Combined type heat exchange unit

A heat exchange unit and compound technology, which is applied in the field of heat exchange units and compound heat exchange units, can solve the problems of inability to effectively recover waste heat resources from waste heat sources, difficulties in reducing the outlet water temperature below 35°C, insufficient driving force of absorption heat pumps, etc. problems, to achieve the effect of reducing the power consumption of water pumps, reducing initial investment, and alleviating insufficient heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

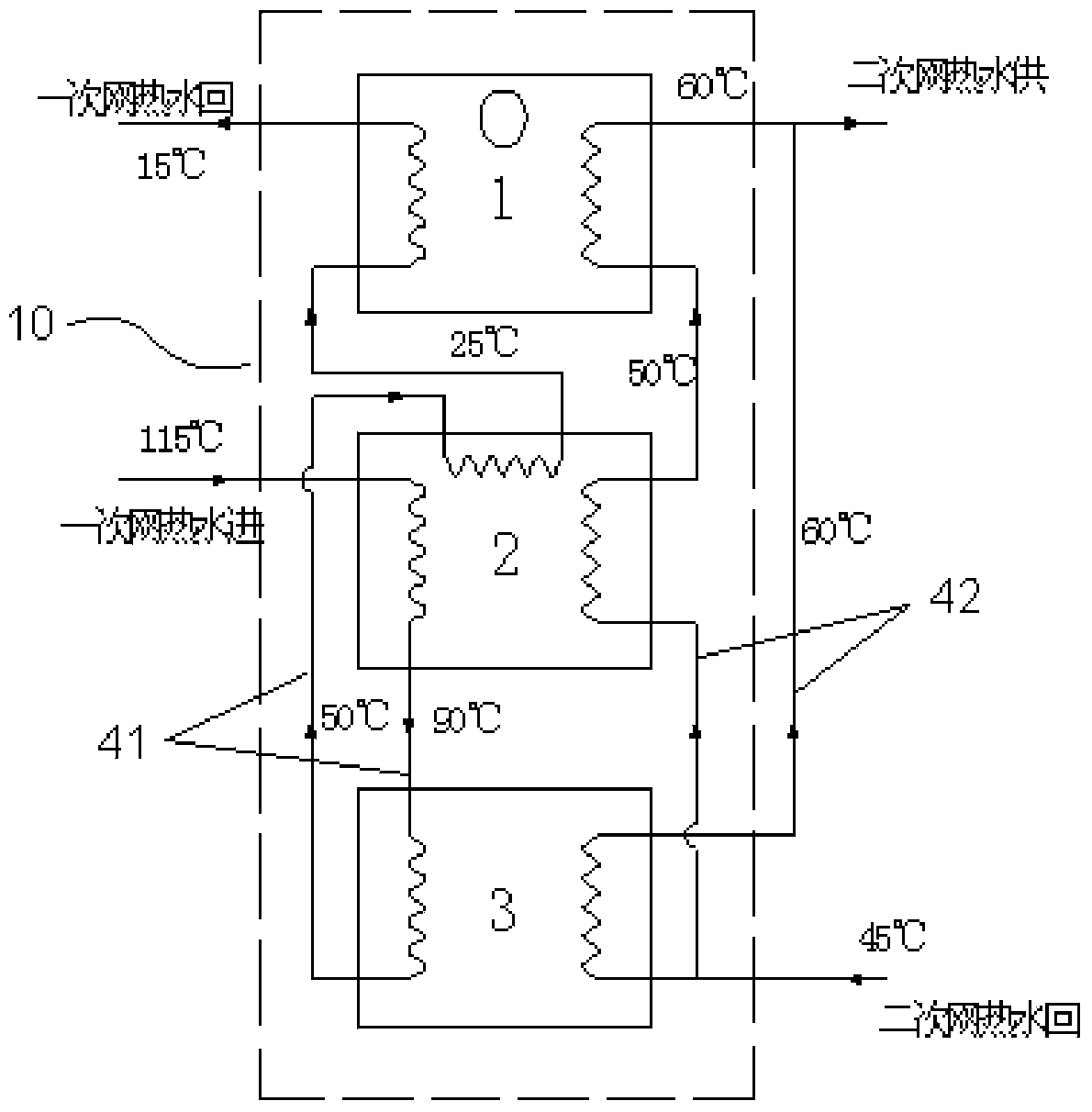

[0029] Embodiment 1: as figure 1As shown, in actual operation, the 115°C primary network hot water inflow output by the centralized heat source enters the generator of the absorption heat pump 2 as the driving heat source to heat the concentrated lithium bromide solution in the absorption heat pump 2; the heat is released and the temperature is lowered to 90°C After left and right, it flows out from the generator of the absorption heat pump 2, and enters the water-water heat exchanger 3 as a heating source to heat the hot water in the secondary network; after the heat release cools down to about 50°C, it flows out of the water-water heat exchanger 3, and then enters The evaporator of the absorption heat pump 2 is used as a low-grade heat source; the evaporator of the compression heat pump 1 is used as a low-grade heat source after the heat release is cooled to about 25°C, and the heat is sent back to the centralized heat source after the heat release is cooled to about 15°C, an...

Embodiment 4

[0031] Embodiment 4: as Figure 4 As shown, in actual operation, the 115°C primary network hot water inflow output by the centralized heat source enters the generator of the absorption heat pump 2 as the driving heat source to heat the concentrated lithium bromide solution in the absorption heat pump 2; the heat is released and the temperature is lowered to 90°C After left and right, it flows out from the generator of the absorption heat pump 2, and enters the secondary water-water heat exchanger 3b as a heating source to heat the hot water in the secondary network; after the heat is released and cooled to about 65°C, it flows from the secondary water-water heat exchanger 3b flow out, and then enter the first-level water-water heat exchanger 3a to heat the hot water in the secondary network; after cooling down to 50°C, it flows out from the first-level water-water heat exchanger 3a, and then enters the evaporator of the absorption heat pump 2 as a low High-grade heat source: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com