Method for coal blending for coking by high-metamorphic-grade weak caking coal

A coal blending coking and high metamorphism technology, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of large particles, easy cracks, and difficult crushing, so as to achieve reasonable utilization of coal resources, reduce coke cracks, and improve The effect of coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

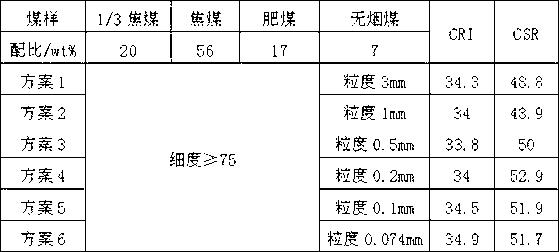

[0025] (1) Determine the optimum pulverization particle size of coal material: see Table 1 for the thermal performance of coking with different particle sizes of highly metamorphic coal material (lean coal).

[0026] Table 1: Thermal properties of coking with different particle sizes of highly metamorphic coal materials

[0027]

[0028] It can be seen from the CRI and CSR in Table 1 that the optimum pulverization particle size of lean coal is 0.1 mm under this ratio.

[0029] (2) Compression of coal briquettes: see Table 2 for the proportion of mixed coal materials.

[0030] Table 2: Proportion of mixed coal materials (weight %)

[0031] coal sample 1 / 3 coking coal coking coal Fat coal lean coal Coal 1 ratio 21.5 60.2 18.3 - Coal 3 ratio 20 56 17 7

[0032] 0.74kg of lean coal finely crushed to 0.1mm is mixed evenly with 9.76kg of coal 1, cold-pressed and formed, and 24.5kg of conventional particle size blended coal is mixed with th...

Embodiment 2

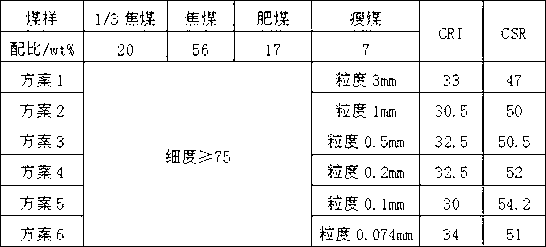

[0034] (1) Determining the optimum pulverization particle size of coal materials: see Table 3 for the thermal performance of coking with different particle sizes of highly metamorphic coal materials (anthracite).

[0035] Table 3: Thermal properties of coking with different particle sizes of highly metamorphic coal materials

[0036]

[0037] From the CRI and CSR in Table 3, it can be seen that the optimum crushing particle size of anthracite is 0.2 mm under this ratio.

[0038] (2) Compression of coal briquettes: See Table 4 for the proportion of mixed coal materials.

[0039] Table 4: Proportion of mixed coal materials (weight %)

[0040] coal sample 1 / 3 coking coal coking coal Fat coal anthracite Coal 1 ratio 21.5 60.2 18.3 - Coal 3 ratio 20 56 17 7

[0041] 0.74kg of anthracite finely crushed to 0.1mm and 9.76kg of coal 1 are evenly mixed, cold-pressed and molded, and 24.5kg of conventional particle size blended coal is mixed wit...

Embodiment 3

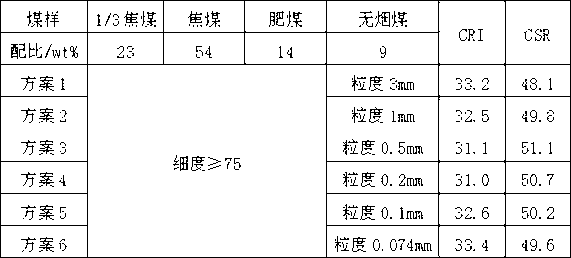

[0043] (1) Determining the optimum pulverization particle size of coal materials: see Table 5 for the thermal performance of coking with different particle sizes of highly metamorphic coal materials (lean coal).

[0044] Table 5: Thermal properties of coking with different particle sizes of highly metamorphic coal materials

[0045]

[0046] From the CRI and CSR in Table 5, it can be seen that the optimum pulverization particle size of lean coal is 0.2mm under this ratio.

[0047] (2) Compression of coal briquettes: See Table 6 for the proportion of mixed coal materials.

[0048] Table 6: Proportion of mixed coal materials (weight %)

[0049] coal sample 1 / 3 coking coal coking coal Fat coal lean coal Coal 1 ratio 25.2 59.4 15.4 - Coal 3 ratio 23 54 14 9

[0050] 0.95kg of anthracite finely crushed to 0.1mm and 9.55kg of coal 1 are evenly mixed, cold-pressed and molded, and 24.5kg of conventional particle size blended coal is mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com