Corrugated web box-section steel-concrete combined arch

A corrugated web, concrete-filled steel tube technology, applied in arch beams, bridge door beams, etc., can solve the problems of limiting flange plates, bending and torsional instability of steel arches, low bearing capacity, etc., to improve out-of-plane stable bearing capacity performance, improved compressive strength and ductility, improved effect of local buckling loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

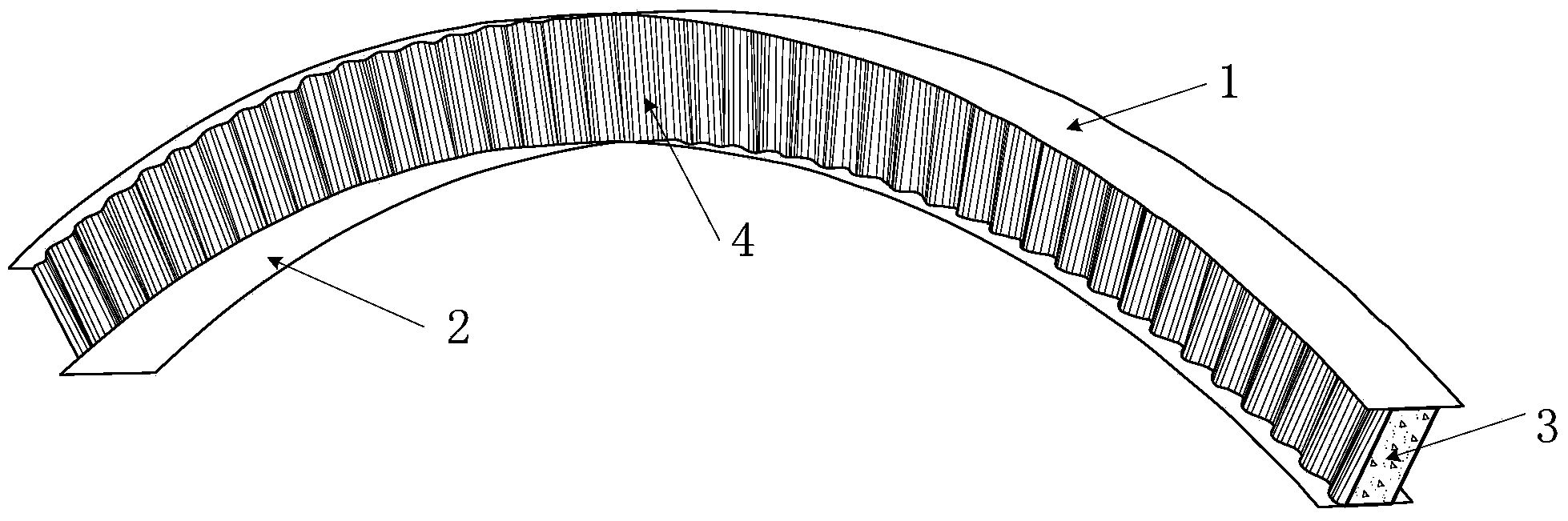

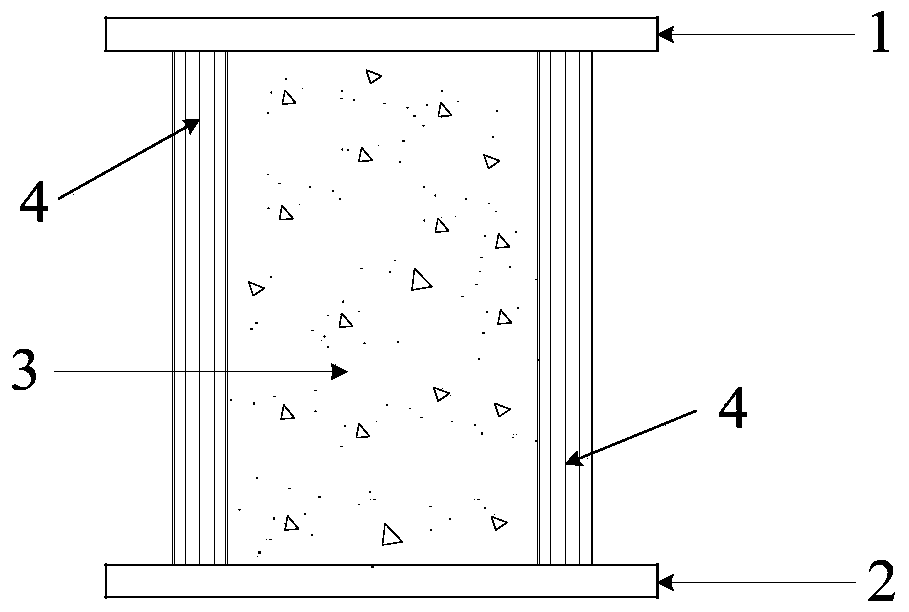

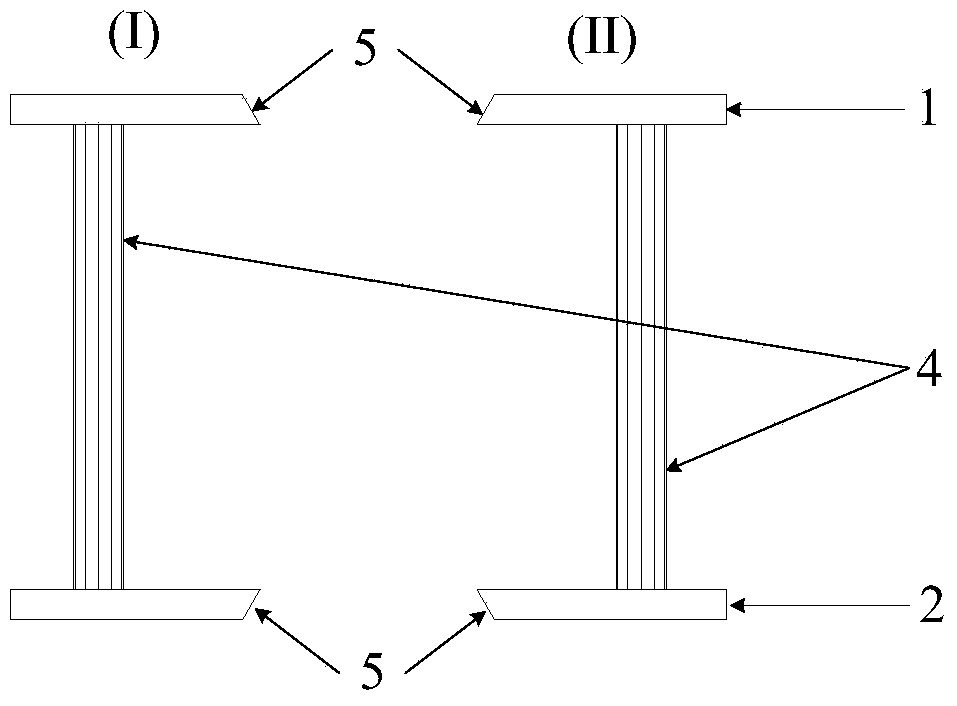

[0014] Attached below Figure 1~5 , to describe the implementation of the present invention in detail.

[0015] As shown in the figure, a corrugated-web box-section steel-concrete composite arch consists of the following components:

[0016] 1——upper flat flange plate;

[0017] 2——lower flat flange plate;

[0018] 3 - core concrete;

[0019] 4 - corrugated web;

[0020] 4-1——Trapezoidal corrugated steel plate;

[0021] 4-2——Sinusoidal corrugated steel plate;

[0022] 5——Single-sided bevel of upper and lower flat flange plates;

[0023] 6——Single-side groove butt weld of upper and lower flat flange plates.

[0024] A corrugated web box-section steel-concrete composite arch proposed by the present invention consists of two corrugated web I-section steel arches (I) and (II) passing through the upper flat flange plate (1) and the lower flat flange plate (2) It is formed by direct butt welding along the axis of the arch; the core concrete is poured into the box section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com