Technique for processing nutritional health-care bean curd skin

A processing technology and bean curd technology, applied in cheese substitutes, dairy products, food science, etc., can solve problems such as difficult maintenance, high energy consumption, and long production lines, so as to reduce manpower and power, ensure product quality, and occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

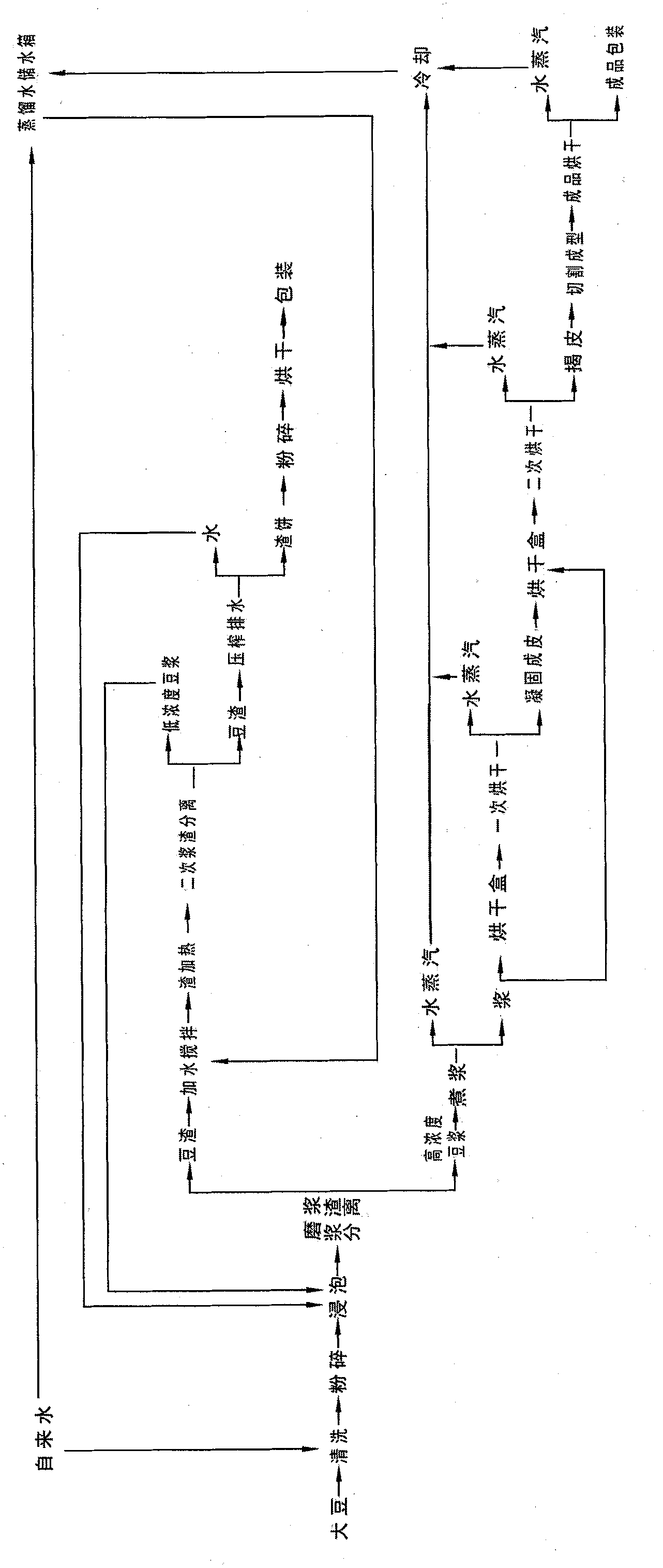

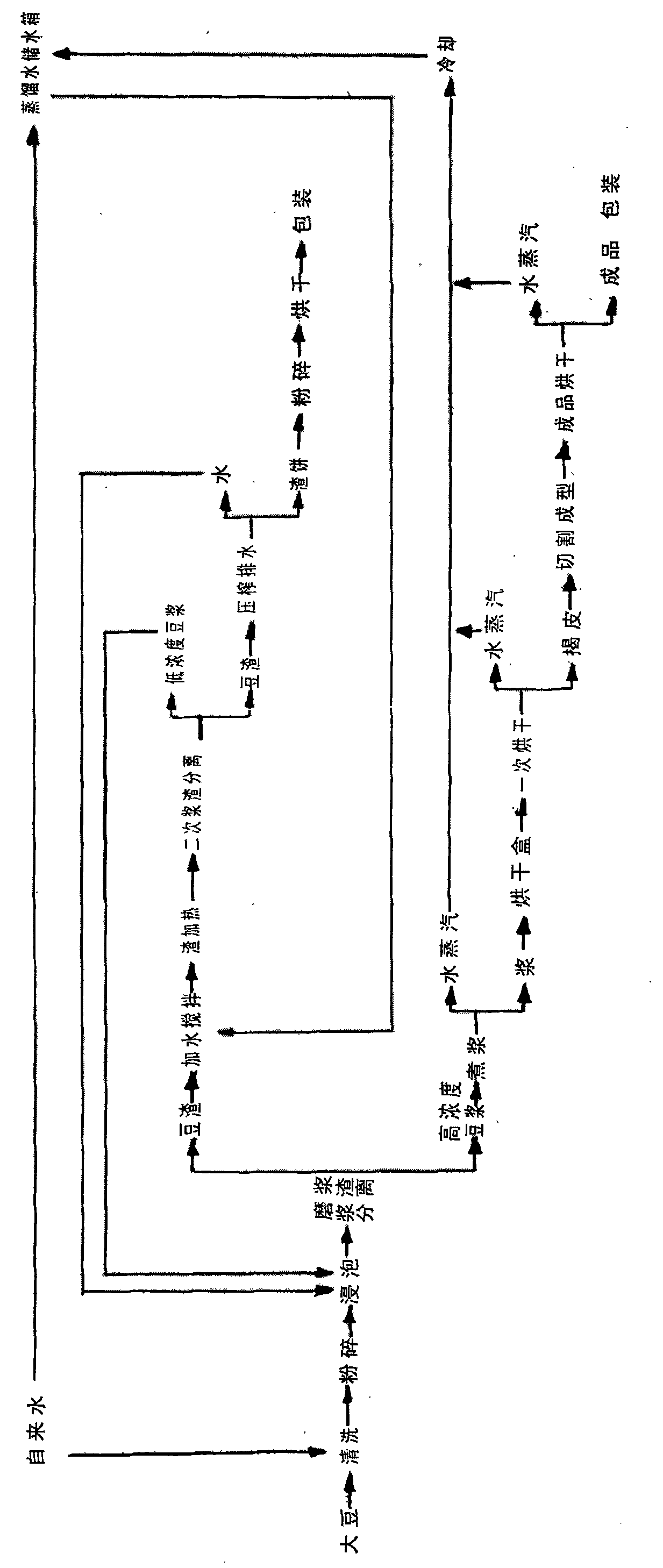

Method used

Image

Examples

Embodiment Construction

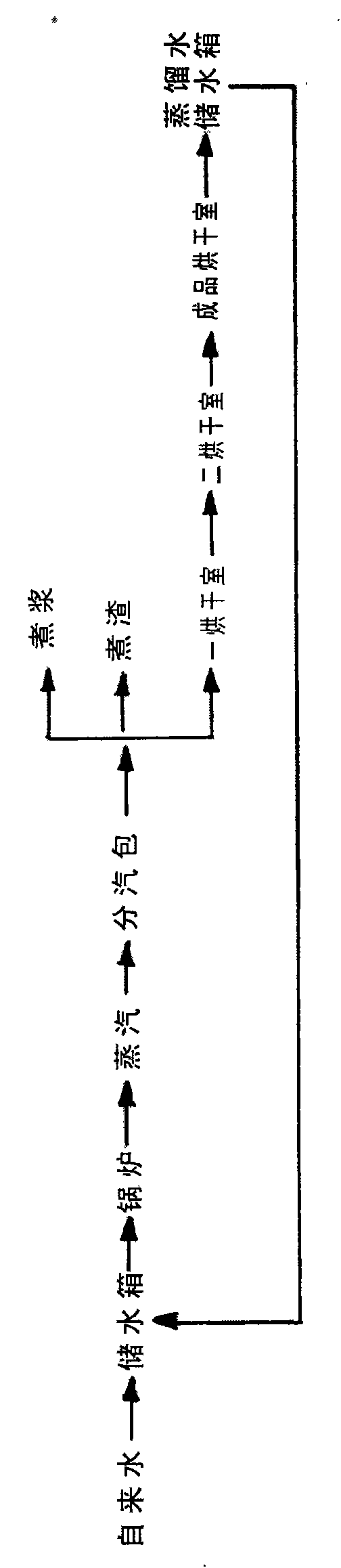

[0015] Such as Figure 4 As shown, the drying box is a square frame, the bottom of the box is provided with partitions 1, and the drying box is divided into several equal parts, and the four sides of the frame are respectively provided with ventilation grouting ports 2.

[0016] Take 100% soybeans as raw material to prepare bean skin technology:

[0017] 1. Remove impurities from soybeans, wash them, and crush them into granules.

[0018] 2. Put the crushed soybeans into a soaking container, and add water 5 times the weight of the soybeans.

[0019] 3. After soaking for about 30 minutes, start the agitator fixed on the soybean soaking container, stir the raw materials in the container evenly, and then turn on the switch at the lower end of the container, and the raw materials will flow into the slurry-slag separation type refiner at the lower end of the switch by itself In the hopper, pulp and slag are separated.

[0020] 4. After the yellow high-concentration soybean milk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com