Furan resin self-setting sand, its production method and casting sand mold

A technology of furan resin and self-hardening sand, which is applied in the field of foundry sand mold and furan resin self-hardening sand, can solve the problem of insufficient strength, and achieve the effects of improving strength, high strength and easy production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

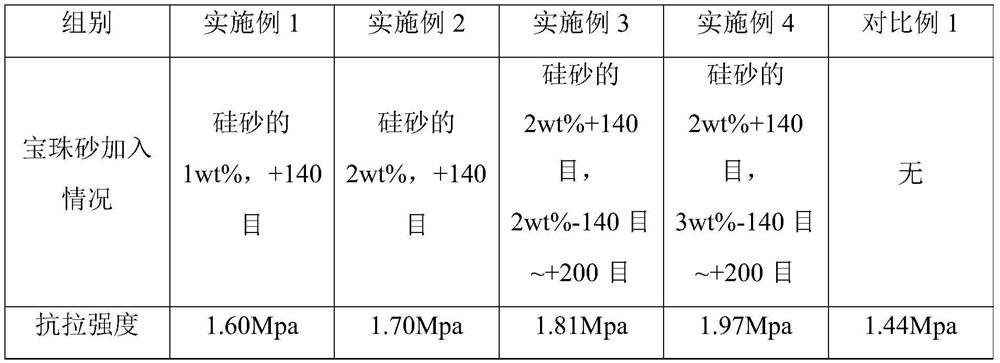

[0040]Weigh 1Kg of Dalin sand, then add +140 mesh pearl sand with 1wt% Dalin sand weight, and mix in a bowl-type sand mixer for 1 min. Add 50wt% furan resin curing agent (that is, 0.6wt% Dalin sand weight) to the mixed sand, and then mix for 30s. Then add 1.2wt% furan resin by weight of Dalin sand and mix for another 30s.

Embodiment 2

[0042] Weigh 1Kg of Dalin sand, then add 2wt% Dalin sand weight +140 mesh pearl sand, and mix in a bowl-type sand mixer for 1 min. Add 50wt% furan resin curing agent (that is, 0.6wt% Dalin sand weight) to the mixed sand, and then mix for 30s. Then add 1.2wt% furan resin by weight of Dalin sand and mix for another 30s.

Embodiment 3

[0044] Weigh 1Kg of dalin sand, then add 2wt% dalin sand weight of +140 mesh pearl sand and 2wt% dalin sand weight of -140 mesh to +200 mesh pearl sand, and mix in a bowl type sand mixer for 1min. Add 50wt% furan resin curing agent (that is, 0.6wt% Dalin sand weight) to the mixed sand, and then mix for 30s. Then add 1.2wt% furan resin by weight of Dalin sand and mix for another 30s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com