Patents

Literature

34results about How to "Meet anti-seepage requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral casting process for reinforced concrete wastewater tank in predrilling engineering

ActiveCN103015719AShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

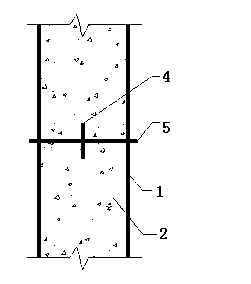

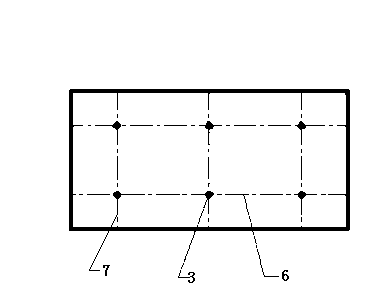

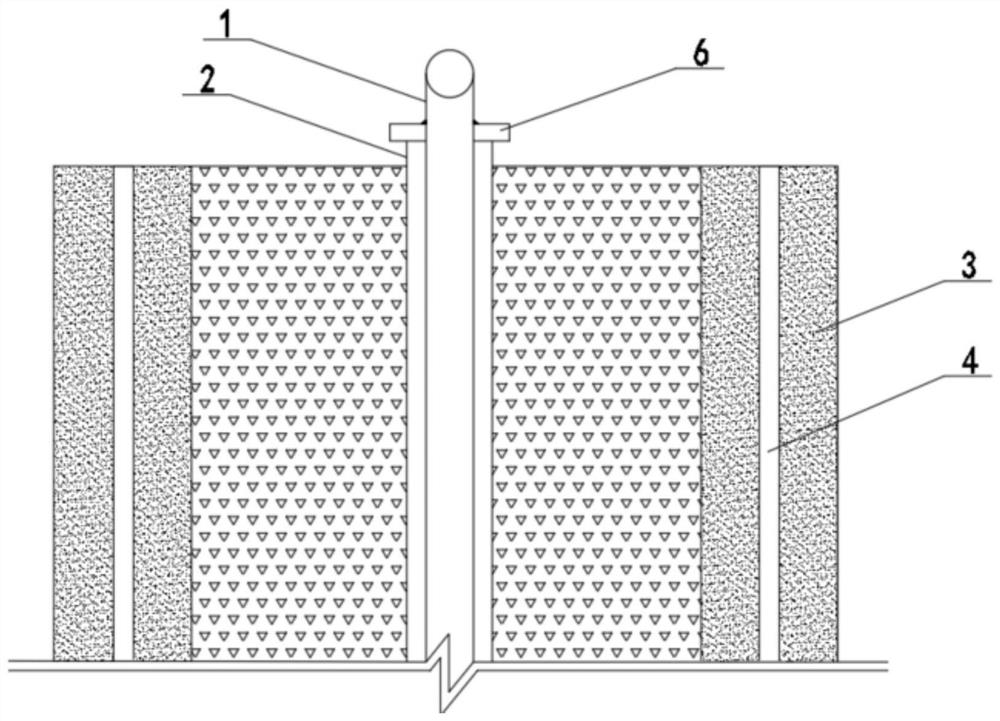

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

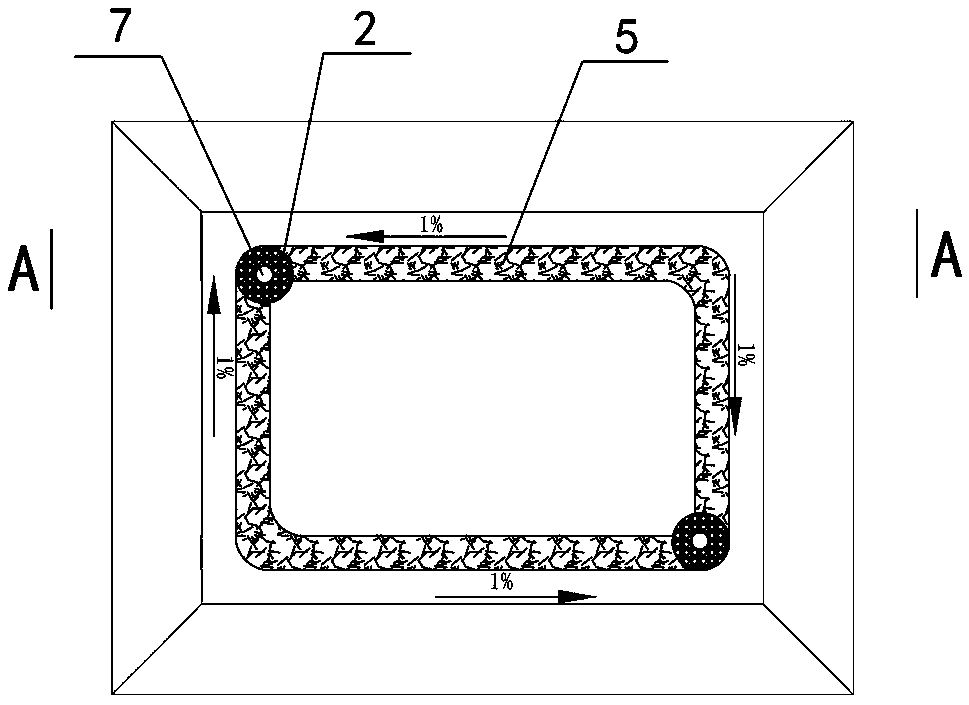

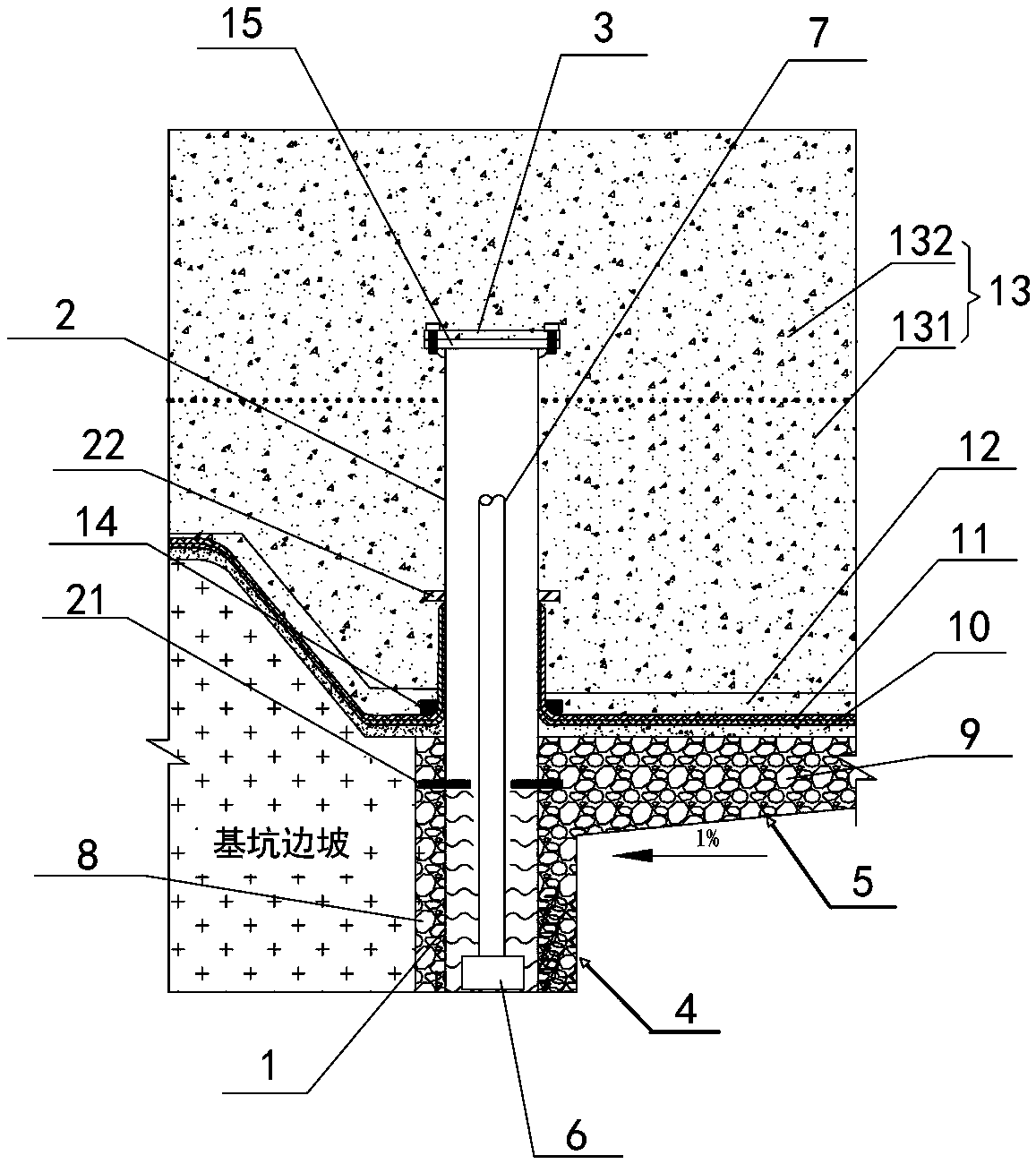

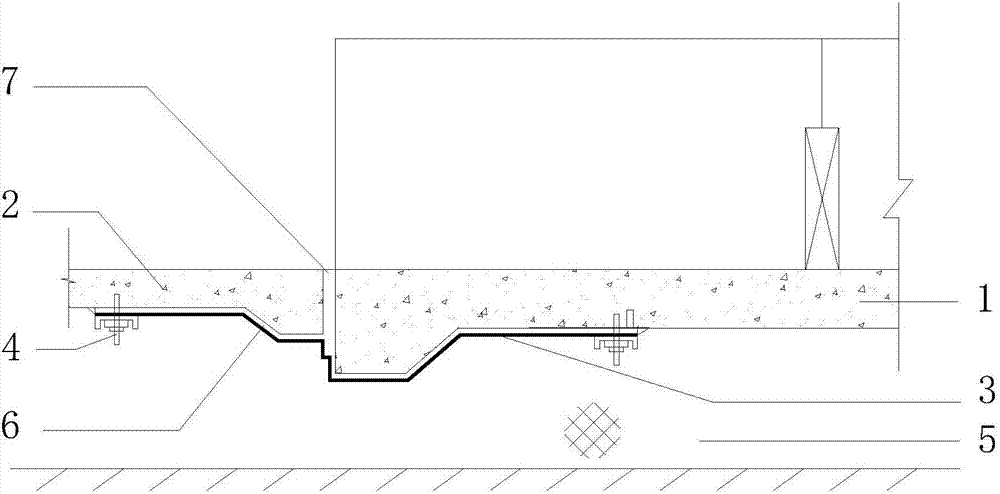

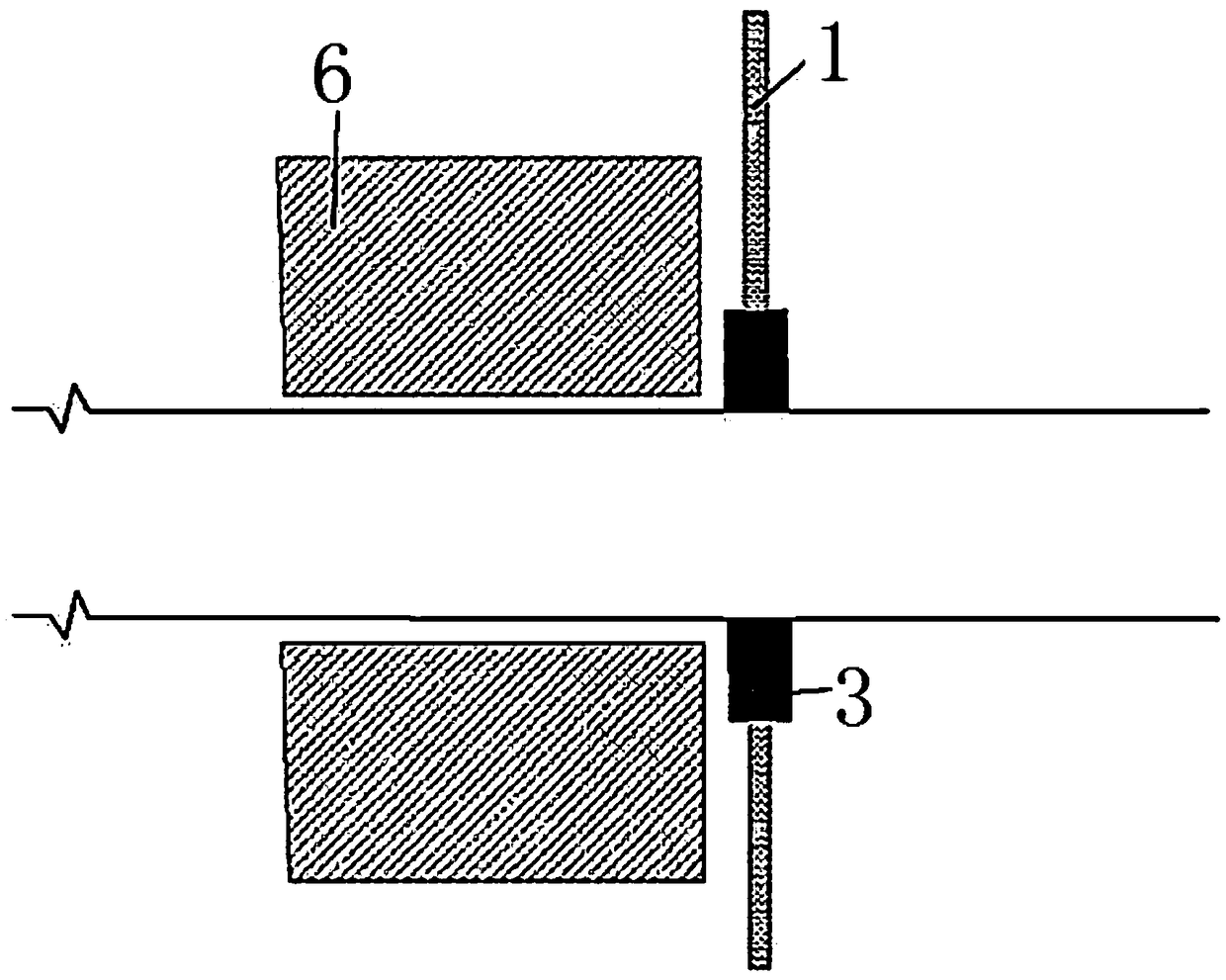

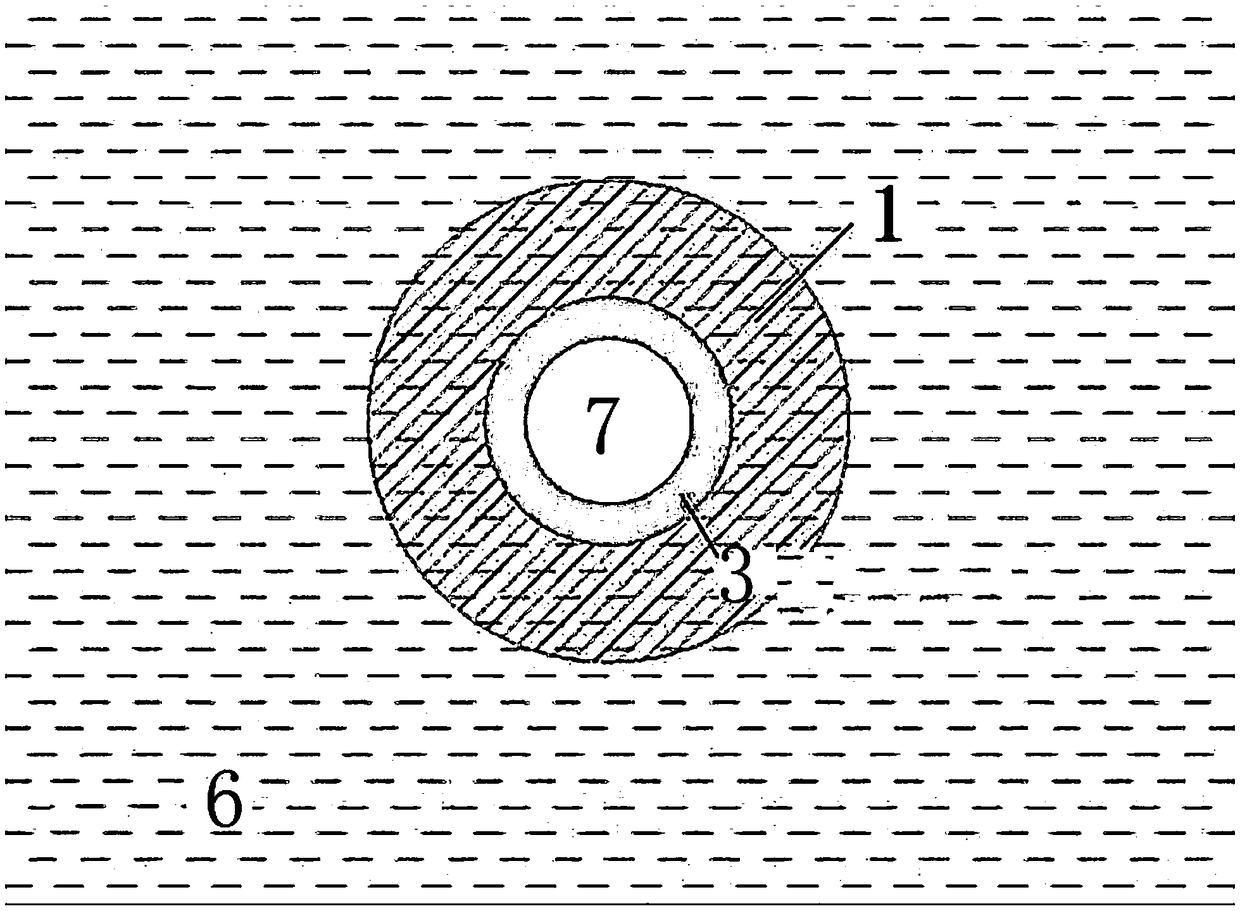

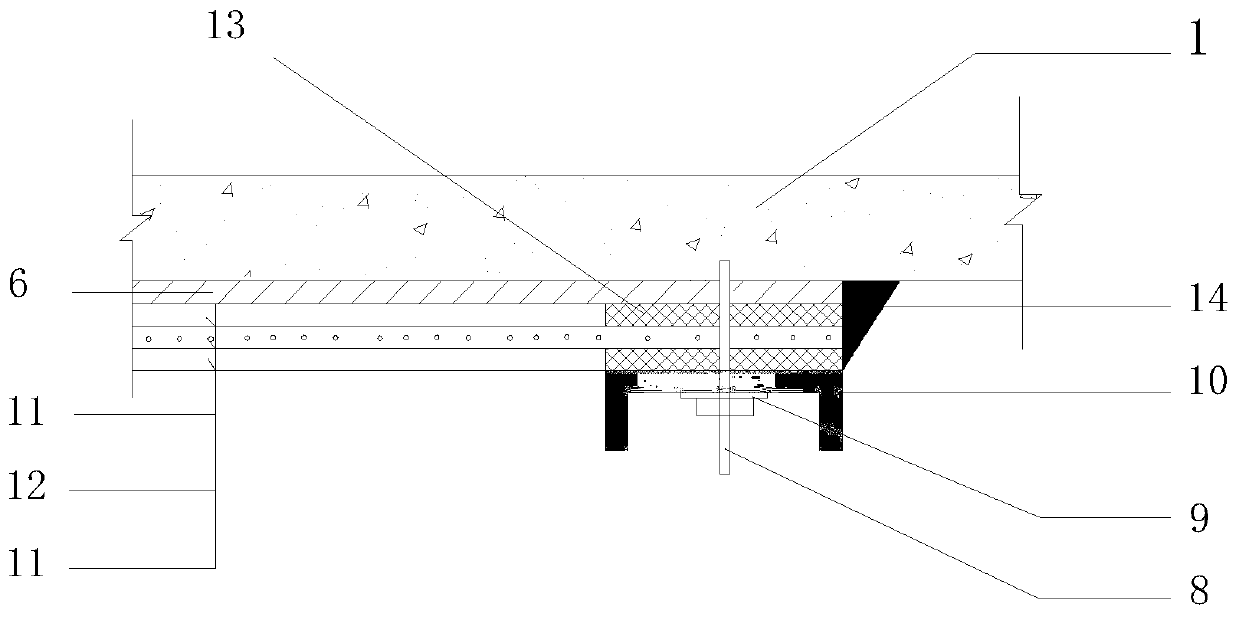

Raft built-in dewatering structure, sealing-well structure of dewatering well and sealing-well method

PendingCN109898533AAvoid secondary blockageMeet construction requirementsFoundation engineeringSurface waterProtection layer

The invention discloses a raft built-in dewatering structure, a sealing-well structure of a dewatering well and a sealing-well method, and relates to the technical field of the building construction.The raft built-in dewatering structure is arranged at the bottom of a foundation pit, and comprises a drainage ditch, a water collection pit, a well pipe, a water pump, an outer drainage pipe and electric wires, wherein the well pipe comprises a sand-free filter pipe and a water guide pipe, the sand-free filter pipe is embedded in the water collection pit, the top of the sand-free filter pipe is lower than the upper surface of the drainage ditch, the water guide pipe is arranged on the top of the sand-free filter pipe, the top of the water guide pipe exceeds the upper surface of the drainage ditch, and the top of the water guide pipe is provided with a cover plate in a covered mode. According to the raft built-in dewatering structure, the technical problems that the dewatering well is arranged at a local ponding position, sealing is conducted before concrete pouring of a base plate, then the base plate construction is conducted, if the surface water level is high and the water volume is large, the concrete pouring can not be conducted in time when sealing is conducted, resulting in a base plate cushion layer and a waterproof and protective layer being buoyed by the buoyancy of groundwater due to sealing, thus the base plate cushion and the waterproof and protective layer are destroyed are solved.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR +1

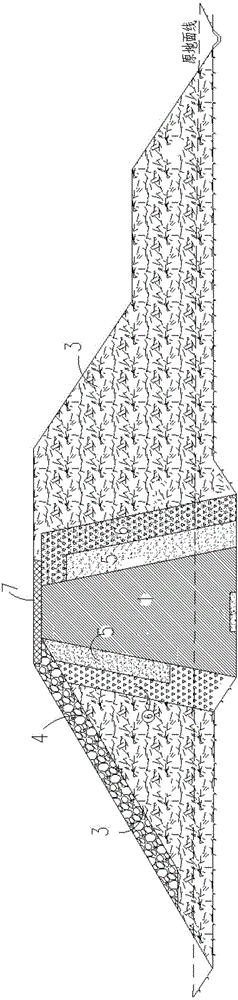

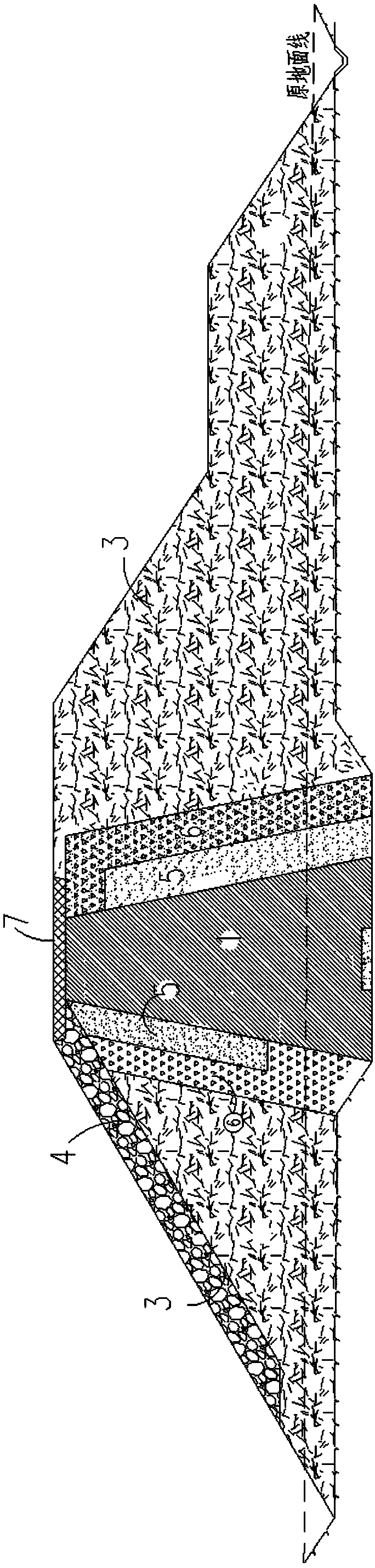

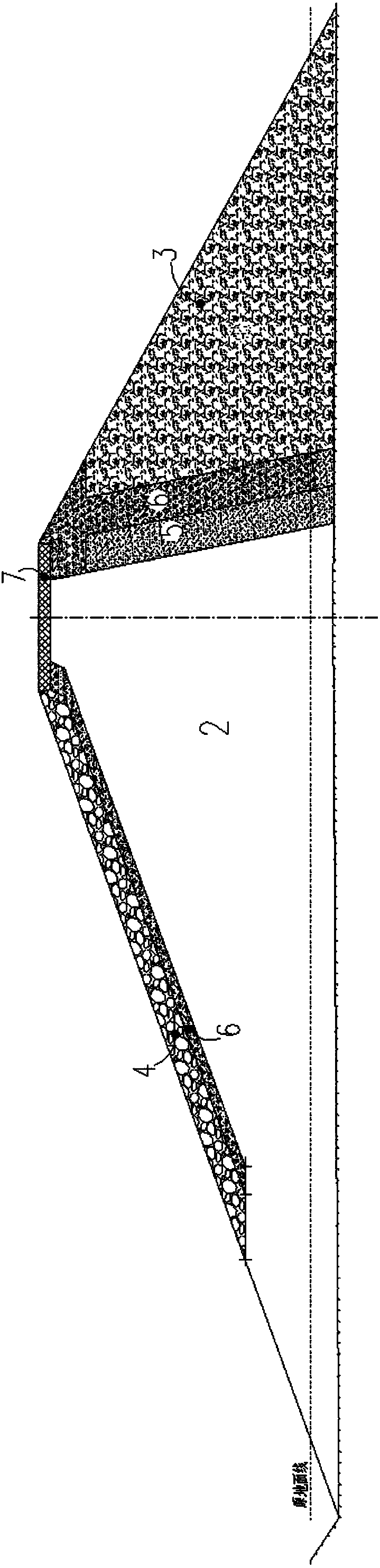

Treatment method of peat soil dam foundation

ActiveCN106381880AReduce liquidityEasy to dig out and transportSoil preservationSoil strengthSoil horizon

The invention relates to a treatment method of a peat soil dam foundation. For the dam section of a clay core-wall rockfill dam, gravels are scattered so as to enhance bearing capability, a pump pit is arranged for draining, and consolidation grouting and curtain grouting are carried out so as to ensure the stability and permeability of the dam foundation. For the dam section of a homogeneous soil dam, a pipe culvert and a draining ditch are buried, peat soil is cleared after draining and airing, a transition section is built after a residual soil layer is air-dried, and finally, ramming is carried out. For the dam section of an earth-rock dam, a cofferdam is built at the upstream section for blocking water, a draining open canal is dug for drainage, and rock powder is scattered for increasing soil strength; and finally, rock is thrown at the downstream side, and a gallery is built, so that clearing equipment can be driven into marshland for clearing the peat soil. According to the treatment method, the digging and outward transporting of the peat soil are facilitated, and the dam foundation meets seepage preventing requirements; the investment of special desilting equipment and the arrangement of a seepage preventing wall are avoided, and at the same time, large-area soil replacement is avoided; and when construction quality is ensured, the construction cost is greatly reduced.

Owner:SINOHYDRO BUREAU 5

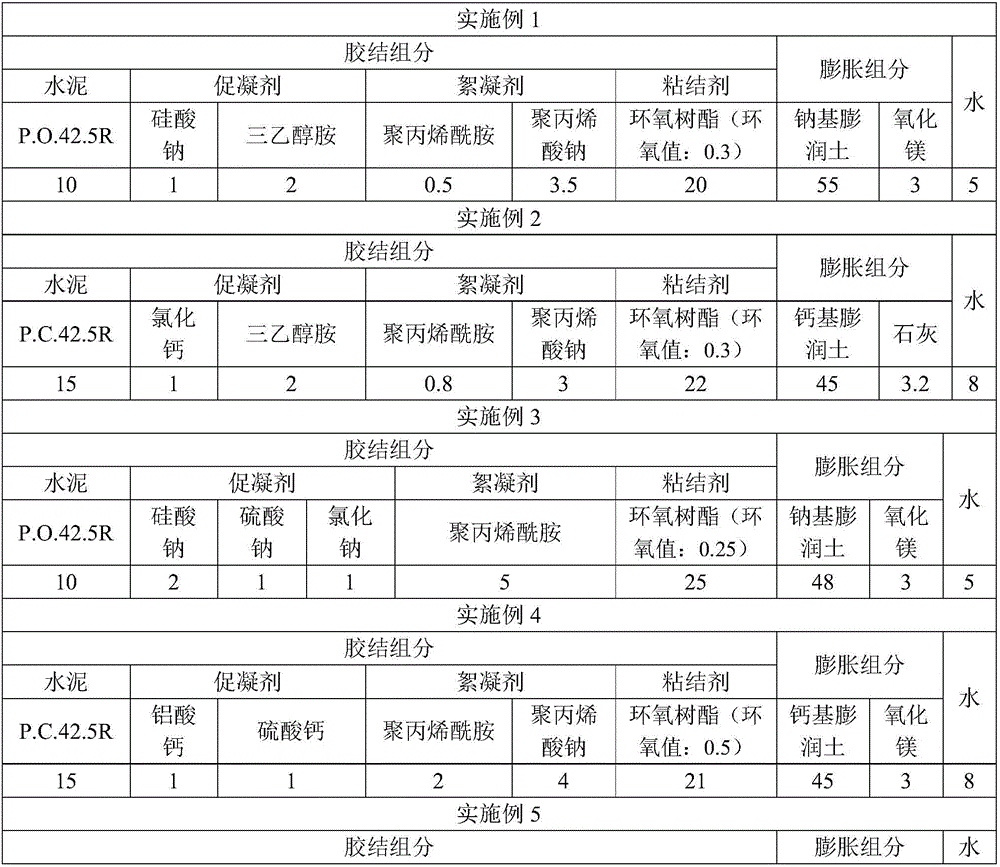

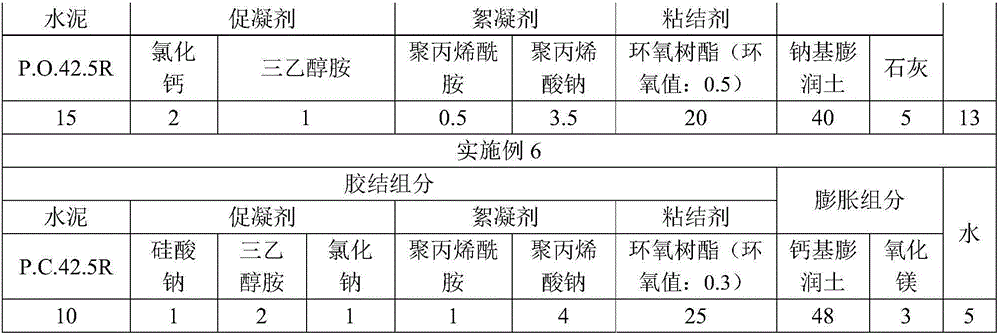

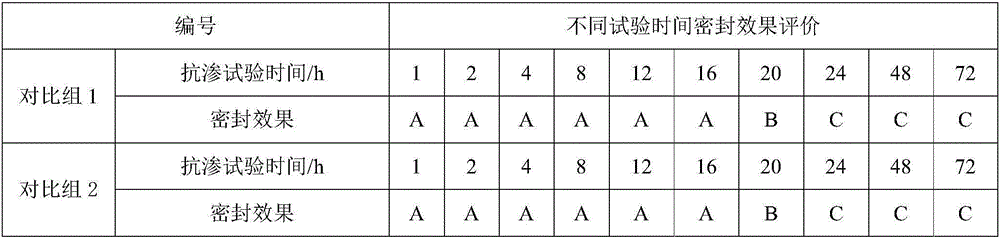

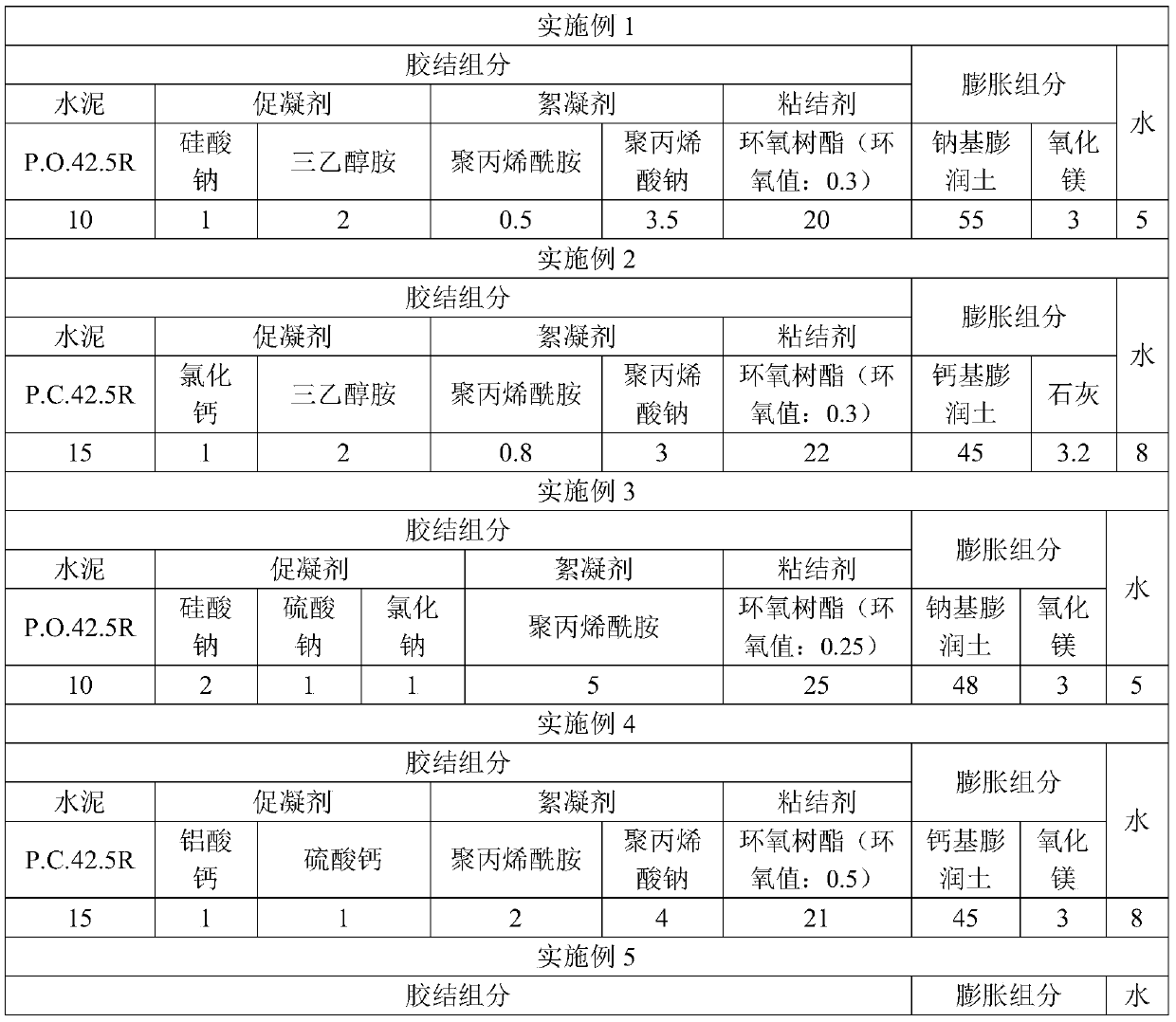

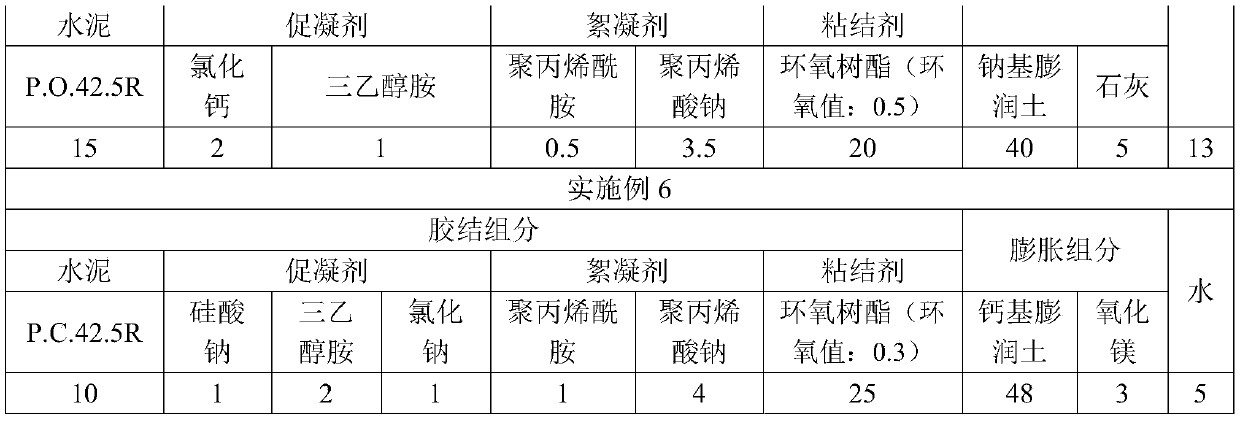

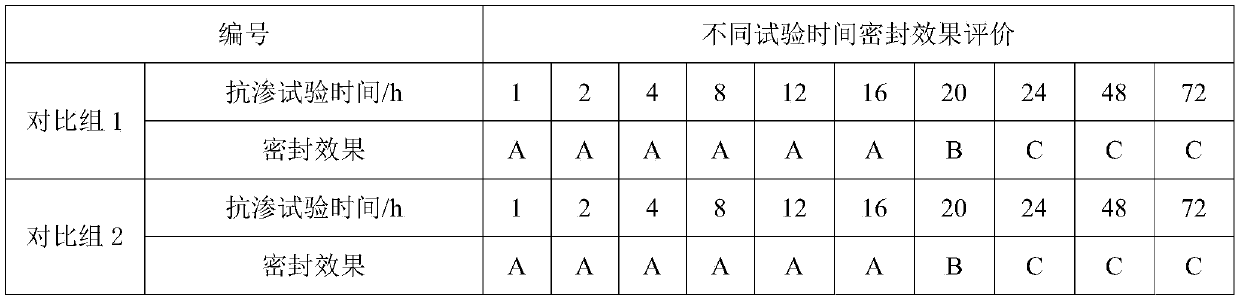

Concrete leakage-proof paste, and preparation method and application thereof

The invention discloses a concrete leakage-proof paste, which is mainly prepared from the following raw materials in percentage by mass: 10 to 20 percent of cement, 2 to 5 percent of coagulant, 3 to 8 percent of flocculant, 20 to 25 percent of binder, 45 to 60 percent of expansion component, and 5 to 15 percent of water. The concrete leakage-proof paste can be applied in a sealing material for a concrete permeability resistance test, also can be applied in a crack repair anti-seepage structure in engineering, has a good sealing anti-seepage effect and stable performance, and can fully meet the anti-seepage requirement.

Owner:中建西部建设西南有限公司 +1

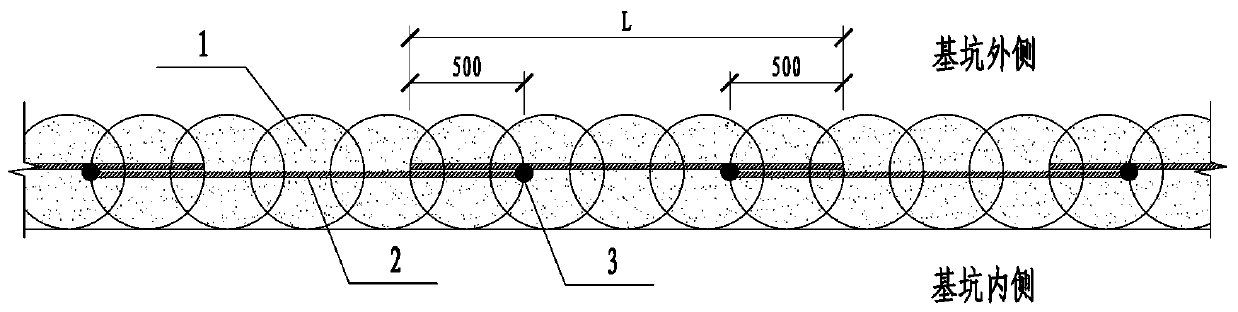

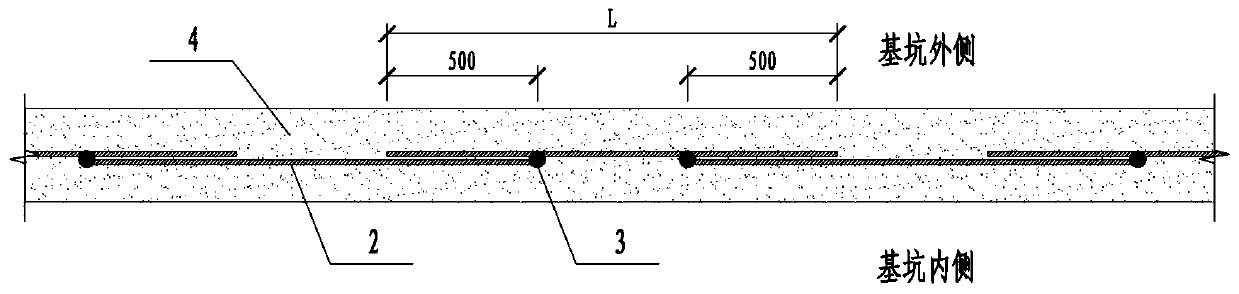

Construction method for inserting impermeable blankets in cement-soil continuous wall to form composite curtain and composite curtain prepared with construction method

InactiveCN111074920ALow costReduce construction costsFoundation engineeringStructural engineeringSoil cement

The invention relates to the technical field of waterproof curtains for foundation pits, and discloses a construction method for inserting impermeable blankets in a cement-soil continuous wall to forma composite curtain and the composite curtain prepared with the construction method. The construction method specifically includes the following steps that (1) the cement-soil continuous wall is constructed according to the conventional method; (2) before initial setting of the cement-soil continuous wall, the impermeable blankets are inserted in the cement-soil continuous wall from the top of the cement-soil continuous wall in the depth direction of the cement-soil continuous wall, every two adjacent impermeable blankets are lap-jointed, and then impermeable materials are injected to the lap-jointed parts of every two adjacent impermeable blankets. Under the conditions that same waterproof and impermeable effects are achieved, the construction method has the advantages that the thicknessof the cement-soil continuous wall can be reduced substantially, the project cost can be saved greatly, the construction cost can be reduced, besides, the influence of the construction process on thestratums and the surroundings is low, when a support structure of a foundation pit is deformed relatively greatly, the waterproof effect of the impermeable blankets is basically not affected, and themethod is particularly applicable to projects which have strict impermeable effects and cement-soil continuous wall curtains are required to be formed through penetration of sand layers.

Owner:周同和

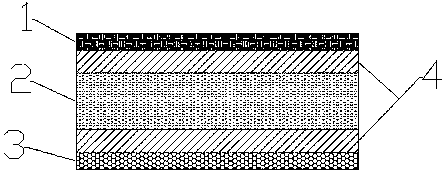

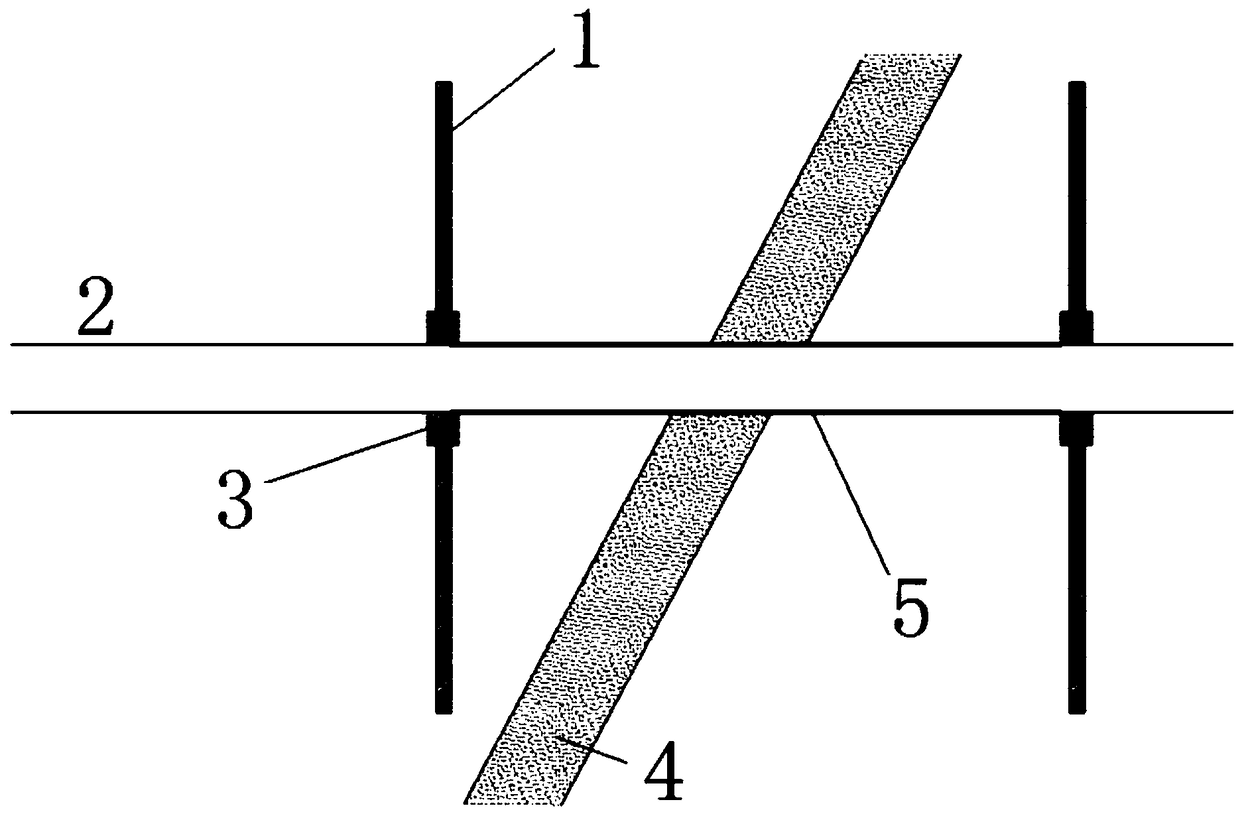

Impervious geosynthetic clay liner

ActiveCN107675680AMeet anti-seepage requirementsActs as a moisture filter bufferLayered productsProtective foundationOrganic solventSodium Bentonite

The invention discloses an impervious geosynthetic clay liner, and belongs to the technical field of waterproof coiled materials. The impervious geosynthetic clay liner comprises a woven cloth layer (1), a buffer layer (4), a bentonite layer (2), a buffer layer (4) and a non-woven cloth layer (3) from top to bottom, wherein the bentonite layer consists of the following raw materials of, by weight,80-100 parts of modified bentonite, 10-20 parts of adhesive, and 30-40 parts of water; the adhesive is formed by mixing polyvinyl alcohol solution and water glass; the buffer layer is mixed liquid prepared by dissolving agar and vital gluten into the water; and the mixed liquid is preheated to spray into organic solvent for standing and layering to prepare gel beads. The impervious geosynthetic clay liner achieves excellent characteristic of impervious performance, and is broad in prospect and application value in the field of the waterproof coiled materials.

Owner:广州腾飞建筑工程材料有限公司

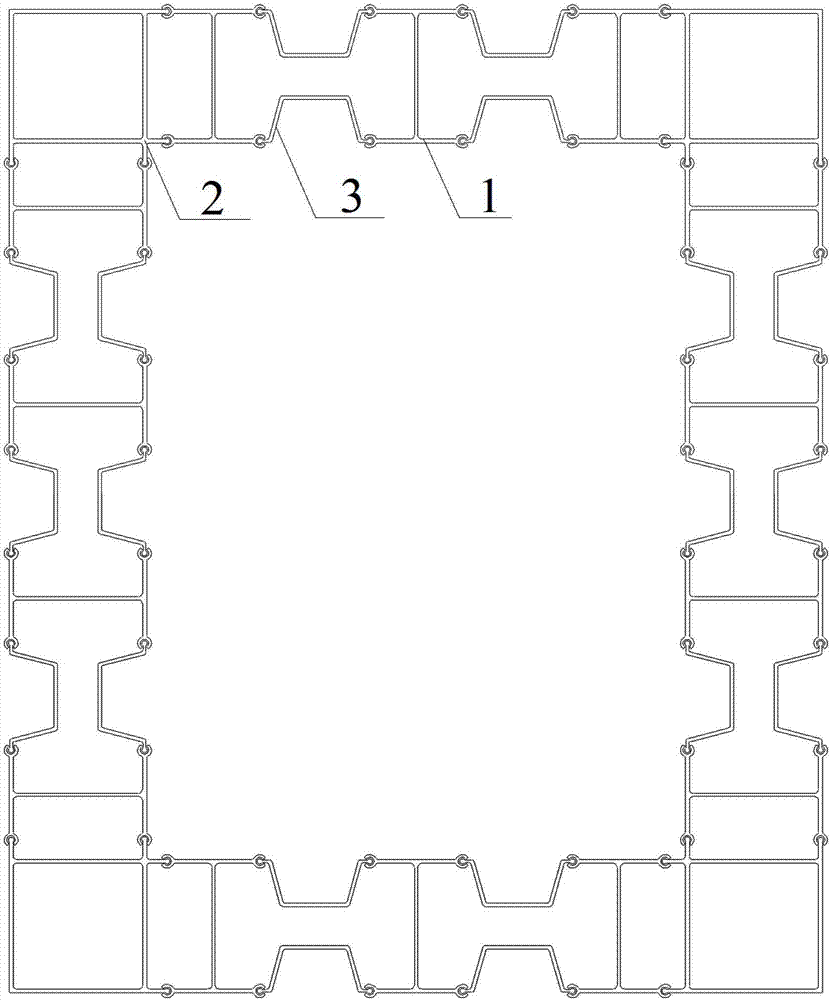

Pre-fabricated specially-shaped hollow pile for deep foundation pit supporting structure and construction method of pre-fabricated specially-shaped hollow pile

InactiveCN104264684ANo pollution in the processSave construction landExcavationsBulkheads/pilesRest positionAbnormal shaped

The invention provides a pre-fabricated specially-shaped hollow pile for a deep foundation pit supporting structure and a construction method of the pre-fabricated specially-shaped hollow pile. The pre-fabricated specially-shaped hollow pile comprises a pre-fabricated specially-shaped hollow pile body with a rectangular side and a strip pre-fabricated specially-shaped hollow pile body. The construction method includes (1) arranging a base layer: placing the pre-fabricated specially-shaped hollow pile body with the rectangular side and a taper base surface in a rectangular position of a base pit along an axis of a wall, sequentially placing the strip pre-fabricated specially-shaped hollow pile bodies with tapered base surfaces in the rest positions, and performing welding connection or reserving gaps among suspension walls of the pre-fabricated specially-shaped hollow pile bodies; using a mechanical method to perform whole or local or single pressing; (2) arranging layers above the base player; aligning and welding the pre-fabricated specially-shaped hollow pile body with a steel plate reserved for welding on the base surface and the pre-fabricated specially-shaped hollow pile body on the base layer in the vertical direction; welding or not welding a suspension wall between the two pre-fabricated specially-shaped hollow pile bodies in the horizontal direction. The pre-fabricated specially-shaped hollow pile is particularly applicable to intermediate and small underground parking garages and operable in construction environment with narrow fields.

Owner:厦门思达通科技有限责任公司

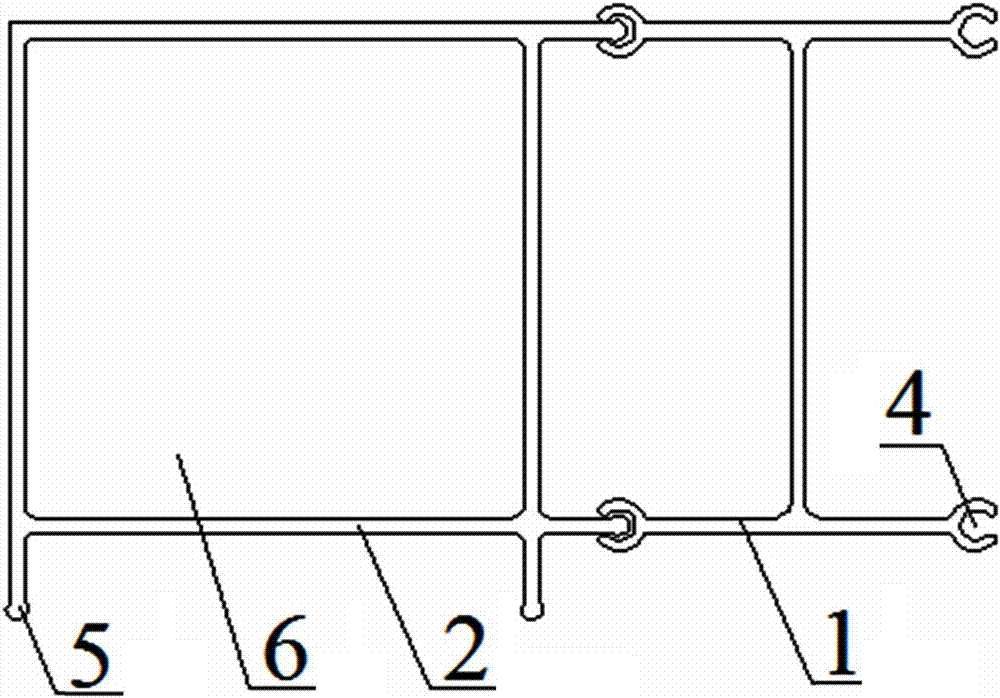

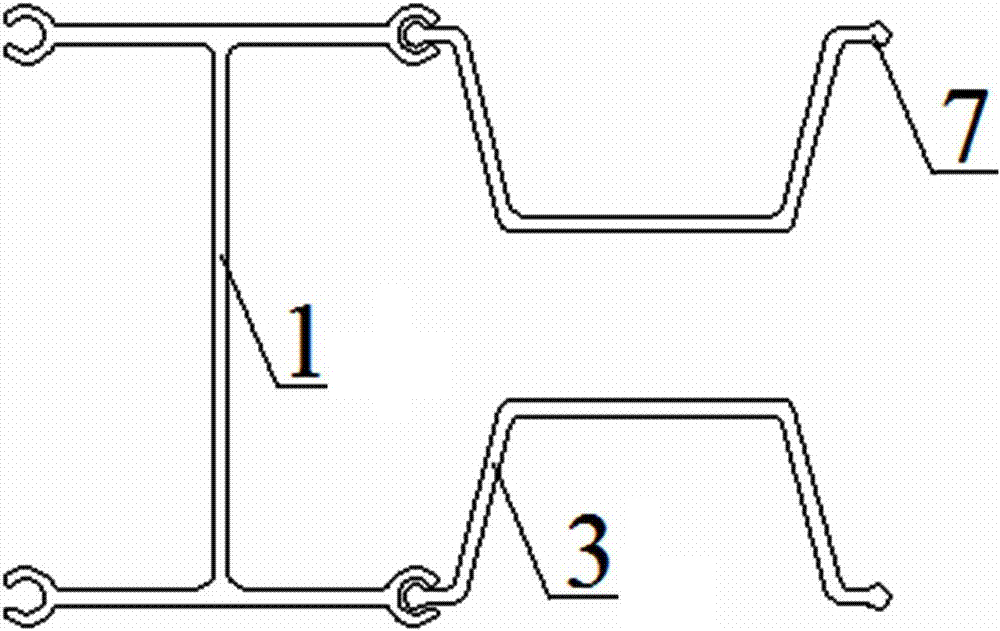

Combined steel structure support pile and construction method

InactiveCN107326896ANo pollution in the processSimple structureExcavationsBulkheads/pilesBasementCantilever

The invention provides and discloses a combined steel structure support pile and a construction method thereof. The combined steel structure support pile comprises special-shaped hollow steel piles with right-angle edges, H-shaped steel piles and U-shaped steel piles. Two cantilevers with the end portions provided with circular balls are arranged on each of the two sides of each special-shaped hollow steel pile with the right-angle edge. Each of two wings of each H-shaped steel pile is provided with two buckles of 3 / 4 arcs. The two ends of each U-shaped steel pile are arranged to be in a circular ball shape. The special-shaped hollow steel piles with the right-angle edges are connected with the H-shaped steel piles through the circular balls on the cantilevers on the pile edges. The U-shaped steel piles are connected with the H-shaped steel piles through the circular balls at the two ends. According to the construction method, the special-shaped hollow steel piles with right-angle edges are arranged at the right-angle corners of the four edges of a foundation pit; along an outer edge line parallel to an underground structure outer wall, paying off of the H-shaped steel piles and the U-shaped steel piles is conducted, and the H-shaped steel piles and the U-shaped steel piles are pressed to sink one by one through a mechanical method; and foundation earthwork is excavated, and steel purlines or steel purlines and steel supports are erected according to the design requirement. The combined steel structure support pile and the construction method are particularly suitable for medium-small-sized basements, underground garages and comprehensive pipe racks, and operation can still be conducted in the construction environment with the narrow field.

Owner:南京市测绘勘察研究院股份有限公司

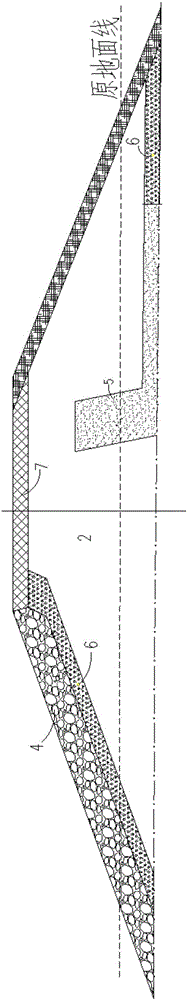

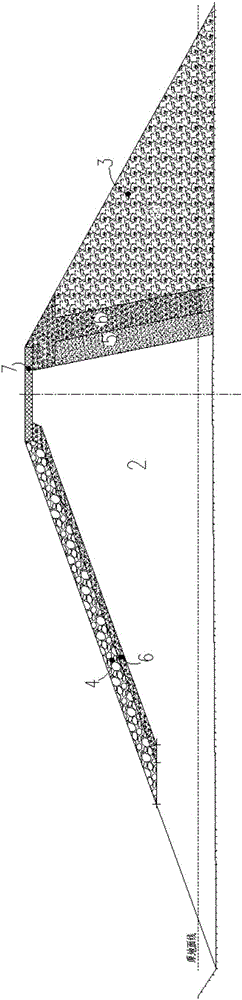

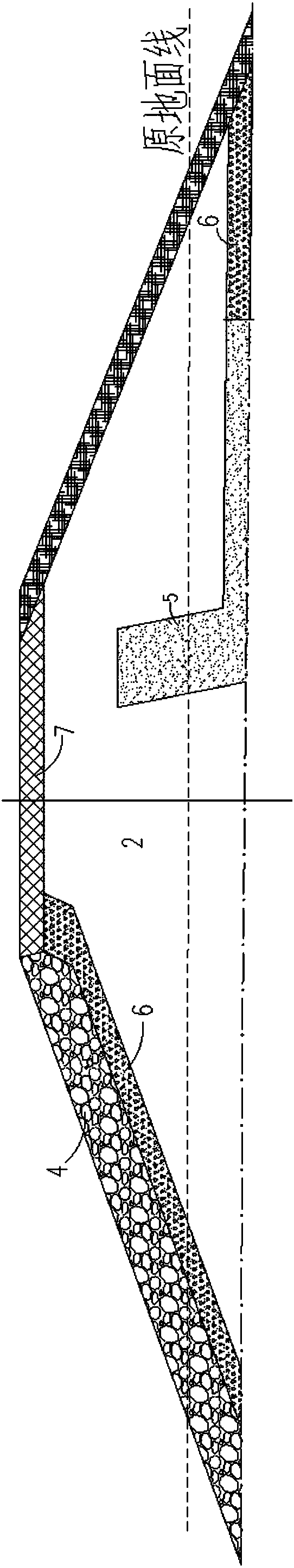

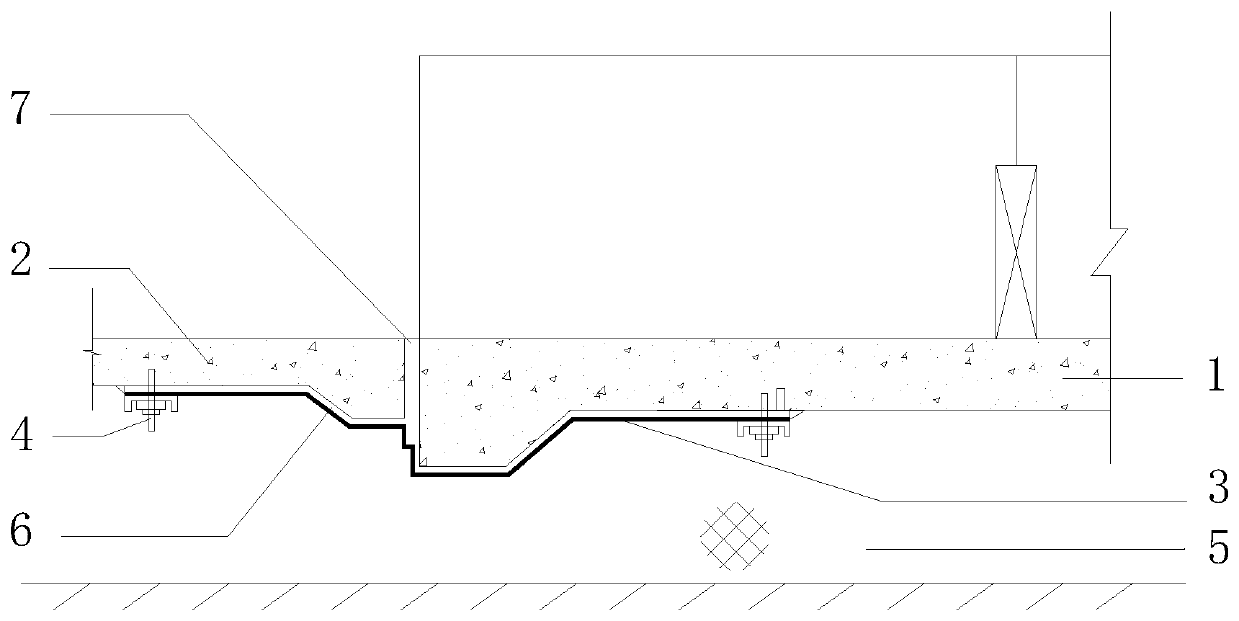

Combined anti-seepage structure for culvert and construction method thereof

InactiveCN107354920AStrong resistance to uneven settlementPlay the role of double insuranceBarrages/weirsGeomembraneSoil mass

The invention discloses a combined anti-seepage structure for a culvert and a construction method thereof. The combined anti-seepage structure for the culvert and the construction method thereof are used for resisting seepage of the culvert and protecting a self anti-seepage system. The anti-seepage system comprises an original anti-seepage structure, a concrete or clay bedding, an anti-seepage structure protection system and a composite geomembrane structure; the adopted main technical scheme is that, a composite geomembrane is paved between a culvert foundation and an upstream anti-seepage bedding, the geomembrane is in seal connection with the bedding and a bottom plate in the horizontal direction, and paved in a stair shape in the perpendicular direction, so that a remaining width for jointly deformation of a membrane and a soil mass is reserved on the geomembrane, and an anti-seepage defense is formed at the joint of the bedding and a gate foundation. The composite geomembrane still can be normally used for preventing seepage when the bedding cracks due to unevenness and settlement.

Owner:SHANDONG UNIV

A prefabricated special-shaped vierendeel pile for deep foundation pit support structure and its construction method

InactiveCN104264684BNo pollution in the processSave construction landExcavationsBulkheads/pilesRest positionBuilding construction

The invention provides a pre-fabricated specially-shaped hollow pile for a deep foundation pit supporting structure and a construction method of the pre-fabricated specially-shaped hollow pile. The pre-fabricated specially-shaped hollow pile comprises a pre-fabricated specially-shaped hollow pile body with a rectangular side and a strip pre-fabricated specially-shaped hollow pile body. The construction method includes (1) arranging a base layer: placing the pre-fabricated specially-shaped hollow pile body with the rectangular side and a taper base surface in a rectangular position of a base pit along an axis of a wall, sequentially placing the strip pre-fabricated specially-shaped hollow pile bodies with tapered base surfaces in the rest positions, and performing welding connection or reserving gaps among suspension walls of the pre-fabricated specially-shaped hollow pile bodies; using a mechanical method to perform whole or local or single pressing; (2) arranging layers above the base player; aligning and welding the pre-fabricated specially-shaped hollow pile body with a steel plate reserved for welding on the base surface and the pre-fabricated specially-shaped hollow pile body on the base layer in the vertical direction; welding or not welding a suspension wall between the two pre-fabricated specially-shaped hollow pile bodies in the horizontal direction. The pre-fabricated specially-shaped hollow pile is particularly applicable to intermediate and small underground parking garages and operable in construction environment with narrow fields.

Owner:厦门思达通科技有限责任公司

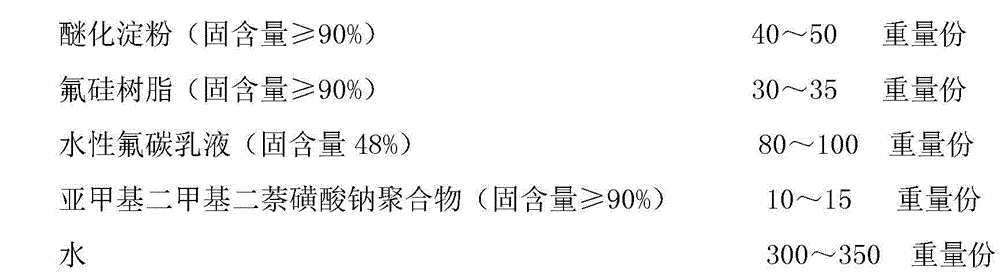

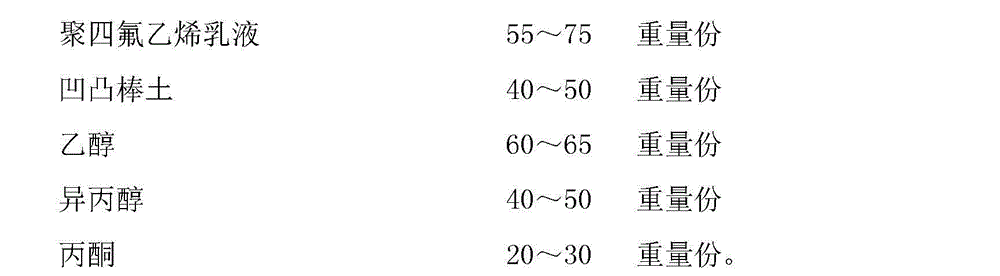

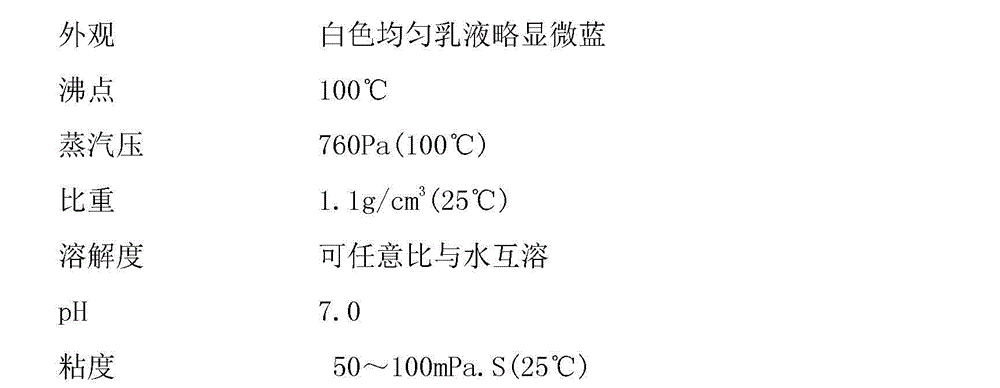

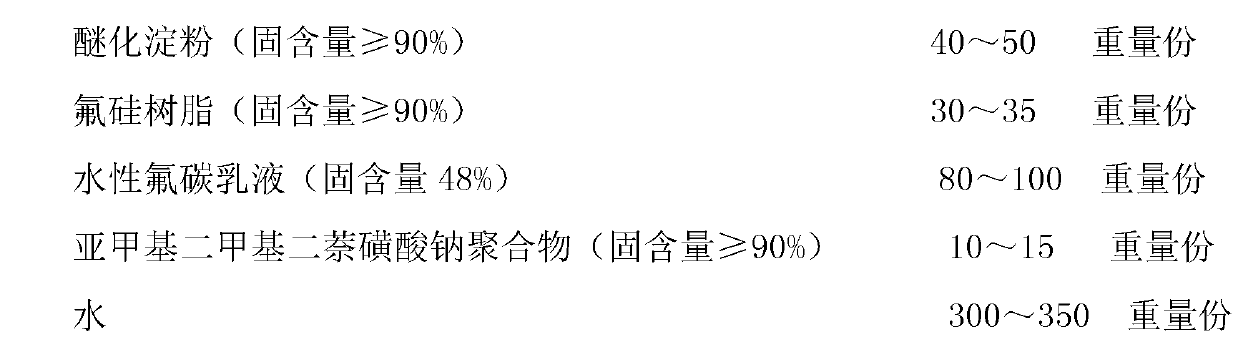

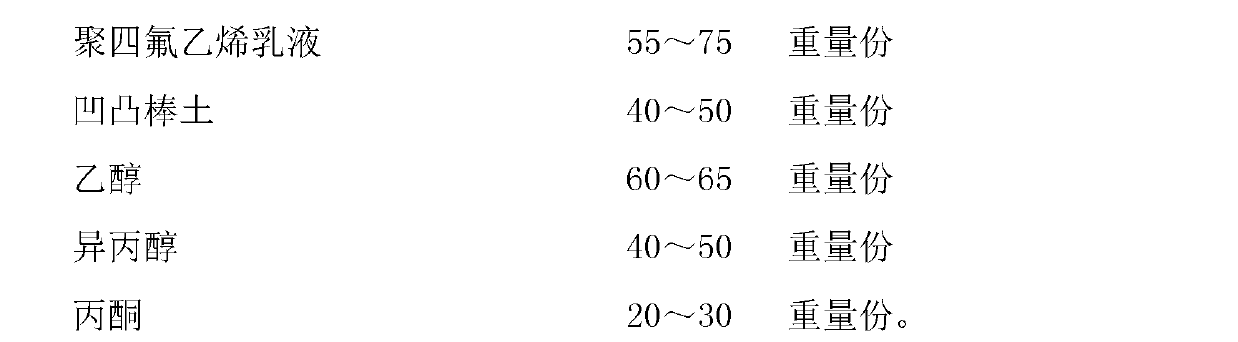

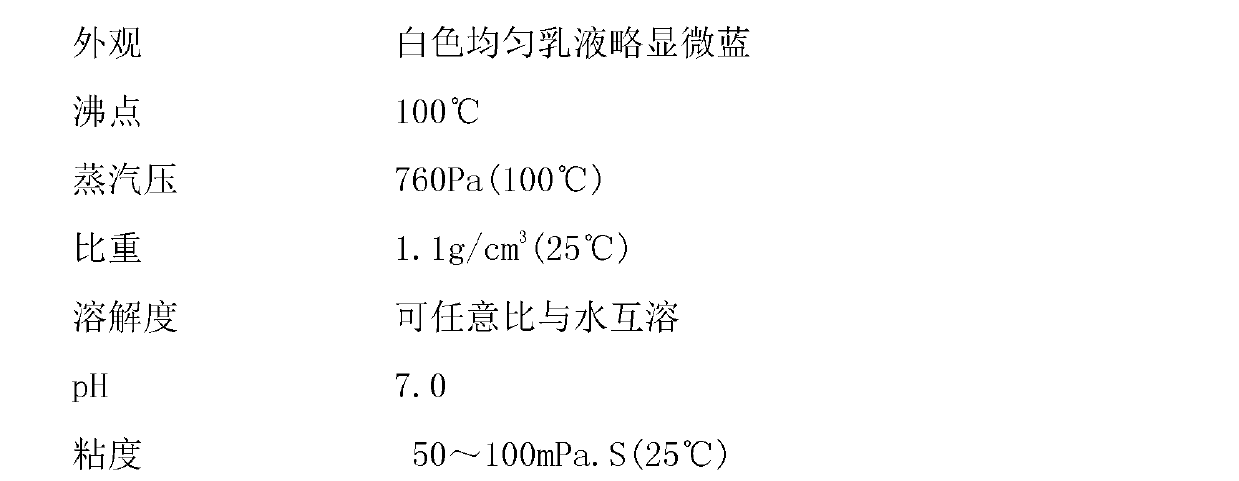

Concrete channel permeability-reducing agent and preparation method and purpose thereof

Disclosed are concrete channel permeability-reducing agent and a preparation method and purpose thereof. The concrete channel permeability-reducing agent comprises, by weight, 40-50 parts of etherified starch (at least 90% of solid content), 30-50 parts of fluorosilicon resin (at least 90% of solid content), 80-100 parts of waterborne fluorocarbon emulsion (48% of solid content), 10-15 parts of methylene dimethyl binaphthol sulfonate polymer (at least 90% of solid content), and 300-350 parts of water. The fluorosilicon resin is synthetic resin formed by mixing fluorine resin and organic silicon resin. The waterborne fluorocarbon emulsion is copolymer of vinyl fluoride and hydroxyl vinyl ether, wherein concentration percentage by weight of fluorine is 8-11.5%, and a main chain contains fluorine atom. The concrete channel permeability-reducing agent is economical in formula, fine in permeability-reducing effect, and long-lasting in function. The preparation method of the concrete channel permeability-reducing agent includes mixing and ultrasonic dispersing. The purpose of the concrete channel permeability-reducing agent is to form a permeability-reducing film on the surface of the concreted channel by roller coating, brush coating or spay coating the permeability-reducing agent on the surface of the concreted channel. By the permeability-reducing film, fine permeability-reducingeffect of the concrete channel can be achieved.

Owner:湖北宗源材料有限公司

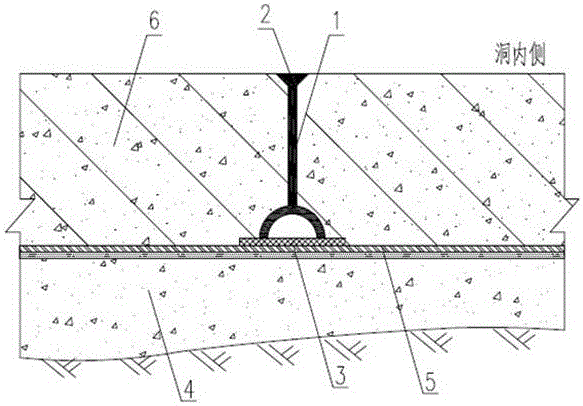

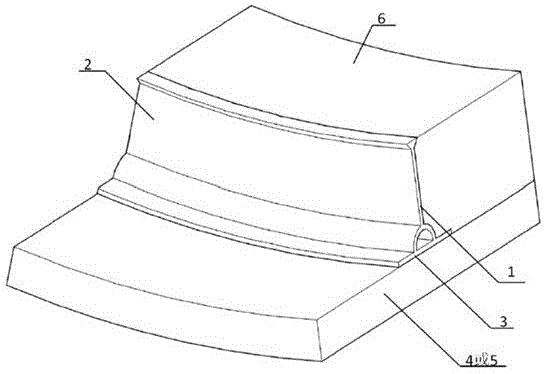

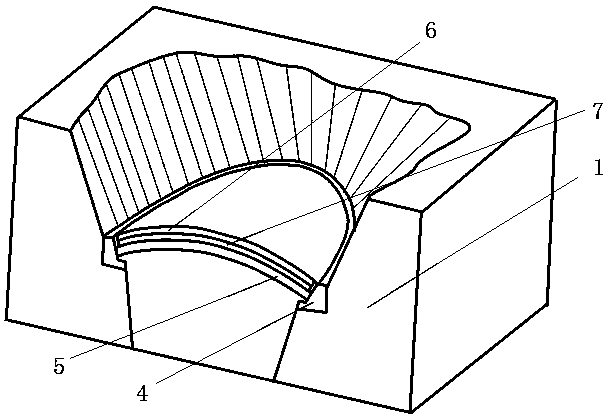

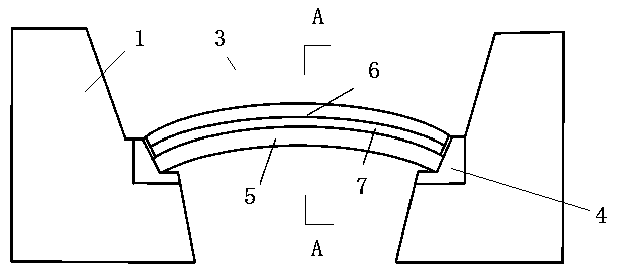

Tunnel lining end template structure with waterproofing and drainage functions

InactiveCN106522990AMeet anti-seepage requirementsSimple construction processUnderground chambersDrainageWaterproofingOperation safety

The invention discloses a tunnel lining end template structure with waterproofing and drainage functions. The tunnel lining end template structure comprises a locating pad and an end template, wherein the locating pad is arranged on a tunnel initial support or the surface of a waterproof plate, and the end template is located at a lining construction joint of a secondary lining. The end, close to the inner side of a tunnel, of the end template serves as a straddle belt, and the other end of the end template is provided with a draining groove. The open end of the draining groove is sealed and buckled through the locating pad so that a seepage flow guiding channel can be formed. By the adoption of the tunnel lining end template structure, the construction technique of the lining construction joint of the tunnel is further simplified, the integrity and waterproofing and drainage performance of the construction joint are improved, the seepage risk of the construction joint is lowered, and operation safety of the tunnel is guaranteed.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +2

Preparation process of environment-friendly low-cost fluoroaluminate cement added with waste bricks

The invention discloses a preparation process of environment-friendly low-cost fluoroaluminate cement added with waste bricks. The cement comprises the following steps of: sequentially preparing a raw material; pretreating the waste bricks to prepare a reclaimed material and clinker; mixing the clinker, the reclaimed material, fly ash, slag, silica fume, gypsum and carbon nanofibers; grinding the mixture until the particle size is 50-150 mu m; adding a polycarboxylate superplasticizer, sodium gluconate, a penetrating agent and water; and performing uniform mixing to obtain the environment-friendly low-cost fluoroaluminate cement. According to the technical schemes of the invention, after the waste bricks are modified, the porosity of the waste bricks can be reduced, the waterproof and anti-seepage performance can be effectively enhanced, meanwhile, the mechanical performance of the cement can be enhanced, the cement is environmentally friendly; and the preparation method of the mortar is simple, convenient to operate and capable of being widely applied and popularized.

Owner:ZHENGZHOU JIANWEN SPECIAL MATERIAL TECH

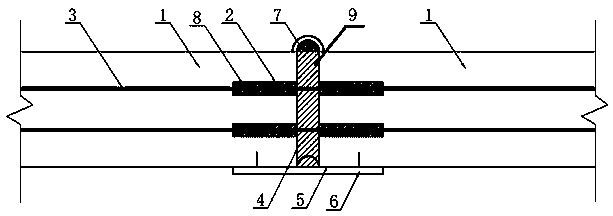

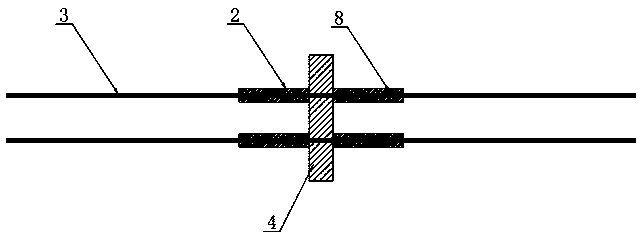

Horizontal joint seam connecting structure suitable for thin panel extrusion deformation

PendingCN110904925AGuaranteed safe operationReduce the likelihood of damageBarrages/weirsEarth-fill damsWater stopRebar

The invention provides a horizontal joint seam connecting structure suitable for thin panel extrusion deformation. The horizontal joint seam connecting structure comprises concrete panels, steel sleeves, reinforcing steel bars, a gap filling material, a water stop copper sheet, a surface water stop structure, asphalt jute and a horizontal seam, wherein the concrete panels are arranged in an inclined mode, and the horizontal seam is transversely formed between adjacent two concrete panels; the reinforcing steel bars pass through the horizontal seam for connecting adjacent two concrete panels, and the gap filling material is arranged in the horizontal seam; the steel sleeves are arranged at the two sides of the horizontal seam and are positioned in the concrete panels; the reinforcing steelbars are positioned in the steel sleeves; the inner parts of the steel sleeves are filled with asphalt jute; the surface water stop structure is arranged on water face of the horizontal seam, and thewater stop copper sheet is arranged on the bottom of the horizontal seam. The horizontal joint seam connecting structure can remarkably reduce the possibility that the position near the horizontal seam is damaged as a result of thin panel extrusion while meeting anti-seepage requirements, and guarantees safe operation of the concrete panels in a high-concrete panel rock-fill dam.

Owner:POWERCHINA XIBEI ENG

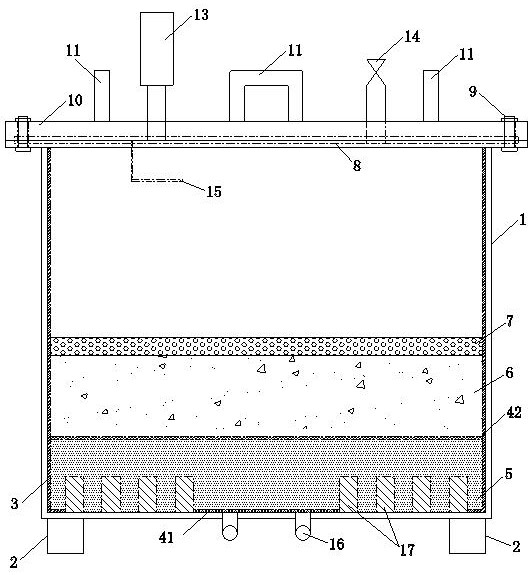

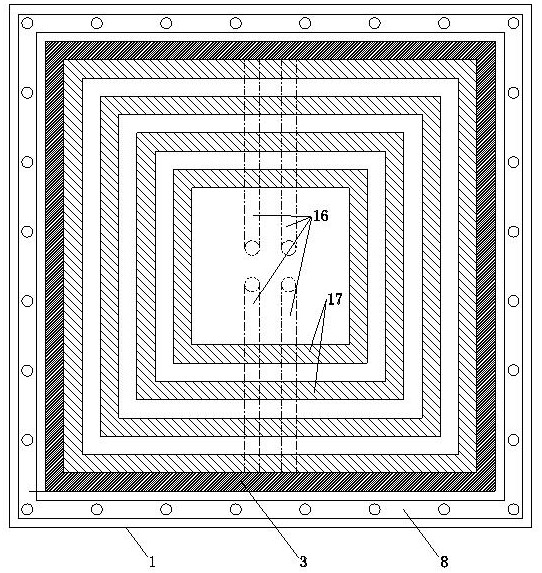

Artificial water body simulation test device for hydrophobic particles and test method thereof

PendingCN111982785AMeet anti-seepage requirementsFacilitate quantitative water injectionPermeability/surface area analysisExhaust valveWater leakage

The invention discloses an artificial water body simulation test device for hydrophobic particles and a test method thereof, belongs to the technical field of anti-seepage breathable materials, and aims to solve the problems that no special equipment is provided for anti-seepage performance testing of the artificial water body anti-seepage structure, the anti-seepage performance of the artificialwater body anti-seepage structure needs to be evaluated according to seepage quantity after construction, results lag and construction cannot be accurately and reasonably guided. The artificial waterbody simulation test device comprises a sealing device, a water inlet, an exhaust valve and a water leakage opening. The water inlet and the exhaust valve penetrate through the top end of the sealingdevice, and the water leakage opening penetrates through the bottom end of the sealing device. The method comprises the steps of side wall sealing treatment, bottom anti-seepage structure laying, experimental device sealing, anti-seepage test and result judgment. By means of the simulation test device, whether the hydrophobic particles and the anti-seepage structure of the hydrophobic particles can meet the anti-seepage requirement of the artificial water body or not is tested before engineering construction of the artificial water body, the hydrophobic particles and the anti-seepage structureare adjusted in time in the design stage, and important engineering significance is achieved.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

Construction method for vertical main pipe protection of hot spring well in foundation pit

ActiveCN111501769BReduce risk of sabotageLow costExcavationsBulkheads/pilesHot springStructural engineering

Owner:CHINA CONSTR FOURTH ENG DIV +1

Nanofiber Waterproof Membrane for River Embankment

ActiveCN106087875BImprove corrosion resistanceAvoid damageConjugated synthetic polymer artificial filamentsMarine site engineeringFiberNanofiber

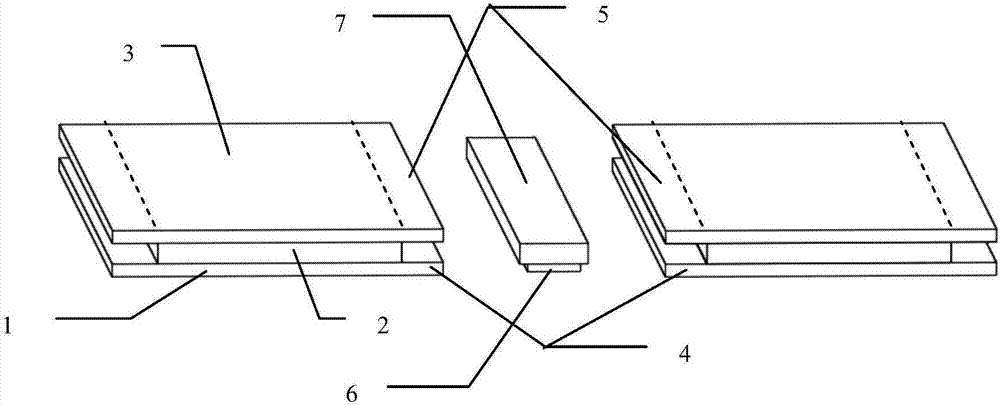

The invention provides a nanofiber waterproof membrane for a river levee. The nanofiber waterproof membrane comprises a plurality of rectangular main membranes in parallel arrangement, and further comprises seam filling membranes which are arranged between the main membranes and can play sealing and connecting roles, wherein each main membrane comprises a first base layer, a first nanofiber layer and a second base layer which are arranged from bottom to top; each seam filling membrane comprises a third base layer and a second nanofiber layer which are arranged from bottom to top; the two sides of the first base layers and the second base layers extend outwards to form first connecting layer sections and second connecting layer sections; the first connecting layer sections are connected with the third base layers of which the widths are equal to those of the first connecting layer sections; the first connecting layer sections and the second connecting layer sections of the adjacent main membranes are mutually connected; and the second nanofiber layers are slightly wider than the third base layers. The nanofiber waterproof membrane is combined with the nanofiber technology, and is low in preparation cost, excellent in impermeability, long in service life and strong in adaptability to the aquatic and geological environment.

Owner:HIDETAKA NANO TECH CO LTD

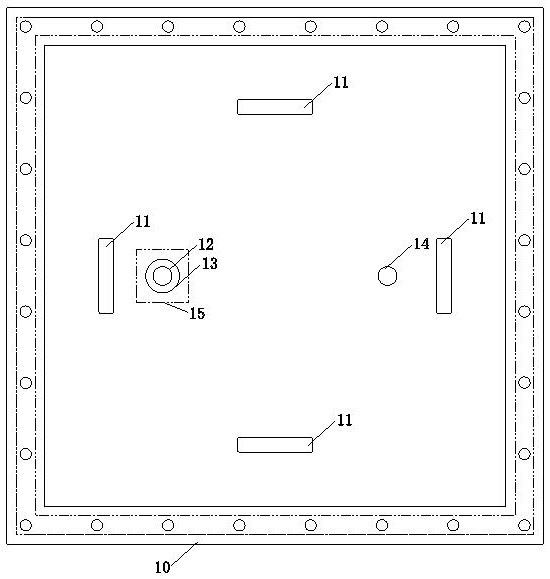

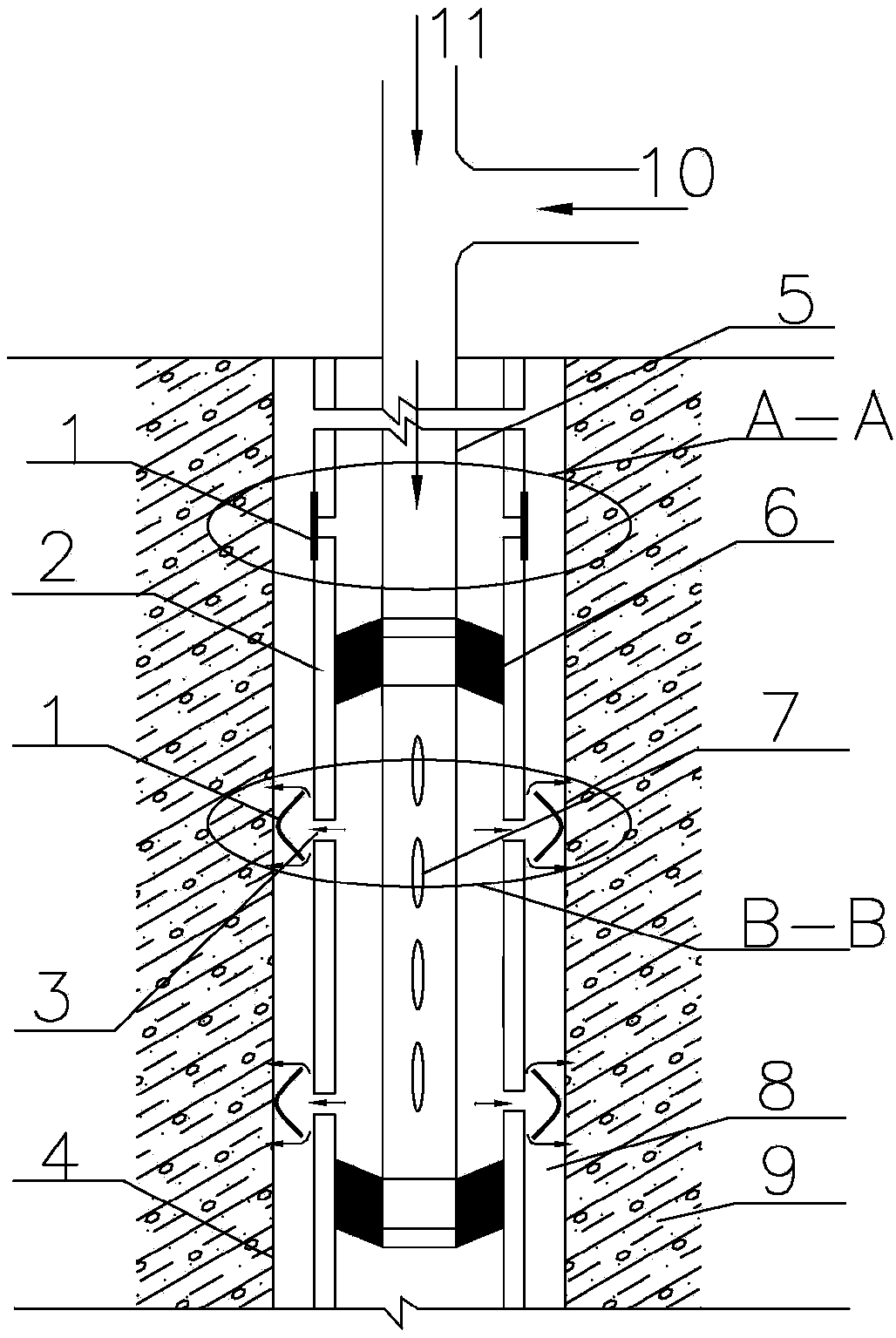

A kind of grouting device and grouting method for floating pebble gravel stratum

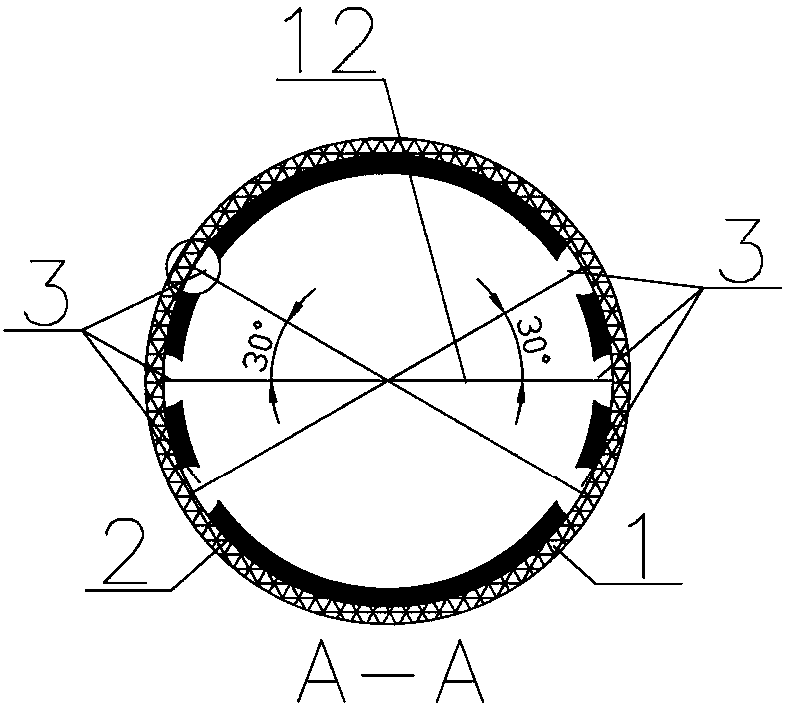

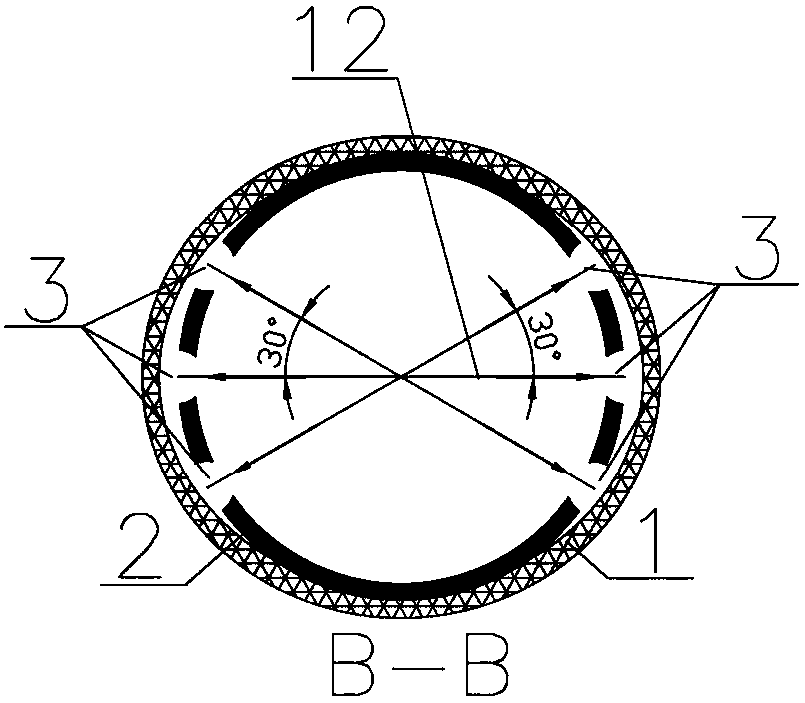

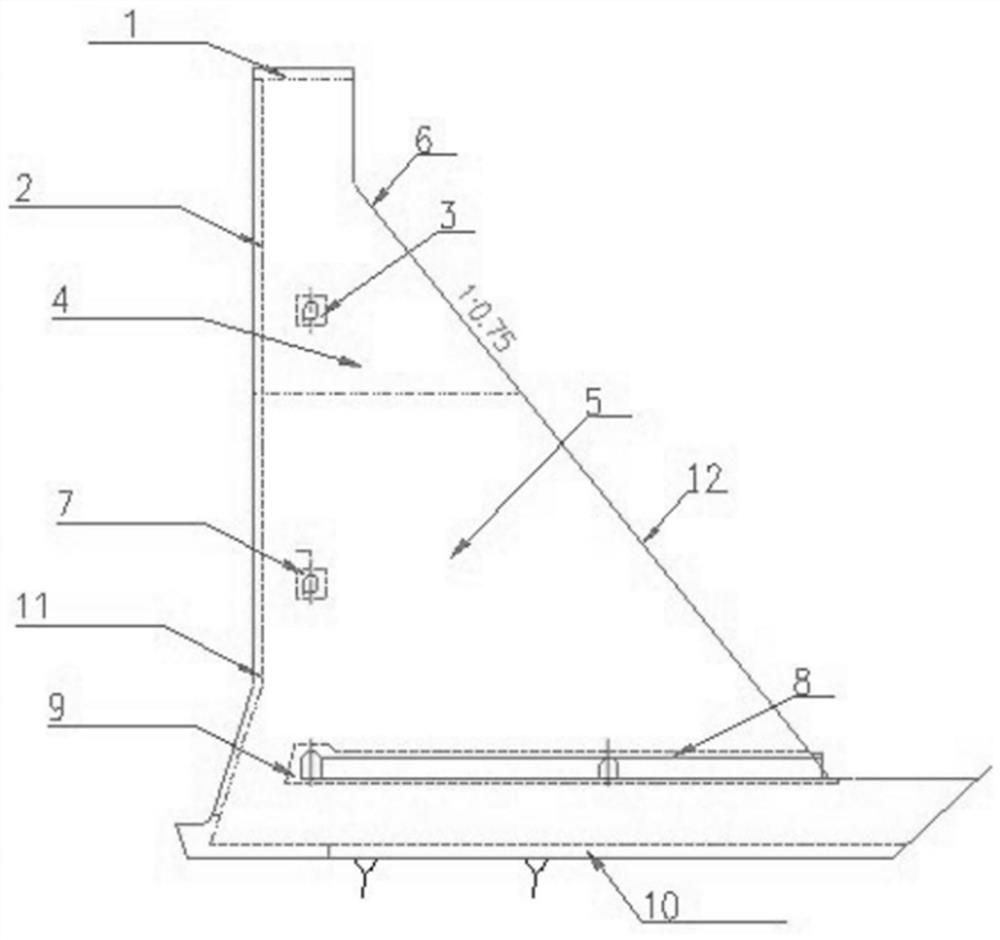

ActiveCN105821884BReduce outflowReduce the effect of diffusion directionFoundation engineeringSlurryEngineering

The invention relates to the technical field of curtain grouting, in particular to a grouting device for gravel-cobble strata. The grouting device comprises outer pipes, outer pipe sealing devices, inner pipes and inner pipe sealing devices, wherein the inner pipes and the inner pipe sealing devices are arranged inside the outer pipes, and each inner pipe is provided with two inner pipe sealing devices; the pipe section located between every two inner pipe sealing devices is an inner pipe grout outlet section, and each inner pipe grout outlet section is provided with inner pipe grout outlets. The grouting device is characterized in that a plurality of orientated opening sets are formed in the wall of each outer pipe in the axial direction of each outer pipe and respectively comprise at least one pair of orientated openings formed in the periphery of one outer pipe, the radial direction of the periphery of any one outer pipe is adopted as the basis radial direction, and all the orientated openings are formed within the range of 0-45 degrees of the basis radial direction. According to the grouting device, the diffusion direction of grout is controllable, the grouting amount is reduced, the grouting efficiency is improved, and the reliability of curtain lap joint is improved. The invention further relates to a grouting method adopting the grouting device. Curtains perpendicular to the seepage direction can be easily formed through the grouting method.

Owner:CHINA WATER RESOURCES PEARL RIVER PLANNING SURVERYING & DESIGNING

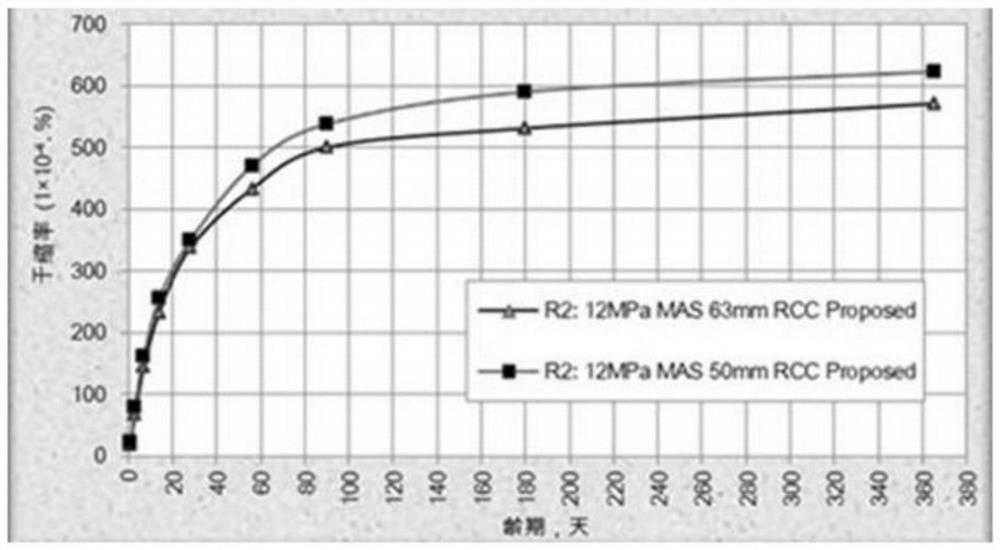

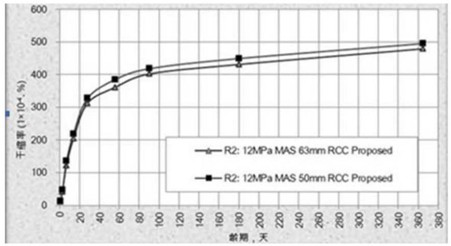

A full-section quasi-three-grade long-age roller compacted concrete construction method

ActiveCN111535323BQuick pavingGuarantee the quality of anti-seepageEmbankmentsRoller-compacted concreteArchitectural engineering

The invention belongs to the technical field of roller compacted concrete construction, and in particular relates to a full-section quasi-three-grade long-age roller compacted concrete construction method, in which appropriate aggregates are selected and the dosage of various materials is determined through a mix ratio test; The mix ratio is verified, and the verification can be completed by the method of passing the roller compacted concrete test section; after the construction of the full-section quasi-three-grade roller-compacted concrete test section is completed, the relevant parameters of the roller-compacted concrete are determined through various experiments; The construction of graded roller compacted concrete; according to the actual situation on site, the present invention combines the roller compacted concrete gravity dams under construction and completed at home and abroad to ensure that the anti-seepage requirements of the dam body are met according to the design of the dam body The optimization and adjustment of the conventional roller compacted concrete construction method can realize the rapid paving of roller compacted concrete under the premise of ensuring the anti-seepage quality of the dam body, which is beneficial to save the construction period and reduce the engineering investment.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

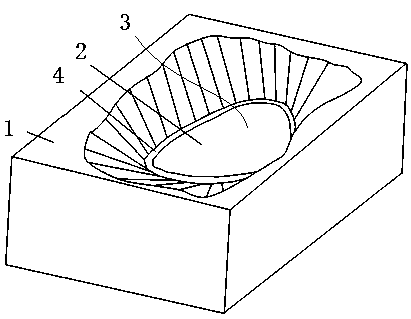

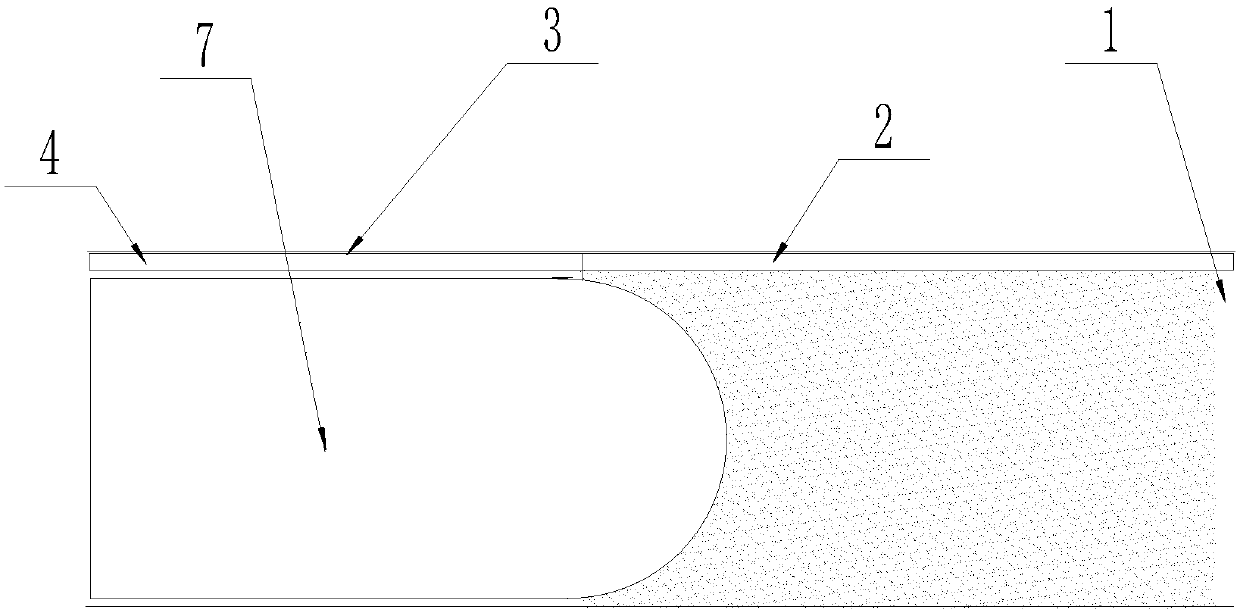

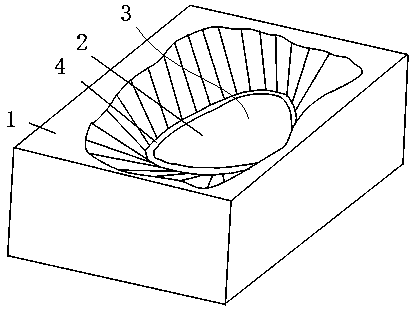

Karst funnel reservoir and its double-curved arch beam-slab sealing structure and construction method

The invention discloses a double-curved-arch-shaped beam plate plugging structure comprising a concrete base arranged in a mode of embracing by one circle along the inner wall of a water leakage channel of a karst funnel. Concrete plates used for plugging the water leakage channel of the karst funnel are arranged in the concrete base; concrete beams used for supporting the concrete plates are arranged under the concrete plates and comprise the cross beams and the longitudinal beams; the two ends of the cross beams and the longitudinal beams are both arranged on the concrete base; and in the vertically-downward view direction, the cross beams and the longitudinal beams are orthogonal mutually, the elevations of the top faces at the intersections of the cross beams and the longitudinal beams are equal, and a double-curved-arch-shaped face grid structure used for supporting the concrete plates is formed on the top faces of the cross beams and the longitudinal beams. The invention further discloses a karst funnel reservoir and a construction method of the double-curved-arch-shaped beam plate plugging structure. According to the karst funnel reservoir and the double-curved-arch-shaped beam plate plugging structure thereof and the construction method, the requirement for plugging the concentrated water leakage channel of the karst funnel can be met.

Owner:东营市大学科技园发展有限责任公司

A preparation process of environmentally friendly and low-cost fluoroaluminate cement by adding waste bricks

Owner:ZHENGZHOU JIANWEN SPECIAL MATERIAL TECH

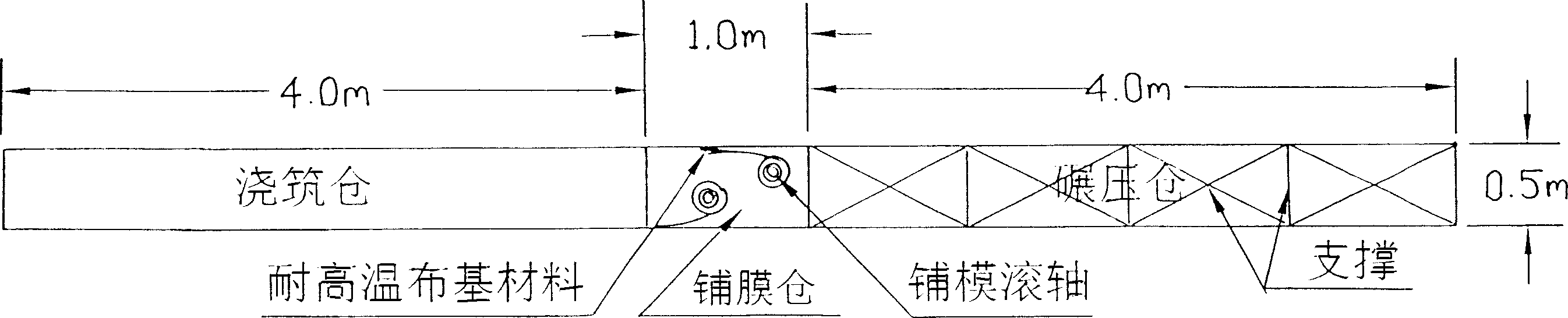

Casting construction method for asphalt concrete anti-infiltration core wall of earth rockfill dam

ActiveCN100335723CEnhance construction temperatureReduce construction temperatureProtective foundationEarth-fill damsMaterials scienceAsphalt concrete

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

Integral Pouring Technology of Reinforced Concrete Wastewater Pool in Pre-drilling Project

ActiveCN103015719BShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

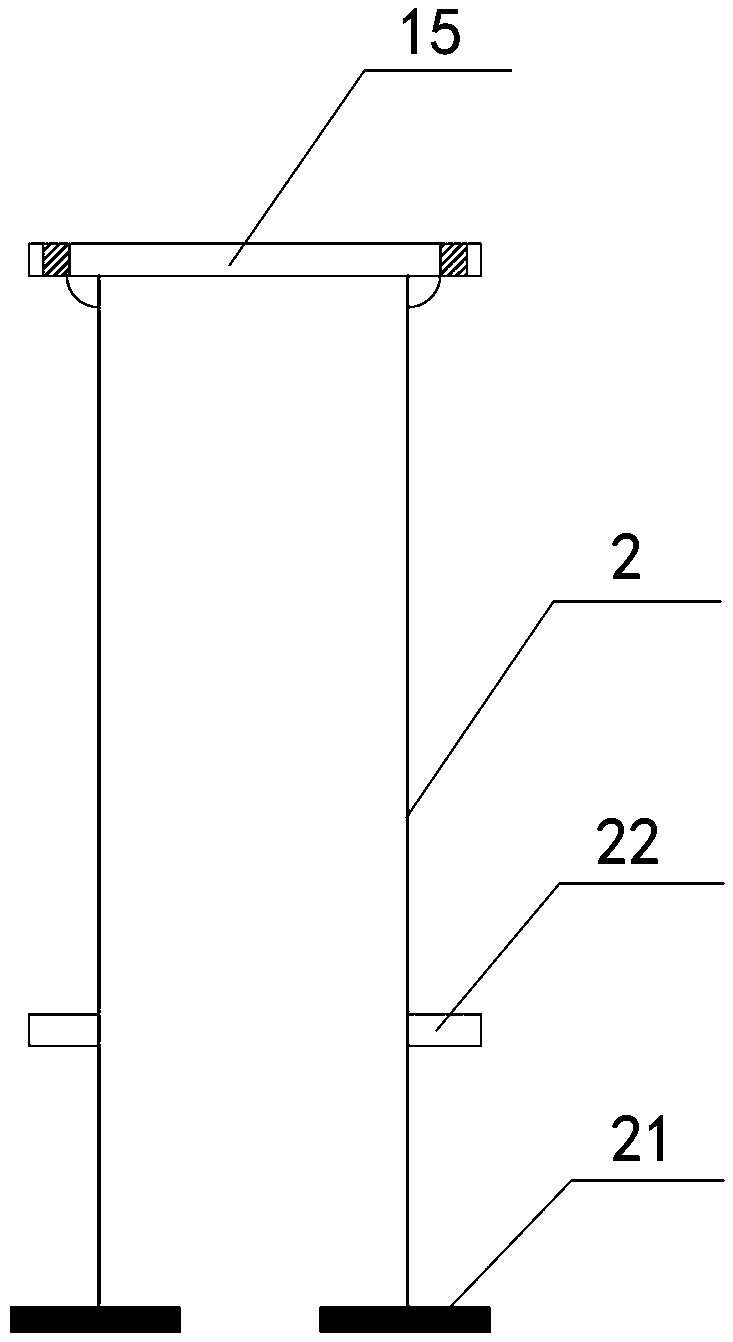

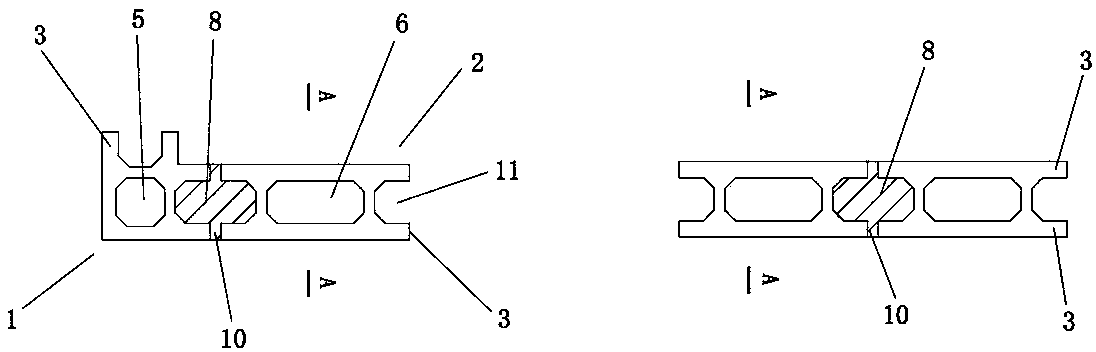

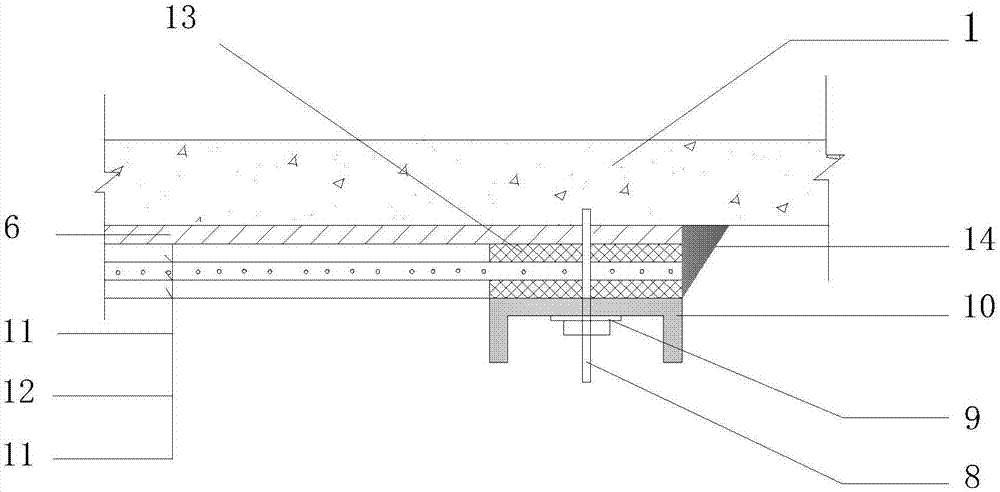

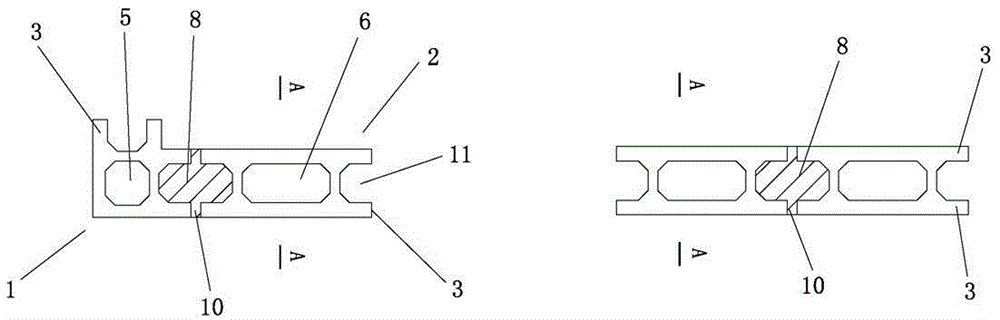

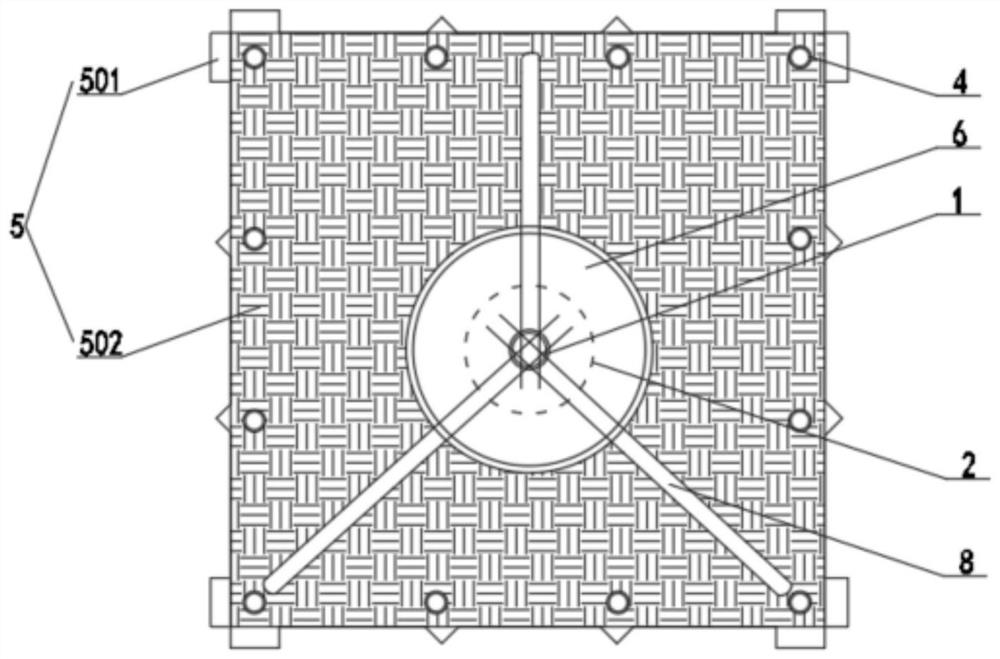

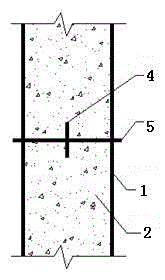

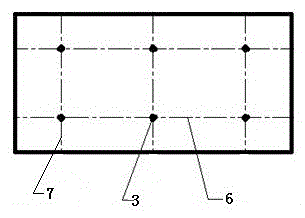

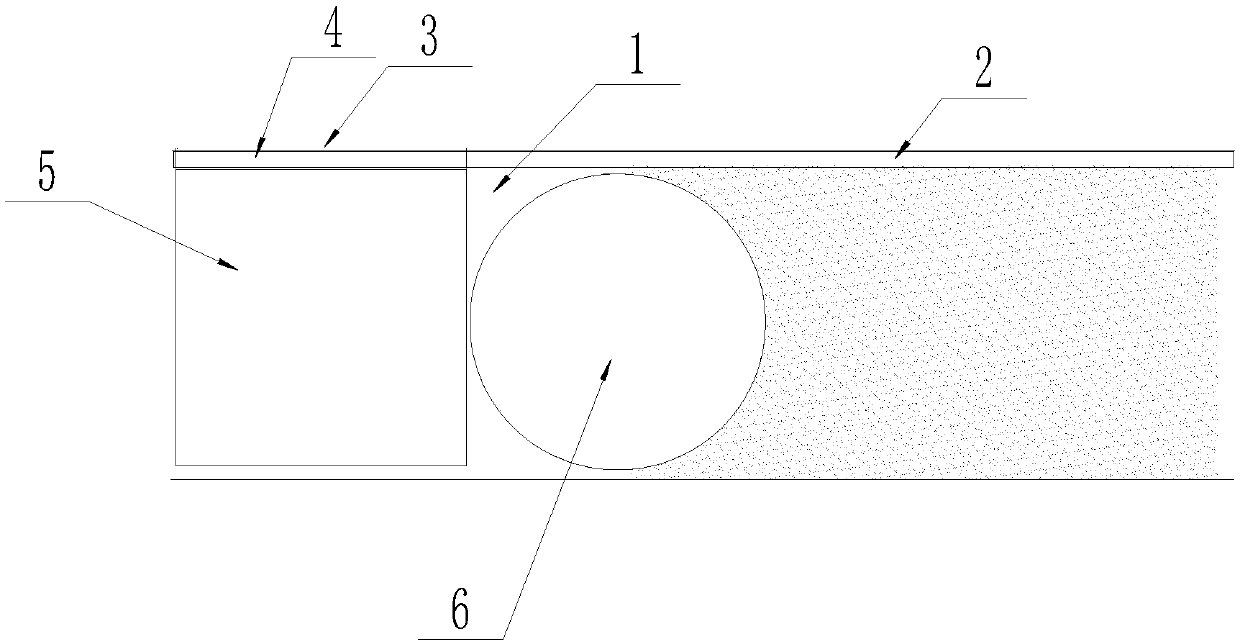

GCL vertical laying structural member and construction process thereof

PendingCN109930558AEfficient vertical layingImprove the quality of laying GCLFoundation engineeringMarine site engineeringArchitectural engineeringBuilding construction

The invention discloses a GCL vertical laying structural member and a construction process thereof. The construction process comprises excavating a groove for laying a vertical anti-seepage special GCL composite component layer; using a GCL composite component vertical laying device or a specially made lifting appliance to place the vertical anti-seepage special GCL composite component layer in the groove; rolling and attaching the laid vertical anti-seepage special GCL composite component layer to a groove wall by a rolling roller; lowering a joint box or a two-in-one joint box, wherein an overlapping area can be rolled for many times to ensure tight fit and improve the anti-seepage performance of the overlapping area. The GCL vertical laying structural member and the construction processthereof have the beneficial effects that the GCL vertical laying construction process is researched and developed according to practical engineering conditions such as the property of flexible anti-seepage coiled materials such as GCL, the construction characteristics of vertical laying and the construction characteristics of an anti-seepage wall, mechanized construction is adopted, the operationis simple and safe, and the construction efficiency is high.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

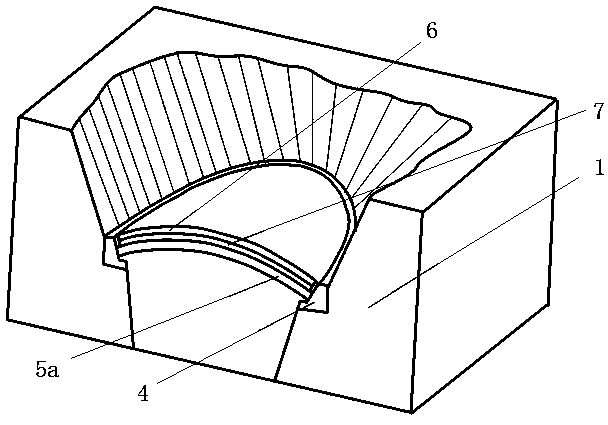

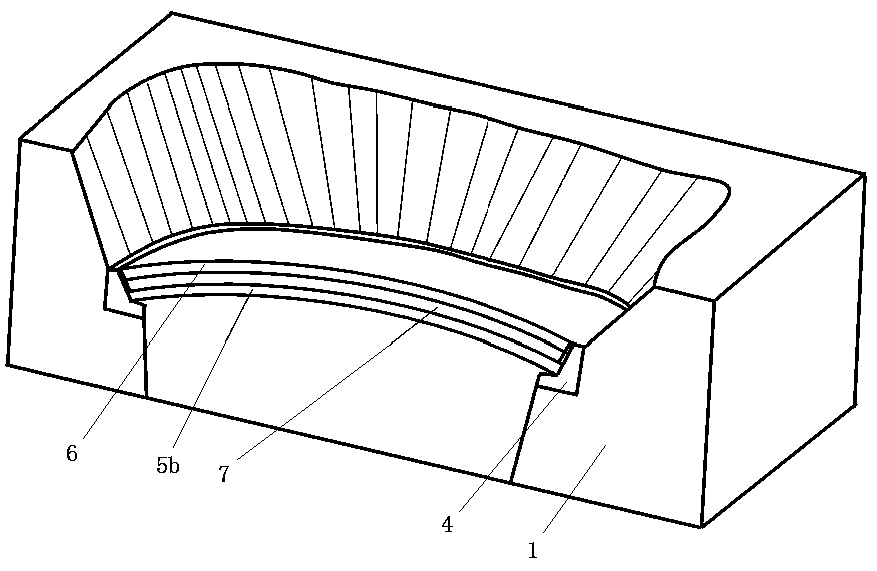

Karst Funnel Reservoir and Its Arched Beam-Slab Closure Structure and Construction Method

ActiveCN107268535BReduce tensionSmall amount of workMarine site engineeringConcrete beamsStructural engineering

The invention discloses an arched beam-slab blocking structure. The arched beam-slab blocking structure comprises a concrete base circumferentially surrounding the inner wall of a natural drainage channel of a karst funnel, concrete slabs for blocking the natural drainage channel of the karst funnel are arranged in the concrete base, at least one concrete beam for supporting the concrete slabs is arranged under the concrete slabs, the concrete beams are arranged at intervals, and the two ends of each concrete beam are arranged on the concrete base. The invention further discloses a karst funnel reservoir and a construction method of the arched beam-slab blocking structure. Through the karst funnel reservoir, the arched beam-slab blocking structure thereof and the construction method, the requirement for blocking the natural drainage channel of the karst funnel can be met.

Owner:东营市大学科技园发展有限责任公司

Treatment method of peat soil dam foundation

The invention relates to a treatment method of a peat soil dam foundation. For the dam section of a clay core-wall rockfill dam, gravels are scattered so as to enhance bearing capability, a pump pit is arranged for draining, and consolidation grouting and curtain grouting are carried out so as to ensure the stability and permeability of the dam foundation. For the dam section of a homogeneous soil dam, a pipe culvert and a draining ditch are buried, peat soil is cleared after draining and airing, a transition section is built after a residual soil layer is air-dried, and finally, ramming is carried out. For the dam section of an earth-rock dam, a cofferdam is built at the upstream section for blocking water, a draining open canal is dug for drainage, and rock powder is scattered for increasing soil strength; and finally, rock is thrown at the downstream side, and a gallery is built, so that clearing equipment can be driven into marshland for clearing the peat soil. According to the treatment method, the digging and outward transporting of the peat soil are facilitated, and the dam foundation meets seepage preventing requirements; the investment of special desilting equipment and the arrangement of a seepage preventing wall are avoided, and at the same time, large-area soil replacement is avoided; and when construction quality is ensured, the construction cost is greatly reduced.

Owner:SINOHYDRO BUREAU 5

Gas axial isolation belt in tunnel gas accumulation area and construction method thereof

InactiveCN109113758APrevent proliferationReduce the risk of osmotic diffusionUnderground chambersGas removalPorosityProcess engineering

The invention discloses a gas axial isolation belt in a tunnel gas accumulation area. The gas axial isolation belt comprises zone grouting belts and gas isolation rings. The zone grouting belts and the gas isolation rings are arranged on the outer sides of the head and tail positions of a tunnel. The tunnel is excavated on a coal seam with gas accumulation, the initial position of the tunnel is constructed with high gas support, the tail end position of the tunnel is constructed with coal penetrating section anti-seepage support, and the coal penetrating section anti-seepage support is constructed at a coal seam penetrating section of the tunnel. A coal seam on the outer side of the coal penetrating section anti-seepage support is arranged as the gas accumulation area. The gas isolation rings and the zone grouting zones are constructed on the outer sides of the head and tail positions of the tunnel, and gas is isolated by the interaction of the gas isolation rings and the zone groutingbelts to prevent the gas from diffusing in the axial direction of the tunnel, and the porosity and permeability coefficient of the area are reduced. The constructed gas axial isolation belt of the gas accumulation area of the tunnel can meet the gas anti-seepage requirements of a tunnel entrance working area, and can especially reduce the gas anti-seepage pressure in the later operation stage.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

A kind of concrete anti-leakage paste and its preparation method and application

The invention discloses a concrete leakage-proof paste, which is mainly prepared from the following raw materials in percentage by mass: 10 to 20 percent of cement, 2 to 5 percent of coagulant, 3 to 8 percent of flocculant, 20 to 25 percent of binder, 45 to 60 percent of expansion component, and 5 to 15 percent of water. The concrete leakage-proof paste can be applied in a sealing material for a concrete permeability resistance test, also can be applied in a crack repair anti-seepage structure in engineering, has a good sealing anti-seepage effect and stable performance, and can fully meet the anti-seepage requirement.

Owner:中建西部建设西南有限公司 +1

Concrete channel permeability-reducing agent and preparation method and purpose thereof

Disclosed are concrete channel permeability-reducing agent and a preparation method and purpose thereof. The concrete channel permeability-reducing agent comprises, by weight, 40-50 parts of etherified starch (at least 90% of solid content), 30-50 parts of fluorosilicon resin (at least 90% of solid content), 80-100 parts of waterborne fluorocarbon emulsion (48% of solid content), 10-15 parts of methylene dimethyl binaphthol sulfonate polymer (at least 90% of solid content), and 300-350 parts of water. The fluorosilicon resin is synthetic resin formed by mixing fluorine resin and organic silicon resin. The waterborne fluorocarbon emulsion is copolymer of vinyl fluoride and hydroxyl vinyl ether, wherein concentration percentage by weight of fluorine is 8-11.5%, and a main chain contains fluorine atom. The concrete channel permeability-reducing agent is economical in formula, fine in permeability-reducing effect, and long-lasting in function. The preparation method of the concrete channel permeability-reducing agent includes mixing and ultrasonic dispersing. The purpose of the concrete channel permeability-reducing agent is to form a permeability-reducing film on the surface of the concreted channel by roller coating, brush coating or spay coating the permeability-reducing agent on the surface of the concreted channel. By the permeability-reducing film, fine permeability-reducing effect of the concrete channel can be achieved.

Owner:湖北宗源材料有限公司

Composite anti-seepage structure for culvert gate and its construction method

InactiveCN107354920BMeet anti-seepage requirementsStrong resistance to uneven settlementBarrages/weirsGeomembraneEngineering

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com