Glue welding connection method

A connection method and glue welding technology, which is applied in the field of material engineering, can solve the problems that the mechanical properties of the joint are difficult to meet the actual use requirements, the application range is narrow, and the connection is difficult, so as to improve material utilization, reduce material loss, and shear strength. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Fusion welding is explained using laser welding as an example.

[0020] step one:

[0021] Clean the sample with acetone before welding. The welding sample is made of magnesium alloy, aluminum alloy, titanium alloy, steel and other metals. It can be welded between the same metal or different metals. Here we take the connection between the same metal of 1.5mm magnesium alloy AZ31B as an example to illustrate. Degrease the joint surface, and clean the surface of the overlapping area with a wire brush after drying to remove the oxide film.

[0022] Step two:

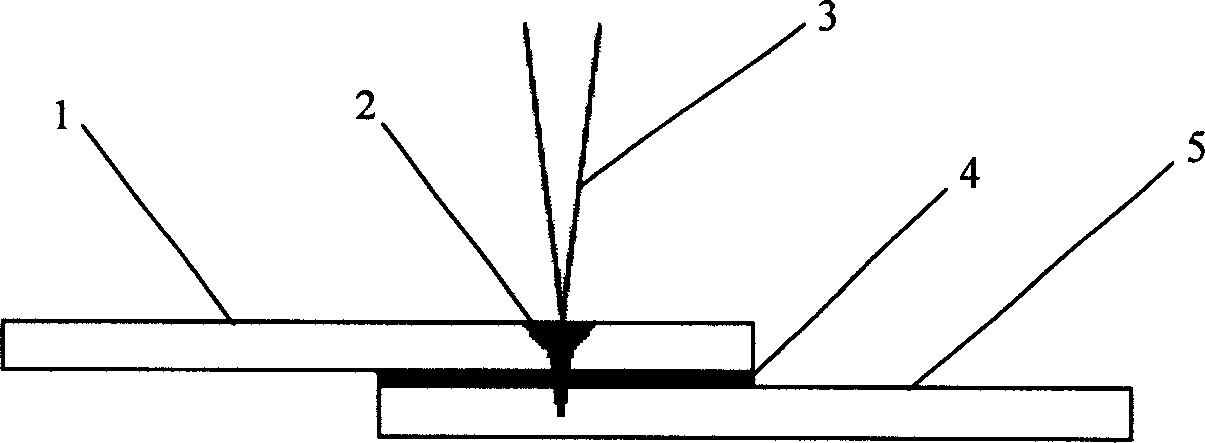

[0023] Apply an adhesive layer 4 between the overlapping areas of the welded sheet 1 and the welded sheet 5, where the adhesive layer generally refers to various cured adhesives, and the thickness of the adhesive layer 4 is 0.5 mm.

[0024] Step three:

[0025] The welding plate 1 and the welding plate 5 are pressed tightly by a welding jig.

[0026] Step four:

[0027] The laser welding process is adopted, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com