Patents

Literature

105results about How to "Round particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiphase-doped nickel-cobalt-manganese ternary anode material and preparation method and application thereof

InactiveCN109768232AEasy to useEnhanced mass transferCell electrodesSecondary cellsChemical LinkageManganese

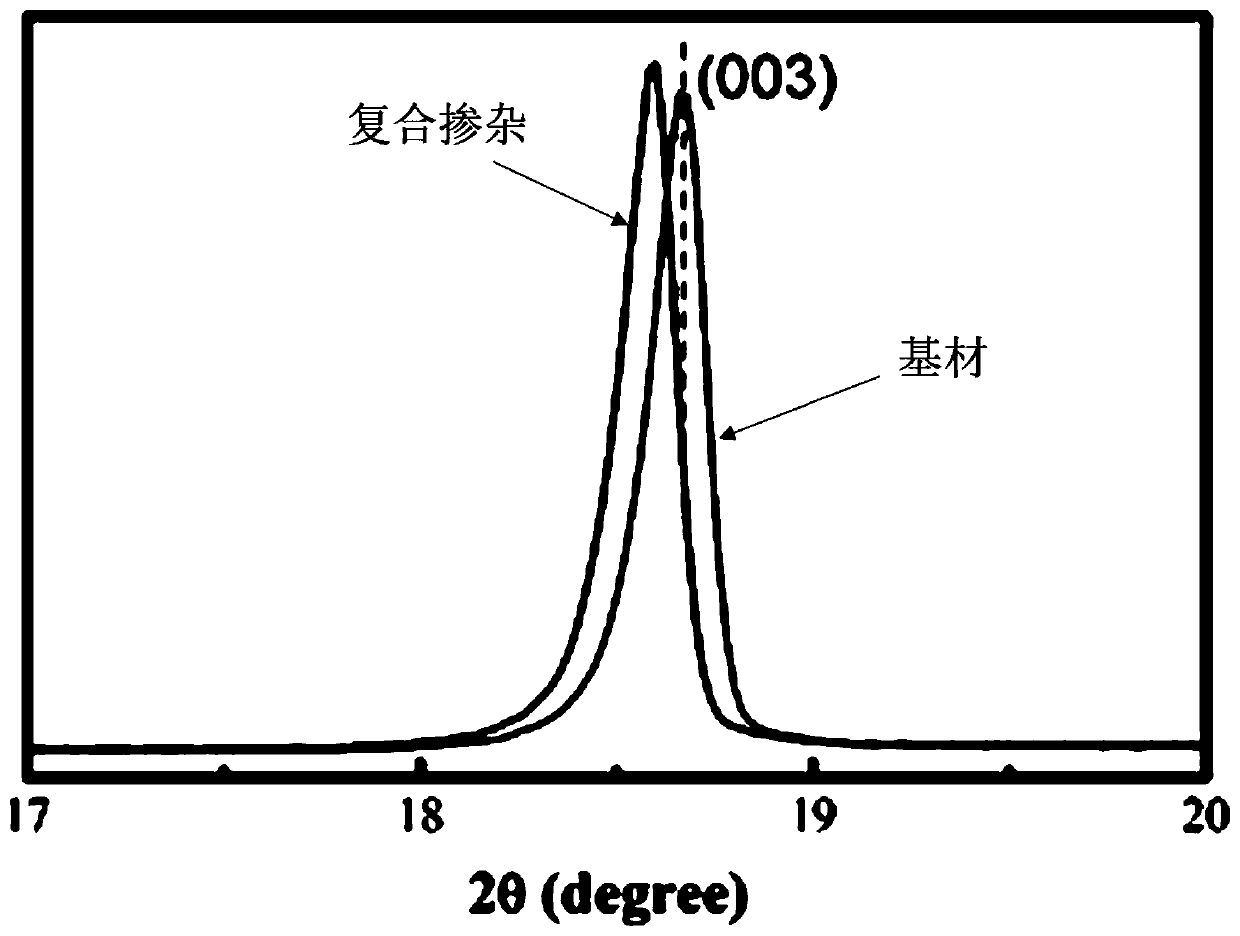

The invention discloses a multiphase-doped nickel-cobalt-manganese ternary anode material and a preparation method and application thereof. The chemical expression of the multiphase-doped nickel-cobalt-manganese ternary anode material is Li<delta>Ni<x>Co<y>Mn<z>MNO<2>, wherein the following relations are met: 0.9<=delta<=1.3; 0.33<=x<=0.98; 0.02<=y<=0.4; 0.02<=z<=0.4; x+y+z=1; a>0, b>0, and0.0024<=a+b<=0.042; M is a principal element in a melting additive; and N is a principal element in a strong chemical-bond energy additive. Meanwhile, the invention discloses the preparation method ofthe multiphase-doped nickel-cobalt-manganese ternary anode material and also discloses application of the multiphase-doped nickel-cobalt-manganese ternary anode material. According to the prepared multiphase-doped nickel-cobalt-manganese ternary anode material, the use effectiveness of the anode material is improved multi-dimensionally by use of the synergistic effect among doped elements.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

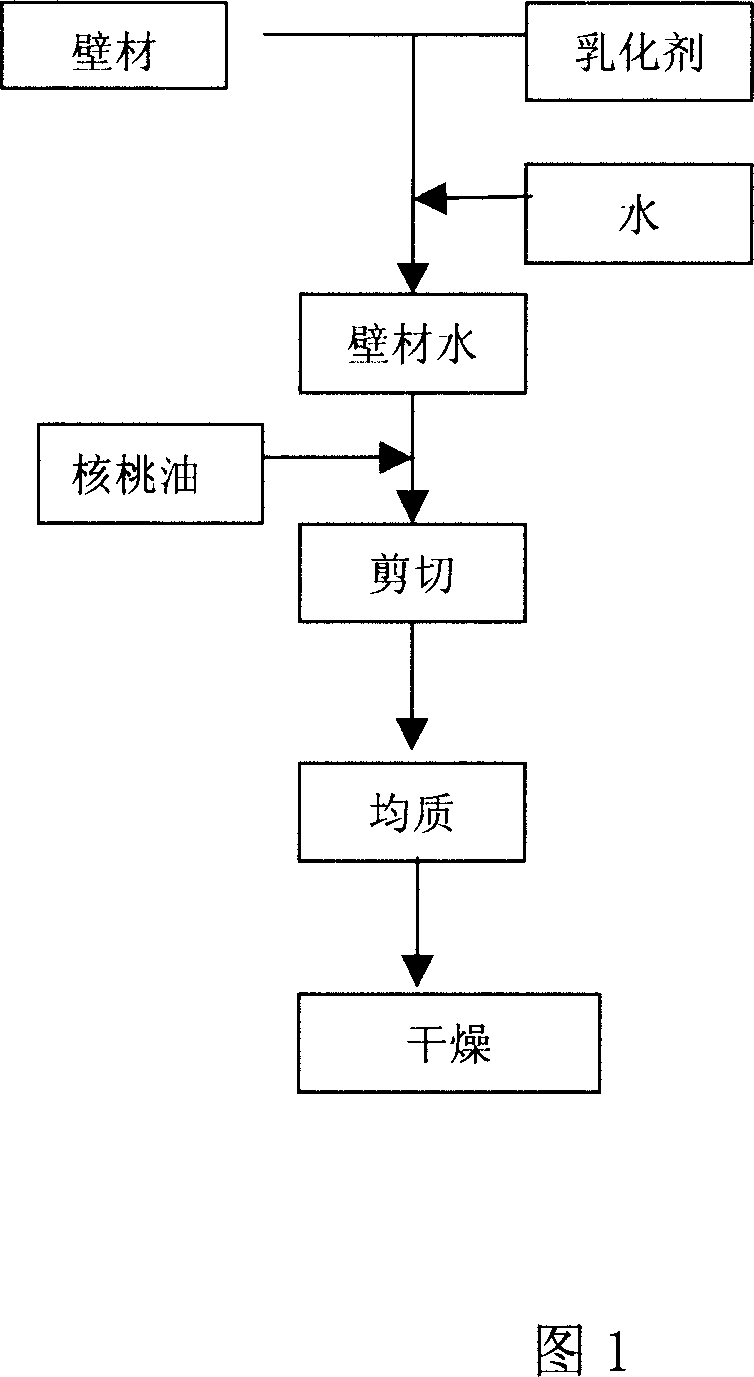

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Grain mould-proof and insect preventive drier and production thereof

InactiveCN1644067ARound particlesLarge specific surface areaBiocideClimate change adaptationHot peppersMildew

An insecticiding mildew-inhibiting desiccant for grains is prepared from attapulgite, bentone, calcium oxide, anthracite, ginger, garlica cloves, tangerine peel, red hot pepper, Chinese prickly ash, fennel and anise through acidifying, grinding, granulating, calcining, baking and mixing. Its advantages are high effect, no pollution and poison, and low cost.

Owner:许庆华

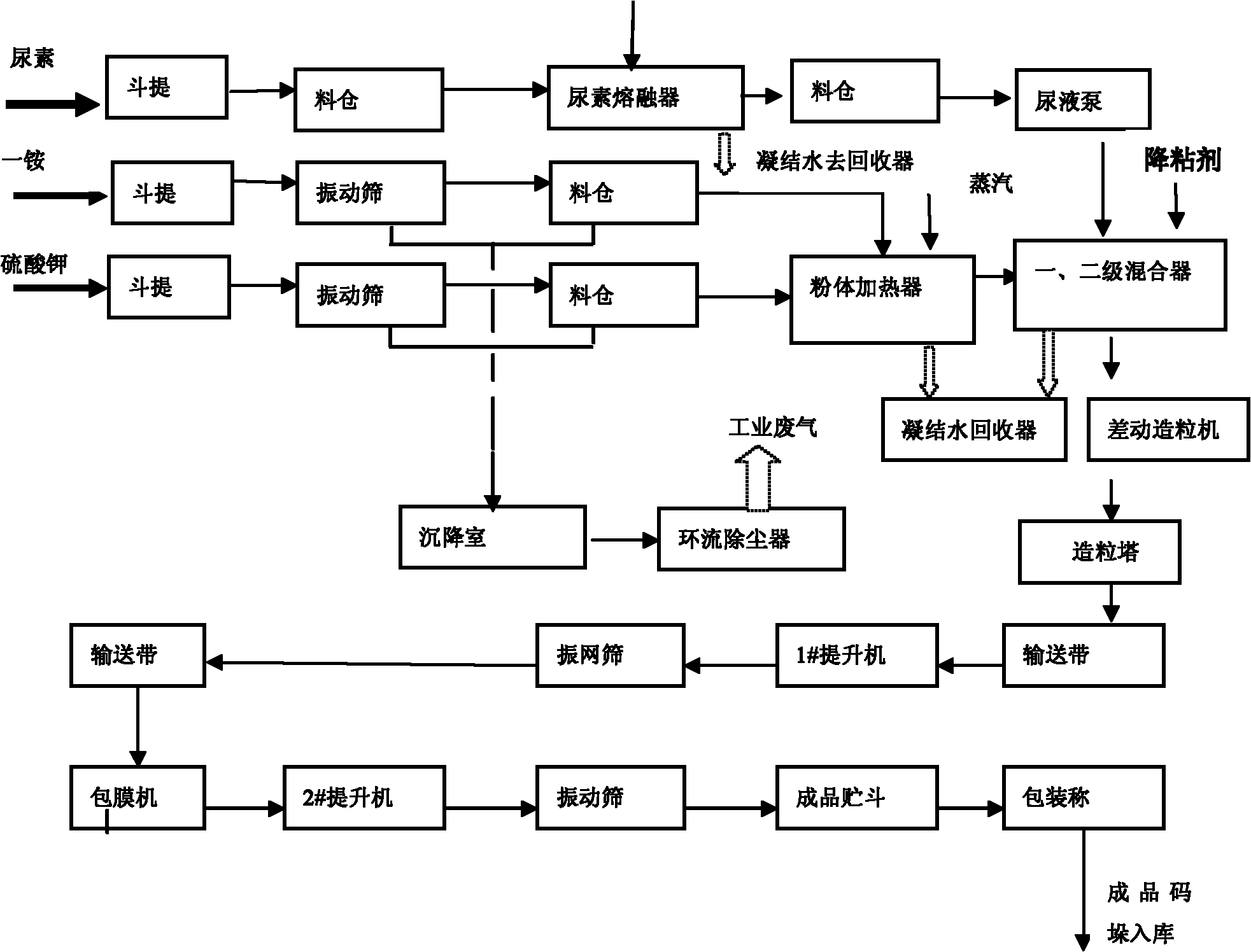

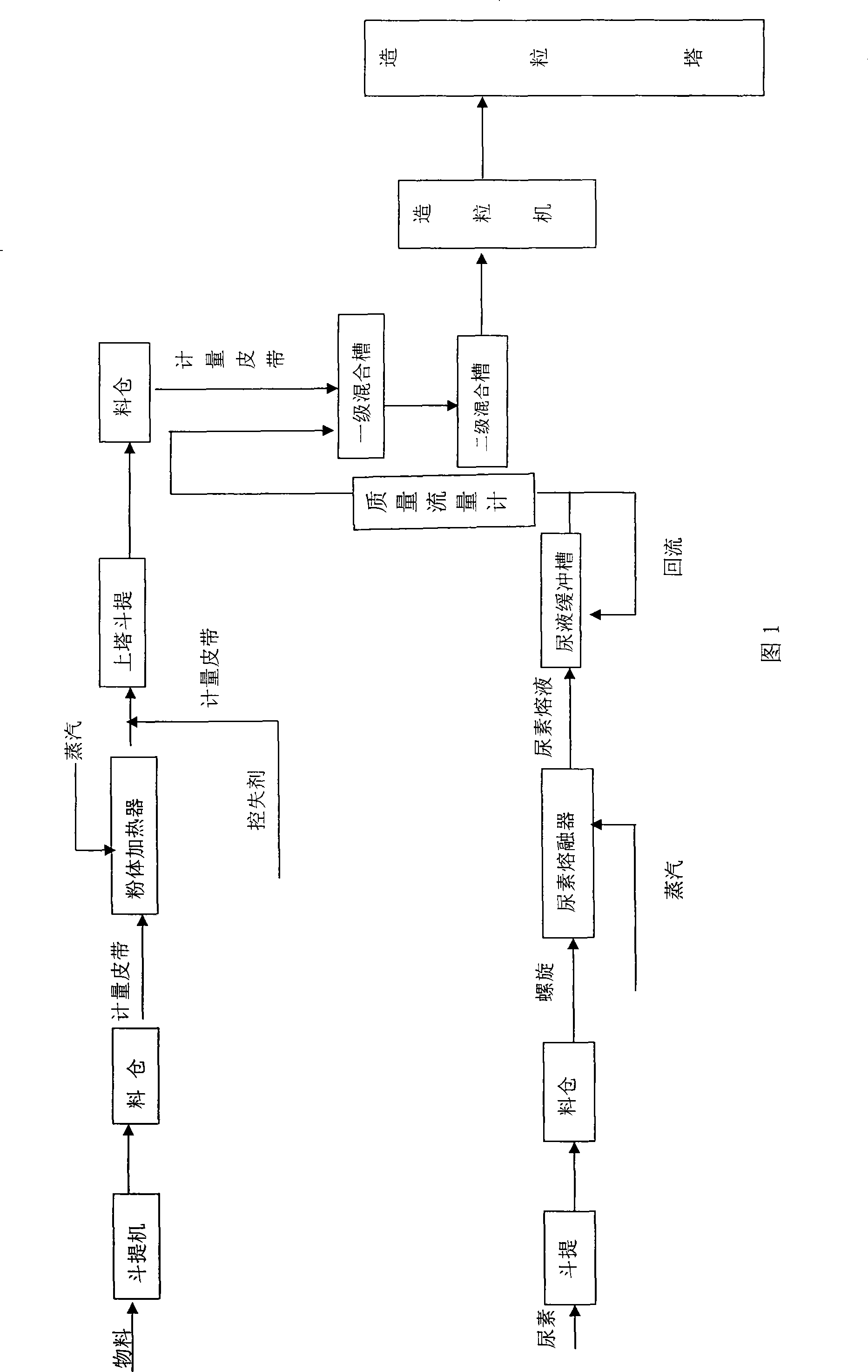

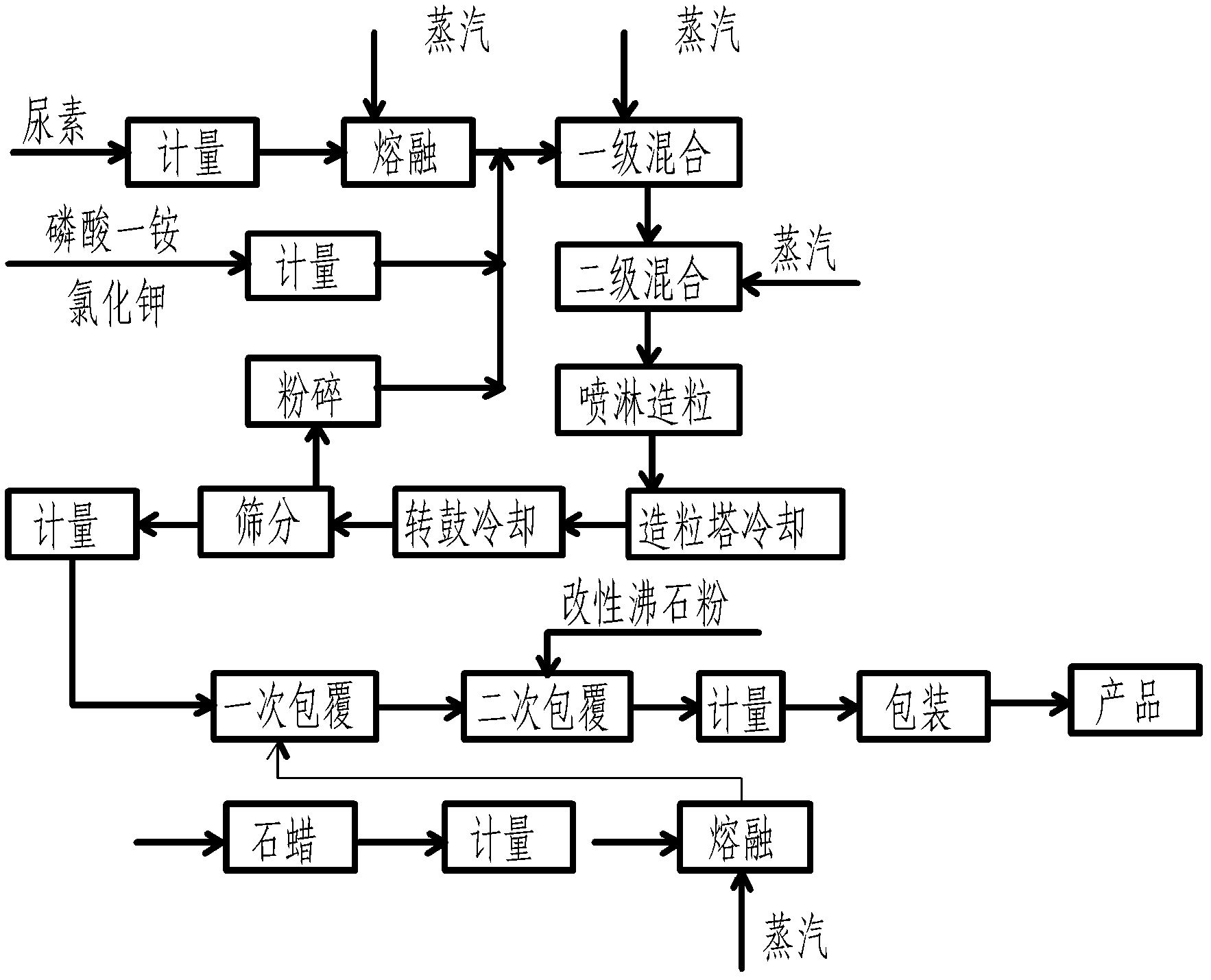

Production process of high tower melt-granulated compound fertilizer

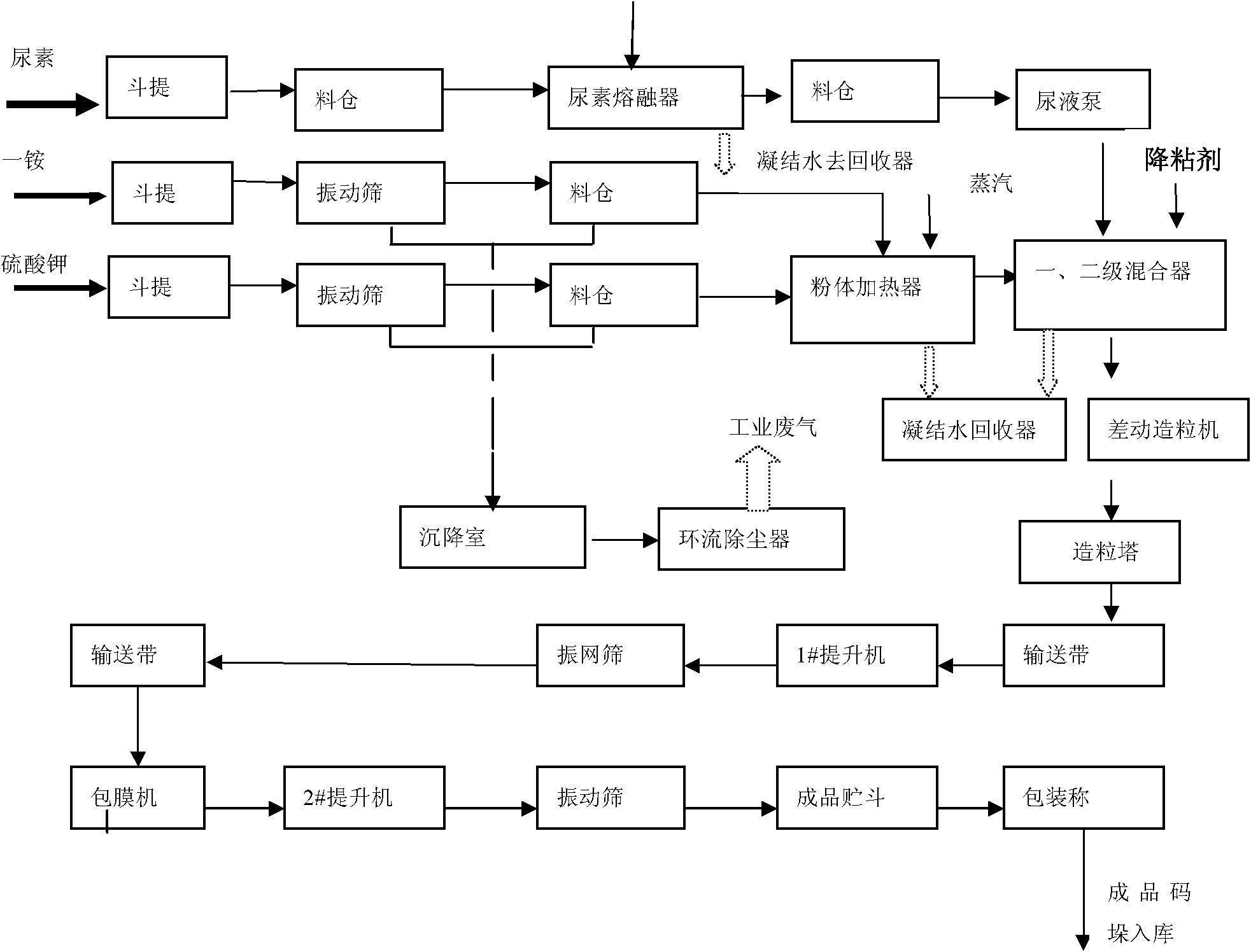

InactiveCN101993277ALower melting temperatureReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumSlurry

The invention relates to a production process of a high tower melt-granulated compound fertilizer. Potassium chloride is added in the process of melting urea, and the temperatures of urine and slurry are reduced according to a characteristic that the melting temperature is reduced after the urea is mixed with the potassium chloride serving as a cosolvent. The liquid solid ratio of the slurry can be regulated so as to reduce the melting temperature of the urea, the melting capacity of urea melting equipment is improved, and the foundation for improving the yield is laid.

Owner:河南财鑫实业化工有限责任公司

Tower-granulated low-nitrogen high-phosphorus urine sulfur radical compound fertilizer and preparation method thereof

InactiveCN102030592AHigh freezing pointParticle smoothFertiliser formsFertilizer mixturesChemistryLignosulfonates

The invention discloses a tower-granulated low-nitrogen high-phosphorus urine sulfur radical compound fertilizer and a preparation method thereof, belonging to a fertilizer mixture. The compound fertilizer is characterized by being prepared from the following raw materials in parts by mass: 34-35 parts of urea, 32-33 parts of monoammonium phosphate, 32-33 parts of potassium sulfate and 1-1.5 parts of viscosity reducer, wherein the viscosity reducer is modified lignosulfonate. The invention provides a tower-granulated low-nitrogen high-phosphorus urine sulfur radical compound fertilizer which can meet the nutrition requirements on nitrogen, phosphorus, potassium and sulfur for crop growth and ensures that the product particles are uniform, smooth, mellow and full, small contraction cavities are formed, natural anti-counterfeiting function is realized, caking of the product is prevented, the compressive strength is relatively high and mechanical fertilizing is convenient to carry out; moreover, the invention also provides a preparation method which has advantages of high technical adaptability, high compatibility, energy conservation, small investment and relatively low production cost. The compound fertilizer disclosed by the invention is applicable to various crops such as rice, cotton, corn, peanut, soybean, wheat, rape and the like as well as medium and high-grade cash cropssuch as vegetable, fruit trees, forest trees, flowers, tea and the like. The content of N is less than 20% by weight, and the content of P2O5 is more than or equal to 15% by weight.

Owner:张超

Method for preparing high tower control release compound fertilizer

ActiveCN101440004ASimple production processEasy accessAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePotassium

The invention relates to a method for preparing a high-tower loss controlled compound fertilizer, and belongs to the technical field of fertilizer. The method comprises the following steps: adding heated monoammonium phosphate or calcium hydrophosphate, potassium chloride or potassium sulphate, powder stuffing into urea melt, and adding loss control agent KS-3 of fertilizer nutrient into the mixture at the same time, fully mixing the additives and the urea melt, quickly compounding each raw material under the action of mechanical stirring at melt temperature of urea into low-temperature mutual melt with certain flow properties, then granulating the mutual melt by adopting a process of spray granulation, and cooling and solidifying spray drops when falling in a granulation tower to pass through rising air flow to form the compound fertilizer with function of controlling loss of the fertilizer nutrient. The method has the advantages of easy process reform, and convenient operation.

Owner:山东金沂蒙生态肥业有限公司

Preparation method of recombined human blood-vessel endothelia inhibin sustained-released microsphere

ActiveCN101396347ARound shapeUniform particle sizePowder deliveryPeptide/protein ingredientsWater in oilSolvent

The invention discloses a method for preparing a recombinant human endostatin sustained release microsphere. In the method, recombinant human endostatin is solved in buffer solution containing protein stabilizer to obtain an inner water phase; lacto-glycolic acid copolymer is solved in mixed organic solvent to obtain an inner oil phase; the mixed solution of the inner water phase and the inner oil phase is dispersed fast to obtain primary emulsion; the obtained primary emulsion is arranged in a stirring vessel which is filled with plant oil or mineral oil containing emulsifier to be stirred into water-in-oil type compound emulsion; the water-in-oil type compound emulsion is stirred continuously to volatilize the mixed organic solvent in the inner oil phase and then is filtered and separated by a microporous filtering film after the microsphere is solidified; the residual plant oil or mineral oil on the surface of the microsphere is washed by the solvent; and the microsphere finished product is obtained after vacuum drying. The microsphere prepared by the method has high drug loading quantity, high entrapment rate, proper burst release quantity and long sustained release period.

Owner:SHANDONG SIMCERE BIO PHARMA CO LTD

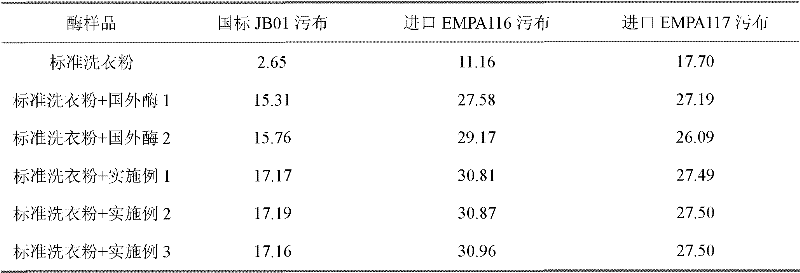

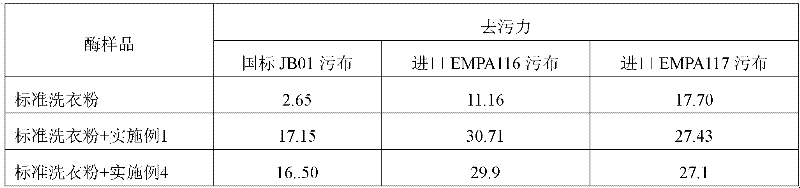

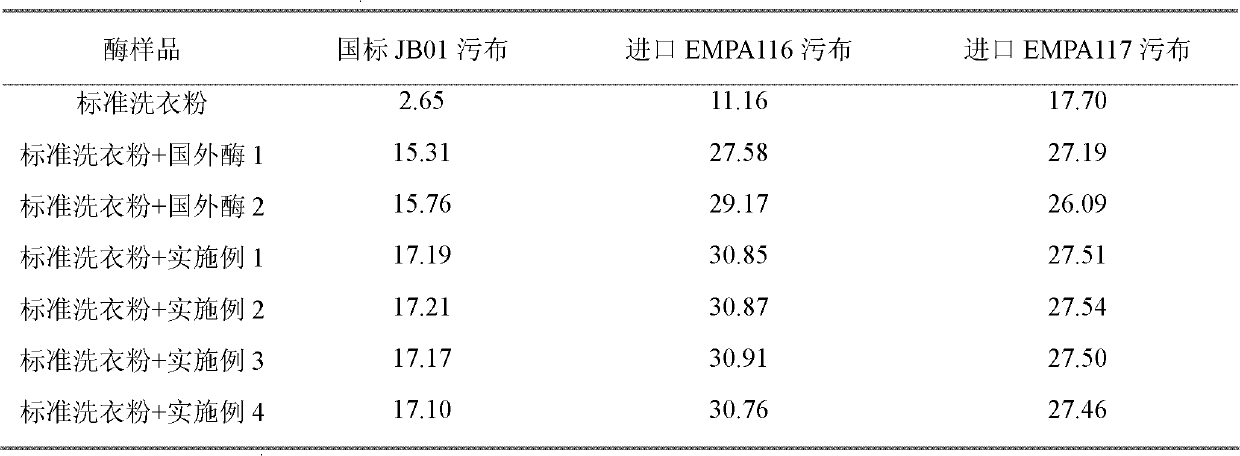

Enzyme particle coated with alkali protease and preparation method thereof

ActiveCN102533708ARound particlesUniform particle sizeEnzyme stabilisationDetergent compounding agentsAlkaline proteaseProteinase activity

The invention relates to an enzyme particle coated with alkali protease and a preparation method thereof. The enzyme particle comprises a blank pellet core and an enzyme layer wrapped outside the blank pellet core. The enzyme particle also comprises an isolation layer and a protection layer which are wrapped on the enzyme layer. The enzyme particle coated with the alkali protease is round and hasno foreign odor and uniform particle size; 20-40 meshes of particles account for at least 90 percent. All properties of the enzyme particle are superior to abroad like products and are shown as follows: the unit weight is 700-900g, i.e. the enzyme particle has very high degree of mixing with washing powder; the enzyme activity of the enzyme particle is as high as 250000U / g-400000U / g; the dissolution velocity is high; the retention period is long, i.e. the enzyme particle can be stored for 6 months at the temperature of 25 DEG C, and the enzyme activity loss is less than 5 percent; the resistance to heat and humidity is good, i.e. the enzyme particle can be stored for 3 months under the conditions that the temperature is 37 DEG C and the humidity is 70 percent, and the enzyme activity lossis less than 10 percent; and a decontamination effect is good.

Owner:QINGDAO VLAND BIOTECH GRP +1

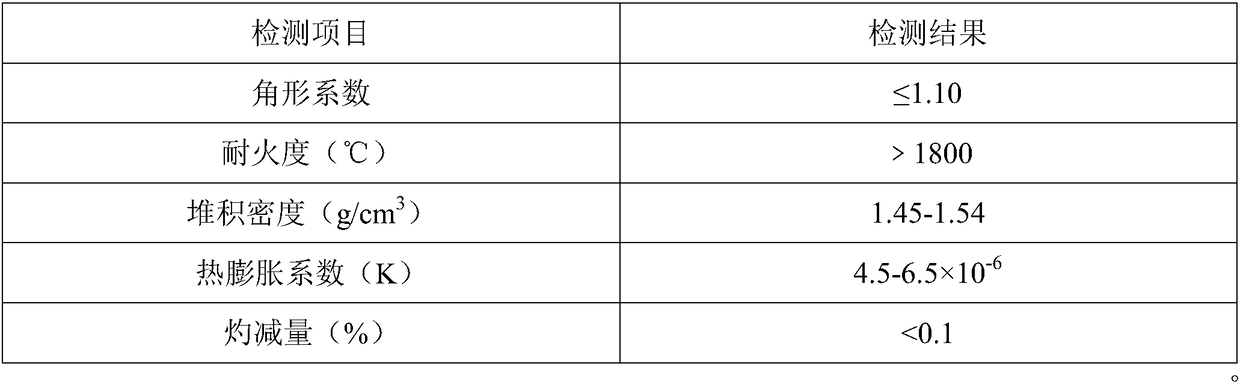

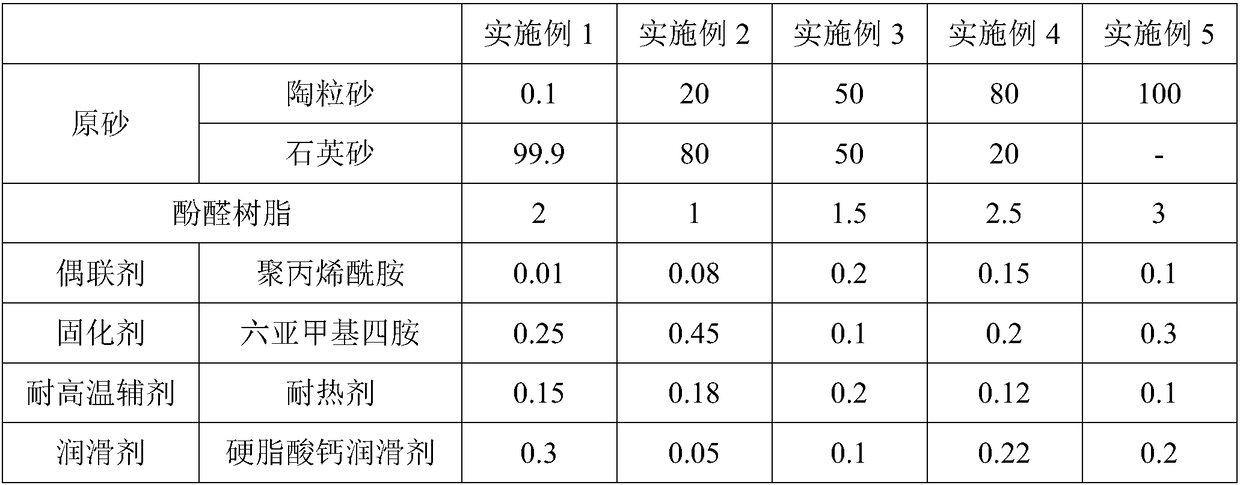

Ceramsite precoated sand and preparation method thereof

ActiveCN108907067AGuaranteed StrengthGuaranteed liquidityFoundry mouldsFoundry coresExpanded clay aggregateEconomic benefits

The invention discloses ceramsite precoated sand and a preparation method thereof, belongs to the field of casting materials, and particularly relates to a sand core for a casting piece or a shell-core material and a preparation method thereof. The provided ceramsite precoated sand is low in cost, good in performance and simple in preparation. The ceramsite precoated sand is prepared from the following raw materials in parts by mass: 100 parts of crude sand, 1-3 parts of phenolic resin, 0.01-0.2 part of a coupling agent, 0.1-0.45 part of a curing agent, 0.1-0.2 part of a high-temperature-resistant adjuvant and 0.05-0.3 part of a lubricant. The crude sand is ceramsite sand or a mixture of the ceramsite sand and quartz sand. The ceramsite precoated sand is prepared by mainly using features of the ceramsite sand which is simple in preparation process, high in fire resistance degree, low in thermal expansion coefficient, good in angular coefficient and the like. The preparation method forthe ceramsite precoated sand is simple and convenient in operation. The obtained ceramsite precoated sand is good in performance, so the ceramsite precoated sand has a good economic benefit.

Owner:南阳仁创砂业科技有限公司

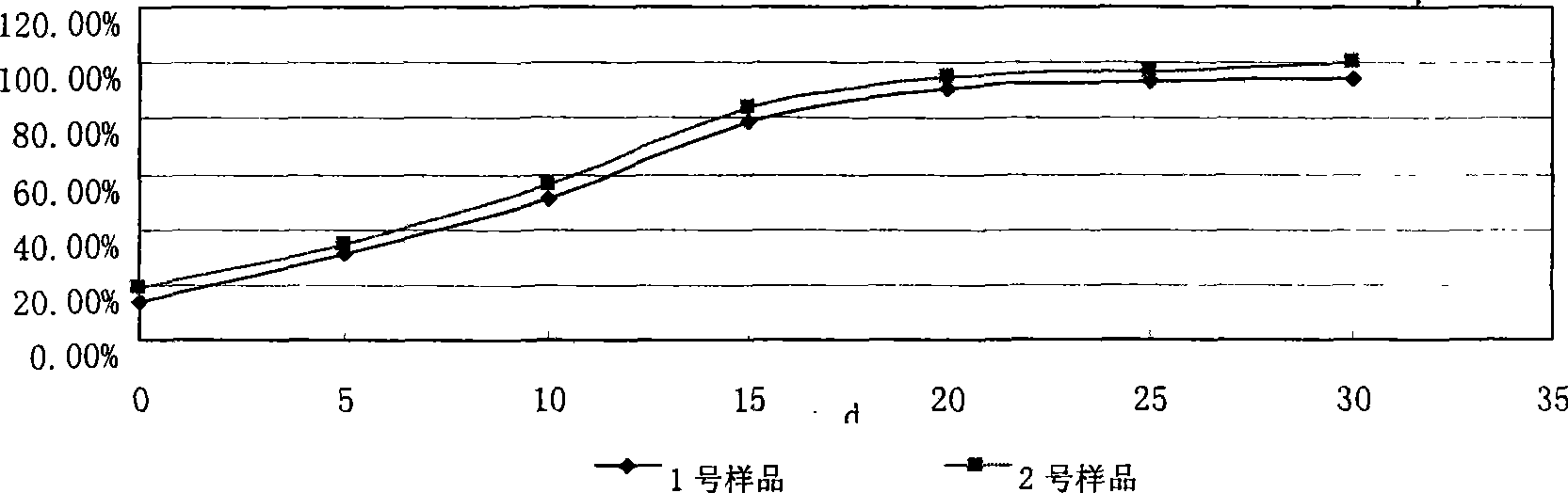

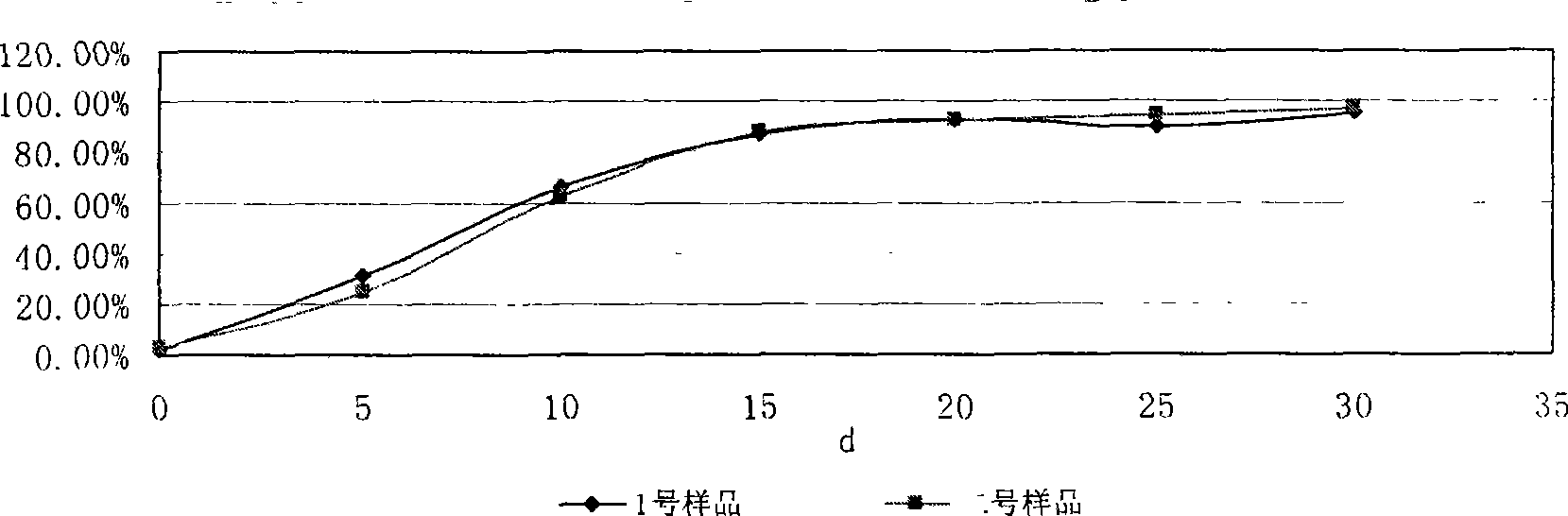

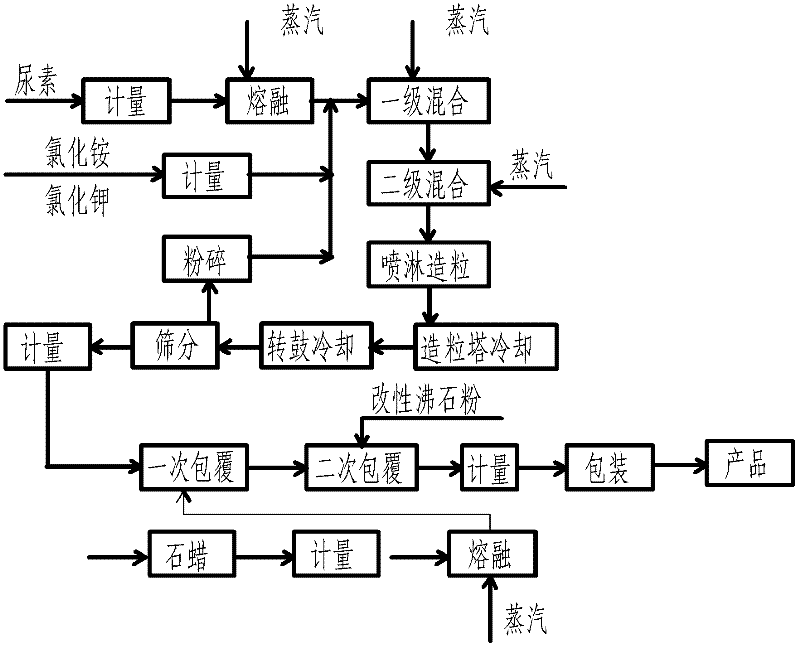

High-tower granulation slow release long-effect chlorine base compound fertilizer and preparation method thereof

The invention relates to a high-tower granulation slow release long-effect chlorine base compound fertilizer and a preparation method thereof, which belong to mixed fertilizers. Firstly, a high-tower granulation device is used for preparing high-tower granulation urea compound fertilizer particles, then, the paraffin primary covering and the modified zeolite powder surface secondary covering are carried out on the urea compound fertilizer particles to obtain the high-tower granulation urea compound fertilizer particles, and the high-tower granulation urea compound fertilizer particles consist of the following ingredients in part by weight: 35 to 50 of urea, 35 to 45 of potassium chloride and 15 to 20 of ammonium chloride. In the paraffin primary covering process, the paraffin consumption is 0.5 percent to 1.2 percent of the mass of the high-tower granulation urea compound fertilizer particles, and the modified zeolite powder consists of the following ingredients in percentage by weight: 1 to 5 of zinc stearate and 95 to 99 of zeolite powder. The invention provides the high-tower granulation slow release long-effect chlorine base compound fertilizer and the preparation method thereof, and the high-tower granulation slow release long-effect chlorine base compound fertilizer is matched with the high-tower granulation device to be used and has the advantages that the slow release effect is good, the fertilizer nutrient utilization rate is high, the process is simple, the production cost is lower, and the soil, atmosphere and water body environment is favorably protected.

Owner:STANLEY AGRI GRP CO LTD

Preparation method of anise volatile oil microcapsules

InactiveCN103156192ARound particlesReduce volatilityFood shapingFood preparationSucroseThermal stability

The invention provides a preparation method of anise volatile oil microcapsules. The method comprises the following steps of: firstly, preparing anise volatile oil; then, preparing a wall material liquid based on Arabic gum and maltodextrin as raw materials, then, adding a mixed emulsifier of monostearin and sucrose ester to obtain lactescence; and mixing the lactescence with heartwood, emulsifying, and spraying and drying to obtain microcapsule particles. The method is simple and accessible. The microcapsule particles prepared are round, uniform in size and full of anise fragrance. The content of the anise volatile oil in each microcapsule is 40-95mg / g, the microencapsulation efficiency is over 95%, and the product has good thermal stability and dissolving dispersion and can be widely applied to the field of foods, daily use chemicals and medicines.

Owner:张达燕

Alkaline proteinase coated micro-pill and preparation method thereof

ActiveCN102433225ARound particlesUniform sizeDetergent compounding agentsPolyvinyl alcoholDissolution

The invention relates to an alkaline proteinase coated micro-pill and a preparation method thereof. The alkaline proteinase coated micro-pill comprises 50-90 wt% of enzyme-containing pill core and 10-50 wt% of coating layer coated on the enzyme-containing pill core, wherein the enzyme-containing pill core is prepared from alkaline proteinase, dextrin, starch, bean flour, lactose, sodium dodecylsulfate, microcrystalline cellulose and corn steep liquor dry powder; and the coating layer is prepared from dextrin, starch, polyvinyl alcohol, sodium dodecylsulfate, sodium sulfate, titanium white andbrilliant blue. The alkaline proteinase coated micro-pill has the advantages of round and complete particles, no peculiar smell and uniform size; the 30-60 mesh particles account for more than 99%; and the main properties of the alkaline proteinase coated micro-pill are superior to those of like products abroad: compared with washing powder, the alkaline proteinase coated micro-pill has better mixing uniformity, higher dissolution rate and longer storage time.

Owner:QINGDAO VLAND BIOTECH GRP +1

Method for producing basic magnesium carbonate

InactiveCN1579940AUniform particlesSmall particlesMagnesium carbonatesMagnesium hydroxideSurface-active agentsAqueous solution

The invention discloses a suspension method to produce dispersant used by high polymer, especially powder inorganic dispersant: deploying MgCl2 to be aqueous solution whose chroma is 1-2 percent and Na2CO3 8-10 percent; putting the part Na2CO3 solution into kettle reactor, keeping the temperature 60-65deg.C, mixing and adding remnant Na2CO3 and MgCl2 solution; cold bleaching after lowering of charge, namely, using clean water to rinse more than 3 times; then hot bleaching, keeping the temperature 130-150deg.C for 3 hours and ending the reaction. In the invention, the diameter of powder is 20-50nm and cover area is 2 orders of magnitude bigger, which can make suspension liquid system stable for a long time and make particle of high polymer equality, thin, round and not needing using with surface active agent.

Owner:PEN MAKING FACTORY SHANGHAI

Method for producing granular potassium sulfate

ActiveCN102690144ARound particlesFlat surfacePotassium fertilisersFertilizer mixturesPolyoxyethylene castor oilPrill

The present invention relates to a method for producing granular potassium sulfate, belonging to the technical field of fertilizer manufacturing. The method includes the specific steps of preparation of an adhesive and granulation of powdery potassium sulfate. The preparation of the adhesive includes the following steps: adding water to a reactor having a jacket so as to dissolve polyvinyl alcohol; adding polyoxyethylene castor oil at a preset temperature; adding polyoxyethylene octyl phenol ether and dibutyl phthalate according to a formula; cooling the mixture after a certain reaction time; adding sodium silicate for a certain time of reaction at a certain temperature to obtain the adhesive. The granulation of the powdery potassium sulfate includes the following steps: adding the powdery potassium sulfate with fineness less than 60 mesh to a disk or a rotary drum granulator; adding the prepared adhesive proportionately to the rotating materials to perform granulation, drying, cooling and screening are performed on the granulated material to produce a product. The granular potassium sulfate produced by the method in the invention is advantaged in round and uniform particle, smooth surface and high particle strength, being capable of being directly applied and being used as raw material of a blending fertilizer.

Owner:HENAN LEEF FERTILIZER

Nano zinc oxide enteric-coated pellet and preparation method thereof

InactiveCN109276561AAchieve antidiarrheal effectRealize that most of zinc oxide exerts anti-diarrheal effect in molecular form in the small intestineInorganic active ingredientsDigestive systemIsolation layerTalc / Zinc Oxide

The invention relates to a nano zinc oxide enteric-coated pellet and a preparation method thereof. Existing zinc oxide products for preventing and controlling piglet diarrhea are no longer able to meet market demands. The nano zinc oxide enteric-coated pellet sequentially comprises a zinc oxide pellet core, an isolation layer, an enteric layer and a protective layer from inside to outside. The selected zinc oxide raw material is pharmaceutical grade 99% zinc oxide which is subjected to nano treatment or ordinary feed grade zinc oxide with a purity of more than 95%, the zinc oxide particle sizeis below 3,000 mesh, and the nano zinc oxide enteric-coated pellet is prepared from the raw materials in parts by mass: 30-90 parts of the nano zinc oxide pellet core, 0-40 parts of the sum of the isolation layer and the protective layer and 10-30 parts of the enteric layer. According to the nano zinc oxide enteric-coated pellet and the preparation method thereof, excessive zinc is avoided, zincpollution is reduced, the dosage is small, zinc emissions in animal faeces are greatly reduced, soil pollution is prevented, and environmental protection is achieved.

Owner:浙江诚缘生物科技有限公司

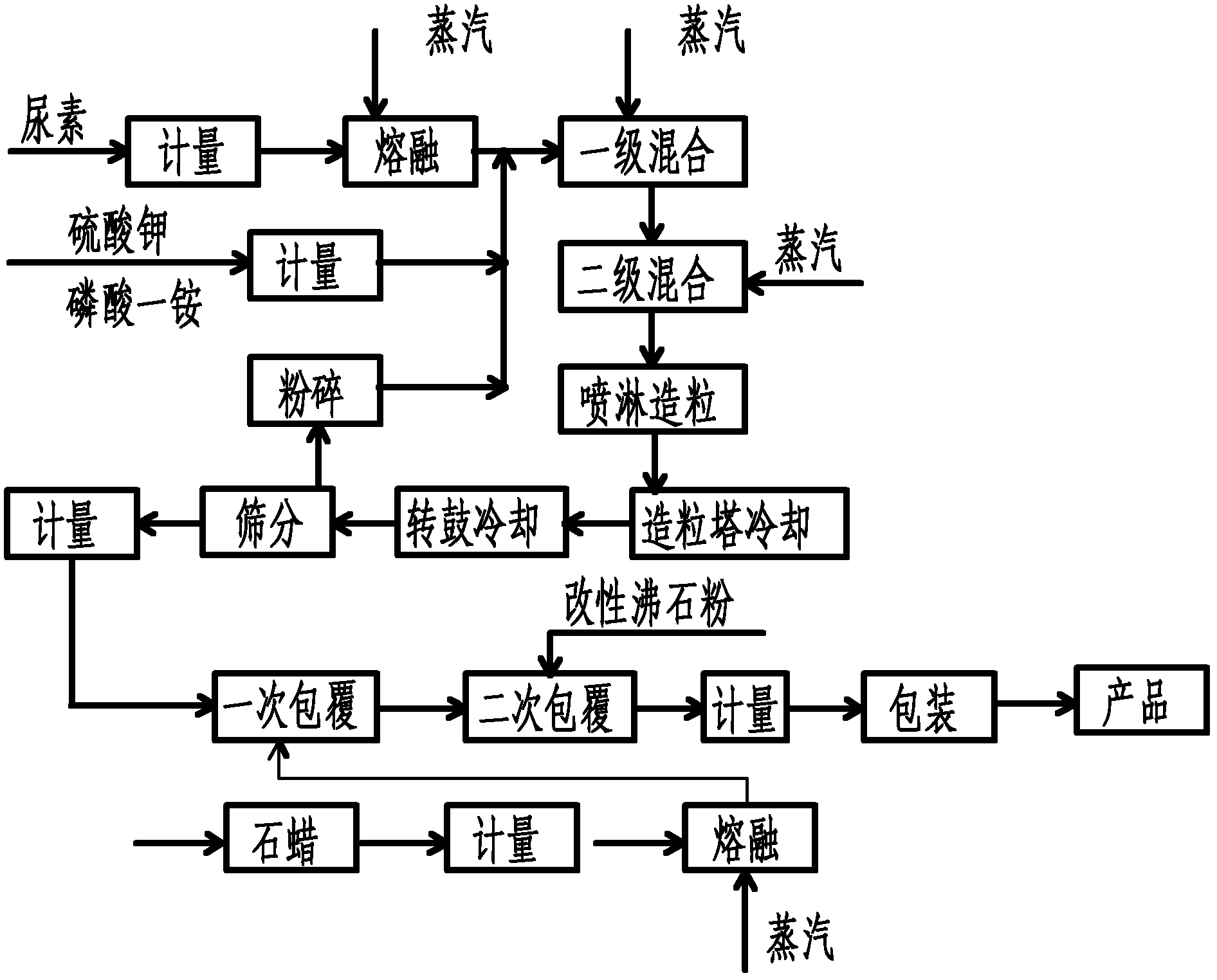

Tower granulation slow release long-acting nitrogen phosphorus potassium compound fertilizer and preparation method thereof

The invention discloses a tower granulation slow release long-acting nitrogen phosphorus potassium compound fertilizer and a preparation method thereof, and belongs to compound fertilizers. The preparation method comprises the following steps of: preparing tower granulation urea-based compound fertilizer granules by using a tower granulation device; and then performing wax primary coating and modified zeolite powder surface secondary coating on the urea-based compound fertilizer granules to prepare tower granulation urea-based compound fertilizer granules, wherein the tower granulation urea-based compound fertilizer granules consist of the following raw materials in parts by weight: 33-50 parts of urea, 10-26 parts of monoammonium phosphate and 30-41 parts of potassium chloride; the amount of used wax is 0.5-1.0 percent of the mass of the tower granulation urea-based compound fertilizer granules; and the modified zeolite powder consists of the following raw materials in percentage by weight: 1-5 percent of zinc stearate and 95-99 percent of zeolite powder. The tower granulation slow release long-acting nitrogen phosphorus potassium compound fertilizer which has the advantages of good slow release effect, high fertilizer nutrient utilization rate, simple process, low cost and contribution to environmental protection in use with the tower granulation device and the preparation method thereof are provided.

Owner:STANLEY AGRI GRP CO LTD

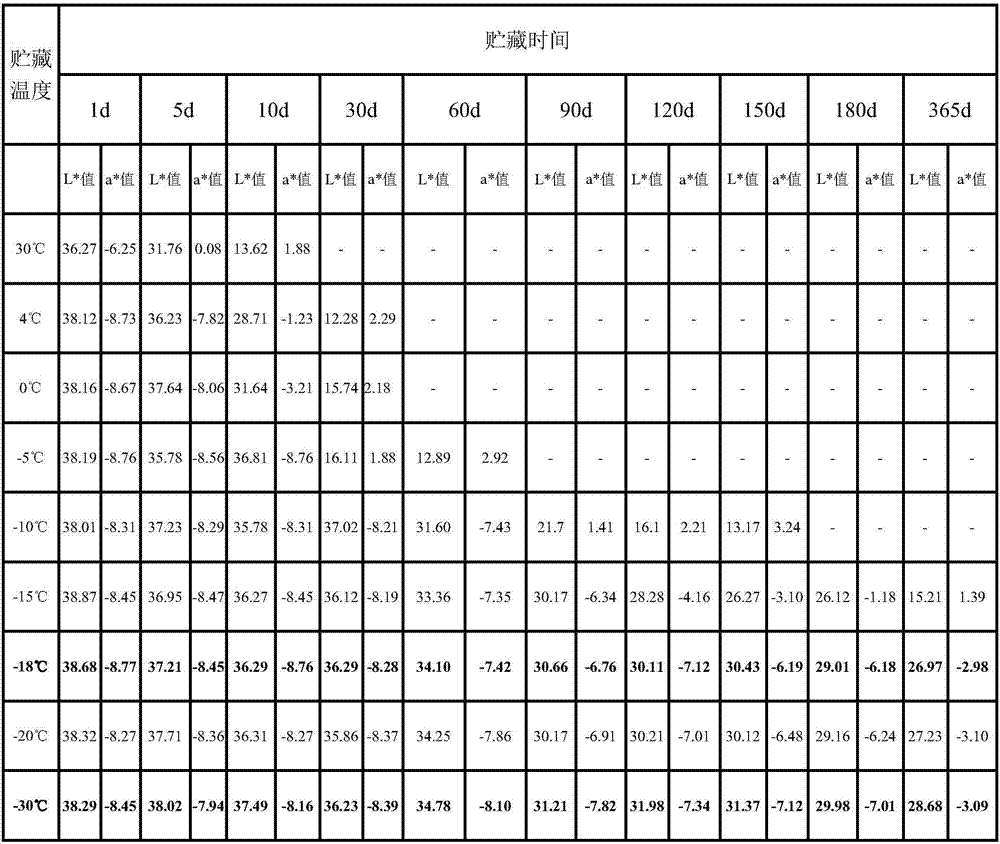

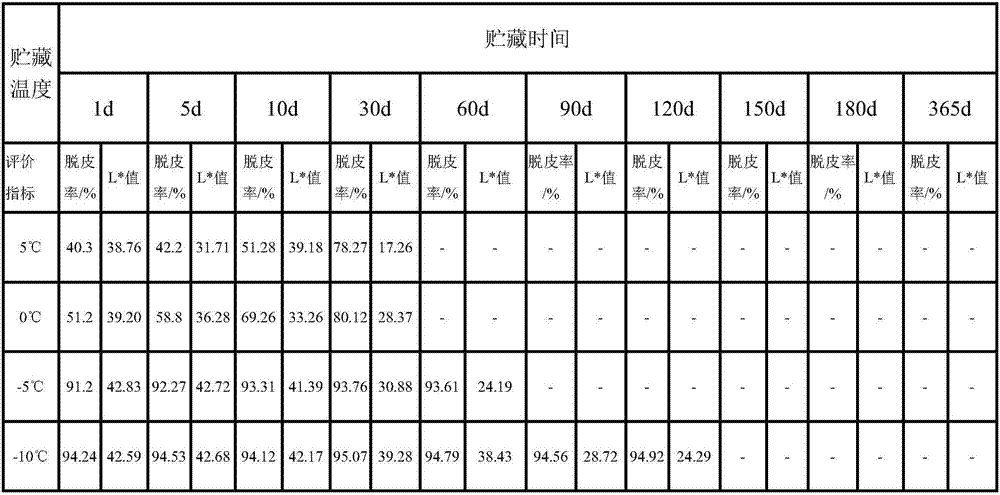

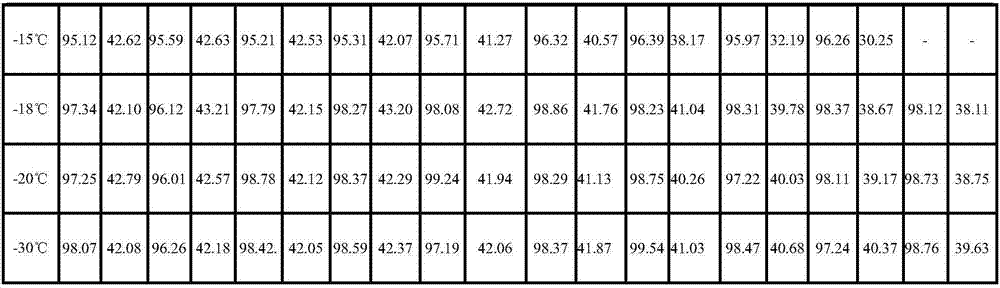

Quick peeling method of piper nigrum fruits through freezing

ActiveCN107028201AColor unchangedNatural colorVegetable peelingFood treatmentPiper lepturumHorticulture

The invention relates to the field of green and safe processing and treating of foods, in particular to a quick peeling method of piper nigrum fruits through freezing. The quick peeling method comprises three steps of precooling, freezing and peeling. According to the peeling method, firstly fresh piper nigrum fruits are frozen, then the frozen piper nigrum fruits are stored, and the unfrozen piper nigrum fruits can be directly peeled through mechanical and electronic integration so that white piper nigrum fruits are prepared. The prepared white piper nigrum fruits are smooth in surfaces, mellow and full in granules, quietly-elegant in color, rich in fragrance and free from any peculiar smell, the fragrance of the white piper nigrum fruits is substantially elevated, the quality of the white piper nigrum fruits is excellent, and the quick peeling method is suitable for large-scale industrialized continuous production.

Owner:HAINAN UNIVERSITY

Microencapsulated animal drug and preparation method thereof

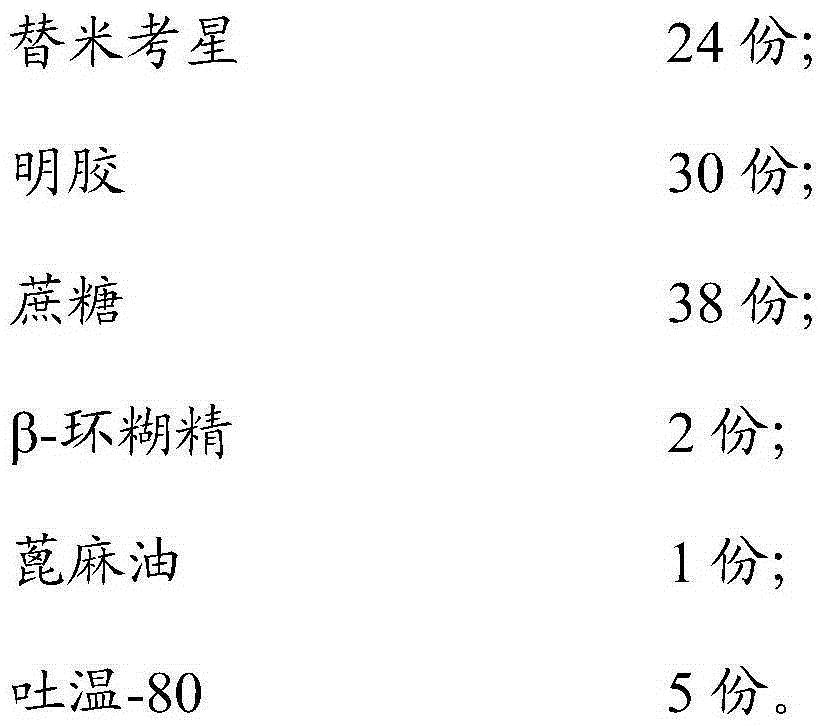

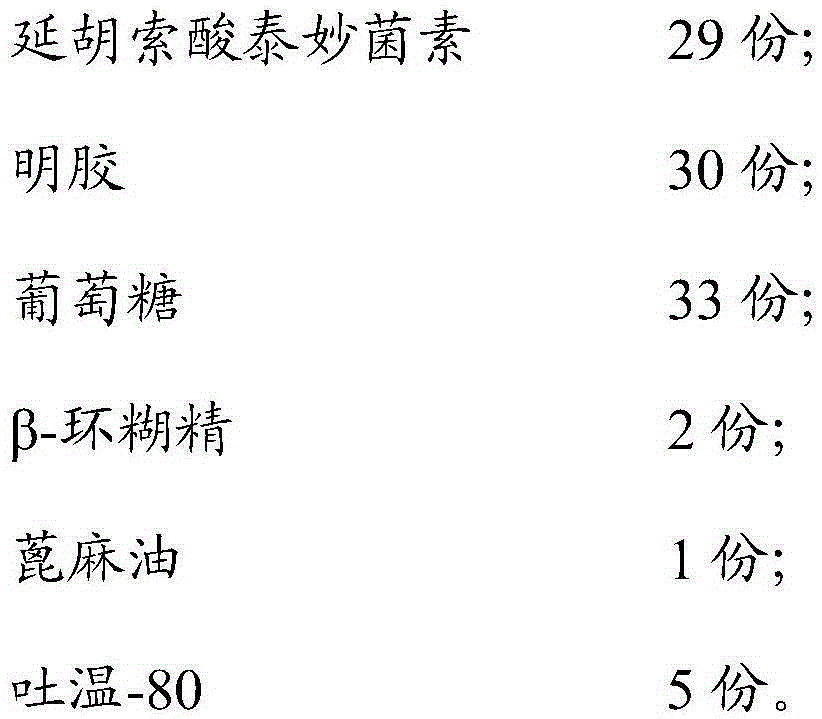

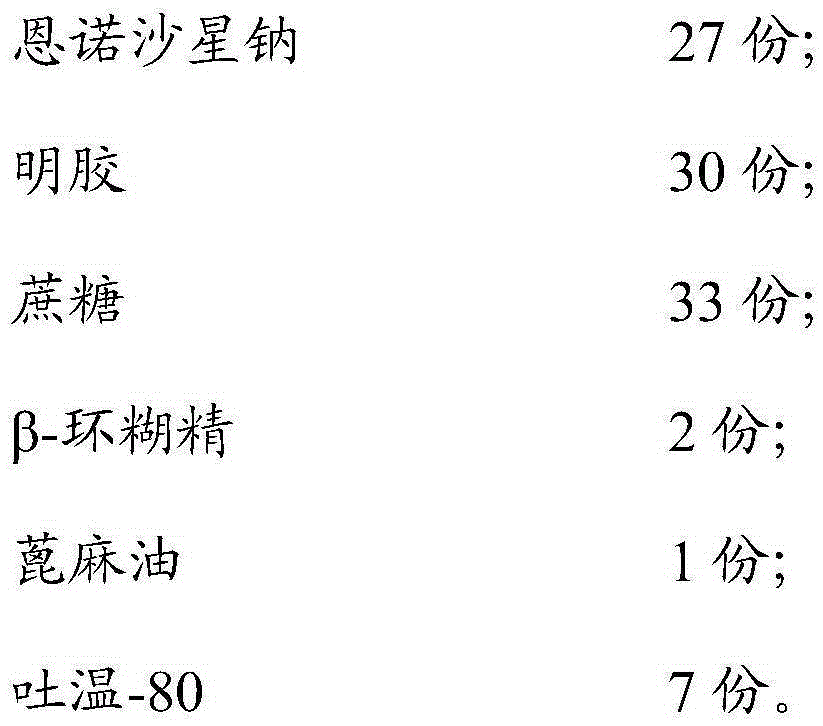

InactiveCN105287433ARound particlesCapsule coating effect is goodMacromolecular non-active ingredientsEster active ingredientsOil phaseSolvent

The invention discloses a microencapsulated animal drug which comprises the following synthesis raw materials in parts by weight: 9-29 parts of drug, 56-86 parts of wall material and 3-7 parts of an emulsifying agent. The invention further relates to a preparation method for the microencapsulated animal drug. The preparation method comprises the following steps: 1) preparing raw materials, 2), dissolving the wall material into water so as to obtain a water phase A; 3), dissolving the drug into a solvent, and adding the emulsifying agent so as to obtain an oil phase B; 4), under the condition of high shearing and high stirring, adding the oil phase B into the water phase A, stirring and emulsifying at a high speed and heating to remove the solvent so as to obtain microemulsion; 5), adding the obtained microemulsion into a spray granulation tower and mixing the microemulsion with corn starch or rice bran, and carrying out spray-drying, so as to obtain the microencapsulated animal drug granules or powder. The microencapsulated animal drug prepared through the preparation method disclosed by the invention is good in covering effect and good in flowing properties and the purposes of masking the smell, preventing dampness, and improving drug stability and drug bioavailability are realized.

Owner:GUANGDONG WENS DAHUANONG BIOTECH

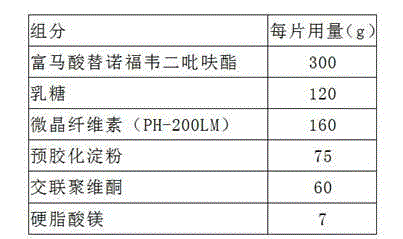

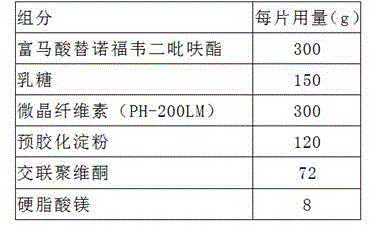

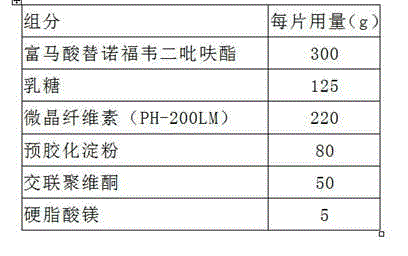

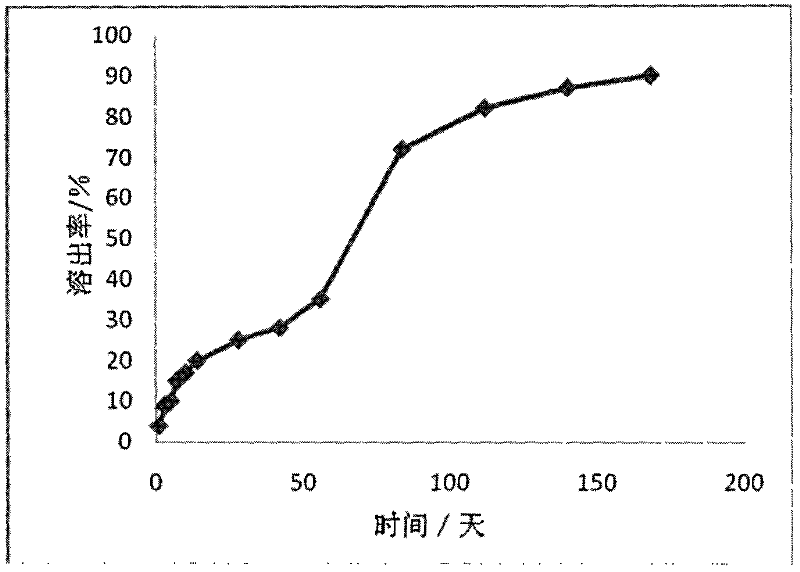

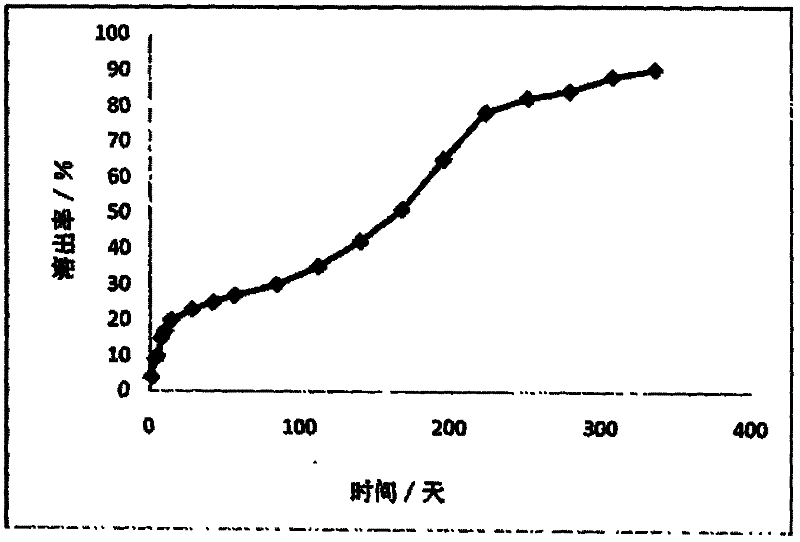

Readily soluble tenofovir disoproxil fumarate tablets and preparation method thereof

ActiveCN104688700AIntermediate fluidityRound particlesOrganic active ingredientsAntiviralsDissolutionChemistry

The invention belongs to the technical field of medicinal preparations and in particular relates to readily soluble tenofovir disoproxil fumarate tablets and a preparation method thereof. The readily soluble tenofovir disoproxil fumarate tablets are prepared by taking tenofovir disoproxil fumarate as a raw material and a pharmaceutically acceptable auxiliary component as an auxiliary material, and adopting a fluidized bed granulation tabletting process and a wet activity dry granulation tabletting process, wherein the auxiliary material comprises microcrystalline cellulose, pregelatinized starch, lactose, crosslinking carboxymethyl cellulose sodium, Cellactose 80 and magnesium stearate. The readily soluble tenofovir disoproxil fumarate tablets provided by the invention have the advantages of relatively good intermediate fluidity, mellow and full granules, uniform size, high dissolution rate and the like, and can obviously improve the dissolution rate of a medicament in water, and by virtue of significantly improving the dissolution rate of the medicament, the biological utilization degree of an oral administration medicament is improved.

Owner:SHANDONG WEIFANG PHARMA FACTORY

Method for producing sustained-release granular potassium chloride fertilizer

ActiveCN102690142AShort processEasy to operatePotassium fertilisersFertilizer mixturesFertilizerInlet temperature

The invention relates to a method for producing a sustained-release granular potassium chloride fertilizer and belongs to the technical field of manufacture of fertilizers. The method comprises the specific steps of: preparation of a membrane coating agent and a granular potassium chloride coating membrane; adding linseed oil, glycerin, polyether and calcium naphthenate into a high-temperature reaction kettle, reacting for 2 hours at the temperature of 250 DEG C, putting the materials into a low-temperature reaction kettle, regulating the temperature of the materials to be 60 DEG C, adding toluene diisocynate (TDI-80) to the low-temperature reaction kettle, and simultaneously adding dimethylbenzene in batches; uniformly agitating and mixing, heating to raise the temperature to 80-95 DEG C, reacting for a period of time, cooling to 50-55 DEG C, adding methanol to agitate for a period of time, and adding cobalt naphthenate, lead naphthenate, diacetylmonoxime to uniformly agitate the mixture. A certain amount of granular potassium chloride is added into a fluidized bed coating machine, the air inlet temperature of the fluidized bed coating machine is controlled to be 70-100 DEG C, the wind pressure of an inlet is controlled, the membrane coating agent is sprayed into potassium chloride particles at the ratio to perform membrane coating, the potassium chloride particles are cooled and sieved, and the qualified particles are packaged to obtain the finished product after being coated by the membrane.

Owner:HENAN LEEF FERTILIZER

Method for producing granular potassium chloride

InactiveCN102690143AParticle roundingFlat surfacePotassium fertilisersFertilizer mixturesChloride potassiumFertilizer

The invention relates to a method for producing granular potassium chloride and belongs to the technical field of manufacture of fertilizers. The method comprises the specific steps of preparation of a binder and pelleting of powdered potassium chloride; adding polyacrylic emulsion, whose solid content is 53%, in water in a container to uniformly agitate the polyacrylic emulsion and water, then sequentially adding benzyl alcohol, ethylene glycol, sodium benzoate and polyvinyl butyral in proportions, and fully and uniformly agitating the mixture. The process may be batch production or continuous production. If the process is batch production, the powdered potassium chloride is added to a disk pelletizer, and the binder is sprayed into rotary materials in proportion and pelletized into balls. The product is prepared by drying, cooling and sieving. If the process is continuous production, the powdered potassium chloride is added to a disk or rotary drum granulator; the binder is continuously sprayed into the rotary material in proportion and pelletized into balls, and the product is prepared by drying, cooling and sieving. The product is round and intact in particles, smooth in surface and high in strength. The product can be used as a bulk-blended fertilizer material. The top potassium oxide content of the product can be up to 59.5%.

Owner:HENAN LEEF FERTILIZER

Method for preparing purple sand slime containing tourmaline iron sand

The invention provides a method for preparing purple sand slime containing tourmaline iron sand. Ore and raw tourmaline scattered in a soft clay ore bed are artificially selected, purple sand ore is stacked in the open air in winter and summer for natural weathering, the weathered raw ore is aired, dried, ground by means of a hard stone mill and smashed into 60-mesh fine powder, 80-mesh fine powder and 120-mesh fine powder, and after the tourmaline ore is smashed and ground and ore powder is screened out by a 140-mesh sieve, water is added, the materials are mixed, evenly stirred and sealed for ageing; vacuum pugging, clay strip pressing, sealing and ageing are repeated for 3-5 times, and the purple sand slime containing the tourmaline iron sand is prepared. The slime prepared through the method is original, pure, free of chemical raw materials and artificial pigment and not likely to crack when purple sand ceramic products are fired, and the manufactured purple sand ceramic products are natural, environmentally friendly, good in quality, natural in texture, fine and smooth in hand feeling, good in light transparency and water color and good in color generation. Meanwhile, the purple sand slime has the effects of improving water quality and promoting blood microcirculation.

Owner:宜兴市帛玉碧砂艺术品有限公司

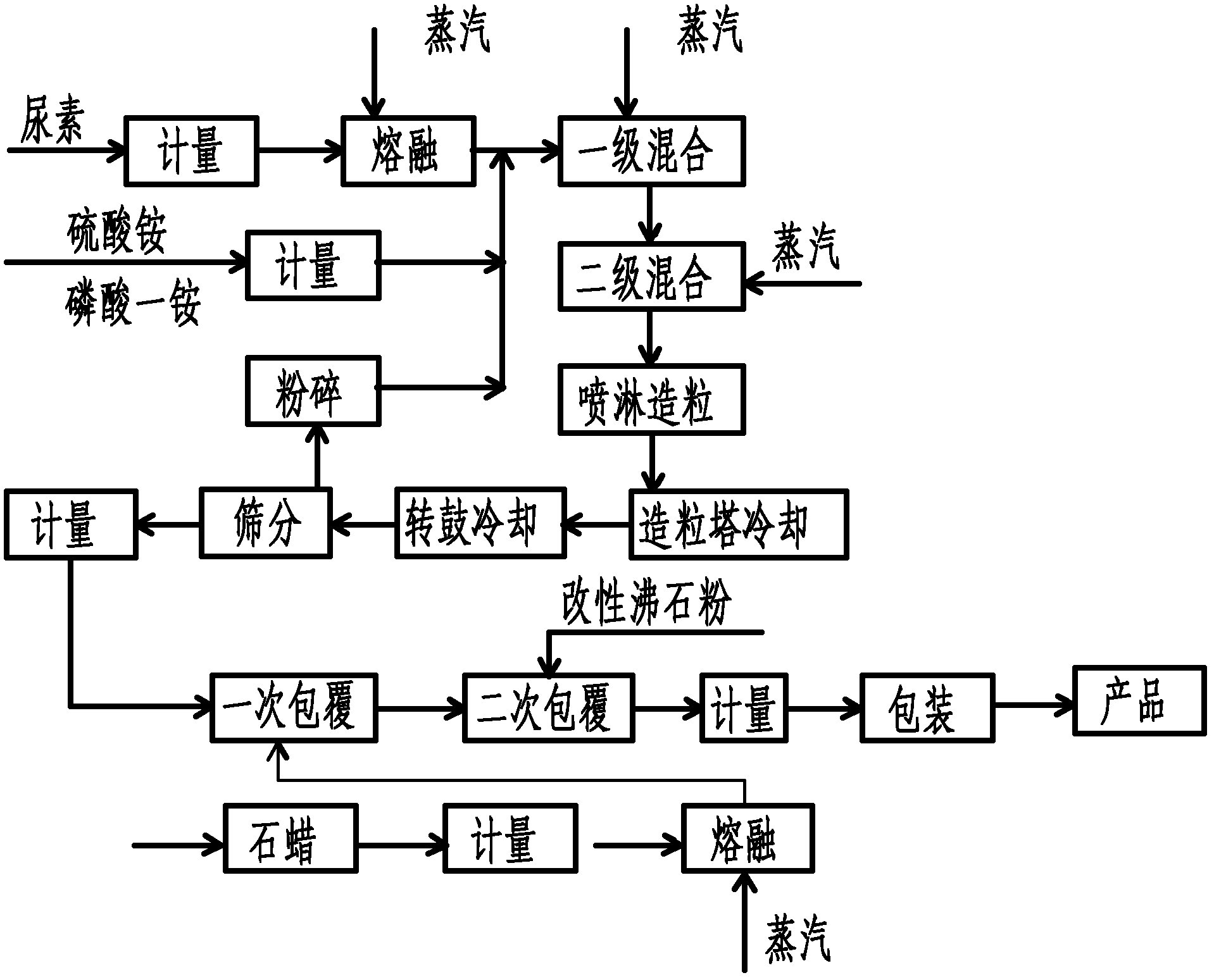

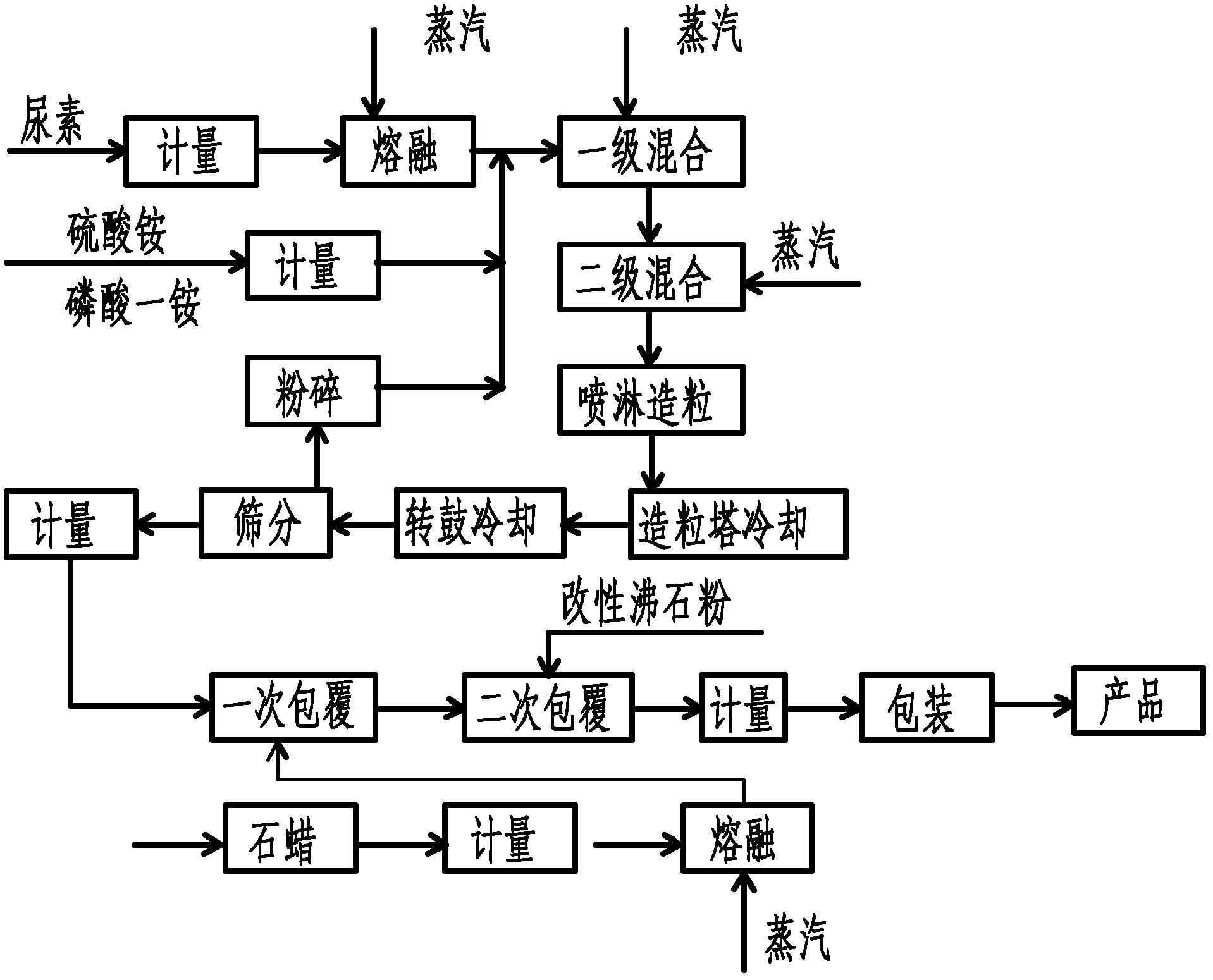

High-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer and preparation method thereof

ActiveCN102603386AImprove Nutrient Utilization EfficiencyGood sustained release effectFertilizer mixturesPhosphateAmmonium sulfate

The invention discloses a high-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer and a preparation method of the high-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer, and belongs to compound fertilizers. High-tower granulation urea compound fertilizer particles are prepared by a high-tower granulation device, then wrapped by paraffin for the first time and wrapped by modified zeolite powder for the second time, so that the high-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer is prepared. The high-tower granulation urea compound fertilizer particles consist of the following raw materials in parts by weight: 33 to 43 parts of urea, 26 to 38 parts of monoammonium phosphate and 19 to 41 parts of ammonium sulfate; the using amount of the paraffin for wrapping for the first time is 0.5 to 1.0 percent of the mass of the high-tower granulation urea compound fertilizer particles; andthe modified zeolite powder consists of the following raw materials in parts by weight: 1 to 5 parts of zinc stearate and 95 to 99 parts of zeolite powder. The preparation method can be mated with the high-tower granulation device, and the high-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer has a good slow-release effect and high fertilizer nutrient utilization rate, is simple in process, relatively low in production cost and beneficial for soil, atmosphere and water environment protection.

Owner:STANLEY AGRI GRP CO LTD +1

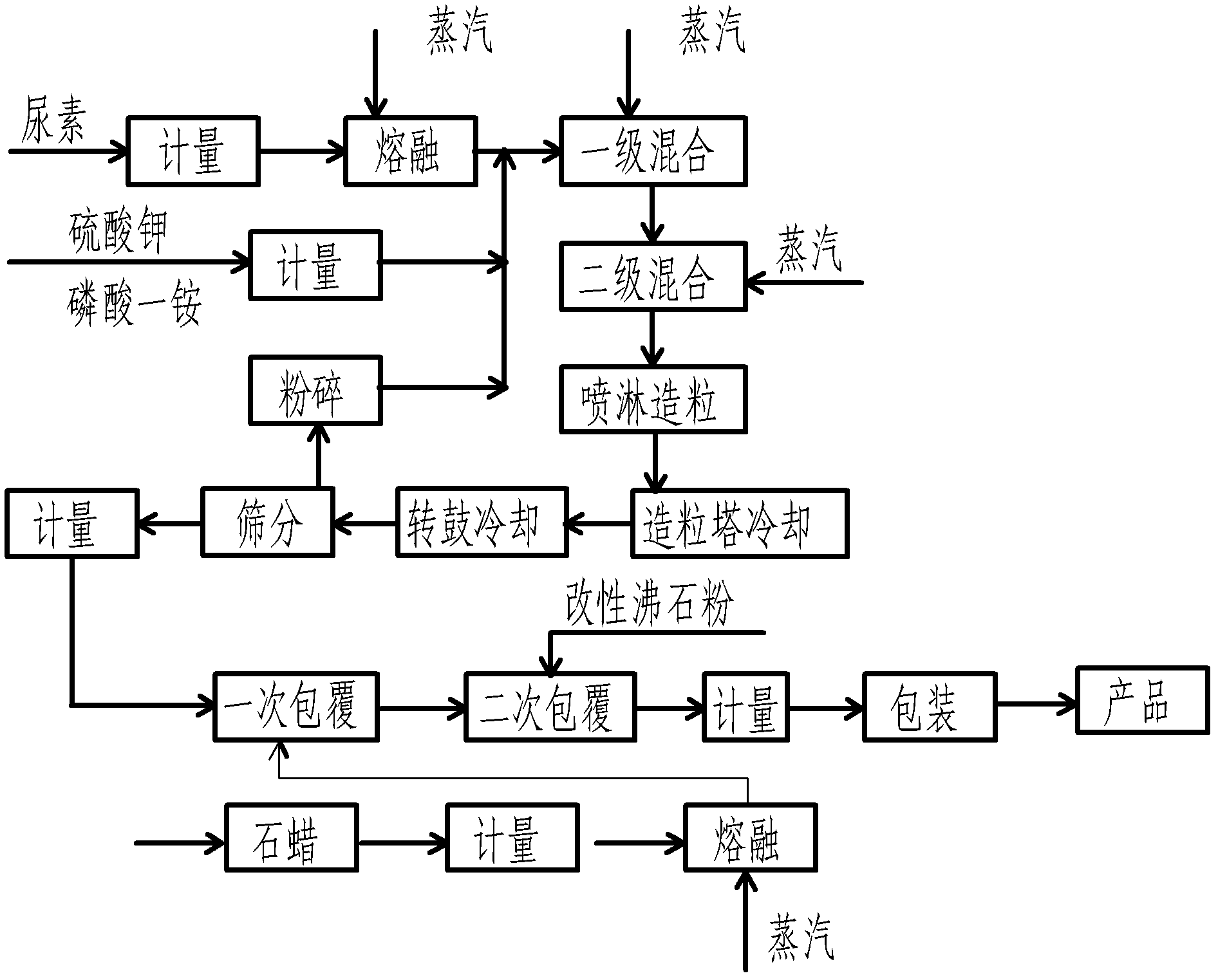

High tower-granulated sustained-release long-acting sulfur-based nitrogen-phosphor-potassium compound fertilizer and preparation method thereof

ActiveCN102320875AImprove Nutrient Utilization EfficiencyHigh Potassium Sulfate ContentFertilizer mixturesParaffin waxPhosphate

The invention discloses a high tower-granulated sustained-release long-acting sulfur-based nitrogen-phosphor-potassium compound fertilizer and a preparation method thereof, and belongs to the field of compound fertilizers. The preparation method comprises the following steps of preparing urea compound fertilizer particles through a high tower granulation device, carrying out first coating of the urea compound fertilizer particles with paraffin, and then carrying out second surface coating with modified zeolite powder to obtain the high tower-granulated sustained-release long-acting sulfur-based nitrogen-phosphor-potassium compound fertilizer. The urea compound fertilizer particles obtained by high tower granulation comprises: by weight, 35 to 50 parts of urea, 20 to 25 parts of monoammonium phosphate, and 30 to 40 parts of potassium sulfate. A use amount of the paraffin is 0.5 to 1.0% of the weight of urea compound fertilizer particles obtained by high tower granulation. The modified zeolite powder comprises: by weight, 1 to 5% of zine stearate and 95 to 99% of zeolite powder. The high tower-granulated sustained-release long-acting sulfur-based nitrogen-phosphor-potassium compound fertilizer can be utilized in conjunction with a high tower granulation device, has good sustained-release effects, a high fertilizer utilization rate and high potassium sulfate content, and is be beneficial for protection of soil, air and water environments. The preparation method has simple processes and low costs.

Owner:STANLEY AGRI GRP CO LTD

A kind of ammonification method to process weathered coal to produce potassium sulfate type compound fertilizer and its manufacturing method

InactiveCN102276355AImprove water retentionImprove fertilizer supply capacityFertilizer mixturesSulfurOrganic matter

The invention belongs to the technical field of compound fertilizer production, and relates to an ammoniation method to process weathered coal to produce potassium sulfate type compound fertilizer and a manufacturing method thereof. It is formed by adding powdered weathered coal to the traditional ammoniated granulation potassium sulfate compound fertilizer production and activated by ammonia and acid. The product of the invention has reasonable compatibility and balanced nutrients, and has the functions of improving soil, stimulating the development of plant roots and improving fertilizer utilization rate, and is a new type of sulfur-based compound fertilizer rich in organic matter and various nutrient elements.

Owner:SHANDONG SHOUGUANG DADI LVYUAN FERTILIZER IND

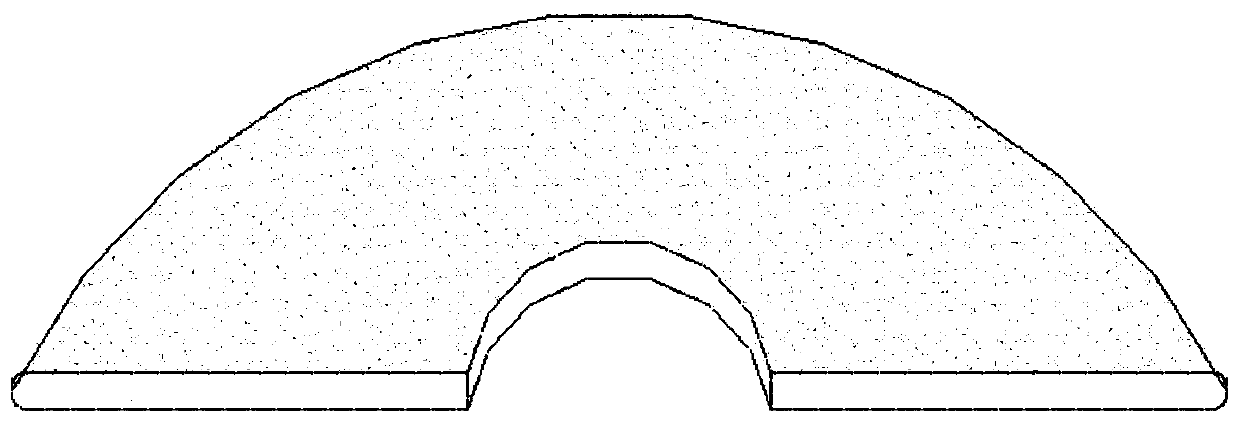

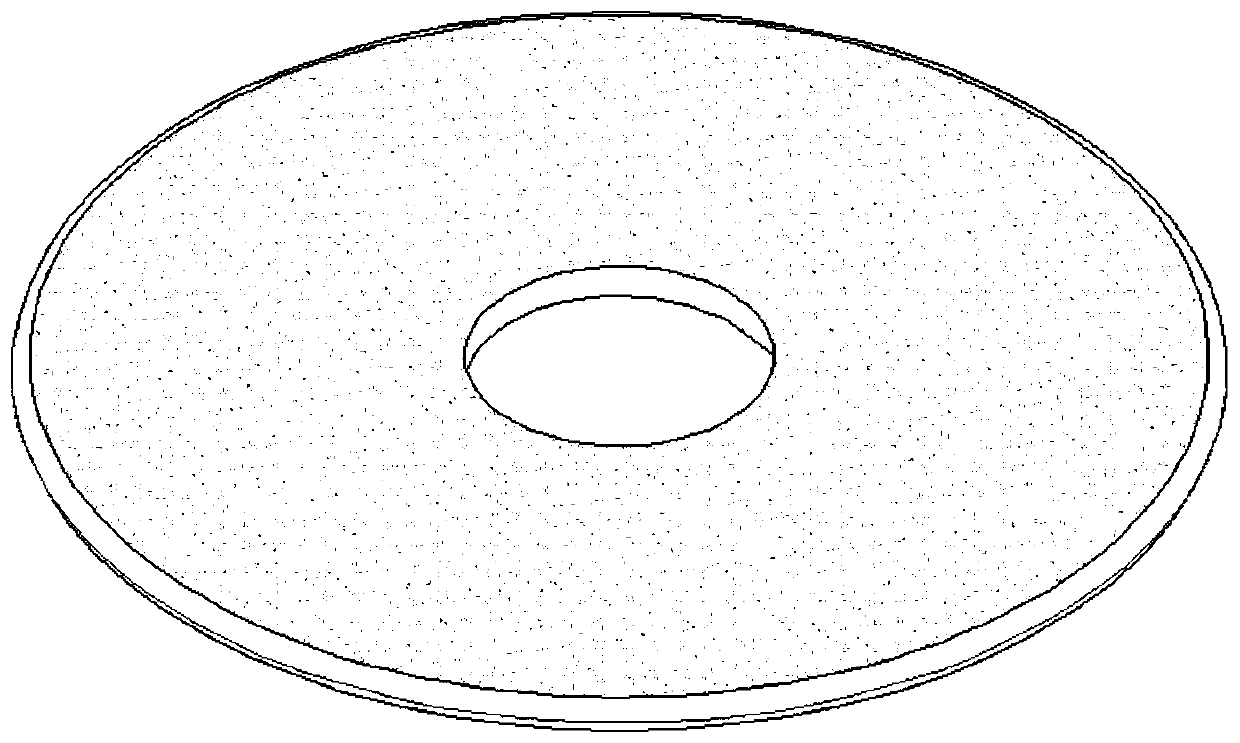

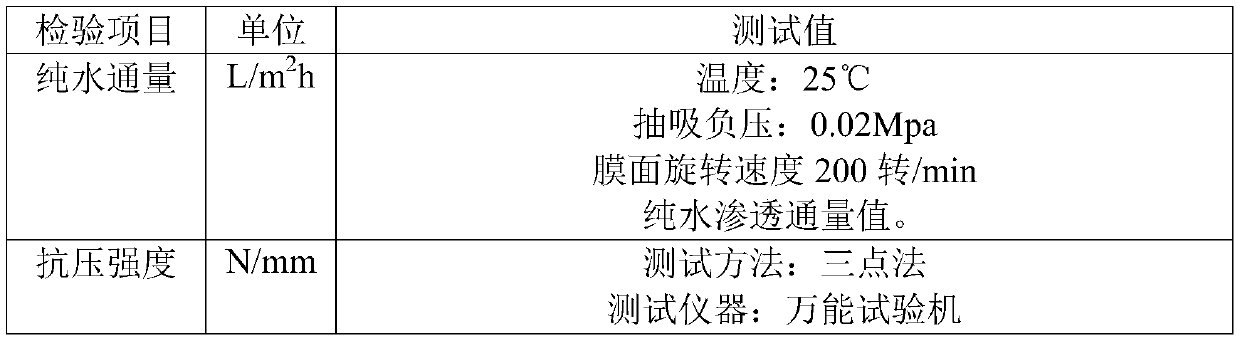

Preparation method of shaft disc type rotary ceramic membrane

The invention relates to the technical fields of porous ceramic materials and membrane separation, in particular to a preparation method of a shaft disc type rotary ceramic membrane. The preparation method is mainly characterized in that a microsphere ceramic raw material is selected as aggregate of a support body, ceramic fibers are selected as a transition layer, beta-silicon carbide is selectedas a membrane layer, and the shaft disc type rotary ceramic membrane is formed by pressing through a hydraulic press and firing through a low-temperature liquid phase process. The preparation methodhas the characteristics of being low in sintering temperature, low in production energy consumption, simple in process method, low in equipment requirement, low in production cost and investment cost,flexible to control, easy to form, suitable for industrial customization and capable of meeting large-scale production; and the shaft disc type rotary ceramic membrane prepared by the method has thecharacteristics of good hydrophilicity, large permeation flux, high porosity, a high yield, no need of forming a diversion trench, good acid and alkali resistance and long service life.

Owner:ZHEJIANG SCI-TECH UNIV

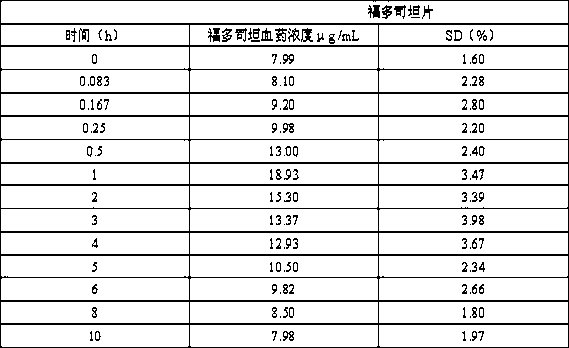

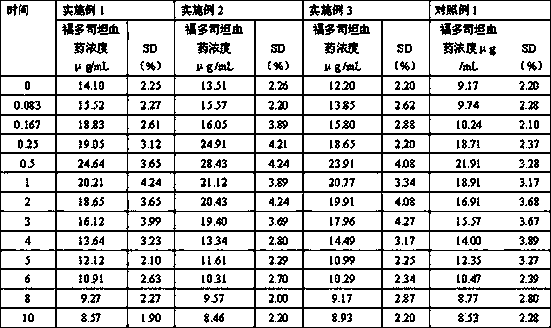

Fudosteine inhalant composition

InactiveCN108078964AUniform contentIncrease the amount of deposition in the effective partPowder deliveryOrganic active ingredientsFUDOSTEINEMedicine

The invention belongs to the technical field of medicine, and relates to a fudosteine inhalant and a preparation method thereof. The fudosteine inhalant provided by the invention is prepared from 60 to 90 percent of fudosteine and 10 to 40 percent of lactose, wherein the percentage is the mass percentage; the particle diameter D90 of the fudosteine is preferably 2 mu m to 5 mu m. The invention provides a fudosteine dry powder inhalant with high bioavailability.

Owner:DISHA PHARMA GRP +1

Method for producing granulated compound fertilizer by granulating through urea tower

InactiveCN102001871AReduce energy consumptionRound particlesFertiliser formsUrea compound fertilisersSlurryTower

The invention discloses a method for producing granulated compound fertilizer by granulating through a urea tower, comprising the following steps of: heating and mixing a urea melted ammonium nitrate solution and fertilizer for producing the compound fertilizer according to the proportion in a mixer to prepare compound fertilizer mixed slurry; and spraying and granulating the mixed material by a spray head of a granulator, cooling, screening, metering and packaging the granules. The invention belongs to a novel production process of the compound fertilizer. Compared with the prior art, the invention can be directly used for producing the granulated compound fertilizer in the urea tower so as to simplify the production process of the compound fertilizer.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

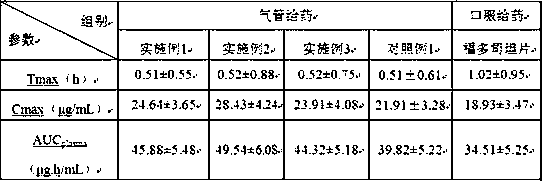

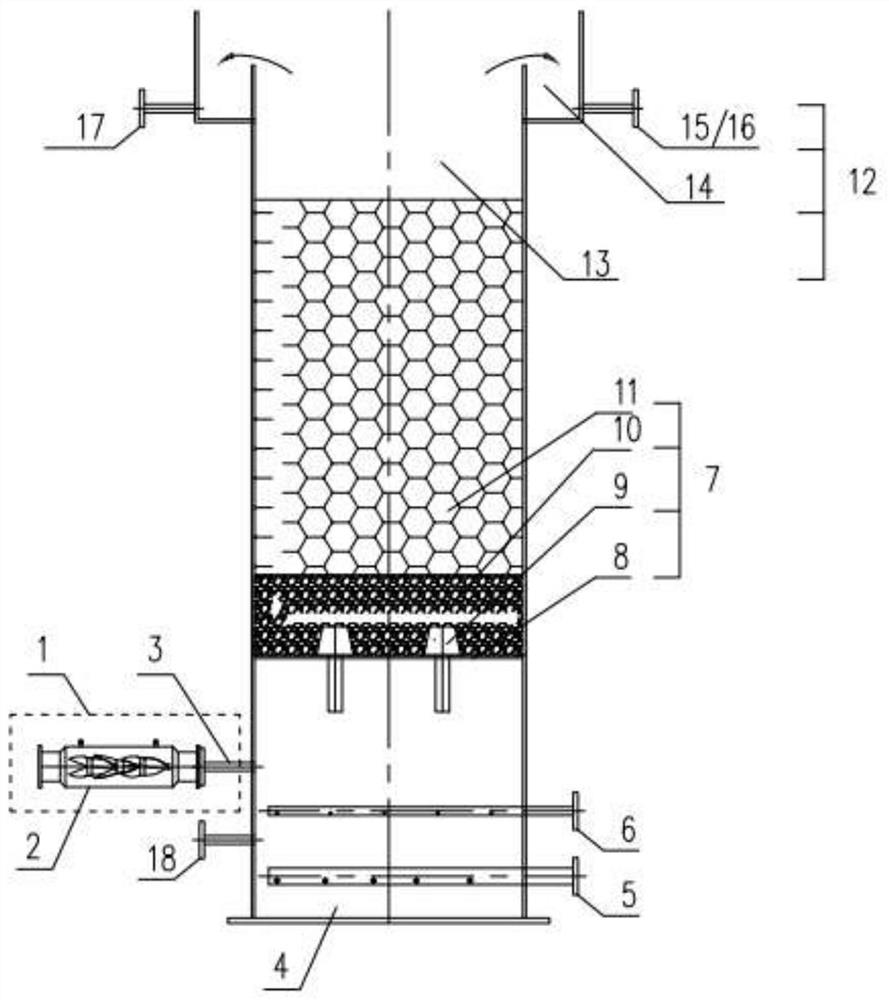

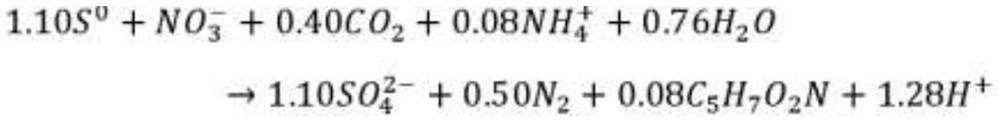

UAD biological filter tower system based on sulfur autotrophy and denitrification method

PendingCN112919732AAchieve removalLow running costWater treatment parameter controlBiological treatment regulationNitrogen removalBiofilm

The invention relates to the technical field of sewage treatment and denitrification, and discloses a UAD biological filter tower system and method based on sulfur autotrophy, and the biological filter tower system comprises a water inlet mixing unit, a nitrogen removal uniform distribution unit, a biological membrane reaction unit and a water collection and drainage unit. Furthermore, the invention discloses a denitrification method based on the system. According to the method, autotrophic denitrifying bacteria are fixed in a high-specific-surface-area filler of an upflow biological filter tower, sulfur powder is used as an electron donor required by autotrophic denitrification, and nitrate nitrogen in sewage is degraded and removed under the condition that an organic carbon source does not need to be additionally added. The system has the advantages of high nitrogen removal efficiency, high treatment load, excellent effluent quality, intelligent operation control and the like, and is suitable for nitrogen removal treatment of high nitrate nitrogen industrial wastewater and nitrogen removal upgrading of municipal sewage secondary effluent.

Owner:CEEP CO LTD

Versatile anti caking additive for chemical fertilizer and its manufacturing methods

InactiveCN1431179ADoes not affect active ingredientsWell-proportioned particlesSpecial surfacesCoatingsNitrogenStearic acid

A broad-spectrum ant-blocking agent for chemical fertilizer is prepared from stearic acid and monoethanolamine through heating, reaction while stirring, cooling and slicing. Its advantages are high effect, broad spectrum, and no poison and pollution.

Owner:戴星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com