A cement kiln high-efficiency waste heat recovery power generation system and method

A waste heat recovery and power generation system technology, applied in the direction of improving energy efficiency, waste heat treatment, steam superheating, etc., can solve the problems of low heat source quality and waste heat recovery efficiency, so as to improve power generation efficiency and technical and economic indicators, improve taste and waste heat recovery volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

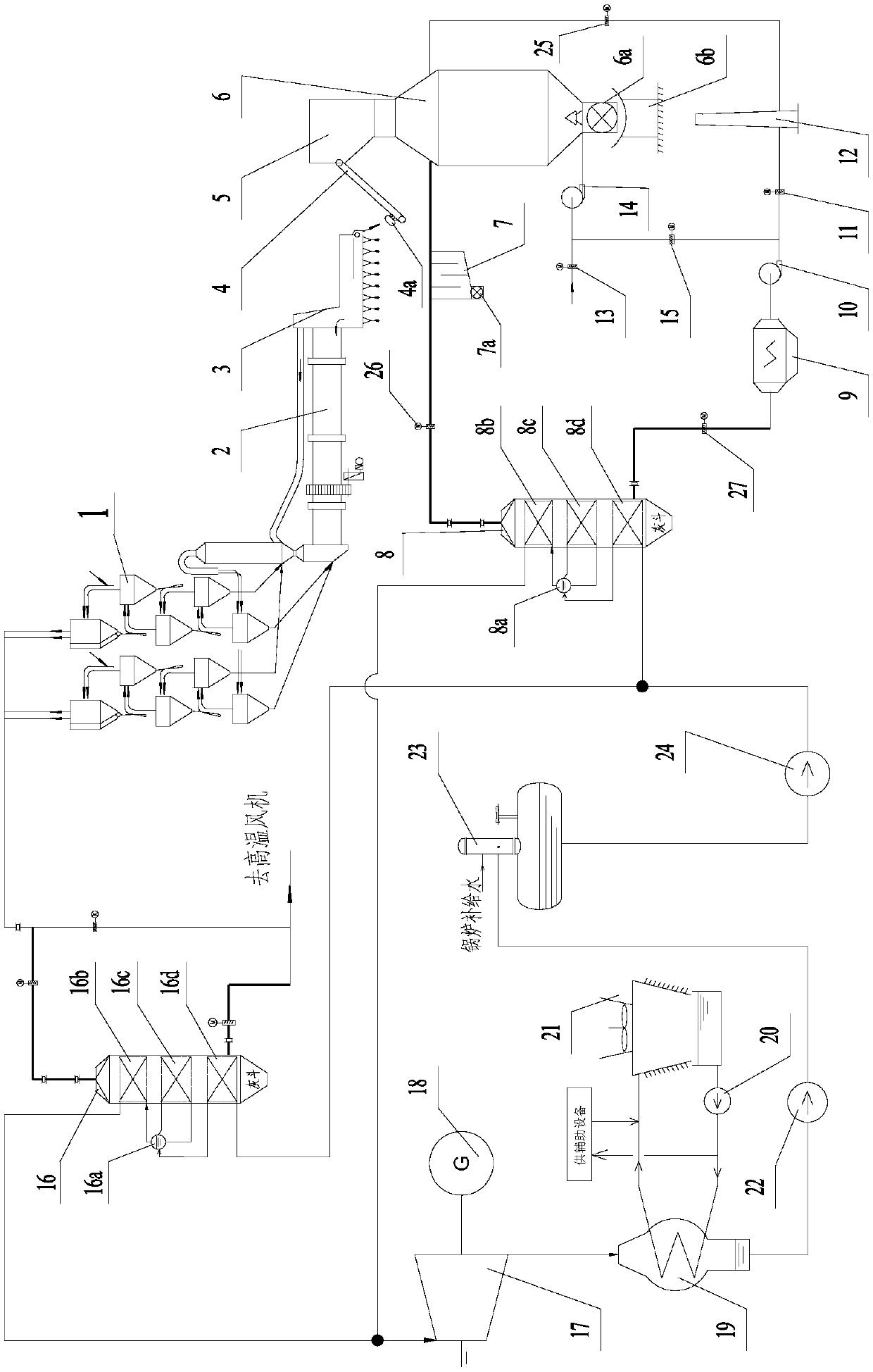

[0015] Such as figure 1 As shown, a cement kiln high-efficiency waste heat recovery power generation system includes clinker cascade cooling device, waste heat recovery device, steam turbine power generation device, circulating cooling water device and waste gas treatment device.

[0016] Clinker cascade cooling device includes grate cooler 3, inclined bridge hoisting device 4, trolley 4a, material receiving hopper 5, vertical cooling device 6, unloading device 6a, belt transport device 6b, cold air valve 13, low temperature blower 14 The outlet of the rotary kiln 2 is connected to the inlet of the grate cooler 3, the outlet of the grate cooler 3 is connected to the trolley 4a, the trolley 4a is placed on the inclined bridge hoisting device 4, and the inclined bridge hoisting device 4 is connected to the receiving funnel 5, The lower part of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com