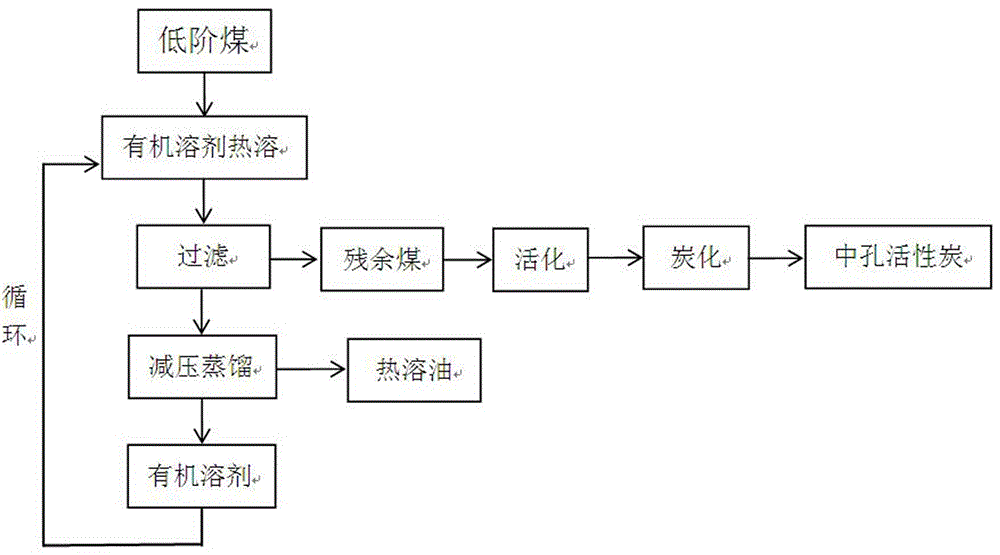

Process for preparing hot melt oil and mesoporous activated carbon simultaneously from low-rank coal

A low-rank coal and activated carbon technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, etc., can solve the problems such as the influence of coal-based activated carbon on the pore-forming performance, and achieve national security issues and cheap and easy-to-obtain raw materials , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Weigh about 10g of Datong low-rank raw coal with a particle size of less than 0.018mm and place it in a 300ml high-pressure reactor, add benzene solvent along the wall of the reactor, the amount of solvent added is 50ml, the protective gas used is high-purity nitrogen, and the air is replaced three times. And adjust the pressure to 3MPa. Set the temperature program, then heat at a heating rate of 3°C / min, stir at 300r / min while heating, when the temperature rises to the set temperature of 320°C, the pressure becomes 9MPa, start timing, after 3 hours of reaction, the program automatically stops Heating and starting to cool down. At this time, immediately open the drain valve at the bottom of the autoclave, and use the pressure in the autoclave to press out the solvent and hot solution products, and press them into the storage tank through a 0.45um filter plate, and the reaction device is naturally cooled. to room temperature. After cooling to room temperature, add 100ml...

Embodiment 2

[0061] Weigh about 10g of Datong low-rank clean coal with a particle size less than 0.018mm and place it in a 300ml high-pressure reactor, add 100ml of benzene solvent along the wall of the reactor, use high-purity nitrogen as the protective gas, and replace the air three times. And adjust the pressure to 2MPa. Set the temperature program, then heat at a heating rate of 5°C / min, and stir at 300r / min while heating, when the temperature rises to the set temperature of 320°C, the pressure becomes 7MPa, start timing, after 2 hours of reaction, the program automatically stops Heated, and began to cool down to room temperature with cooling water, opened the autoclave and transferred the residual coal to a vacuum filter, washed it with ethanol for 5 times, dried it in a vacuum oven at 80°C, weighed until constant weight, and calculated The thermal melting rate is 35.2%. Use a double-necked distillation flask to transfer all the solvents in the receiver, and use a vacuum distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com