Patents

Literature

73results about How to "Guaranteed impermeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

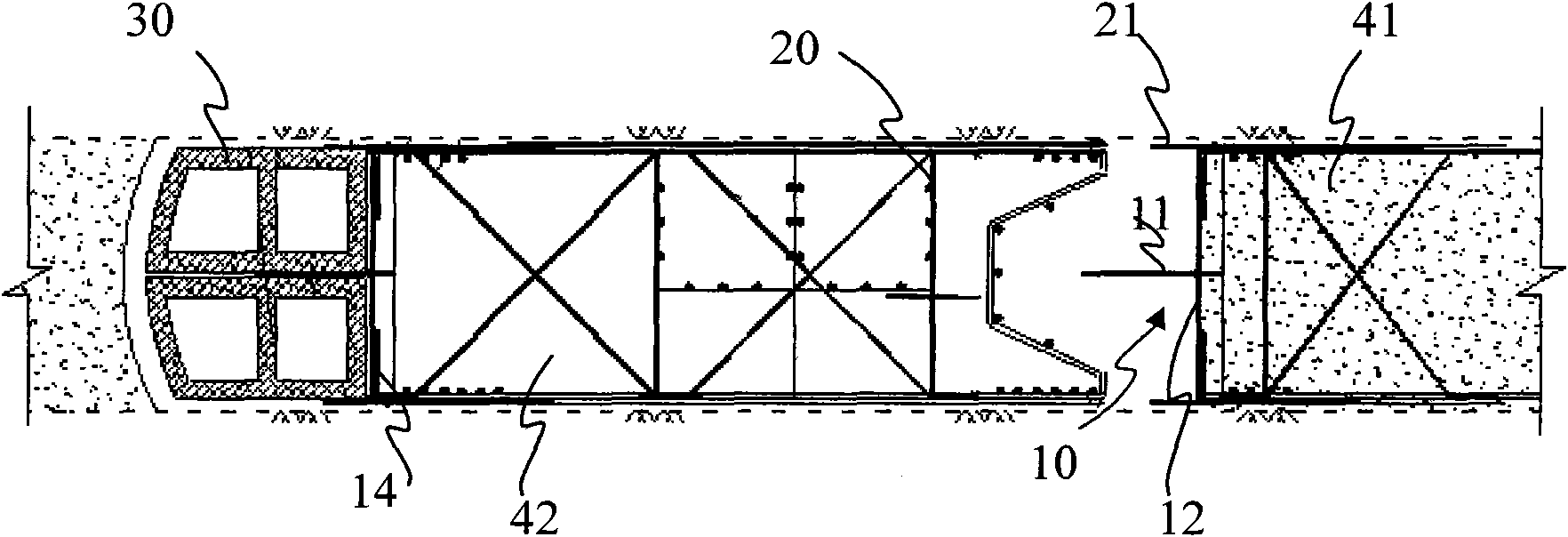

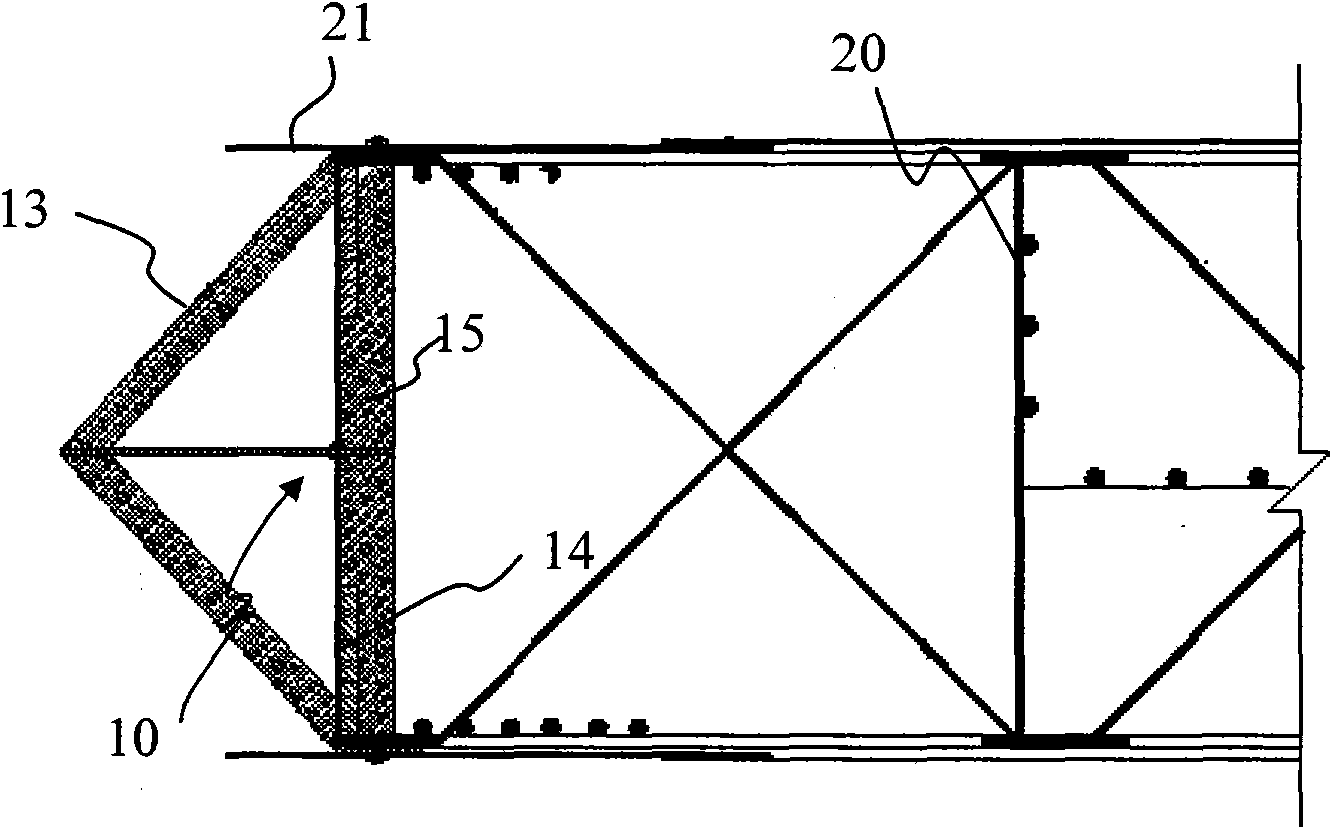

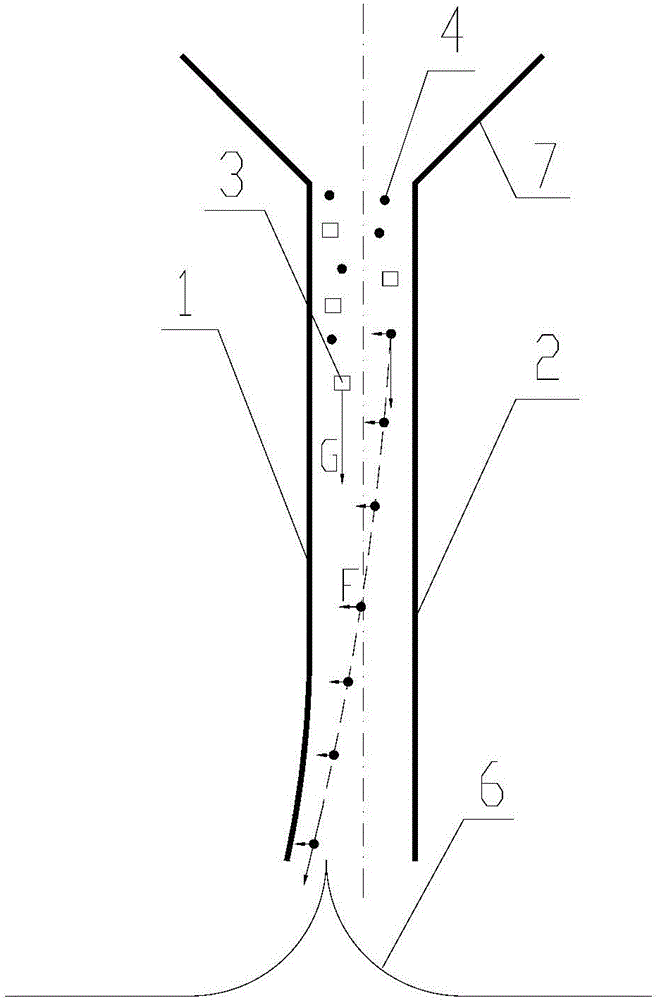

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

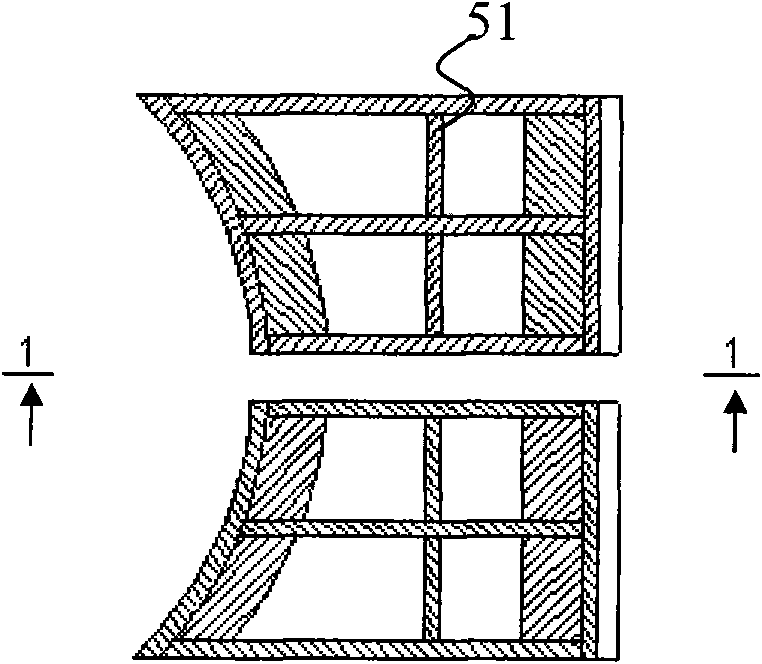

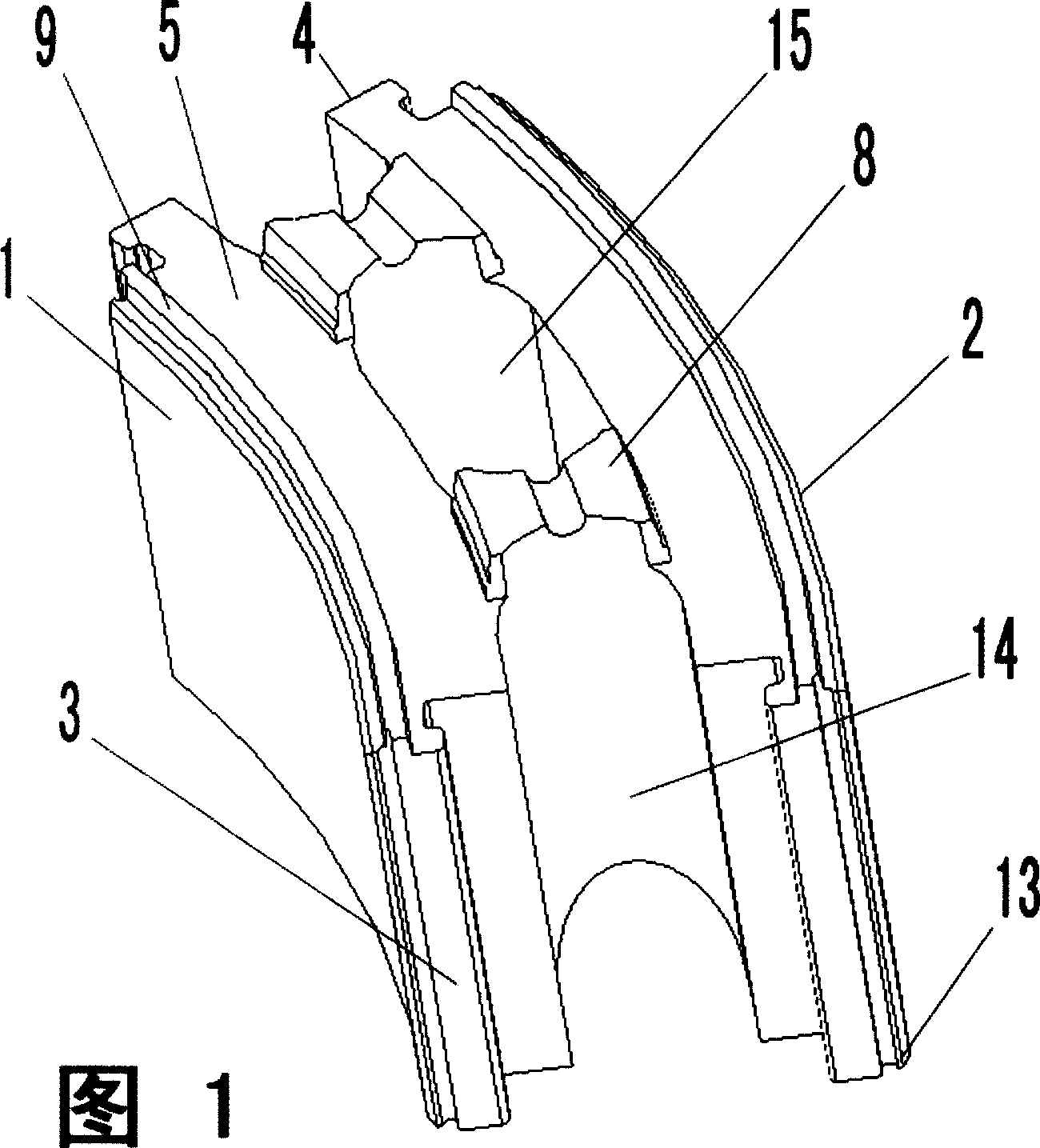

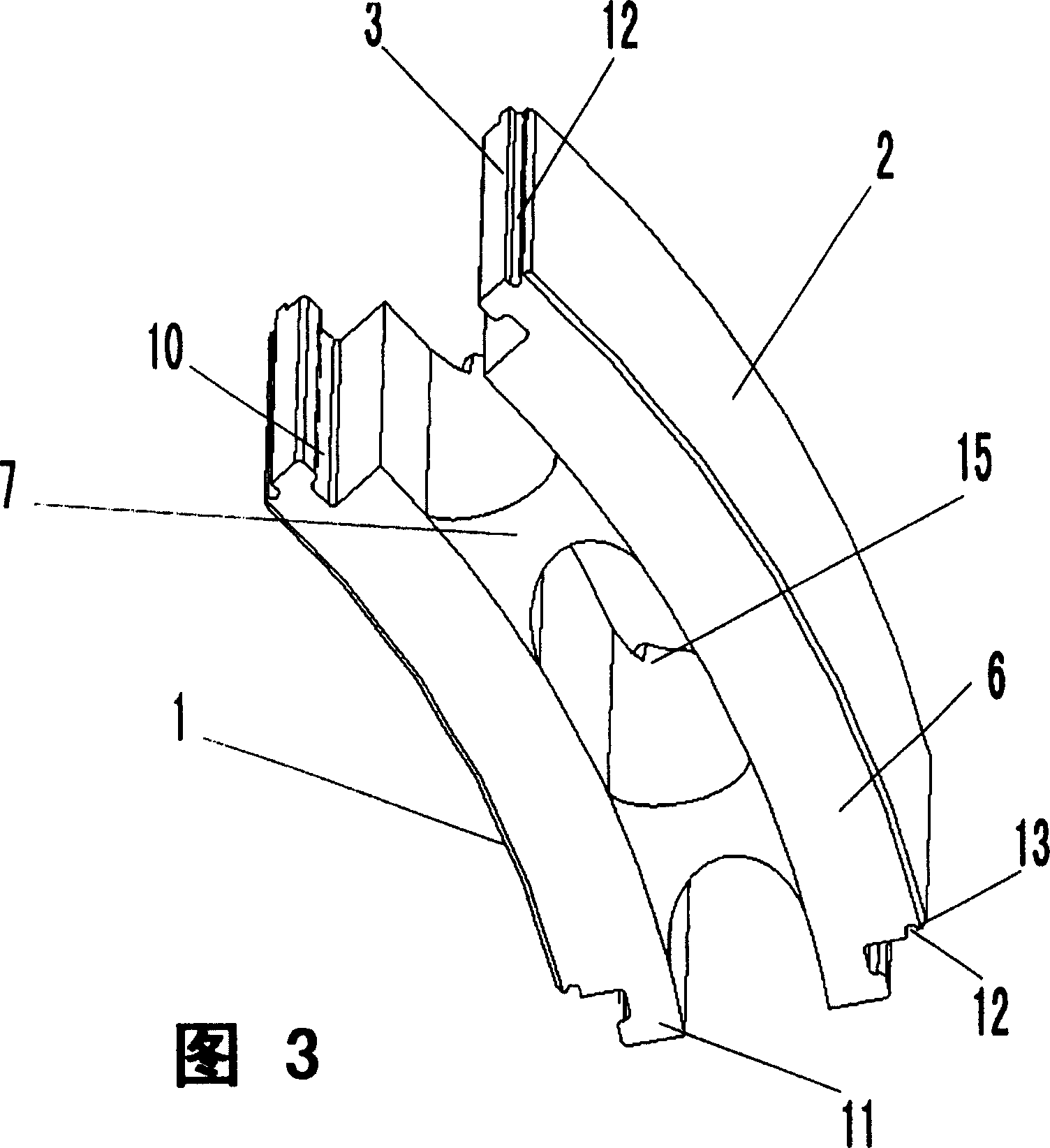

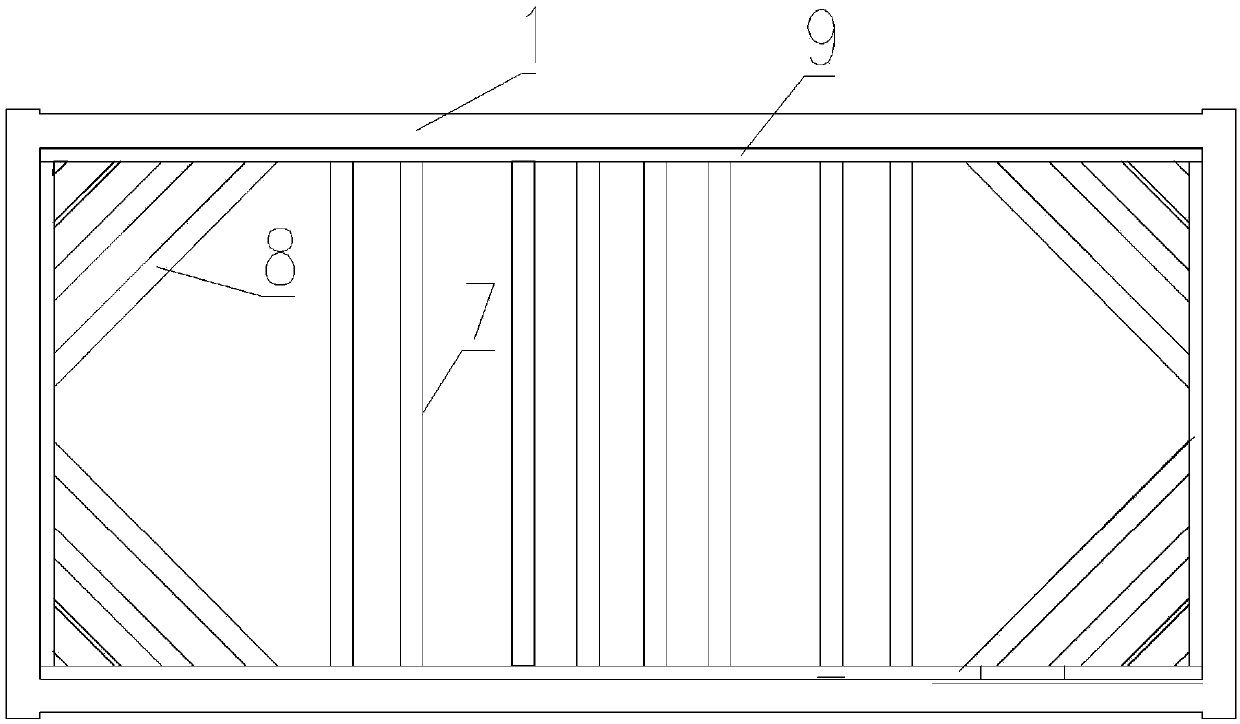

Wall module of well walls and method for building wall bodies of well walls by using module

InactiveCN1431375APrevent subsidenceImprove stress resistanceArtificial islandsBuilding componentsConvex structureStructural engineering

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Wall module of well walls and method for building wall bodies of well walls by using module

InactiveCN1206429CPrevent subsidenceImprove sturdinessArtificial islandsBuilding componentsSolid wallLine tubing

The invention relates to a shaft wall module and a shaft wall construction method using the module. The object of the present invention is to provide a module with convenient construction and a firm shaft wall. The modules of the present invention realize the mutual alignment and clamping of the modules during the masonry process through the convex-concave structure arranged on the surface of the modules, and pour concrete into the holes and grooves reserved on the modules Using slurry and / or inserting reinforcing ribs to construct the well wall body into a whole with different load-bearing properties, so as to improve the strength of the well wall body. Through the predetermined connection mode with the auxiliary components, the flexible connection relationship with the steps and the connection port of the external pipeline is realized.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

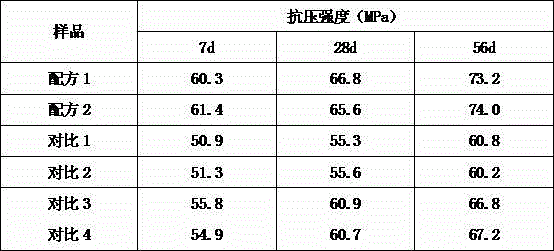

High-toughness concrete composition

The invention discloses a high-toughness concrete composition. The high-toughness concrete composition comprises following raw materials, by weight, 300 to 500 parts of cement, 30 to 50 parts of phosphorous slag powder, 50 to 150 parts of fly ash, 1000 to 1100 parts of a coarse aggregate, 600 to 750 parts of a fine aggregate, 5 to 15 parts of a water reducer, 5 to 15 parts of mixed fiber, 10 parts of polyvinylpyrrolidone, and 130 to 180 parts of water. The high-toughness concrete composition possesses high toughness, excellent deformability, and relatively high tensile strength and bending strength, and is capable of improving integrity and seismic resistance of structures effectively, and ensuring impermeability and durability of the structures.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

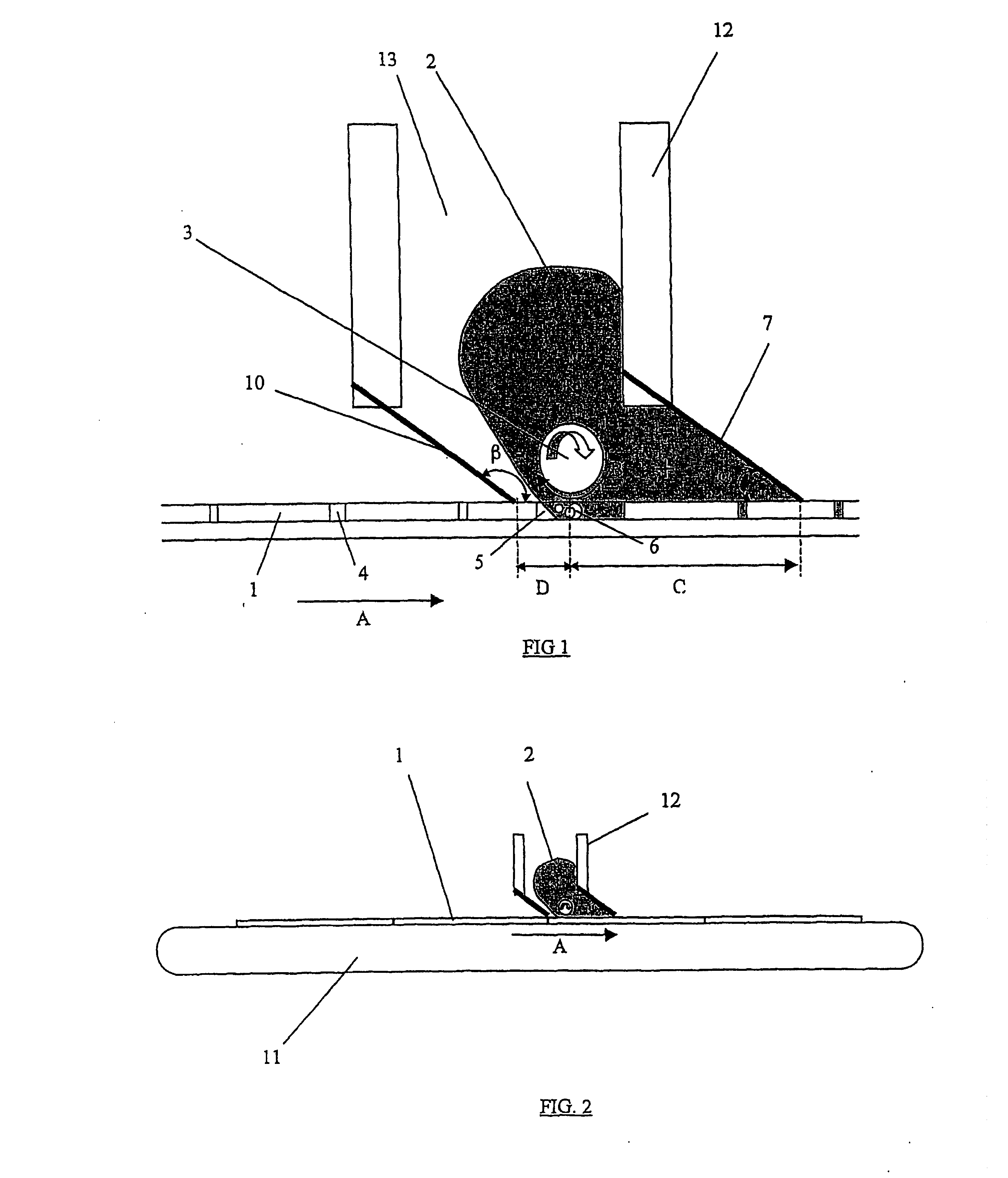

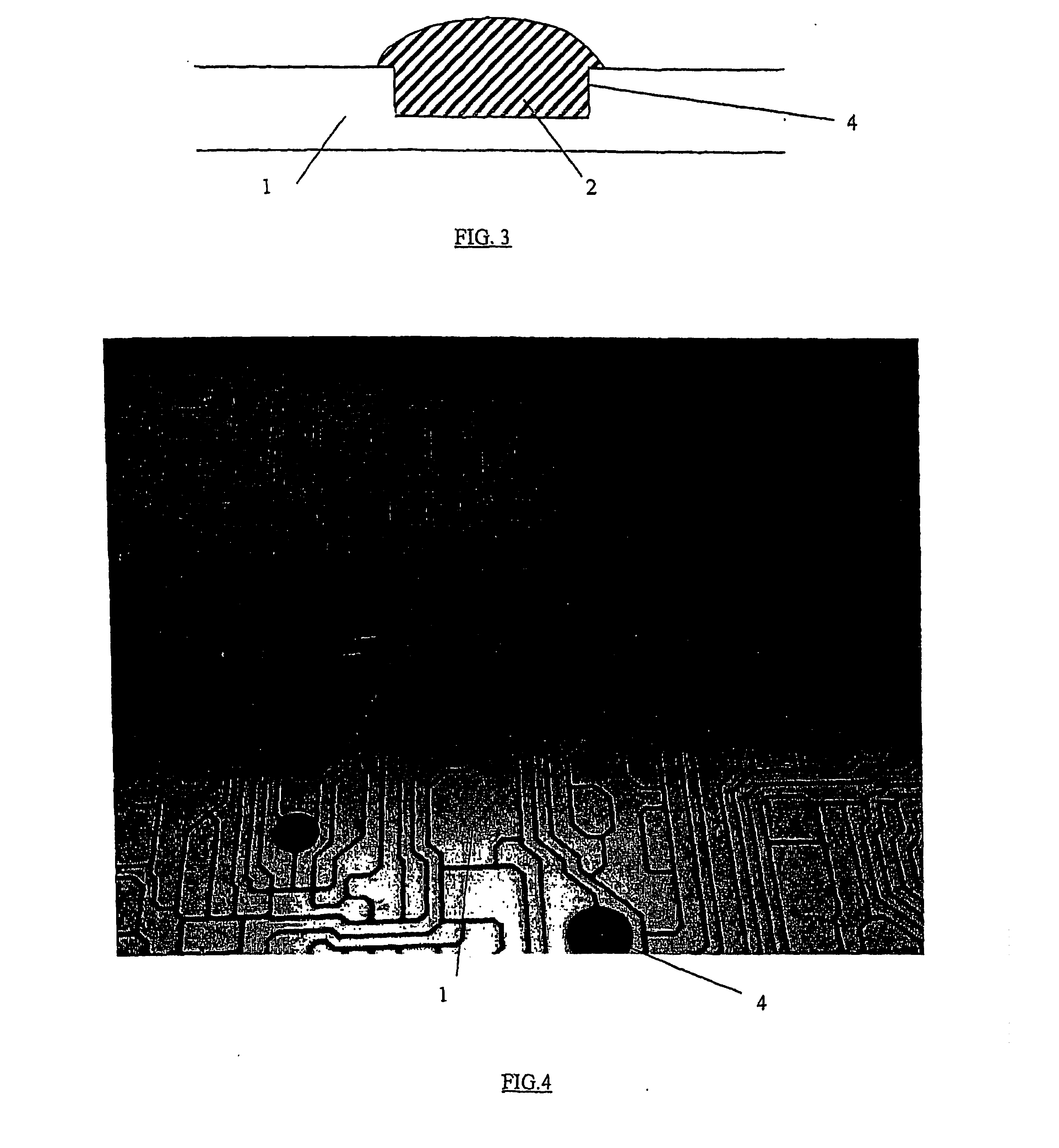

Method and device for filling zones situated in hollows or between tracks with a viscous product on a printed circuit board and apparatus using such a device

InactiveUS20070057027A1Guaranteed impermeabilityAvoid disturbing hydrodynamic effectLiquid surface applicatorsPrinted circuit aspectsRelative displacementEngineering

The invention relates to a method and device for filling areas located in hollows (4) which do not open out onto the surface of a substrate (1) without a mask or silk screen. According to the invention, said method consists in associating the following objects according to the order of the direction of relative displacement of a head (12) of a filling product (2) in relation to the substrate (1) i.e. a spreading element (10) for the product to be filled (2) on the surface of the substrate (1); an element for displacing (3) the filling product (2) in the area to be filled (4); an element (7) for adjusting the thickness or raking off the excess filling product (2) such that the above-mentioned filling product (2) remains constantly in contact with the area to be filled (4) from the beginning of the filling operation until raking off of the excess product.

Owner:NOVATEC SA

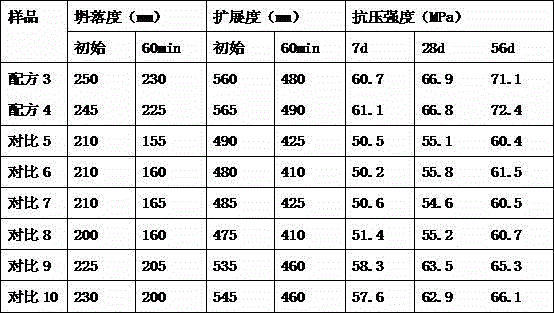

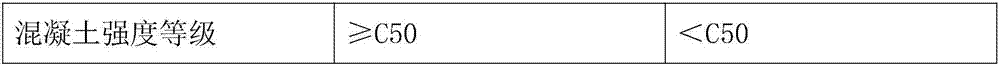

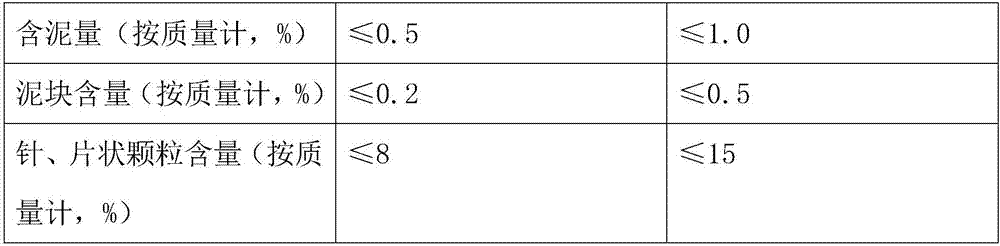

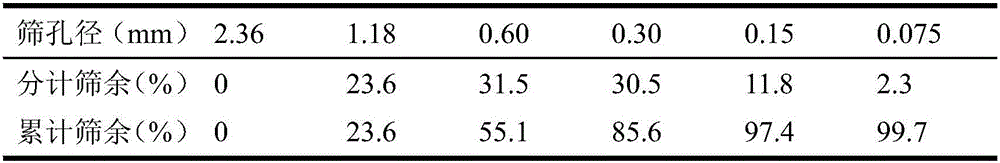

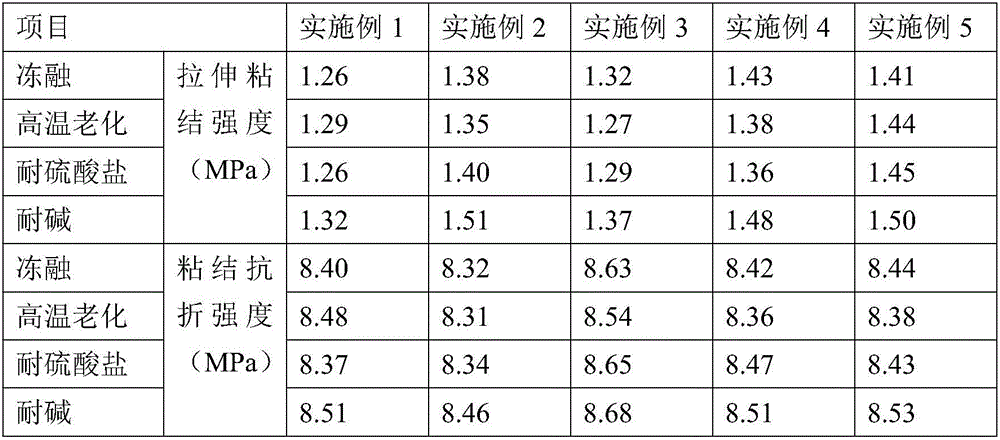

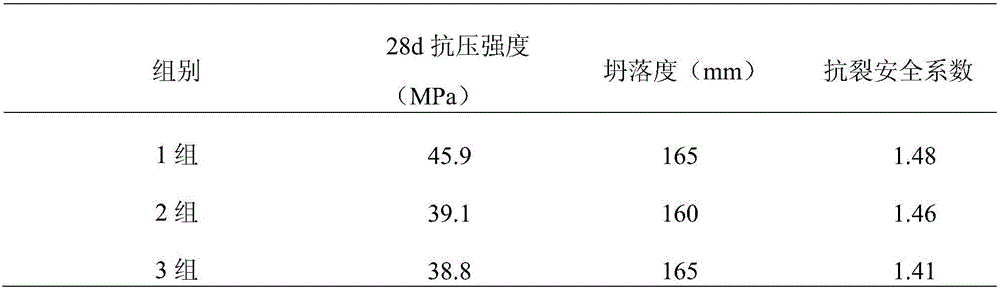

Construction technology of machine-made sand fair-faced concrete

The invention discloses a construction technology of machine-made sand fair-faced concrete and belongs to the technical field of concrete. The construction technology of the machine-made sand fair-faced concrete includes the following specific steps of S1, assembling frameworks; S2, tying rebars; S3, preparing machine-made sand fair-faced concrete mixture; S4, pouring in the frameworks; S5, vibrating and compacting the concrete in the frameworks by a vibrating bar; and S6, removing the frameworks and conducting hydrating maintenance by adoption of plastic films. the machine-made sand fair-faced concrete prepared through the construction technology can guarantee workability, liquidity, pumpability, strength and anti-permeability performance of the concrete. The dried concrete surface is uniform in color, and high in flatness and smoothness, the concrete can be used as decoration materials directly, therefore a plastering layer and a surface layer are omitted, the project cost is reduced, and the quality problems of hollowing, falling and cracking caused by the plastering technology are eliminated.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

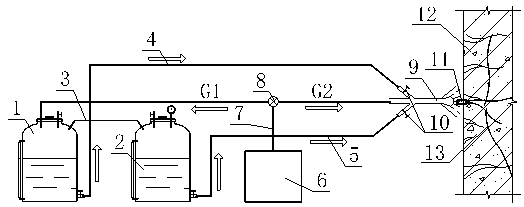

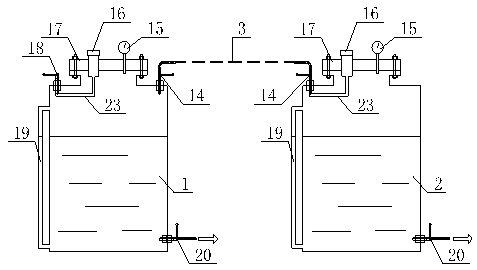

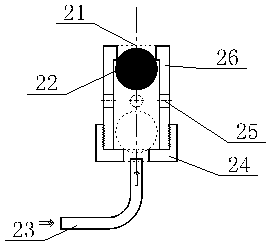

Double-fluid single-system air pressure energy storage grouting machine and grouting process

PendingCN108374567ASmooth entryEliminate the effects of dilutionBuilding repairsWater leakageEngineering

The invention discloses a double-fluid single-system air pressure energy storage grouting machine and a grouting process. The objective of the invention is to provide the structurally simple groutingmachine capable of efficiently controlling the water leakage of underground buildings and the grouting process. The grouting machine mainly comprises an energy storage grouting tank for first fluid, an energy storage grouting tank for second fluid, an air compressor, a proportioning mixer, intake opening and closing valves, liquid level indicators, a pressure-balancing communicating pipe, balancing communicating valves, an expansion grouting nozzle and the like. The flow of the grouting process is as follows: the expansion grouting nozzle is buried; a two-way valve is switched to a position G1of an air supply pipe; the air compressor is opened to supply pressured air to the energy storage grouting tanks; the two-way valve is switched to a position G2 of the air supply pipe; the air compressor applies pressure to the air supply pipe; high-pressure air is directly pressurized into water leakage cracks of a grouted body via the expansion grouting nozzle; grout outlet valves of the energystorage grouting tank for the first fluid and the energy storage grouting tank for the second fluid are opened to start grouting; the grouting proportion of the first fluid and the second fluid is controlled by the proportioning mixer; after pressure reaches a set termination pressure, grouting is kept for a certain period of time; the expansion grouting nozzle is taken out; and the grouting opening is sealed.

Owner:安徽国信建设集团有限公司 +2

Waterproof flexible cement-based dry-mixed overlay repairing mortar

InactiveCN105906265AImprove freeze-thaw resistanceStrong water retention capacityDefoamerNatural sand

The invention discloses a waterproof flexible cement-based dry-mixed overlay repairing mortar. A dry mixed material includes, by weight, 22-39 parts of ordinary Portland cement, 2-18 parts of fly ash, 0.9-2.1 parts of rubber powder, 0.05-0.45 parts of cellulose ether, 0.03-0.3 parts of a defoamer, 0.02-0.15 parts of an expanding agent, and 40-75 parts of natural sand. During usage, water accounting for 10-20% of the total mass of the mortar is added to the dry mixed material to obtain the waterproof flexible cement-based dry-mixed overlay repairing mortar. The fly ash refines the internal structure of the cement-based repairing mortar, and by means of compounding effects of the additives, the mortar is ensured to have flexibility and anti-permeability and excellent flexural strength and compressive strength. The 3d compressive strength of the mortar is 20-30 MPa and 28 d compressive strength of the mortar is 36-45 MPa, so that the mortar can satisfy repairing strength demand of common concrete building external walls.

Owner:WUHAN UNIV OF TECH

High-strength concrete composite material and preparation method thereof

The invention discloses a high-strength concrete composite material which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of fiber, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of composite rare earth, 10-20 parts of magnesium silicate granules, 140-200 parts of sand, 140-200 parts of macadam and 30-50 parts of water. The product is high in anti-cracking ability and small in loaded crack width and has long-term durability. Moreover, the interaction of composite concrete is improved, the material performance is far higher than basic performance of common concrete, main indexes of the concrete are obviously improved, a temperature crack is avoided, and the strength, freezing resistance and anti-permeability of the concrete are guaranteed.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

Preparation method of rubber asphalt concrete

ActiveCN105801049AHigh strengthGuaranteed StrengthSolid waste managementCrack resistancePolymer science

The invention discloses a preparation method of rubber asphalt concrete. The preparation method comprises the following steps of: (I) sufficiently stirring and uniformly mixing portland cement, mineral powder fly ash, stainless steel powder and green mud at 180-190 DEG C; adding rubber asphalt; and stirring at 180-190 DEG C to obtain a mixture; (II) mixing limestone and blast furnace slag; calcining at 500-700 DEG C for 20-30 minutes; cooling; adding limestone and blast furnace slag into the mixture, and stirring at 180-190 DEG C for 4-8 minutes; adding water and high-calcium wastewater; and continuously stirring at 180-190 DEG C for 2-4 minutes to obtain a mixture; and (III) performing layered pouring of the mixture, vibrating and curing at 15-25 DEG C for 5-10day to obtain the rubber asphalt concrete. By adopting the preparation method disclosed by the invention, the compressive strength and crack resistance of the rubber asphalt concrete can be obviously enhanced.

Owner:CCCC THIRD HIGHWAY ENG

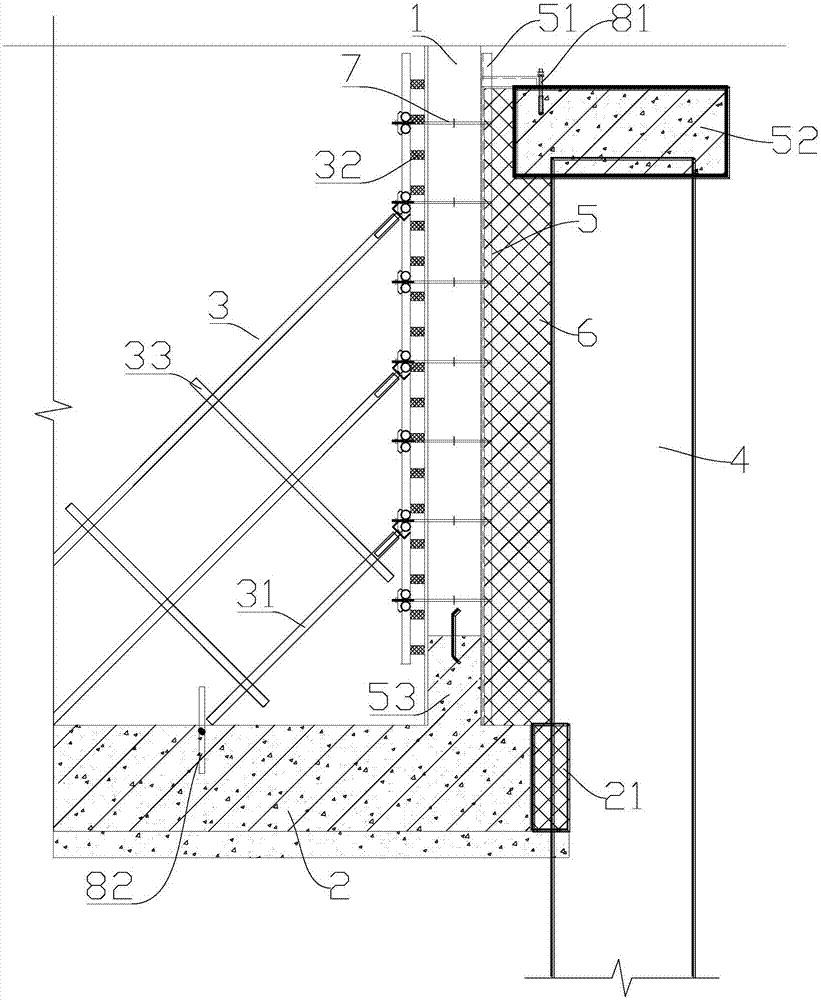

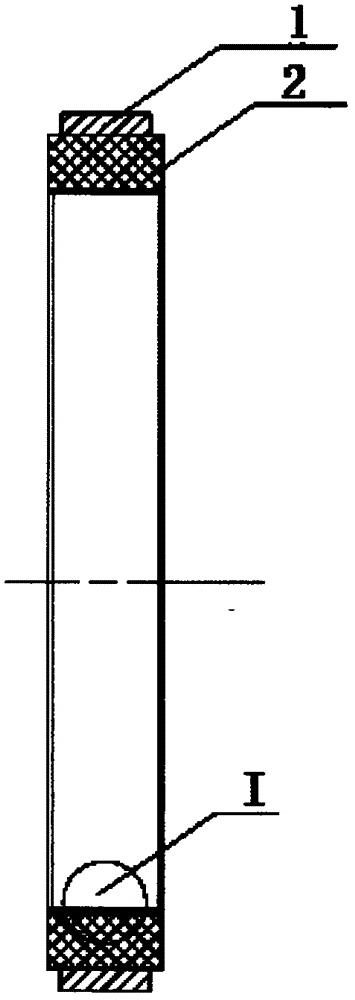

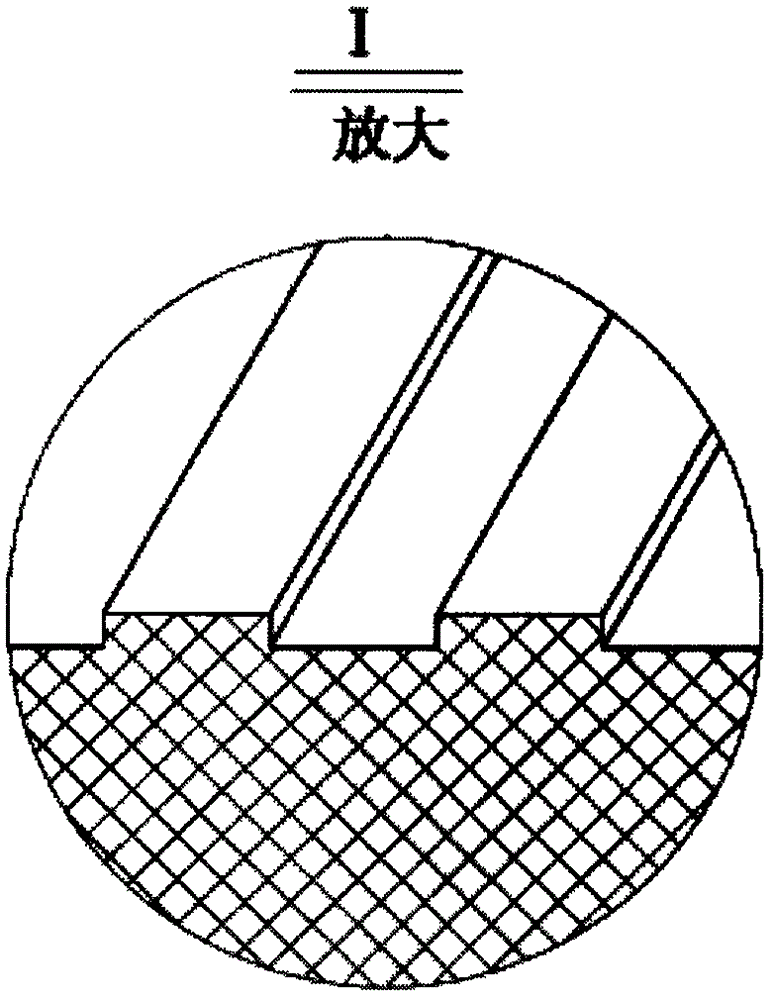

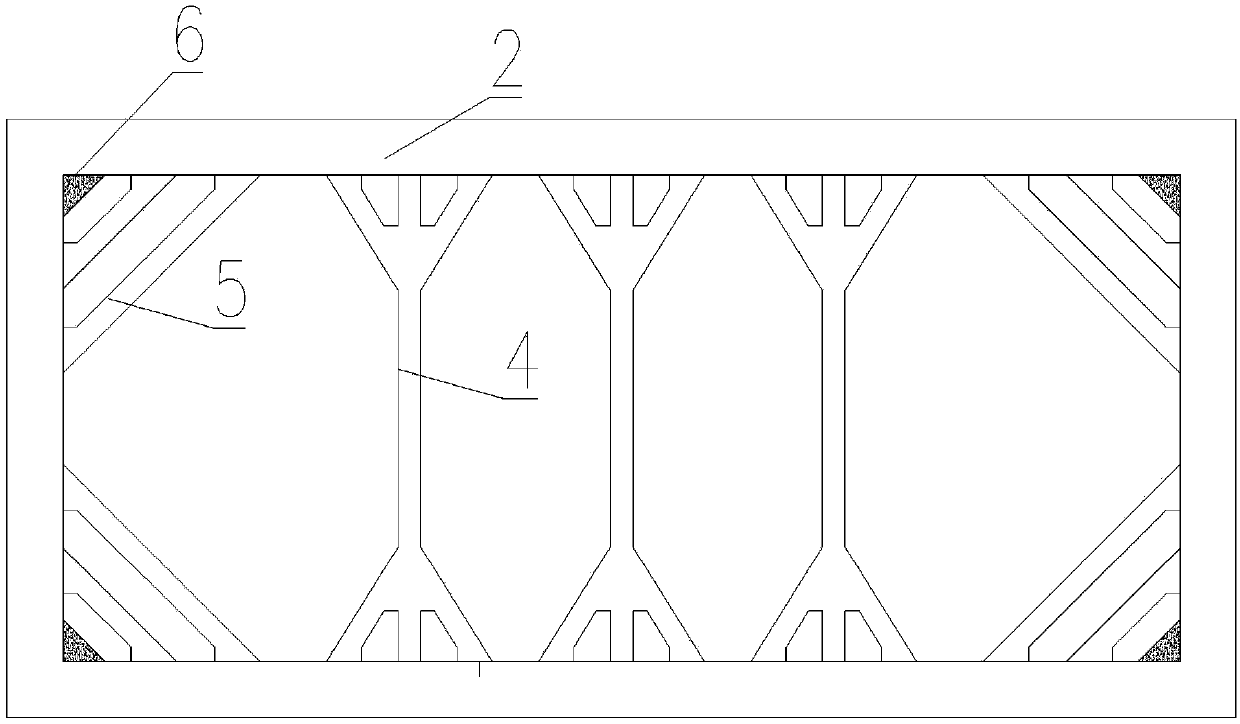

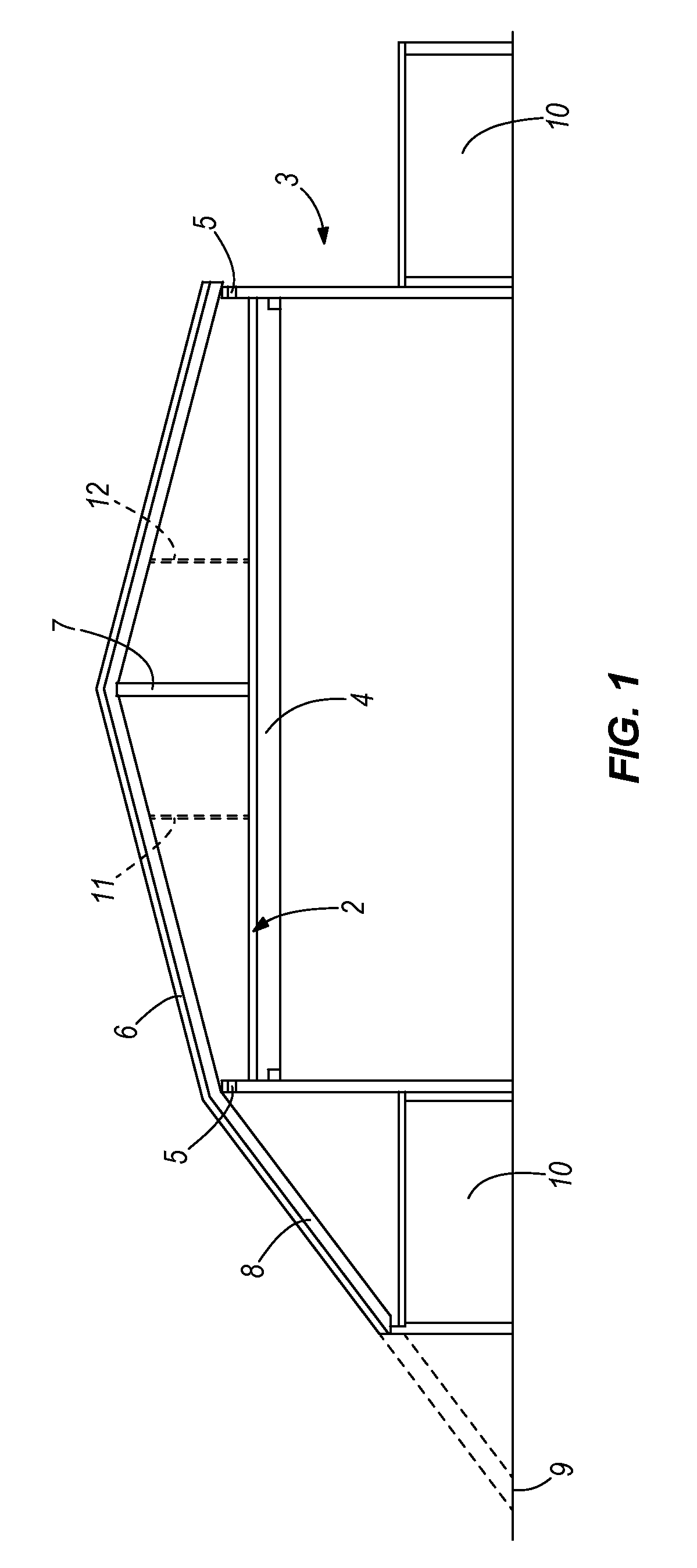

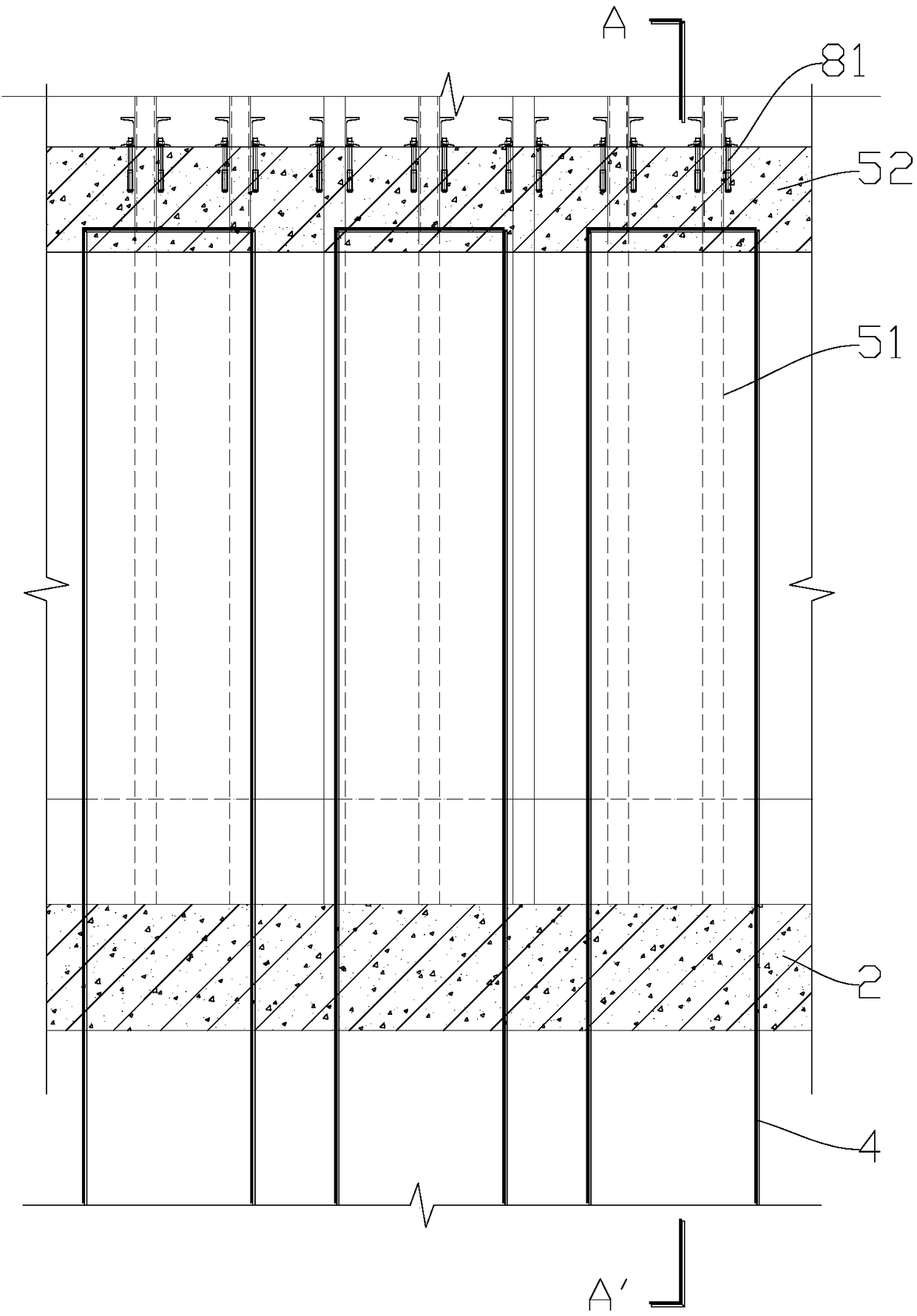

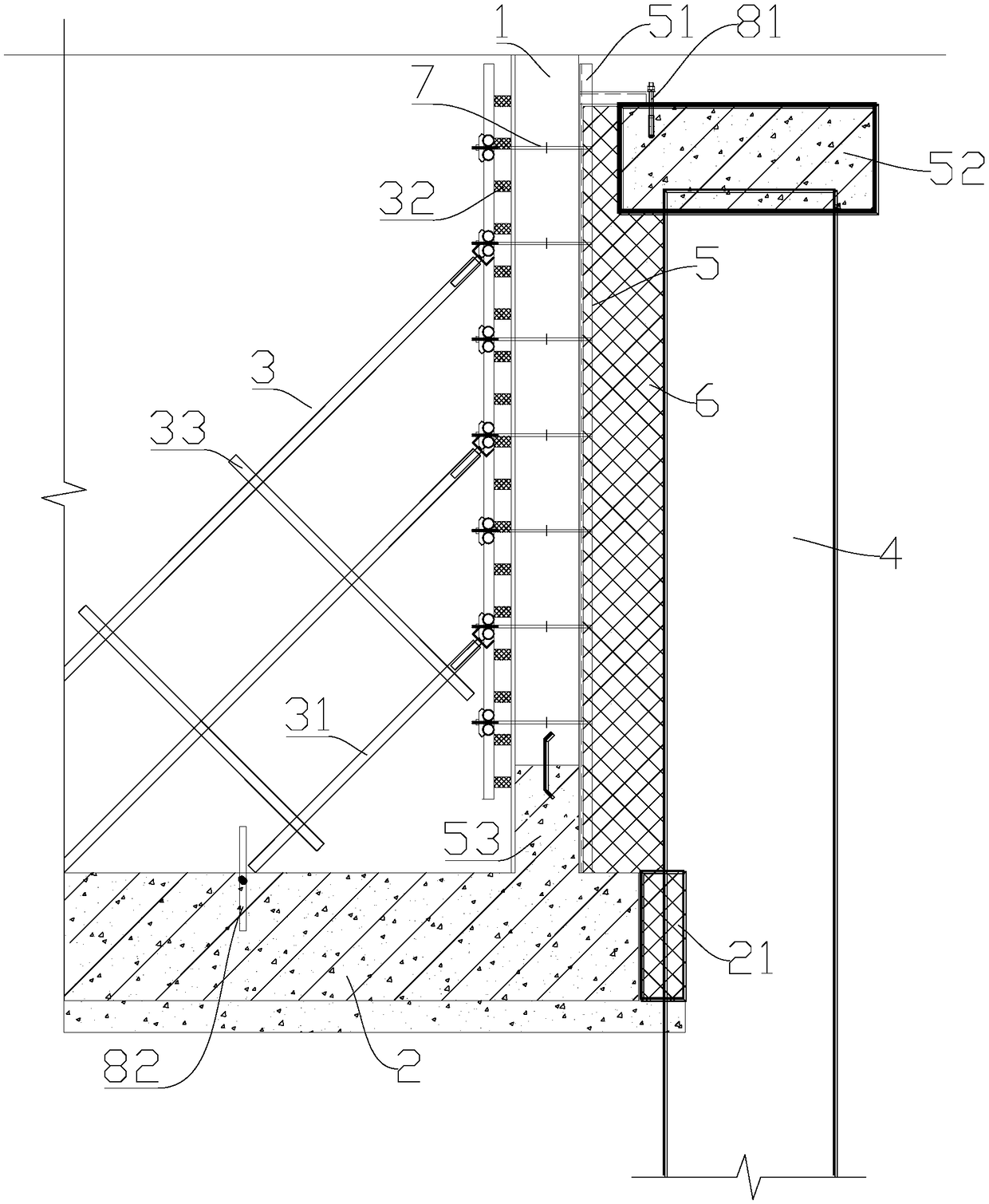

Basement narrow space outer wall construction structure and method

ActiveCN107575025AGuarantee the construction qualityImprove waterproof performanceAuxillary members of forms/shuttering/falseworksBuilding material handlingBasementSupporting system

The invention relates to a basement narrow space outer wall construction structure and method. The construction structure comprises an outer wall steel bar framework, a raft plate, an inner side supporting system and support piles, wherein the outer wall steel bar framework is arranged on the periphery of an outer wall area; the raft plate is arranged at the bottom of the outer wall area; the inner side supporting system is arranged on the inner side of the outer wall area; and the support piles are arranged on the outer side of the outer wall area. The basement narrow space outer wall construction structure further comprises an outer side supporting system arranged on the outer side of the outer wall area. The outer side supporting system comprises a plurality of pieces of channel steel vertically arranged between the outer wall area and the support piles. The outer side supporting system is arranged between the outer wall area and the support piles. The outer side supporting system and the inner side supporting system are connected into a whole to jointly resist lateral pressure formed in the outer wall concrete pouring process, and the outer wall construction quality can be guaranteed. The cost is low, and the basement narrow space outer wall construction structure and method are suitable for all similar narrow space formwork erecting projects.

Owner:CAMCE WHU DESIGN & RES CO LTD

Manufacturing method for carbon-graphite floating ring

InactiveCN105276192AGuaranteed impermeabilityImprove air tightnessEngine sealsInterference fitAdhesive

The invention discloses a manufacturing method for a carbon-graphite floating ring. According to the manufacturing method, combination surfaces of a graphite ring and a peripheral metal inlaid ring are combined reliably, thermal conductivity and electrical conductivity are good, and no blister scar is generated. According to the technical scheme for implementing the manufacturing method, the carbon-graphite ring and the metal inlaid ring which have working allowances are processed firstly, and the carbon-graphite ring is in interference fit with the metal inlaid ring; then the metal inlaid ring is heated to 280-320 DEG C in a heating furnace, the carbon-graphite ring is rapidly arranged in the metal inlaid ring in the interference fit mode, and the carbon-graphite ring and the metal inlaid ring are cooled naturally; afterwards, a floating ring assembly formed after inlaying is placed in a vacuum reaction kettle, thermosetting resin is added, micro gaps between the carbon-graphite ring and the metal ring are fully filled with the thermosetting resin, and the thermosetting resin is sintered at a high temperature to be completely carbonized; and finally finish machining is carried out, and the finished floating ring is obtained. Through the manufacturing method, the problems that according to a traditional process, the carbon-graphite ring and the metal inlaid ring are combined through high-temperature adhesive, a great number of gaps are formed between combination surfaces, and leakage occurs to the combination position under high pressure are solved.

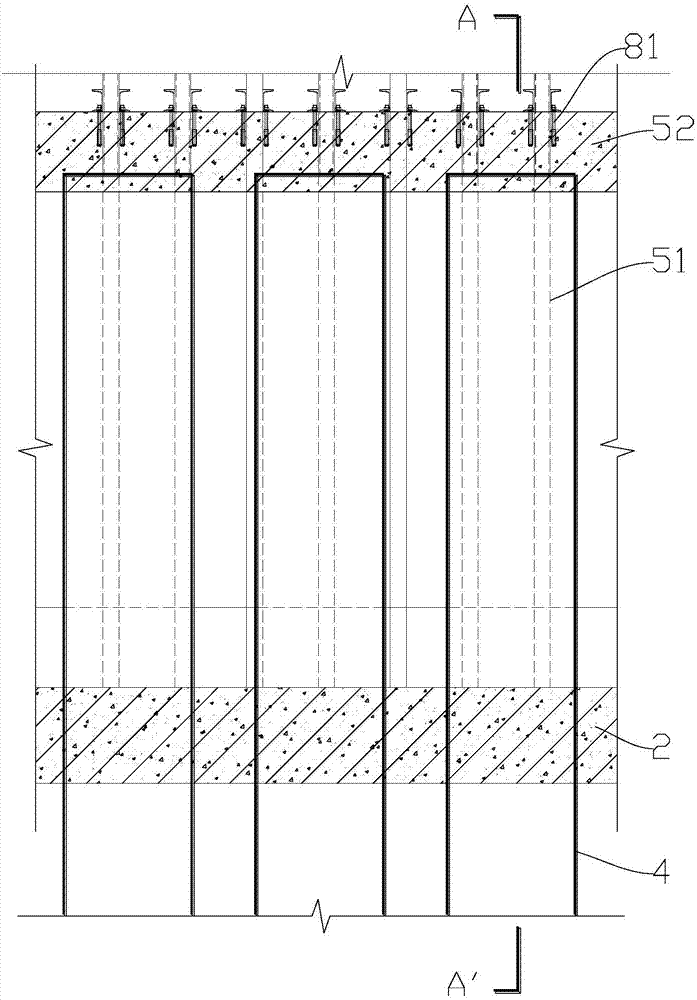

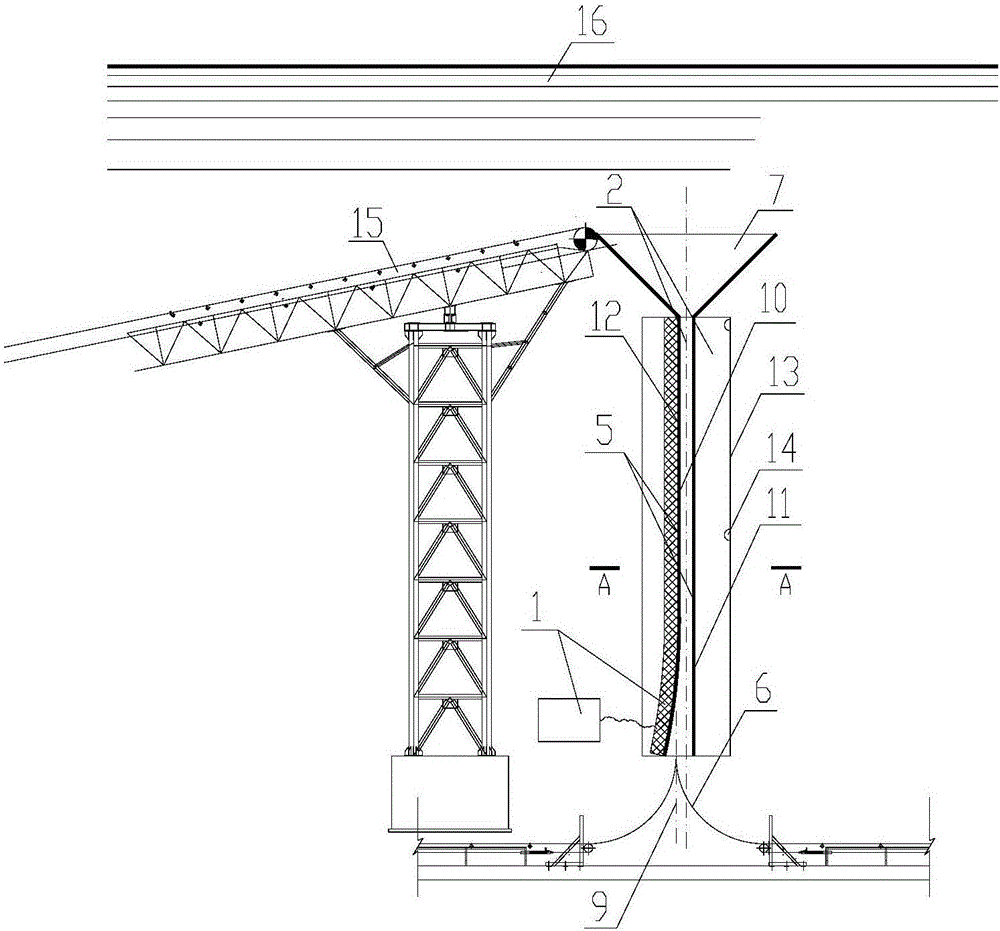

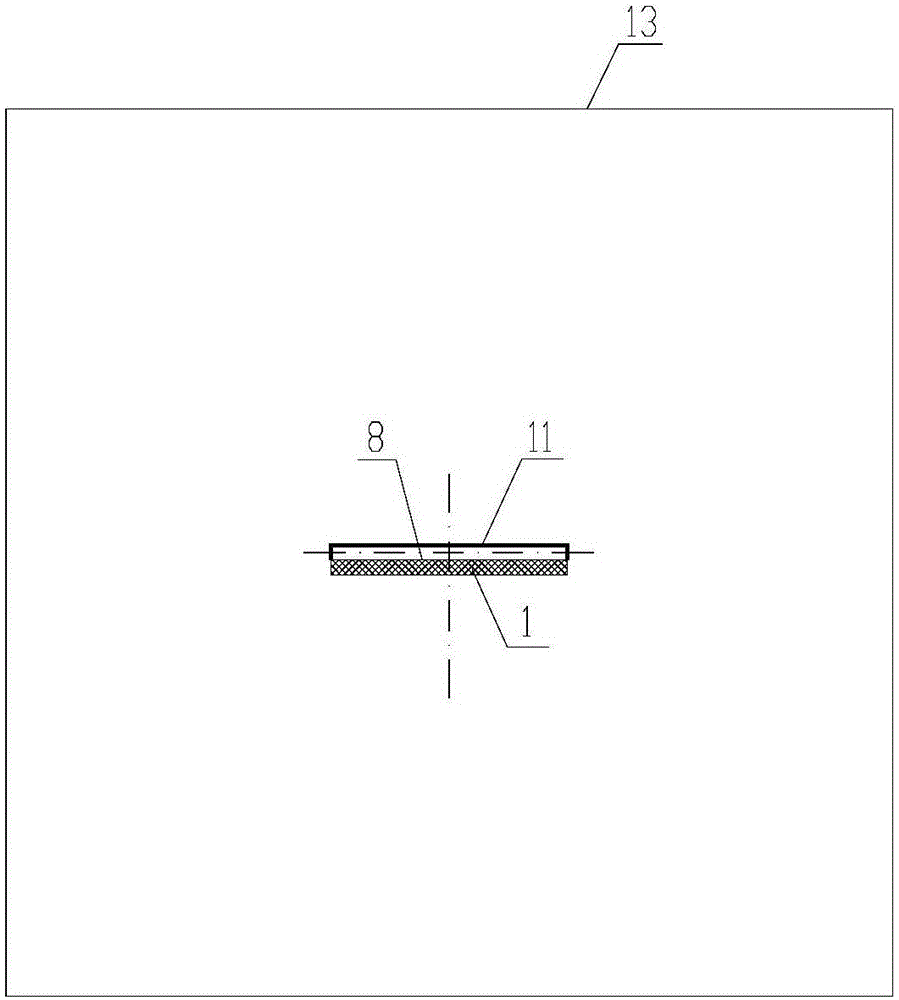

Construction method of super-deep shield shaft in water-rich weak stratum

ActiveCN109630127AImprove construction efficiencyImprove construction safetyShaft liningRebarCushioning

The invention discloses a construction method of a shield shaft. The method comprises the following steps that 1, an underground continuous wall enclosure structure of the shaft is constructed; 2, thestratum at the end of the shield shaft is reinforced; 3, the upper 20-m portion of the shaft is divided into four layers, and excavation and erection of a steel bracing support system are conducted layer by layer; 4, the lower portion of the shaft is divided into five layers, and the fifth layer to the ninth layer of the shaft are excavated separately; 5, the pit bottom of the shaft is treated, pile head concrete of an uplift pile is broken and removed at first, then the bottom is manually cleaned, base cushioning and water proofing construction is carried out, finally, bottom plate steel ribs are tied, and concrete is poured; 6, a shaft support is disassembled, and side walls and columns are constructed. The construction method of the shield shaft has the advantages that through construction methods of vertical layering, construction from top to bottom and support at first and afterwards excavation, the construction efficiency of the shield shaft is effectively improved; by setting the steps of reinforcing a shield receiving end, the shield receiving end is effectively protected against damage in the construction process of the shaft.

Owner:中铁隧道集团二处有限公司

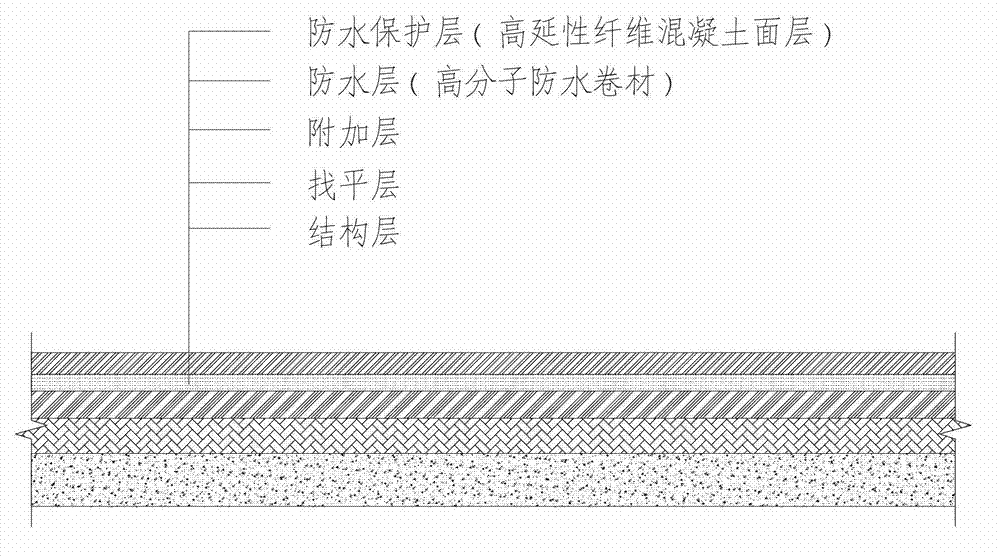

Anti-cracking protective mortar for roof waterproof layer

The invention discloses anti-cracking protective mortar for a roof waterproof layer, which solves the problems that the conventional roof waterproof layer is high in brittleness, easy to crack and poor in durability. The anti-cracking protective mortar consists cement, fly ash, silica fume, sand, polyvinyl alcohol (PVA) fiber and water, wherein in percentage by mass, the ratio of the cement, the fly ash, the silica fume, the sand to the water is 1: 0.9: 0.1: 0.76: 0.58; and based on the total volume after the cement, the fly ash, the silica fume, the sand and the water is mixed uniformly, the volume of the PVA fiber is 1.5 percent. The anti-cracking protective mortar has the characteristics of high strength, high ductility, durability and good anti-cracking performance, and can effectively prevent tearing of the waterproof layer due to temperature stress, improve and ensure the waterproof performance and the anti-penetrability performance of a roof, also improve the durability of the roof waterproof layer and prolong the service life of the roof waterproof layer.

Owner:西安五和新材料科技集团股份有限公司

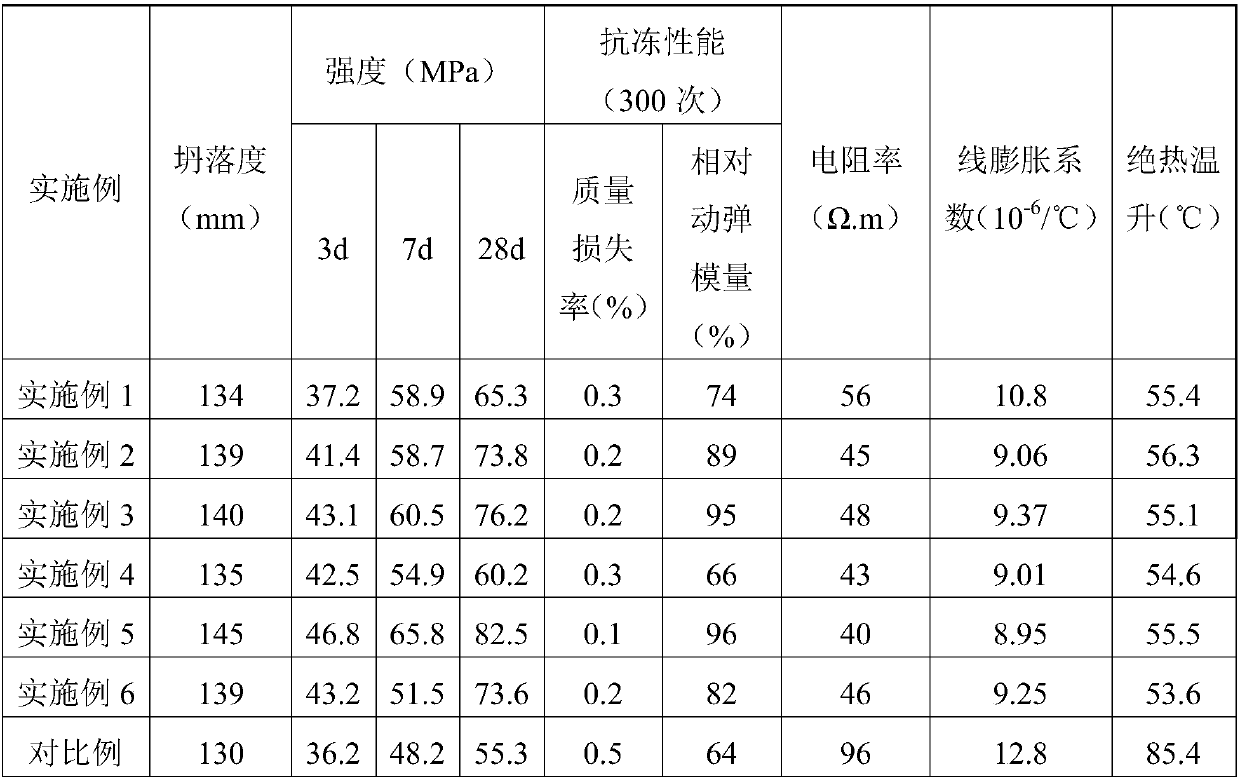

Mass conductive concrete based on ironmaking dedusting ash

The invention discloses mass conductive concrete based on ironmaking dedusting ash. The mass conductive concrete is prepared from components in parts by mass as follows: 100 parts of cement, 1-100 parts of fly ash, 1-80 parts of blast furnace slag powder, 1-25 parts of the ironmaking dedusting ash, 120-240 parts of yellow sand, 10-20 parts of blast furnace slag iron particles, 0-360 parts of gravel with the particle size of 5-25 mm, 4-10 parts of a water reducer, 10-25 parts of copper fiber, 1-15 parts of polyphenylacetylene, 1-15 parts of polyvinylpyrrolidone and 3-100 parts of water. The concrete has good anti-penetrability performance, anti-freezing performance, low hydration heat and conductive performance, the conducting performance of concrete can be sustained under the network conductive effect and the tunneling effect, and the mass conductive concrete has great functions in the aspects of electrical engineering, industrial static electricity prevention, inside diagnosis of hugestructures, snow removal on pavements in winter and the like and has broad application.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

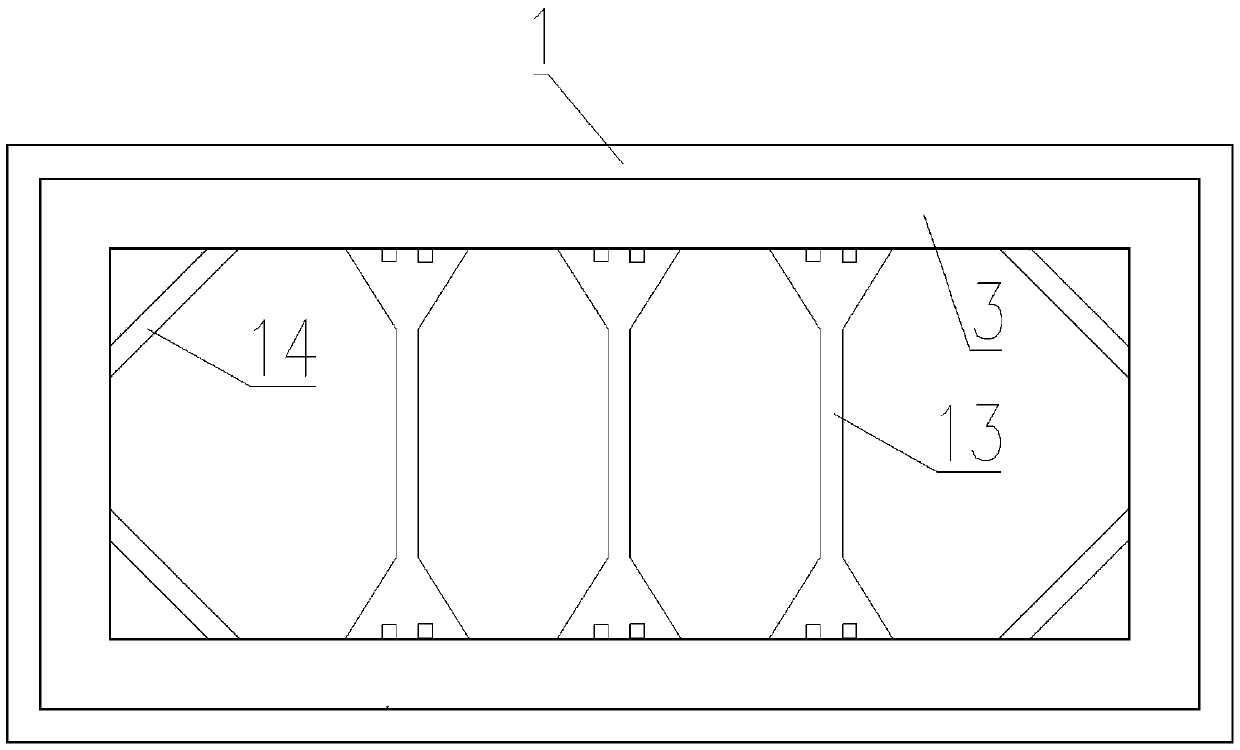

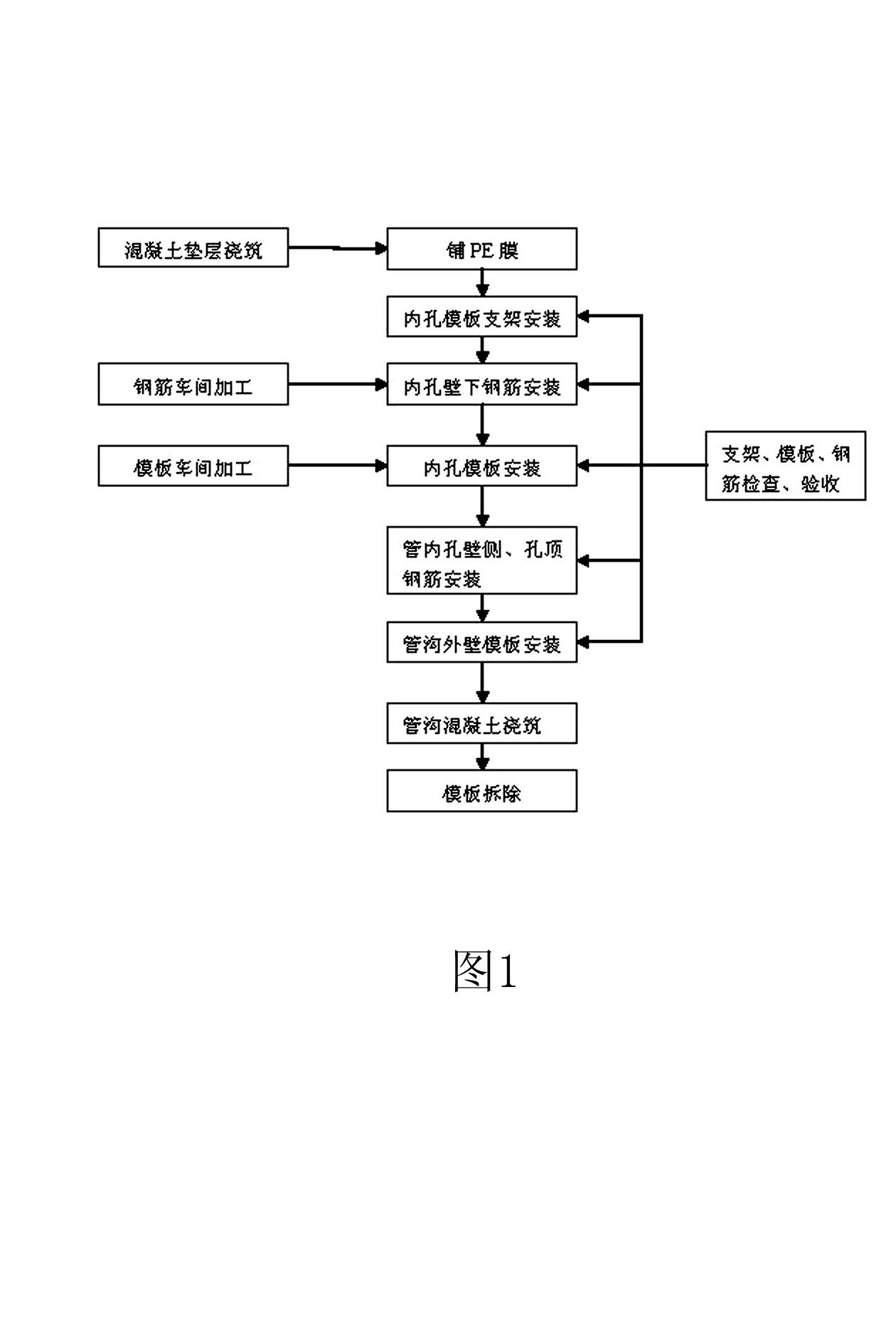

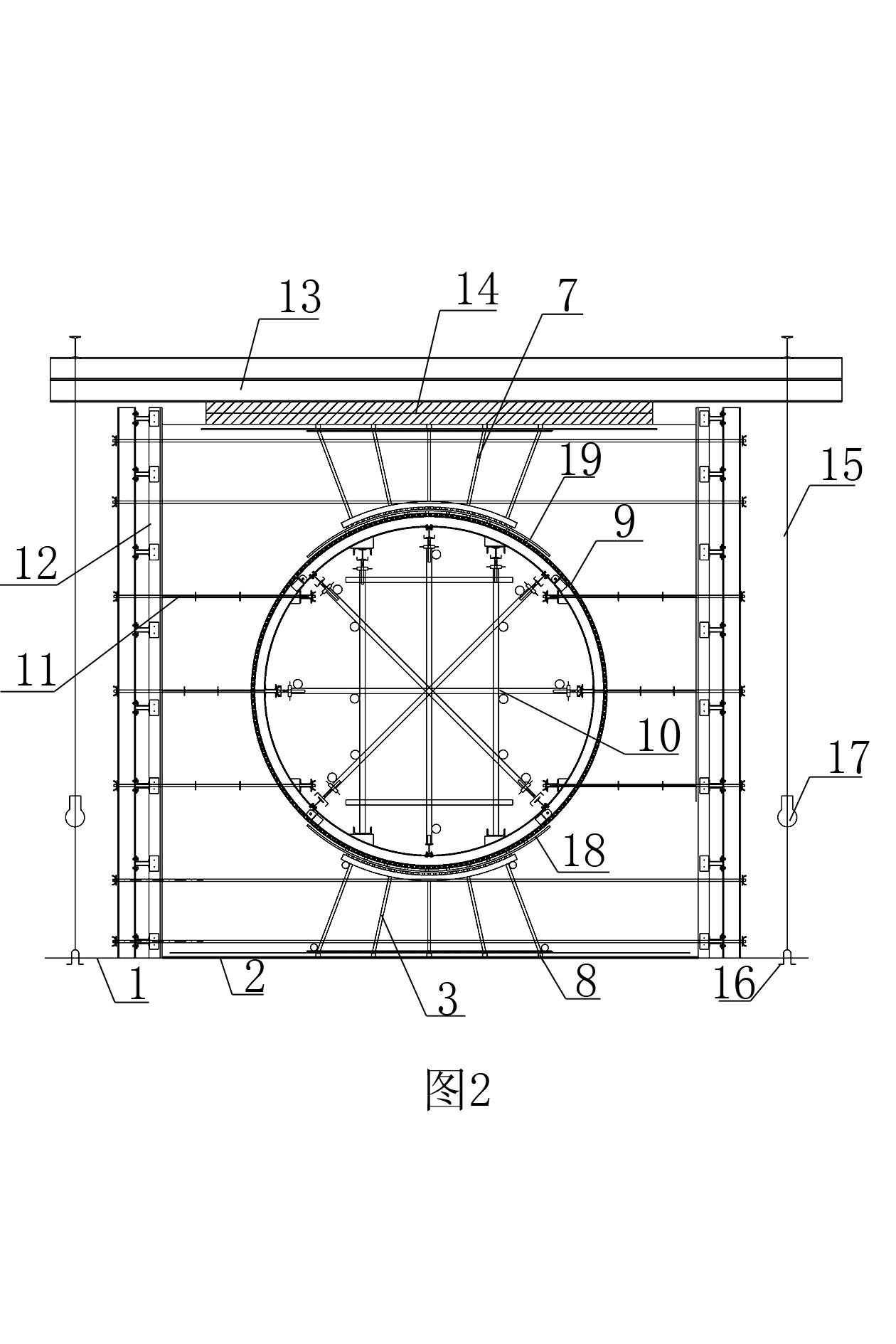

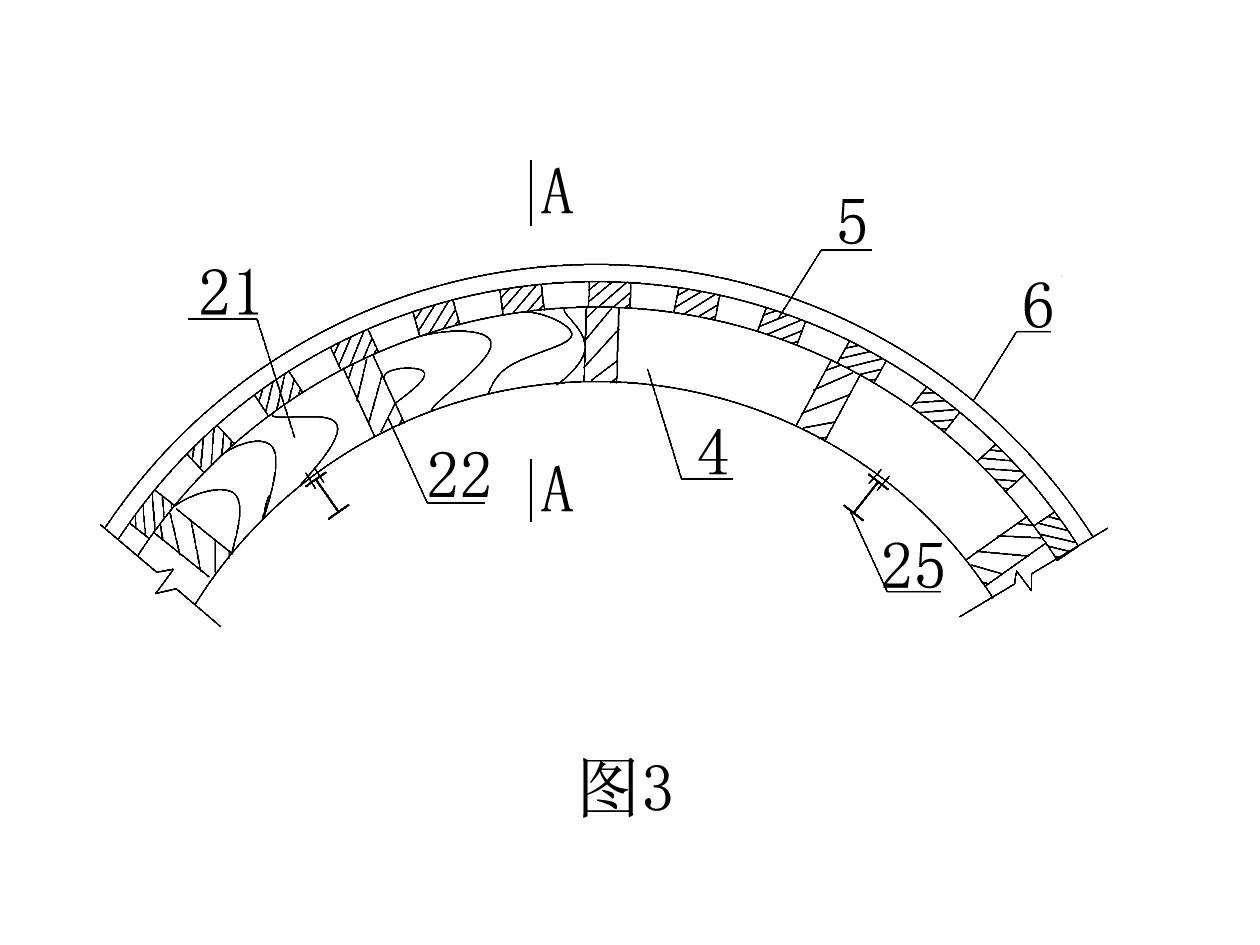

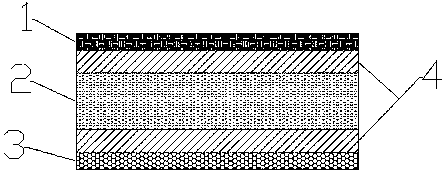

Full-section overall casting construction method for circulating water pipe ditch of nuclear power plant

InactiveCN102322149AGuaranteed impermeabilityGuaranteed corrosion resistanceForms/shuttering/falseworksBuilding material handlingNuclear powerWater pipe

The invention relates to a full-section overall casting construction method for a circulating water pipe ditch of a nuclear power plant. The method comprises the following steps of: processing an inner porous template of a pipe ditch into a complete round one at one time; and arranging a PE (Polyurethane) film sliding layer on the upper surface of a concrete cushion layer. Thus, one-time overall casting of the pipe ditch is realized, meanwhile, the pipe ditch is formed through full-section overall casting molding, an anti-float measure which is bonded through a wire rope is arranged outside the pipe ditch according to the anti-float requirement of the full-section overall casting molding, construction defects such as restriction between structural concrete and cushion layer concrete during construction, production of cracks and the like are avoided, and the method can be widely applied to construction of the circulating water pipe ditch of the nuclear power plant.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Recycled concrete beneficial to improvement of impermeability and preparation method thereof

InactiveCN113233825AImprove impermeabilityEasy to prepareSolid waste managementPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses recycled concrete beneficial to improvement of impermeability and a preparation method of the recycled concrete. The recycled concrete is prepared from 50-90 parts of fly ash, 160-240 parts of cement, 25-45 parts of slag powder, 750-1100 parts of modified recycled coarse aggregate, 300-550 parts of natural fine aggregate, 90-120 parts of modified recycled PET (Polyethylene Terephthalate) plastic particles, 5-8 parts of an additive and water, the additive comprises a water reducing agent, an air entraining agent, an early strength agent and a waterproof agent, and the recycled concrete comprises the following components in parts by weight: 75 parts of fly ash, 210 parts of cement, 30 parts of slag powder, 960 parts of modified recycled coarse aggregate, 320 parts of natural fine aggregate, 95 parts of modified recycled PET plastic particles, 0.5 part of the water reducing agent, 1.6 parts of the air entraining agent, 7.5 parts of the early strength agent, 2.3 parts of the waterproof agent and water. According to the recycled concrete beneficial to improvement of impermeability and the preparation method thereof, batch and rapid preparation of the recycled concrete is facilitated, the quality of the recycled concrete is ensured, improvement of the impermeability of the recycled concrete is facilitated, and reutilization of the recycled concrete is ensured.

Owner:JINHUA VOCATIONAL TECH COLLEGE

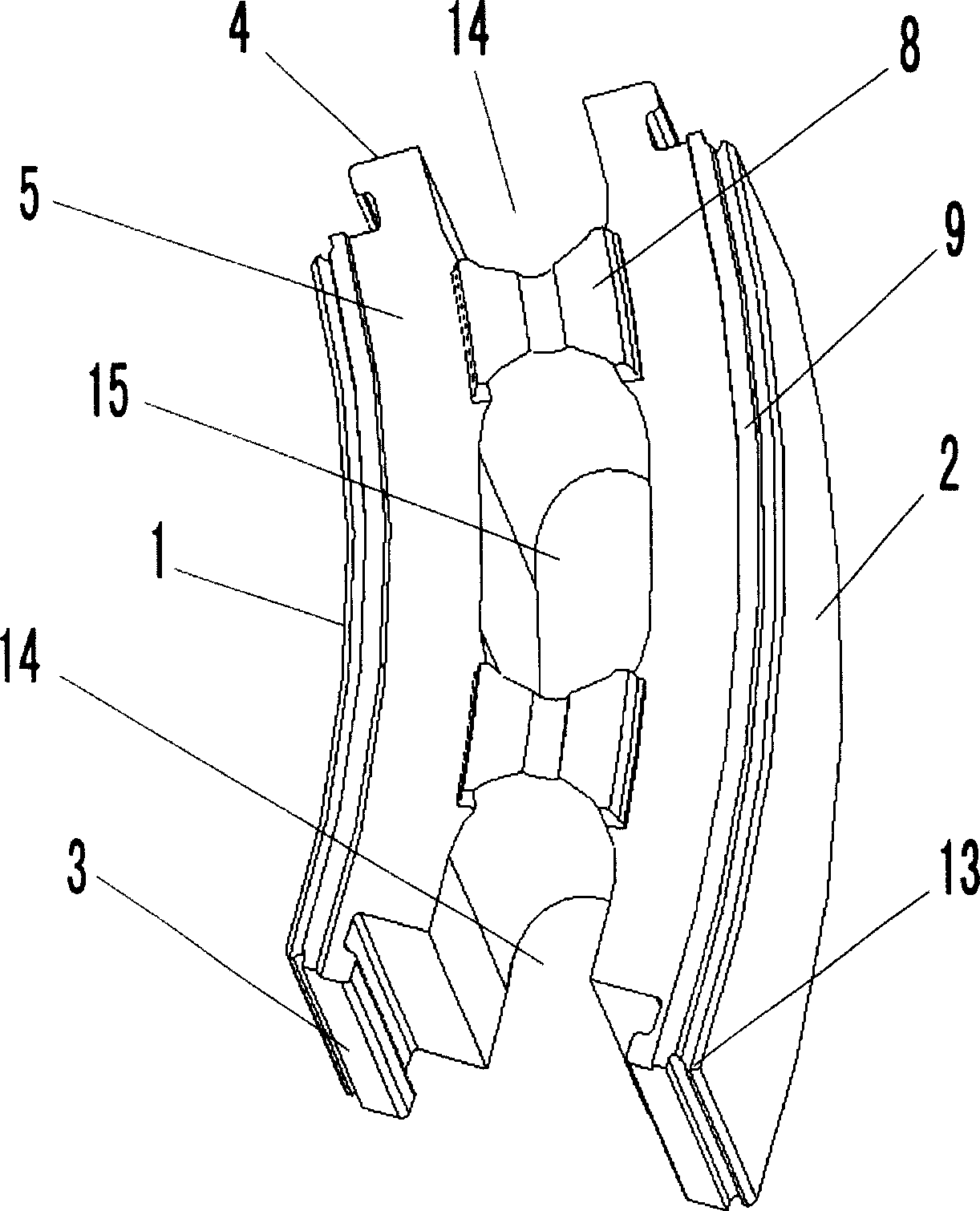

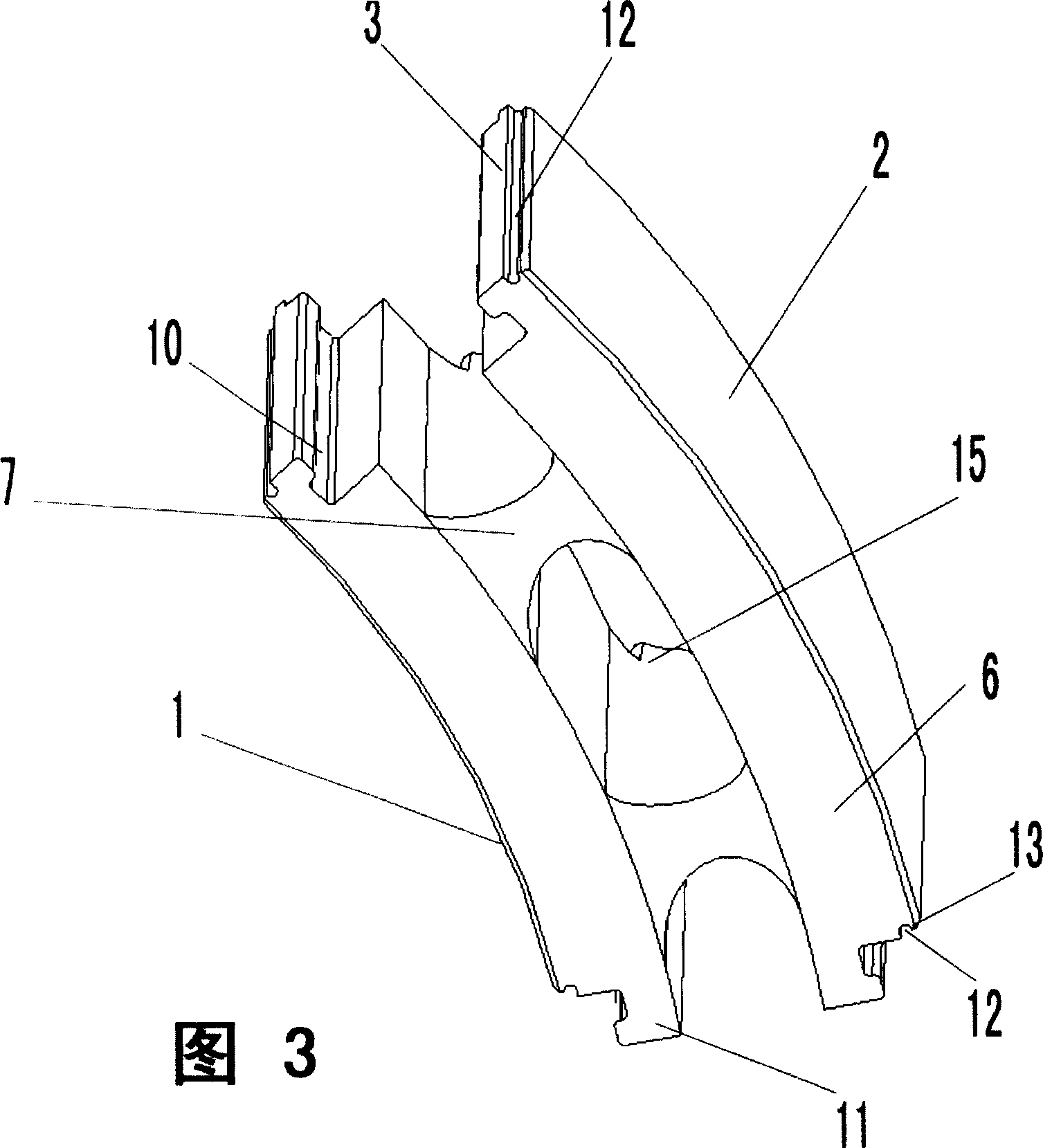

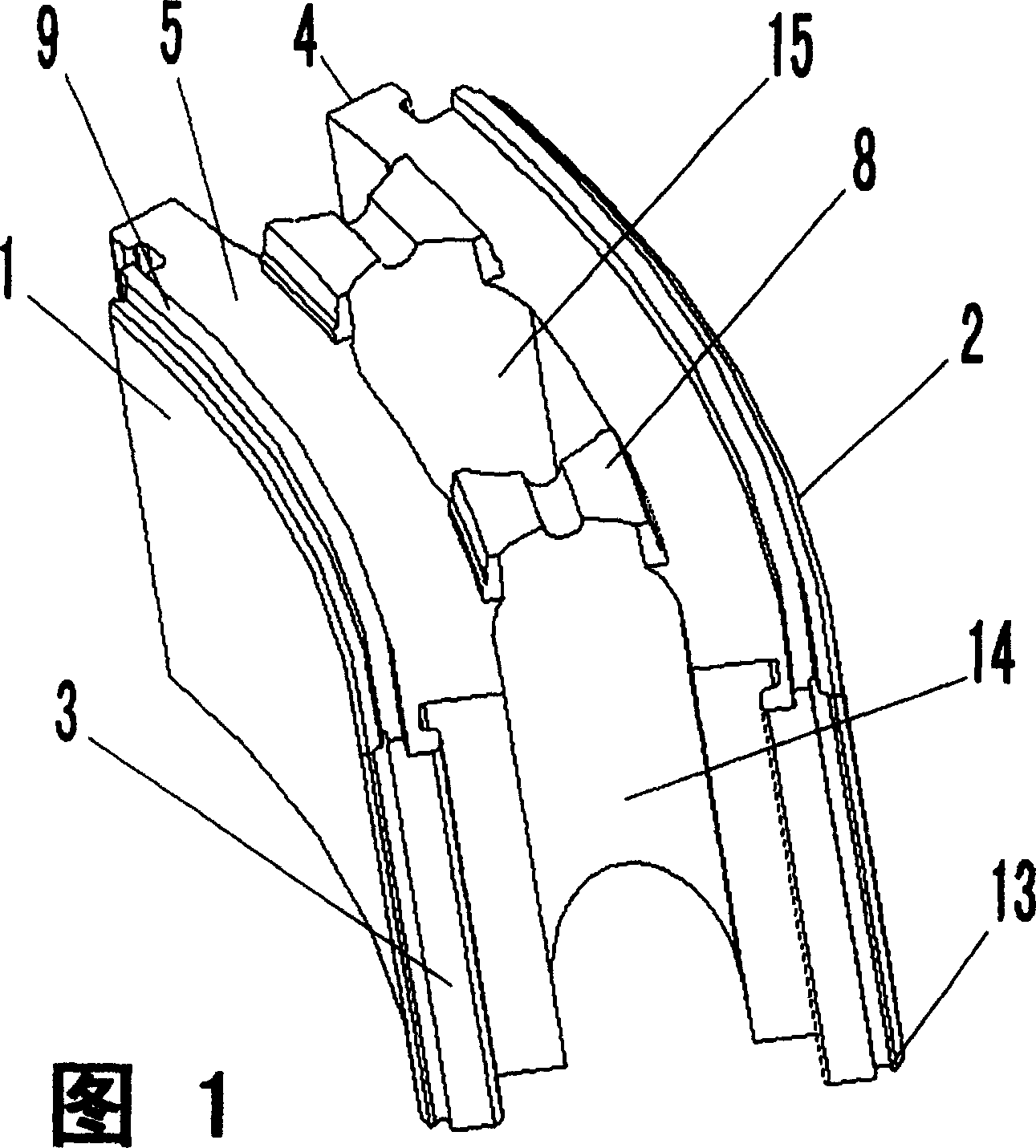

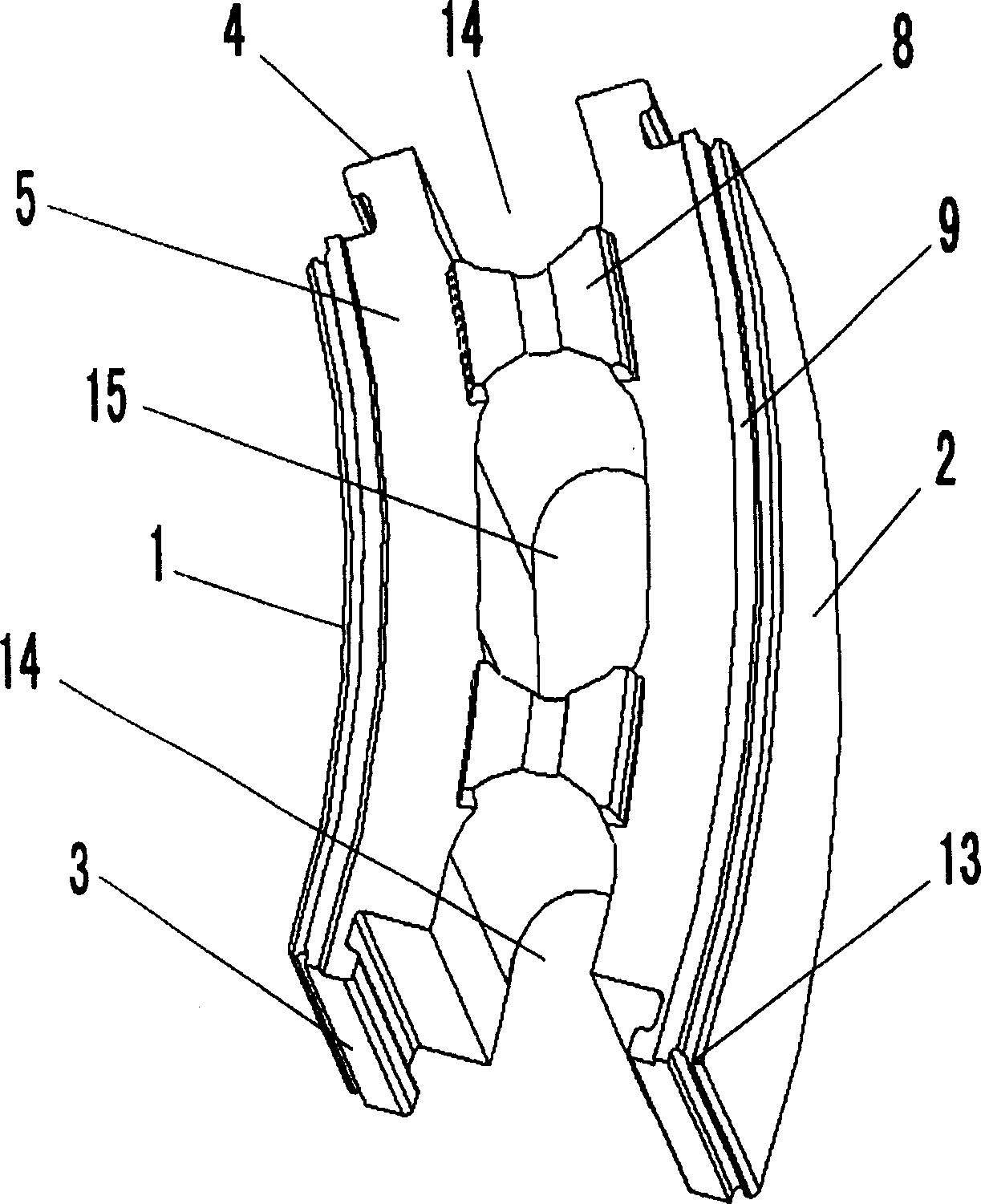

Impervious geosynthetic clay liner

ActiveCN107675680AMeet anti-seepage requirementsActs as a moisture filter bufferLayered productsProtective foundationOrganic solventSodium Bentonite

The invention discloses an impervious geosynthetic clay liner, and belongs to the technical field of waterproof coiled materials. The impervious geosynthetic clay liner comprises a woven cloth layer (1), a buffer layer (4), a bentonite layer (2), a buffer layer (4) and a non-woven cloth layer (3) from top to bottom, wherein the bentonite layer consists of the following raw materials of, by weight,80-100 parts of modified bentonite, 10-20 parts of adhesive, and 30-40 parts of water; the adhesive is formed by mixing polyvinyl alcohol solution and water glass; the buffer layer is mixed liquid prepared by dissolving agar and vital gluten into the water; and the mixed liquid is preheated to spray into organic solvent for standing and layering to prepare gel beads. The impervious geosynthetic clay liner achieves excellent characteristic of impervious performance, and is broad in prospect and application value in the field of the waterproof coiled materials.

Owner:广州腾飞建筑工程材料有限公司

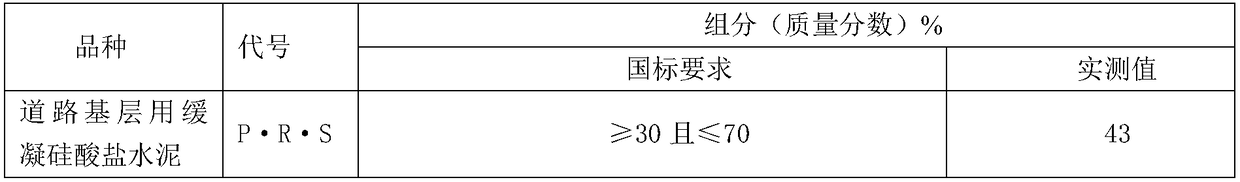

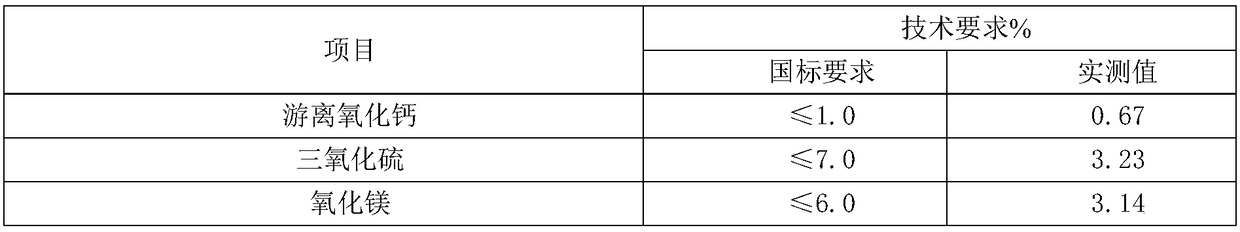

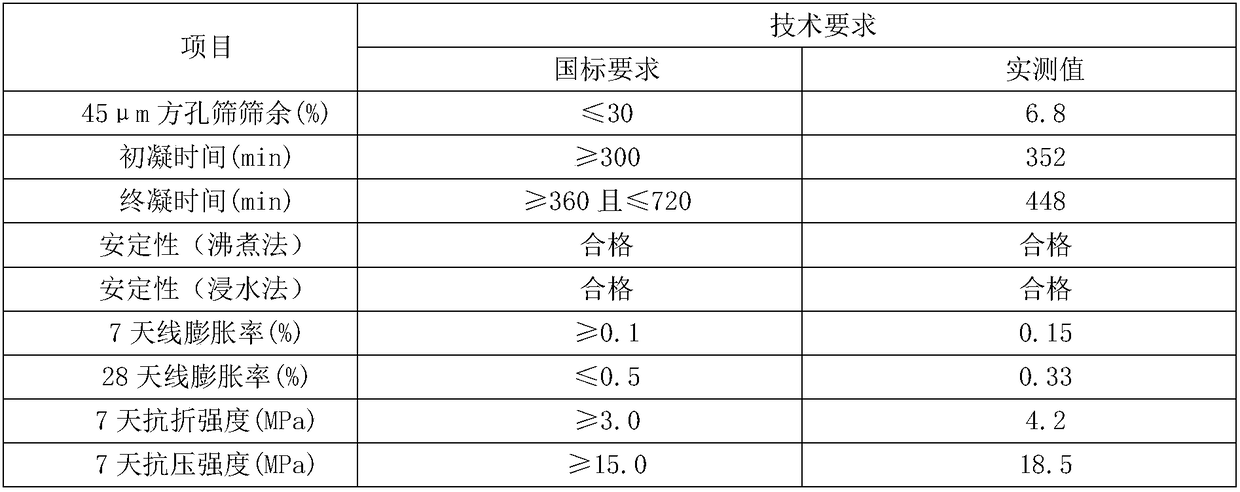

Delayed coagulation Portland cement for road base layer and production method

InactiveCN109503006AGuaranteed frost resistanceGuaranteed crack resistanceCement productionCrack resistanceSlag

The invention discloses delayed coagulation Portland cement for a road base layer and a production method. The delayed coagulation Portland cement comprises the following raw materials in percentage by mass: 50% of clinker, 7% of flue gas desulfurization gypsum, 7% of limestone, 6% of slag, 30% of coal ash and 0.8% of grinding aids. The production method comprises the following steps: crushing theclinker, the flue gas desulfurization gypsum, the limestone, the slag and the coal ash, pre-homogenizing, carrying powder grinding, and making a crude material by using a conventional method; preheating and partially decomposing the crude material by using a cycle preheater; sintering in a cement rotary furnace so as to obtain clinker, further rapidly decomposing carbonate in the rotary furnace,and carrying out a series of solid phase reactions; putting the cement clinker and the grinding aids into a ball mill, and finally milling the cement clinker into appropriate granularities by using the ball mill. By adopting the delayed coagulation Portland cement for the road base layer, multiple use function property requirements such as freezing resistance, cracking resistance, permeation resistance, impact resistance, wearing resistance and erosion resistance of the cement can be ensured, resources can be comprehensively utilized, and remarkable social benefits can be made.

Owner:DATONG JIDONG CEMENT CO LTD

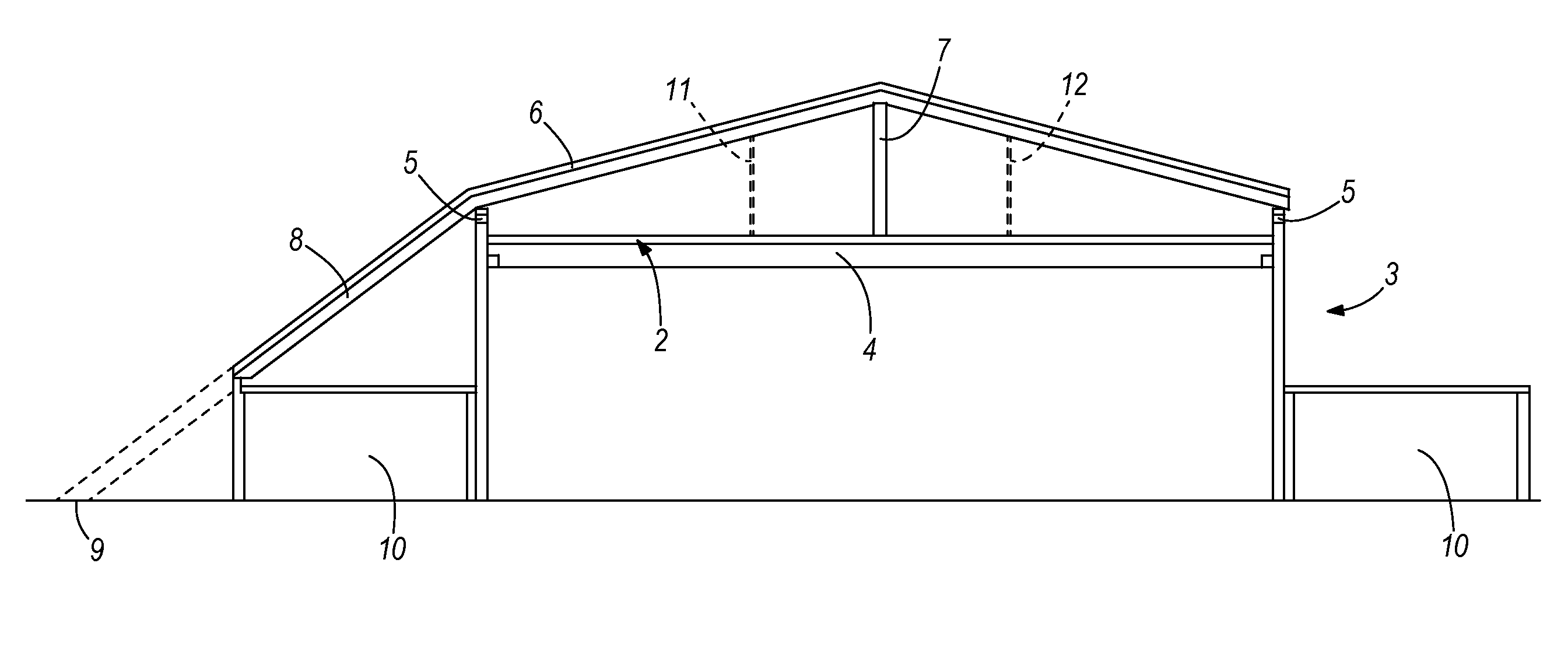

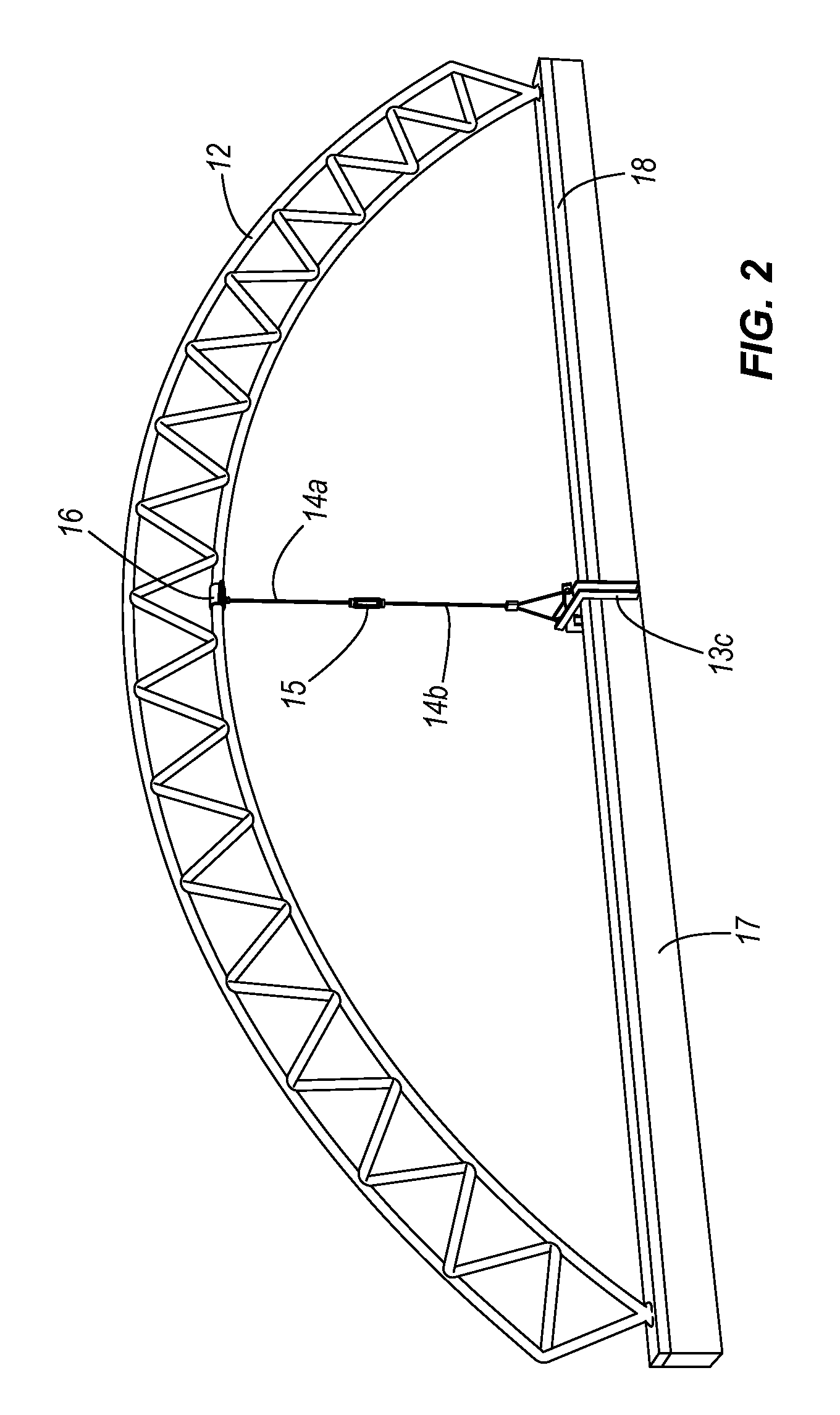

Device for the renovation of flat roofs

InactiveUS20080196320A1Easy to installLow production costBuilding roofsRoof covering using flexible materialsBiomedical engineeringFlat roof

The present invention relates to a device for the renovation of a flat roof of a building, while at least partially maintaining the old roof structure, with at least three attachment devices for attaching a second roof disposed over the flat roof being renovated, the second roof being made of a flexible, tensible surface material which is disposed by means of the at least three attachment devices over the flat roof such that it covers the area of the flat roof.

Owner:TERRA CONSULTING

Method for pouring ABR (Acrylate Butadience Rubber) reaction tank baffle

ActiveCN102635237AGood molding qualityGuaranteed impermeabilityTreatment with anaerobic digestion processesBuilding material handlingRebarSteel tube

The invention discloses a method for pouring an ABR (Acrylate Butadience Rubber) reaction tank baffle. The method comprises the following steps: 1) binding reinforcing bar nets: binding double-layer reinforcing bar nets by using reinforcing bars and binding stirrups between the double-layer reinforcing bar nets; 2) bracing formworks: respectively bracing beam supporting formworks on two sides of a beam reinforcing bar net, bracing plate supporting formworks on two sides of a plate reinforcing bar net, bracing an axilla supporting formwork outside an axilla reinforcing bar net, and meanwhile, supporting and fixing by using a longitudinal supporting rod and a horizontal supporting rod of a scaffold, and fixing and supporting the bottom of the plate reinforcing bar net on a steel tube of the scaffold; 3) pouring concrete: pouring a part below a preformed hole, a part from the preformed hole to the axilla and the beam with concrete layer by layer in turn; and 4) dismounting the formworks: dismounting the formworks when the concrete strength is 100%. The beam and plate of the ABR reaction tank baffle are integrally poured according to the method disclosed by the invention, so that the construction cold seam does not exist between the beam and plate and the forming quality is excellent.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Separation system for removing biotite from artificial sand

InactiveCN106733176ASimple structureAchieve the purpose of eradicatingMagnetic separationManufacturing technologyEngineering

The invention discloses a separation system, particularly discloses a separation system for removing biotite from artificial sand, and belongs to the technical field of design and manufacturing of water-power engineering building material production equipment. The separation system for removing biotite from artificial sand is convenient to operate, simple in structure and capable of effectively removing biotite from artificial sand. The separation system comprises a magnetic selection mechanism and a material separation mechanism. When biotite mixed in artificial sand runs in the material separation mechanism along with the artificial sand, the biotite is separated out of the artificial sand through the magnetic selection mechanism.

Owner:POWERCHINA CHENGDU ENG

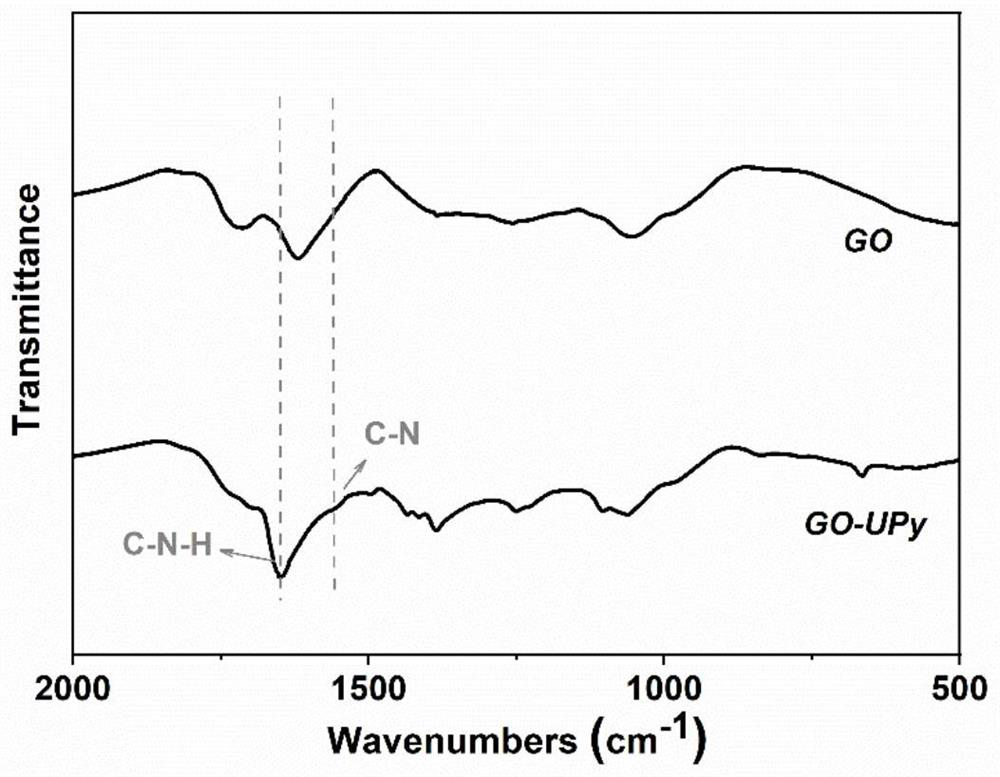

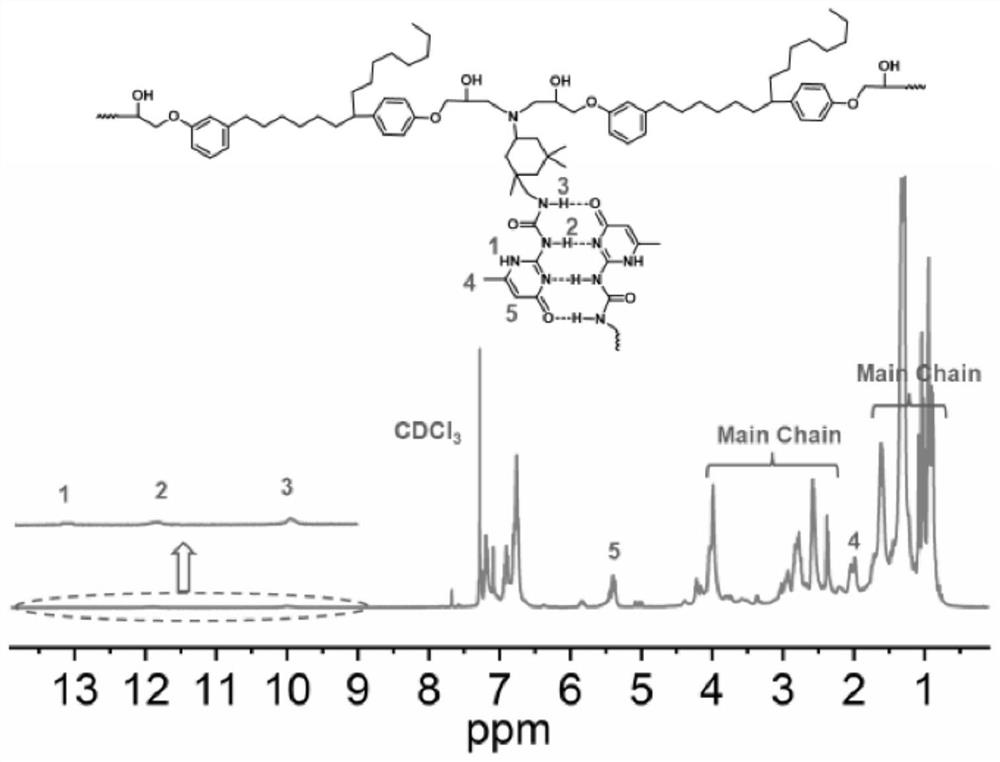

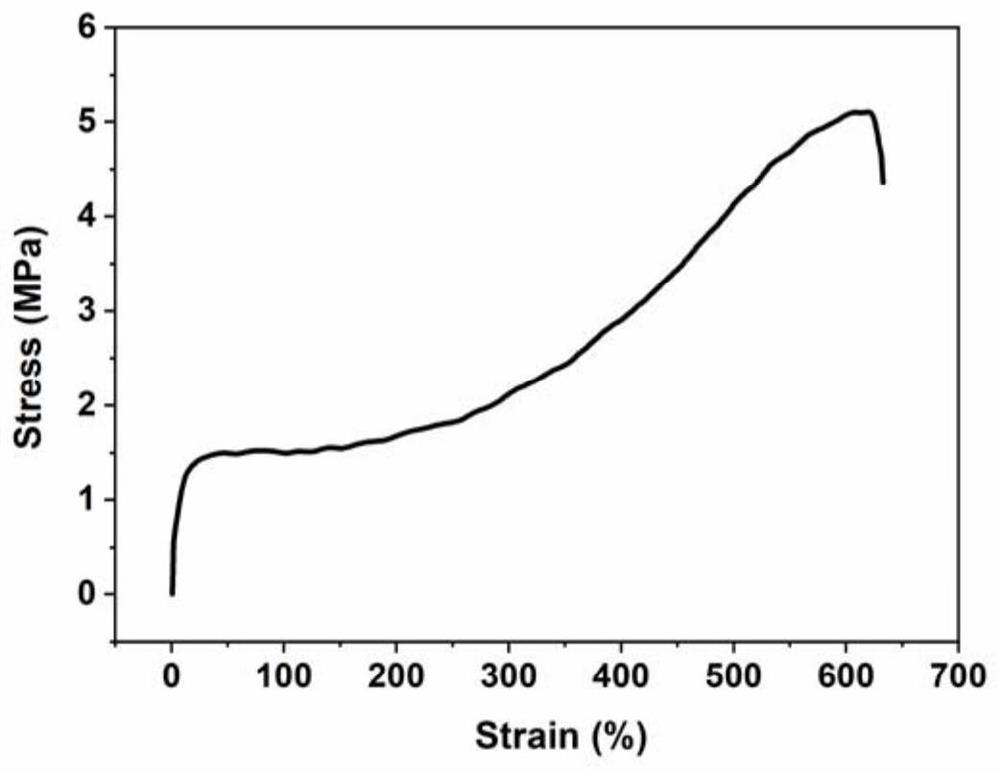

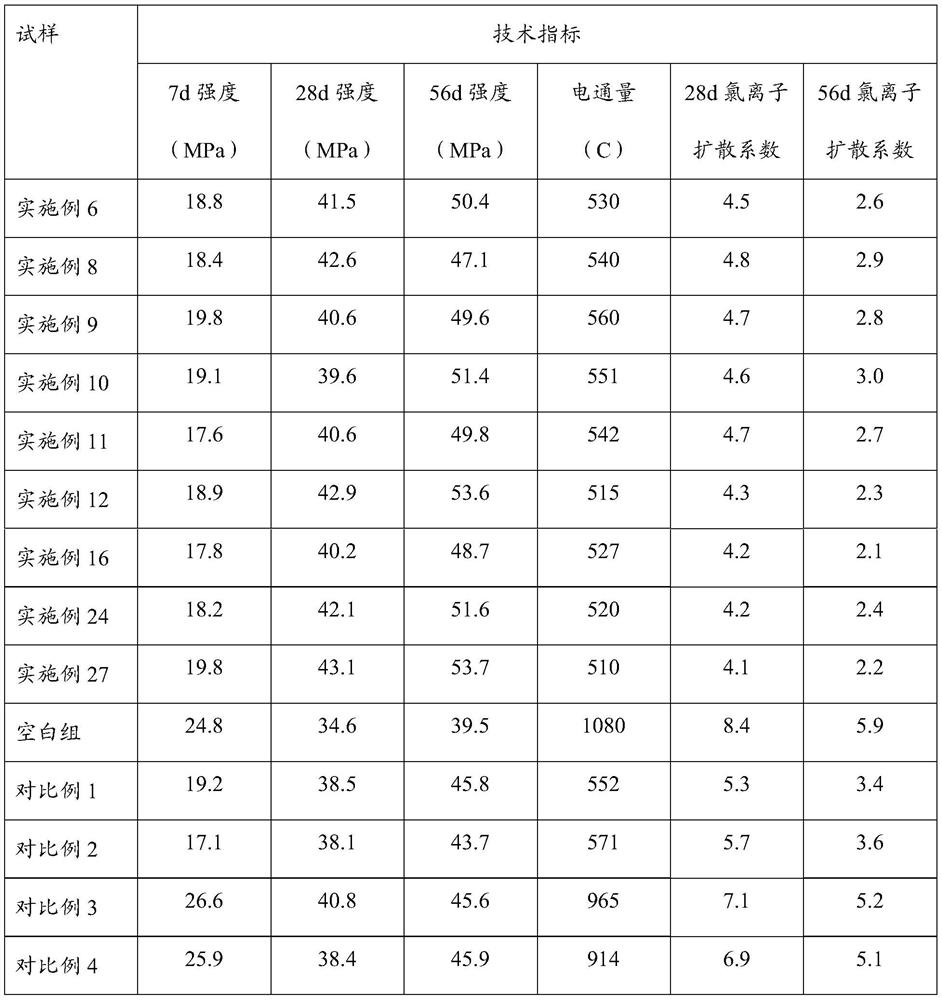

Bio-based nano composite epoxy coating inspired by nacre as well as preparation method and application of bio-based nano composite epoxy coating

InactiveCN114479610AImprove mechanical propertiesGuaranteed impermeabilityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceIsophorone

The invention particularly relates to a bio-based nano-composite epoxy coating inspired by a nacreous layer as well as a preparation method and application of the bio-based nano-composite epoxy coating. Graphene oxide modified by reversible quadruple hydrogen bond 2-ureido-4 [1H]-pyrimidone-isocyanate molecules is used as a hard inorganic phase, and a self-repairing bio-based epoxy polymer system is used as a soft organic phase; the self-repairing bio-based epoxy polymer system comprises bio-based cardanol epoxy resin, an isophorone diamine curing agent and isophorone diamine with 2-ureido-4 [1H]-pyrimidone (UPy) on a branched chain, and a highly homogeneous bionic layered nano-composite coating is formed through solvent evaporation and prepolymer crosslinking film formation induction. The bionic nano-composite coating prepared by the method has good mechanical property, rapid self-repairing capability and good corrosion resistance, the preparation process is simple and controllable, the raw materials are green and environment-friendly, and the bionic nano-composite coating can be widely applied to the technical field of metal surface protection of electronic devices, engineering equipment and the like.

Owner:广东腐蚀科学与技术创新研究院 +1

Polymer modifier for concrete, preparation method thereof, and impermeable and waterproof concrete

The invention discloses a polymer modifier for concrete. The polymer modifier for concrete comprises a polymer emulsion and an interface modifier, and the interface modifier comprises silica sol and asilane coupling agent; and the addition amount of the polymer emulsion to the interface modifier is 1:(0.2-1). A preparation method of the polymer modifier comprises the following steps: weighing thepolymer emulsion, the silica sol and the silane coupling agent according to the weight ratio; mixing the silica sol, the silane coupling agent and the polymer emulsion, and performing ultrasonic treatment to obtain a mixed solution. An impermeable and waterproof concrete comprises 230-360 parts of cement, 60-100 parts of fly ash, 28-50 parts of an expanding agent, 650-820 parts of fine aggregate,950-1100 parts of coarse aggregate, 4.35-5.85 parts of a water reducing agent, 100-150 parts of water, 0.85-1.35 parts of an antifoaming agent and 40-80 parts of the polymer modifier. The interface modifier can enhance the dispersity of the polymer emulsion in the cement system, enhance the binding power between the polymer emulsion and cement, enhance the strength of the concrete and enhance theimpermeability and waterproofness of the concrete.

Owner:中铁二局第二工程有限公司

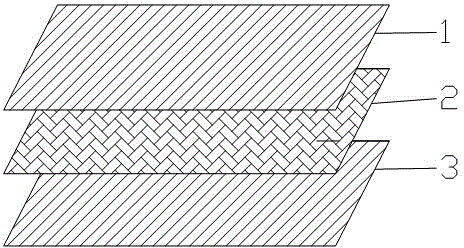

Functional SFS nonwoven fabric with characteristics of ultraviolet ray resistance, permeation resistance and moisture permeation

InactiveCN105479870AImprove tear resistanceExcellent abrasion resistanceSynthetic resin layered productsProtective garmentSurface layerTear resistance

The present invention relates to a functional SFS nonwoven fabric with characteristics of ultraviolet ray resistance, permeation resistance and moisture permeation. The functional SFS nonwoven fabric is characterized in that the functional SFS nonwoven fabric is formed by compounding an upper surface layer (1), a microporous moisture permeation film layer (2) and a lower surface layer (3), wherein the upper surface layer (1) and the lower surface layer (3) are made from polypropylene, and the microporous moisture permeation film layer (2) is made from a polyethylene and calcium carbonate mixing material. According to the present invention, the upper surface layer and the lower surface layer use the spunbond nonwoven fabric layers so as to ensure a certain strength, good tear resistance and good abrasion performance; the middle layer uses the microporous moisture permeation film so as to ensure good permeation resistance and good moisture permeation; and the upper layer spunbond cloth and the lower layer spunbond cloth are subjected to ultraviolet ray post-finishing processing so as to provide the anti-ultraviolet ray function, such that the SFS material has the anti-ultraviolet ray function.

Owner:江阴金凤特种纺织品有限公司

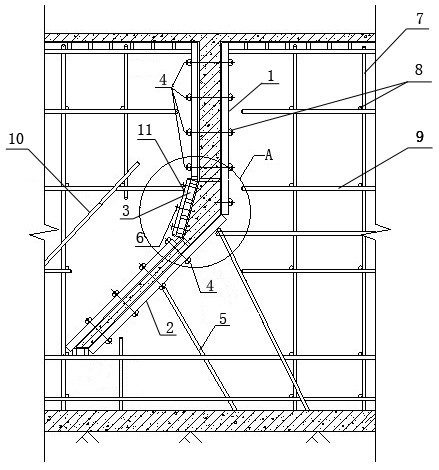

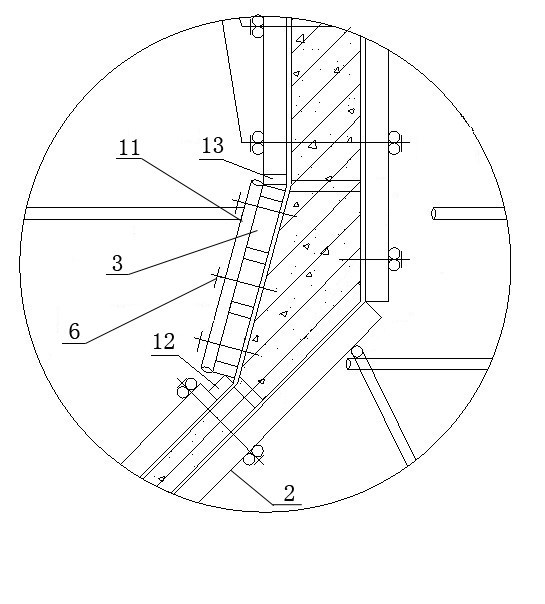

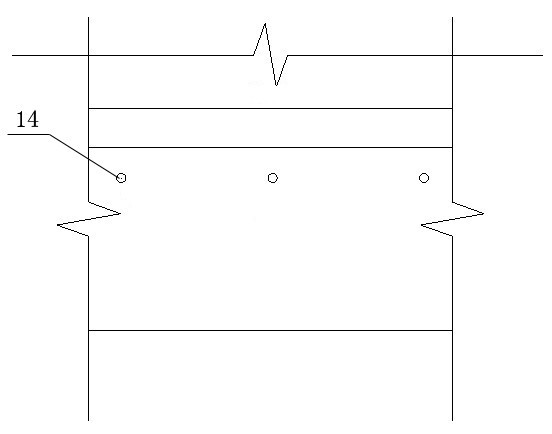

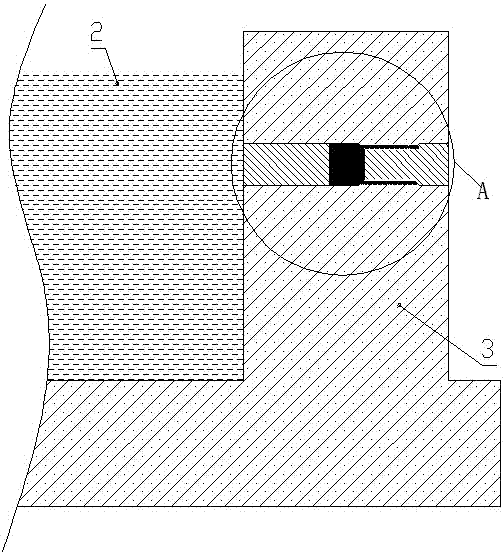

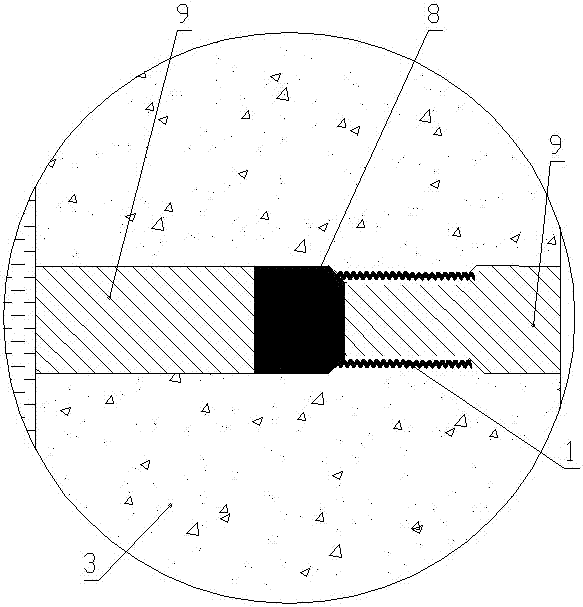

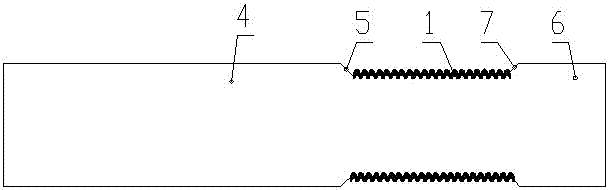

Thin-walled concrete tie screw waterstop structure and process

ActiveCN107246148ASimple structureIncreased durabilityAuxillary members of forms/shuttering/falseworksThin walledHydraulic pressure

The invention discloses a thin-walled concrete tie screw waterstop structure, comprising a plastic bellows arranged in a thin-walled concrete tie screw hole; the part of the tie screw hole in front of the plastic bellows is a front reamed hole, the part of the tie screw hole in rear of the plastic bellows is provided with a rear reamed hole, the tail end of the front reamed hole is provided with a water-swellable waterstop plug, and all the front reamed hole, the rear reamed hole and the plastic bellows are sealed with grout. The invention also discloses a construction method of the thin-walled concrete tie screw waterstop structure; the construction method comprises the steps of first, mounting a plastic bellows sleeve and tie screws; second, pouring, and removing forms; third, reaming; fourth, mounting the water-swellable waterstop plug; fifth, filling with grout; sixth, adding a water-swellable waterstop lug to the backwater side in case of underground water. The thin-walled concrete tie screw waterstop structure has high hydraulic pressure resistance, high structural tightness and durability, and good convenience of construction.

Owner:河南省水利第一工程局集团有限公司

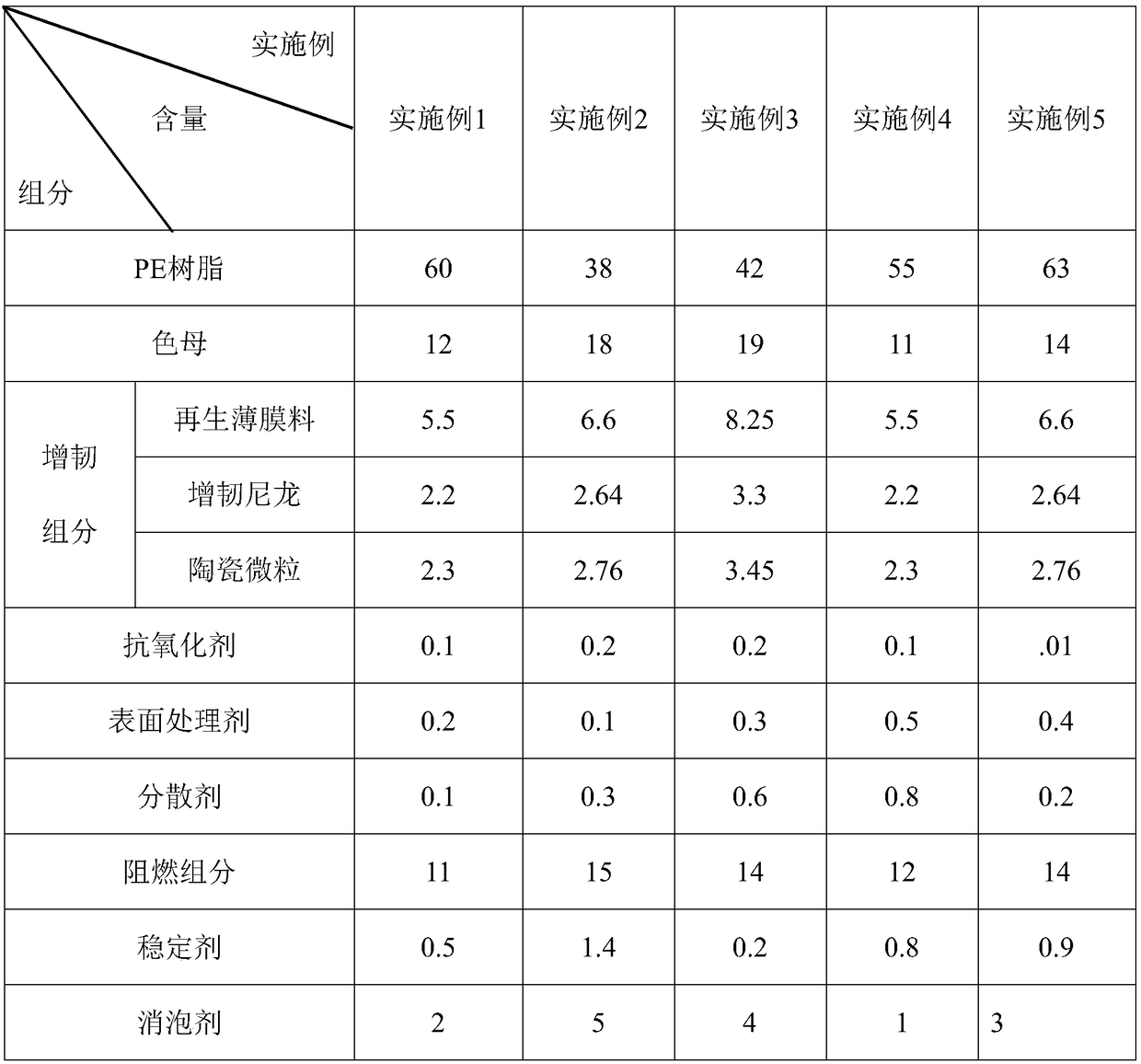

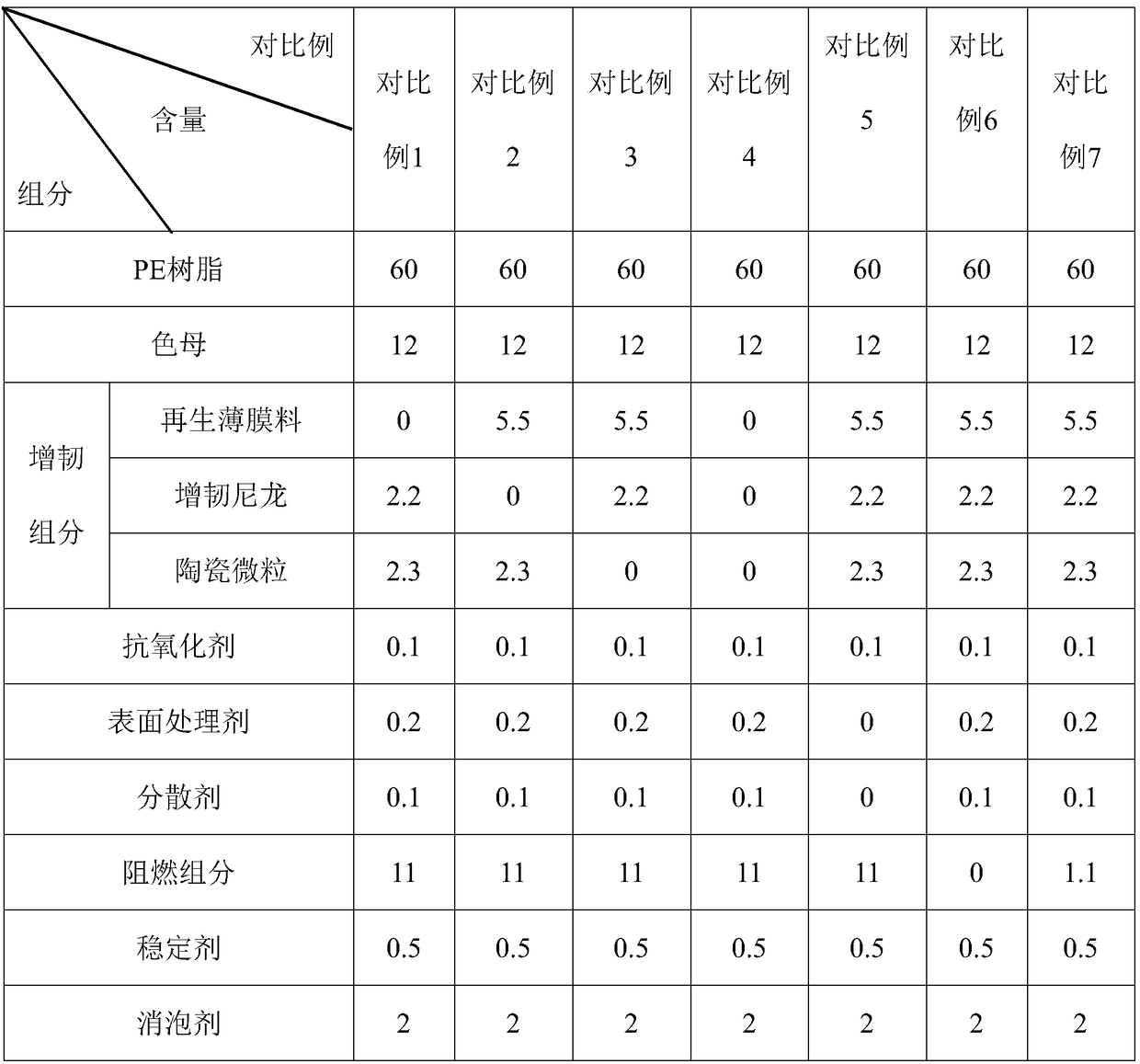

PE pipe and production process thereof

InactiveCN109265800AImprove insulation performanceImprove impermeabilityAntioxidantCompressive strength

The invention discloses a PE pipe and a production process thereof. The PE pipe is prepared from the following components in corresponding parts by weight: 35-65 parts of PE resin, 10-20 parts of color master batch, 10-15 parts of toughening components, 0.1-0.2 part of antioxidant, 0.1-0.5 part of surface conditioning agent, 0.1-1 part of dispersing agent and 10-15 parts of flame retardant component, wherein the toughening components comprise a regenerated film material, toughening nylon and ceramic fine particles in weight ratio of (40-60%):(20-32%):(8-35%), and the regenerated film materialis a mixture prepared from recycled waste PE resin and toughening nylon by mixing, melting and cooling. By the arrangement, as a part of the toughening components, the regenerated film material effectively improves the toughness of pipes, and also is substituted for a toughening agent to greatly reduce the production cost; as collocated materials, the toughening nylon and the ceramic fine particles play an effective role of reinforcement, and also can enable the pipes to have good waterproof and heat-insulation effects; and the ceramic fine particles also provide good compressive strength, sothe pipes can adapt to higher lateral water pressure, and the application range of the pipes is expanded.

Owner:武汉升瑞通管业有限公司

Construction structure and construction method of exterior wall in narrow space of basement

ActiveCN107575025BGuarantee the construction qualityImprove waterproof performanceAuxillary members of forms/shuttering/falseworksBuilding material handlingBasementSupporting system

The invention relates to a basement narrow space outer wall construction structure and method. The construction structure comprises an outer wall steel bar framework, a raft plate, an inner side supporting system and support piles, wherein the outer wall steel bar framework is arranged on the periphery of an outer wall area; the raft plate is arranged at the bottom of the outer wall area; the inner side supporting system is arranged on the inner side of the outer wall area; and the support piles are arranged on the outer side of the outer wall area. The basement narrow space outer wall construction structure further comprises an outer side supporting system arranged on the outer side of the outer wall area. The outer side supporting system comprises a plurality of pieces of channel steel vertically arranged between the outer wall area and the support piles. The outer side supporting system is arranged between the outer wall area and the support piles. The outer side supporting system and the inner side supporting system are connected into a whole to jointly resist lateral pressure formed in the outer wall concrete pouring process, and the outer wall construction quality can be guaranteed. The cost is low, and the basement narrow space outer wall construction structure and method are suitable for all similar narrow space formwork erecting projects.

Owner:CAMCE WHU DESIGN & RES CO LTD

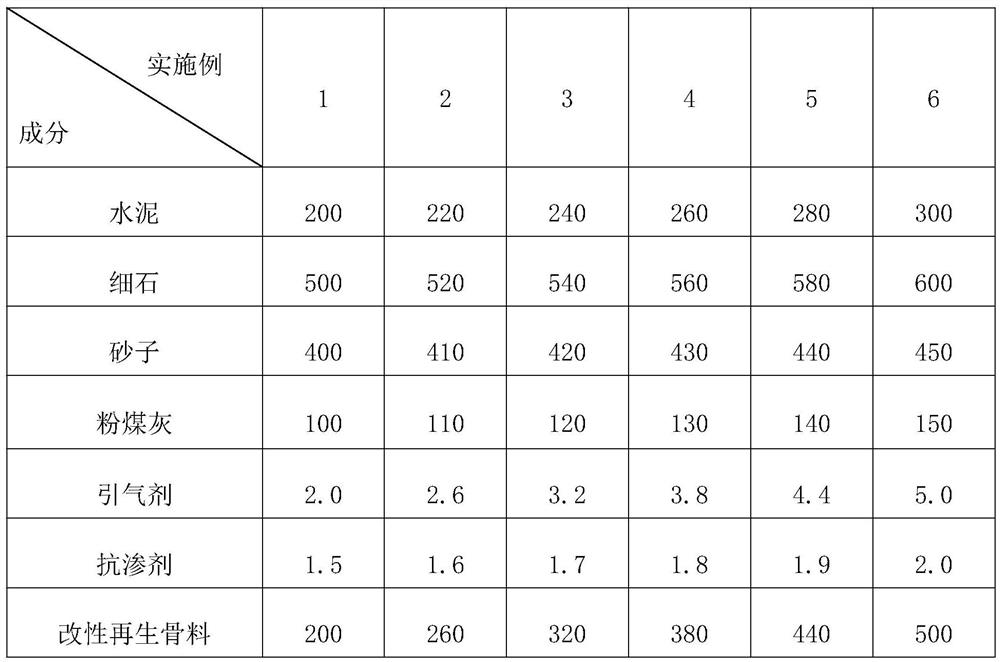

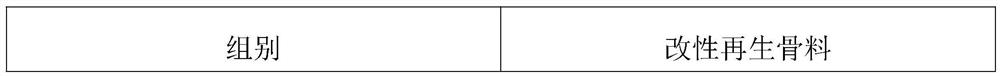

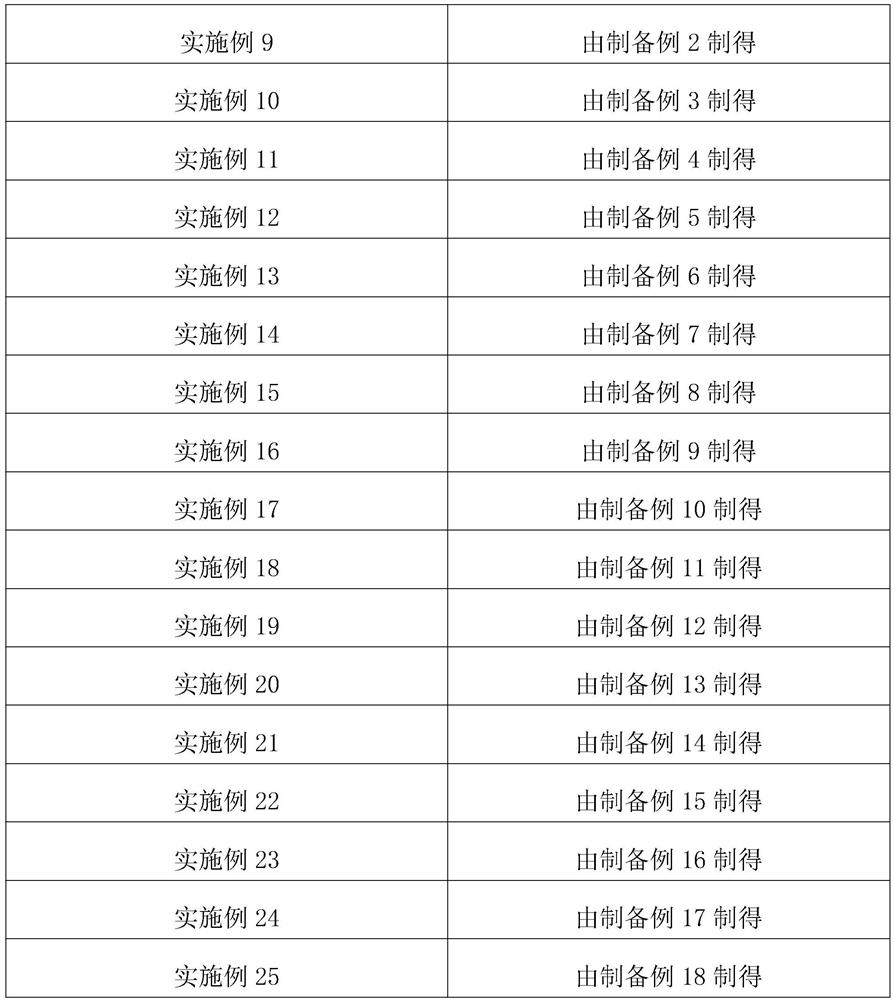

Environment-friendly impervious concrete and preparation method thereof

InactiveCN113501696AExcellent waterproof and impermeabilityCompact structureEnvironmental engineeringPre treatment

The invention relates to environment-friendly impervious concrete and a preparation method thereof. The invention relates to environment-friendly impermeable concrete, which is prepared from the following components in parts by weight: 200 to 300 parts of cement; 500 to 600 parts of fine stone; 400 to 450 parts of sand; 100 to 150 parts of fly ash; 2 to 5 parts of an air entraining agent; 1.5 to 2.0 parts of an anti-permeability agent; and 200 to 500 parts of modified recycled aggregate. The modified recycled aggregate is prepared by the following steps: a, pretreatment: firstly, performing impurity removal, crushing and screening on waste concrete blocks, and then heating and stirring the waste concrete blocks and a pickling solution in vacuum to prepare the recycled aggregate; and b, modification treatment: heating and stirring the recycled aggregate and the modification liquid, freezing and drying, and crushing and screening to obtain the modified recycled aggregate. Modification liquid is prepared from modified sol and modified filler; and modification sol is prepared from nanoscale silicon dioxide sol, sodium methylsilanolate and triethanolamine. The concrete provided by the invention has the advantages of environmental protection and impermeability.

Owner:上海楼诚混凝土有限公司

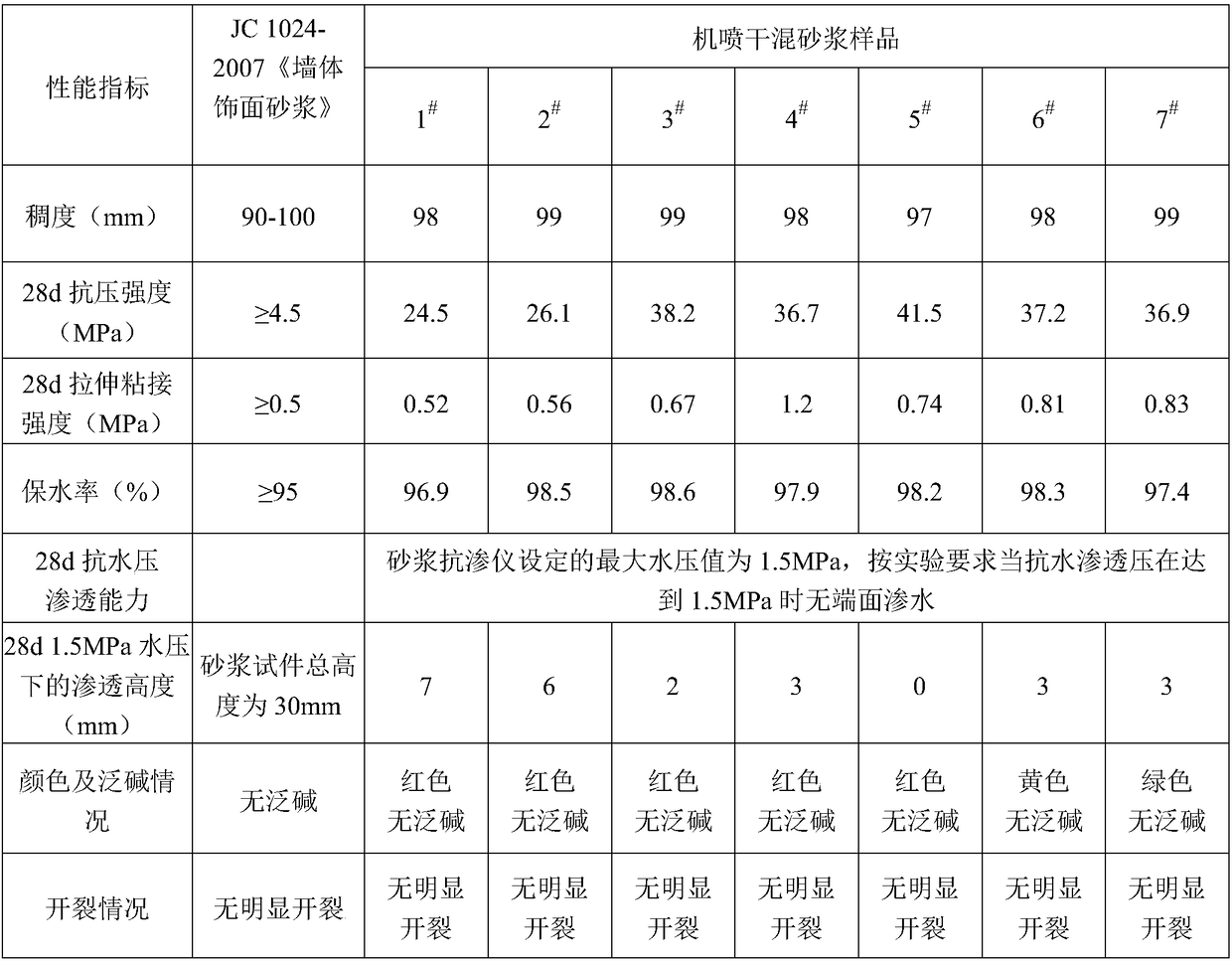

High-anti-permeability bright-color mechanized spraying dry-mixed mortar

The invention provides high-anti-permeability bright-color mechanized spraying dry-mixed mortar. The mortar comprise the following raw materials in parts by weight: 9-19 parts of ordinary Portland white cement, 0-10 parts of mineral powder, 11-12 parts of coarse whiting powder, 0.9-1 part of pigment, 66-69 parts of fine aggregate white quartz sand, 0.33-1.32 parts of rubber powder and 0.1-0.2 partof a water reducing agent. The dry-mixed mortar disclosed by the invention is a mortar composition with advantages of excellent field constructability, sag resistance and water retaining capacity andhigh anti-permeability property, and the high-anti-permeability bright-color mechanized spraying dry-mixed mortar can maintain excellent color uniformity in adverse weather, is low in cost and can beapplied to multiple basal planes and complicated construction environments.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com