Patents

Literature

30results about How to "Reduce processing failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

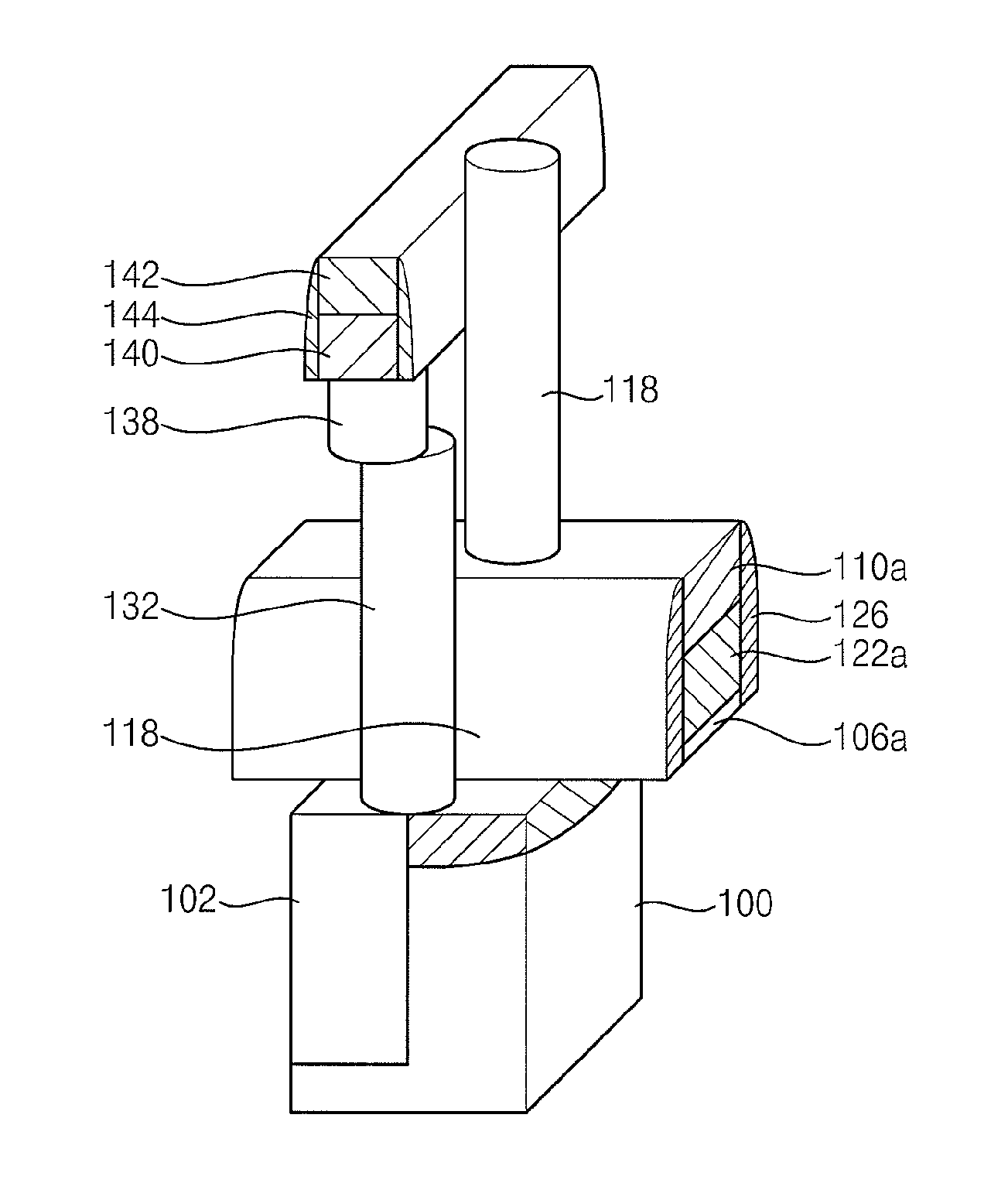

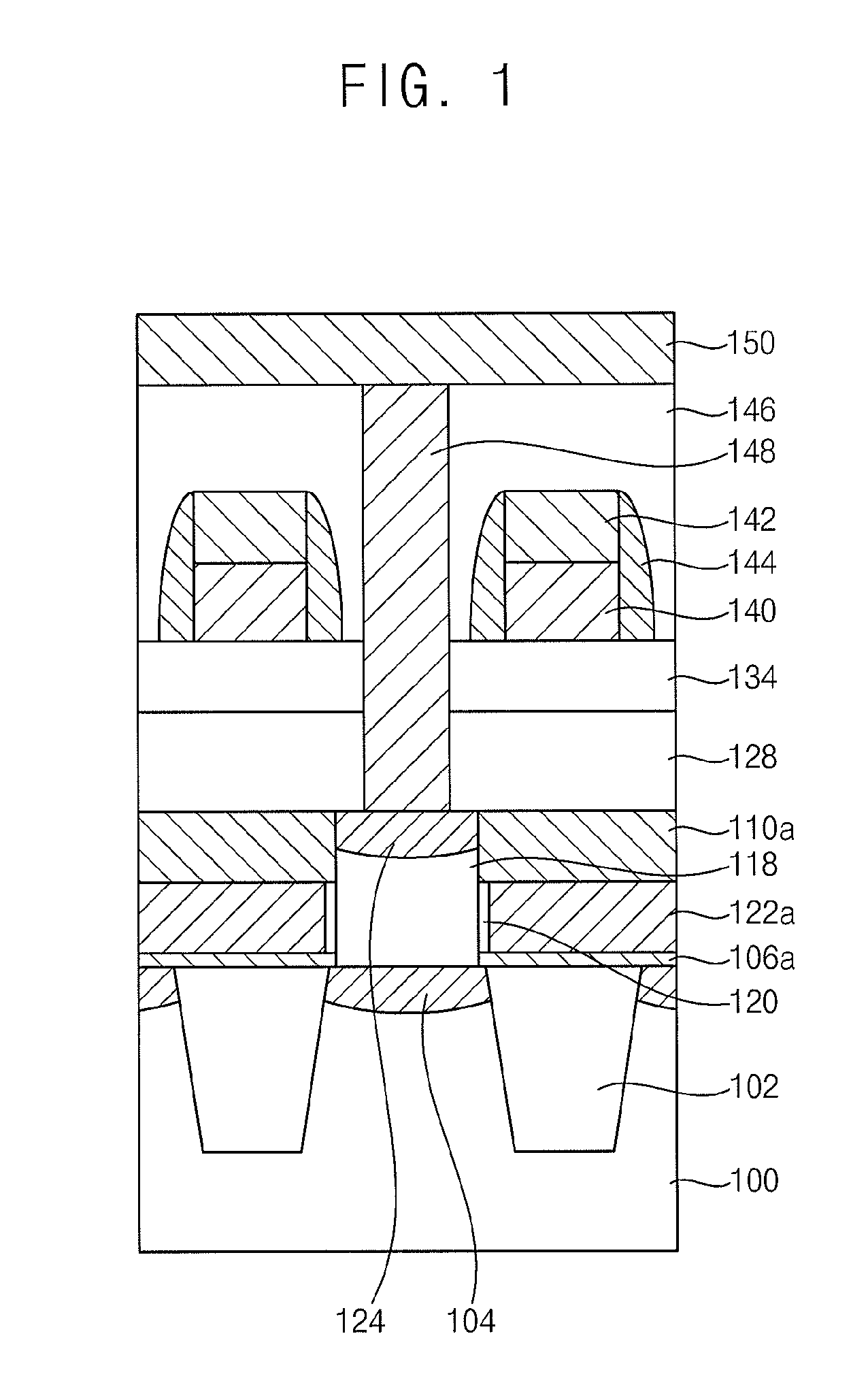

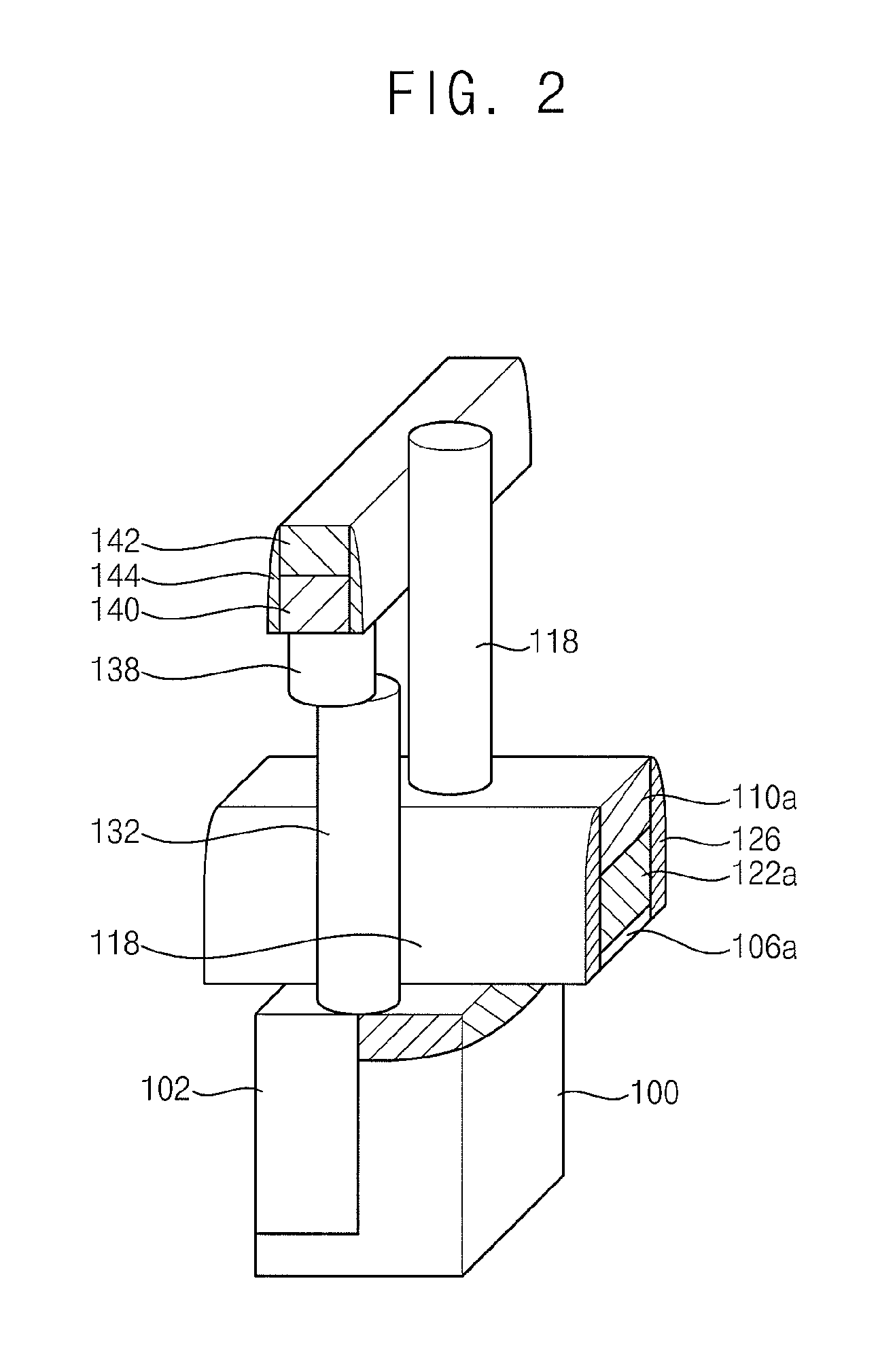

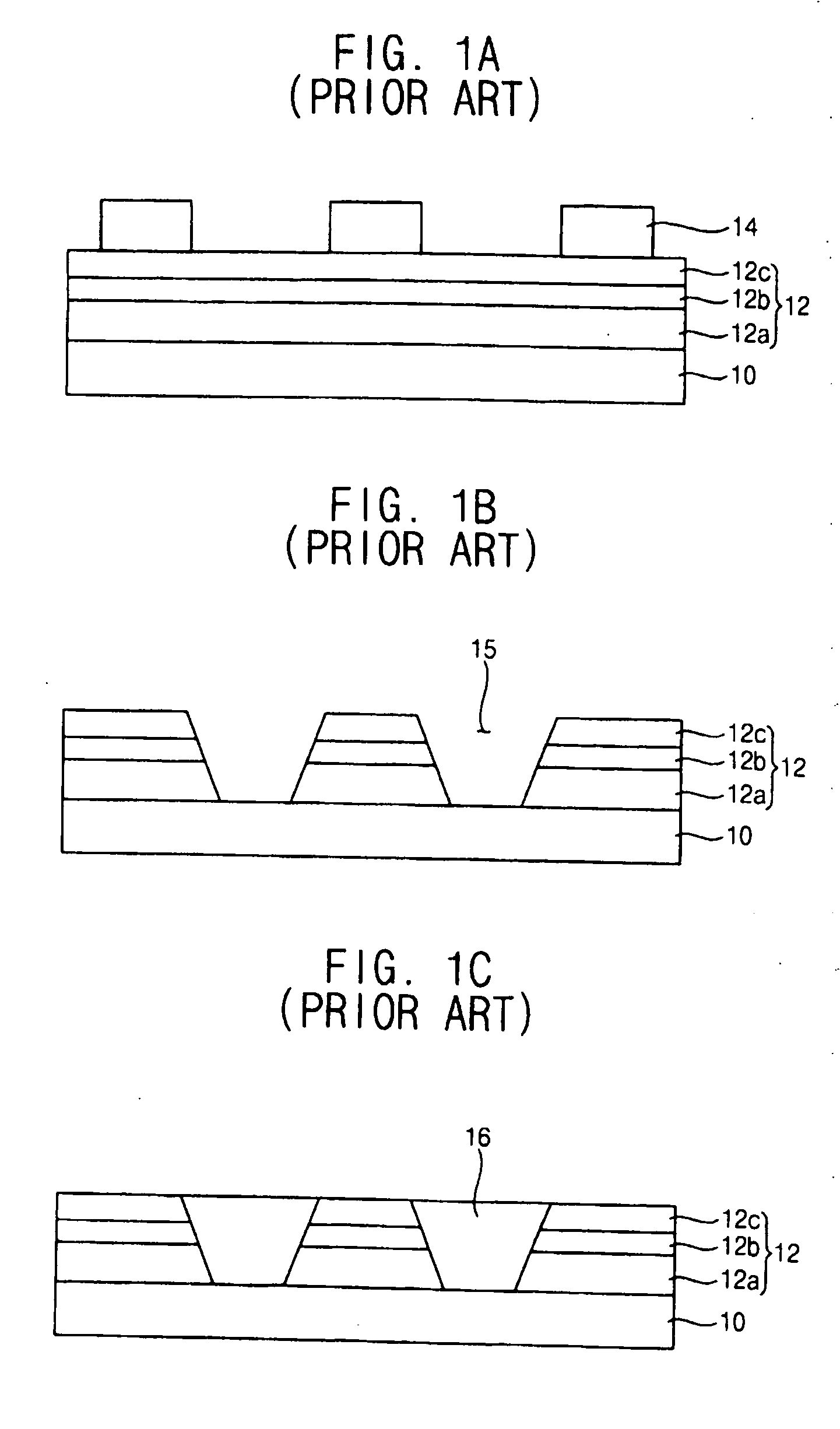

Method of manufacturing a vertical-type semiconductor device and method of operating a vertical-type semiconductor device

ActiveUS20110211399A1Improve performanceHighly integratedTransistorSolid-state devicesDevice materialSingle crystal

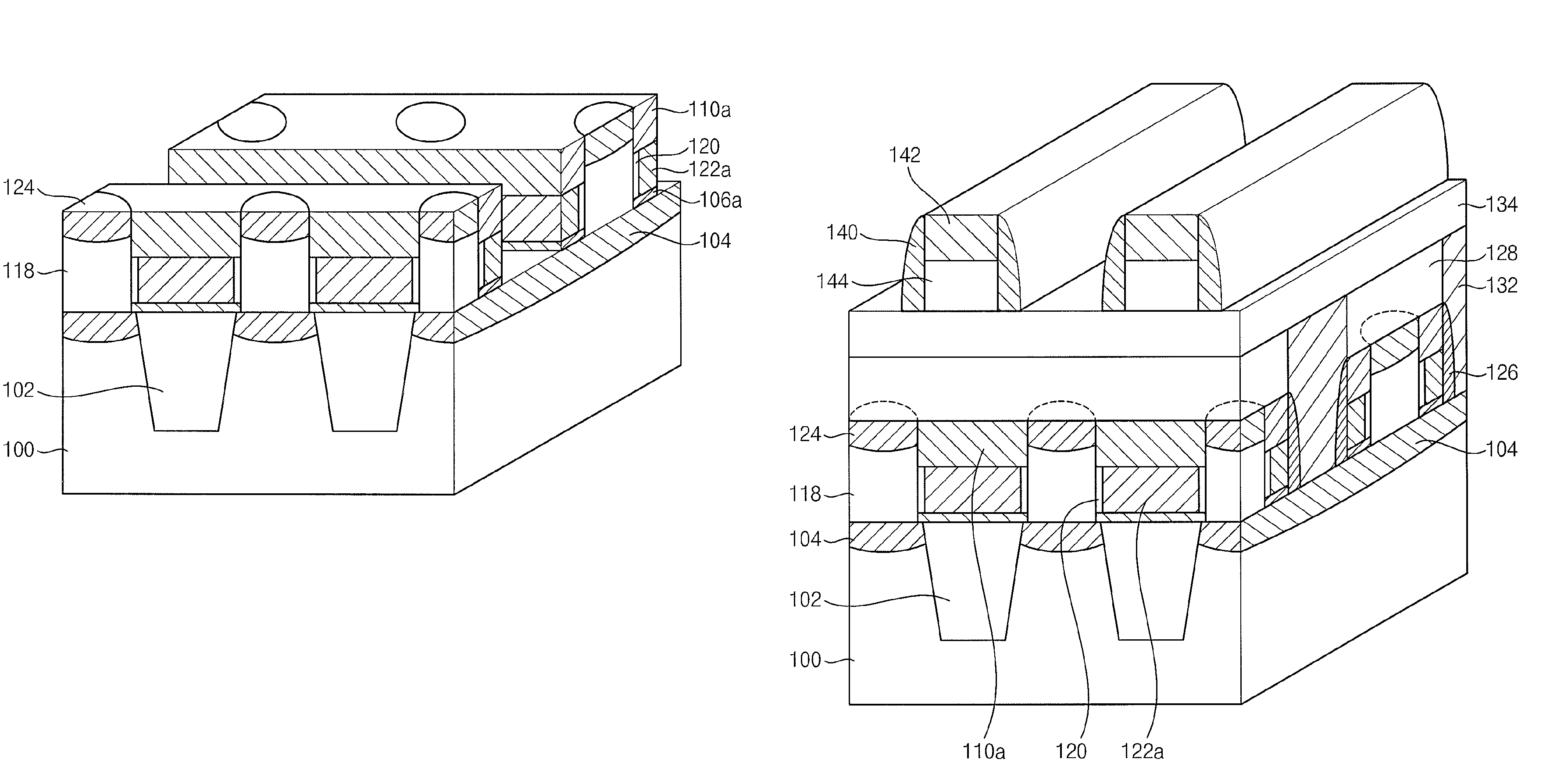

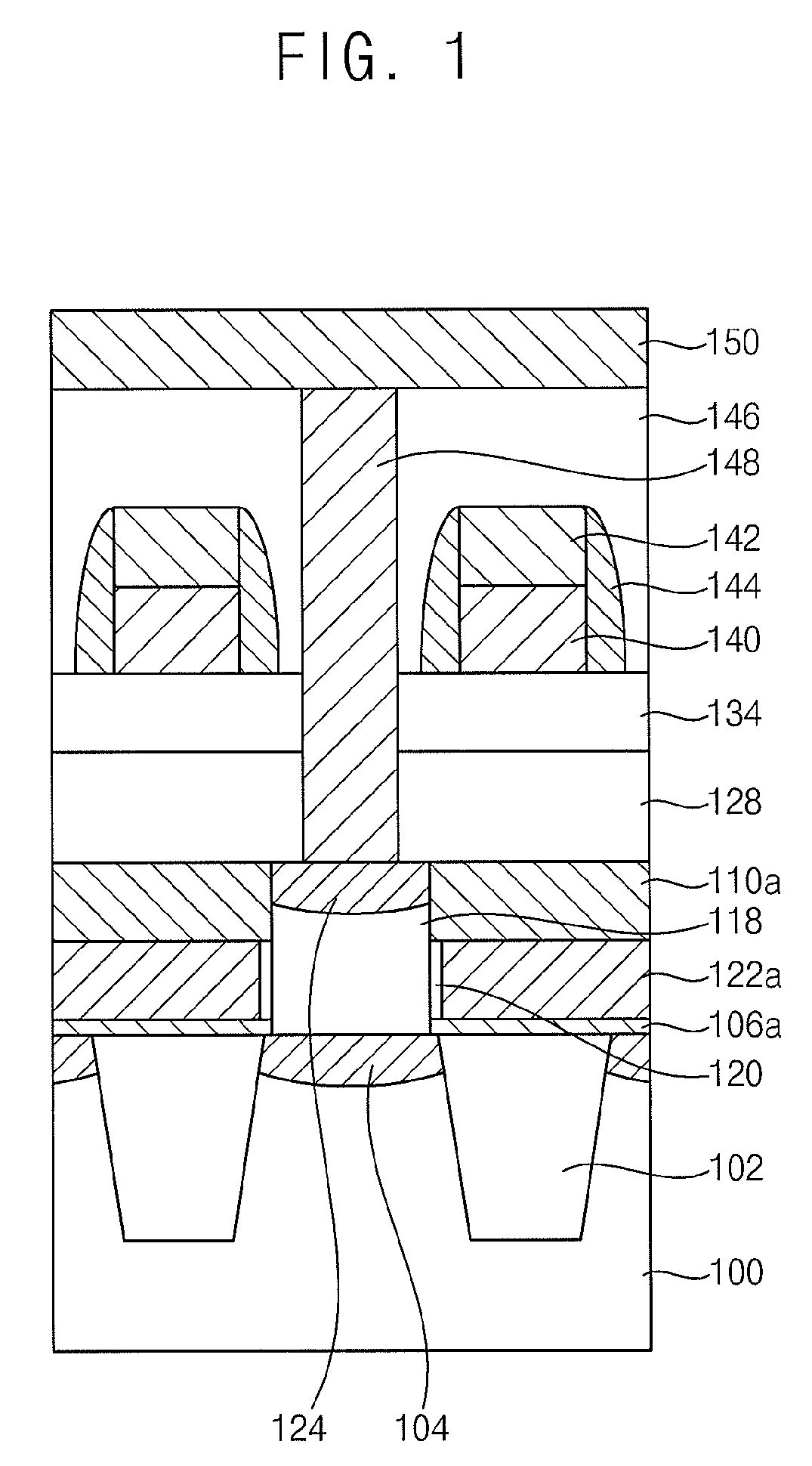

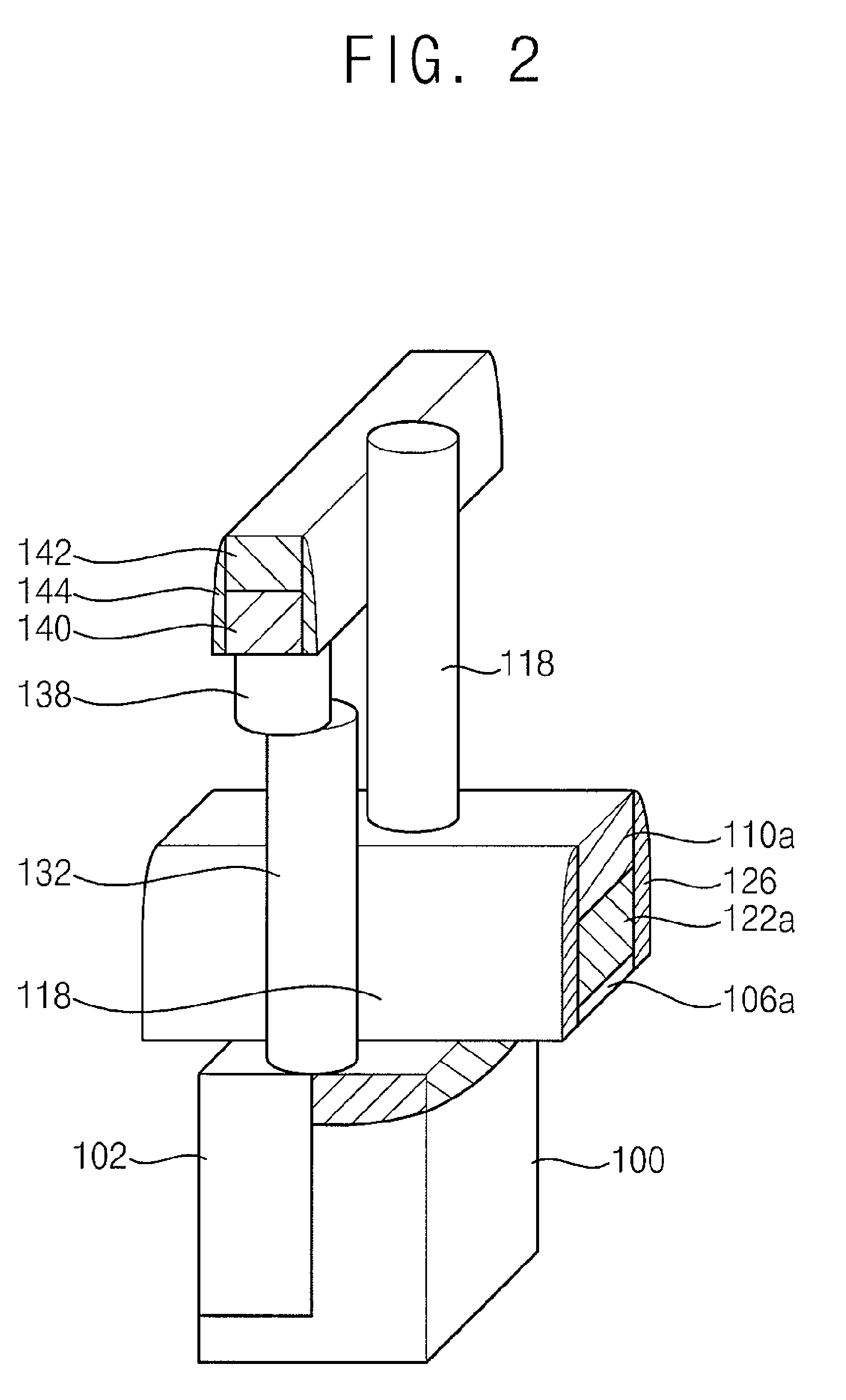

In a vertical-type semiconductor device, a method of manufacturing the same and a method of operating the same, the vertical-type semiconductor device includes a single-crystalline semiconductor pattern having a pillar shape provided on a substrate, a gate surrounding sidewalls of the single-crystalline semiconductor pattern and having an upper surface lower than an upper surface of the single-crystalline semiconductor pattern, a mask pattern formed on the upper surface of the gate, the mask pattern having an upper surface coplanar with the upper surface of the single-crystalline semiconductor pattern, a first impurity region in the substrate under the single-crystalline semiconductor pattern, and a second impurity region under the upper surface of the single-crystalline semiconductor pattern. The vertical-type pillar transistor formed in the single-crystalline semiconductor pattern may provide excellent electrical properties. The mask pattern is not provided on the upper surface of the single-crystalline semiconductor pattern in the second impurity region, to thereby reduce failures of processes.

Owner:SAMSUNG ELECTRONICS CO LTD

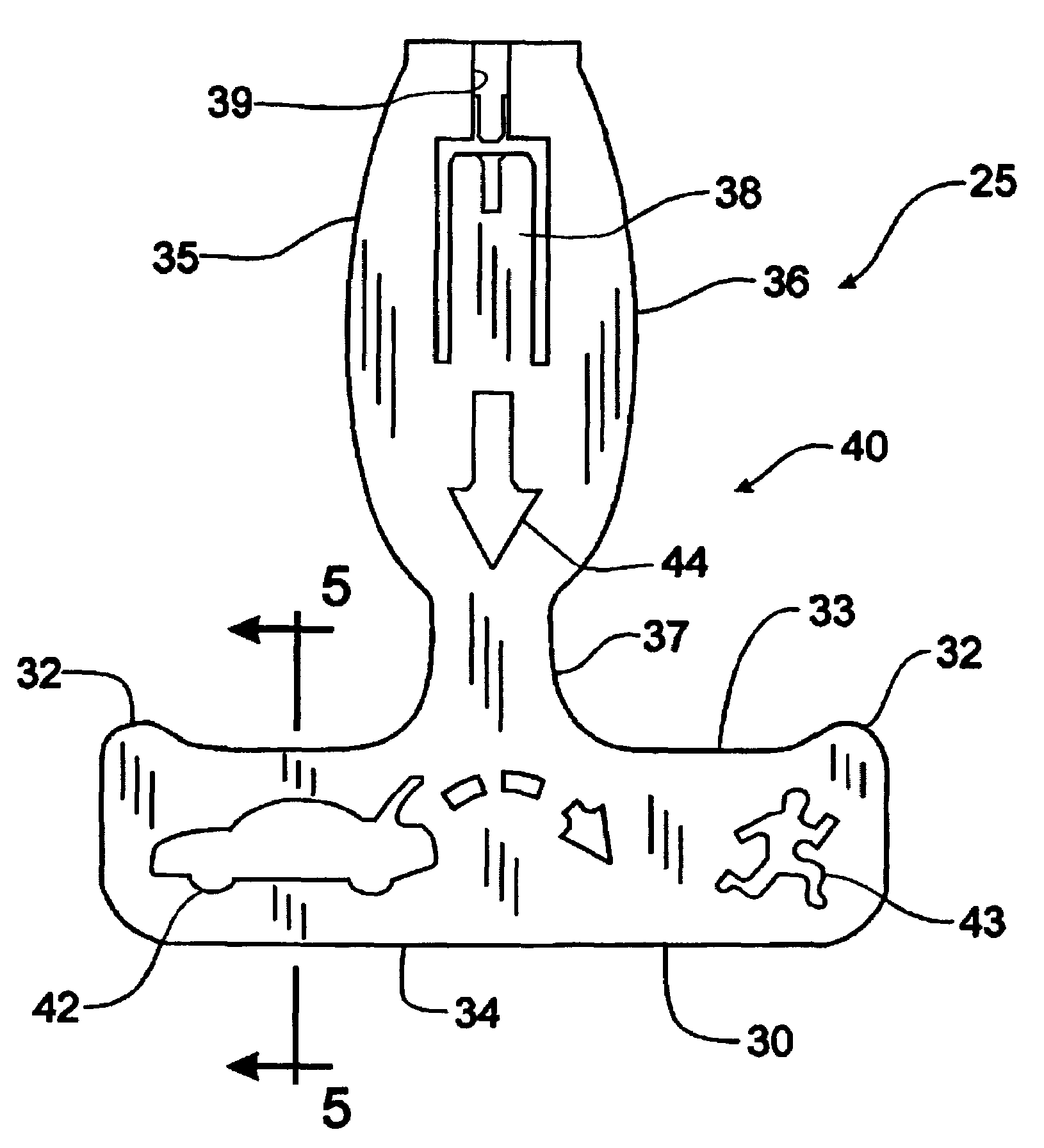

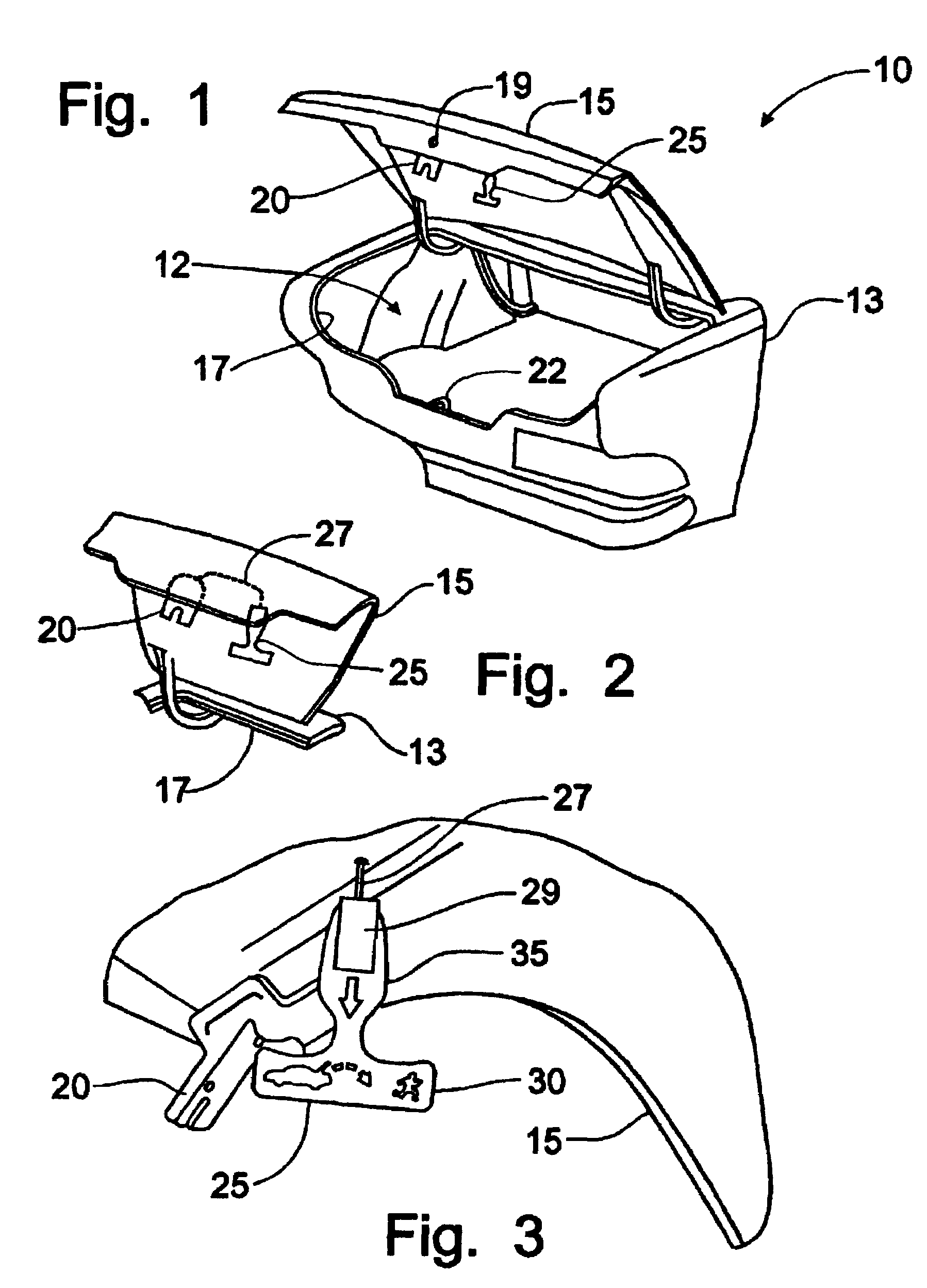

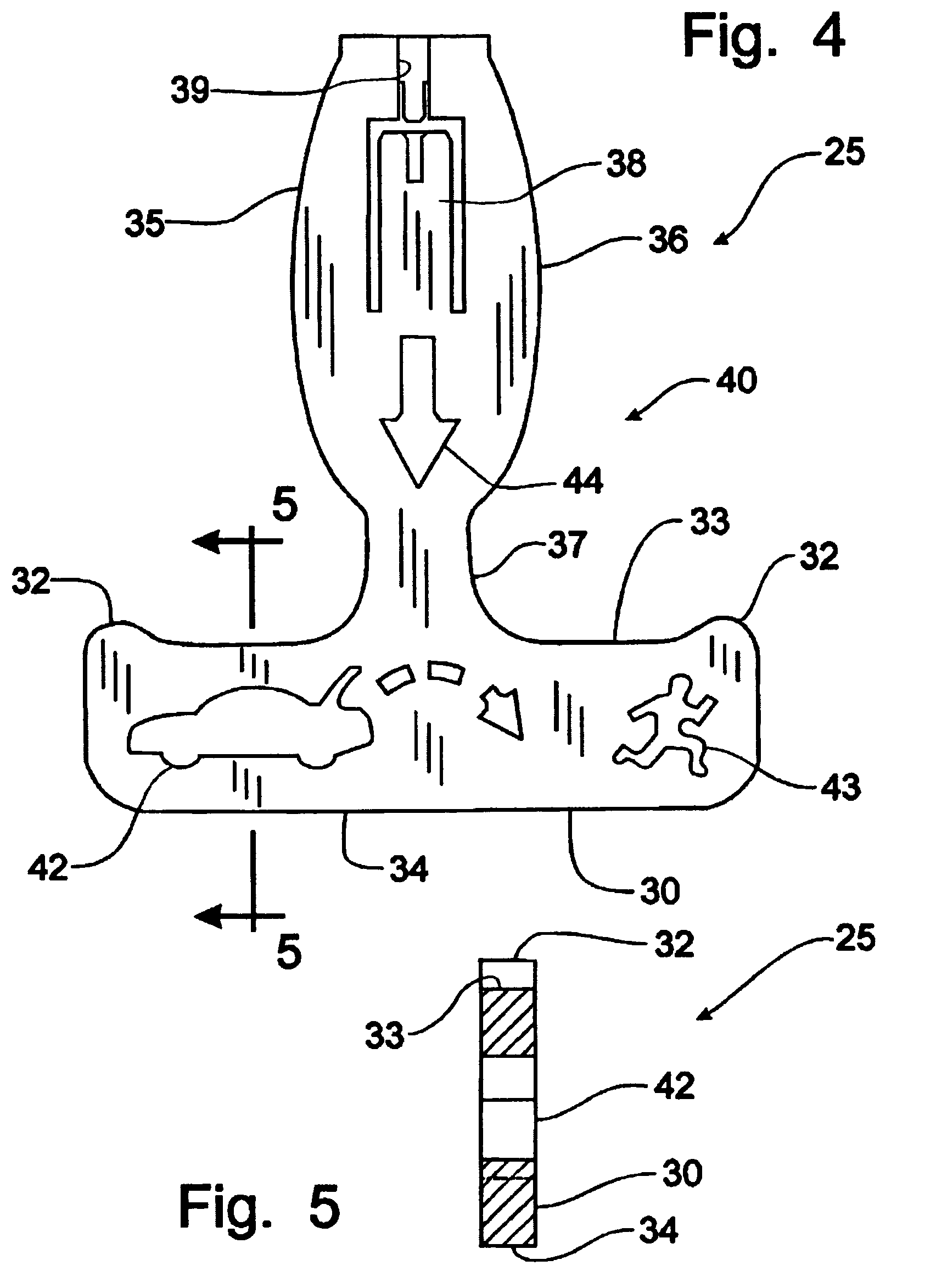

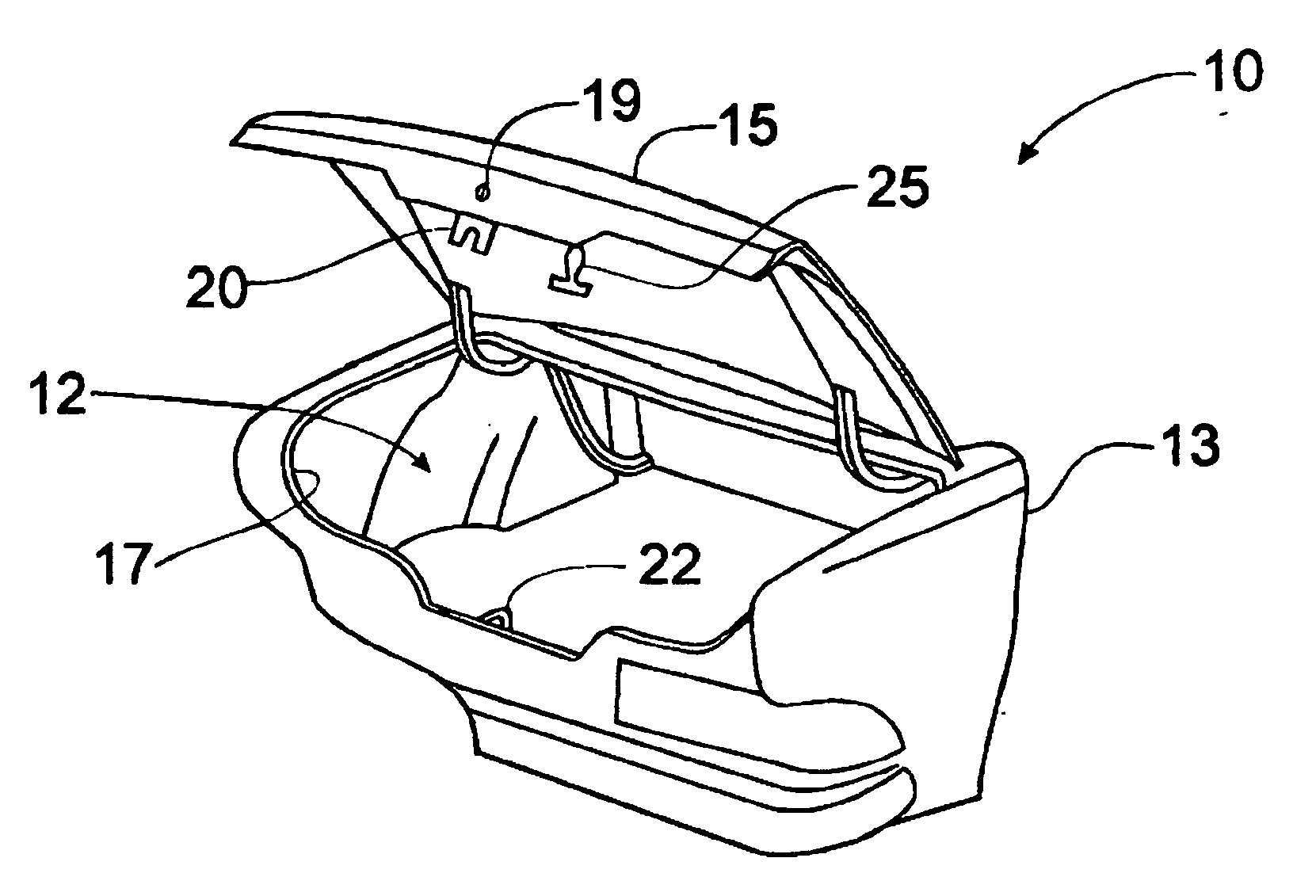

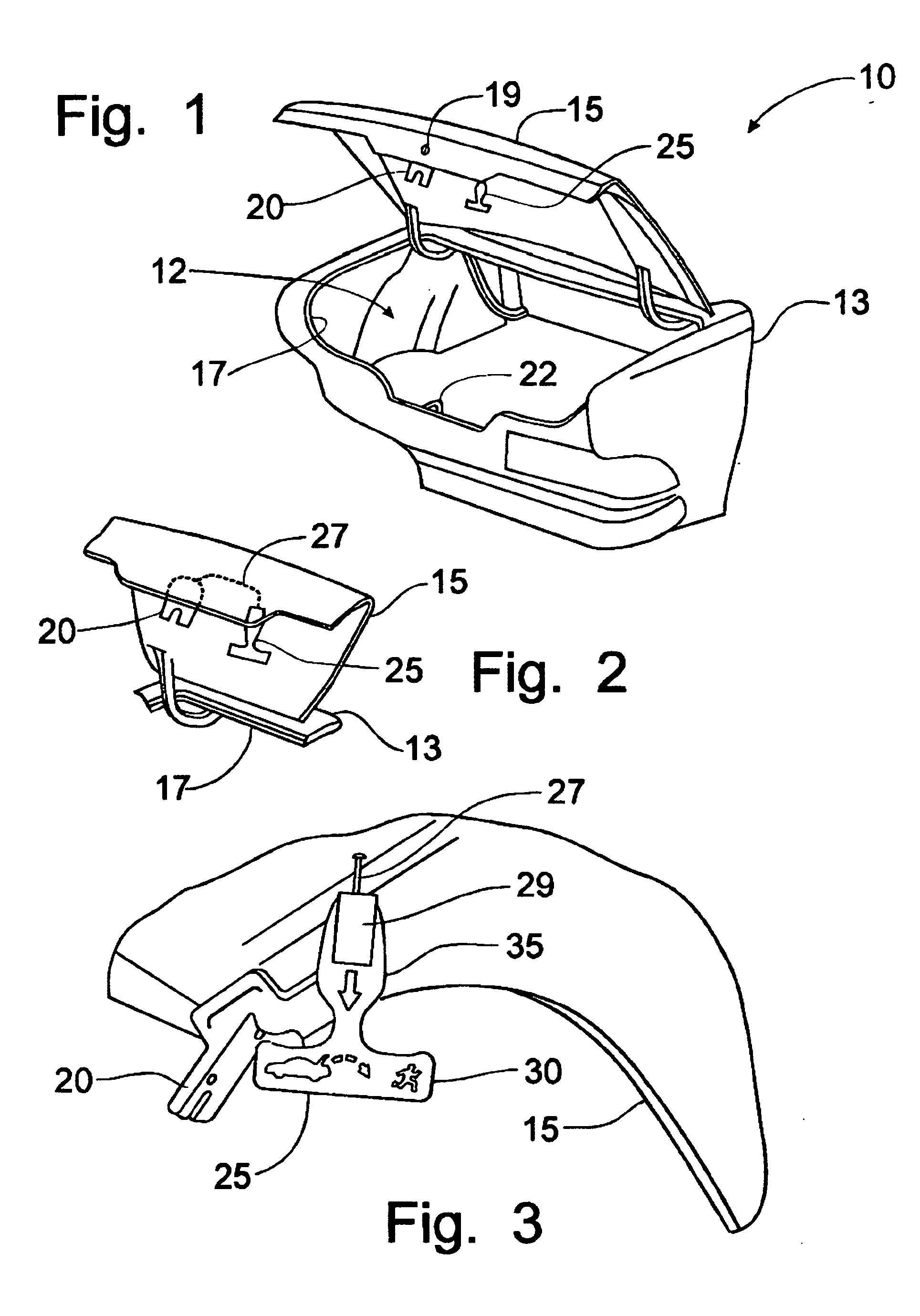

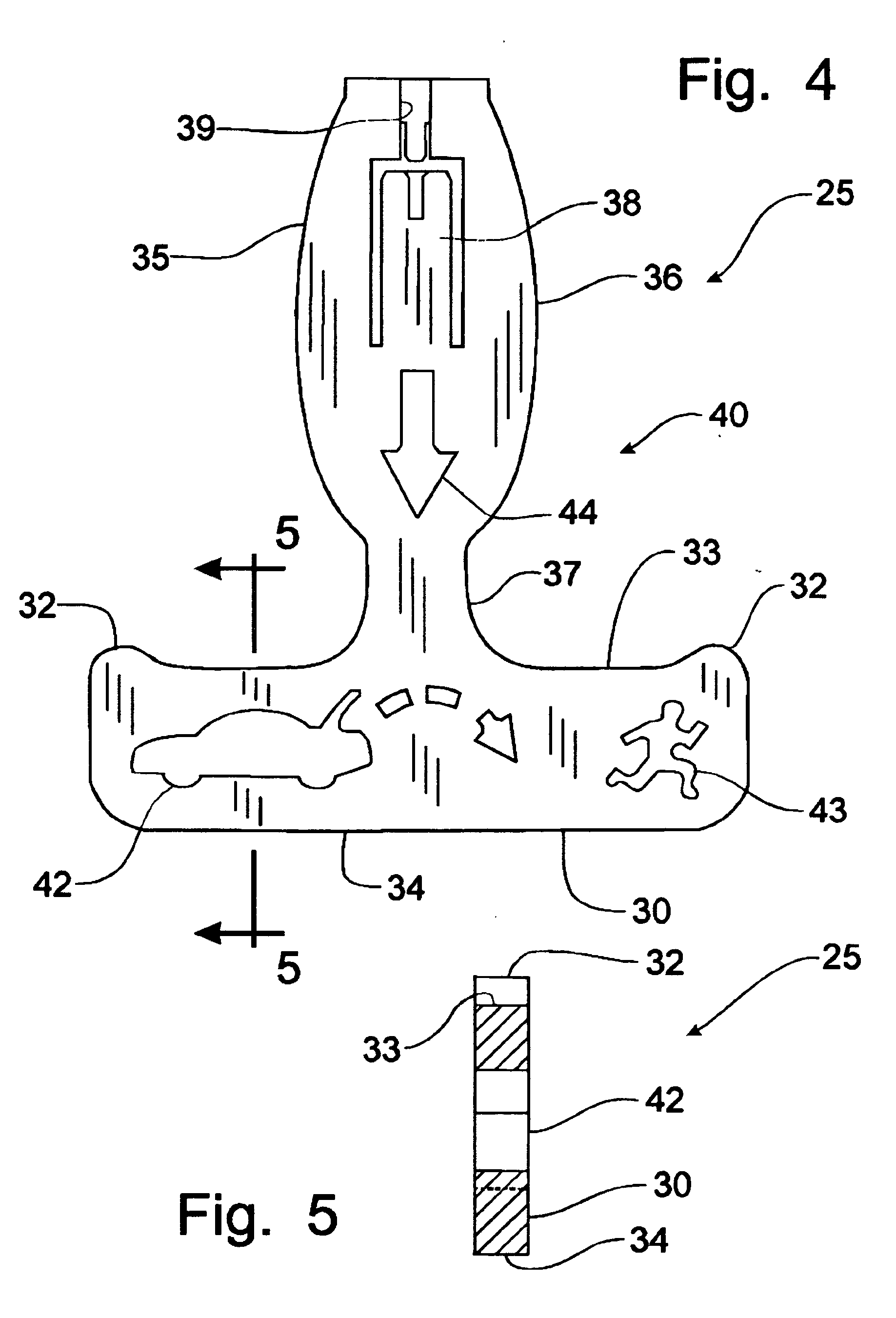

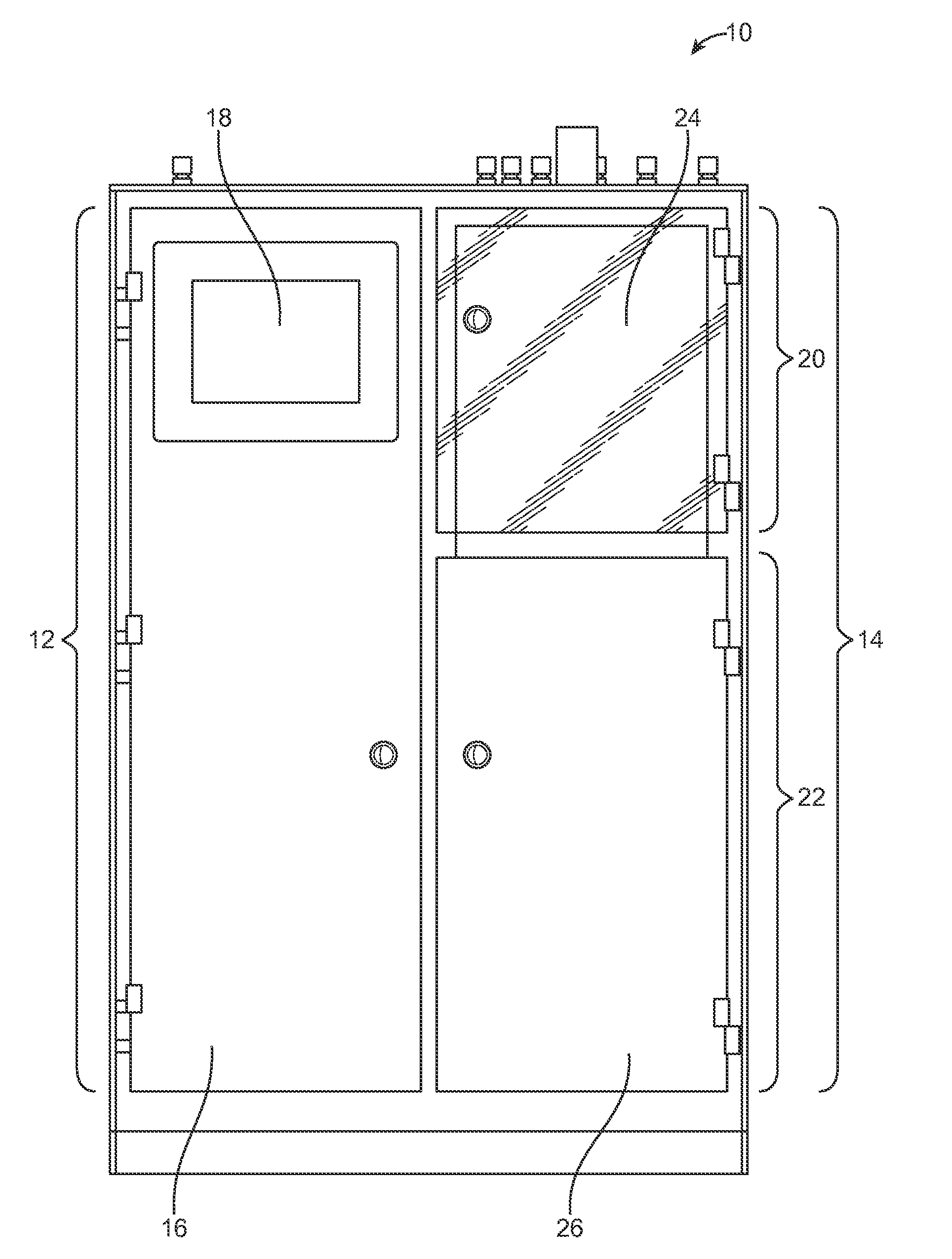

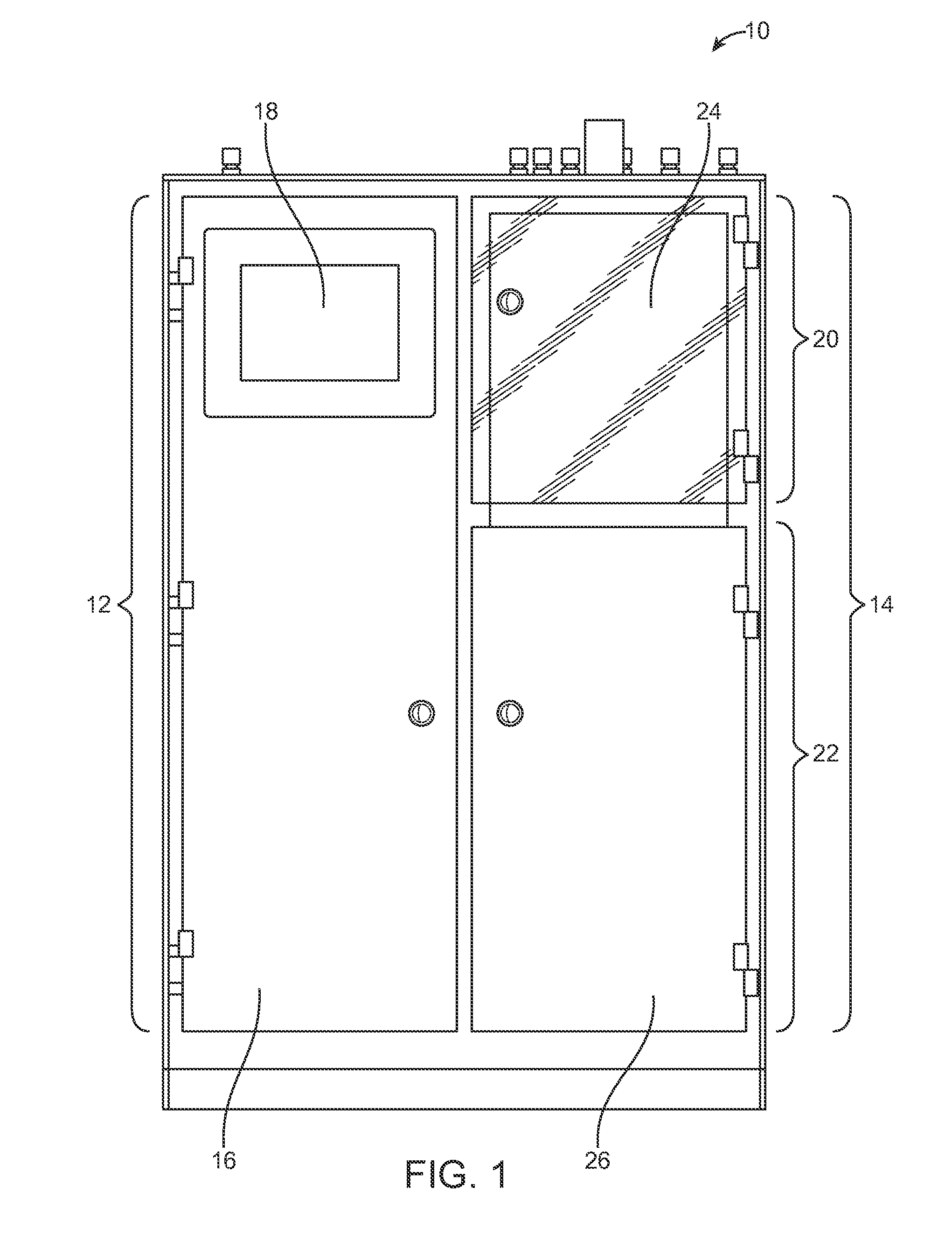

Trunk release handle for automobiles

ActiveUS7029138B2Visibility of providingHigh degreeVehicle locksOptical signallingVisibilityGraphics

An emergency trunk release handle for an automobile displays the graphics explaining the use and function of the handle by cutting out the material from the handle. Forming the emergency release handle from a phosphorescent plastic material that can be formed by a molding process, such as injection molding, the cut-out graphics show as darkened areas, when viewed in the dark confines of an automobile trunk, to provide a high degree of visibility for the graphics. The graphics are also visible when seen against the dark carpet in the interior of an opened trunk cavity. The formation of the graphics is accomplished by coring the mold in the configuration of the desired graphics and by forming the plastic material in the mold around the cores. The resultant handle structure is thus formed in a cost effective manner that reduces the process failure potential during the manufacturing of the handle.

Owner:FORD GLOBAL TECH LLC

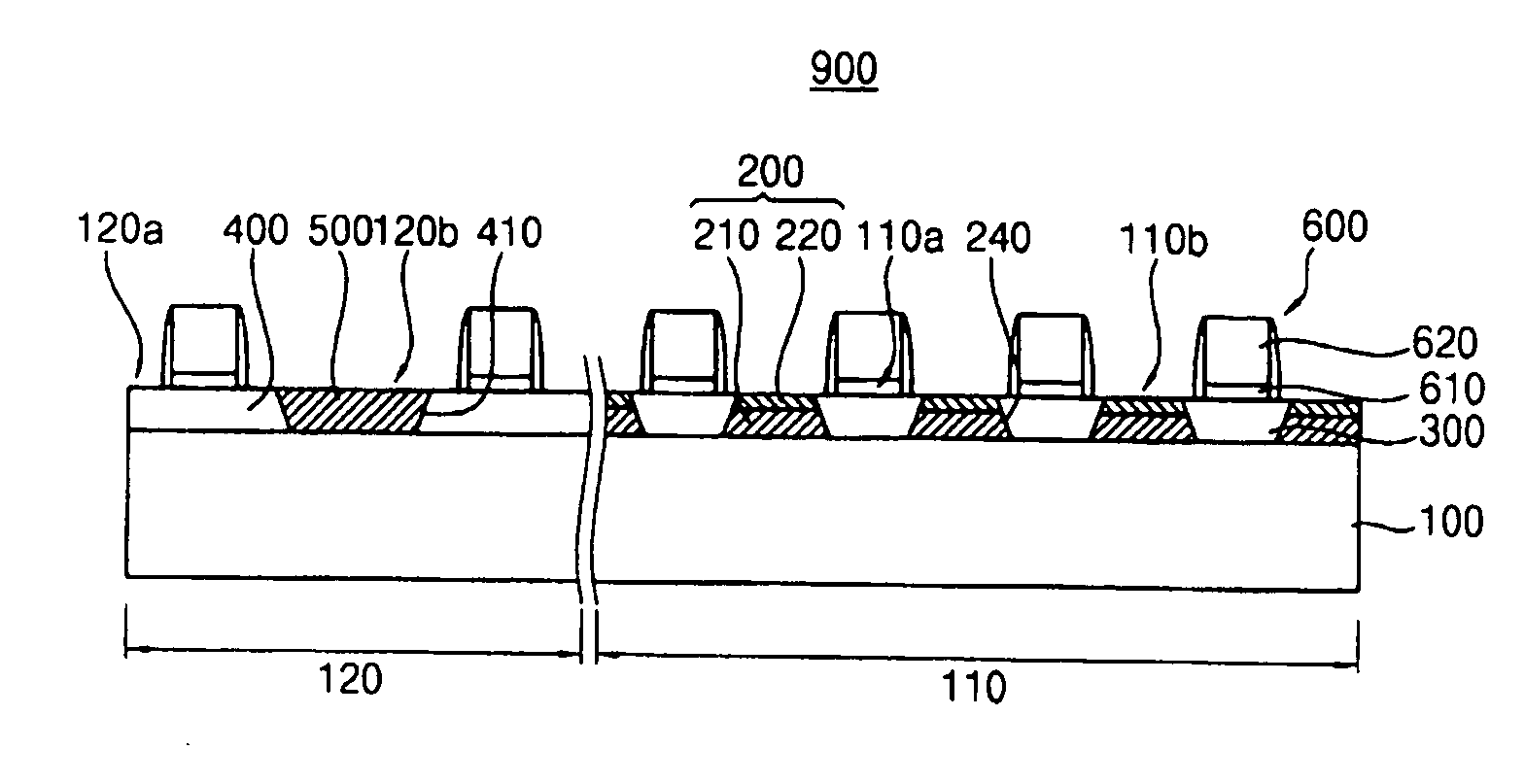

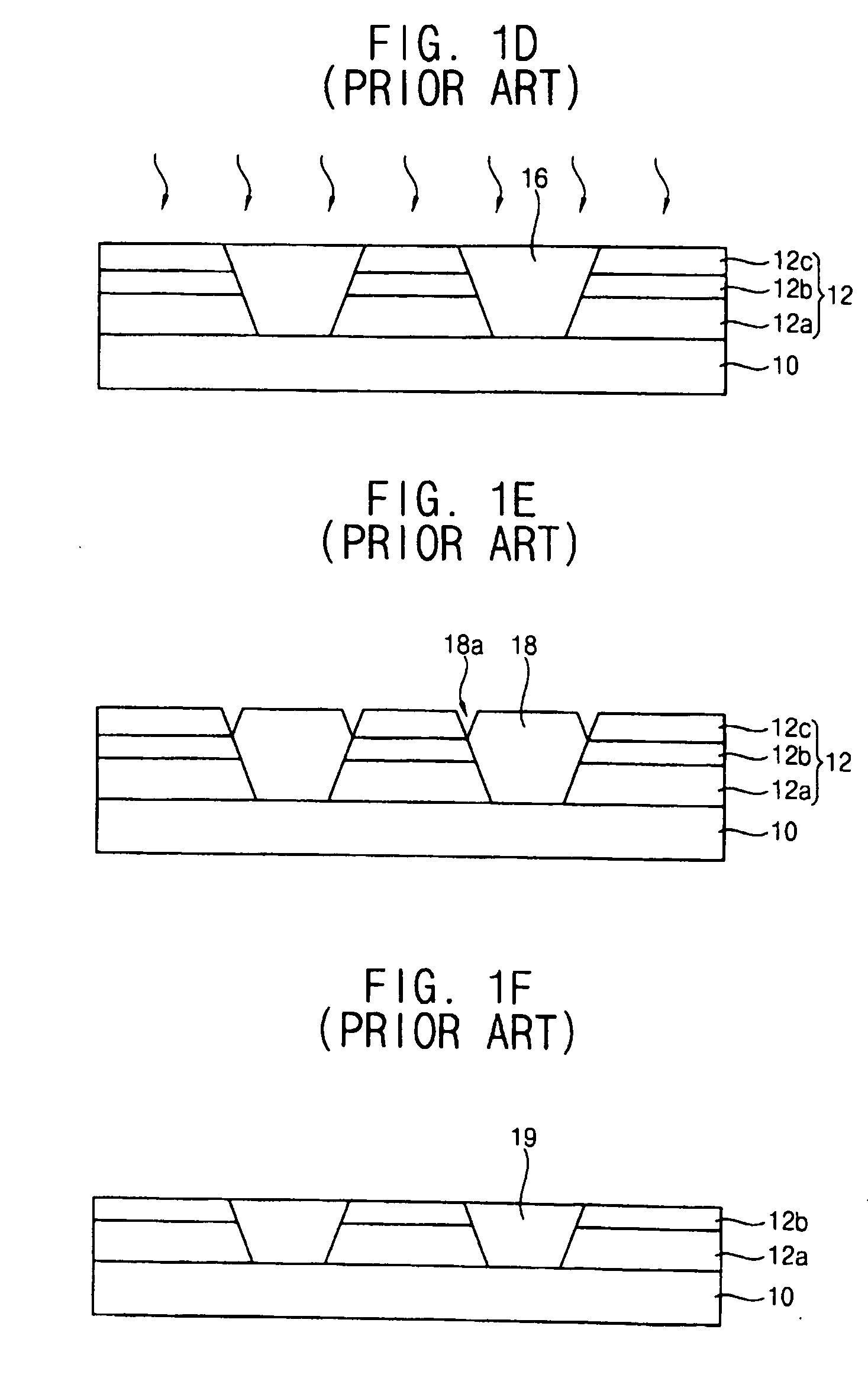

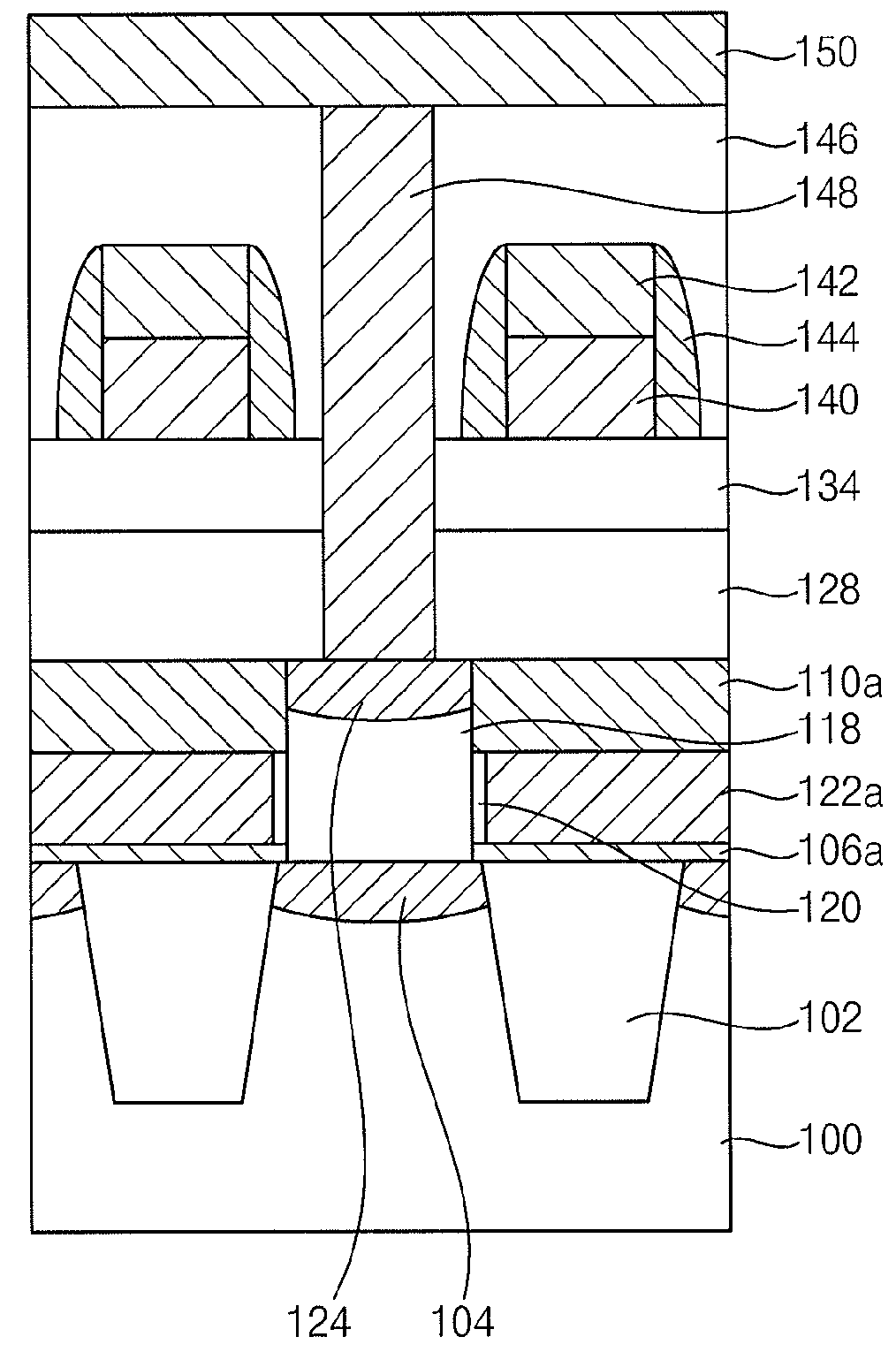

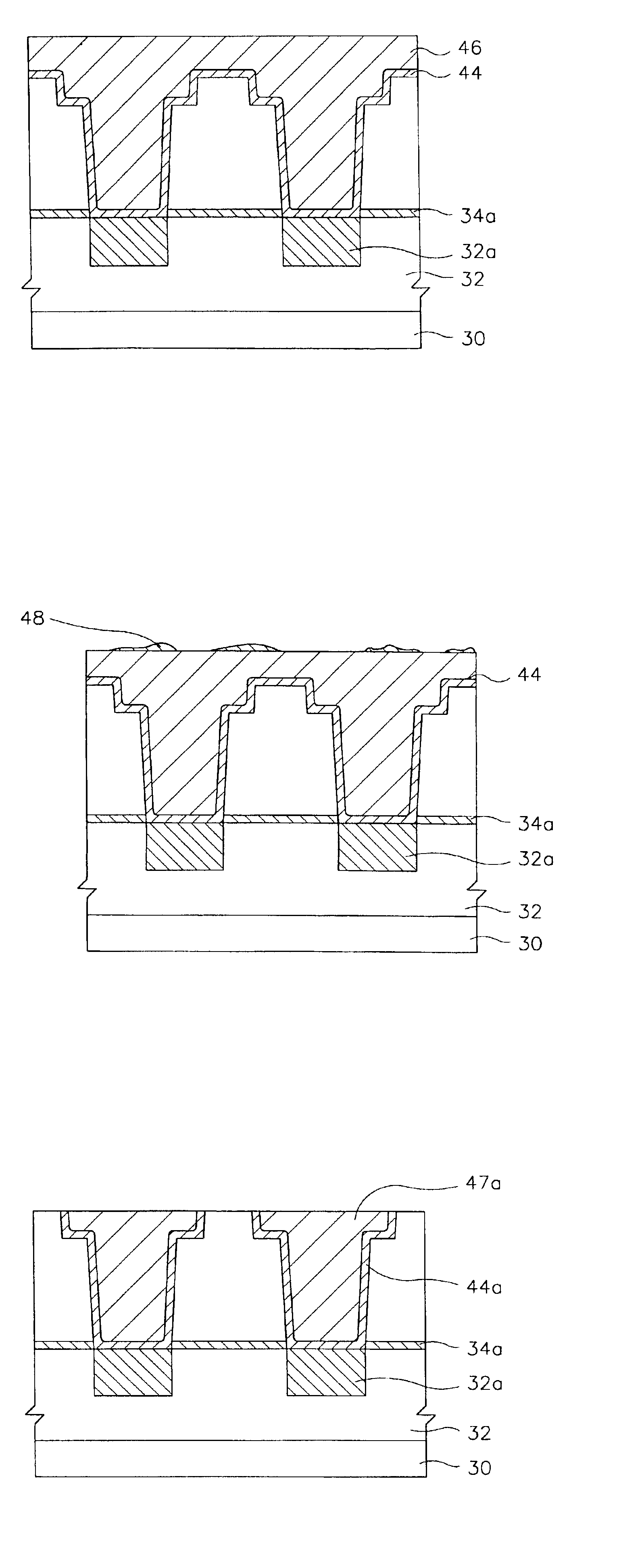

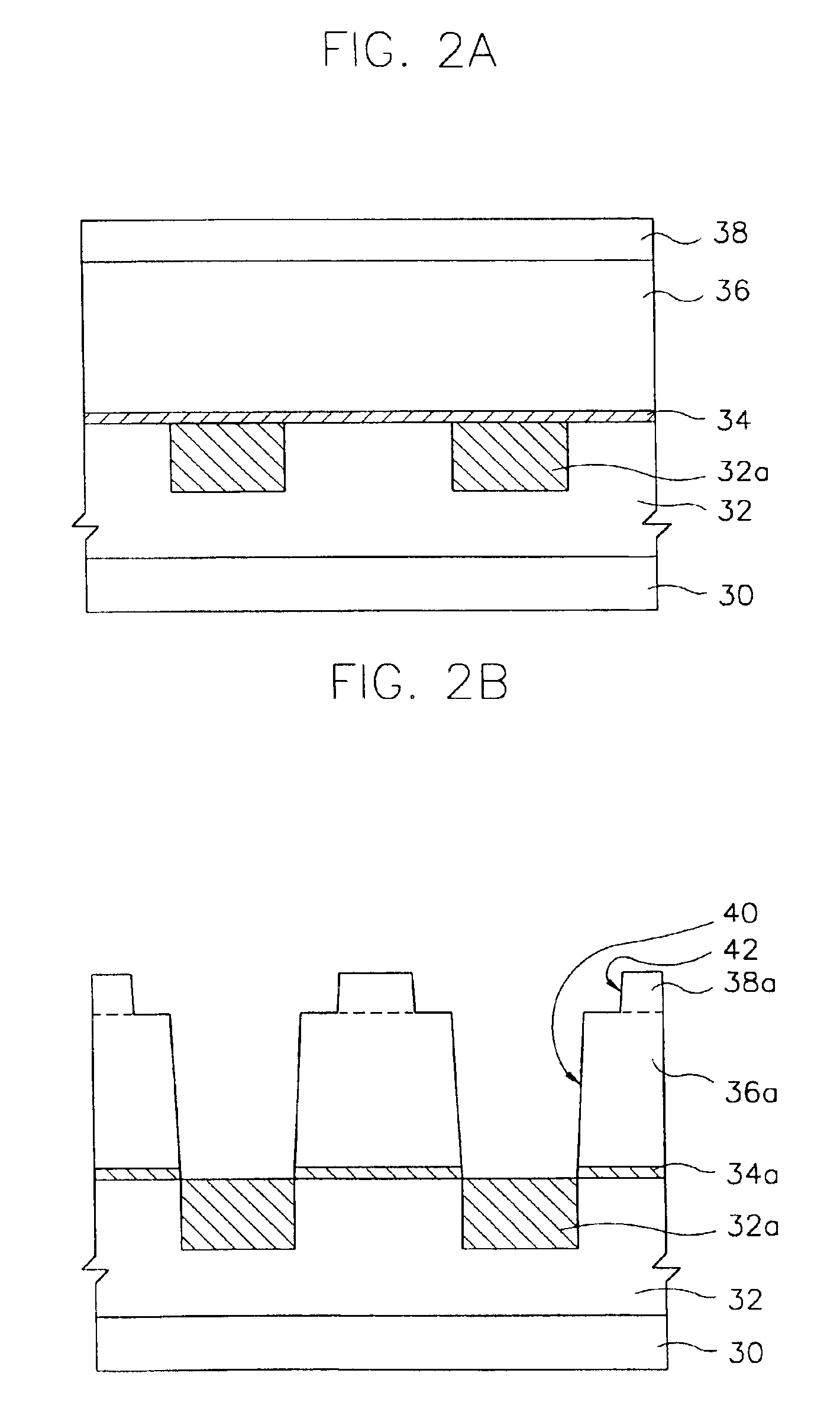

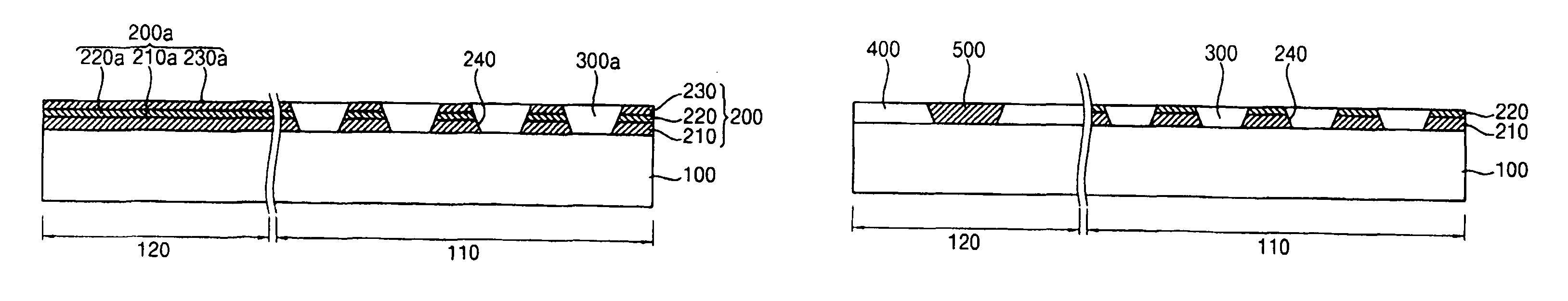

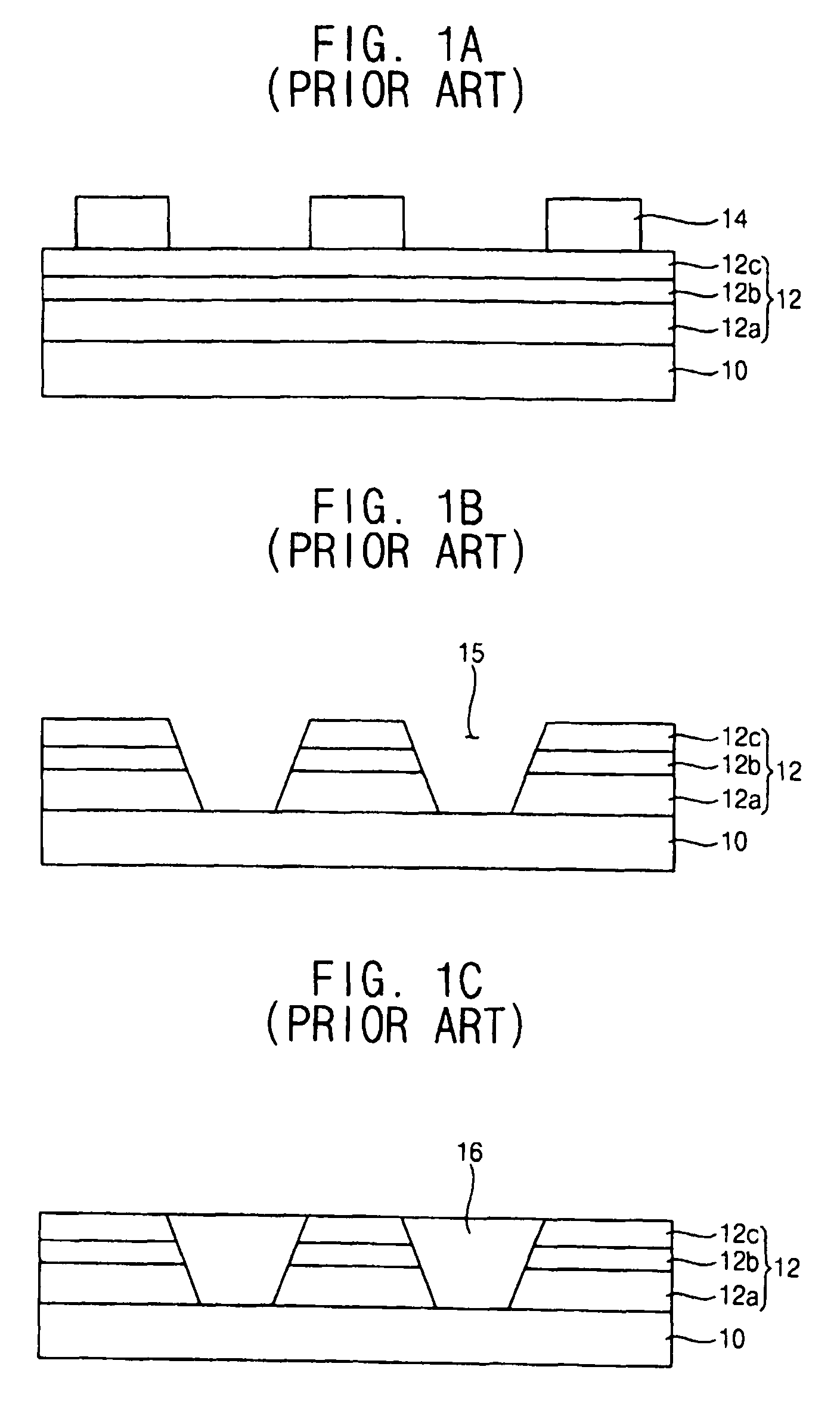

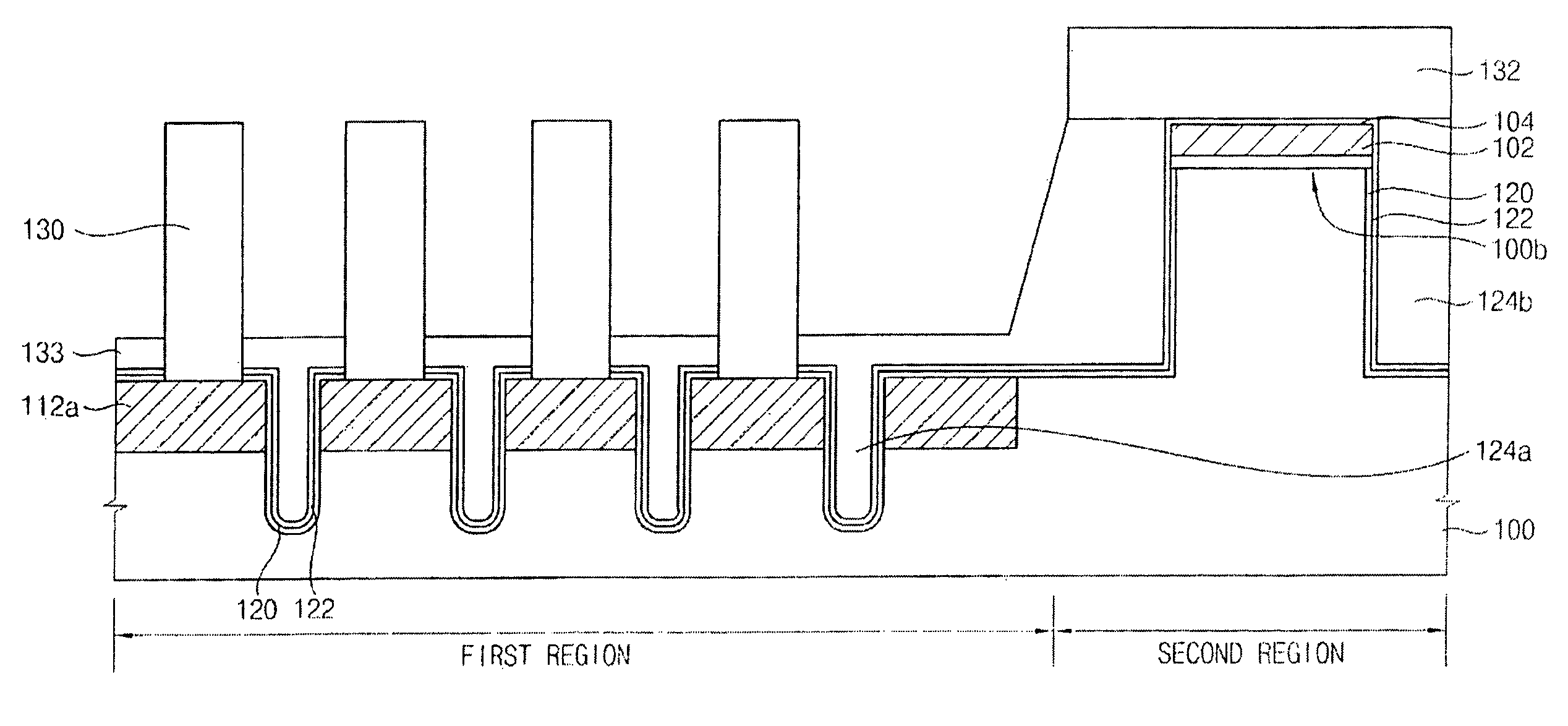

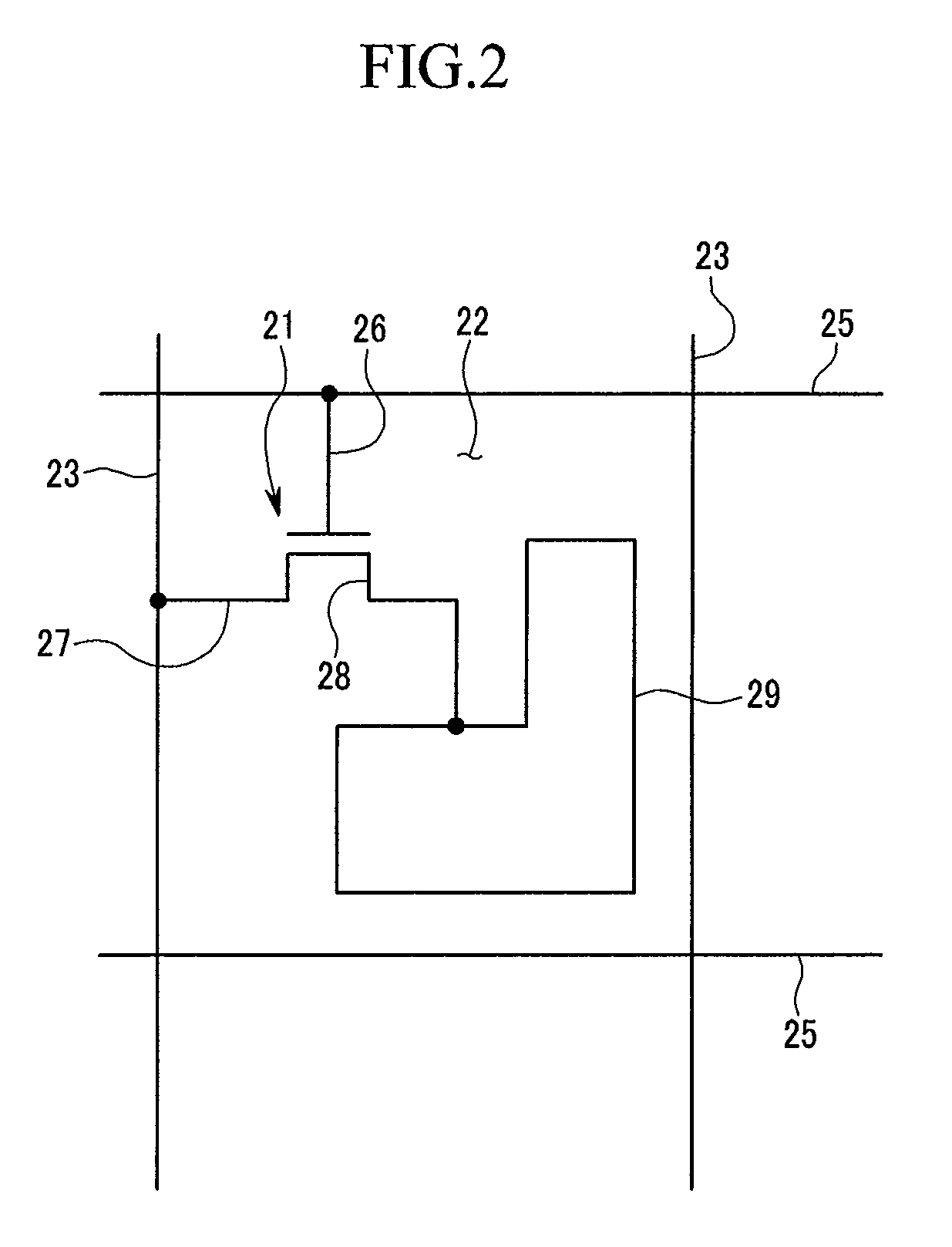

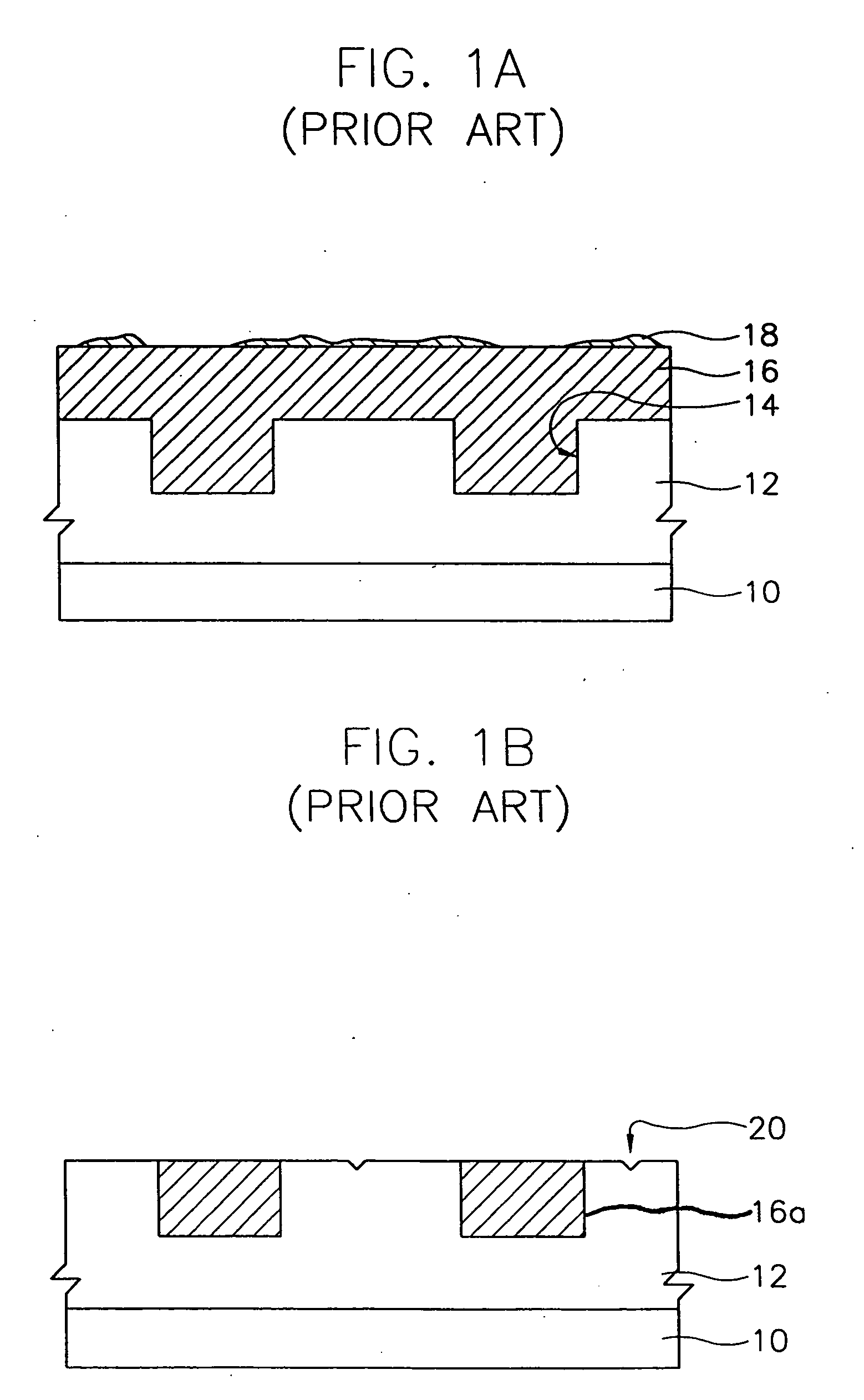

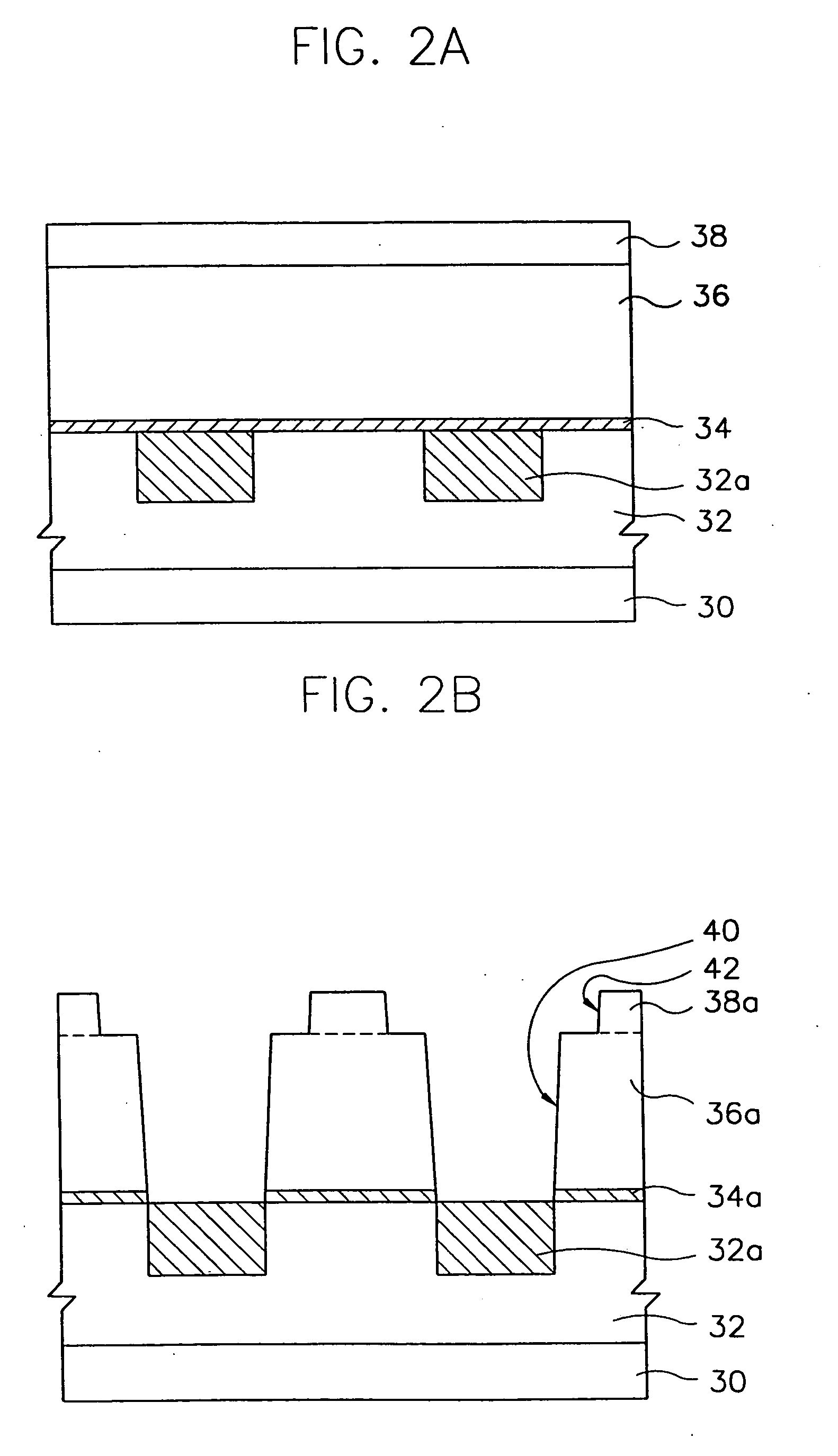

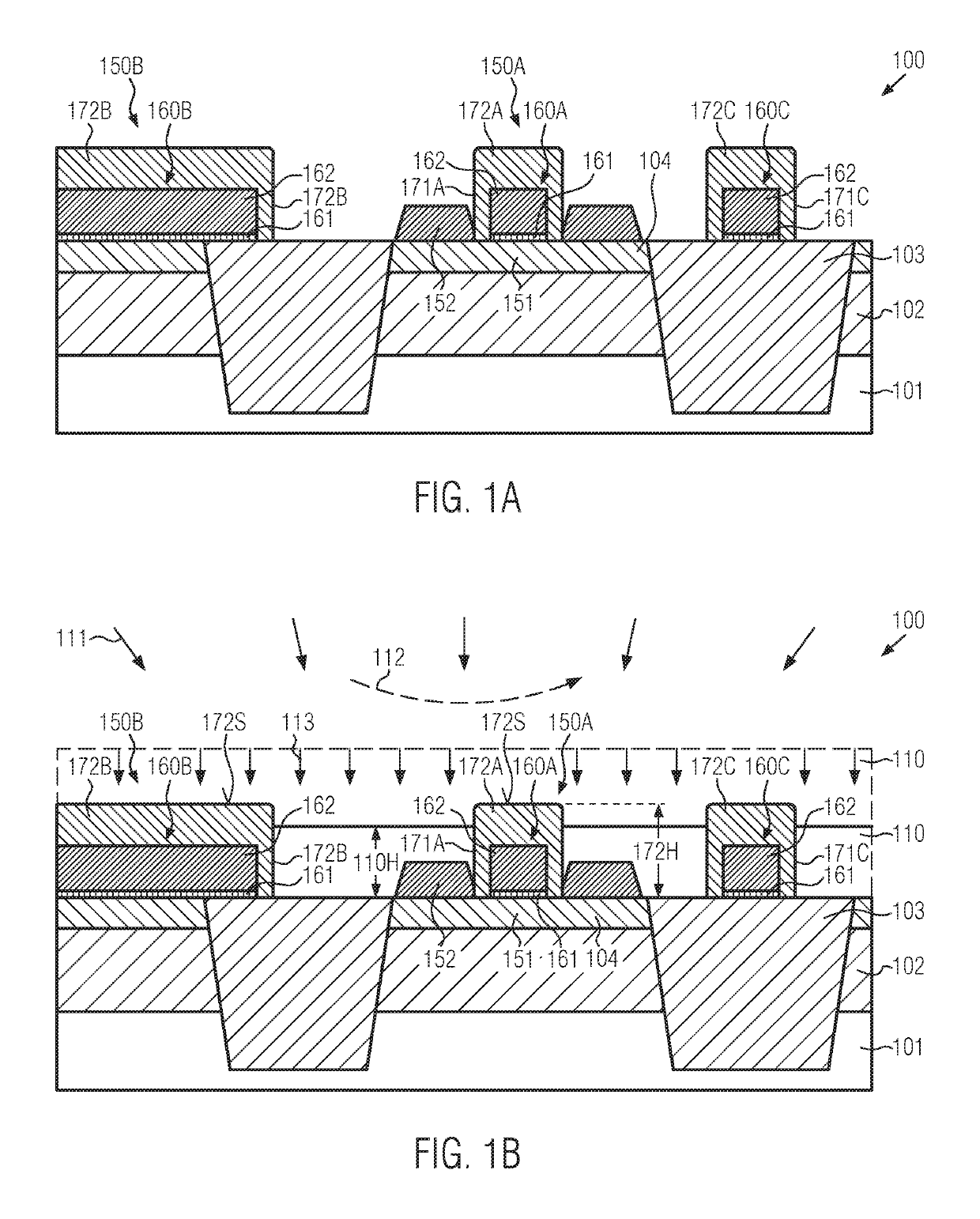

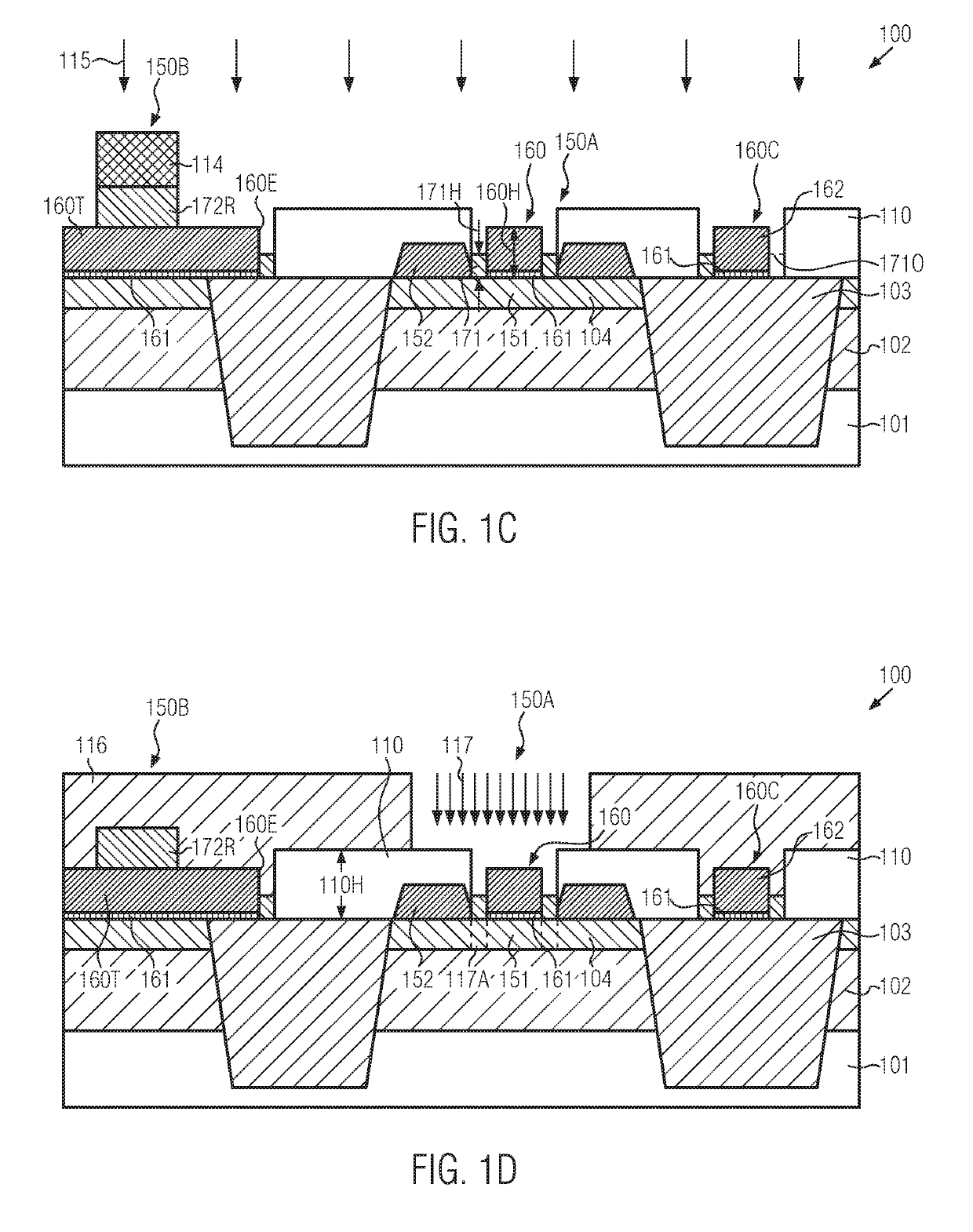

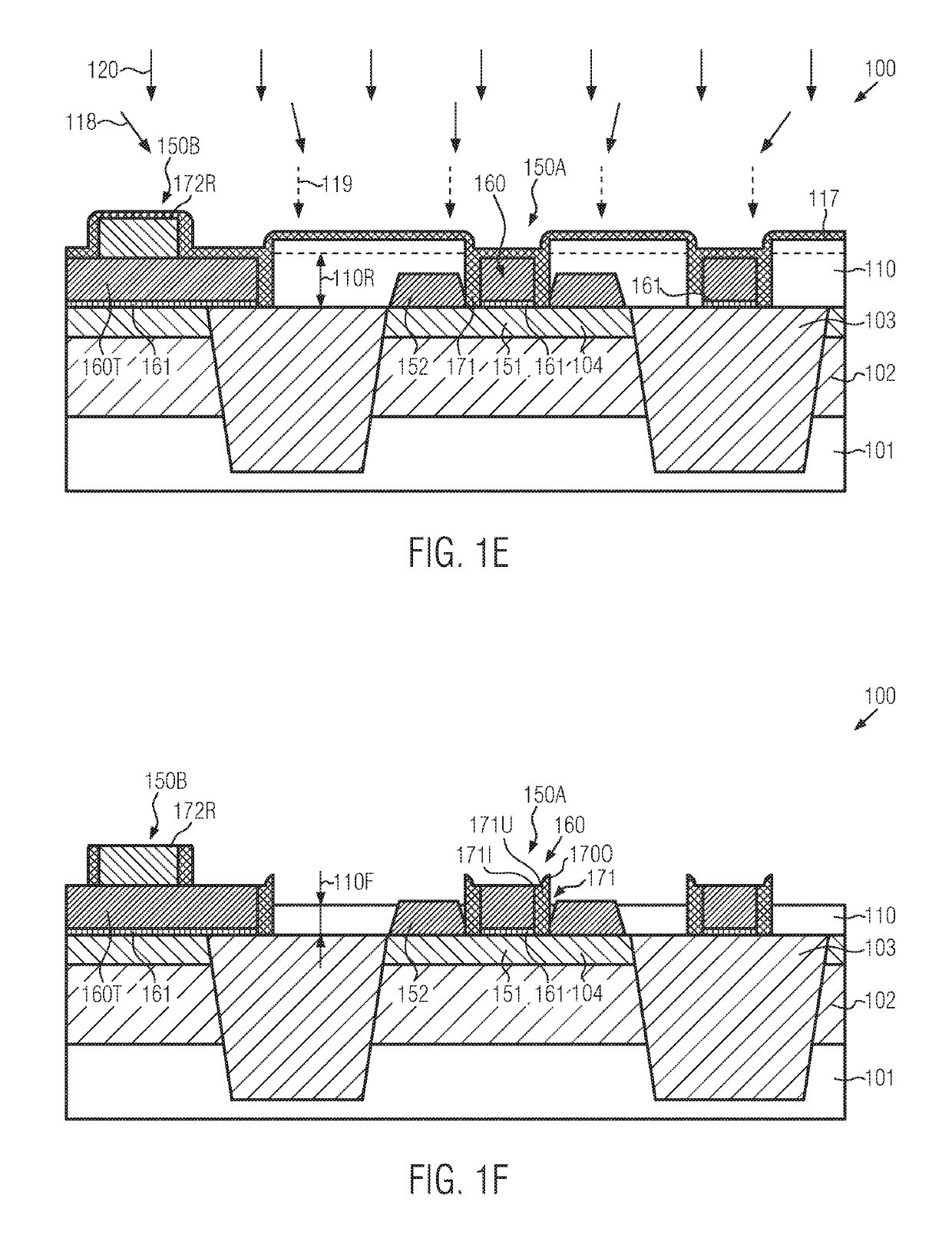

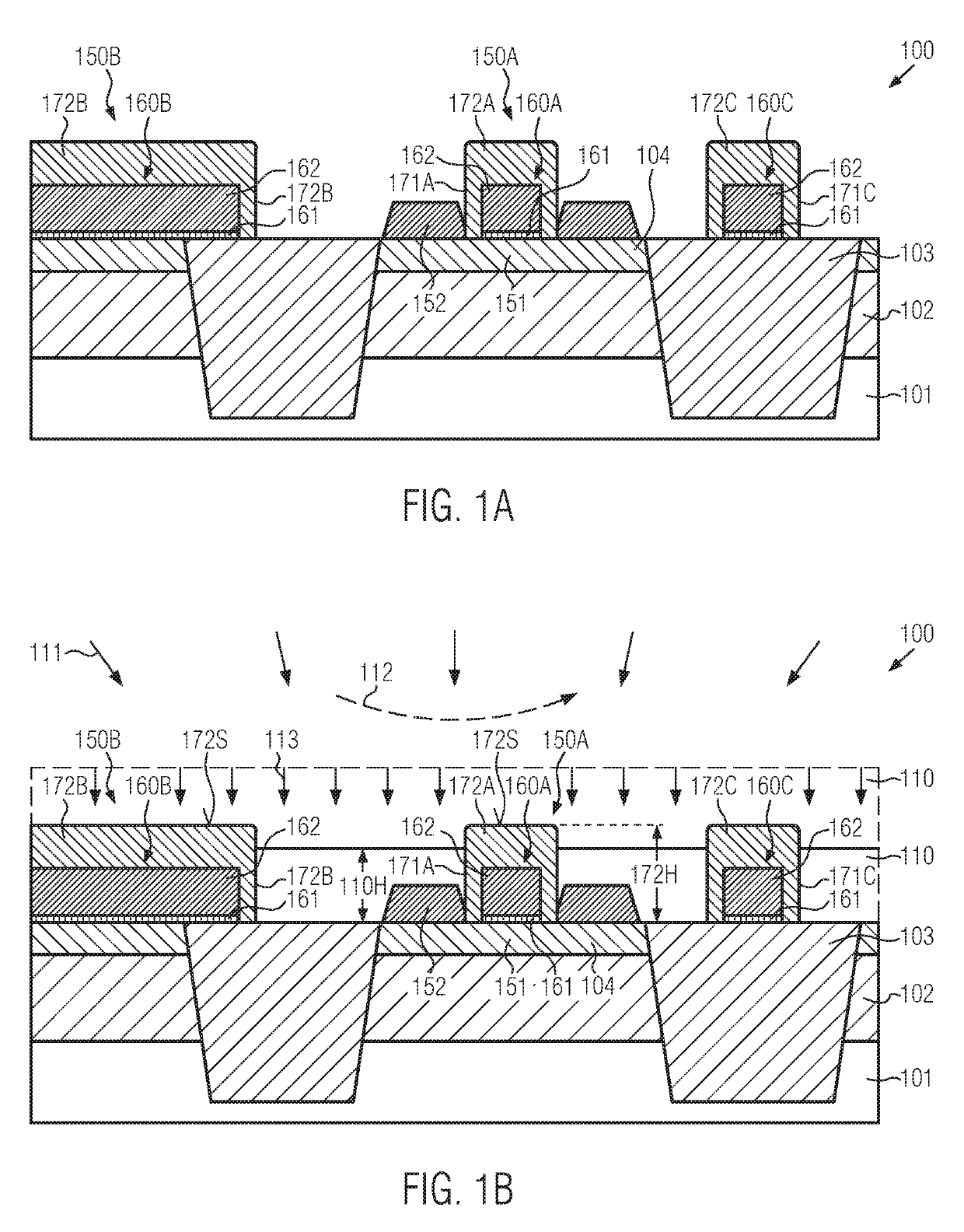

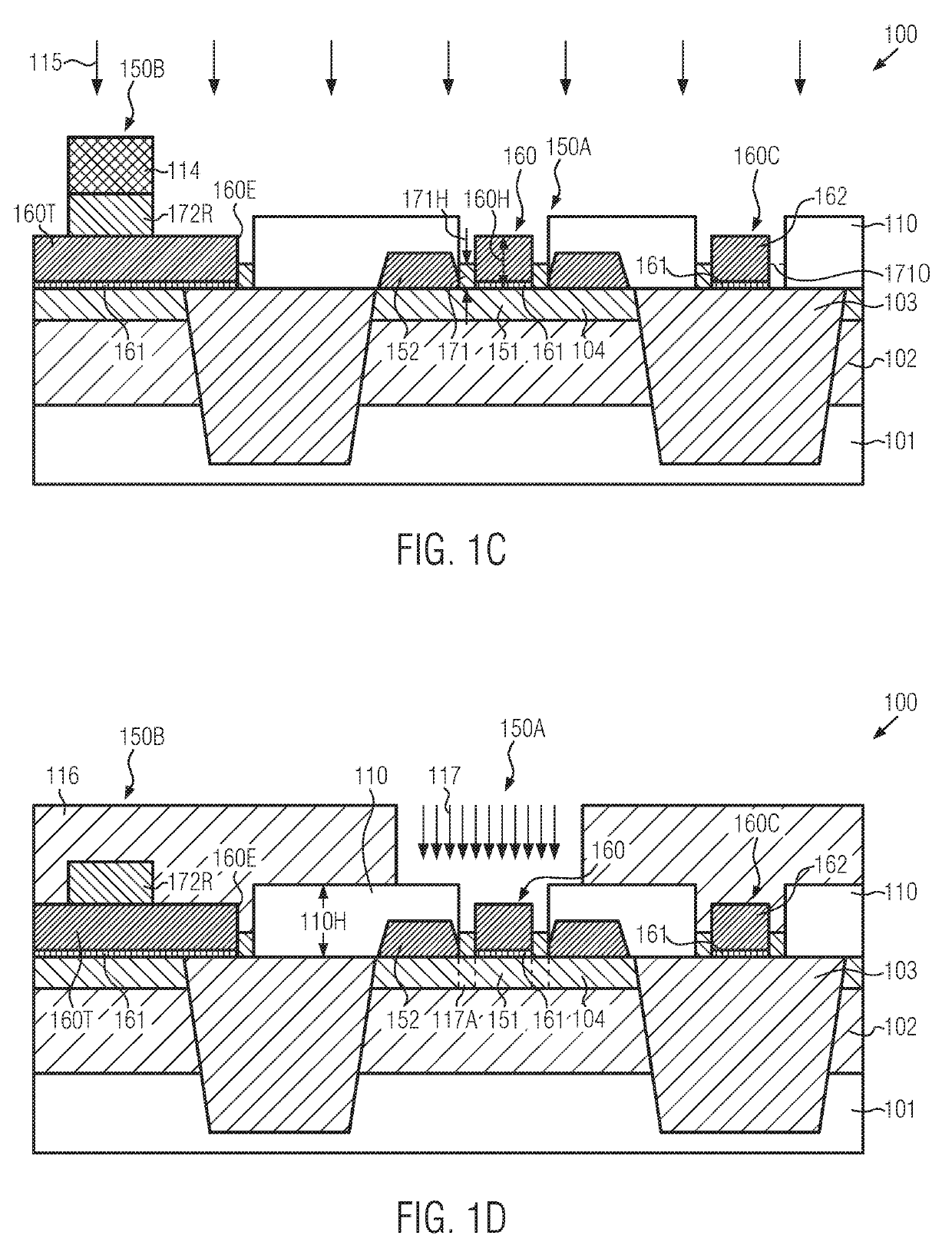

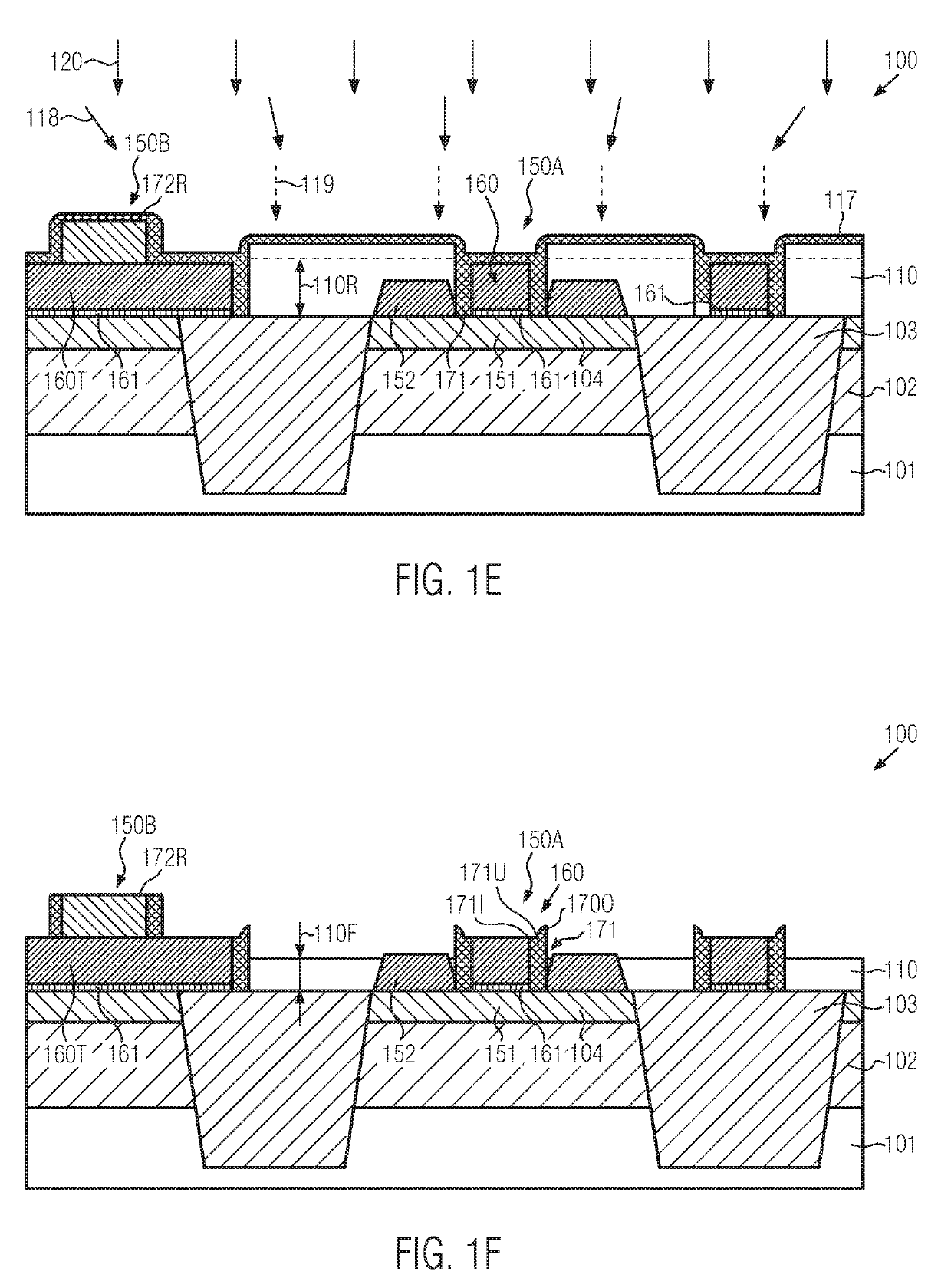

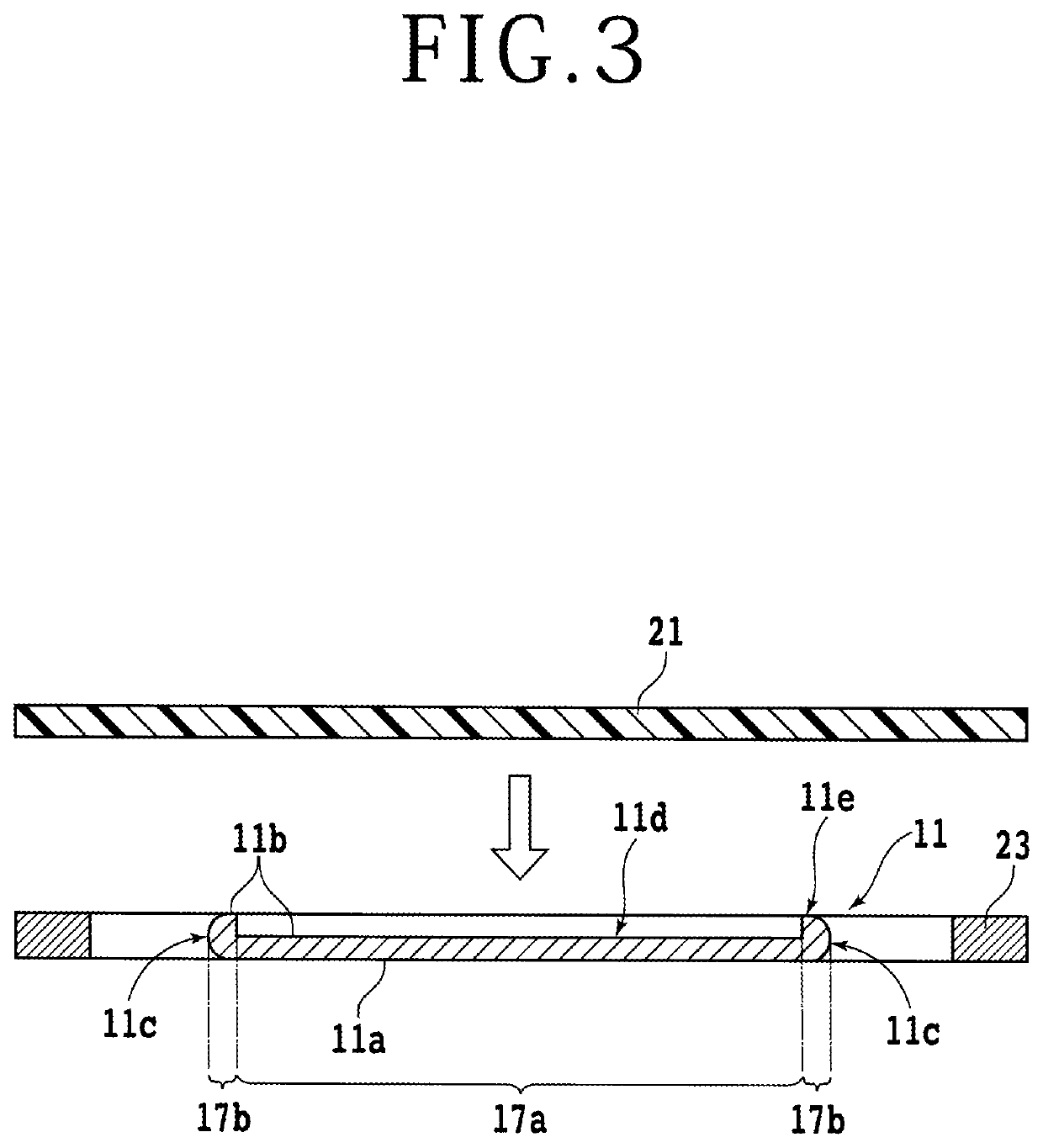

Method of manufacturing a semiconductor device

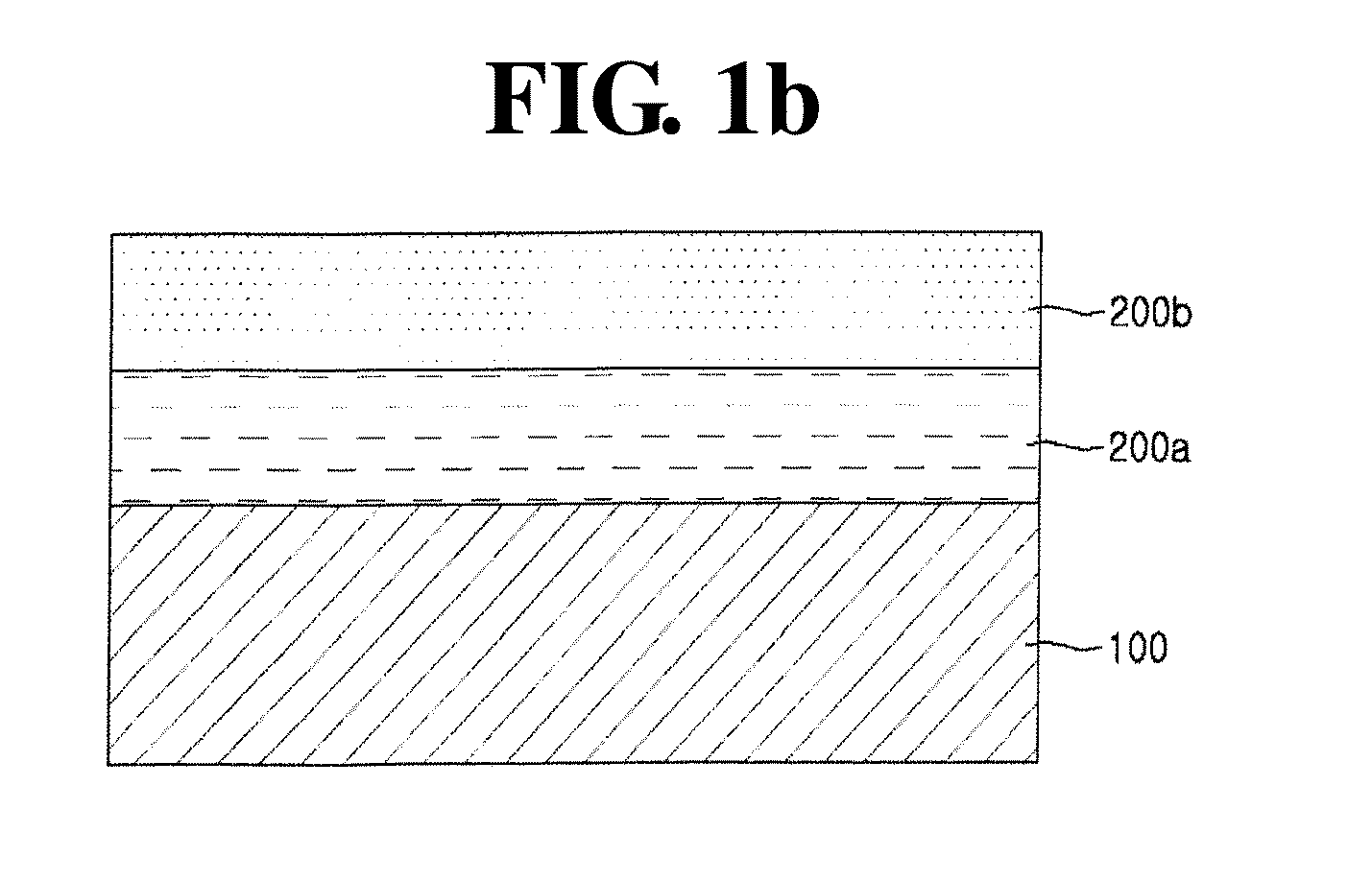

ActiveUS20090155979A1Reduce processing failureProcess can be minimizedSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerLattice defects

In a semiconductor device and a method of manufacturing the same, a first insulation layer is removed from a cell area of a substrate and a first active pattern is formed on the first area by a laser-induced epitaxial growth (LEG) process. Residuals of the first insulation layer are passively formed into a first device isolation pattern on the first area. The first insulation layer is removed from the second area of the substrate and a semiconductor layer is formed on the second area of the substrate by a SEG process. The semiconductor layer on the second area is patterned into a second active pattern including a recessed portion and a second insulation pattern in the recessed portion is formed into a second device isolation pattern on the second area. Accordingly, grain defects in the LEG process and lattice defects in the SEG process are mitigated or eliminated.

Owner:SAMSUNG ELECTRONICS CO LTD

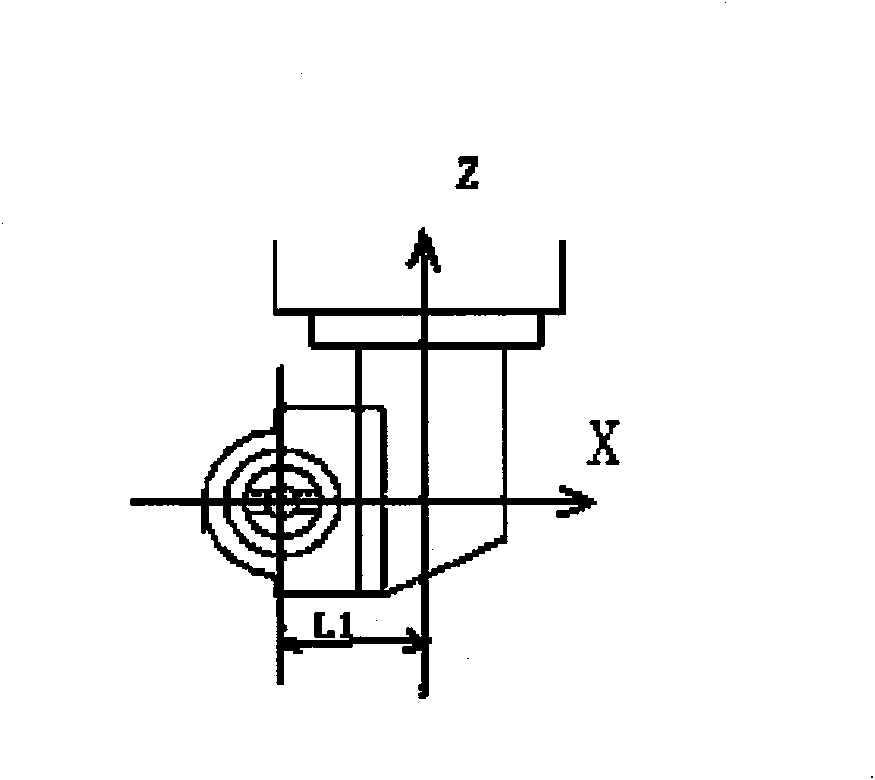

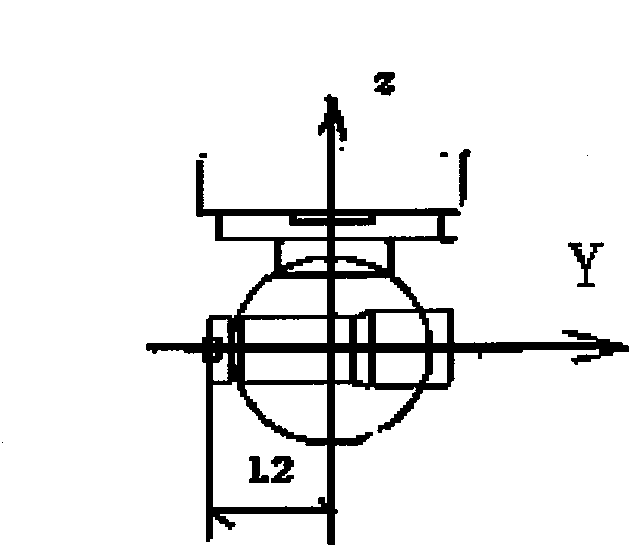

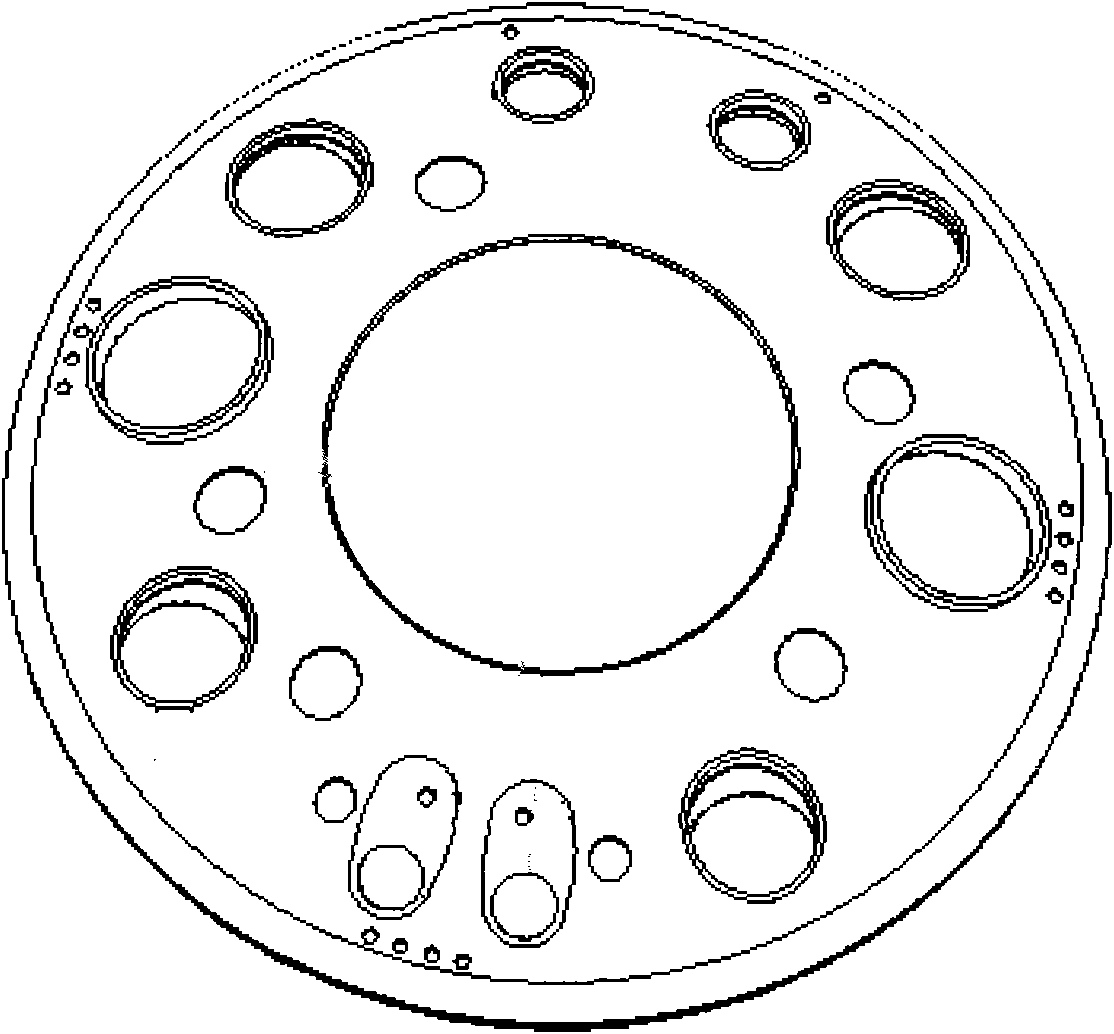

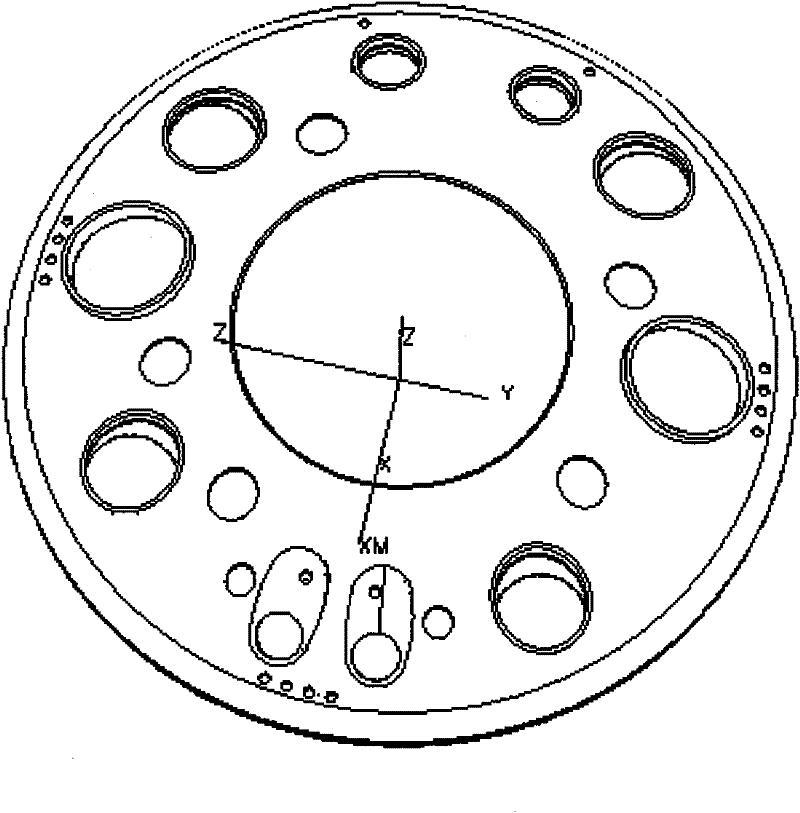

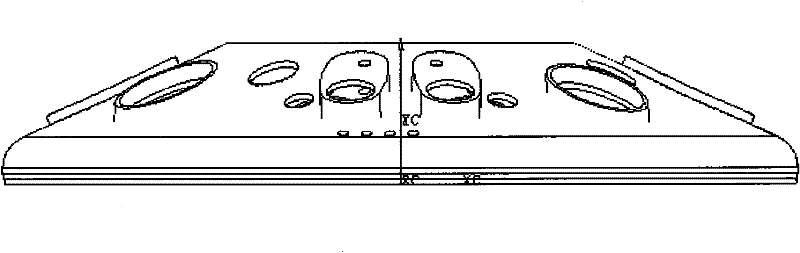

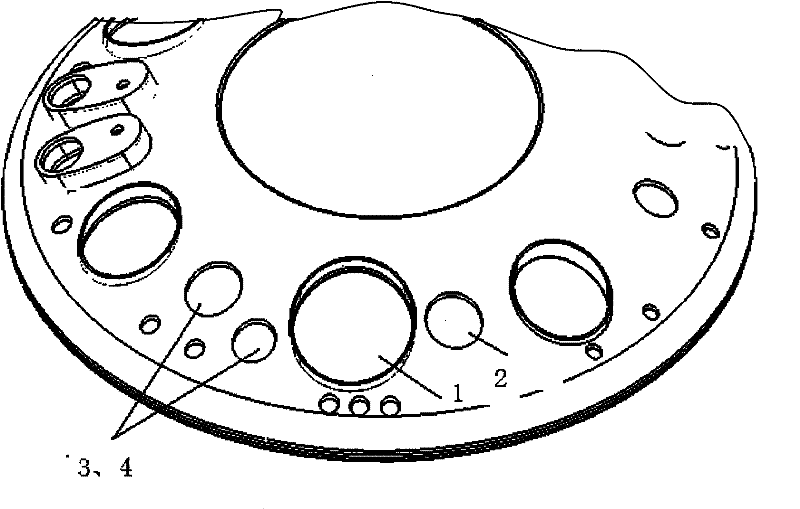

Method for machining spatial hole by using large ellipsoid on numerical control boring-milling machine

ActiveCN101920453ASolve complex computing problemsReduce processing failureOther manufacturing equipments/toolsNumerical controlNumerical controlEngineering

The invention discloses a method for machining spatial holes by using a large ellipsoid on a numerical control boring-milling machine. The method comprises the following steps of: determining the range and the clamping datum of a machined hole by applying a software analysis workpiece; compiling a numerical control machining program of the spatial hole; checking the numerical control machining program by applying simulation software; clamping and correcting according to a numerical control requirement and machining the spatial hole with an allowance; detecting the spatial position precision of the machined hole, adjusting the numerical control machining program according to a detection result and then machining the spatial hole to a required precision; and repeatedly clamping and machining a spatial hole in another range until holes on the workpiece are all machined. The invention has the advantages that multiple groups of spatial holes on the large ellipsoid can be machined by using a numerical control boring-milling machine, thereby meeting the requirement on the position precision; the maximum utilization ratio of a process is realized without being limited by the system of the numerical control boring-milling machine, and the compiling of the machining program can be finished only by updating part models and mathematical parameters; and the process is safe and reliable and has high efficiency.

Owner:CHINA FIRST HEAVY IND +1

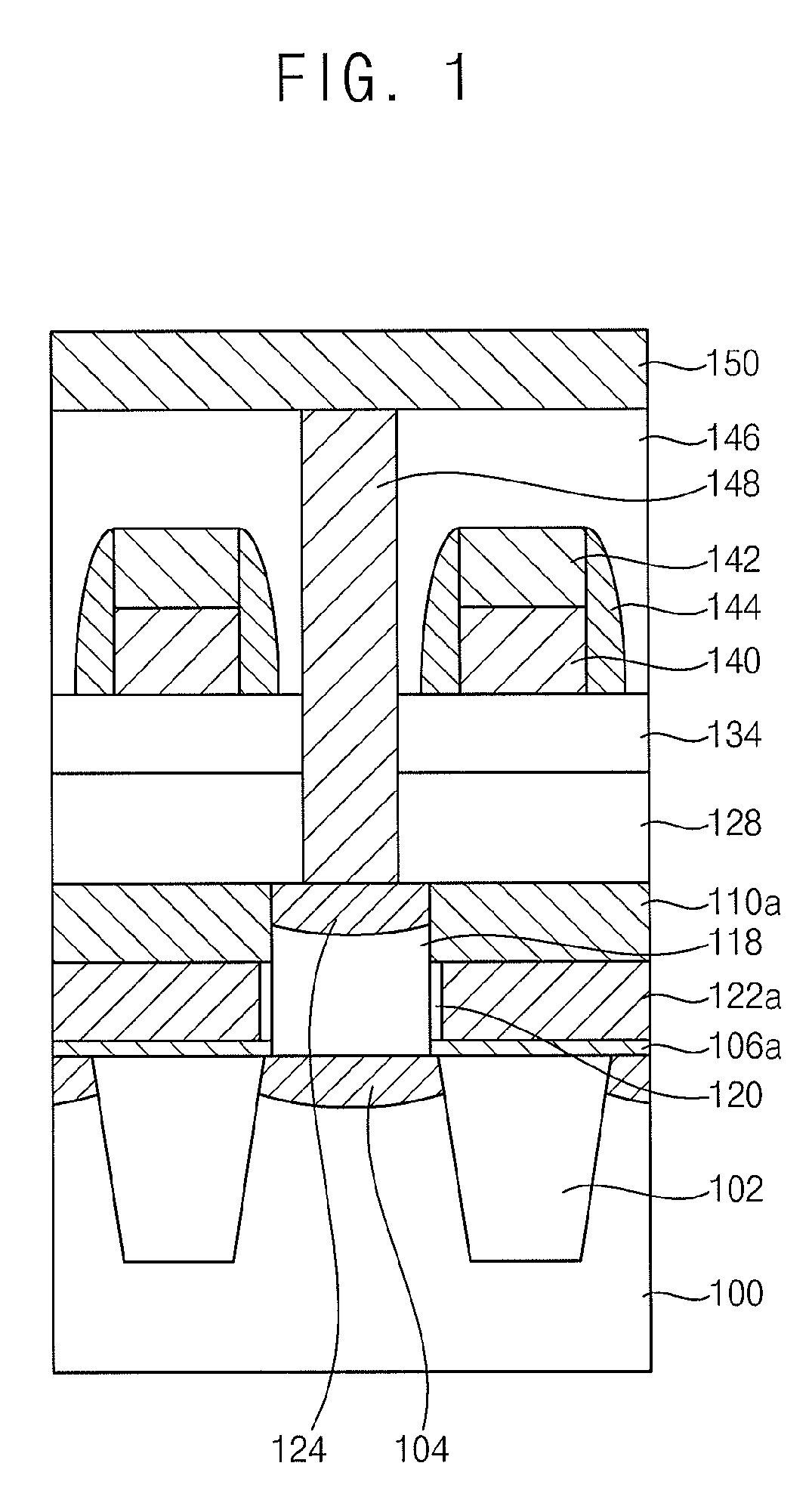

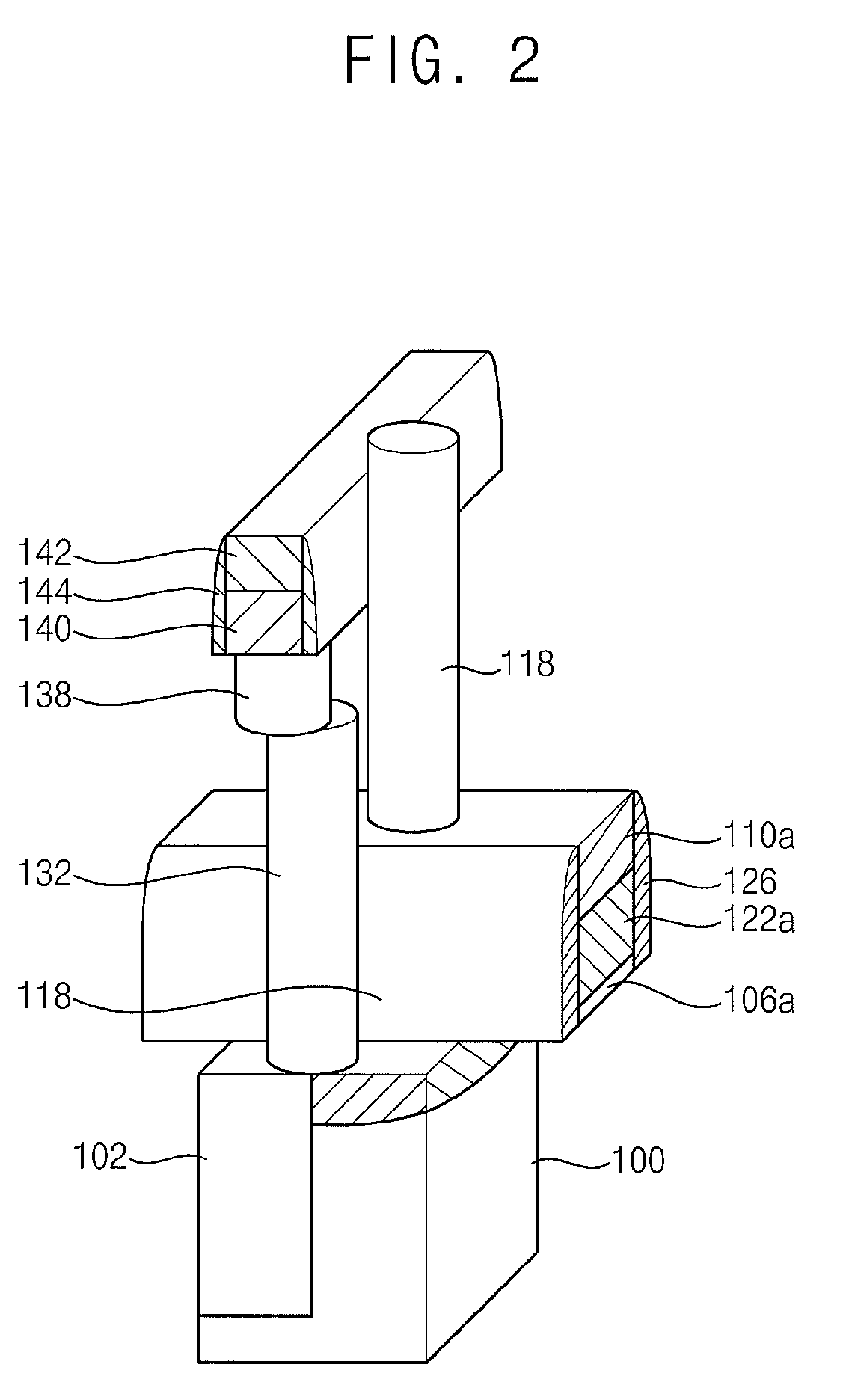

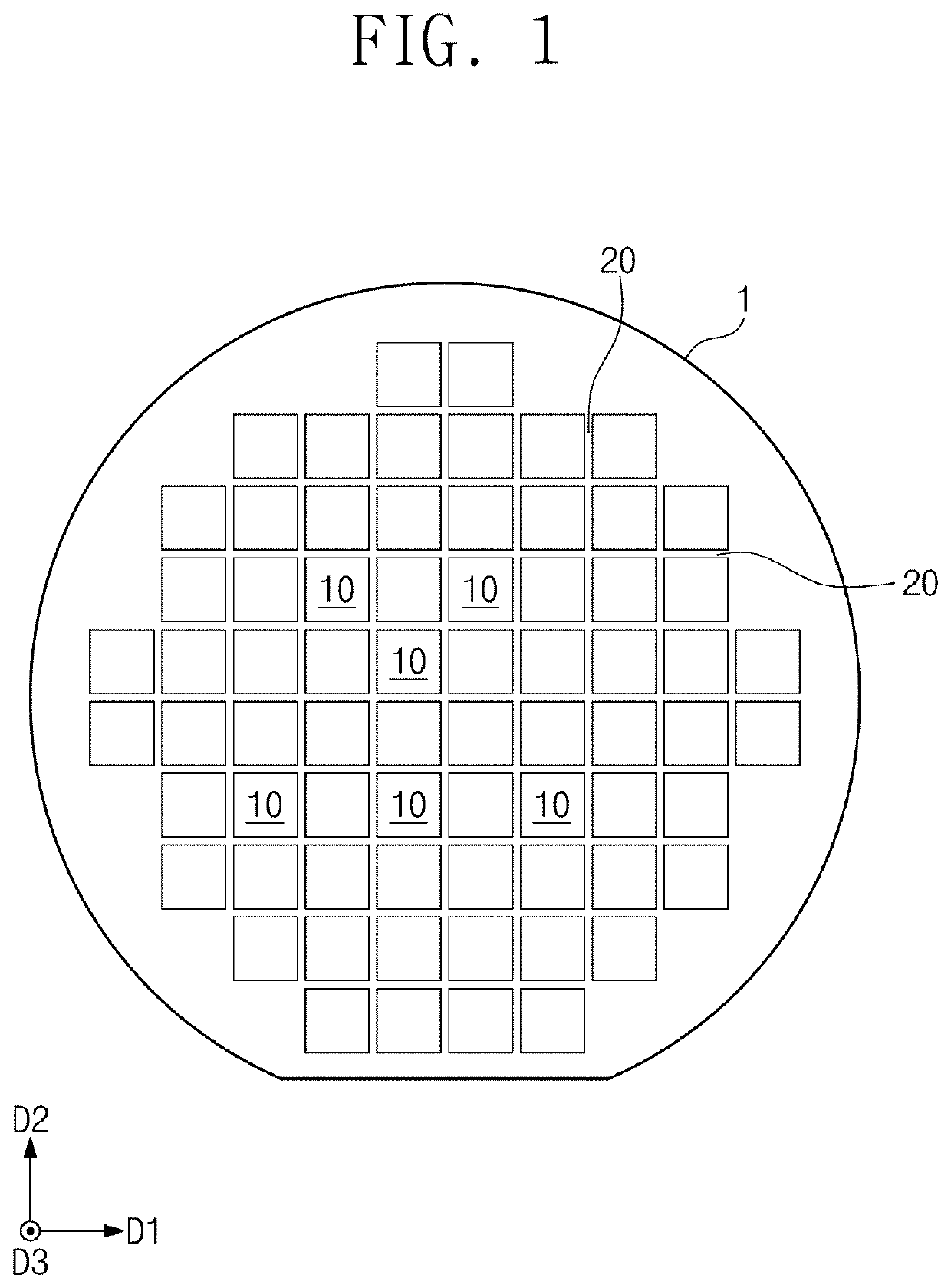

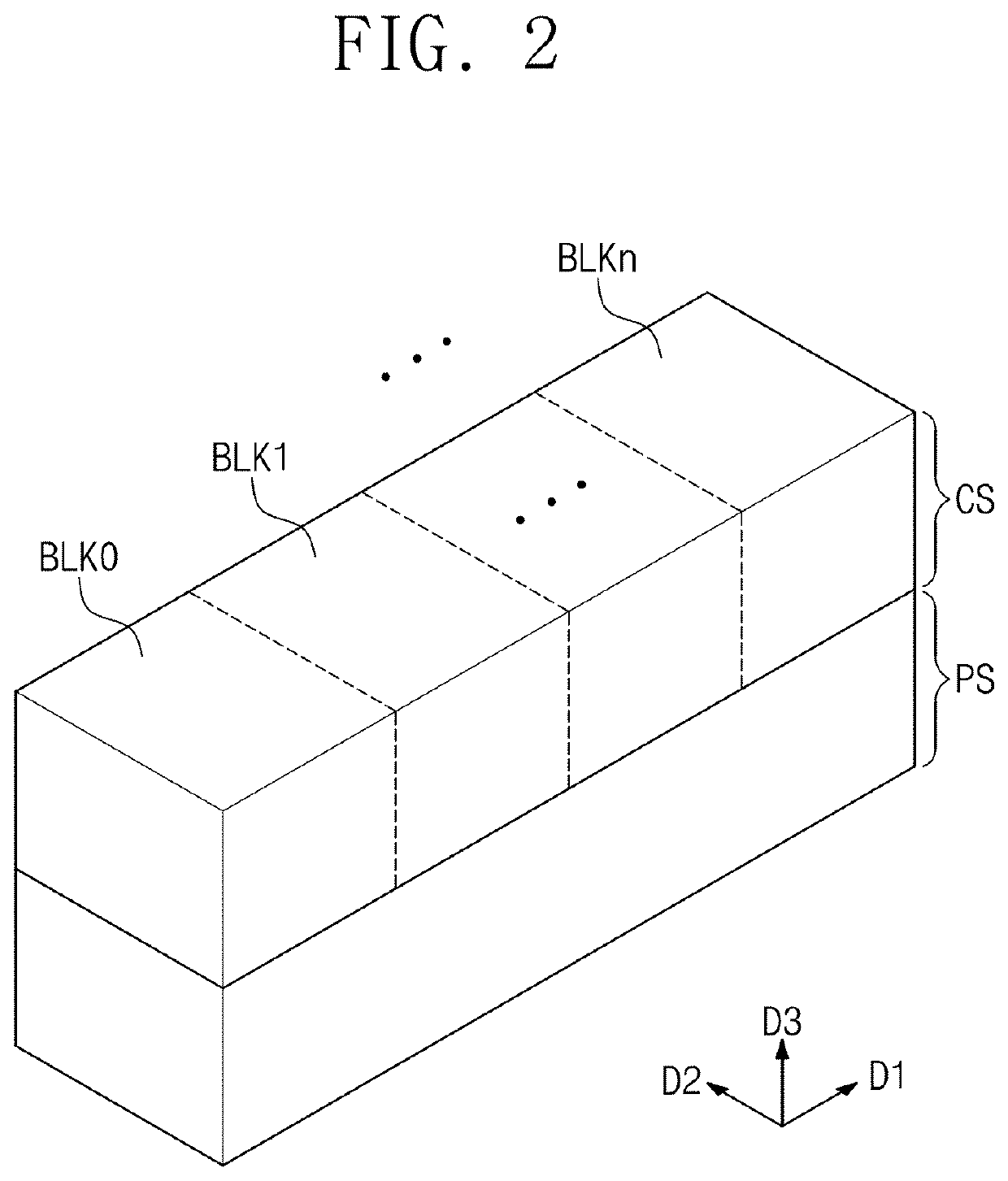

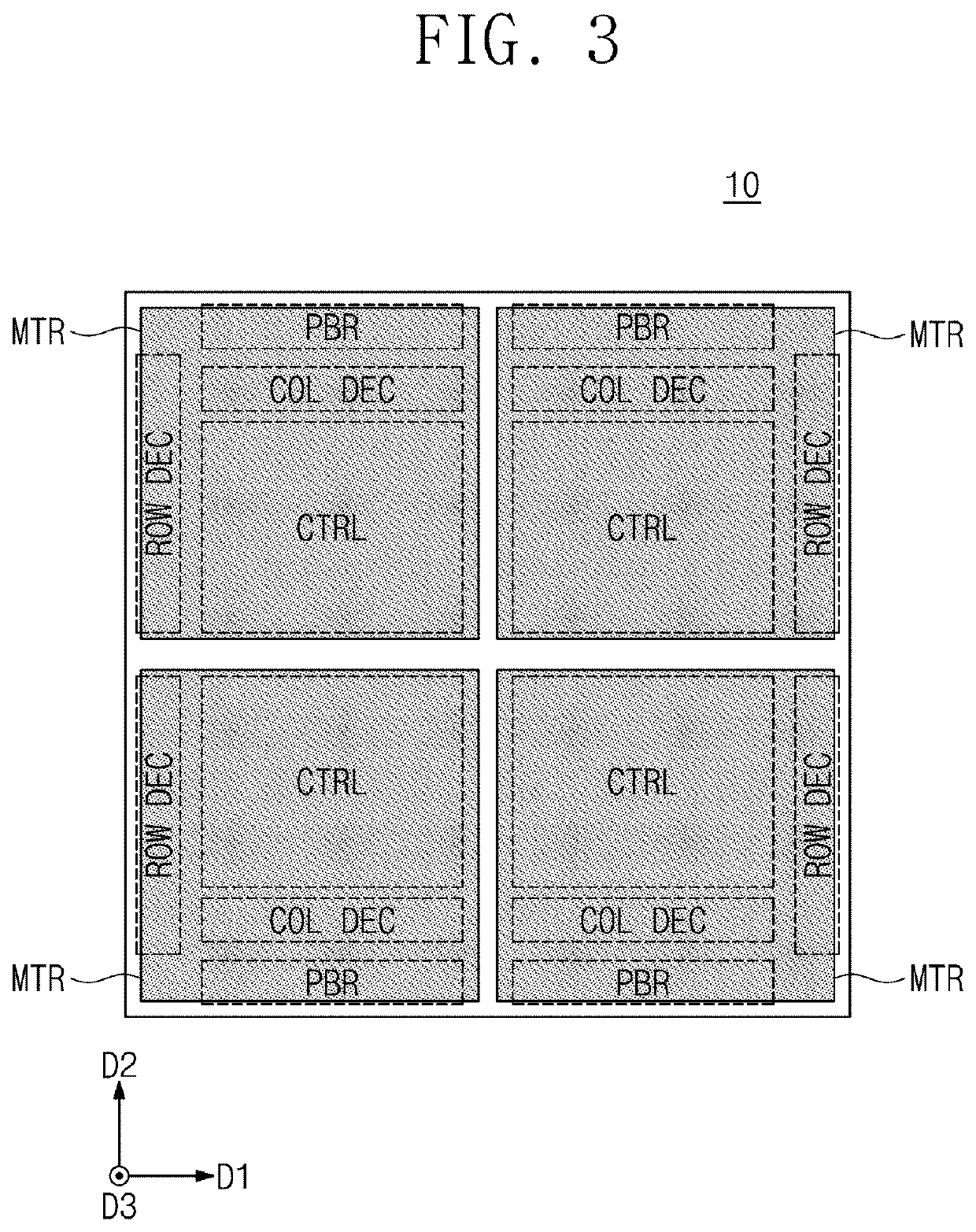

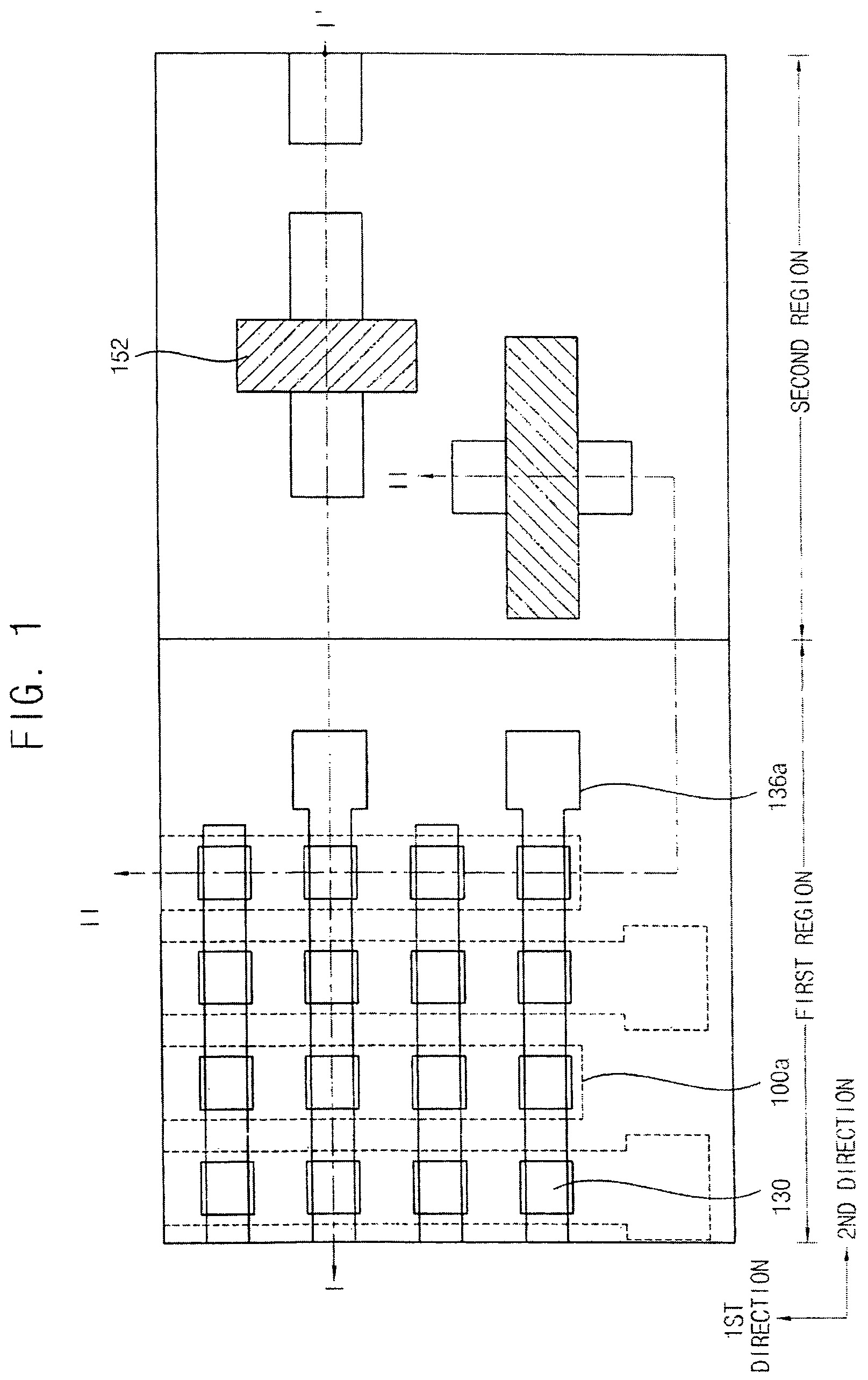

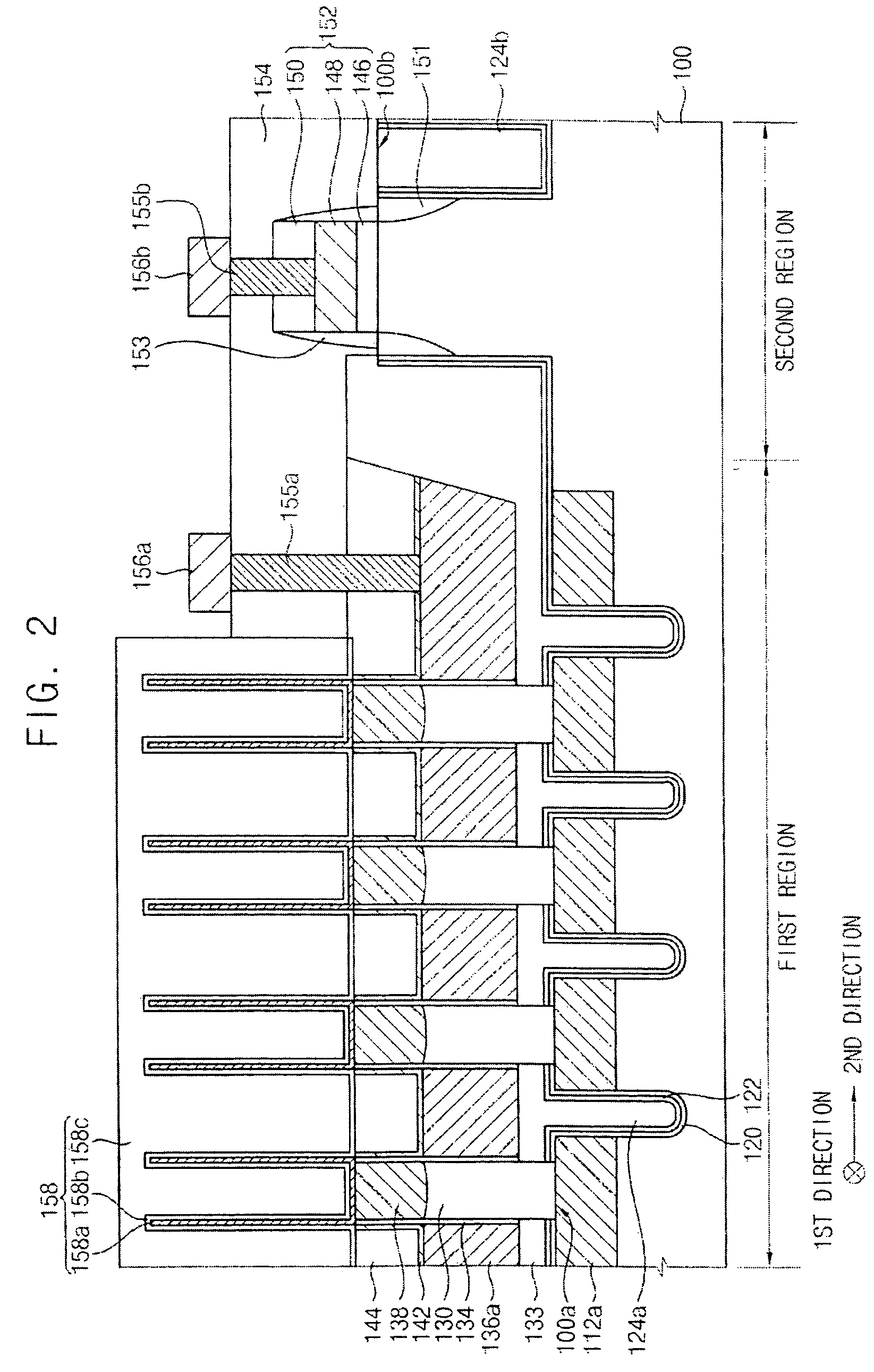

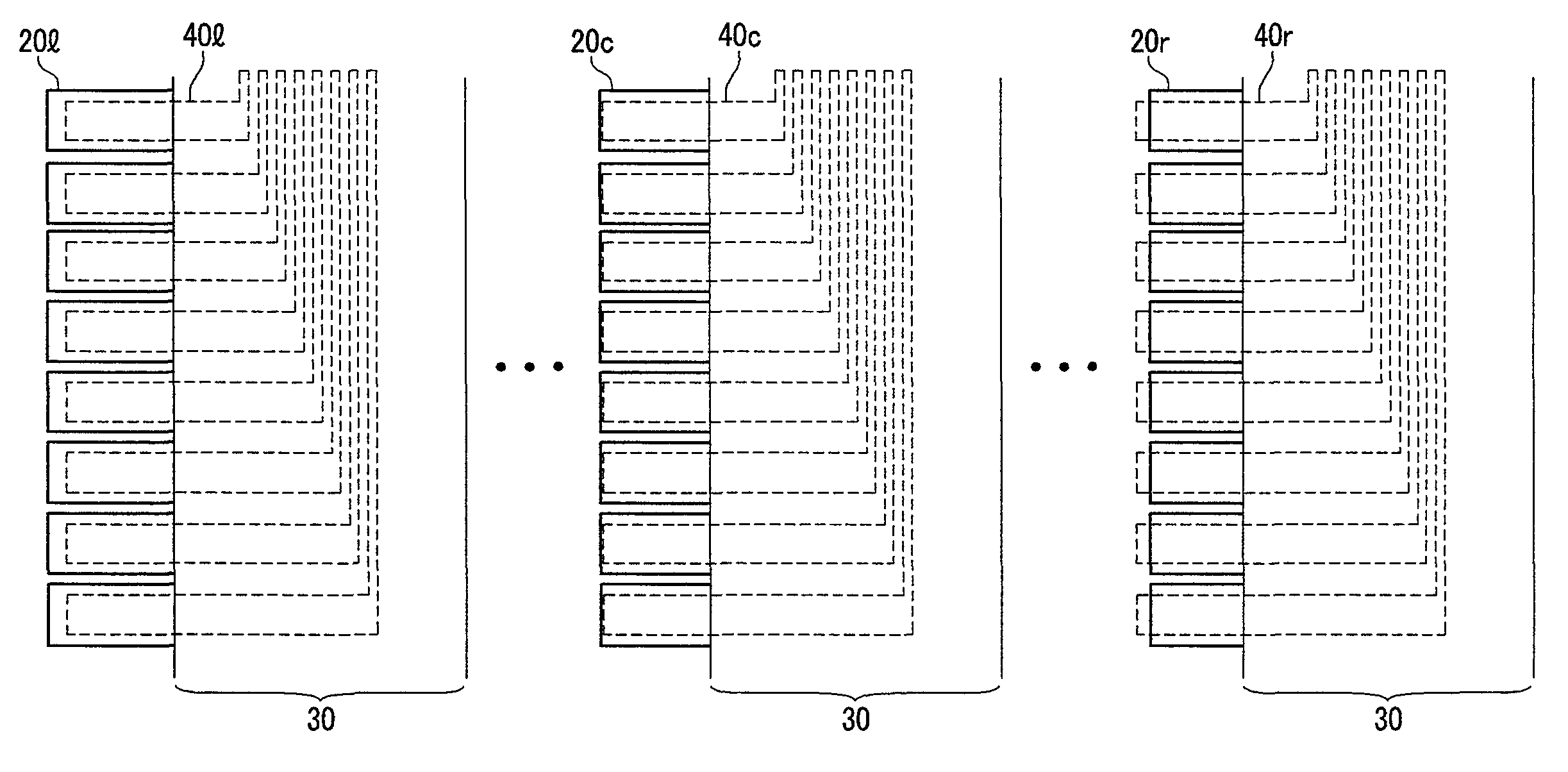

Vertical-type semiconductor device

ActiveUS20090302377A1Improve performanceHighly integratedTransistorSolid-state devicesDevice materialEngineering

In a vertical-type semiconductor device, a method of manufacturing the same and a method of operating the same, the vertical-type semiconductor device includes a single-crystalline semiconductor pattern having a pillar shape provided on a substrate, a gate surrounding sidewalls of the single-crystalline semiconductor pattern and having an upper surface lower than an upper surface of the single-crystalline semiconductor pattern, a mask pattern formed on the upper surface of the gate, the mask pattern having an upper surface coplanar with the upper surface of the single-crystalline semiconductor pattern, a first impurity region in the substrate under the single-crystalline semiconductor pattern, and a second impurity region under the upper surface of the single-crystalline semiconductor pattern. The vertical-type pillar transistor formed in the single-crystalline semiconductor pattern may provide excellent electrical properties. The mask pattern is not provided on the upper surface of the single-crystalline semiconductor pattern in the second impurity region, to thereby reduce failures of processes.

Owner:SAMSUNG ELECTRONICS CO LTD

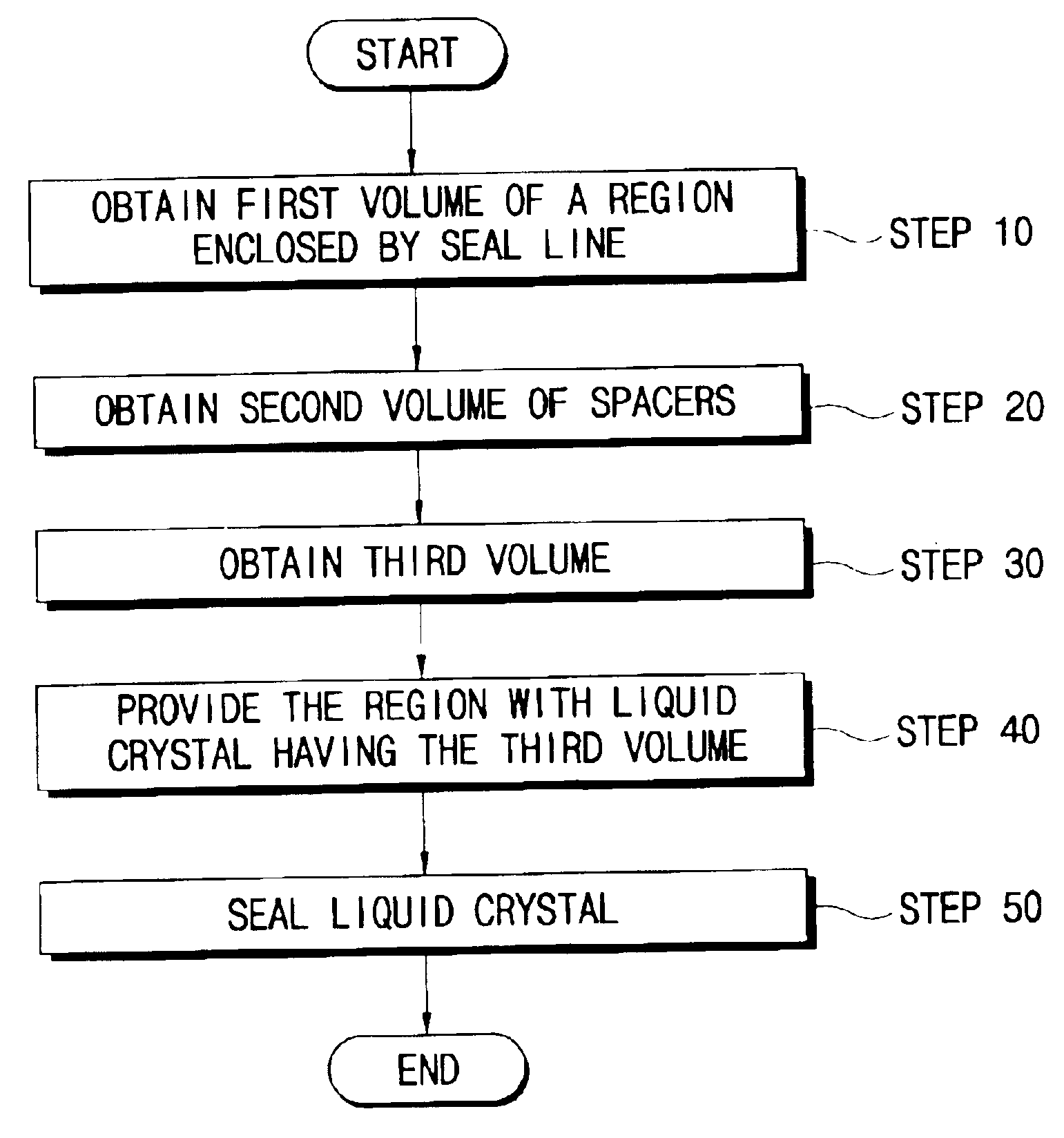

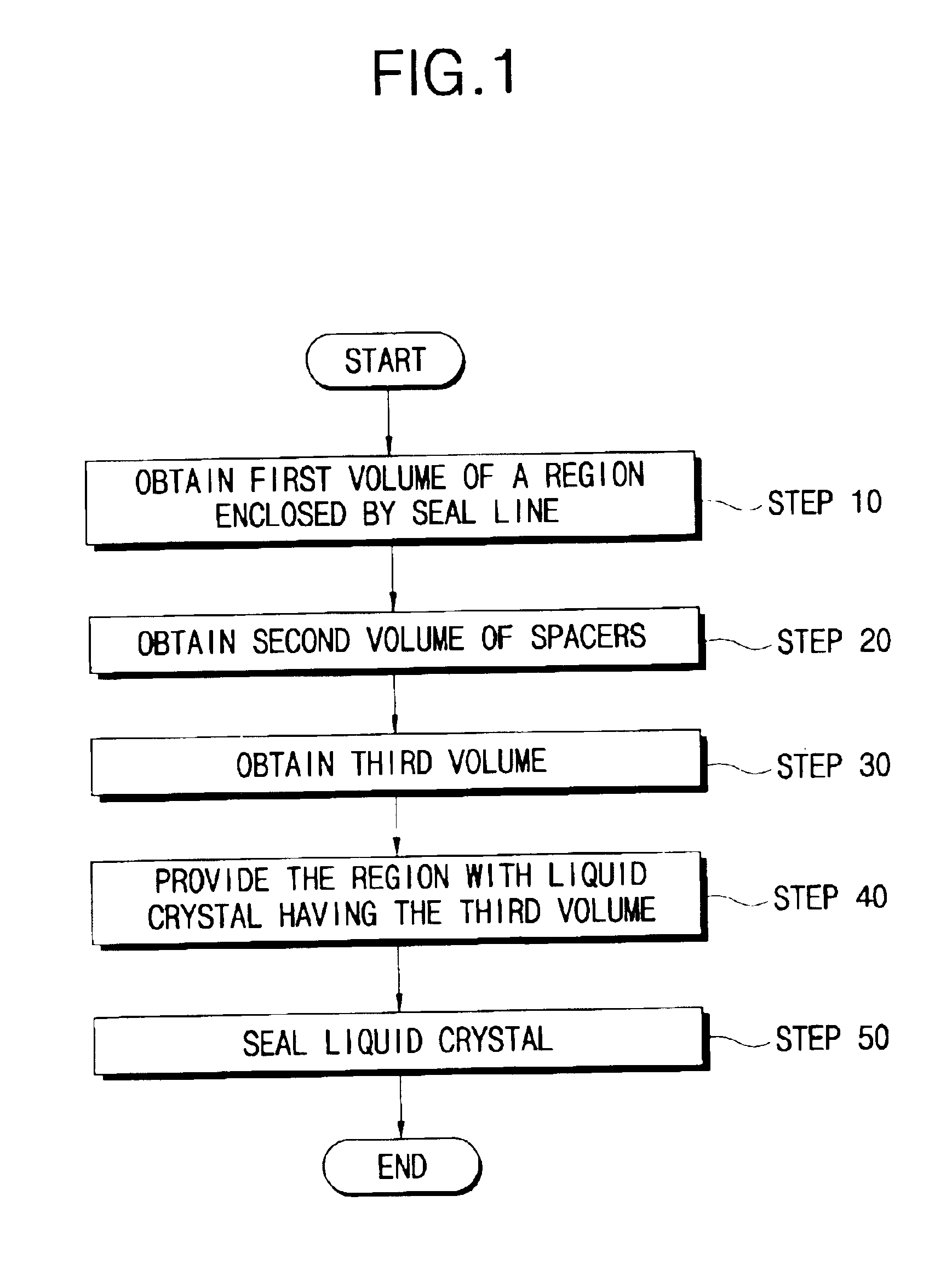

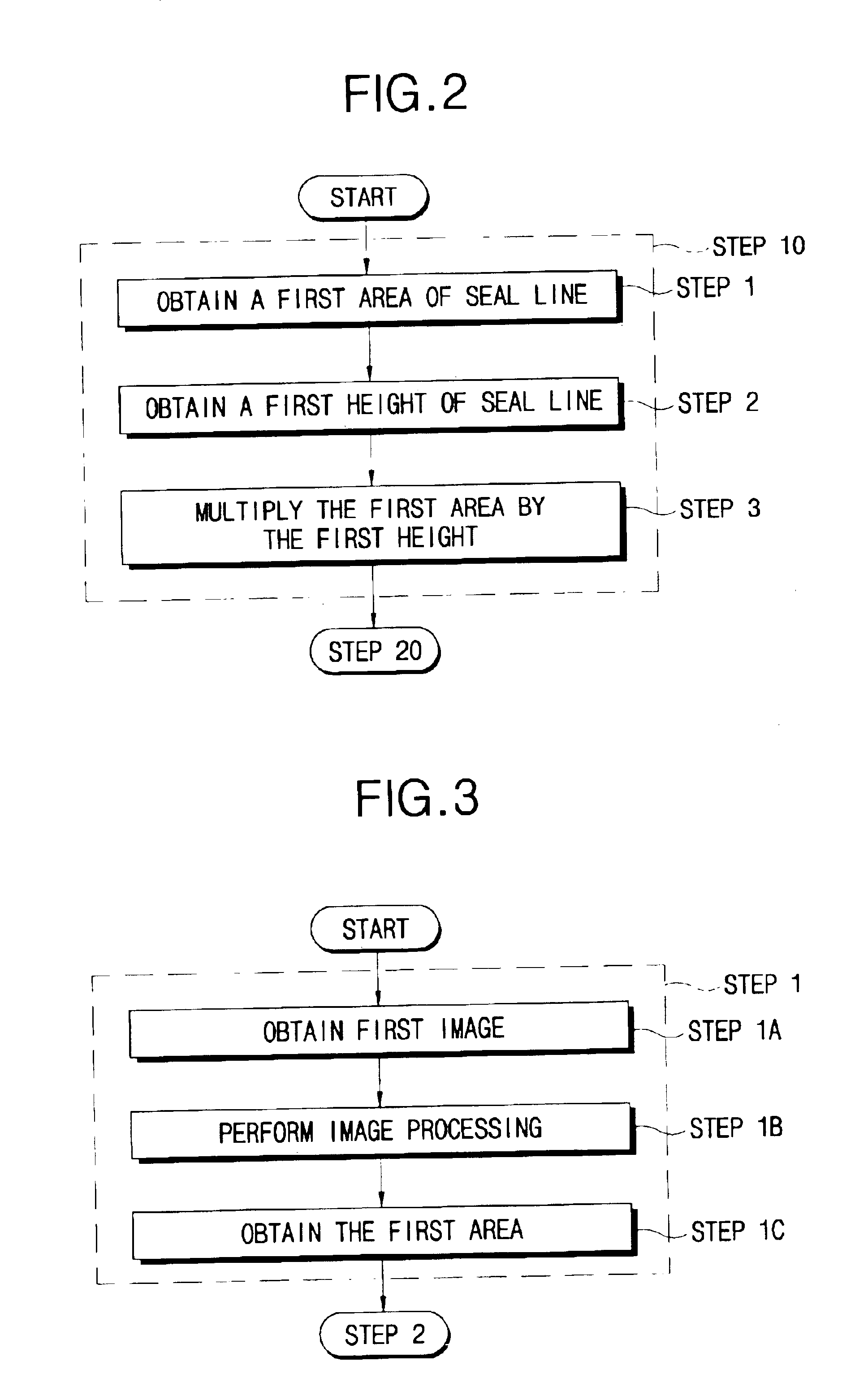

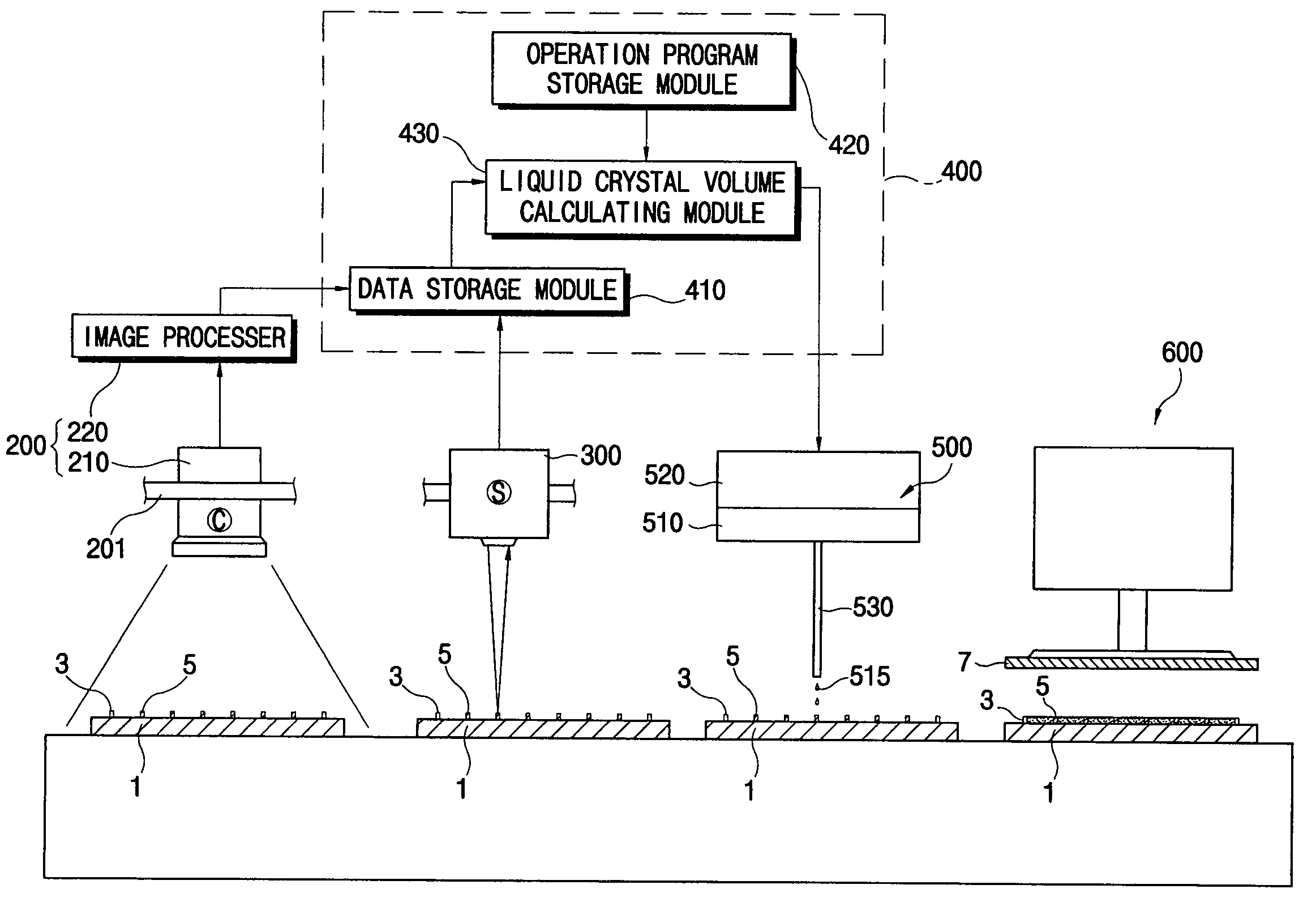

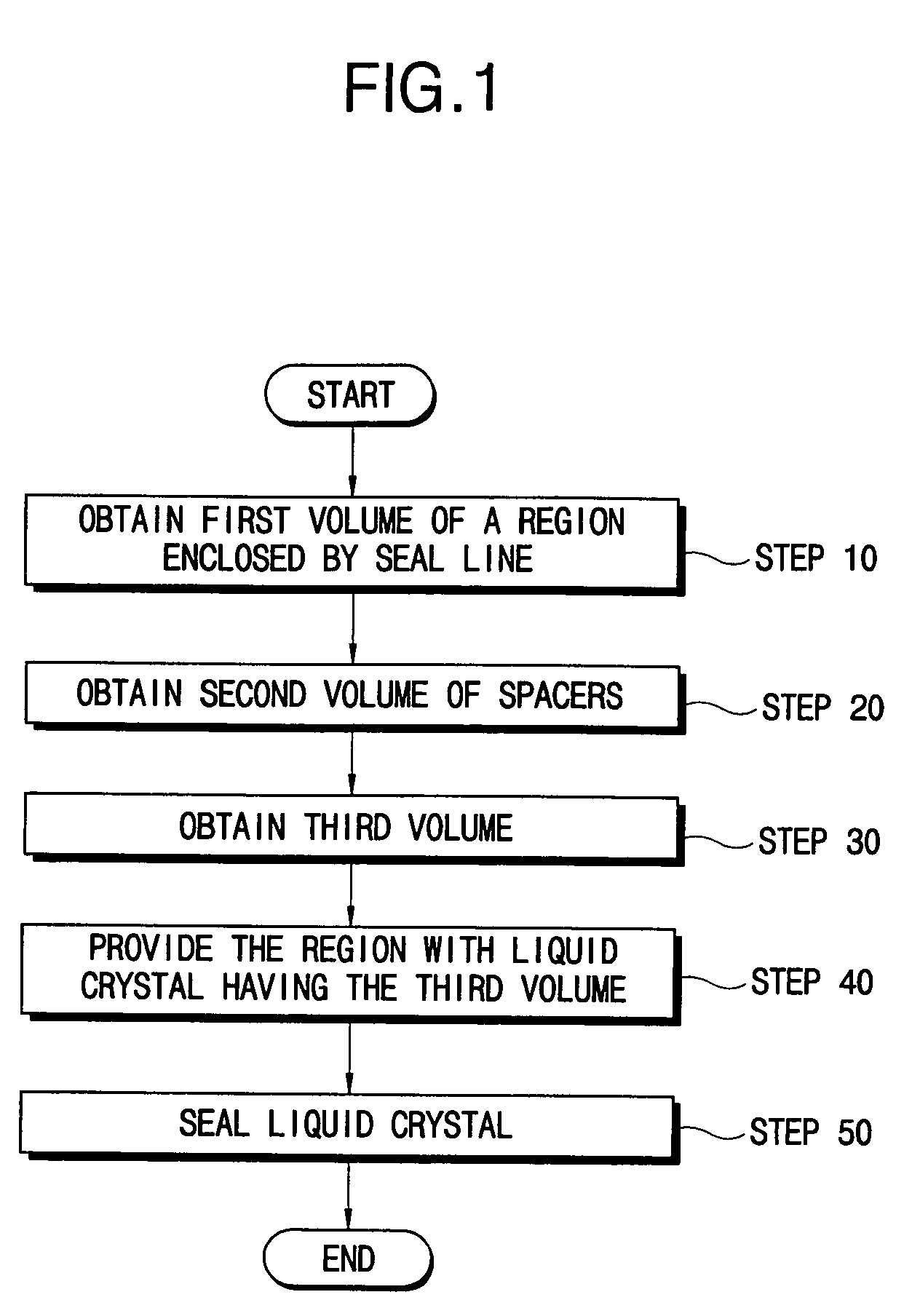

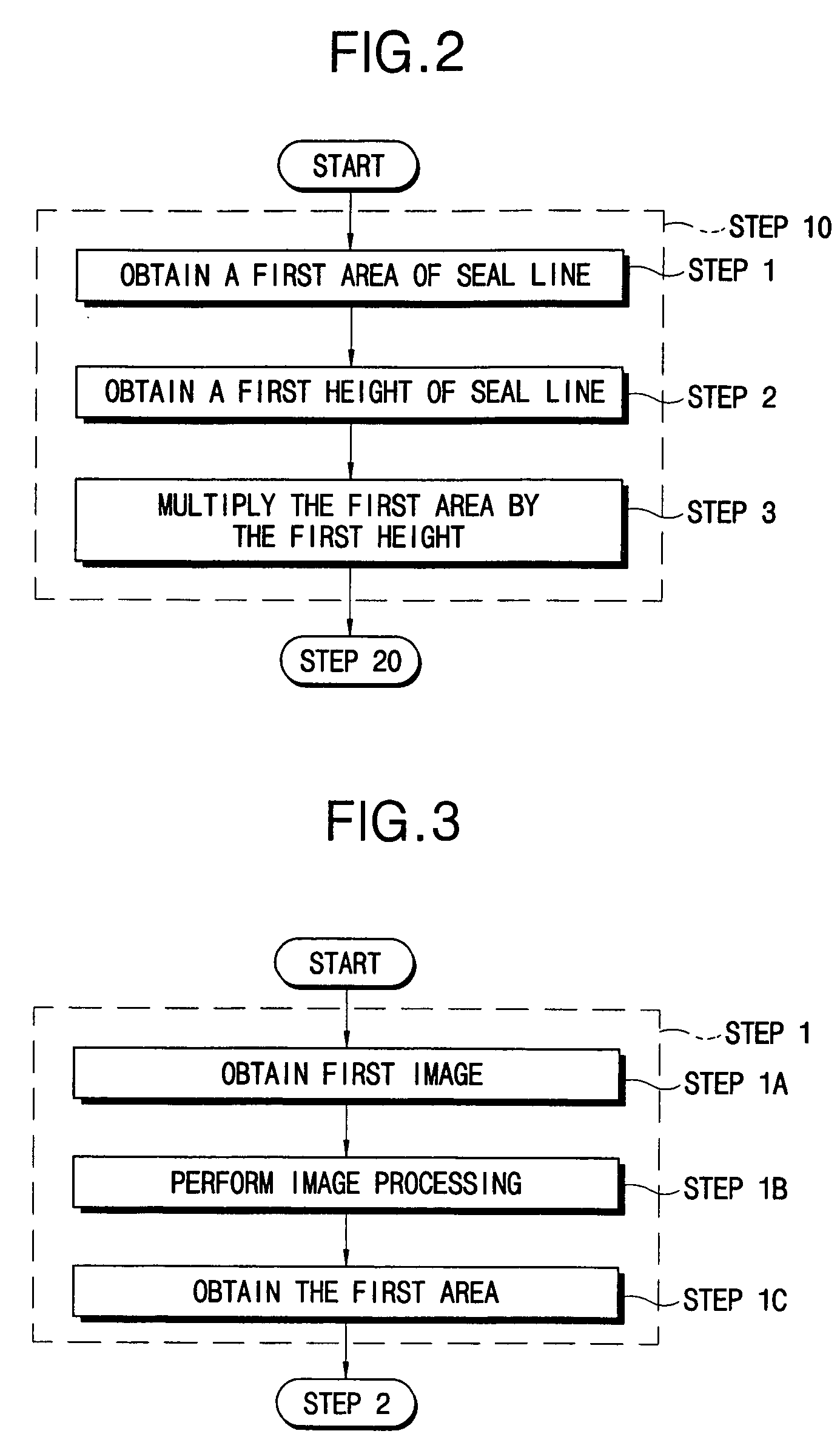

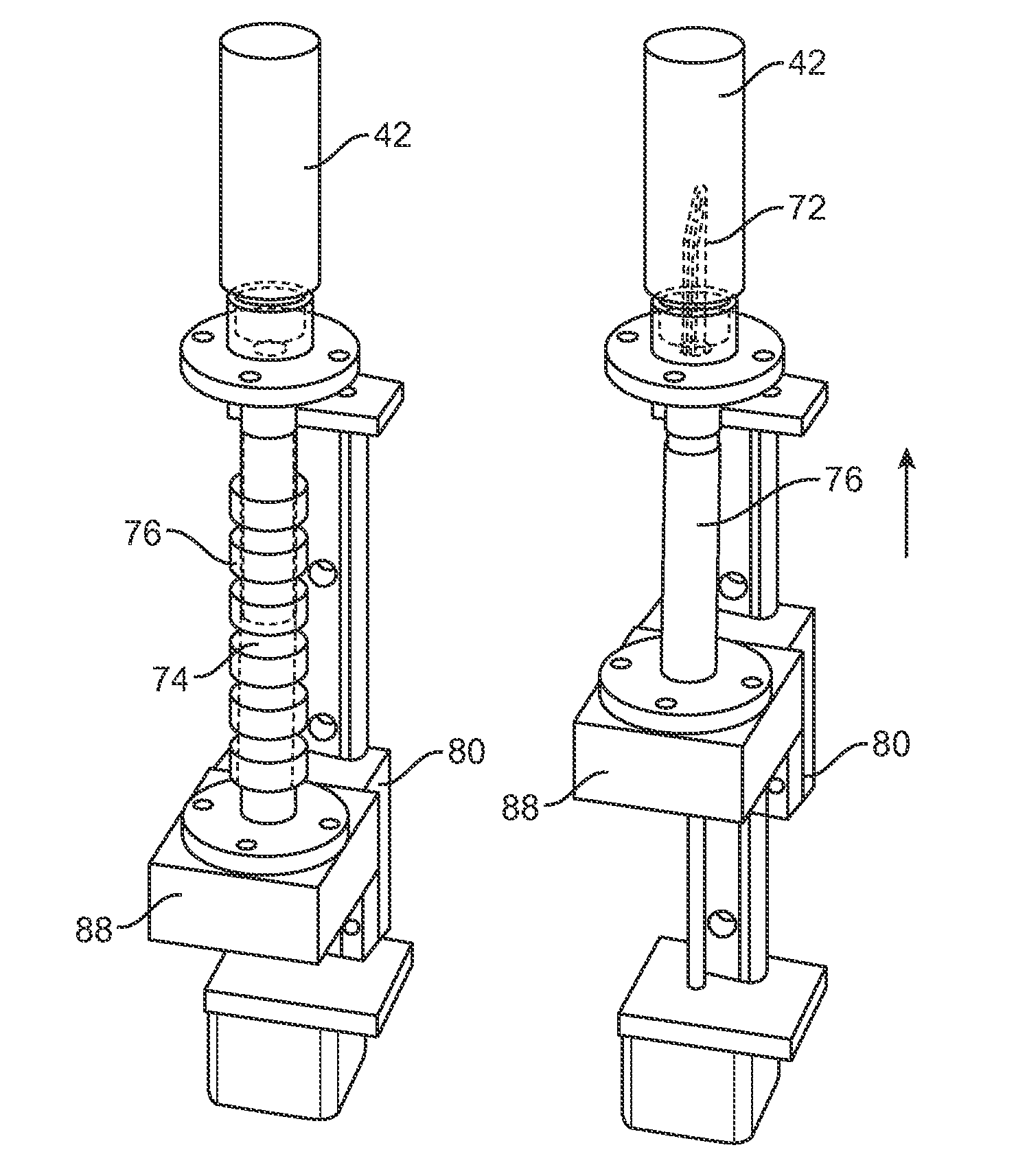

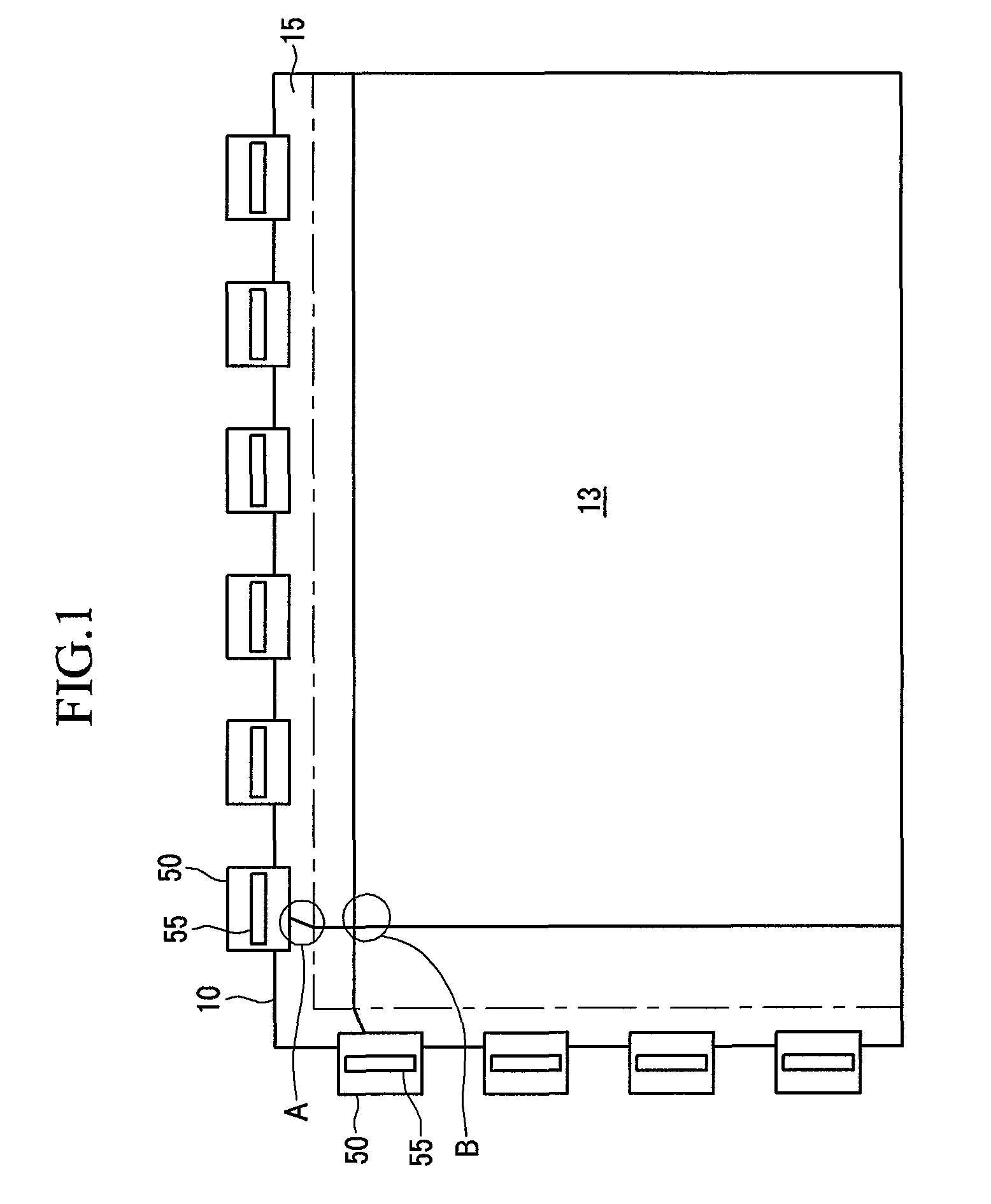

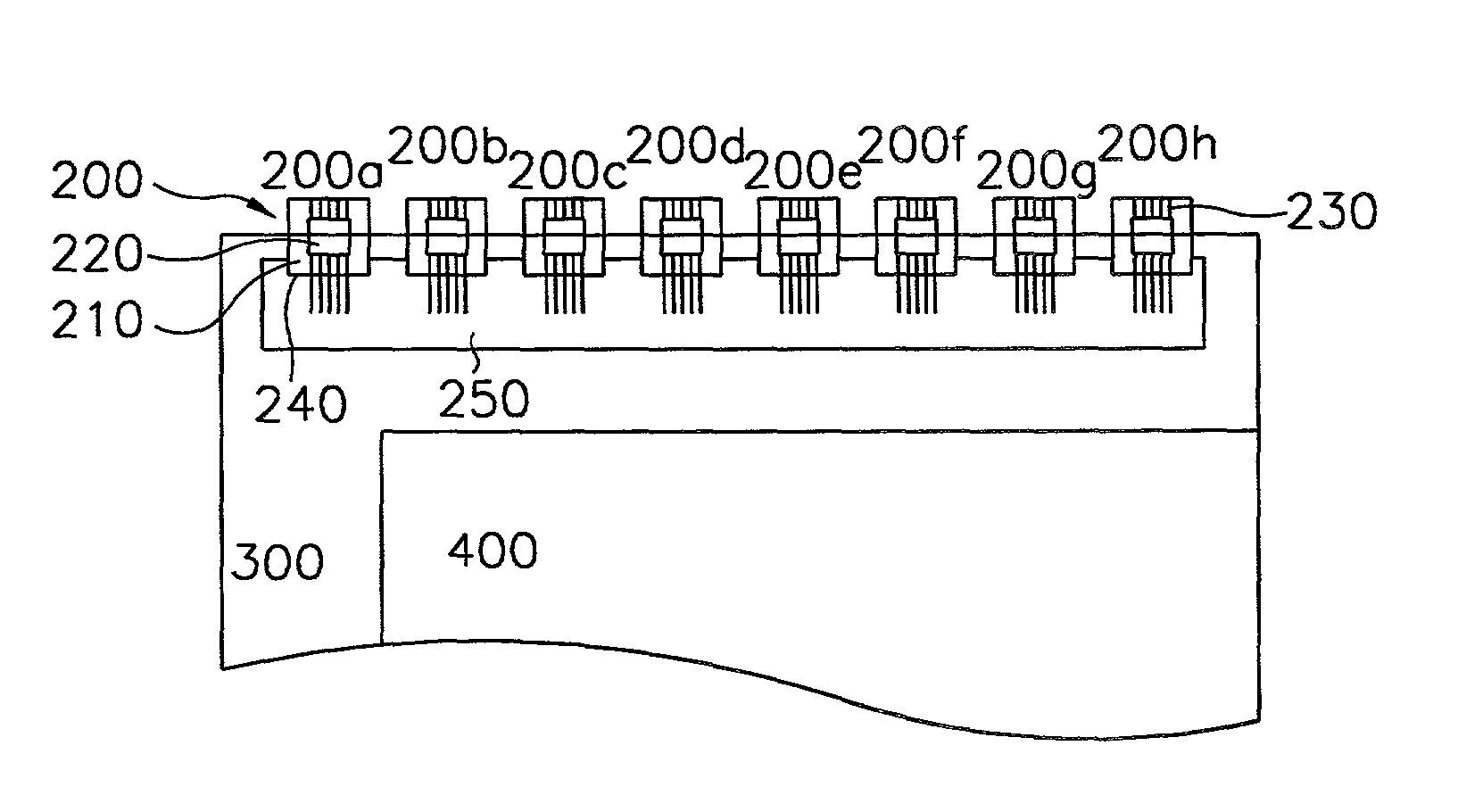

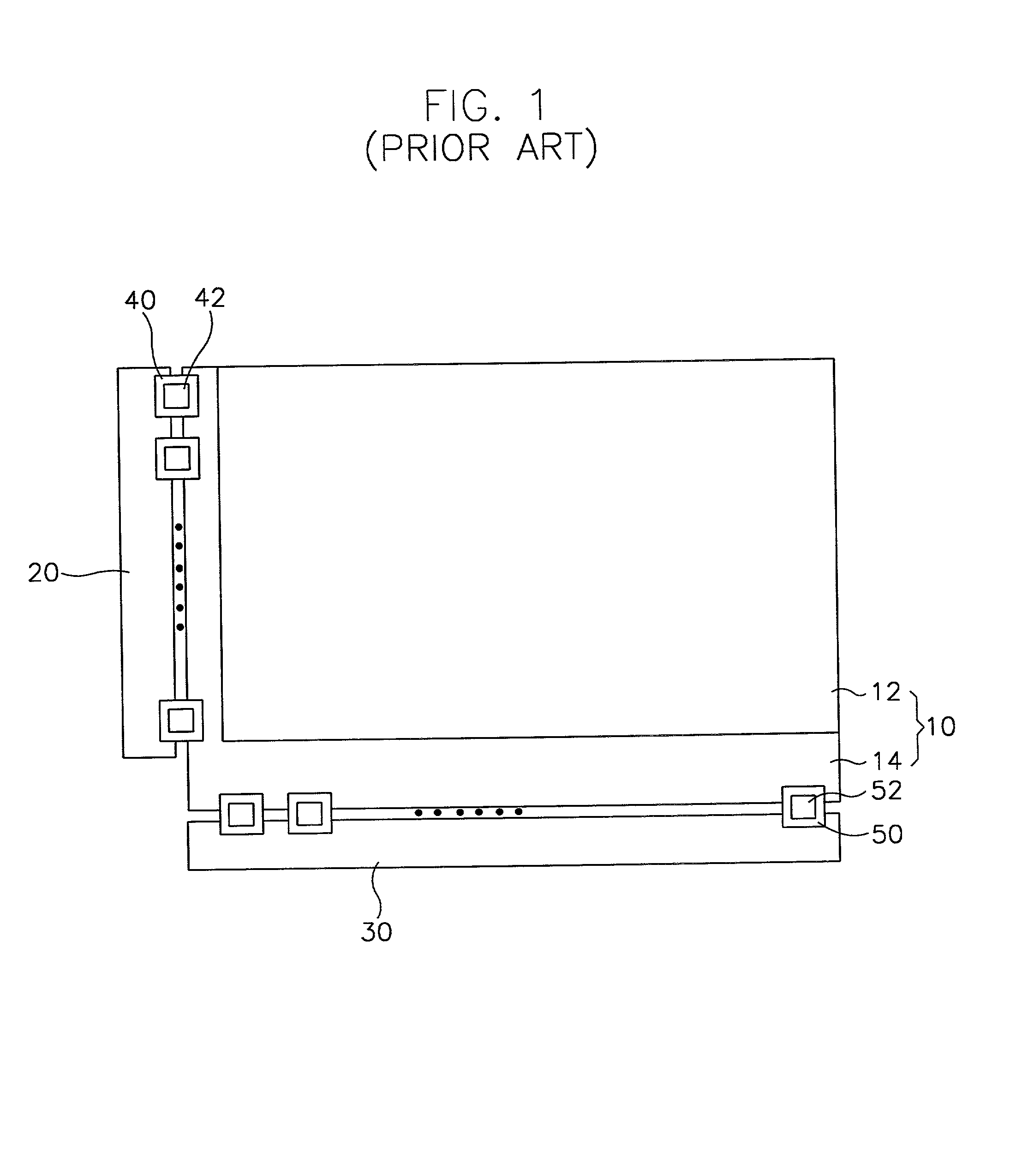

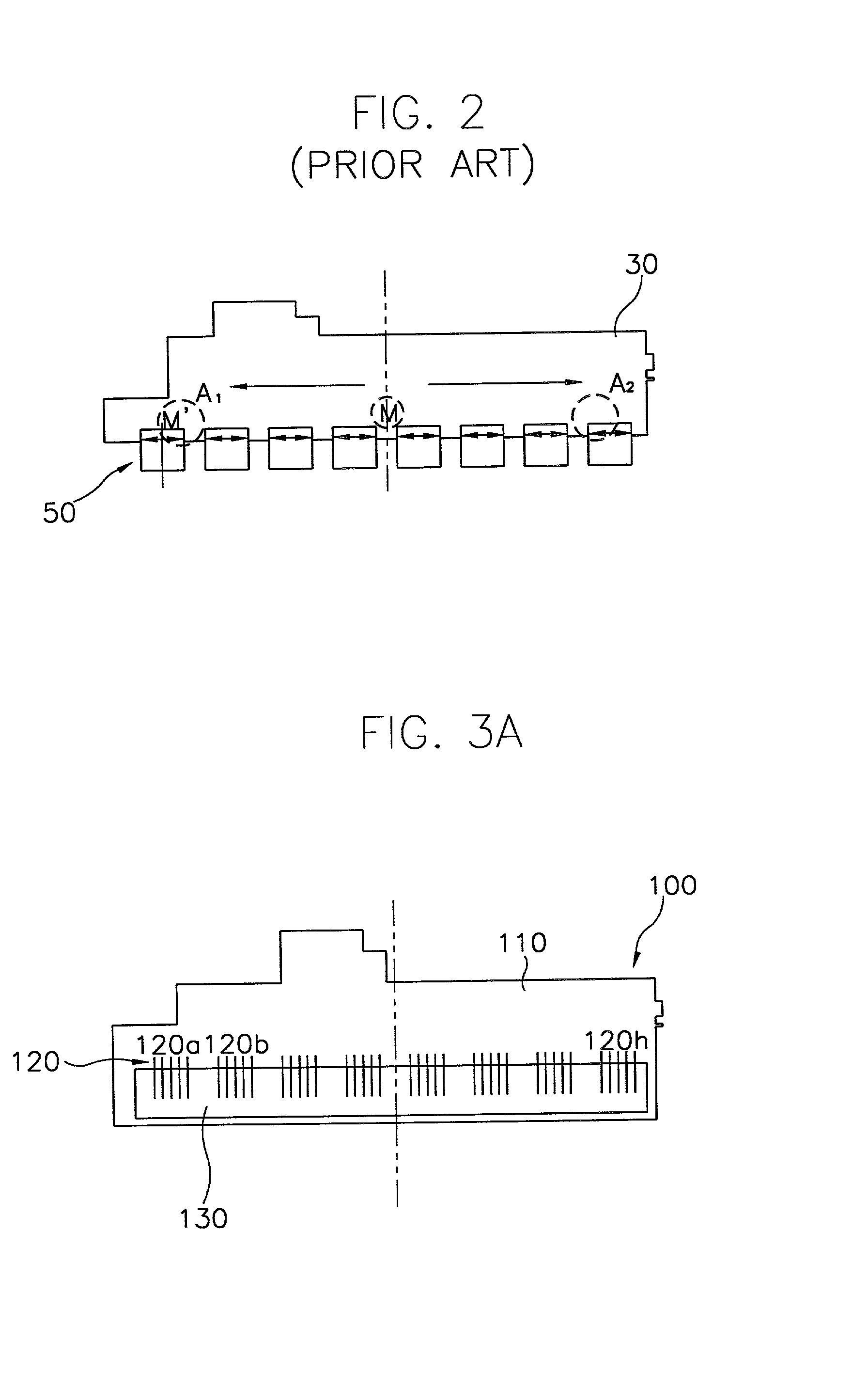

Method of filling liquid crystal display panel with liquid crystal and liquid crystal filling system performing the same

InactiveUS6954251B2Reduce processing failureAccurate liquid volumeNon-linear opticsLiquid-crystal displayEngineering

In a method of filling a liquid crystal display panel with liquid crystal and a liquid crystal filling system using the method, a seal line and spacers are formed on a color filter substrate. A first volume defined by the seal line and a second volumes defined by the spacers are obtained. An amount of liquid crystal to be supplied into a region enclosed by the seal line is precisely calculated based on the first and second volumes. Shortage of the liquid crystal supplied into the LCD panel and overflow of the liquid crystal can be avoided. Accordingly, the steps for supplying the liquid crystal into the LCD panel may be reduced, and simultaneously peripheral regions of the LCD panel be prevented from being contaminated by the liquid crystal while the liquid crystal is filled into the LCD panel.

Owner:SAMSUNG DISPLAY CO LTD

Method of manufacturing a truck release handle for automobiles

InactiveUS20060028031A1Visibility of providingHigh degreeVehicle locksDisplay meansVisibilityGraphics

An emergency trunk release handle for an automobile displays the graphics explaining the use and function of the handle by cutting out the material from the handle. Forming the emergency release handle from a phosphorescent plastic material that can be formed by a molding process, such as injection molding, the cut-out graphics show as darkened areas, when viewed in the dark confines of an automobile trunk, to provide a high degree of visibility for the graphics. The graphics are also visible when seen against the dark carpet in the interior of an opened trunk cavity. The formation of the graphics is accomplished by coring the mold in the configuration of the desired graphics and by forming the plastic material in the mold around the cores. The resultant handle structure is thus formed in a cost effective manner that reduces the process failure potential during the manufacturing of the handle.

Owner:FORD GLOBAL TECH LLC

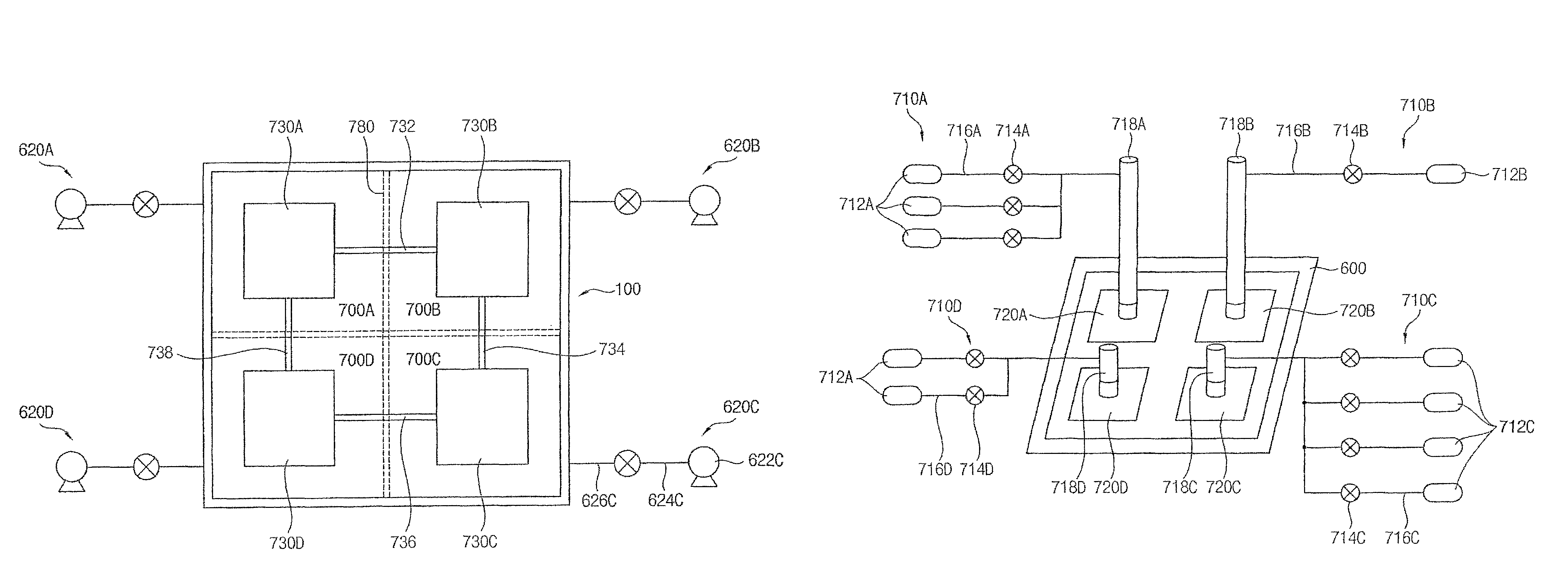

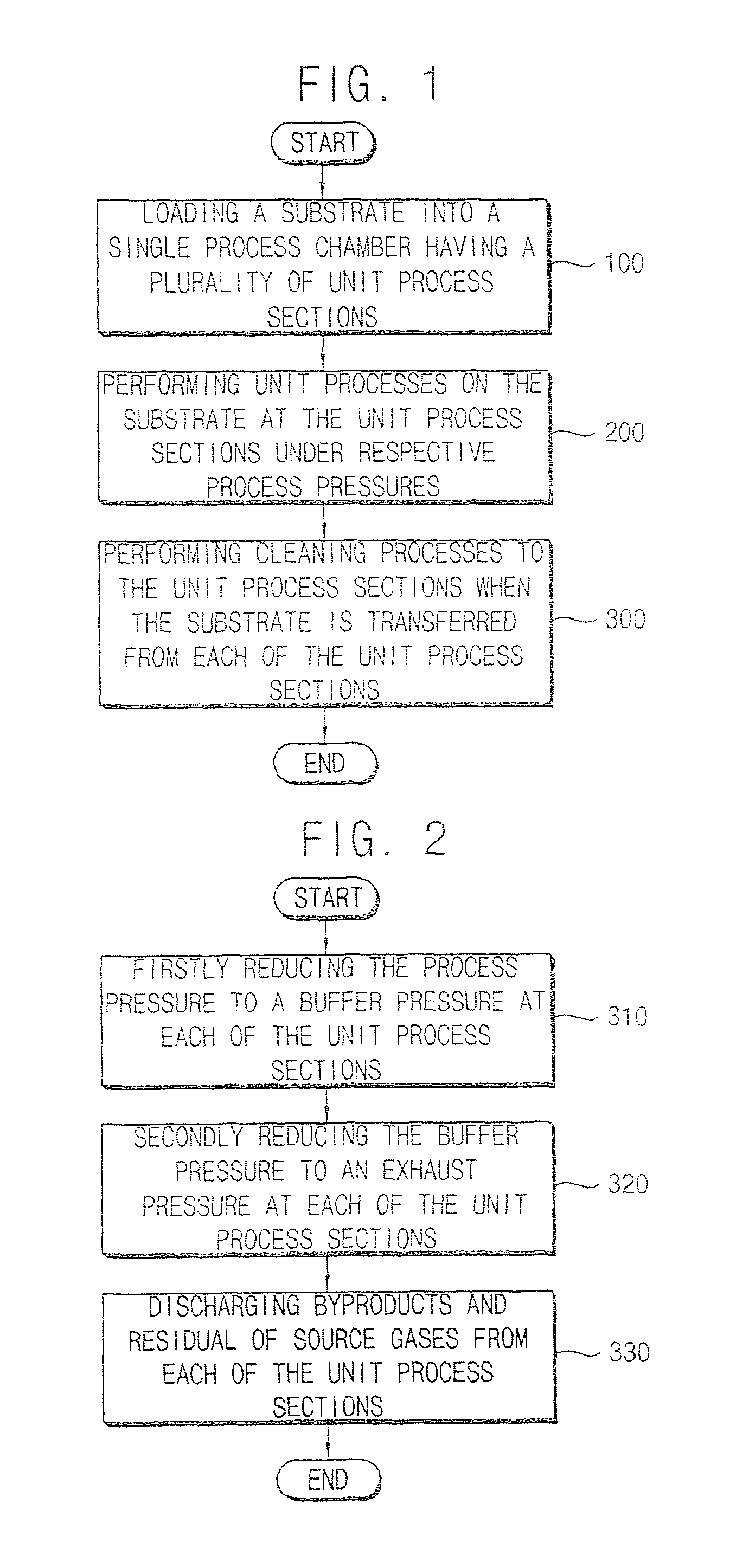

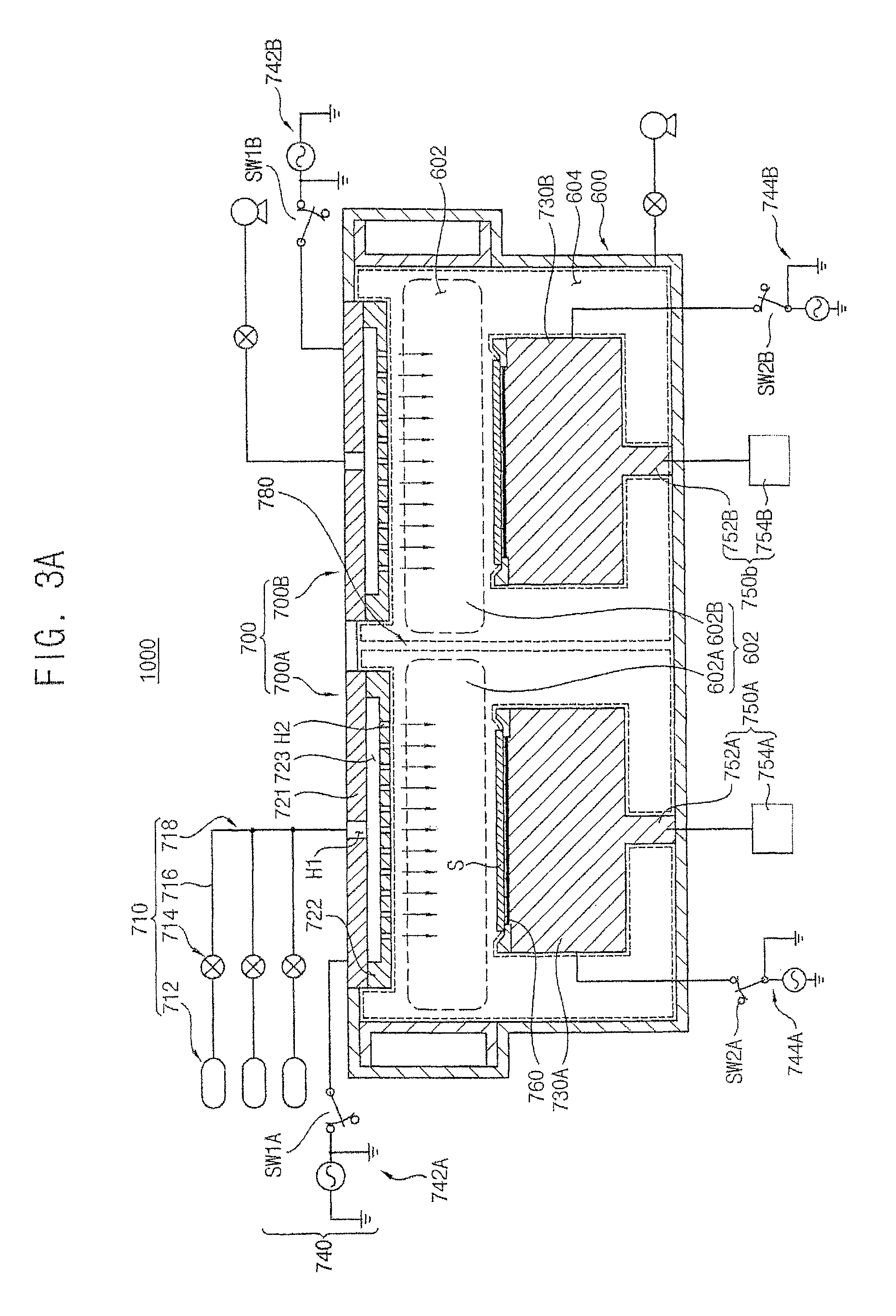

Method of manufacturing a semiconductor device

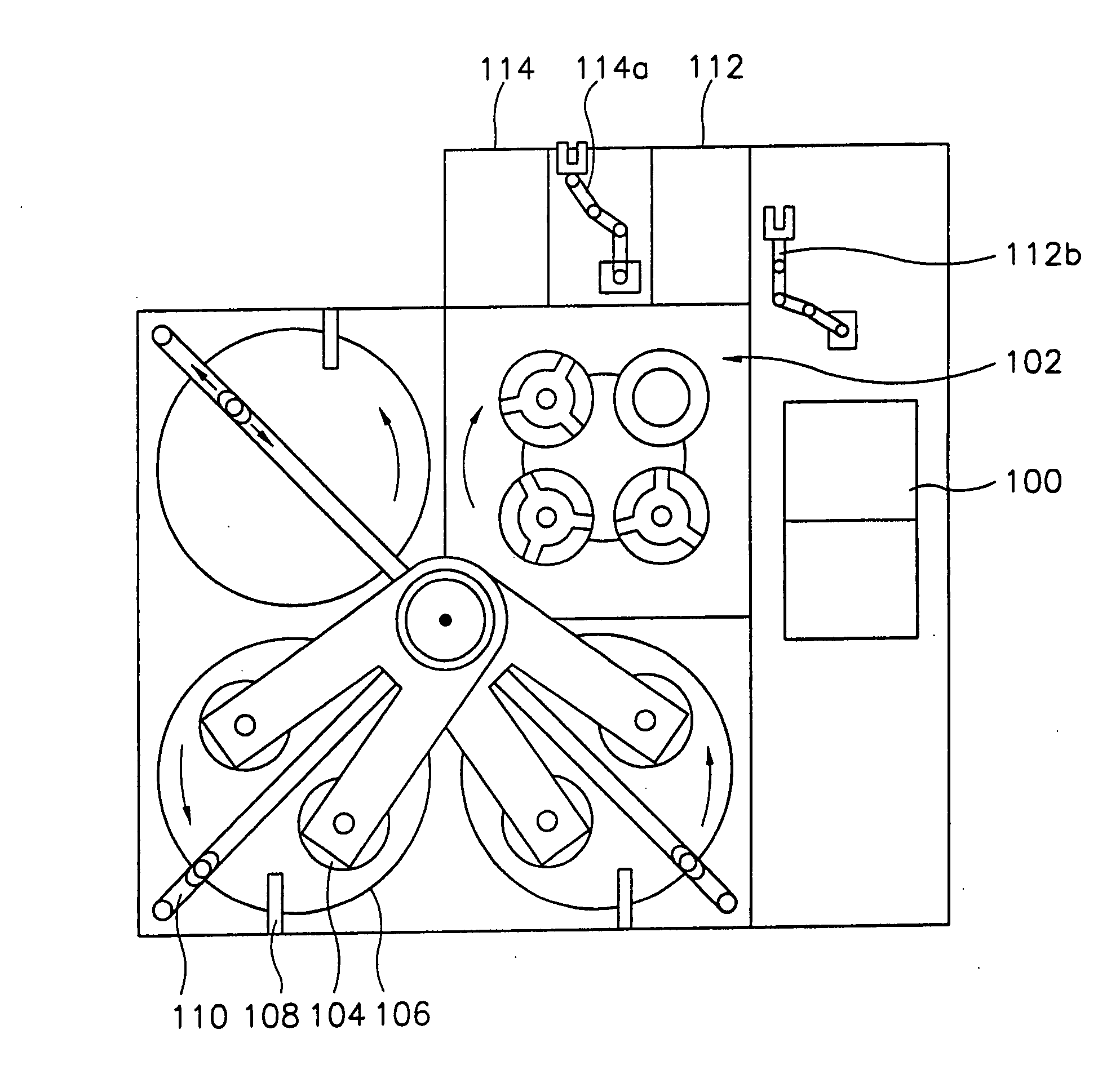

ActiveUS8696921B2Improve reliabilityOperation periodDecorative surface effectsHollow article cleaningDevice materialEngineering

In a method of manufacturing a semiconductor device, a substrate is loaded to a process chamber having, unit process sections in which unit processes are performed, respectively. The unit processes are performed on the substrate independently from one another at the unit process sections under a respective process pressure. The substrate sequentially undergoes the unit processes at the respective unit process section of the process chamber. Cleaning processes are individually performed to the unit process sections, respectively, when the substrate is transferred from each of the unit process sections and no substrate is positioned at the unit process sections. Accordingly, the process defects of the process units may be sufficiently prevented and the operation period of the manufacturing apparatus is sufficiently elongated.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of filling liquid crystal display panel with liquid crystal and liquid crystal filling system performing the same

InactiveUS20050206833A1Reduce the number of stepsMinimize processing timeNon-linear opticsColor gelLiquid crystal

In a method of filling a liquid crystal display panel with liquid crystal and a liquid crystal filling system using the method, a seal line and spacers are formed on a color filter substrate. A first volume defined by the seal line and a second volumes defined by the spacers are obtained. An amount of liquid crystal to be supplied into a region enclosed by the seal line is precisely calculated based on the first and second volumes. Shortage of the liquid crystal supplied into the LCD panel and overflow of the liquid crystal can be avoided. Accordingly, the steps for supplying the liquid crystal into the LCD panel may be reduced, and simultaneously peripheral regions of the LCD panel be prevented from being contaminated by the liquid crystal while the liquid crystal is filled into the LCD panel.

Owner:SAMSUNG DISPLAY CO LTD

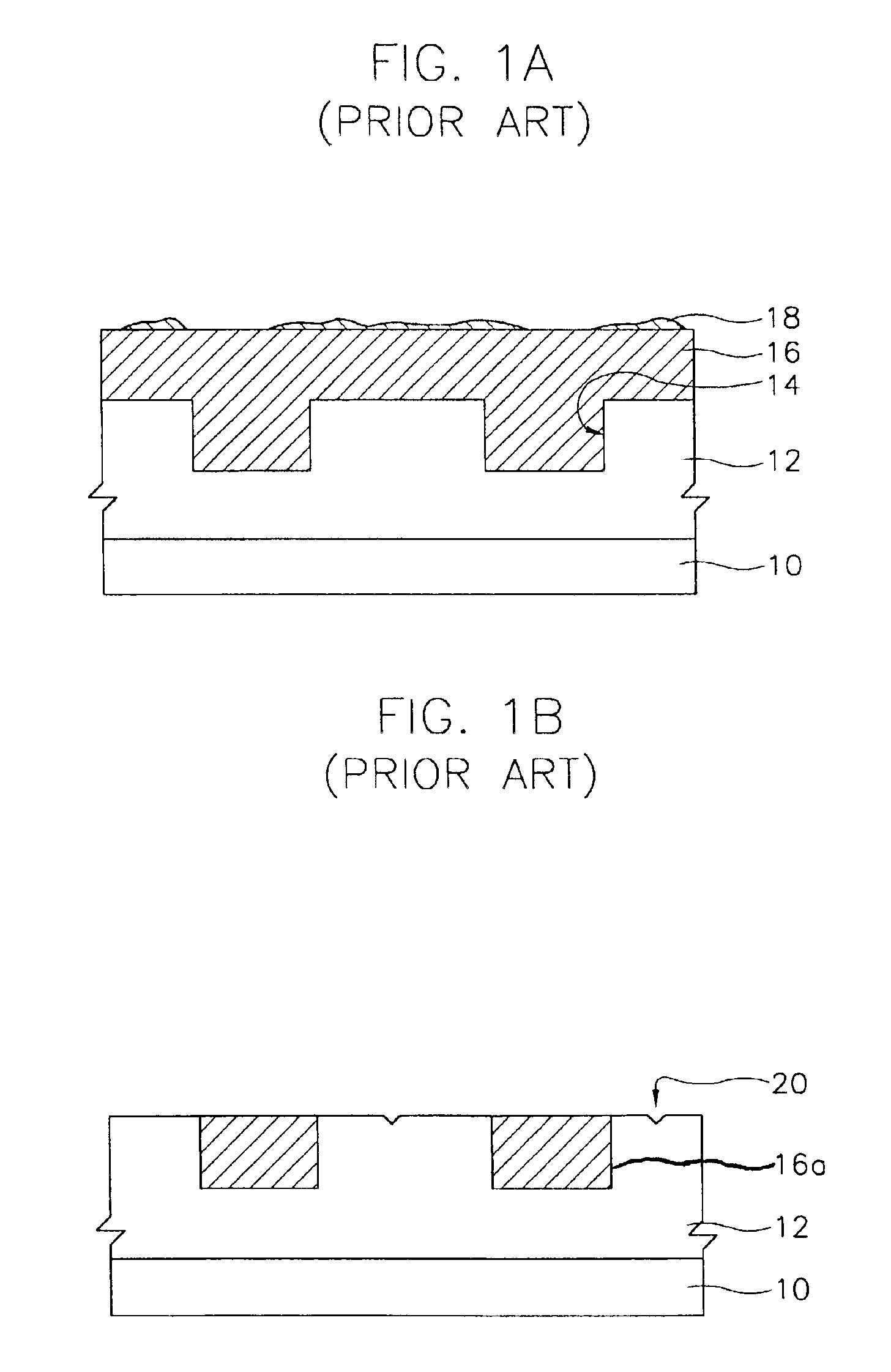

Method and apparatus for polishing a copper layer and method for forming a wiring structure using copper

InactiveUS6924234B2Easy to flattenFabrication can be reducedSemiconductor/solid-state device manufacturingSurface oxidationProcess failure

In a method and apparatus for polishing a Cu metal layer and a method for forming Cu metal wiring, Cu oxide created by a surface oxidation of a Cu metal layer is removed from the wafer. The Cu metal layer, in which Cu oxide is removed, is polished. By polishing the Cu metal layer using the above method, process failures, such as scratches, caused by the presence of remnants of Cu oxide during subsequent polishing can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

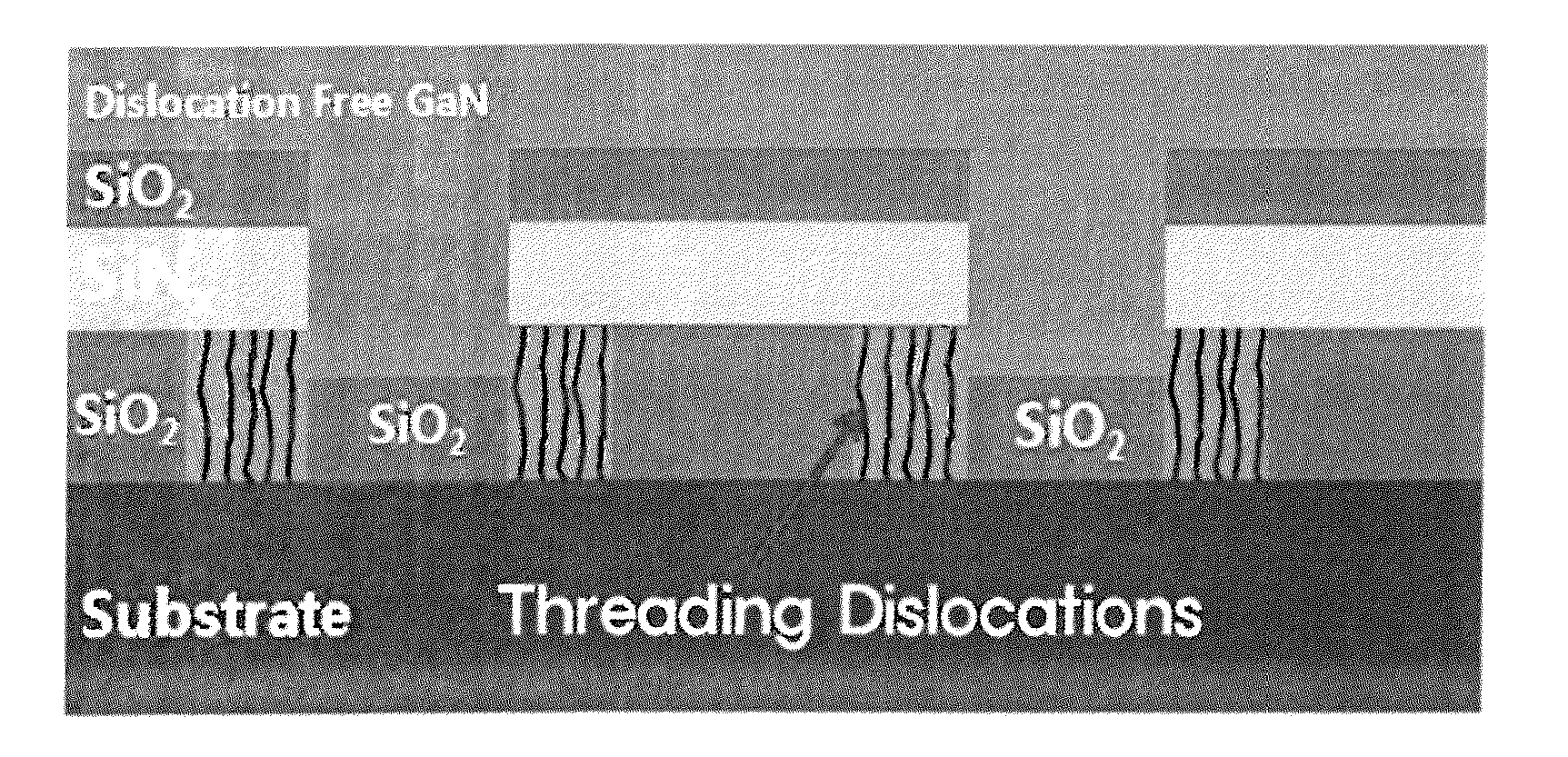

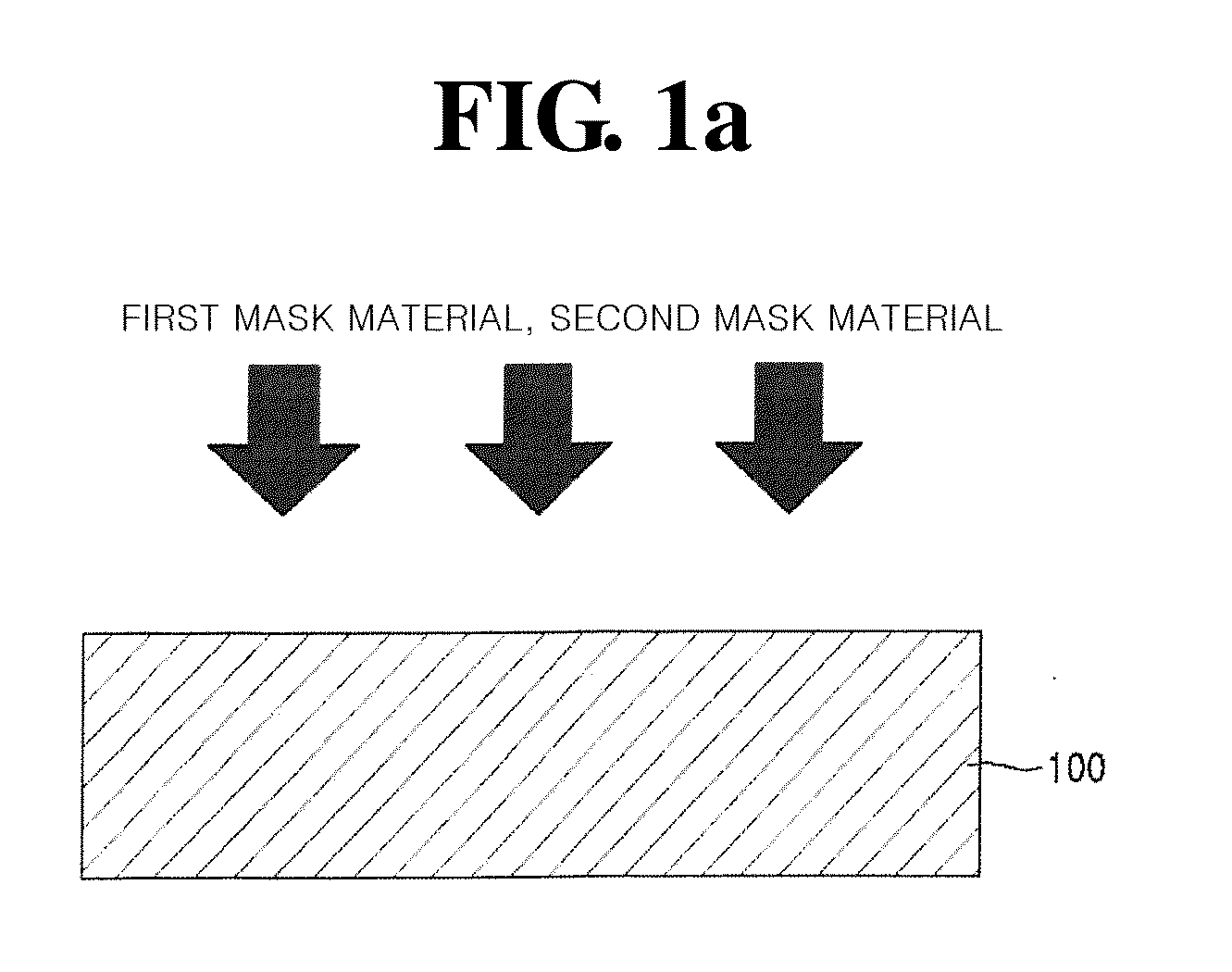

Method for growing nitride-based semiconductor with high quality

ActiveUS20160093492A1Reduce process failureImprove reliabilitySemiconductor/solid-state device manufacturingMask layerSemiconductor

Owner:GWANGJU INST OF SCI & TECH

Vertical-type semiconductor device

ActiveUS7960780B2Improve performanceHighly integratedTransistorSolid-state devicesDevice materialEngineering

In a vertical-type semiconductor device, a method of manufacturing the same and a method of operating the same, the vertical-type semiconductor device includes a single-crystalline semiconductor pattern having a pillar shape provided on a substrate, a gate surrounding sidewalls of the single-crystalline semiconductor pattern and having an upper surface lower than an upper surface of the single-crystalline semiconductor pattern, a mask pattern formed on the upper surface of the gate, the mask pattern having an upper surface coplanar with the upper surface of the single-crystalline semiconductor pattern, a first impurity region in the substrate under the single-crystalline semiconductor pattern, and a second impurity region under the upper surface of the single-crystalline semiconductor pattern. The vertical-type pillar transistor formed in the single-crystalline semiconductor pattern may provide excellent electrical properties. The mask pattern is not provided on the upper surface of the single-crystalline semiconductor pattern in the second impurity region, to thereby reduce failures of processes.

Owner:SAMSUNG ELECTRONICS CO LTD

Three-dimensional semiconductor memory device

ActiveUS11404434B2Improve integration densityReduce processing failureSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsMechanical engineering

A semiconductor memory device includes horizontal patterns disposed on a peripheral circuit structure and spaced apart from each other in a first direction. Memory structures are disposed on the horizontal patterns. The memory structures include source structures and electrode structures. A division structure is disposed between adjacent horizontal patterns in the first direction and is configured to separate the source structures of adjacent memory structures from each other. An etch stop pattern is disposed between the horizontal patterns at a level lower than a level of the source structures. The etch stop pattern is connected to a lower portion of the division structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of manufacturing a semiconductor device including forming a single-crystalline semiconductor material in a first area and forming a second device isolation pattern on a second area

ActiveUS7851327B2Reduce processing failureProcess can be minimizedSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSemiconductor materials

Owner:SAMSUNG ELECTRONICS CO LTD

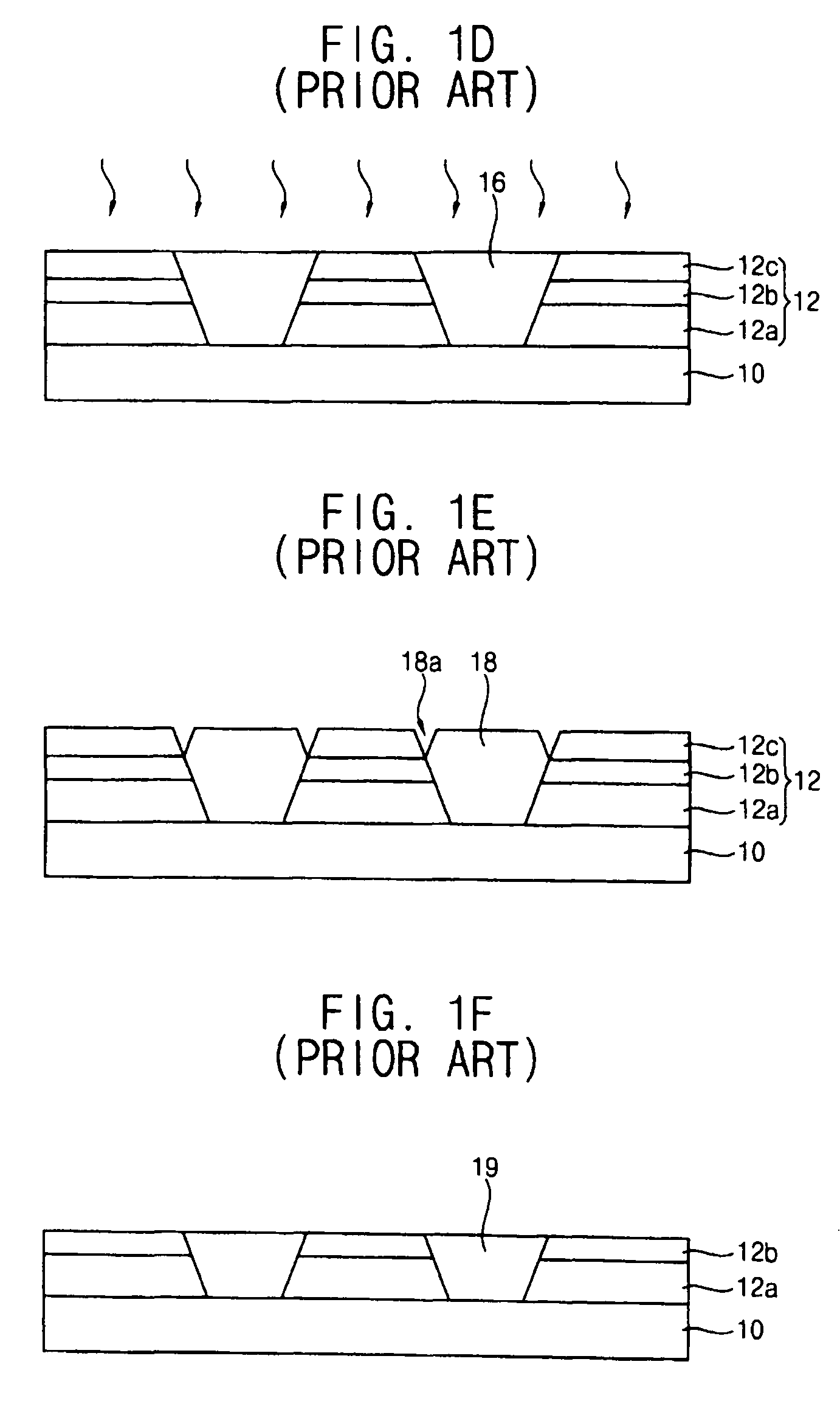

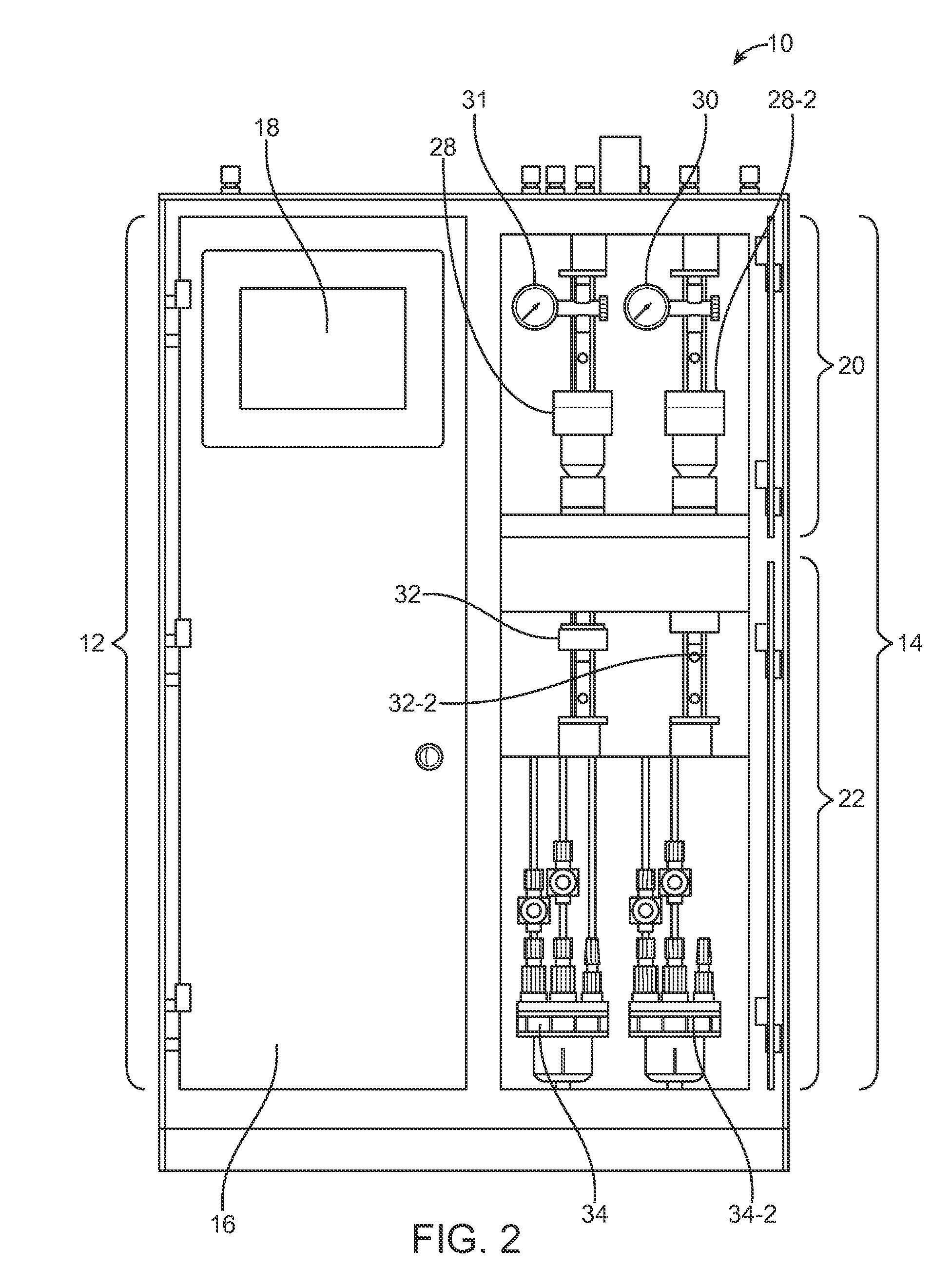

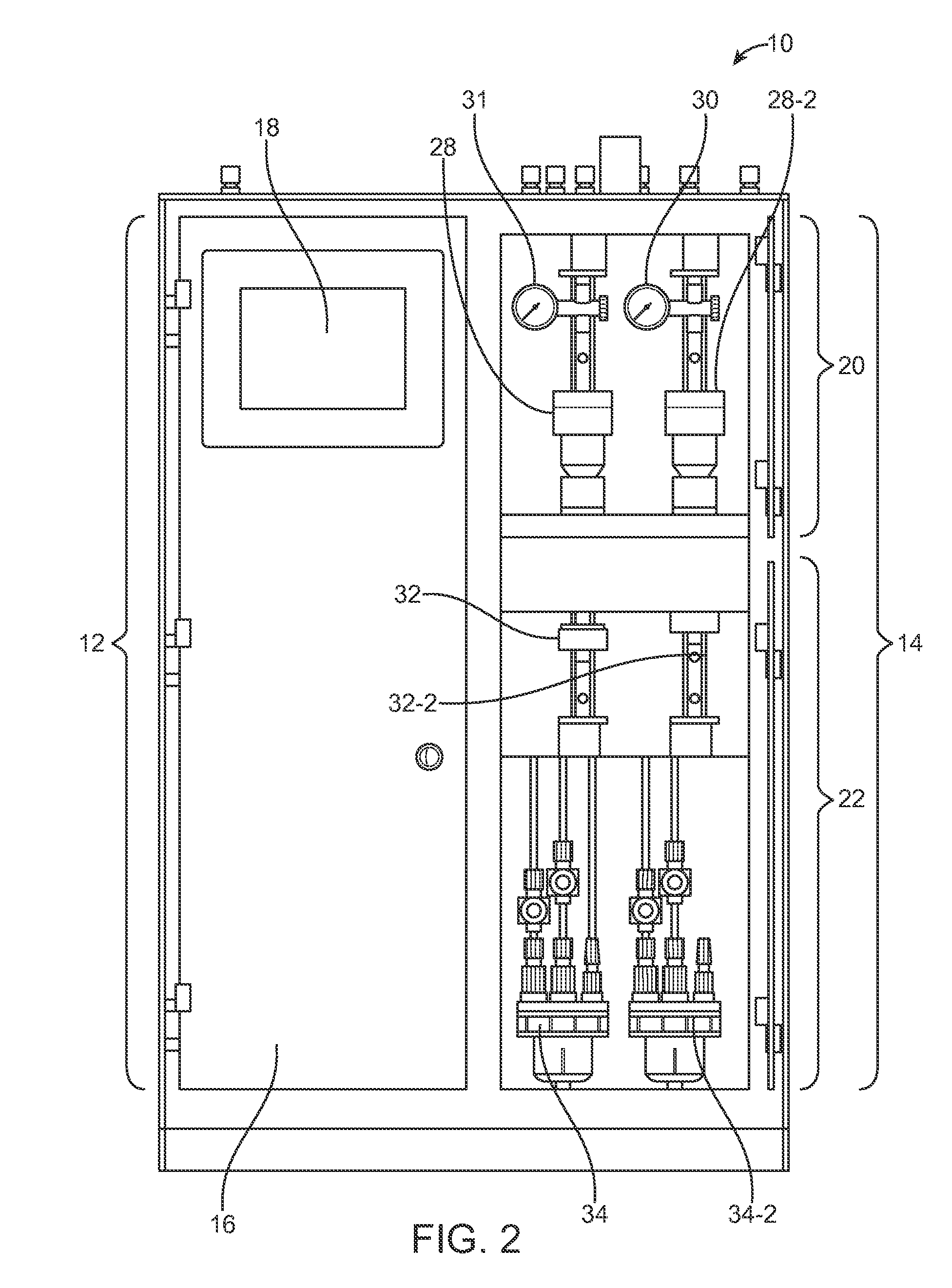

Defined dosing atmospheric temperature and pressure vapor deposition system

ActiveUS9562288B2Improve securityImprove productivityChemical vapor deposition coatingGas phaseAtmospheric temperature

A closed chemical introduction system used to deliver active ingredients in liquid chemical to a chemical vapor deposition system includes a robust, moisture-free cartridge containing a defined dose of liquid chemical. The cartridge is placed on a mounting slot specially configured to receive the cartridge. Upon initiating the system, a first linear mechanical actuator securely holds the cartridge in the slot, while an extraction lance attached to a second linear mechanical actuator punctures the cartridge from the bottom, extracts the liquid chemical and delivers it to a vaporization chamber. The vaporization chamber evaporates the liquid chemical and delivers the vapors containing the active ingredients to the chemical vapor deposition system. The chemical vapor deposition system may include a treatment chamber, a conveyor, a compressed clean air system to provide separate treatment compartments within the chamber, a moisture system, a chemical vapor system, and a neutralization system to neutralize harmful byproducts.

Owner:DIAMON FUSION INT

Methods of manufacturing semiconductor devices

ActiveUS8435855B2Reduce processing failureExcellent electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A method of manufacturing a semiconductor device, the method including providing a substrate, the substrate including single crystalline silicon and having the first region and a second region; growing a pillar from a top surface of the substrate in the first region; forming a vertical channel transistor including a first gate structure such that first gate structure surrounds a central portion of the pillar; and forming a second transistor on the second region of the substrate such that the second transistor includes a second gate structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film transistor array panel

InactiveUS8058653B2Reduce processing failureIncreased junctionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

A thin film transistor array panel is provided according to one or more embodiments. In an embodiment, the thin film transistor array panel includes: a base substrate that has a display area and a peripheral area; a plurality of thin film transistors that are formed in the display area; a plurality of signal input pads that are formed in the peripheral area and that are formed long in a first direction; and a plurality of signal lines that are connected to the thin film transistors and the signal input pads, wherein at least a part of each of the plurality of signal input pads is arranged in a line along the first direction.

Owner:SAMSUNG DISPLAY CO LTD

Method and apparatus for polishing a copper layer and method for forming a wiring structure using copper

InactiveUS20050148292A1Easy to flattenFabrication can be reducedEdge grinding machinesSemiconductor/solid-state device manufacturingSurface oxidationProcess failure

In a method and apparatus for polishing a Cu metal layer and a method for forming Cu metal wiring, Cu oxide created by a surface oxidation of a Cu metal layer is removed from the wafer. The Cu metal layer, in which Cu oxide is removed, is polished. By polishing the Cu metal layer using the above method, process failures, such as scratches, caused by the presence of remnants of Cu oxide during subsequent polishing can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

Defined dosing atmospheric temperature and pressure vapor deposition system

ActiveUS20140322445A1Improve securityImprove productivityChemical vapor deposition coatingPhysical chemistryEnvironmental engineering

A closed chemical introduction system used to deliver active ingredients in liquid chemical to a chemical vapor deposition system includes a robust, moisture-free cartridge containing a defined dose of liquid chemical. The cartridge is placed on a mounting slot specially configured to receive the cartridge. Upon initiating the system, a first linear mechanical actuator securely holds the cartridge in the slot, while an extraction lance attached to a second linear mechanical actuator punctures the cartridge from the bottom, extracts the liquid chemical and delivers it to a vaporization chamber. The vaporization chamber evaporates the liquid chemical and delivers the vapors containing the active ingredients to the chemical vapor deposition system. The chemical vapor deposition system may include a treatment chamber, a conveyor, a compressed clean air system to provide separate treatment compartments within the chamber, a moisture system, a chemical vapor system, and a neutralization system to neutralize harmful byproducts.

Owner:DIAMON FUSION INT

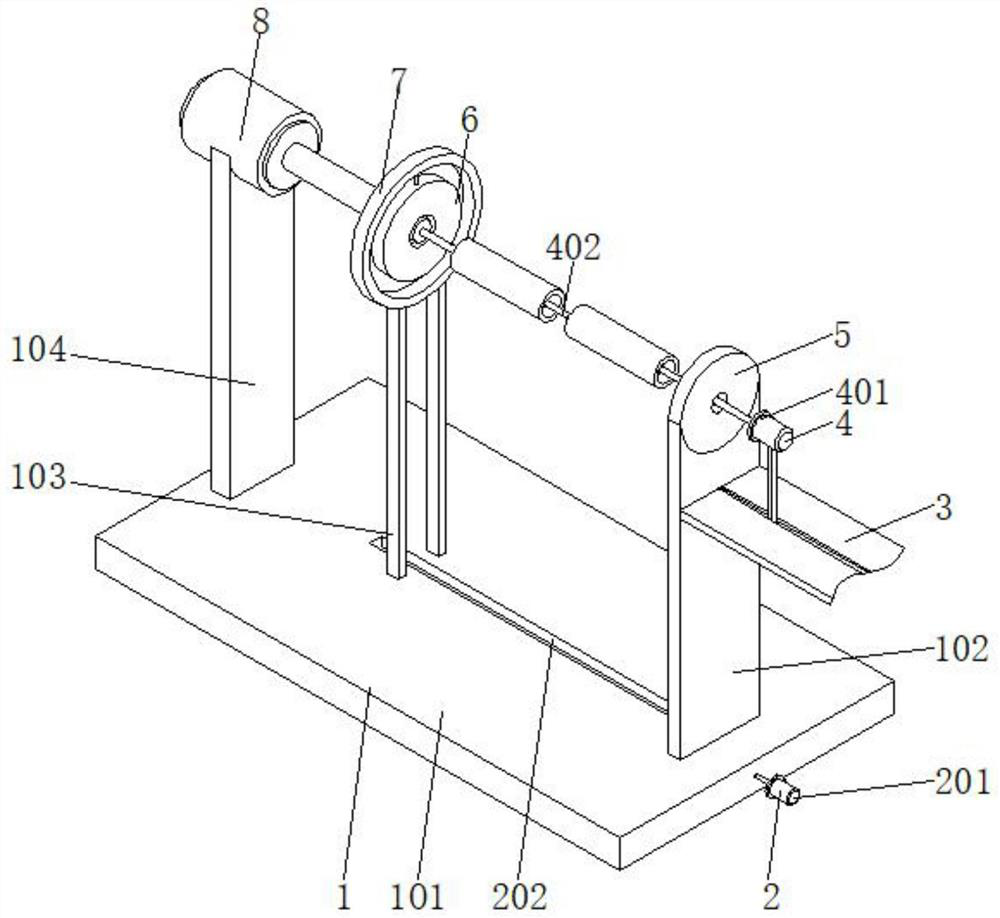

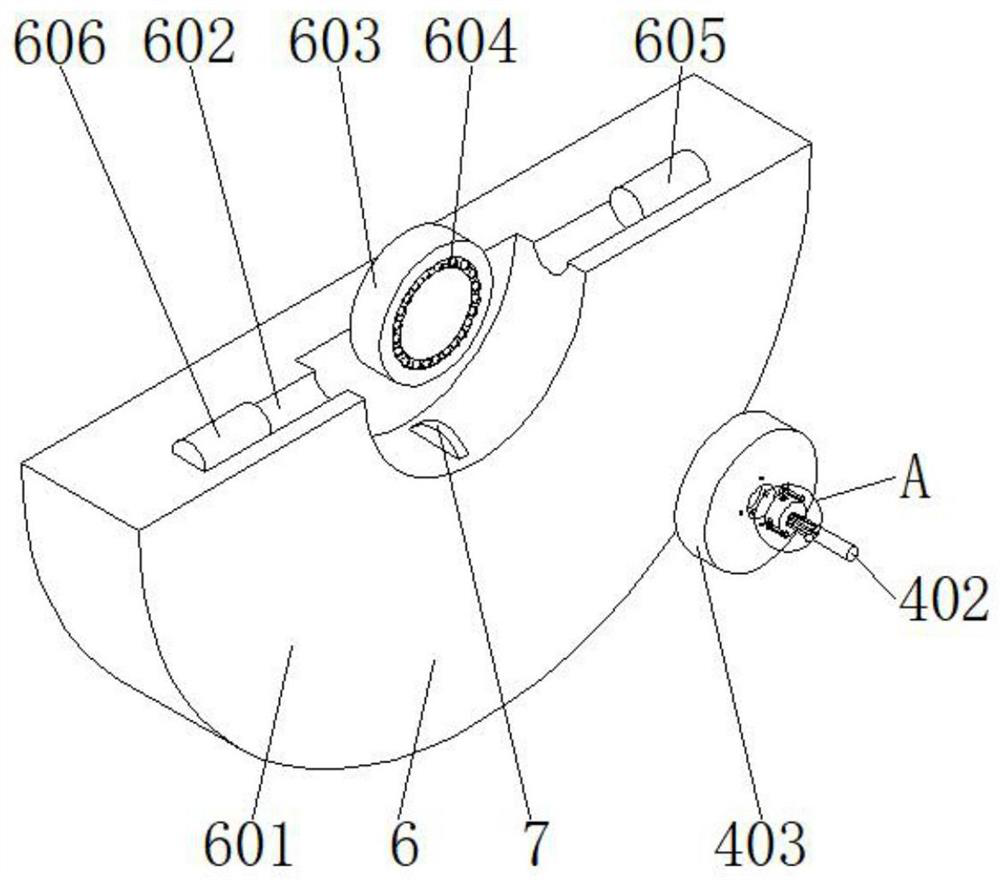

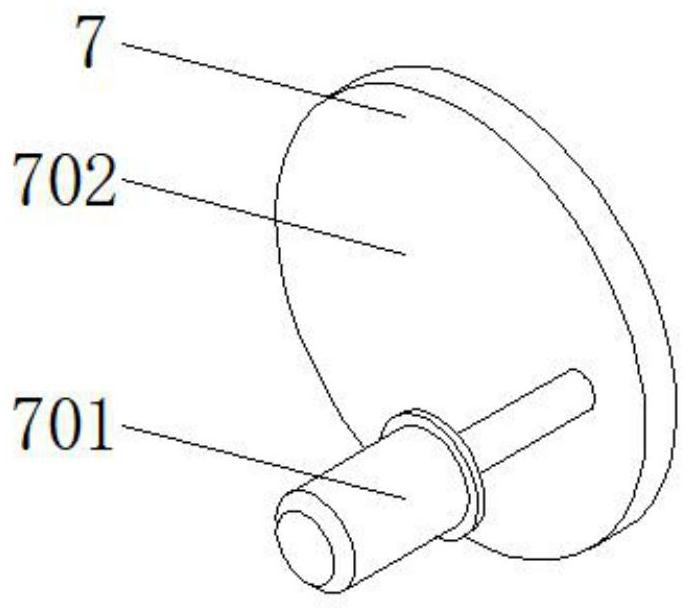

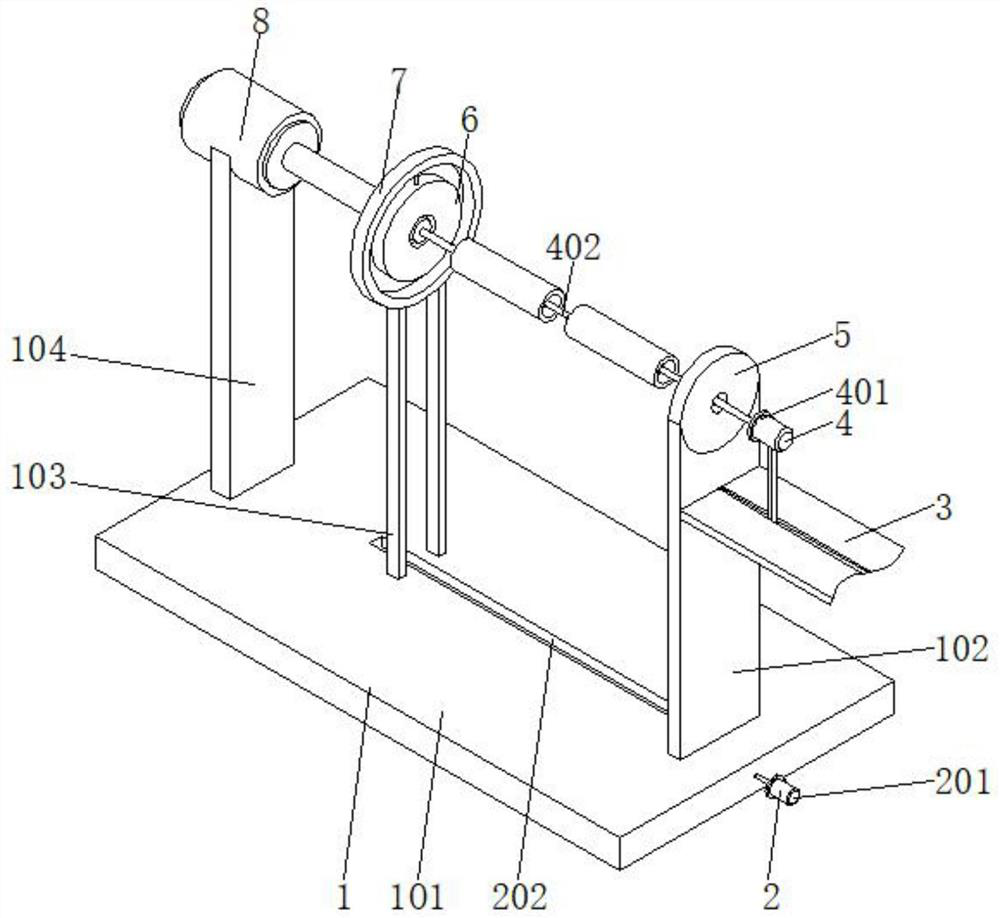

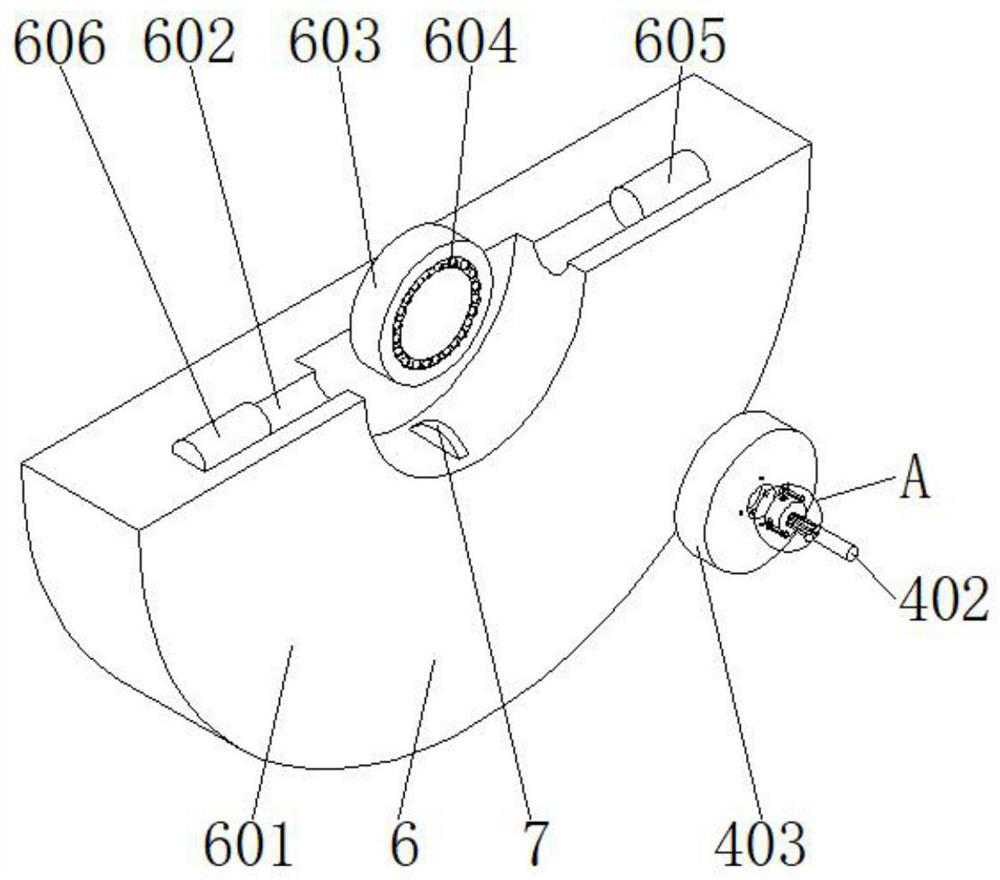

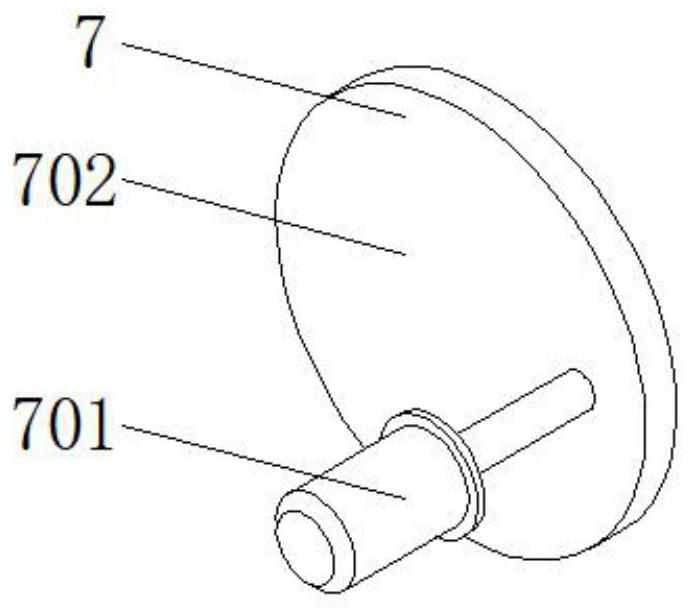

Friction welding machine capable of rolling and leveling workpiece

ActiveCN112247719AReduce processing failureQuick sandingEdge grinding machinesGrinding wheel securing apparatusFriction weldingElectric machinery

The invention relates to the technical field of friction welding, in particular to a friction welding machine capable of rolling and leveling a workpiece. The friction welding machine comprises a mounting frame mechanism, wherein the mounting frame mechanism comprises a base, a first mounting frame is fixed to the top end of the base, a second mounting frame is fixed to the position, located at one side of the first mounting frame, of the top end of the base, and a third mounting frame is fixed to the position, located at one side of the second mounting frame, of the top end of the base; and adriving motor is installed at the top end of the third mounting frame, the output end of the driving motor is connected with a second clamping mechanism, and an eccentric mechanism is connected to the position, located on the outer wall of the second clamping mechanism, of the top end of the second mounting frame. According to the friction welding machine, through the arrangement of a connectingmechanism and a grinding mechanism, a grinding head can be rapidly mounted or dismounted through the connecting mechanism, the process is convenient, and after welding is completed through the grinding mechanism, a weld joint can be rapidly ground, the purpose of rolling leveling after welding is completed is achieved, the machining difficulty needed by the workpiece is reduced, and therefore theproduction cost is reduced.

Owner:湖南坤鼎数控科技有限公司

Cap removal for gate electrode structures with reduced complexity

ActiveUS10475901B1Reduce material lossEasy to useTransistorSolid-state devicesFilling materialsEngineering

The present disclosure relates to manufacturing techniques and respective semiconductor devices in which the capping material of gate electrode structures may be removed together with portions of the capping material of resistors on the basis of a highly controllable directional etch process, wherein raised drain and source regions may be protected on the basis of a fill material.

Owner:GLOBALFOUNDRIES U S INC

Method for decreasing misalignment of a printed circuit board and a liquid crystal display device with the printed circuit board

ActiveUS7764351B2Increase process marginReduce processing failurePrinted circuit assemblingPrinted circuit aspectsProduction rateLiquid-crystal display

A method for improving a misalignment of a printed circuit board and a liquid crystal display device with the printed circuit board are disclosed. A printed circuit board having a substrate and PCB lands formed at a portion of the substrate in the horizontal direction is provided and a tape carrier package having TCP leads corresponding to the PCB lands is also provided. The intervals among the PCB lands are amended by the thermal expansion amount of the substrate. After the printed circuit board and the tape carrier package are aligned, the printed circuit board and the tape carrier package are connected to each other by the thermo-compression bonding process. The misalignment due to the thermo-compression bonding process can be improved, decreasing the processing failures and increasing the productivity.

Owner:SAMSUNG DISPLAY CO LTD

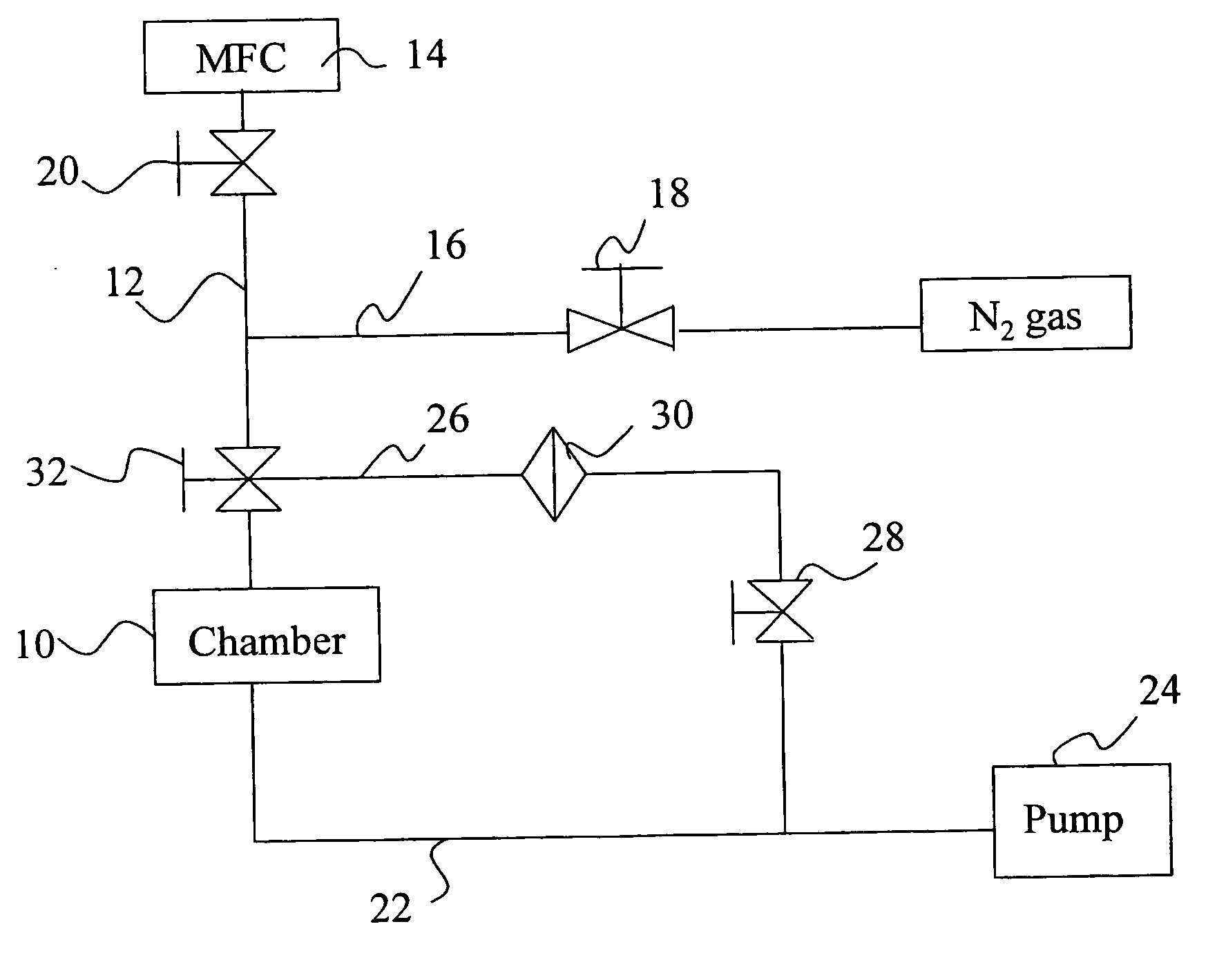

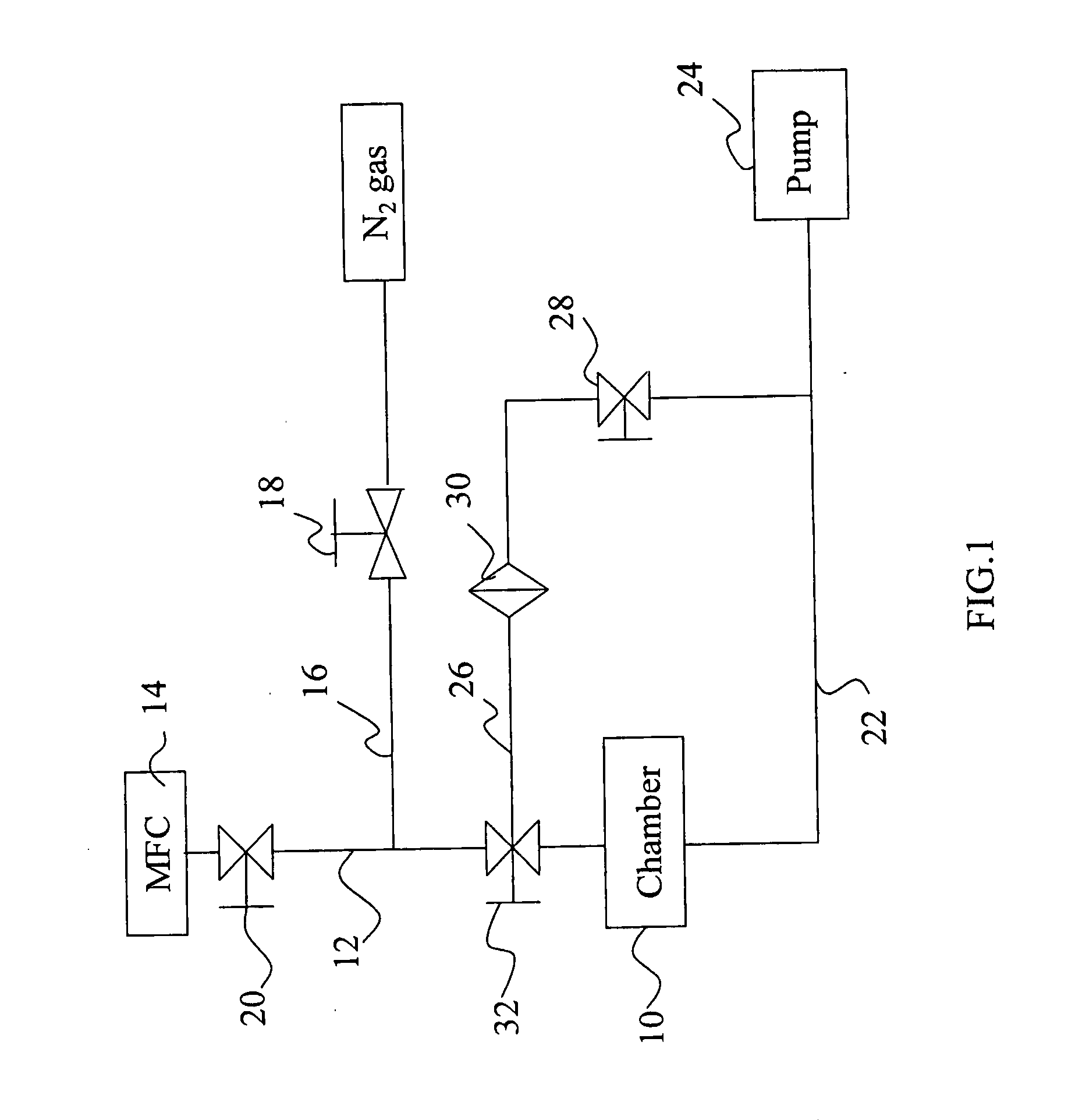

Piping design for high density plasma process chamber

InactiveUS20080023084A1Efficient solutionAvoid processing failureServomotor componentsPipeline systemsHigh densityProduct gas

The present invention discloses a piping design for a high density plasma process chamber, wherein an extra pipe is added to between a process chamber and a mass flow controller, and the extra pipe together with a pump is used to drain out the gas, which cannot be monitored by the mass flow controller and survives in a gas injection pipe, lest the remaining gas pollute the deposited film or react with the process gas to induce an explosion in the succeeding deposition process.

Owner:GRACE SEMICON MFG CORP

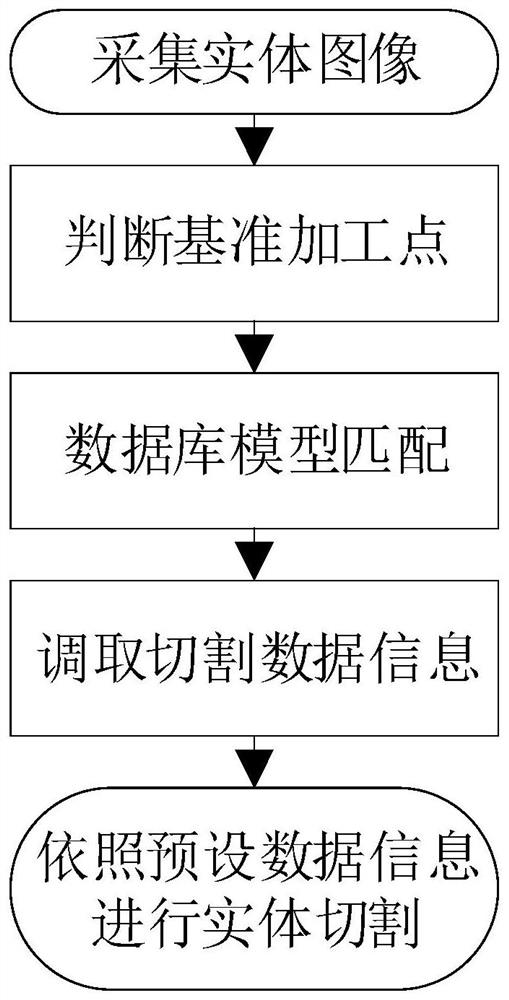

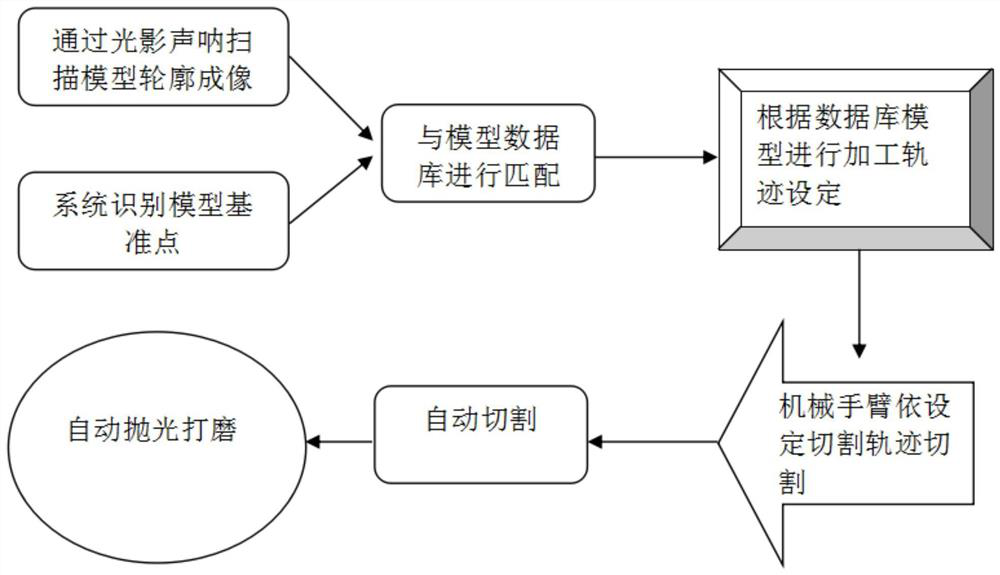

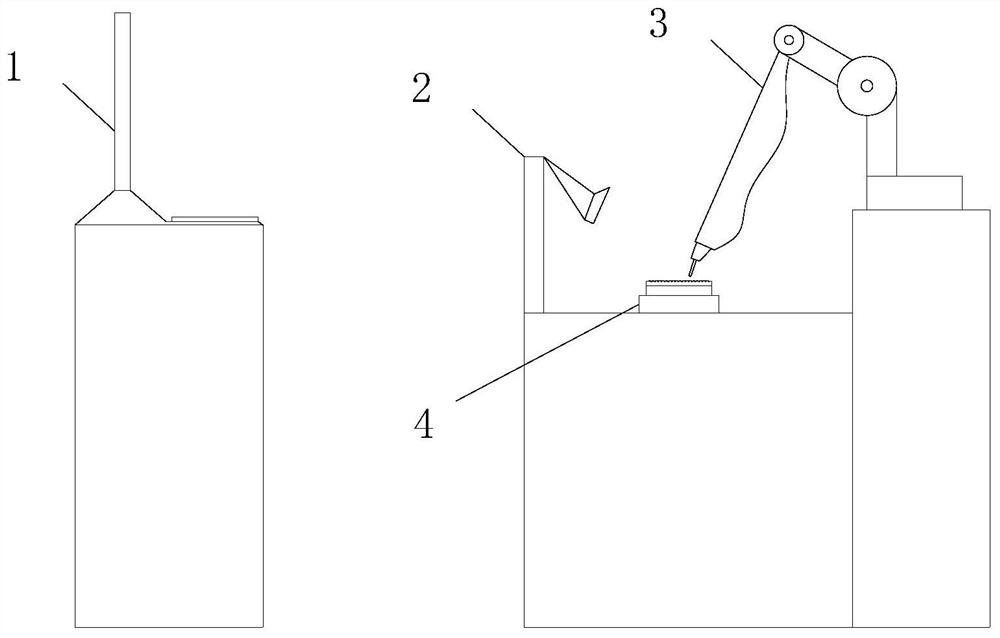

Invisible tooth appliance solid model recognition processing technology

InactiveCN112435752AIncrease productivityReduce processing failureMedical simulationOthrodontics3d imageComputer graphics (images)

The invention is suitable for the technical field of invisible tooth appliance processing, and provides an invisible tooth appliance solid model recognition processing technology. The technology comprises the following steps: sequentially scanning model contours to generate three-dimensional images, and carrying out identifiable positioning on positioning reference points marked on a model; matching the three-dimensional images generated by scanning with a preset model database, determining a database model to perform datum point matching positioning, and obtaining a paired database model; carrying out cutting contour line setting through the paired database models, and transmitting set contour line data to an automatic mechanical arm; and carrying out trajectory cutting of the mechanicalarm according to set contour line data and coordinate datum points. According to the method, the production efficiency of a traditional production process is improved, and machining failures caused bythree-dimensional coordinate errors or identification recognition errors in identification type information scanning and positioning are reduced.

Owner:TIANJIN ZHENGLI TECH CO LTD

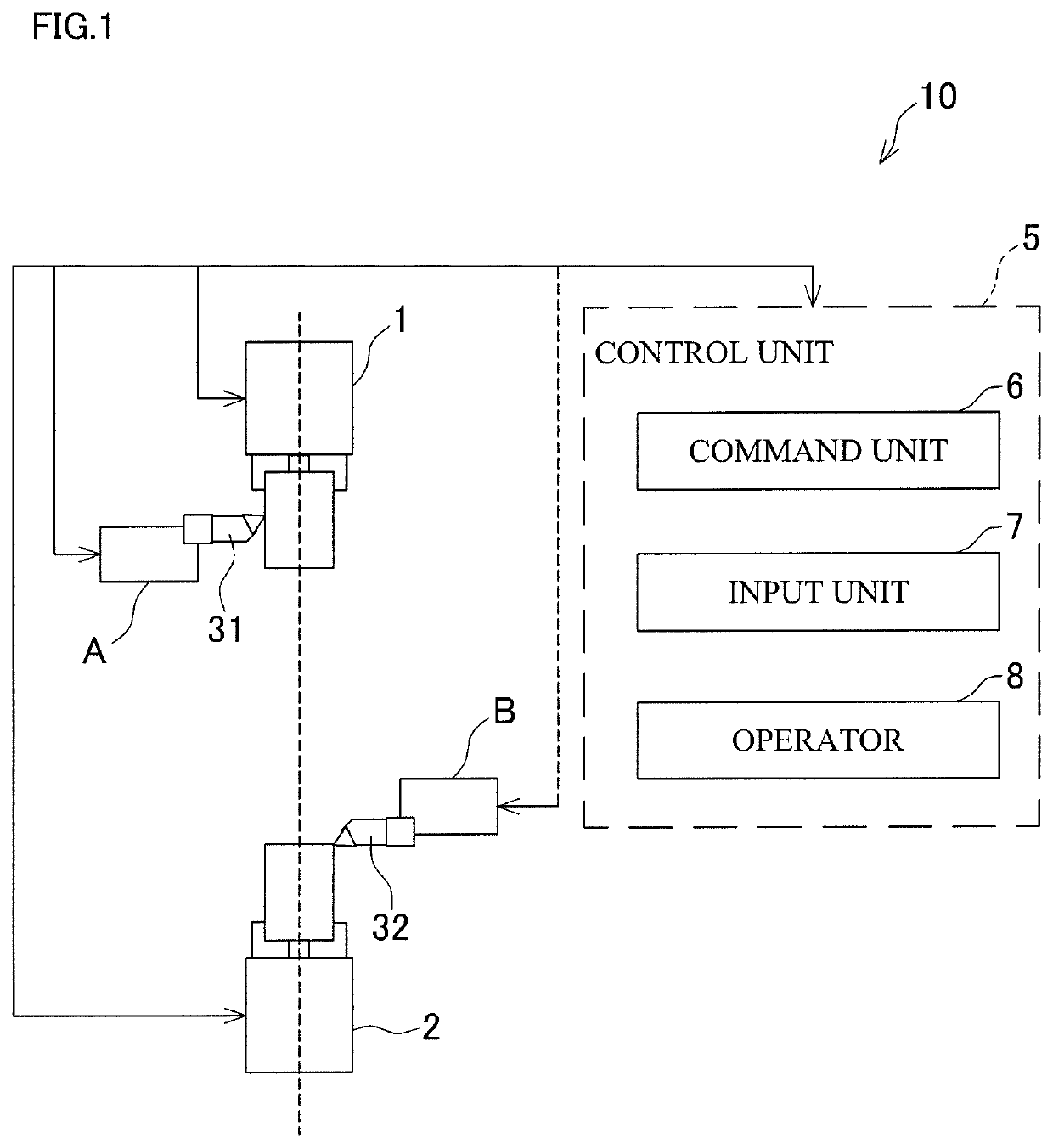

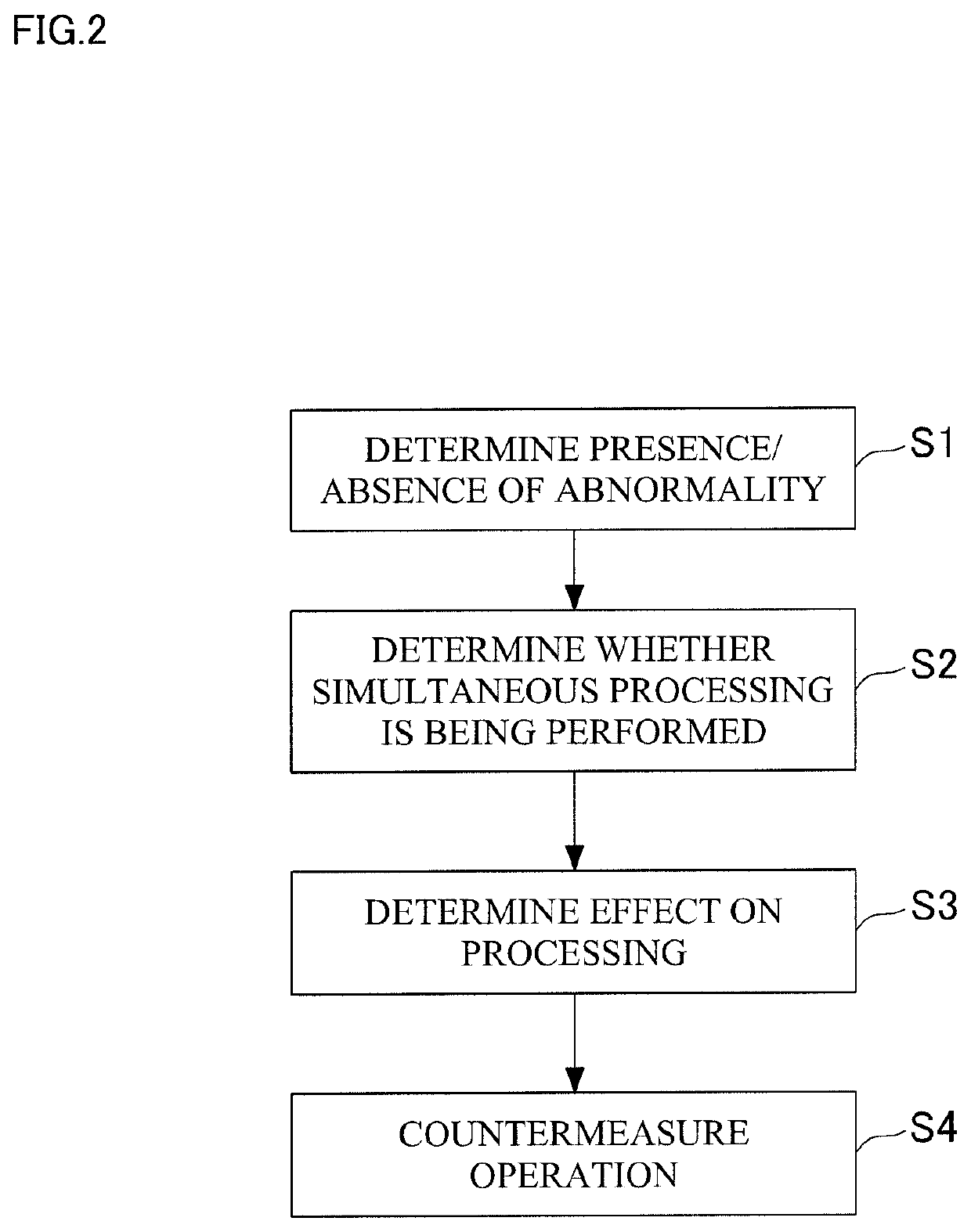

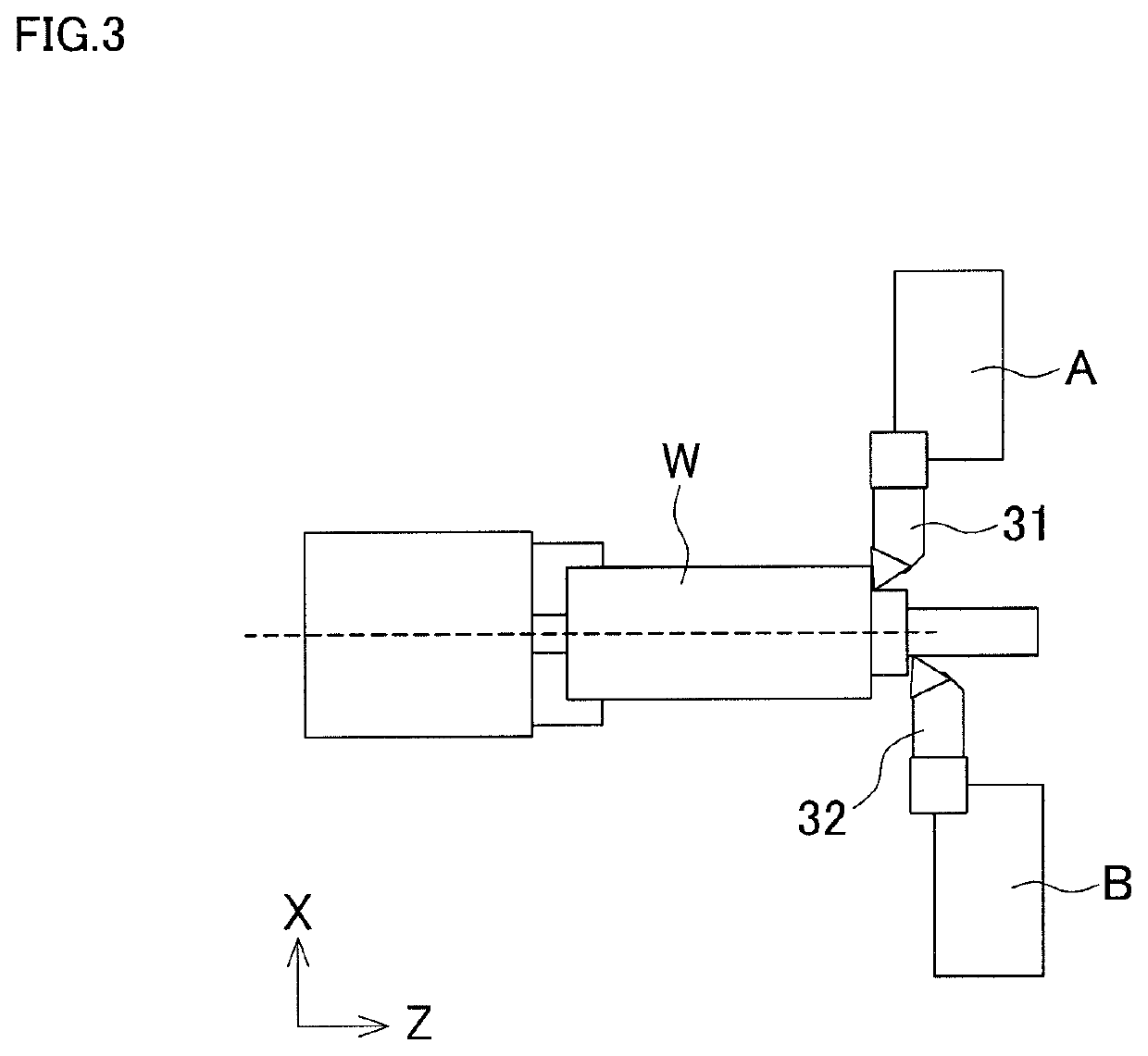

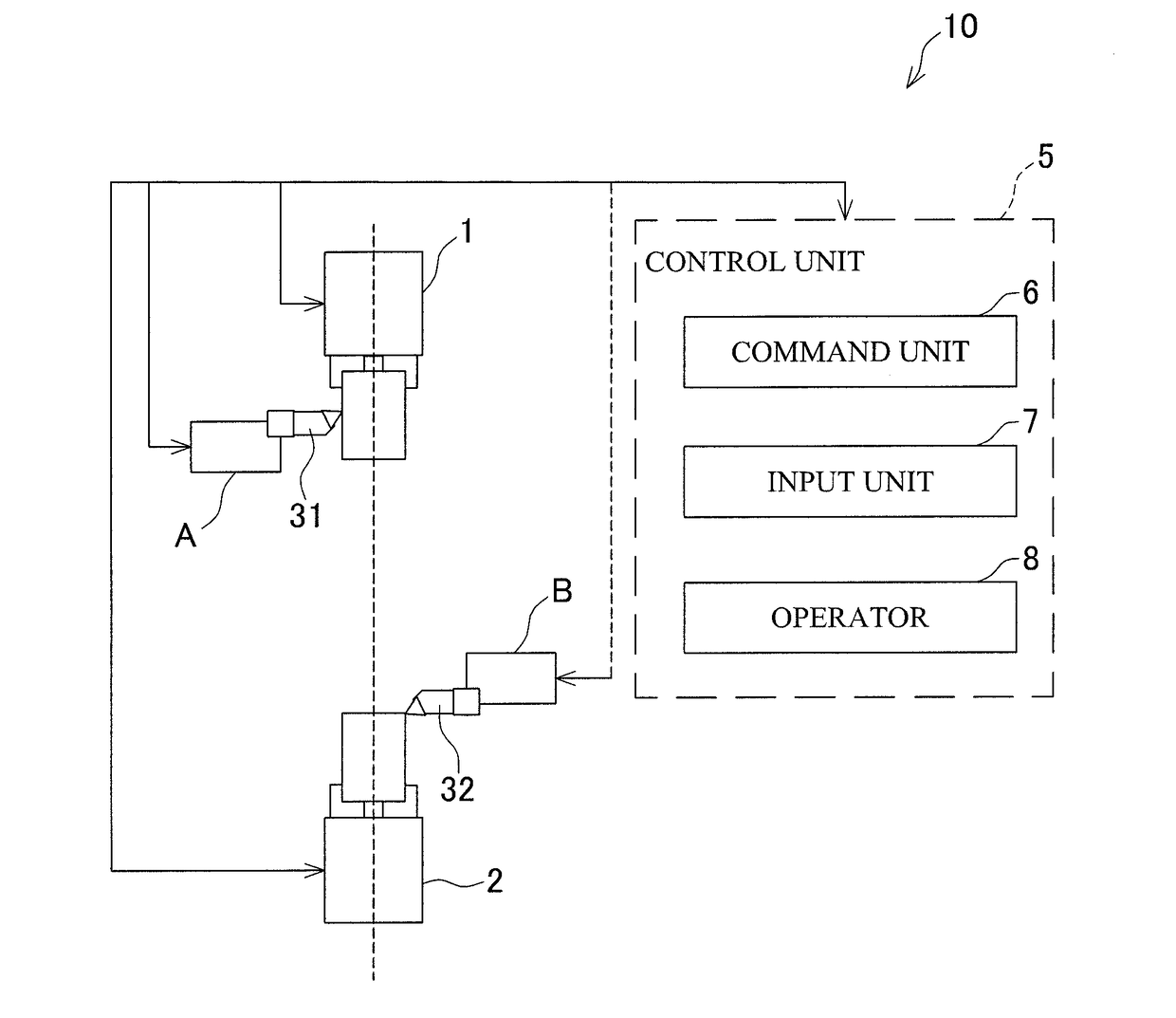

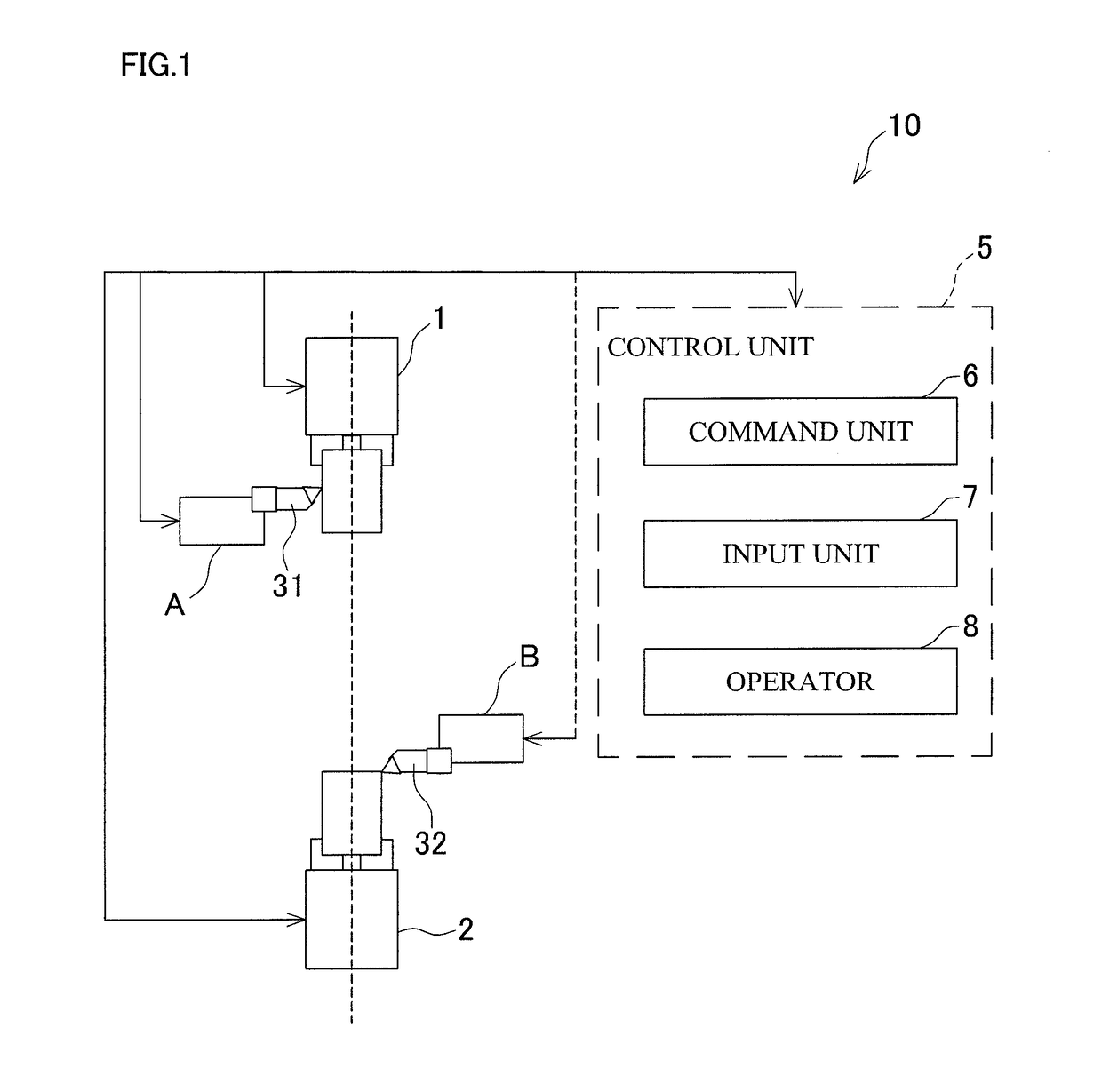

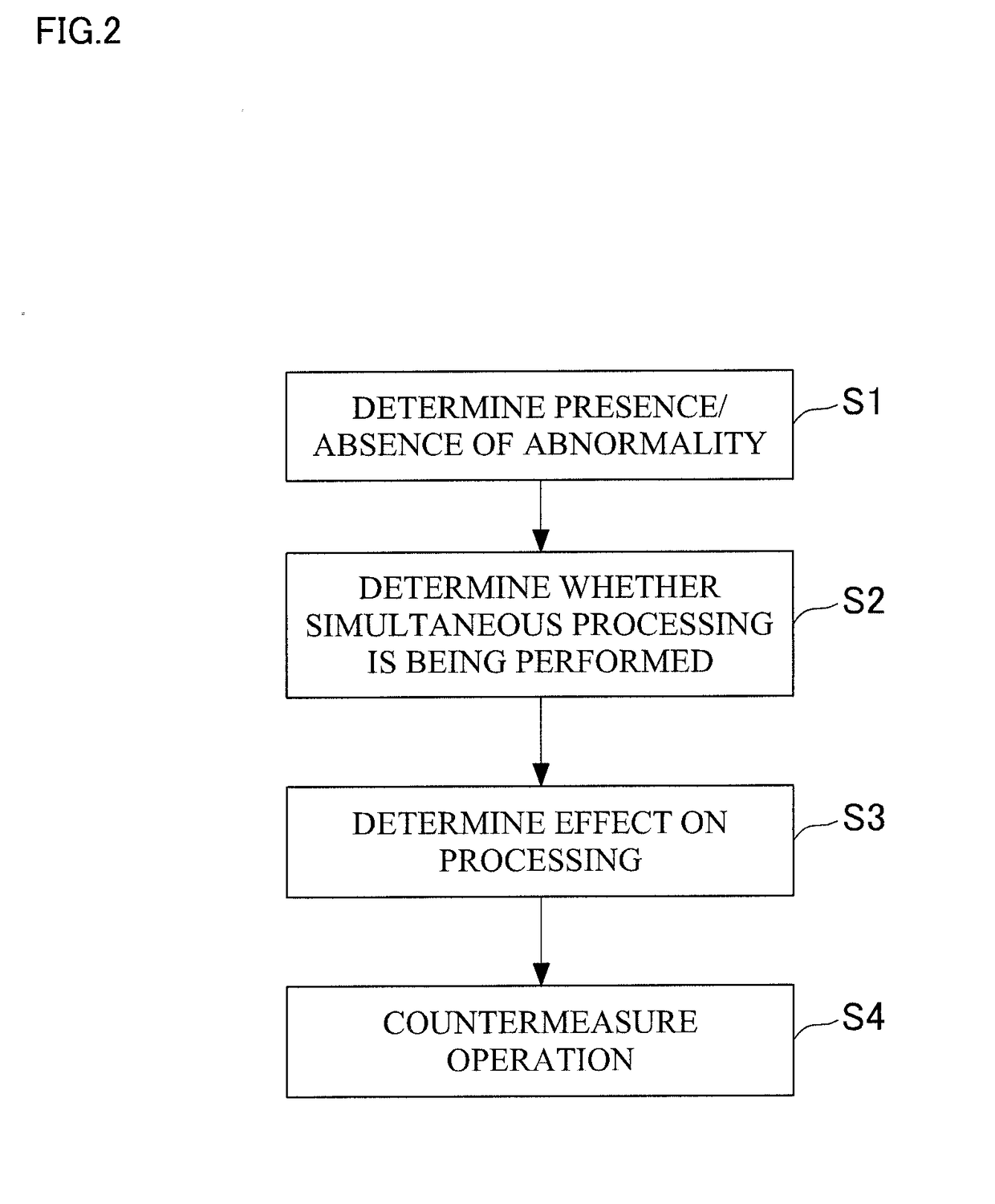

Operational control method in machine tool

ActiveUS10913121B2Effect processingReduce laborProgramme controlAutomatic/semiautomatic turning machinesControl engineeringMachine tool

Owner:OKUMA CORP

Operational control method in machine tool

ActiveUS20180243833A1Effect processingReduce laborProgramme controlAutomatic/semiautomatic turning machinesEngineeringMachine tool

An operational control method is provided for a machine tool that includes a plurality of tool holders with a cutting-tool. The machine tool relatively moves the tool holders with respect to a workpiece to process the workpiece. The operational control method includes determining whether an abnormality has occurred in the cutting-tool during a processing or not, determining whether a simultaneous processing in which at least two or more of the tool holders perform the processings to an identical workpiece is being performed or not and whether the cutting-tool having the detected abnormality is the cutting-tool that is performing the simultaneous processing or not when the abnormality is detected, and causing the tool holder with the cutting-tool having the detected abnormality to take an abnormality avoidance operation and another of the tool holders to take a response operation based on a determination result at the determining of the simultaneous processing.

Owner:OKUMA CORP

Method for machining spatial hole by using large ellipsoid on numerical control boring-milling machine

ActiveCN101920453BSolve complex computing problemsReduce processing failureOther manufacturing equipments/toolsNumerical controlNumerical controlEngineering

The invention discloses a method for machining spatial holes by using a large ellipsoid on a numerical control boring-milling machine. The method comprises the following steps of: determining the range and the clamping datum of a machined hole by applying a software analysis workpiece; compiling a numerical control machining program of the spatial hole; checking the numerical control machining program by applying simulation software; clamping and correcting according to a numerical control requirement and machining the spatial hole with an allowance; detecting the spatial position precision of the machined hole, adjusting the numerical control machining program according to a detection result and then machining the spatial hole to a required precision; and repeatedly clamping and machining a spatial hole in another range until holes on the workpiece are all machined. The invention has the advantages that multiple groups of spatial holes on the large ellipsoid can be machined by using a numerical control boring-milling machine, thereby meeting the requirement on the position precision; the maximum utilization ratio of a process is realized without being limited by the system of thenumerical control boring-milling machine, and the compiling of the machining program can be finished only by updating part models and mathematical parameters; and the process is safe and reliable andhas high efficiency.

Owner:CHINA FIRST HEAVY IND +1

Cap removal for gate electrode structures with reduced complexity

ActiveUS20190326409A1Reduce material lossReduce process complexityTransistorSolid-state devicesFilling materialsEngineering

The present disclosure relates to manufacturing techniques and respective semiconductor devices in which the capping material of gate electrode structures may be removed together with portions of the capping material of resistors on the basis of a highly controllable directional etch process, wherein raised drain and source regions may be protected on the basis of a fill material.

Owner:GLOBALFOUNDRIES US INC

A friction welding machine capable of rolling and leveling workpieces

ActiveCN112247719BReduce processing failureQuick sandingEdge grinding machinesGrinding wheel securing apparatusFriction weldingElectric machinery

The invention relates to the technical field of friction welding, in particular to a friction welding machine capable of rolling and leveling workpieces. It includes a mounting frame mechanism, the mounting frame mechanism includes a base, a No. 1 mounting frame is fixed on the top of the base, and a No. 2 mounting frame is fixed on the side of the No. One side of No. 2 mounting frame is fixed with No. 3 mounting frame, and the top of described No. 3 mounting frame is equipped with driving motor, and the output end of described driving motor is connected with No. 2 clamping mechanism, and the top of described No. 2 mounting frame is positioned at The outer wall of the No. 2 clamping mechanism is connected with an eccentric mechanism. In the present invention, by setting the connection mechanism and the grinding mechanism, the connection mechanism can quickly install or disassemble the grinding head, and the process is convenient. After the welding is completed, the grinding mechanism can quickly polish the weld seam, so that the welding is completed and rolled The purpose of leveling is to reduce the processing failure required by the workpiece, thereby reducing production costs.

Owner:湖南坤鼎数控科技有限公司

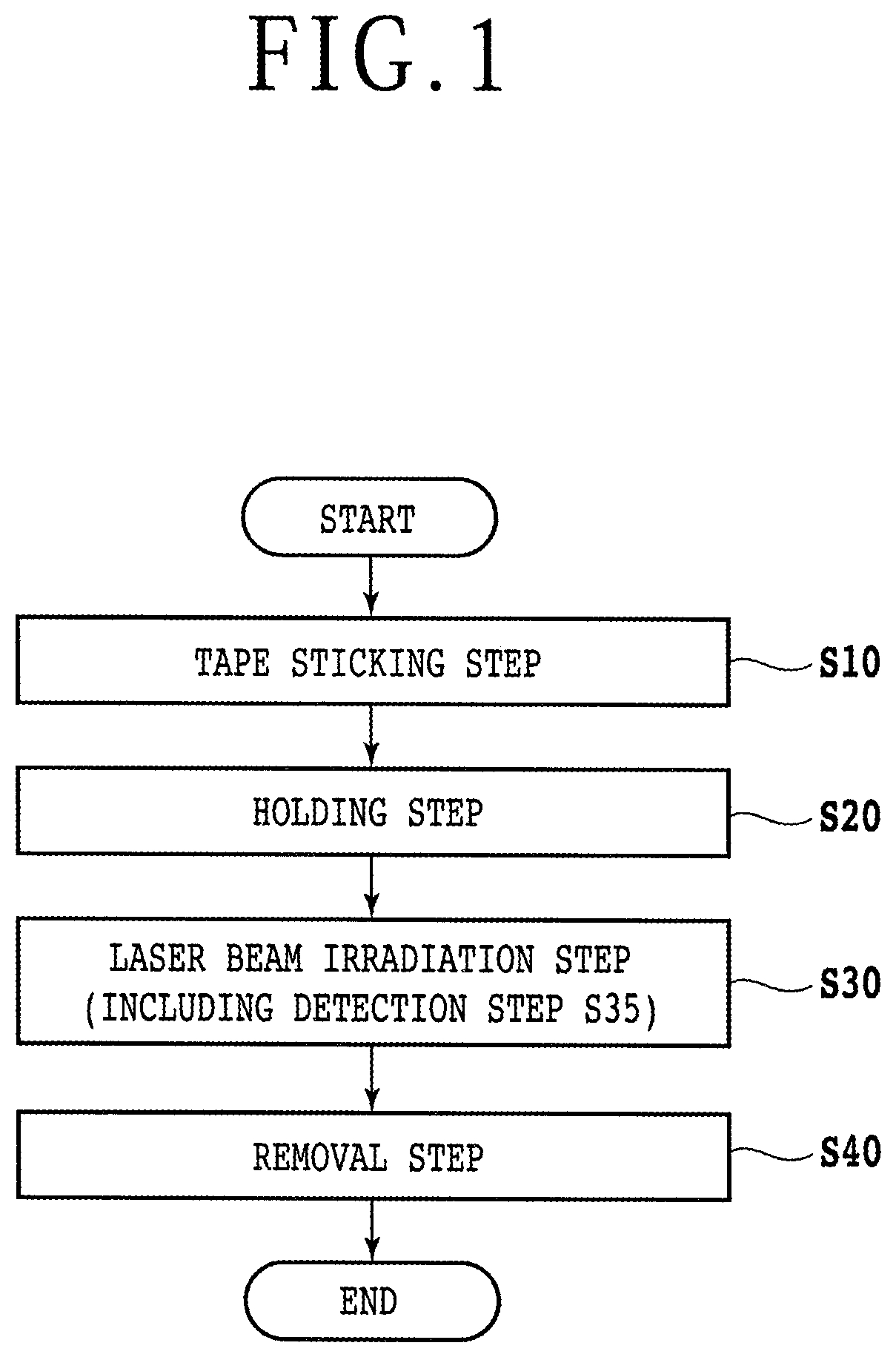

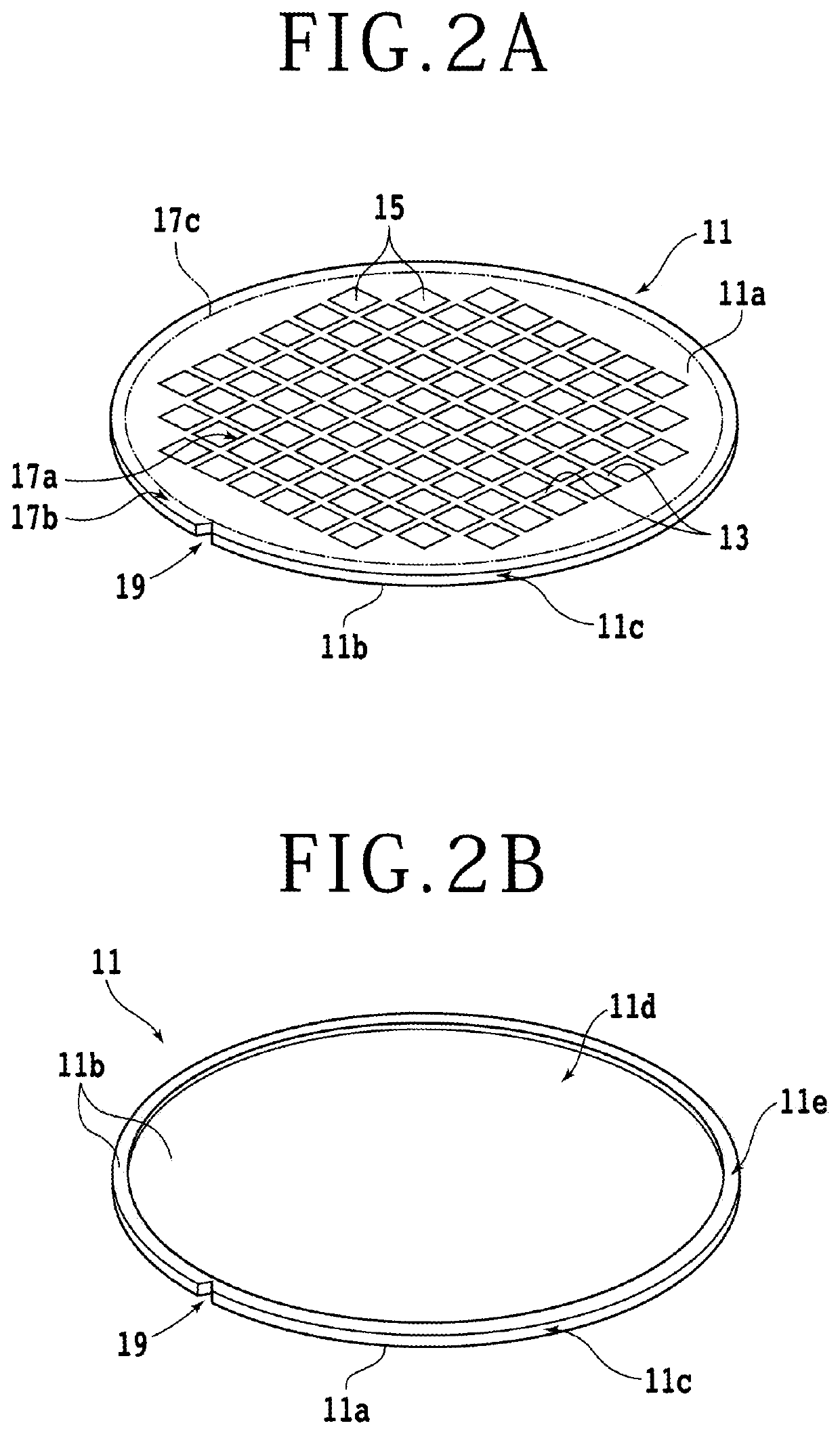

Processing method of workpiece

PendingUS20220108882A1Reduce processing failureReturn of the laser beam to the laser oscillator can be suppressedSolid-state devicesSemiconductor/solid-state device manufacturingCircular discAngle of incidence

A processing method of a workpiece with a circular disc shape includes sticking a tape to one surface of the workpiece and integrating the workpiece and a frame through the tape, holding the workpiece by a holding unit with the interposition of the tape, and irradiating the other surface of the workpiece located on the opposite side to the one surface with a pulsed laser beam having such a wavelength as to be absorbed by the workpiece from the side of the other surface. In irradiating the laser beam, the other surface is annularly irradiated with the laser beam in the state in which the orientation of the laser beam is adjusted in such a manner that the laser beam has an angle of incidence formed due to inclination with respect to a normal to the other surface of the workpiece by a predetermined angle.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com