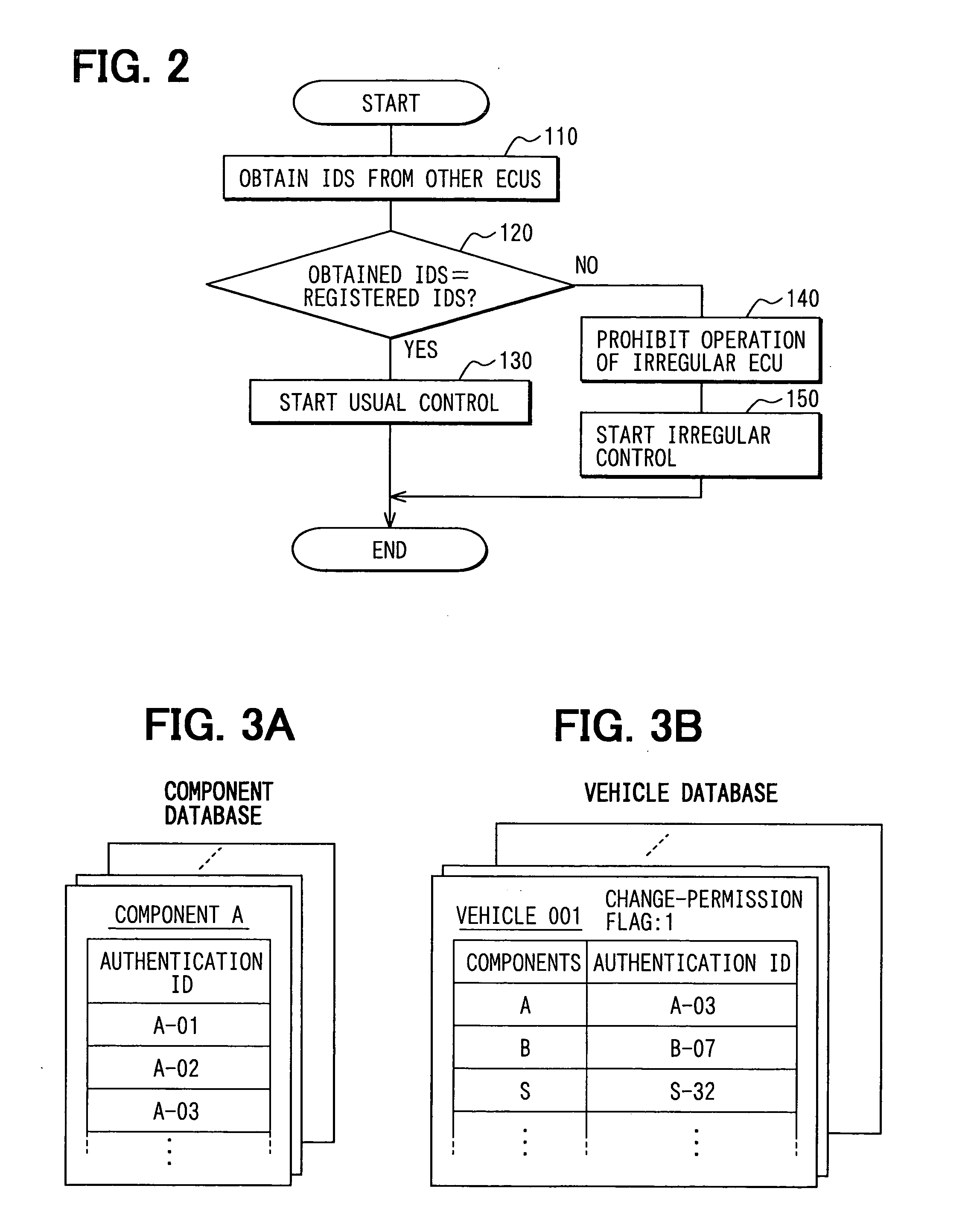

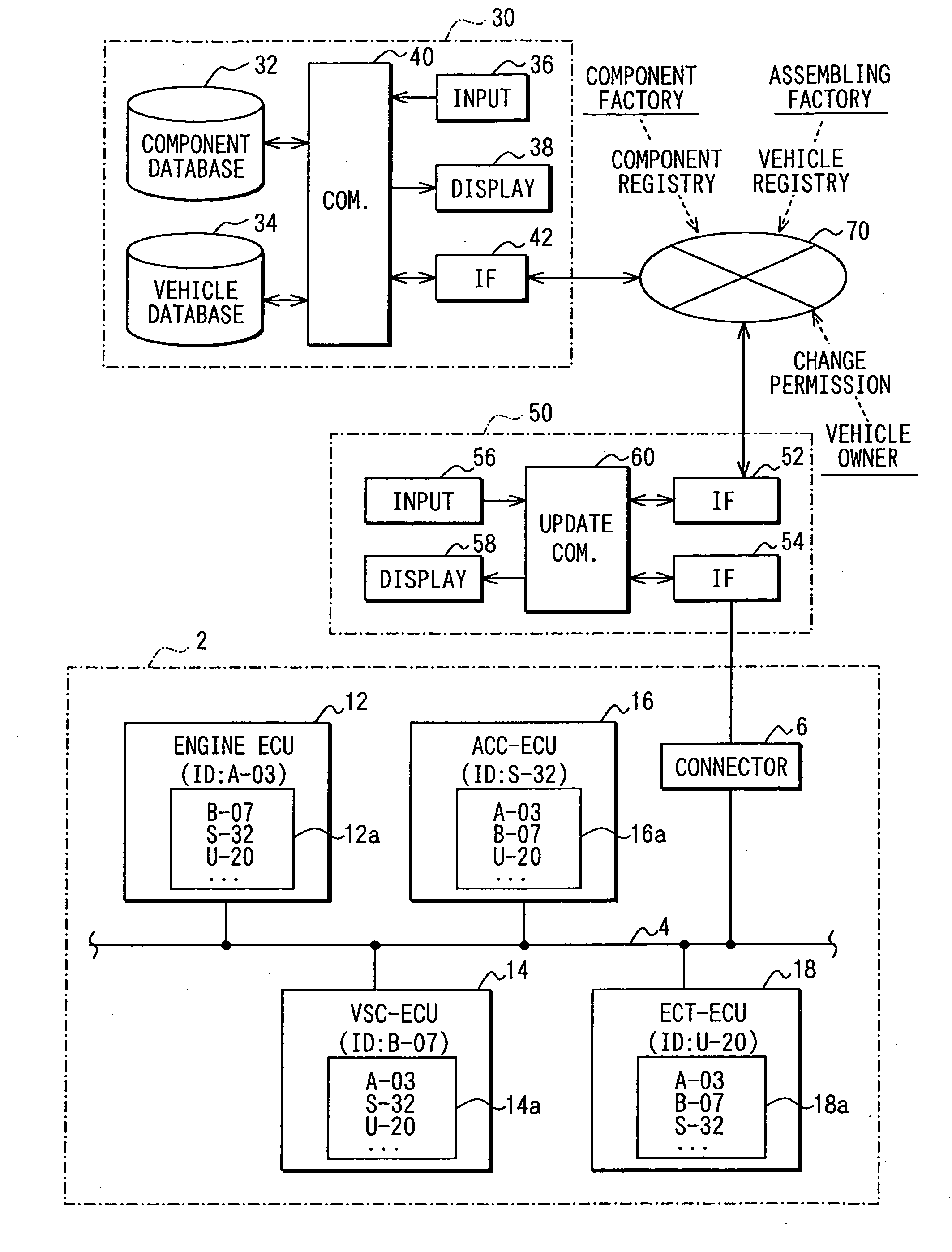

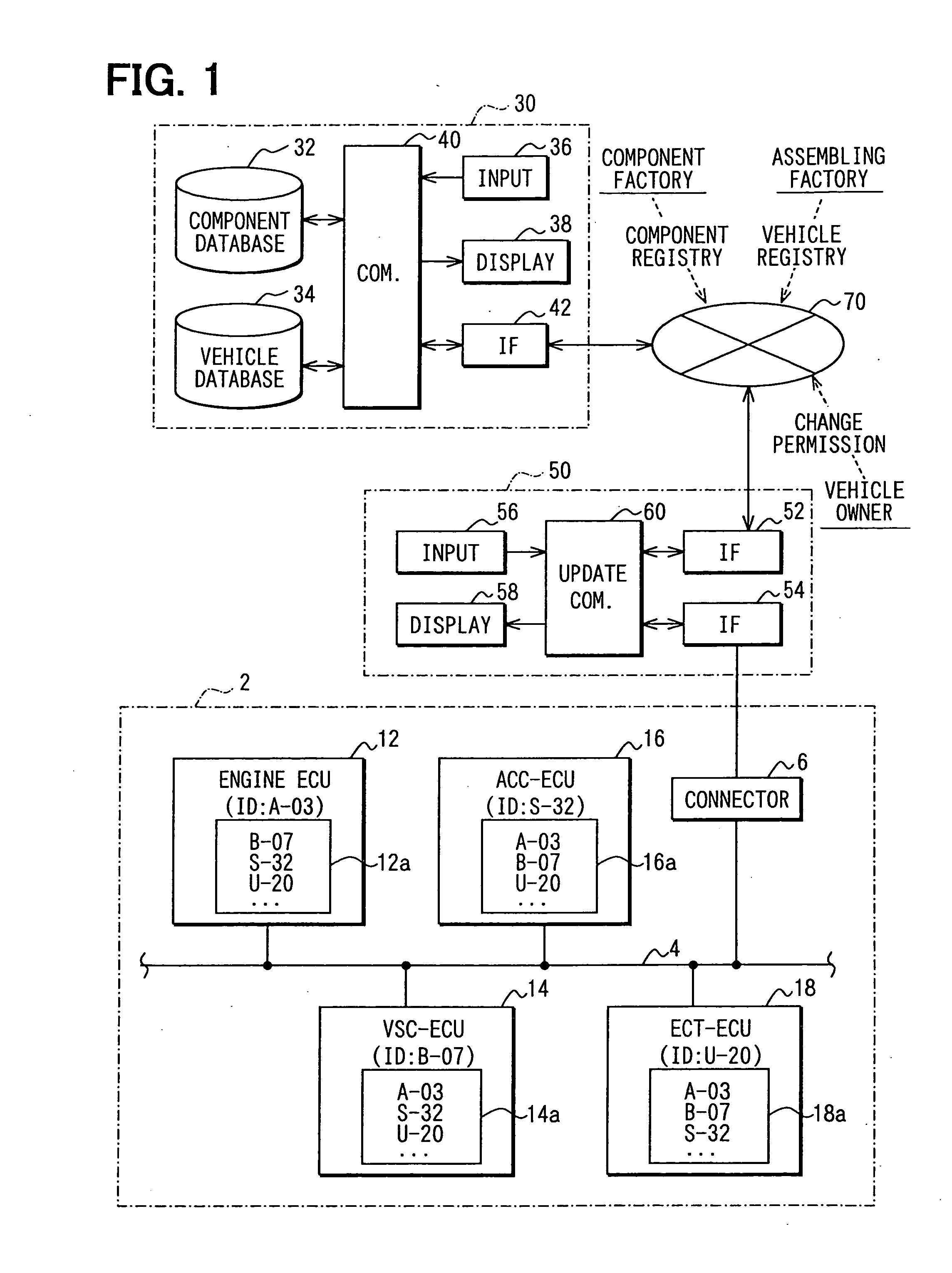

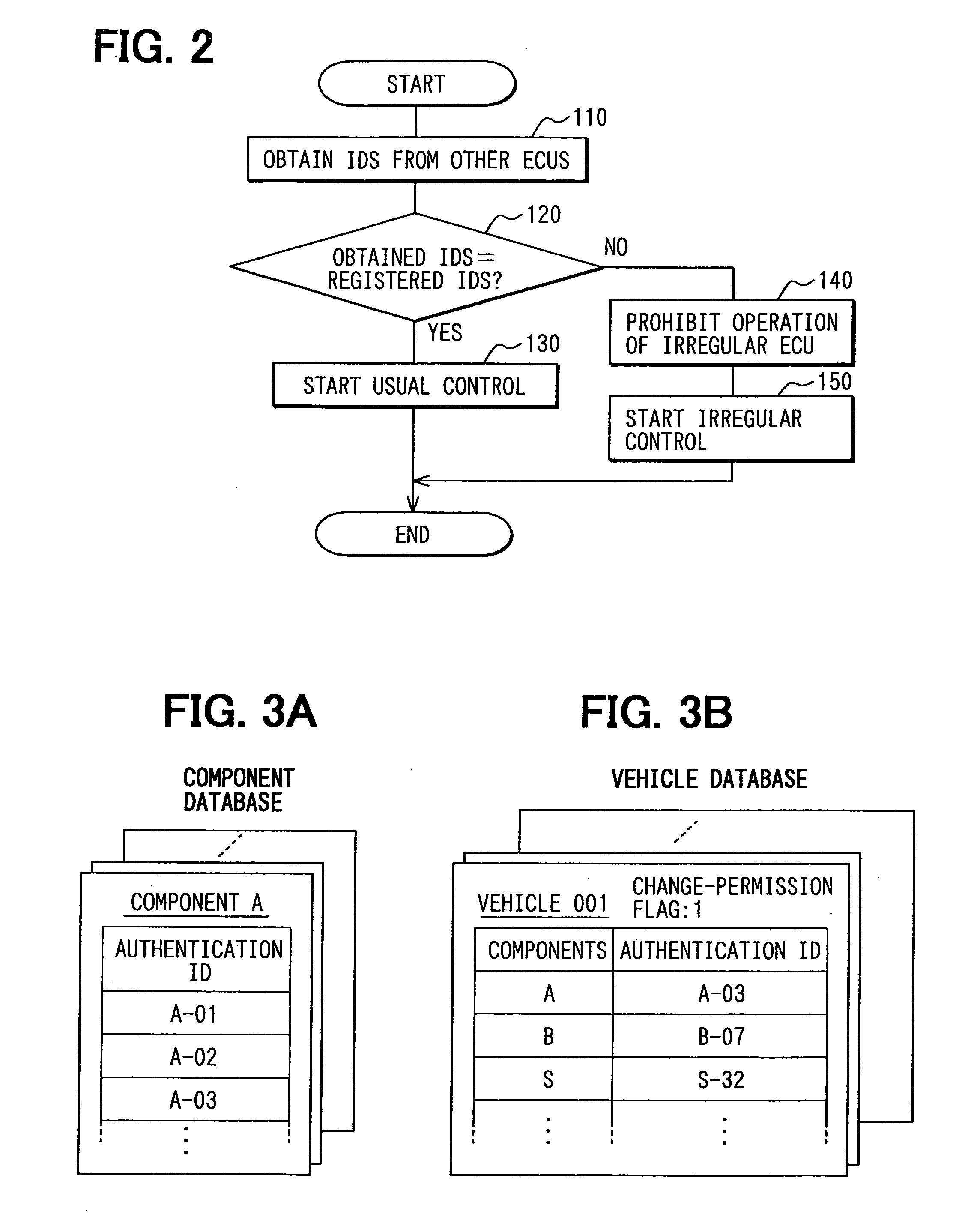

Method and system for vehicle component management, method and system for vehicle component management data update, and vehicle component management center

InactiveUS20050192716A1Reduce the power requiredReduce incidenceVehicle testingRegistering/indicating working of vehiclesEngineeringAuthentication

Each of ECUs constituting a system of a vehicle is registered with authentication IDs of other ECUs. The each of ECUs determines whether the other ECUs are regular by comparing the registered IDs with authentication IDs newly obtained from the other ECUs when the system is started. When a certain ECU within the other ECUs is determined to be not regular, the certain ECU is prohibited from being used in this system. Further, when a new ECU is substituted or added, a terminal confirms whether the new ECU is unused in another vehicle and is thereby enabled to be usable by transmitting an authentication ID of the new ECU to a management center. When the new ECU is confirmed to be enabled to be usable, authentication IDs registered in the respective ECUs are updated.

Owner:DENSO CORP

Real-time digital x-ray imaging apparatus

InactiveUS7319736B2Exact reproductionBetter optimizedTomosynthesisRadiation measurementAcquisition rateElectron

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality. In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface. The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal. It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

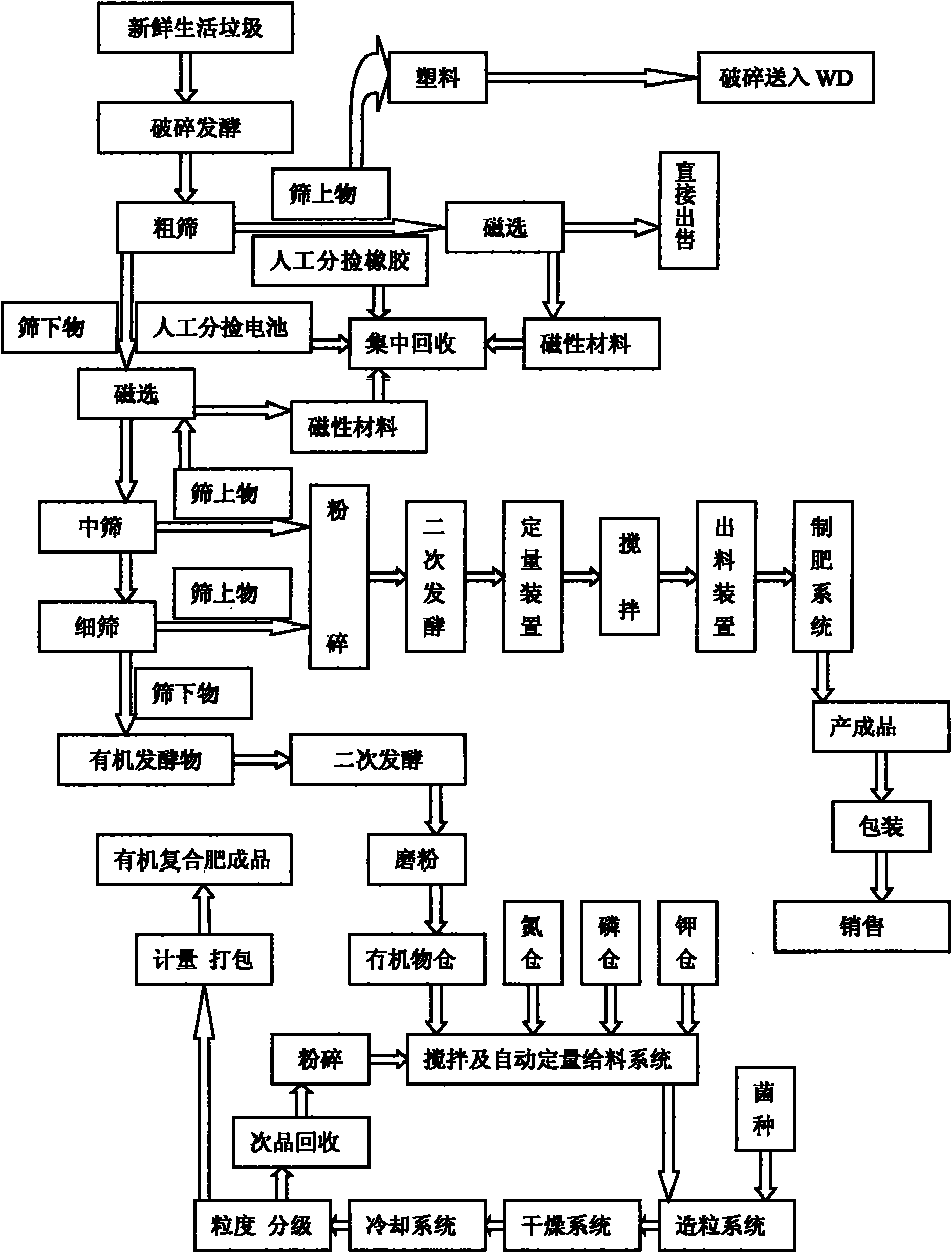

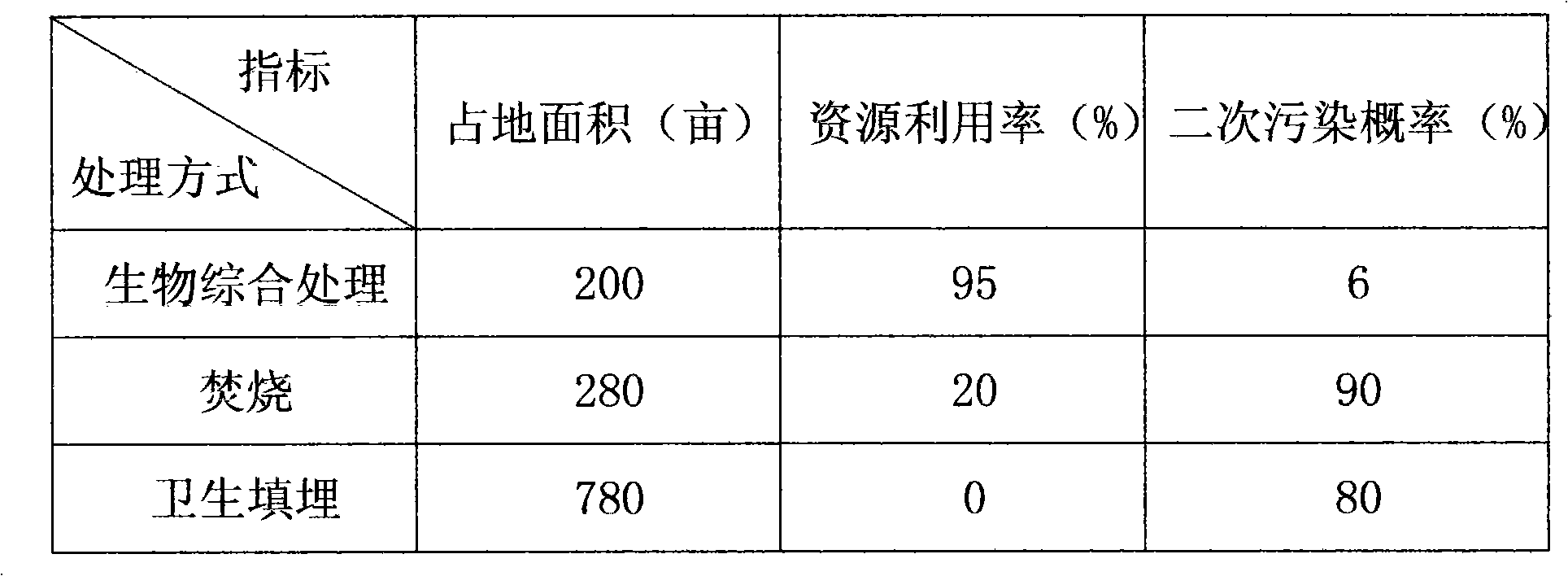

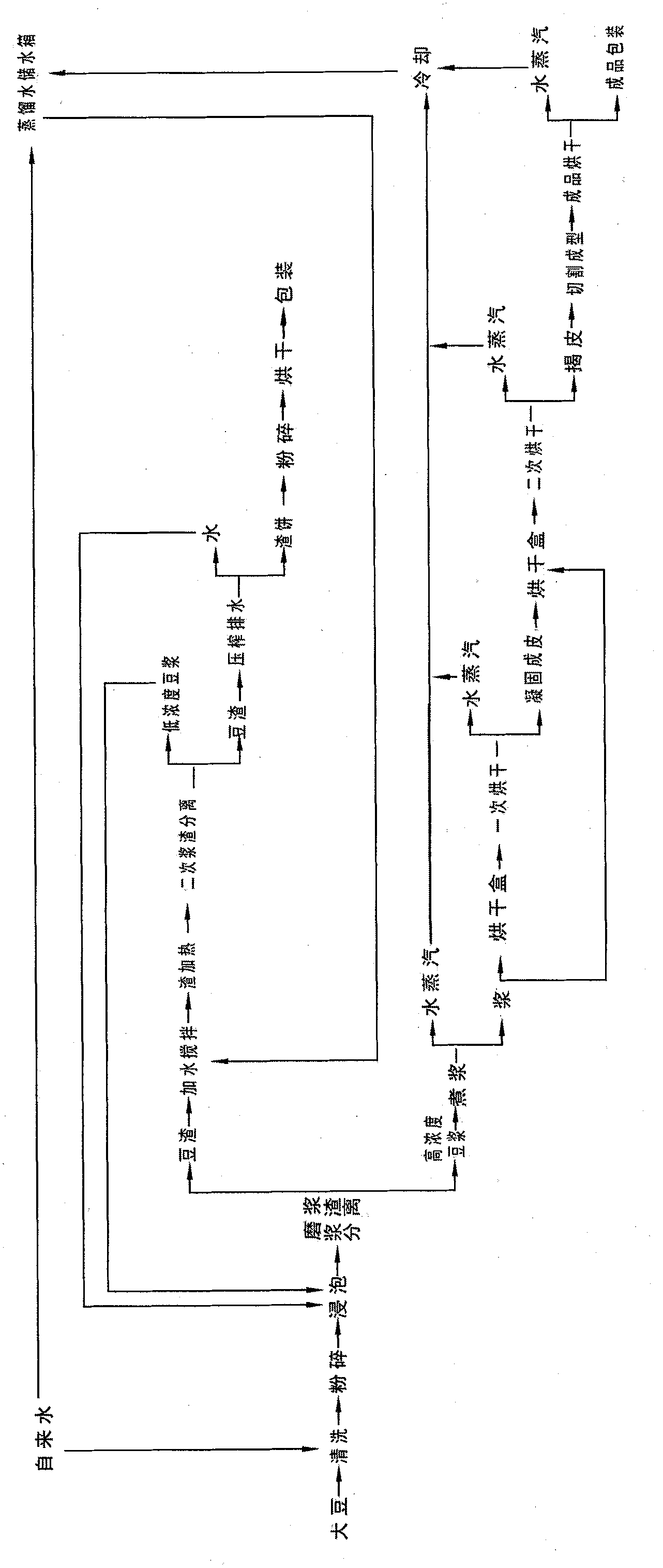

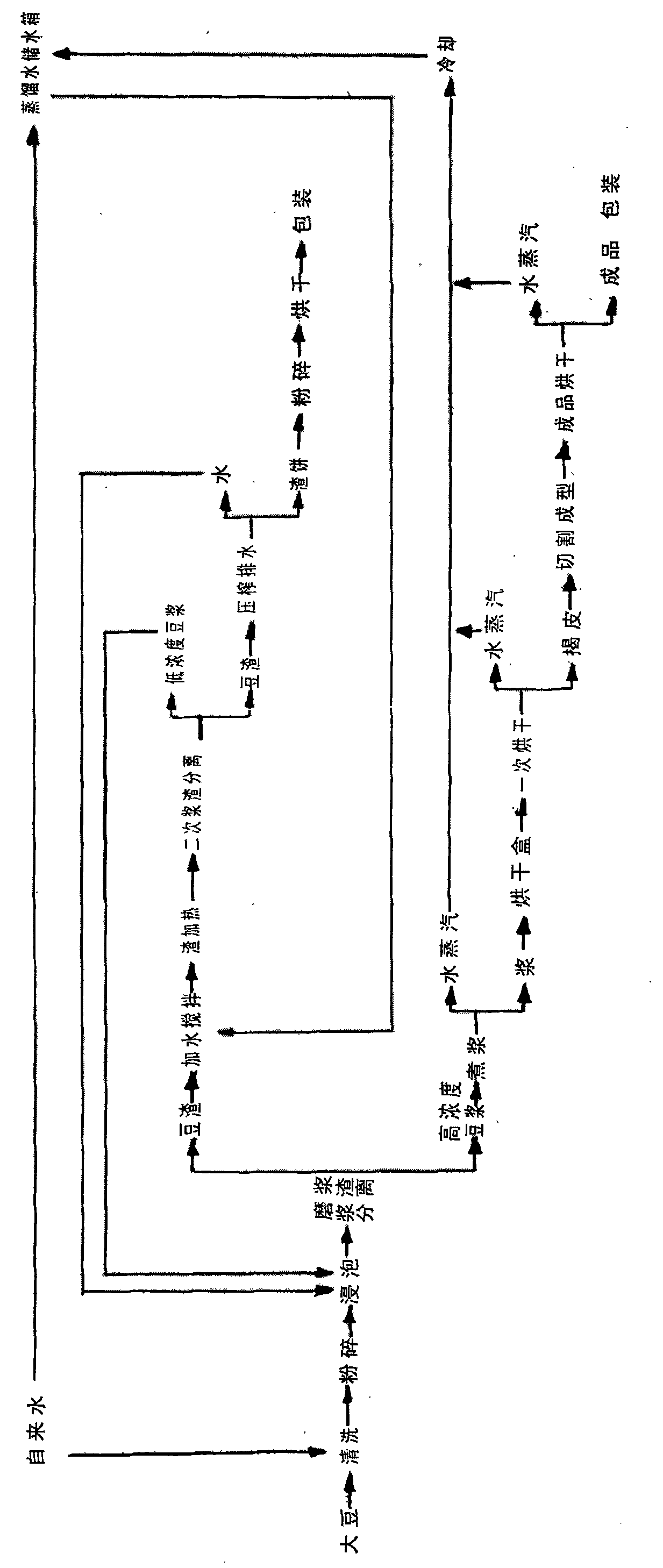

House refuse treatment method

InactiveCN102009057ASave spaceReduce the power requiredSolid waste disposalClimate change adaptationBrickCrushed stone

The invention discloses a house refuse treatment method, which comprises the following steps: crushing and fermenting refuse at normal pressure and under normal pressure; executing a screening process, crushing large or large-grain inorganic materials among oversize materials on a coarse screen, and making an urban coal material; coarsely screening, crushing stone and brick blocks among oversize materials on a medium screen, and making a roadbed material or pavior brick base material; making fertilizer by using organic materials or fermented products of the organic materials among the oversize materials and undersize materials of the medium screen and a fine screen, wherein materials with recycling value among magnetic materials screen out are sold directly, and materials without recycling value are collected and subjected to innocent treatment; and performing manual sorting, wherein materials with recycling value are directly sold. When the method is used for refuse treatment, the construction investment is small, the operation cost is low, the operation is simple, the treatment effect is desirable, and the resource recycling degree is high. The method can be widely used for treatment of refuse of different sizes and qualities without causing secondary pollution.

Owner:中山市祥源环保工程有限公司

Real-time digital x-ray imaging apparatus

InactiveUS20060126780A1Exact reproductionBetter optimizedMaterial analysis using wave/particle radiationRadiation/particle handlingAcquisition rateElectron

An x-ray diagnostic apparatus and methods performs Real-Time Digital Radiography with particular application in dental x-ray imaging modalities, such as Orthopantomography, Scannography, Linear Tomography and Cephalography, by using a versatile and modular electronic unit, featuring ultra fast computation capability to serve diversified image sensor typology and scanning modality. In Digital Orthopantomography and Scannography, a plurality of tomographic images at different depths of the jaw can be generated, based on the pre-selection made by the user interface. The image processing unit utilizes for the tomo-synthesis of the diagnostic image an accurate and economic digital simulator of the radiographic film speed, including a digital frequency synthesizer fed with film cassette speed digital input and high resolution clock signal, ensuring accurate and reproducible phase continuity of the output frequency signal. It also introduces an automatic adaptation of the frame acquisition rate in frame transfer mode, based on the actual speed of the cassette unit. By this method the dynamic of the exposure signal is reduced, and a better optimization of the signal response of the x-ray detector is achieved.

Owner:GENDEX

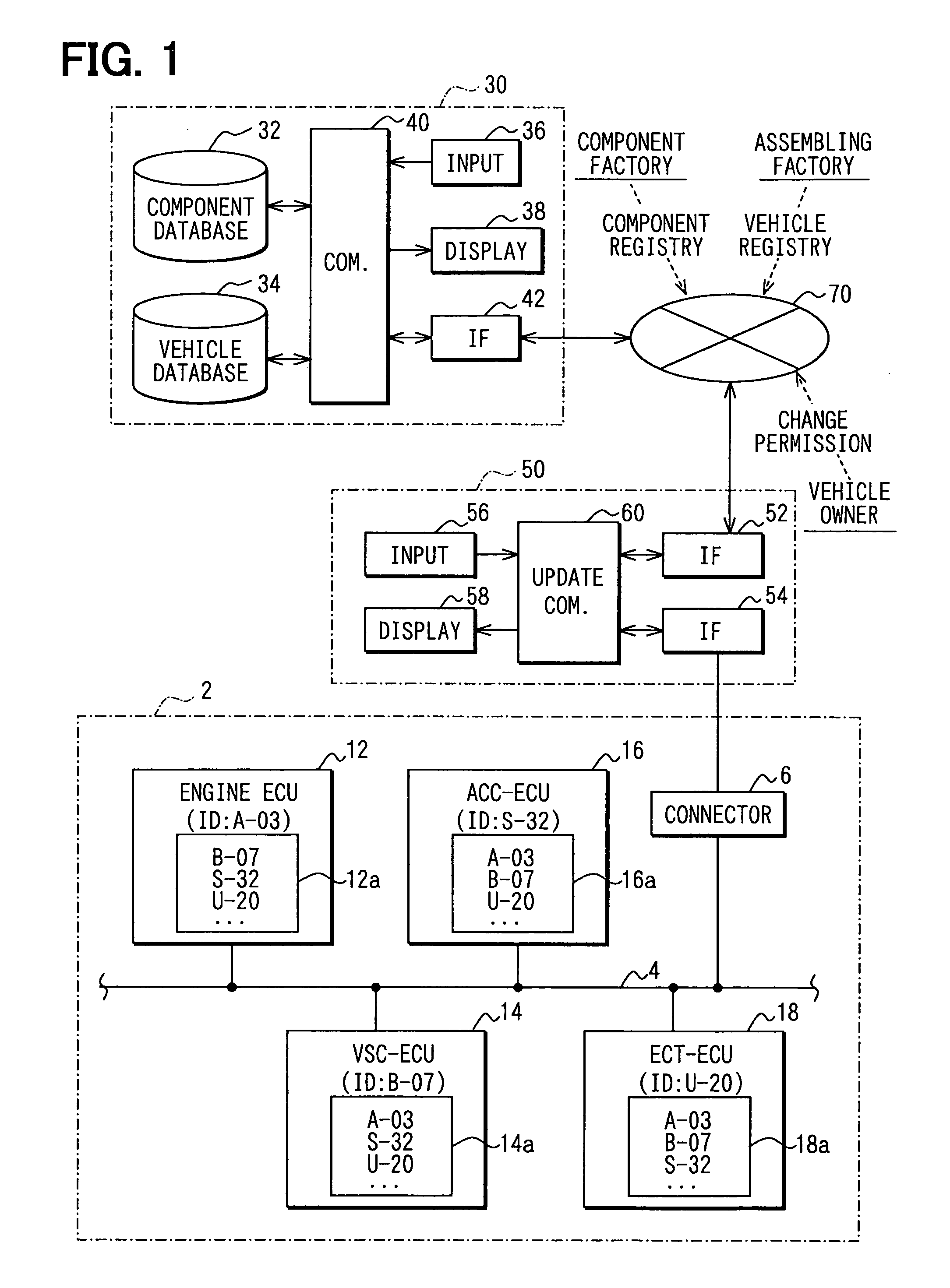

System for vehicle component management, system for vehicle component management data update, and vehicle component management center

InactiveUS20070005197A1Reduce the power requiredReduce incidenceData processing applicationsDigital data processing detailsEngineeringAuthentication

Each of ECUs constituting a system of a vehicle is registered with authentication IDs of other ECUs. The each of ECUs determines whether the other ECUs are regular by comparing the registered IDs with authentication IDs newly obtained from the other ECUs when the system is started. When a certain ECU within the other ECUs is determined to be not regular, the certain ECU is prohibited from being used in this system. Further, when a new ECU is substituted or added, a terminal confirms whether the new ECU is unused in another vehicle and is thereby enabled to be usable by transmitting an authentication ID of the new ECU to a management center. When the new ECU is confirmed to be enabled to be usable, authentication IDs registered in the respective ECUs are updated.

Owner:DENSO CORP

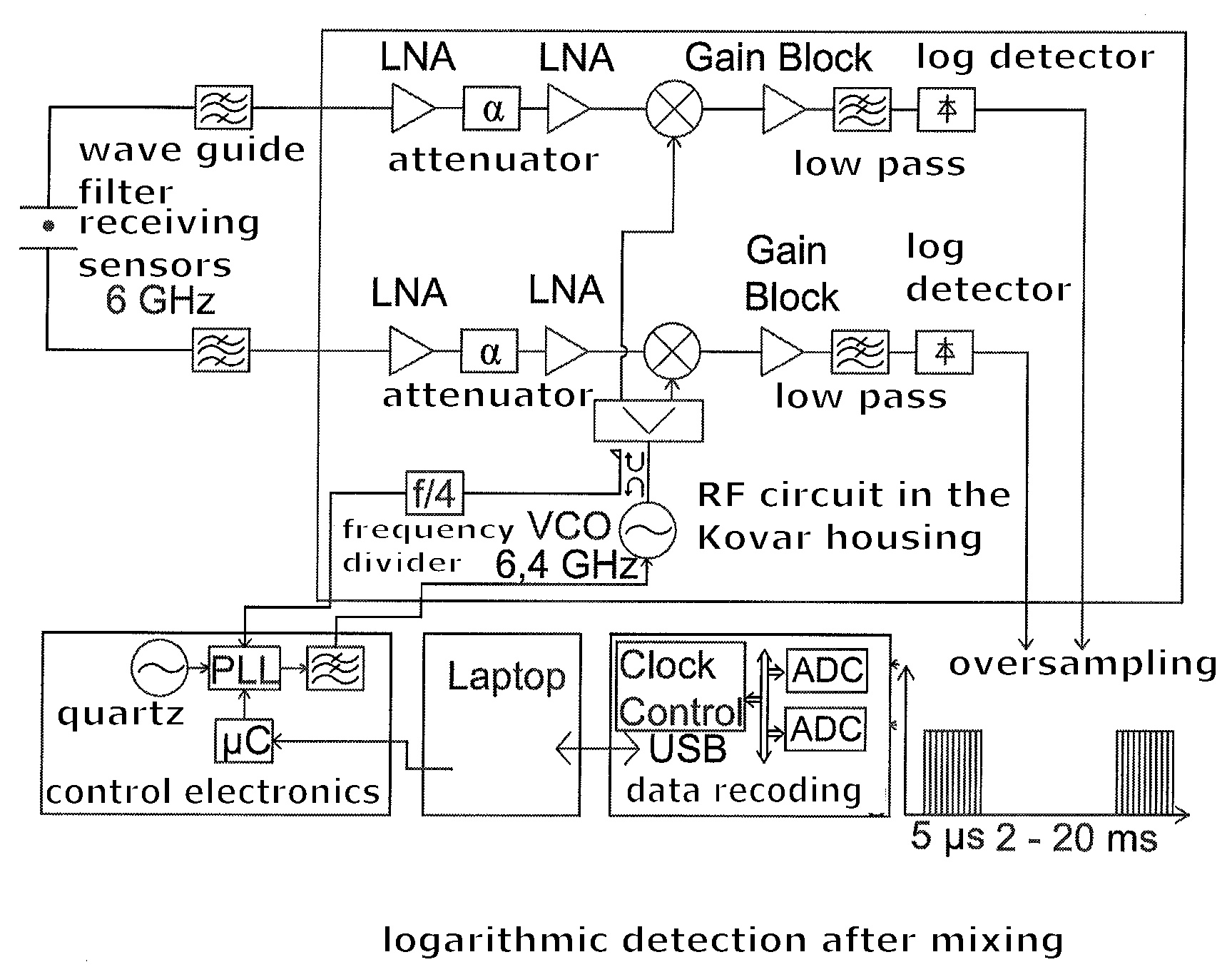

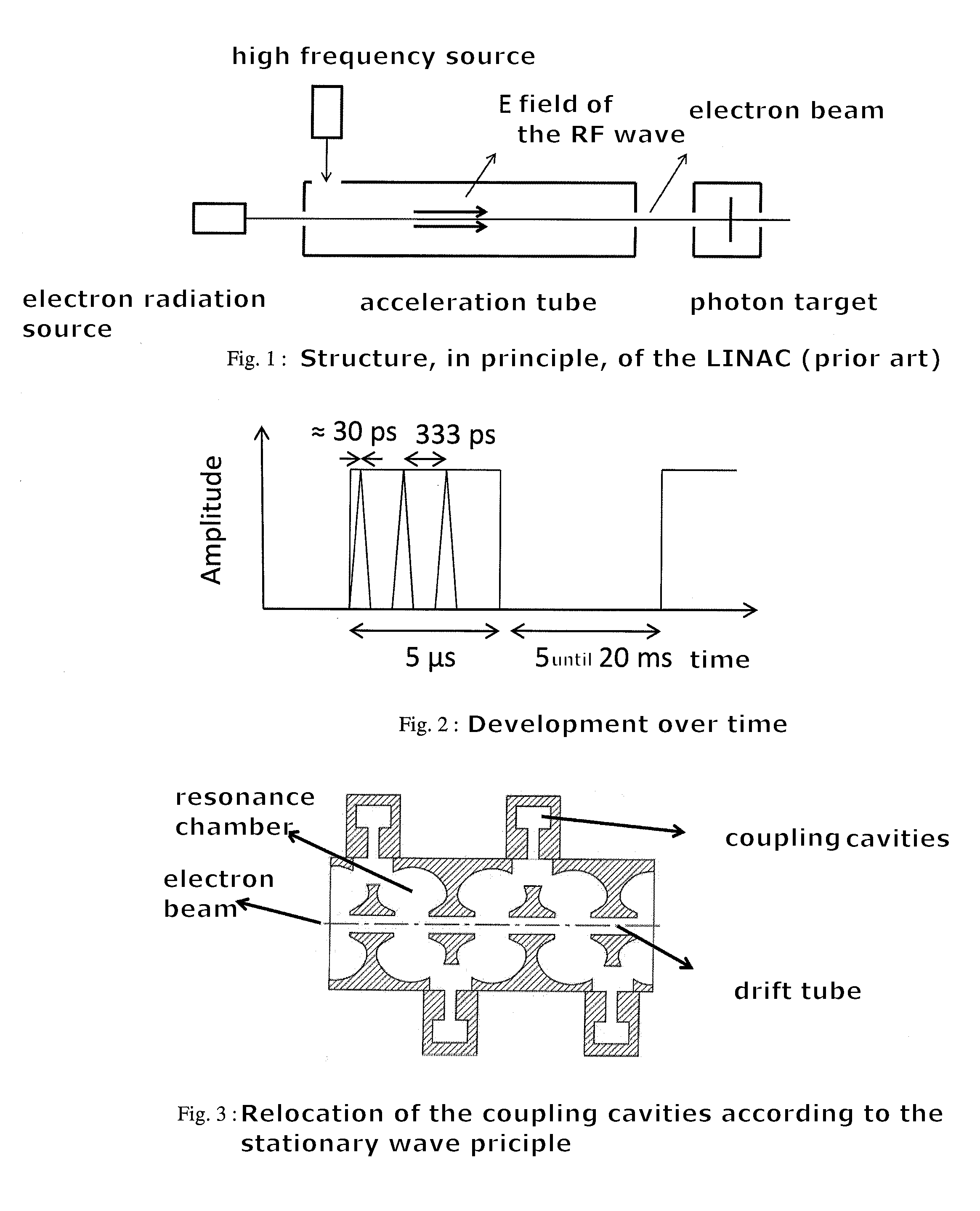

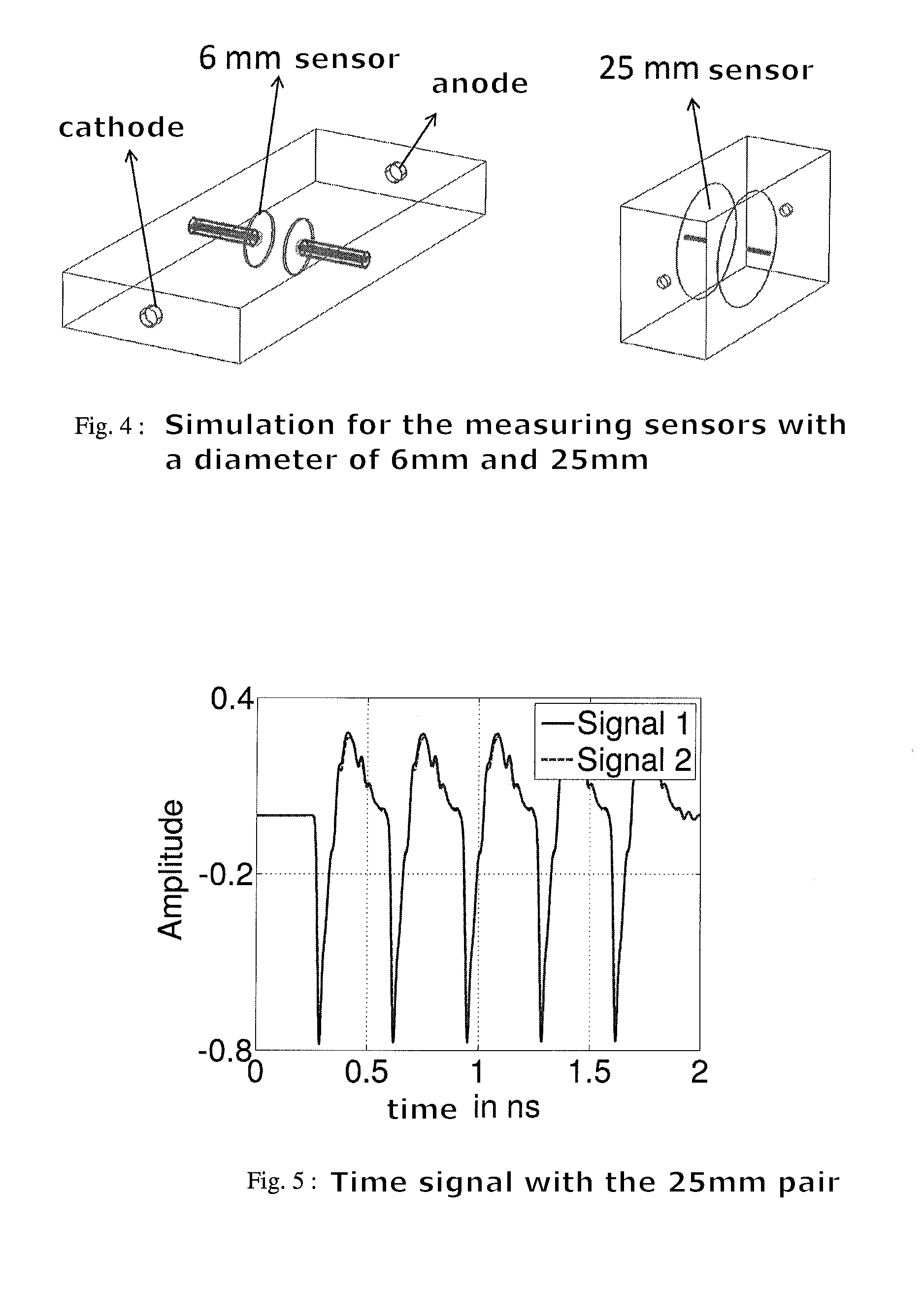

Beam position monitor for electron linear accelerator

ActiveUS20120262333A1Low hardware complexityHigh frequency selectivityAcceleratorsRadio wave reradiation/reflectionFrequency mixerDrift tube

Owner:CRUISE MUNICH GMBH

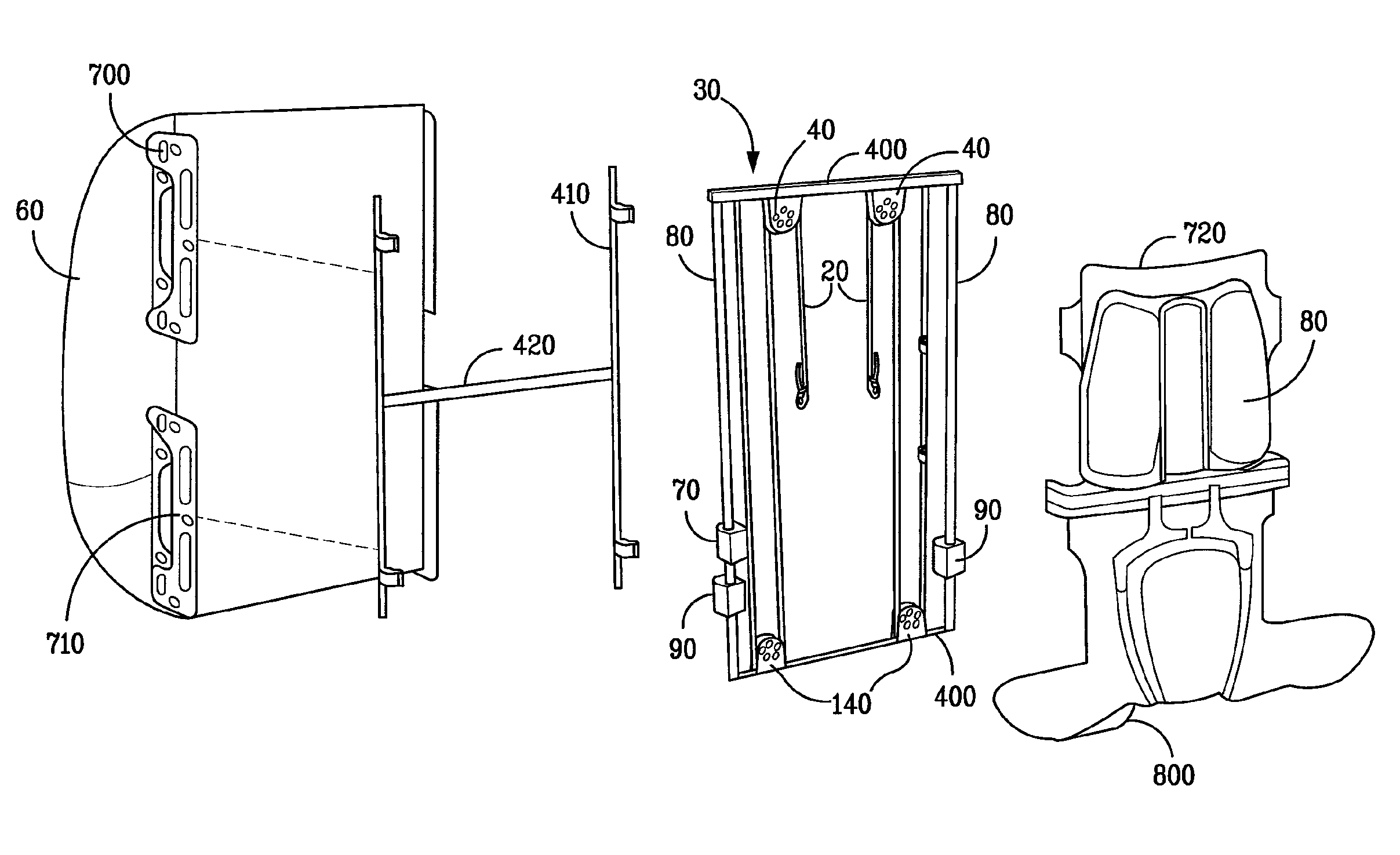

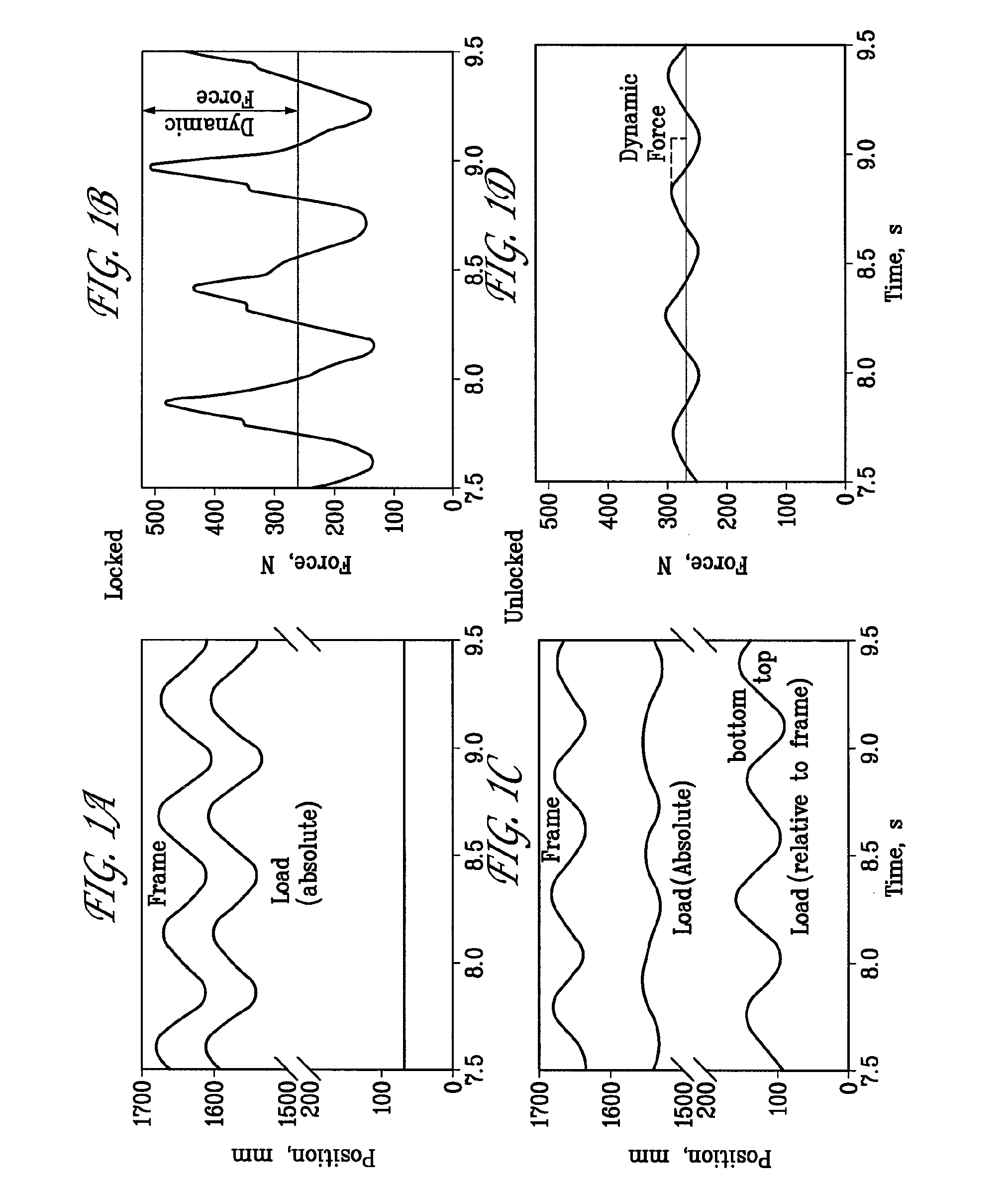

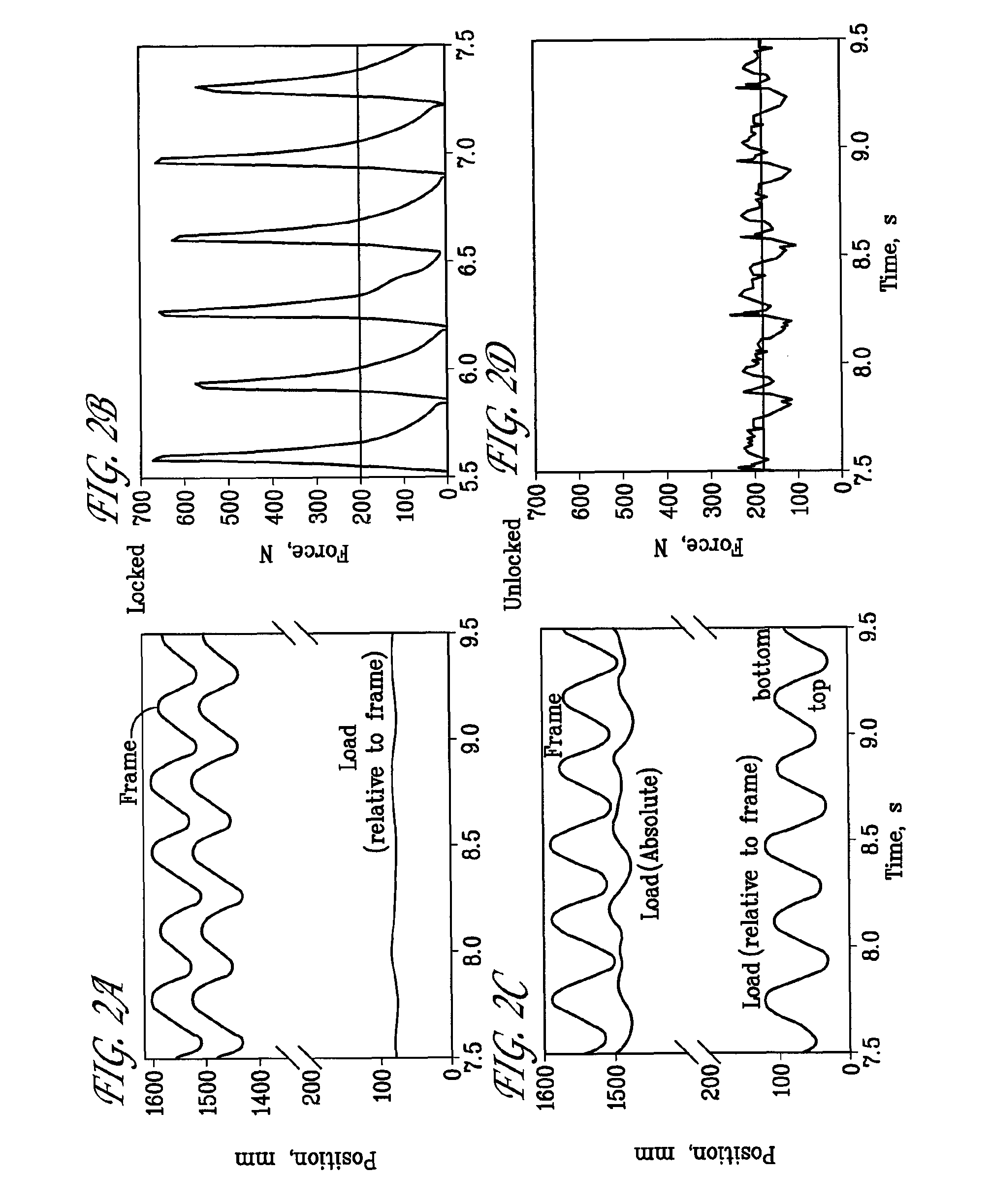

Suspended load ergonomic backpack

ActiveUS7931178B2Reduce the power requiredReduce rateTravelling sacksFrom muscle energyCompliant mechanismGear wheel

A suspended-load backpack designed to permit the load to move relative to the wearer during walking and running so that the large movements between the load and the wearer of the backpack reduce the fluctuations of vertical motion of the load with respect to ground. Because the hip (and thus the pack body) goes up a down a good deal during walking, a large relative movement between the wearer and the load reduces the absolute excursion of the load. This movement may be, in turn, transferred to a motor through, for example, a rack and pinion gear, to convert the mechanical movement to electrical or mechanical energy. Such movement of the suspended-load relative to the wearer also reduces the forces on the wearer's body while walking or running, thus reducing the likelihood of orthopedic injury. The suspended-load backpack includes a suspension system having a first portion connected to shoulder straps directly or through an interface and a second portion connected to the pack body and a compliant mechanism that permits the second portion of the suspension system and the pack body to move up and down relative to the first portion of the suspension system in accordance with a gait of the wearer of the backpack.

Owner:LIGHTNING PACKS

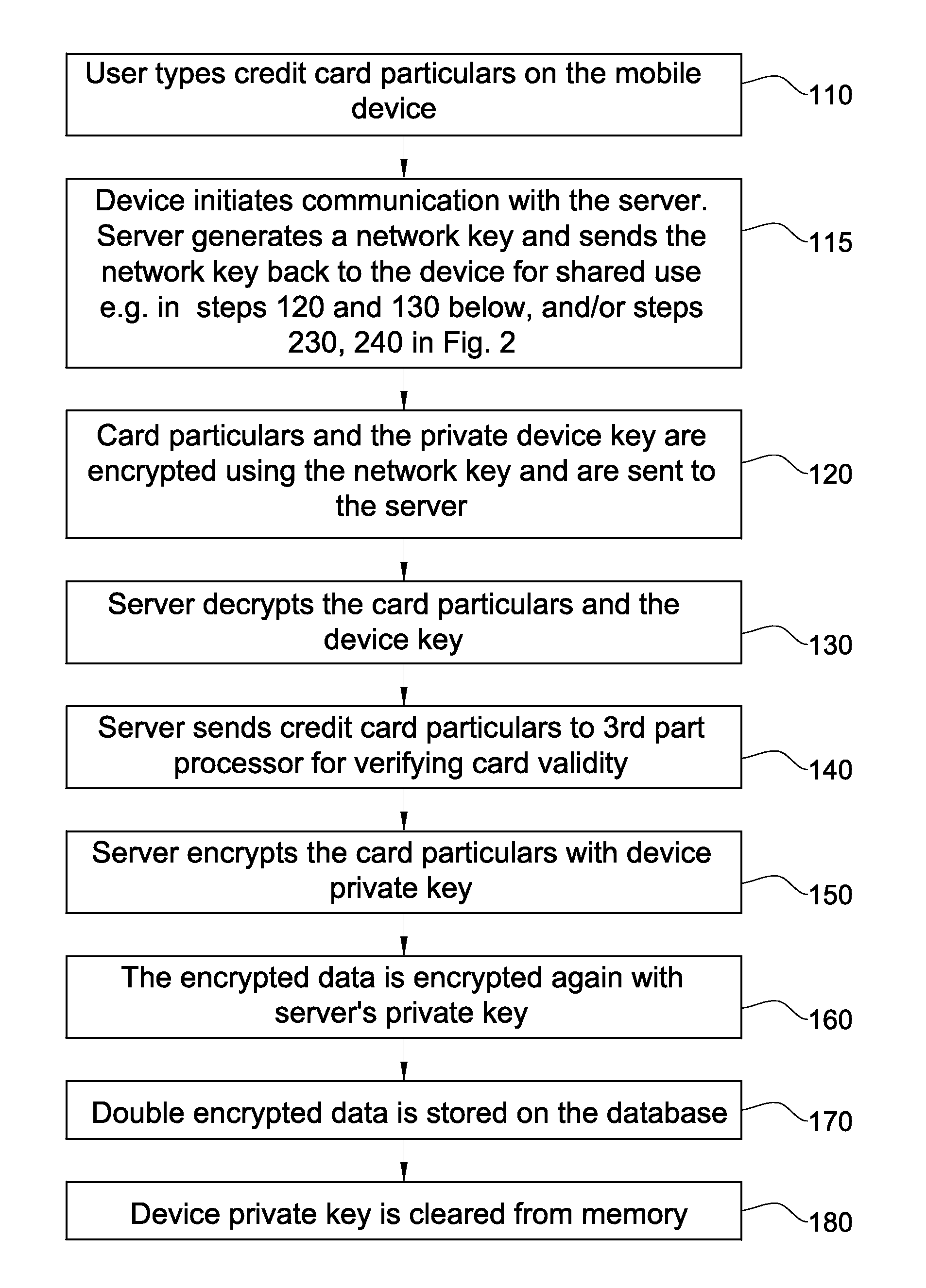

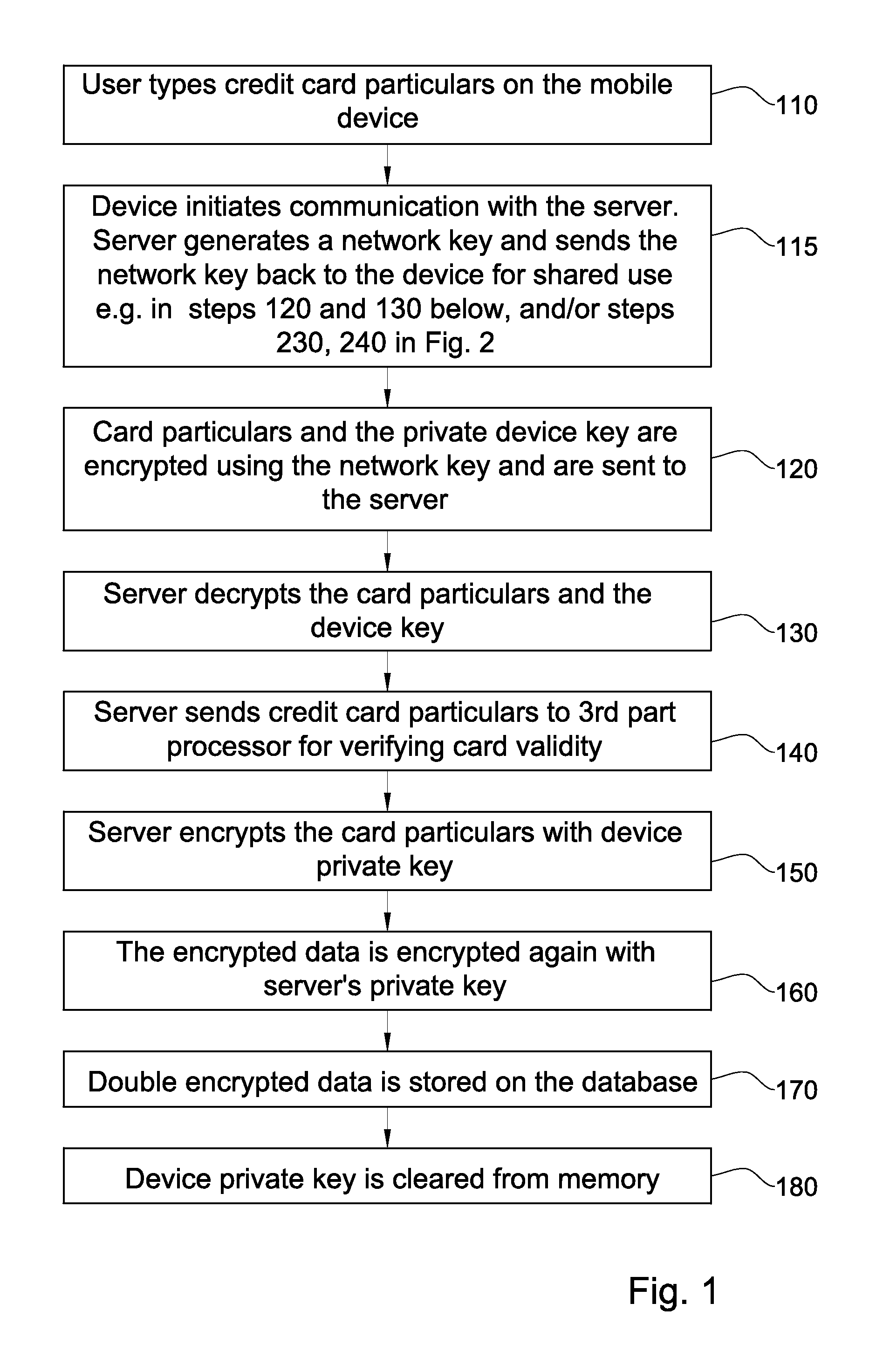

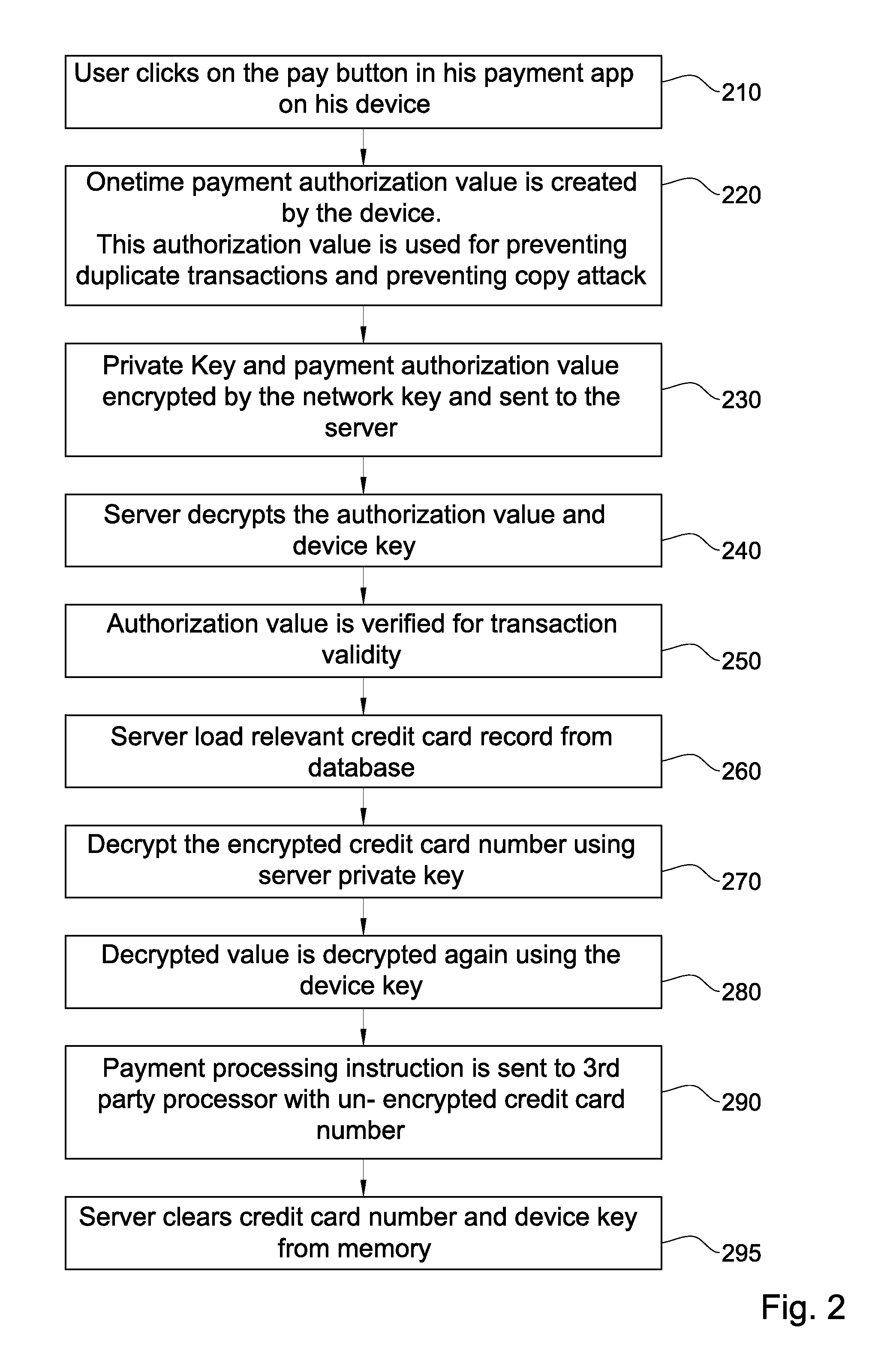

Hack-Deterring System for Storing Sensitive Data Records

ActiveUS20130268752A1Reduce the power requiredUser identity/authority verificationSecurity arrangementCentral databaseData recording

A mobile communication system comprising a multiplicity of mobile devices, and a server communicating with the mobile devices via a communication network, and a central database which is in data communication with the server and which is operative for storing sensitive data encrypted using at least one key, at least a portion of which is provided, only on certain occasions, by an individual one of the mobile devices and is not retained between the occasions by the central database.

Owner:ZOOZ MOBILE

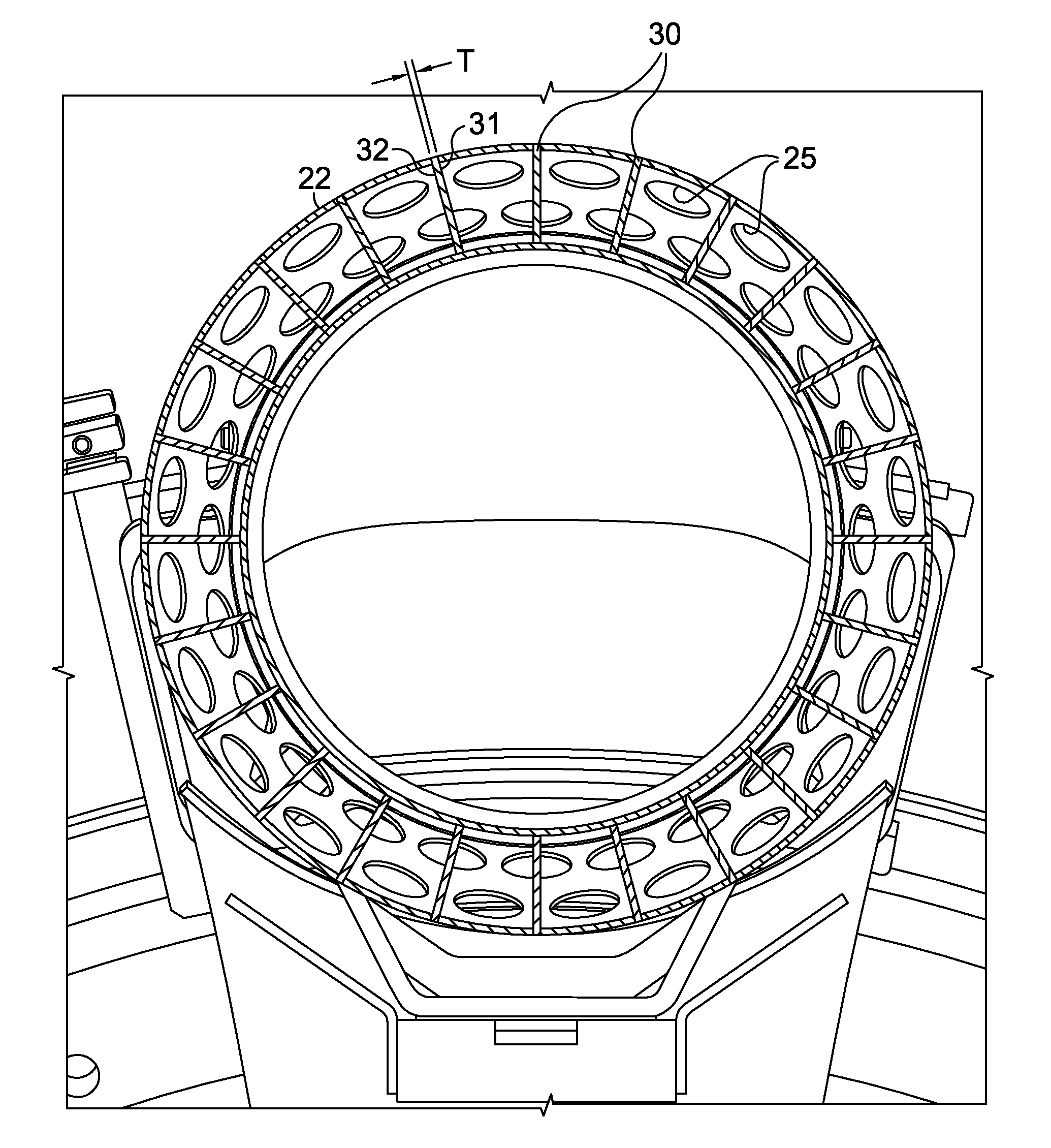

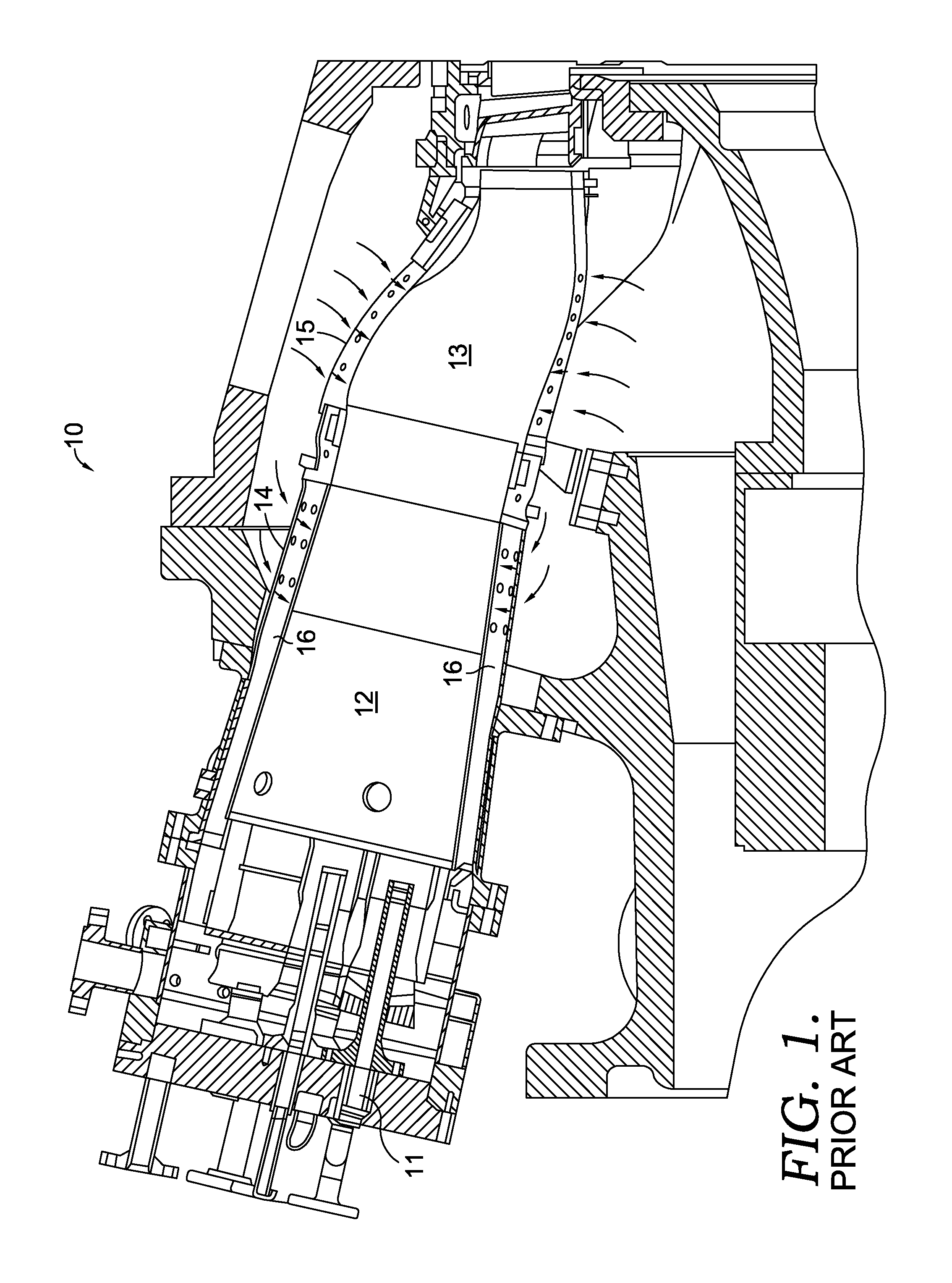

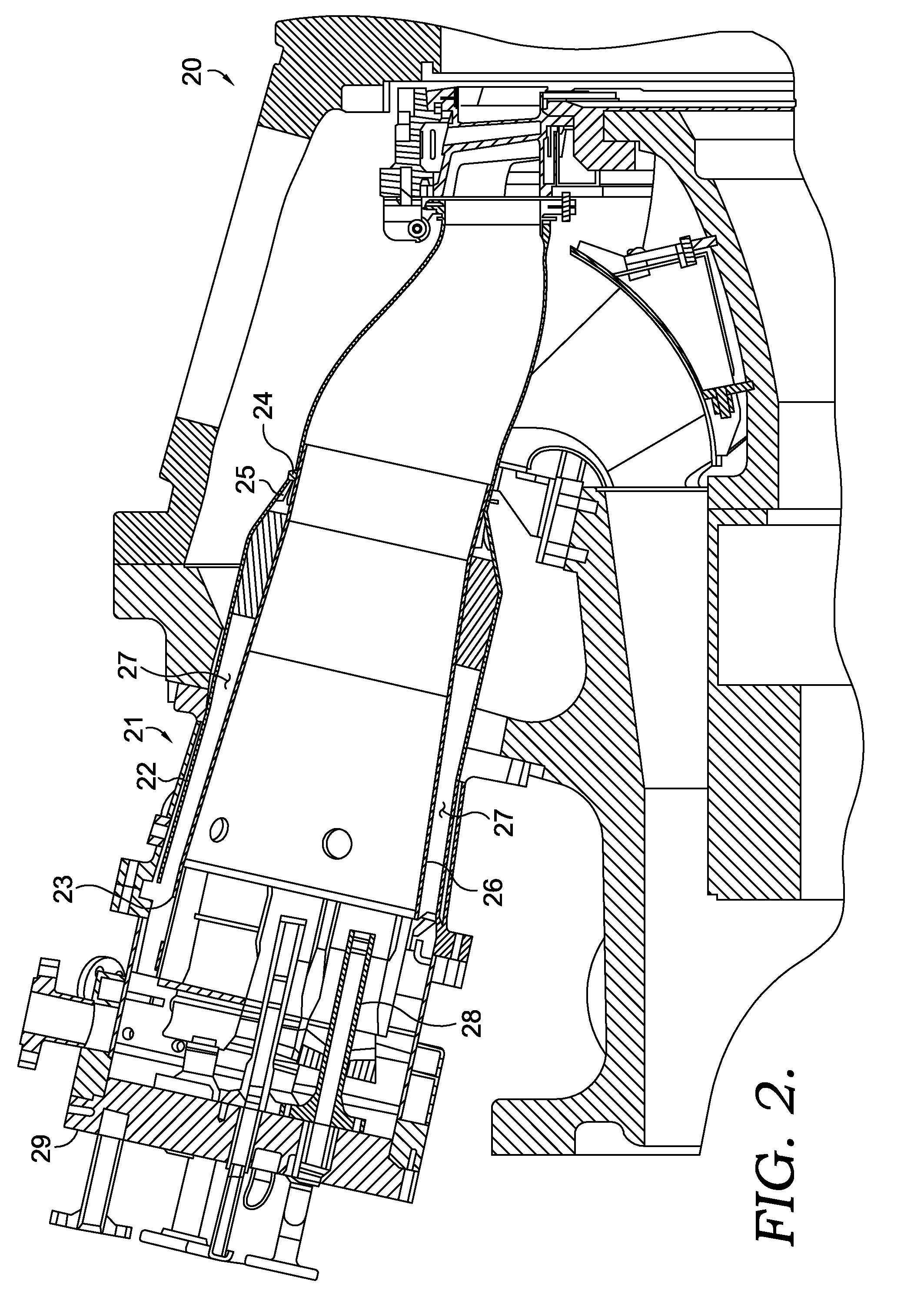

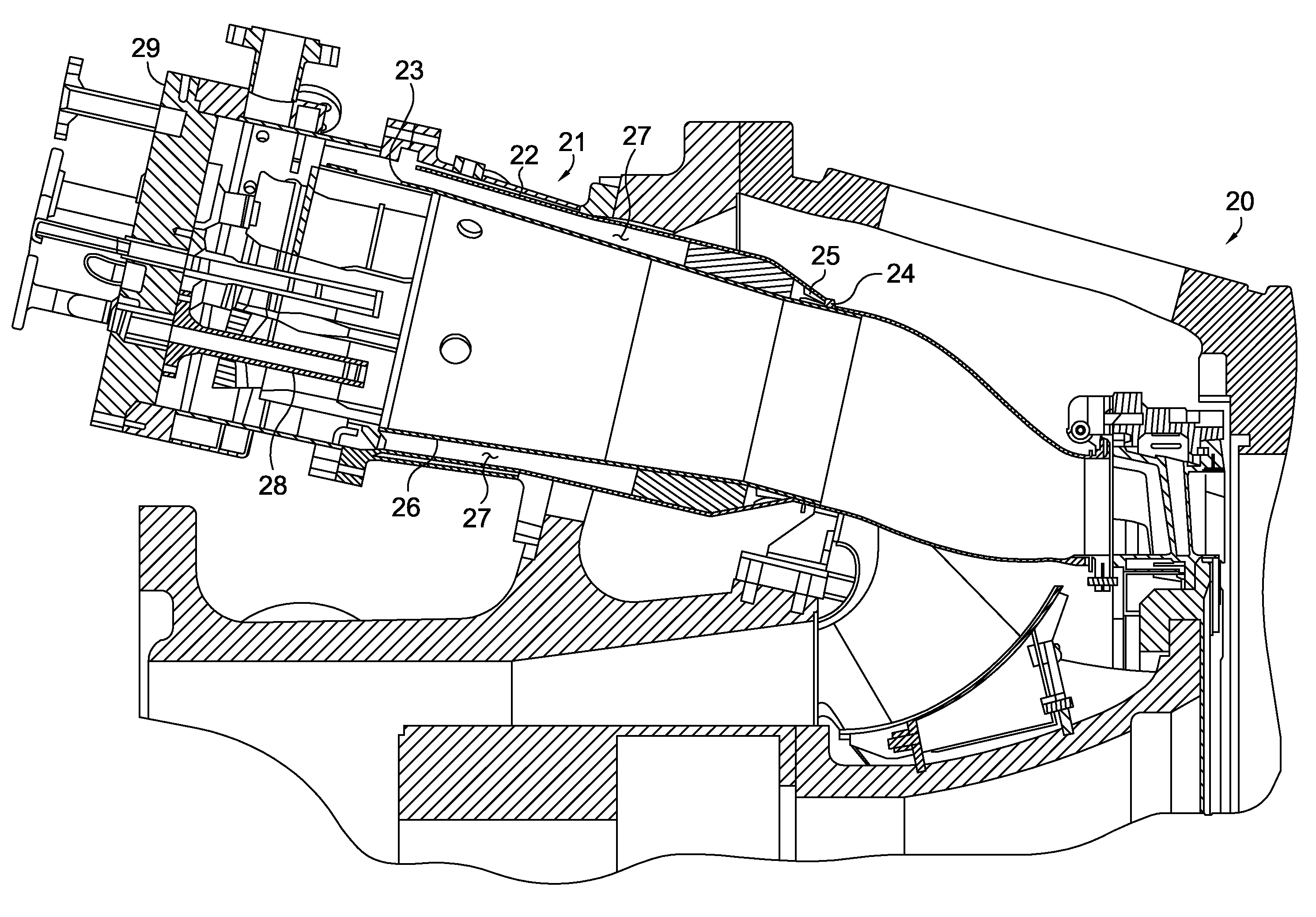

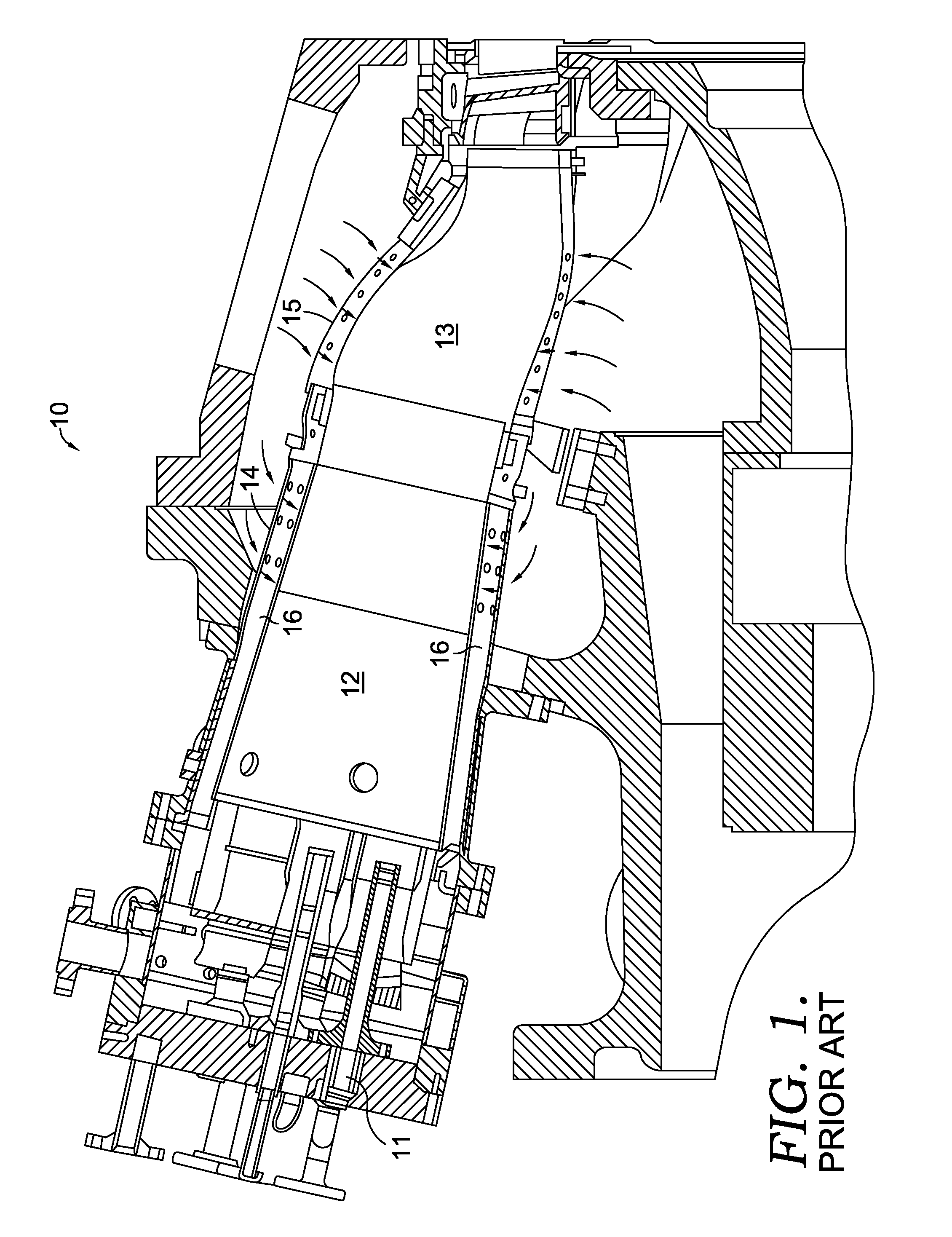

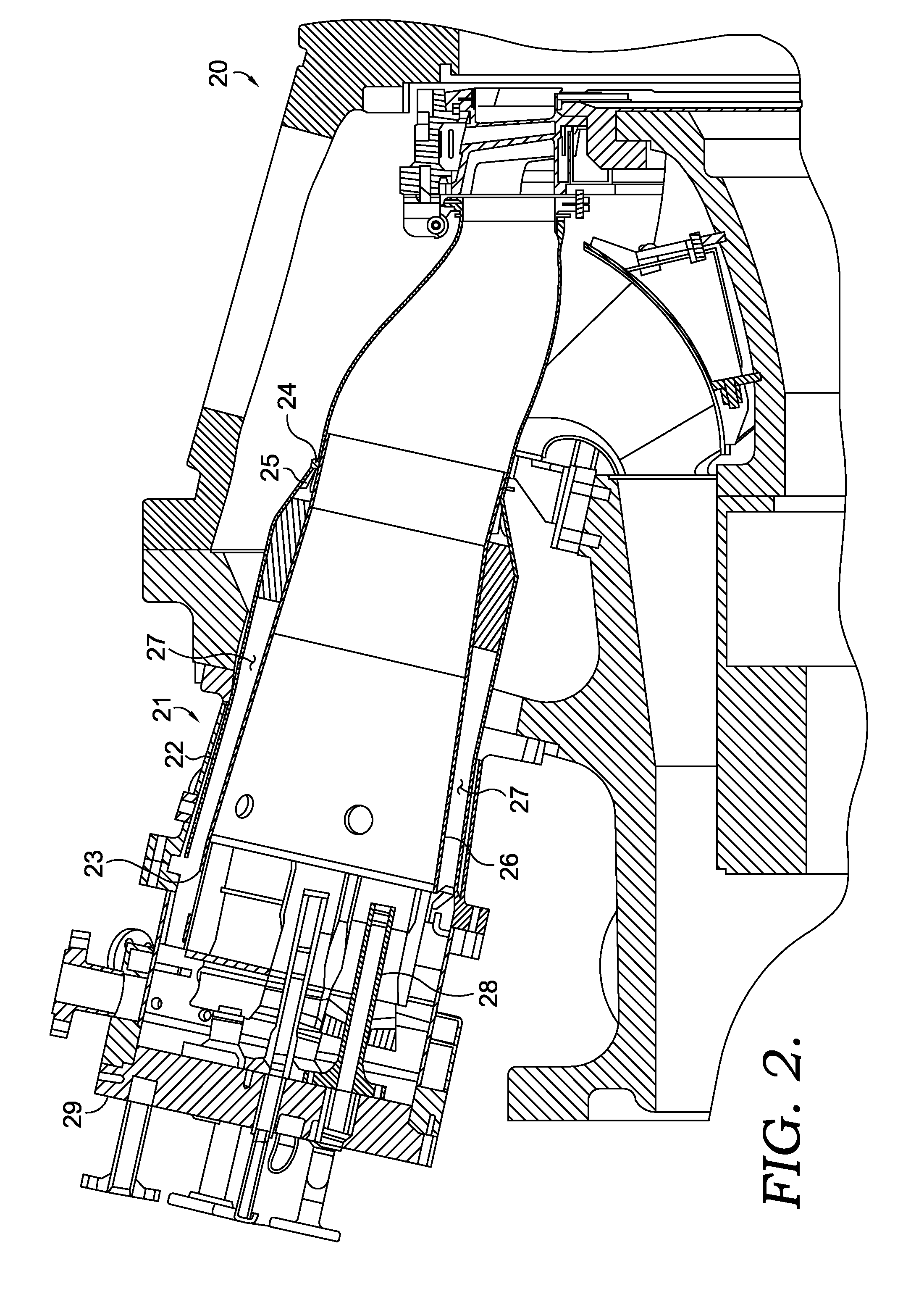

Airflow distribution to a low emissions combustor

ActiveUS20090139238A1Improve combustion stabilityLow NOxContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

An apparatus and method of providing a gas turbine combustor having increased combustion stability and reducing pressure drop across a gas turbine combustor is disclosed. A plurality of vanes is fixed to a flow sleeve radially between the flow sleeve and a combustion liner. The plurality of vanes serve to direct a flow of air entering the region between the flow sleeve and combustion liner in a substantially axial direction, such that components of tangential velocity are removed thereby providing a more uniform flow of air the combustion chamber and reducing the amount of pressure lost due attempting to straighten the airflow by pressure drop alone.

Owner:ANSALDO ENERGIA SWITZERLAND AG

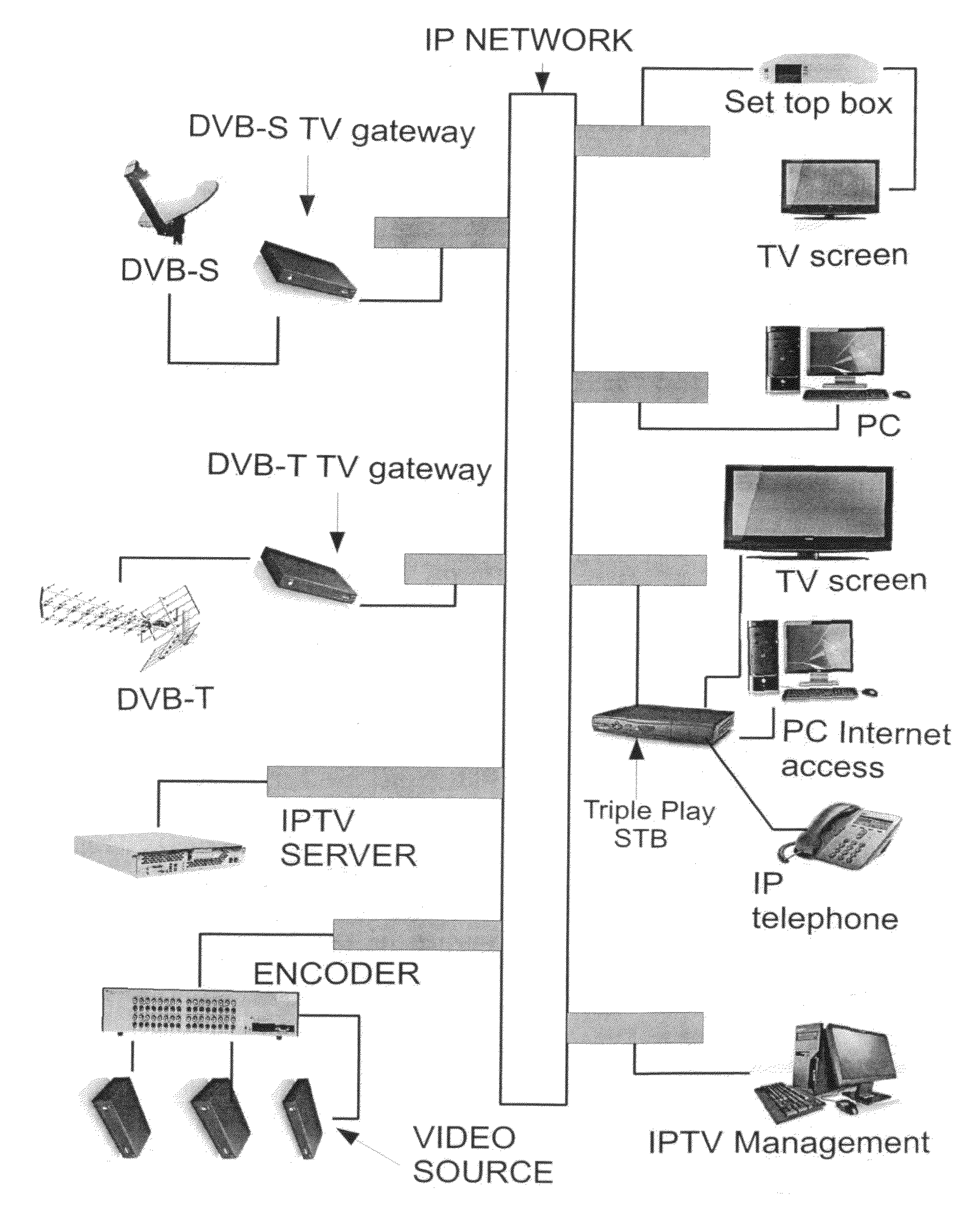

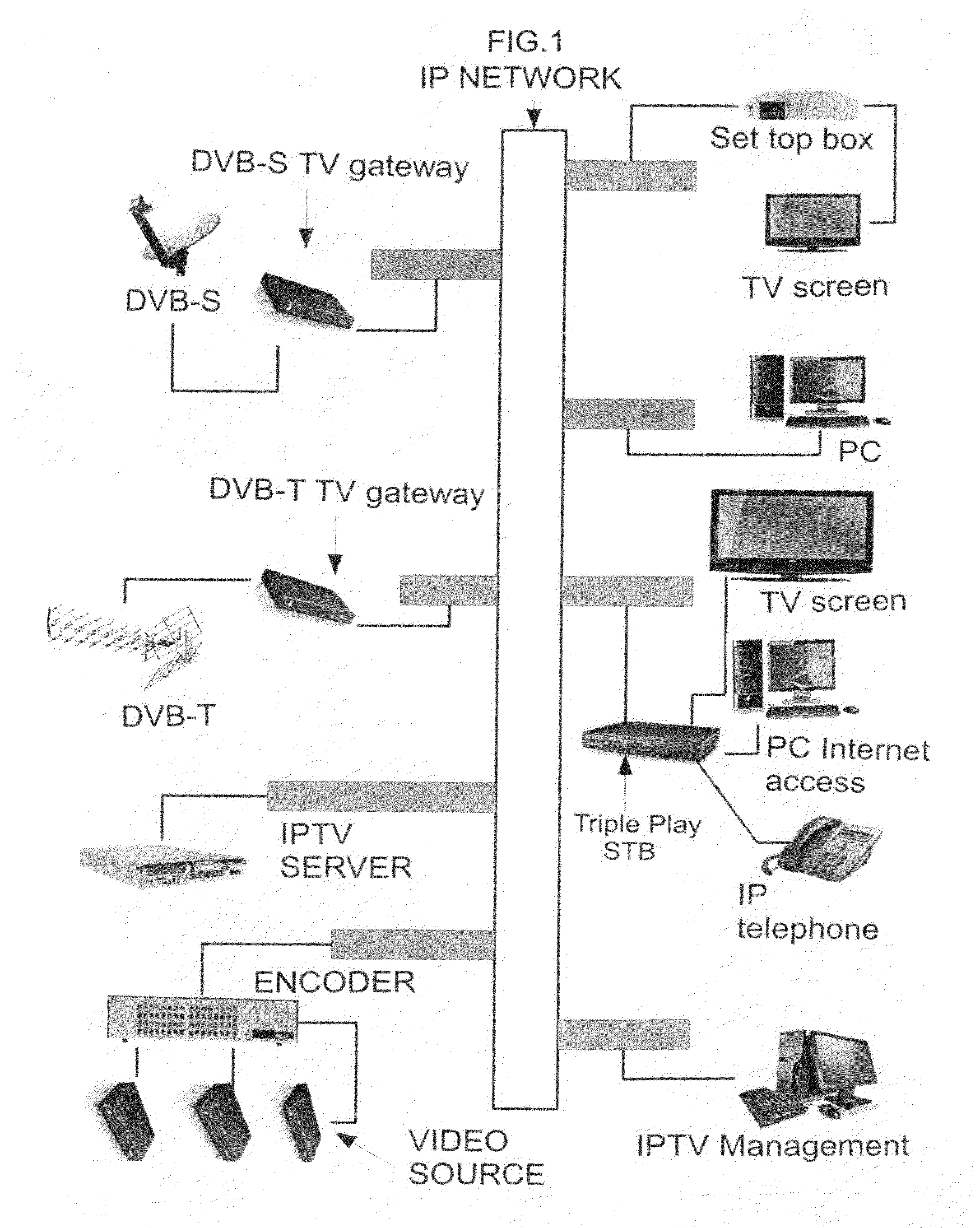

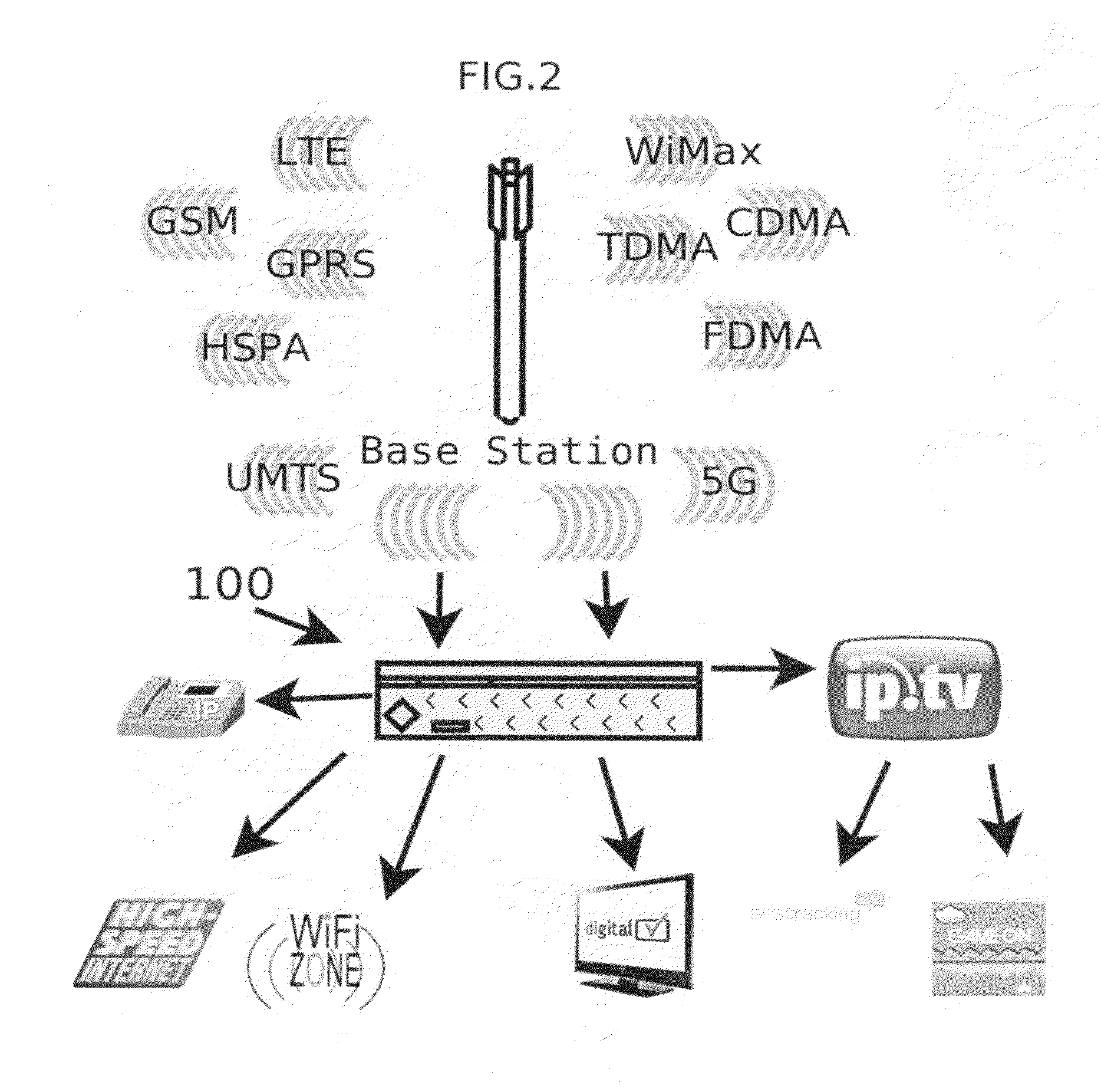

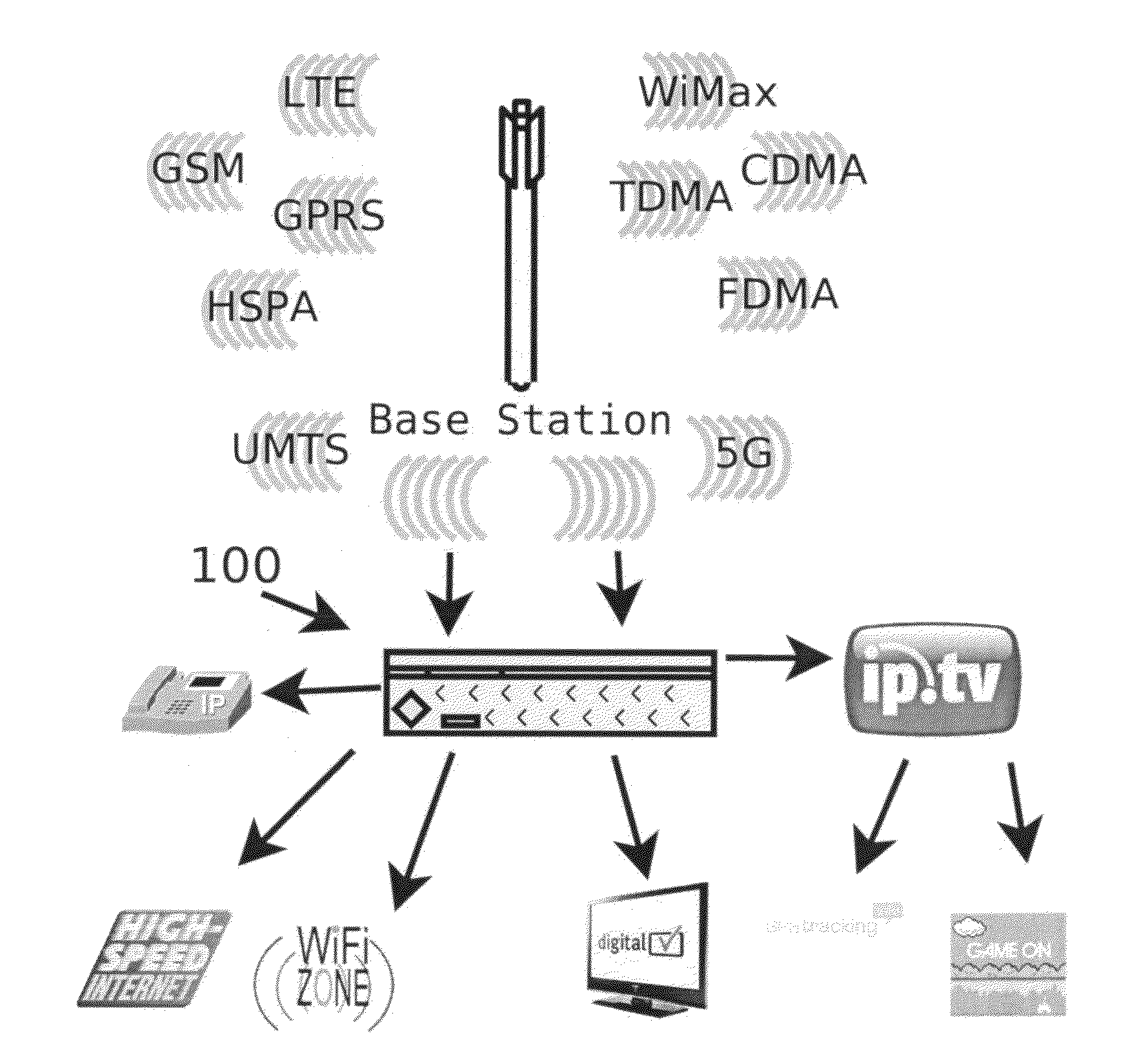

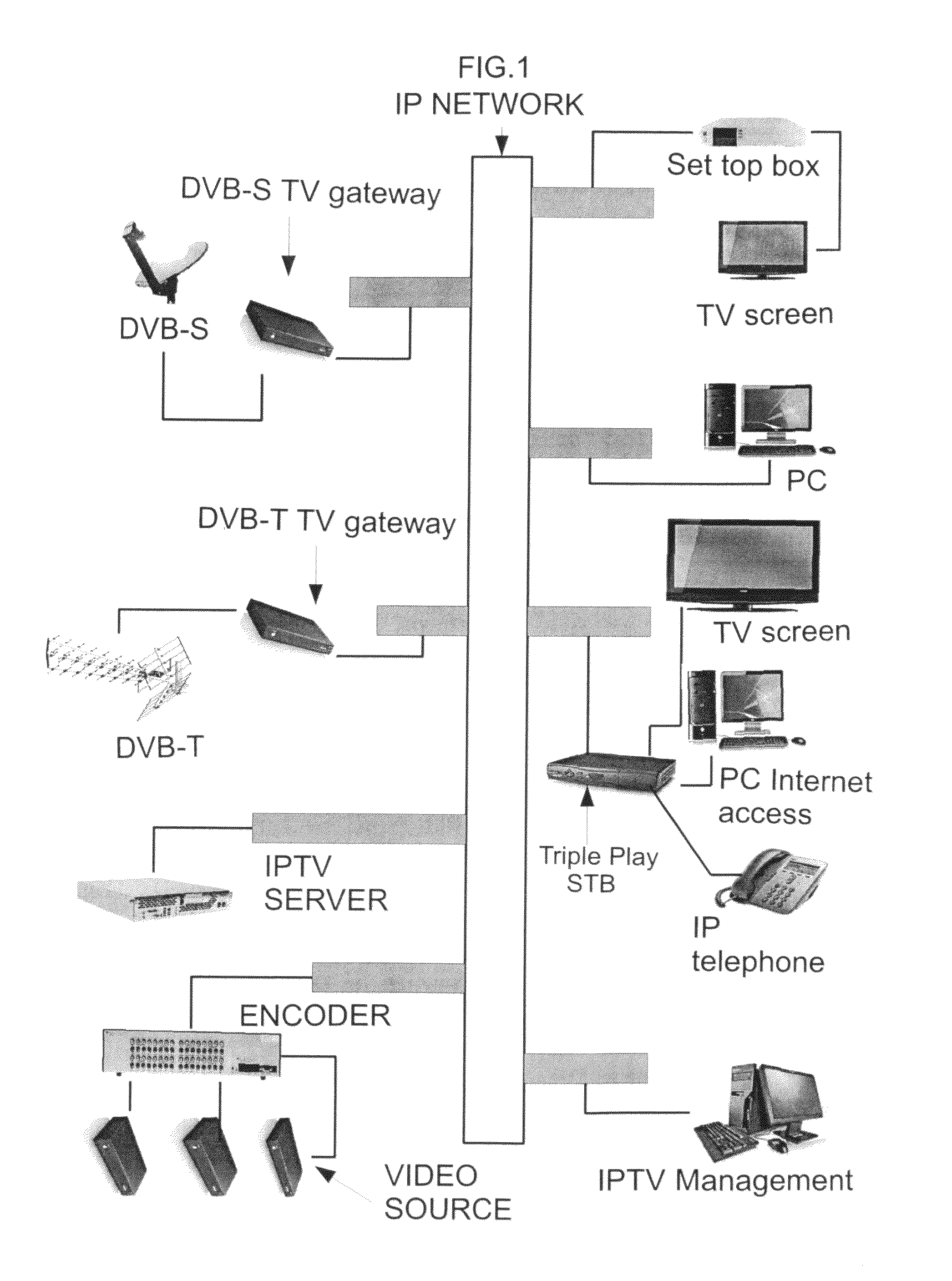

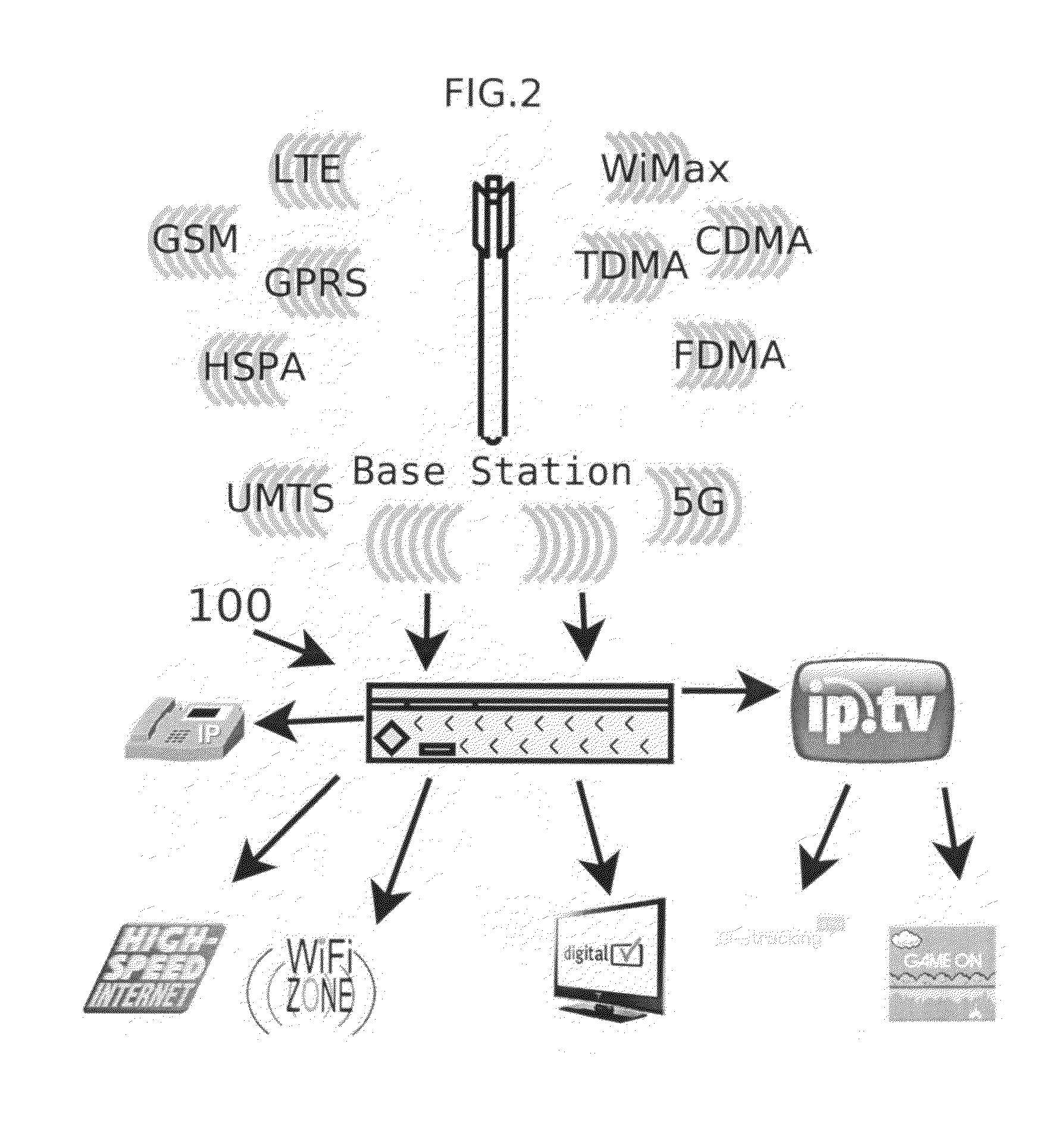

Advanced wireless IPTV set top box

InactiveUS20120304238A1Data being receivedReduce the power requiredTwo-way working systemsSelective content distributionRadio networksModem device

An advanced wireless IP STB is provided with multiple built-in antennas capable of capturing plural downstream transmissions simultaneously on dedicated receivers using different modem technologies without the use of wires to the home. The proposed solution facilitates the advanced wireless IP STB being able to receive multiply sourced data traffic, including, for example, IPTV, digital TV, web TV, radio web, internet chat: written, voice and video, GPS tracking locator signals, media player web support, web based video gaming, You Tube and the like video streaming, TV surveillance, video intercom surveillance, and much more. The advanced wireless IP STB is configured to be able to establish a broadband (internet) session through previously assigned or negotiated channel assignments between one or more modems and plural remote wireless infrastructures widely deployed in a municipality, such as WIMAX, LTE, WCDMA, CDMA 1×, TDSCMA, GSM, GPRS, EDGE, 5G or the like.

Owner:AMAZING SETTOPBOX HLDG LLC

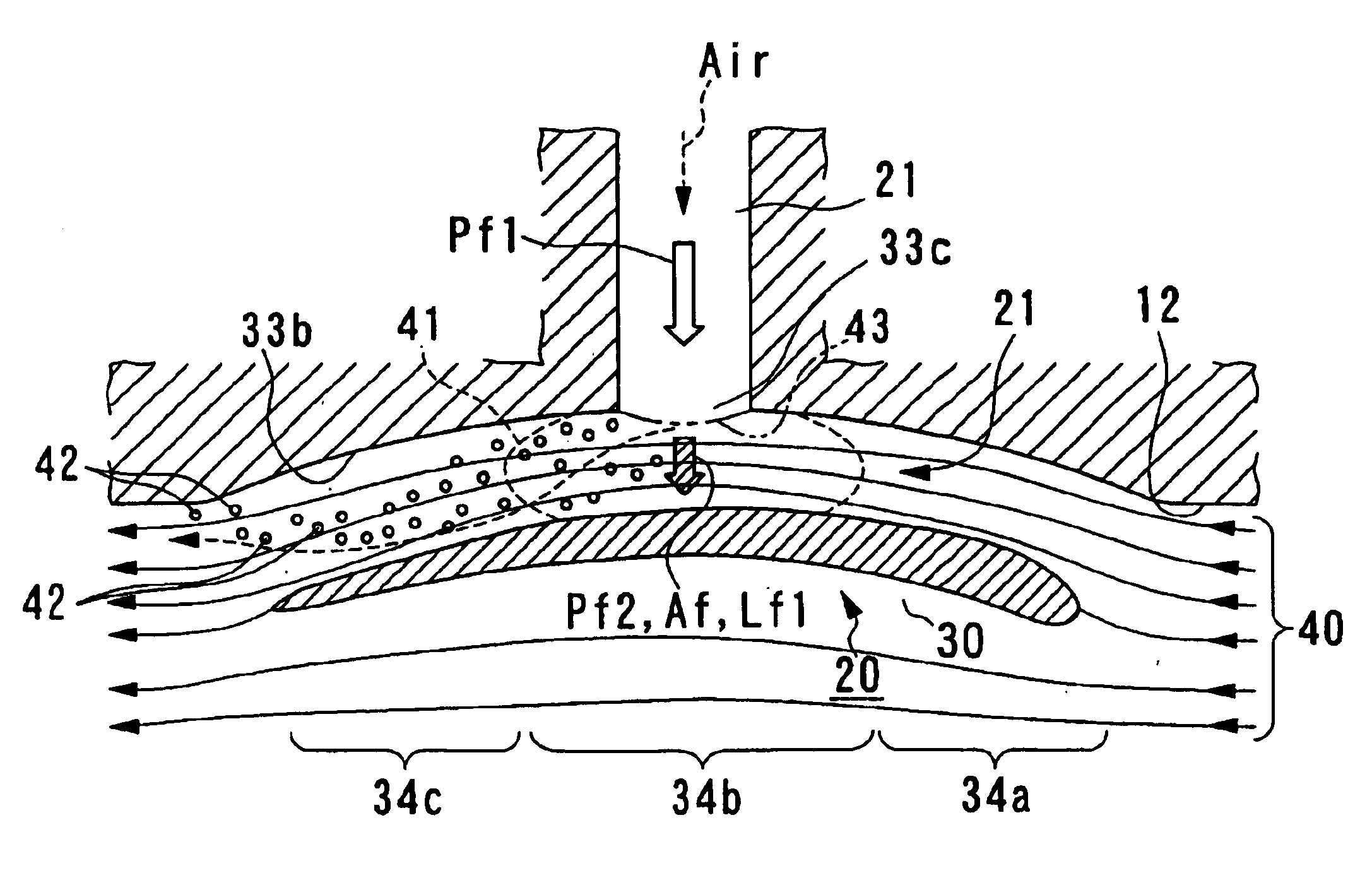

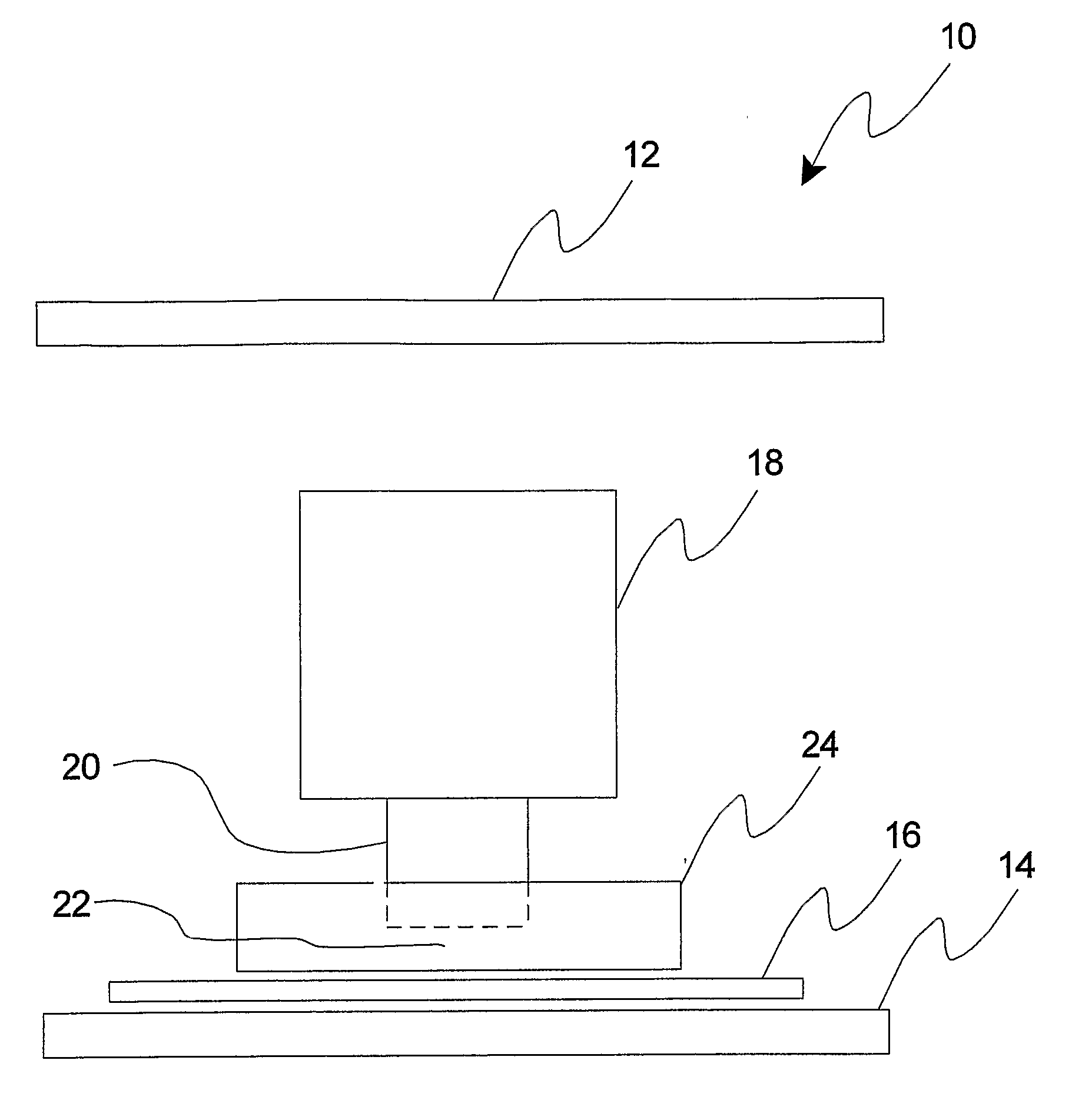

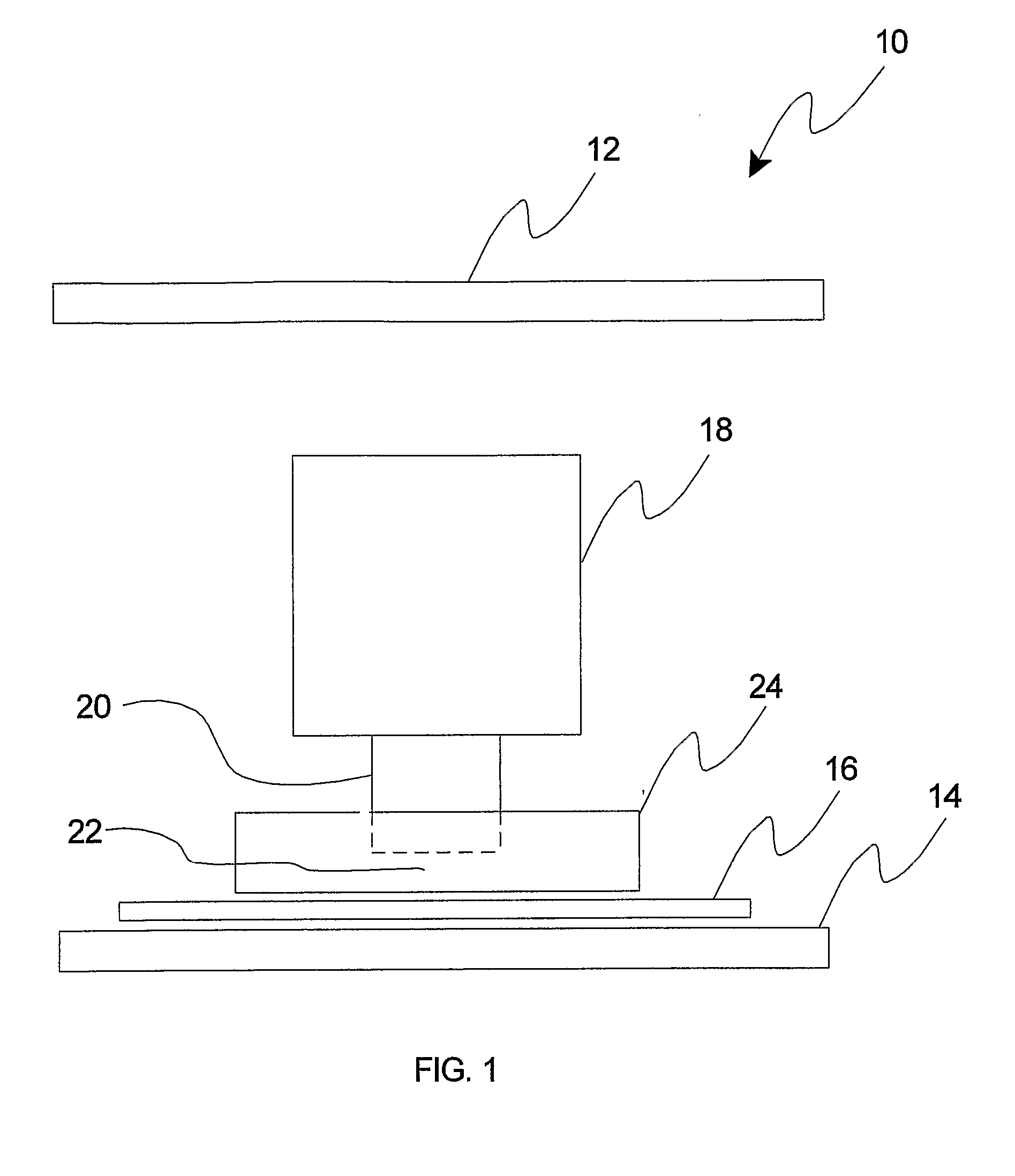

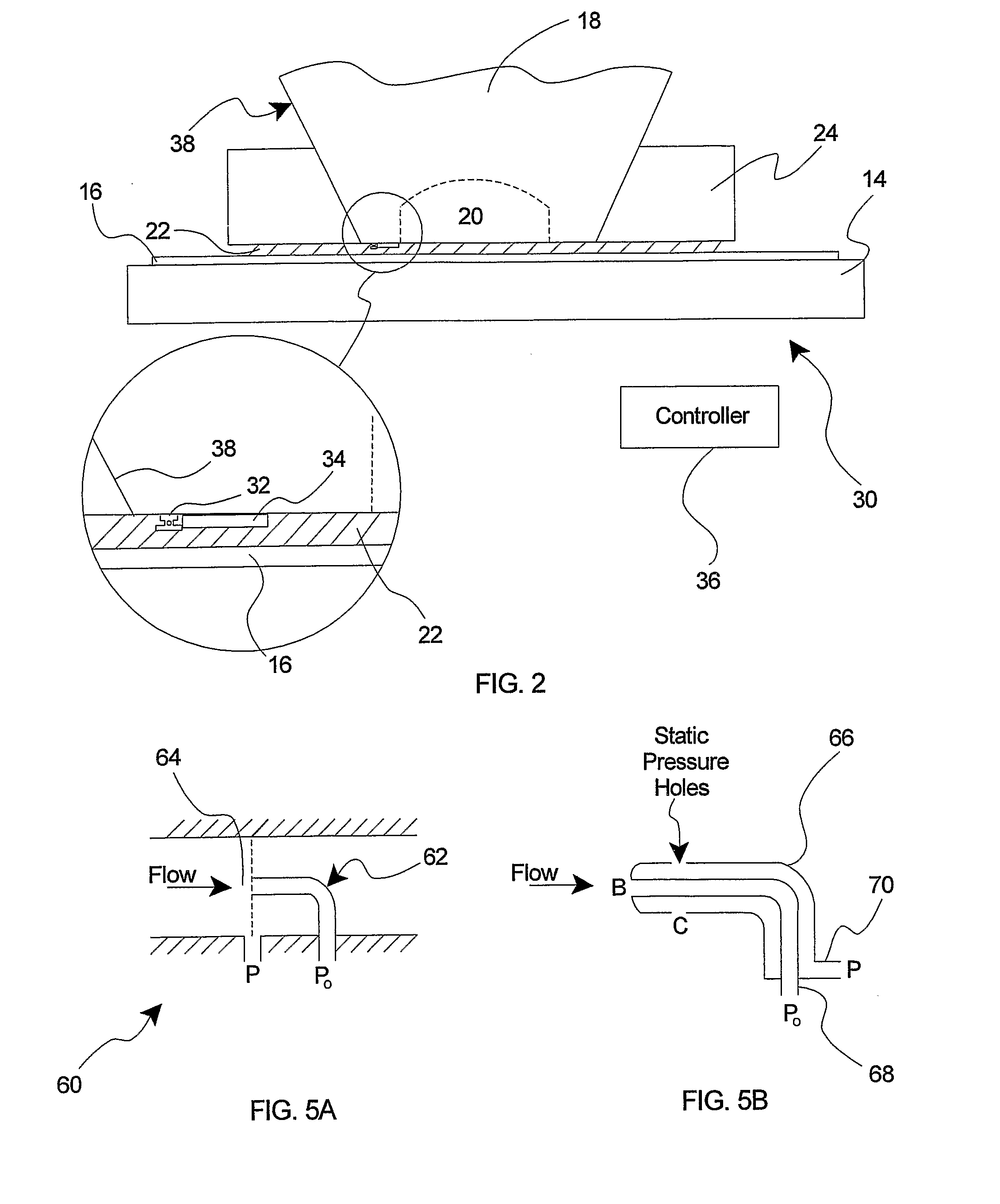

Dynamic fluid control system for immersion lithography

InactiveUS20070177118A1Reduce the power requiredVirus peptidesPhotomechanical apparatusFluid controlControl system

A dynamic fluid control system and method capable of reducing dynamic forces from the fluid on the last optical element (20) and substrate stage (14) caused by the motion of the immersion fluid. The system includes an imaging element (12) that defines an image and a stage (14) configured to support a substrate (16). An optical system (18) is provided to project the image defined by the imaging element onto the substrate. The optical system (18) includes a last optical element (20). A gap (22) filled with immersion fluid is provided between the substrate (16) and the last optical element (20). A dynamic force control system (34) is provided to maintain a substantially constant force on the last optical element and the stage (14) by compensating for dynamic changes of the immersion fluid caused by the motion of the immersion fluid through the gap and / or movement of the stage.

Owner:NIKON CORP

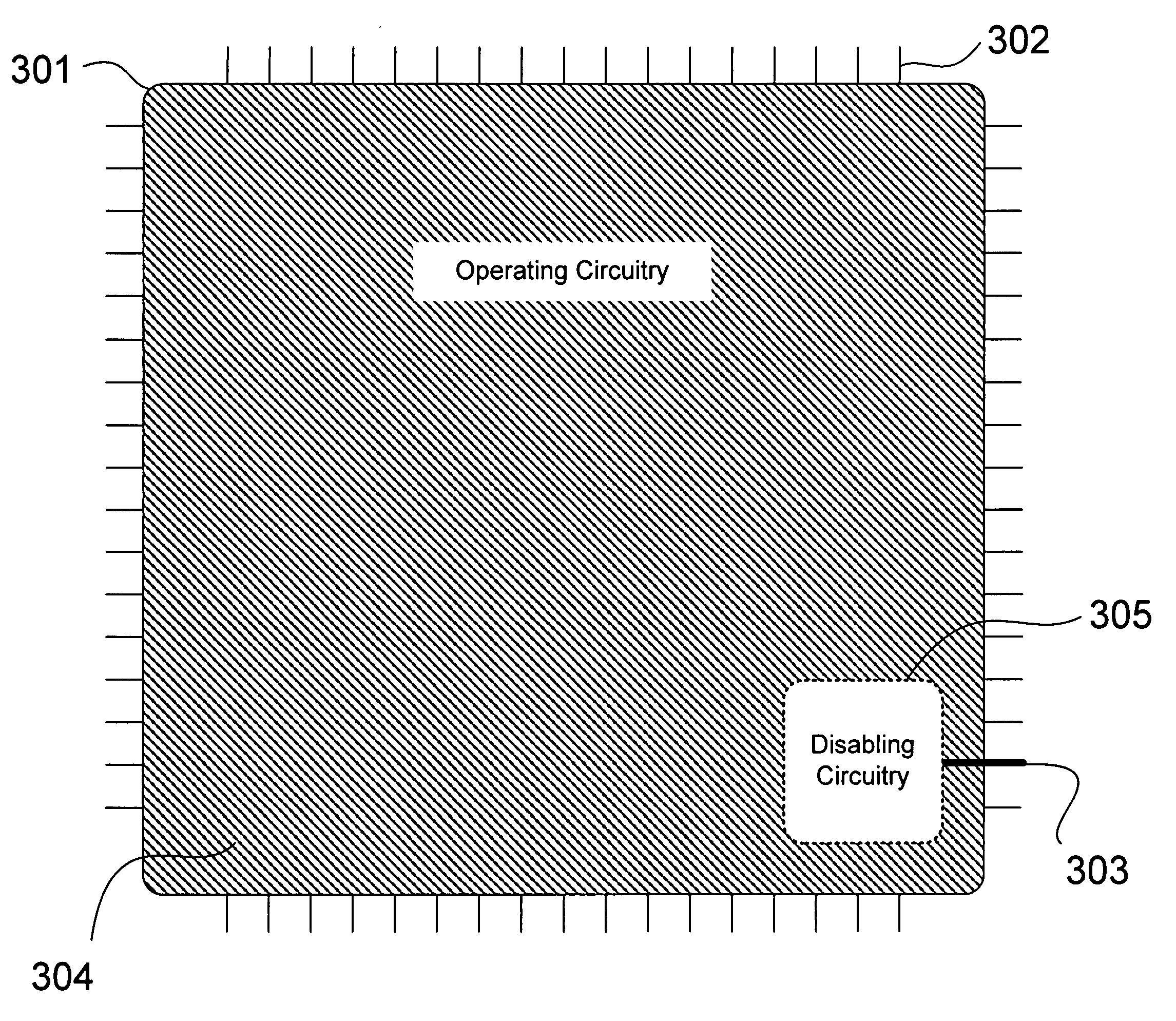

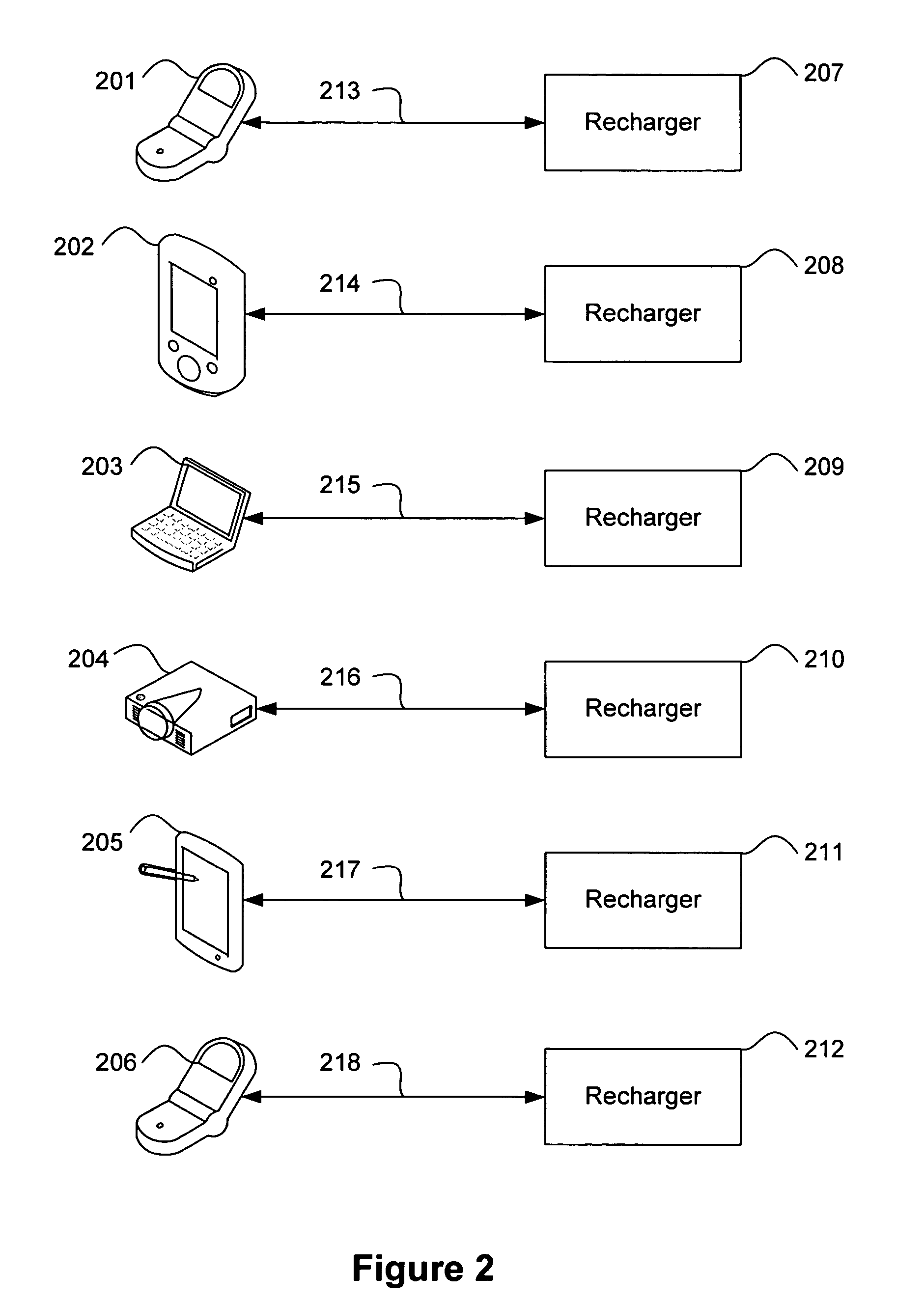

Deterring theft and unauthorized use of electronic devices

InactiveUS20060036781A1Reduce the power requiredReplacement is difficult and time-consumeUnauthorised/fraudulent call preventionEavesdropping prevention circuitsMemory controllerCell memory

A system and method are provided for reducing a potential thief's motivation to steal an electronic device, by rendering the device inoperative at some time after it is stolen. The mechanism used to deter theft may include a modified primary integrated circuit chip in the electronic device, such as the central processing unit (CPU), a memory controller chip, or a primary input / output (I / O) chip. The chip may be important enough to the normal operation of the electronic device such that without normal operation of the chip, the electronic device also would not operate normally, thus rendering the electronic device partially or fully disabled. A “recharger” device may be used to recharge, or reset the operability of the chip.

Owner:MICROSOFT TECH LICENSING LLC

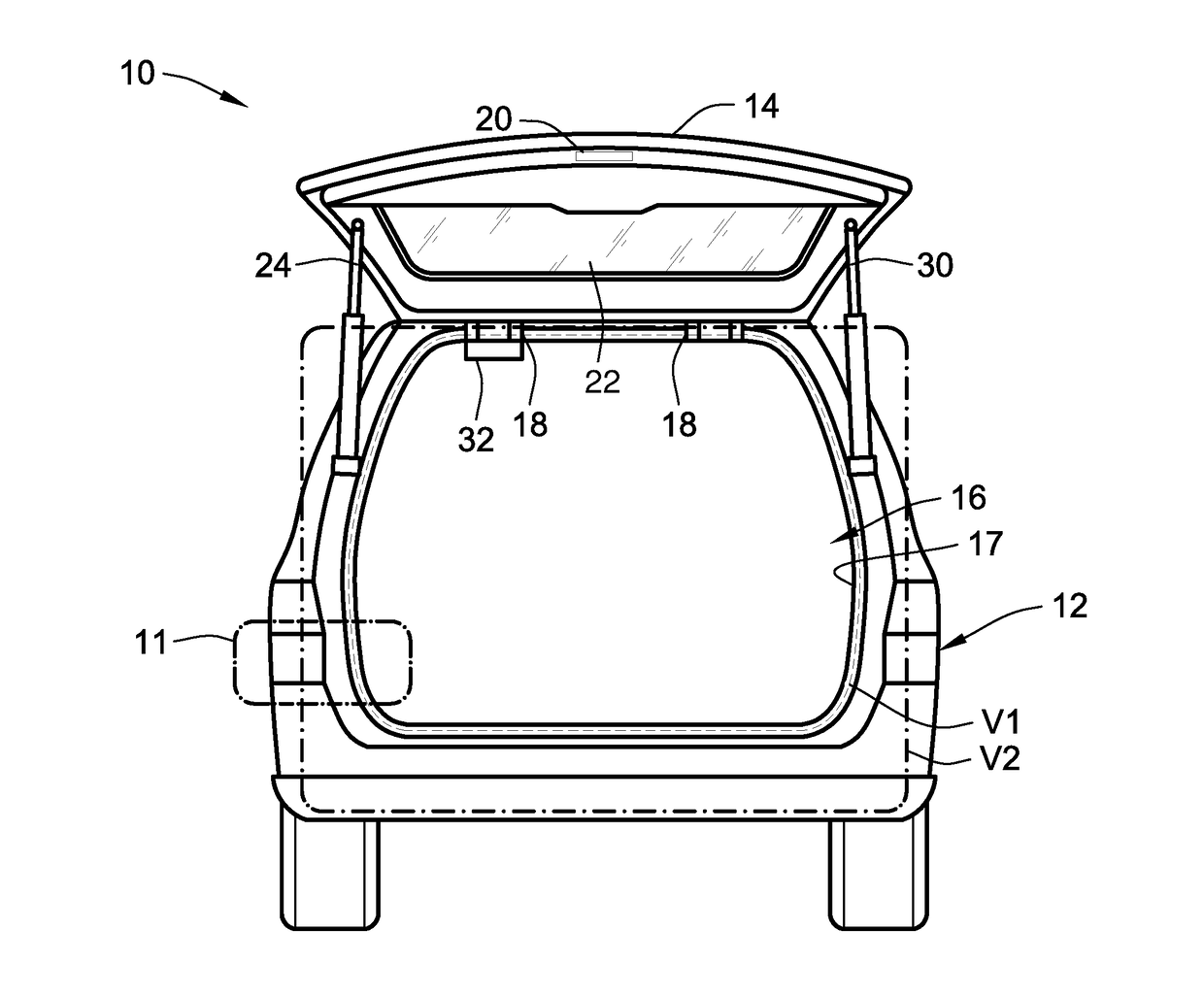

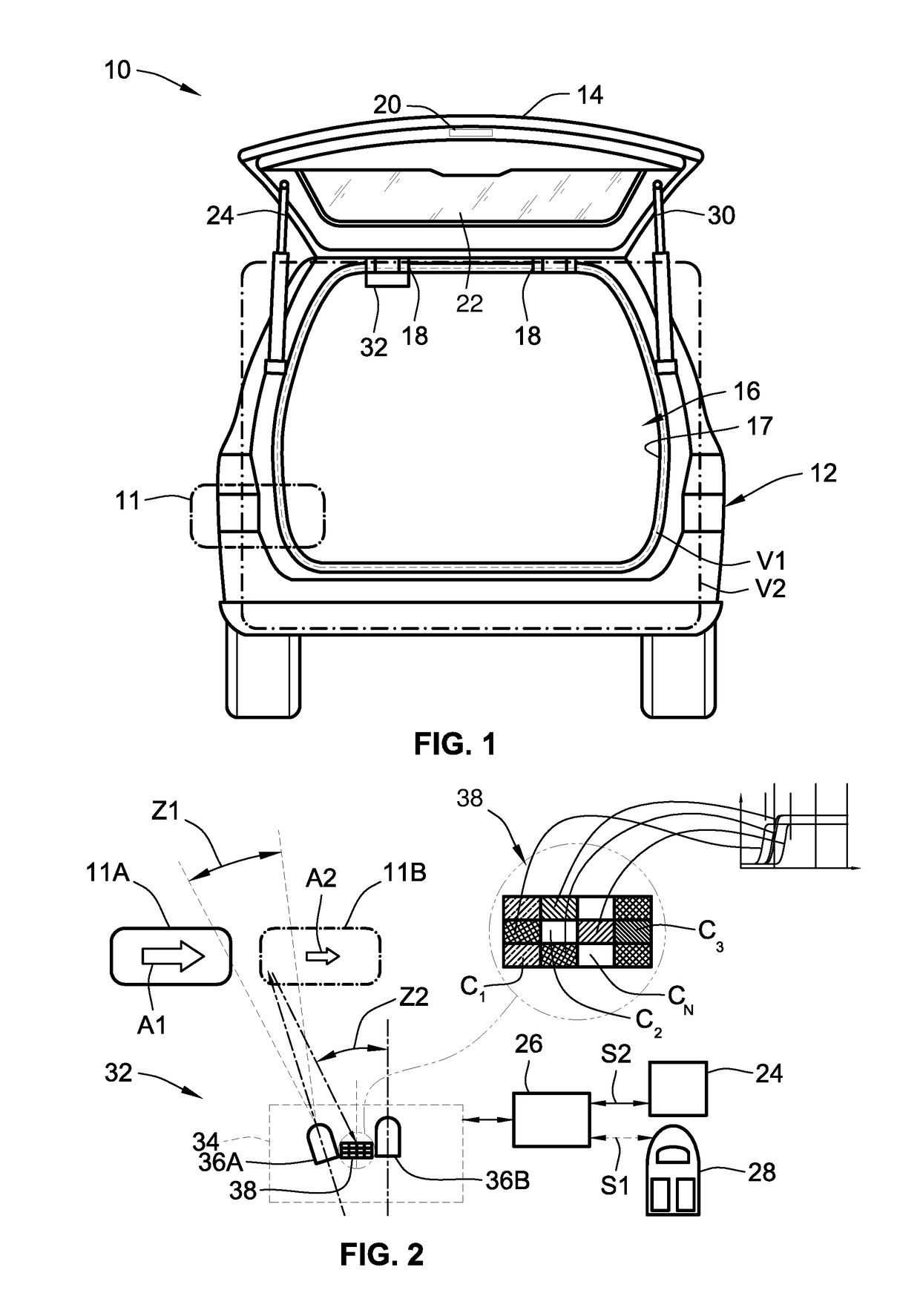

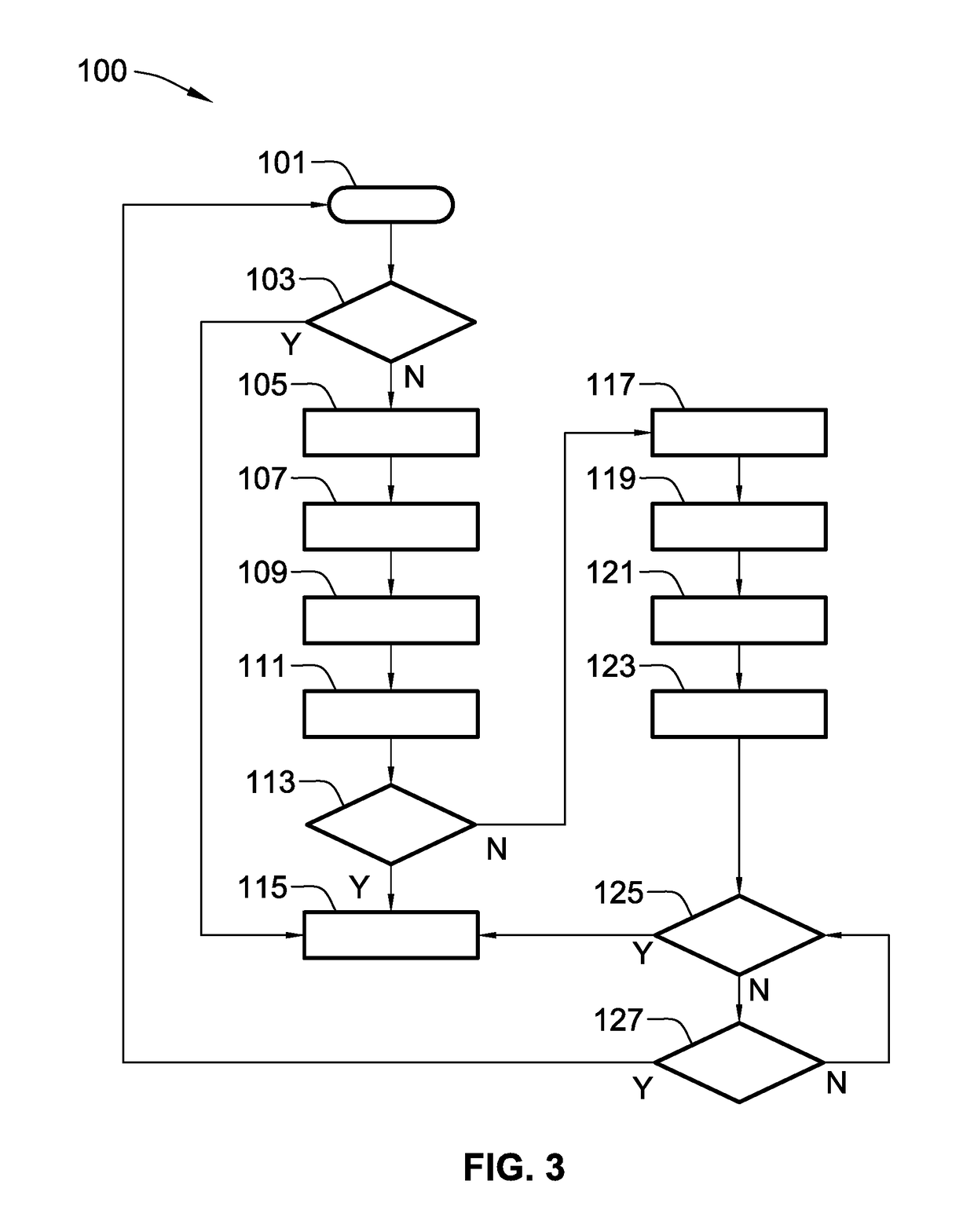

Foreign object detection systems and control logic for vehicle compartment closure assemblies

ActiveUS20180321758A1Prevent theftAvoid damageInput/output for user-computer interactionInstrument arrangements/adaptationsEngineeringControl logic

Disclosed are object detection systems for automated compartment closure assemblies, methods for operating such systems, and motor vehicles with a power liftgate assembly and foreign object detection capabilities. A method is disclosed for detecting objects obstructing the path of an automated closure assembly. The method includes receiving a command signal to move the closure assembly to an open or closed position, and receiving gesture-sensitive sensor signals with a location and velocity of an object within a supervision field. Responsive to the object being inside a protected zone within the supervision field or the object's velocity being towards the protected zone, commanding an automated driving mechanism to: slow the closure assembly's speed; if the object is still located inside the protected zone after a calibrated period of time, stop the closure assembly; and if the object moves outside the protected zone, increase the closure assembly speed to a default speed.

Owner:GM GLOBAL TECH OPERATIONS LLC

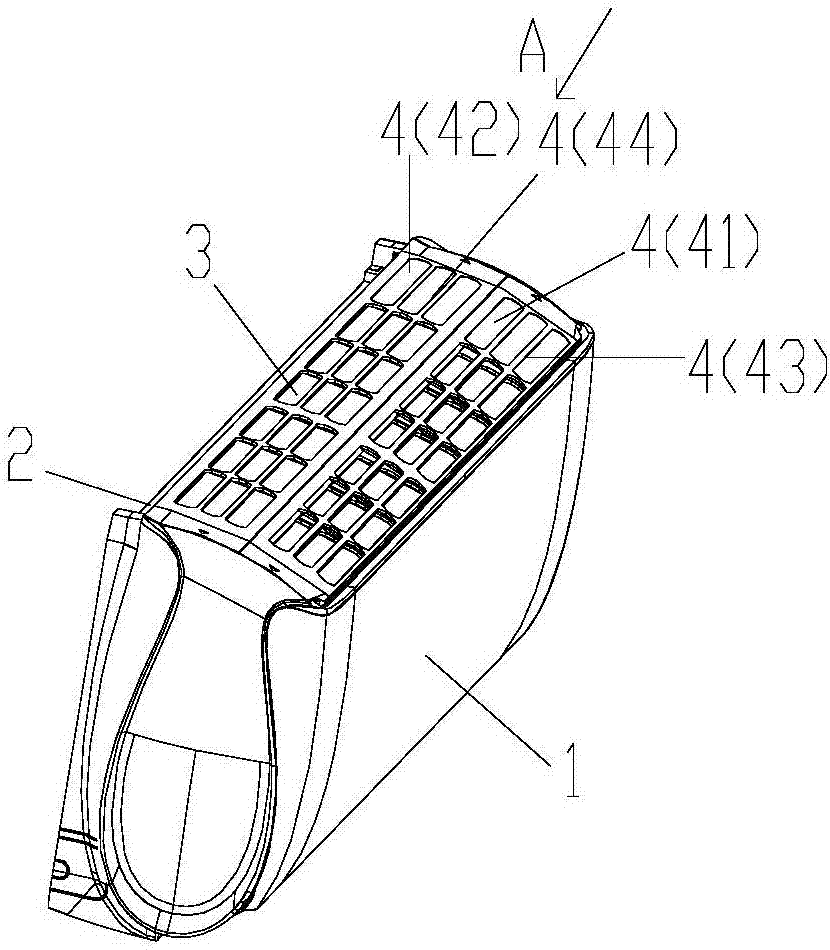

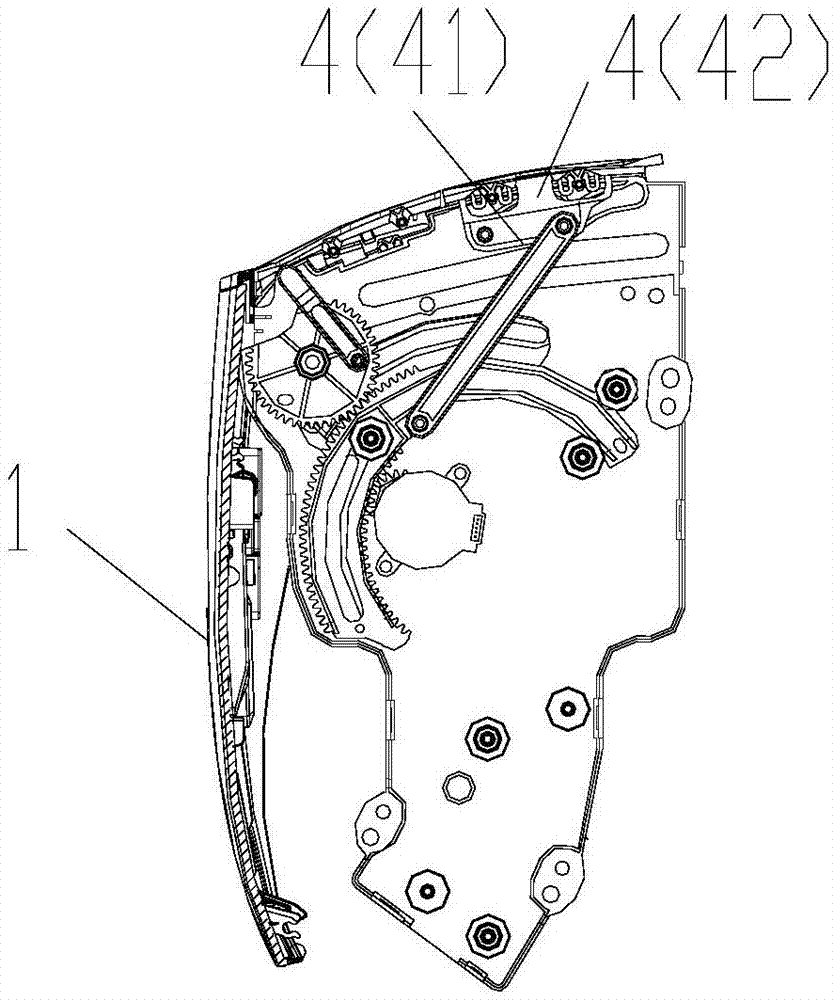

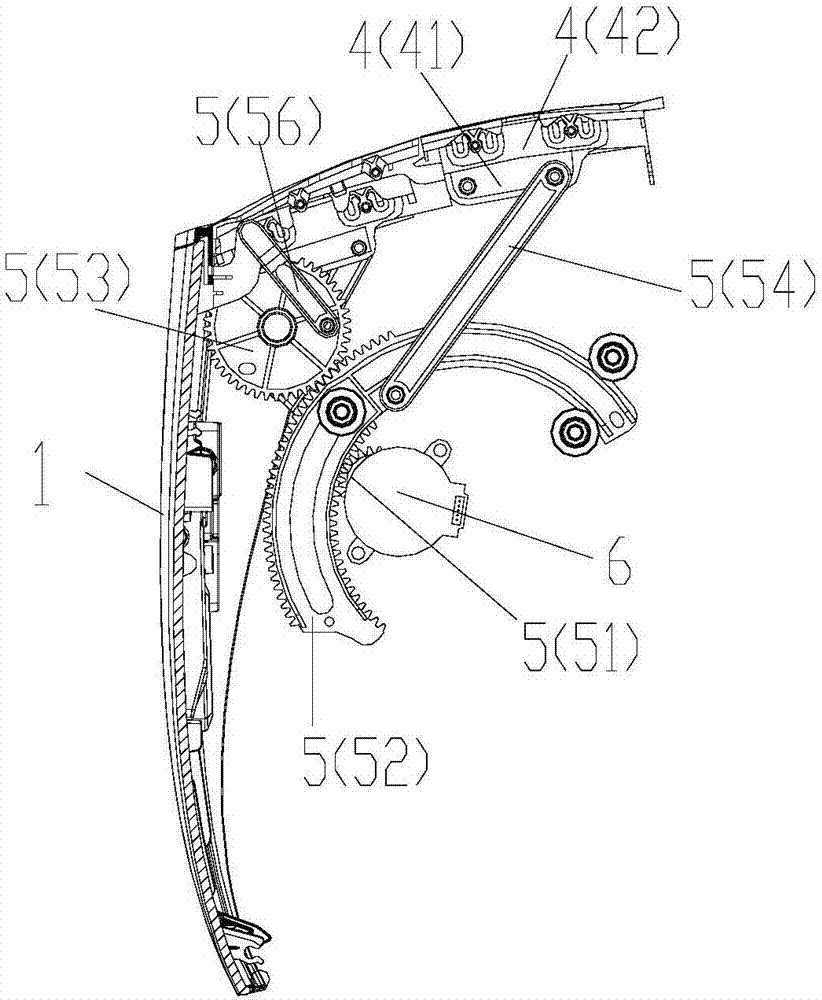

Air conditioner indoor unit, air conditioner and control method of air conditioner indoor unit

ActiveCN107300250AImprove heat transfer effectIncrease intake flowLighting and heating apparatusEfficient regulation technologiesEngineeringAir purification

The invention provides an air conditioner indoor unit, an air conditioner and a control method of the air conditioner indoor unit. The air conditioner indoor unit comprises a panel (1), a shell (2), an air inlet (3), an air purification device (4) and a driving device (5). The air inlet (3) is formed in the shell (2). The air purification device (4) is arranged on the air inlet (3). The driving device (5) can drive the air purification device to move to open the air inlet (3) and meanwhile drive the panel to move to open an air inflow region covered with the panel. The air purification device comprises a first filtering part and a second filtering part. The first filtering part independently moves relative to the second filtering part. The air inflow region covered with the panel can be opened by opening the panel, the air inflow area is further increased, the air inflow flow is increased, the heat exchange efficiency is improved, and the heat exchange effect of the air conditioner indoor unit is improved without filtering.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

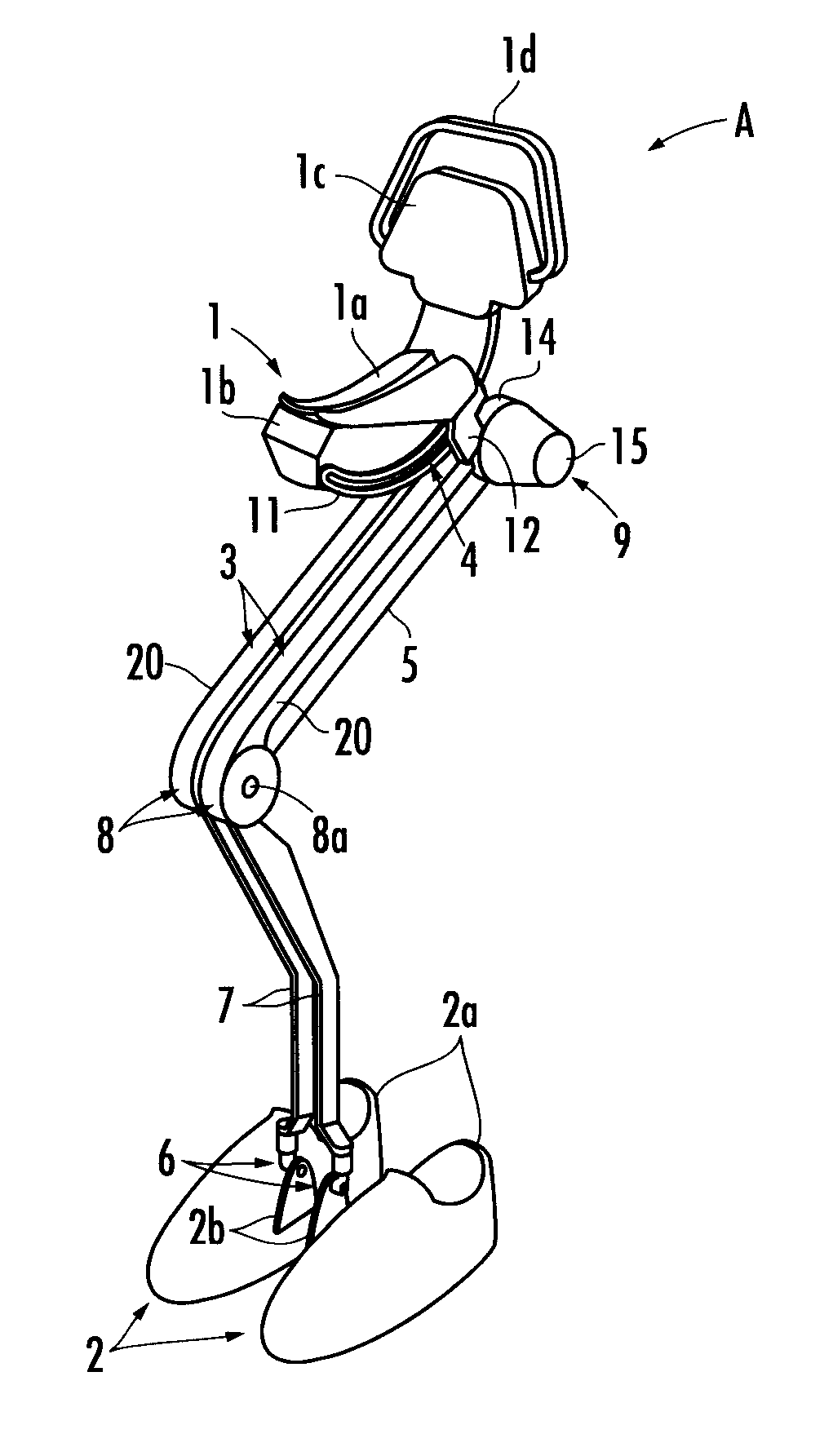

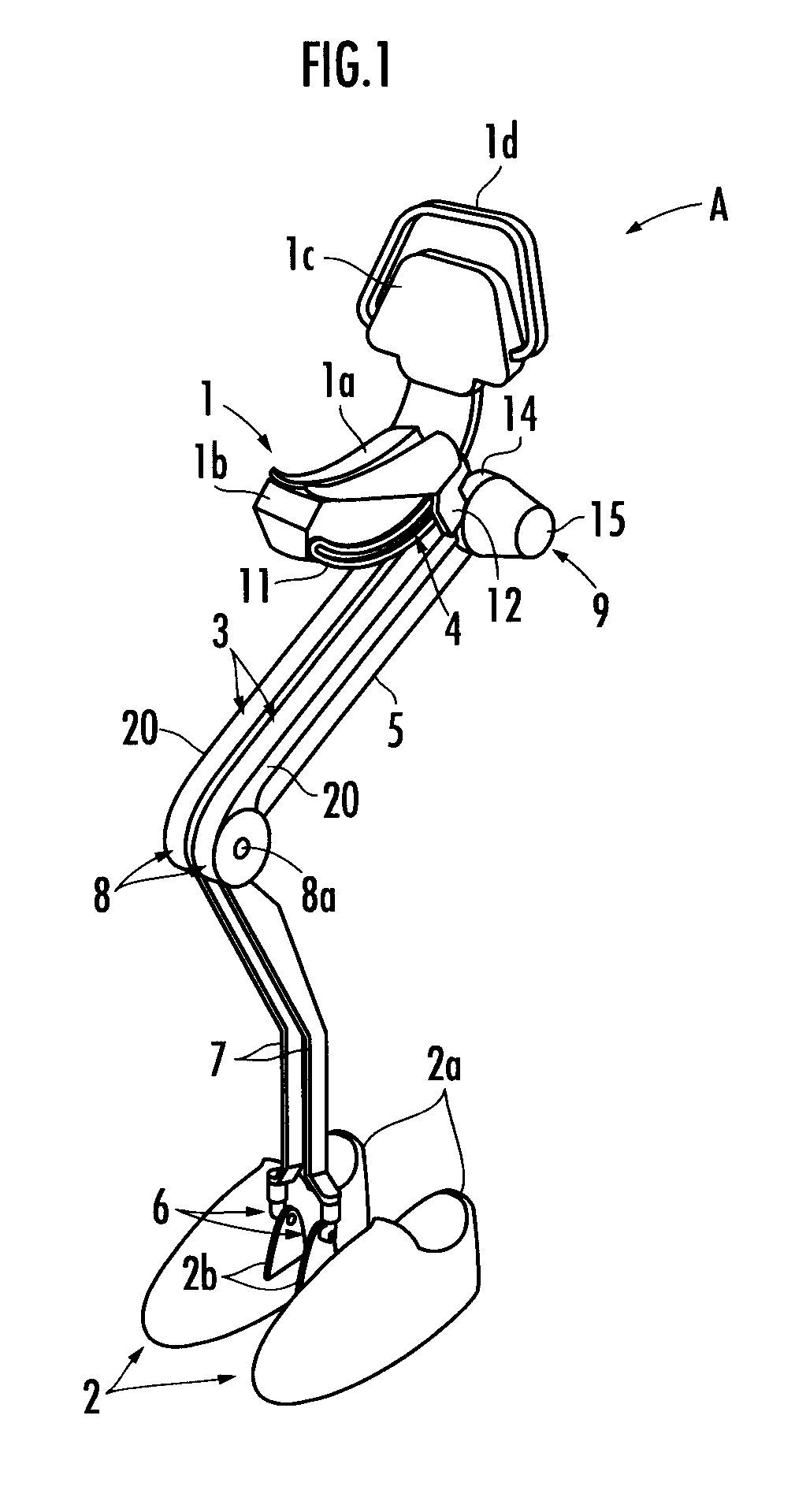

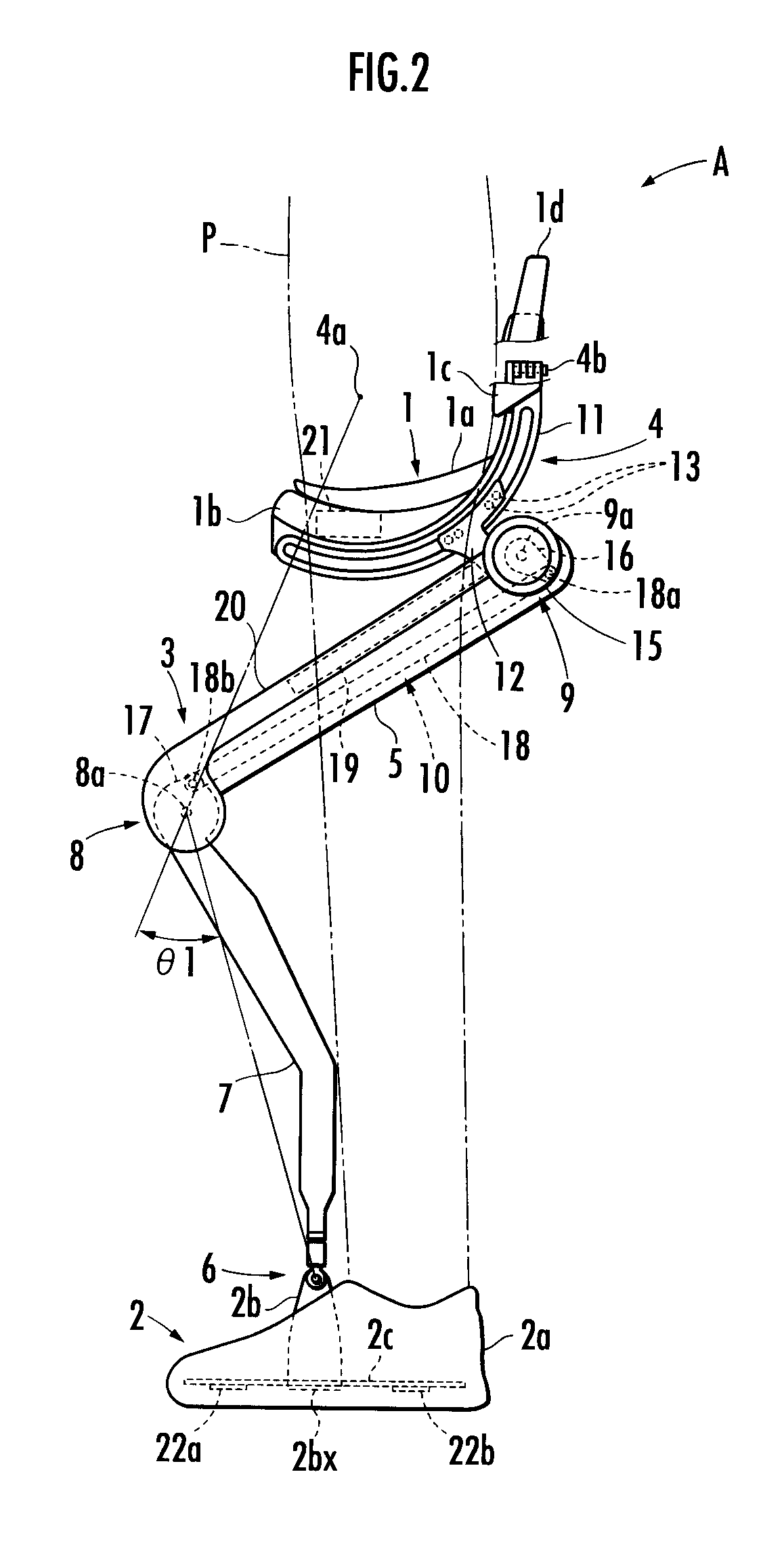

Motion assisting device

InactiveUS20100130894A1Curb energy consumptionBlock valueChiropractic devicesWalking aidsLower limitElectricity

A motion assisting device comprises a first index value measuring means 65 which measures a first index value indicating a remaining energy amount of an electrical storage device 19 and power regulation means 63 and 64 each of which regulates the motive power of an electric actuator 9 after the time point of measuring the first index value at least according to the first index value measured by the first index value measuring means 65. The power regulation means 63 and 64 regulate the motive power of the electric actuator 9 so that the remaining energy amount of the electrical storage device 19 is maintained at a predetermined lower limit or greater until the end time point of a desired operating time of the motion assisting device A.

Owner:HONDA MOTOR CO LTD

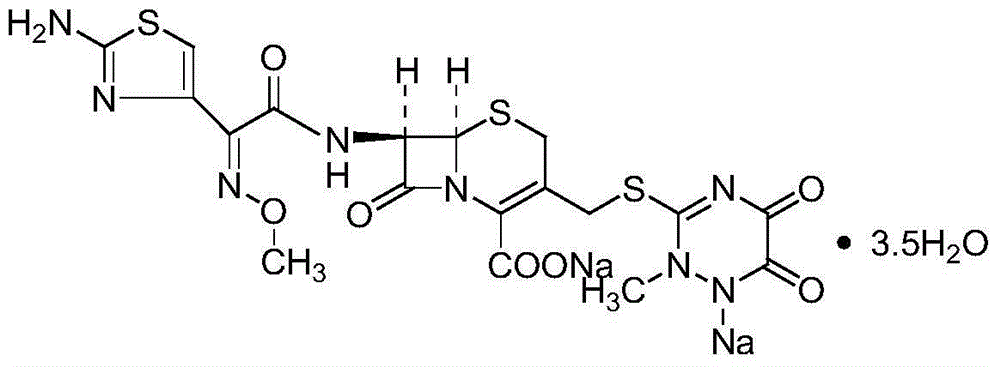

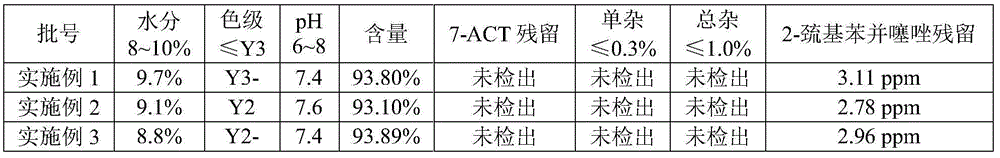

Preparation method of ceftriaxone sodium

The invention provides a preparation method of ceftriaxone sodium. The preparation method includes steps of (1) cooling dichloromethane, methyl alcohol and water mixed solvent, adding 7-ACT and AE (active ester) and trimethylamine, controlling the temperature and timing to react; (2) sequentially adding sodium hydrogen sulfite, sodium acetate and sodium hydroxide and stirring; adding extractant, stirring, standing and splitting phase; extracting extractant by water and splitting phase, and combining water phase; (3) adding extractant under water-phase stirring, transferring to and filling in a pressure container, removing air bubbles and vibrating hermetically, and taking out after freezing with temperature controlled; (4) removing organic phase, adding activated carbon after solids are melted, stirring to decolorize, and filtering in a decarbonized and aseptic manner; adding filtrate into solvent to crystalize, filtering, washing, drying and packaging. The preparation method is low in technique cost, moderate and safe in reaction conditions, convenient to operate and facilitates industrial production, and the obtained product conforms to quality requirements and has the advantages of few impurities and good crystal forms.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

Advanced wireless IPTV set top box

InactiveUS8819757B2Data being receivedReduce the power requiredAnalogue secracy/subscription systemsClosed circuit television systemsModem deviceRadio networks

An advanced wireless IP STB is provided with multiple built-in antennas capable of capturing plural downstream transmissions simultaneously on dedicated receivers using different modem technologies without the use of wires to the home. The proposed solution facilitates the advanced wireless IP STB being able to receive multiply sourced data traffic, including, for example, IPTV, digital TV, web TV, radio web, internet chat: written, voice and video, GPS tracking locator signals, media player web support, web based video gaming, You Tube and the like video streaming, TV surveillance, video intercom surveillance, and much more. The advanced wireless IP STB is configured to be able to establish a broadband (internet) session through previously assigned or negotiated channel assignments between one or more modems and plural remote wireless infrastructures widely deployed in a municipality, such as WIMAX, LTE, WCDMA, CDMA 1×, TDSCMA, GSM, GPRS, EDGE, 5G or the like.

Owner:AMAZING SETTOPBOX HLDG LLC

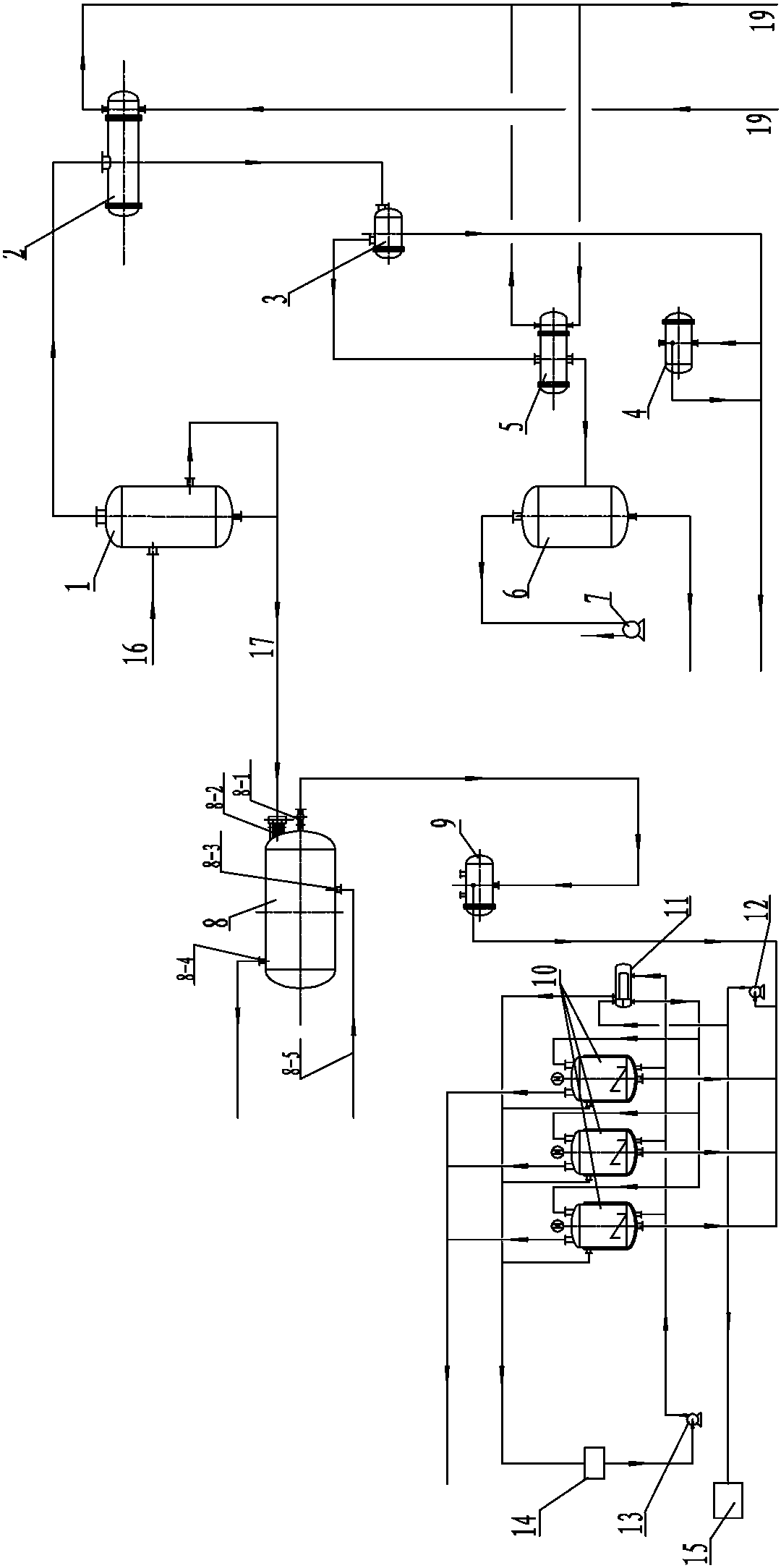

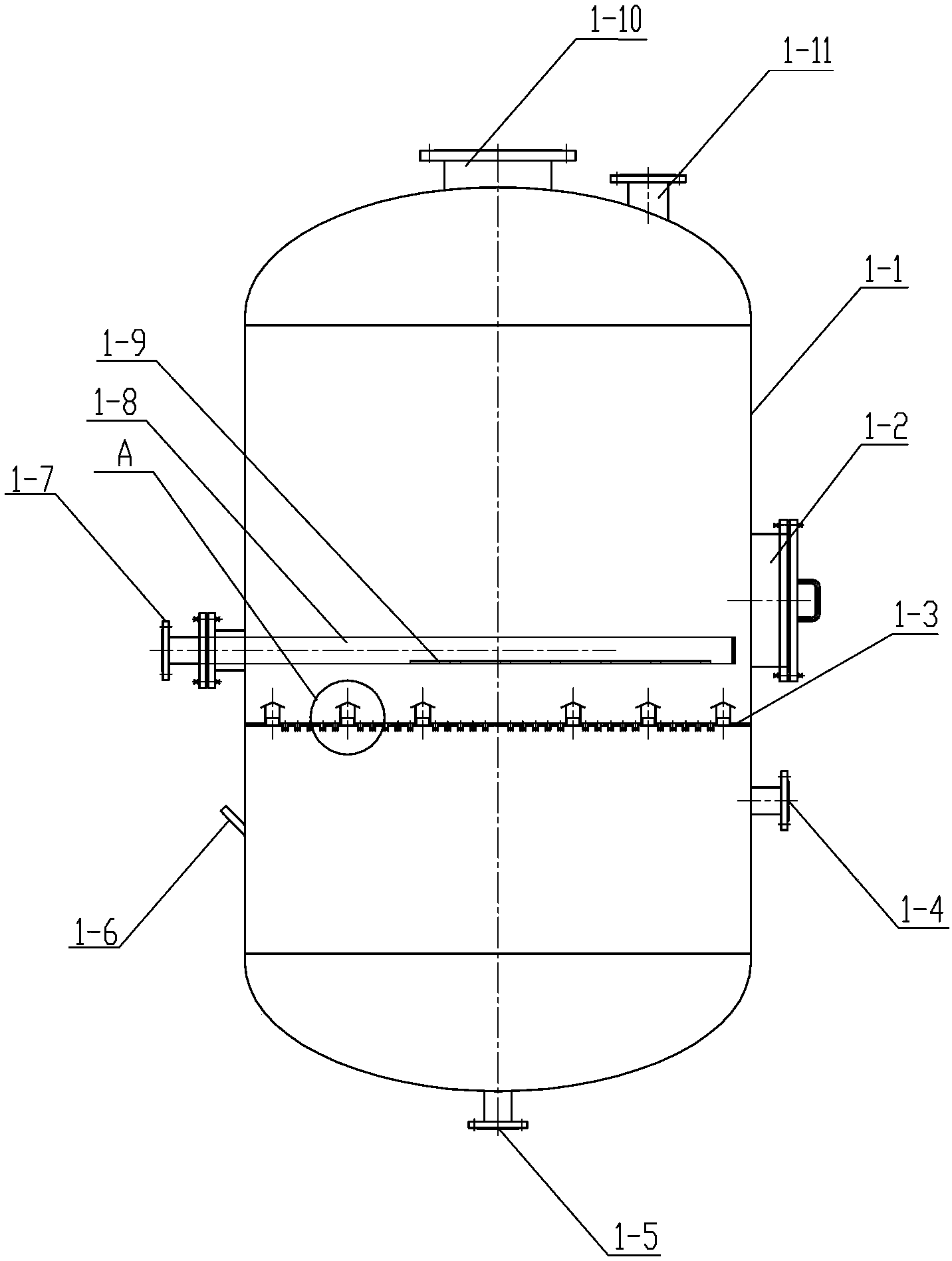

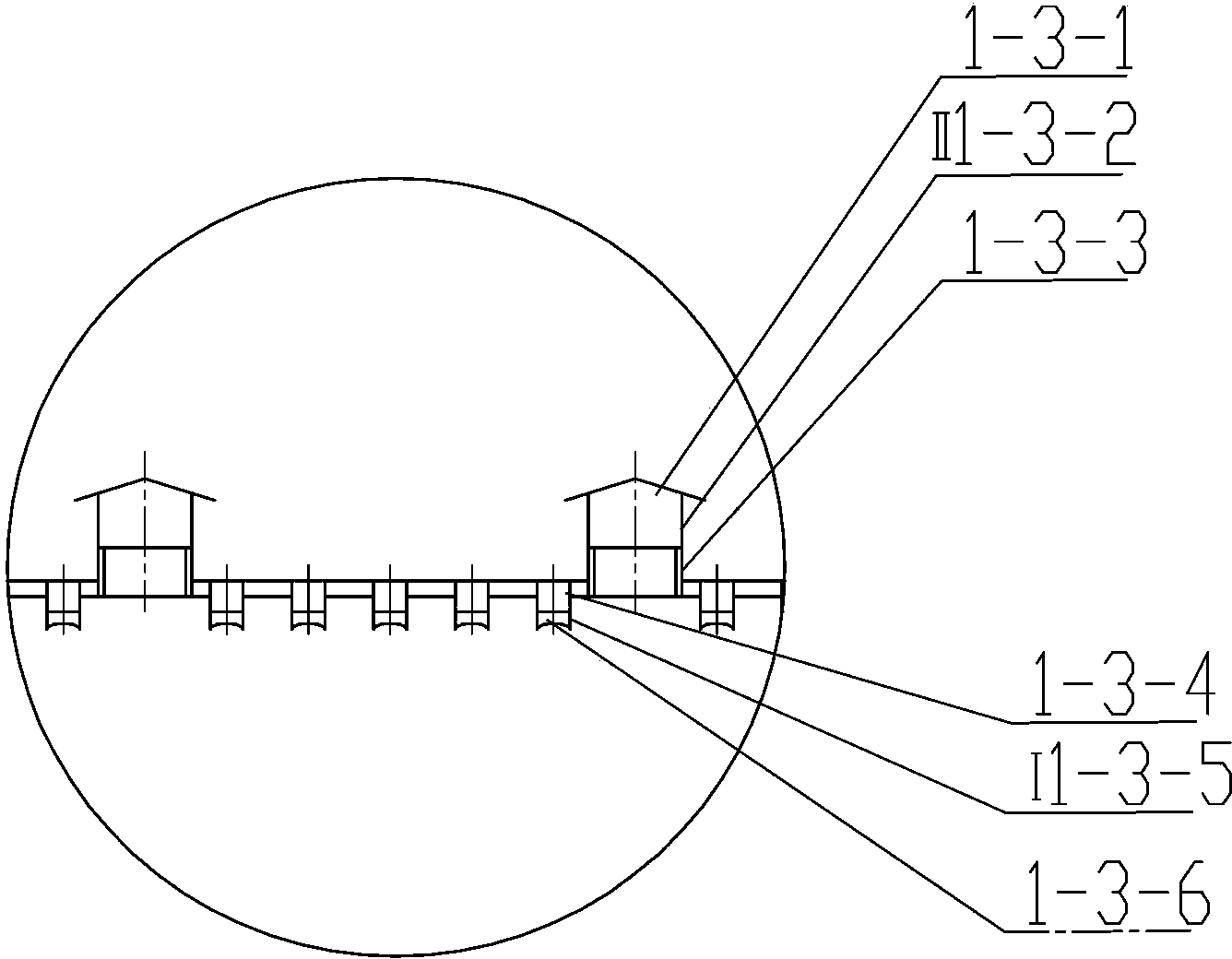

System for producing modified coal tar pitch and preparation method thereof

ActiveCN103756704AReduce consumptionReduce the power requiredWorking-up pitch/asphalt/bitumenTarProcess engineering

The invention relates to a system for producing modified coal tar pitch and a preparation method of the modified coal tar pitch. The method comprises the following steps: feeding mid-temperature pitch from a revaporizer of a tar processing device into modified intermediate pitch processing equipment with a flash oil-gas treatment device through a pipeline, allowing the flash oil and gas generated by flashing through a vacuum flasher to enter heavy oil treatment equipment for performing separation and condensation recycling on heavy wash oil fraction, and feeding the modified intermediate pitch generated by flashing into pitch modification reaction equipment for producing modified coal tar pitch. According to the system and the method, various indexes of the modified coal tar pitch are obviously improved, the energy and power consumption is greatly reduced, and pollutant escape in the whole reaction process is avoided.

Owner:ANSHAN XINGDE ENG TECH

Airflow distribution to a low emissions combustor

ActiveUS7685823B2Improve combustion stabilityLow NOxContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

An apparatus and method of providing a gas turbine combustor having increased combustion stability and reducing pressure drop across a gas turbine combustor is disclosed. A plurality of vanes is fixed to a flow sleeve radially between the flow sleeve and a combustion liner. The plurality of vanes serve to direct a flow of air entering the region between the flow sleeve and combustion liner in a substantially axial direction, such that components of tangential velocity are removed thereby providing a more uniform flow of air the combustion chamber and reducing the amount of pressure lost due attempting to straighten the airflow by pressure drop alone.

Owner:ANSALDO ENERGIA SWITZERLAND AG

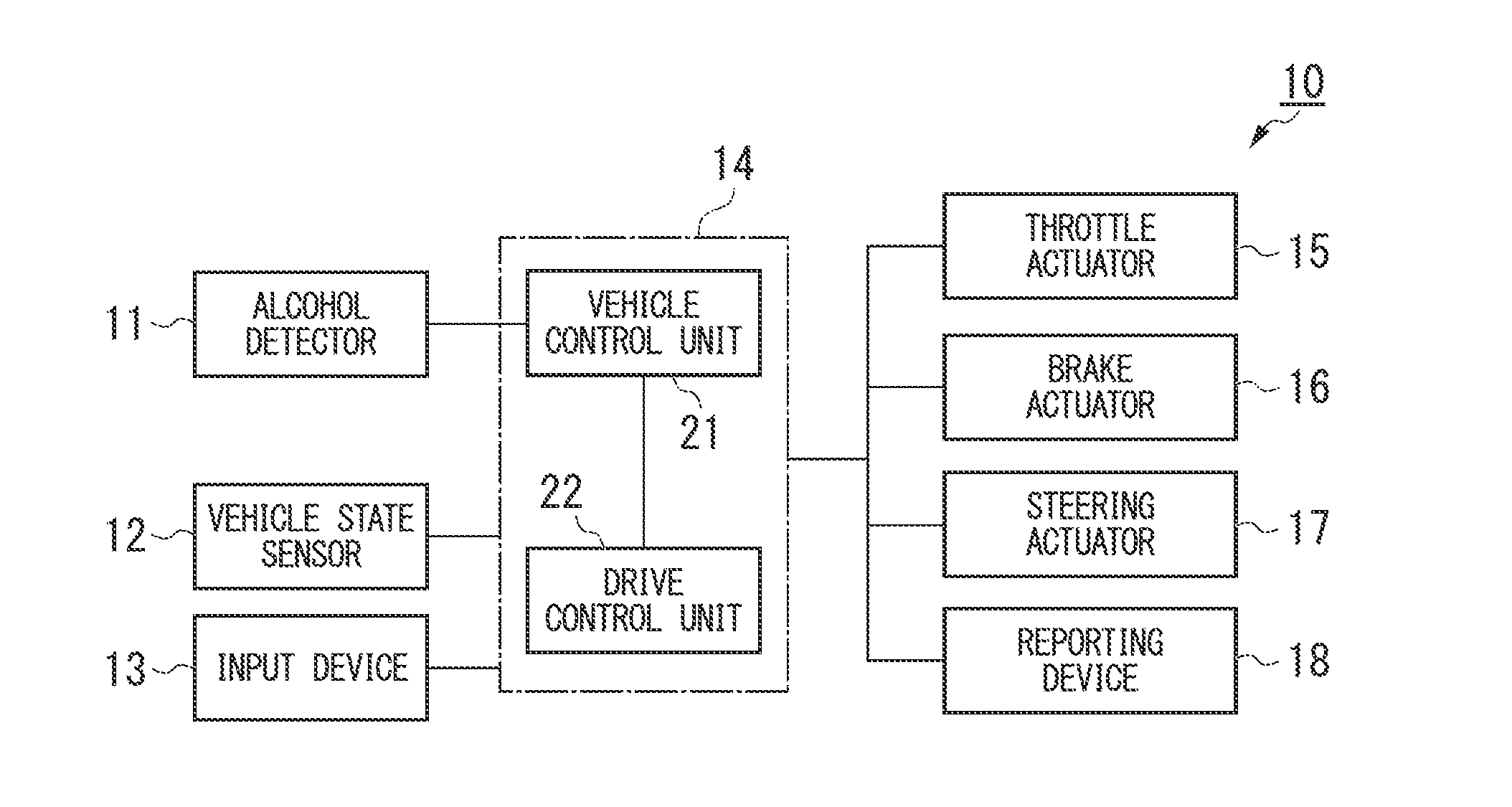

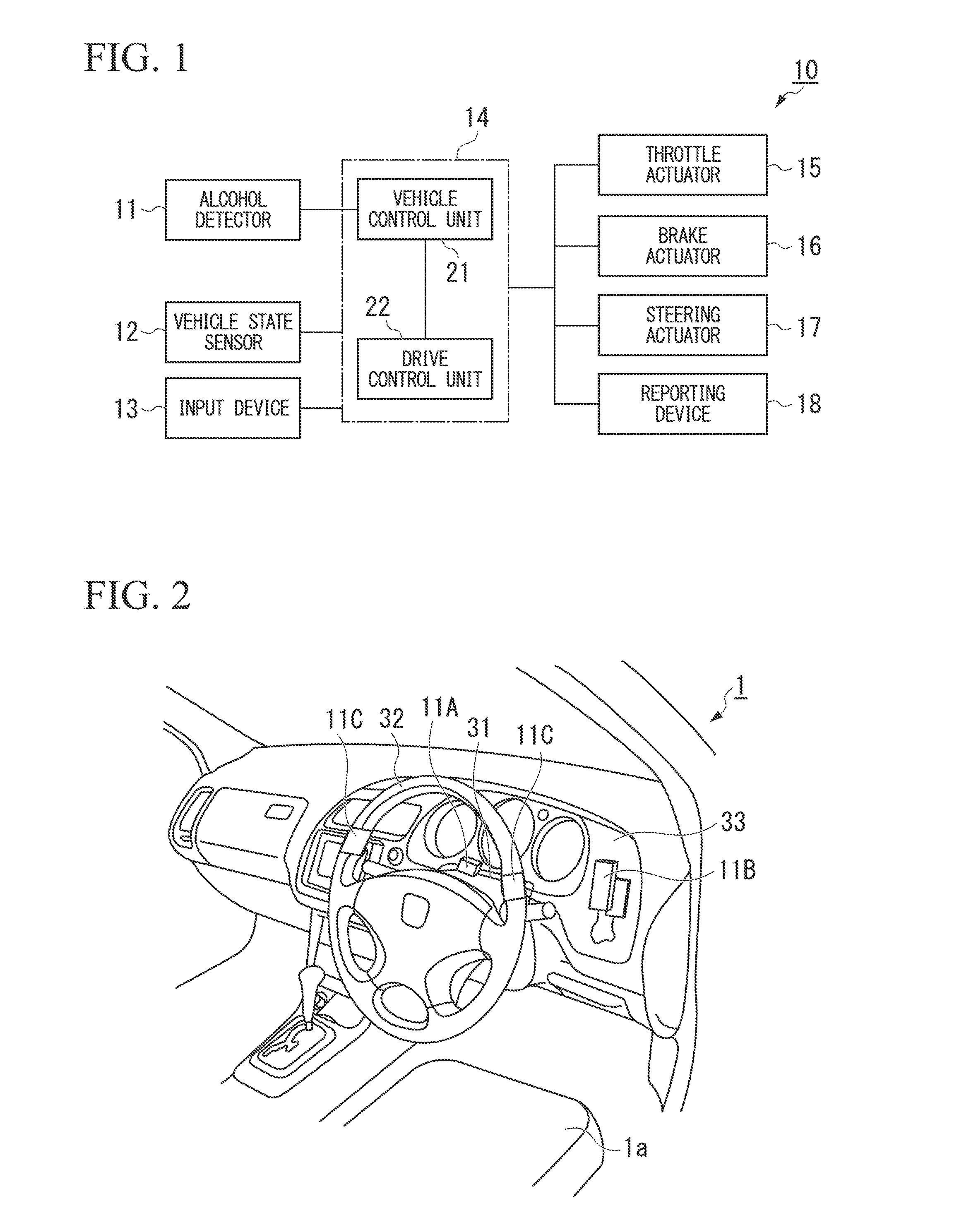

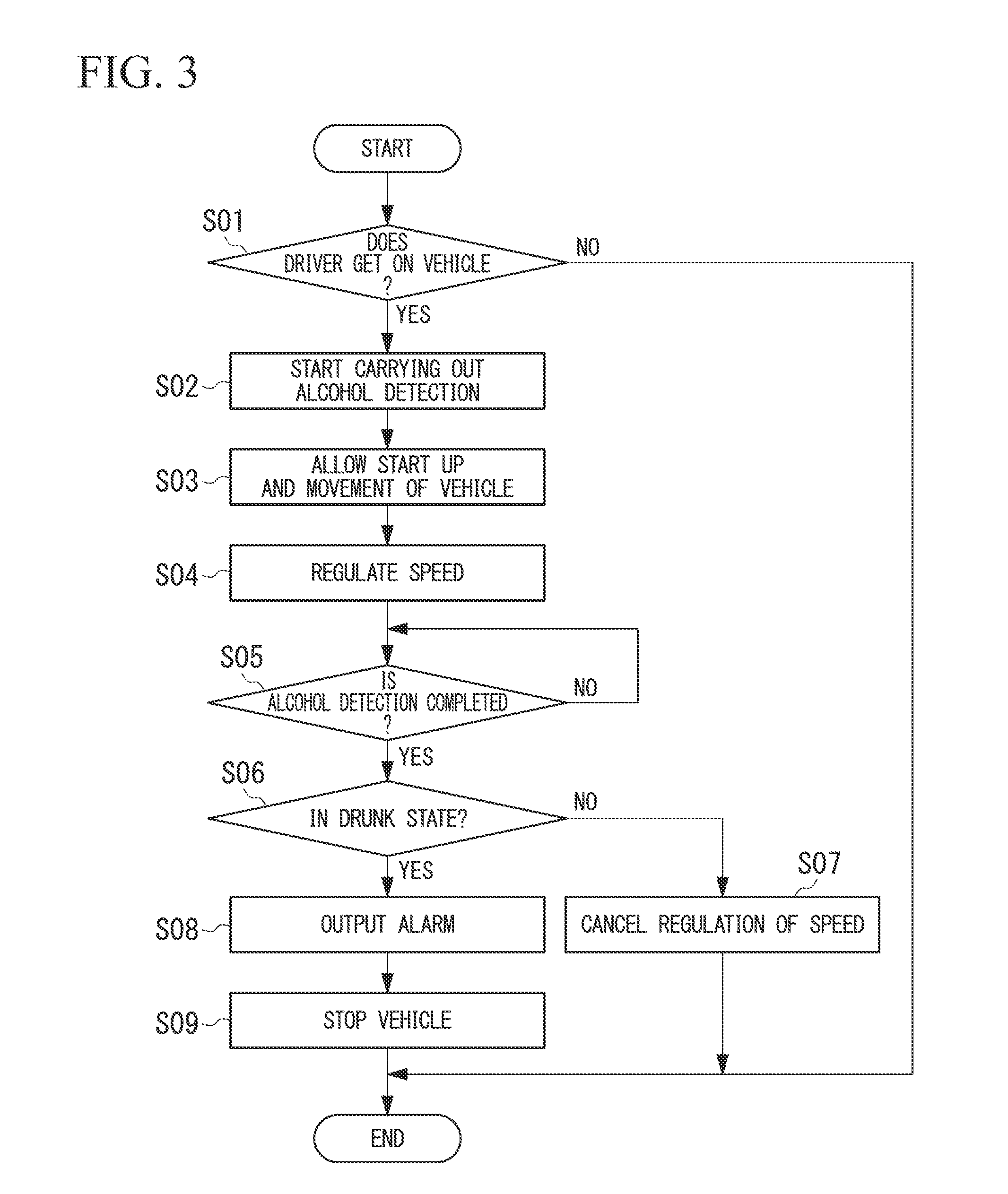

Vehicle control system

ActiveUS20140297061A1Ensure convenienceReduce motivationDigital data processing detailsTractorsCar doorEngineering

A vehicle control system includes an alcohol detector which detects an alcohol intake level of a driver of a vehicle; and a controller which determines whether the driver is a drunk person based on a detection result obtained from the alcohol detector, and which stops the vehicle when a determination result that the driver is the drunk person is obtained. After a door of the vehicle is switched from a closed state to an open state, and before an operation of a start-up of the vehicle is performed, the controller controls the alcohol detector so that a detection of the alcohol intake level is started, and allows a travelling of the vehicle before the detection result is output from the alcohol detector.

Owner:HONDA MOTOR CO LTD

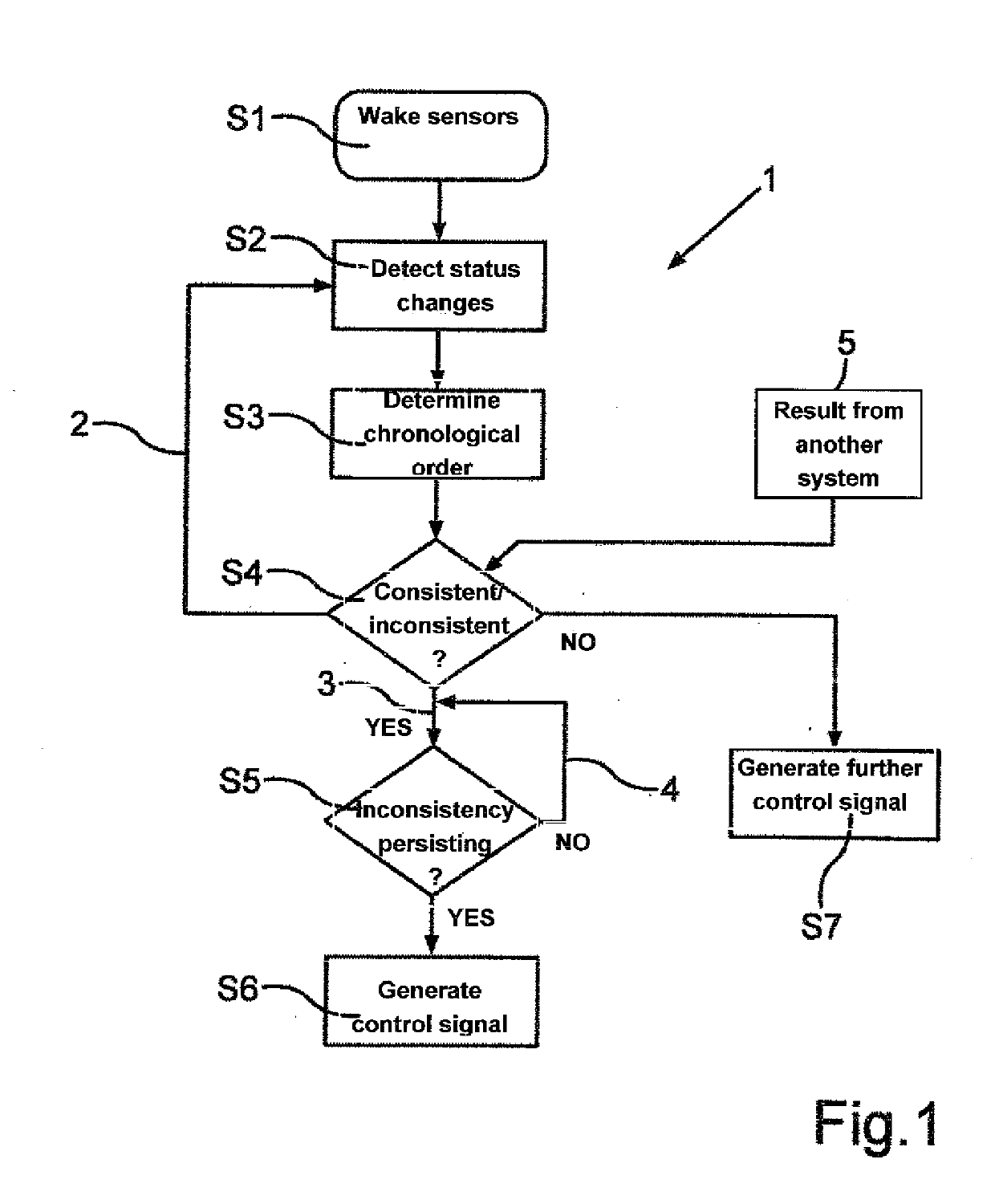

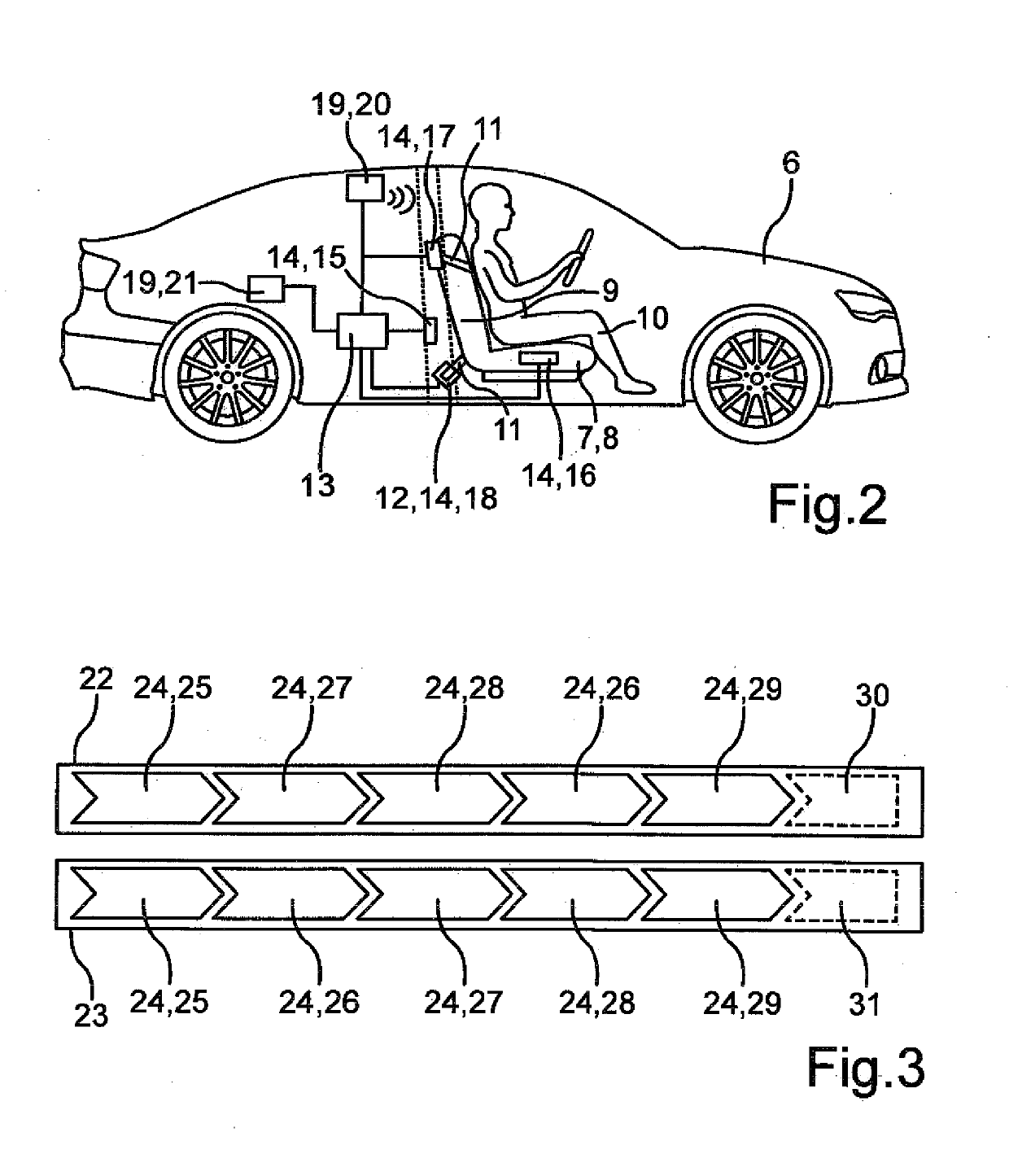

Method for operating a safety system for a motor vehicle, safety system and motor vehicle

ActiveUS20190111889A1Enhanced securityImprove visibilityBelt control systemsPedestrian/occupant safety arrangementSafe systemSeat belt

In a method for operating a safety system of a motor vehicle, a corresponding safety system, and a motor vehicle equipped with such safety system, status signals from several sensor devices are captured by the safety system, wherein the status signals indicate respective status change of a functional unit of the motor vehicle. Thereafter, a chronological order of the status changes is determined and evaluated to detect a consistency or an inconsistency with the proper application of a seat belt of the motor vehicle. If an inconsistency is detected and it persists over a predetermined period of time, a control signal is transmitted by the safety system to a safety device of the motor vehicle.

Owner:AUDI AG

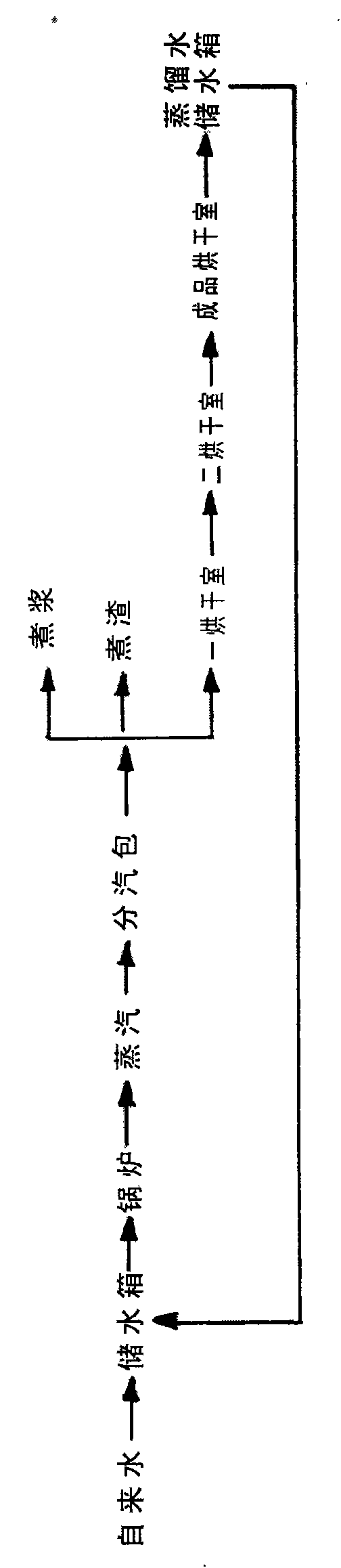

Technique for processing nutritional health-care bean curd skin

InactiveCN102067916AImprove flatnessSmall footprintCheese manufactureFood scienceBiotechnologySmall footprint

The invention discloses a technique for processing nutritional health-care bean curd skin, which comprises the following steps of: cleaning, crushing and soaking soybean, separating soybean milk and dreg, heating, performing secondary milk and dreg separation, putting the obtained soybean milk in a drying box, drying the soybean milk to obtain bean curd skin, and cutting the bean curd skin. The technique has direct current flows; and the whole process from soaking the raw material to pulping, boiling and feeding in the drying box is of self flowing mode. Manpower and power are reduced, and fault rate is reduced. A vehicle-mounted drying box is adopted in the technique, and the drying vehicle has small floor area, so the area of a drying chamber is saved. The drying box is cast by using a die and made of polyethylene acrylonitrile butadiene styrene (ABS) material and has smooth surface, so the drying box is favorable for stripping and cleaning. Compared with the prior art, when products of the same number are processed, the technique can save work efficiency by 6 times, save soybean by 30 percent, save coal by 50 percent and save water by 95 percent. In the technique for processing the product by using the soybean containing 13 percent of water, the yield is 76 to 80 percent, the water content of the product is 8 to 10 percent, and the rest moisture is evaporated during processing the product and then reclaimed. After the produced soybean dreg serving as a byproduct is squeezed and drained, the rest soybean dreg is dried by using waste heat of a boiler flue, and the dried soybean dreg is a raw material for multiple products, so the utilization rate of the soybean reaches 100 percent. By the technique, chemical additive is not added during processing of the product, and zero discharge during production of the product is realized.

Owner:方辉宇

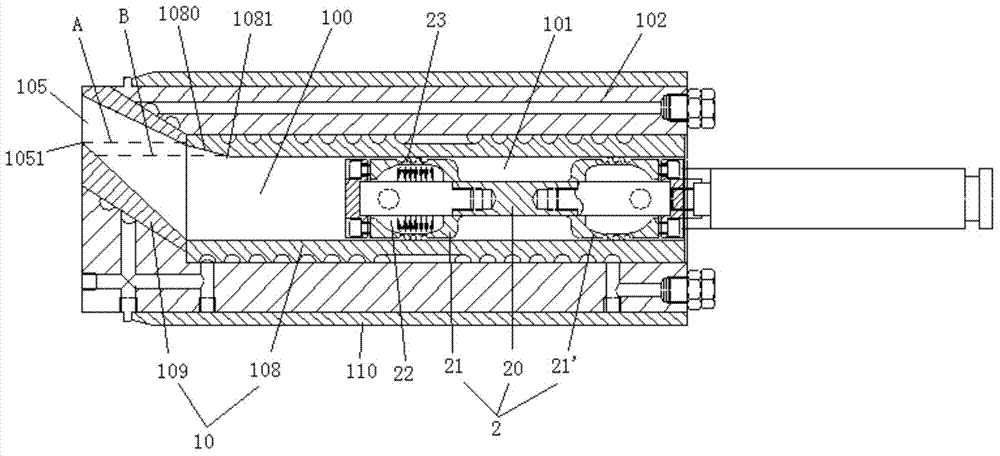

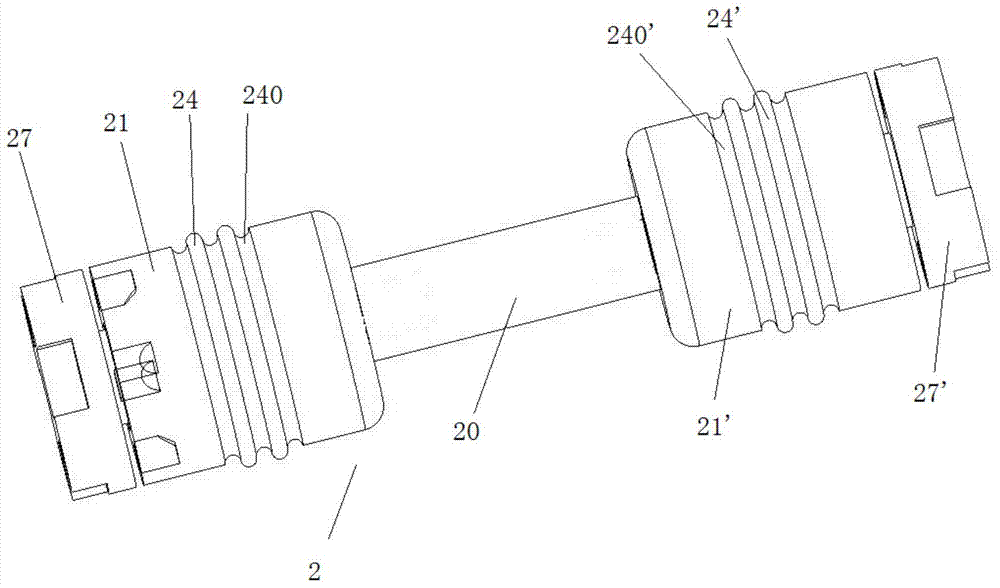

Material injection device of die casting machine

The invention discloses a material injection device of a die casting machine. The material injection device comprise a material cylinder and a plunger, wherein the material cylinder is used for containing molten metal liquid, the plunger is arranged in an inner cavity of the material cylinder, the material cylinder comprises a flat part and a gooseneck part which are in transition connection by an inclining part, the lowest point of the inclining part is lower than the lowest point of a material outlet of the gooseneck part, the plunger comprises a plunger head and a second plunger head which are connected by a plunger rod, a non-pressure chamber for containing the molten metal liquid is formed among the plunger head, the second plunger head, the plunger rod and the flat part, a pressure chamber for containing to-be-injected molten metal liquid is formed among the plunger head, the gooseneck part and the flat part, and a one-way flowing device is arranged between the non-pressure chamber and the pressure chamber, is sealed during material injection, and is opened in the plunger resetting process. The material injection device of the die casting machine has the advantages that the die casting cycle is short, the production efficiency is high, the qualified rate of products is higher, the heating temperature of the metal liquid is lowered, and the service life of a die and other parts is prolonged.

Owner:苏州圣美特压铸科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com