Water-soluble yeast beta-dextran and preparation thereof

A dextran and water-soluble technology, which is applied in the field of preparation of water-soluble yeast β-glucan, can solve the problems of restricting large-scale applications and increasing production costs, and achieve simple process, reduced impurity content, and increased yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

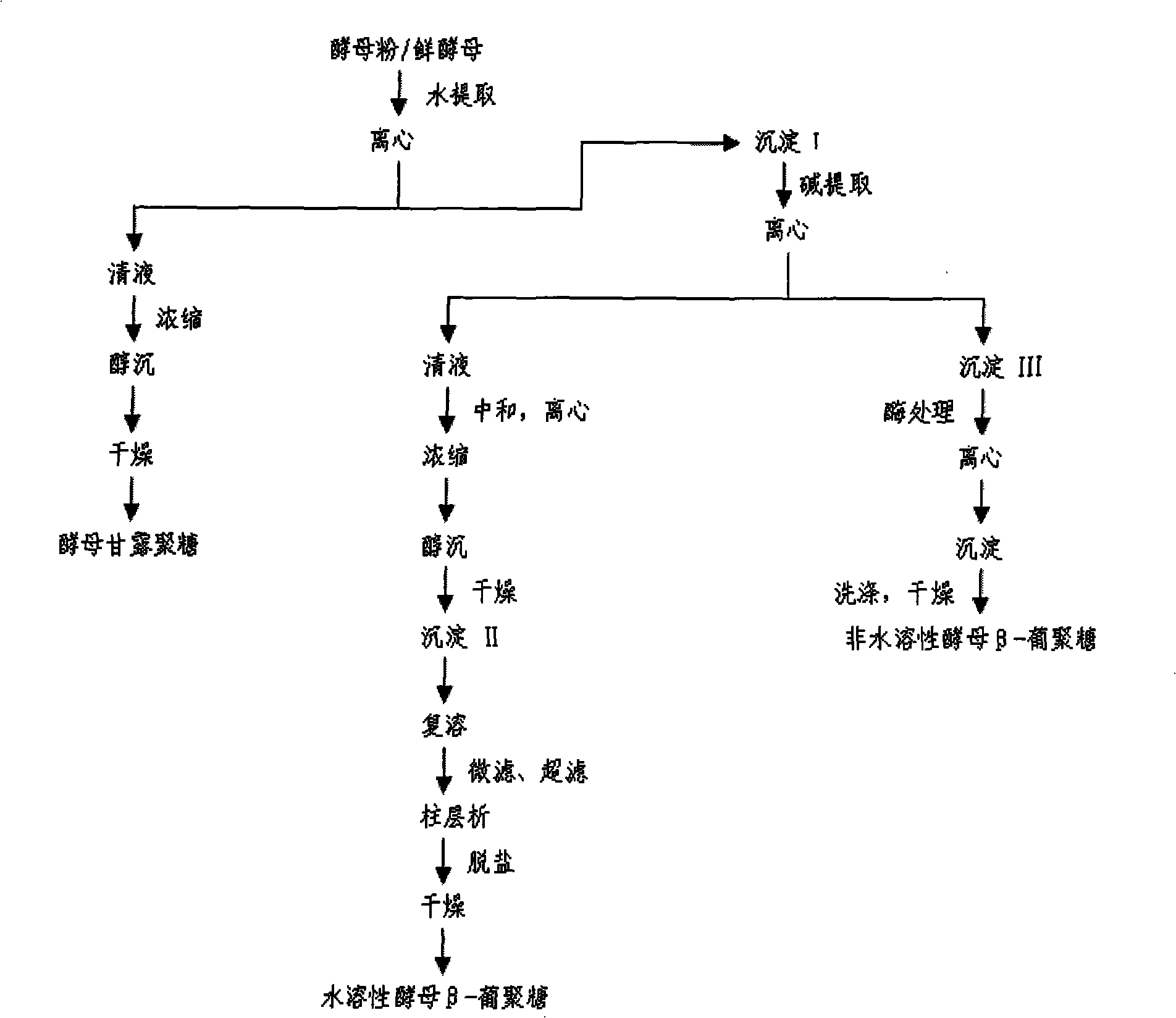

Method used

Image

Examples

Embodiment 1

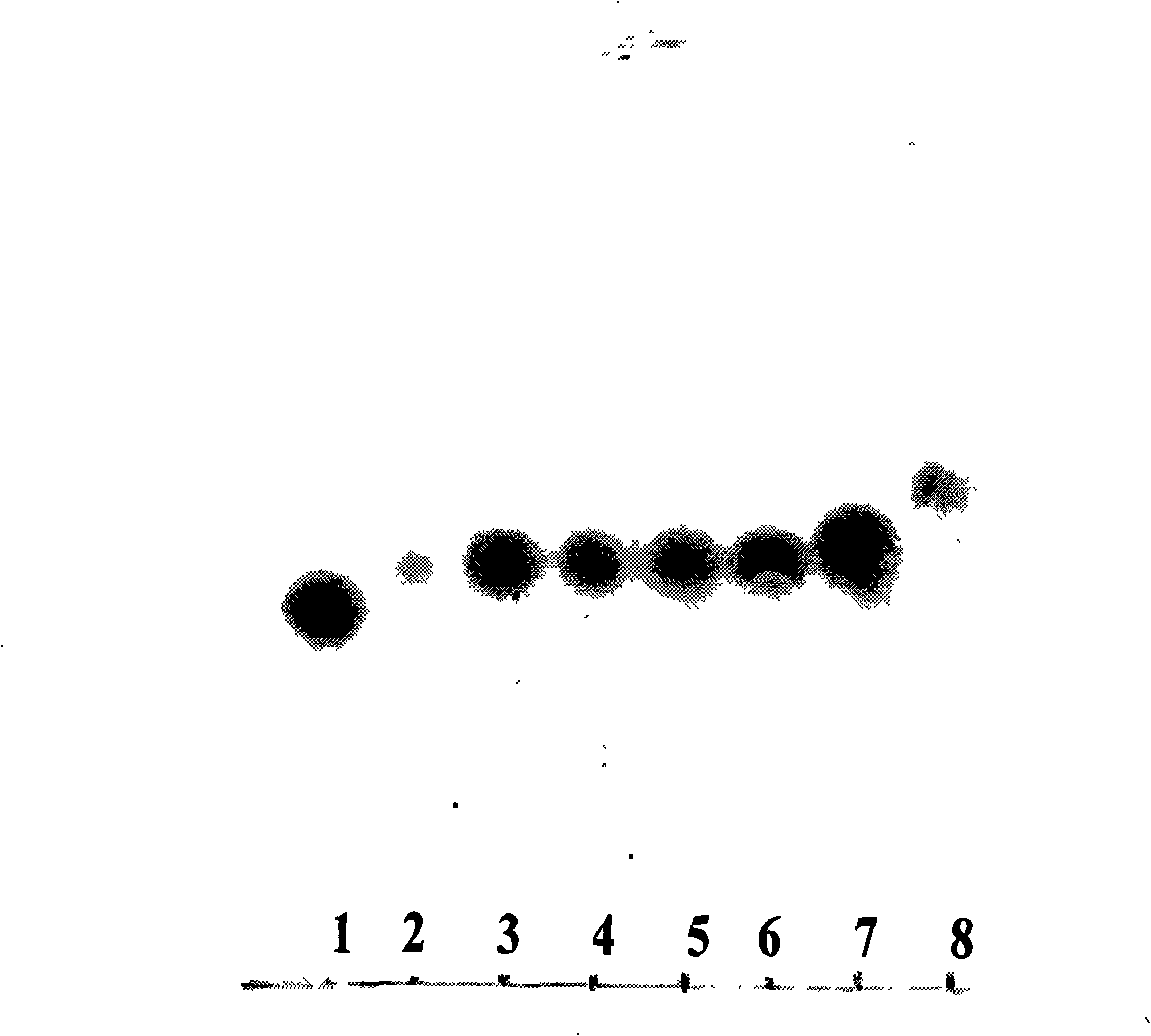

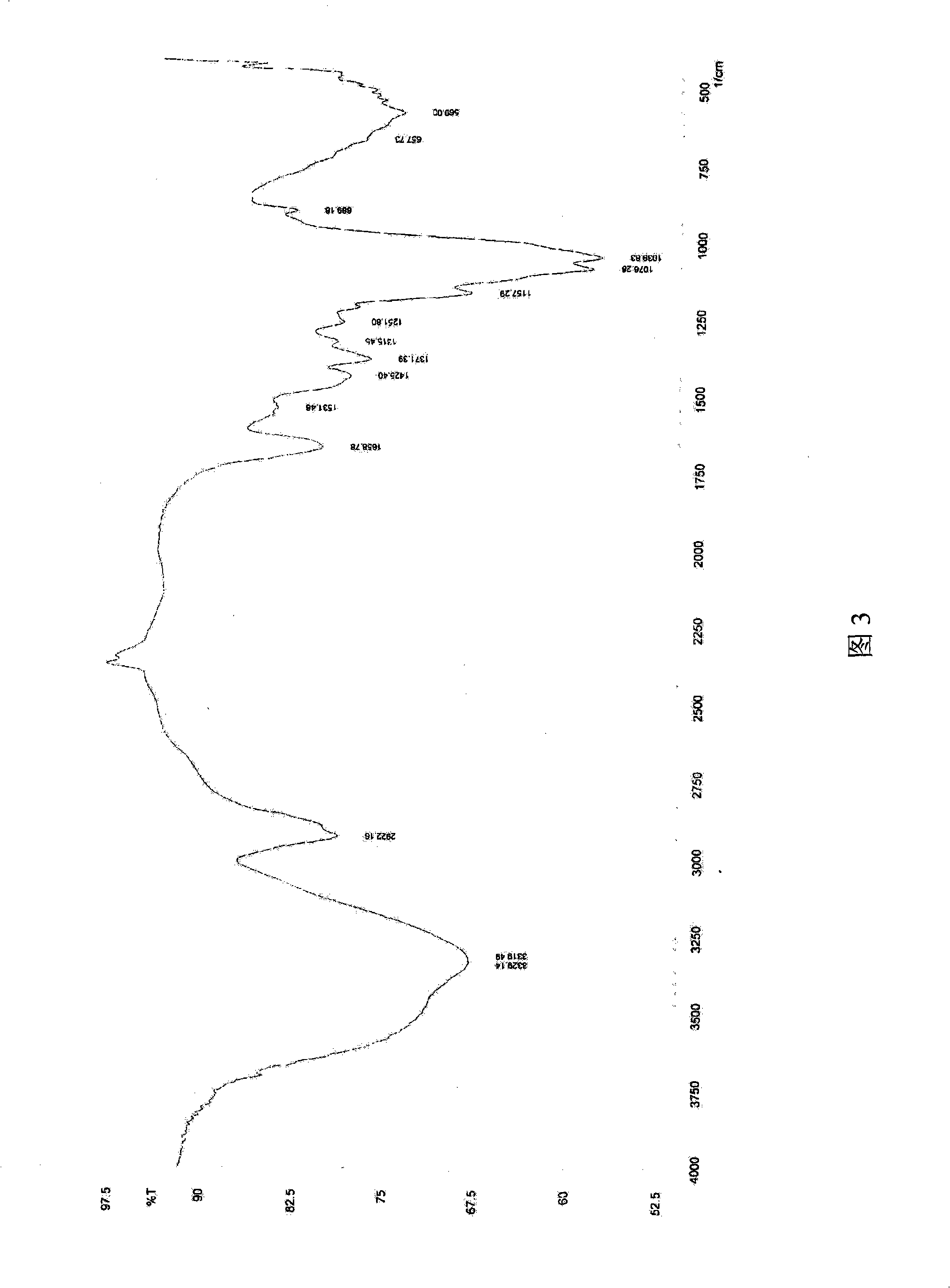

[0039] Take 200g of yeast powder, add 2L of purified water, extract at 80°C for 1h, centrifuge at 4000r / min for 10min, collect the precipitate I, concentrate the supernatant, precipitate with alcohol, and dry to obtain yeast mannan; then add 2L of 4 % (w / v) sodium hydroxide solution, stirred at 60° C. for 1 h, centrifuged at 5000 r / min for 20 min, and collected alkali extraction precipitate III. The supernatant was neutralized to PH6.0 with 30% citric acid, after cooling to room temperature, centrifuged at 5000r / min for 10min, the supernatant was concentrated to 1 / 5 of the volume of the original supernatant, and 95% ethanol was added to make the alcohol concentration in the alcohol solution After reaching 80%, the alcohol is precipitated, and the water-soluble yeast β-glucan is obtained after precipitation and drying. The β-glucan content of the product is 85%, and the yield is 15%. Add 2L of water to Alkaline Extraction and Precipitation III, adjust the pH to 8.0, add 2g of a...

Embodiment 2

[0042] Add 2L of purified water to 200g of yeast powder, extract at 100°C for 1h, centrifuge at 4000r / min for 10min, collect the precipitate I, concentrate the supernatant, precipitate with alcohol, and dry to obtain yeast mannan; then add 2L of 10% Sodium hydroxide, stirred at 80°C for 1 h, centrifuged at 3000 r / min for 20 min, and collected the alkali extraction precipitate III. The supernatant was neutralized to pH 7.0 with 10% (w / v) hydrochloric acid. After being cooled to room temperature, it was centrifuged at 3000r / min for 15 minutes. The concentration reaches 80%, alcohol precipitation, precipitation and drying to obtain water-soluble yeast β-glucan, the β-glucan content of the product is 90%, and the yield is 12%. Add 2L of water to Alkaline Extraction Precipitation III, adjust the pH to 7.0, add 1g of papain, enzymatically hydrolyze at 50°C for 16h, collect the precipitate, and dry to obtain 26g of non-water-soluble yeast β-glucan with a content of 95.1%.

[0043] W...

Embodiment 3

[0045] Add 1.2L of purified water to 100g of yeast powder, extract at 121°C for 1.5h, centrifuge at 4000r / min for 10min, collect the precipitate I, concentrate the supernatant, precipitate with alcohol, and dry to obtain yeast mannan; then add 2L of 6 % sodium carbonate solution, stirred and reacted at 60°C for 2h, centrifuged at 12000r / min for 8min, and collected the alkali extraction precipitate III. The supernatant was neutralized to pH 6.0 with 10% (w / v) acetic acid. After cooling to room temperature, it was centrifuged at 12,000 r / min for 5 minutes. The concentration reaches 80%, alcohol precipitation, precipitation and drying to obtain water-soluble yeast β-glucan, the β-glucan content of the product is 85%, and the yield is 10%. Add 1.2 L of water to the alkali extraction precipitation III, adjust the pH to 8.0, add 2 g of alkaline protease, and perform enzymatic hydrolysis at 60°C for 16 hours, collect the precipitate, and dry it to obtain non-water-soluble yeast β-glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com