Method for adjusting and controlling melting temperature of coal ash by combining coal blending with auxiliary agent

A technology of combined regulation and additives, applied in fuel additives, petroleum industry, fuel, etc., can solve the problems that the adjustment method is difficult to achieve the desired effect, the ash content increases, and the calorific value decreases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

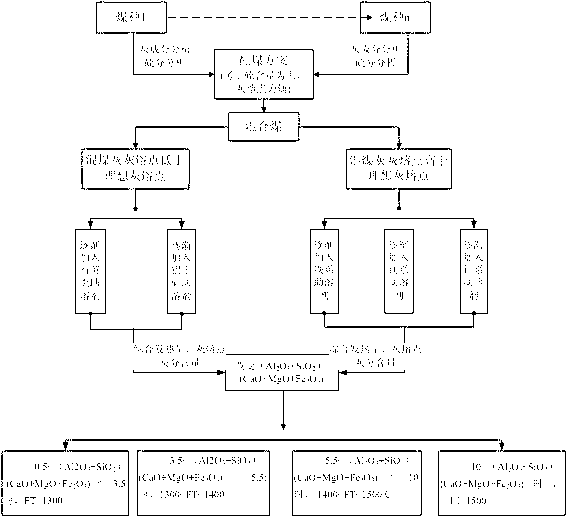

Image

Examples

Embodiment 1

[0017] Example 1: Sampling two or more types of coal whose coal ash melting temperature needs to be blended, standard ashing, measuring the ash composition and ash melting point, and measuring the sulfur content at the same time. During the process of coal blending, under the premise of ensuring S<1%, the ratio of different coal types is gradually changed to adjust the ash melting point of the blended coal. When mixing coals with different ash melting points, the ratio between them is based on the mass ratio, and the ratio is random. The two coals can be mixed according to 1:9, 2:8, 3:7, 4:6 The ratio is gradually changed, and then the result of the test shall prevail.

[0018] When the ash melting point cannot reach the design temperature through coal blending, by adding additives, change (Al 2 o 3 +SiO2 2 ) / (CaO+MgO+Fe 2 o 3 ) mass ratio to adjust the flow temperature of coal ash. (Al 2 o 3 +SiO2 2 ) / (CaO+MgO+Fe 2 o 3 ) The relationship between the mass ratio and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com