Patents

Literature

862results about How to "Guaranteed quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

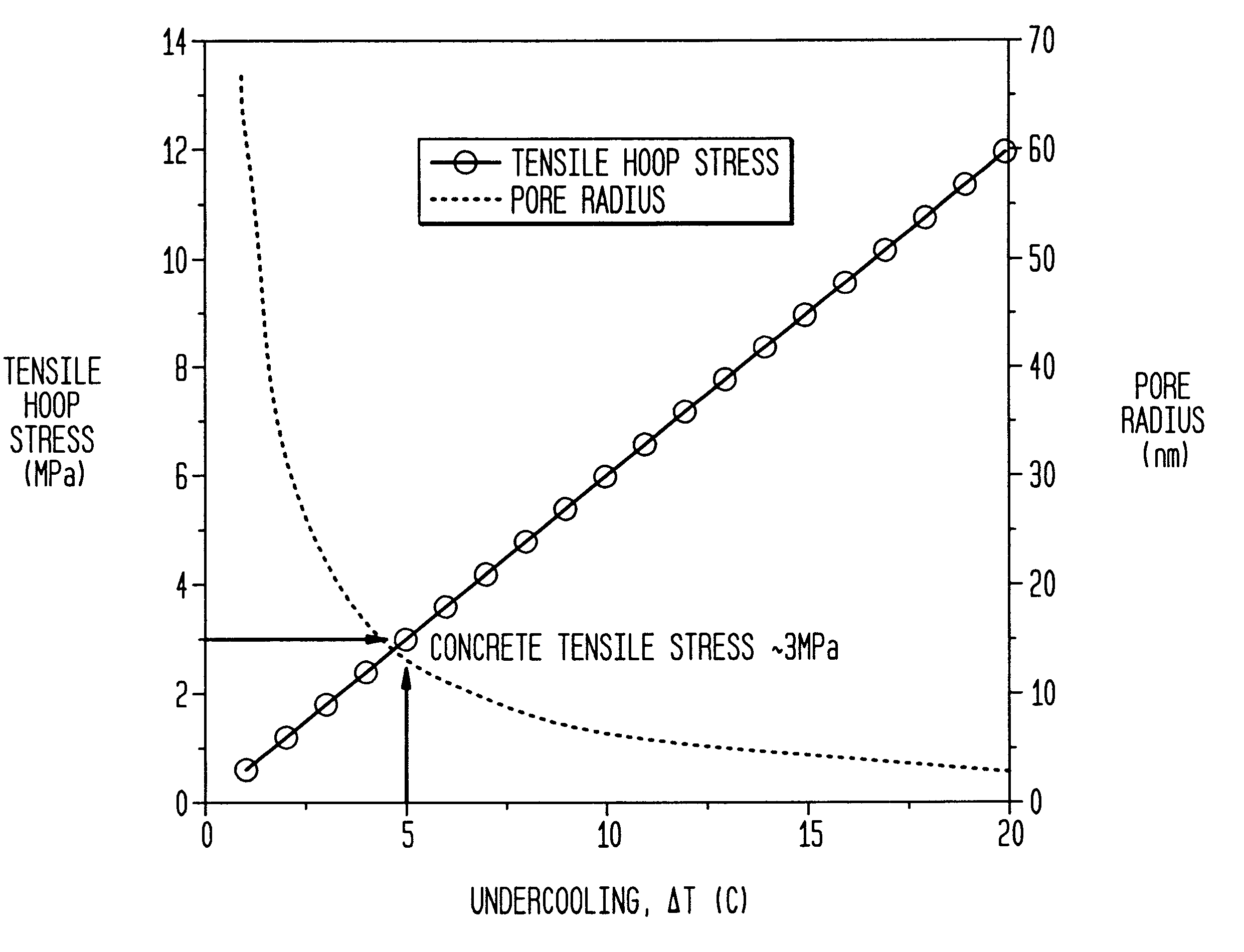

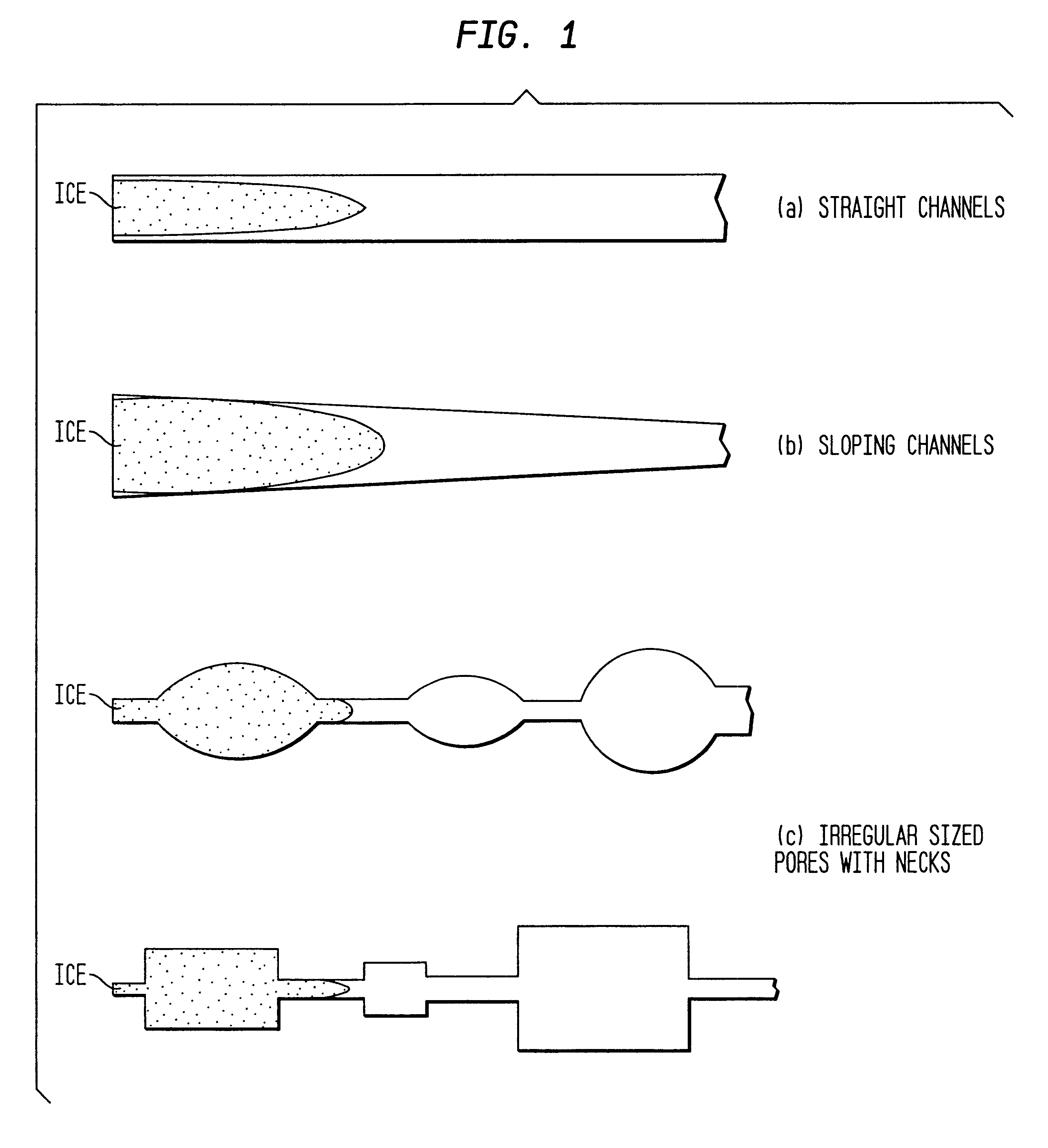

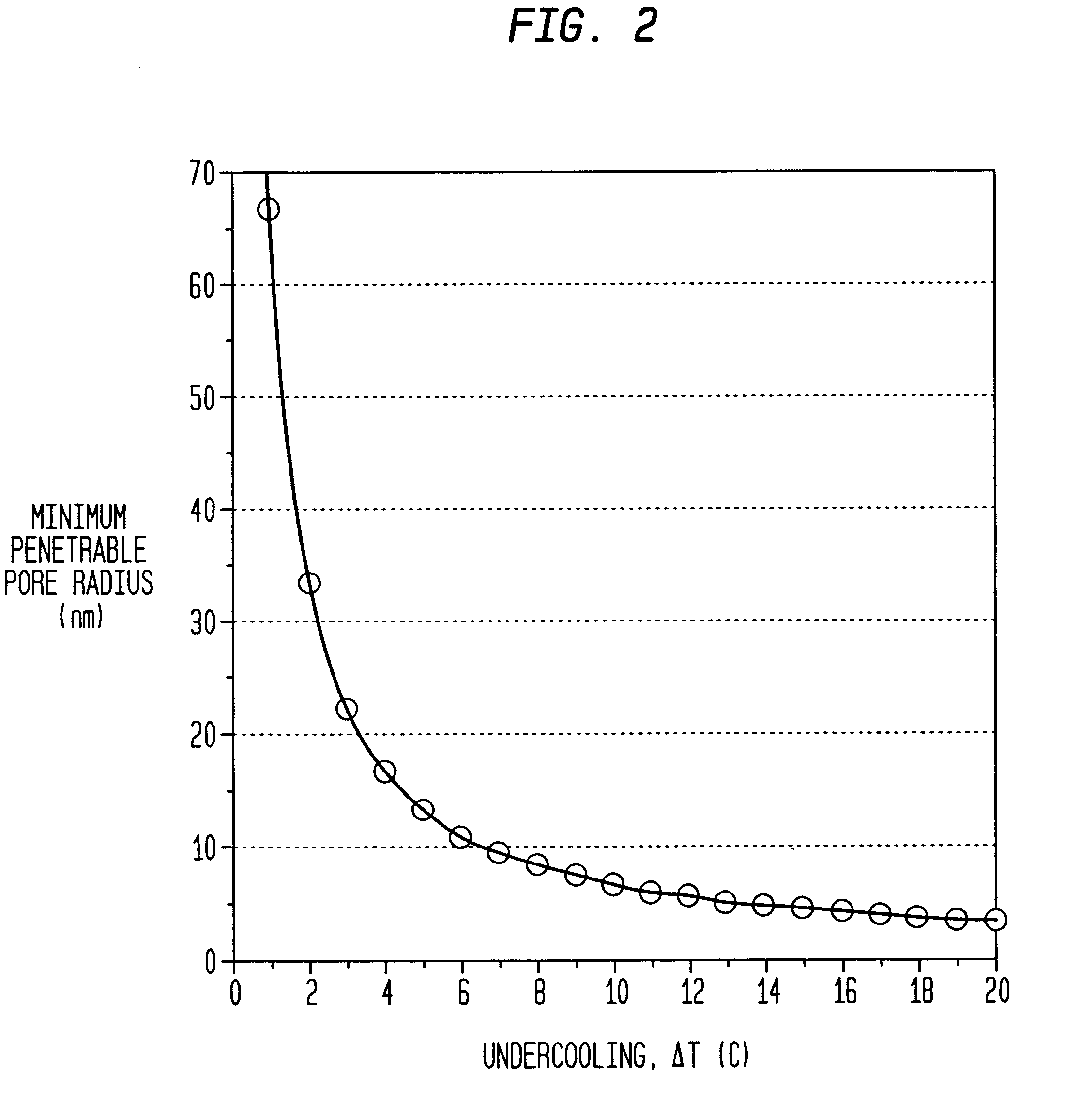

Methods of protecting concrete from freeze damage

A method of protecting a cementitious mixture from freeze damage is provided. The method consists of incorporating an entrainment air composition into the cementitious mixture to form air voids in the concrete, and further adding an effective agent for nucleating ice, preferably, in the air voids, such that upon the freezing of concrete formed from the cementitious mixture, ice is nucleated in the air voids. In one embodiment, the air entrainment composition includes ceramic shells, which could be impregnated with an agent for nucleating ice such as metaldehyde.

Owner:THE TRUSTEES FOR PRINCETON UNIV

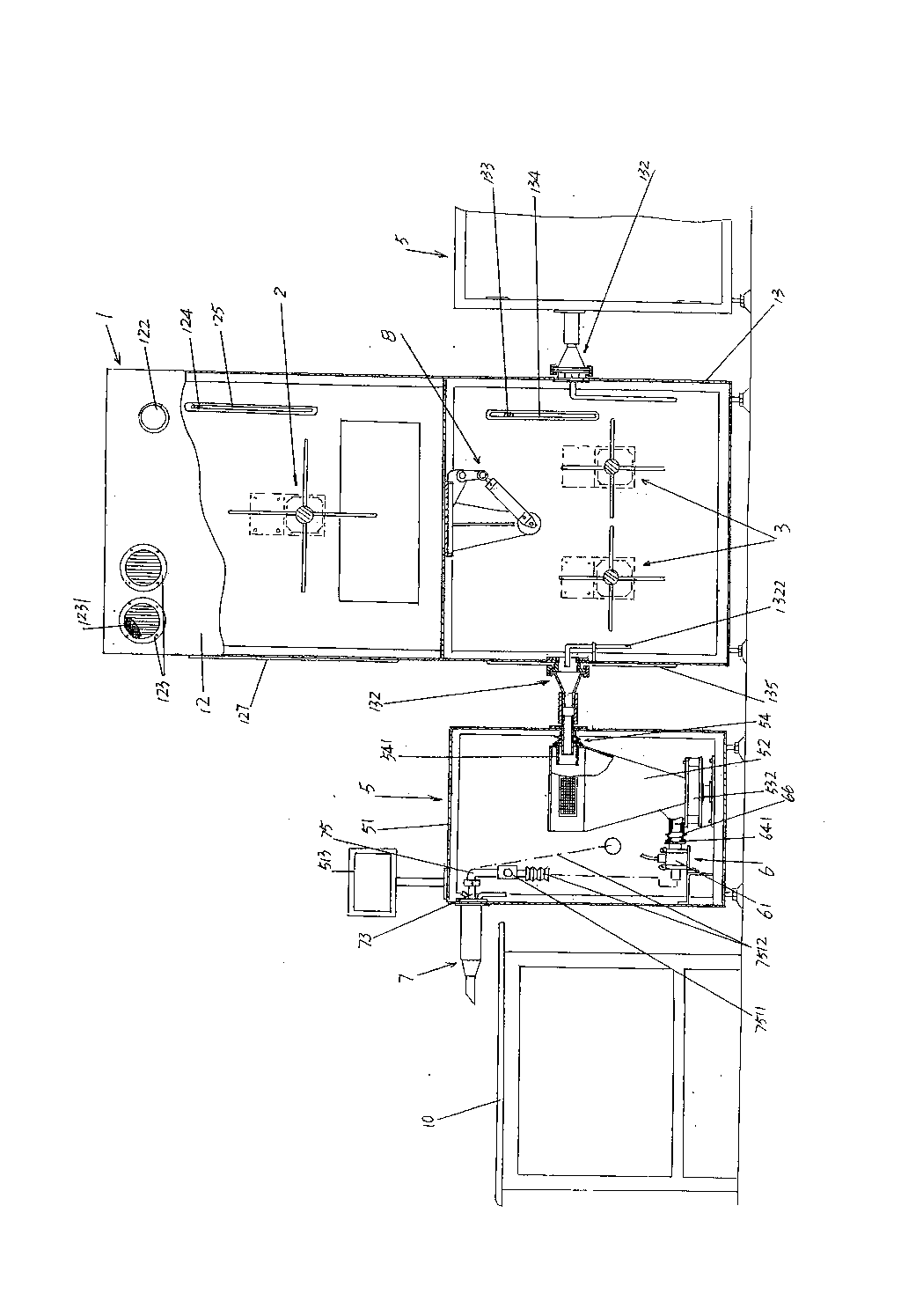

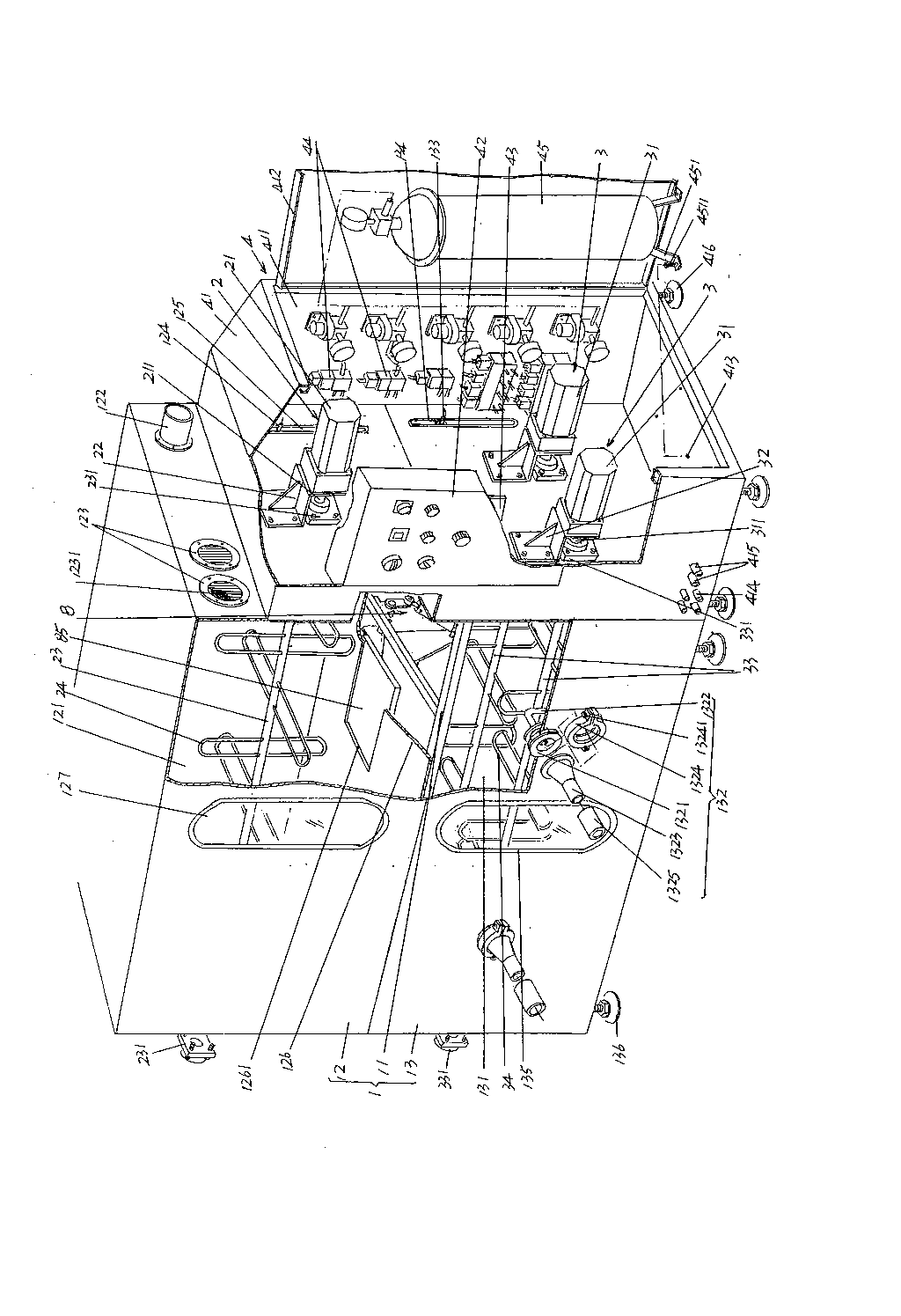

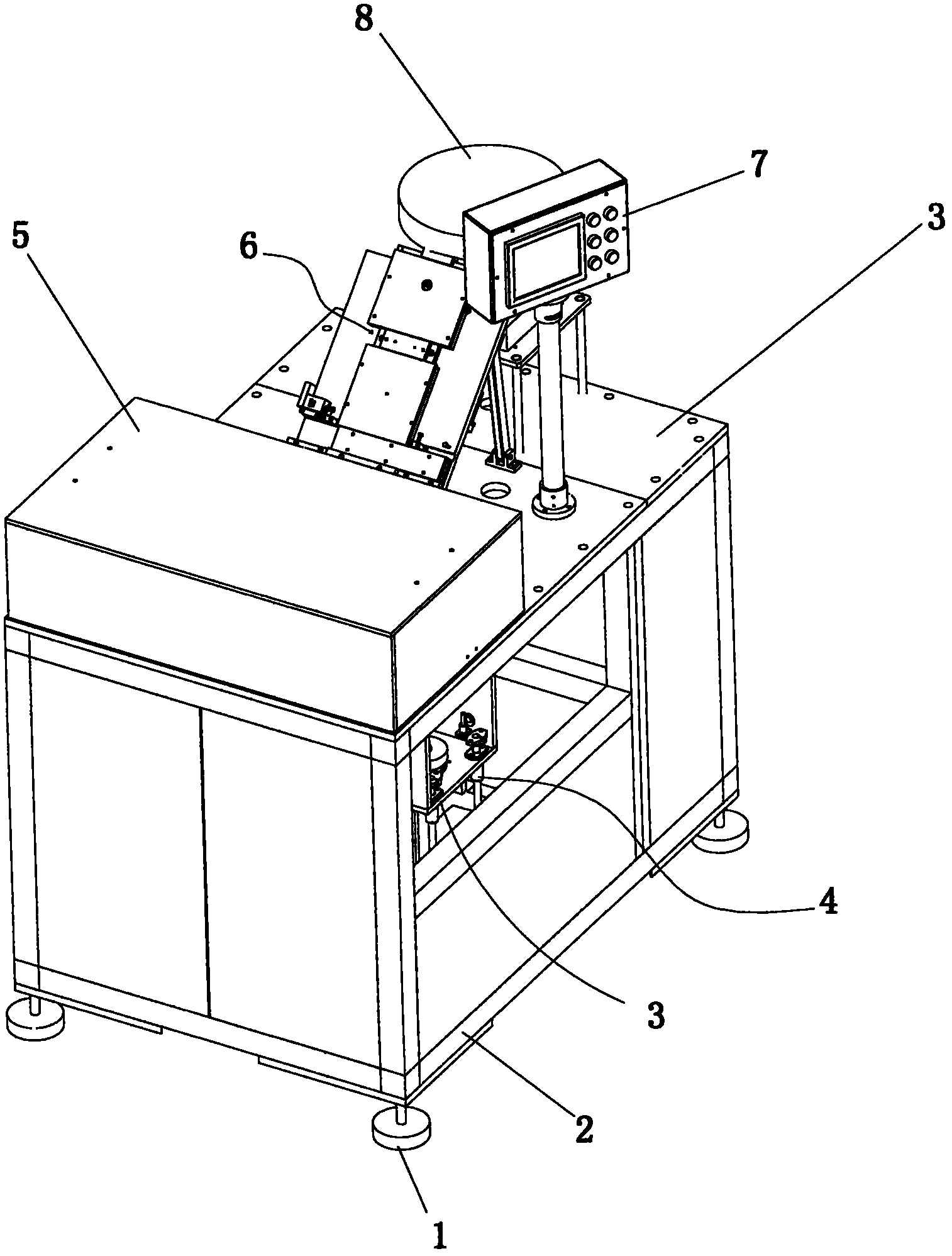

Automatic down filling machine

ActiveCN103101871AReduce escapeNo escapeUpholstery manufactureClothes making applicancesMagnetic valveEngineering

The invention discloses an automatic down filling machine, and belongs to the technical filed of a stowage unit for down and feather filled products. The automatic down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanism, an electrical automatic control mechanism, a pair of weighing metering mechanisms, a pair of down output mechanisms, a pair of down filling heads and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. The first down stirring mechanism is used for stirring down in a down storage box cavity, and the second down stirring mechanism is used for stirring down in a down delivering box cavity. The pair of weighing metering mechanisms is connected with a pair of down leading out connector pipelines on two sides of the down delivering box, the pair of down output mechanisms is connected with the pair of weighing metering mechanisms, the pair of down filling heads is connected with the pair of down output mechanisms in a matched mode, and the box cavity channel start-and-stop mechanism is placed on the box frame. The electrical automatic control mechanism is provided with an electrical box body, a control panel, a programmable controller, a group of magnetic valves and a high-pressure air storage tank. The automatic down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, showing good down filling efficiency, reducing operation intensity of workers, eradicating down wasting and showing good automatic control effect.

Owner:苏州比阳特服装设备有限公司

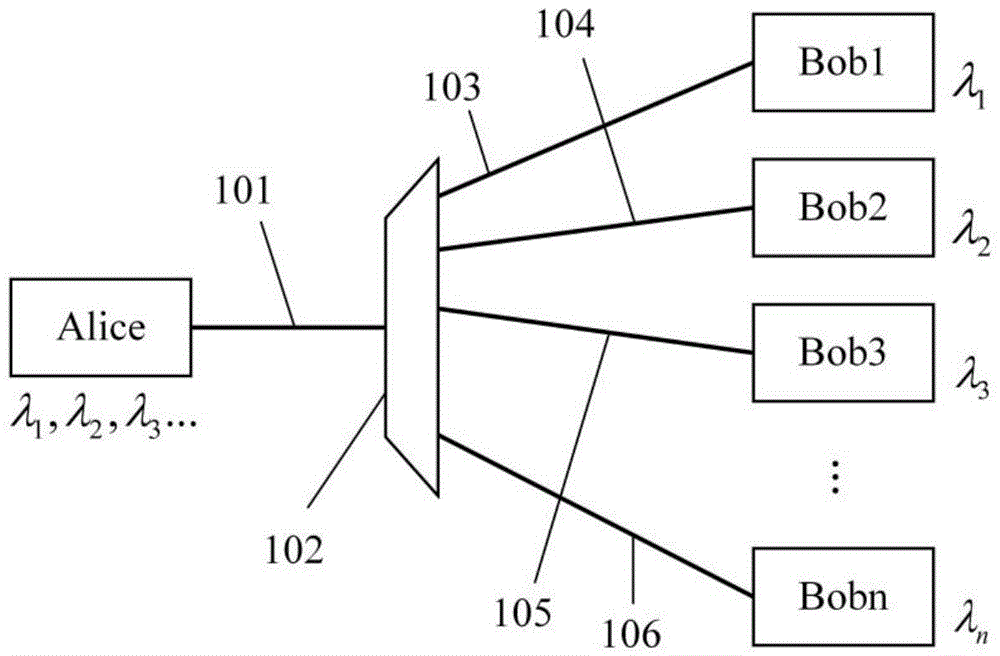

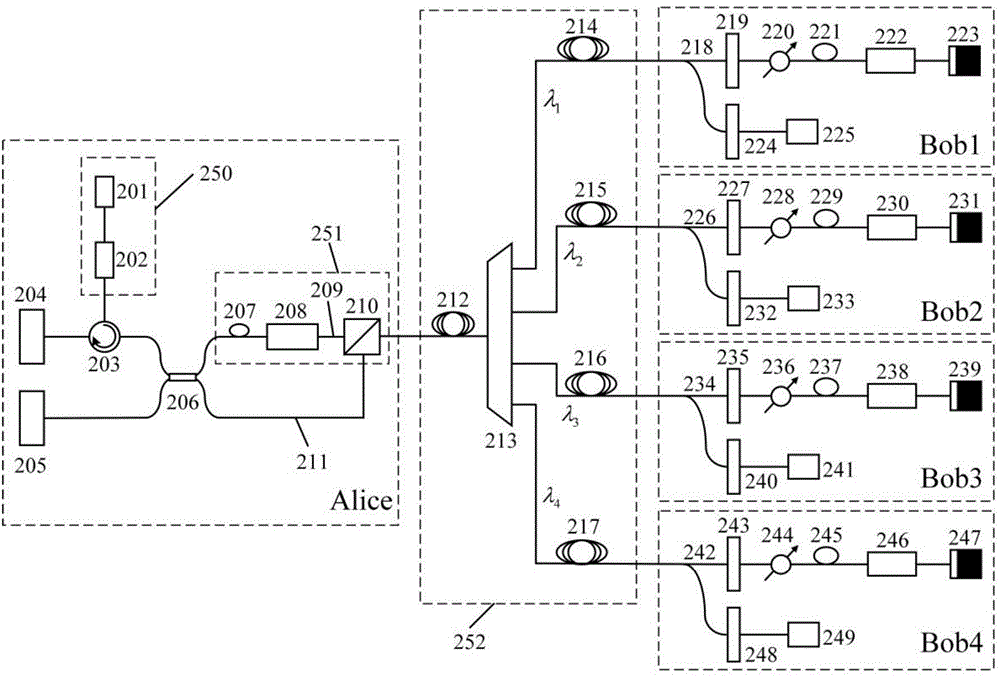

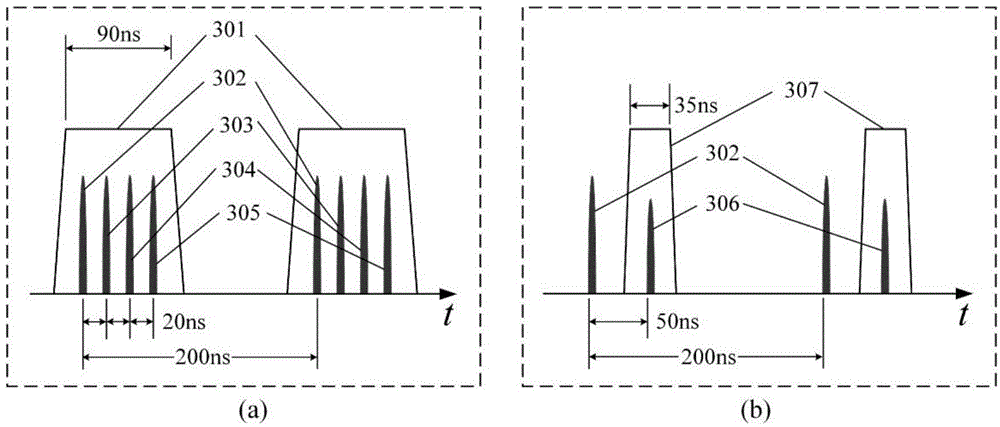

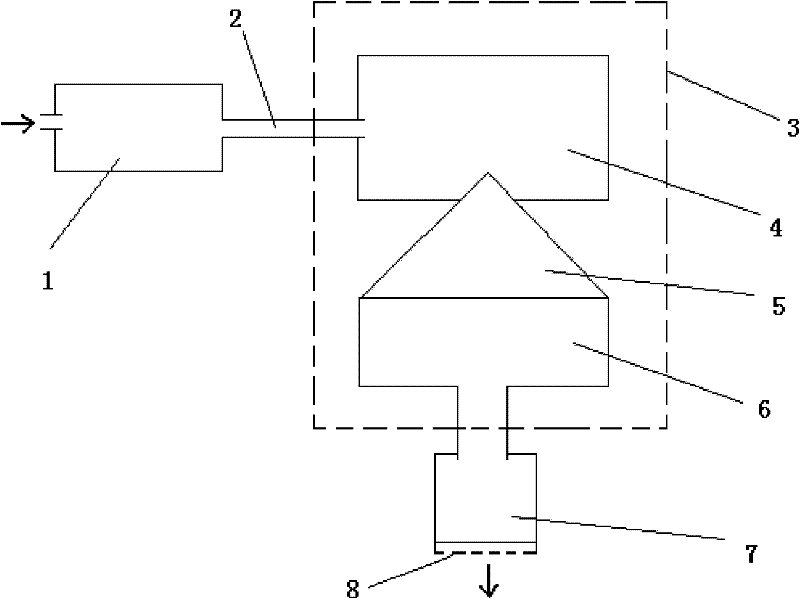

Multi-user wavelength division multiplexing QKD network system and secret key distributing and sharing method thereof

ActiveCN104092538AReduced pulse generation and control costsEnsure Stability and ConsistencyKey distribution for secure communicationWavelength-division multiplex systemsWavelength-division multiplexingComputer security

The invention discloses a multi-user wavelength division multiplexing quantum key distribution network system and a secret key distributing and sharing method thereof. The system comprises an Alice control end, a pulse conveying line and a Bob user end. The secret key distributing and sharing method comprises two stages of secret key distributing and sharing, wherein Alice and a plurality of Bob users carry out quantum secret key distributing and storing, and secret key priority is set; and Alice uses a secret key with low priority for encrypting a secret key with high priority into a ciphertext, then the ciphertext is sent to a user with low priority, the user with the low priority uses the secret key with low priority for decrypting the ciphertext, and the secret key with high priority is obtained. The system is reasonable, convenient to operate and low in cost, users in a network are relatively independent, the stability of the secret key generating rate of a single user is guaranteed, the secret key generating rate cannot be decreased along with increasing of users, meanwhile, a two-level equal-difference frequency space wave length planning scheme and an accurate pulse delaying technology are used, and mutual interference of pulses between different users is removed.

Owner:GUANGDONG INCUBATOR TECH DEV CO LTD

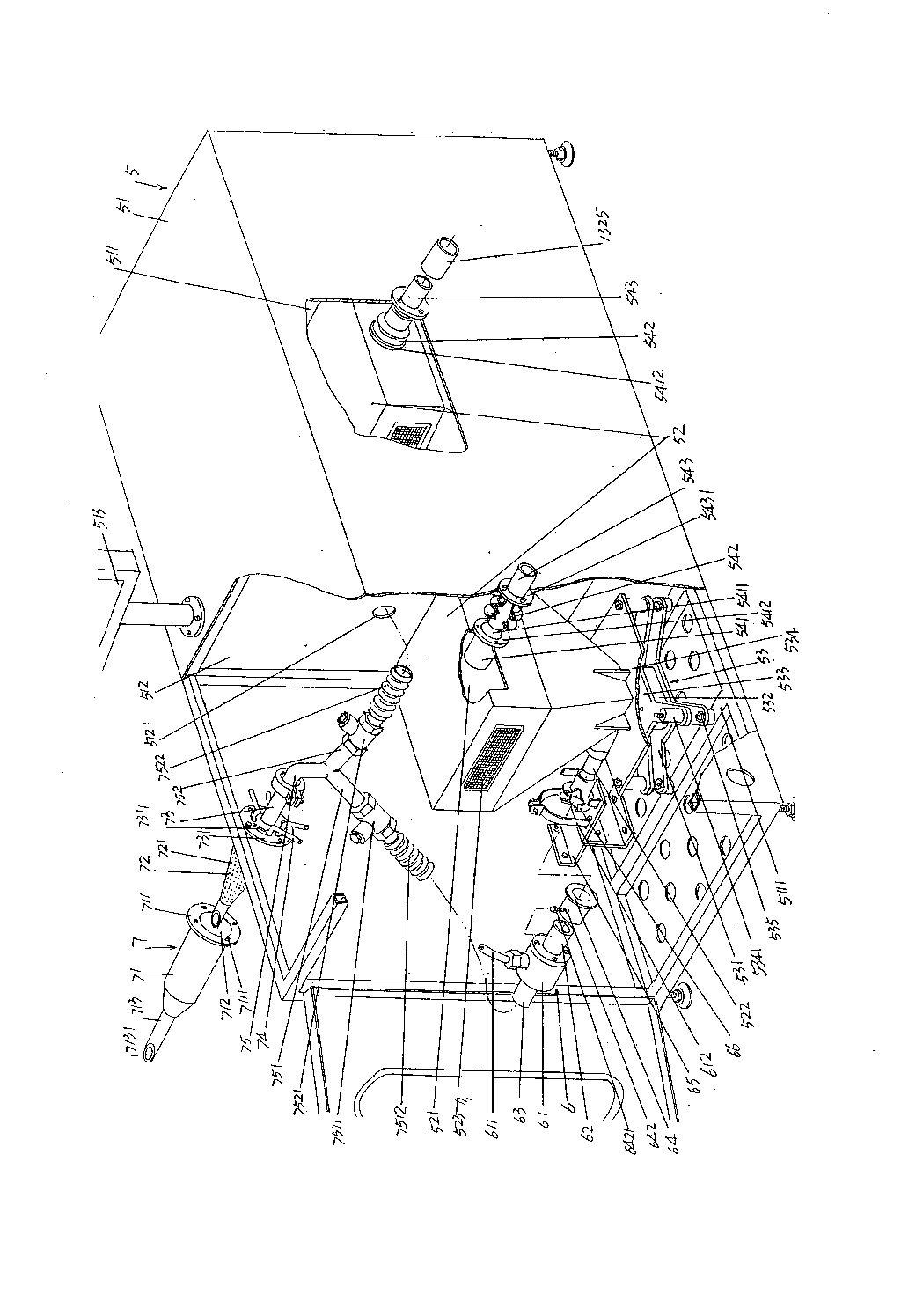

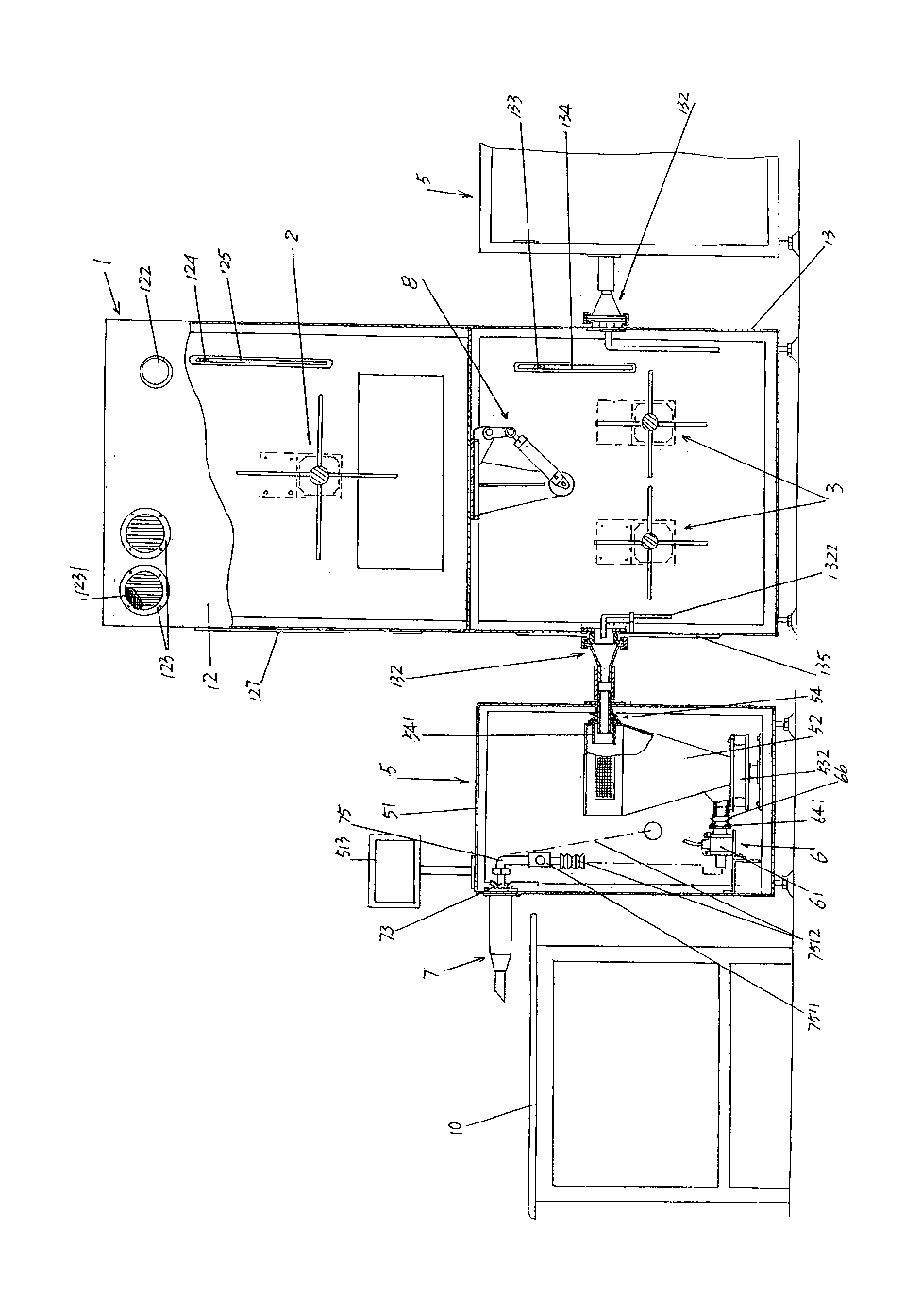

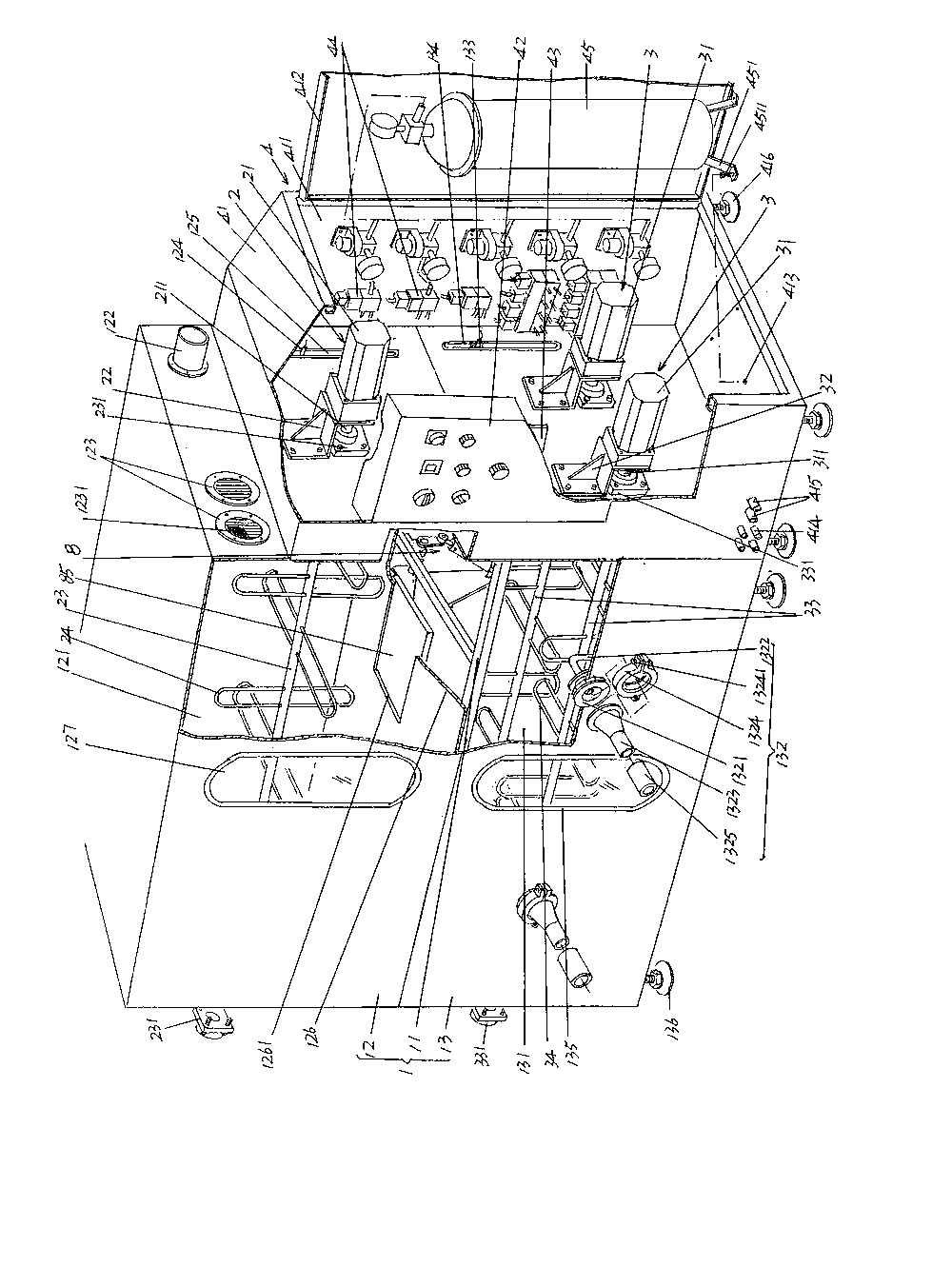

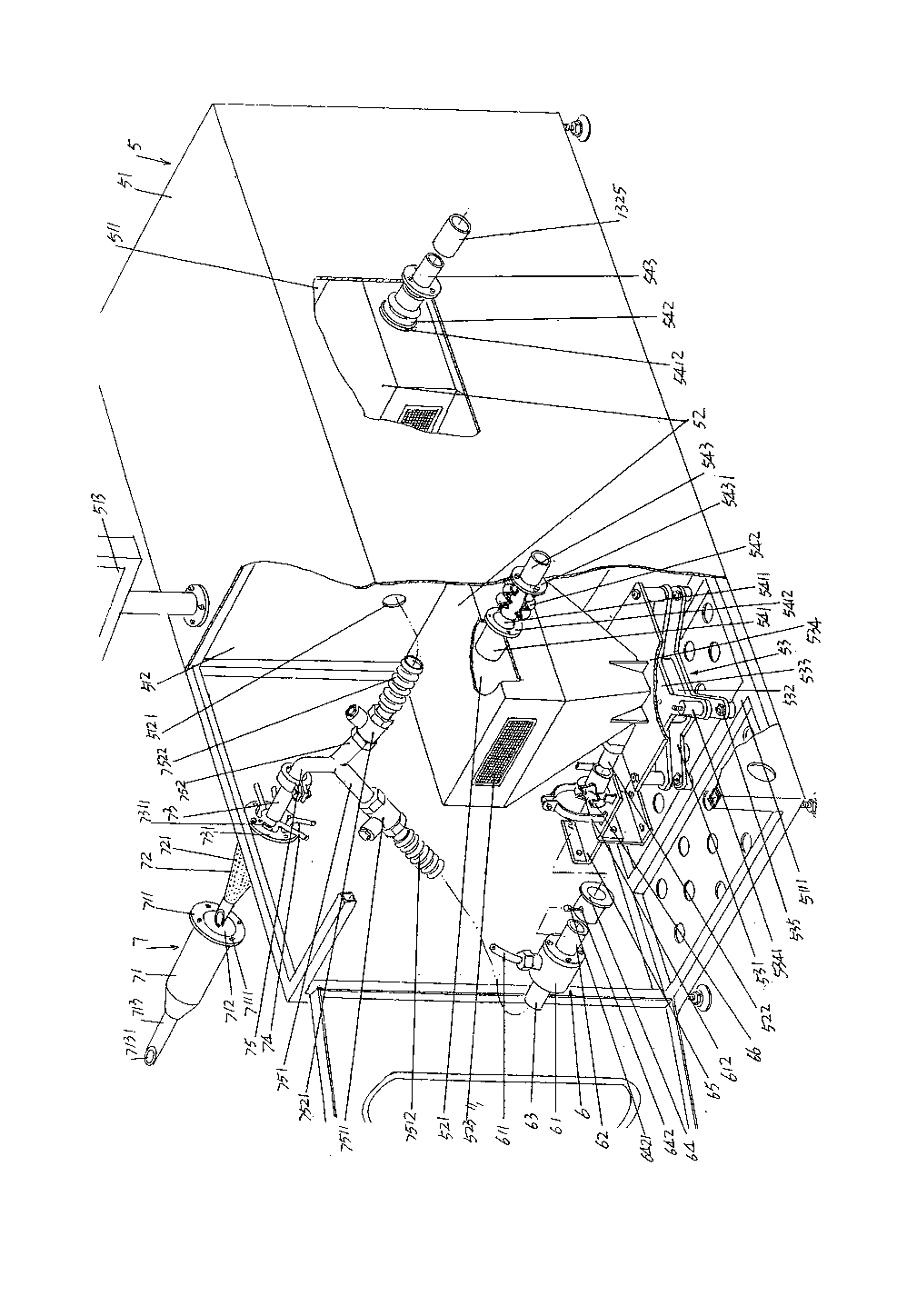

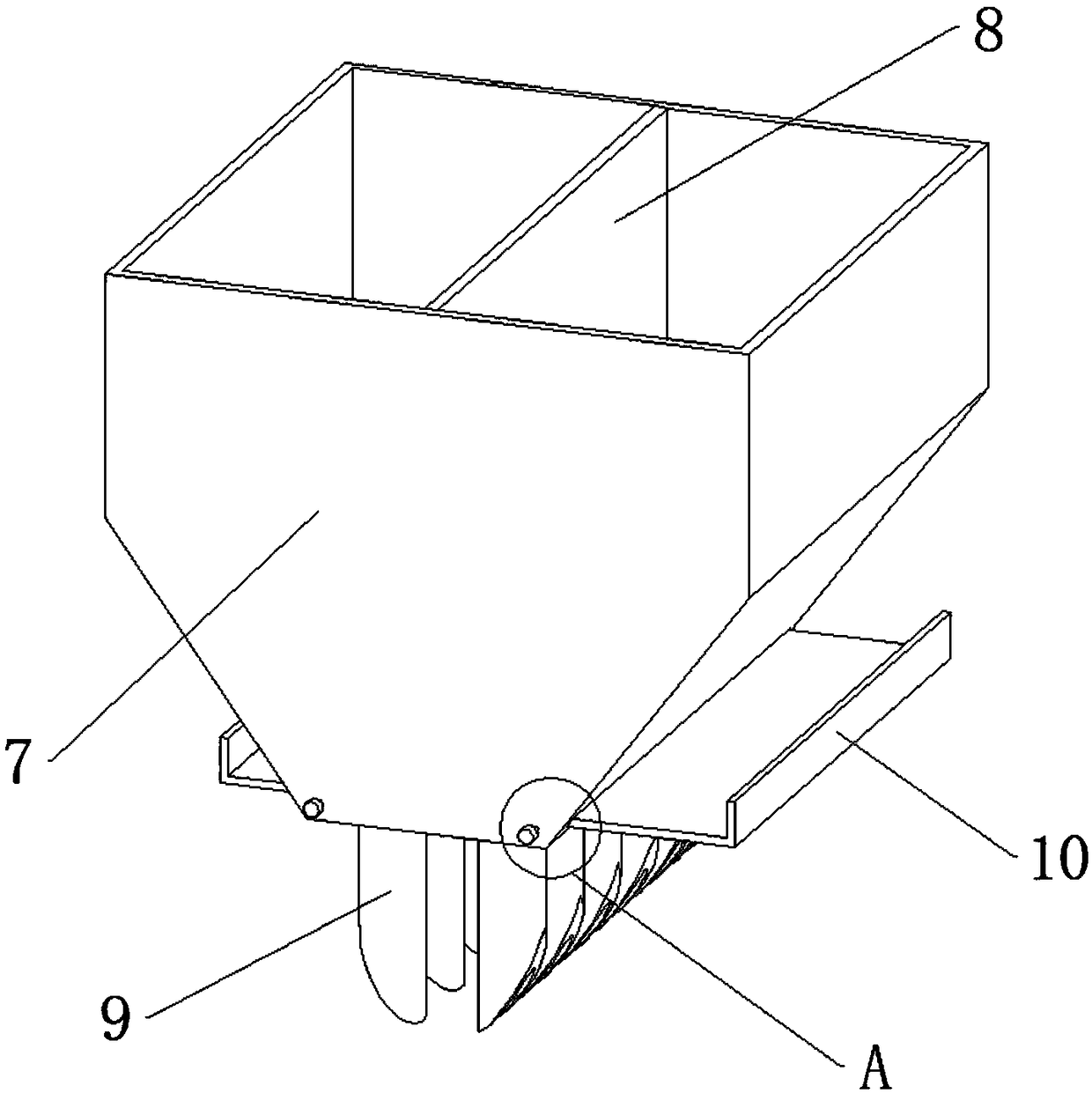

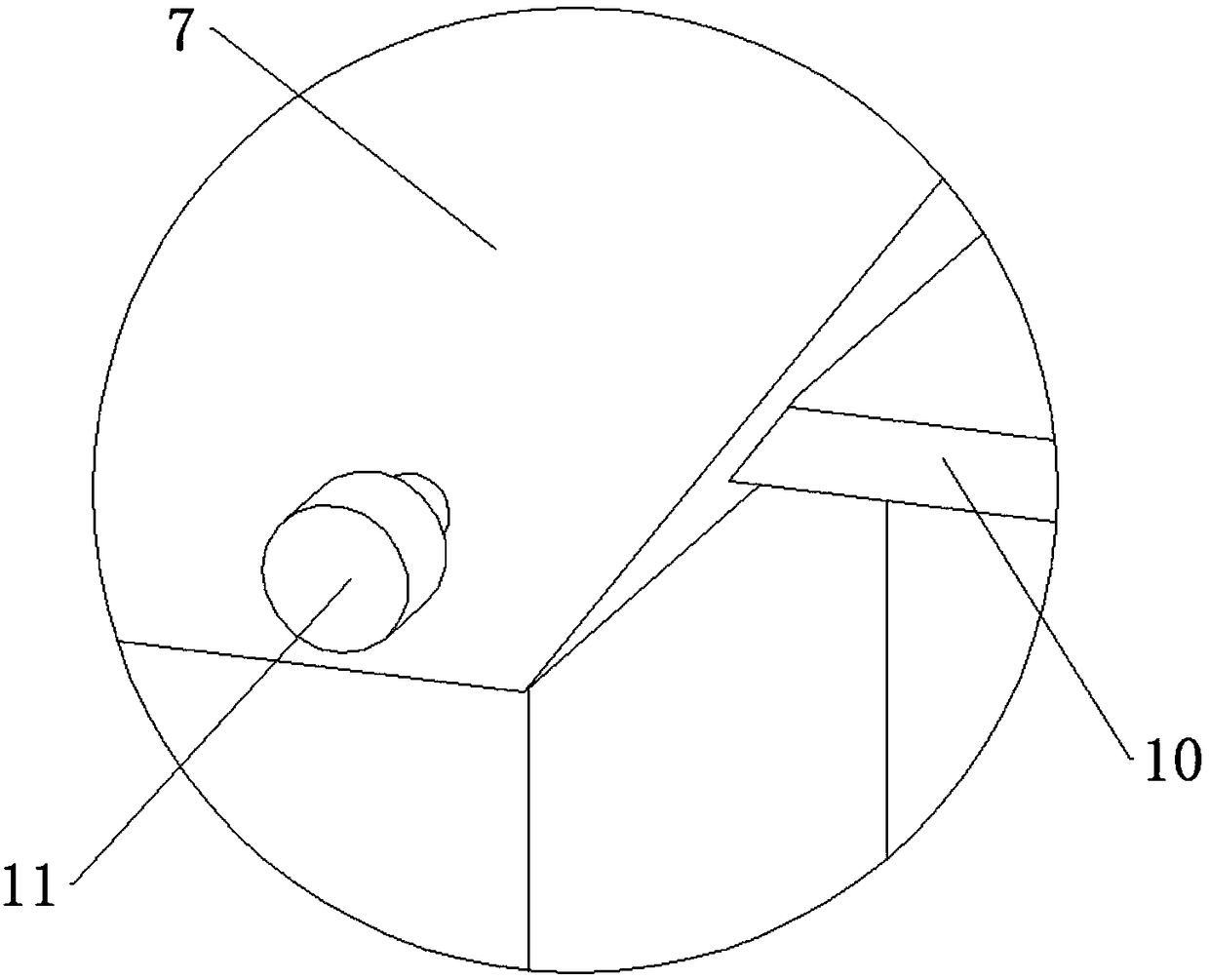

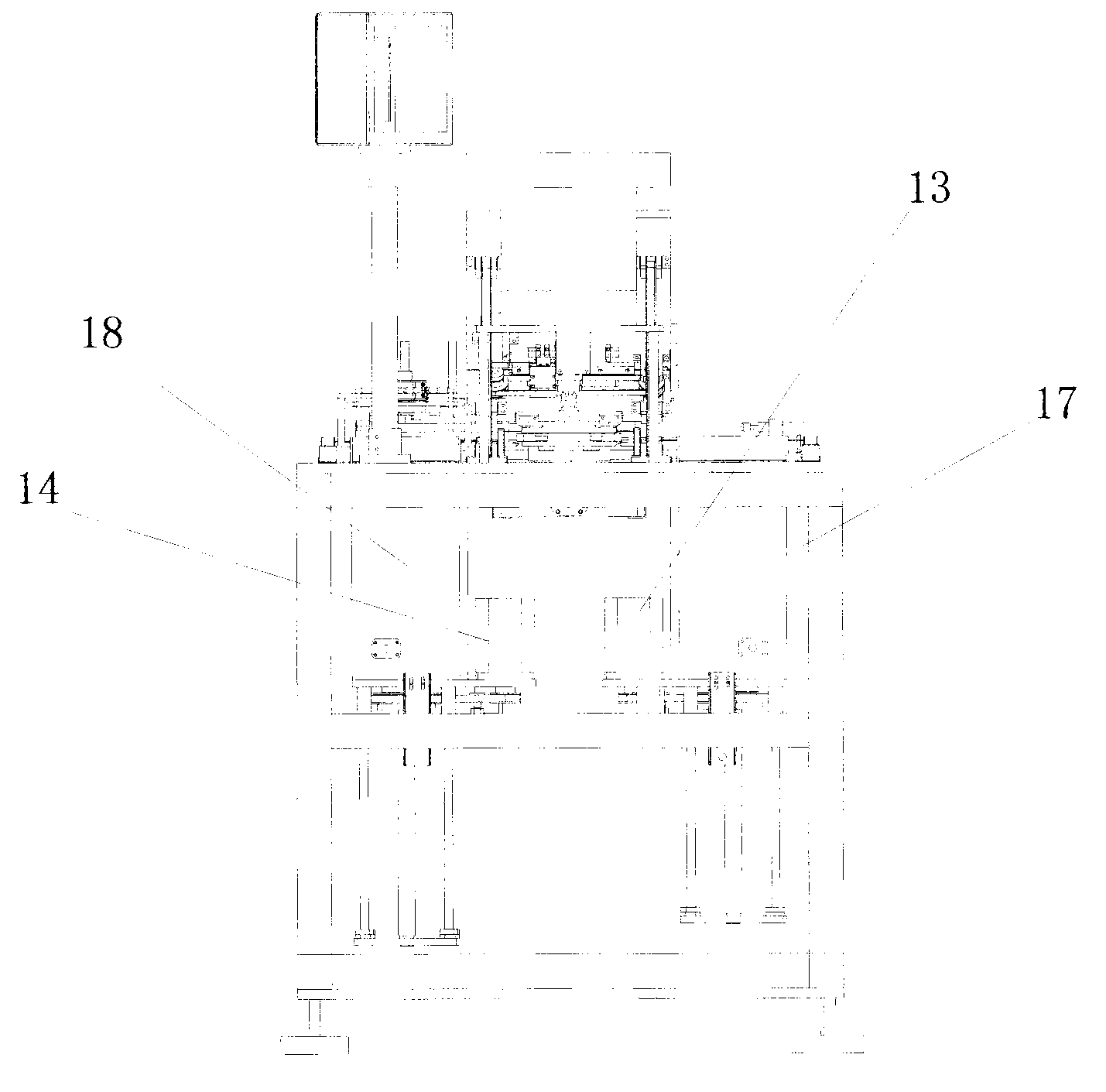

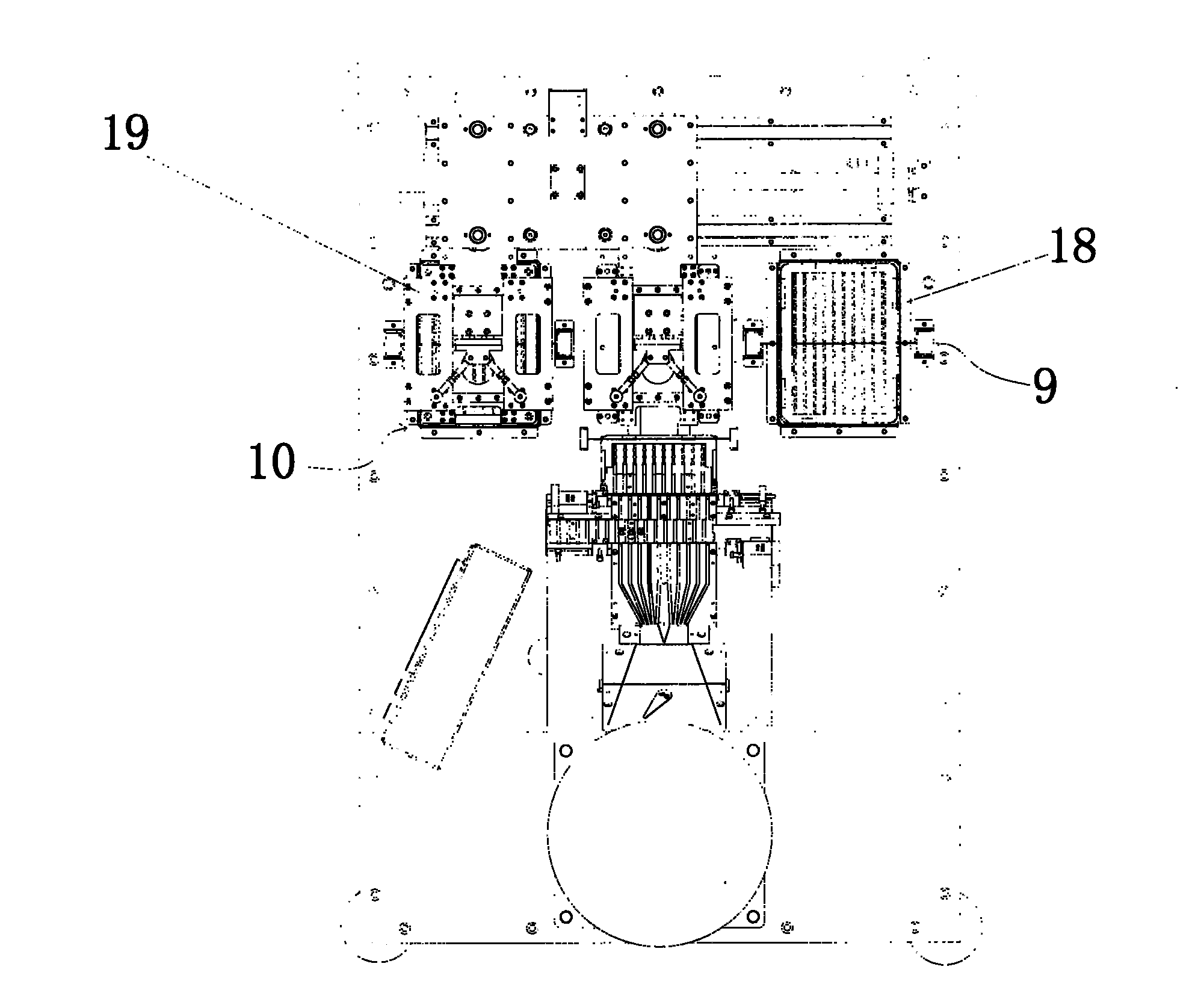

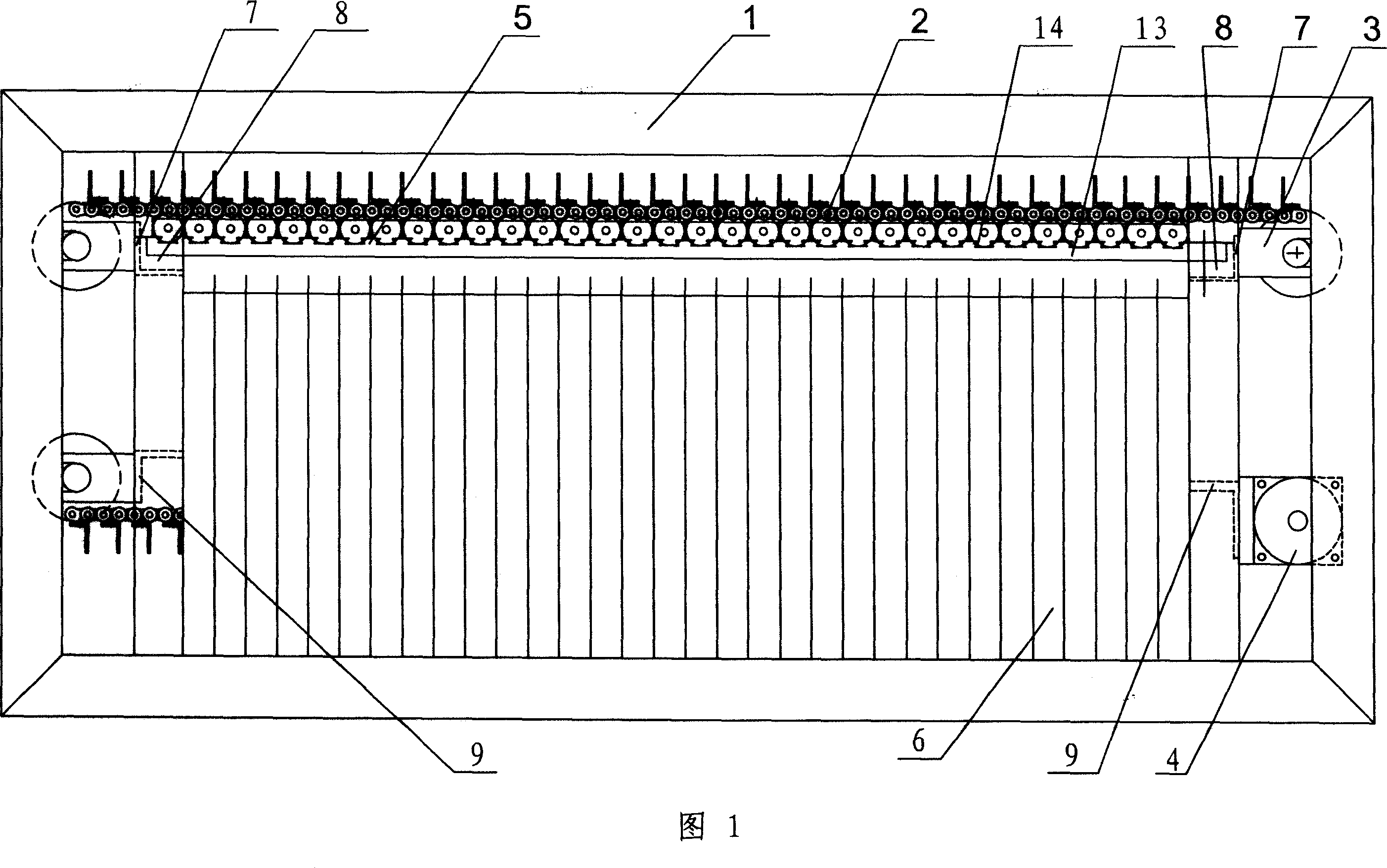

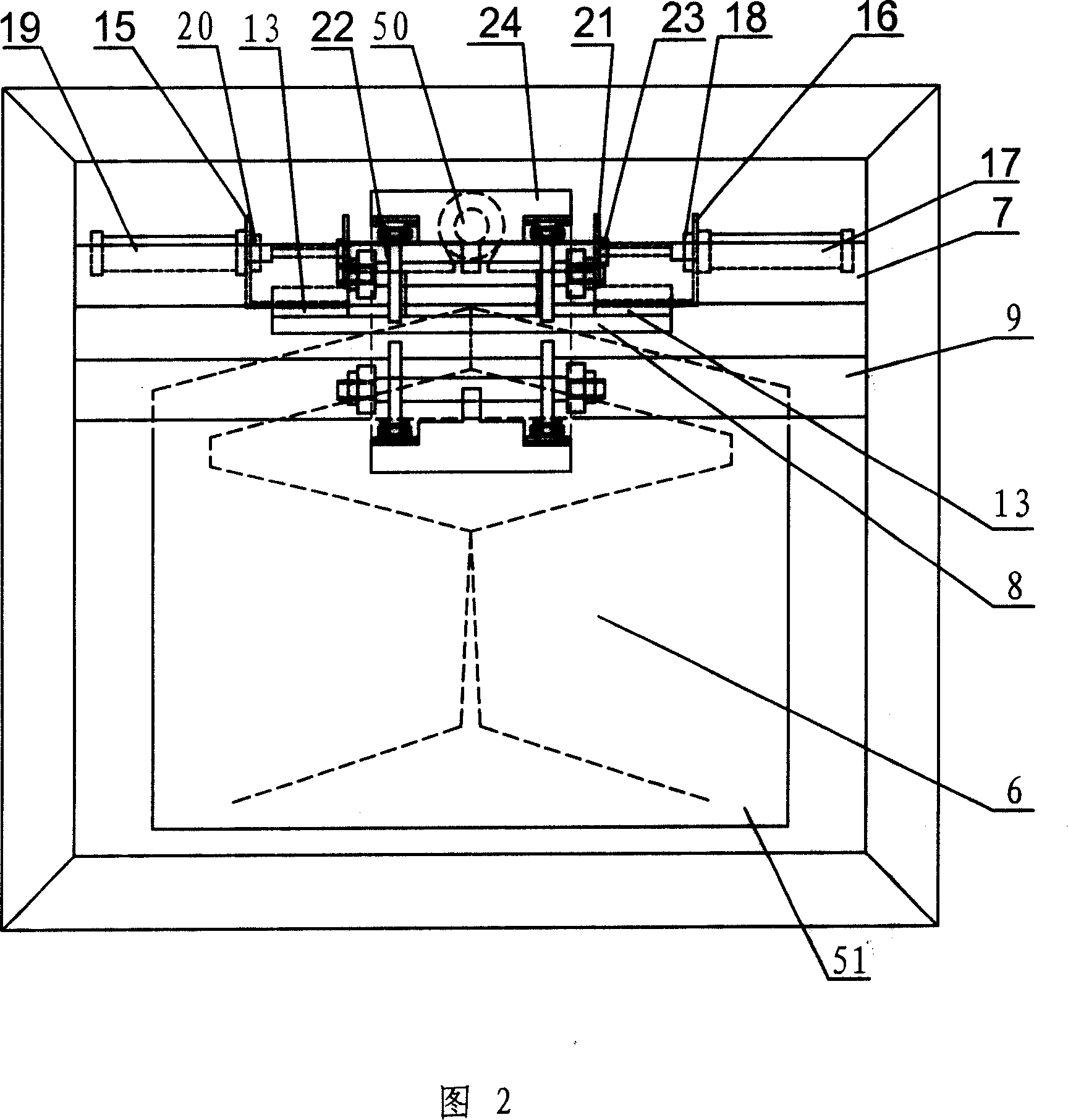

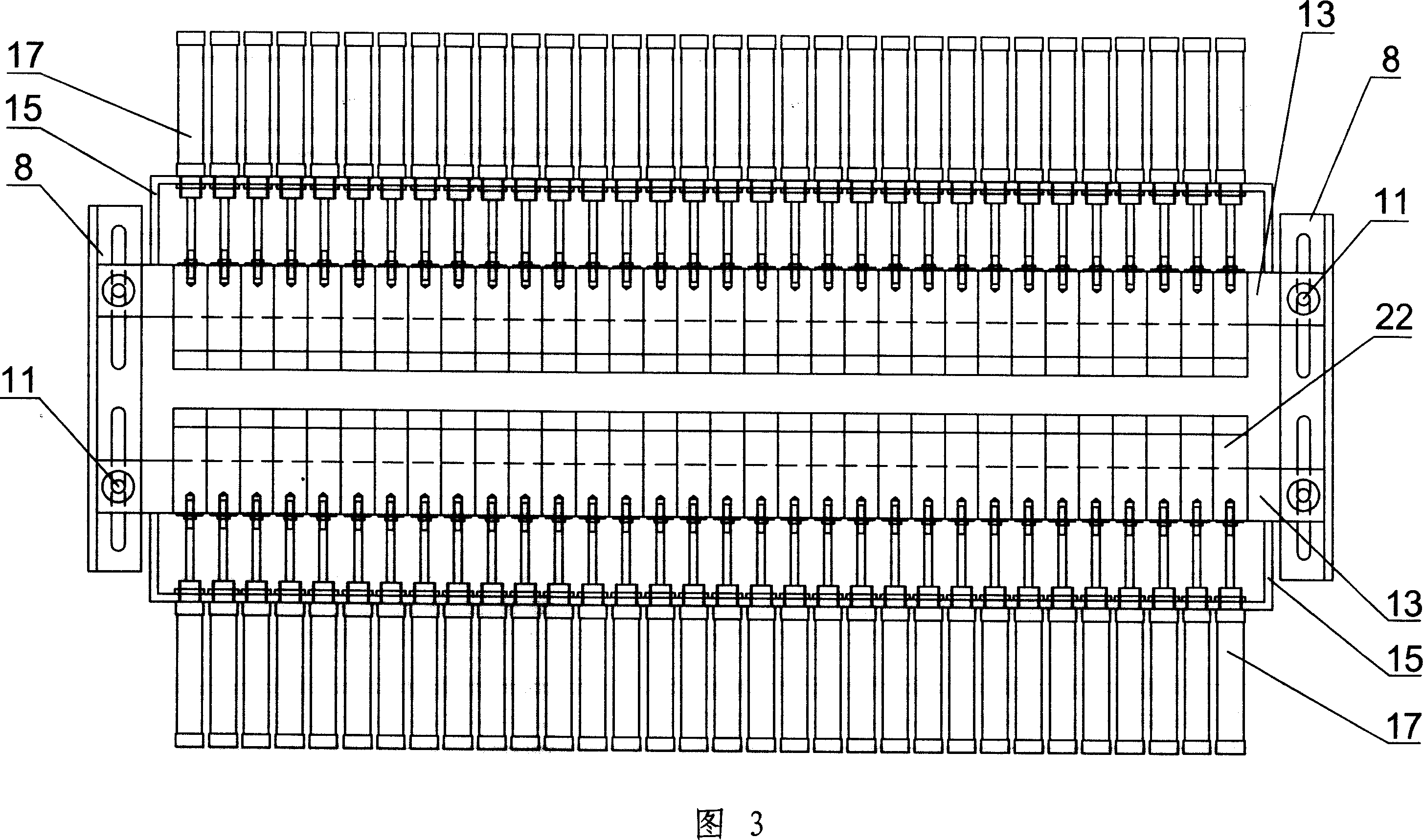

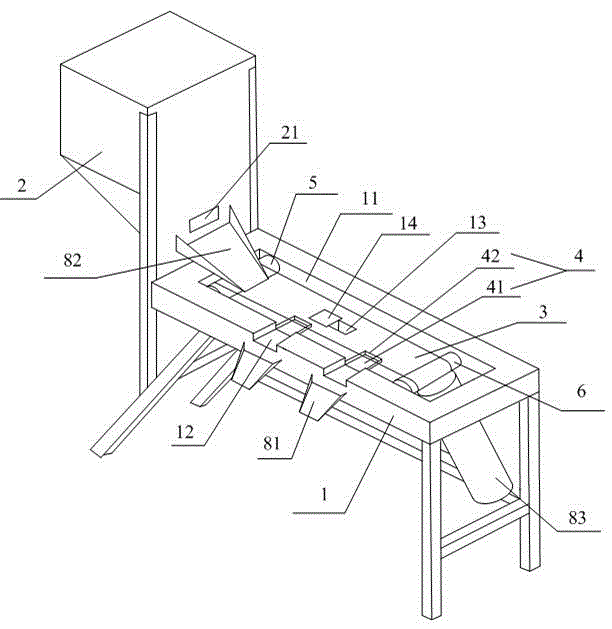

Automatically quantitative down filling machine

ActiveCN103101873AQuantity GuaranteeGuaranteed cleanlinessUpholstery manufactureClothes making applicancesAutomatic controlClean environment

The invention discloses an automatically quantitative down filling machine, and belongs to the technical field of stowage equipment for down and feather filled products. The automatically quantitative down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanisms, an electrical automatic control mechanism, a weighing metering mechanism, a down output mechanism, a down filling head and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. A down lead-in connector, an air window and a down storage quantity signal collector are placed on the down storage box in a matched mode, and a down lead-out connector and a down quantity signal collector are placed on the down delivering box in a matched mode. The first stirring mechanism is used for stirring down inside a down storage box cavity, and the second stirring mechanism is used for stirring down inside a down delivering box cavity. The electrical automatic control mechanism is placed on one side of the box body in a matched mode. The weighing metering mechanism is connected with a down lead-out connector pipeline of the down delivering box, the down output mechanism is connected with the weighing metering mechanism, the down filling head is connected with the down output mechanism in a matched mode, and the box cavity channel start-and-stop mechanism is matched with a bottom plate of the down storage box. The automatically quantitative down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, being good in down filling efficiency and light in operation intensity, guaranteeing a clean environment of operation site and eradicating down wasting.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

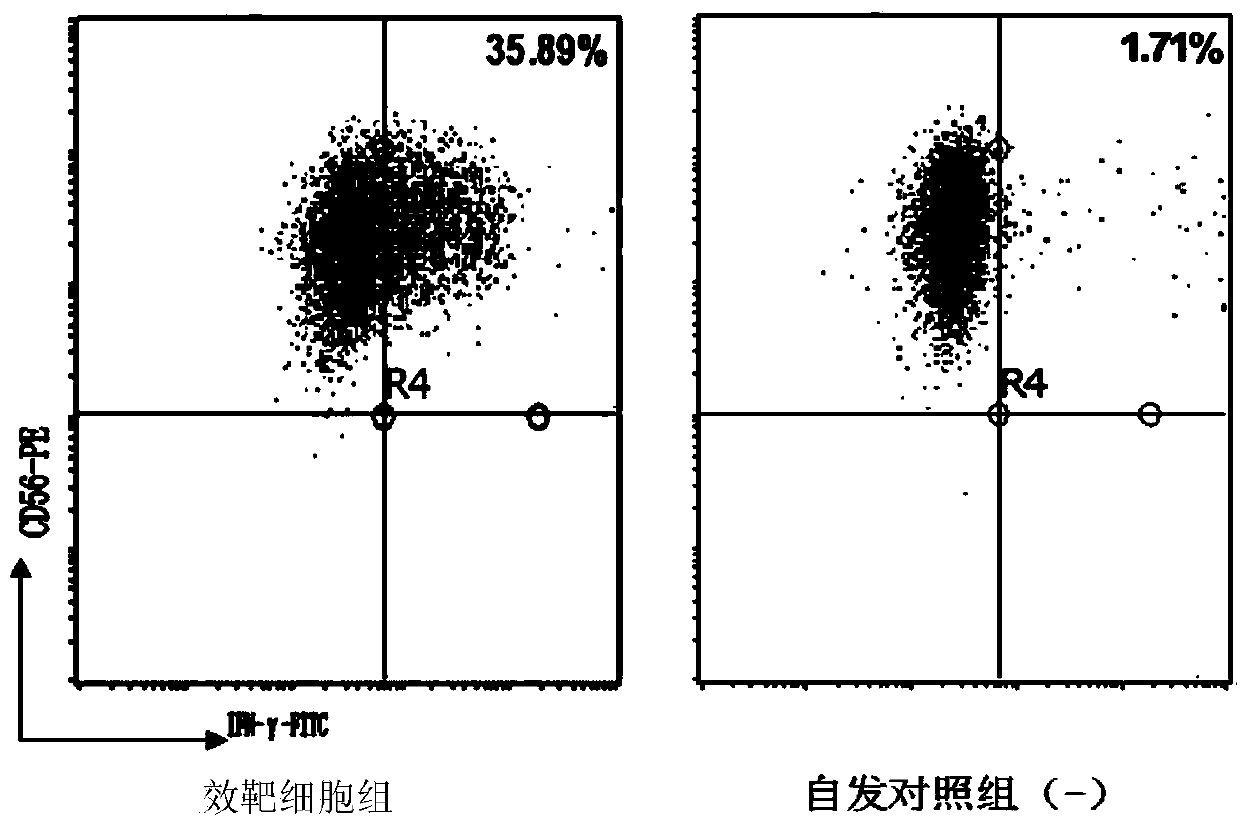

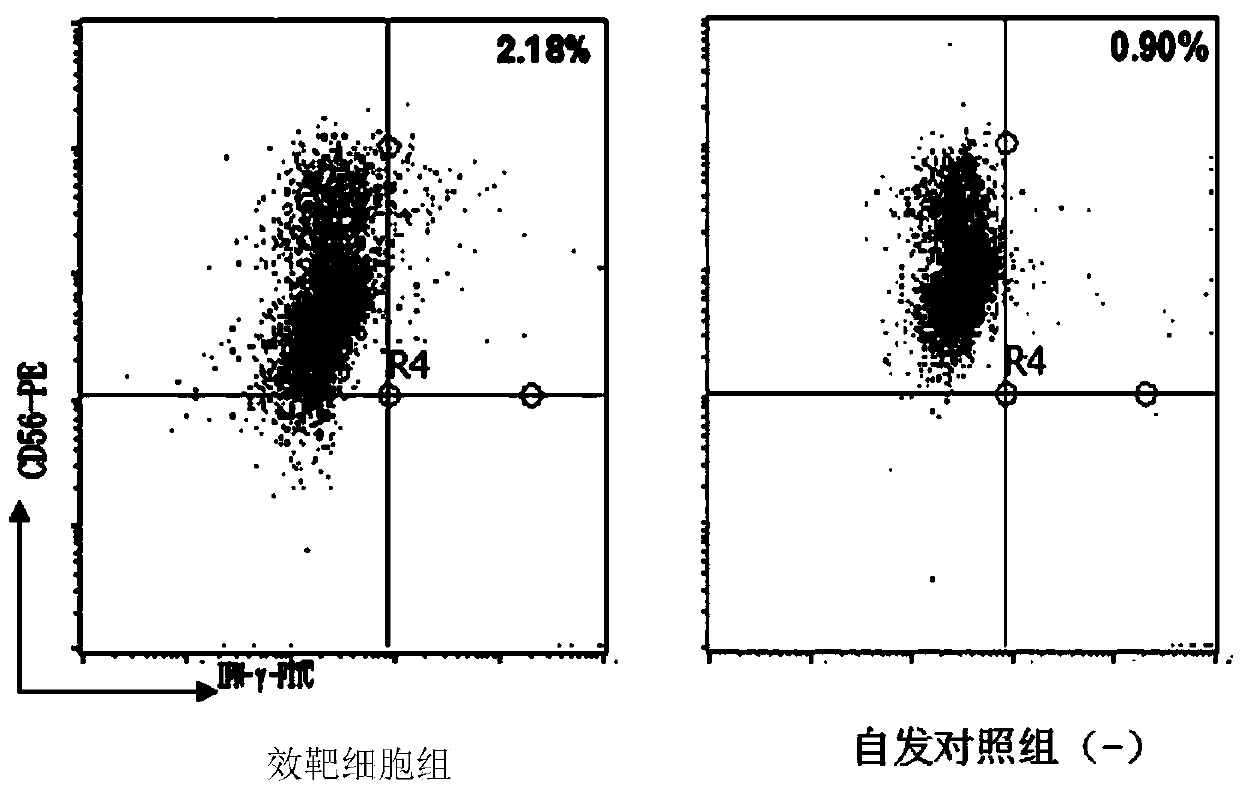

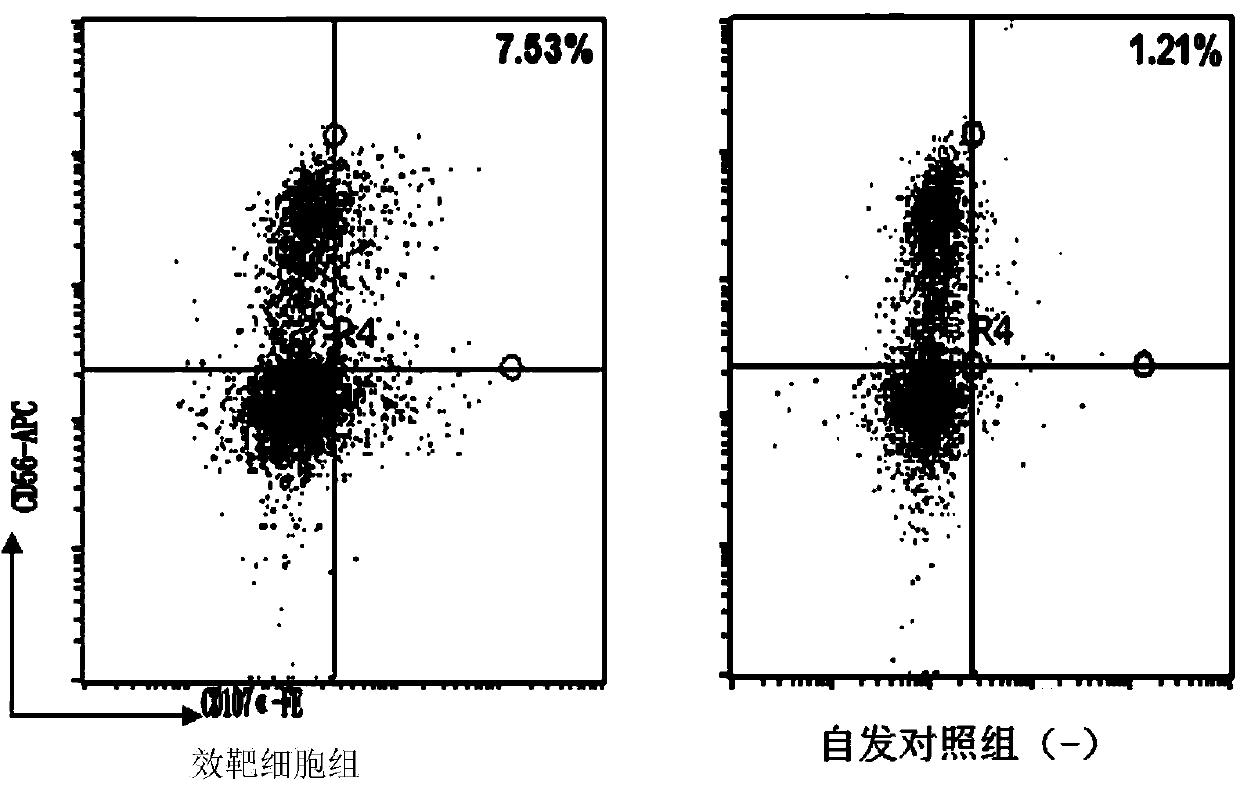

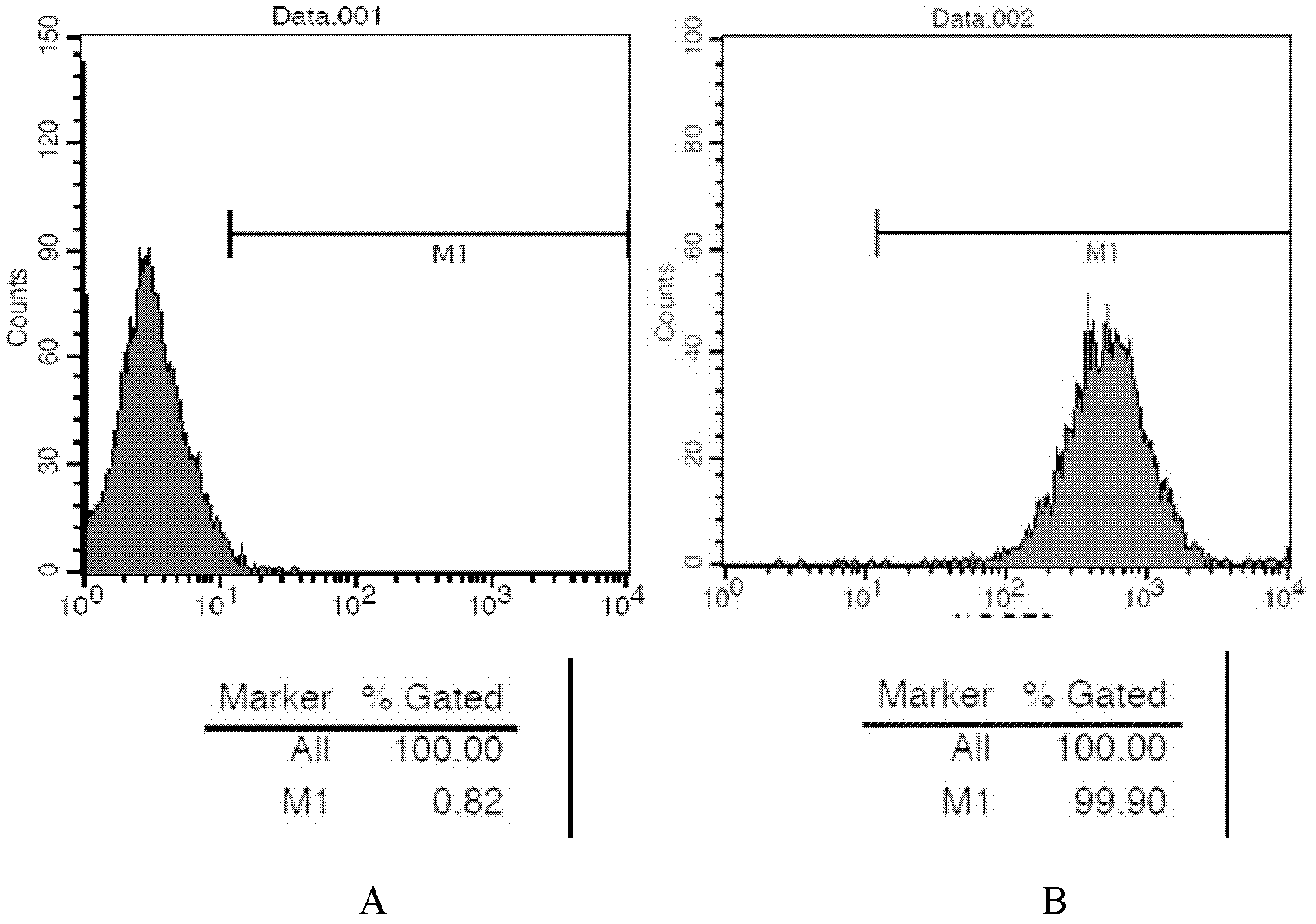

Method for simultaneous and efficient amplification of CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells

ActiveCN104357390AHigh purityHigh activityBlood/immune system cellsAdoptive cellular immunotherapySerum free media

The invention discloses a method for simultaneous and efficient amplification of CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells. The method comprises the steps as follows: the concentration of separated PBMC (peripheral blood mononuclear cells) is adjusted by a serum-free medium containing autologous plasma, an Anti-CD16 antibody, IL-2 and IL-15 are added, and then the mixture is transferred into a T175 culture flask for culture; an Anti-CD3 antibody and an Anti-CD137 antibody are added; a serum-free medium containing the autologous plasma, IL-2 and IL-15 is supplemented every two days according to the cell growth condition; the cell concentration is controlled to be about 1.5*10<6> / ml; and after culture is performed for 14-21 days, large quantities of high-purity CD<3+>CD<56+>CIK cells and CD<3->CD<56+>NK cells can be obtained simultaneously, and the total cell quantity can reach an effective value of the cell quantity required for adoptive cellular immunotherapy clinically for tumor. The method for simultaneous and efficient amplification of the CD<3+>CD<56+>CIK cells and the CD<3->CD<56+>NK cells is simple, convenient, effective and high in cell killing activity.

Owner:HRYZ (SHENZHEN) BIOTECH CO +1

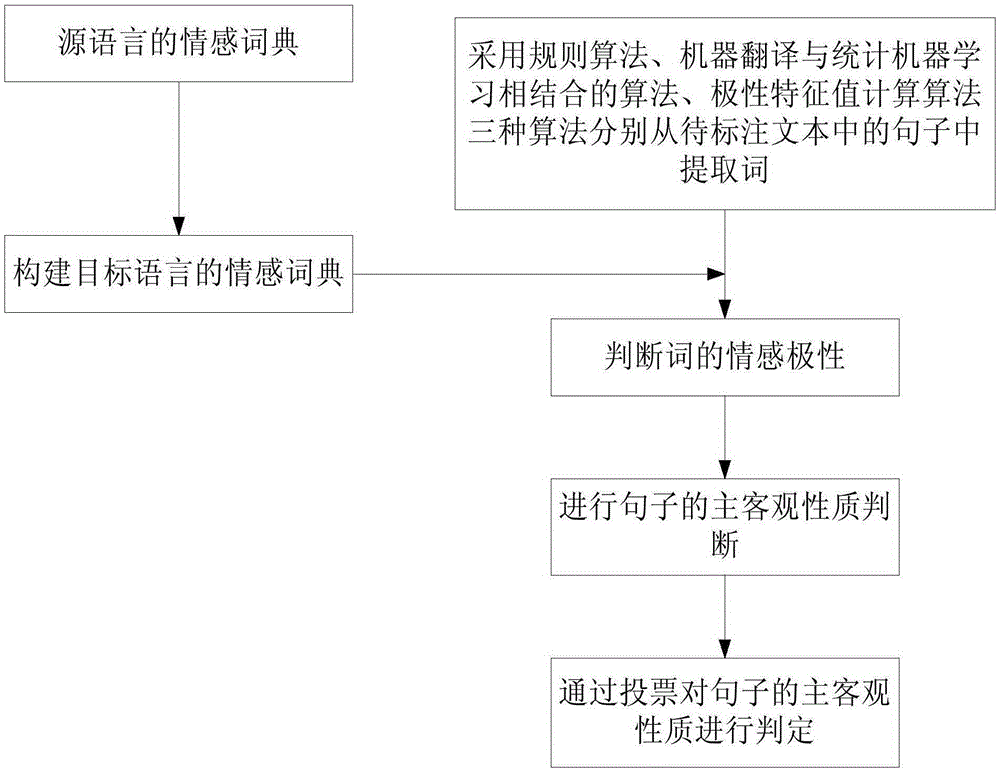

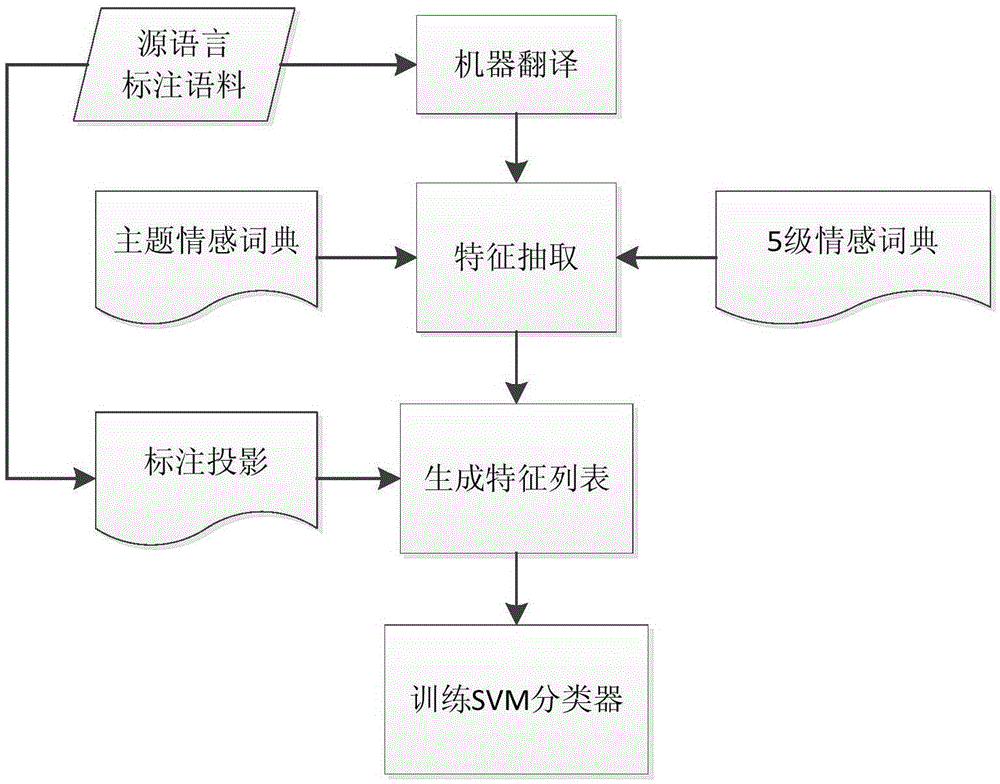

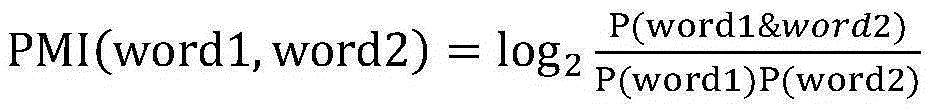

Voting based classification method for cross-language subjective and objective sentiments

ActiveCN105320960ASolve the scarcityGuaranteed quantityNatural language translationCharacter and pattern recognitionClassification methodsHabit

The present invention discloses a voting based classification method for cross-language subjective and objectives sentiments. The method comprises the following steps of: S1, constructing a target language sentiment dictionary according to a source language sentiment dictionary; S2, separately adopting three algorithms of a rule algorithm, a combination algorithm of machine translation and statistical machine learning, and a polarity eigenvalue calculation algorithm to extract words from a sentence of a to-be-tagged text, determining sentiment polarity of the words according to the constructed target language sentiment dictionary, and further determining subjective and objective nature of the sentence; and S3, acquiring subjective and objective nature determination results of the sentence, obtained according to the three algorithms, and determining the subjective and objective nature of the sentence by voting. The method can fully consider contexts and usage habits of a target language on the premise of keeping certain accuracy, effectively solves the problem that a tagged corpus of the target language is scarce, and further improves classification accuracy on the premise of ensuring the recall rate.

Owner:BEIHANG UNIV

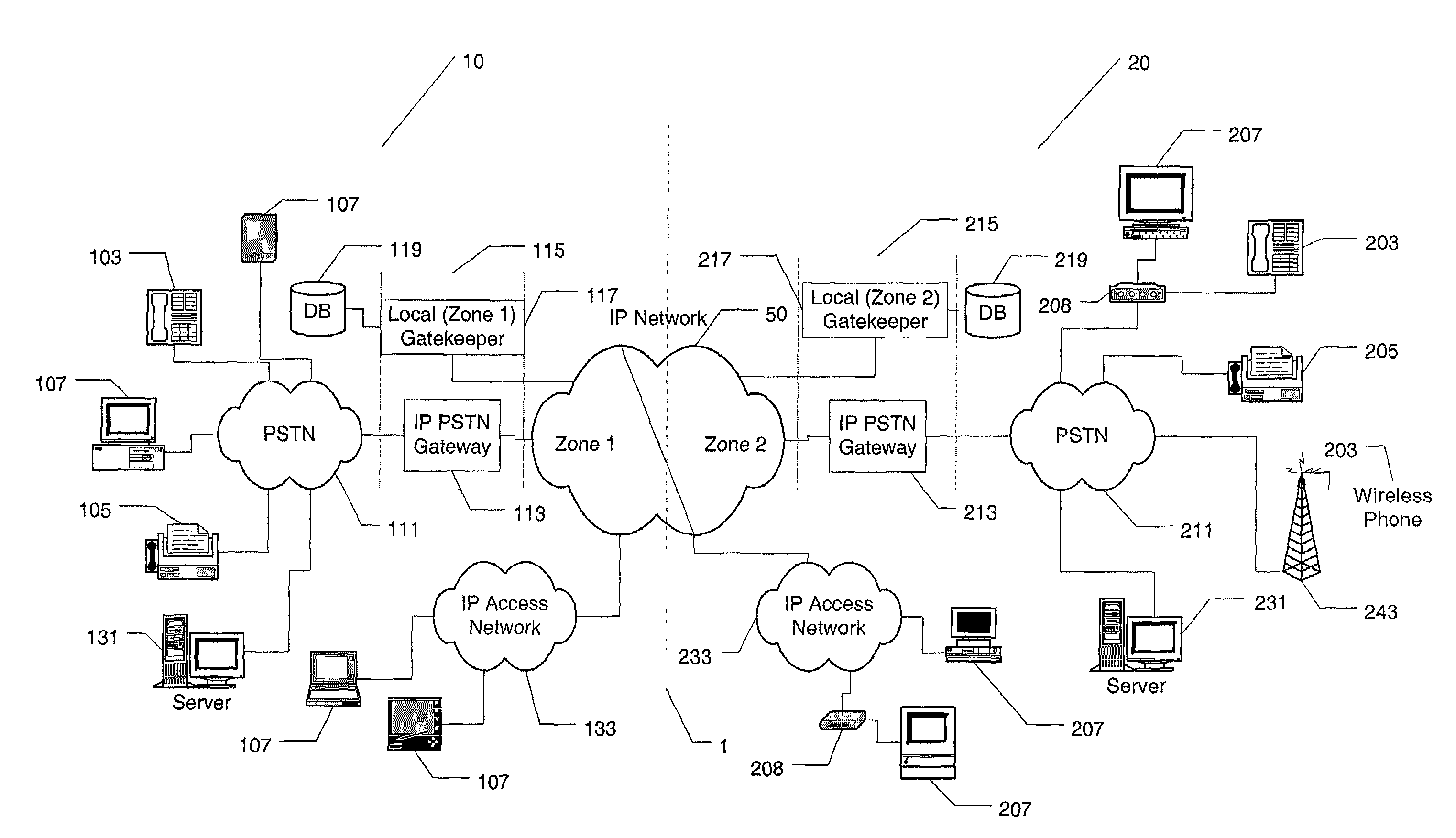

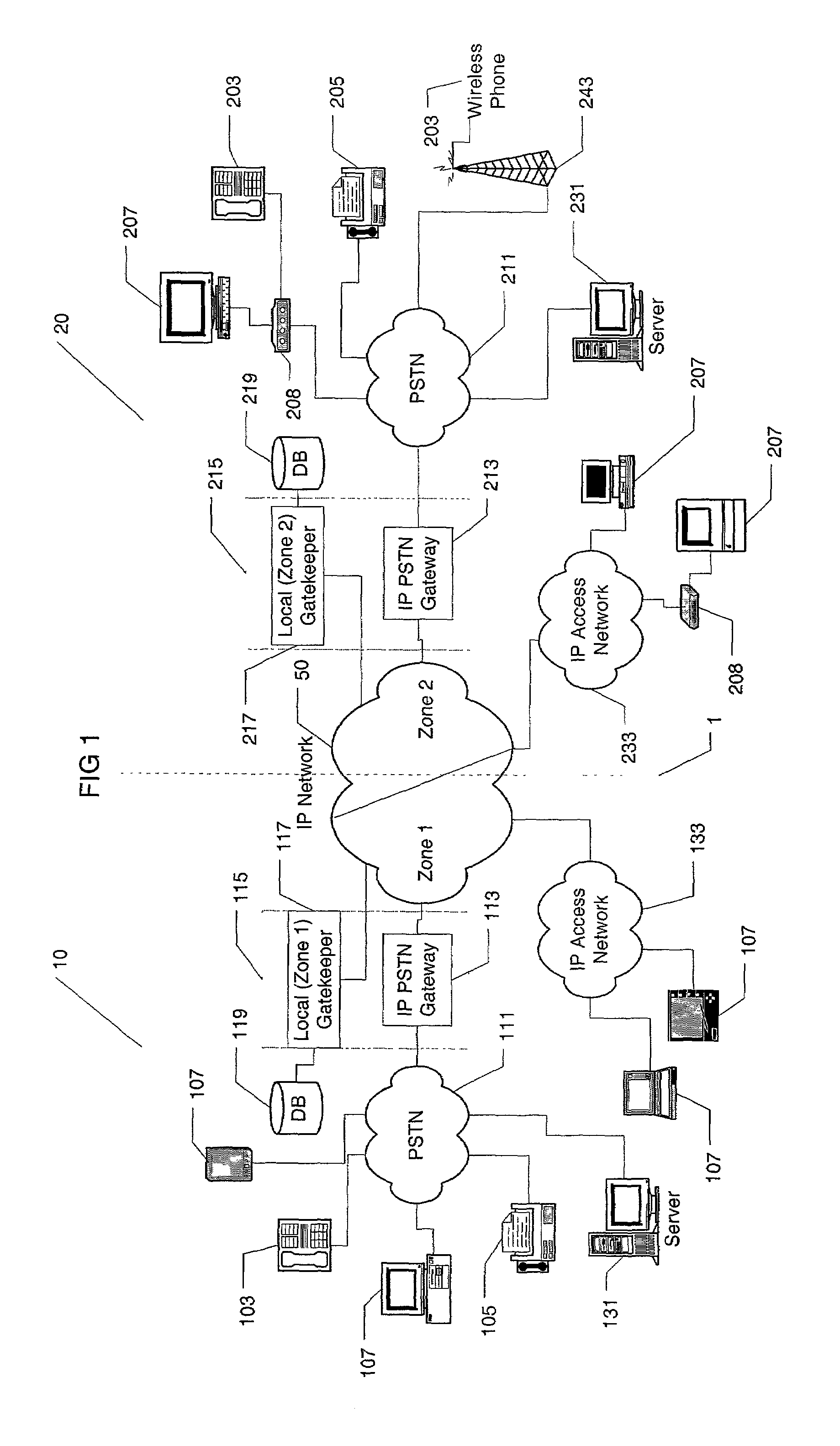

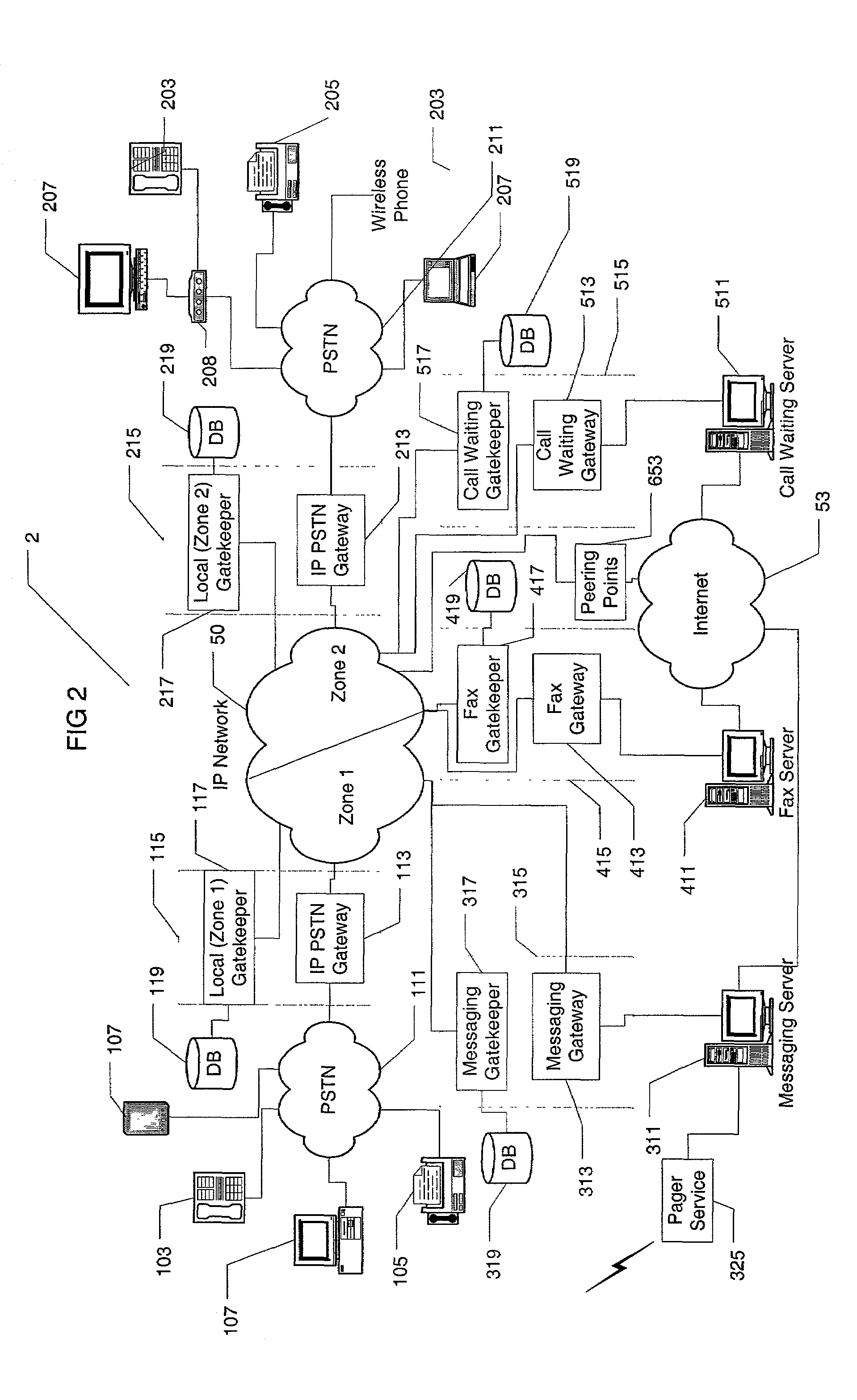

Allocation of channel capacity in multiservice networks

InactiveUS7346043B1Efficient use ofReserving capacityMultiplex system selection arrangementsError preventionCyber operationsComputer network

Methods are described which enable the operator of a network such as an Internet protocol (IP) network to allocate ingress and egress channel capacity for the use by different services or for use by different service providers. The methods can prevent a service provider or a service from overusing network capacity. The methods also enable the network operator to temporarily allocate unused capacity if demand for a service exceeds previously allocated capacity. Further a method is described whereby capacity on a Voice over Internet protocol (VoIP) network is sold to service providers with guarantees for the number of available channels, where the channel capacity guarantees could be global, or by any type of subdivision. In addition to having a committed channel capacity, the service provider could be allowed to exceed the committed capacity whenever excess capacity is available on the network.

Owner:VERIZON SERVICES GROUP +2

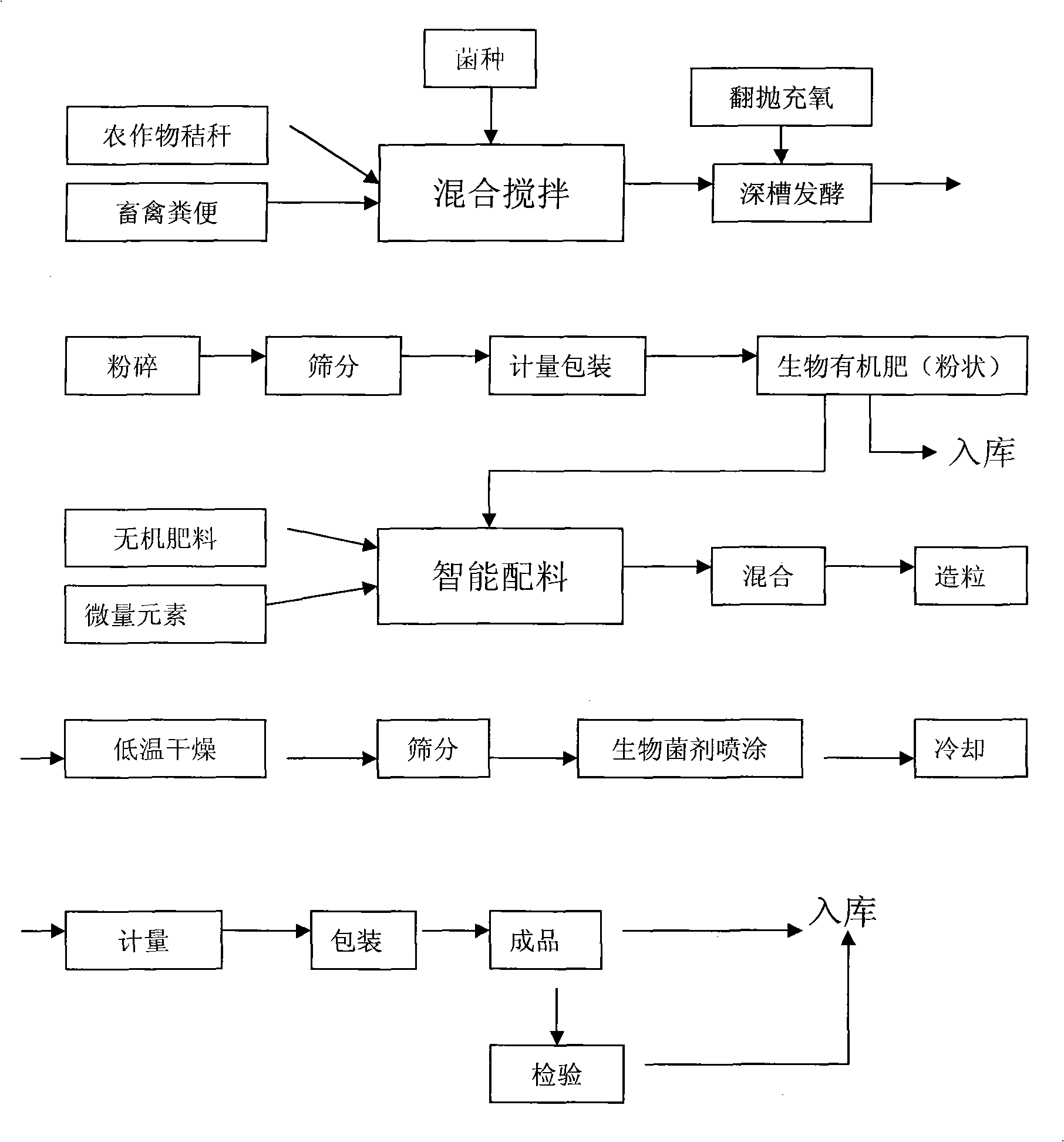

Production process of biological-organic-inorganic ternary compound fertilizer

InactiveCN101676243AShorten the decay cycleReduce nutrient lossBio-organic fraction processingOrganic fertiliser preparationChemistryOrganic component

The invention provides a production process of a biological-organic-inorganic ternary compound fertilizer which is prepared by the following steps: mixing crop stalks, such organic components as livestock manures and active biological agents, regulating the carbon nitrogen ratio from 26 to 35, PH from 5.5-8.2 and moisture from 40% to 65% according to the organic matter contents of the crop stalksand the livestock manures, fermenting the mixture at minus15-75 DEG C for 20-50 days and ensuring the living bacteria count to be 0.03-0.2 billion / g, carrying out turning and oxygenating, fermenting in deep tanks and grinding on the mixture to prepare the biological organic fertilizers, mixing the biological organic fertilizers with the inorganic fertilizers and trace elements and simultaneously adopting the low-temperature drying process after extruding granulation and the biological agent spraying and cooling technology. The method can greatly shorten the decay period, ensure little nutrientloss and little generating capacity of sour gases in the processes of fermentation and decay and complete decay and fermentation, can enhance the stress resistance of the crops, ensure obvious disease-resistant effects and high survival rates of specific functional bacteria and has wide application. Through field contrast tests, both the production and income are increased by 10-25% by applying the biological organic fertilizer.

Owner:辽宁元亨生物科技有限公司

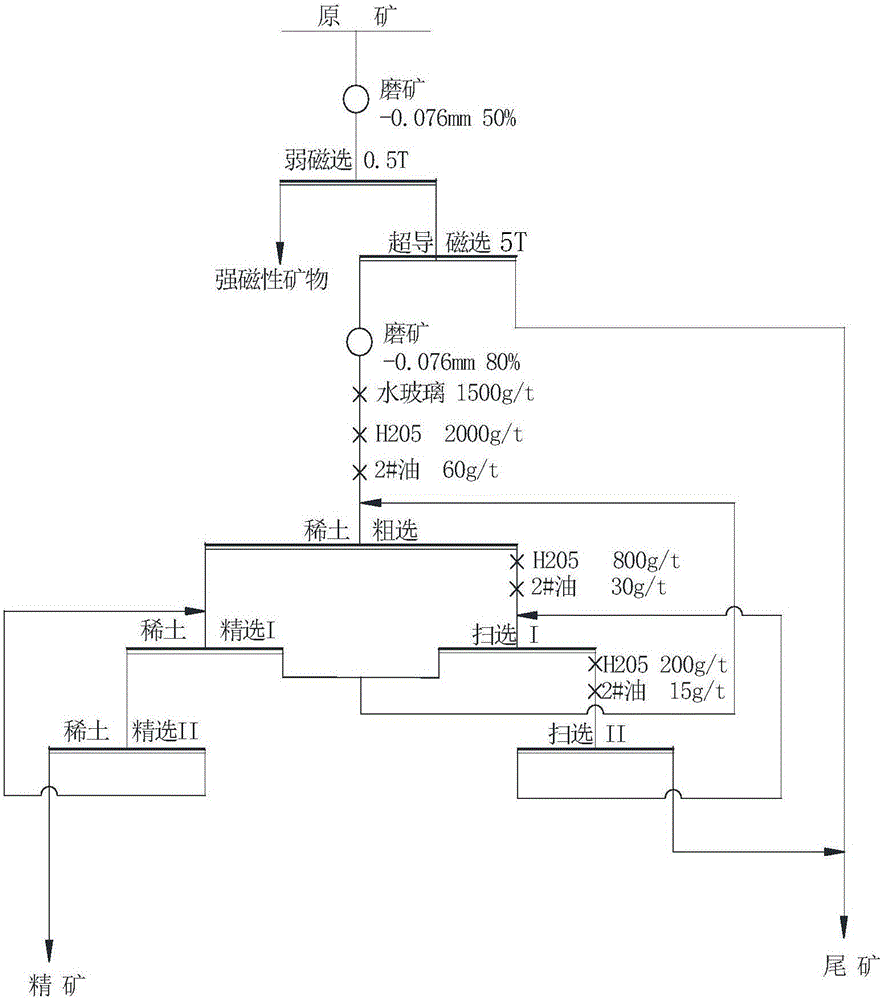

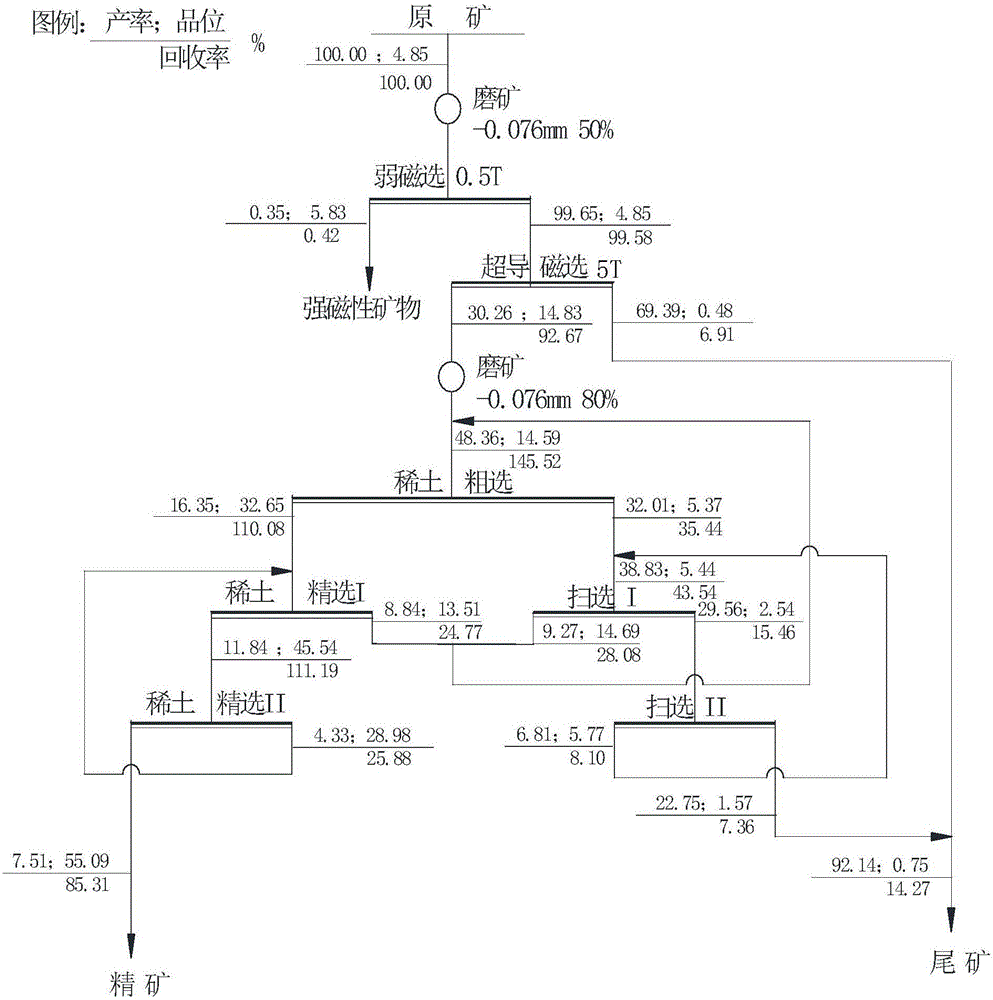

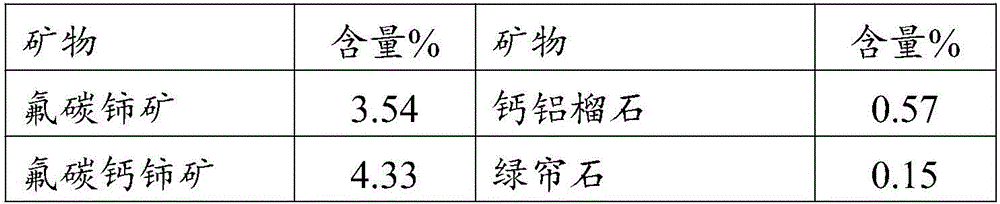

Beneficiation method of rare earth ore

ActiveCN106799300AReduce the amount requiredQuality assuranceWet separationRare earthUltimate tensile strength

The invention discloses a beneficiation method of rare earth ore. The beneficiation method comprises the steps that crude ore is subjected to crushing and ore grinding till the crude ore with the fineness being -0.076 mm accounting for 50% or above, low intensity magnetic separation is carried out to remove strongly magnetic minerals, then superconducting magnetic separation rougher flotation is carried out to obtain rare earth rough concentrates, the rare earth rough concentrates are ground till the rare earth rough concentrates with the fineness being -0.076 mm accounting for 80% or above, conventional flotation work is carried out, and final rare earth ore concentrates are obtained; conventional flotation work includes the processes of one-section rougher flotation, two-section concentration and two-section scavenging; according to low intensity magnetic separation, the magnetic field intensity ranges from 0.1 T to 0.5 T, and the magnetic field force is (3-15)*10<5>kA<2> / m<2>; and according to superconducting magnetic separation, the magnetic field intensity is larger than 0.5 T, and the magnetic field force is larger than 3*10<7>kA<2> / m<2>. According to the method, the high-grade rare earth rough concentrates can be obtained through superconducting magnetic separation, a large quantity of tailings can be thrown out, the grading efficiency is high, the two-section ball grinding ore feeding quantity is greatly reduced, grinding and selecting energy consumption is reduced, the rare earth grade of the obtained rare earth ore concentrates is improved, and the recovery rate is high.

Owner:江苏旌凯中科超导高技术有限公司

Method for stocking high-quality broiler chickens in understorey purse net manner

The invention discloses a method for stocking high-quality broiler chickens in an understorey purse net manner. The method comprises the steps of: 1. selecting a forest land; 2. dividing the forest land, building a barton shed; 3. carrying out understorey adaptive raising; and 4. carrying out understorey stocking. Chicks need to be brooded for 35 days to 40 days before the time of stopping heat supplication, after the birth for 0-22 days, the chicks are fed by using a chick feed containing 21 percent of protein in a qualified factory, and fed for above 8 times every day within one week. According to the method, the understorey purse net stocking is adopted, foods, such as grasses in the forest land, and fresh air, sufficient sunshine, and proper temperature and humidity in the forest land are fully utilized, and because of factors such as small density of raised chickens in the forest land, free movement of the chickens, and few emergencies, the chickens are healthy, and are strong in premonition; and diseases can be effectively reduced, the quality and the quantity of the excellent-quality broiler chickens are ensured, and the market competitiveness is enhanced.

Owner:KAILI HONGRUI ANIMALS BIRDS CULTIVATION COOPERATION

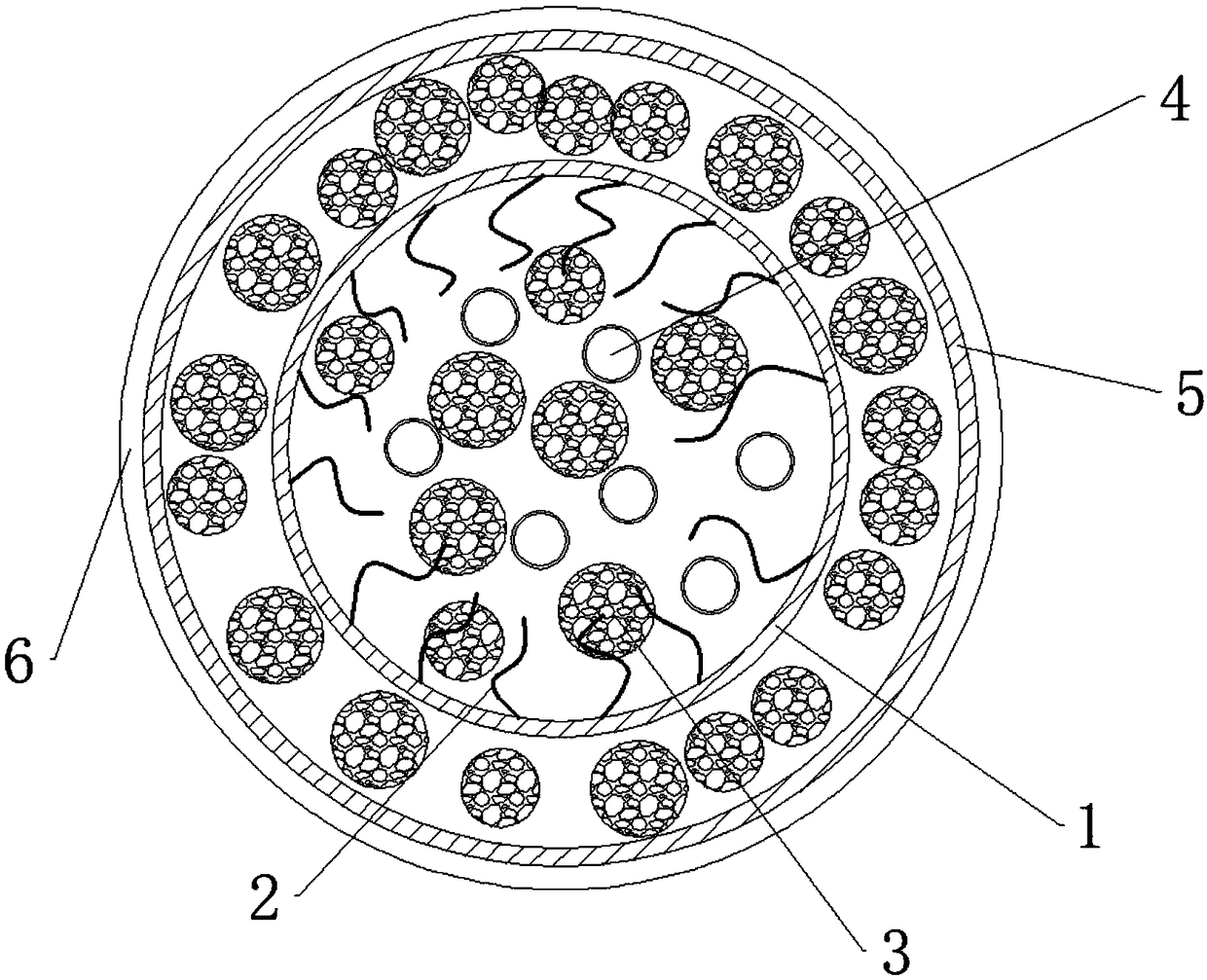

Microbial sustained-release sphere for soil repairing

The invention discloses a microbial sustained-release sphere for soil repairing, and belongs to the technical field of soil repairing. The microbial sustained-release sphere comprises a sustained-release sphere, wherein the sustained-release sphere comprises an inner water-soluble membrane, and the inside of the inner water-soluble membrane coats a plurality of microbial carrier spheres and microbial degradable plastic film spheres, which are distributed alternately; soil repairing microbial flora is adhered to the microbial carrier spheres; the microbial degradable plastic film spheres are filled with hydrogen peroxide; a plurality of straw fiber ropes which are uniformly distributed are fixedly connected on the inner wall of the inner water-soluble membrane, and are in a puffed shape; after being dosed into soil, the sustained-release spheres can be gradually degraded under the moisture effect along with time passing for constantly repairing the soil, the number of microbes can be constantly ensured, multiple dosage is not required, labor and materials can be saved, and the using method is diversified since the microbial sustained-release spheres can be dosed into soil optionallyin a turbid liquid manner.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

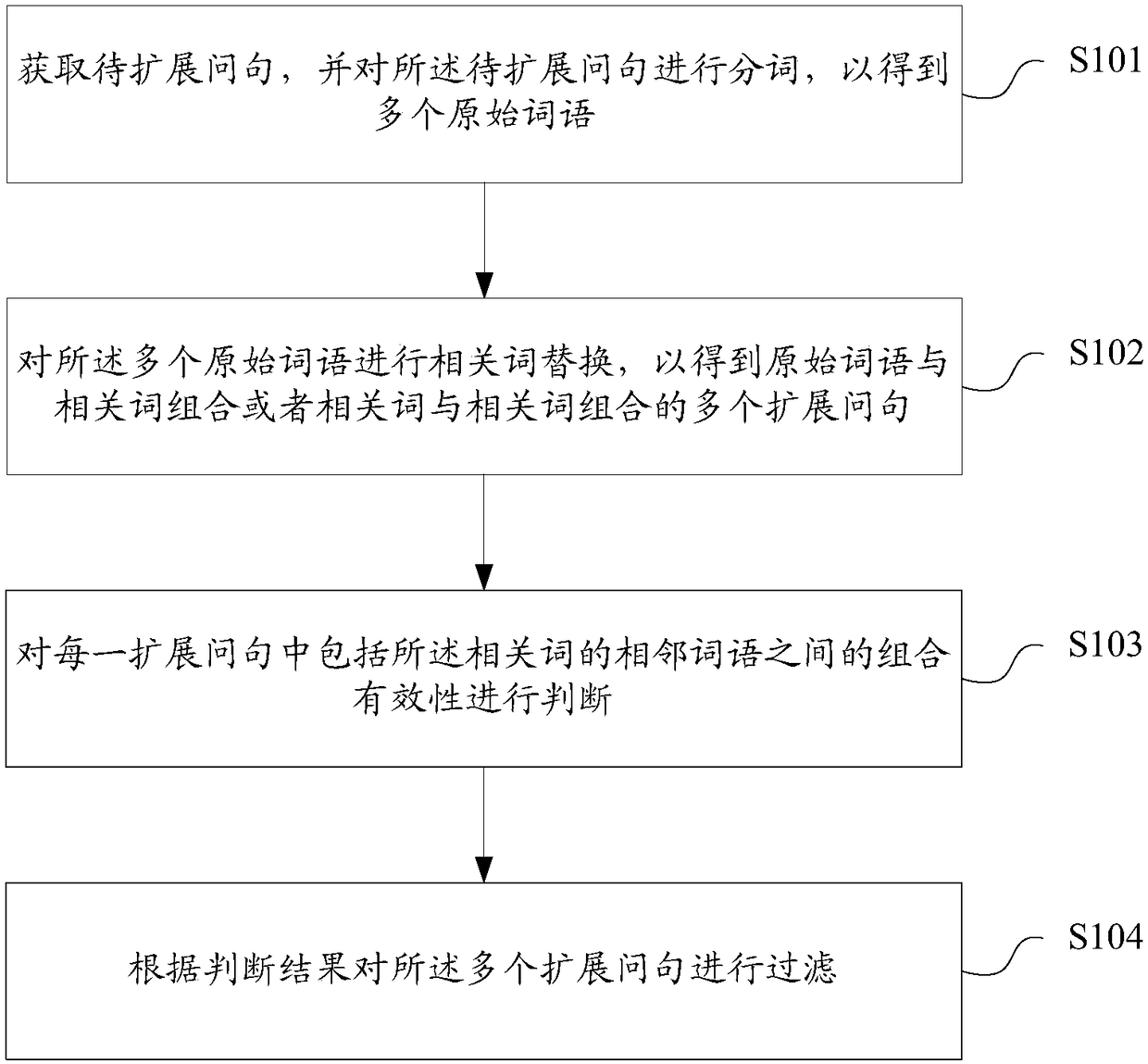

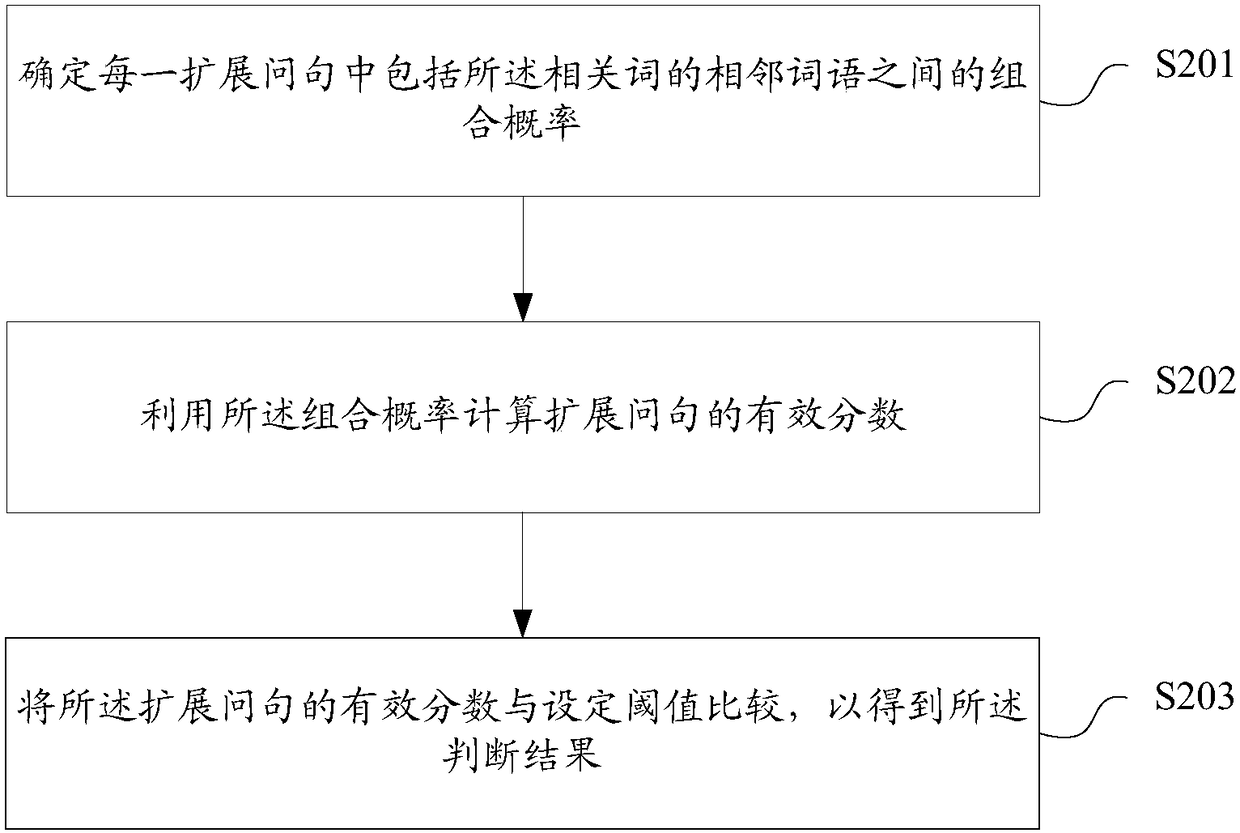

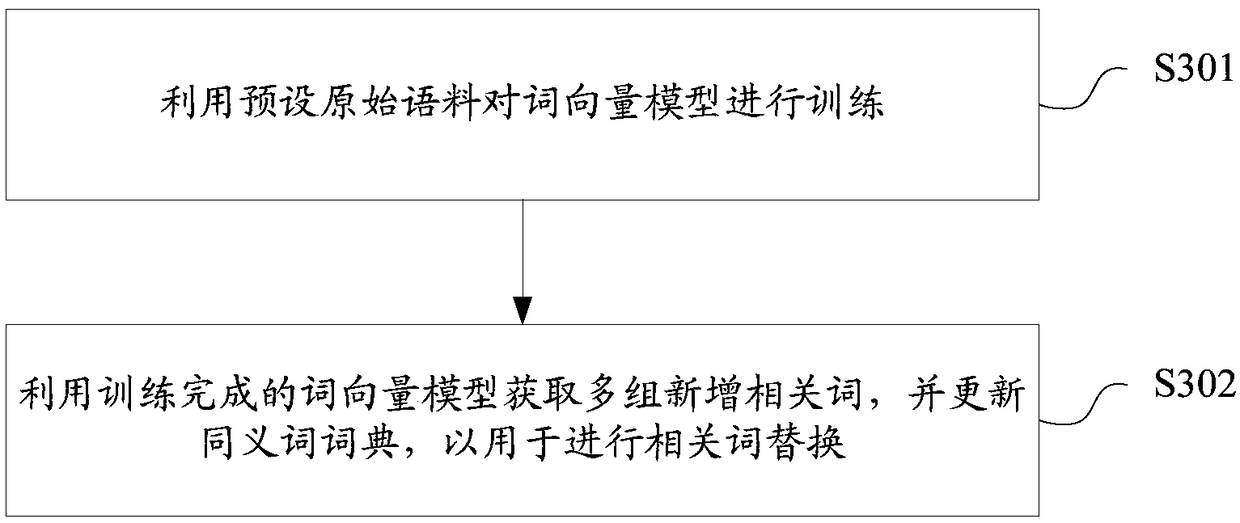

Question extension method and device, storage medium and terminal

InactiveCN108090169AGuaranteed validityImprove timeliness and accuracySpecial data processing applicationsExtension methodTheoretical computer science

The invention discloses a question extension method and device, a storage medium and a terminal. The question extension method comprises the steps of obtaining a question to be extended, performing word segmentation on the question to be extended to obtain multiple original words; performing related word substitution on the multiple original words so as to obtain multiple extended questions obtained by combining the original words and the related words or combining the related words; judging the effectiveness of the combination of the related words and adjacent words in each extended question;according to the judgment result, filtering the multiple extended questions. According to the technical scheme, the extended questions can be automatically generated, and the effectiveness of the extended questions is ensured.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

Method for preparing alcohol-free compound enzyme of Nan helianthus tuberosus No. 9 and fruits and vegetables

ActiveCN105455135AJuicyStrong aromaFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFruit FlavorLactic acid fermentation

The invention discloses a method for preparing an alcohol-free compound enzyme of Nan helianthus tuberosus No. 9 and fruits and vegetables. The method comprises the steps of helianthus tuberosus pretreatment, fruit and vegetable pretreatment, mixing and blending, fermentation, blending with a functional sweetener, and the like. According to the method, the novel compound enzyme of fruits and vegetables, which is low in sugar, alcohol-free, and rich in prebiotics, dietary fiber and other beneficial components, has both a fruit flavor and a lactic fermented flavor and integrates nutrition and health, can be obtained in short time.

Owner:JIANGSU BIQINGYUAN MARINE BIOTECH CO LTD

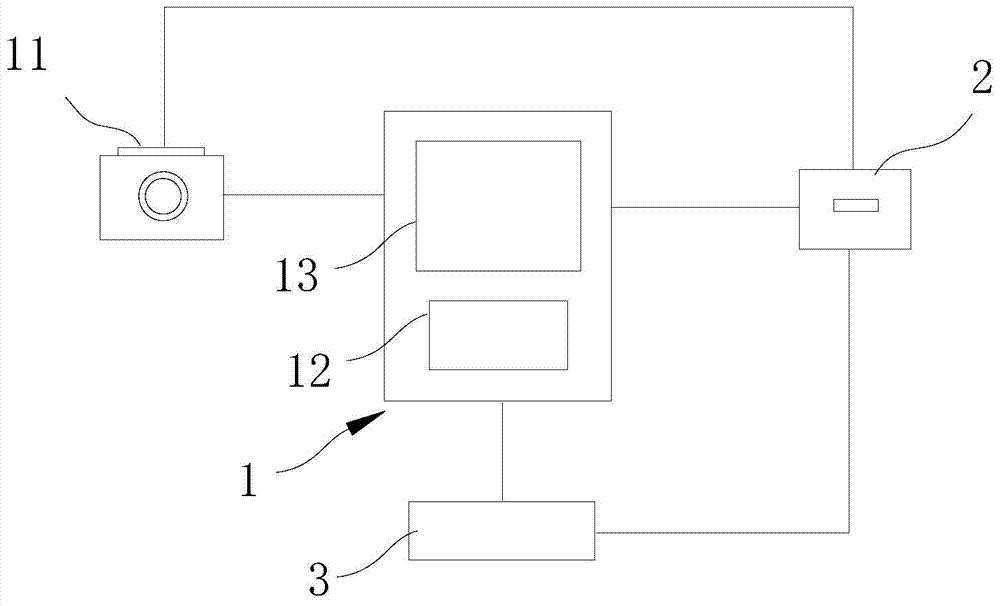

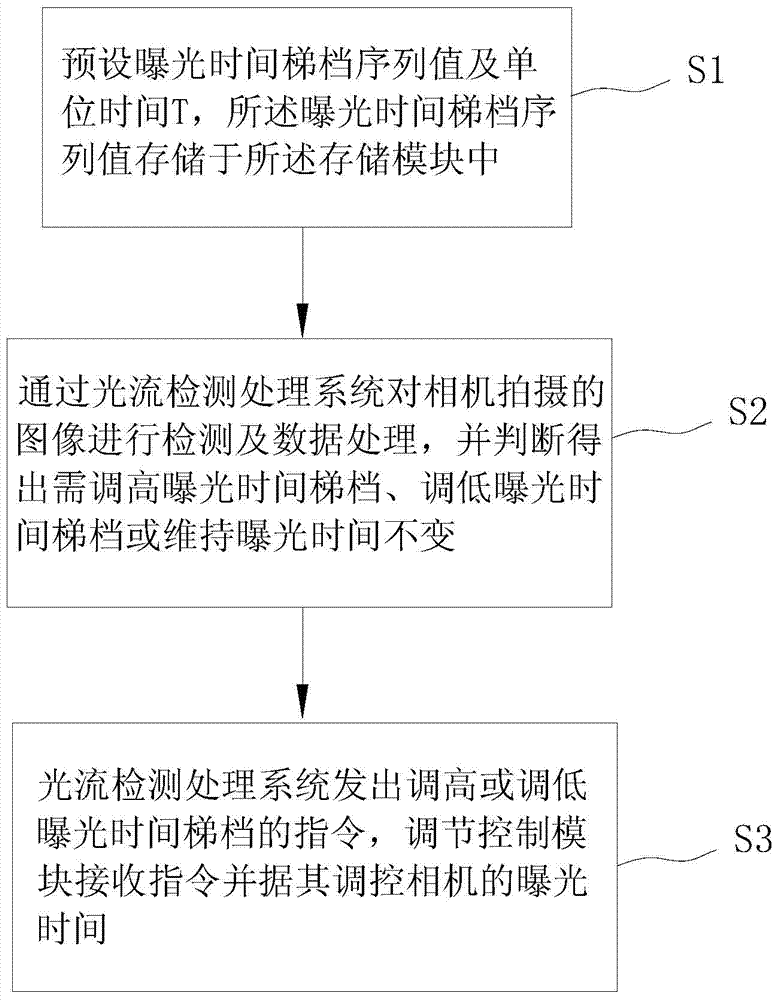

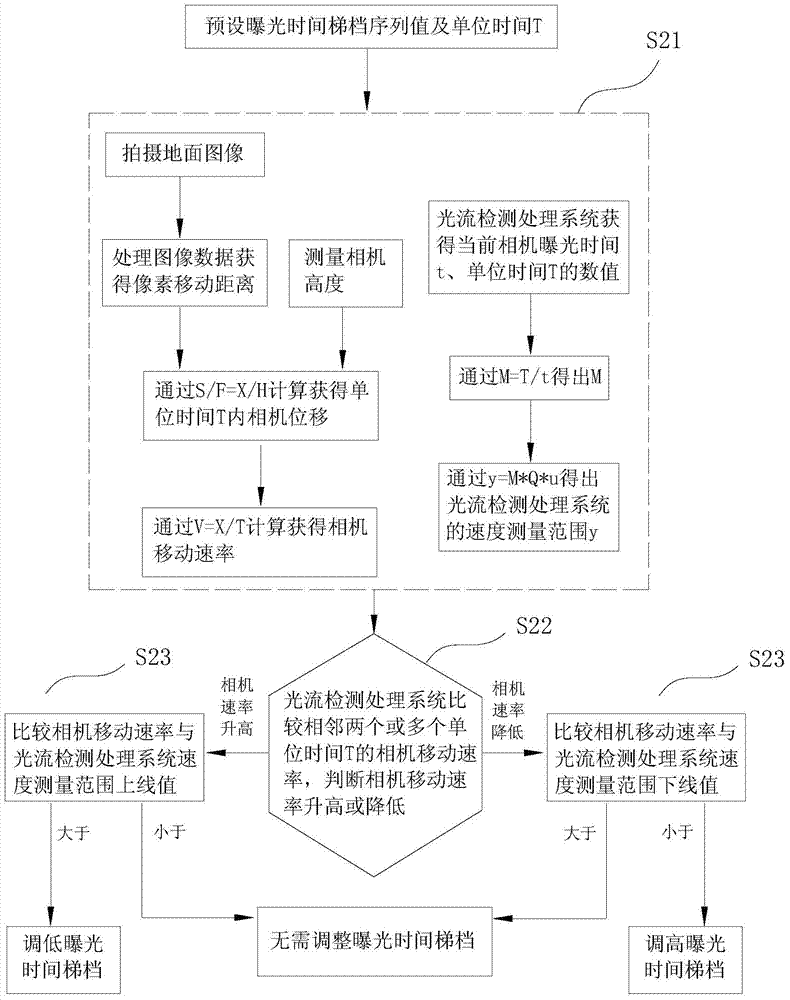

Adaptive camera exposure time adjustment device and method

PendingCN104853113AAdjust exposure timeGuaranteed quantityTelevision system detailsColor television detailsOptical flowUnmanned air vehicle

The invention discloses an adaptive camera exposure time adjustment device and a method. the method comprises steps: an exposure time grade sequence value and a unit time are preset; detection and data processing are carried out on an image photographed by the camera via an optical flow detection and processing system, and an exposure time grade which needs to be adjusted higher, an exposure time grade which needs to be adjusted lower and an exposure time which needs to be kept unchanged are judged and obtained; the optical flow detection and processing system sends an instruction for adjusting the exposure time grade higher or adjusting the exposure time grade lower, and an adjustment control module receives the instruction and adjusts the exposure time of the camera according to the instruction. According to the scheme of the invention, during a process during which the camera moves at a high speed along with an unmanned aerial vehicle, the exposure time of the camera can be adjusted adaptively in real time, and the number and the quality of the photographed images can be ensured.

Owner:ZEROTECH (BEIJING) INTELLIGENCE TECH CO LTD

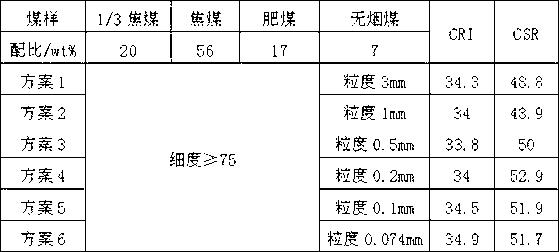

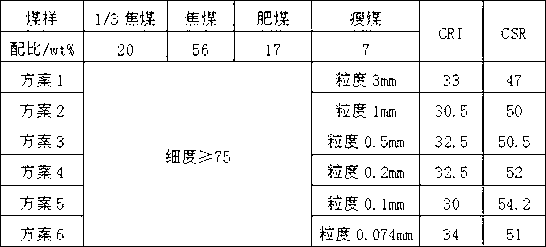

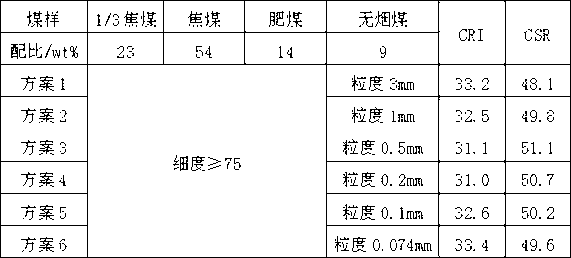

Method for coal blending for coking by high-metamorphic-grade weak caking coal

InactiveCN102994130AReduce crackingQuality improvementSpecial form destructive distillationGranularityEngineering

The invention discloses a method for coal blending for coking by high-metamorphic-grade weak caking coal. The method comprises the following steps of: (1) crushing high-metamorphic-grade coal into different granularity gradients, respectively blending the high-metamorphic-grade coal under each granularity with other caking coals to carry out coking, detecting a quality index of obtained coke and determining the best crushing granularity of the high-metamorphic-grade coal; (2) blending non-high-metamorphic-grade coals in the blended coal and dividing into a coal part 1 and a coal part 2, blending the high-metamorphic-grade coal which is crushed to the best granularity with the coal 1 according to the previous proportion and pressing and molding a coal block, and mixing the high-metamorphic-grade coal which is crushed to the conventional granularity with the coal 2 according to the previous proportion to obtain blended coal 3; and (3) mixing the molded coal block with the blended coal 3 obtained by the step (2) and coking. The method disclosed by the invention can improve the adding amount of the weak caking coal on the premise that the quality of the coke is guaranteed, so that the effects of reasonably utilizing a coal resource and optimizing a coal blending structure are realized.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Full automatic packing machine for button cells

The invention discloses a full automatic packing machine for button cells, which comprises a machine frame, a bottom board and a vibrating disk, wherein the bottom board is arranged on the machine frame; and a blanking mechanism for automatically putting the button cells and uniformly placing the button cells in a packing box, a displacement mechanism for pushing a product tool for placing the packing box to carry out fore-and-aft movement, a box transferring mechanism for transferring an empty packing box and a packing box filled with cells, a loading mechanism for automatically filling up the empty packing box and a finished product discharging mechanism for automatically discharging the packing box filled with cells are further arranged on the machine frame. The full automatic packing machine for the button cells has the advantages of being full automatic in work, high in production efficiency and low in cost, and the market competitive power is improved.

Owner:DONGGUAN CITY TIANXIANG AUTOMATION EQUIP

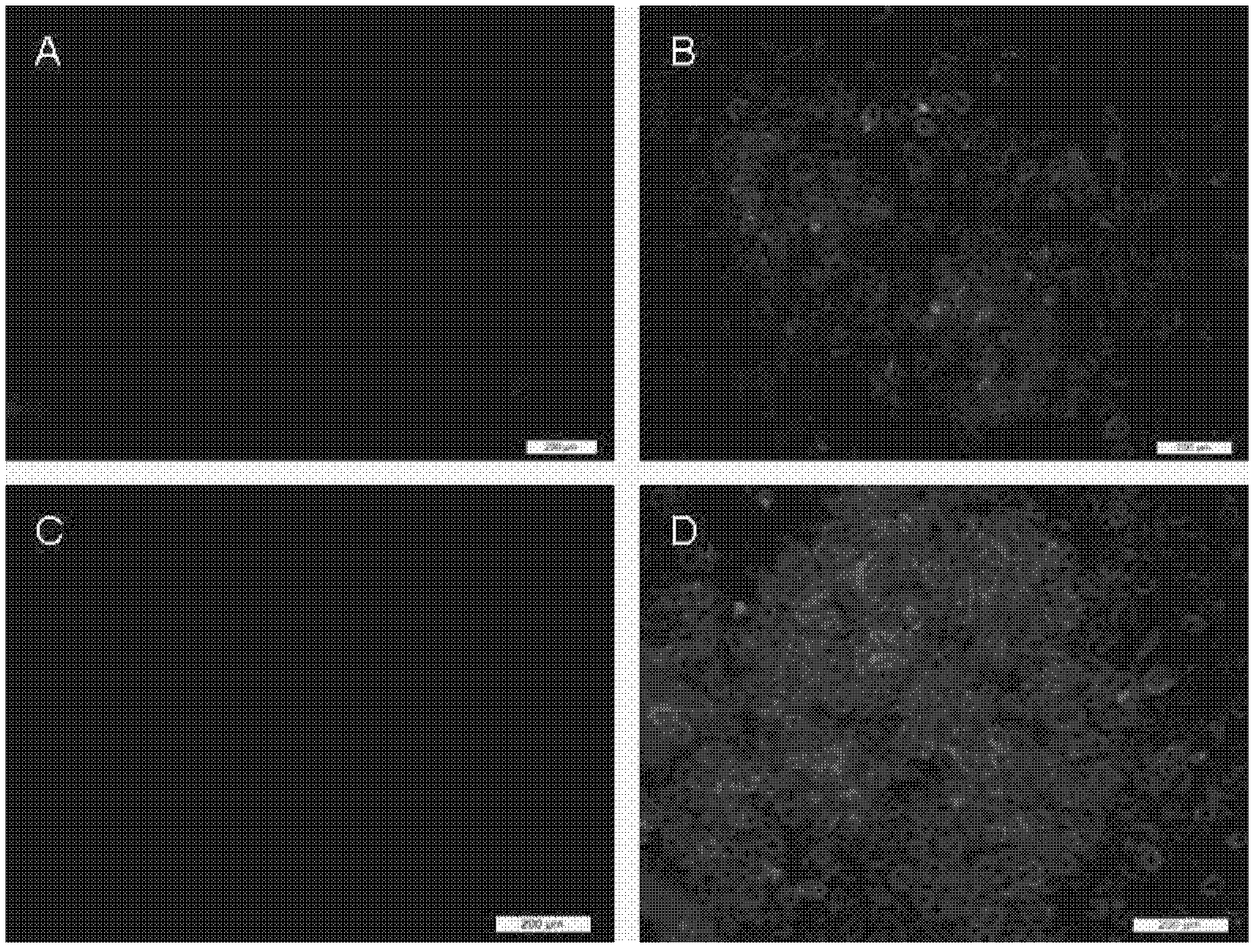

Clinic-level adipose-derived stem cell preparation and storage methods

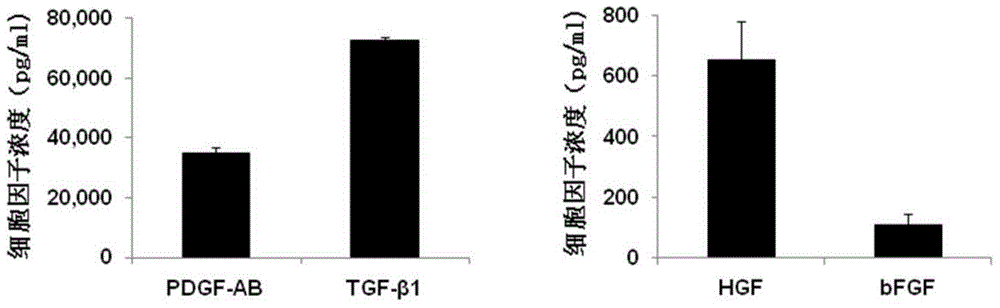

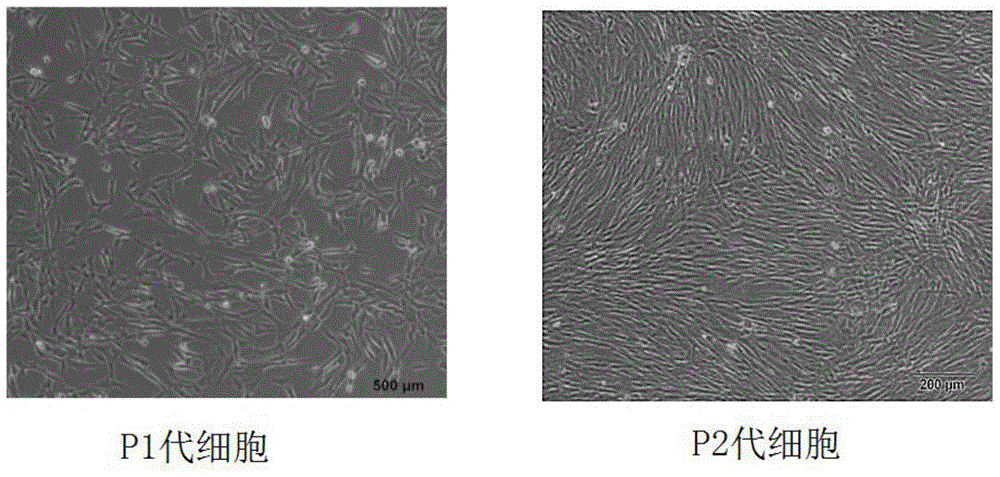

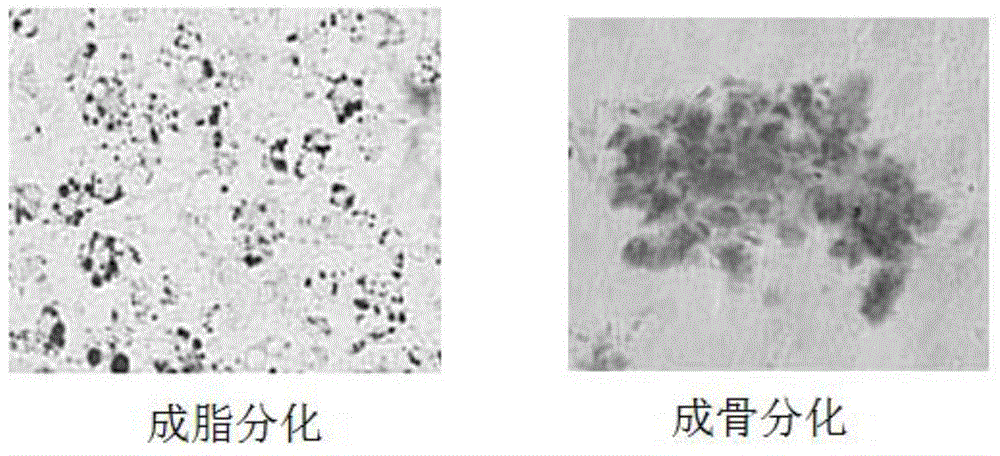

InactiveCN105132370AAvoid pathogenic and allergic reactionsImprove securityDead animal preservationSkeletal/connective tissue cellsMotilityCell expansion

The invention discloses clinic-level adipose-derived stem cell preparation and storage methods. Mesenchymal stem cell culture of a fat tissue source is performed by adopting a serum-free complete medium without animal source protein pollution, safety and effectiveness are realized, immunogenicity is avoided, the rate of increase of ADSCs can be better maintained, a plateau period is prolonged, an expansion multiple of each generation of cells is greatly improved, and the clinic treatment number is ensured; the serum-free complete medium is applied to preparation of clinic-level ADSCs for the first time; a fat tissue is collected from the abdomen and can be taken discontinuously repeatedly, thus avoiding damage to the adipose-derived stem cells in a liposuction process; the ADSCs are prepared by using a wall adherence method, thus increasing the primary cell yield and lowering the cost; an adopted novel serum-free cell frozen preservation solution meets a clinical application standard, reduces the use amount of DMSO, does not obviously influence the motility rate, phenotype and doubling time of the ADSCs, can be directly used in clinic infusion after reviving, is convenient to transport, and ensures the safety of clinic treatment.

Owner:丛秀丽

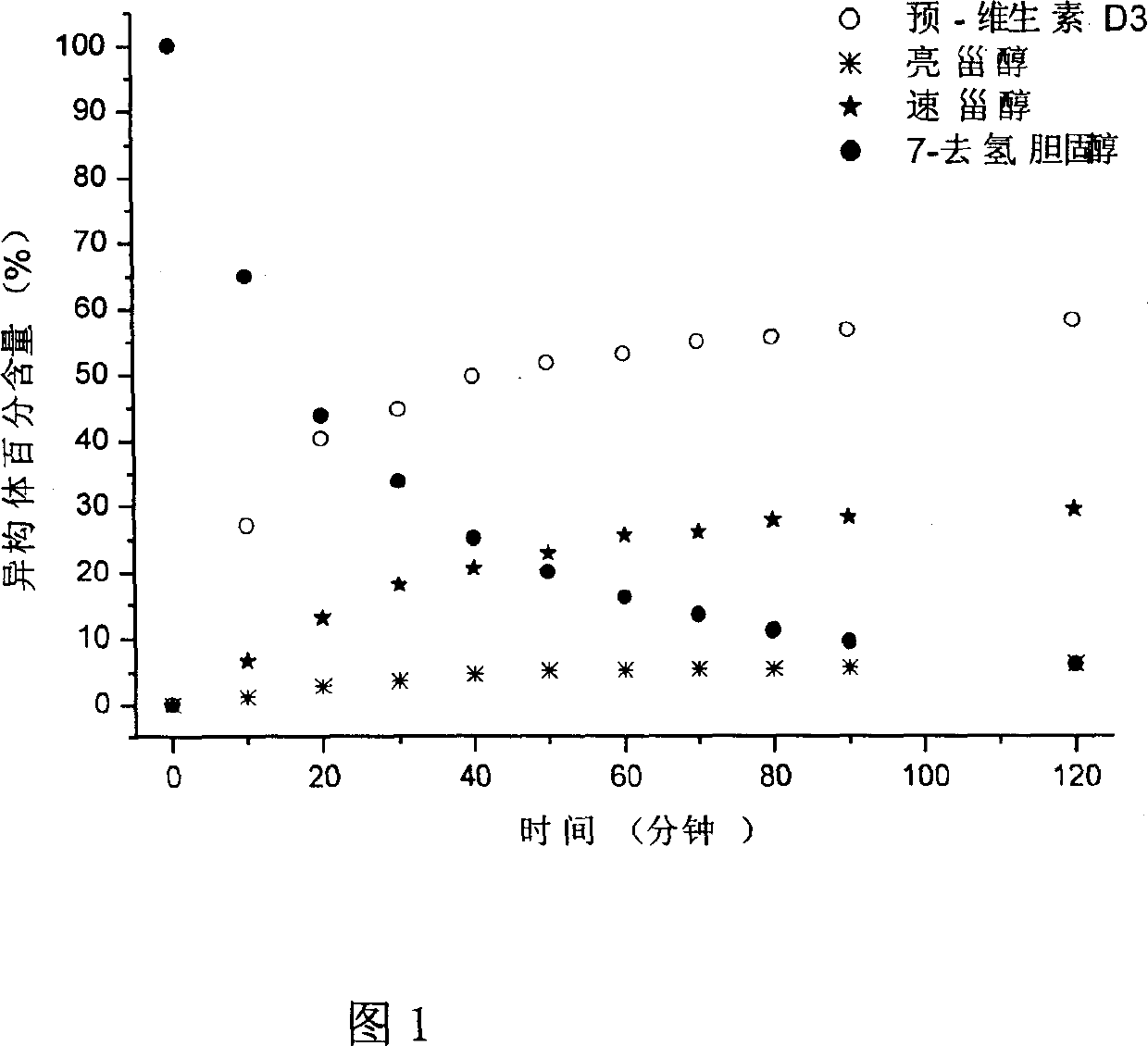

Photochemical method for synthesizing vitamine D3

A photochemical process for synthesizing VD3 includes such steps as dissolving 7-dehydrocholesterol in the mixture of polar solvent and non-polar solvent, adding antioxidizing agent, stirring, light radiating at 23-30 deg.C, evaporating, adding polar solvent, separating the unreacted 7-dehydrocholesterol, adding maleic acid anhydride and aqueous solution of KOH or NaOH while stirring to obtain viscose material, dissolving in refined oil, vacuum heating to 60-70 deg.C and vacuum relief. Its advantage is high output rate about 70%.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

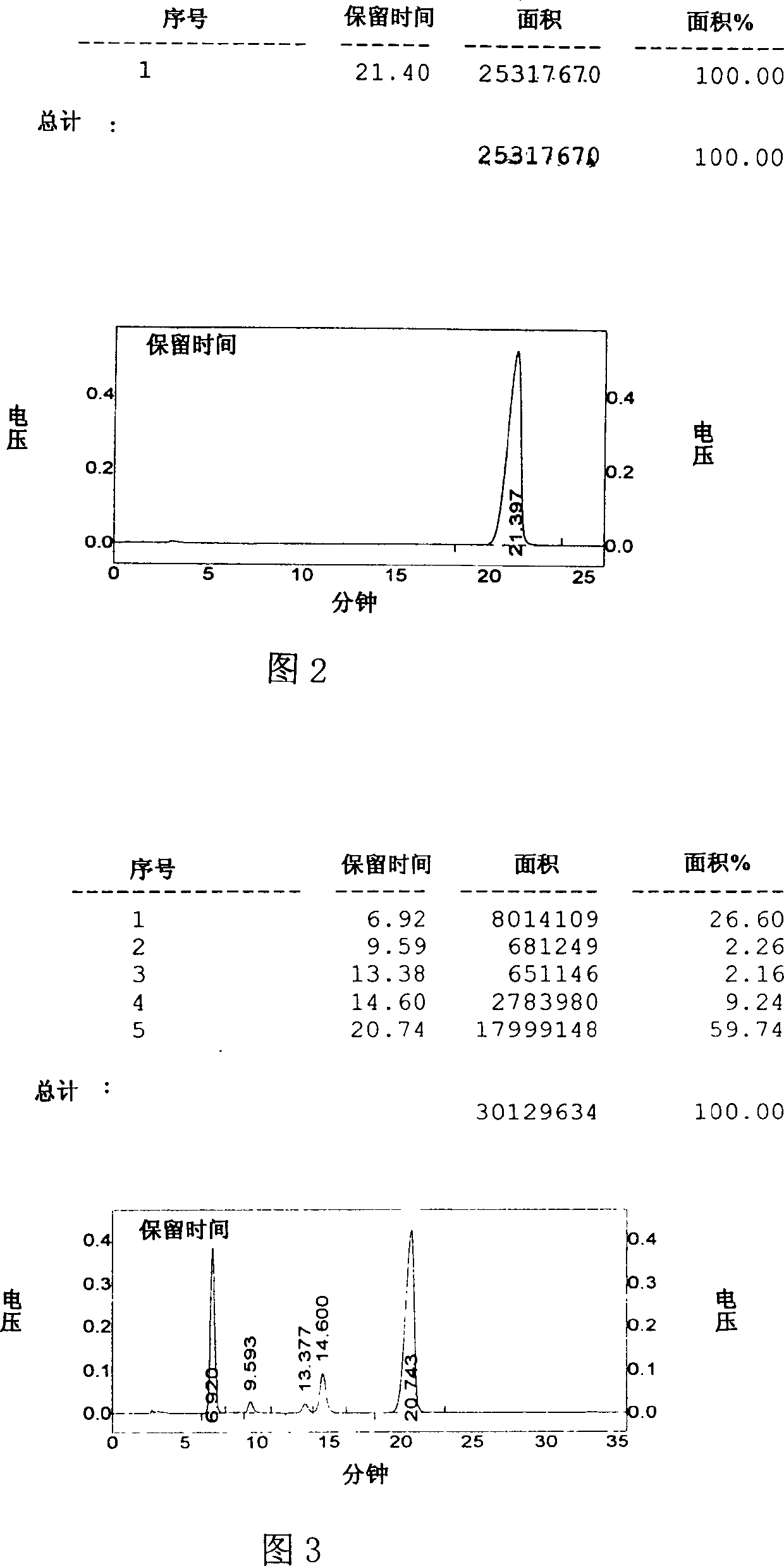

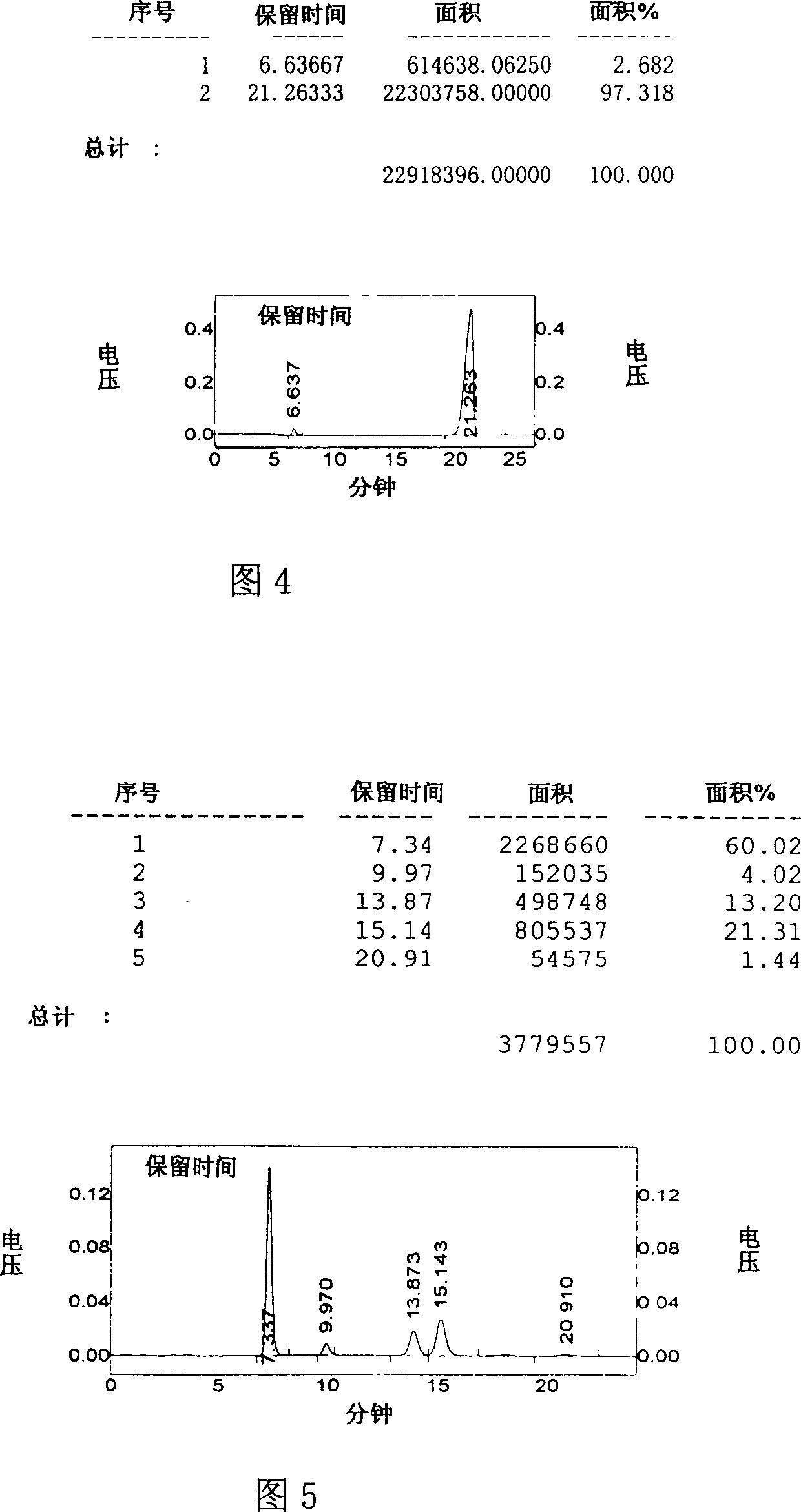

Nutritional feed for suckling sow and preparation method of feed

InactiveCN104171388ARestore fitnessImprove growth healthFood processingAnimal feeding stuffAnimal scienceEmbryo

The invention discloses a nutritional feed for a suckling sow and a preparation method of the feed. The nutritional feed comprises the following raw materials in parts by weight: 140-180 parts of yellow bean powder, 100-150 parts of corns, 80-100 parts of wheat powder, 20-30 parts of maize embryo cakes, 40-50 parts of pumpkin powder, 60-80 parts of tofu residues, 3-5 parts of chicken powder, 2-3 parts of lard oil, 6-10 parts of peanut powder, 0.5-1 part of large red jujubes, 8-12 parts of nitraria tangutorum bobr fruit residues, 6-12 parts of sea buckthorn fruit residues, 2-3 parts of dark plums, 1-3 parts of dark plum beans, 5-7 parts of crucian carp, 0.05-1 part of soy, 0.05-1 part of rice vinegar, 0.1-0.2 part of sesame oil, 2-3 parts of asparagus lettuce, 1-2 parts of codonopsis pilosula, 1-2 parts of astragalus membranaceus, 1-3 parts of loranthus parasiticus, 1-2 parts of coix seeds, 2-3 parts of fish meal, 10-20 parts of wheat straws, 15-30 parts of fine rice bran, 5-10 parts of a phagostimulant and a proper amount of water. The feed is high in protein content and can promote physical restoration, milk secretion and healthy growth of the sow.

Owner:HUAIBEI JIAJI AGRI SCI & TECH CO LTD

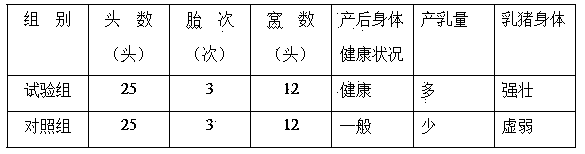

Flight trainer virtual head-up display method through augmented reality technology and flight trainer virtual head-up display system thereof

ActiveCN106530894AEasy to masterGuaranteed quantityInput/output for user-computer interactionCosmonautic condition simulationsFlight experienceHead-up display

The invention provides a flight trainer virtual head-up display method through the augmented reality technology and a flight trainer virtual head-up display system thereof, and belongs to the technical field of flight trainer virtual display. The method comprises the following steps that a virtual scene is constructed according to the map data acquired in advance; the image of the virtual scene is processed through a digital image processing method so that significance information of the scene image can be obtained; an augmented reality model is constructed through a mode recognition algorithm with combination of the significance information, and the augmented reality model is superposed to the virtual scene; and the head-up display frame in the virtual scene is embedded in an existing visual system to be displayed in the video scene. The invention also relates to the system based on the method. The complex environment of high-altitude flight of the pilot can be vividly displayed, and the actual flight experience can be simulated to the greatest extent; and the topographic map can be reflected in the training cabin by using the augmented display technology so as to assist the trainee to experience the real flight.

Owner:北京捷安申谋军工科技有限公司

Earthen pond breeding method of procambarus clarki

InactiveCN101664011AGuaranteed quantityEasy to graspClimate change adaptationPisciculture and aquariaShrimpProcambarus

The invention discloses an earthen pond breeding method of procambarus clarki. The method comprises the following technical steps: (1) pond reconstructing, cleaning and sterilizing; (2) preparing before parent shrimp breeding; (3) parent shrimp breeding; (4) fodder feeding; (5) daily management; (6) wintering management; (7) seedling cultivation; and (8) seedling catching. After the testing of themethod, a large number of seedlings are produced in a base of about 5,000 mu (1 mu is about 666.7 square meters), more than 50,000 shrimps can be bred per mu, and specifications are 140 to 160 high-quality shrimp seedlings per kilogram, thus offering safeguard for the breeding of grown shrimp. Though the breeding amount of lobster individuals is small, survival rate is relatively high. A large amount of parent shrimps ensures the amount of seedlings. The breeding of procambarus clarki is not synchronous and seedling specifications in a pond are inconsistent, but seedlings required by production can be bred and demand for future breeding can be fulfilled. With batches of seedlings, future production and development can be guaranteed.

Owner:章文敏

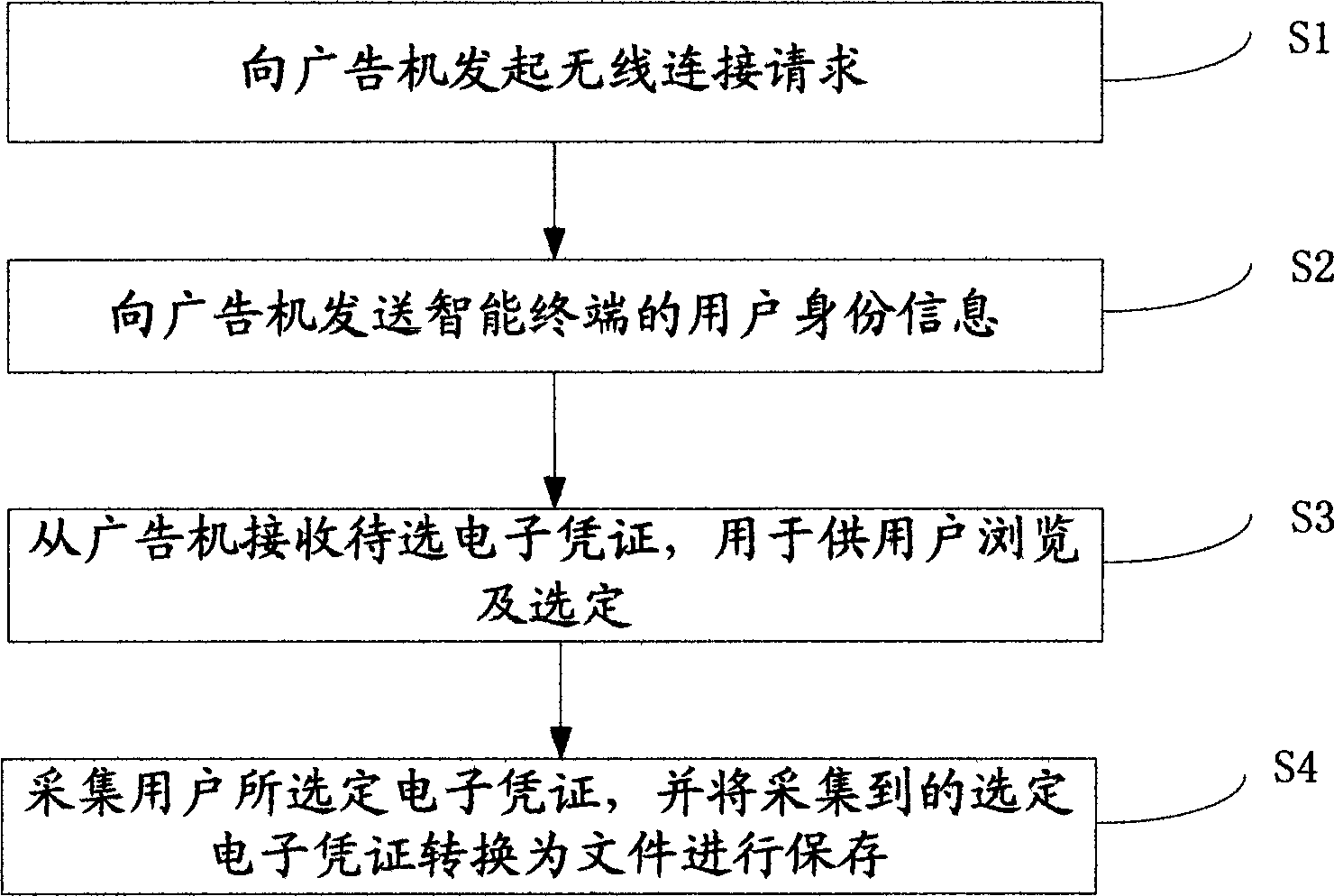

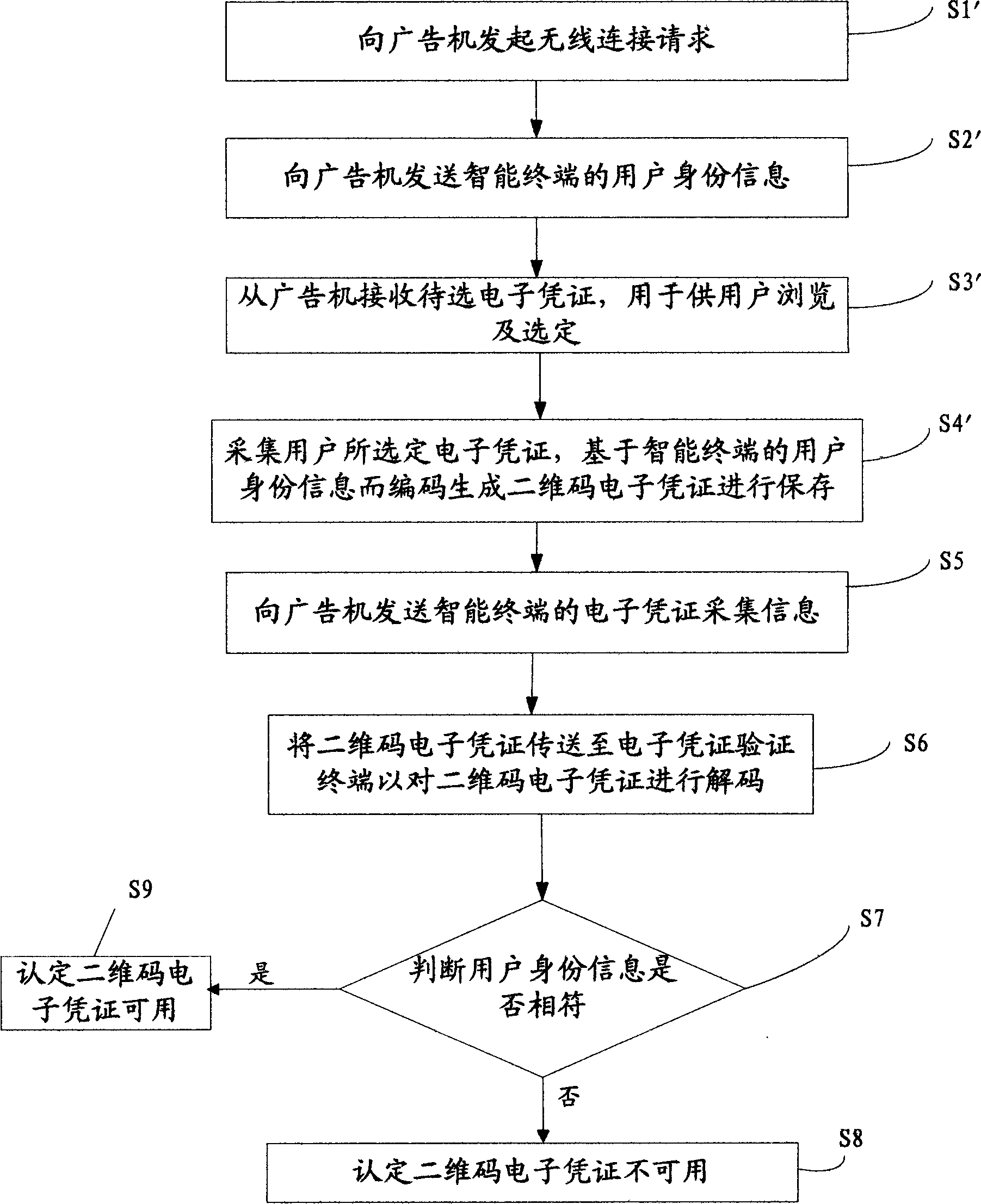

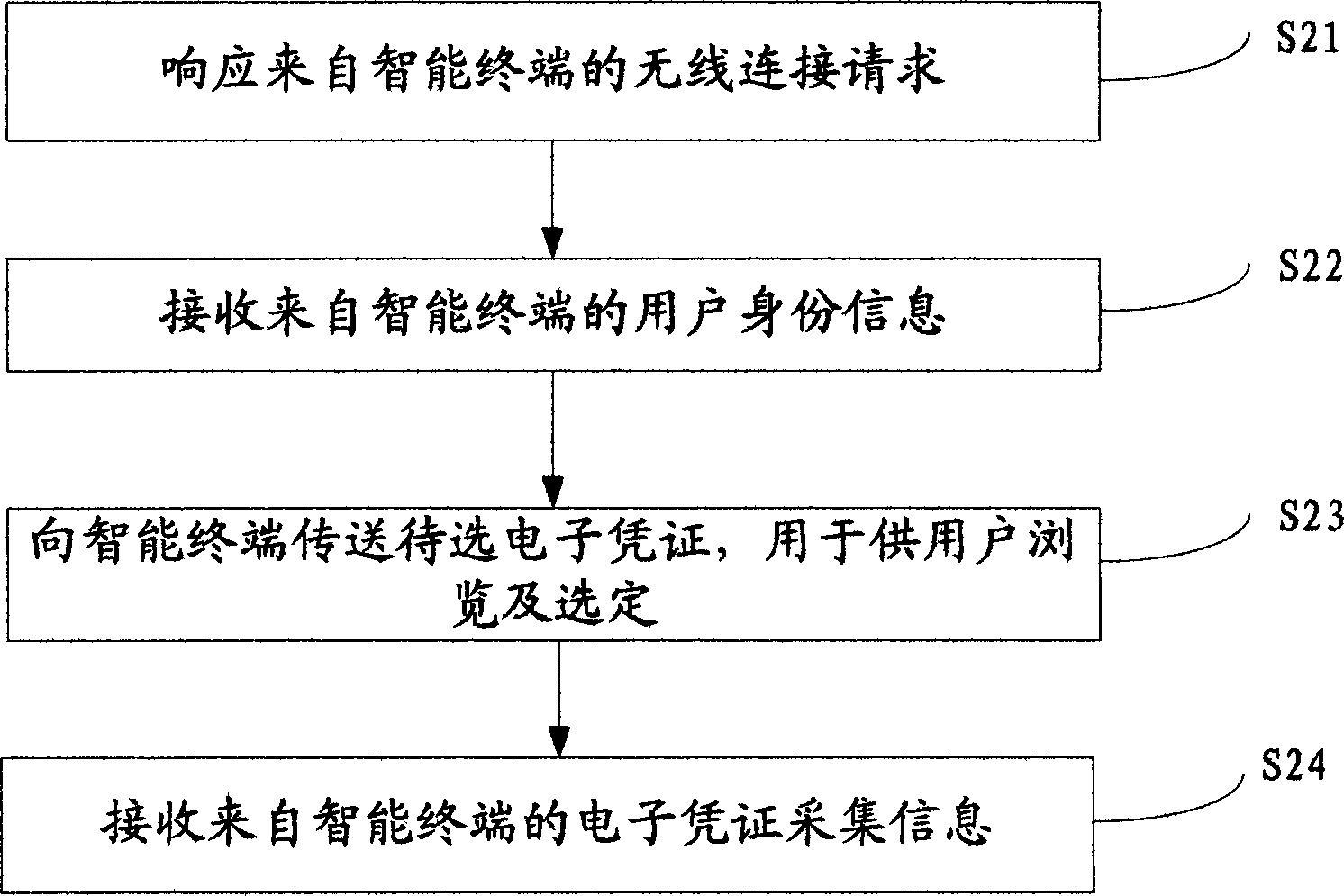

Electronic certificate acquiring and dispensing method, intelligent terminal and advisement player

InactiveCN103226778ANo need to increase labor costsPrevent copyingMarketingTerminal equipmentWireless data transmission

The invention provided an electronic certificate acquiring method for enabling an intelligent terminal to acquire an electronic certificate from an advertisement player. The method comprises the following steps: a wireless connection request is initiated to the advertiser player; user identity information of the intelligent terminal is sent to the advertiser player; to-be-selected electronic certificates are received from the advertiser player and used for browse and selection by a user; and further, electronic certificates selected by the user are acquired, and are converted into a document for storage. According to the method, the electronic certificates on the advertiser player are transmitted to the intelligent terminal in a wireless data transmission manner, and the user of the intelligent terminal can enjoy favorable price at corresponding retailers by virtue of the electronic certificates obtained from the advertiser player. Therefore, not only the labor cost for dispensing the electronic certificates is saved, but also release and acquisition of the targeted electronic certificates are provided. The invention further provides an electronic certificate dispensing method, the intelligent terminal adopting the electronic certificate acquiring method, and the advertiser player adopting the electronic certificate dispensing method.

Owner:刘婷

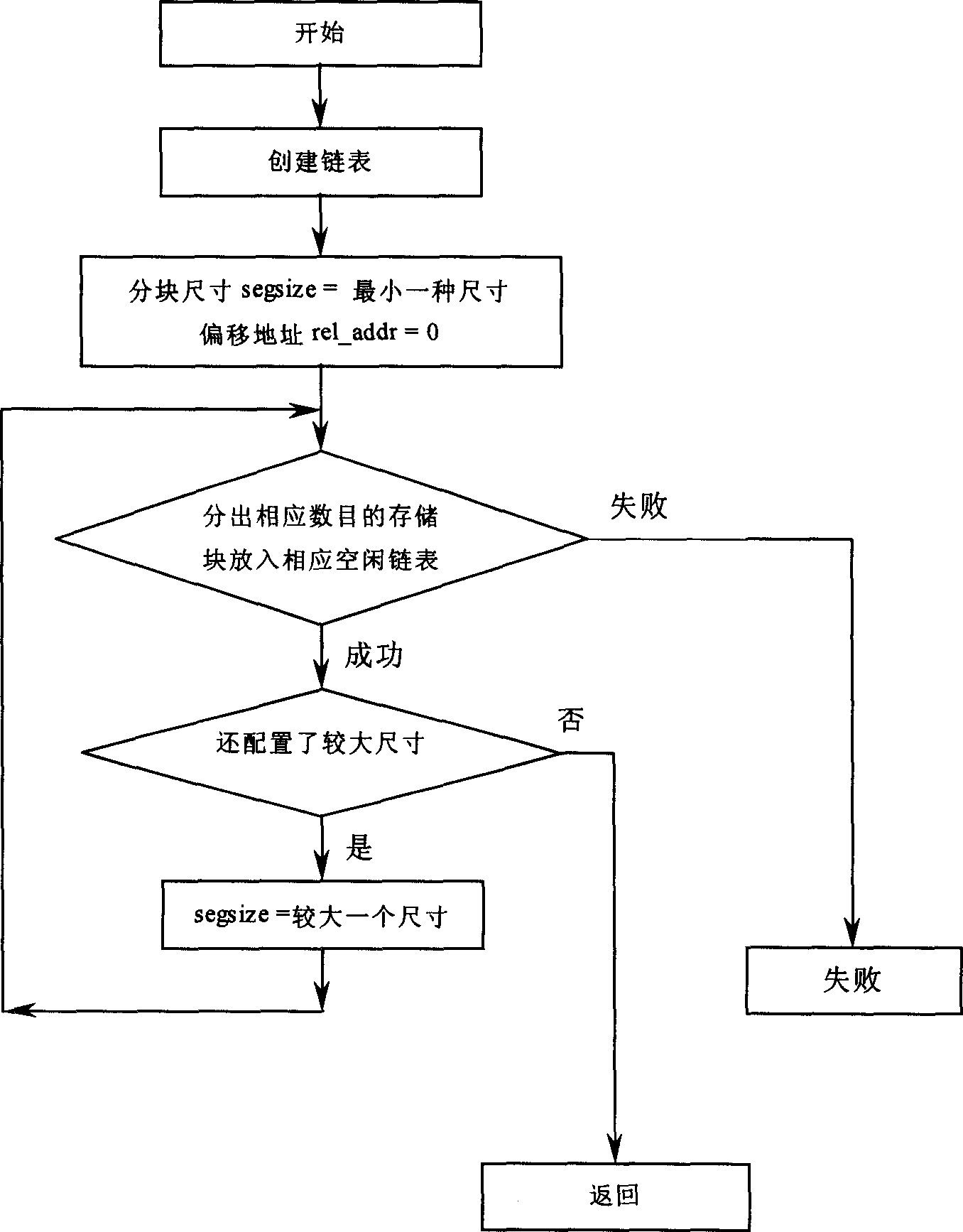

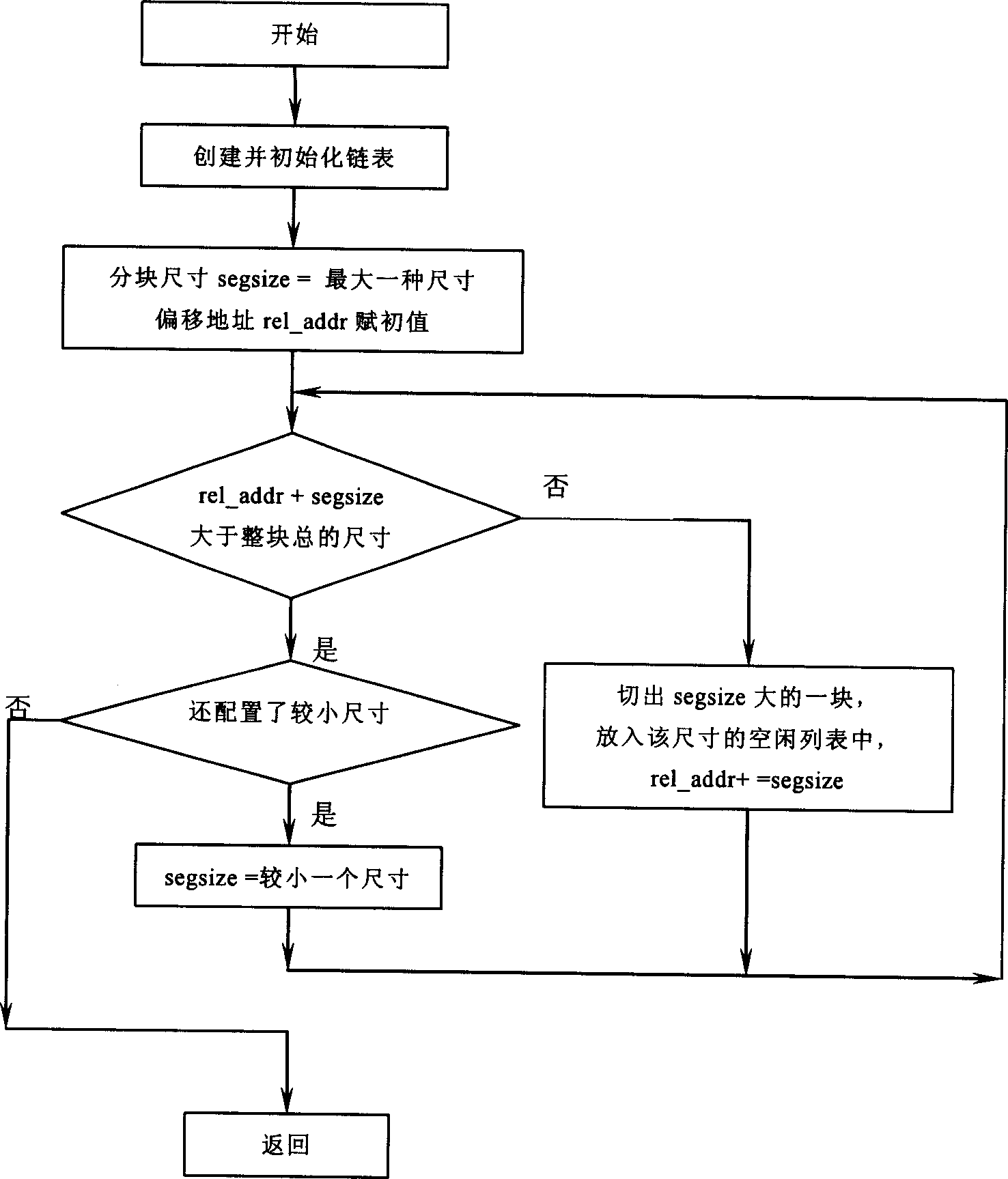

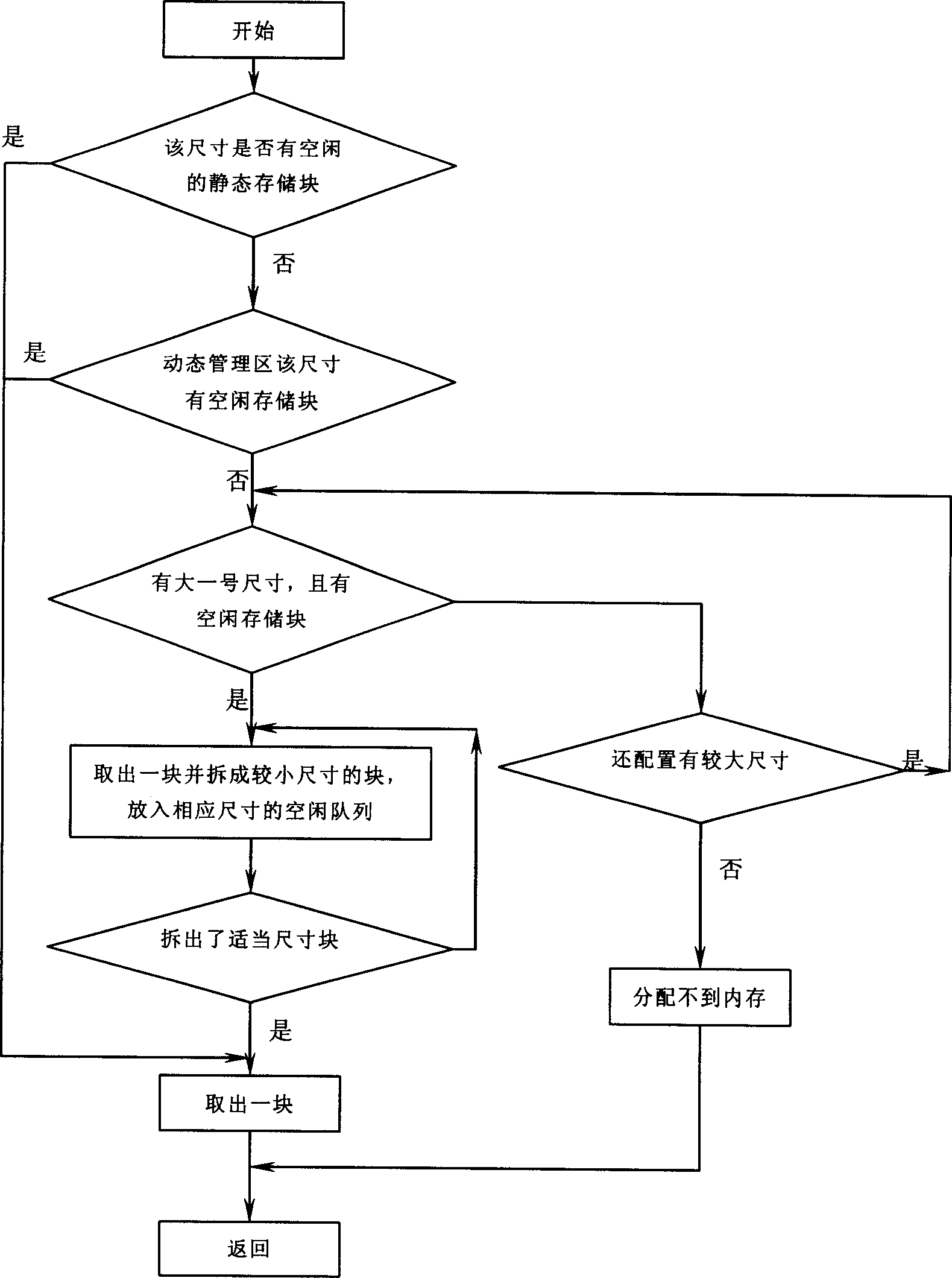

Method for storage area management with static and dynamic joint

InactiveCN1489334AReduce tensionMitigation efficiencyData switching networksSelection arrangementsLimited resourcesDynamic storage

The method divides the memory area into two portions: one portion is partitioned into static memory blocks in several sizes defined in advance; the other portion is shared dynamic memory area. In static memory, certain number of blocks is allocated for different memory sizes, and blocks will not be split or mergered. The shared dynamic memory area can be allocated dynamically. It is guaranteed that each memory block in various sizes possesses a minimum quantity in order to meet basic application. Meanwhile, limited resources of memory area are utilized fully. The invention assures service efficiency and utilization rate of memory area, solves conflict between shortage of memory area and low availability factor, as well as avoids complex maintenance in operation. The method is applied to management for each memory, data table and periphery memory area, as well as can manages multiform or / and multiple memory areas.

Owner:ZTE CORP

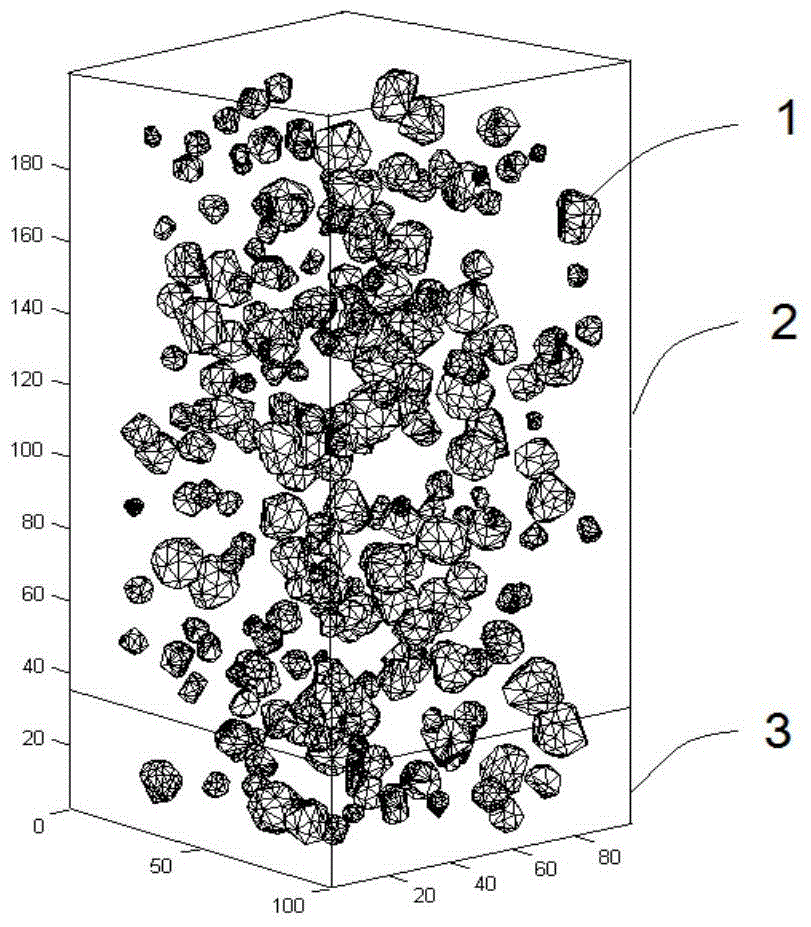

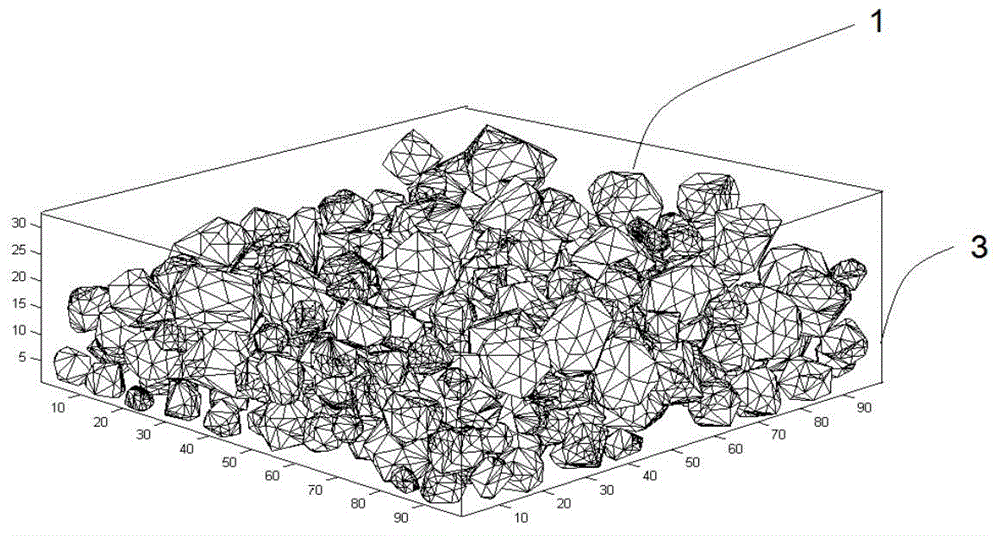

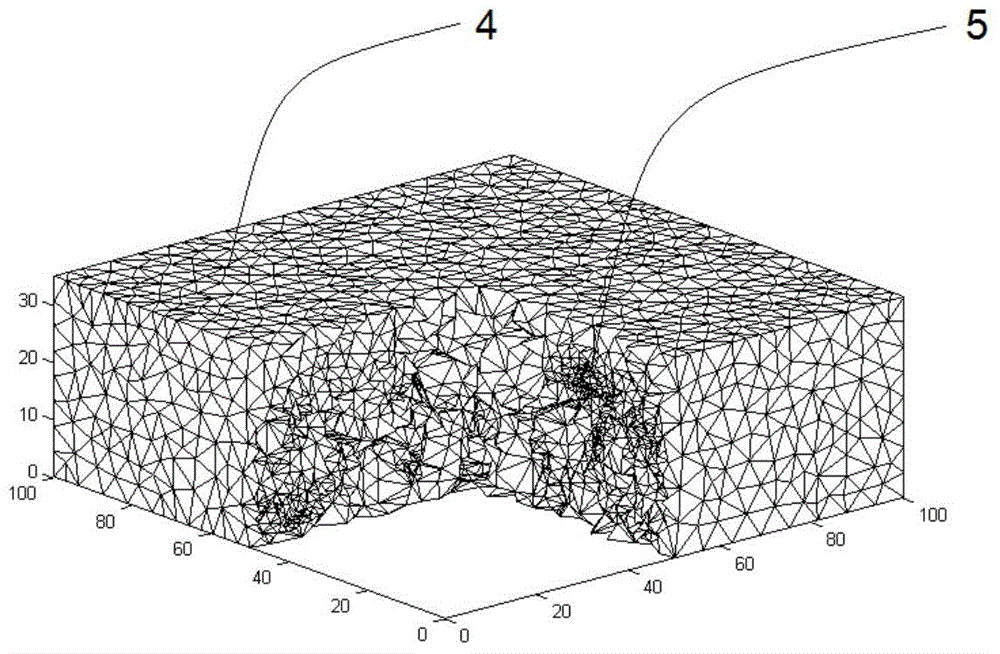

Modeling method of dispersed-phase reinforced composite material meso-structure

ActiveCN104899393AGuaranteed uniformityImprove production efficiencySpecial data processing applicationsElement modelModel method

The invention relates to a modeling method of a dispersed-phase reinforced composite material meso-structure. The modeling method comprises the following steps that the shape and the size of a model of a composite material are prepared, and the boundary of the model is determined; the sum of the volumes of particle reinforced phases in different size ranges in the model is prepared; particle models in all the size ranges are generated; the surface of each particle model is divided into finite element grids, and the prepared boundary of the model is divided into finite element grids; shell element attributes are given to the finite element grids; the mode of contact between the particle models and the mode of contact between the particle models and the boundary of the model are defined, and the descending process of particles in the space is simulated through a finite element method; the internal space of the model can be exactly filled with the particle models in all the size ranges; finite element models of the particle models and a finite element model of a substrate are obtained; modeling of the particle reinforced composite material structure is accomplished through the definition of the mode of constraint between the substrate and the particles and the material attributes of the substrate and the particles.

Owner:SHANDONG UNIV

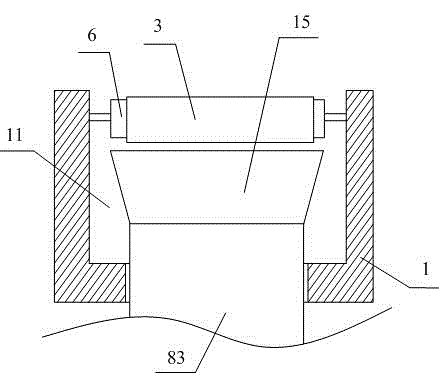

Bearing channel automatic sorting system

The invention relates to the bearing trench automatic selecting system. It aims to the big scatter of inside and outside liners of the bearing in machining, randomly selecting with low matching rate issue, starting with categorization of dimensions of the trenches, selecting rolling ball and the inner liner based on the dimension of the trench size. Currently, manual selection is used with big precision and efficiency change rate. It comprises the selection glide path on the fixed frame, drive mechanism fixed on the frame, support and drive mechanism fixed on the said frame, storage cabin installed inside the frame. It is selected based on the automatic measurement of the inside and outside trench dimensions.

Owner:HEILONGJIANG UNIV

Inducing method for directional differentiation of human umbilical cord mesenchymal stem cells into liver cells

ActiveCN102250829AMaintain biological characteristicsMaintain biological activityArtificial cell constructsVertebrate cellsDexamethasoneMesenchymal stem cell

The invention provides an induced culture method of liver cells, particularly provides a method for directional induced differentiation of human umbilical cord mesenchymal stem cells into liver cells and more particularly relates to a method for staged directional induced differentiation of human umbilical cord mesenchymal stem cells into liver cells by extracting human umbilical cord mesenchymal stem cells from abandoned umbilical cords through a cell climbing sheet technique, culturing the extracted stem cells, and adding an epidermal growth factor, dexamethasone, a liver cell growth factor, oncostatin and the like.

Owner:中源协和生物细胞存储服务(天津)有限公司

Capsule sorting mechanism with high sorting efficiency

InactiveCN104475363AReduce labor intensityReduce displacementSortingEngineeringUltimate tensile strength

The invention relates to a capsule sorting mechanism with high sorting efficiency. The capsule sorting mechanism comprises a rack, wherein a rectangular cavity and a waste conveyor trough are formed in a mounting base of the rack, a drive roll and a driven roll are arranged in the rectangular cavity, and a transparent conveying belt is wound on the drive roll and the driven roll; an inlet of the waste conveyor trough is communicated with the rectangular cavity, an outlet of the waste conveyor trough is formed in the side surface of the mounting base, and a first lower chute is formed under the outlet of the waste conveyor trough; a second lower chute is formed in the lower end of a discharge hole of a hopper in front of the rack, and the lower end of the second lower chute is positioned right above the transparent conveying belt; a temporary discharge hole is formed in the bottom of the rectangular cavity, a cover board covers the temporary discharge hole, and the cover board is articulated at the bottom of the rectangular cavity; and a delivery pipe is arranged at the rear end of the mounting base. The capsule sorting mechanism is convenient and has a labor-saving effect, the labor intensity is alleviated, the sorting efficiency is improved, capsule contamination can be avoided, overflow capsules can be prevented from treatment, the production efficiency is improved, the treatment procedure is reduced, the high-efficiency and high-quality production requirement is met and the production process is optimized.

Owner:成都贝发信息技术有限公司

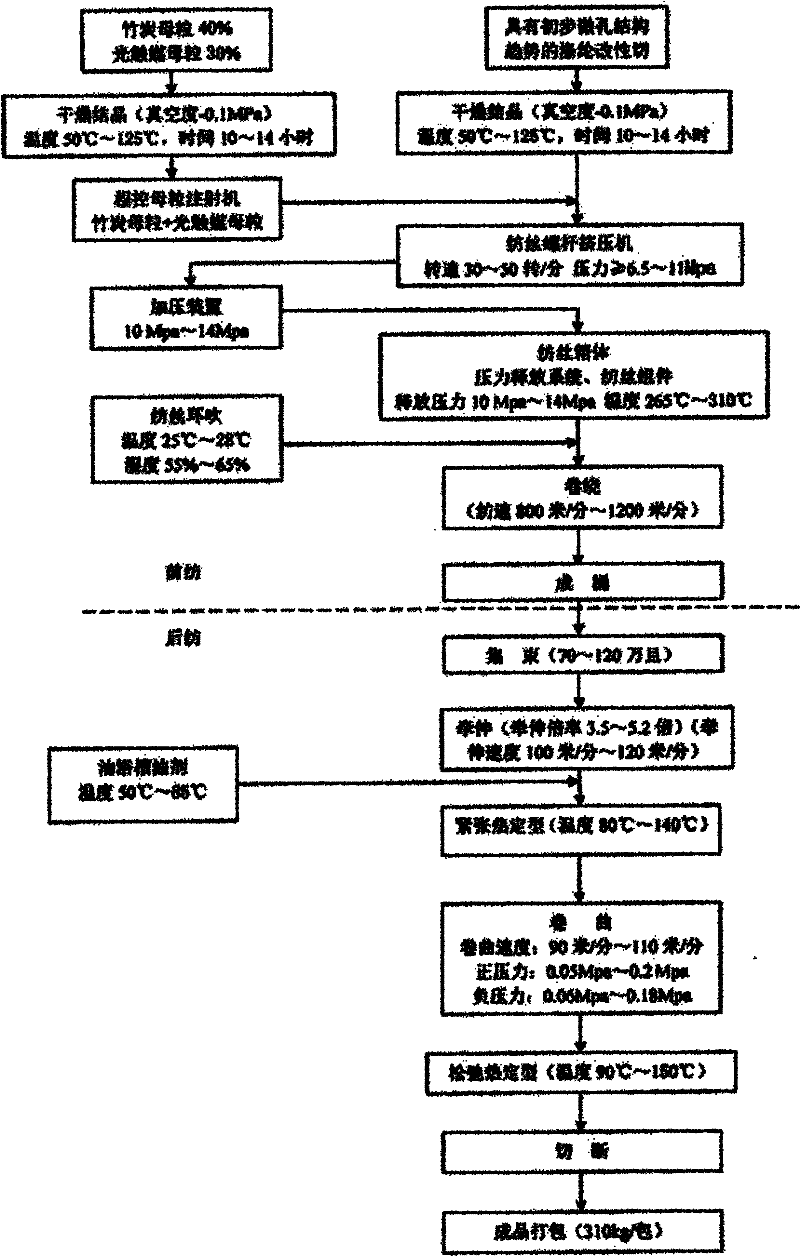

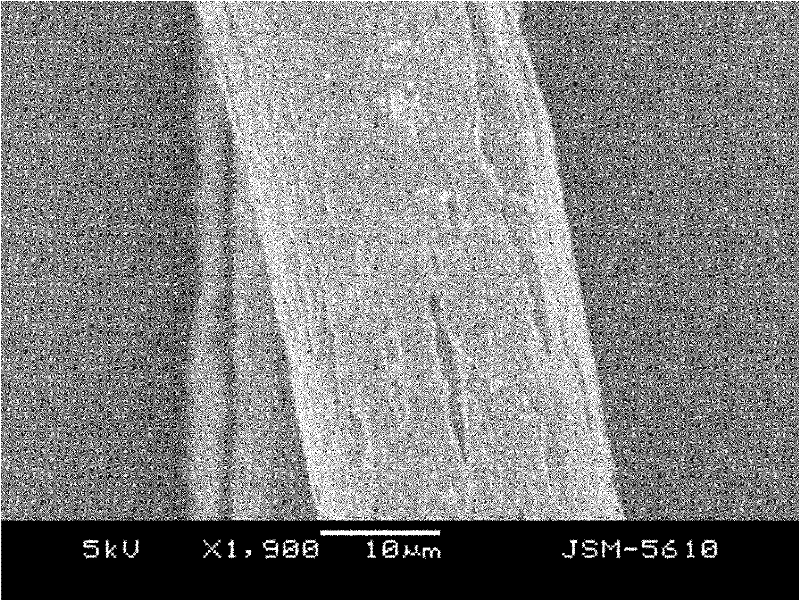

Microporous photocatalyst bamboo charcoal polyester modified short fiber and preparation method thereof

ActiveCN102174719AMeet the needs of colorImprove adsorption capacityMelt spinning methodsFilament-forming treatmentPolyesterSurface layer

The invention belongs to the spinning field, and relates to a microporous photocatalyst bamboo charcoal polyester modified short fiber and preparation thereof. For the microporous photocatalyst bamboo charcoal polyester modified short fiber, the surfaces and the inside have irregular microporous structures, all micropores penetrate through each other, photocatalyst compound micro powder and bamboo charcoal micro powder are uniformly distributed on the external surfaces, surface layers and insides of the whole short fiber as well as the surface and inside of each micropore, and the photocatalyst compound micro powder and the bamboo charcoal micro powder respectively account for 1.05-1.35wt% and 1.8-2.6wt% of the short fiber. The fiber provided by the invention is an environment-friendly one which has the functions of harmful gas and harmful microorganism absorption, bacterium resistance, mould proofing, deodorization, far infrared wave transmission, moisture absorption, quick drying and the like. Under the irradiation of light rays, the absorbed harmful gas and harmful microorganisms can be decomposed into carbon dioxide and water, thus the functions of purifying the air and cleaning the environment are achieved. Under the condition of illumination, the short fiber can be circularly and continuously used and can play corresponding roles.

Owner:绍兴上虞弘强纺织新型材料有限公司

Argon arc cladding iron-based powder

InactiveCN101954549AImprove distributionHigh hardnessArc welding apparatusWelding/cutting media/materialsMetallurgyDirect current

The invention relates to argon arc cladding iron-based powder, which belongs to the technical field of material surfaces. The powder is characterized by consisting of the following raw materials in percentage by weight: 40 to 60 percent of ferrotitanium with 25.0 to 35.0 percent of Ti, 10 to 25 percent of ferrovanadium with more than 75 mass percent of V, 15 to 30 percent of ferrochromium with more than 70 mass percent of Cr, 0 to 5 percent of ferroboron with more than 15 mass percent of B and 5 to 15 percent of graphite with less than 0.1 mass percent of C, wherein the particle sizes of the raw materials such as the ferrotitanium, ferrovanadium, ferroboron, ferrochromium, graphite and the like are 40 to 200 meshes. The powder is uniformly mixed with water glass or an organic binder and is precoated on the surface (the thickness is between 0.5 and 1.5mm) of a workpiece or is prepared into a bar with the diameter of phi2 to 4mm; after being dried, a powder precoating or the bar is clad on the surface of the workpiece by using the argon arc as a heat source so as to form a wear-resisting cladding layer; a tungsten electrode is a 2-percent thorium-tungsten electrode with the diameter of phi3 to 4mm and is used as a positive electrode with direct current; the flow rate of argon gas is 8 to 12L / min; the current is 120 to 160A; and the arc voltage is 15 to 20V. The cladding powder has low cost and the hardness of the cladding layer is up to HRC 55 to 63.

Owner:SHANDONG JIANZHU UNIV

Culturing method for sapling of Chinese pine or Chinese juniper by container in greenhouse

InactiveCN1552184AExtended growing seasonHigh degree of lignificationSeed and root treatmentCultivating equipmentsJuniperBiology

A method for culturing the saplings of pine or juniper by use of containers and plastic hot shed includes such steps as building a plastic hot shed, germinating the seeds of pipe or juniper, perforating on the bottom of earth basin, preparing matrix soil from agricultural field soil, raw clay, organic fertilizer and N,P and K fertilizers, disinfecting the matrix soil, loading in earth basins, sowing, irrigating, covering by a layer of fine sandy soil, spraying mitrofen, and controlling temp and humidity. Its advantages are short breeding time and high germination rate.

Owner:华利军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com