Patents

Literature

173results about How to "Reduce material loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

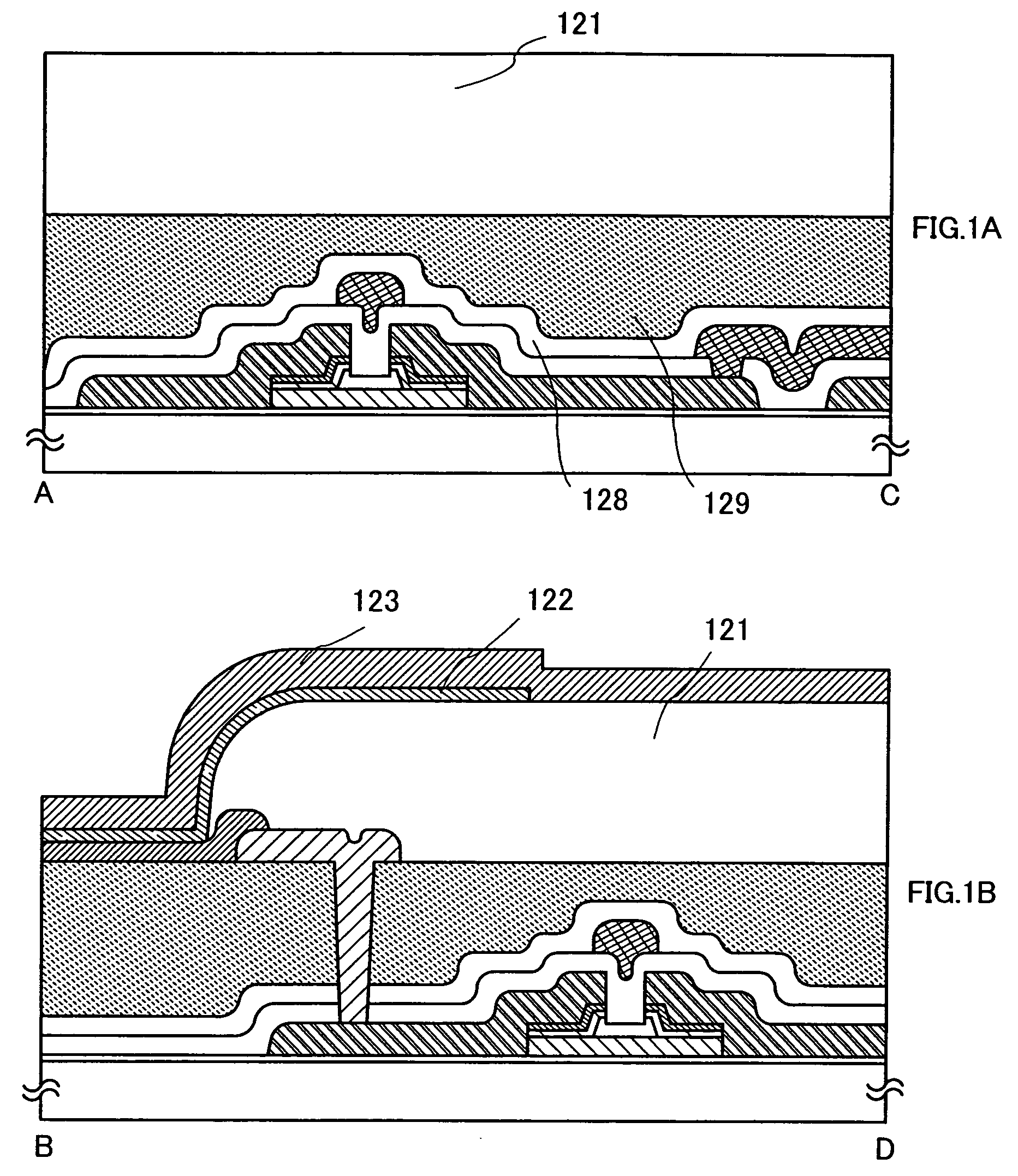

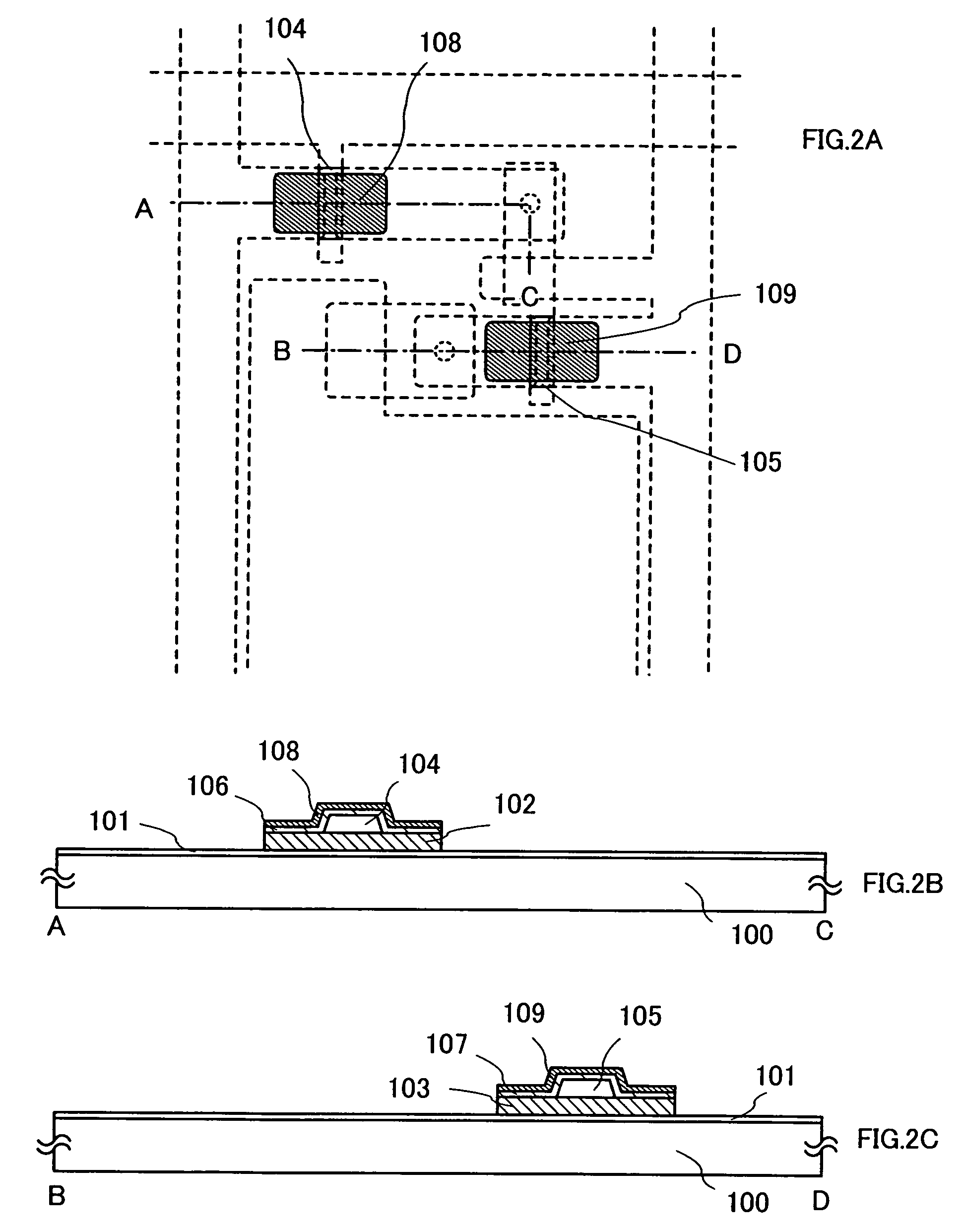

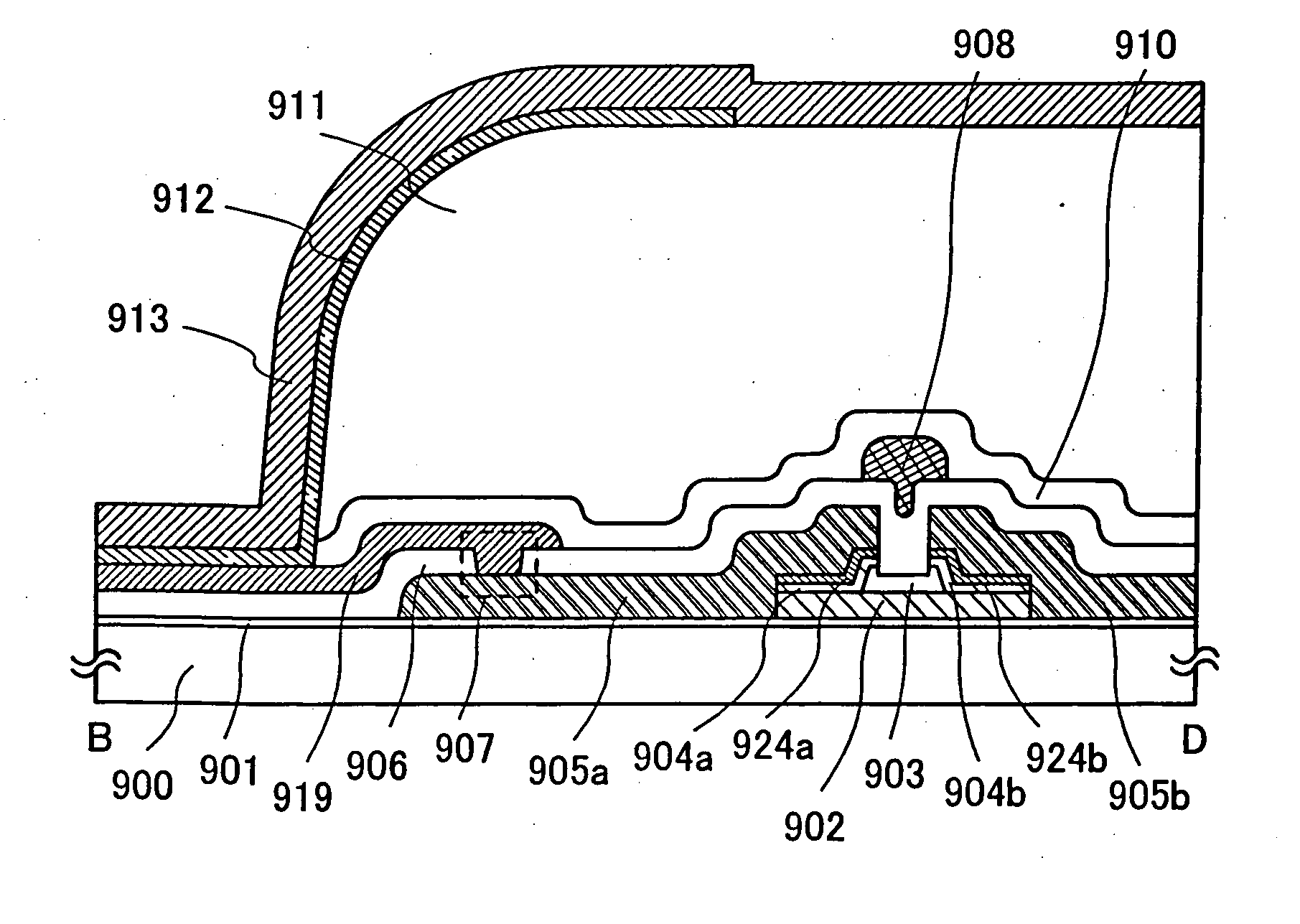

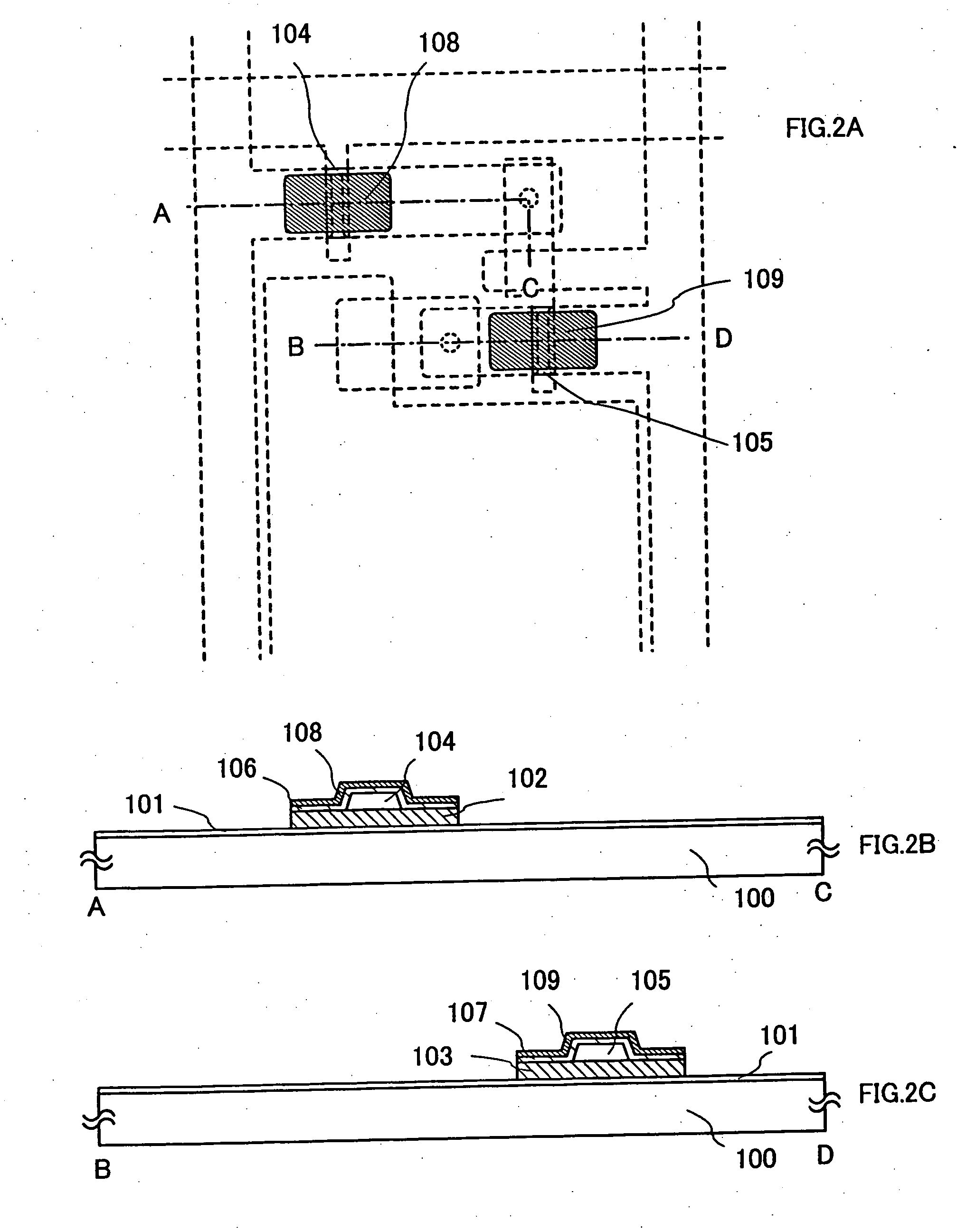

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060169973A1Stable formationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

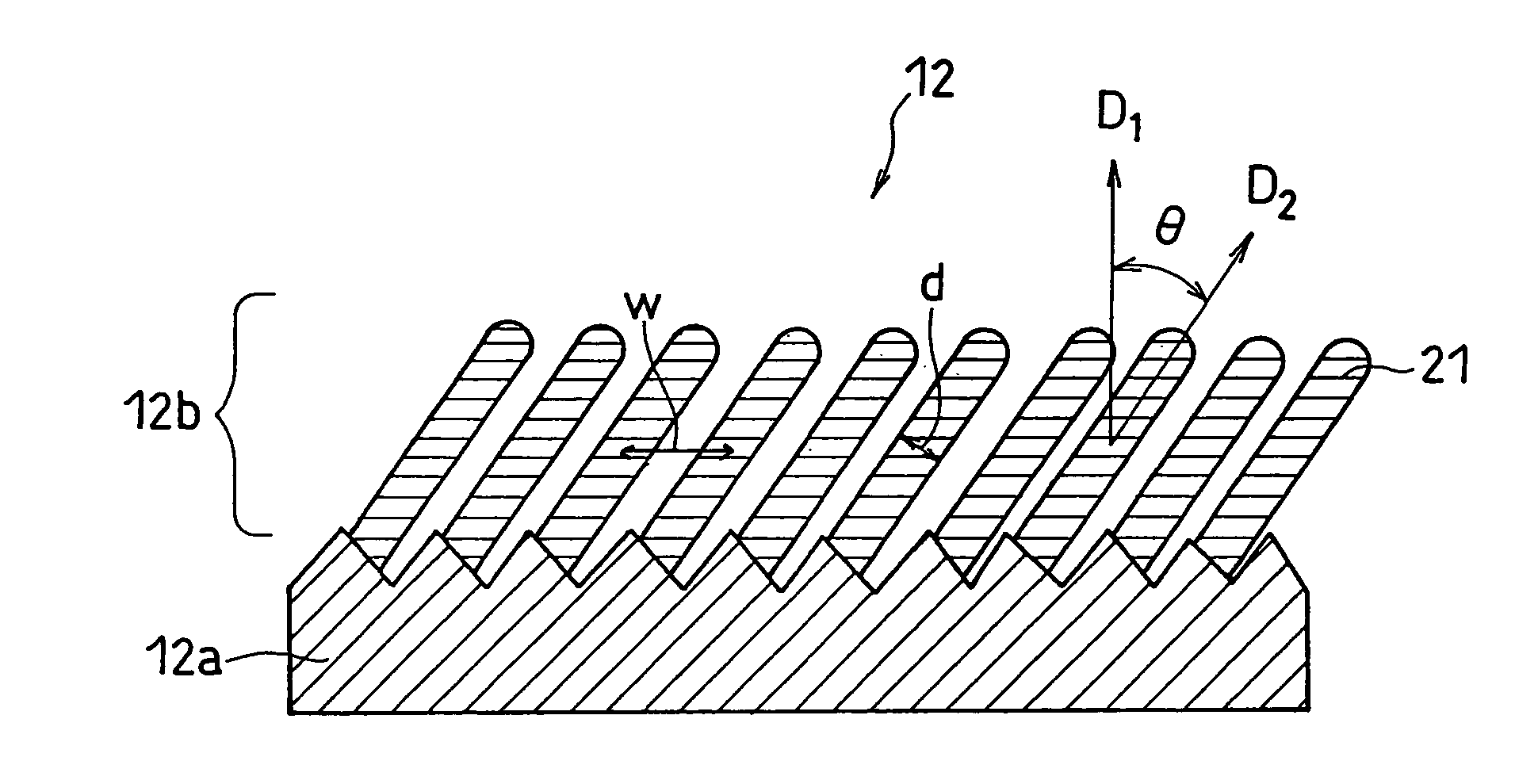

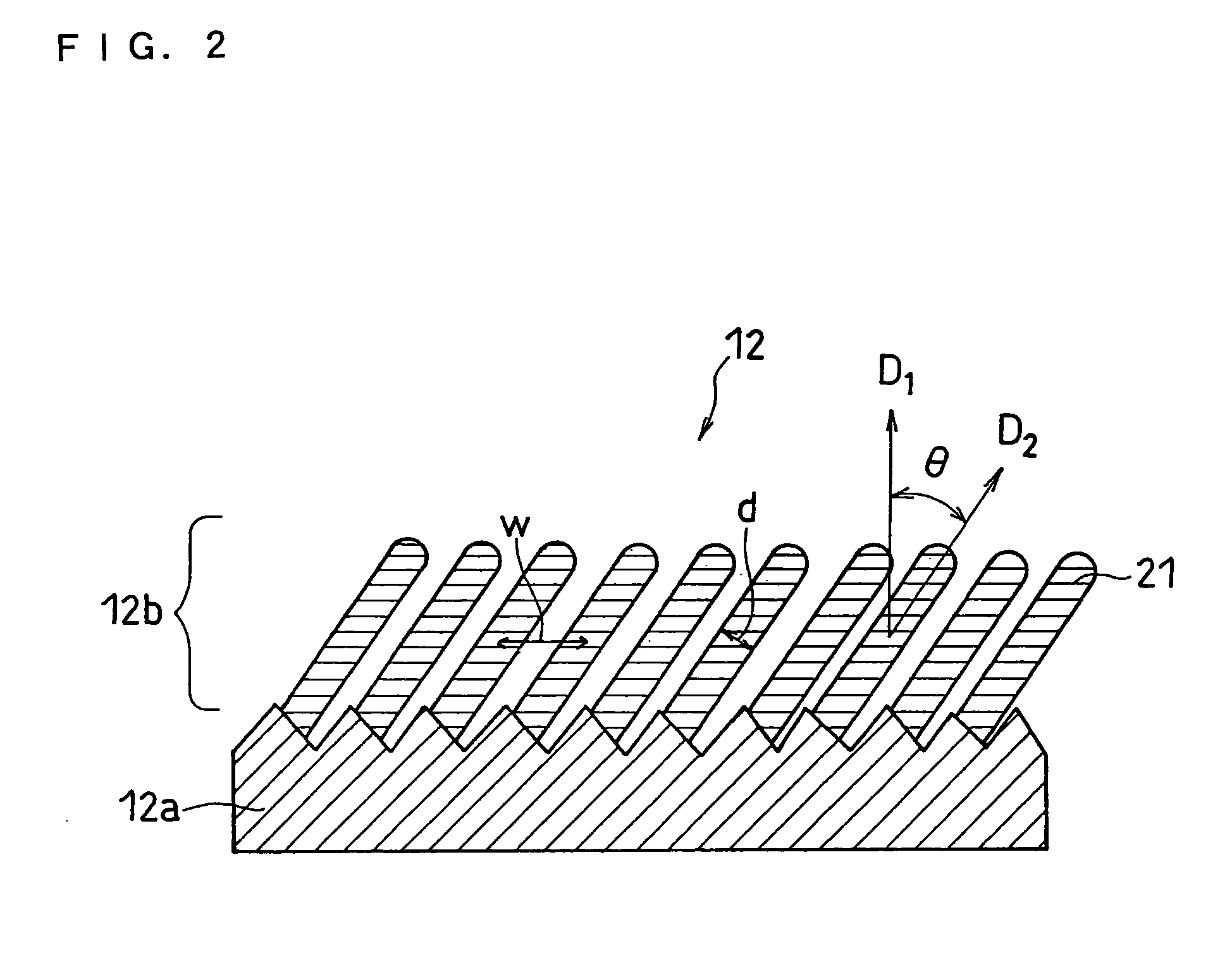

Lithium secondary battery

InactiveUS20070031733A1Negative currentEasy dischargeFinal product manufactureElectrode carriers/collectorsLithiumSilicon

In order to enhance charge and discharge efficiency and to improve cycle characteristics by increasing a facing area between a positive electrode active material and a negative electrode active material, in a negative electrode for lithium secondary battery having a current collector and an active material layer carried on the current collector, the active material layer includes a plurality of columnar particles. The columnar particles include an element of silicon, and are tilted toward the normal direction of the current collector. Angle θ formed between the columnar particles and the normal direction of the current collector is preferably 10°≦θ<90°.

Owner:PANASONIC CORP

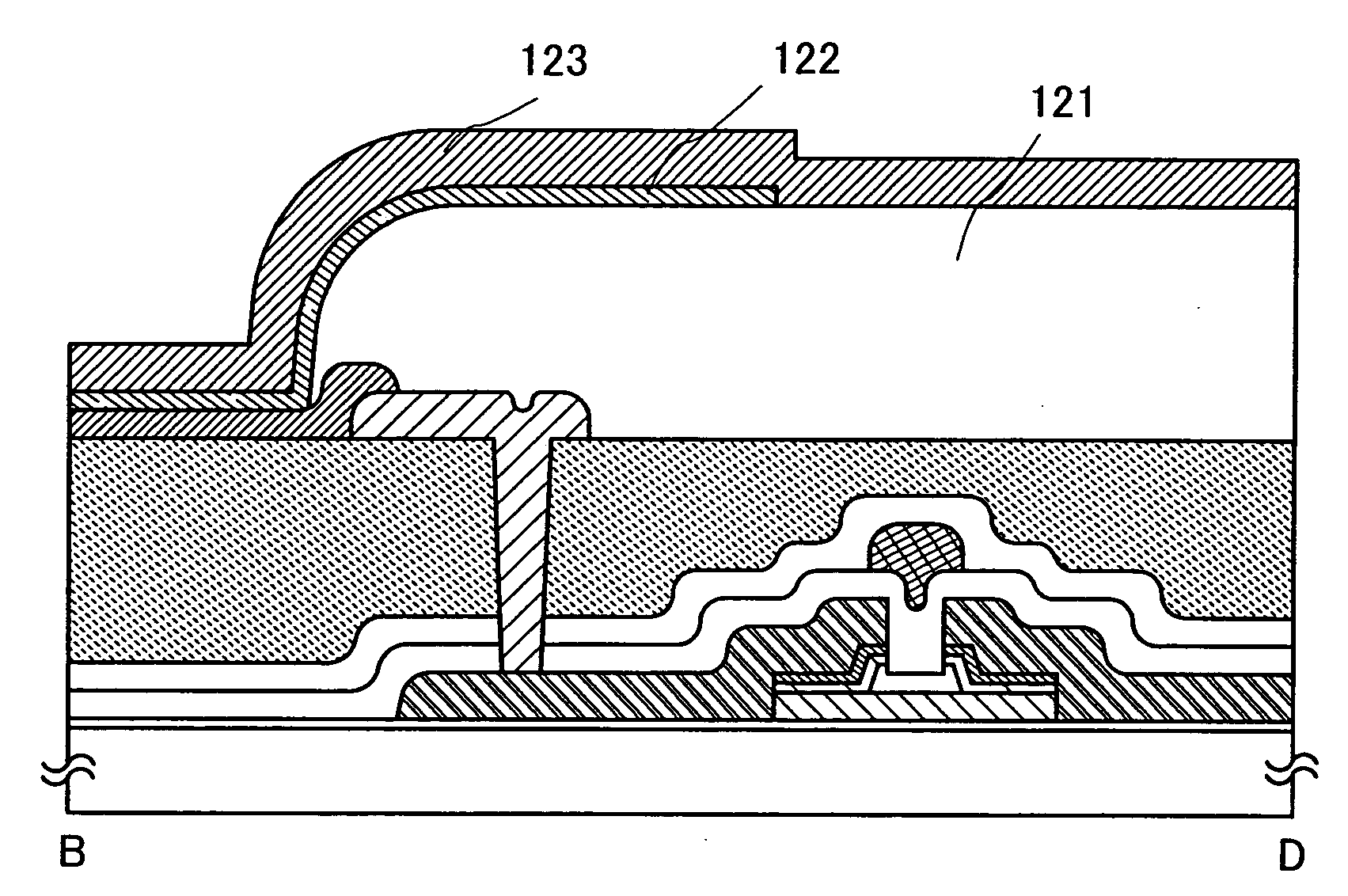

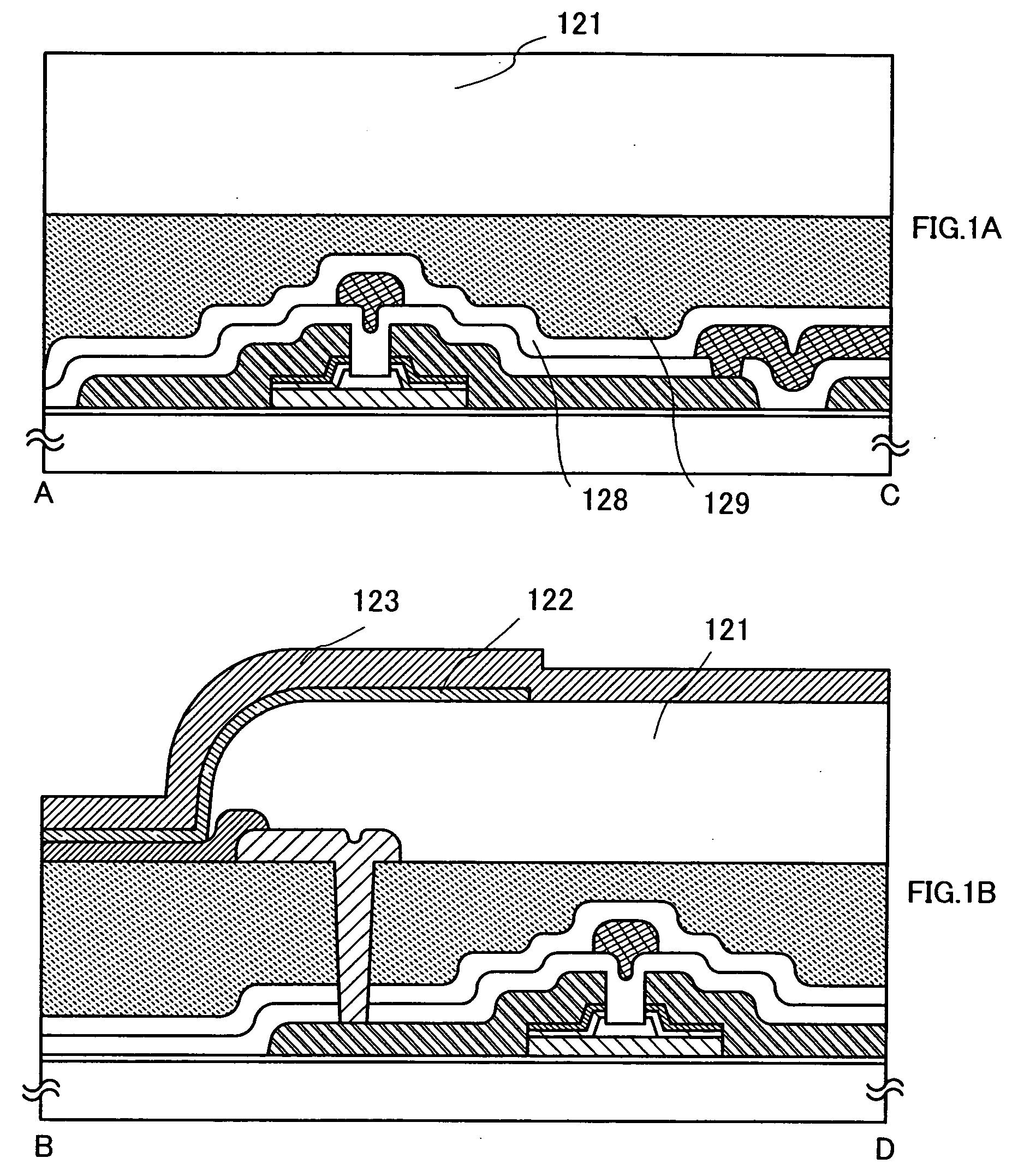

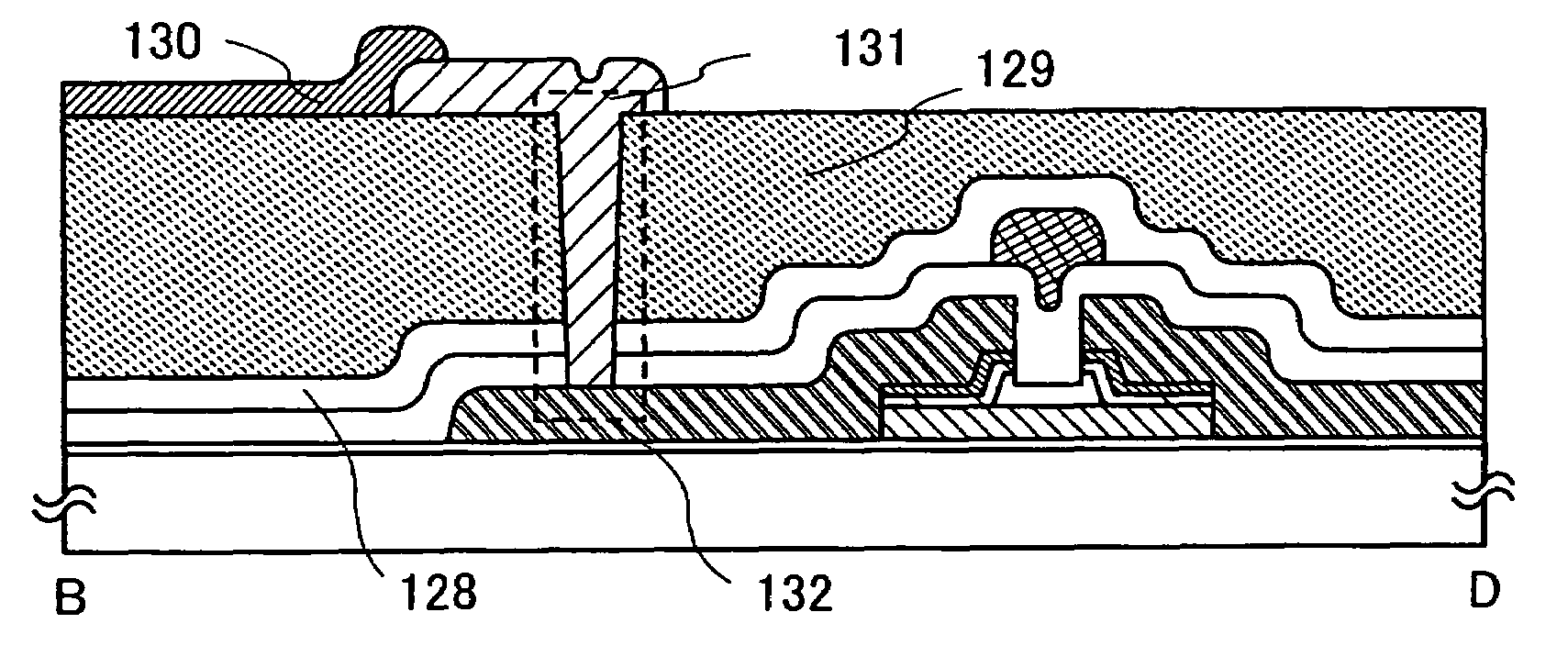

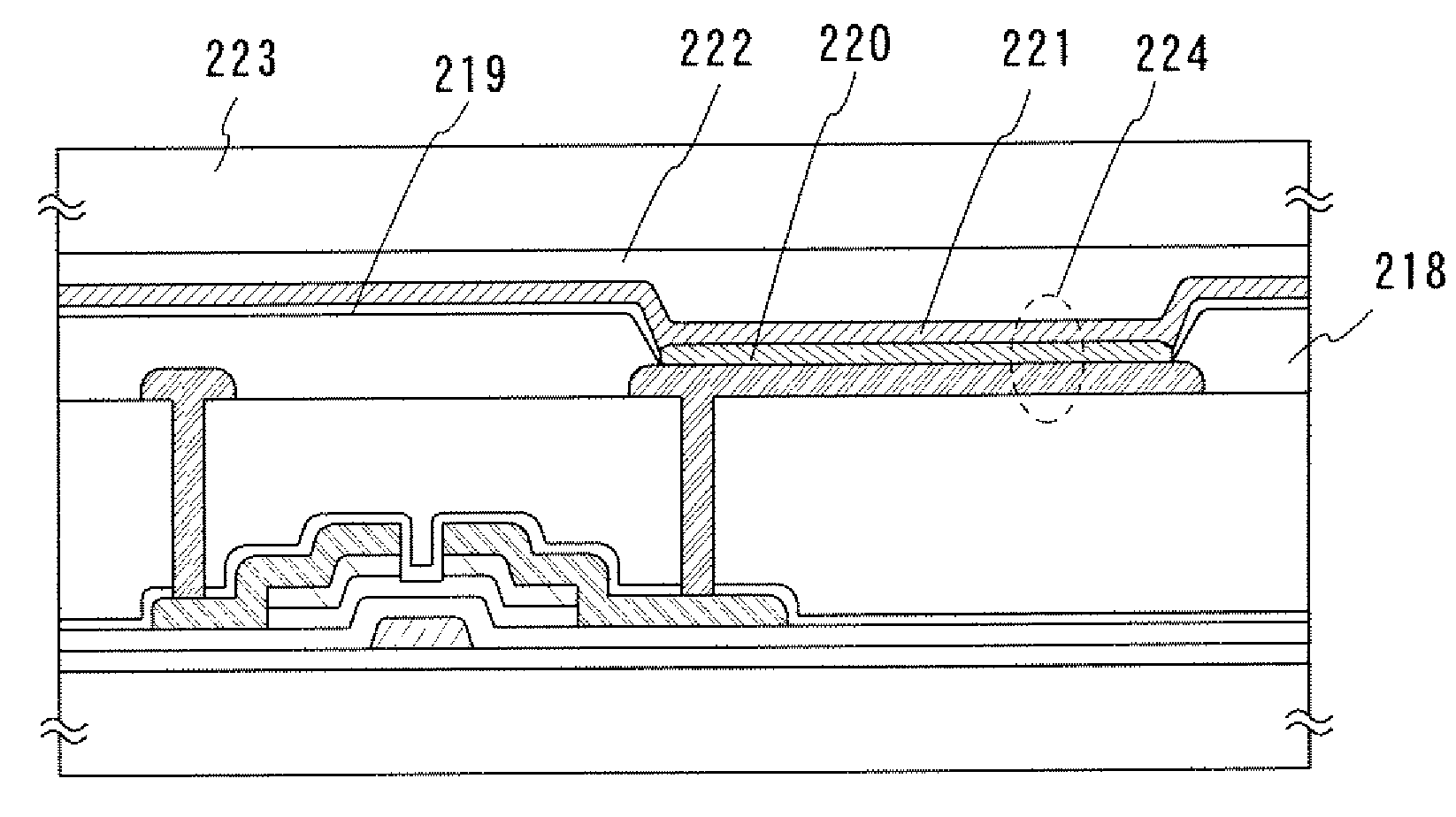

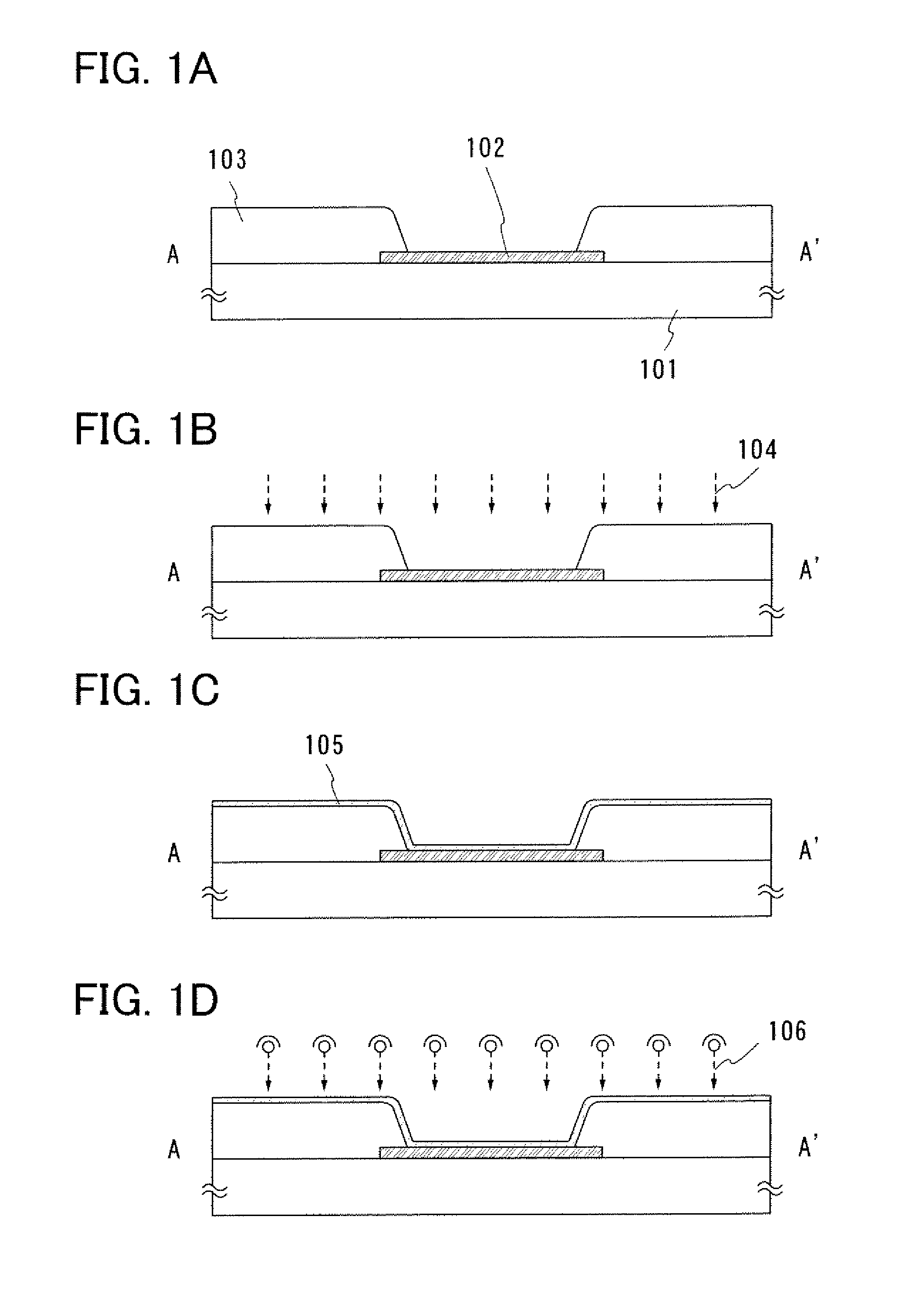

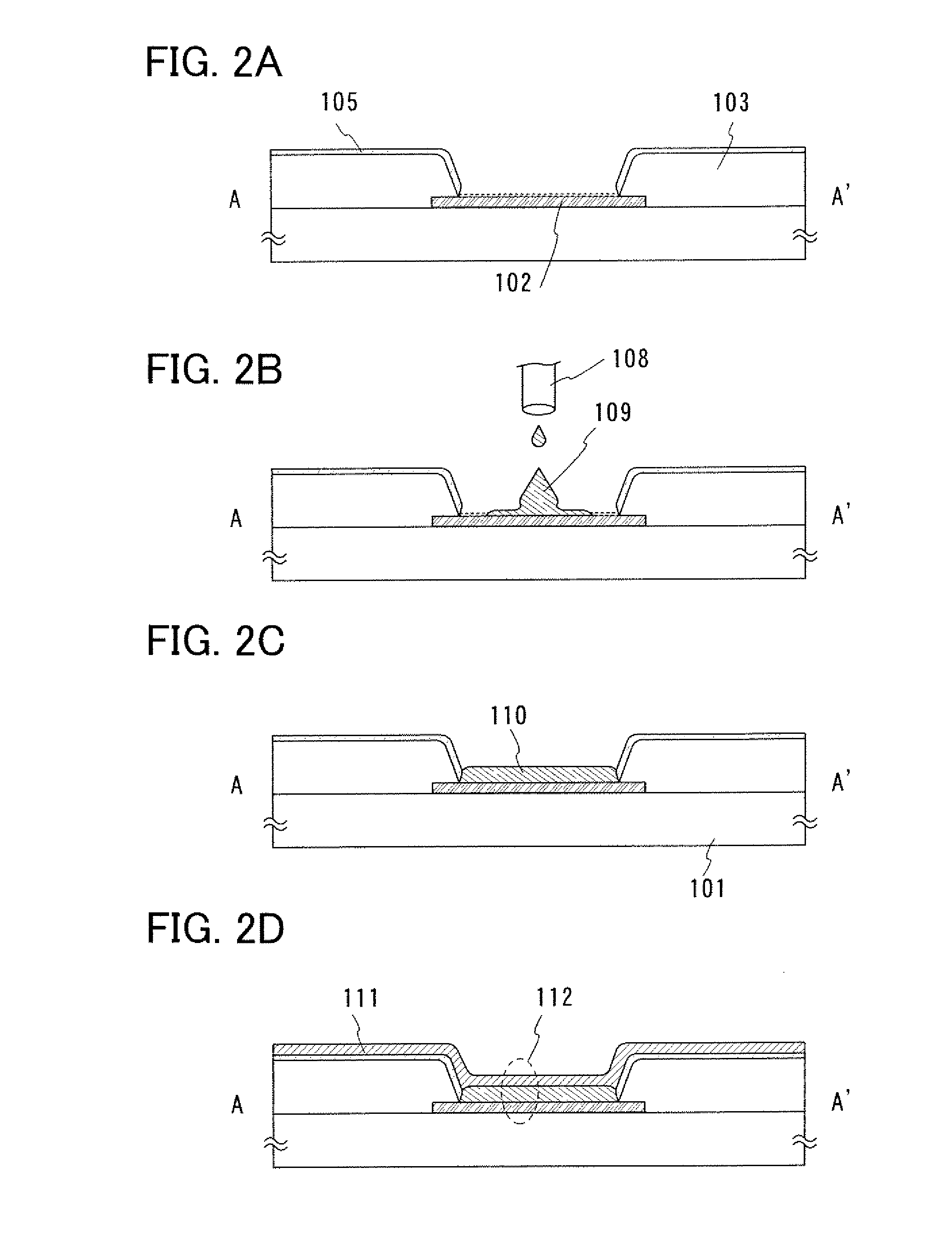

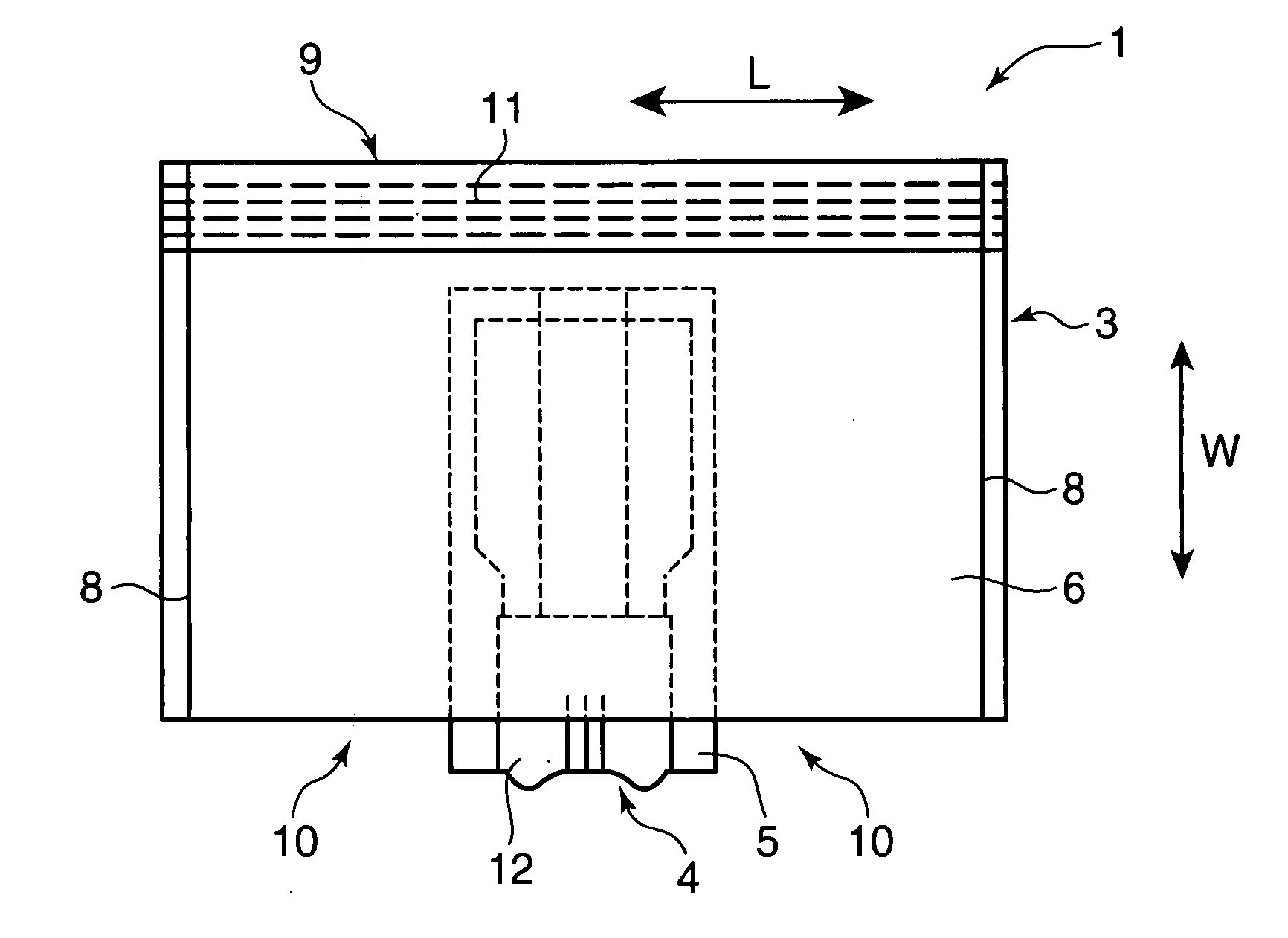

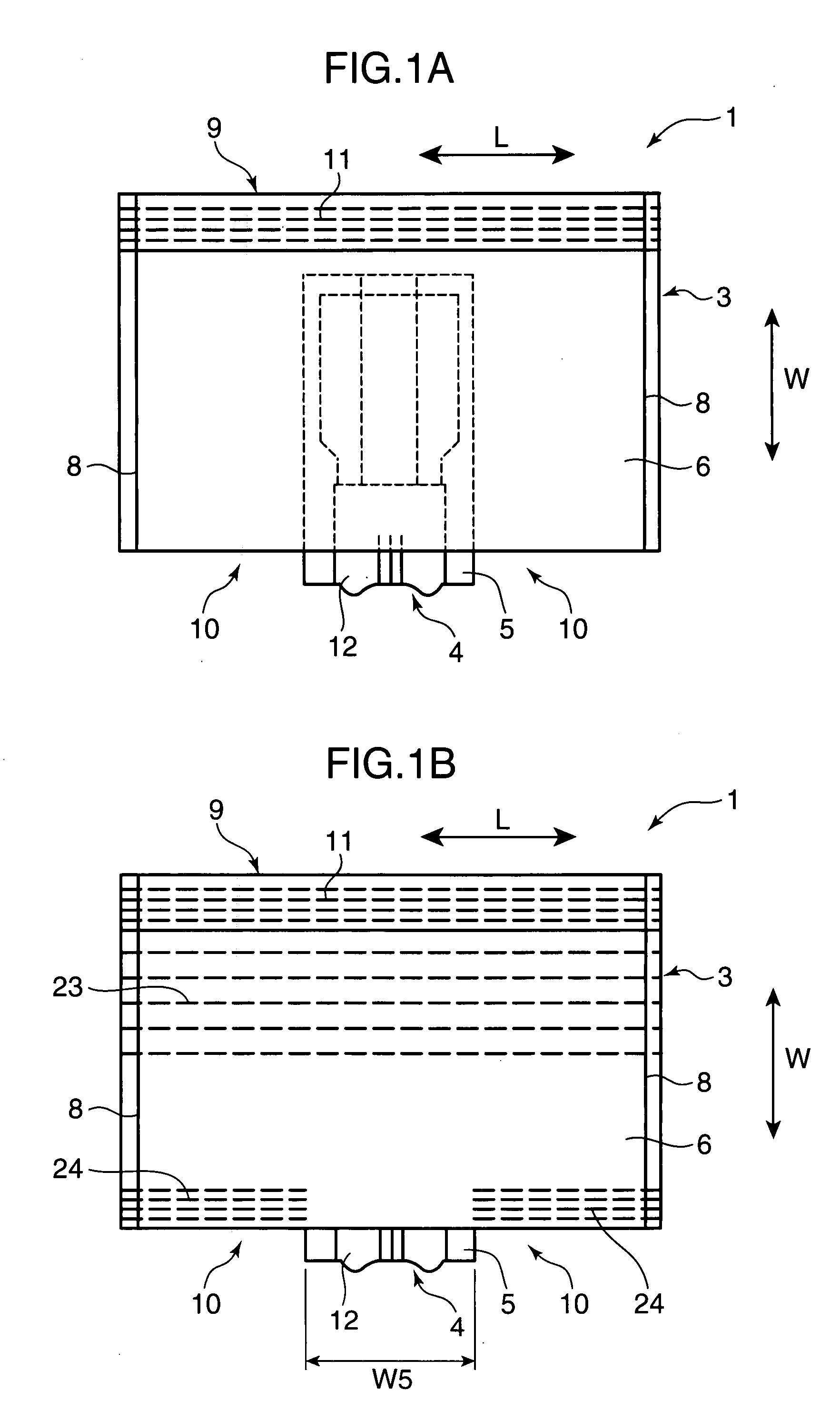

Method for manufacturing display device

InactiveUS20060046336A1Improve mobilityLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a method for manufacturing a display device having a TFT that can be operated at high speed while using a small number of photomasks and improving the utilization efficiency of materials, where the threshold value is difficult to be varied. In the invention, a catalytic element is applied to an amorphous semiconductor film and the amorphous semiconductor film is heated to form a crystalline semiconductor film. After removing the catalytic element from the crystalline semiconductor film, a top-gate type thin film transistor with a planar structure is manufactured. Moreover, by using the droplet discharging method where an element of a display device is formed selectively, the process can be simplified, and loss of materials can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

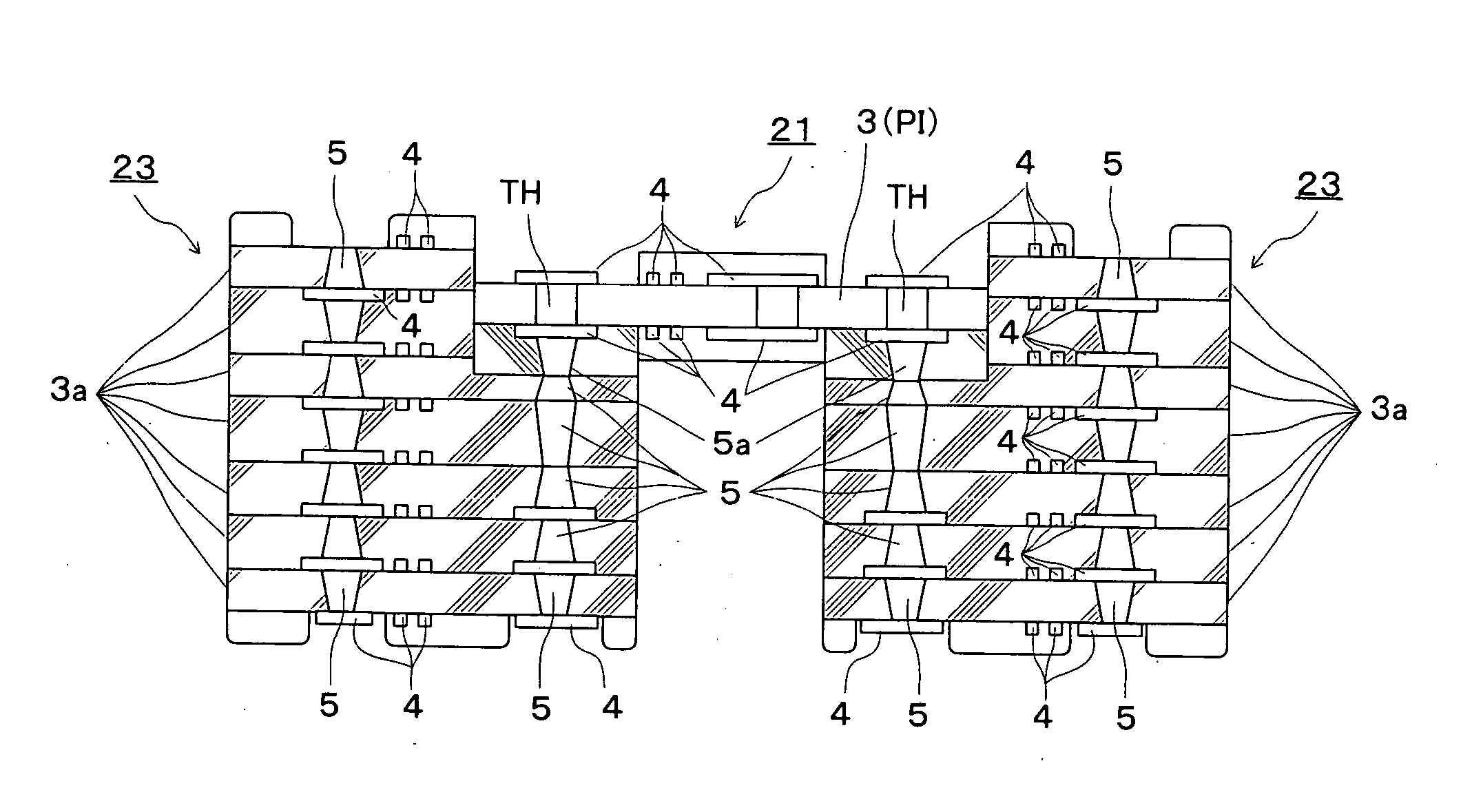

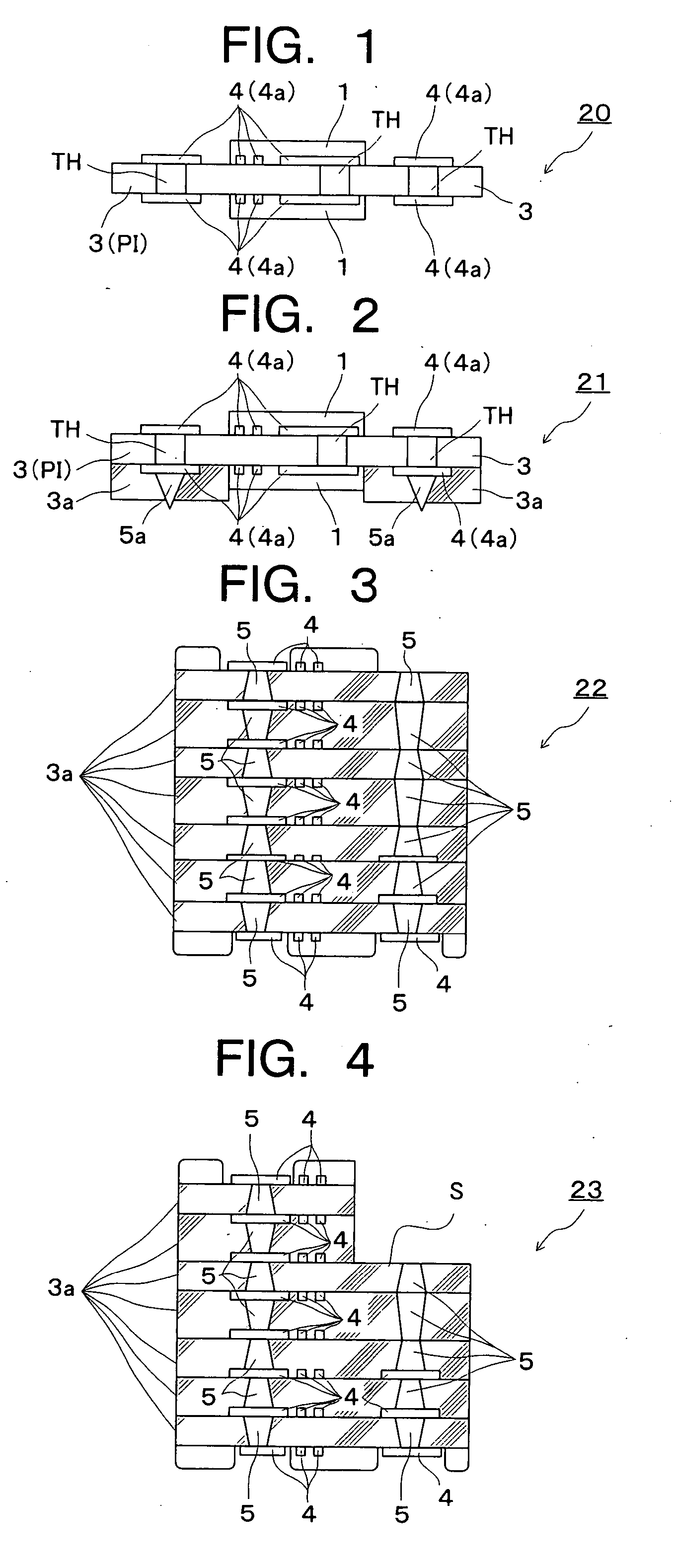

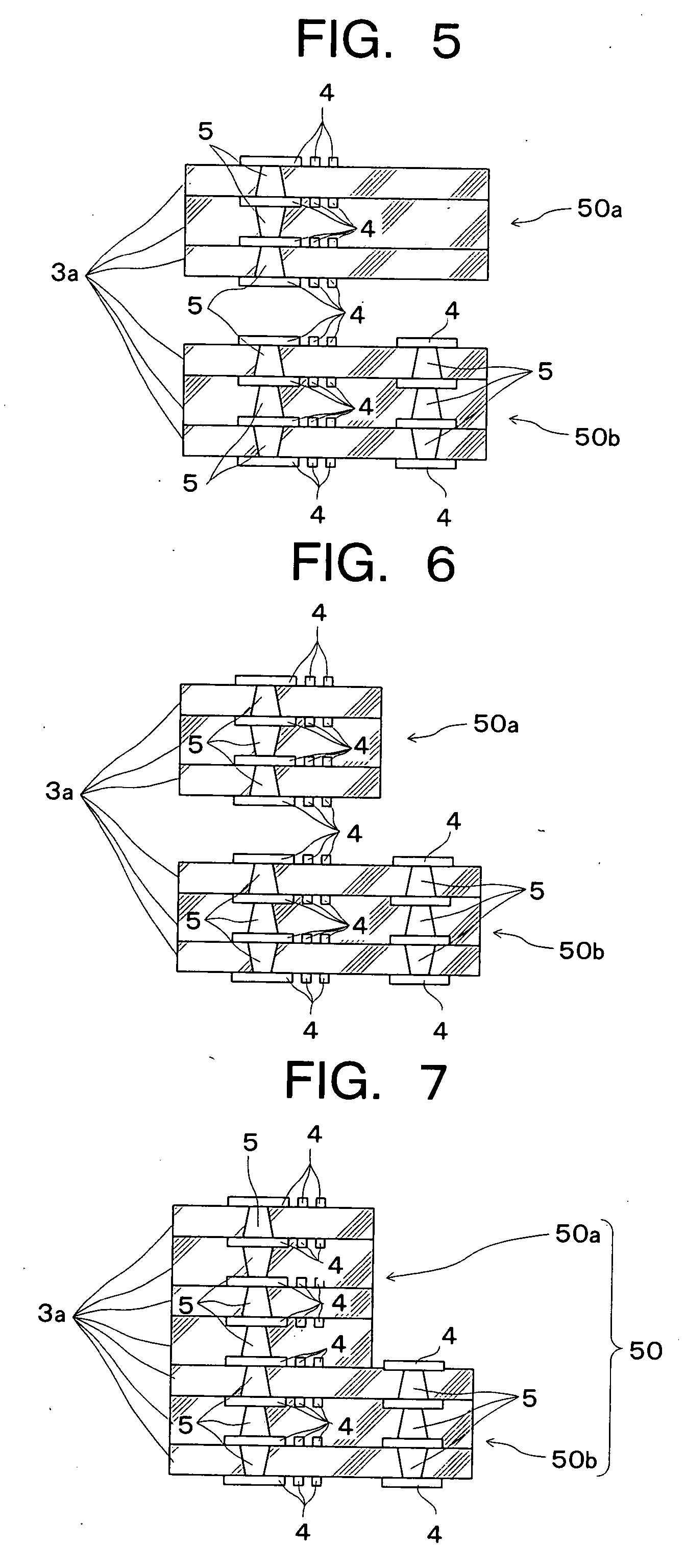

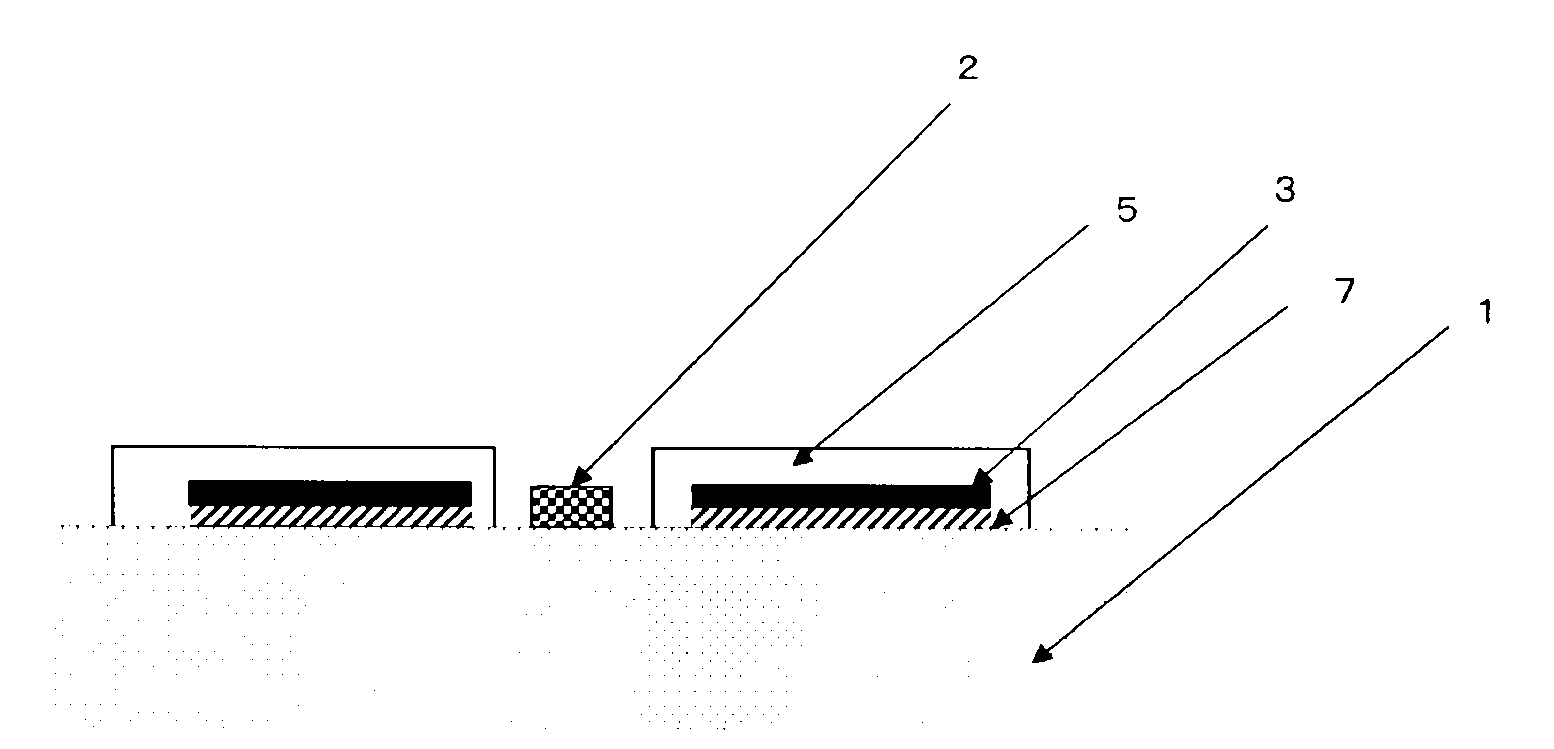

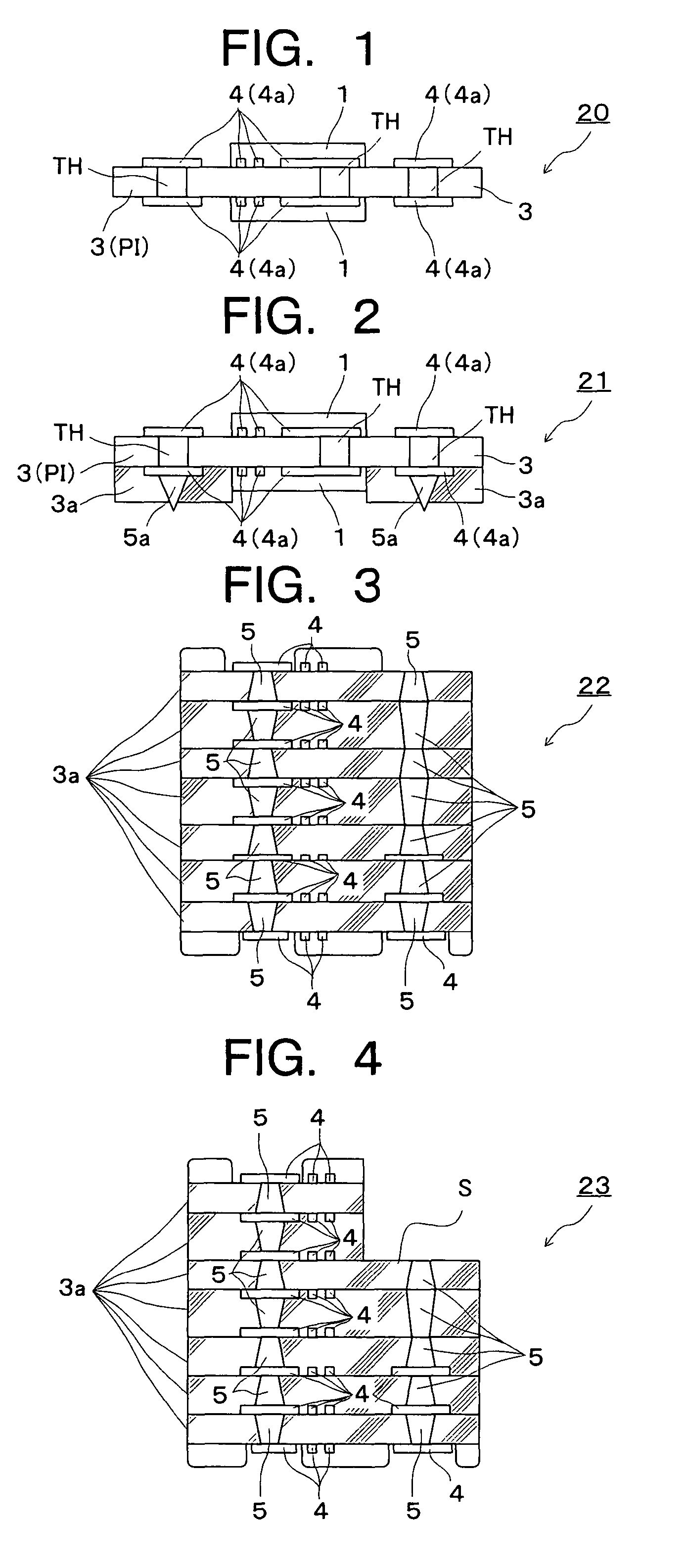

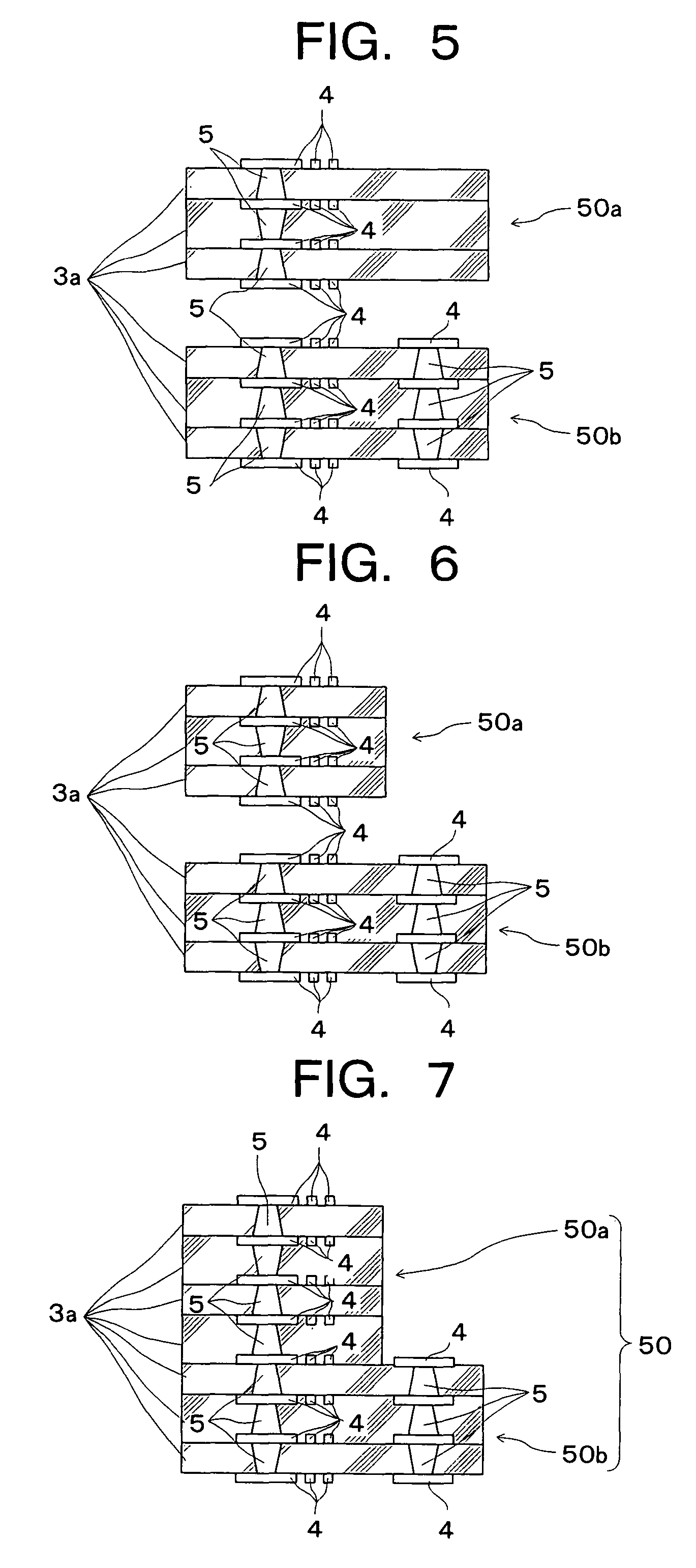

Rigid-Flexible Board and Method for Manufacturing the Same

InactiveUS20070281505A1High aspect ratioSimple molding processPrinted circuit assemblingLamination ancillary operationsEngineeringYield ratio

A rigid-flexible board and a method for manufacturing the same can be provided, whereby the material yield ratio can be enhanced and the productive yield can be also enhanced. A rigid board with a step for connection and a flexible board with a connector at the edge thereof are formed independently. Then, the connecting area is spot facing processed so that the depth of the thus obtained depressed portion is equal to or lower than the thickness of the flexible board. The connector of the flexible board is electrically connected to the vertical wiring area of the depressed portion.

Owner:DAI NIPPON PRINTING CO LTD

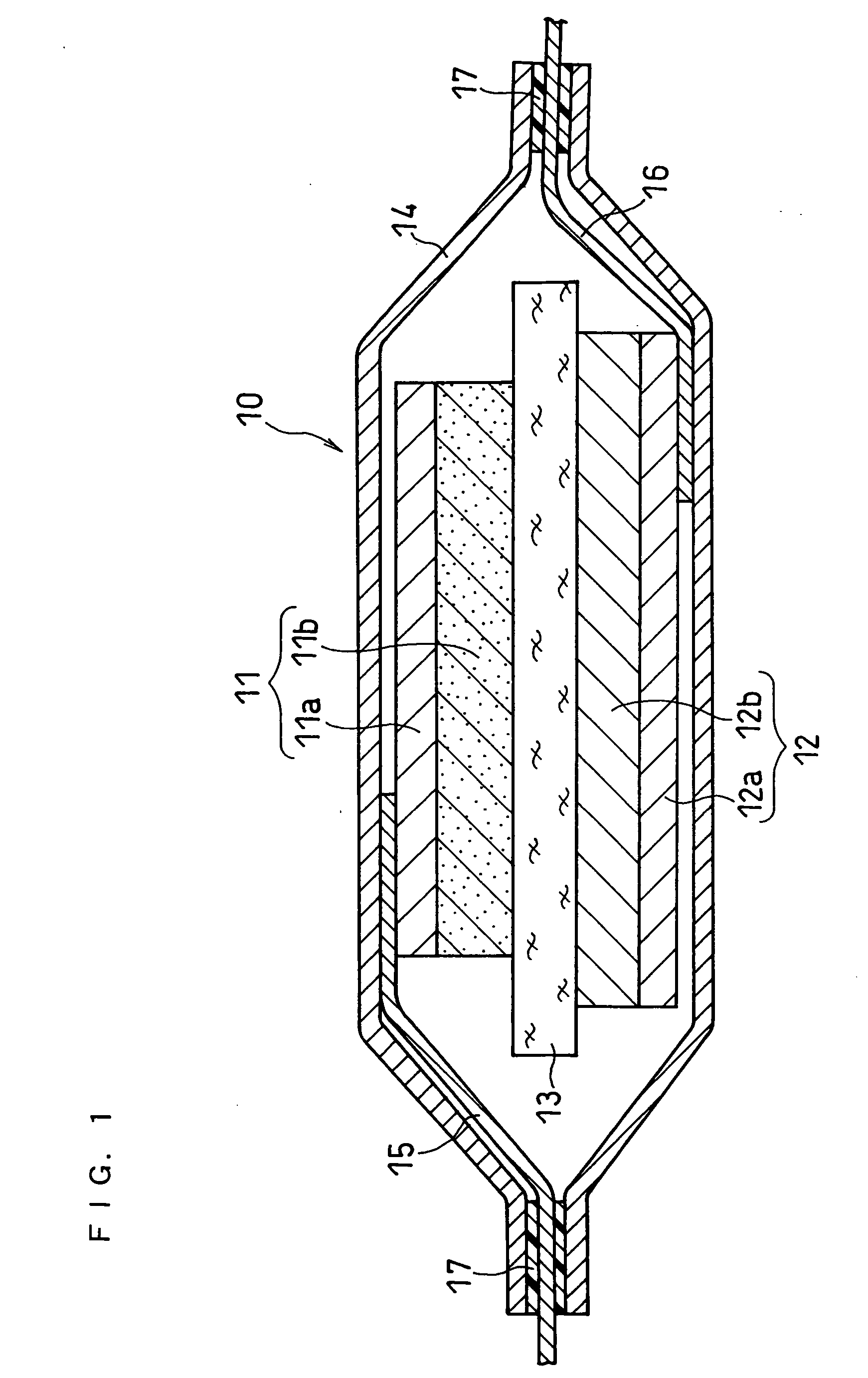

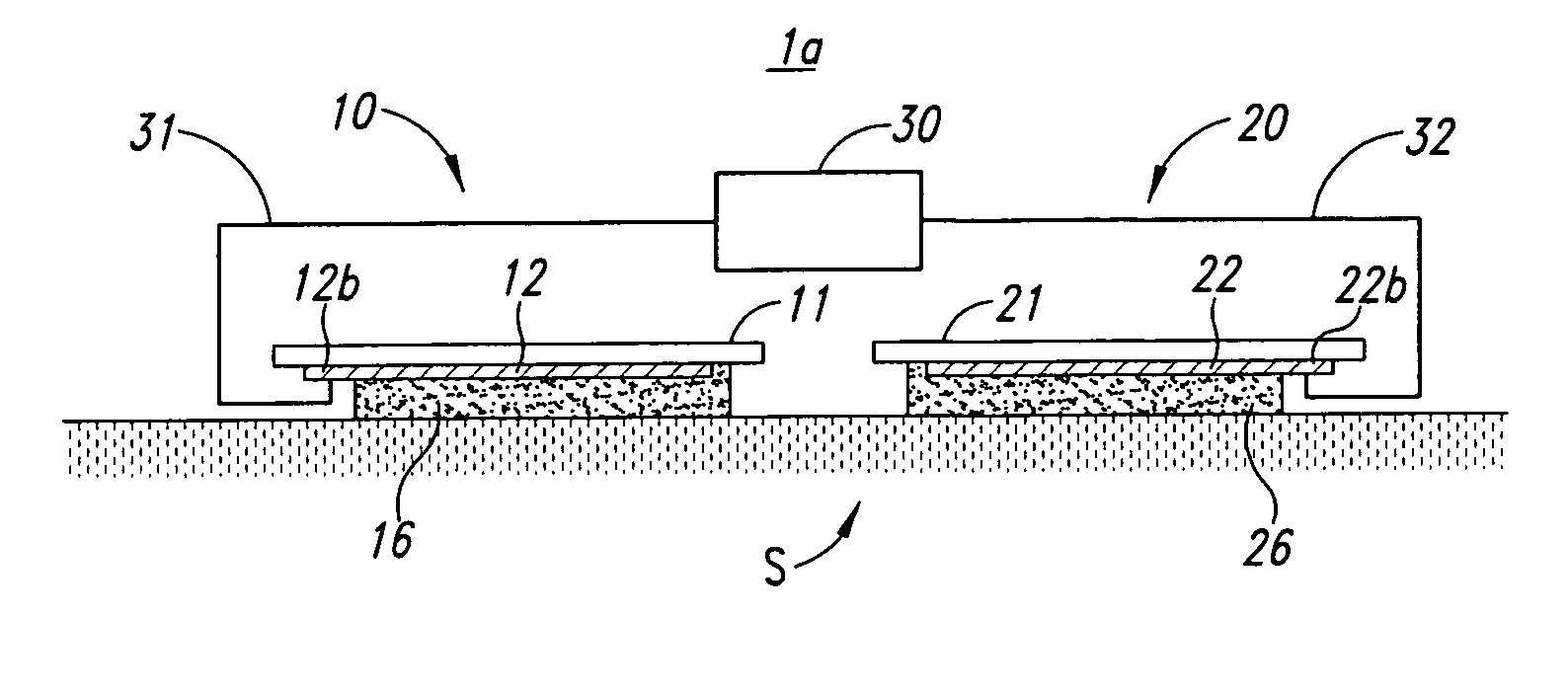

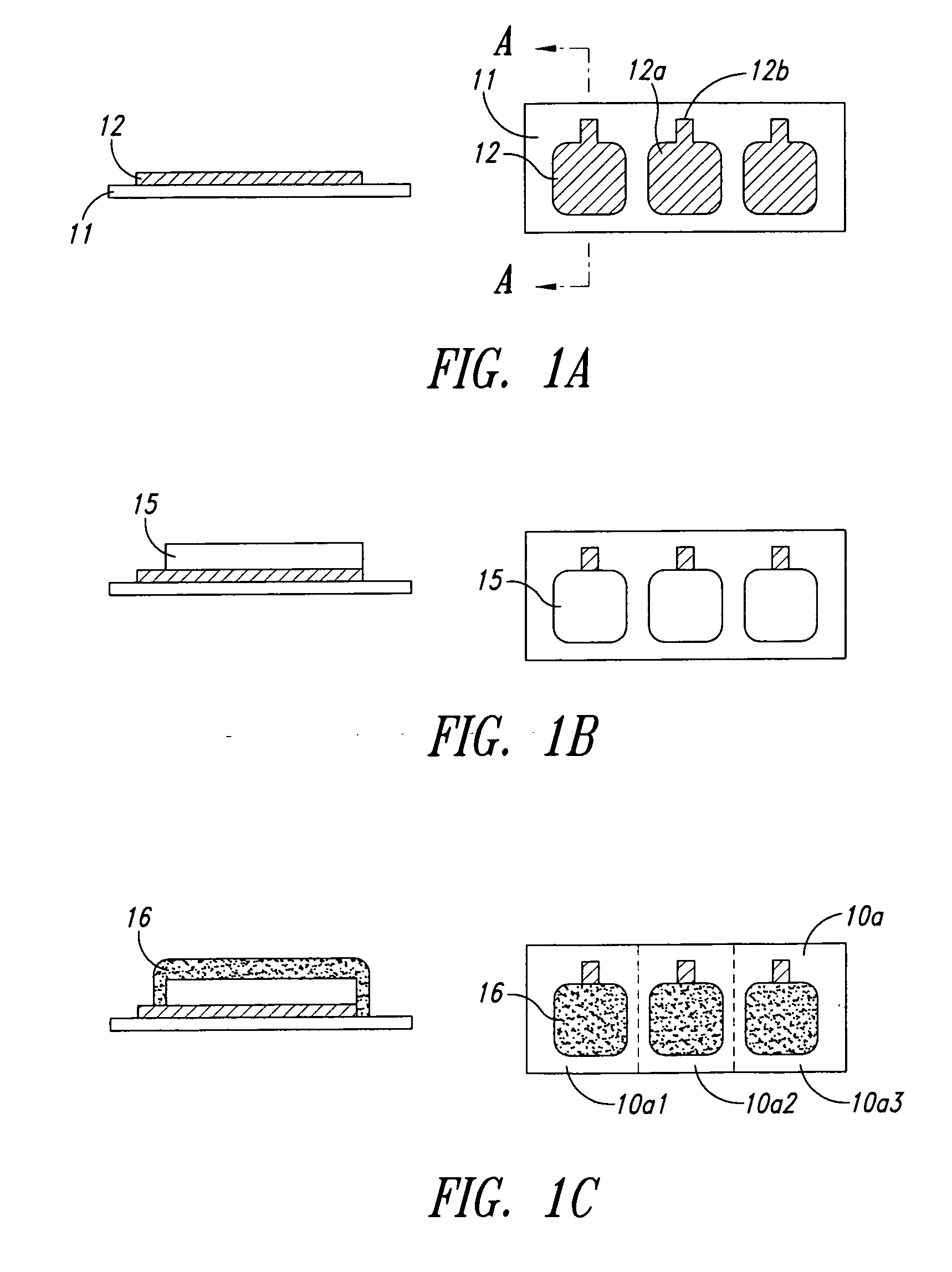

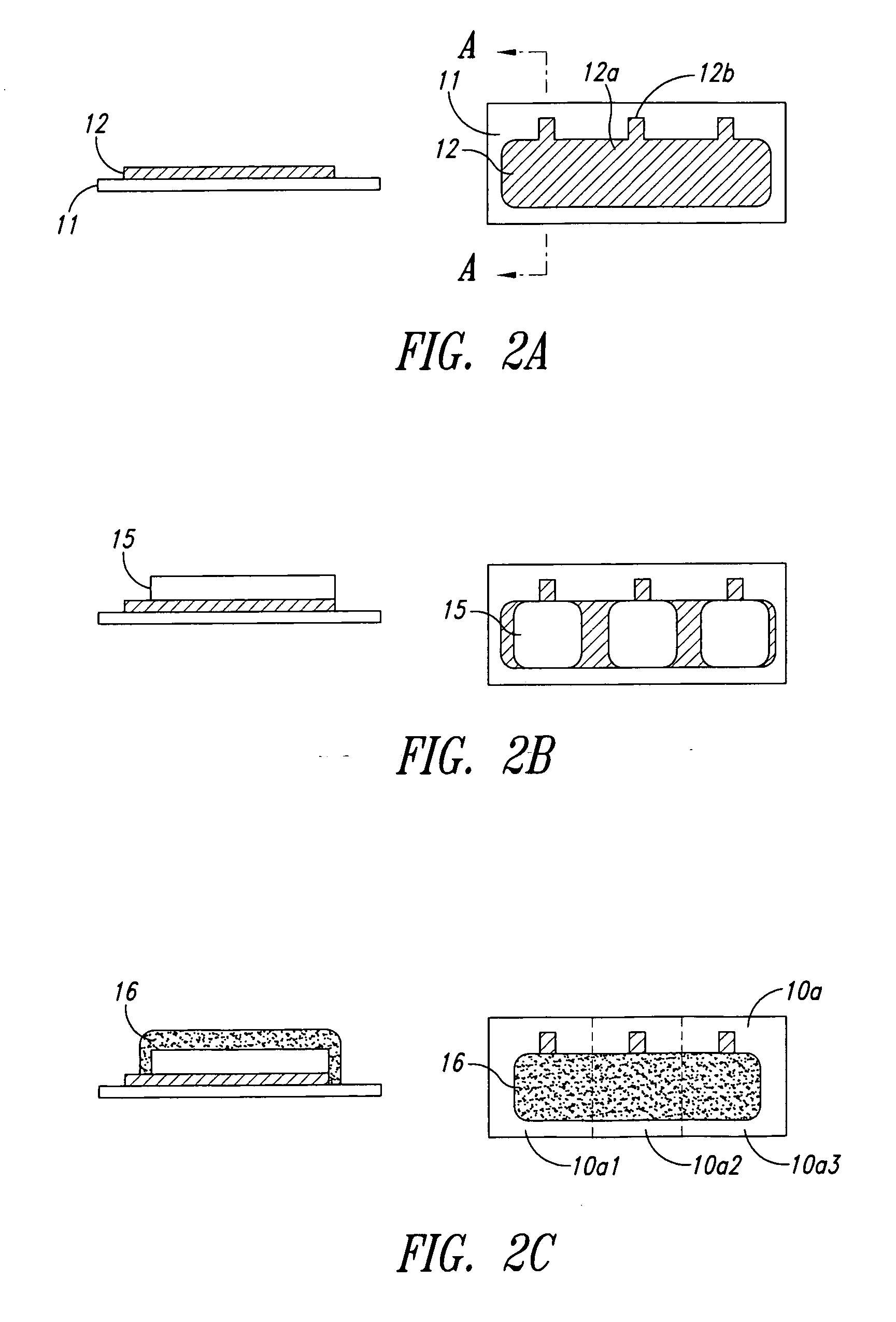

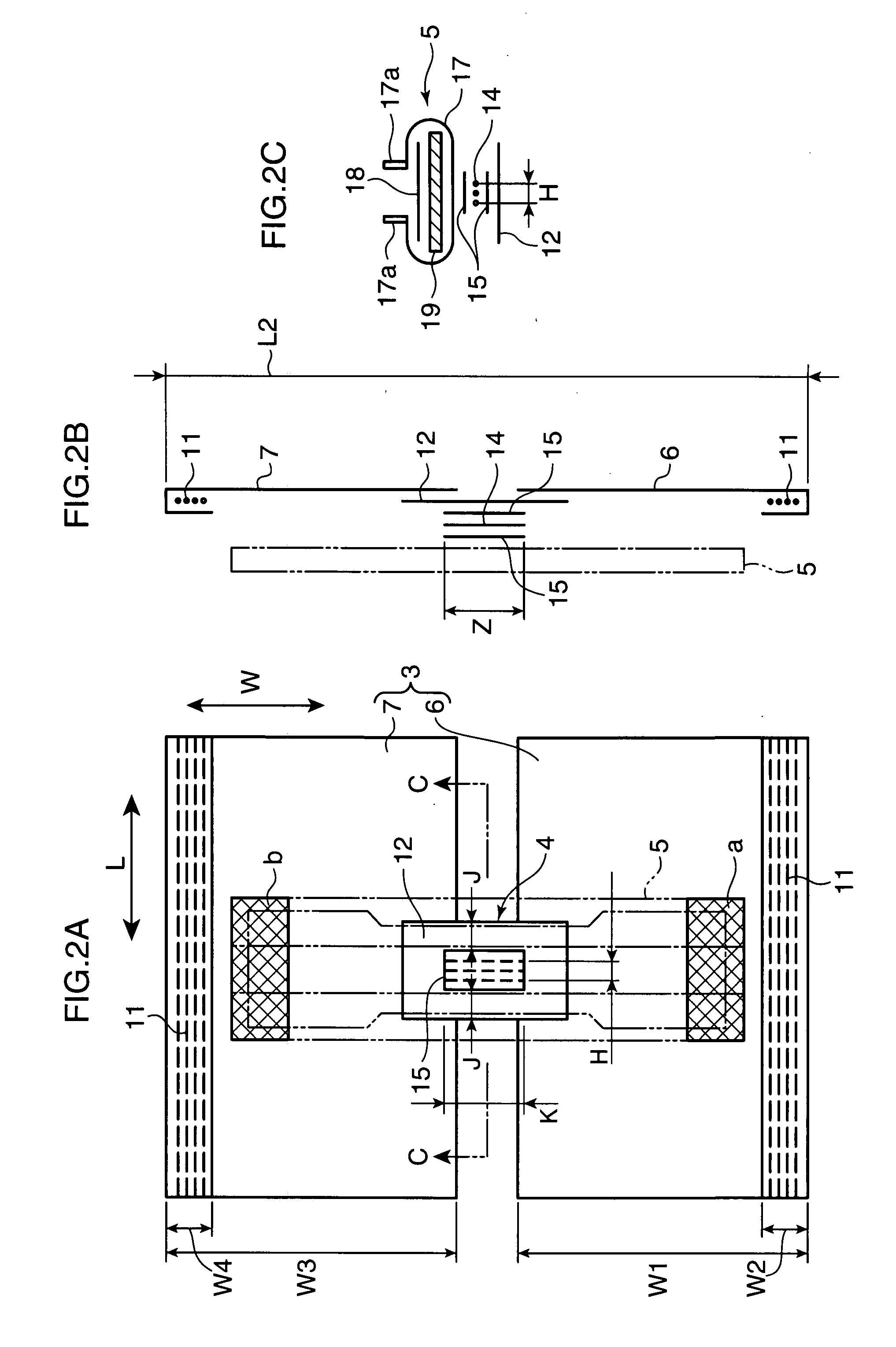

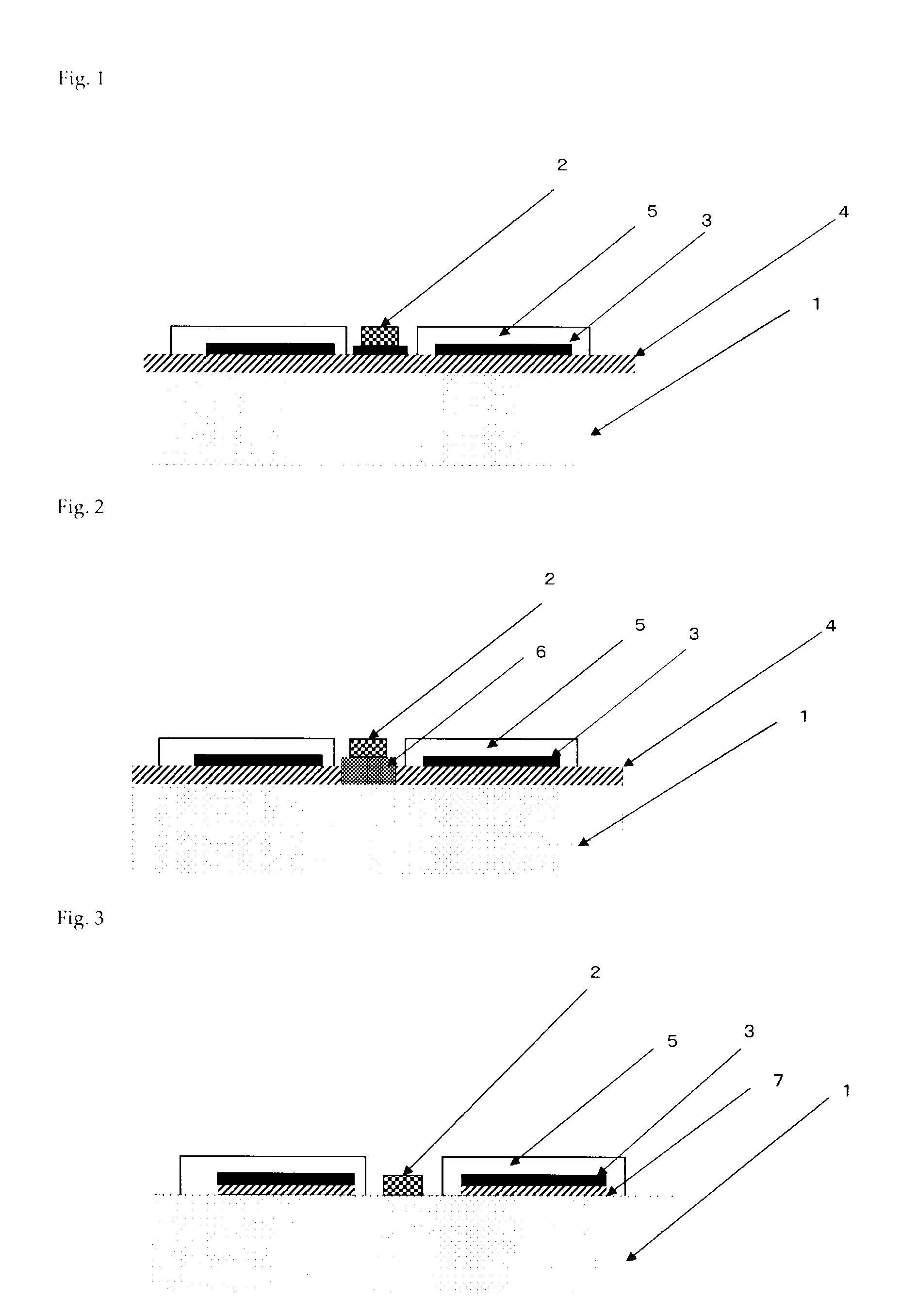

Iontophoresis device and method of producing the same

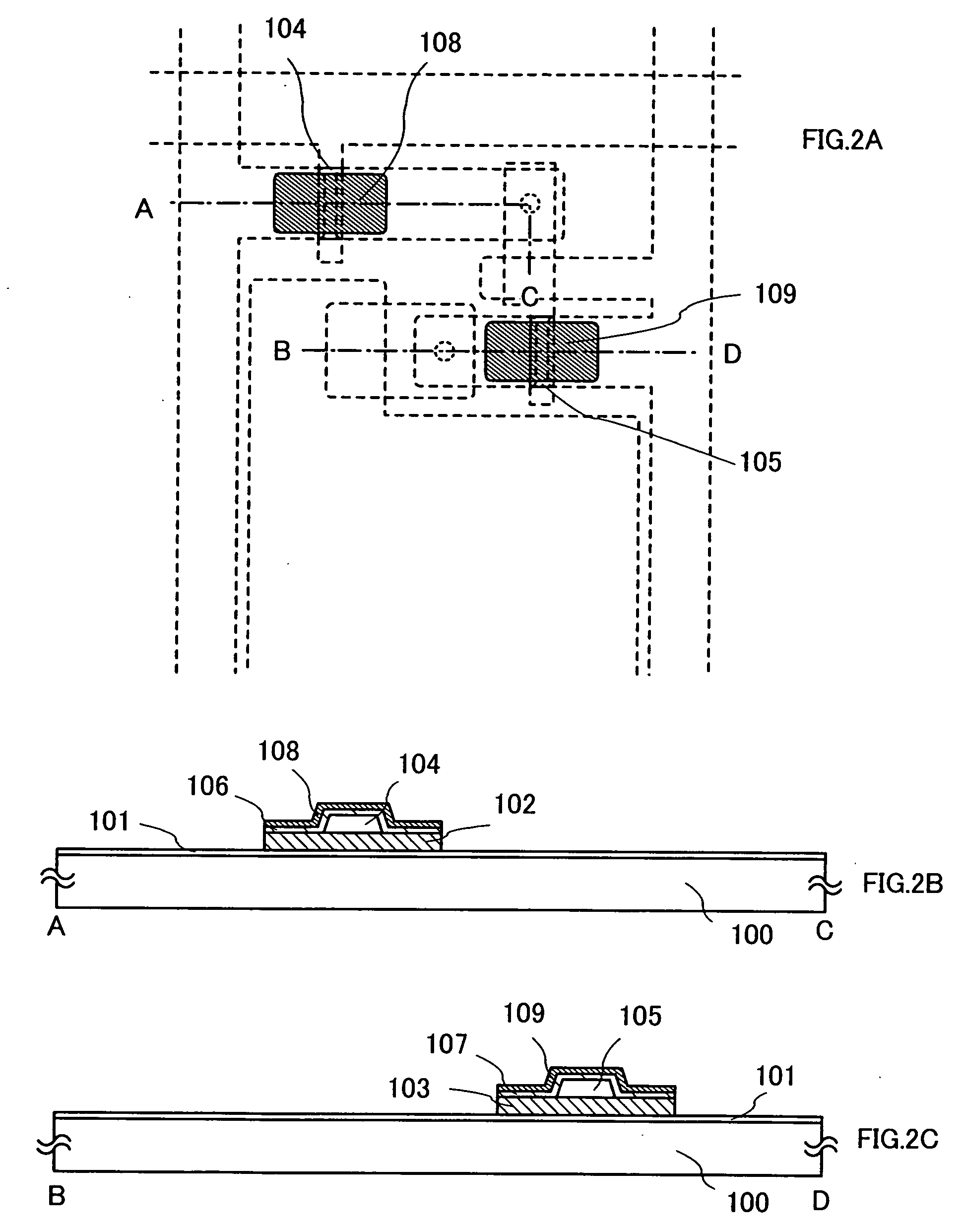

InactiveUS20070066930A1Reduce material lossSimple processElectrotherapyLamination ancillary operationsBiological bodyElectrical polarity

An iontophoresis device and method of producing the same may reduce material loss during the course of production of a conventional iontophoresis device, and may allow for easy automation of production processes and increases in production scale. The iontophoresis device may be used for administering drug ions of a first polarity generated by dissociation of a drug to a living body, and may comprise: a first conductive layer formed on a surface of a first substrate; a drug layer made of a drug coating containing the drug, the drug layer being laminated on the first conductive layer; and a first ion exchange layer made of an ion exchange coating containing an ion exchange resin having an exchange group introduced thereto, the ion exchange group having a counter ion to the first polarity ions, the first ion exchange layer being laminated on the drug layer.

Owner:TITI ELLEBEAU INC

Method for manufacturing display device

InactiveUS7247529B2Increase speedReduce the numberSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides a method for manufacturing a display device having a TFT that can be operated at high speed while using a small number of photomasks and improving the utilization efficiency of materials, where the threshold value is difficult to be varied. In the invention, a catalytic element is applied to an amorphous semiconductor film and the amorphous semiconductor film is heated to form a crystalline semiconductor film. After removing the catalytic element from the crystalline semiconductor film, a top-gate type thin film transistor with a planar structure is manufactured. Moreover, by using the droplet discharging method where an element of a display device is formed selectively, the process can be simplified, and loss of materials can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

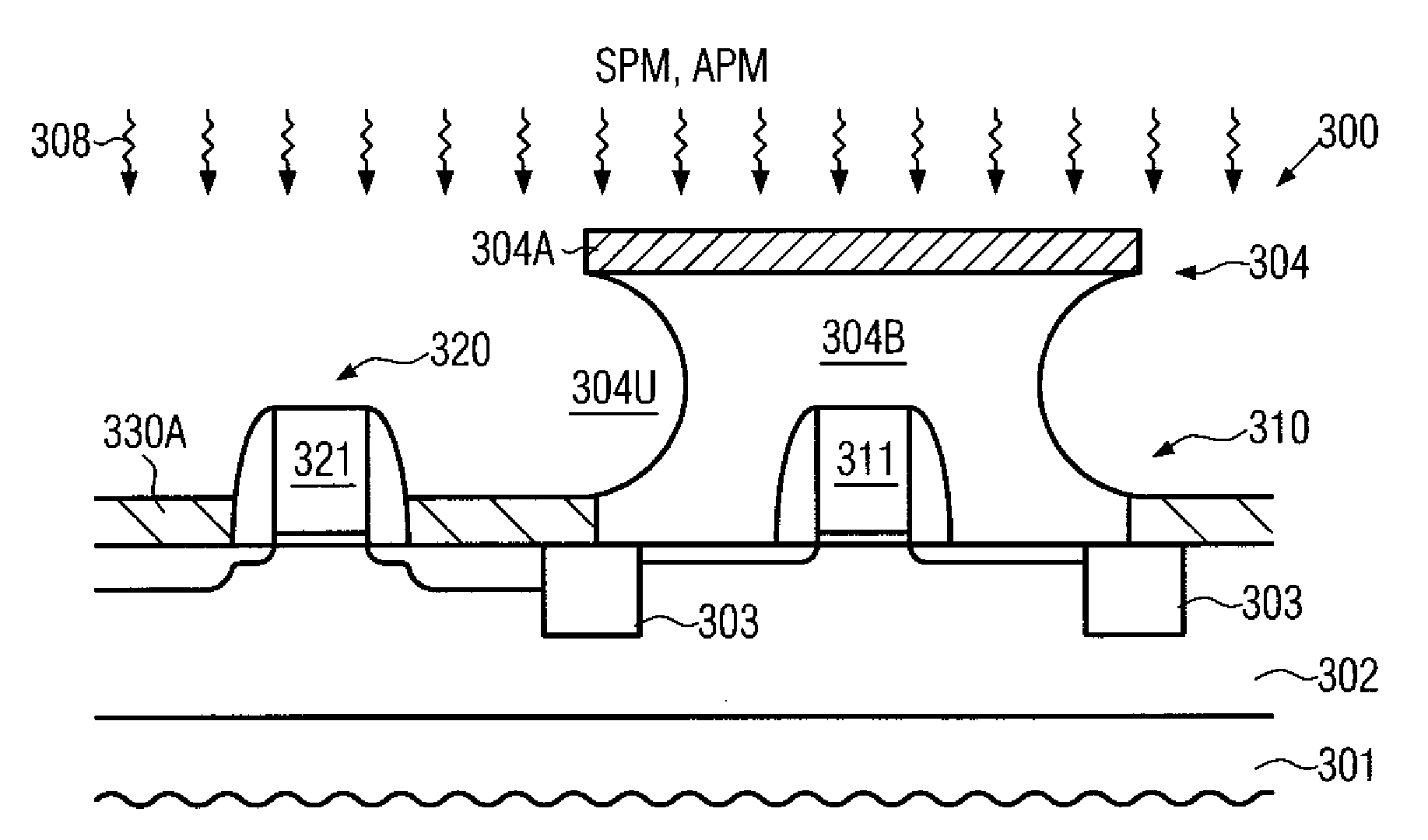

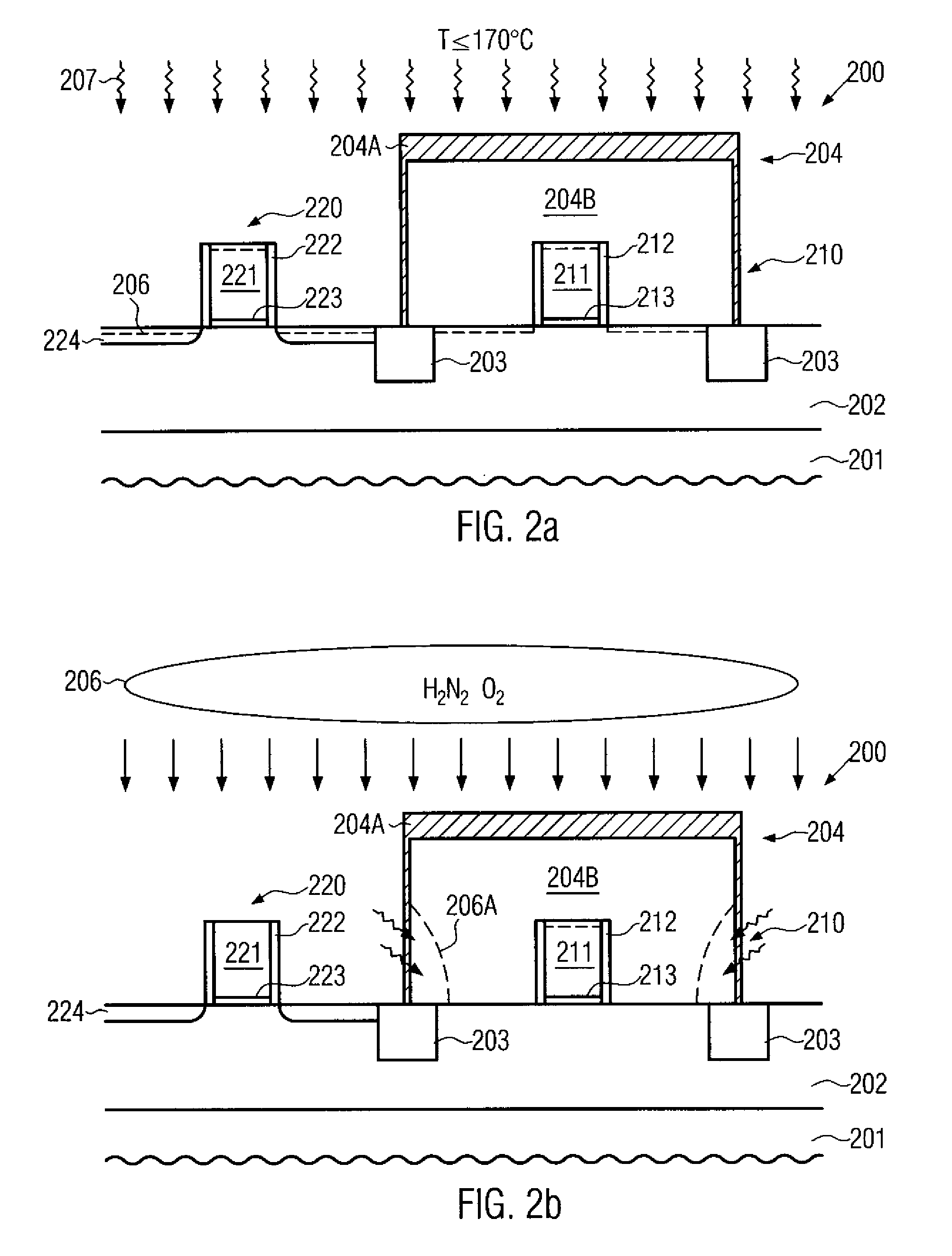

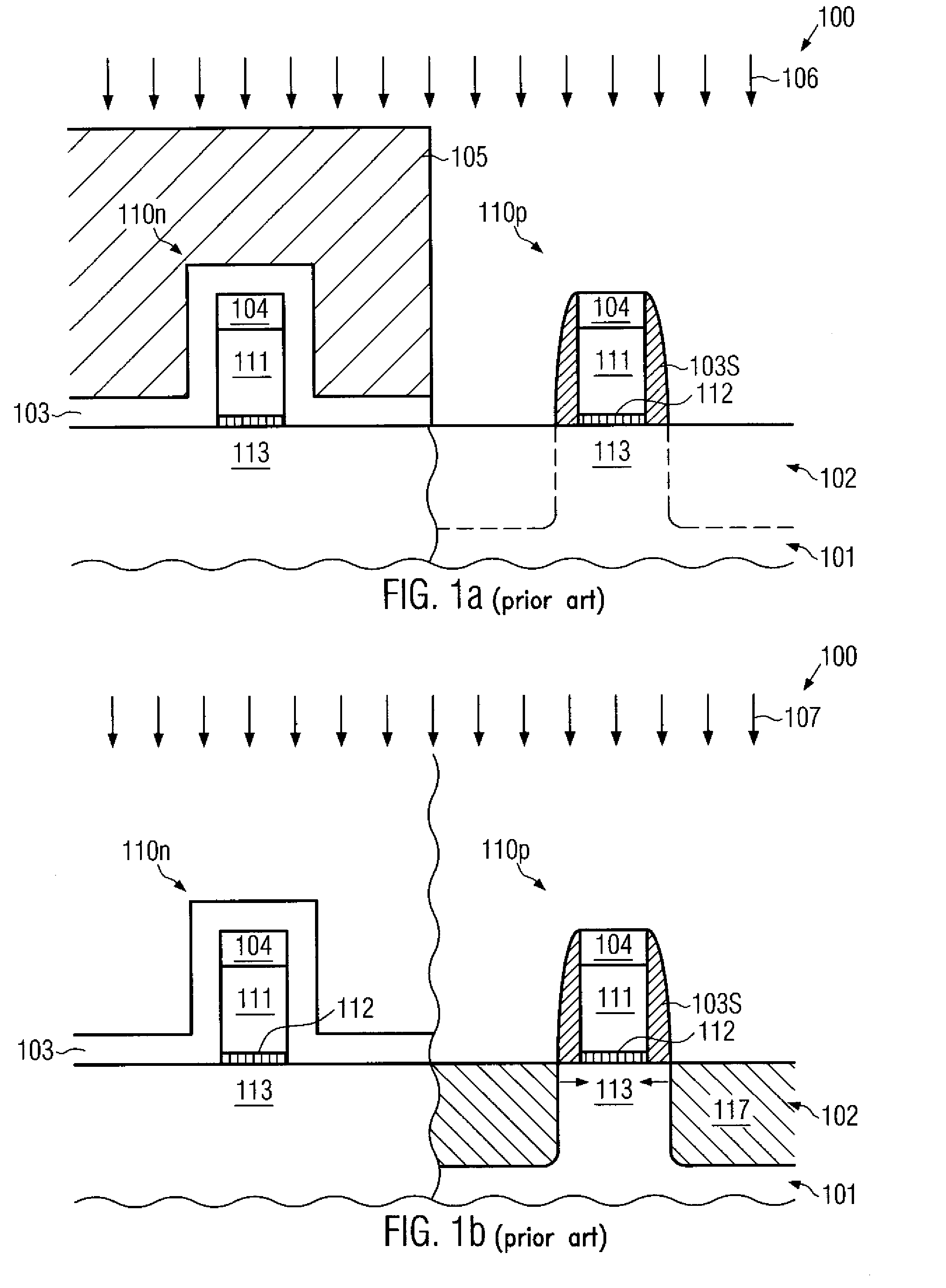

Technique for removing resist material after high dose implantation in a semiconductor device

ActiveUS20080160729A1Reduce material lossHigh selectivityPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistAmount of substance

Resist masks exposed to high-dose implantation processes may be efficiently removed on the basis of a combination of a plasma-based etch process and a wet chemical etch recipe, wherein both etch steps may include a highly selective etch chemistry in order to minimize substrate material loss and thus dopant loss in sophisticated semiconductor devices. The first plasma-based etch step may provide under-etched areas of the resist mask, which may then be efficiently removed on the basis of the wet chemical etch process.

Owner:ADVANCED MICRO DEVICES INC

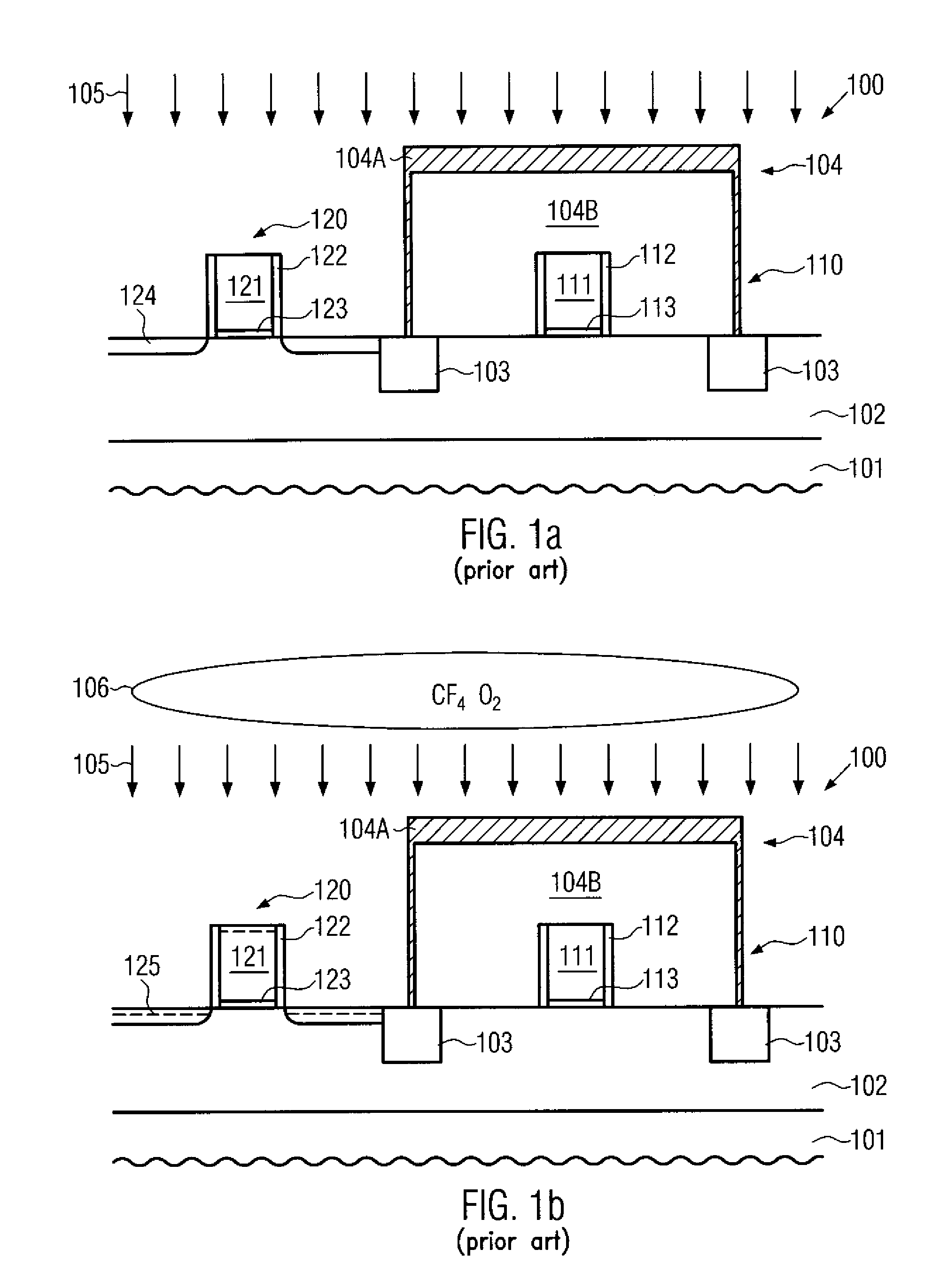

Amorphous carbon contact film for contact hole etch process

InactiveUS20060170058A1Reduce underlie material lossImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSFluorine doping

A semiconductor device including a contact etch stop layer and contact hole formation method for reduced underlying material loss and improved device performance, the method including providing a semiconductor substrate including an active region including a CMOS device, STI structures, and metal silicide regions; forming a fluorine doped amorphous carbon layer over the active region; forming a PMD layer on the fluorine doped amorphous carbon layer; dry etching contact holes in the PMD layer to expose the fluorine doped amorphous carbon layer; and, removing the fluorine doped amorphous carbon layer according to a dry stripping process.

Owner:TAIWAN SEMICON MFG CO LTD

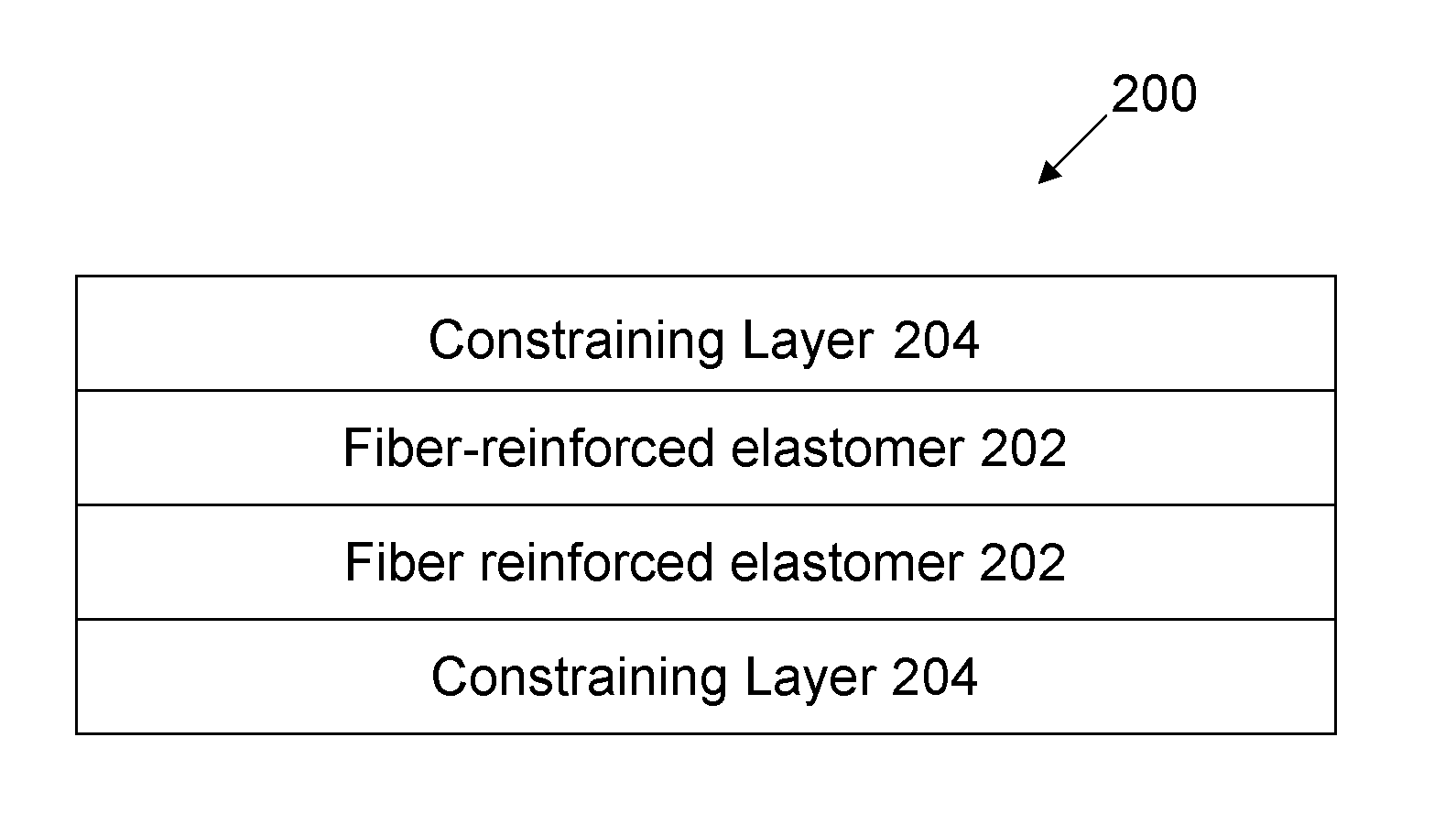

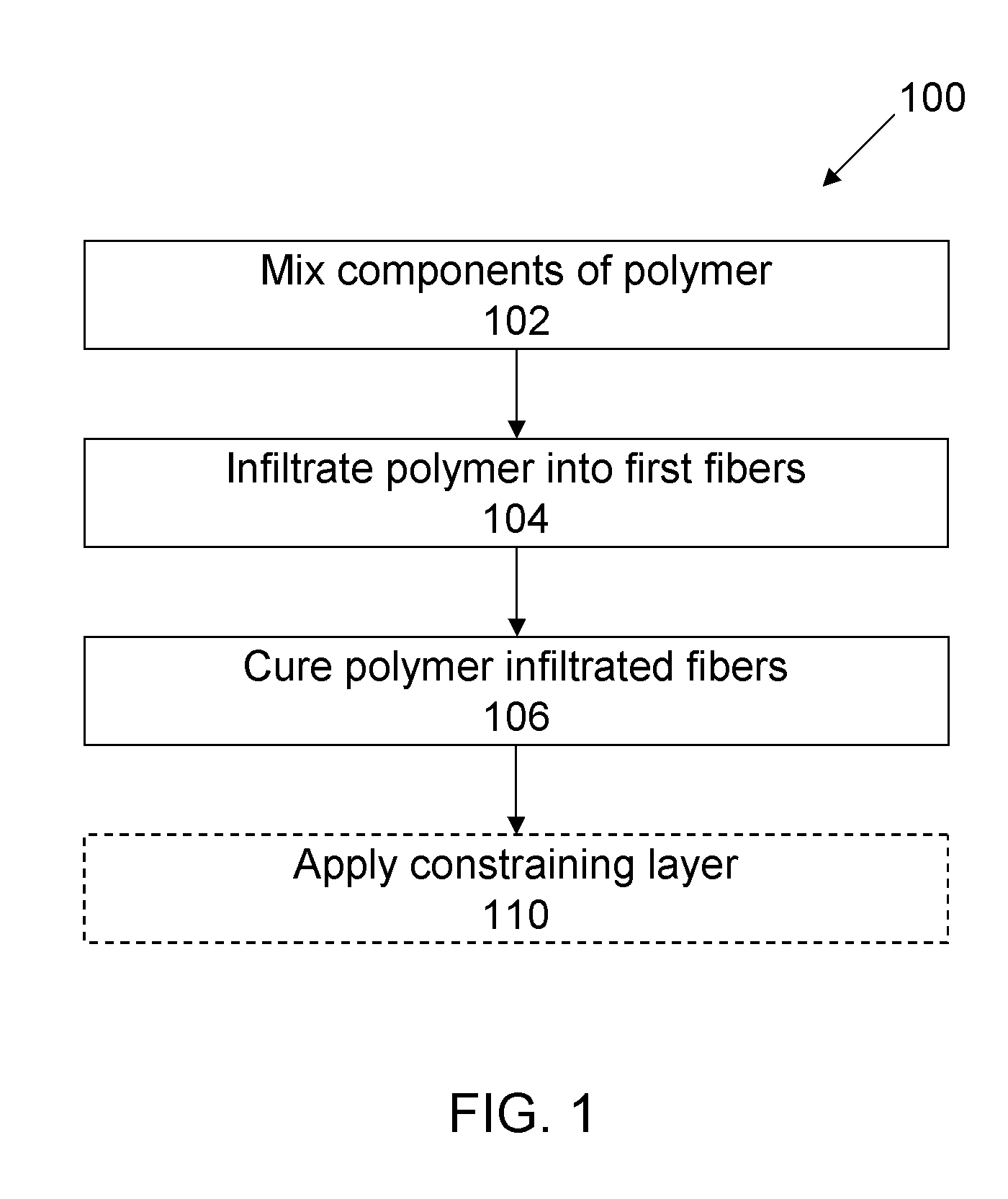

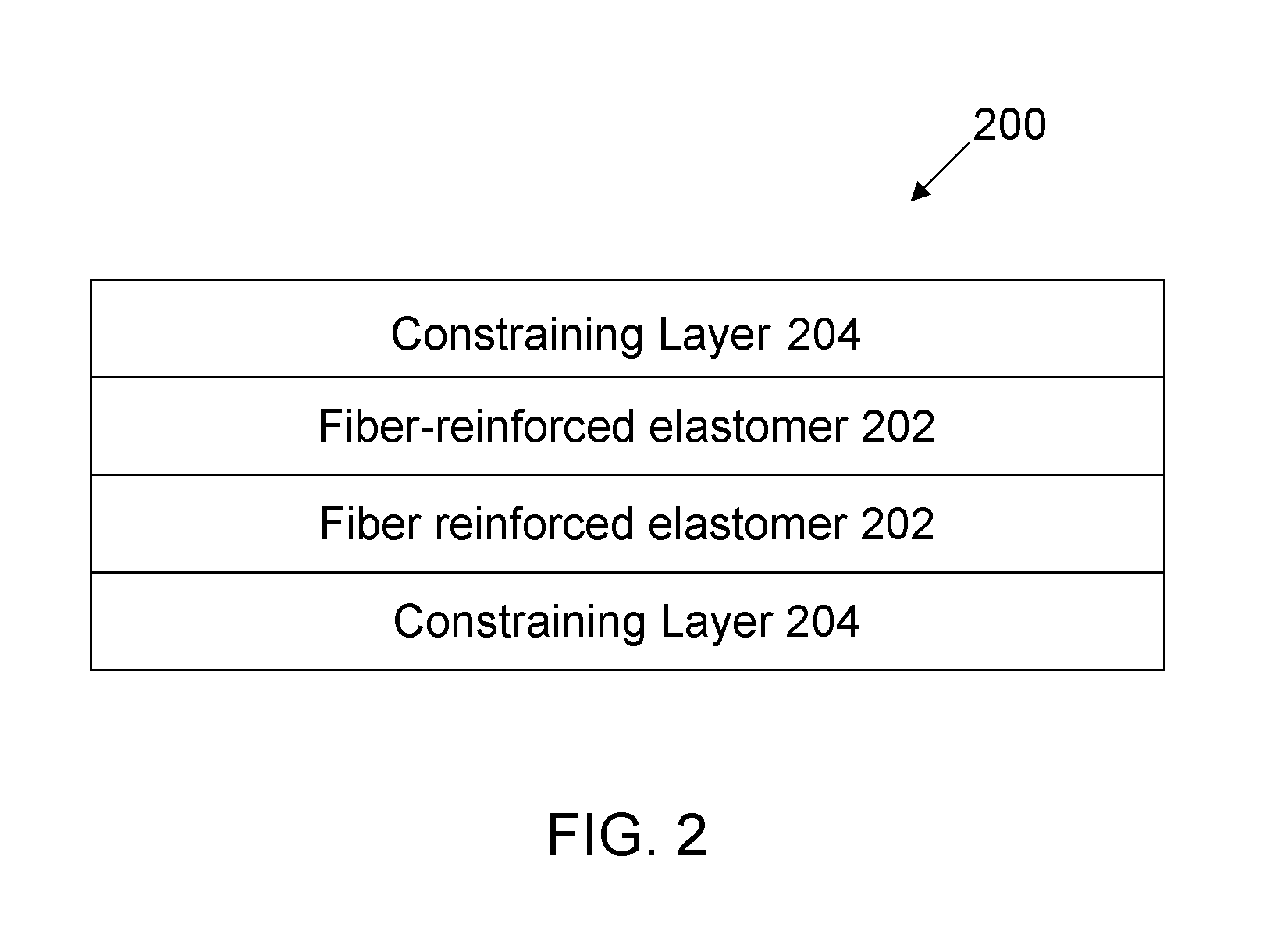

Polymer composites possessing improved vibration damping

ActiveUS20120313307A1Increase dampingIncrease system loss factorLaminationWood working apparatusPolymer compositesCenter frequency

Fiber-reinforced polymer composites possessing improved damping ability are provided. In one aspect, the fibers provide the composite with a relatively high dynamic modulus over a broad range of frequencies for a given temperature. In another aspect, the polymer may comprise a viscoelastic polymer possessing a relatively high loss factor for a given frequency and temperature. The polymer may be further tailored to control the center frequency at which the maximum loss factor of the polymer is achieved. The composite so formed exhibits a relatively small reduction in loss factor with significant increase in dynamic modulus over a broad range of frequencies for a given temperature. As a result, a structure damped by the composite exhibits a relatively high, constant loss factor as compared to conventional damping materials. Thus, embodiments of the disclosed composites dissipate significantly more energy during each vibration cycle than conventional damping materials.

Owner:THE BF GOODRICH CO

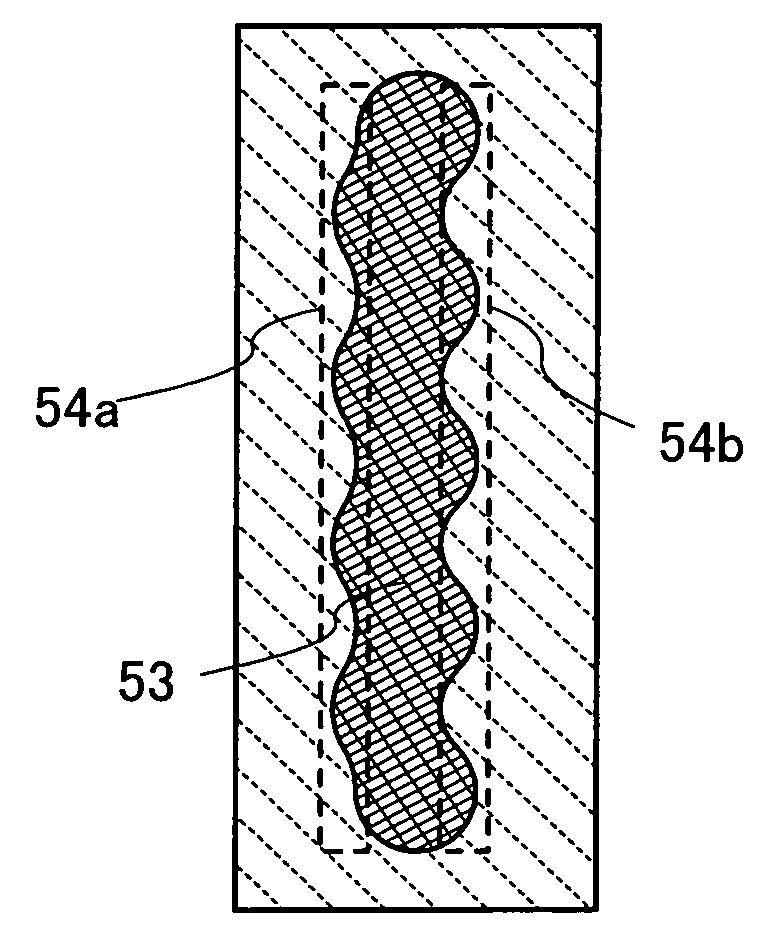

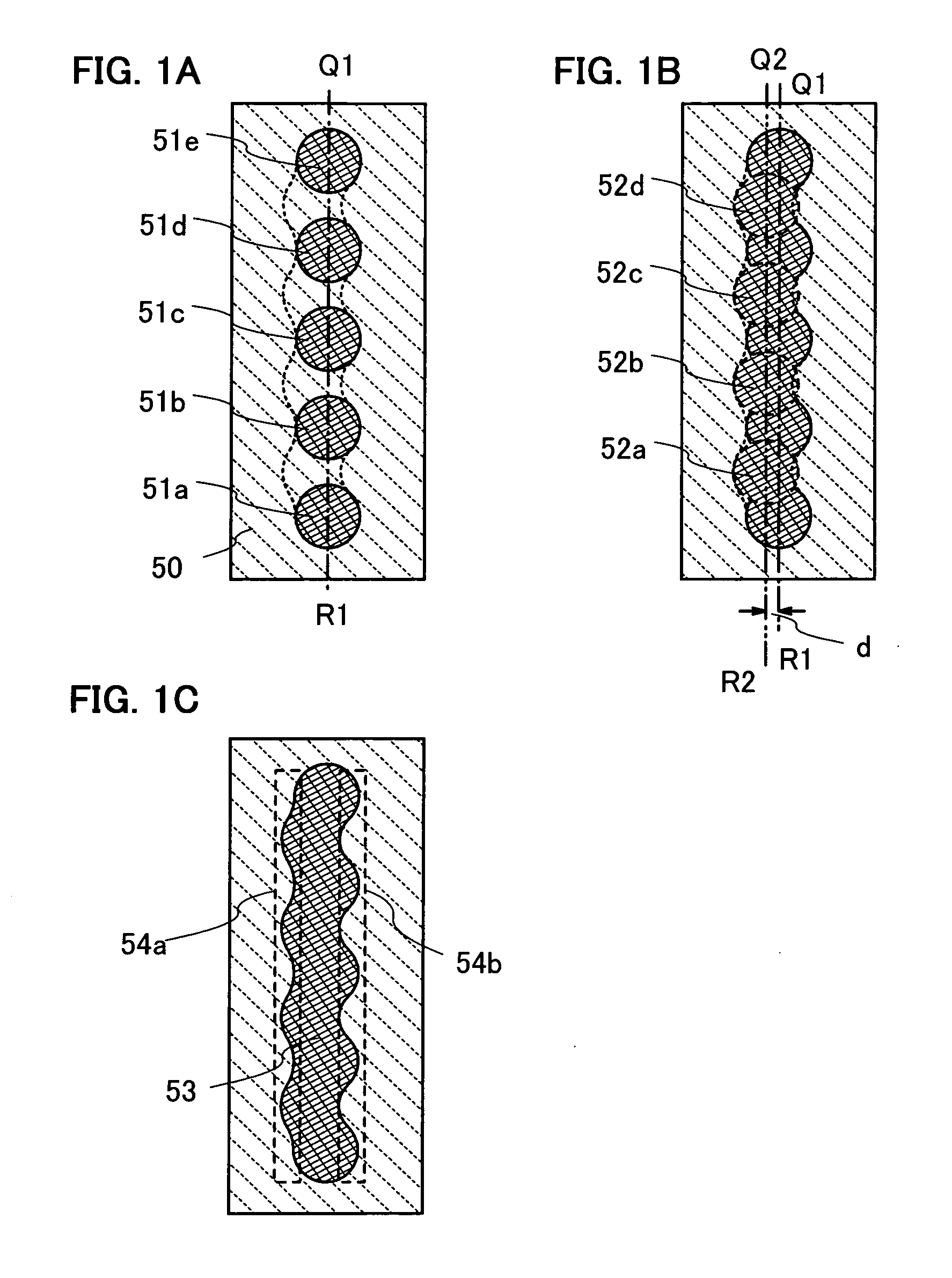

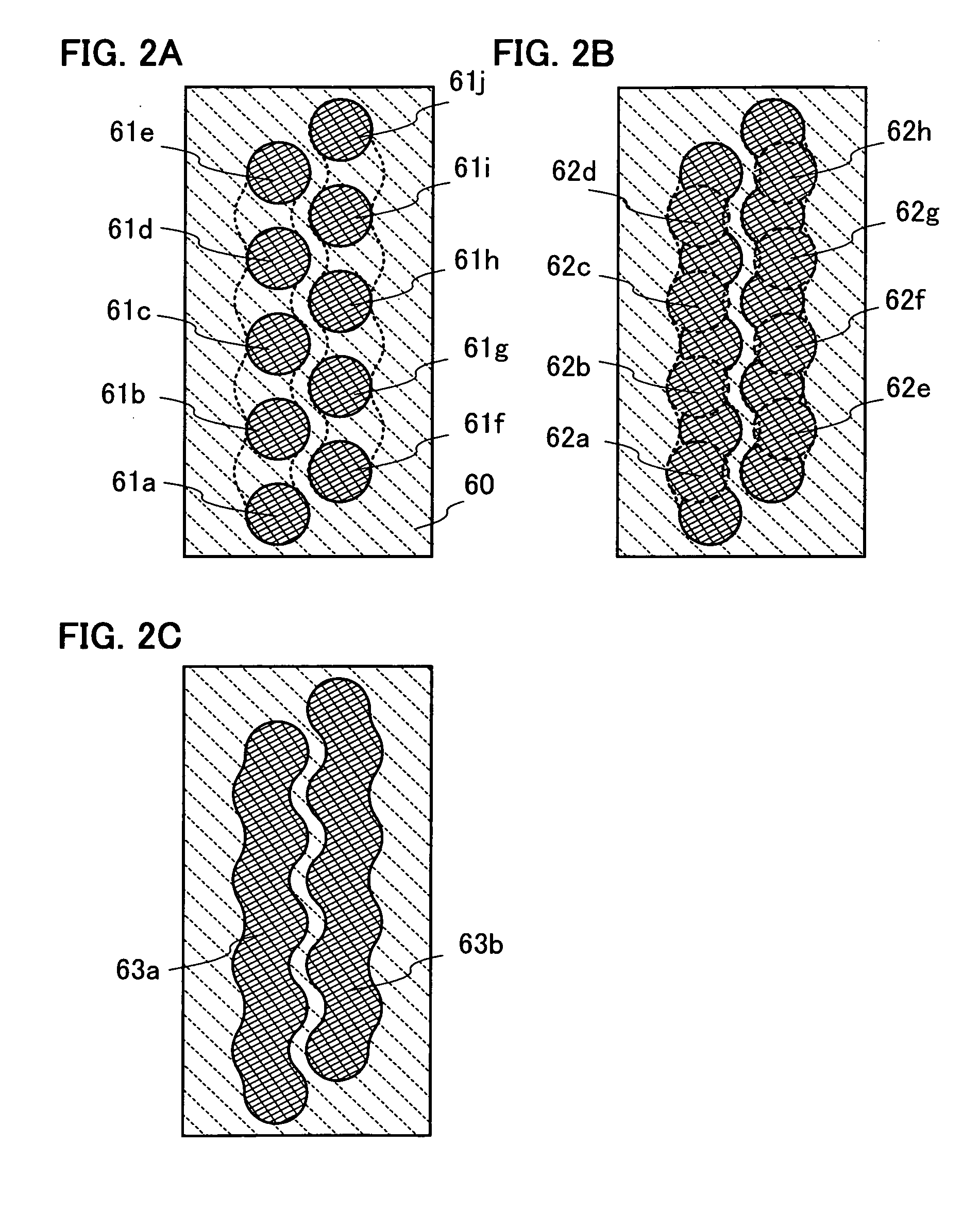

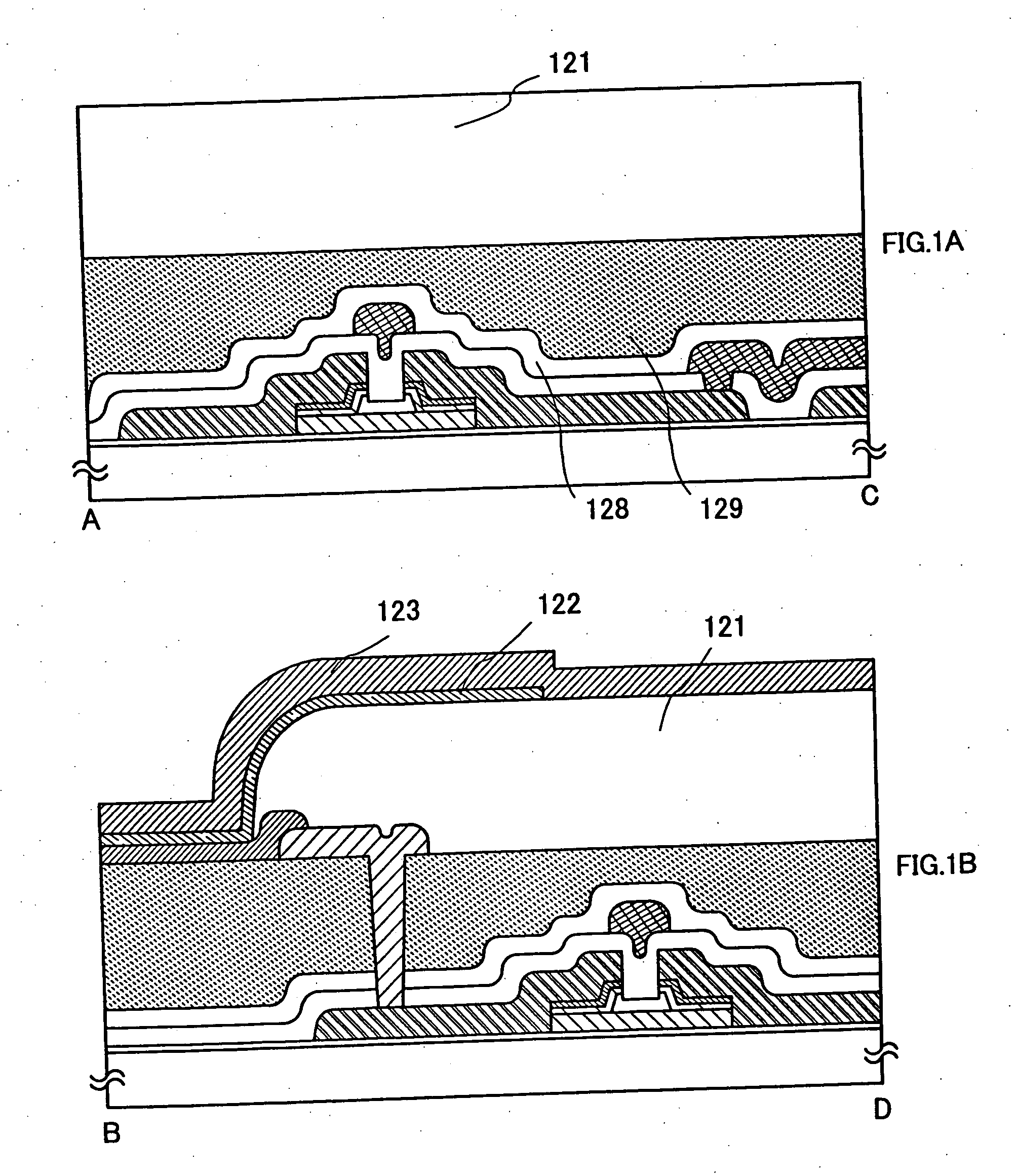

Method for forming pattern, method for manufacturing light emitting device, and light emitting device

ActiveUS20090008667A1Increasing number of manufacturing stepLow costElectroluminescent light sourcesSolid-state devicesSilanesLength wave

Oxidation treatment is performed to the surface of a substrate provided with a photocatalytic conductive film and an insulating film; treatment with a silane coupling agent is performed, so that a silane coupling agent film is formed and the surface of the substrate is modified to be liquid-repellent; and the surface of the substrate is irradiated with light of a wavelength (less than to equal to 390 nm) which has energy of greater than or equal to a band gap of a material for forming the photocatalytic conductive film, so that only the silane coupling agent film over the surface of the photocatalytic conductive film is decomposed and the surface of the photocatalytic conductive film can be modified to be lyophilic.

Owner:SEMICON ENERGY LAB CO LTD

Powder metal rotating components for turbine engines and process therefor

InactiveUS20070020135A1Reduce rateReduce yield lossTurbinesTransportation and packagingMechanical propertyPrecipitation

A process for producing turbine rotors and other large rotating components of power-generating gas turbine engines using powder metallurgy techniques. The process involves forming a powder of a gamma prime or gamma double prime precipitation-strengthened nickel-based superalloy whose particles are about 0.100 mm in diameter or smaller. The powder is placed in a can and consolidated to produce an essentially fully dense consolidation, which is then hot worked to produce a billet of a size sufficient to form a forging of at least 2300 kg. The billet is forged at a temperature and strain rate to produce a forging with a uniform fine grain of ASTM 10 or finer. Thereafter, the forging may undergo a heat treatment to achieve a desired balance of mechanical properties while retaining a uniform grain size of ASTM 10 or finer.

Owner:GENERAL ELECTRIC CO

Method for manufacturing display device

InactiveUS20070262318A1Increase speedReduce the numberSolid-state devicesDiodeDisplay deviceEngineering

The present invention provides a method for manufacturing a display device having a TFT that can be operated at high speed while using a small number of photomasks and improving the utilization efficiency of materials, where the threshold value is difficult to be varied. In the invention, a catalytic element is applied to an amorphous semiconductor film and the amorphous semiconductor film is heated to form a crystalline semiconductor film. After removing the catalytic element from the crystalline semiconductor film, a top-gate type thin film transistor with a planar structure is manufactured. Moreover, by using the droplet discharging method where an element of a display device is formed selectively, the process can be simplified, and loss of materials can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

Wearing article and method of manufacturing the same

ActiveUS20090312739A1Reduce material lossReduce facility costsLamination ancillary operationsLaminationEngineering

A wearing article capable of suppressing the occurrence of a loss of materials and an increase of the cost of facilities and a method of manufacturing the same are provided. A wearing article includes a waist portion (3) formed in a ring shape capable of continuously surrounding the waist of the wearer and using one of openings as a waist opening (9), and a crotch portion (4) joined to the waist portion (3) across an opening on the opposite side to the waist opening (9) so that the crotch portion (4) and the waist portion (3) define a pair of leg openings (10) for the wearer to put through his legs individually. Shirring is formed in the crotch portion (4) so as to shorten the distance between the mutually opposing inner surfaces of the waist portion (3) connected to each other by the crotch portion (4).

Owner:ZUIKO CORP

Method for recovering valuable elements in waste lithium ion battery electrode material

ActiveCN107955879AReduce sorting costsReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention discloses a method for recovering valuable elements in waste lithium ion battery electrode materials. The method comprises steps of roasting the waste lithium ion battery electrode materials in an inert gas atmosphere, the roasting temperature is 200 -600 DEG C, the time is 30-360 minutes, and the roasting slag is obtained; mixing the obtained roasting slag and an acidic solution with [H+] concentration of 0.5~8 mol / L according to the mass ratio of 1:3~10; leaching at the leaching temperature of 30-90 DEG C and leaching time of 1-8 hours, leach liquor and leach residues are filtered to be obtained; the leach liquor is used for recovering nickel, cobalt, manganese, aluminum and lithium, and the leach residues are used for preparing negative electrode materials. According to the method for recovering valuable elements in waste lithium ion battery electrode materials, a leaching reducing agent does not need to be additionally added, the battery sorting and recycling costs are reduced, the positive and the negative electrode materials can be recovered at the same time, and the economic benefits of lithium battery recovery can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

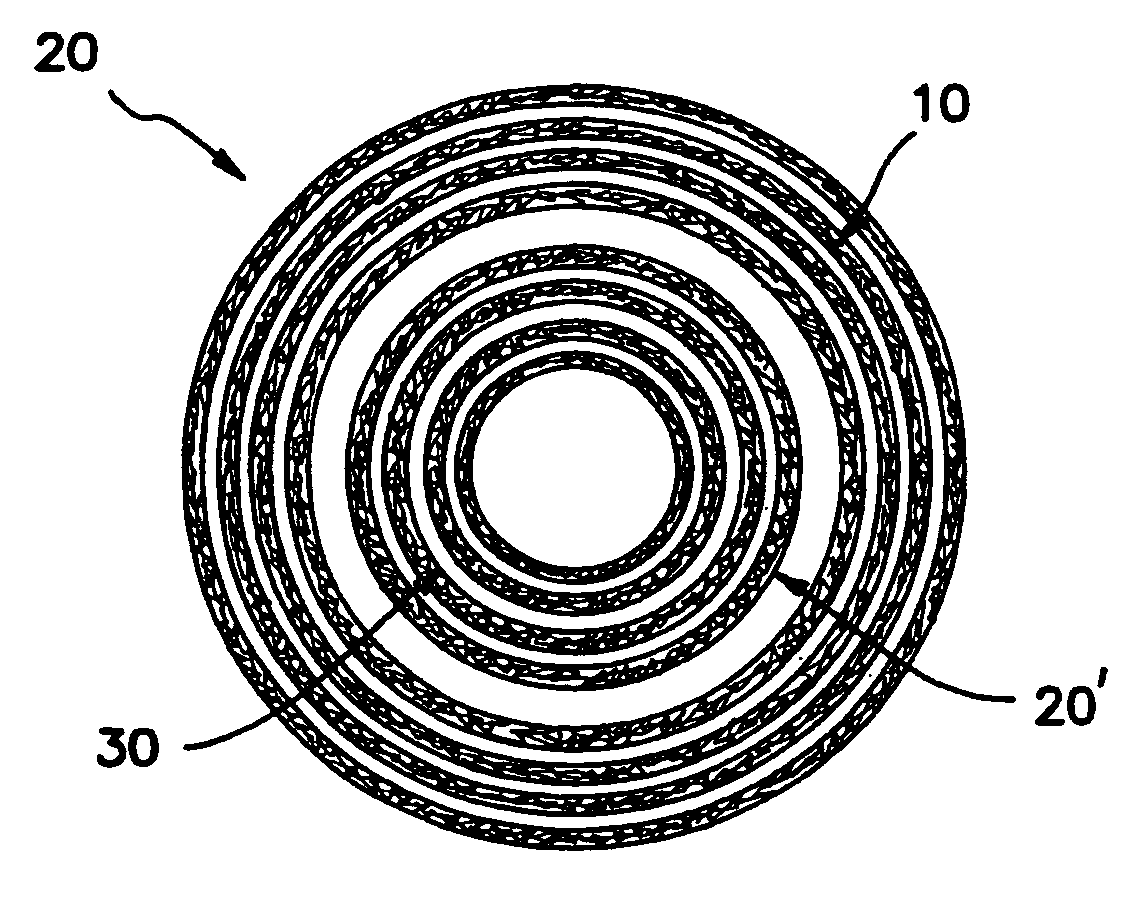

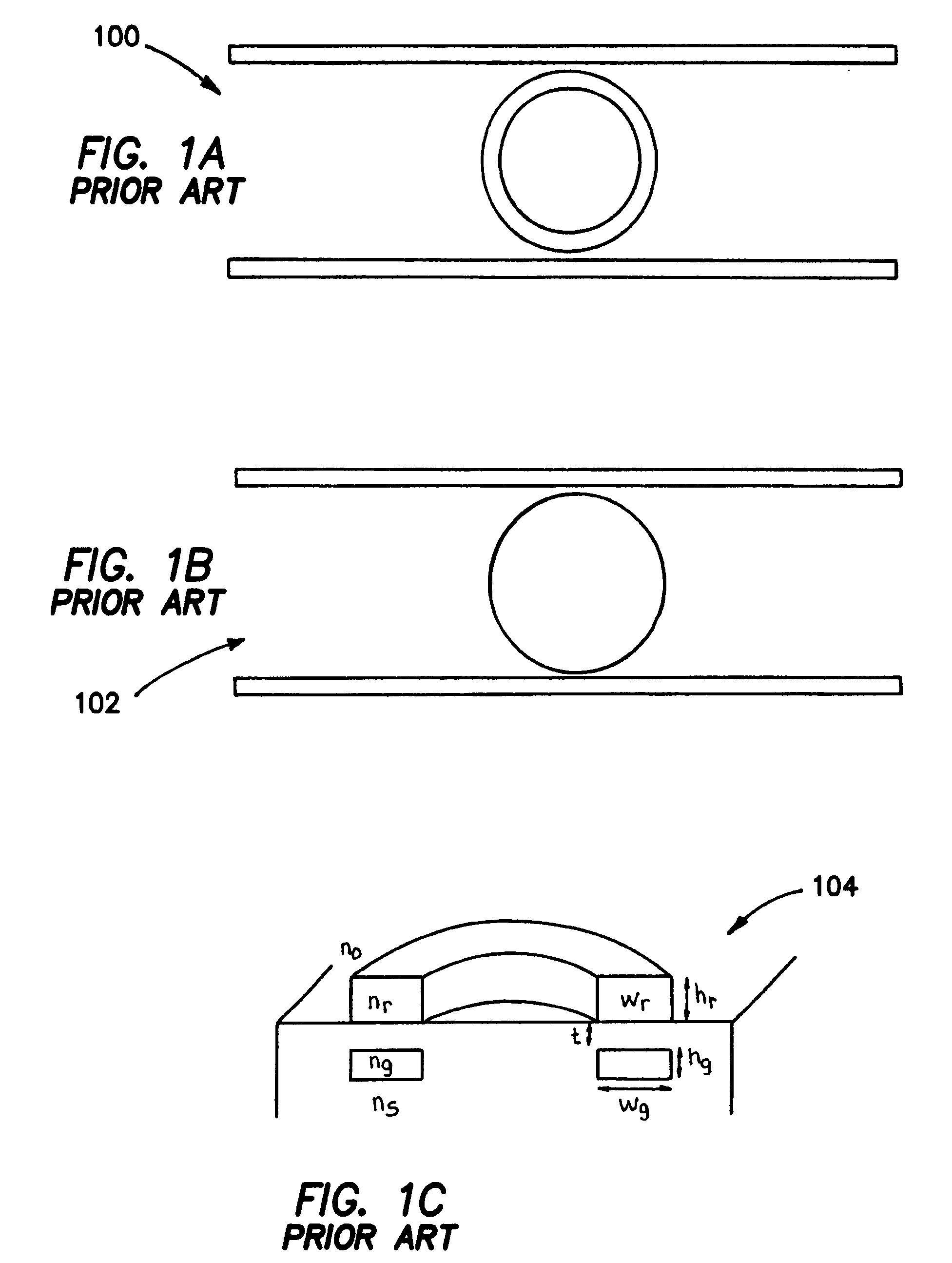

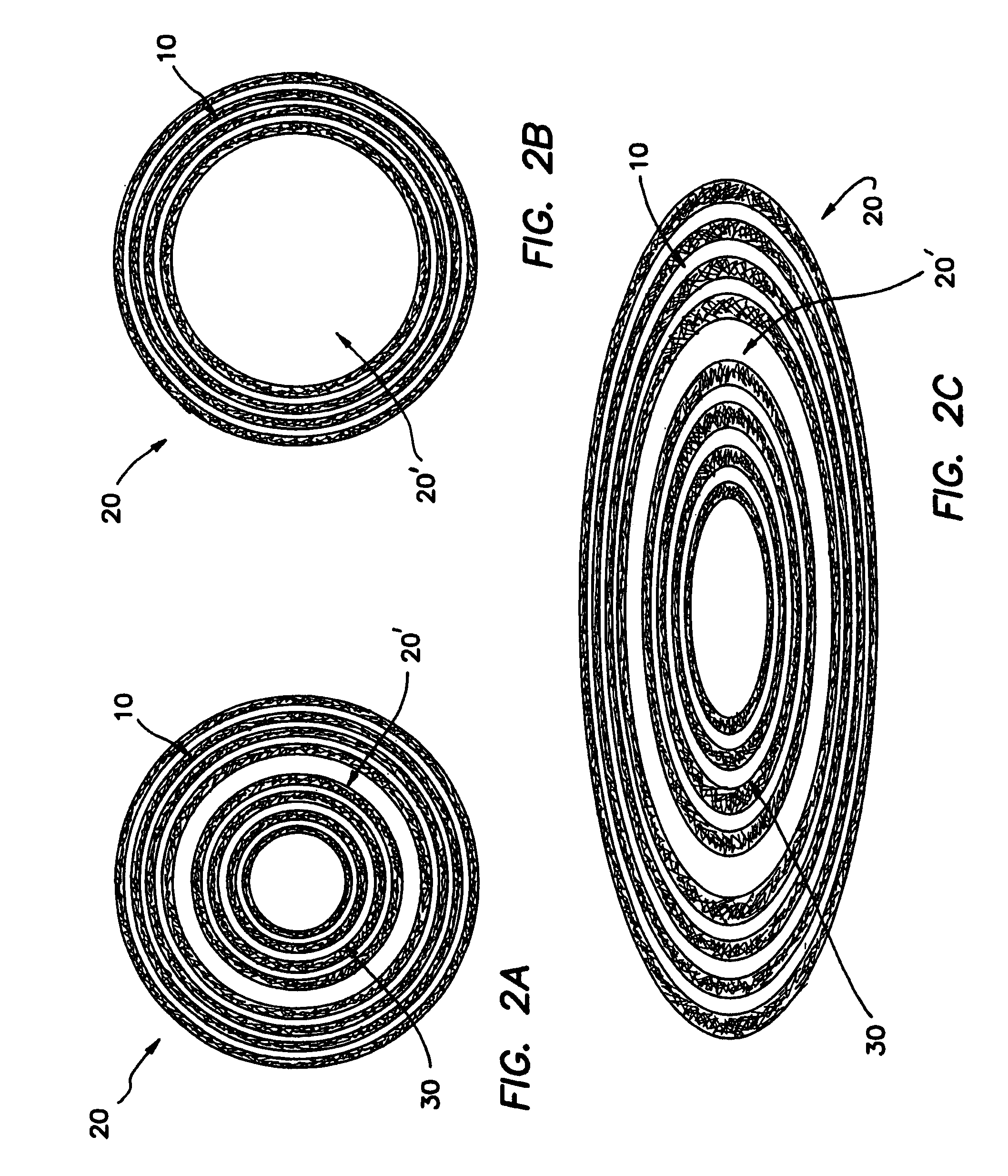

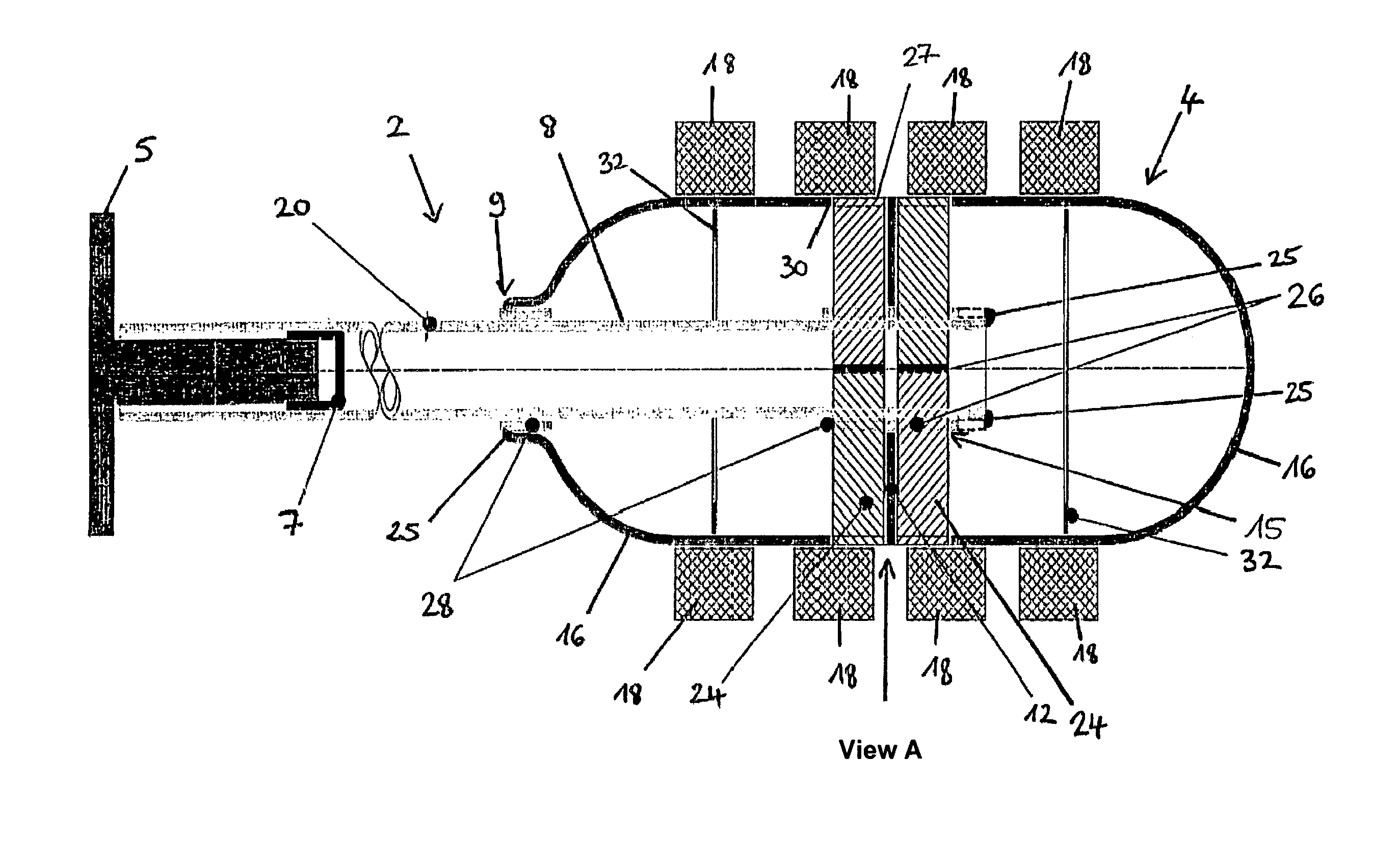

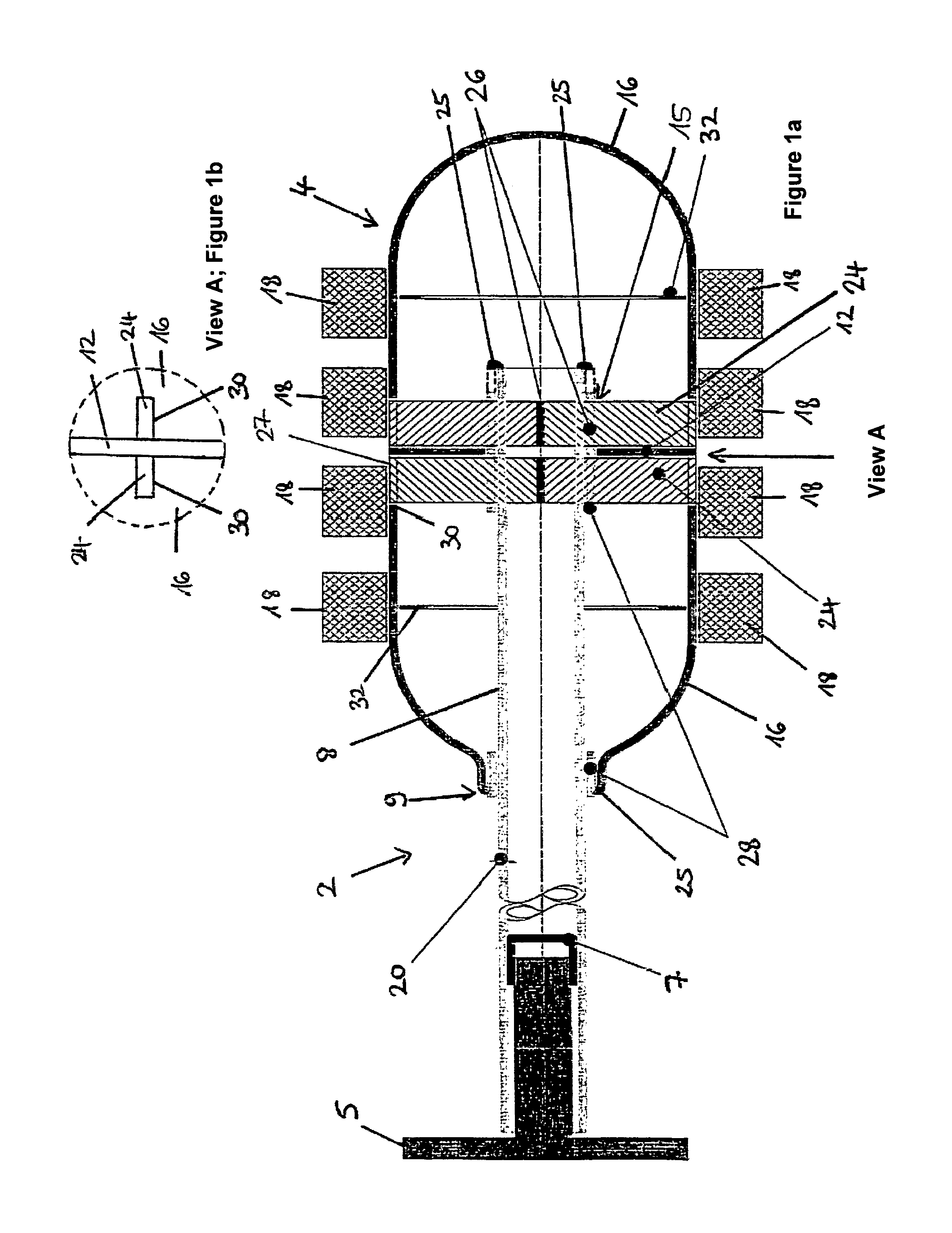

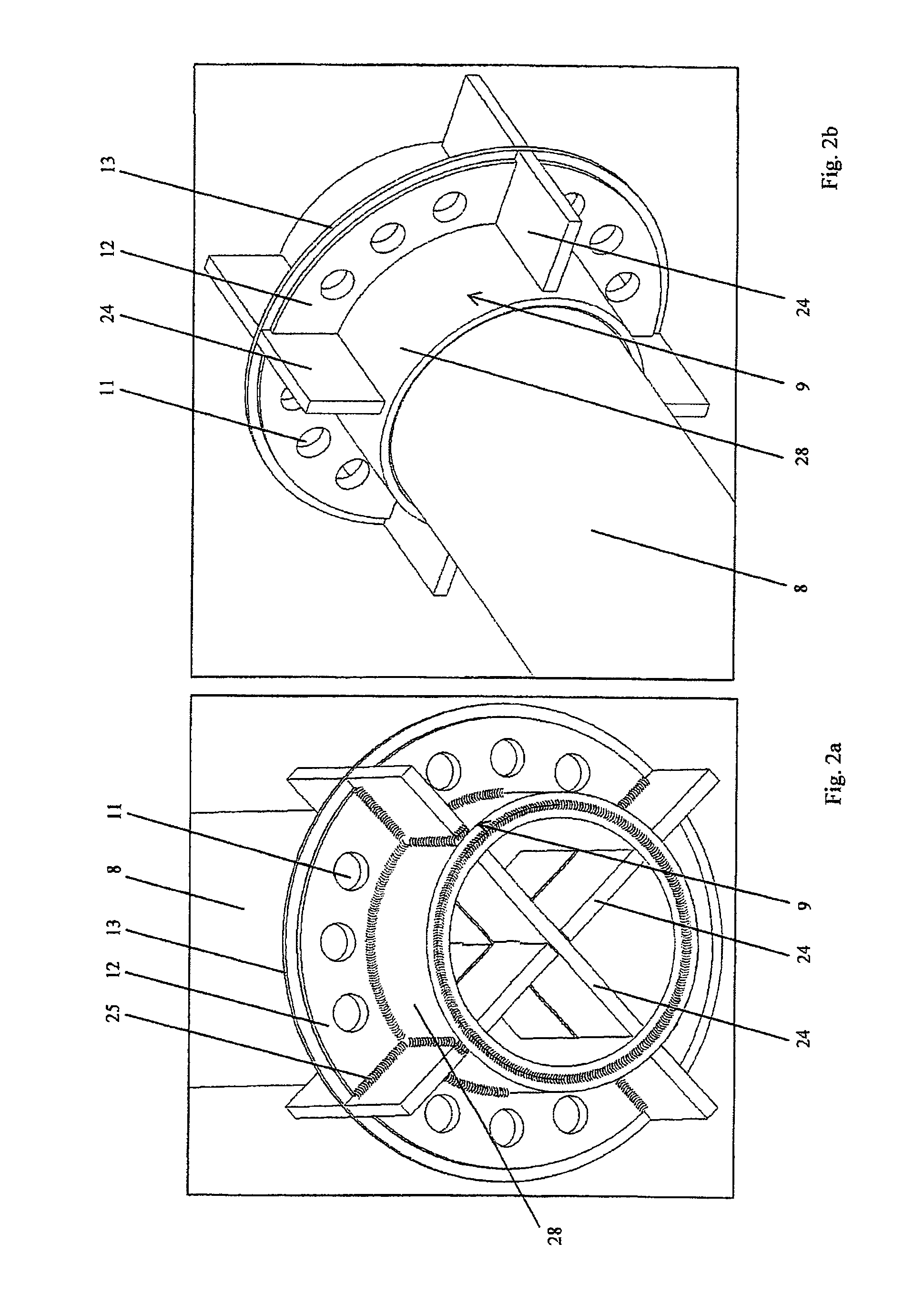

Radial Bragg ring resonator

InactiveUS7099549B2Reduces bending lossSmall bending radiiLaser detailsLaser optical resonator constructionDevice formSpectrum analyzer

A resonator structure is presented comprising a closed loop resonator having a distributed Bragg reflector for confining the light within the guiding core. In one embodiment the light is confined from both the internal and the external sides of the device forming a guiding channel (defect) or just by the external side forming a disk resonator. Although the perfectly circular shape is generally preferred, the resonator could be of any closed loop shape such as an ellipse, etc. Although not mentioned explicitly throughout the text, the Bragg reflectors can of any type of distributed reflector such as, for example, a photonic bandgap crystal where the Bragg reflector is constructed by series of holes in a dielectric material. The resonator structure can be used in various applications, such as optical filters, lasers, modulators, spectrum analyzers, wavelockers, interleave filters, and optical add drop multiplexers.

Owner:CALIFORNIA INST OF TECH

Glue welding connection method

InactiveCN1663729AIncreased shear strengthReduce material lossWelding apparatusFatigue IntensityEngineering

The invention is the glue welding method and belongs to the material engineering technology field. It relates to the new jointing method adopting glue joint and welding. The procedure is: coat a layer of glue on the overlap areas of the surfaces of the two layers of the waiting materials, then adopt welding hot resource overlapping to realize fine joint of the adapters. The invention can fulfill the effective integrate of mechanic joint, metallurgy joint and chemical joint, improve the loading capacity, the fatigue intensity, the cut intensity, solve the problem of hard jointing of same or different metals, reduce the material wastage and meet the demand of the practical project. The invention is suitable for the jointing of magnesium alloy, Al alloy, Ti alloy and steel and obtains the joints with fine performance.

Owner:DALIAN UNIV OF TECH

Apparatus for use in the glass industry and method for processing molten glass

ActiveUS8434329B2Extended service lifeReduce stepsRotary stirring mixersGlass furnace apparatusMaterials scienceMolten glass

Apparatus, which is suitable for being surrounded by molten glass, the apparatus having a shank which has at least one at least partially seamless tube consisting of an oxide dispersion-strengthened PGM material, the shank having at least one thickened portion on which an actuating device is arranged.

Owner:UMICORE AG & CO KG

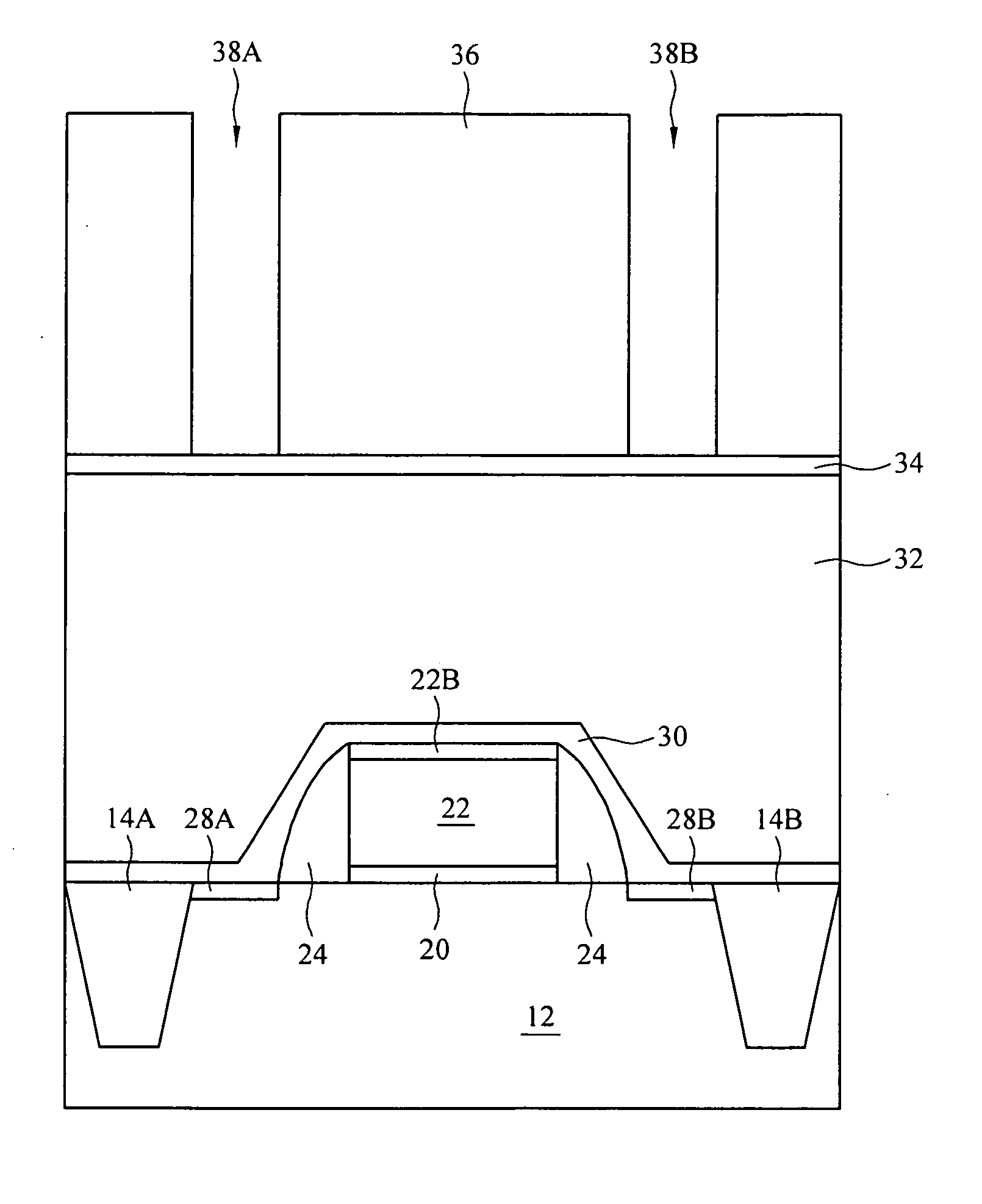

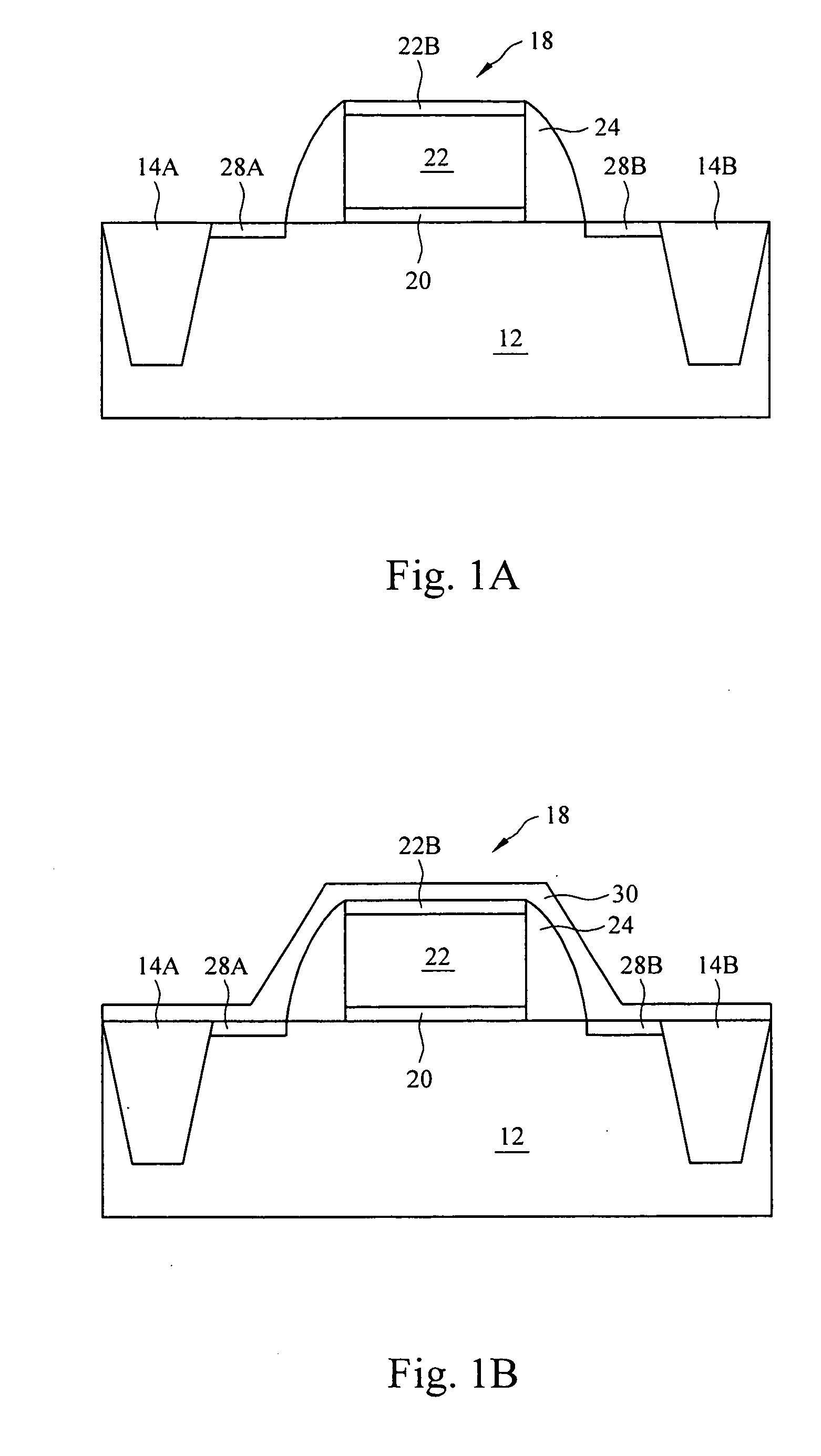

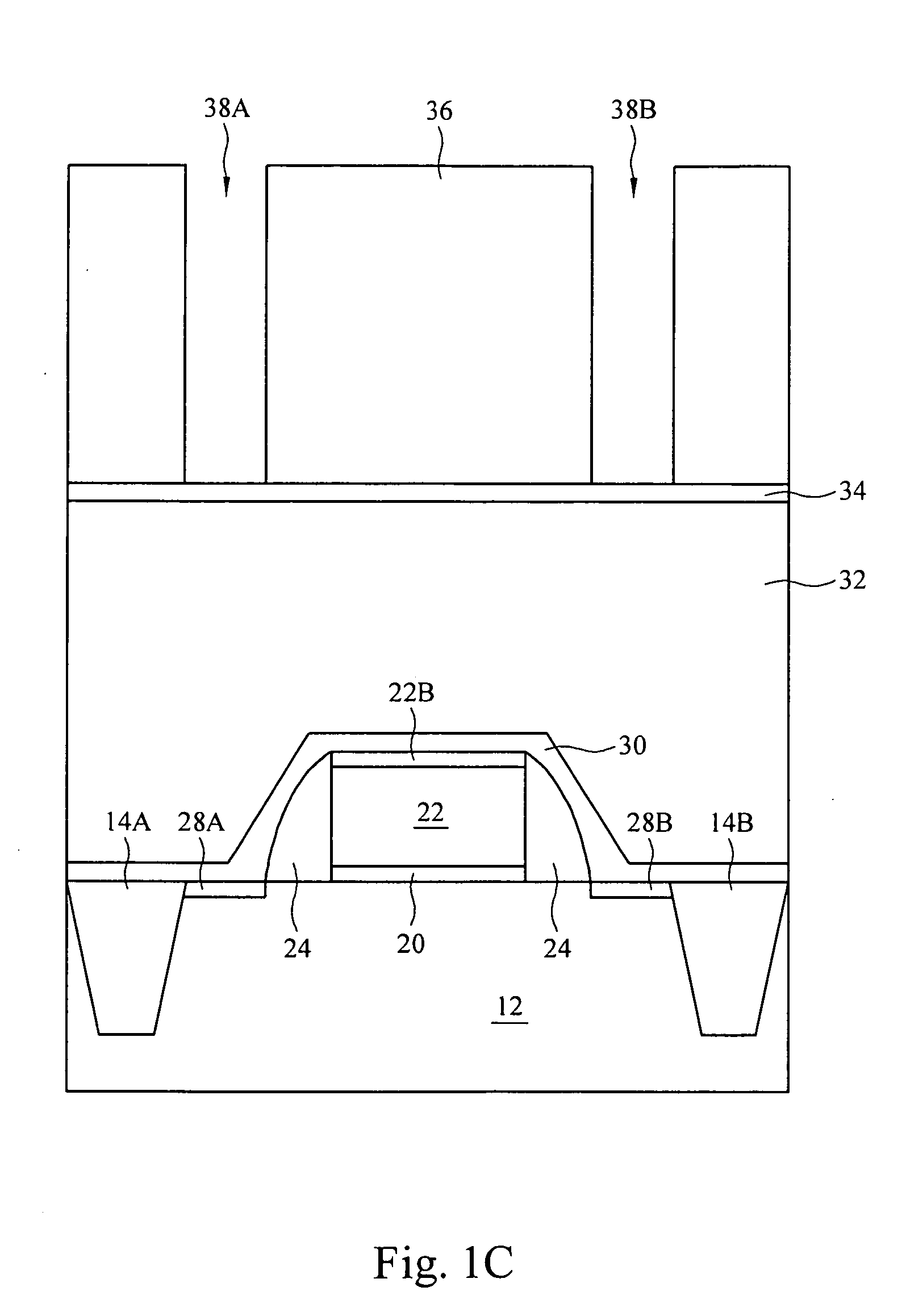

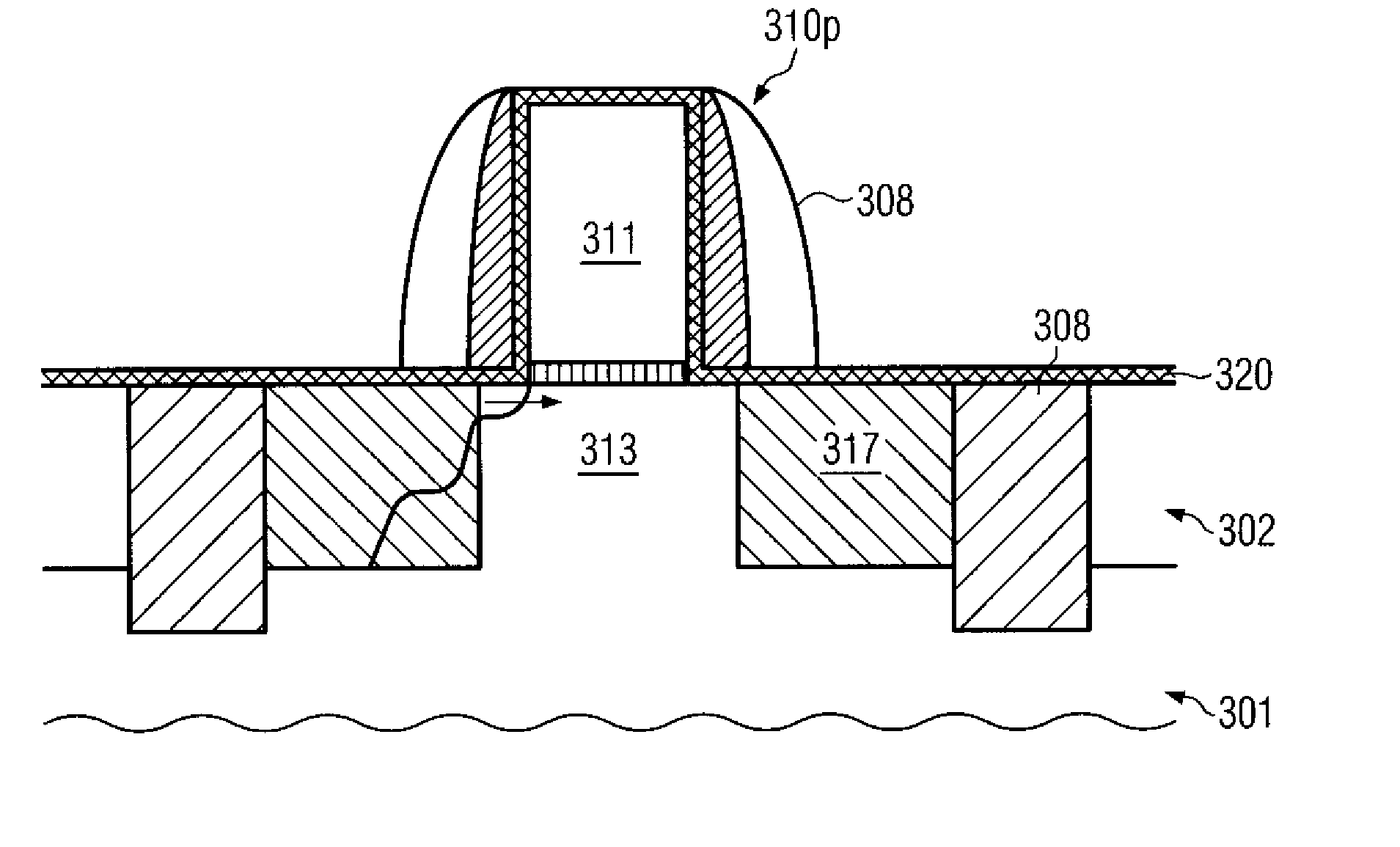

Method for forming silicon/germanium containing drain/source regions in transistors with reduced silicon/germanium loss

ActiveUS20080182371A1Reduce material lossLower performance requirementsSolid-state devicesSemiconductor/solid-state device manufacturingSalicideSemiconductor materials

By providing a protection layer on a silicon / germanium material of high germanium concentration, a corresponding loss of strained semiconductor material may be significantly reduced or even completely avoided. The protection layer may be formed prior to critical cleaning processes and may be maintained until the formation of metal silicide regions. Hence, high performance gain of P-type transistors may be accomplished without requiring massive overfill during the selective epitaxial growth process.

Owner:GLOBALFOUNDRIES US INC

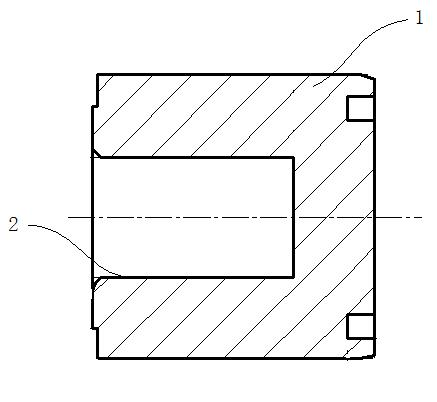

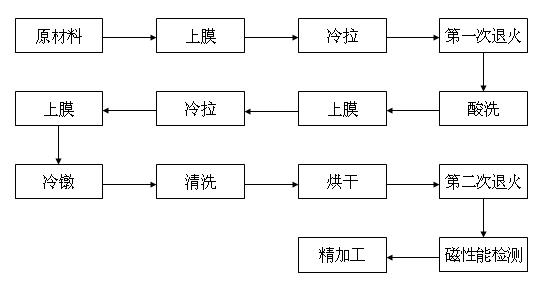

Processing technology of static iron core of electromagnetic valve

The invention relates to a processing technology of a static iron core of an electromagnetic valve, which has the advantages of reducing the material spillage and improving the magnetic performance of the static ion core. The technology comprises the following steps of: performing cold drawing, primary annealing treatment, secondary cold drawing on linear ferrite serving as raw material, and carrying out cold heading on the material to form a part blank; performing secondary annealing treatment on the part blank, detecting the magnetic performance of the part and performing surface finishing treatment if the part is qualified. According to the processing technology, cutting processing is replaced with cold drawing and cold heading, annealing treatment is performed after the part is formed, the magnetic perforamnce of the final part is enhanced, and the material utilization rate in the static iron core processing process is improved.

Owner:SHAOXING KANGJIAN PRECISION STAINLESS STEEL

Thermal expansion engineering for polycrystalline aluminum nitride sintered bodies

ActiveUS20120146023A1Easy to optimizeReduce material lossPolycrystalline material growthSemiconductor/solid-state device manufacturingPolycrystalline aluminumSemiconductor materials

Disclosed are methods and materials useful in the preparation of semiconductor devices. In particular embodiments, disclosed are methods for engineering polycrystalline aluminum nitride substrates that are thermally matched to further materials that can be combined therewith. For example, the polycrystalline aluminum nitride substrates can be engineered to have a coefficient of thermal expansion (CTE) that is closely matched to the CTE of a semiconductor material and / or to a material that can be used as a growth substrate for a semiconductor material. The invention also encompasses devices incorporating such thermally engineered substrates and semiconductor materials grown using such thermally engineered substrates. The thermally engineered substrates are advantageous for overcoming problems caused by damage arising from CTE mismatch between component layers in semiconductor preparation methods and materials.

Owner:INTERSOUTH PARTNERS VI +5

Terpene resin and preparation method thereof

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Substrate comprising aluminum/graphite composite, heat dissipation part comprising same, and LED luminescent member

ActiveUS20110316038A1Efficient productionReduce material lossSemiconductor/solid-state device detailsSolid-state devicesFlexural strengthThermal expansion

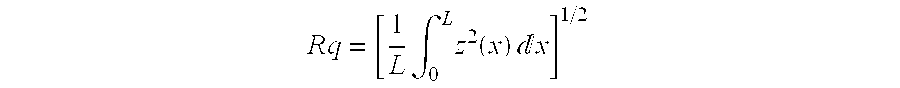

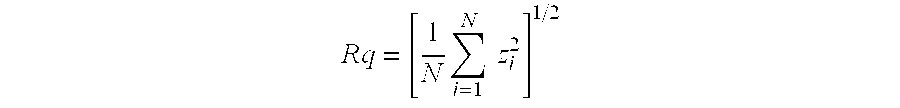

A process for producing a substrate, which comprises processing an aluminum / graphite composite into plates having a thickness of 0.5-3 mm using a multi-wire saw under the following conditions (1) to (4): (1) the wires have abrasive grains bonded thereto which are one or more substances selected from diamond, C—BN, silicon carbide, and alumina and have an average particle diameter of 10-100 μm; (2) the wires have a diameter of 0.1-0.3 mm; (3) the wires are run at a rate of 100-700 m / min; and (4) the composite is cut at a rate of 0.1-2 mm / min. The aluminum / graphite composite has a surface roughness (Ra) of 0.1-3 μm, a thermal conductivity at 25° C. of 150-300 W / mK, a ratio of the maximum to the minimum value of thermal conductivity in three perpendicular directions of 1-1.3, a coefficient of thermal expansion at 25-150° C. of 4×106 to 7.5×10−6 / K, a ratio of the maximum to the minimum value of coefficient of thermal expansion in three perpendicular directions of 1-1.3, and a three-point bending strength of 50-150 MPa.

Owner:DENKA CO LTD

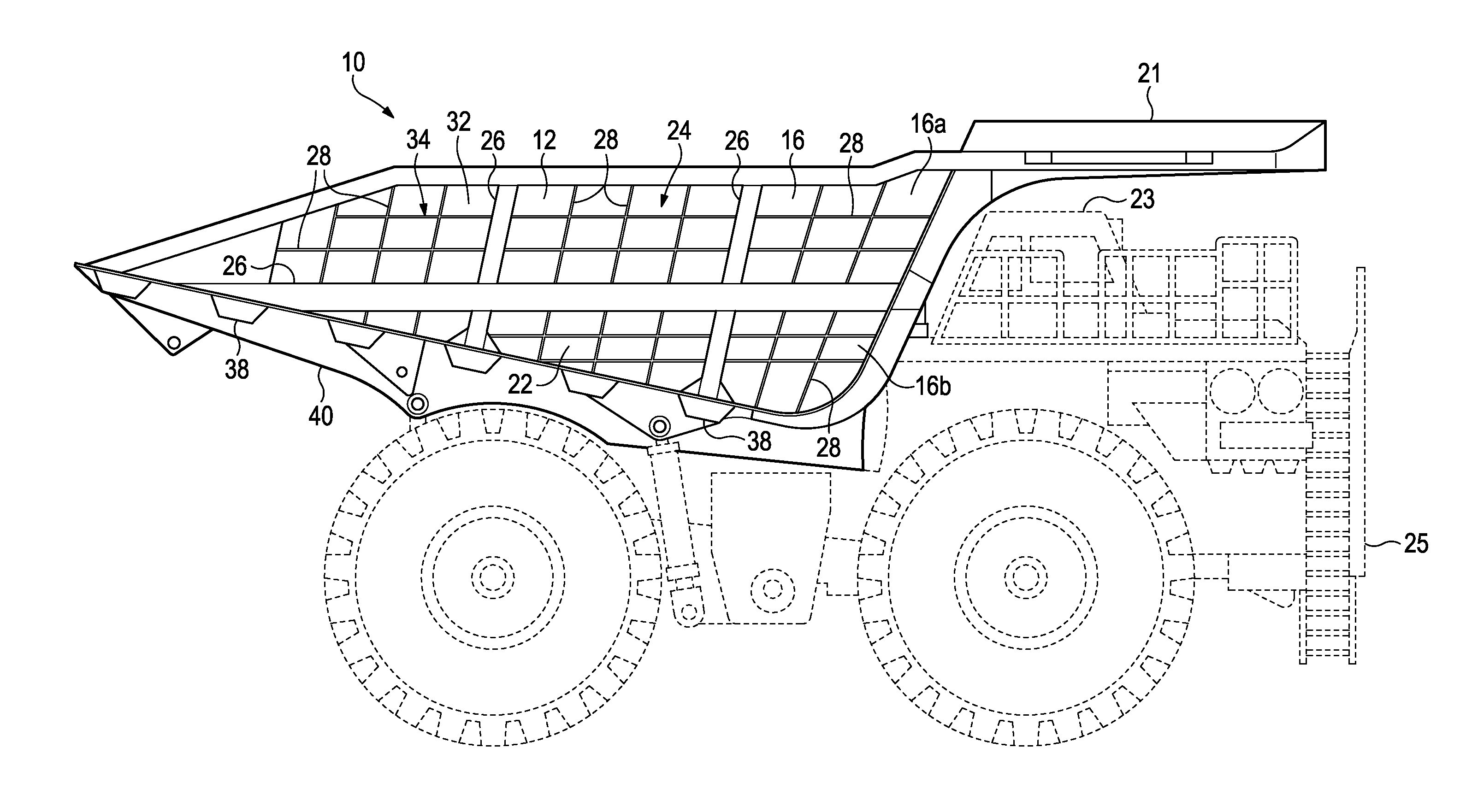

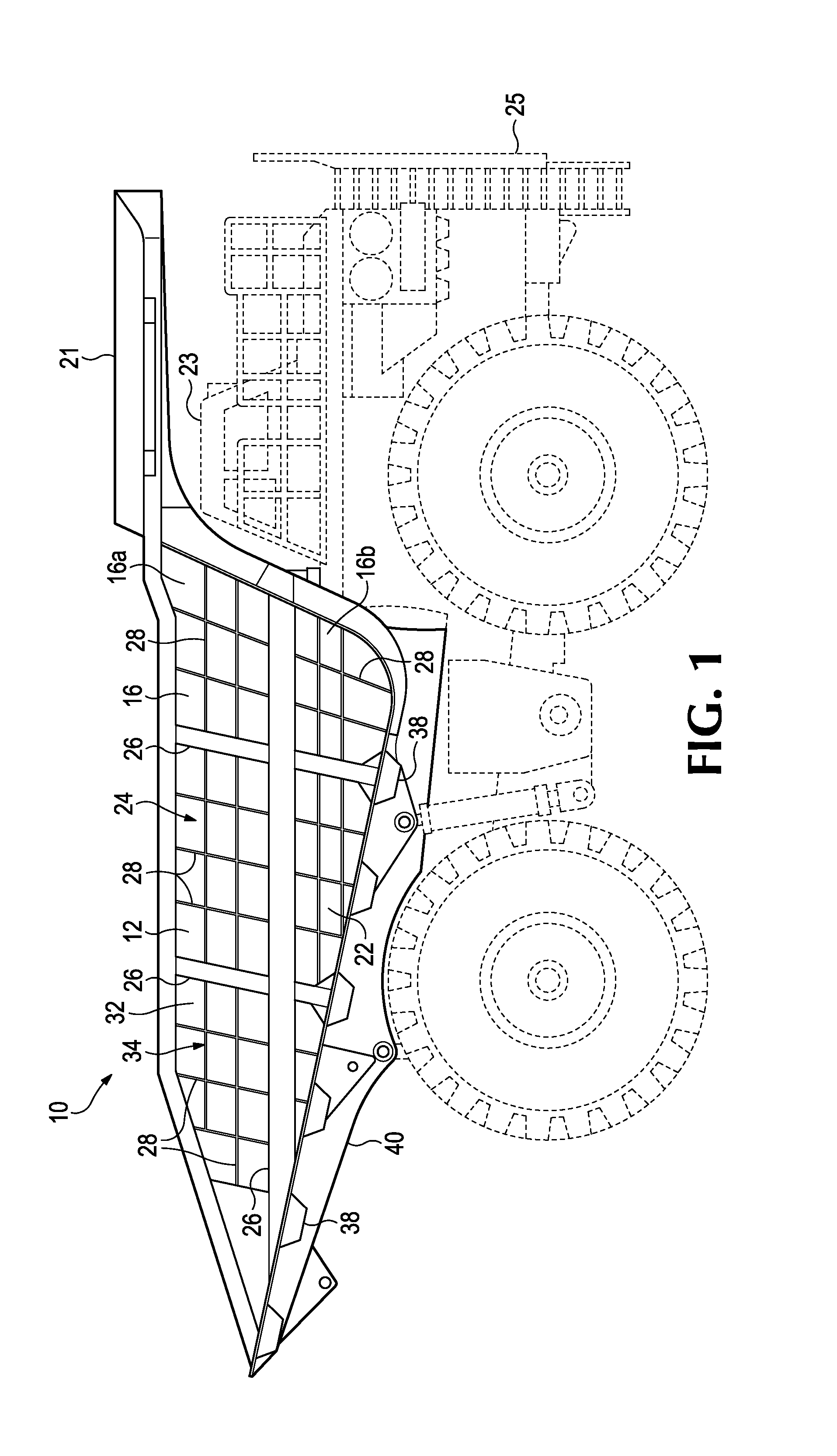

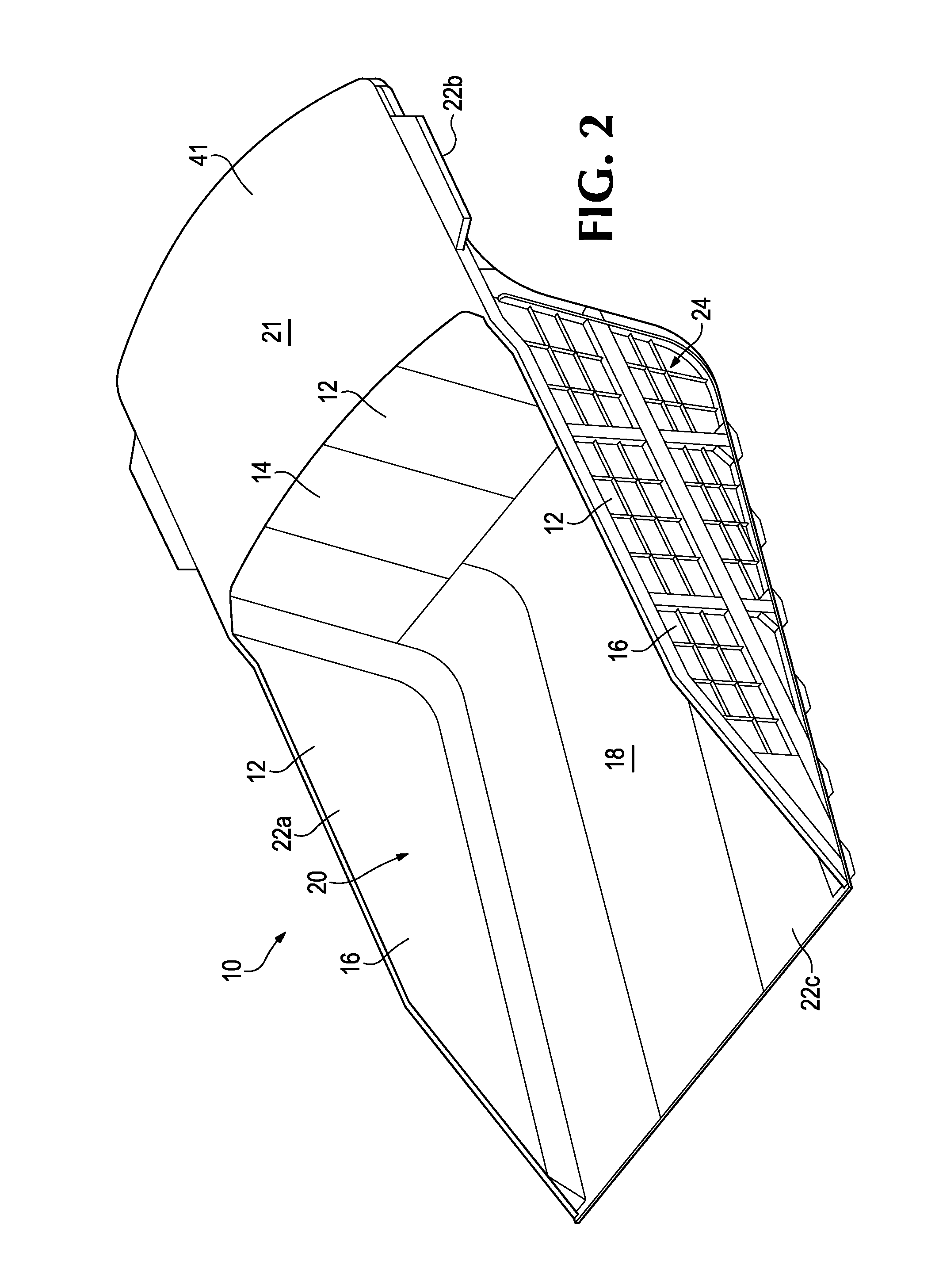

Truck Body For Mining Vehicle

InactiveUS20140015279A1Small sectionLoss of strength and stabilityLoading/unloading vehicle arrangmentMonocoque constructionsTruckSurface plate

A truck body for use with a mining dump truck uses a support structure having primary and secondary supports fixed to panels defining the hauling cavity. The use of primary and secondary supports in combination with thinner plate steel produces a stable, ultra-light truck body that enables a larger load of mined material to be transported in a single haul cycle. The provision of a larger hauled load results in a substantial increase in the efficiency of the mining operation and reduced costs.

Owner:ESCO CORP

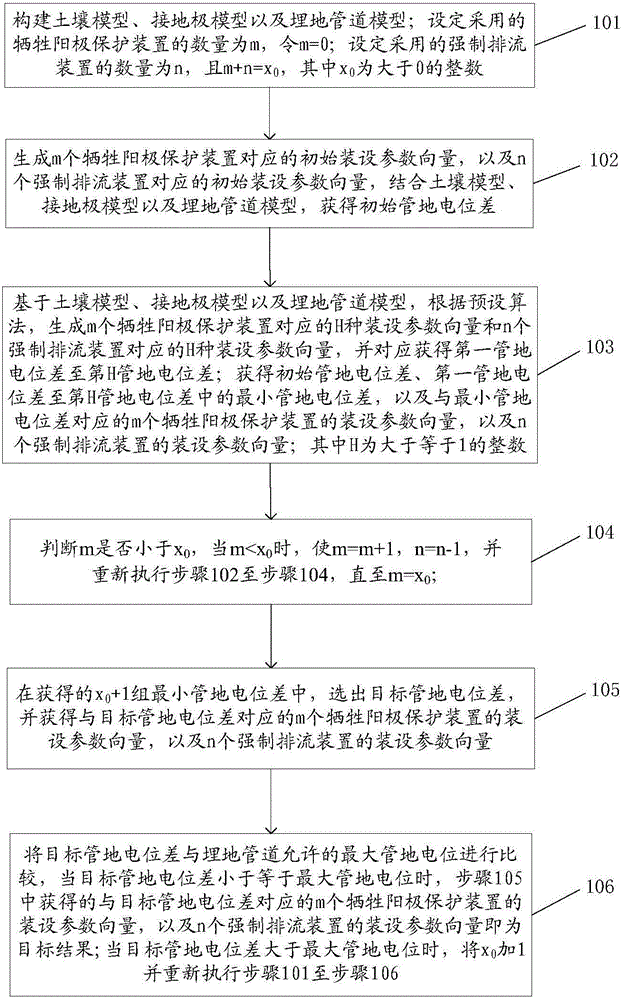

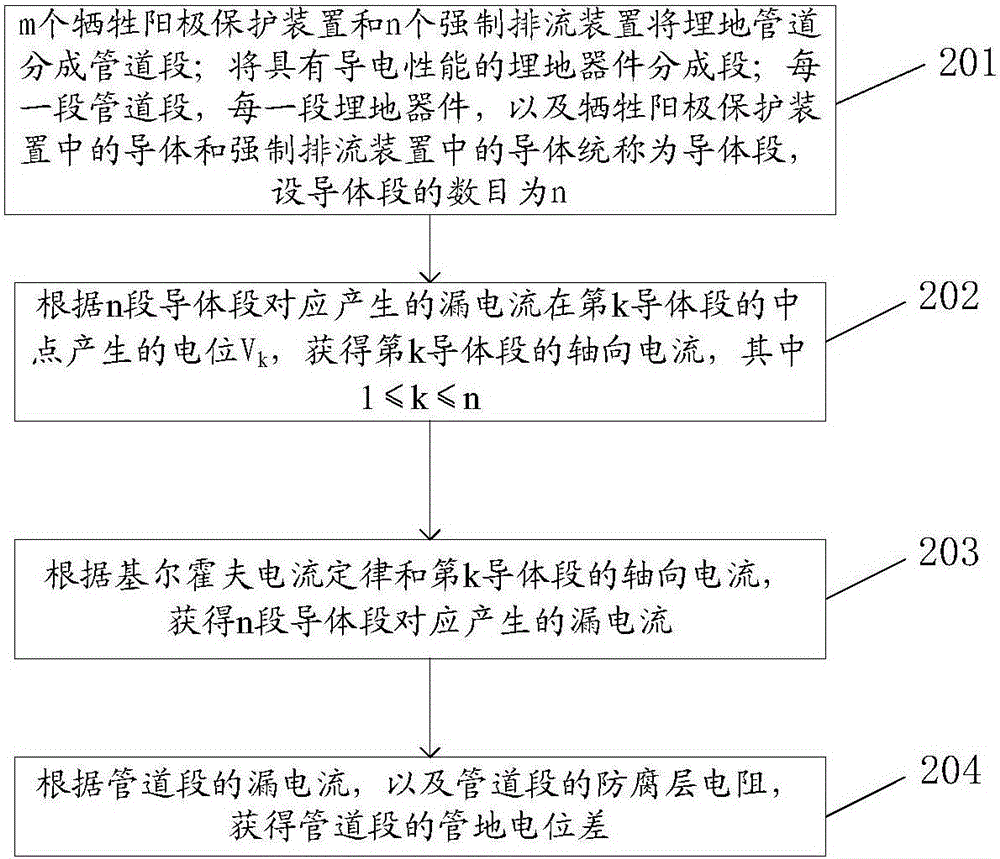

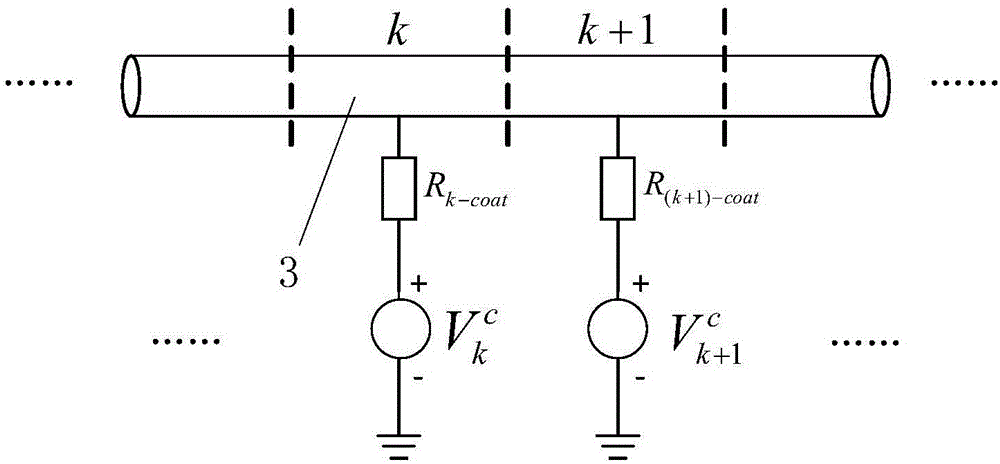

Buried pipeline cathode protection method and system

The invention discloses a buried pipeline cathode protection method and system, relates to the technical field of buried pipeline protection, and aims at solving the problems that a method for conducting cathode protection on a buried pipeline according to the experience is low in accuracy, and standard operation procedures are lacked. The buried pipeline cathode protection method comprises the steps that the ground potential difference of an initial pipe and the ground potential differences from a first pipe to an nth pipe are obtained; the ground potential difference of a target pipe and a corresponding installation parameter vector are obtained; then, the ground potential difference of the target pipe and the allowed maximum pipe ground potential of the buried pipeline are compared, and when conditions are met, the obtained installation parameter vector corresponding to the ground potential difference of the target pipe is a target result; or otherwise, the number of anodic sacrifice protection devices and the number of forced drainage devices are adjusted till the conditions are met. The buried pipeline cathode protection method is used for optimal arrangement of buried pipeline cathode protection devices.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

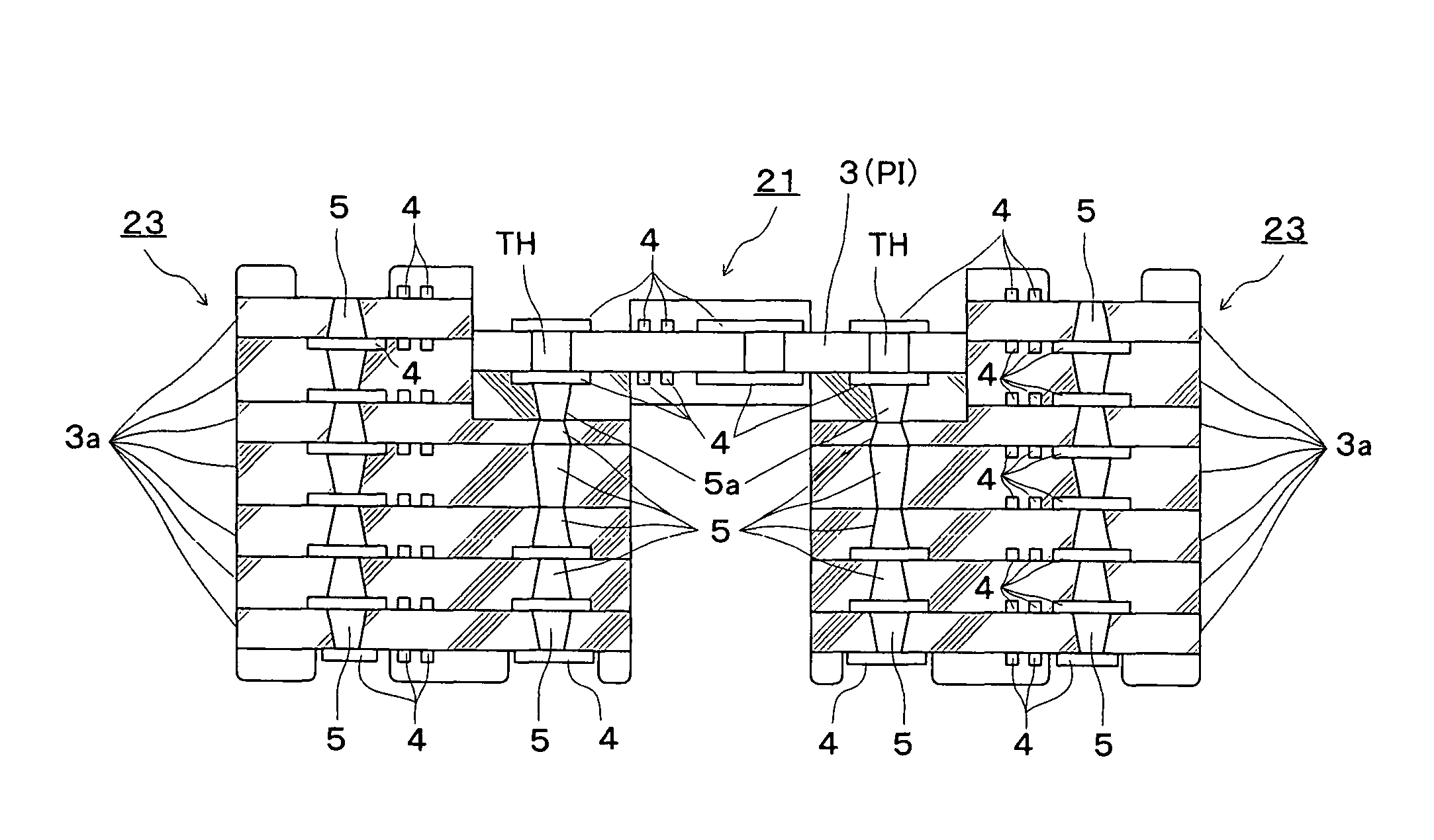

Rigid-flexible board and method for manufacturing the same

InactiveUS7815441B2High aspect ratioSimple molding processPrinted circuit assemblingLamination ancillary operationsEngineeringYield ratio

A rigid-flexible board and a method for manufacturing the same can be provided, whereby the material yield ratio can be enhanced and the productive yield can be also enhanced. A rigid board with a step for connection and a flexible board with a connector at the edge thereof are formed independently. Then, the connecting area is spot facing processed so that the depth of the thus obtained depressed portion is equal to or lower than the thickness of the flexible board. The connector of the flexible board is electrically connected to the vertical wiring area of the depressed portion.

Owner:DAI NIPPON PRINTING CO LTD

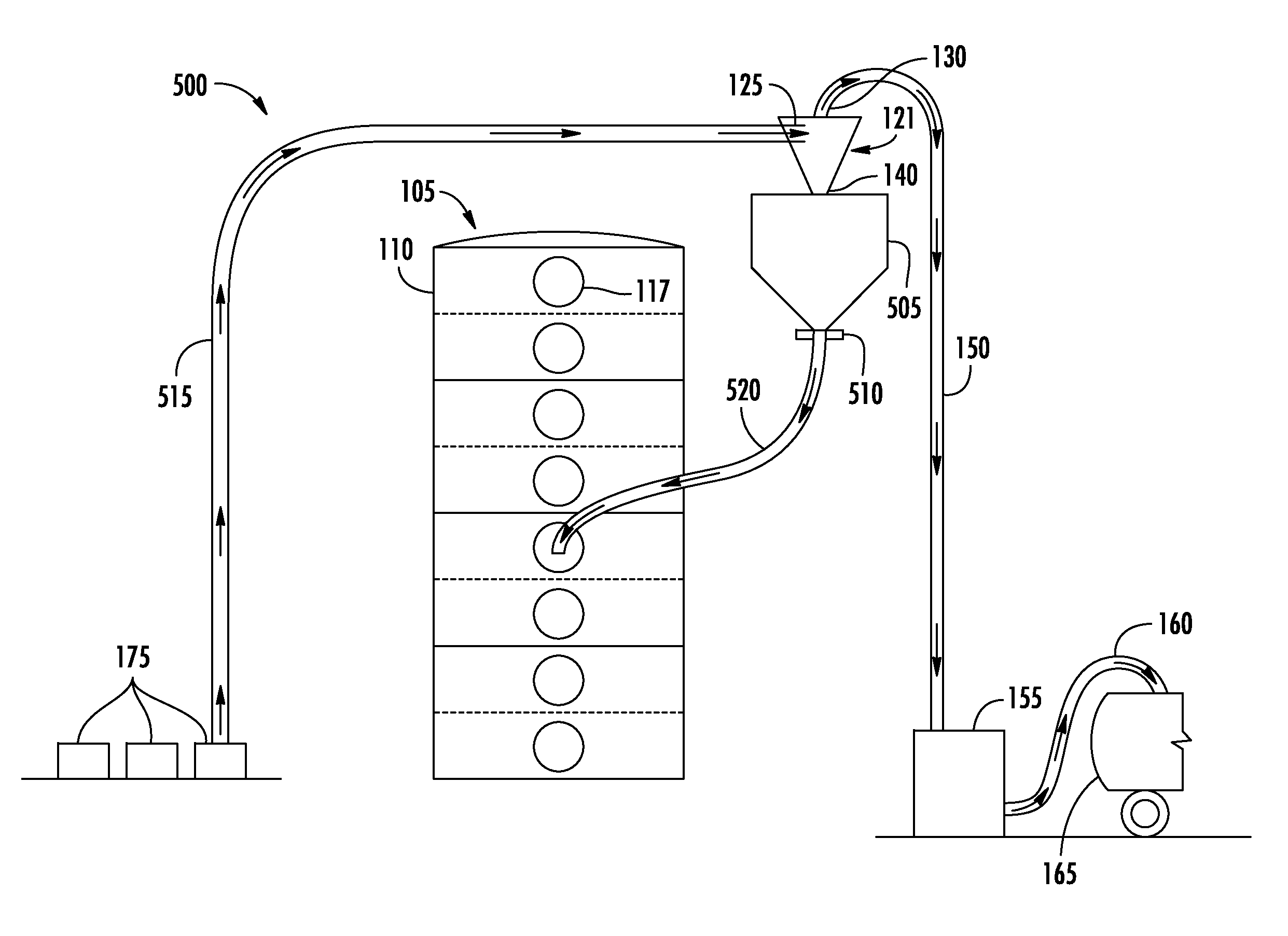

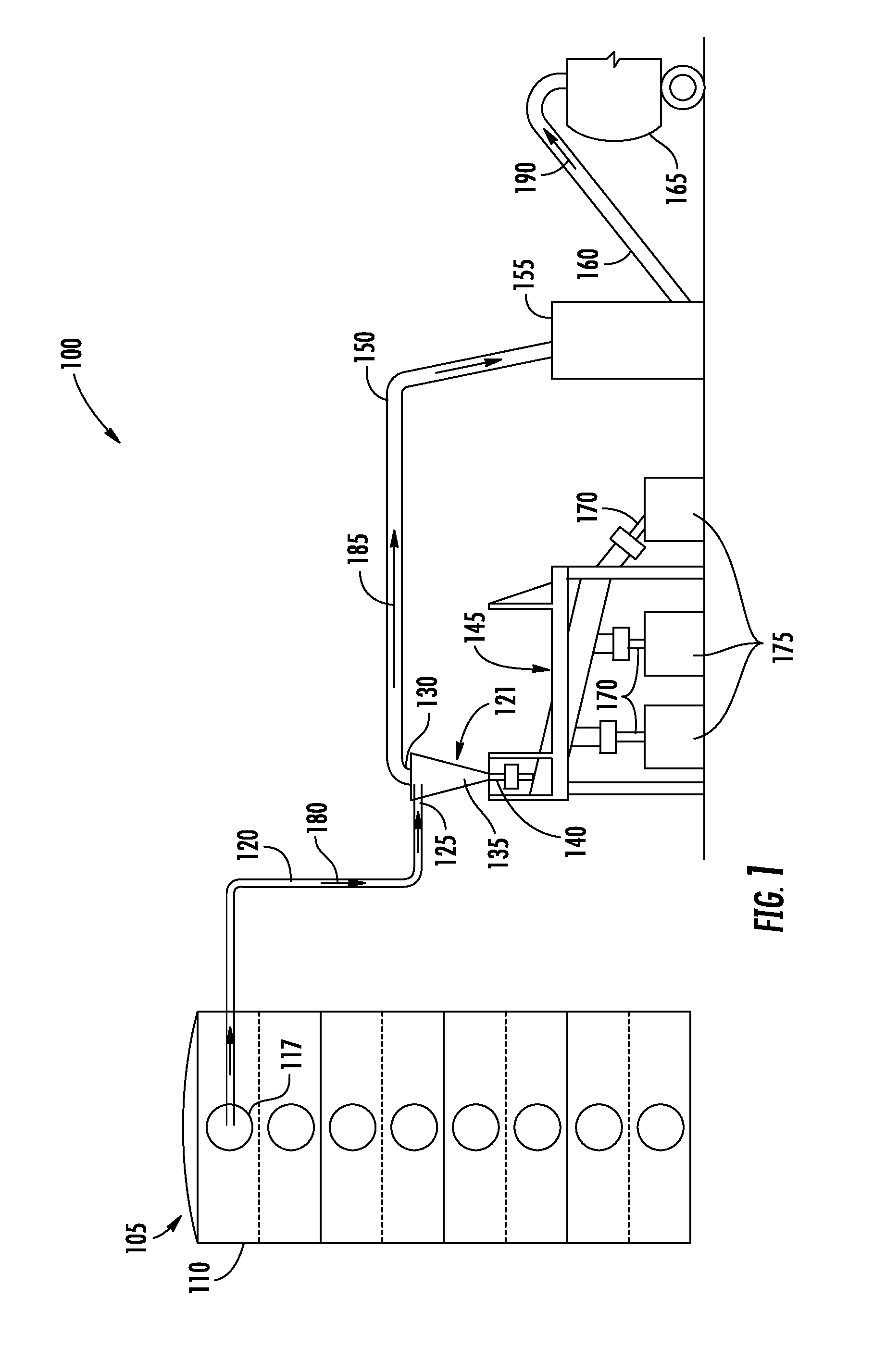

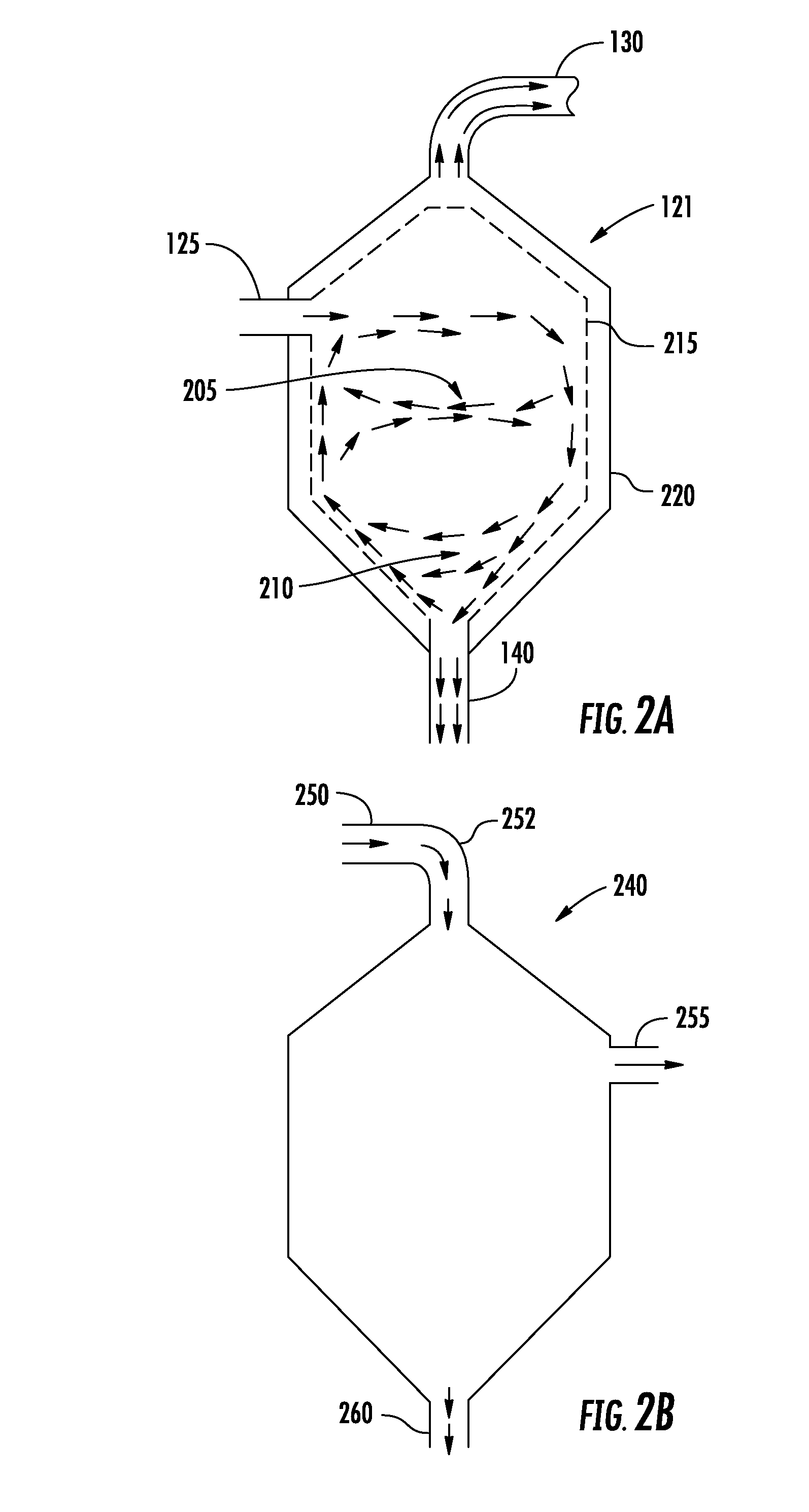

Systems and methods for converter bed unloading and loading

InactiveUS20140255133A1Reduce material lossEasily replaceableReversed direction vortexGas current separationEngineeringPhencyclone

A system and method for loading material from a converter bed, such as that in a converter of an acid plant, is provided. The system, may include a vacuum source; a dust collector connected to the vacuum source by a first vacuum hose; a cyclone operatively connected to the vacuum source through the dust collector, wherein the cyclone may be connected to the dust collector by a second vacuum hose; a drop-out hopper operatively attached to the cyclone by a valve, such as an air actuated valve, wherein the drop-out hopper includes a first feed hose; and one or more material storage containers operatively associated with the cyclone via a second feed hose. The method of loading material into a converter bed may include providing a system for loading the material in the converter bed; setting up the system; and loading the material into the converter bed.

Owner:CYCLONE CATALYST PROPERTIES LLC

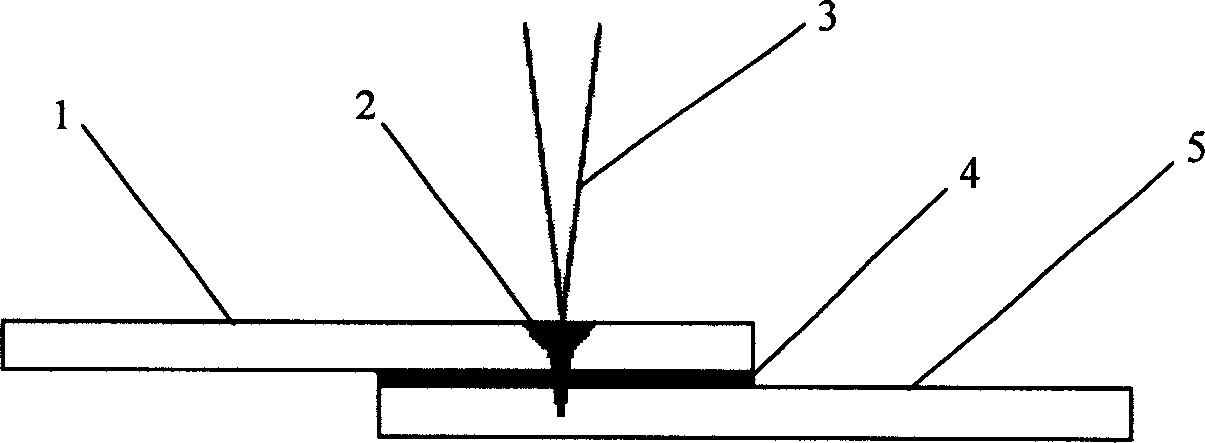

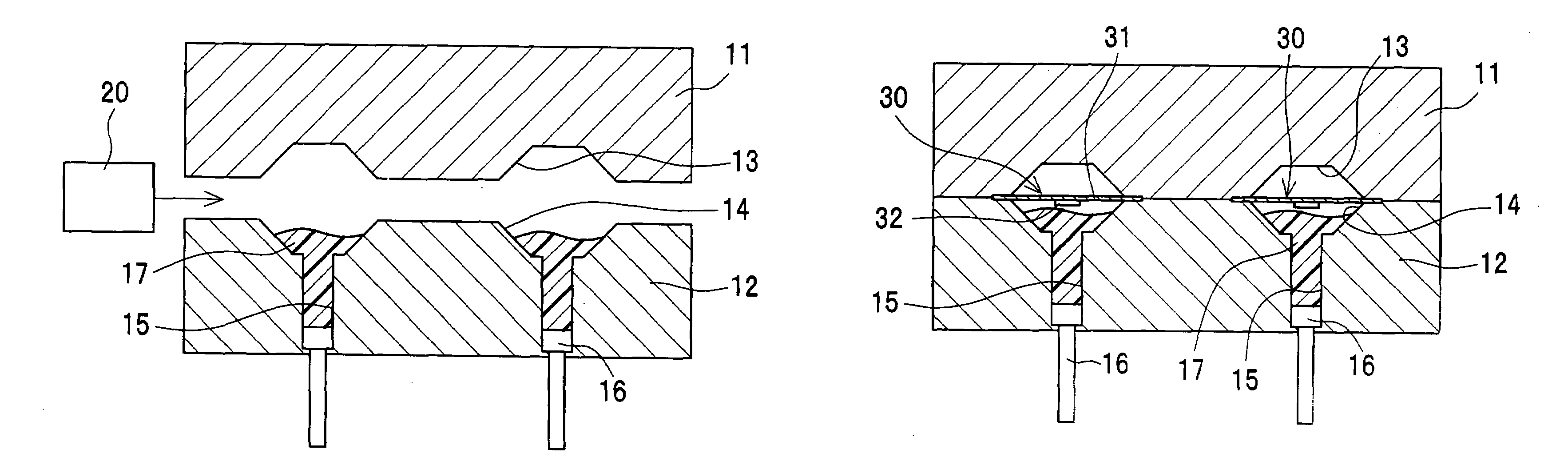

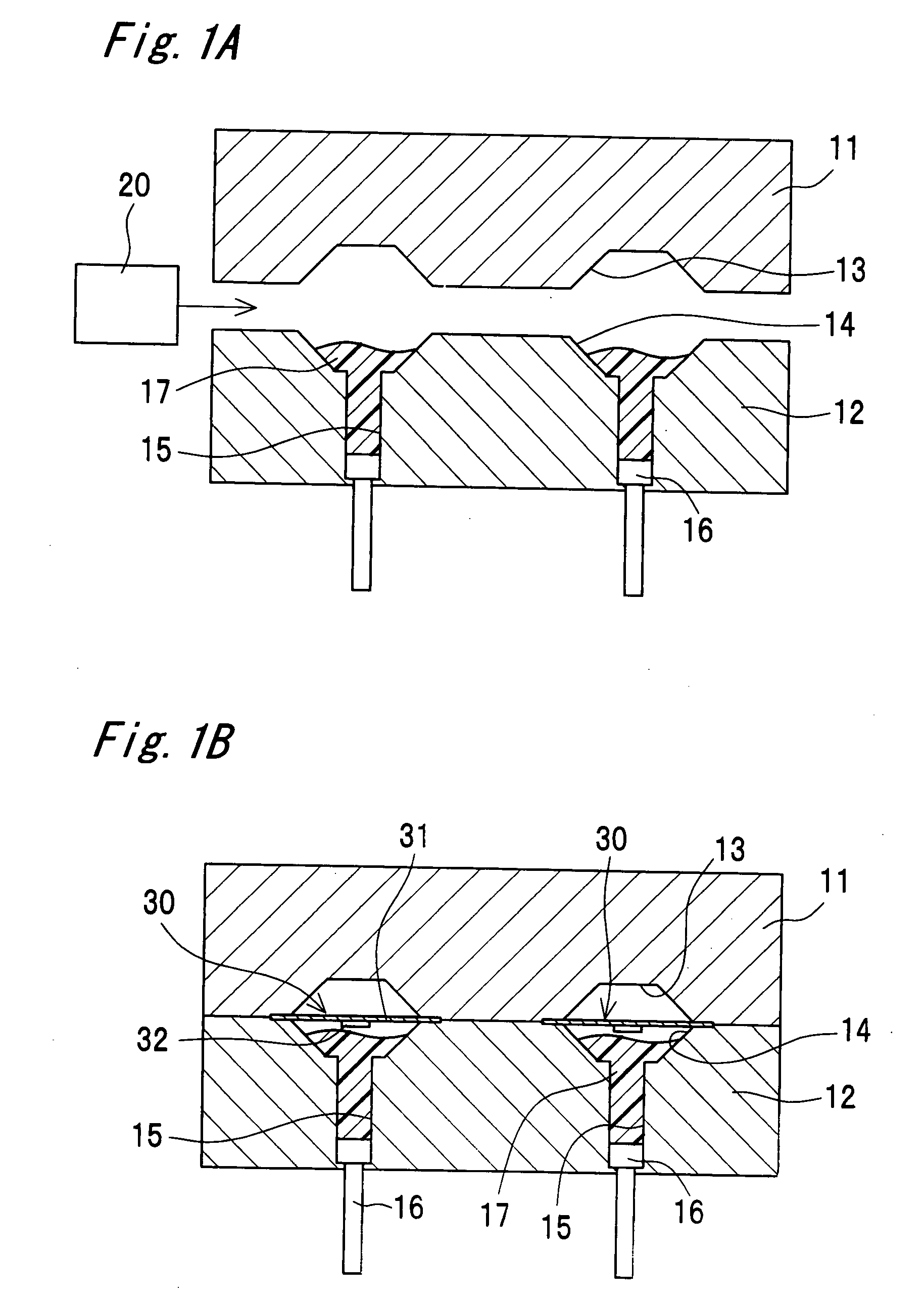

Semiconductor device manufacturing method and semiconductor device manufacturing apparatus

InactiveUS20070181903A1Reduce material lossLess generationSolid-state devicesSemiconductor/solid-state device manufacturingLiquid stateMetal mold

A semiconductor device manufacturing method includes the steps of filling a cavity and a resin reservoir hole in a lower metal mold with a liquid-state resin, holding a semiconductor element between the lower metal mold and an upper metal mold, injecting the resin in the resin reservoir hole into the cavity to seal the semiconductor device with the resin. Thus, the semiconductor device having almost no voids and less material loss is manufactured with high accuracy.

Owner:SHARP KK

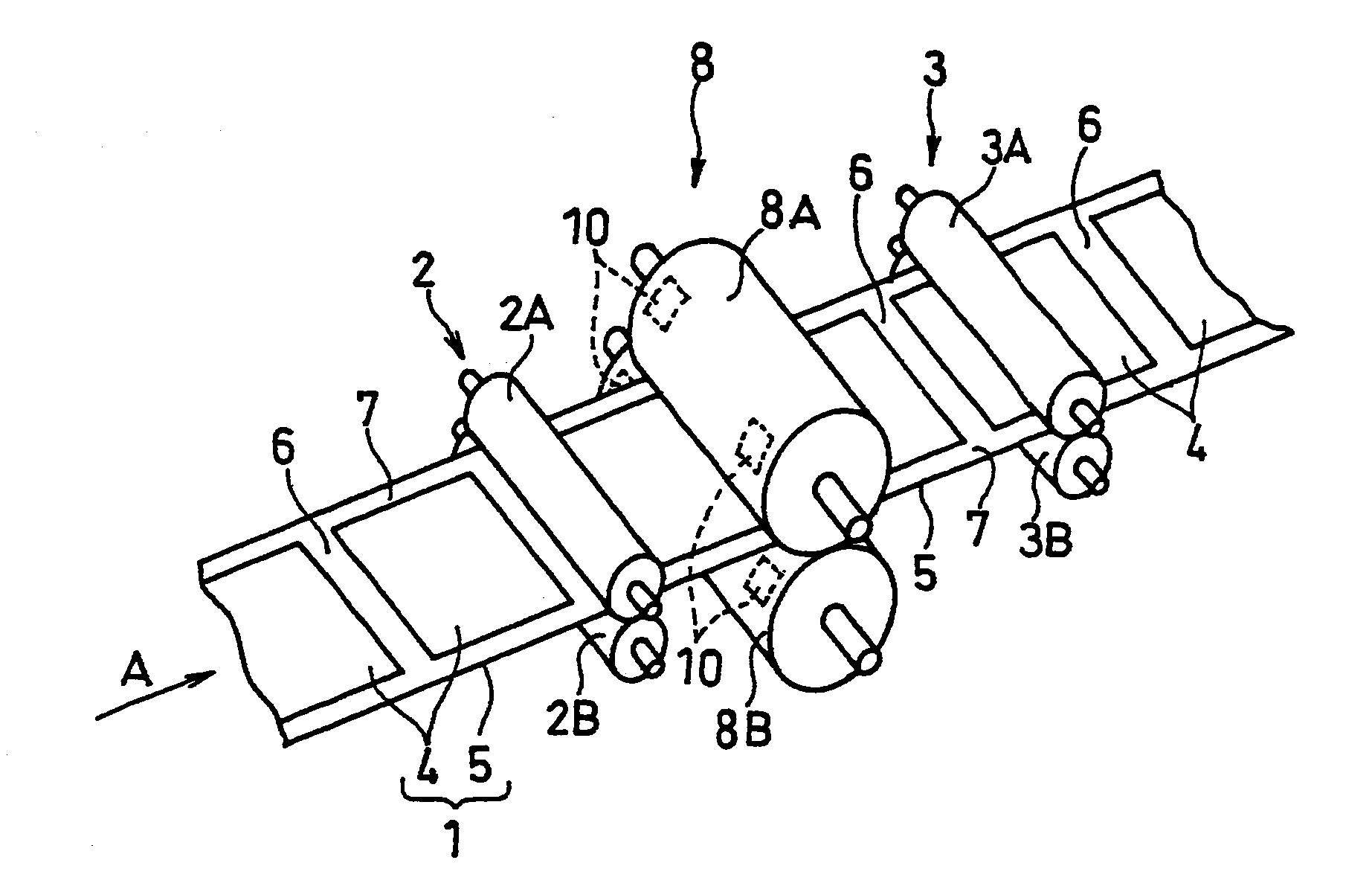

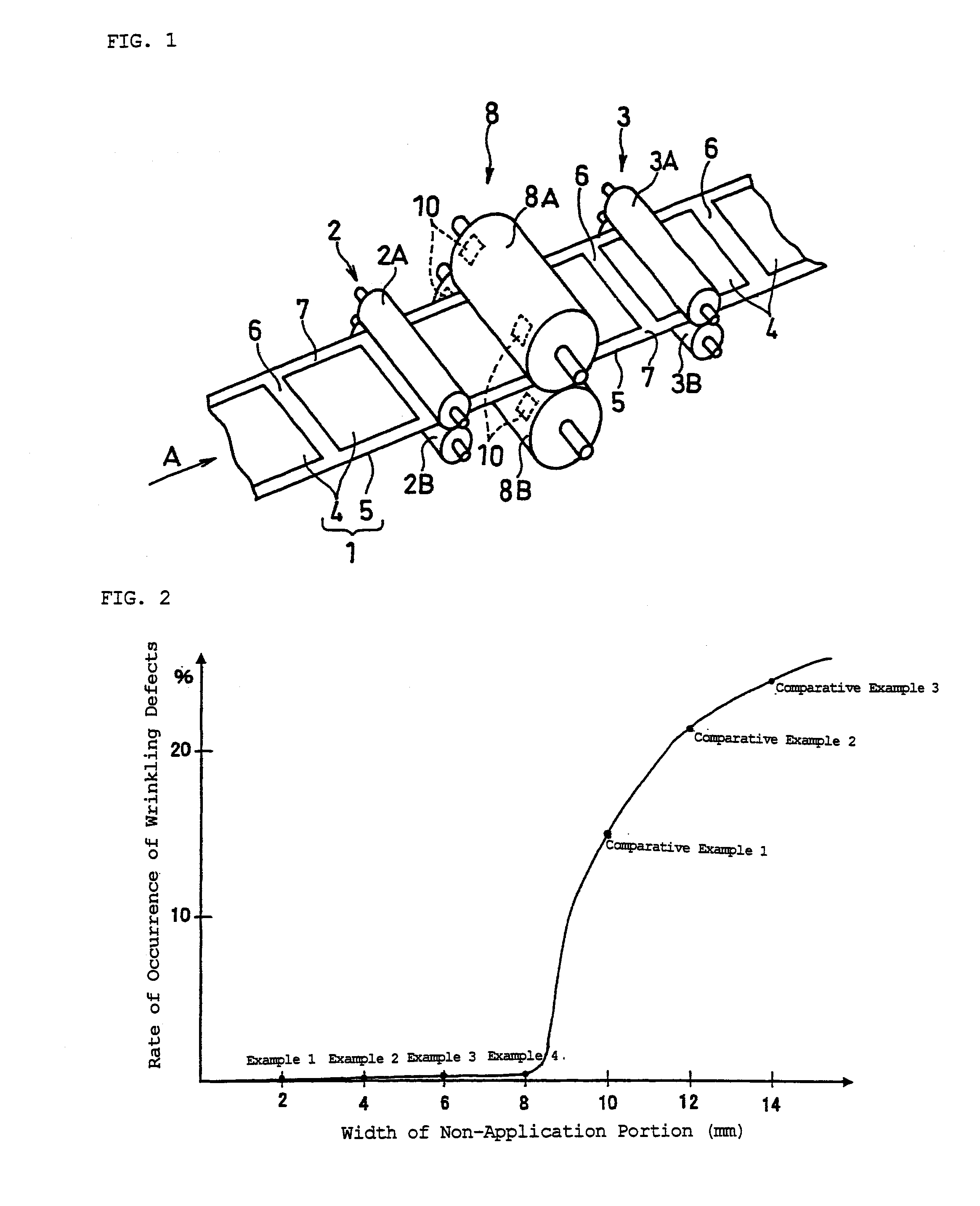

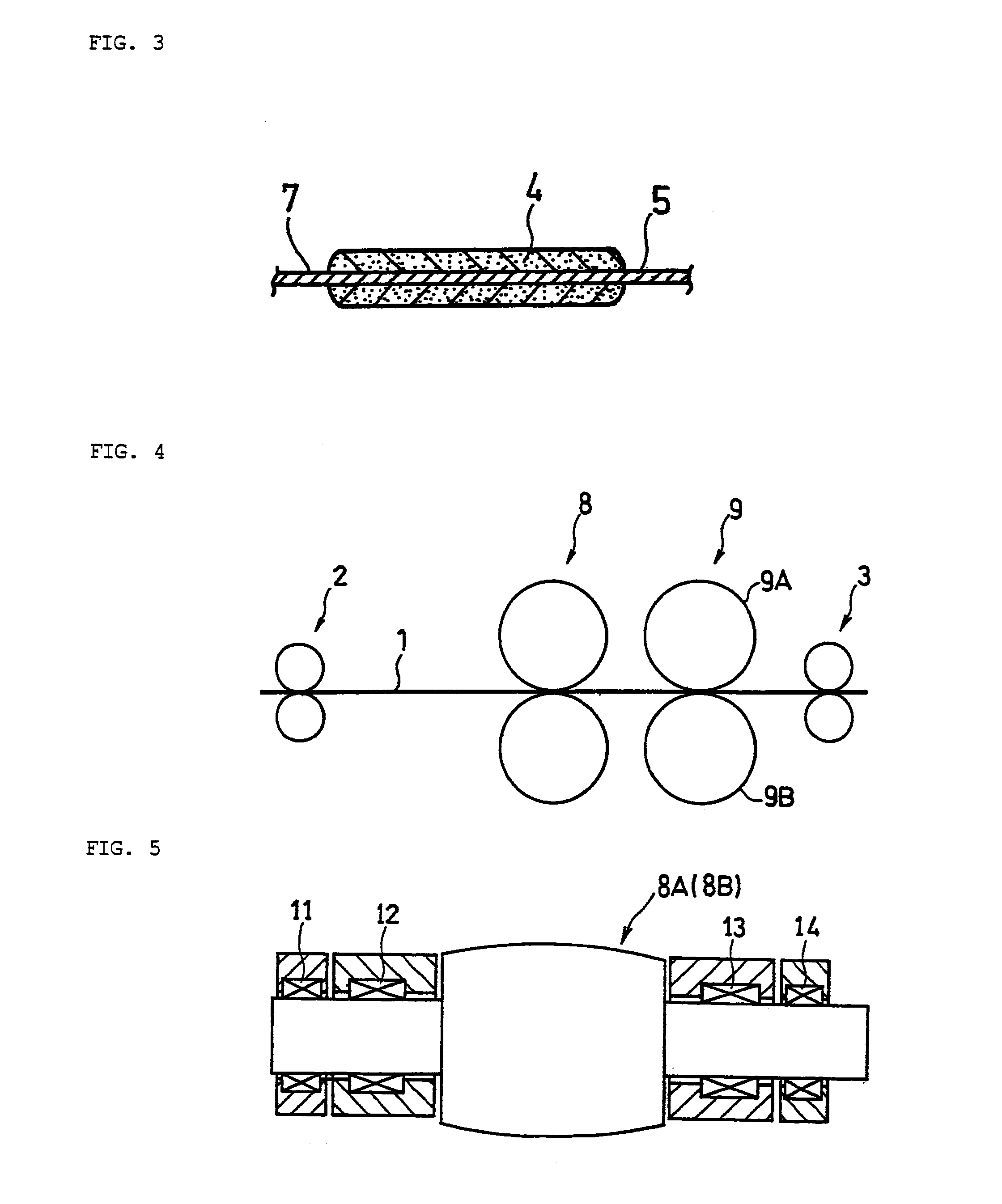

Method for producing electrode plate for battery

InactiveUS20100330267A1Reduce generationReduce the number of stepsSecondary cellsElectrode collector coatingEngineeringElectrical equipment

A production method of the present invention includes steps of: (a) obtaining a first electrode plate precursor 1 by applying an electrode active material onto at least one of surfaces of a long strip-shaped current collector so as to form an active material layer, (b) rolling an electrode plate precursor so that the active material layer has a predetermined thickness, and (c) obtaining plural strips of electrode plates by cutting the rolled electrode plate precursor to a desired width. In the step (a), non-application portions onto which an active material is not applied are formed on both edges of the electrode plate precursor in the width direction. The step (d) of removing the non-application portions is carried out simultaneously with the step (c). Accordingly, it is possible to improve production efficiency and reduce material losses by decreasing quality defects that occur in the step of rolling the electrode plate precursor.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for reducing ammonium content in paper-making reconstituted tobacco

The invention relates to a method for reducing ammonium content in paper-making reconstituted tobacco, belongs to the technical field of the paper-making reconstituted tobacco and is an improvement of an existing method for producing paper-making reconstituted tobacco. The improvement refers to that an electrodialysis ammonium removing process composed of a tobacco raw material extracting solution pretreating procedure and an electrodialysis ammonium removing procedure is added after a tobacco raw material solid-liquid separation process and before a process of concentrating extracting solution to prepare a coating material, wherein a, the tobacco raw material extracting solution pretreating procedure includes that insoluble solids with granular size larger than 200nm and colloidal substances in an extracting solution are removed by a ceramic membrane microfiltration technology; b, the electrodialysis ammonium removing procedure is finished in an electrodialysis device with a conductivity meter, and a working curve about correlation between a conductivity drop rate and ammonium removing amount after ammonium is removed by light-room raw materials is utilized to control the ammonium removing amount. The method for reducing the ammonium content in the paper-making reconstituted tobacco has the advantages that ammonium ion removing rate is high in the tobacco raw material extracting solution, raw material loss is less, ammonium ion content is convenient to control, cost is low, and an application value is high.

Owner:YUNNAN RES INST OF TOBACCO SCI

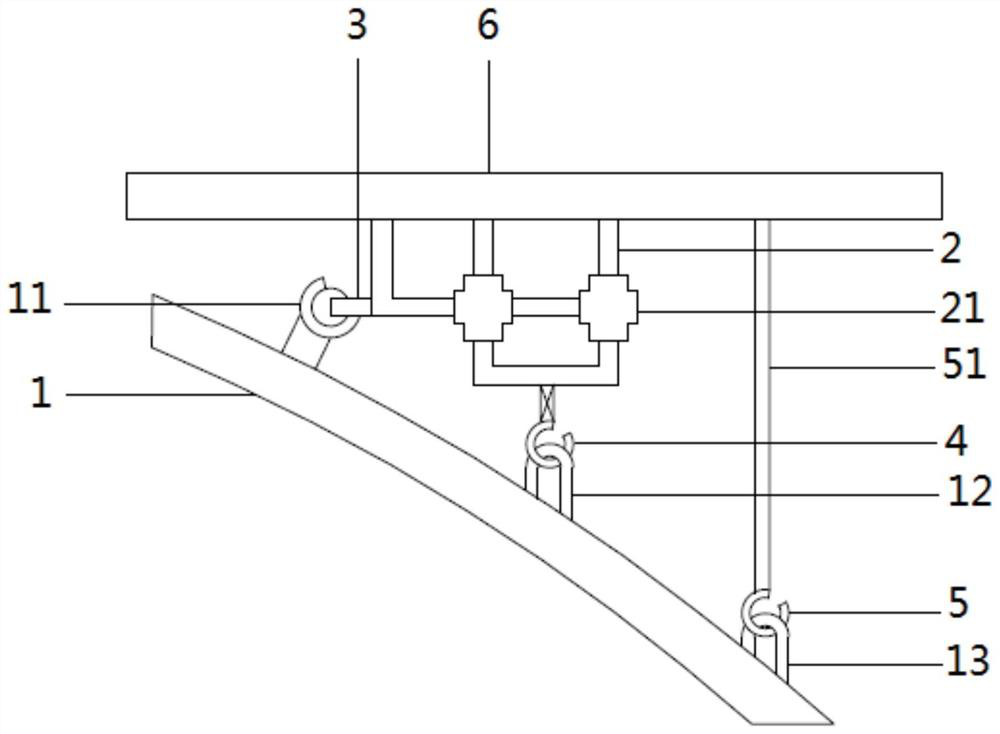

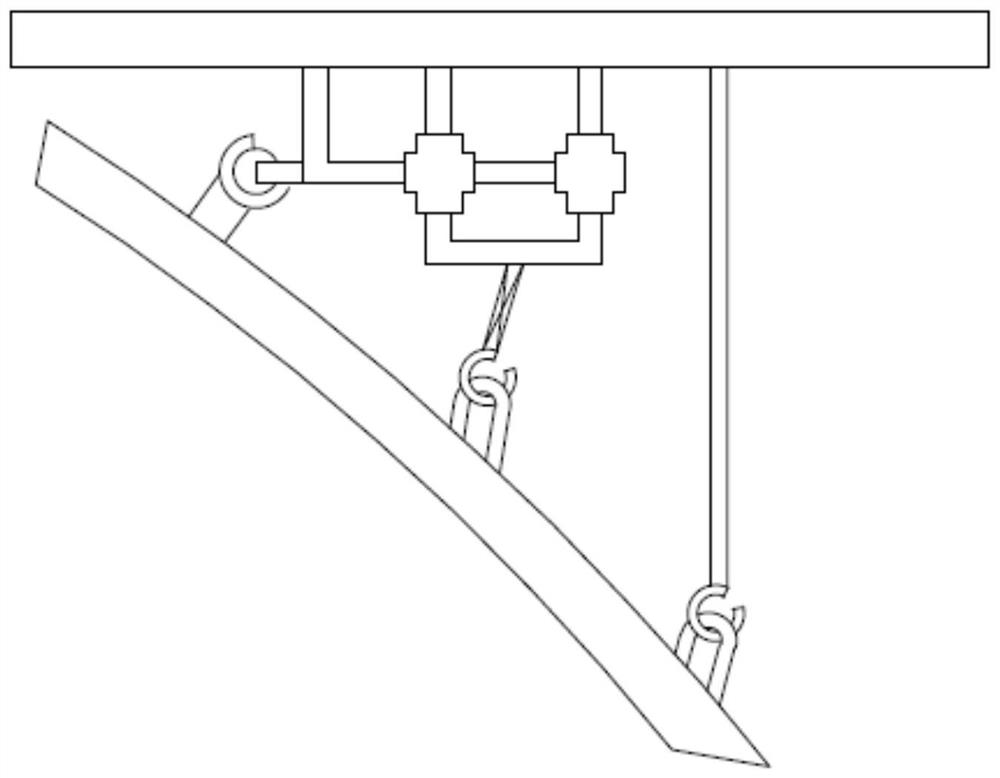

Optimized mounting structure for dome type ceiling and mounting method

PendingCN111608319AImprove installation efficiencyReduce material lossCeilingsStructural engineeringMechanical engineering

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com