Patents

Literature

413results about How to "Avoid direct discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

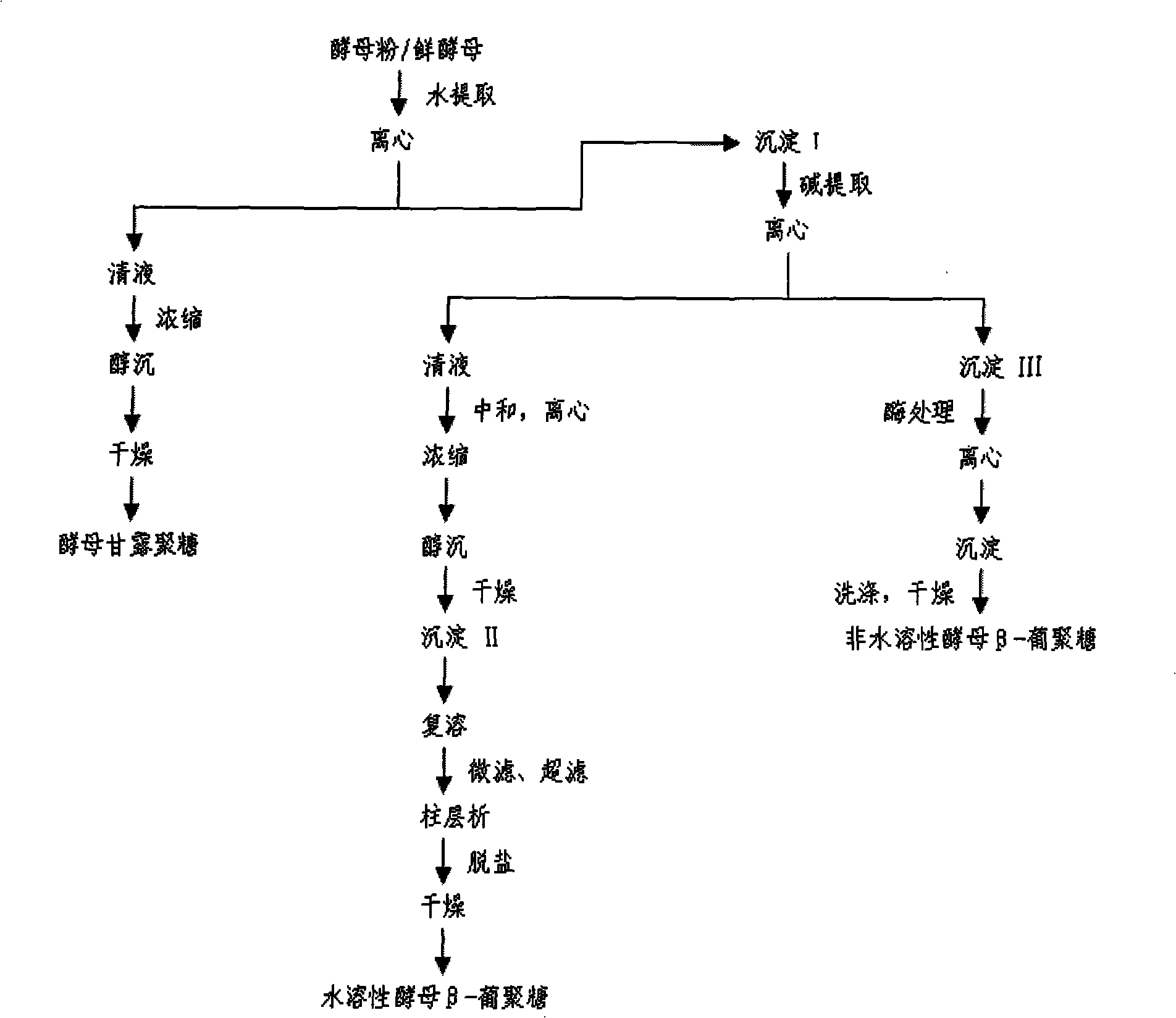

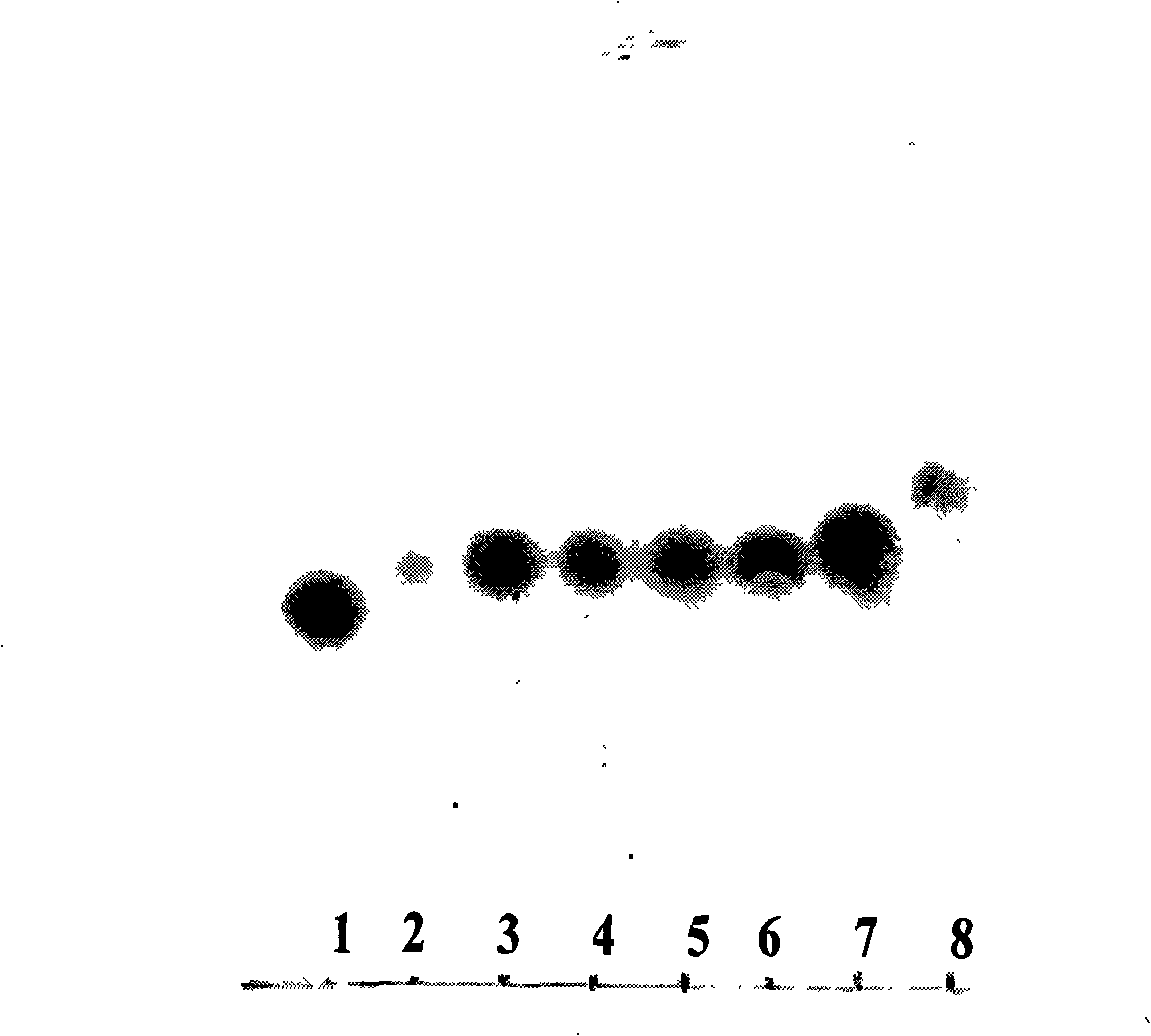

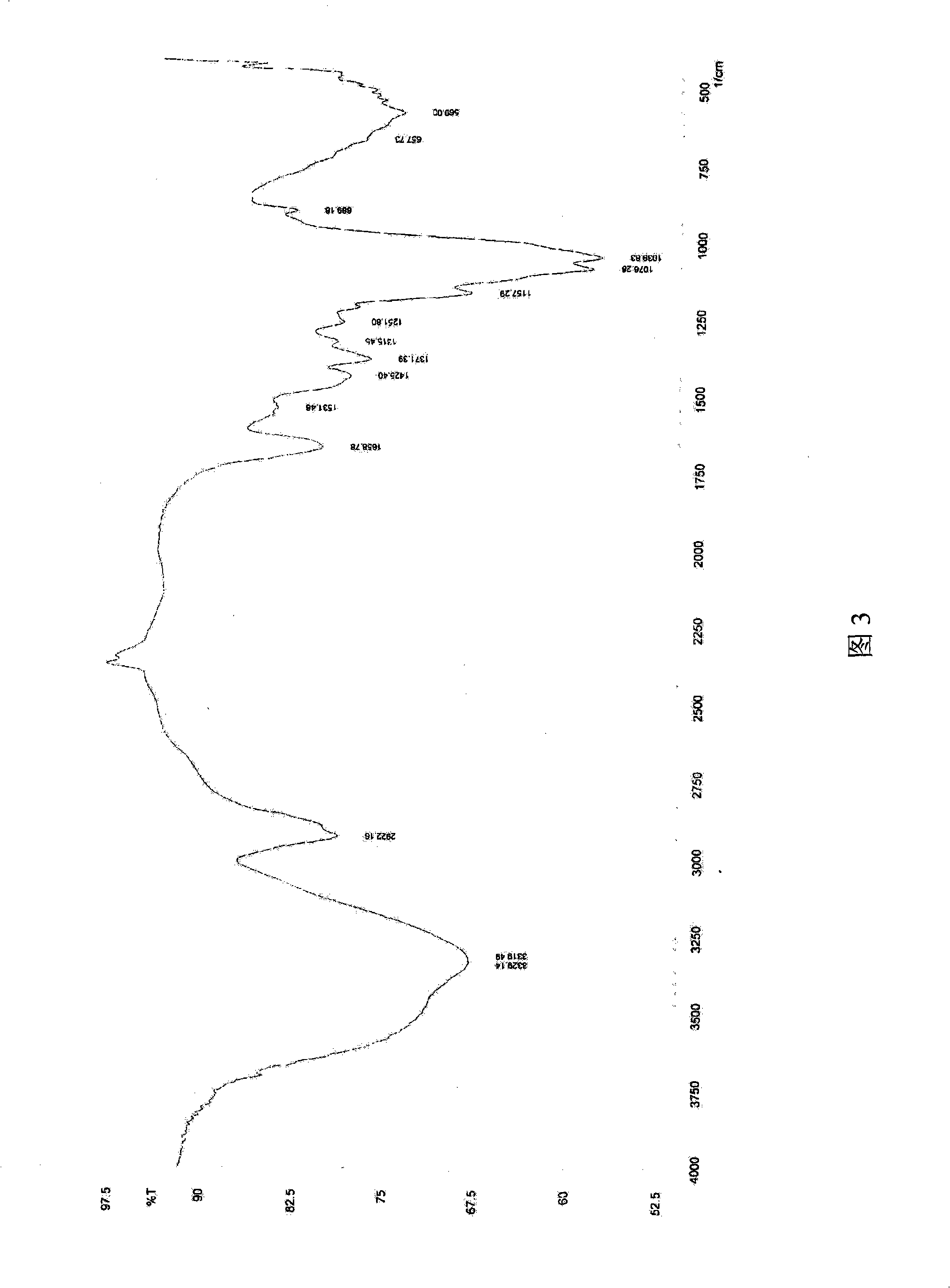

Water-soluble yeast beta-dextran and preparation thereof

ActiveCN101353383AAchieve maximum utilizationSimple processMilk preparationImmunological disordersYeastDairy foods

The invention relates to a water-soluble barm Beta-dextran and a preparation method thereof. In the water-soluble barm Beta-dextran chain, Beta-1, 3-dextran is taken as a main chain, Beta-1, 6-dextran is taken as a branched chain, the molecular weight is 0.08 to 0.2 million Daltun. The preparation method of the water-soluble barm Beta-dextran includes the following steps of: water extraction, alkali extraction and impurity processing. The preparation technique of the invention is simple; the technique parameters are easy to be operated and controlled; both the yield and the purity of the product water-soluble barm Beta-dextran are higher. The obtained water-soluble barm Beta-dextran has remarkable immune activation effect and especially can improve the phagocytic function and the antibody formation capacity of a macrophage to a large extent, thereby improving the body immunity and resistance. The water-soluble barm Beta-dextran can be widely applied in the fields such as food, dairy food and drinks, etc.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Method for producing flavourings cooking wine

ActiveCN101130730ASimple processEasy to operateAlcoholic beverage preparationFood preparationYeastWork in process

The invention discloses a manufacturing method of flavouring cooking wine, which comprises the following steps: adopting yellow water, squeezing liquid of distiller's grain, wine end and special cavity wine as raw material; predisposing the raw material; boiling; dispensing; filtering; blending the yellow water and distiller's grain with weight rate at 1. 5-5: 1 to do basylous action through hypercritical CO2 extraction; adding 0. 05-0. 1% aromatic yeast in the slurry; culturing at 30 deg. c for 2-5d; adding the cultured slurry into 0. 1-0. 5%. composite condiment material to boil 10-20 min; cooling to 33-35 deg. c to add 20-50% wine end to blend to produce the semi-product; dispensing the semi-product with special cavity wine and edible salt according to the standard of SB / T10416-2007 flavouring cooking wine. The invention prevents environmental pollution of yellow water, wine end and distiller's grain to realize maximum resource transition utility, which saves a large amount of grain and simplifies the technique and operation with low cost and rapid effect in comparison with traditional brewing technique.

Owner:SICHUAN TUOPAI SHEDE WINE

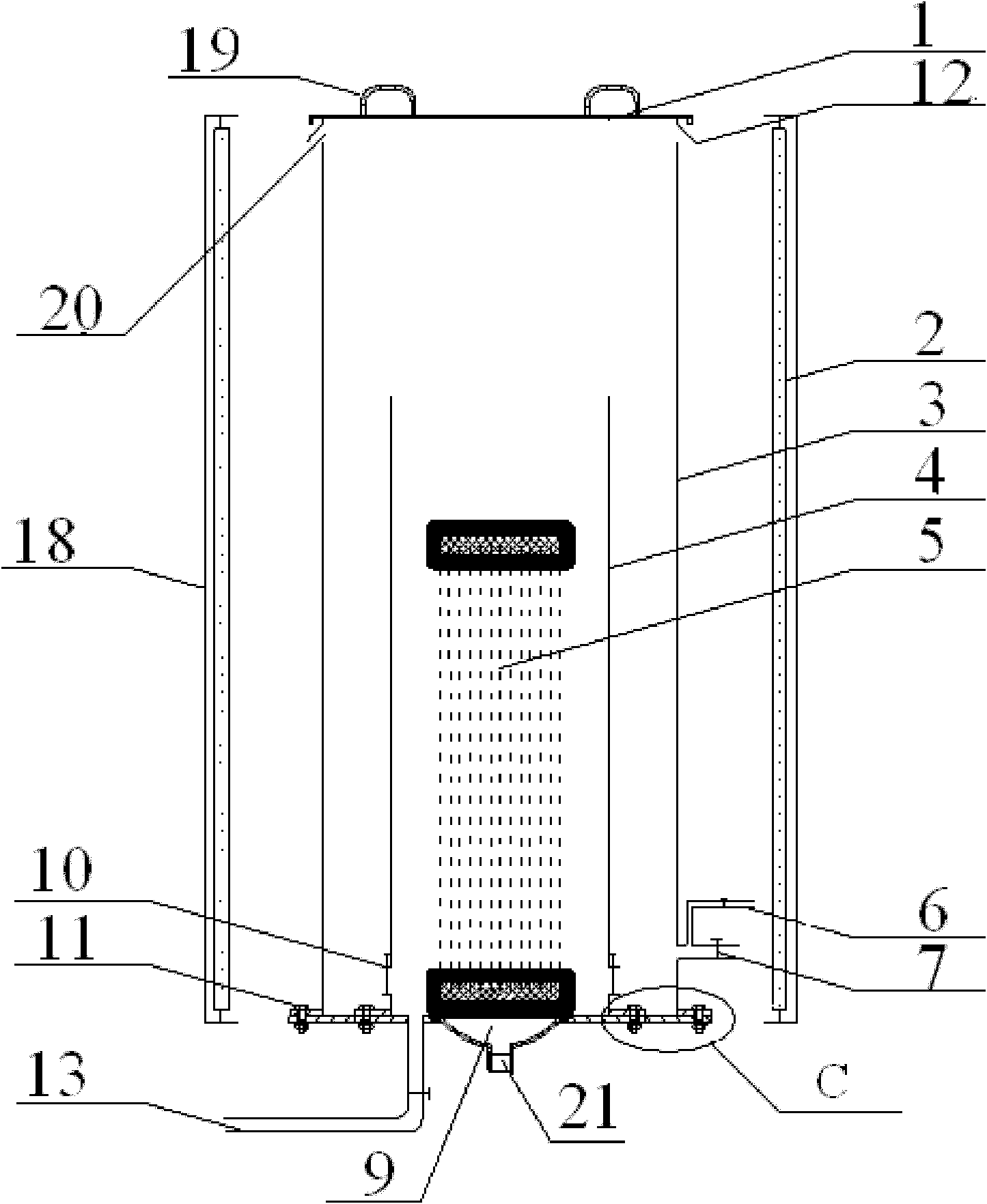

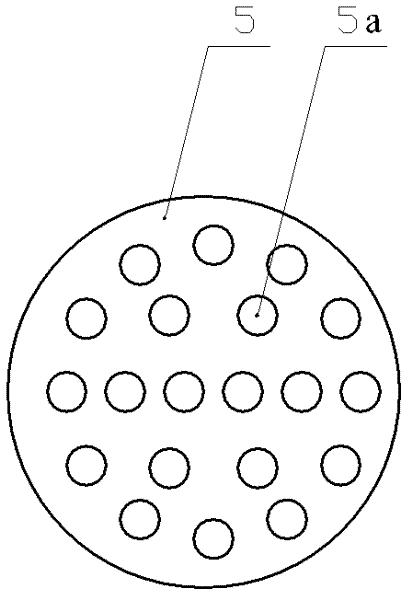

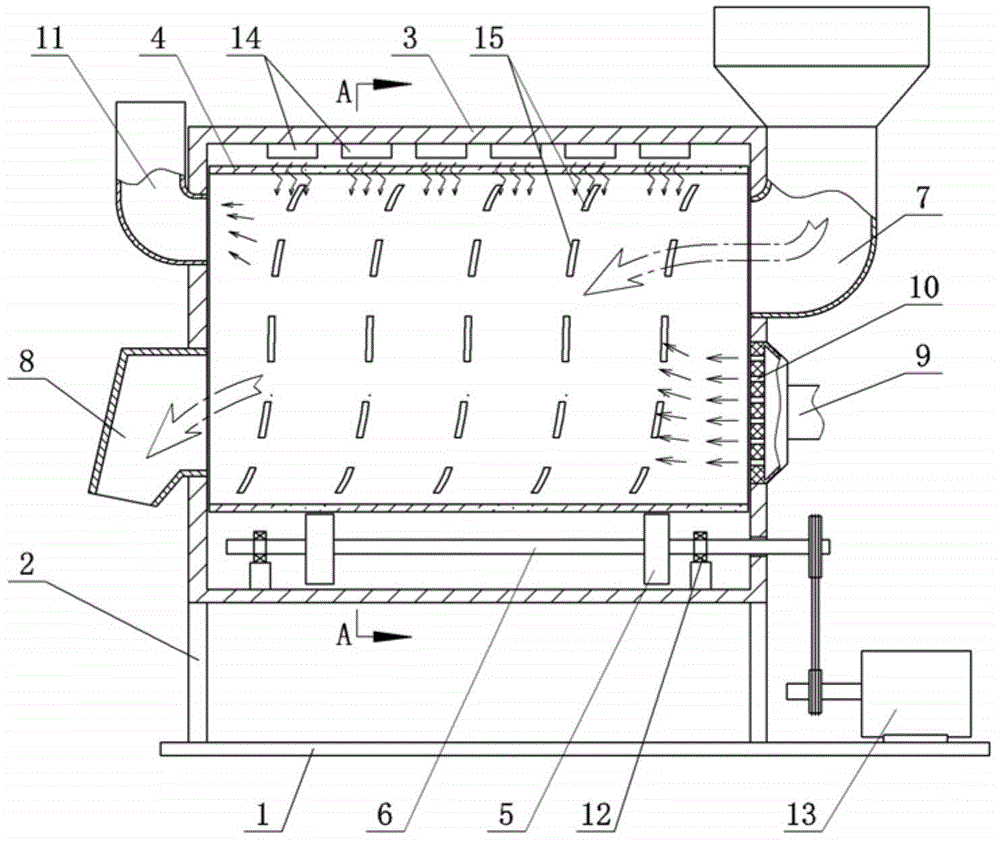

Membrane type photobioreactor for enhancing microalgae culturing

InactiveCN101985595AEasy to fixIncrease mass transfer rateBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorEngineering

The invention discloses a membrane type photobioreactor for enhancing microalgae culturing. The membrane type photobioreactor comprises an external light source, a bottom plate, an inner sleeve and an outer sleeve, wherein the inner sleeve and the outer sleeve are vertically arranged on the bottom plate; the outer sleeve is positioned on the outer side of the inner sleeve and surrounds the inner sleeve; the top end of the outer sleeve is horizontally provided with a transparent top cover plate, the top of the outer sleeve is provided with a plurality of air outlets and the bottom of the outersleeve is provided with a discharge port; the bottom of the inner sleeve is provided with a plurality of exchange holes; the bottom plate is provided with an air inlet which is surrounded by the inner sleeve; the air outlets are positioned above the top end of the inner sleeve; the bottom plate is vertically provided with a membrane component which is positioned inside the inner sleeve; and the bottom edge of the membrane component is hermetically fixed with the bottom plate and surrounds the air inlet. The membrane type photobioreactor for enhancing microalgae culturing has the advantages ofsimple structure, simplicity and convenience in operation, stable performance, larger specific surface area and light transmission efficiency; and by using the membrane component, the gas is uniformly distributed, and the photobioreactor can be independently used or connected with a track pool for amplified culturing of the microalgae.

Owner:ZHEJIANG UNIV

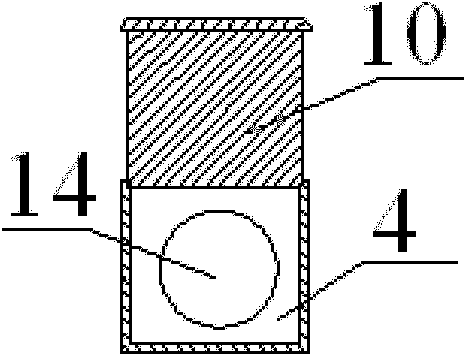

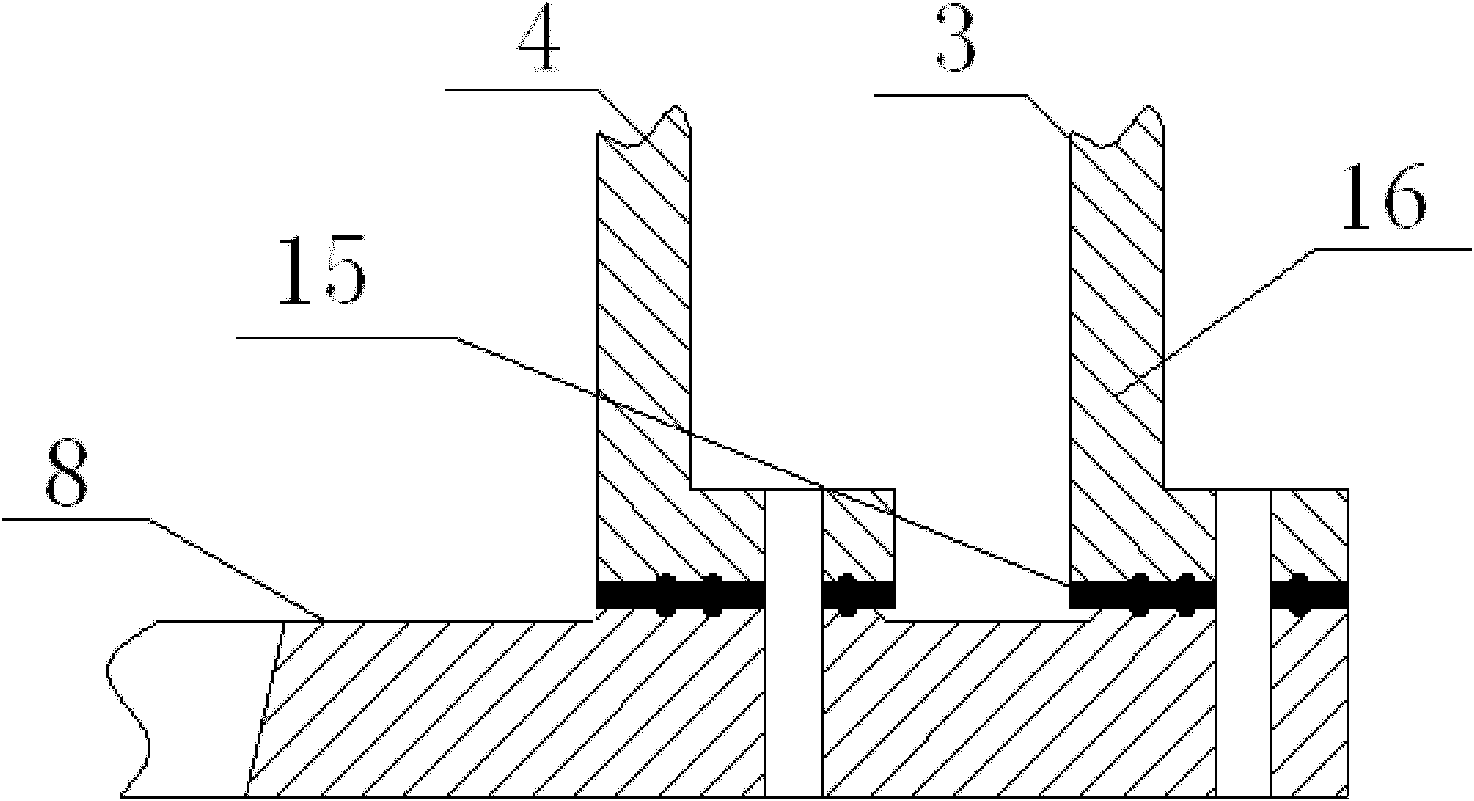

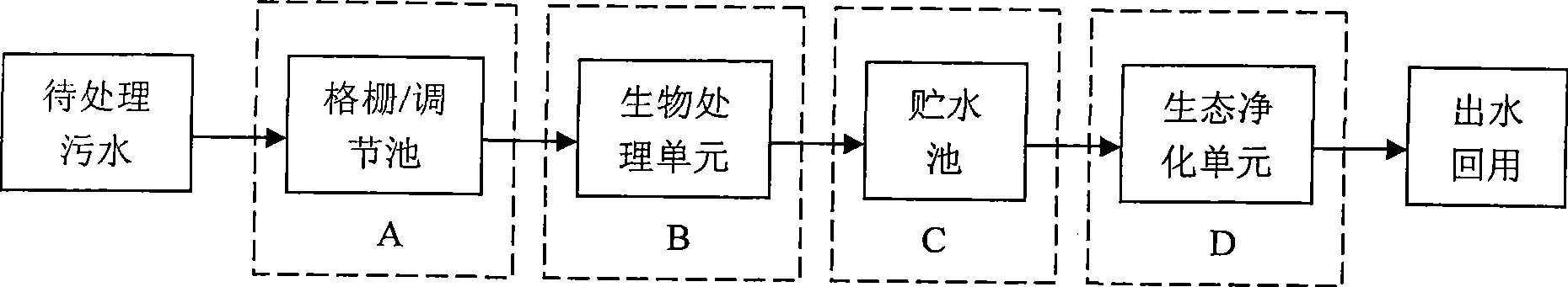

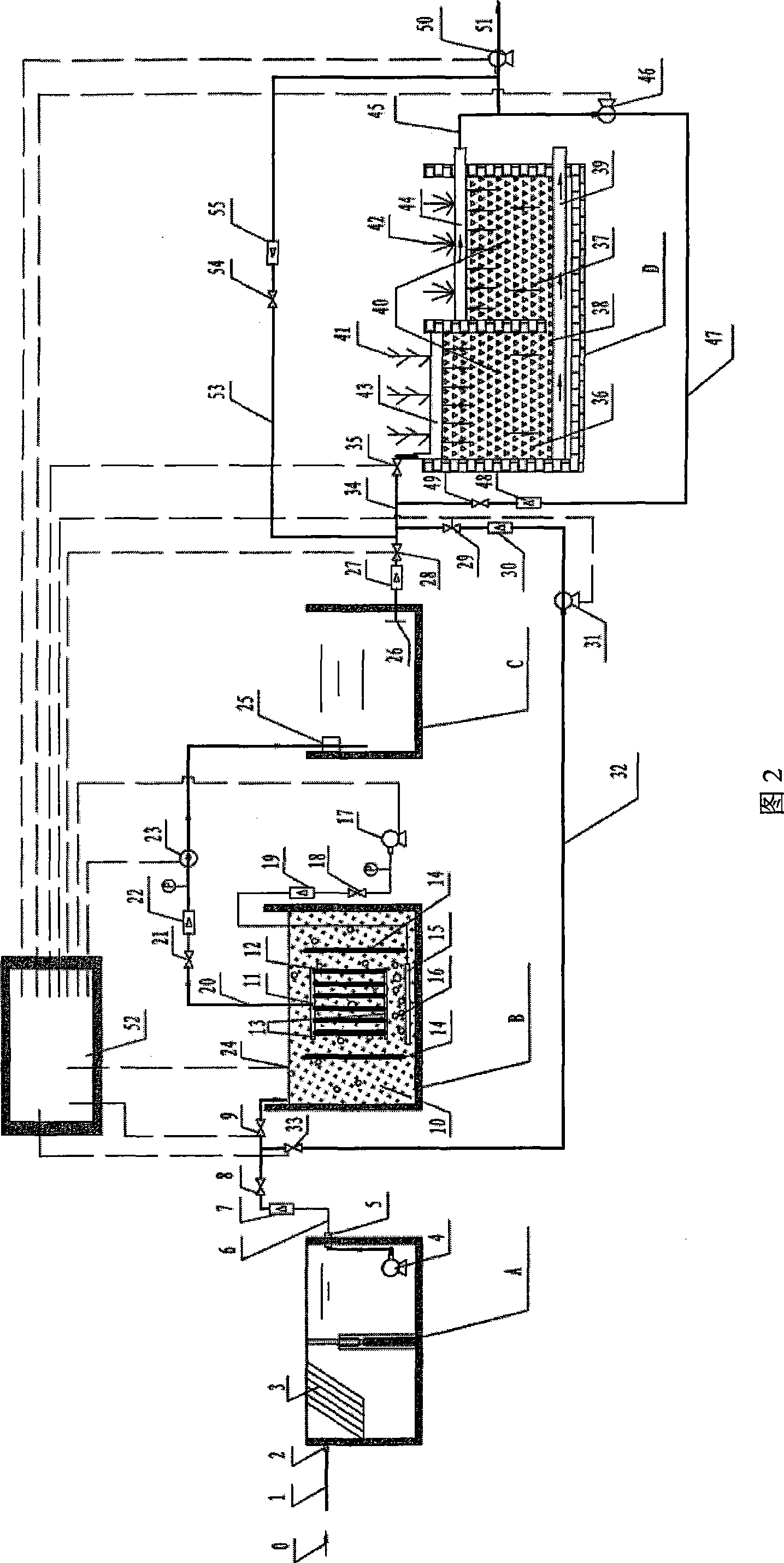

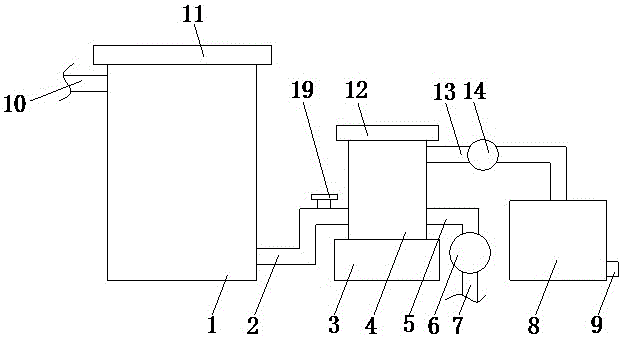

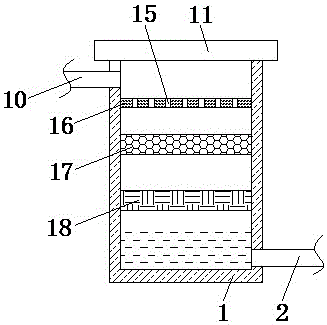

Bio-ecological combination method for effluent purification and reclamation and apparatus

ActiveCN101381155AImprove effluent qualityLow costWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentConstructed wetlandParticulates

The invention discloses a method and a device for biological ecological assemblage for sewage purification and recycling. The method comprises the following steps: A. sewage to be treated passes through a grate / regulating reservoir, and large particulate materials are removed; B. the sewage treated in step A is pumped into an integral membrane bioreactor, and permeates a membrane when pumped by a pump; C. the sewage treated in step B flows into an intermediate water reservoir; and D. the sewage flowing out in step C enters into a composite vertical current manual wetland by graded means. The device comprises four units: the grate / regulating reservoir, the integral membrane bioreactor, the water reservoir and the composite vertical current manual wetland, wherein various units are connected through pipes and controlled by valves. Bypass pipes are arranged on outlets of the various units of the grate / regulating reservoir, the integral membrane bioreactor, the water reservoir and the composite vertical current manual wetland, and combined modes of series connection, shunt connection and parallel connection of the integral membrane reactor and the composite vertical current manual wetland are realized by adjusting valves, so that the method is easy, is simple and convenient to operate, has high operation efficiency and low cost, and realizes sewage purification and direct recycling.

Owner:INST OF AQUATIC LIFE ACAD SINICA

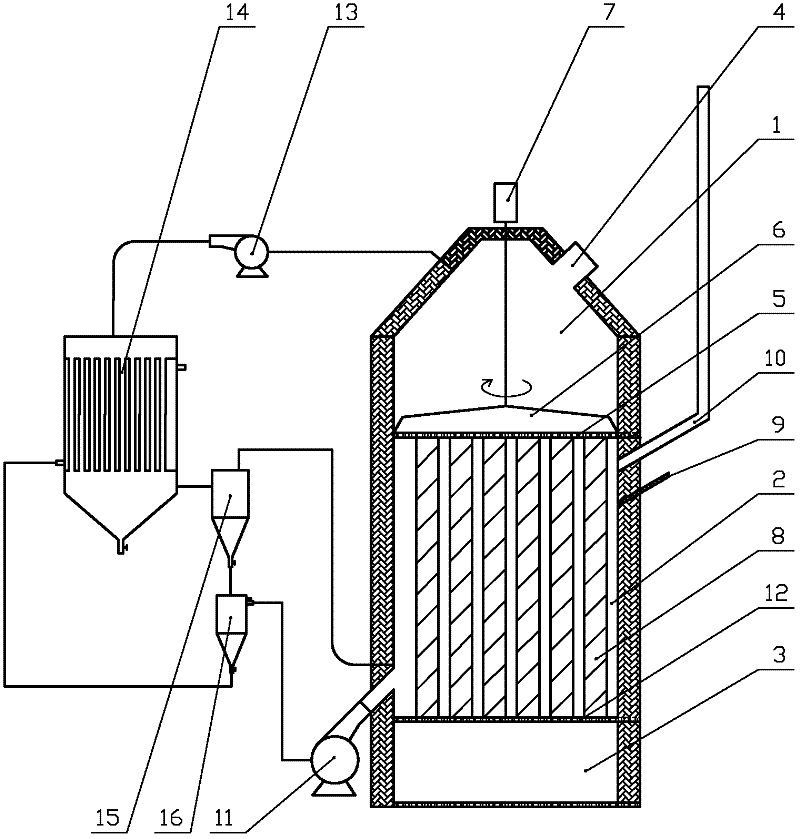

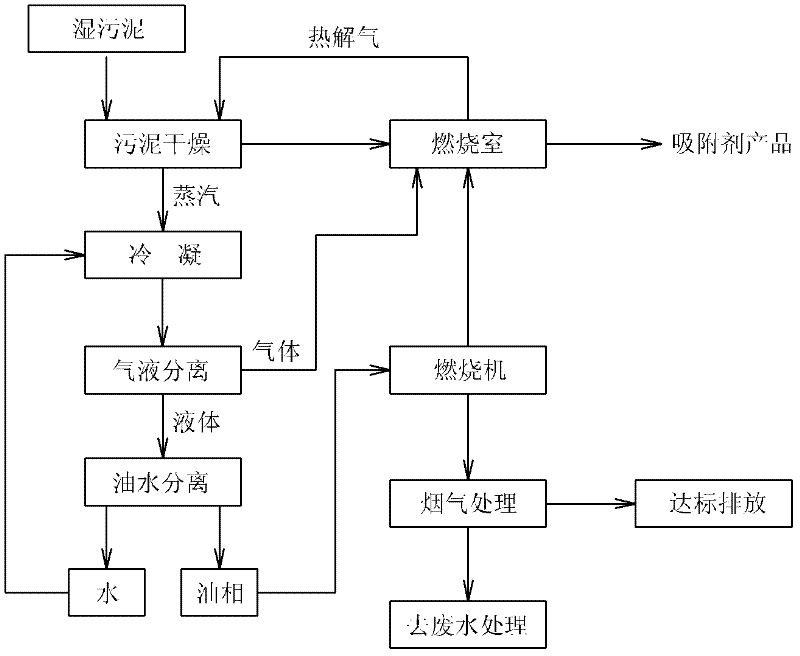

Printing and dyeing sludge pyrolysis treatment device and sludge treatment method

InactiveCN102344234APollution controlAvoid direct dischargeSludge treatment by pyrolysisByproduct vaporizationCombustion chamberSludge

The invention discloses a printing and dyeing sludge pyrolysis treatment device which successively comprises a sludge chamber, a combustion chamber and a product collecting chamber from top to bottom, wherein a feed port is arranged on the sludge chamber, and a support plate with holes is arranged between the sludge chamber and the combustion chamber; the combustion chamber is connected with a combustion engine, and a pyrolysis cavity is arranged in the combustion chamber; and a dump valve is arranged between the combustion chamber product collecting chamber. The invention also discloses a printing and dyeing sludge treatment method. In the invention, by adopting the vertical arrangement from top to bottom, the automatic flowing nature of the substance is fully utilized, and the problems of high viscosity and hard feeding of printing and dyeing sludge are solved. Sludge drying, pyrolysis, pyrolysis gas recycling and control are integrated, and energy consumption is effectively reduced. Not only is the recycling of the printing and dyeing sludge realized, but also the harm to environment is greatly lowered. Therefore, the demands of industry development and environmental protection can be well adapted and satisfied.

Owner:GUANGZHOU UNIVERSITY

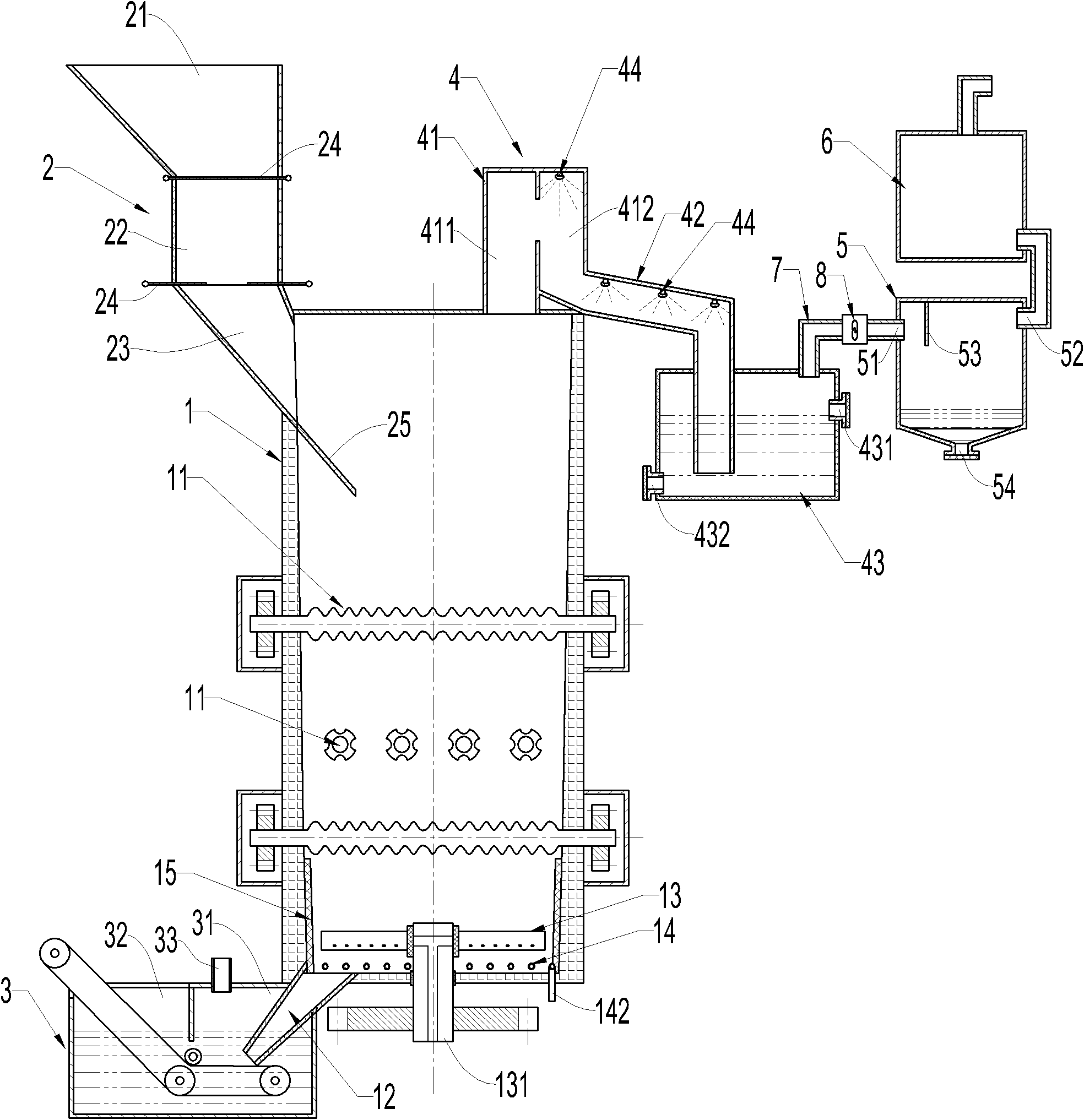

A biomass waste pyrolysis furnace system

The invention relates to a cracking furnace system of biomass garbage. The system provided by the invention comprises a furnace body, a feeding mechanism, a slag catching container, a gas washing tower, an oil-gas separating tower and a gas collecting tower; the upper part of the furnace body is provided with the feeding mechanism, the top part is connected with the gas washing tower, the middle part is provided with fire grates, and the bottom part is provided with an agitating blade, an air discharging device and a slag discharging pipe, wherein firstly, the furnace body utilizes more than one layer of fire grate and supplies multiple layers of supporting to be matched with the double-movable-flashboard feeding mechanism and the agitating blade so that the biomass is more completely cracked; secondly, the slag catching container is supplied so that the temperature of high-temperature slag can be reduced and percolate and the like which are produced by the garbage can be all consumed; the generated cracking gas not only is clean and low-temperature, but also can be easier to be separated from oil after the cracking gas passes through the gas washing tower, thereby simplifying theflow of oil-gas separation. According to the system provided by the invention, sewage, oil and steam which are generated in the cracking process can be circulated to the furnace to be combusted and be further cracked so that a harmless treatment is finally achieved.

Owner:FUJIAN BOYI ENVIRONMENTAL PROTECTION TECH

Method for preparing high-purity low-chlorine electroplating-grade cupric oxide

InactiveCN103101957AAvoid bringing inGuaranteed purityEnergy inputCopper oxides/halidesDecompositionCarbonization

The invention discloses a method for preparing high-purity low-chlorine electroplating-grade cupric oxide. According to the method, copper, liquid ammonia and high-purity carbon dioxide are taken as raw materials, stronger ammonia water is prepared firstly, carbonated ammonia water is obtained through introducing the high-purity carbon dioxide into the stronger ammonia water and controlling carbonization degree, the carbonated ammonia water reacts with the copper under certain air pressure so as to prepare copper-ammonia complexation liquid, the copper-ammonia complexation liquid is then subjected to heating, ammonia distilling, separating, washing, drying and sieving so as to prepare high-purity heavy basic copper carbonate, and the heavy basic copper carbonate is then subjected to heating calcination and decomposition, thereby preparing the high-purity low-chlorine electroplating-grade cupric oxide. According to the method, the carbon dioxide is directly used as a raw material, so that the problems of the traditional method that impurities, such as heavy metal ions and chloride ions, are introduced by raw materials used in the production of basic copper carbonate are solved, the rate of reaction is increased, the production cycle is shortened, the production efficiency is greatly increased, and products are low in impurity content, high in purity, high in activity and wider in application; and meanwhile, the method is high in yield, low in energy consumption, and low in cost and hardly causes pollution.

Owner:TAIXING SMELTING PLANT

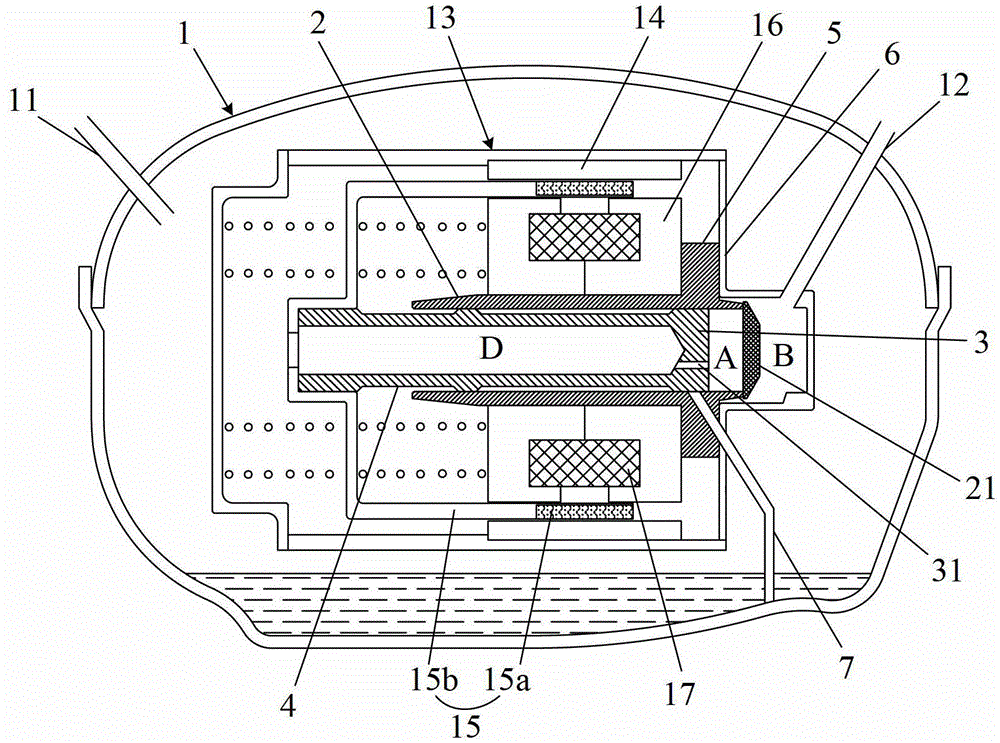

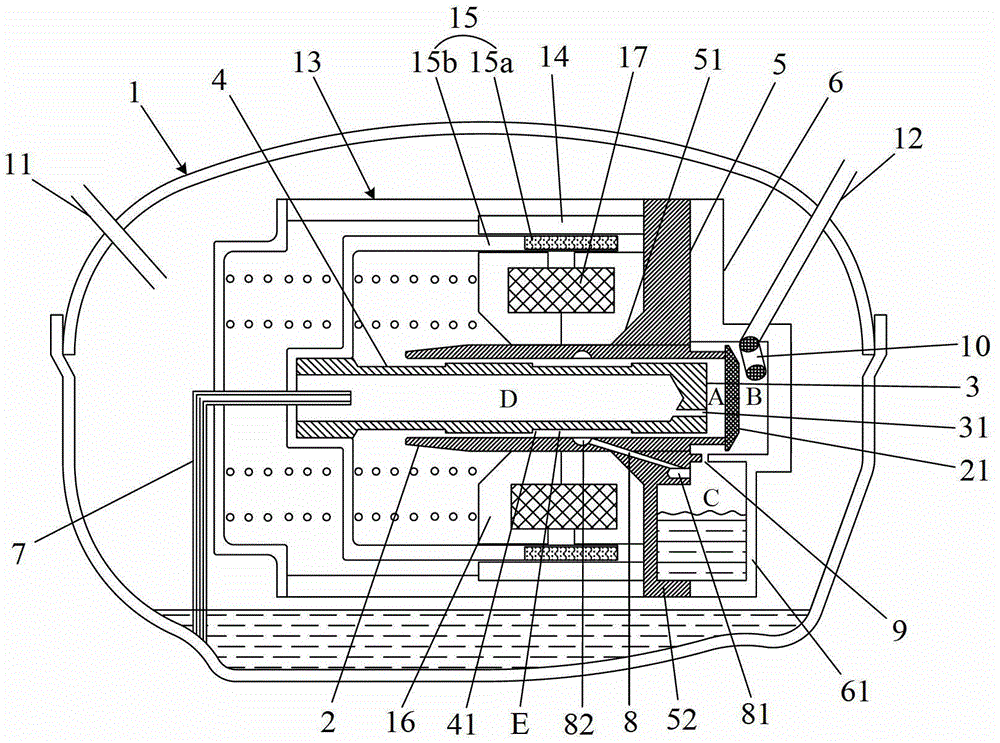

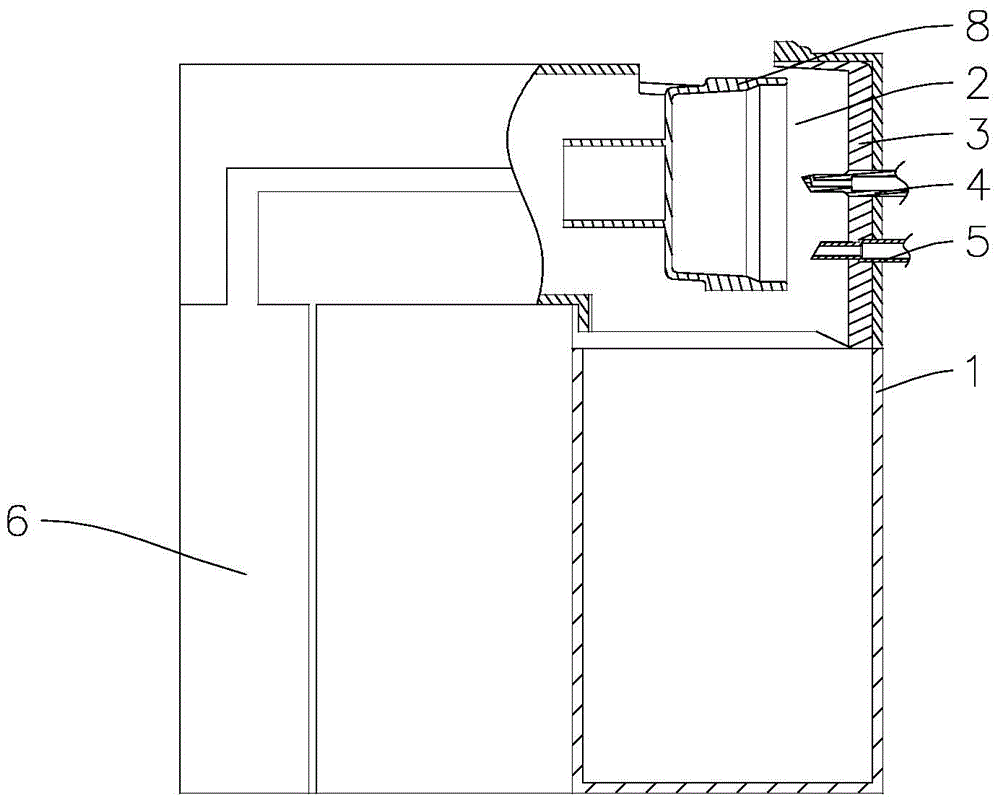

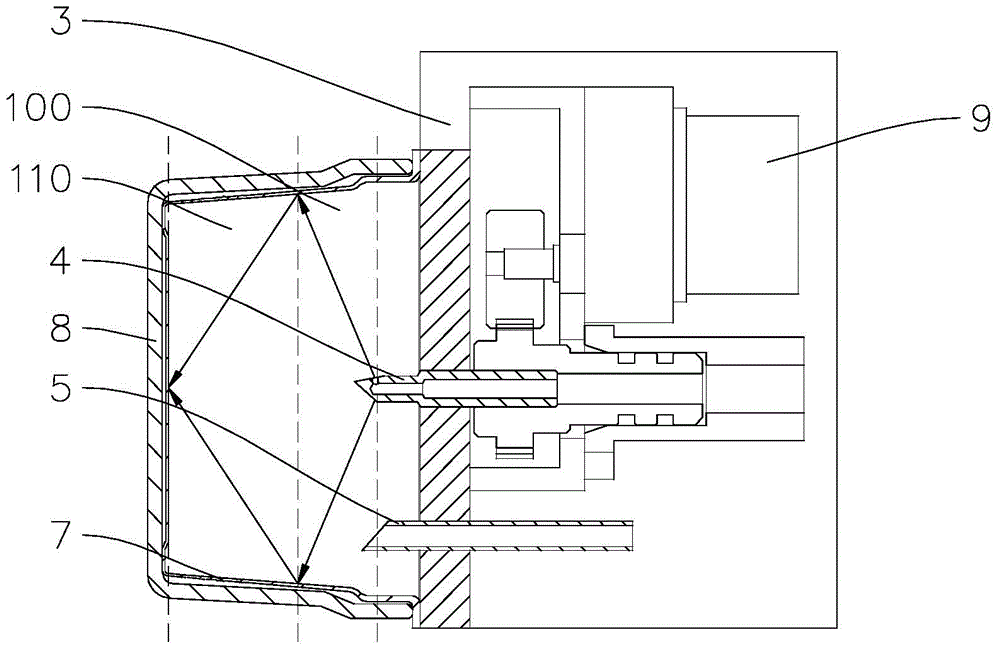

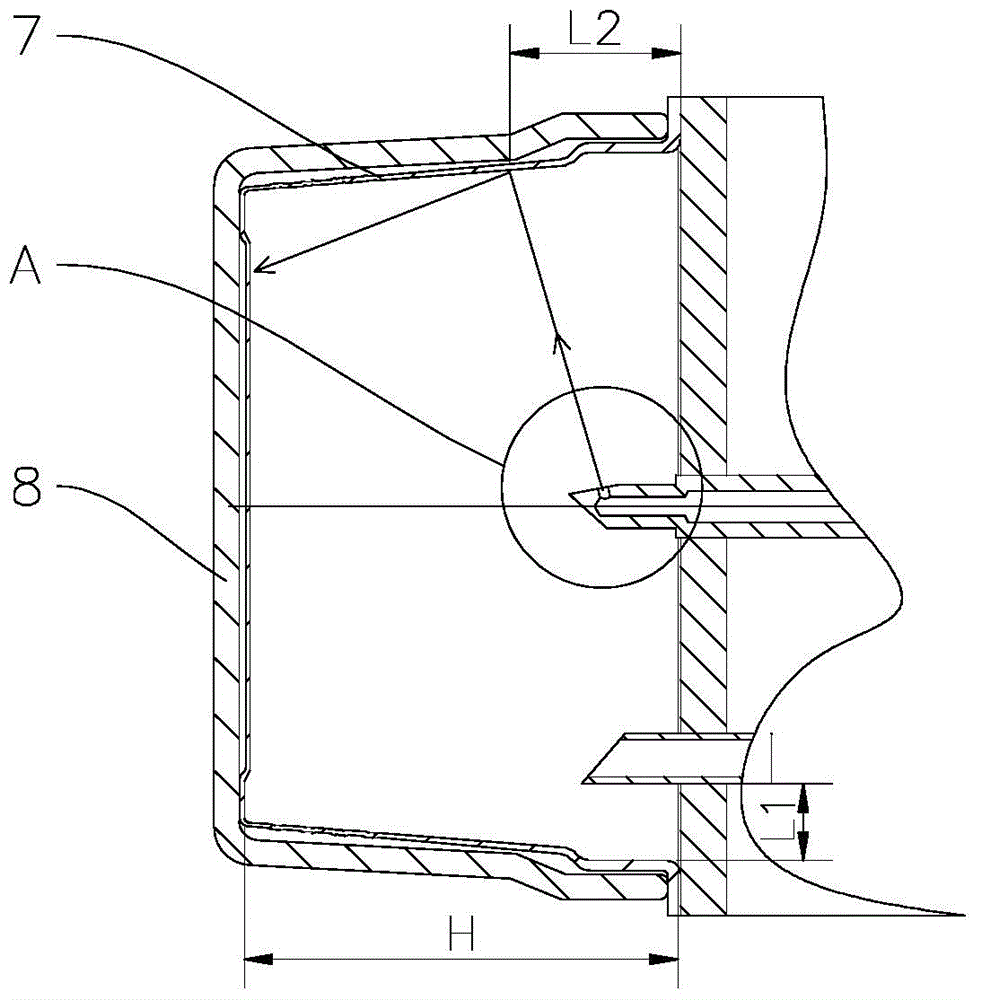

Linear compressor and oil lubricating method thereof

ActiveCN104033353AAvoid wear and tearImprove performancePositive displacement pump componentsPiston pumpsLinear compressorHigh pressure

The invention provides a linear compressor and an oil lubricating method thereof. The linear compressor comprises an outer casing which accommodates refrigerating mediums and lubricating oil; an air cylinder, a piston and a piston shaft are arranged inside the outer casing; a gap is formed between the air cylinder and the piston shaft; a flange plate is configured on the outer peripheral surface of the air cylinder; an air cylinder cover is fixed on the flange plate; an exhaust valve is arranged on the internal side of the air cylinder cover on the end portion of the air cylinder; space which is defined by the piston, the air cylinder and the air cylinder cover is separated into a compression chamber and an exhaust chamber which are communicated through the exhaust valve; the linear compressor is provided with an oil storage air chamber which is communicated with the exhaust chamber and the gap; the lubricating oil is connected with the compression chamber through an oil suction pipe; the lubricating oil enters into the compression chamber through the oil suction pipe due to relative movement between the piston and the air cylinder; the lubricating oil and the refrigerating mediums are mixed inside the compression chamber to form into high pressure gas-oil mixture; the high pressure gas-oil mixture is discharged into the exhaust chamber; partial high pressure gas-oil mixture enters into the oil storage chamber and the gap is full of the partial high pressure gas-oil.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

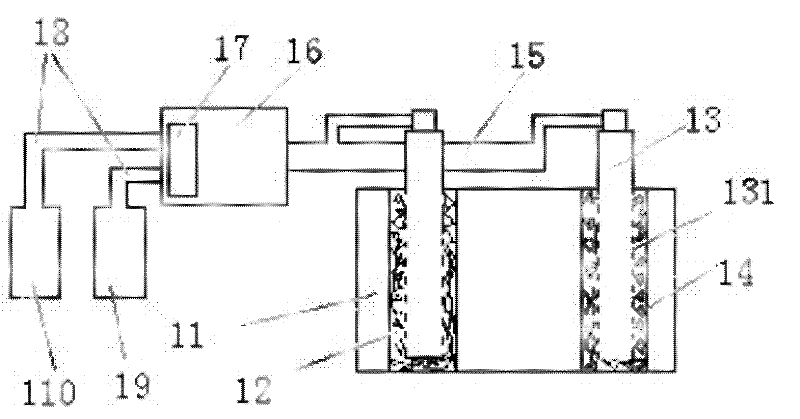

Beverage making method of horizontal type rotation beverage making machine

The invention discloses a beverage making method of a horizontal type rotation beverage making machine. The beverage making machine comprises a machine base with a brewing cavity, a brewing head, a water inlet pricking needle arranged at the brewing head, a leading-out pricking needle arranged at the brewing head, a liquid supply mechanism for supplying liquid to the brewing head and a brewing cup for containing a material bag; and one end of the brewing head is connected with the liquid supply mechanism, and the other end of the brewing head supplies the liquid to the interior of the material bag. The beverage making method includes the water inlet step, the making step and the beverage discharging step; a driving device is additionally used in the making step to drive the water inlet pricking needle to rotate, so that a jet flow area is formed by the water inlet pricking needle, beverage powder is flushed by liquid flow in the jet flow area so as to be mixed and dissolved, and therefore mixing dissolution of the liquid and the beverage powder is quickened; in addition, the beverage powder is sufficiently dissolved, residues are avoided, and the taste and the nutritive value of a beverage are improved; meanwhile, the rotation jet flow motion is formed by the water inlet pricking needle in the rotation process, dissolution of the beverage powder is better promoted, and the making efficiency and the taste of the beverage are improved.

Owner:JOYOUNG CO LTD

Method for preparing high-purity low-chloride electroplated copper oxide

InactiveCN103011250AAvoid bringing inGuaranteed purityCopper oxides/halidesDistillationCarbonization

The invention discloses a method for preparing high-purity low-chloride electroplated copper oxide. The method comprises the following steps: taking copper, liquid ammonia and high-purity carbon dioxide as raw materials; preparing stronger ammonia water at first; then pumping high-purity carbon dioxide into the stronger ammonia water; preparing and obtaining carbonated ammonia water through controlling the carbonization degree; achieving reaction between the carbonated ammonia water and copper under a certain air pressure to obtain a copper and ammonia complexing solution; preparing heavy high-purity cupric subcarbonate through heating, ammonia distillation, separation, washing, drying and screening; and heating, calcining and decomposing the heavy cupric subcarbonate to obtain high-purity low-chloride electroplated copper oxide. According to the invention, as carbon dioxide serves as the raw material, the problem that the raw material for producing cupric subcarbonate by adopting a traditional method carries heavy metal ions, chloride ion and other impurities is solved, the reaction speed is increased, the production period is shortened, the production efficiency is greatly improved, the impurity content is low, high purity and activity are realized, and the product can be applied more widely. The method has the advantages of high yield, low energy consumption, little pollution and low cost.

Owner:TAIXING SMELTING PLANT

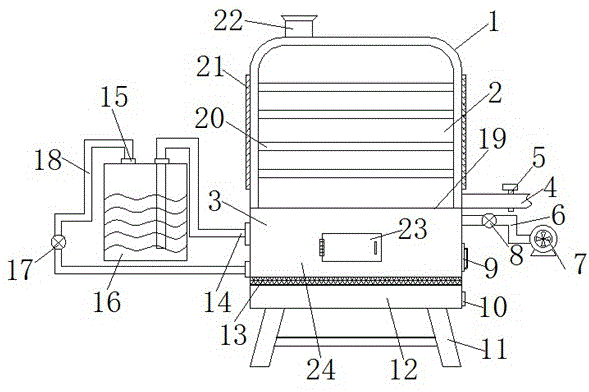

Energy-saving and environment-friendly boiler

InactiveCN105605557ASimple structureEasy to useEmission preventionSolid fuel combustionCombustion chamberSlag

The invention discloses an energy-saving and environment-friendly boiler which comprises a boiler body. An inner cavity of the boiler body is divided by a partition plate into a water tank and a combustion chamber. The water tank is located on the top of the combustion chamber. An insulation jacket is arranged on the periphery of the water tank in a surrounding mode. A ceramic heat conductive pipe is fixedly installed in the water tank. An inner cavity of the combustion chamber is divided by a small-hole partition net into a combustion bin and a dust collection bin. One side of the combustion bin and one side of the dust collection bin are provided with a slag outlet and a dust discharge outlet respectively. The front face of the combustion bin is further provided with a fuel inlet. One side of the combustion bin is fixedly connected with an air blower through an air inlet pipe. According to the energy-saving and environment-friendly boiler, the structure is simple, use is convenient, oxygen can be provided into the combustion chamber, fuel is more sufficiently combusted, energy is saved, heat preservation can be achieved for the water tank, the heat loss is greatly reduced, direct emission of harmful gas is avoided, and the natural environment is effectively protected.

Owner:林丽芳

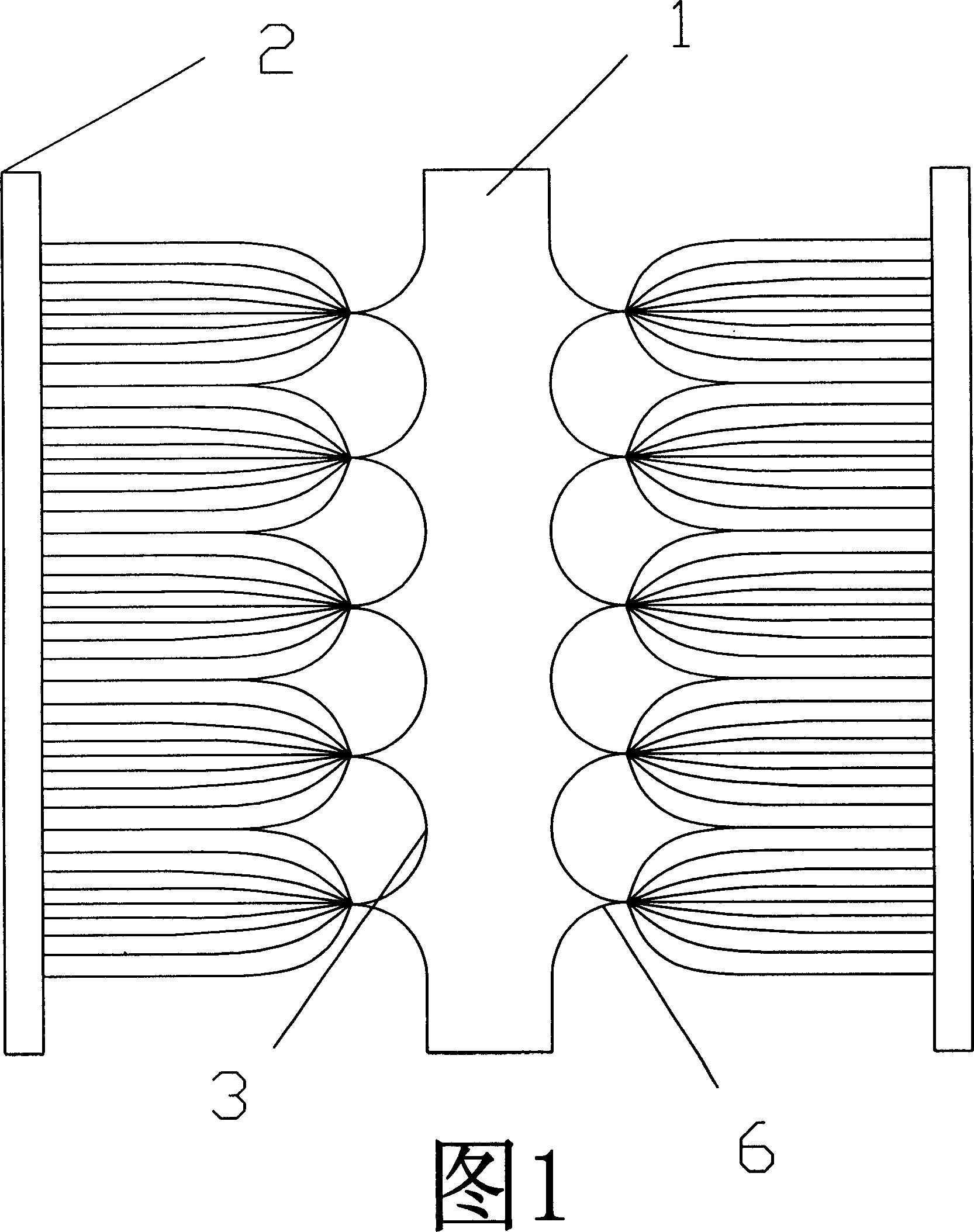

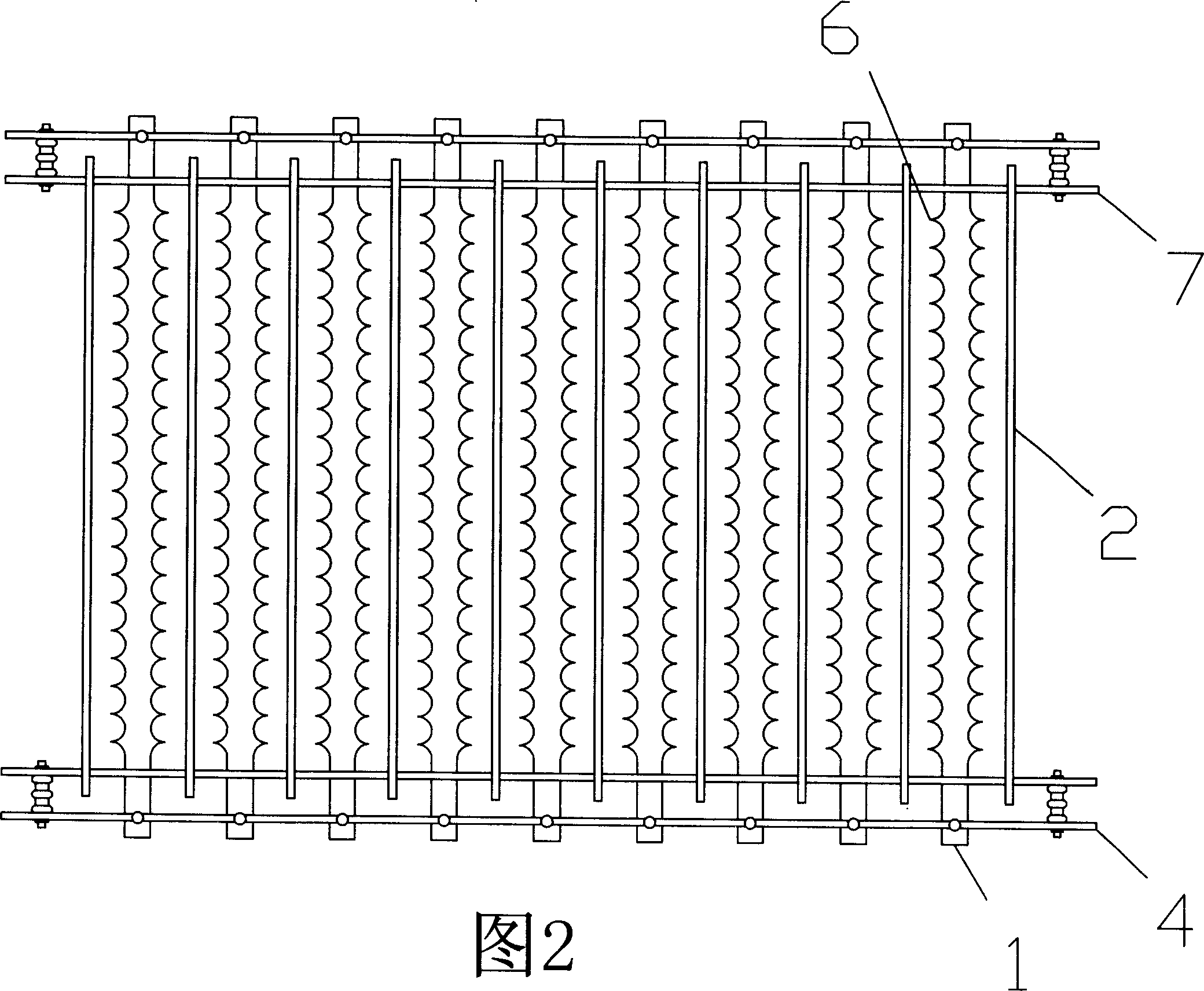

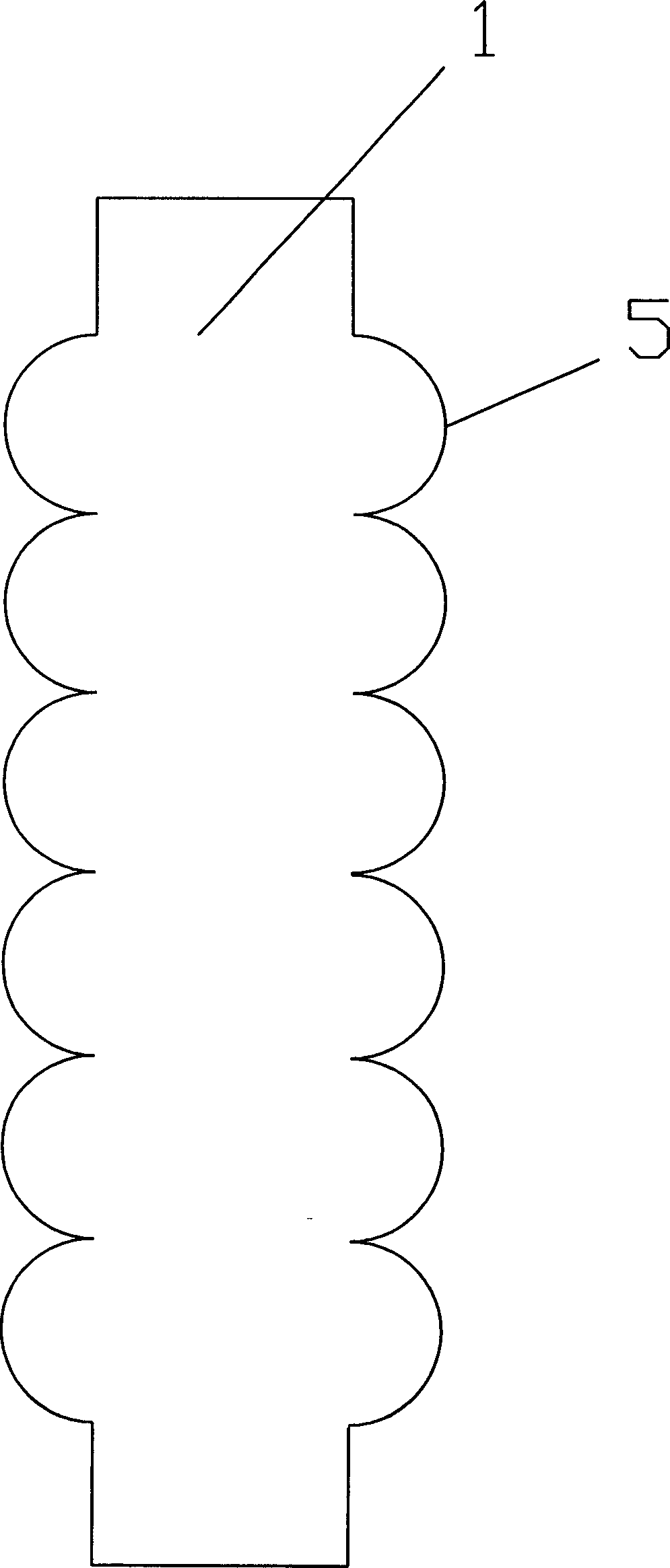

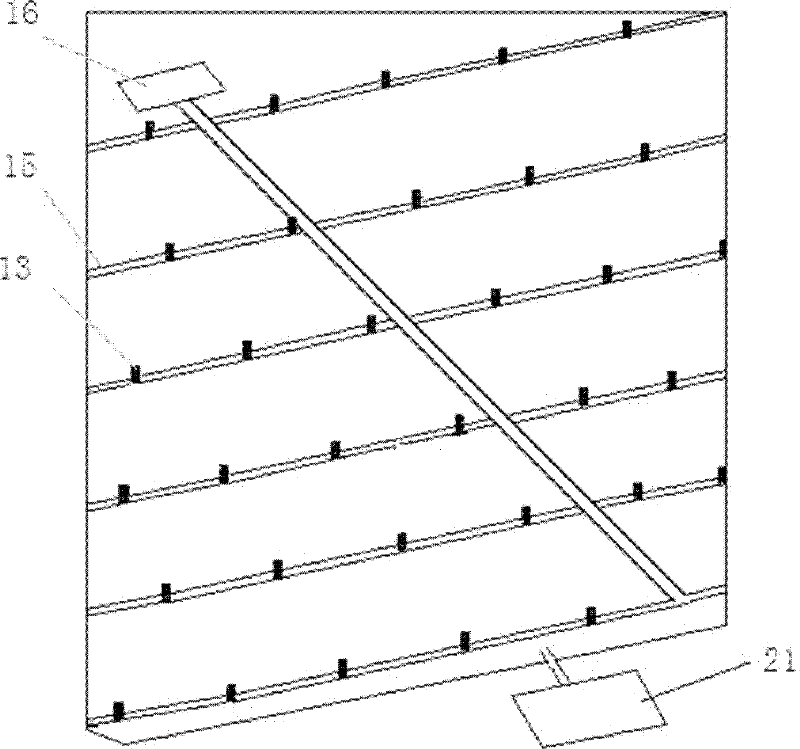

Planar electric field generator of high voltage electrostatic cooker hood

InactiveCN1712138AImproved oil fume purification abilityLow costElectrode constructionsElectric fieldCooker

A flat plate type electric field generator for the high-voltage electrostatic oil soot exhauster has at least one group of positive and negative plate electrodes. Said flat positive plate electrode has several arc holes. The surface of said negative plate electrode is perpendicular to the surface of said positive one. Its advantages are high cleaning power to oil soot, and less power consumption.

Owner:佛山市顺德区永涛环保科技开发有限公司

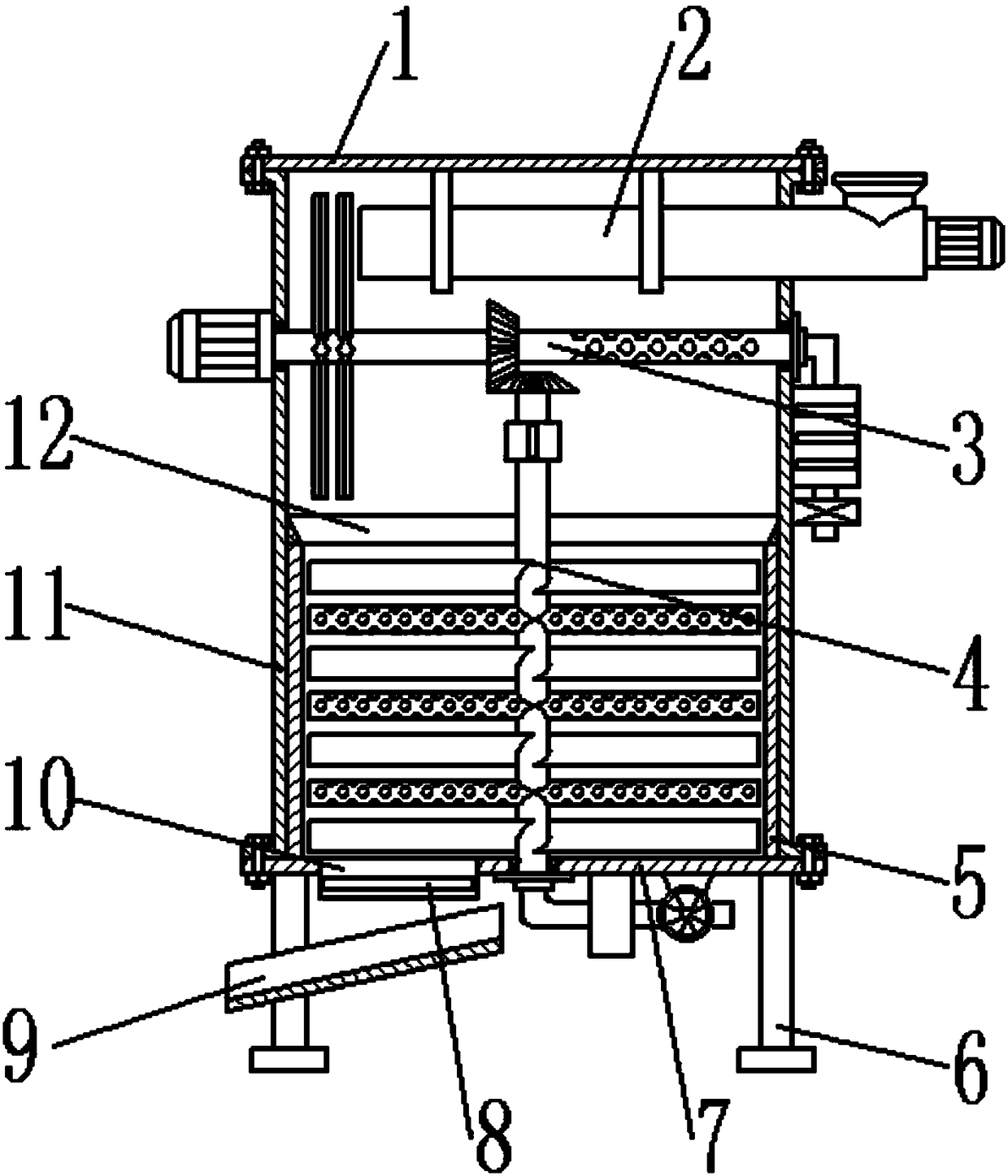

Feed crushing and drying device for animal husbandry breeding

InactiveCN108142967AEasy to crushCrushed fullyFeeding-stuffDrying gas arrangementsFiltrationEngineering

The present invention provides a feed crushing and drying device for animal husbandry breeding. The feed crushing and drying device comprises a tank body; a top cover is arranged at an opening place of a top part of the tank body and a bottom cover is arranged at an opening place of a bottom of the tank body; a material discharge pipe is fixedly welded on a left side of a surface of the bottom cover; a material guide plate is arranged right below the material discharge pipe; a drying cylinder is arranged in a middle and lower part of an internal wall of the tank body; a material feeding deviceis arranged on a top part inside the tank body; a material crushing and filtering device is arranged inside the tank body right below the material feeding device; and a stirring and drying device isarranged inside the drying cylinder. The material feeding device guides a feed to be crushed into the tank body in a constant speed. The material crushing and filtering device conducts cutting and crushing of the feed added in the material feeding device, exports moisture generated during drying processes of the feed, conducts adsorption filtration of the moisture, and prevents feed dust from directly being discharged in polluted air. The stirring and drying device conducts full stirring and turning of the crushed feed and uses hot air to conduct drying treatment of the feed.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

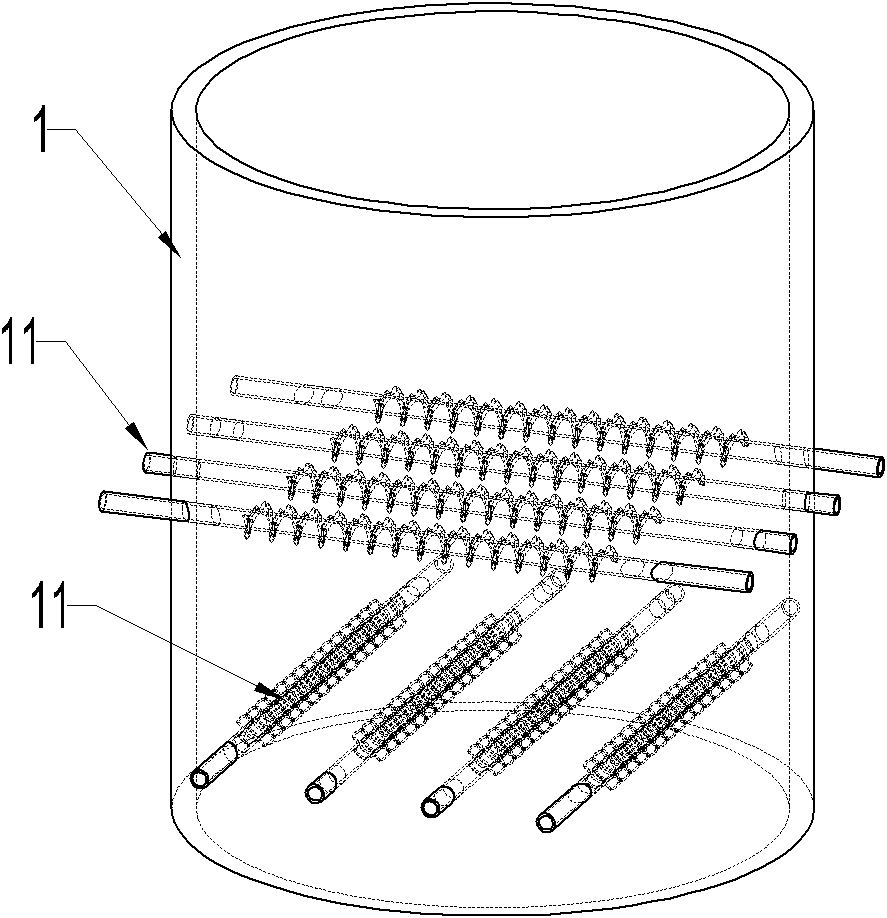

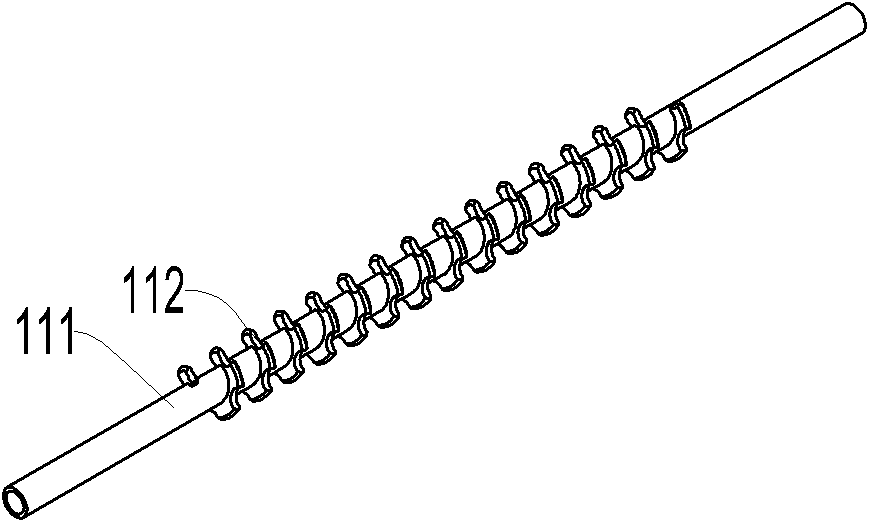

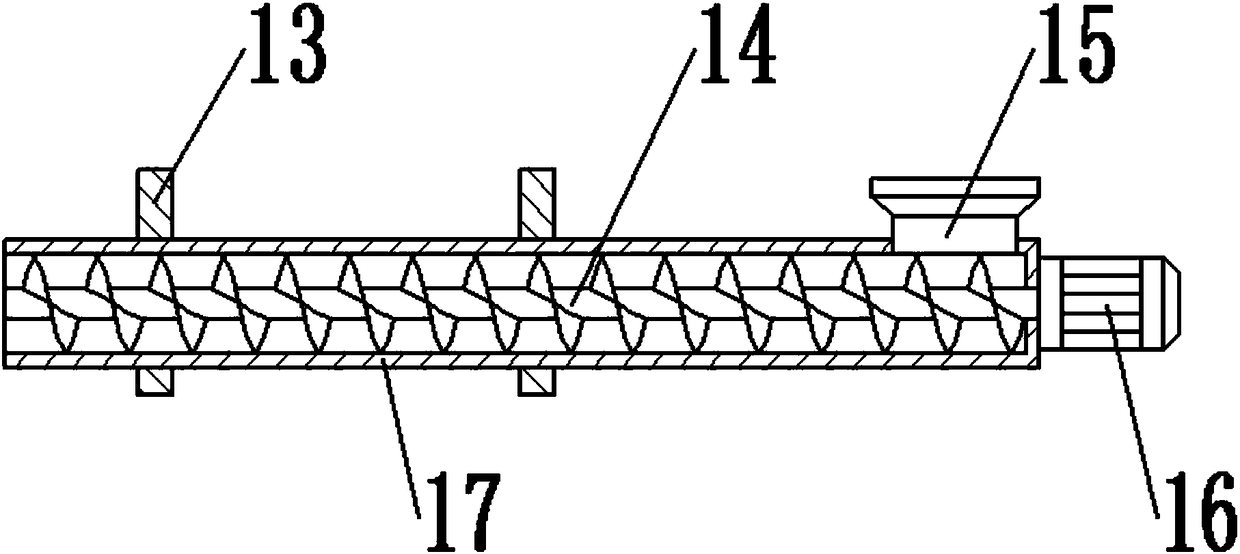

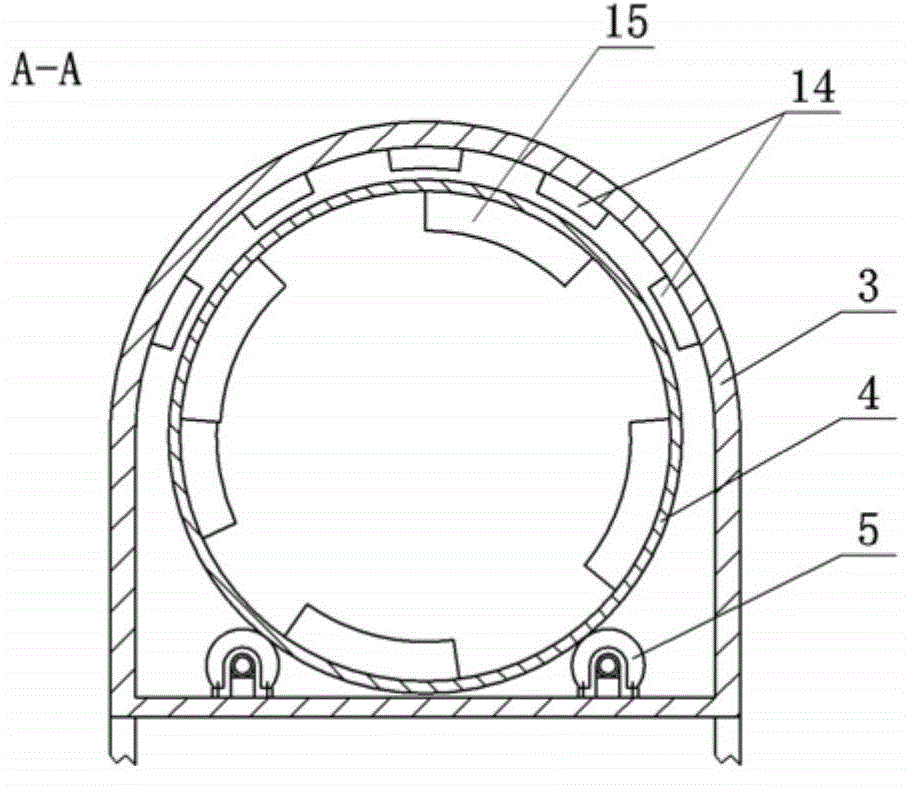

Dual-heating interior spiral drum type biomass material dryer

InactiveCN104807304ASave heatReduce lossDrying gas arrangementsDrying machines with non-progressive movementsWater vaporProcess engineering

The invention discloses a dual-heating interior spiral drum type biomass material dryer. A sealing tank is fixedly arranged on a bracket, wherein a heating device is arranged inside the sealing tank and used as a main heating source; a drum, a carrier roller and a transmission mechanism are arranged in the sealing tank; the carrier roller and the transmission mechanism are used for supporting the drum; a feeding hopper and a hot air intake pipe are arranged at one end of the sealing tank; the hot air intake pipe is used as an auxiliary heating source; a discharge outlet and a damp air exhaust opening are formed in the other end. The dual-heating interior spiral drum type biomass material dryer is capable of lowering heat energy of a hot air channel, thus the hot air channel is mainly used for accelerating the flowing of water vapor in the drum and is not utilized as a main heat source; improvement and storage of heat energy in the drum are facilitated, thus high-temperature hot air flow is prevented from being directly discharged, drying efficiency is improved and loss of heat energy is reduced.

Owner:周杨一帆

Method and system for integrated treatment and recycling of domestic waste landfill

InactiveCN102284466AImprove the appearance of the environmentAvoid direct dischargeWaste processingSolid waste disposalBiogasDomestic waste

The invention discloses a method and system for integrated treatment and recycling of domestic garbage landfills. The method includes recycling and recycling methane generated in garbage landfills; adopting circular self-purification treatment for leachate of garbage landfills methods for treatment; ecological restoration of the landfill surface. Through the above technical scheme, the present invention realizes the integrated treatment and recycling of the triple pollution of methane, leachate and solid waste in domestic waste landfills.

Owner:深圳相控科技股份有限公司

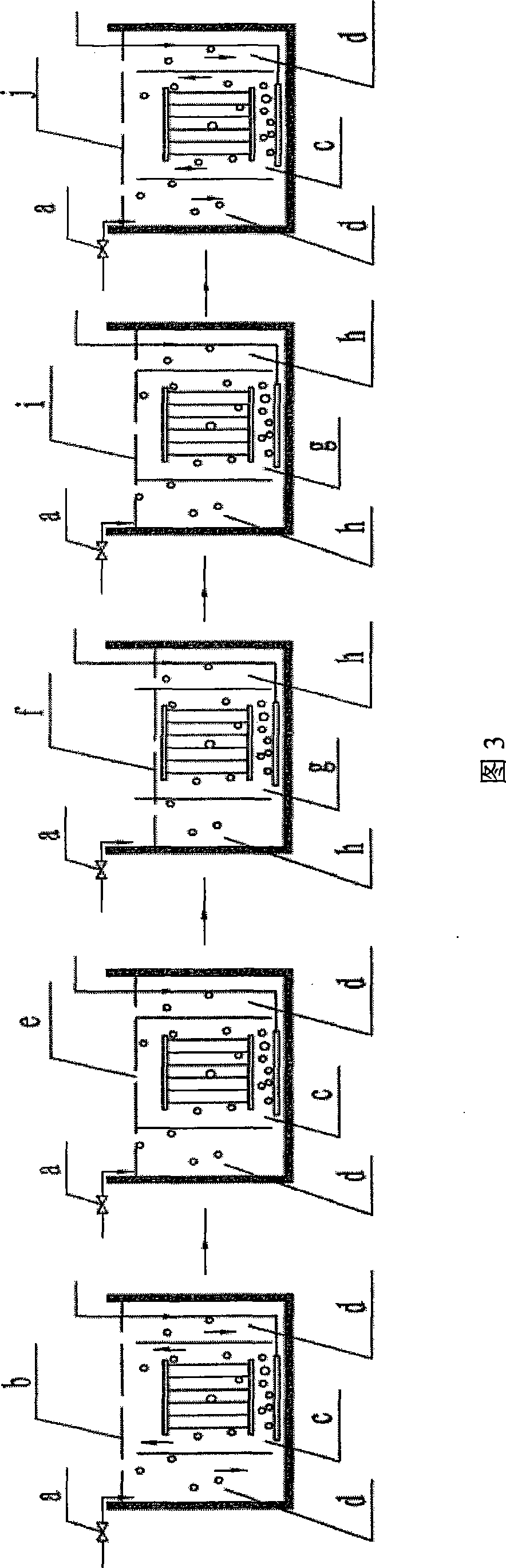

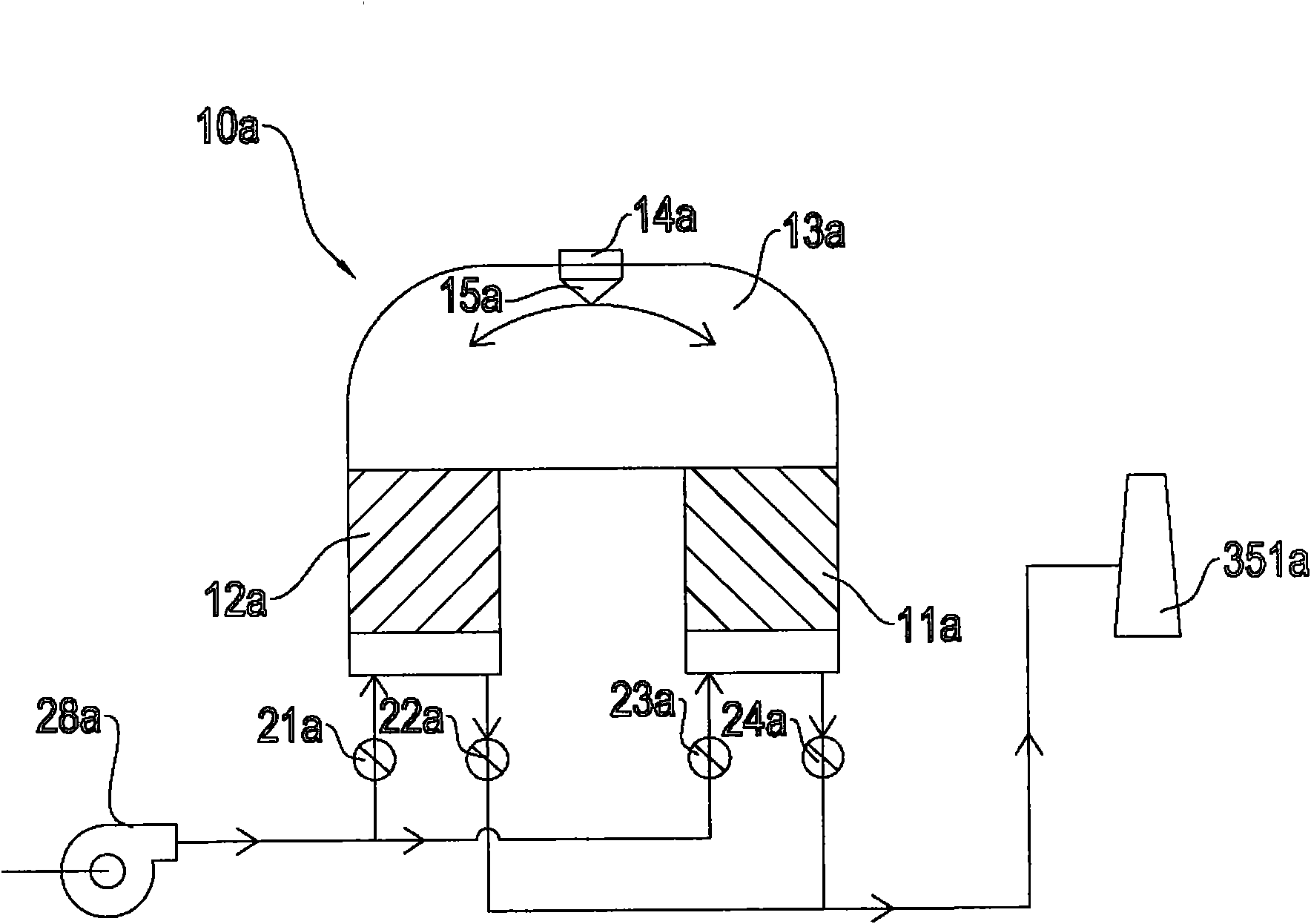

External gas removing type heat-storage incinerator

InactiveCN101561145AQuality improvementAvoid pollutionIncinerator apparatusHigh concentrationInlet valve

The invention relates to an external gas removing type heat-storage incinerator which comprises a heat-storage incinerator, an exhaust gas main pipeline, a windmill, an exhaust gas inlet valve bank, a leading control valve bank, an external gas blast pipeline and an external gas control valve, wherein the exhaust gas main pipeline is connected with a ventilating pipeline of the heat-storage incinerator, the exhaust gas inlet valve bank and the leading control valve bank are arranged on the exhaust gas pipeline so as to control and switch the pipeline to control the flow direction of the exhaust gas in the pipeline, the tail end of the exhaust gas main pipeline is provided with the windmill to form wind pressure to suck the gas in the pipeline, one end of the external gas blast pipeline is connected with the exhaust gas main pipeline to supply gas into the exhaust gas main pipeline and a heat-storage bed, the external gas control valve is arranged on the external gas blast pipeline to control the ingress and the egress of the external gas, therefore, when the heat-storage incinerator switches a gas flowing direction, the external gas blast pipeline is controlled to supply gas, and the high-concentration pollution of the heat-storage incinerator for switching the gas flow directions of two towers is eliminated to remove the exhaust gas pollution.

Owner:DESICCANT TECH CORP

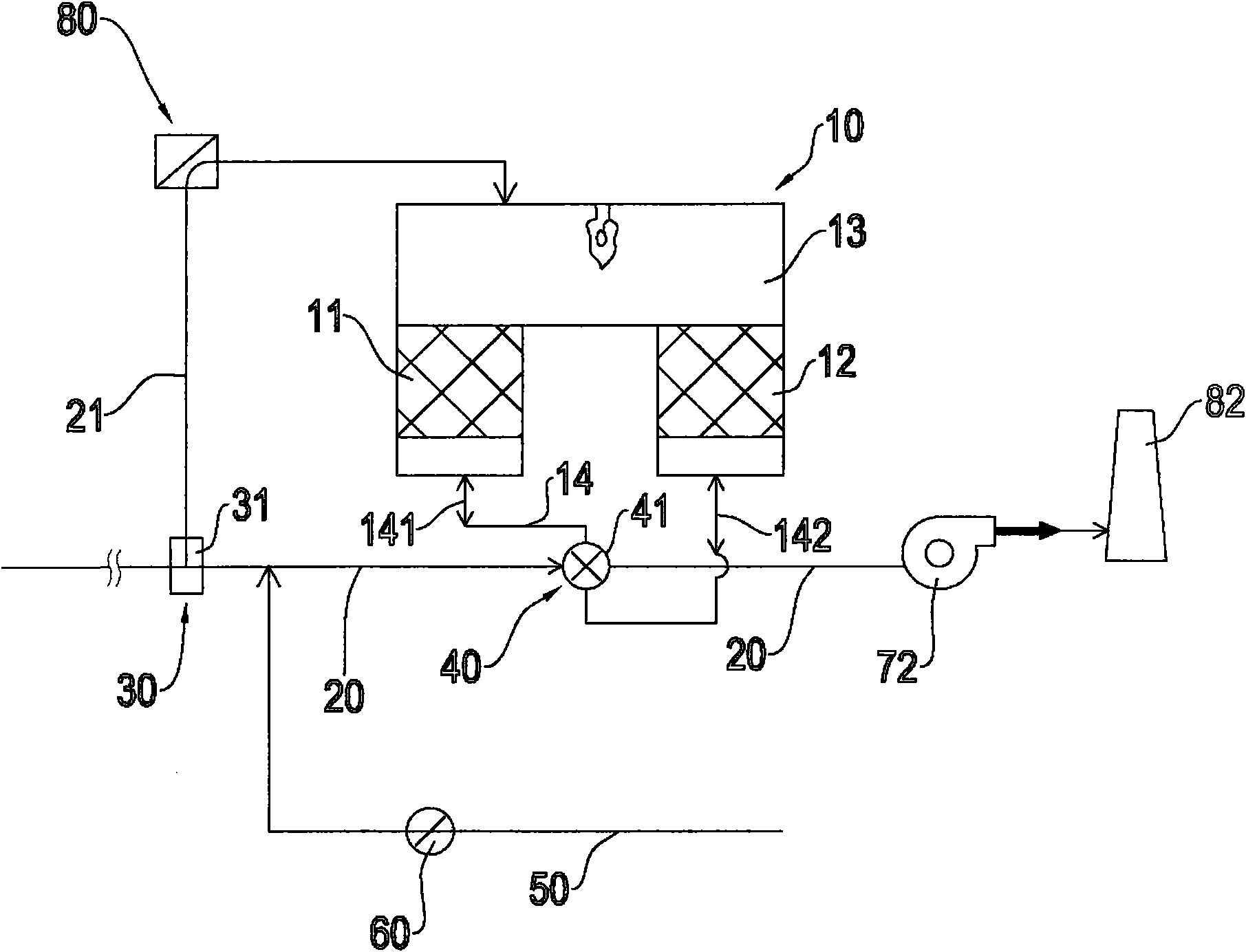

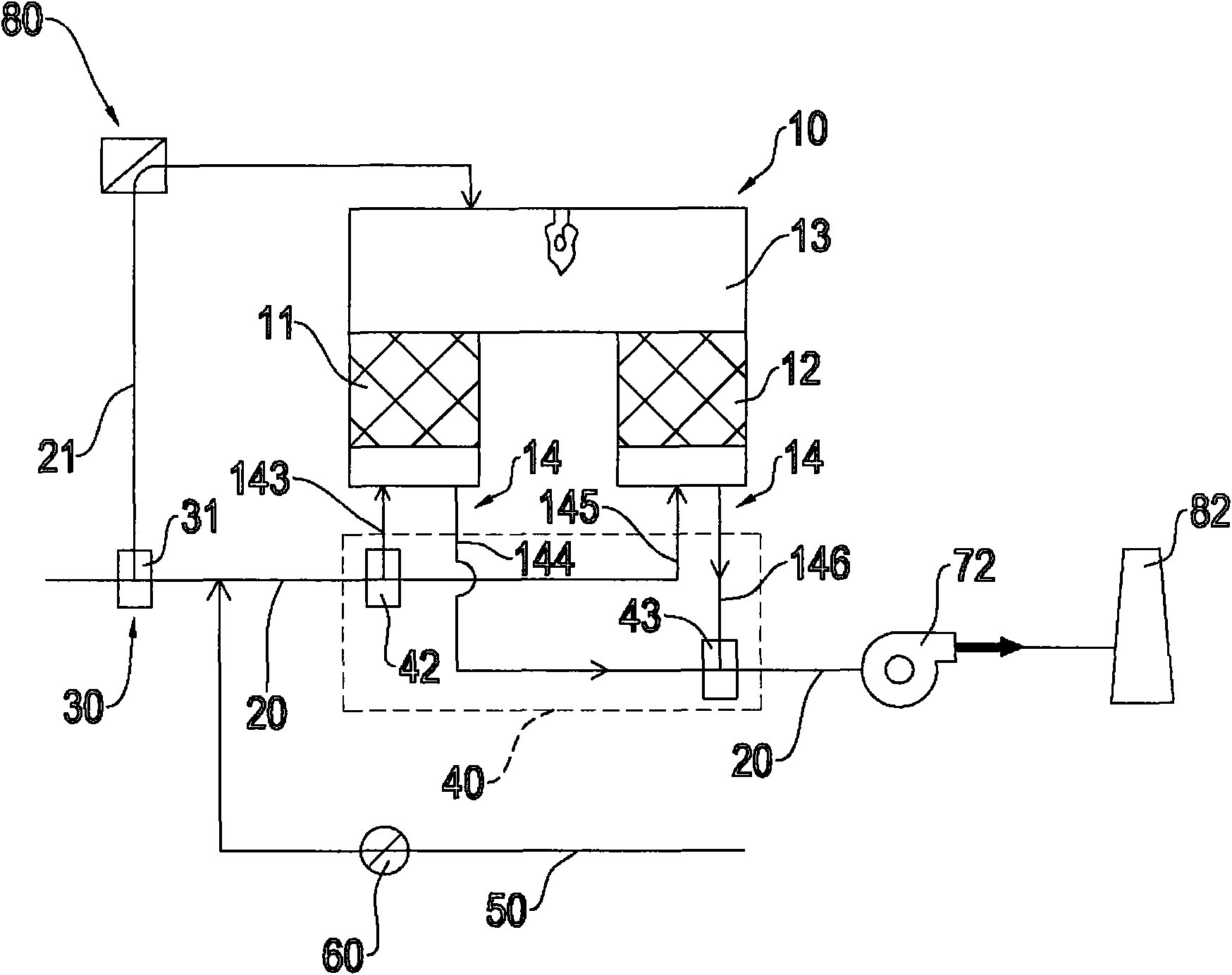

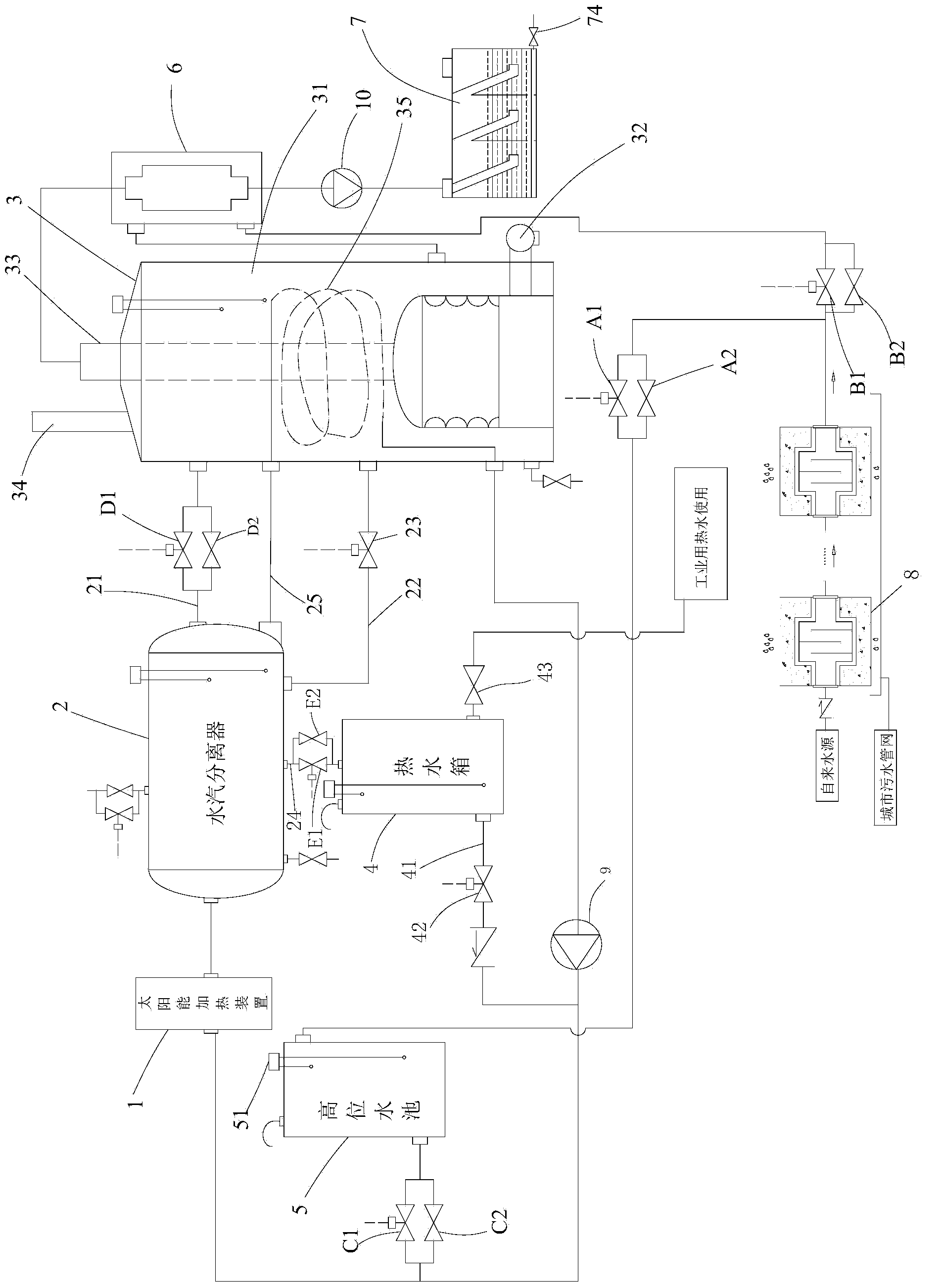

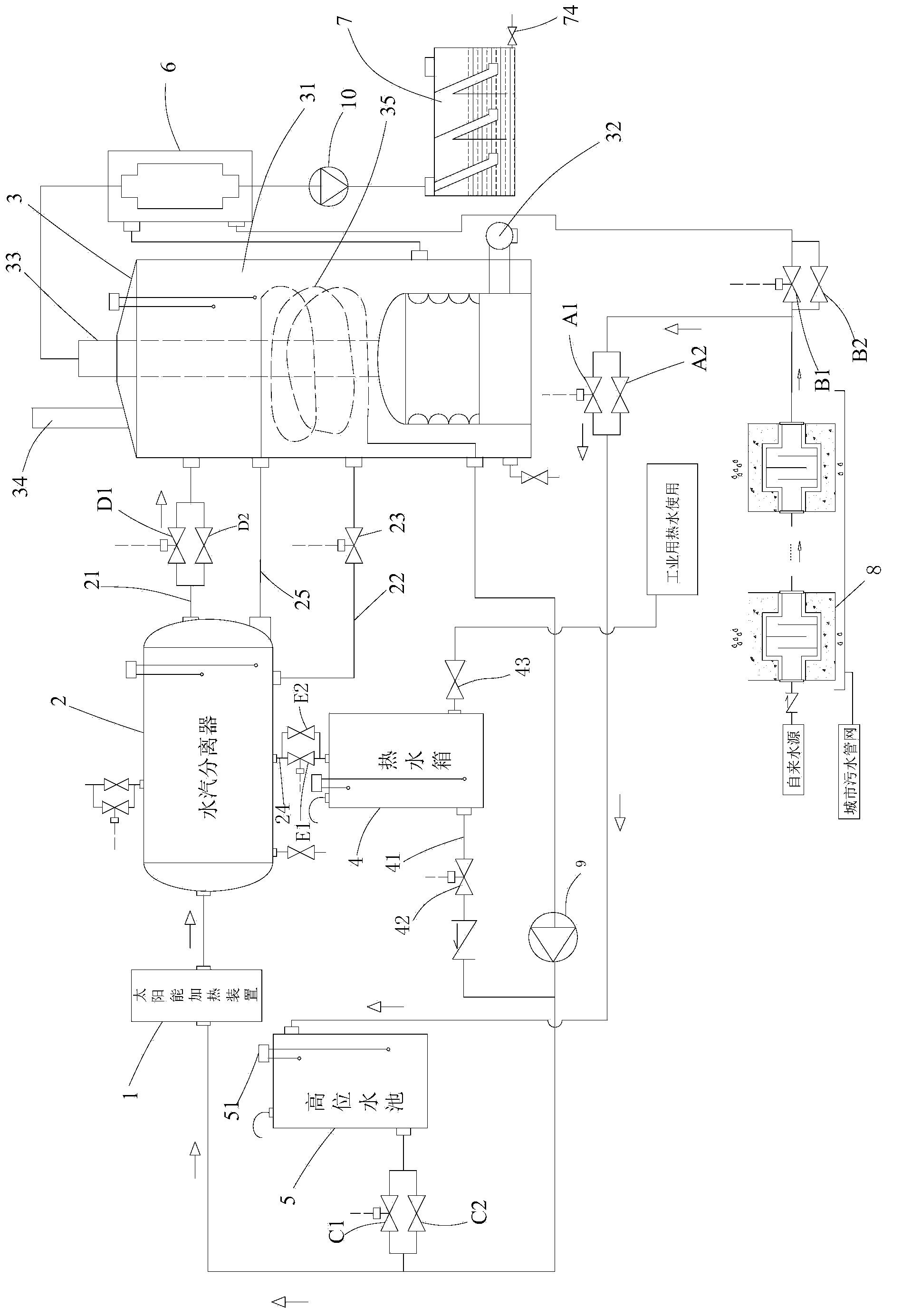

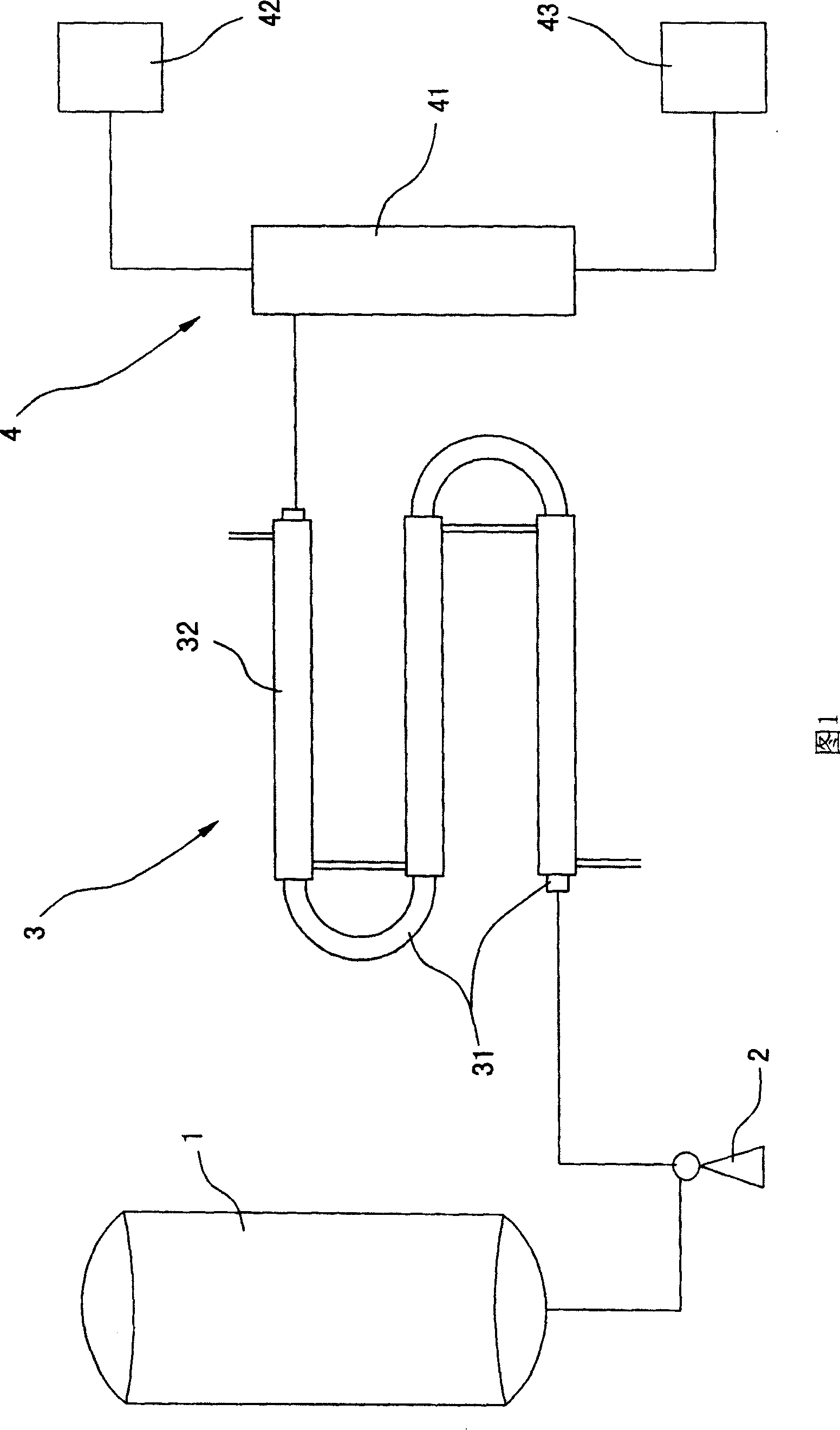

Thermodynamic system and method with mixed application of solar energy and fuel oil gas boiler

ActiveCN103727518AReduce usageMeet supply requirementsSteam generation heating methodsSolar heat devicesFuel oilEngineering

The invention relates to a thermodynamic system and method with the mixed application of the solar energy and a fuel oil gas boiler. The system comprises a solar heating device, a water-steam separator and the fuel oil gas boiler. The solar heating device comprises a water inlet and a water outlet which is connected with the water-steam separator. The fuel oil gas boiler comprises a boiler inner cavity, a combustor arranged in the inner cavity of the boiler, a steam conveying pipe arranged on the upper portion of the inner cavity of the boiler and a heat exchanging coil which is arranged in the inner cavity of the boiler. The inner cavity of the boiler comprises a water storage layer and a steam layer which is arranged above the water storage layer and communicated with the steam conveying pipe. The outlet of the heat exchanging coil is communicated with the water inlet of the solar heating device through a circulation pipe, and the circulation pipe is provided with a circulation pump. The lower portion of the water-steam separator is provided with a communicating pipe communicated with the heat exchanging coil. Due to the fact that the solar heating device and the fuel oil gas boiler are used in cooperation, the requirements for supplying steam and hot water are achieved, the fuel oil is reduced, and the thermodynamic system has the advantages of fully utilizing the solar energy, saving energy and reducing emissions.

Owner:无锡景锡锅炉有限公司

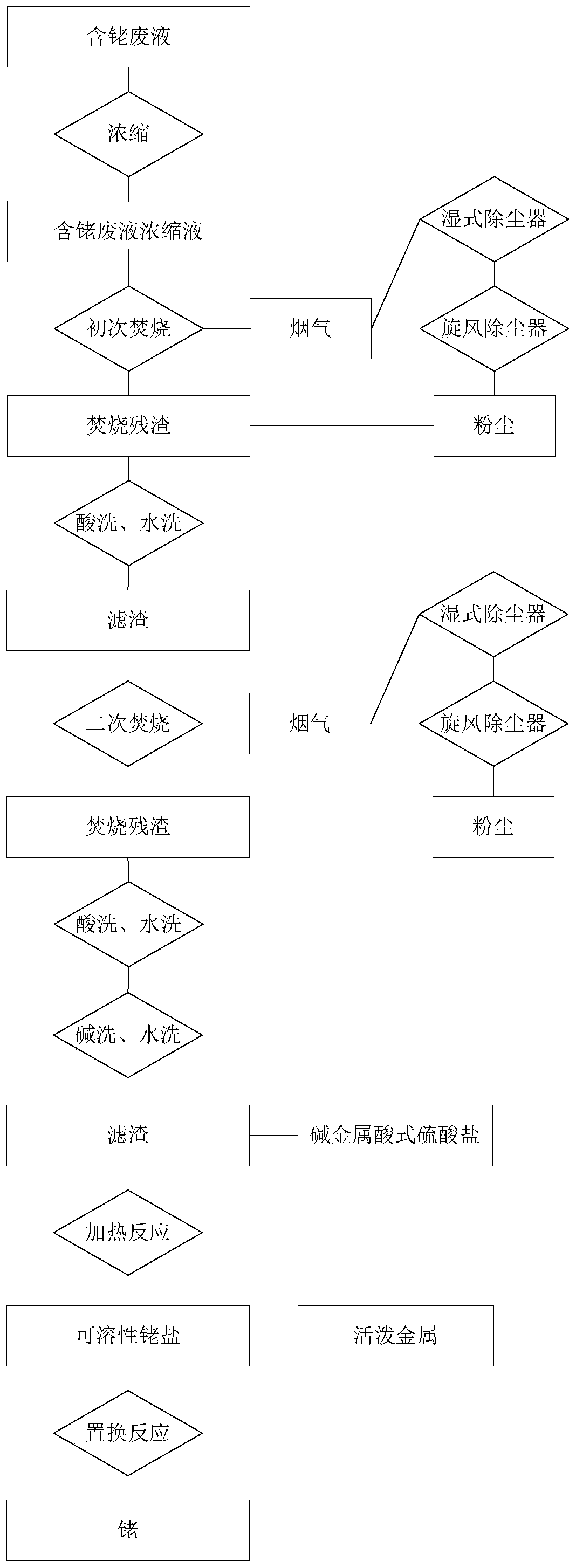

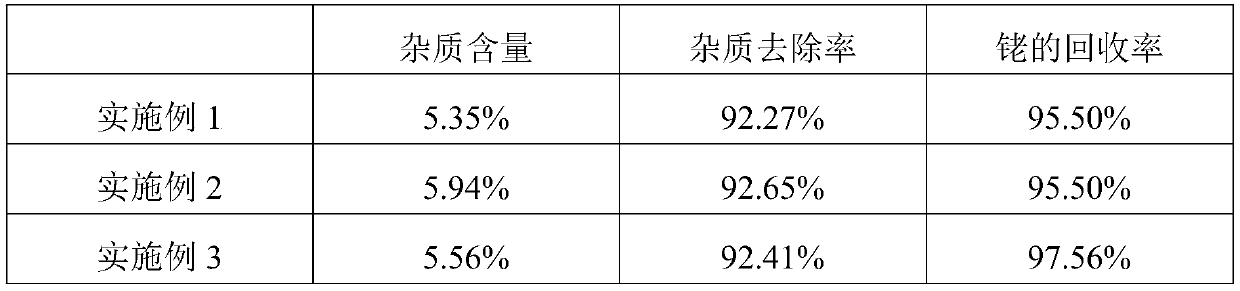

Method for recovering rhodium from rhodium-containing waste liquid

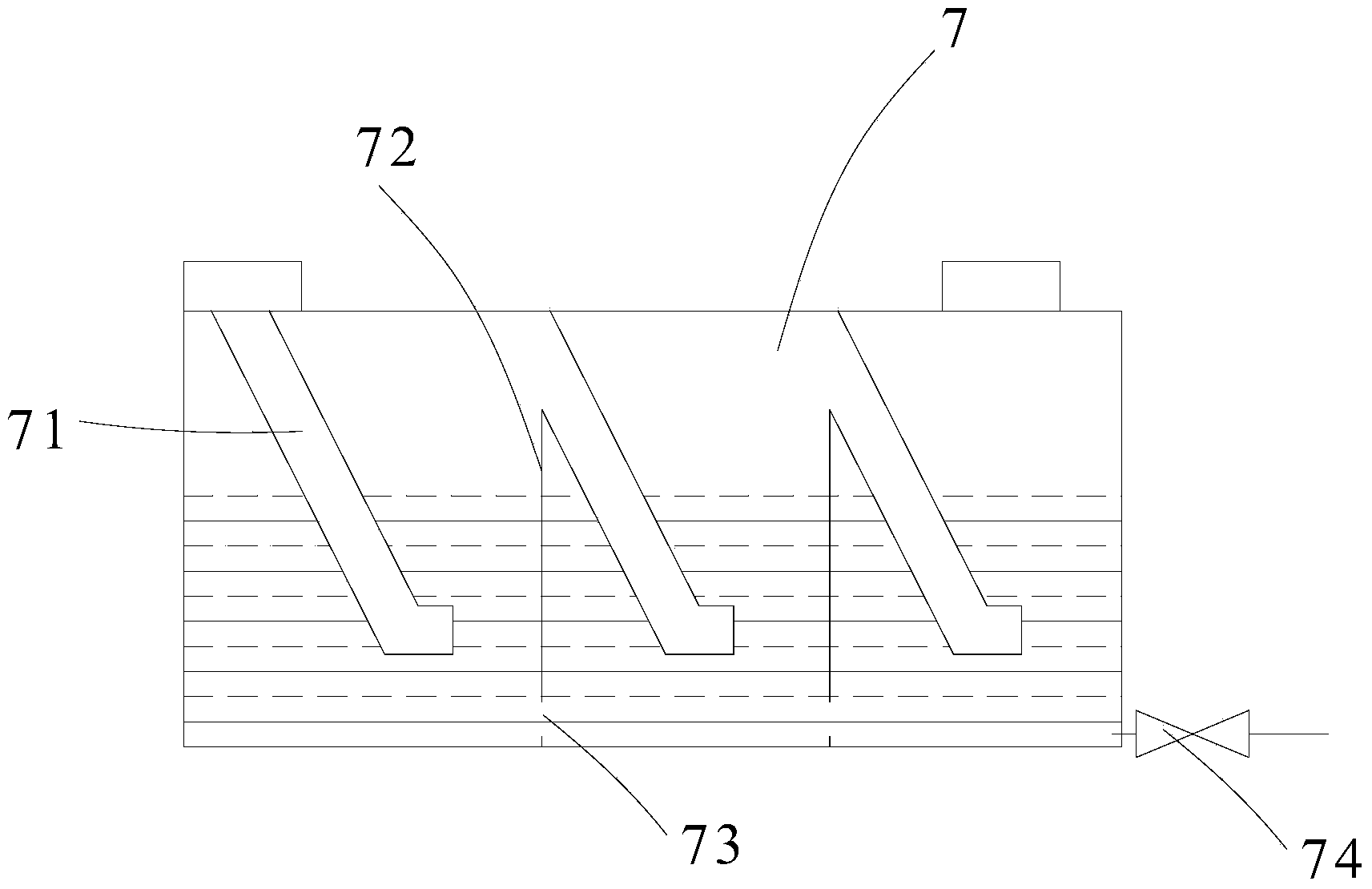

ActiveCN111020200AAvoid direct dischargeAvoid direct discharge of pollutionProcess efficiency improvementFlue gasEnvironmental engineering

The invention belongs to the field of rhodium recovery, and particularly discloses a method for recovering rhodium from rhodium-containing waste liquid. The method comprises the following steps of concentrating the rhodium-containing waste liquid to evaporate light components, mixing wood chips, carrying out primary incineration on the rhodium-containing waste liquid concentrated solution to obtain rhodium-containing carbon residues, and carrying out acid pickling and water washing; carrying out secondary incineration on the rhodium-containing carbon residues to obtain rhodium-containing ash residues, and carrying out acid pickling, water washing, alkali washing and water washing to completely remove acid-soluble and alkali-soluble impurities; in the primary incineration and secondary incineration processes, enabling flue gas to pass through a wet dust collector and a cyclone dust collector, collecting dust in the flue gas, avoiding direct emission of the flue gas to pollute the environment, and reducing rhodium loss in the incineration process; and combining the dust with incineration residues, reacting with alkali metal acid sulfate to generate soluble rhodium salt, and reactingthe soluble rhodium salt with active metal to obtain rhodium. According to the process, the rhodium loss in the incineration process can be reduced, the rhodium yield can be improved, impurities in the rhodium-containing ash residues can be removed, the rhodium enrichment degree is higher, and the recovery process is simplified.

Owner:山东博苑医药化学股份有限公司

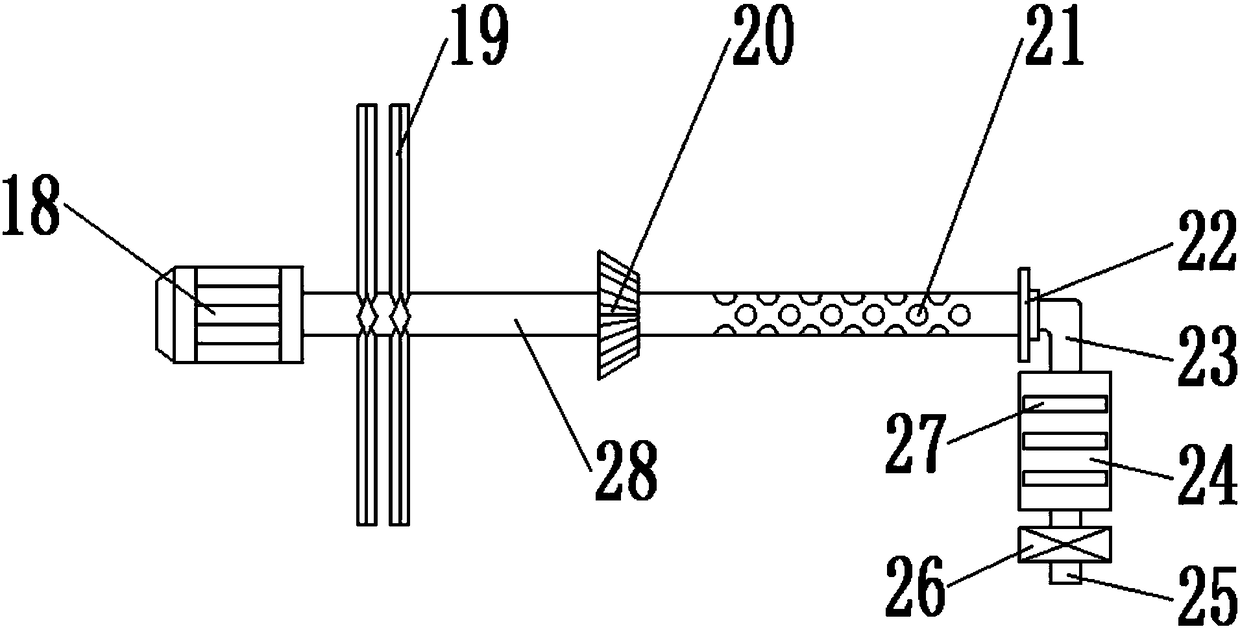

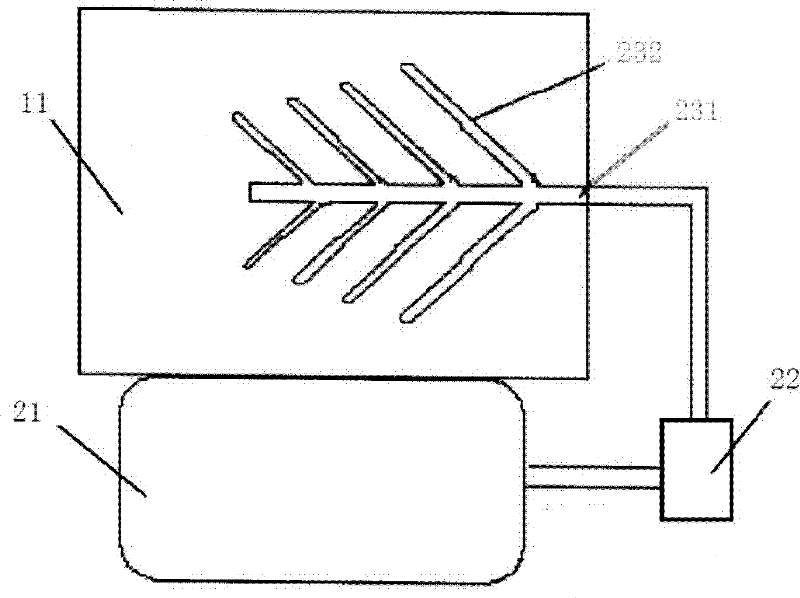

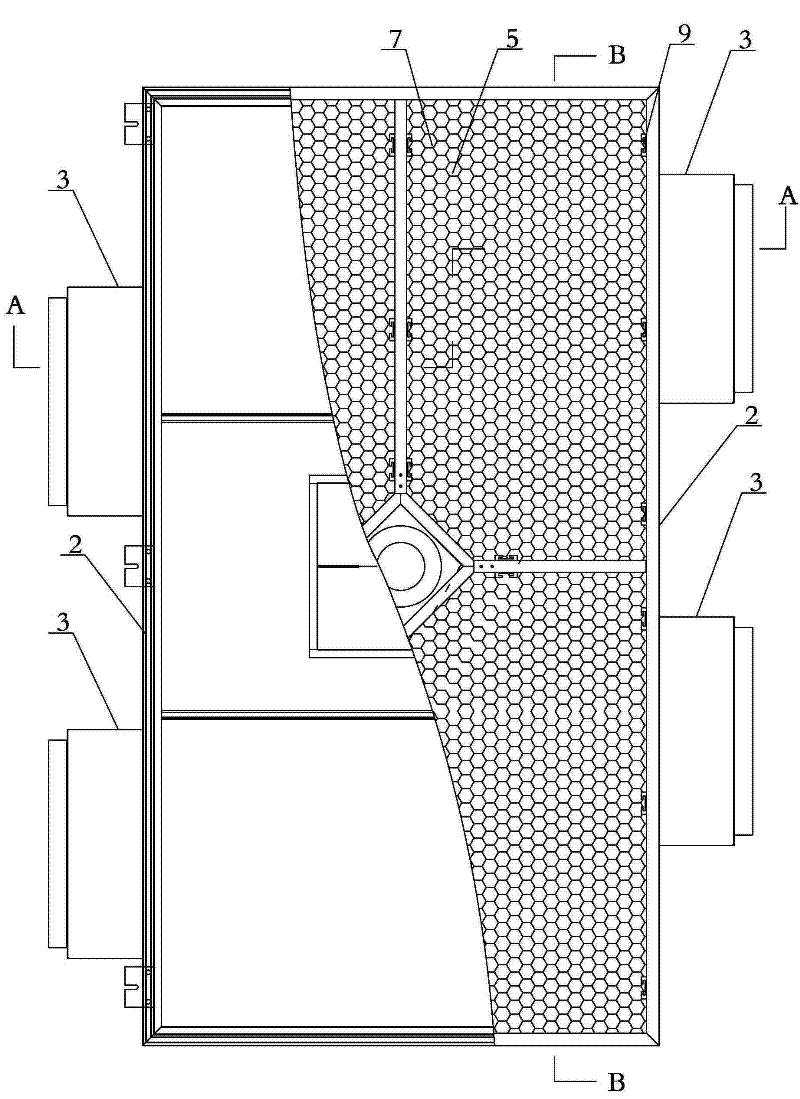

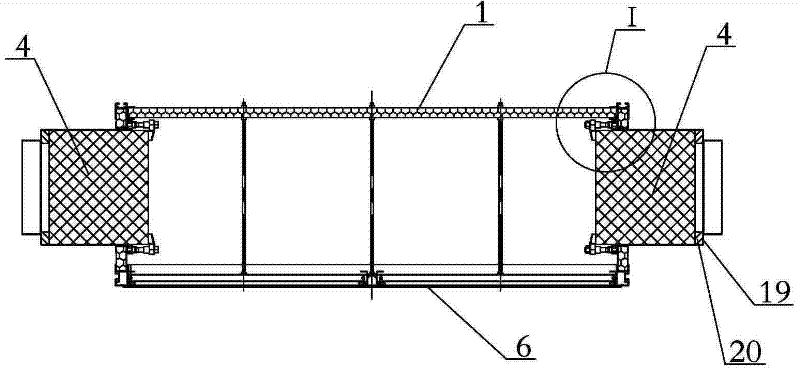

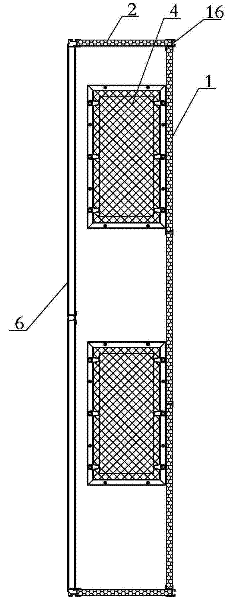

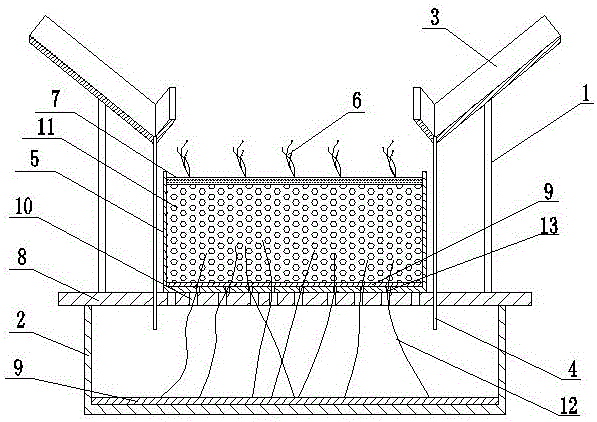

Purification layer flow air supply ceiling of operating room

ActiveCN102226570AImprove cleanlinessBig room for expansionDucting arrangementsLighting and heating apparatusAir filterOperating theatres

The invention belongs to the technical field of an outlet for leading or distributing the air for indoors or occasions, such as the air flow diffuser of a ceiling. The invention solves the problems that a high-efficiency filter box is arranged above the air inlet of a static pressure box in the prior art according to the direction of an airflow; a high-efficiency filter and an air mixer are arranged in the box; a uniform distributor is arranged in the air inlet of the static pressure box; the parts are multiple; the cost is high; and the bacteria which are easily multiplied in the space of a box influence the health of patients. The purification layer flow air supply ceiling of an operating room provided by the invention comprises a box (1), wherein the air inlet (3) is formed at the sidewall (2) of the box (1); an air filter (4) is arranged in the air inlet (3); and an air ventilation layer (6) is formed in the lower port (5) of the box (1) and provided with net holes (7) which are uniformly distributed. In the purification layer flow air supply ceiling provided by the invention, the relatively uniform air pressure is formed to be uniformly exhausted from the whole panel after the flow in the whole cavity is mixed; and the redundant pipeline cavities for storing the air are arranged at the periphery of the box, thereby guaranteeing the air in the box to be clean.

Owner:铭铉(江西)医疗净化科技有限公司 +1

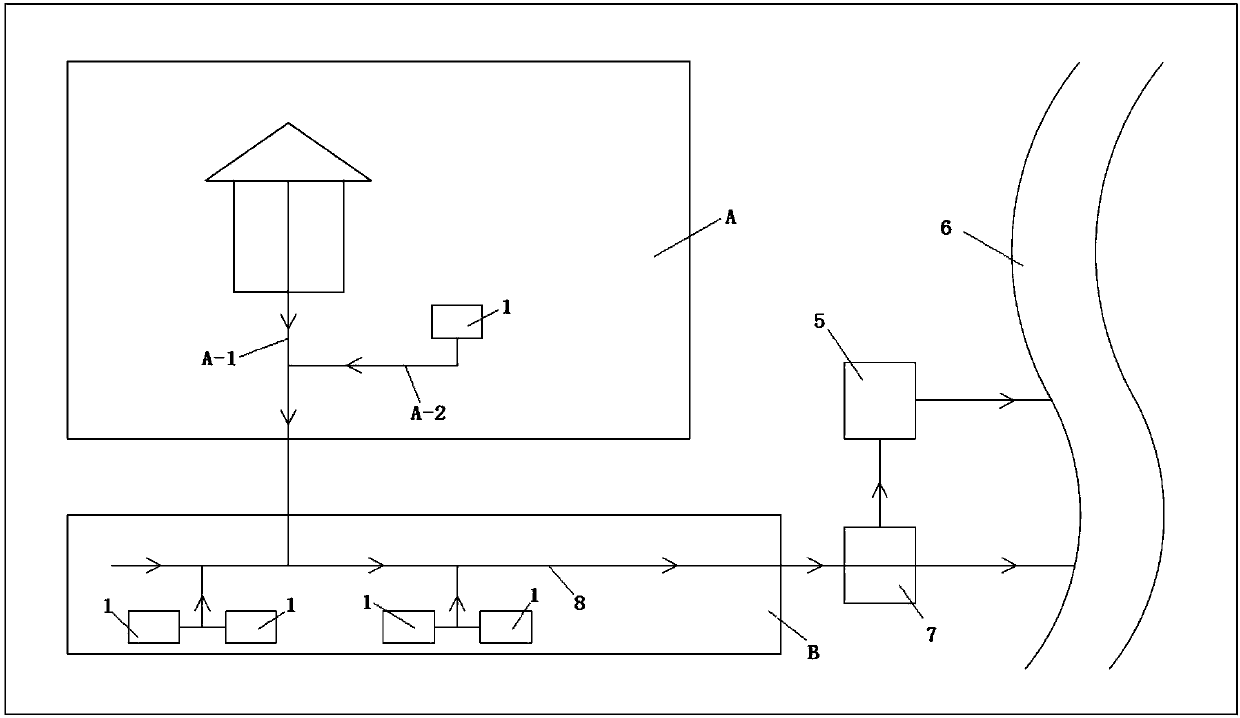

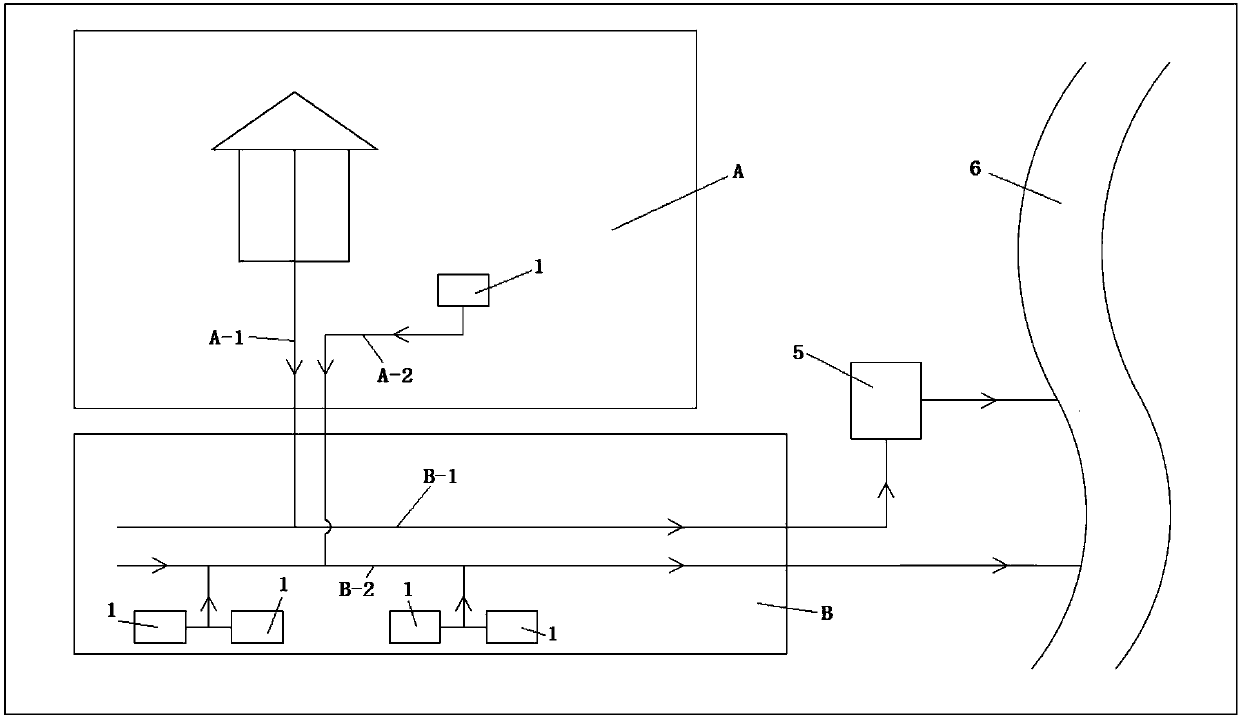

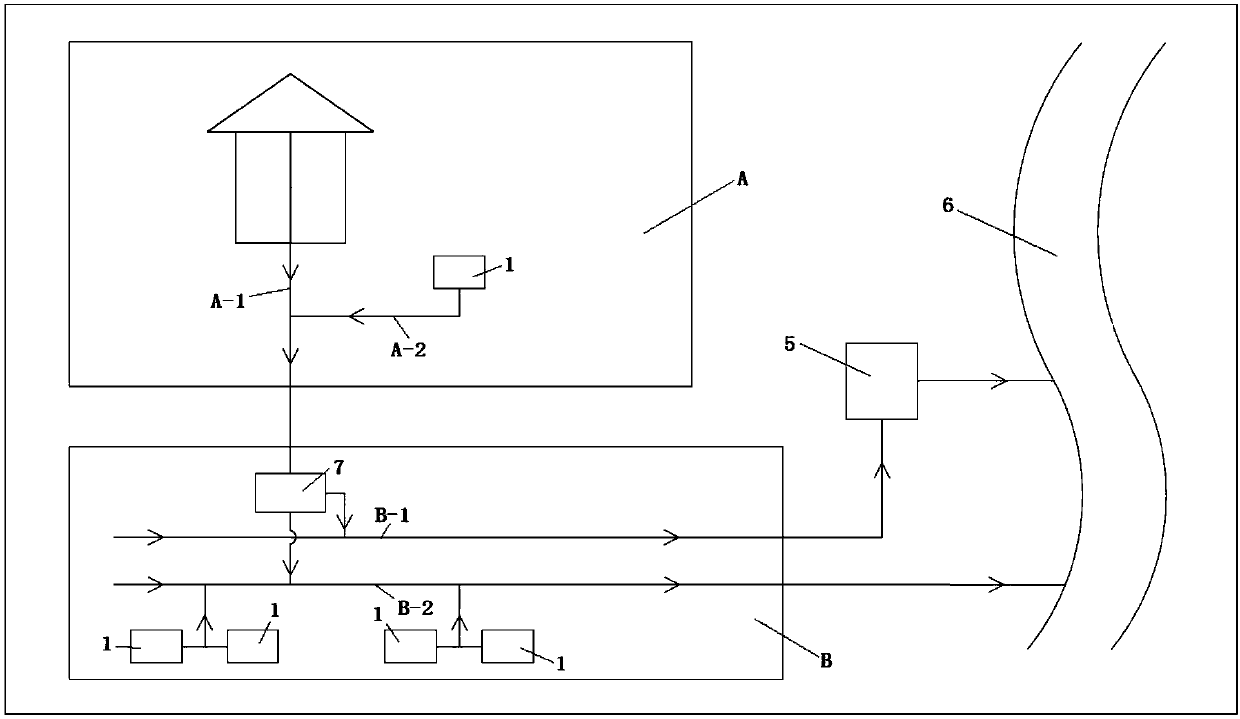

Non-point pollution control system for combined sewer system and control method thereof

PendingCN107747345ASimple structureEasy to buildSewerage structuresSewage drainingStormwater treatmentSewage

The invention discloses a non-point pollution control system for a combined sewer system and a control method thereof. The system comprises a trunk sewer, a storm-water sewer and rain and sewage pipes, and also comprises one or more unit areas, and a sewage pipe and a rainwater pipe are disposed in each unit area. Outlets of each sewage pipe and the corresponding rainwater pipe are communicated with an inlet of the corresponding rain and sewage pipe. Outlets of the rain and sewage pipes are connected with an inlet of the trunk sewer, and an outlet of the trunk sewer is provided with a sewage treatment plant. An outlet of the storm-water sewer is communicated with natural water. The non-point pollution control system is characterized in that the trunk sewer is provided with first rainwatertreatment systems, water inlets of the first rainwater treatment systems are communicated with the rain and sewage pipes, and drainage ends of the first rainwater treatment systems are respectively communicated with the trunk sewer and the storm-water sewer. The system and control method are simple in structure and convenient to construct, and efficient treatment of sewage and preliminary rainwater in regions divided by administrative functions in a city can be achieved just by building diversion treatment systems in the limited regions of municipal roads.

Owner:WUHAN SHENGYU DRAINING SYST

Producer and production method for aromatic fluoride compound

InactiveCN100384795CLower requirementEmission reductionHalogenated hydrocarbon preparationFluorideChemistry

Producer and production of aromatic fluorine compound are disclosed. The outlet port on bottom of diazotizing reactive kettle is connected with material transferring pump, outlet of transferring pump is connected to thermal decomposing piping reactor and outlet of piping reactor is communicated with receiver. The production consists of diazotization reaction, thermal decomposition process and separation process. The thermal decomposition process is carried out by transferring material in diazotizing reactive kettle to thermal decomposing reactor and controllable thermal decomposing. It has less consumption and higher production efficiency.

Owner:解卫宇

Chlorine removal agent, and method and application for removing chlorine from waste acid wastewater by using same

InactiveCN110255799ALow priceEasy to getWater contaminantsWaste water treatment from metallurgical processIonChemistry

The invention belongs to the technical field of waste water and waste liquid treatment and recycling, and particularly relates to a chlorine removal agent, and a method and an application for removing chlorine from waste acid wastewater by using same. The method comprises the following steps: firstly, heating the acid wastewater to a certain temperature, then adding a proper amount of a dechlorinating agent, continuously heating and stirring the system for a certain time to efficiently remove chloride ions in the waste acid wastewater, and absorbing chlorine generated in the reaction process by using alkali liquor. The reaction principle is different from that of the prior art: chlorine ions in the contaminated acid wastewater are oxidized into chlorine by means of the principle of oxidation reduction and the high oxidation potential of a chlorine removal agent or an intermediate product in the reaction process, and the chlorine is volatilized due to the fact that the chlorine is not dissolved in an acidic solution. The concentration of chloride ions in the waste acid wastewater treated by the method is lower than 20 mg / L, so that the concentration of chloride ions in the waste acid wastewater meets the recycling requirement. The method not only solves the problem of removal of chloride ions in the acid wastewater, but also has low requirements on equipment, and realizes resource recovery of chlorine in the wastewater.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

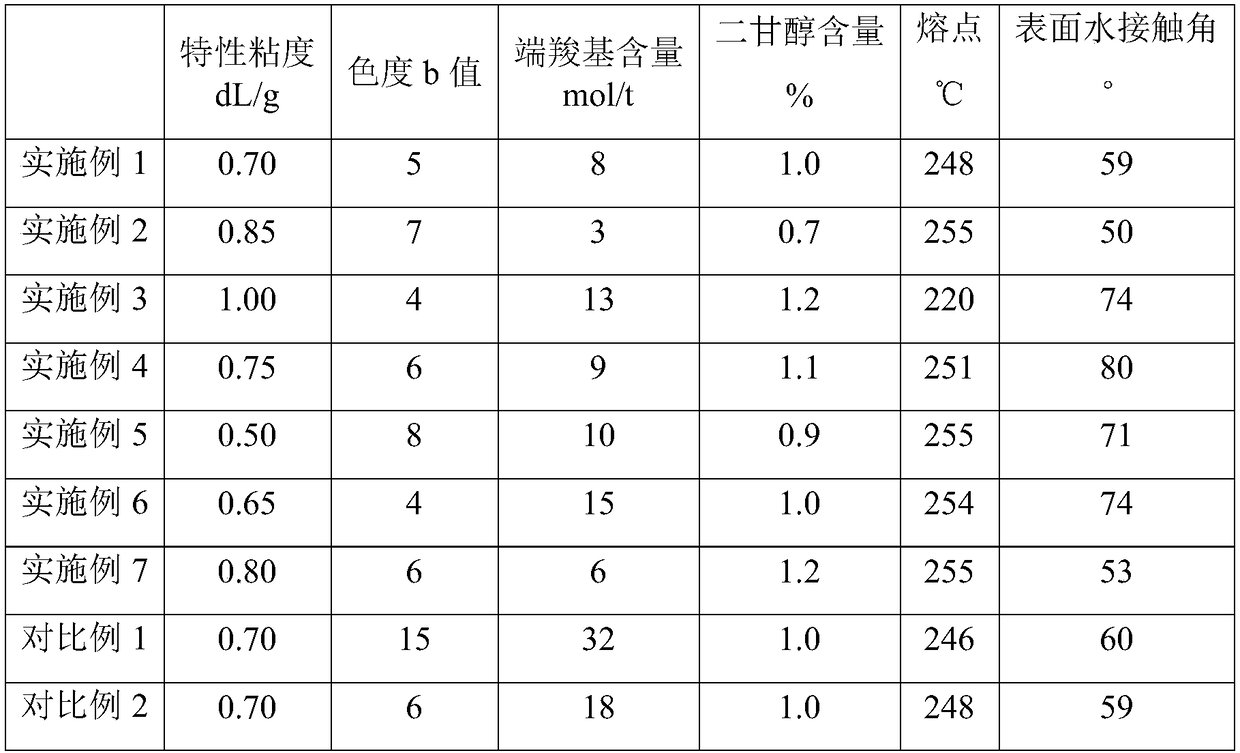

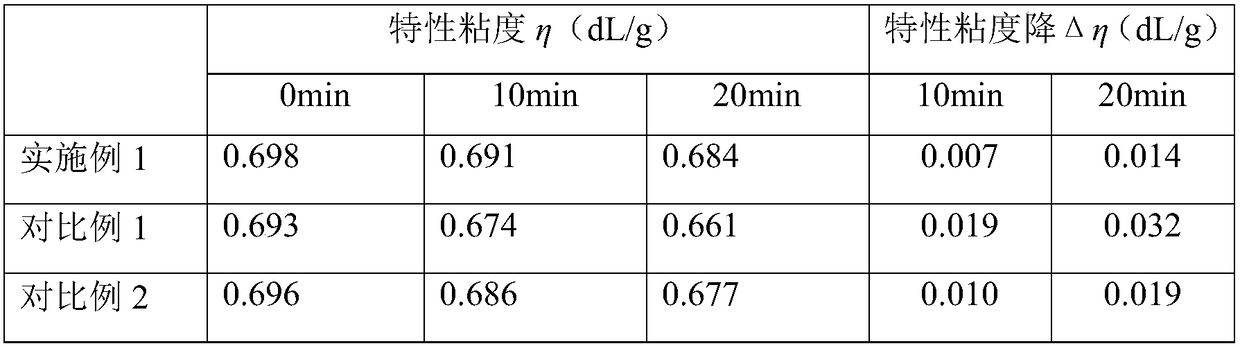

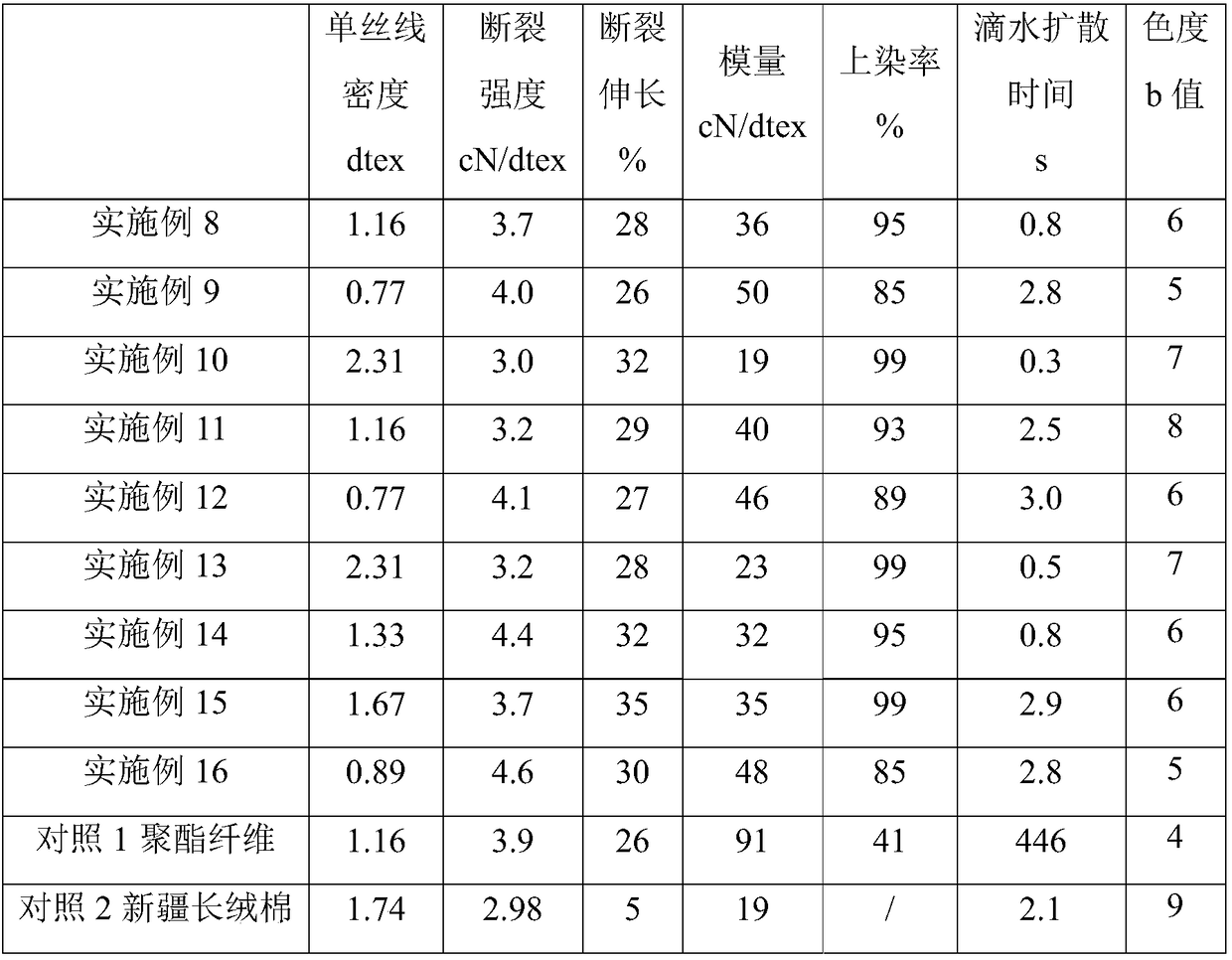

Hydrophilic polyester fiber and preparation method thereof

ActiveCN108193303AViscosity drop becomes smallerGood moisture absorptionSpinnerette packsMonocomponent copolyesters artificial filamentChemistryMetal alkoxide

The invention belongs to the technical field of textile fibers, and particularly relates to a hydrophilic polyester fiber and a preparation method thereof, wherein the hydrophilic polyester fiber is obtained by carrying out melt spinning on a hydrophilic polyester, and the hydrophilic polyester is obtained by polymerizing a ethylene glycol terephthalate oligomer and polyether diol under the actionof a titanium metal alkoxide, a polyhydroxy compound and a phosphorus compound / hindered phenol compound / acetate complex. According to the present invention, the hydrophilic polyester fiber has characteristics of yellowing resistance, reduced viscosity reduction during molding processing, good moisture absorption performance, good normal pressure dyeing performance, no heavy metal pollution, softhand feeling and excellent hue.

Owner:CHINA TEXTILE ACADEMYTIANJINSCI & TECH DEV CO LTD +1

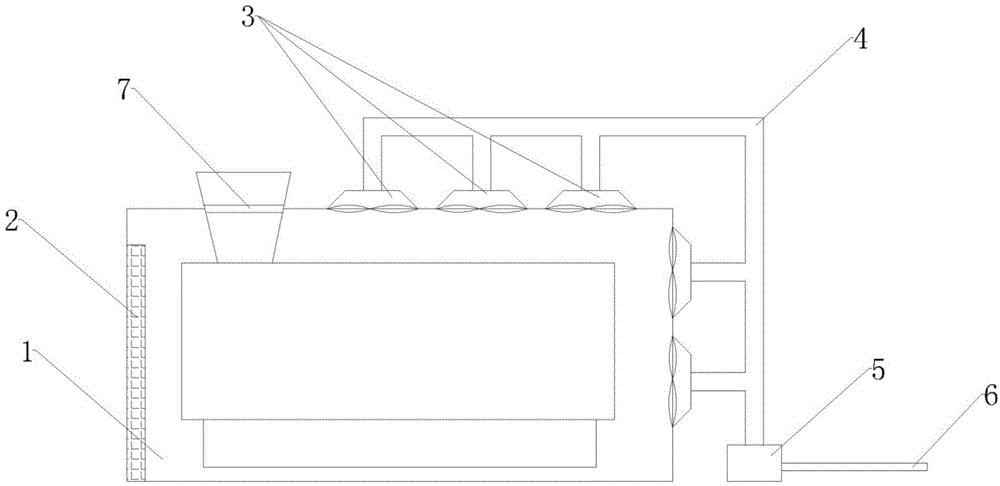

Waste gas recovery device for injection molding machine

The invention discloses a waste gas recovery device for an injection molding machine. The waste gas recovery device for the injection molding machine is provided with a sealed box body, a box body door, a hopper hole, a plurality of gas suction devices, a plurality of waste gas pipelines, a waste gas treatment machine and a gas discharge pipe. The injection molding machine can be arranged in the waste gas recovery device, a hopper of the injection molding machine is arranged in the hopper hole, an operator can go in and out through the box body door, the gas suction devices arranged on the wall of the sealed box body can be used for absorbing harmful gases produced by the injection molding machine, the gas suction devices are connected by a pipeline, the harmful gases can be treated after being conveyed into the waste gas treatment machine, and then treated gases are discharged outside from the gas discharge pipe. The waste gas recovery device can be used for absorbing the harmful gases, thus improving the work environment and being good for the health of workers; furthermore, the device is simple in structure and low in manufacturing cost and maintenance cost, thus being widely popularized and used.

Owner:常州大恒塑料制品有限公司

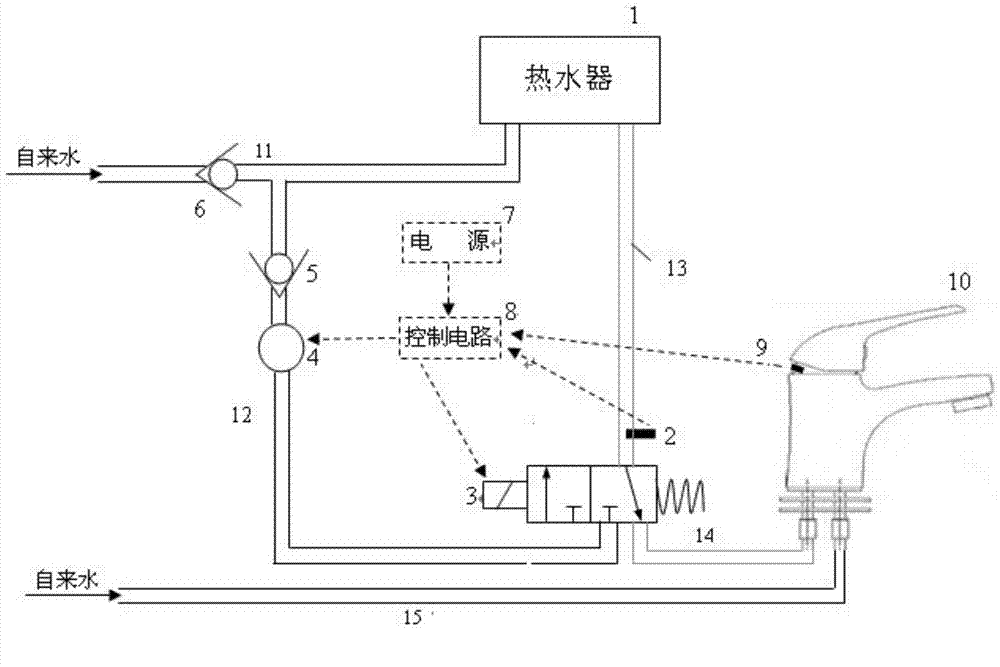

Water-saving control device

The invention discloses a water-saving control device. When hot water is required to be drained, a switch on a water tap is started and is connected with a control circuit and a temperature control sensor detects a temperature value; when the temperature is lower than a set value, the control circuit outputs a high level, a solenoid valve and a water pump are started and cold water in a third pipeline flows into a water heater through the solenoid valve and a second pipeline; when the temperature is higher than or equal to the set value, the control circuit outputs a lower level, the solenoid valve and the water pump are closed and hot water in the third pipeline flows into the water tap through the solenoid valve and a fourth pipeline and flows out. According to the water-saving control device disclosed by the invention, direct drainage of the cold water when the water tap is just opened is avoided, and thus the waste of fresh water resources is avoided and water resources are saved.

Owner:SUZHOU VOCATIONAL UNIV

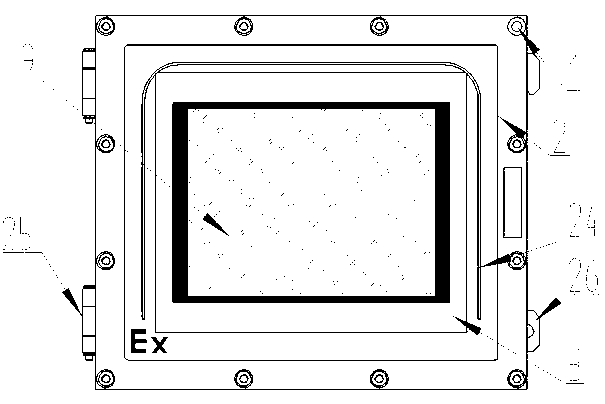

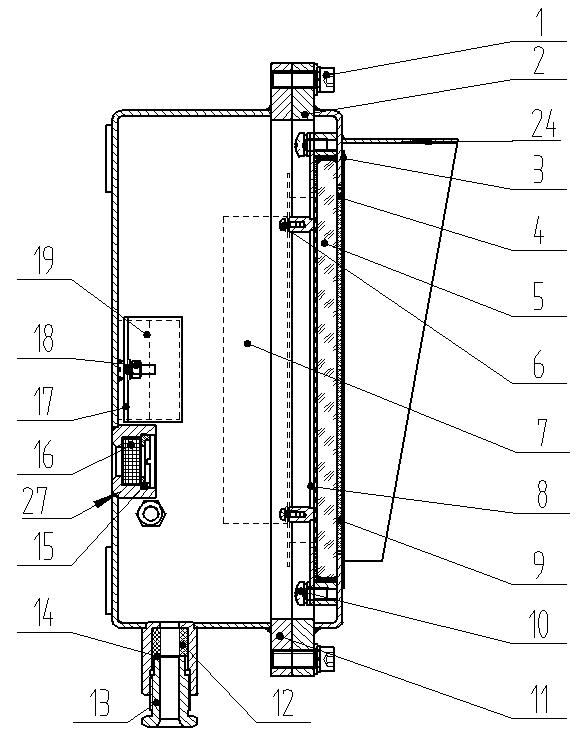

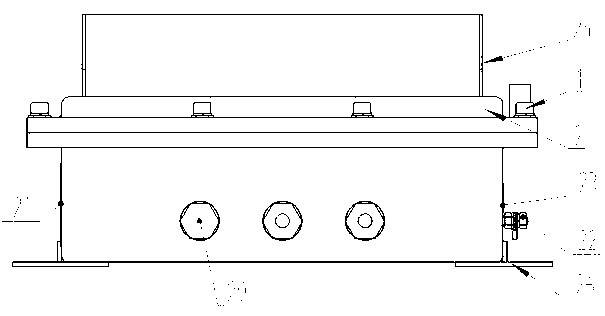

Anti-explosion touch screen

InactiveCN103105992AImprove scalabilityAvoid direct dischargeInput/output processes for data processingEpoxyGrating

The invention belongs to the field of anti-explosion electrical facilities. The anti-explosion touch screen comprises a box body [11], a box cover [2], a resistance touch screen [4], a touch screen control plate [7], window glass [5], wherein the box body [11] and the box cover [2] are fastened to form a sealing space. A hole larger than the resistance touch screen is formed in the box cover welded with a fixing column which is matched with a screw to fix a window pressure plate and to press a window rubber mat and the window glass on the box cover. The window glass and the fixing column are sealed by epoxy resin glue. The resistance touch screen is stuck on the window glass. The anti-explosion touch screen is characterized by further comprising a polyvinyl chloride (PVC) film [3] covered on the resistance touch screen [4] and guard grating [19] fixed on the inner side of the box body, an audio speaker device [27] welded inside the box body, and fire net [16] arranged inside the audio speaker device [27].

Owner:TIANJIN LONGDIAN ELECTRIC ENG

Recycled type sewage purification equipment

InactiveCN106365370AEffective filteringEfficient recyclingTreatment involving filtrationMultistage water/sewage treatmentWater resourcesEngineering

The invention discloses recycled type sewage purification equipment. The equipment comprises a filtering chamber, one side surface of the filtering chamber is fixedly connected to a first water aqueduct, the other side surface of the filtering chamber is fixedly connected to a second water aqueduct, the inside of the filtering chamber is provided with a filtering plate, a first filtering layer and a second filtering layer respectively, leak holes distributed with an equal distance are formed in the filtering plate, one end of the second water aqueduct far from the filtering chamber is fixedly connected to one side surface of a distillery, and the bottom of the distillery is provided with a heater. The recycled type sewage purification equipment can conduct effective filtering treatment and recycling on the sewage, and effectively avoid direct discharge of sewage and water resource waste. Sewage utilization rate is high, water resource recovery efficiency is high, effect of circulation and purification is better, purification is more diversified, and operation is simple. The equipment is practical and convenient, thus the problems of inferior sewage purification effect and water resource waste is effectively solved.

Owner:无锡市富能金属制品有限公司

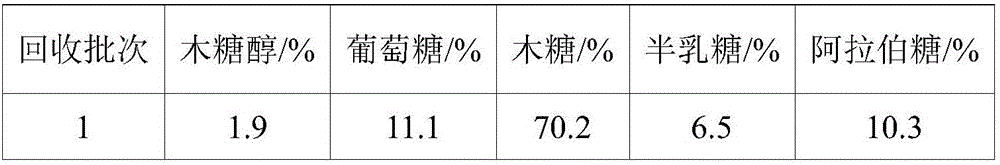

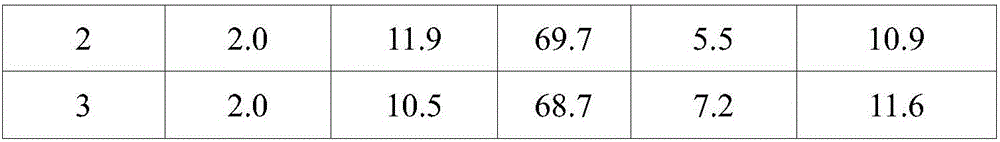

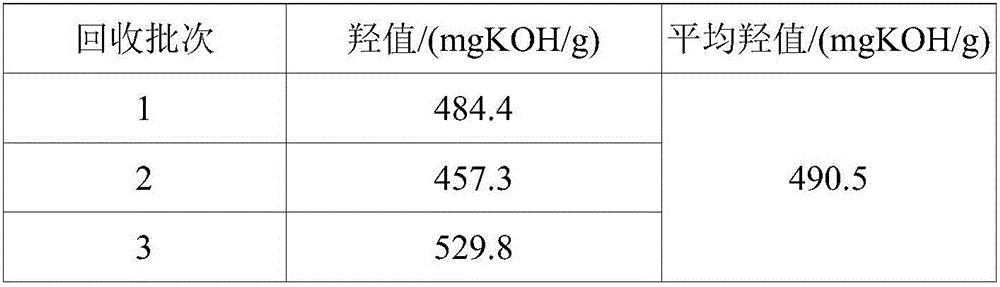

Preparation method of hemicellulose-based polyether polyol

The invention discloses a preparation method of hemicellulose-based polyether polyol. The preparation method comprises the following steps: enabling hemicellulose and glycerol to be subjected to ring-opening polymerization reaction with propylene oxide under the action of a solvent and a catalyst and under the conditions that the temperature is 90 DEG C to 150 DEG C and the pressure is less than 0.6MPa, so as to prepare the hemicellulose-based polyether polyol. The solvent is selected from dimethylformamide, toluene and dioxane; the catalyst is selected from potassium hydroxide, potassium methoxide, potassium hydroxide and sodium methoxide; the mass ratio of raw materials is that the ratio of m(propylene oxide) to m(hemicellulose) to m(glycerol) is (5 to 10) : 2 : (0 to 1); the mass dosage of the solvent is 3 to 8 times that of the hemicellulose and the dosage of the catalyst is 2 percent to 8 percent of the mass of the hemicellulose. According to the method disclosed by the invention, the polyhydroxy hemicellulose recycled from viscose fiber wastewater is used as the raw material for preparing the hemicellulose-based polyether polyol and the hemicellulose-based polyether polyol can be used for preparing rigid polyurethane foam, so that waste resources can be effectively and reasonably utilized and the environment pressure is alleviated; the utilization rate of the waste resources is high and the cost is low, so that the practicability is very good.

Owner:NANJING FORESTRY UNIV +1

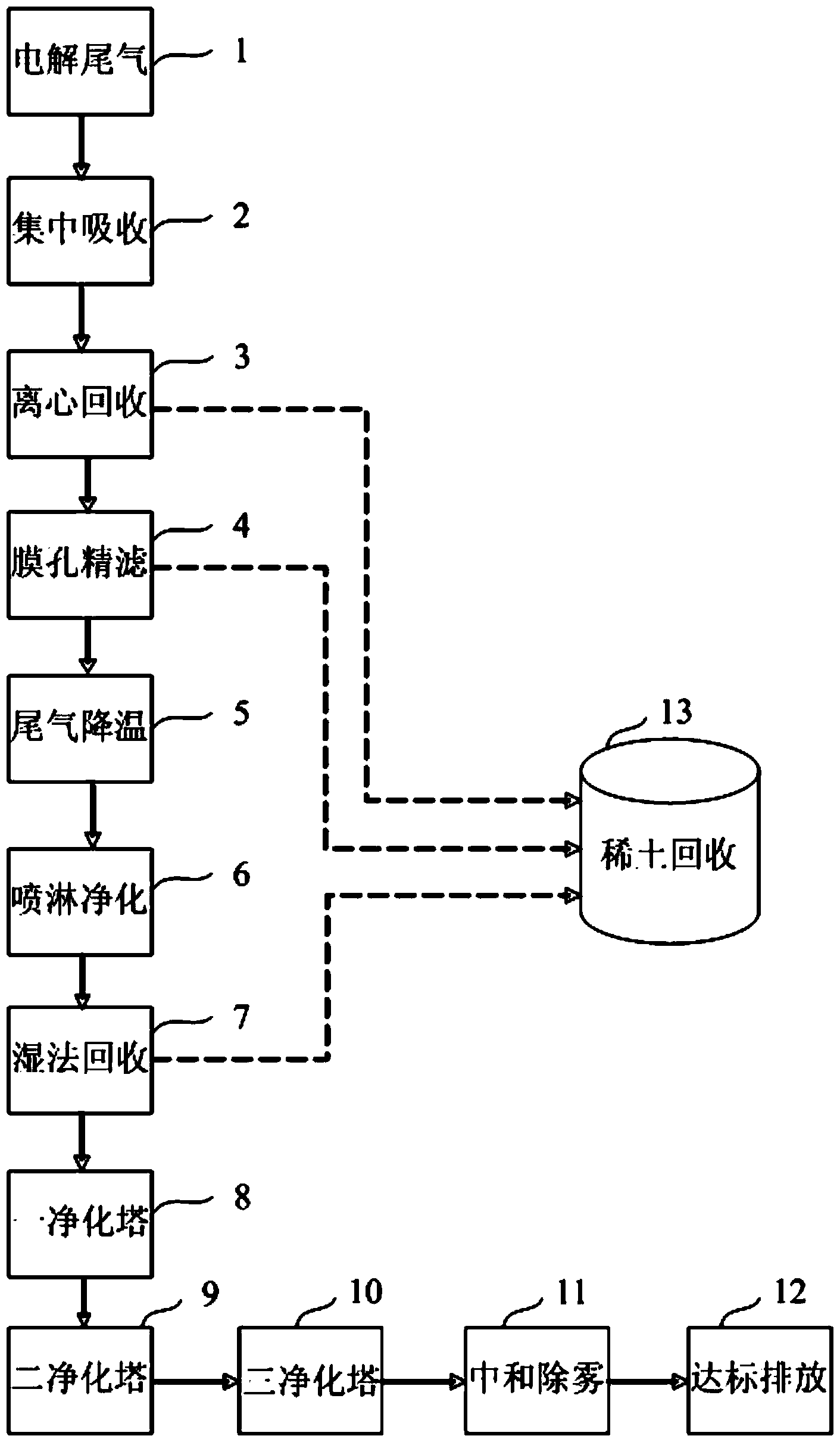

System for processing exhaust gas of rare earth electrolysis process

The invention provides a system for processing exhaust gas of a rare earth electrolysis process. By virtue of the system, the exhaust gas produced after electrolyzing of the rare earth firstly flows through an exhaust gas absorbing device; the exhaust gas is intensively collected and then conveyed to a rear earth recycling device; the residual rare earth in the exhaust gas is recycled, so that the loss of the material is avoided; the exhaust gas after recycling of the rare earth is conveyed to an exhaust gas cooling device, so that the high-temperature electrolysis exhaust gas is cooled, thus direct emission of the high-temperature exhaust gas is avoided; the cooled exhaust gas is conveyed to an exhaust gas purifying device, so that acid gas and dust remaining in the exhaust gas are purified, thus direct emission of the acid gas is avoided; finally, the exhaust gas is conveyed to an exhaust gas neutralizing device, so that the exhaust gas reaches the emission standard, thus safe emission of the electrolysis exhaust gas is achieved.

Owner:NINGBO FUNENG NEW MATERIAL

Combined flower box with rain collecting and dirt filtering functions

InactiveCN106171594ANormal plantingDischarge in timeGeneral water supply conservationSelf-acting watering devicesEngineeringPlant soil

The invention provides a combined flower box with rain collecting and dirt filtering functions and relates to the technical field of municipal engineering. An upper cover with water-permeable holes is arranged on the upper portion of a water tank, a flower box body is arranged on the upper cover, flower box water-permeable holes are formed in the bottom of the flower box body, a plant soil layer, a ceramsite pervious concrete layer and a dirt filtering layer are distributed in the flower box body from top to bottom, water absorbing ropes are arranged in the flower box water-permeable holes and the water-permeable holes in the upper cover in a penetrating mode, and the upper ends of the water absorbing ropes are disposed in the ceramsite pervious concrete layer; rain collecting awnings are arranged on the outer side of the flower box body, and water guide pipes are arranged between the rain collecting awnings and the water tank. By means of the combined flower box, rainwater can be supplied to flowers and grass for growth for a long time, and manual flower watering frequency is reduced; the ceramsite pervious concrete layer and the dirt filtering layer are arranged in the flower box body, so pollutants in rainwater can be effectively filtered away, and environment protection is benefited; the rain collecting awnings also have a sun-shading function, and the outer side of the flower box body at the upper end of the water tank can be used for people to sit and rest.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com