Patents

Literature

1031 results about "Ion adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoscale intercalation materials on carbon powder, process for production, and use thereof

InactiveUS20110281176A1Shorten charging timeIncreased usable storage capacityMaterial nanotechnologyElectric discharge heatingMethods of productionOxide coating

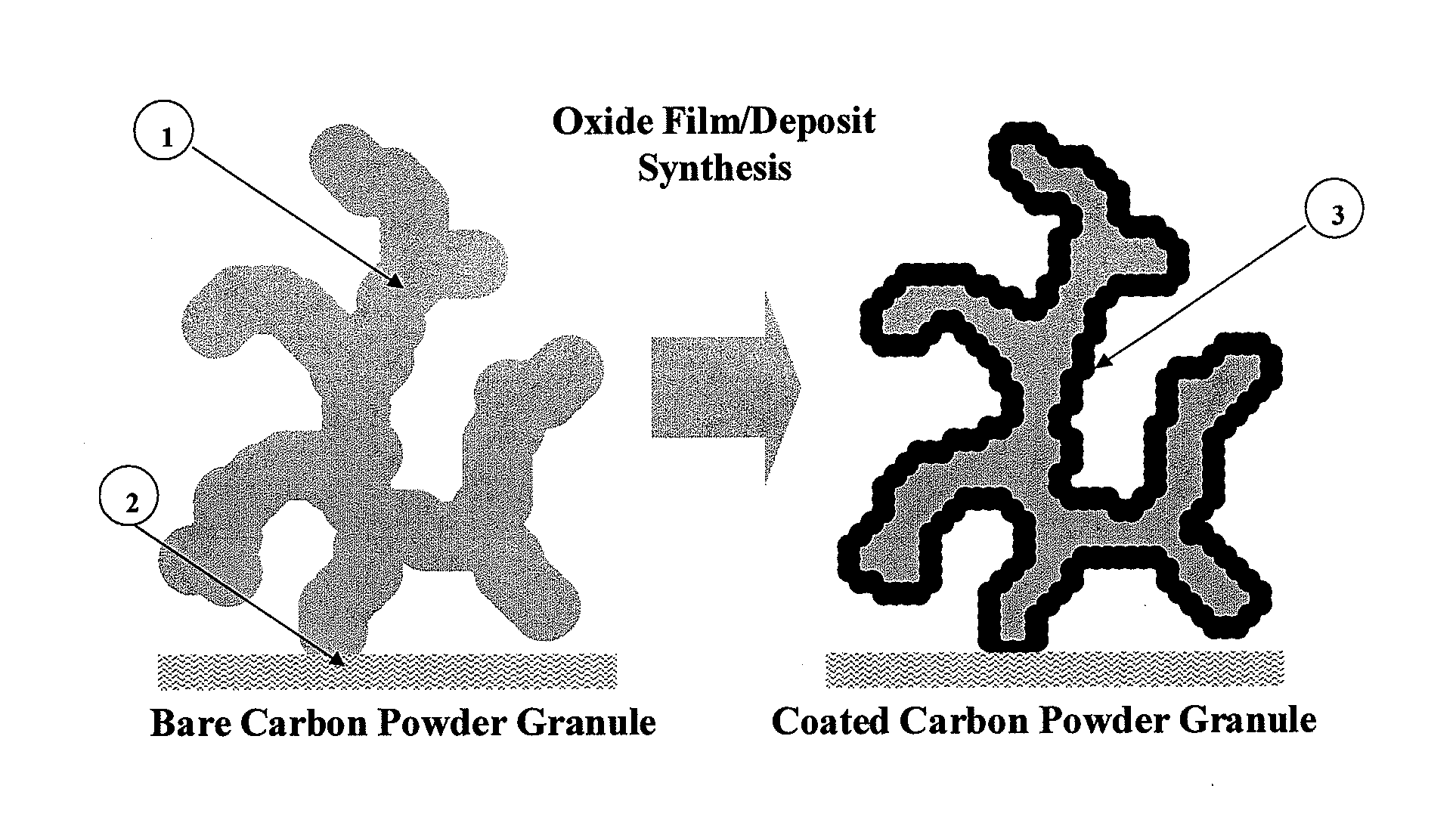

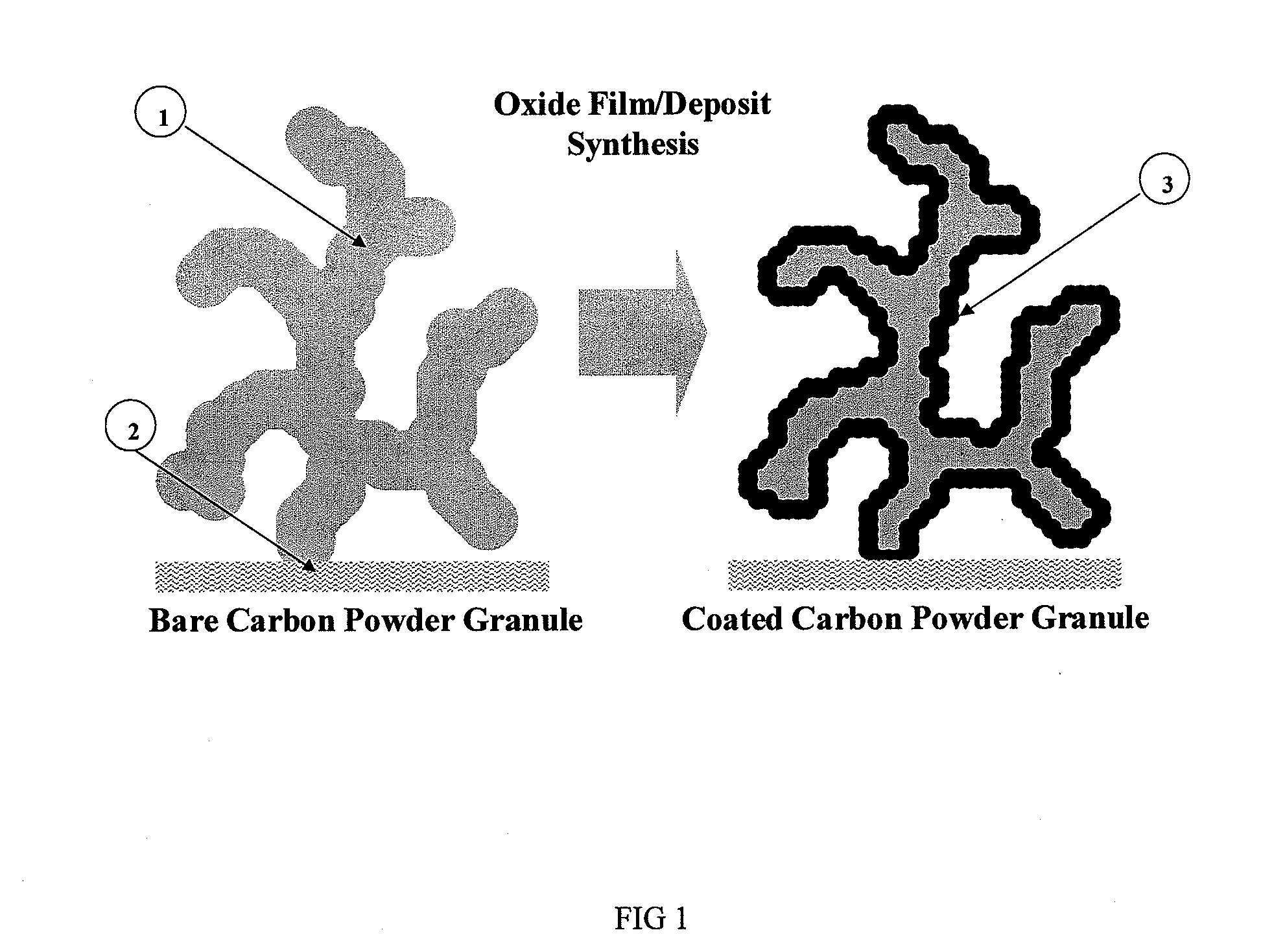

An electrode material is created by forming a thin coating or small deposits of metal oxide as an intercalation host on a carbon powder. The carbon powder performs a role in the synthesis of the oxide coating, in providing a three-dimensional, electronically conductive substrate supporting the metal oxide, and as an energy storage contribution material through ion adsorption or intercalation. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

Sodium alginate-acrylamide composite aquagel, and preparation method and application thereof

ActiveCN105504166AReduce or even avoid stress defectsAvoid stress defectsWater/sewage treatment by sorptionBiocompatibility TestingSewage treatment

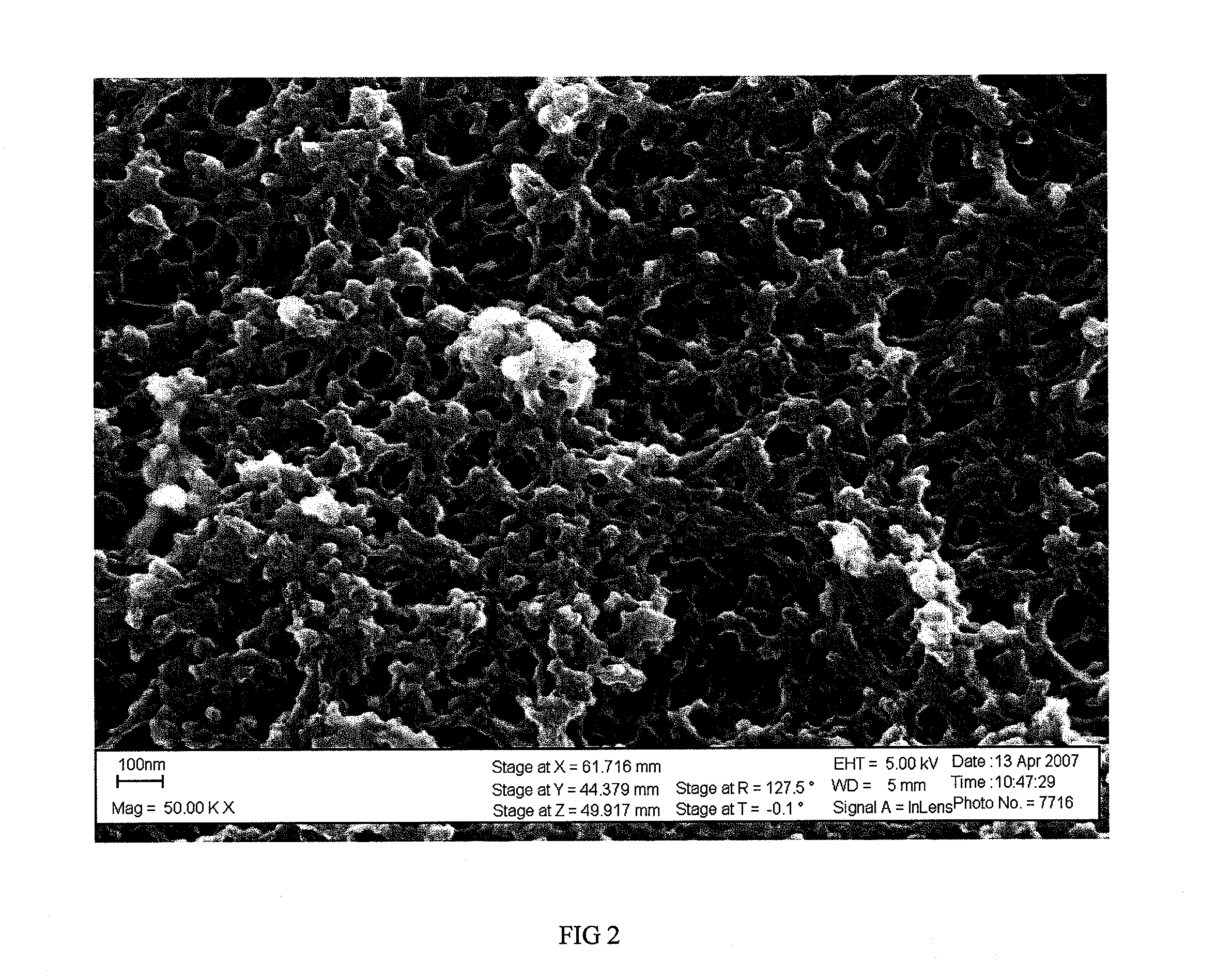

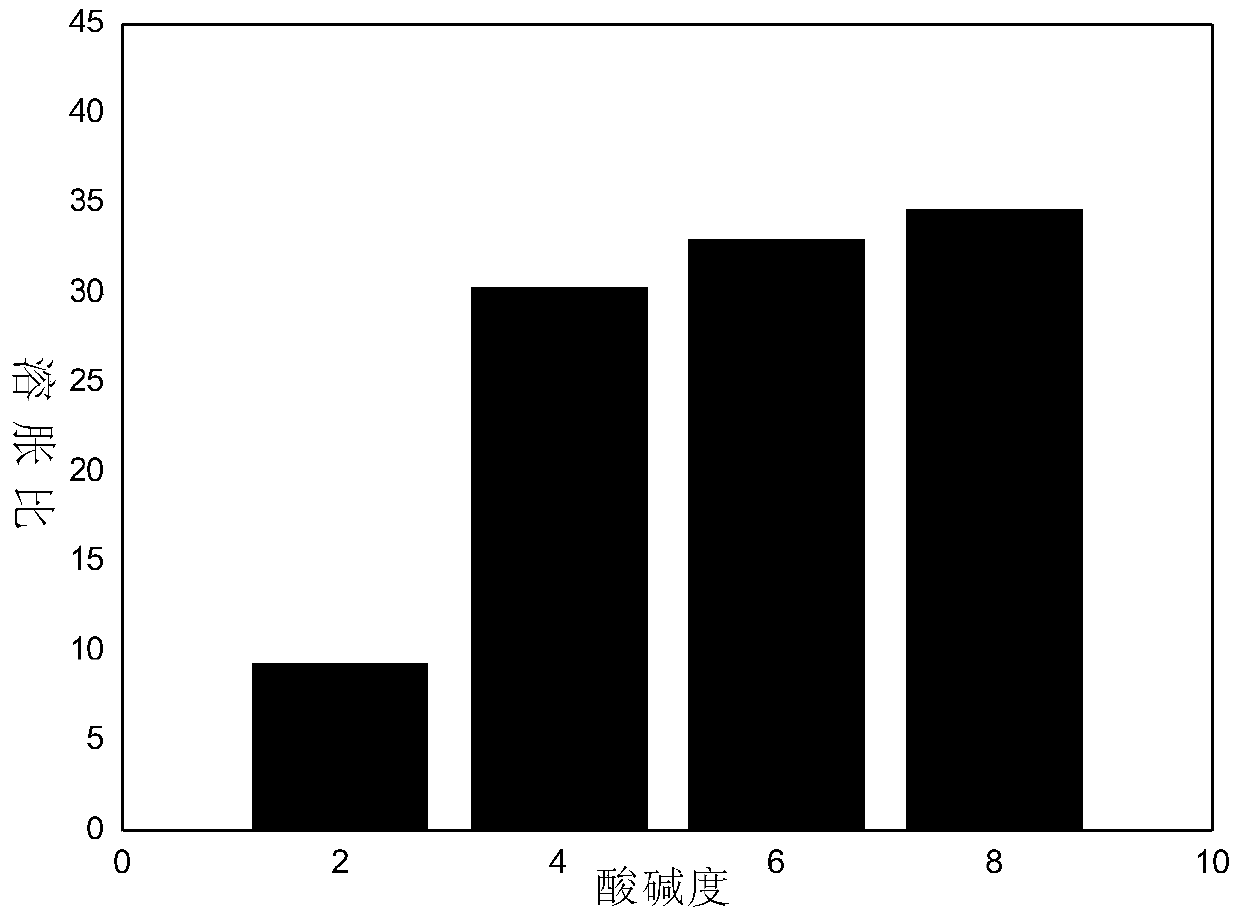

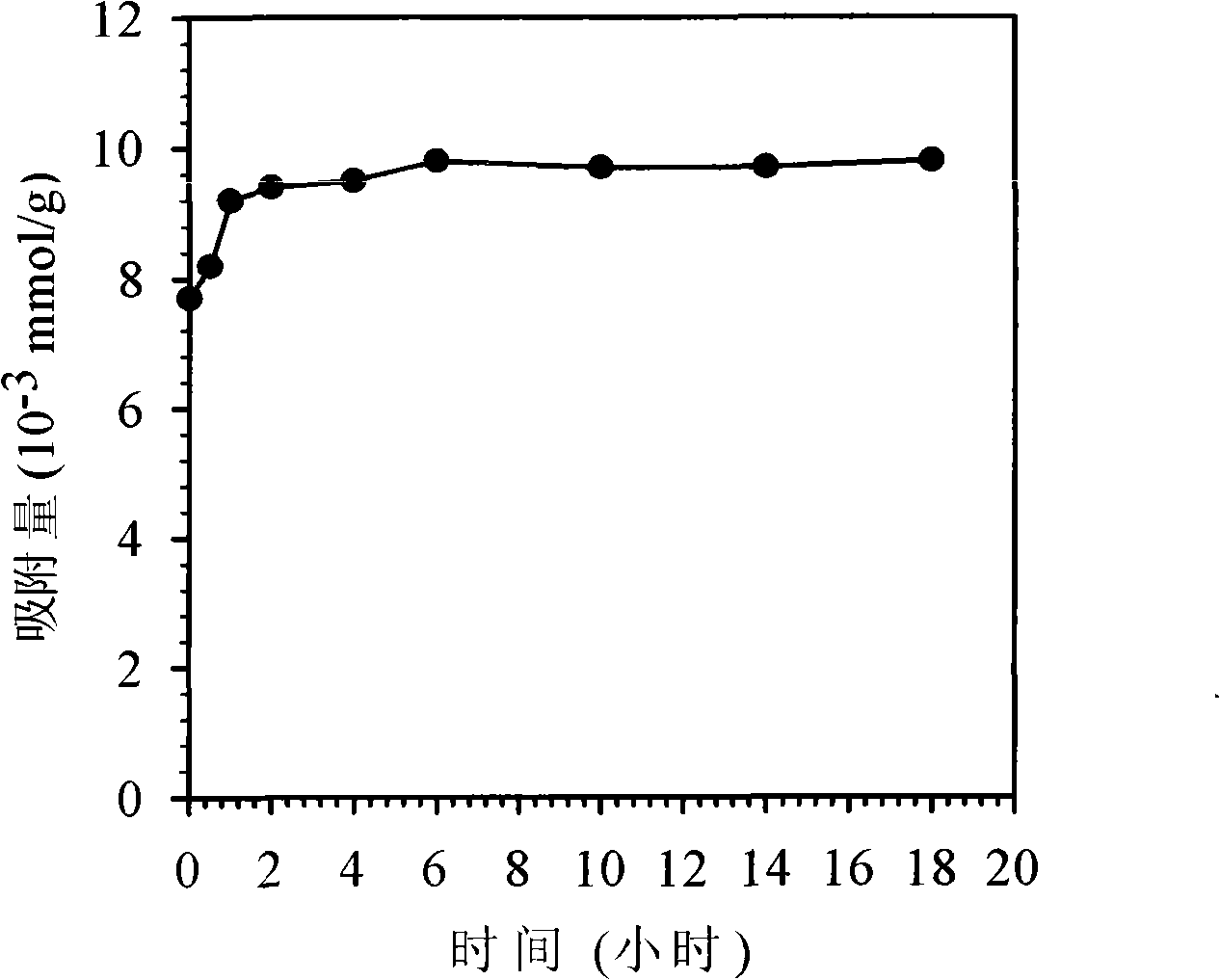

The invention discloses a sodium alginate-acrylamide composite aquagel. The preparation method comprises the following steps: 1) proportionally dissolving sodium alginate and acrylamide in water, and uniformly mixing; 2) sequentially adding a crosslinking agent and an initiator, carrying out vacuum degassing treatment, and adding a catalyst; and 3) transferring the obtained mixed solution into a glass mold, and heating to react, thereby obtaining the sodium alginate-acrylamide composite aquagel. The sodium alginate-acrylamide composite aquagel has favorable multivalent ion adsorption capacity and biocompatibility. By combining the polyacrylamide network with the graft copolymerization action of the sodium alginate and acrylamide, the mechanical properties of the aquagel are effectively enhanced. The aquagel is sensitive under the condition of different pH values, can generate intermolecular interactions with multiple cationic dyes and heavy metal ions, and is applicable to the fields of chemical substance adsorptive separation, sewage treatment and the like.

Owner:WUHAN UNIV OF TECH

Method for removing heavy metal ions in water by using graphene oxide sheet

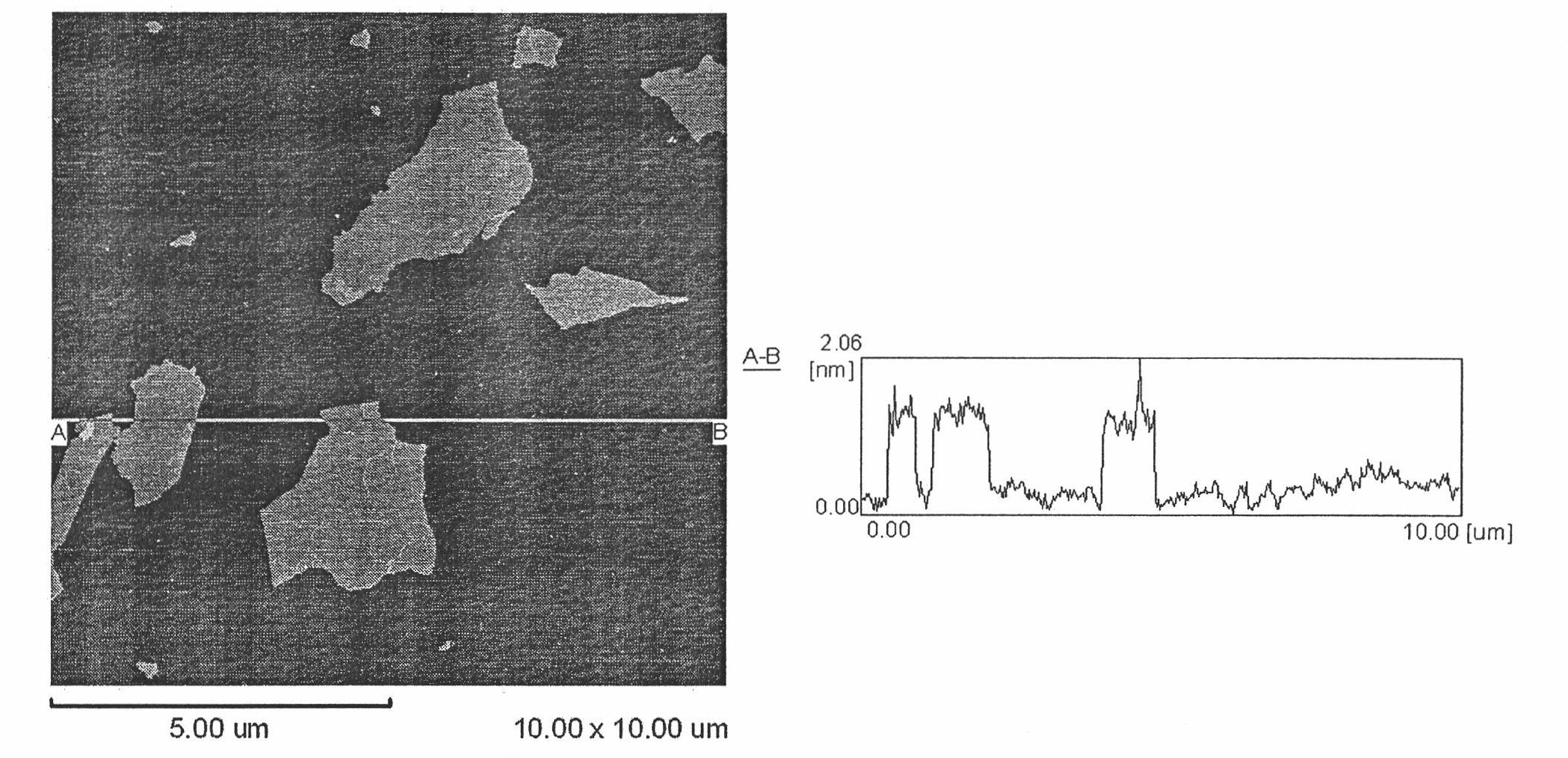

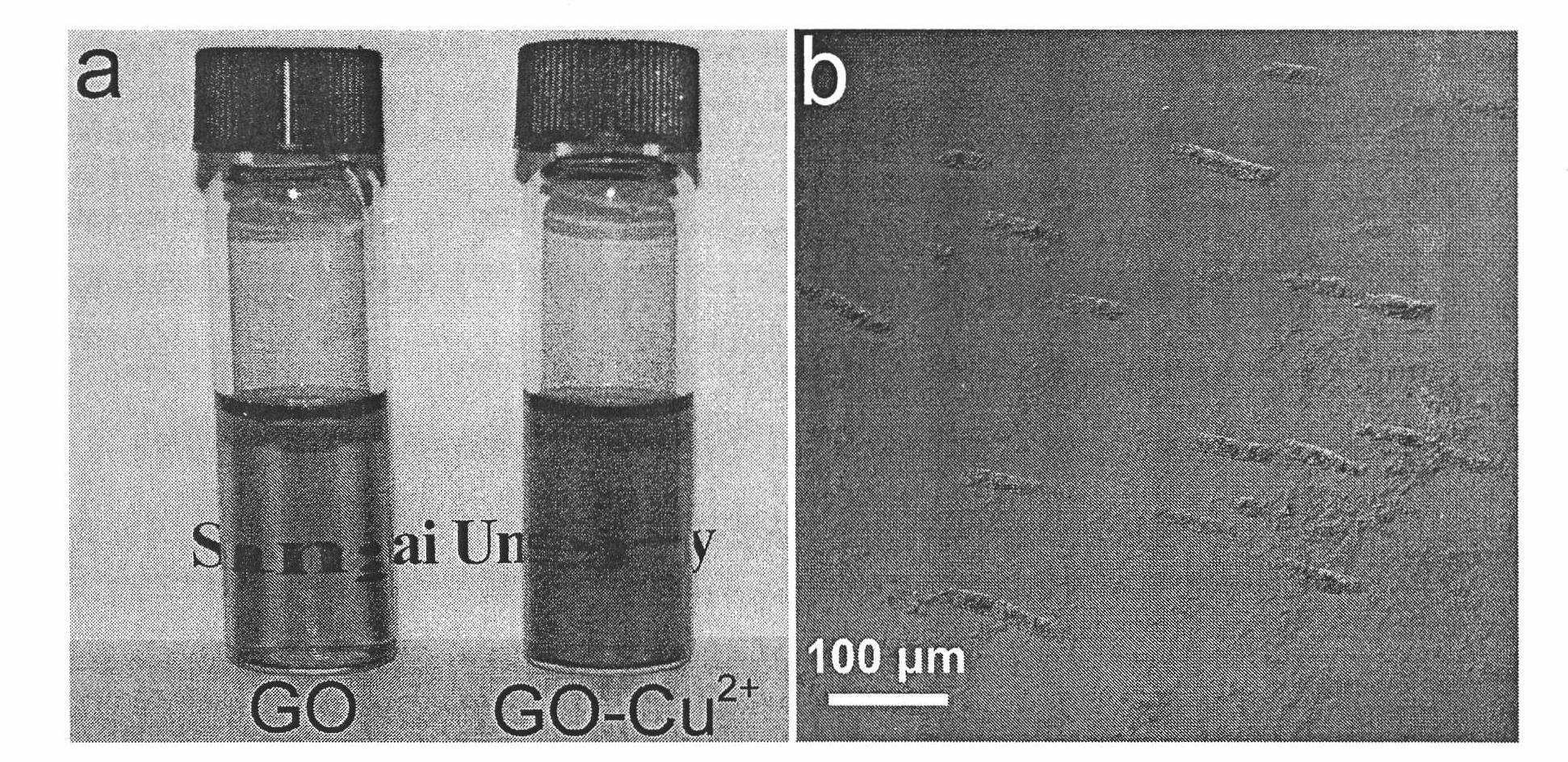

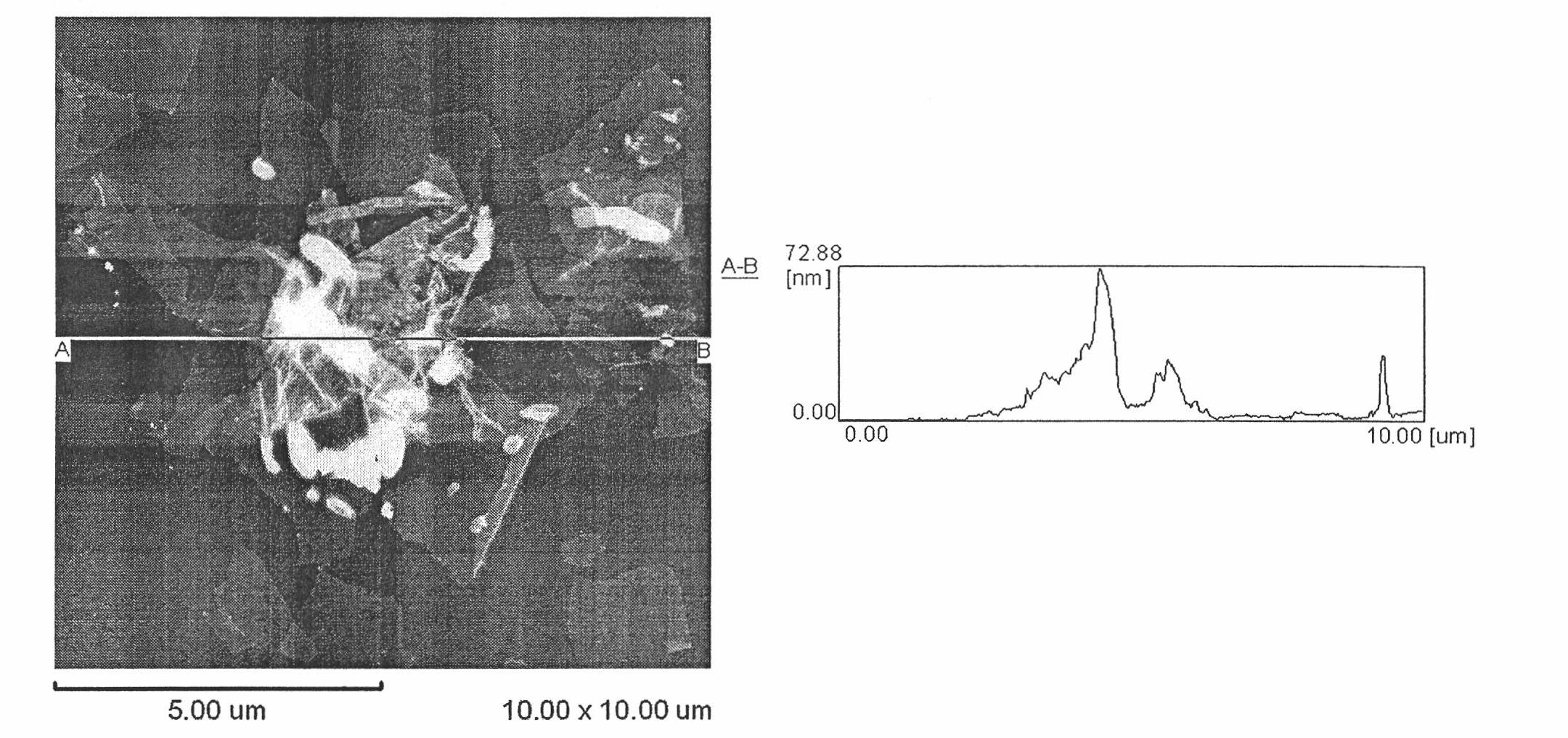

InactiveCN101973620AGood biocompatibilityIncrease surface areaOther chemical processesWater contaminantsSorbentPollution

The invention relates to a method for removing heavy metal ions in water by using a graphene oxide sheet, which belongs to the technical fields of water purification and environmental protection. In the invention, the graphene oxide sheet is used as an adsorbent of the heavy metal ions, wherein the graphene oxide sheet is of a monatomic layer two-dimensional structure and has a huge specific surface while ensuring no obvious toxicity. In the purification process of the method, the operations are simple without pollution, and the copper ion adsorption efficiency is 10 times that of the active carbon. In the invention, the graphene oxide sheet adsorbing the metal ions can be recovered to the single sheet structure by a centrifugal separation or dialysis method and can be recycled.

Owner:SHANGHAI UNIV

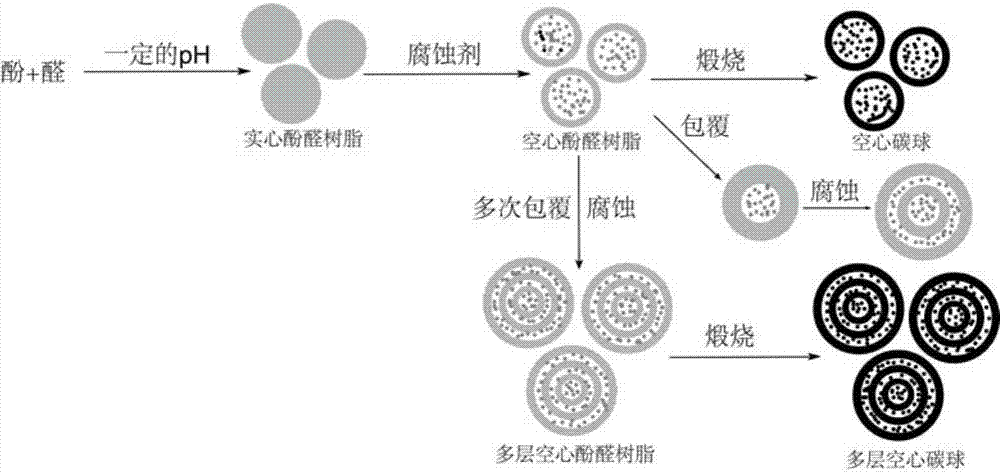

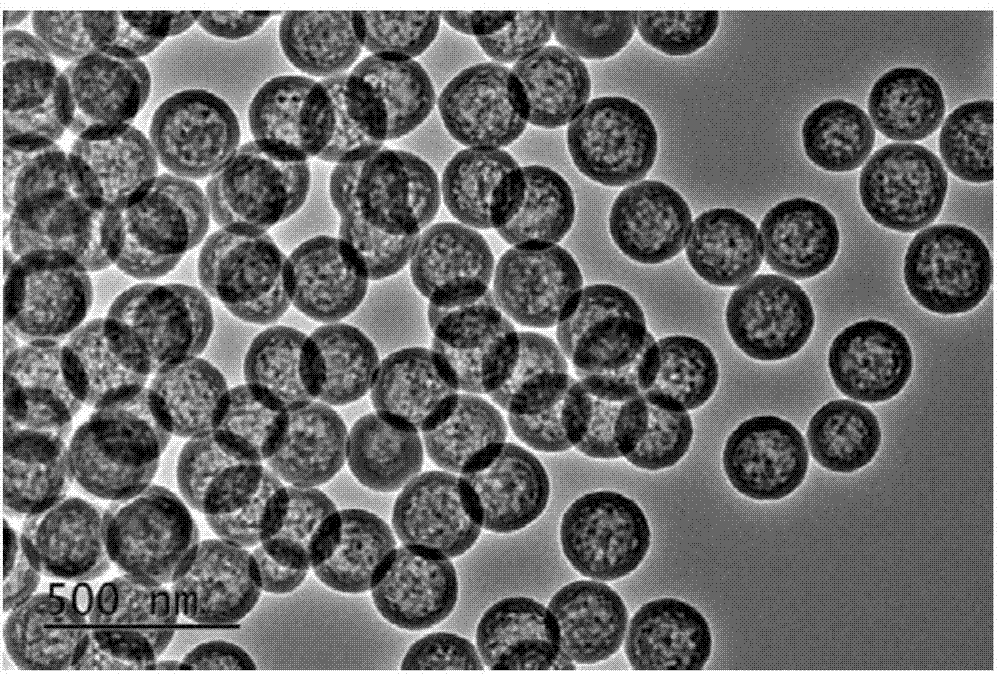

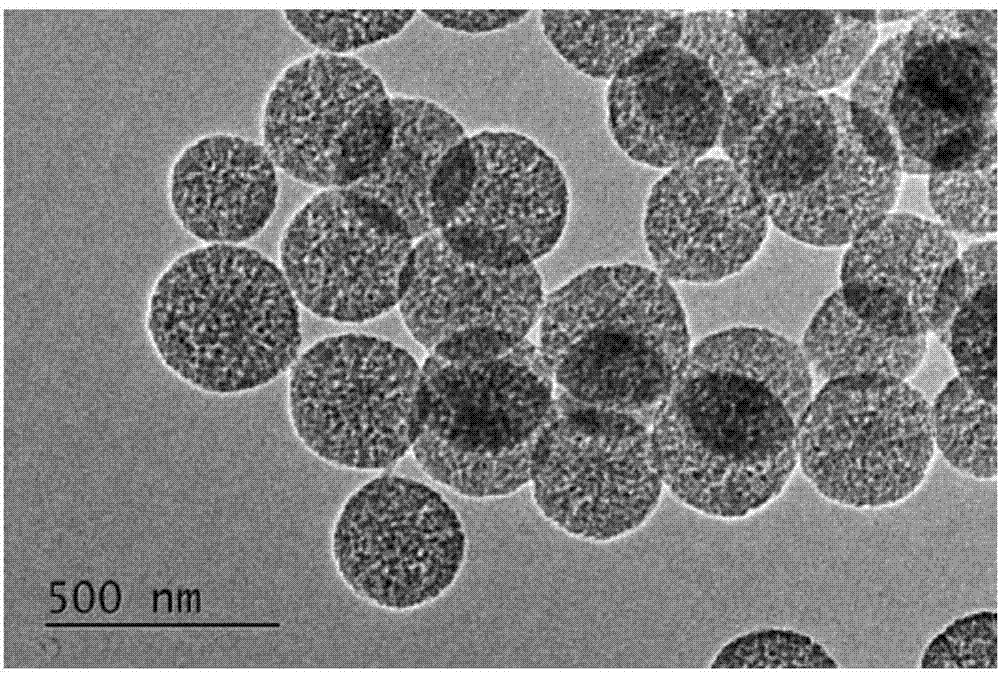

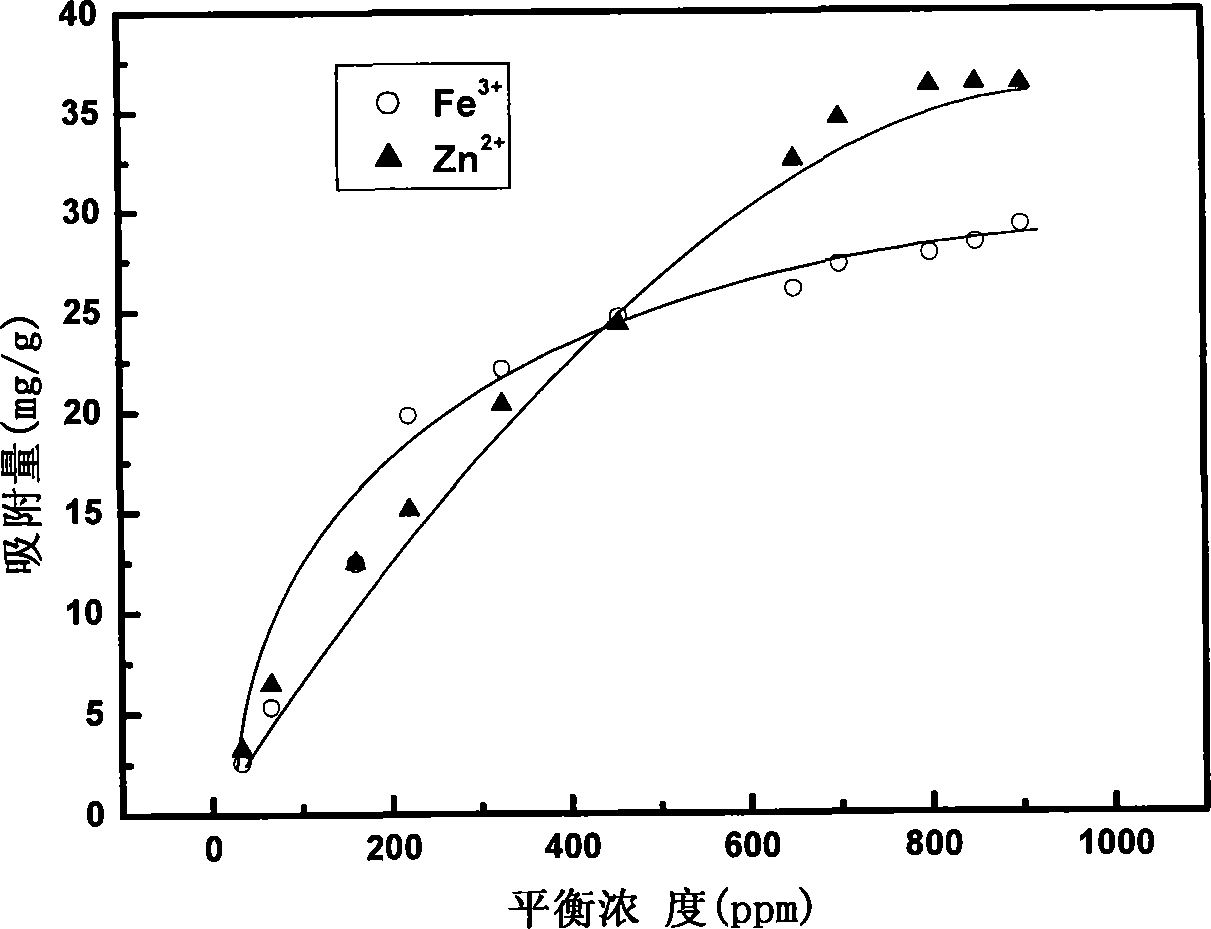

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

ActiveCN104843665AEasy to operateMild reaction conditionsMaterial nanotechnologySolubilityIn situ polymerization

The invention discovers and proposes a characteristic that interior species of phenolic resin are nonuniform in distribution in a polymerization process, and discloses a method for preparing a hollow carbon sphere by utilizing the characteristic of phenolic resin. The method comprises: (1) putting phenol into water or a solvent, adjusting the pH, then adding aldehyde and stirring at a certain temperature for a period of time; (2) adding a corrosive agent in a reaction system, stirring at a certain temperature, and selectively removing a part with a relatively low polymerization degree inside a polymer by utilizing a solubility difference of interior species for different solvents, to obtain an intermediate product, that is, a hollow sphere of phenolic resin polymer; and (3) calcining the intermediate product that is obtained in step (2) in an inertia or reducing atmosphere, naturally cooling to room temperature, and thus completing preparation of the hollow carbon sphere. The method is simple and practicable, and the prepared hollow carbon sphere is uniform in shape and controllable in dimension. Moreover, by utilizing a characteristic that the phenolic resin can be in-situ polymerized on surfaces of different nanometer particles, on one hand, a multi-layer hollow structure can be prepared in a multi-cladding and layer-by-layer corrosion manner, and on the other hand, the different nanometer particles can also be packaged in a cavity in an in-situ mode, so as to prepare a nuclear shell or egg yolk-nuclear structure. The prepared hollow carbon sphere has a potential application value in aspects of silicon-carbon negative electrode material, Li-S battery, supercapacitor, heavy metal ion adsorption, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of composite flocculant capable of adsorbing heavy metal ions and composite flocculant product through

InactiveCN103274509AIncrease the scope of applicationImprove flocculation efficiencyWater contaminantsWater/sewage treatment by flocculation/precipitationHeavy metalsIon adsorption

The invention relates to a preparation method of a chitosan compound flocculant which can effectively remove organic pollutants in water, can adsorb heavy metal ions such as nickel, chromium and lead in water and has high heavy metal ion adsorption capacity and high adsorption efficiency and a chitosan compound flocculant product thereof. The chitosan compound flocculant product is prepared by adopting chitosan as a raw material, glutaraldehyde as a crosslinking agent and washed and acid pickled attapulgite as a modifier. The preparation method of the compound flocculant capable of adsorbing heavy metal ions has the characteristics of simple technology, low cost, no special equipment and easy industrial implementation, the compound flocculant reduces dosage of chiston, and cost is reduced.

Owner:TIANJIN JINLIN WATER TREATMENT SCI & TECH CO LTD

Method for preparing etherification luffa and application of it in metallic ion adsorption

InactiveCN101239306AEasy to makeImprove performanceOther chemical processesWater/sewage treatment by sorptionCelsius DegreeChloroacetic acids

The present invention provides a etherifying luffa method and an application in the metal ion adsorption, belonging to natural high polymer material modification or wastewater disposal technical field. The method is mixing the natural luffa with m moderate NaOH alcohol solution, alkalization under the temperature 25-80 Celsius degree, or alkalization by microwave interval radiation, then obtaining alkalization luffa by reflowing, washing, filtering, drying in the thermostatic waterbath; the etherifying luffa is obtained by dispersing with NaOH solution, reacting with the chloroacetic acid alcoholic solution, filtering, washing, drying. The luffa comes from variety of natural resources, and biodegradation, and treating process is relatively simple, partly substituting high molecular synthetic material in aspect of the sewage treatment, and having advantages such as friendly to the environment.

Owner:SHANGHAI UNIV

Heavy metal ion adsorbed film and preparation

InactiveCN101254457AImprove stabilityGood regeneration performanceOther chemical processesWater/sewage treatment by sorptionCross-linkPolymer science

The invention relates to a heavy metal ion adsorption film and a production method thereof. The heavy metal ion adsorption film is composed of polyvinyl alcohol and amido polymers at a polyvinyl alcohol / amido polymer ratio of (95:5) to (20:80). The amido polymers are polyvinyl amine, polyallylamine and branched polyethylene. The amido polymers are introduced into the aqueous solution of polyvinyl alcohol and then the resulting mixture undergoes crosslinking reaction with a cross-linking agent to form a three-dimensional polymer network. The method is simple, feasible and free of organic solvents. The introduction of amido groups can efficiently increase the water swellability of polyvinyl alcohol film and simultaneously enhance the adsorbability of the film to heavy metal ions.

Owner:威海金钰环保科技有限公司

Biological adsorbing agent with adsorption capacity of heavy metal ion, and producing method and application thereof

ActiveCN101274268ANot easy to dissolveReduce crystallinityOther chemical processesWater/sewage treatment by sorptionSorbentEnvironmental engineering

The invention relates to a biology adsorbent and a preparation method thereof as well as application of the preparation method in heavy metal ion adsorption. The biology adsorbent is characterized in that hybrid blending material which has heavy metal ion adsorption capability is prepared by the capability of biological polymer such as microcrystalline cellulose, chitin, chitosan, etc. which can be dissolved in ionic liquid; the ionic liquid is chloridized 1-butyl-3-methyl imidazole salt and chloridized 1-allyl-3-methyl imidazole salt; the preparation of the adsorbent adopts two types: a drying type and a freeze-drying type; the ionic liquid used in the method can be recovered; the prepared adsorbent can be automatically degraded in environment; the preparation method and the prepared adsorbent in the method cause no secondary environmental pollution.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Electrochemical Cell, Related Material, Process for Production, and Use Thereof

InactiveUS20140211370A1Large capacityHybrid capacitor electrolytesHybrid capacitor electrodesElectricityDesorption

The present invention relates to an electrochemical energy storage device referred to herein as a Metal / Ion Pseudo-Capacitor (MIPC). The MIPC stores charge through reversible metal electro-deposition and dissolution processes as anode functionality and ion adsorption / desorption processes, faradaic processes or both as cathode functionality.

Owner:IONOVA TECH

Metal monoatom-doped carbon nanomaterial catalytic carrier, and preparation method and application thereof

ActiveCN109248712AStable structureImprove electrochemical performanceMaterial nanotechnologyCatalyst carriersNitrogenPolysulfide

The invention discloses a metal monoatom-doped carbon nanomaterial catalytic carrier, and a preparation method and application thereof. The metal monoatom-doped carbon nanomaterial catalytic carrier comprises a nitrogen-containing carbonaceous core-shell structure formed by coating a carbonaceous core with a nitrogen-containing carbon shell and metal monoatoms distributed in the nitrogen-containing carbonaceous core-shell structure. The metal monoatom-doped carbon nanomaterial catalytic carrier provided by the invention has rich porous structures, a high specific surface area, strong polysulfide ion adsorption capacity and an electrochemical catalysis function. When the metal monoatom-doped carbon nanomaterial catalytic carrier is applied as a lithium sulfide positive-electrode carrier, asecondary battery is allowed to achieve rapid activation (0.1 C) at a low cut-off voltage (3 V); an electrode structure can ensure the structural stability of the nanomaterial during electrochemical cycles, and high and prominent electrochemical cycle stability is obtained; the utilization rate of the active material of the battery is significantly improved; the overall electrochemical performanceof the battery is greatly improved; and the battery can be quickly charged and discharged.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

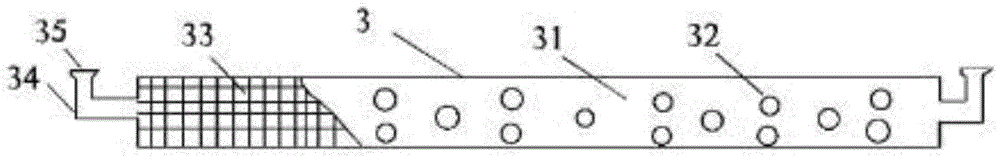

Ion-adsorption-type rare earth in-situ leaching method and leaching system thereof

ActiveCN104694746AEliminate the effects ofPreventing Induced Landslide DisastersProcess efficiency improvementEcological environmentSoil science

The invention belongs to the technology of in-situ leaching mining, and particularly relates to an ion-adsorption-type rare earth in-situ leaching method and a leaching system thereof. A non-excavation directional drilling machine is used for carrying out mechanical drilling of injection wells and liquid-collecting roadways instead of using manual excavation, The quantity of the injection wells is decreased, the injection wells are changed into curved pipes and are buried in a mine body. Therefore, the phenomenon that rainwater infiltrates into channels is reduced, a landslide triggered by the in-situ leaching is prevented, the construction is simple, the construction cycle is short, the cost is low, the safety performance is improved, the waste earth discharge is reduced, and the ecological environment is protected.

Owner:JIANGXI UNIV OF SCI & TECH

Preparation method of biomass activated carbon rich in nitrogen and oxygen

The invention belongs to the technical field of special functional activated carbon materials, and provides a preparation method of biomass activated carbon rich in nitrogen and oxygen. The method comprises the following specific steps: adding a certain quantity of biomass raw materials into a solution containing nitrogen and alkaline substances; transferring all the substances into a hydrothermal reaction kettle; reacting at a certain temperature for a certain time period; at the end of the reaction, naturally cooling to a room temperature; taking a product out, and drying; performing high-temperature carbonization activation on the dried product in a high-temperature tubular furnace in a protective gas atmosphere for a certain time period; at the end of the reaction, naturally cooling; repeatedly washing the product with water, and drying to obtain a nitrogen-rich biomass activated carbon product. In the biomass activated carbon rich in the nitrogen and the oxygen, prepared with the method, nitrogen and oxygen heteroatoms are introduced, so that the water wetting property and electrolyte ion adsorption performance of a carbon material are enhanced. The method can be widely applied to pollutant treatment, separation of mixtures, electrode materials, and the like, and has a wide application prospect.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

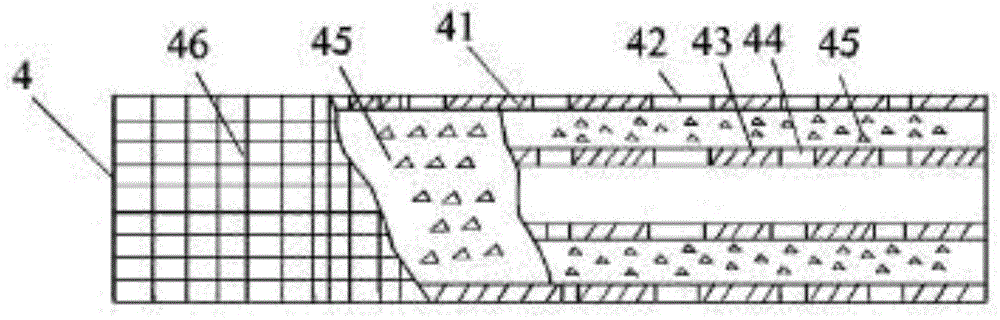

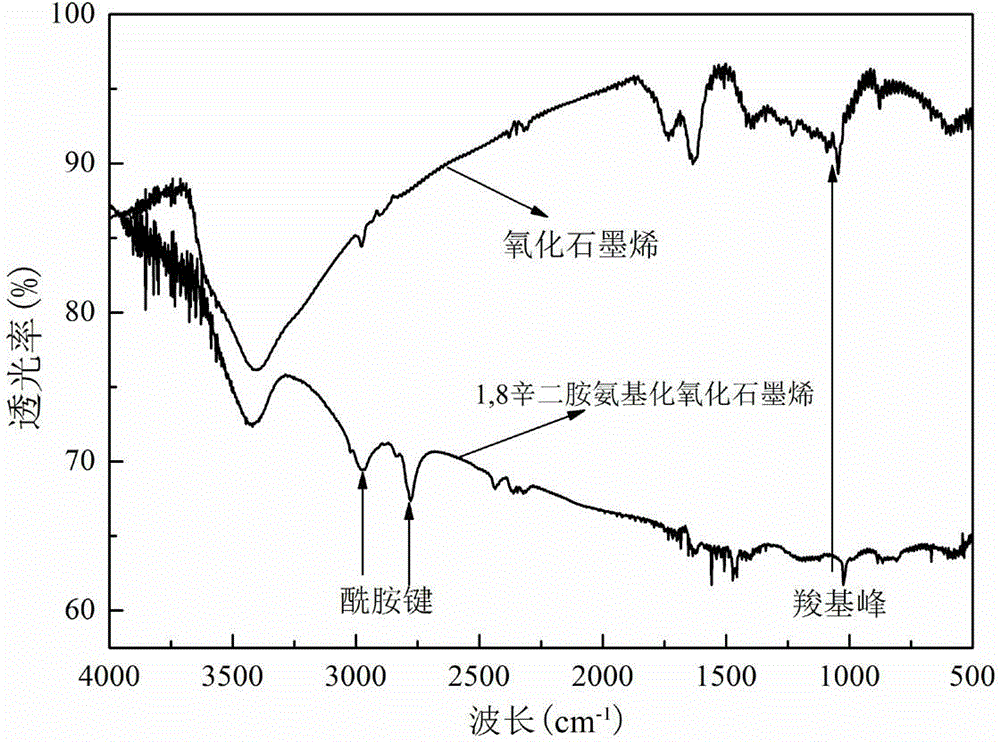

Preparation method and application of aminated graphene film

The invention belongs to the field of film preparation and in particular relates to a preparation method and application of an aminated graphene film. According to the specific technical scheme, the method comprises the following steps: performing pre-activating treatment on carboxyl groups on graphene oxide, and carrying out a chemical reaction between the activated carboxyl group and an amino compound, so that amino is grafted to the graphene oxide; and performing suction filtration to prepare the aminated graphene film. The aminated film is applied to the fields of inorganic salt ion adsorption, sea water desalination and the like by utilizing the adsorptive action between positive charges of the amino on the film and inorganic salt negative ions and the adsorptive action between negative charges on the graphene oxide and positive ions. In addition, a reaction can be carried out between the amino on the film and CO2 gas, so that the film can be applied to capturing CO2 gas in flue gas in cement or power industry.

Owner:NANJING XINYUE MATERIAL SCI & TECH +2

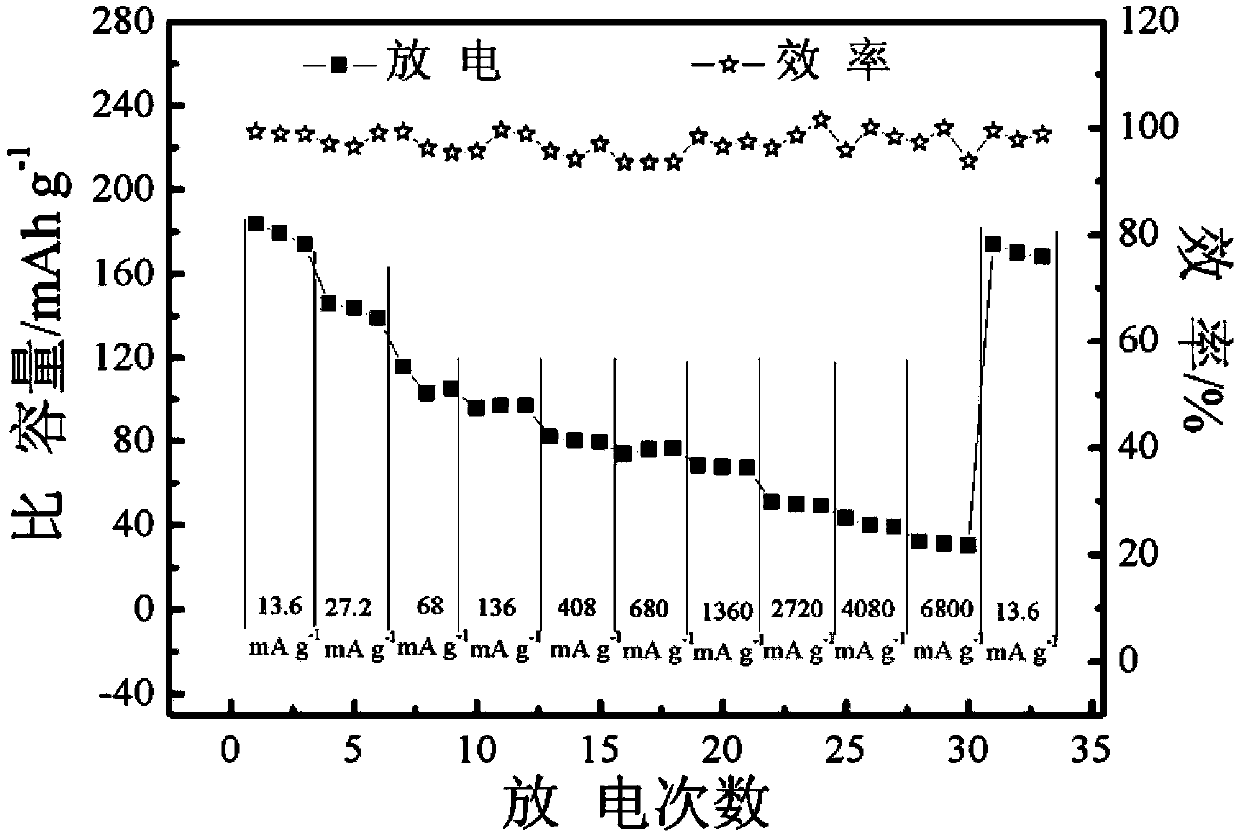

Aqueous rechargeable magnesium/zinc ion capacitor battery

The invention provides an aqueous rechargeable magnesium / zinc ion capacitor battery. A positive plate comprises a positive current collector and a coating layer, wherein the coating layer is coated on the positive current collector and contains a positive active substance which is lambda-MnO2 in a three-dimensional tunnel spinel structure. A negative plate comprises a negative current collector and a coating layer, wherein the coating layer is coated on the negative current collector and contains a negative active substance which is a carbon-based material of an ion-adsorption / desorption super-capacitor in a porous structure. An electrolyte solution is a water solution containing magnesium ions or zinc ions. The concentration of the magnesium ions or the zinc ions in the electrolyte solution is 0.5mol / L to 10mol / L. By virtue of the aqueous electrolyte solution, the cost is reduced, the safety performance is improved, and environmental pollution is avoided; the aqueous rechargeable magnesium / zinc ion capacitor battery is long in cycle life, large in energy density and applicable to large-current charge and discharge, and is power storage equipment with wide application prospect.

Owner:HARBIN ENG UNIV

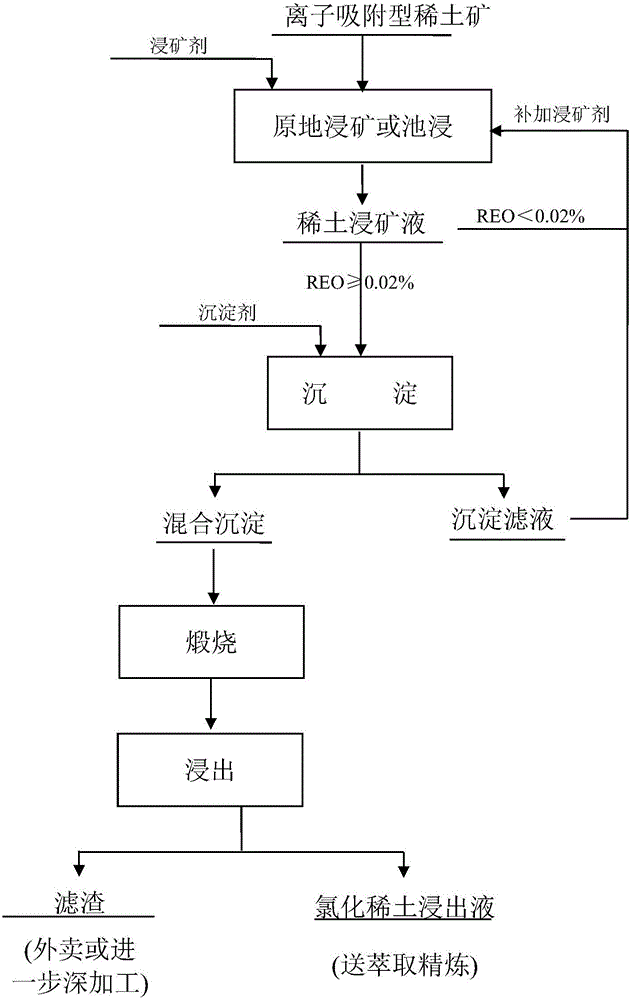

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

ActiveCN105803226AEfficient separationAchieve purificationProcess efficiency improvementAluminum canRare earth

The invention relates to a method for extracting rare earth and aluminum from ion adsorption type rare earth ores. The method includes the steps that (1), ore leaching is performed, wherein an ore leaching agent is added for in-situ ore leaching or pond leaching, and rare earth ore leaching liquid with the rare earth concentration higher than 0.02% is obtained; (2), precipitation is performed, wherein solid and liquid separation is performed after a precipitation agent is added into the rare earth ore leaching liquid for precipitation, and precipitated filter liquor and mixed precipitate containing rare earth and aluminum are obtained; (3), calcination is performed, wherein the mixed precipitate containing rare earth and aluminum is calcinated, and calcinated products containing rare earth oxide and alpha-aluminum oxide are obtained; and (4), leaching out is performed, wherein solid and liquid separation is performed after a chlorination leaching agent is added into the calcinated products containing rare earth oxide and alpha-aluminum oxide for leaching out, chlorinated rare earth leaching-out liquid and filter residues containing alpha-aluminum oxide are obtained, rare earth oxide is extracted from the chlorinated rare earth leaching-out liquid, and aluminum oxide fine products are extracted from the filter residues containing alpha-aluminum oxide. The method is simple in technology, precipitation is directly performed without impurity removal, and by means of the dissolution property difference of the calcinated products in an acid environment, the rare earth and the aluminum can be separated and recycled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Ion-adsorption-type rare earth extracting method

ActiveCN103266224AImprove leaching rateIncrease sedimentation rateProcess efficiency improvementAluminum IonPollution

The invention relates to an ion-adsorption-type rare earth extracting method. The method comprises the following steps of: by taking an aqueous solution containing magnesium sulfate or the magnesium sulfate and / or ferric sulfate or the magnesium sulfate and / or aluminum sulfate as main components as an ore leaching agent, leaching ion-adsorption-type rare earth ore; dissolving rare earth ions in the rare earth ore with magnesium, ferric and aluminum ions and the like in an iron exchanging manner, thereby obtaining a leachate; and by taking magnesium hydrate or magnesium oxide or magnesium carbonate as a precipitator, thereby generating a rare earth hydrate or a rare earth carbonate. The method is simple in process and strong in raw material adaptability, and can be used for economically and effectively leaching the rare earth from the ion-adsorption-type rare earth ore, thereby completely avoiding the problem of ammonia nitrogen pollution caused by an existing leaching process. Therefore, the method is a sanitary production process.

Owner:JIANGXI UNIV OF SCI & TECH

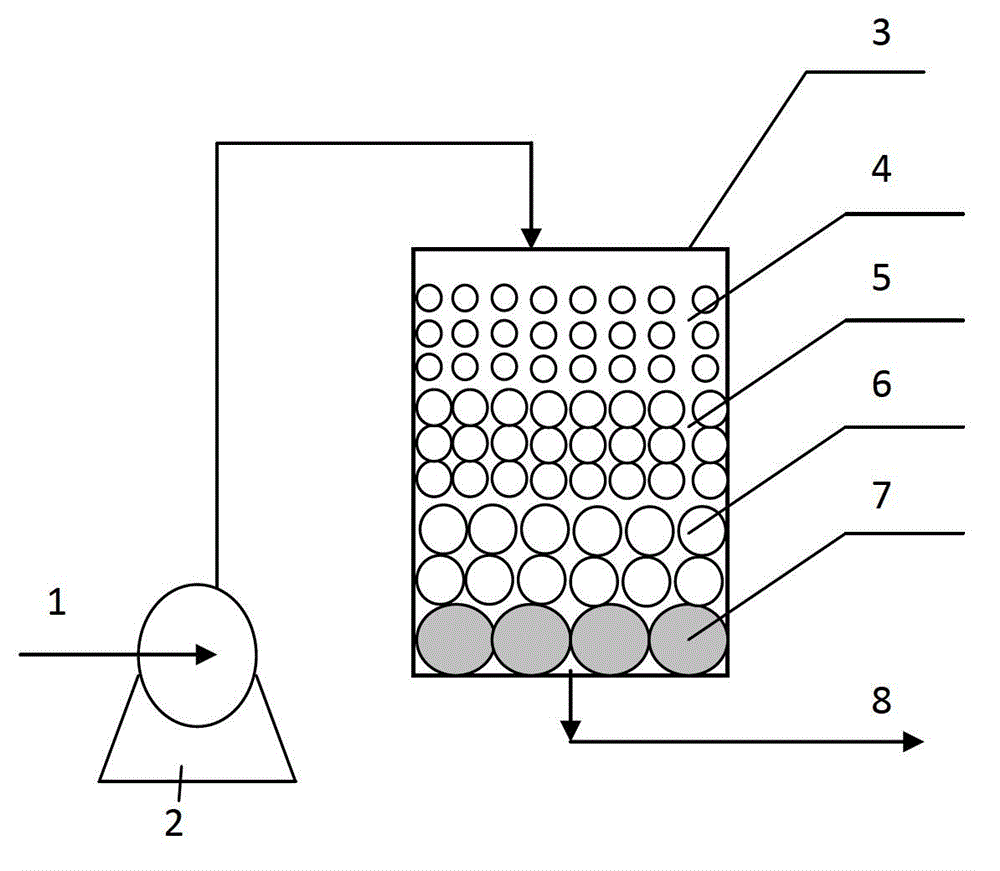

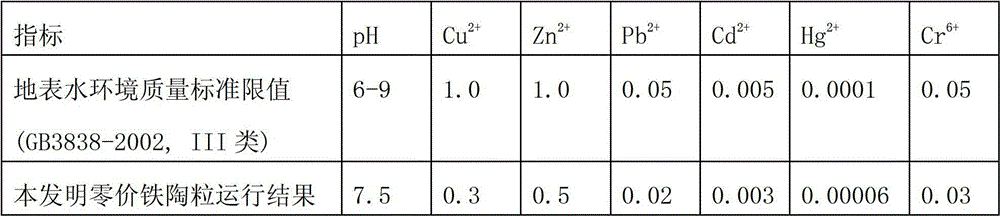

Ceramsite for heavy metal wastewater treatment, preparation method and applications thereof

ActiveCN102718544ARaw materials are easy to getLow priceOther chemical processesAlkali metal oxides/hydroxidesExpanded clay aggregateWater quality

The invention discloses a ceramsite for heavy metal wastewater treatment, a preparation method and applications thereof. Ceramsites contain bentonite or kaolin, nanoscale zero-valent iron powder or activated carbon. The ceramsite prepared by the method is 3-20 mm spherical particles with density of 1.15 g / cm<3>, bulk density of 814 kg / m<3>, strength of 5 MPa and specific surface area of 33 m<2> / gand has the advantages that the integral form is intact, the pores are developed, and the internal pores are communicated. The preparation method is shown in the specification for details. The raw materials of the ceramsite are easily obtained and are low in cost; the preparation method and the equipment used are simple and are convenient to operate; the ceramsite has excellent heavy metal ion adsorption and reduction performance; the removal efficiency for all heavy metal ions is more than 99% under the condition of high load of Cu<2+>, Zn<2+>, Pb<2+>, Cd<2+>, Cr<6+> and Hg<2+> in wastewater; the yielding water meets the third level water quality requirement of state environmental quality standards for surface water; and the ceramsite has high heavy metal adsorption capacity which is up to 50-200 mg / g. The ceramsite disclosed by the invention is mainly used as an adsorption carrier for heavy metal wastewater treatment.

Owner:PEKING UNIV

Microporous aluminum-salt lithium adsorbent, preparation method therefor, filler and lithium ion enriching method

ActiveCN106076243AOvercome the problem of high dissolution rateControl areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A heavy metal ion adsorption type PS hollow fiber ultrafiltration membrane and a preparing method thereof

ActiveCN104587852AImprove adsorption capacitySelf-supportingSemi-permeable membranesOther chemical processesFiberUltrafiltration

A heavy metal ion adsorption type PS hollow fiber ultrafiltration membrane and a preparing method thereof are disclosed. After a spinning solution is prepared, the hollow fiber ultrafiltration membrane is prepared by a dry-wet spinning method. The spinning solution comprises polysulfone, additives, a solvent and a pore forming agent. Compared with the prior art, the heavy metal ion adsorption type hollow fiber ultrafiltration membrane belongs to hollow fiber ultrafiltration membranes, has characteristics of a self-supporting property, large membrane area of an assembly, large flux, and the like, and is good in pressure resistance and high in adsorptive property for heavy metal ions. A preparing process of the membrane is simple, stable and prone to industrialization. The adsorption effects for heavy metal ions are obvious.

Owner:VONTRON TECH CO LTD

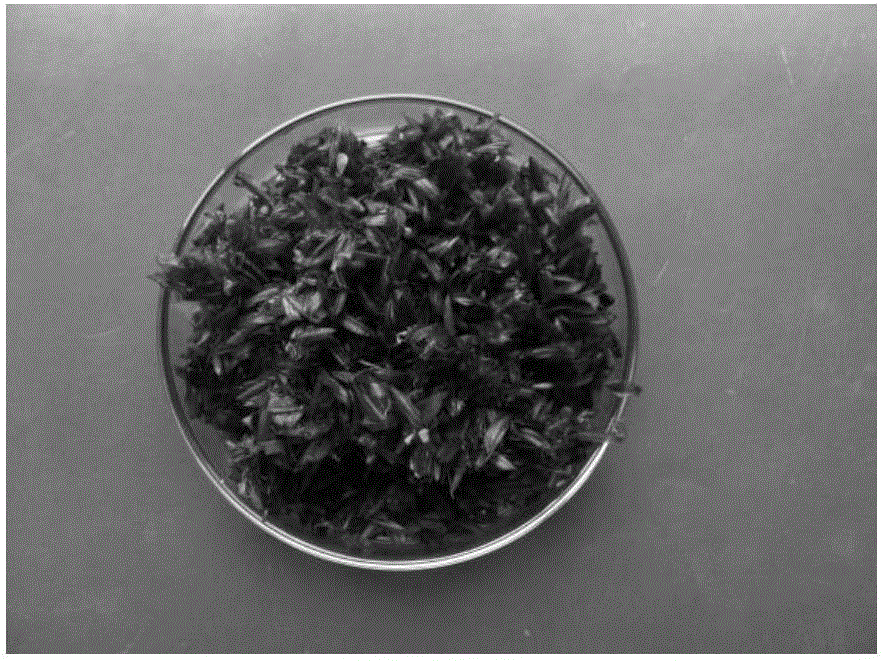

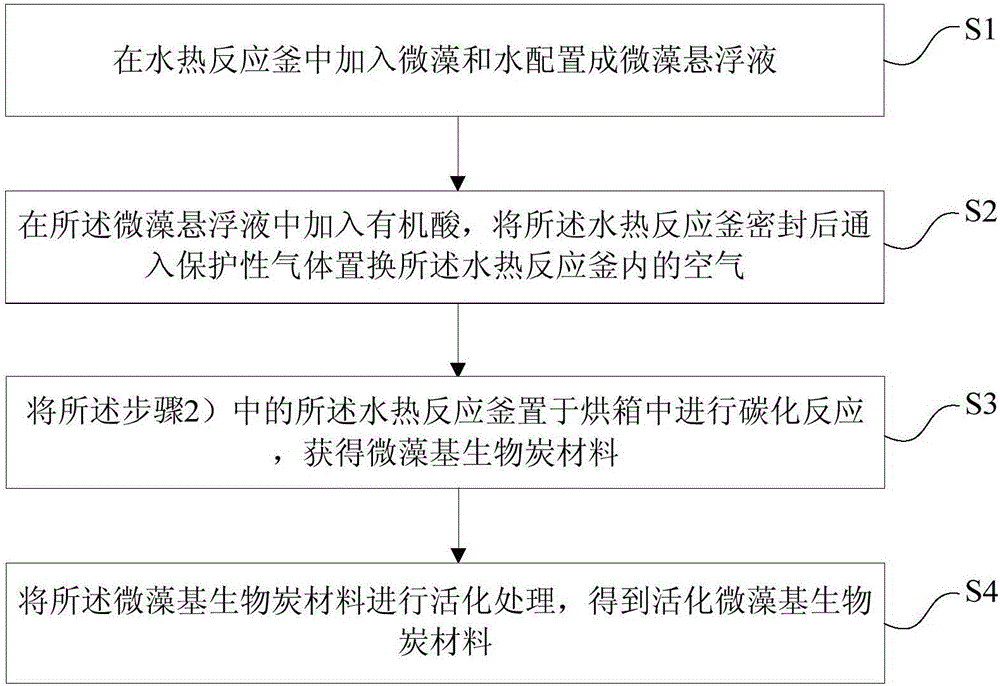

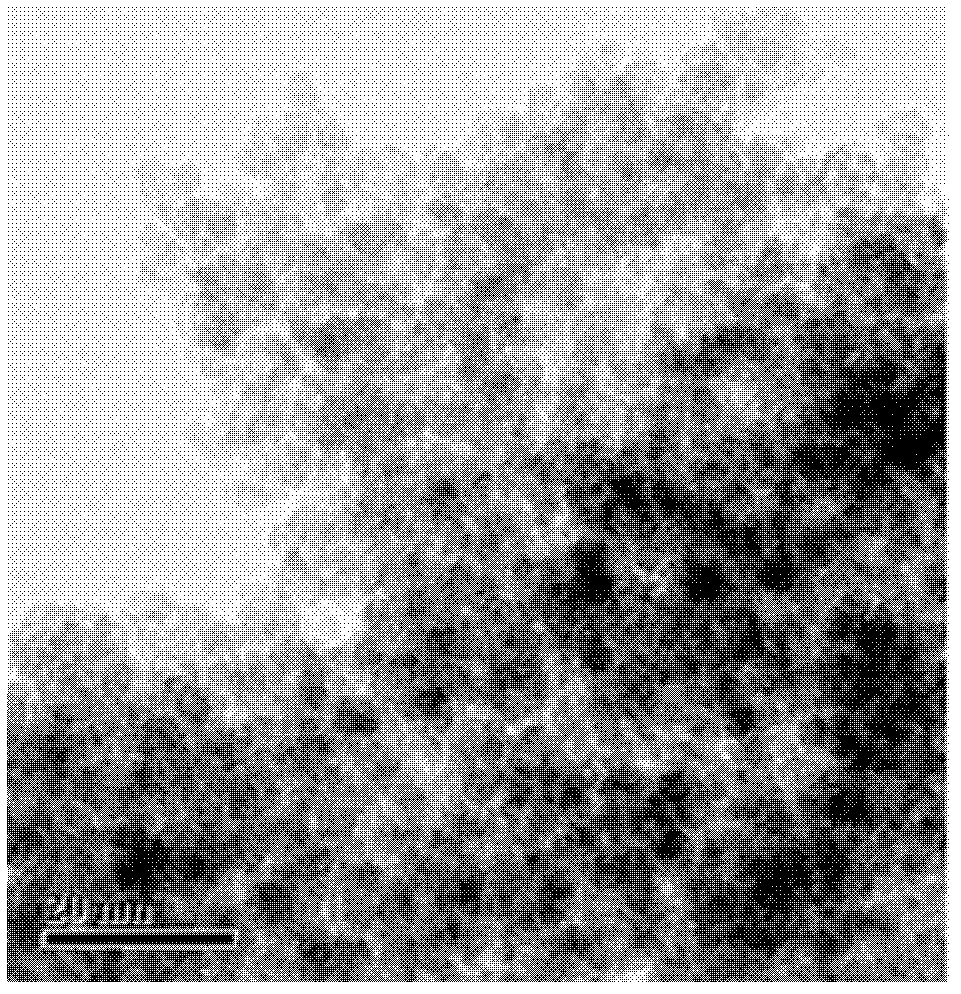

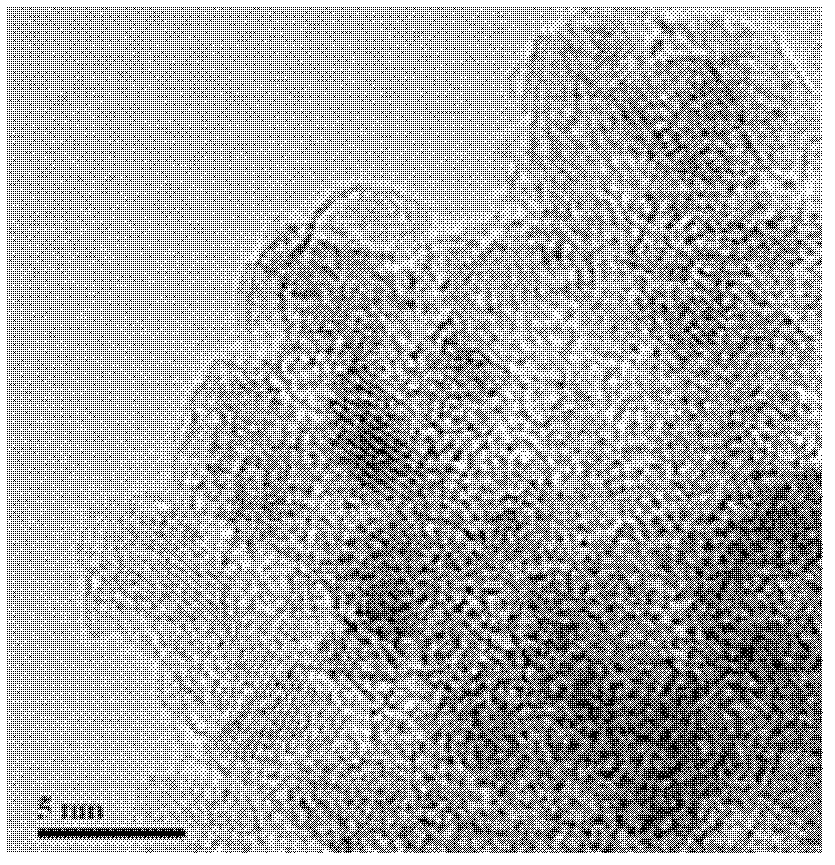

Preparation method of microalga-based biochar material for heavy metal ion adsorption

InactiveCN105800588AShorten the growth cycleImprove reproductive abilityOther chemical processesOrganic acidNitrogen

The invention provides a preparation method of a microalga-based biochar material for heavy metal ion adsorption. The preparation method comprises the following steps that 1, microalgae and water are added into a hydrothermal reaction kettle to prepare microalga suspension liquid; 2, organic acid is added into the microalga suspension liquid, and after the hydrothermal reaction kettle is sealed, protective gas is introduced into the hydrothermal reaction kettle to replace air in the hydrothermal reaction kettle; 3, the hydrothermal reaction kettle in the step 2 is placed in a drying oven for a carbonation reaction, and the microalga-based biochar material is obtained; 4, activating treatment is performed on the microalga-based biochar material, and the activated microalga-based biochar material is obtained. According to the preparation method, biochar is prepared through hydrothermal carbonization by taking the nitrogen-containing microalgae as the raw material, and then activated modification is performed on the biochar through a KOH activating method and a NH3 activating method separately by taking the biochar as a precursor; the activated microalga-based biochar material obtained through activated modification has micro-mesoporous structures, the large specific surface area and the large pore volume, and the adsorption capacity of porous charcoal is greatly improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Cellulose acetate/ titanium dioxide composite nanofiber adsorption film and preparation method thereof

InactiveCN103898676AImprove adsorption capacityIncrease the adsorption rateOther chemical processesNon-woven fabricsFiberCellulose acetate

The invention discloses a cellulose acetate / titanium dioxide composite nanofiber adsorption film and a preparation method of the cellulose acetate / titanium dioxide composite nanofiber adsorption film, and belongs to a preparation technology of nanometer materials. The method includes the following processes that firstly, alcoholization processing is conducted on titanium dioxide, the surface of titanium dioxide is made to be provided with hydroxyl (TiO2-OH), and a titanium dioxide solution is prepared by dispersing titanium dioxide in deionized water; cellulose acetate is dissolved into a solvent, and a transparent cellulose acetate solution is obtained; the titanium dioxide solution and the cellulose acetate solution are mixed, and electrostatic spinning is conducted, wherein the high-voltage static adjusting range is from 16 kV to 30 kV, the flow speed of an injection pump ranges from 0.05 mL / h to 0.3 mL / h, and the receiving distance ranges from 10 cm to 20 cm. The preparation method is simple in process, and the prepared cellulose acetate / titanium dioxide composite nanofiber adsorption film has the advantage of being high in heavy metal ion adsorption capacity and adsorption rate.

Owner:TIANJIN POLYTECHNIC UNIV

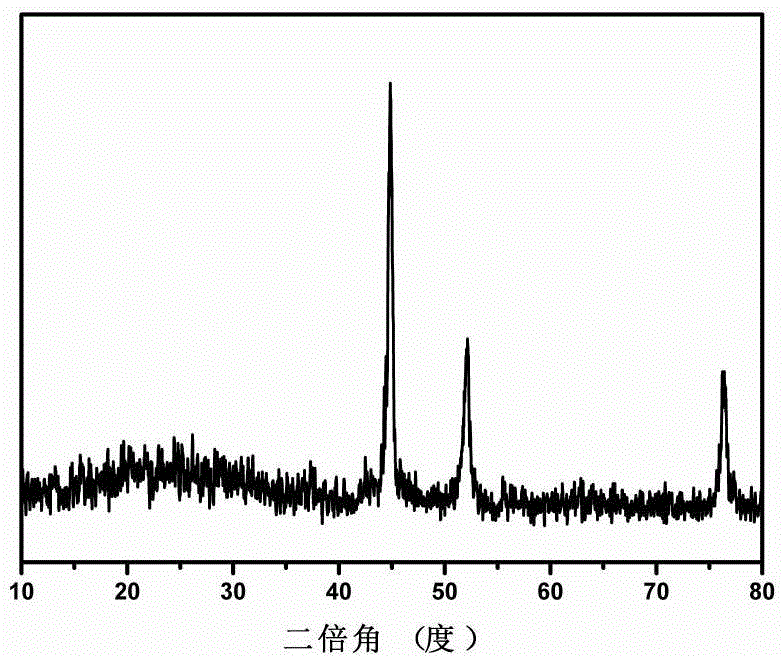

Preparation method of magnetic Fe3O4 nanoparticles and its application in adsorption and separation of heavy metal ions

InactiveCN102275998ARaw materials are cheap and easy to getThe synthesis method is simpleOther chemical processesFerroso-ferric oxidesWater useSynthesis methods

The invention relates to a preparation method of magnetic Fe3O4 nanoparticles and application thereof in adsorption and separation of heavy metal ions, belonging to the technical field of nanomaterials as well as adsorption and separation treatment application of heavy metal ions in industrial and agricultural wastewater. The preparation method comprises the following steps: firstly preparing a ferric chloride solution with water used as a solvent by using a hydrothermal synthesis method, and then adding ascorbic acid to obtain a solution; and adding hydrazine hydrate to the resulting solution, then transferring to a stainless steel reaction kettle to react, after the reaction is finished, centrifugally separating, and washing and drying the obtained precipitate to obtain the magnetic Fe3O4 nanoparticles. The preparation method provided by the invention has the advantages of inexpensive and easily available raw materials and simple synthesis method; Fe3O4 prepared by the preparation method has good adsorption property to As and Cr metal ions, and the removal rate can be more than 90%; and the obtained magnetic Fe3O4 nanoparticles can be widely used in adsorption and separation of As and Cr in the industrial and agricultural wastewater.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

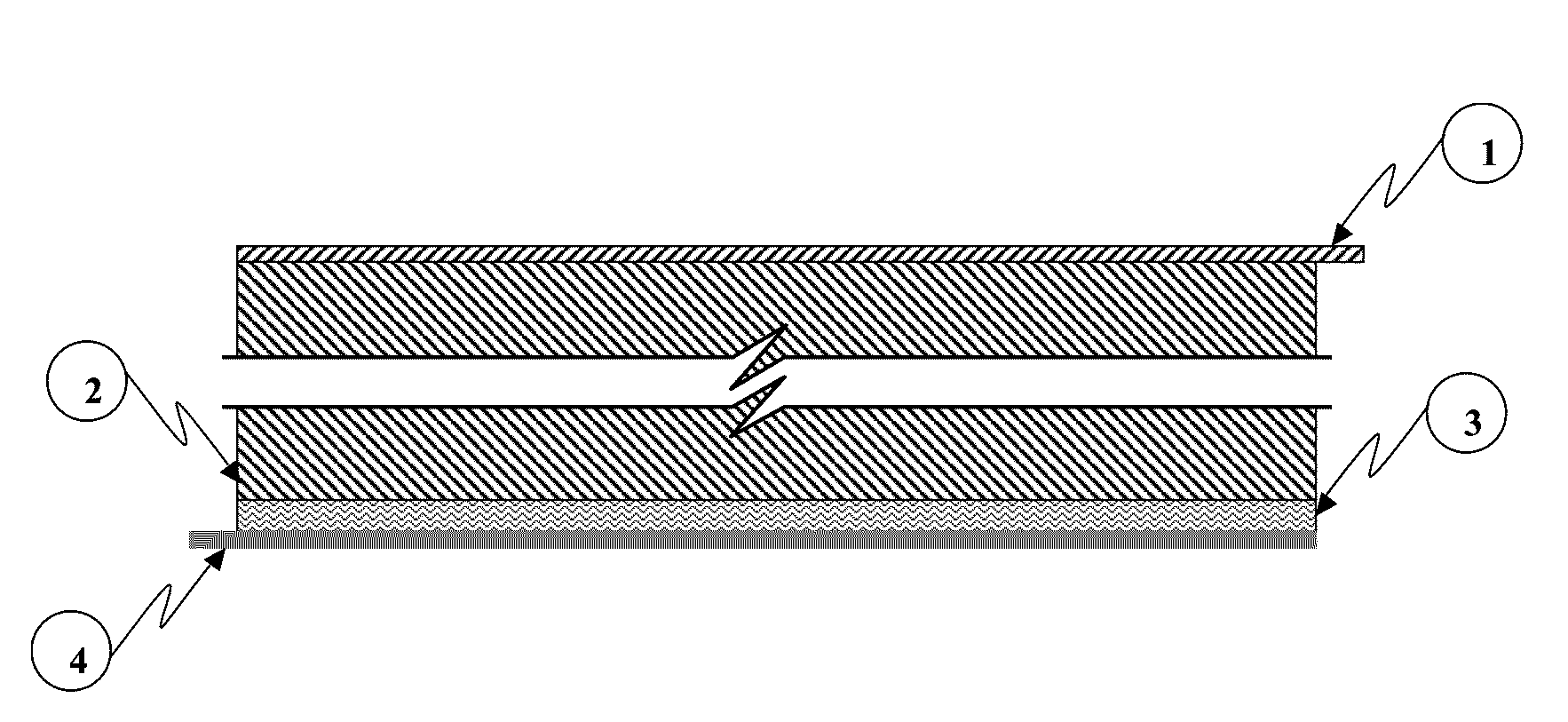

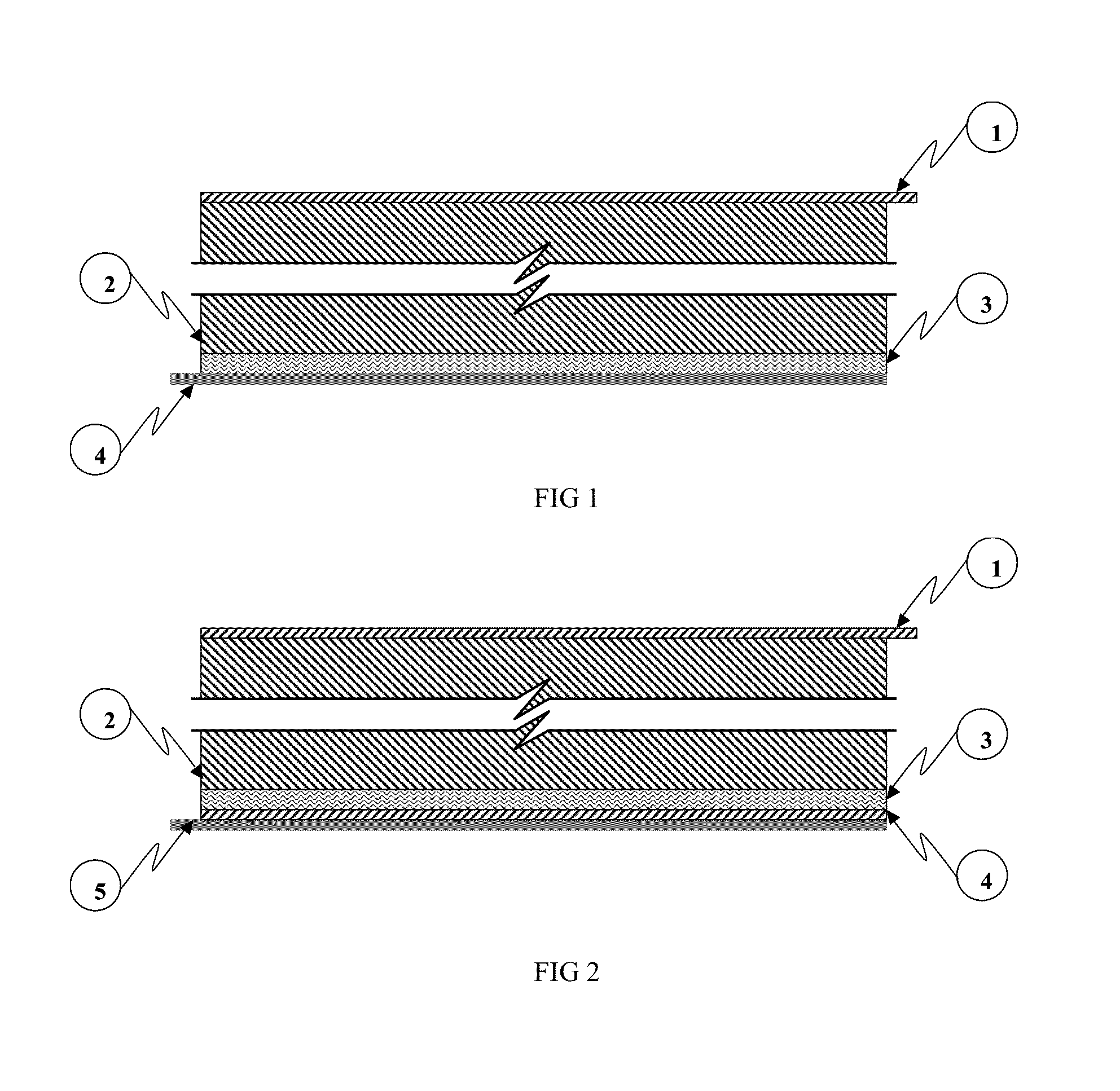

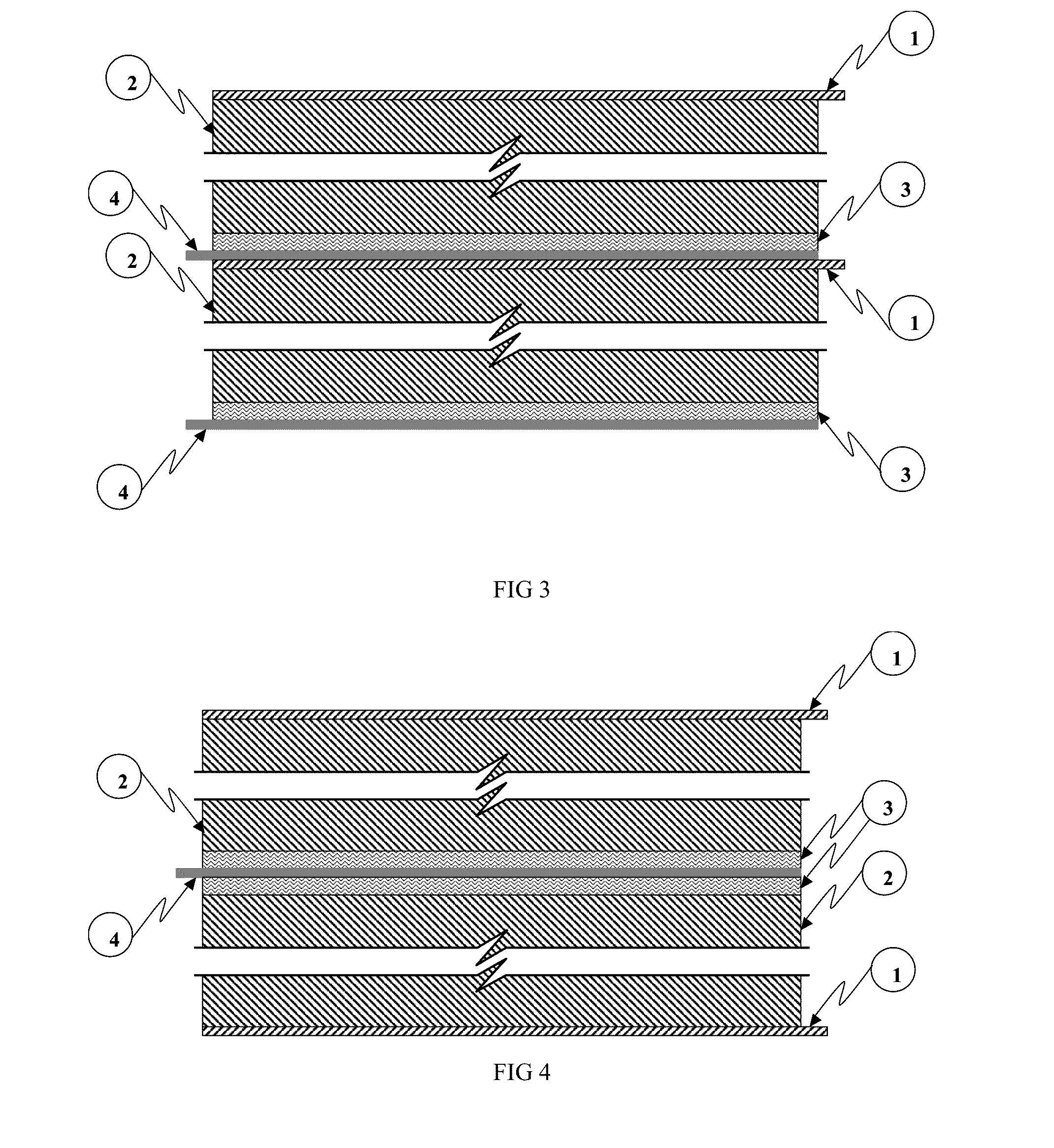

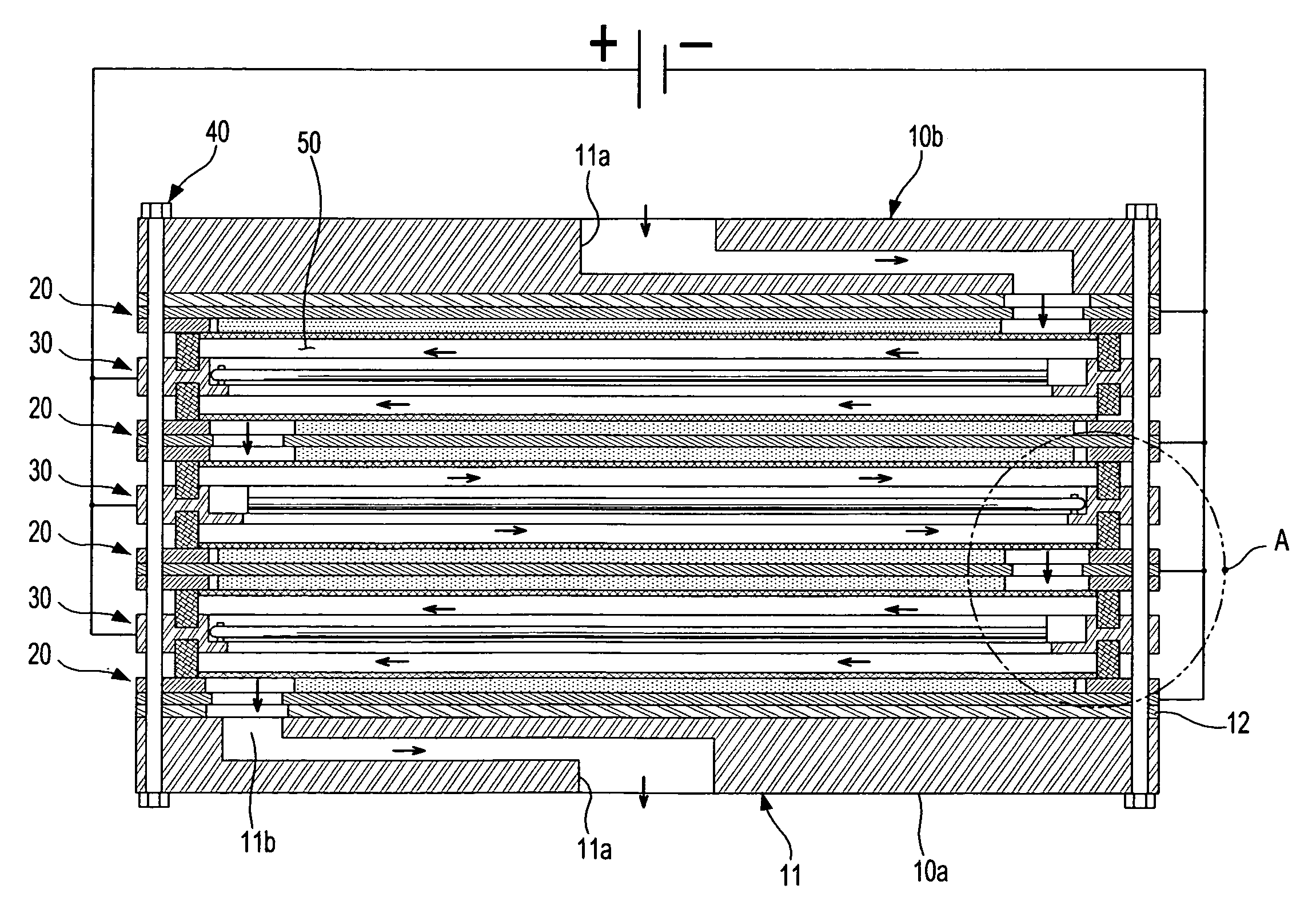

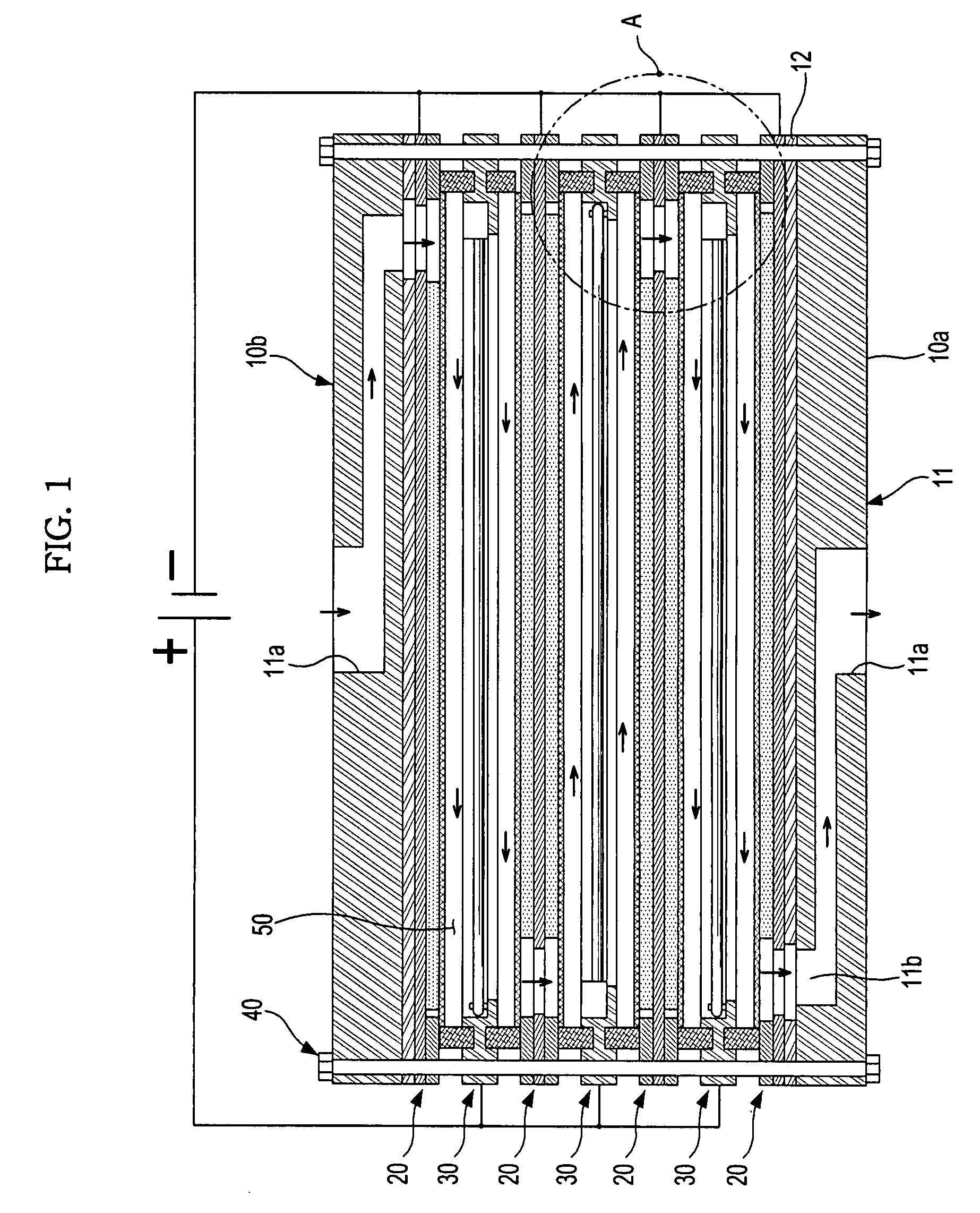

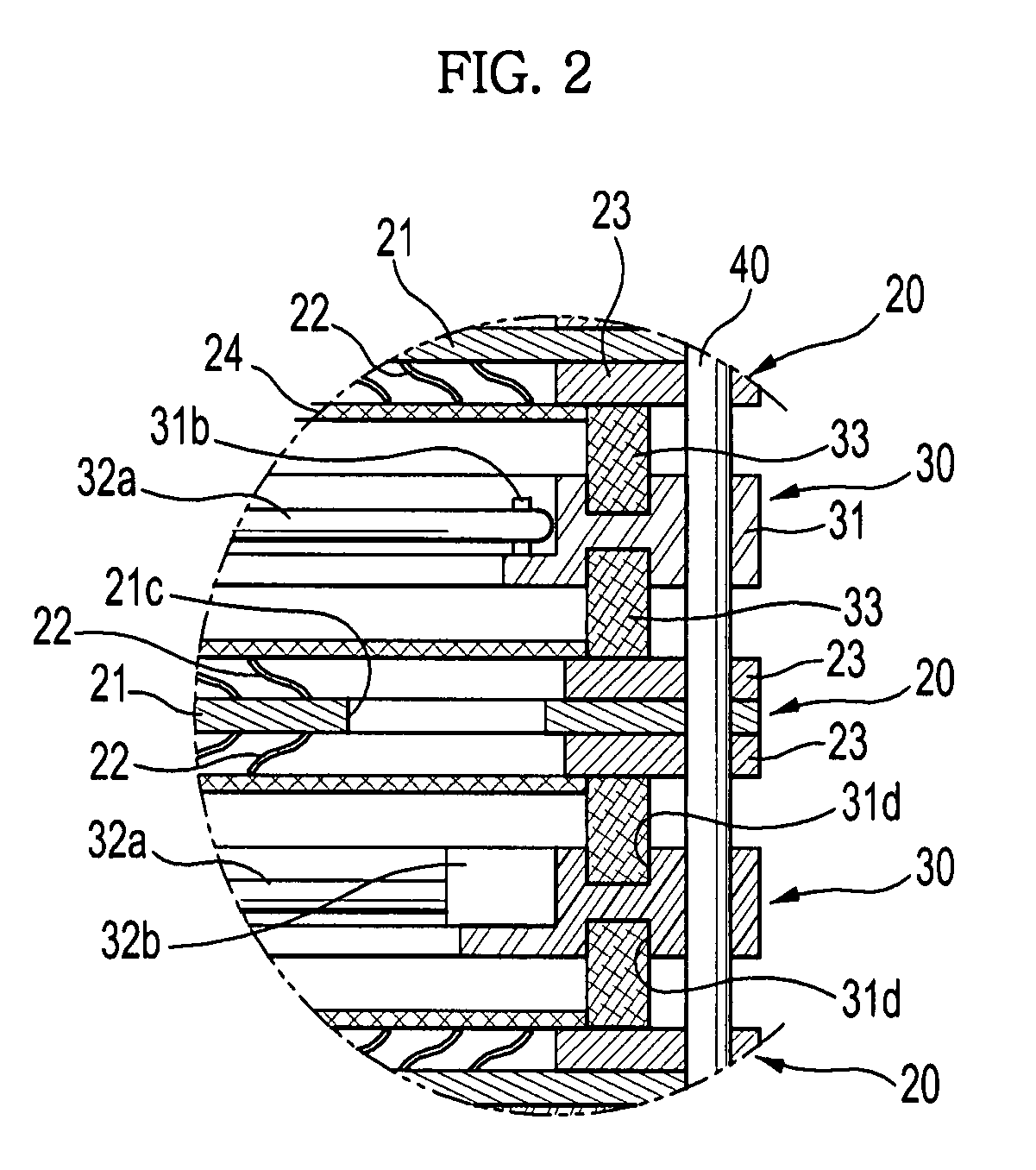

Deionization apparatus, electrode module for the same and method for manufacturing the same

InactiveUS20100078327A1Increase productivityReduce manufacturing costAdhesive processesSludge treatmentIon adsorptionEngineering

In the deionization apparatus, among a pair of electrode modules to which a power is applied, only one electrode module includes an electrode capable of adsorbing ions to impart an ion-adsorption capability thereto and the other electrode module includes an electrode having no ion-adsorption capability not to impart an ion-adsorption capability thereto, to remove only one of cations and anions, in order to improve production efficiency and reduce manufacturing costs.

Owner:SAMSUNG ELECTRONICS CO LTD

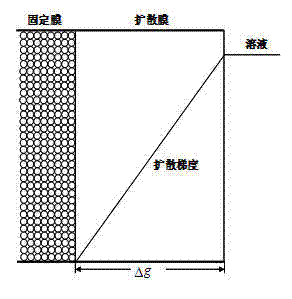

Improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement and preparation method thereof

InactiveCN102507388AImprove physical strengthLittle flexibilitySurface/boundary effectMoisturePolyacrylamide

The invention provides an improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement. The improved phosphorus fixing film is a polyacrylamide gel film containing zirconium dioxide (ZrO2) and is characterized in that ZrO2 particles of which the particle size is less than or equal to 5mu m are uniformly distributed on the surface of the phosphorus fixing film. A preparation method of the improved phosphorus fixing film comprises the following steps: uniformly mixing ZrO2 powder with the moisture content of 45-55% with an acrylamide solution at the weightmeasurement ratio of (1:3)-(1:6); grinding and then carrying out ultrasonication; standing for removing precipitates, adding tetramethylethylenediamine of which the volume is (1:1600)- (1:1400) of that of acrylamide and a 10% ammonium persulfate solution of which the volume is (1:60)-(1:40) of that of acrylamide, uniformly mixing and injecting into a glass mold; horizontally placing the glass mold at room temperature; After the zirconium powder is freely precipitated, raising the temperature to 40-60DEG C until the mixed solution forms a gel film; and soaking in de-ionized water for more than 12 hours, thus obtaining the phosphorus fixing film. The phosphorus fixing film provided by the invention can be used for maintaining high phosphorus ion adsorption capacity and simultaneously improving the resolution ratio of DGT in phosphorus analysis.

Owner:HOHAI UNIV

Heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane

ActiveCN102527261AReduce dosageLow priceSemi-permeable membranesOther chemical processesFiberMass ratio

The invention discloses a heavy metal ion adsorption type polyvinylidene fluoride (PVDF) hollow fiber membrane. The invention belongs to the technical field of membranes and in particular relates to a preparation technology for an organic-inorganic hybrid hollow fiber membrane. The heavy metal ion adsorption type PVDF hollow fiber membrane comprises modified attapulgite, wherein the mass ratio of the PVDF to the modified attapulgite is (1:0.01)-(1:0.1). The heavy metal ion adsorption type PVDF hollow fiber membrane has the advantages that high pressure resistance is achieved, a supporting body is not required, a membrane component has any sizes and shapes and large filling density, and unit volume membrane area and flux are large. In addition, the hybrid membrane is high in spinning performance, the spinning membrane-forming process is simple in process, and cost is low.

Owner:TIANJIN POLYTECHNIC UNIV

Metallic ion adsorption material and preparation method thereof

InactiveCN101269318AImprove adsorption capacityExcellent physical and chemical propertiesOther chemical processesWater/sewage treatment by sorptionCross-linkPollution

The invention relates to an adsorbing material, in particular to an adsorbing material used for absorbing metal ion in waste water and a preparation method thereof. Under the action of a catalyst, aminopolysaccharides or oilmeal, polyalcohols, isocyanate and vesicant are loaded through polymerization on a urethane foam cross-linked network. The adsorption material can effectively adsorb metal irons in wasted water, thereby solving the pollution of metal irons fundamentally. The adsorbing material has good adsorption of metal irons. The chitosan and oil meal are loaded on the urethane network so as to obtain a novel porous adsorption material which has good physical and chemical performance, larger surface area, good adsorption ability and simple preparation method. The adsorption material is suitable for disposal of waste water containing heavy metal irons characterized by large flow rate and low concentration.

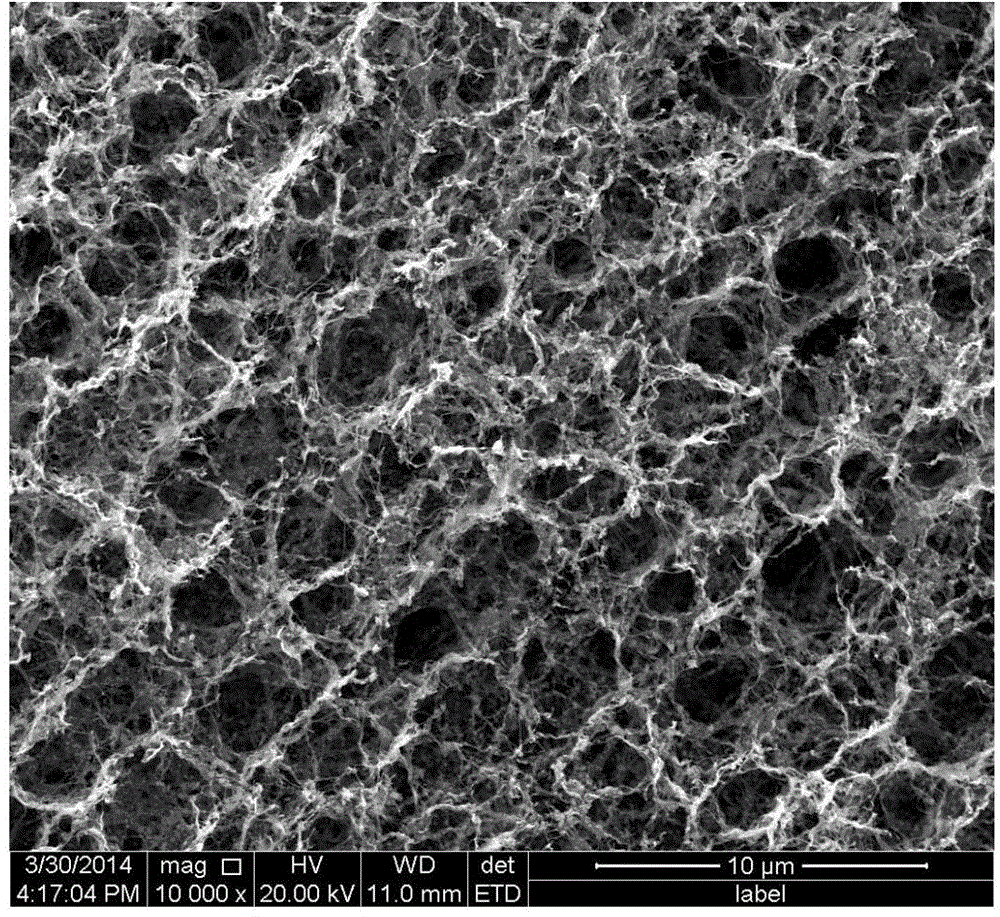

Preparing method for three dimensional bacterial cellulose-derived carbon nano fiber/metal particle composite aerogel

The invention relates to a preparing method for a three dimensional bacterial cellulose-derived carbon nano fiber / metal particle composite aerogel and belongs to the field of a carbon nano fiber / metal composite nano material. The preparing method comprises the steps of firstly dipping bacterial cellulose aquogel into a metal salt solution for water heating, then moving into an alkaline solution to obtain a bacterial cellulose / metal hydroxide or oxyhydroxide compound by thermal sedimentation, and then obtaining the bacterial cellulose-derived carbon nano fiber load metal nano particle composite aerogel by high temperature cracking. The preparing method has the advantages of simple preparing process, environment friendliness, capability of large-scale preparing and the like. In addition, the three dimensional material prepared by the method has a porous network structure and good conductivity, metal particles are uniformly loaded on carbon nano fibers, and the preparing method has broad application prospect in the application such as photoelectric catalysis, electrochemistry and heavy metal ion adsorption.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing heavy metal ion adsorption materials of crop straws

InactiveCN103992446ANo pollution in the processNo protectionOther chemical processesWater/sewage treatment by sorptionAdsorption equilibriumPhytic acid

The invention relates to a method for preparing heavy metal ion adsorption materials of crop straws. The method is characterized by comprising the following processing steps: adding straw powder into N, N-dimethyl formamide; putting the straw powder and the N, N-dimethyl formamide into an ultrasonic rinsing tank for ultrasonic cleaning at a certain temperature for a certain time; then adding phytic acid and urea into the above system, heating to 50-90 DEG C, cooling products to a room temperature after reaction for a certain time, and then precipitating, washing, drying and grinding the products to obtain phytic acid modified straws; neutralizing itaconic acid with NaOH, then adding the phytic acid modified straws, acrylamide, vinyl pyrrolidone and cross-linking agents, after the mixture is fully stirred, gradually heating to 40-60 DEG C, and finally slowly and dropwise adding redox initiators into the polymerization system to initiate a polymerization reaction that lasts for 3-5 hours; after the polymerization is completed, performing precipitation, washing and drying to obtain the heavy metal ion adsorption materials of crop straws. The adsorption capacity reaches 50-800mg / g for heavy metal ion water solutions of which the initial concentration is 100-1000mg / l, and adsorption equilibrium is reached after adsorption at the room temperature for 50-150 min.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

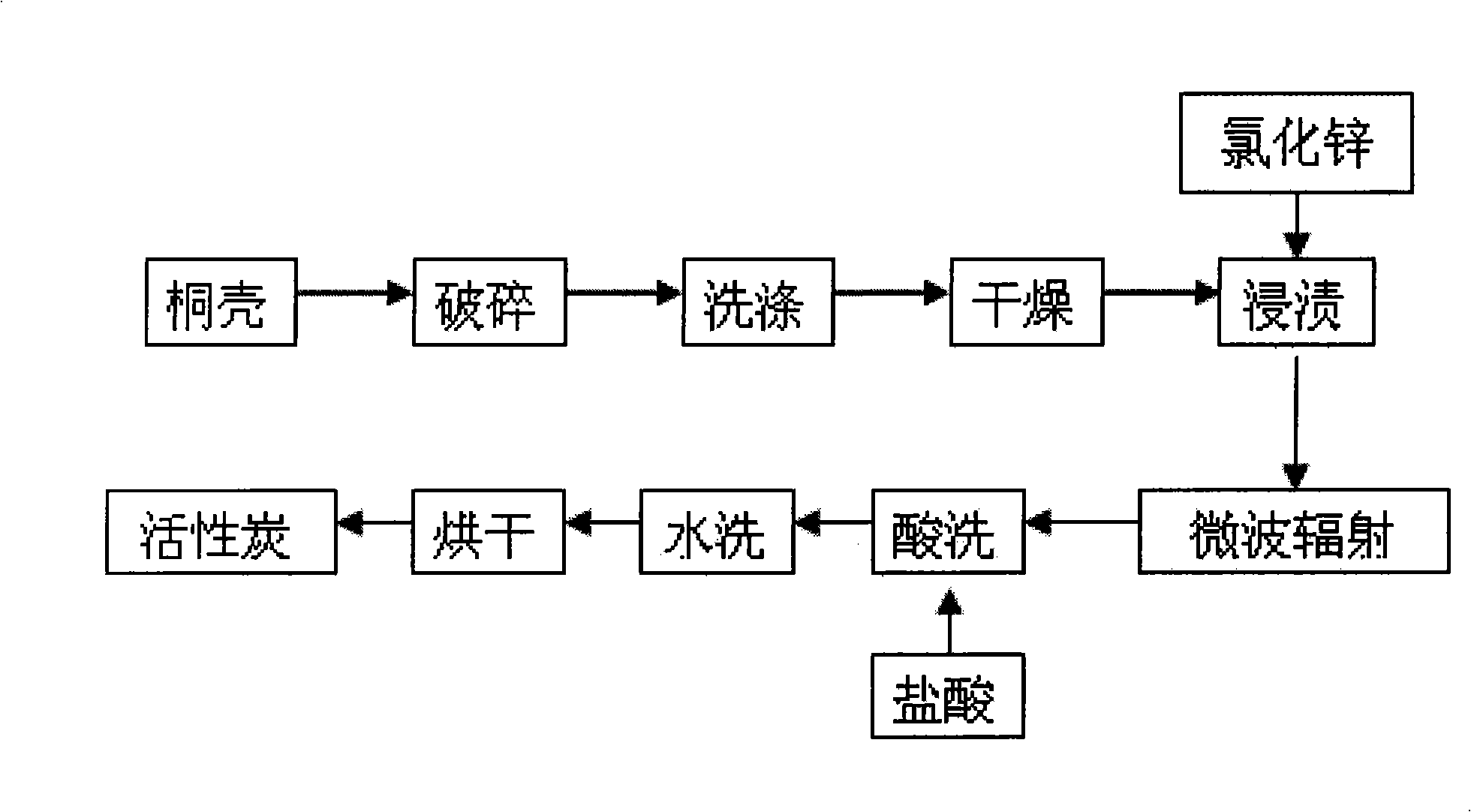

Method for preparing tung cell-based active carbon by zinc chloride chemical activation method

The invention relates to a method which can adopt the zinc chloride chemical activation method to prepare tung nutshell into active carbon. The technical proposal is as follows: 1) zinc chloride and tung nut shell are added into distilled water, stirred and soaked at 80DEG C and moisture is evaporated. 2) The mixture is placed in a high temperature activation furnace and nitrogen is firstly pumped in; at the speed of 200-300mL / min and under the protection of nitrogen, the mixture is heated to 350-900DEG C for activating reaction which lasts for 30-300 min to prepare primary products. 3) The mixture is arranged in a microwave high temperature activation furnace and heated by microwave radiation under the protection of nitrogen, the microwave radiation lasts for 8-20 min, and carbonization and activation are finished at the same step to prepare the primary products of active carbon. 4) The products are immersed in hydrochloric acid, then soaked by hot distilled water for two times, dried at 105 DEG C for 12 hours and weighed for calculating the yield. The method can successfully transform tung nutshell into active carbon, the specific surface area and the pore volume of which can reach 1602m <2> / g and 1.115mL / g respectively; the maximum methylene blue adsorption value can reach 300mg / g, while copper ion adsorption rate can exceed 99%.

Owner:FUJIAN NORMAL UNIV

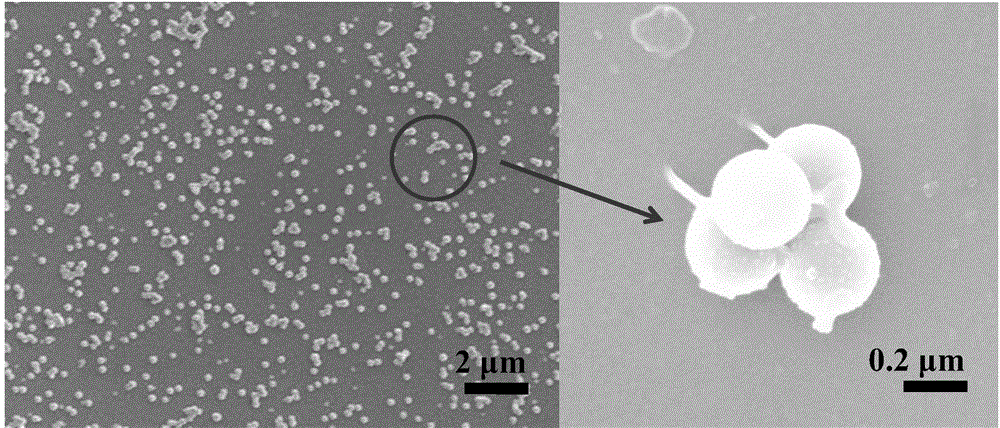

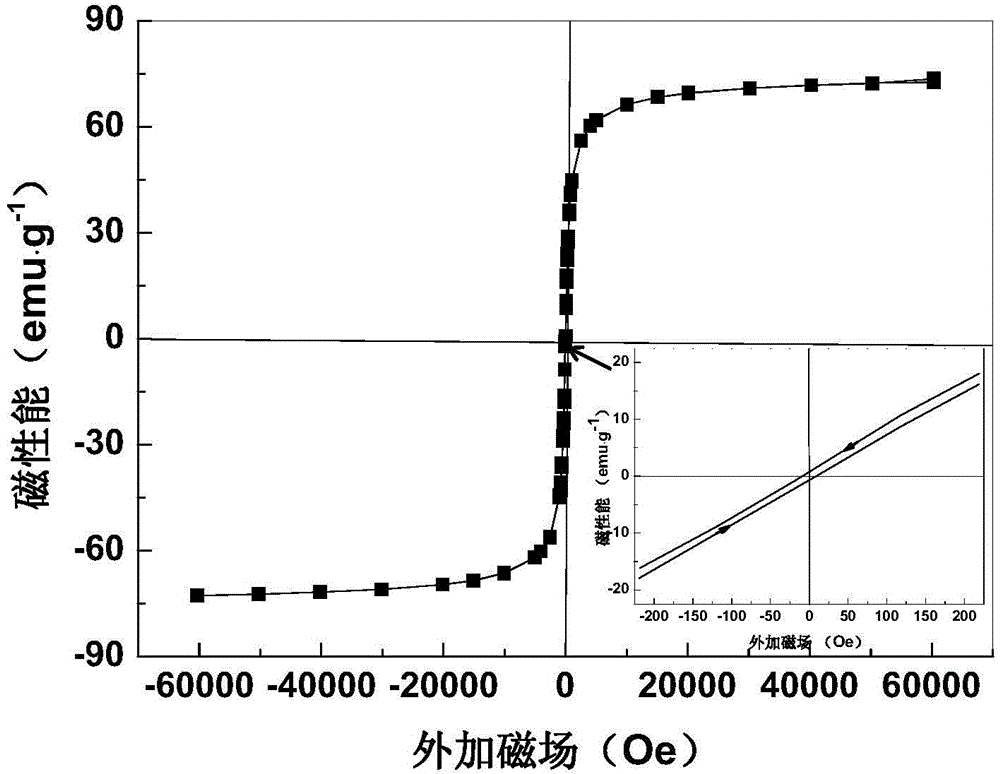

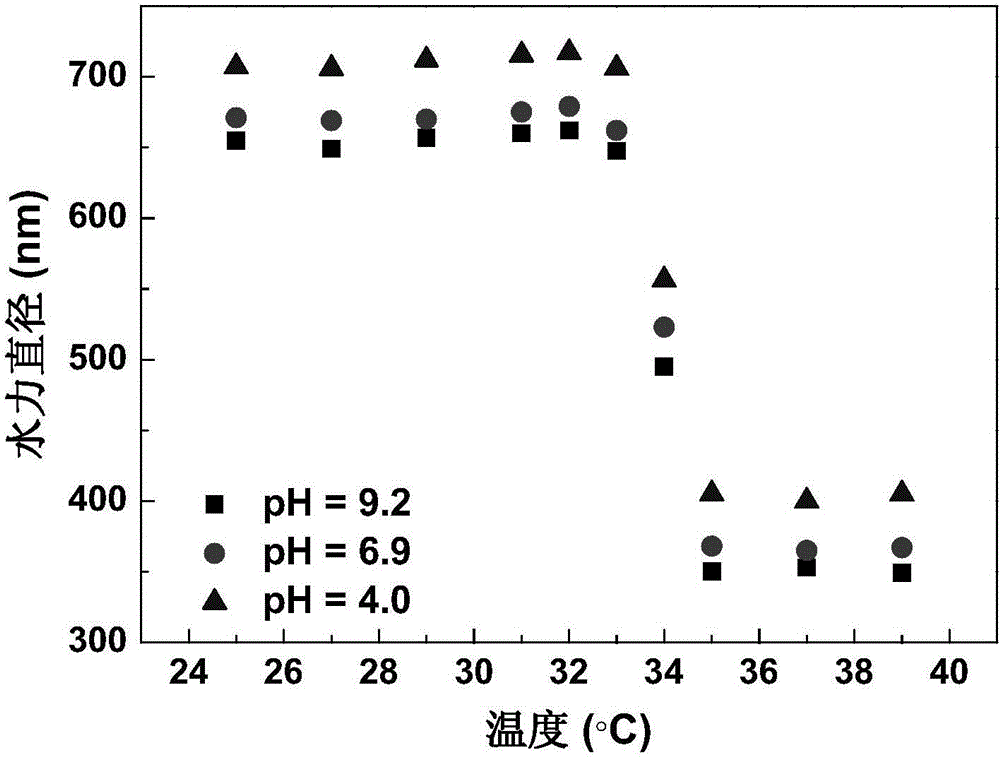

Intelligent hydrogel as well as preparation method and application thereof

ActiveCN104592449ALarge adsorption capacityEasily achieve separabilityOther chemical processesWater/sewage treatment by sorptionSmart hydrogelsDesorption

The invention discloses an intelligent hydrogel as well as a preparation method and an application thereof and a hydrogel. The intelligent hydrogel is P(NIPAM-co-CS) / Fe3O4 and comprises iron oxide, N-isopropyl acrylamide and chitosan. The preparation method comprises the following steps: dissolving FeCl2.4H2O and FeCl3.6H2O in a mixed solvent of ethanol and water and reacting to prepare hydrophilic Fe3O4 nanoparticles under the protection of nitrogen and by adopting ammonia water as a precipitating agent; ultrasonically dispersing the prepared Fe3O4 nanoparticles in a chitosan liquid, adding a temperature-sensitive monomer N-isopropyl acrylamide and in the presence of a crosslinking agent and an initiator and by adopting tetramethylethylenediamine as an accelerator, carrying out polymerization reaction to prepare the intelligent hydrogel P(NIPAM-co-CS) / Fe3O4 by virtue of a micro-emulsion polymerization method. The intelligent hydrogel can be applied in the preparation of a water body heavy metal ion adsorption-desorption agent for removing heavy metal ions in water body.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com