Patents

Literature

401results about How to "Excellent surface appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed thermoplastic polyurethanes

InactiveUS7202284B1Improve cell structureExcellent surface appearanceCoatingsPolymer scienceMicrosphere

Process for the preparation of foamed thermoplastic polyurethanes characterized in that the foaming of the thermoplastic polyurethane is carried out in the presence of thermally expandable microspheres.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

Glass substrate and method for manufacturing the same, cover glass and method for manufacturing the same, personal digital assistant, and display device

ActiveUS20160357294A1Flatness of thinExcellent surface appearanceDevices with sensorCharacter and pattern recognitionDisplay deviceEngineering

In a glass substrate for extracting therefrom a plurality of cover glasses to protect a protection object, plural concave portions are provided in a front surface or back surface of the glass substrate. The glass substrate includes plural thin portions formed by providing the plural concave portions and a thick portion connecting to the thin portion, and a haze value of the thin portion is 8% or less.

Owner:ASAHI GLASS CO LTD

Artificial suede-type leather and process for producing the same

InactiveUS20060035556A1Good light fastnessBrilliant colorationSynthetic resin layered productsWoven fabricsPolyesterLight irradiation

This invention relates to a suede-like artificial leather using ultra-fine polyester fibers and a polyurethane, and provides a suede-like artificial leather free from the occurrence of specking and having graceful surface appearance and high light fastness. The suede-like artificial leather comprising a fiber-entangled substrate mainly containing ultra-fine polyester fibers with a fiber fineness of 0.7 dtex or less and a polyurethane, and is dyed, and is wherein said polyurethane contains at least one each of yellow pigments, red pigments and blue pigments, and that said artificial leather satisfies all of the following properties (1) through (3) as measured by the methods described in the specification; (1) The infrared reflectance at 850 nm is 60% or more; (2) The surface temperature during light irradiation is 105° C or lower; (3) The light fastness is class 3 or better. Especially since the suede-like artificial leather of this invention has high light fastness, it can be most suitably used for car seats.

Owner:TORAY IND INC

Hard surface cleaning compositions, premoistened wipes, methods of use, and articles comprising said compositions or wipes and instructions for use resulting in easier cleaning and maintenance, improved surface appearance and/or hygiene under stress conditions such as no-rinse

InactiveUS20050153857A1Easy to useImprove hygieneNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrophilic polymersSurface cleaning

Owner:PROCTER & GAMBLE CO

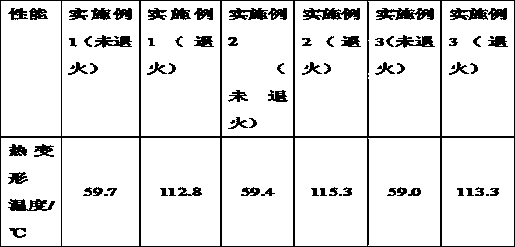

Aluminum alloy and preparation method thereof

The invention discloses aluminum alloy and a preparation method thereof. The aluminum alloy comprises, by weight, 4.0%-11.0% of Zn, 2.0%-3.0% of Mg, 0-0.3% of Si, 0-0.4% of Ti, 0-0.2% of Cu, 0-0.01% of Zr, 0-0.01% of Cr, 0-0.01% of Mn, less than 0.1% of Fe and the balance Al and accessory impurities. The weight ratio of Zn to Mg is 2-6. According to the aluminum alloy, the surface appearance defects such as fibrous structure stripes and surface yellowing in the anodic oxidation treatment process of commercial 7xxx-series (such as 7075, 7050 and 7055) high-strength aluminum alloy are overcome, high strength and good anodic oxidation treatment surface appearance of the aluminum alloy are integrated, the strength of the aluminum alloy for existing electronic equipment body shells is further improved, and the requirement of electronic equipment lighting and thinning development for aluminum alloy materials for the equipment body shells is effectively met; meanwhile, the application field of the 7xxx-series high-strength aluminum alloy also can be expanded.

Owner:AAC MICROTECH CHANGZHOU

Flame retardant thermoplastic elastomers

ActiveUS20120037396A1No negative effect on elasticityGood mechanical propertyRubber insulatorsAntifouling/underwater paintsEtherInsulation layer

A flame-retardant thermoplastic elastomer compound is disclosed having polyphenylene ether, a hydrogenated styrene block copolymer, at least one solid non-halogenated phosphorus containing flame retardant, and a nucleated olefinic polymer. The compound has a before-aging tensile elongation of >200% and an after-aging tensile elongation residual of at least 75%, according to the UL 62 test, which makes it useful as an insulation layer, a jacketing layer, or both for protected electrical lines such as alternating current wire and cable products, accessory cables, and variety of injection molded electrical or electronic parts.

Owner:AVIENT CORP

Crosslinked composition comprising a core/shell copolymer, method of obtaining same and uses thereof

InactiveUS20090306246A1Excellent surface appearanceEasy to processSolesSpecial tyresElastomerPolyolefin

The invention relates to is a crosslinked composition containing in parts by weight: 20 to 100 parts of at least one elastomer (I), 2 to 50 parts of at least one core / shell copolymer (II), and 0 to 100 parts of at least one thermoplastic polymer (III). The invention also relates to a method of producing one such crosslinked composition, which is characterized in that it consists in: mixing an elastomer and a core / shell copolymer optionally in the presence of: a grafted polyolefin, a plasticizer, fillers and / or additives, and a suitably-selected crosslinking system, and subsequently crosslinking said mixture at a suitable temperature. In a preferred embodiment of the invention, the mixture is crosslinked at a temperature of between 150 and 320° C. The invention method be carried out in an internal mixer, or, alternately, in a twin-screw extruder or a Buss®-type co-kneader. Depending on the case, the resulting mass is calendared or extruded, cooled and subsequently granulated. The granules thus obtained are then ready to be transformed, by means of heating, into sheets, plates, extrusions, tubes or other desired products. The invention further relates to the use of one such composition in the production of ducts, pipes, tubing, couplers or similar for conveying fluids, such as the fluid transfer conduits, pipes and other elements which are used in the automobile industry in braking, cooling, steering and air-conditioning systems. The inventive crosslinked composition can also be used in the production of belts, tires, electrical cable sheaths, and shoe soles.”

Owner:ARKEMA FRANCE SA

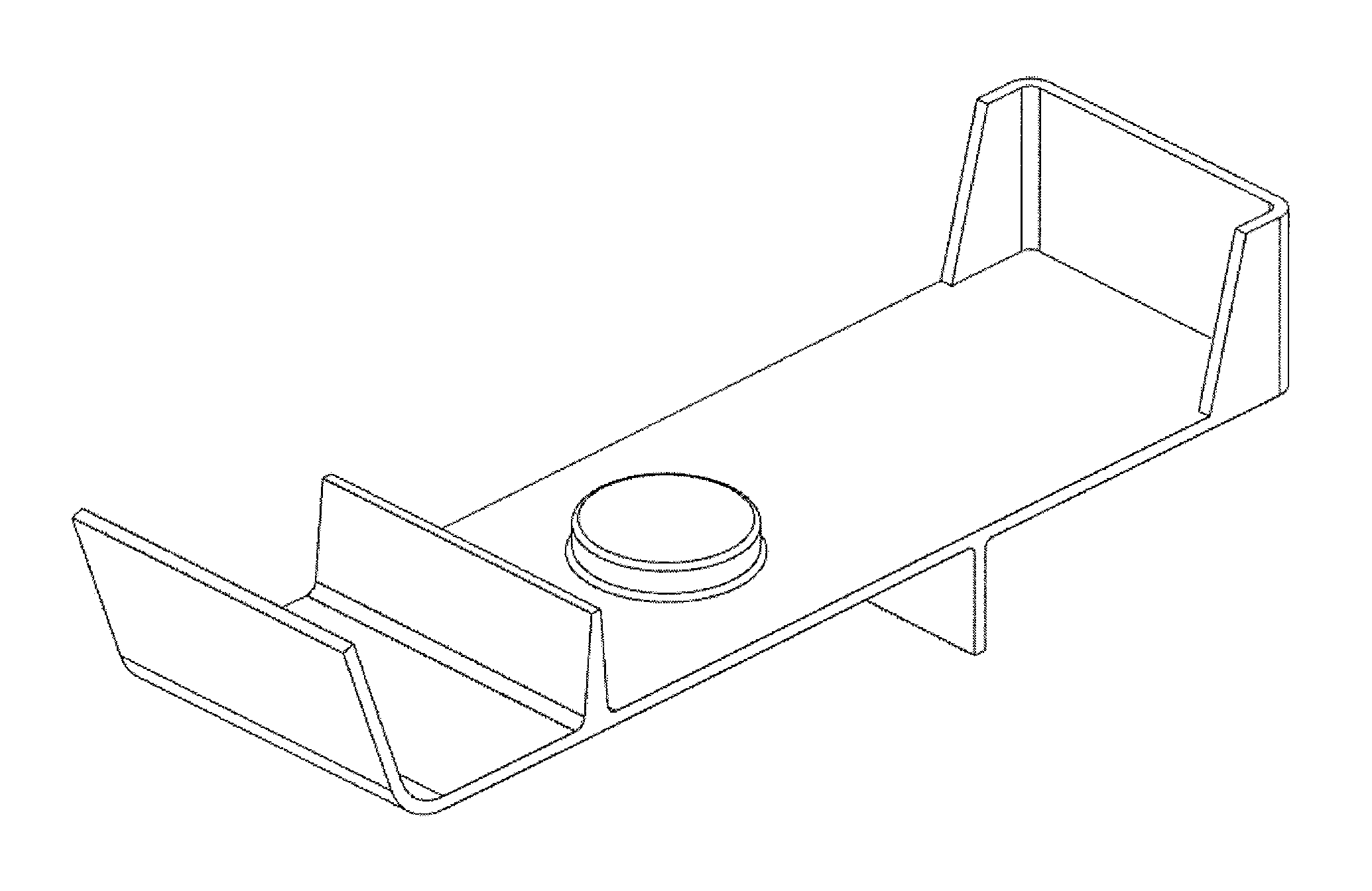

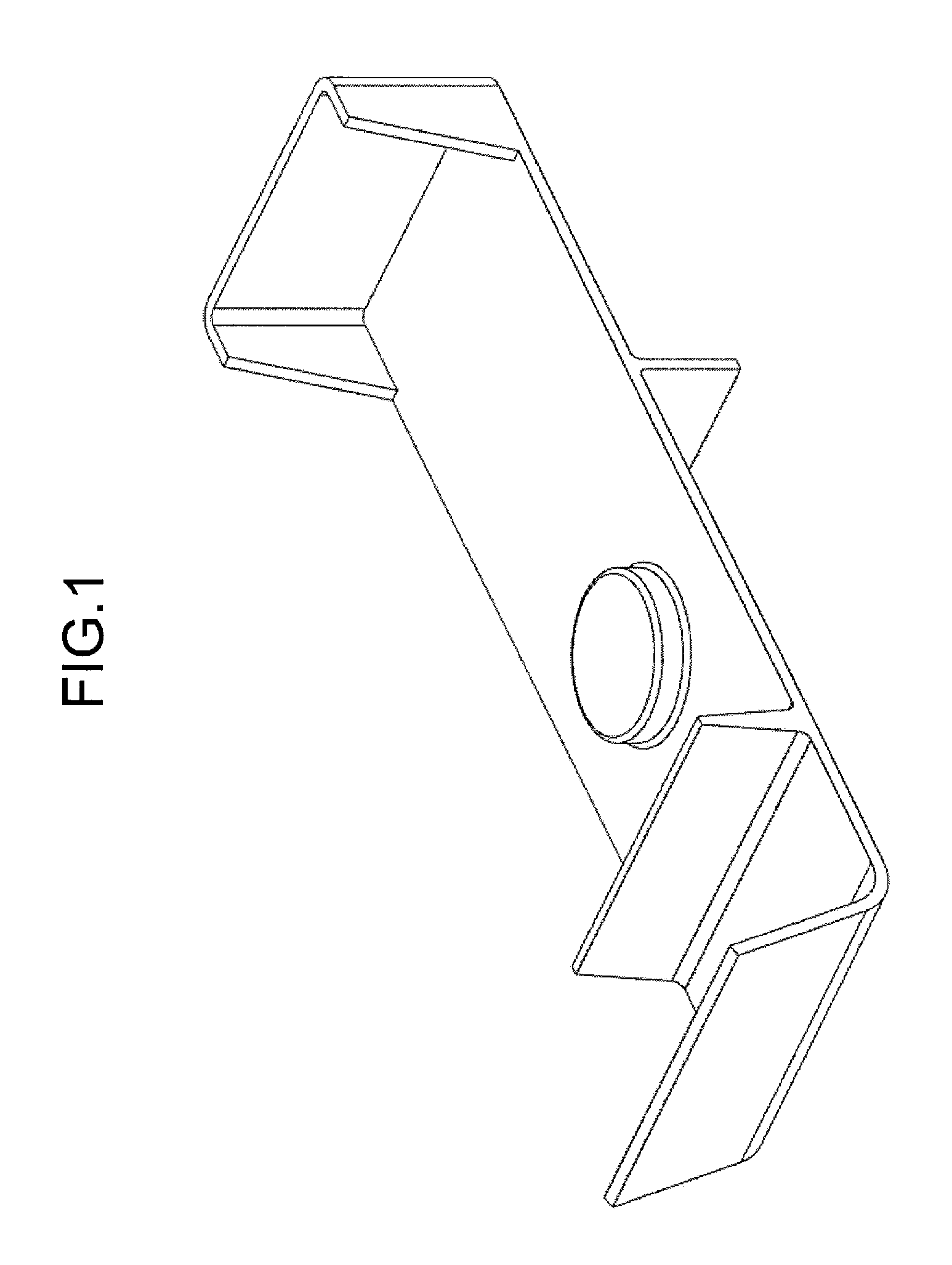

Shaped Product Constituted by Fiber-Reinforced Composite Material

InactiveUS20130344282A1Improve rigidityExcellent surface appearanceDecorative surface effectsDuplicating/marking methodsPolymer scienceFiber bundle

The present invention relates to a shaped product being excellent in isotropy constituted by a fiber-reinforced composite material in which discontinuous reinforcing fibers are isotropic in a plane and are two-dimensionally oriented in the thermoplastic resin, the reinforcing fibers contained in the shaped product includes a reinforcing fiber bundle (A) constituted by the reinforcing fibers of the critical single fiber number defined by formula (1) or more, a ratio of the reinforcing fiber bundle (A) to the total amount of the reinforcing fibers in the shaped product is 20 vol % or more and less than 90 vol %, and the average number (N) of the reinforcing fibers in the reinforcing fiber bundle (A) satisfies formula (2):Critical single fiber number=600 / D (1)0.7×104 / D2<N<1×105 / D2 (2)wherein D is an average fiber diameter (μm) of the reinforcing fibers.

Owner:TEIJIN LTD

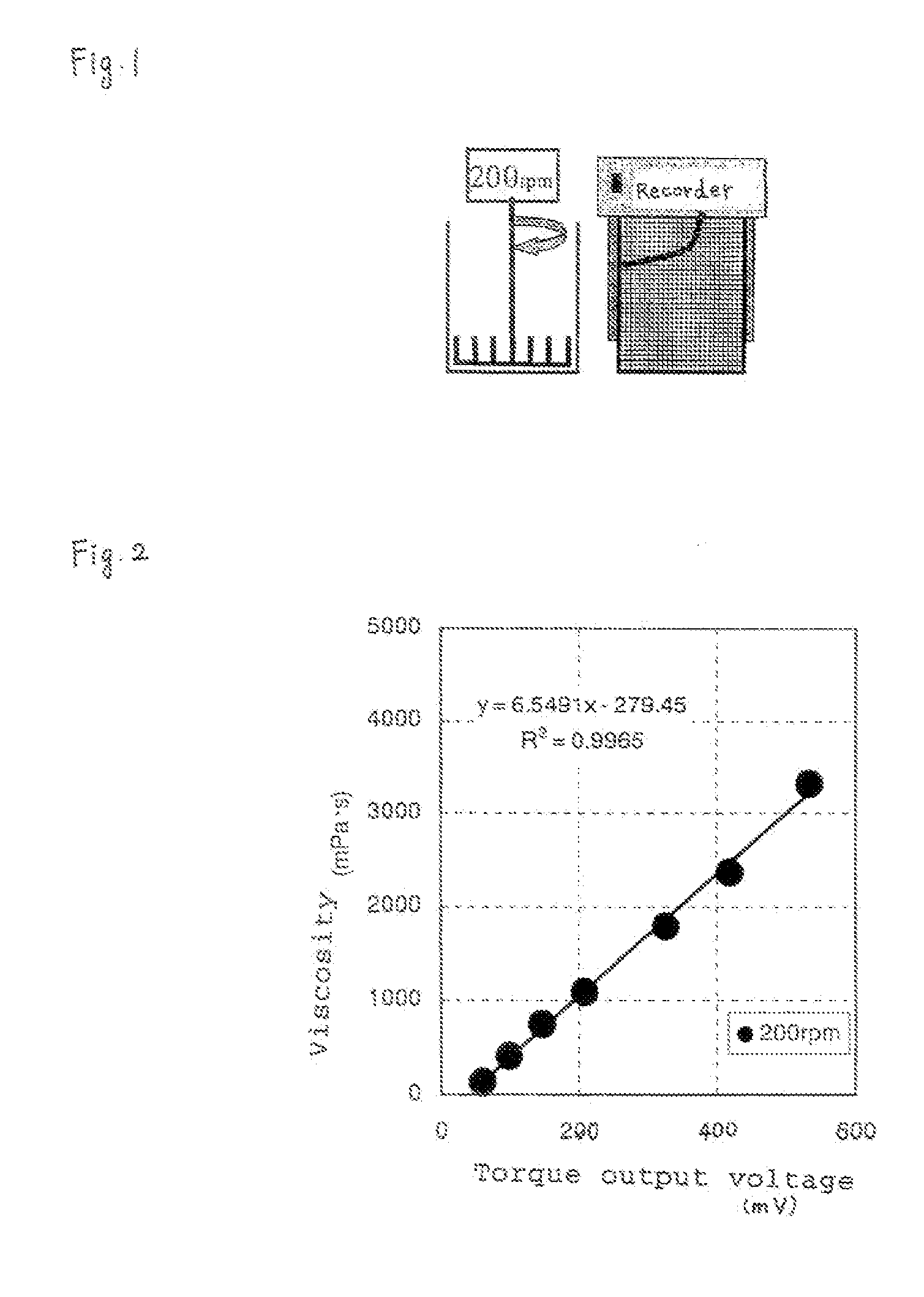

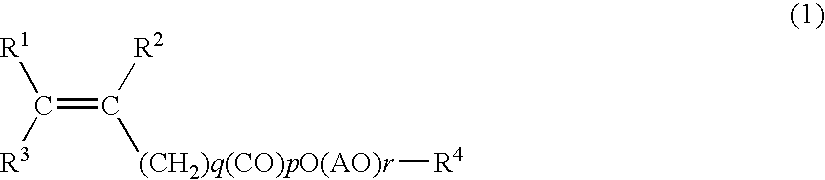

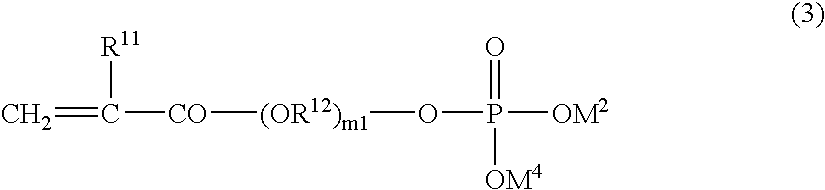

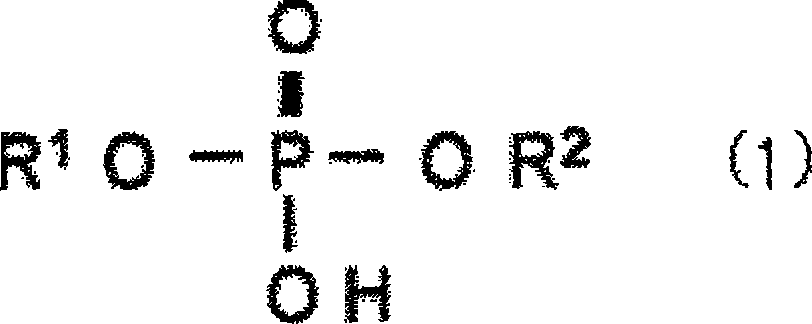

Hydraulic composition dispersant

The present invention relates to a hydraulic composition dispersant containing a polycarboxylic acid-based polymer A having a carboxylic acid group and an oxyalkylene group and / or an oxystyrene group such as polymers obtained by copolymerizing a specified monomer 1 such as an ethylenic unsaturated carboxylic acid derivative having a polyoxyalkylene group with a specified monomer 2 such as a (meth)acrylic acid, and a polymer B obtained by copolymerizing the monomer 1, a monophosphate-based monomer 3 and a diphosphate-based monomer 4.

Owner:KAO CORP

Electrically conductive resin composition and production process thereof

InactiveUS6919394B2Reduction factorExcellent surface appearanceNanotechSpecial tyresPolyamideElectrostatic coating

An electrically conductive resin composition comprising a polyamide, a polyphenylene ether, an impact modifier and an electrically conductive filler, not less than 50 wt. % of all of the filler used being preliminarily compounded with a mixture containing the impact modifier and the polyphenylene ether, wherein electrical conductivity having a level in which electrostatic coating is possible, a low coefficient of linear expansion and high surface appearance have been accomplished at the same time, and wherein generation of fines caused by pelletizing on extruding has been suppressed.

Owner:ASAHI KASEI KK

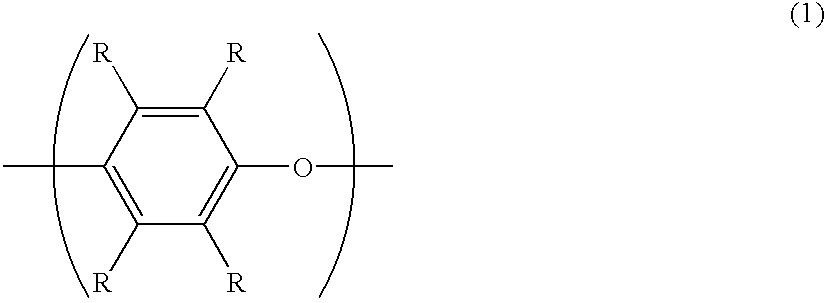

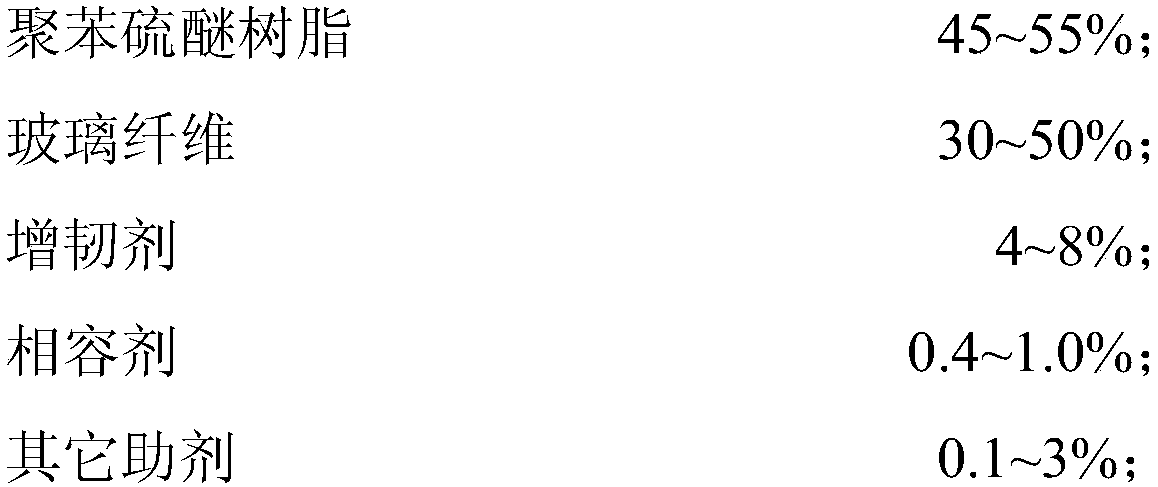

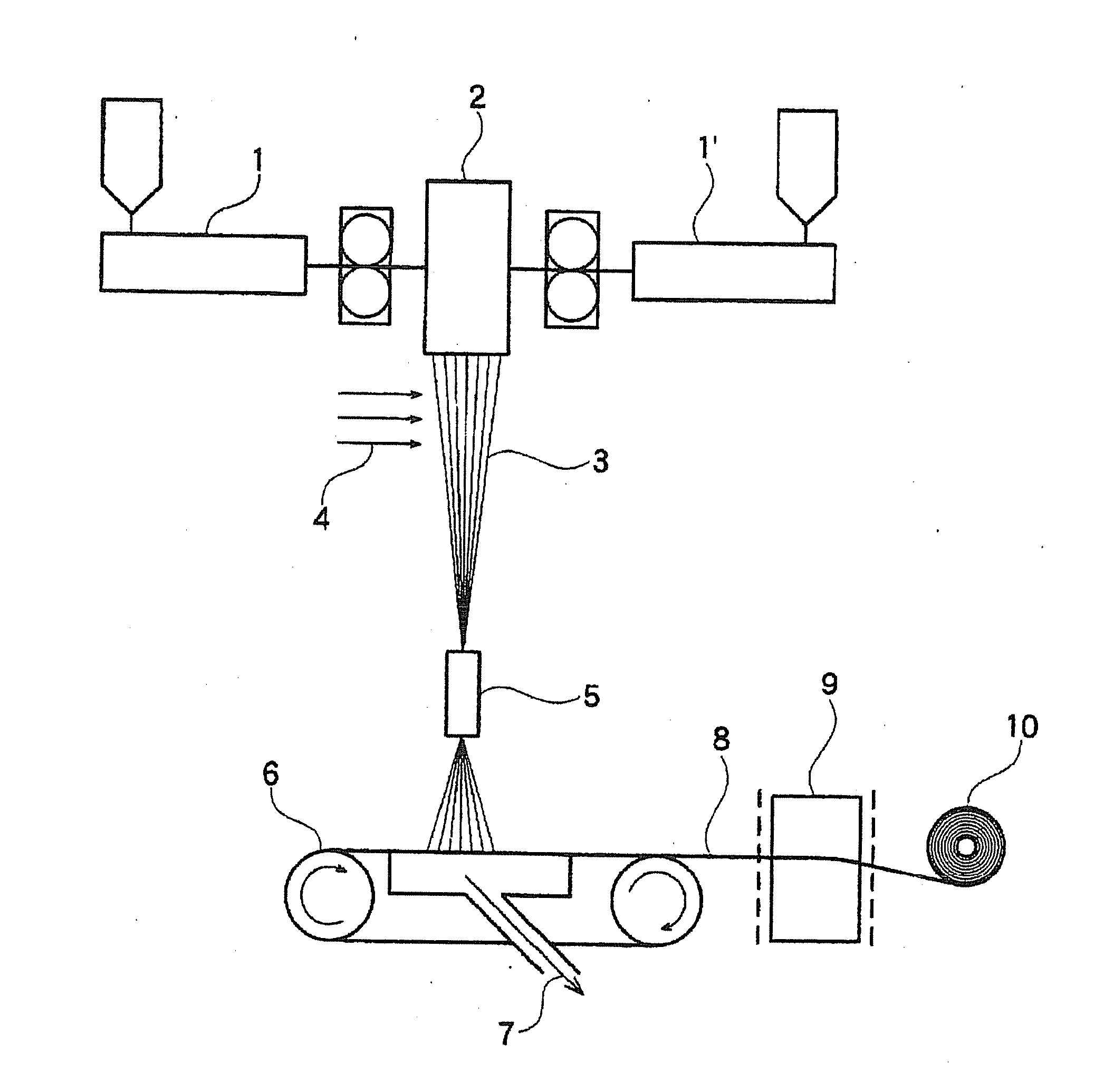

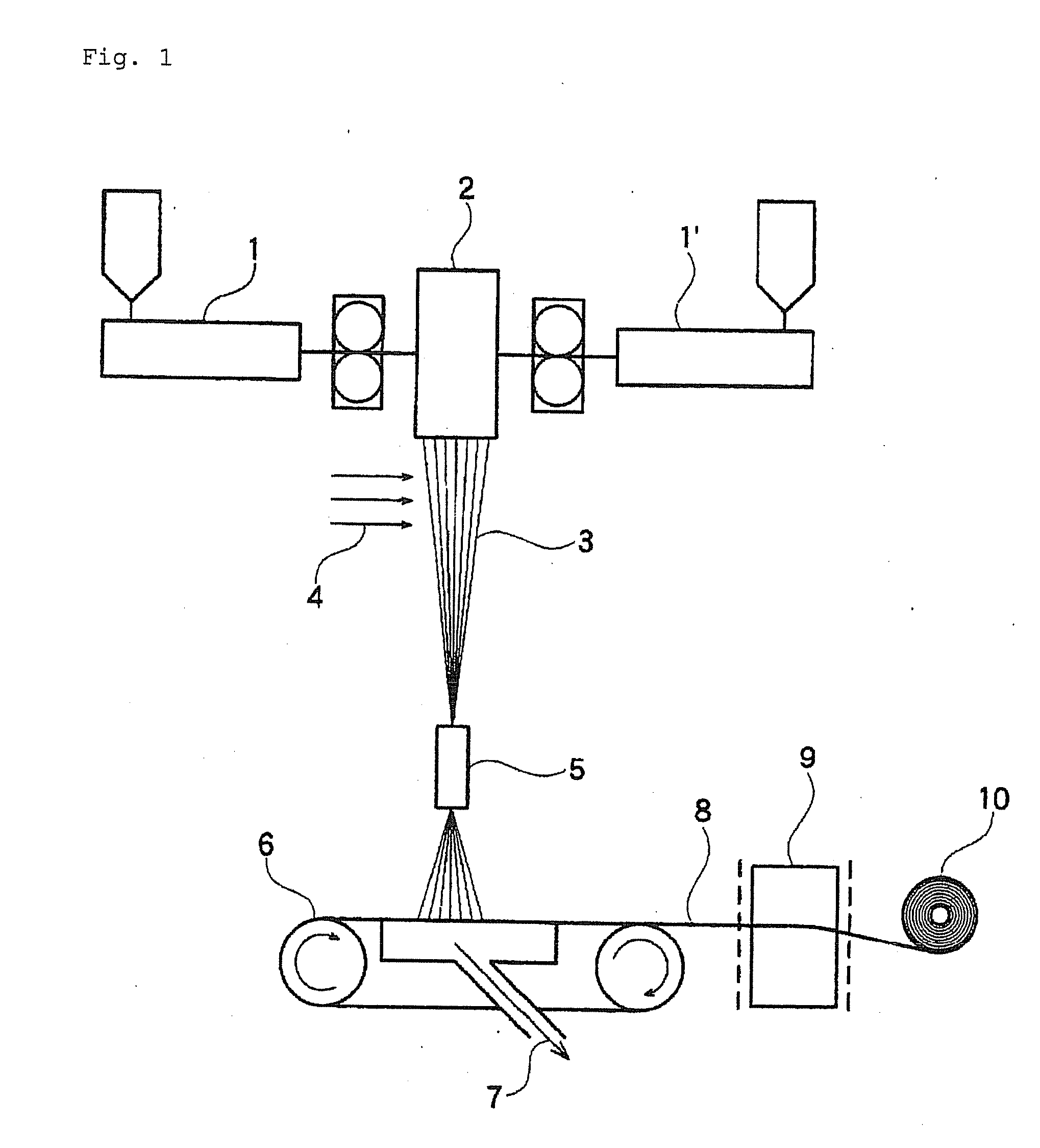

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

Polypropylene Nonwoven Fabric and Use Thereof

ActiveUS20080014819A1Excellent in appearance propertyExcellent in stretch propertyFilament/thread formingAdhesive dressingsResidual strainPolymer science

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

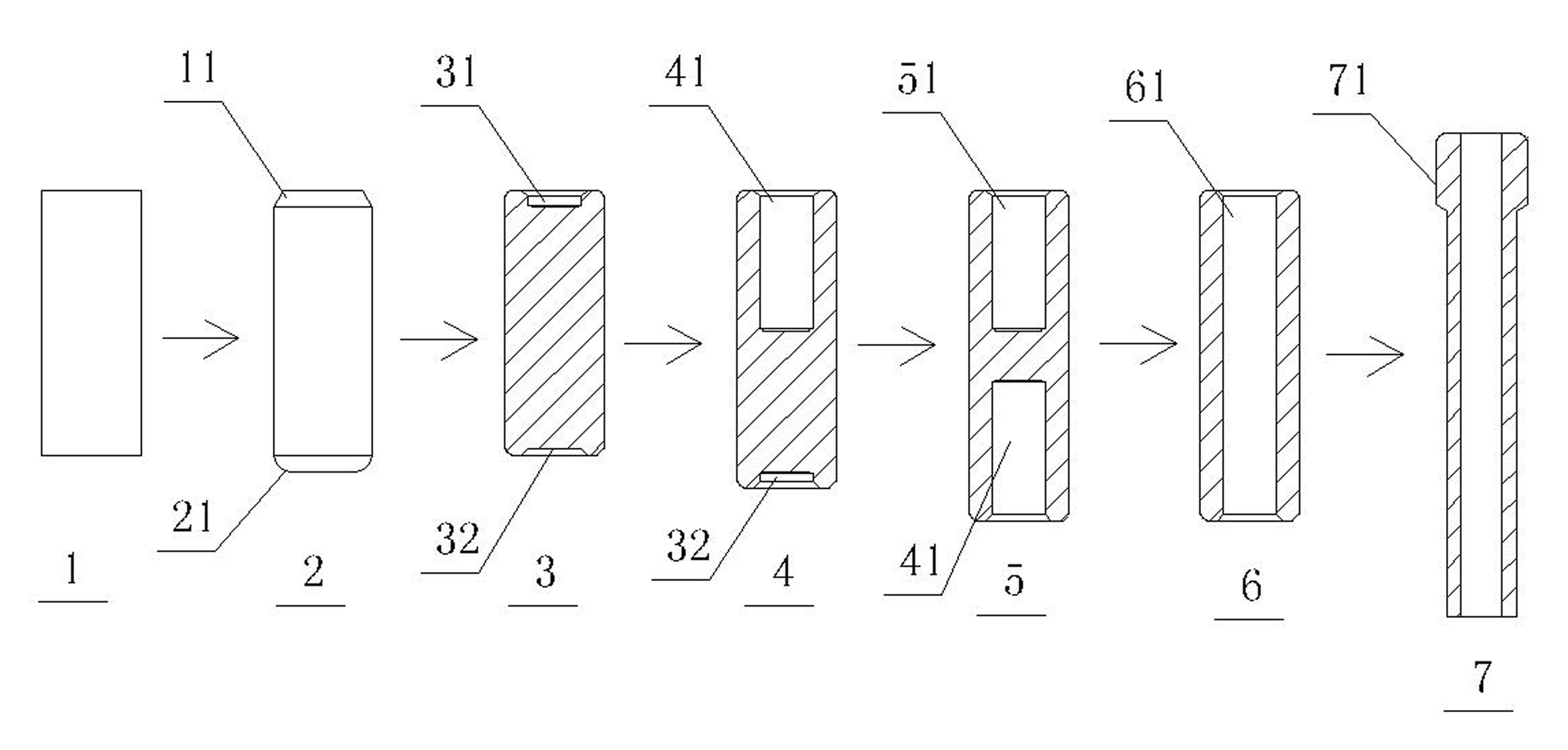

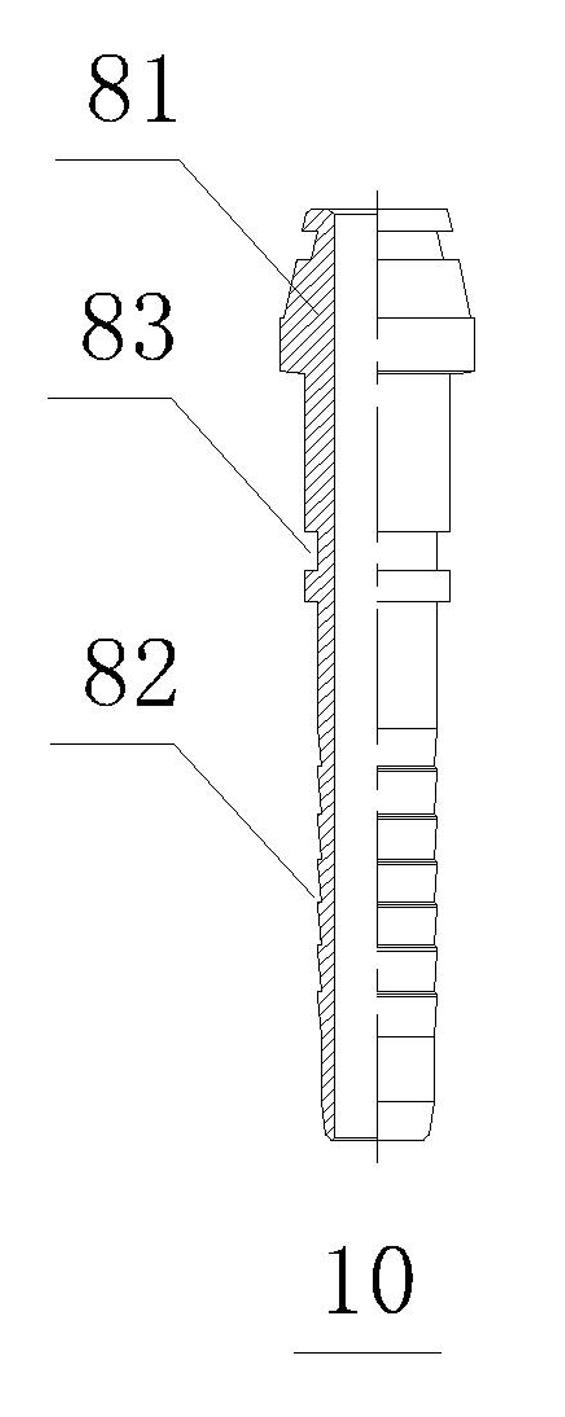

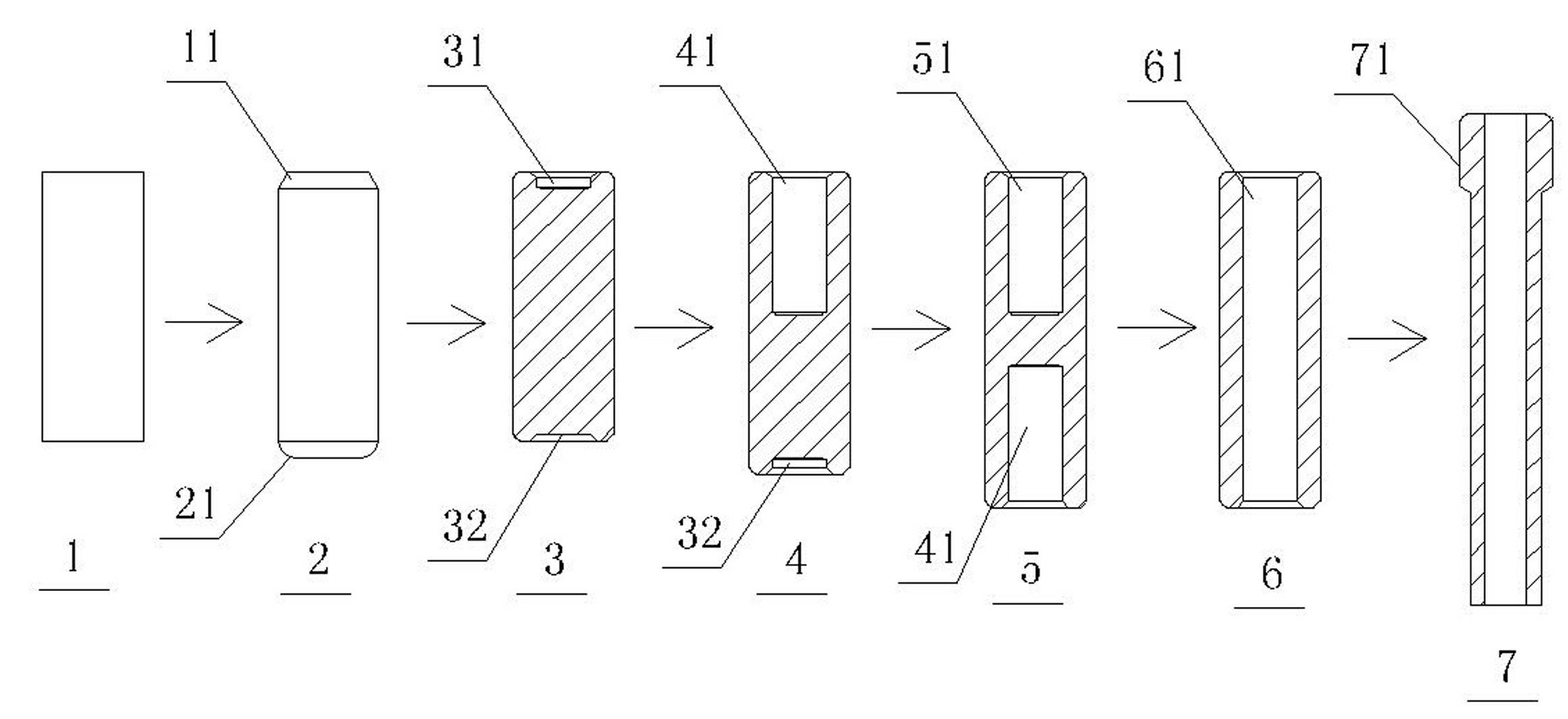

Method for manufacturing hose connector core

The invention provides a method for manufacturing a hose connector core, which comprises the following steps of: performing spheroidizing annealing on a wire rod blank material serving as a raw material; performing phosphate coating surface treatment on the wire rod blank material subjected to spheroidizing annealing; performing fine drawing sizing, and cutting a wire rod finished product material subjected to fine drawing sizing into single hose connector core blank materials; and manufacturing the blank of the hose connector core by using a seven-station cold heading method and a cold heading machine. The wire rod material is used for replacing a straight bar material and a broken material, so that the requirement of multi-station cold heading continuous production can be met, and the loss of a material head and a material tail is reduced; stations are reasonably designed, so that the physical property and the quality of a product are improved, and the product has good surface appearance; a material part is easily subjected to plastic deformation in the cold extrusion process, and the loss of a die is low; and finish machining production speed is doubled.

Owner:YUYAO HANGYI AUTOMOBILE PARTS

Composite polyamide shaped articles

ActiveUS20100215920A1Reduce manufacturing costShort cycleAdhesive processesDecorative surface effectsPolymer sciencePolyamide

Owner:RHODIA OPERATIONS SAS

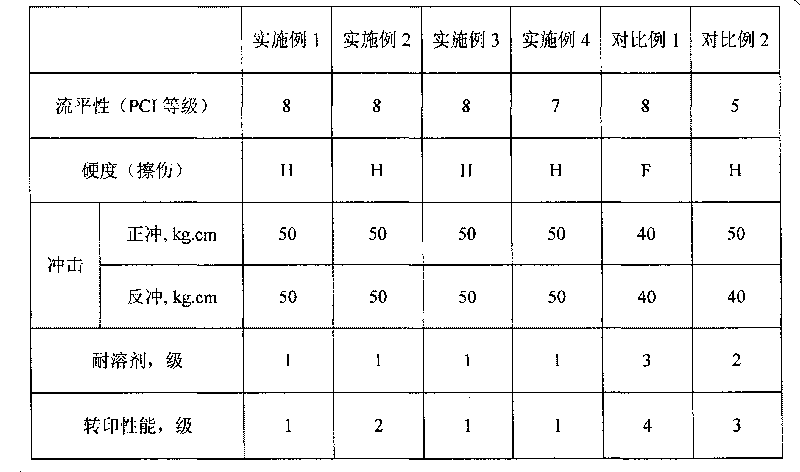

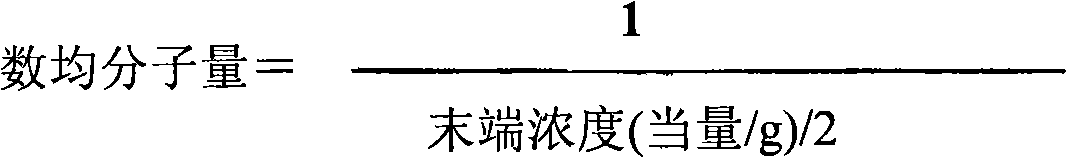

Polyester resin for mixed powder coating and preparation method thereof

ActiveCN101704945AUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsLow temperature curingAdipic acid

The invention relates to the field of powder coatings, in particular to a polyester resin for a mixed thermal transfer powder coating and a preparation method thereof. The polyester resin for the mixed thermal transfer powder coating comprises the following components and contents: 1 mole percent of acids, 1.05-1.20 mole percent of alcohols, 10-15wt% of trimellitic anhydride and 0.1-1.0wt% of recomposed onium salts, wherein the alcohols accounting for the total alcohol mol percent comprise 10-90 mol% of neopentyl glycol, 0-45 mol% of dimethyl-1,3-propanediol, 0-20 mol% of ethanediol, 10-25 mol% of diethylene glycol; and the acids accounting for the total acid mol percent comprise 80-100 mol% of terephthalic acid, 0-10 mol% of m-phthalic acid and 0-10 mol% of mol% of adipic acid. The functionality of the polyester resin is regulated according to the amount of the branched components of the trimellitic anhydride, thus the obtained cured film has better surface appearance, low temperature (160 DEG C) curing is realized, the curing percent of film coating at low temperature is high, the curing film has fine solvent resistance and the transfer-printed transfer printing film is clear, vivid and easy to tear.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

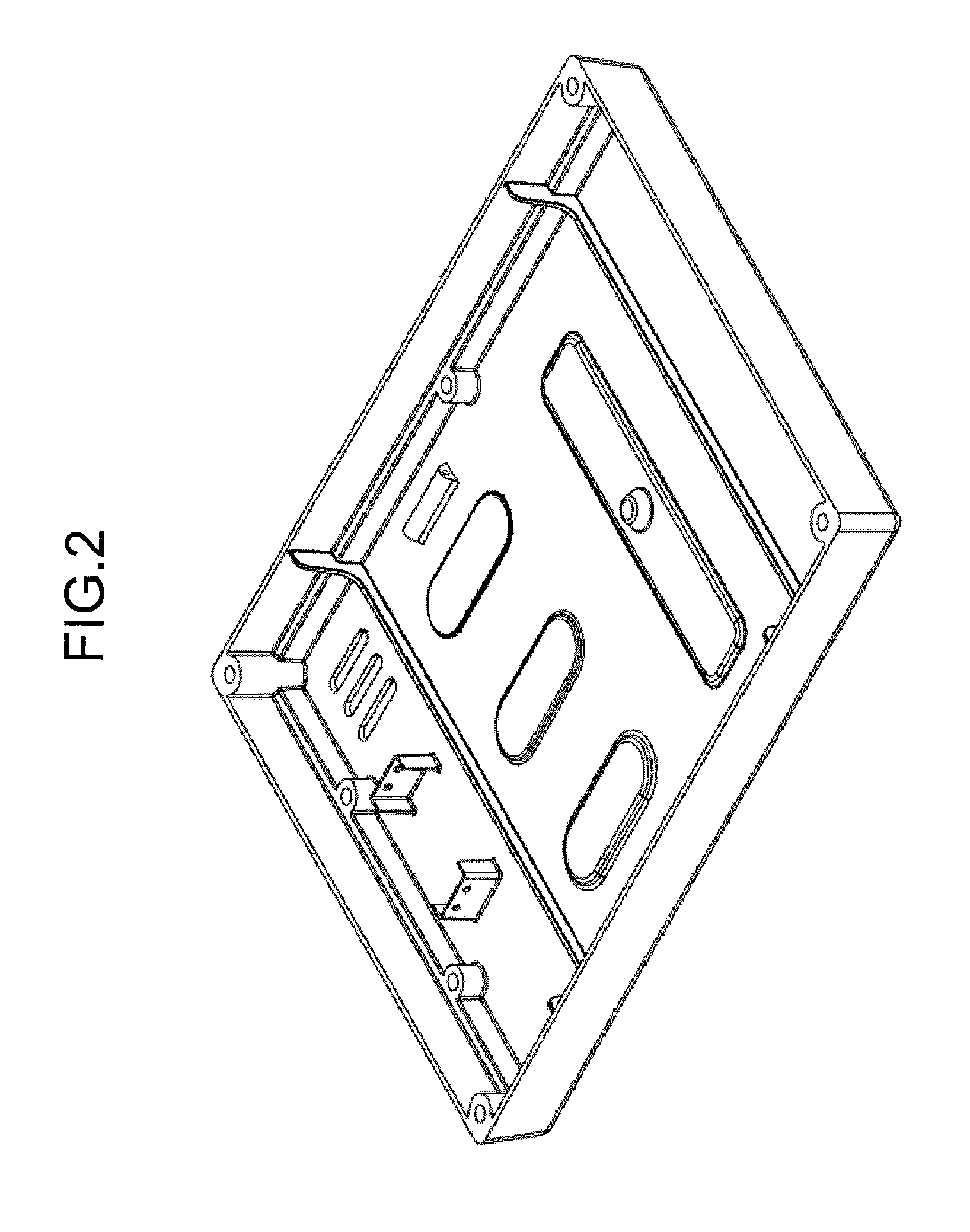

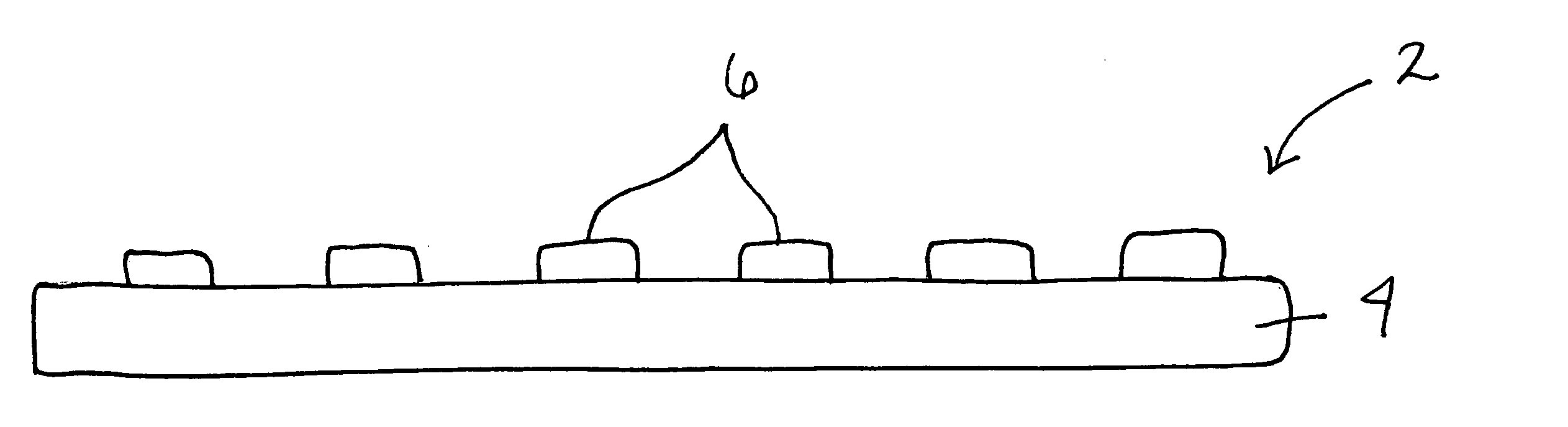

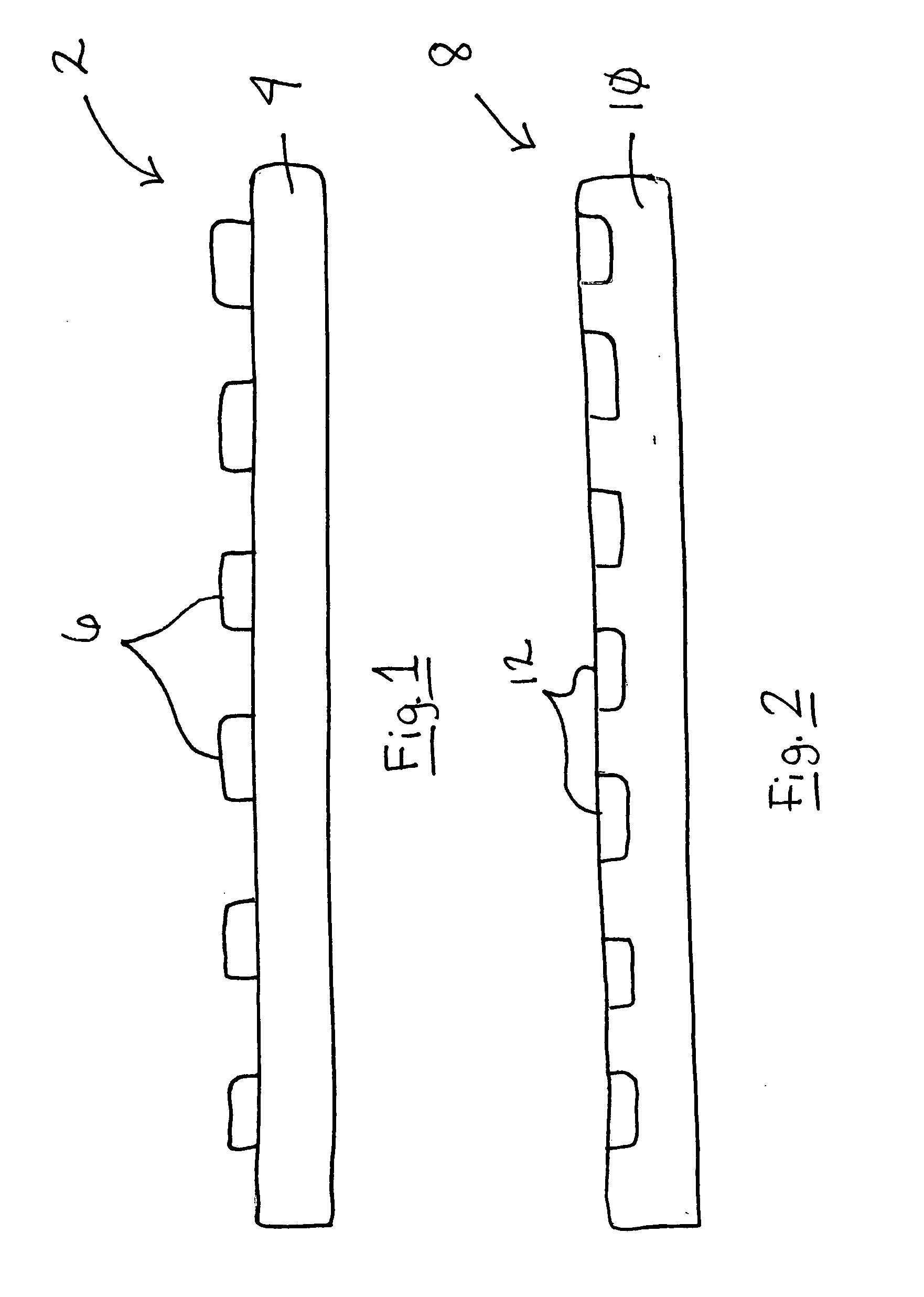

Multidensity liner/insulator having reinforcing ribs

InactiveUS20050191921A1Improve performanceImproved compressive and flexural propertyAdhesive processesLamination ancillary operationsFiberFibrous Glass

A liner / insulator including a base layer of fibrous material and a plurality of ribs of fibrous insulation material thermally bonded to said base layer. The fibrous material is constructed of either (a) thermoplastic polymer staple fibers and thermoplastic bicomponent fibers, (b) glass staple fibers and thermoplastic bicomponent fibers and (c) a combination of (a) and (b).

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

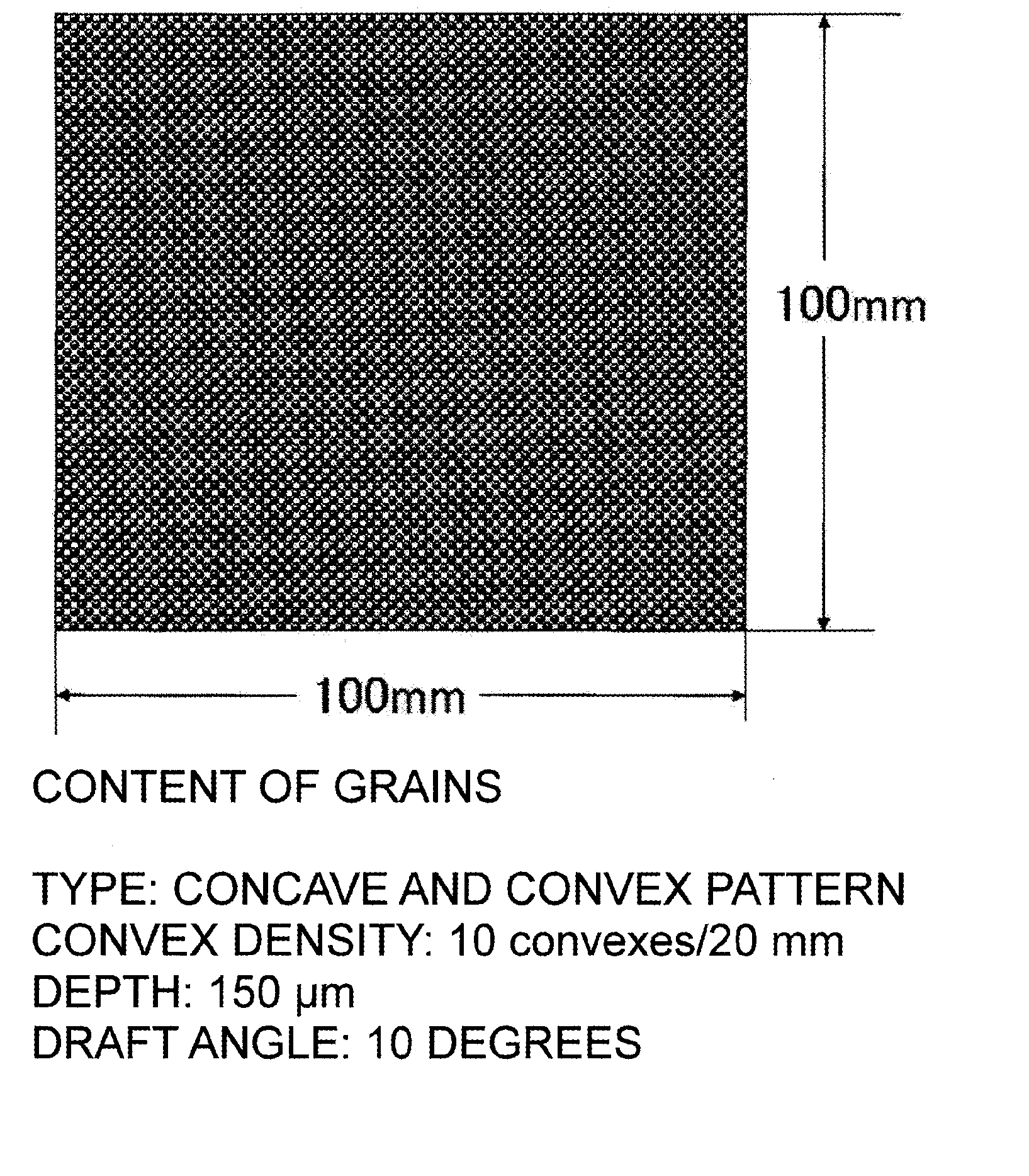

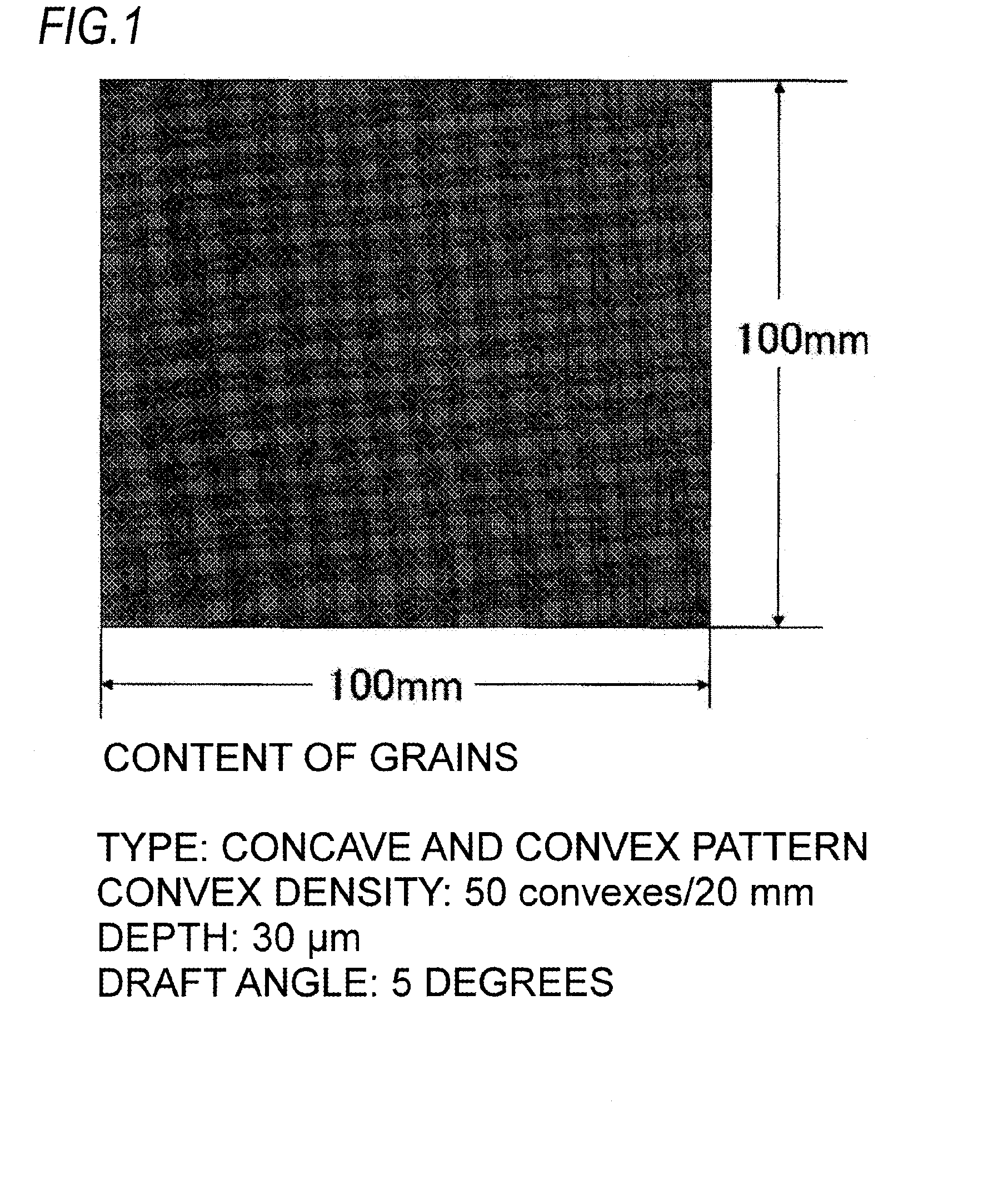

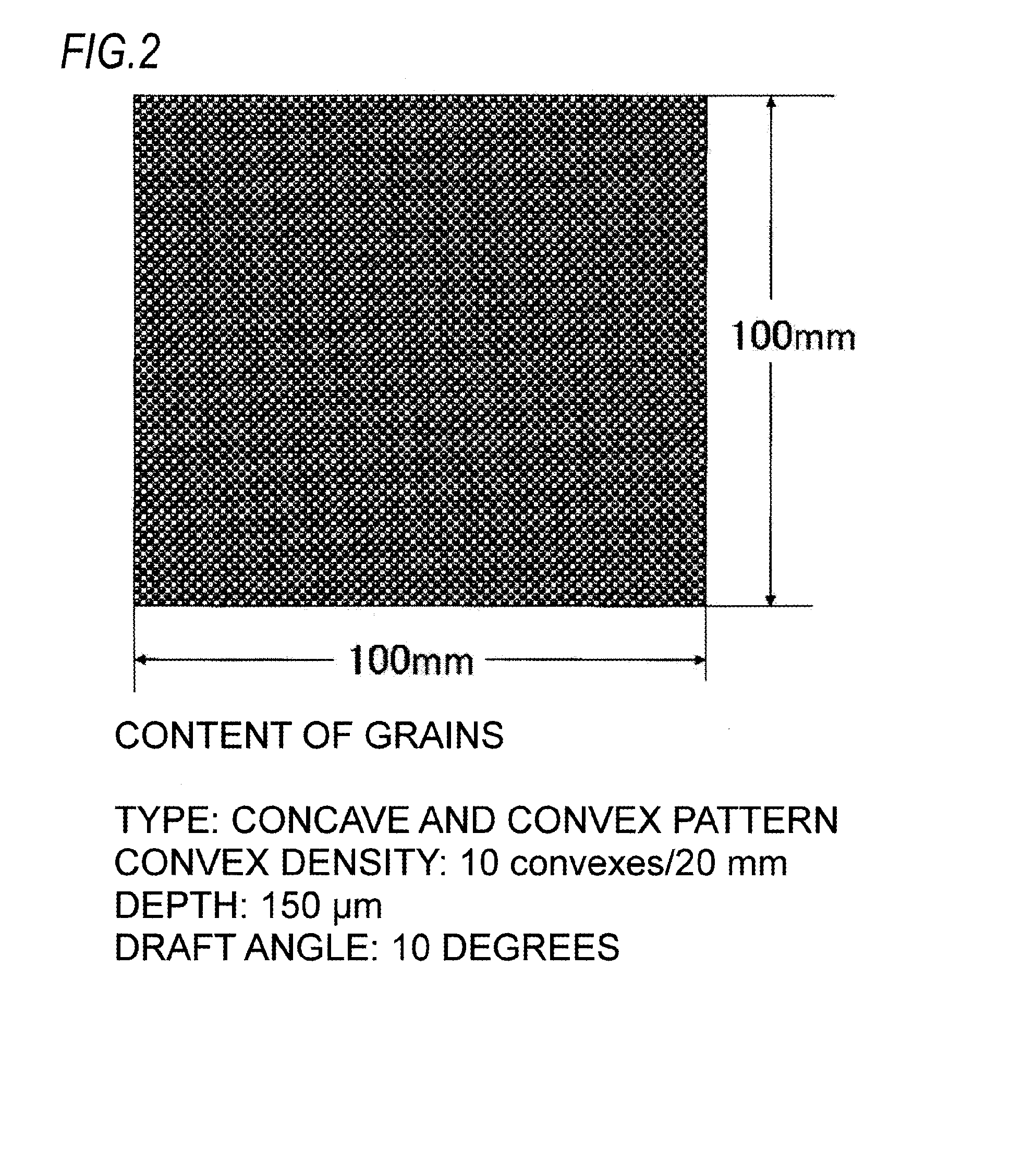

Shaped Product Made of Fiber-Reinforced Composite Material and Having Excellent Surface Appearance

ActiveUS20140186584A1Lightening surface appearanceLighten the total weightWood working apparatusFlat articlesPolymer scienceFiber bundle

There is provided a shaped product made of a fiber-reinforced composite material including reinforcing fibers having an average length of 5 mm or more and 100 mm or less and a thermoplastic resin, in which a volume fraction of reinforcing fibers (Vf=100×volume of reinforcing fibers / (volume of reinforcing fibers+volume of thermoplastic resin)) is 5 to 80%, grains are formed on a surface of the shaped product, and a ratio of a reinforcing fiber bundle (A) including the reinforcing fibers of a critical number of single fiber or more, the critical number defined by Formula (1), to the total amount of the reinforcing fibers is 20 Vol % or more and 99 Vol % or less:Critical number of single fiber=600 / D (1)(wherein D is an average fiber diameter (μm) of single reinforcing fiber).

Owner:TEIJIN LTD

Melt tension improver for polyolefin resins and process for producing the same

A melt tension enhancer for polyolefin resins that contains polytetrafluoroethylene and a polymer of an alkyl (meth)acrylate of 5-30 carbon atoms, and a process for its production. Its addition to polyolefin resins enhances the melt tension of the polyolefin resins without impairing the surface appearance of their molds.

Owner:MITSUBISHI CHEM CORP

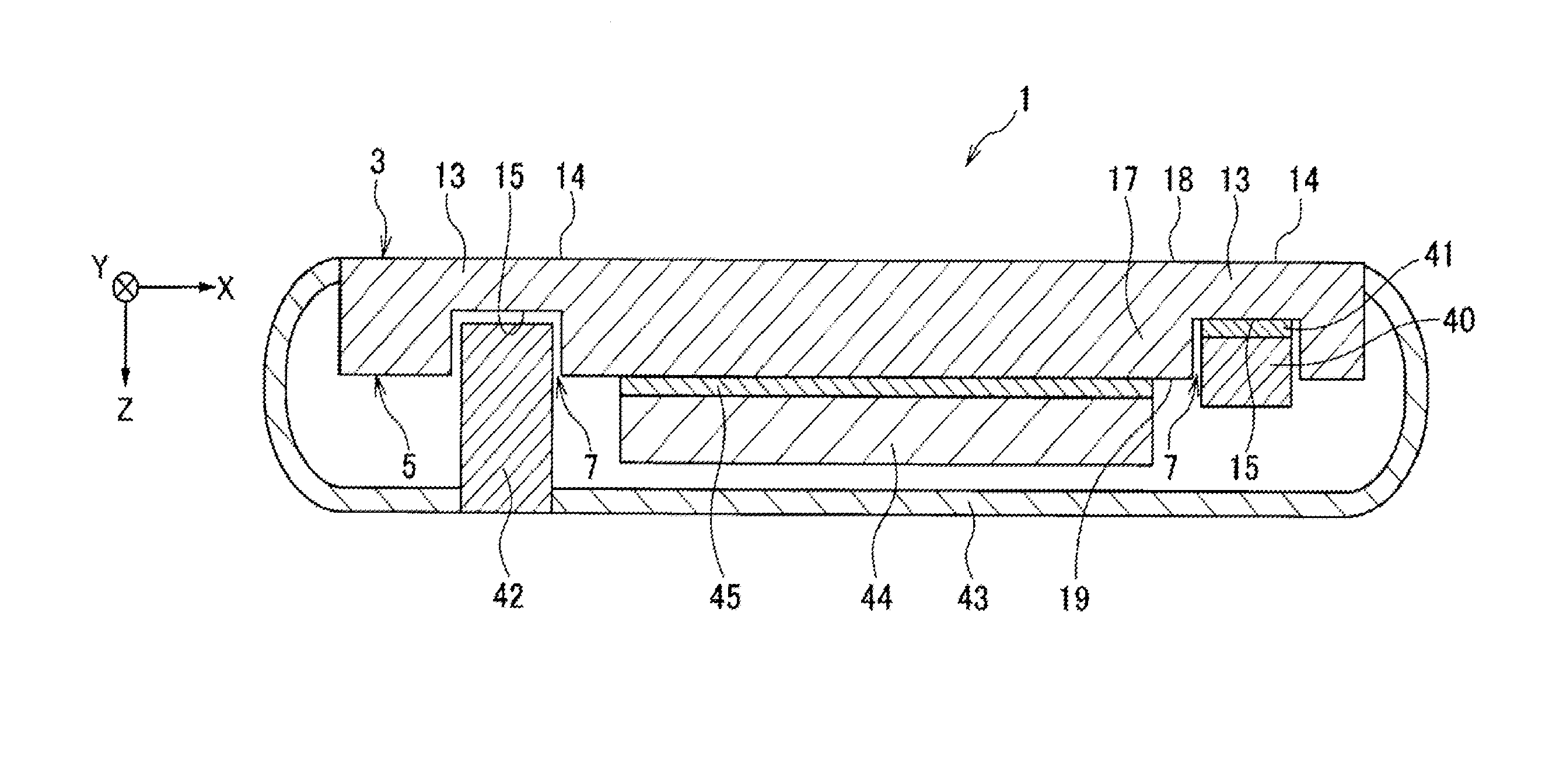

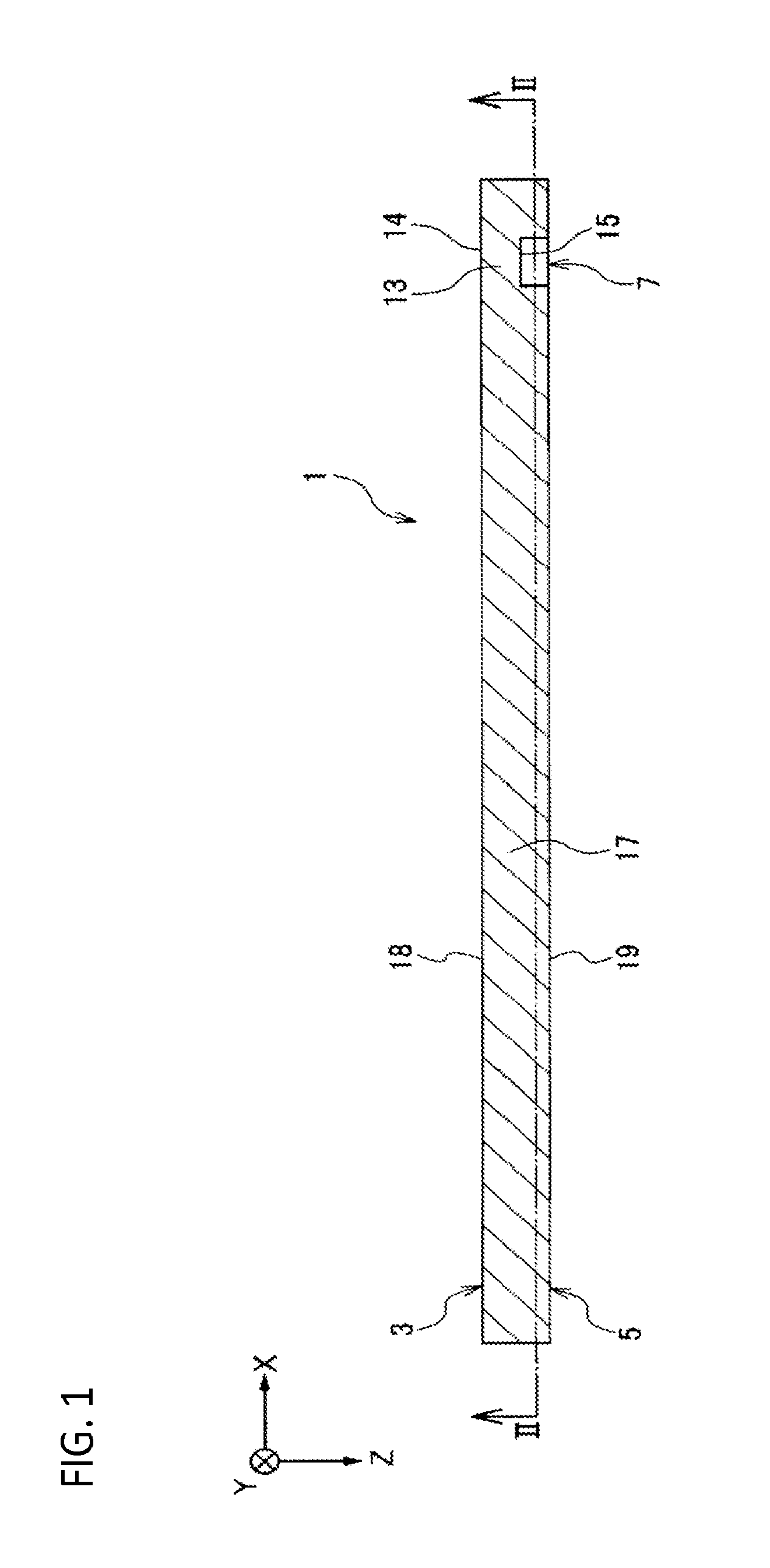

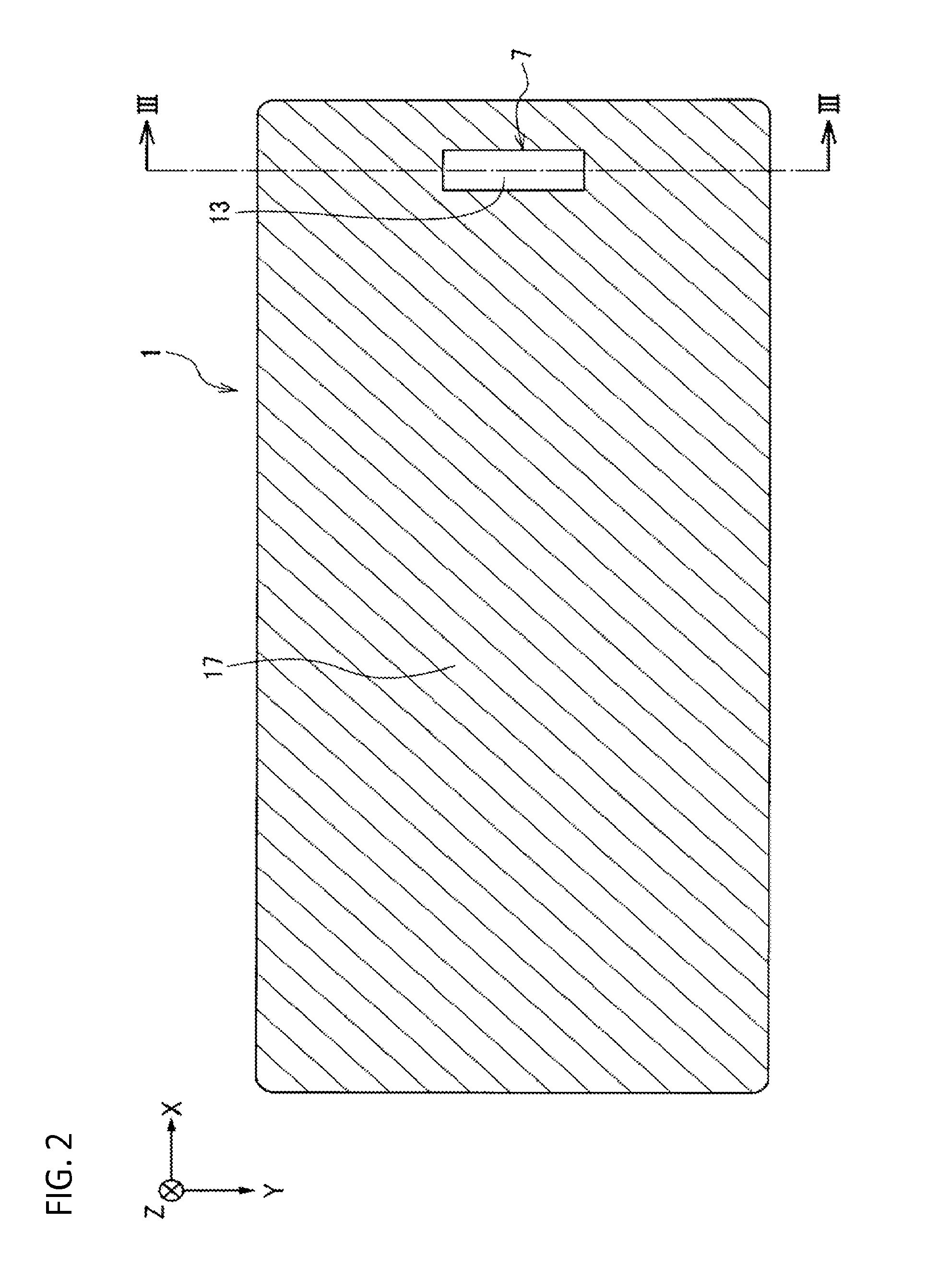

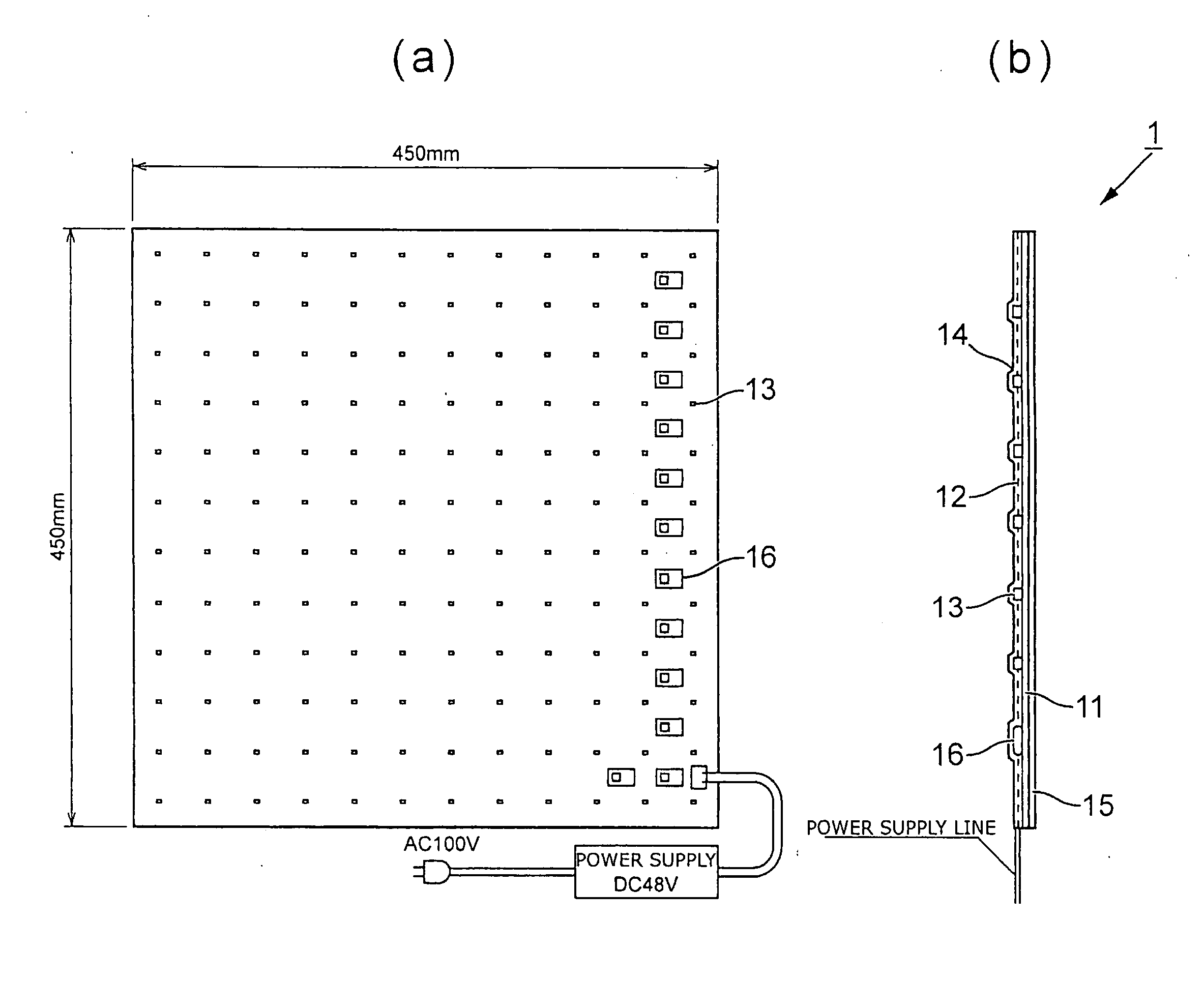

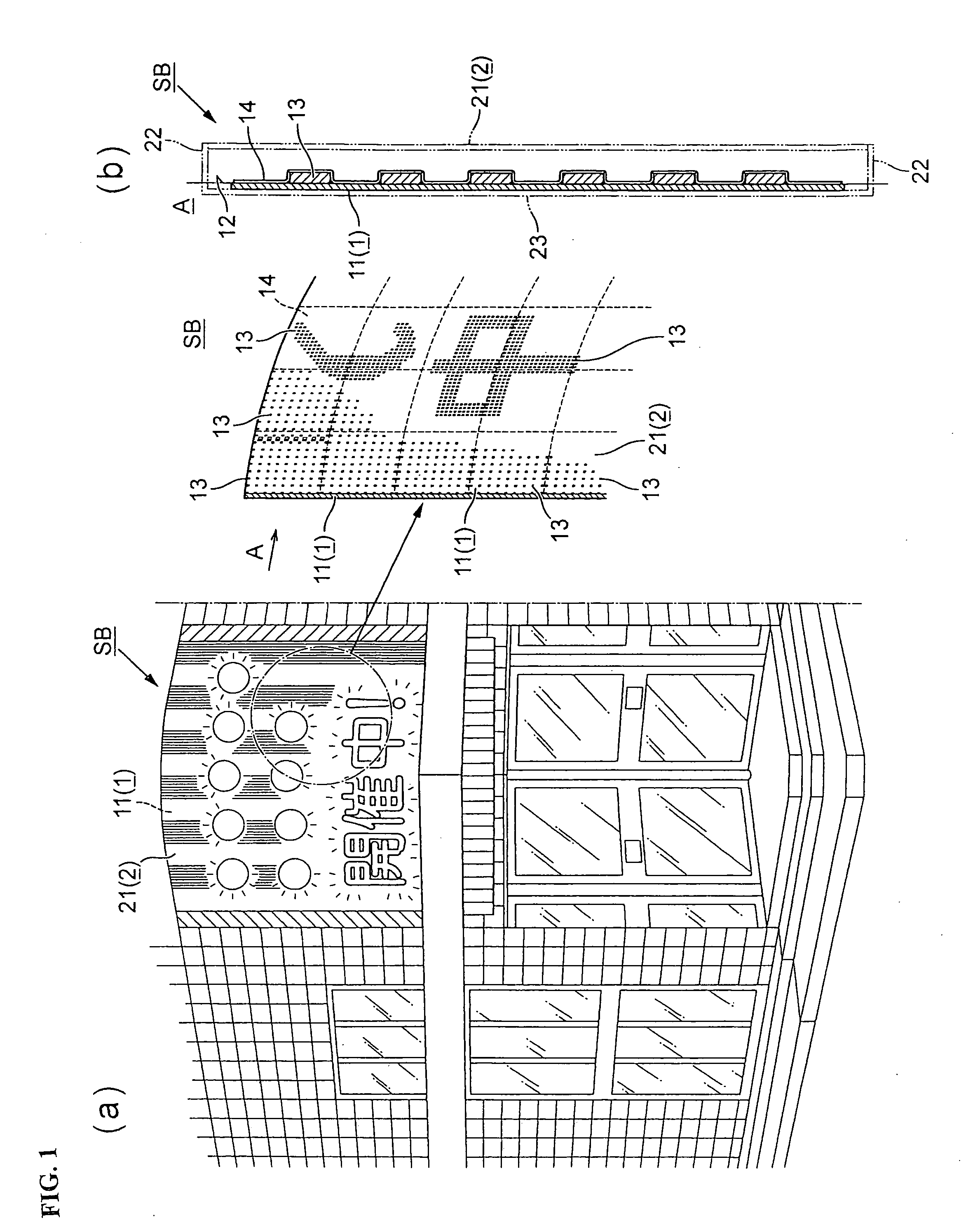

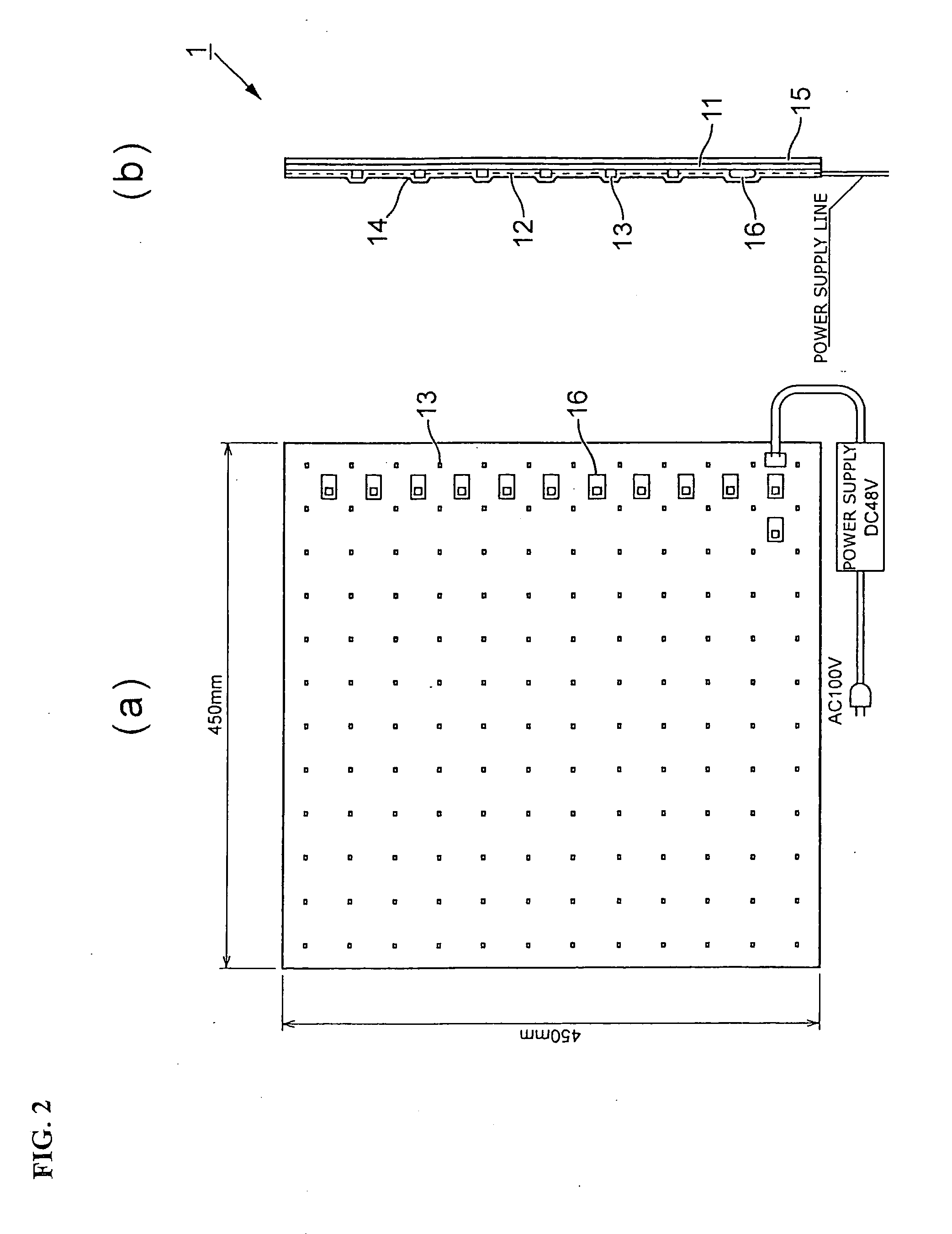

Surface emitter and internally illuminated sign incorporating the same

InactiveUS20100212198A1Increase forceSusceptible to heatPoint-like light sourceLighting elementsVacuum pressureElectrical and Electronics engineering

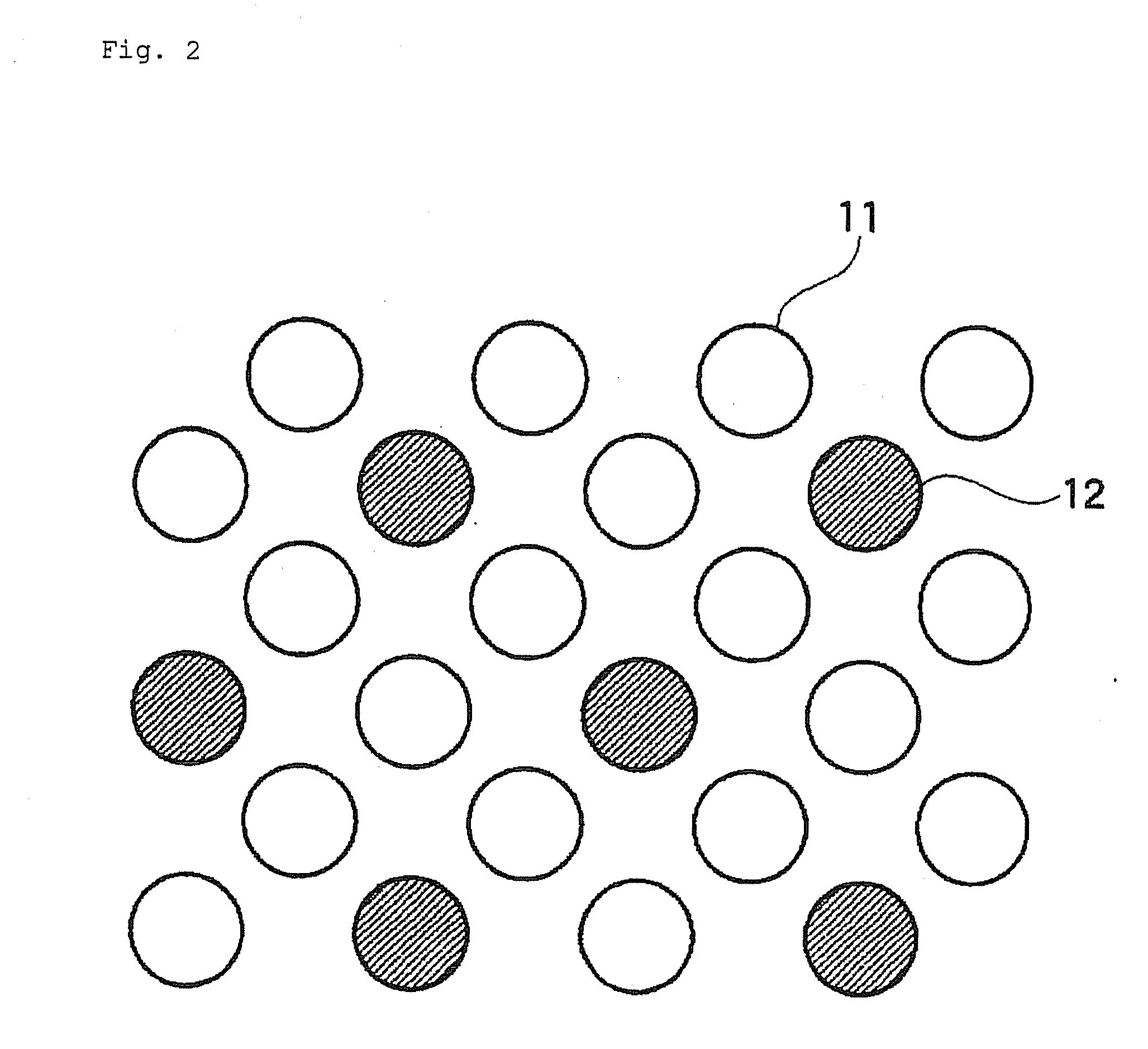

To provide a novel surface emitter incorporating an LED element improved in waterproofness or other practical functionality to enable the surface emitter to be used not only for a sign but also for other various applications, in appearance and in workability, and an internally illuminated sign incorporating the same surface emitter. A surface emitter 1 according to the present invention has a flexible substrate 11 having electric wiring 12, a plurality of LED elements 13 disposed substantially regularly on the substrate 11, and a top film 14 disposed on the LED elements 13 in a stretched manner. When the top film 14 is disposed on the substrate 11 in a stretched manner, the top film 14 is applied to the substrate 11 to come into close contact with projections and depressions formed by the LED elements 13. More specifically, a vacuum pressure bonding process is used in which a space between the LED elements 13 and the top film 14 is evacuated, and the top film 14 is heated and pressure-bonded to the surface of the LED elements 13.

Owner:AMCREW INC

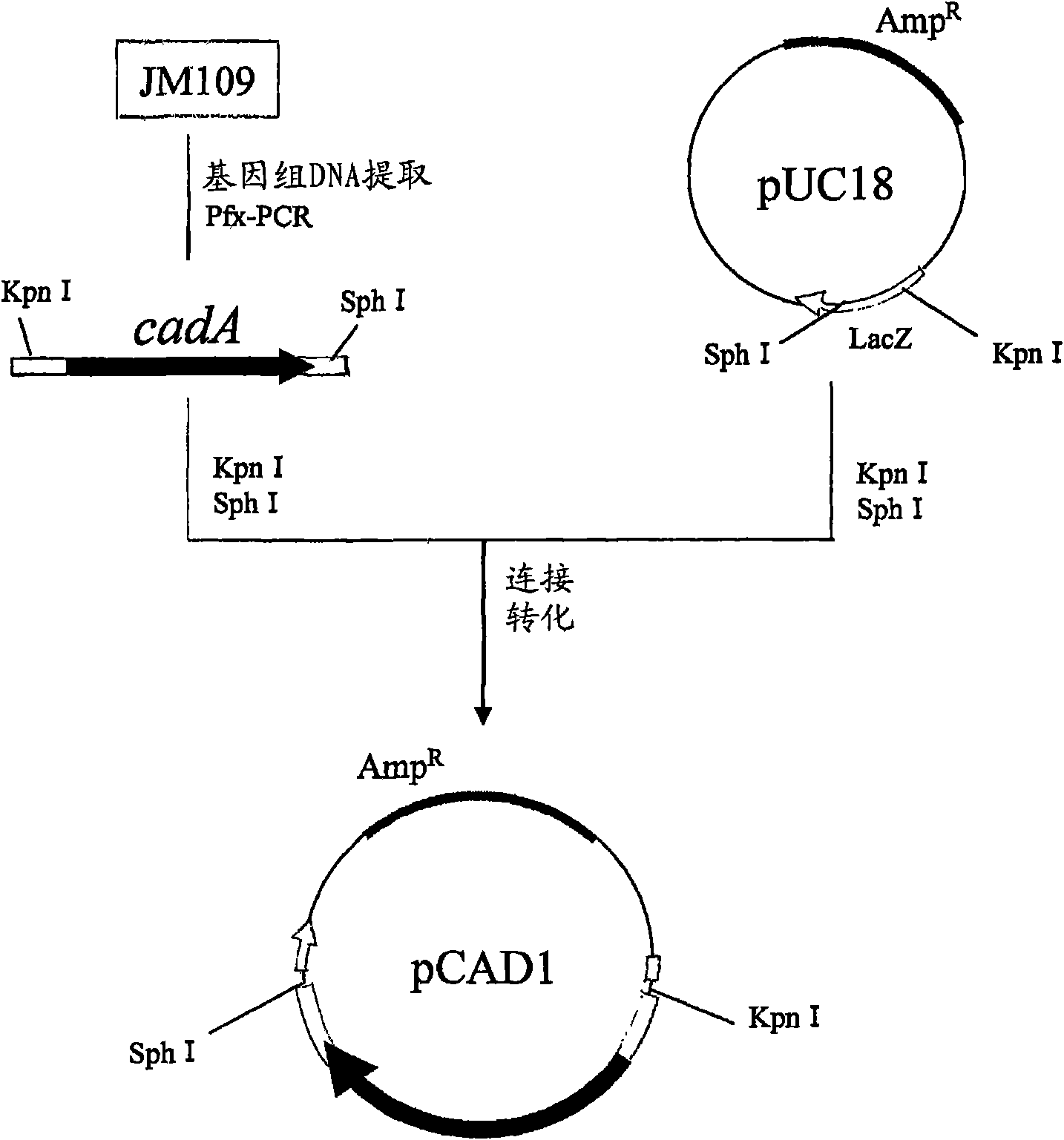

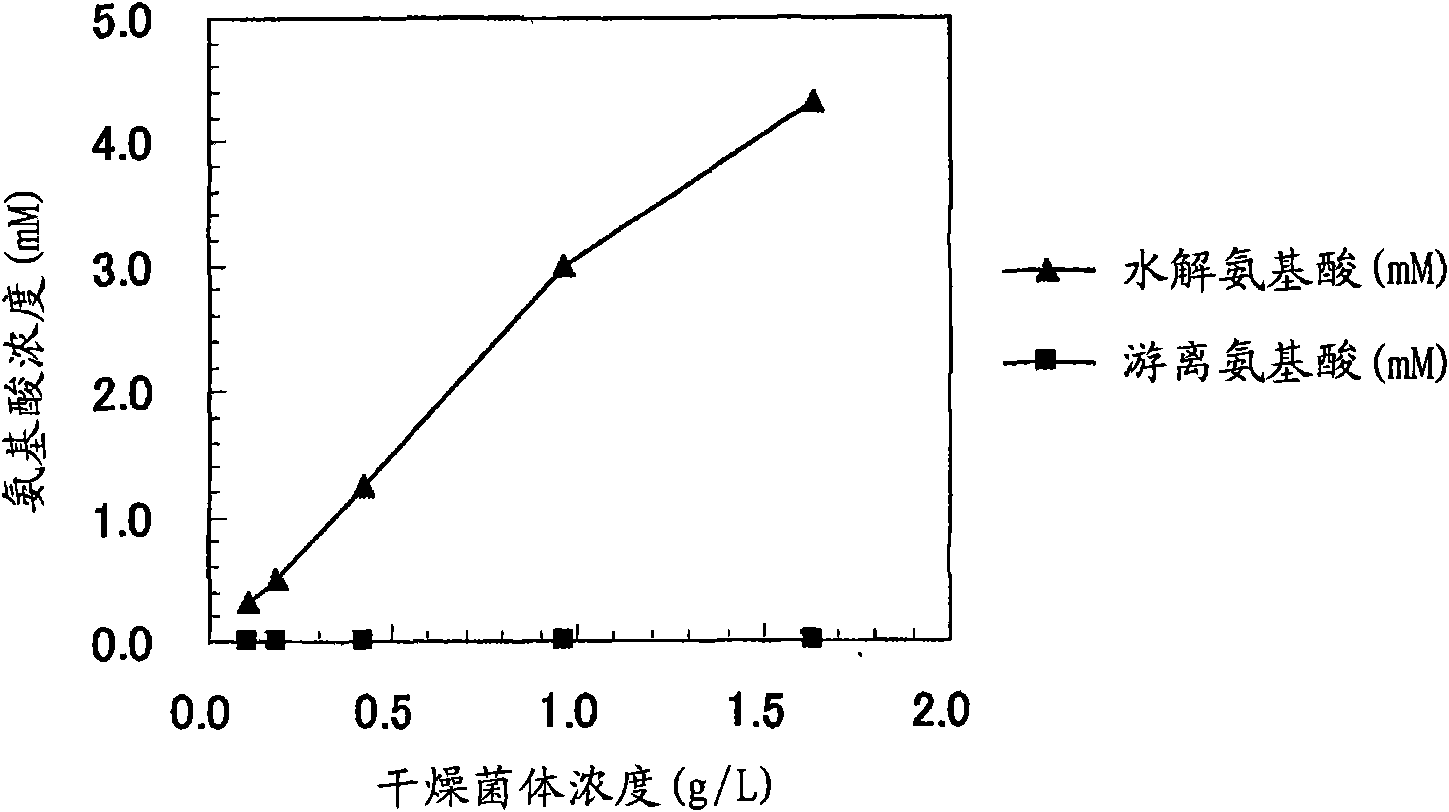

Cadaverine salt, aqueous cadaverine salt solution, polyamide resin, molded article and process for producing cadaverine salt and aqueous cadaverine salt solution

ActiveCN101578256AExcellent surface appearancePrevent surface appearance defectsAmino compound purification/separationRecombinant DNA-technologyCadaverineOrganic compound

To improve problems of the content of trifunctional and higher organic compounds, fish-eyes of a film and its flowability in injection molding occurring in the existing techniques, the total content of trifunctional and higher organic compounds of cadaverine salts is regulated to 90 ppm or less. To improve the fish-eyes (F / E) of a polyamide resin film and its flowability in injection molding and the amount of high-molecule impurities contained in the polyamide resin, an aqueous cadaverine salt solution, from which high-molecule impurities having a molecular weight of 12,000 or more have been removed, is prepared. To easily and economically produce a cadaverine solution by which defects in the surface appearance such as fish-eyes can be prevented in the case of using it as a starting material of a polyamide resin film or the like, moreover, the amount of microbial cells employed in the reaction is regulated within a definite range.

Owner:MITSUBISHI RAYON CO LTD

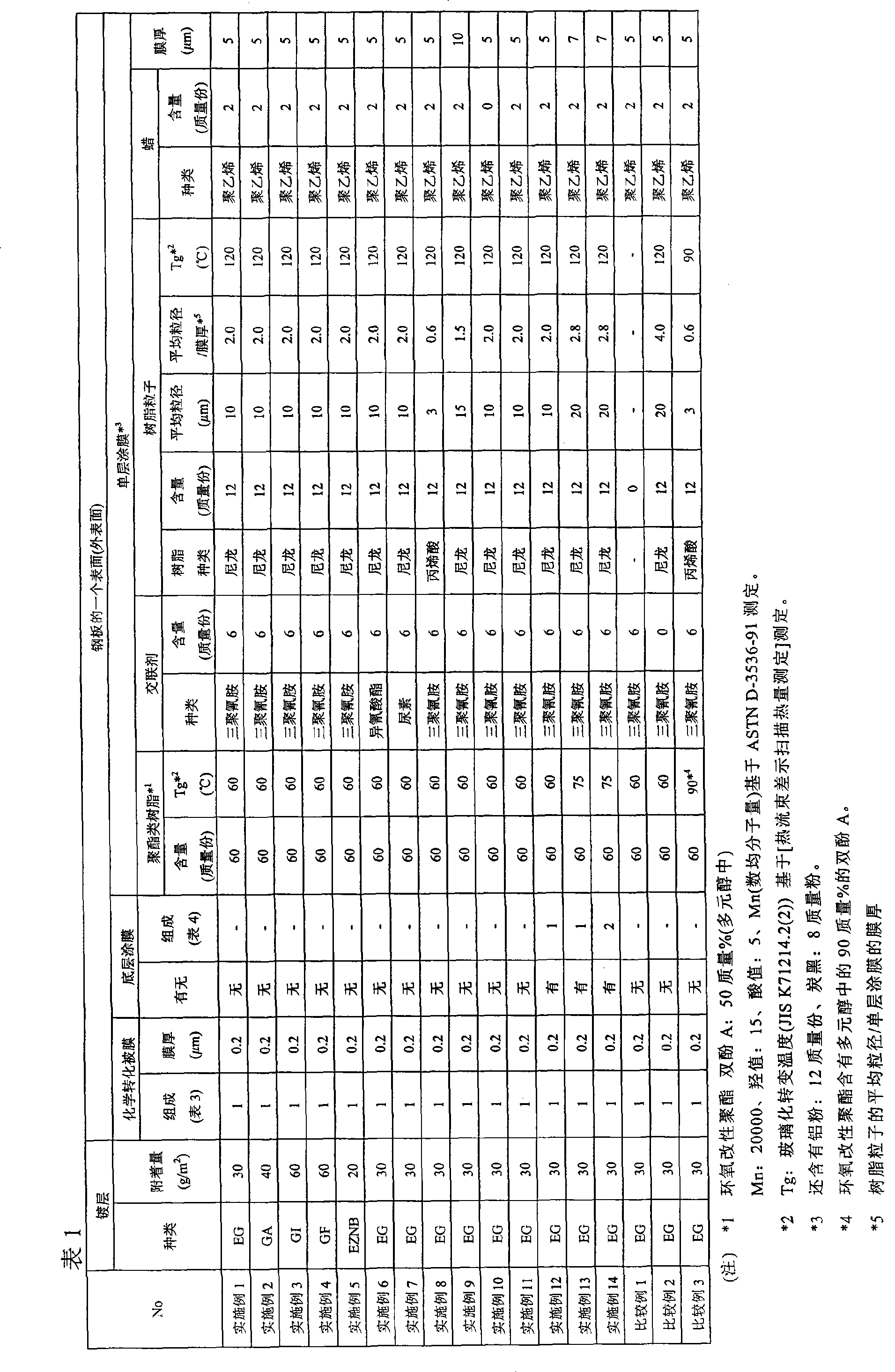

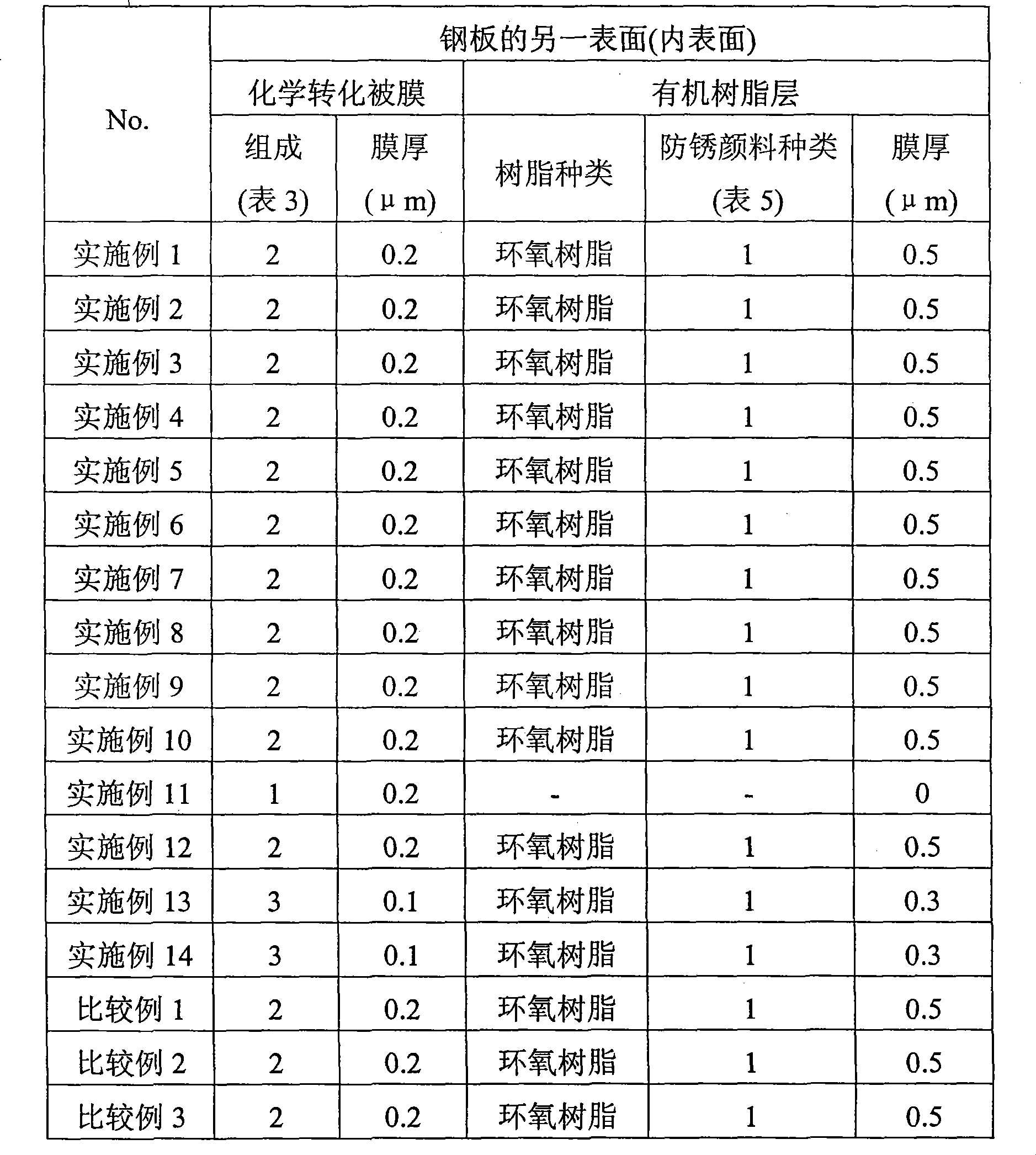

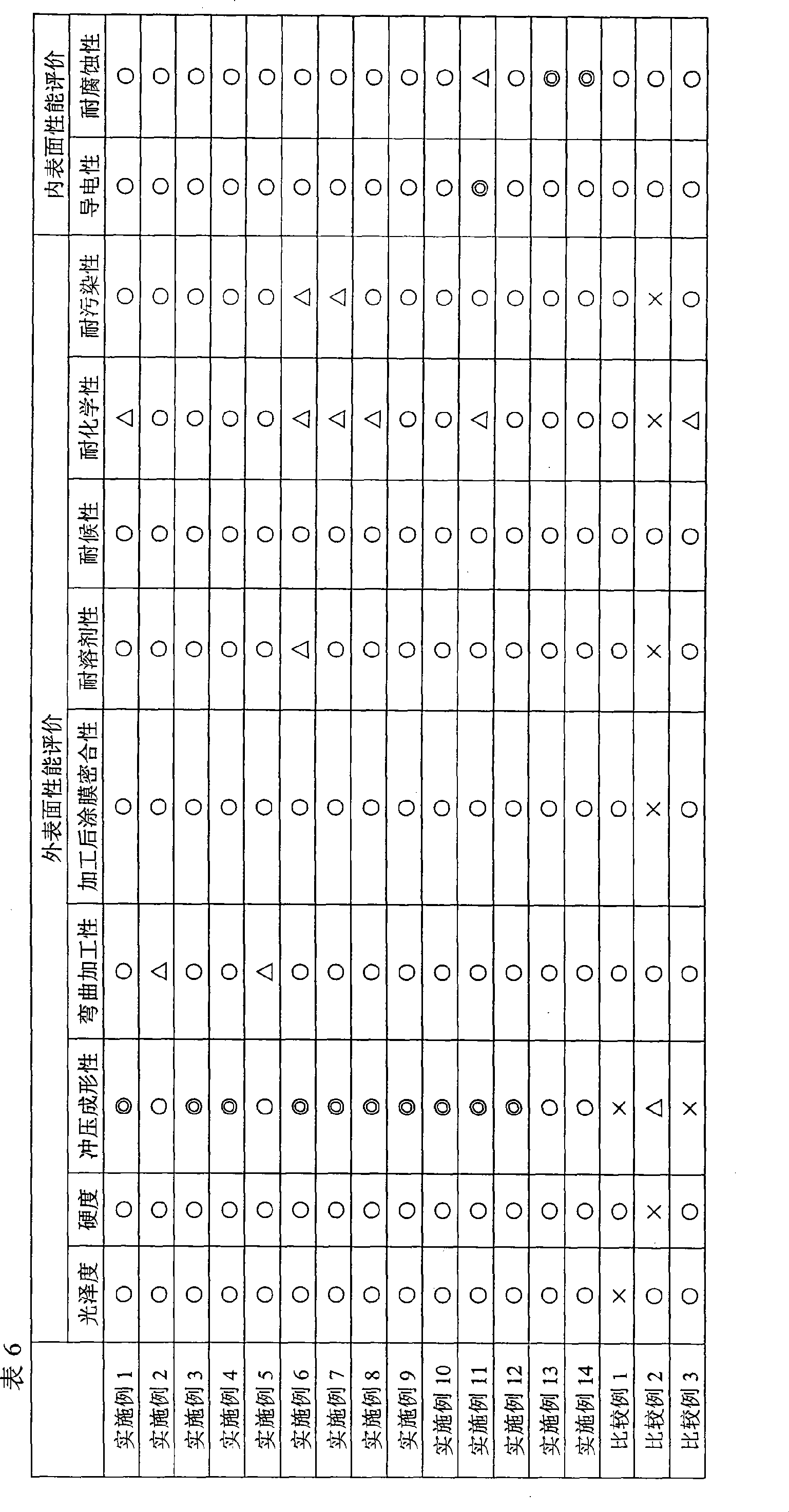

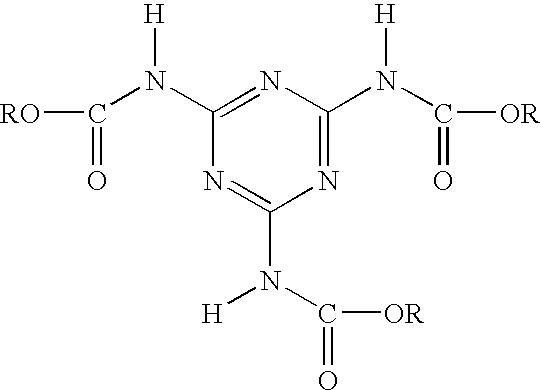

Coated steel sheet, works, panels for thin televisions and process for production of coated steel sheet

ActiveCN101394998AExcellent adhesionGood solvent resistanceHot-dipping/immersion processesPretreated surfacesPolymer scienceWeather resistance

Owner:JFE STEEL CORP

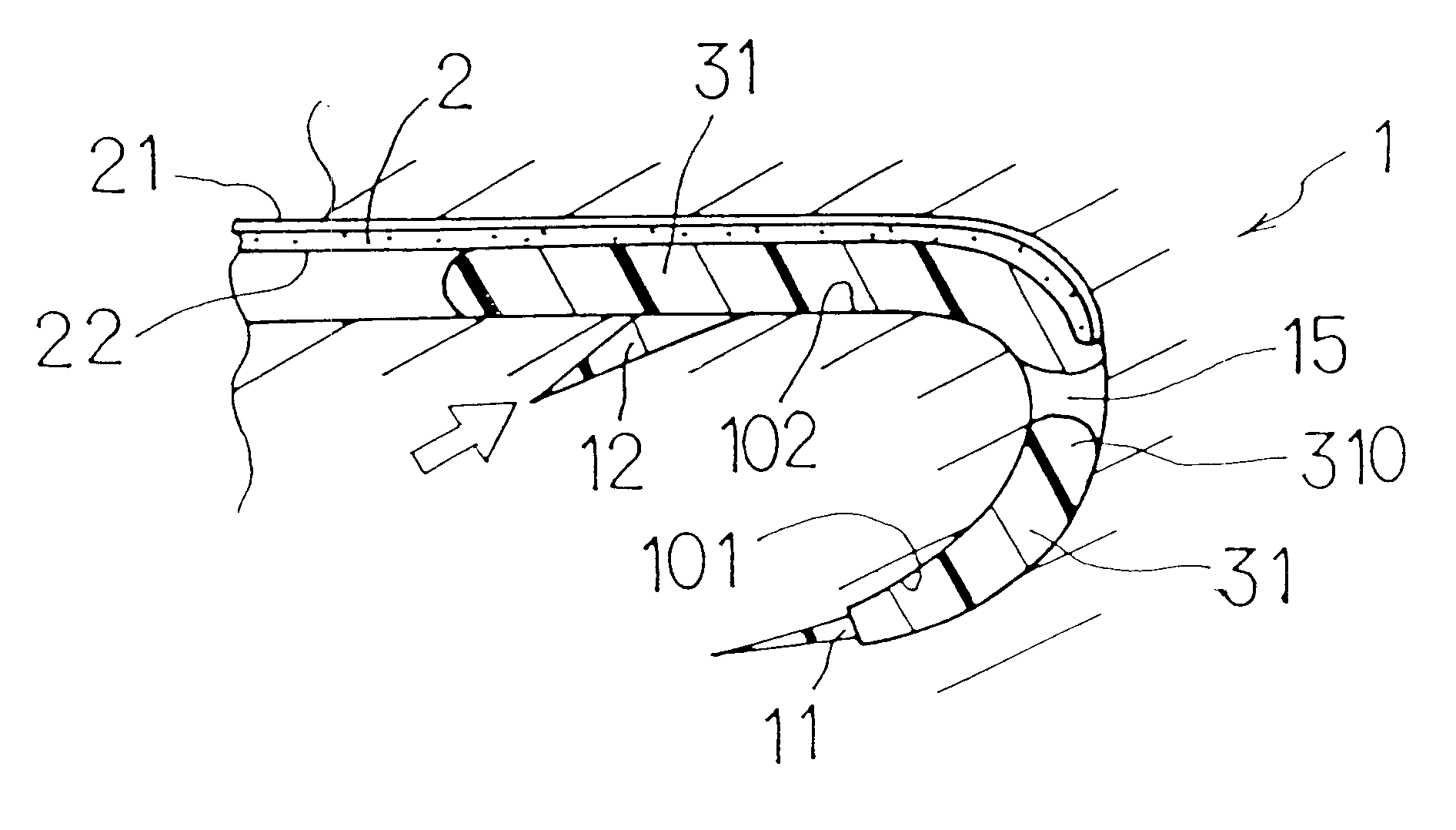

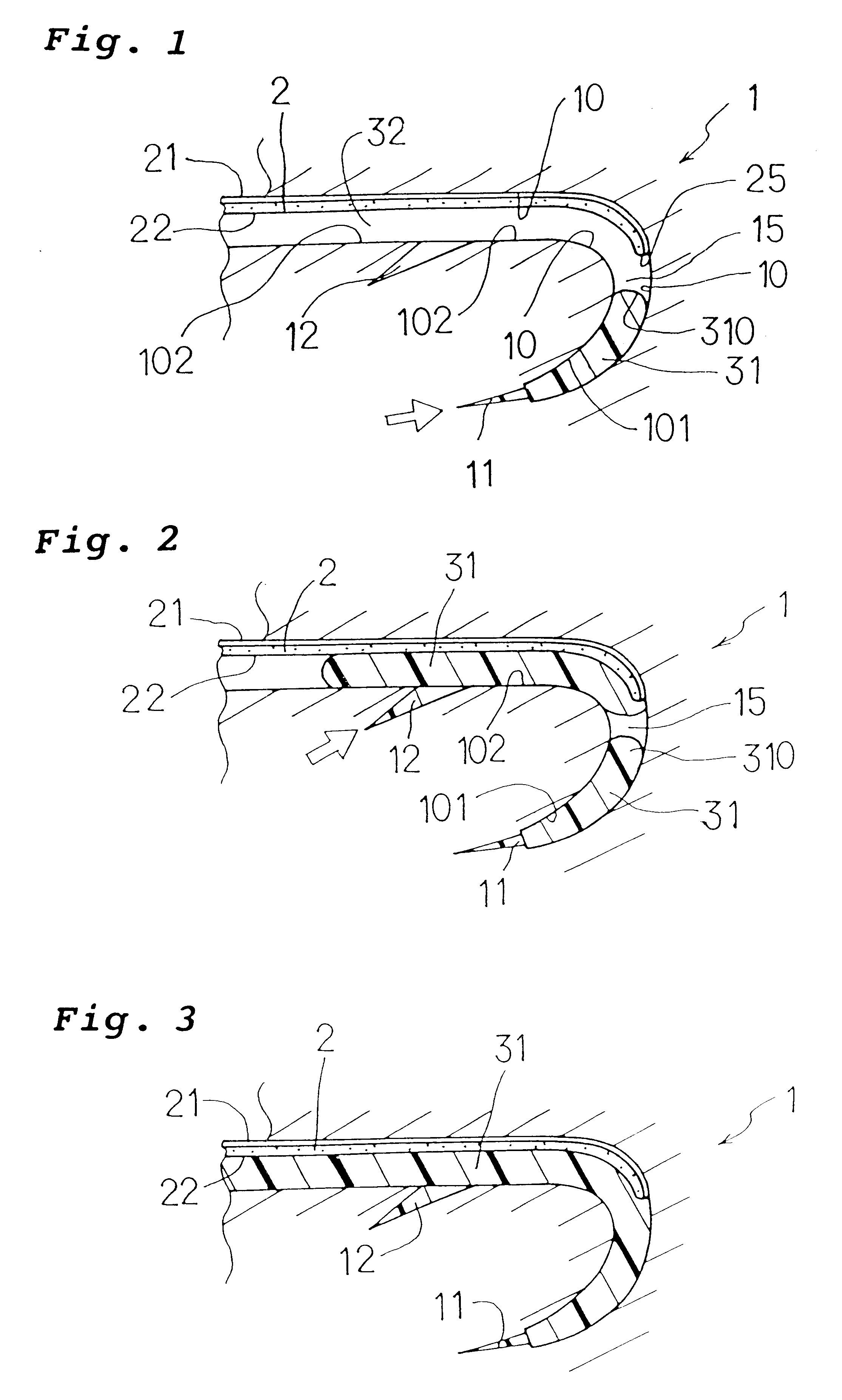

Methods for molding resin-molded articles

InactiveUS6342176B2Prevent intrusionSatisfactory surface appearanceTailstocks/centresMouldsShell moldingSynthetic resin

The object of the invention is to provide a method for molding a resin-molded article having an excellent surface appearance without any resin-intrusion part on the front surface of a skin thereof. In the invention, the skin is placed on a part of a inner wall of a mold and then injecting a synthetic resin into a cavity of the mold to effect an integral molding of a resin-molded article having the skin on a part thereof, wherein a mold having a first gate on a first inner wall part located on the part other than the back surface of the skin placed on the inner wall of said mold and a second gate on a second inner wall part which faces the back surface of the skin placed on the inner wall is employed; and wherein the synthetic resin is first injected from said first gate until the tip portion of the synthetic resin comes close to the edge of said skin, and then the synthetic resin is injected from the second gate.

Owner:TOYODA GOSEI CO LTD

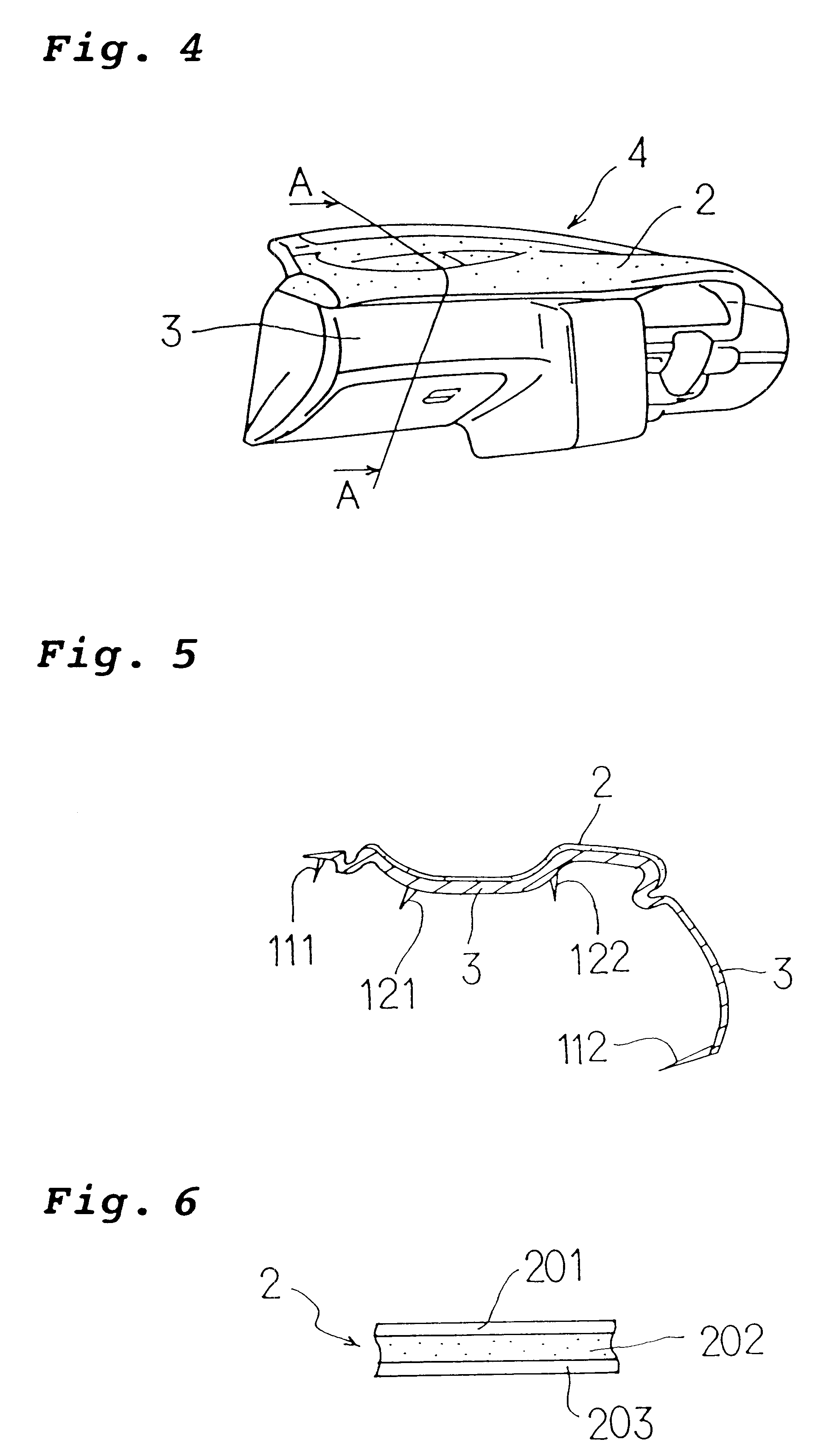

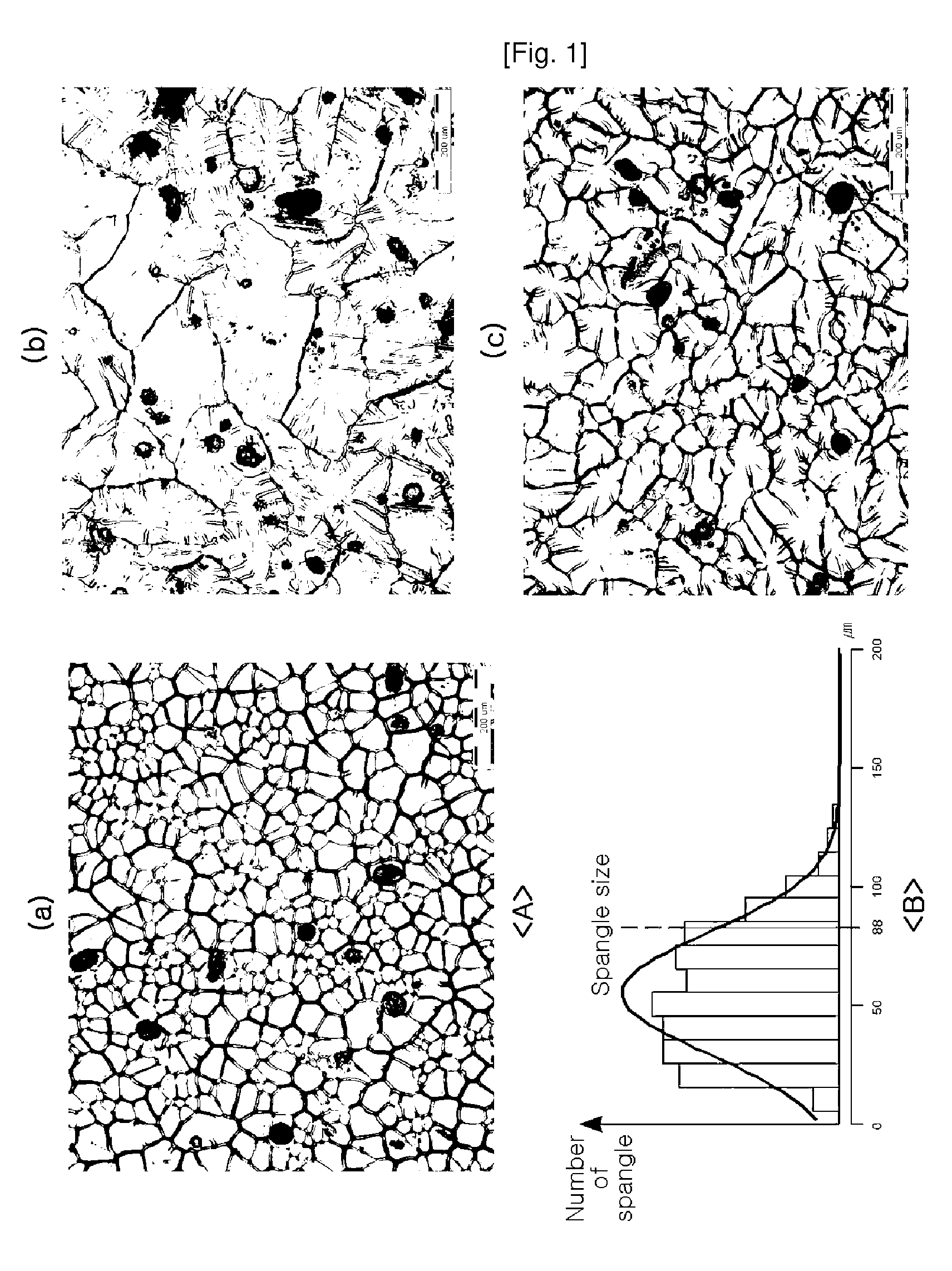

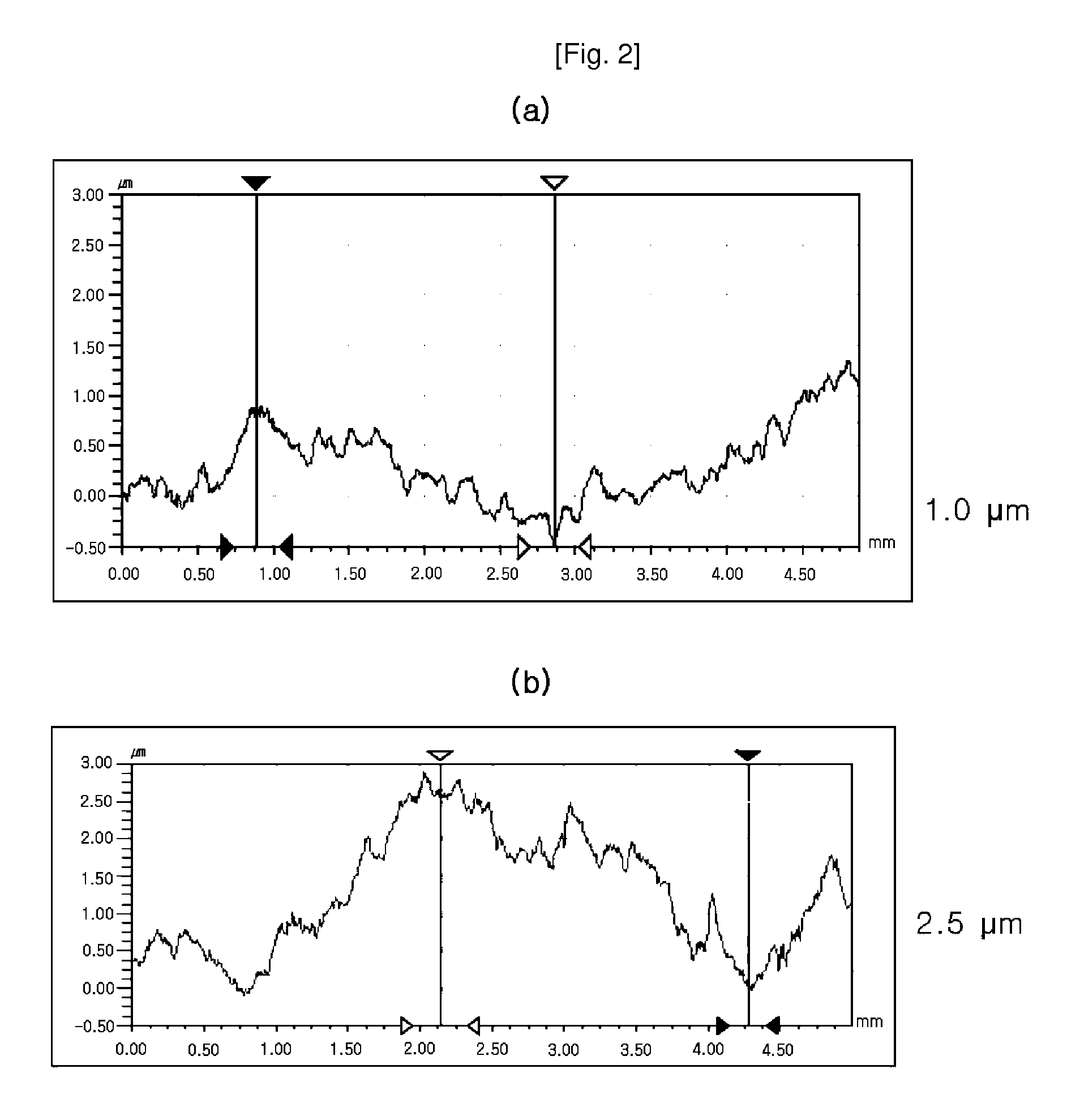

Galvanized Stell-Sheet Without Spangle, Manufacturing Method Thereof and Device Used Therefor

ActiveUS20080206592A1Increase resistanceExcellent surface appearanceHot-dipping/immersion processesPretreated surfacesSheet steelMagnification

A spangle-free, hot-dip galvanized steel sheet, and a method and device for manufacturing the same. The hot-dip galvanized steel sheet is characterized in that a solidified zinc crystal of hot-dip galvanized layer has an average crystalline texture particle diameter of 10 to 88 μm and there is no solidification traces of dendrites upon observing under a microscope at a magnification of 100×. The method comprises dipping a steel sheet in a bath of a zinc-coating solution containing 0.13 to 0.3% by weight of aluminum; air-wiping the steel sheet to remove an excess of the coating solution; spraying water or an aqueous solution on the air-wiped steel sheet, using a steel sheet temperature in the range of a hot-dip galvanization temperature to 419° C. as a spray initiation temperature and using a steel sheet temperature in the range of 417° C. to 415° C. as a spray completion temperature; passing sprayed liquid droplets of water or aqueous solution through a mesh-like high-voltage charged electrode which is electrically charged with a high voltage of −1 to −50 kV; and allowing the electrode-passed liquid droplets to be bound to the surface of the steel sheet and hereby being served as solidification nuclei of molten zinc.

Owner:POHANG IRON & STEEL CO LTD

Method for producing a multilayer coating and the use thereof

InactiveUS7087146B2Excellent surface appearanceEasy to moveLiquid surface applicatorsElectrolysis componentsMetallurgyPhysical chemistry

A process for producing a multicoat system on a substrate, in which a) an electrodeposition coating film is deposited on the substrate, b) the electrodeposition coating film is predried by heating to a predrying temperature for a predetermined period, c) a coat of a surfacer is applied to the electrodeposition coating film, and d) the electrodeposition coating film and the coat of the surfacer are baked together at elevated temperatures, and in which the predrying temperature in step b) is equal to the temperature (Tp) or lies above the temperature (Tp) at which the loss factor tan δ, which is the quotient formed from the loss modulus E″ and the storage modulus E′, of the unbaked electrodeposition coating material shows a maximum, and the use of the resulting multicoat system.

Owner:BASF COATINGS AG

Adhesive composition for optical use

InactiveUS20120177912A1Uniform thicknessIncreased durabilityLayered productsPolyureas/polyurethane adhesivesOligomerHeat resistance

Disclosed is an adhesive composition for optical use and, more particularly, an adhesive composition which includes; 30 to 80 wt. % of a mono-functional urethane acrylate oligomer having a weight average molecular weight of 10,000 and 35,000, 10 to 60 wt. % of an acrylate monomer; and 0.1 to 10 wt. % of a free radical photo-initiator, so as to retain physical properties of the adhesive composition such as coating property and adhesiveness and, in addition, reduce incurring of setting shrinkage during photo-polymerization, thereby exhibiting a uniform thickness and excellent surface appearance, durability such as heat resistance and moist heat resistance, and storage elasticity. Moreover, the inventive composition does not contain an alternative solvent, thus enabling manufacturing of a thick film type adhesive film.

Owner:DONGWOO FINE CHEM CO LTD

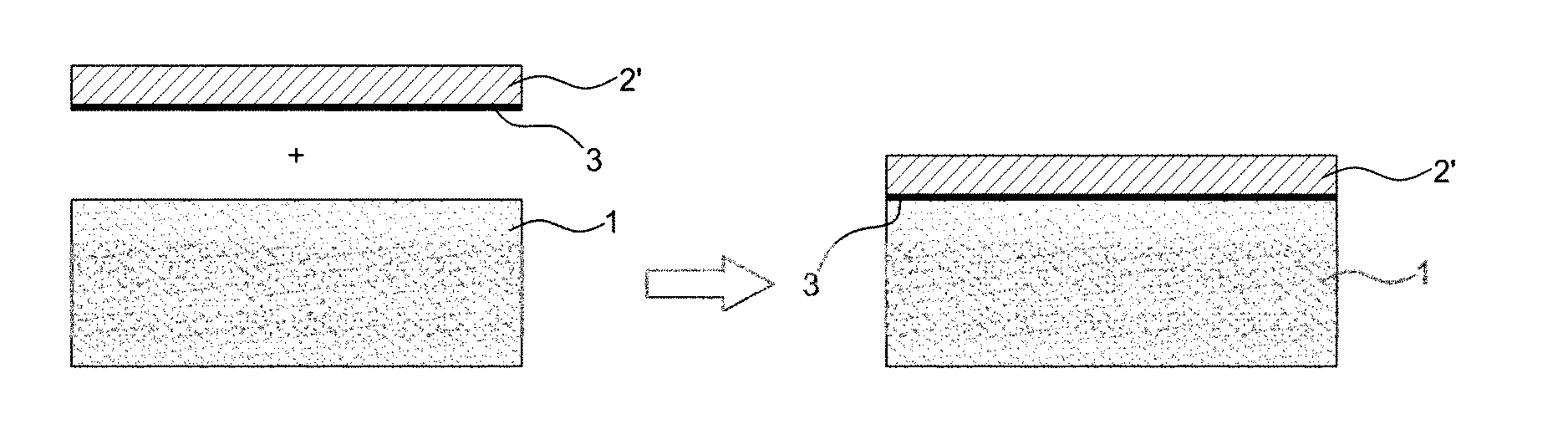

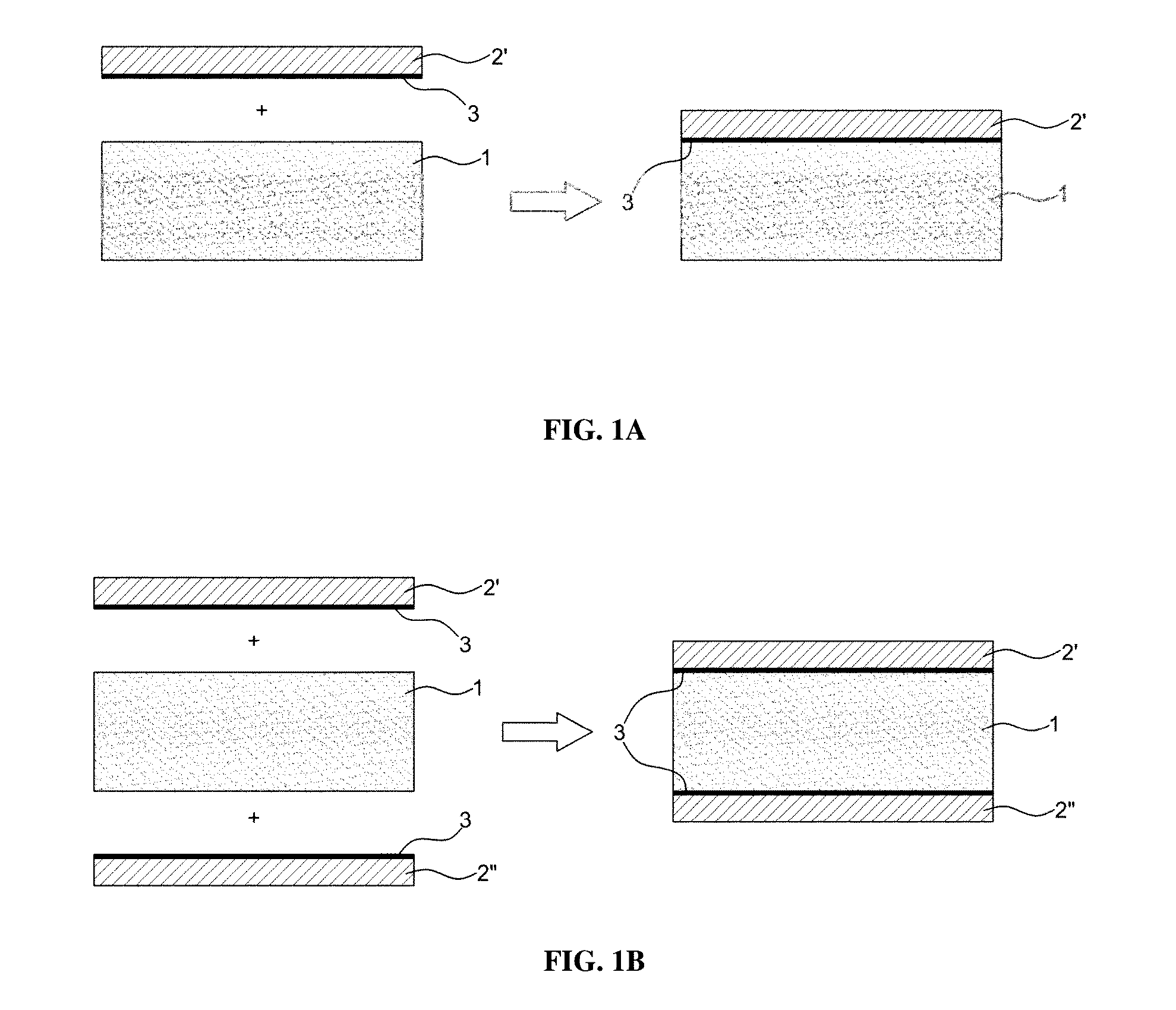

Sound absorbing and insulating material with superior moldability and appearance and method for manufacturing the same

ActiveUS20160297174A1Improve flame retardant performanceImprove heat resistanceLamination ancillary operationsThermal insulationHeat resistanceNonwoven fabric

The present invention relates to a sound absorbing and insulating material with superior moldability and appearance and a method for manufacturing the same, more particularly to a sound absorbing and insulating material consisting of an inner layer 1 formed of a first nonwoven fabric mainly formed of a heat-resistant fiber and a binder uniformly distributed inside the first nonwoven fabric and maintaining the three-dimensional structure inside the first nonwoven fabric and an outer layer 2′, 2″ formed of a second nonwoven fabric mainly formed of a heat-resistant fiber, wherein the outer layer is stacked on one or both sides of the inner layer, and a method for manufacturing the same. The sound absorbing and insulating material of the present invention has superior sound-absorbing property, flame retardancy, heat resistance, heat-insulating property and high-temperature moldability. In addition, there is no concern of deterioration of surface appearance caused by leakage of the binder due to the presence of the outer layer.

Owner:HYUNDAI MOTOR CO LTD

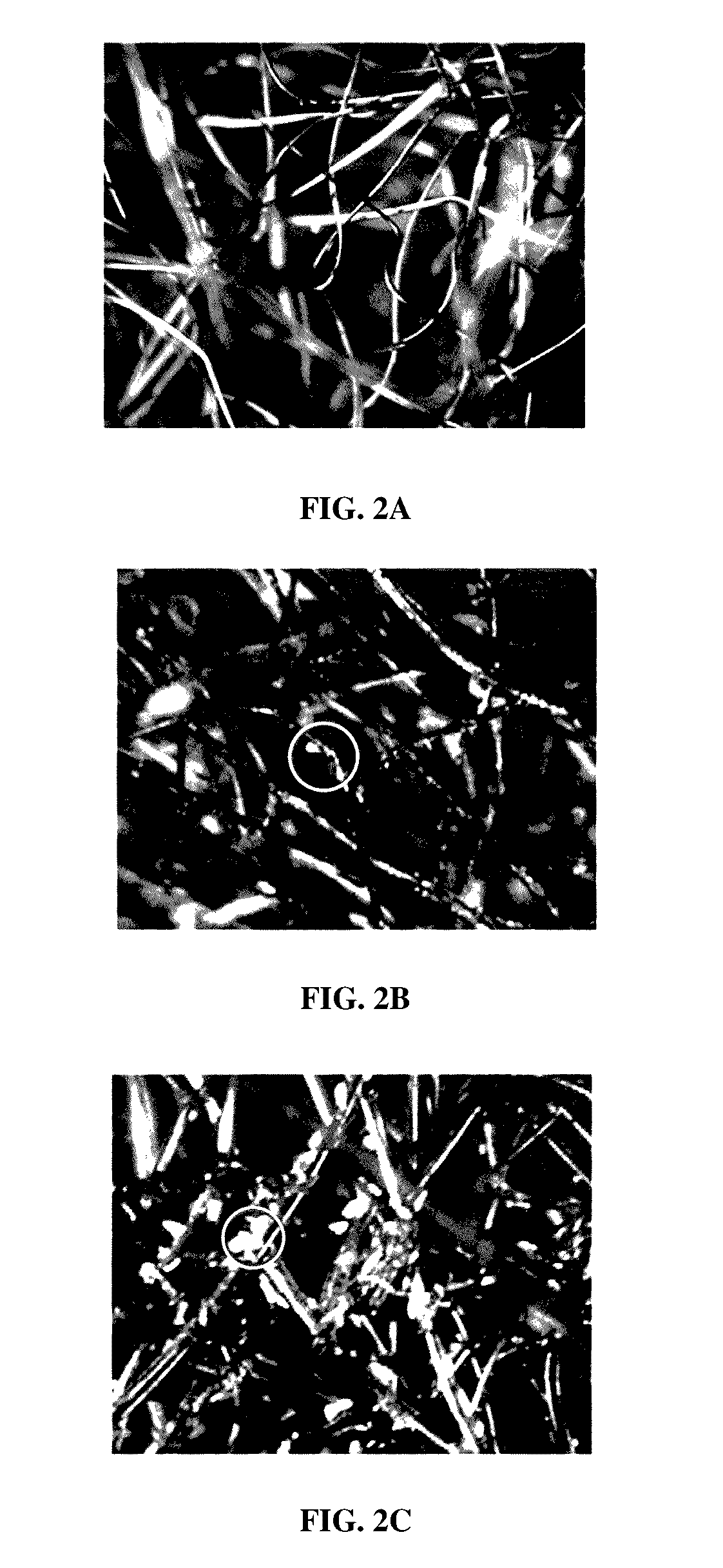

Bamboo fiber/polylactic acid composite material and preparation method thereof

The invention discloses a bamboo fiber / polylactic acid composite material and a preparation method thereof. The bamboo fiber / polylactic acid composite material specifically comprises the following rawmaterials in parts by weight: 60-80 parts of polylactic acid, 10-30 parts of talcum powder, 3-15 parts of modified bamboo fibers, 2-15 parts of a flexibilizer, 0.1-0.3 part of a coupling agent, 0.1-0.3 part of an antioxidant, 0.2-0.6 part of an auxiliary antioxidant, 0.2-0.5 part of a lubricating agent, 0.2-1 part of a nucleating agent, 0.1-0.3 part of an anti-floating fiber agent and 0.5-3 partsof a hydrolysis resistance agent. According to the composite material disclosed by the invention, the bamboo fibers are modified and thermally treated, the bamboo fibers and talcum powder are treatedby using the coupling agent, and according to a certain mixing sequence and suitable extrusion process parameters, the problems that the bamboo fiber / polylactic acid composite material is rough in surface and has silver filaments and local black spots and the compatibility between the polylactic acid and the bamboo fibers is poor are solved.

Owner:浙江明江新材料科技股份有限公司

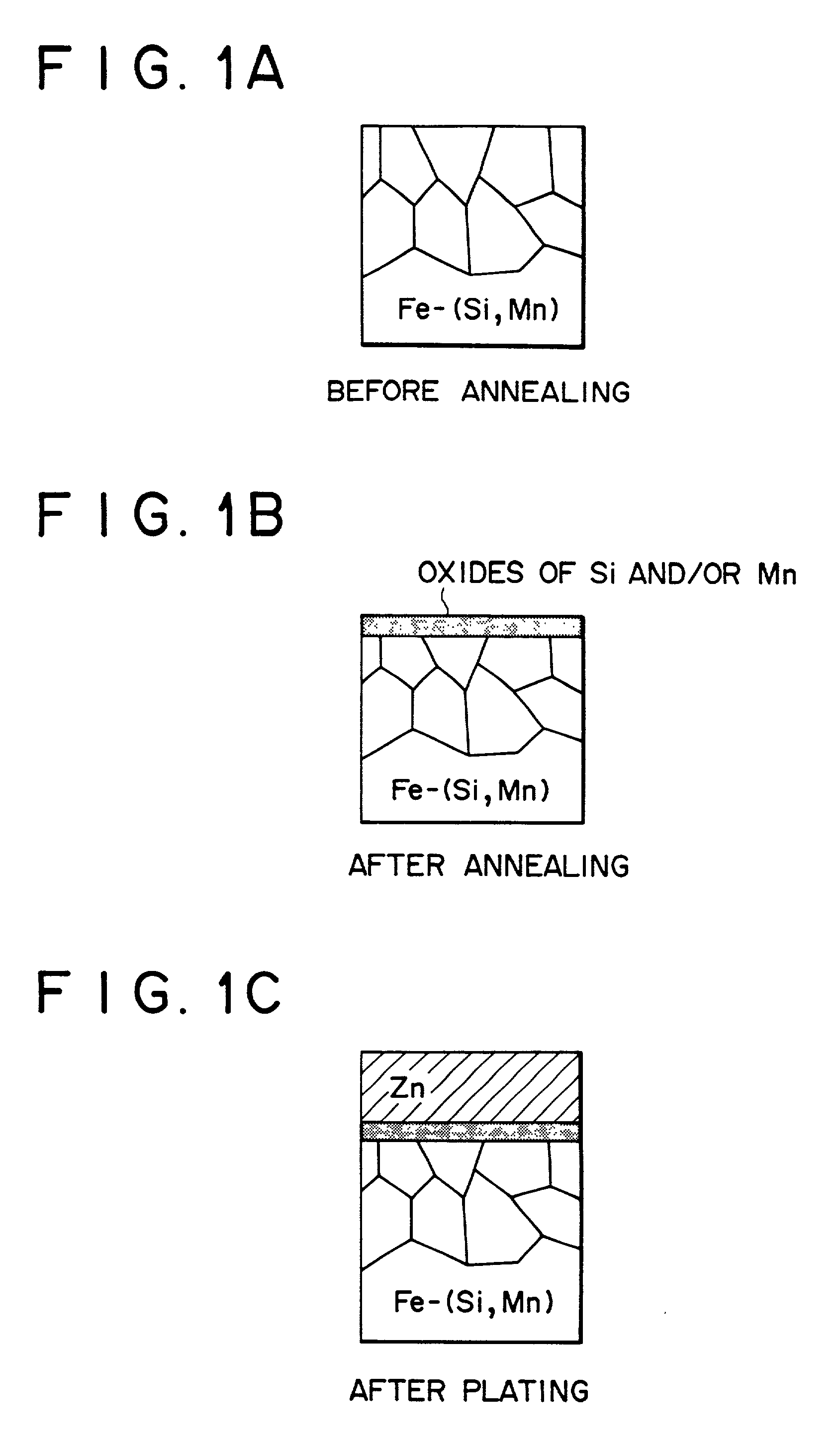

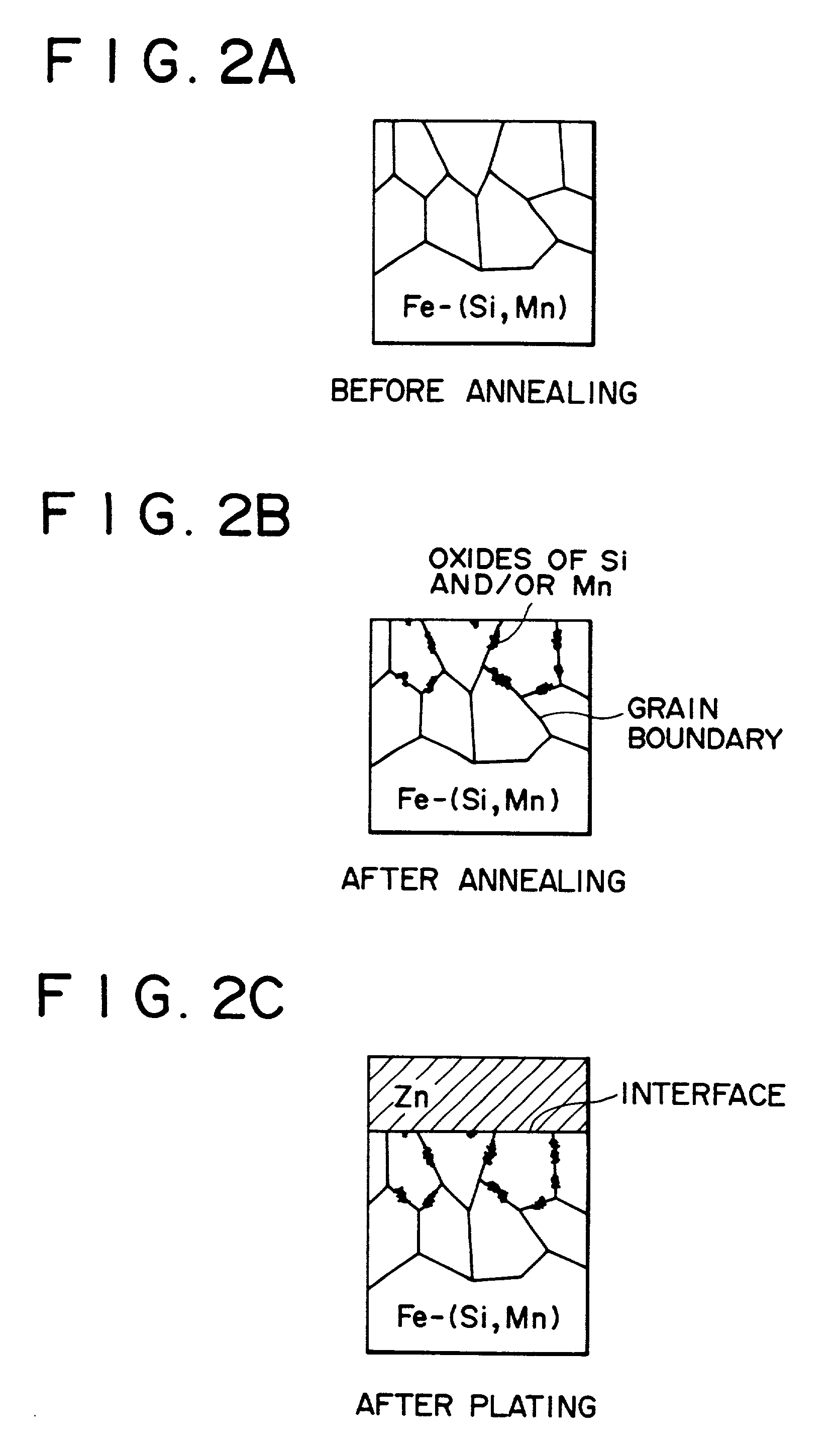

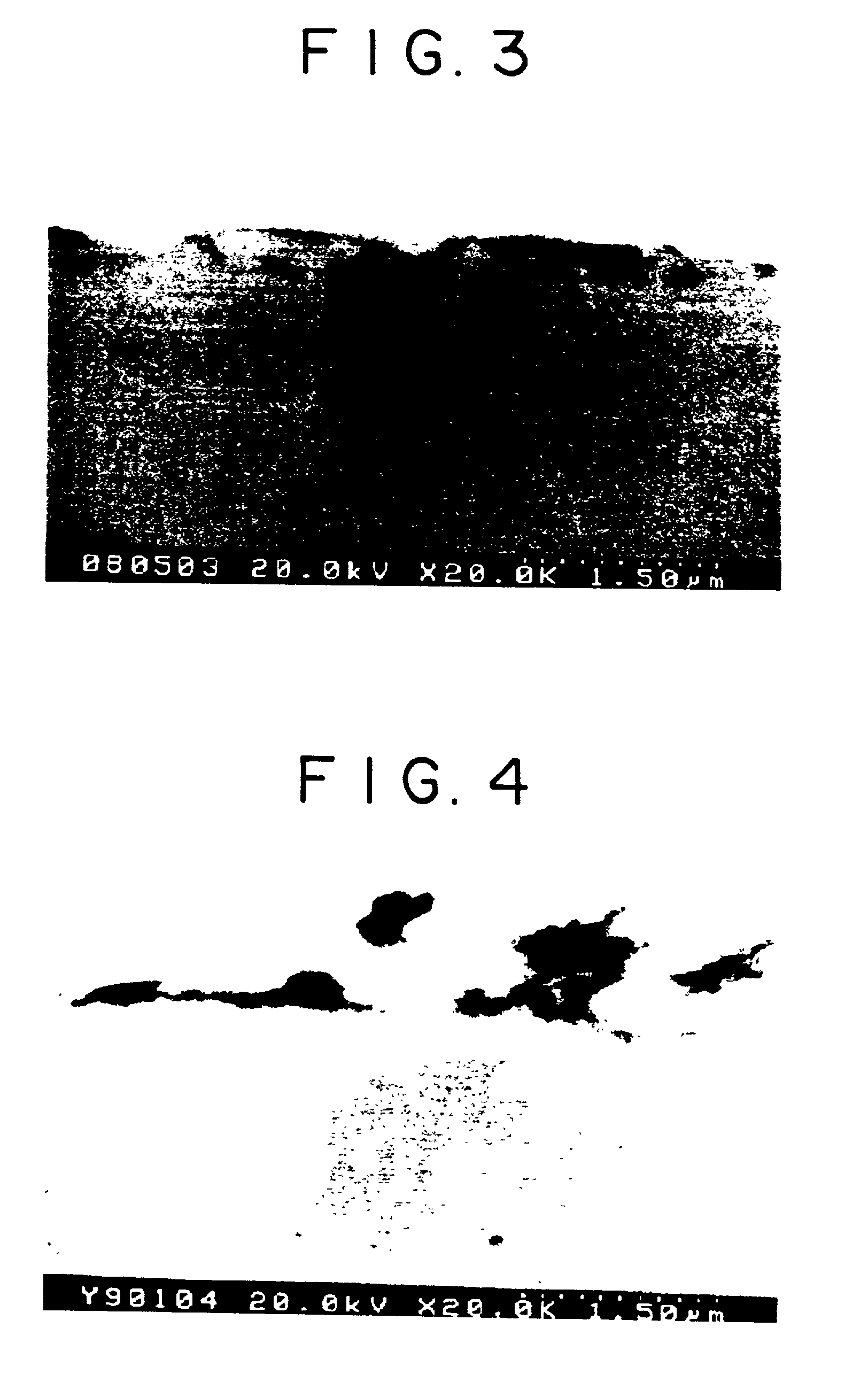

Hot-dip galvanized steel sheet

InactiveUS20010031377A1Improve surface conditionHigh tensile strengthHot-dipping/immersion processesDomestic articlesSheet steelScanning electron microscope

A hot-dip galvanized steel sheet composed of a basis steel sheet containing Si in an amount of 0.05-2.5 mass % and Mn in an amount of 0.2-3 mass % and a hot-dip galvanized zinc layer formed on the surface thereof, wherein said hot-dip galvanized zinc layer is formed in such a way that there is an Si-Mn enriched phase which is found, by observation under a scanning electron microscope or a transmission electron microscope, in the vicinity of the interface in a region no shorter than 50 mum in the cross section perpendicular to the interface between the basis steel sheet and the hot-dip galvanized zinc layer, said Si-Mn enriched phase containing more than twice as much Si and / or Mn as the basis steel sheet and extending over a length no more than 80% of the length of the interface observed. This hot-dip galvanized steel sheet is free of bare spots even in the case where the basis steel sheet contains Si and Mn in a comparatively large amount and hence is liable to suffering bare spots.

Owner:KOBE STEEL LTD

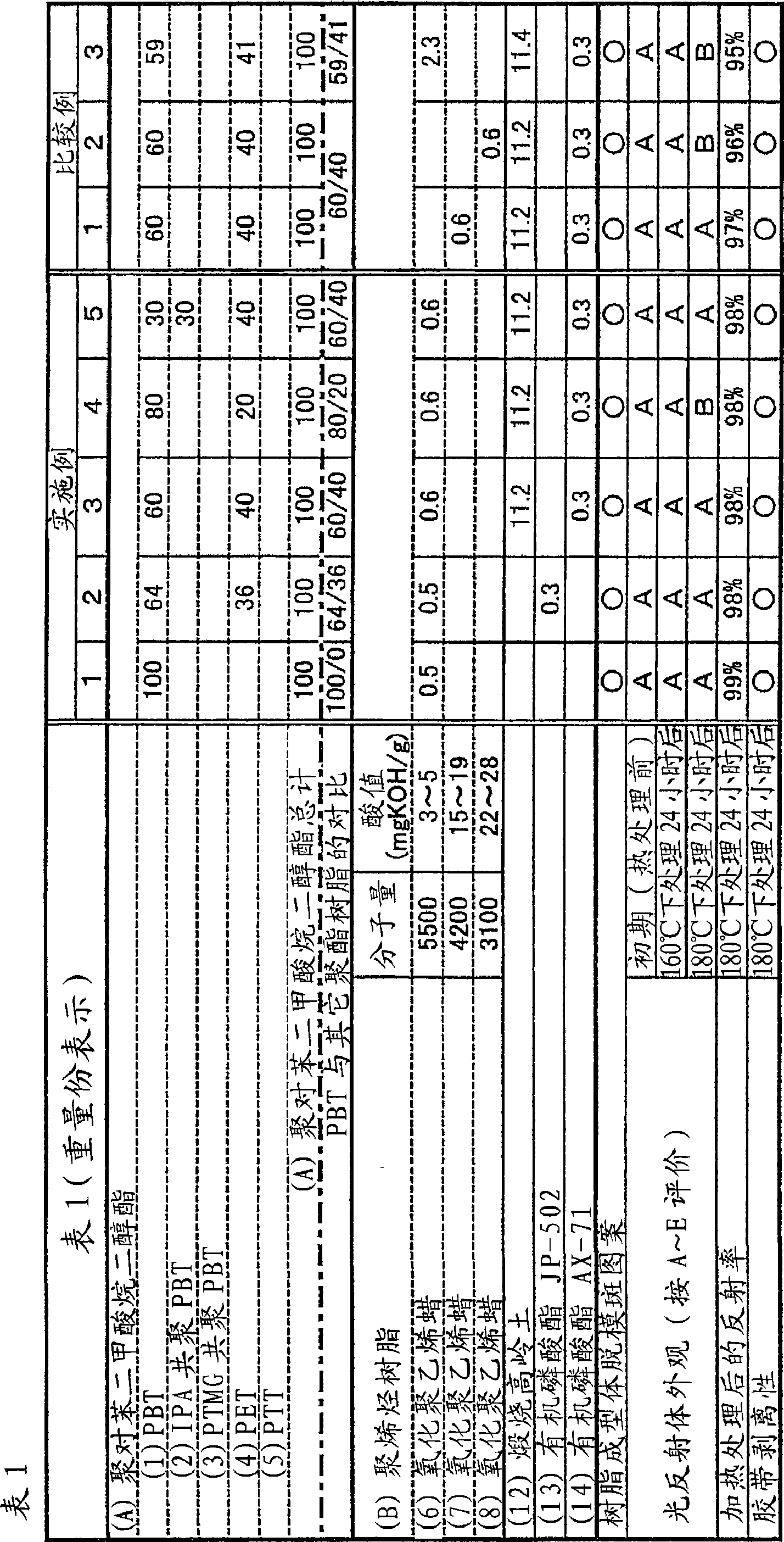

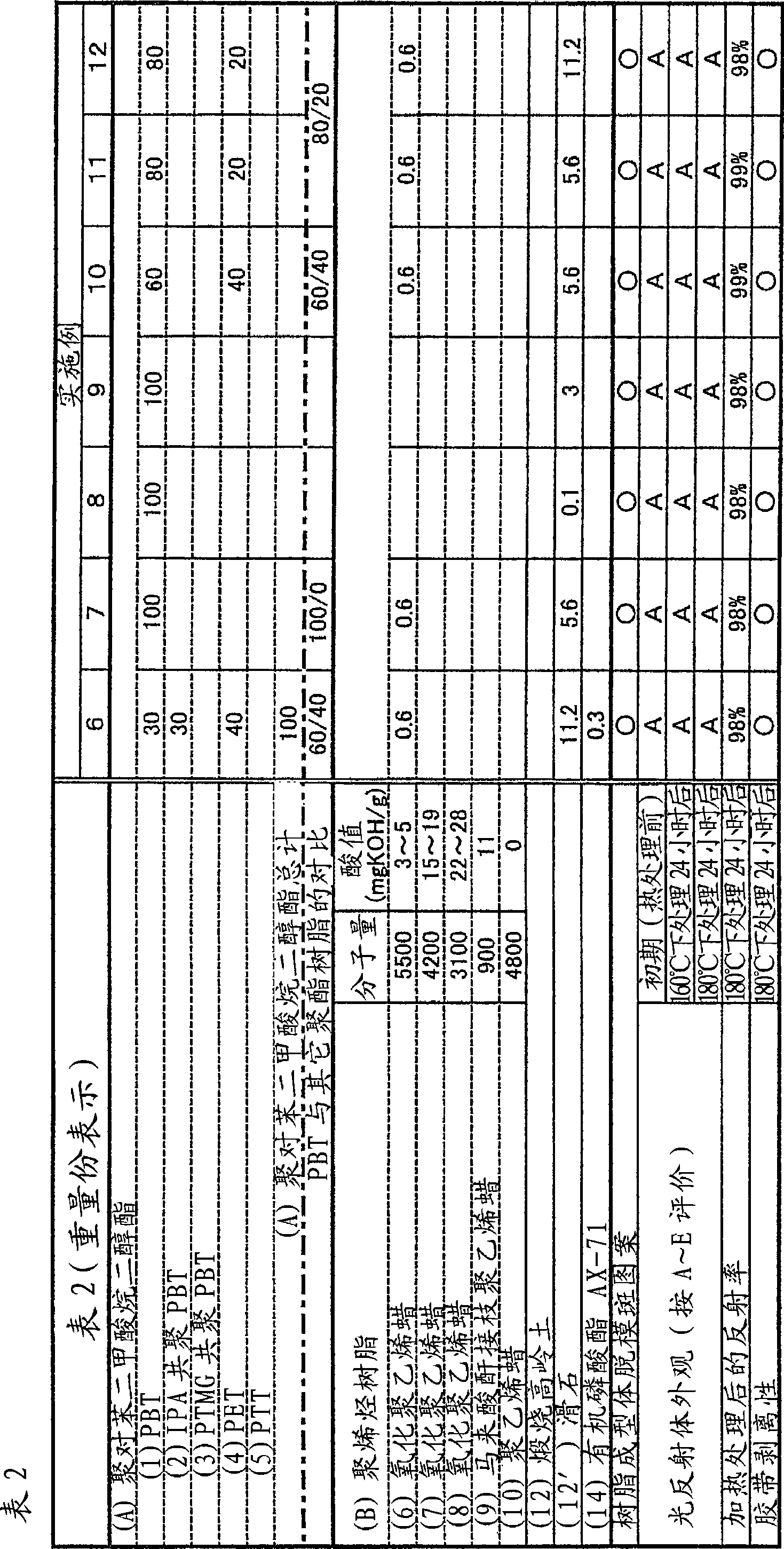

Polyester resin composition and light reflector

ActiveCN101501133AImprove surface propertiesGood light reflection performanceMirrorsMetal layered productsPolyolefinAcid value

A polyester resin composition for light reflector base, causing only a small amount of outgas in the process of molding a light reflector base or producing a light reflector, excellent in adhesiveness with a metal film layer provided to the surface of the light reflector base, and capable of keeping high luminance even when exposed under high-temperature atmospheres will be provided. The polyester resin composition for light reflector base of the present invention, on the surface of which a light reflecting layer is provided, contains (A) 100 parts by weight of polyester resin, and (B) 0.05 to 2 parts by weight of modified polyolefin resin having a weight-average molecular weight of 2,000 or larger, and an acid value of larger than 1 mg KOH / g and smaller than 10 mg KOH / g.

Owner:MITSUBISHI ENG PLASTICS CORP

Granular inorganic filler, process for producing filler and resin compositions containing same

InactiveCN1476471AImprove mechanical propertiesExcellent surface appearancePigment treatment with organosilicon compoundsPigment physical treatmentApparent densityPolyresin

Provided are a granular inorganic filler which is highly effective in improving the physical properties of resins and excellent in working efficiency, working atmosphere, productivity and economical efficiency, a process for producing the filler, and resin compositions excellent in mechanical properties, surface appearance, flame retardance and antiblock properties. The filler is produced by granulating a mixture comprising inorganic filler particles having a mean particle diameter of 0.01 to 20 mum and a binder in such a way as to give an apparent density of 0.1 to 3.0 g / ml and a breakage rate of 5 to 80 wt %. The resin compositions are prepared by adding the granular inorganic filler to resins.

Owner:MATSUMURA SANGYO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com