Fish tank heating rod structure

A technology of heating rods and fish tanks, applied in fish farming, application, animal husbandry, etc., can solve the problems of easy heating, large heating area, etc., and achieve the effect of easy heating, large heating area, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

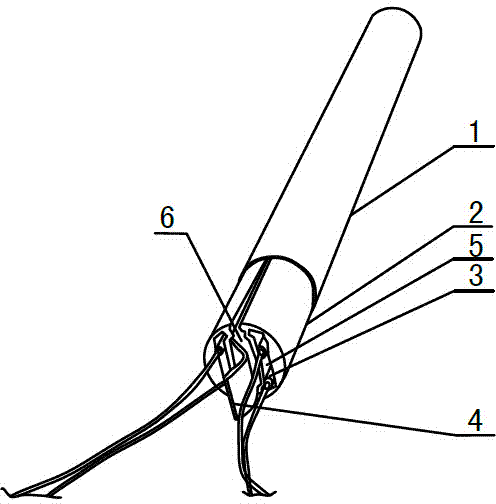

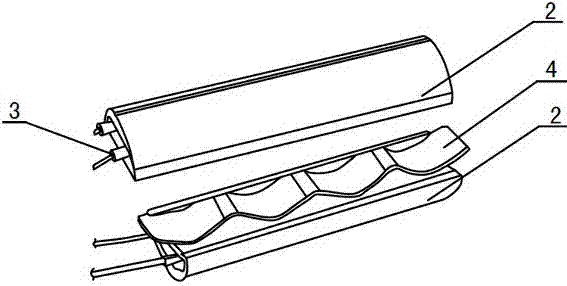

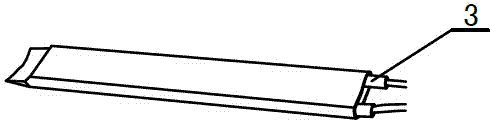

[0025] Such as Figure 1-4 As shown, the fish tank heating rod structure described in the embodiment of the present invention includes a heating tube 1 and two heating fins 2, the heating tube 1 is a hollow cylindrical structure and one or both of the bottom surfaces are set as open ends, The inside of the heating tube 1 is provided with two heating sheets 2 with a semicircular longitudinal section, and there is a clamping groove 6 between the two heating sheets 2, and a spring piece 4 is fixedly inserted inside the clamping groove 6, and the spring piece 4 is composed of several arc-shaped surfaces, thus forming a wavy surface structure;

[0026] Correspondingly, the protrusions on both sides of the outer surface of the spring piece 4 press against the inner side of the heating piece 2 respectively, thereby pushing each piece of heating piece 2 to the inner wall surface of the heating tube 1, so that the heating piece 2 can support and bounce off more Close to the tube wall ...

Embodiment 2

[0028] Such as Figure 1-4 As shown, the fish tank heating rod structure described in the embodiment of the present invention includes a heating tube 1 and two heating fins 2, the heating tube 1 is a hollow cylindrical structure and one or both of the bottom surfaces are set as open ends, Two heating sheets 2 are arranged inside the heating tube 1, and a spring sheet 4 is inserted between the two heating sheets 2;

[0029] The protrusions on both sides of the outer surface of the spring sheet 4 press against the inner side of the heating sheet 2 respectively, thereby pushing each heating sheet 2 to the inner wall surface of the heating tube 1, so that the heating sheet 2 can be supported and bounced closer to the heating tube 1 to achieve the effects of large heating area, easy heating, and fast heating; at the same time, each heating sheet 2 is provided with a heating rod 3 inside.

Embodiment 3

[0031] Such as Figure 1-4 As shown, the fish tank heating rod structure described in the embodiment of the present invention includes a heating tube 1 and two heating fins 2, two heating fins 2 are arranged inside the heating tube 1, and there is a clip between the two heating fins 2. Groove 6 and a spring piece 4 is fixedly inserted inside the clamping groove 6, and the spring piece 4 is a wavy curved surface structure;

[0032] Correspondingly, both sides of the outer surface of the spring sheet 4 press against the inner side of the heating sheet 2 respectively, thereby pushing each heating sheet 2 to the inner wall surface of the heating tube 1, so that the heating sheet 2 can be supported and bounced closer to the heating tube 1 the tube wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com