Method and apparatus for polishing a copper layer and method for forming a wiring structure using copper

a technology of cu and wiring structure, which is applied in the direction of grinding machines, manufacturing tools, edge grinding machines, etc., can solve the problems of cu being rapidly diffused into silicon or other metal layers, affecting the quality of cu wiring,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

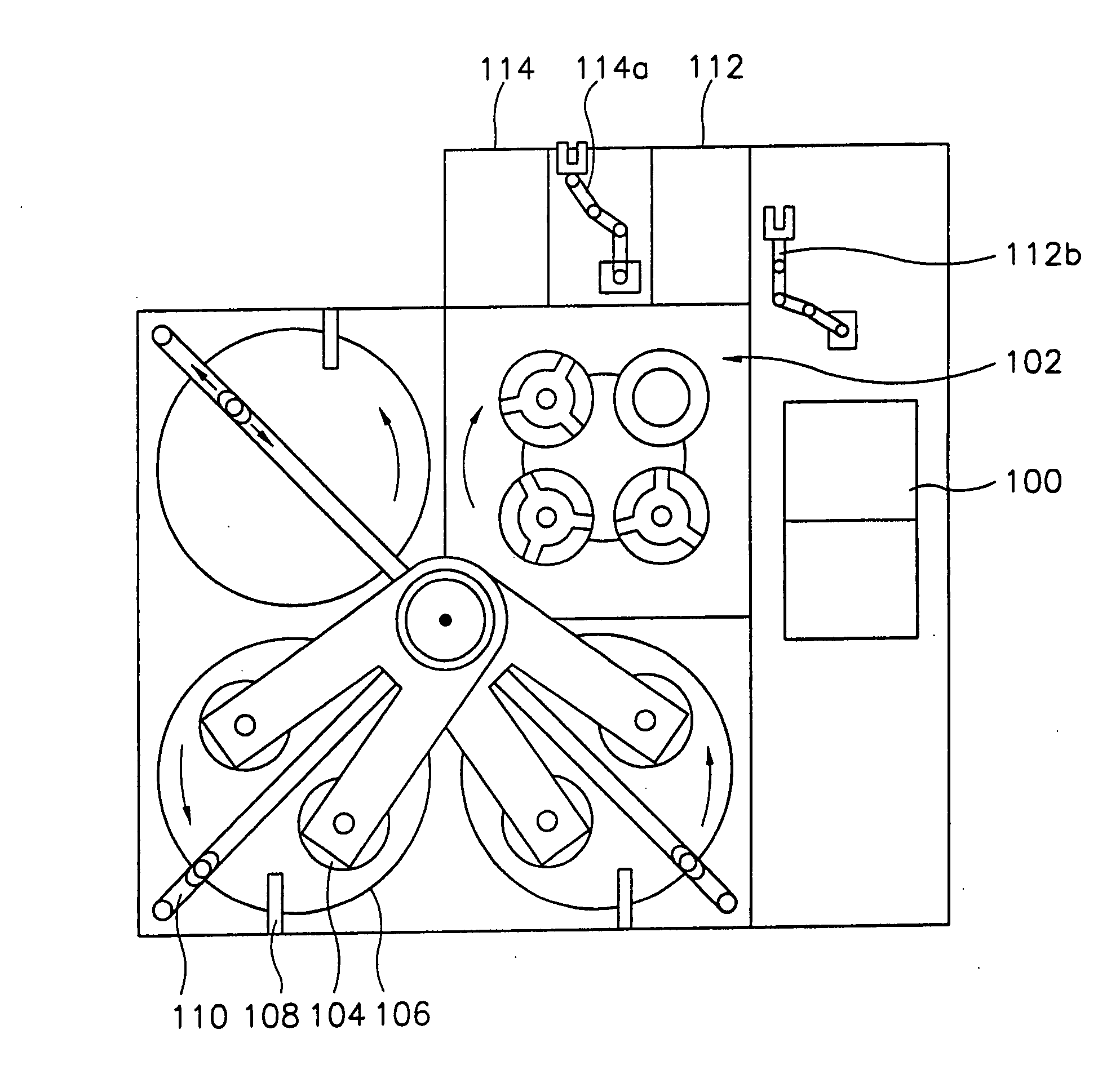

Image

Examples

Embodiment Construction

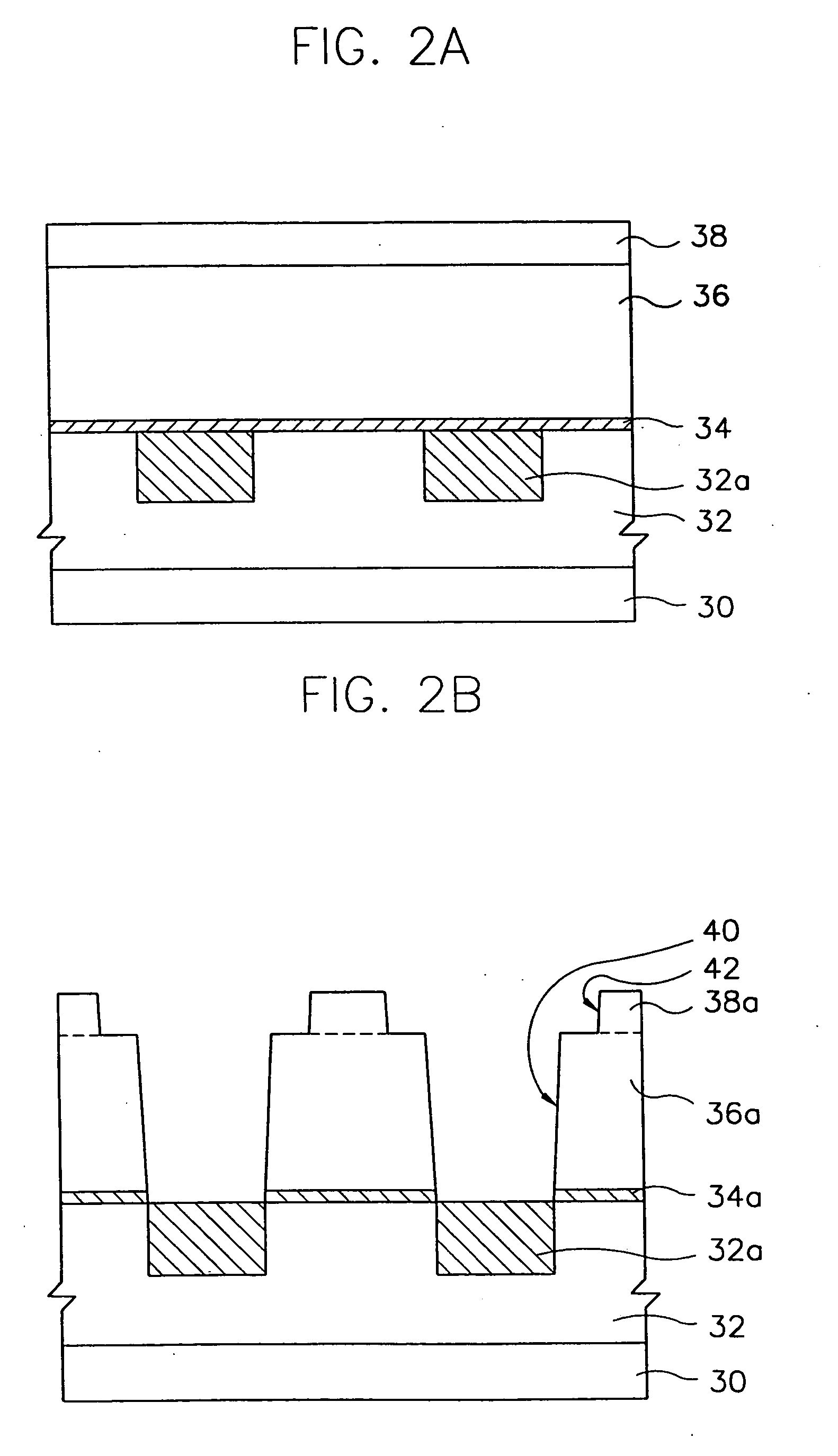

[0027] Hereinafter, a method for polishing a Cu metal layer according to one embodiment of the present invention will be described.

[0028] Initially, a silicon wafer having a Cu metal layer as an uppermost layer thereof is prepared. In order to form the Cu metal layer, a relatively thin Cu seed layer is formed, which is, in effect, a pre-treatment process for forming the Cu metal layer. The Cu seed layer is used as an electrode during a subsequent Cu plating process. Then, Cu is plated on the Cu seed layer through an electroplating process, thereby forming the Cu metal layer. By performing the electroplating process, pure Cu metal is extracted on a surface of a cathode by an electrolysis action. The Cu metal formed by the electroplating process has a metastable state, in which crystal grains are non-uniformly arranged. For this reason, the Cu metal layer is annealed (heat-treated) for crystallizing the Cu metal layer. The annealing (or heat-treating) process is carried out, for exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com