Buckle type LED light source drive integrated lamp

A LED light source and buckle-type technology, applied in the field of lighting, can solve the problems of high manufacturing cost, inconvenient, time-consuming and labor-intensive installation, and achieve the effect of no need for bolt connection, fast installation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

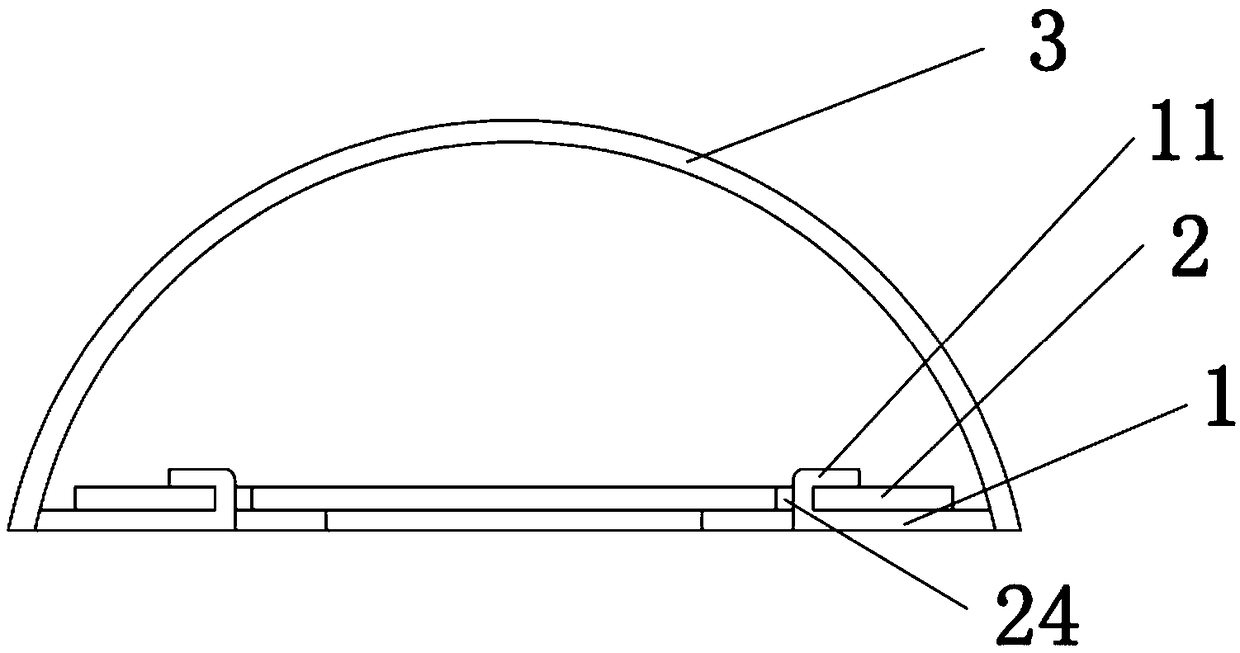

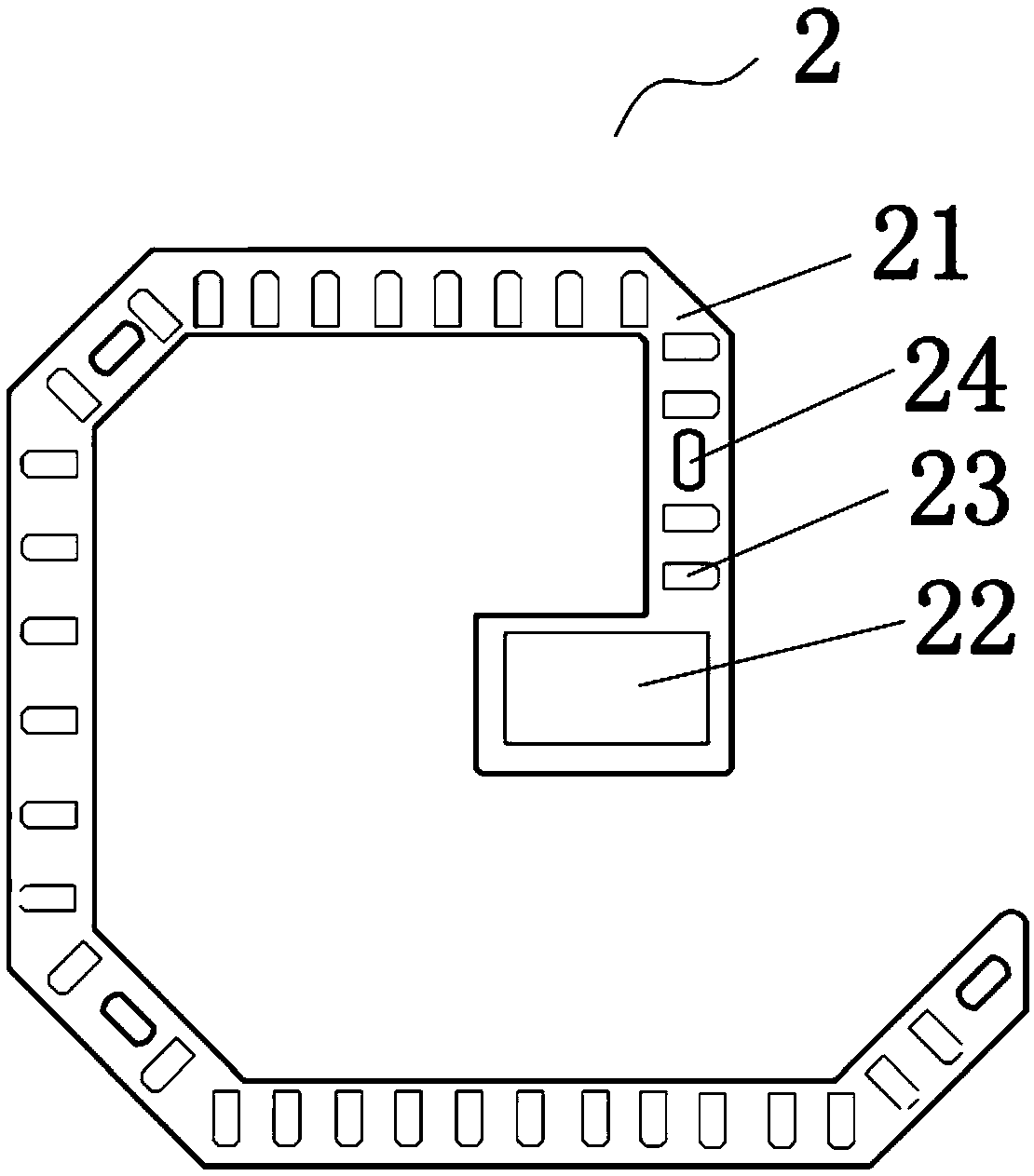

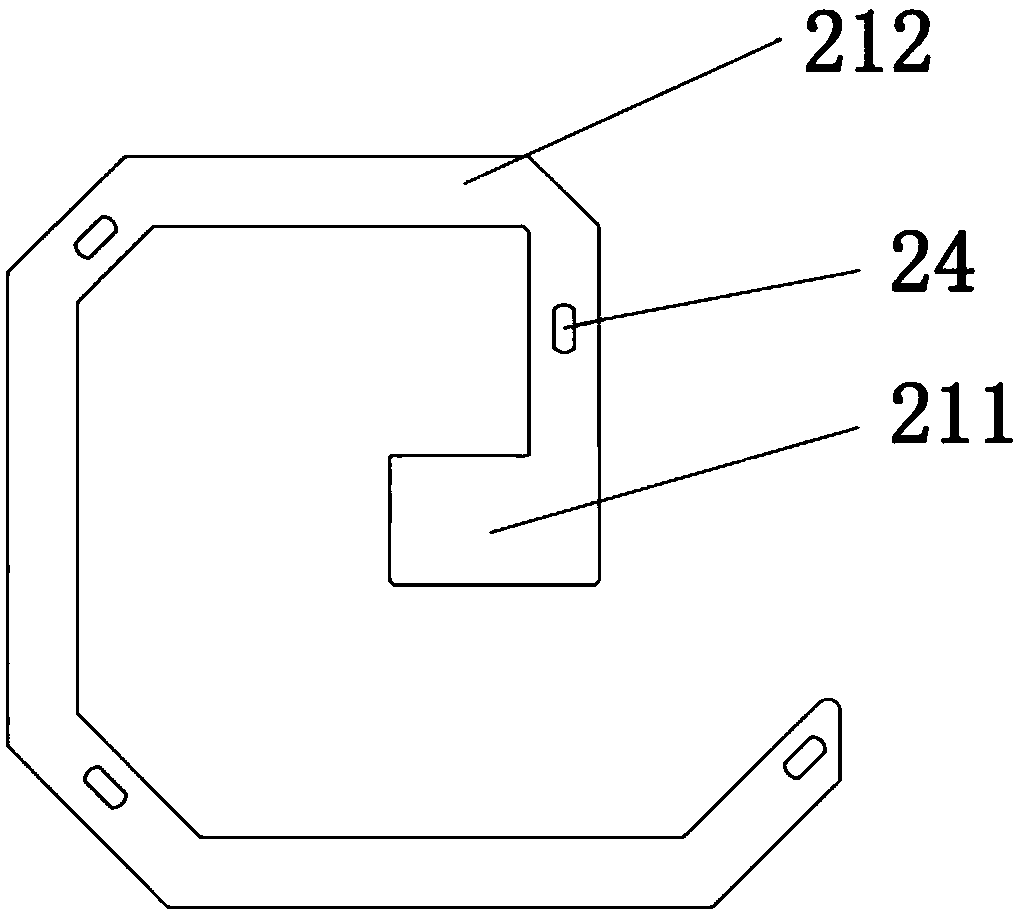

[0019] Such as Figures 1 to 4 As mentioned above, the present invention provides a snap-on LED light source driving integrated lamp that can be quickly installed with the lamp holder 1 and can connect the LED light source 23 and the driving circuit 22 together.

[0020] It includes a lamp holder 1, an LED light source lamp board 2 connected with the lamp holder 1, and a lampshade 3 connected with the lamp holder 1. The lamp holder 1 is provided with N connection buckles 11, so that the lamp holder 1 directly connected to the LED light source lamp board 2; the connecting buckle 11 is formed by bending the opening hole on the lamp holder 1, showing a strip shape, the opening hole can be bent, this structure makes the lamp holder 1 It directly becomes a buckle and can play a binding role. Since the strip-shaped hole on the lamp holder 1 of this design is inserted into the fixing hole 24 of the LED light source lamp board 2 during use and bent, the LED light source lamp board 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com