Patents

Literature

142results about How to "Compliant with Green Chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

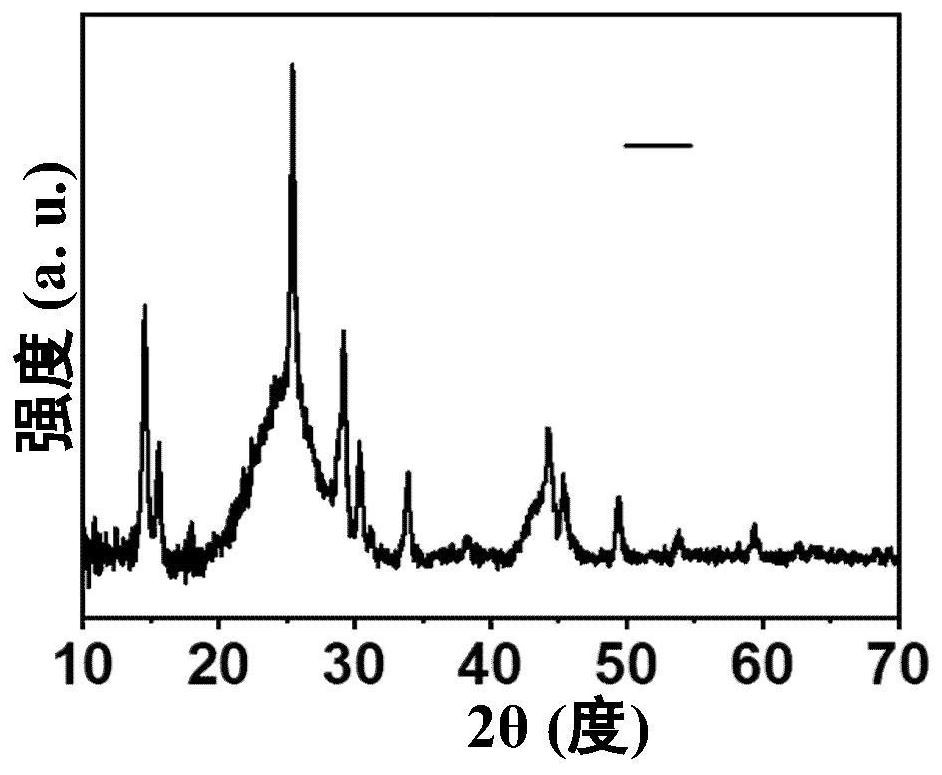

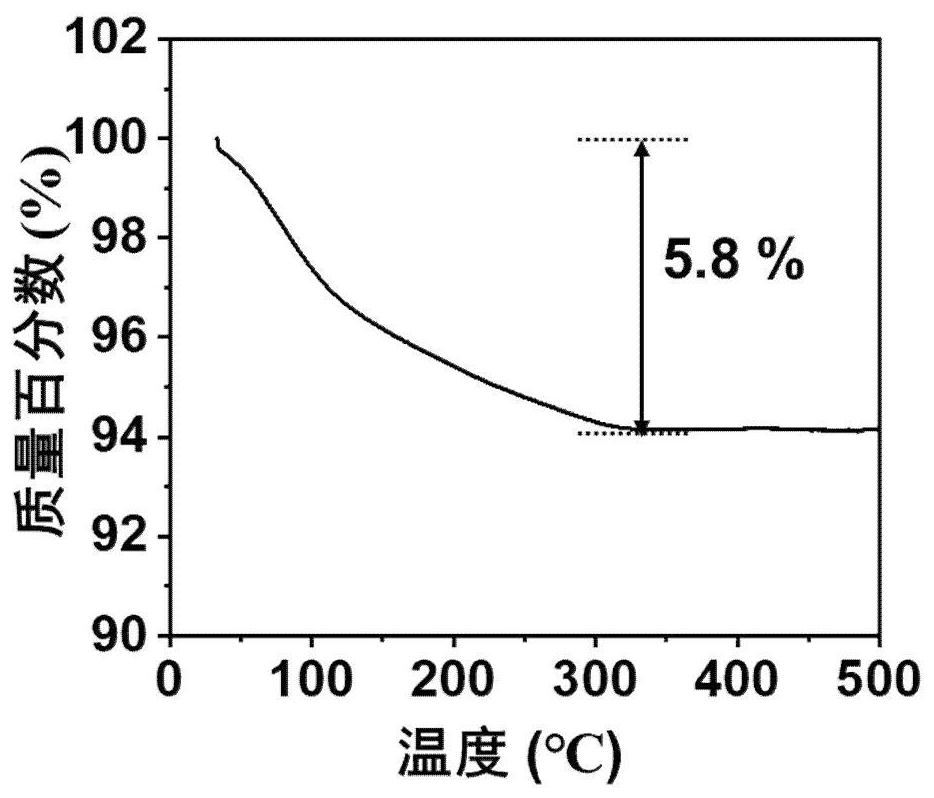

Three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3>/C micrometer flower electrode material and preparation method and application thereof

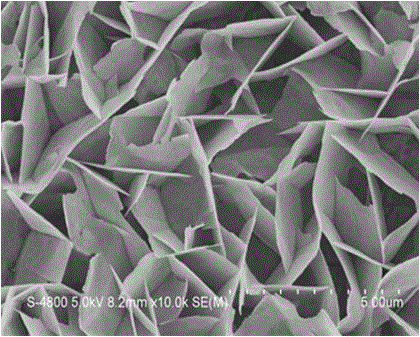

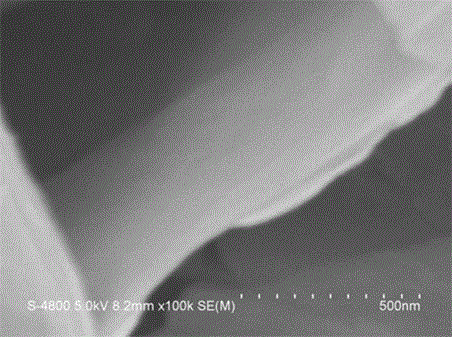

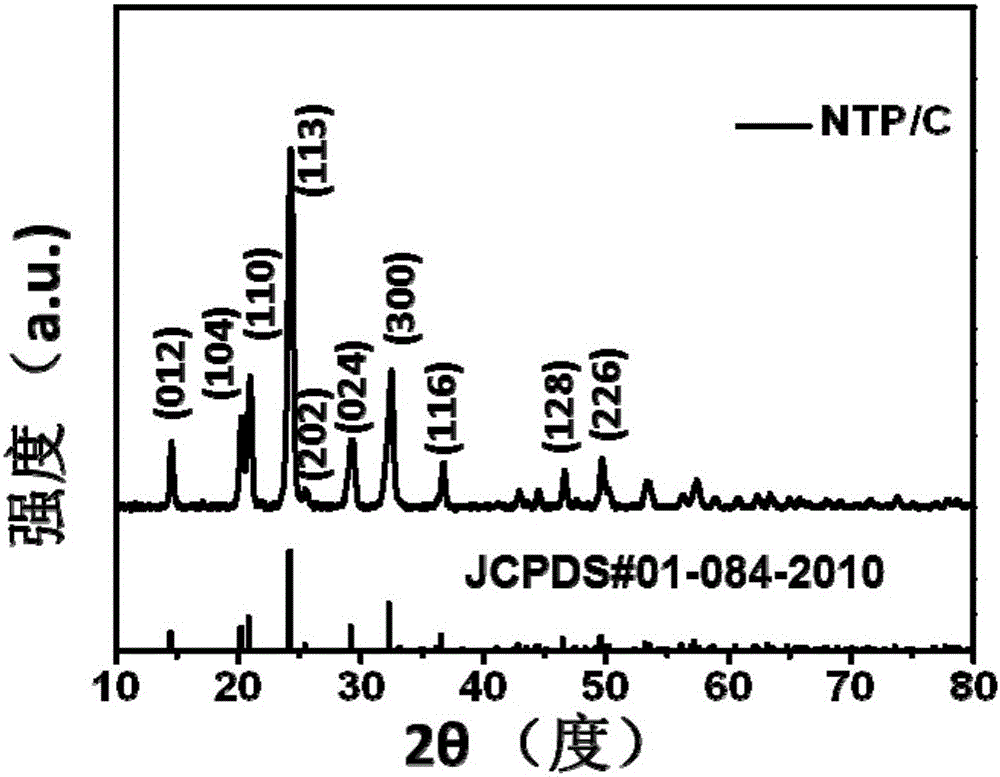

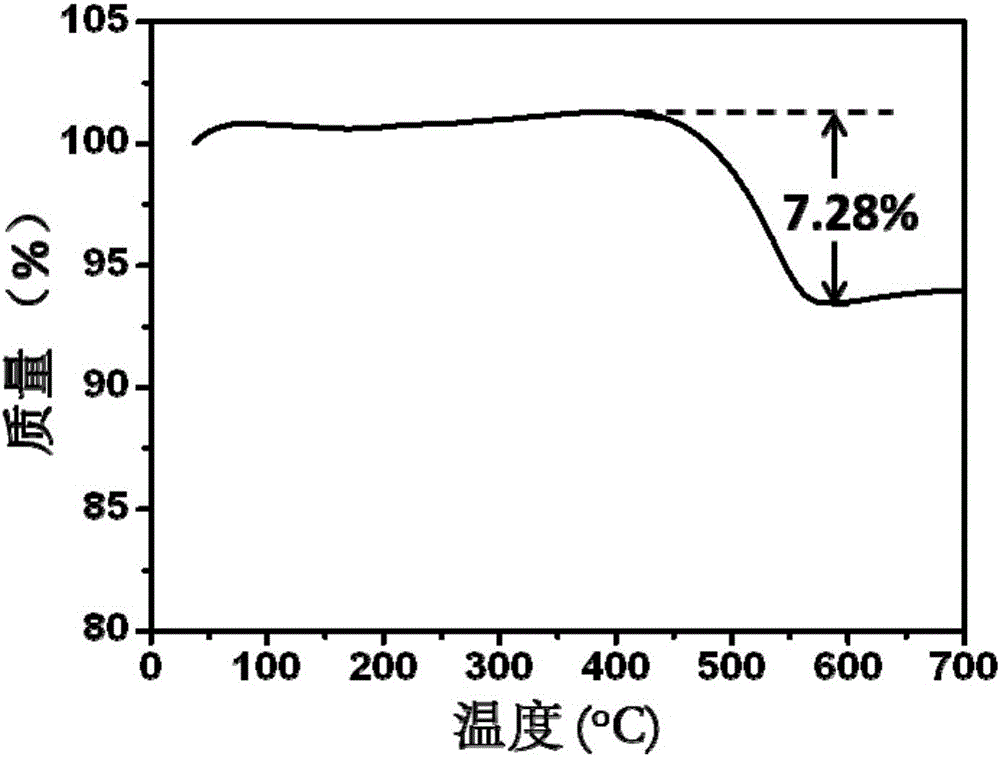

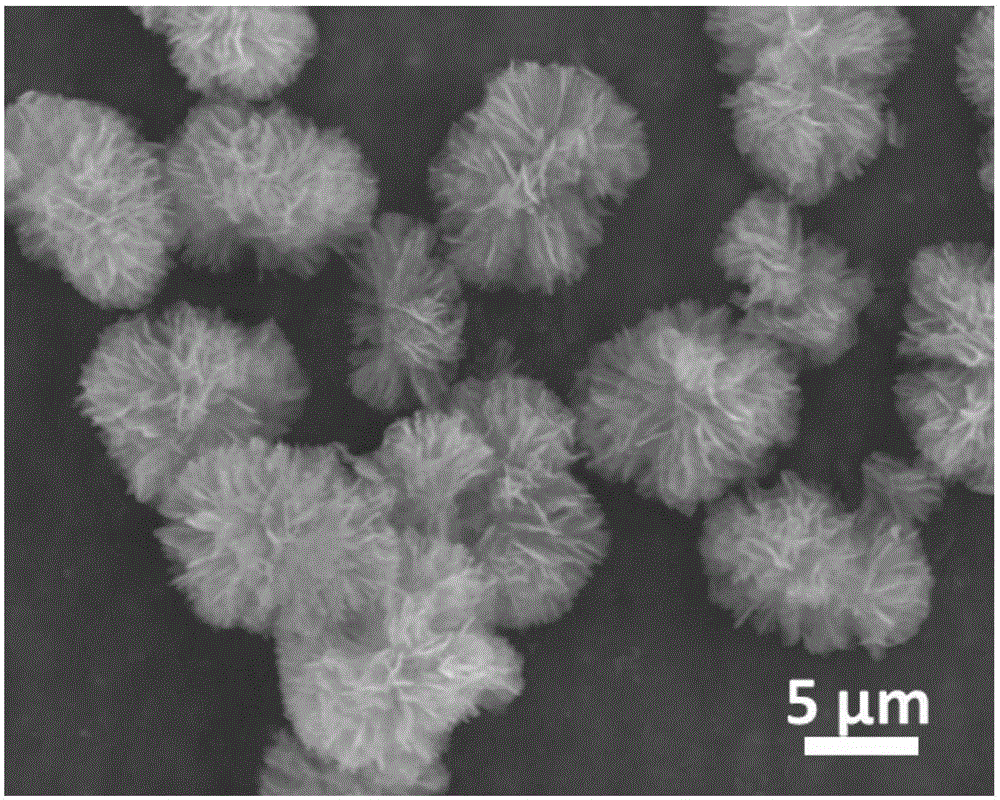

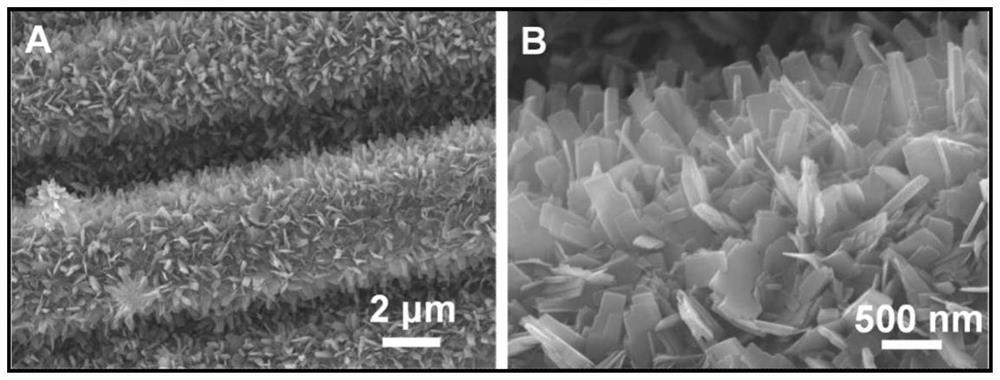

The invention relates to a three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material and a preparation method and application thereof. The diameter of the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material is 5-10 micrometers, the thickness of a carbon-clad NaTi<2>(PO<4>)<3> / C nanosheet subunit is only 1-5 nanometers, mesopores with pore diameters of 2-30 nanometers are formed in the carbon-clad NaTi<2>(PO<4>)<3> / C nanosheet subunit, the thickness of a surface carbon layer is 2-5 nanometers, and the nanosheet subunits are in over joint to form a three-dimensional conductive network. The three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material has the advantages that the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower is prepared by a simple and practical solovothermal method combined with a high-temperature calcination method, and is endowed with excellent high rate performance and stable long-circulation capability when taken as a positive electrode active material of a sodium ion battery. The process is simple, the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material is high in practicable and is high in safety coefficient, the requirement on a device is low due to the adoption of the solovothermal method and the calcination processing, production can be expanded, and market promotion is promoted.

Owner:WUHAN UNIV OF TECH

Method for preparing barium sulfate and zinc sulfide

InactiveCN101205077AIncrease profitImprove protectionCalcium/strontium/barium sulfatesZinc sulfidesSulfateMirabilite

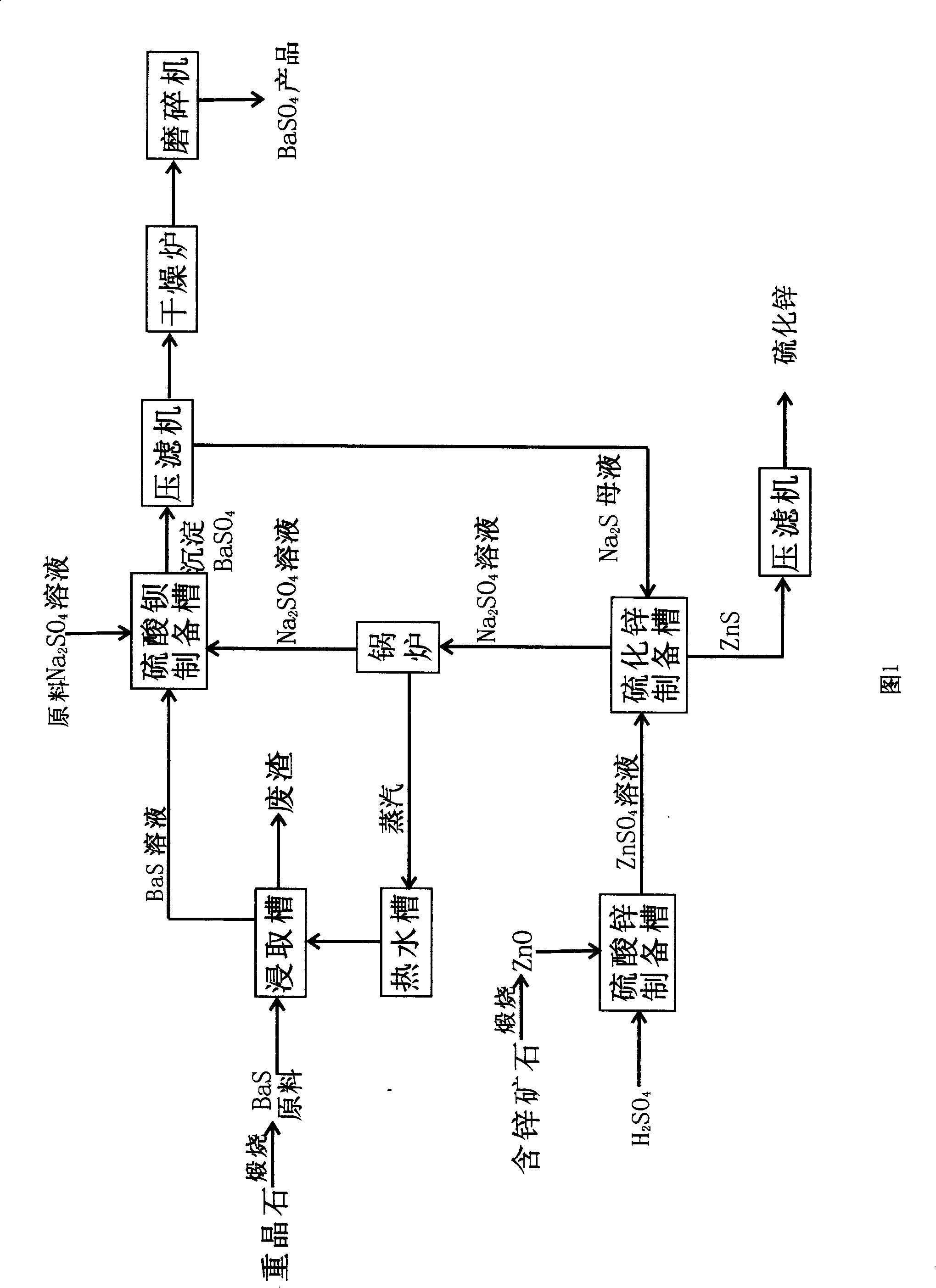

The invention discloses a method for preparing barium sulfate and zinc sulphide, which takes barites and zinc containing ore as principal material and includes the following steps: firstly, black ash raw material which contains more than 50% of barium sulphide prepared by the mixed calcinations of barites and coal is leached to get pellucid barium sulphide solution; secondly, the barium sulphide solution reacts with mirabilite to get barium sulfate products after filter pressing separation, drying and grinding; thirdly, zinc oxide obtained by the calcinations of the zinc containing ore reacts with sulphuric acid, and zinc sulfate solution is prepared by the purification of reacting solution; fourthly, depurative zinc sulfate solution reacts with vulcanized alkali containing mother liquor which is prepared after the separation of the barium sulfate from the reacting resultant obtained from step two to get zinc sulphide after filter pressing separation; the sodium sulfate containing mother liquor which is separated from zinc sulphide is put into a boiler for concentration; the steam formed heats the leach barium sulfide water; the concentrated sodium sulfate containing solution reacts with barium sulfide to prepare precipitated barium sulfate.Due to the adoption of closed cycle, the invention has the advantages of simple operation, high yield, energy conservation and environmental protection.

Owner:LUOYANG HONGYUAN BARIUM SALT CHEM IND INST

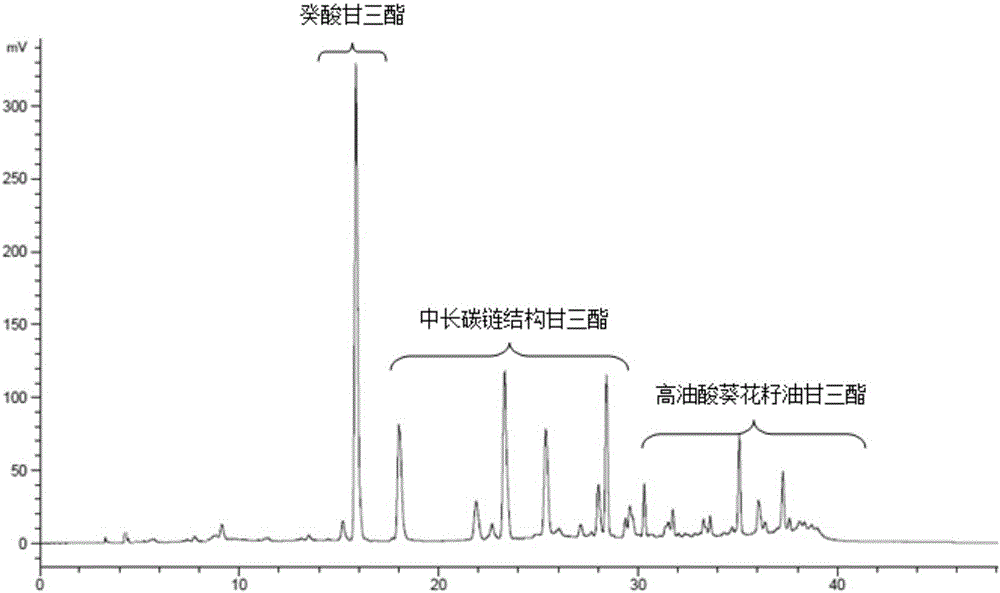

Method for enzymatically synthesizing medium-long chain structure triglyceride

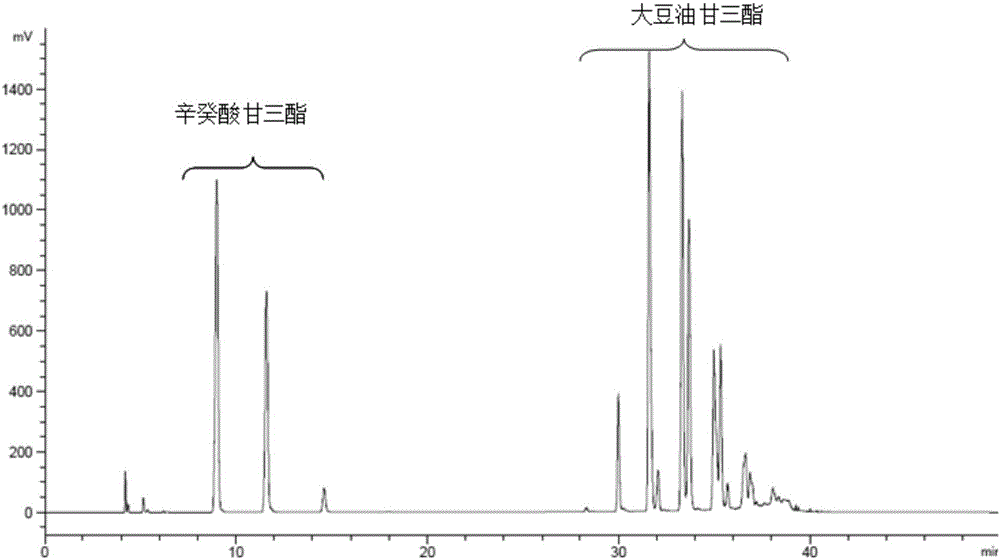

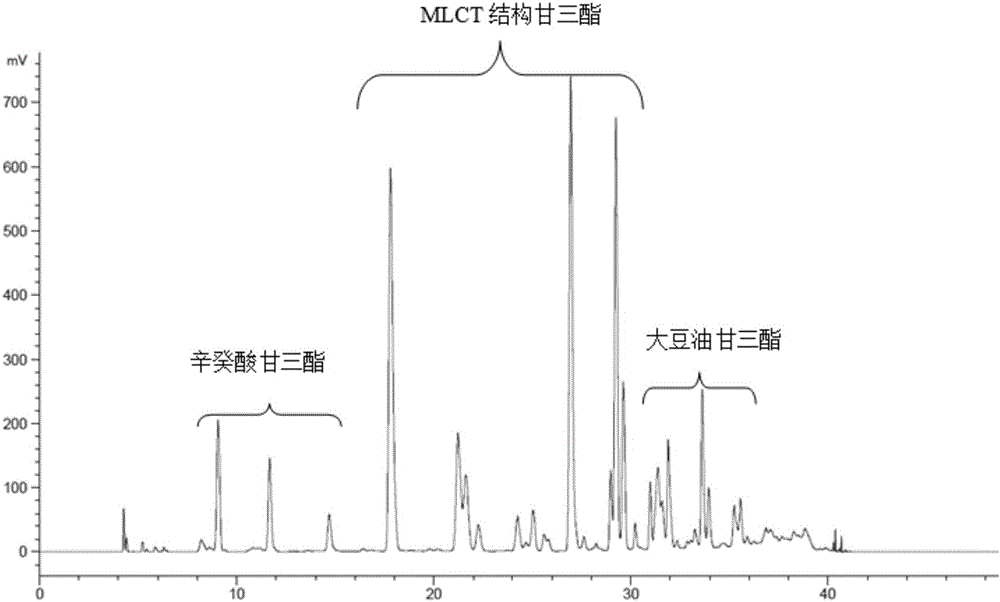

The invention discloses a method for enzymatically synthesizing medium-long chain structure triglyceride. Long-chain triglyceride and medium-chain triglyceride are mixed according to a certain mass ratio, lipase is added in a solvent-free system, stirring and reacting are carried out for a period of time at certain temperature, a transesterification reaction is carried out, and a product containing medium-long chain structure triglyceride is obtained. The method for enzymatically synthesizing medium-long chain structure triglyceride is high in reaction speed, high in conversion rate and mild in reaction condition, is efficient and fast, meets green chemistry and is huge in application potential, and large-scale industrial popularization is convenient.

Owner:JIANGNAN UNIV

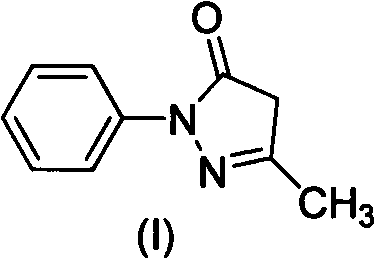

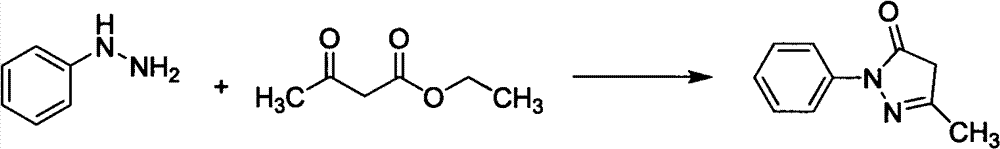

Preparation method for edaravone

The invention discloses a preparation method for edaravone. The preparation method comprises a step of subjecting hydrazinobenzene and ethyl acetoacetate to a cyclization reaction under a solvent-free condition and action of an acid so as to prepare edaravone, wherein the usage amount of the acid is 0.02 to 10 equivalent of the molar weight of hydrazinobenzene. The preparation method provided by the invention has the advantages of mild conditions, fast reaction, safety, reliability, easy and convenient operation, low cost, almost quantitative completion of the reaction, capacity of obtaining a high purity (greater than 98%) crude product which accords with medicinal standards after simple recrystallization, and suitability for industrial production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

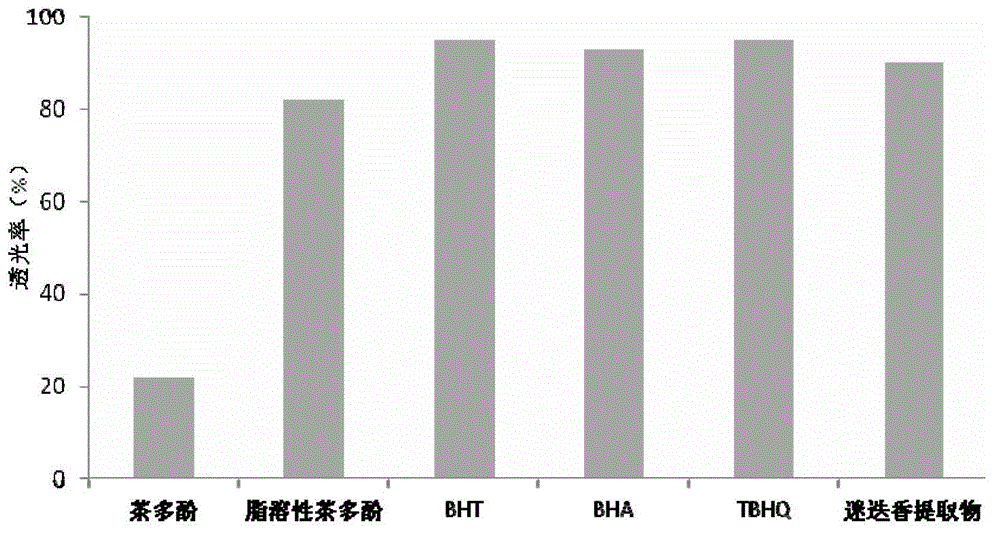

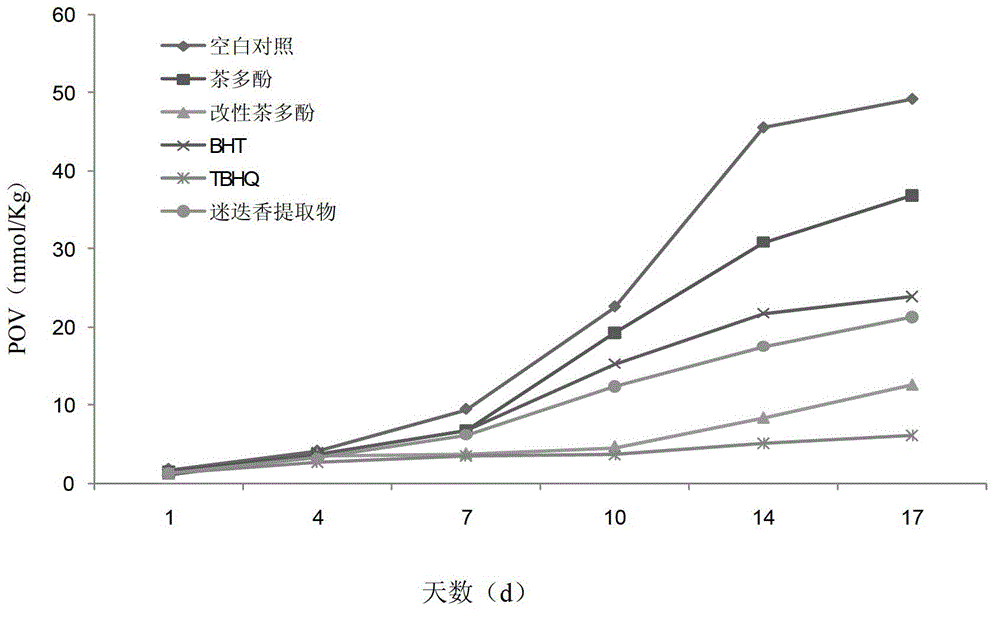

Method for synthetizing liposoluble tea polyphenols by enzymic method

InactiveCN102747117ACompliant with Green ChemistryConform to the environmentFermentationFood additiveChemical synthesis

The invention relates to a method for synthetizing liposoluble tea polyphenols by an enzymic method, belonging to the biosynthesis field of food additives. Modified liposoluble tea polyphenols are synthetized by conducting catalytic reaction between the tea polyphenols and fatty acid vinyl ester in an organic solvent system through lipase. Compared with a traditional chemical synthesis, the enzymic method disclosed by the invention has the advantages of mild reaction condition, fewer side effects, fewer reaction steps, simplicity, controllability, environment-friendliness, relative simplicity in production separation, and the like. Therefore, a modifying method for the tea polyphenols, which is effective, rapid and capable of satisfying the trends of green chemistry and environment-friendliness, is provided.

Owner:JIANGNAN UNIV

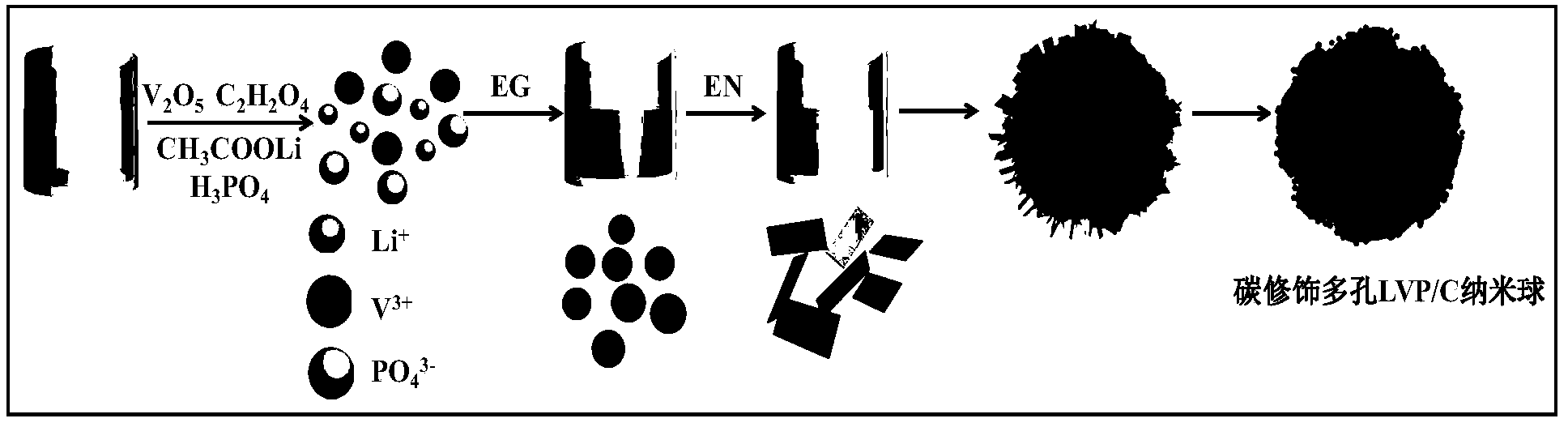

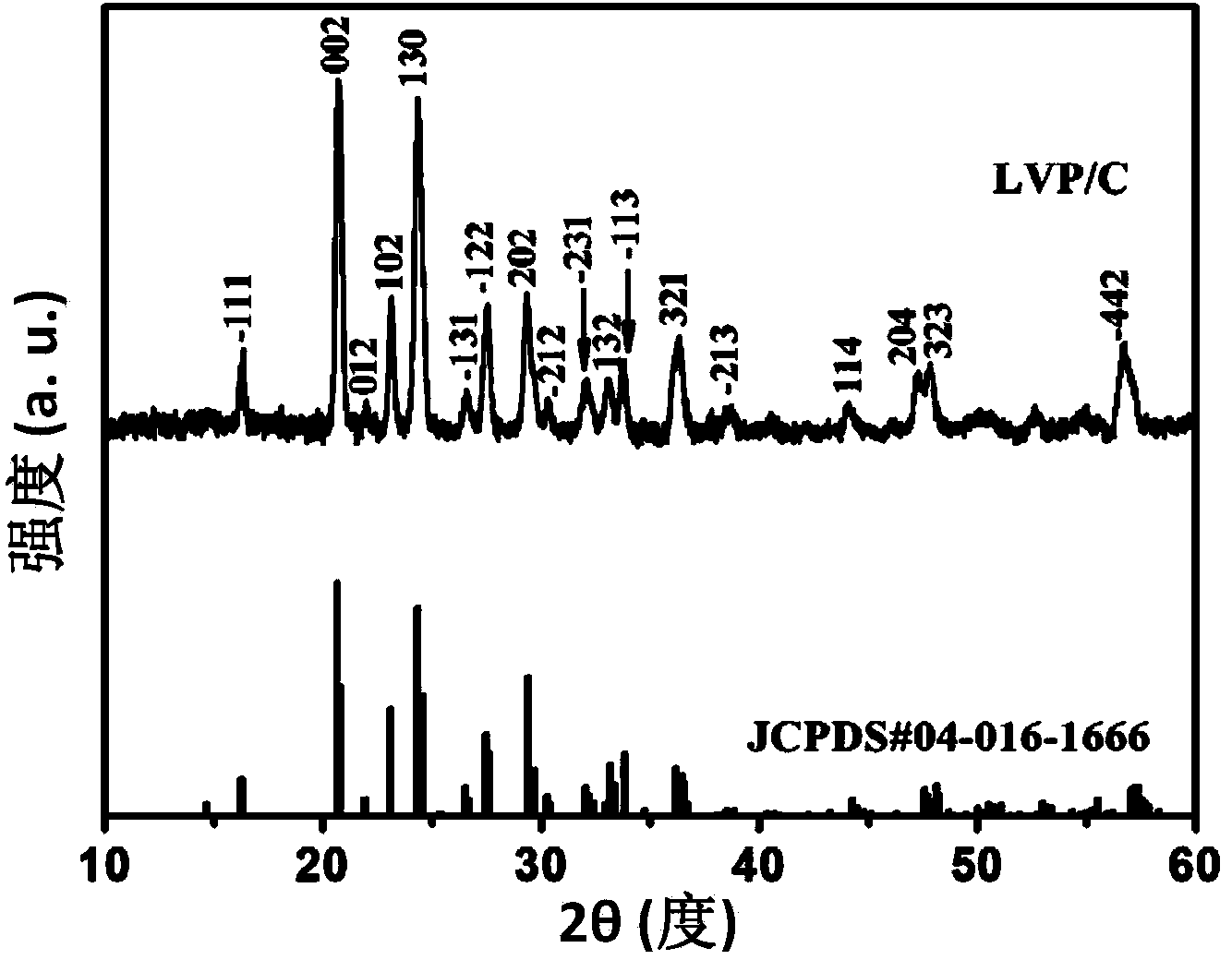

Carbon-decorated porous lithium vanadium phosphate nanosphere material as well as preparation method and application thereof

ActiveCN104134799AIncrease powerGood cycle stabilityMaterial nanotechnologyCell electrodesLithium electrodeOxalate

The invention discloses a carbon-decorated porous lithium vanadium phosphate nanosphere material as well as a preparation method and application thereof. Lithium vanadium phosphate particles coated with a carbon layer are connected with one another to form the carbon-decorated porous lithium vanadium phosphate nanosphere material which is characterized in that lithium vanadium phosphate particles are connected with one another by a three-dimensional carbon net, and the three-dimensional carbon net covers lithium vanadium phosphate. The preparation method comprises the following steps: adding a vanadium source, namely vanadium pentoxide, and oxalic acid into distilled water, and agitating until vanadium pentoxide and oxalic acid are dissolved; sequentially adding a phosphorus source, a lithium source, glycol and ethylenediamine; carrying out hydrothermal reaction on the materials to obtain a precursor solution; drying the precursor solution to obtain a red brown solid; and grinding, pre-sintering, grinding and calcining the solid to finally obtain the black three-dimensional carbon-decorated porous lithium vanadium phosphate nanosphere material. When being used as a positive active material of a lithium ion battery, the carbon-decorated porous lithium vanadium phosphate nanosphere material has the characteristics of high power and high cycling stability; the preparation process is simple, and the nanosphere material can be obtained by combining a hydrothermal method with a solid-state sintering method; the nanosphere material is high in feasibility and easy to amplify, meets the requirements of green chemistry, and is suitable for market popularization.

Owner:皮玉强

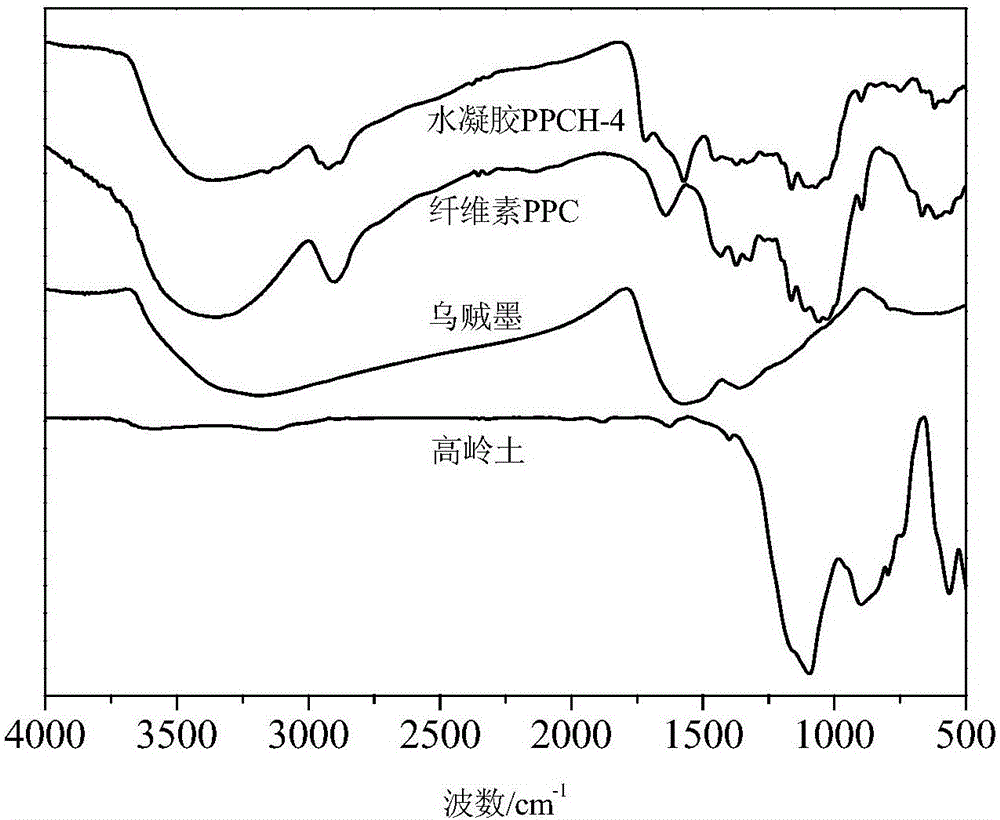

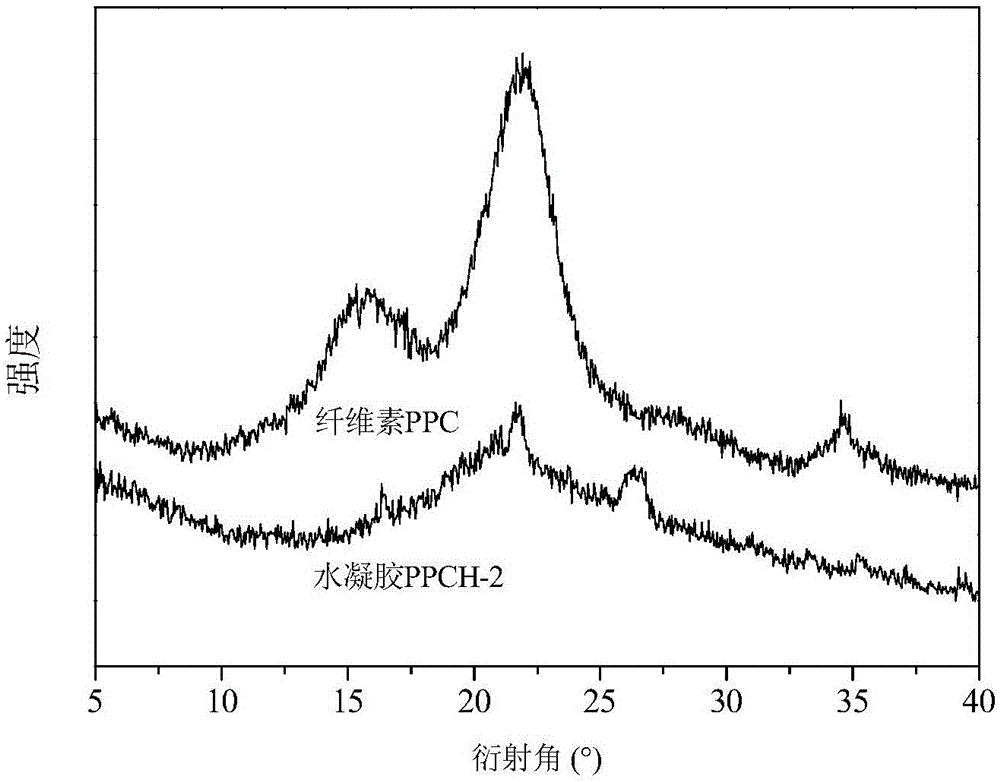

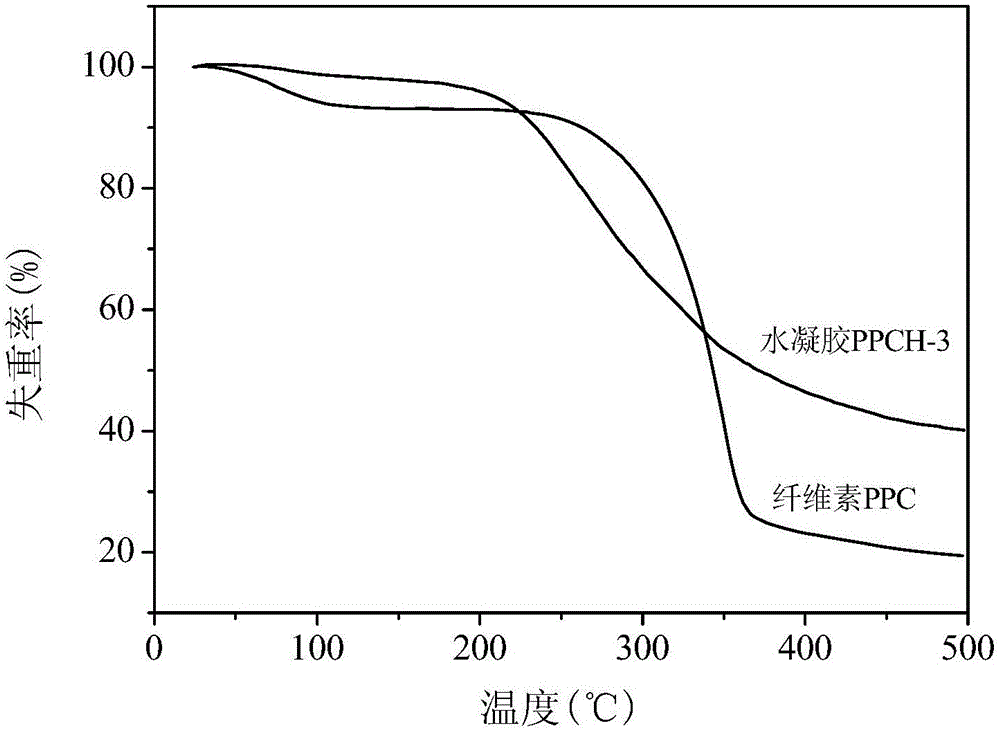

Novel pineapple peel residue cellulose-g-acrylic acid-kaolin-cuttlefish ink hydrogel and preparation method and application thereof

The invention discloses novel pineapple peel residue cellulose-g-acrylic acid-kaolin-cuttlefish ink hydrogel and a preparation method and application thereof. The preparation method comprises the steps that pineapple peel residues are taken as raw materials to be cleaned, dried, smashed, bleached and treated through alkali liquor, and then pineapple peel residue cellulose is obtained; the pineapple peel residue cellulose is stirred to be dissolved in ionic liquid through heating, and grafting modification is conducted by taking ammonium persulfate as an initiator, taking N,N-methylene bisacrylamide as a cross-linking agent and taking acrylic acid as a monomer; kaolin and cuttlefish ink are added, after reacting is completed, a product is cooled to room temperature and soaked and washed by adding distilled water, freeze drying is conducted, and then the hydrogel is obtained. According to the novel pineapple peel residue cellulose-g-acrylic acid-kaolin-cuttlefish ink hydrogel, the adopted raw materials are rich in source, convenient and easy to obtain and good in economy; the technology that the pineapple peel residue cellulose is modified and then prepared into the hydrogel is simple and short in reaction time, the thermal stability of the hydrogel can be improved through the cuttlefish ink and the kaolin, and the obtained hydrogel has a good application prospect in the fields of waste water treatment and adsorption materials.

Owner:SOUTH CHINA UNIV OF TECH

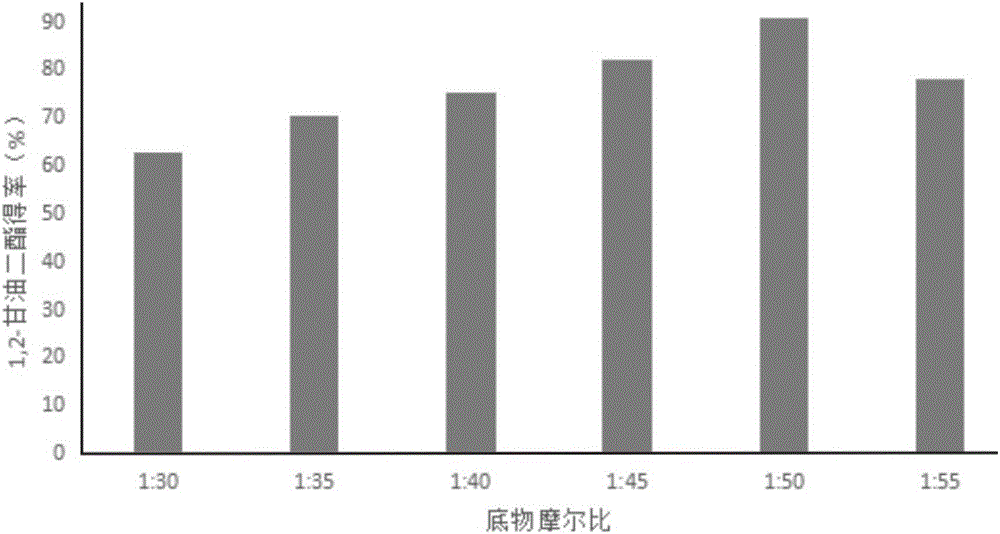

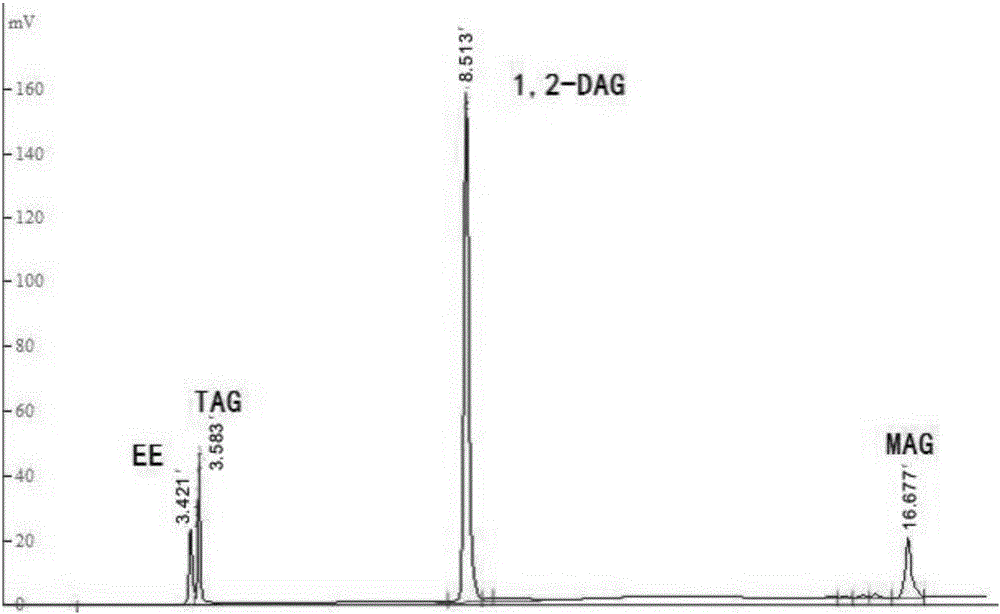

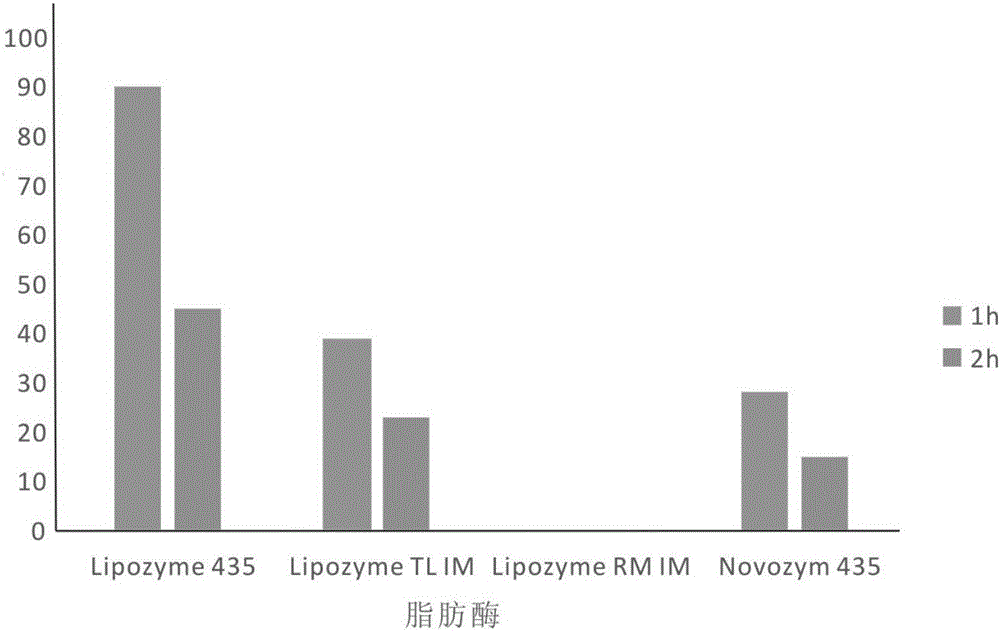

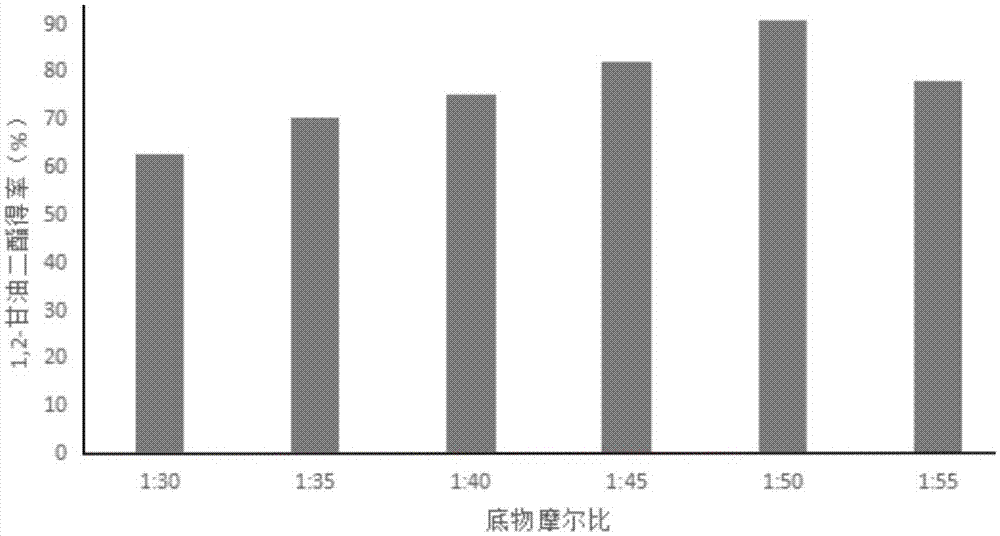

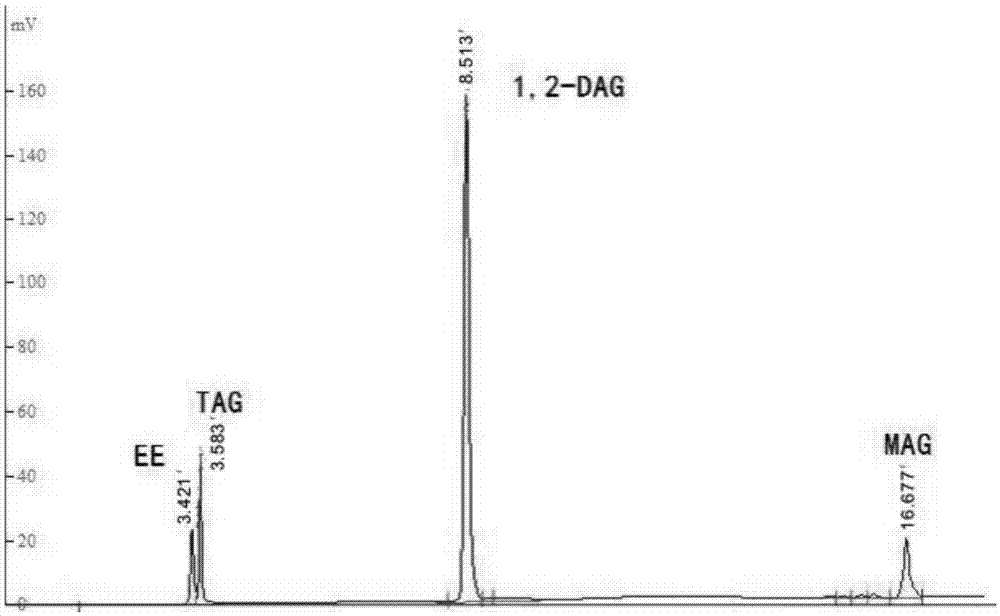

Method for enzymatic synthesis of 1,2-diacylglycerol and method for purifying obtained 1,2-diacylglycerol

ActiveCN106399405ASource of reductionWide variety of sourcesOrganic compound preparationFatty acids production/refiningEnzymatic synthesisVegetable oil

The invention discloses a method for enzymatic synthesis of 1,2-diacylglycerol and a method for purifying obtained 1,2-diacylglycerol. The enzymatic synthesis method comprises the steps that vegetable oil and an organic solvent are mixed based on a molar ratio of 1 to 10-100; after stirring and emulsification, immobilized lipase with the mass accounting for 2 to 20% of the total mass of a substrate is added; after reaction for 0.5 to 6 hours at a temperature of 20 to 70 DEG C, centrifugal removing of lipase is carried out to obtain a product containing 1,2-diacylglycerol. The purification method comprises the step that two-step-crystallization-process-based purification is carried out on the product and two kinds of organic solvents. The purity of the purified 1,2-diacylglycerol can reach up to 100%. According to the method for synthetizing 1,2-diacylglycerol and the method for purifying the obtained 1,2-diacylglycerol provided by the invention, the reaction rate can increase obviously and the yield is high; the product is easy to purify and the purity is high. The methods conforming to a green chemistry concept have advantages of being high in efficiency, being fast in speed, and being convenient for industrial production.

Owner:JIANGNAN UNIV

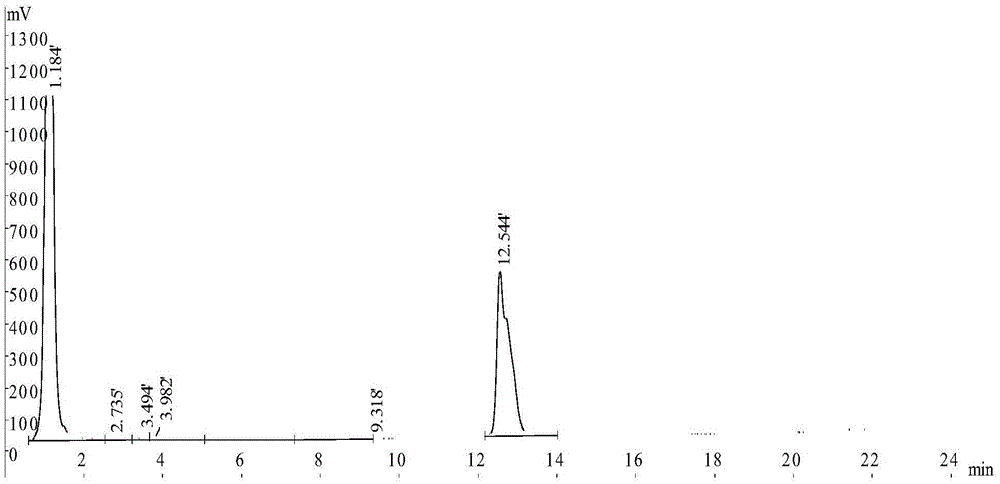

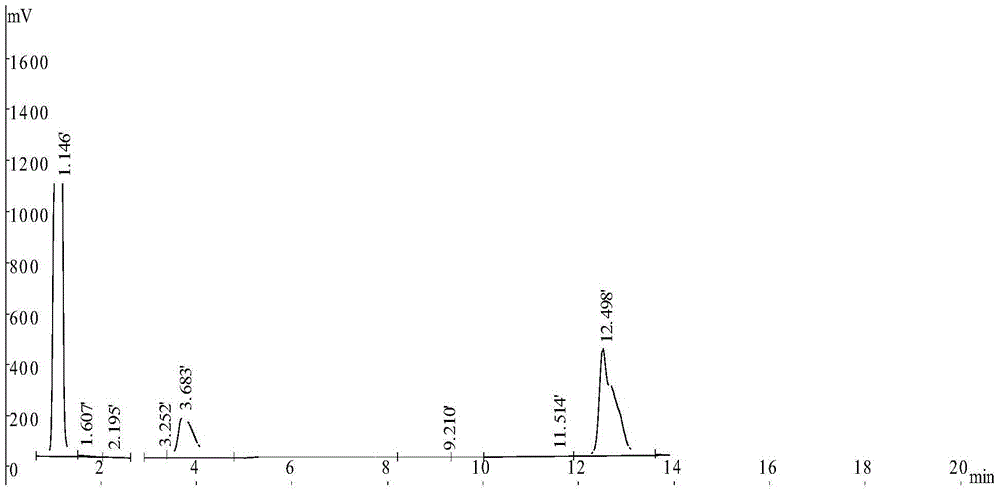

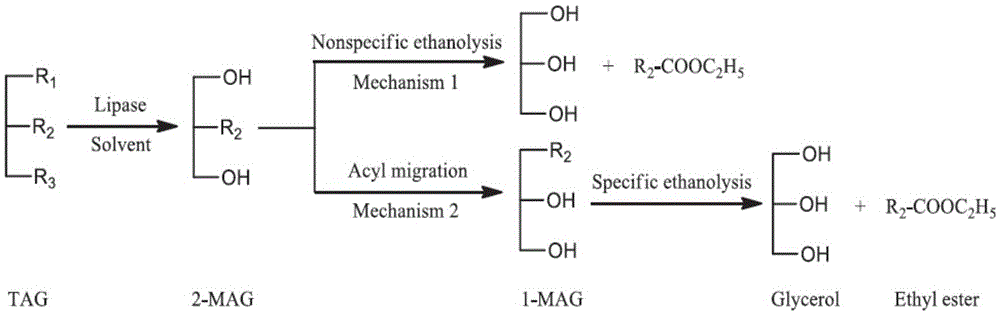

Method for synthesizing Sn-2-monoglyceride through enzymic method

The invention discloses a method for synthesizing Sn-2-monoglyceride through an enzymic method. The method comprises the steps that glyceride and ethyl alcohol are mixed according to the mass ratio of 1:(1-10), in a solvent-free system, lipase is added, reacting under stirring is performed for a period of time at a certain temperature, an ethanolysis reaction is performed, and a product containing the Sn-2-monoglyceride is obtained. According to the method, an acyl transfer side reaction is inhibited through the specificity and high efficiency of enzymes by controlling the reaction conditions, and the reaction conversion rate is very high; meanwhile, the synthesizing time is shortened, the whole process is easy to control, the reaction conditions are mild, the cost can be greatly lowered through recycling of the enzymes, large-scale industrialization promotion is facilitated, and the application potential of the method is great.

Owner:JIANGNAN UNIV

VO2(B)/carbon cloth self-supporting material as well as preparation method and application thereof

InactiveCN112436118AIncrease energy densityGood magnification performanceCell electrodesSecondary cellsElectrical batteryVanadium(V) oxide

The invention relates to a VO2(B) / carbon cloth self-supporting material as well as a preparation method and application thereof. The VO2(B) / carbon cloth self-supporting material is directly obtained through adopting a one-time hydrothermal method, the prepared VO2(B) is of a nanosheet structure, the width of nanosheets is 100-300 nm, the sizes of the nanosheets are uniform, and loads on carbon cloth are very uniform. The preparation method comprises the following steps of: firstly, adding vanadic oxide and oxalic acid into distilled water, and reacting them under a water bath heating conditionto obtain a blue clear solution; adding a H2O2 solution with the mass fraction of 30% into the blue clear solution, and uniformly stirring the mixture; adding absolute ethyl alcohol into the mixture,and uniformly stirring the mixture; transferring the obtained precursor solution into a reaction kettle, and putting carbon cloth for hydrothermal reaction; and cleaning the obtained active materialwith pure water for multiple times, and drying in a vacuum drying oven to finally obtain the VO2(B) / carbon cloth self-supporting zinc ion battery positive electrode material. The preparation method has the advantages of simple process, mild reaction conditions and excellent electrochemical performance of the material.

Owner:HUAZHONG AGRI UNIV

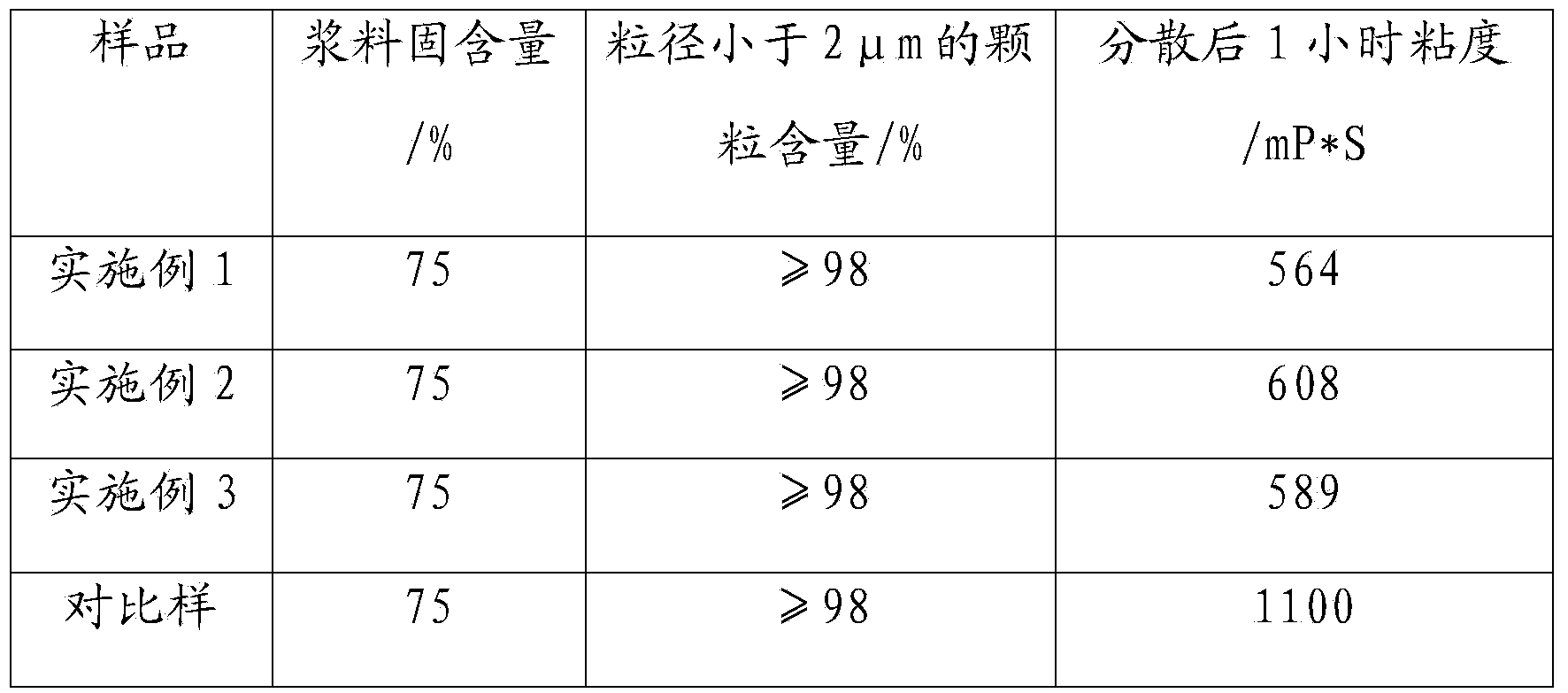

Preparation of efficient ground calcium carbonate grinding dispersant by photo-initiating room-temperature RAFT (Reversible Additive Fragment Transfer) polymerization

InactiveCN104031190AMolecular weight controllableAvoid postprocessingTransportation and packagingMixingSolventGreen chemistry

The invention discloses a preparation method of an efficient ground calcium carbonate grinding dispersant by photo-initiating room-temperature RAFT (Reversible Additive Fragment Transfer) polymerization. The method comprises the following steps: adding a vinyl carboxylic ester monomer, a polythio ester chain transfer agent and a photoinitiator into a solvent and bubbling for 15-30 minutes by nitrogen; illuminating to react for 3-12 hours by an ultraviolet lamp, wherein the central wavelength of the ultraviolet lamp is 365nm and incident light passes through a wave cutoff sheet with the wave cutoff range greater than 254nm; after reaction, mixing the obtained solution with an NaOH solution, hydrolyzing for 3-10 hours at 80-120 DEG C, carrying out reduced pressure distilling to remove the solvent and alcohol byproducts, then, adding the NaOH solution to adjust the pH to 4-8 and adding water to adjust the solid content to 41-43% to obtain the efficient ground calcium carbonate grinding dispersant. Compared with conventional free radical polymerization, the method has the advantages of controllable molecular weight, narrow distribution of molecular weight and no free countra-ions introduced in the initiating process. The method has the following characteristics of simple treatment, pure product and low energy consumption and meets modern green chemistry.

Owner:DSSUN NEW MATERIAL SHANDONG

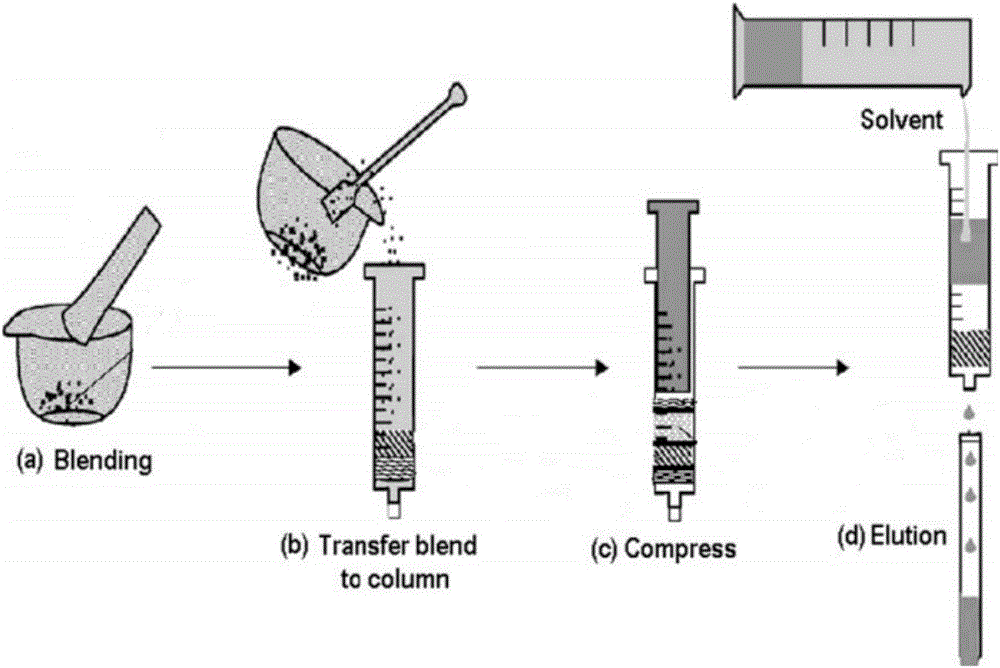

Extracting and detecting method for flavonoid in radix sophorae subprostratae

ActiveCN106770839AReduce usageConvenient Quantitative DetectionComponent separationEmulsionFlavanone

The invention provides an extracting and detecting method for flavonoid in radix sophorae subprostratae. The flavonoid to be detected is lupinifolin and radix sophorae subprostratae chroman flavanone C which are respectively called flavone 1 and flavone 4 for short. The extracting and detecting method disclosed by the invention creatively combines a matrix solid-phase dispersion extraction technology with a reverse micro-emulsion electrokinetic chromatography technology, utilizes combination of an offline enrichment technology and an online enrichment technology to achieve secondary enrichment of the flavonoid in the radix sophorae subprostratae and is beneficial to quantitative detection of the flavonoid in the radix sophorae subprostratae. Furthermore, the extracting and detecting method disclosed by the invention is implemented in a microscale system, the used medical materials and experiment drug reagents are all in a microgram level, the use amount of harmful chemical reagents is small, and safety, economical performance and environmental friendliness are achieved.

Owner:ZHEJIANG UNIV OF TECH

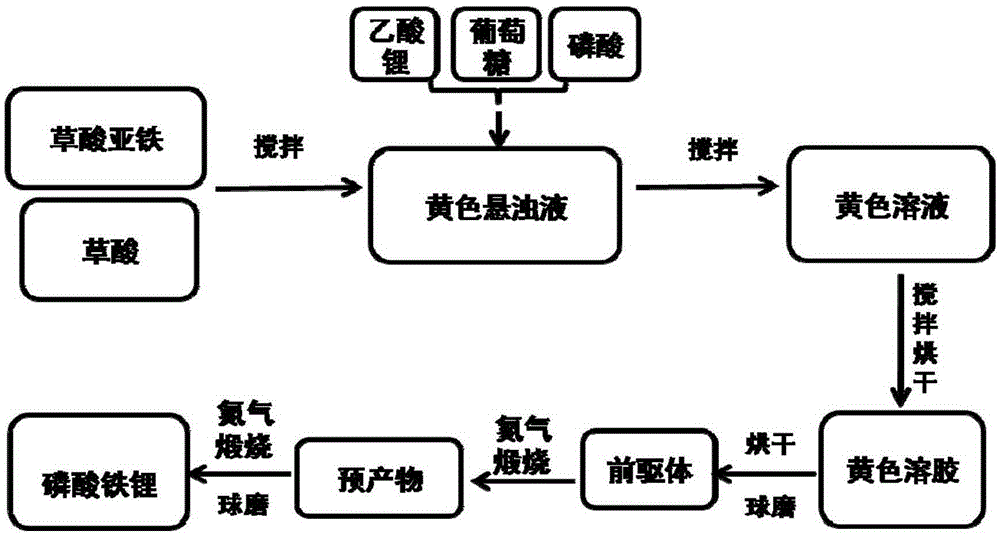

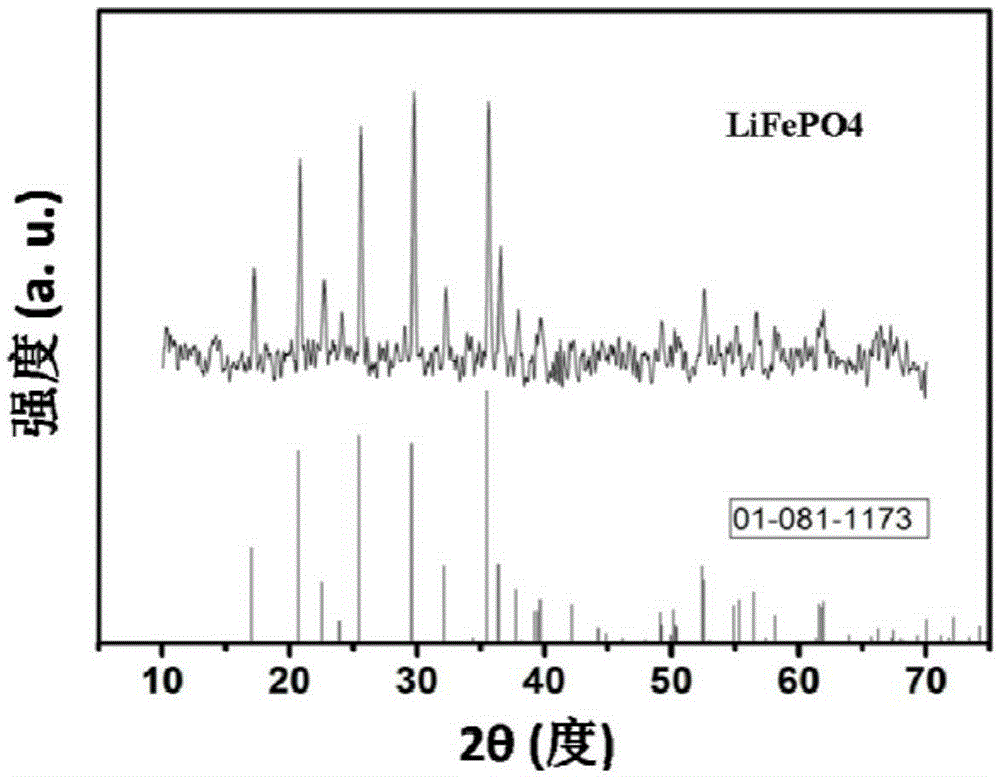

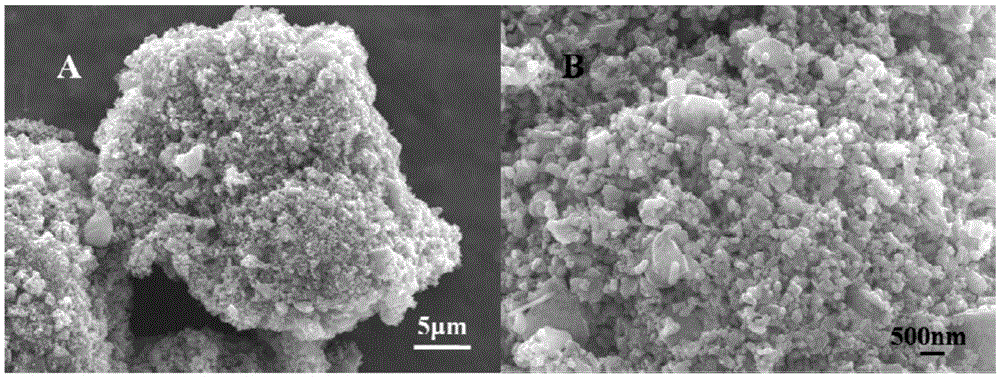

Lithium iron phosphate cathode material with carbon coating in situ and preparation method thereof

ActiveCN105244481AImprove discharge capacityImproved magnification performanceMaterial nanotechnologyCell electrodesCarbon layerLithium-ion battery

The invention provides a lithium iron phosphate cathode material with carbon coating in situ and a preparation method thereof. A product is prepared by a liquid phase ball milling method, the particle surface of the product is coated with a uniform carbon layer, particles are connected to one another by an amorphous carbon net, and the grain size of the particles is 100 to 200 nanometers. The preparation method mainly comprises preparation of precursor powder and the preparation of the product. The lithium iron phosphate cathode material is synthesized by the liquid phase ball milling method, the particle grain size of the product is nano scale, the particles are uniformly distributed, and the lithium iron phosphate cathode material has the obvious advantages of high specific surface area, low charge mass transfer resistance and improvement on electron and ion conductivity. By carbon coating in situ, bulk conductivity among active substance particles and between an active substance and a conductive agent is improved, the impedance among the particles is reduced, the electrochemical performance is excellent, market promotion at a large scale is facilitated, and the lithium iron phosphate cathode material can serve as a positive material of a lithium ion battery.

Owner:曹余良

Method for synthesizing 1,2-diglyceride with an enzymic method

ActiveCN105441494ASource of reductionWide variety of sourcesFermentationOrganic solventVegetable oil

The invention discloses a method for synthesizing 1,2-diglyceride with an enzymic method. The method comprises the steps of mixing vegetable oil with an organic solvent according to the mole ratio of 1:10 to 100, stirring, emulsifying, then adding immobilized lipase of which the mass is 2 to 20% of the total mass of substrates, reacting for 0.5 to 6 h at the temperature of 20 to 70 DEG C, and centrifuging to remove the lipase, so as to obtain a product which contains the 1,2-diglyceride. The synthetic method provided by the invention has the advantages of high yield, high efficiency, rapidity and convenience in industrial production and conforms to green chemistry, the reaction rate can be obviously increased, and the product is easy to purify.

Owner:JIANGNAN UNIV

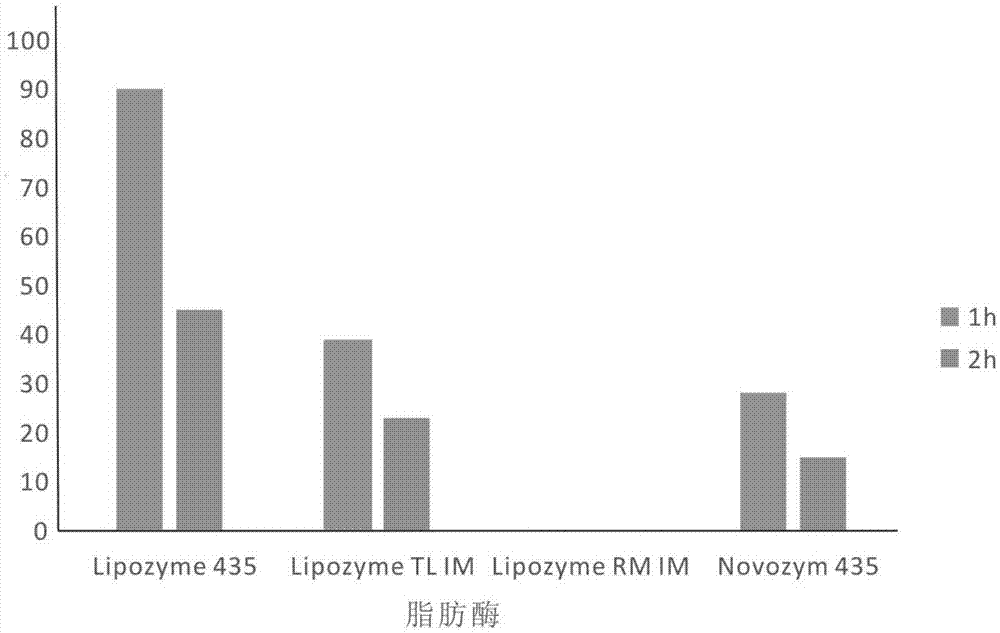

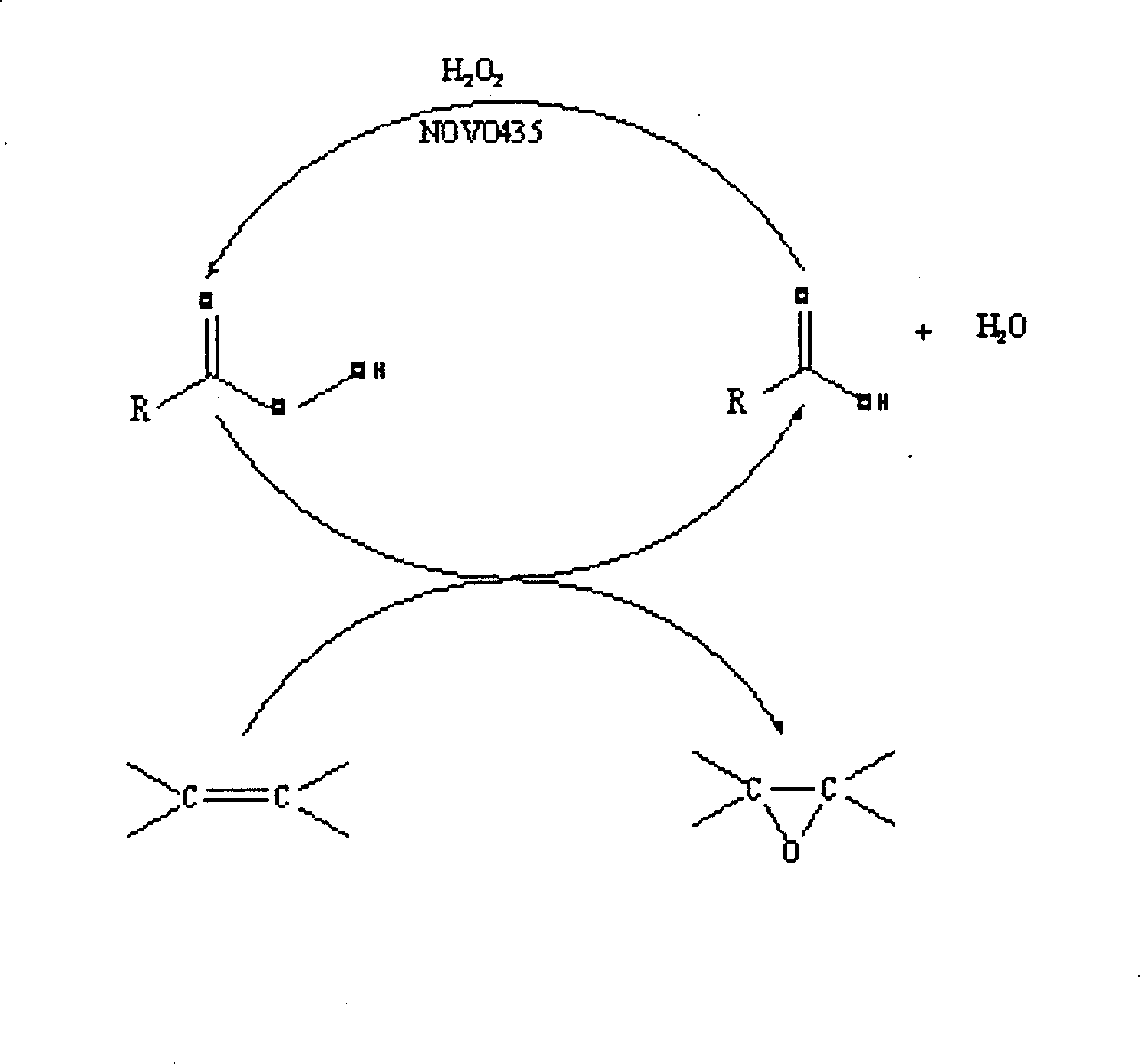

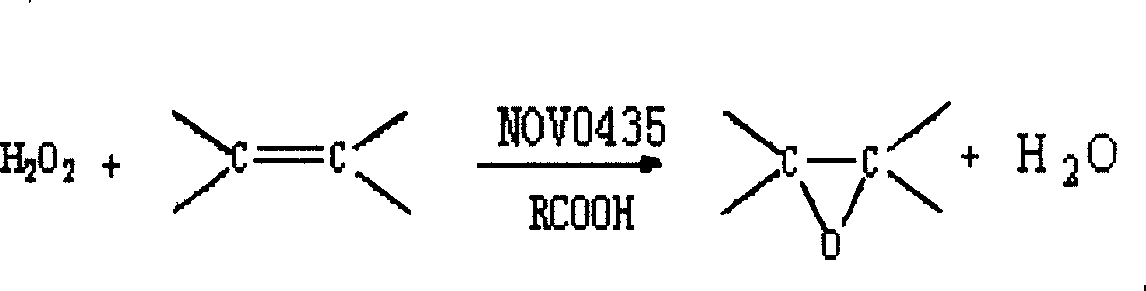

Method for preparing epoxy flax oil by catalytic oxidation of lipase

InactiveCN101230367ALow costSimple operation processChemical recyclingFermentationWater bathsOrganic acid

The invention relates to a method in which lipase can be used for catalyzing and oxidize linseed oil to prepare epoxidized linseed oil. The method is that refined linseed oil, solvent, organic acid and catalyst can be added into a reaction container which is positioned in a constant-temperature water bath; and then hydrogen peroxide can be dropped into to conduct the reaction. Lipase catalyst can be recycled by filtering, and filtrate can be moved into a separating funnel to separate out organic phases. And then the organic phases can be decompressed and distilled after being diluted to be neutral to obtain the outcome epoxidized linseed oil. The operational art of the method is simple, and the reaction condition is moderate. In addition, organic acid, solvent and catalyst which are added all can be recycled and reused; and another material hydrogen peroxide can be converted into water without pollution after the reaction, thereby avoiding producing a large amount of industrial pollution and saving material; moreover, the cost of the outcome is low, which meets the current requirements of green chemical and atomic economy.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

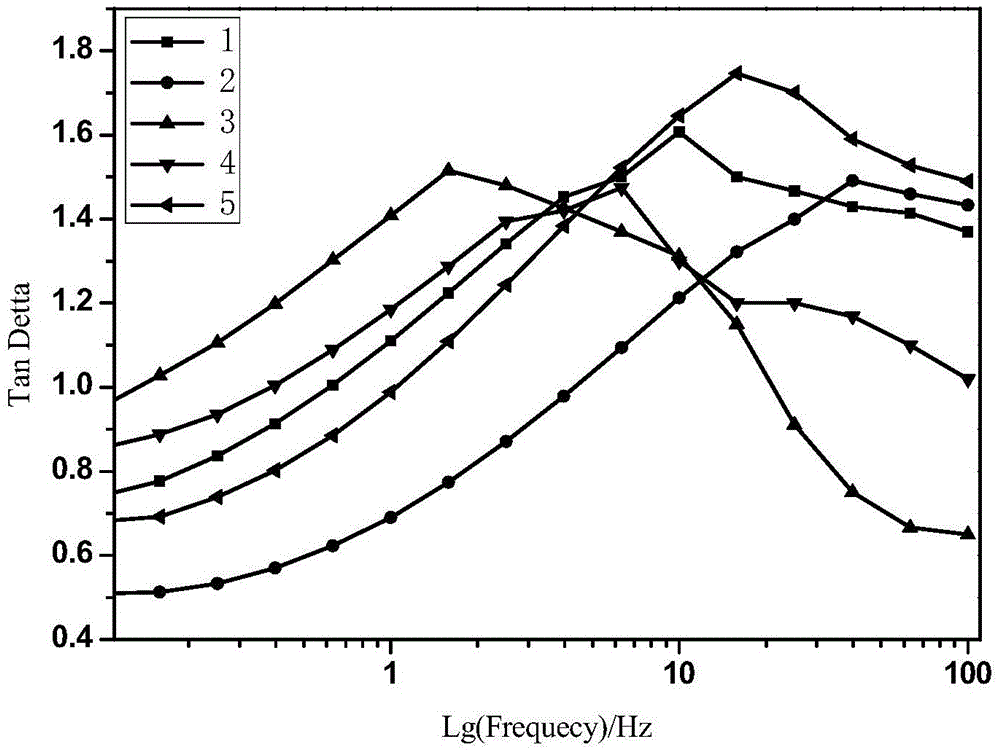

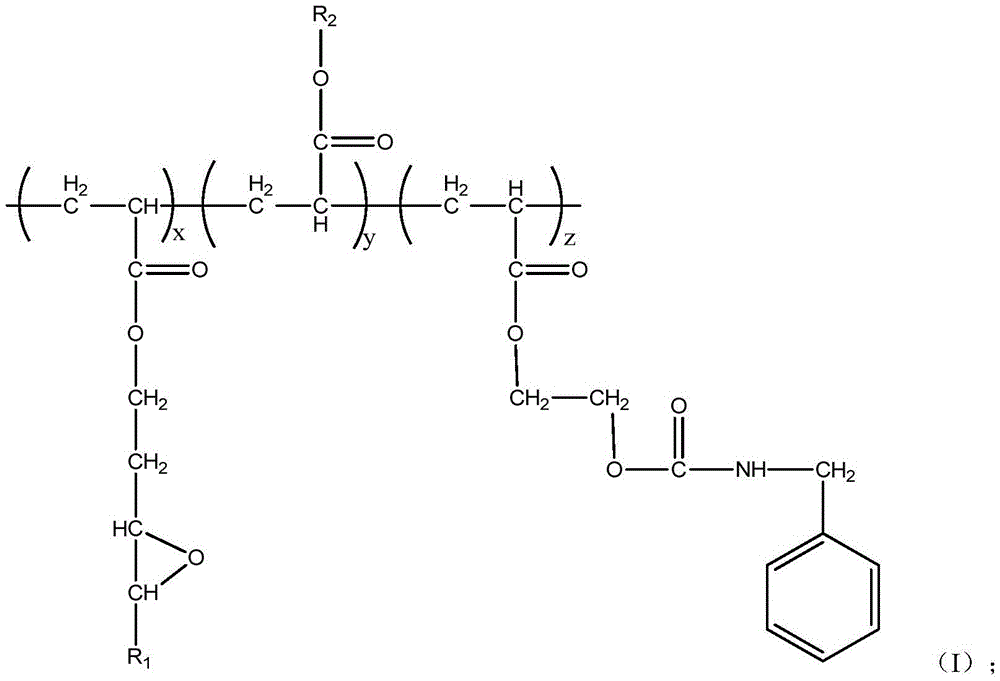

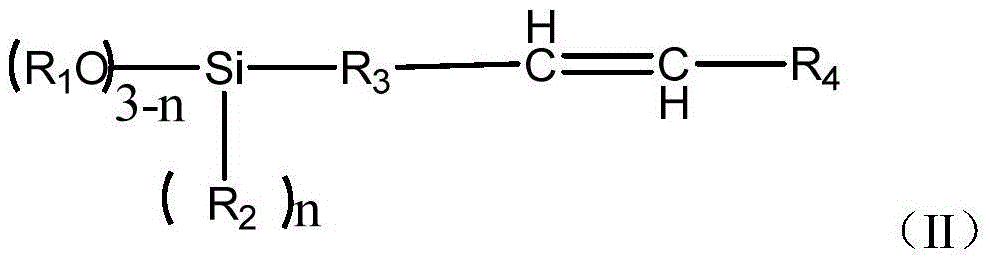

UV polymerization type body foamed damping material and preparation method thereof

ActiveCN105585985AImprove performanceLower glass transition temperatureNon-macromolecular adhesive additivesGraft polymer adhesivesFoaming agentSolvent free

The invention discloses a UV polymerization type body foamed damping material. The UV polymerization type body foamed damping material comprises components in parts by weight as follows: 20-30 parts of an acrylate copolymer, 70-75 parts of a reactive diluent, 0.5-0.8 parts of a photoinitiator and 1-5 parts of hollow inorganic nanoparticles. The high-performance damping material is prepared through UV polymerization, and a solvent-free and pollution-free product is realized thoroughly. The hollow inorganic nanoparticles are taken as an inorganic body foaming agent, the product density can be controlled precisely according to requirements through control of adding amount of the hollow inorganic nanoparticles, and the loss factor of the product can be controlled and increased. The damping material has the advantages of excellent initial adhesion, persistent adhesion, peel strength, interfacial wettability and high loss factor.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

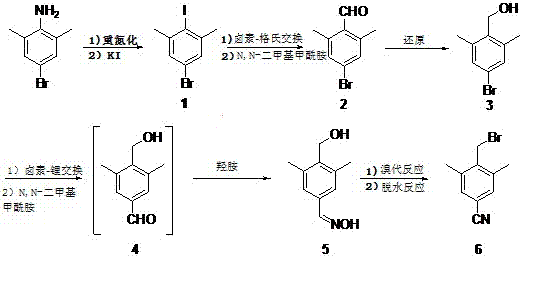

Preparation method of 3, 5-dimethyl-4-bromomethylbenzonitrile

ActiveCN102643213AReduce usageSimple and fast operationCarboxylic acid nitrile preparationOrganic compound preparationHydroxylamineGrignard reagent

The invention discloses a preparation method of 3, 5-dimethyl-4-bromomethylbenzonitrile. The preparation method comprises the following steps: selectively synthesizing an important intermediate, namely aryl aldehyde by utilizing a Grignard reagent and different exchange capacities of bromine and iodine in 2, 6-dimethyl-4-bromoiodobenzene, reducing to get benzyl alcohol, then utilizing halogen-lithium exchange reaction to get an aryl aldehyde compound, further reacting with hydroxylamine to get oxime, dehydrating to get cyan and further synthesizing the 3, 5-dimethyl-4-bromomethylbenzonitrile. According to the preparation method disclosed by the invention, a highly toxic metal cyanide can be avoided, the risk is reduced, and the preparation method is more environment-friendly and in line with the aim of green chemistry; and simultaneously, the route is simple and convenient to operate, the complex post-treatment process is avoided, the production cost is reduced, and the preparation method further has great industrial application prospects.

Owner:暨明医药科技(苏州)有限公司

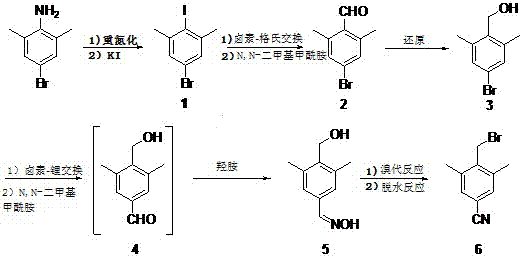

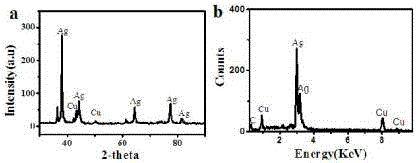

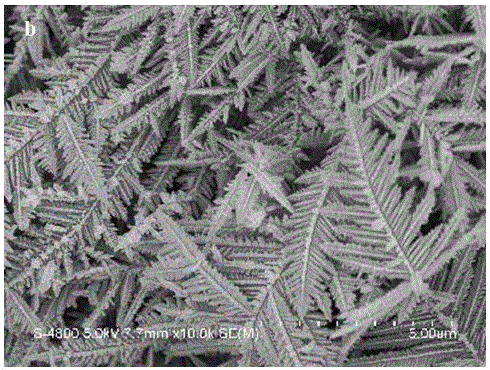

Preparation method of silver nano-dendrites

InactiveCN106112007ALow energy consumptionGood electrical conductivityTransportation and packagingMetal-working apparatusCopperSalt solution

The invention provides a preparation method of silver nano-dendrites. The preparation method comprises the following steps that (1) a copper bar is washed, specifically, the copper bar is washed with acetone, ethanol, diluted hydrochloric acid and distilled water under ultrasonic conditions correspondingly; and (2) the silver nano-dendrites are prepared, specifically, at room temperature, univalence silver salt is dissolved into distilled water and completely dissolved through stirring, and a solution with the concentration of 0.01-0.1 mol / L is prepared; the cleaned copper bar is placed into a 5 mL test tube, the univalence silver salt solution is dropped into the test tube with a gum cap dropper to conduct a reaction for 5-120 seconds at norm temperature; after completion of the reaction, the copper bar on which black substances grow is washed with the distilled water and is dried naturally in the air, and then nanocrystals are obtained. The preparation method has the advantages of being high in reproducibility, easy and convenient to operate, low in synthesis cost and suitable for industrialized application. The prepared silver nano-dendrites are large in specific surface area and can make full contact with a substance to be tested to make an electro-catalytic reaction sufficient and efficient.

Owner:岳佐星

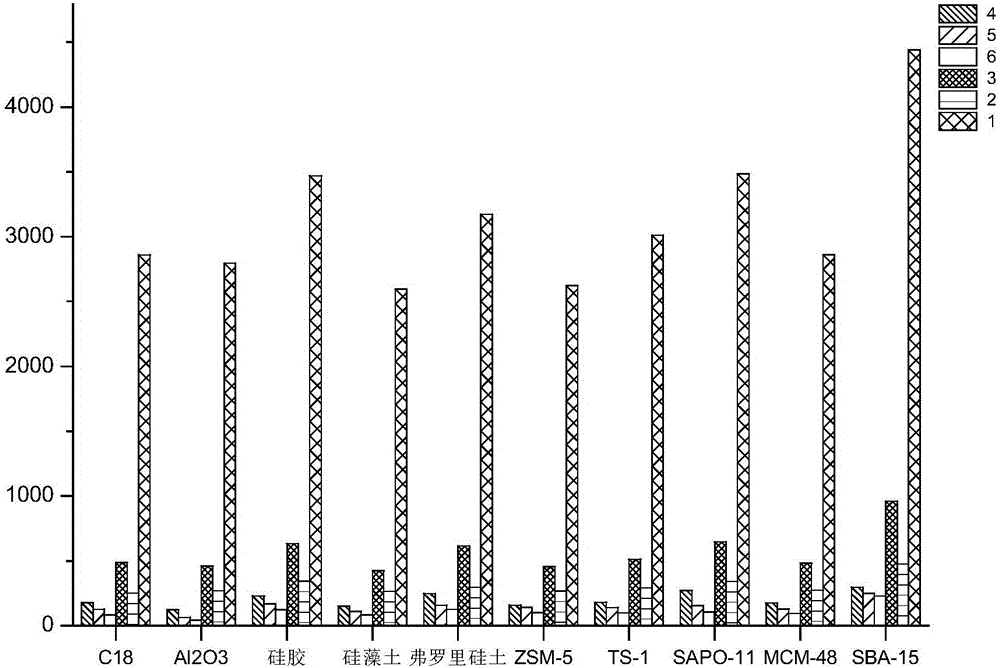

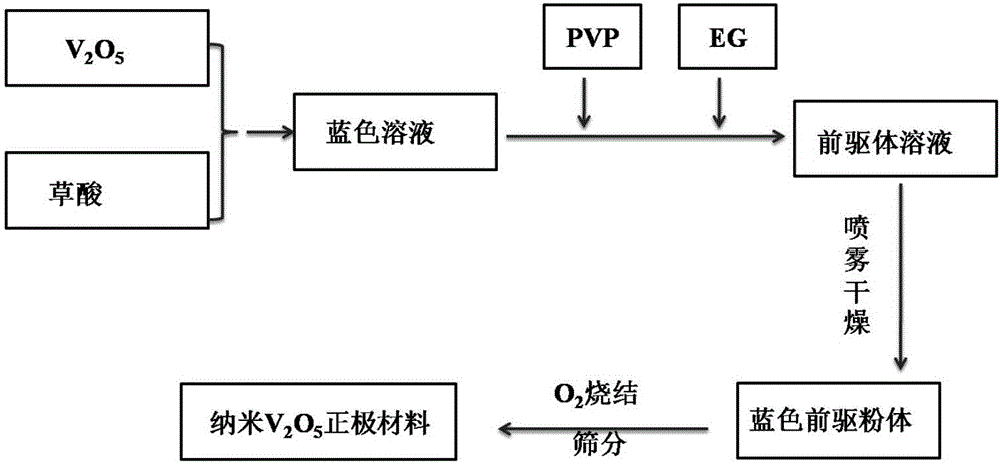

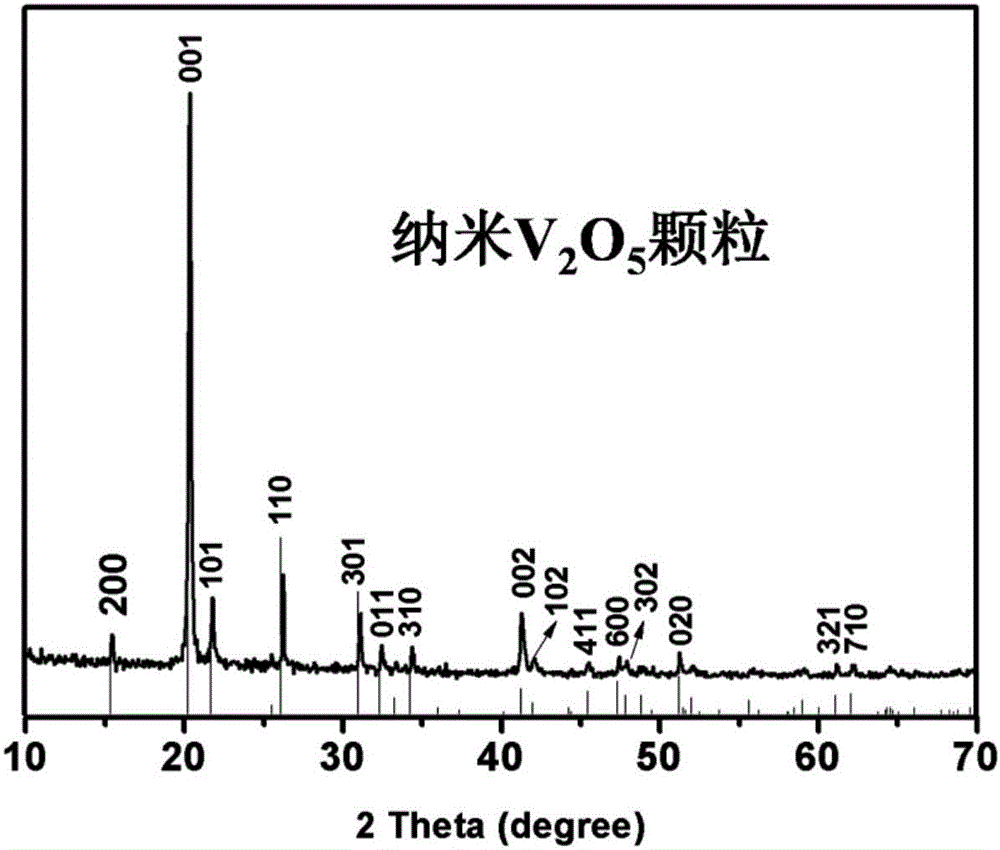

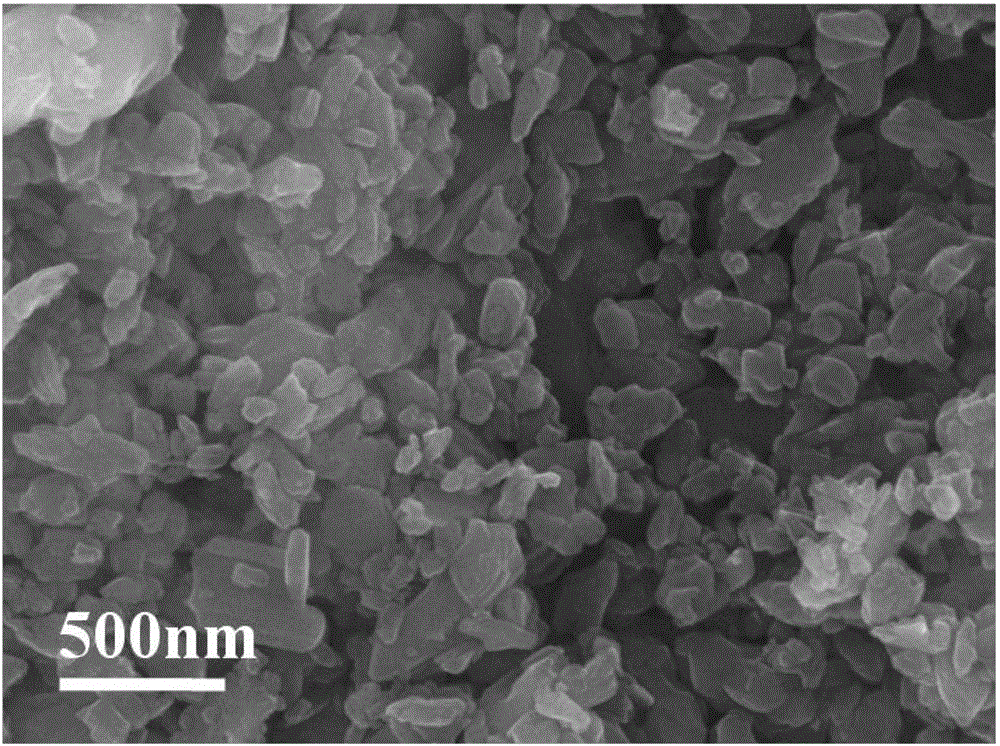

Preparation method and application of nanometer vanadium pentoxide anode material suitable for industrial production

ActiveCN106745251AWide variety of sourcesSimple processMaterial nanotechnologyCell electrodesElectrochemistryLithium-ion battery

The invention provides a preparation method and an application of a nanometer vanadium pentoxide anode material suitable for industrial production. The preparation method comprises the following steps: adding a vanadium source and oxalic acid into deionized water to form a blue solution; respectively adding an additive and ethylene glycol into the blue solution to obtain a blue precursor solution; spray-drying the blue precursor solution to obtain a blue precursor powder; conducting aerobic sintering on the blue precursor powder, and screening to obtain a product. The liquid phase spray drying technique is adopted, the product particle is on the nanometer scale, the distribution of the product particle is even, the product has an excellent electrochemical performance, the source of the raw materials is wide, the preparation process is simple, the cost is low, the industrialization of the product is easy, and the product can serve as an anode active material for a lithium ion battery.

Owner:周双双

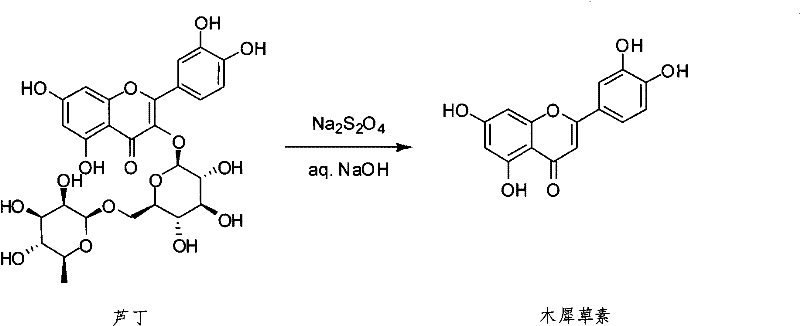

Method for synthesizing luteolin

The invention discloses a method for synthesizing luteolin, comprising the following steps of: adding rutin at the room temperature of 20-30DEG C in alkali water and stirring for dissolving; adding a reducing agent of sodium hydrosulfite with equivalent weight of 6.3 once, continuously heating up to 100DEG C and stirring for 12 hours; after the HPLC (High Performance Liquid Chromatography) monitoring reaction is finished, cooling, adding dilute hydrochloric acid or dilute sulfuric acid, adjusting the pH to be 3-4, standing for 24 hours for separating out a solid and filtering; washing a filtering cake with water twice to remove salts contained in the product; and drying to obtain a crude product, continuously crystalizing with ethanol to obtain a pure product with the purity being more than 95 percent. Compared with the prior art, the invention has the advantages of high synthetic efficiency, high yield, low energy consumption, low pollution, greenness, environmental protection and the like and is easy for industrialized production.

Owner:西安炎黄经方医药研发有限公司

Method for deacidifying rice bran oil by using enzymic method

ActiveCN105802730AMild reaction conditionsReduce process costFatty-oils/fats refiningNutrientRice Bran Extract

The invention discloses a method for deacidifying rice bran oil by using an enzymic method. The method comprises the following steps: mixing rice bran oil with glycerinum, adding lipase which accounts for 2-7% of the total mass of a substrate, enabling the component to react for 5-7 hours in a vacuum device, feeding a product into a nitrogen cooling device, cooling to 25-30 DEG C, and centrifuging so as to remove lipase, thereby obtaining the deacidifed rice bran oil. The method for deacidifying rice bran oil by using the enzymic method, which is disclosed by the invention, is low in rice bran oil acid value, high in nutrient element retention rate, efficient and rapid in reaction, and is a rice bran oil deacidification method which is green and applicable to industrial production.

Owner:JIANGNAN UNIV

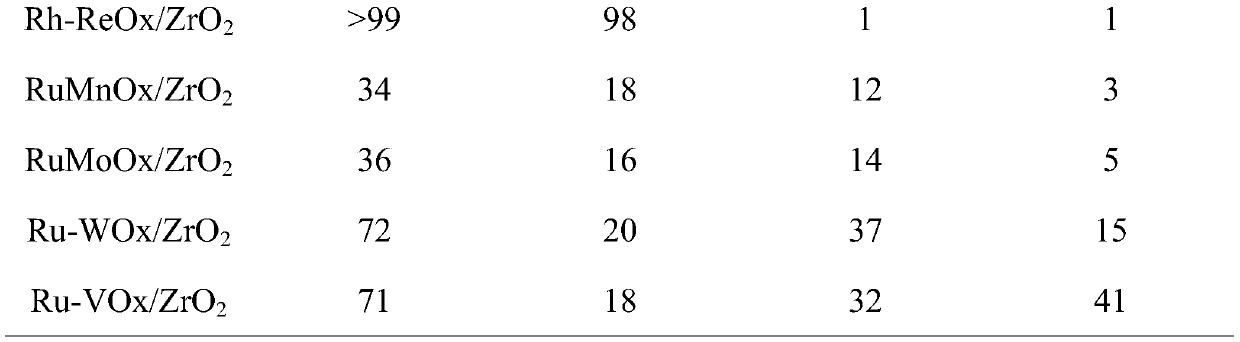

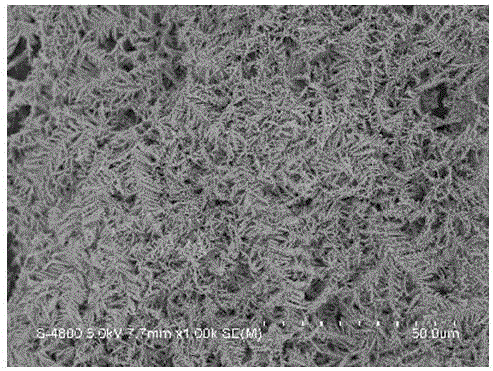

Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition

InactiveCN108727241AEffective Phase Transfer CatalysisSynthetic process conditions are mildOrganic chemistryOrganic compound preparationChromatographic separationNitroalkene

The invention relates to calix[4]thiourea diaminocyclohexane derivatives and a method thereof for catalyzing asymmetric Michael addition. An Michael addition catalytic reaction is performed on nitroolefin and 1,3-dicarbonyl ketone as raw materials, the calix[4]thiourea diaminocyclohexane derivatives as a phase transfer catalyst and water / toluene as a solvent, after the reaction, the solvent is concentrated, and a product is obtained by column chromatographic separation on silica gel. The calix[4]thiourea diaminocyclohexane derivatives adopt mild synthesis process conditions and are high in catalysis efficiency, water / toluene is taken as the solvent for asymmetric Michael addition catalyzed by the derivatives, reaction speed and yield can be increased greatly by water addition, and the catalyst has a phase transfer catalysis function. Better ee value can be obtained by the catalytic reaction at room temperature, and the derivatives have broad application prospect.

Owner:CHANGZHOU UNIV

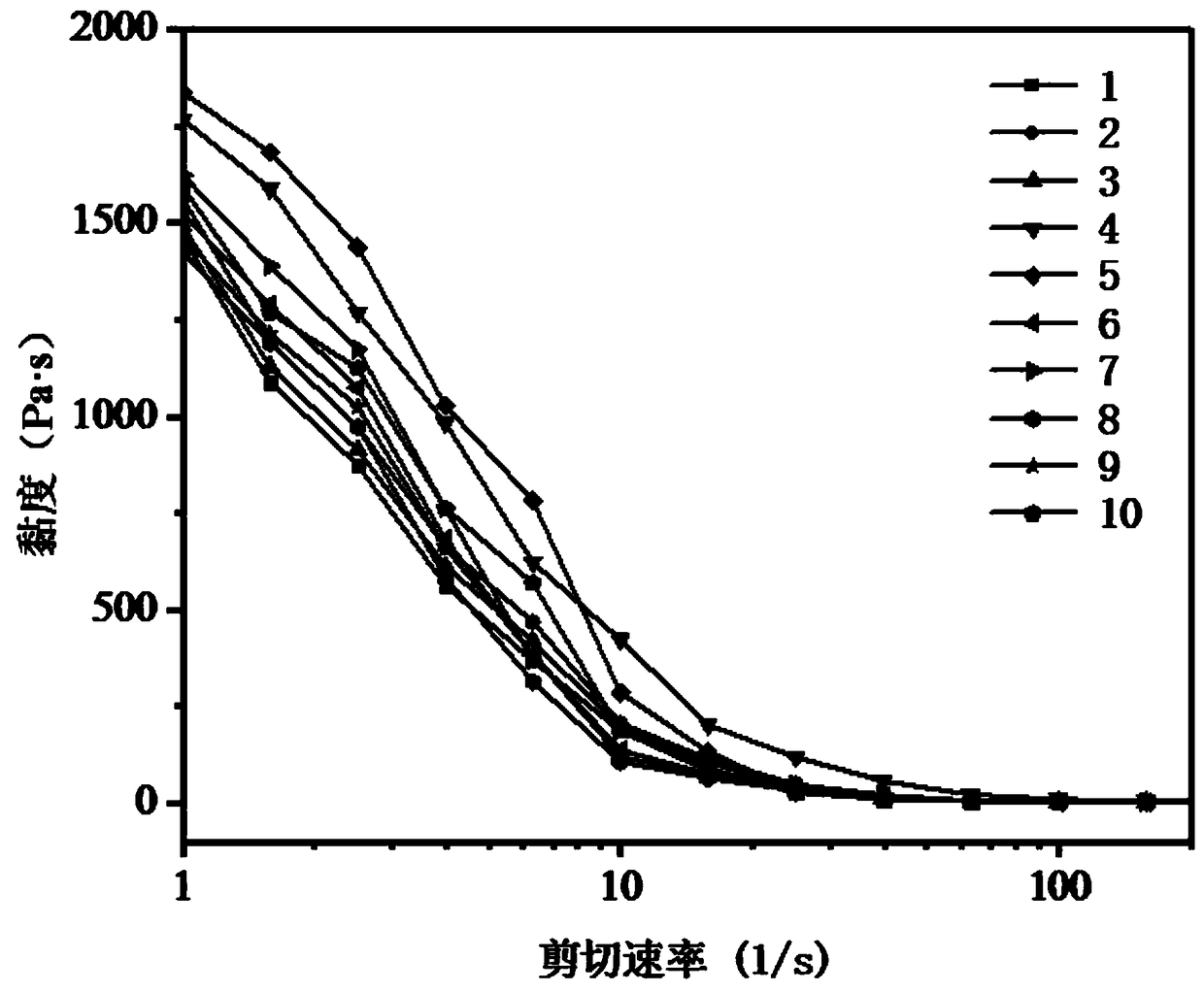

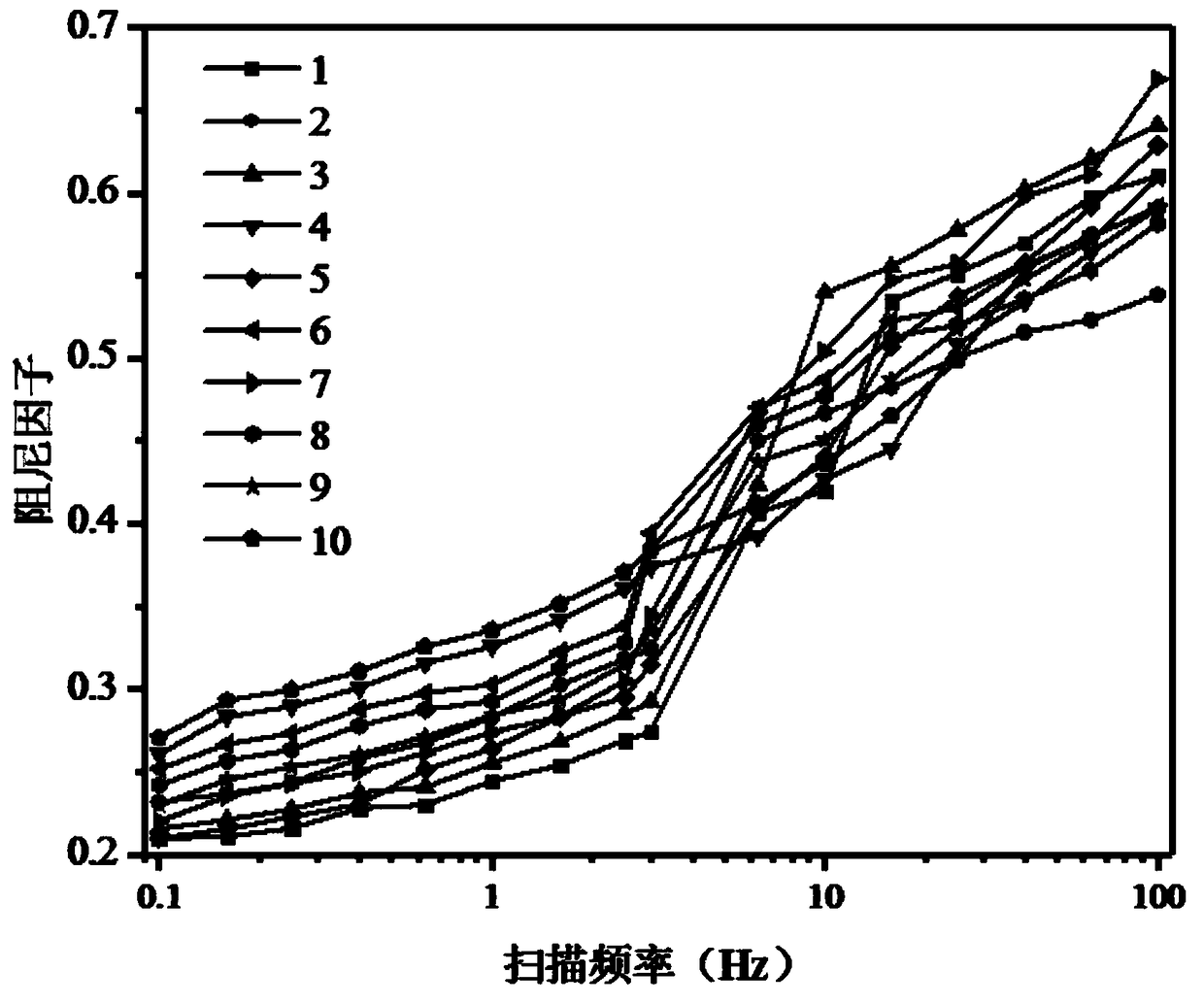

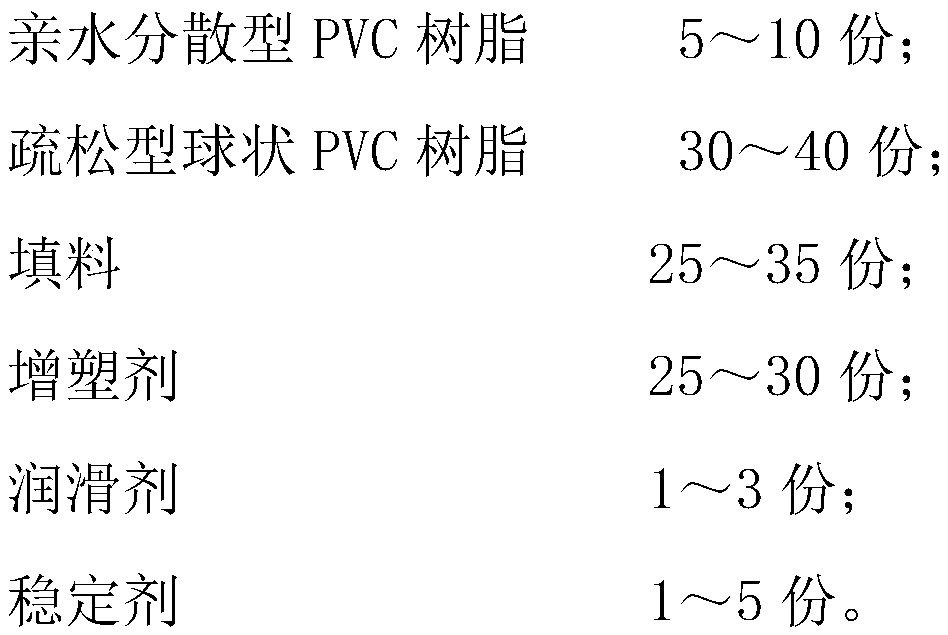

Damping composition containing hydrophilic dispersing type PVC resin and preparation method of damping composition

The invention discloses a damping composition containing hydrophilic dispersing type PVC resin. The damping composition containing the hydrophilic dispersing type PVC resin comprises the following components: the hydrophilic dispersing type PVC resin, loose type spherical PVC resin, filler, a plasticizer, a lubricating agent and a stabilizing agent. According to the damping composition, the loosetype spherical PVC resin is used as a matrix, and by the hydrophilic dispersing type PVC resin, a coating can be waterborne. The damping composition is in low VOC type, and has the advantages of environmental protection, mechanical spraying capability, good properties such as mechanical property and damping property and the like.

Owner:HUBEI UNIV

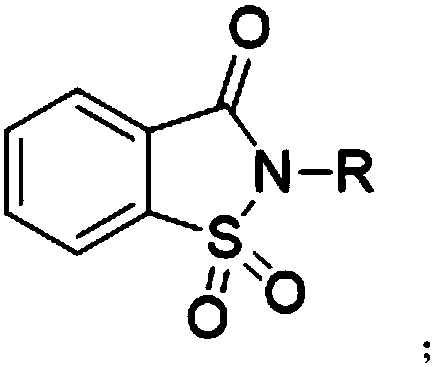

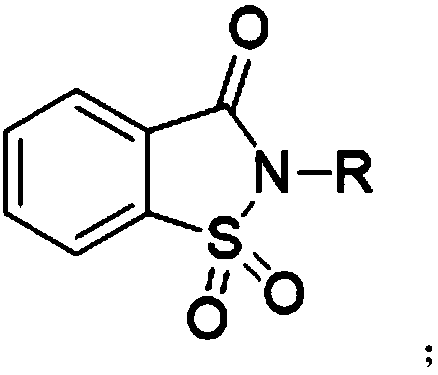

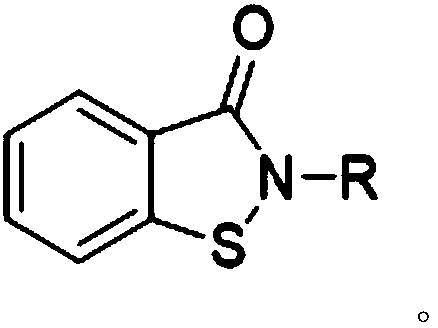

Synthesis method for preparing saccharin

The invention provides a synthesis method for preparing saccharin, which comprises the following steps: carrying out an oxidation reaction on a 1,2-benzisothiazolin-3-one compound and an oxidant, andoxidizing thioether of the 1,2-benzisothiazolin-3-one compound into sulfamide by the oxidant, thereby obtaining the o-benzoyl sulfamide compound. Compared with a traditional saccharin production process, the saccharin synthesis method has the advantages of being simple in process, low in cost, efficient in separation, small in pollution and the like, and more conforms to green chemistry.

Owner:SHANGHAI JIAO TONG UNIV

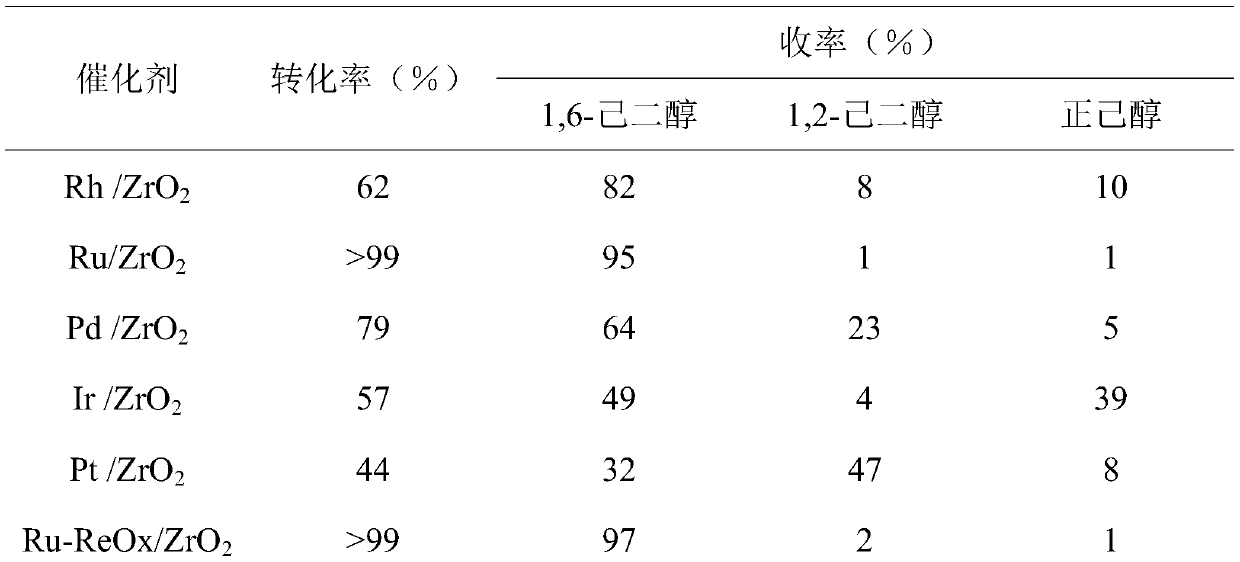

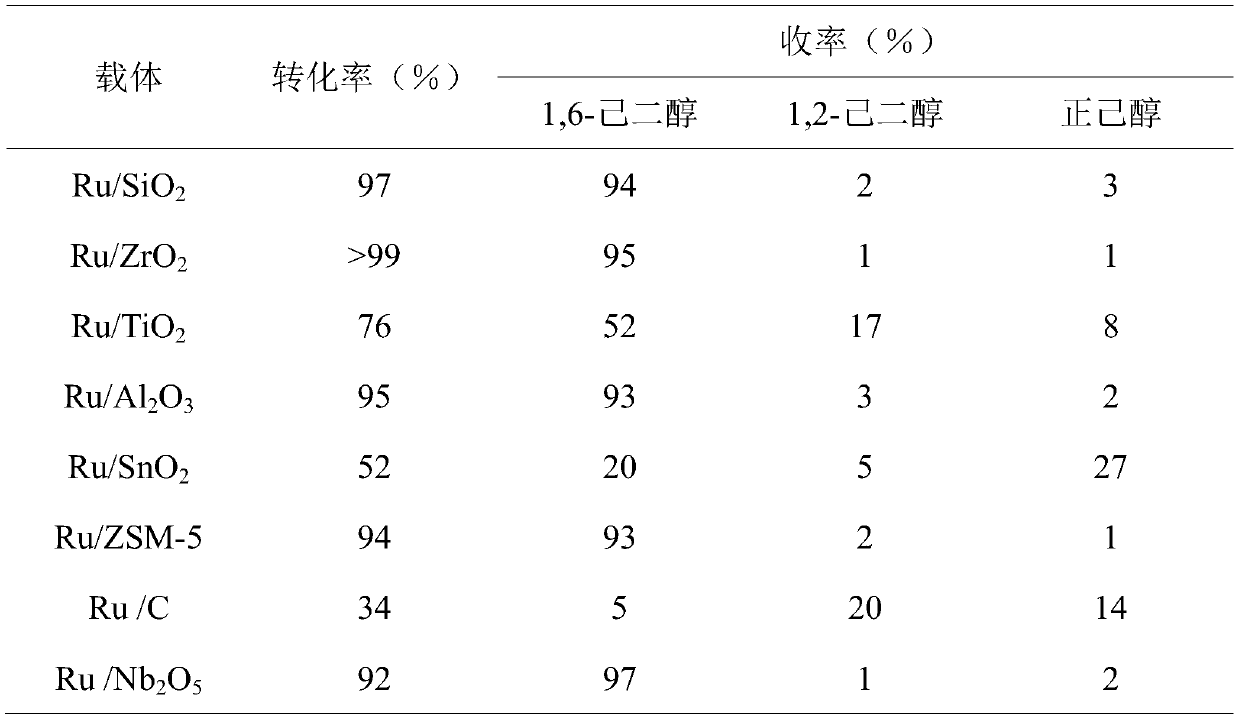

Method for preparing 1,6-hexanediol by catalytic hydrogenolysis of 1,2,6-hexanetriol

ActiveCN109748777ARaw material resources are renewableCompliant with Green ChemistryPreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsSolid acidRenewable biomass

The invention provides a method for preparing 1,6-hexanediol by catalytic hydrogenolysis of 1,2,6-hexanetriol. According to the method, 1,2,6-hexanetriol is taken as a raw material and undergoes a one-step catalytic hydrogenolysis process in the presence of a catalyst and solid acid to realize high conversion rate and high yield of 1,2,6-hexanetriol to prepare 1,6-hexanediol. The technical route provided by the method has the characteristics of short reaction time, high conversion rate of raw materials and high yield of 1,6-hexanediol, and the raw materials can be obtained from renewable biomass resources, so that the method has the advantage of not relying on fossil resources.

Owner:DALIAN UNIV OF TECH

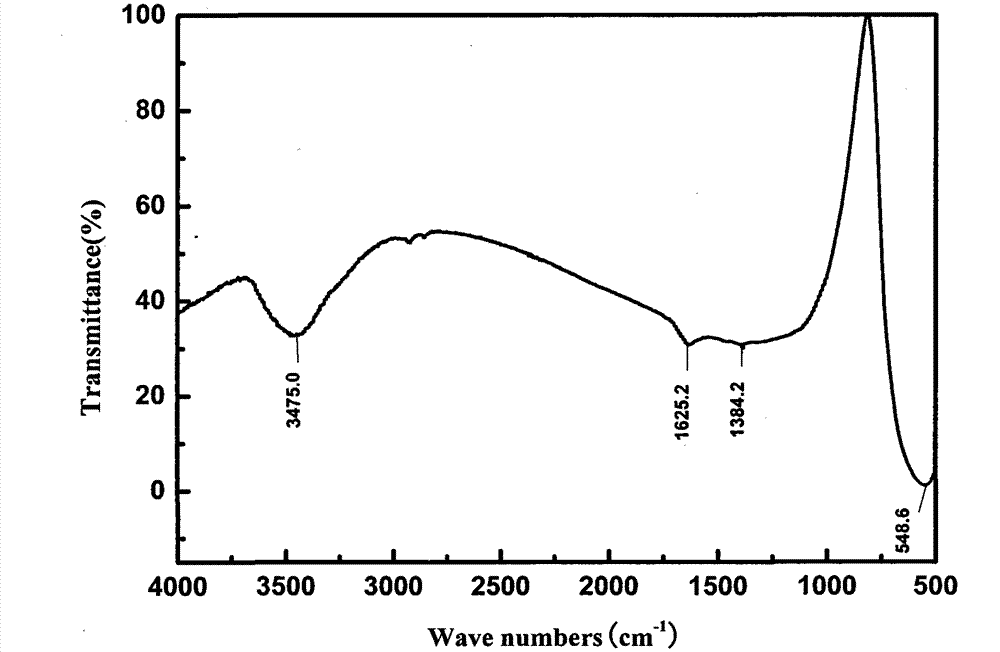

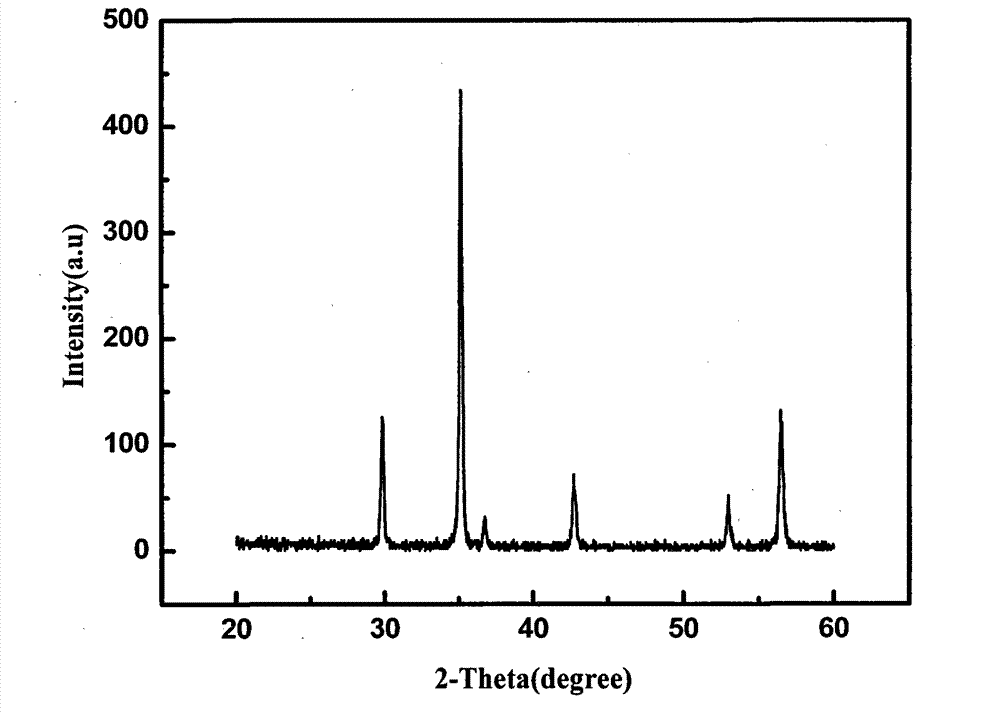

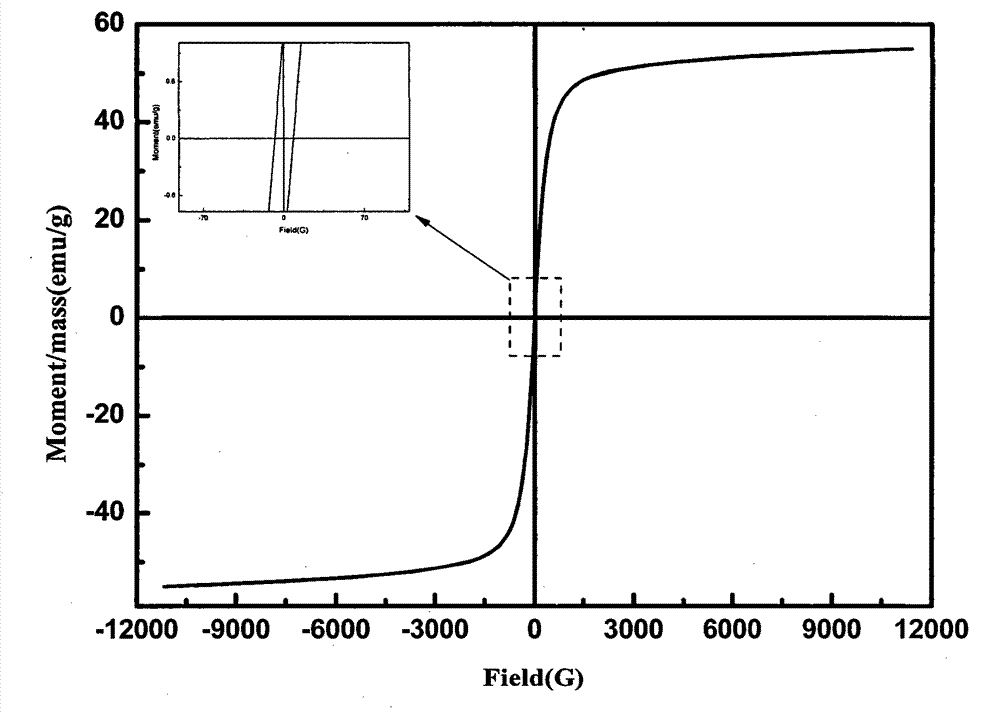

Method for preparing manganese-zinc ferrites through carrying out acid dipping on low-grade manganese ores and carrying out ferromanganese remaining and impurity removal

The invention discloses a method for preparing manganese-zinc ferrites through carrying out acid dipping on low-grade manganese ores and carrying out ferromanganese remaining and impurity removal, relating to a preparation method for magnetic materials. The method disclosed by the invention is implemented by taking low-grade manganese ores as raw materials through the steps of carrying out acid leaching on the raw materials; simultaneously adjusting the pH value of the obtained product and adding iron powder and an impurity removal reagent into the obtained product; after the impurity removal is completed, adding ferric sulfate and zinc sulfate into the obtained product so as to obtain a solution containing manganese, zinc and iron; sequentially carrying out precipitation and aging on the obtained solution so as to obtain a precursor of a manganese-zinc ferrite; and carrying out sintering on the precursor so as to obtain a finished manganese-zinc ferrite product. According to the invention, through fully using manganese and iron in low-grade manganese ores, the comprehensive utilization of resources is realized, so that the method is low in price of raw materials, simple in process steps and low in production cost, and basically achieves an effect of zero emission in the technological process, therefore, the method completely conforms to the requirements of energy conservation and emission reduction; and a soft magnetic material manganese-zinc ferrite prepared by using the method disclosed by the invention has excellent magnetic properties. The method disclosed by the invention can be widely used for preparing various magnetic materials, and magnetic materials prepared by using the method disclosed by the invention can be widely used as wave-absorbing materials in the electronic industry and military fields.

Owner:CHONGQING UNIV

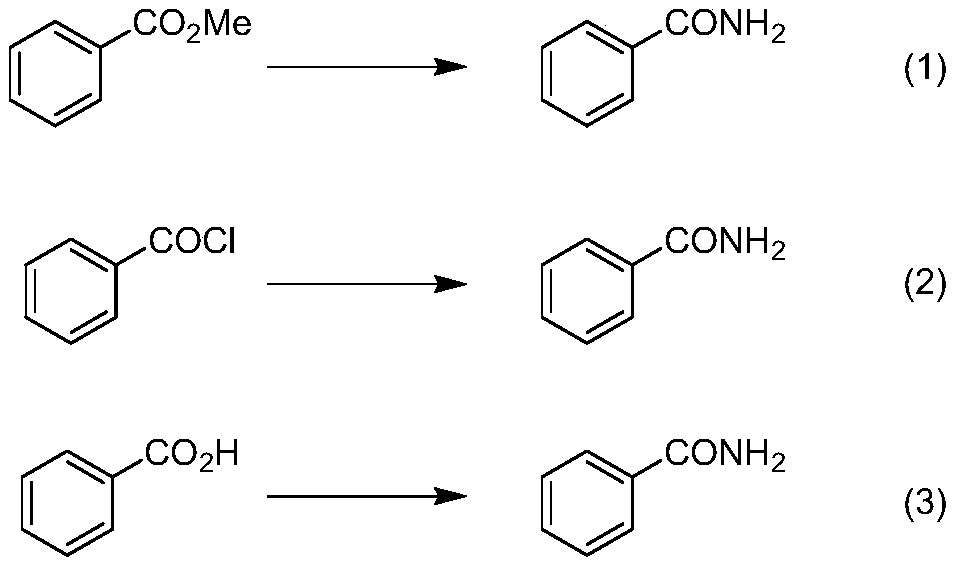

Preparation method of aromatic amide compound

PendingCN111362822ALow costReduce pollutionOrganic compound preparationCarboxylic acid amides preparationCombinatorial chemistryStereochemistry

The present invention provides a preparation method of an aromatic amide compound. In an organic solvent, under the effect of a catalyst, an aromatic acid compound and an amine source are subjected toa dehydration reaction to obtain the aromatic amide compound, wherein the aromatic acid compound is an aromatic acid, a substituted aromatic acid, a heterocyclic aromatic acid or a substituted heterocyclic aromatic acid; and the substituent group of amide is any substituent group of H, a C1-C8 straight-chain alkyl or branched-chain alkyl group, a benzene ring or an aromatic ring. The aromatic amide compound is an important chemical intermediate, and the synthesis method is mild in reaction condition and high in yield.

Owner:中国平煤神马控股集团有限公司 +1

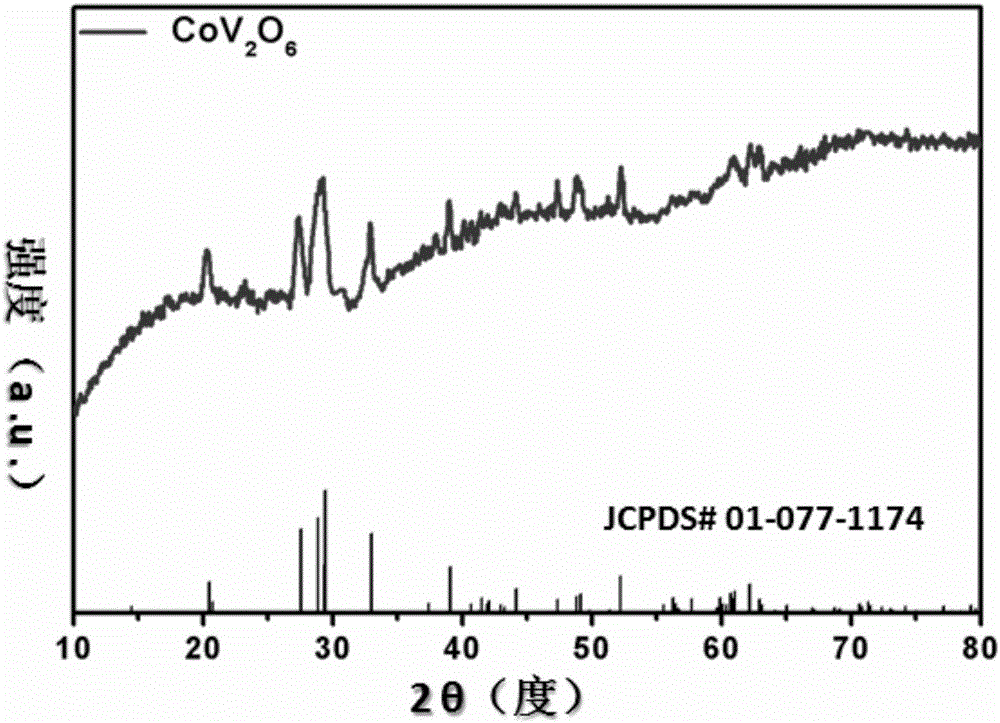

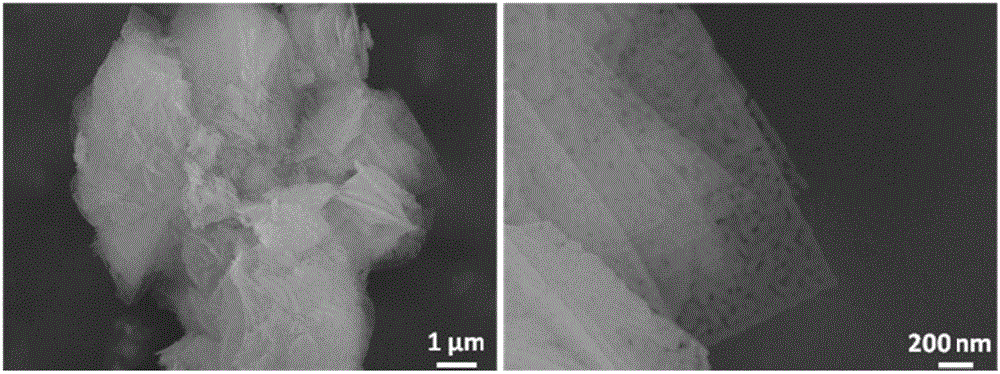

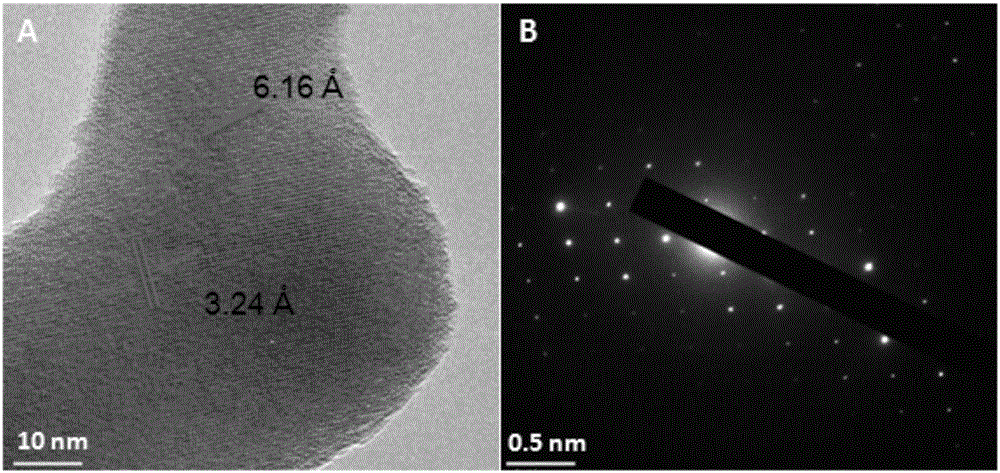

Porous CoV2O6 nanosheet electrode material and preparation method and application thereof

ActiveCN105140509ALarge specific surface areaIncrease contact areaCell electrodesSecondary cellsWater bathsAmmonium metavanadate

The invention relates to a porous CoV2O6 nanosheet electrode material and a preparation method thereof, the nanometer has a uniform morphology, the dimension is 4-10 mu m, the surface has an obvious porous structure, the aperture is 10-50 nm, and the nanometer is prepared by the following steps: 1) adding acetylene black into water, stirring the water, adding cobaltous acetate and stirring together, so that the acetylene black can be completely immersed into the water; 2) adding ammonium metavanadate into deionized water, dissolving with water-bath, adding the obtained solution drop by drop into the solution obtained in the step 1), stirring at normal temperature, and obtaining a precursor; 3) drying the obtained precursor in a water-bath condition, grinding and calcining with air, and obtaining the nanosheet. When the nanometer provided by the invention is used as a lithium ion battery cathode active material, high capacity and good cycle stability are shown; the invention has the advantages of simple technology, good feasibility, easy amplification and green chemistry.

Owner:WUHAN UNIV OF TECH

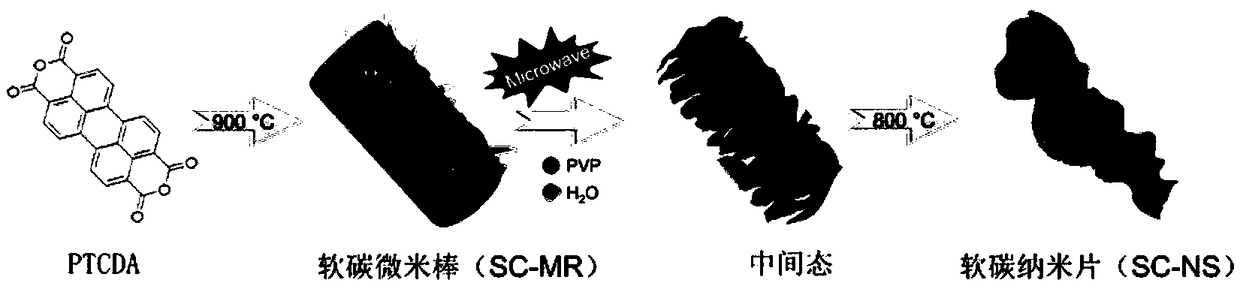

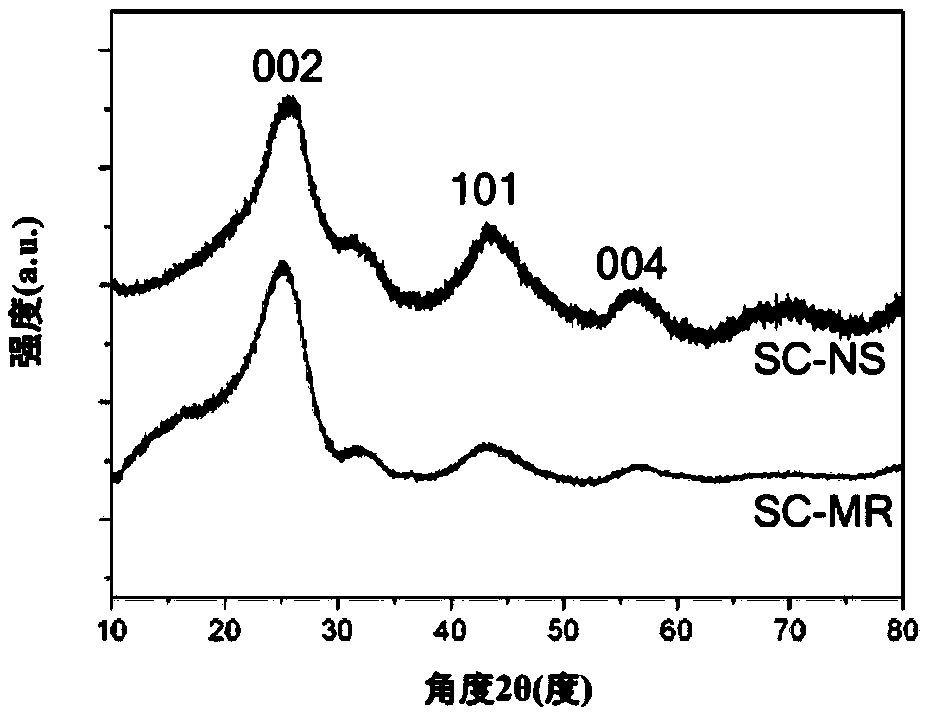

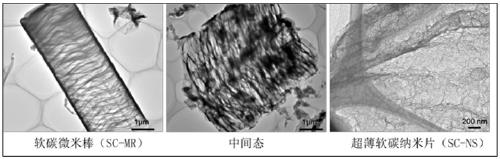

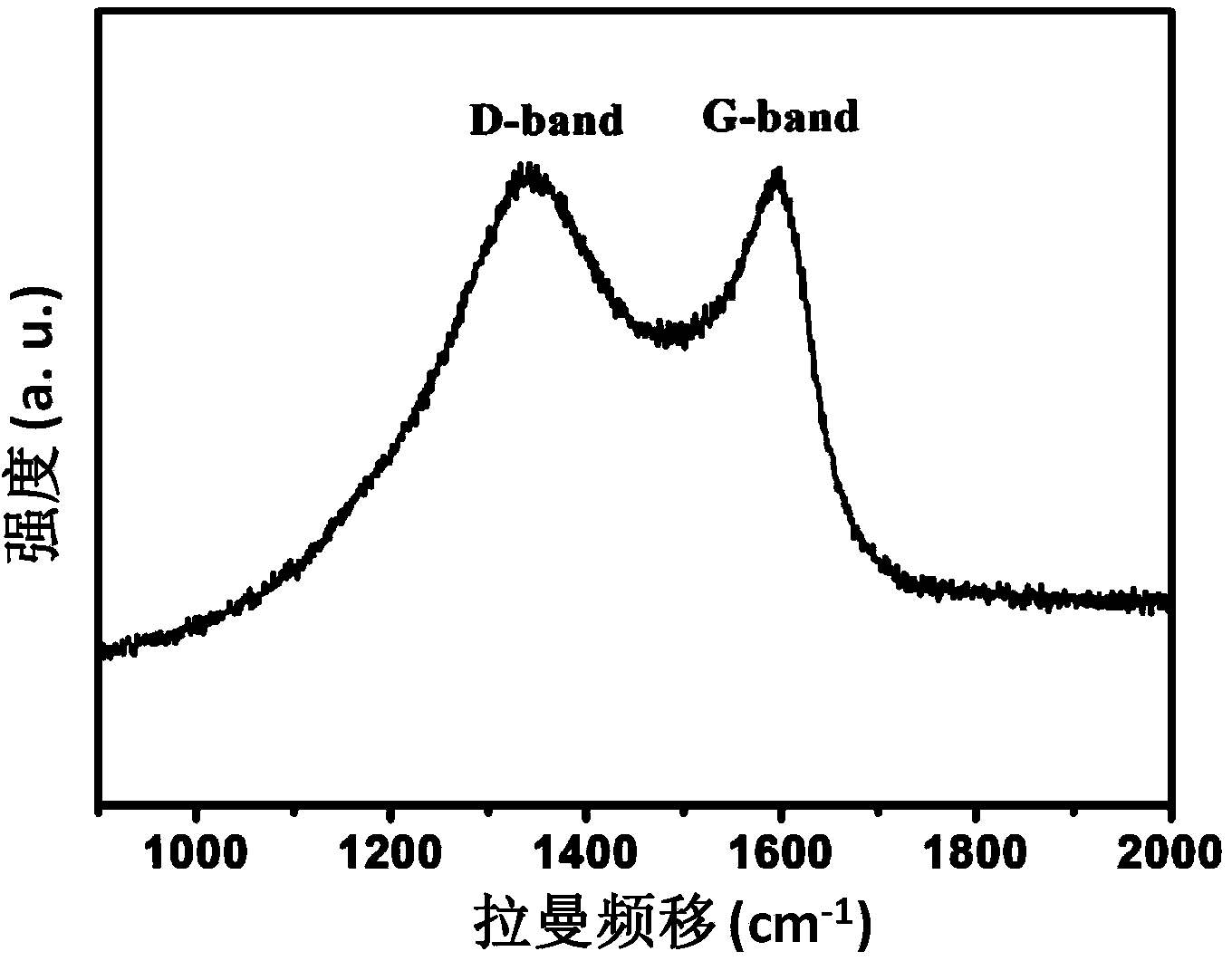

Microporous ultra-thin soft carbon nanosheet, and preparation method and application thereof

ActiveCN109449440ALarge specific surface areaStable structureMaterial nanotechnologyNegative electrodesElectrochemical responseElectrolytic agent

The invention relates to a microporous ultra-thin soft carbon nanosheet electrode material, and a preparation method and an application thereof. The thickness of the microporous ultra-thin soft carbonnanosheet electrode material is 20-30nm, and the morphology is a nanosheet having a uniform size; the microporous ultra-thin soft carbon nanosheet electrode material has a surface with a pleated structure; and the microporous ultra-thin soft carbon nanosheet electrode material has a large number of micropores and defect sites at the edge of a crystal lattice to provide additional ion storage sites. The microporous ultra-thin soft carbon nanosheet electrode material provided by the invention has the beneficial effects that the microporous ultra-thin soft carbon nanosheet electrode material hasa larger specific surface area and a large number of microporous structures than the conventional soft carbon electrode material, thereby and not only enhancing the diffusion performance of ions in amaterial body, but also increasing active interfaces between the material and the electrolyte, enhancing the kinetics of the material in an electrochemical reaction process, improving the capacitivecapacity contribution, exhibiting excellent rate performance and and achieving rapid charge and discharge.

Owner:WUHAN UNIV OF TECH

Preparation method of beta-nickel hydroxide nanosheets

InactiveCN106241896ANo pollution in the processReduce energy consumptionNanotechnologyNickel oxides/hydroxidesNickel saltHydrazine compound

The invention provides a preparation method of beta-nickel hydroxide nanosheets. The preparation method comprises the following steps: (1) cleaning treatment of a copper bar: the copper bar is washed with acetone, ethanol, 2 mol / L dilute hydrochloric acid and distilled water under ultrasonic conditions; (2) preparation of the beta-nickel hydroxide nanosheets: at room temperature, bivalent nickel salt and alkali are respectively dissolved in distilled water and stirred until the bivalent nickel salt and alkali are dissolved; the bivalent nickel salt solution and the alkali solution with the equal volume amount are weighted and poured into a reaction kettle, the cleaned copper rod is put into the reaction kettle, the reaction kettle is sealed, the mixture is allowed to react at 180 DEG C for 8-12 hours, the copper rod growing with a blue-green substance is washed by distilled water and then naturally dried, so as to obtain the nanosheets. The method is high in reproducibility, simple and convenient to operate, low in synthesis cost and suitable for industrial preparation, the surface of the metal copper is uniformly covered with the nanosheets, the nanosheets have a large specific surface area and can be fully contacted with the object to be detected, and the copper bar with the nanosheets can be used as the electrode to detect hydrazine hydrate and hydrogen peroxide in water.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition](https://images-eureka.patsnap.com/patent_img/7c46d7ac-c168-4c43-b645-f55ee7583e0b/BDA0001668876310000021.png)

![Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition](https://images-eureka.patsnap.com/patent_img/7c46d7ac-c168-4c43-b645-f55ee7583e0b/BDA0001668876310000041.png)

![Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition Calix[4]thiourea diaminocyclohexane derivatives and method thereof for catalyzing asymmetric Michael addition](https://images-eureka.patsnap.com/patent_img/7c46d7ac-c168-4c43-b645-f55ee7583e0b/BDA0001668876310000071.png)