Method for determining optimal particle size of finely ground gas coal participating in coking and coal blending

A definite method and fine crushing technology, applied in the field of coking, can solve the problem of high energy consumption of coal grinding, and achieve the effect of reasonable particle size and stable coke quality

Active Publication Date: 2010-05-12

武汉钢铁有限公司

View PDF1 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the particle size is too large, the particle size of the inert component will be large, which will make it the crack center

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

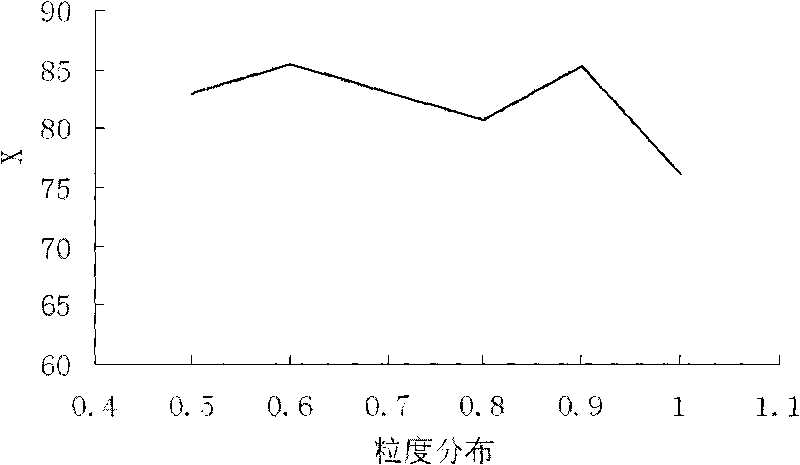

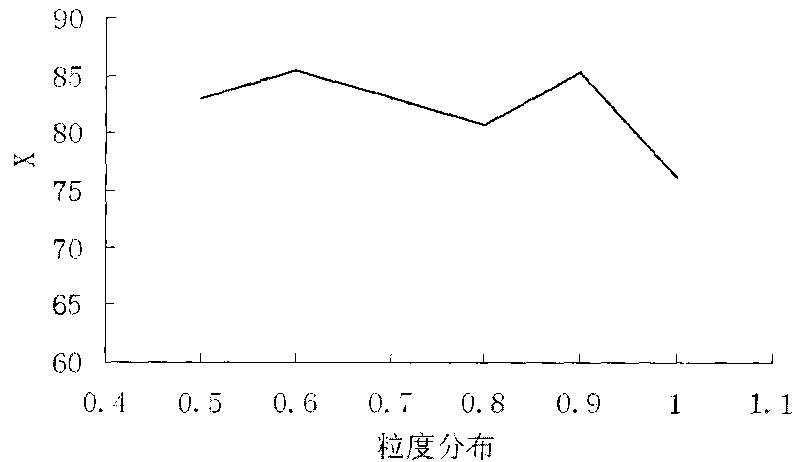

The invention relates to a method for determining the optical particle size of finely ground gas coal participating in coking and coal blending, which comprises the following steps: firstly, grinding the gas coal according to the different particle size grinding grades; secondly, mixing with a single coal respectively by the same proportion, and obtaining the mixed coal; thirdly, placing all the mixed coal in crucibles respectively, heating at the temperature of 850 DEG C plus or minus 10 DEG C for 13-20 minutes, and weighing the coke weight m respectively; fourthly, rotating in a caking index rotary drum for 250 plus or minus 50 turns respectively, screening respectively, and weighing the coke weight m1 respectively; fifth, further placing into the caking index rotary drum for rotating for 250 plus or minus 50 turns, screening, and weighing the coke weight m2 respectively; sixth, putting all the m, m1 and m2 into a formula that X is equal to (30*m1+70* m2)/m+10 for calculation; and seventh, determining the particle size value with the maximum X value as the optimal particle size of the finely ground gas coal. The method can ensure the reasonable particle size of the coal entering a furnace and lead the quality of the produced coke to be stable.

Description

technical field [0001] The invention relates to the technical field of coking, in particular to a method for coking coal blending, in particular to a method for determining the optimum particle size of finely pulverized gas coal involved in coking coal blending. Background technique [0002] Gas coal is a kind of coking coal with low degree of deterioration, high volatile content, high content of inert components, and high hardness. Due to the high content of inert components and large size of gas coal, the best way to use it is to use pre-crushing Fine crushing treatment; however, the particle size required for blending into gas coal should be appropriate, neither too large nor too fine. If the particle size is too large and the particle size of the inert component is large, it will become the crack center of coke. If the particle size is too small, the energy consumption of coal grinding will be too large due to its high hardness. How to choose the appropriate particle si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/02C10B57/04

Inventor 陈鹏薛改凤张雪红项茹宋子逵鲍俊芳张前香万基才刘尚超周森林

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com