Patents

Literature

81results about How to "Increase waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

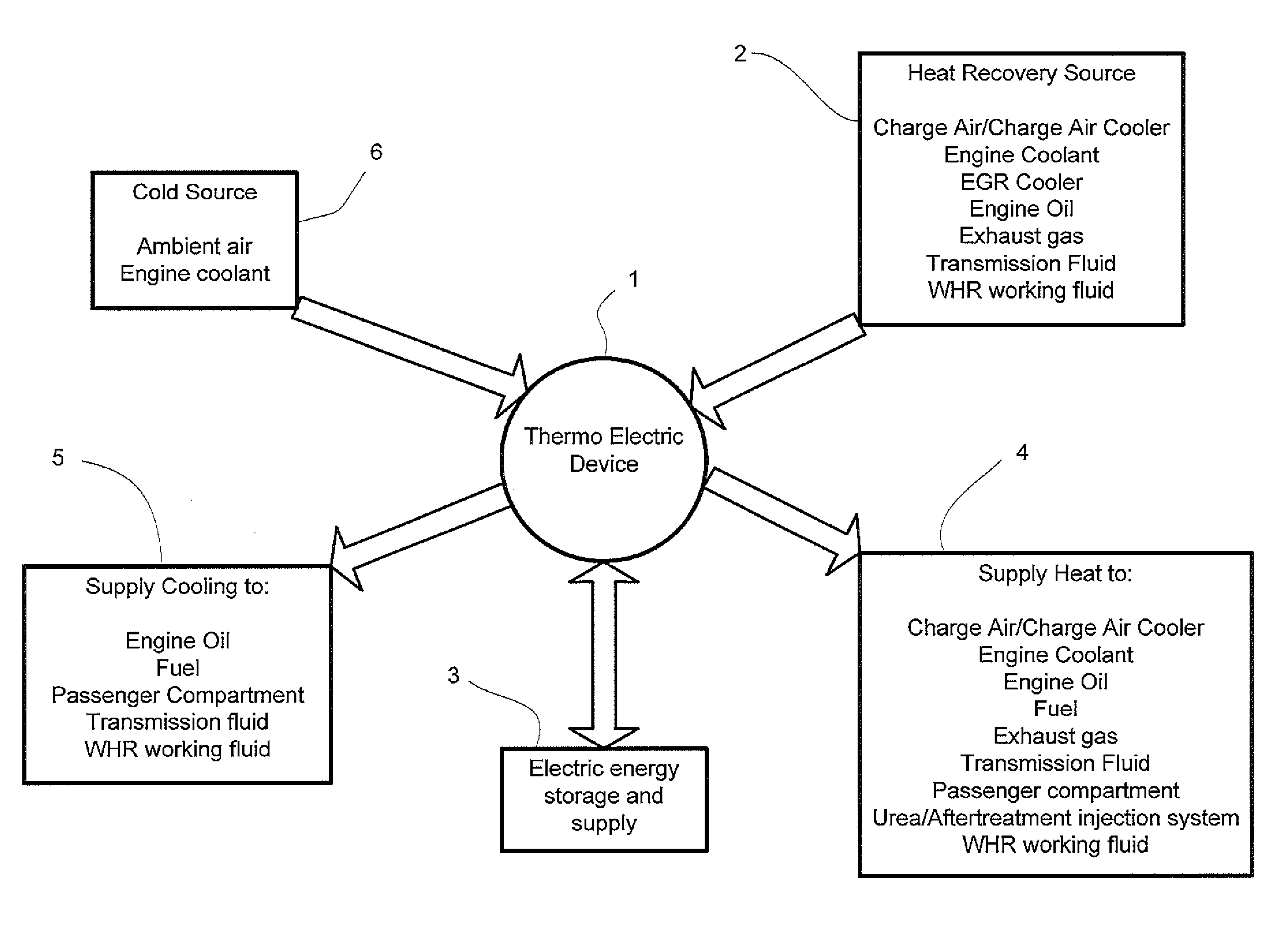

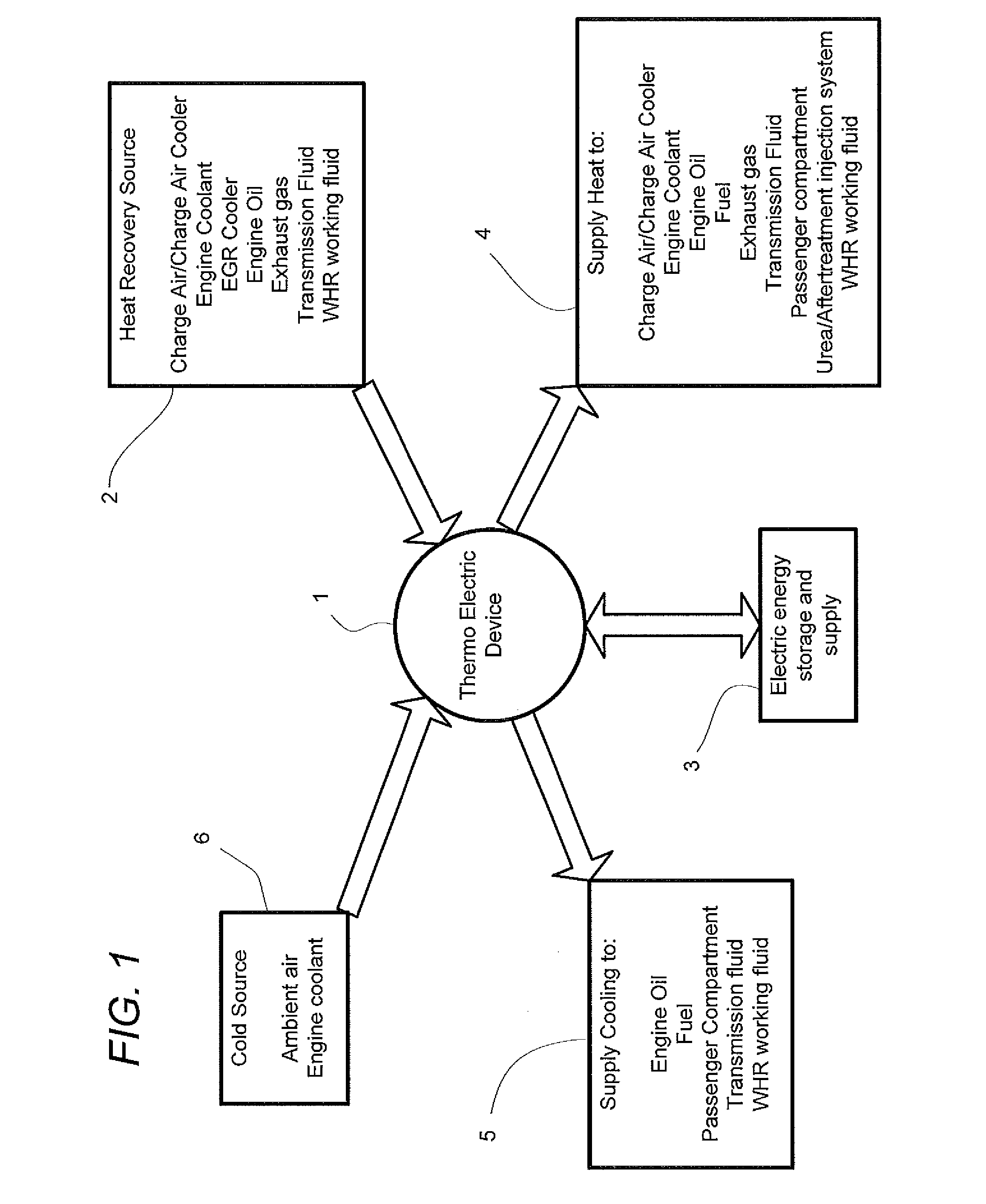

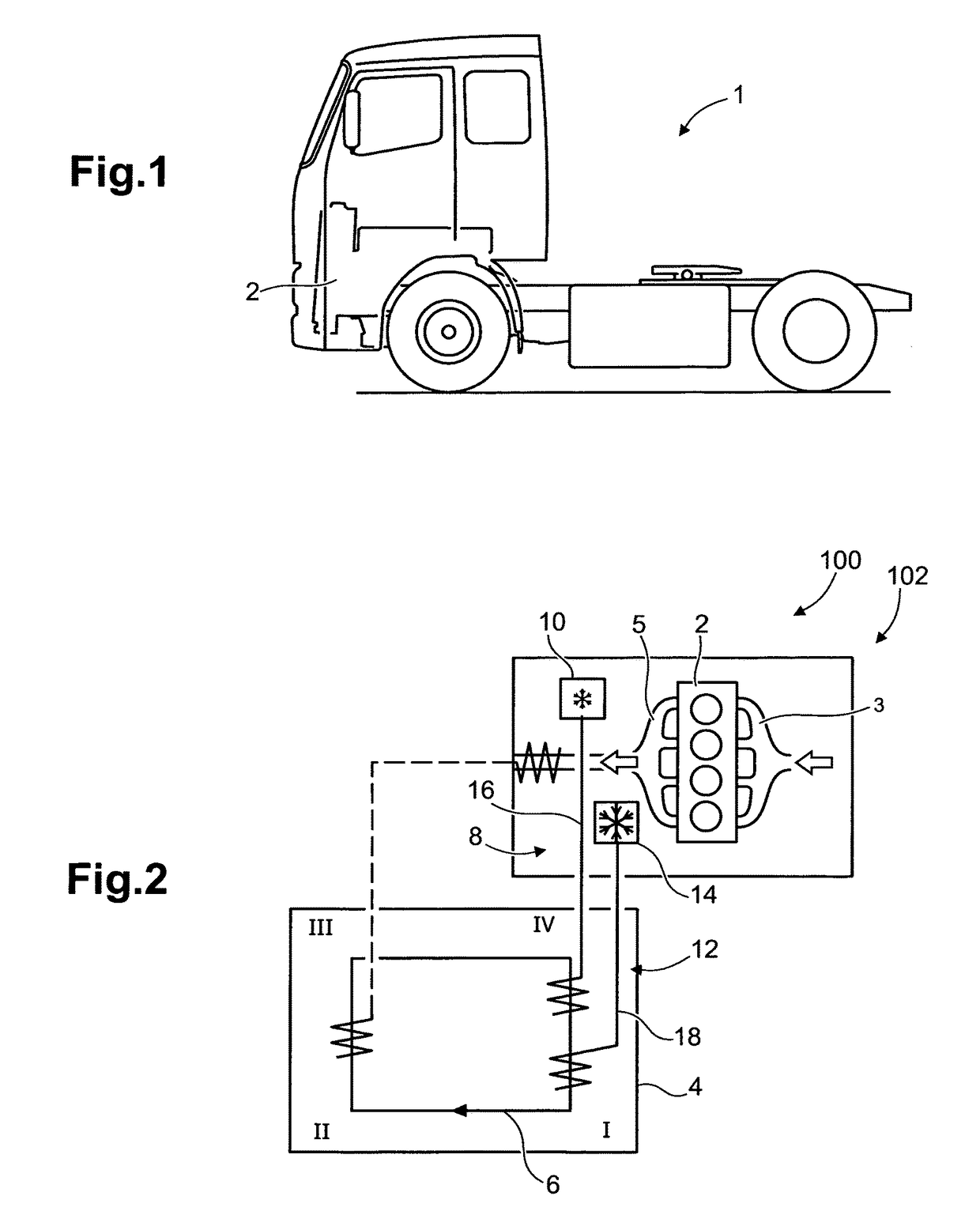

Thermoelectric recovery and peltier heating of engine fluids

InactiveUS20130219872A1Shorten the timeFacilitates heat recoveryElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

A waste heat recovery apparatus and process for use with an internal combustion engine includes a thermo electric apparatus that connects to components of the internal combustion engine to transfer heat between components, generate electric energy from heat extracted from components needing cooling, and convert electric energy to heat energy to transfer to components needing heating.

Owner:MACK TRUCKS

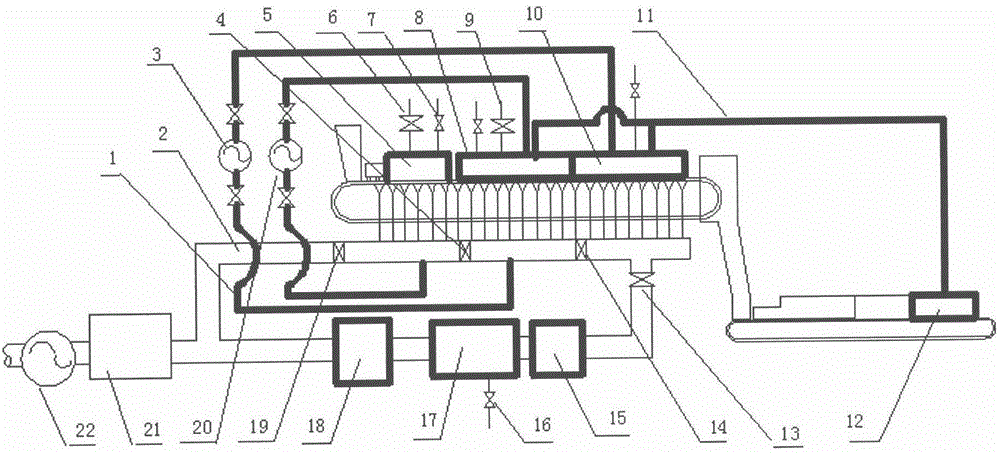

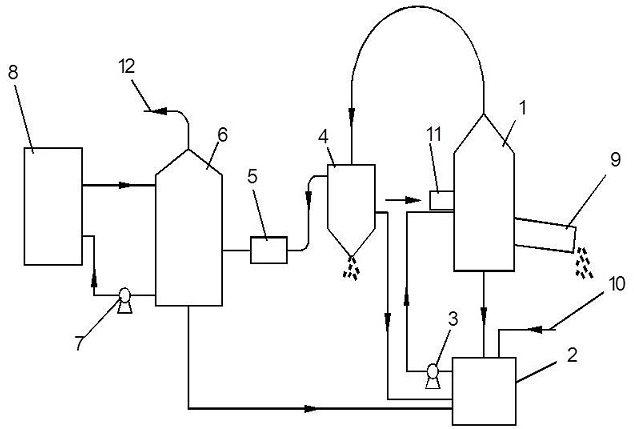

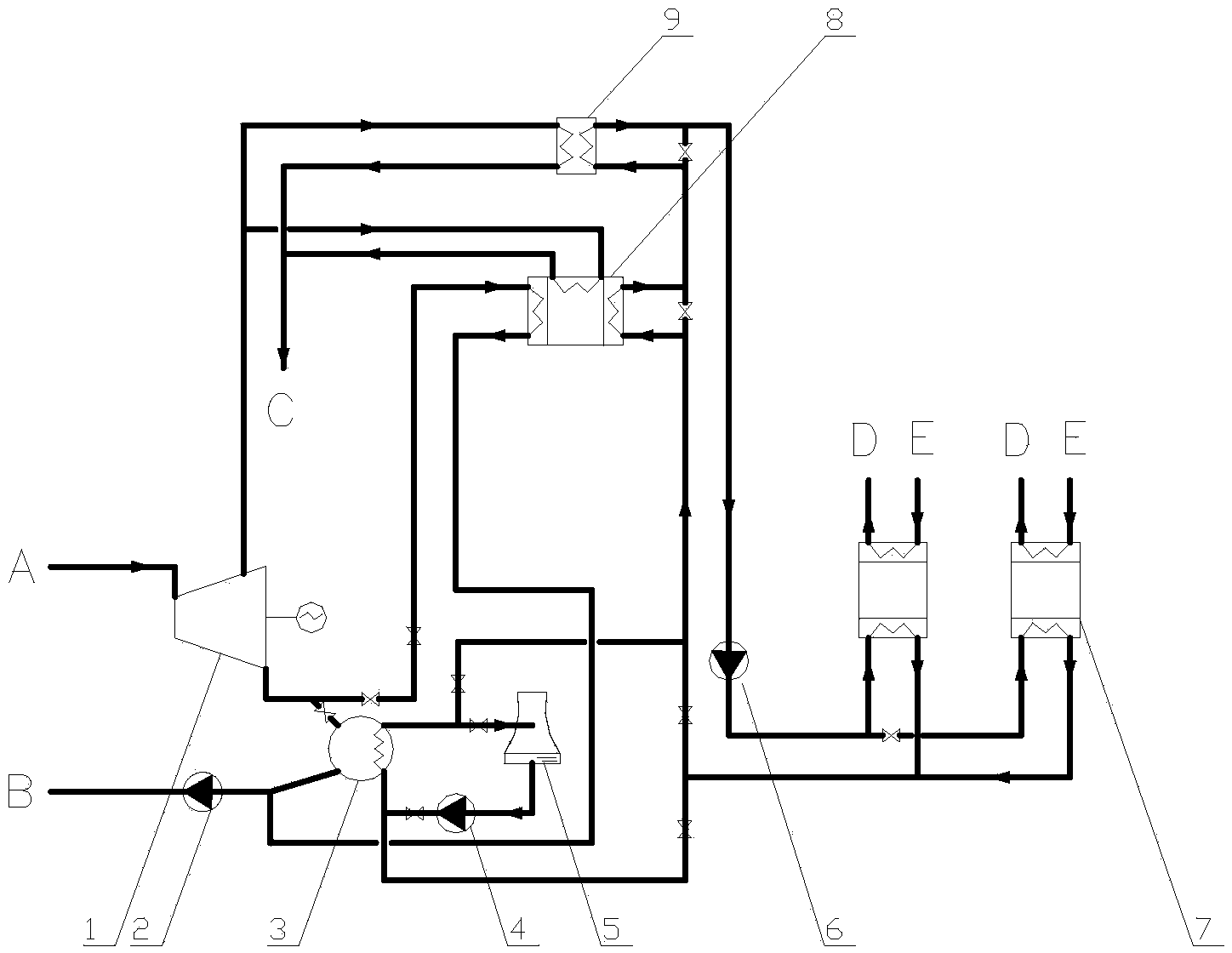

Sintering flue gas energy-saving type denitrification system

ActiveCN104792186AIncrease waste heat recoveryRealize joint denitrification processEnergy industryIncreasing energy efficiencyWaste heat recovery unitFlue gas

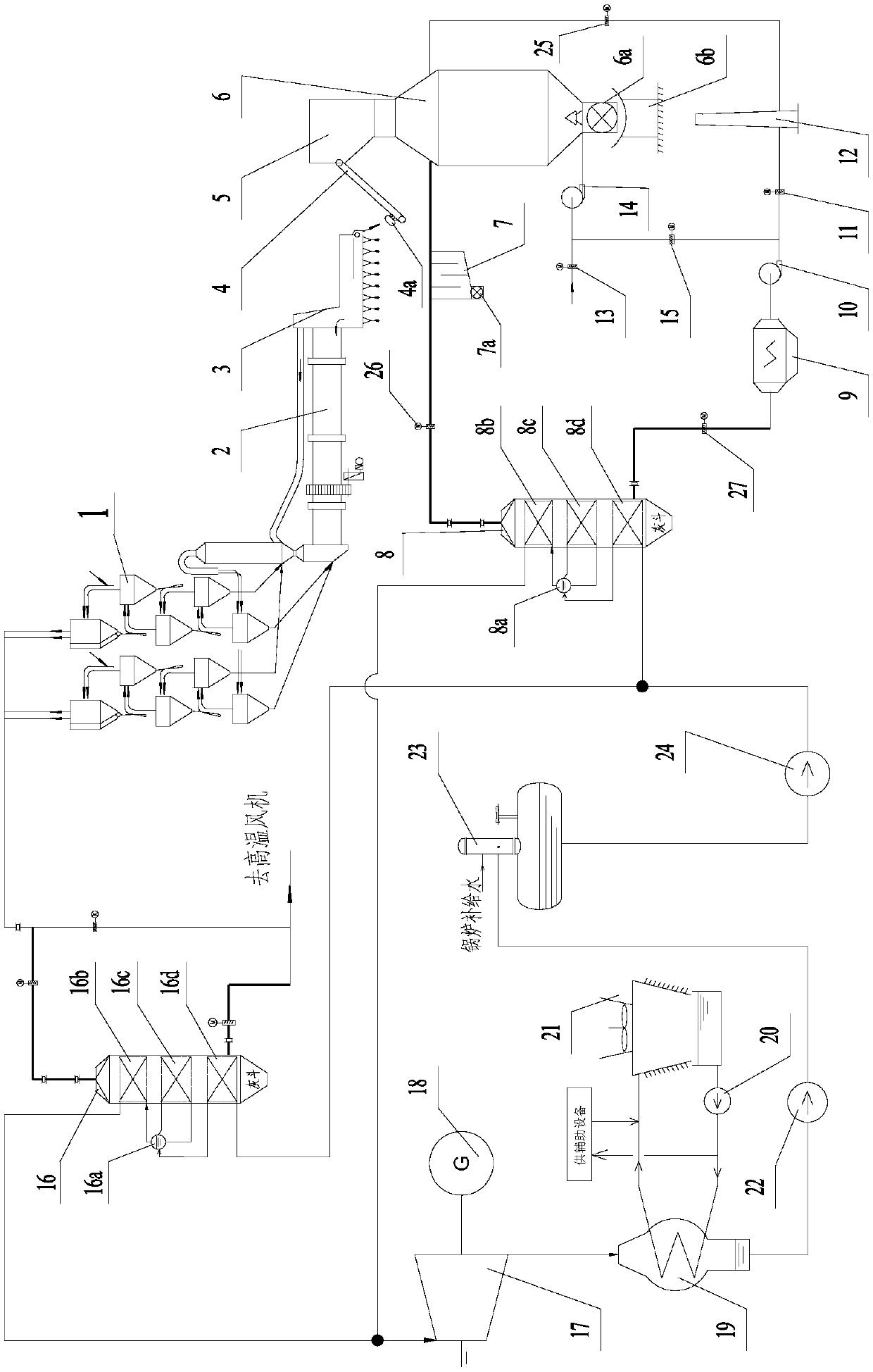

The invention discloses a sintering flue gas energy-saving type denitrification system. The sintering flue gas energy-saving type denitrification system comprises a denitrification device, a heat exchanger, a circulating fan and an ammonification device. The sintering flue gas energy-saving type denitrification system fully uses waste heat of a sintering process, the sintering flue gas efficient denitrification is achieved, and the flue gas waste heat is recovered. The sintering flue gas energy-saving type denitrification system can greatly reduce nitrogen oxide discharge amount of sintering flue gas and improve the waste heat recovery level of the sintering process.

Owner:孙慕文

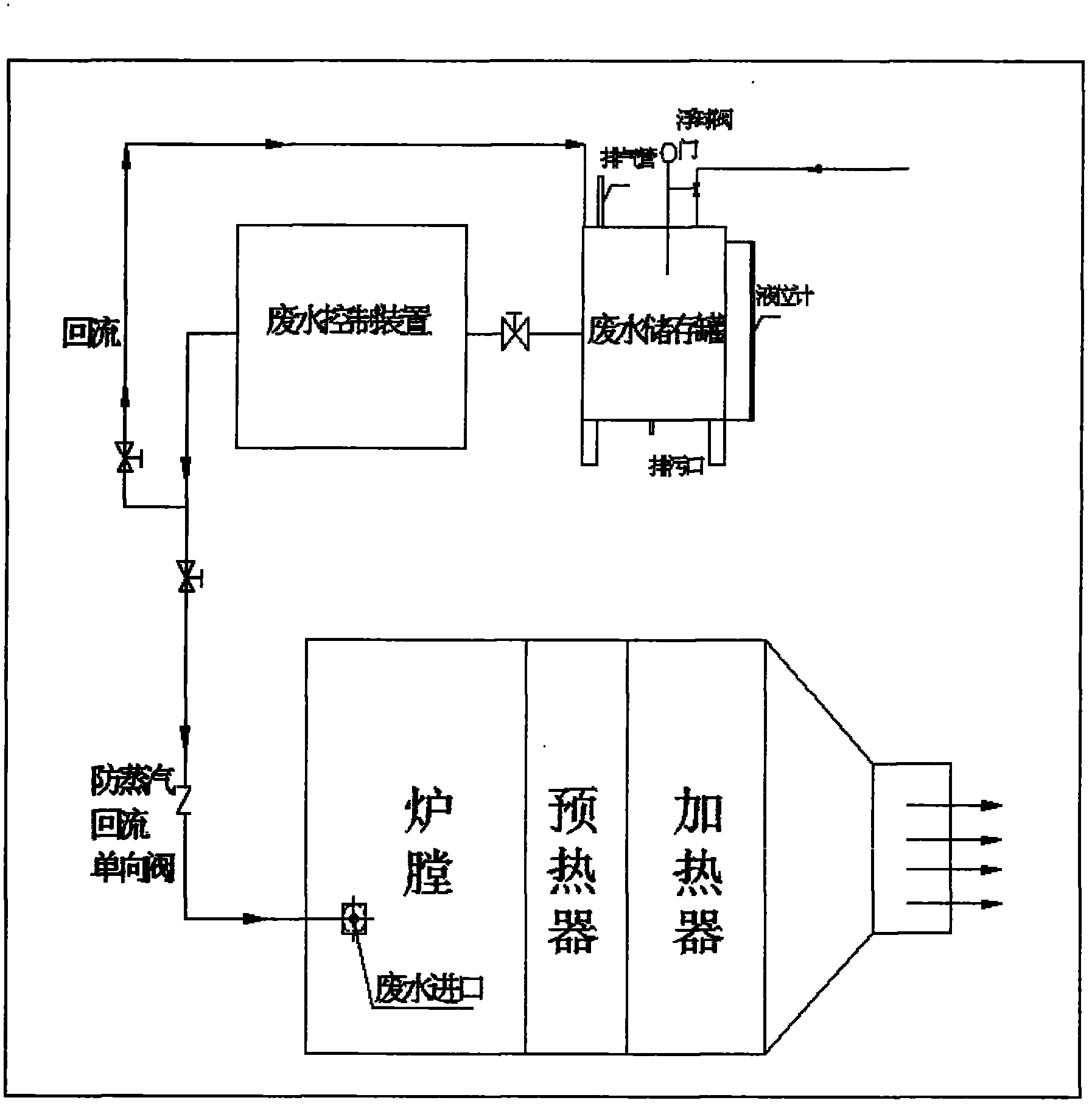

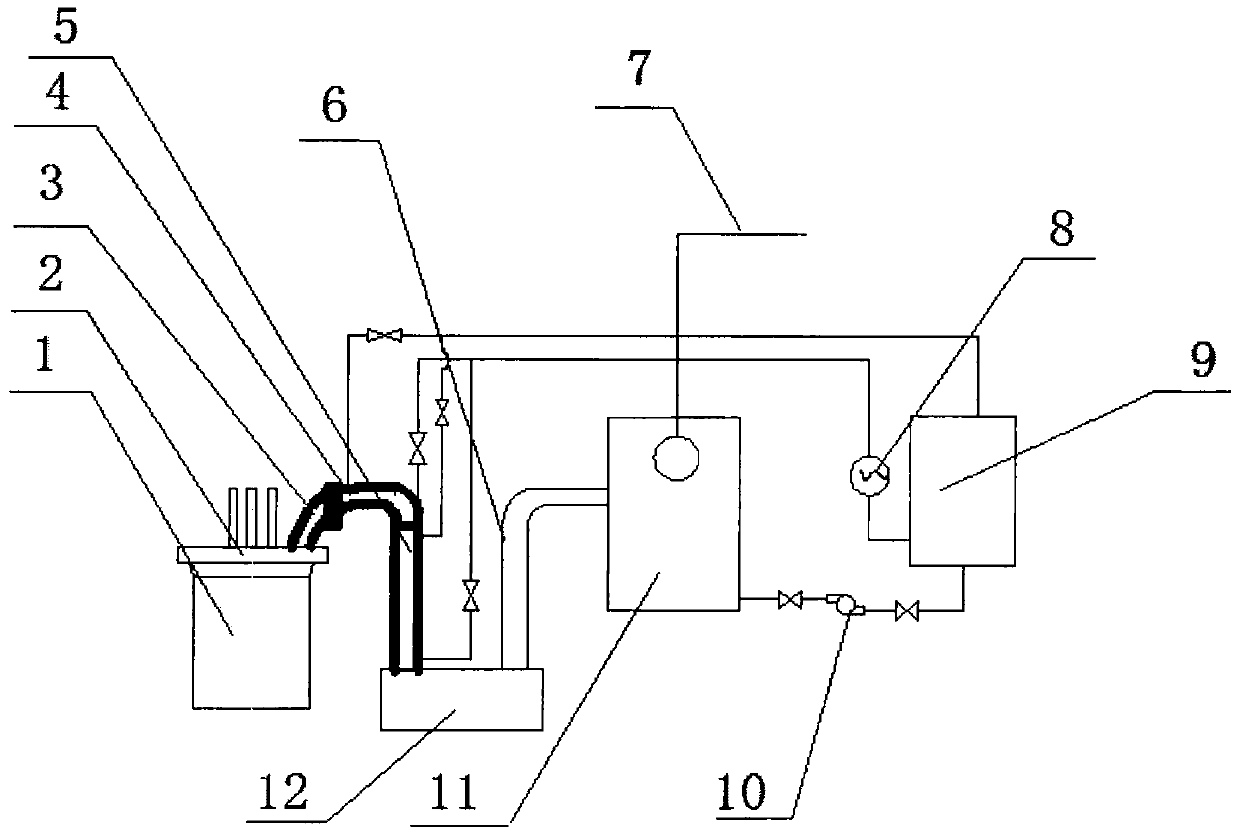

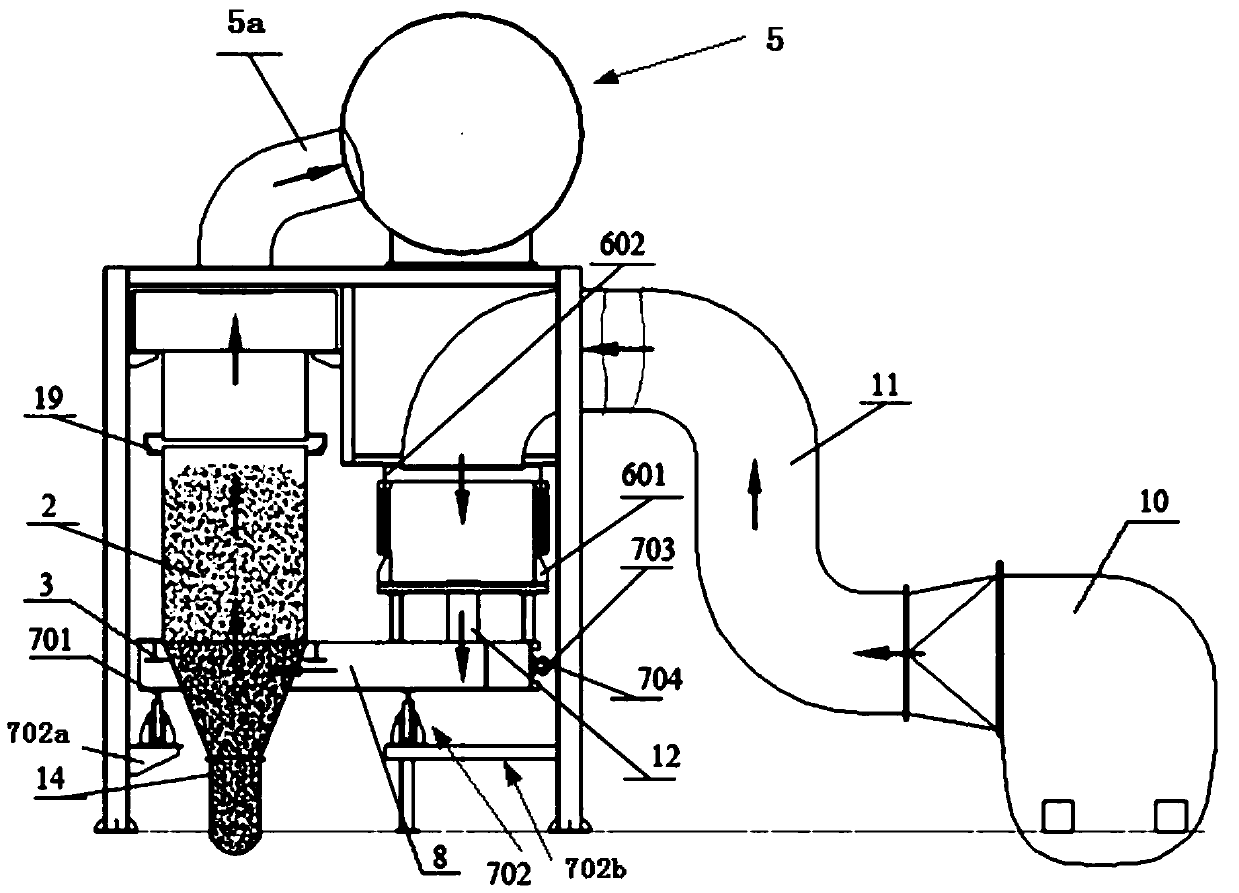

Blast furnace smelting slag water quenching waste steam waste heat recovery system

InactiveCN102424868AImprove waste heat utilization efficiencyIncrease waste heat recoveryLighting and heating apparatusProcess efficiency improvementBlast furnace smeltingWastewater

The present invention provides a blast furnace smelting slag water quenching waste steam waste heat recovery system. The system comprises a blast furnace slag water quenching apparatus, a slag quenching water circulation apparatus and a waste steam waste heat recovery apparatus. The blast furnace slag water quenching apparatus comprises a smelting slag groove, a water quenching apparatus and a slag discharging and conveying belt. The slag quenching water circulation apparatus comprises the water quenching apparatus, a water circulating tank, a water quenching pump and a water supplying pipe. The waste steam waste heat recovery apparatus comprises the water quenching apparatus, a three-phase separator, a fan, a heat exchanger, a hot water pump and a low-temperature user. The method of the present invention is different from the method in the prior art, wherein the recovery of the slag quenching waste water waste heat is adopted to recover the smelting slag waste heat by the method in the prior art, and the waste heat in the waste steam generated from the smelting slag quenching by the recovered water is adopted to recover the smelting slag waste heat by the method of the present invention, the water quality of the waste steam is better than the water quality of the waste water, such that the disadvantages of high hardness of the waste water, equipment scaling, equipment blocking and the like in the prior art are overcome. According to the present invention, the slag quenching waste steam waste heat is effectively recovered; the system has advantages of energy saving and emission reduction, and environmental protection; the collected waste heat can be used to meet the requirements of the low-temperature user.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

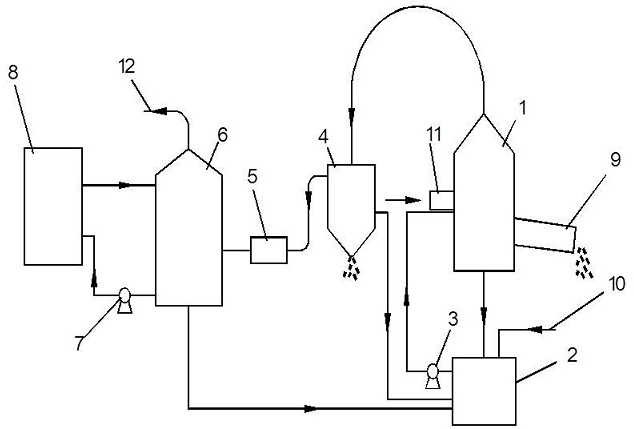

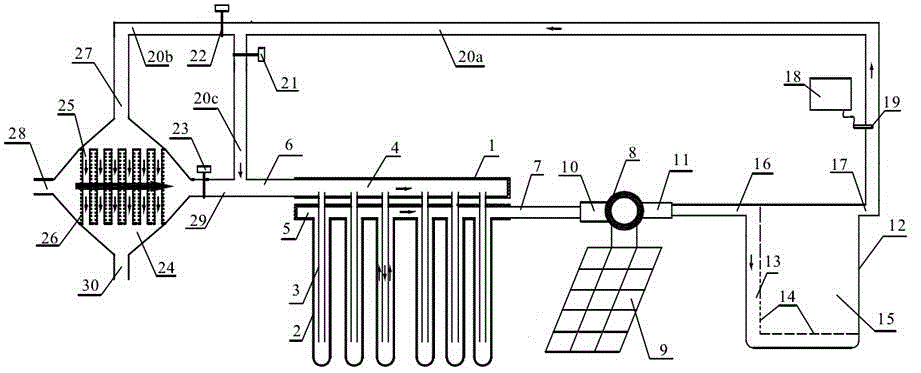

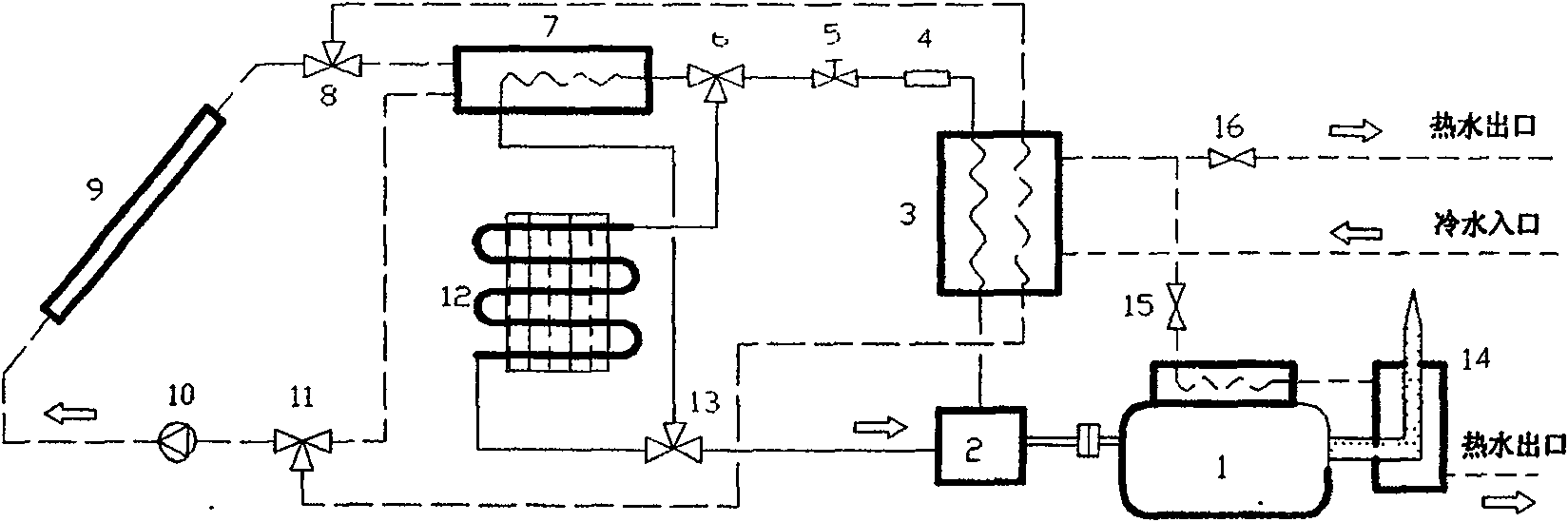

Solar-gas engine heat pump heating device and its operation method

InactiveCN1869553AImprove performanceReduce consumptionInternal combustion piston enginesSolar heat devicesIntermediate heat exchangerEngineering

The invention is a solar-gas engine heat pump heating device, namely a heating device integrating the solar energy utilization technique with the gas engine heat pump technique, composed of solar heat collecting system, gas engine heat pump system and water circuit circulating system and comprising engine, compressor, heat preservation water tank, expansion valve, tee valve, intermediate heat exchanger, heat collector, air source evaporator, fume heat exchanger and flow regulating valve. And it has three different working modes: when external solar radiation intensity is enough high, the gas engine heat pump does not work and it can meet the requirements by directly utilizing solar energy; when the solar radiation intensity is so low that the water temperature in the water tank is very low, the heat pump is switched on and works with the air as heat source; and when the solar radiation intensity is intermediate, the gas engine heat pump works with the solar heated working medium as heat source. And it can in all weathers and continuously supply 80-90 deg.C hot water.

Owner:SOUTHEAST UNIV

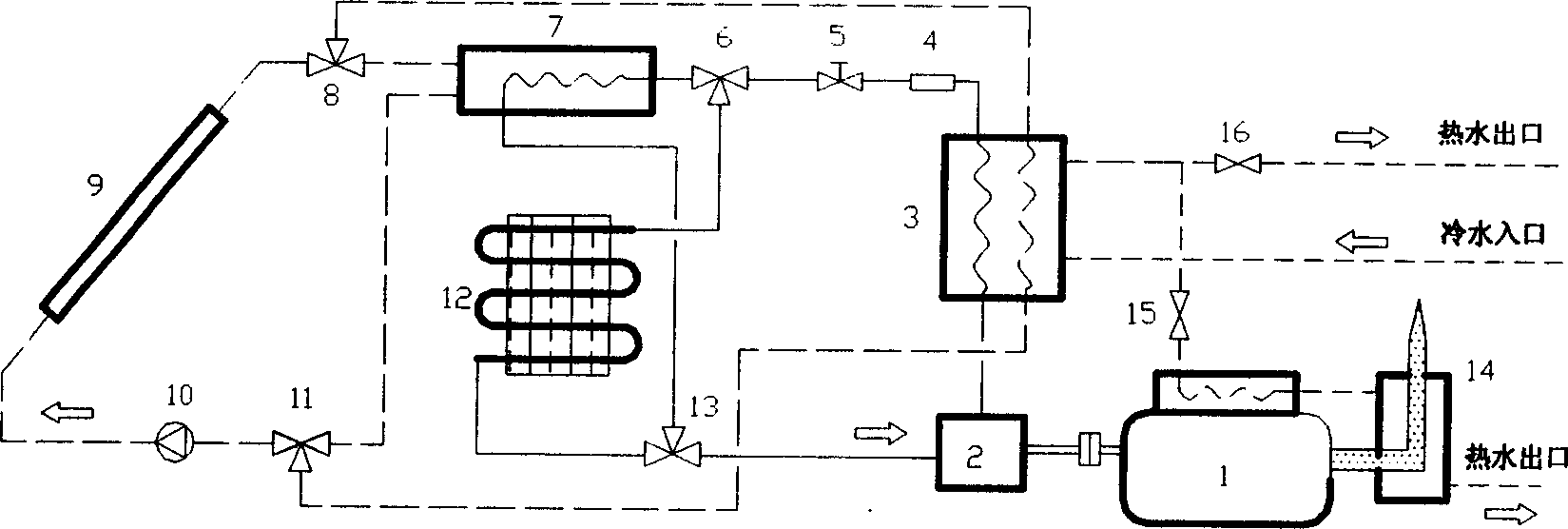

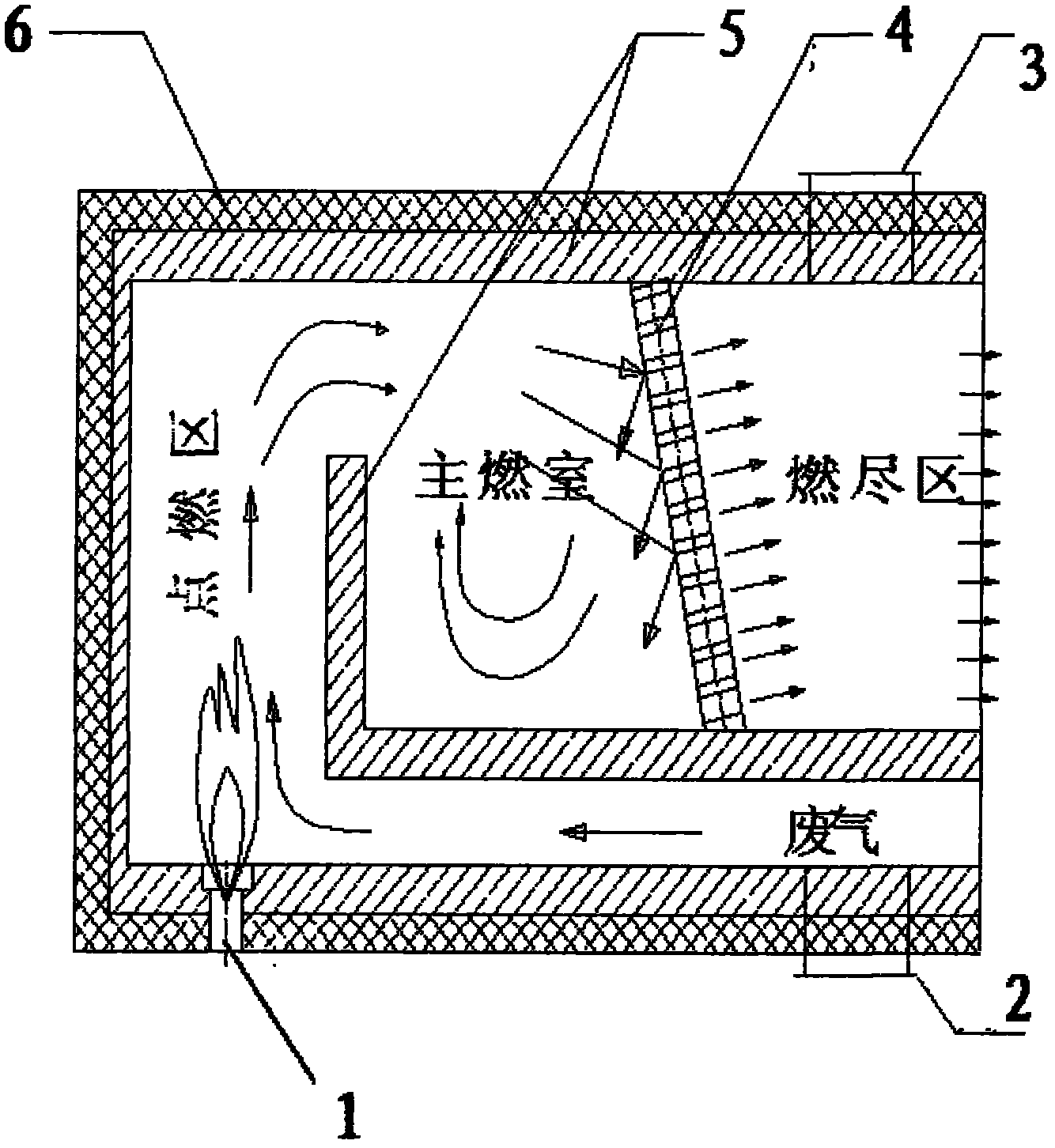

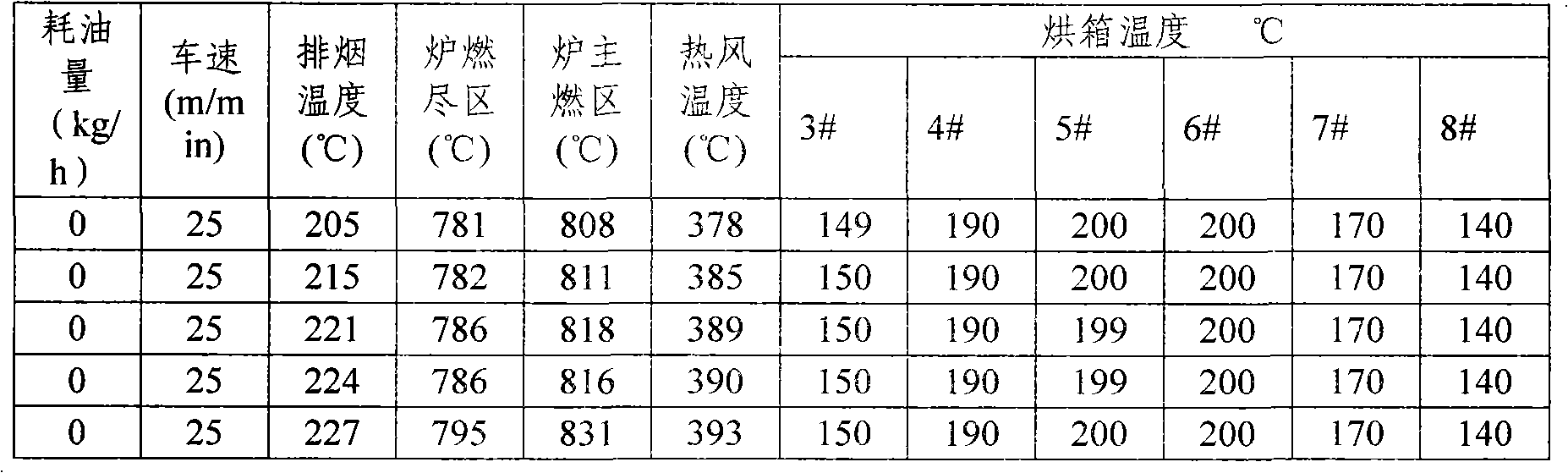

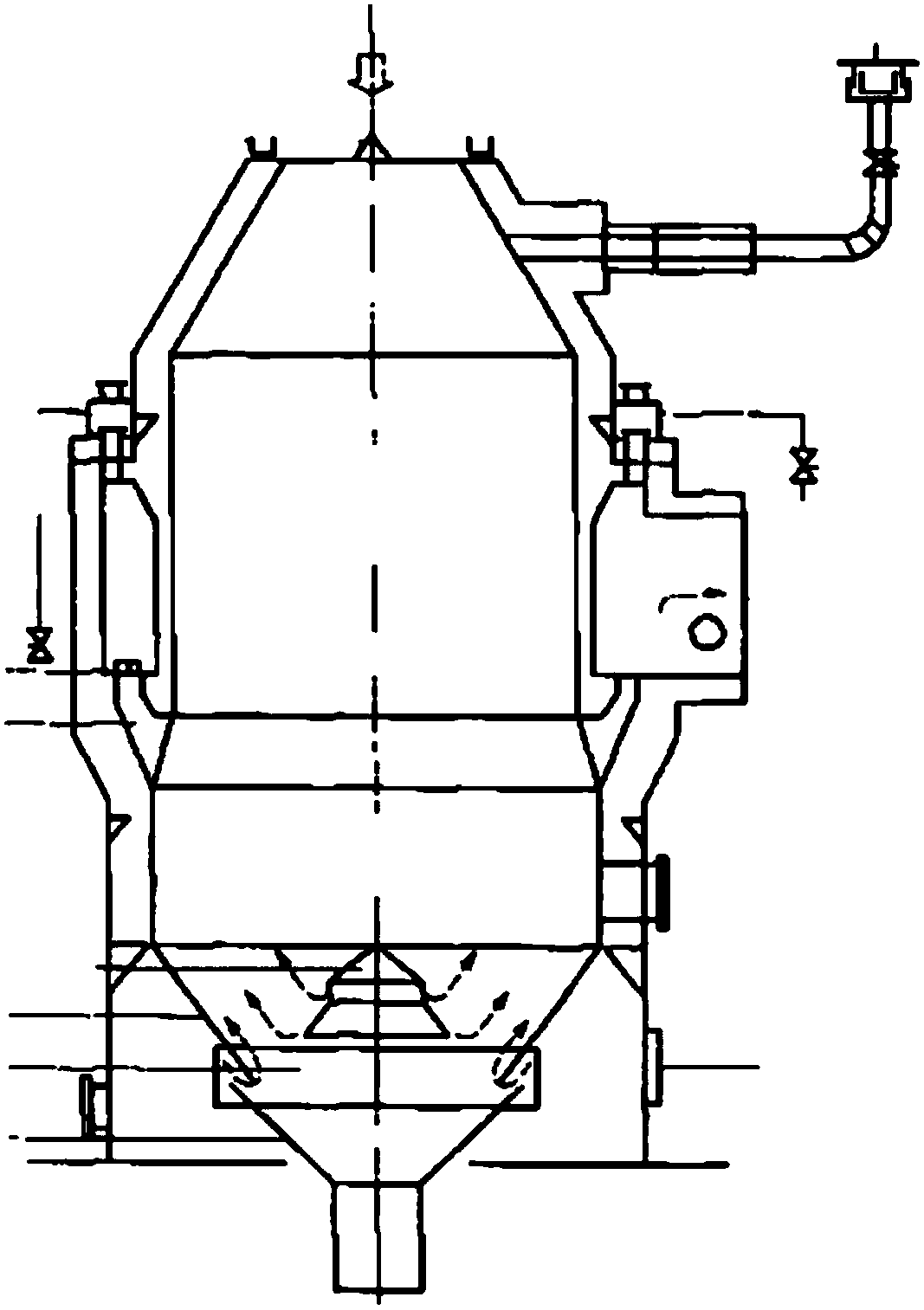

Direct-combustion heat-accumulating-type incineration treatment device and treatment method thereof

InactiveCN102338390ABurn fullyAchieve energy saving effectIncinerator apparatusCombustion chamberDirect combustion

The invention discloses a direct-combustion heat-accumulating-type incineration treatment device, which comprises a direct-current incinerator. The interior and the wall of the hearth of the direct-current incinerator are respectively provided with a divider wall made of a heat accumulating material to divide the hearth into a combustion zone, a main combustion chamber, an after-combustion zone and a waste gas channel, wherein a porous wall made of the heat accumulating material is arranged between the main combustion chamber and the after-combustion zone. When waste gas enters the combustion zone from the waste gas channel to be ignited, the waste gas with high flow rate enters the combustion chamber, and rebounds after meeting the porous wall, and a gas flow turns back to be mixed together with a new gas flow to form a mixed flow state; and smoke enters the after-combustion zone after being rectified through the porous wall. Moreover, the invention also discloses a treatment method for the direct-combustion heat-accumulating-type incineration treatment device.

Owner:西安宝昱热工机电有限公司

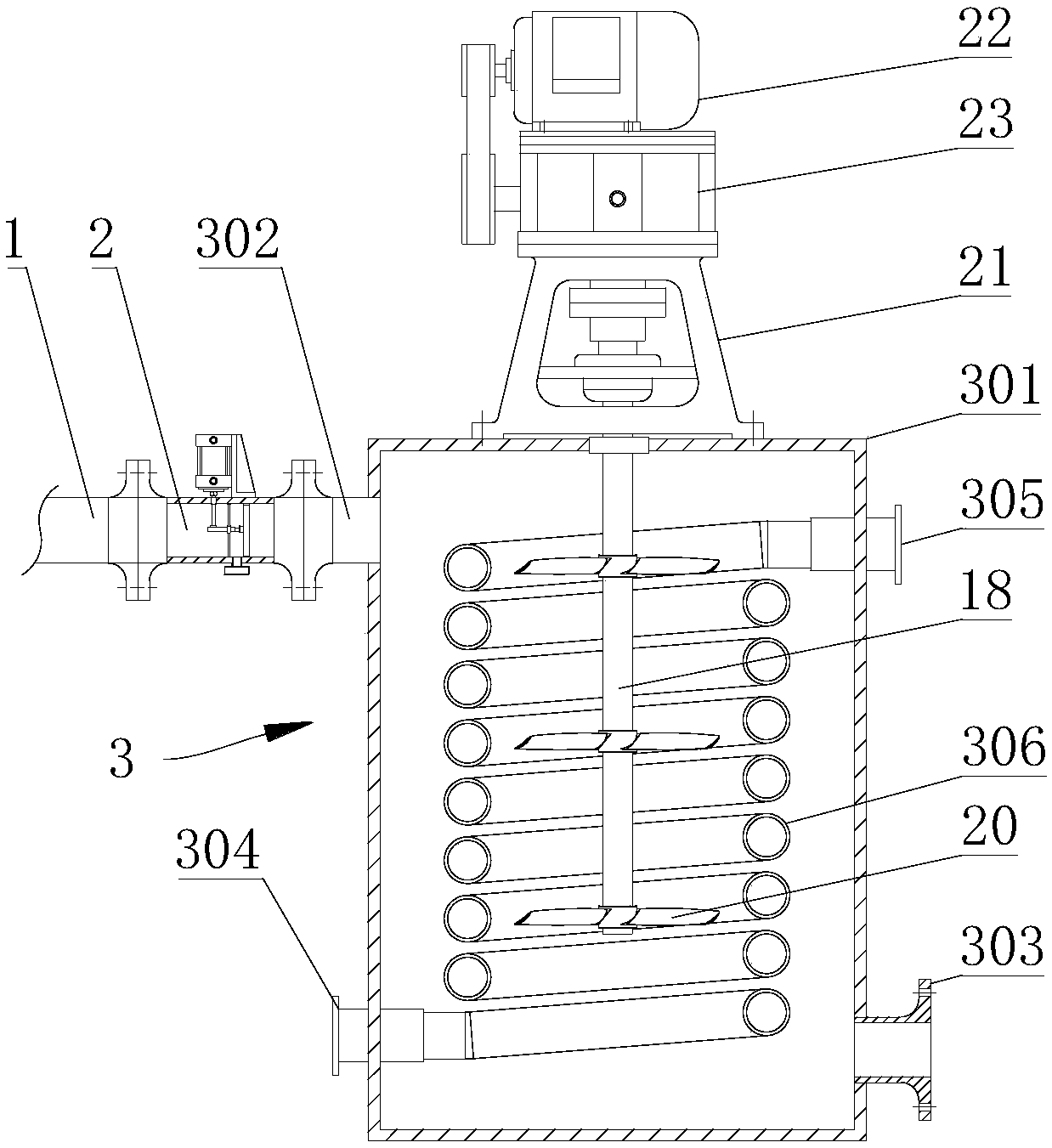

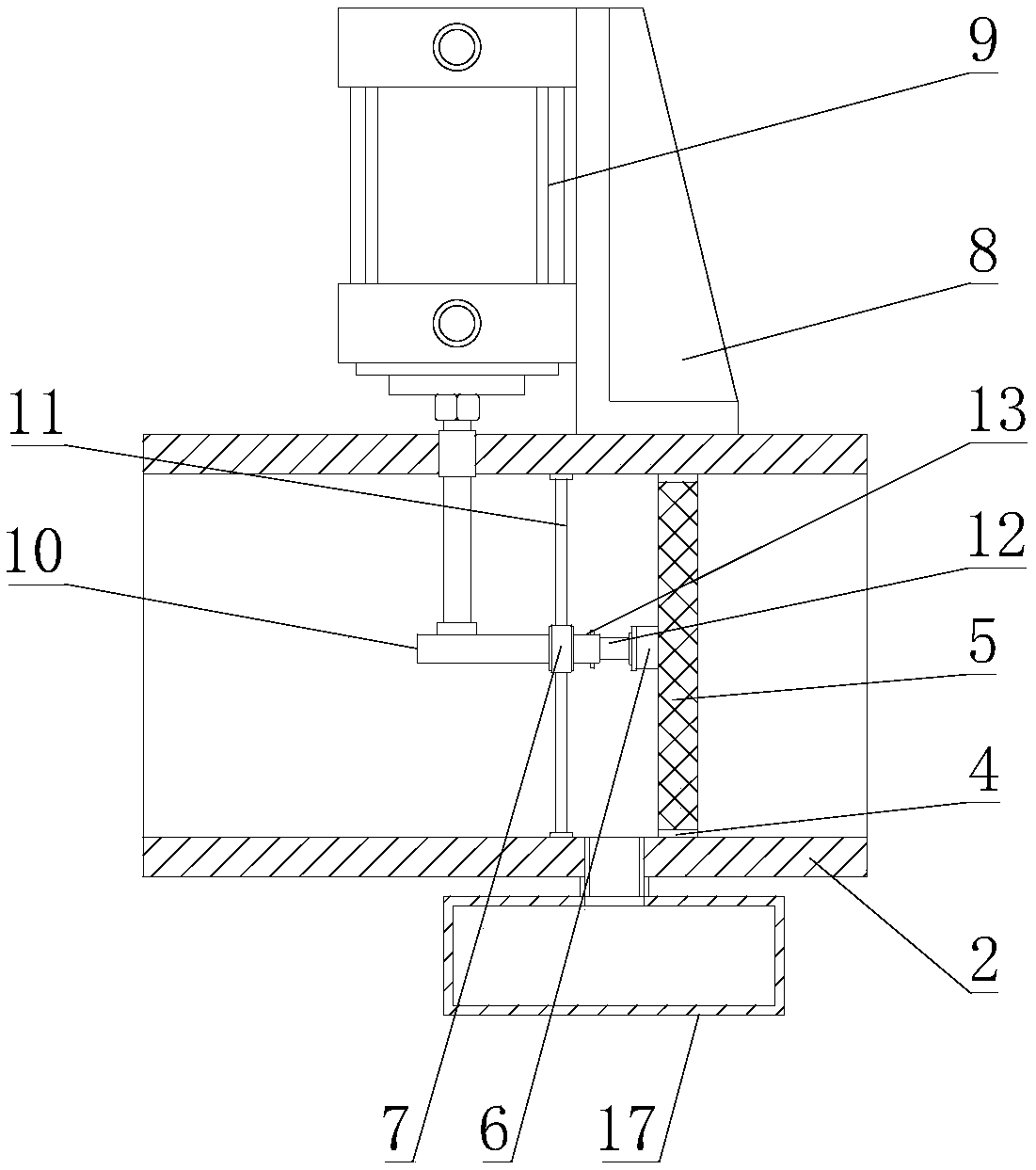

Evaporator capable of utilizing waste heat

PendingCN109489440AAvoid cloggingImprove heat utilizationIncreasing energy efficiencySteam generation using hot heat carriersEngineeringSoot

The invention discloses an evaporator capable of utilizing waste heat. The evaporator comprises a soot gas inlet pipe, a dust removing square pipe and an evaporator body; the soot gas inlet pipe is inflange connection to the inlet end of the dust removing square pipe, the evaporator body comprises a casing and further comprises a hot fluid inlet pipe, a hot fluid outlet pipe, a cold fluid inlet pipe, a cold fluid outlet pipe and a spiral heat exchange pipe which are fixedly welded to the casing, the hot fluid inlet pipe is in flange connection to the outlet end of the dust removing square pipe, a filter mesh frame is fixedly welded to the inner pipe wall of the dust removing square pipe, the inner wall of the filter mesh frame is fixedly connected with a filter net, a comb brush for cleaning the filter net is arranged on the side, close to the soot gas inlet pipe, of the filter net, and the comb brush moves vertically in the dust removing square pipe along with a sliding sleeve. According to the evaporator, hot soot gas is used for exchanging heat with cold water in the evaporator, and therefore hot steam can be used for production and life; and soot particles are filtered out through the filter net to avoid blockage of the evaporator, the heat utilization rate is high, the structure is simple, operation is easy, and energy saving and environmental protection are achieved.

Owner:江苏世林博尔制冷设备有限公司

Heat accumulating type flue gas waste heat recovery device

InactiveCN101893402ASolve the problem of unstable qualityReduce consumptionHeat storage plantsFlue gasProcess engineering

The invention provides a heat accumulating type flue gas waste heat recovery device. The device consists of a heat accumulator and a heat exchanger, wherein the heat accumulator comprises a heat accumulator barrel and at least one heat accumulating body arranged in the middle or on the inner wall of the heat accumulator barrel, the front end of the heat accumulator barrel is provided with a flue gas inlet, and a rear end outlet of the heat accumulator is connected with the heat exchanger directly or by a flue; and a flue gas outlet is formed at the tail end of the heat exchanger. The heat accumulating body is made of a solid heat accumulation material or a phase-change heat accumulation material (PCM material). The heat accumulating type flue gas waste heat recovery device has the advantages of suppressing temperature fluctuation of flue gas removing, effectively increasing recovery rate of waste heat and improving waste heat output quality, reducing production energy consumption of enterprises to the maximum degree, and fully meeting flue gas waste heat recovery requirements of various industrial furnaces and industrial boilers.

Owner:CHONGQING GIENT HEATING IND

Flue gas waste heat recovery unit

ActiveCN104180523AIncrease discharge temperatureReduce consumptionStorage heatersAir heatersWaste heat recovery unitFlue gas

The invention relates to a flue gas waste heat recovery unit which comprises a flue gas unit, a generator unit, a condenser unit, an absorber unit, a water return pipe and a water supply pipe. The flue gas unit is sequentially connected with the generator unit, the condenser unit and the absorber unit to form a flue gas heat exchanging path; the outlet of the generator unit is connected with the inlet of a solution-to-solution heat exchanger, the outlet of the absorber unit is divided into two paths: one path is merged with the outlet of the solution-to-solution heat exchanger to be connected with the inlet of a solution-to-water heat exchanger through a solution spray pump, the outlet of the solution-to-water heat exchanger is connected with a solution spray mechanism in the absorber unit, the other path is connected with the inlet of a solution-to-solution heat exchanger through a solution circulating pump, and the outlet of the solution-to-solution heat exchanger is connected with a dilute solution spray mechanism through the generator unit so as to form a solution heat exchanging and circulating loop; the outlet of the condenser unit is connected with the inlet of a water-to-water heat exchanger through a condense water spray pump, the outlet of the water-to-water heat exchanger is connected with a condense water spray mechanism through the condenser unit to form a condense water heat exchanging and circulating loop; the water return pipe is connected with a water-to-water heat exchanger unit and the inlet of a solution-to-water heat exchanger, and the water supply pipe is connected with the water-to-water heat exchanger and the inlet of the solution-to-water heat exchanger.

Owner:TSINGHUA UNIV +1

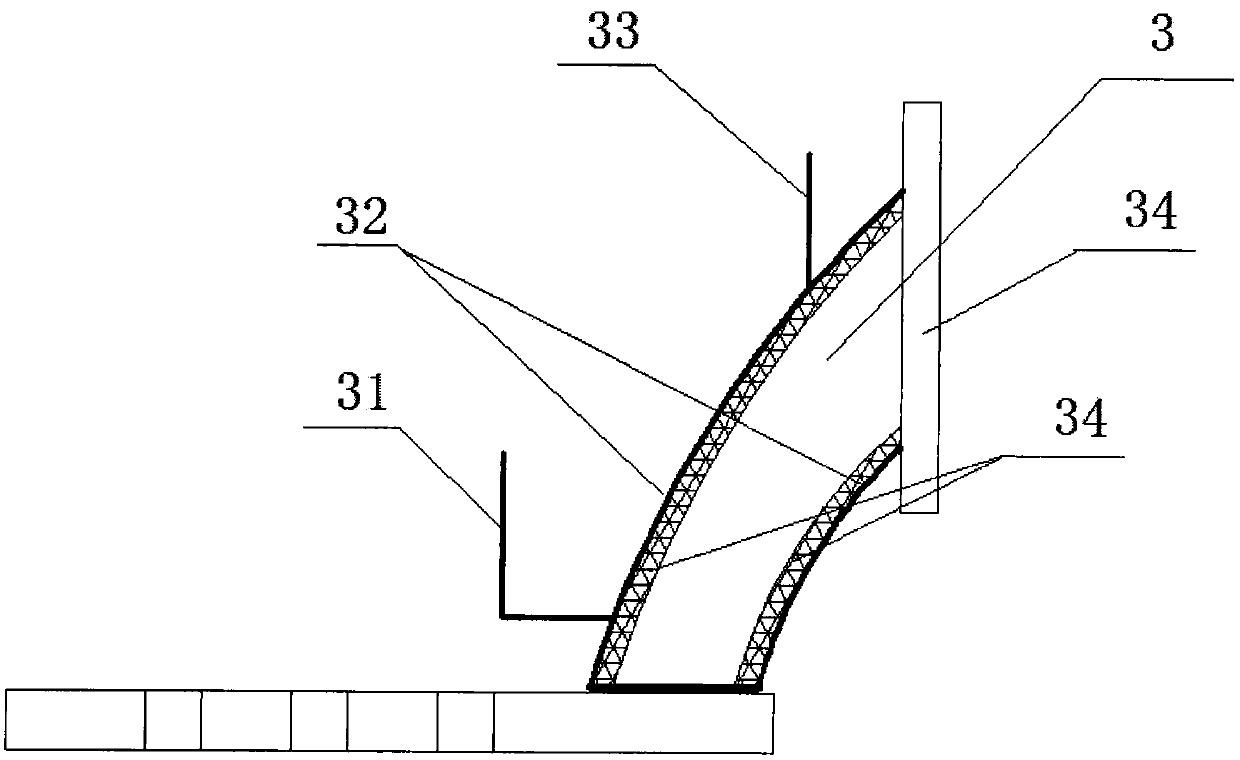

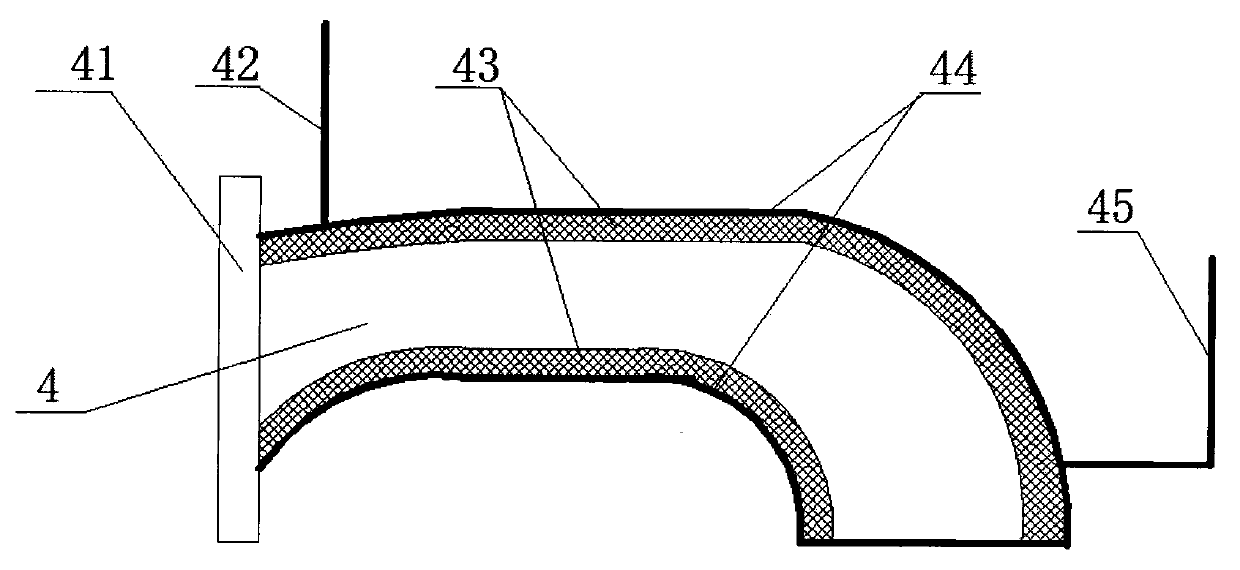

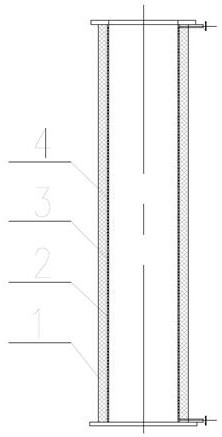

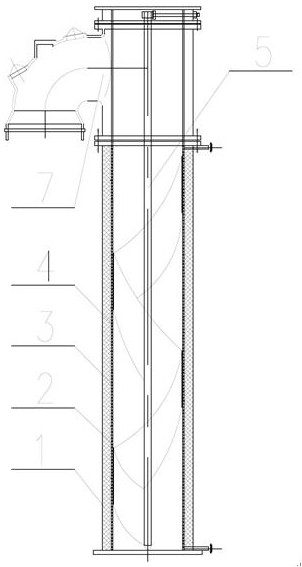

Efficient cement kiln waste heat recovery and power generation system and method

ActiveCN106640221AImprove efficiencyImprove economyRotary drum furnacesIncreasing energy efficiencyProcess engineeringTurbine

The invention provides an efficient cement kiln waste heat recovery and power generation system and method, and belongs to the technical field of cement kiln waste heat utilization. The waste heat recovery and power generation system comprises a clinker stepped cooling device, a waste heat recycling device, a turbine power generation device, a cyclic cooling water device and a waste gas treating device. The clinker stepped cooling device comprises a grate cooler and a vertical cooling device. Sensible heat of clinker can be recycled in a stepped mode through the grate cooler and the vertical cooling device. By means of the cooling way, a large quantity of low-temperature waste gas at the tail of a conventional grate cooler is prevented from being directly exhausted, the level of kiln head waste heat resources and the waste heat recovery quantity are improved, and the cement kiln waste heat recovery and power generation efficiency and technical and economical indexes are effectively improved.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

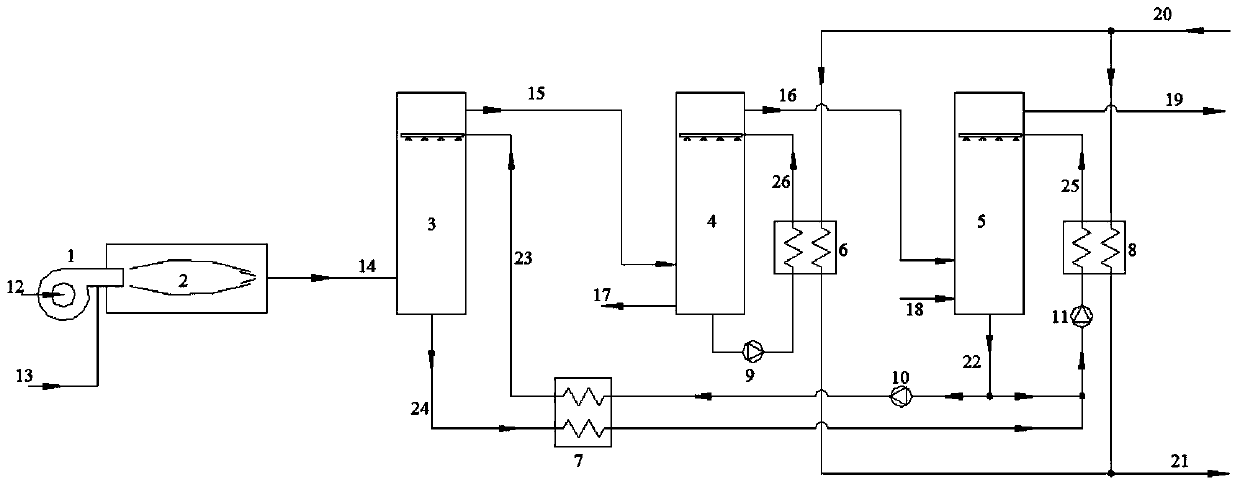

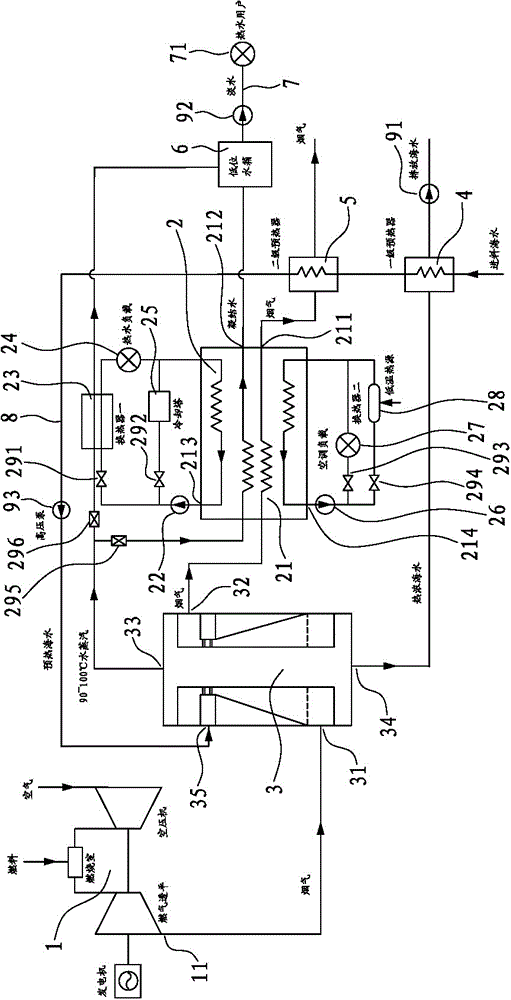

Low-vacuum absorption-type composite heat pump residual heat supply system based on ultra-great-temperature-difference heat supply network

InactiveCN103438492ASafe and reliable workIncrease heating rateLighting and heating apparatusEnergy efficient heating/coolingWater basedCogeneration

The invention relates to a low-vacuum absorption-type composite heat pump residual heat supply system based on an ultra-great-temperature-difference heat supply network, and belongs to the field of residual-heat-recovery-type cogeneration based on low-vacuum circulation water heating as well as absorption-type heat exchange. The low-vacuum absorption-type composite heat pump residual heat supply system comprises an absorption-type heat pump residual heat recovery device, a peak adjusting heater, a heat supply network ultra-great-temperature-difference heat exchange machine set as well as pipeline components. The low-vacuum absorption-type composite heat pump residual heat supply system is characterized by also comprising a direct dead steam recovery device as a water-based heat loading source of the heat supply network; a cold side inlet of the device is connected with a water return pipe of the heat supply network, and an outlet of the device is connected with a water inlet of an absorption-type heat pump heat supply network; a water outlet of the absorption-type heat pump heat supply network is connected with a water of a heat supply network of the peak adjusting heater; a water outlet of the heat supply network of the peak adjusting heater is connected with a water supply pipe of the heat supply network; dead steam enters the direct dead steam recovery device and the absorption-type heat pump evaporator. The low-vacuum absorption-type composite heat pump residual heat supply system provided by the invention is relatively higher in efficiency for thermal power plants than that in the conventional recovery mode for extracting residual heat from cooling water, can improve the dead steam residual heat utilization quantity by more than 1-2 times, and is especially suitable for central heat supply systems of middle and large sized turbosets.

Owner:张茂勇

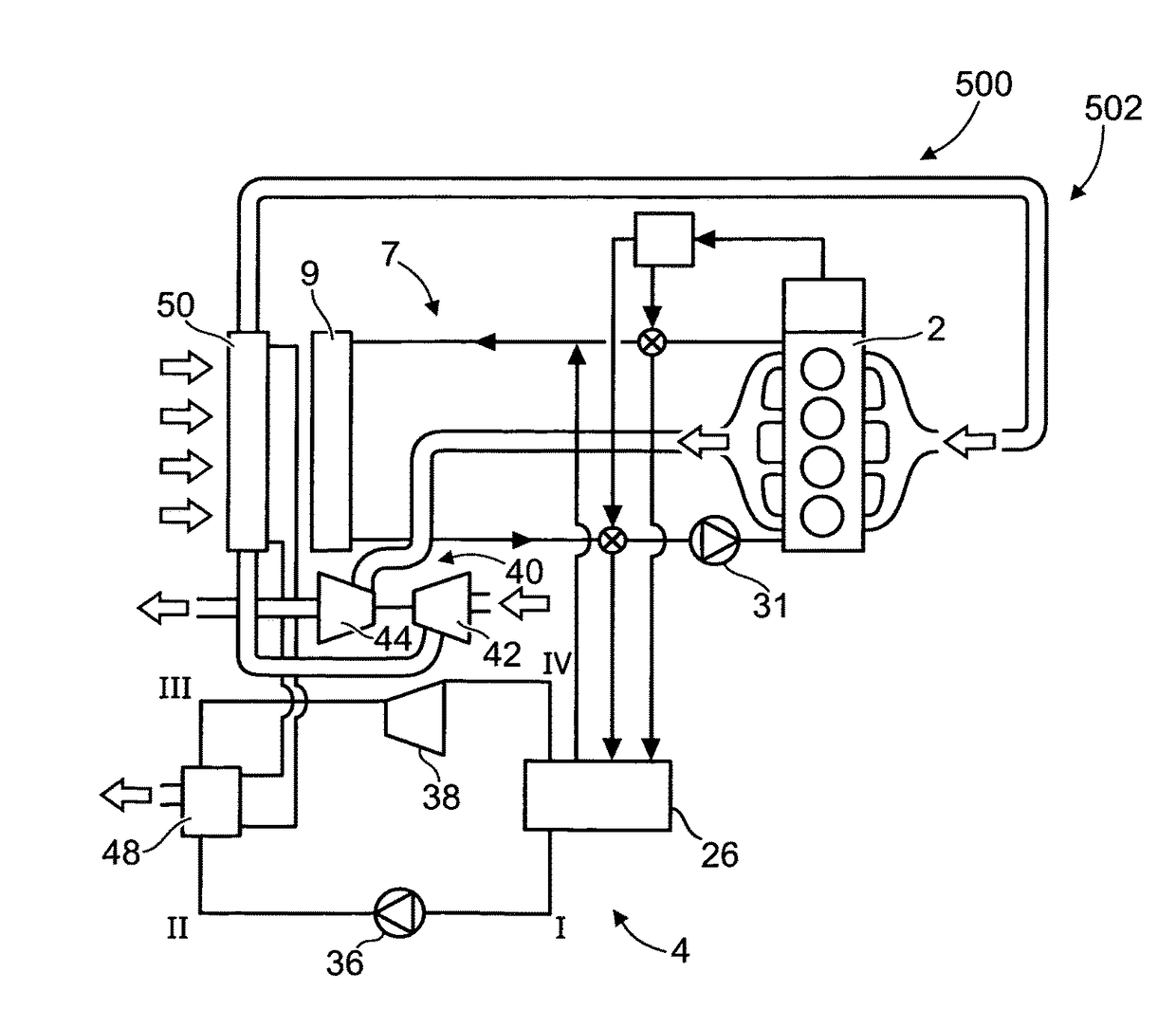

A waste heat recovery device

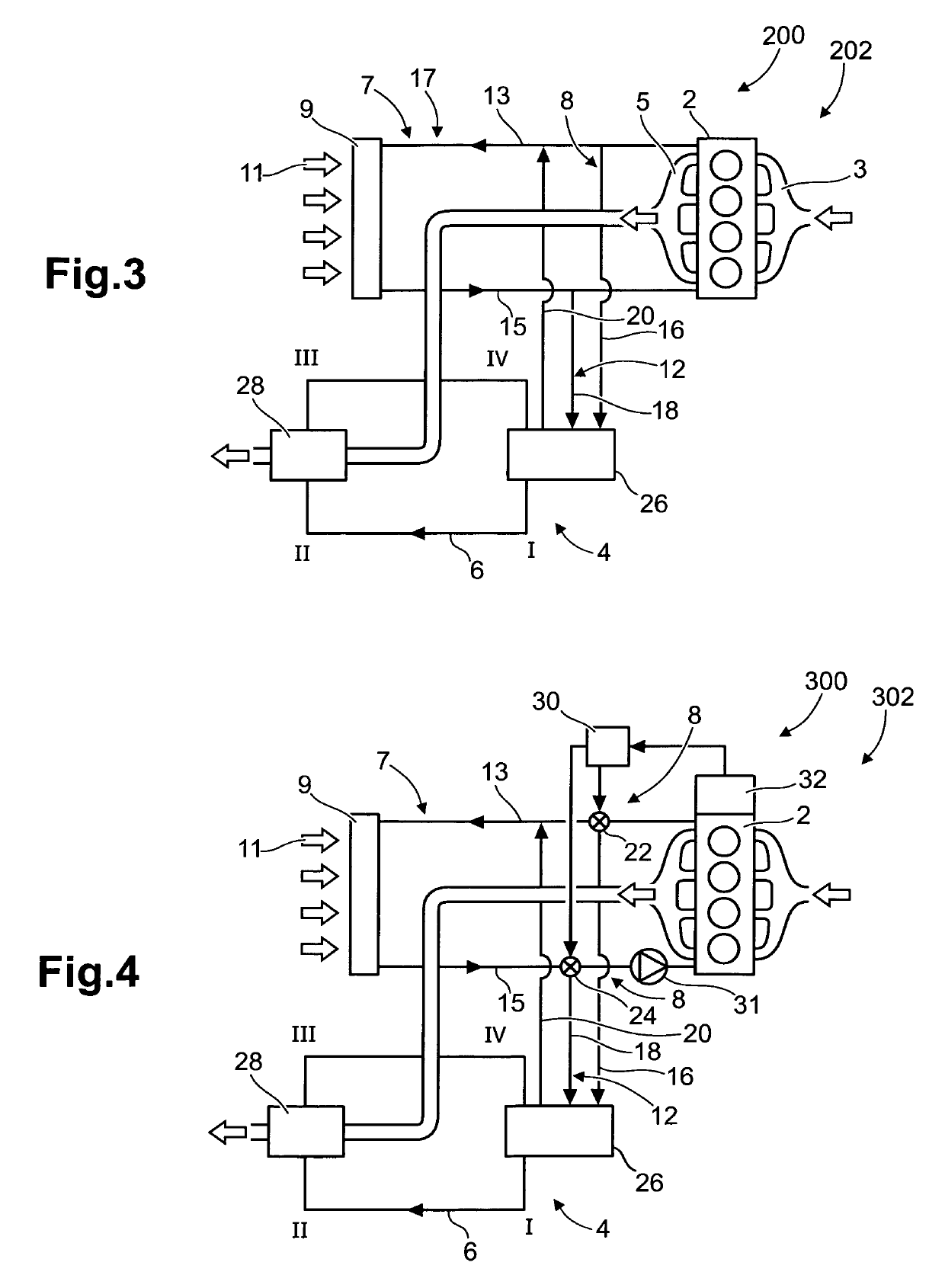

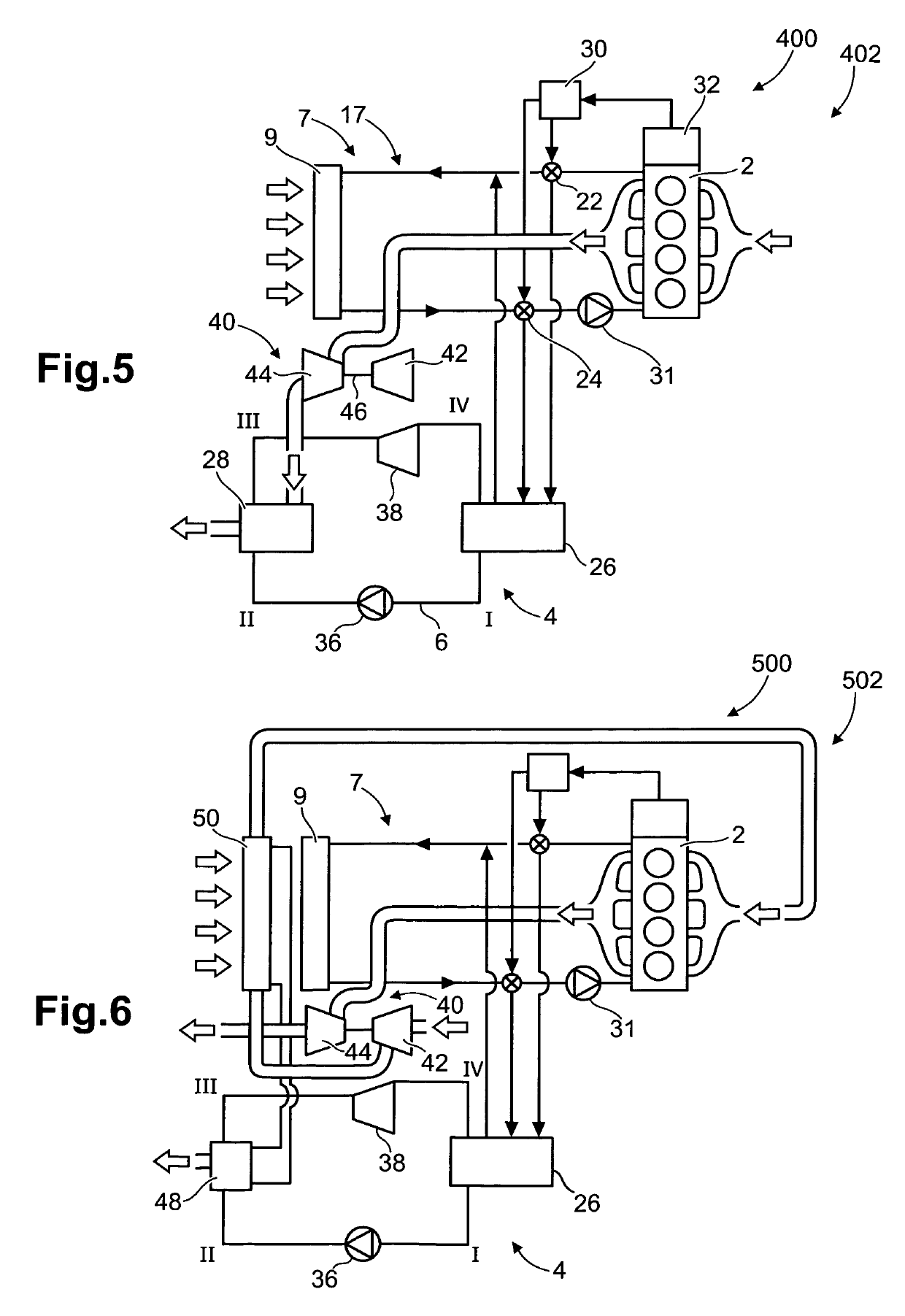

ActiveUS20170152766A1Improve cooling effectIncrease waste heat recoveryInternal combustion piston enginesExhaust apparatusWaste heat recovery unitWorking fluid

A device for recovery of waste heat generated during operation of an internal combustion engine includes a thermodynamic engine, which includes a working fluid circulation circuit and is configured for recovery of the waste heat a first arrangement for providing a first coolant from a first source for heat exchange with the working fluid in the working fluid circulation circuit, and at least one further arrangement for providing a further coolant from a further source for heat exchange with the working fluid in the working fluid circulation circuit, wherein the further source is at different heat level than the first source during operation of the internal combustion engine.

Owner:VOLVO LASTVAGNAR AB

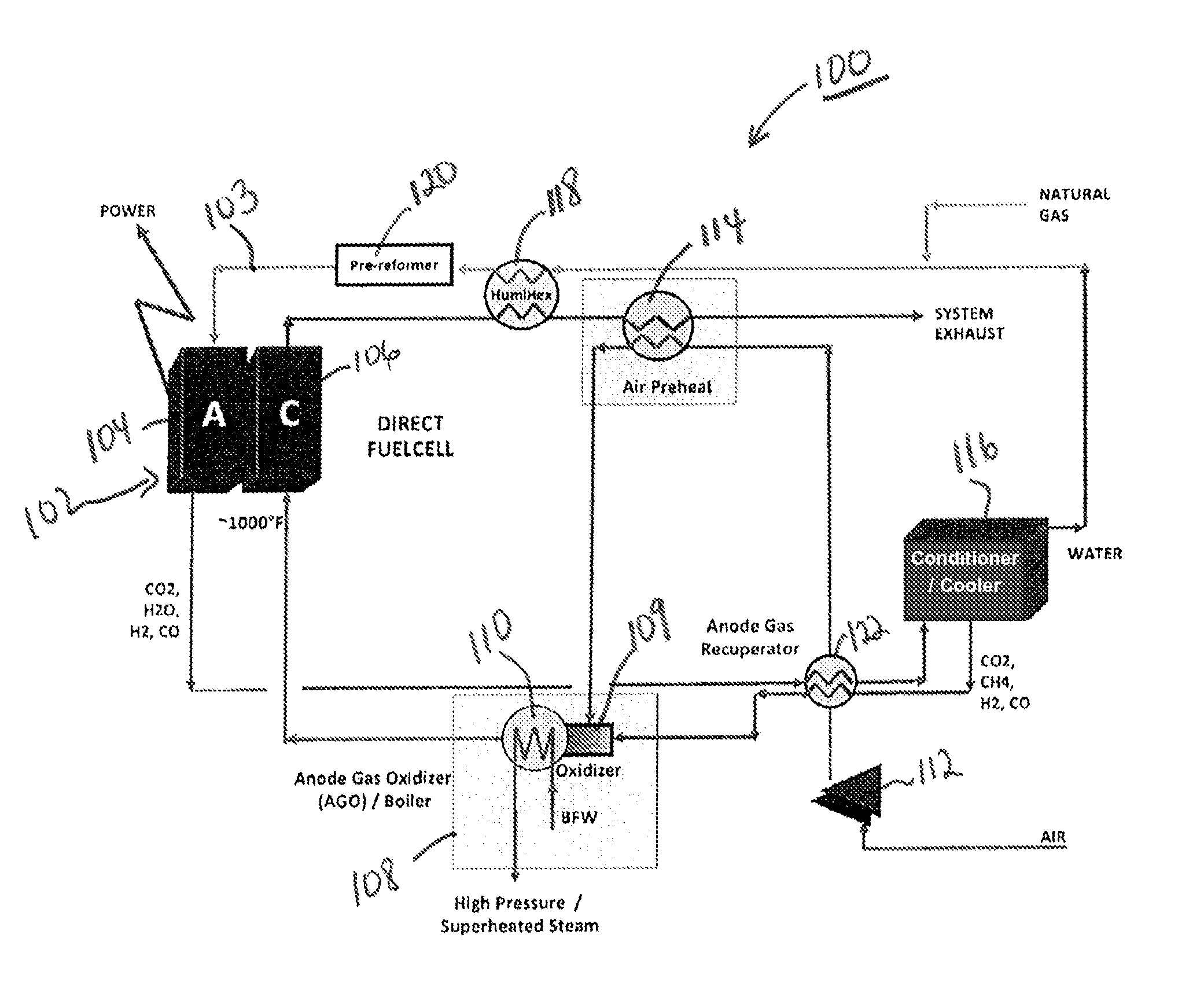

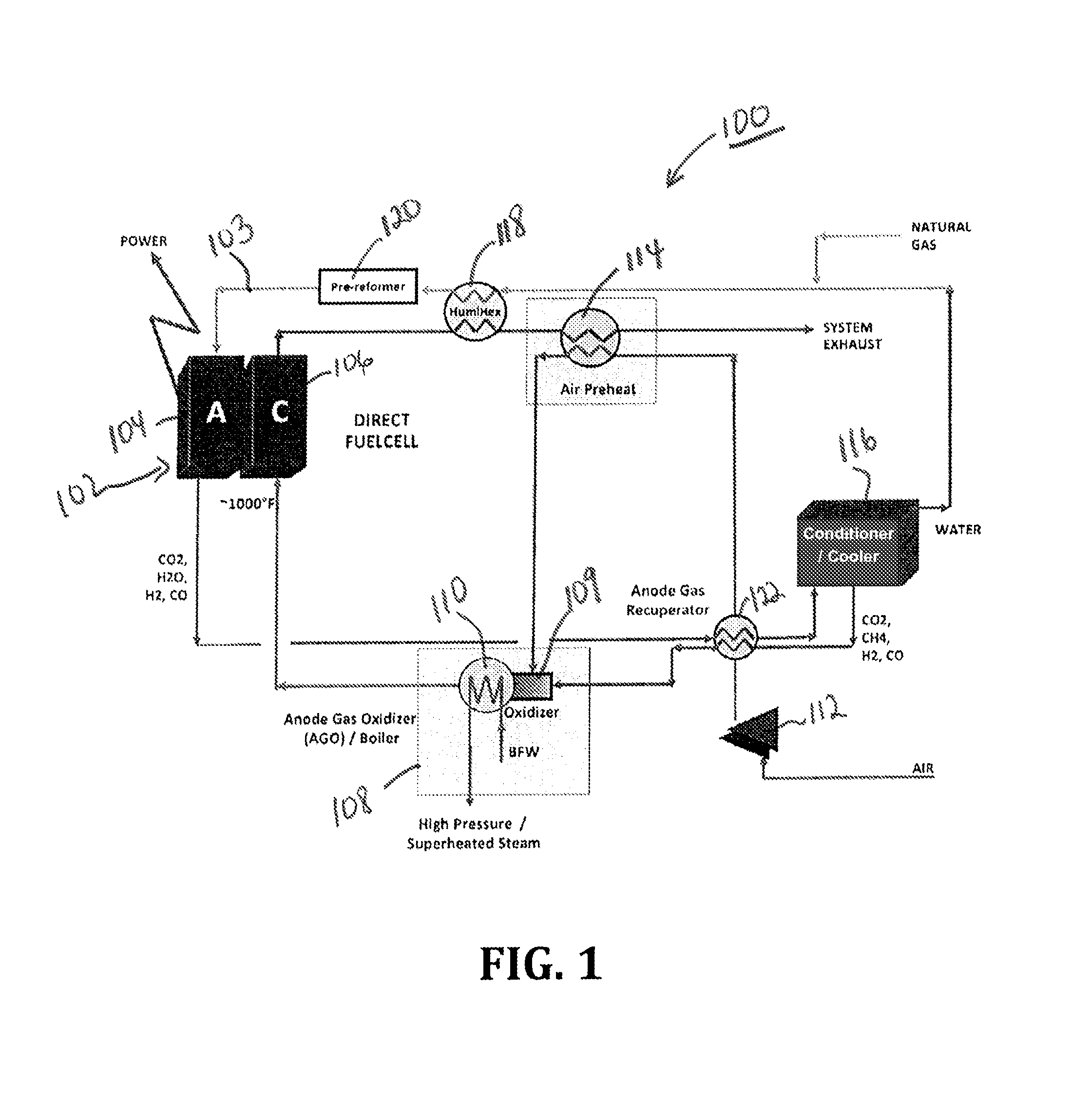

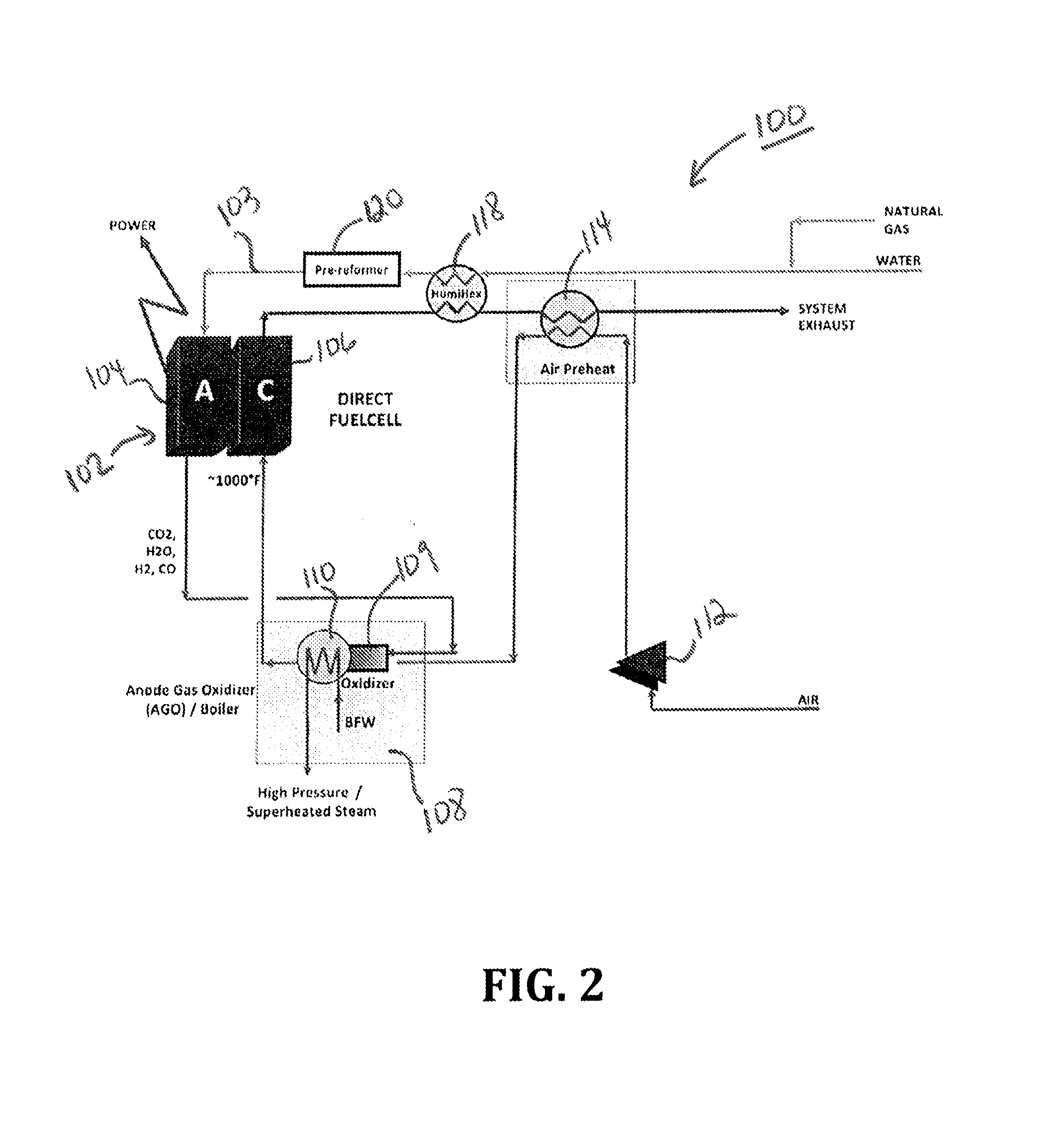

Fuel cell system with waste heat recovery for production of high pressure steam

ActiveUS20160149233A1Increase waste heat recoveryImprove pressure resistanceFuel cell heat exchangeFinal product manufactureWaste heat recovery unitFuel cells

A fuel cell system for generating electrical power and high level heat comprising at least one high temperature fuel cell stack having an anode side and a cathode side and adapted to generate electrical power, and a gas oxidizer / high level heat recovery assembly comprising an oxidizer adapted to oxidize one or more of exhaust output from the at least one high temperature fuel cell stack and a gas derived from the exhaust, and to generate high level heat, and a high level heat recovery system adapted to recover the high level heat generated in the oxidizer.

Owner:FUELCELL ENERGY INC

Novel solar drying system

InactiveCN104406393ARaise the outlet temperatureImprove overall utilizationSolar heating energySolar heat devicesEngineeringTuyere

The invention discloses a novel solar drying system. The novel solar drying system comprises a solar air heat gatherer, an air blower, a solar battery, a drying box, a temperature and humidity controller, a valve and a heat exchanger. The novel solar drying system is characterized in that the heat exchanger is provided with a first air inlet, a second air inlet, a first air outlet and a second air outlet; an insert pipe is arranged in each vacuum heat gathering pipe of the solar air heat gatherer, and the insert pipes are connected with an air buffer backflow zone header after passing through the top of a hot air flow passage zone header; the air blower is arranged between the air outlet of the heat gatherer and the air inlet of the drying box; an air flow passage zone is arranged in the side of the inside of the drying box near the air blower, and a material drying zone is arranged at the other side; an induction probe of the temperature and humidity controller is arranged at the air outlet of the drying box; an air return pipeline led from the air outlet of the drying box is divided into two branches, one branch is connected with the first air inlet of the heat exchanger through a second valve, the other branch is further divided into two passages after passing through the first valve, one passage is directly connected with the air inlet of the heat gatherer header, and the other passage is connected with the first air outlet of the heat exchanger through a third valve.

Owner:YUNNAN NORMAL UNIV

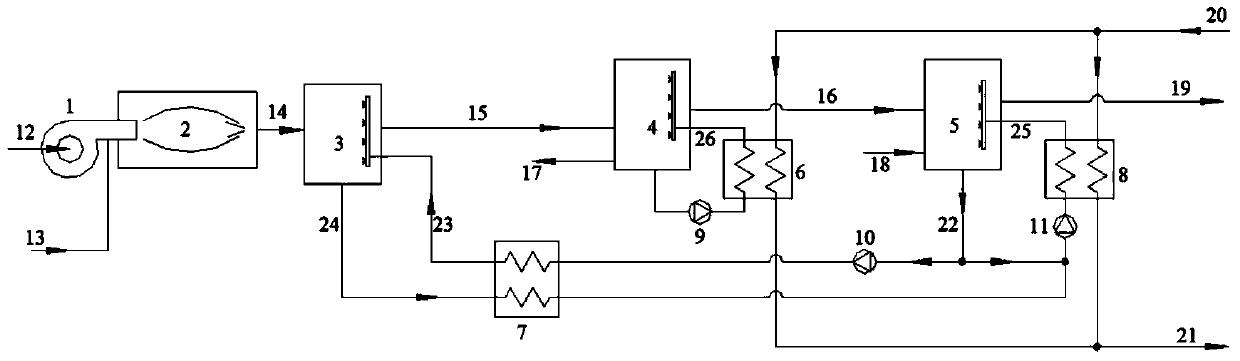

Low vacuum ejector heat pump composite waste-heat heating supply system based on huge temperature-difference heat supply network

InactiveCN103453567ASafe and reliable workIncrease heating rateLighting and heating apparatusEnergy industryWater basedPipe fitting

The invention relates to a low vacuum ejector heat pump composite waste-heat heating supply system based on a huge temperature-difference heat supply network, and belongs to the field of waste-heat recovery type combined heat and power generation based on low vacuum circulation water heating and heat exchange of an ejector heat pump. The system is characterized by comprising an ejector heat pump waste-heat recovery device, a dead-steam direct recovery device, a pitch peak heater, a heat supply network huge temperature-difference heat exchange unit and a pipe fitting, wherein the dead steam is taken as a water-based load heat source of the heat supply network; a cold-side inlet of the dead steam direct recovery device is connected with a water return pipe of the heat supply network; an outlet is connected with a heat supply network water inlet of an ejector heat pump condenser; then the dead steam is sent to the pitch peak heater to be heated to the required temperature, and then exhausted out; at last, the dead steam is sent into the dead-steam direct recovery device, and an ejection port in the ejection section of the ejector heat pump. The system can be used for a thermal power plant with higher efficiency than the conventional recovery way that waste-heat is extracted from cooling water, the utilization amount of the dead-steam waste heat can be improved by more than 1-2 times, while the investment is only a part of that of an absorption heat pump.

Owner:张茂勇

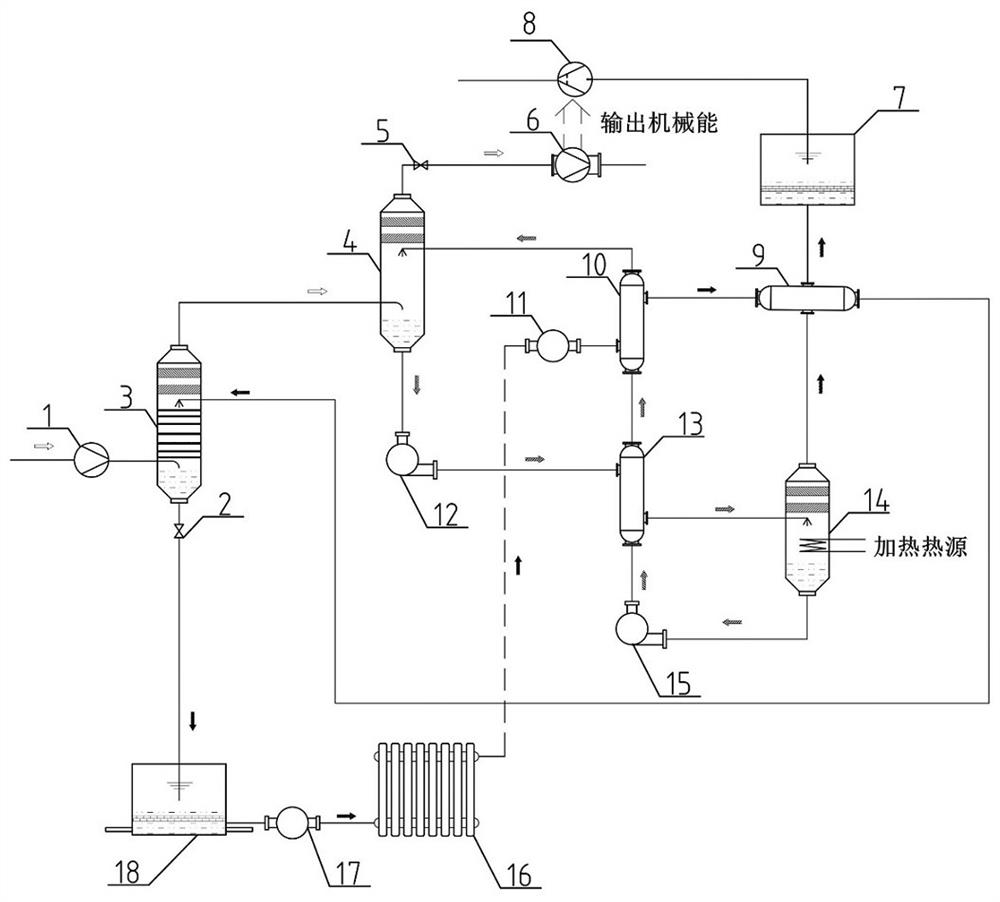

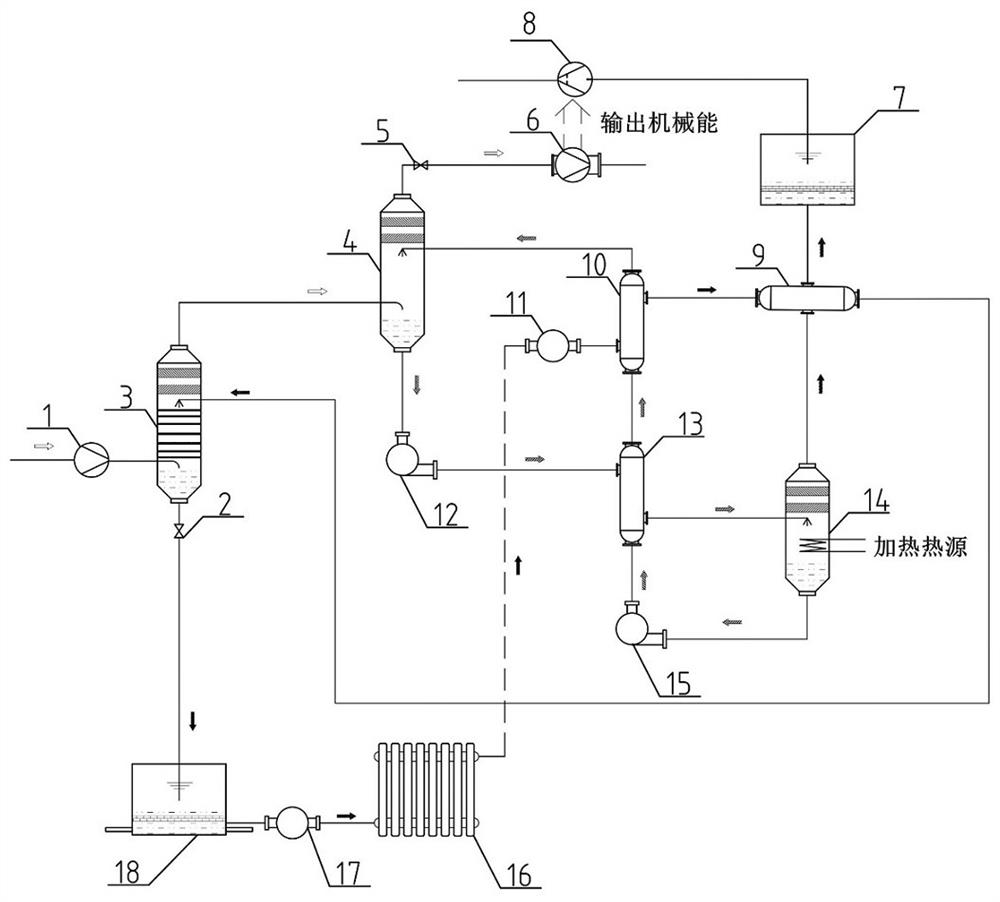

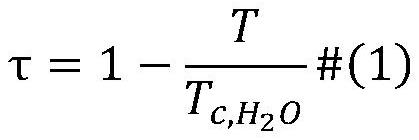

Semi-open high-temperature heat pump system and working method thereof

ActiveCN111306787AImprove heat transfer efficiencyIncrease temperatureMechanical apparatusEvaporators/condensersEngineeringVacuum pump

The invention provides a semi-open high-temperature heat pump system. The system comprises a compressor, a contact condenser, a heat exchanger, an evaporator, a water purifier, a cold water pump, a hot water pump, a circulating water pump and a vacuum pump. An exhaust port of the compressor is connected with the contact condenser, the contact condenser is connected with the evaporator through theheat exchanger, the evaporator is connected with the compressor air suction port through an upper exhaust port, an outlet of the water purifier is correspondingly connected with the compressor, the contact condenser and the evaporator through the cold water pump, a lower outlet of the evaporator is connected with the contact condenser through the circulating water pump, the upper part of the contact condenser is connected with the vacuum pump, and the lower part of the contact condenser is connected with the hot water pump. According to the system, water is adopted as a circulating working medium, and the contact condenser with high heat transfer efficiency is adopted, so that the system has the characteristics of being environment-friendly and high in efficiency, can recover low-temperature waste heat of 50 DEG C or above, and provides high-temperature hot water of 90 DEG C or above. Compared with the prior art, the system effectively reduces the heat transfer thermal resistance, improves the heat transfer efficiency, effectively recovers the low-temperature waste heat, improves the heat source quality, and achieves reuse.

Owner:JIANGSU UNIV OF SCI & TECH

Coke oven hydrogen utilization method and system

ActiveCN111718738AEliminate attachmentConducive to lightweightCoke ovensCarbonizationCracking reaction

The invention relates to the field of coke furnaces, particularly to a coke oven hydrogen utilization method and system. The method is especially suitable for hydrogen-rich comprehensive utilization of raw coke oven gas in different coke curing periods of a coke oven coking process. The method comprises the following steps: sequentially introducing hydrogen-rich raw coke oven gas obtained in a later period of coking from one or more carbonization chambers into another carbonization chamber or a plurality of other carbonization chambers which are just filled with coal through a raw coke oven gas pipe duct system; allowing the introduced hydrogen-rich raw gas to form a hydrogen-rich environment in the carbonization chambers which are just filled with the coal; and enabling a cracking reaction to realize conversion to a light target product by controlling, adjusting and inducing the cracking reaction of the raw gas. The furnace tops of the carbonization chambers have high-temperature hydrogen which has very high activation energy and can undergo a hydrogenation reaction with graphite at the top of the carbonization chambers for secondary cracking of coal tar, so the charring procedureof opening a furnace cover 10-20 minutes ahead of time in the processes of combustion and decoking is eliminated, tar yield is increased, and coke oven productivity is improved.

Owner:葛霖

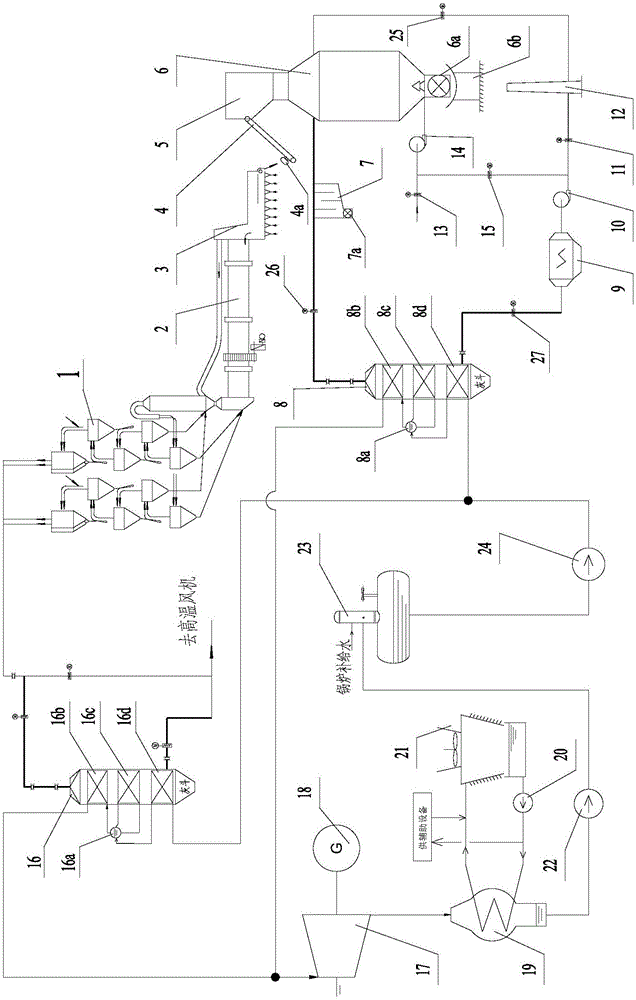

A cement kiln high-efficiency waste heat recovery power generation system and method

ActiveCN106640221BImprove efficiencyImprove economyRotary drum furnacesIncreasing energy efficiencyWaste heat recovery unitProcess engineering

The invention provides an efficient cement kiln waste heat recovery and power generation system and method, and belongs to the technical field of cement kiln waste heat utilization. The waste heat recovery and power generation system comprises a clinker stepped cooling device, a waste heat recycling device, a turbine power generation device, a cyclic cooling water device and a waste gas treating device. The clinker stepped cooling device comprises a grate cooler and a vertical cooling device. Sensible heat of clinker can be recycled in a stepped mode through the grate cooler and the vertical cooling device. By means of the cooling way, a large quantity of low-temperature waste gas at the tail of a conventional grate cooler is prevented from being directly exhausted, the level of kiln head waste heat resources and the waste heat recovery quantity are improved, and the cement kiln waste heat recovery and power generation efficiency and technical and economical indexes are effectively improved.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

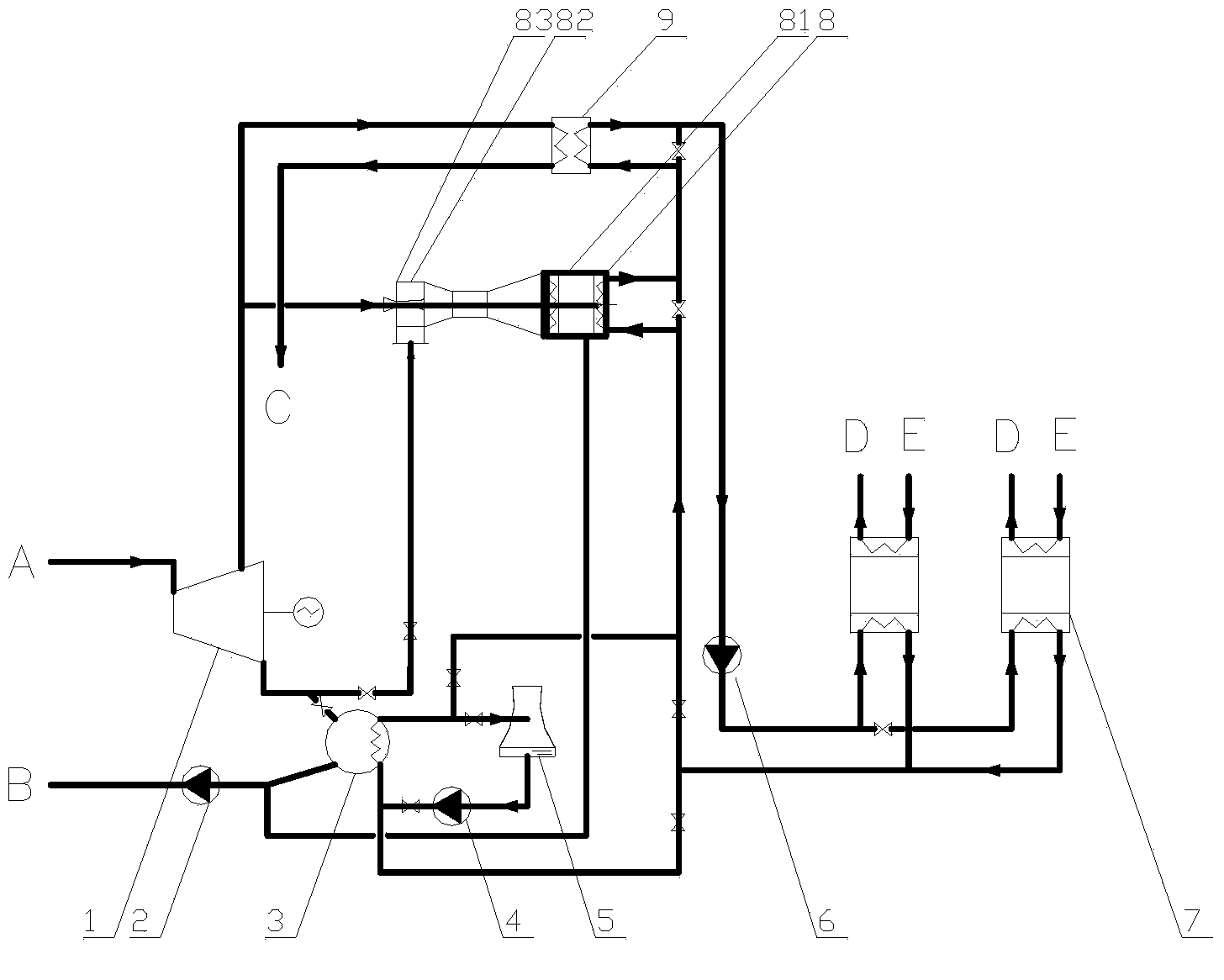

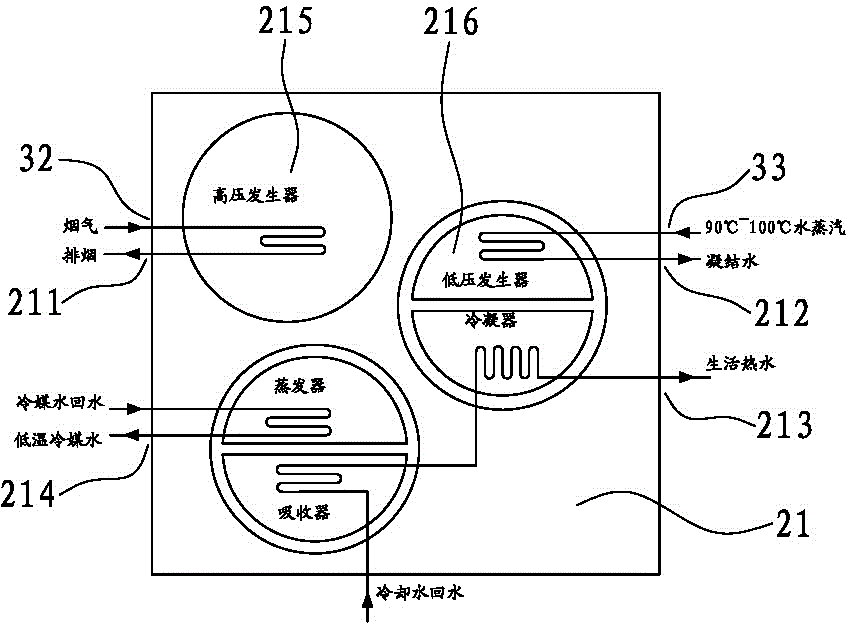

Cooling, heating, water supplying and power supplying combined system with flue gas heat gradient utilization function coupled with seawater desalination technology

ActiveCN103115457BHigh utilization rate of waste heat recoveryLower exhaust gas temperatureGeneral water supply conservationSeawater treatmentThermal energyLithium bromide

Owner:JIMEI UNIV

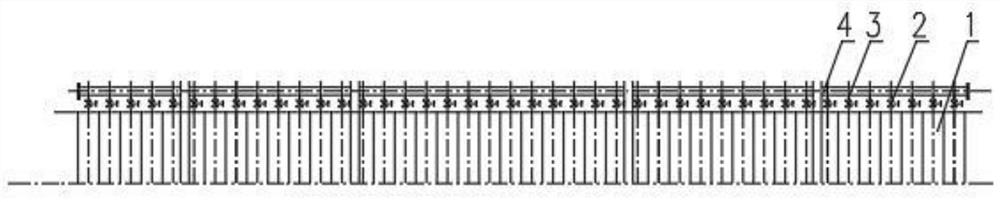

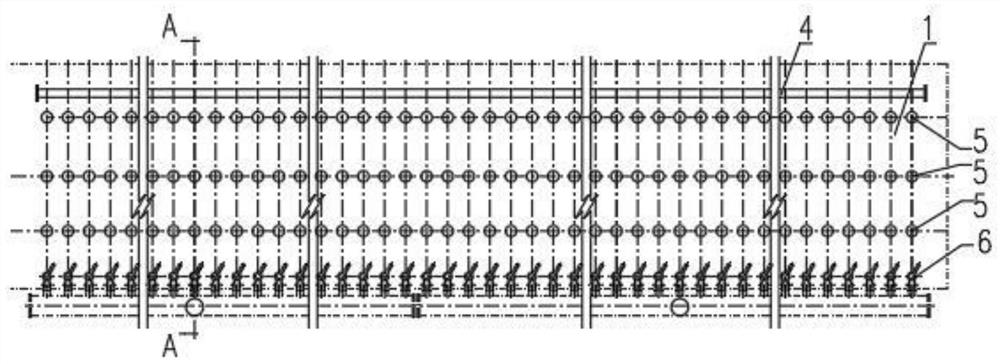

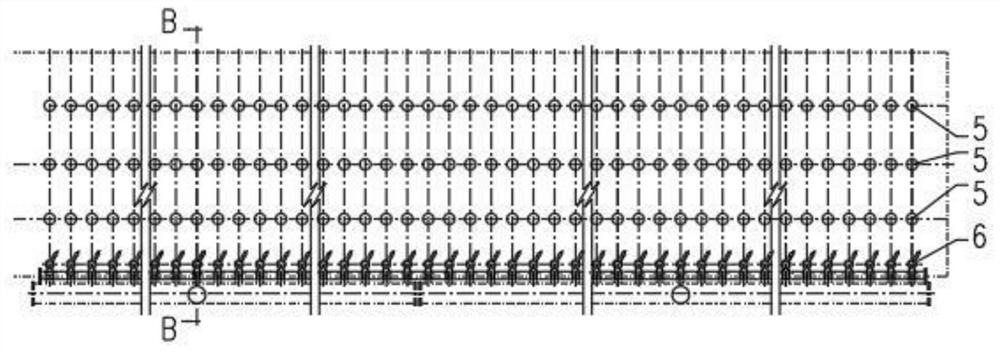

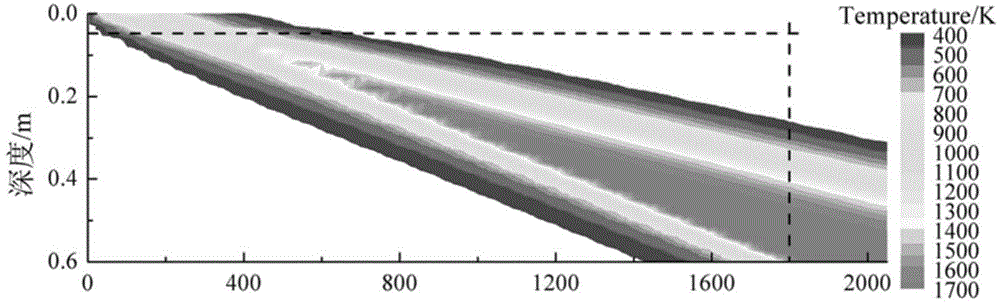

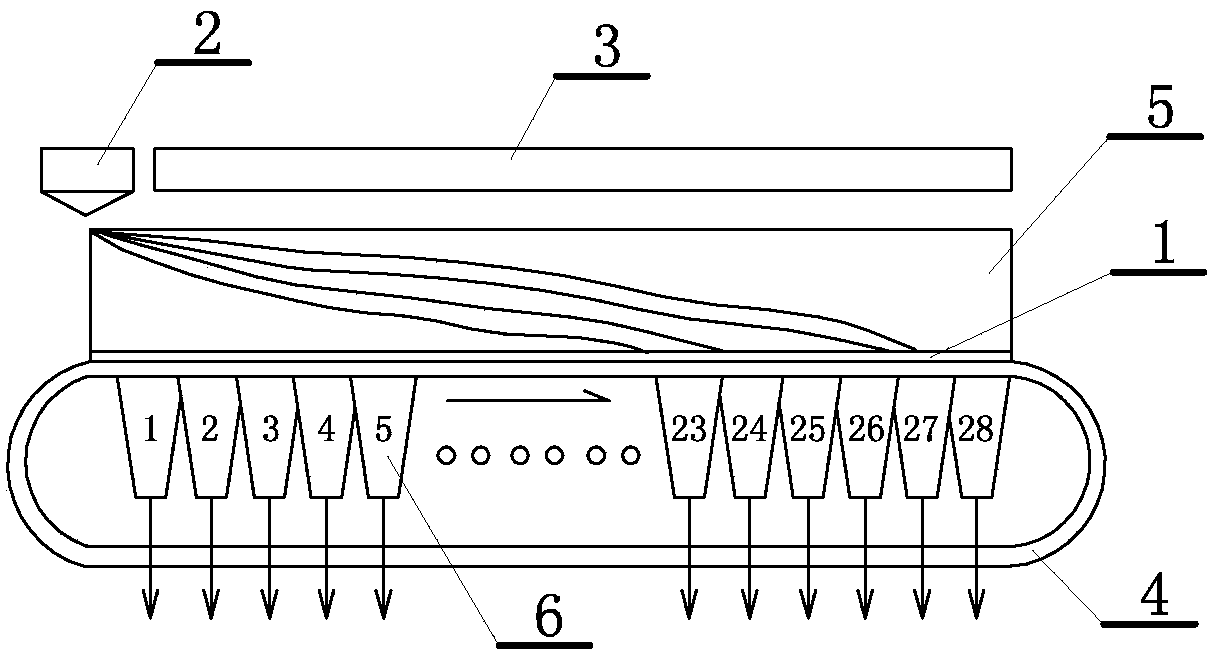

Temperature distributing cooling method and temperature distributing unloading device for sintered ores

ActiveCN106323013AAchieve separationSolve the problem of traditional cooling processCharge manipulationHandling discharged materialMetallurgyHot Temperature

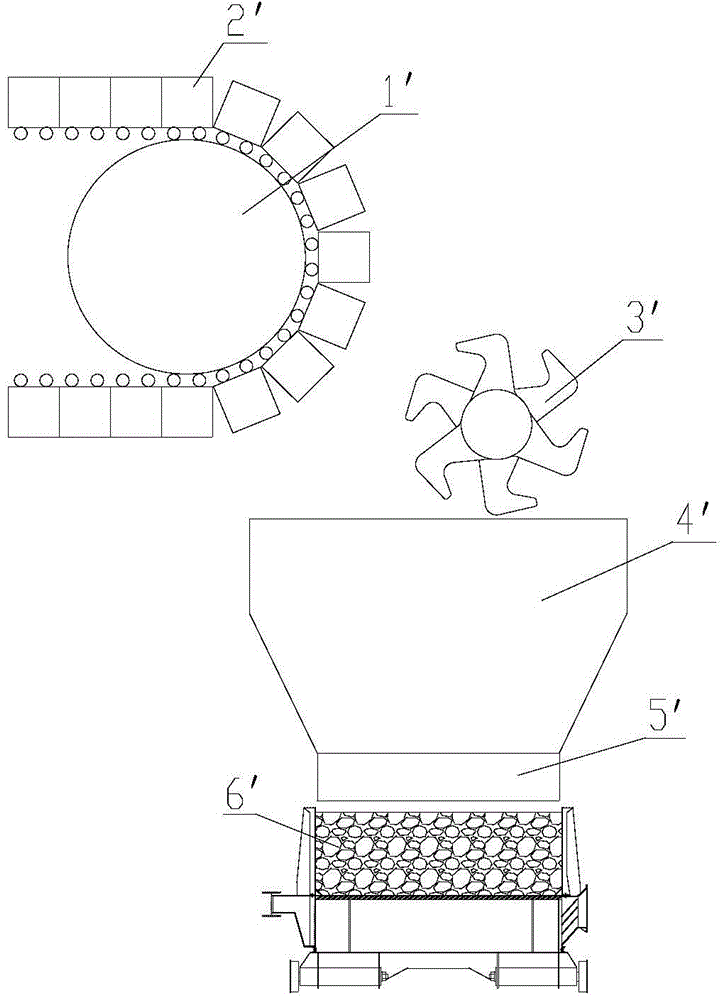

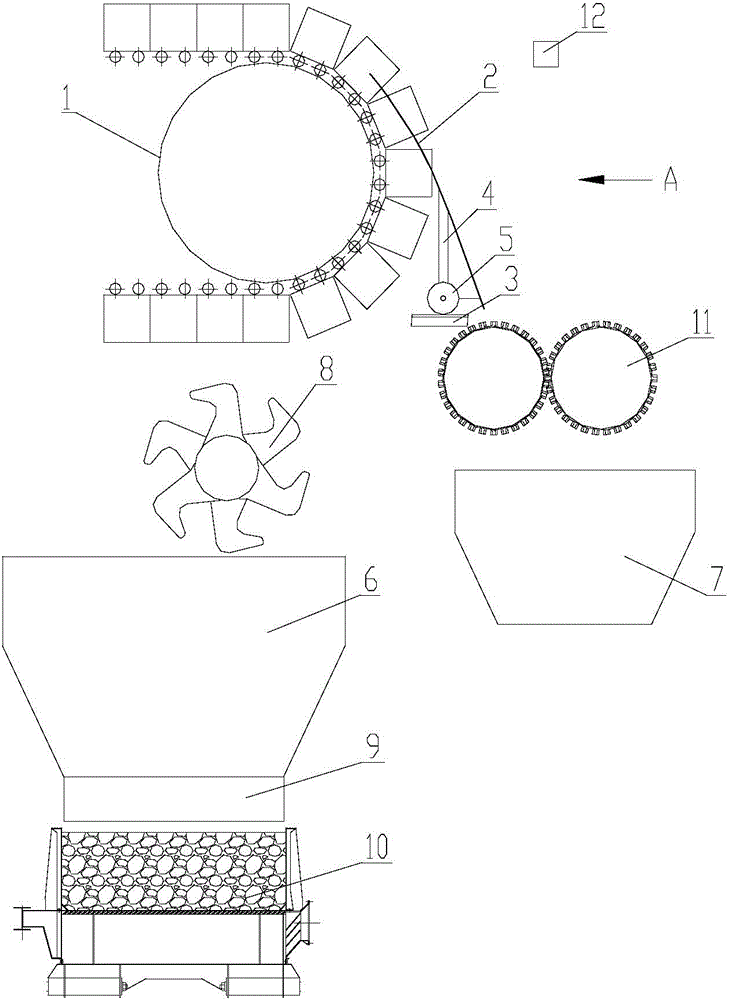

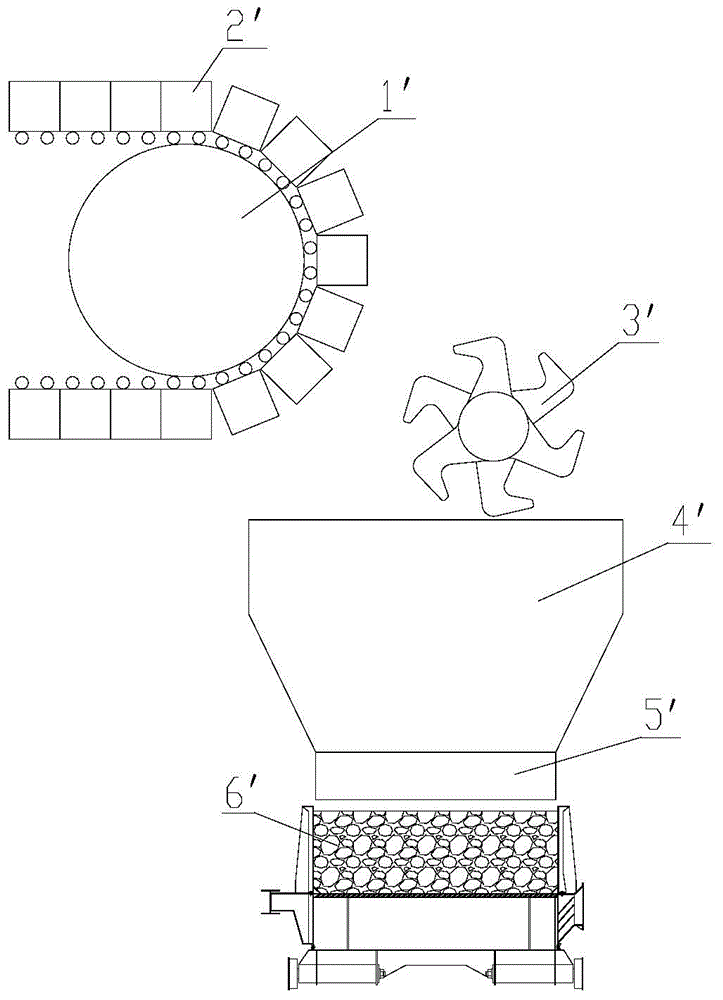

The invention discloses a temperature distributing cooling method for sintered ores. The method comprises the following steps of: determining a sintered ore layer, the temperature of which is lower than the unloading temperature of a ring cooling machine, as a low-temperature sintered ore layer and determining a sintered ore layer, the temperature of which is higher than the unloading temperature of the ring cooling machine, as a high-temperature sintered ore layer according to the temperature distribution of the sintered ore layer in a trolley of a sintering machine in the tail part of the sintering machine; performing temperature distributing unloading on the tail part of the sintering machine so as to separate the low-temperature sintered ore layer and the high-temperature sintered ore layer, wherein the low-temperature sintered ore layer which is crushed does not enter the ring cooling machine but is directly conveyed to a follow-up screening step, and the high-temperature sintered ore layer which is crushed enters the ring cooling machine for a cooling operation. The process method can remarkably reduce the handling capacity of the sintered ores in the ring cooling machine by improving the unloading mode of the sintered ores and the material distributing mode on the ring cooling machine, so that the cost of the ring cooling machine is lowered, and the waste heat recovery amount of the sintered ores is improved. The invention further discloses a temperature distributing unloading device used by the method.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Sinter distributed temperature cooling method, sinter time-sharing unloading trolley and distributed temperature unloading device

ActiveCN105987612AReduce processingReduced area and air volumeCharge manipulationHandling discharged materialTime-sharingScreening procedures

The invention discloses a sinter distributed temperature cooling method. The method comprises the following steps: determining sinter layers with temperatures lower than the unloading temperature of a circular cooler as low temperature sinter layers and determining other sinter layers as high temperature sinter layers according to temperature distribution of sinter layers in a sintering machine trolley at the tail of a sintering machine; and carrying out time-sharing unloading during unloading at the tail of the sintering machine to achieve separation of the low temperature sinter layers and the high temperature sinter layers, wherein the low temperature sinter layers do not enter the circular cooler but are directly conveyed to a follow-up screening procedure after being crushed, and the high temperature sinter layers enter the circular cooler to undergo cooling operation after being crushed. The method has the beneficial effects that the handling capacity of the sinter in the circular cooler can be obviously reduced, the cost of the circular cooler can be reduced and the sinter waste heat recovery can be increased by improving the sinter unloading method and the method of sinter distribution on the circular cooler. The invention also discloses a sinter time-sharing unloading trolley and a distributed temperature unloading device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

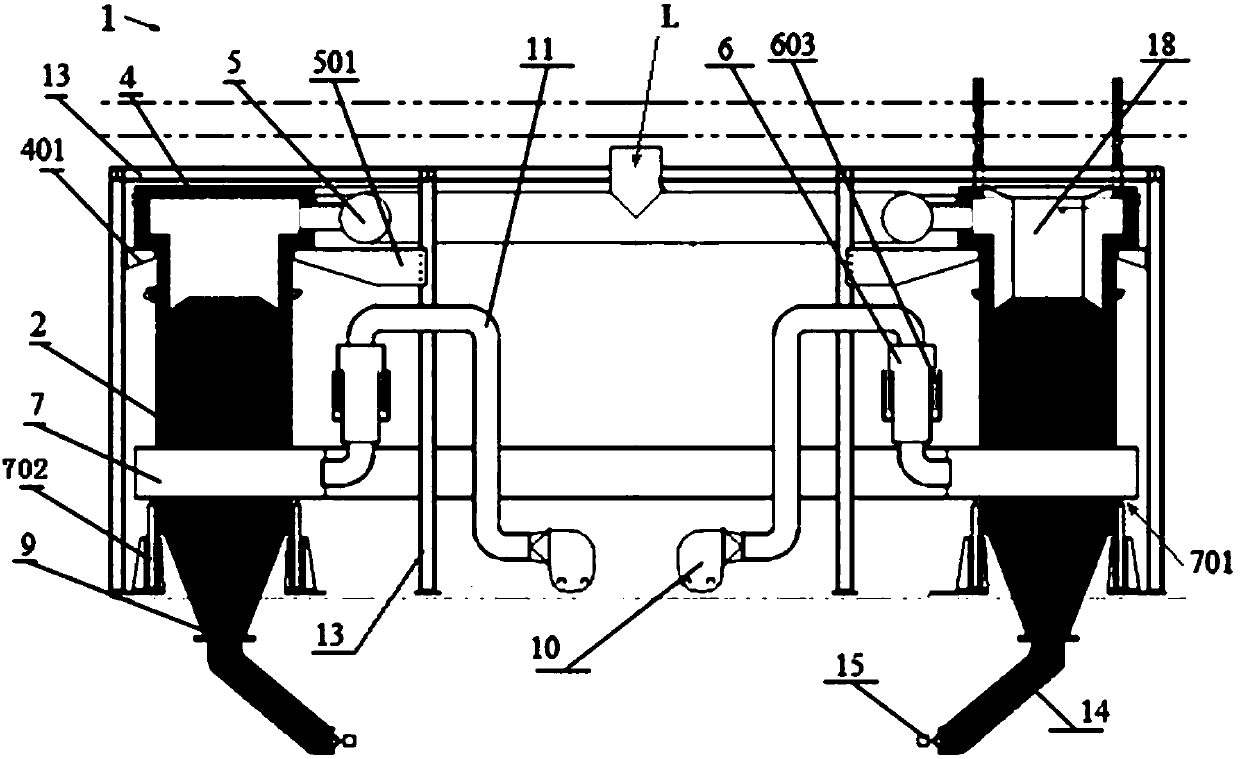

Intelligently-controlled open type compression absorption heat pump system for water and waste heat recovery

ActiveCN113686052AGuaranteed solution flowAdjust absorbencyHeat pumpsHeat recovery systemsData connectionAbsorption heat pump

The invention provides an intelligently-controlled open type compression absorption heat pump system for water and waste heat recovery. An outlet of a gas pipeline is connected with a contact heat exchanger, a circulating solution pump I is arranged on a pipeline between an absorber and a solution heat exchanger, and a circulating solution pump II is arranged on a pipeline between a regenerator and the solution heat exchanger; and a temperature and humidity and / or pressure sensor is arranged at a gas outlet at the upper portion of the contact heat exchanger and used for detecting the temperature and humidity and / or pressure of exhausted gas, and the circulating solution pump I, the circulating solution pump II and the temperature and humidity and / or pressure sensor are in data connection with a controller. The controller automatically adjusts the compression power of the circulating solution pump I and the circulating solution pump II according to the detected temperature and humidity and / or pressure, so that the flow of absorption solutions entering the absorber and the regenerator is adjusted to meet the requirements of water vapor absorption and solution regeneration in gas, and the moisture content parameter of the gas outlet is further changed. The power of the circulating solution pump I and the power of the circulating solution pump II are controlled through the temperature and pressure of outlet gas of the contact heat exchanger, the flow of the solutions entering the absorber and the regenerator can be guaranteed, and then the absorption and regeneration effects are adjusted; and finally, the temperature and pressure parameters of the gas in the contact heat exchanger and the absorber are kept in a relative balance state, and the system has extremely high engineering practical significance.

Owner:SHANDONG UNIV

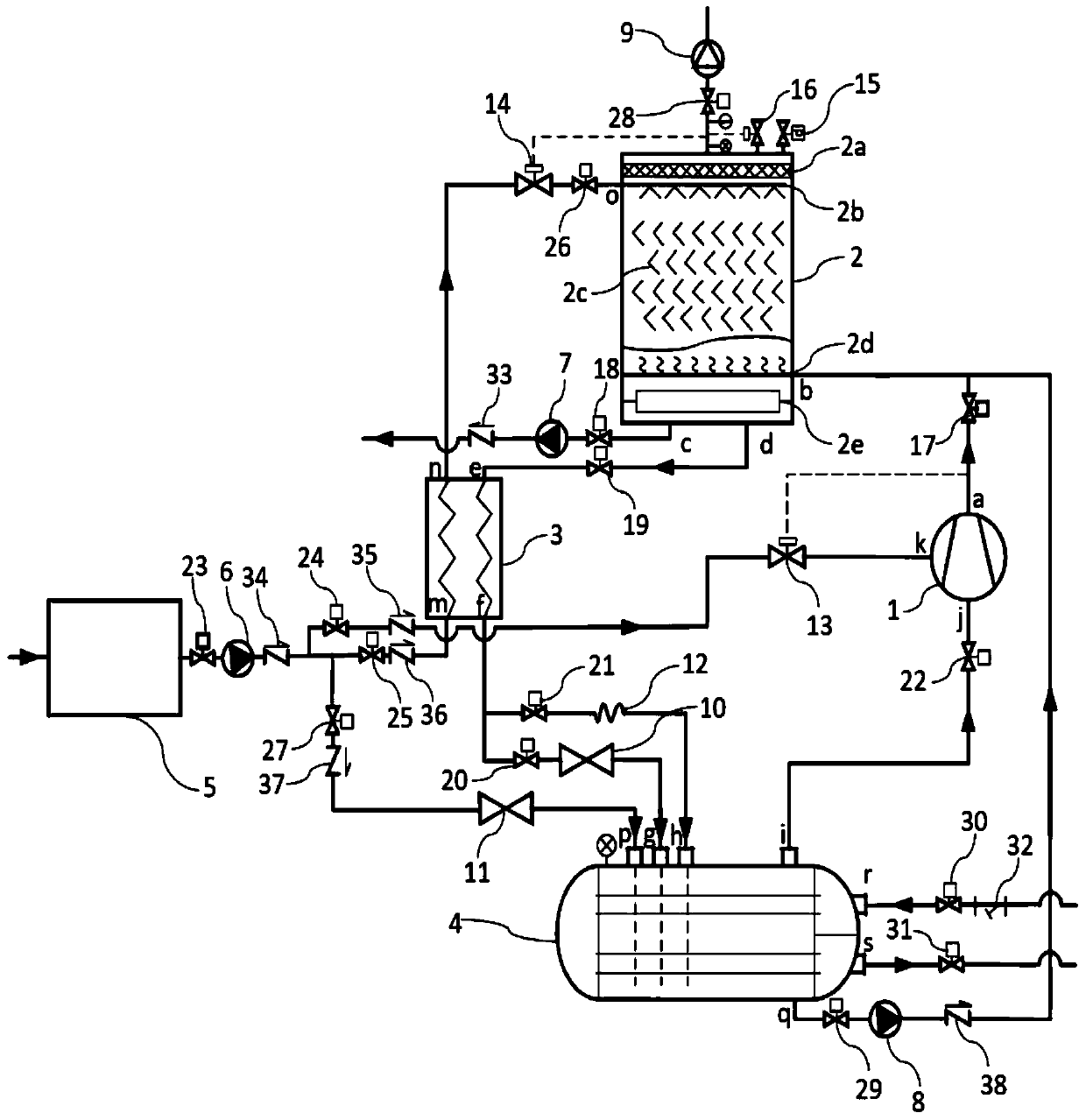

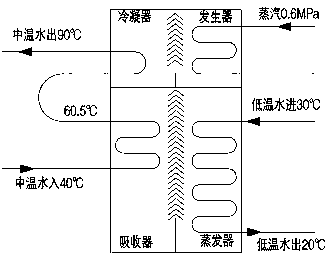

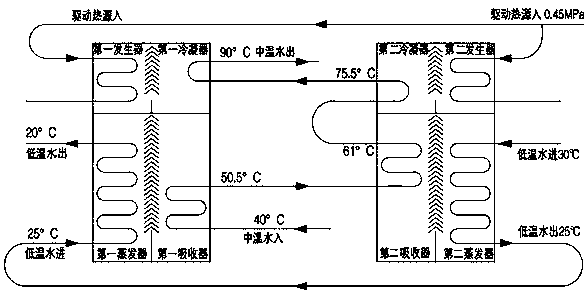

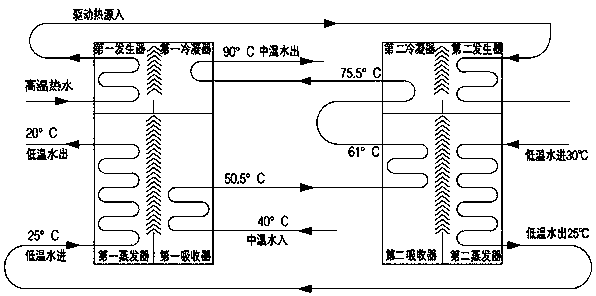

Compound type two-stage lithium bromide absorption type heat pump and working method

InactiveCN108507219AReduce the temperatureExtended service lifeBoilers/analysersClimate change adaptationUnit generatorWarm water

The invention discloses a compound type two-stage lithium bromide absorption type heat pump and a working method. The lithium bromide absorption type heat pump comprises two lithium bromide heat pumpunits which are mutually connected; the first lithium bromide heat pump unit comprises a first evaporator, a first generator, a first absorber and a first condenser which are mutually connected; the second lithium bromide heat pump unit comprises a second evaporator, a second generator, a second absorber and a second condenser which are mutually connected; and the output end of a heat exchange pipe of the first absorber sequentially communicates with heat exchange pipes of the second absorber, the second condenser and the first condenser. The invention further discloses the working method of the compound type two-stage lithium bromide absorption type heat pump. On the one hand, under the conditions that medium warm water and low warm water conditions are certain, the temperature of the unit generators is reduced, and the service life of the units is prolonged; on the other hand, the steam discharge range of the units is enlarged, the type selection of the units is reduced advantageously, and the cost is reduced; and the units are very convenient to manufacture.

Owner:BROAD AIR CONDITIONING CO LTD

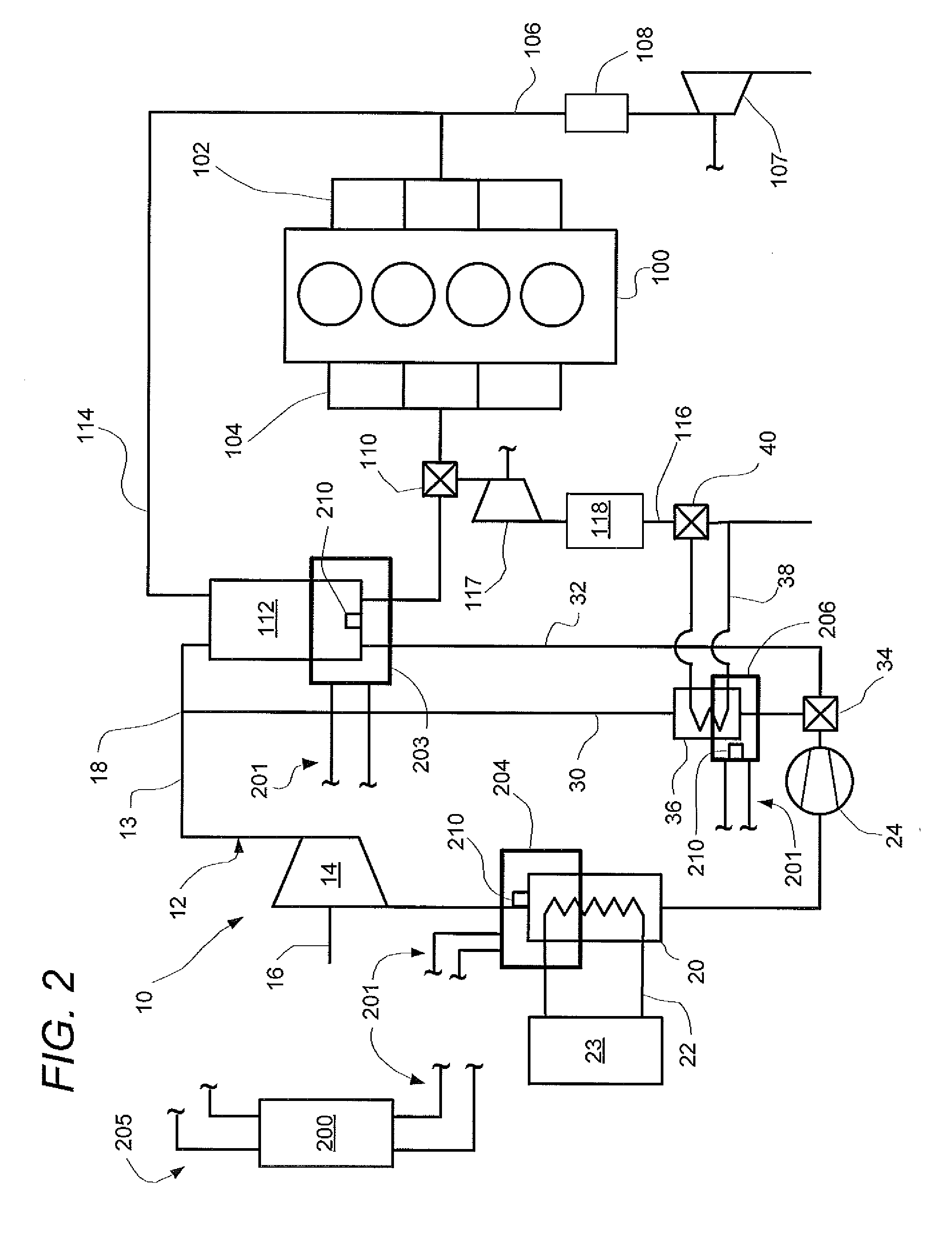

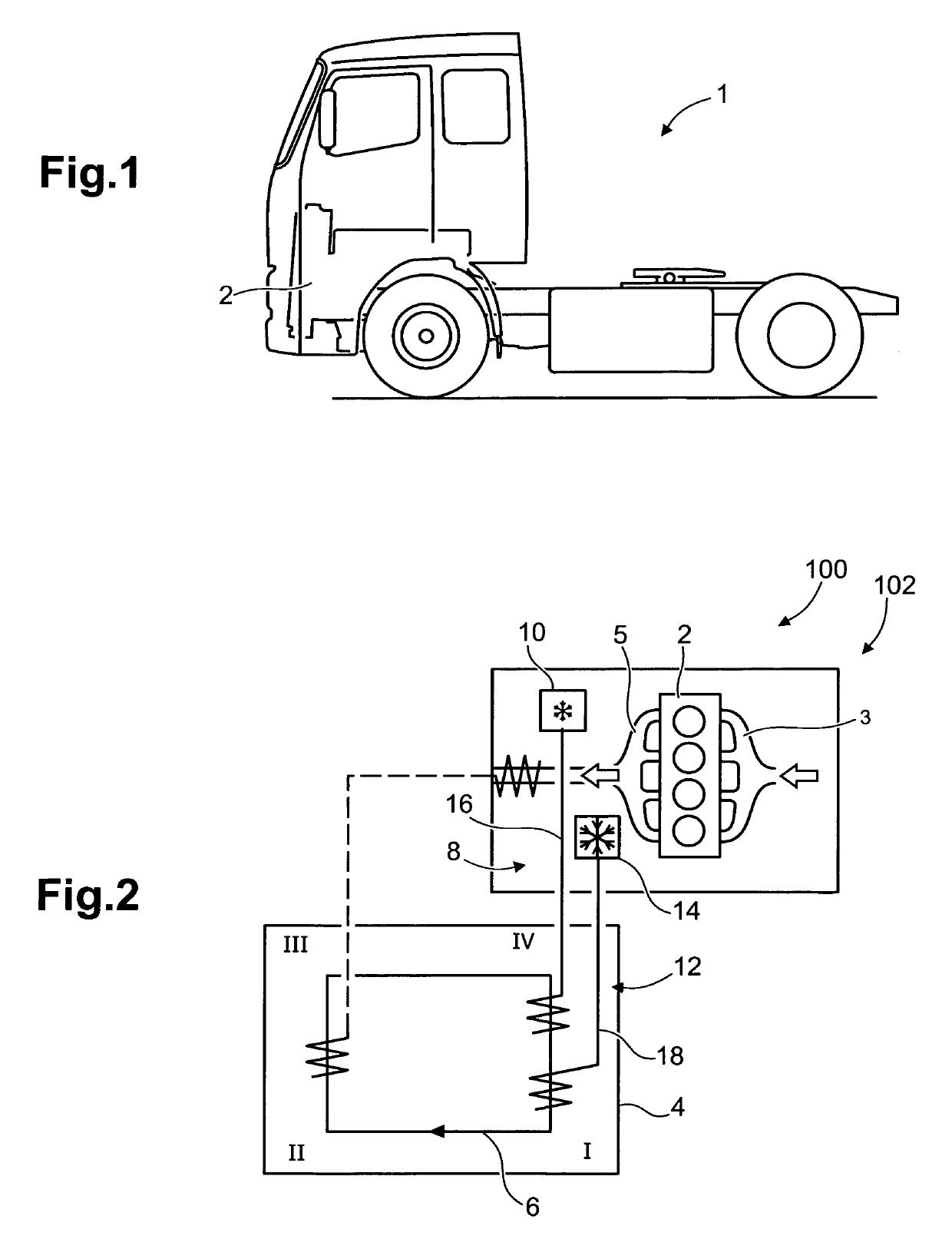

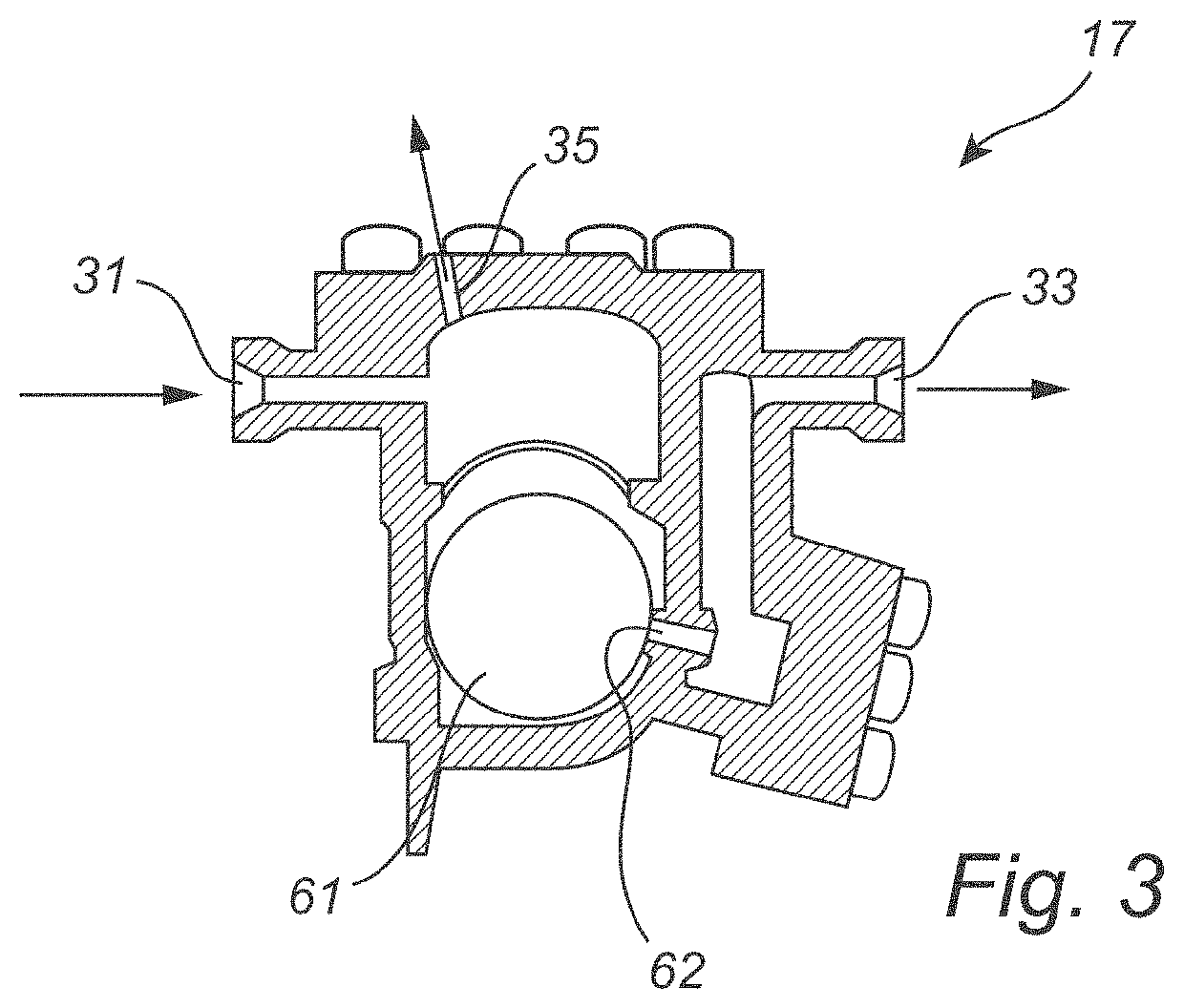

Internal combustion engine waste heat recovery (WHR) device including multiple cooling sources for a WHR condenser

ActiveUS10323548B2Increase waste heat recoveryCost effectiveInternal combustion piston enginesExhaust apparatusWorking fluidEngineering

A device for recovery of waste heat generated during operation of an internal combustion engine includes a thermodynamic engine, which includes a working fluid circulation circuit and is configured for recovery of the waste heat a first arrangement for providing a first coolant from a first source for heat exchange with the working fluid in the working fluid circulation circuit, and at least one further arrangement for providing a further coolant from a further source for heat exchange with the working fluid in the working fluid circulation circuit, wherein the further source is at different heat level than the first source during operation of the internal combustion engine.

Owner:VOLVO LASTVAGNAR AB

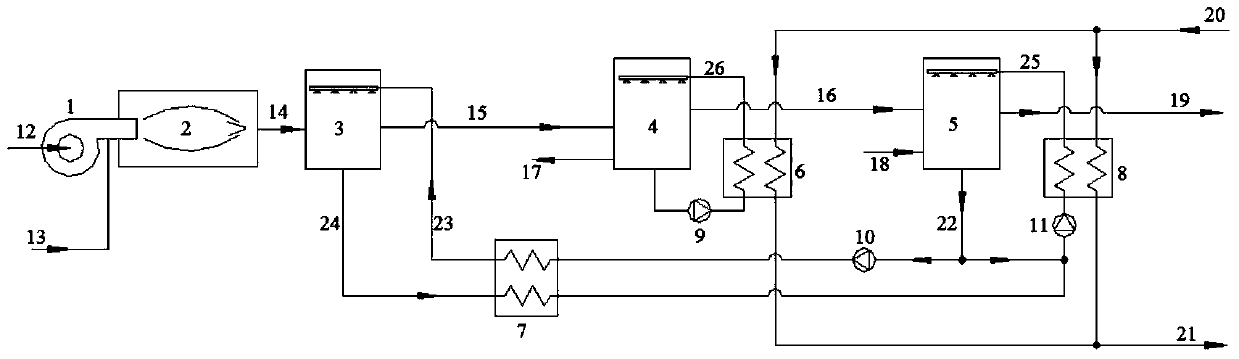

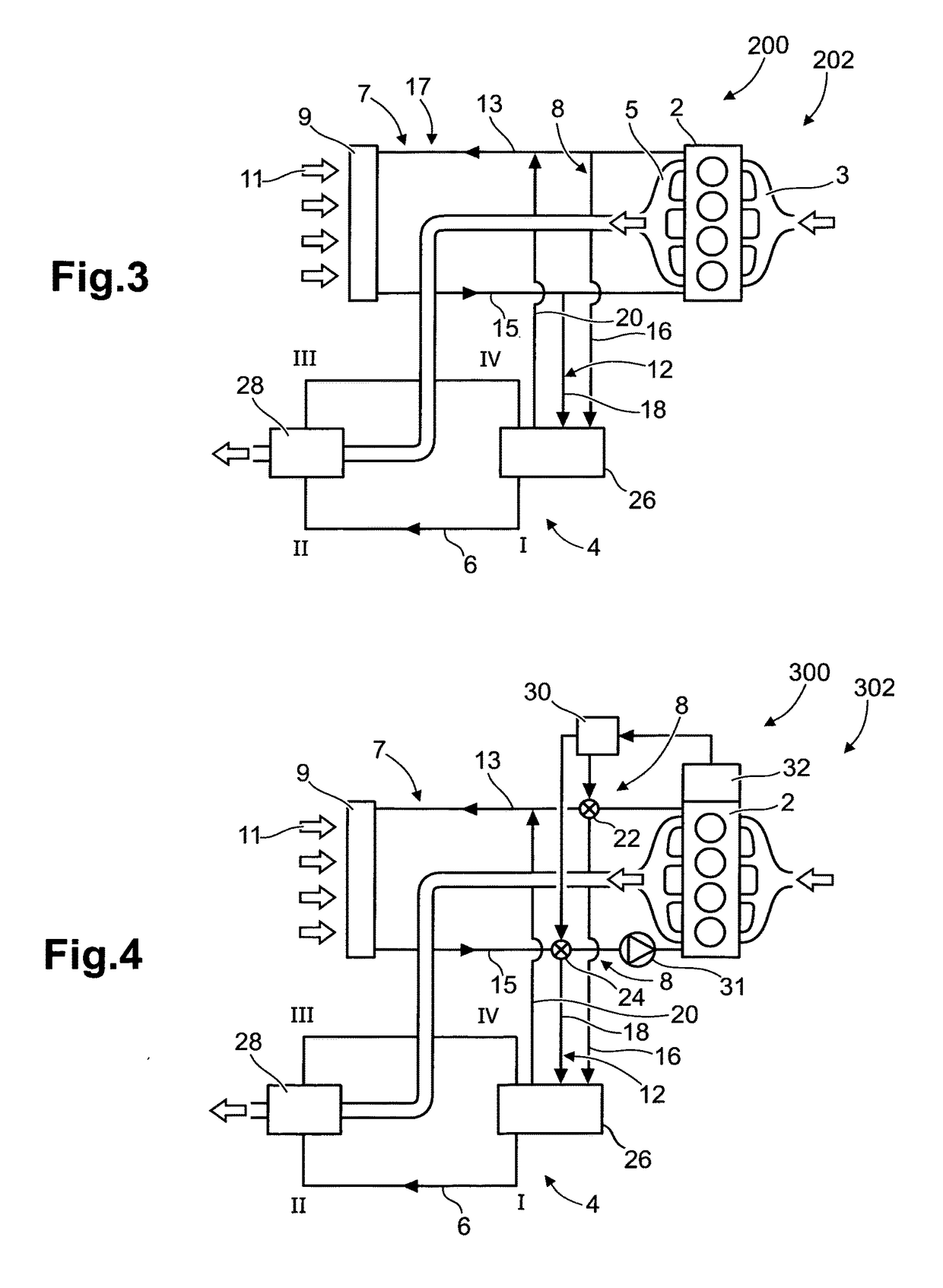

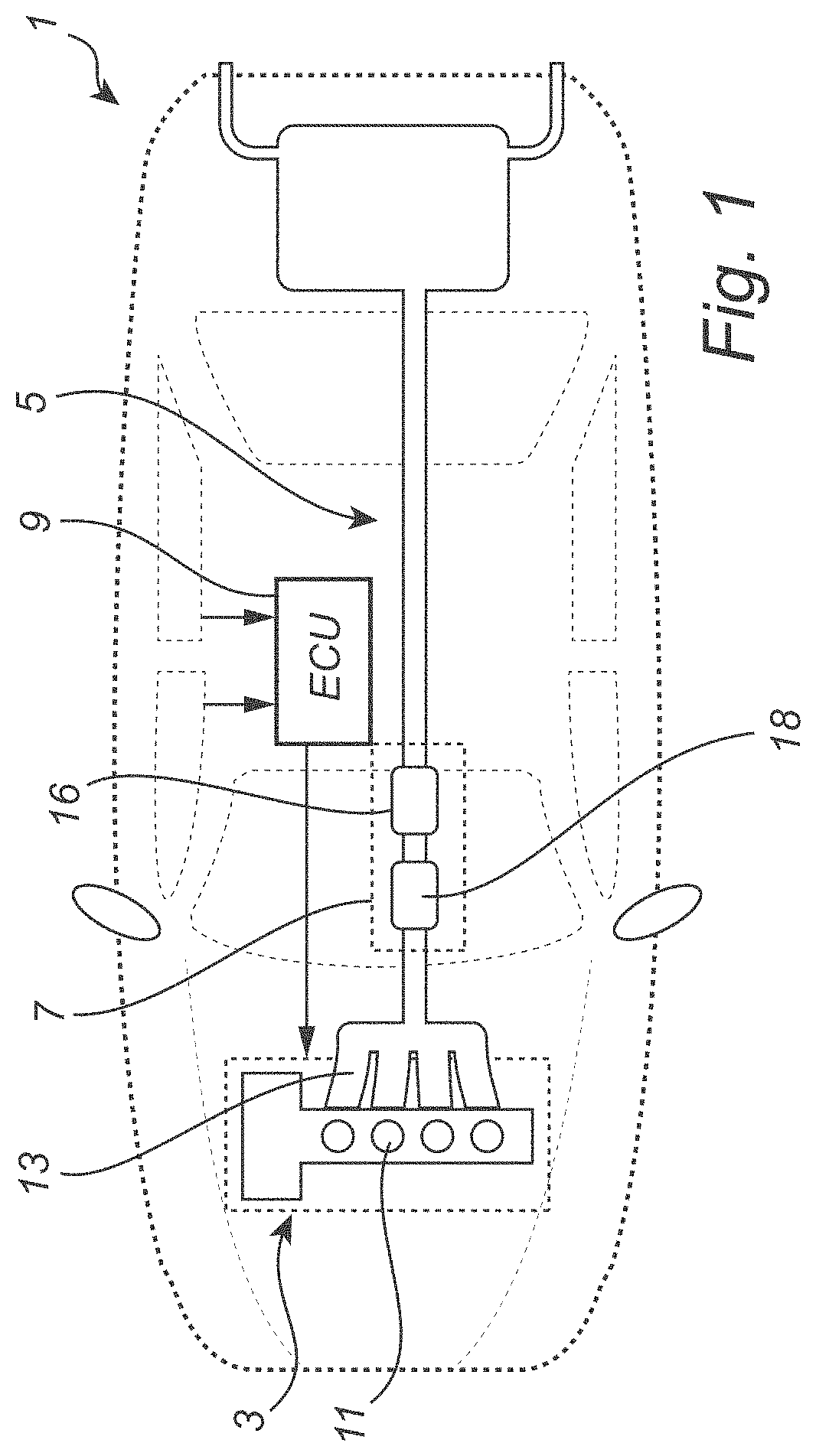

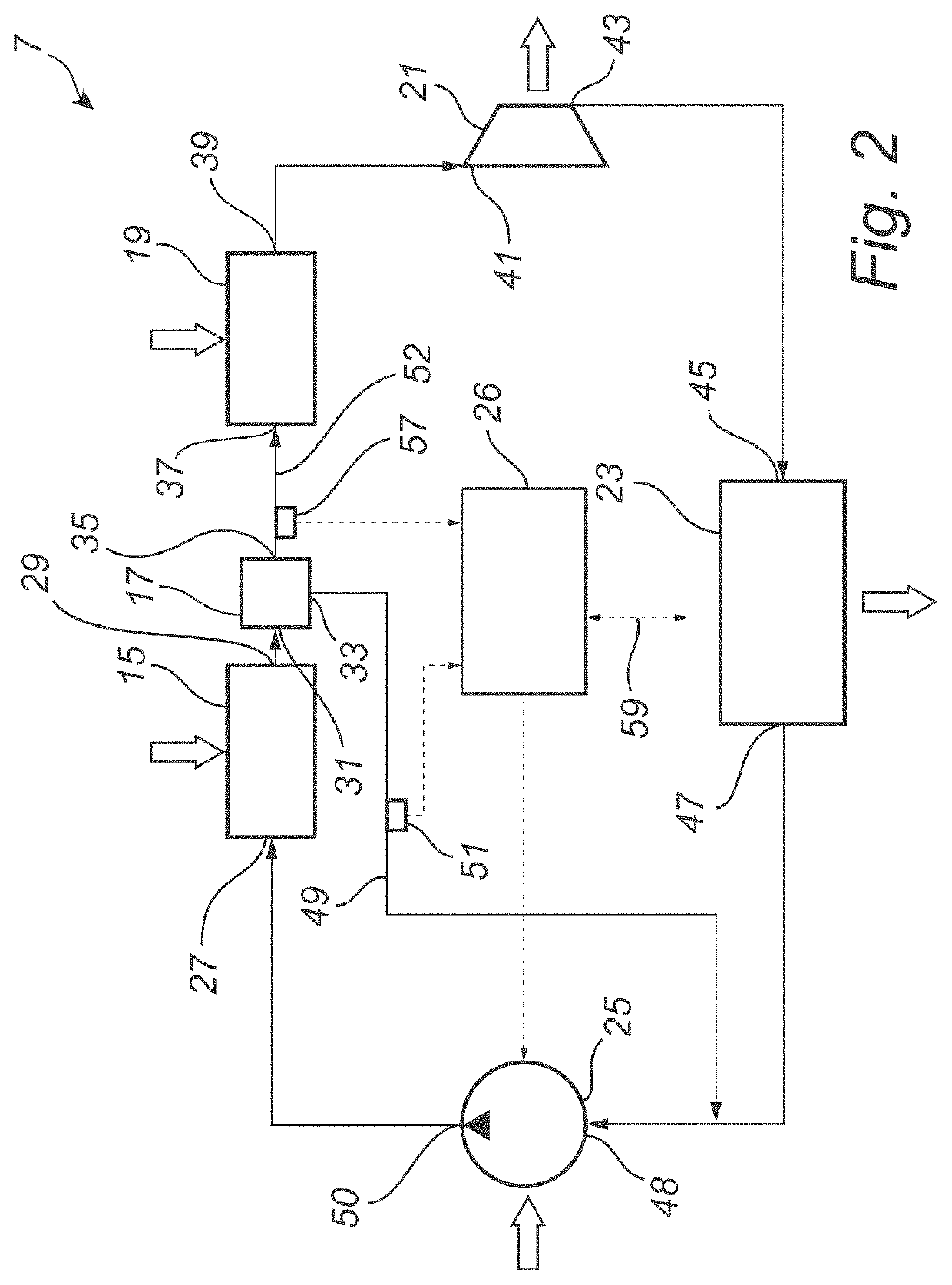

Two stage compact evaporator for vehicle waste heat recovery system

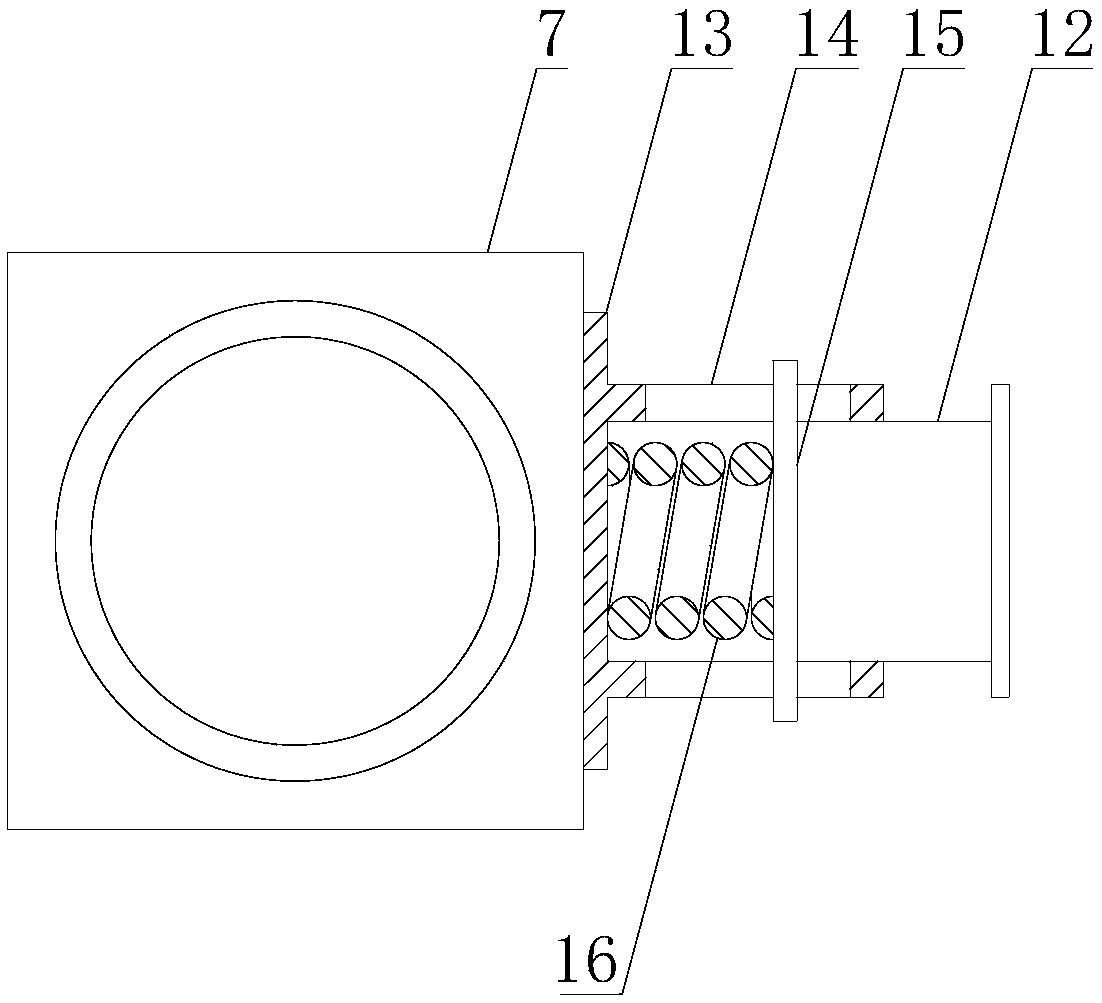

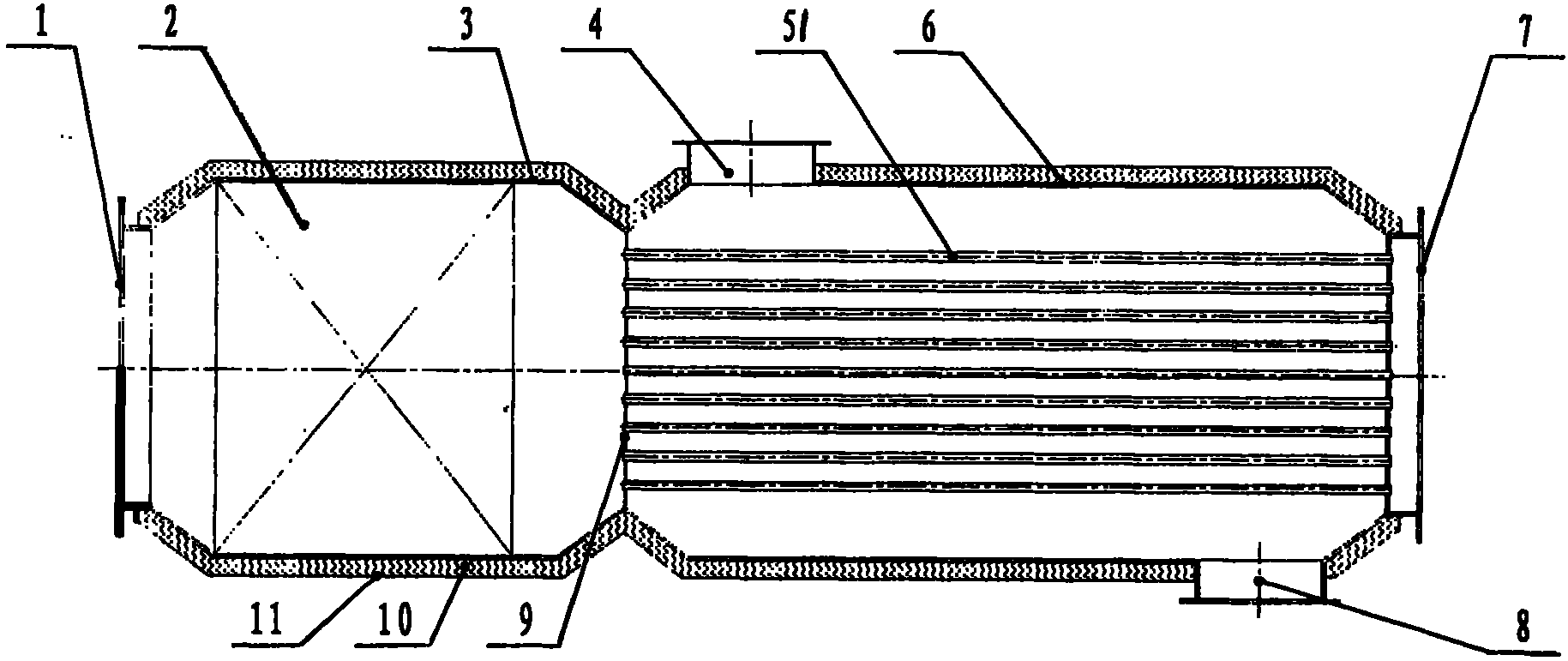

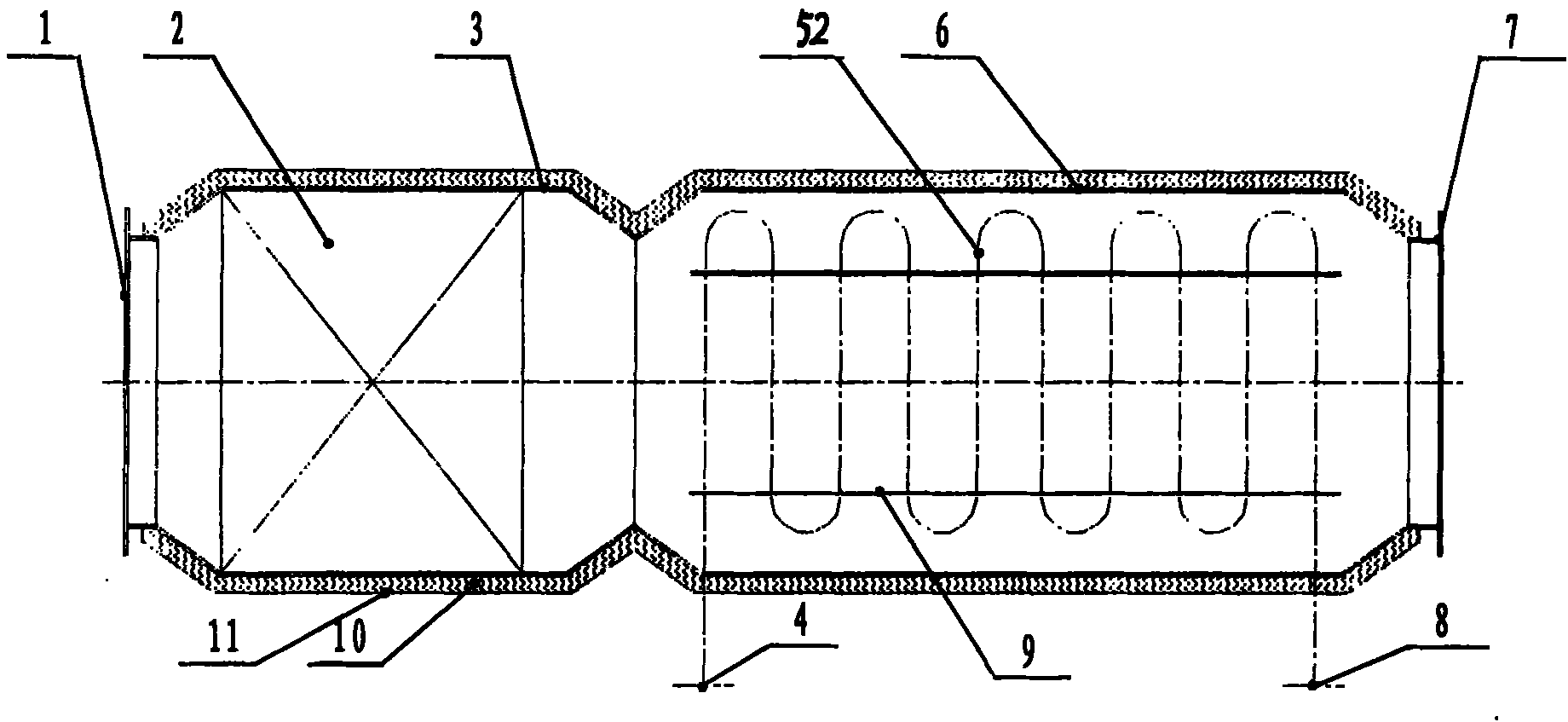

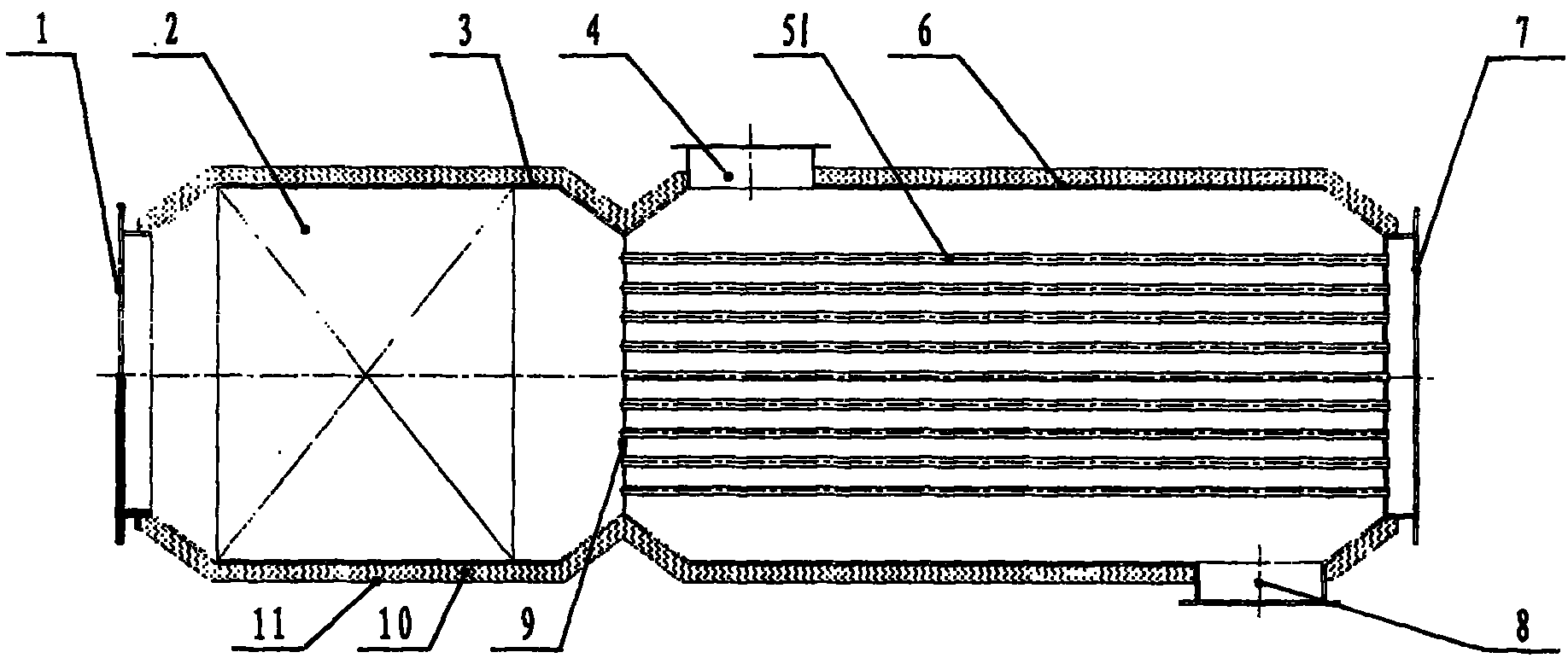

ActiveUS10914266B2High working tempRobust retainer of heatEvaporators/condensersCompression machines with several evaporatorsWorking fluidEngineering

A compact two-stage evaporator waste heat recovery (WHR) device (7) is disclosed, and a system using the device. The device recovers energy from waste heat passing through the device and transfers that energy to a Rankine Cycle working fluid also passing through the device. The device includes a first and second evaporator (15); and, a state separator (17) connected between the outlet of the first evaporator and the inlet of the second evaporator. The state separator (17) separates the working fluid into liquid and vapor. The liquid is re-cycled to the inlet of the first evaporator (15); the vapor is sent to the inlet of the second evaporator (19) for superheating. An overall WHR system using the device further includes an expander (21), condenser (23), and pump (25). The system further includes control circuitry (26) for controlling operation of the waste heat recovery device (7) itself and the WHR system.

Owner:VOLVO CAR CORP

Open type compression absorption heat pump system for water heat recovery in high-temperature and high-humidity gas

ActiveCN113686051AEasy to recycleImprove utilizationHeat pumpsHeat recovery systemsAbsorption heat pumpControl valves

The invention provides an open type compression absorption heat pump system for water heat recovery in high-temperature and high-humidity gas. An outlet of a gas pipeline is connected with a contact heat exchanger, a gas pressure adjusting device is arranged on the gas pipeline, the contact heat exchanger is connected with an absorber, a gas outlet at the upper end of the absorber is connected with an expansion machine, and a first pressure control valve is arranged on a pipeline between the absorber and the expansion machine; a circulating water inlet is connected with a solution water heat exchanger, the solution water heat exchanger is connected with a condenser, the condenser is connected with the contact heat exchanger, the lower end of the contact heat exchanger is connected with a circulating water tank, the circulating water tank is connected with a user side heat output device, and the user side heat output device is connected with the solution water heat exchanger; the absorber is connected with a solution heat exchanger, the solution heat exchanger is connected with a regenerator, the regenerator is connected with the solution heat exchanger, the solution heat exchanger is connected with the solution water heat exchanger, and the solution water heat exchanger is connected with the absorber; the regenerator is connected with the condenser, and the condenser is connected with a vacuum pump; and the expansion machine conveys energy to the vacuum pump. According to the system, utilization of waste heat of high-temperature and high-humidity gas, recovery of water, capturing of pollutant components and reuse of gas expansion work can be further realized, and the system has extremely strong engineering practical significance.

Owner:SHANDONG UNIV

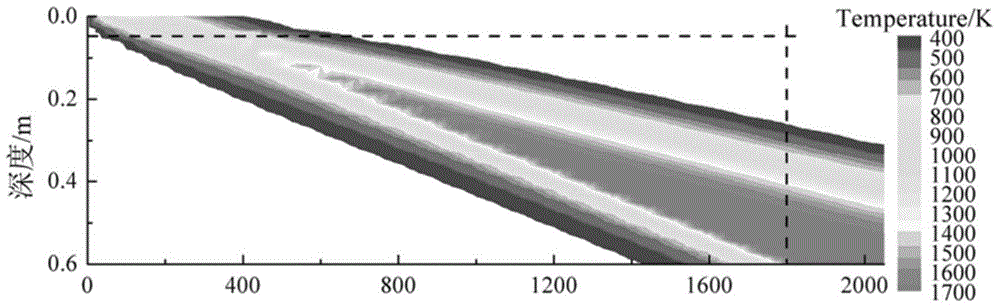

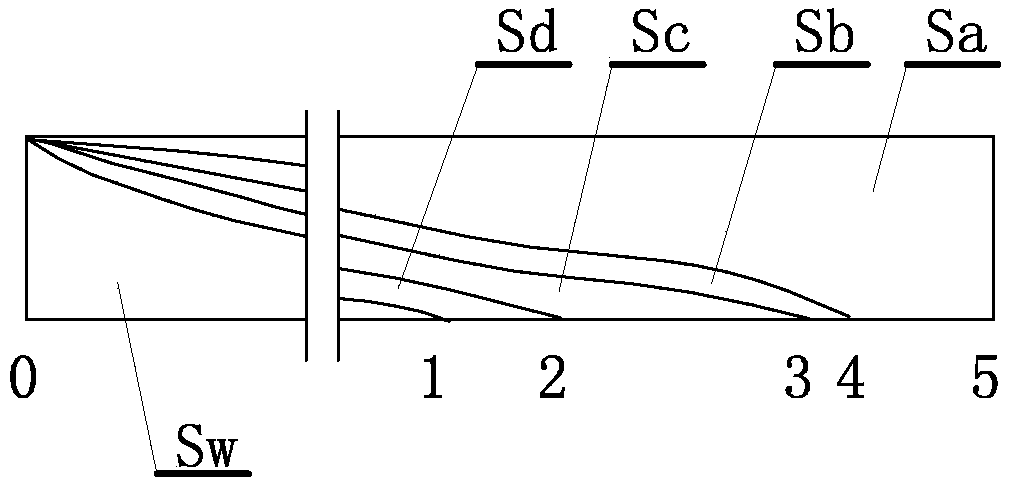

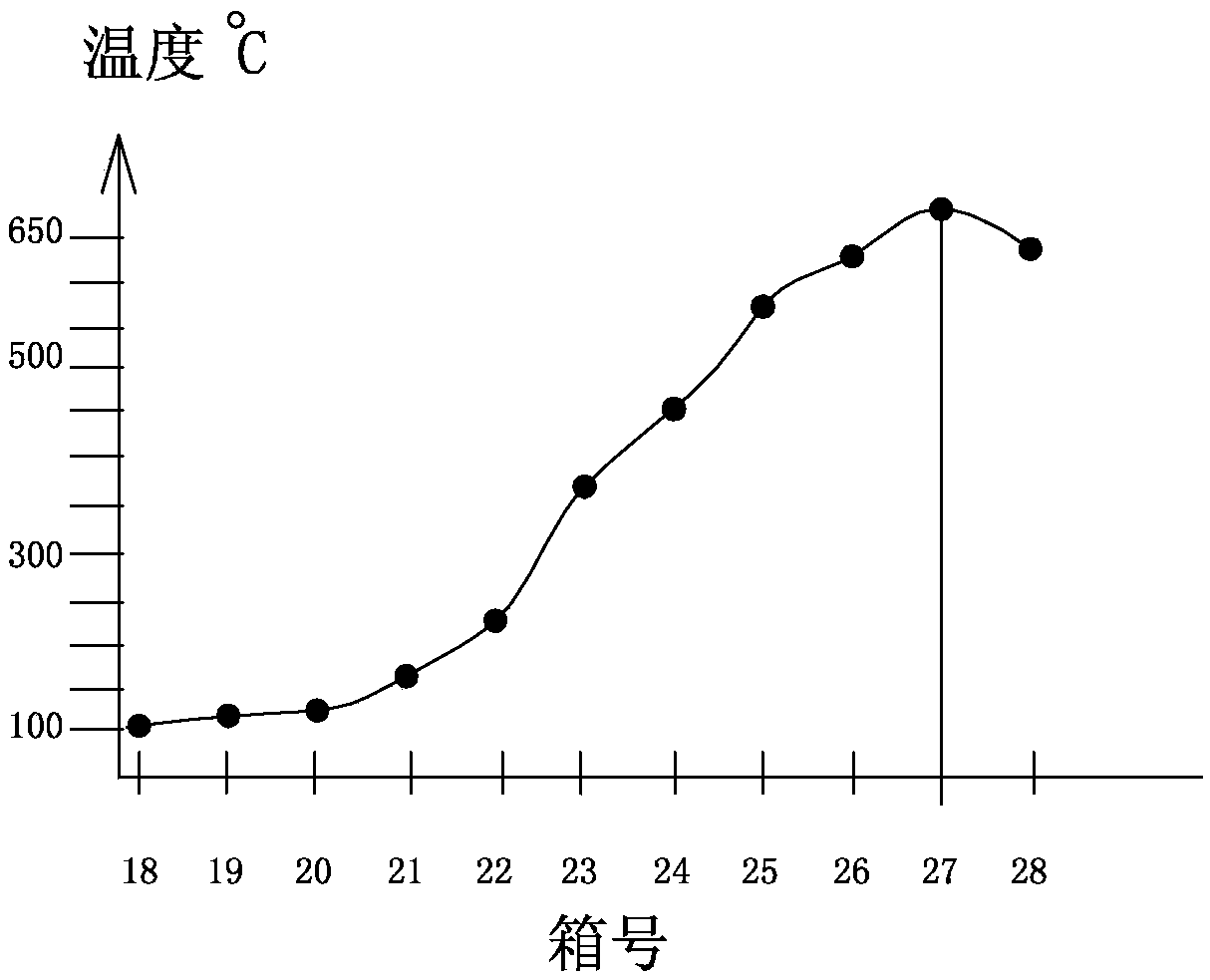

Waste heat recovery method for improving stability of unstable waste heat resource in sintering process

ActiveCN107726869AImprove sintering qualityReduce return rateIncreasing energy efficiencyControl devices for furnacesRecovery methodWaste heat recovery unit

The invention discloses a waste heat recovery method for improving the stability of an unstable waste heat resource in the sintering process. According to the waste heat recovery method, in the sintering process, temperature data of a plurality of wind chambers are acquired; a longitudinal temperature variation curve of sintering ores on a sintering ore deposit section is simulated according to the temperature data; the conveying speed of a conveyor belt and an air draft negative-pressure regulation valve of each wind chamber are regulated according to ingredient data and thickness of raw ores, so that the highest temperature point of the temperature variation curve is located at the last arranged wind chamber of the tail end of the sintering ore deposit section. By means of the method, the accuracy of the sintering final temperature reaches up to 90% or more, and the waste heat recovery rate can be increased by 5% or more; moreover, the quality of the sintering ores can be improved, and the return mire rate is reduced by 1% or more.

Owner:BEIJING ZHINENG XIANGYING ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD

Protecting device for flue gas ducts of electric arc furnace

InactiveCN104197694AExtended service lifeIncrease waste heat recoveryLighting and heating apparatusElectric arc furnaceFlue gas

The invention discloses a protecting device for flue gas ducts of an electric arc furnace. The protecting device comprises a furnace lid of the electric arc furnace, a furnace lid water-cooling gas duct, a moving water-cooling gas duct, a fixed gas duct, a burning settling chamber and the like, wherein high temperature-resistant abrasion-resistant casting materials are poured on the inner sides of the furnace lid water-cooling gas duct of the electric arc furnace, the moving water-cooling gas duct and the fixed gas duct entering the burning settling chamber. The protecting device can greatly prolong service lives of the furnace lid water-cooling gas duct, the moving water-cooling gas duct and the fixed gas duct, and the service lives are prolonged to 1.5 years or above from 3 months in average at present.

Owner:孙慕文

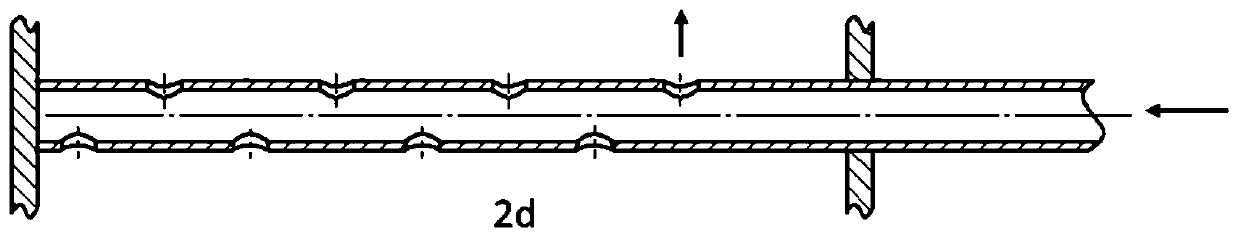

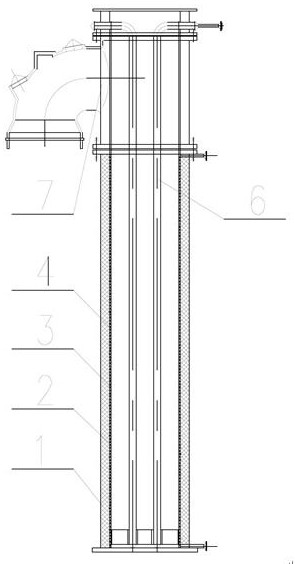

Membrane type fixed bed catalyst raw coke oven gas waste heat recovery and hydrogen utilization ascending pipe

PendingCN112680241AEliminate attachmentConducive to lightweightEnergy inputGas purification by catalytic conversionTemperature controlPtru catalyst

The invention discloses a membrane type fixed bed catalyst crude gas waste heat recovery and hydrogen utilization ascending pipe. The pipe comprises an ascending pipe shell and a bridge pipe tee joint; a raw gas channel is formed in the ascending pipe, and the ascending pipe further comprises a cylinder wall heat preservation layer, a temperature control and waste heat recovery device, an anti-corrosion ceramic layer and a membrane type fixed bed catalyst layer; the inner layer of the pipe wall of the shell of the ascending pipe is a barrel wall heat preservation layer, a temperature control and waste heat recovery device is arranged on the inner ring of the barrel wall heat preservation layer, and a working medium for taking away waste heat of raw coke oven gas is introduced into the temperature control and waste heat recovery device; an anti-corrosion ceramic layer is attached to the surface of the outer layer of the temperature control and waste heat recovery device, or a mixed layer formed by combining the anti-corrosion ceramic layer and a membrane type fixed bed catalyst layer is attached to the surface of the outer layer. According to the invention, the hydrogen-rich raw coke oven gas is subjected to directional reaction at a proper temperature under the action of the catalyst, the technical bottleneck problem in the existing coke oven production process is eliminated, the reliability and stability of the riser are improved, and the long-term stable and safe operation of the system is facilitated.

Owner:扬州优为节能科技有限公司

Solar-gas engine heat pump heating device and its operation method

InactiveCN100547321CImprove performanceReduce consumptionInternal combustion piston enginesSolar heat devicesIntermediate heat exchangerEngineering

The invention is a solar-gas engine heat pump heating device, namely a heating device integrating the solar energy utilization technique with the gas engine heat pump technique, composed of solar heat collecting system, gas engine heat pump system and water circuit circulating system and comprising engine, compressor, heat preservation water tank, expansion valve, tee valve, intermediate heat exchanger, heat collector, air source evaporator, fume heat exchanger and flow regulating valve. And it has three different working modes: when external solar radiation intensity is enough high, the gas engine heat pump does not work and it can meet the requirements by directly utilizing solar energy; when the solar radiation intensity is so low that the water temperature in the water tank is very low, the heat pump is switched on and works with the air as heat source; and when the solar radiation intensity is intermediate, the gas engine heat pump works with the solar heated working medium as heat source. And it can in all weathers and continuously supply 80-90 deg.C hot water.

Owner:SOUTHEAST UNIV

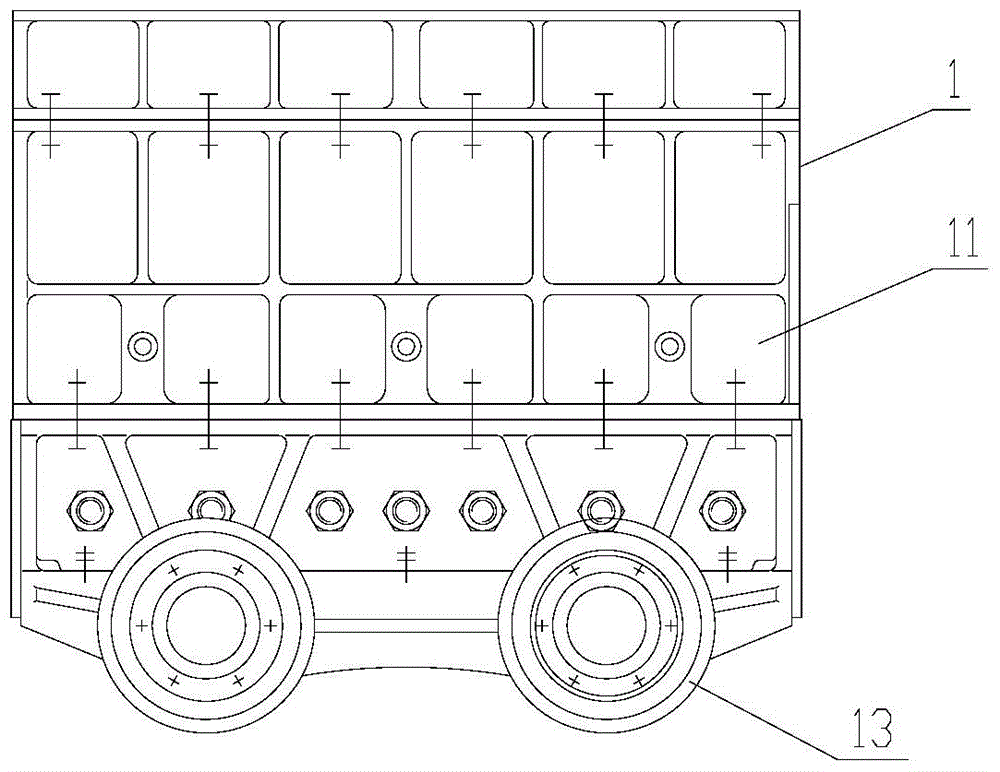

Movable tank type cooler and sinter cooling method

ActiveCN107796227AUniform flow fieldStructural factors to eliminate air leakageHandling discharged materialWaste heat treatmentFlueWaste heat

The invention discloses a movable tank type cooler. The cooler comprises 1) a ring-groove-shaped cooling bin, 2) a drive device driving the ring-groove-shaped cooling bin to move, 3) an annular hot air cover arranged on the ring-groove-shaped cooling bin, 4) at least one hot air collecting pipe connected to the top or the side portion of the hot air cover, 5) a cooling air flue arranged on the inner side of the ring-groove-shaped cooling bin, 6) an annular rotation rack arranged at the bottoms of the ring-groove-shaped cooling bin and the cooling air flue, 7) an ore discharging bucket arrangedat the lower portion of the ring-groove-shaped cooling bin, 8) a plurality of cooling draught fans and 9) a cooling air communication pipe. The cooling air flue comprises a cooling air flue moving base and a cooling air flue fixing cover. An air passing beam is arranged in the annular rotation rack in a hollow manner. Air outlets of the cooling draught fans communicate with the cooling air flue through cooling air pipes corresponding to the cooling draught fans. The cooling air communication pipe is arranged between the cooling air flue moving base and the annular rotation rack. According tothe movable tank type cooler, all air leakage links are eliminated, good sealing performance of movable tank cooling is guaranteed, and the waste heat recycling amount is greatly increased.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com