Patents

Literature

942 results about "Coal blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal blending is the process of mixing coals after coal has been mined to achieve quality attributes that are desirable for the coal’s intended application (e.g. steam generation, coking). The quality attributes that are most important in blending will differ from one mine site to another and also depend on how the coal seams vary in quality and their final intended use. In thermal coals, quality attributes of interest often include ash, volatile matter, total Sulfur, and gross calorific value. For coking coals, additional attributes are sometimes considered including crucible swelling number, fluidity, and RoMax.

Coal coking blending method

InactiveCN101081989AOvercome accuracyOvercome usabilityCoke ovensSolid fuelsProcess engineeringCoal blending

The present invention is coking blend method with gas coal, and different kinds of coking coal with required vitrinite reflectance distribution are blended. The blended coals include gas-fat coal 5-10 wt%, fat coal 5-20 wt%, 1 / 3 coking coal 30-45 wt%, coking coal 30-45 wt% and lean coal 10-18 wt%. The method of the present invention has reasonable utilization of the coking coal resource, accurate coal blending and high coke quality.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Coke coal blending ratio and coking method thereof

The present invention is one kind of coke coal blending ratio and coking process. The coke coal consists of fat coal 20-23 weight portions, coking coal 50-55 weight portions, 1 / 3 coking coal 15-20 weight portions, and lean coal 8-12 weight portions. The compounded coal has the quality including ash content 9-10 %, sulfur content 0.65-0.73 %, volatile component 24-26 %, G value 83-88, Ymm of 16-20, and Xmm of 20-30. The quality parameters, vitrinite reflectances and microscopic ingredients of the said four kinds of coal are specifically defined. During the coking process, the mixed coal material is sintered at 1200 deg.c for not less than 16 hr. The present invention can obtain coke with high strength.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

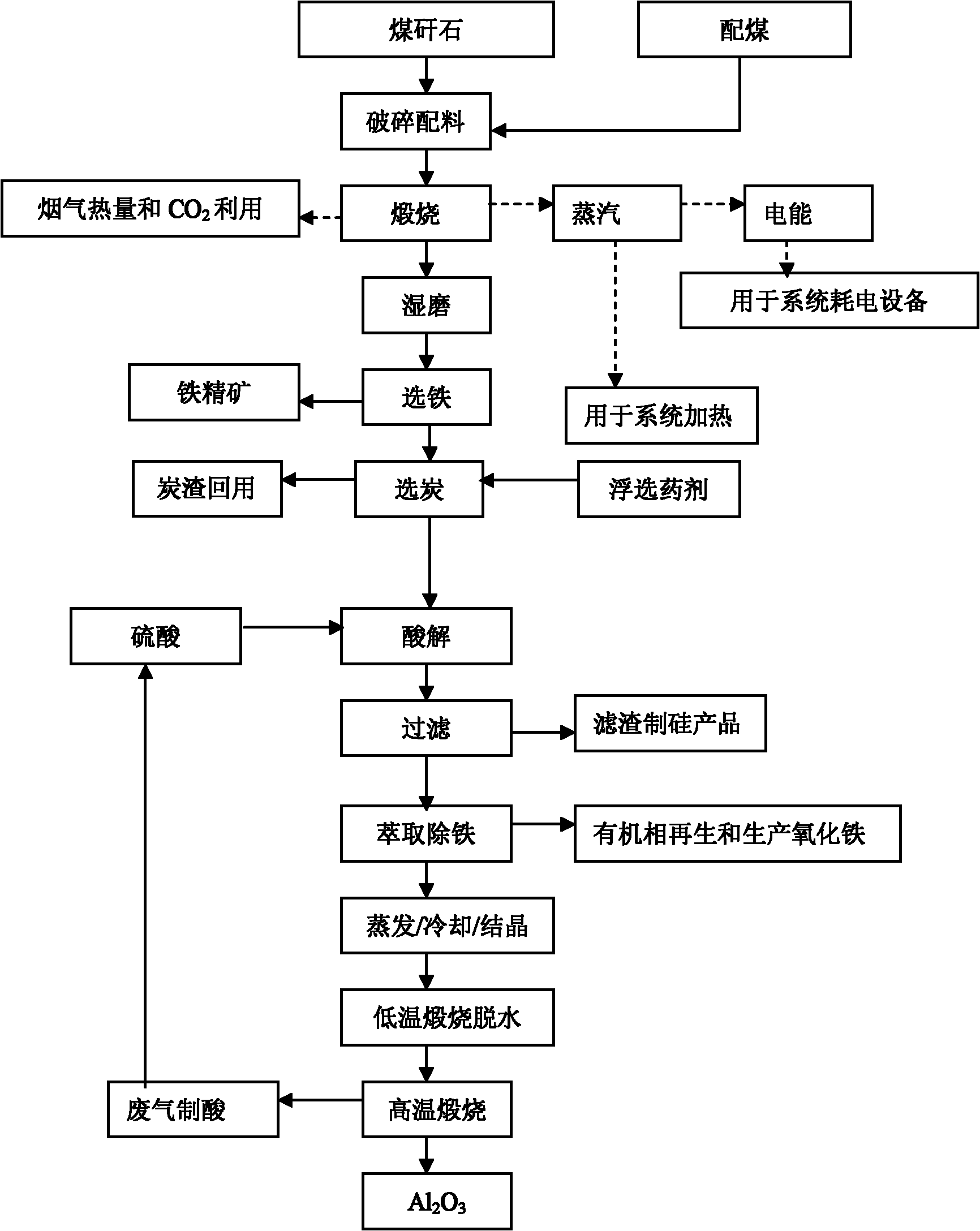

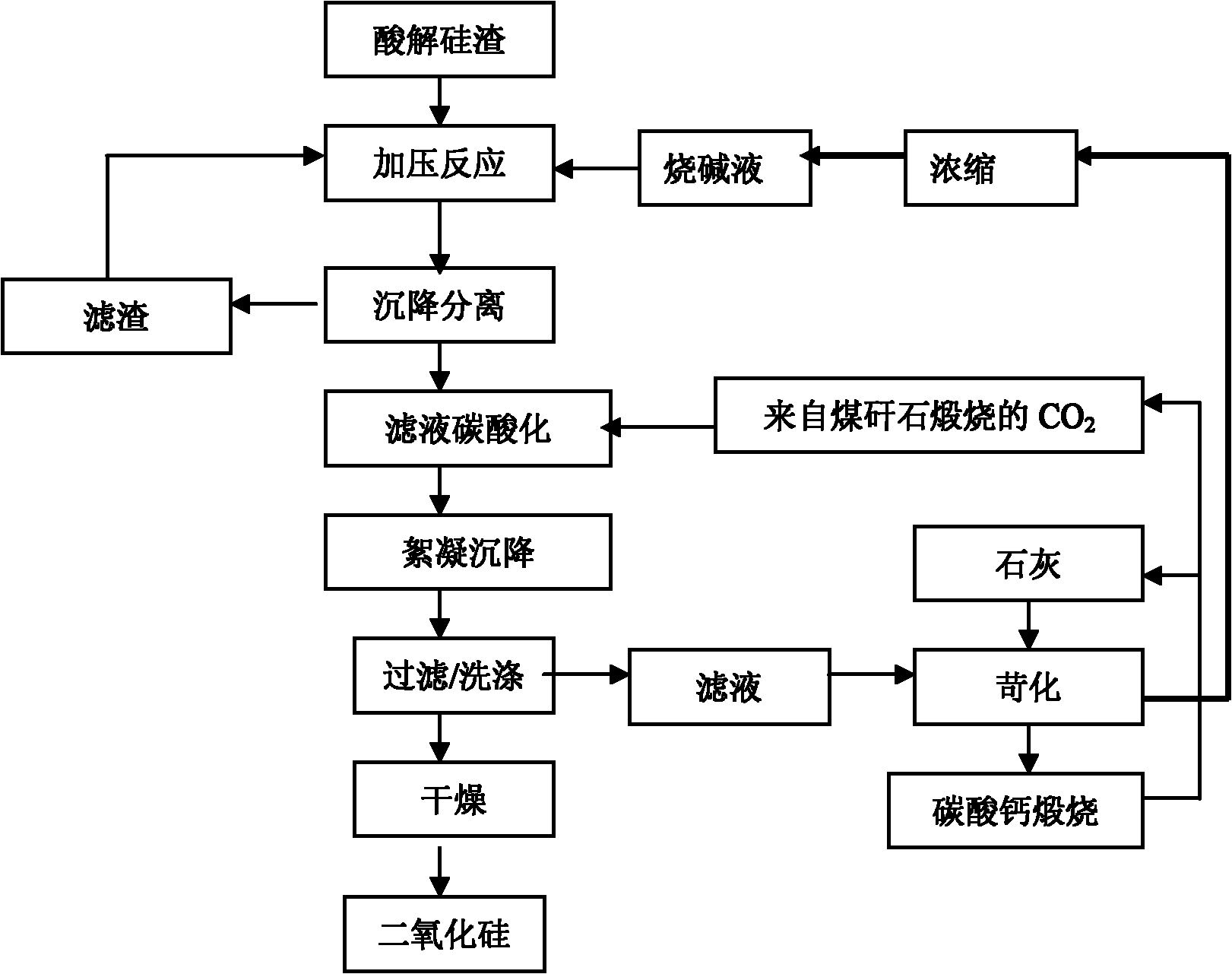

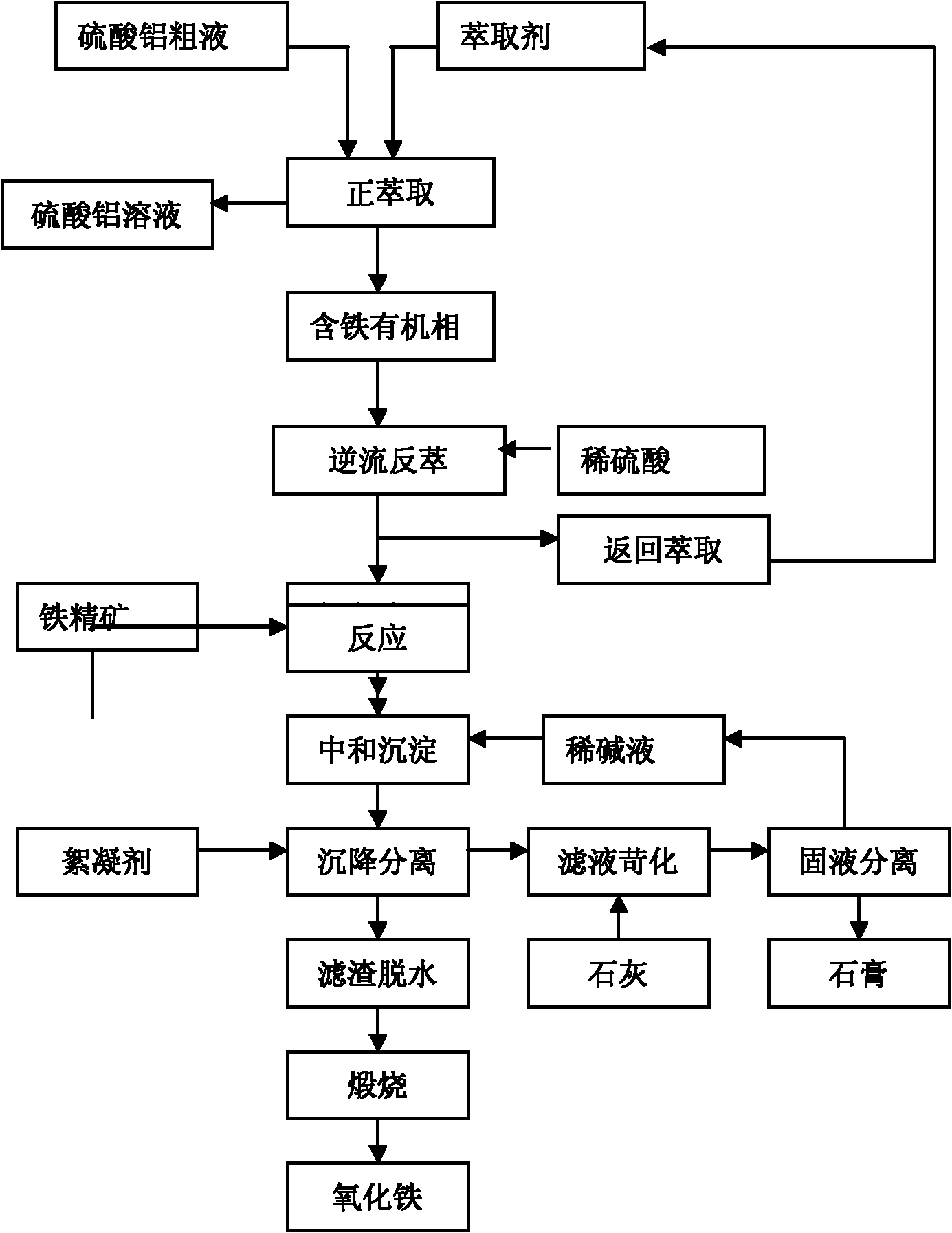

Method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes

InactiveCN101913632AEfficient use ofMeet steamSilicaCalcium/strontium/barium sulfatesBiological activationCoal blending

The invention relates to a method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes. Coal blending is carried out according to heating value conditions after the gangue is pretreated, gangue activation is achieved while calcination generation is carried out, and the produced electricity and steam are supplied for a system to use; the aluminum oxide is extracted from the ashes by an acid method, the monox is extracted by an alkaline method, and the ferric oxide is extracted by comprehensive utilization of by-products; and acid, alkaline, lime, an extractant andCO2 which are required by each craft link are recycled inside the system. The invention has the beneficial effects that gangue reclamation is implemented by using the method; the energy and the chemical components in the gangue are fully utilized; the discharge amounts of greenhouse gases and waste ashes are greatly reduced, and the economic benefit of the system is improved; and the method is a novel technology of gangue greening and high added-value utilization, and has obvious competitive advantage.

Owner:KUNMING UNIV OF SCI & TECH +1

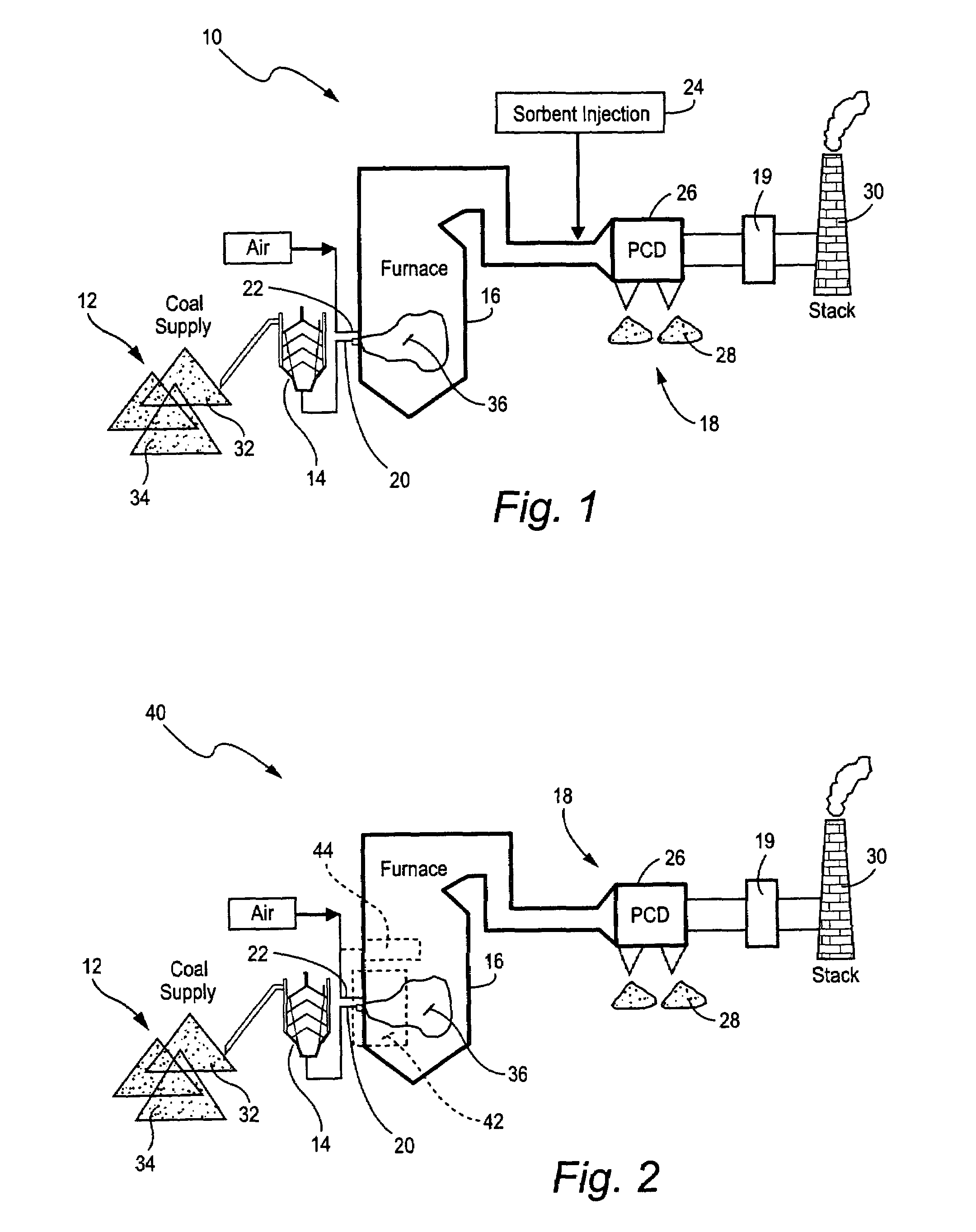

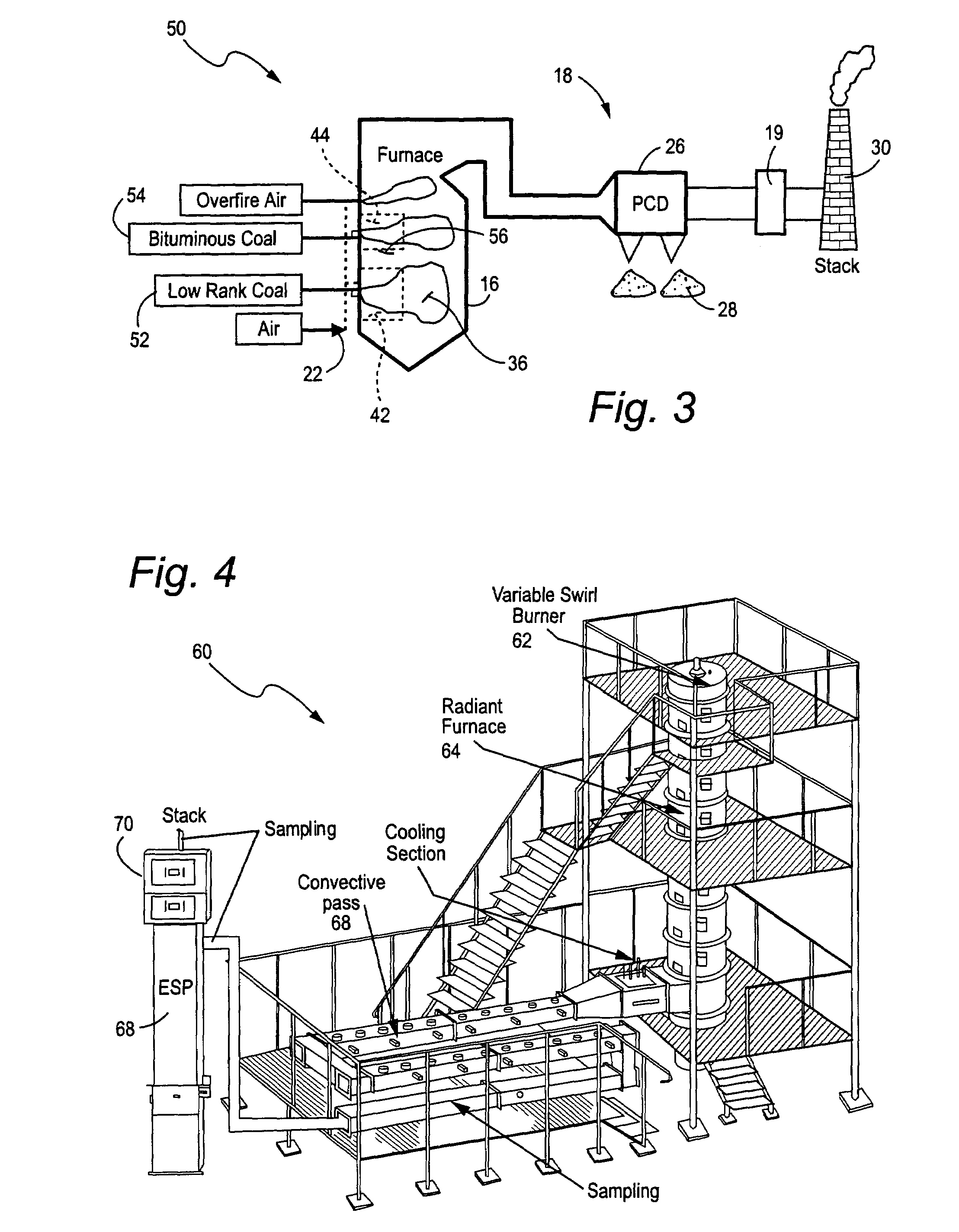

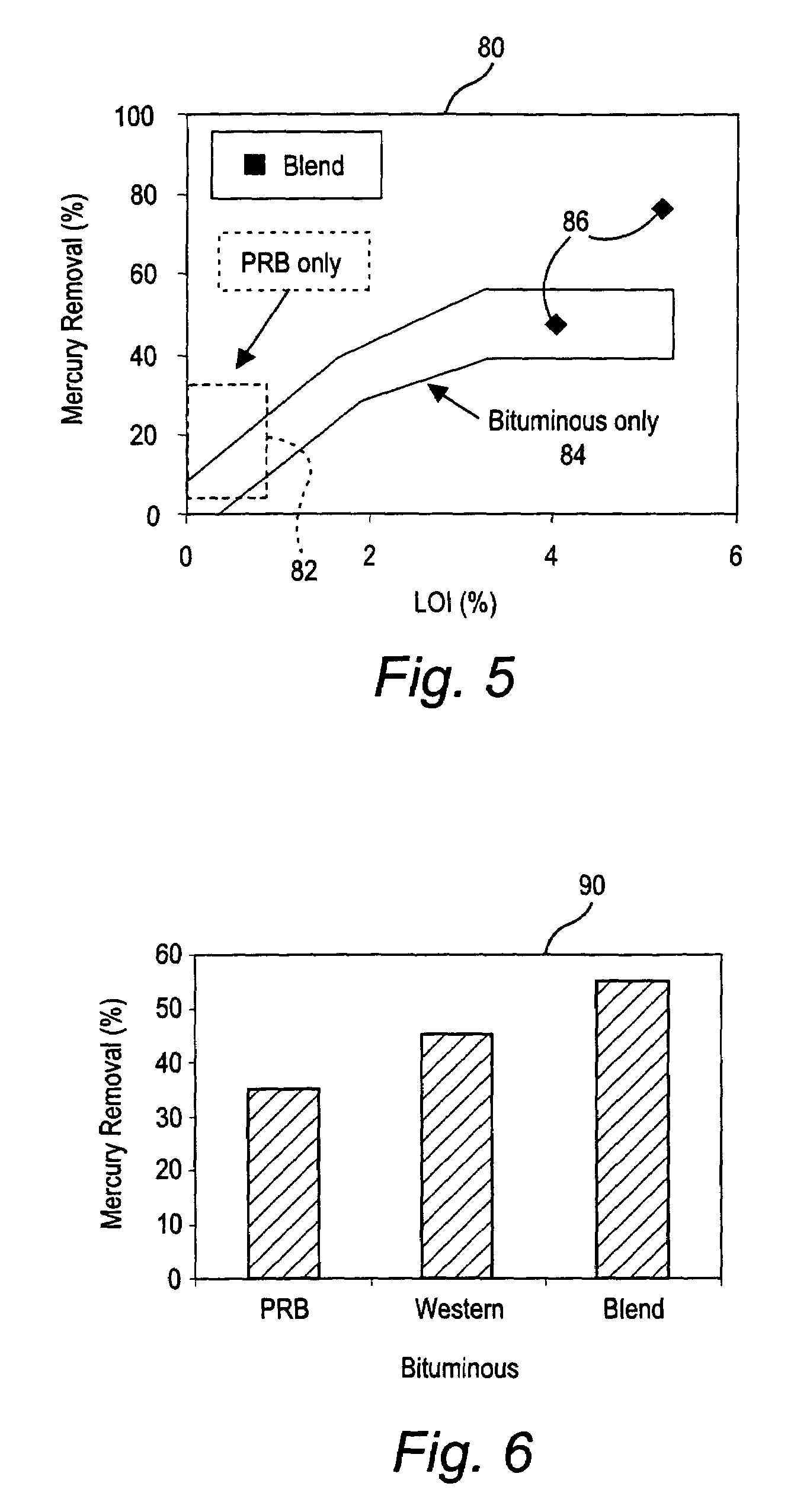

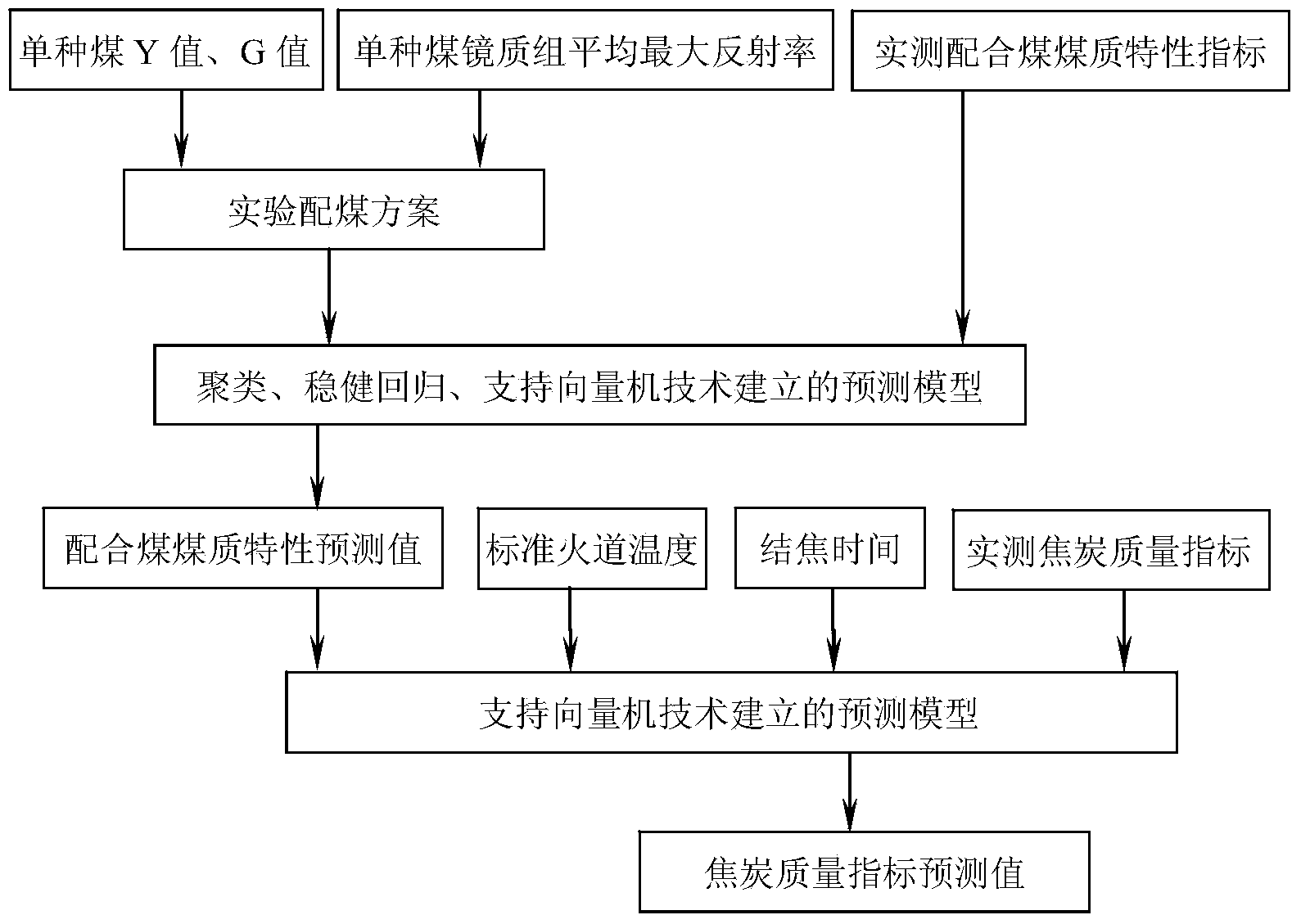

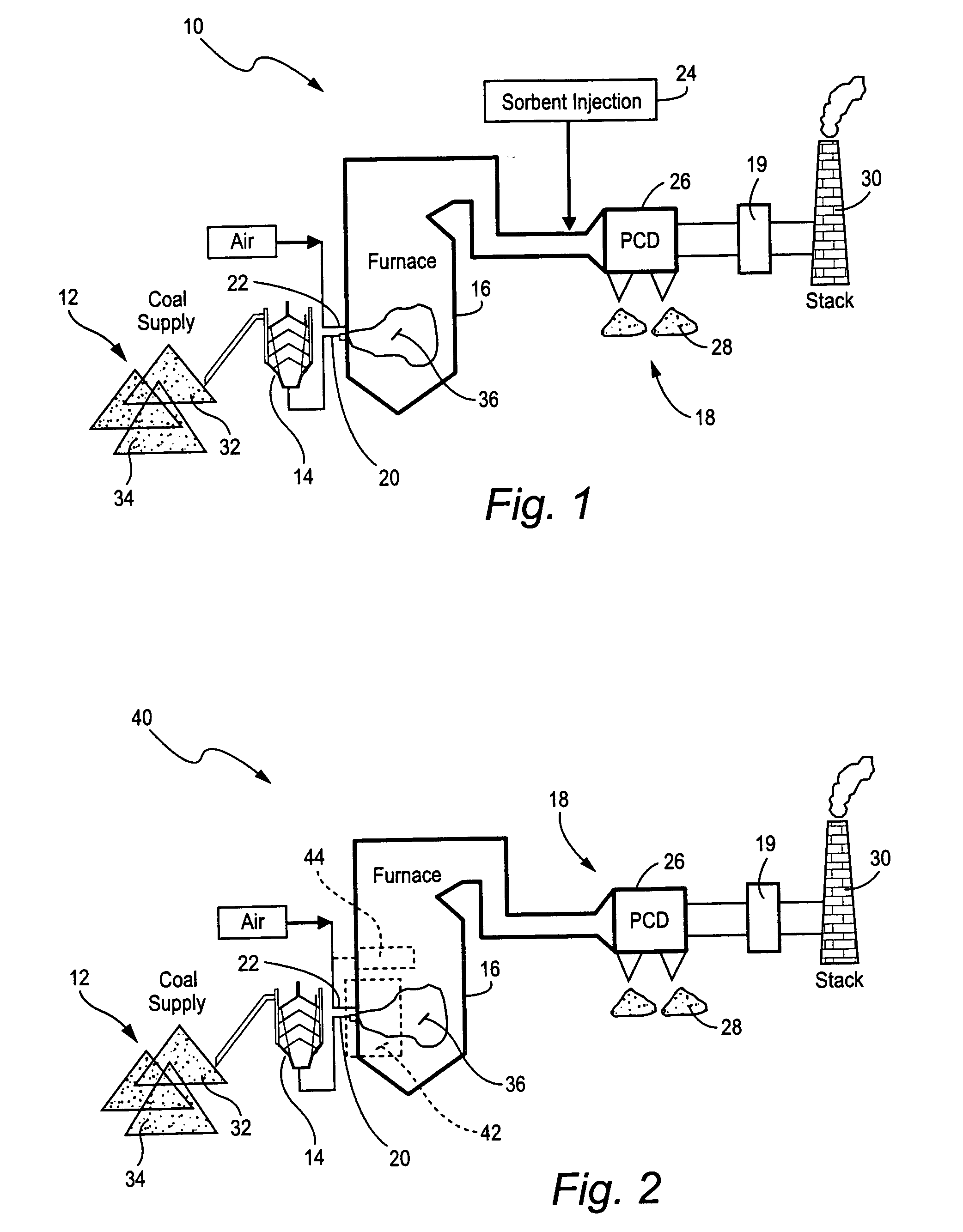

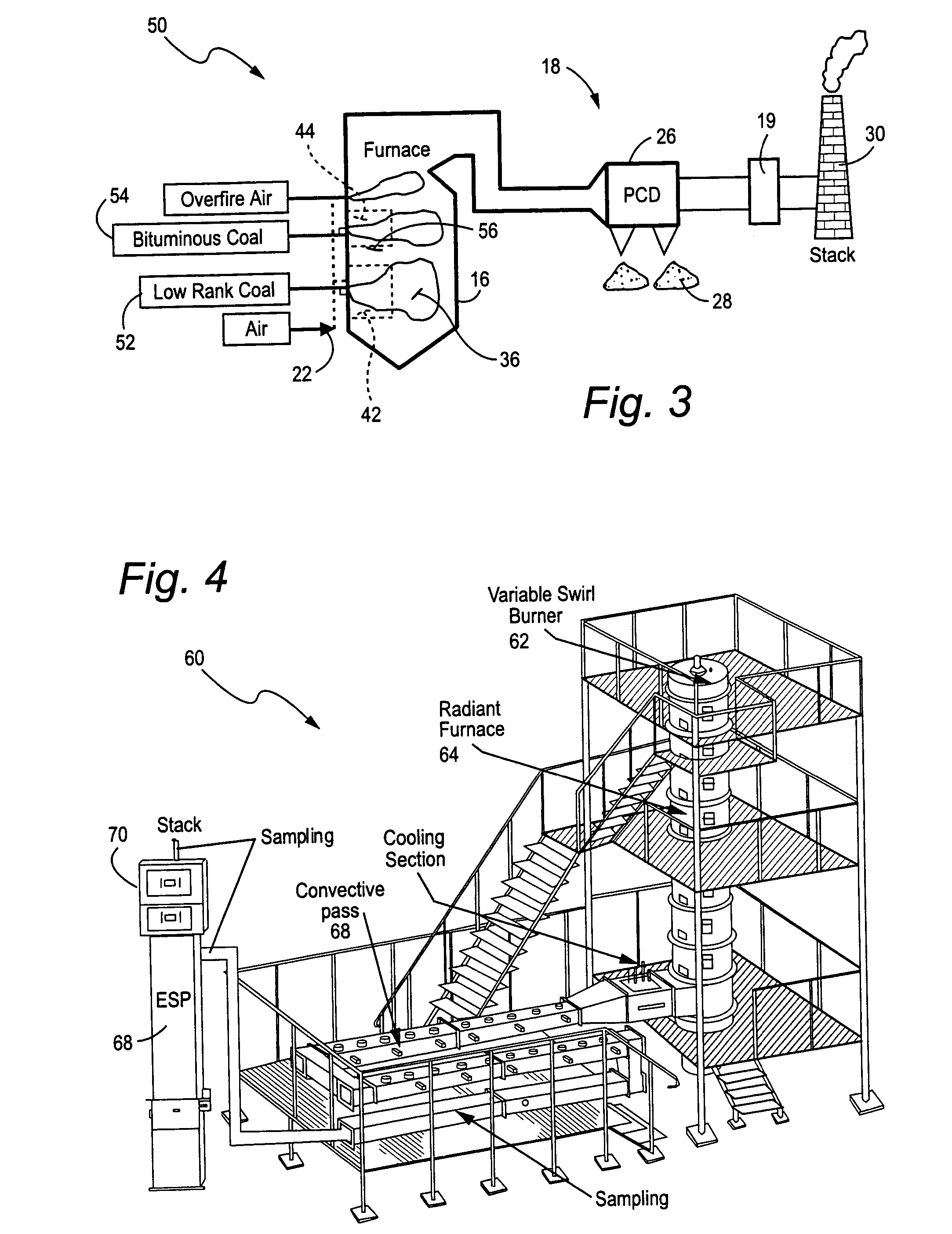

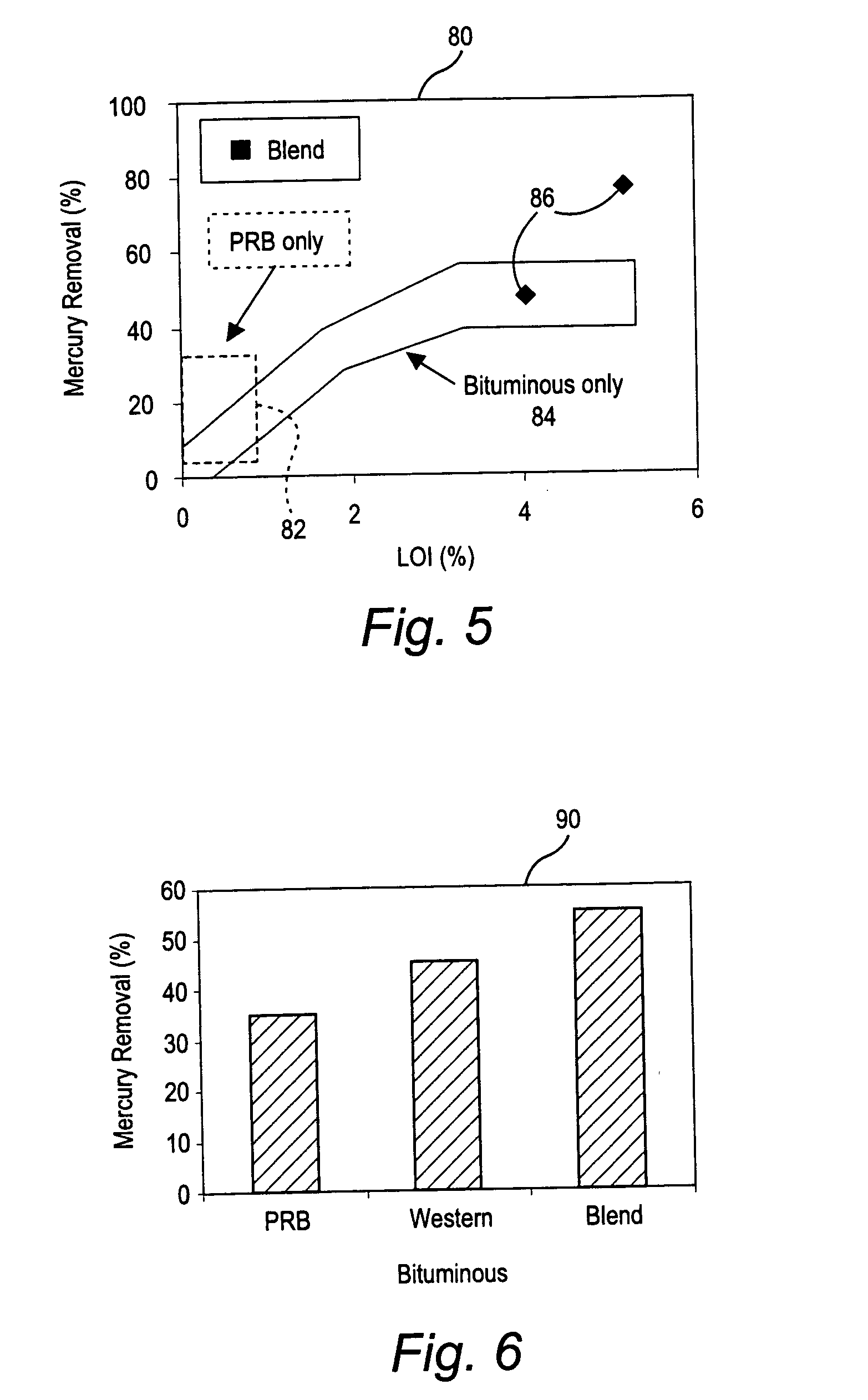

Mercury reduction system and method in combustion flue gas using coal blending

ActiveUS7381387B2Reduce gas emissionsGas treatmentUsing liquid separation agentCombustion systemCombustion

A method to reduce mercury in gas emissions from the combustion of low rank coal in a combustion system including: combusting coal having a low chlorine content in the combustion system, wherein elemental mercury (Hg0) is released in the flue gas produced by the combustion of the low rank coal; releasing chlorine into the flue gas by combusting a coal having a high chlorine in the combustion system; reacting the elemental mercury and released chlorine in the flue gas to oxidize the mercury; adsorbing at least a portion of the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

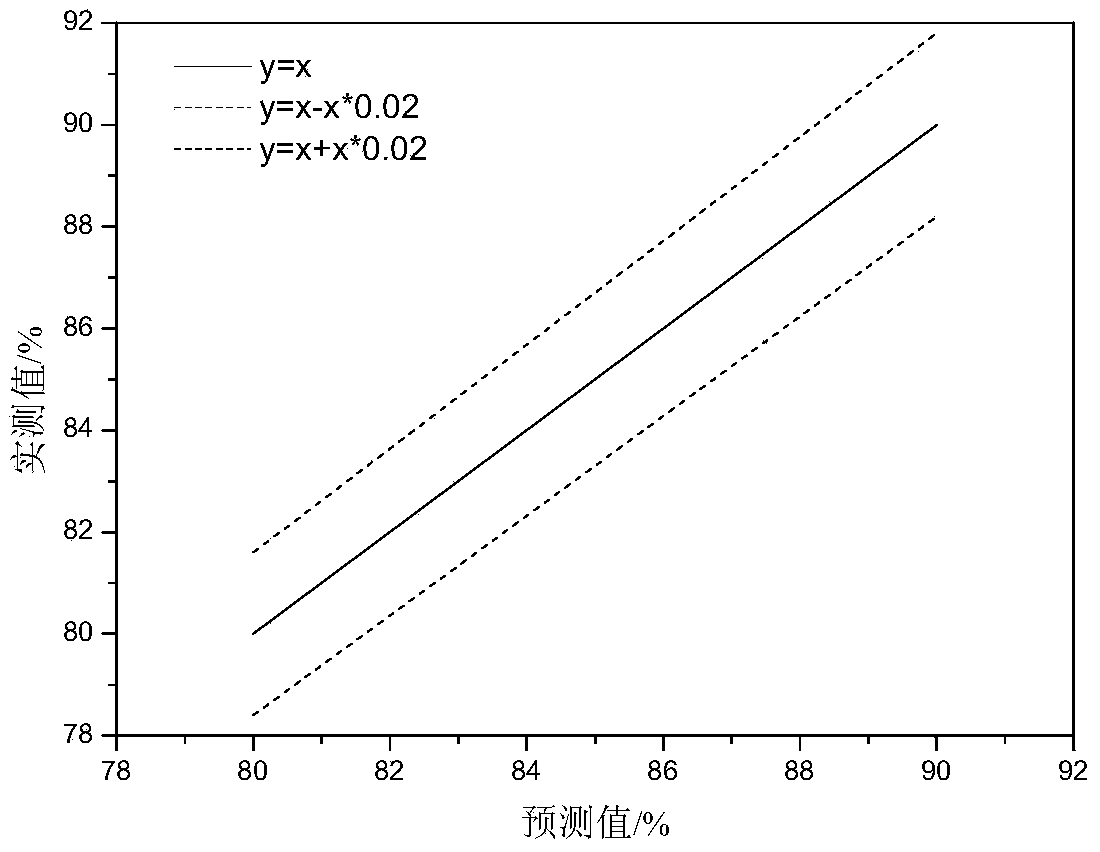

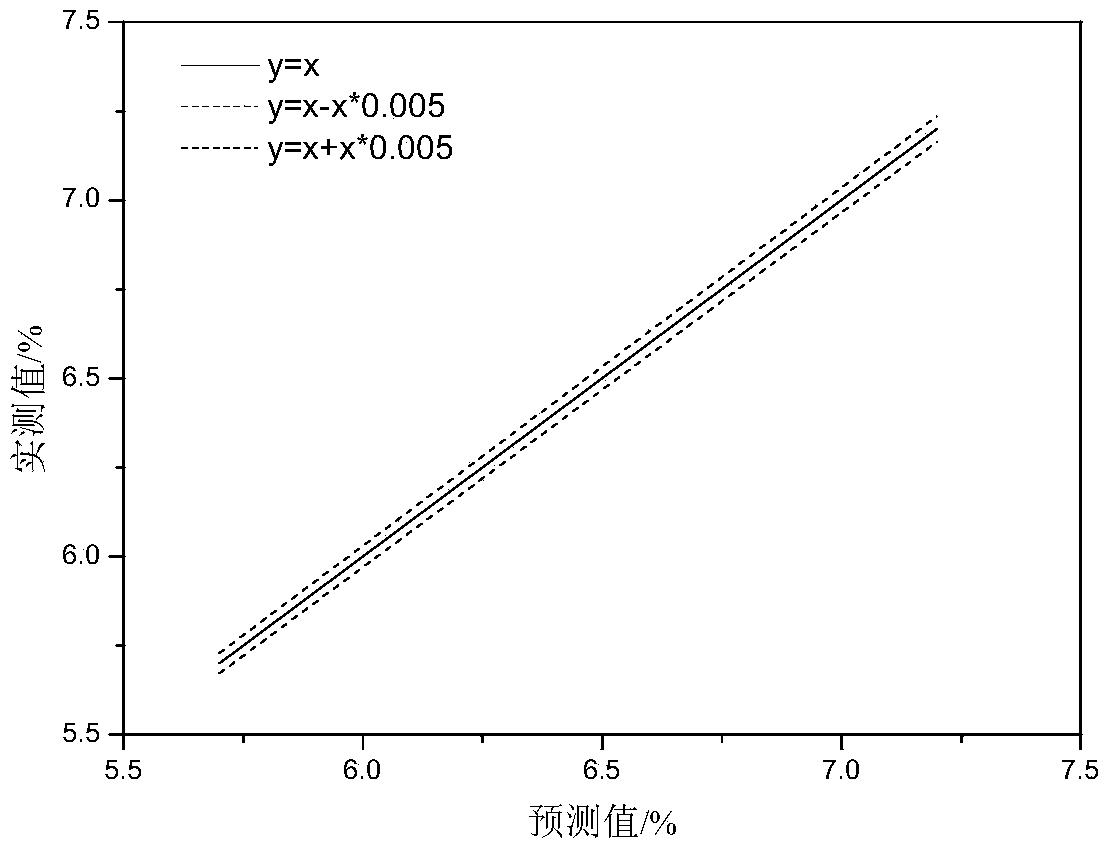

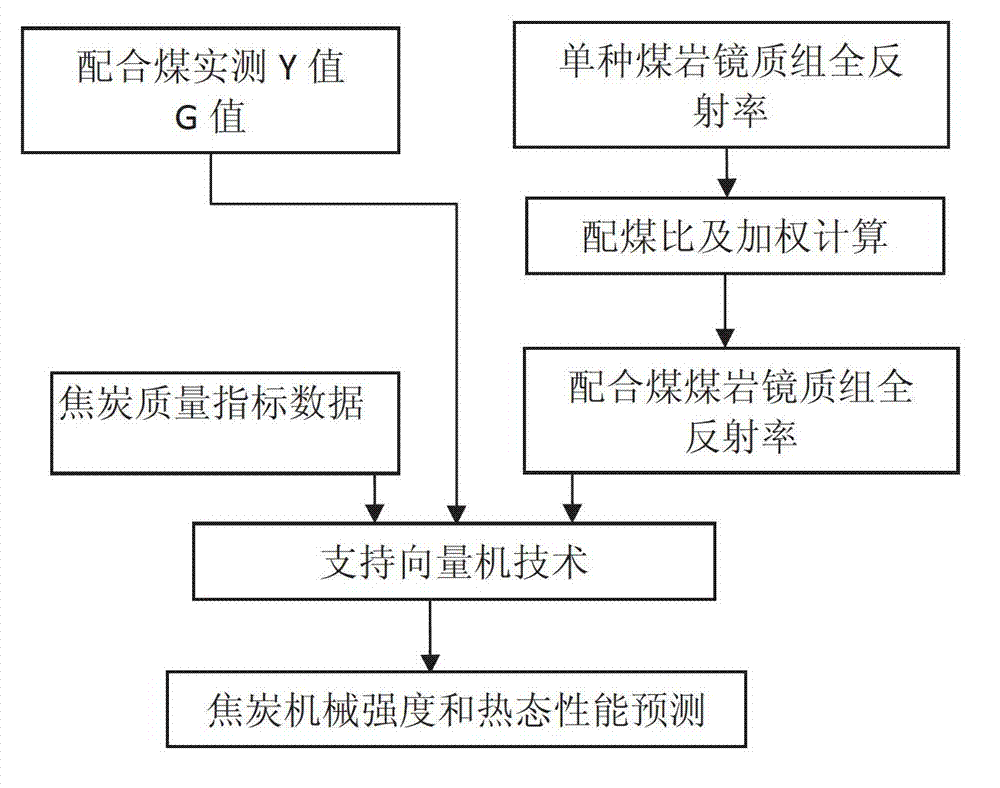

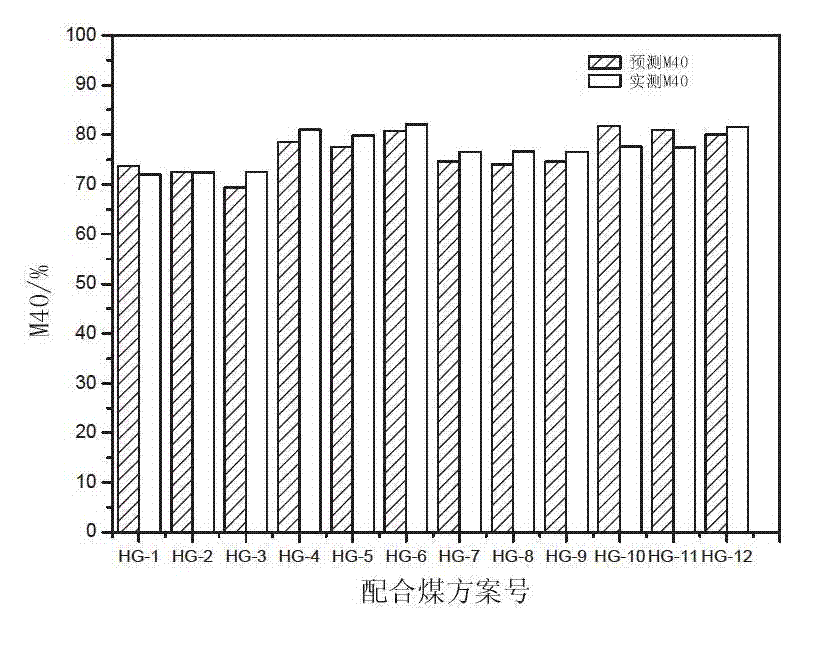

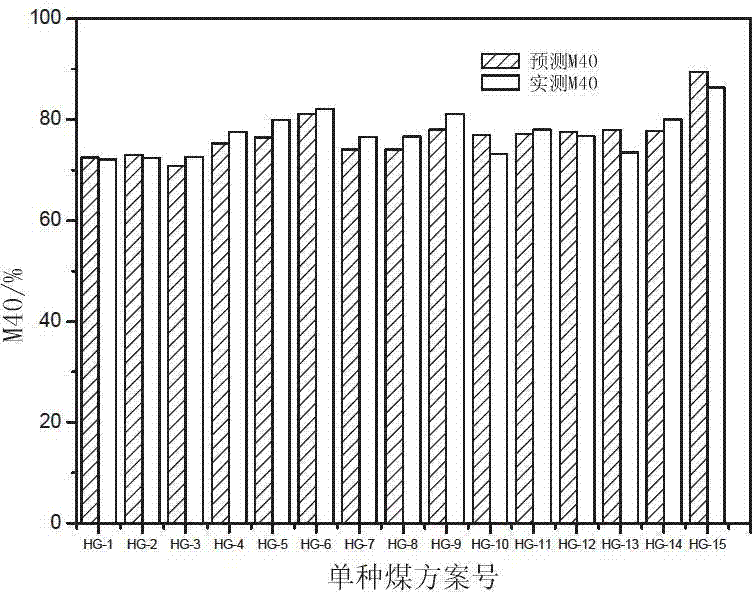

Method for predicting coke quality through coking coal nonlinear optimization coal blending

InactiveCN103853915AHigh precisionInput variables cover a wide rangeSpecial data processing applicationsSupport vector machineEngineering

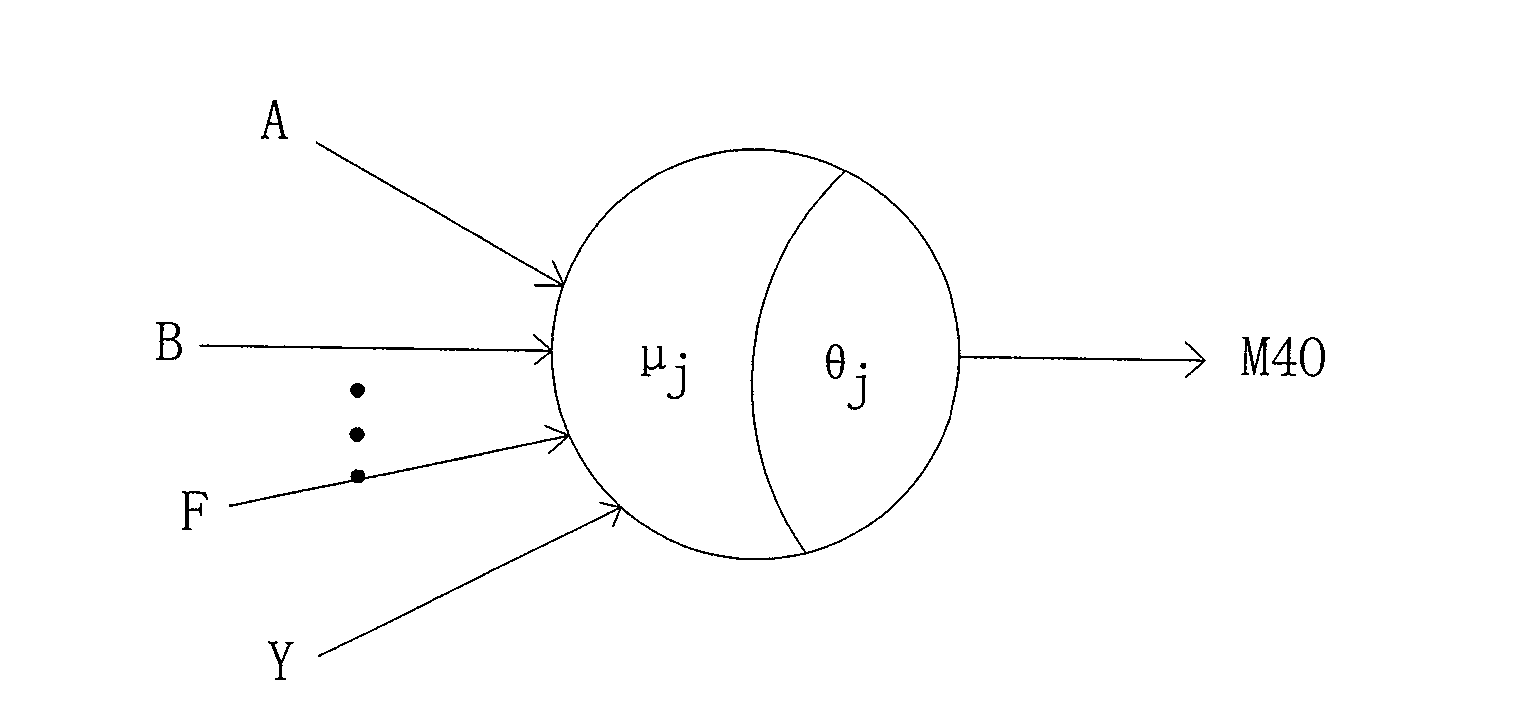

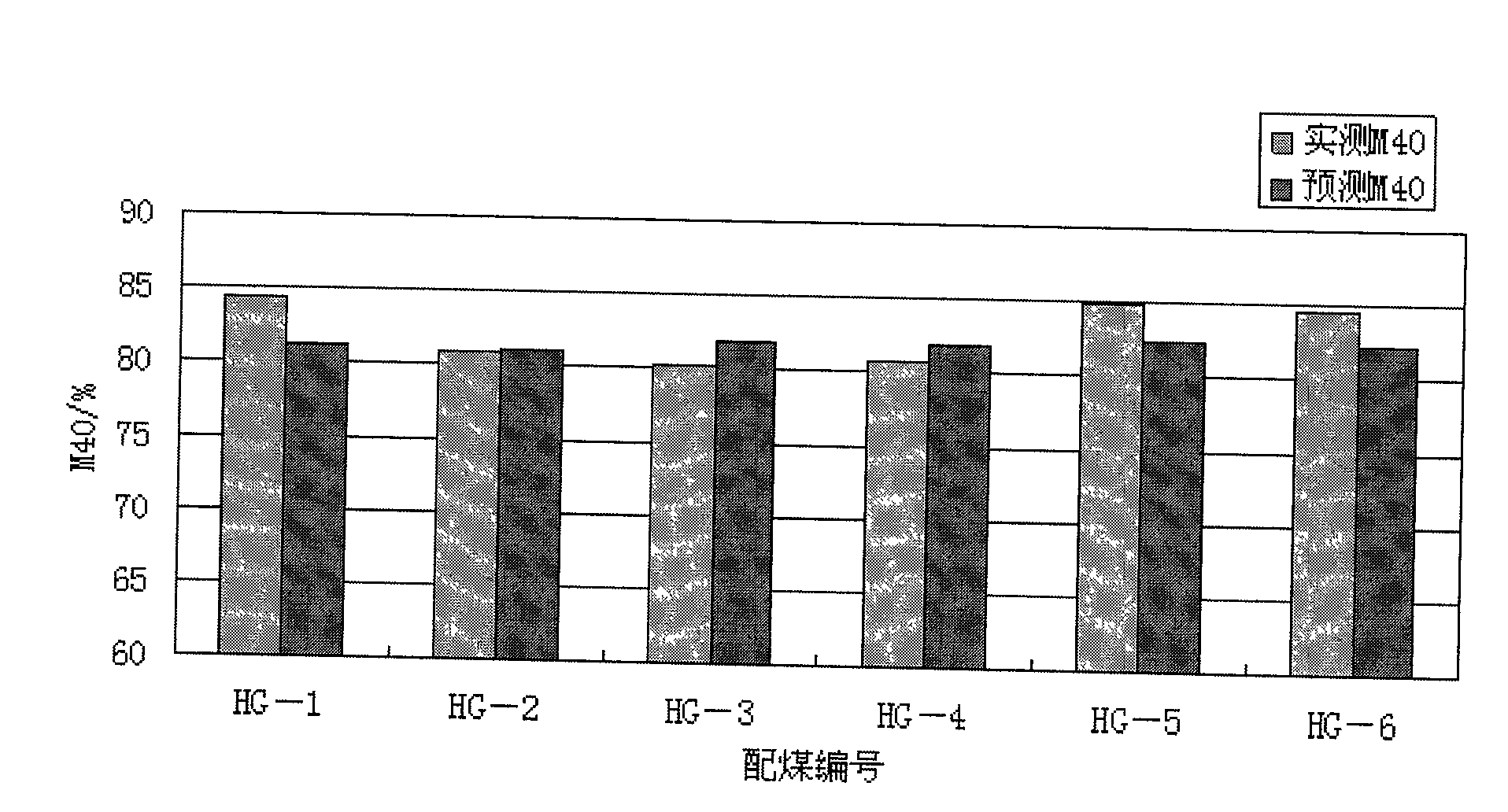

The invention provides a method for predicting coke quality through coking coal nonlinear optimization coal blending and provides an important technical guarantee for keeping the stability of coke produced by coke making enterprises and improving the coke quality. The method is characterized in that the indexes of the coke are predicted through a support vector machine technique, a single coal caking property index including two factors, i.e. a gelatinous layer index Y value and a caking index G value, coal blending ratio, a coal and rock index as shown by the accompanying drawing, coking time t and coke oven standard flue temperature T (machine side temperature Tm and coke side temperature Tk) are used as input parameters, then the mechanical strength M40 and M10, the hot performance CRI (Coke Reactivity Index) and CSR (Coke Strength after Reaction) of the coke are used as output parameters, a nonlinear relationship between the input parameters and the output parameters is obtained by training the support vector machine and accordingly the mechanical strength and the hot performance index of the predicted coke are obtained. The method for predicting coke quality through coking coal nonlinear optimization coal blending has the advantages that the influence factors in various aspects in the coke making process are fully considered and the prediction results are enabled to be more scientific and accurate.

Owner:UNIV OF SCI & TECH LIAONING +1

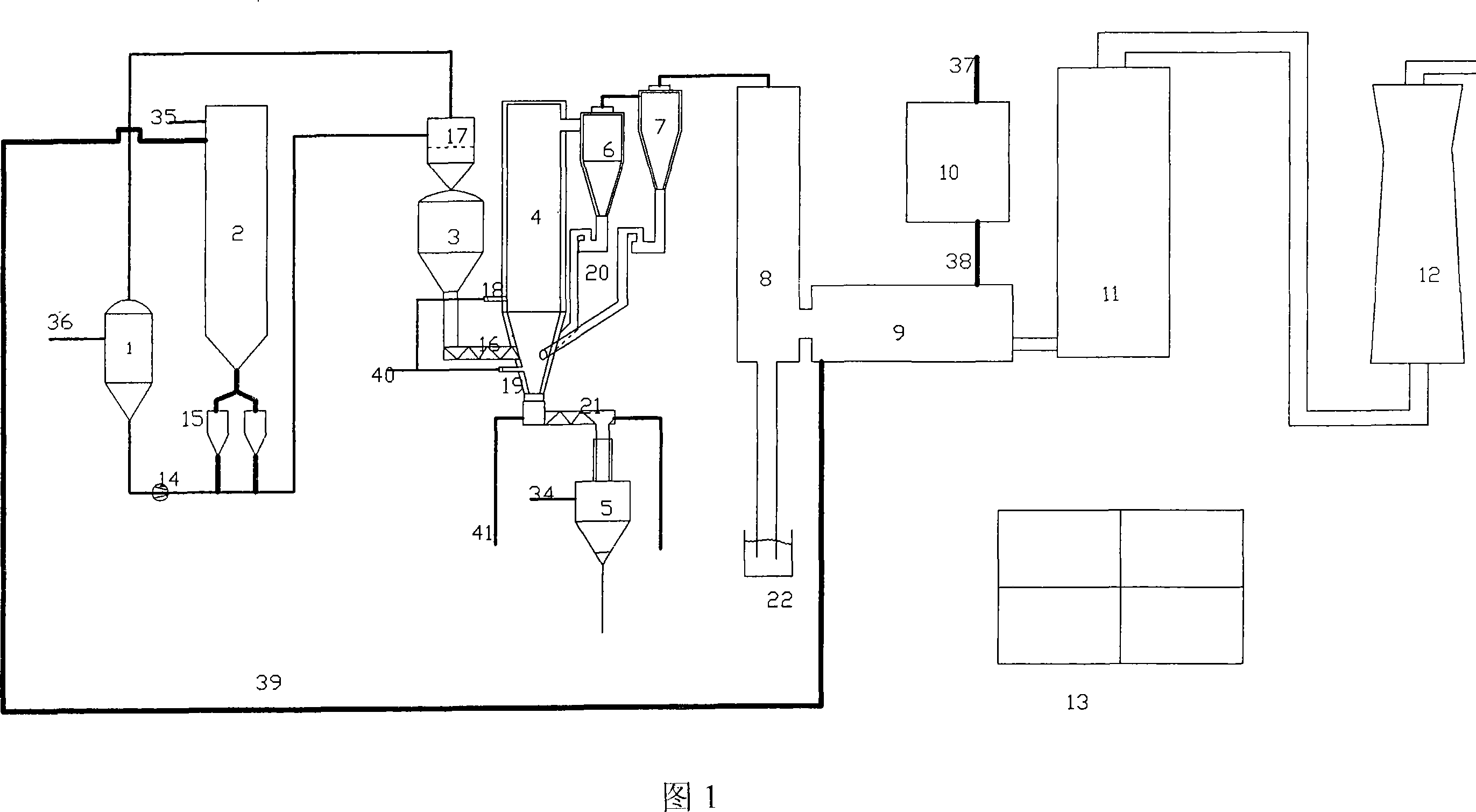

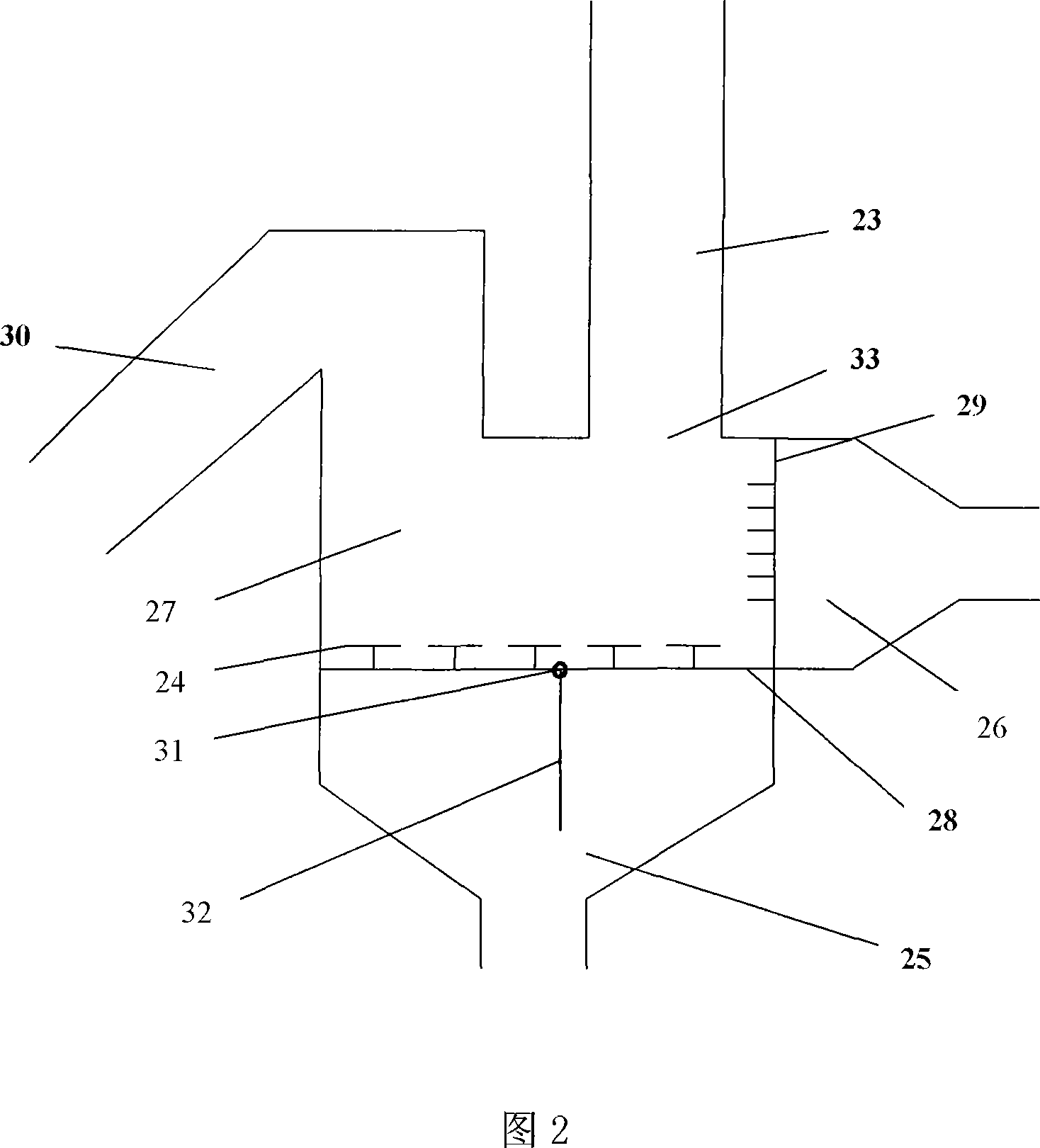

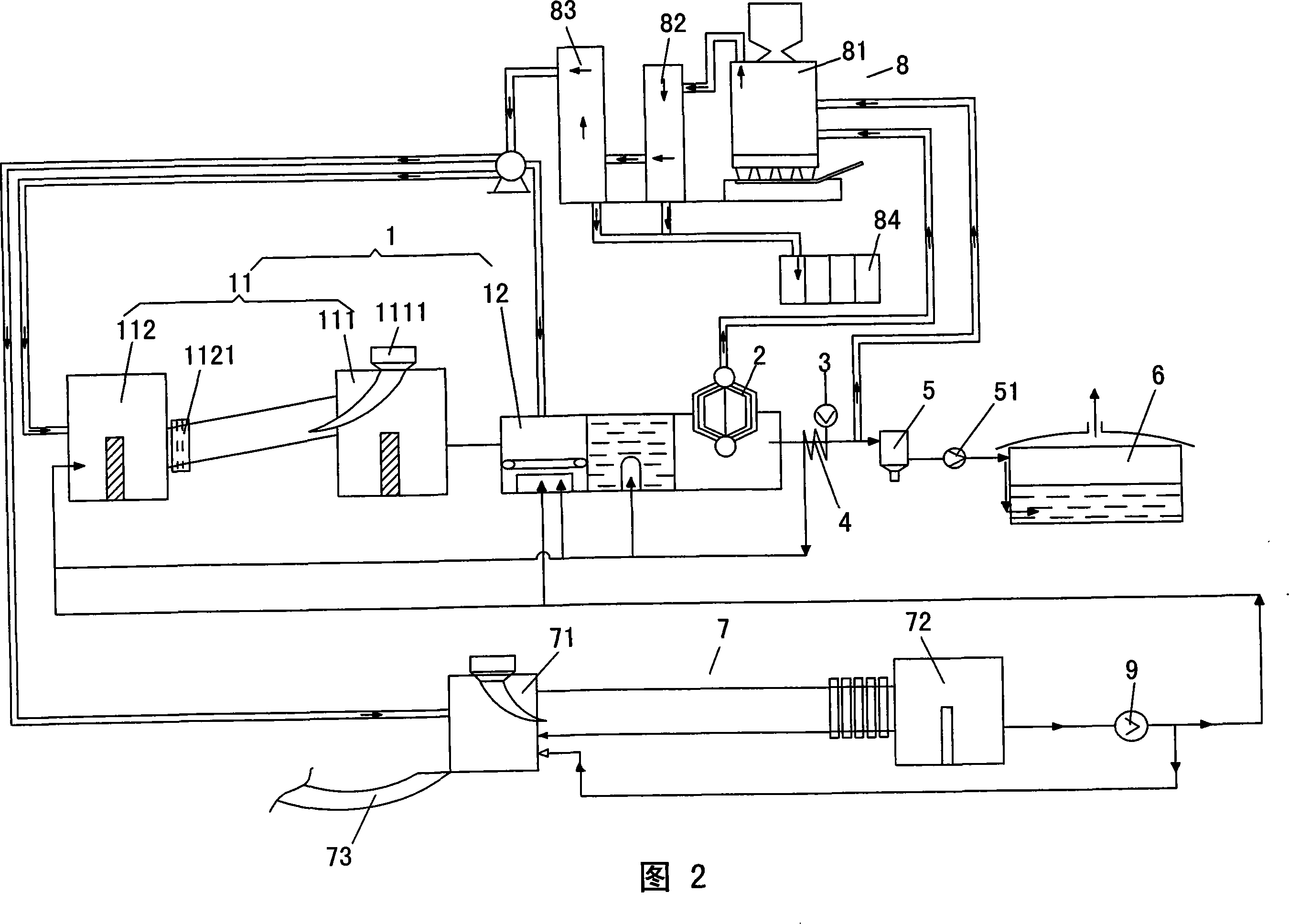

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

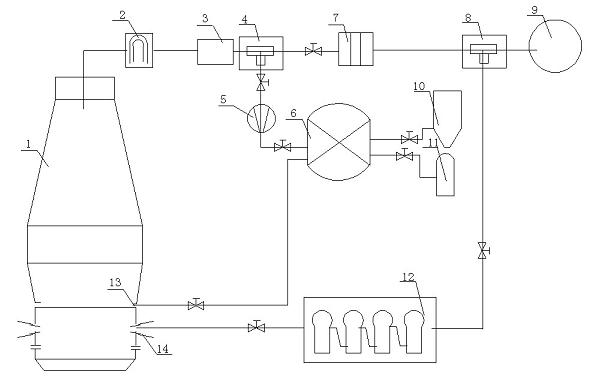

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

Method for coal blending coking through utilizing Gieseler fluidity index

The invention relates to a coal blending coking method, and especially relates to a method for coal blending coking through utilizing a Gieseler fluidity index to mainly solve technical problems of heavy workload, long test period and the like existing in the application of multiple index coal blending which simultaneously relates to many independent variables. The method comprises the following steps: 1, carrying out coal blending according to the following mass percentages: 10-15% of 1 / 3 coking coal, 22-30% of gas coal, 20-25% of rich coal, 30-38% of coking coal and 0-5% of lean coal; 2, combining with coal quality control to make the combined coal ash percentage be 9-10%, the sulfur percentage be 0.8-0.9%, the logarithm value of the largest fluidity be 2.2-3.0 and the largest fluidity temperature of the Gieseler fluidity be 437-442DEG C; 3, fragmenting the obtained mixed coal: fragmenting the mixed coal obtained after the coal combination in step 2; 4, coking: sending the fragmented mixed coal to a coal coking furnace, and coking for 17-21h according to a coke cake center temperature of 950-1050DEG C; and 5, cooling after coke discharging, and carrying out coke quality detection.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

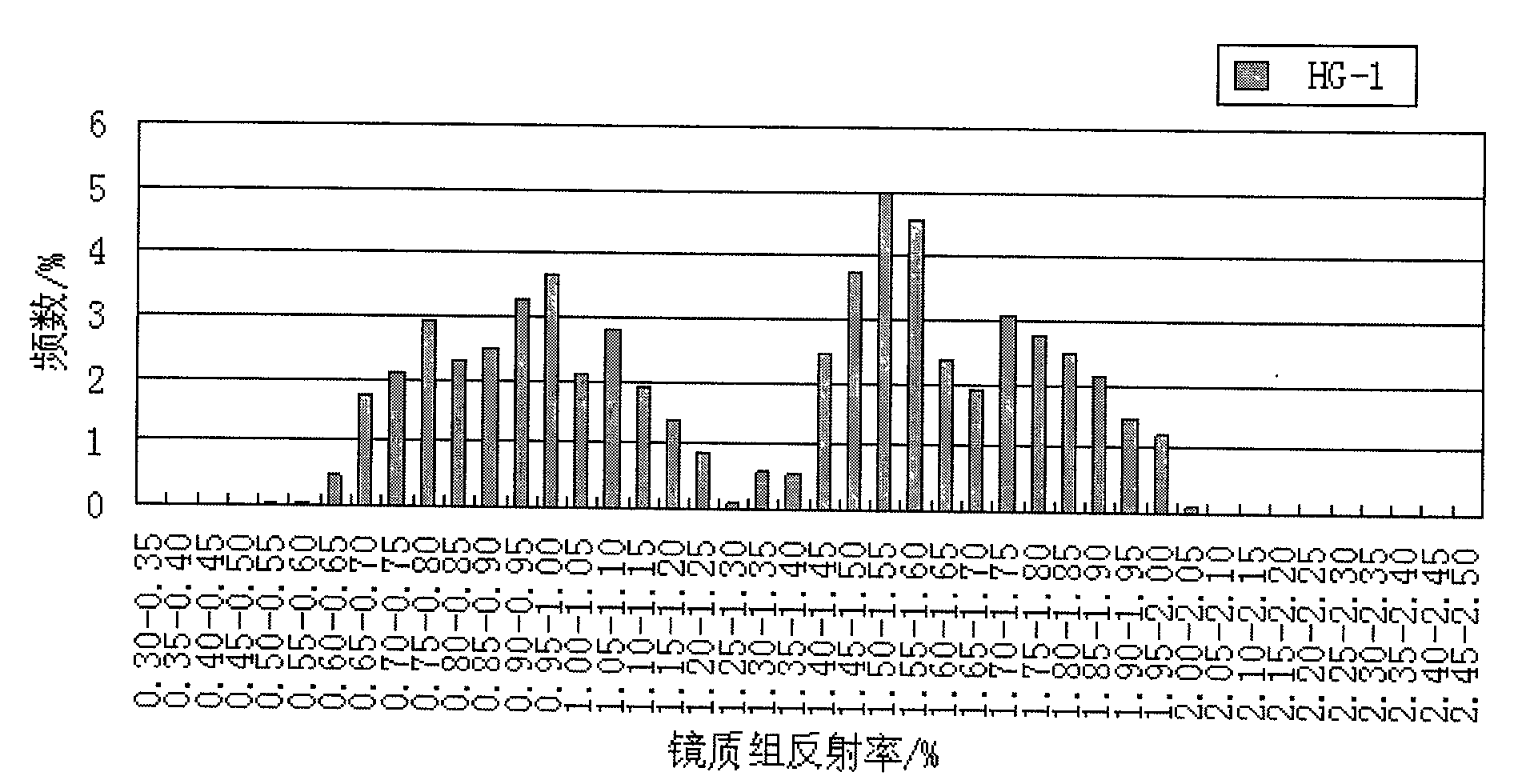

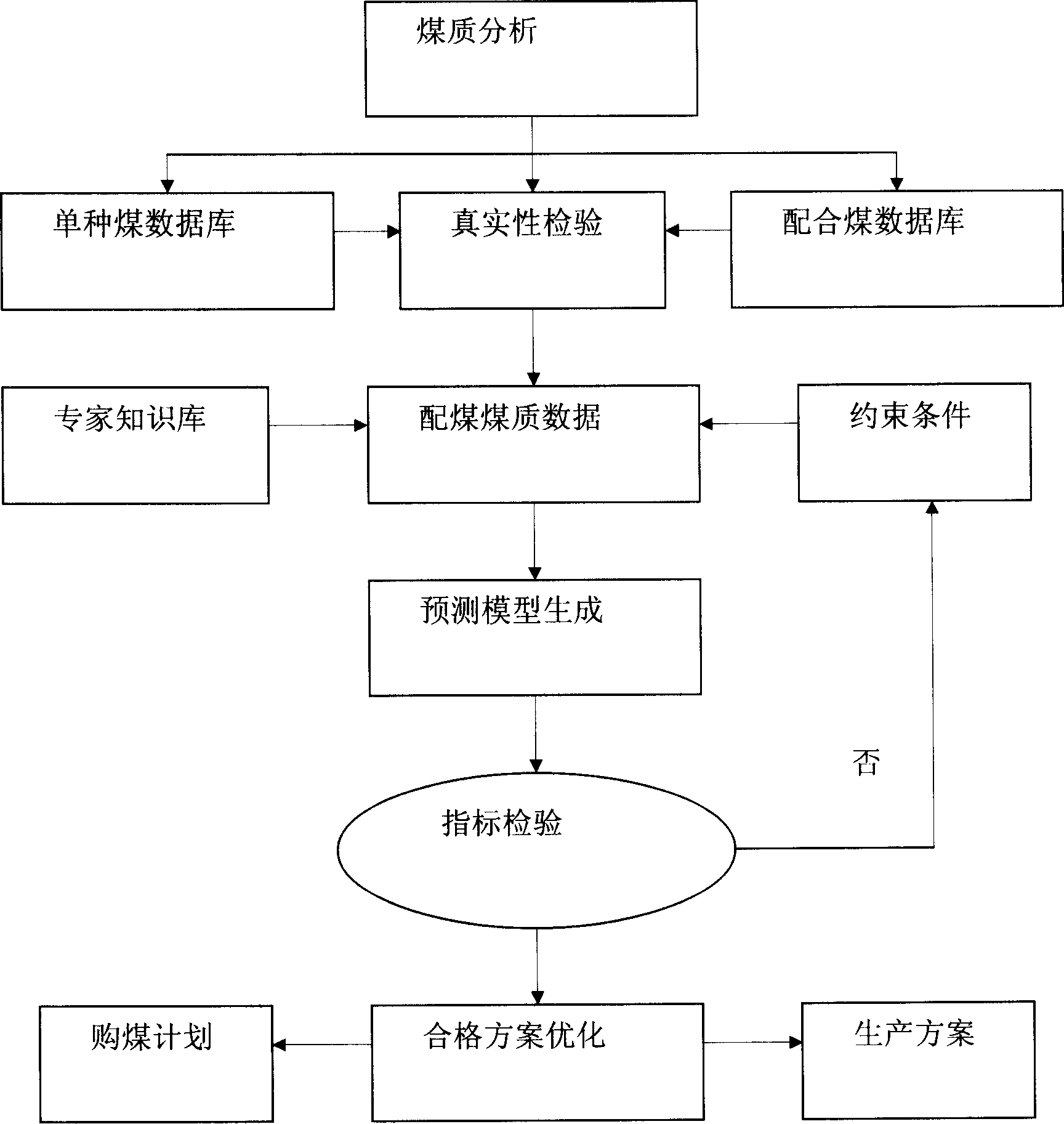

Method for predicting mechanical strength and thermal properties of coke

ActiveCN101661026AAccurate predictionControl coke qualityMaterial analysisUltimate tensile strengthCalculation methods

The invention relates to a method for predicting the mechanical strength and thermal properties of coke. In the method, vitrinite reflectance distribution of coal is used as a main input parameter to predict the mechanical strength and thermal property indexes of the coke. The prediction of the mechanism strength index of the coke is realized by a BP neural network, and the prediction of the thermal property index is realized by the BP neural network or a calculation method. The method can ensure the effective use of coke coal resources, scientifically and accurately predict the cold strengthand thermal property of the coke, guarantee the quality of the coke, reduce coal blending cost, realize scientific coal blending and implement a coal blending expert system.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Process for preparing coal-based agglomerated activated carbon

The invention discloses a process for preparing coal-based agglomerated activated carbon. The process has the following beneficial effects: the non-caking coal produced in the wide ditches is taken as a main raw material; the special caking coal type, namely gas-fat coal, is blended in the coal blending procedure; furthermore, the oxidation procedure is added in the process; the process parameters such as pulverized coal particle distribution, forming pressure, coal activation temperature and time and the like in the general production process are adjusted; at the same time, the slow carbonization technology is used instead of the traditional rapid carbonization procedure; and oxygen-enriched air is fed into activation equipment. The coal-based activated carbon prepared by the process can ensure the product strength and bulk density on the basis of satisfying the iodine adsorption of the activated carbon and is better in industrial application value.

Owner:SHENHUA XINJIANG ENERGY

Device and method for top gas enrichment utilization of blast furnace

InactiveCN102220443AReduce cloggingAvoid damageBlast furnace detailsIncreasing energy efficiencyReduction rateEngineering

The invention relates to a device and method for top gas enrichment utilization of a blast furnace, in particular to a device and method for using top gas in a blast furnace production process, belonging to the field of smelting pig iron with the blast furnace. The device is characterized in that: a tee joint is arranged on a pipeline between a gas purifying and de-dusting system and an excess pressure power generation device; a gas pressurization device, a gasification furnace and a gas back-eject hole which is formed on the blast furnace are connected through the pipeline and a valve to form one way of the tee joint; the gasification furnace is provided with an oxygen supply pipeline and a coal blending device; the enriched gas, after being pressurized, enters the gasification furnace and is subjected to gasification reaction with oxygen and powder coal in the pressurized gasification furnace; a reaction product is ejected into the blast furnace for smelting iron through the back-eject hole which is formed on the blast furnace; the excess pressure power generation device is respectively connected with a hot blast heater, a power plant boiler pipeline and a valve through a gas distributor to form another way of the tee joint; and the generated hot air is fed into the blast furnace through a nozzle. The device has the advantages of novel conception, simple process flow, easiness in implementation, safety and reliability in operation and capabilities of increasing the calorific value of gas, ejecting back to smelt iron, increasing the indirect reduction rate, reducing the coal ratio, reducing blast furnace slag and CO2 emission, regulating and controlling the width of a cohesive zone of the blast furnace, ensuring long-term smooth running of the blast furnace, avoiding diffusion of the top gas, saving energy and contributing to environment friendliness.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for adjusting and controlling melting temperature of coal ash by combining coal blending with auxiliary agent

ActiveCN103060054AGuaranteed sulfur contentLow calorific valueFuel additivesMass ratioPulverized fuel ash

The invention discloses a method for adjusting and controlling the melting temperature of coal ash by combining coal blending with an auxiliary agent, belonging to methods for adjusting the melting temperature of the coal ash. The method comprises the following steps of: uniformly mixing two or more types of coals with different ash melting temperatures according to different mass ratios, and preliminarily adjusting the melting temperature of the coal ash; and selecting an appropriate auxiliary agent, putting the auxiliary agent into the mixed coal, and adjusting the flowing temperature of the coal ash by changing the mass ratio of (Al2O3+SiO2) / (CaO+MgO+Fe2O3). The flowing temperature of the coal ash is raised or lowered by using a combined adjusting and control technology of blending of coals with different ash melting points and adding of auxiliary agents. Firstly, the sulfur content is adjusted by mixing different coals and the flowing temperature of the coal ash is preliminarily adjusted, and then a small quantity of auxiliary agent is used for adjusting the flowing temperature (FT) of the coal ash to reach a designed temperature. The auxiliary agent is added according to the following standards: (1) when (Al2O3+SiO2) / (CaO+MgO+Fe2O3) is more than 0.5 and less than or equal to 3.5, the FT is less than 1,300 DEG C; (2) when (Al2O3+SiO2) / (CaO+MgO+Fe2O3) is more than 3.5 and less than or equal to 5.5, FT is more than 1,300 DEG C and less than 1,400 DEG C; (3) when (Al2O3+SiO2) / (CaO+MgO+Fe2O3) is more than 5.5 and less than or equal to 10, FT is more than 1,400 DEG C and less than 1,500 DEG C; and (4) when (Al2O3+SiO2) / (CaO+MgO+Fe2O3) is more than 10, FT is more than 1,500 DEG C. By adopting the method, the sulfur content of the mixed coal can be adjusted while the melting temperature of the coal ash is adjusted and controlled, so that the utilization market of coals is well optimized and expanded.

Owner:CHINA UNIV OF MINING & TECH

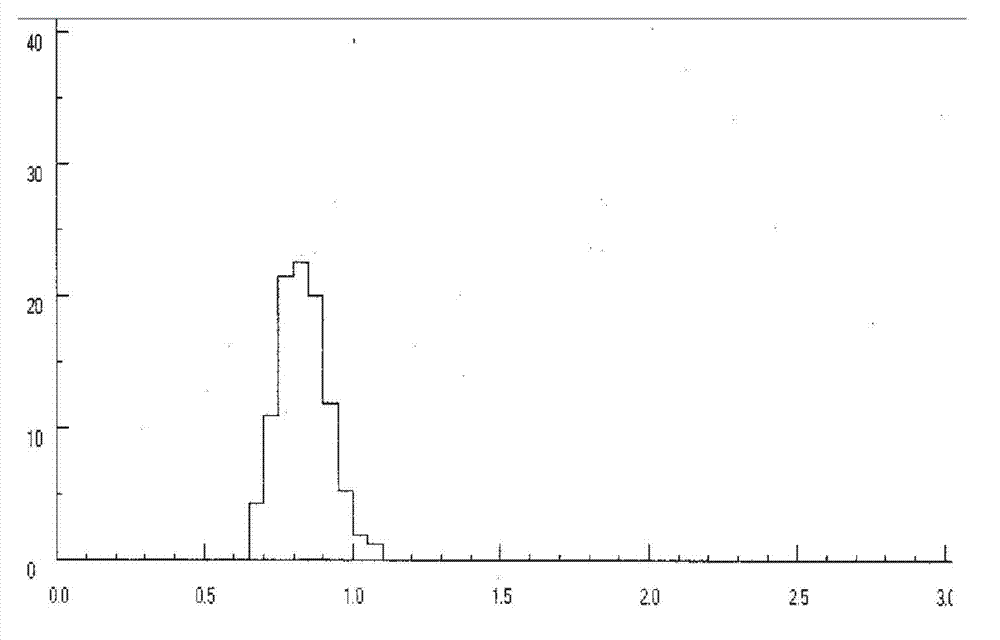

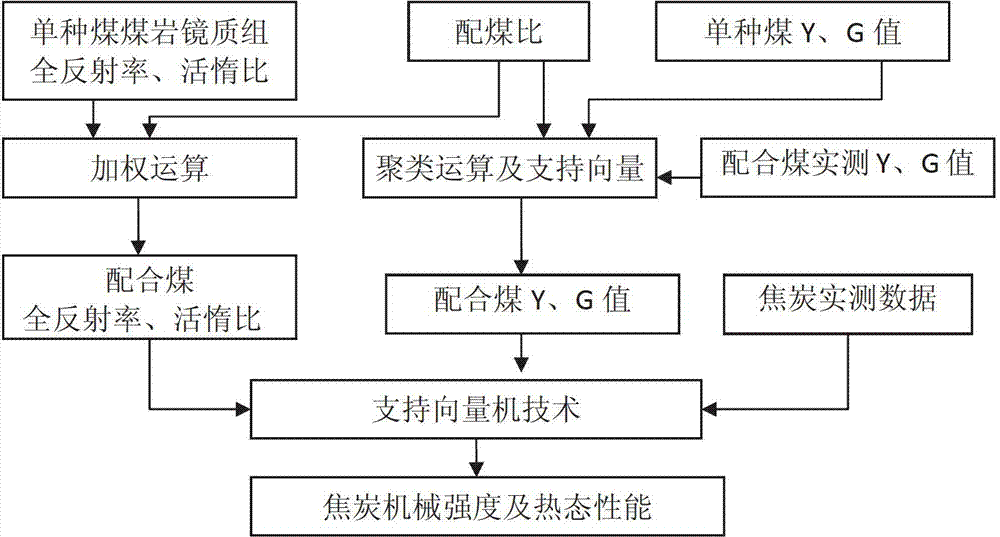

Method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance

ActiveCN102890144AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineThermal state

The invention discloses a method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance, thereby providing important technical assurance for the improvement of the stability and quality of coke produced by a coke making enterprise. The method provided by the invention comprises the following steps of: establishing a coking coal resource information database, and inputting the caking property index of coking blended coal and the coal rock index of single coking coal into the coking coal resource information database; and establishing a coke quality prediction model through a support vector machine, and then predicting the quality index of the coke according to the coal-quality caking property index level of the coking blended coal, wherein the coal-quality caking property index level comprises two factors, namely the maximum thickness value Y of a gelatinous layer and a caking index value G, and comprises coal rock vitrinite total-component reflectance and the liver-inert ratio of macerals. The method provided by the invention is capable of characterizing the maximum thickness value Y of the gelatinous layer indicating the quantity of metaplast in the softening process of the coking coal and indicating the caking property quality of the metaplast, thereby realizing the prediction process with the goal of predicting the mechanical strength and thermal state performance of the coke.

Owner:UNIV OF SCI & TECH LIAONING

Physical method energy-saving cleaning technique for manufacturing active carbon

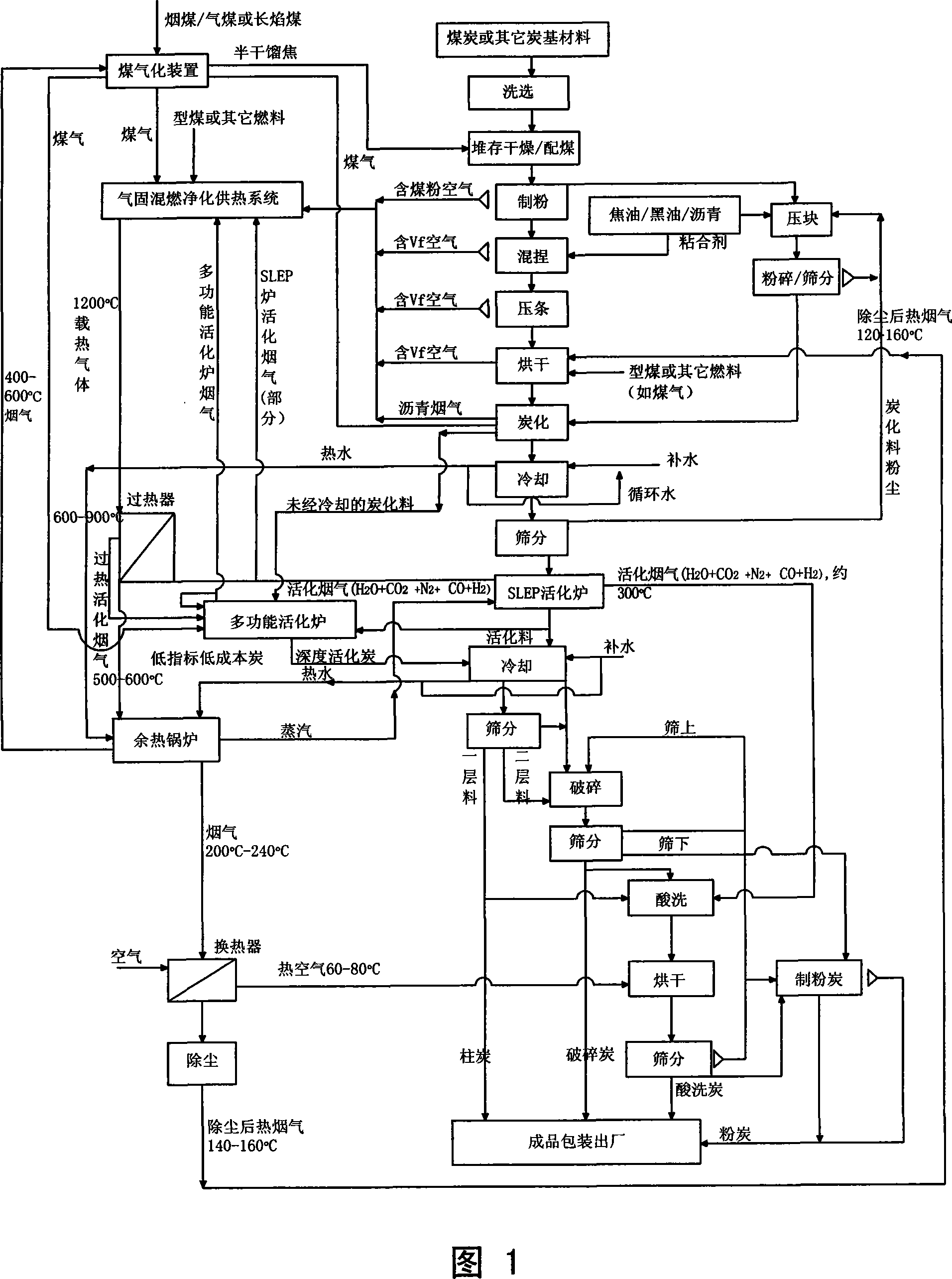

The invention relates to a technology for manufacturing activated carbon by a physical method of energy saving and cleaning, which includes the processes of mixing kneading and plating or coal blending and briquetting, airing strip, carbonization, screening, activating, screening and packaging as well as packaging after screening material and making into powder activated carbon to traditional milling, coal powder and tar. The technology adjusts and adds the processes: air with coal powder in the milling workshop, air with Vf (organic volatile) generated in the process of mixing kneading, plating and drying, pitch smoke generated in the process of charring, parts of smoke in a SLEP activated-stove, smoke in a multifunction activated-stove, coal gas out of a coal gasification device or other fuel are sent into a heating system of gas fixing, mixed burning and purifying for burning; through a waste heat boiler, generated heat loading gas generates steam for activating technology to use; tail gas is used for generating coal gas and drying material; after been heated, parts of smoke of the SLEP activated-stove is supplied for the multifunction activated-stove. The technology of the invention increases material yield, power source application which does not pollute the environment.

Owner:山西佳净环保工程有限公司

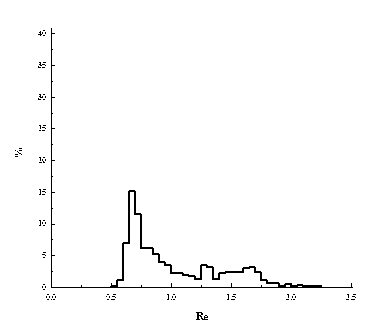

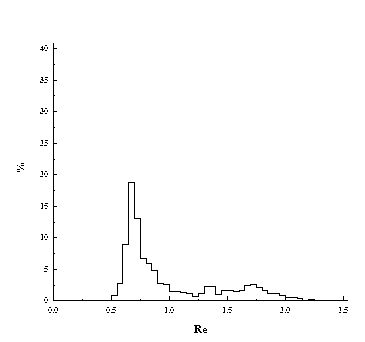

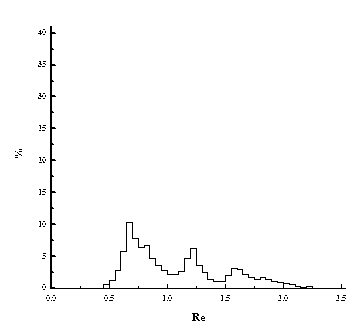

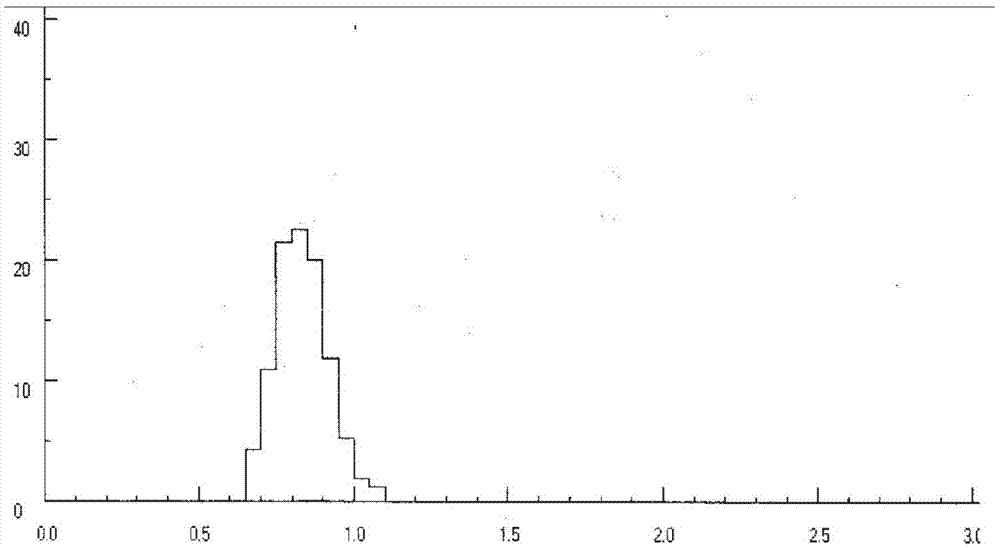

Coal-rock blending method suitable for tamping coking

InactiveCN102816577AGuaranteed cold performance of tamped cokeGuaranteed Cold PerformanceCoke ovensVolumetric Mass DensityComputer science

The invention relates to a coal-rock blending method suitable for tamping coking. The technical scheme includes: step one, subjecting single coal for coking to detection of processes and coal-rock properties and calculating an active-idle ratio A / I; step two, matching according to the active-idle ratio A / I, the maximum mean reflectivity of vitrinite and distribution proportion of random reflectivity Re of the vitrinite, and if the A / I of blended coal after blending is 2.0-2.5, 1.00-1.40%, and distribution histogram of the random reflectivity Re of the vitrinite of the blended coal is continuous, then starting step four; step three, repeating the step two if the conditions are not met; step four, taking blended coal samples for detection of the maximum thickness of gelatinous layer Y value, if the Y value ranges from 10mm to 15mm, then completing the coal blending; step five, if the Y value is not between 10mm to 15mm, circulating the step two; and step six, furnacing for coking after tamping, wherein the tamping density is 1.10-1.15g / cm3. The coal-rock blending method suitable for the tamping coking can refine the blended coal after the tamping coking, expand utilization range of coking coal resources and improve coke quality.

Owner:WUHAN UNIV OF SCI & TECH +1

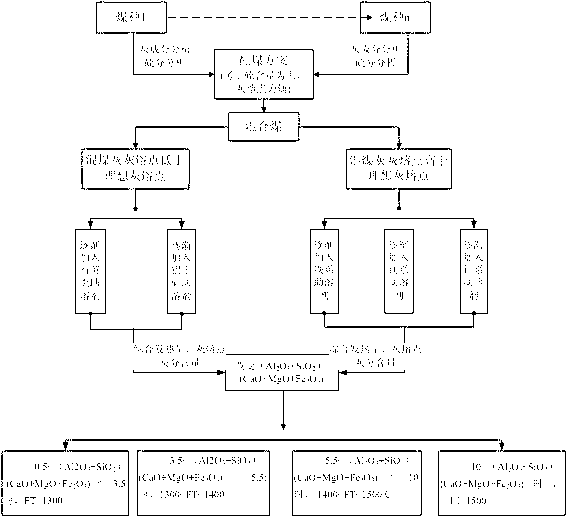

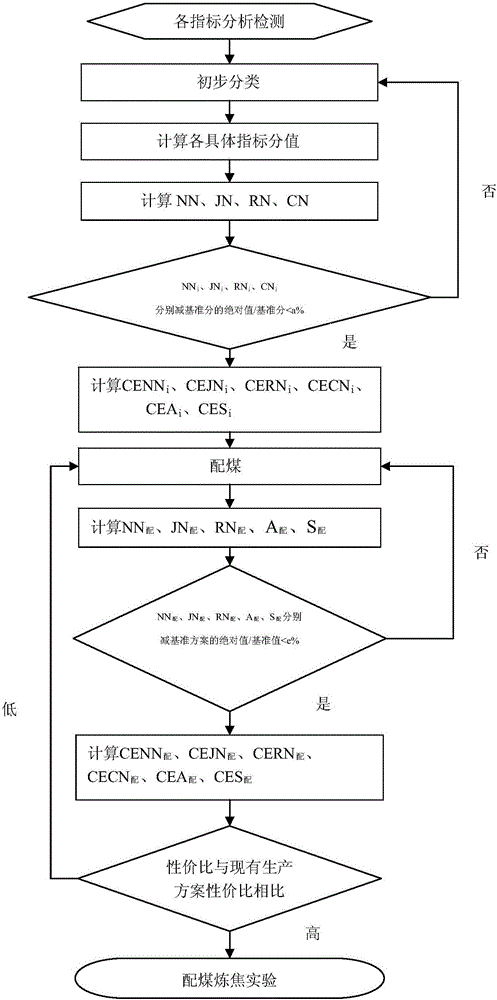

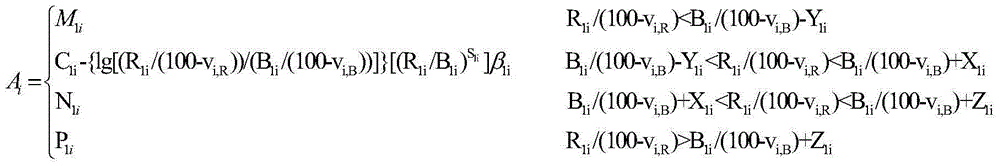

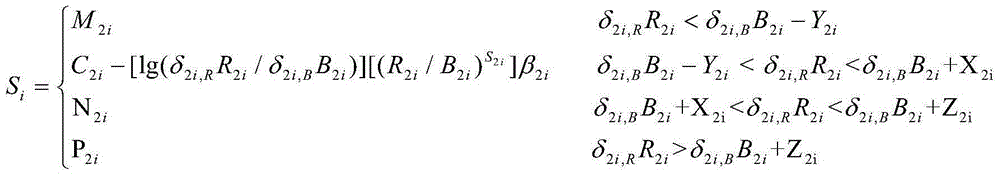

Coking raw material applicability classification, comprehensive quality evaluation and coal blending guiding method

ActiveCN105062531ASolve the problem of huge quality gapMeet the need to control the thermal properties of cokeCoke ovensProcess engineeringCaking

The invention provides a coking raw material applicability classification, comprehensive quality evaluation and coal blending guiding method. According to the method, specific indexes of coking raw materials and the mass index of solid products obtained from coking of the coking raw materials are integrated into three single indexes including caking capacity, coking capacity and a thermal property index according to the corresponding relations with coke quality indexes, and applicability classification is performed on the coking raw materials; the three single indexes are then integrated with ash content and sulfur content value indexes into an comprehensive capacity index, and six price-performance ratio indexes are formed through correlation between the three single indexes, the one comprehensive capacity index, the ash content and sulfur content value indexes and the price; after the applicability classification, coking coal blending is performed according to the three single indexes of the coking raw materials, the one comprehensive capacity index and the ash content and sulfur content value indexes, the six indexes for coal blending are controlled to be within plus / minus e%*a reference scheme score (e ranges from 5 to 10), the price-performance ratio of the six indexes for coal blending is calculated, an optimal coal blending scheme is determined, and refined and optimized coal blending is realized.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Method for performing nonlinear prediction on coke quality on basis of cohesiveness and coal-rock indexes of single coal

ActiveCN102890145AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineAir quality index

The invention discloses a method for performing nonlinear prediction on coke quality on the basis of cohesiveness and coal-rock indexes of single coal, which provides important technical guarantee for improving the stability and quality of coke produced by coke making enterprises. The method comprises the following steps of: establishing an information database storing qualities and coke quality indexes of the single coal for coking, and inputting the cohesiveness indexes and the coal-rock indexes of the single coal for coking into the coal information database; establishing a coal quality prediction model, and predicting quality indexes of matched coal by virtue of a clustering and support vector machine; defining the quality indexes of the matched coal, and predicting quality indexes of the coke according to the quality indexes of the single coal; and establishing a model for predicting the crushing strength and abrasive resistance of the coke. The invention further provides a coke quality prediction system with optimized coal blending of coal-rock, which aims to stabilize and improve the coke quality and reduce the coal blending cost, can form a prediction model with multiple parameters and high accuracy for the coal quality indexes and the coke quality indexes, and simultaneously, has a real-time updating function or a manual intervention function.

Owner:UNIV OF SCI & TECH LIAONING

Method for calculating thermal property of coke and control method therefor

This invention relates ti coke heat quality preprocess and control method. First enterprise coal using history is analyzed to get coal resource database information and certain coal caking capacity and evaluation information to coke quality contribution. Expert system knowledge base is built, it relates to coal resource situation, coal blending and coking technique, transportation, coke quality goal, coal blending cost etc. each single coal using constraint condition is ensured according to the knowledge base, optimization coal blending ratio is ensured by using nonlinear planning and simulation evolution algorithm. Coke quality predicted value under optimization match is predicted by coke quality prediction model to produce optimization coal ratio, coal blending slot operation is auto controlled by computer to correct control model according to practical production. This method can solve the problems in coking coal resource effective using, coke heat control and low cost coal blending.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

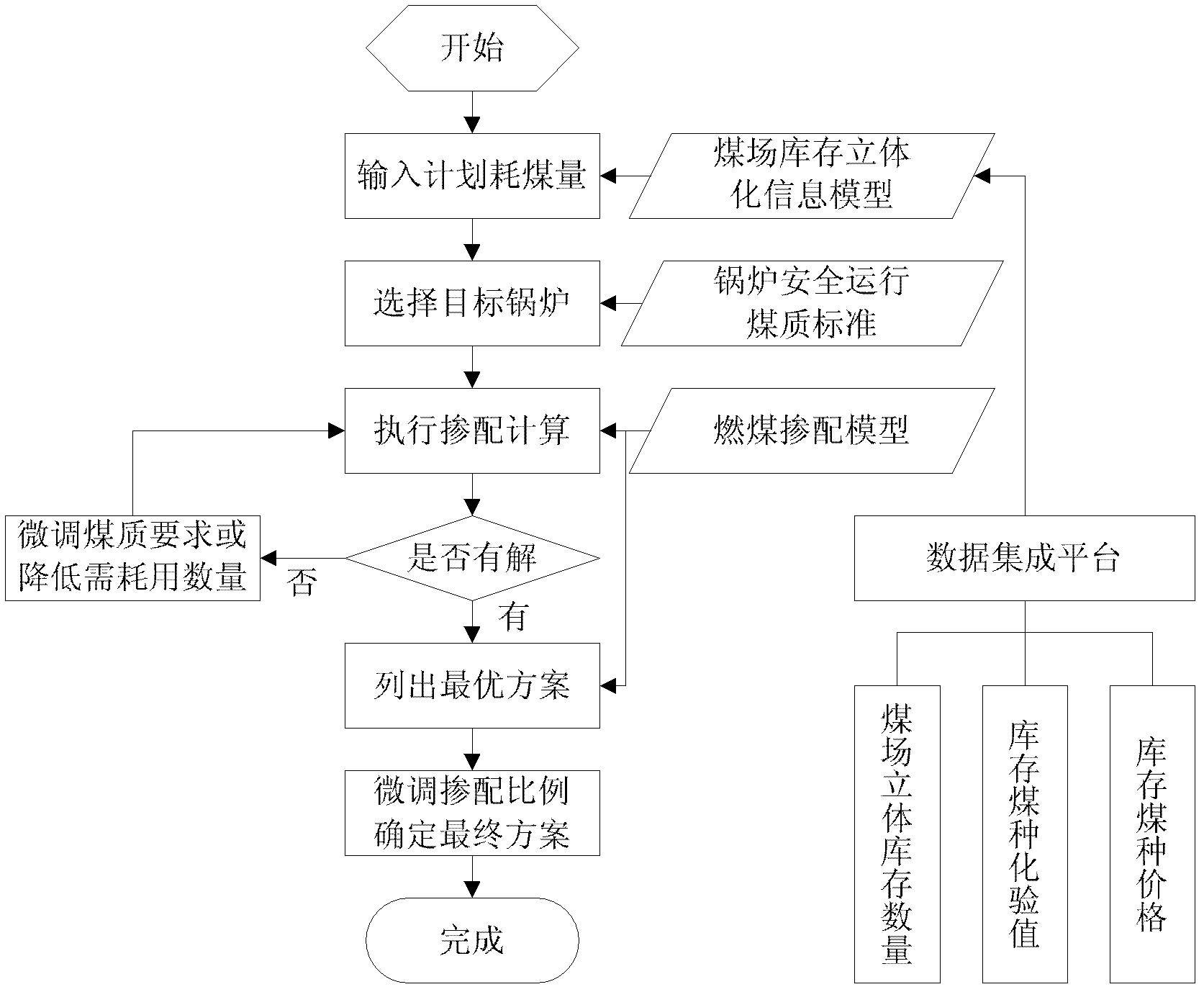

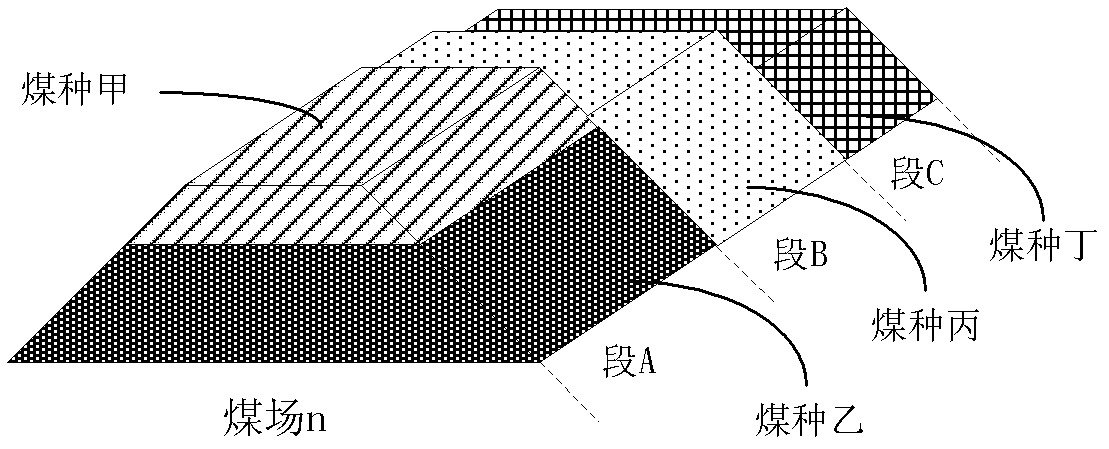

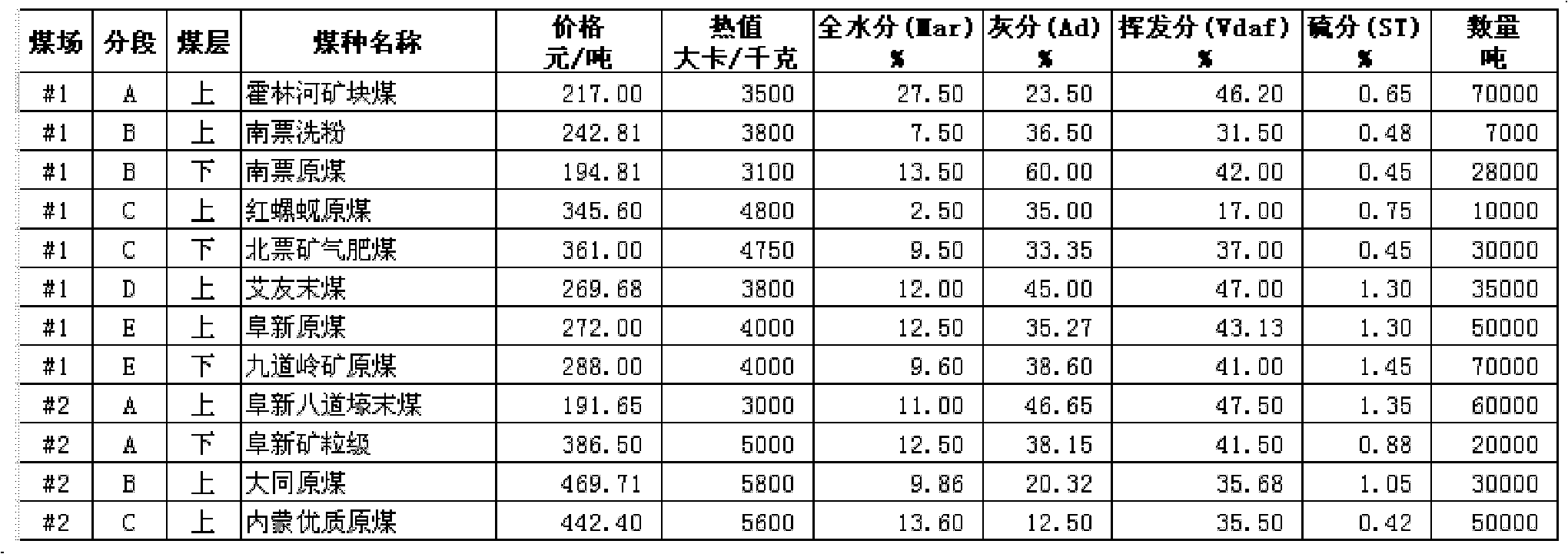

Fire coal blending method of thermal power plants

InactiveCN102592249AGuaranteed safe burningReduce the price per unit of energy consumptionData processing applicationsInformation repositoryCombustion

The invention discloses a fire coal blending method of thermal power plants, which belongs to the technical field of thermal power generation and automation and includes: building a coal yard inventory three-dimensional information model database according to coal yard inventory information; building a boiler combustion standard information base according to requirements of each boiler on coal quality and boiler self influence factors; generating a constraint condition according to the boiler combustion standard information base and the coal yard inventory three-dimensional information model database, and building a fire coal economical objective function to obtain a fire coal blending model; and calculating all fire coal blending proportion schemes when the boilers consume standard coal with a set quantity according to the fire coal blending model, and selecting a scheme with topmost layer coal as the optimum scheme. The fire coal blending method is most economical, reduces unit energy consumption price and improves economic benefit of power generation enterprises under the premise of ensuring boiler safe combustion.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

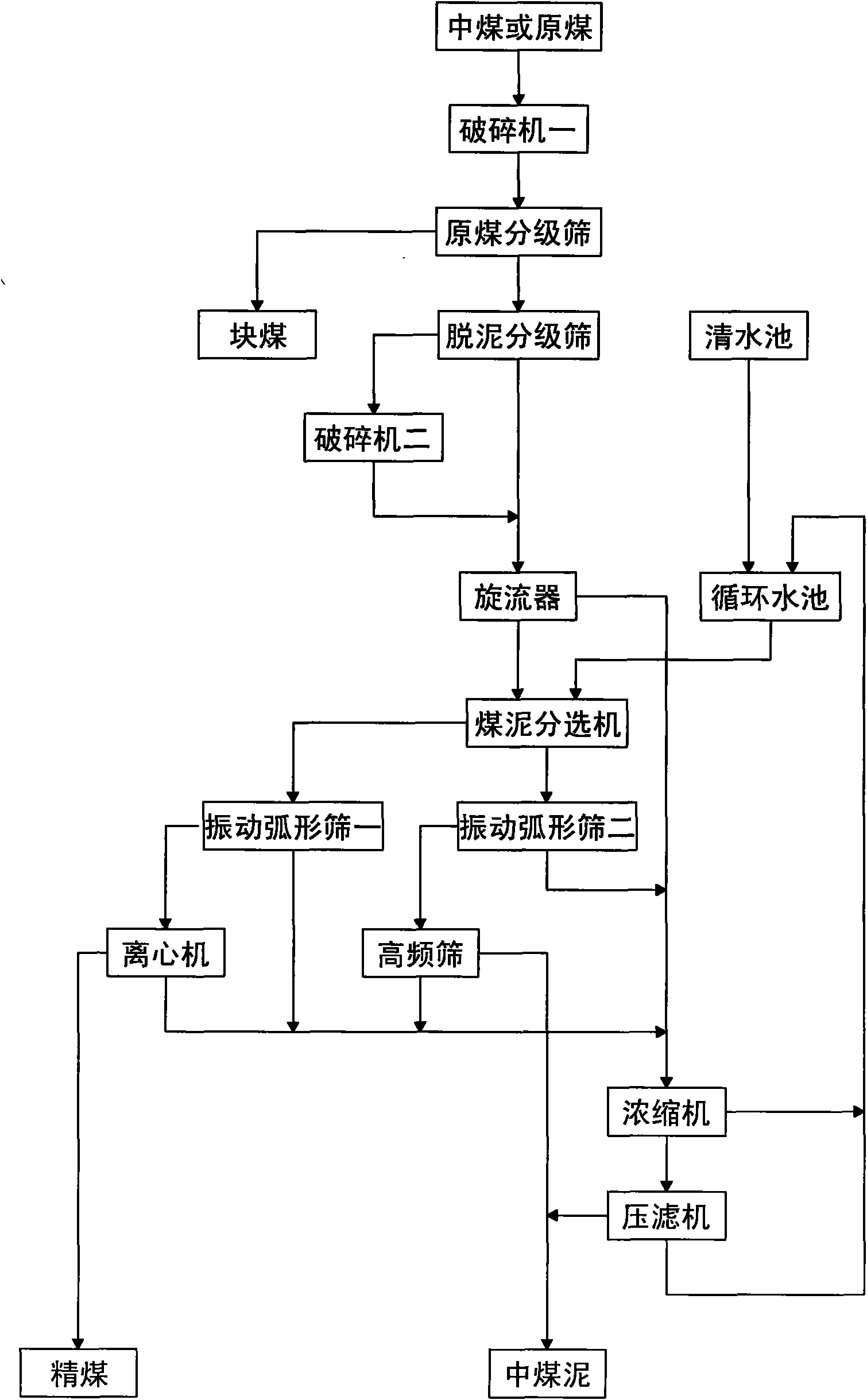

Process for selecting cleaned coals from gangue coals of raw coals and middling coals

The invention relates to a process for selecting cleaned coals from gangue coals of raw coals and middling coals, which adopts a method of desliming before selection and performing separation in a coal-slime separator after crushing. The process can select the cleaned coals from the gangue coals in the raw coals and the middling coals generated from coking coals after being cleaned, has the advantages of simple process, low coal dressing cost and high efficiency, is free from using flotation reagents, recycles water resources and is free from causing pollution to the environment, and the produced cleaned coals are applied to formcoke coal blending or export sales, and the middling coals and coal slimes are used as raw materials for producing moulded coals and biomass moulded coals.

Owner:勃利县森清能源开发有限公司

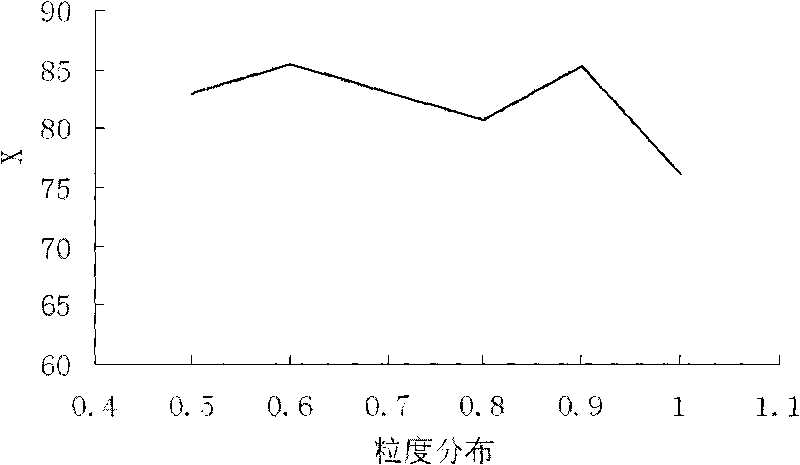

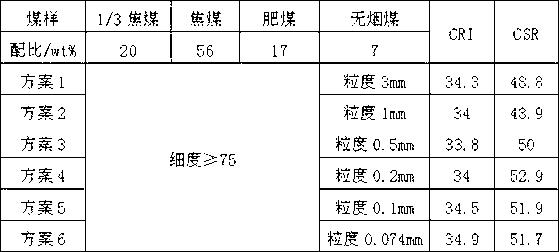

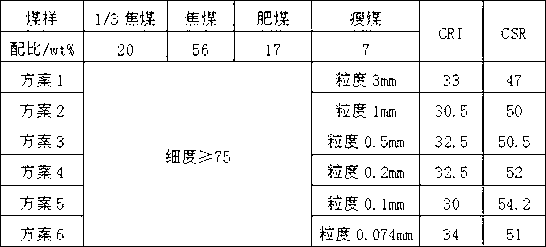

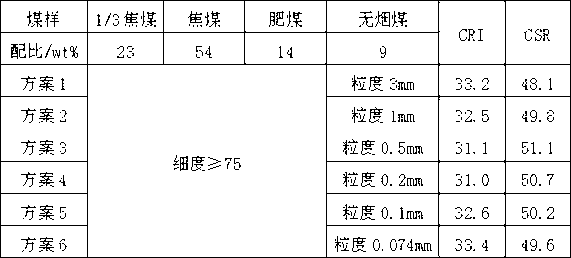

Method for determining optimal particle size of finely ground gas coal participating in coking and coal blending

ActiveCN101706406AReasonable granularityQuality improvementCoke ovensParticle size analysisCrucibleCoal blending

Owner:武汉钢铁有限公司

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

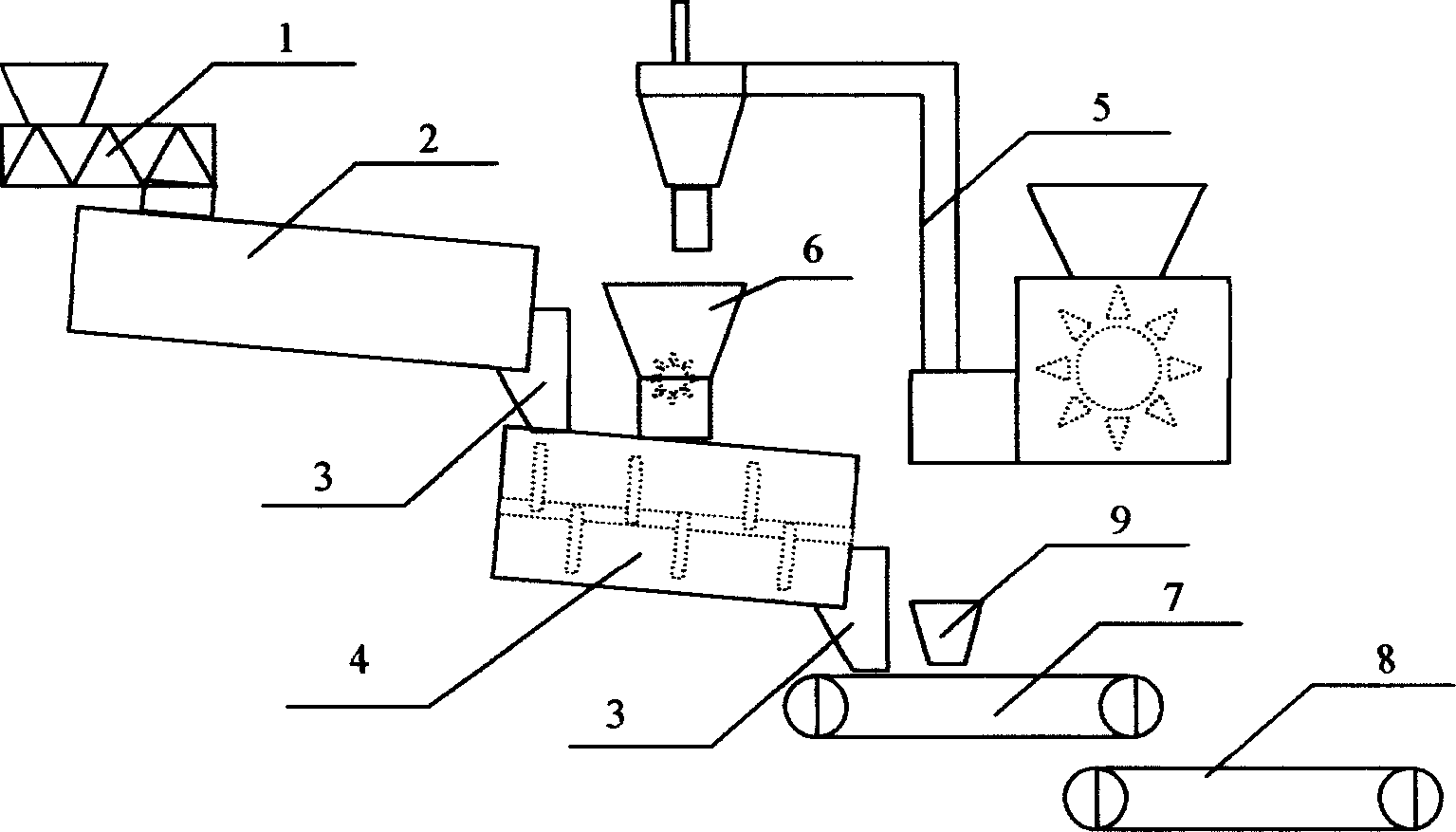

Waste plastic processing method for increasing coke strength and its apparatus system

The invention publishes a kind of process method of plastic waste to improve coke's intensity and the setting system. It relates to technique and setting of plastic waste. The characteristic of process method of the plastic waste follows this. teat the plastic waste by hot-melt method and then carbonize it with coal blending by special ratio to improve the quality of coke. The setting system is composed by feedway, breaking plant, heat flux plant, hot-melt plant, carrying vehicle and coking and coal blending mixing device. The invention's advantage rest with that many complicated working processes are not needed such as air sizing and graining because of hot-melt process. It can solve the problem that mixture of plastic and coal liquating is not odds and can reduce or eliminate the use of additives. So the quality of coke can be improved by plastic waste or additives and the the working cost and operating cost can be reduced by far.

Owner:SHOUGANG CORPORATION

Mercury reduction system and method in combustion flue gas using coal blending

ActiveUS20050036926A1Reduce mercury in gas emissionReduce gas emissionsGas treatmentUsing liquid separation agentCombustion systemSorbent

A method to reduce mercury in gas emissions from the combustion of low rank coal in a combustion system, said method including: combusting coal having a low chlorine content in the combustion system, wherein elemental mercury (Hg0) is released in the flue gas produced by the combustion of the low rank coal; releasing chlorine into the flue gas by combusting a coal having a high chlorine in the combustion system; reacting the elemental mercury and released chlorine in the flue gas to oxidize the mercury; adsorbing at least a portion of the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

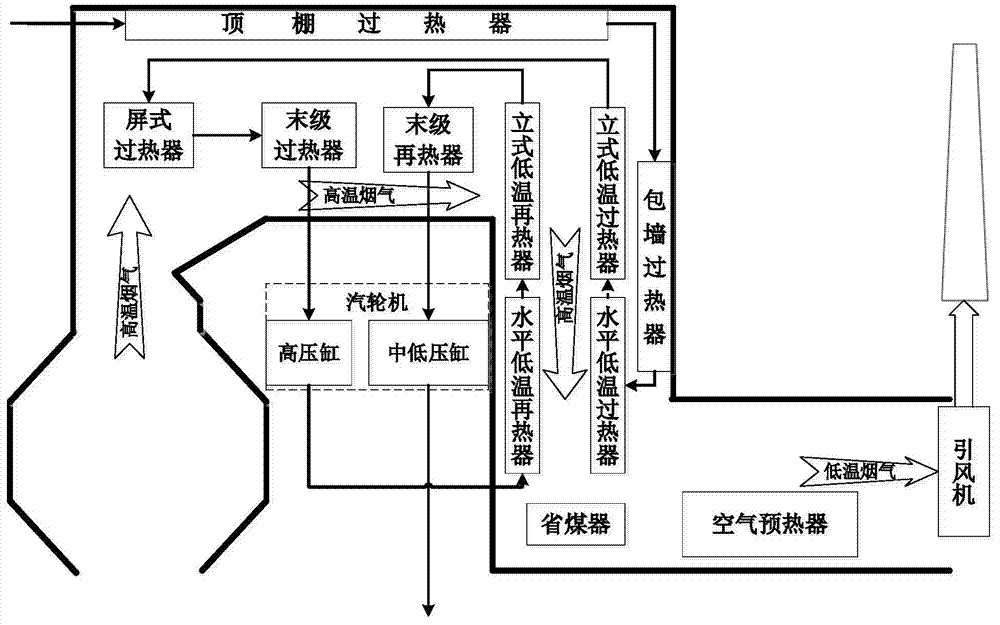

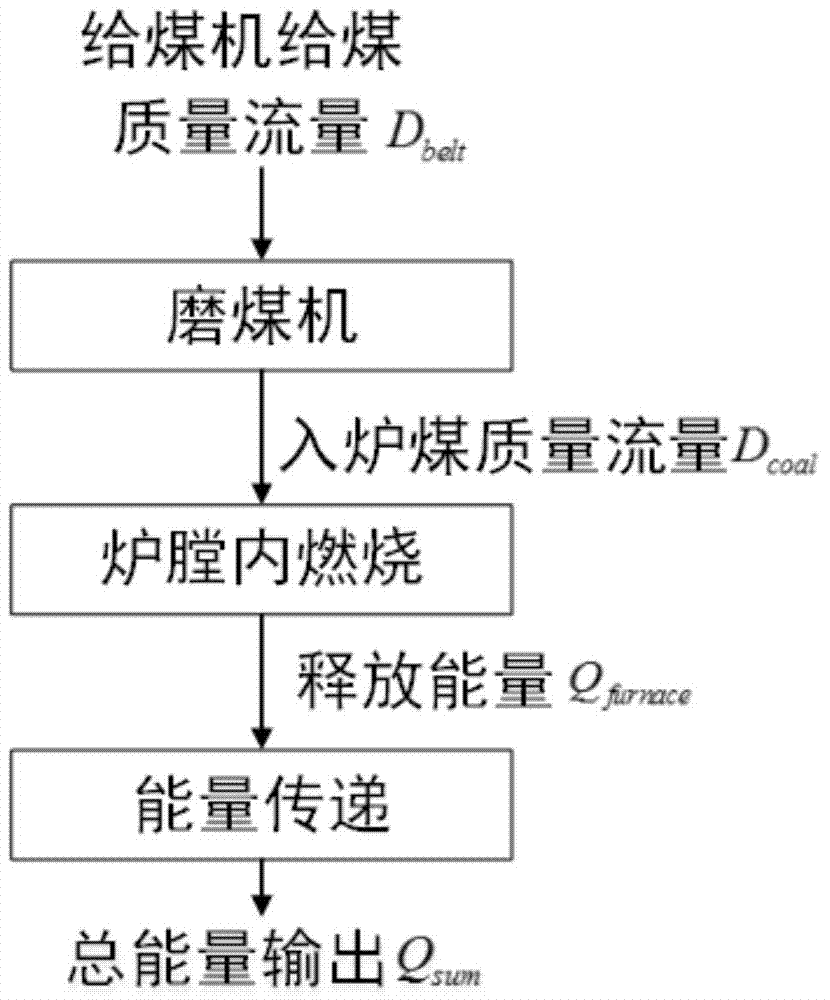

Real-time identification method for fired coal lower heating value of coal-fired power plant

ActiveCN103674333ARealize online identificationStable productionCalorimeterRelational modelMeasurement point

The invention provides a real-time identification method for a fired coal lower heating value of a coal-fired power plant. The real-time identification method includes the steps of (1) obtaining boiler structure parameters according to a boiler operation design discipline, and reading an operation condition measurement point real-time value at the given moment from a real-time database of a DSC, (2) calculating the specific enthalpy and the density of working media and the specific heat and the density of smoke based on a working medium physical property parameter base and a smoke physical property parameter base, (3) correcting main steam flow masses based on a relation model of main steam adjustment door opening degrees and the main steam flow masses, (4) respectively calculating corresponding energy output of various parts on the boiler side and total energy output at the given moment according to a boiler-side complete-flow-path mechanism model, (5) building a transfer function model between coal feeding flow masses of a coal feeder and the fired coal flow masses, and (6) building a transfer function model between the fired coal flow masses and the total energy output. The real-time identification method is used for on-line identification on the fired coal lower heating value, and has the application potential of combustion and coal blending optimization.

Owner:SHANGHAI JIAO TONG UNIV

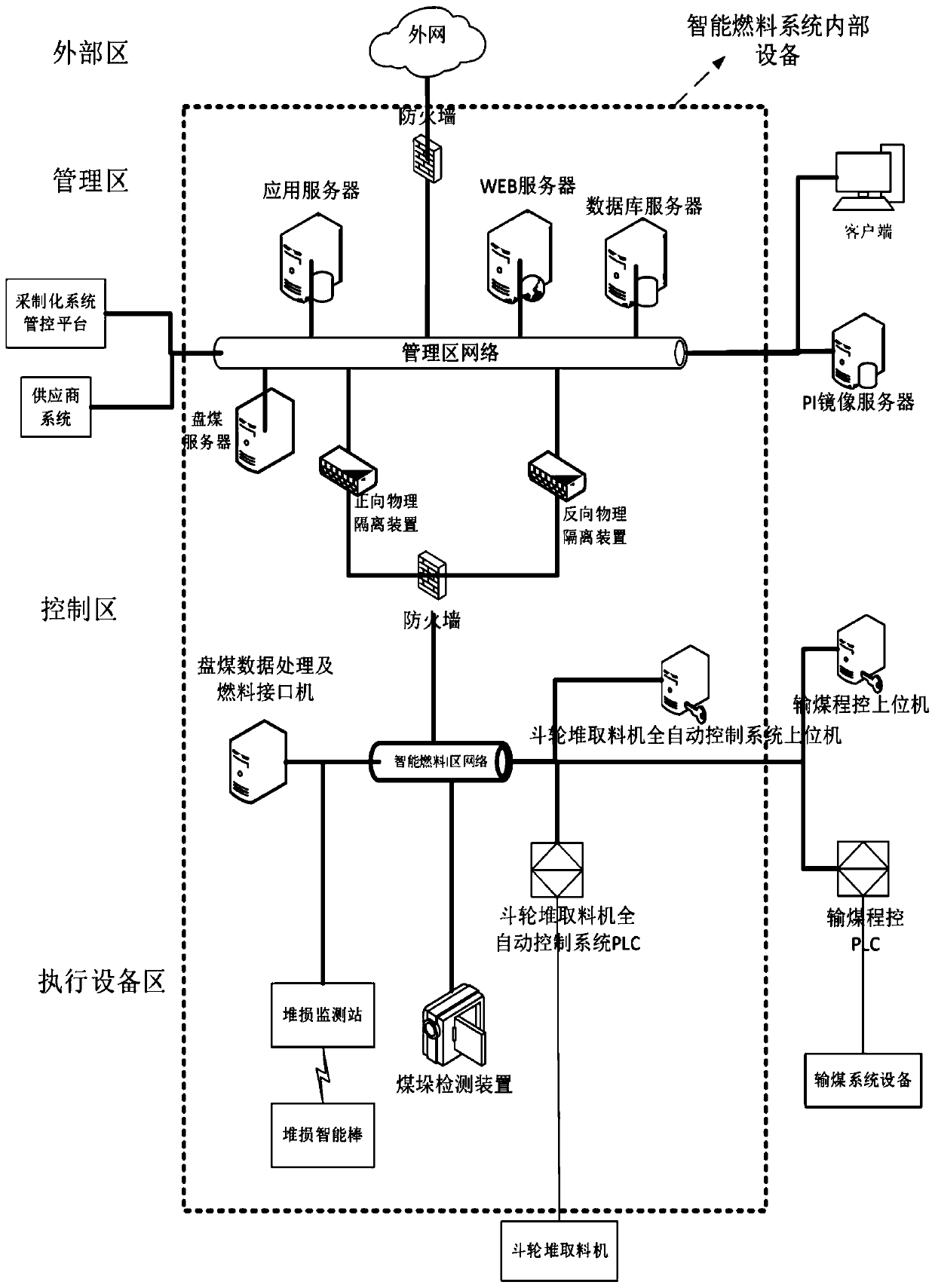

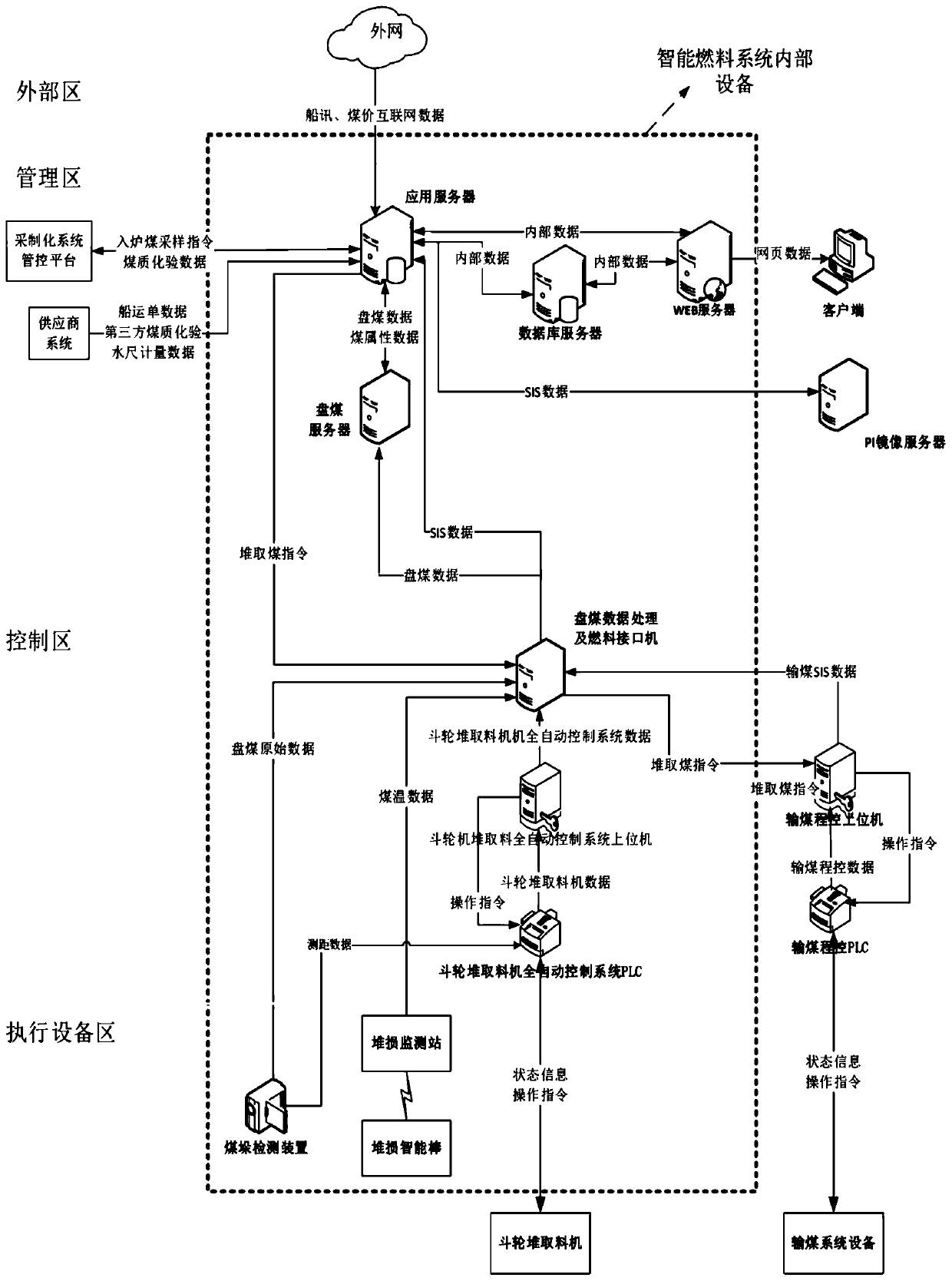

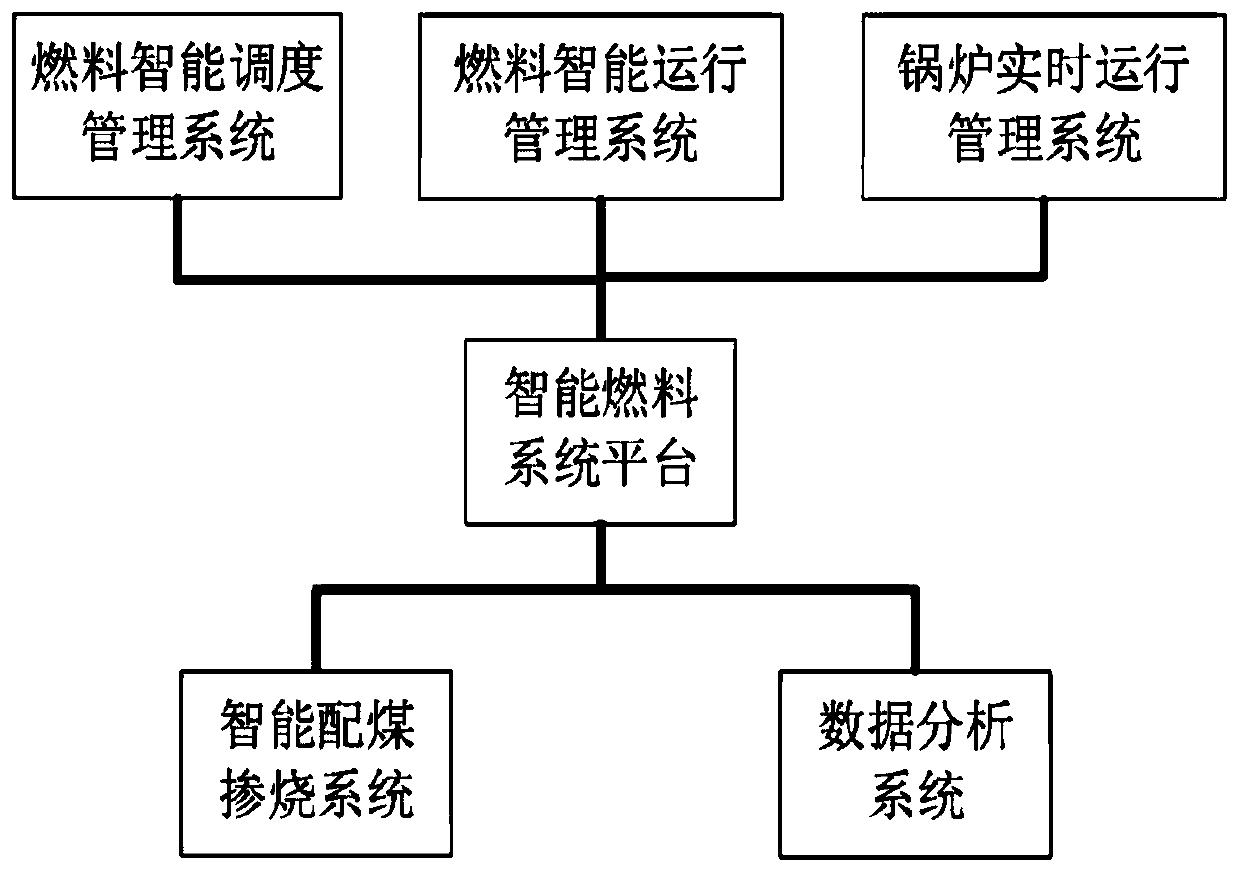

Real-time intelligent fuel system for water transport coal-fired power plant

InactiveCN109782726AAchieve integrationReal-time graspResourcesProgramme total factory controlAutomatic controlWater transport

The invention discloses a real-time intelligent fuel system for a water transport coal-fired power plant. The hardware equipment of the system includes a bucket wheel stacker-reclaimer automatic control system, a real-time coal check system, a coal temperature detecting device, a server, and the like; the hardware equipment of the system includes a system platform, an intelligent coal blending combustion system, a fuel intelligent dispatching management system, a fuel intelligent operation management system, a boiler real-time operation management system, a data analysis system and the like. Under the framework of an intelligent power plant, the data gaps of the whole process of fuel management are bridged through the fully automatic bucket wheel capable of accurate three-dimension positioning; intelligent coal stacking and in-boiler coal intelligent blending and combustion are realized through a combustion characteristic prediction-based intelligent coal blending technology; the automatic correlation of the types and quality of coal which is combusted real time in a boiler can be realized through a coal bunker intelligent layering technology; and an automatic coal blending technology, a plurality of metering devices used in a whole process, and an in-boiler coal type-based sampling technology are adopted to realize the intelligent balanced analysis of the coal quantity and coal quality in the whole process of fuel management.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

Russian fat coal participant coking and coal blending method

The invention discloses a Russian fat coal participant coking and coal blending method, which comprises a step of mixing and blending various single coking coals. The single coking coals in percentage by weight comprise 0-6 percent of gas coal, 8-12 percent of Russian fat coal, 15-18 percent of 1 / 3 coking coal of G being more than 85, 12-15 percent of 1 / 3 coking coal of G being less than 85, 15-20 percent of coal of G being more than 85, 20 percent of coal of G being less than 85 and 15-20 percent of lean coal. Under the process condition without stage crushing, coal briquette process or tamping coking, the method of the invention reasonably and efficiently utilizes the Russian fat coal, the coke quality is not deteriorated, and the coal blending cost can be reduced.

Owner:武汉钢铁有限公司

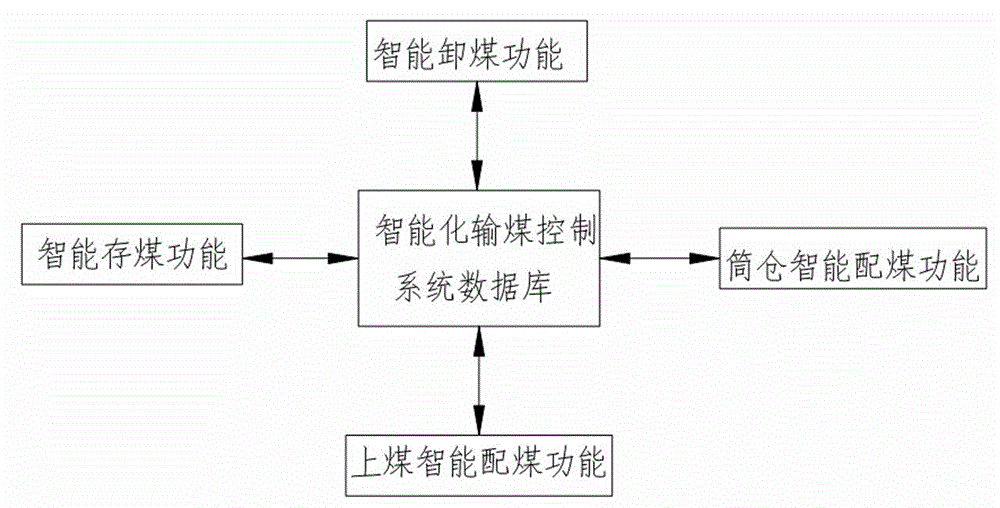

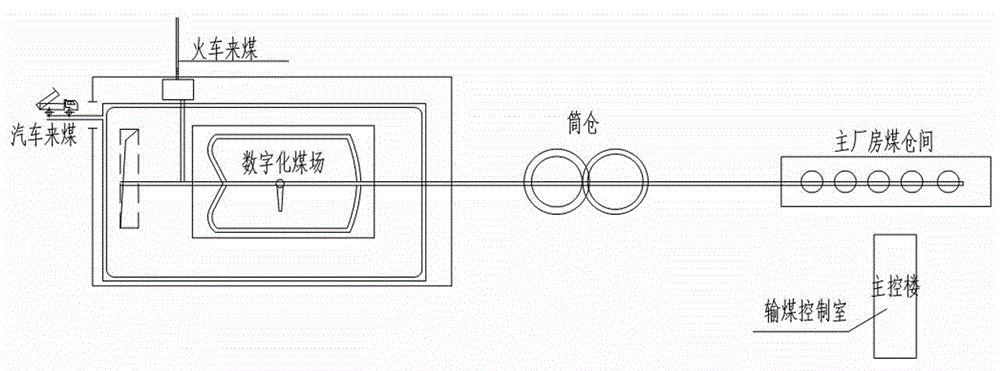

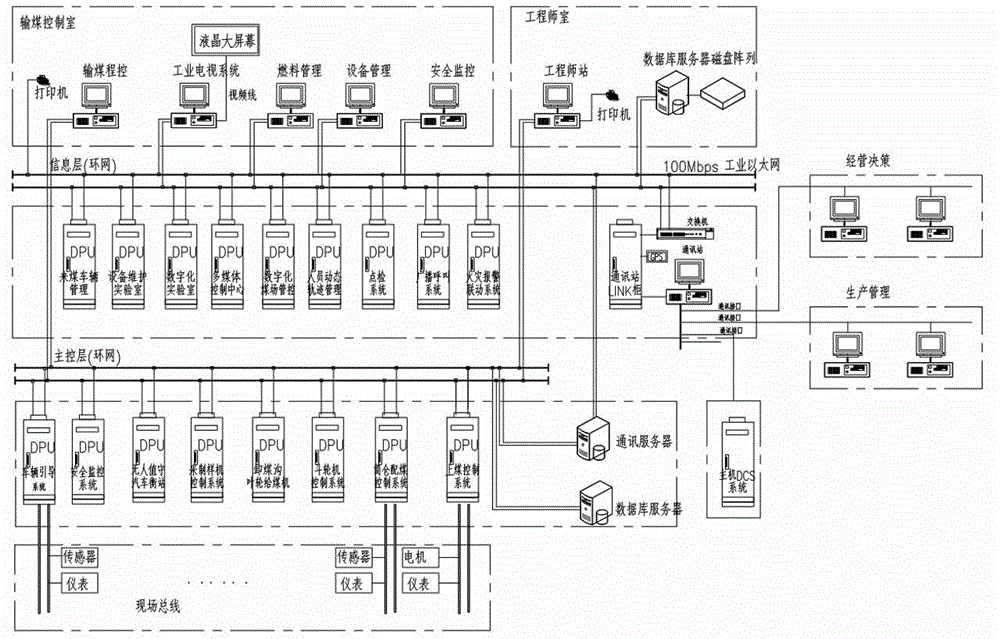

Novel intelligent coal conveying control system based on FCS on-site bus technology

InactiveCN104483952AReduce calorific value difference lossAchieving the goal of reducing staff and increasing efficiencyProgramme total factory controlSystem integrationCombustion

The invention provides a novel intelligent coal conveying control system based on the FCS on-site bus technology. The novel intelligent coal conveying control system based on the FCS on-site bus technology comprises a coal unloading system, a digital coal filed control system, a coal feeding system, a silo mixed coal blending combustion control system and a sub-system. The purposes of reducing labor and increasing efficiency are realized for a thermal power plant. Through intelligent coal combustion management, the heat value difference loss of as-fired coal caused by management loopholes is reduced. Through the automatic selection of system processes and routes, energy increase caused by operation habits of operators is reduced, and the additionally increased fuel cost is effectively reduced. Unattended operation of a coal conveying site is realized, the labor intensity of coal conveying workers is largely relieved, and the work environment is improved. The FCS on-site bus technology has the advantages of reducing the hardware number and investment, saving installation expenses, saving maintenance expenses, realizing high system integration initiative of users, improving accuracy and reliability of the system and the like, and truly realizes a full-distribution type system with concentrated information and disperse control.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

Method for coal blending for coking by high-metamorphic-grade weak caking coal

InactiveCN102994130AReduce crackingQuality improvementSpecial form destructive distillationGranularityEngineering

The invention discloses a method for coal blending for coking by high-metamorphic-grade weak caking coal. The method comprises the following steps of: (1) crushing high-metamorphic-grade coal into different granularity gradients, respectively blending the high-metamorphic-grade coal under each granularity with other caking coals to carry out coking, detecting a quality index of obtained coke and determining the best crushing granularity of the high-metamorphic-grade coal; (2) blending non-high-metamorphic-grade coals in the blended coal and dividing into a coal part 1 and a coal part 2, blending the high-metamorphic-grade coal which is crushed to the best granularity with the coal 1 according to the previous proportion and pressing and molding a coal block, and mixing the high-metamorphic-grade coal which is crushed to the conventional granularity with the coal 2 according to the previous proportion to obtain blended coal 3; and (3) mixing the molded coal block with the blended coal 3 obtained by the step (2) and coking. The method disclosed by the invention can improve the adding amount of the weak caking coal on the premise that the quality of the coke is guaranteed, so that the effects of reasonably utilizing a coal resource and optimizing a coal blending structure are realized.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

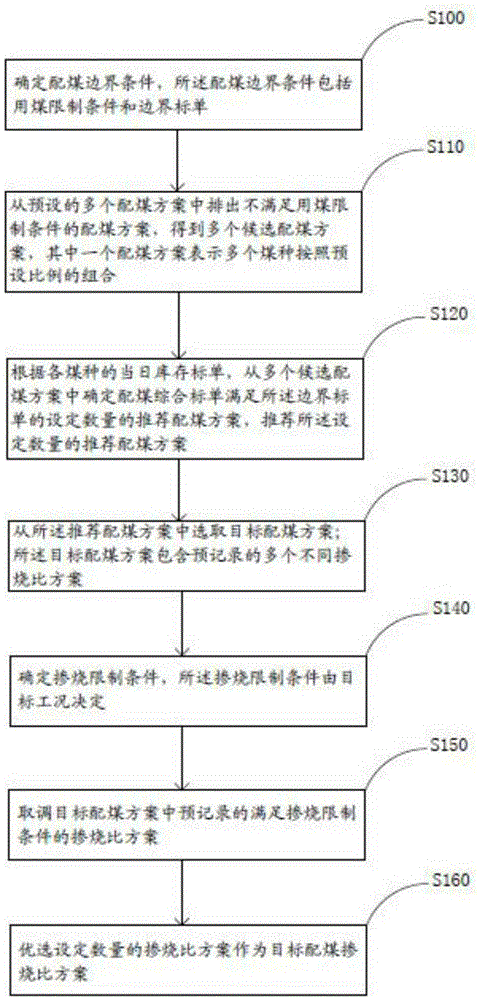

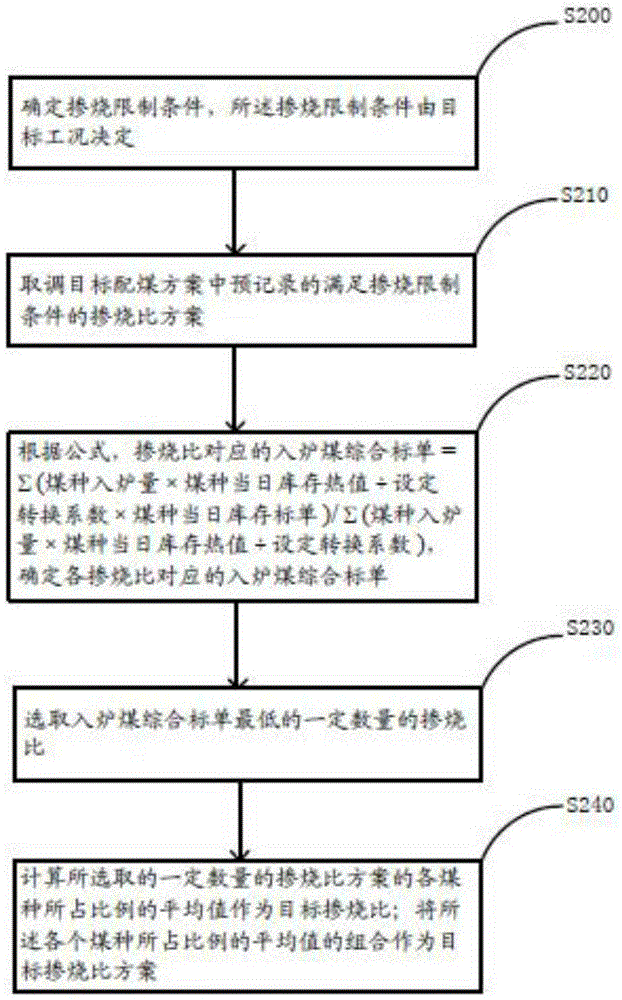

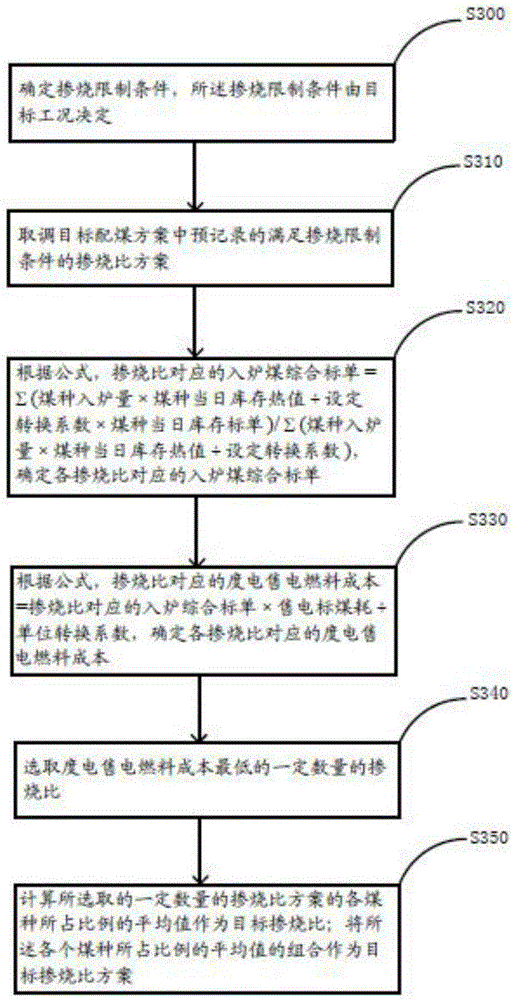

A thermal power plant fuel total value optimizing method and system

ActiveCN105320116AImprove economyReduce power generation costsTotal factory controlProgramme total factory controlCombustionEngineering

The invention provides a thermal power plant fuel total value optimizing method and system. The total value optimizing method comprises a coal blending and blending combustion method and a purchase plan optimizing method. The coal blending and blending combustion method is used for selecting a target coal blending and blending combustion ratio solution for a target working condition of a coal burning power generation system. The purchase plan optimizing method is used for making a target purchase strategy for the coal burning power generation system. The method is high in economical efficiency, reduces the cost of coal burning power generation and uses the coal blending and blending combustion optimizing method to guide the fuel purchase plan optimizing.

Owner:深圳市出新知识产权管理有限公司

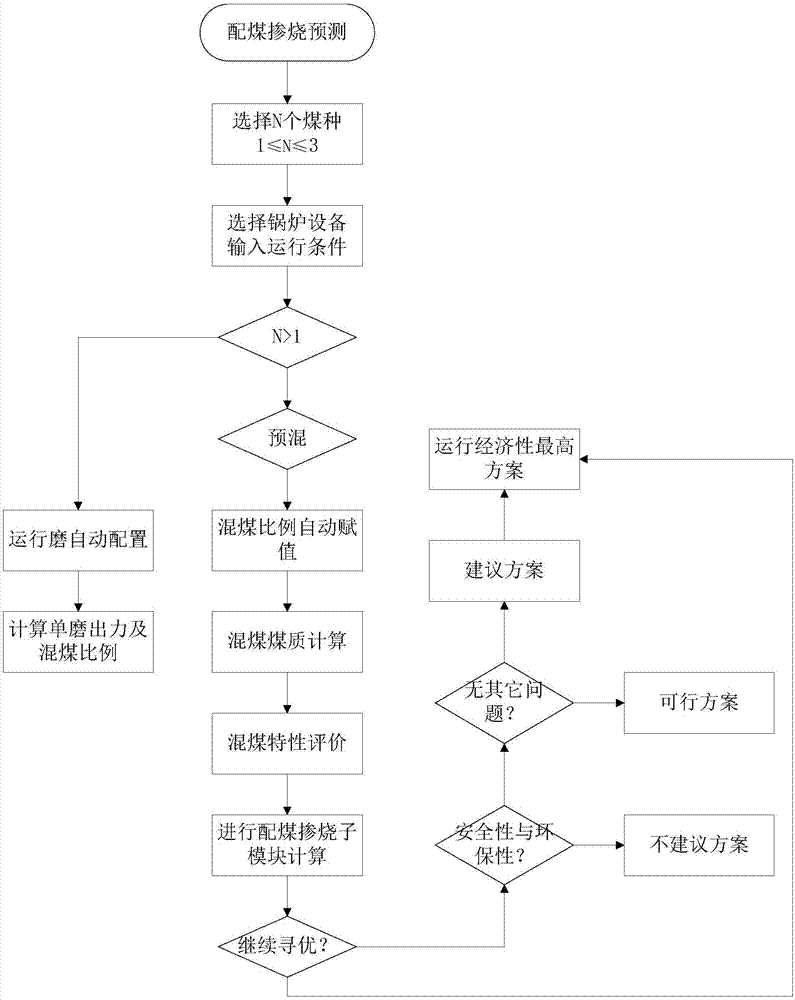

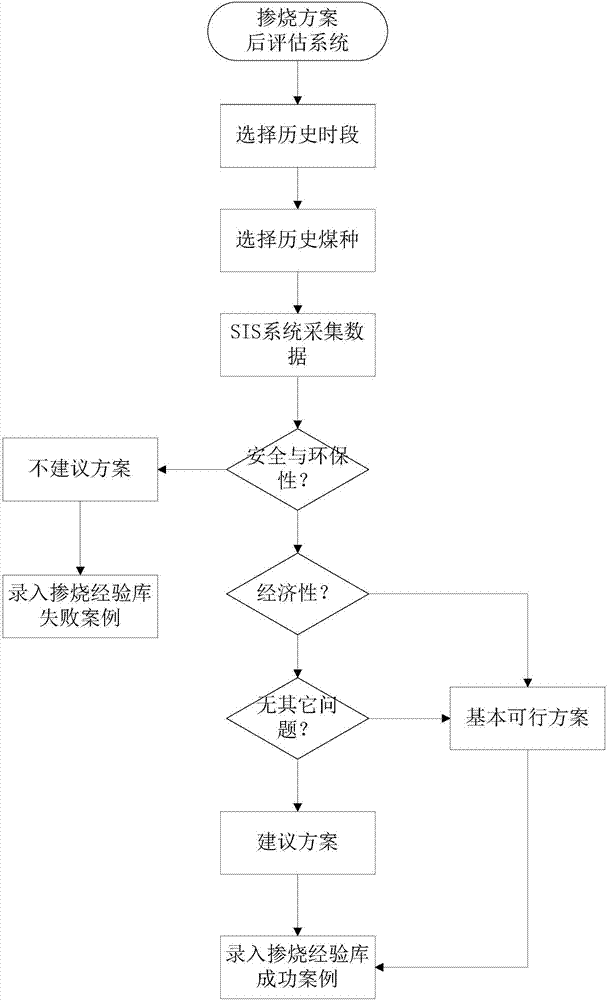

Mixed-coal blending combustion prediction system with post-evaluation system

InactiveCN107316104AReal-time assessment of safe operation levelGuarantee long-term safe operationForecastingResourcesCombustionFeature data

The invention discloses a mixed-coal blending combustion prediction system with a post-evaluation system. During mixed-coal blending combustion of various kinds of coal in a power plant, design parameters, structure features and fuel feature data of the power plant are combined to pre-judging a blending combustion scheme for configuring different kinds of coal and blending combustion proportions for a unit, so burning tests can be reduced, environmental protection and safety risks are avoided and operation economy of the unit is improved. Post-evaluation is performed on the scheme about the mixed-coal blending combustion prediction suggestion through operation data of actual blending combustion to verify whether the scheme is feasible. According to the invention, proper, simple and effective decision technical support is provided for research of mixed coal blending combustion of a target power plant and theoretical and application foundation is laid for the development of the mixed-coal blending combustion technology.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com