Preparation method of fly ash-based zeolite molecular sieve for adsorbing VOCs

A technology of zeolite molecular sieve and fly ash, applied in the direction of separation methods, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of reducing the cost of waste gas treatment, achieve improved hydrophobicity, simple preparation process, and improve silicon-alumina than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

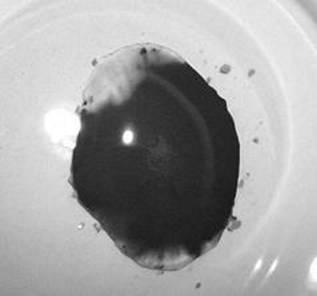

Image

Examples

Embodiment 1

[0023] (1) Dry and grind the fly ash until the specific surface area is 320m 2 / kg, then add 2mol / L hydrochloric acid, stir and heat at 100°C for 30min, then suction filter, wash with water, and dry to obtain pretreated fly ash.

[0024] (2) Add the pretreated fly ash obtained in step (1) into the reactor, add 7mL of sodium hydroxide solution (10mol / L) to each 1g of pretreated fly ash, and stir at 70°C by microwave heating Reflux reaction for 30min.

[0025] (3) Pour the solid-liquid mixture obtained in step (2) into a high-pressure reactor for aging for 6 hours to form a stable zeolite molecular sieve crystal nucleus, and then crystallize at 130°C for 5 hours. After the crystallization is completed, suction filter and dry the filter residue , Grinding to obtain the first product of the fly ash-based zeolite molecular sieve, and the adsorption value of the first product to toluene was measured to be 8 mg / g.

[0026] (4) Add 20mL of cetyltrimethylammonium bromide solution (CT...

Embodiment 2

[0028] (1) Dry and grind the fly ash until the specific surface area is 356m 2 / kg, then add 2mol / L hydrochloric acid, stir and heat at 100°C for 40min, then suction filter, wash with water, and dry to obtain pretreated fly ash.

[0029] (2) Add the pretreated fly ash obtained in step (1) into the reactor, add 9mL of sodium hydroxide solution (8mol / L) to each 1g of pretreated fly ash, and stir at 90°C by microwave heating Reflux reaction for 45min.

[0030] (3) Pour the solid-liquid mixture obtained in step (2) into a high-pressure reactor for aging for 4 hours to form a stable zeolite molecular sieve crystal nucleus, and then crystallize at 120°C for 3 hours. After the crystallization is completed, suction filter and dry the filter residue , Grinding to obtain the primary product of the fly ash-based zeolite molecular sieve, the adsorption value of the primary product to toluene was measured to be 7mg / g.

[0031] (4) Add 15mL of cetyltrimethylammonium bromide solution (CTAB...

Embodiment 3

[0033] (1) Dry and grind the fly ash until the specific surface area is 384m 2 / kg, then add 2mol / L hydrochloric acid, stir and heat at 100°C for 60min, then suction filter, wash with water, and dry to obtain pretreated fly ash.

[0034] (2) Add the pretreated fly ash obtained in step (1) into the reactor, add 11mL of sodium hydroxide solution (6mol / L) to each 1g of pretreated fly ash, and stir at 80°C by microwave heating Reflux reaction for 60min.

[0035] (3) Pour the solid-liquid mixture obtained in step (2) into a high-pressure reactor for aging for 8 hours to form a stable zeolite molecular sieve crystal nucleus, and then crystallize at 110°C for 10 hours. After the crystallization is completed, suction filter and dry the filter residue , Grinding to obtain the primary product of the fly ash-based zeolite molecular sieve, and the adsorption value of the primary product to toluene is measured to be 10 mg / g.

[0036] (4) Add 30mL of cetyltrimethylammonium bromide solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com