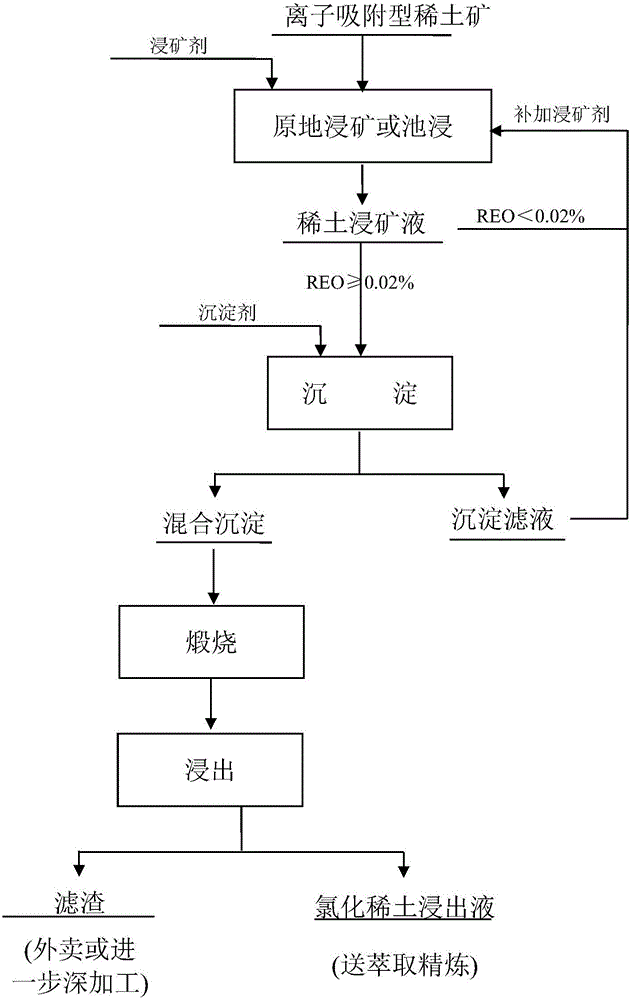

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

An ion adsorption type, rare earth ore technology, applied in the field of extracting rare earth and aluminum, can solve the problems of increasing the production cost of rare earth, many rare earth inclusions, and a large amount of investment, and achieves the effect of realizing impurity recycling, cleaning metallurgical process, and improving production income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The ion-adsorption type rare earth ore in a rare earth mining area in Ganzhou adopts the in-situ leaching process, and ammonium sulfate is used as the leaching agent for leaching treatment. The concentration of rare earth in the obtained rare earth leaching solution is 0.64g / L, and the concentration of aluminum is 2.86 g / L, the pH value of the rare earth leaching solution is 4.2.

[0035] Use solid ammonium carbonate as a precipitant, add it to the rare earth leaching solution while stirring, the amount of ammonium carbonate added is 1.5 times the sum of the molar amounts of rare earth and aluminum in the rare earth leaching solution, and the pH of the precipitation mother solution after stirring for 15 minutes After aging for 2 hours, put it into a filter tank or a filter press for solid-liquid separation to obtain a precipitate filtrate and a mixed precipitate containing rare earth and aluminum. Then send the mixed precipitate containing rare earth and aluminum to the...

Embodiment 2

[0039] The ion-adsorption type rare earth ore in a rare earth mining area in Hunan adopts the in-situ leaching process and uses ammonium sulfate as the leaching agent for leaching treatment. The concentration of rare earth in the obtained rare earth leaching solution is 0.39g / L, and the concentration of aluminum is 1.17 g / L, the pH value of the rare earth leaching solution is 4.5.

[0040] Use solid magnesium bicarbonate as a precipitant, add it to the rare earth leaching solution while stirring, the amount of magnesium bicarbonate added is twice the sum of the molar amounts of rare earth and aluminum in the rare earth leaching solution, and precipitate after stirring for 0.5h The pH of the mother liquor is 6.9, the stirring is stopped and the solid-liquid separation is carried out to obtain a precipitate filtrate and a mixed precipitate containing rare earth and aluminum. Then send the mixed precipitate containing rare earth and aluminum to the next process, add leaching agen...

Embodiment 3

[0044] The ion-adsorption type rare earth ore in a rare earth mining area in Guangxi adopts the in-situ leaching process and uses ammonium sulfate as the leaching agent for leaching treatment. The concentration of rare earth in the obtained rare earth leaching solution is 0.53g / L, and the concentration of aluminum is 5.64 g / L, the pH value of the rare earth leaching solution is 4.4.

[0045] Use saturated ammonium bicarbonate solution as a precipitating agent, add it to the rare earth leaching solution while stirring, the amount of saturated ammonium bicarbonate added is 2.5 times the sum of the molar amounts of rare earth and aluminum in the rare earth leaching solution, after stirring for 1 hour The pH of the precipitation mother liquor is 7.1, the stirring is stopped and aged for 1 hour, and then the solid-liquid separation is carried out to obtain the precipitation filtrate and the mixed rare earth precipitation containing rare earth and aluminum. Then send the mixed preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com