UAD biological filter tower system based on sulfur autotrophy and denitrification method

A biological filter tower, sulfur autotrophy technology, applied in biological treatment adjustment methods, biological treatment devices, chemical instruments and methods, etc., can solve difficult to achieve denitrification treatment effect, high operating cost, secondary pollution, organic matter content Low problems, to achieve the effect of high film hanging efficiency, high processing load, and reduced equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated in conjunction with the accompanying drawings and specific embodiments:

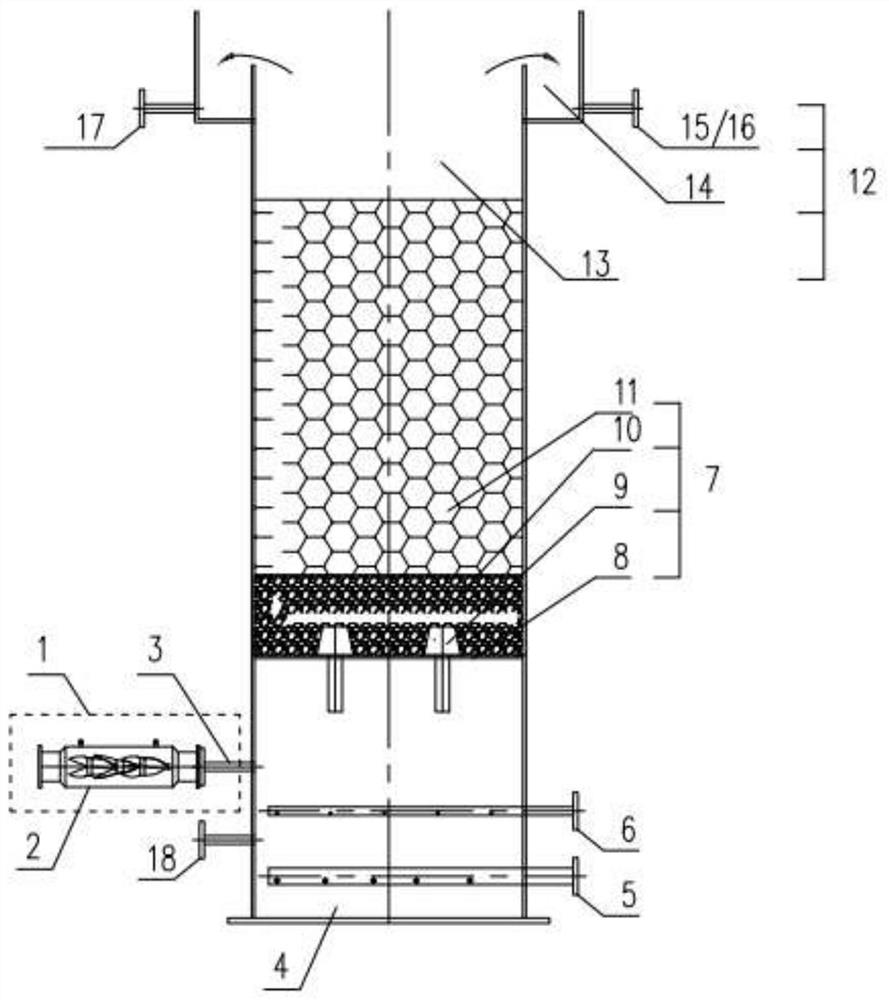

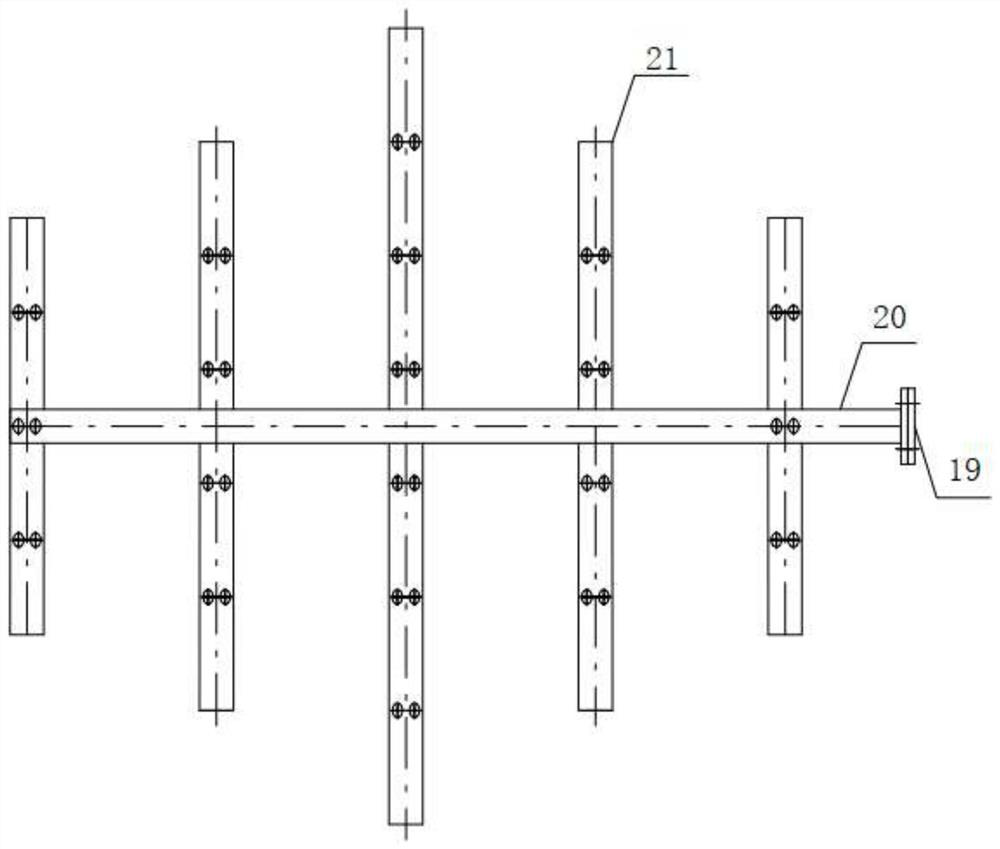

[0028] Such as figure 1 As shown, a sulfur-based UAD biofine tower system comprising an inlet unit, a liquid-free unit, a biofilm reaction unit, a collecting water supply unit.

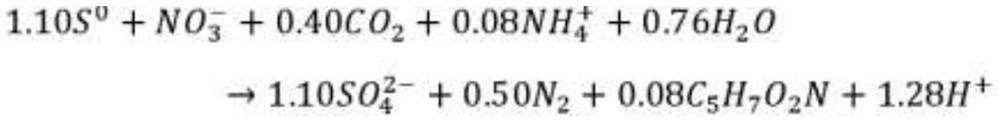

[0029] Based on the device, the early stage needs to carry out microbial culture in the early stage, and the microorganisms employed are taken from the strain, and the nitrogen-containing wastewater is used to cultivate. After the sludge was cultured in about two weeks, the sulfurized culture of the UAD biofine tower was carried out, domesticated and cultured with digested sludge with self-numerous properties. During the culture, a nutrient solution is added every two days and replaces the supernatant. The main component of the nutrient solution is a wastewater mixed with sodium carbonate, sulfur solution, and the domestication time is around 14d, and the water NO is measured. 3 -N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com