Patents

Literature

43results about How to "High adsorption value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy metal-contaminated soil remediation agent and preparation method thereof

InactiveCN105567247AHigh porosityHigh adsorption valueOther chemical processesOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

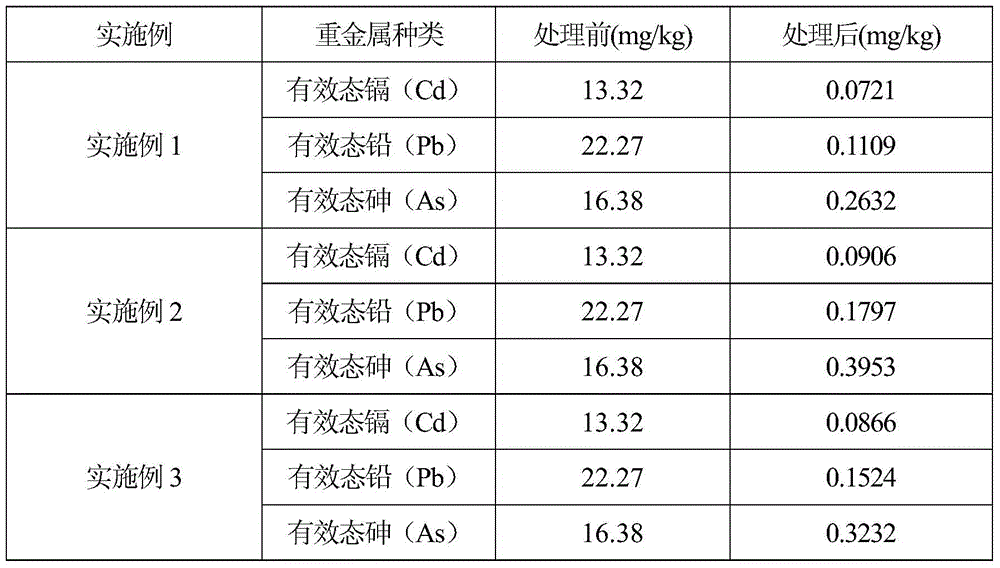

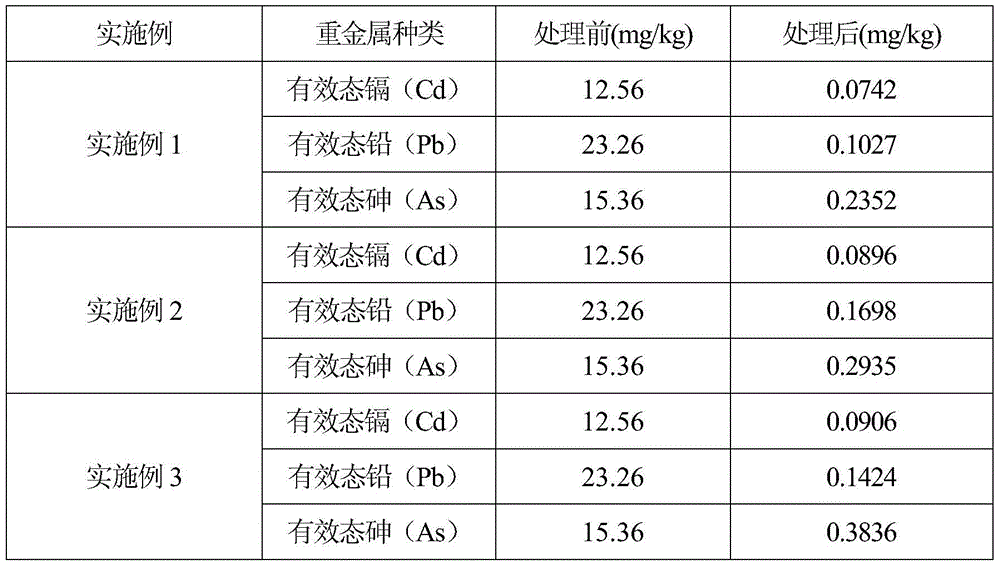

The invention provides a heavy metal-contaminated soil remediation agent. The remediation agent is prepared from, by weight, 30%-45% of quick lime, 10%-25% of biomass charcoal, 10%-15% of kieselguhr, 10%-15% of sodium bentonite, 10%-15% of activated aluminum oxide, 5%-10% of nitrilotriacetic acid, 1%-5% of sodium lignin sulfonate and 1%-5% of sodium dodecyl sulfate. A preparation method comprises the steps that the quick lime, the biomass charcoal, the kieselguhr, the sodium bentonite, activated aluminum oxide, nitrilotriacetic acid, sodium lignin sulfonate and sodium dodecyl sulfate are stirred and mixed to be uniform according to the weight ratio, and then the soil remediation agent is prepared. The prepared soil remediation agent has the good effect when cadmium-lead-zinc-mercury compound contaminated soil is remedied.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

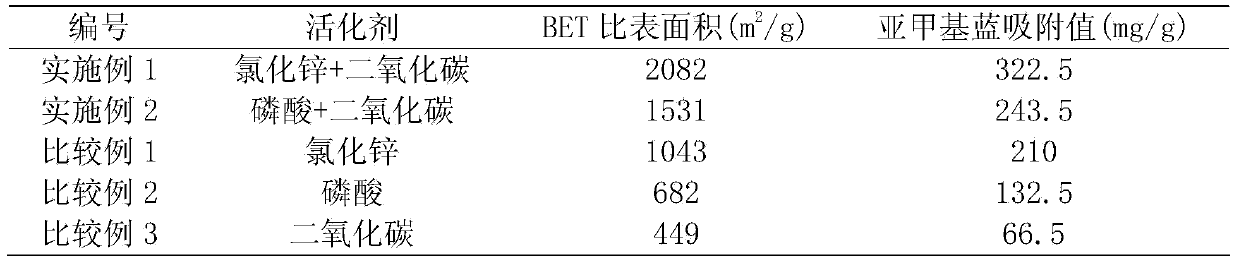

Method for preparing active carbon by taking biomass pyrolytic carbon as raw material

InactiveCN104003387AIncrease added valueImprove performanceCarbon compoundsActivation methodFiltration

The invention relates to a method for preparing active carbon by taking biomass pyrolytic carbon as a raw material, and relates to post processing of the biomass pyrolytic carbon. The method comprises the following steps: cleaning the pyrolytic carbon, stirring, then standing and depositing, drying the pyrolytic carbon floating on an upper layer, and then crushing; preparing a chemical activating agent solution, then mixing, stirring and soaking with the pyrolytic carbon, then drying a soaked mixed solution to obtain a mixed material; and heating the mixed material to 300-800 DEG C at an inert gas atmosphere, introducing a physical activating agent to obtain an active carbon semi-finished product, then adding hydrochloric acid, mixing, then carrying out suction filtration, then cleaning residual hydrochloric acid, and drying to obtain an active carbon finished product. The method disclosed by the invention carries out activating treatment on the biomass pyrolysis of agricultural and forestry wastes and the like, can be used for furthest recycling the agricultural and forestry wastes and can obviously increase the added value of the pyrolytic carbon and obtain the active carbon with excellent property; compared with a product prepared by independently using a chemical activation method or a physical activation method, the prepared active carbon is much larger in specific area, more developed in pore and higher in methylene blue adsorption value.

Owner:XIAMEN UNIV

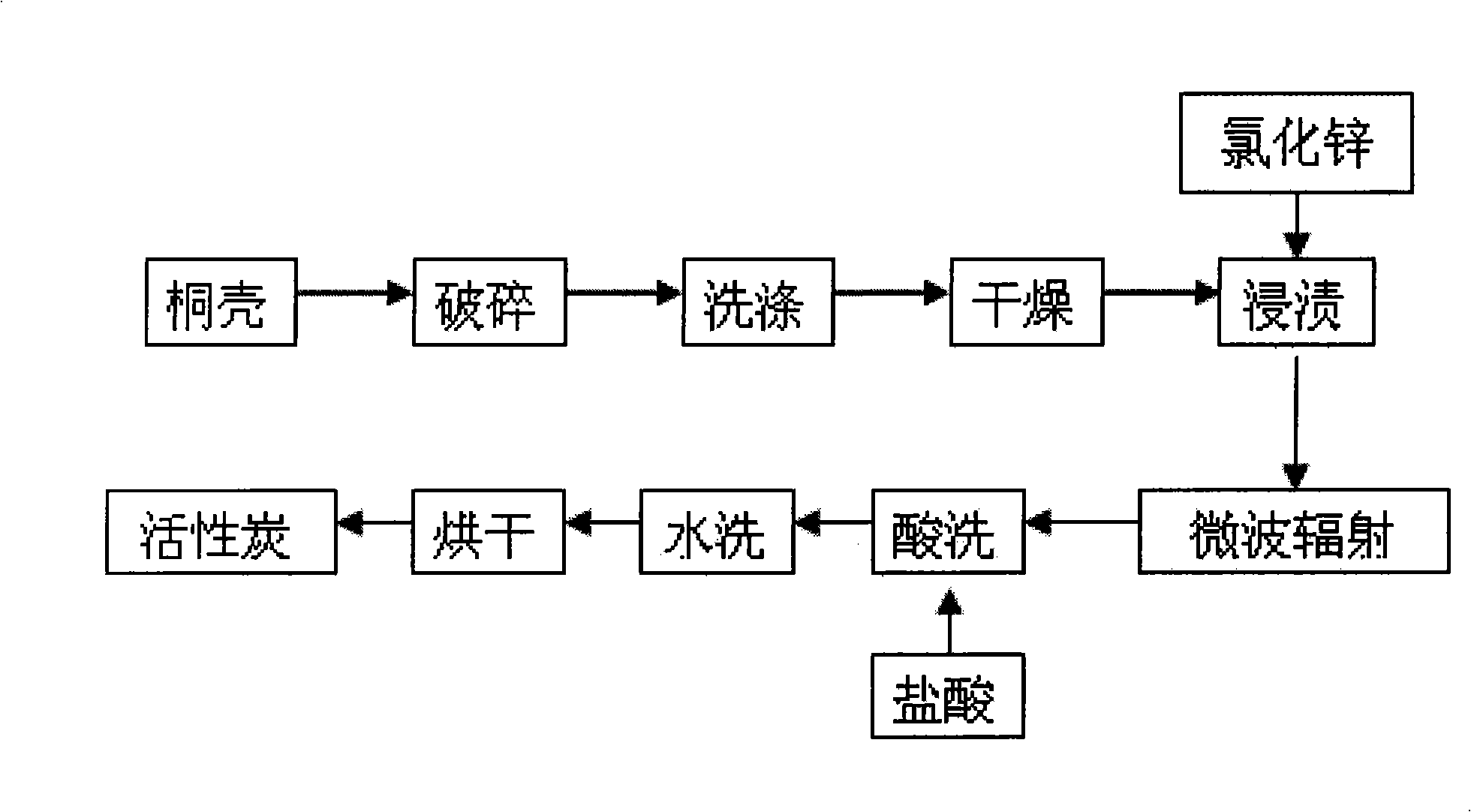

Method for preparing tung cell-based active carbon by zinc chloride chemical activation method

The invention relates to a method which can adopt the zinc chloride chemical activation method to prepare tung nutshell into active carbon. The technical proposal is as follows: 1) zinc chloride and tung nut shell are added into distilled water, stirred and soaked at 80DEG C and moisture is evaporated. 2) The mixture is placed in a high temperature activation furnace and nitrogen is firstly pumped in; at the speed of 200-300mL / min and under the protection of nitrogen, the mixture is heated to 350-900DEG C for activating reaction which lasts for 30-300 min to prepare primary products. 3) The mixture is arranged in a microwave high temperature activation furnace and heated by microwave radiation under the protection of nitrogen, the microwave radiation lasts for 8-20 min, and carbonization and activation are finished at the same step to prepare the primary products of active carbon. 4) The products are immersed in hydrochloric acid, then soaked by hot distilled water for two times, dried at 105 DEG C for 12 hours and weighed for calculating the yield. The method can successfully transform tung nutshell into active carbon, the specific surface area and the pore volume of which can reach 1602m <2> / g and 1.115mL / g respectively; the maximum methylene blue adsorption value can reach 300mg / g, while copper ion adsorption rate can exceed 99%.

Owner:FUJIAN NORMAL UNIV

Burn-free coal-ash-based geological polymer high performance adsorbing material preparation method

InactiveCN106362680AHigh specific surface areaHigh selective adsorptionOther chemical processesAluminium silicatesPhenolEnergy conservation

The invention provides a burn-free coal-ash-based geological polymer high performance adsorbing material preparation method which comprises the following steps: a, preprocessing a solid raw material; b, preparing a base material, wherein solid waste coal ash containing rich aluminosilicate is utilized as the solid raw material, an alkali activator is utilized as a liquid raw material, and the solid raw material and the liquid raw material are evenly mixed to react at a temperature of 20 to 100 DEG C to form a base; c, forming a base material, i.e., forming the evenly-mixed solid and liquid raw materials into a base sample through granulation molding or casting molding or extrusion molding; d, maintaining the base sample; e, washing and drying. The method can save energy, is simple in preparation technology, can reduce production cost, can be used to produce a high performance geological polymer adsorbing material in a large scale, and the waste coal ash of coal-fired power plants is utilized as a raw material to prepare the adsorbing material at a room temperature; thus, the problem of coal ash stack and waste and the environmental problems caused by the coal ash stack and waste are solved, and industrial organic waste gas and waste water containing phenol can be treated in a mode of using waste to treat waste.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

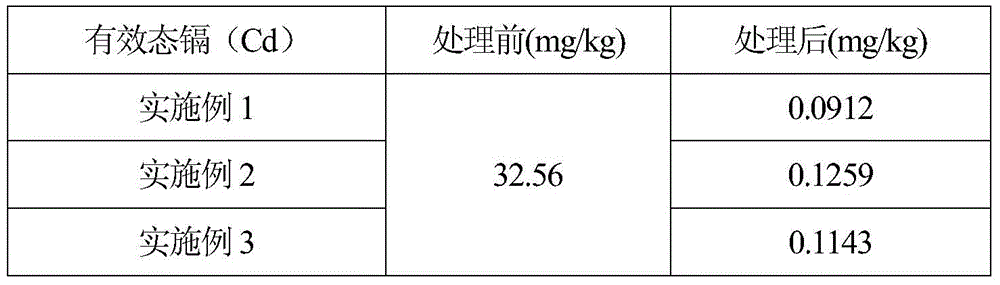

Cadmium contaminated soil restoring agent and using method and application thereof

InactiveCN105713616AHigh porosityHigh adsorption valueAgriculture tools and machinesOther chemical processesIron powderTherapeutic effect

The invention provides a cadmium-contaminated soil remediation agent, which consists of the following components by weight ratio: 30-50% of biomass charcoal, 10-20% of iron powder, 10-20% of plant ash, 10-20% of sodium sulfide, Zeolite 10‑20%; the above components fully exert synergistic effects, and through reduction, precipitation, adsorption, improvement, and adjustment of PH value, the effective cadmium in the soil is greatly reduced, and the prepared soil remediation agent can be used to repair cadmium-contaminated soil. With good effect, the restoration agent of the present invention has the advantages of simple preparation method, feasibility and good treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Oxidation treatment method for carrier carbon surface

InactiveCN101269345AGood dispersionHigh adsorption rateCatalyst carriersCatalyst activation/preparationEnergy controlUltrasonic radiation

The invention relates to a method of oxidation process on the surface of a carrier carbon, including the following steps that: powdered activated carbon is mixed with nitric acid solution with a concentration ranging from 2 to 12 percent by the weight ratio of 1:3 to 30 to make a powdered activated carbon suspension which is processed by ultrasonic radiation for 20-120min at the temperature between 30 DEG C and 60 DEG C, wherein, the ultrasonic energy is controlled between 1 and 10W / cm<2>. The suspension is filtered and the residue is cleaned by water until the pH value of the washing water ranges from 6.5 to 7. After drying, under the protection of nitrogen, the residue is processed at the high temperature between 800 DEG C and 1100 DEG C for 5 to 15min by microwave with the frequency of 2450 MHz and the power ranging from 200W to 850W. The method provided by the invention can remove most oxygen-functional groups on the surface of the activated carbon, improve the alkalinity and the specific surface area on the surface of the activated carbon and reduce the ash content of the activated carbon. Besides, the method provided by the invention has the advantages of short processing time, high processing efficiency, environmental protection and energy conservation.

Owner:CHENZHOU GAOXIN PLATINUM

Heavy metal pollution soil restoration agent and application thereof

InactiveCN105542792AHigh porosityHigh adsorption valueAgriculture tools and machinesOther chemical processesThioureaTherapeutic effect

The invention provides a heavy metal pollution soil restoration agent which is composed of the following components in percentage by weight: 30-45% of biomass charcoal, 10-25% of alpha-cyclodextrin, 10-15% of glucose, 10-15% of iron powder, 10-15% of ferrous sulfate, 5-10% of polyacrylamide, 1-5% of sodium sulfide and 1-5% of thiocarbamide. The soil restoration agent has favorable effects on restoring cadmium / lead / zinc / mercury combined pollution soil. The restoration agent has the advantages of simple and feasible preparation and favorable treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

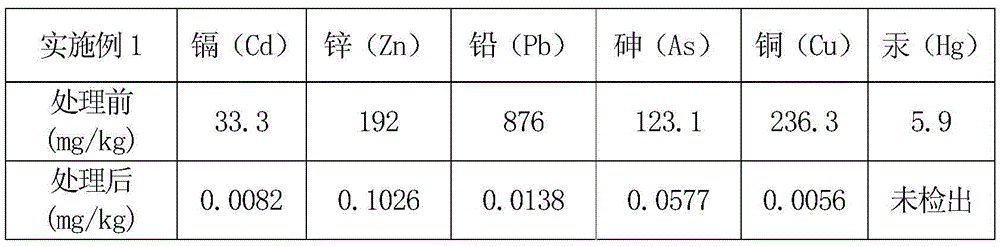

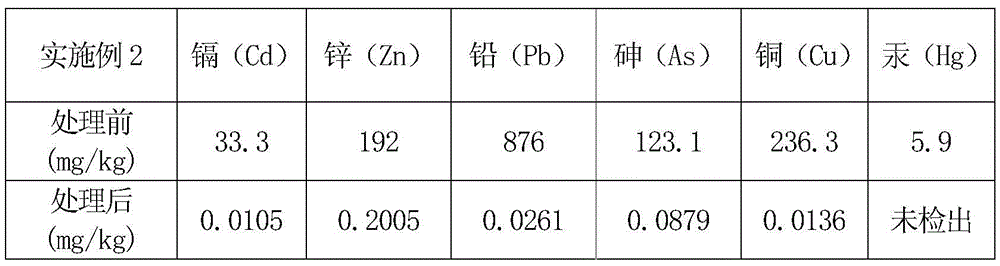

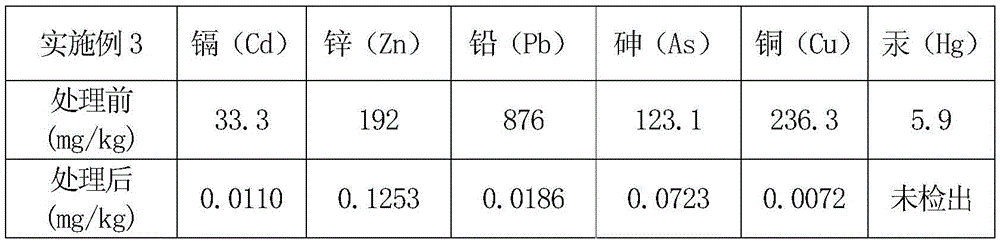

Soil remediation agent

InactiveCN105623667AHigh porosityHigh adsorption valueOrganic fertilisersSoil conditioning compositionsSodium BentoniteCadmium Cation

The invention provides a soil remediation agent. The soil remediation agent is composed of, by weight, 10-25% of hydroxyl calcium phosphate, 30-45% of biomass charcoal, 10-15% of sodium sulfide, 10-15% of sodium bentonite and 10-15% of ammonium phosphate. The soil remediation agent is effective in remediation of soil contaminated by cadmium, lead, zinc, arsenic, copper and mercury.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

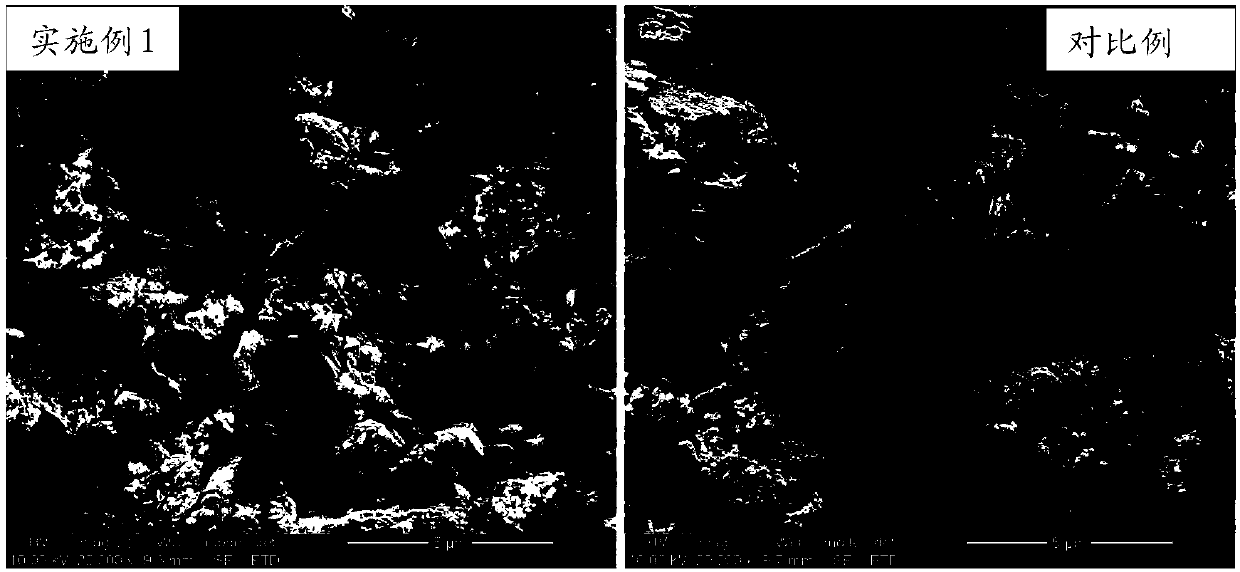

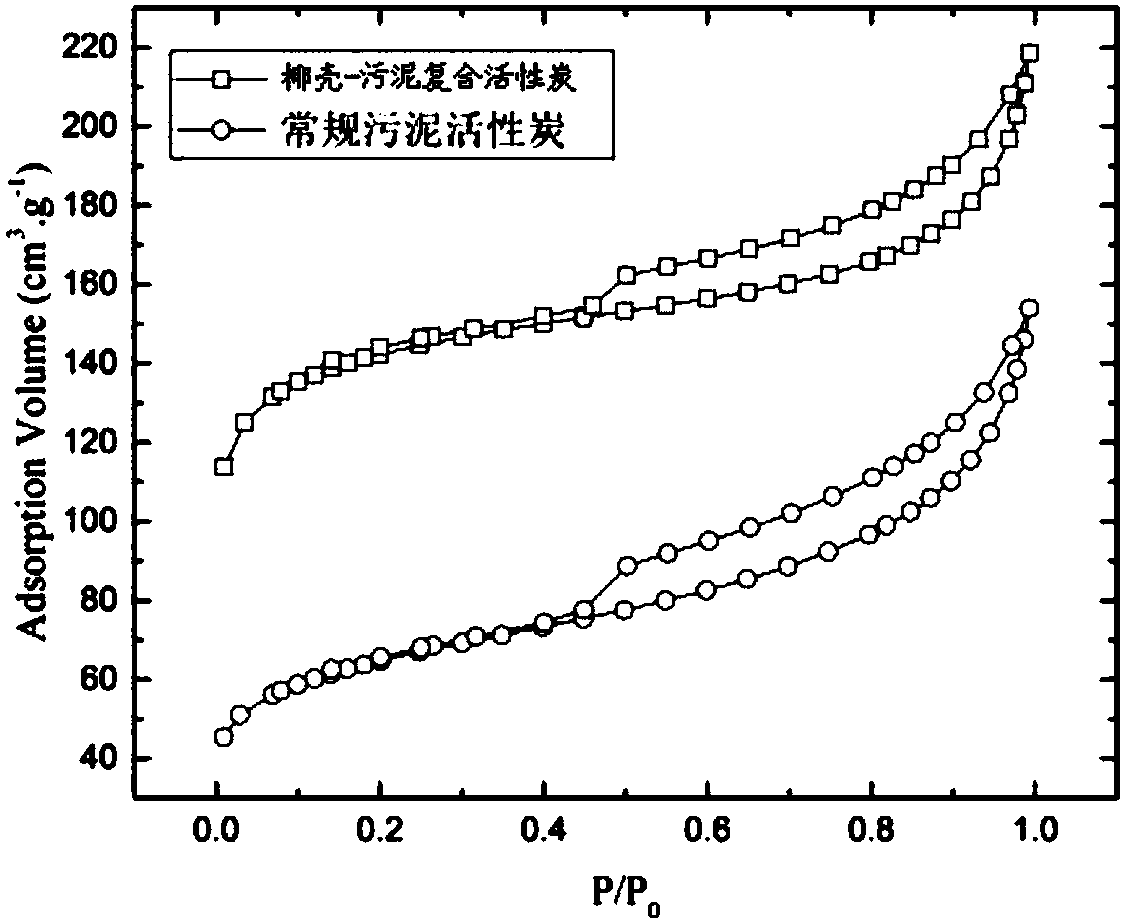

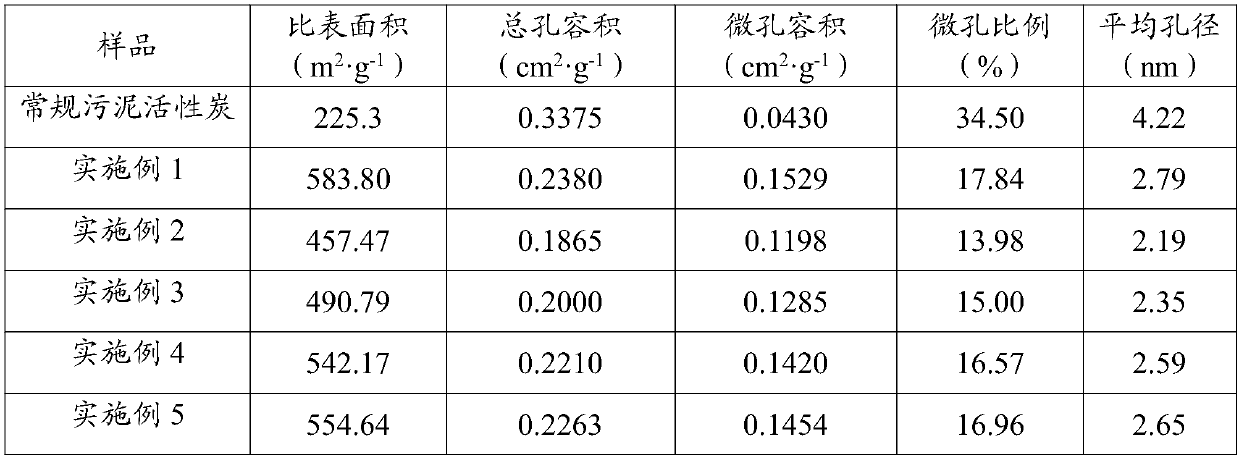

Coconut shell-mud composite active carbon as well as preparation method and application thereof

InactiveCN108033448ALarge specific surface areaHigh adsorption valueCarbon compoundsOther chemical processesActivated carbonMunicipal sewage

The invention provides a preparation method of coconut shell-mud composite active carbon, and belongs to the field of waste water treatment. A two-step chemical activation method is adopted to transform residual sludge coming from urban sewage treatment into the coconut shell-mud composite active carbon having economical value, so that the residual sludge of urban sewage treatment plants is recycled, and stabilization, reduction, hazard-free treatment and recycling of the sludge are realized. The method has the characteristics of simple process and low cost, and the prepared coconut shell-mudcomposite active carbon product has the characteristics of rich pores and high adsorption performance. Coconut shell is doped into the sludge to prepare the coconut shell-mud composite active carbon,so that the carbon content of raw materials is increased, and the defects of lower carbon content of the raw materials mud and higher ash content are overcome. The coconut shell-mud composite active carbon prepared with the method has the advantages of larger specific-surface area, high adsorption value and good adsorption effects on hexavalent chromium and dyes in a water body, and is suitable for being popularized in the field of water treatment.

Owner:SOUTHWEST PETROLEUM UNIV +1

Soil remediation agent and restoration stabilizing remediation method for hexavalent-chromium-contaminated soil

InactiveCN108555007AHigh porosityHigh adsorption valueContaminated soil reclamationOrganic fertilisersPorosityChar

The invention discloses a soil remediation agent and a restoration stabilizing remediation method for hexavalent-chromium-contaminated soil. The soil remediation agent is composed of the following rawmaterials of, by mass, 35%-45% of calcium polysulfide, 15%-25% of biomass charcoal and 35-45% of ferrous sulfate, wherein the sum of the mass percentages of the raw materials is 100%. The restorationstabilizing remediation method for the hexavalent-chromium-contaminated soil comprises the step that the soil remediation agent is added into the chromium-contaminated soil. According to the remediation agent, the biomass charcoal is obtained through vacuum pyrolysis of biomass, and the biomass charcoal prepared under the vacuum condition is high in porosity and adsorption value; rice straw biomass serves as a raw material, resources are fully utilized, and environmental pollution caused by burning of the rice straw biomass is avoided; and the biomass charcoal obtained through vacuum pyrolysis has the advantages of being large in specific surface area, rich in pore canal, liable to adsorb various heavy metal ions, and capable of reducing the concentration of the mobility heavy metal ionsin the soil.

Owner:HUATIAN ENG & TECH CORP MCC +2

Soil heavy metal passivator and preparation method and application thereof

InactiveCN105567248AHigh porosityHigh adsorption valueOther chemical processesContaminated soil reclamationSoil heavy metalsTherapeutic effect

The invention provides a heavy metal polluted soil remediation agent which is prepared from, by weight, 30-50% of biomass charcoal, 10-30% of alpha-cyclodextrins, 10-20% of zeolite, 5-10% of polyacrylamide, 5-10% of glucose and 5-10% of sodium sulphide. The preparation method comprises the steps that the biomass charcoal, the alpha-cyclodextrins, the zeolite, the polyacrylamide, the glucose and the sodium sulphide are evenly mixed according to the mass ratio, and therefore the soil remediation agent is prepared. The obtained soil remediation agent has the good effect on remedying cadmium, lead, zinc and copper composite polluted soil, and has the advantages that the method is simple and feasible, and the treatment effect is good.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Heavy metal cadmium and lead composite polluted soil restoration agent and preparing method thereof

InactiveCN105733602AHigh porosityHigh adsorption valueContaminated soil reclamationOrganic fertilisersSulfateMaterials science

The invention provides a heavy metal cadmium and lead composite polluted soil restoration agent.The restoration agent is prepared from, by weight, 30-50% of biomass charcoal, 5-10% of kieselguhr, 20-30% of ferrous sulfate, 5-10% of starch and 10-20% of chitosan.According to the preparing method, the biomass charcoal, the kieselguhr, ferrous sulfate, the starch and chitosan are mixed according to the mass ratio, and stirred fully and uniformly to obtain the prepared soil restoration agent.The prepared soil restoration agent has a good effect when restoring cadmium and lead composite polluted soil.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Novel ion exchange fiber and its application

InactiveCN102872833AEasy to prepareHigh adsorption valueOther chemical processesFibre typesChemical treatmentPolystyrene

The invention discloses a novel ion exchange fiber and its application. The ion exchange fiber is directly prepared by directly selecting raw materials having ion exchange functions without obtaining functional groups through a chemical treatment of grafting. The preparation method of the ion exchange fiber is simple, is in favor of the industrialized continuous production of products, and has a low economic cost. The ion exchange fiber prepared in the invention has the advantages of large exchange capacity, fast elution and adsorption speed, and the like. The filament diameter and the exchange capacity of the ion exchange fiber prepared in the invention are 5-100mum and 3.0-5.8mmol / g respectively. The matrix fiber of the ion exchange fiber has good comprehensive performances comprising good mechanical performances, high temperature resistance, acid and alkali resistance and the like. The preparation method of the novel ion exchange fiber comprises the following steps: mixing the raw materials comprising polystyrene (PS) and polyethylene (PE) with a compatilizer according to a certain weight ratio, adjusting an optimum spinning temperature, and carrying out melt spinning to prepare the base material of the ion exchange fiber; and carrying out chemical treatment of the base material to prepare the cation exchange fiber having sulfonic groups. The novel ion exchange fiber can be widely applied to the environmental protection field, the medicine and health field, the metallurgical filed, the water treatment field, the chemical adsorption field, the resource recovery field and the like.

Owner:冯淑芹

Novel adsorptive material for treating air pollution and its preparing method

InactiveCN1748858AEasy to useIncrease profitOther chemical processesDispersed particle separationCalcium hypochloriteActive carbon

The novel adsorptive material for treating polluted air consists of active carbon or charcoal 50-100 weight portions and additive 0-50 weight portions, and the additive may be silicon colloid, calcium hopochlorite, anhydrous cup sulfate, anhydrous calcium chloride or calcium oxide. The preparation process includes first reinforced activation of active carbon or charcoal, the subsequent mixing with additive, and final vacuum packing. The present invention can adsorb, digest and degrade toxic matter in air effectively, and inhibit and kill virus in air. It is safe, efficient, low in power consumption, healthy, environment friendly, multifunctional and excellent in technological performance.

Owner:黎伯忠

Preparation method of fly ash-based zeolite molecular sieve for adsorbing VOCs

PendingCN111186844AHigh adsorption valueImprove hydrophobicityGas treatmentOther chemical processesMolecular sieveFiltration

The invention provides a preparation method of a fly ash-based zeolite molecular sieve for adsorbing VOCs. The preparation method specifically comprises the following steps: (1) reacting fly ash withhydrochloric acid at 100 DEG C, carrying out suction filtration, performing washing with water, and conducting drying to obtain pretreated fly ash; (2) reacting the pretreated fly ash with a sodium hydroxide solution for 30-60 minutes; (3) aging a reaction solid-liquid mixture for 4-8 hours, crystallizing the mixture at 110-130 DEG C for 3-10 hours, drying filter residues, and grinding the filterresidues to obtain a primary product; and (4) adding 15 mL-30 mL of a CTAB solution into every 1 g of the primary product, performing modifying for 20-40 minutes, and successively performing suction filtration, drying and grinding to obtain the CTAB-modified fly ash-based zeolite molecular sieve. The CTAB-modified fly ash-based zeolite molecular sieve is prepared from fly ash, preparation processis simple, production efficiency is high, fly ash solid waste can be digested, production cost and energy consumption can be reduced, and large-scale production is facilitated.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing high-purity zinc oxide by using zinc-acetate-carrying waste activated carbon

InactiveCN105668610AQuality improvementReduce environmental pollutionZinc oxides/hydroxidesCombustible gas purificationAir atmosphereActivated carbon

The invention relates to a method for preparing high-purity zinc oxide by using zinc-acetate-carrying waste activated carbon, belonging to the technical field of waste resource comprehensive recycling. The method comprises the following steps: by using zinc-acetate-carrying waste activated carbon as the raw material, carrying out microwave regeneration treatment, wherein the heating rate of the industrial microwave oven is controlled at 10-110 DEG C / minute, the microwave roasting temperature is 400-800 DEG C, and the holding time is 20-40 minutes; and after the regeneration treatment, naturally cooling at room temperature to generate a product of which the upper layer is zinc oxide and the lower layer is regenerated activated carbon, and finally, separating to obtain the zinc oxide and regenerated activated carbon. According to the method, the spent catalyst generated in the vinyl acetate production process is used as the raw material, and the microwave heating rate, roasting temperature and holding time are controlled in an air atmosphere to implement the regeneration of the zinc-acetate-carrying spent catalyst and the preparation of the high-purity zinc oxide, thereby providing a novel method for the reutilization of waste and preparation of high-purity zinc oxide, and further promoting the green development of activated carbon material and nonferrous metal zinc industries.

Owner:KUNMING UNIV OF SCI & TECH

Heavy-metal compound contaminated soil remediation agent and application

InactiveCN105689385AHigh porosityHigh adsorption valueAgriculture tools and machinesContaminated soil reclamationTherapeutic effectNitrilotriacetic acid

The invention provides a heavy-metal compound contaminated soil remediation agent. The remediation agent is composed of the following ingredients in percentage by weight: 30-50% of biomass charcoal, 10-20% of ethylenediaminetetraacetic acid, 10-20% of polyacrylamide, 10-20% of nitrilotriacetic acid, 5-10% of alpha-cyclodextrin, and 5-10% of starch, wherein the abovementioned components adequately exert a synergistic effect, the content of effective-state heavy metal in the soil is greatly reduced through the effect of chelation, precipitation, adsorption, improvement, pH value adjustment and the like, and the prepared soil remediation agent has a good effect during remediation for cadmium-lead-arsenic compound contaminated soil. The remediation agent provided by the invention has the advantages of being simple and feasible in preparation method, and good in treatment effect.

Owner:内蒙古浩天生物科技有限公司 +1

Regeneration method of low-carbon-loss activated carbon

ActiveCN106512973AEfficient regenerationHigh adsorption valueOther chemical processesCombustible gas purificationActivated carbonPre treatment

The invention discloses a regeneration method of low-carbon-loss activated carbon. Activated carbon is pretreated by iron or an iron compound as a catalyst at lower temperature, and the synergic actions of dilution and ultrasonic washing are performed; and thus, the regenerated activated carbon with high adsorptive value is obtained under the conditions of low energy consumption and mild conditions, and the carbon loss can be reduced to a large extent.

Owner:CENT SOUTH UNIV

Cadmium-lead-arsenic compound contaminated soil remediation agent and application thereof

InactiveCN105754609AHigh porosityHigh adsorption valueContaminated soil reclamationOrganic fertilisersTherapeutic effectDodecylsulfonic acid

The invention provides a cadmium-lead-arsenic compound contaminated soil remediation agent, prepared from the following components by a weight ratio: 30-50% of biomass charcoal, 10-20% of diammonium hydrogen phosphate, 10-20% of trisodium phosphate, 10-20% of sodium dodecyl sulfate and 10-20% of starch; the components give full play to the synergy, and effective state of cadmium, lead and arsenic in soil are greatly reduced by carrying out chelation, precipitation, absorption, improvement, PH value adjustment and the like on the components; the prepared soil remediation agent has a good effect in remediation of the cadmium-lead-arsenic compound contaminated soil; the remediation agent provided by the invention has the advantages of being simple and feasible in preparation method as well as good in treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Metal-organic framework and ionic liquid composite material, preparation method thereof and application of composite material

ActiveCN109894086AHigh adsorption valueNo pollution in the processOther chemical processesDispersed particle separationViscous liquidMetal-organic framework

The invention relates to a metal-organic framework and ionic liquid composite material, a preparation method thereof and an application of the composite material. The method includes the steps: 1) ionic liquid preparation: dissolving 1, 2-dibromoethane and N-(3-aminopropyl) imidazole in acetone, performing stirring reaction for 18-24 hours at normal temperature to obtain dark brown viscous liquid,and centrifuging and washing mixture to obtain ionic liquid; 2) metal-organic framework and ionic liquid composite material preparation: dissolving ionic liquid in methyl alcohol, adding 2-methylimidazole, stirring mixture for 12 hours at the normal temperature to obtain ionic liquid solution, pouring the prepared ionic liquid solution into methanol solution of cobalt nitrate, stirring mixture for 10minutes, standing for 24 hours to obtain purple sediment, and centrifuging, washing and drying the purple sediment to obtain the metal-organic framework and ionic liquid composite material. The metal-organic framework and ionic liquid composite material has high adsorptive valued for carbon dioxide and is non-toxic, green and environmentally friendly.

Owner:WUHAN UNIV OF TECH

Preparation method of cotton stalk based activated carbon

InactiveCN106495151ARaise interest ratesImprove adsorption capacityCarbon compoundsOther chemical processesActivated carbonCarbonization

The invention discloses a preparation method of cotton stalk based activated carbon. The method includes the steps: (1) crushing cotton stalks, soaking the crushed cotton stalks by the aid of sodium hydroxide solution for 8-24 hours, and filtering and drying mixture; (2) carbonizing the cotton stalks treated in the step (1) at the temperature ranging from 250 DEG C to 450 DEG C, and washing the cotton stalks to neutral after carbonization to obtain the cotton stalk based activated carbon. According to the preparation method, cotton stalk resources are effectively utilized, atmospheric pollution caused by incineration of the cotton stalks is avoided, the preparation method is simple in preparation process, high in efficiency and low in cost, the yield of the activated carbon can reach 30% or more, and the prepared activated carbon has excellent adsorbing effect on metal copper ions in water.

Owner:TARIM UNIV

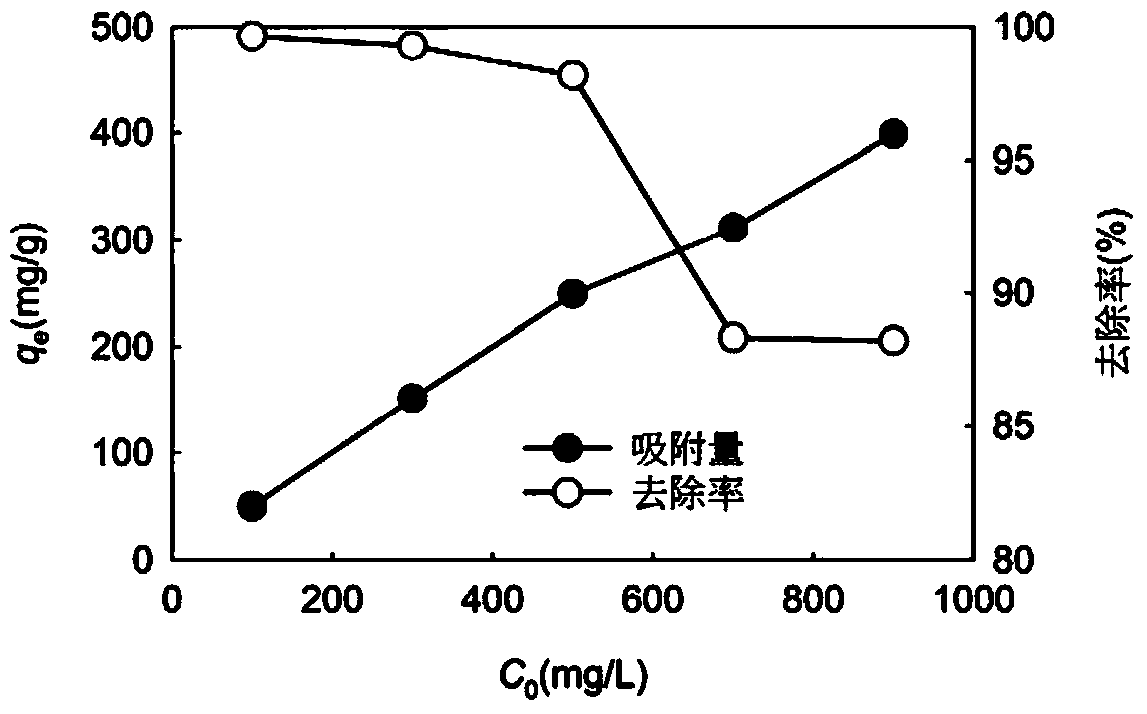

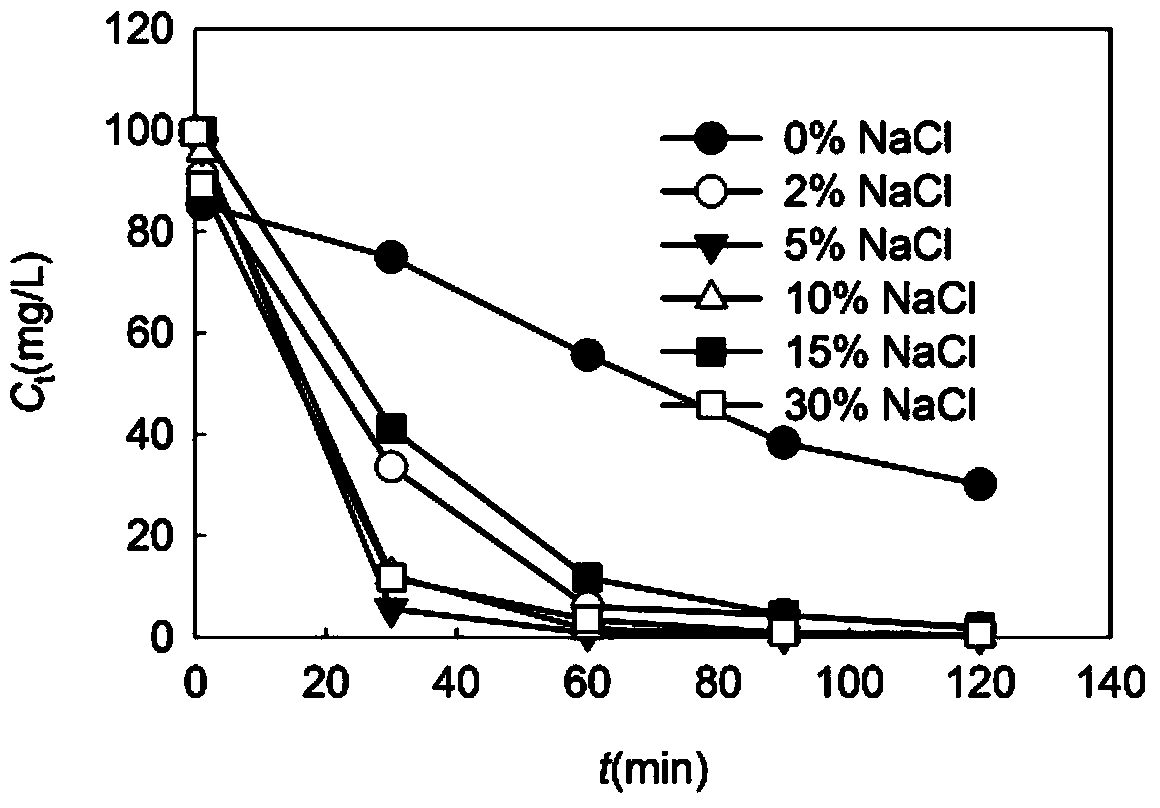

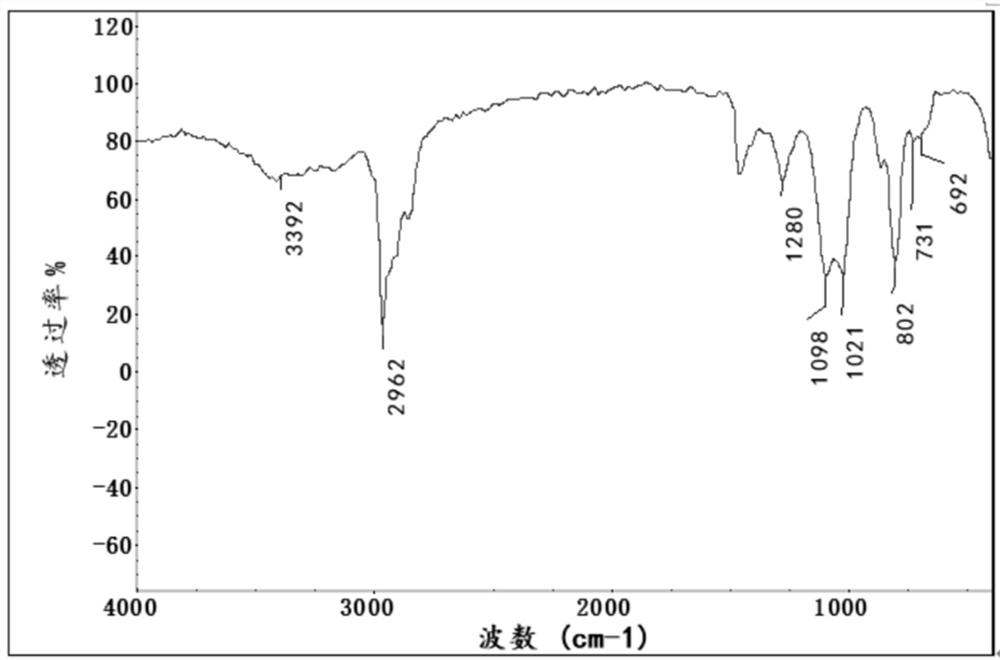

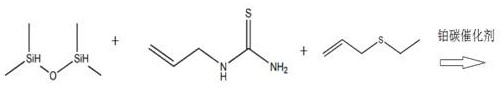

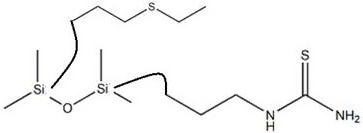

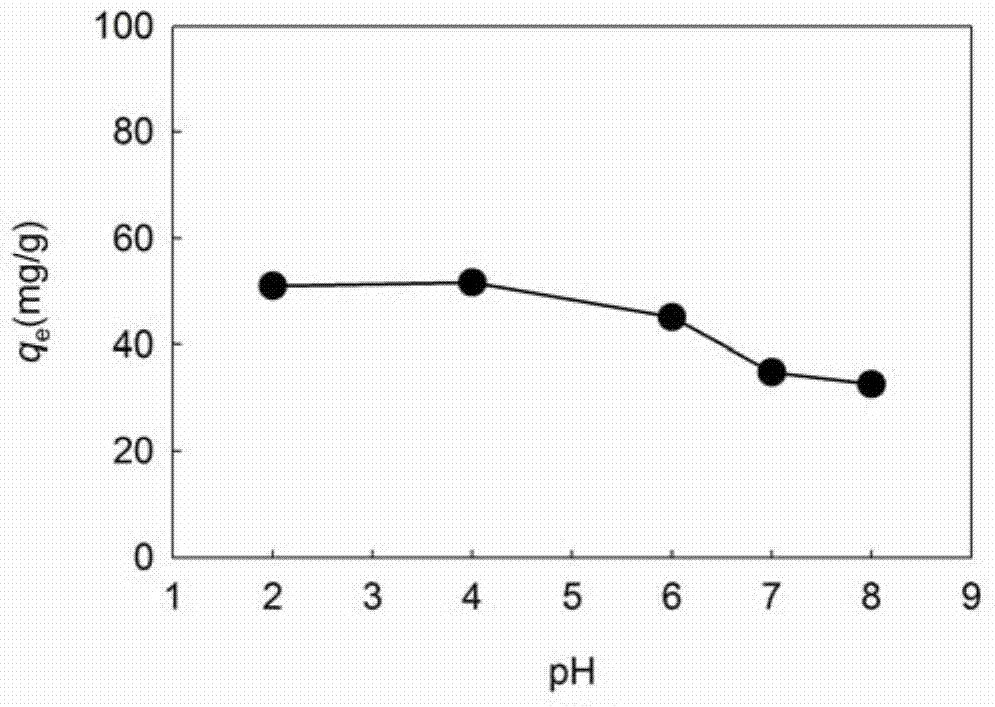

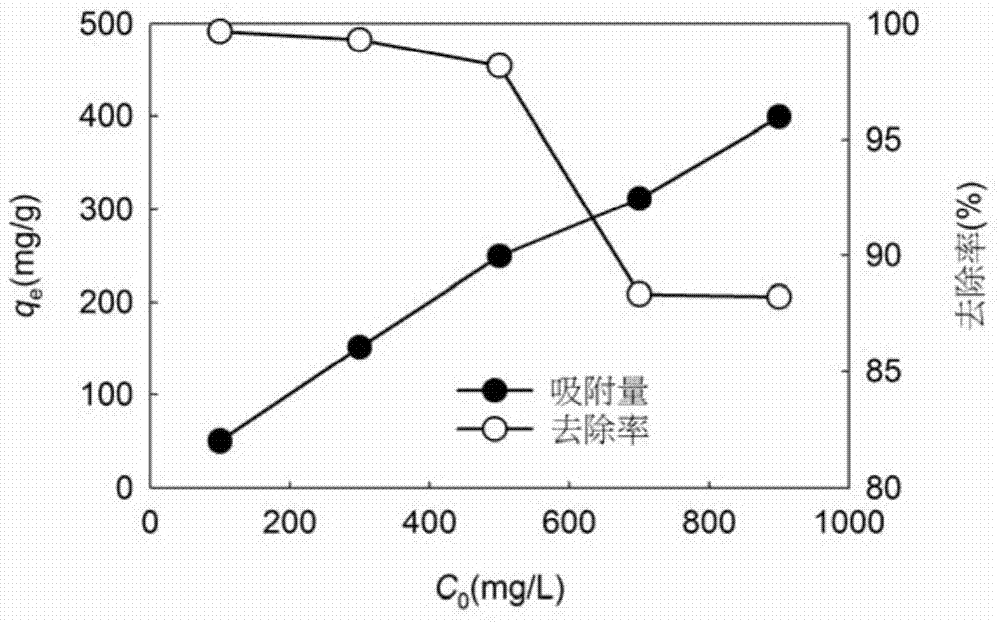

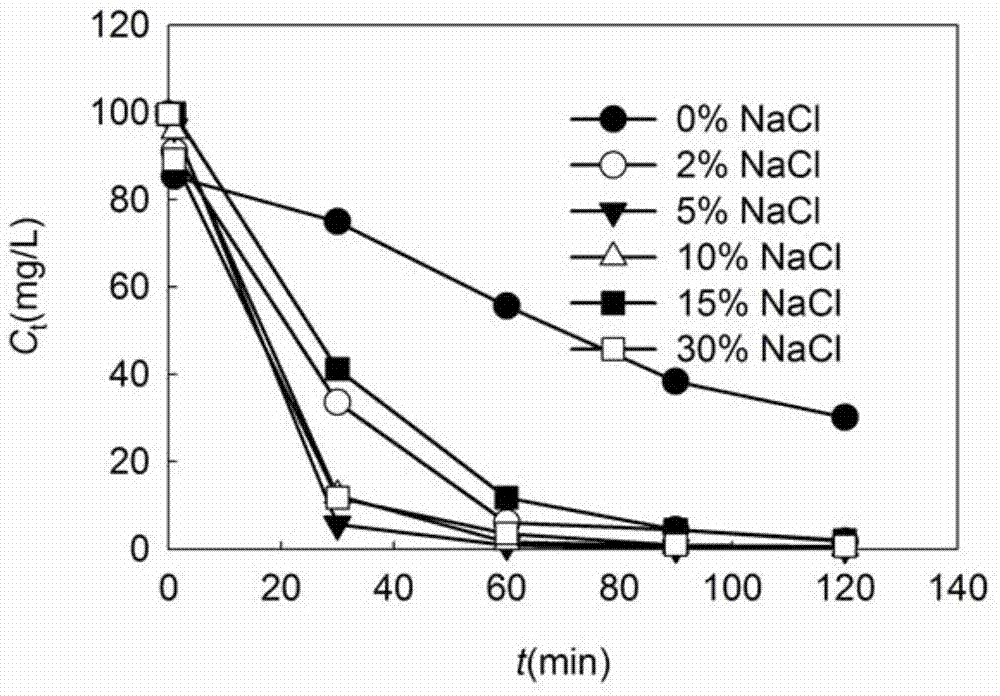

Method used for removing malachite green from waste water with sunflower seed shell biomass carbon adsorbent

ActiveCN103663606AHigh adsorption valueLarge adsorption capacityOther chemical processesWater/sewage treatment by sorptionMalachite greenMalachite green stain

The invention discloses a method used for removing malachite green from waste water with sunflower seed shell biomass carbon adsorbent, and belongs to the technical field of waste water processing. The method comprises following steps: the sunflower seed shell biomass carbon adsorbent prepared via microwave heating, and sodium chloride are added into waste water containing 100 to 900mg / L malachite green and with a pH value of 2 to 8, adsorption is performed for 2 to 24 hours at a temperature of 20 to 60 DEG C, an obtained mixture is filtered for separation, and a filtrate is adjusted to be neutral, and then is discharged. The method used for removing malachite green from waste water is simple, cost is low, and no secondary pollution is caused.

Owner:BEIJING UNIV OF TECH

A method and application of using industrial solid waste to prepare desulfurization adsorbent

ActiveCN108295806BHigh strengthImprove wear resistanceIon-exchange process apparatusGas treatmentBuretteSorbent

Owner:柳晶(长春)环保科技有限公司

Method for regenerating activated carbon by steam

ActiveCN111889091AReduce lossesGuaranteed mechanical strengthOther chemical processesCombustible gas purificationActivated carbonChemical reaction

The invention relates to the field of environmental protection, in particular to a method for regenerating activated carbon through steam. The method comprises the steps of carbon drying, thermal regeneration and regenerated carbon collection. According to the method for regenerating the activated carbon by steam, a plurality of methods are adopted to jointly inhibit chemical reaction between water vapor and a carbon material. By utilizing a balance principle, hydrogen and carbon monoxide are added into high-temperature medium water vapor, the reaction can be inhibited by increasing the concentration of a product, and the carbon loss is reduced; on the other hand, the silane-based sulfide inhibitor is added into the waste activated carbon, the oxidation-reduction reaction can be inhibitedat the same time, the reaction between the carbon material and water vapor is reduced through the combined action, the loss of the carbon material is reduced to the maximum extent, and the mechanicalstrength and the surface performance of the carbon material are guaranteed; according to the technical scheme, the method is low in cost and environmentally friendly, is purely green circular economyand can be applied to activated carbon reproduction on a large scale.

Owner:浙江红狮环保股份有限公司

A method for removing malachite green in wastewater by using sunflower seed shell biochar adsorbent

ActiveCN103663606BHigh adsorption valueLarge adsorption capacityOther chemical processesWater/sewage treatment by sorptionMalachite greenMalachite green stain

The invention discloses a method used for removing malachite green from waste water with sunflower seed shell biomass carbon adsorbent, and belongs to the technical field of waste water processing. The method comprises following steps: the sunflower seed shell biomass carbon adsorbent prepared via microwave heating, and sodium chloride are added into waste water containing 100 to 900mg / L malachite green and with a pH value of 2 to 8, adsorption is performed for 2 to 24 hours at a temperature of 20 to 60 DEG C, an obtained mixture is filtered for separation, and a filtrate is adjusted to be neutral, and then is discharged. The method used for removing malachite green from waste water is simple, cost is low, and no secondary pollution is caused.

Owner:BEIJING UNIV OF TECH

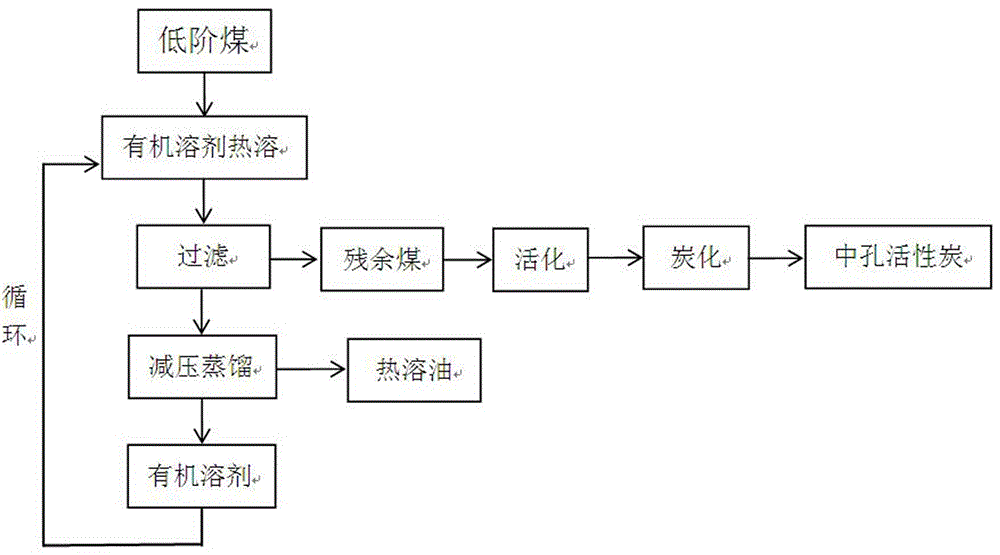

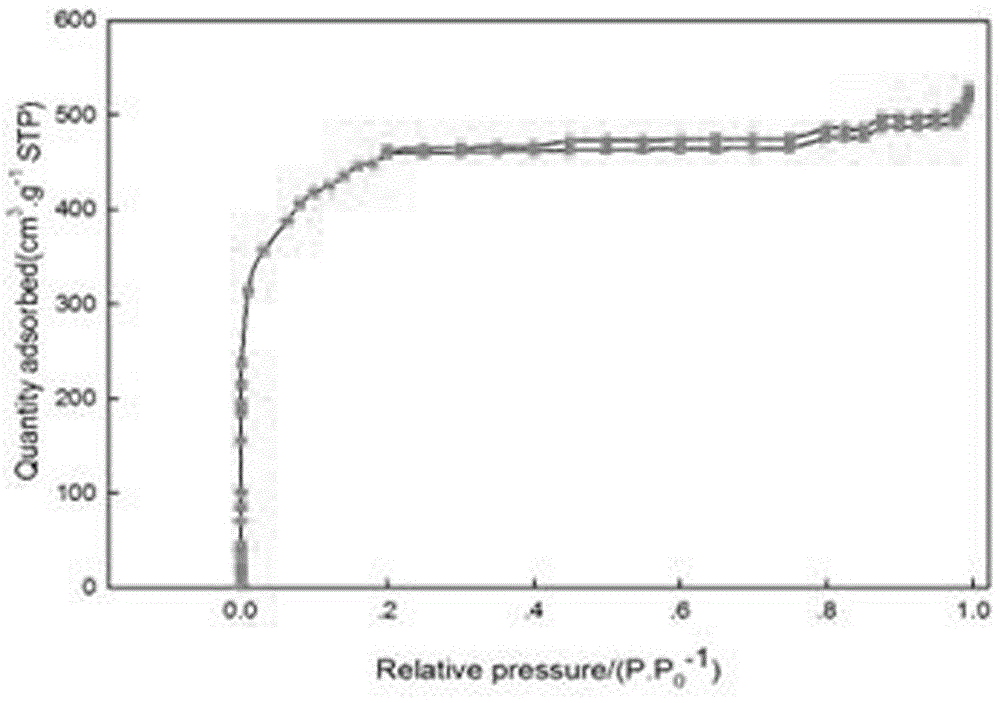

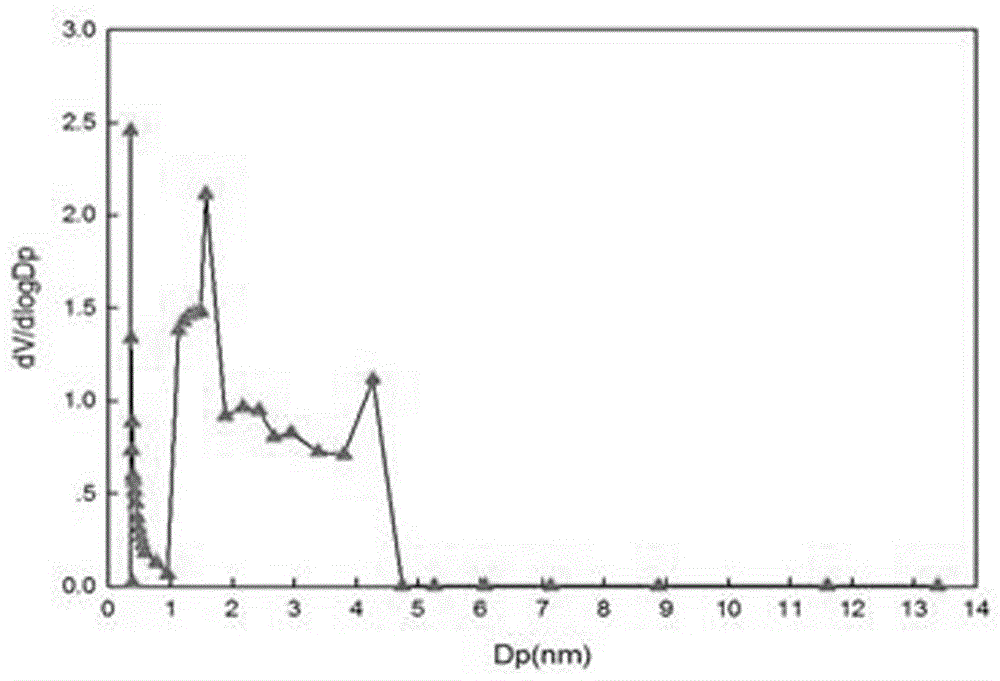

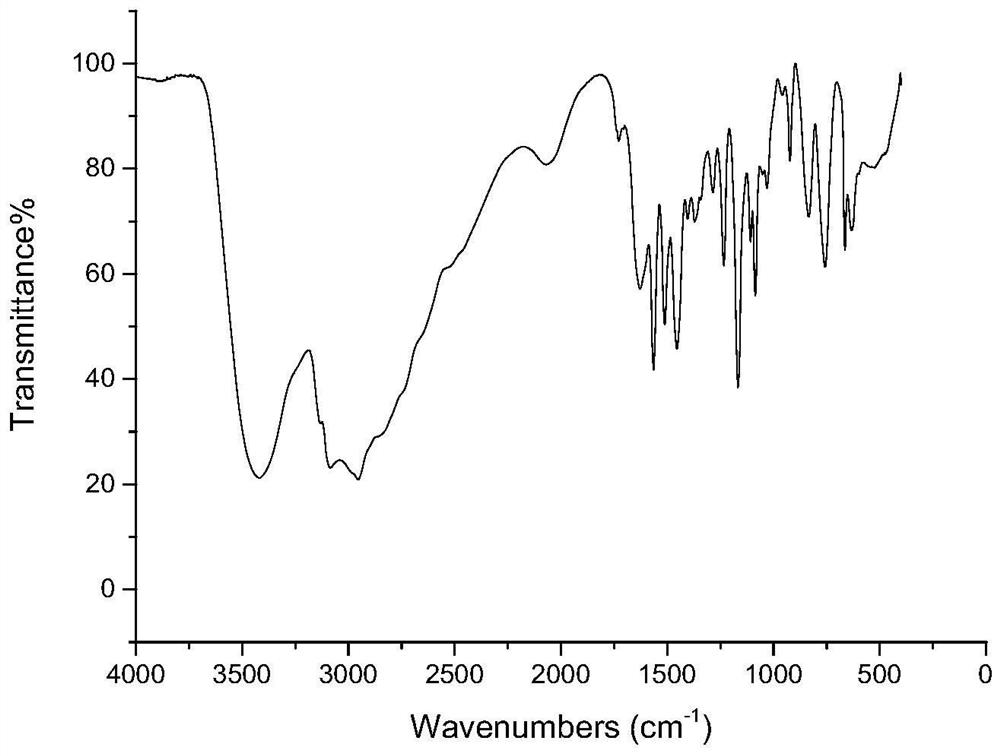

Process for preparing hot melt oil and mesoporous activated carbon simultaneously from low-rank coal

InactiveCN106423054AAvoid processing powerAvoid the problem of three wastesCarbon compoundsOther chemical processesActivated carbonActivation method

The invention relates to the field of coal-based oil preparation and coal-based activated carbon preparation, in particular to a process for preparing hot melt oil and mesoporous activated carbon simultaneously from low-rank coal and aims to provide the process for preparing the hot melt oil and the mesoporous activated carbon simultaneously from the low-rank coal. The process comprises steps as follows: S1, low-rank coal is crushed, dried and subjected to organic solvent supercritical hot melting, and a hot melt product and residual coal are obtained; S2, the obtained hot melt product and residual coal are filtered and separated; S3, the hot melt product is separated with a reduced pressure distillation method, and hot melt oil and an organic solvent are obtained; S4, activated carbon is prepared from the residual coal with a chemical activation method. The process is simple, raw materials are easy to obtain, the production cost is reduced, clean and high-added-value utilization of the coal is realized, the supercritical hot melting process of coal under the solvent action and the significance of loss of residual coal micromolecules for preparation of activated carbon with the activation method after supercritical hot melting is finished are introduced for the first time.

Owner:SHANXI DATONG UNIV

A kind of regeneration method of activated carbon with low carbon loss

ActiveCN106512973BEfficient regenerationHigh adsorption valueOther chemical processesCombustible gas purificationActivated carbonFerric

The invention discloses a regeneration method of low-carbon-loss activated carbon. Activated carbon is pretreated by iron or an iron compound as a catalyst at lower temperature, and the synergic actions of dilution and ultrasonic washing are performed; and thus, the regenerated activated carbon with high adsorptive value is obtained under the conditions of low energy consumption and mild conditions, and the carbon loss can be reduced to a large extent.

Owner:CENT SOUTH UNIV

A method of regenerating activated carbon

ActiveCN106345440BHigh adsorption valueIncrease productionOther chemical processesCombustible gas purificationActivated carbonPhysical chemistry

The invention discloses a method for regenerating activated carbon. Firstly, pretreatment is performed under relatively low temperature, and then the short-time activating regenerating reaction is performed. The two steps are synergic with each other, so that the temperature and time required by the traditional method for regenerating activated carbon are greatly reduced, the purposes of saving energy and reducing consumption can be achieved, and the yield, quality and regenerating efficiency of the activated carbon also can be increased.

Owner:CENT SOUTH UNIV

A metal-organic framework and ionic liquid composite material and its preparation method and application

ActiveCN109894086BHigh adsorption valueNo pollution in the processOther chemical processesDispersed particle separationViscous liquidMetal-organic framework

The present invention relates to a metal organic framework and ionic liquid composite material and its preparation method and application. The steps of the preparation method are as follows: 1) Preparation of ionic liquid: 1,2-dibromoethane and N-(3-aminopropyl Base) Dissolve imidazole in acetone, stir and react at room temperature for 18-24 hours to obtain dark brown viscous liquid, obtain ionic liquid by centrifugal separation and washing; 2) Preparation of metal organic framework and ionic liquid composite material: dissolve ionic liquid in methanol , then add 2-methylimidazole, stir at room temperature for 12 hours to obtain an ionic liquid solution, then pour the resulting ionic liquid solution into a methanol solution of cobalt nitrate, stir for 10 minutes, and let stand for 24 hours to obtain a purple precipitate, which is centrifuged, washed, and dried A composite material of metal-organic framework and ionic liquid was obtained. The metal-organic framework and ionic liquid composite material provided by the invention has a high adsorption value for carbon dioxide, and the material is non-toxic and environmentally friendly.

Owner:WUHAN UNIV OF TECH

Novel adsorptive material for treating air pollution and its preparing method

InactiveCN100391591CEasy to useIncrease profitOther chemical processesDispersed particle separationCalcium hypochloriteActive carbon

The novel adsorptive material for treating polluted air consists of active carbon or charcoal 50-100 weight portions and additive 0-50 weight portions, and the additive may be silicon colloid, calcium hopochlorite, anhydrous cup sulfate, anhydrous calcium chloride or calcium oxide. The preparation process includes first reinforced activation of active carbon or charcoal, the subsequent mixing with additive, and final vacuum packing. The present invention can adsorb, digest and degrade toxic matter in air effectively, and inhibit and kill virus in air. It is safe, efficient, low in power consumption, healthy, environment friendly, multifunctional and excellent in technological performance.

Owner:黎伯忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com