Patents

Literature

30results about How to "Increase out-of-plane stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

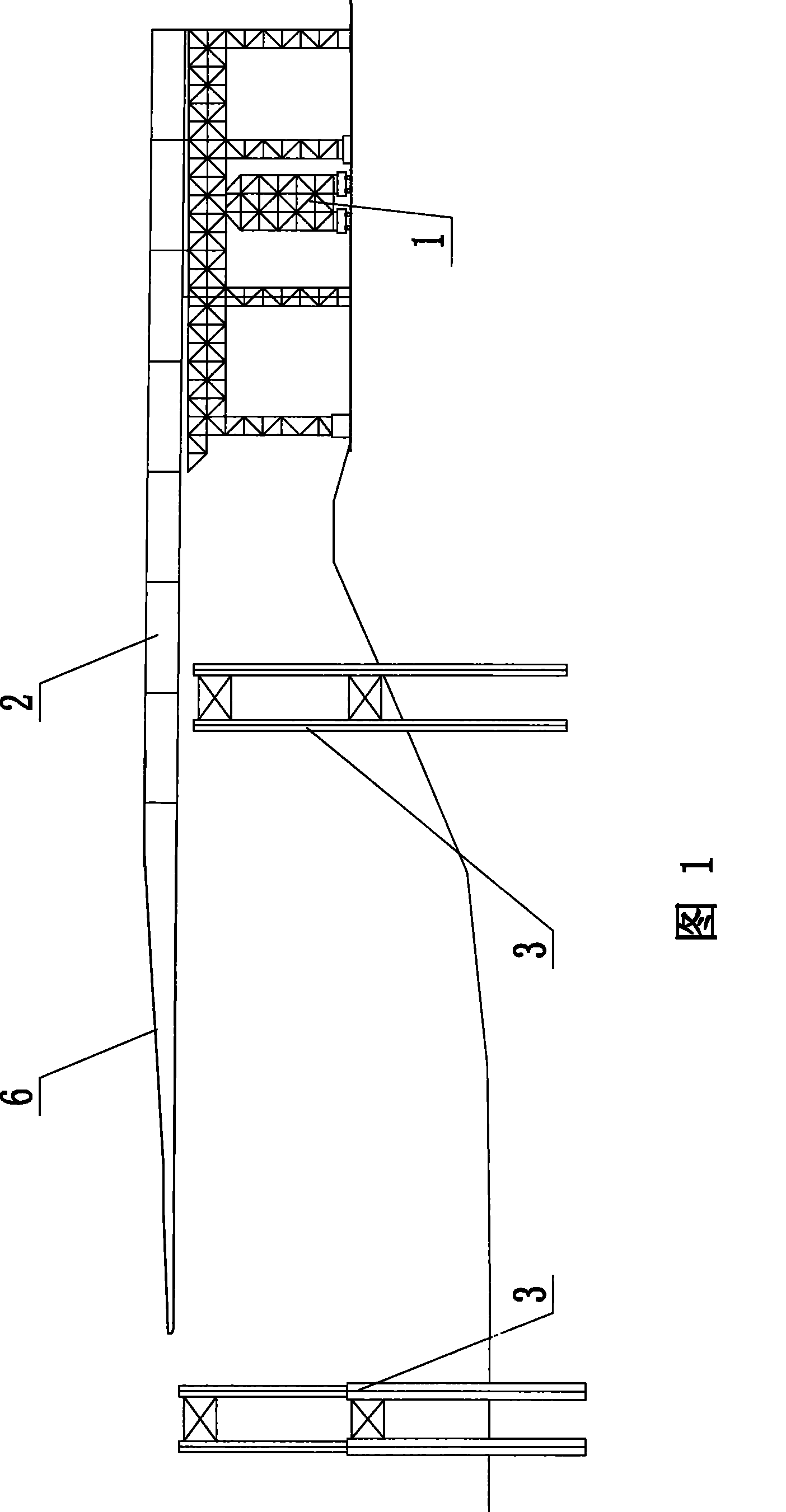

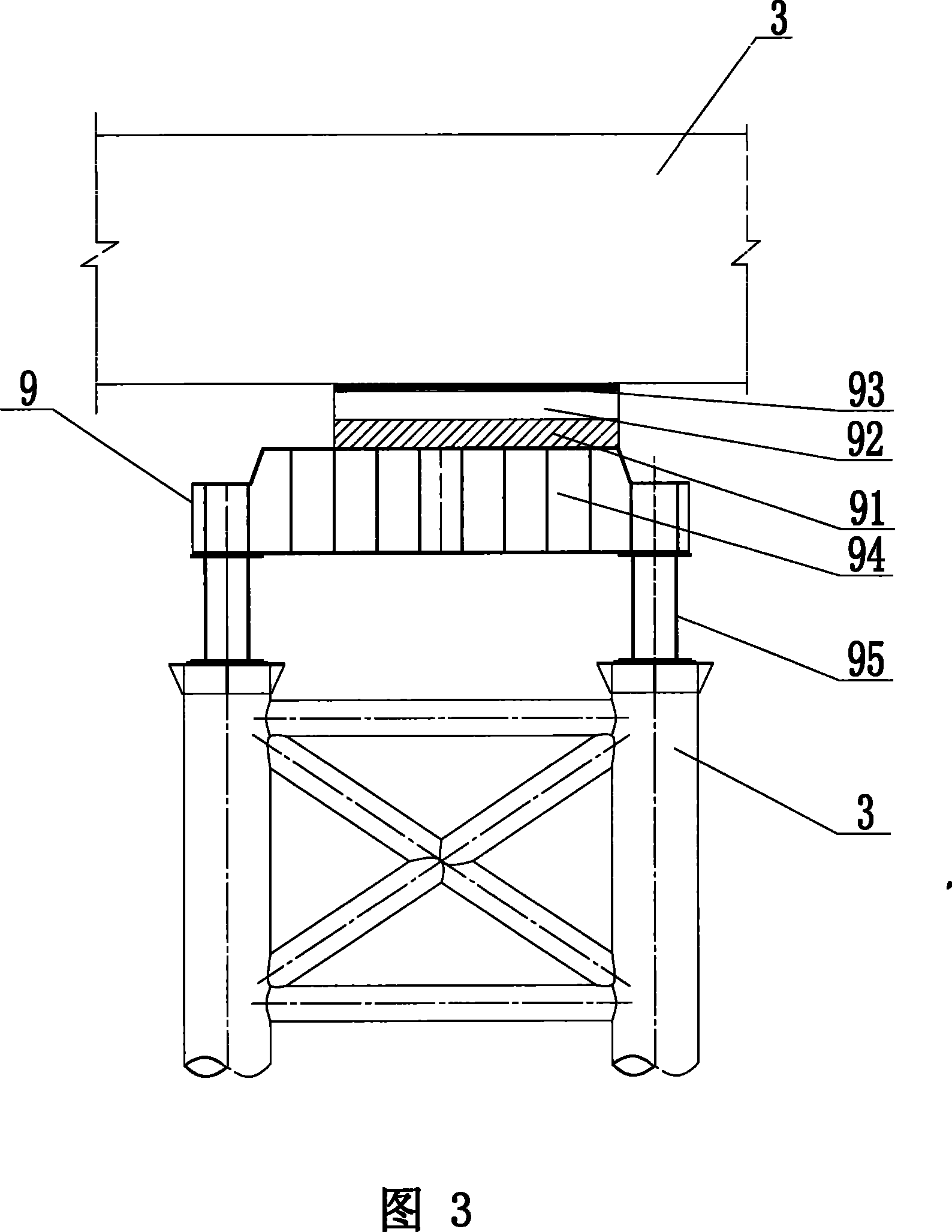

Steel box beam erection method for self-anchored suspension bridge

InactiveCN101078198ASave manpower and costImprove efficiencyBridge erection/assemblyEngineeringSteel box girder

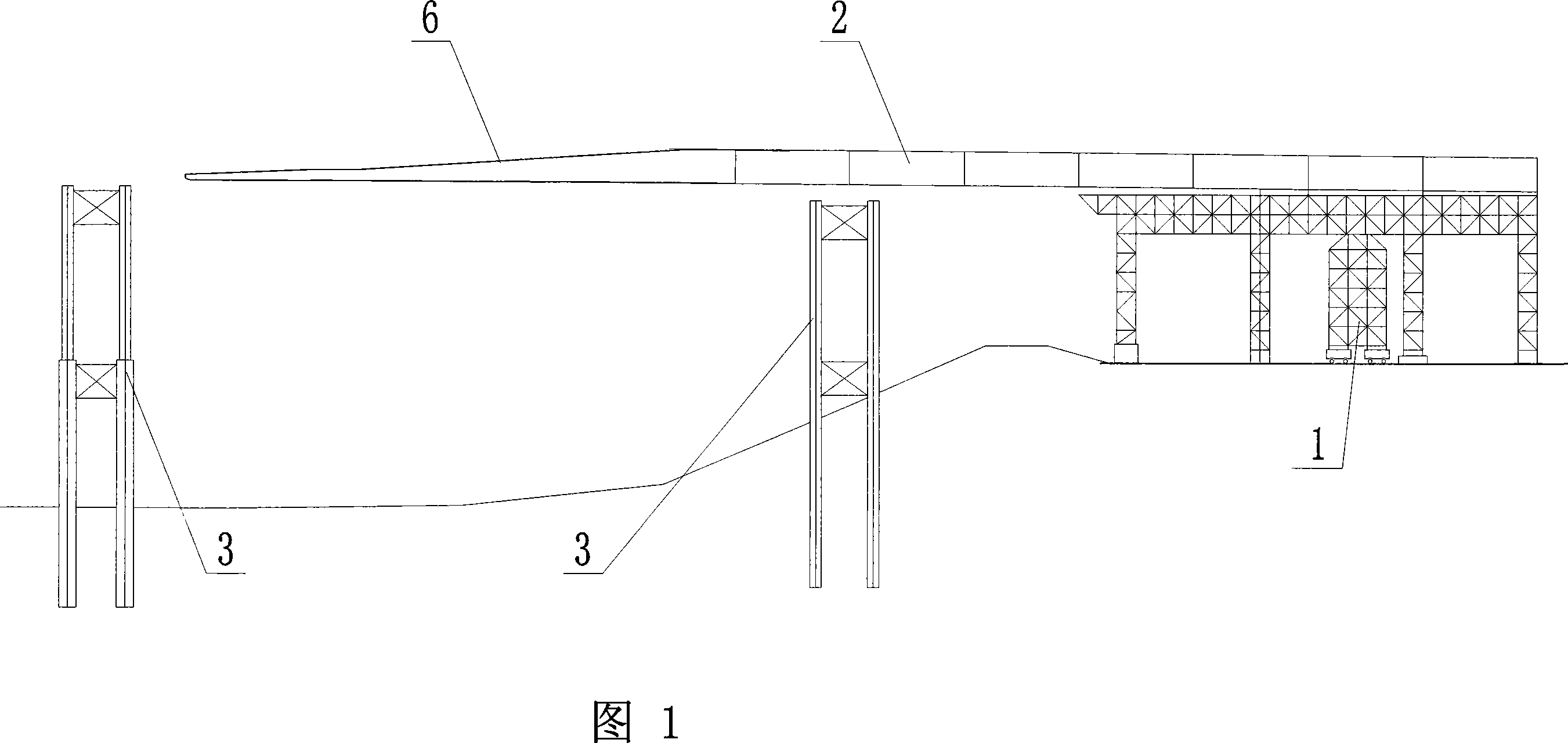

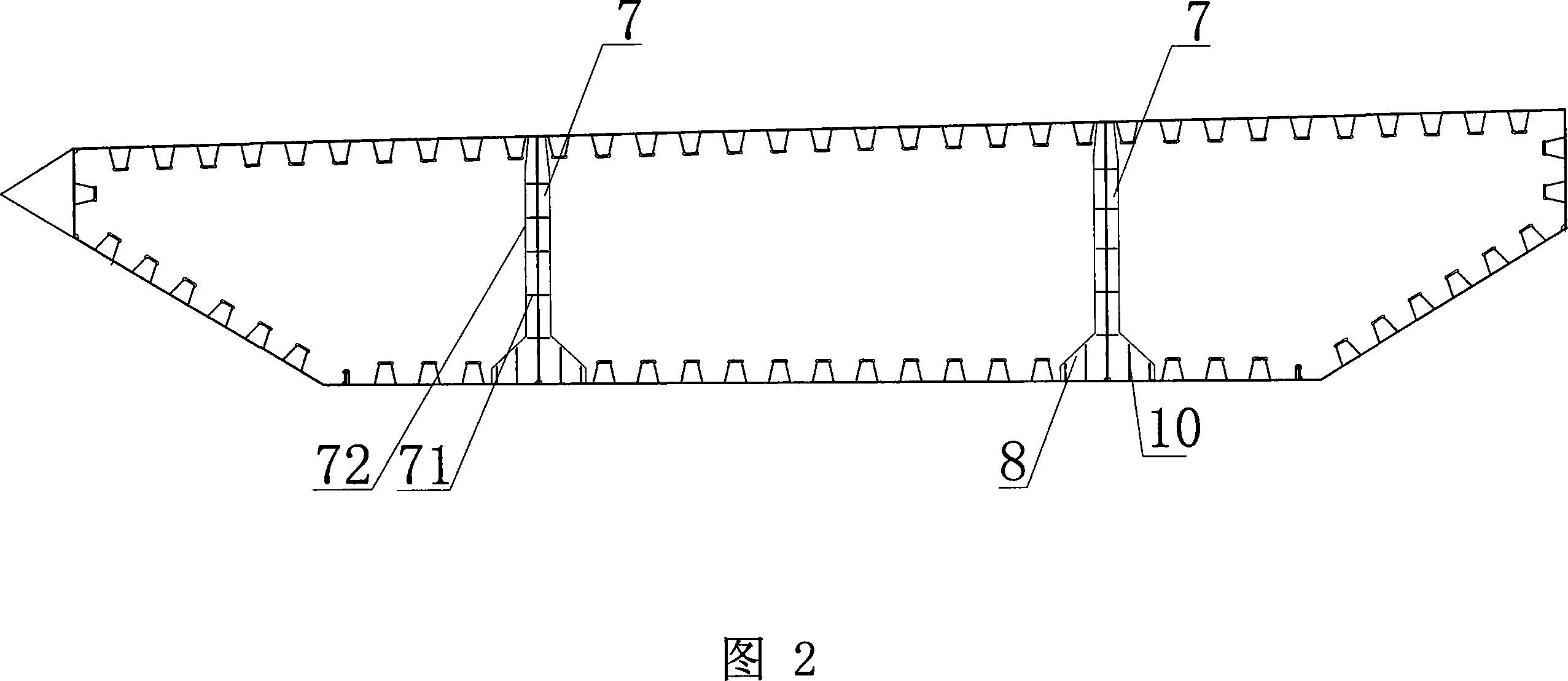

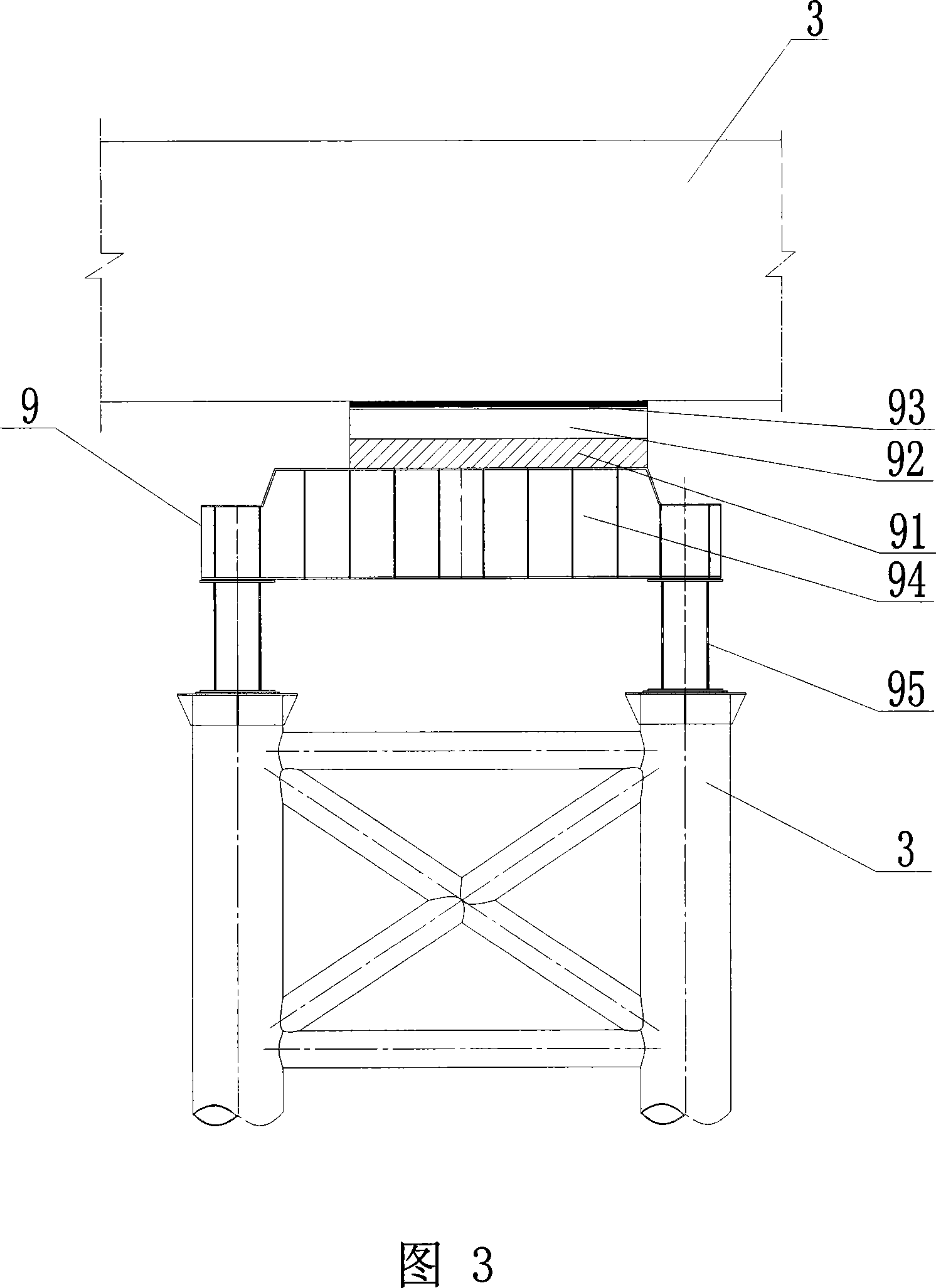

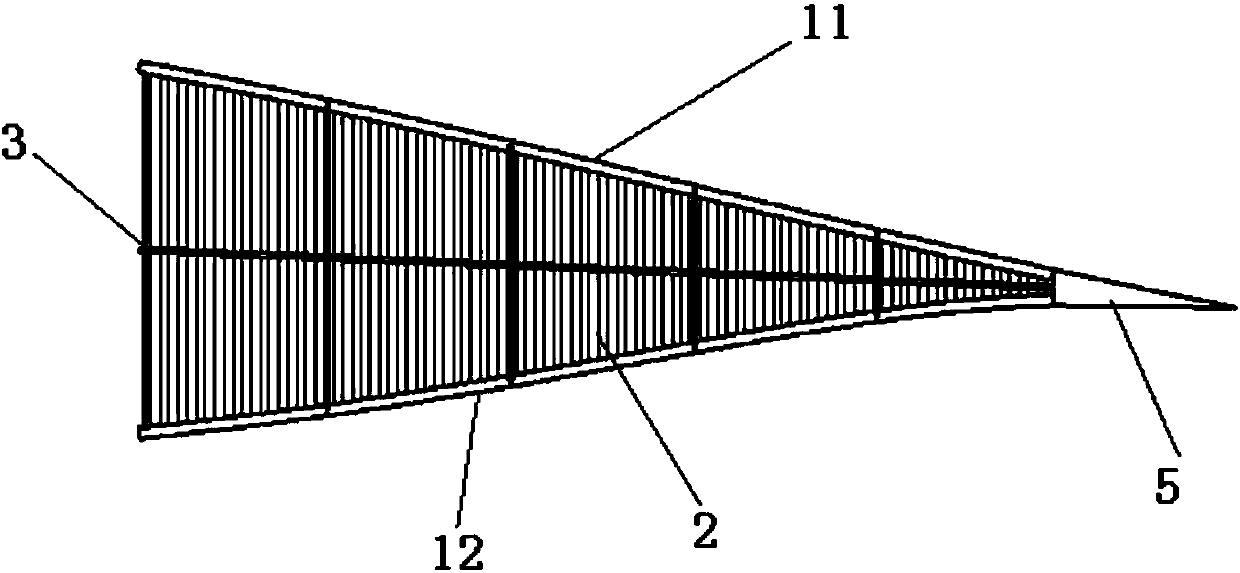

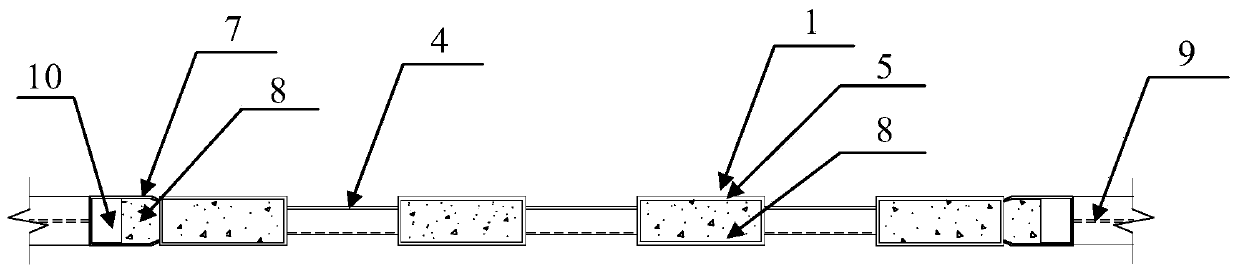

The invention discloses a method for steel-box beam erection applied in self-anchored suspension bridge. Procedures comprise that (1) the support for steel-box beam is set on bank or in no-navigation area and steel-box beam is preassembled with dividing segments on the support for steel-box beam; (2) temporary piers for steel-box beam, which satisfy waterway grade, are set in the waterway suspended by the suspension bridge; (3)preassembled steel-box beam is pushed forwards by pushing or dragging method so that the steel-box beam moves to temporary piers for steel-box beam from the support for steel-box beam and the steel-box beam is supported by temporary piers; then the steel-box beam is preassembled in dividing segments and it is pushed or dragged continuously so that preassembled steel-box beam moves forwards and it passes through temporary piers for steel-box beam on waterway in turn to achieve the opposite bank. The invention is provided with simple construction and it can be applied in waterway with busy suspension and higher waterway grade.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

Variable-curvature wing trailing edge

InactiveCN108045553AIncrease out-of-plane stiffnessMeet load requirementsWing adjustmentsOut of planeTrailing edge

The invention relates to the field of variable airplane structural design, in particular to a variable-curvature wing trailing edge. The variable-curvature wing trailing edge comprises a herringbone structure made of an elastic material, an upper skin, a lower skin, heating pieces, a wingtip and a flexible honeycomb, wherein the upper skin and the lower skin are both made of a shape memory alloy and fixedly arranged on the upper surface and the lower surface of the herringbone structure, the shape memory alloy of the upper skin is configured to be lengthened when the heating temperature is higher than the preset temperature and recover and keep the original shape when the heating temperature is lower than the preset temperature, and the shape memory alloy of the lower skin is configured tobe shortened when the heating temperature is higher than the preset temperature and recover and keep the original shape when the heating temperature is lower than the preset temperature; the heatingpieces are arranged on the upper skin and the lower skin; and the position among the skins and the herringbone structure is filled with the flexible honeycomb. By the adoption of the variable-curvature wing trailing edge, through differential motion deformation of the upper skin and the lower skin, the wing trailing edge is driven to deflect, the out-of-plane stiffness of a whole wing trailing edge structure is greatly improved, and a variable airplane structure bearing requirement is met.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

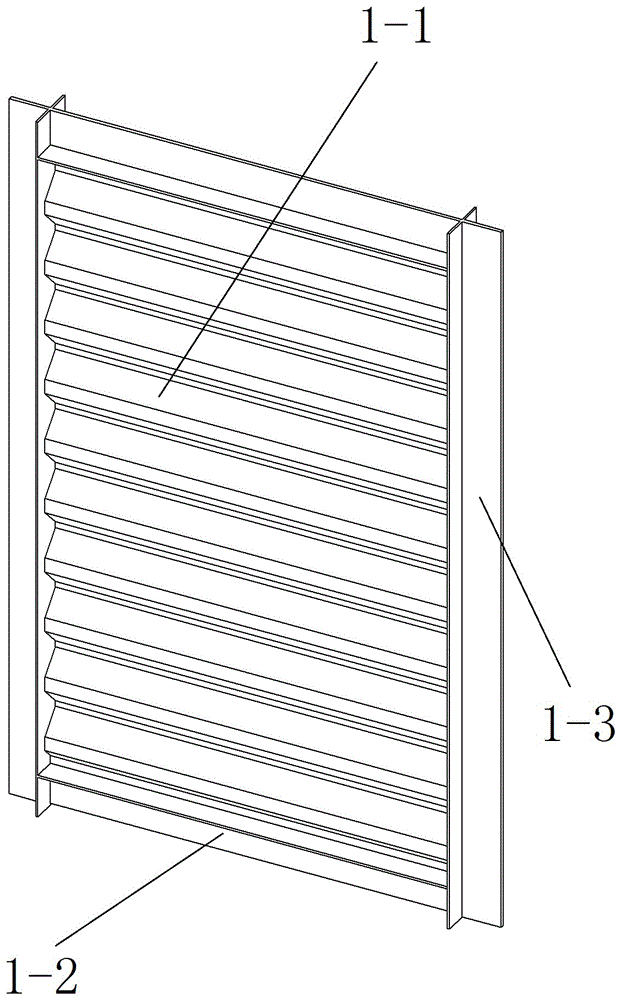

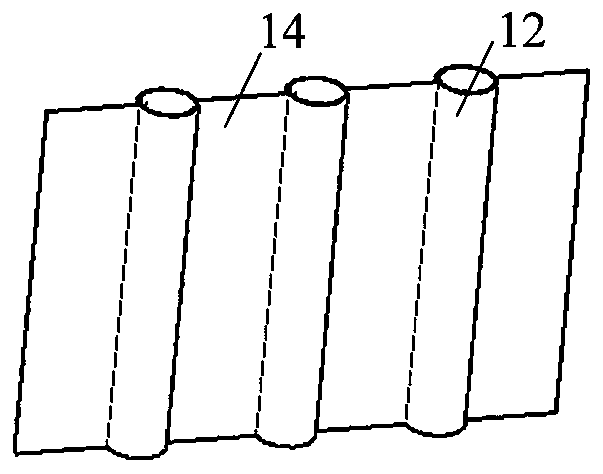

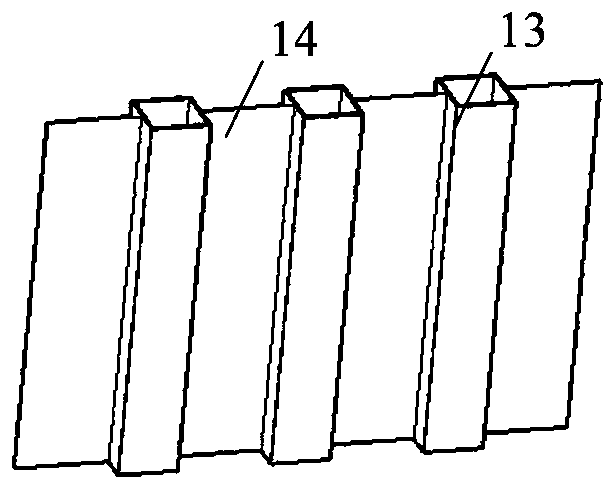

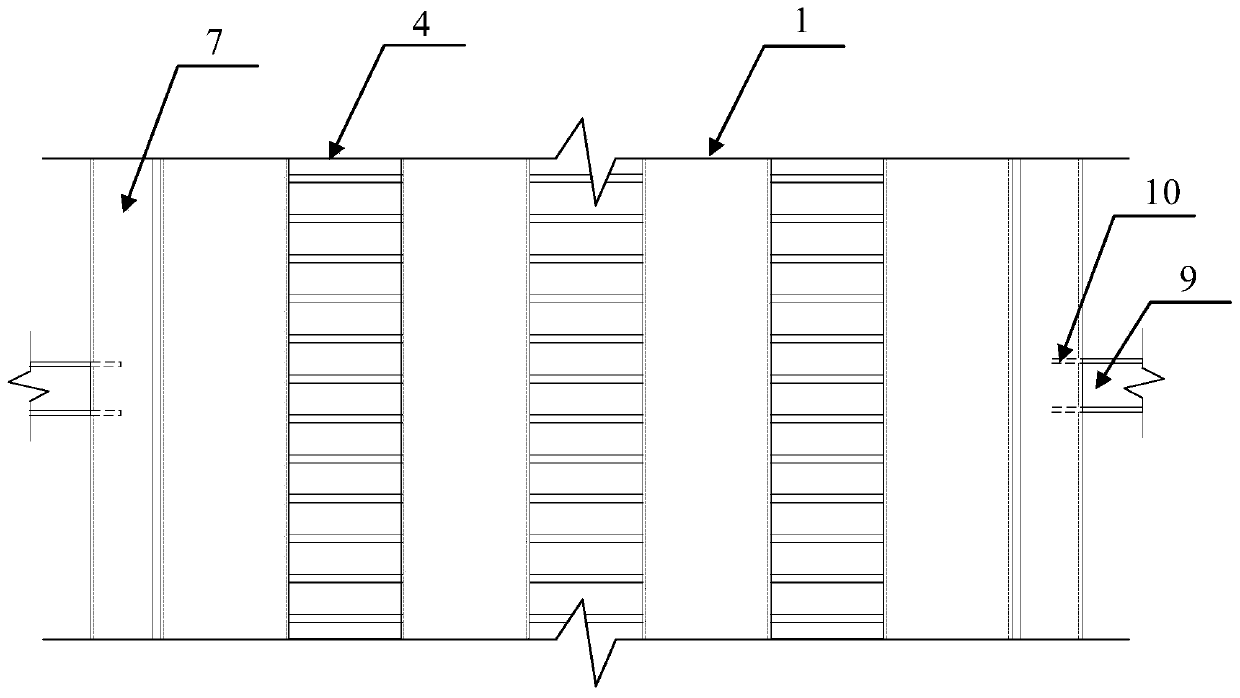

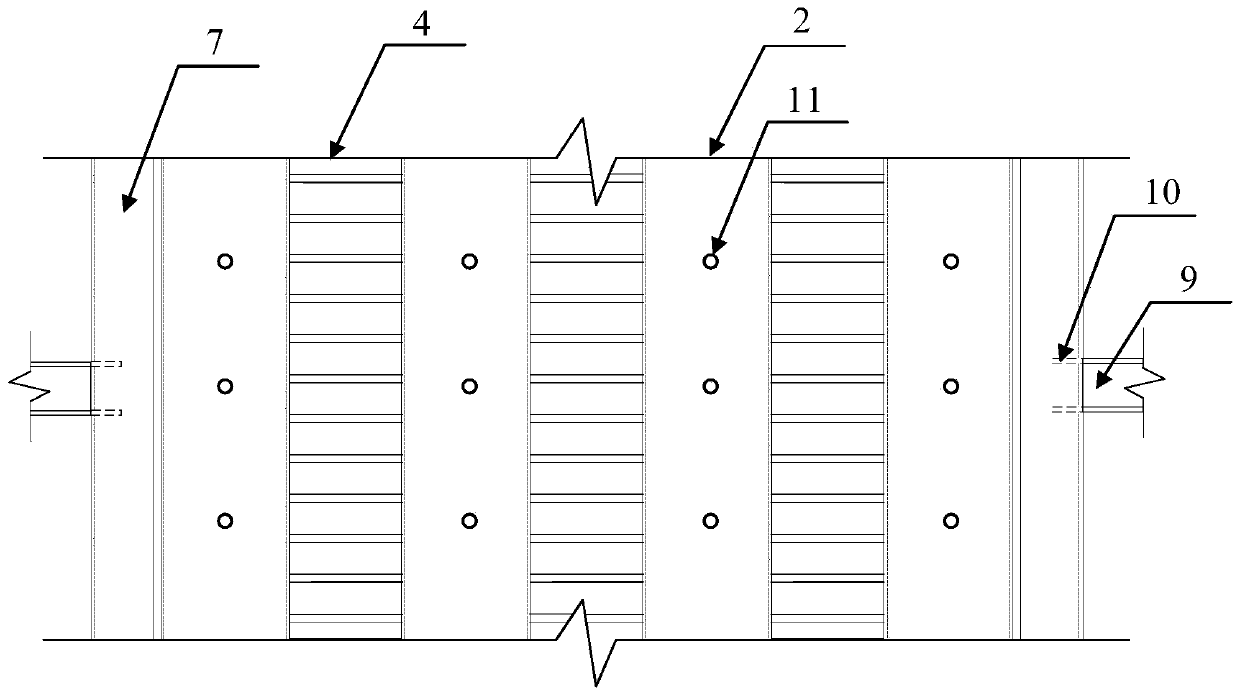

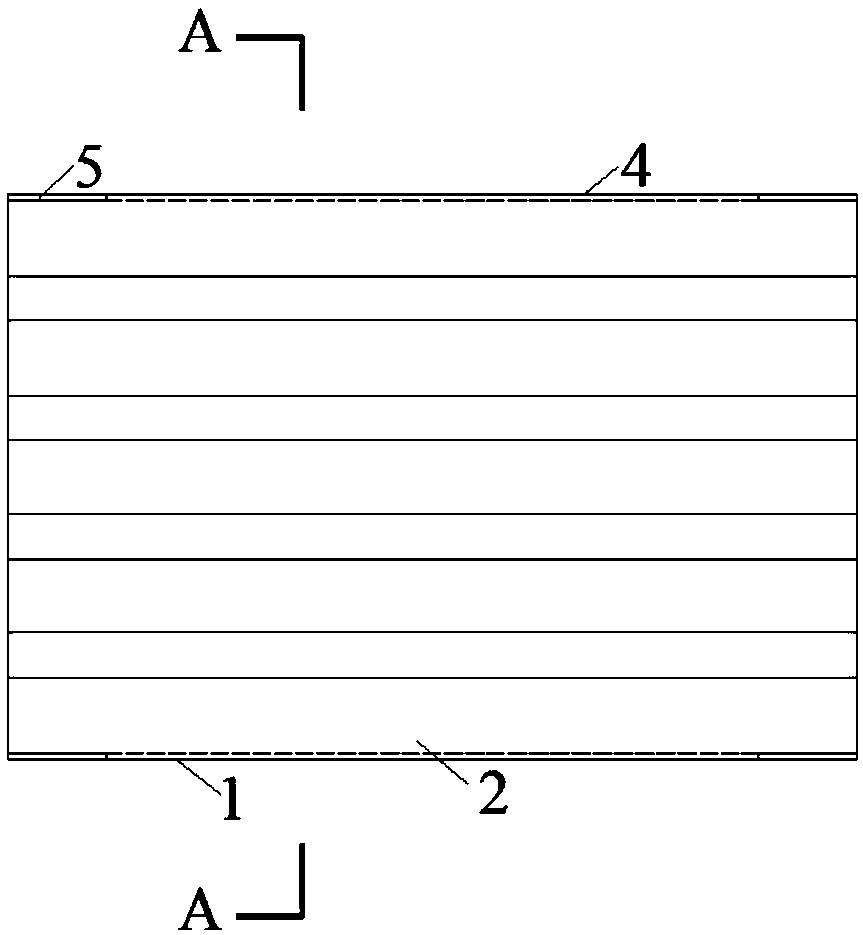

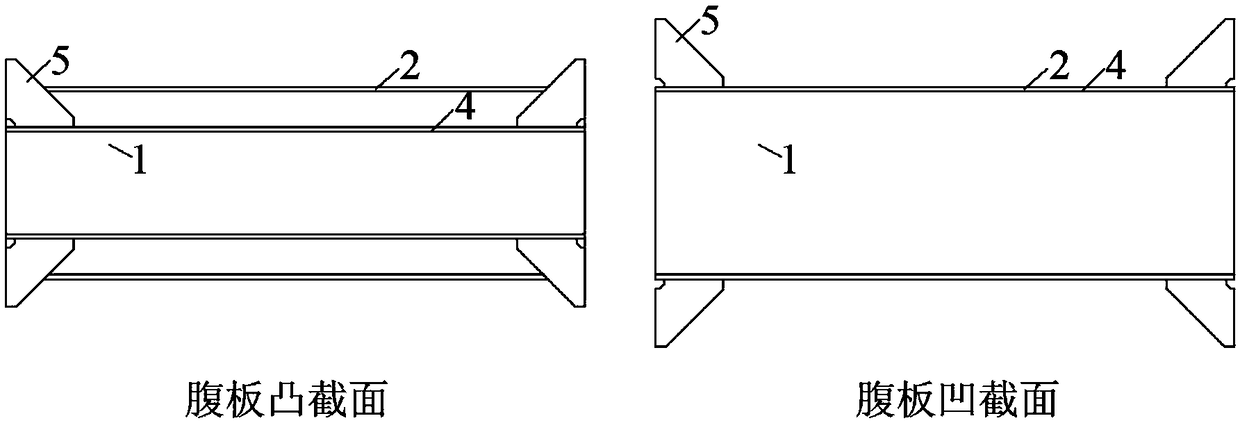

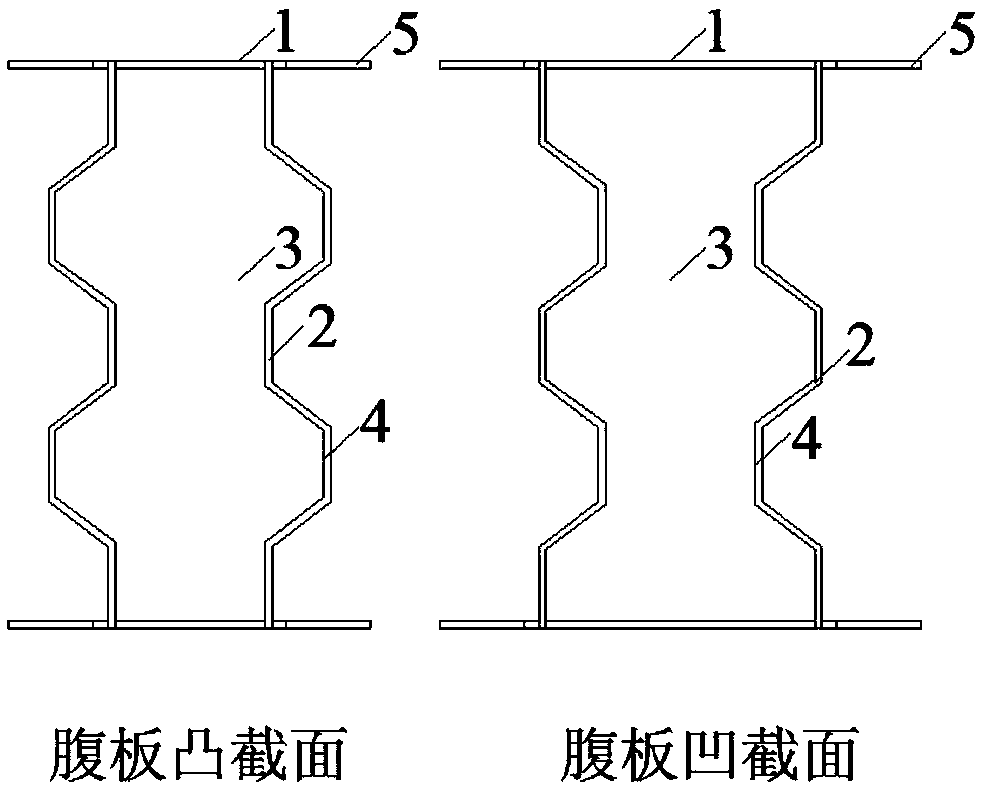

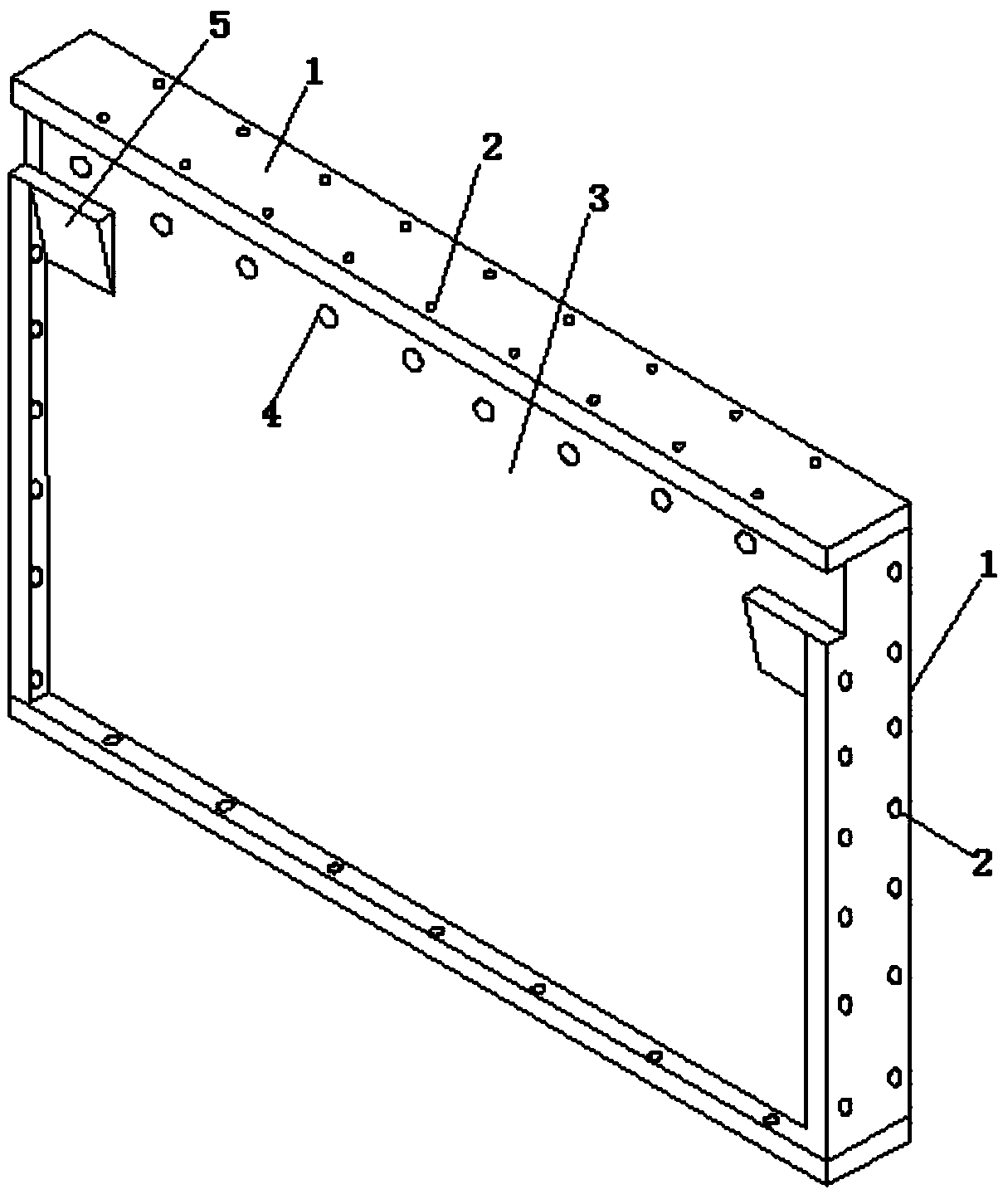

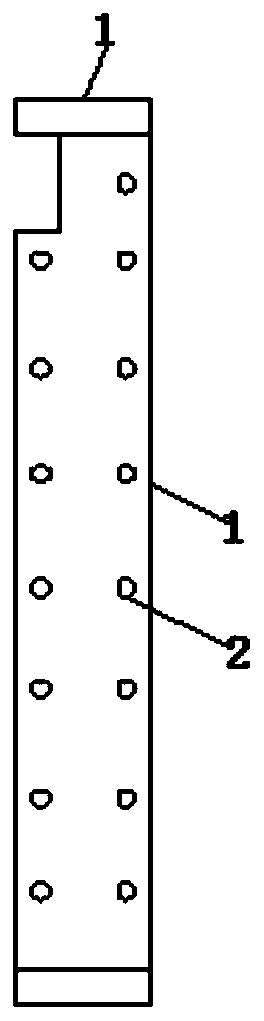

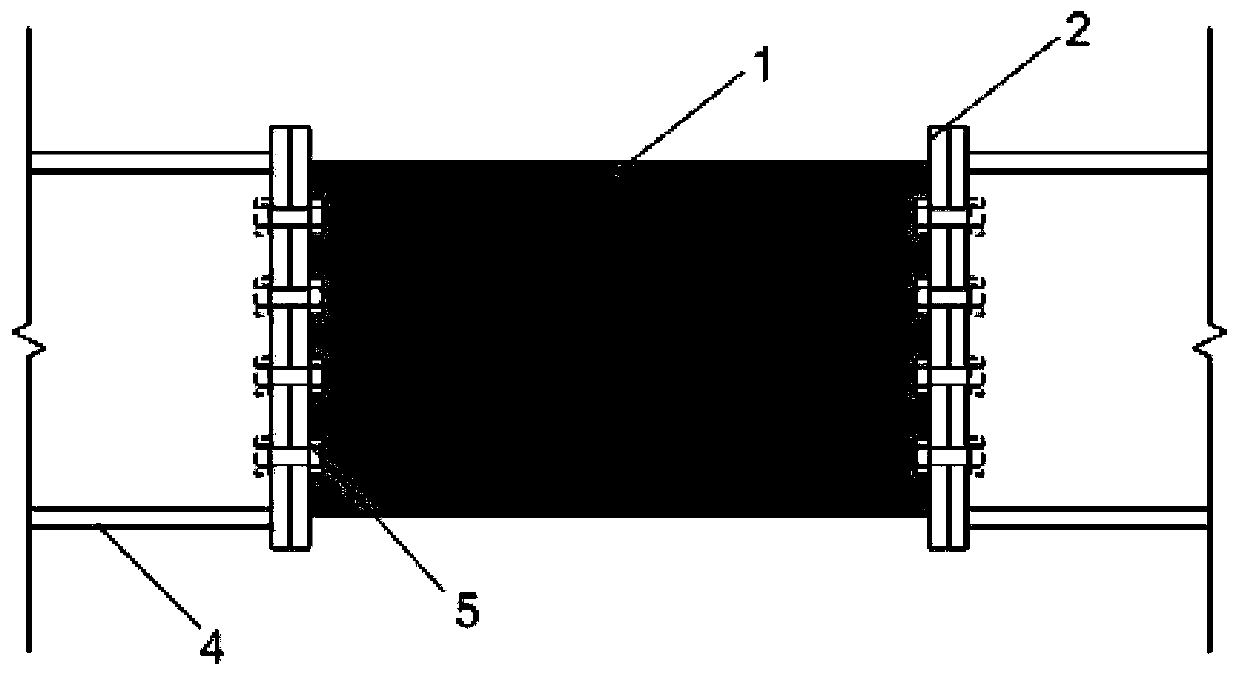

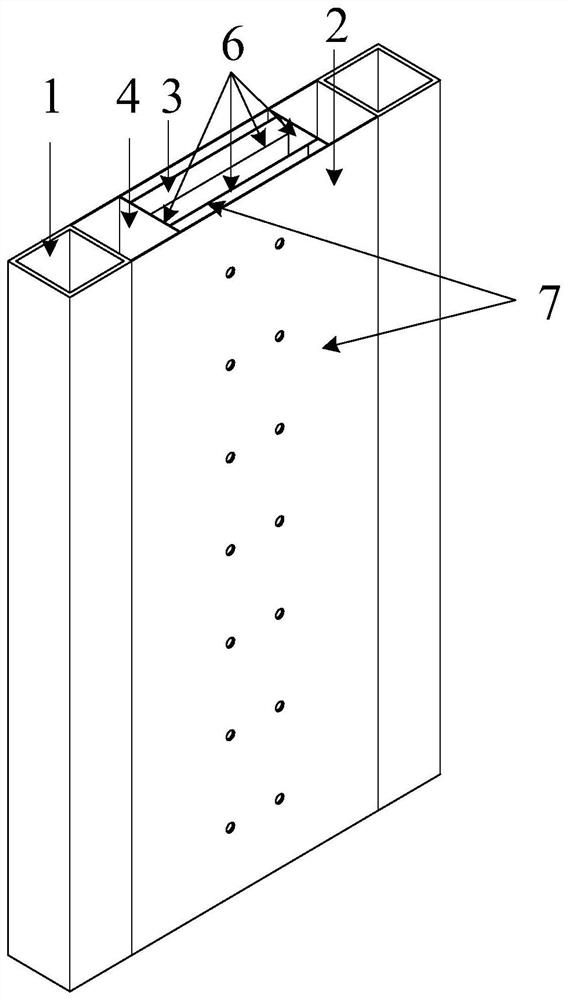

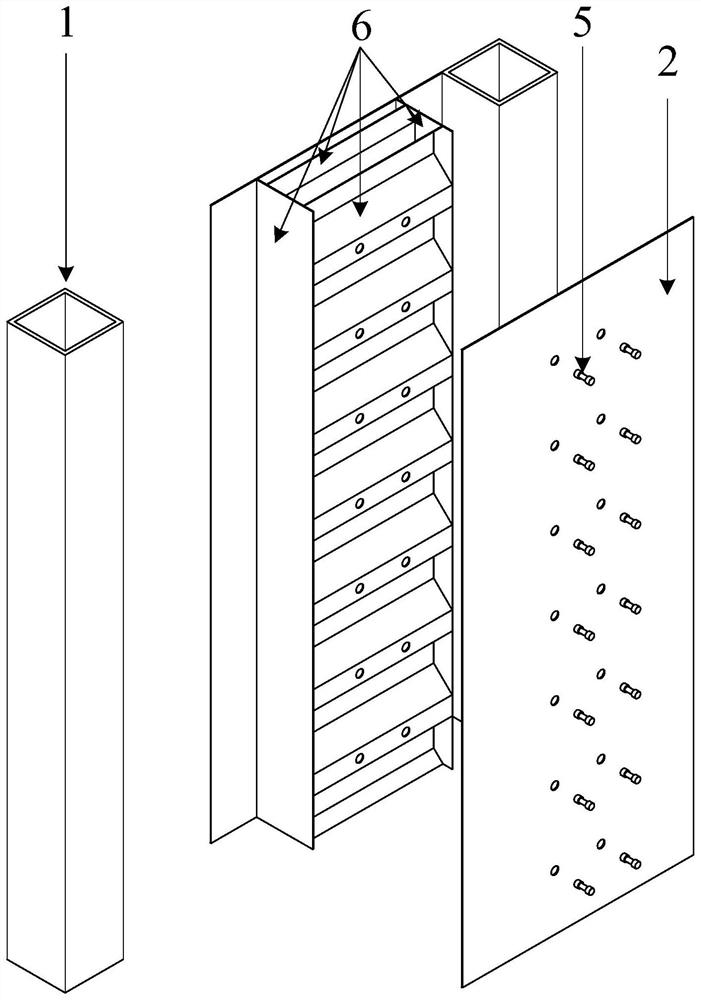

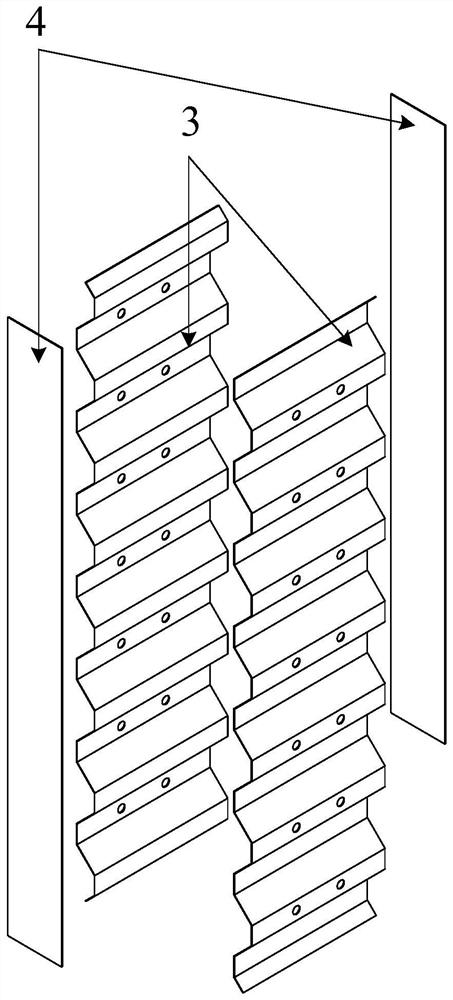

Assembled corrugated steel plate shear wall

InactiveCN105735528AIncreased shear buckling loadImprove use comfort performanceWallsSheet steelStructure system

The invention discloses an assembled corrugated steel plate shear wall, which comprises one or a plurality of basic assembling units and an edge framework, wherein the basic assembling units are spliced through high-strength screw bolts and are connected with the edge framework; and each basic assembling unit is formed by transverse connecting elements, longitudinal connecting elements and corrugated web plates through welding. The assembled corrugated steel plate shear wall provided by the invention has the advantages that each basic assembling unit is formed by the corrugated web plates, so that the shear buckling load of a steel plate wall can be greatly improved; the use comfort of the steel plate shear wall structure is improved; the outer rigidity of the basic assembling unit surface of the assembled corrugated steel plate shear wall is great; and the transportation is convenient and fast. The lateral force resisting structure system of the assembled corrugated steel plate shear wall adopts field splicing by high-strength screw blots; the construction is convenient and fast; the quality is easy to guarantee; the assembled corrugated steel plate shear wall conforms to the industrial development trend of a building; and wide market application prospects are realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Integral casting process for reinforced concrete wastewater tank in predrilling engineering

ActiveCN103015719AShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

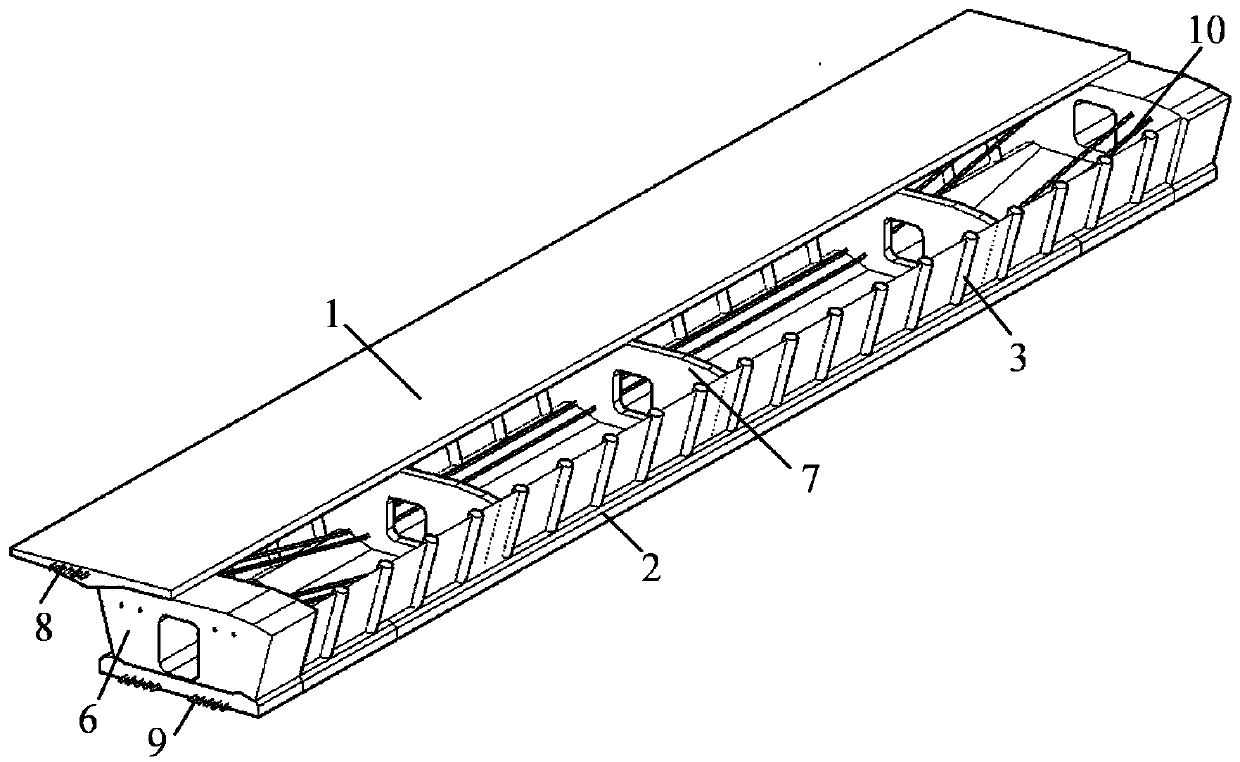

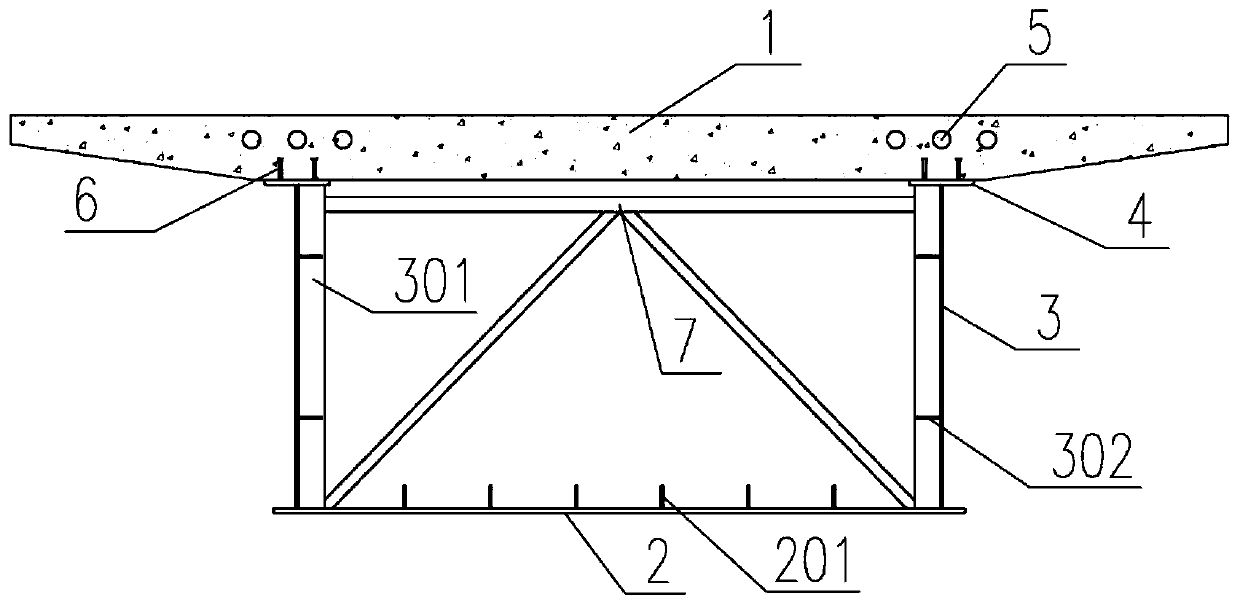

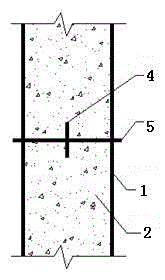

Reinforced concrete combined box girder with steel tube-steel plate combined web

PendingCN110067185ASolve crackingLose weightBridge structural detailsBridge materialsReinforced concretePre stress

The invention discloses a reinforced concrete combined box girder with a steel tube-steel plate combined web, and relates to the technical field of bridge projects. The reinforced concrete combined box girder with the steel tube-steel plate combined web mainly includes a concrete roof, a concrete floor, a striping structure and a steel tube-steel plate combined web. The steel tube-steel plate combined web, the concrete roof and the concrete floor are connected to form a box girder main body, and the striping structure is arranged at the two end fulcrums and the middle of the box girder main body. According to the reinforced concrete combined box girder with the steel tube-steel plate combined web, the self-weight of a bridge is reduced, the spanning capacity of the bridge is enhanced, thecracking of a web is avoided, the efficiency of prestress putting is improved, and the secondary internal force caused by temperature effect and shrinkage and creep of concrete is decreased. Therefore, the advantages of two materials, steel and the concrete, are fully taken, and so good economic efficiency is provided.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

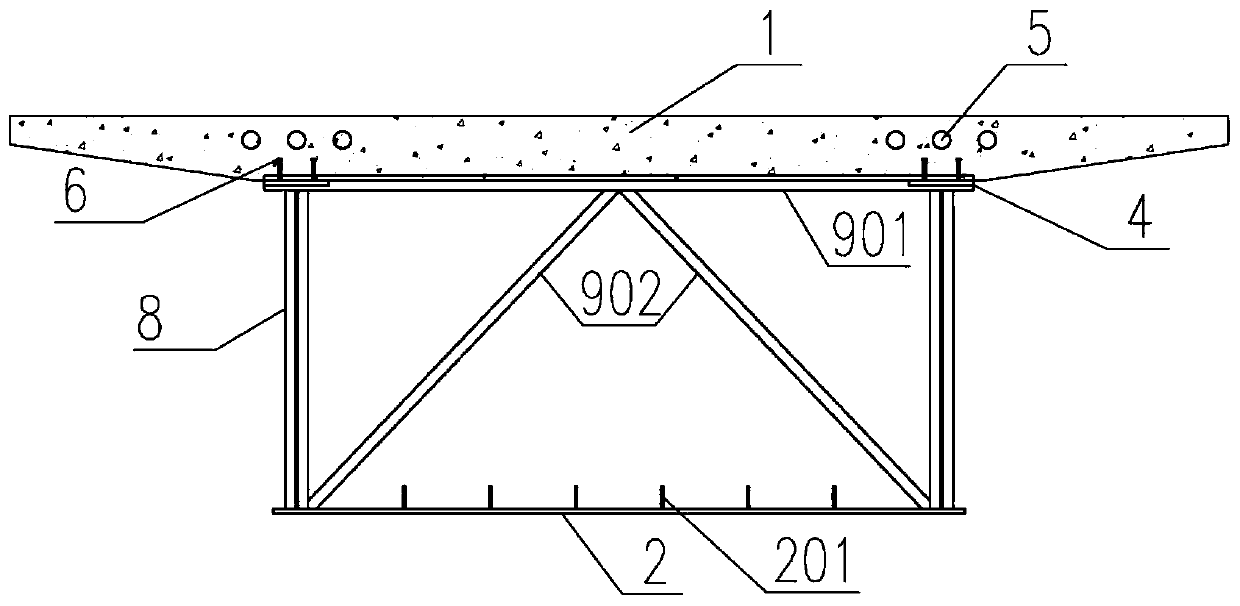

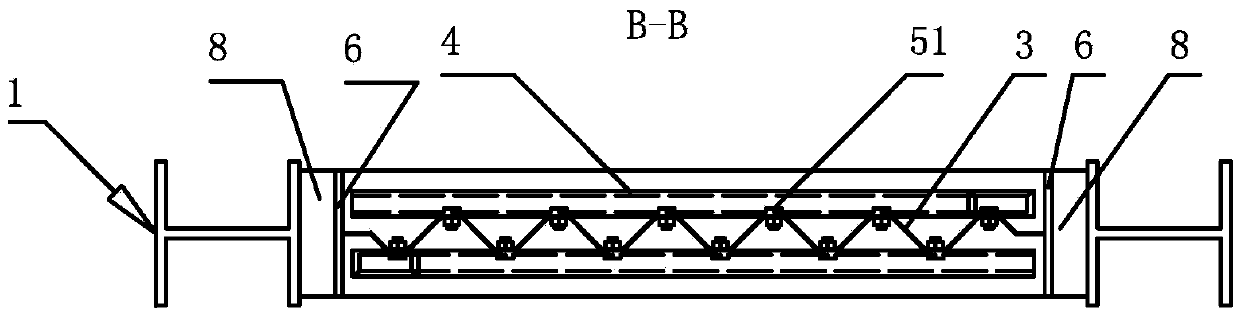

Steel pipe stiffened web steel-concrete composite box girder

PendingCN110067186AImprove integrityIncrease stiffnessBridge structural detailsBridge materialsMetallurgyCross bracing

The invention discloses a steel pipe stiffening web steel-concrete composite box girder. The steel pipe stiffened web steel-concrete composite box girder comprises a concrete top plate, steel pipe stiffening webs, a steel bottom plate, cross-bracing structures and an upper flange plate, the steel bottom plate is welded to the lower edge of the steel pipe stiffening webs on both sides, the upper edge of the steel pipe stiffening webs is welded to the upper flange plate, and the steel pipe stiffening webs, the steel bottom plate and the upper flange plate are welded into a groove-type steel structure; the concrete top plate is connected to the top part of the upper flange plate through a connecting part, the steel pipe stiffening webs, the steel bottom plate, the upper flange plate and the concrete top plate form a box girder structure, and a plurality of cross-bracing structures are arranged in a support point of the box girder and the middle of the box girder. According to the steel pipe stiffening web steel-concrete composite box girder, the longitudinal stiffness of steel webs and the upper flange plate can be reduced, the prestressing efficiency is improved, meanwhile the deformation coordination ability of the concrete top plate and the steel structure is coordinated, secondary internal force generated by shringkage and creep of concrete and temperature are reduced.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

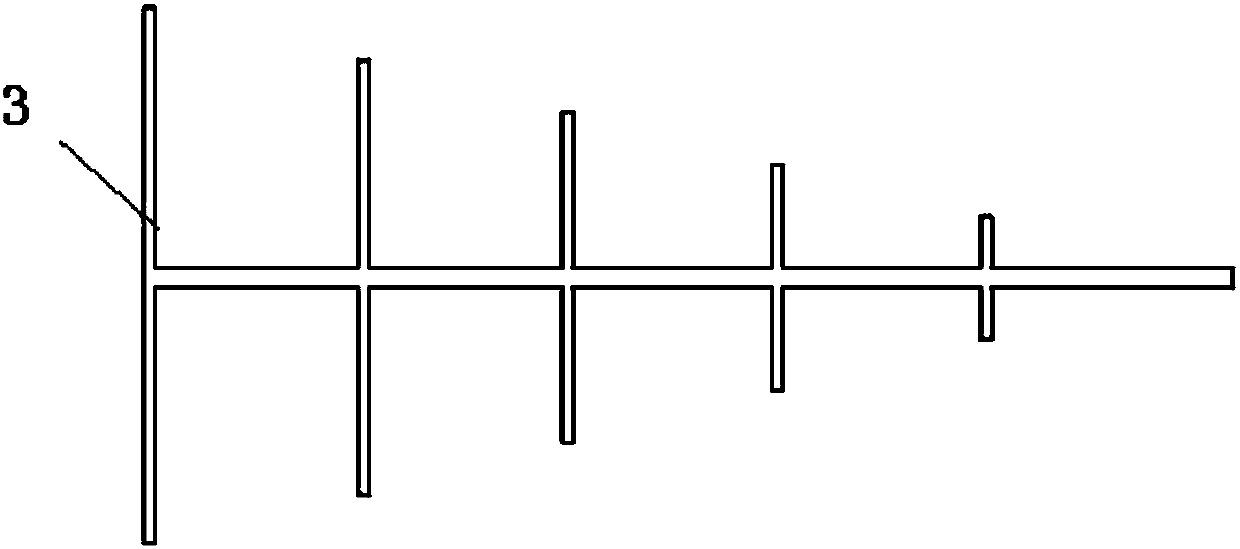

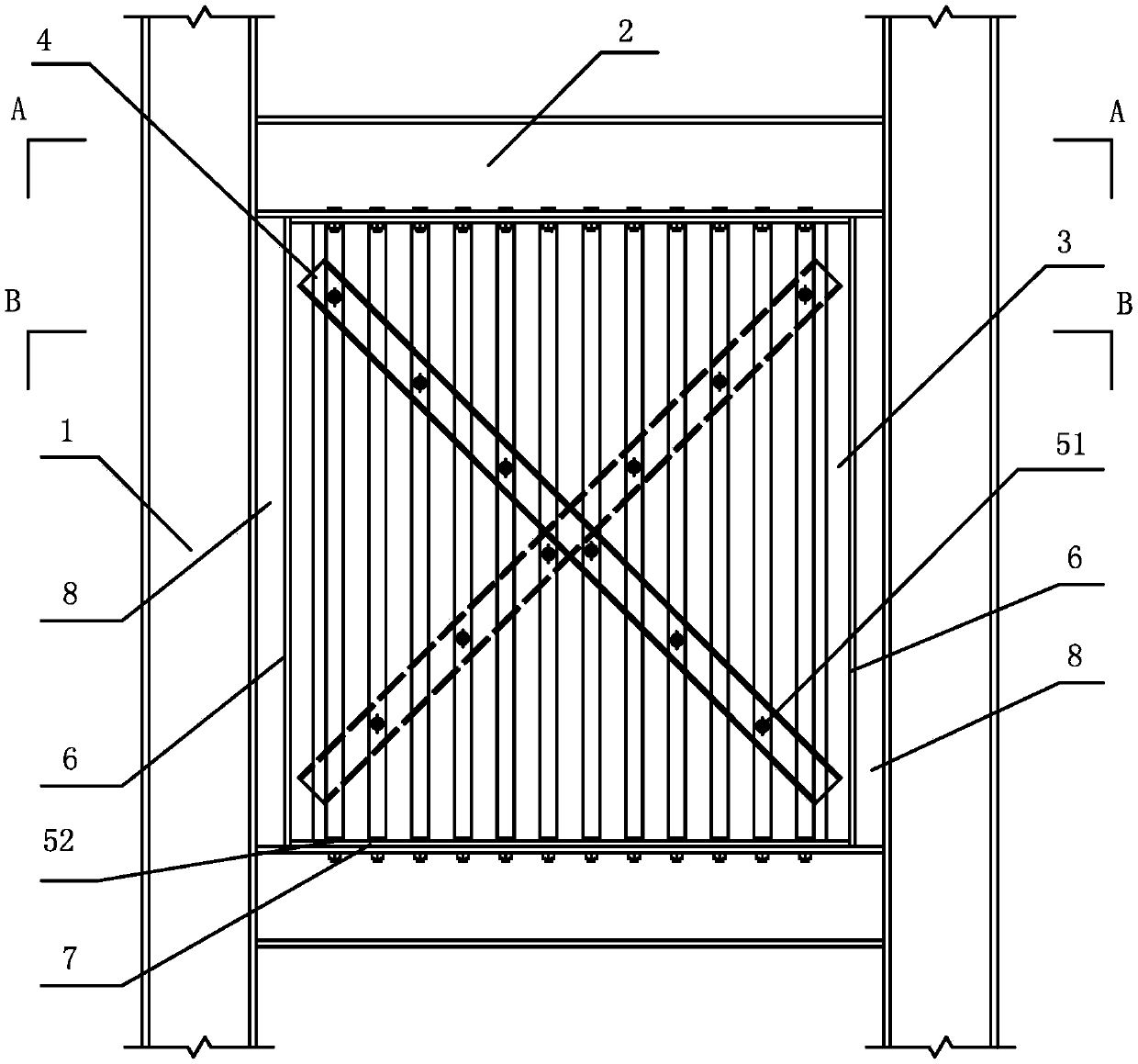

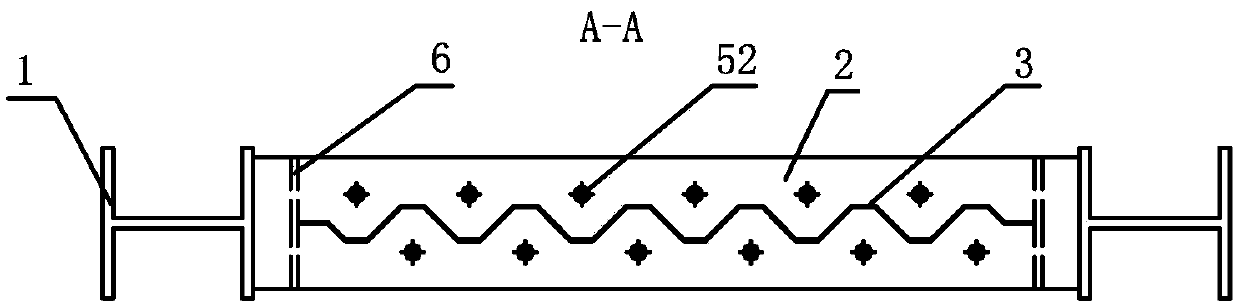

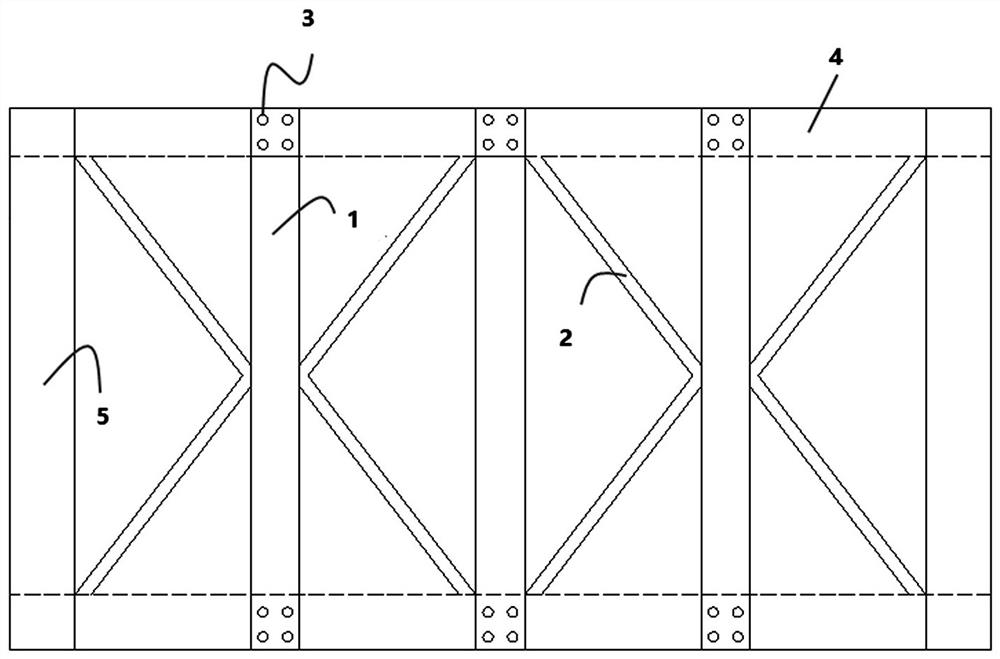

Intersecting reinforcement profiled steel plate shear wall with broadside slotting

InactiveCN106436969AIncrease vertical stiffnessReduce out-of-plane deformationWallsProtective buildings/sheltersSheet steelLevel line

The invention discloses an intersecting reinforcement profiled steel plate shear wall with broadside slotting. The profiled steel plate shear wall comprises an embedded steel plate which is arranged in a margin plate, a lengthways end plate or a crosswise end plate is arranged between the embedded steel plate and the margin frame, a gap is arranged between a margin frame column and the lengthways end plate; the embedded steel plate adopts corrugated profiled steel plate which sets the corrugation direction as a vertical direction, and two sides of the embedded steel plate are respectively connected with two profiled steel reinforcing ribs, wherein one of the two profiled steel reinforcing ribs is arranged in a direction which forms an included angle of 45 degrees with a horizontal line, and the two profiled steel reinforcing ribs are perpendicular to each other. The embedded steel plate has large vertical stiffness; the gap between the end plate and the margin frame column can not only eliminate a probable additional bending moment generated by the embedded steel plate on the margin frame column, but can also release dimension error of the broadside of the profiled steel plate; the profiled steel reinforcing ribs which are in cross arrangement restricts the relative position of the corrugated profiled steel plate in a corrugation plane; meanwhile, the profiled steel plate shear wall can be designed into a fabricated lateral force resisting component, thus realizing a sharp improvement in field assembly degree, and reducing workload in field construction.

Owner:TIANJIN UNIV

Steel-concrete combined special-shaped lattice column

ActiveCN111549906AFast on-site assemblyEasy constructionStrutsPillarsSteel tubeMechanical engineering

Owner:山东彤创建筑科技有限公司

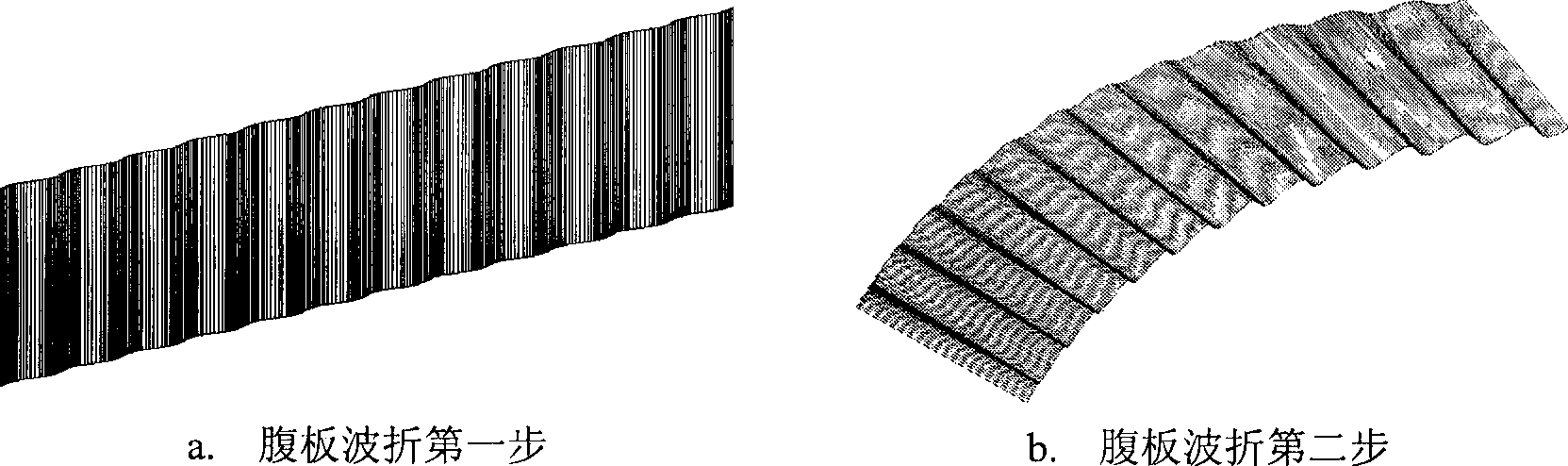

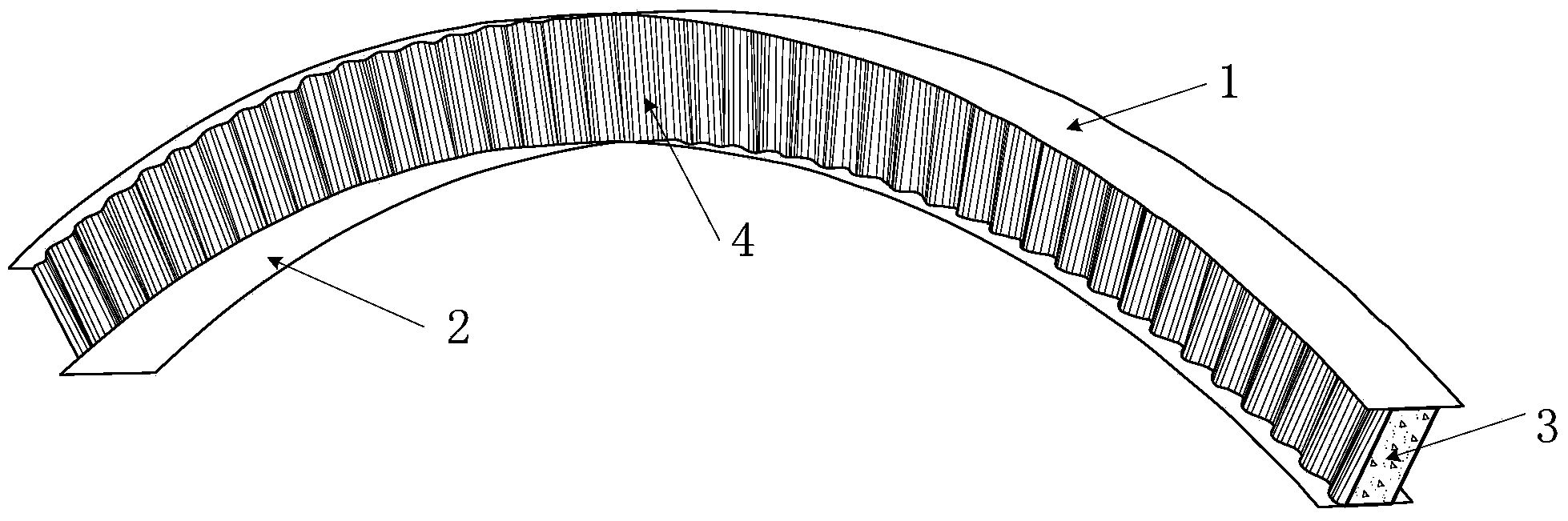

Wave web steel arch structure

InactiveCN101509303AHigh local buckling strengthIncrease out-of-plane stiffnessArched girdersPortal framesSheet steelWave shape

The invention relates to a novel wave-shaped ventral sheet steel arch structure, belonging to the technical field of structure engineering. The steel arch structure is composed of an upper flange slab, a lower flange slab and a wave-shaped arch ventral sheet which are connected by welding; the upper flange slab and the lower flange slab are hot rolled steels; and the wave-shaped arch ventral sheet is rolled by cool bending equipment from a regular thin and plane steel sheet. The wave-shaped arch ventral sheet is a uniform wave-shaped arch ventral sheet rolled by cool bending forming equipment from a regular strip-shaped steel sheet, then waves of different ranges and depths are rolled by the cool bending forming equipment, the ventral sheet automatically bends to form an arch, and the wave-shaped arch ventral sheet of different ratios of rise to span can be formed by adjusting the depth ratio of the upper wave range and the lower wave range of the ventral sheet. The wave-shaped arch ventral sheet steel arch structure provided by the invention is convenient in forming processing of the arch ventral sheet and saves material, has high partial bending strength of the wave-shaped ventral sheet and high surface external rigidity and is an excellent arch steel structure.

Owner:TSINGHUA UNIV

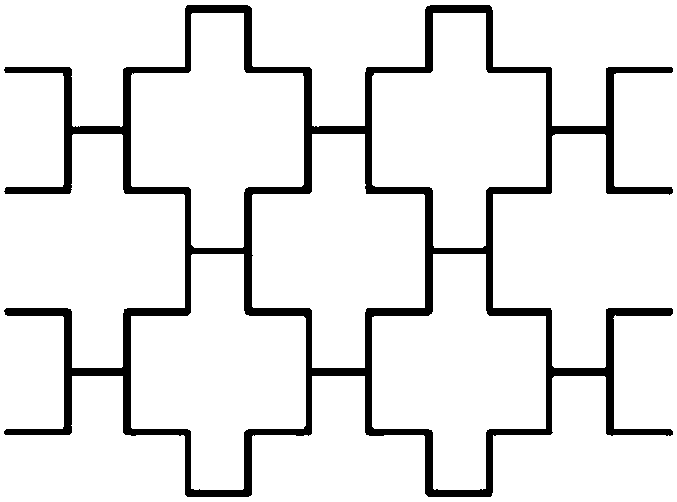

Shear wall composed of corrugated steel sheets and concrete-filled steel tubular members

PendingCN110284624AIncreased bending stiffnessImprove synergistic performanceWallsCold formedSheet steel

The invention relates to a shear wall composed of corrugated steel sheets and concrete-filled steel tubular members and belongs to the technical field of structural engineering. The shear wall comprises the rectangular concrete-filled steel tubular members or concrete-filled steel tubular members provided with split bolts, the corrugated steel sheets and C-shaped section cold forming sectional steel vertical edge members. The rectangular concrete-filled steel tubular members are formed in a cold roll forming mode or a welding mode. The multiple concrete-filled steel tubular members or the multiple concrete-filled steel tubular members provided with the split bolts are connected with the corrugated steel sheets in sequence in a welding mode, so that a main pressure-bearing framework of the shear wall is formed. According to the shear wall formed by directly welding the concrete-filled steel tubular members and the corrugated steel sheets, section plates can be directly connected during upper and lower shear wall splicing, the shortcoming that inner partition plates of a continuous multi-cavity shear wall fail to be connected directly during splicing, and consequentially, axial force transmission is interrupted is overcome, and the material utilization efficiency is greatly improved; and the shear wall has the advantages of high bearing efficiency, flexible plane arrangement and the like.

Owner:TSINGHUA UNIV

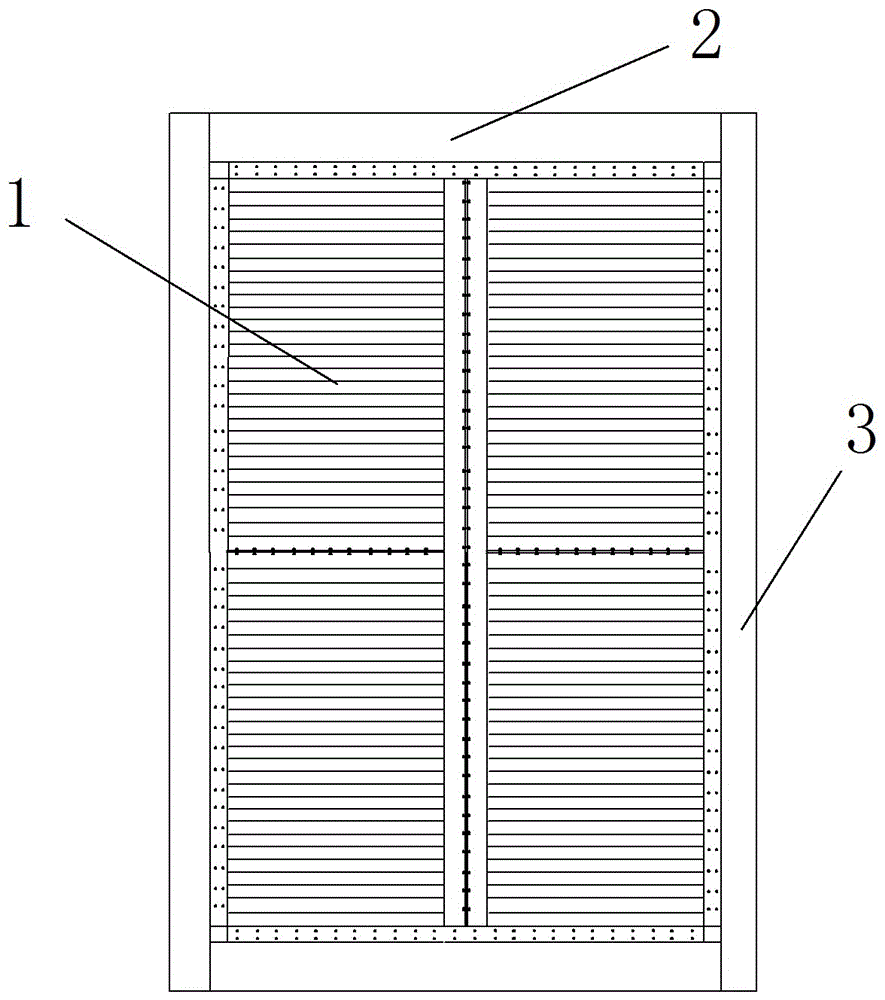

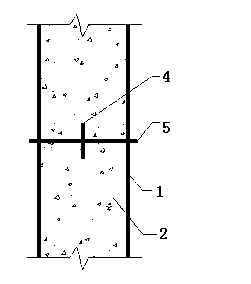

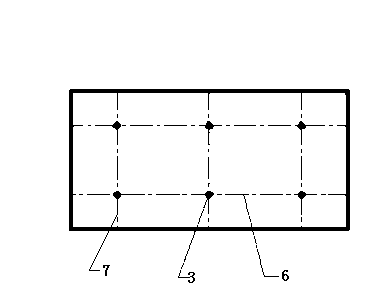

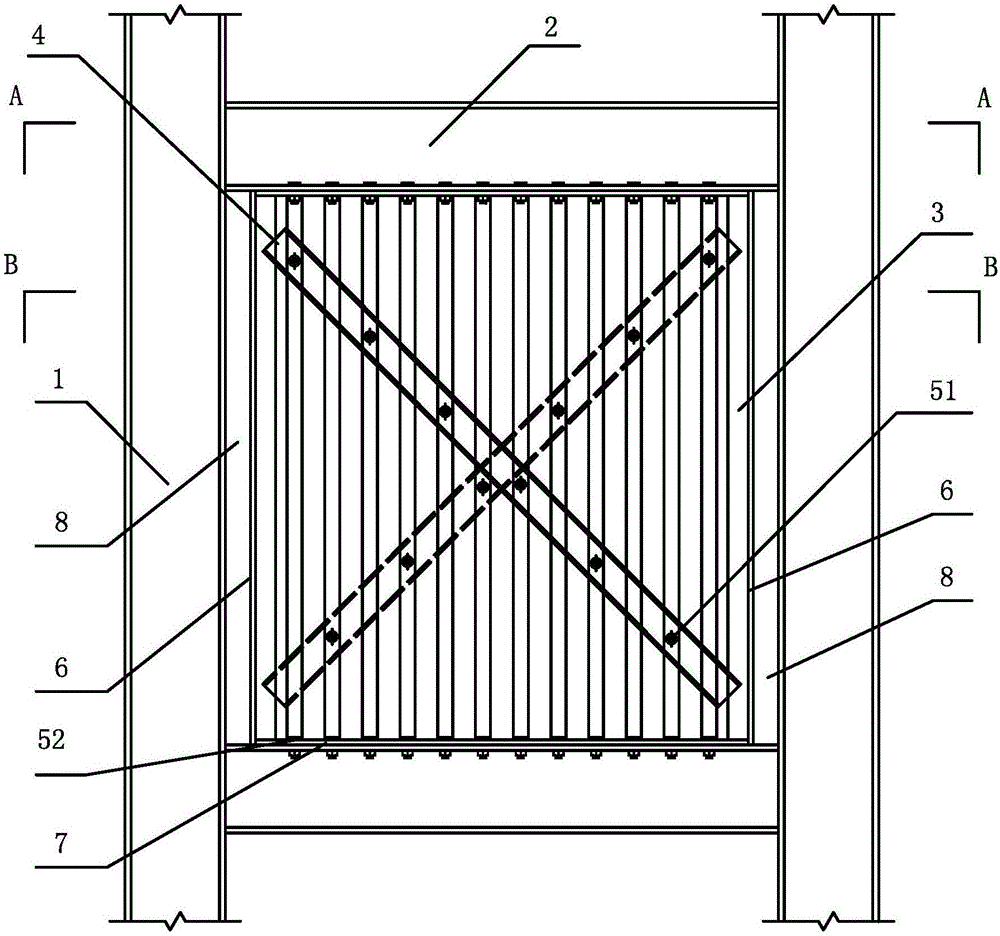

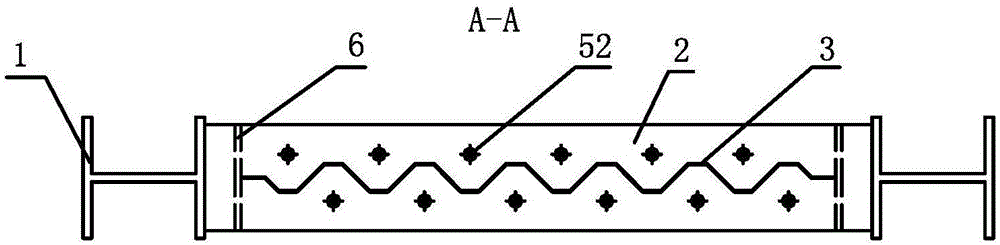

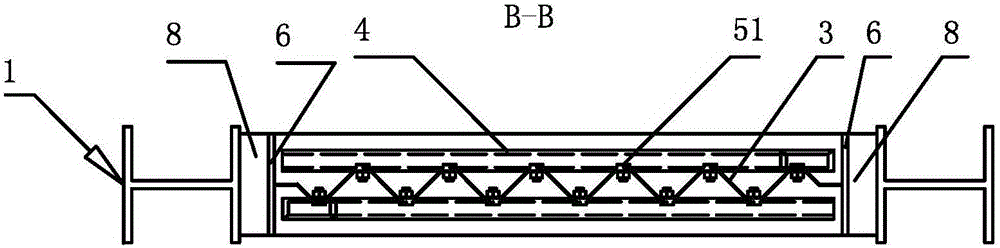

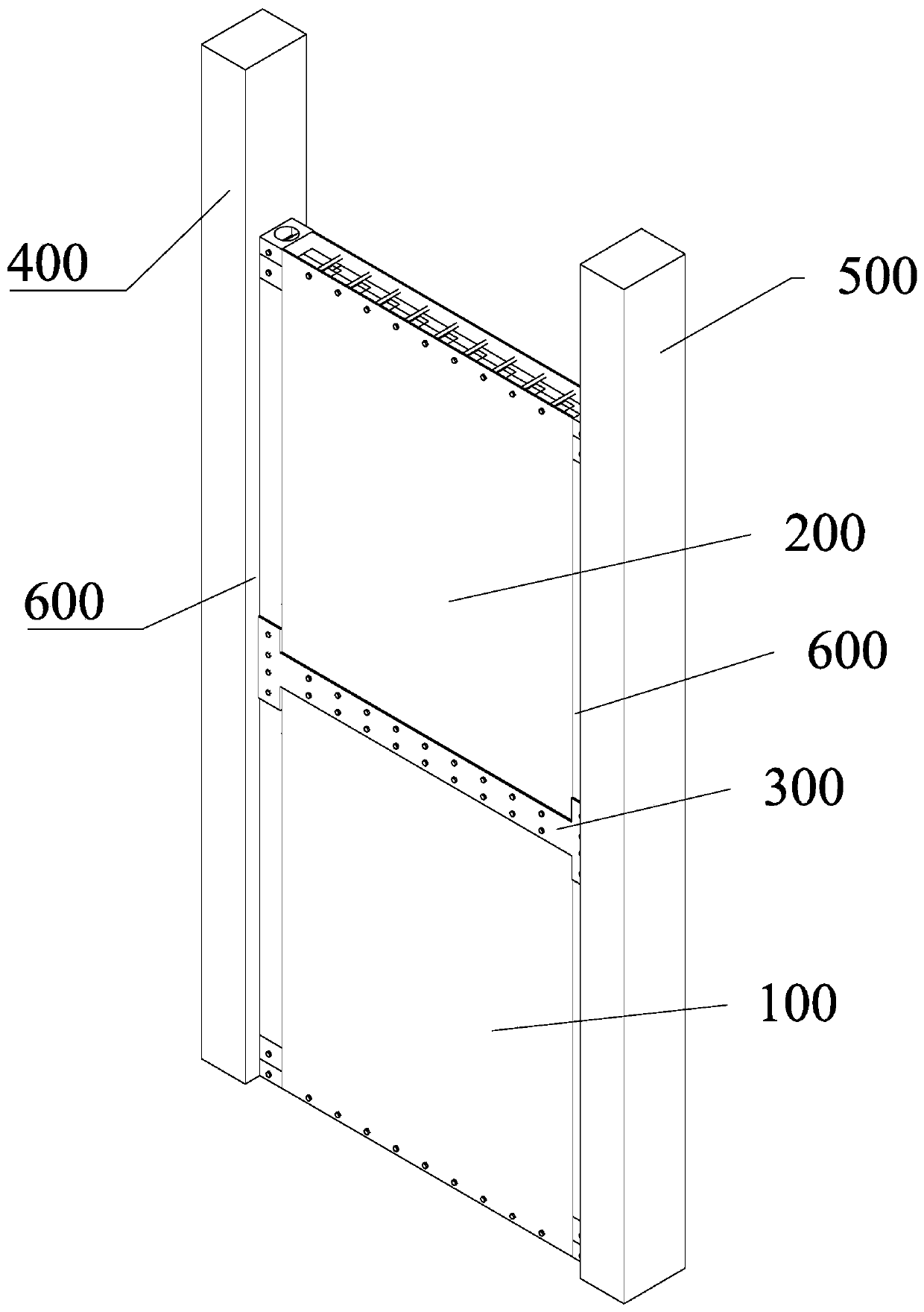

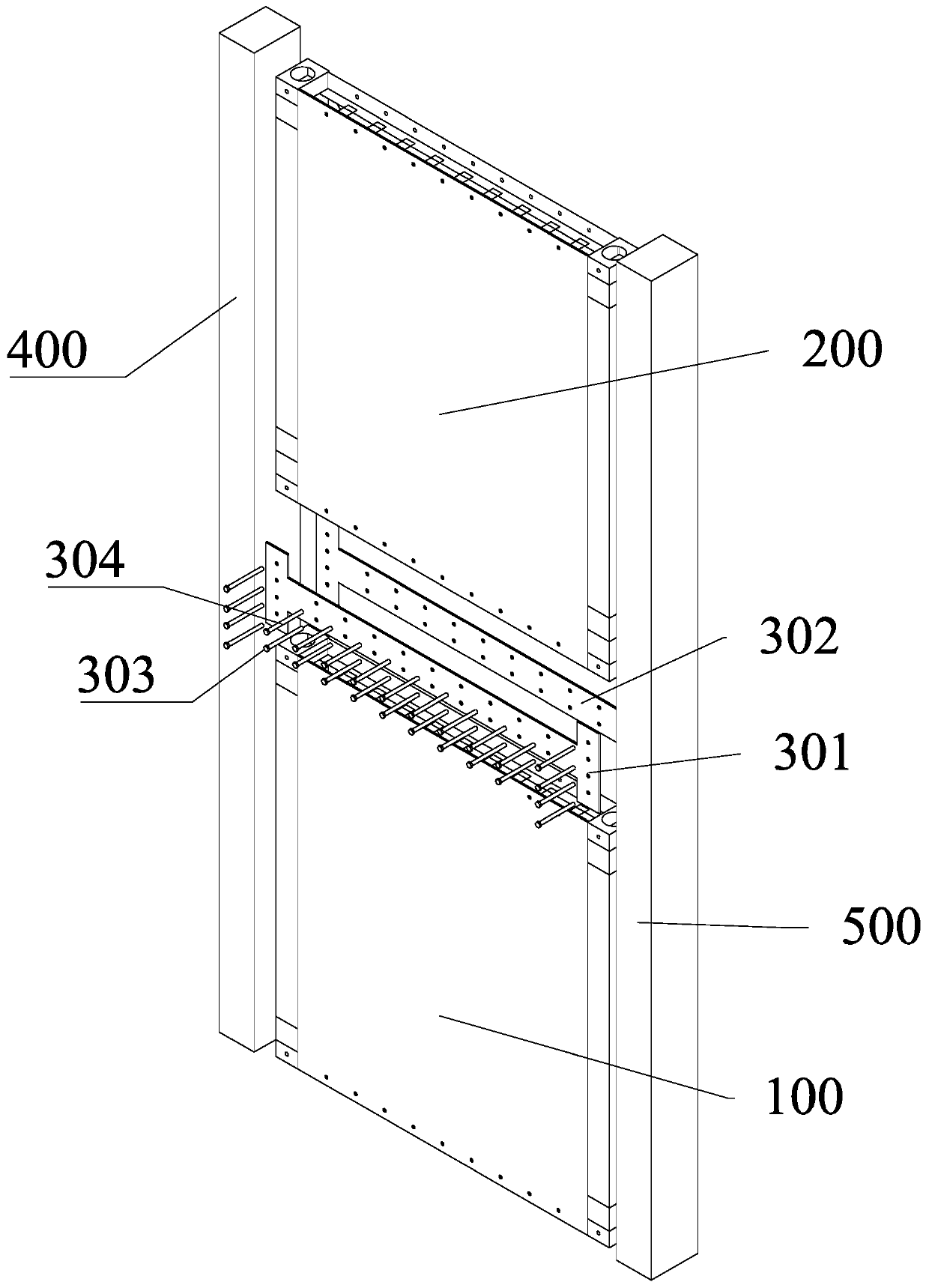

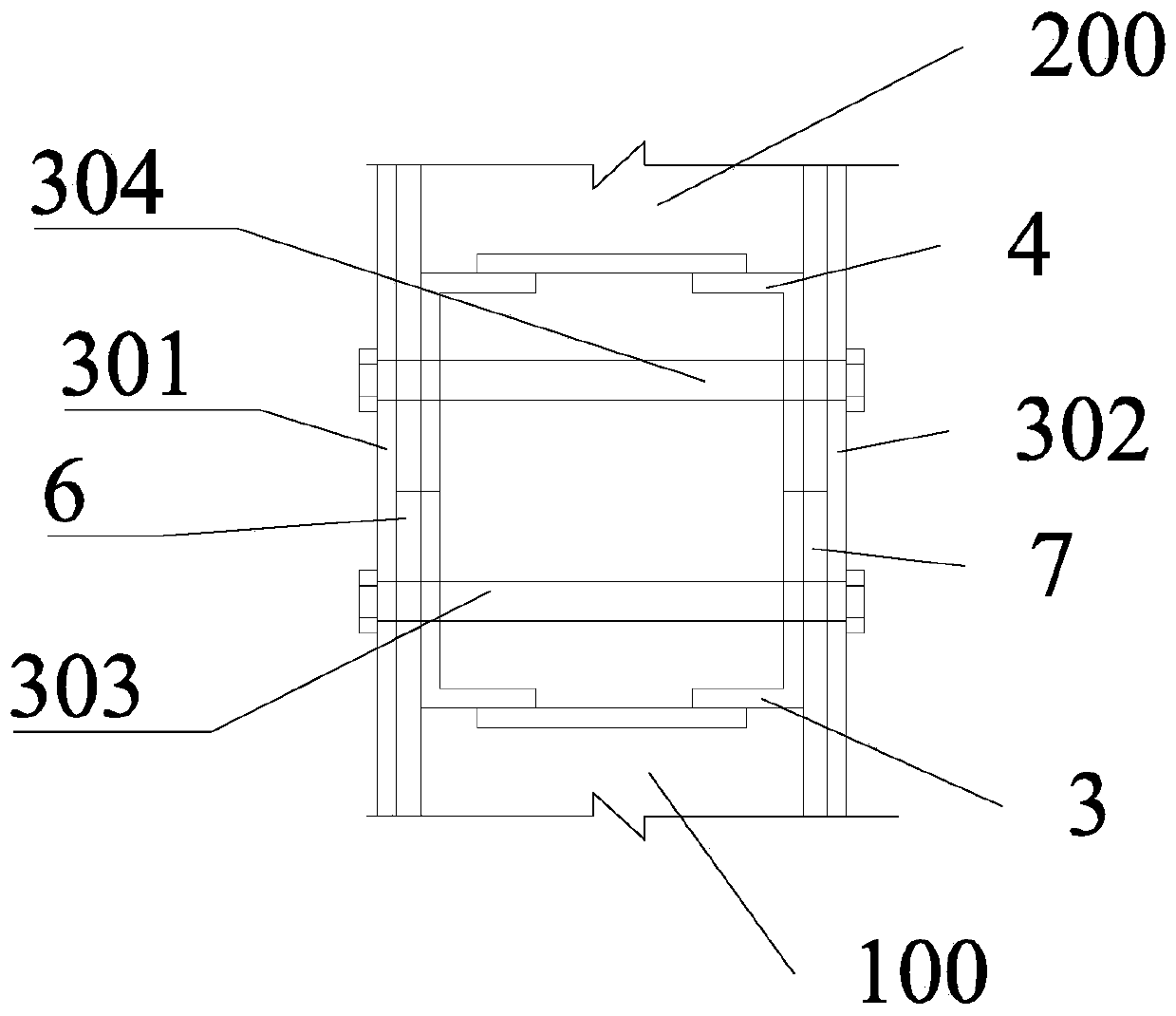

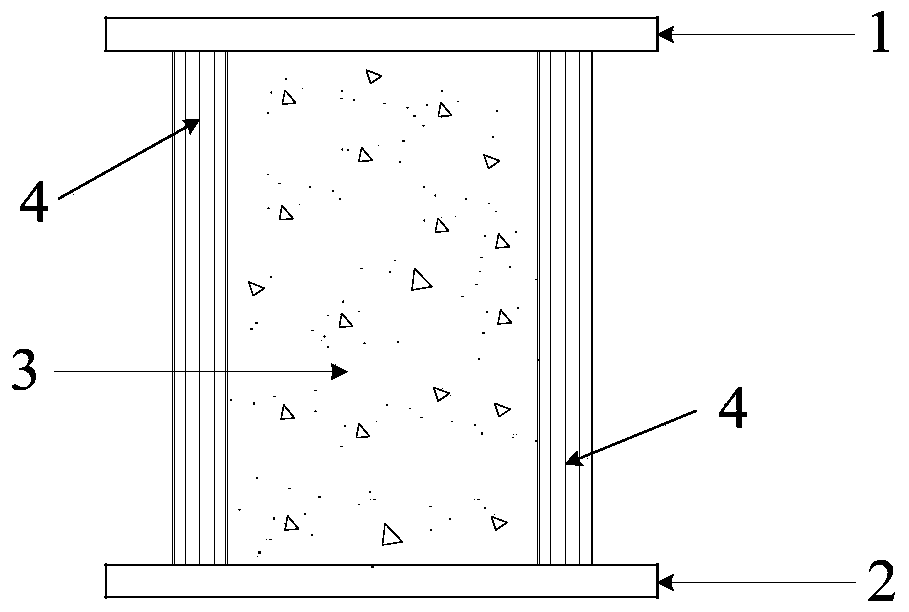

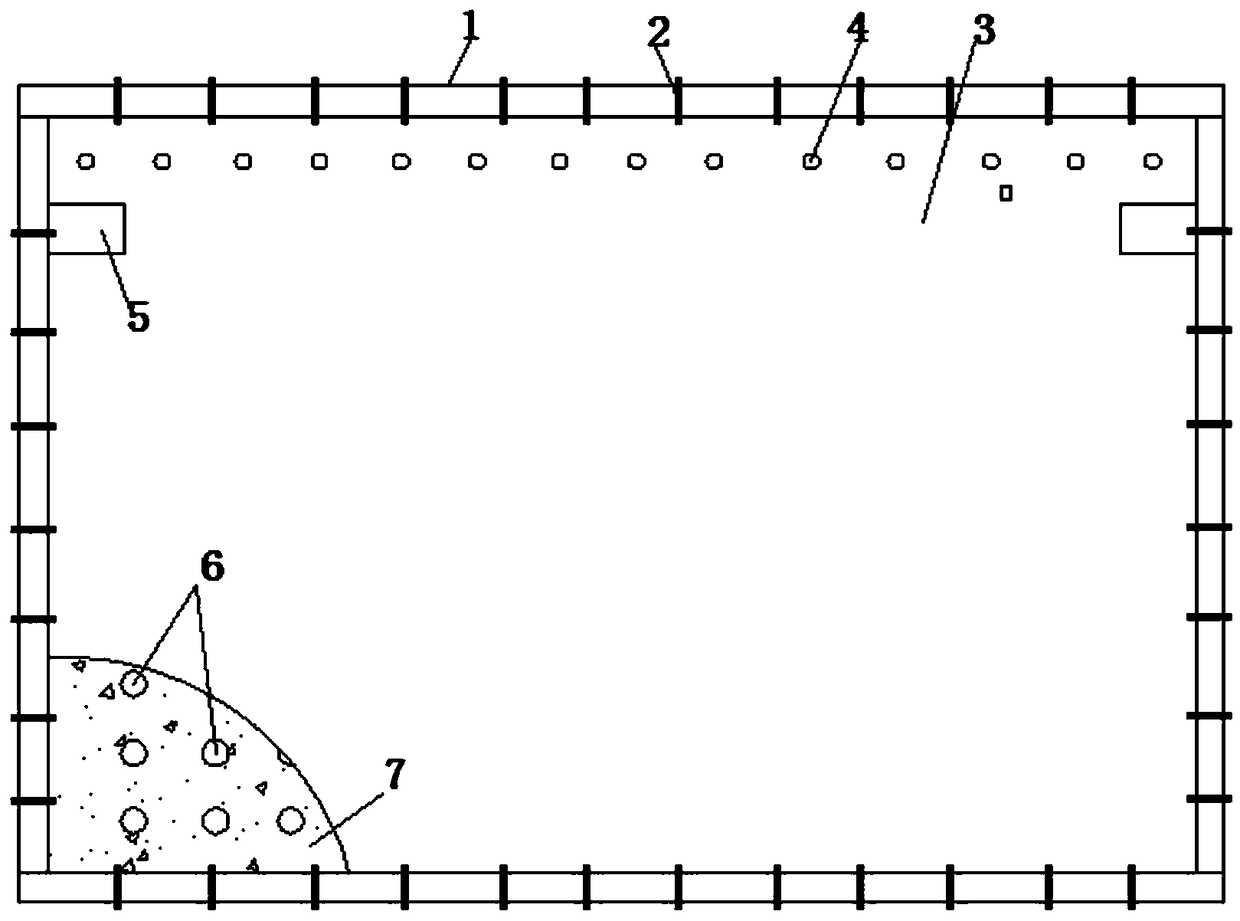

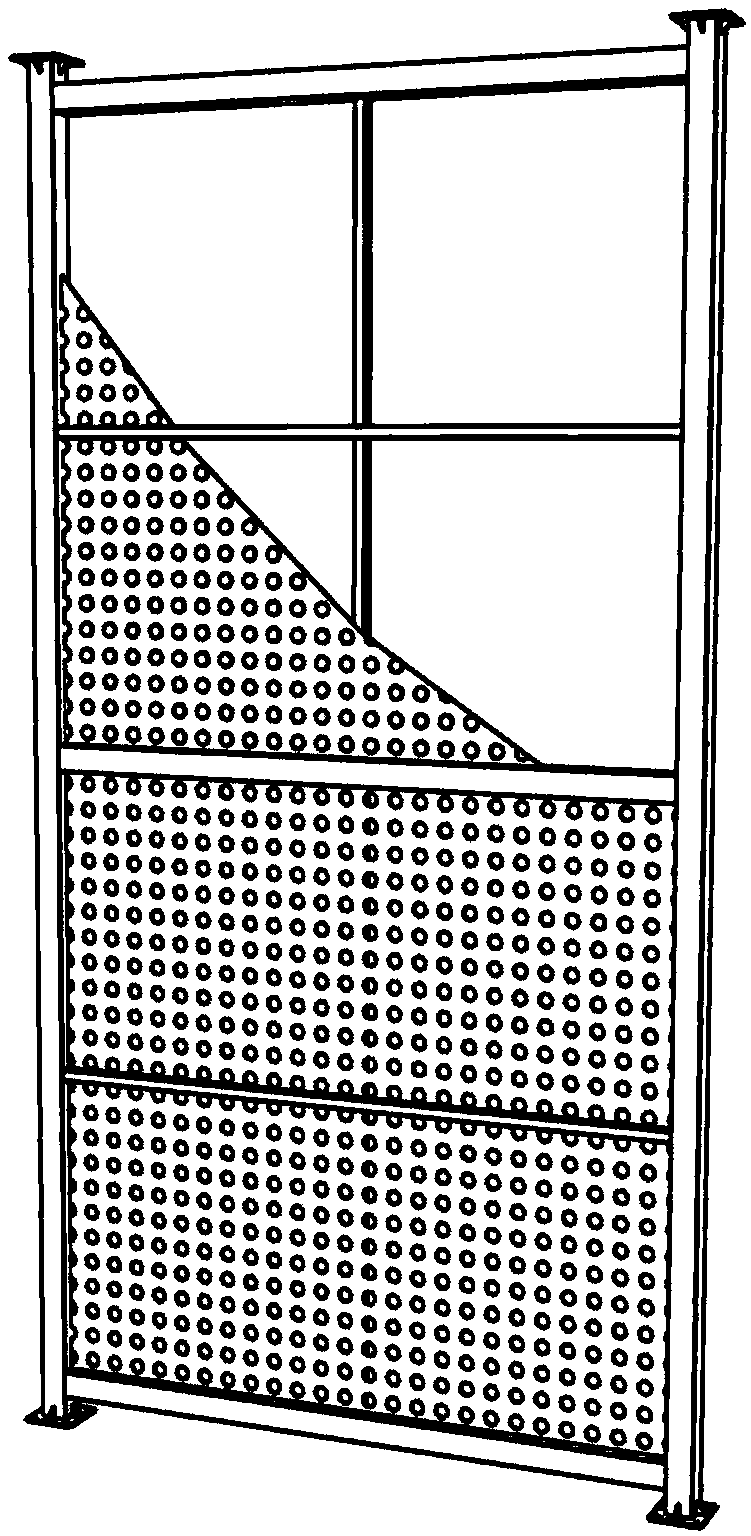

Fabricated shear wall with steel plate stud combined type diagonal bracing and construction method

PendingCN110512765AIncrease out-of-plane stiffnessIncrease height-to-thickness ratio limitWallsIn planeLateral stiffness

The invention discloses a fabricated shear wall with a steel plate stud combined type diagonal bracing and a construction method. The fabricated shear wall comprises a first shear wall unit and a second shear wall unit, wherein the first shear wall unit and the second shear wall unit are stacked up and down, and the first shear wall unit and the second shear wall unit are connected and fixed witha connecting mechanism; the first shear wall unit and the second shear wall unit are provided with shear wall structures; a shear wall frame is formed by enclosing a left concealed column, an upper concealed beam, a right concealed column and a lower concealed frame; a first facade steel plate and a second facade steel plate are fixed to the front side and the rear side of the shear wall frame; diagonal bracing members are fixed in the shear wall frame; and each diagonal bracing member comprises two steel plates, the two steel plates cross each other to form an X-shape structure, studs are arranged on the steel plates, and concrete is poured in the shear wall units. According to the fabricated shear wall with the steel plate stud combined type diagonal bracing and the construction method,the in-plane lateral stiffness, shear bearing capacity, bending bearing capacity, ductility and energy consumption of the shear wall are improved through the design of the diagonal bracing members, the shear wall units can be pre-installed in advance, and on-site construction is facilitated.

Owner:SOUTH CHINA UNIV OF TECH +2

Axial-rib corrugated web steel-concrete composite coupling beam

InactiveCN108612258AIncrease out-of-plane stiffnessSuppresses out-of-plane deformationWallsLoad-supporting elementsEngineeringRebar

The invention provides an axial-rib corrugated web steel-concrete composite coupling beam which at least comprises a plurality of steel flanges, steel corrugated webs, high-damping concrete, butt welds and stiffening plates. According to the axial-rib corrugated web steel-concrete composite coupling beam, after the steel flanges and the corrugated steel webs are assembled in a factory into a coupling beam steel box, the high-damping concrete is poured on site with the coupling beam steel box as a formwork; the corrugated steel webs have large out-of-plane stiffness, and thus out-of-plane deformation of the composite coupling beam wrapped with a steel plate can be effectively restrained; the steel flanges and the steel corrugated webs are connected through the butt welds, and thus the connecting strength is ensured; the high-damping concrete is used, and thus the obvious advantages in the bearing capacity, energy dissipation capacity and stiffness are achieved; and compared with a flatweb composite coupling beam, the structure of the axial-rib corrugated web has the more excellent anti-seismic performance. The axial-rib corrugated web steel-concrete composite coupling beam is suitable for connecting of steel-concrete composite shear walls in a high-rise hybrid structure system; compared with a reinforced concrete connecting beam, the axial-rib corrugated web steel-concrete composite coupling beam can better meet the demands of the overall structure for deformation and energy dissipation of the connecting beam and has good construction convenience, and the engineering construction cost is saved while the construction progress is accelerated.

Owner:TONGJI UNIV

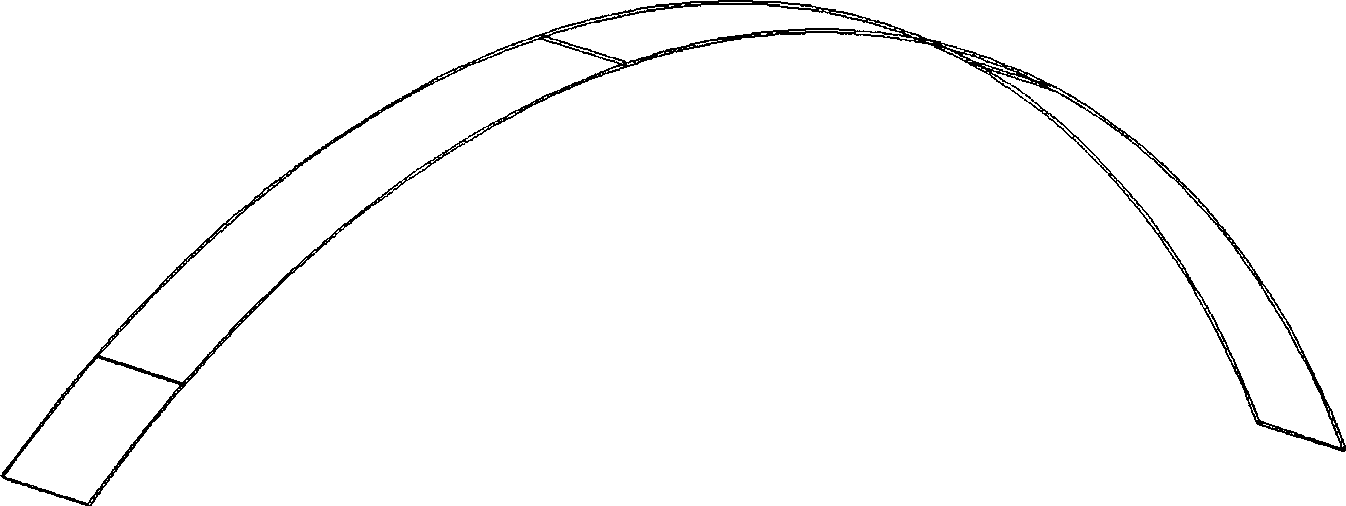

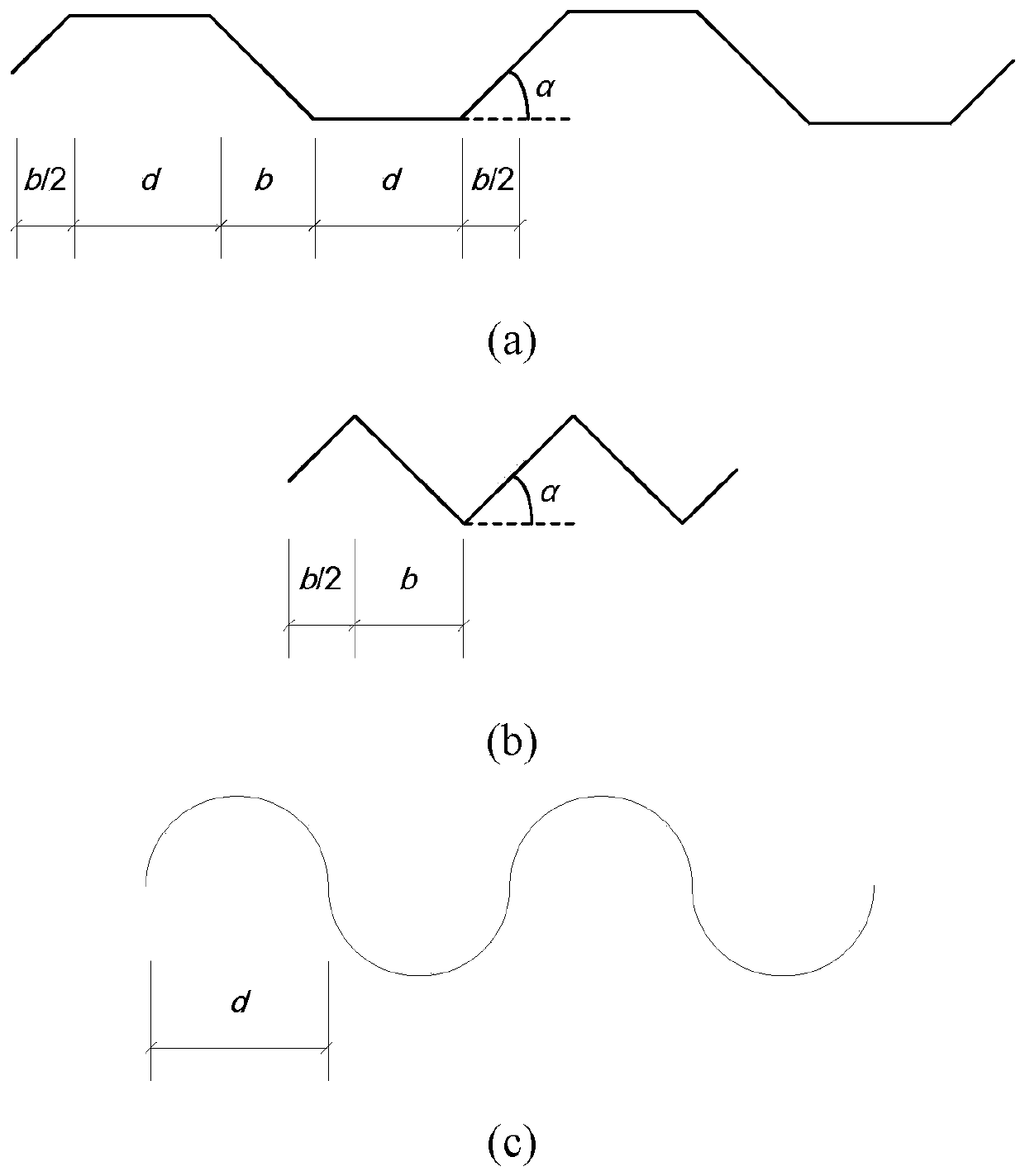

Corrugated web box-section steel-concrete combined arch

InactiveCN103643765AClear division of laborHigh compressive strengthArched girdersPortal framesButt weldingOut of plane

Belonging to the field of structural engineering, the invention relates to a corrugated web box-section steel-concrete combined arch. The combined arch is characterized in that it is formed by direct butt welding of two corrugated web H-shaped section steel arches through an upper flat flange plate and a lower flat flange plate along the arch axis direction; and concrete is poured into the box-section to form a steel tube concrete combined arch structure. The corrugated web H-shaped section steel arches have a biaxial symmetric H-shaped section or uniaxial symmetric H-shaped section, and the corrugated web is a trapezoidal zigzag steel plate or sinusoidal wave steel plate. The combined arch provided by the invention is a large span space structure member with superior overall mechanical performance, and has the characteristics of convenient manufacturing, clear labor division of section stress. The box-section has strong torsional stiffness and arch axial out-of-plane flexural rigidity. The restraint function provided by the corrugated web improves the compressive strength and ductility of core concrete, and the supporting effect provided by the core concrete strengthens the local stability of the corrugated web and the flange plates.

Owner:TSINGHUA UNIV

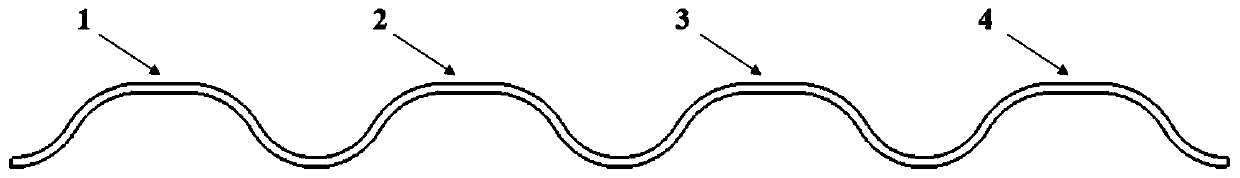

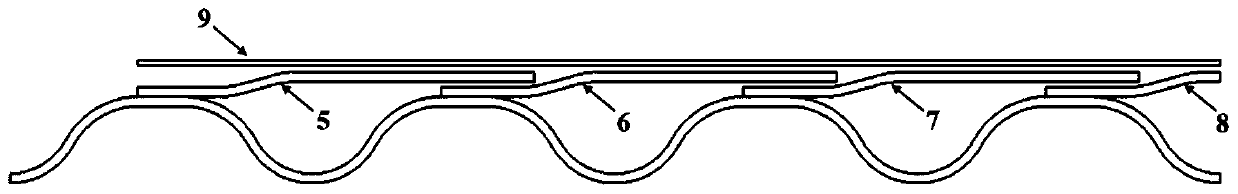

Corrugated structure-based sliding type flexible composite material skin

ActiveCN111319752AIncrease out-of-plane stiffnessSmooth aerodynamic surfaceWing adjustmentsElastomerAerodynamic load

The invention relates to a corrugated structure-based sliding type flexible composite material skin. The corrugated structure-based sliding type flexible composite material skin is composed of a composite material corrugated plate, composite material thin plates and an elastomer layer. The connection relations of the composite material corrugated plate, the composite material thin plates and the elastomer layer are as follows: the composite material thin plates are bonded on the horizontal cementing surfaces of the composite material corrugated plate; the left side of each composite material thin plate is cemented on a corresponding horizontal cementing surface at a wave crest, and is in lap joint with one composite material thin plate at an adjacent wave crest at the right side; and the elastomer layer is tightly attached to the composite material thin plates. The characteristic that the composite corrugated plate has large rigidity in a corrugated direction and the characteristic that the composite thin plates have large out-of-plane rigidity are combined, and therefore, a large deformation function can be achieved, out-of-plane aerodynamic loads can be resisted. The corrugated structure-based sliding type flexible composite material skin has the advantages of simple structure and low weight. The flexible skin scheme for a morphing wing is practical and feasible.

Owner:BEIHANG UNIV

Assembled double steel plate combined shear wall structure with rib plates and construction method of structure

PendingCN109235702APrevent bucklingReduce crack widthWallsBuilding material handlingEngineeringOut of plane

Owner:刘凯 +1

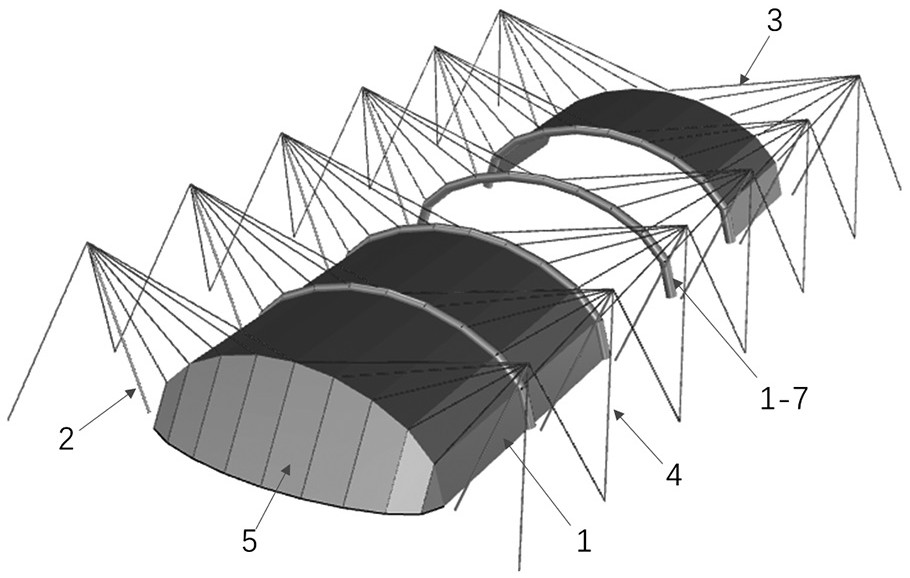

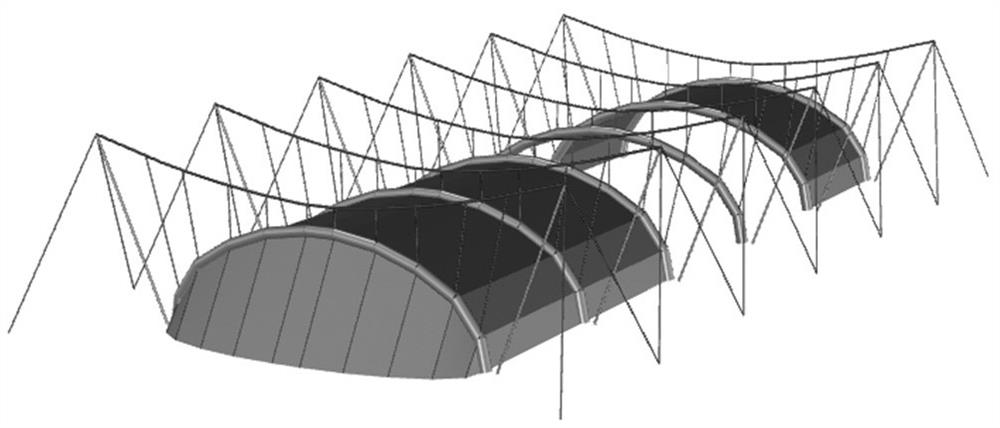

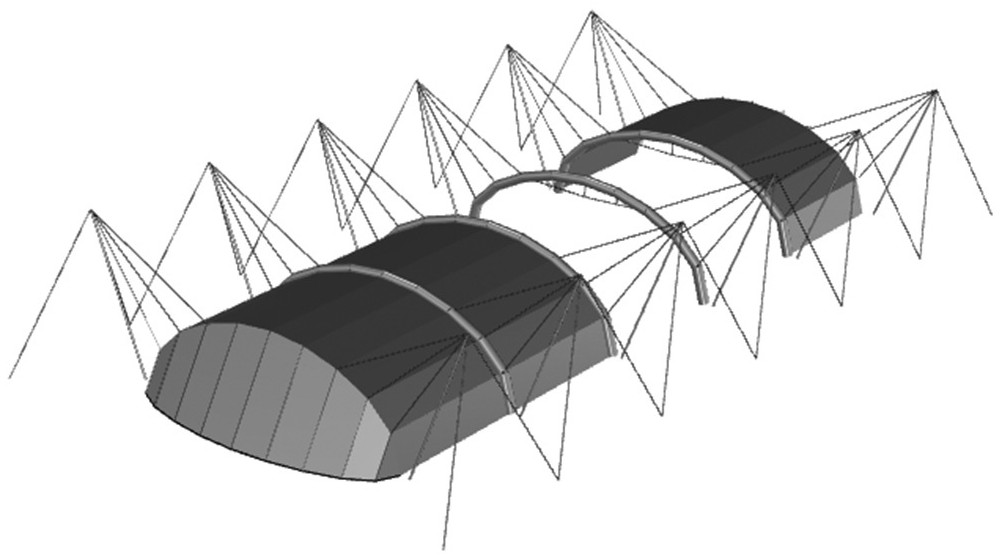

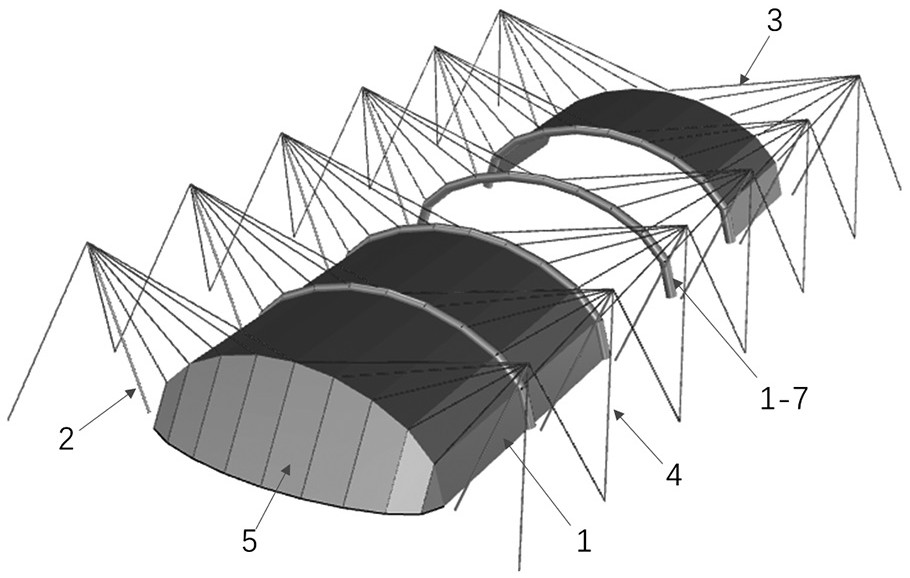

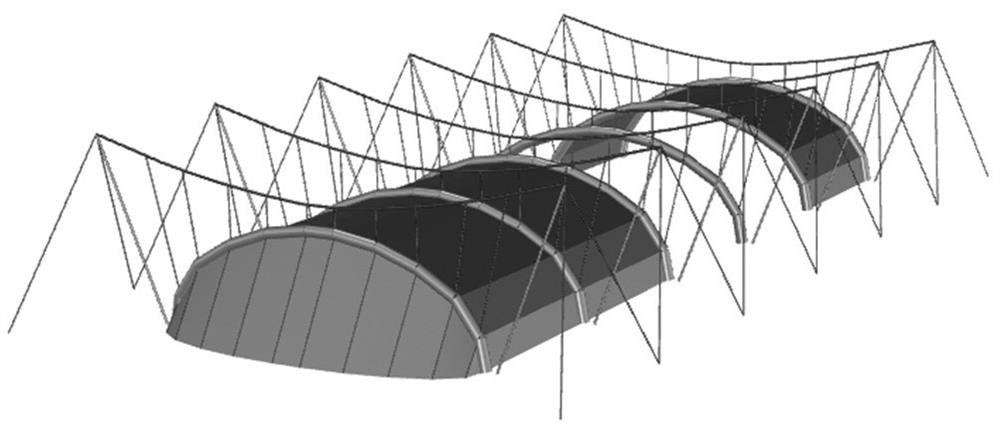

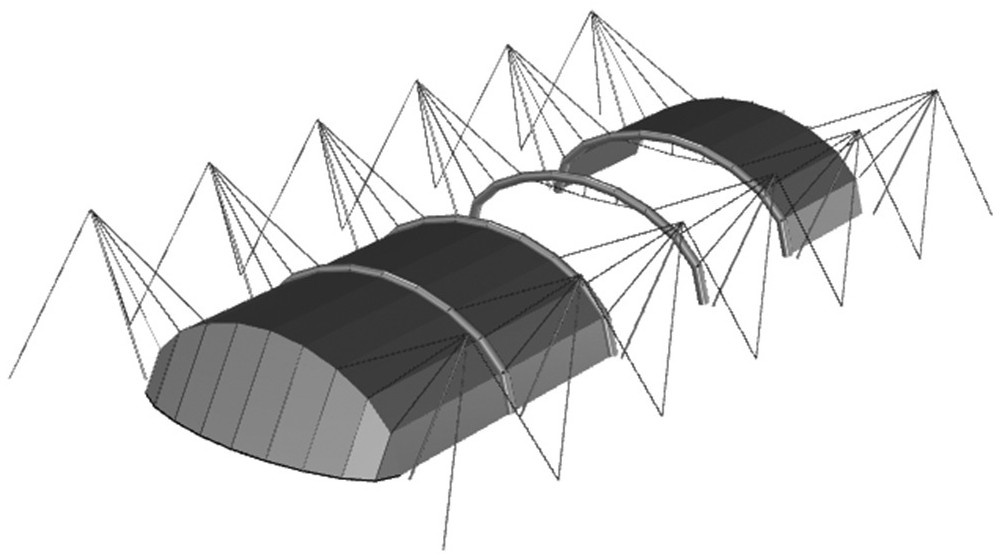

Unidirectional tension metal sheet space structure and construction method

ActiveCN114517532AReasonable forceLess materialBuilding roofsArched structuresPre stressSpatial structure

The invention relates to a one-way tension metal sheet space structure, which is used for a large-span building, and comprises a metal sheet which is formed by tension and forms the space structure; the steel columns are arranged on the two sides of the space structure span; one ends of the tension cables are fixedly connected to the top ends of the steel columns on the two sides, and the other ends are connected with the metal sheets from the two sides of the space structure span; one end of the back cable is connected with the top end of the steel column; and the gable plates are arranged at the two ends of the metal thin plate and provided with gable back cables. The stress structure and the building envelope structure are integrally designed, the metal sheets are formed by applying in-plane prestress in a tensioning mode, the whole structure can be continuously arranged in a multi-span mode, and good plane adaptability and good economic performance are achieved. The structure system can be used for building a super-large-span temporary and permanent closed stockyard engineering structure system with the span exceeding 300 m, and has the advantages of being safe, reliable, reasonable in design, economical in material, easy and convenient to construct and the like.

Owner:NORTH CHINA INST OF SCI & TECH

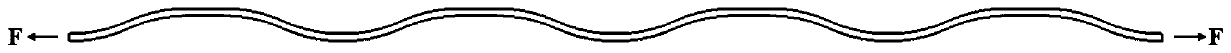

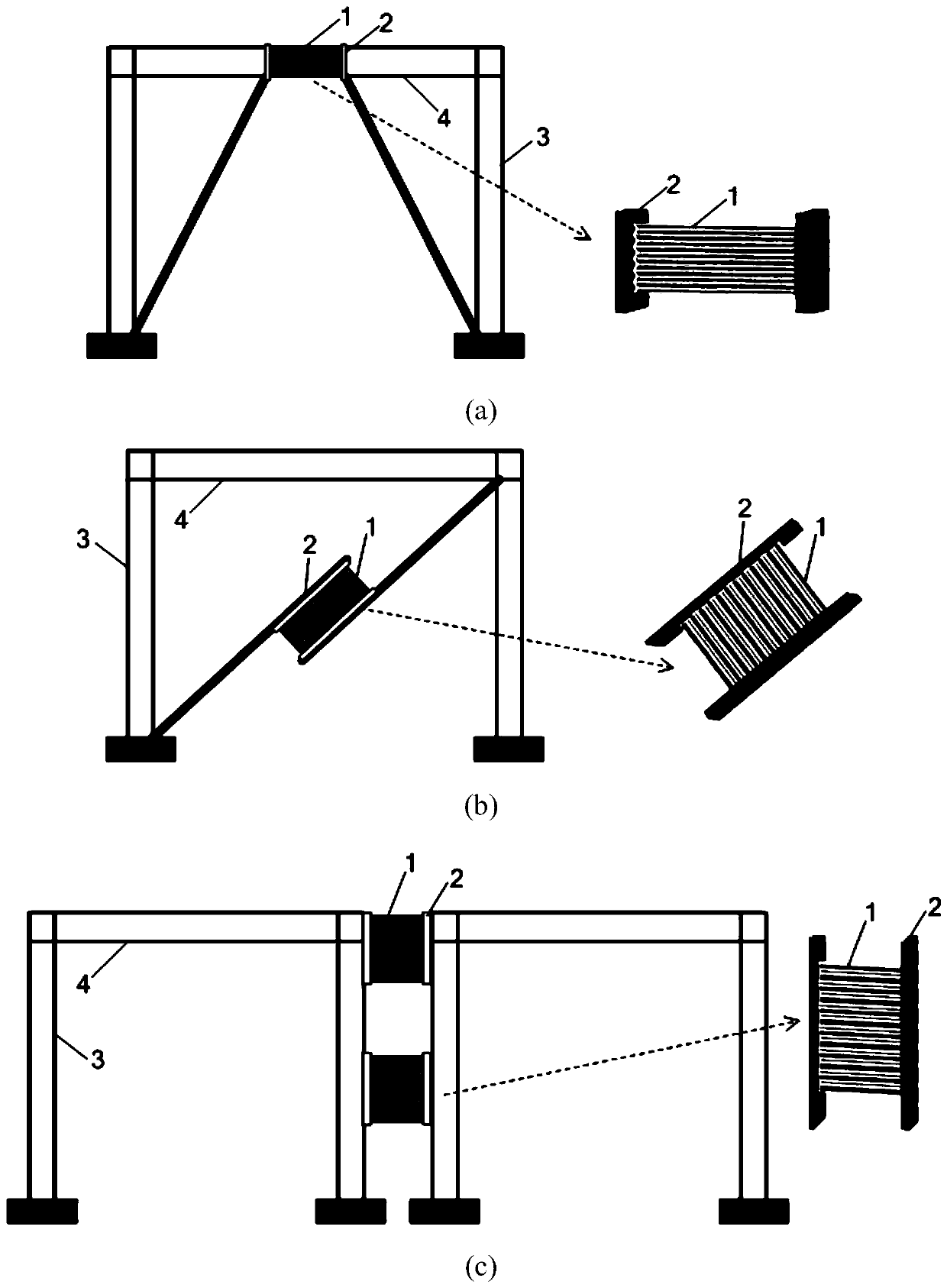

Corrugated type replaceable energy dissipation device with controllable performance

PendingCN111119364AEasy to manufactureEasy to install on siteProtective buildings/sheltersShock proofingManufacturing technologyClassical mechanics

The invention belongs to the technical field of constructional engineering seismic energy dissipation, and provides a corrugated type replaceable energy dissipation device with the controllable performance. The device is mainly composed of a corrugated steel plate and two connecting plates. The corrugated steel plate is of an integrated structure, and the two ends of the corrugated steel plate arewelded to the connecting plates respectively, so that an I-shaped structure is formed. Out-plane buckling can be effectively avoided due to corrugations of the corrugated steel plate, the out-plane rigidity is improved, then, in-plane bearing capacity and rigidity degeneration are remarkably lowered, a hysteresis curve is full, and the energy dissipation capacity is improved. By changing the included angle between the connecting plates and the directions of corrugated lines, the bearing capacity and the rigidity of the corrugated steel plate can be adjusted, steel plate alignment is enhancedor weakened, and then the actual requirements of different projects for dampers can be precisely matched. Compared with the prior art, the manufacturing technology is simple, the steel plate performance is stable, installation is convenient, the device has the advantages that the energy dissipation capacity is high, the bearing capacity and rigidity are controllable, after an earthquake, the device can be replaced, and therefore the using function of the structure can be rapidly recovered, and the device can be used for improving the structure post-earthquake function restorability.

Owner:DALIAN UNIV OF TECH

A cross-stiffened steel plate shear wall with side slits

InactiveCN106436969BIncrease vertical stiffnessReduce out-of-plane deformationWallsProtective buildings/sheltersSteel plate shear wallVertical stiffness

The invention discloses an intersecting reinforcement profiled steel plate shear wall with broadside slotting. The profiled steel plate shear wall comprises an embedded steel plate which is arranged in a margin plate, a lengthways end plate or a crosswise end plate is arranged between the embedded steel plate and the margin frame, a gap is arranged between a margin frame column and the lengthways end plate; the embedded steel plate adopts corrugated profiled steel plate which sets the corrugation direction as a vertical direction, and two sides of the embedded steel plate are respectively connected with two profiled steel reinforcing ribs, wherein one of the two profiled steel reinforcing ribs is arranged in a direction which forms an included angle of 45 degrees with a horizontal line, and the two profiled steel reinforcing ribs are perpendicular to each other. The embedded steel plate has large vertical stiffness; the gap between the end plate and the margin frame column can not only eliminate a probable additional bending moment generated by the embedded steel plate on the margin frame column, but can also release dimension error of the broadside of the profiled steel plate; the profiled steel reinforcing ribs which are in cross arrangement restricts the relative position of the corrugated profiled steel plate in a corrugation plane; meanwhile, the profiled steel plate shear wall can be designed into a fabricated lateral force resisting component, thus realizing a sharp improvement in field assembly degree, and reducing workload in field construction.

Owner:TIANJIN UNIV

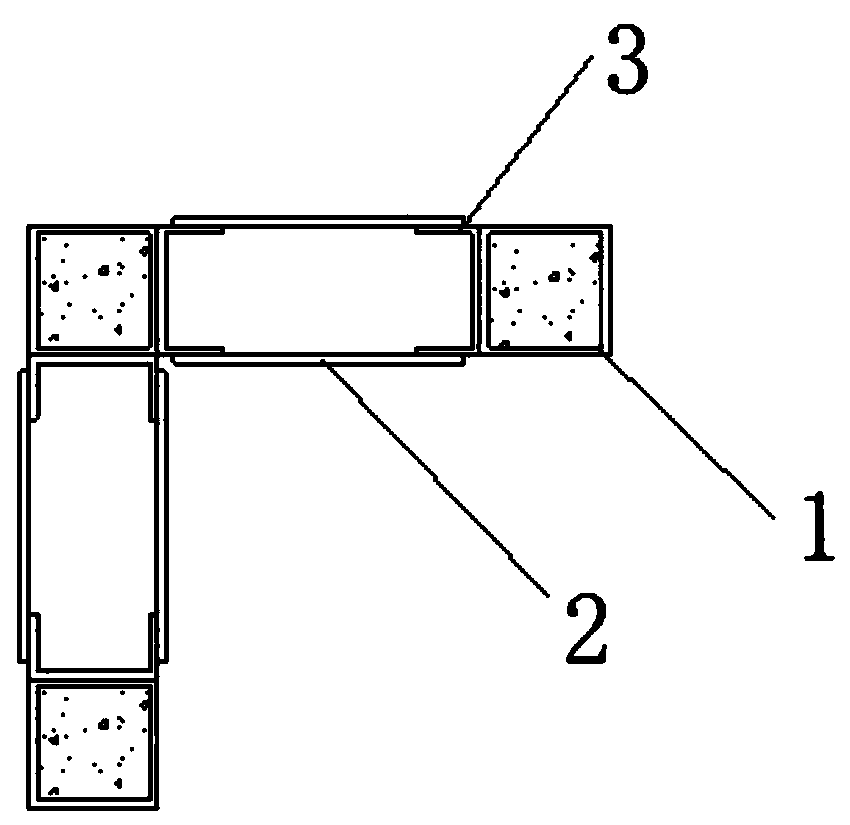

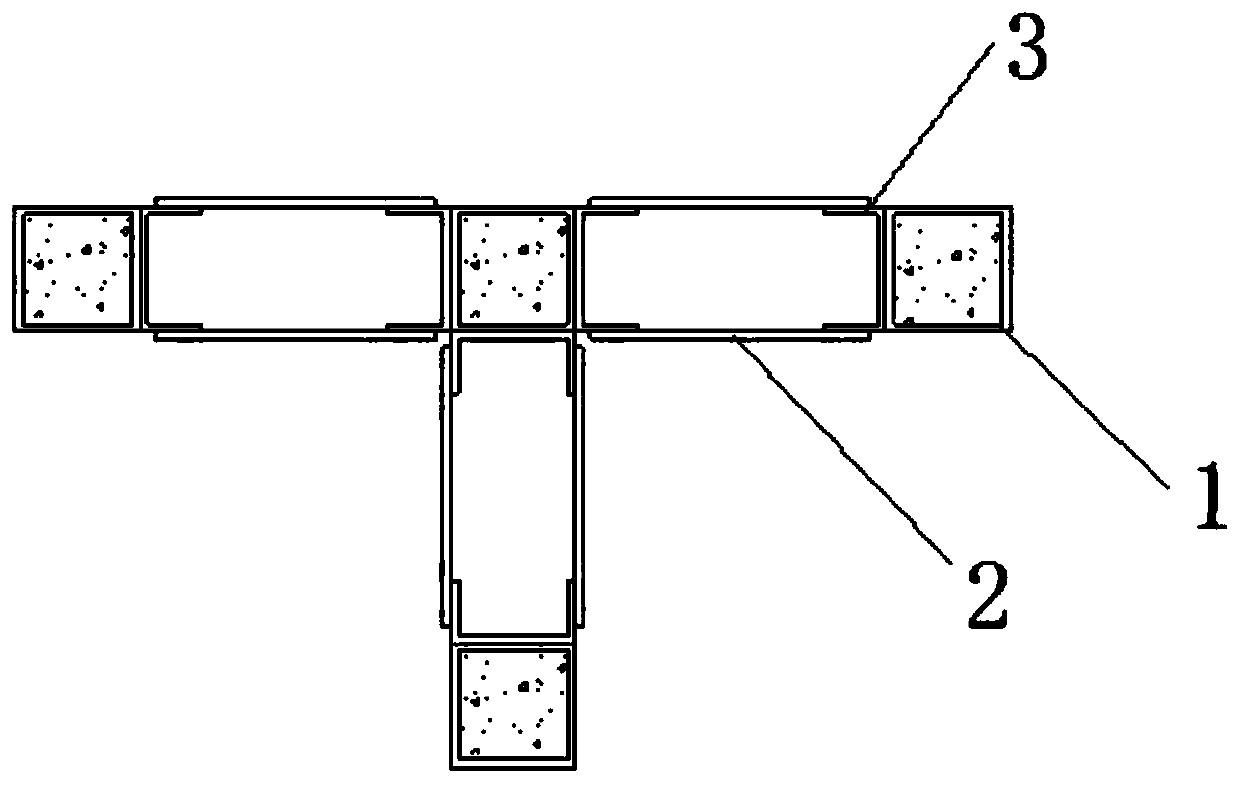

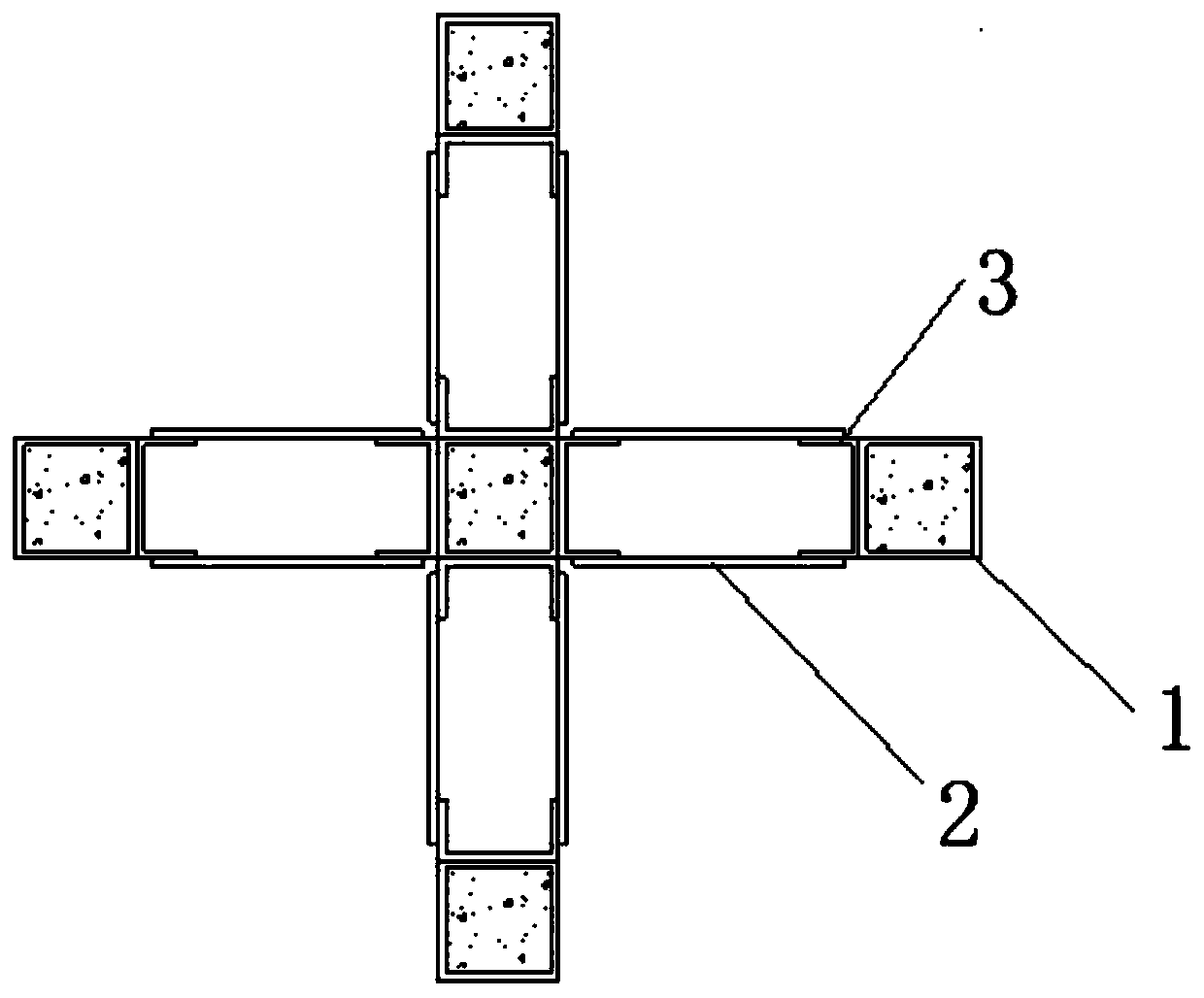

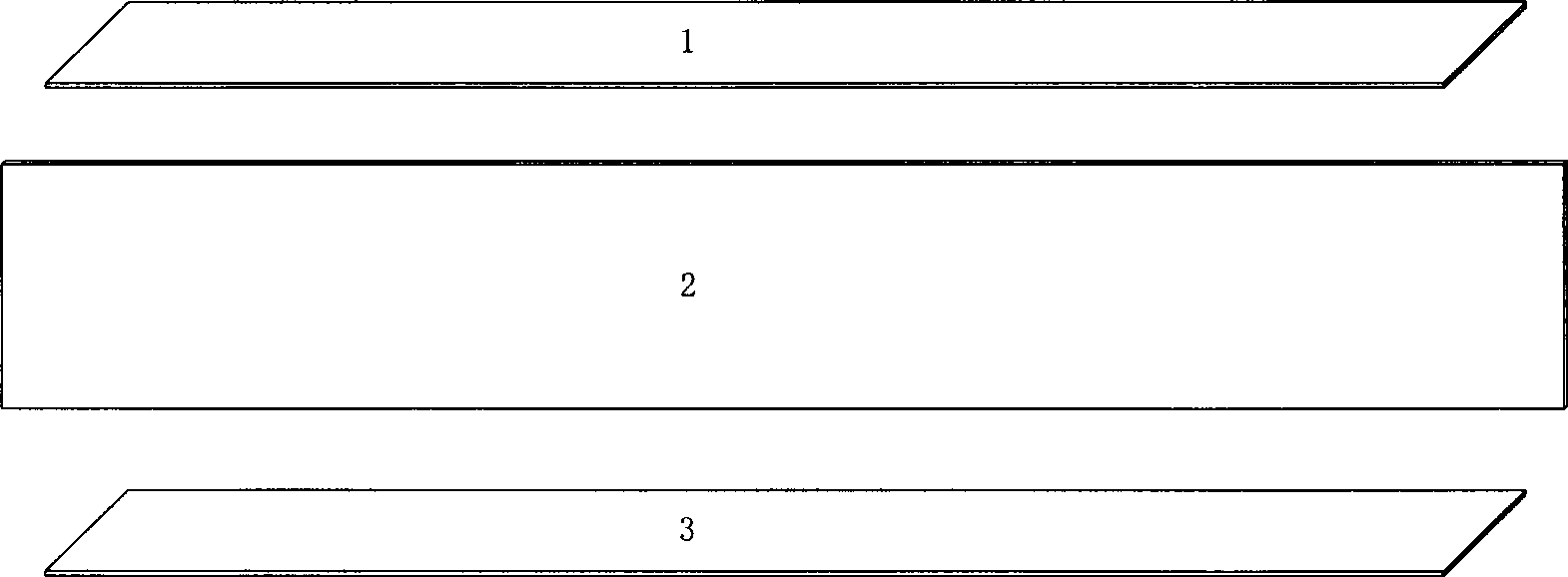

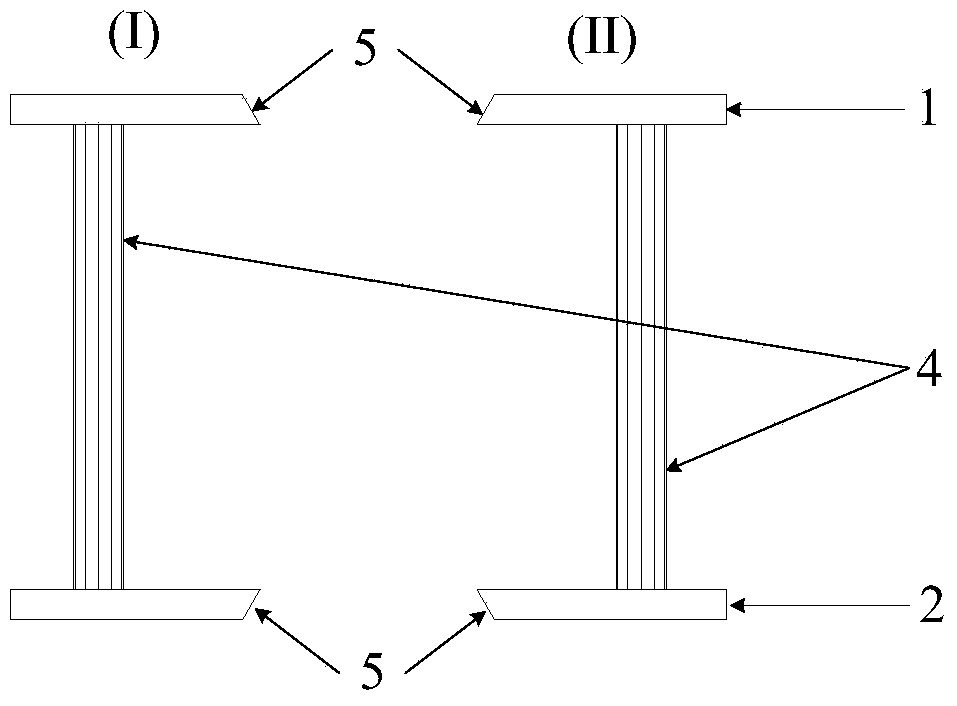

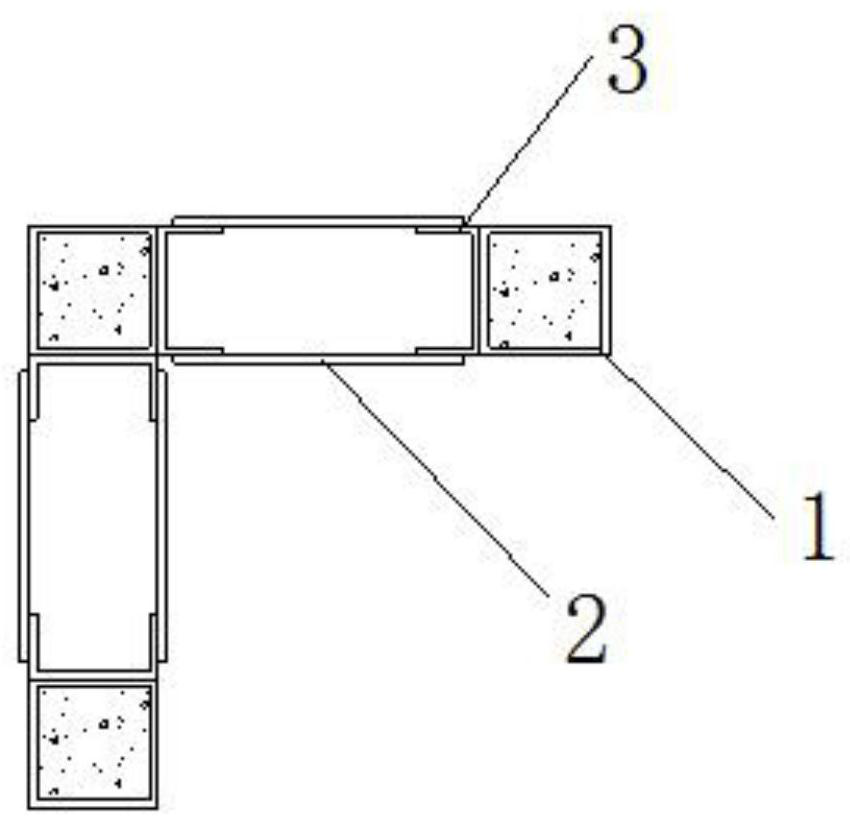

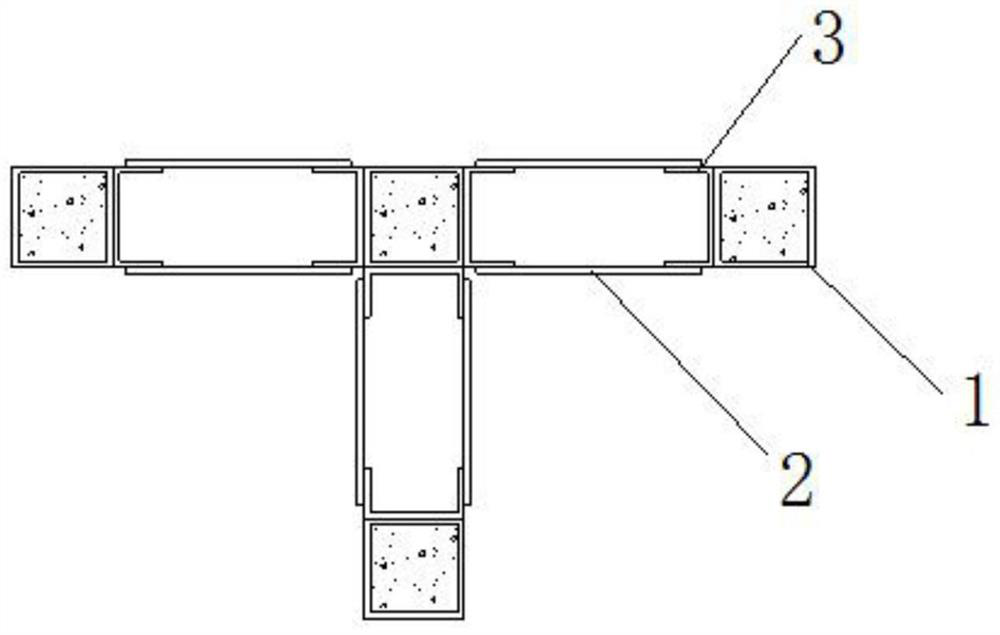

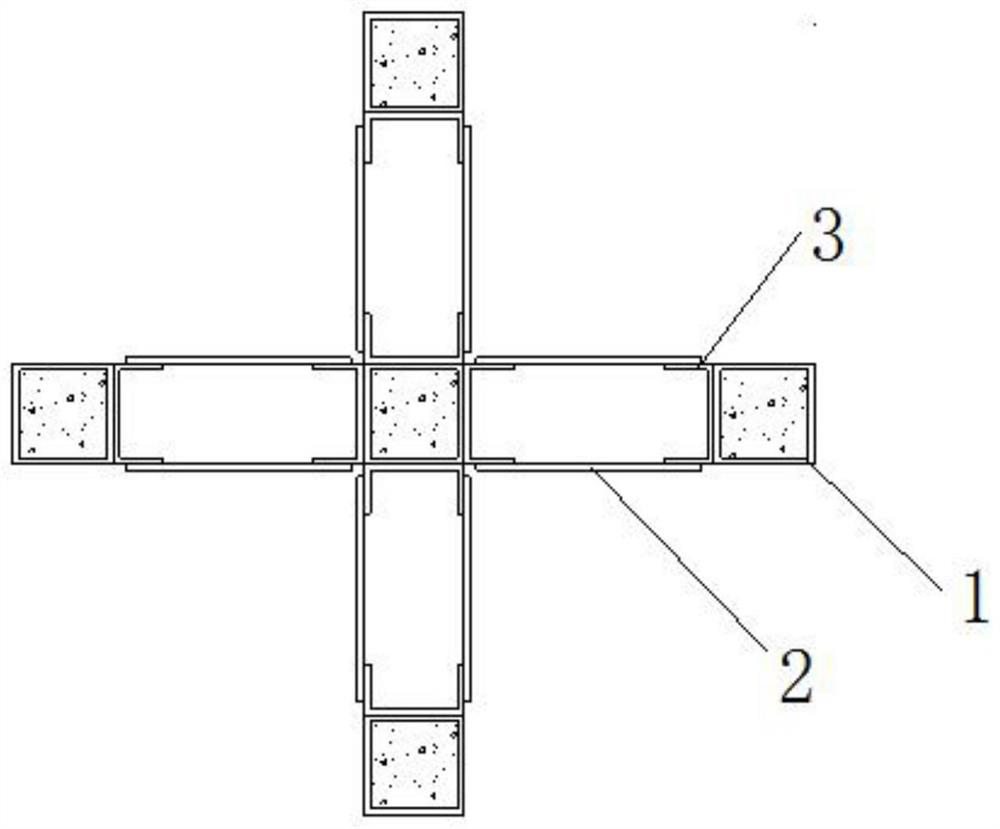

A steel-concrete composite special-shaped lattice column

ActiveCN111549906BFast on-site assemblyEasy constructionStrutsPillarsThermal insulationArchitectural engineering

The invention relates to the technical field of steel structure houses and public buildings, in particular to a steel-concrete combined special-shaped lattice column. The combined special-shaped lattice column provided by the present invention is composed of square steel pipe concrete column, channel steel, and strips. There are two structural types, namely type I and type II, and each has three cross-sectional forms, which are "L" type , "T" and "Ten" shapes; Bolt-assembled K-shaped strips are used for connection. The present invention overcomes the problems of inflexible structural arrangement, difficulty in factory prefabrication of components and low degree of standardization of components in the prior art, and most of the components used can be prefabricated in the factory. Prefabricated autoclaved blocks form an "intelligent" combined special-shaped lattice column integrating structure, heat preservation and sound insulation.

Owner:山东彤创建筑科技有限公司

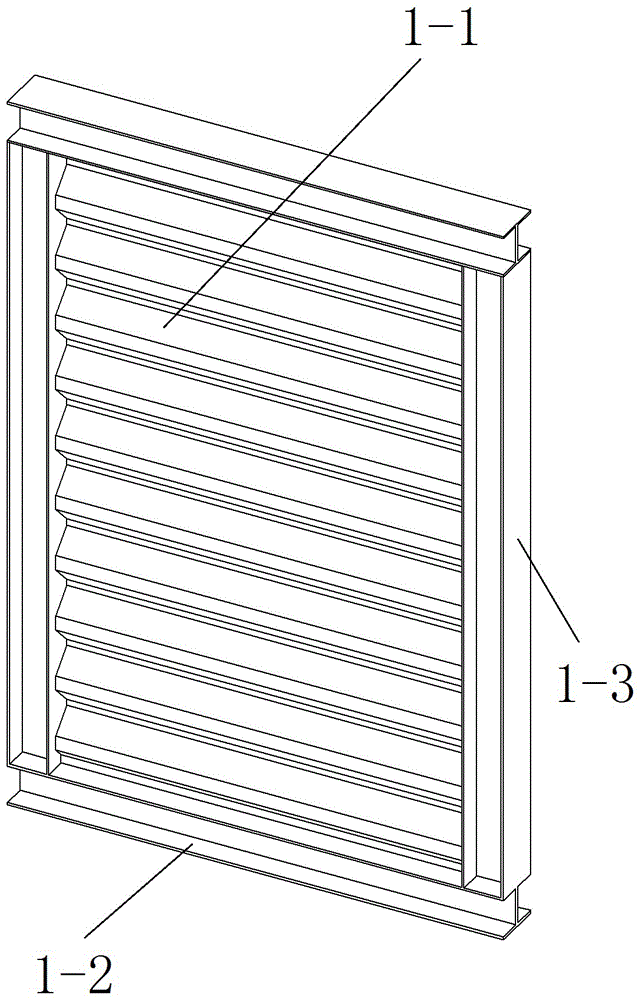

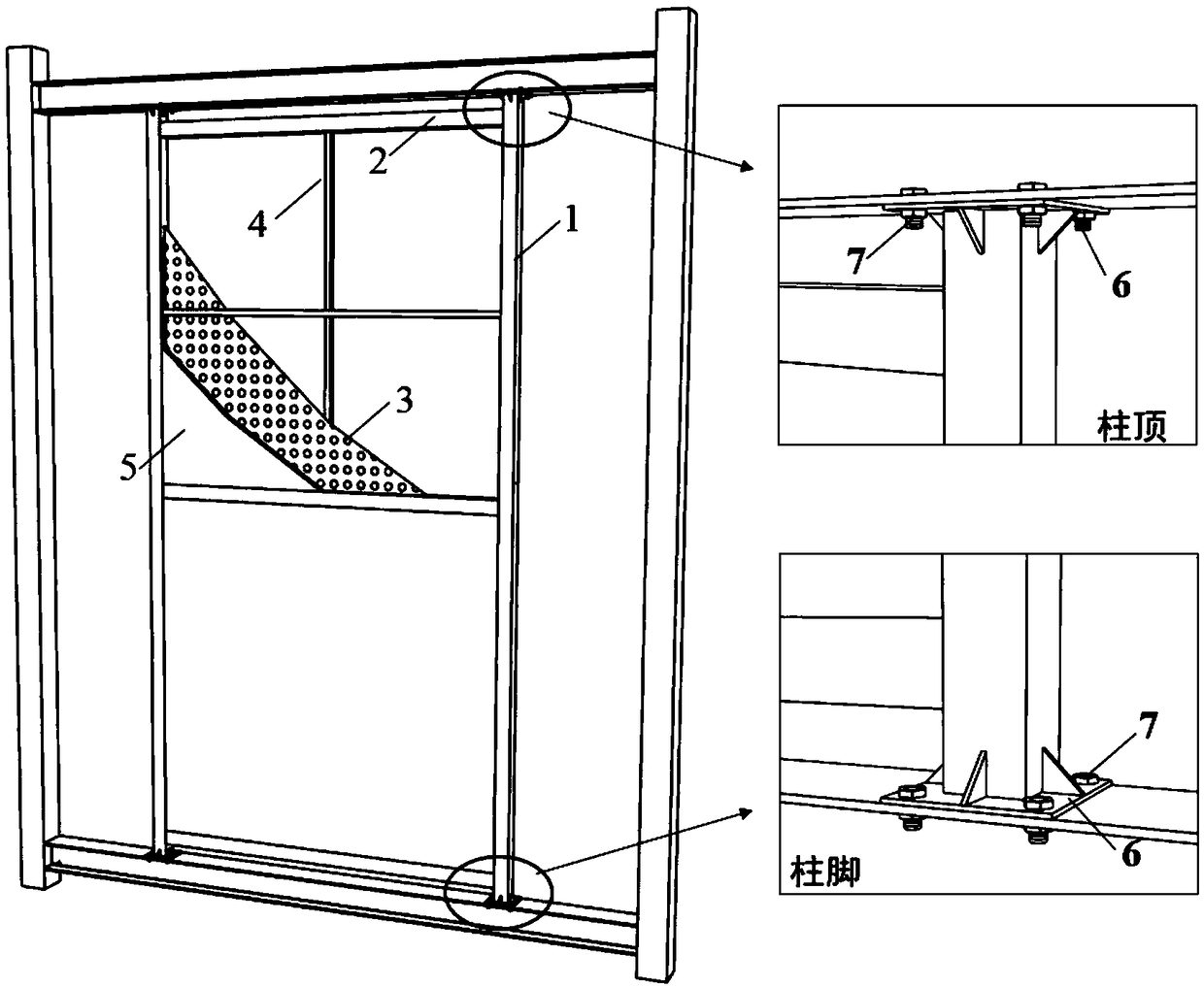

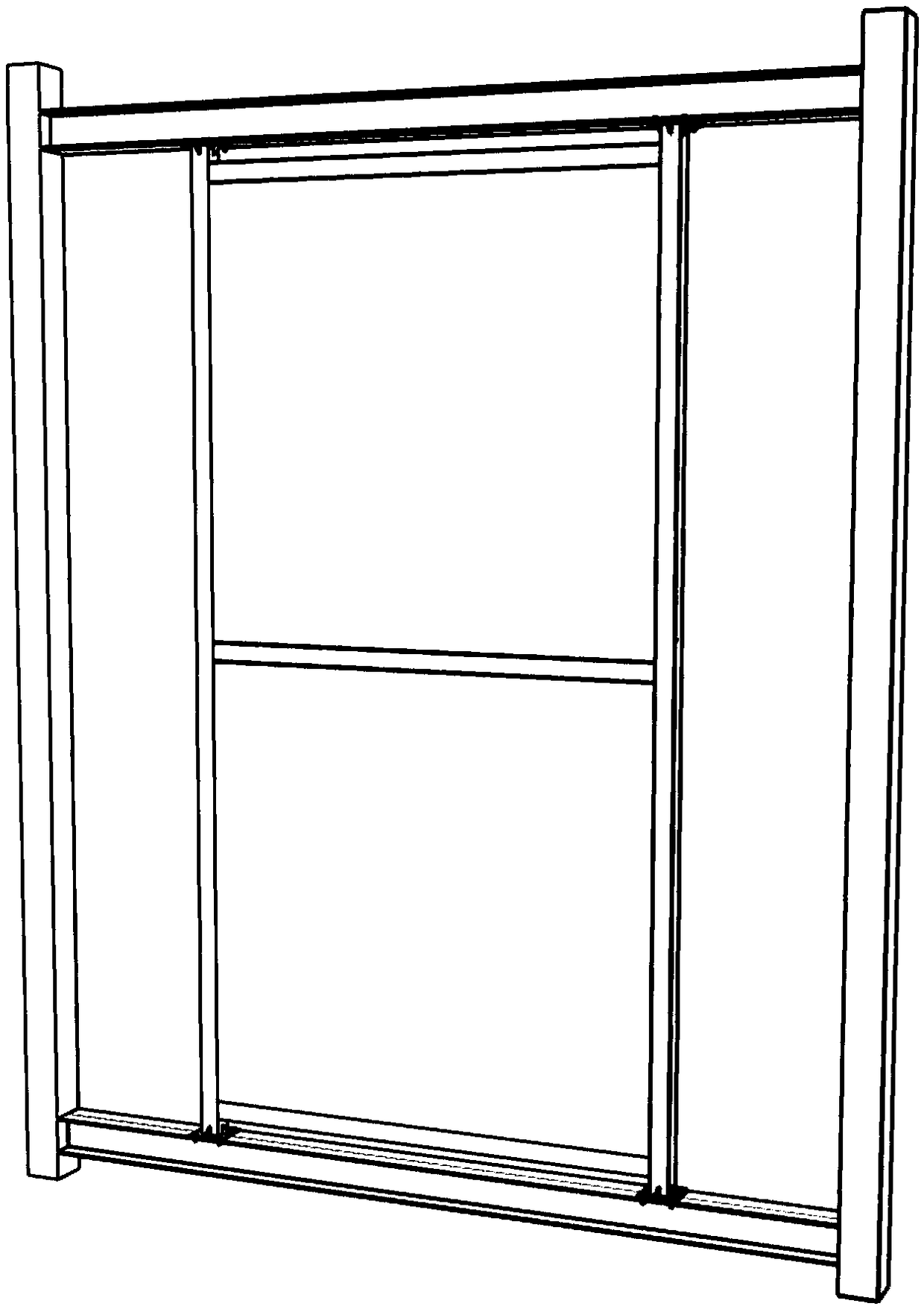

Fabricatedsash type frame type light steel frame-punching thin steel plate-concretecomposite wall

InactiveCN108625507ASimple constructionGood bearing capacity and shock resistanceWallsProtective buildings/sheltersSteel platesSteel tube

The invention relates to a fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wall. A concrete-filled steel tube frame column, a concrete-filled steel tube frame beam and a concrete-filled steel tube frame rib together form a light steel frame sash of a wall board, and form a compositewall steel skeleton with a punching thin steel plate to improve integrity of the wall board. A framework is erected and the concrete is poured; after maintenance, the fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wallis formed, and only connection bolts are needed for assembling the composite wall onto an external structure. The fabricated composite wall has good bend-resisting and shear-resisting capacities, out-of-plane stiffness, and good anti-seismic performance; and meanwhile, the wall board is manufactured in a factory, and is assembled on-site, and therefore the common quality problem caused by site construction is effectively solved; construction efficiency of a project is greatly improved; and work amount of the project is lowered. The fabricated composite wall is suitable for being widely popularized and used in the structure of low and multi-storey rural house structures in villages and towns, and plays an important role in promoting improvement of the traditional rural house structure technology.

Owner:BEIJING UNIV OF TECH +1

Corrugated steel plate recycled concrete anti-seismic sound-insulation shear wall

InactiveCN111764537AReduce usageShorten the construction periodConstruction materialWallsClassical mechanicsSoundproofing

The invention discloses a corrugated steel plate recycled concrete anti-seismic sound-insulation shear wall. The shear wall comprises an anti-seismic energy consumption structure, a damping sound-insulation structure and a bearing structure, wherein the anti-seismic energy consumption structure comprises a plurality of strip-shaped steel plates, edge beams, edge columns and inclined supports; thedamping sound-insulation structure comprises steel plates, elastic cement gum, corrugated steel plates and steel partition plates; the bearing structure comprises recycled concrete, corrugated steel plates, studs and the like; and the bearing structure, the damping sound-insulation structure and the anti-seismic energy consumption structure are sequentially arranged from inside to outside to formthe shear wall. The shear wall can overcome the defects of an existing steel plate shear wall and has the advantages of being resistant to seismic, insulating sound, reducing construction waste and the like.

Owner:FUZHOU UNIV

Integral Pouring Technology of Reinforced Concrete Wastewater Pool in Pre-drilling Project

ActiveCN103015719BShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Modularized fabricated double-steel-plate shear wall

PendingCN113718997APlay a linearPlay a surface constraint effectWallsBuilding reinforcementsMachiningIndustrial engineering

The invention relates to a modularized fabricated double-steel-plate shear wall, and belongs to the field of structural engineering. The double-steel-plate shear wall is formed by welding two edge columns and an integral steel plate shear wall unit. Based on the concept of improving the elastic shear buckling load and the shear bearing capacity of the shear wall, inner stiffening units are arranged to conduct buckling constraint on outer side steel plates, and the bearing capacity and out-of-plane rigidity of the double-steel-plate shear wall are improved. The machining of the inner stiffening units and the assembly of the double-steel-plate shear wall can both adopt mature processes, and the machining difficulty is greatly reduced compared with that of a traditional double-steel-plate shear wall.

Owner:BEIJING UNIV OF TECH

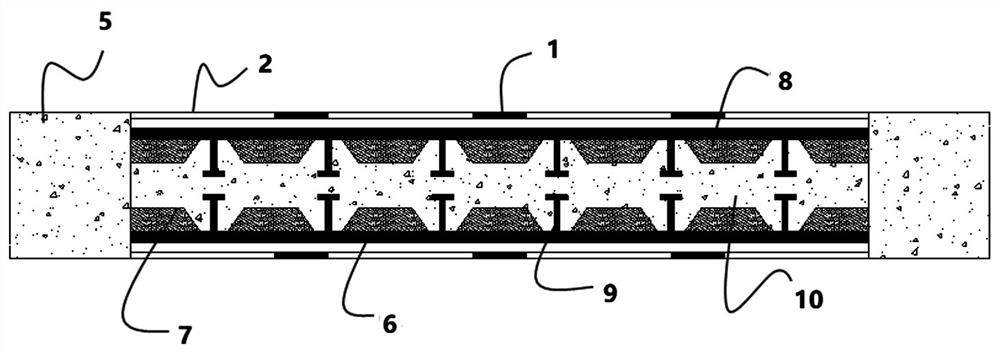

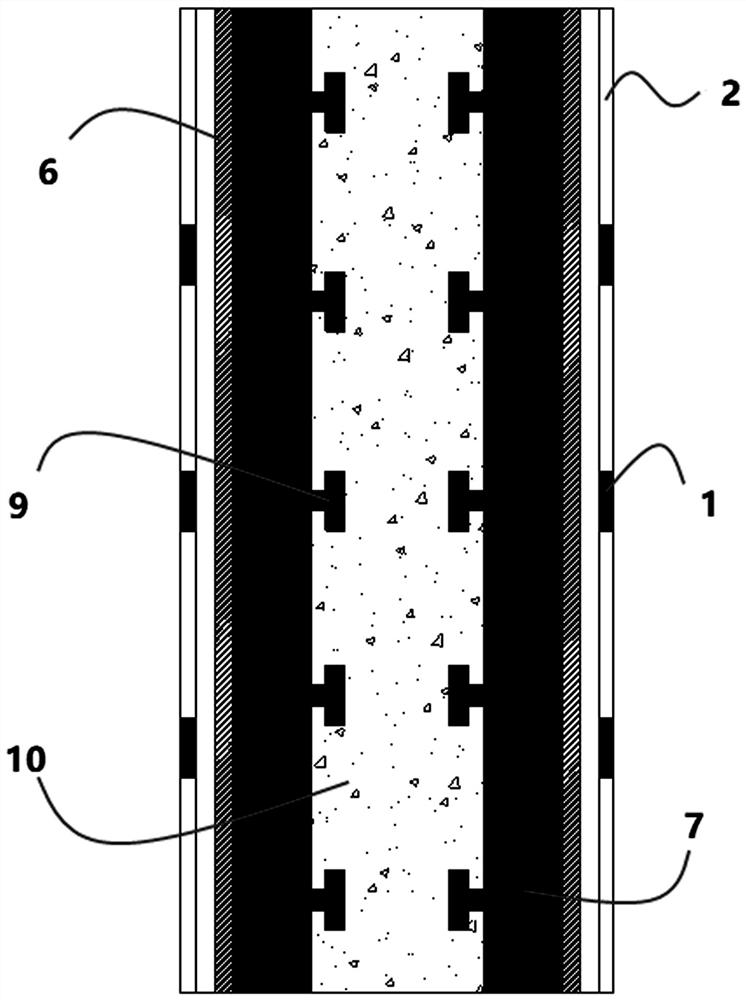

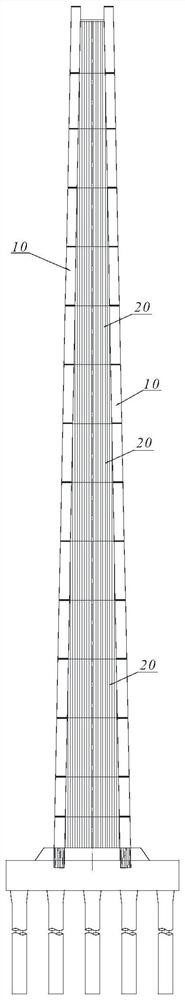

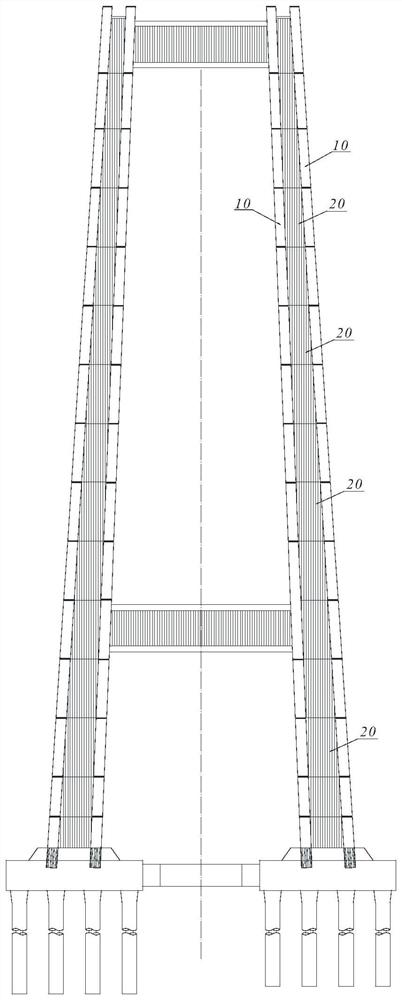

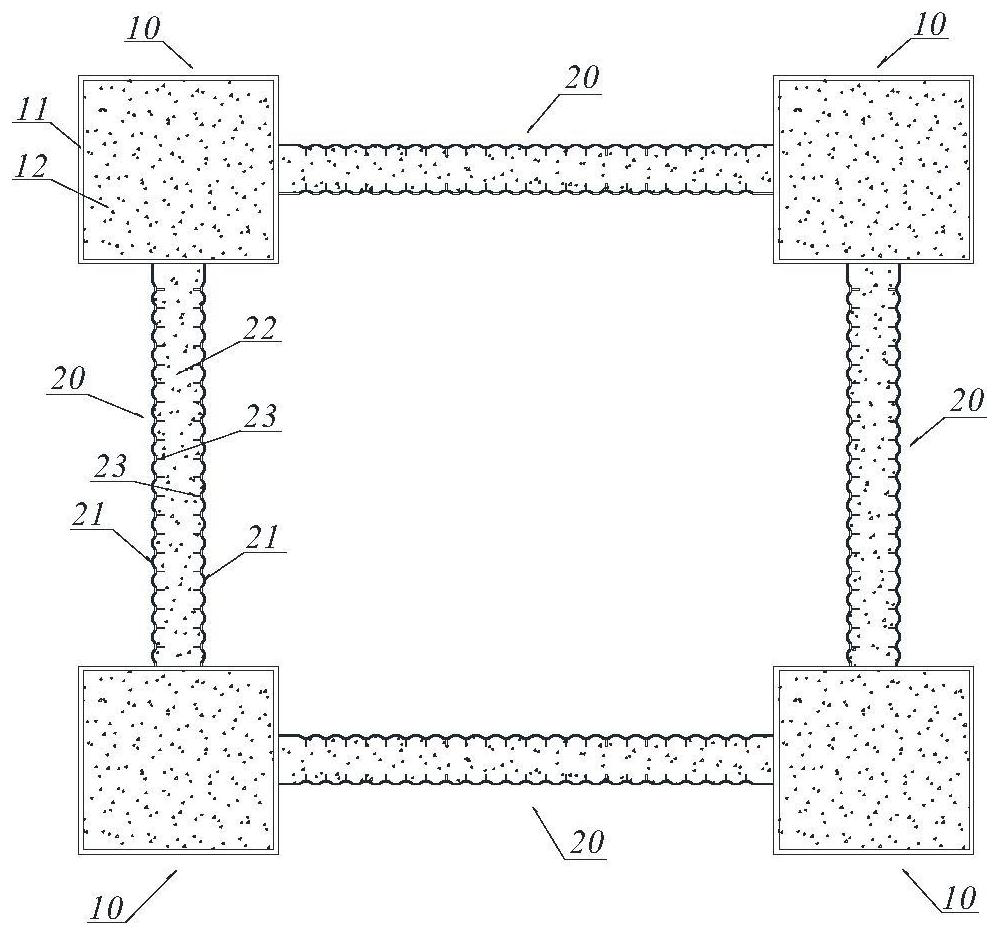

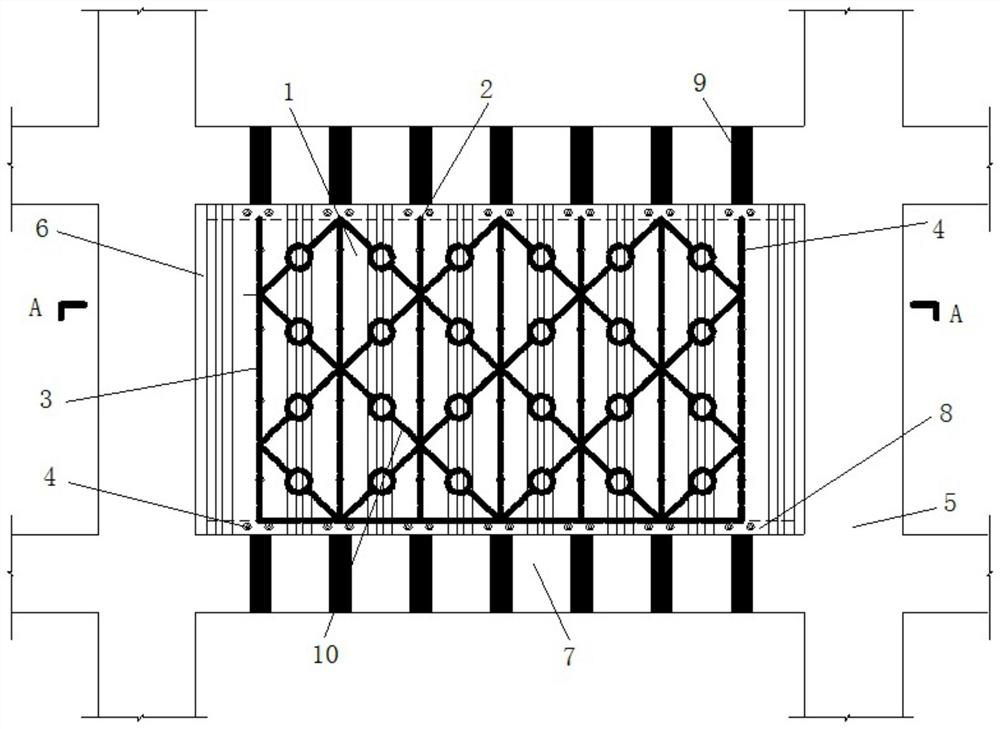

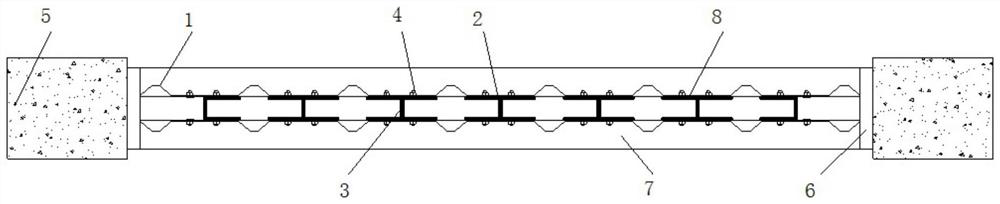

Corrugated steel plate and concrete combined web plate for square steel tube suspension bridge cable bent tower

PendingCN114737476AIncrease out-of-plane stiffnessIncreased shear buckling capacitySuspension bridgeBridge structural detailsTowerSteel tube

The invention relates to a corrugated steel plate and concrete combined web plate for a square steel tube suspension bridge cable bent tower, which is used for effectively improving the shear bearing capacity, the compression bearing capacity and the ductility of the web plate, reducing the structural earthquake response while reducing the self weight, and is convenient to construct. The web is composed of a pair of corrugated steel plates, web concrete and semi-opening shear connectors, the corrugated steel plates are arranged in the thickness direction of the web at intervals, wave crest parts and wave trough parts of the corrugated steel plates extend in the width direction of the web, and the two ends of the corrugated steel plates in the width direction are welded to the outer walls of the square steel tubes of the square steel tube concrete stand columns. The semi-open shear connecting pieces are arranged at equal intervals in the height direction of the web plate, are arranged according to the width of the web plate and are correspondingly welded and fixed on the inner walls of the pair of corrugated steel plates; a cavity between the pair of corrugated steel plates is filled with the web concrete in a pouring mode, and the web concrete is connected with the corrugated steel plates on the two sides through the semi-opening shearing force connecting pieces to form a whole structure.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

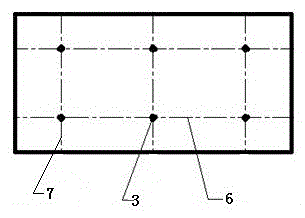

Open-hole square steel pipe truss profiled steel plate shear wall and its construction method

ActiveCN110173063BAvoid devolatilizationPrevent penetrationWallsBuilding material handlingEarthquake resistanceRc frames

The invention discloses a hole opening square steel pipe truss profiled steel plate shear wall and a construction method. The shear wall comprises two profiled steel plates, wherein square steel pipetrusses are arranged between the two profiled steel plates and comprise chord members and web members. The profiled steel plates comprise a plurality of wave crest positions. Holes are formed in the square steel pipe trusses and correspond to the wave crest positions of the profiled steel plates. The shear wall is arranged between a frame beam and a frame column. A gap is reserved between the shear wall and the frame column. For a non-ductile reinforced concrete frame structure, the hole opening square steel pipe truss profiled steel plate shear wall is a novel reinforcement method, is a novelstructural member which is developed on the basis of a profiled steel plate shear wall and a flat steel plate combined shear wall, and has the advantages of being small in cross section size, large in side rigidity resistance, high in anti-seismic property and the like.

Owner:CHANGZHOU INST OF TECH

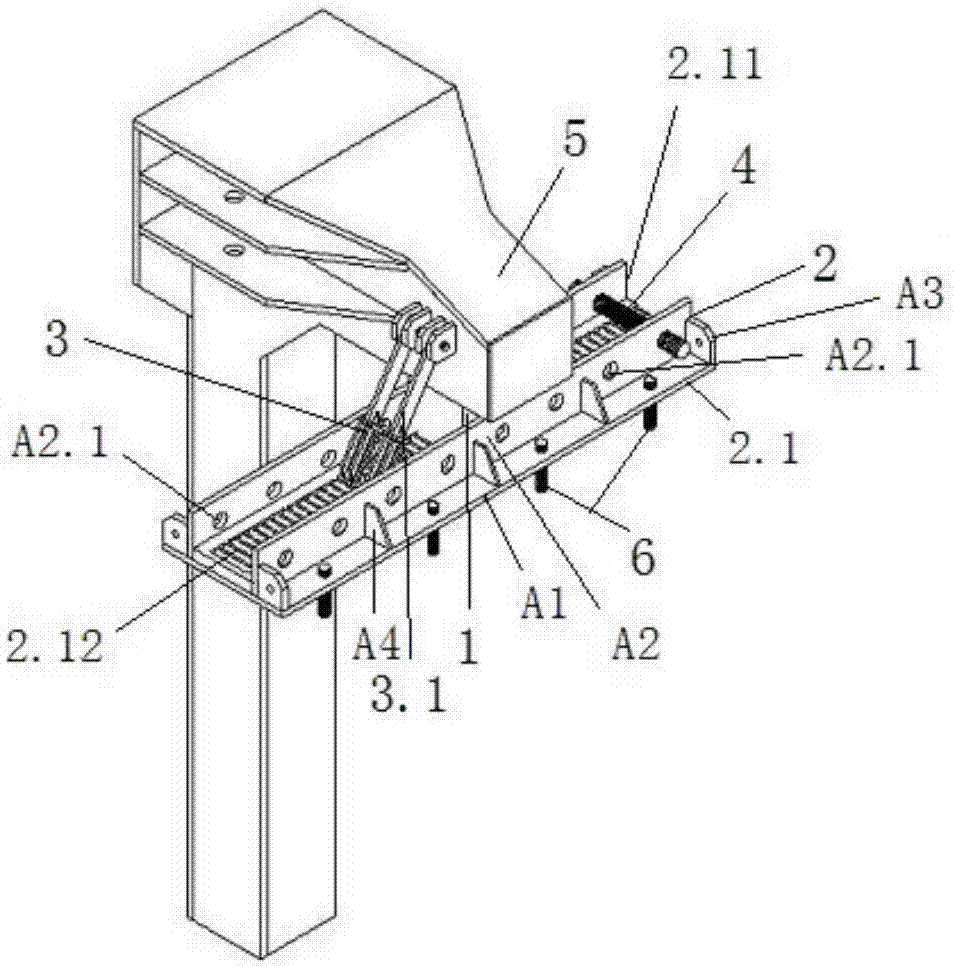

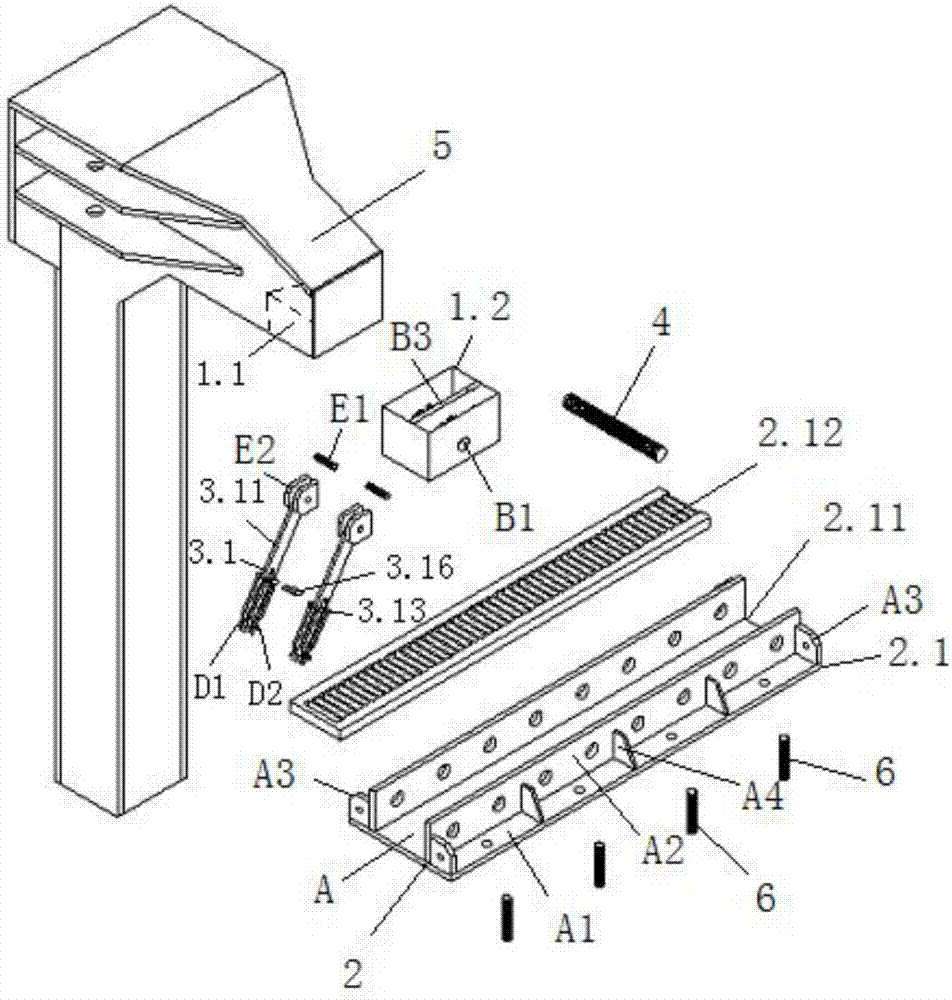

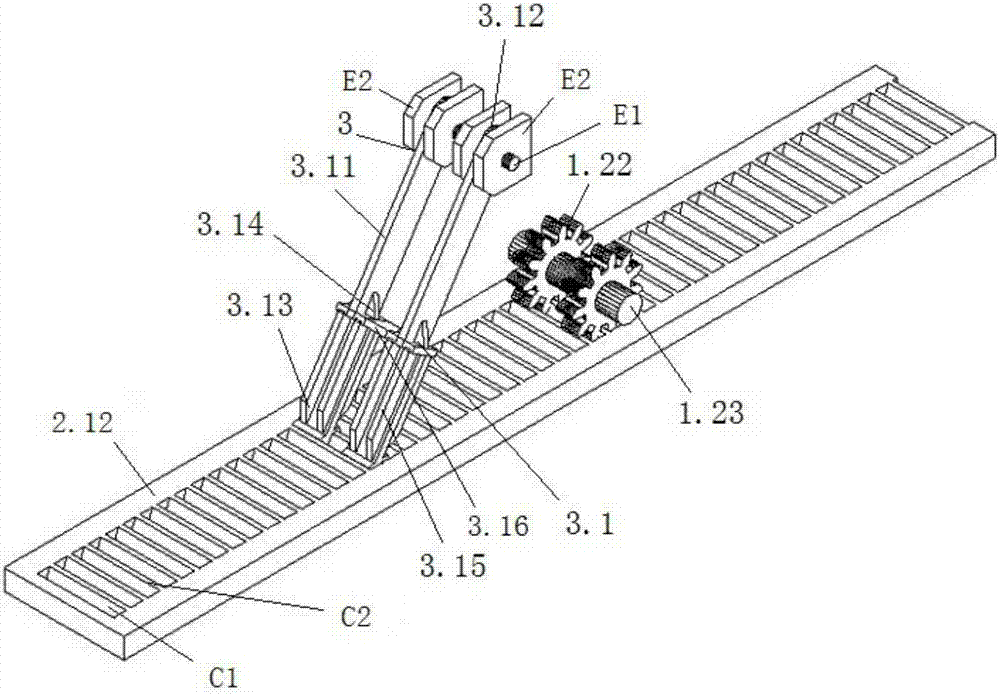

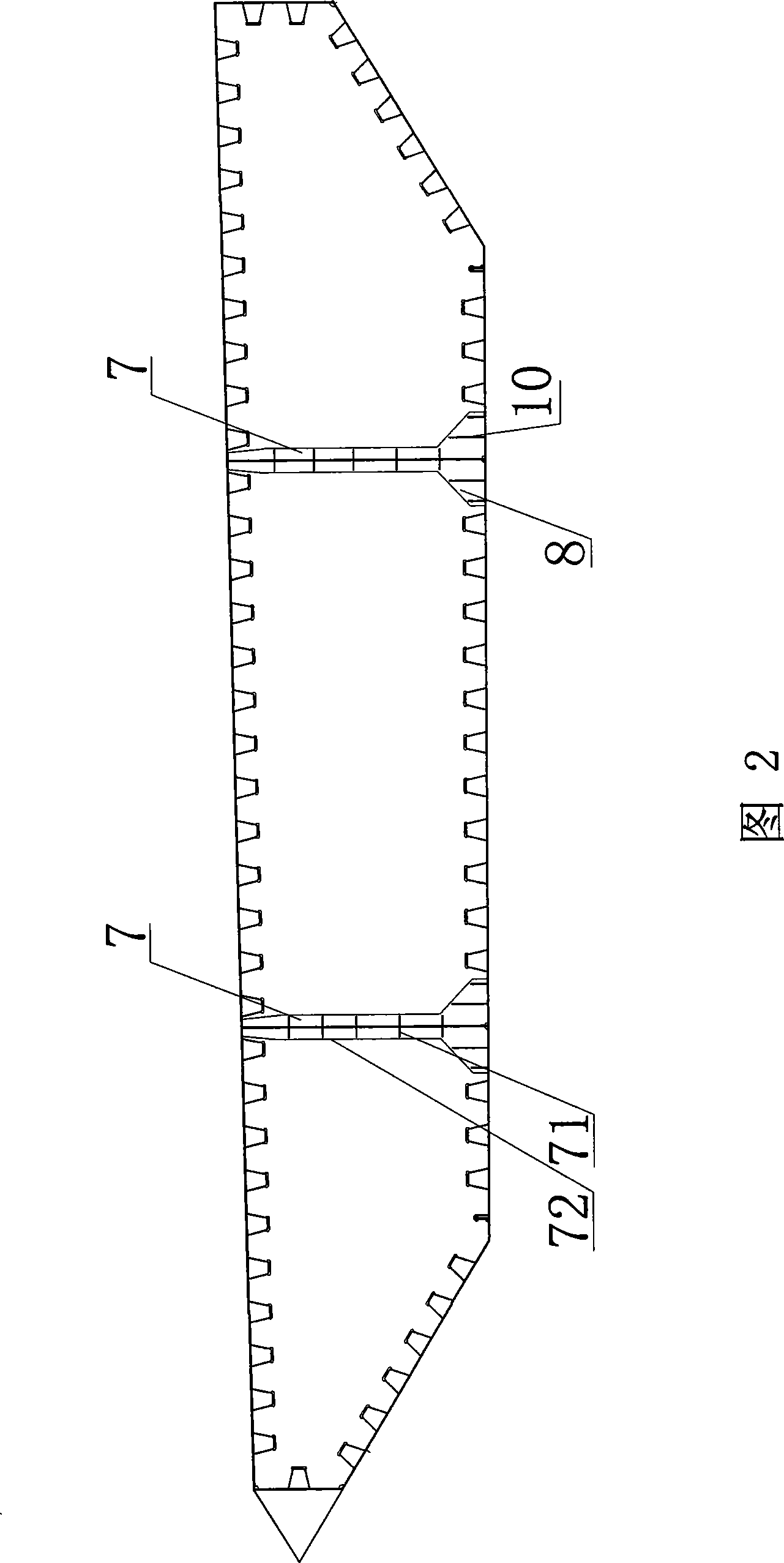

Hanging basket with self-locking wheel track type running gear and running method of hanging basket using said running gear

The invention provides a hanging basket with a self-locking wheel track type running gear; the hanging basket comprises running parts matched in number with and located one by one with hooks of the hanging basket; the running part comprises a running structure, a track structure and a defense structure; the running structure comprise a power source and a roll-boat; the track structure comprises a track single body; the track single body comprises a fixed track and a sawtooth plate; the defense structure is used for preventing the whole roll-boat to go backward. The technical effects are that the whole machine is concise in structure and low in cost; modularization design can be realized by several large parts, so installation, maintenance and replacement are convenient; the running structure, the track structure and the defense structure are combined so as to allow the hanging basket to walk, thus resisting sliding force of the hanging basket in an automatic running process, and preventing the backward effect of the hanging basket in the running or adjusting process; the hanging basket is easy to control and good in stability; the invention also provides a hanging basket running method using said running gear; the method is easy to control and strong in practical values.

Owner:GUIZHOU ROAD & BRIDGE GRP

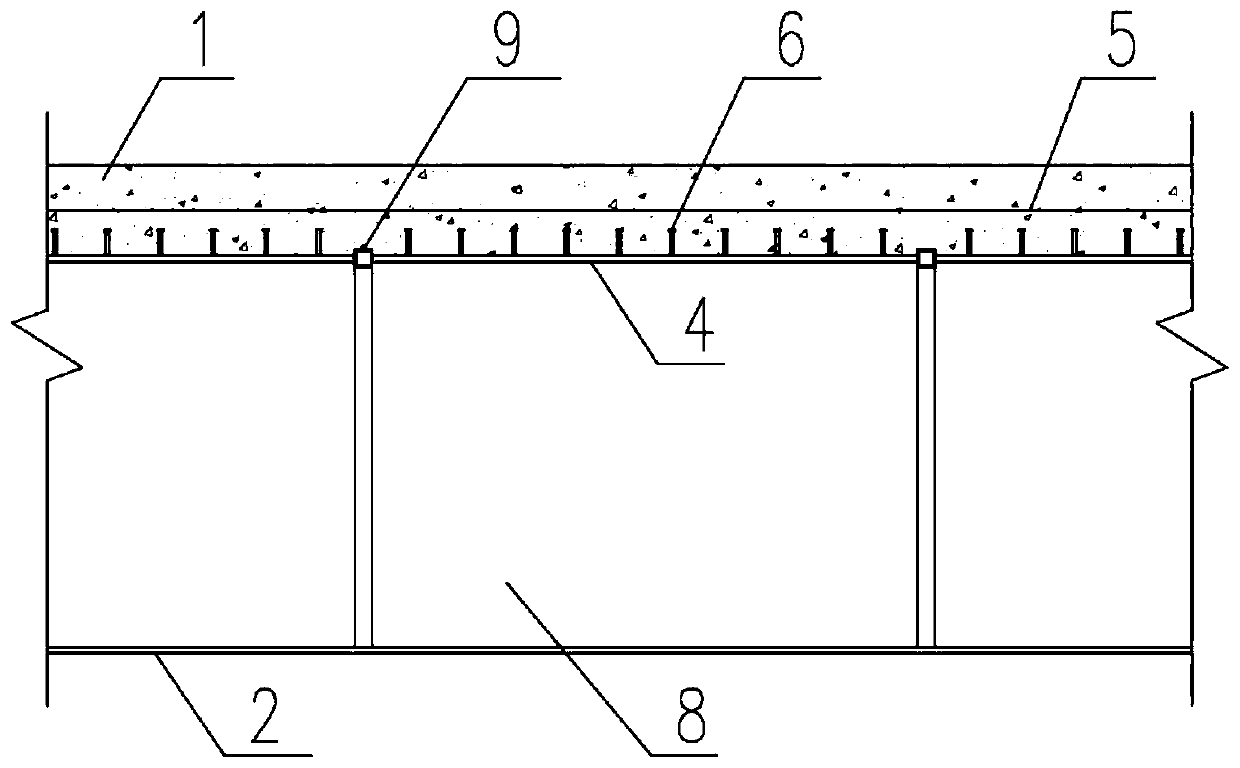

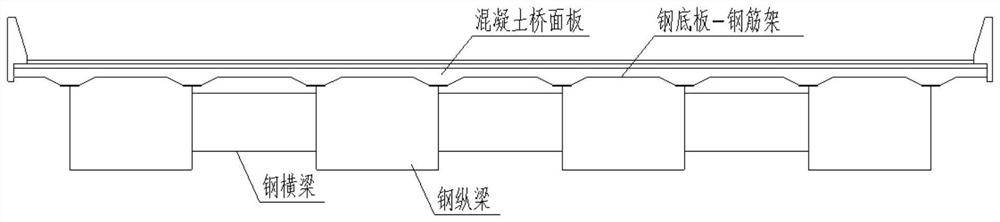

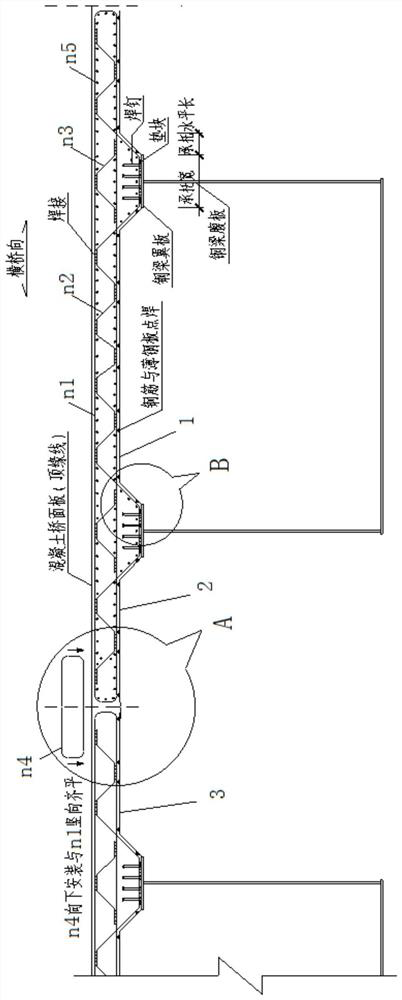

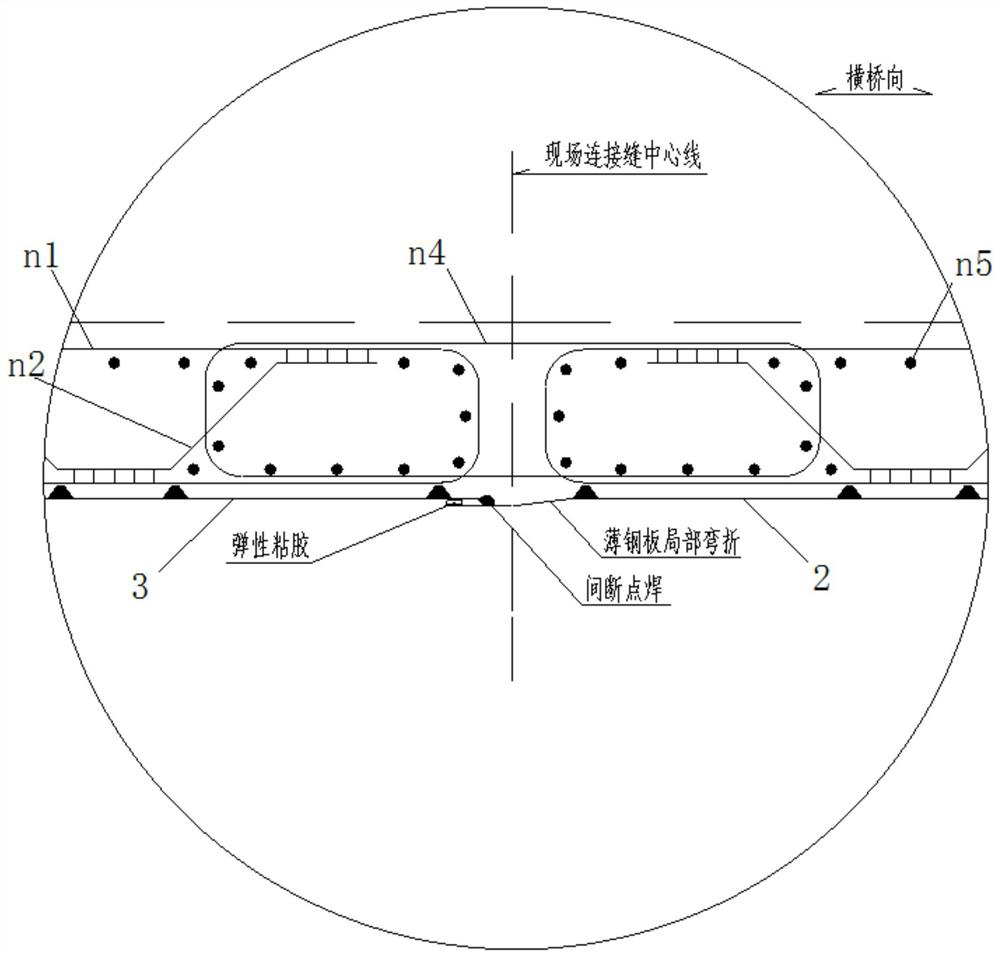

Steel-concrete composite beam with steel bar trusses and steel plates as temporary supports and construction method

PendingCN112878169AReduce the risk of working at heights on siteFast construction on siteBridge erection/assemblySheet steelArchitectural engineering

The invention discloses a steel-concrete composite beam with steel bar trusses and steel plates as temporary supports and a construction method. The steel-concrete composite beam comprises a concrete bridge deck, a plurality of steel longitudinal beams and a plurality of groups of steel cross beams, wherein the steel longitudinal beams and the steel cross beams are arranged below the concrete bridge deck; the plurality of steel longitudinal beams and the plurality of groups of steel cross beams are alternately arranged; the steel longitudinal beams are fixed to the concrete bridge deck through steel bar frame-thin steel plate structures arranged below the concrete bridge deck; gaps exist between the upper flange plates of the steel cross beams and the steel bar frame-thin steel plate structures; and the steel bar frame-thin steel plate structure comprises a plurality of thin steel plates, a plurality of transverse steel bar trusses, a plurality of post-installed annular steel bars and a plurality of longitudinal steel bars. During construction, the transverse steel bar trusses are welded and mounted; then the steel bar frame-thin steel plate structure sections are hoisted to form steel longitudinal beam-steel bar frame-thin steel plate structure combined sections; and the steel longitudinal beam-steel bar frame-thin steel plate structure combined sections are transported and installed, and finally bridge deck concrete is poured. The on-site high-altitude operation risk is further reduced, and the on-site construction speed is increased.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

One-way tensioned metal sheet space structure and construction method

ActiveCN114517532BReasonable forceLess materialBuilding roofsArched structuresPre stressSpatial structure

The invention relates to a one-way tensioned metal sheet space structure, which is used for large-span buildings, comprising: a metal sheet, which is formed by tensioning, and the metal sheet forms a space structure; One end of the cable is connected and fixed to the top of the steel columns on both sides, and the other end is connected to the metal sheet from both sides of the spatial structure span; the back cable is connected to the top of the steel column at one end, and the other end is fixed to the ground; the gable plate is set on the metal sheet At both ends, the gable panels set the gable back cable. The force-bearing structure of the present invention is designed in an integrated manner with the building envelope, and the metal sheet is stretched and formed by applying in-plane prestress. The structure system of the invention can be used for constructing a super-span temporary and permanent closed stockyard engineering structure system with a span of more than 300 meters, and has the advantages of safety, reliability, reasonable design, economical materials, simple construction and the like.

Owner:NORTH CHINA INST OF SCI & TECH

Steel box beam erection method for self-anchored suspension bridge

InactiveCN101078198BGuaranteed unobstructedImprove erection efficiencyBridge erection/assemblyEngineeringSteel box girder

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

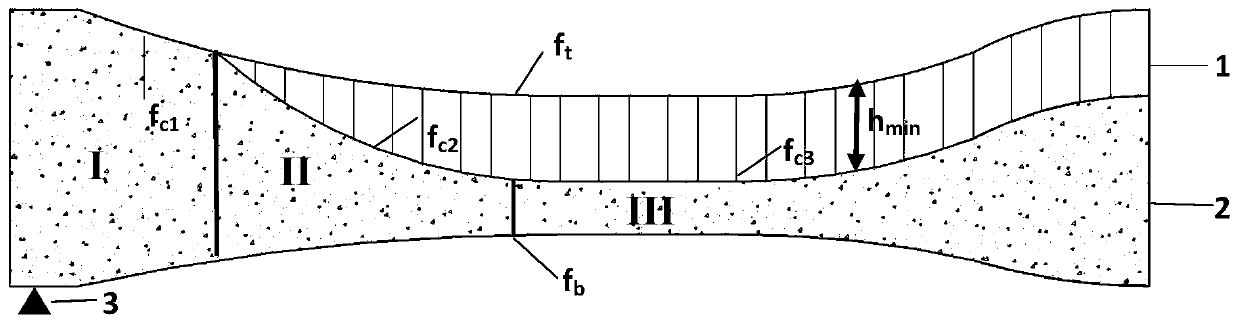

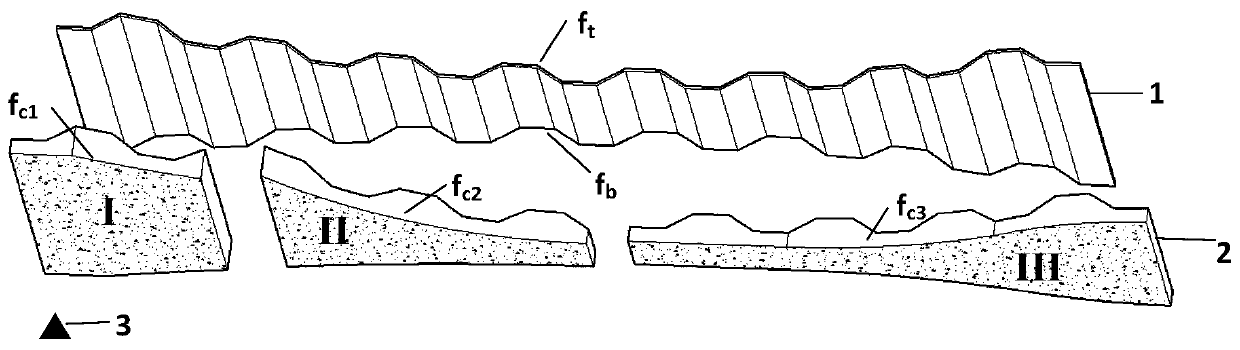

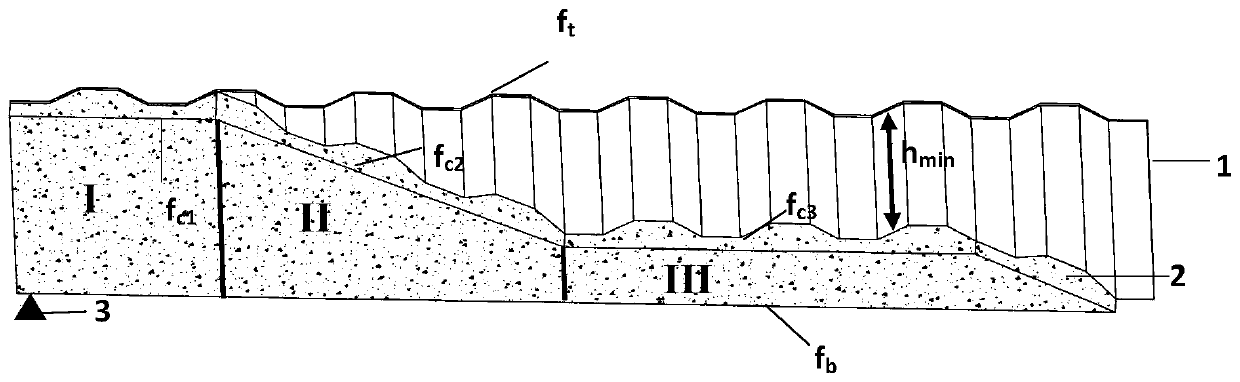

Variable-cross-section corrugated steel plate-concrete combined plate structure

The invention relates to a variable-cross-section corrugated steel plate-concrete combined plate structure. The combined plate consists of a variable-cross-section corrugated steel plate and lining concrete, wherein the lining concrete comprises three portions including a full-cross-section segment I, a transition-cross-section segment II and a minimum-cross-section segment III which are sequentially arranged along the longitudinal direction of the corrugated steel plate from a fulcrum to bear the shear force, which becomes small from large, of the corrugated plate in the longitudinal direction. The full-cross-section segment ensures that the top surface and the bottom surface of the corrugated steel plate are superposed to the top surface and the bottom surface of the concrete; the transition-cross-section segment II smoothly connects the full-cross-section segment I with the minimum-cross-section segment III; by the minimum-cross-section segment III, the buckling strength of the cross section of the combined plate is improved, and finally, the combined plate structure with light weight, strong shear resistance and good buckling stability is obtained.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com