Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

An underground diaphragm wall and steel plate water-stopping technology, applied in sheet pile walls, water conservancy projects, underwater structures, etc., can solve the problems of difficult protection, difficult pulling, short seepage curve, etc., and increase the anti-leakage performance. , Guarantee impermeability, improve the effect of shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

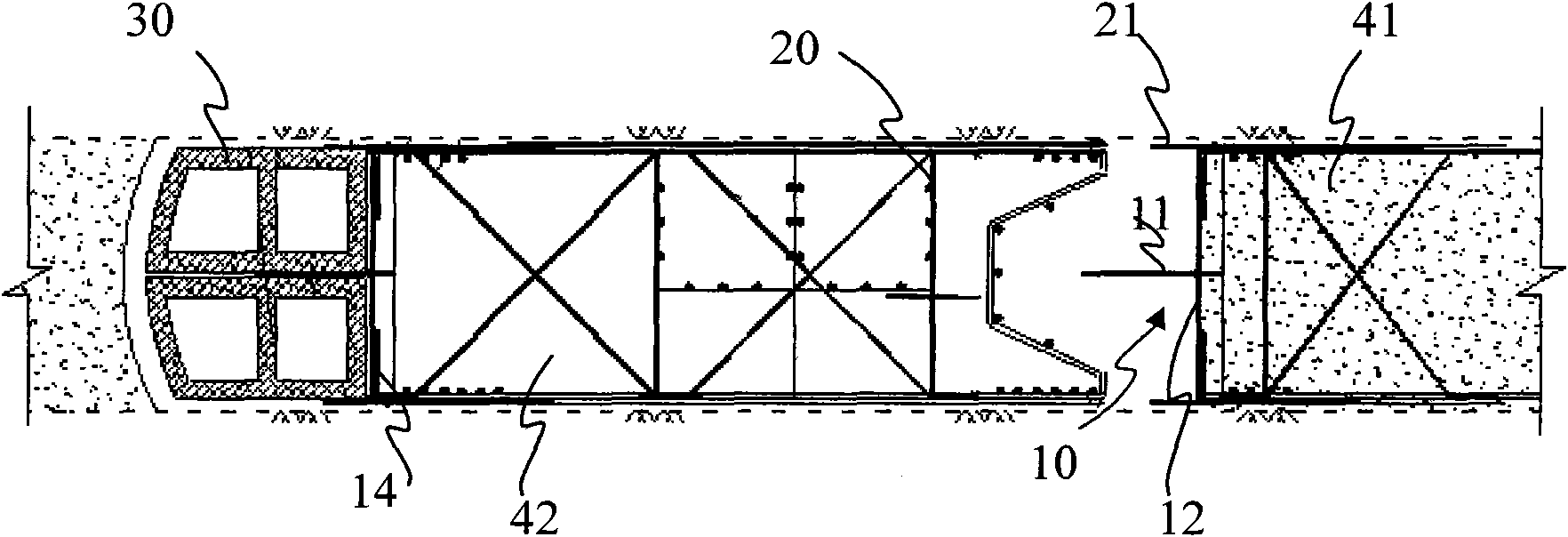

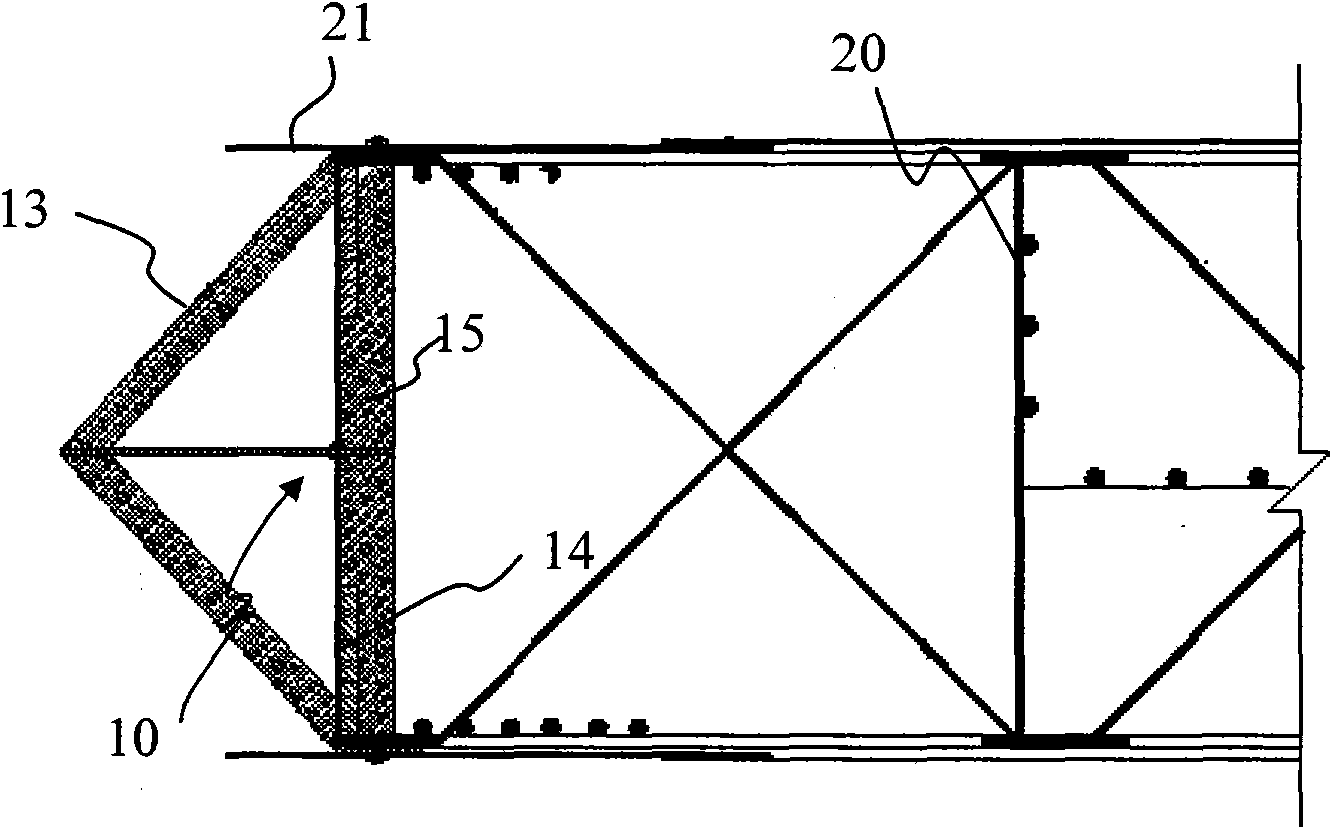

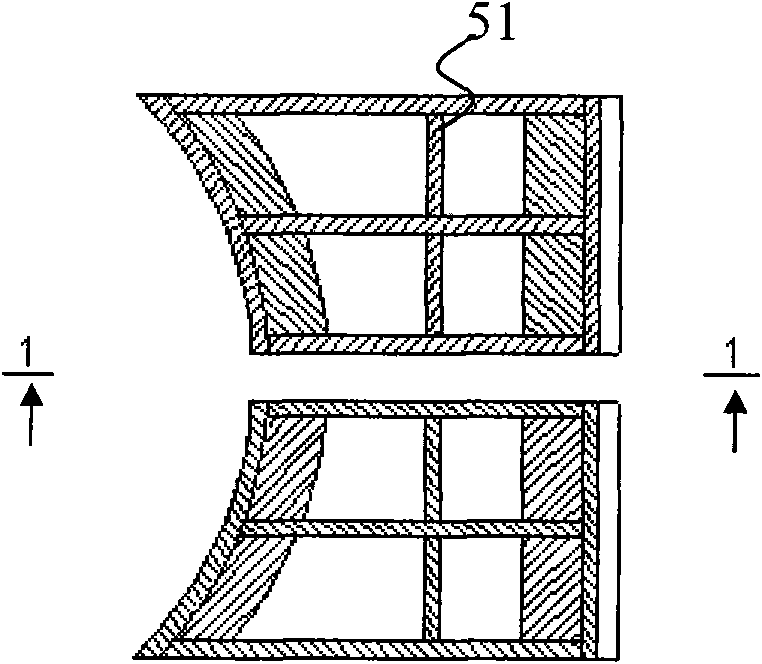

[0032] The cross-steel plate water-stop joint of the underground diaphragm wall and the construction method provided by the invention have good effects on the water-stop performance and shear strength of the ultra-deep underground diaphragm wall joint. The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0033] The waterproof performance of the joints of the ultra-deep underground diaphragm wall is very important to the safety of the foundation pit excavation. Since the foundation pit of the embodiment project enters the silt layer from 30m, a depressurization well is set in the pit before the excavation to carry out dewatering in the foundation pit. A large water head difference is formed inside and outside the pit. Once there is a danger of water leakage from the enclosure joints, it will be extremely difficult to plug the leak, which will have a fatal impact on the safety of the foundation pit and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com