Patents

Literature

2197results about How to "Increase the heating area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

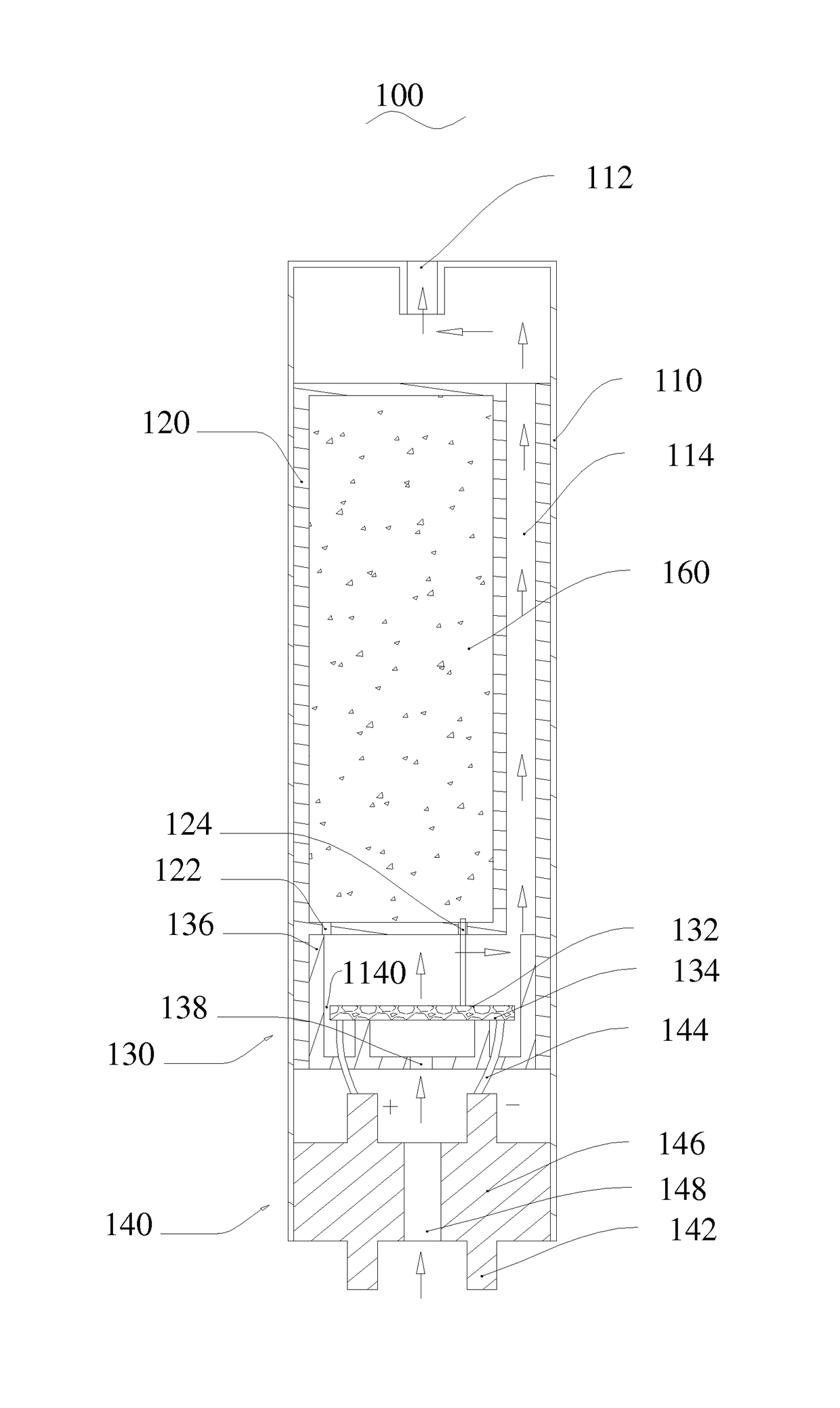

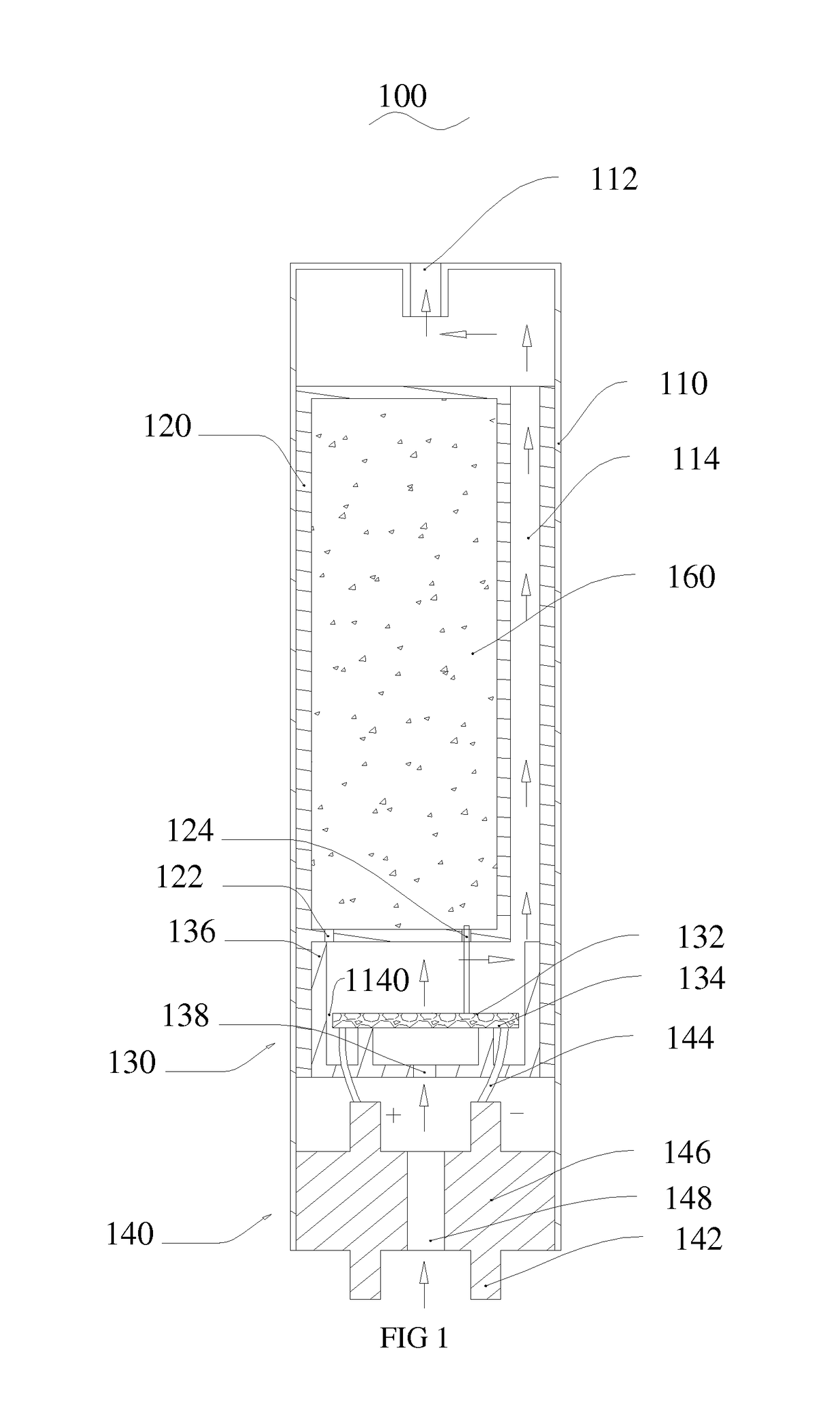

Electronic cigarette

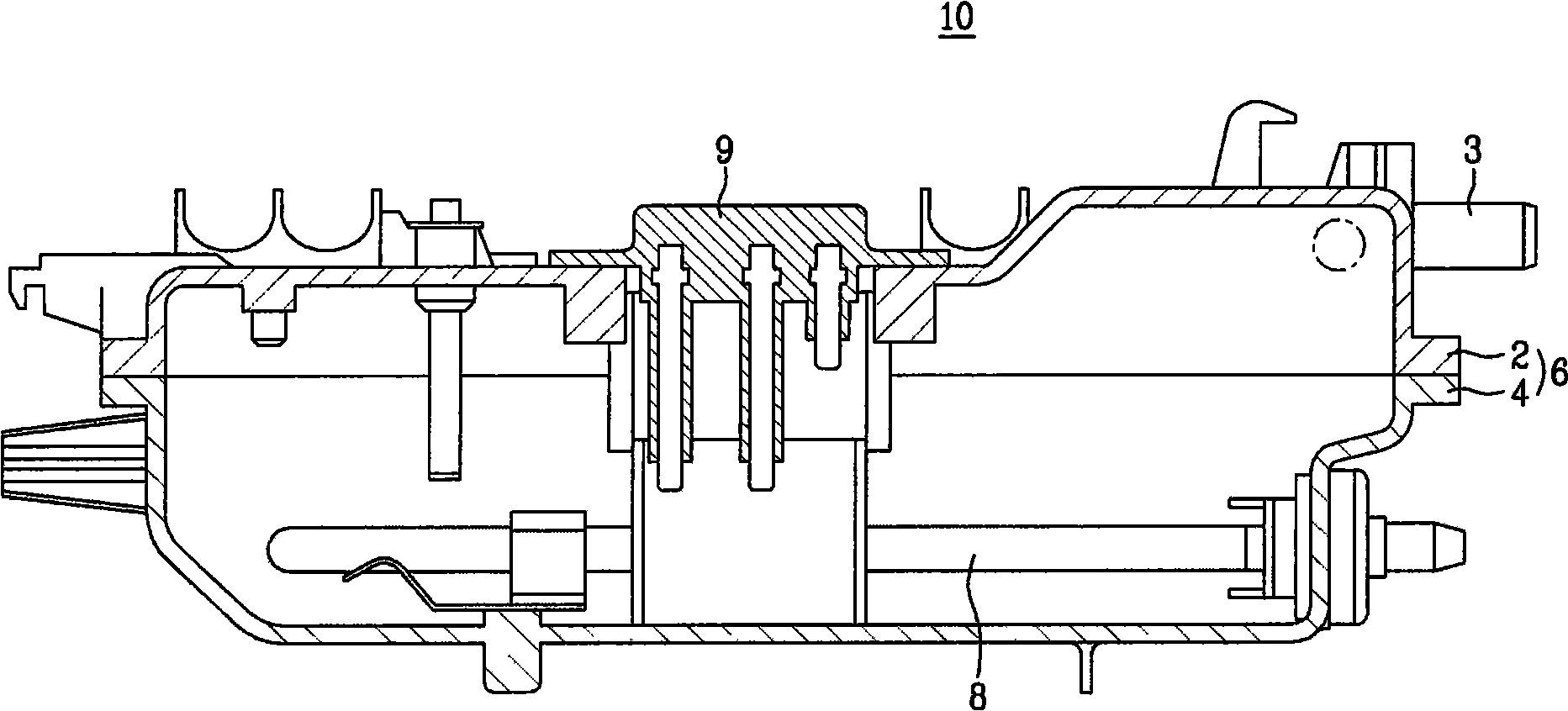

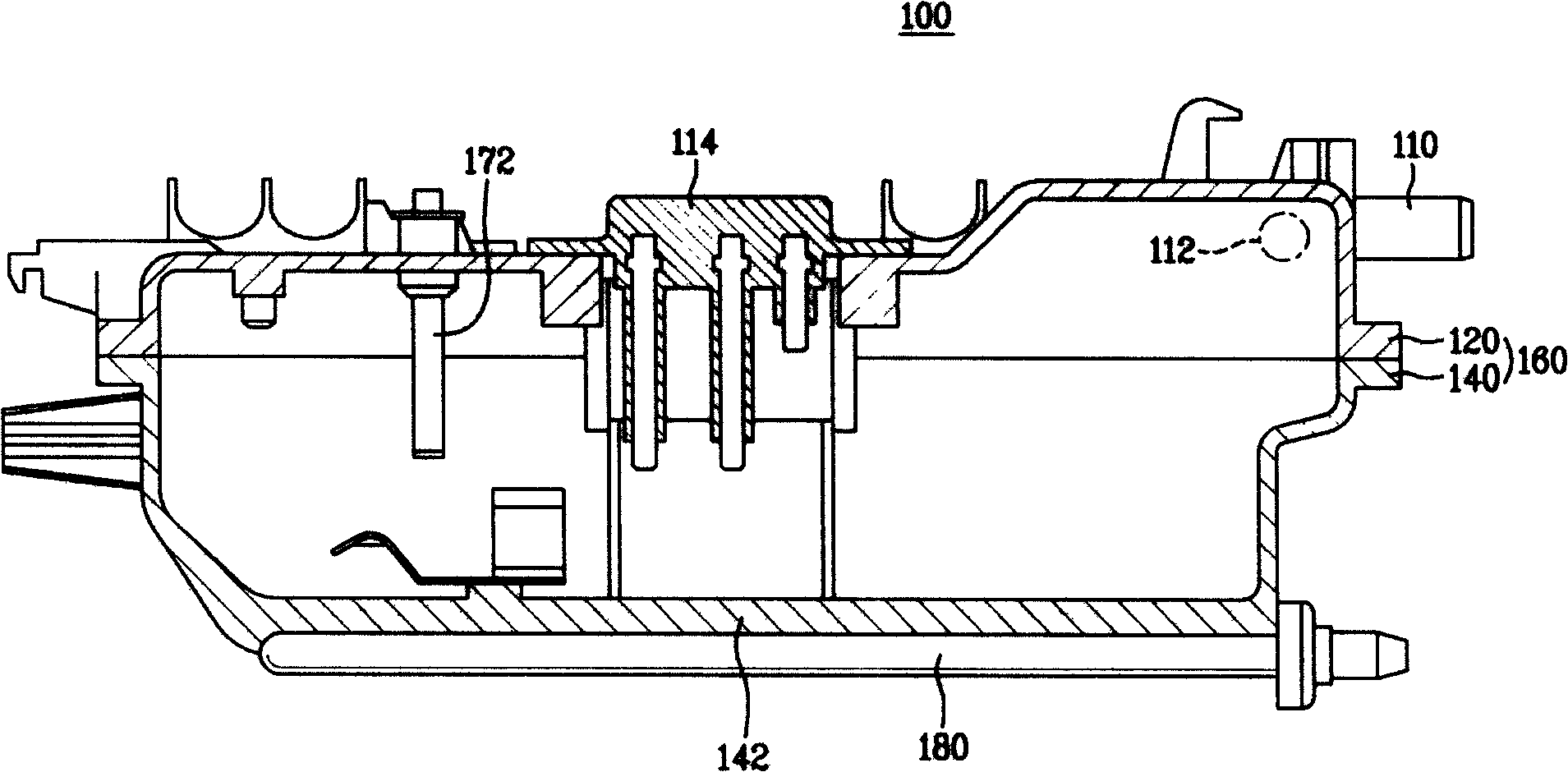

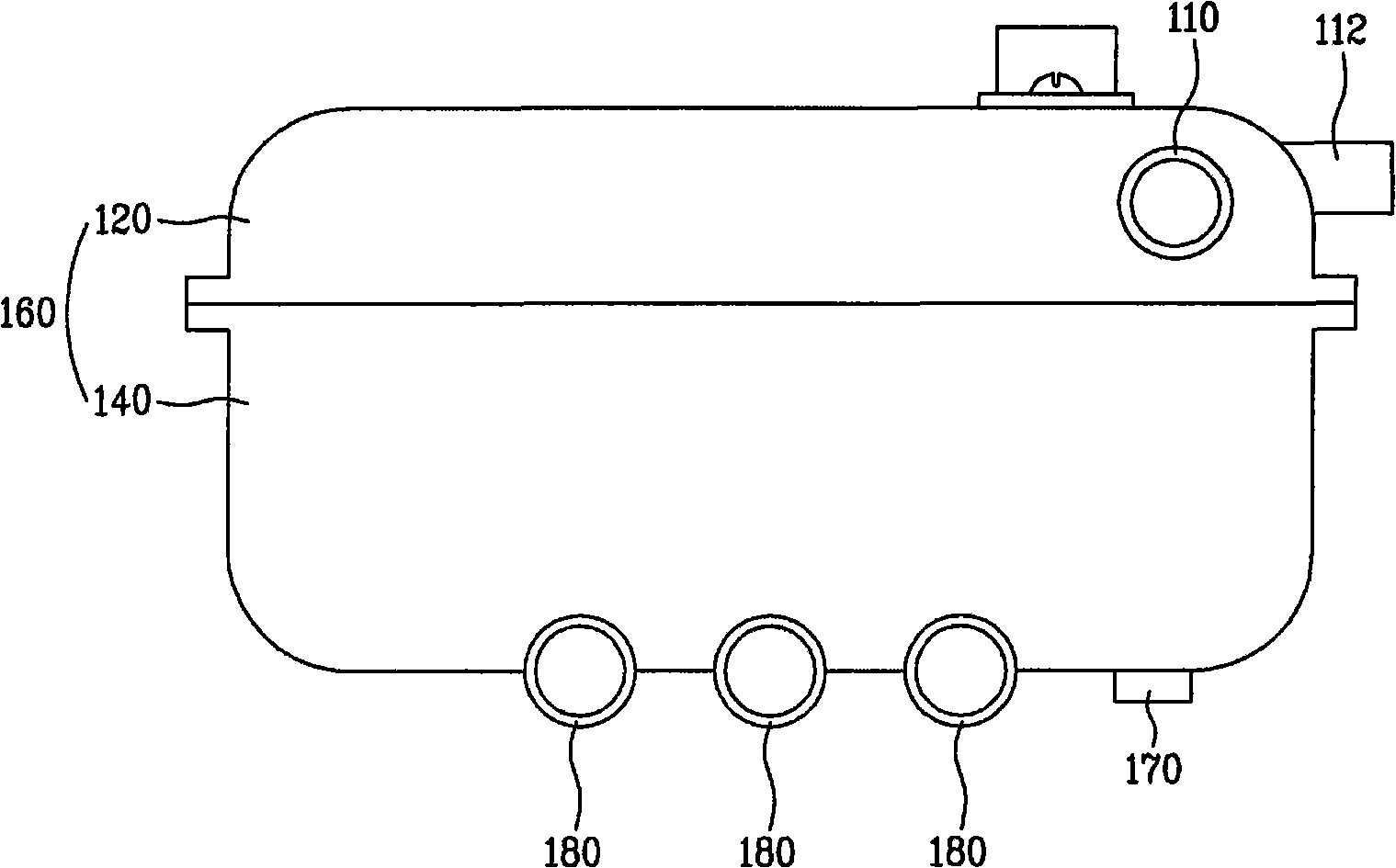

ActiveUS20150090279A1Easily inhale smokeProne to feverTobacco pipesTobacco devicesEngineeringElectronic cigarette

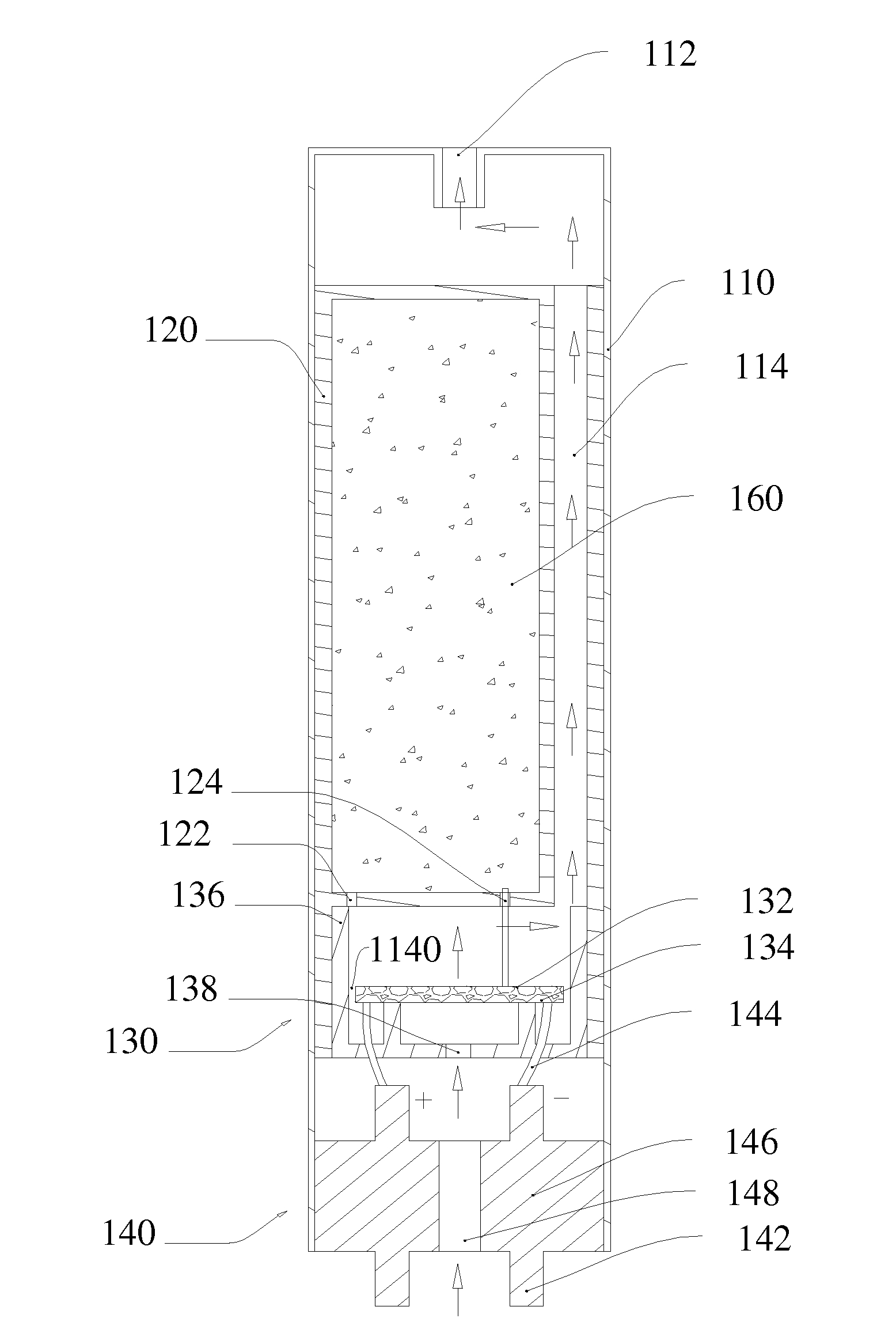

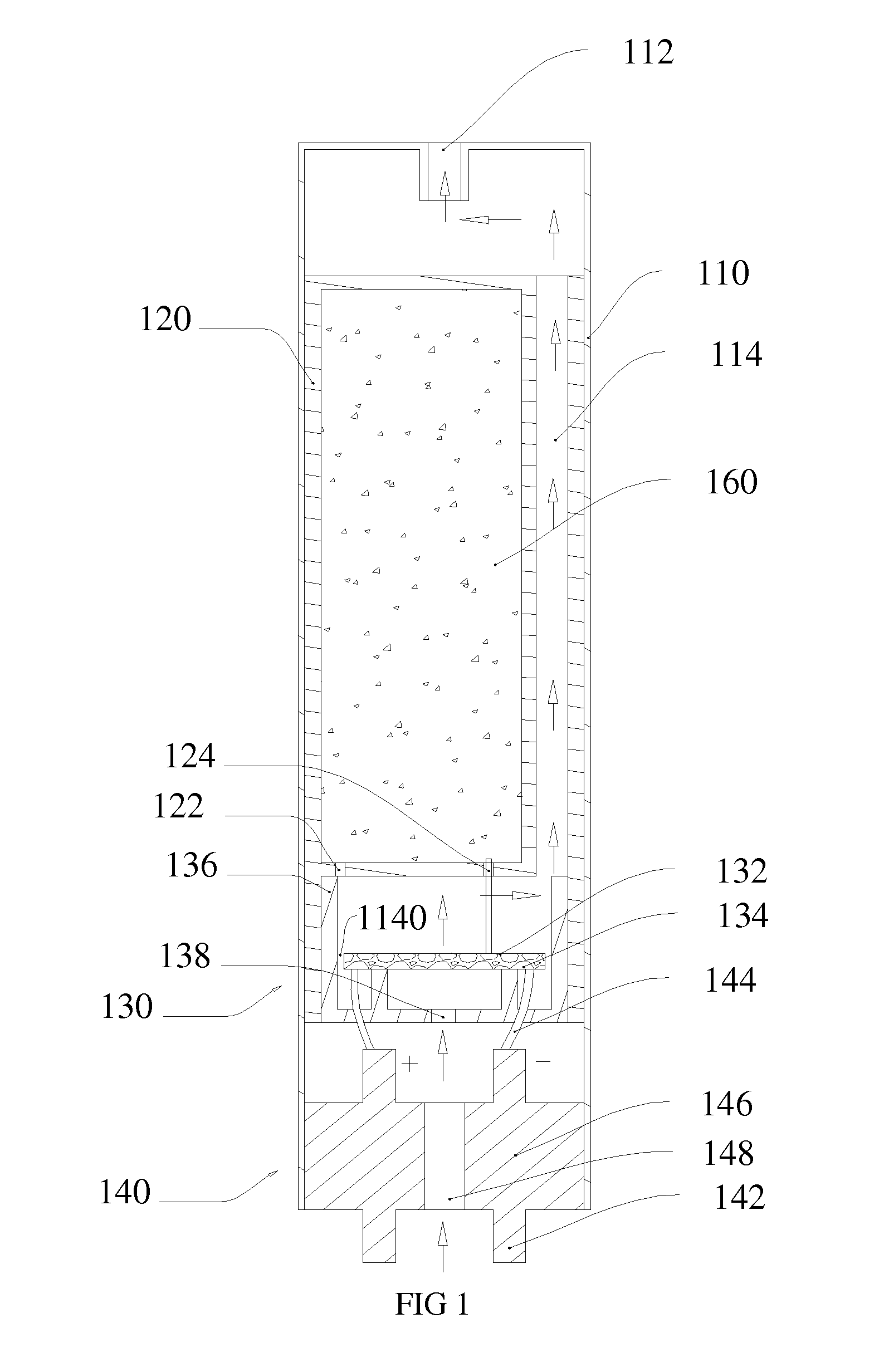

An electronic cigarette is provided, which includes: a housing, a liquid reservoir, and an atomizer assembly. The housing has a chimney formed therein; the liquid reservoir is used for storing liquid; the atomizer assembly received in the housing. The atomizer assembly includes a heating plate capable of absorbing liquid. An outer surface of the heating plate is in contact with the air in the chimney.

Owner:SHENZHEN SMOORE TECH LTD

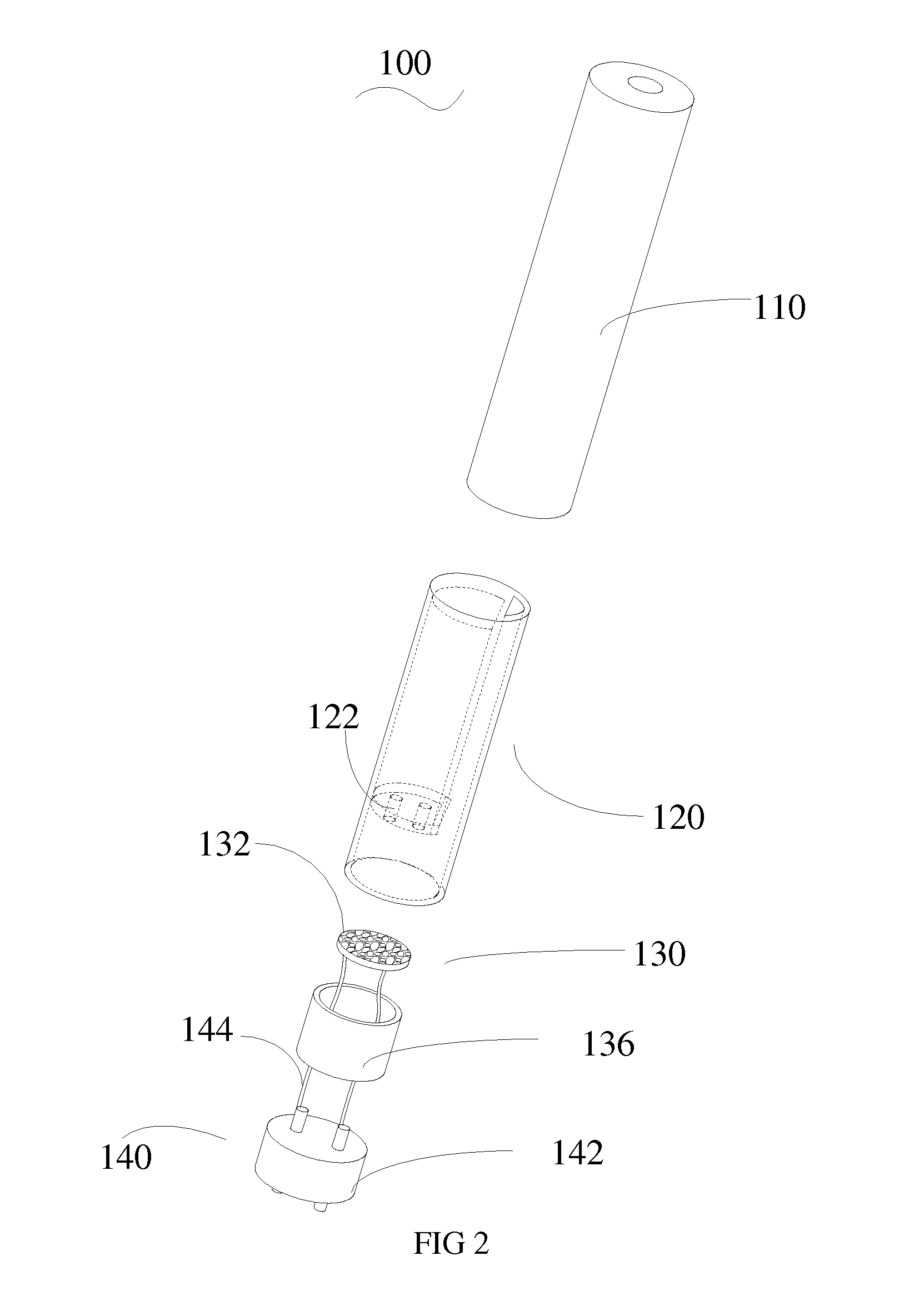

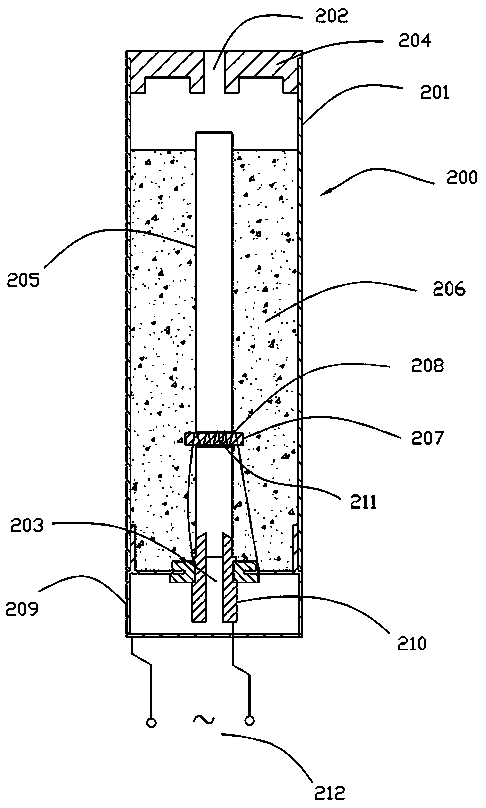

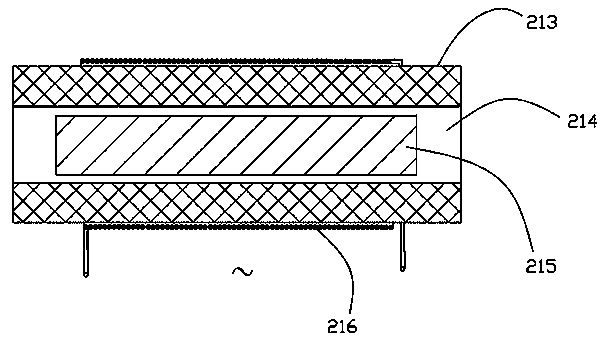

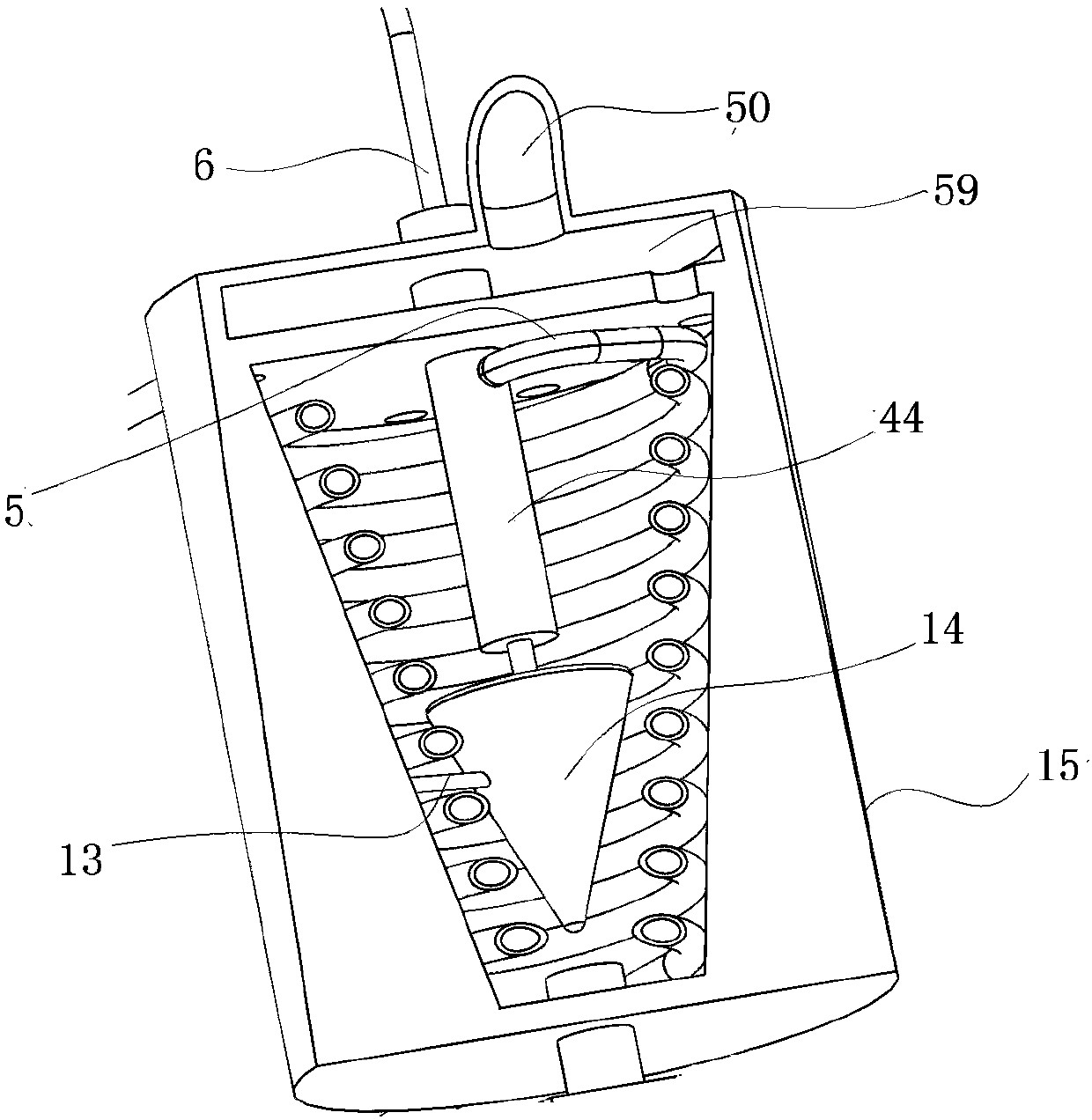

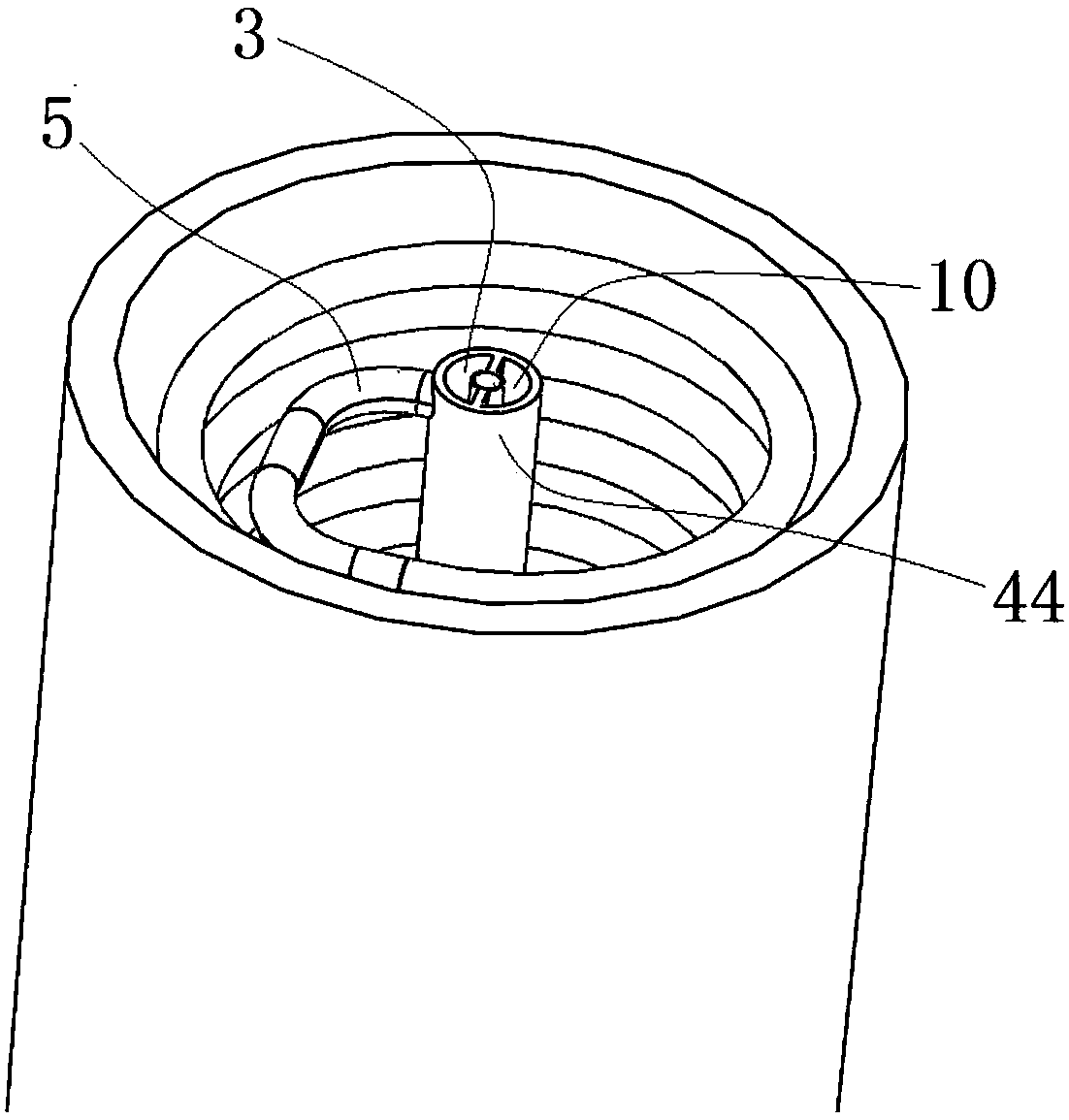

Smoke generator and electronic cigarette with same

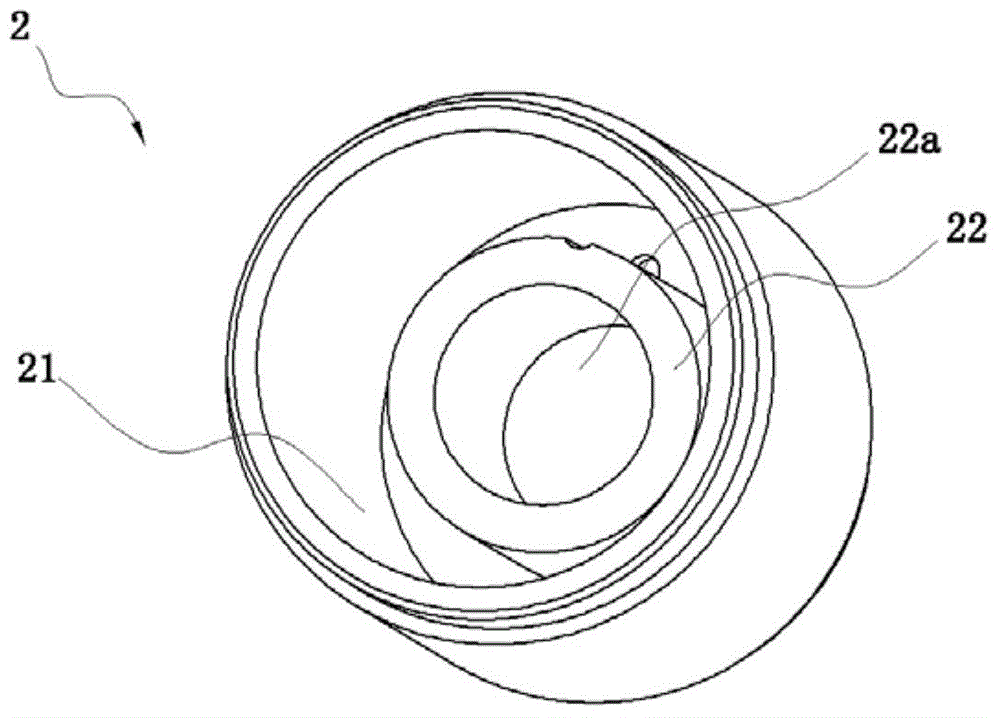

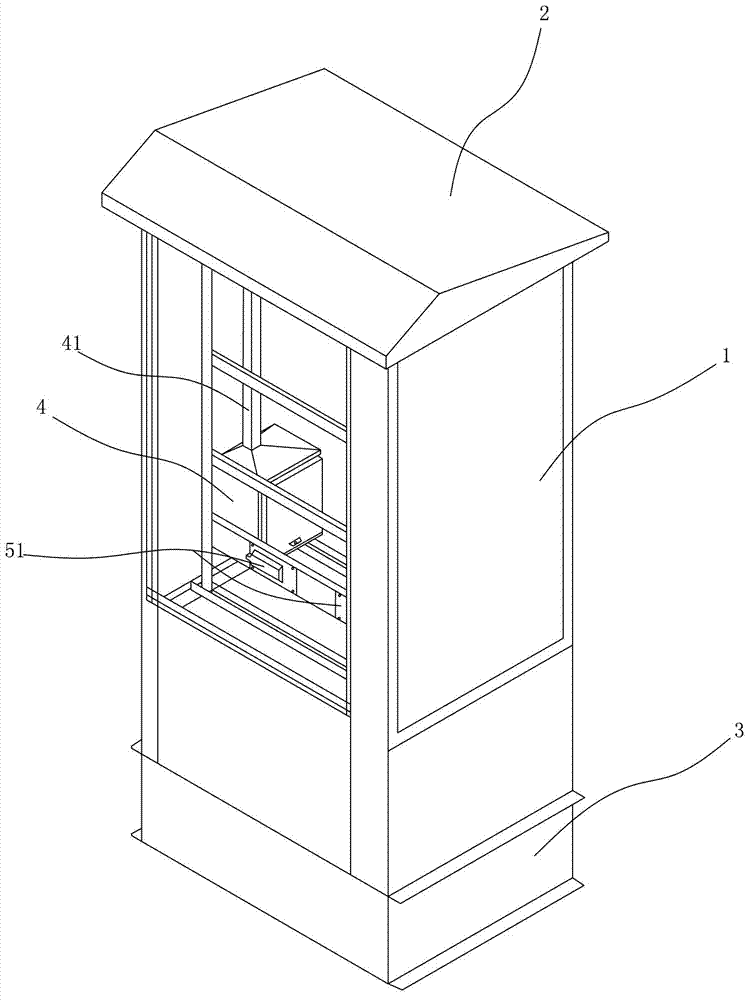

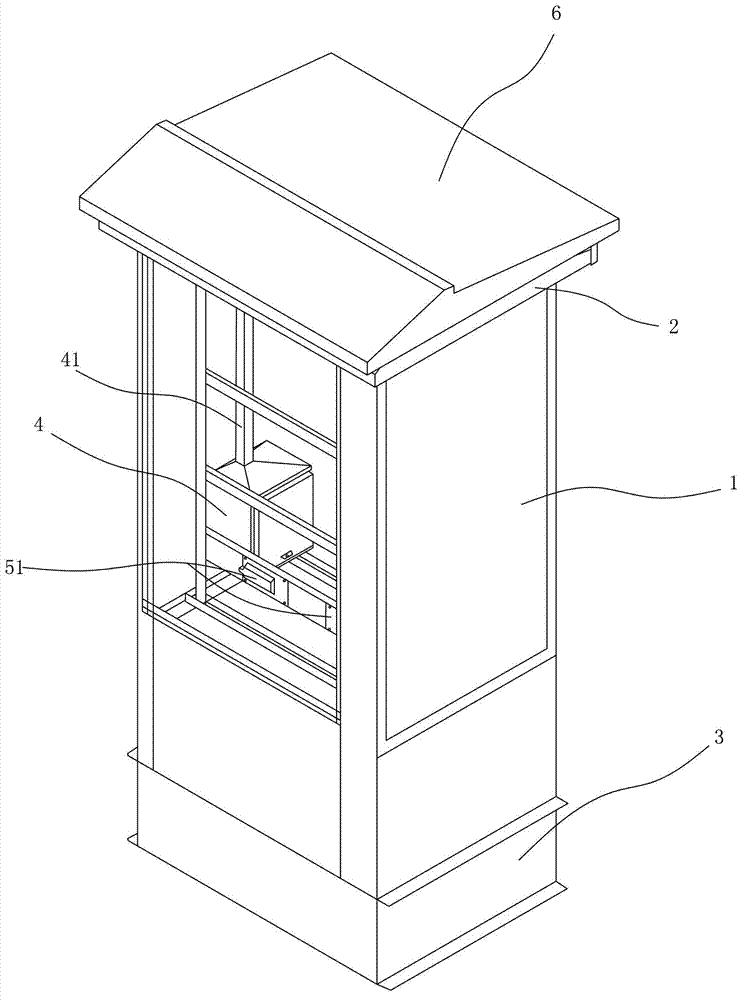

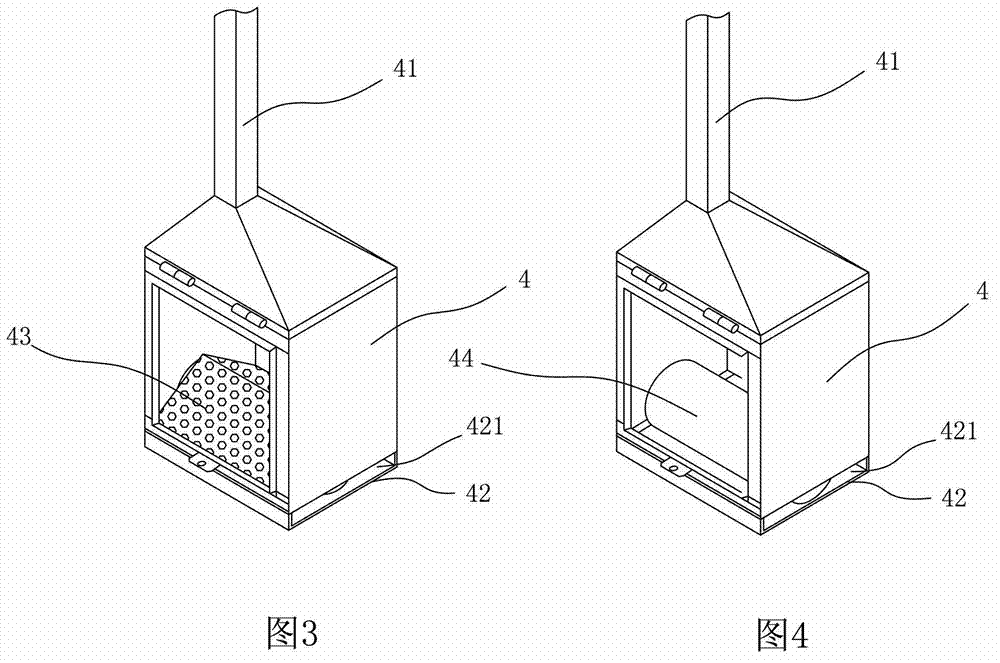

InactiveCN103689812ASimple structureFully heatedTobacco devicesElectronic cigaretteAlternating current

The invention discloses a smoke generator and an electronic cigarette with the same. The smoke generator comprises a shell and a heating component. The shell is provided with a smoke inlet hole and a smoke outlet hole, and the heating component is arranged in the shell. The shell is further provided with an accommodating area used for storing smoke generating materials. The heating component comprises a metal component and an induction coil wound on the periphery of the metal component. Two ends of the induction coil are connected with an alternating-current power source. The heating component is used for directly heating the smoke generating materials in the accommodating area or permeating from the accommodating area to enable the smoke generating materials to generate smoke which is then exhausted from the smoke outlet hole. Compared with smoke generators with conventional atomizing modes, the smoke generator has the advantages that the smoke generating materials are atomized by a heating mode in which vortexes are generated through electromagnetic induction, so that the smoke generator is large in heating area, full in atomization and the like.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Electronic cigarette

ActiveUS9603389B2Increase surface areaPromote atomizationTobacco devicesInhalatorsElectronic cigaretteEngineering

An electronic cigarette is provided, which includes: a housing, a liquid reservoir, and an atomizer assembly. The housing has a chimney formed therein; the liquid reservoir is used for storing liquid; the atomizer assembly received in the housing. The atomizer assembly includes a heating plate capable of absorbing liquid. An outer surface of the heating plate is in contact with the air in the chimney.

Owner:SHENZHEN SMOORE TECH LTD

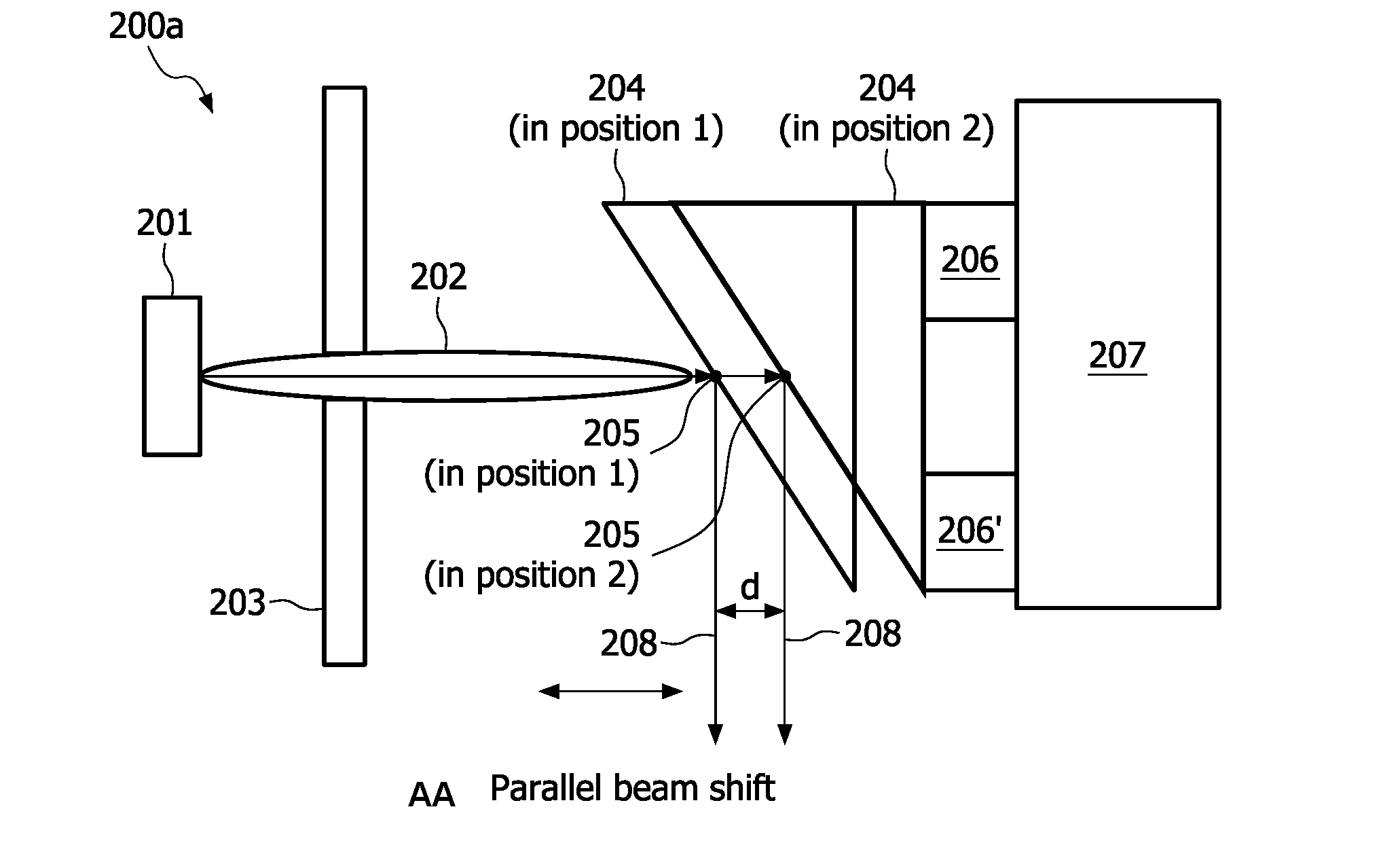

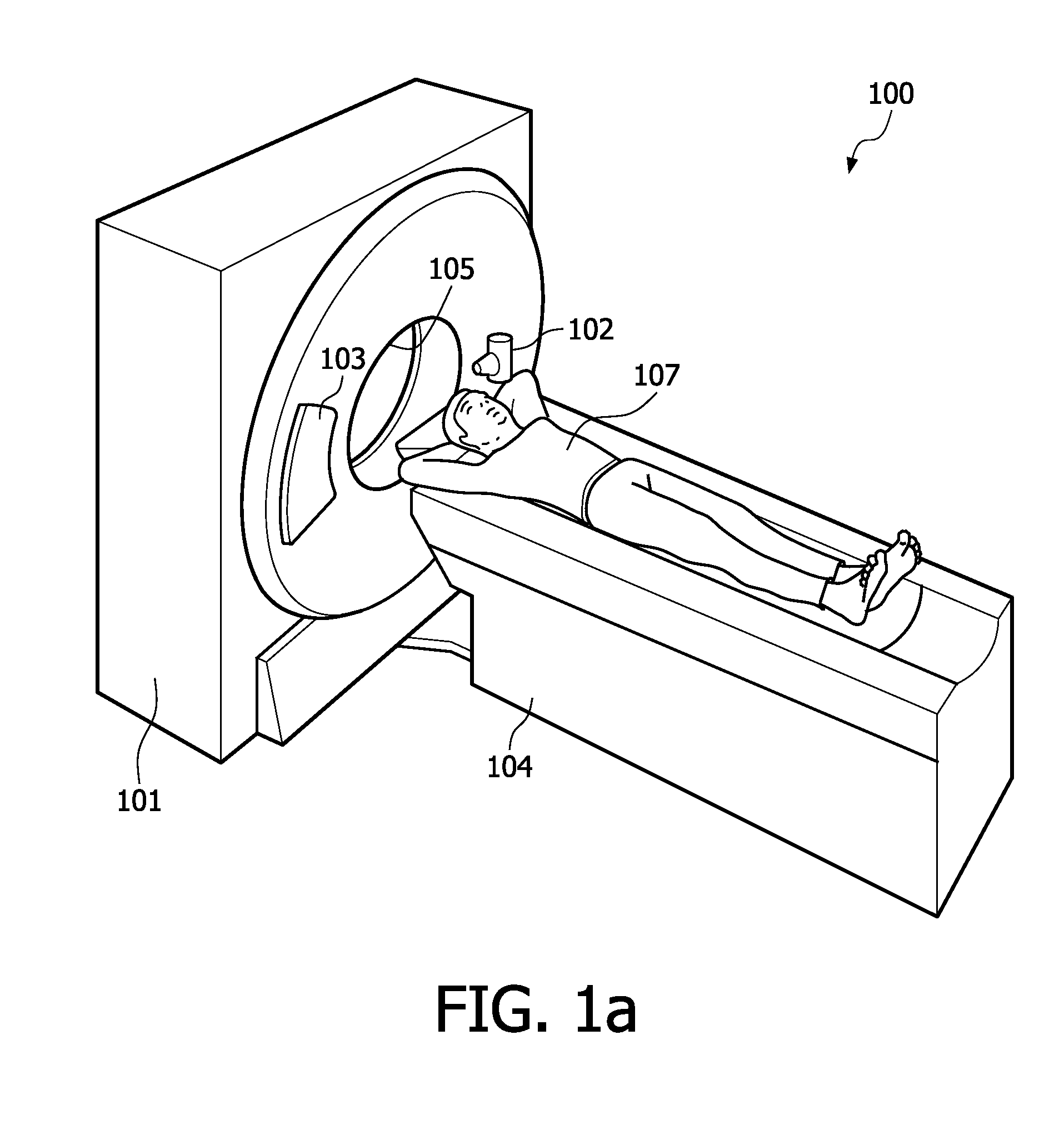

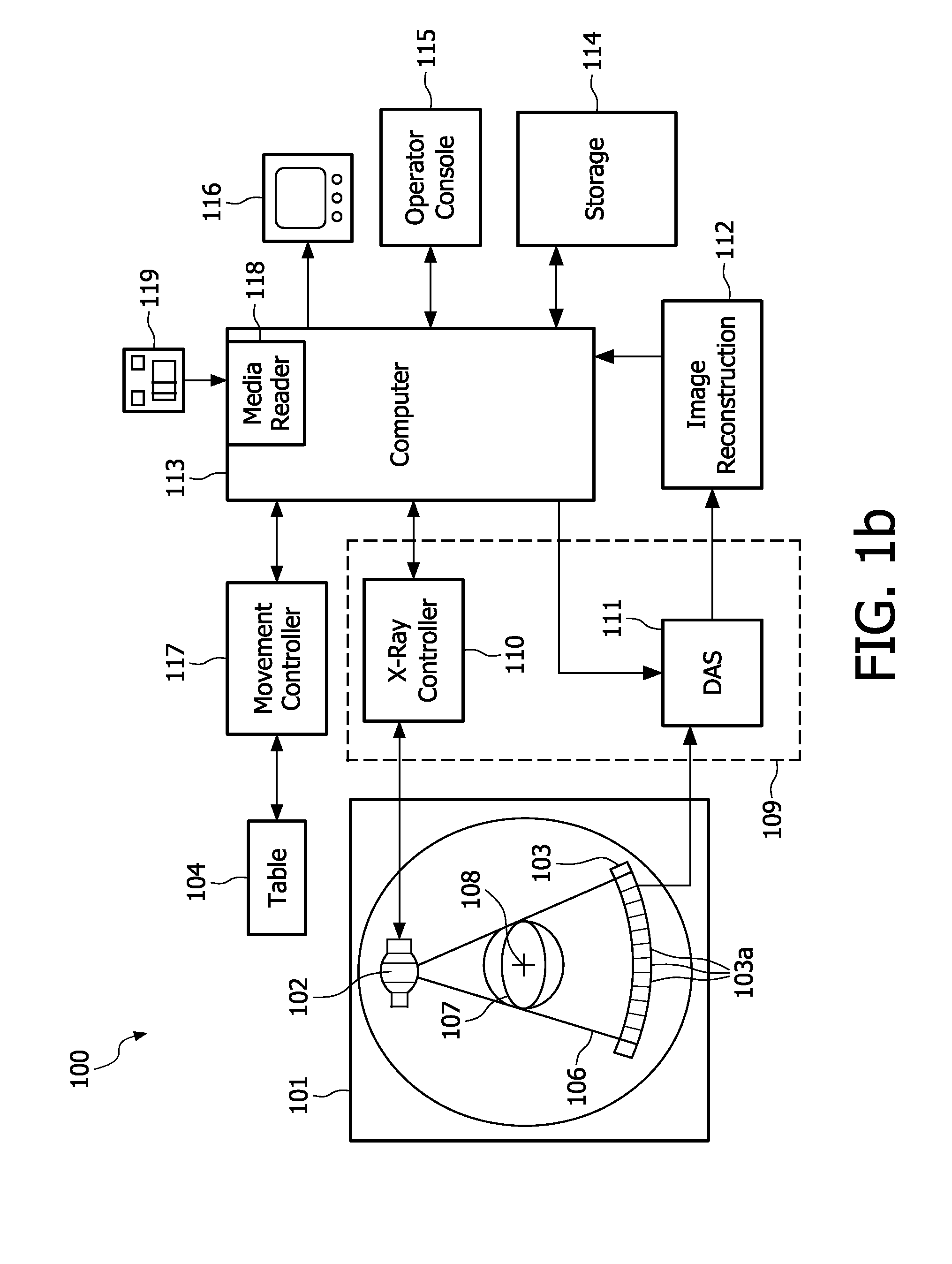

X-ray system with efficient anode heat dissipation

InactiveUS20110051895A1Increase the heating areaIncrease powerX-ray tube electrodesCathode ray concentrating/focusing/directingHigh resolution imagingX-ray

X-ray systems for use in high-resolution imaging applications with an improved power rating are provided. An X-ray source comprises at least one integrated actuator unit (206, 206′, 206a or 206b) for performing at least one translational and / or rotational displacement by moving the position of the X-ray source's anode (204, 204′, 204a′ or 204b′) relative to a stationary reference position. This helps to overcome power limitations due to an overheating of the anode at its focal ̂spot position (205). In addition to that, a focusing unit (203) for allowing an adapted focusing of the anode's focal spot (205) which compensates deviations in the focal spot size resulting from said anode displacements and / or a deflection means (211, 21 Ia or 21 Ib) for generating an electric and / or magnetic field deflecting the electron beam (202, 202a or 202b) in a direction opposite to the direction of the rotary anode's displacement movement may be provided.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

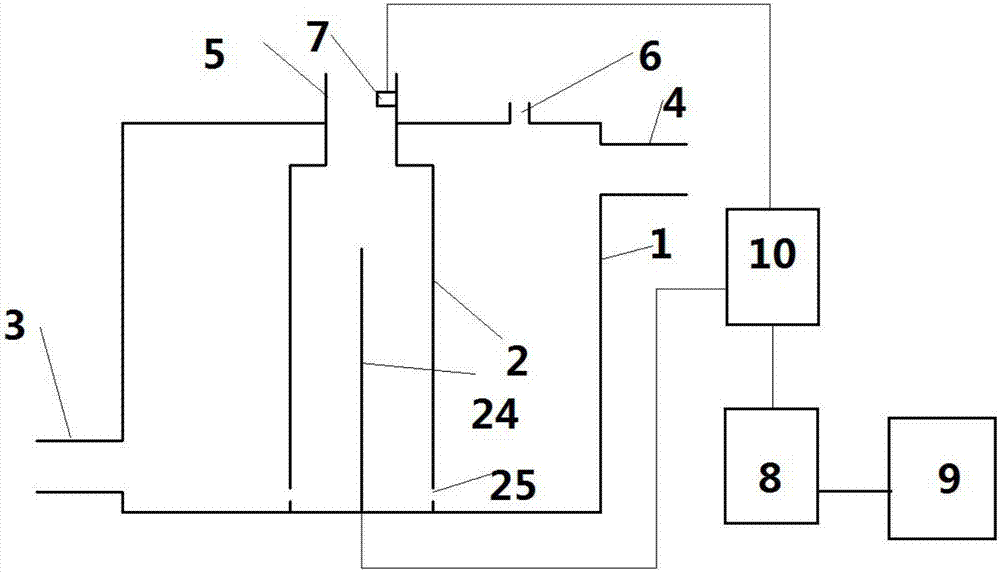

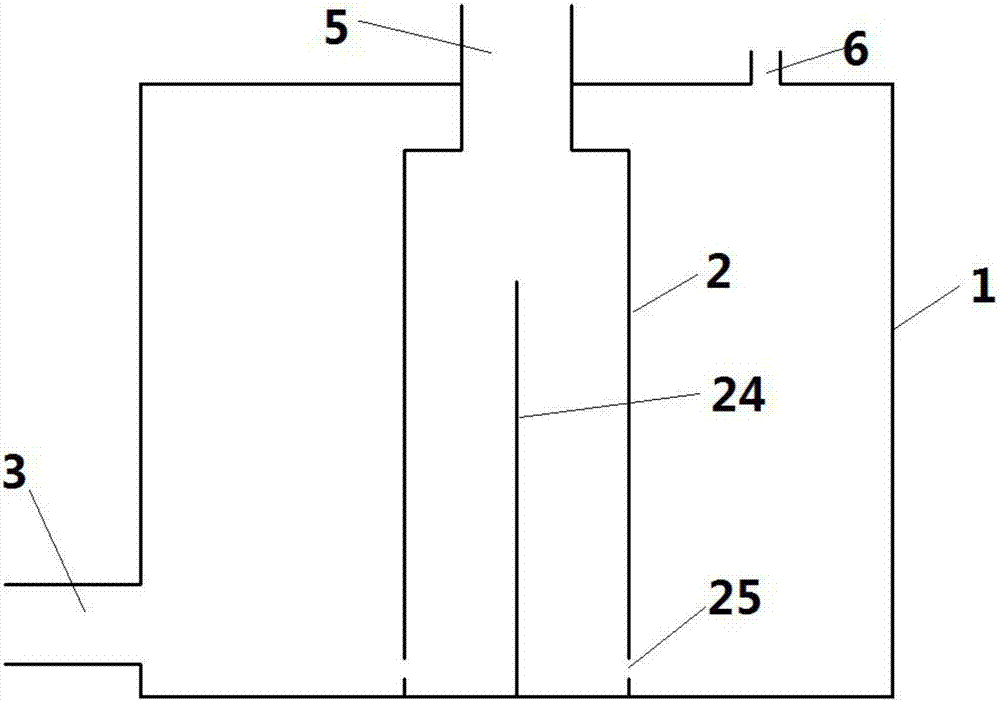

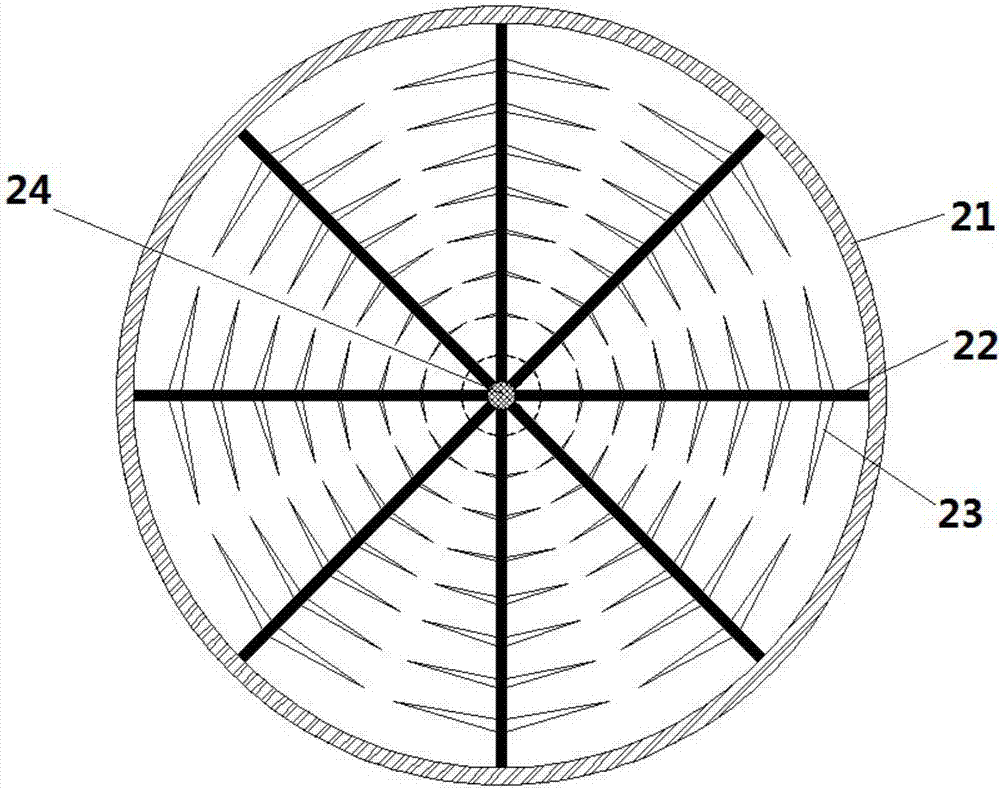

Vapor generator for intelligently controlling vapor temperature

ActiveCN107327821AEnergy savingImprove securitySteam generation heating methodsEnergy industryVapor generatorElectric heating

The invention provides a vapor generator for intelligently controlling vapor temperature. The vapor generator comprises a box, an electric heating pipe, a cold water inlet and a vapor outlet. The cold water inlet is formed in the side wall of the box. The upper portion of the box is provided with an exhausting opening. The electric heating pipe is arranged in the box and comprises an outer pipe and an electric heater arranged in the outer pipe. The electric heating pipe is arranged in the vertical direction. A water input channel is formed in the lower portion of the electric heating pipe to ensure that water in the box can enter the electric heating pipe to be heated. The upper portion of the electric heating pipe is connected with the vapor outlet. The vapor outlet is provided with a temperature sensor and used for measuring temperature of the vapor outlet. The temperature sensor, the electric heating device and a controller are in data connection. The vapor generator of the new structure is designed, vapor can be generated fast and efficiently, moreover, the vapor generator has the beneficial effects of carrying out heating fast, enabling temperature distribution to be uniform and being safe and reliable, and the heating efficiency is improved.

Owner:安徽省皖晨电子科技有限公司

Cigarette column applicable to low-temperature cigarettes

ActiveCN105614945AEasy to addEasy to removeTobacco treatmentTobacco devicesHeat conductingEngineering

The invention discloses a cigarette column applicable to low-temperature cigarettes. The cigarette column comprises the following components in parts by weight: 100 parts of tobacco particles, 0.05-2.0 parts of tobacco essence, 1-15 parts of heat-conducting component and 1-20 parts of bonding agent. The cigarette column is wholly cylindrical or disc-shaped, the size of the cigarette column is slightly smaller than that of a tobacco filling cavity of the existing smoking set for the low-temperature cigarettes, so that the addition is easy, and the removal is also easy; a large amount of pores are formed inside, so that the suction is easy, simultaneously the heated area and the heated uniformity of the suctioning material can be improved and smoke can be rapidly formed at a lower temperature; and the cigarette column contains the heat-conducting component, so that the heat conduction in the cigarette column can be greatly accelerated in suction, and the cigarette column is beneficial to improving the heat uniformity and rapidly forming smoke.

Owner:CHINA TOBACCO HUNAN INDAL CORP

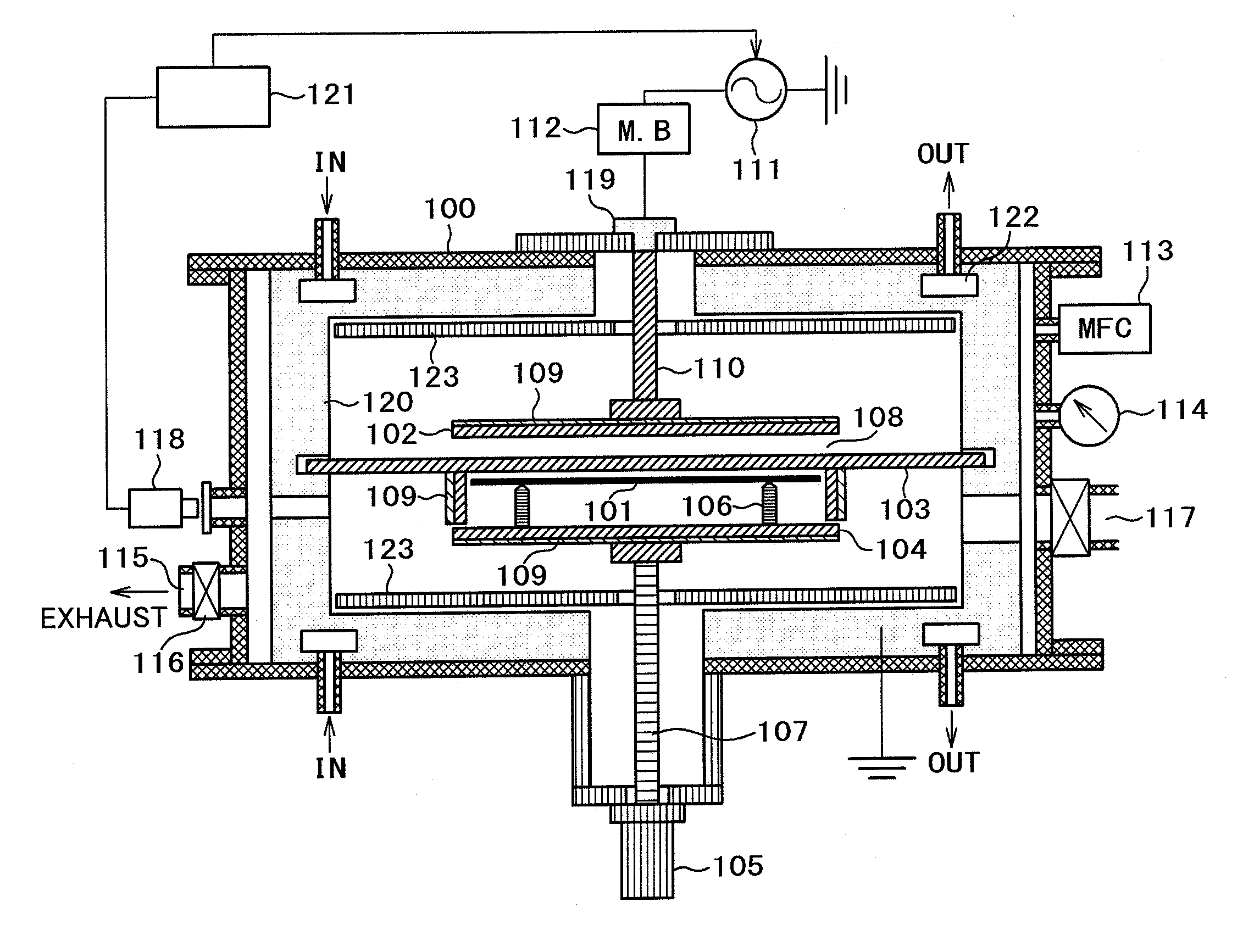

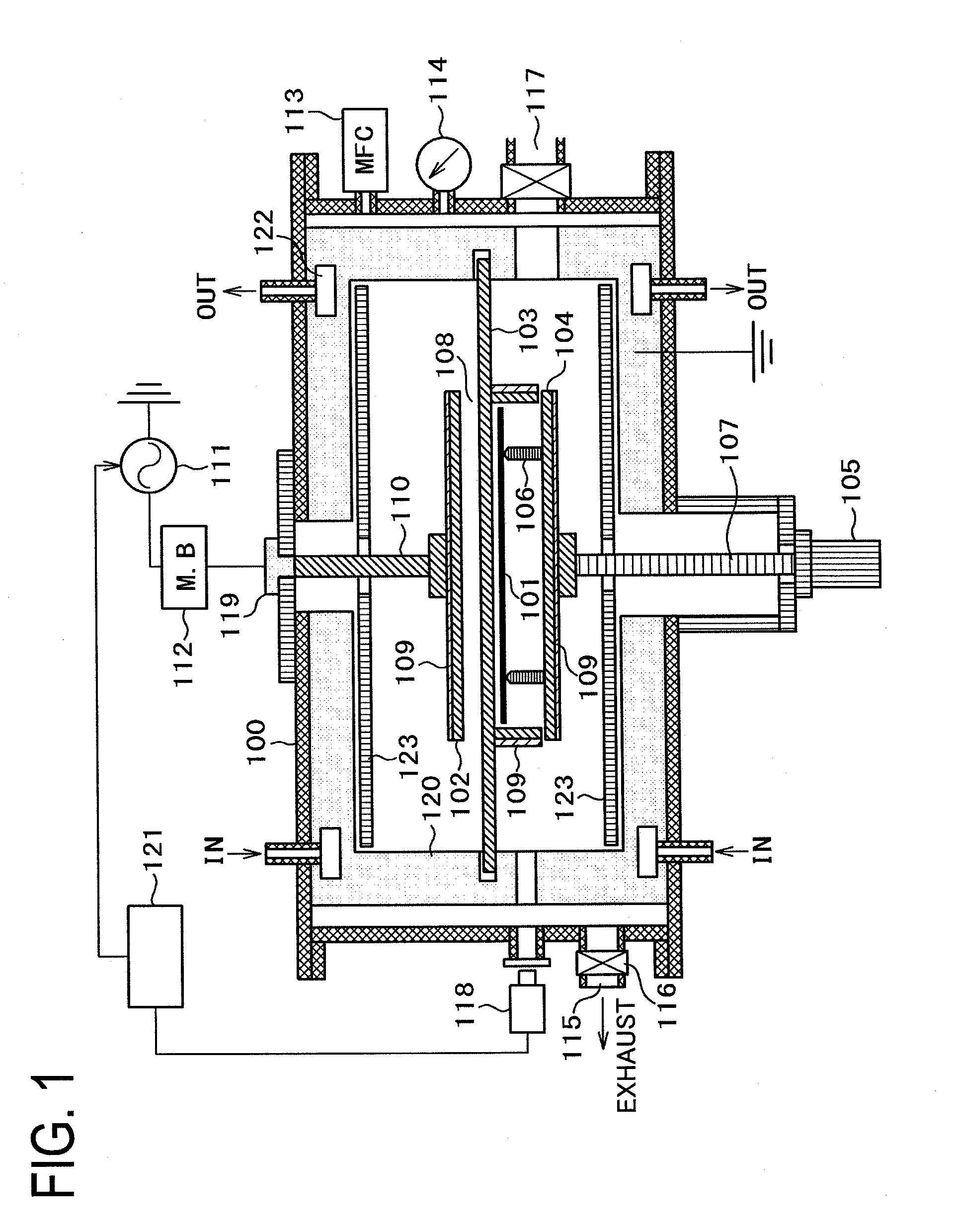

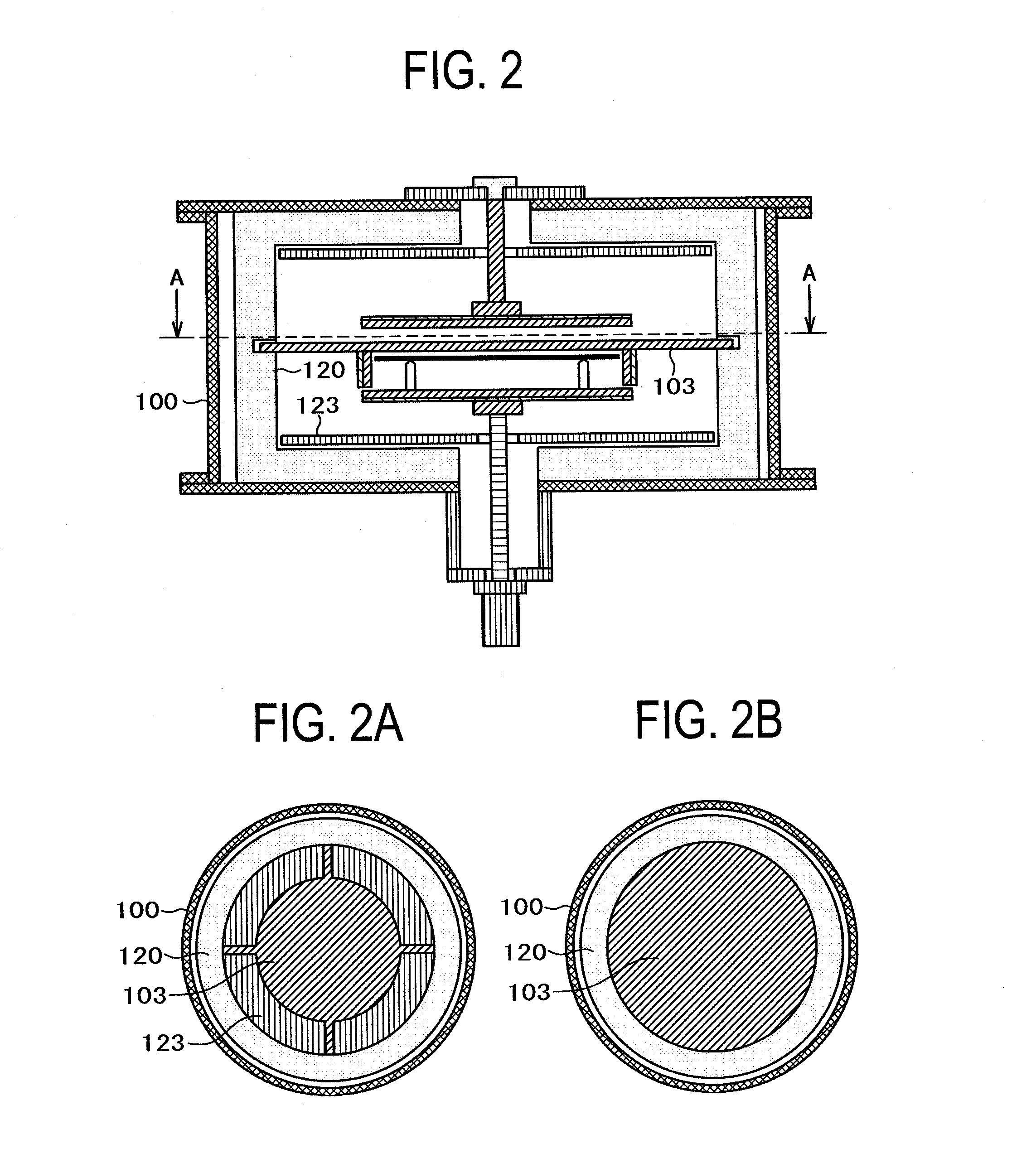

Heat treatment apparatus

ActiveUS20130112670A1High thermal efficiencyReduce surface roughnessElectric discharge tubesSemiconductor/solid-state device manufacturingSurface roughnessThermal treatment

Provided is a heat treatment apparatus that is high in thermal efficiency and can reduce surface roughness of a substrate to be treated even when a specimen is heated at 1200° C. or higher.The heat treatment apparatus heating the specimen includes a heating plate heated by plasma formed in an area of a gap to heat the specimen.

Owner:HITACHI HIGH-TECH CORP

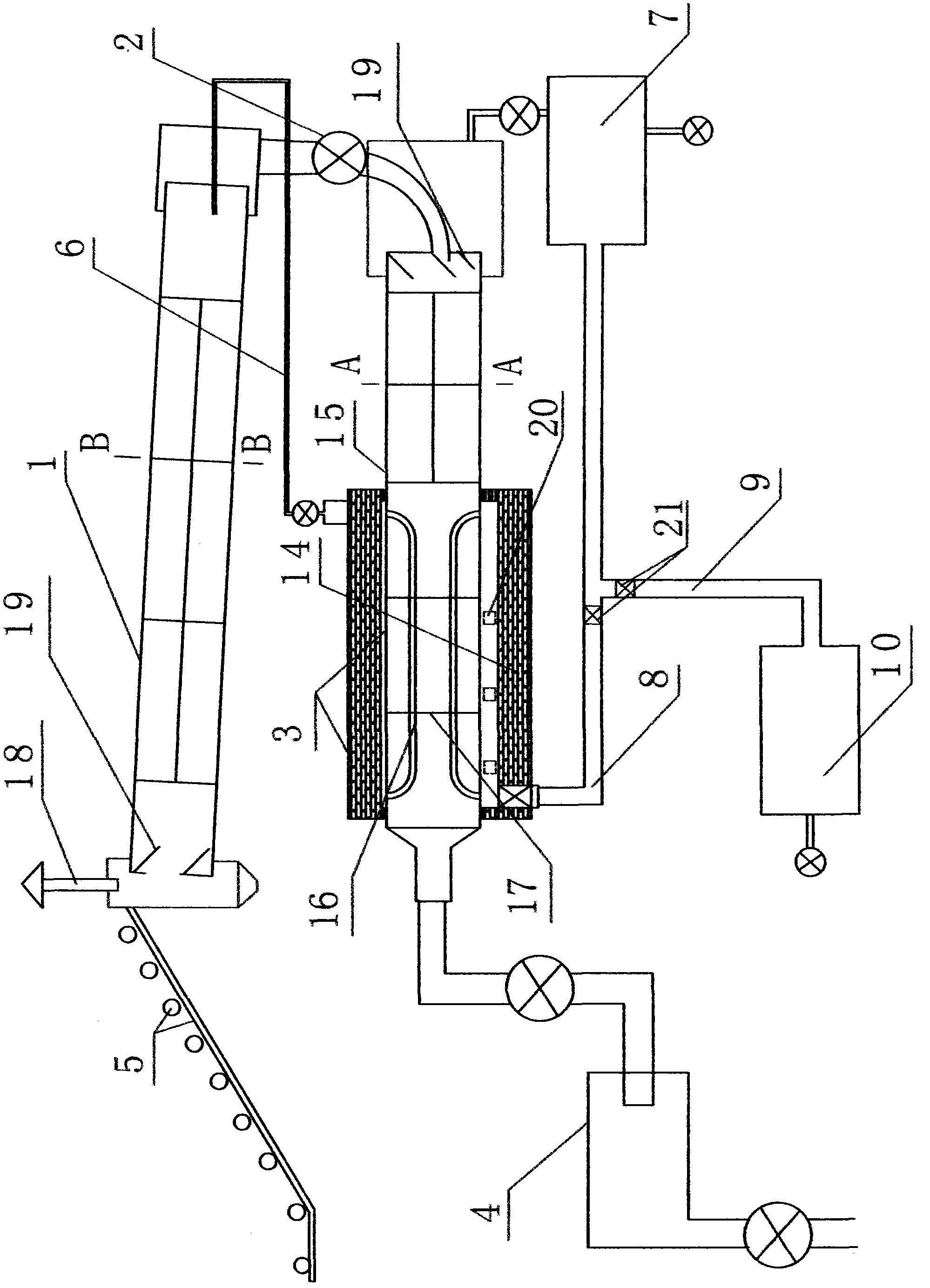

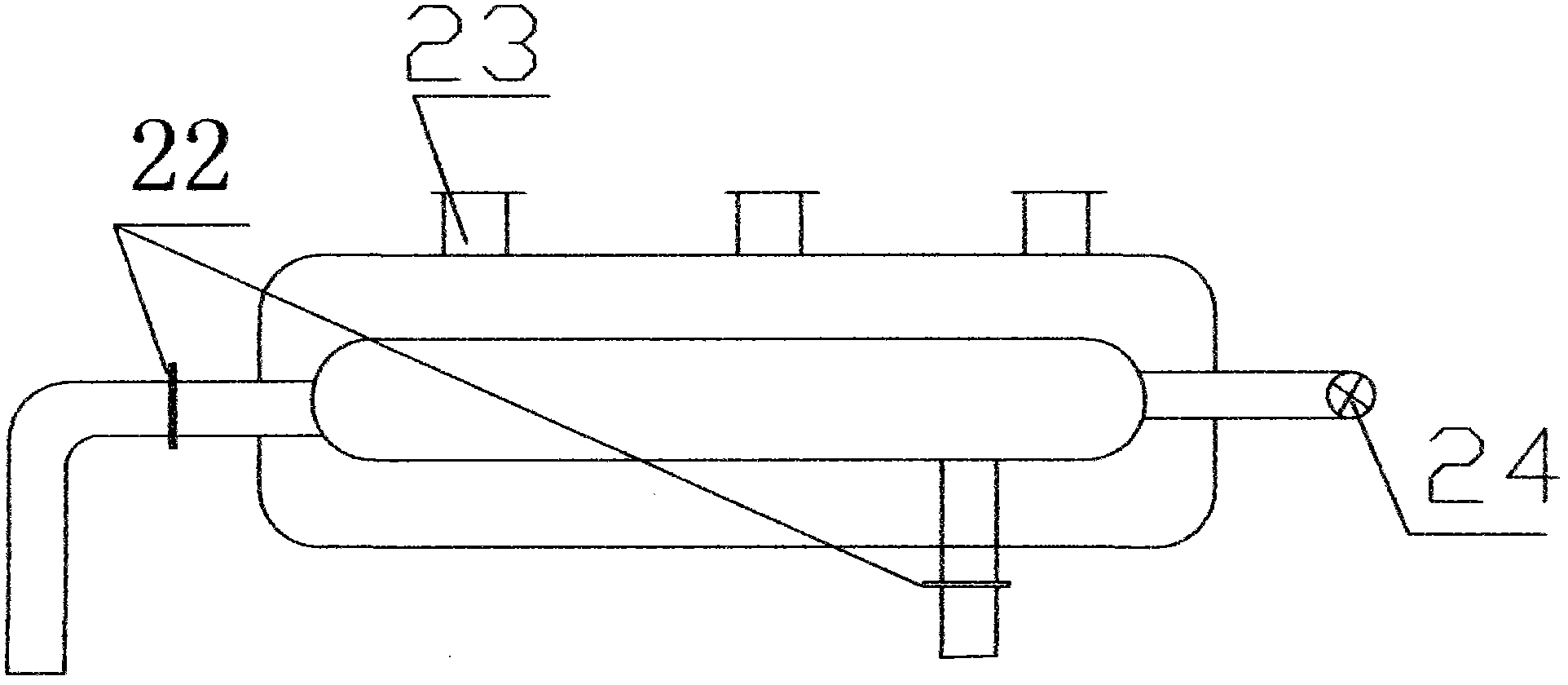

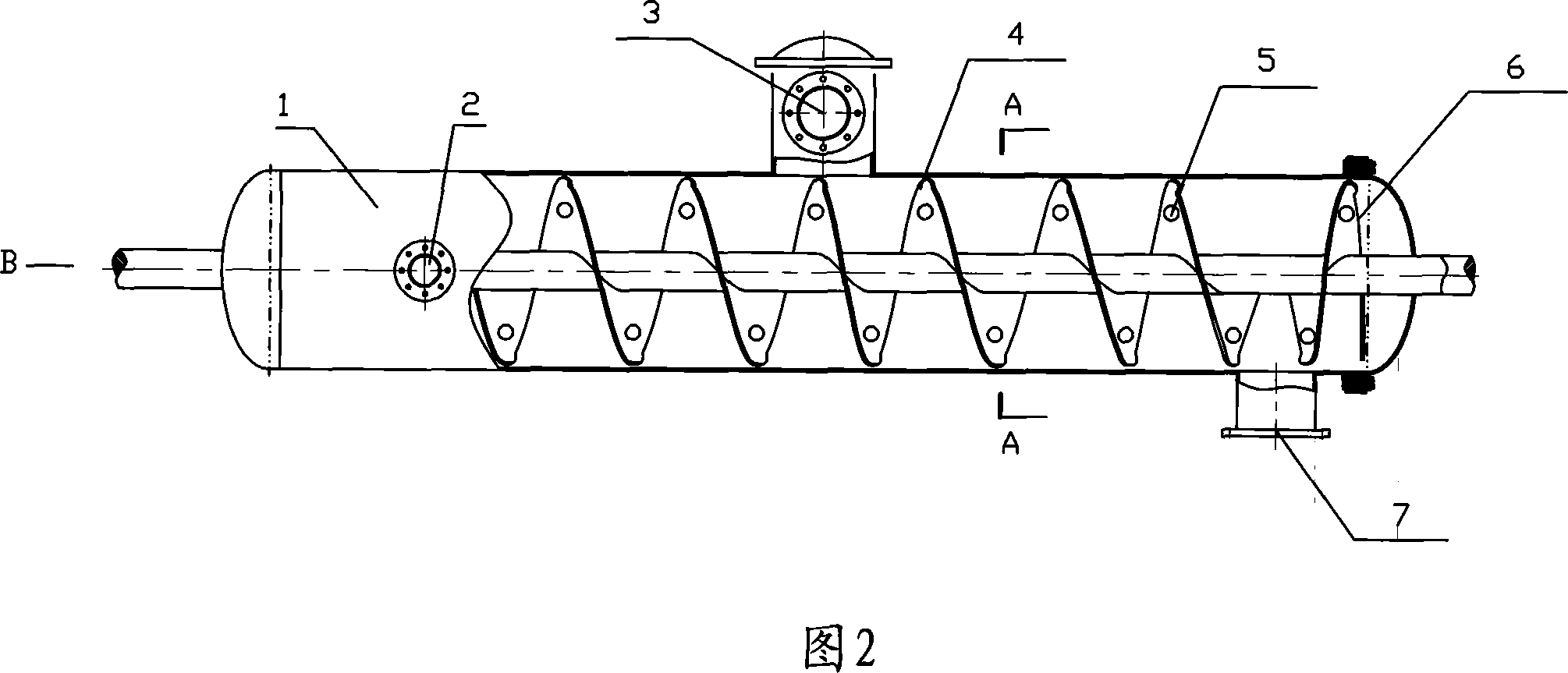

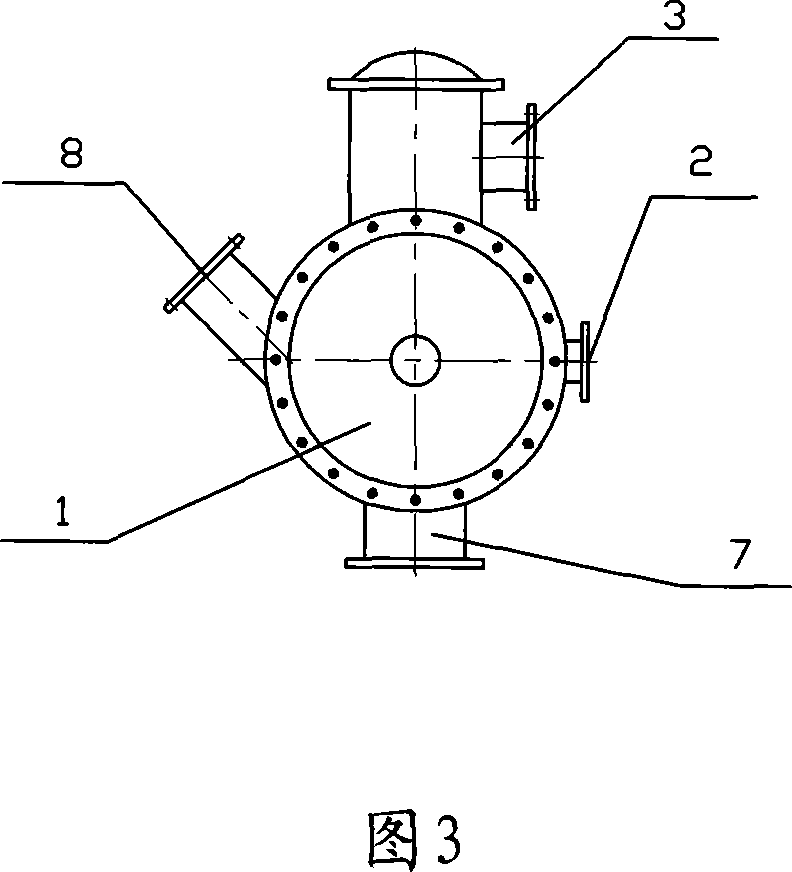

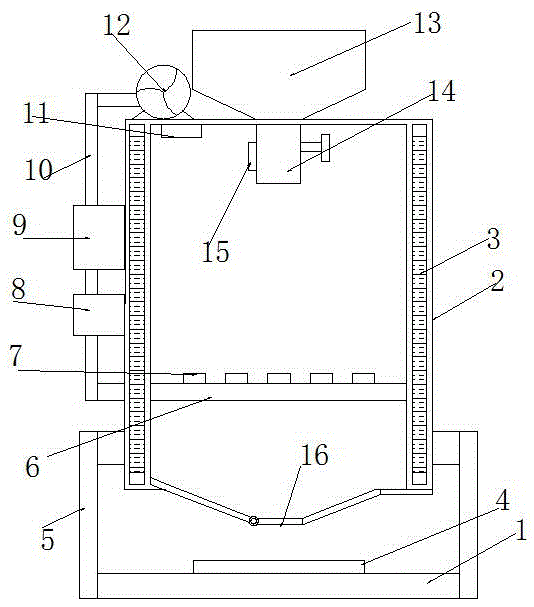

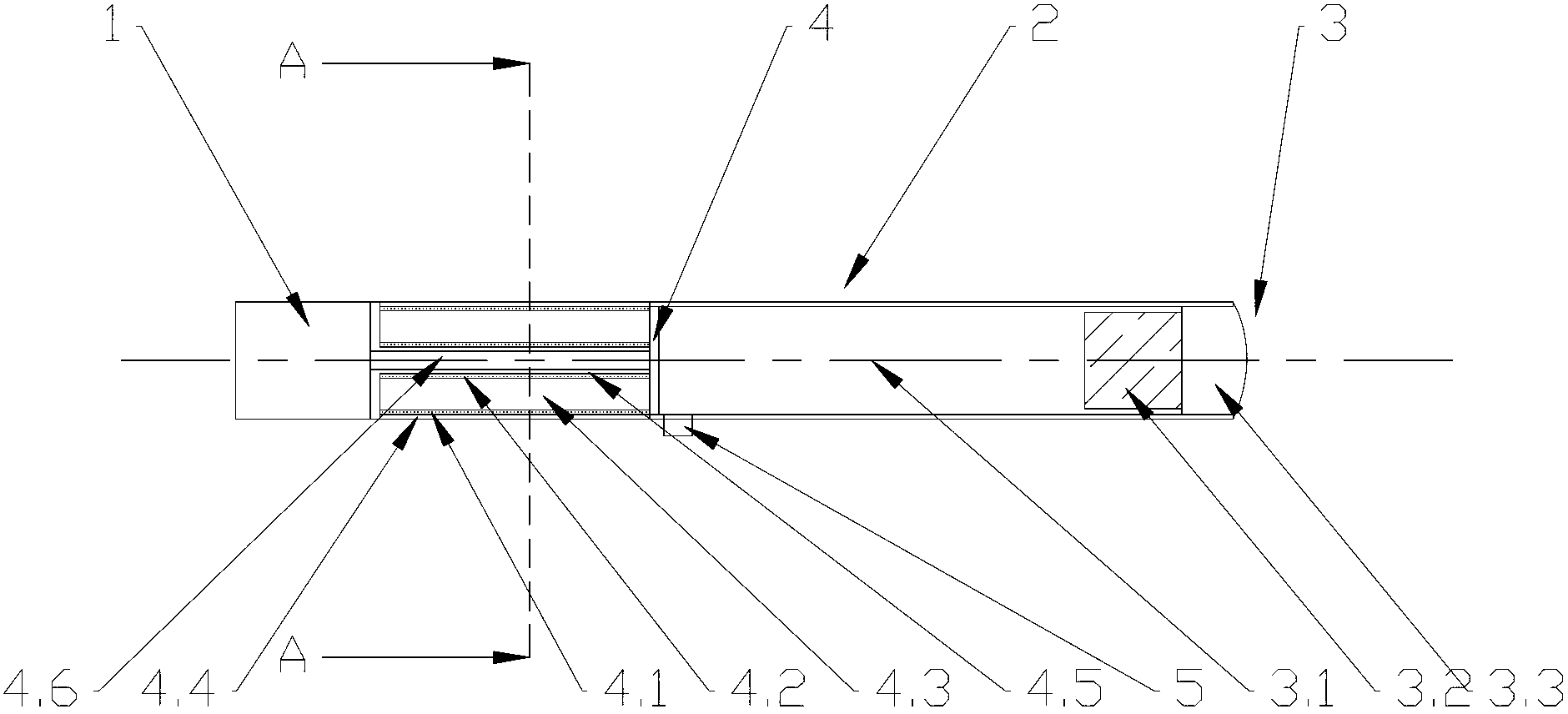

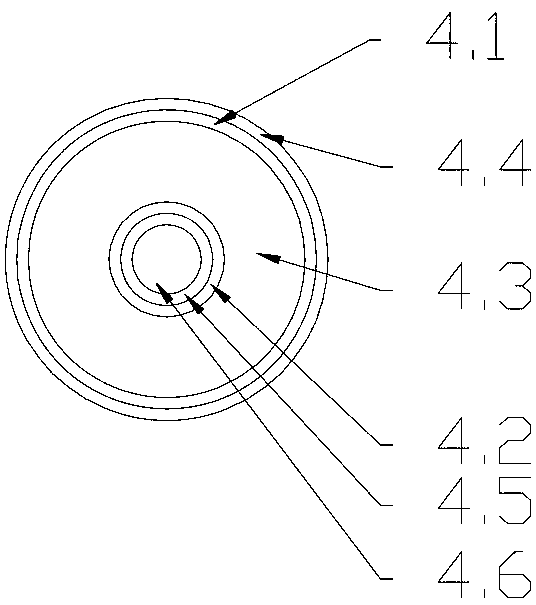

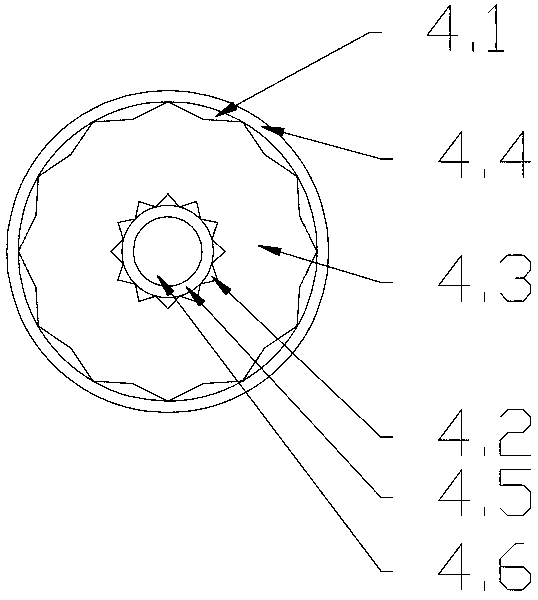

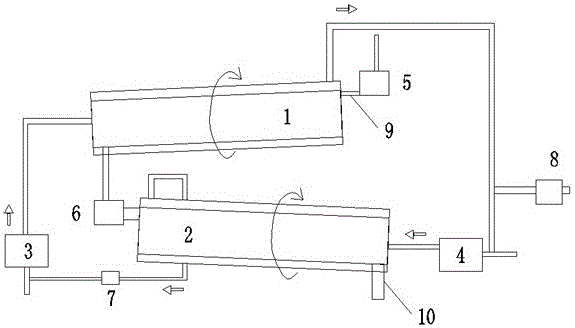

Continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment

ActiveCN102032553AImprove ergonomicsHigh thermal efficiencyDirect heating destructive distillationBiofuelsCombustion chamberEngineering

The invention discloses continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment. The equipment comprises raw material conveying equipment, a rotary drying furnace and a rotary charring furnace, and is characterized in that: the raw material conveying equipment is connected with the rotary drying furnace and connected with the rotary charring furnace through a star-like feeder; a material which is pyrolytically charred by the rotary charring furnace is discharged through a charred material outlet; the rotary charring furnace comprises a hearth and a rotary furnace; one path of high-temperature hot gas produced by combustion of an oxygen-containing combustion chamber is conveyed into the hearth of the rotary charring furnace through a flue to enter a charring section; the rotary furnace comprises a barrel, an inner heating tube and a baffle ring; one end head of the inner heating tube is fixed on the barrel wall on one side and passes through the baffle ring to be fixed on the barrel wall on the other side of the baffle ring; after the high-temperature hot gas passes through the hearth through the flue, certain high-temperature hot gas enters one end head of the inner heating tube, is discharged out of the other end head of the inner heating tube, enters a waste heat conveying pipe and is conveyed into the rotary drying furnace through an induced draught fan; and the high-temperature hot gas is conveyed into a biomass boiler through another flue. The equipment can improve the working efficiency of the rotary charring furnace.

Owner:FUJIAN TIANCHUANGLI BIOLOGICAL ENERGY EQUIP

Boiler furnace of circulating fluidized bed with water-cooled column

ActiveCN101196297AEvenly heatedIncreased hydrodynamic safetyFluidized bed combustionApparatus for fluidised bed combustionBoiler furnaceCirculating fluidized bed boiler

The invention relates to a circulating fluid bed boiler furnace with water-cooled posts, which is characterized in that: the water-cooled posts arranged in the boiler furnace are able to provide enough heating area; meanwhile, enough space is left between posts for mixing materials at lower section of the boiler furnace, so as to ensure the concentration, temperature and the evenness of heat transfer; the heating status of the heat face of the water-cooled posts and the wall around the boiler furnace are similar, which is particularly beneficial for enhancing the hydrodynamic force safety of supercritical circulating fluidized bed boiler furnace. The water-cooled posts are able to be internally provided with dusts being able to through with secondary winds at the central area of the boiler furnace. The invention arranges the vertical water-cooled posts encircled by film walls between boiler furnace grid plate and a ceiling and working substance are provided from up to down in the film wall pipe; the external side of the water-cooled post faces to the burning space of the boiler furnace.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

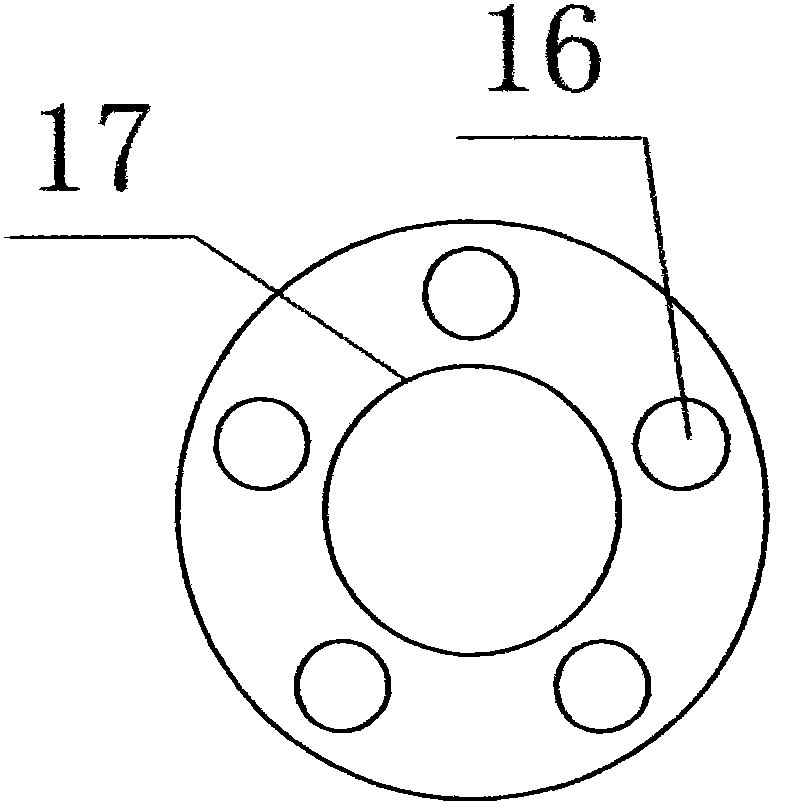

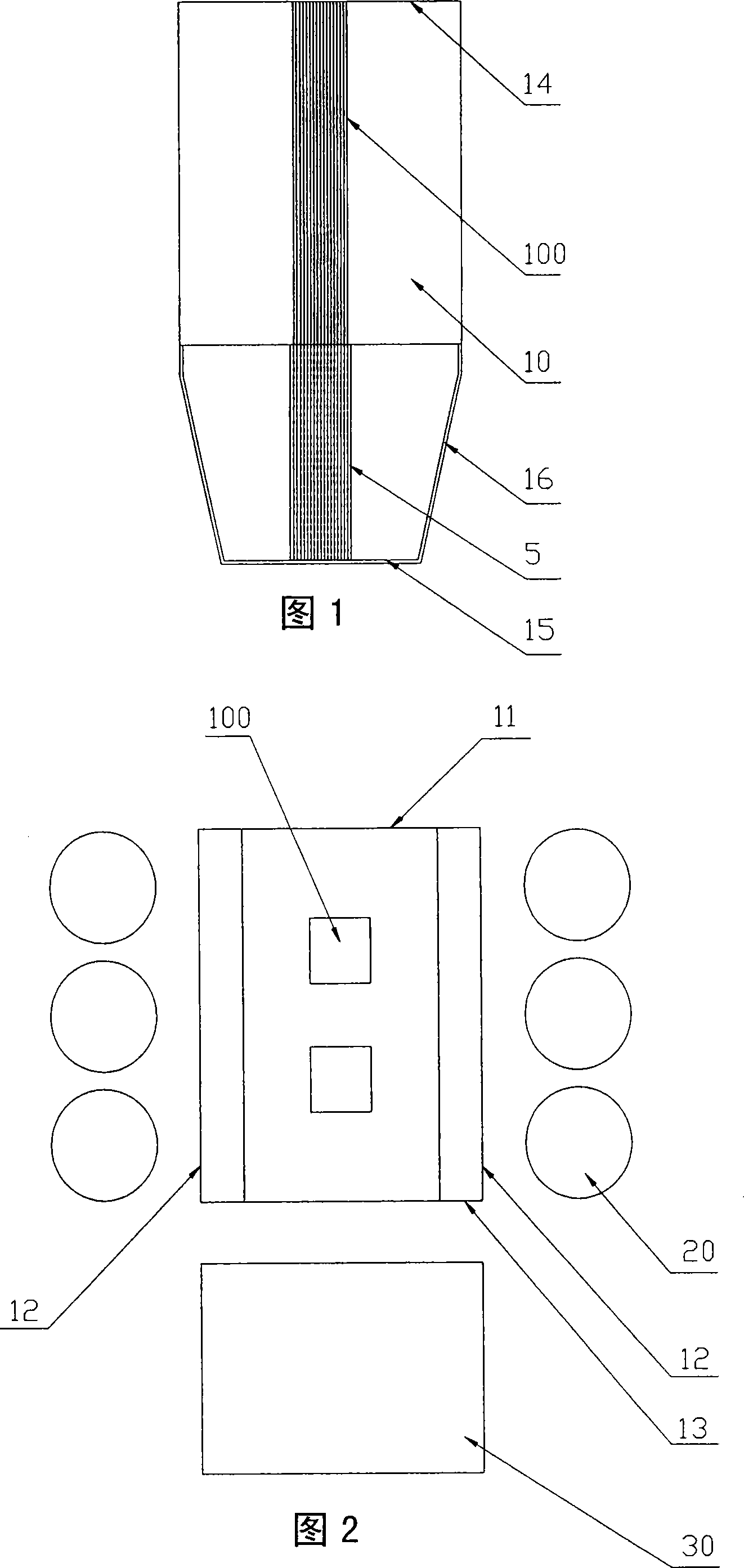

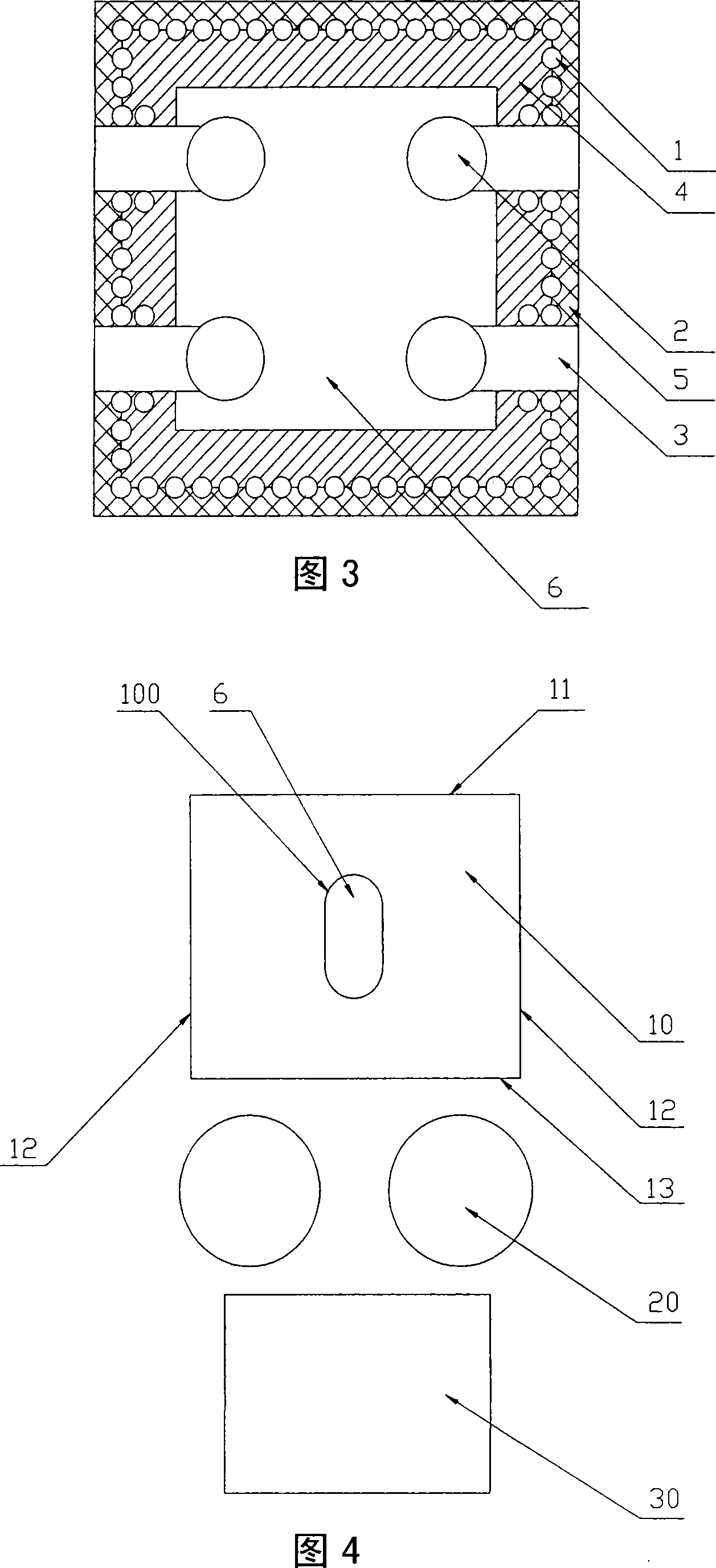

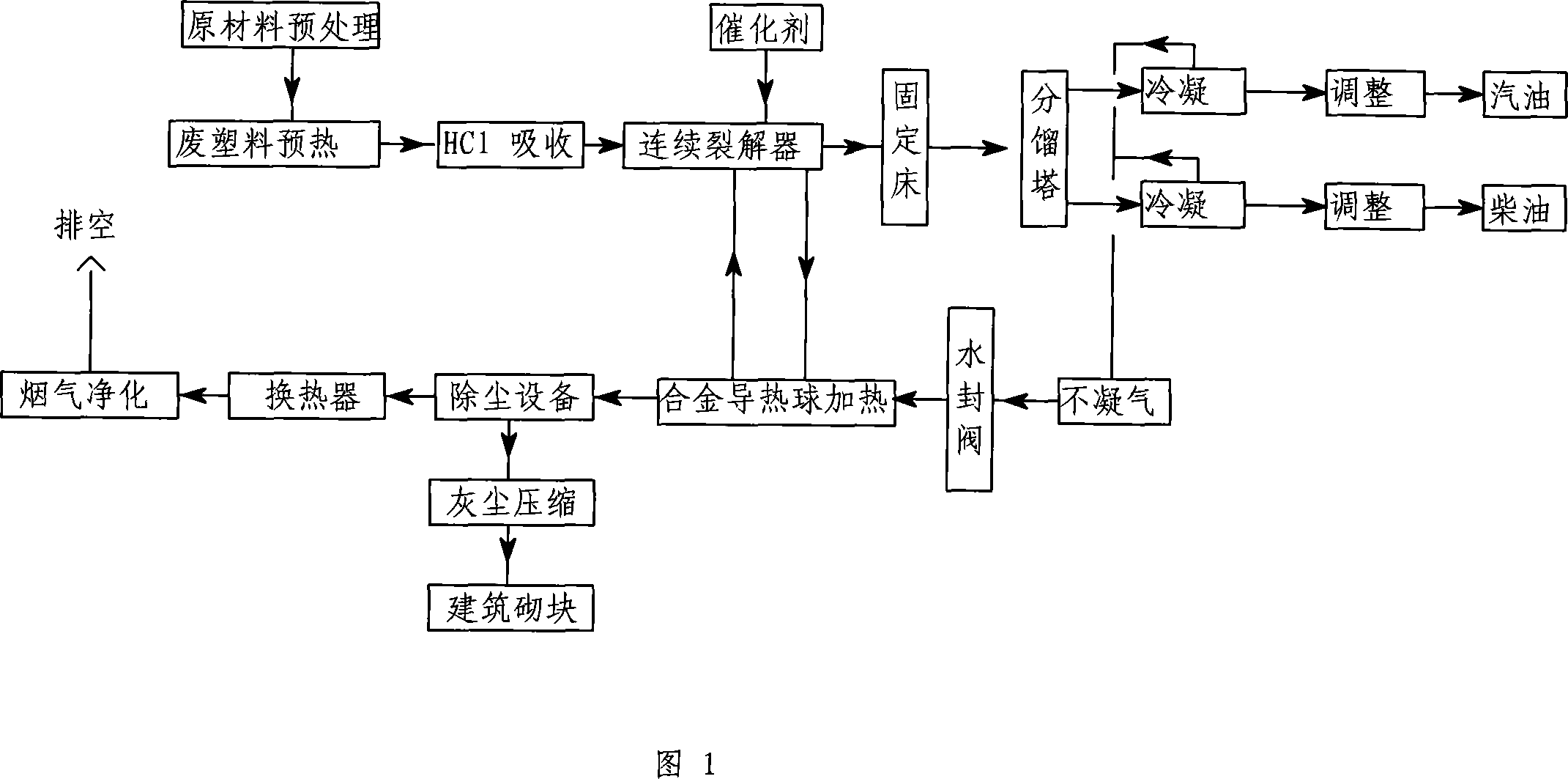

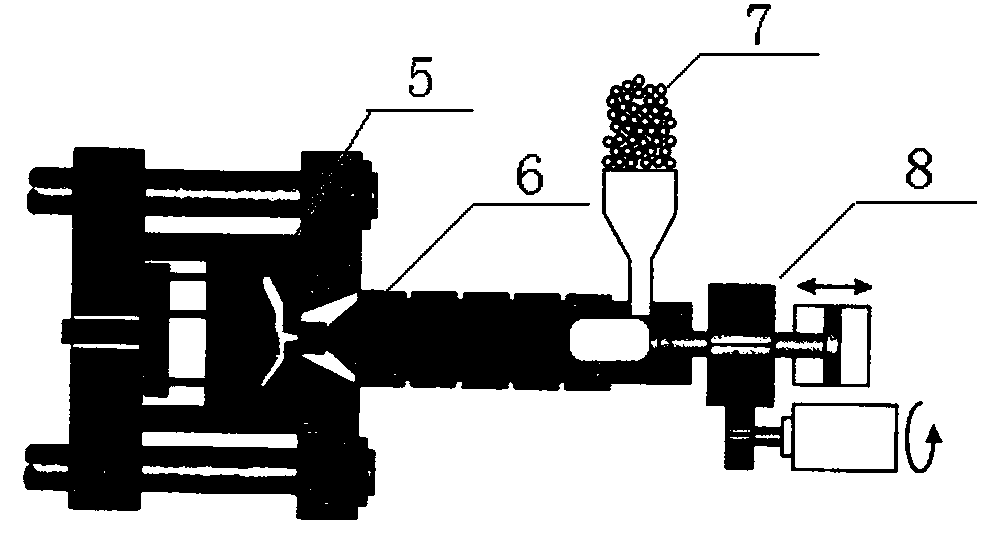

Waste-plastic continuous cracking process and cracker

ActiveCN101074385AFast responseImprove oil qualityLiquid hydrocarbon mixture productionExhaust gasHeat carrier

A process and apparatus for cracking plastic are disclosed. The process is carried out by mixing raw material with solid fluid heat carrier in cracker, moving co-currently, heating, while cracking continuously to obtain final product. Spiral impelling mechanism is arranged in casing, feed inlet and solid heat carrier inlet is arranged at front of casing; solid heat carrier and solid product outlet are arranged at rear of casing. It's cheap, automatic, efficient and convenient. It has no environmental pollution.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

Novel composite cooker and manufacturing method thereof

The invention provides a novel composite cooker which comprises a cooker body with the thickness of 1.5 mm-5.0 mm. The thickness of the cooker wall is successively and progressively decreased by the 2 mm-3 mm space from the upper portion of the plane of a cooker bottom to the edge of the cooker wall. The cooker body comprises an inner layer cooker body and an outer layer cooker body, the inner layer cooker body is made of one of iron, iron-base alloy, stainless steel, titanium and titanium alloy, the outer layer cooker body is made of aluminum alloy or pure aluminum or AZ31B magnesium alloy or magnesium alloy, and a magnetic conduction energy storage layer is pressed on the outer surface of the outer layer cooker body. The materials of the inner surface of the cooker is healthful and sanitary, the heat conduction performance of the outer surface of the cooker is good, the outer surface is light in material, the magnetic conduction energy storage layer is arranged on the outer portion of the cooker bottom, the heat collection effect of the cooker bottom is increased, cooking energy consumption is reduced, and the application range of the cooker is expanded. The invention further provides a manufacturing method of the novel composite cooker. The method is easy to operate, saves materials, reduces cost, and is convenient to implement and beneficial to industrialization of the novel composite cooker.

Owner:WUYI RUIPU KITCHENWARE CO LTD

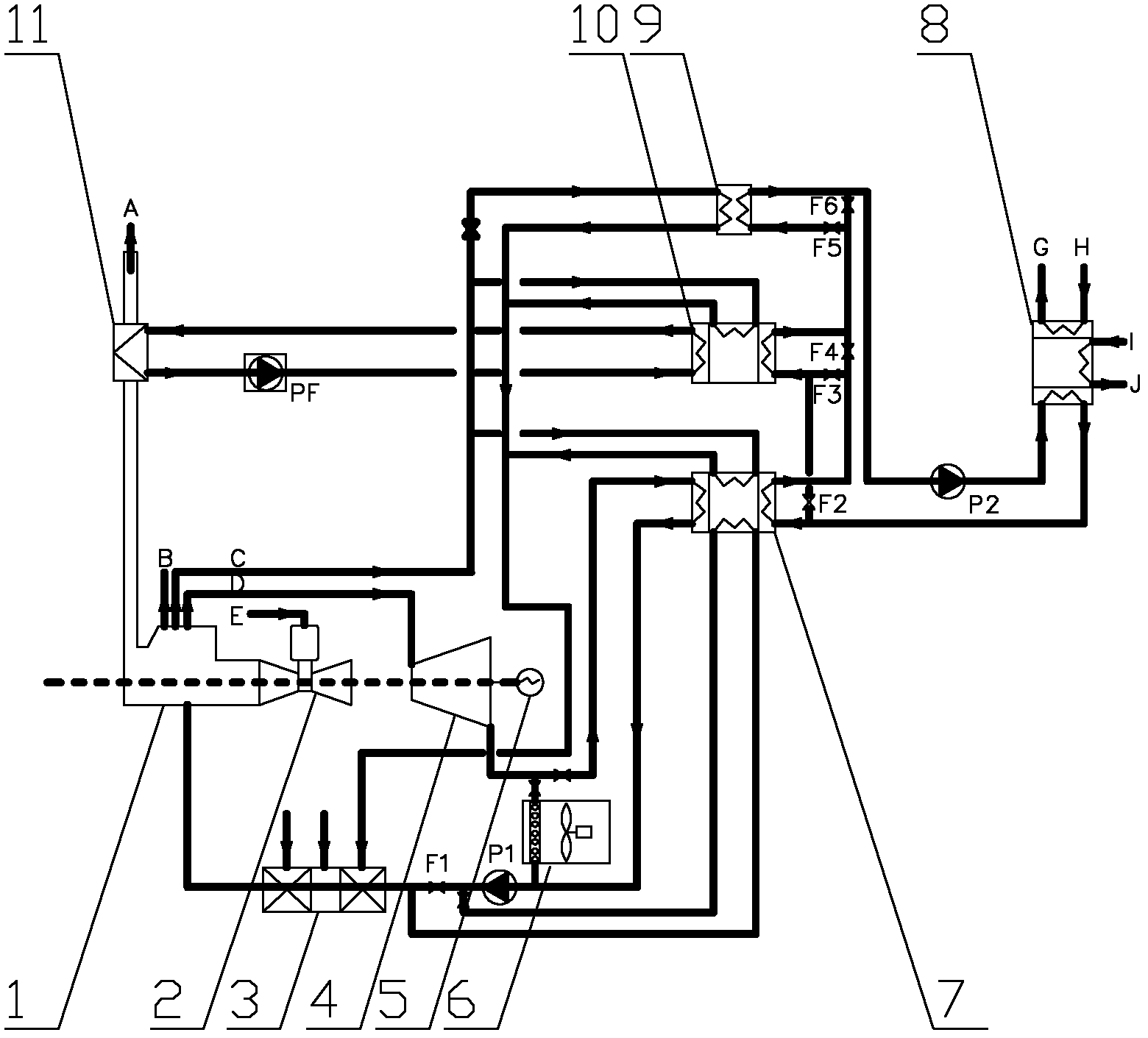

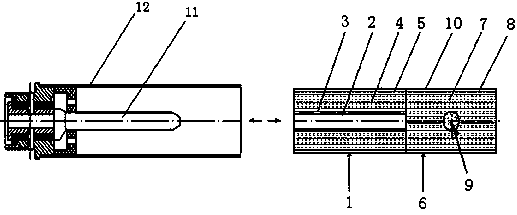

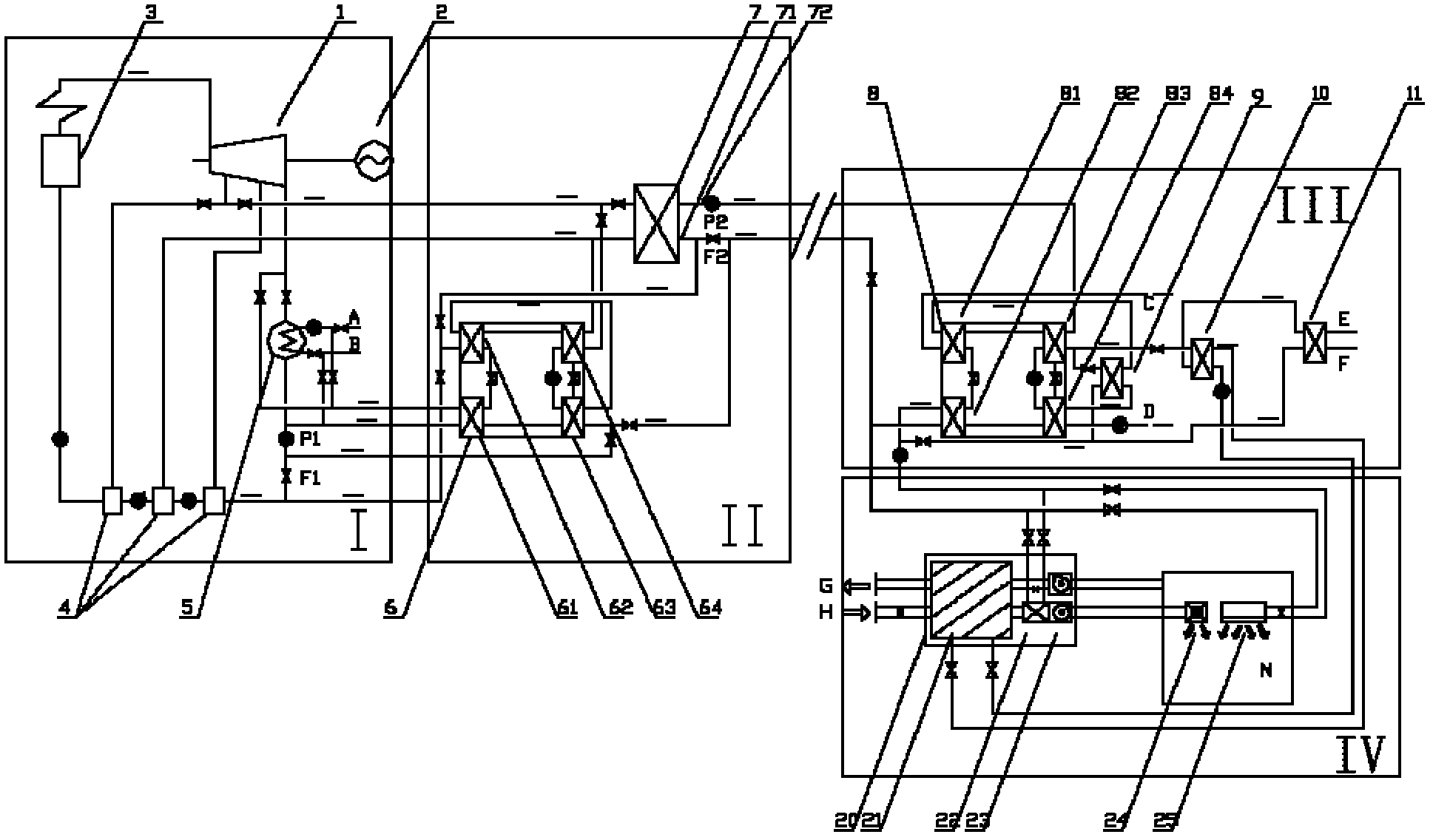

Gas-steam circulation heating-electricity-cooling combined supply system and method for thermal power plant with zero energy loss rate

InactiveCN102359739AIncrease the temperature difference between supply and return waterIncrease feed water temperatureHeat recovery systemsGas turbine plantsEffective energyFlue gas

The invention relates to a gas-steam circulation heating-electricity-cooling combined supply system and a gas-steam circulation heating-electricity-cooling combined supply method for a thermal power plant with zero energy loss rate and belongs to the technical field of gas-steam combined circulation heating-electricity-cooling combined supply. The gas-steam circulation heating-electricity-coolingcombined supply system comprises a heat-electricity combined circulation part, a large temperature difference adsorption waste steam recovery heat pump, a large temperature difference adsorption fluegas recovery heat pump, a flue gas condensation recovery acquisition device, an initial station steam-water heat exchanger, an adsorption heat pump / refrigeration all-in-one machine and the like, wherein the heat-electricity combined circulation part consists of a burning machine, a waste heat boiler, a steam turbine, a generator and the like. An operation regulating method for carrying out combination energy optimization on an integral thermal system, which is based on an adsorption heat-exchange waste heat recovery and large temperature difference heat supply technology and combines a climate compensation technology, is adopted, so that aiming at the characteristics of a gas-steam combined circulation system, the effect that the energy utilization efficiency for once of the thermal powerplant is close to, even exceeds 100 percent is realized. In the invention, energy resources at each energy grade are utilized to drive generating equipment, heating equipment and air-conditioning cold supply equipment, so that the energy-saving effect that compared with a flue gas low heating value, the effective energy output has no energy loss is achieved.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

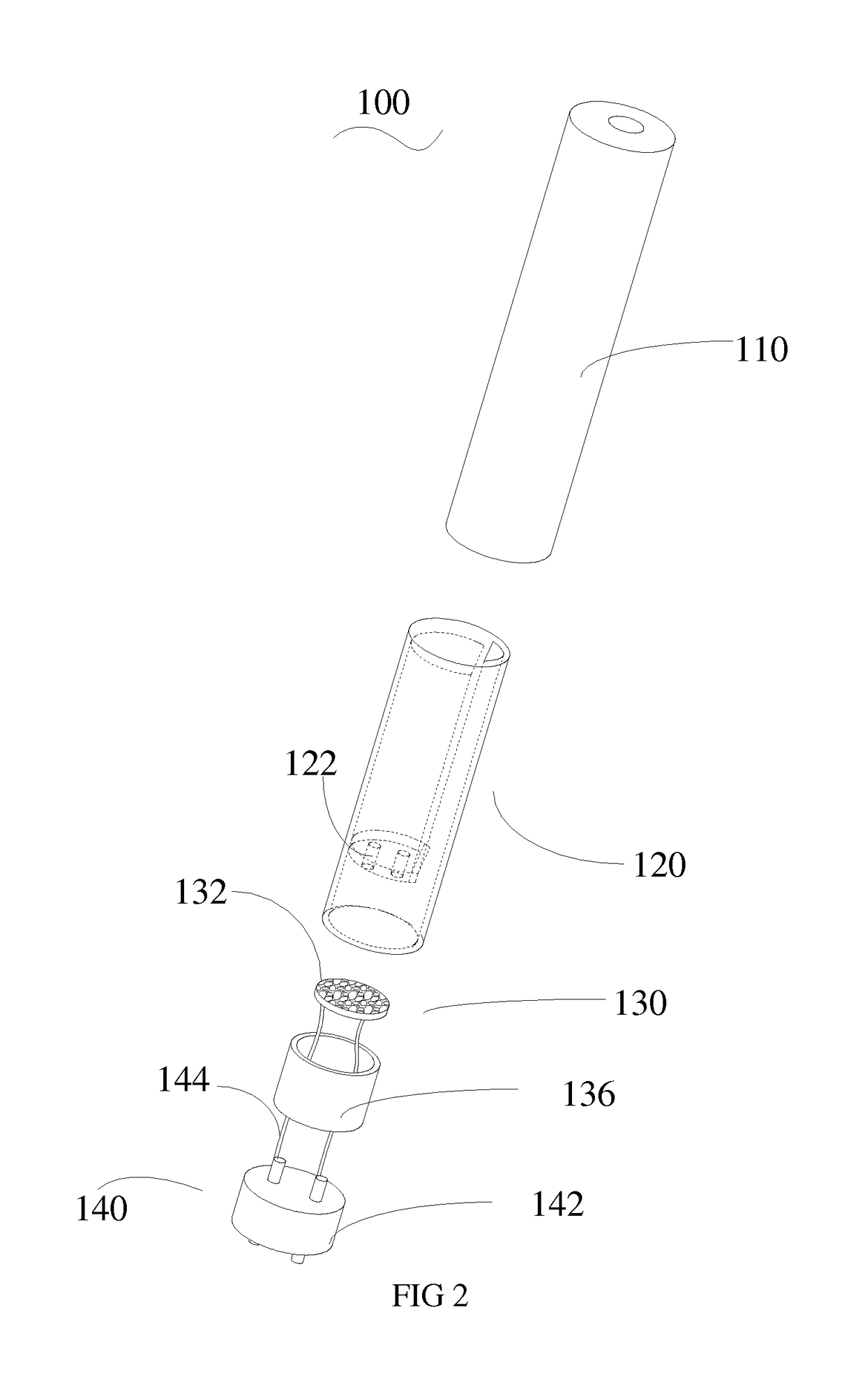

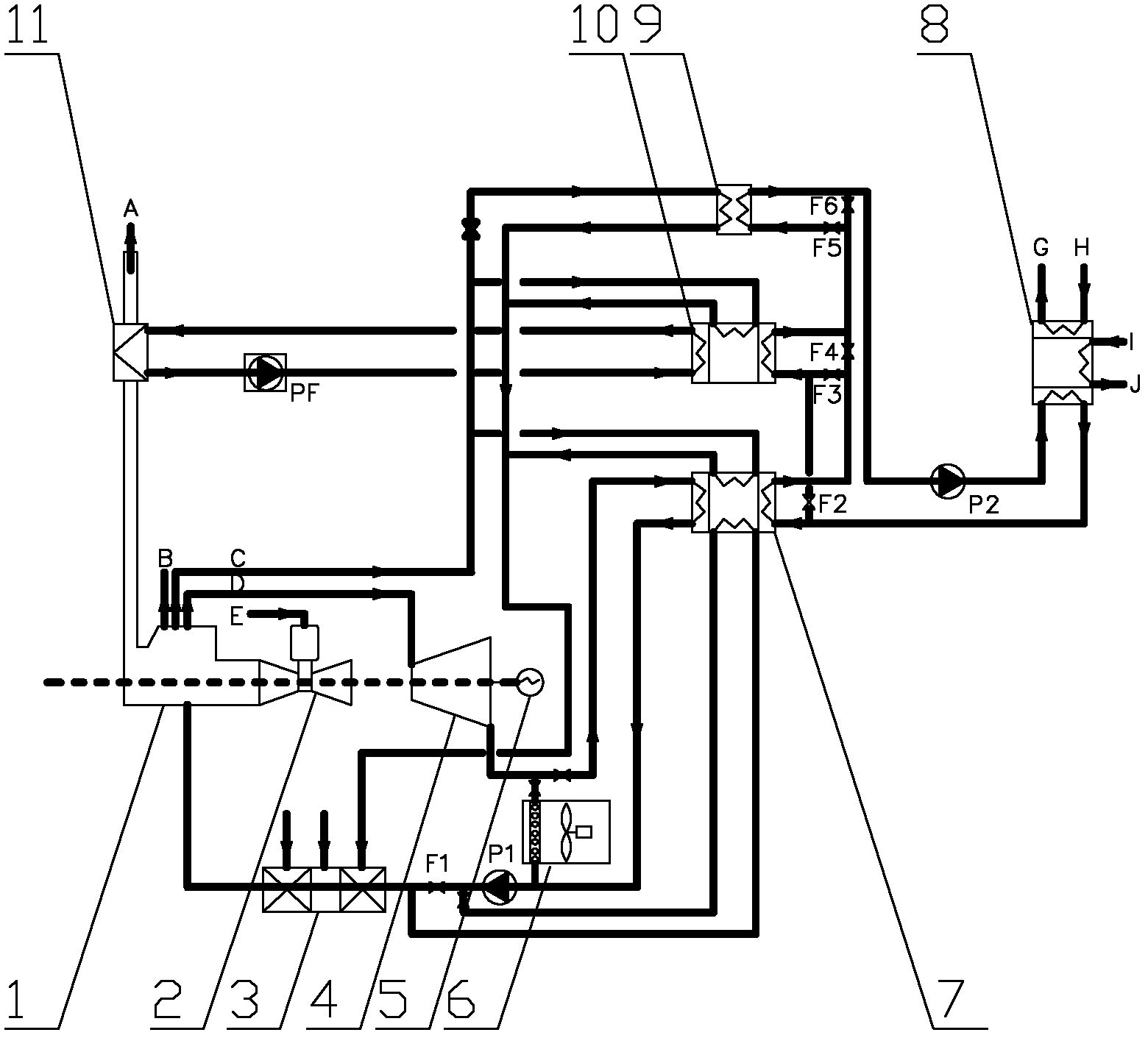

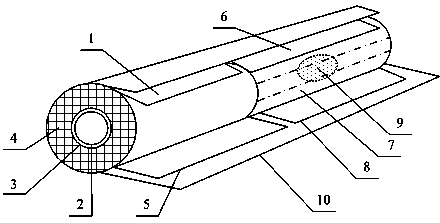

Novel solid-state cigarette core of electronic cigarette and preparation method for novel solid-state cigarette core

InactiveCN104223366AIncrease contact areaIncrease the heating areaTobacco devicesHeater RodEngineering

The invention relates to a novel solid-state cigarette core of an electronic cigarette and a preparation method for the novel solid-state cigarette core, belongs to the technical field of electronic cigarettes, and particularly relates to a solid-state cigarette core of the electronic cigarette and a preparation method thereof. The solid-state cigarette core of the electronic cigarette is prepared by heating an aroma carrier material and has a filtering effect. Through a design of a hollow cigarette core, a contact area between the cigarette core and a heating rod is increased, and a heating area and the heating efficiency of an atomizer are increased; a fibrous material is taken as a carrier to fully adsorb the aroma carrier material, and by indirectly heating the thermosensitive solid aroma carrier material, smoke which can be inhaled by a consumer is formed, and the consumer is endowed with the natural tobacco feel. Meanwhile, through reasonable combination of the paper hollow cigarette core and a filter element, the aroma carrier function and the filtration function of the material are perfectly combined, the smoke which has certain resistance to suction and which can be inhaled by the consumer is formed, the contents of tar and harmful granular matters in the smoke of the electronic cigarette are reduced, the smoking feel similar to the conventional cigarettes is endowed, and the electronic cigarette smoking pleasure is greatly improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

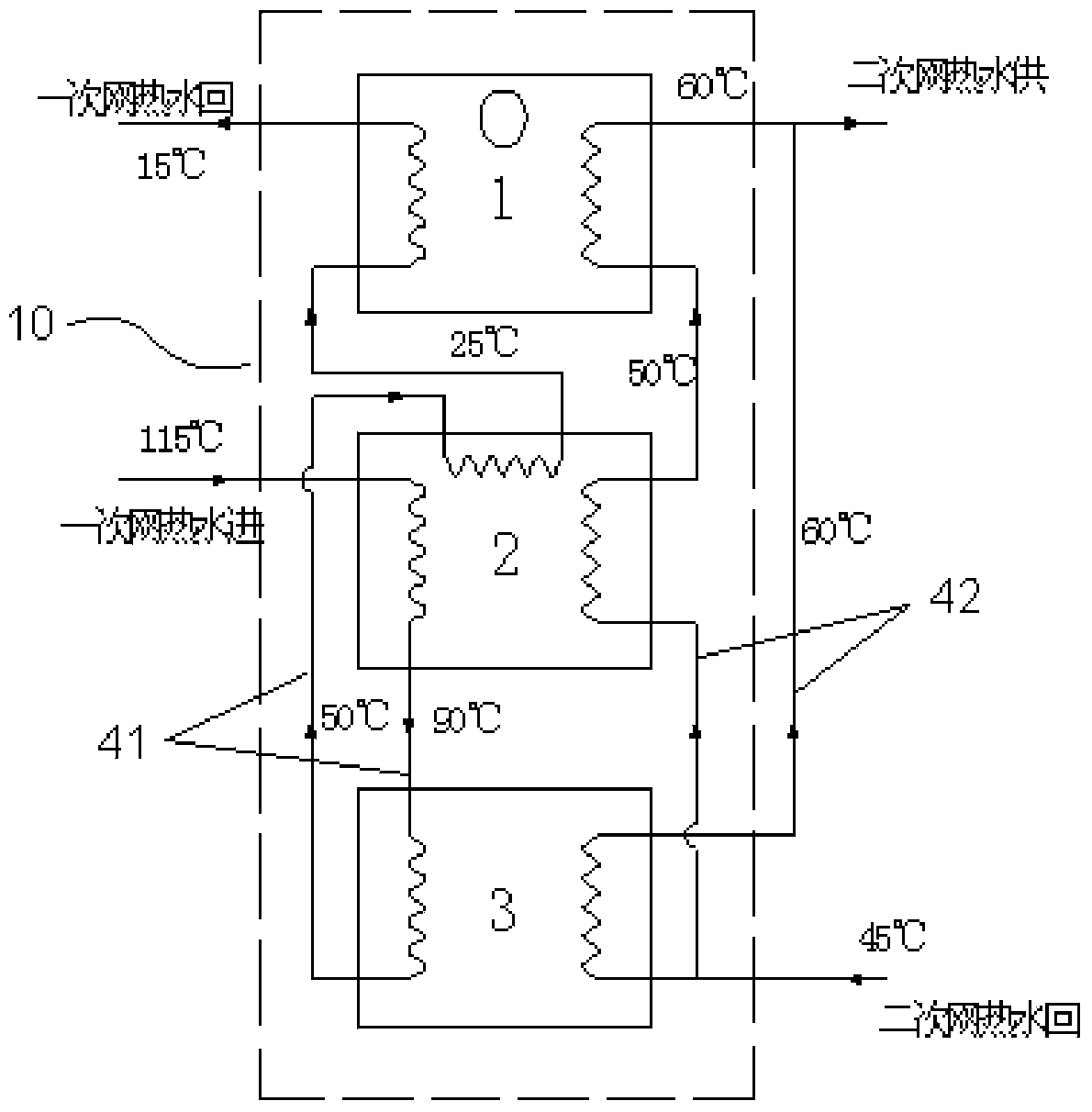

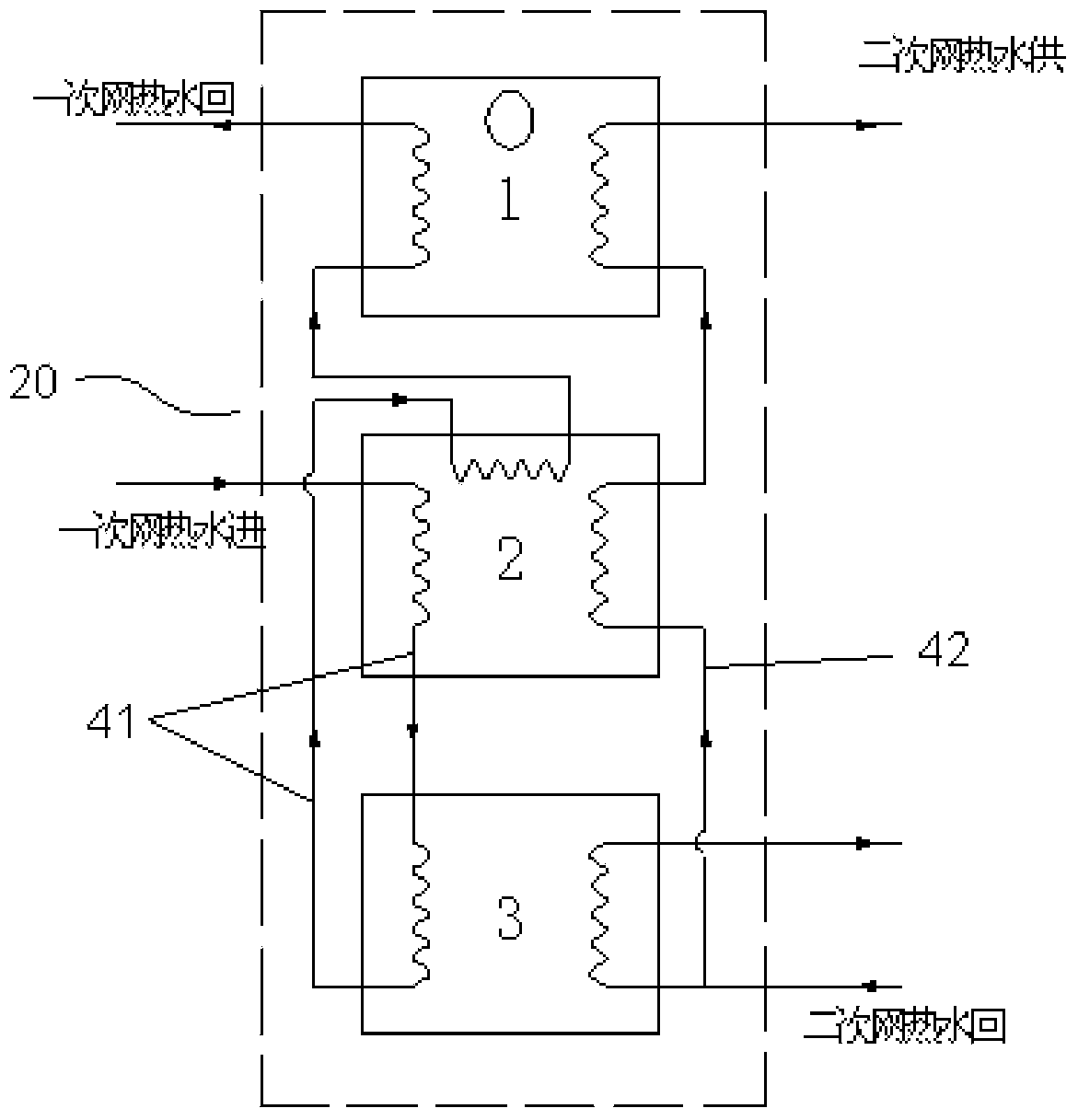

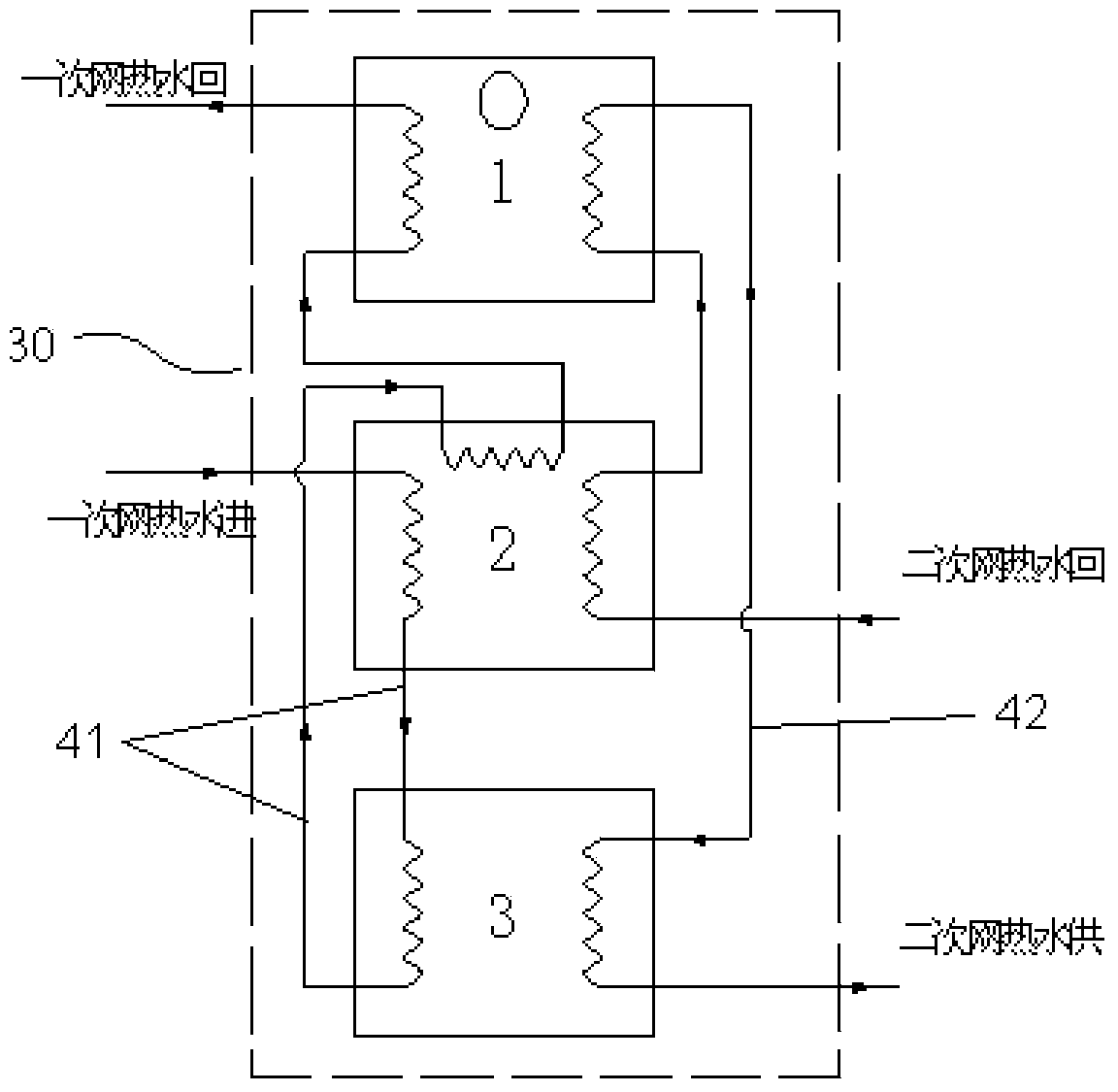

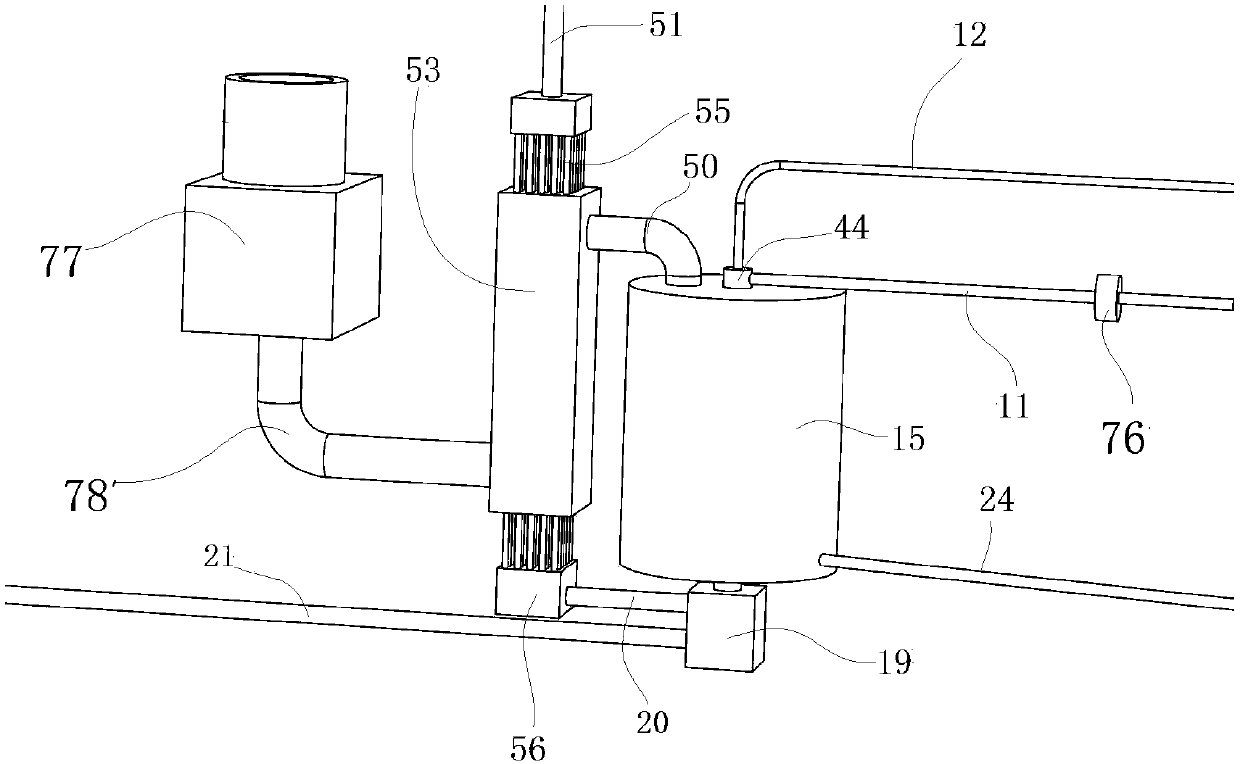

Combined type heat exchange unit

InactiveCN103673035AReduce initial investmentReduce water pump running power consumptionLighting and heating apparatusEnergy efficient heating/coolingHeating systemEvaporator

Owner:TSINGHUA UNIV

Combustion furnace based on liquid ethanol-natural gas composite fuel and method thereof

ActiveCN108050509AFully heatedHeating evenlyCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionCombustion chamberEngineering

The invention discloses a combustion furnace based on liquid ethanol-natural gas composite fuel. The combustion furnace comprises a combustion furnace body, and the combustion furnace body comprises acomposite fuel combustion furnace which is of a cone-shaped circular platform structure with a thin end facing down; the lower end of the composite fuel combustion furnace is coaxially provided witha flame nozzle, and the firing direction of the flame nozzle is vertical upwards; the upper end of the composite fuel combustion furnace is a smoke exhaust wall, and the smoke exhaust wall is providedwith a plurality of smoke outlets; and the combustion furnace is simple in structure, the cone-shaped circular platform type combustion chamber is adopted and matched with an ethanol gasification cone to guide ordinary natural gas jet flames into a trumpet shape, and the flames go forwards by being attached to a heating pipe distributed in a conical spiral form, so that the heating area of the flames is enlarged.

Owner:谢丽萍

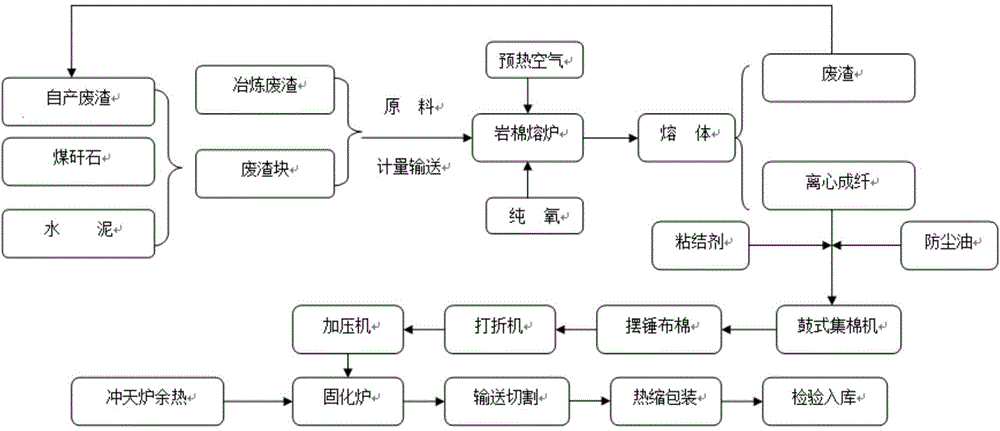

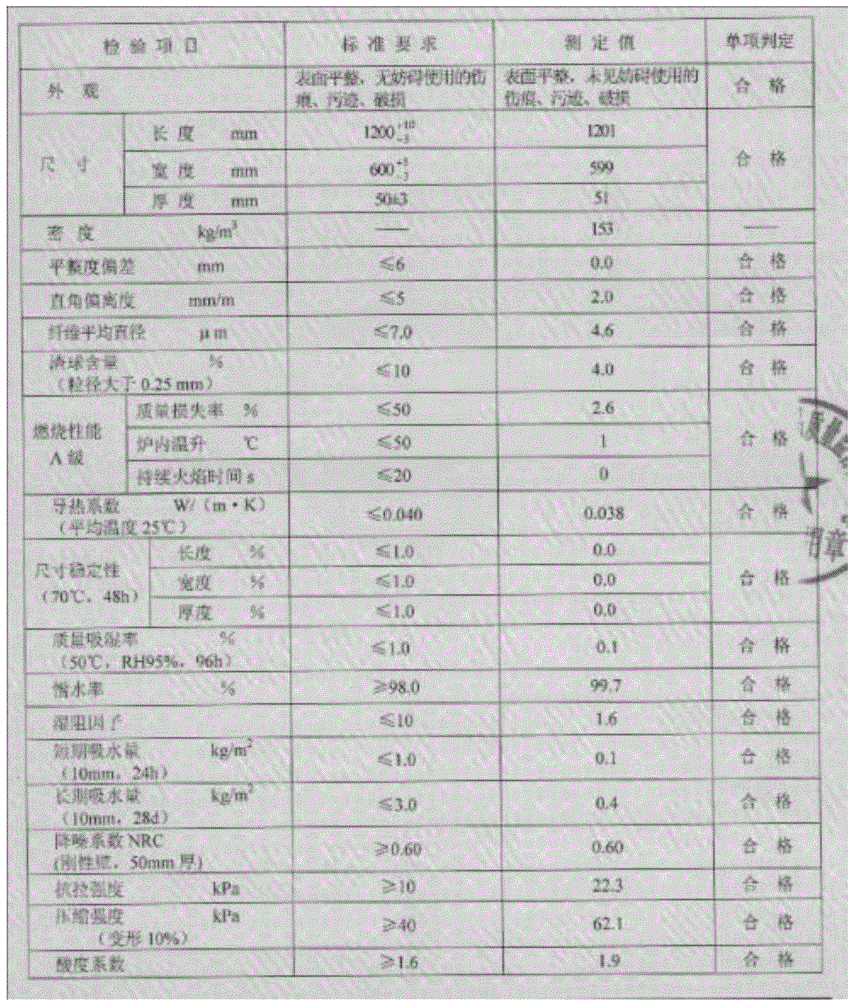

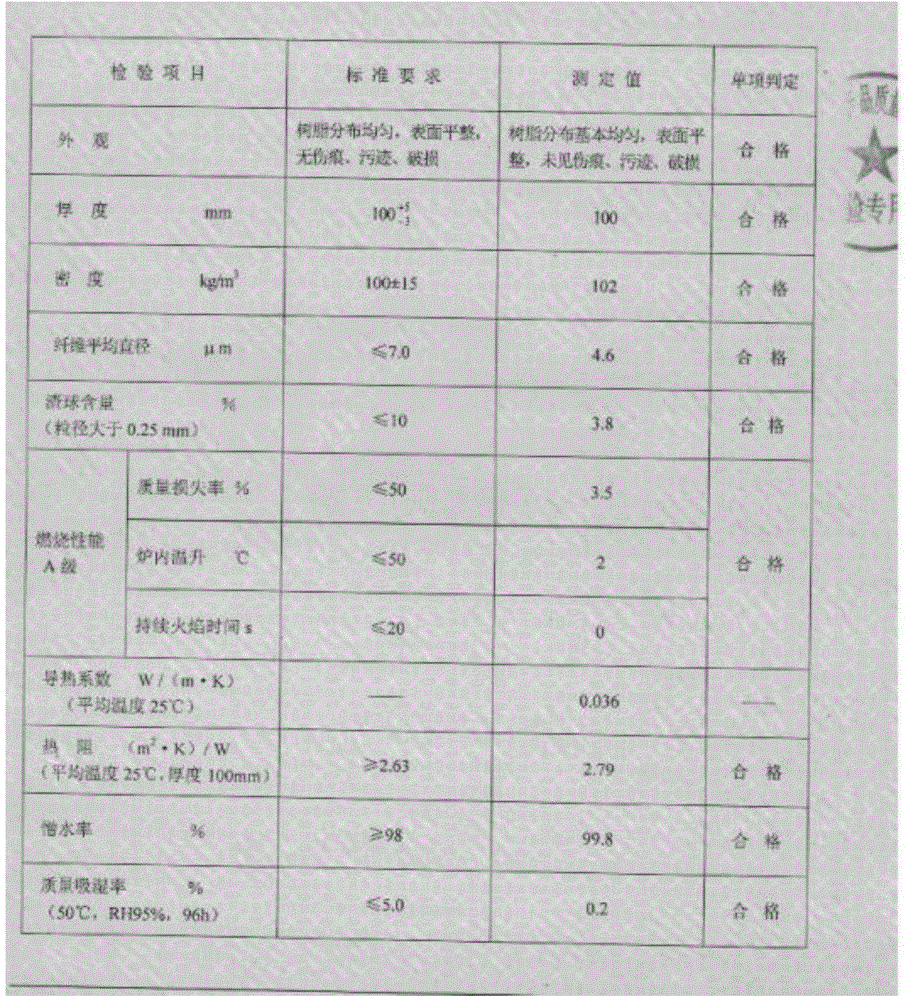

Method and system for producing rock wool by comprehensively utilizing solid wastes

ActiveCN104692648AReduce consumptionLower melting temperatureGlass making apparatusGlass productionFiberAdhesive

The invention discloses a method and system for producing rock wool by comprehensively utilizing solid wastes. The method comprises the following steps: a) uniformly mixing rock wool waste residue, coal gangue and cement in a mass ratio of (50-70):(20-35):(10-20) to prepare an autoclaved waste residue block; b) uniformly mixing the autoclaved waste residue block and smelting waste residue in a mass ratio of (60-80):(20-40) to obtain a mixture; c) melting the mixture at high temperature, and centrifuging at high speed for fiber formation, thereby obtaining fibers; and d) spraying an adhesive, a water repellent and a coupling agent on the fibers, and carrying out wool accumulation, solidification and cutting to obtain the rock wool plate. The method has the advantages of simple technological equipment, low energy consumption and recoverable heat source, is convenient to operate, comprehensively utilizes the solid wastes instead of the traditional basalt and dolomite to produce the rock wool product, and thoroughly solves the problem of solid wastes in the rock wool enterprise.

Owner:TAISHI ROCK WOOL

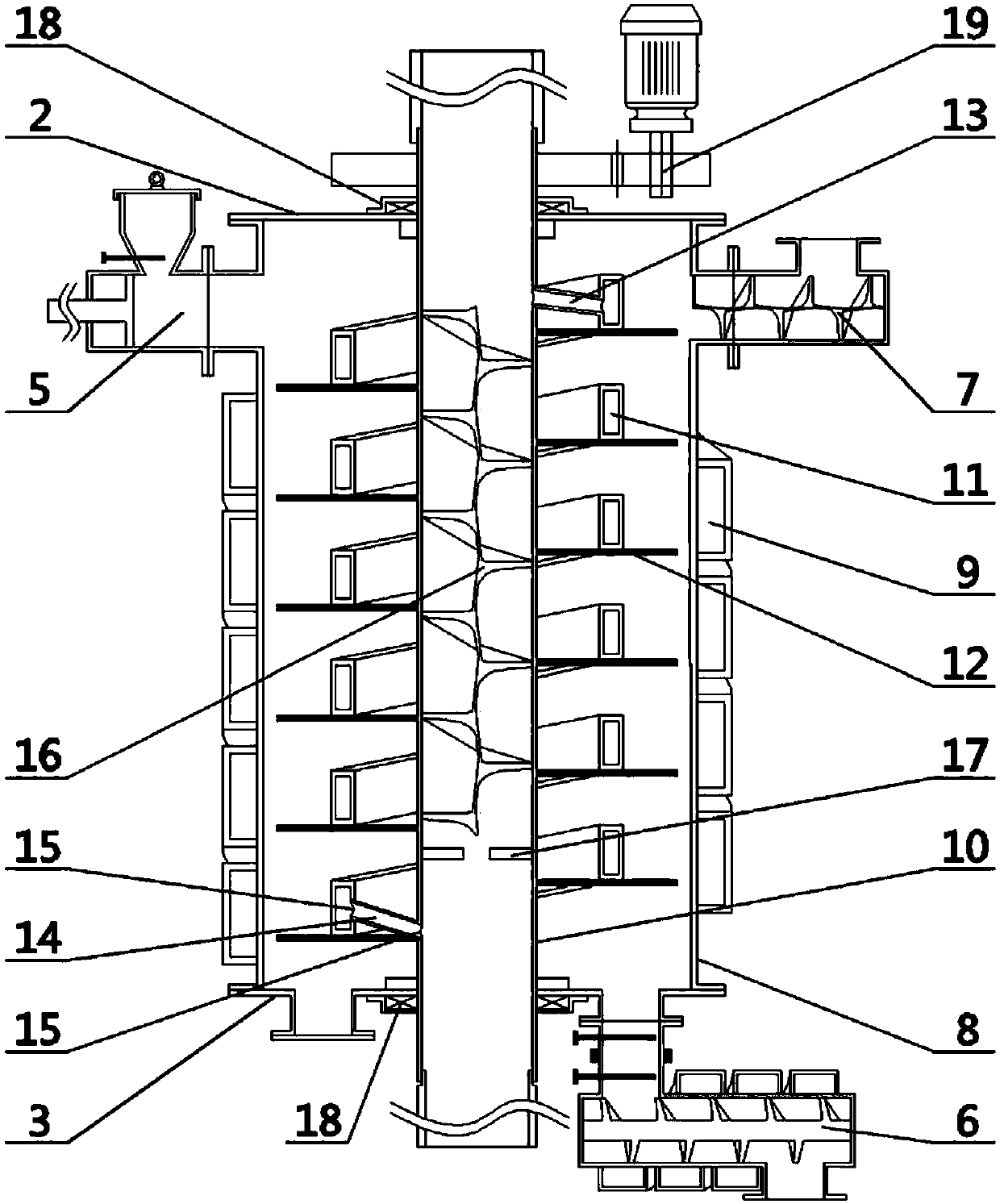

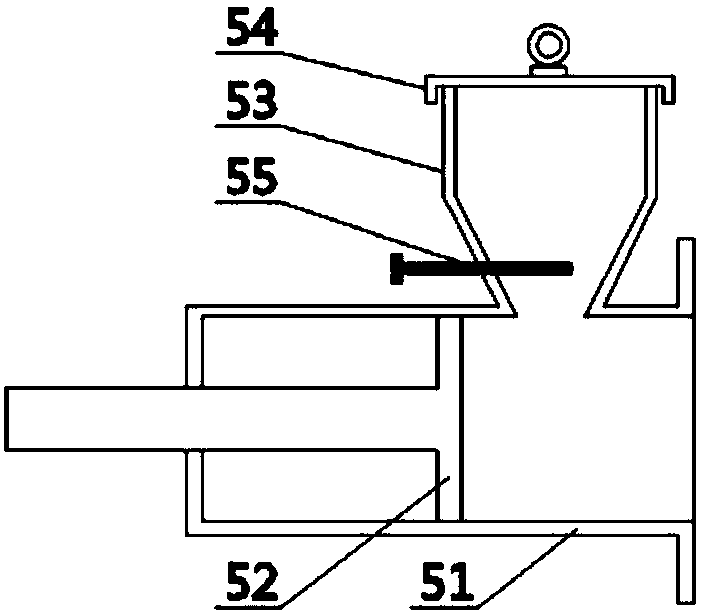

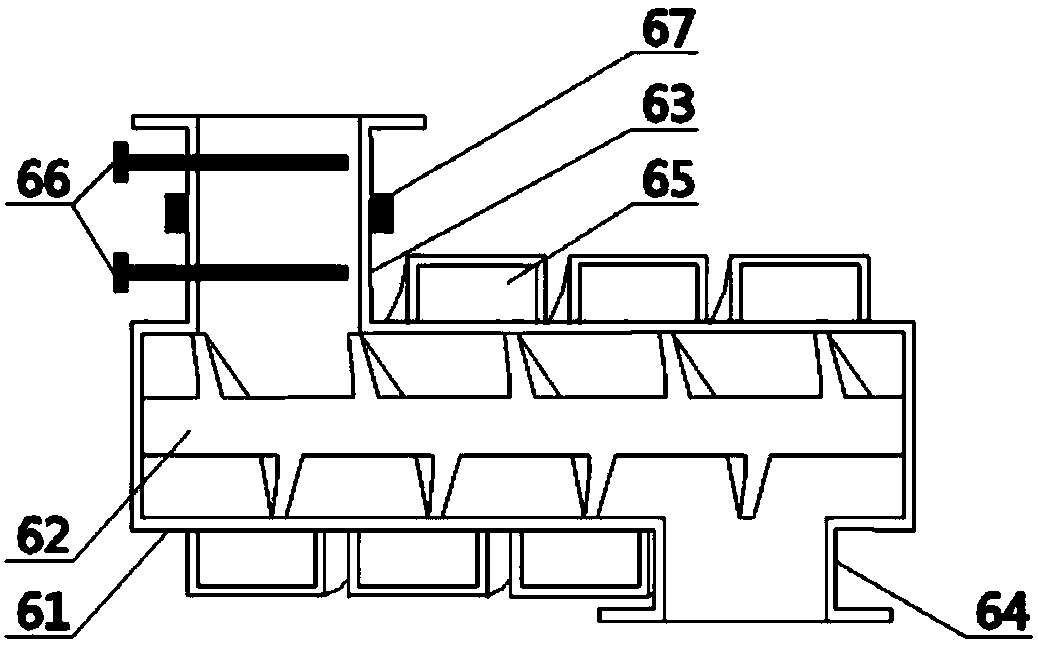

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

Regional heating, cooling and power combined energy system and method based on absorption heat exchange

ActiveCN102331110ABest Energy Saving AdjustmentLow recovery temperatureEnergy efficient heating/coolingClimate change adaptationEngineeringThermal water

The invention relates to a regional heating, cooling and power combined energy system and method based on absorption heat exchange. The system comprises four parts of equipment and is formed by connecting energy transmission and distribution networks formed by pipes with various water pumps and valves; the four parts of equipment are respectively a heat and power plant steam turbine power generation circulation sub system, an absorption dead steam afterheat recycling sub system, an absorption heat exchanging station / energy center and a distributed or semi-centralized air conditioner water heating sub system, wherein the heat and power plant steam turbine power generation circulation sub system is arranged on a thermal power plant and used for generating power and supplying heat; the absorption dead steam afterheat recycling sub system is arranged at an initial station of the thermal power plant and used for increasing the heat supplying and power generating efficiency by using the afterheat; the absorption heat exchanging station / energy center is arranged in a secondary network thermal substation and cold supply station; and the distributed or semi-centralized air conditioner water heating sub system is arranged at the user building and provided to the heat supply / air conditioner user. The method comprises three parts of operation regulation in a heating stage in winter, operation regulation in a cold supply stage in summer and operation regulation in a transitional stage beyond the two stages. According to the invention, the comprehensive energy utilization efficiency of a thermodynamic system can be effectively improved.

Owner:SHENYANG HUAYU GROUND SOURCE HEAT PUMP HEATING

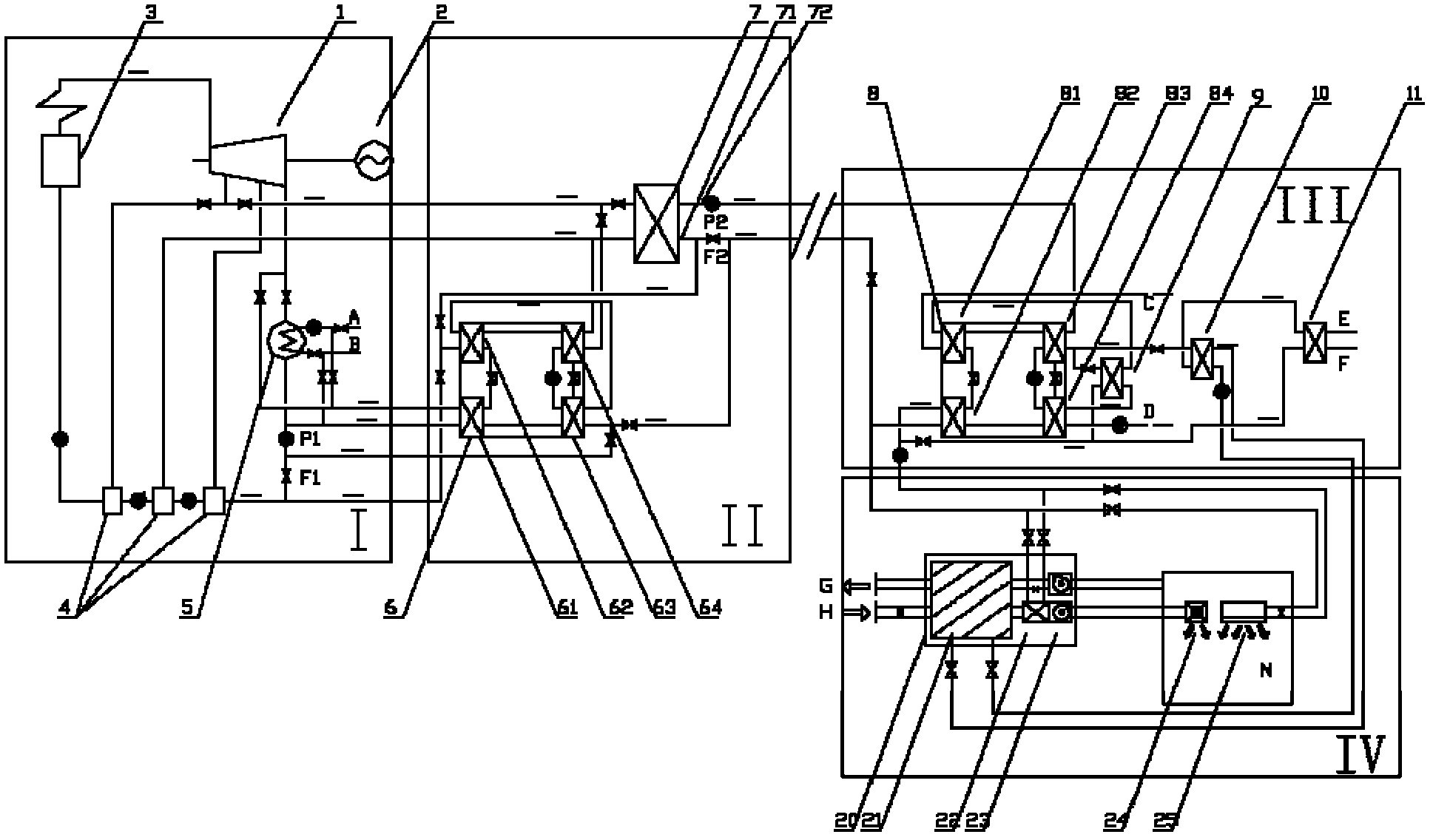

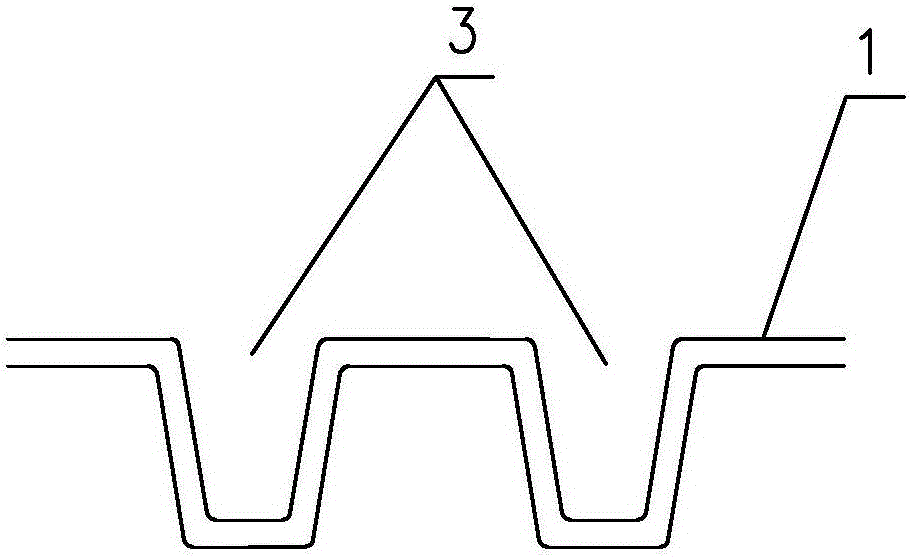

Ultrathin soaking plate and manufacturing method thereof

ActiveCN105865241AIncrease surface areaControl thicknessIndirect heat exchangersManufacturing technologyHeat transmission

The invention discloses an ultrathin soaking plate and a manufacturing method thereof. The ultrathin soaking plate comprises a cover plate and a bottom plate, wherein the peripheral edge of the cover plate and the peripheral edge of the bottom plate are in sealed connection. A groove is formed in the inner surface of the cover plate so that a cavity in a vacuum state can be formed between the cover plate and the bottom plate. A plurality of protrusions arranged in an array manner are distributed in the cavity and located on the bottom face of the groove. The protrusions are hollow pillars formed in a pressing manner. The protrusions are connected with the cover plate and the bottom plate so that the protrusions can be supported between the cover plate and the bottom plate and used for heat transmission between the cover plate and the bottom plate. The outer walls of the protrusions serve as a medium for working fluid to flow towards the bottom plate from the cover plate when the working fluid is evaporated and condensed when encountering cold. The protrusions on the cover plate are in contact with the bottom plate and can support the cavity formed by the cover plate and the bottom plate and be used for heat transmission between the bottom plate and the cover plate; and the outer walls of the protrusions serve as the medium for the working fluid to flow towards the bottom plate from the cover plate when the working fluid is evaporated and condensed when encountering cold. By means of the ultrathin soaking plate and the manufacturing method of the ultrathin soaking plate, the thickness of the soaking plate can be reduced, the protrusions are formed in the pressing manner through a simple stamping technology, the manufacturing technology is simplified, the cost is low, and the ultrathin soaking plate is suitable for large-scale production.

Owner:GUANGZHOU HUAZUAN ELECTRONICS TECH

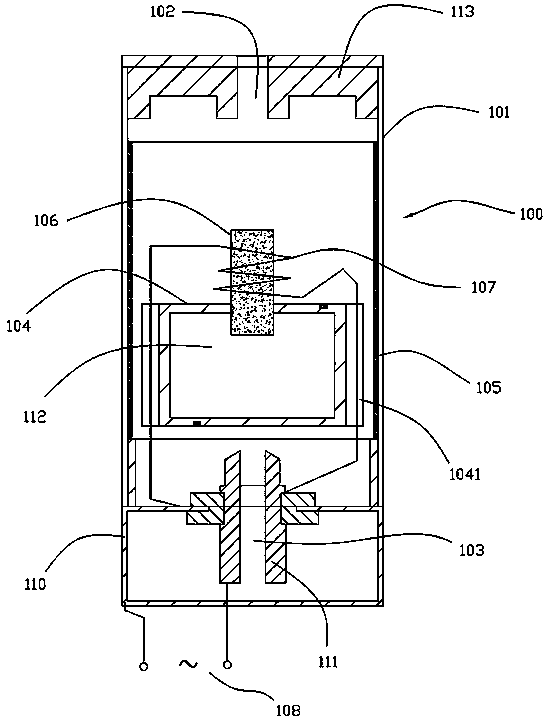

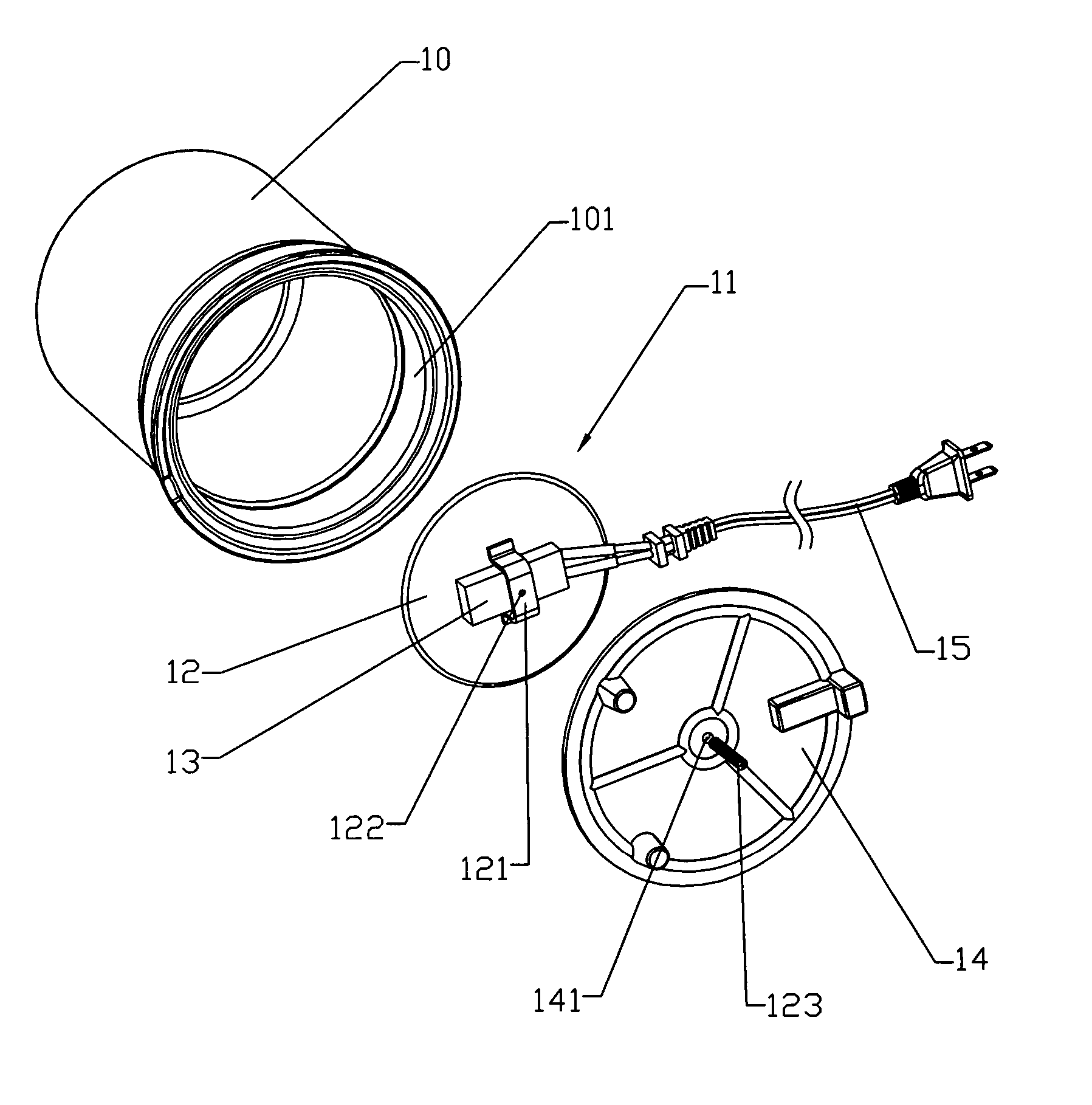

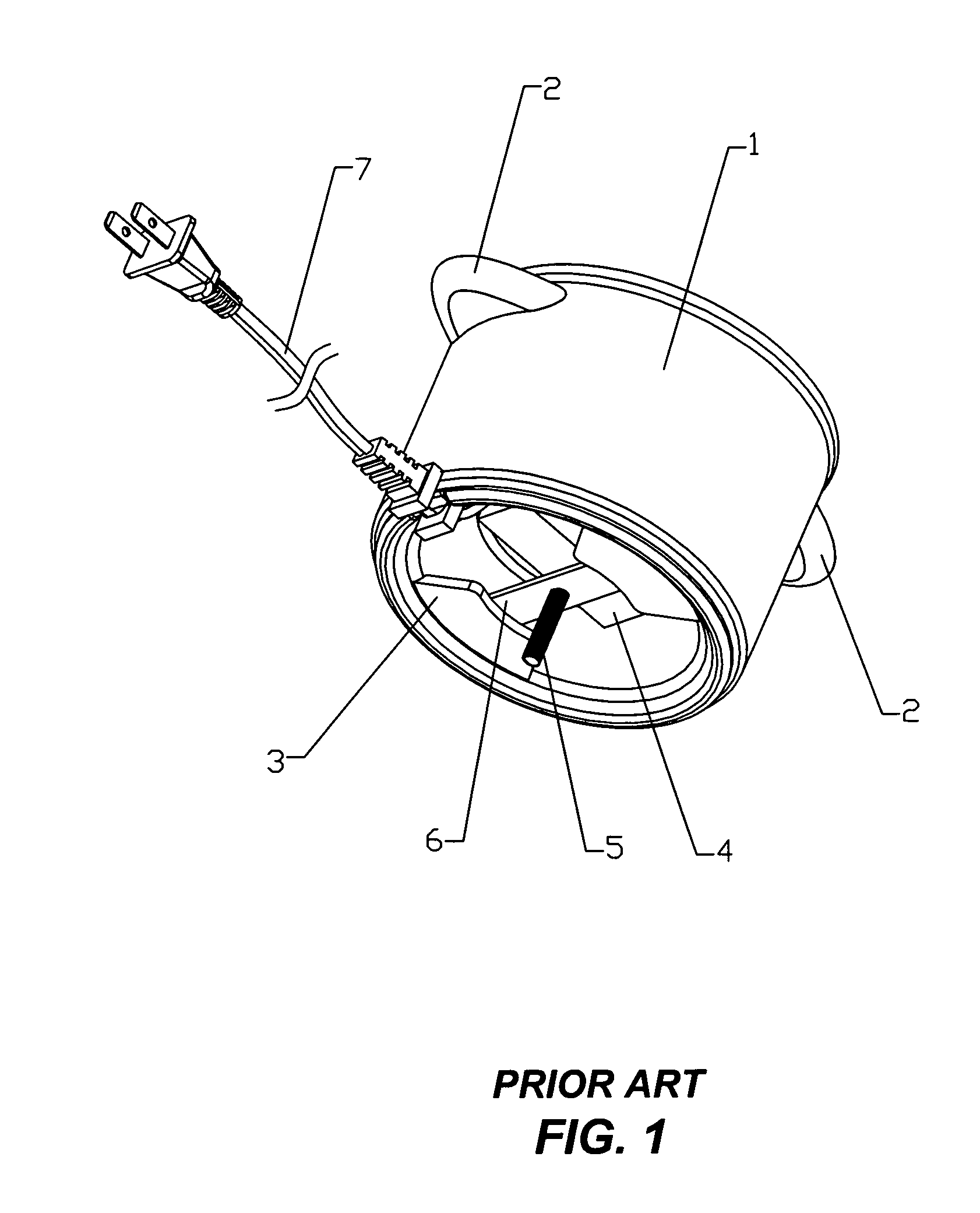

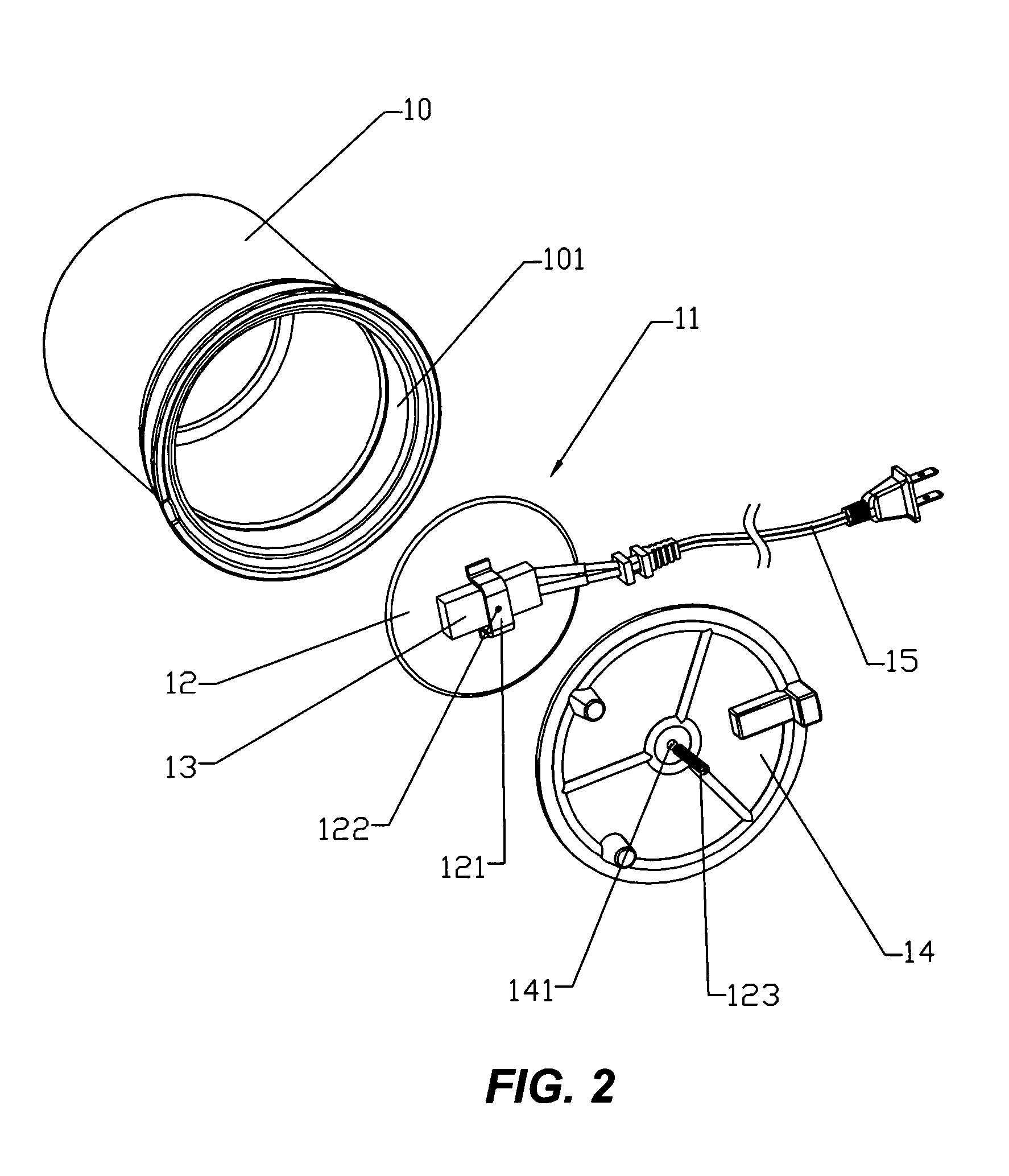

Mini scented wax heating device

InactiveUS20060163240A1Increase the heating areaEvenly heatedGaseous substancesElectric heating for furnacesWaxHeating time

A mini scented wax heating device includes a heating cylinder which is in a penetrating cylindrical form and installs a heating device therein. The heating device comprises a heat plate and a ceramic heating piece attached to the heat plate, and the heat plate is latched to a fixed end of the heating cylinder. The invention uses the heat plate to directly heat the bottom of the heating device. Since the heating device is a mini heating device that heats the heat plate directly by the ceramic heating piece, the heat plate can directly heat and vaporize a piece of scented wax. The invention increases the heating area of the scented wax by the heater, shortens the heating time, and evenly heats the scented wax in the heater, and thus can achieve a better vaporization effect. The invention features a simple structure, a low cost, and a powerful function.

Owner:XIAO MING REN

Aroma-increasing cigarette column applicable to low-temperature cigarette

ActiveCN105725264AEasy suctionIncrease the heating areaTobacco treatmentTobacco devicesChemistryAromatic plants

The invention discloses an aroma-increasing cigarette column applicable to a low-temperature cigarette. The aroma-increasing cigarette column comprises the following components in parts by weight: 100 parts of tobacco particles, 0.05 to 2.0 parts of tobacco essence, 1 to 15 parts of a heat conducting component, 1 to 20 parts of a binding agent, and 1 to 20 parts of an aromatic plant, wherein the aromatic plant is selected from one or more of a flowery aromatic plant, a spicy aromatic plant and a medicinal aromatic plant. The aroma-increasing cigarette column applicable to the low-temperature cigarette provided by the invention is in an integrally cylindrical shape or a disc shape; the size is slightly smaller than that of a tobacco material filling cavity of an existing low-temperature cigarette smoking tool, so that a tobacco material is easy to add and easy to remove; a large number of pores are formed in the aroma-increasing cigarette column, so that a cigarette is easy to smoke; meanwhile, the heating area and the heating uniformity of a smoking material can be improved; smoke is formed quickly under a relatively low temperature; the cigarette column contains the heat conducting component, so that heat conducting in the cigarette column can be accelerated greatly, and the heating uniformity is favourably improved and the smoke is formed quickly.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Tea leaf drying device

InactiveCN105605889AAvoid damageImprove filtering effectDrying solid materials with heatDrying solid materials without heatPulp and paper industryHeat losses

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a base and a drying box. The drying box is arranged above the base, supporting legs are arranged between the drying box and the base, an electromagnetic heating coil is embedded in the wall of the drying box, a feeding hopper is arranged at the upper end of the drying box, a discharging pipe is arranged at the lower end, located in the drying box, of the feeding hopper, an air jet pipe is arranged in the drying box, an air jet port is formed in the upper side of the wall of the air jet pipe, an exhaust port is formed in the upper left end of the drying box, the air outlet end of the exhaust port is connected with a circulating fan, an air outlet of the circulating fan is connected with the air inlet end of the air jet pipe through an air guide pipe, the air guide pipe penetrates through a filtering box and a dehumidifying box in sequence from top to bottom, a discharging door is further arranged at the bottom of the drying box, and a conveying belt is further arranged on a base at the lower end of the drying box. The tea leaf drying device is simple and reasonable in structure, high in heating efficiency and good in drying effect; heat loss is avoided while dryness of air in the drying box is maintained, and thus the effect of saving energy is achieved.

Owner:廖志标

Flue gas condenser

ActiveCN101221021AIncrease the heating areaAvoid erosionStationary tubular conduit assembliesTrickle coolersFlue gasEngineering

The invention discloses a flue gas condenser, comprising an outer casing, a heat exchanging component, a flue gas inlet, a flue gas outlet, a cooling water inlet and a cooling water outlet. The heat exchanging component is a capillary, two ends of which are respectively connected with the cooling water inlet and outlet. Compared with the prior art, the invention enlarges a heated area of the heat exchanging component so as to further recycle heat and to more effectively enhance the heating efficiency of the equipment. Simultaneously, the PTFE and anti-corrosion materials are adopted to effectively prevent the corrosion of acid condensed water so as to avoid early damage due to corrosion to the condenser and to prolong the service life of the equipment.

Owner:FOSHAN SHENGKAI HEAT ENERGY EQUIP CO LTD

Tobacco cigarette with double heating sides

InactiveCN103190706AIncrease the heating areaReduce the harm of second-hand smokeTobacco devicesEngineeringPassive smoker

The invention discloses a tobacco cigarette with double heating sides. The tobacco cigarette comprises a cigarette holder and a smoke chamber. The cigarette holder and the smoke chamber match with each other. A smoke generator and a heating device providing heat sources are arranged in the smoke chamber. The smoke generator is symmetrically arranged around a central shaft of the smoke chamber, one end of the smoke generator is connected with the cigarette holder, while the other end of the smoke generator is connected with the heating device. The smoke generator comprises a tobacco product area, a heating layer of an outer layer is arranged between one outer side wall of the tobacco product area and an inner side wall of the smoke chamber, and a heating layer of an inner layer is arranged on the other outer side wall of the tobacco product area. With the tobacco cigarette with the double heating sides, heating areas of tobaccos are increased; and cigarette burning can be imitated, so that damages to passive smokers and customers caused by the cigarette burning are reduced, and outbreaks of fire due to open flames of the cigarettes are effectively avoided.

Owner:HUBEI CHINA TOBACCO IND +1

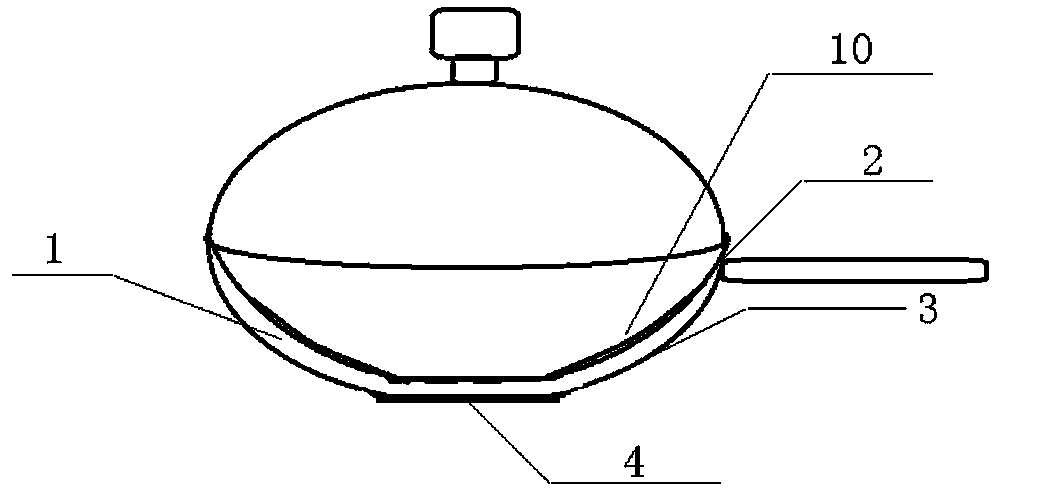

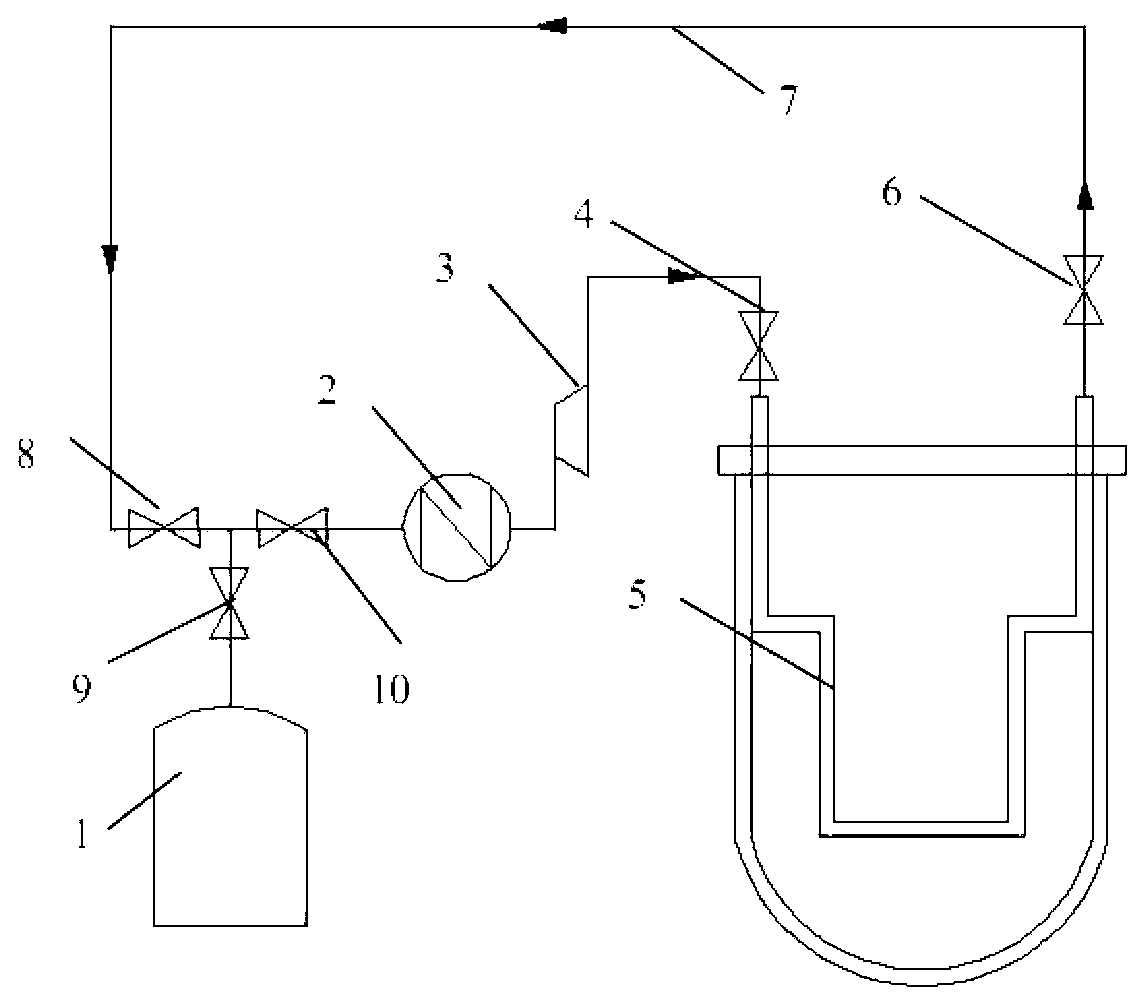

Liquid metal cooling tank type separation system for in-pile cold tank and in-pile hot tank of reactor

InactiveCN103065693AHigh thermal efficiencyImprove insulation performanceNuclear energy generationCooling arrangementReactor systemNuclear engineering

The invention provides a liquid metal cooling tank type separation system for an in-pile cold tank and an in-pile hot tank of a reactor. The separation system comprises a gas storage tank (1), a heater (2), a fan (3), an air inlet valve (4), an in-pile hot partition plate (5), an air outlet valve (6) and a connecting pipeline (7). When the reactor is in operation, the system takes the effect of separating the in-pile hot tank from the in-pile cold tank. At the moment, the air inlet valve (4) and the air outlet valve (6) are in the switching off state and the in-pile partition plate (5) is filled with gas. When the reactor is shut down, the system takes the effect of auxiliary heating of in-pile refrigerant. At the moment, the air inlet valve (4) and the air outlet valve (6) are switched on, the heater (2) and the fan (3) are in operation and gas is introduced into the in-pile hot partition plate (5) from an air inlet and is discharged out of the in-pile hot partition plate (5) from an air outlet. Two functions of separation of the in-pile cold tank from the in-pile hot tank and auxiliary heating of in-pile refrigerant are realized by the same equipment, and thus the complexity of reactor systems is lowered and the economy and the safety of reactors are improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

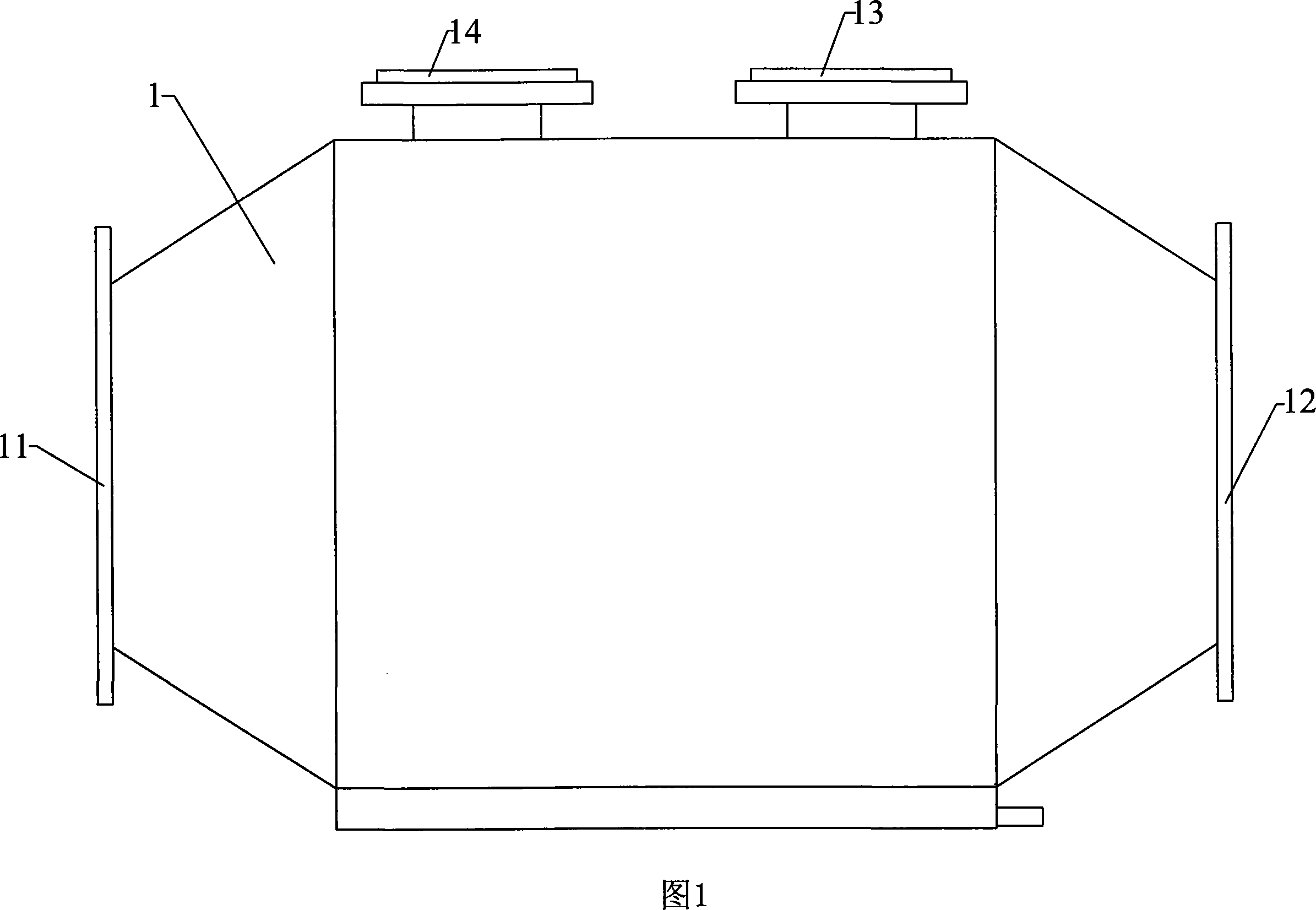

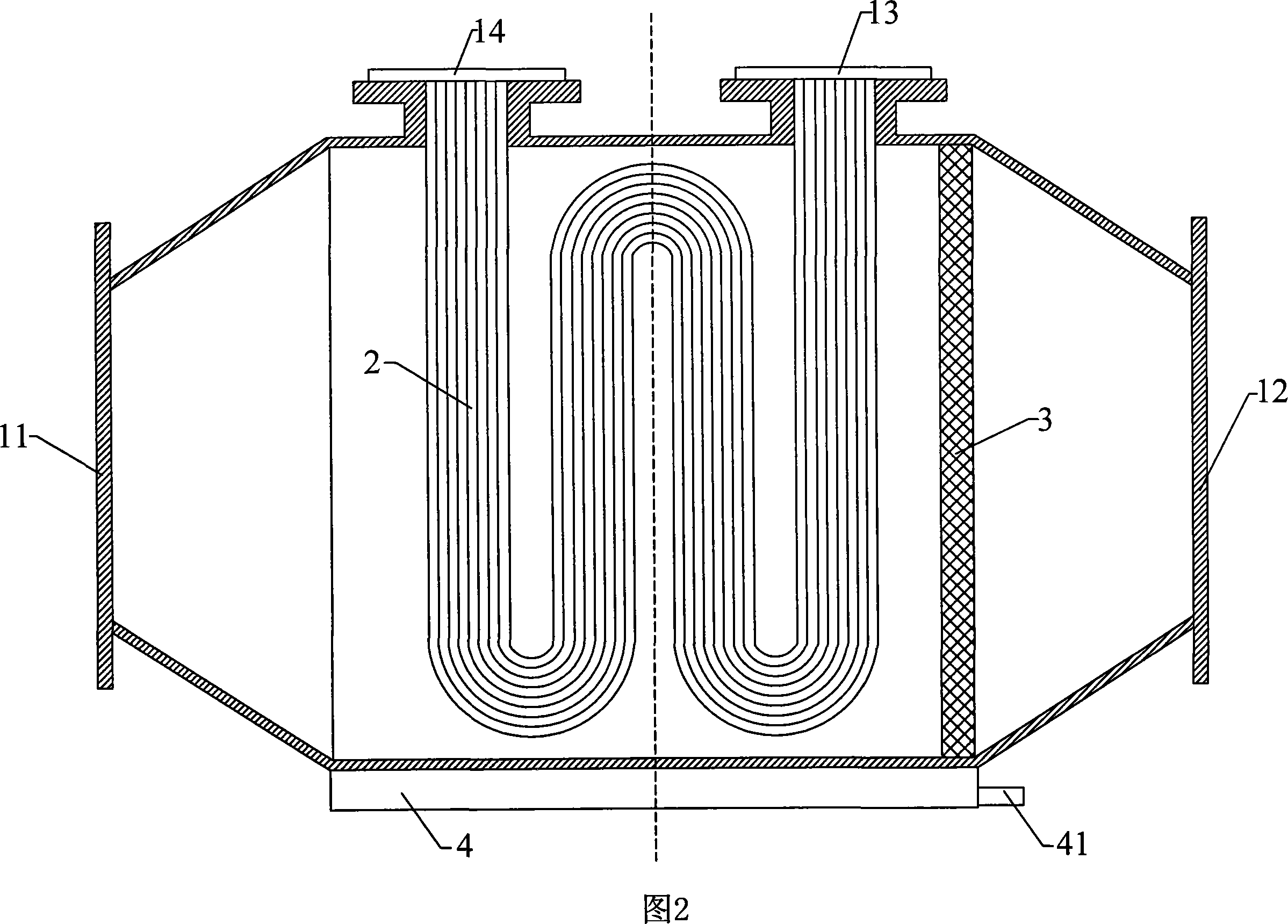

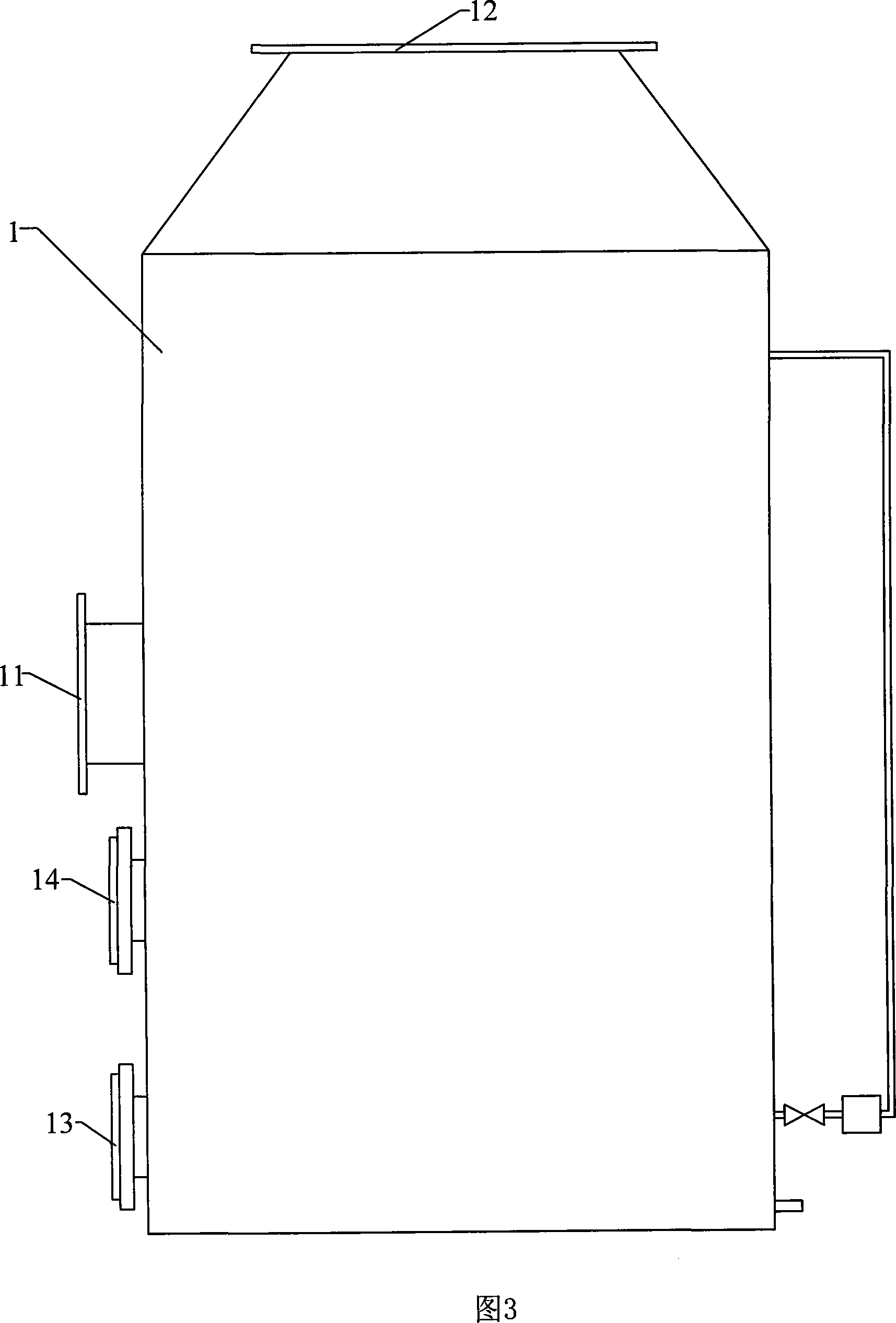

Steam generator

PendingCN101290111AIncrease the heating areaImprove the heating effectBoiler drums/headersSteam generation heating methodsEngineeringHeating effect

Owner:NANJING LG PANDA APPLIANCES

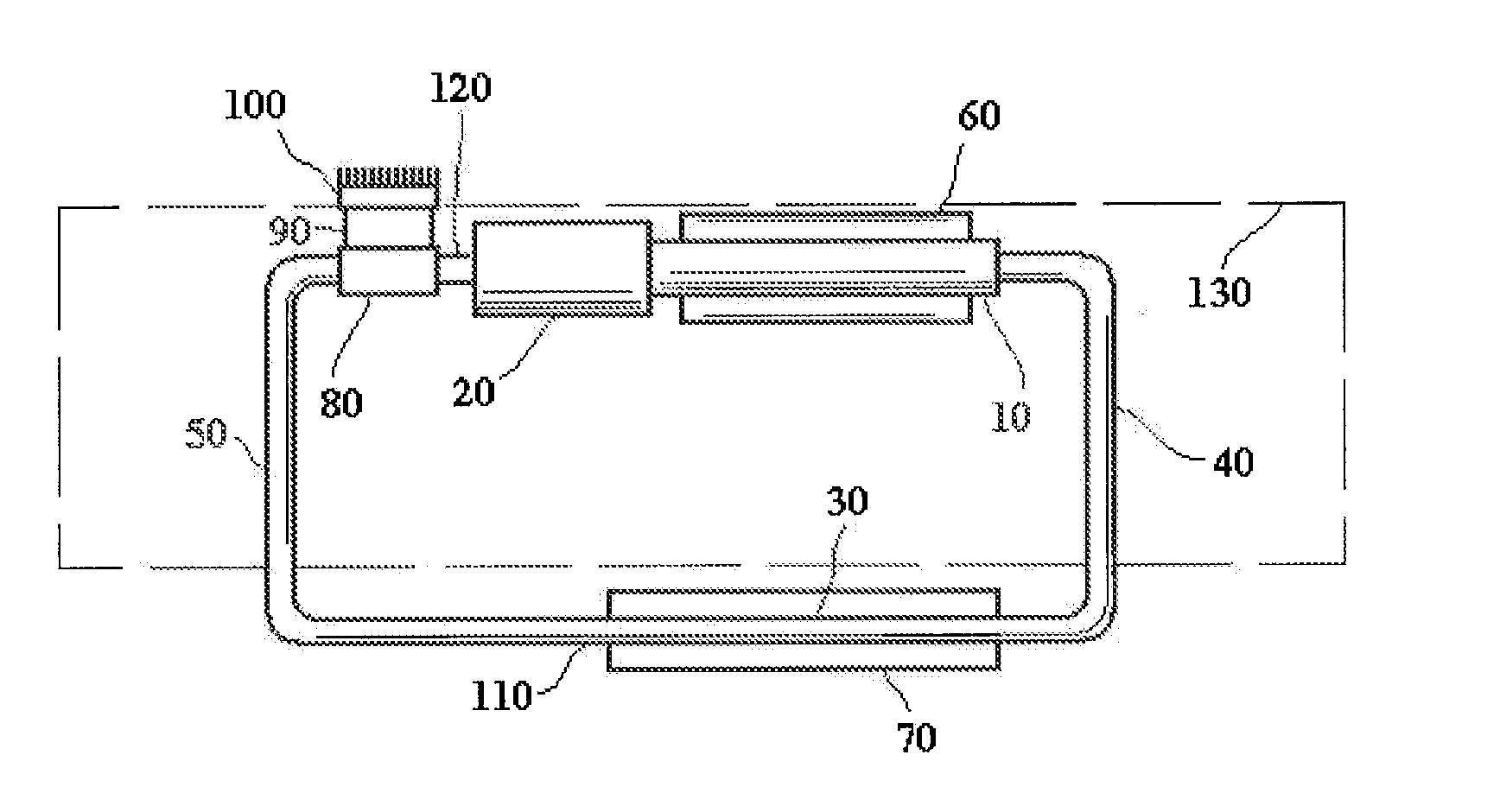

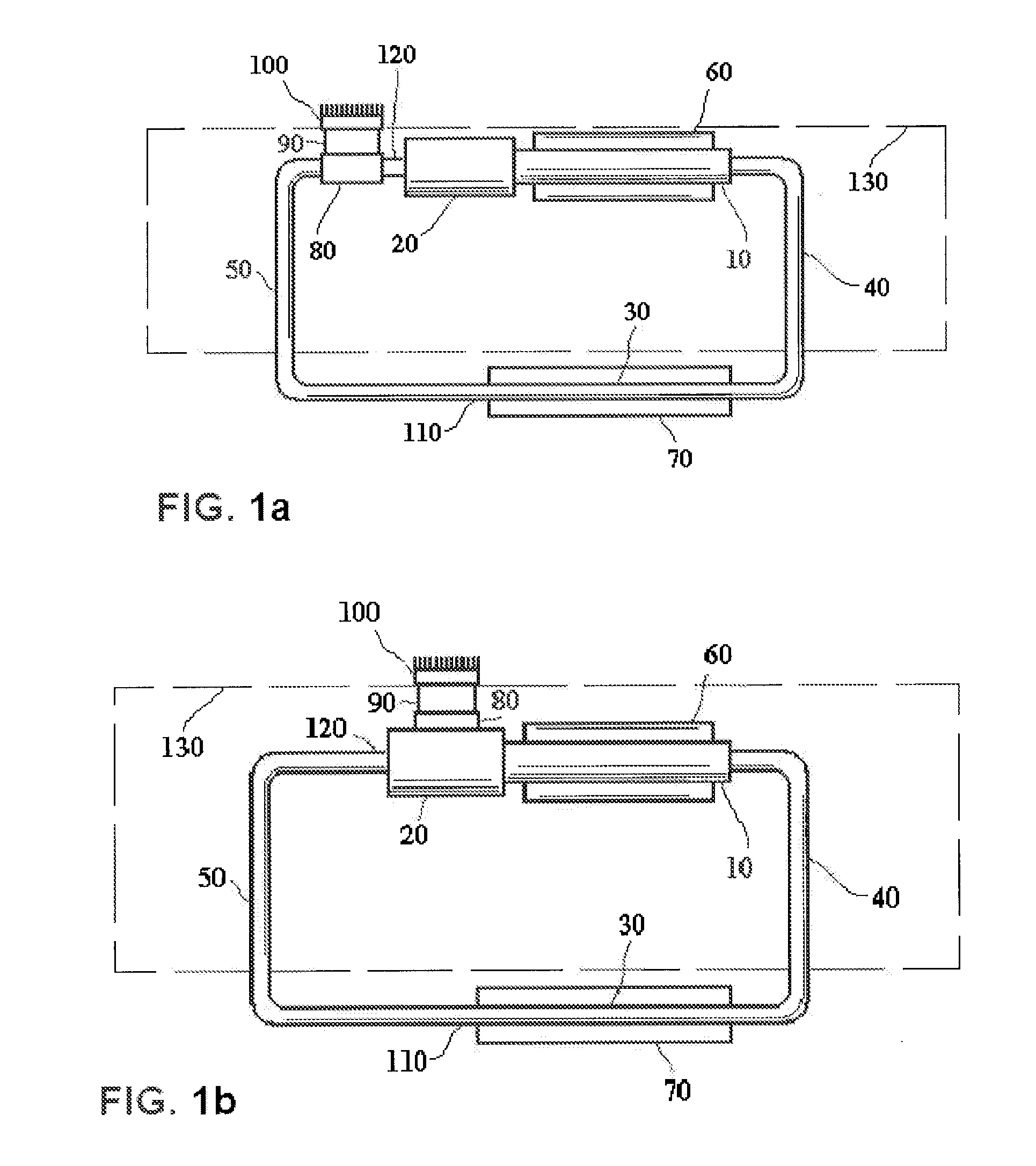

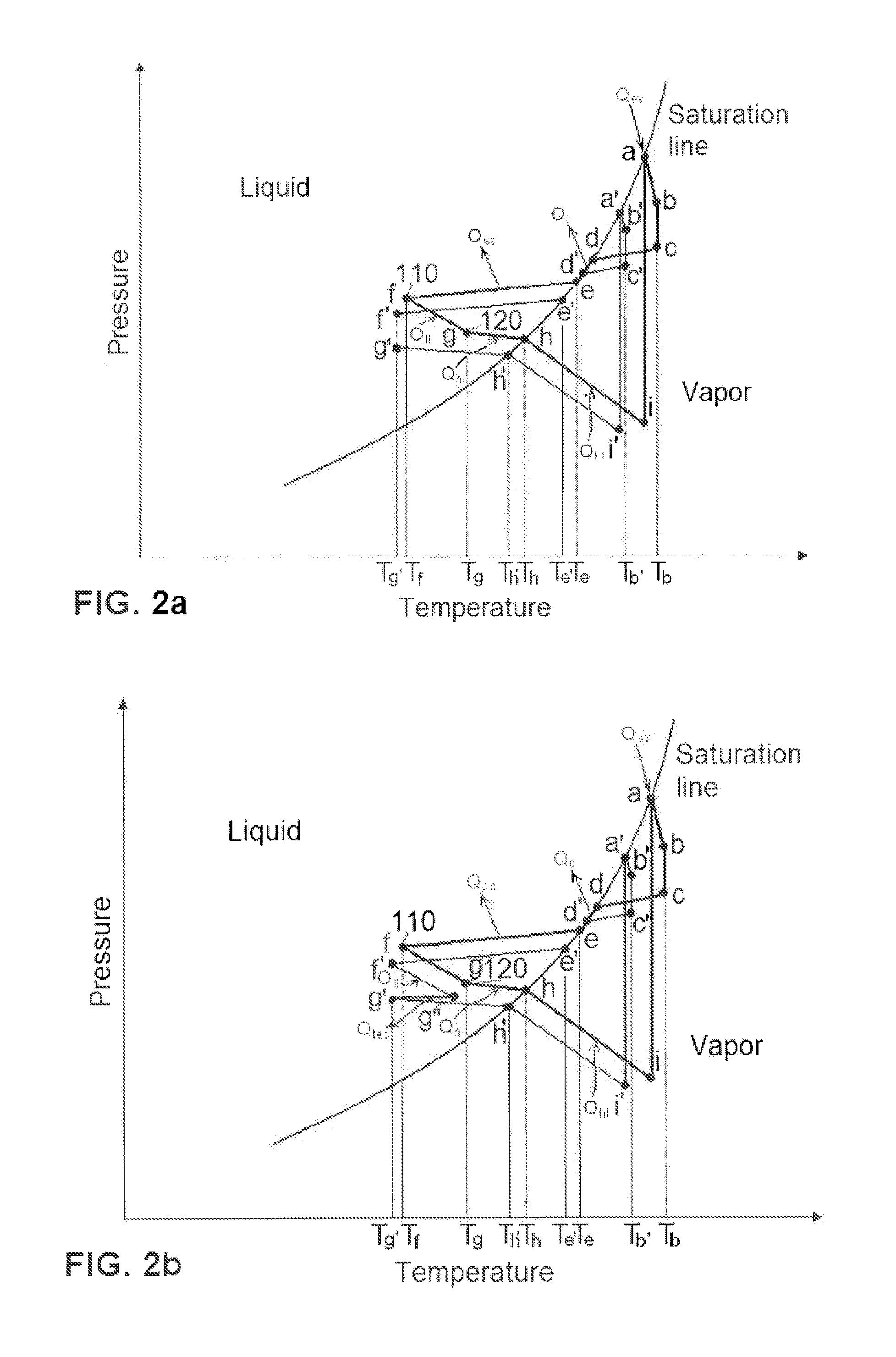

Thermal control device

InactiveUS20120198859A1Improve thermal conductivityImprove performanceSemiconductor/solid-state device detailsSolid-state devicesCold sideEngineering

The invention refers to a thermal control device for controlling the temperature of a heat source by means of transferring heat from the heat source to the ambient environment, through the circulation of a fluid in the device, said device comprising an evaporator (10) collecting heat from the heat source, a condenser (30) rejecting heat to the ambient environment, a compensation chamber (20), and liquid (50) and vapor (40) transport lines connecting the evaporator (10) and the condenser (30), the fluid flowing through said transport lines (40, 50), the device further comprising a thermal electrical cooler (90), the thermal electrical cooler (90) further comprising a thermal saddle (80) attached to the cold side of the thermal electrical cooler (90), and a thermal radiator (100) attached to the hot side of the thermal electrical cooler (90), such that heat is rejected to the ambient environment directly through the thermal radiator (100), when the thermal control device operates in a hot environment, the ambient temperature surrounding the liquid transport line (50) being higher than the temperature of liquid in the exit (110) of the condenser (30).

Owner:IBERICA DEL ESPACIO

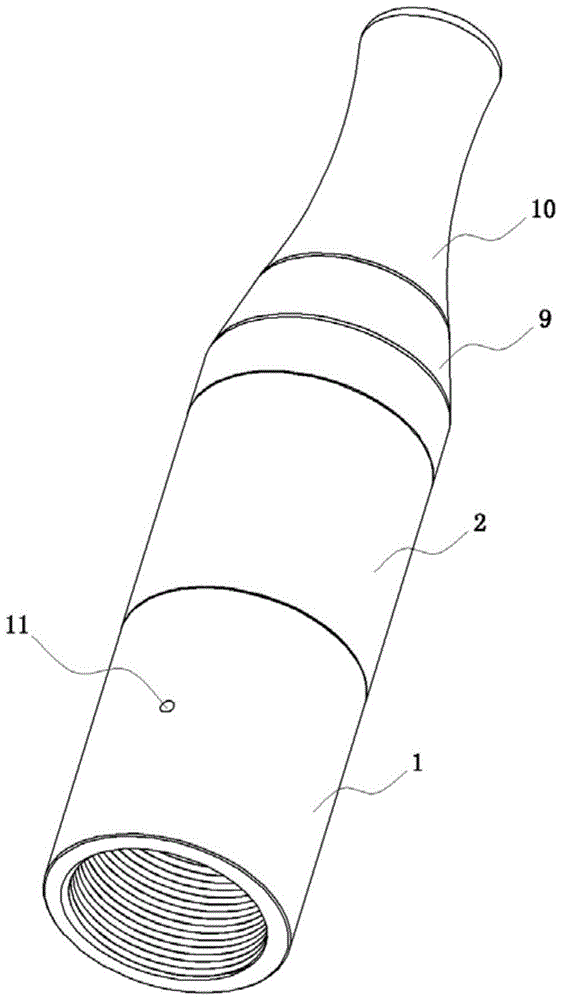

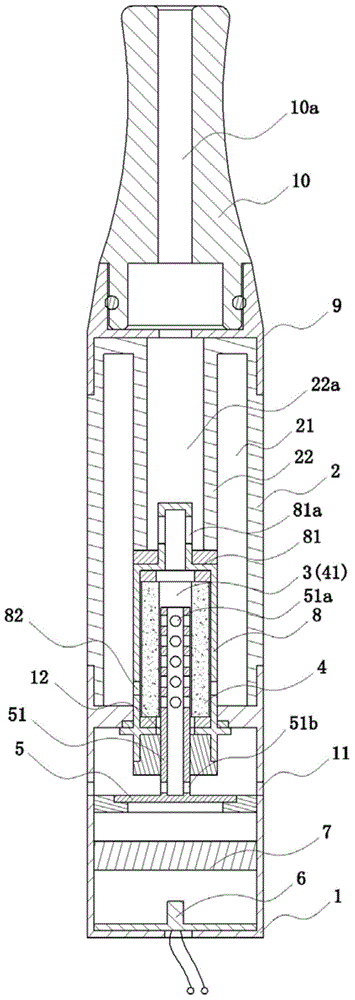

Light source heating atomizer and electronic cigarette employing same

InactiveCN104856235ASimple structureIncrease the heating areaTobacco devicesElectronic cigaretteEngineering

The invention relates to a light source heating atomizer and an electronic cigarette employing the same. The light source heating atomizer comprises a housing, a container, an atomization cavity, a permeating piece, a metal heating element, a light source generator and a lens assembly, wherein the housing is provided with an air inlet hole and an air outlet hole; the container is provided with an accommodating cavity; the air inlet hole and the air outlet hole are both communicated with the atomization cavity; the permeating piece is arranged between the atomization cavity and the container; the metal heating element is mounted in the housing; the light source generator and the lens assembly are mounted in the housing and located below the metal heating element; a light source generated by the light source generator is focused by the lens assembly and then aligned to the metal heating element to heat up the metal heating element; the metal heating element is placed between the permeating piece and the lens assembly. The light source heating atomizer and the electronic cigarette employing the light source heating atomizer have the advantages that the structure is simple, the heating area is large, the temperature is uniform, the atomization effect can be effectively improved and the service life can be effectively prolonged.

Owner:YANJI CHANGBAISHAN TECH SERVICE

Damp-proof terminal box

ActiveCN103247945AGuaranteed tightnessAvoid enteringSubstation/switching arrangement detailsEngineeringMoisture

A damp-proof terminal box comprises a box body and a top cover arranged at the top of the box body. The damp-proof terminal box is characterized in that the top cover comprises an outer cover body and an inner cover body arranged in the outer cover body; a condensation cavity is formed between the outer cover body and the inner cover body; a dehumidification hole communicated with the interior of the box body and the condensation cavity is formed in the inner cover body; an exhaust blower is arranged on the dehumidification hole; condensation screens are arranged in the condensation cavity; breathing holes communicated with the exterior and the condensation cavity are formed in the bottom of the outer cover body; and the exhaust blower lead moisture in the box body into the condensation cavity, the moisture condensed into water droplets after encountering the condensation screens, and the water droplets are discharged to the exterior of box body through the breathing holes. Owing to the arrangement of the condensation cavity, the leak tightness of the box body can be ensured, the moisture is effectively prevented from entering the box body through a dehumidification channel, moisture supplement is cut off from the source, and the damp-proof effect of the damp-proof terminal box is effectively improved.

Owner:STATE GRID CORP OF CHINA +2

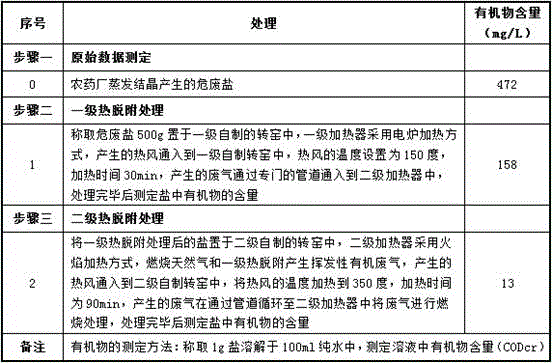

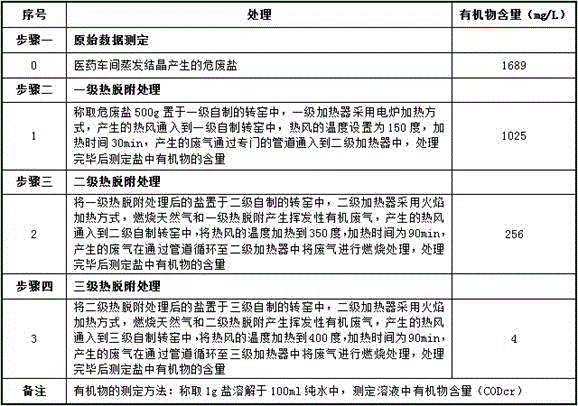

Multi-stage thermal desorption technology and device for waste salt refining

ActiveCN106424112AImprove liquidityTo achieve the purpose of refinementContaminated soil reclamationEconomic benefitsProduct gas

The invention discloses a multi-stage thermal desorption device for waste salt refining. The multi-stage thermal desorption device comprises a first-stage hot air heating furnace, a first-stage rotary kiln, a second-stage hot air heating furnace, a second-stage rotary kiln, feeders and an induced draft fan, wherein a feeding hole and one of the feeders are arranged at the top of the first-stage rotary kiln; the bottom of the first-stage rotary kiln is connected on the feeder of the second-stage rotary kiln through a pipeline; a discharge hole is formed in the bottom of the second-stage rotary kiln; an air outlet of the second-stage hot air heating furnace is connected with the bottom of the second-stage rotary kiln; a pipeline connected with the top of the first-stage rotary kiln is arranged on an air inlet of the second-stage hot air heating furnace; an air outlet of the first-stage hot air heating furnace is connected with the bottom of the first-stage rotary kiln; and a pipeline and the induced draft fan which are connected with the top of the second-stage rotary kiln are arranged on an air inlet of the first-stage hot air heating furnace. The device and a technology provided by the invention are mainly used for refining of waste salt, the structure is simple, the thermal desorption efficiency of organic matters is high, gases generated by thermal desorption are circularly utilized, no tail gas is generated, atmospheric pollution is avoided, and economic benefits and environmental benefits are achieved.

Owner:NANJING GW ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com