Damp-proof terminal box

A terminal box and box technology, applied in electrical components, substation/switch layout details, etc., can solve the problems of abnormal operation, easy damping of the box, increasing the burden of moisture-proof equipment such as drying boxes and exhaust fan heaters, etc. Uniform temperature distribution, improved moisture-proof effect, improved moisture-removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

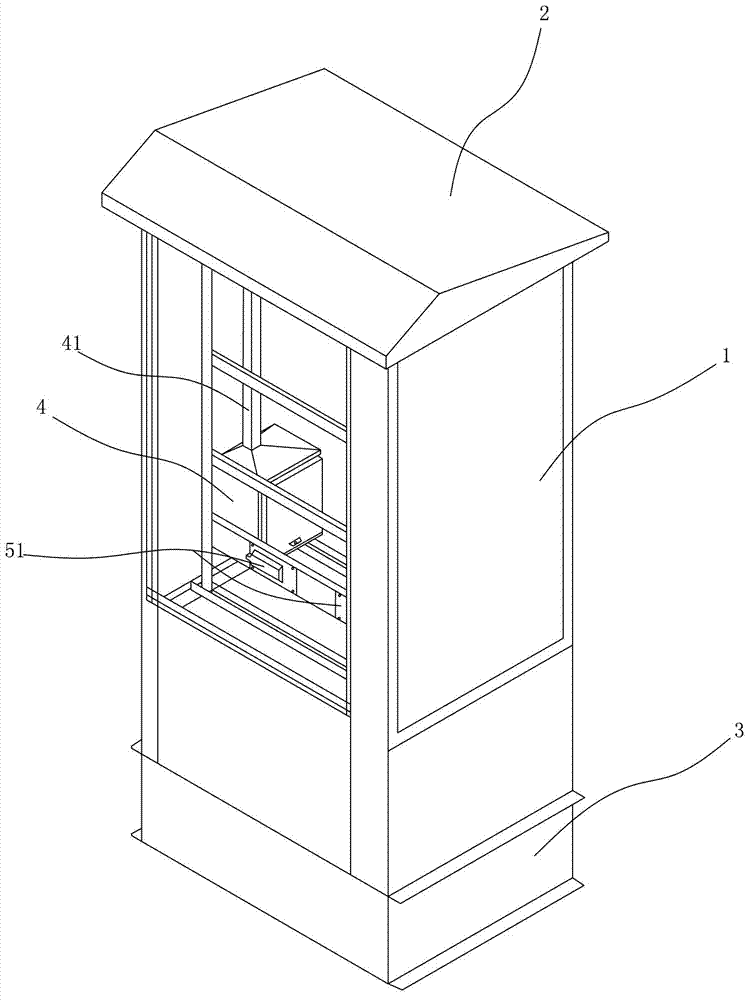

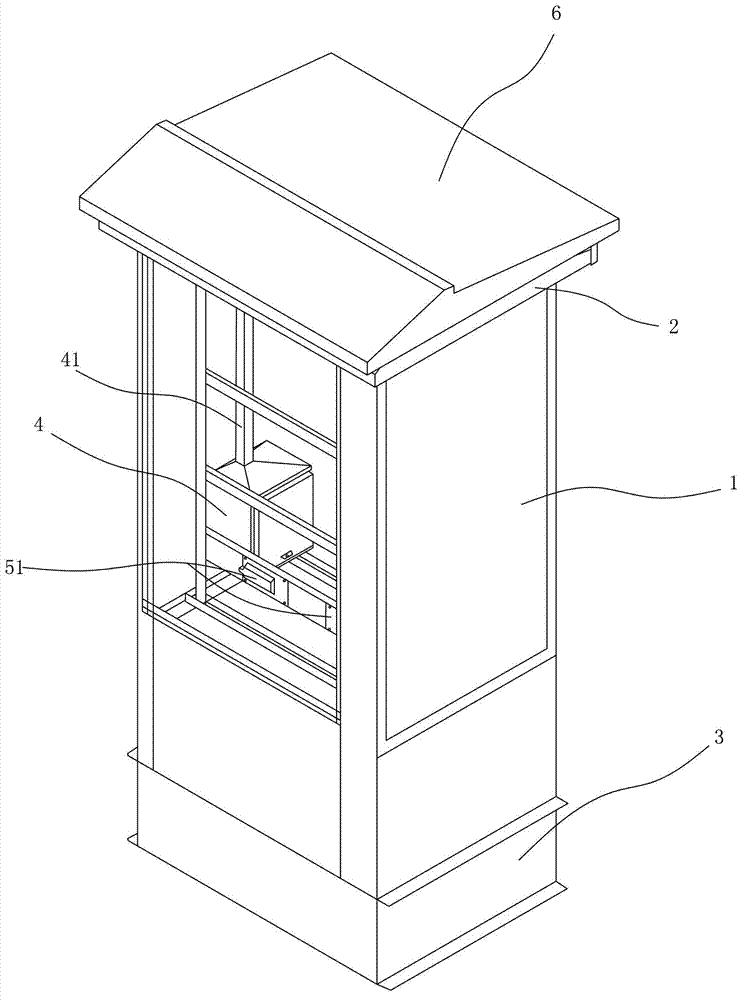

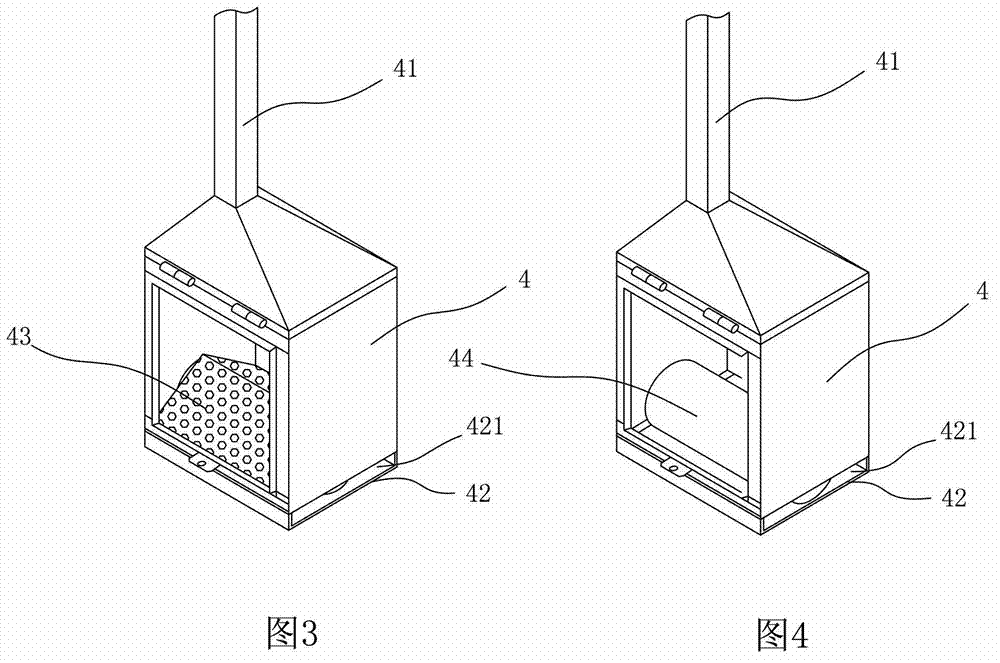

[0032] refer to Figure 1 to Figure 9 As shown, a moisture-proof terminal box includes a base 3, a box body 1 set on the base 3, a top cover 2 set on the top of the box body 1, a sunshade cover 6 set above the top cover 2 and a box body 1 In the drying box 4, the top of the sunshade cover 6 is provided with a vent 61 with side openings.

[0033] The top cover 2 is composed of an outer cover body and an inner cover body arranged in the outer cover body. A condensation chamber A is formed between the outer cover body and the inner cover body. The slanting plate 24 and the two side plates 23 are spliced together. The first slanting plate 25 is larger than the second slanting plate 24. The first slanting plate 25 is provided with a dehumidification hole 261 connecting the inside of the box body 1 and the dew chamber A to drain moisture. An exhaust fan 27 is arranged on the hole 261, and the upper end surface of the first inclined plate 25 is provided with a condensation net 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com