Novel LED (Light Emitting Diode) flat panel down lamp

A flat-panel and downlight technology, applied in the field of lighting, can solve the problems of unsightly lighting and small light-emitting area, and maximize the light-emitting area and enhance the aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

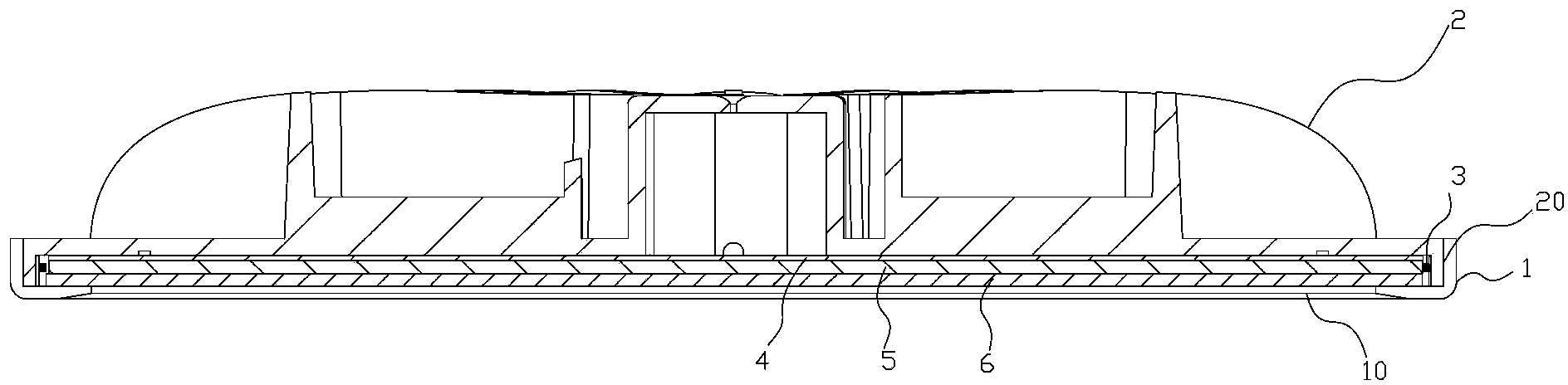

[0009] The present invention as figure 1 As shown, it includes a front cover 1, a rear cover 2 and several LED lighting units 3, the center of the front cover 1 is provided with a light-transmitting opening 10, the front cover 1 is detachably connected to the rear cover 2, and the rear The cover 2 is located above the front cover 1; a reflective sheet 4, a light guide plate 5 and a diffusion plate 6 are sequentially provided between the rear cover 2 and the front cover 1; a bottom of the rear cover 2 is provided with a downward A flange 20 is formed, the reflection sheet 4 , the light guide plate 5 and the diffusion plate 6 are arranged inside the flange 20 , and several LED light emitting units 3 are arranged between the flange 20 and the light guide plate 5 . In the present invention, the front and rear covers can be connected by screws, hooks or threaded knobs.

[0010] The light-transmitting opening 10 is circular or square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com