Patents

Literature

42results about How to "Susceptible to heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for heating material by adjustable mode RF heating antenna array

ActiveUS20100219182A1Susceptible to heatMicrowave heatingInduction current sourcesElectric fieldDipole antenna

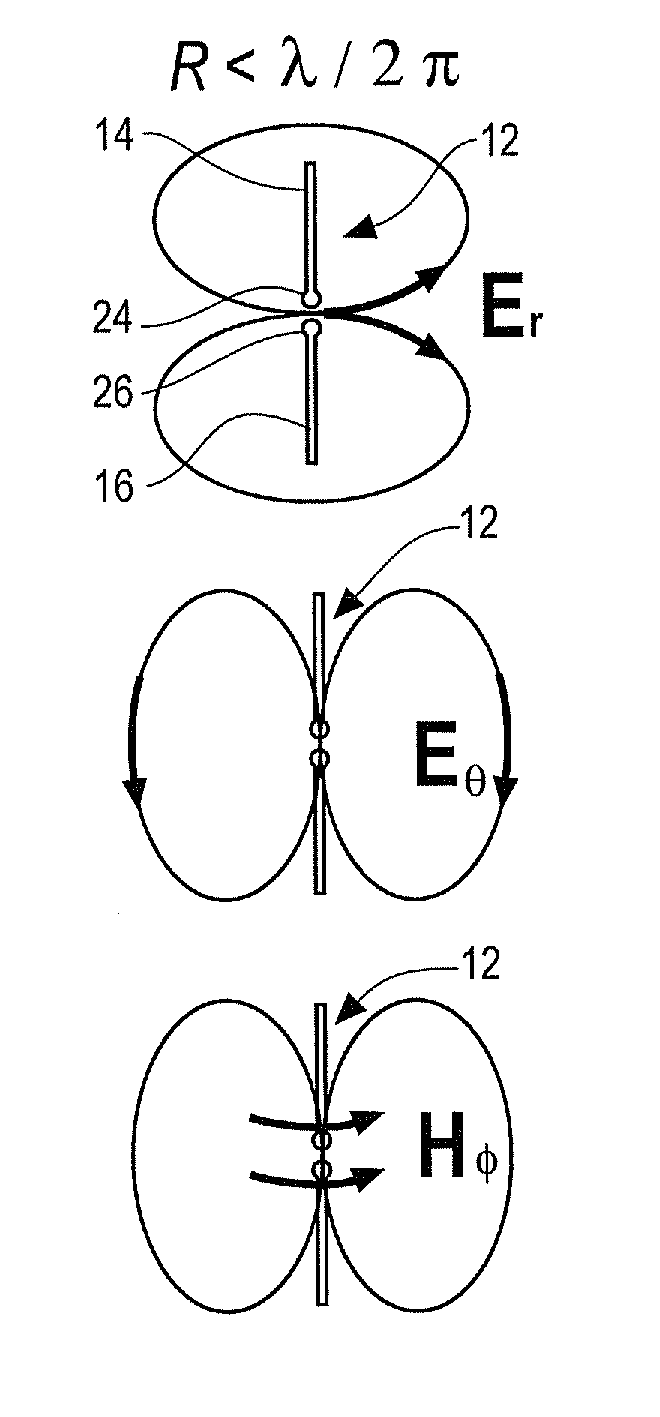

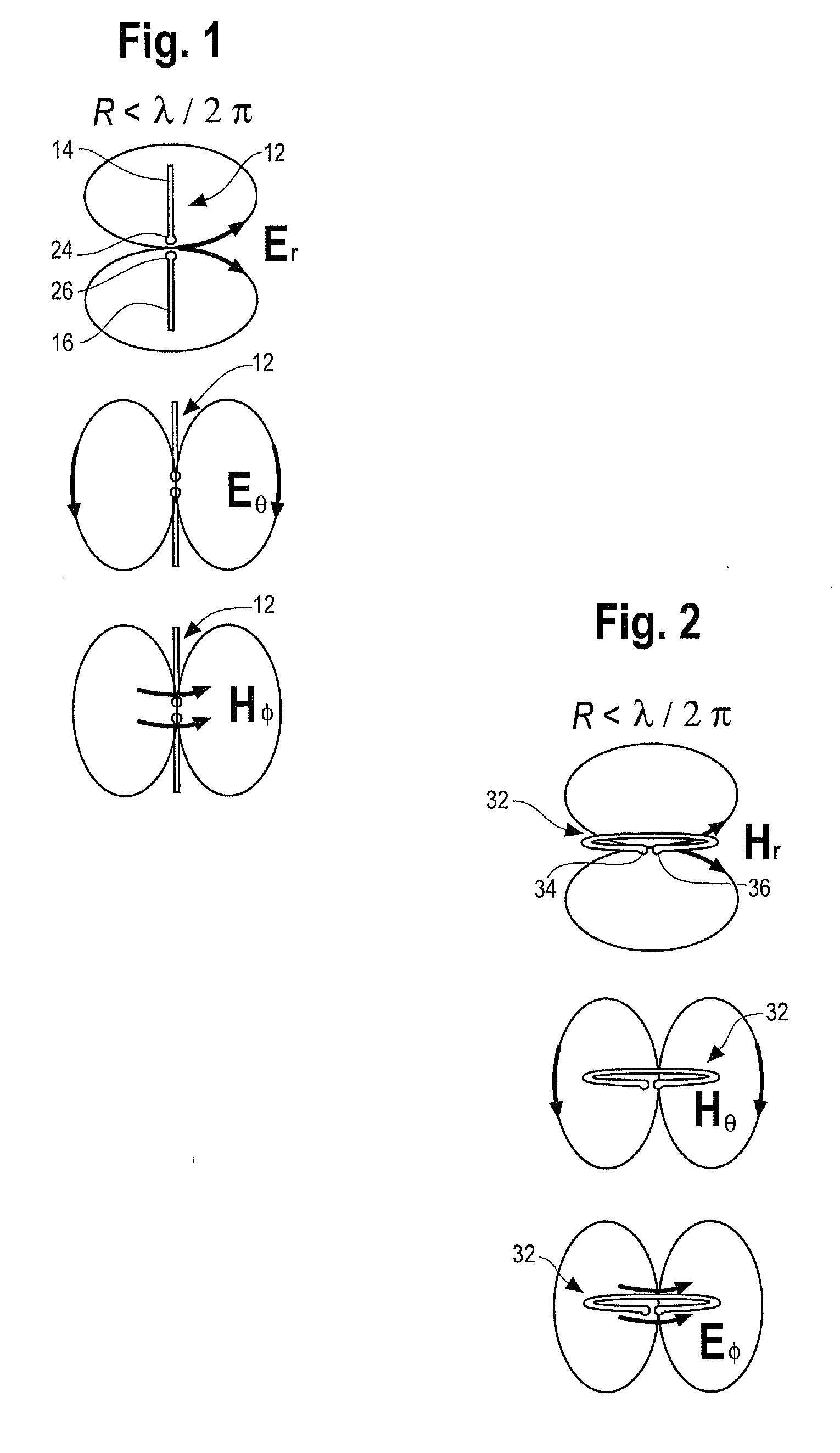

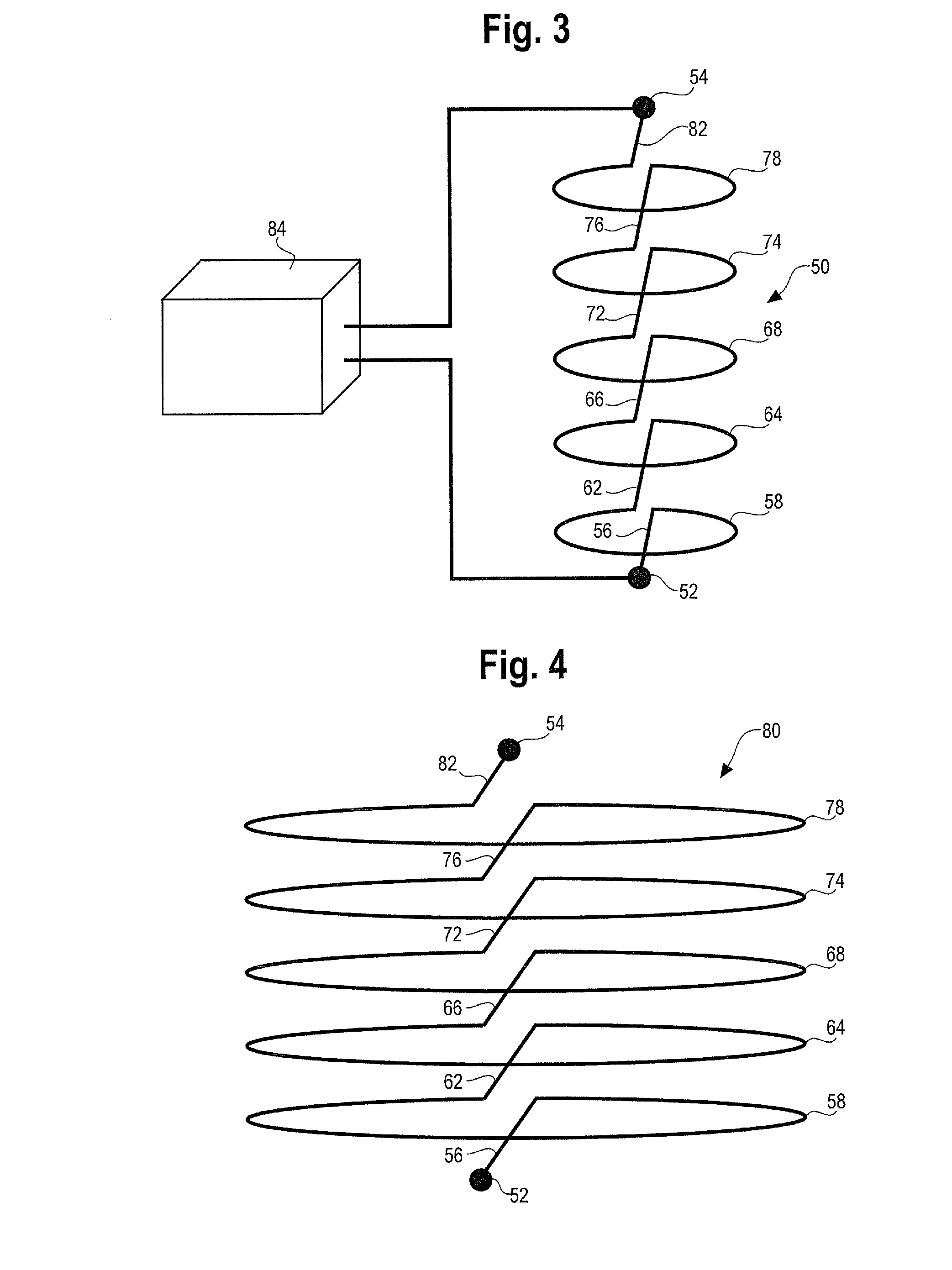

An apparatus for heating a material that is susceptible to RF heating by an RF antenna array. The apparatus includes a source of RF power connected to an antenna array having a plurality of loop antenna sections connected to each other by dipole antenna sections wherein the loop antenna sections and dipole antenna sections create a magnetic near field and an electric near field such that the ratio of magnetic field strength to electric field strength is approximately a predetermined value. Material is heated by the apparatus by placing the material in the near fields of the antenna array and creating magnetic near fields and electric near fields that approximate a ratio that is predetermined to efficiently heat the material and connecting the antenna array to an RF power source.

Owner:HARRIS CORP

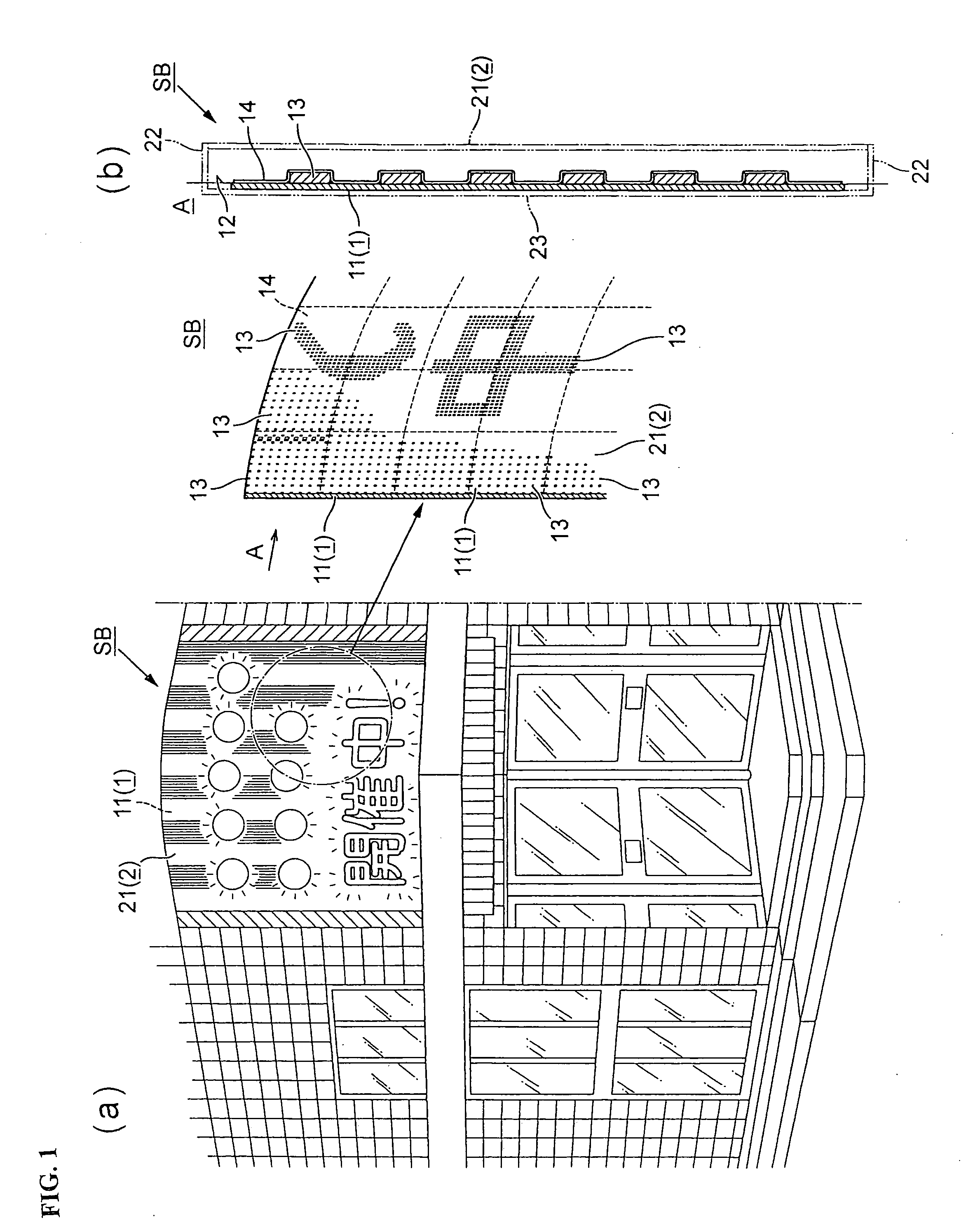

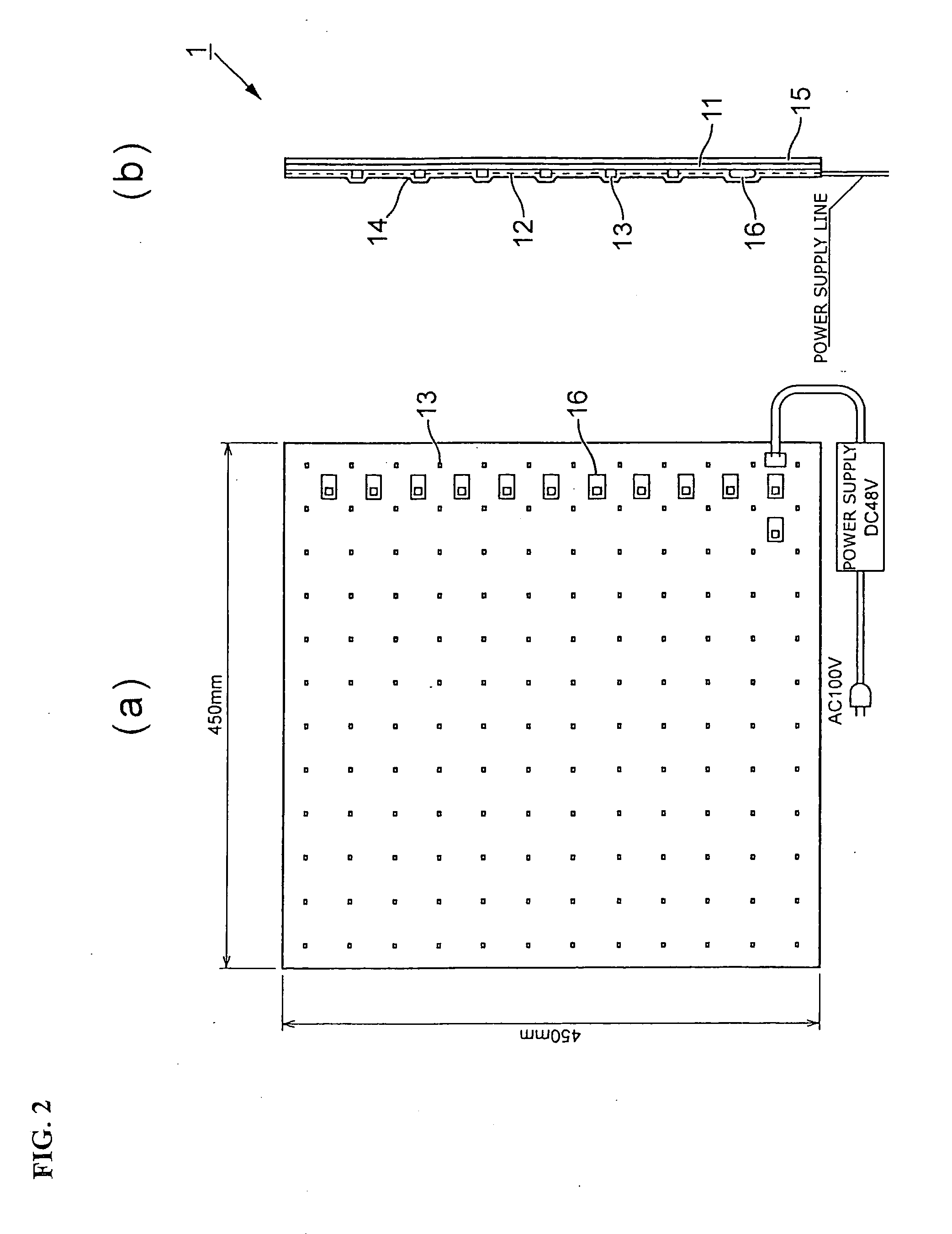

Surface emitter and internally illuminated sign incorporating the same

InactiveUS20100212198A1Increase forceSusceptible to heatPoint-like light sourceLighting elementsVacuum pressureElectrical and Electronics engineering

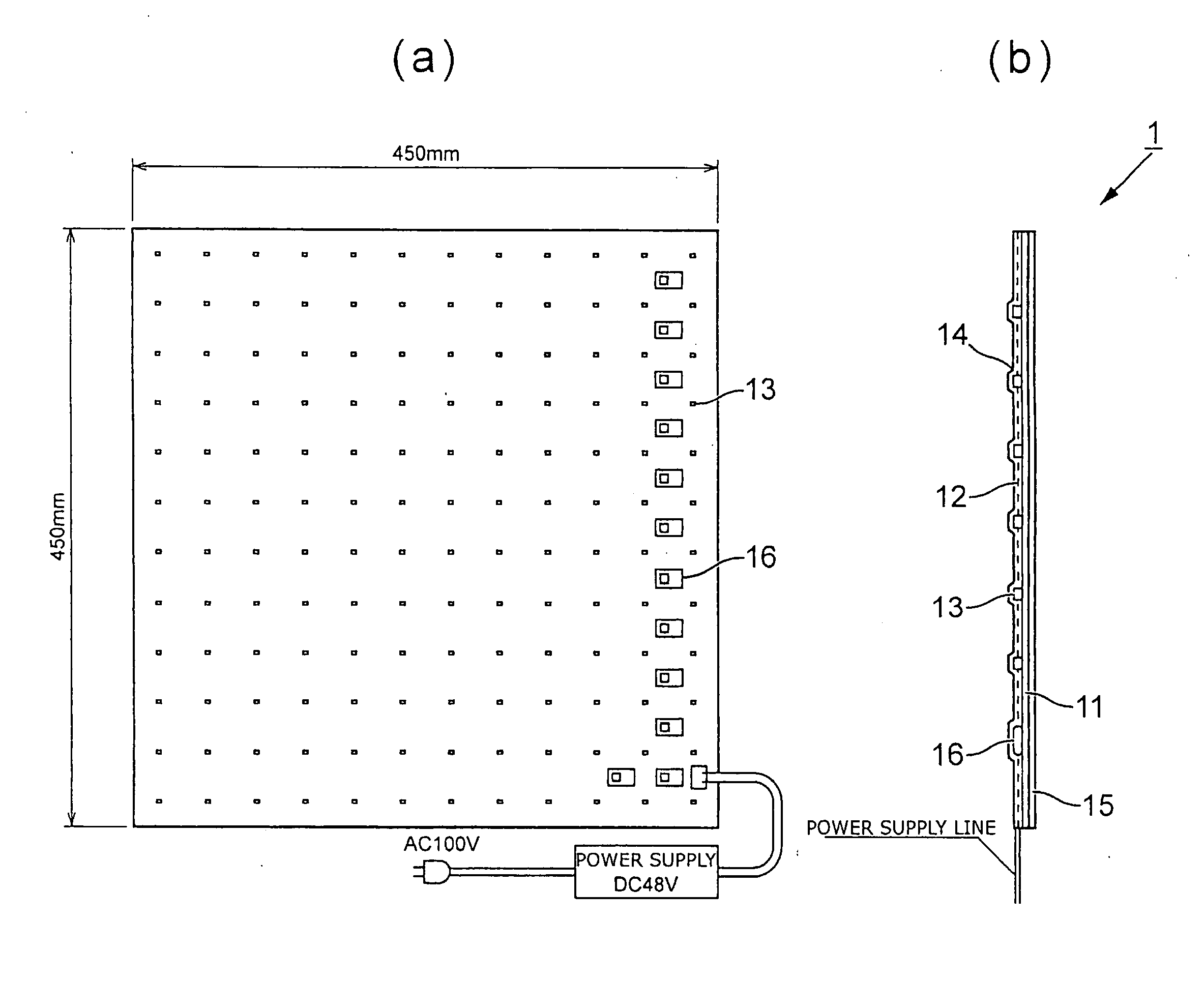

To provide a novel surface emitter incorporating an LED element improved in waterproofness or other practical functionality to enable the surface emitter to be used not only for a sign but also for other various applications, in appearance and in workability, and an internally illuminated sign incorporating the same surface emitter. A surface emitter 1 according to the present invention has a flexible substrate 11 having electric wiring 12, a plurality of LED elements 13 disposed substantially regularly on the substrate 11, and a top film 14 disposed on the LED elements 13 in a stretched manner. When the top film 14 is disposed on the substrate 11 in a stretched manner, the top film 14 is applied to the substrate 11 to come into close contact with projections and depressions formed by the LED elements 13. More specifically, a vacuum pressure bonding process is used in which a space between the LED elements 13 and the top film 14 is evacuated, and the top film 14 is heated and pressure-bonded to the surface of the LED elements 13.

Owner:AMCREW INC

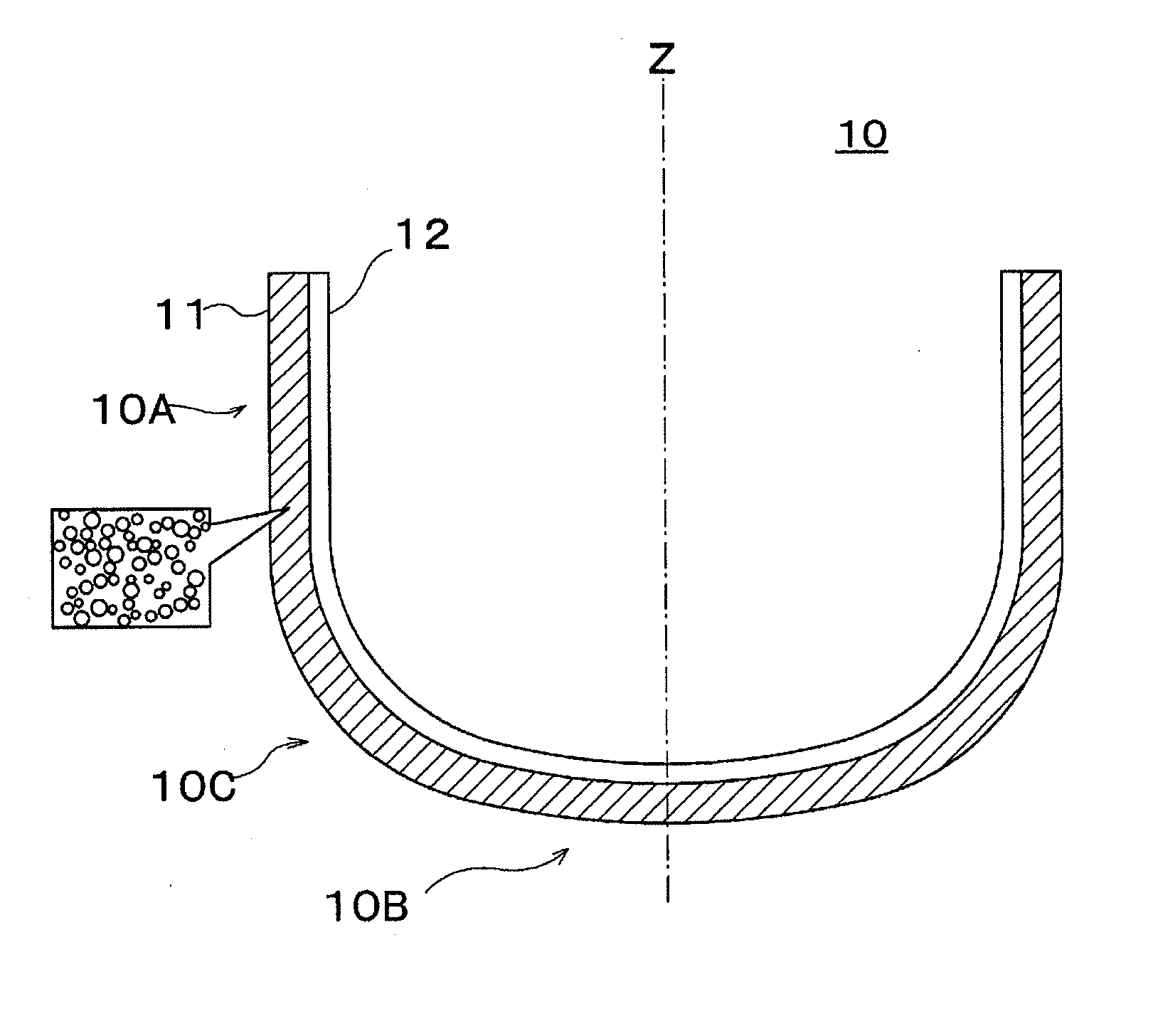

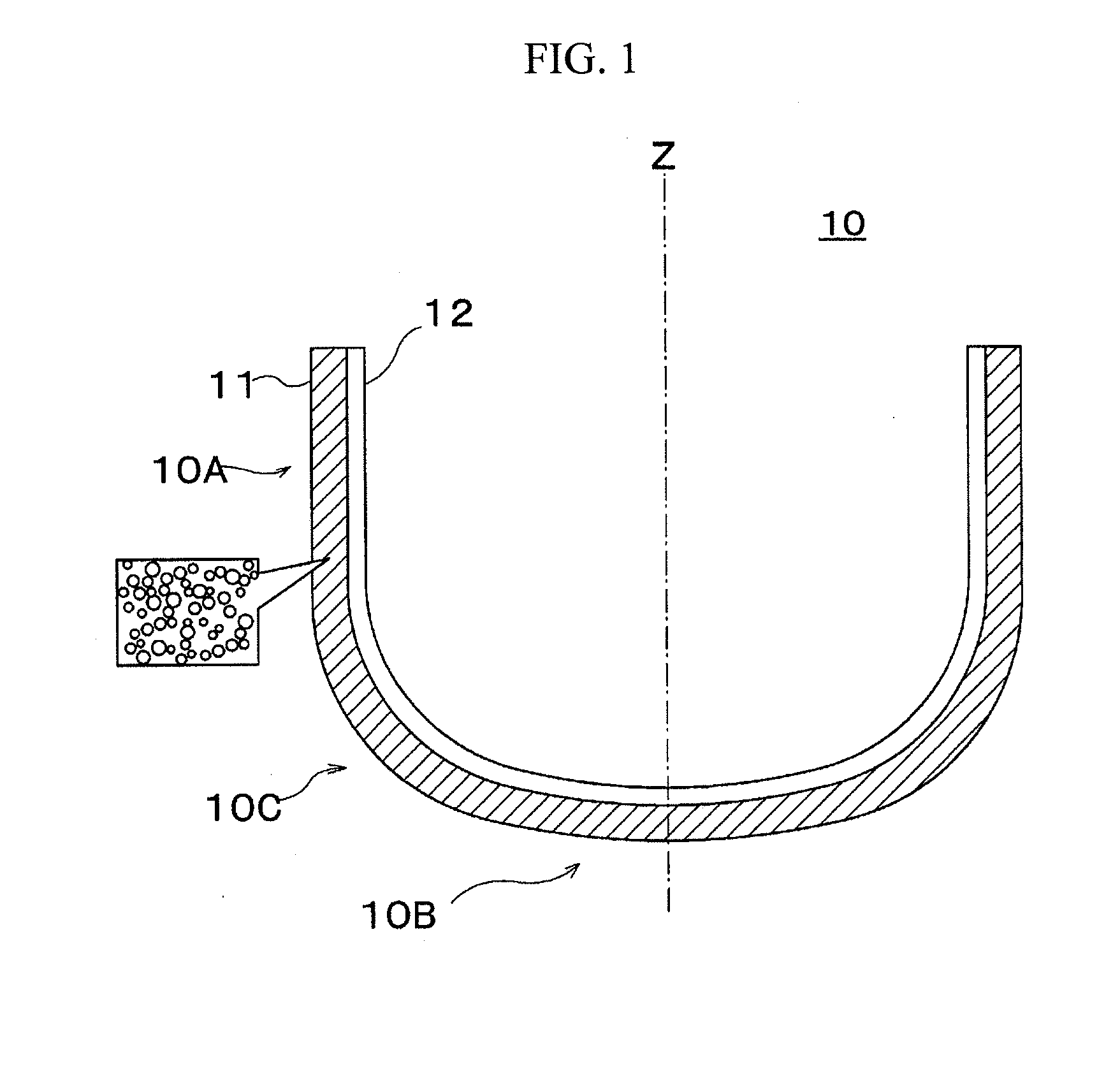

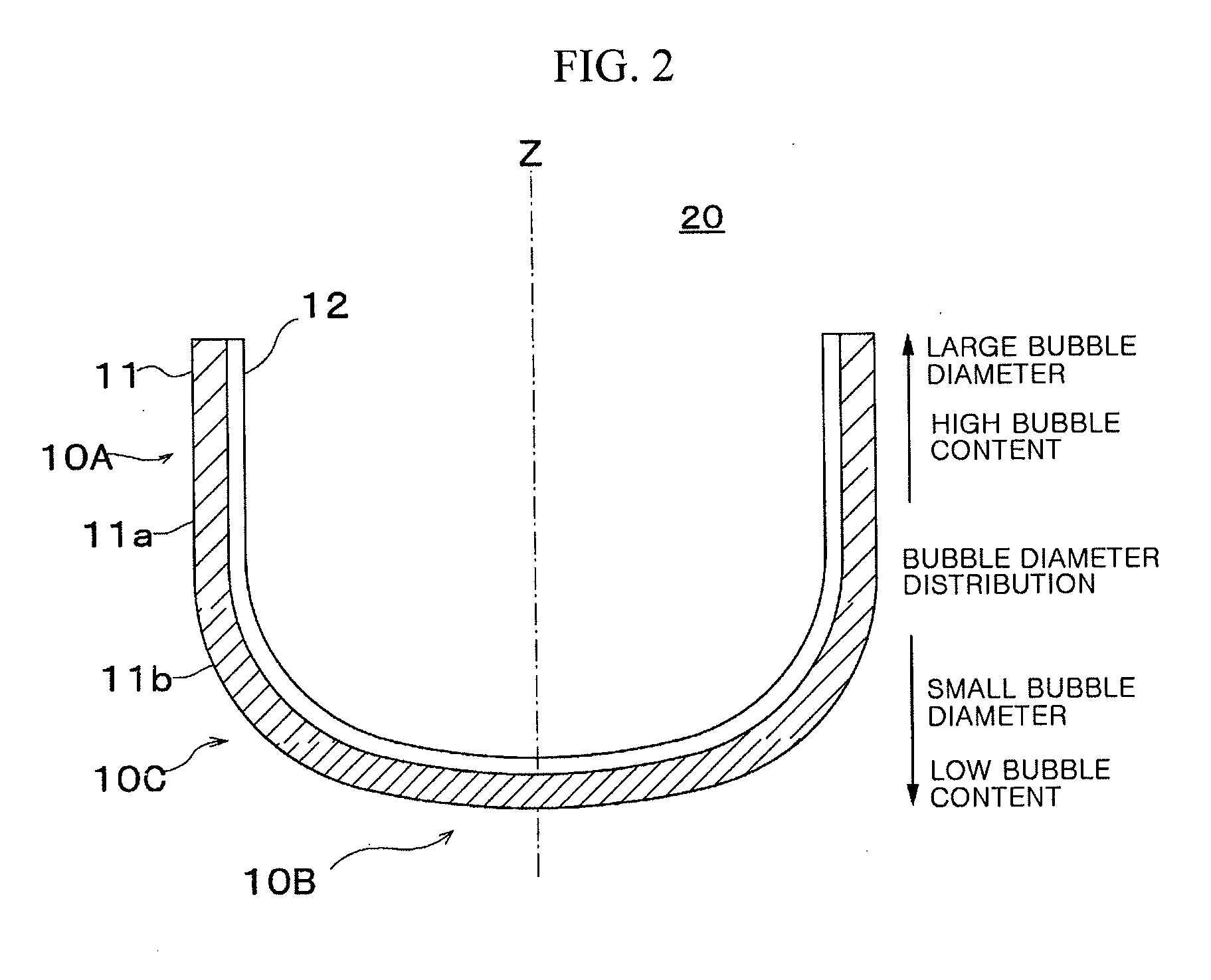

Vitreous silica crucible for pulling silicon single crystal

ActiveUS20100251959A1Improve production yieldShort timeAfter-treatment apparatusPolycrystalline material growthCrucibleRaw material

Provided is a vitreous silica crucible for pulling silicon single crystals, which can melt a silicon raw material in a short time and improve production yield of silicon single crystals by temporal change of an opaque vitreous silica layer. The vitreous silica crucible includes an opaque vitreous silica layer(11) provided on an outer surface thereof and containing plural bubbles, and a transparent vitreous silica layer(12) provided on an inner surface and not containing bubbles substantially. The opaque vitreous silica layer(11) has a bubble diameter distribution in which the content of bubbles having a diameter of less than 40 μm is 10% or more and less than 30%, the content of bubbles having a diameter of 40 μm or more and less than 90 μm is 40% or more and less than 80%, and the content of bubbles having a diameter equal to or more than 90 μm is 10% or more and less than 30%. Relatively small bubbles contained in the opaque vitreous silica layer(11) contribute to the thermal conductivity of a crucible at an initial pulling stage, and relatively large bubbles contained in the opaque vitreous silica layer are expanded through a long-term pulling process to thereby largely contribute to the warmth retaining property of the crucible at a later pulling stage.

Owner:JAPAN SUPER QUARTZ CORP

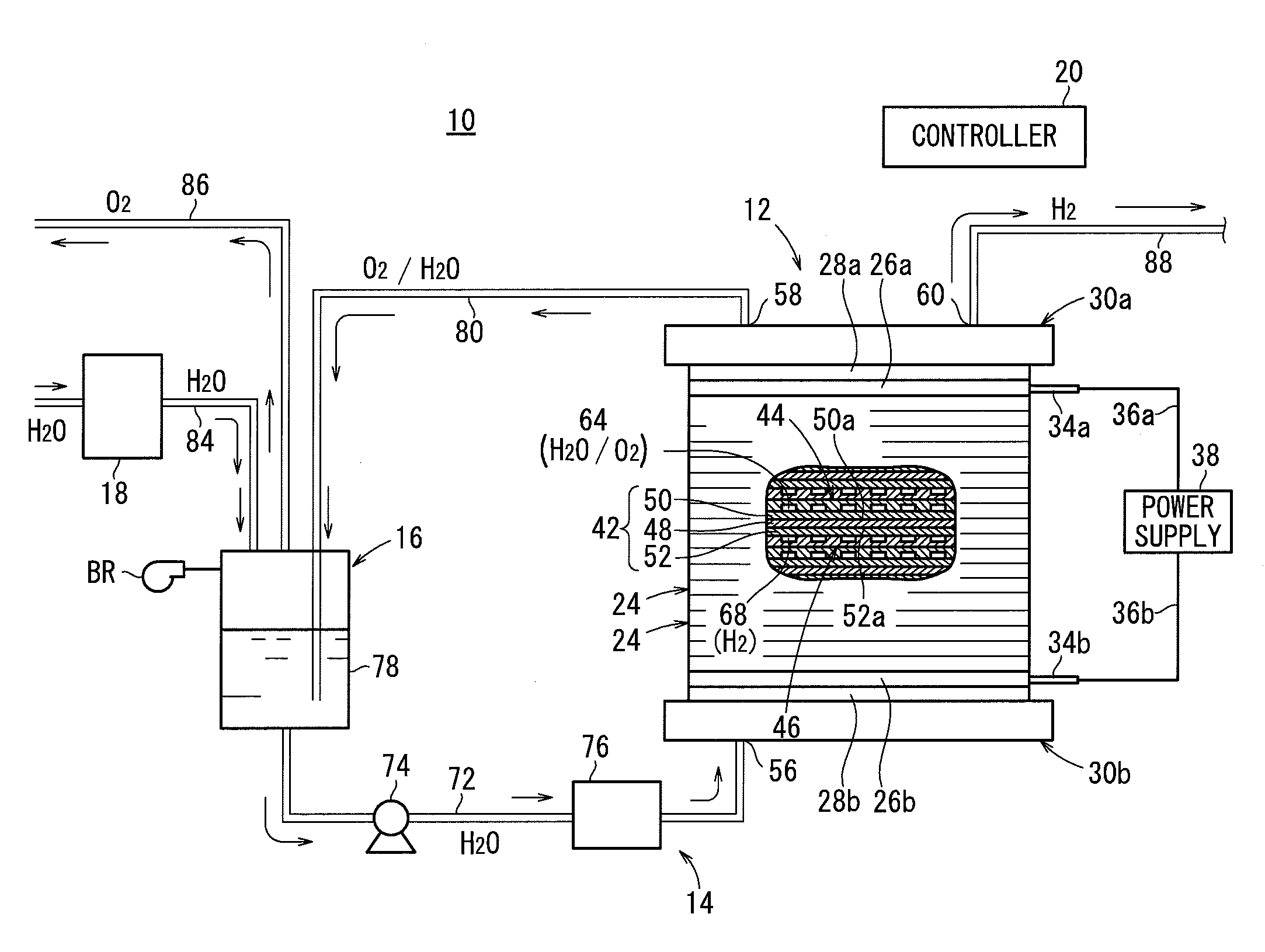

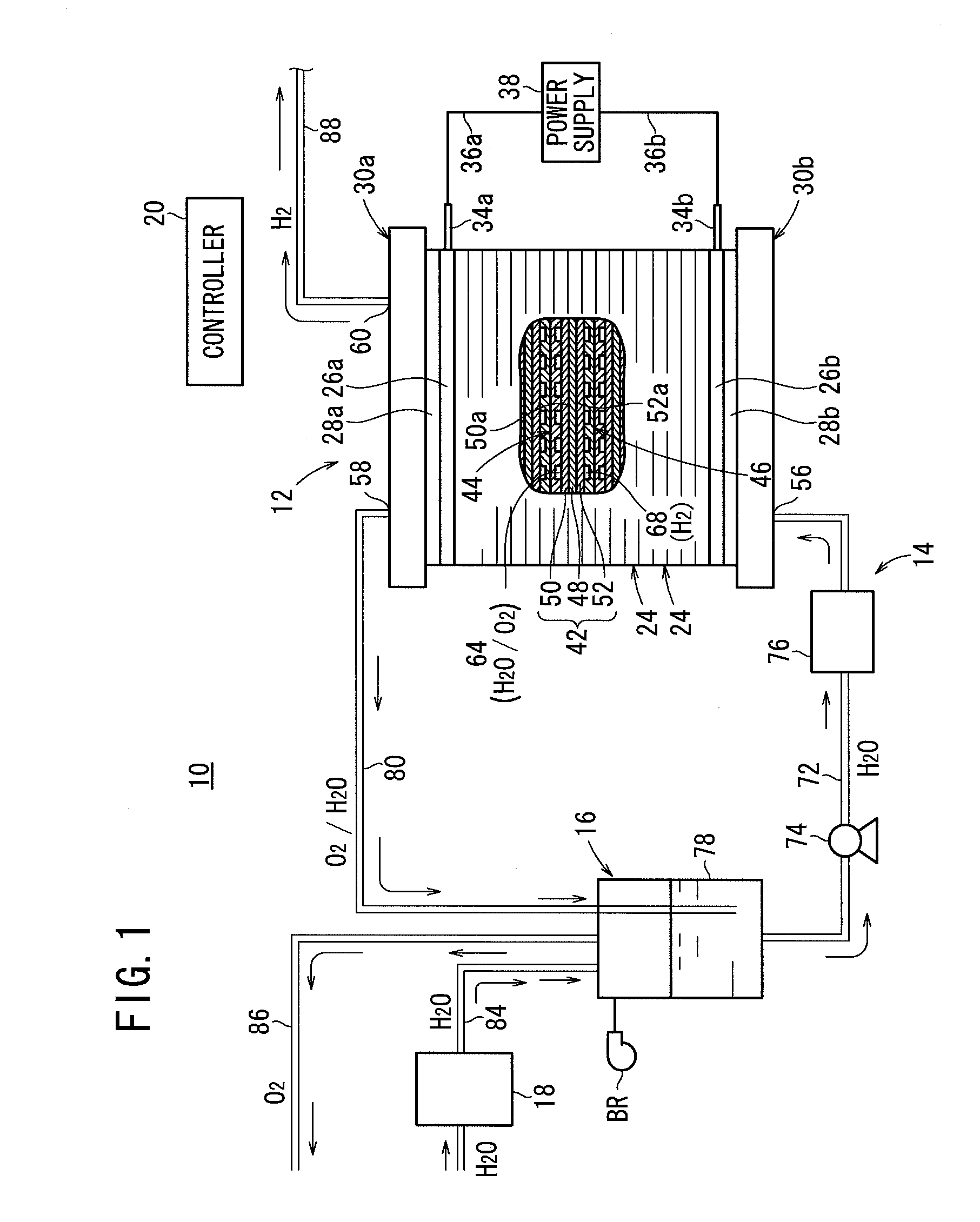

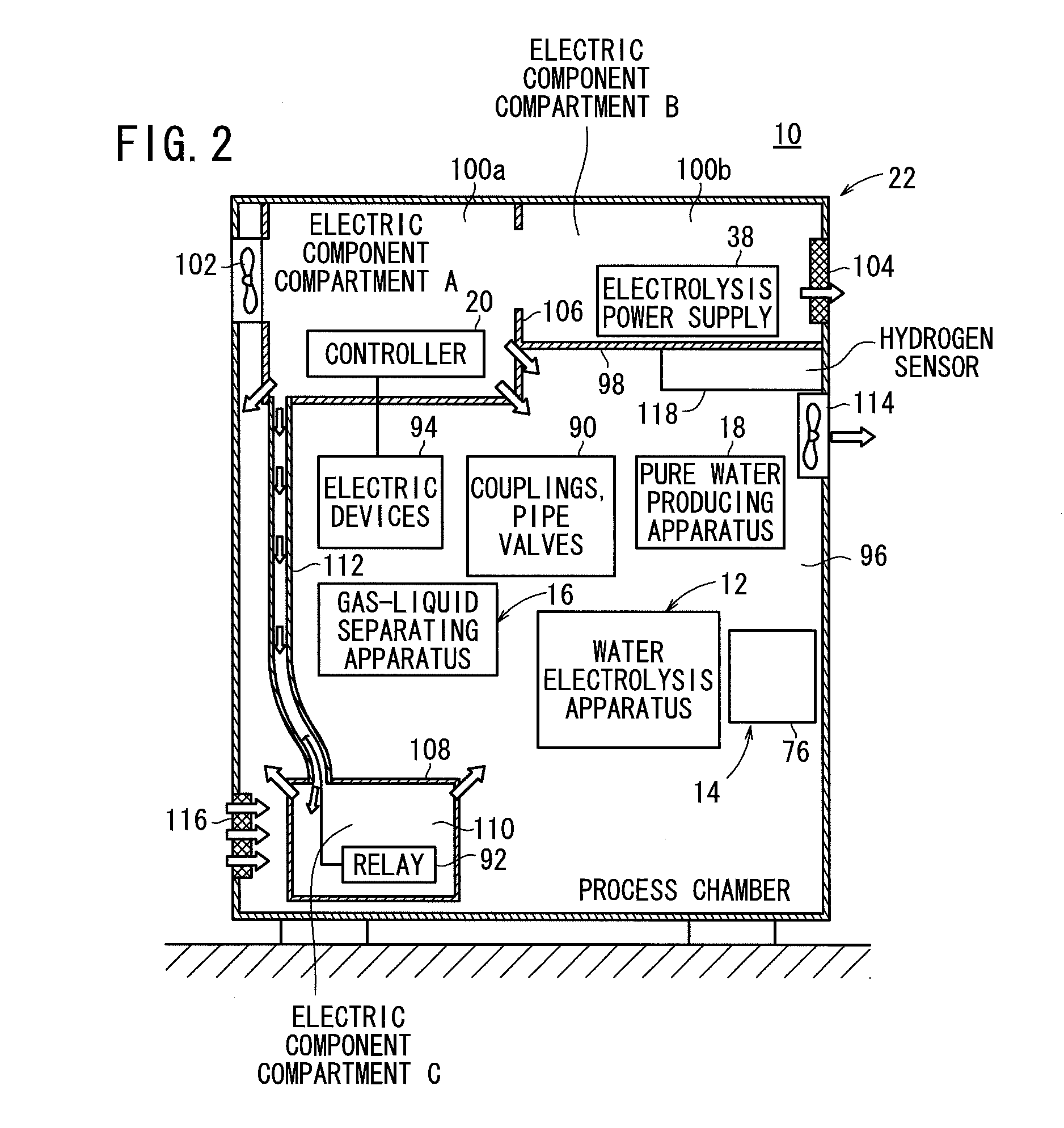

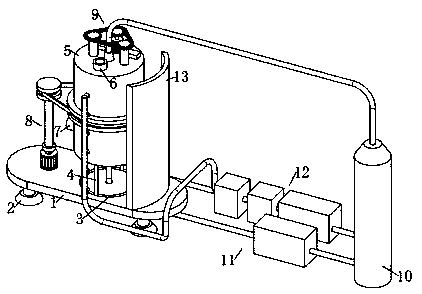

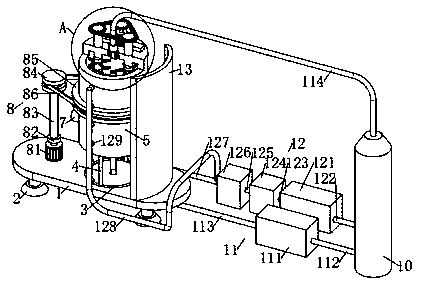

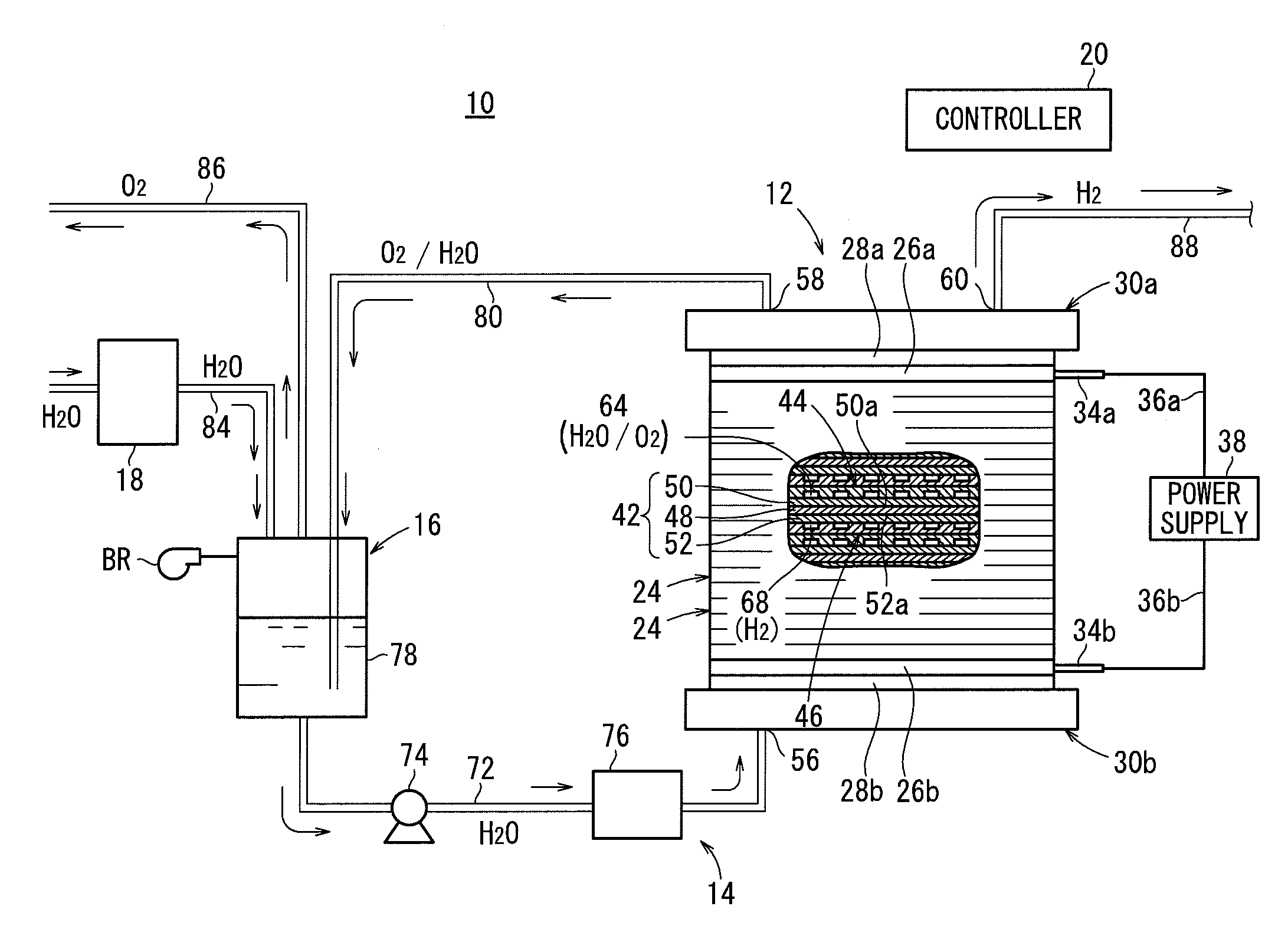

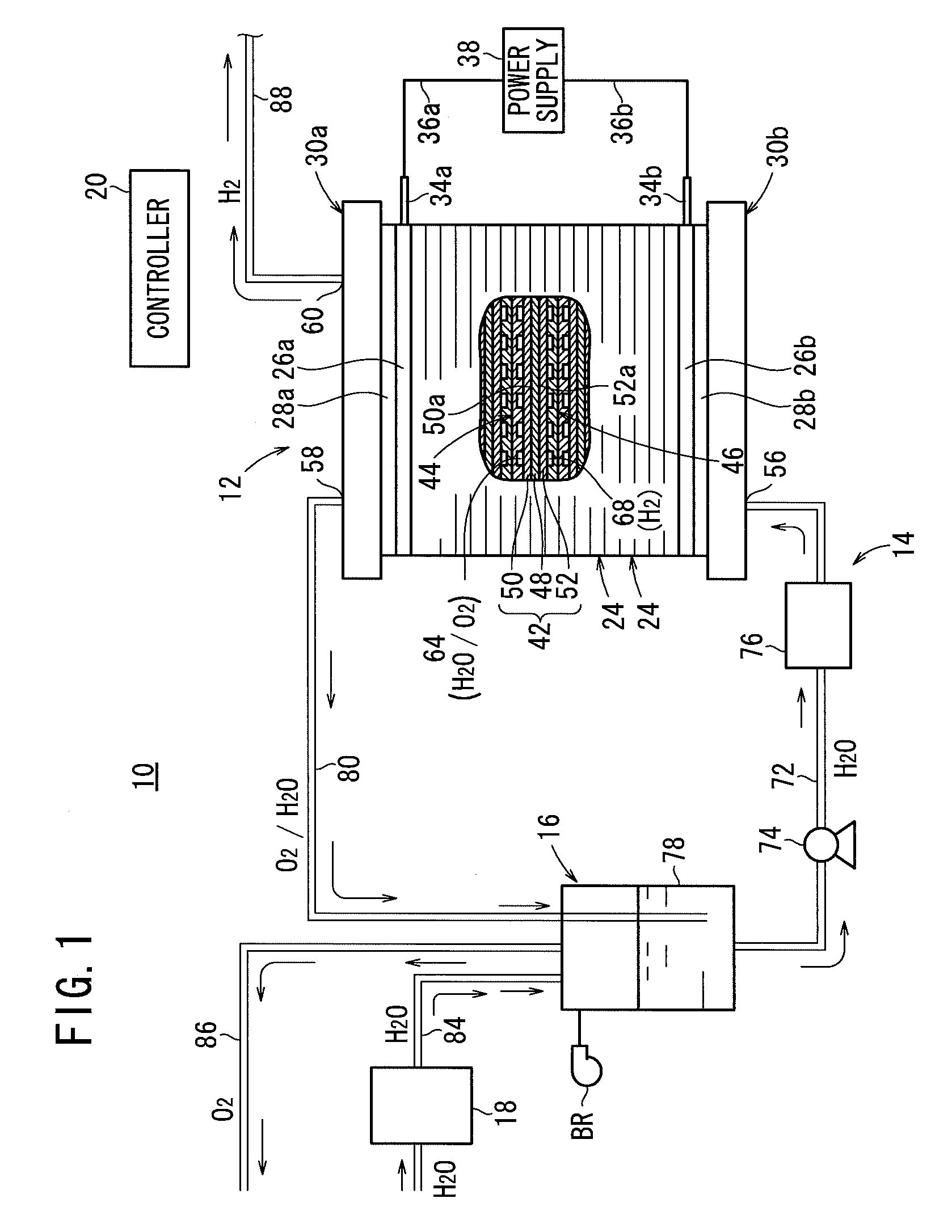

Water electrolysis system and method of operating same

ActiveUS20110240486A1Economical and simpleSmall amount of heatCellsPhotography auxillary processesHigh pressure hydrogenEngineering

A water electrolysis system includes a water electrolysis apparatus for producing high-pressure hydrogen by electrolyzing pure water and a casing. The casing defines therein an accommodating chamber accommodating the water electrolysis apparatus etc. therein, first electric component compartments separate from the accommodating chamber and housing a controller and an electrolysis power supply therein, the first electric component compartments having first fans for introducing external air, and a second electric component compartment separate from the accommodating chamber and housing a relay, the second electric component compartment being connected to the first electric component compartments by a pipe.

Owner:HONDA MOTOR CO LTD

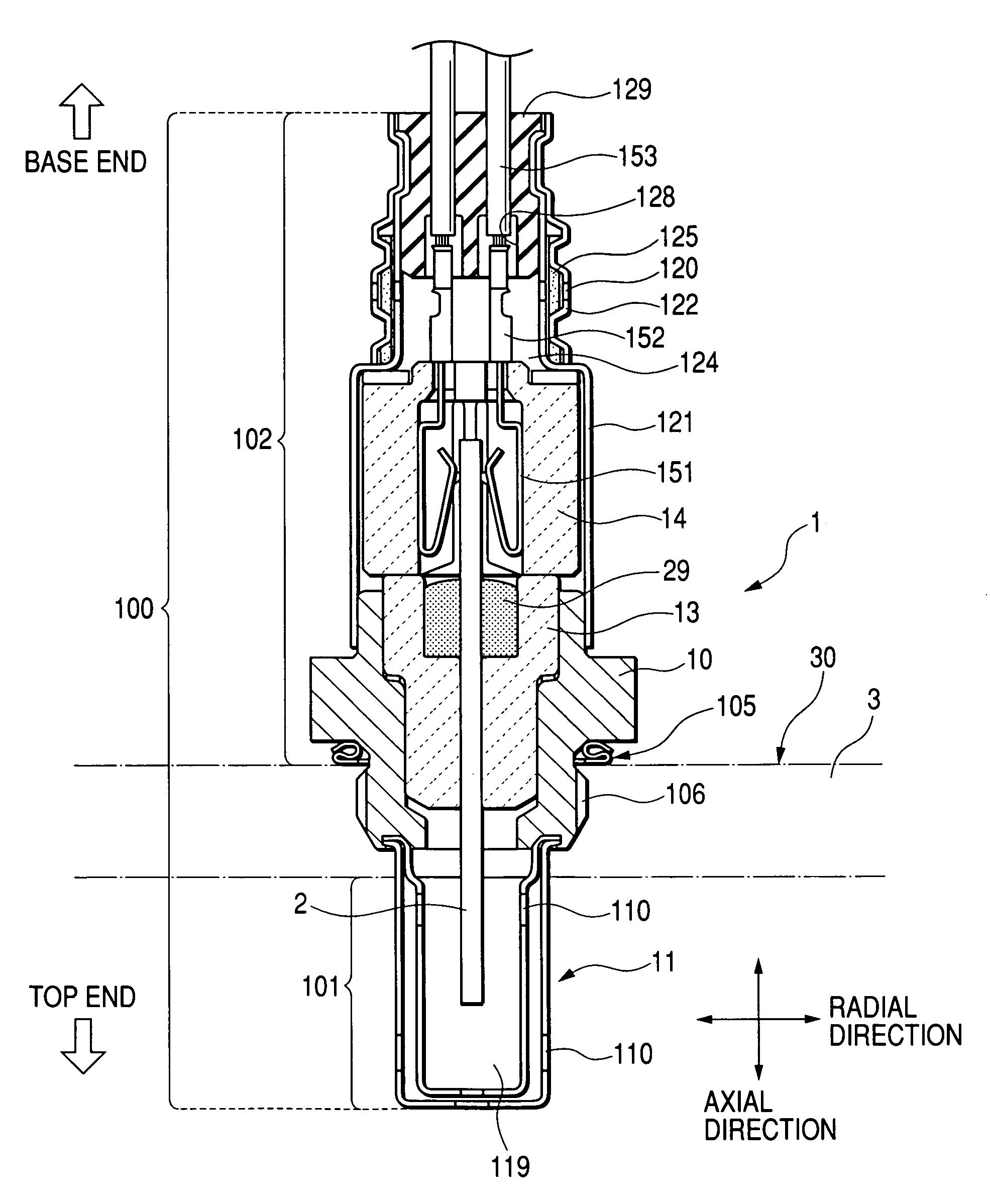

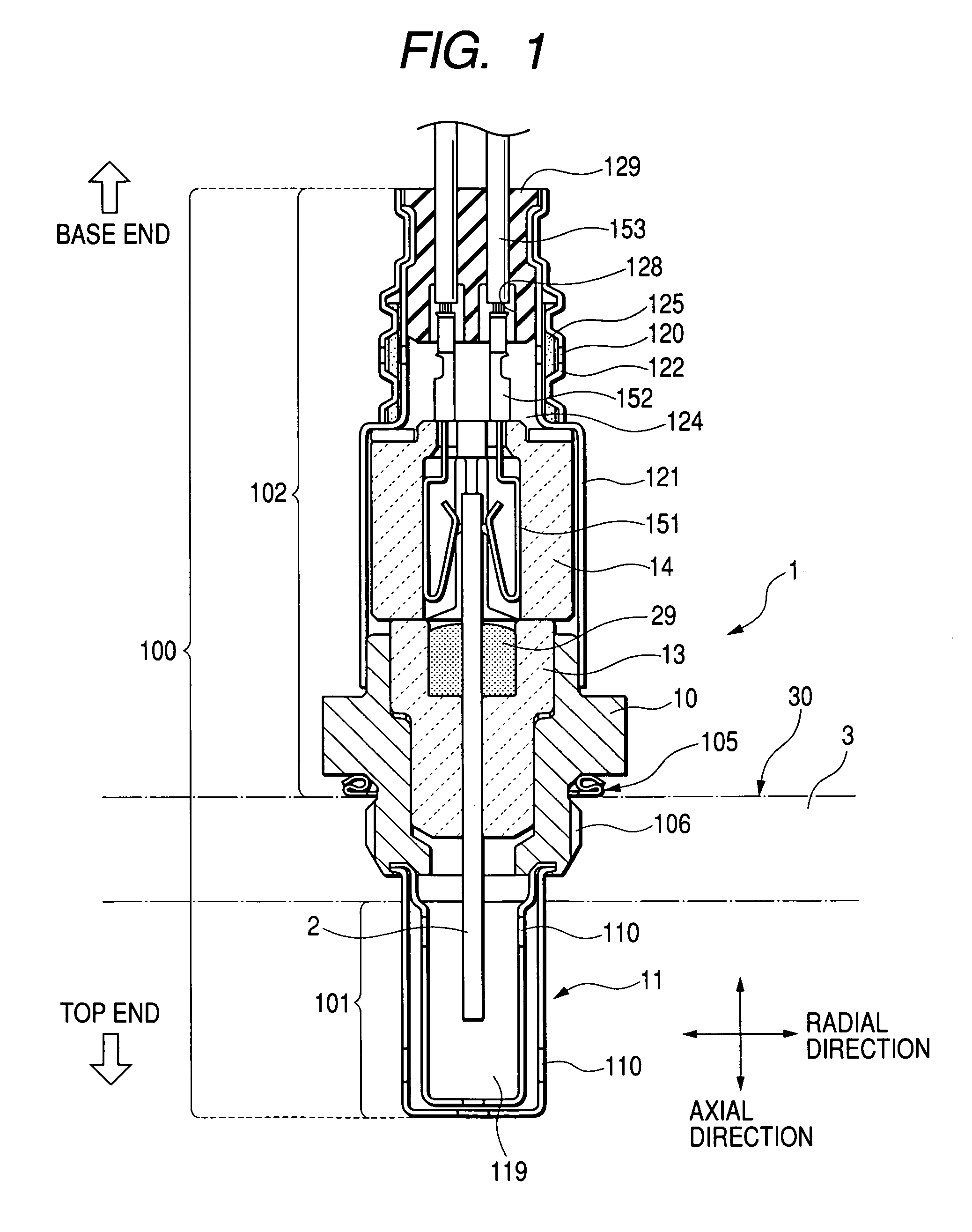

Gas sensor

ActiveUS7066009B2Reduce heat transferLess raisableWithdrawing sample devicesMaterial analysis by electric/magnetic meansEmissivityThermal impact

In a gas sensor internally including a sensing element for measuring a specific gas concentration of a measured gas, an outer surface thereof has a measured gas surface exposed to a measured gas and an atmosphere surface exposed to the atmosphere, and at least a portion of the atmosphere surface has an emissivity equal to or lower than 0.3. Preferably, this emissivity is a value with respect to an electromagnetic wave having a wavelength of 0.5 to 1 μm, and the a region of the atmosphere surface, contributing 60% or more of the atmosphere surface, has an emissivity equal to or lower than 0.3. This provides a gas sensor less susceptible to radiant heat and less temperature-increasable.

Owner:DENSO CORP

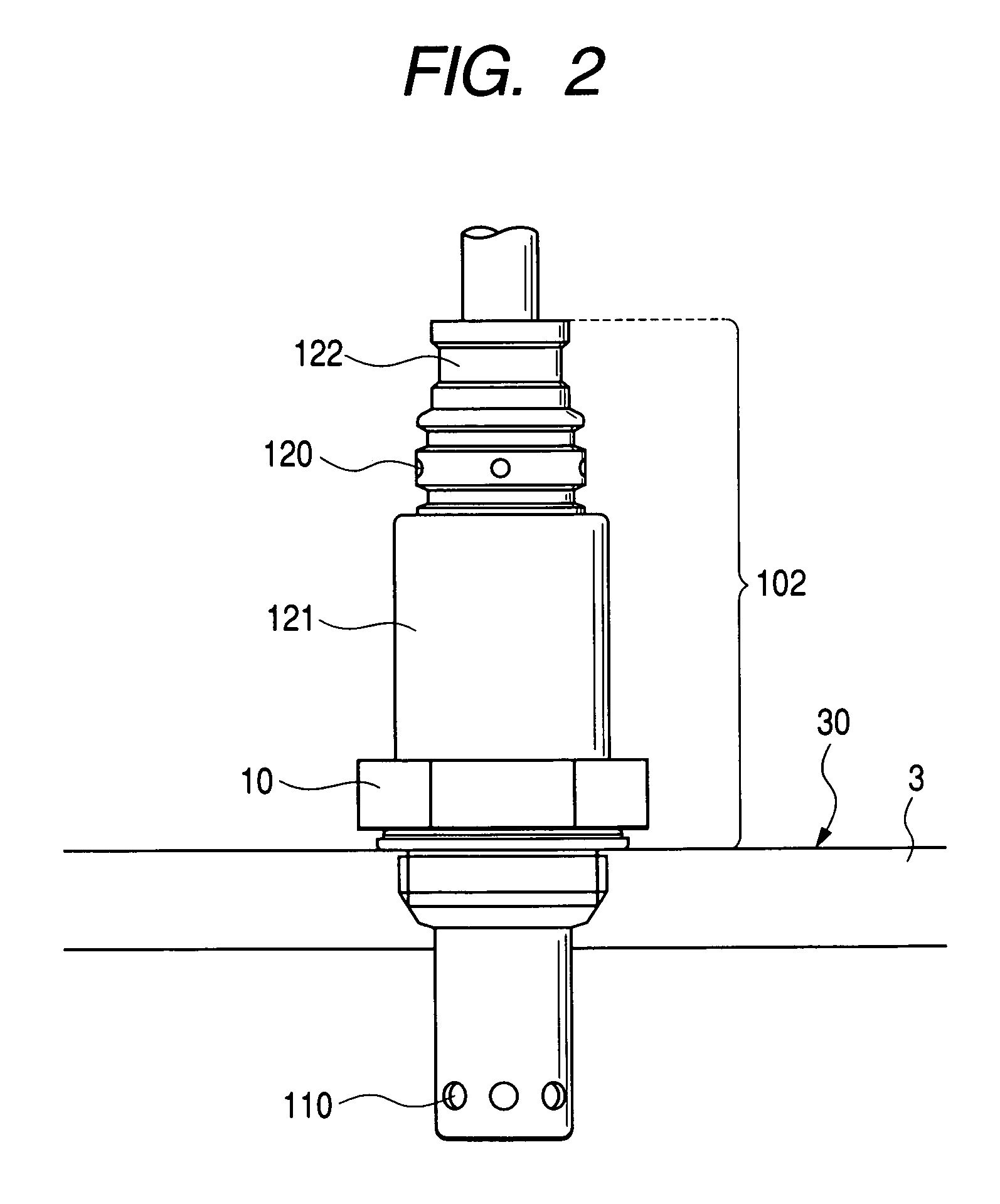

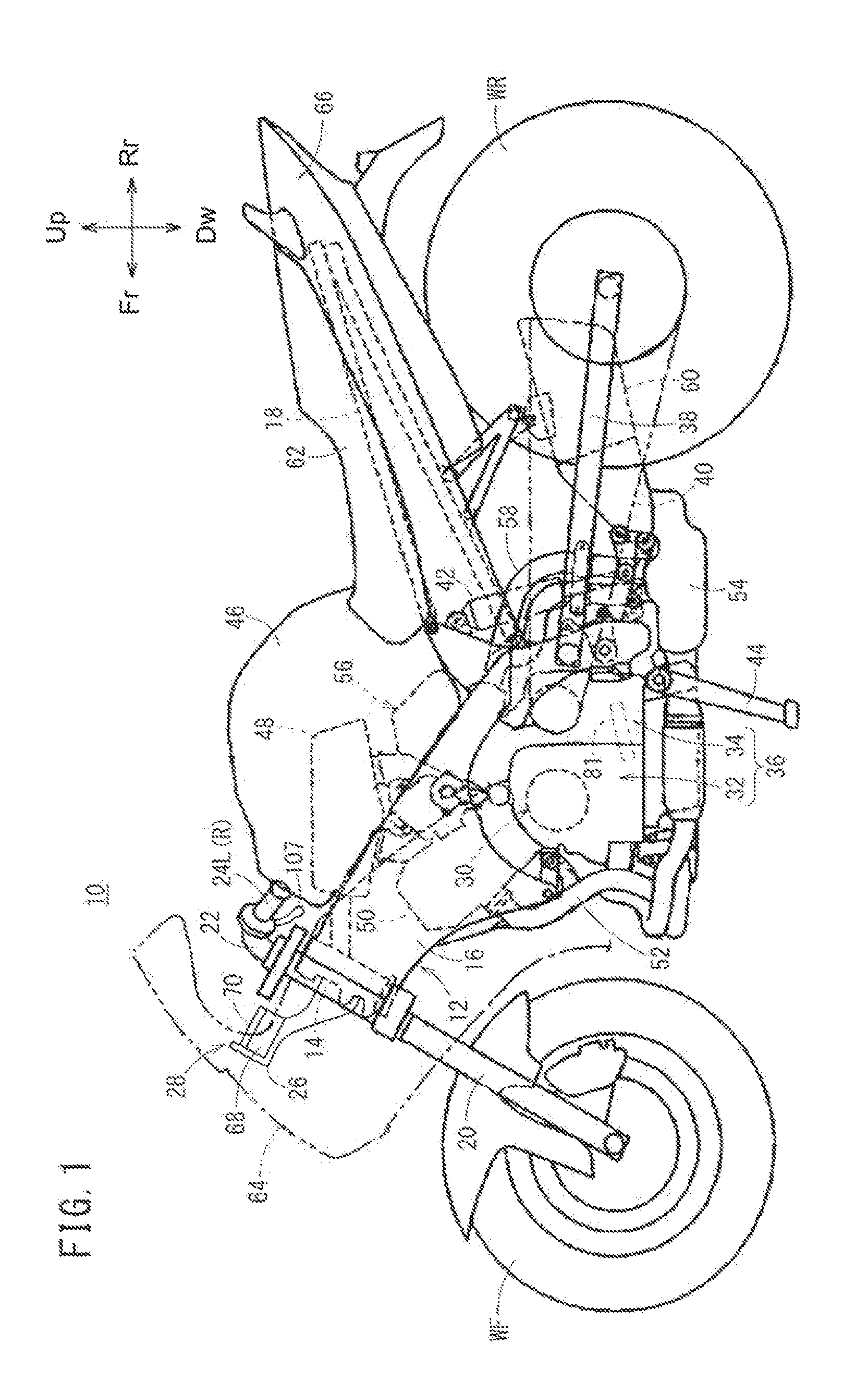

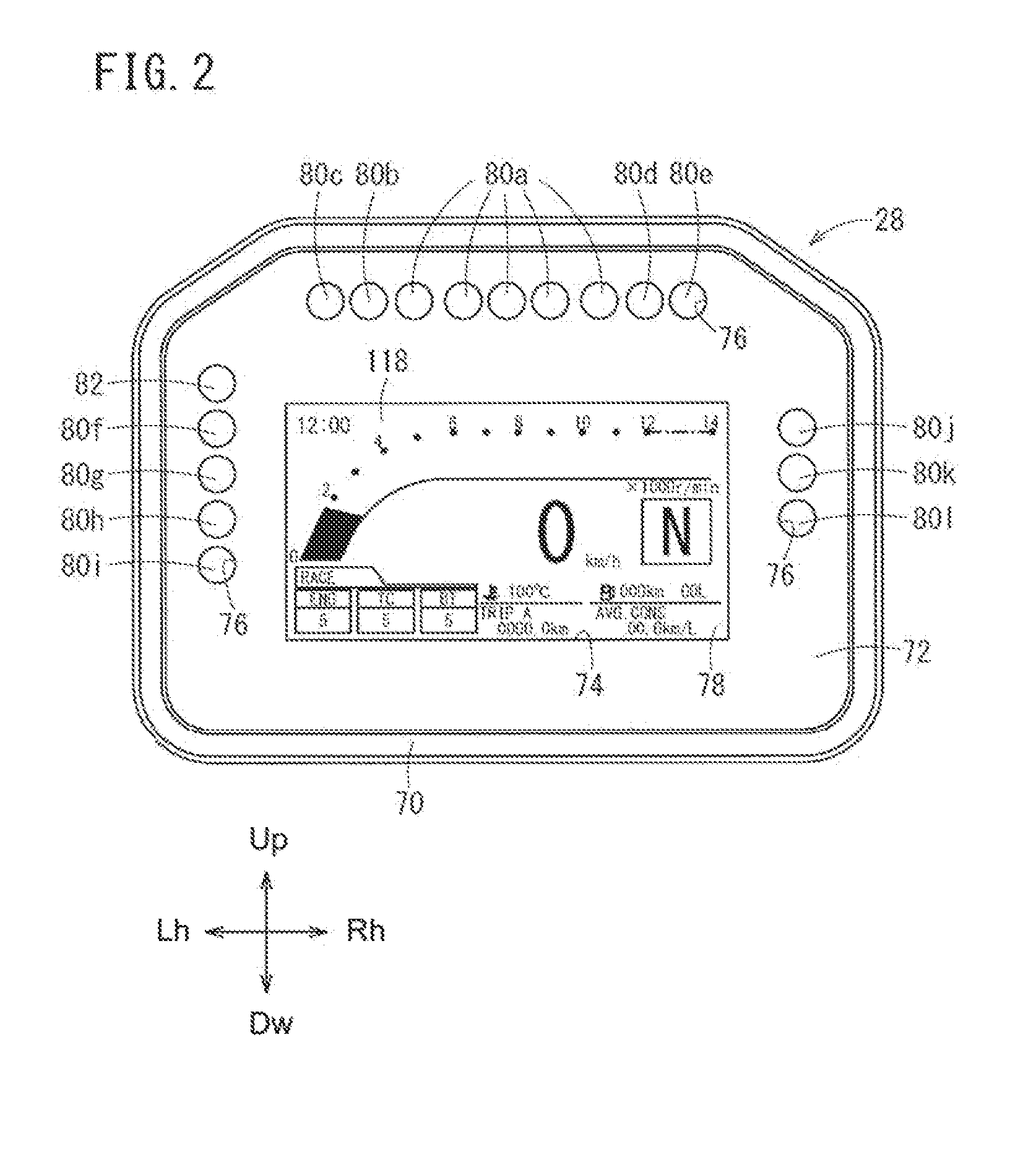

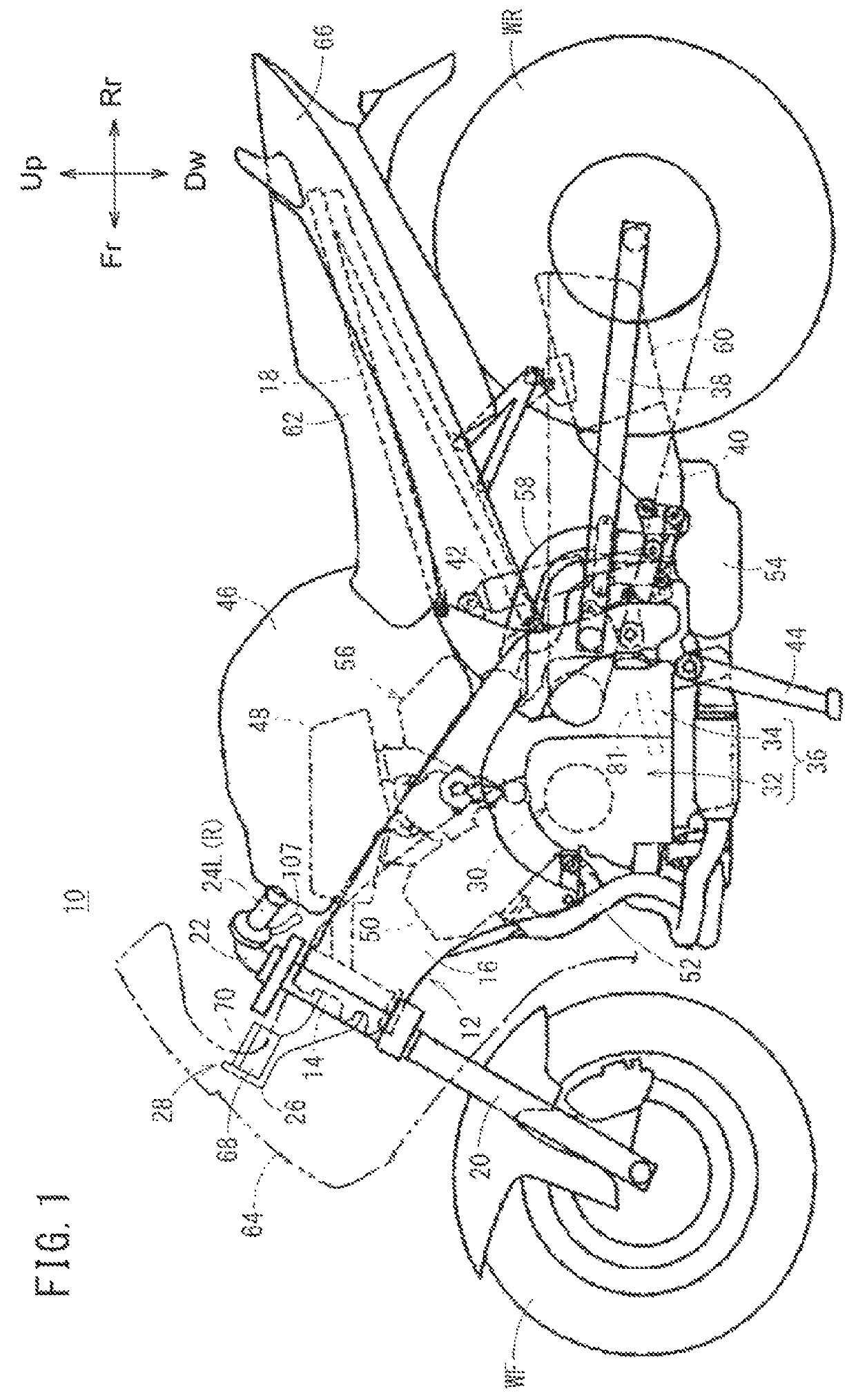

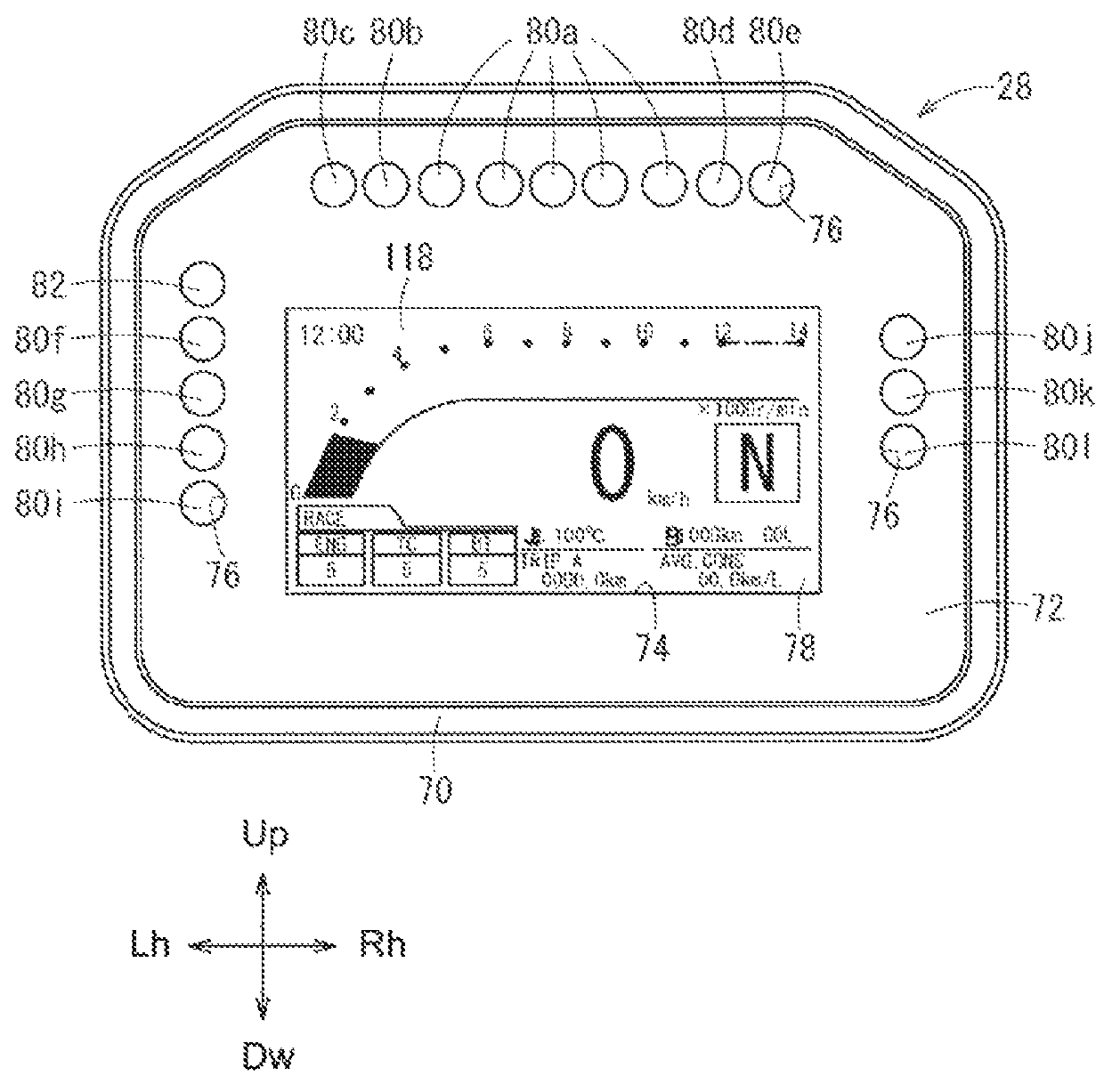

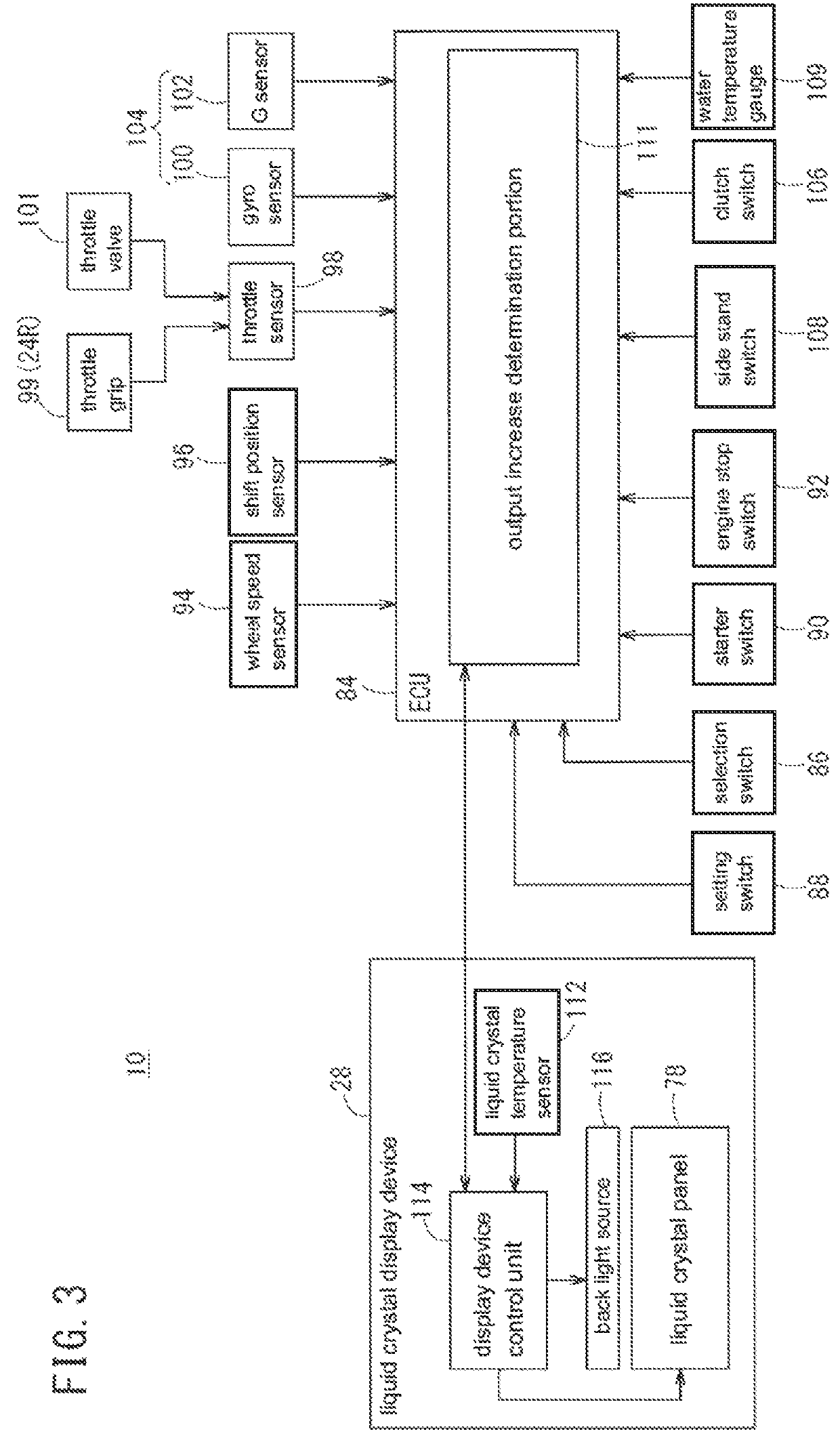

Liquid crystal display device, motorcycle including same, and method of using same

InactiveUS20150185545A1Raise the temperature of the liquidIncrease productionInstrument arrangements/adaptationsCycle equipmentsLiquid-crystal displayDark color

A liquid crystal display device of a motorcycle is configured and arranged to rapidly warm up a liquid crystal panel at cool temperatures, without requiring an additional heating member. The liquid crystal display device includes a control unit, for controlling a liquid crystal panel, and a backlight. When the temperature of liquid crystal is lower than a predetermined value, or when it is within a fixed time period after turning on an ignition switch, as a warm-up period, the control unit increases power supplied to the backlight to a larger amount than that in a normal display state, to increase the amount of back light, and temporarily changes the entire display surface to a darker color, in order to increase the amount of light absorbed by the liquid crystal panel, simultaneously reducing the amount of light penetrating the display surface, and thereby speeding up warming of the liquid crystal panel.

Owner:HONDA MOTOR CO LTD

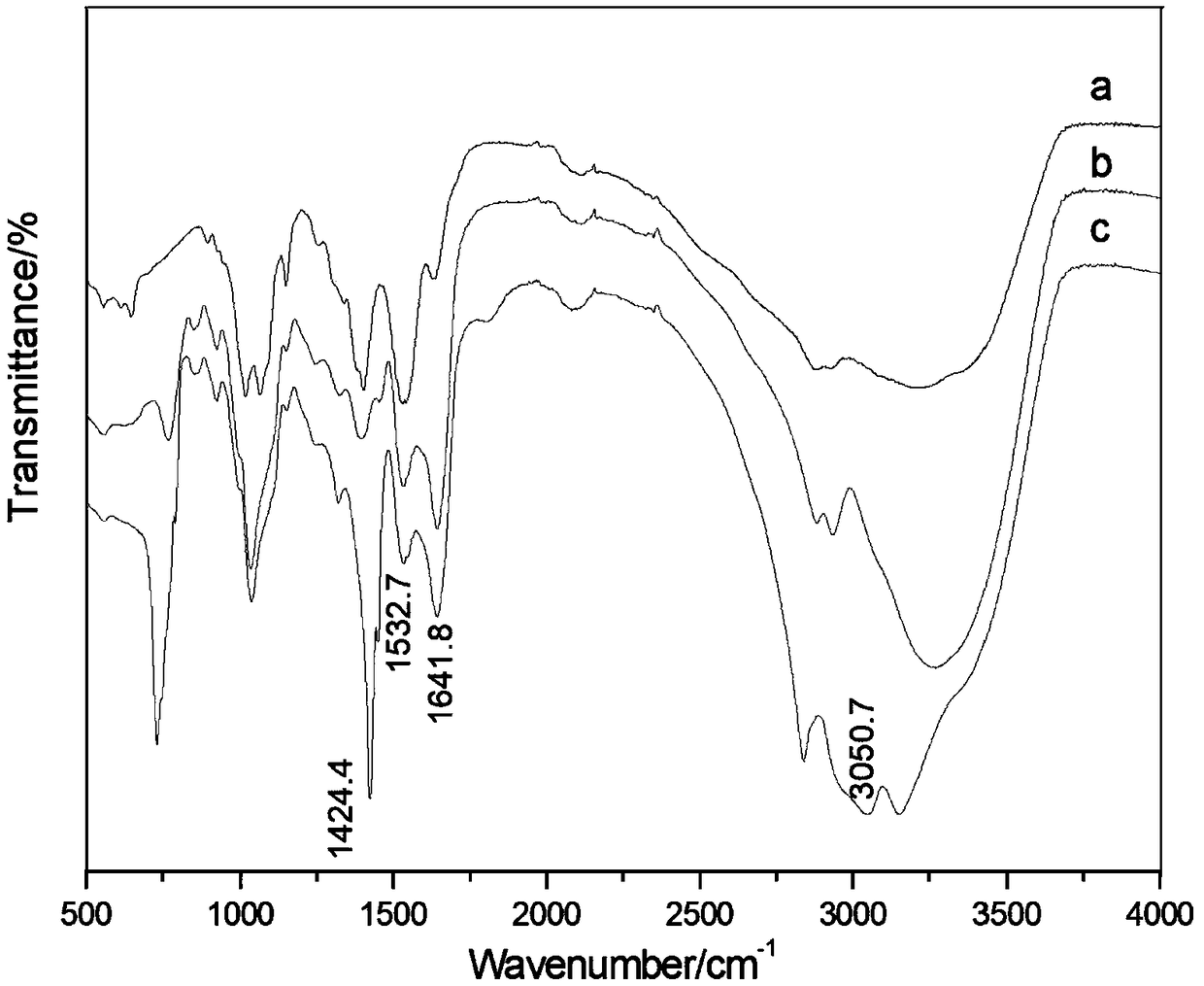

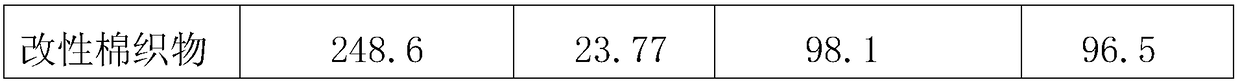

Chitosan sericin compound finishing agent and finishing method for cotton fabrics

ActiveCN109137511AImprove stabilitySusceptible to heatBiochemical fibre treatmentLight resistant fibresCotton fibreLoss rate

The invention provides a chitosan sericin compound finishing agent and a finishing method for cotton fabrics. A preparation method for the compound finishing agent comprises the following steps that 1), chitosan is dissolved; 2), chitosan is oxidized; 3), the finishing agent is prepared; the finishing method for the cotton fabrics particularly comprises the following steps that 1), cotton fabricsare pre-treated; 2), the cotton fabrics are soaked; 3), the cotton fabrics are subjected to after-treatment; under the microwave radiation, after a TEMPO oxidation system is adopted for conducting C6modifying treatment on the chitosan, the chitosan and sericin are subjected to covalent cross-linking to obtain a novel ecological textile dyeing and finishing auxiliary agent, higher stability is achieved regarding the environmental condition, and the novel ecological textile dyeing and finishing auxiliary agent cannot be easily heated and influenced by environmental changes; when a cross-linkingagent is not added, the compound finishing agent directly treats cotton fiber products, the cotton fiber products have antibacterial and wrinkle proof functions and good function durability, and after the cotton products are washed, the sericin loss rate can be better controlled; by adopting the compound finishing agent, functional modification of the cotton products meets multiple requirements of ecology, multi-functionality and durability.

Owner:ANHUI AGRICULTURAL UNIVERSITY

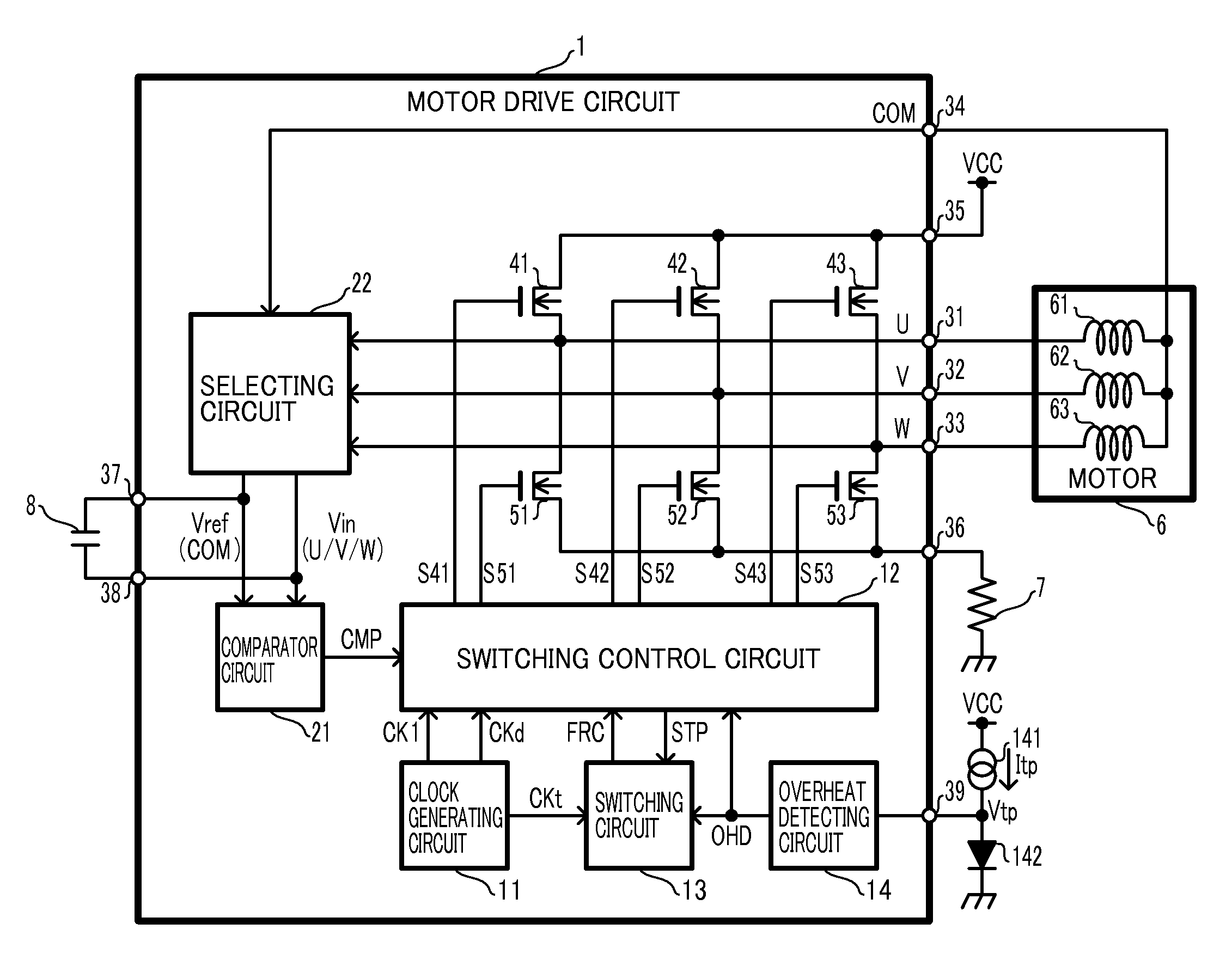

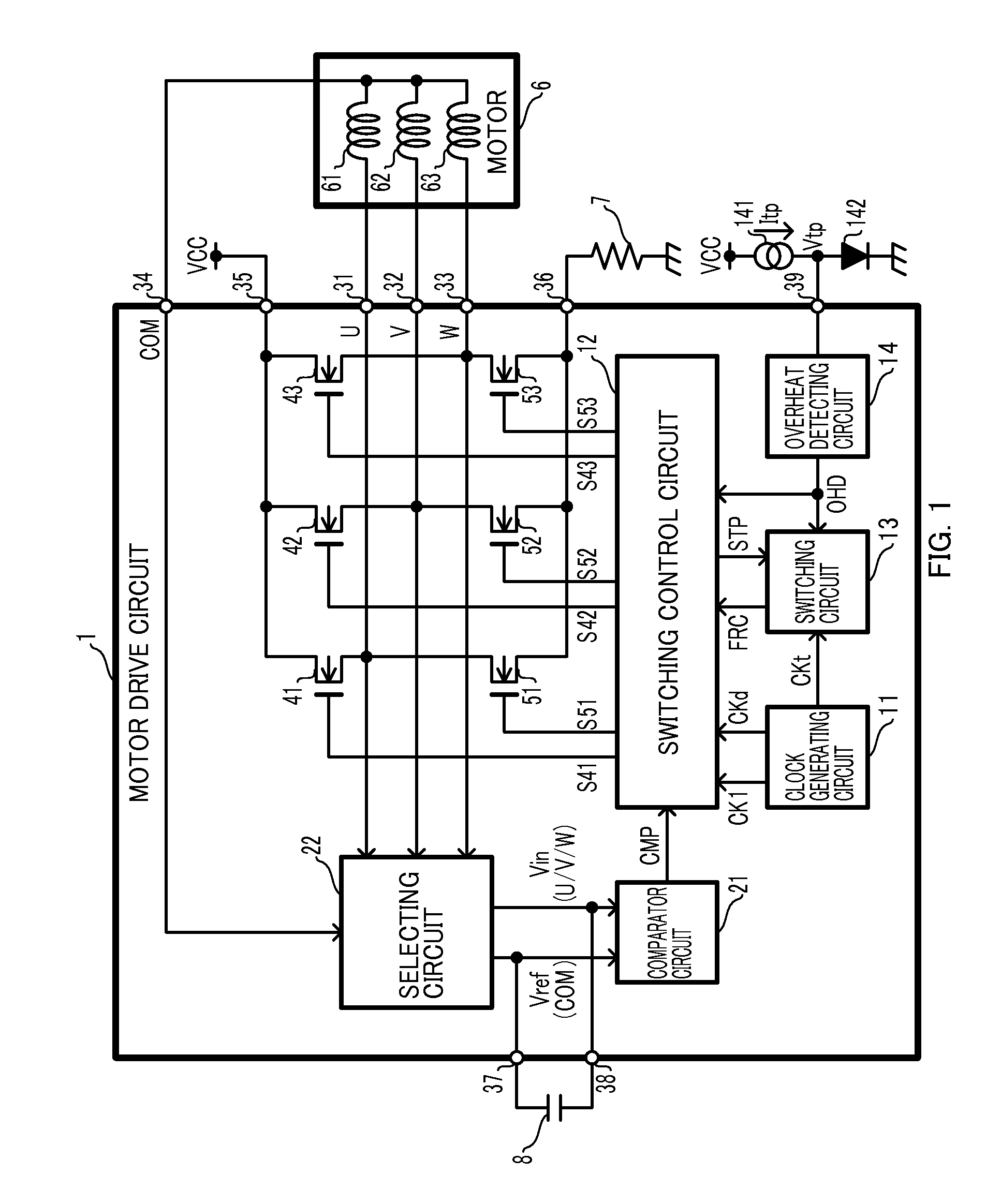

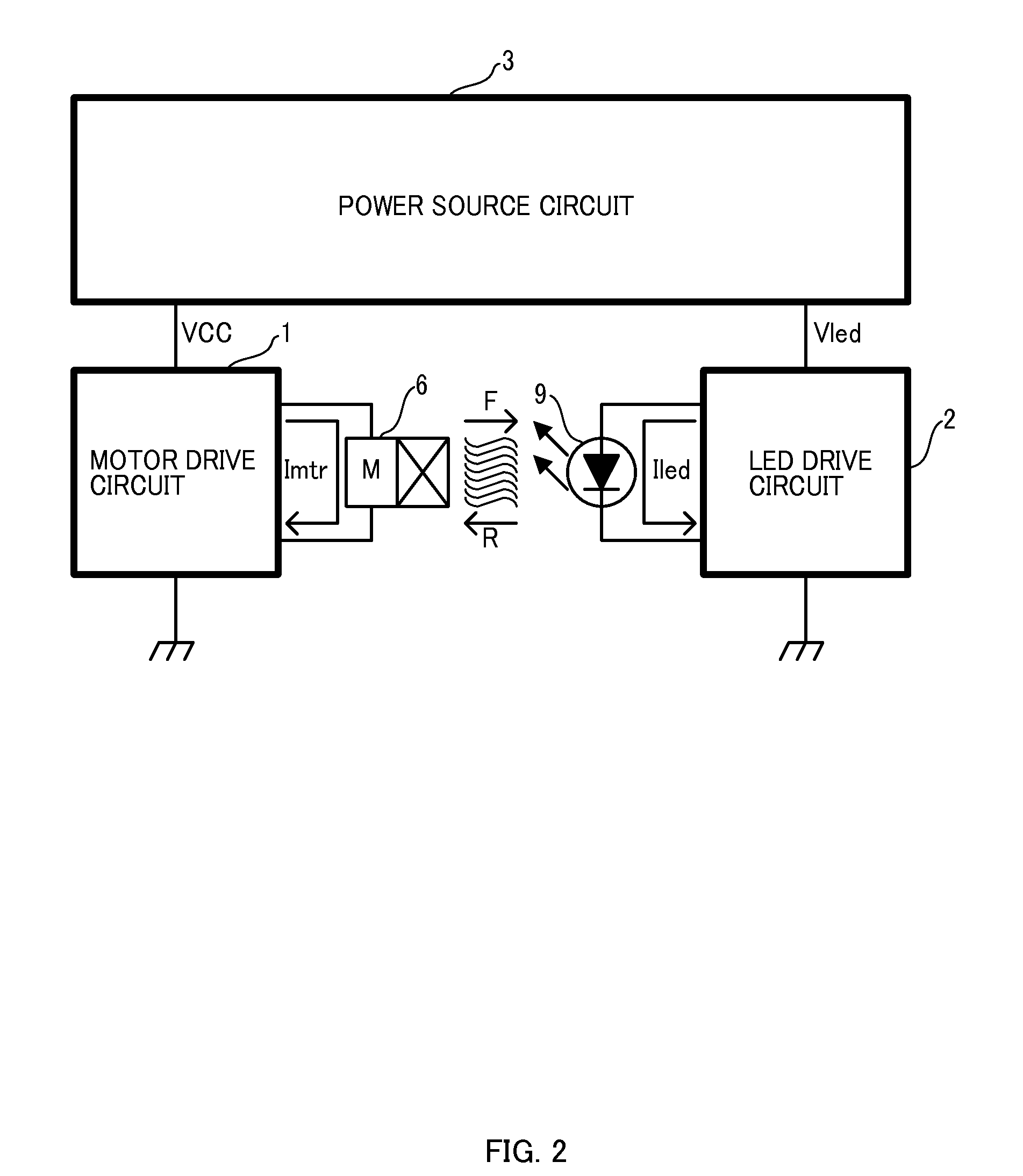

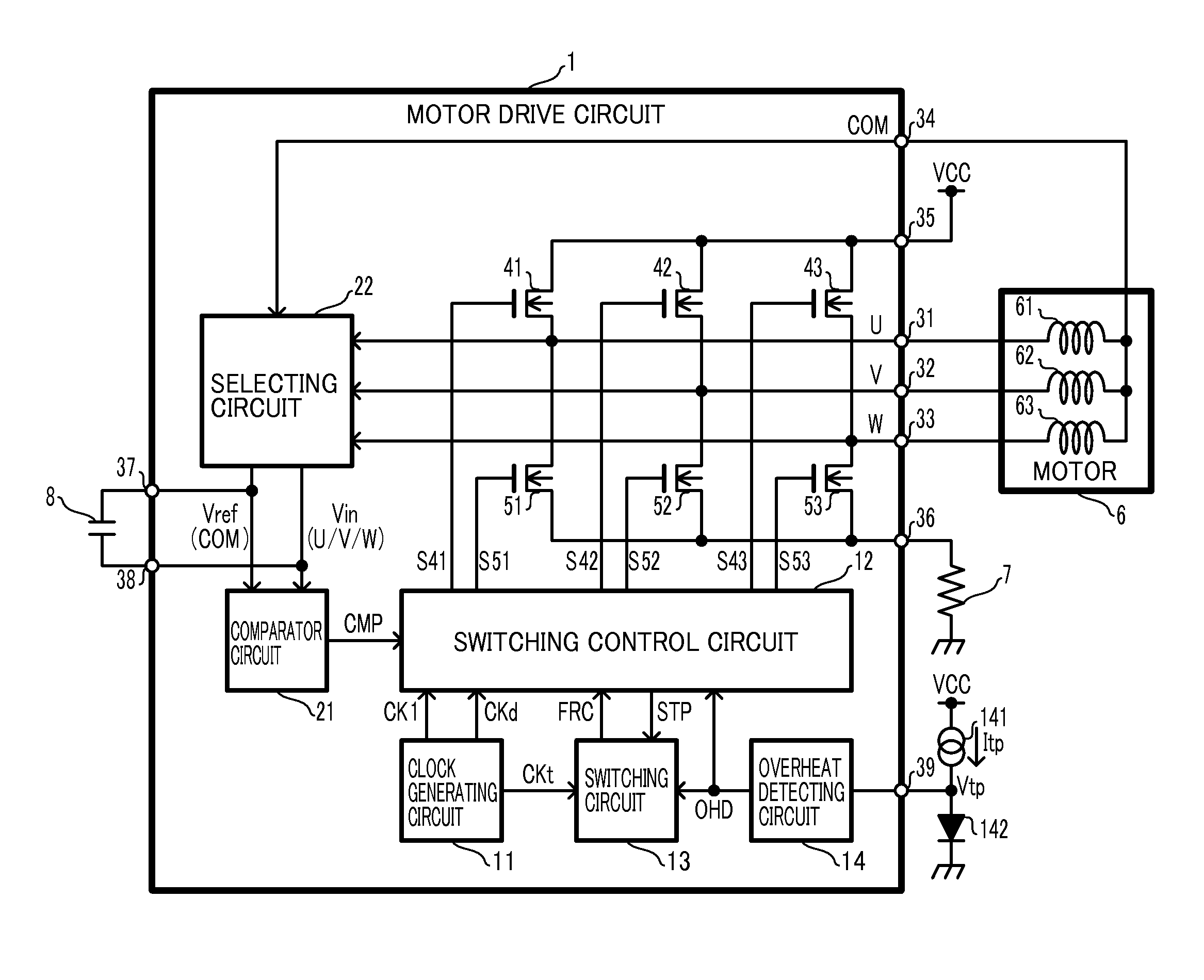

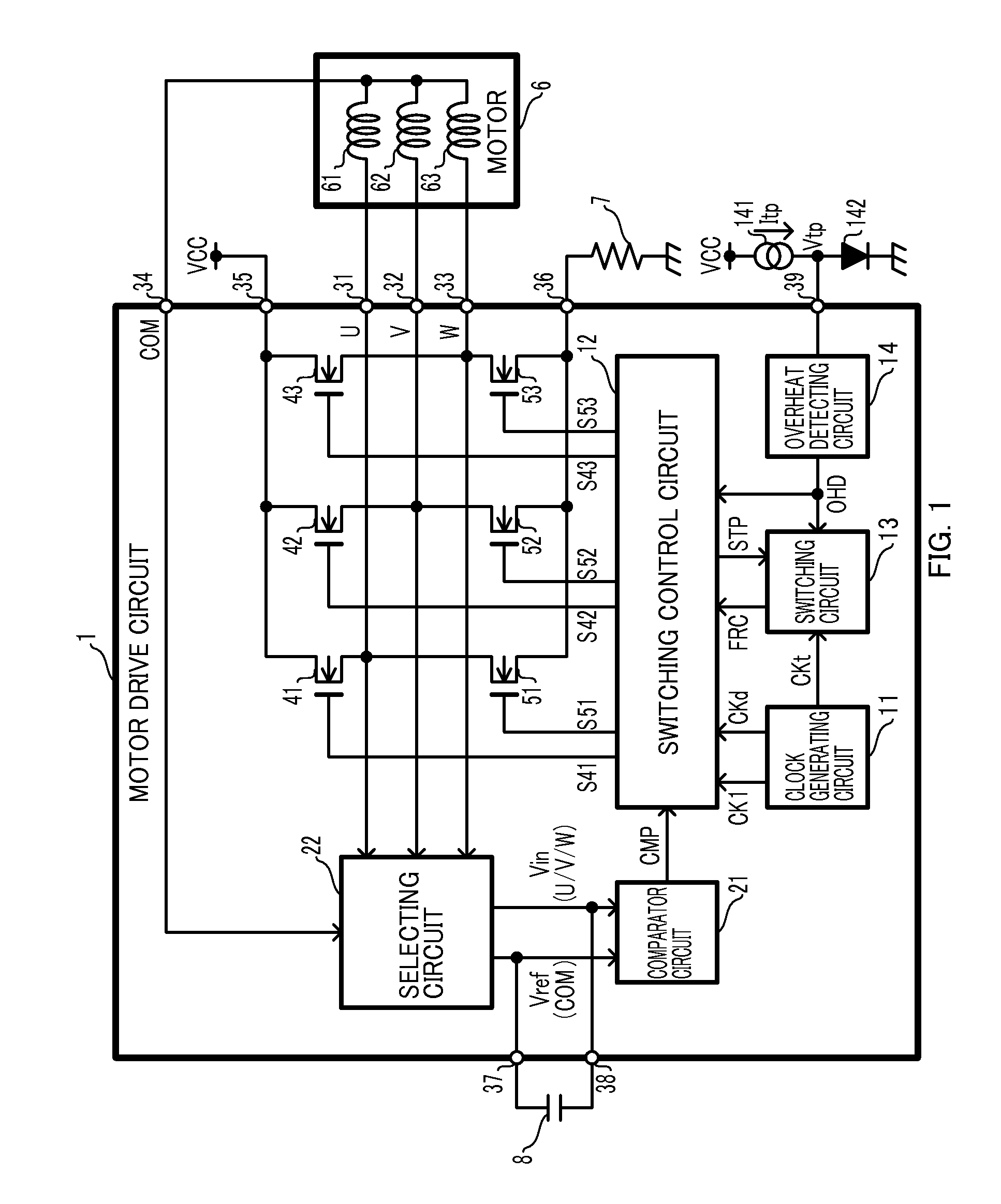

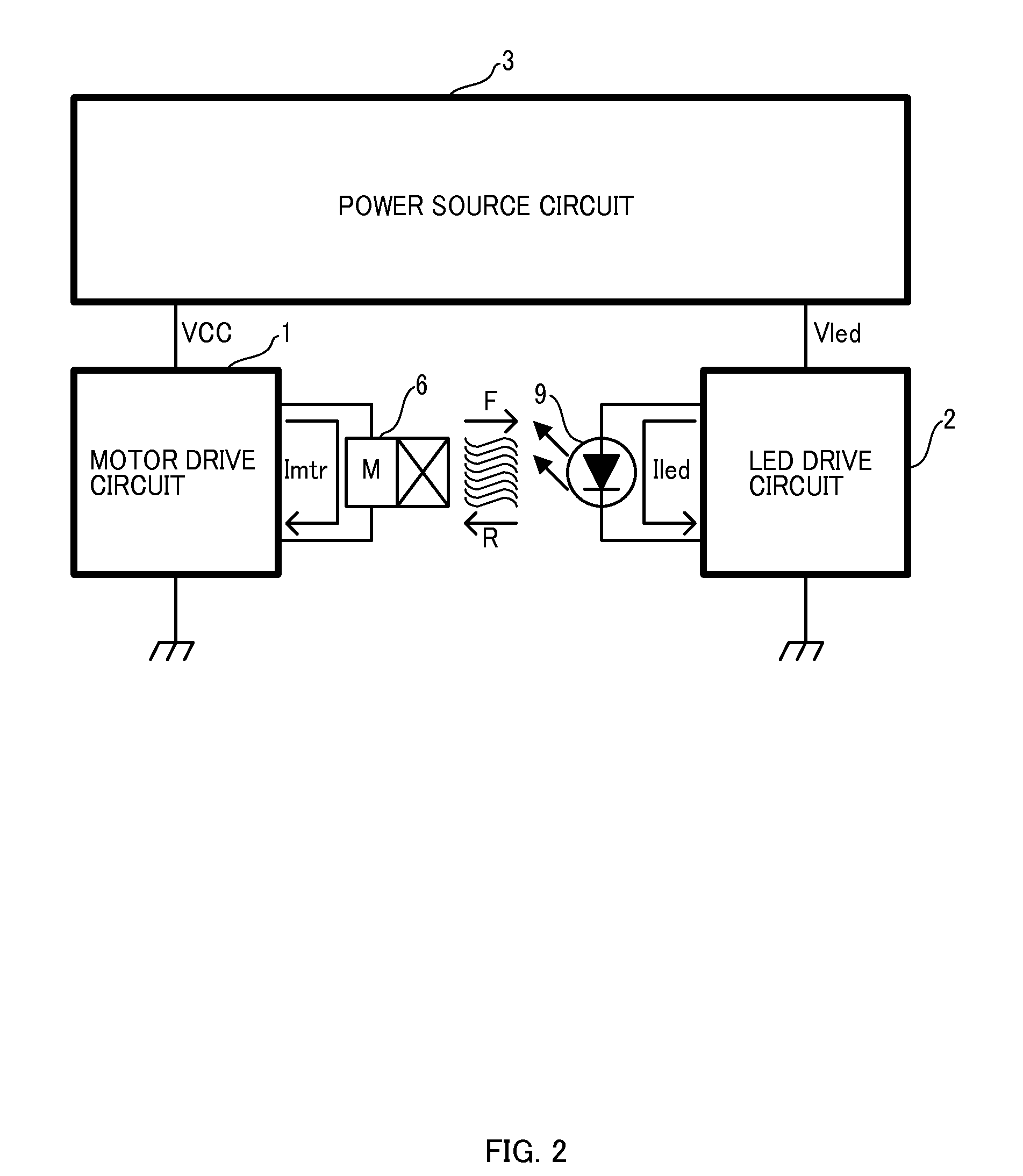

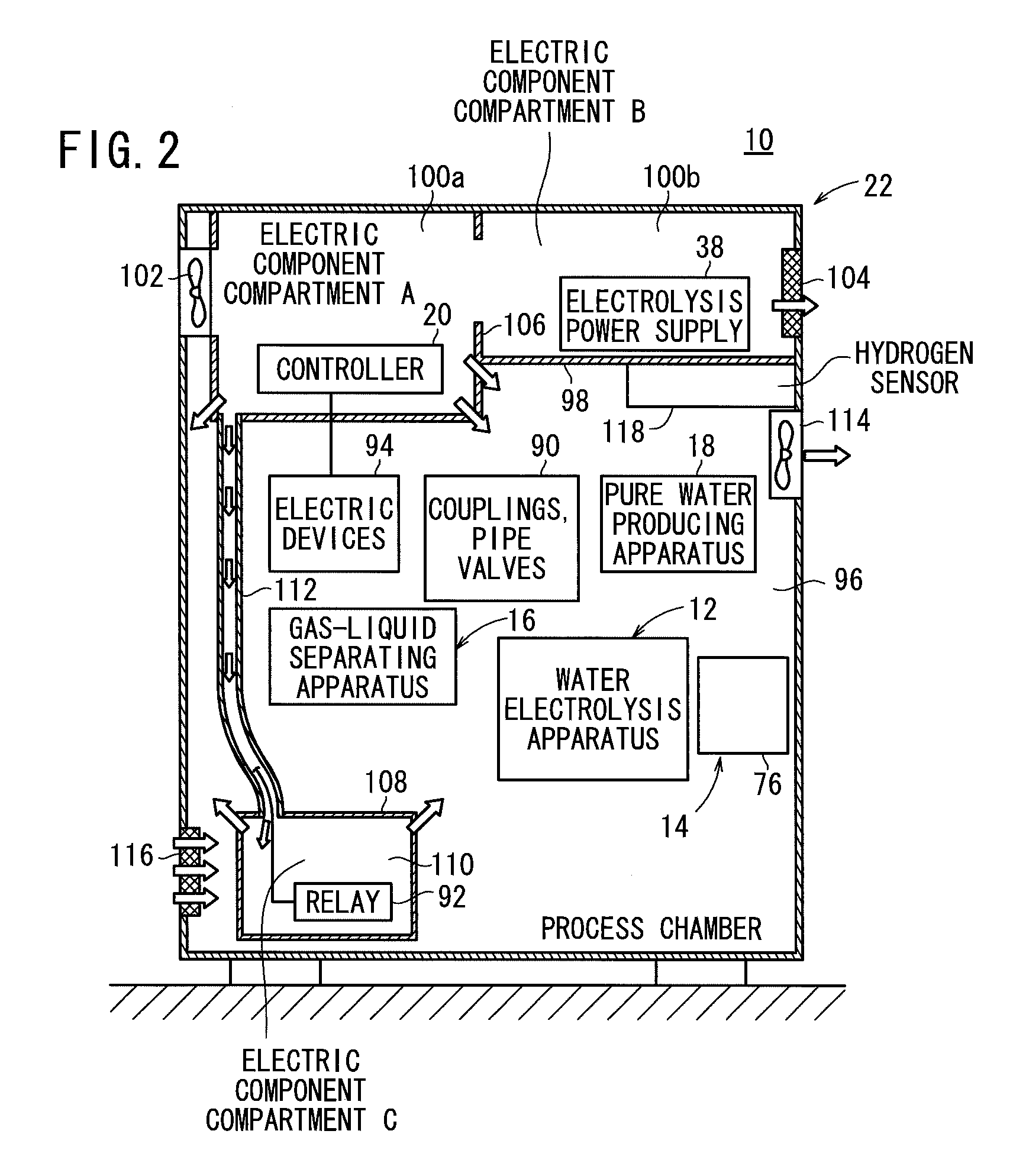

Motor Drive Circuit and Illumination Apparatus

InactiveUS20120068605A1Low heat generationLow efficiencySingle motor speed/torque controlTemperatue controlDriver circuitDriving current

A motor-drive circuit includes: an output transistor configured to supply a drive current to a motor for a cooling fan; a switching-control circuit configured to control switching of the output transistor so that the motor rotates in a first direction, or rotates in a second direction opposite to the first direction; and a switching circuit configured to, when a first time has elapsed since start of rotation of the motor in the first direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the first direction and thereafter rotates in the second direction, and configured to, when a second time has elapsed since start of rotation of the motor in the second direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the second direction and thereafter rotates in the first direction.

Owner:SEMICON COMPONENTS IND LLC

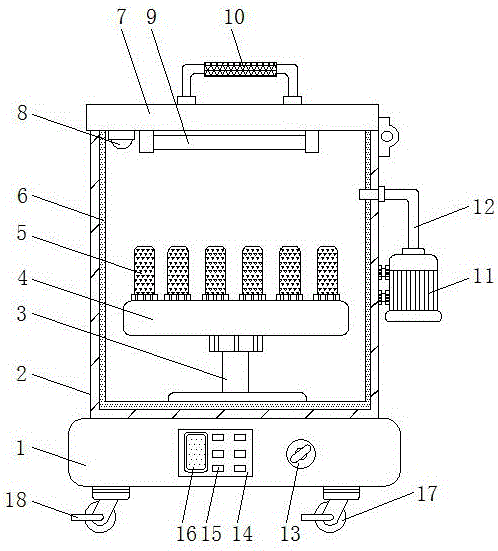

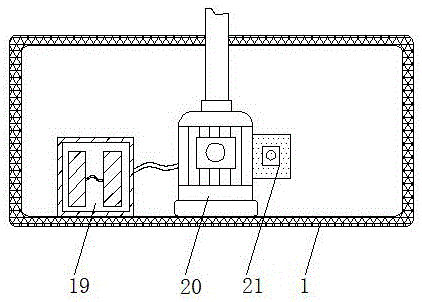

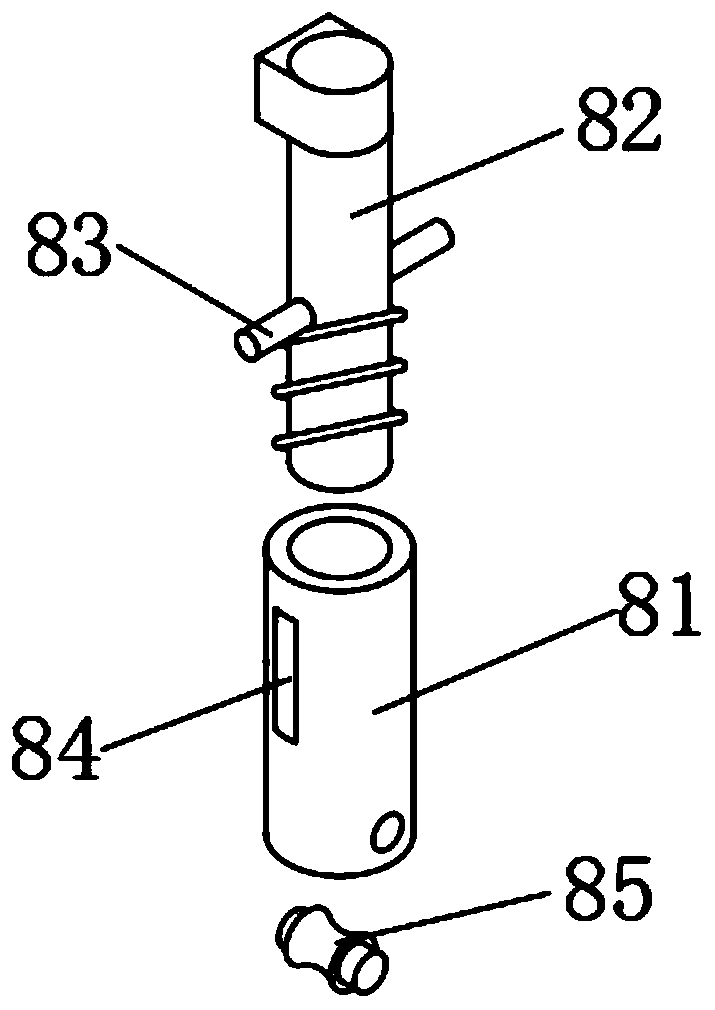

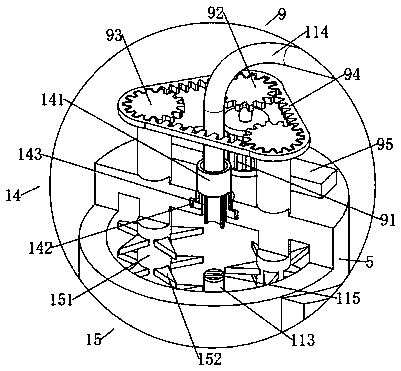

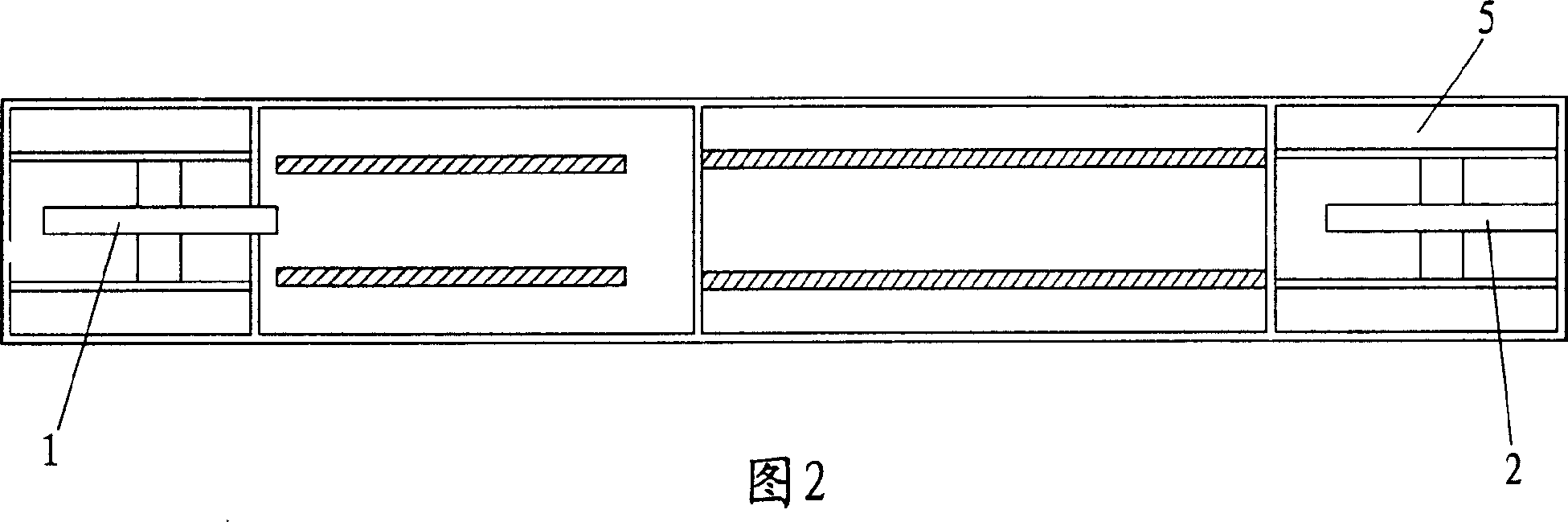

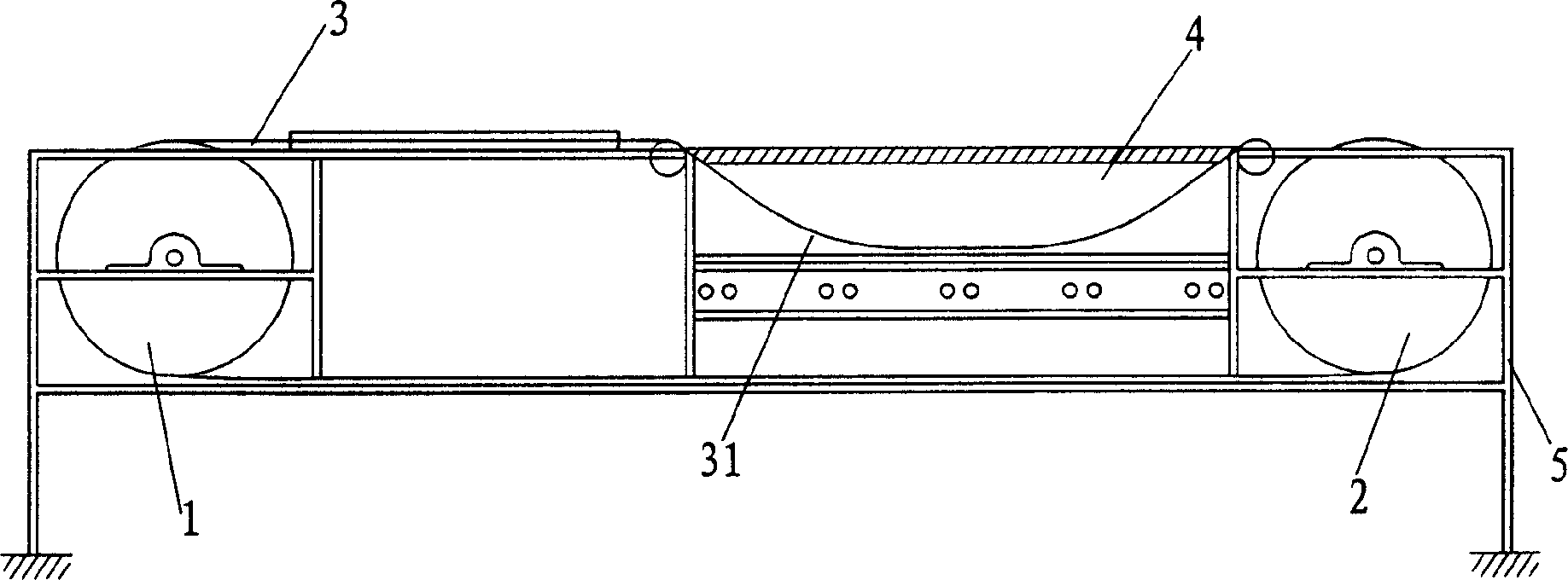

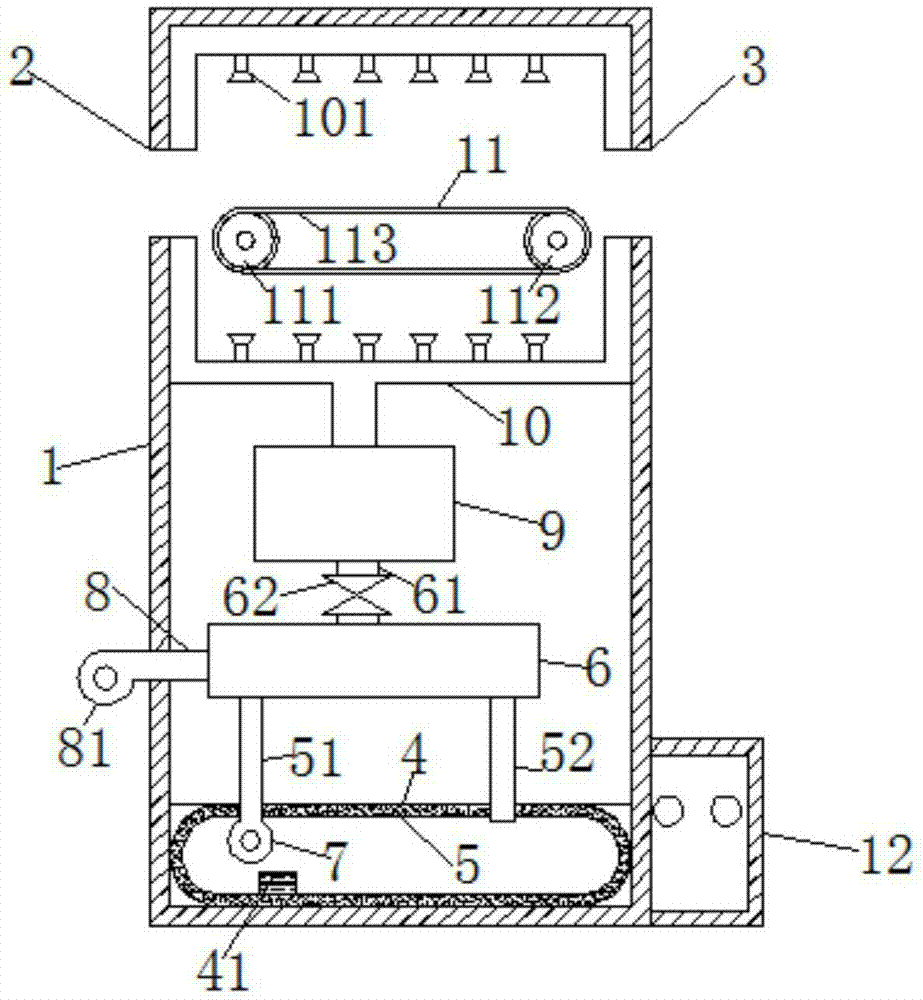

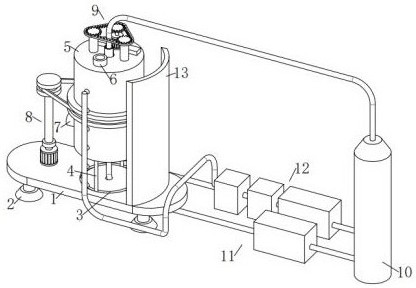

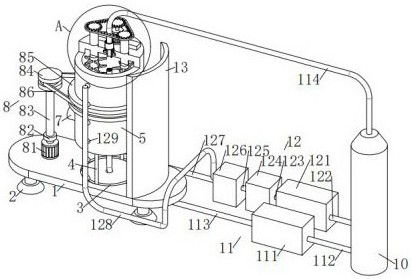

Rotary bearing drying device

InactiveCN106382797ASusceptible to heatEvenly heatedDrying gas arrangementsDrying chambers/containersRotary stageCoupling

The invention discloses a rotary bearing drying device. The rotary bearing drying device comprises a base, a drying box and a seal cover. A rotary motor is installed in the base. A rotary table is installed at the bottom end in the drying box through a rotary shaft, and the bottom end of the rotary shaft is connected with an output rotary shaft of the rotary motor through a coupling. Clamping shafts are installed on the upper surface of the rotary table in an equally spaced mode. An insulating layer is arranged on the inner wall of the drying box, and a warm air machine is installed on the outer wall of the drying box. A temperature sensor and a drying irradiation lamp are arranged on the inner side of the seal cover. According to the rotary bearing drying device, the rotary motor is installed in the base and can drive bearings on the clamping shafts to rotate through the rotary shaft, thus the bearings can be heated uniformly, the drying effect is good, hot air and high-temperature irradiation can be used for drying the bearings simultaneously, so that the drying speed of the bearings is increased. In addition, the occupied space is small, and the drying temperature is easy to control.

Owner:HUNAN MEIBEIDA TECH CO LTD

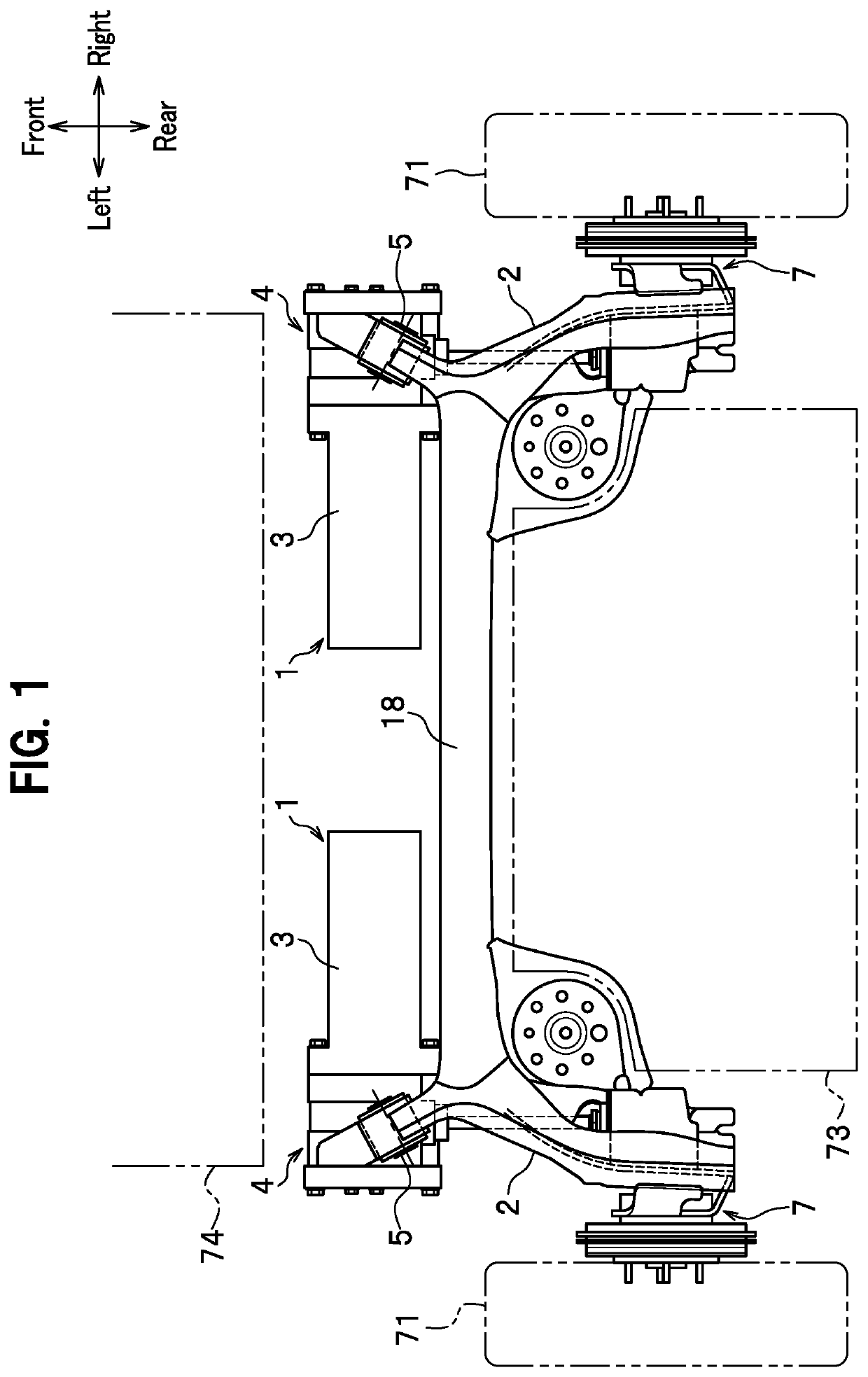

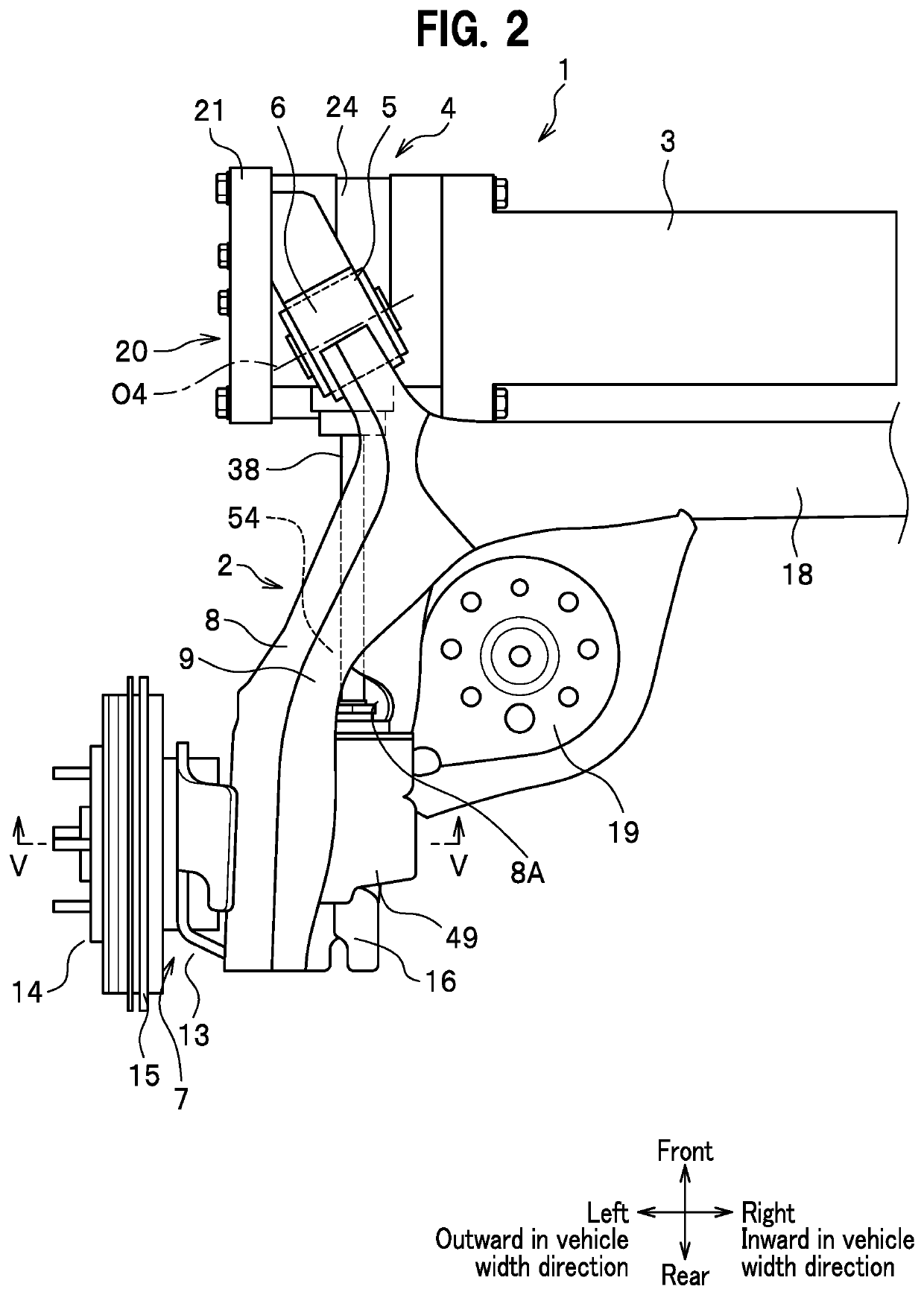

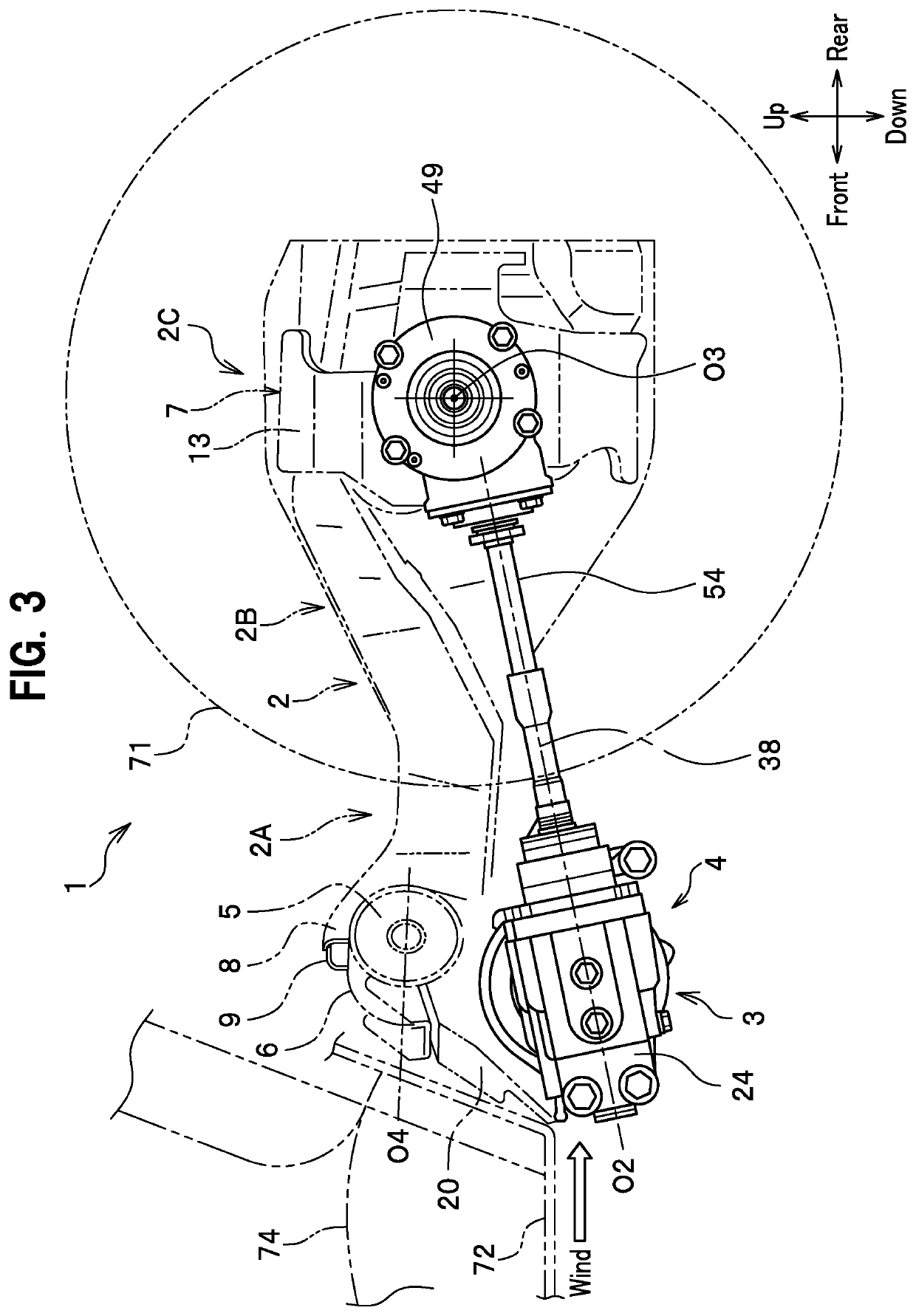

Motor drive device

ActiveUS20200009959A1Simple structureReduce the impactInterconnection systemsMotor depositionTrailing armElectric machinery

A motor drive device includes: a trailing arm that extends in a vehicle front-rear direction and includes a vehicle body-side attachment portion and wheel-side support portion, the vehicle body-side attachment portion formed on a forward portion side of the trailing arm and coupled to a vehicle body via a rubber bush, the wheel-side support portion formed on a rear side of the trailing arm and supporting a rear wheel; and a motor that is supported by the trailing arm and drives the rear wheel. The motor and the rubber bush are disposed in such a way that motor and the rubber bush are seen as being substantially aligned in a vehicle up-down direction when viewed in a vehicle width direction.

Owner:HITACHI ASTEMO LTD +2

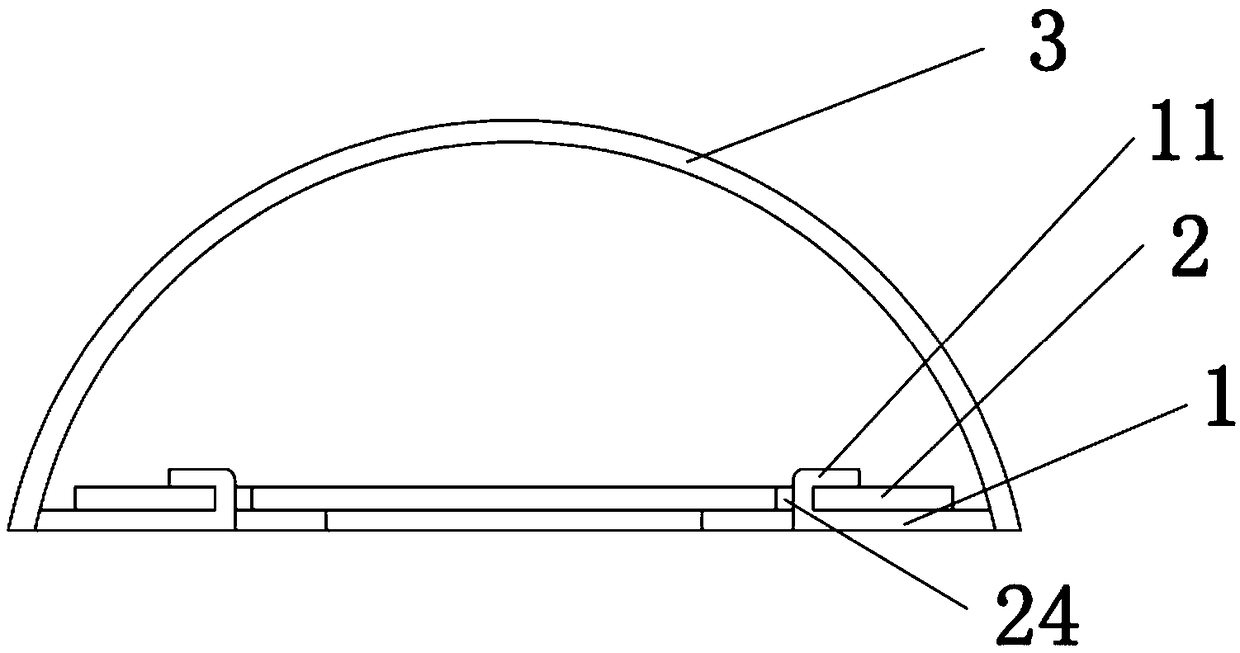

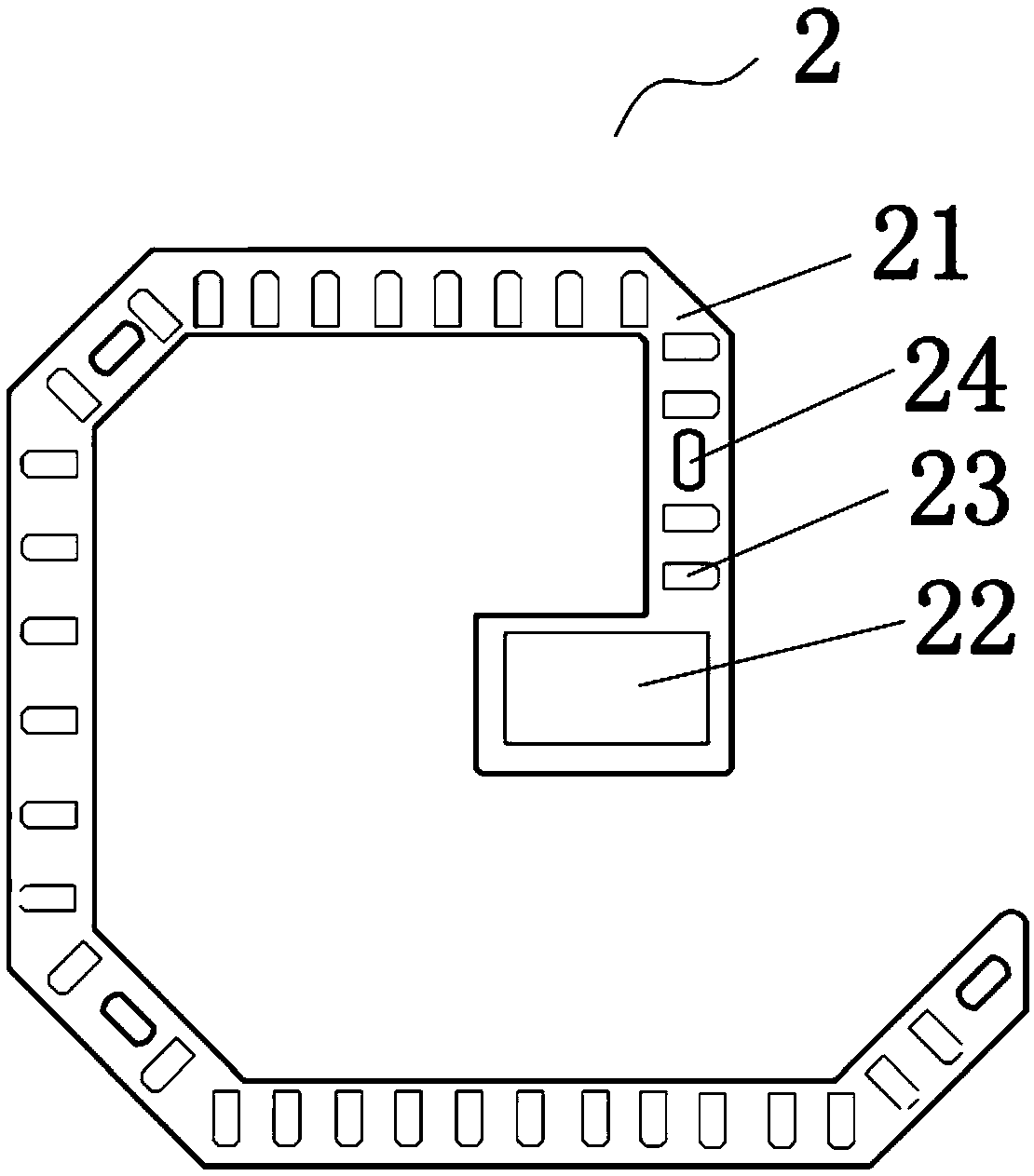

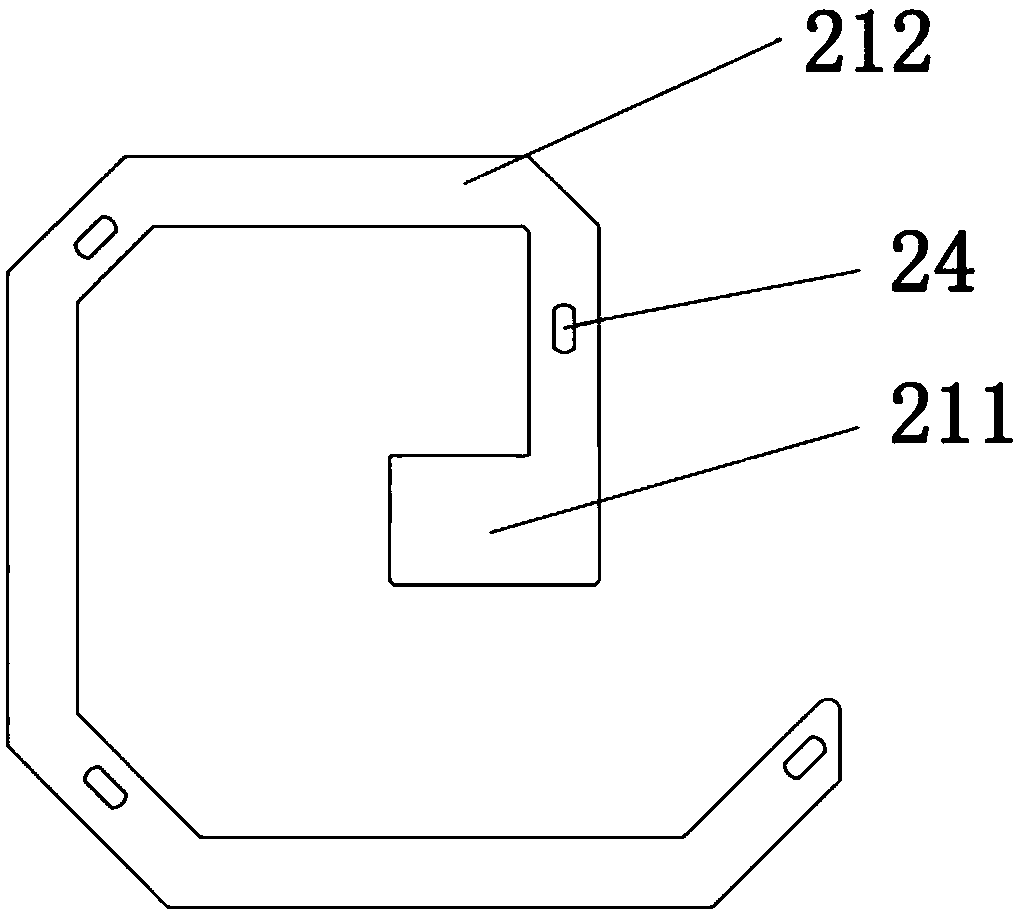

Buckle type LED light source drive integrated lamp

InactiveCN109268708AMaximize the light emitting areaQuick installationElectrical apparatusElectric circuit arrangementsEngineeringAluminum substrate

The invention relates to a buckle type LED light source drive integrated lamp. The buckle type LED light source drive integrated lamp comprises a lamp holder, an LED light source lamp panel connectedwith the lamp holder, and a lampshade connected with the lamp holder. N connecting buckles are arranged on the lamp holder, the connecting buckles are formed by bending open pore pieces on the lamp holder and are in strip-shaped piece forms, and the open hole pieces can be bent. The LED light source lamp panel comprises an aluminum substrate, a drive circuit and an LED light source, wherein the drive circuit and the LED light source are arranged on the aluminum board. The drive circuit is connected with the LED light source. N fixing holes cooperatively connected with the connecting buckles ofthe lamp holder are formed in the aluminum substrate. The buckle type LED light source drive integrated lamp has the advantages that the lamp holder and the LED light source lamp panel are rapid to mount, bolt connection is not needed, convenience and time saving are achieved, and the cost is reduced; the drive circuit and the LED light source are integrally arranged on the aluminum substrate, and the manufacturing and mounting cost of products is reduced; the aluminum substrate is in G-shaped structural design, a mounting part of the drive circuit is not easily heated, and the light emittingarea of the LED light source lamp panel is maximal.

Owner:陈方圣

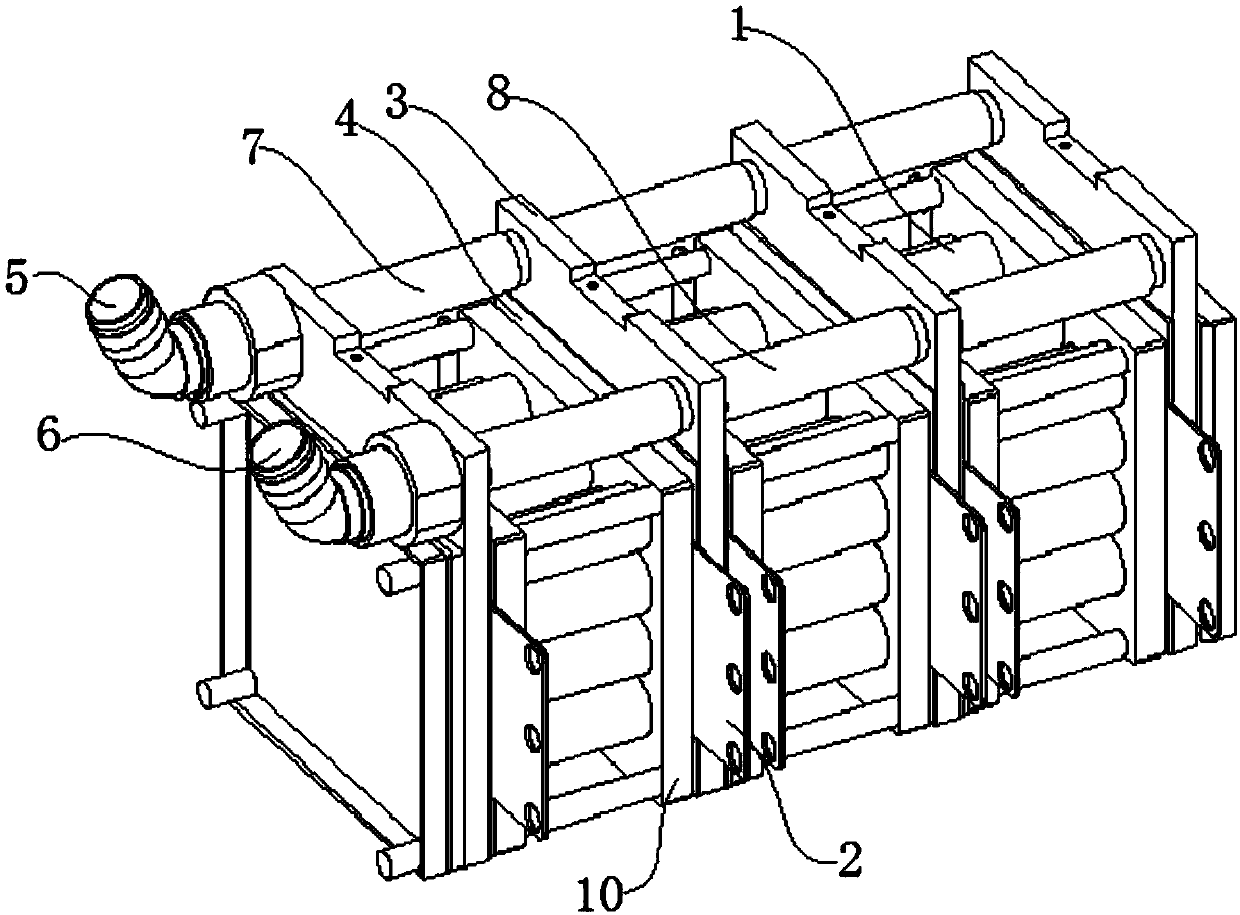

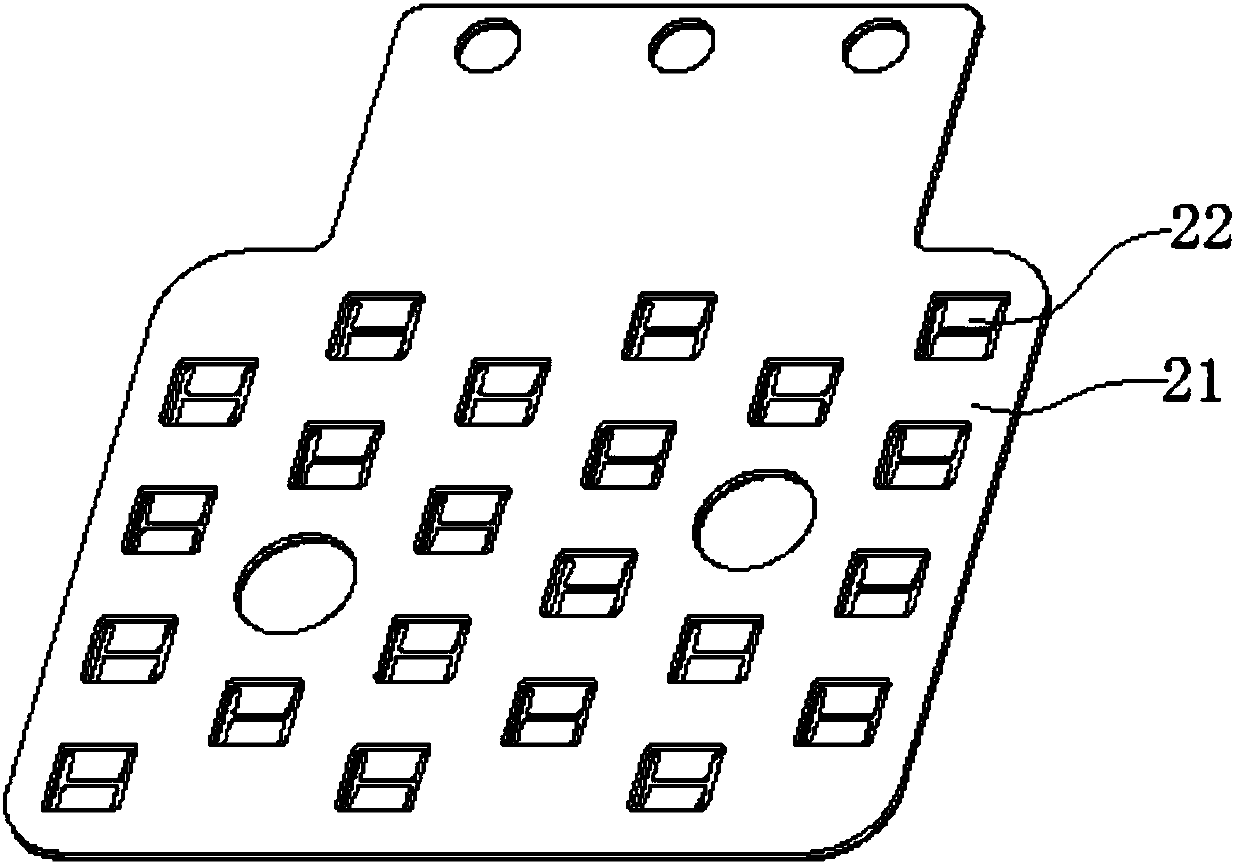

Battery module assembly

PendingCN107834131AHeating up fastThermal controlSecondary cellsElectrical batteryElectrical and Electronics engineering

The invention discloses a battery module assembly, which comprises battery modules and conducting strips, wherein the conducting strips are used for leading out positive electrodes and negative electrodes of the battery modules; the conducting strips are arranged at end parts of the battery modules; the battery module assembly also comprises heat exchange plates; the heat exchange plates are provided with heat exchange passages capable of circulating heat exchange mediums; the heat exchange passages are provided with inlets and outlets; the heat exchange plates and the conducting strips are arranged in parallel along a longitudinal direction of the battery modules and further make contact in a heat conduction manner. In the battery module assembly, the heat exchange plates are correspondingly arranged for the conducting strips; the temperature drop or the temperature rise can be carried out on the heat exchange plates through the heat exchange mediums circulated on the heat exchange plates; further, the temperature drop or the temperature rise can be carried out on the battery module through the heat exchange plates and therefore, the battery module assembly can be used for effectively solving the problem that a battery module assembly is poor in heat radiation effect.

Owner:SHENZHEN COOLTEK ELECTRIC VEHICLE COOLING TECH CO LTD

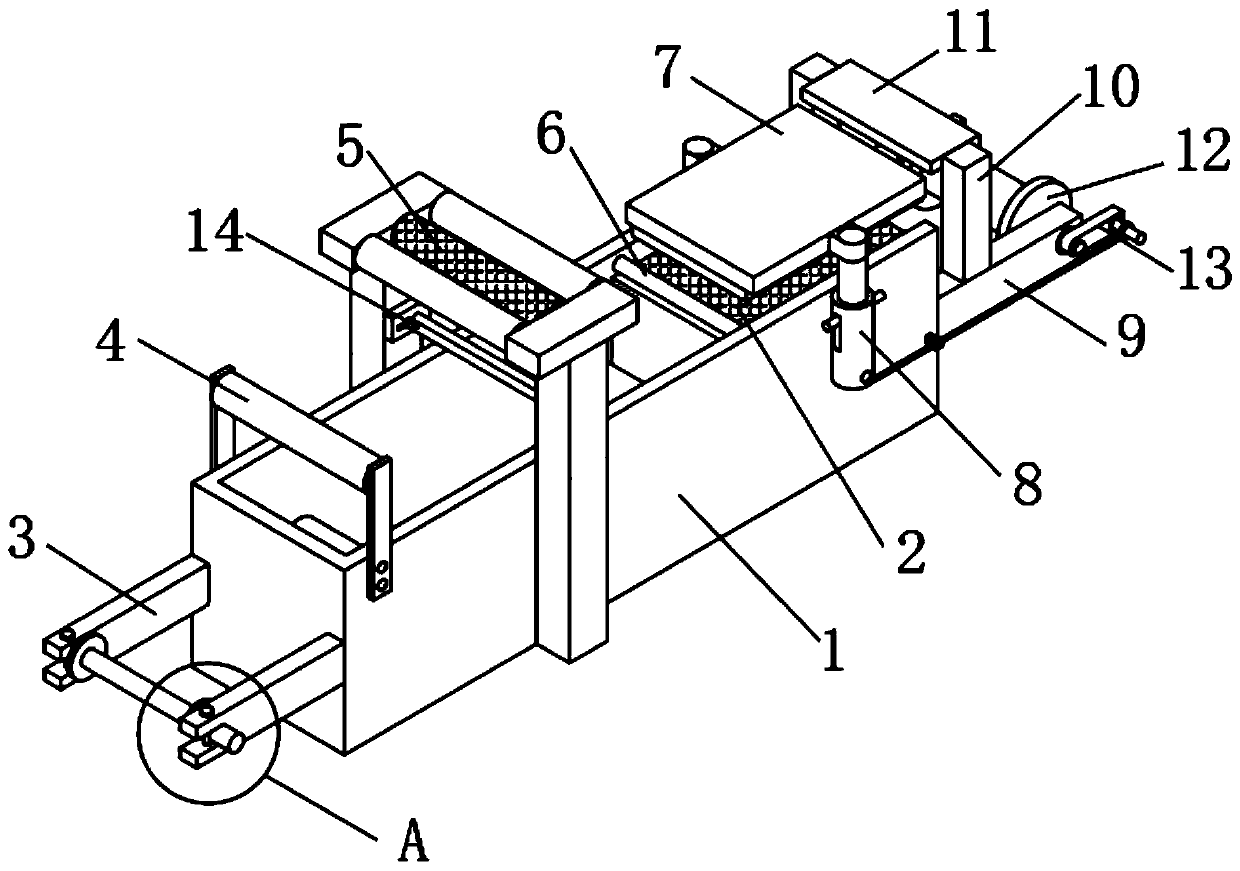

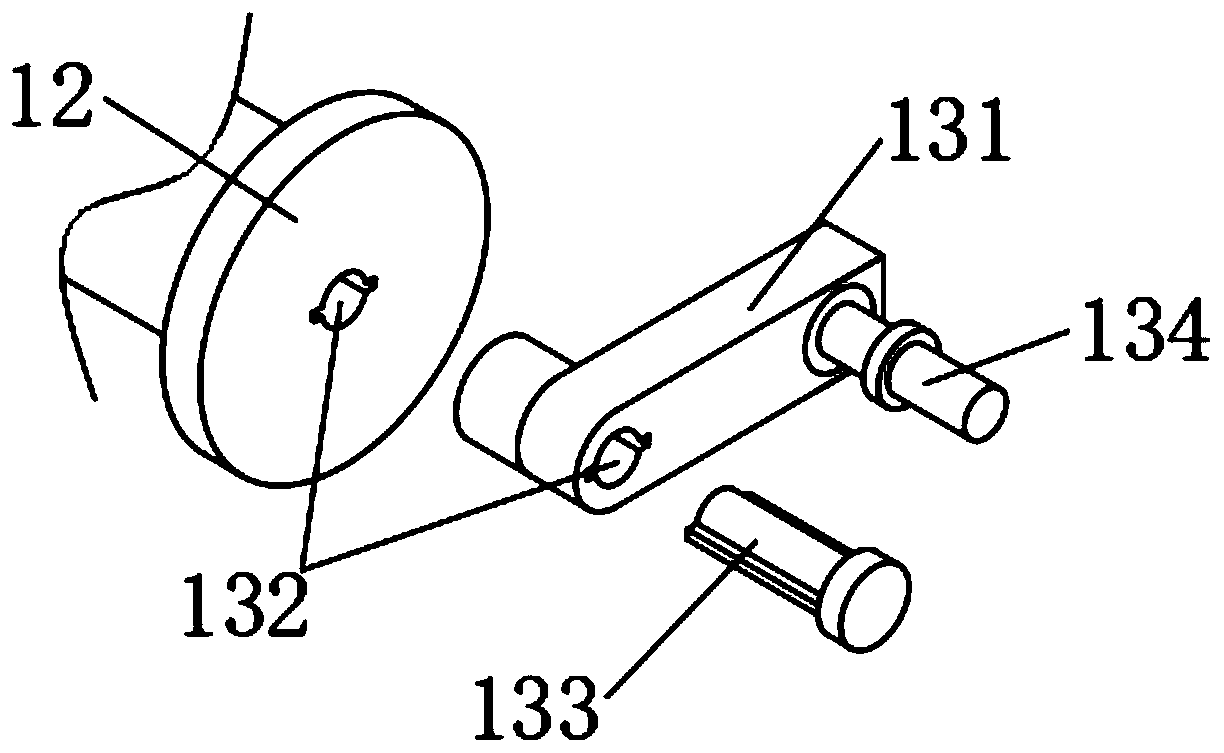

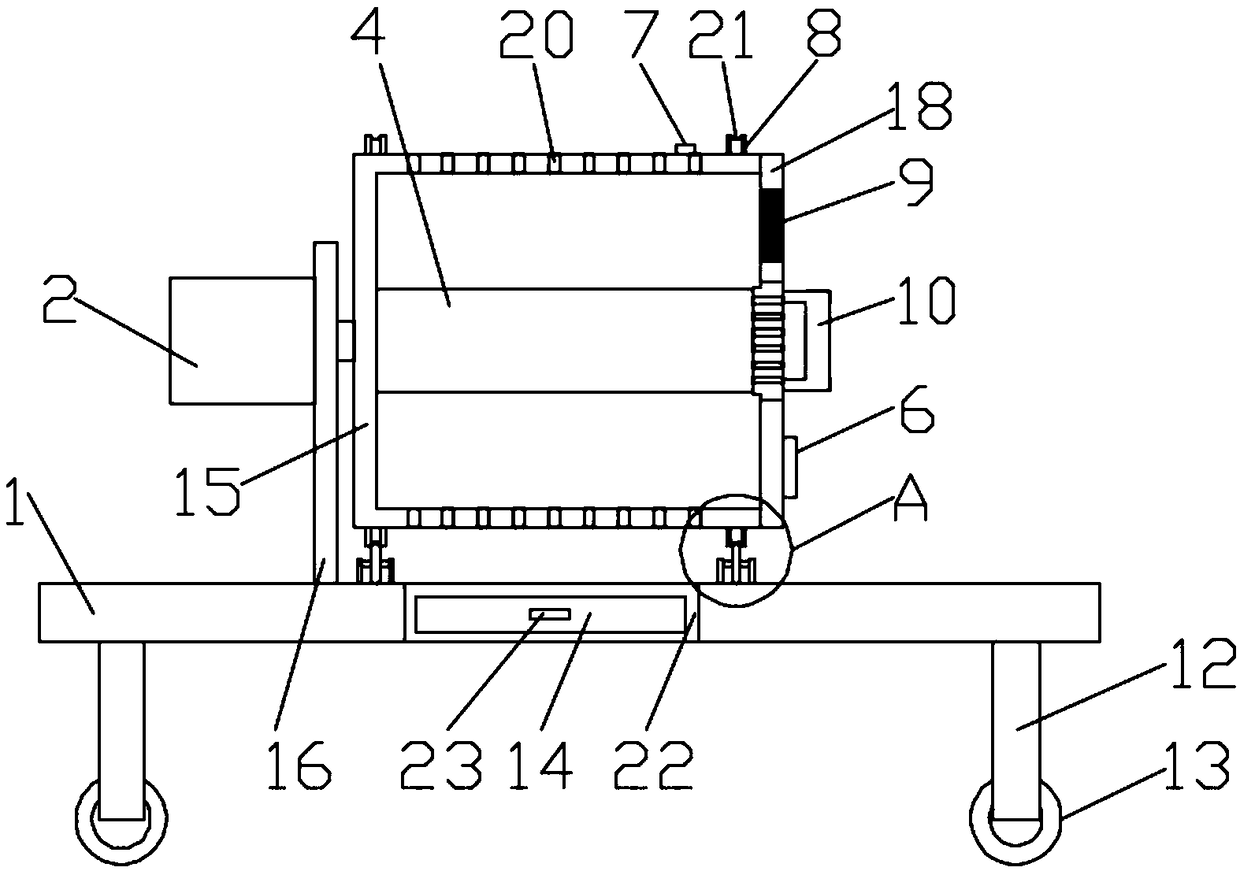

Textile fabric printing and dyeing equipment and operation method thereof

InactiveCN111593517ALess fluffAvoid misalignmentPlaten pressesSingeingTextile printerMechanical engineering

The invention relates to the technical field of textile printing and dyeing, in particular to textile fabric printing and dyeing equipment and an operation method thereof. The textile fabric printingand dyeing equipment comprises a dyeing tank and a printing table, the printing table is fixedly connected to the side face of the dyeing tank, a feeding rod is fixedly connected to the left side of the dyeing tank, a cloth pressing assembly is arranged on the upper surface of the dyeing tank, a printing plate is arranged on the upper surface of the printing table, and lifting assemblies are fixedly connected to the two sides of the printing plate; and a supporting rod is fixedly connected to the side, far away from the dyeing tank, of the printing table, a drying fan is fixedly connected to the upper surface of the supporting rod, a winding roller is arranged at the tail end of the supporting rod, rotating assemblies are arranged on the two sides of the winding roller, and the rotating assemblies are in transmission connection with the lifting assembly through steel cables. According to the textile fabric printing and dyeing equipment, cloth is wound by adjusting a rotating handle, when the rotating handle moves away from a fixed sleeve, the printing plate is dragged by the steel cables to move downwards for printing, and when the rotating handle moves to be close to the fixed sleeve, the printing plate moves upwards to reset under the action of a spring on the outer surface of a movable rod.

Owner:严悦

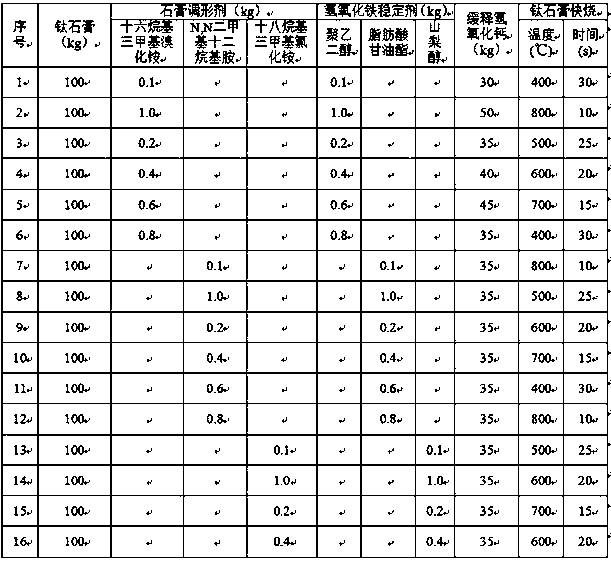

Method for separating iron and sulfur from titanium dioxide wastewater

ActiveCN110128039APromotes crystal growthGood for liquid-solid separationMaterial nanotechnologyFerric oxidesFerric hydroxideCyclonic separation

The invention discloses a method for separating iron and sulfur from titanium dioxide wastewater, and the method comprises the following steps: adding gypsum seed crystals, a gypsum shape adjusting agent and a ferric hydroxide stabilizer into the titanium dioxide wastewater, uniformly mixing, adding slow-release calcium hydroxide, and performing cyclonic separation to obtain titanium gypsum and asolution containing nano ferric hydroxide; filtering the titanium gypsum by pressing, and quickly burning the titanium gypsum to obtain a gypsum cementing material; and adding a coagulant into the solution containing the nano ferric hydroxide to obtain a ferric hydroxide precipitate, performing liquid-solid separating, adding a shaping agent into the ferric hydroxide precipitate, mixing uniformly,adding into an autoclave to crystallize to obtain ferric oxide red. The method has low production cost and high efficiency, and realizes high-quality recycling of resources.

Owner:SOUTHWEAT UNIV OF SCI & TECH

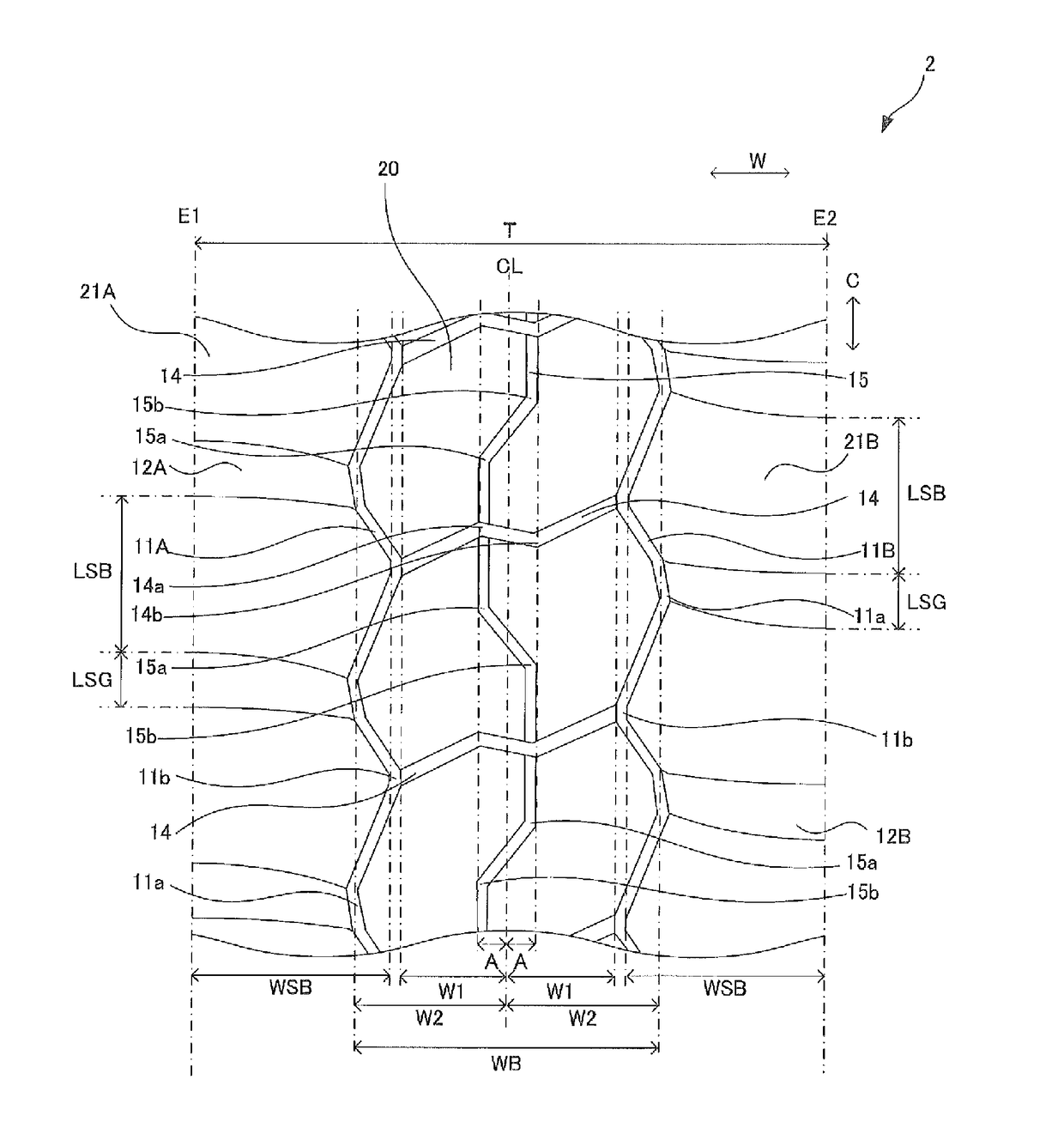

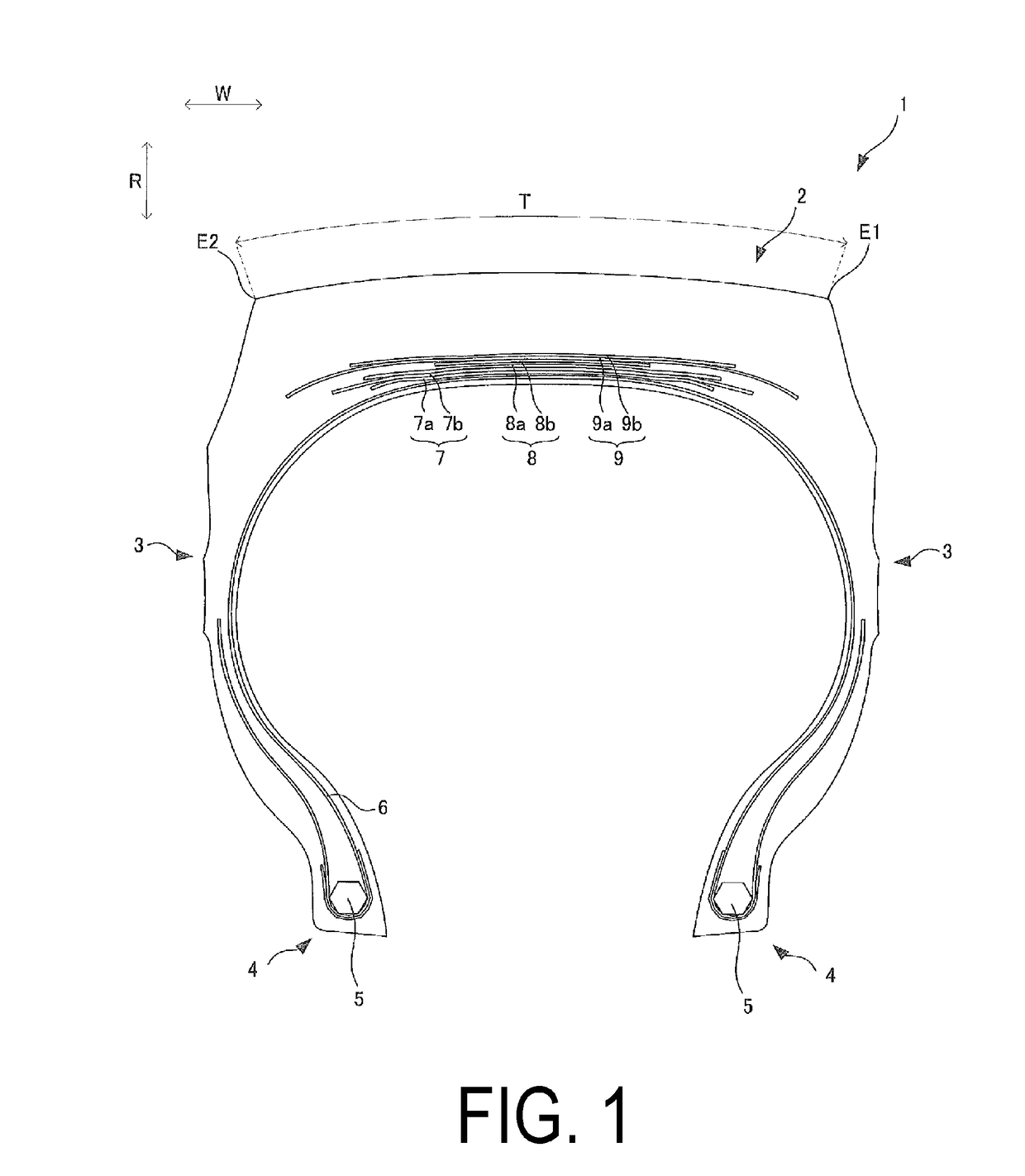

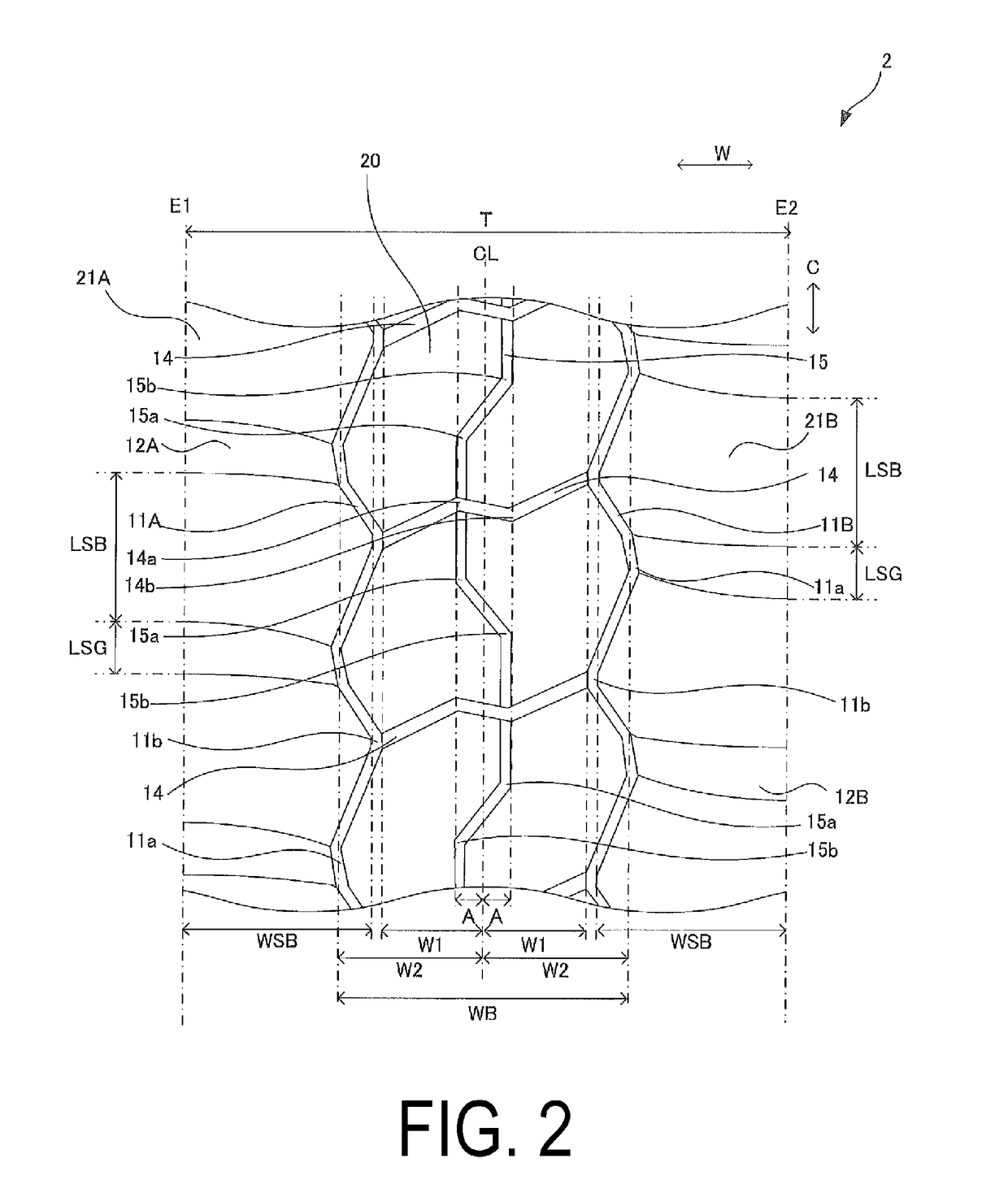

Pneumatic Tire

ActiveUS20170239999A1Heat build-up resistance can be improvedIncrease resistanceHeavy duty tyresTyre tread bands/patternsEquatorAutomotive engineering

A pneumatic tire includes a plurality of center lug grooves disposed at intervals in a tire circumferential direction that extend crossing a tire equator line and include a first groove turning portion and a second groove turning portion; a plurality of shoulder lug grooves disposed in the intervals between the plurality of center lug grooves in the tire circumferential direction extending outward in the tire width direction, an inner end in the tire width direction being disposed outward of an end of the center lug groove in the tire width direction; a pair of circumferential main grooves to which the ends of the center lug grooves and the inner ends of the plurality of shoulder lug grooves in the tire width direction alternately connect; and a circumferential secondary groove disposed around the entire circumference of the pneumatic tire with a wave-like shape.

Owner:THE YOKOHAMA RUBBER CO LTD

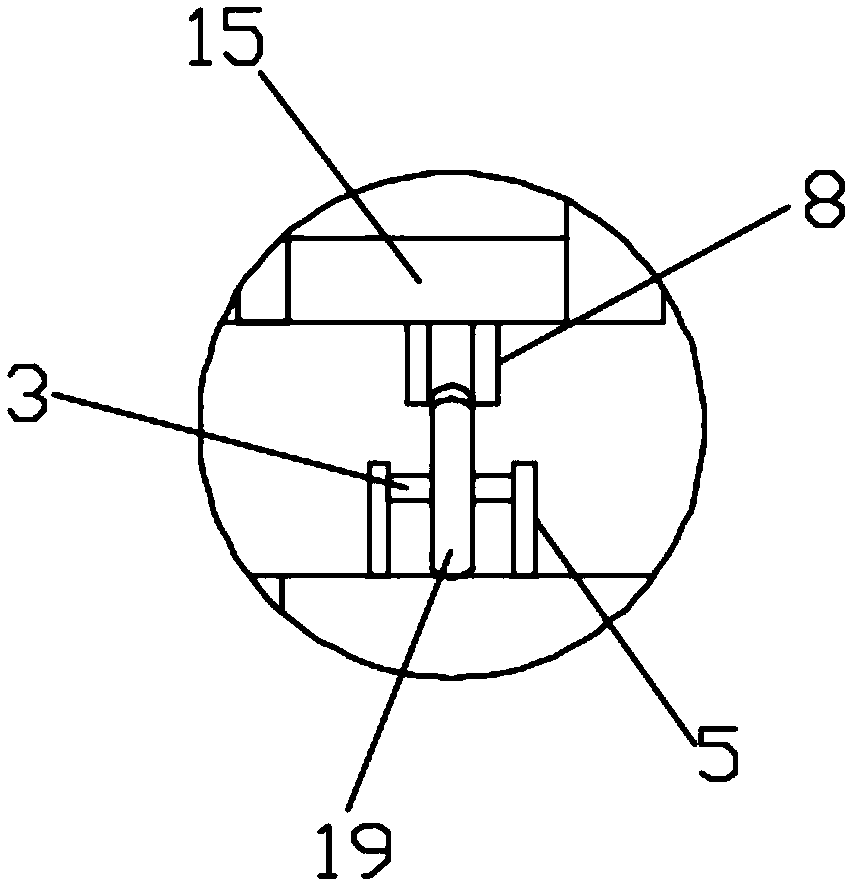

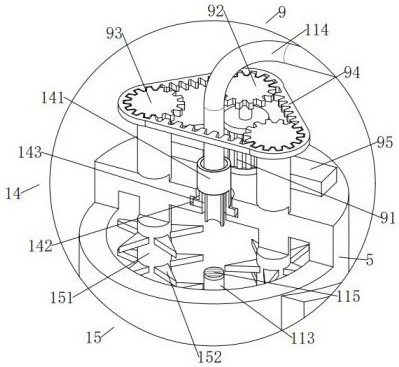

Thermal regeneration device for waste rubber and thermal regeneration method thereof

ActiveCN111518313AEfficient mixingImprove mixing effectPlastic recyclingHeat regenerationNitrogen gas

The invention discloses a thermal regeneration device for waste rubber and a thermal regeneration method thereof, belonging to the technical field of regeneration processing and utilization of waste rubber. The thermal regeneration device comprises: a base, wherein supporting legs are arranged at four corners of the bottom of the base; a stirring barrel, which is arranged on the upper side of thebase, wherein a plurality of T-shaped rotating supporting rods which are uniformly distributed are arranged at the bottom of the stirring barrel, a feeding hole is formed in the top of the stirring barrel, a sealing cover plate is arranged on the feeding hole, a discharging hole is formed in the lower left corner of the end part of the stirring barrel, and a discharging valve is arranged on the discharging hole; an annular T-shaped limiting rotating groove, which is formed in the top of the base, wherein the T-shaped ends of the T-shaped rotating supporting rods are arranged on the inner wallof the annular T-shaped limiting rotating groove in a sliding mode; and a first transmission mechanism, which is arranged on the top of the base and located at the left side of the stirring barrel. According to the stirring device, nitrogen is recycled and changed into liquid nitrogen for realizing better cooling, a conception is ingenious, stirring and heating effect is extremely good, and the device has outstanding substantive features and remarkable progress.

Owner:RIZHAO CHENHUI RUBBER&PLASTICS PROD

Tea leaf drying device

InactiveCN108759372AConvenient for centralized processingReduce the burden onPre-extraction tea treatmentTea dryingDrive motorEngineering

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a base and a barrel body with an opening at one end, wherein mesh holes are uniformly distributed in the side wall of the barrel body, a supporting rod is fixedly connected to the upper end of the base, a driving motor is fixedly connected to the side wall of the supporting rod, and an output shaft of the driving motor penetrates through the side wall of the supporting rod; two supporting devices are arranged at the upper end of the base, each supporting device comprises two supporting plates which are fixedly connected to the upper end of the base, a rotating shaft is rotationally connected between the two supporting plates, and a rolling wheel is fixedly connected to the rotating shaft; and the tail end of the output shaft of the driving motor is fixedly connected to the barrel body. The tea leaf drying device has the advantages that the structural design is reasonable, the operation is simple, tealeaves can be heated uniformly, the drying effect is good, the tea leaves are baked through charcoal fire so that the taste of the tea leaves can be improved, and the tea leaf debris leaks to a drawer so that centralized processing can be facilitated and the burden of an operator can be reduced.

Owner:黄奔皓

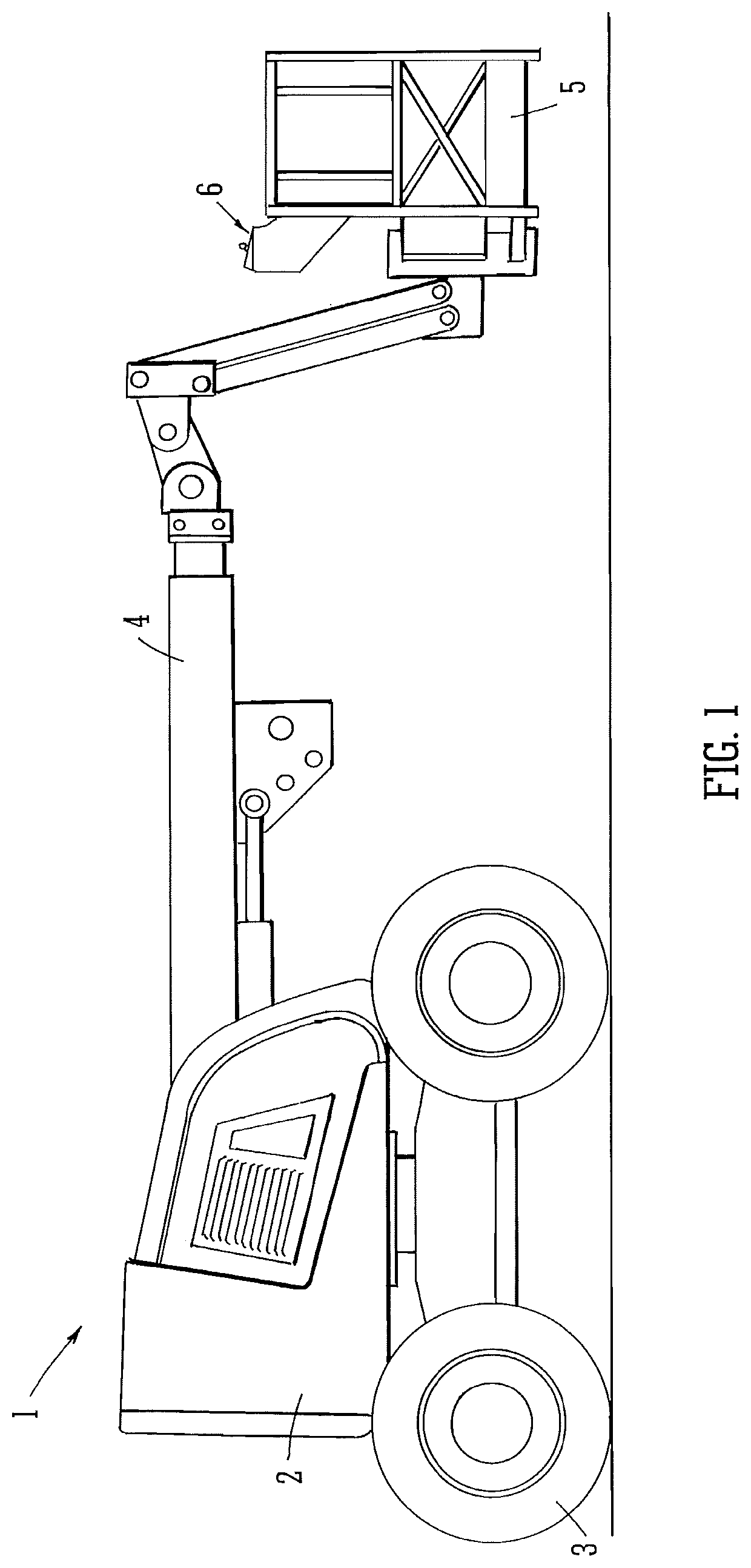

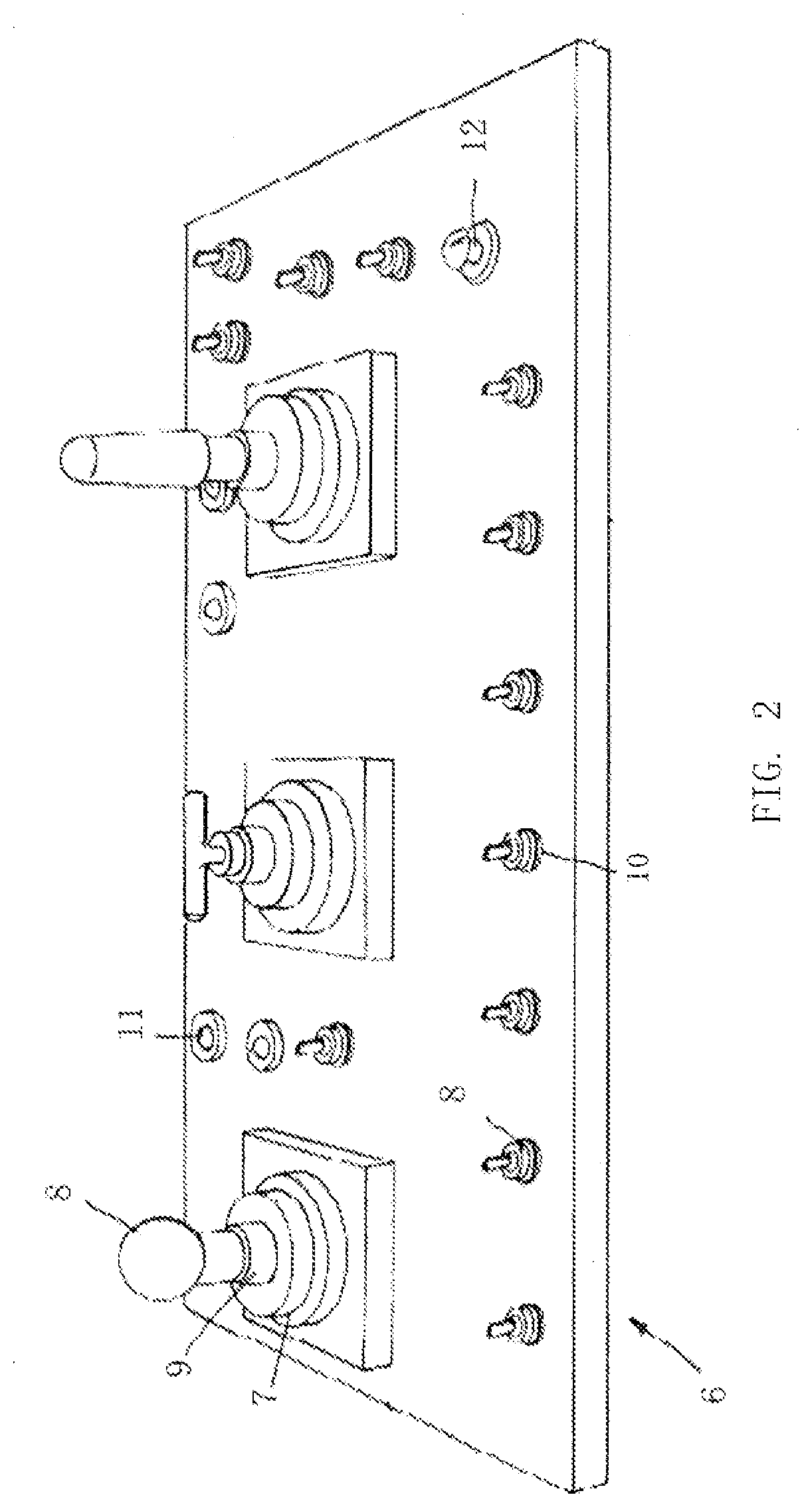

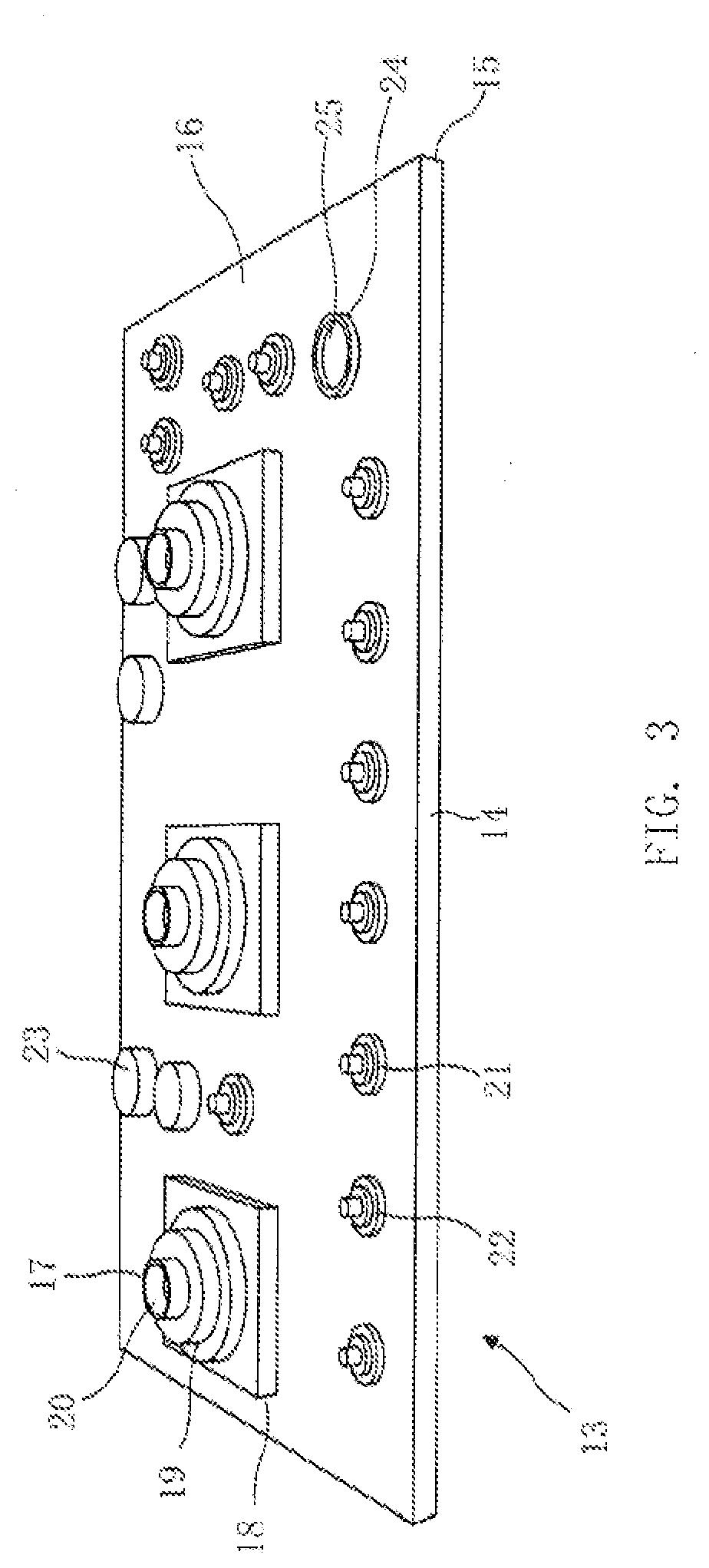

Protective barrier for a control panel

InactiveUS20200180925A1Risk minimizationImprove the immunityControl mechanismDashboard fitting arrangementsElastomerProtection layer

The present invention relates to a mobile elevating work platform comprising a control panel, said control panel (6) comprising a protective barrier (13) on an outer surface thereof, wherein the protective barrier comprises an elastomer. The present invention also relates to a method for providing a control panel with a protective barrier (13), which comprises the steps of obtaining a three-dimensional profile of an outer surface of a control panel, creating a mould from the three-dimensional profile, providing an elastomer and shaping the elastomer in the mould, curing the elastomer to form the protective barrier and fitting the protective barrier to the control panel. The present invention also relates to a mobile elevating work platform (MEWP) comprising a control panel (6) and a rigid shell (26) for protecting the control panel.

Owner:CONTROL SHELL LTD

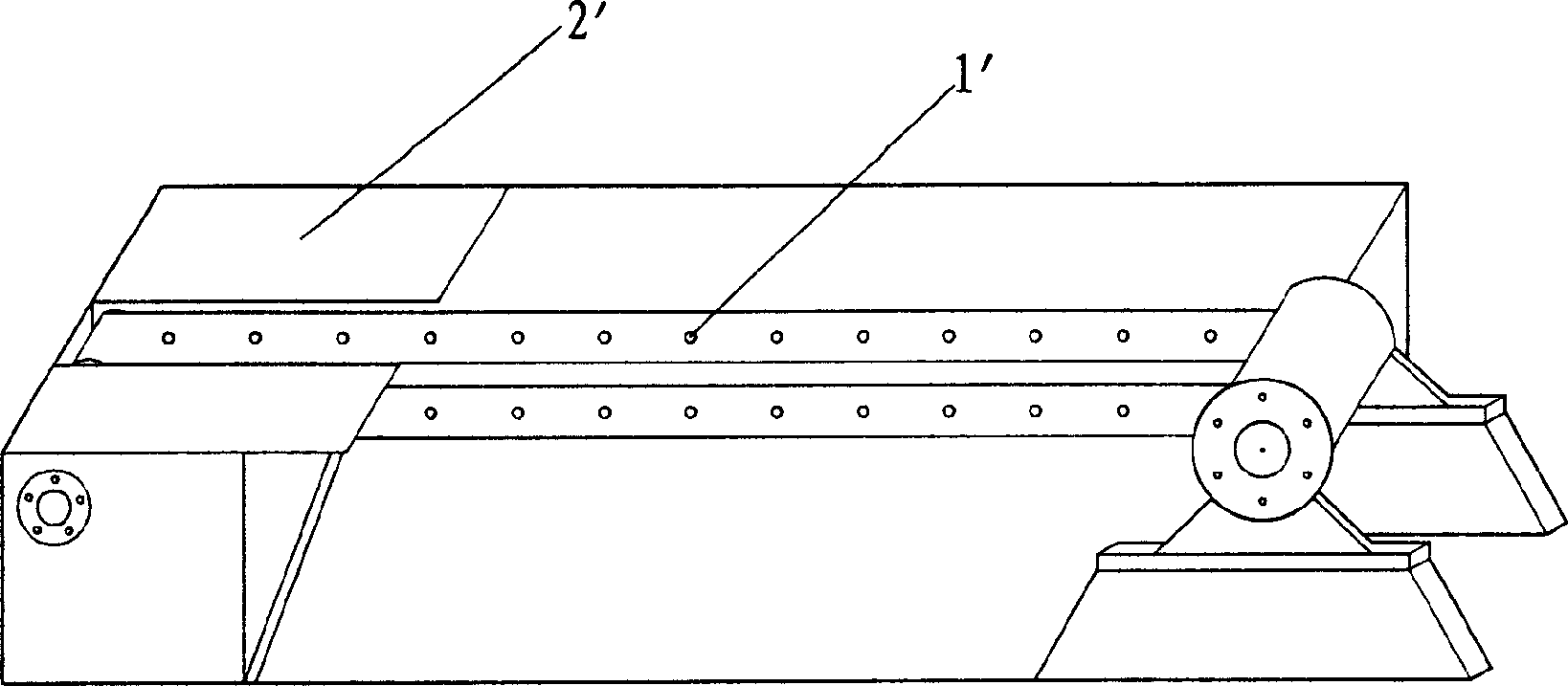

Modular sleeve forming method and its device

A method for preparing the shaped sleeve includes such steps as sleeving the blank on a shaping mould, putting it in water tank, heating the water, and making water temp constant for a certain time. Its advantages are high heat conducting speed, less loss of heat and high thermal uniformity.

Owner:厦门富懋塑料工业有限公司

Motor drive circuit and illumination apparatus

InactiveUS8736214B2Low heat generationLow efficiencyDC motor speed/torque controlTemperatue controlDriving currentMotor drive

A motor-drive circuit includes: an output transistor configured to supply a drive current to a motor for a cooling fan; a switching-control circuit configured to control switching of the output transistor so that the motor rotates in a first direction, or rotates in a second direction opposite to the first direction; and a switching circuit configured to, when a first time has elapsed since start of rotation of the motor in the first direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the first direction and thereafter rotates in the second direction, and configured to, when a second time has elapsed since start of rotation of the motor in the second direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the second direction and thereafter rotates in the first direction.

Owner:SEMICON COMPONENTS IND LLC

Water electrolysis system and method of operating same

ActiveUS8361304B2Economical and simpleSmall amount of heatCellsPhotography auxillary processesHigh pressure hydrogenEngineering

A water electrolysis system includes a water electrolysis apparatus for producing high-pressure hydrogen by electrolyzing pure water and a casing. The casing defines therein an accommodating chamber accommodating the water electrolysis apparatus etc. therein, first electric component compartments separate from the accommodating chamber and housing a controller and an electrolysis power supply therein, the first electric component compartments having first fans for introducing external air, and a second electric component compartment separate from the accommodating chamber and housing a relay, the second electric component compartment being connected to the first electric component compartments by a pipe.

Owner:HONDA MOTOR CO LTD

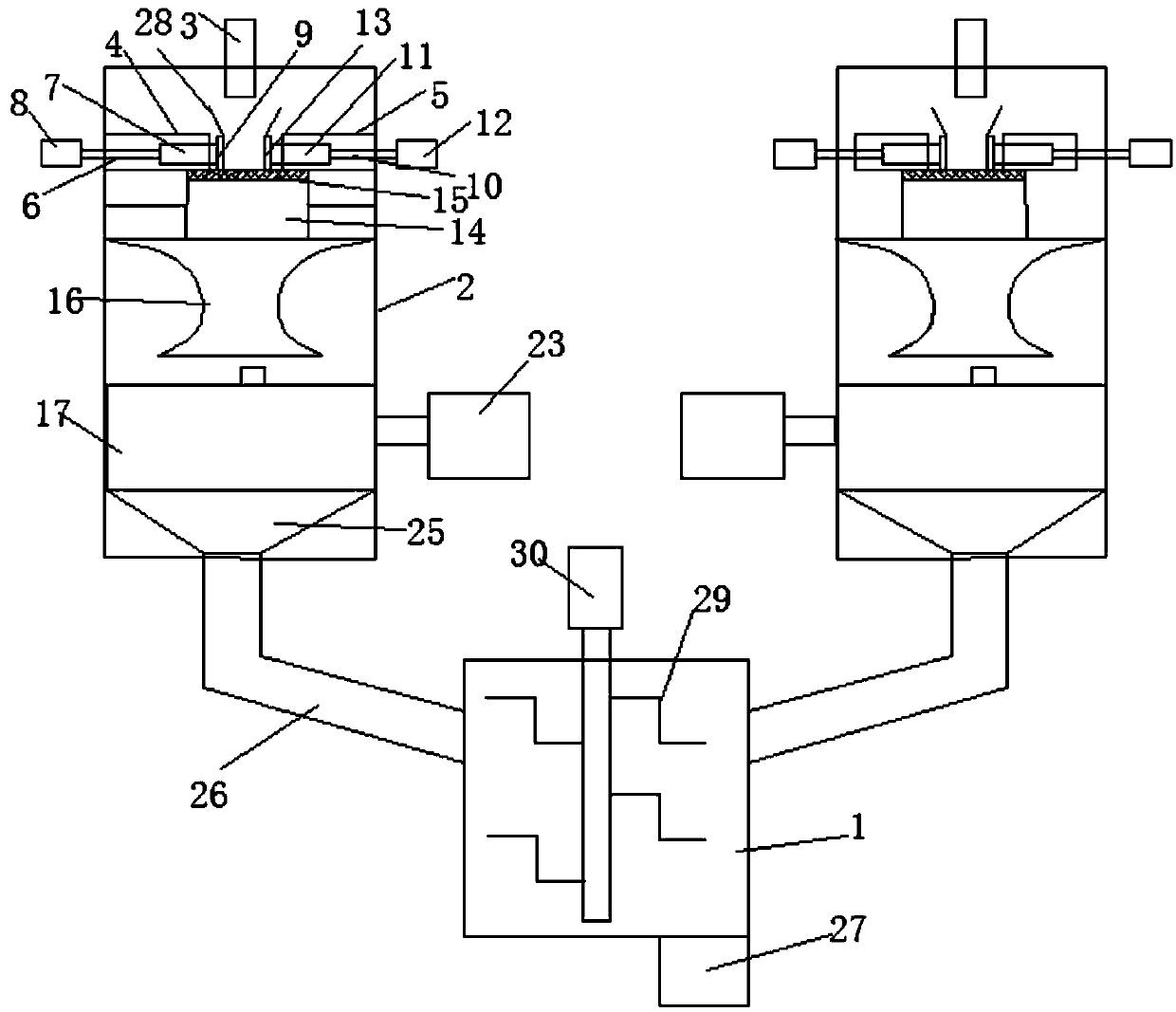

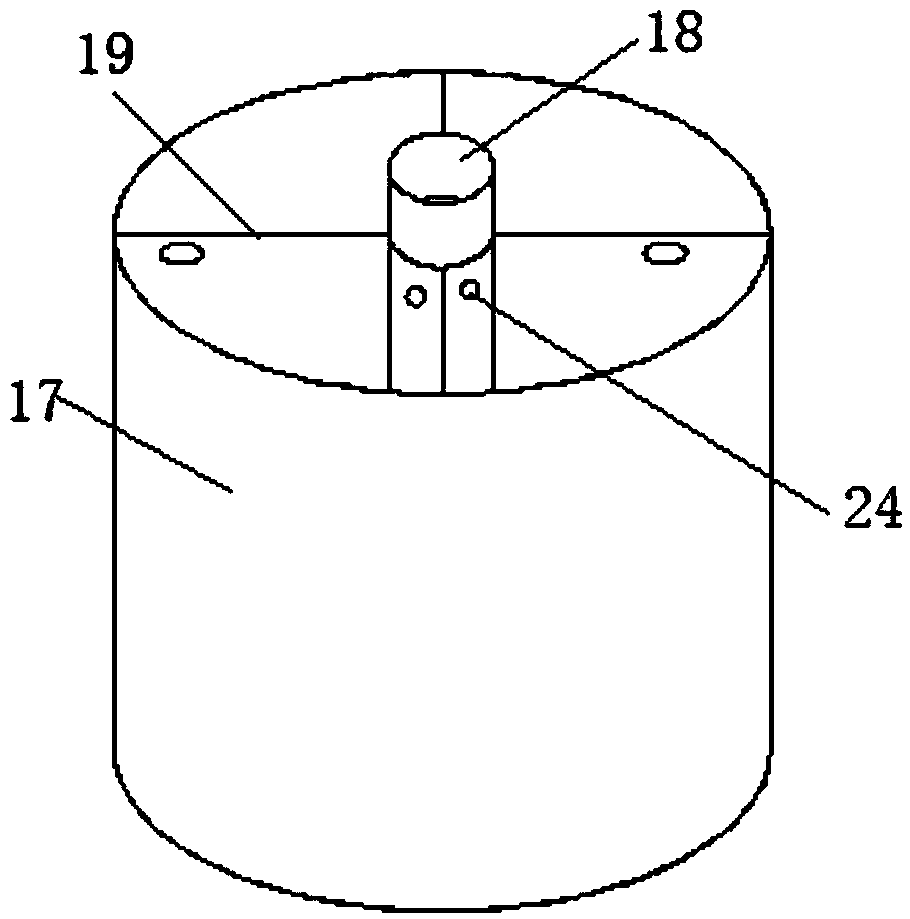

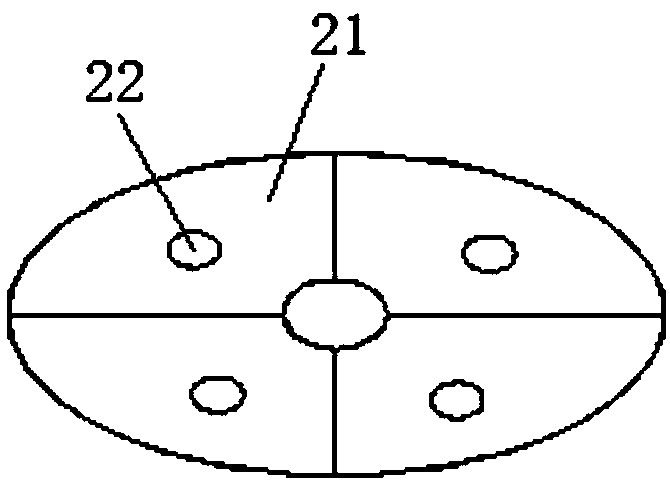

Multi-component alloy melting and mixing device

The invention discloses a multi-component alloy melting and mixing device. According to the invention, each metal melting furnace comprises a shell; the top end of each shell is provided with a feeding inlet; a crushing unit is arranged below each feeding inlet; each crushing unit comprises a first guiding drum and a second guiding drum which are located at a same height and are in opposite arrangement; the left end of each first guiding drum and the right end of each second guiding drum are correspondingly and fixedly connected with and arranged on the inner walls of a shell; a first pull rodand a first compression column are arranged in each first guiding drum; and the left end of each first pull rod extends out of a shell and is connected with a first air cylinder. According to the invention, each crushing unit is arranged below a feeding inlet, and raw materials are successively crushed and heated, so the raw materials are easily heated and molten; a material distribution unit isarranged below each crushing unit, and the raw materials are heated in a plurality of melting chambers, so the raw materials are more easily heated; meanwhile, a sieve is arranged at the lower part ofeach melting chamber, and no unmelted particles enter a mixing drum, so a mixed melt liquid has good quality and is free of impurities; and a furnace body has novel design structure and is easy to operate.

Owner:巢湖云海镁业有限公司

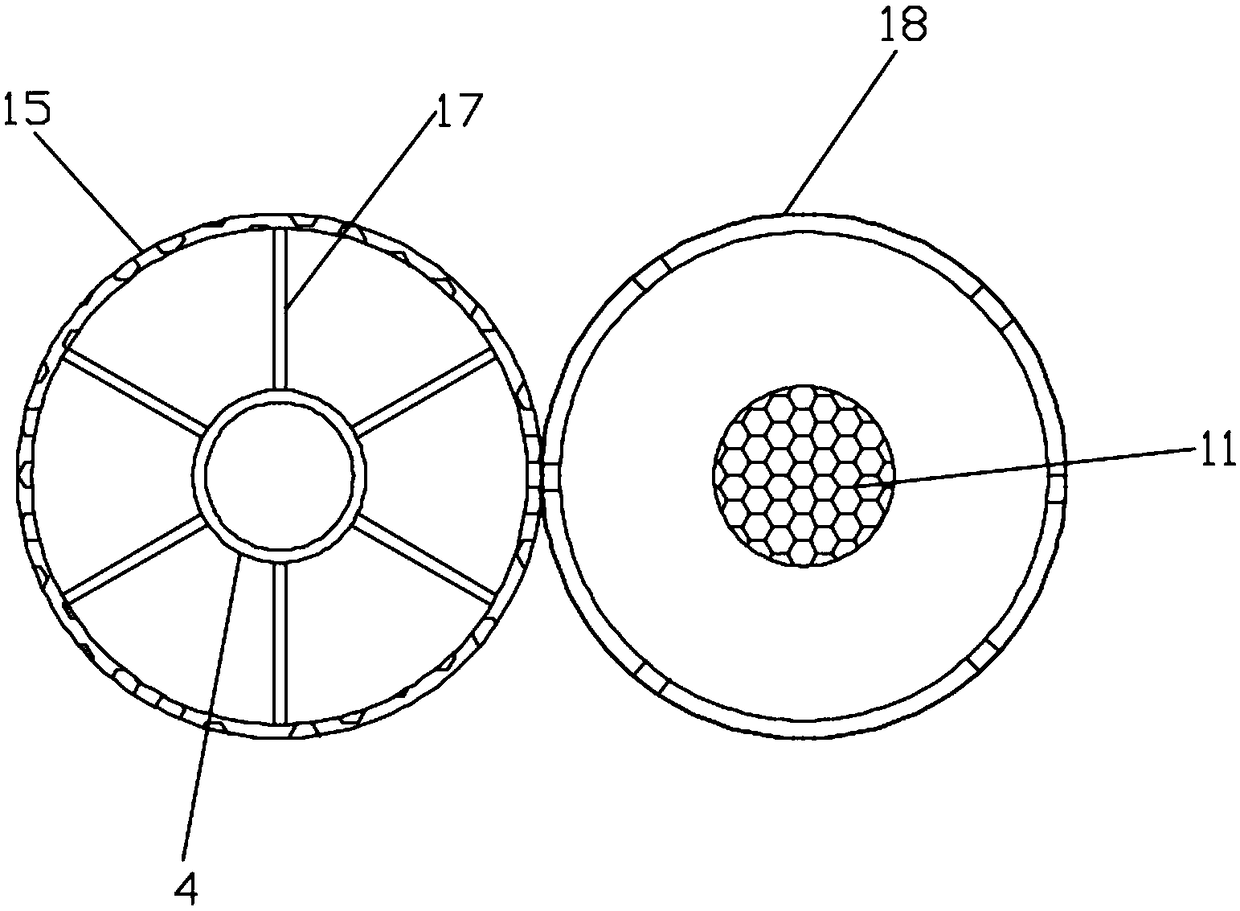

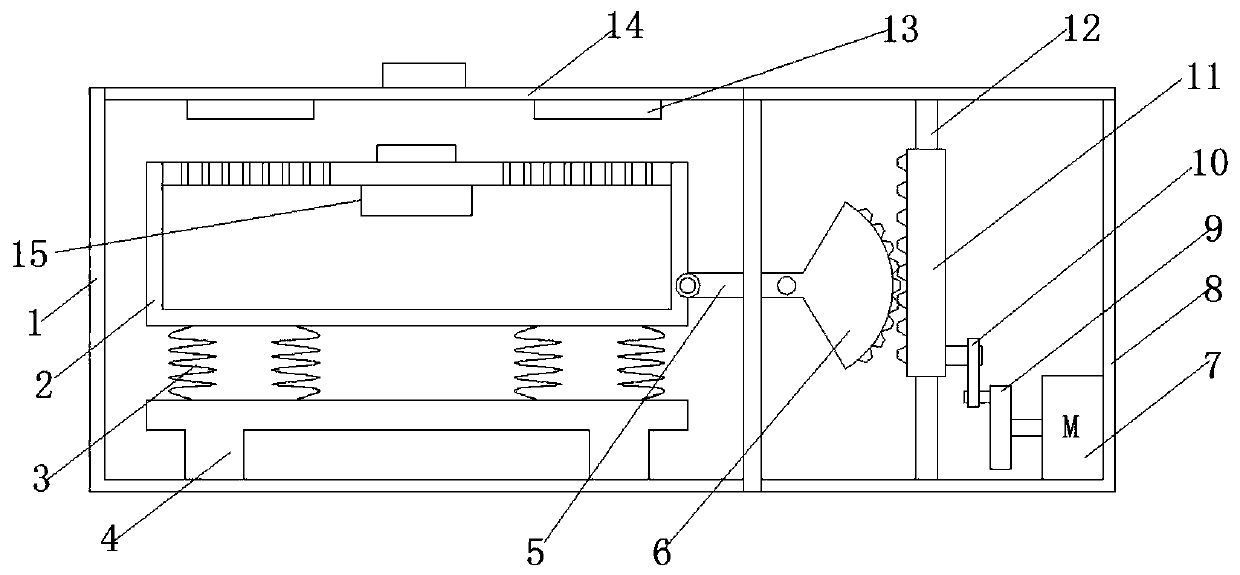

Plastic strip drying device for masterbatch processing

The invention discloses a plastic strip drying device for masterbatch processing. The plastic strip drying device for masterbatch processing includes a drying barrel; the side wall of the drying barrel is provided with a device box; the inner bottom of the device box is provided with a driving motor; the end of an output shaft of the driving motor is fixedly connected with a first connecting rod;a second connecting rod is rotationally connected to the end of the first connecting rod away from the driving motor; a fixed rod is arranged inside the device box; a movable rod is sleeved at the middle of the fixed rod; the second connecting rod is rotationally connected to the movable rod; a first straight tooth is arranged on one side of the movable rod; a rotating rod is rotationally connected to the inner side wall of the device box; and the side walls of the drying barrel and the device box are provided with two strip-type grooves of the same size and corresponding positions. The plastic strip drying device for masterbatch processing is reasonable in structure design and simple in operation, which is conducive to uniform heating of the plastic strip and improves the drying efficiency of the plastic strip.

Owner:安徽精卫医用材料科技有限公司

Uniformly drying corrugated board energy-saving drying device

InactiveCN106871626AEvenly heatedSusceptible to heatDrying gas arrangementsPhysical paper treatmentGas compressorInductor

The invention discloses an energy-saving drying device for corrugated cardboard with uniform drying. The bottom of the inner cavity of the housing is provided with a heating water tank, the inner cavity of the heating water tank is provided with a heating device, and the inner cavity of the heating water tank is provided with an inductor, and the heating water tank is respectively connected by a hot water pipe and a cold water pipe. Heater, one end of the hot water pipe is provided with a water pump, one end of the first hot air pipe is connected to an air compressor, the top of the air compressor is provided with a second hot air pipe, and the second hot air pipe extends It is located on the inner wall around the casing, and the second hot air pipe is evenly equipped with air nozzles. The uniformly dried corrugated cardboard energy-saving drying device is simple to manufacture and low in cost. cost and energy consumption.

Owner:CHONGQING CITY FULING DISTRICT XIONGXIANG PAPER PROD CO LTD

Liquid crystal display device comprising a warm-up configuration and a normal configuration, motorcycle including same, and method of using same

InactiveUS9377648B2Raise the temperature of the liquidIncrease productionStatic indicating devicesInstrument arrangements/adaptationsLiquid-crystal displayDark color

A liquid crystal display device of a motorcycle is configured and arranged to rapidly warm up a liquid crystal panel at cool temperatures, without requiring an additional heating member. The liquid crystal display device includes a control unit, for controlling a liquid crystal panel, and a backlight. When the temperature of liquid crystal is lower than a predetermined value, or when it is within a fixed time period after turning on an ignition switch, as a warm-up period, the control unit increases power supplied to the backlight to a larger amount than that in a normal display state, to increase the amount of back light, and temporarily changes the entire display surface to a darker color, in order to increase the amount of light absorbed by the liquid crystal panel, simultaneously reducing the amount of light penetrating the display surface, and thereby speeding up warming of the liquid crystal panel.

Owner:HONDA MOTOR CO LTD

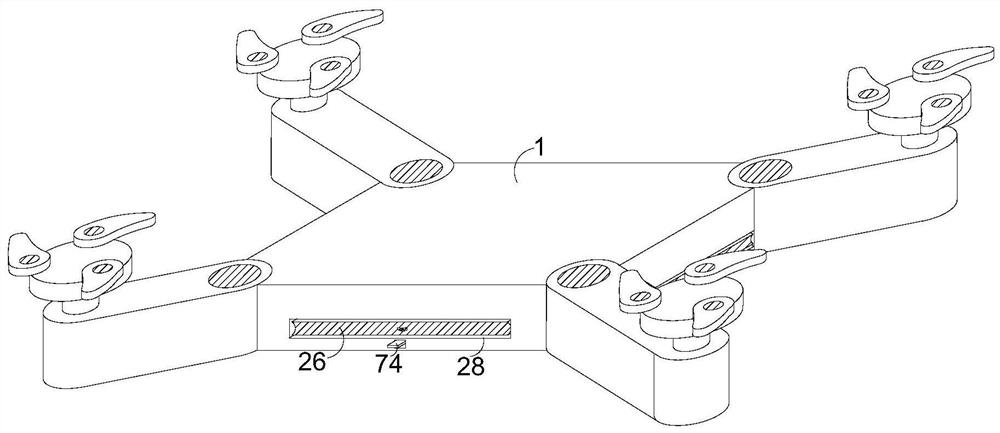

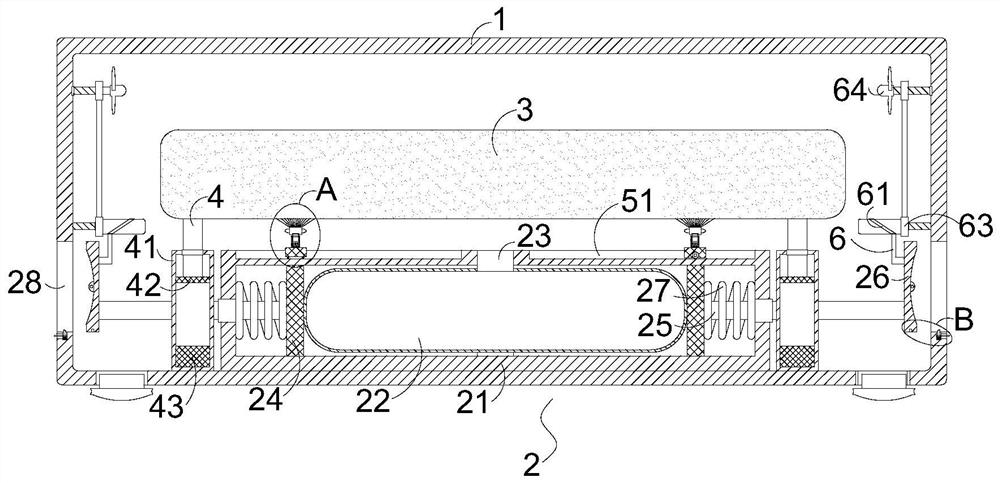

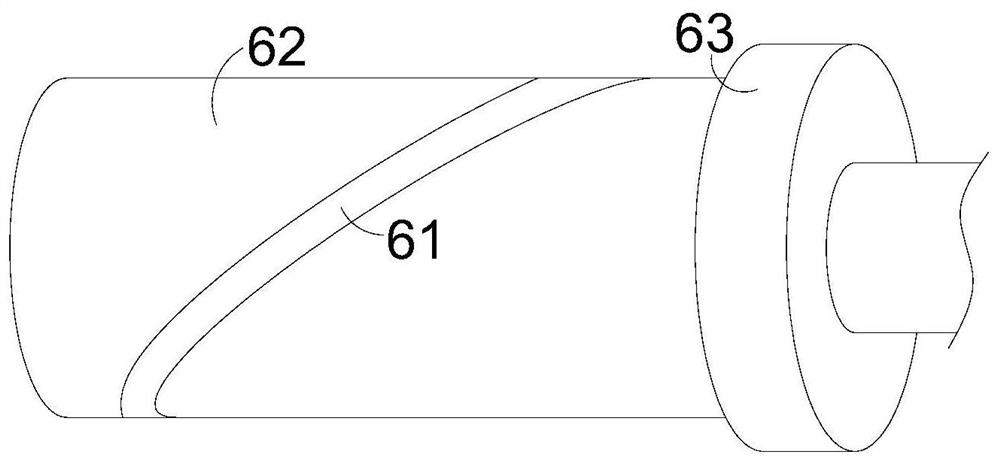

Sag and crossing measuring device based on aerial photography of unmanned aerial vehicle

InactiveCN113479329AEasy to measureSusceptible to heatAircraft componentsOptical rangefindersUncrewed vehicleElectric machinery

The invention relates to a sag and crossing measuring device based on aerial photography of unmanned aerial vehicle, which comprises a shell, an air cooling mechanism and a ventilation opening are arranged at the bottom of the inner surface of the shell, a rubber plug is plugged in the ventilation opening, four L-shaped rods are arranged in the shell, and the four L-shaped rods are symmetrically and fixedly connected to the air cooling mechanism; a locking assembly is arranged between the shell and the air cooling mechanism, an unmanned aerial vehicle body is arranged above the air cooling mechanism, the four corners of the bottom face of the unmanned aerial vehicle body are each fixedly connected with a set of ejector rods, and the windward arc plates in the four sets of windward arc plates in different directions can constantly extrude the air bag back and forth all the time. Therefore, in the flight process of the unmanned aerial vehicle, a motor, a circuit board, electrical elements and the like in the unmanned aerial vehicle main body are not prone to aging and damage due to heating, and the circuit board is not prone to softening. Therefore, the service life of the motor, the circuit board, electrical elements and the like in the unmanned aerial vehicle body is not easily shortened due to heating.

Owner:泰昌科技(杭州)有限公司

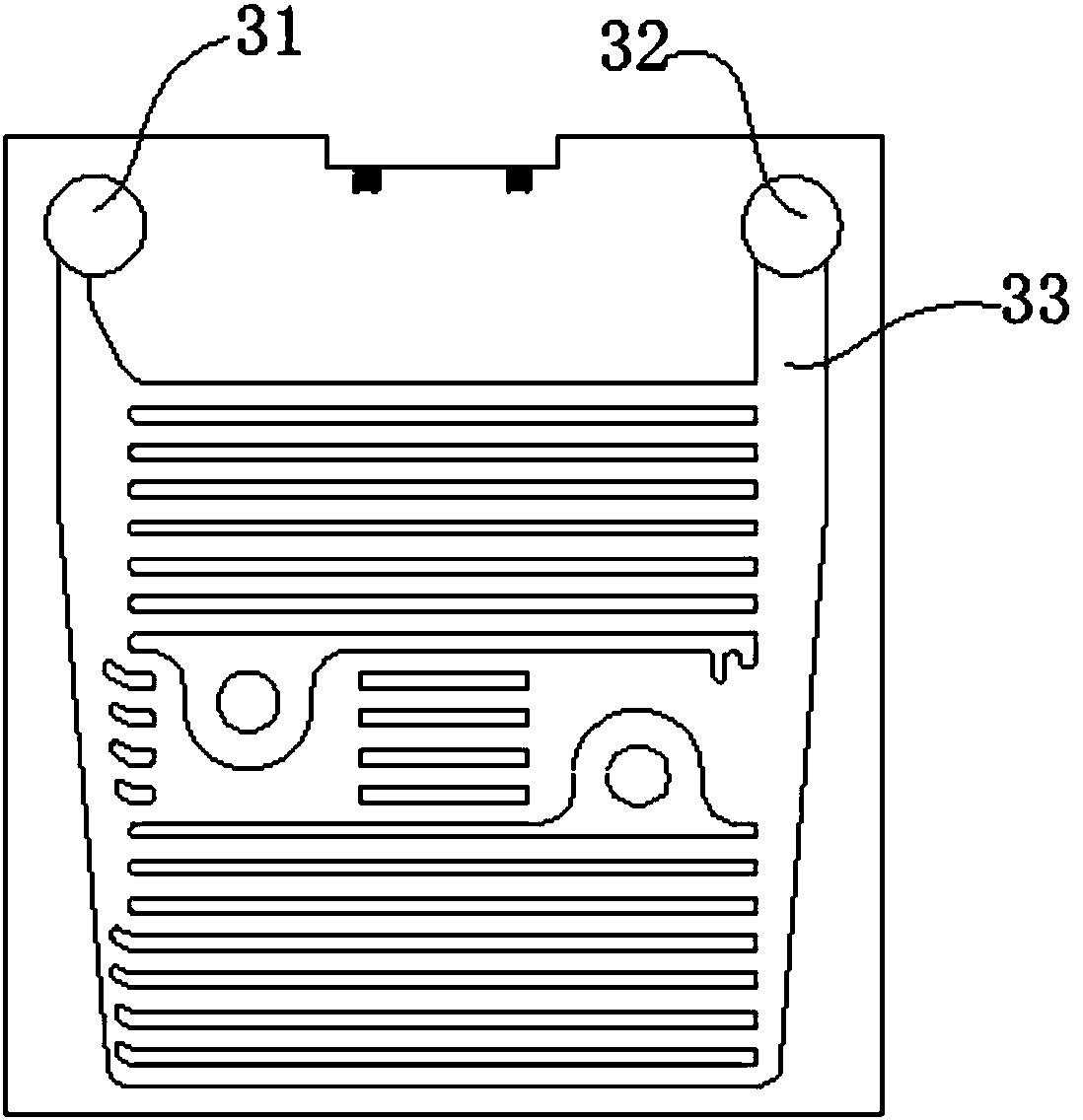

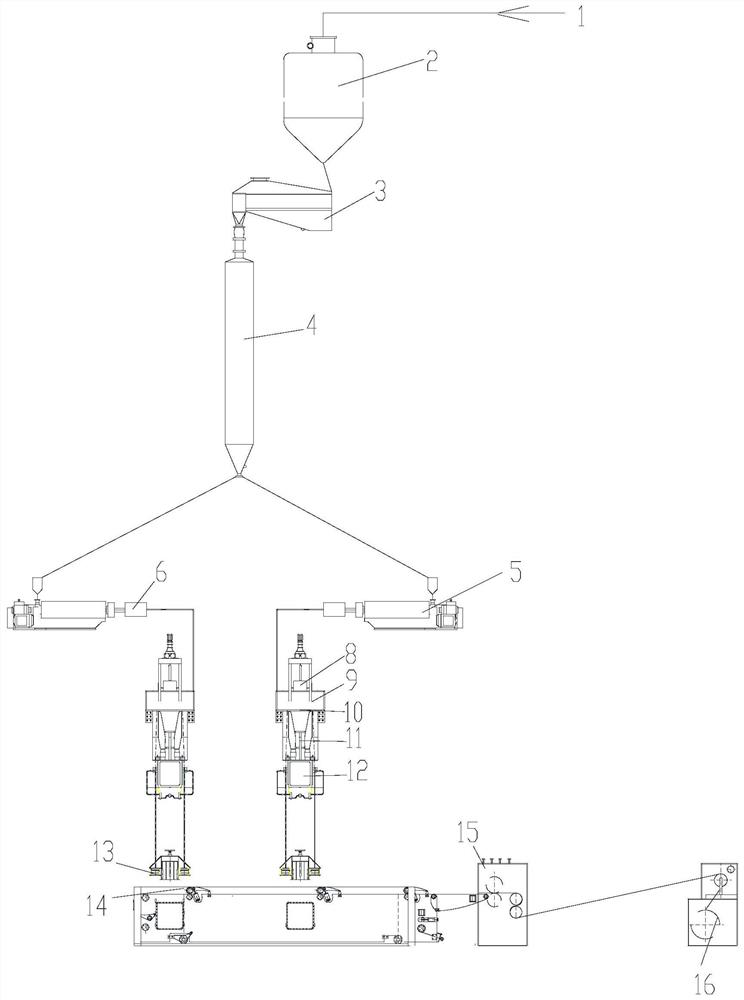

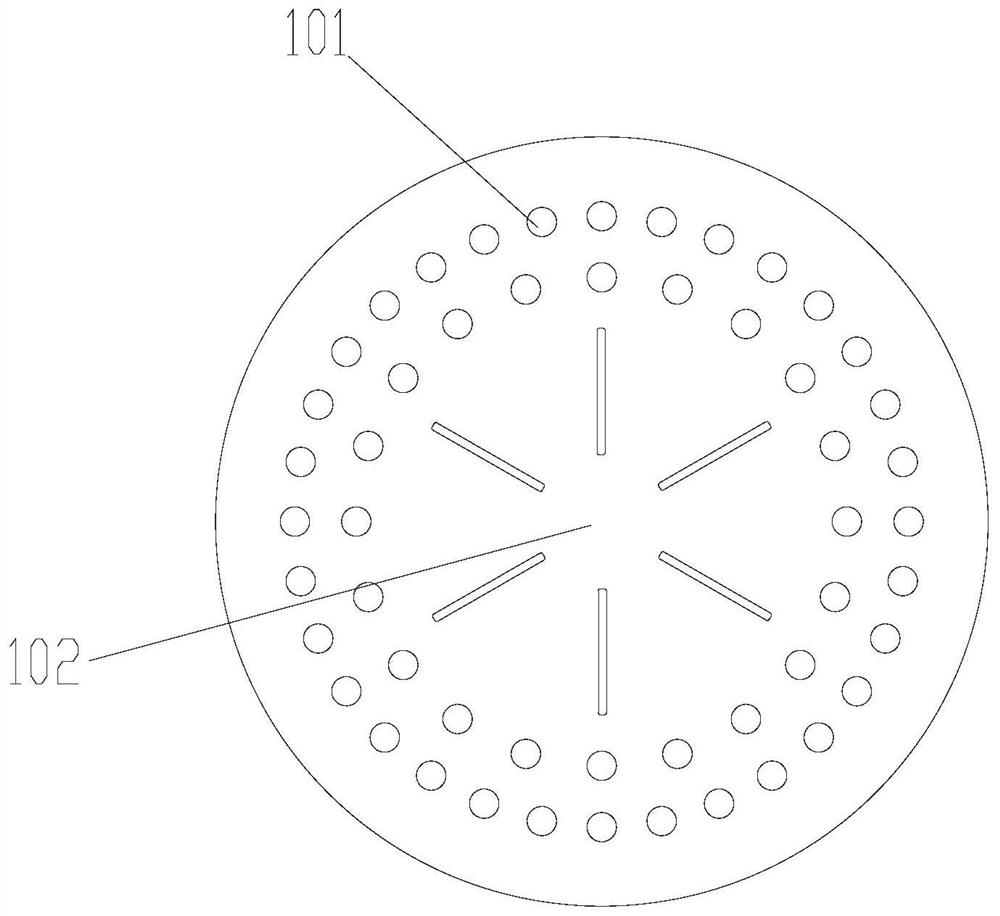

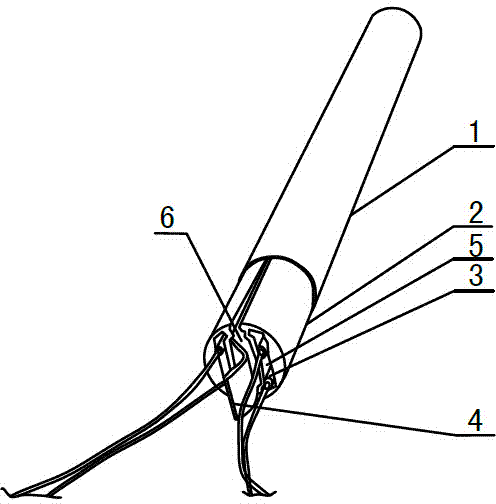

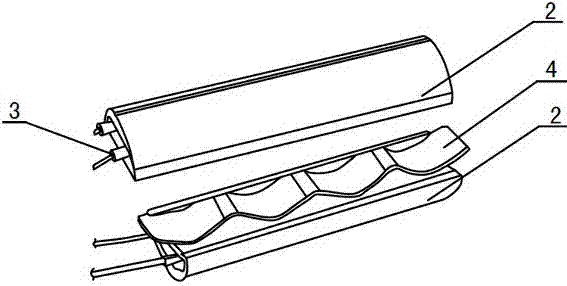

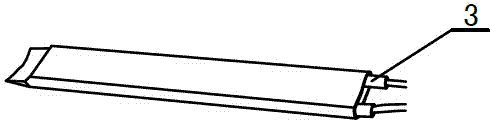

Spinneret plate, equipment and method for manufacturing high-gram-weight spun-bonded hot-rolled non-woven fabrics

ActiveCN112575397AApparent fusion bondingAvoid stratificationMelt spinning methodsNon-woven fabricsYarnAnnular array

The invention relates to a spinneret plate for manufacturing high-gram-weight spun-bonded hot-rolled non-woven fabrics. The spinneret plate comprises a spinneret plate body, a plurality of circular holes and a plurality of linear holes are formed in the spinneret plate body, the multiple circular holes form a circular hole area, the multiple linear holes form a linear hole area, the circular holearea is positioned on the periphery of the linear hole area, the multiple linear holes are distributed in an annular array, the extension lines of the multiple linear holes in the length direction allpass through the circle center of the annular array, and the multiple circular holes are further distributed in an annular array. A method for manufacturing the high-gram-weight spun-bonded hot-rolled non-woven fabrics is characterized by comprising the following steps of PET raw material preparation, air flow conveying, pre-crystallization, drying, spinneret plate melt spinning, cross air blow cooling, air flow drafting, yarn swinging and web forming, hot rolling reinforcement and winding. A special spinneret plate hole design with the same plate and different deniers is adopted, and two spinneret holes with different sectional areas and different shapes are formed in the same spinneret plate, so that fibers with different deniers (diameters) and different crystallinity degrees are spun.

Owner:FOSHAN S L P SPECIAL MATERIALS

Fish tank heating rod structure

InactiveCN104322431AIncrease the heating areaSusceptible to heatPisciculture and aquariaPhysicsEngineering

The invention relates to a fish tank heating rod structure, which comprises a heating tube and two heating sheets, wherein the two heating sheets are arranged inside the heating tube, a clamp groove is formed between the two heating sheets, in addition, a leaf spring is fixedly inserted inside the clamp groove and consists of a plurality of arc-shaped surfaces, and the two sides of the outer surface of the leaf spring are respectively and tightly propped against the inner sides of the heating sheets, so each heating sheet is pushed to the inner wall surface of the heating tube, the inside of each heating sheet is provided with a gap, and in addition, a heating rod is placed inside each gap. The fish tank heating rod structure has the beneficial effects that one spring is clamped between the two heating sheets, and through the tension of the spring, the heating sheets can be supported and propped open, and can be closer to the tube wall of the heating tube, so no cavity is formed between the outer heating tube and the inner heating sheets; the fish tank heating rod structure has the advantages that the heated area is large, the heated effect can be easily achieved, the heating speed is high, and the like; one gap is formed in the middle part of each heating sheet and is used for containing the corresponding heating rod.

Owner:李伟

Ethylene-vinyl alcohol copolymer composition, pellets, and multilayer structure

ActiveUS11407888B2Ultraviolet absorbabilityImprove thermal stabilityBottlesSynthetic resin layered productsPolymer scienceUv absorber

An ethylene-vinyl alcohol copolymer composition contains: (A) an ethylene-vinyl alcohol copolymer; (B) a styrene derivative; and (C) an iron compound; wherein the iron compound (C) is present in an amount of 0.01 to 5 ppm on a metal basis based on the weight of the ethylene-vinyl alcohol copolymer composition. The ethylene-vinyl alcohol copolymer composition has ultraviolet absorbability even without a known ultraviolet-absorbing agent blended therein, and is excellent in heat stability and reduced susceptibility to coloration.

Owner:MITSUBISHI CHEM CORP

A waste rubber thermal regeneration device and thermal regeneration method thereof

Owner:RIZHAO CHENHUI RUBBER&PLASTICS PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com