High-brightness light-emitting diode (LED) panel lamp

A technology of LED panel light and LED light bar, applied in lighting device, cooling/heating device of lighting device, light source, etc., can solve the problems of affecting lighting effect, reducing light-emitting area, increasing thickness, etc., saving materials and saving The effect of production cost and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

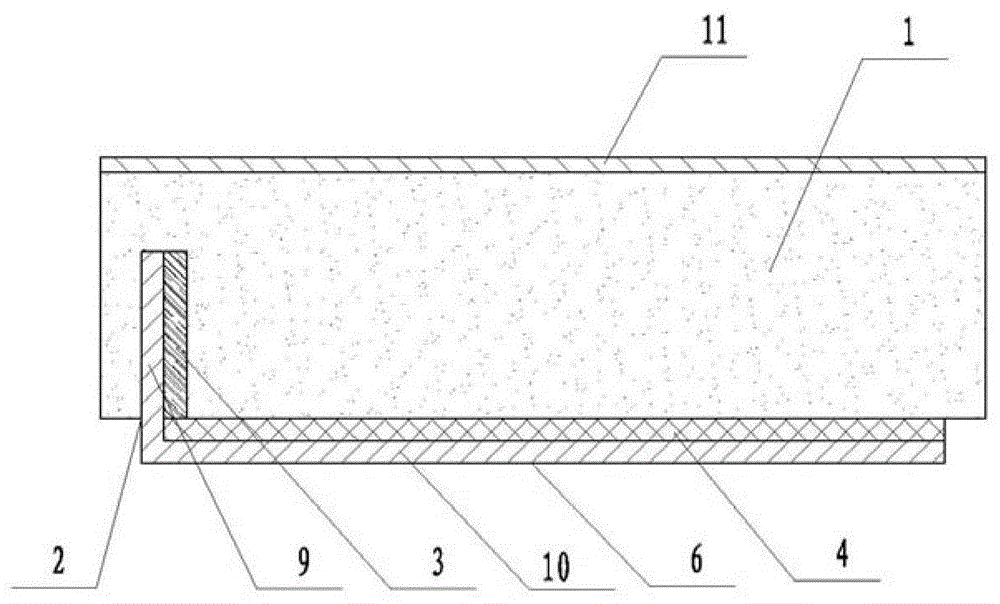

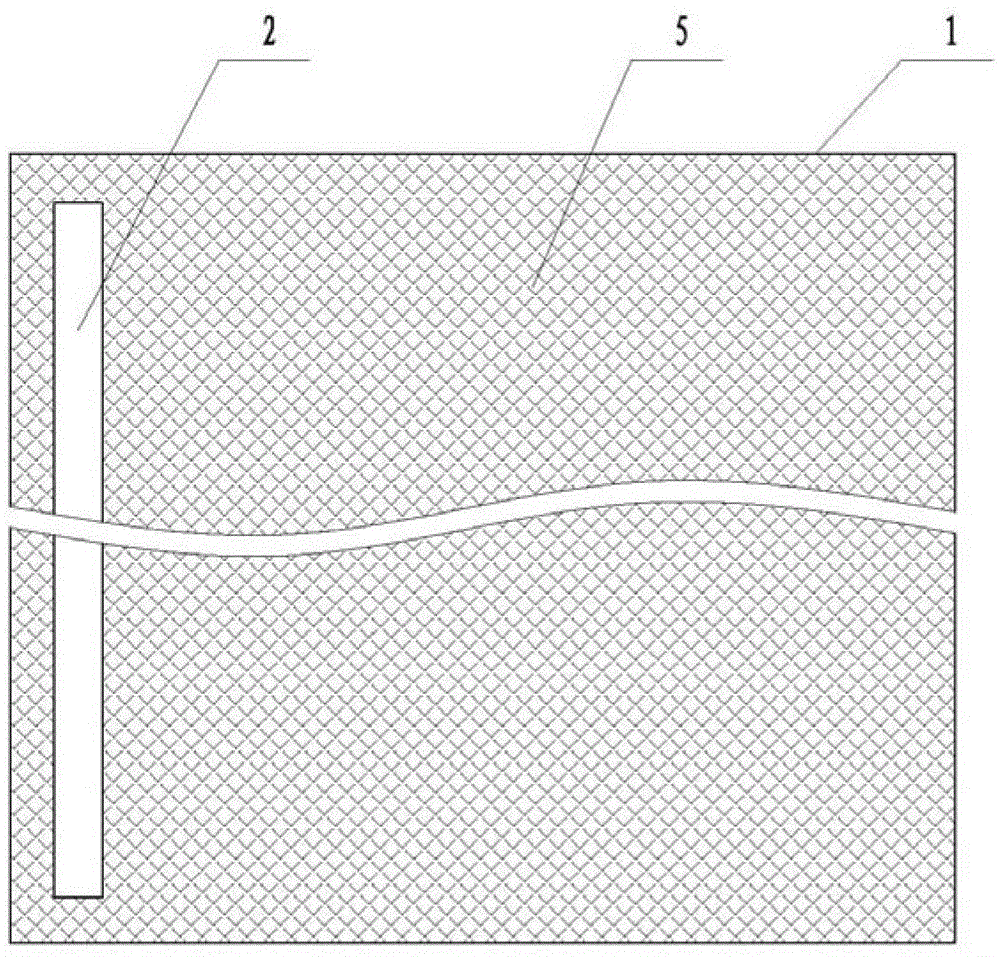

[0031] see figure 1 , figure 2 , image 3 As shown, a high-brightness LED flat panel light in this embodiment includes a light guide plate 1, a slot 2 is provided on the light guide plate, and an LED light bar 3 is arranged in the slot. The lower end of the light guide plate is provided with a reflector 4; the bayonet of the card slot is set on the left edge of the bottom surface of the light guide plate, and the card slot is vertically downward; the bottom surface of the light guide plate is arranged with dots 5; the dots are evenly distributed, and its shape It can be circular, V-shaped, rectangular, polygonal, etc. The dots are designed based on optical principles. The dots described in this embodiment are V-shaped dots formed by criss-cross rectangular arrays. The lengths of the light plates are equal, the lateral length of the rectangular array is equal to the width of the light guide plate, and the area size and dot pitch of the rectangular array can be adjusted accor...

Embodiment 2

[0037] The high-brightness LED panel light in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

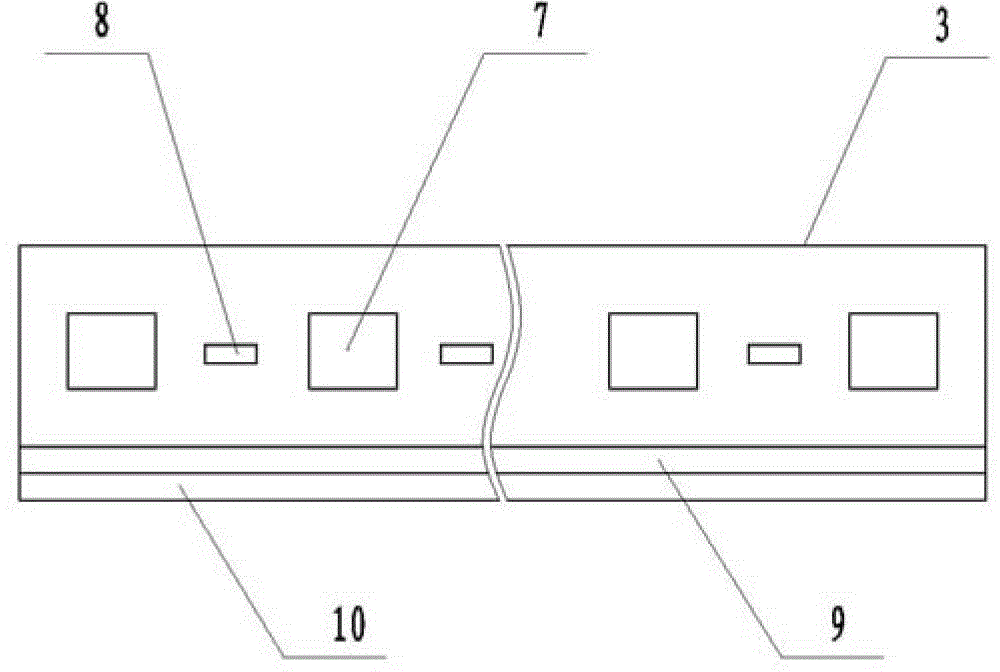

[0038] see Figure 4 , Figure 5 As shown, in this embodiment, in order to make the installation of the backplane and the light guide plate more firm, two card slots 101 can be provided on the light guide plate, and the bayonets of the two card slots are respectively provided on the bottom surface of the light guide plate The left and right edges of the left and right edges, the card slots are all vertically downward; a clamping plate 102 is vertically provided at the left and right ends of the pressing plate, and the LED light bar is installed on the right side wall of the left clamping plate The two clamping plates and the two card slots are correspondingly clamped; thus, the two ends ...

Embodiment 3

[0040] The high-brightness LED panel light in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0041]see Figure 6 , Figure 7 As shown, the section of the backboard in this embodiment is shape setting; in order to improve the brightness of the flat panel lamp as a whole, two card slots are provided on the light guide plate in this embodiment; a card board is provided at both ends of the pressure plate, and the two card boards are equipped with LED light bar 201; in this embodiment, two LED light bars are connected in parallel; in order to facilitate the placement of wires for parallel connection of two LED light bars, a wiring groove 202 can be provided at the edge of the bottom surface of the light guide plate; The two ends of the wiring trough communicate with the two card sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com