Patents

Literature

791results about How to "Three wastes less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

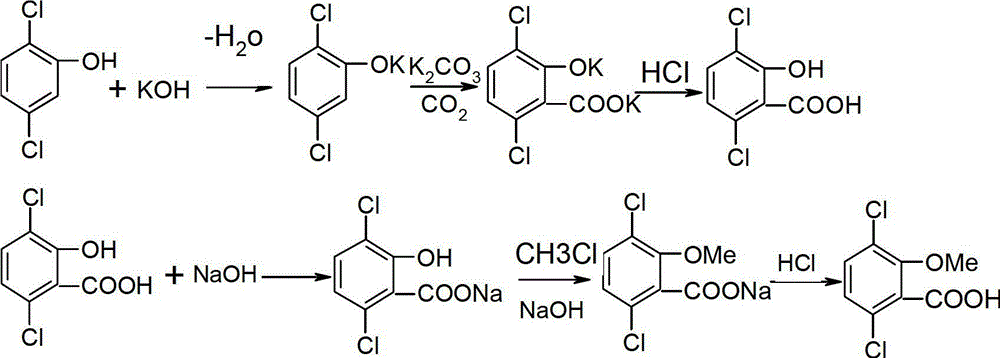

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

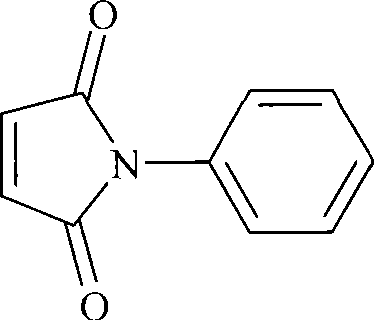

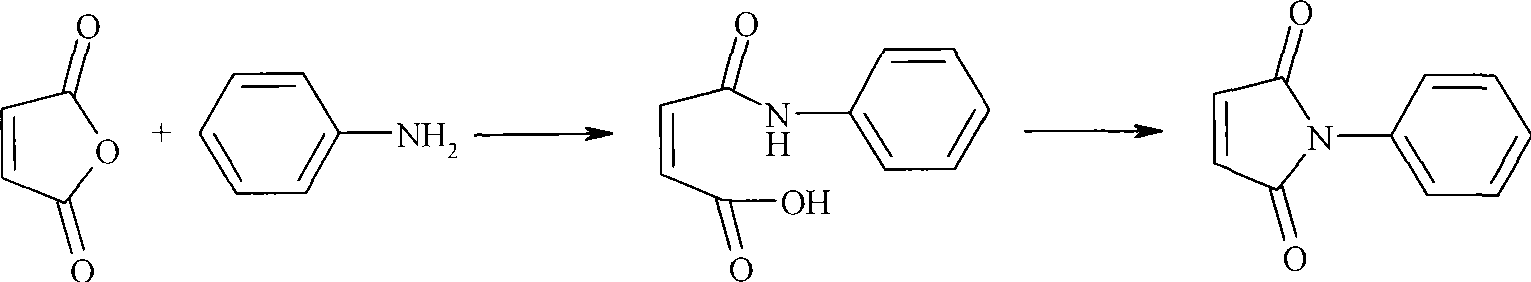

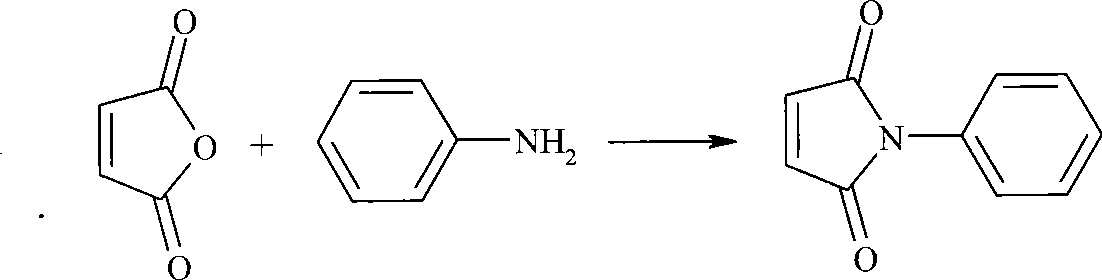

Preparation of N-phenyl maleimide

The invention discloses a method for preparing N-benzyl maleimide which adopts maleic anhydride and aniline as raw materials to take imidation reaction in benzene reaction solvent in the presence of an inhibitor and a mixed dehydration catalyst to obtain the target product of the invention. The purity of the N-benzyl maleimide prepared by the one-step method of the invention reaches more than 98.5 percent, and the yield is 90-92 percent. Compared with the prior art, the method has the advantages of less reaction time, short period and safe and convenient operation. A post-processing method of directly drying out the solvent and recycling the solvent is adopted, so that the yield is improved, three wastes are reduced, the operational environment is improved and the quality of products is stable. The method is applied to the large-scale industrial production.

Owner:SHANGHAI HUAYI GRP CO

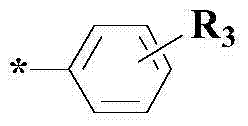

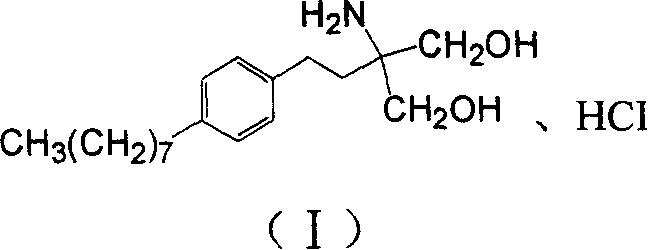

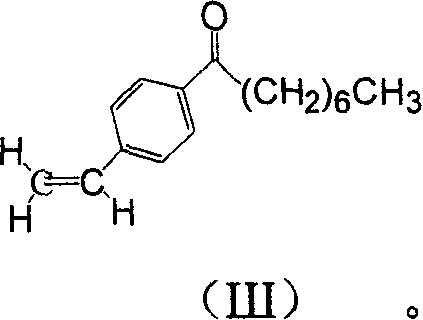

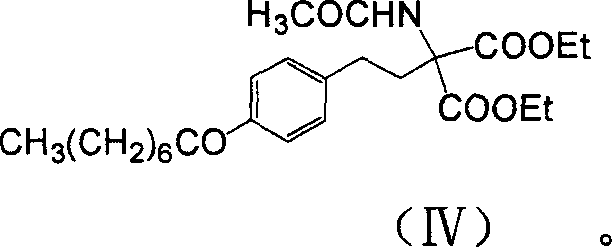

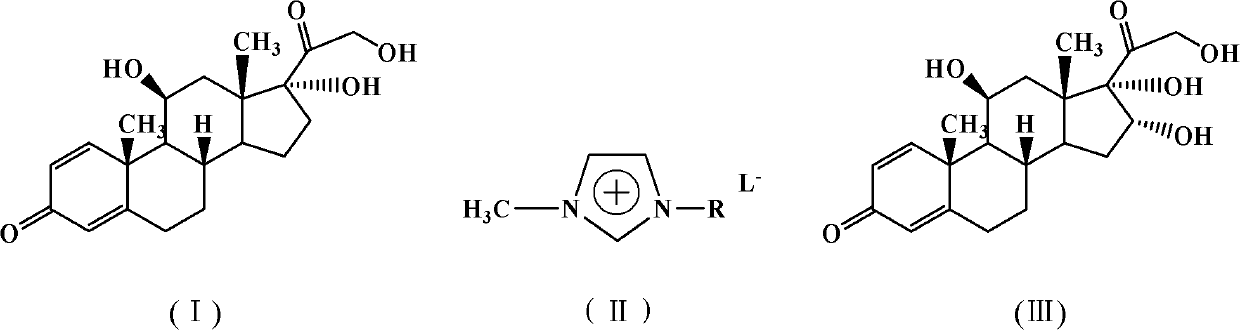

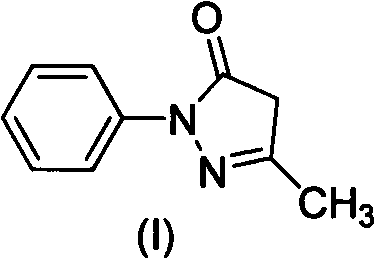

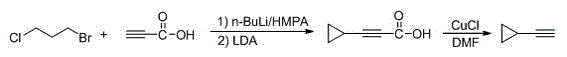

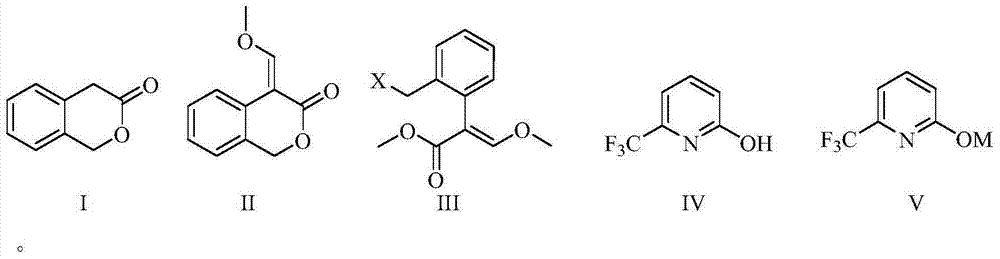

2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method

InactiveCN1765872AAtom utilization is highThree wastes lessOrganic compound preparationAmino compound preparationHydrogen compoundsEthyl phosphate

The invention provides a preparation method for (I) 2- amido -2-[2-(4- alkyl phenyl)ethyl]-1ú¼3- propanediol, which comprises: using alkyl benzene (II) as initial material, with Lewis acid existing, to take Friedel-Crafts acylating reaction with 3- halogenated propionyl chloride and generate beta- halogenated alkylpropiophenone (IV); reducing IV by hydride to obtain 3- nitro -1-(4- alkyl phenyl) propanol (V); preparing 2- nitro -2- methylol -4-(4- alkyl phenyl)-1ú¼4butanediol (VI) by hydroxymethylation; reducing nitro and removing benzalcoholhydroxy to VI and obtaining the objective product.

Owner:江苏吴中苏药医药开发有限责任公司 +1

Preparation method of synthesizing bivalirudin from solid phase polypeptide

ActiveCN101033249AConvenient sourceReduce usagePeptide-nucleic acidsPeptide preparation methodsSide chainWang resin

This invention discloses a preparation method of solid-phase peptide synthesizing bivalirudin. It includes the following steps: taking any one of triphenyl methyl chloride resin, 4-methyl-triphenyl methyl chloride resin, 4-methoxy-triphenyl methyl chloride resin, 2-chlorine-triphenyl methyl chloride resin, or Wang resin as the starting raw materials, connecting amino acids in turn according to the method of solid-phase synthesis, to get a protective 28-peptide resin, removing Fmoc-protective group in turn, side-chain protecting group and cutting the peptide to get a crude, then purifying the crude through C18 (or C8) high-pressure column to get bivalirudin exquisite article. In this invention, the peptide yield of every step is more than 99%, and the total yield is 14%.

Owner:SHANGHAI SOHO YIMING PHARMA

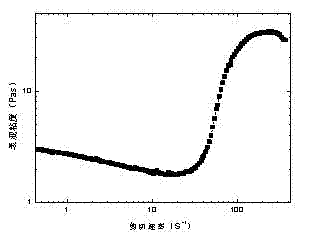

Preparation method and use of shear thickening fluid

The invention relates to the technical field of organic silicon polymer application and provides a preparation method of a shear thickening fluid. The preparation method realizes compatible matching of micro / nano-particles and a dispersion medium and improves system shear thickening effects and system storage stability. The shear thickening fluid is prepared by mixing micro / nano-particles and an organic silicon polymer, wherein a mass ratio of the micro / nano-particles to the organic silicon polymer is (1-3): (2-4). The preparation method is simple and has short preparation time. The shear thickening fluid obtained by the preparation method has stable quality, can be mass-produced easily, has low energy consumption, produces less three wastes and has a low cost. The invention also provides a use of the shear thickening fluid in a liquid protection composite material. The liquid protection composite material prepared from the shear thickening fluid has no toxicity and no pollution and is suitable for a human body and industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for synthesizing triptorelin from solid phase polypeptide

ActiveCN101357936AConvenient sourceReduce usagePeptide preparation methodsBulk chemical productionSide chainFreeze-drying

The invention discloses a preparation method of solid phase peptide synthesis triptorelin, which includes the following steps: with Rink Amide AM resins or Rink Amide MBHA resins as starting materials, amino acids with protective groups are sequentially connected according to solid phase synthesis, so as to obtain protective decapeptide resins, and meanwhile crude products are obtained by sequentially removing Fmoc-protective groups and synchronously removing side-chain protective groups and cutting peptides, and triptorelin elaborate products are prepared after the crude products are separated and purified by C18 (or C8 ) column and freeze-dried. The preparation method is stable in technology, convenient in raw and auxiliary material sources, short in production cycle, high in yield, stable in quality, low in production cost and high in transpeptidase yield. Besides, as the preparation method avoids using poisonous reagents, such as hydrogen fluoride, and the like, the pollution of three wastes is low, purification yield is over 25 percent and each step of transpeptidase yield is above 98 percent; the yield after cutting peptides is 78.8 percent and the total yield is 25.4 percent.

Owner:SHANGHAI SOHO YIMING PHARMA

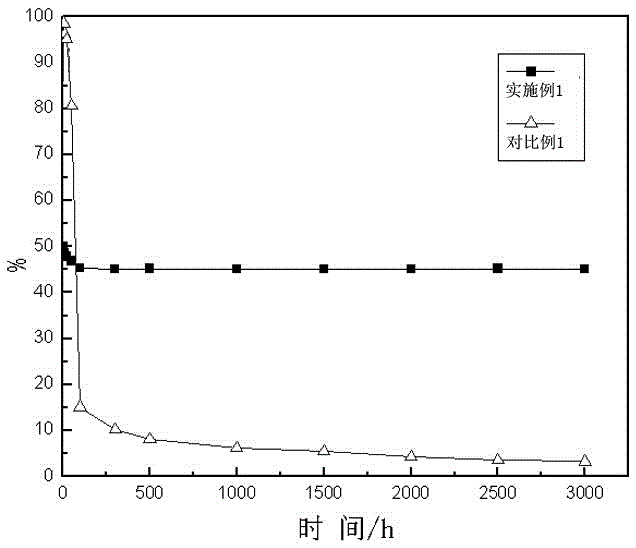

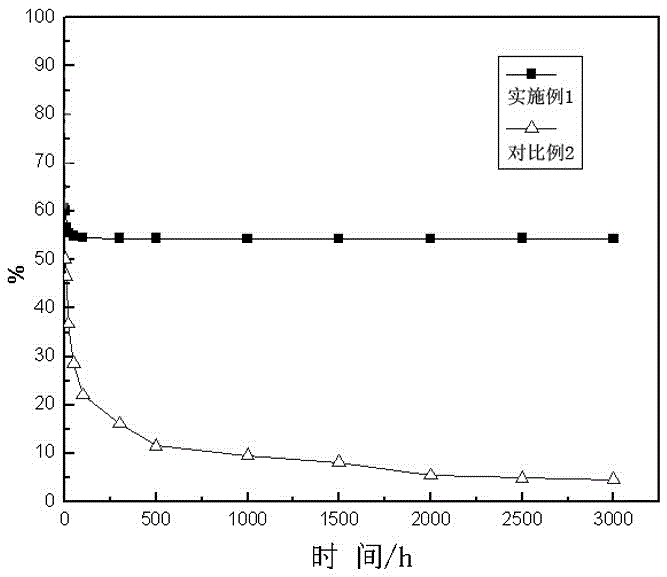

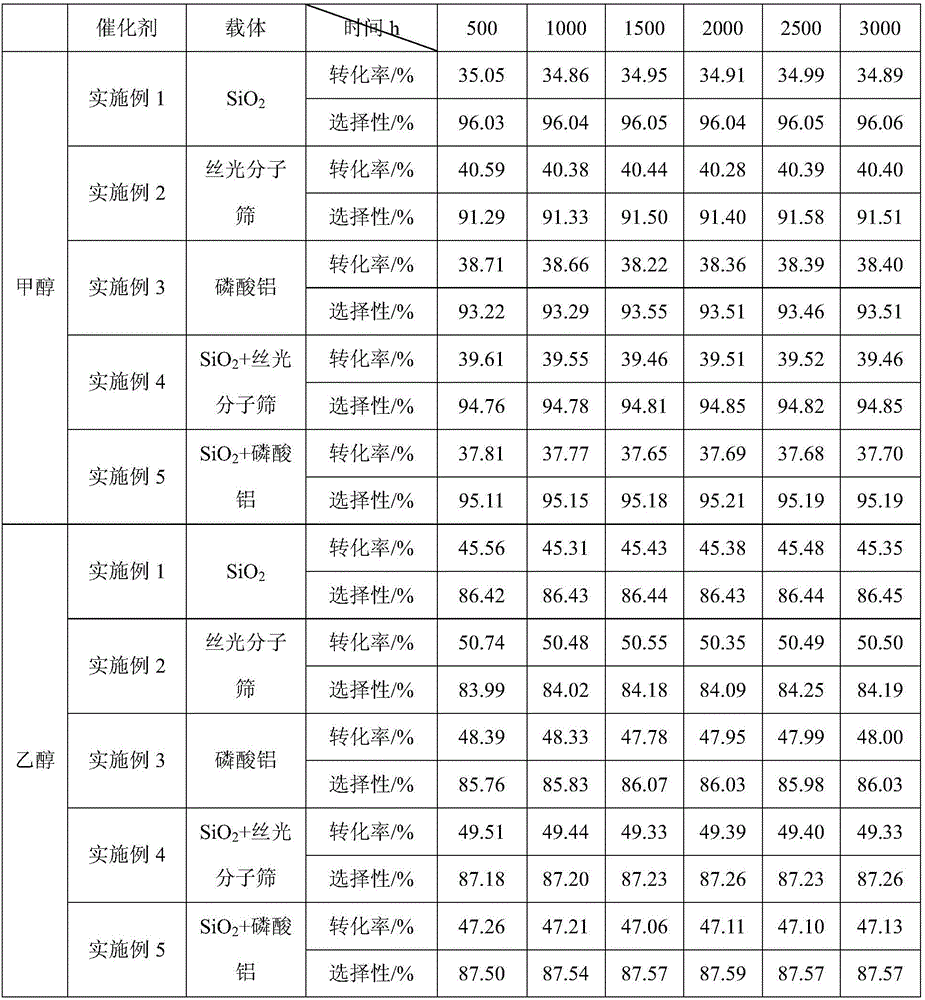

Catalyst special for O-alkylation production of aromatic ether and method for producing aromatic ether

ActiveCN106215959AExtended service lifeImprove stabilityMolecular sieve catalystsEther preparation by compound dehydrationReaction temperaturePhosphoric acid

The invention provides a catalyst special for O-alkylation production of aromatic ether and a method for producing aromatic ether. The catalyst is a supported catalyst, wherein transition metal or precious metal serves as an active component, a mixture of any one of ammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium phosphate and phosphoric acid and any one of potassium hydroxide, potassium carbonate, sodium hydroxide and sodium carbonate serves as an auxiliary, one or a mixture of an oxide carrier, clay and a molecular sieve serves as a carrier, the weight carrying amount of the active component is 0.1-5%, and the weight carrying amount of the auxiliary is 0.1-1%. The method comprises the steps that phenol and alkyl alcohol are catalyzed to react through the catalyst, wherein the mole ratio of phenol to alkyl alcohol in the raw materials is 1:(3-10), the catalyzing reaction is carried out in a gas-solid phase continuous flowing reaction device, and the catalyzing reaction temperature is 230-300 DEG C. The one-way service life of the catalyst reaches 3000 h or longer, and the problems that a catalyst used in the existing aromatic ether production process is short in service life, and consequently continuous industrial production of aromatic ether cannot be achieved are solved.

Owner:张旻捷

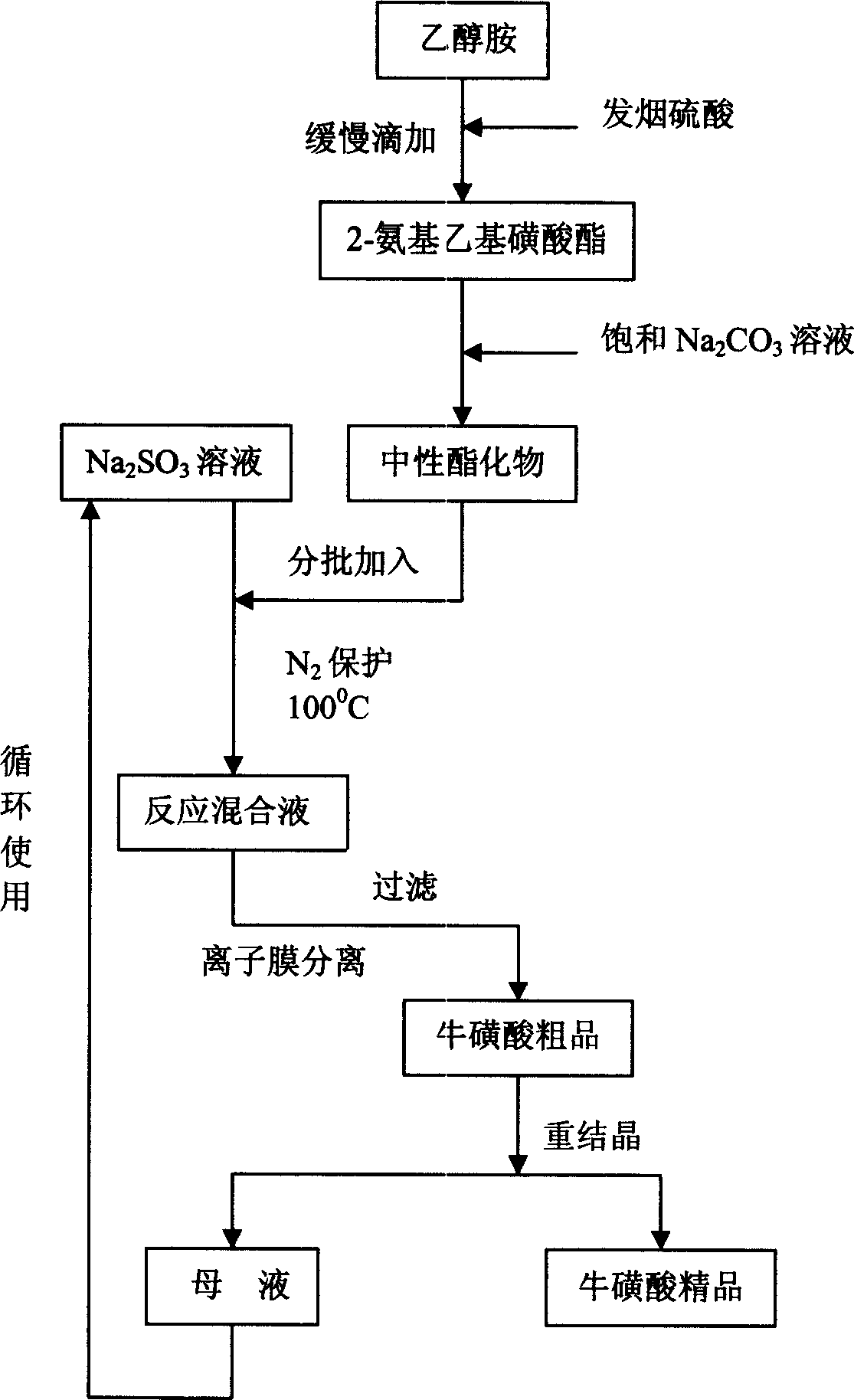

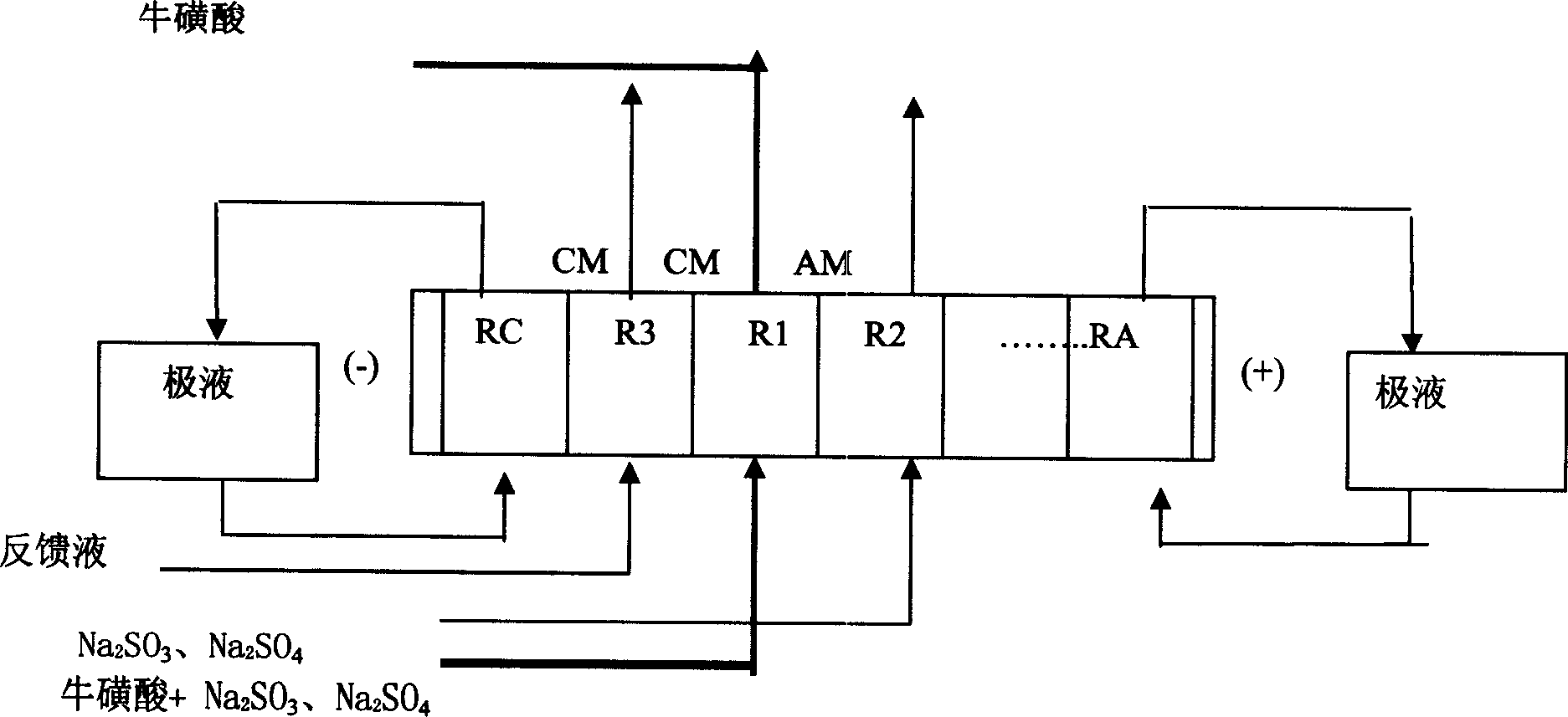

Technique of ion membrane process for preparing taurine

InactiveCN1626511ACaused byExtended service lifeOrganic compound preparationSulfonic acid preparationTaurine synthesisInorganic salts

A process for preparing taurine includes preparing the mixture containing taurine from ethanolamine by cyclc method, separating out inorganic salt by feedback type elecric dialysis with ion membrane, crystallizing taurine in solution, and using the residual mother liquid for next reduction reaction. Its advantages are high output rate and high current efficiency.

Owner:ZHEJIANG UNIV

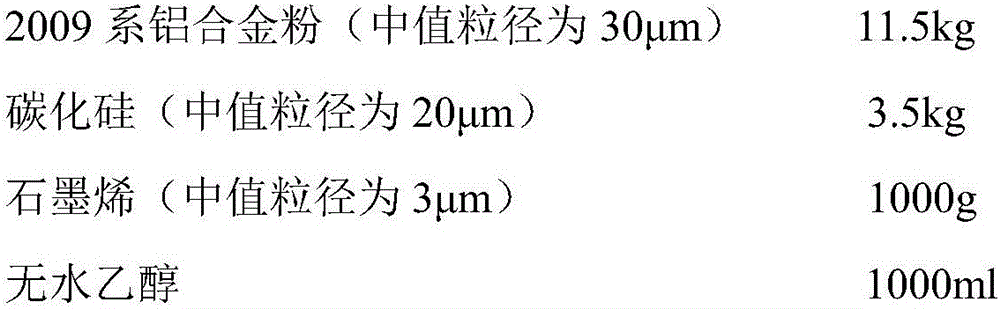

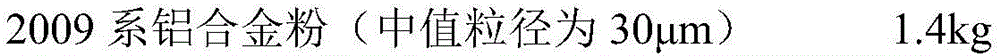

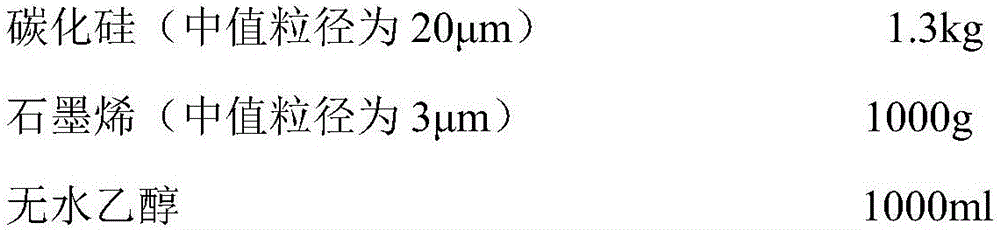

Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

ActiveCN106591666AImprove reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal diffusivityElectronic packaging

The invention relates to a graphene enhanced aluminium-based silicon carbide composite and a preparation method thereof. The composite comprises the following substances by volume percent: 40% to 70% of silicon carbide and 0.5% to 5% of graphene, and the balance being aluminium alloy. The composite is prepared through the powder metallurgy method and is obtained through the steps of blending, powder mixing, bagging, vacuum degassing and hot iso-hydrostatic forming treatment. The composite has the advantages of high thermal conductivity, high strength, high plasticity, light weight, good thermal diffusivity, isotropy, and the like, and becomes a second-generation electronic packaging material with wide application.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

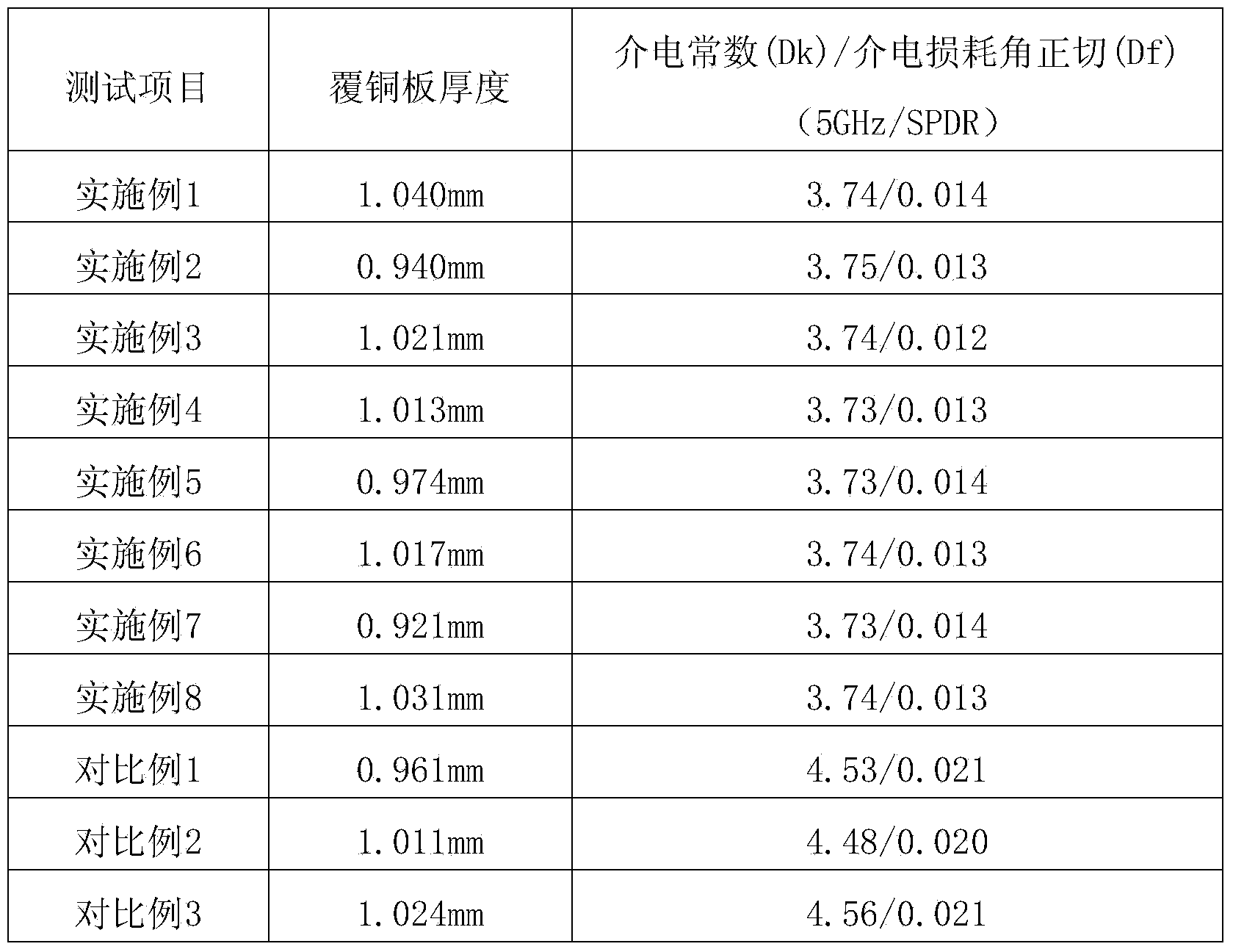

Preparation method of polyphenyl ether adhesive and copper-clad plate thereof

ActiveCN104263306AImprove solubilityImprove liquidityNon-macromolecular adhesive additivesSynthetic resin layered productsGlass fiberEpoxy

The invention discloses a polyphenyl ether adhesive. The adhesive is characterized by being prepared by mixing the following raw materials in parts by mass: 100 parts of a resin composition, 0-15 parts of a flame retardant, 20-30 parts of a powder material, 0.1-2 parts of a curing accelerator and 50-100 parts of a solvent, wherein the resin composition is prepared by mixing the following raw materials in parts by mass: 20-65 parts of modified low-molecular weight polyphenyl ether resin, 15-40 parts of epoxy resin, 20-40 parts of benzoxazine resin and 3-9 parts of bismaleimide resin. The adhesive is prepared by the following steps: preparing the modified low-molecular weight polyphenyl ether resin, preparing the resin composition, preparing the polyphenyl ether adhesive and the like. The copper-clad plate is prepared by the steps of preparing a polyphenyl ether glass fiber cloth prepreg from the polyphenyl ether adhesive by application of a gluing machine, and preparing the copper-clad plate by a vacuum press. The copper-clad plate prepared by the method has excellent dielectric property.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

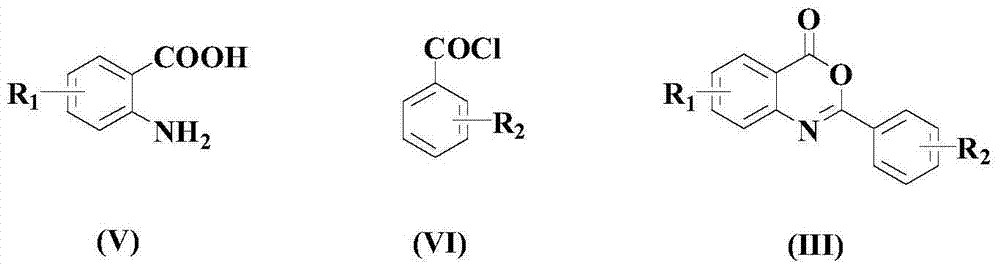

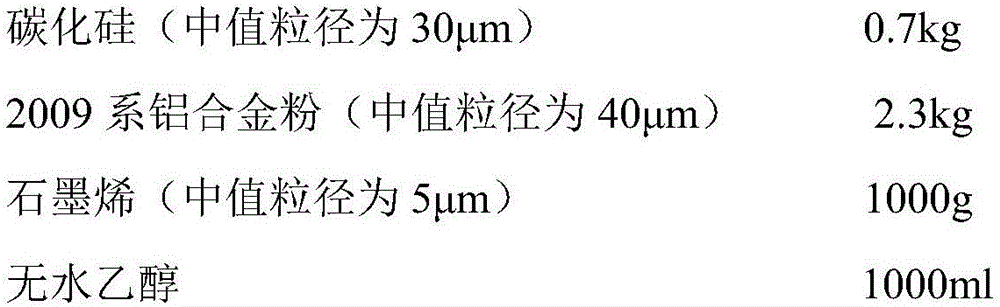

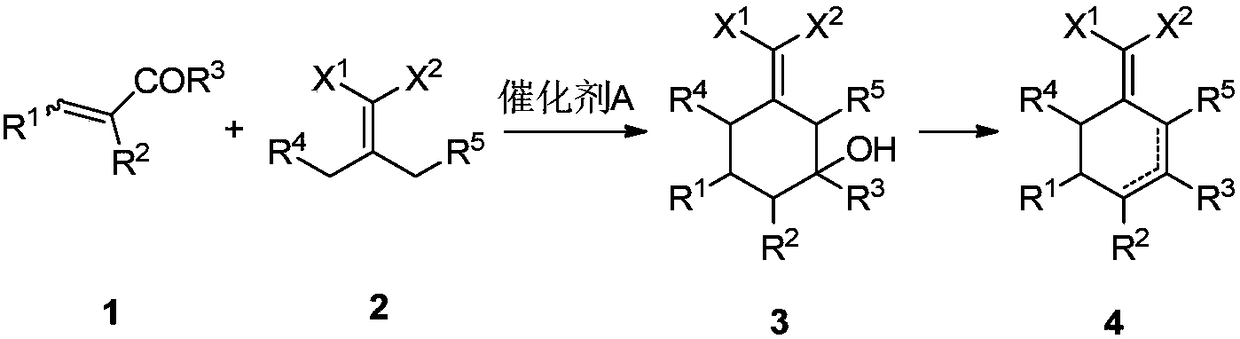

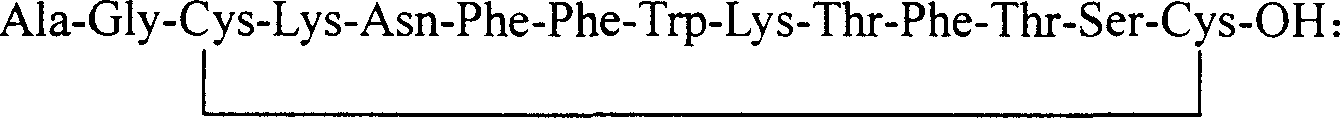

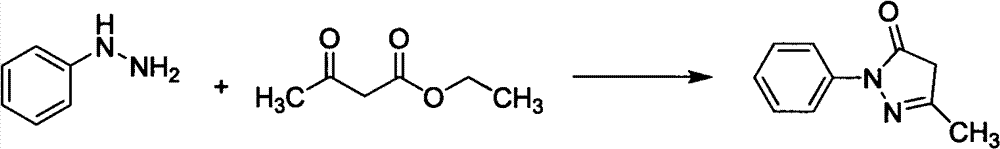

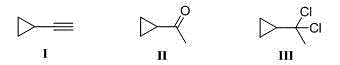

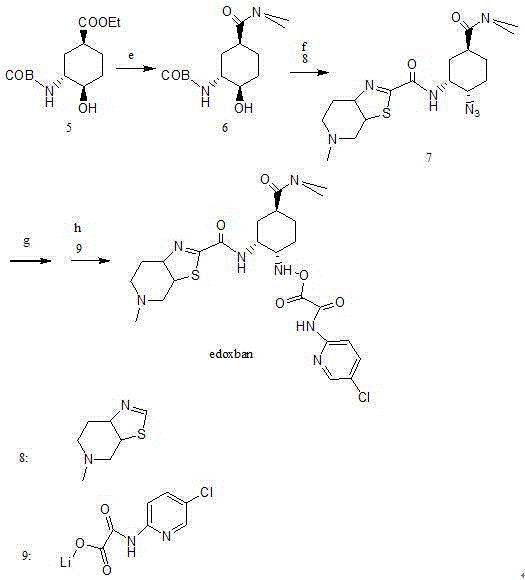

Process for producing 2,2-bis[3-amido-4-(4-aminophenoxy)phenyl] hexafluoropropane

InactiveCN101245028AThree wastes lessShort timeOrganic compound preparationAmino-hyroxy compound preparationPhenyl groupMother liquor

The invention relates to a preparation method of 2,2-double(3-amino-4-(4-amino phenoxy)phenyl)hexafluoropropane, comprising the steps as following, after being put into a solvent system of the solution of palladium or carbon hydrazine hydrate and saturated fatty alcohol for reaction for 1 to 5 hours with the temperature of 70 to 85 DEG C, the 2,2-double(3-amino-4-(4-nitro phenoxy)phenyl)hexafluoropropane is filtered when being hot, mother liquor is cooled off, pure water is dripped in, crystal products are precipitated, filtered, and dried in vacuum, and crystals of the 2,2-double(3-amino-4-(4-amino phenoxy)phenyl)hexafluoropropane are gained. The preparation method has the simple operation, needs no subsequent refining and purifying technique, takes little time, has the products with the high yield and the purity of more than 99 percent, and is suitable for industrial production.

Owner:DONGHUA UNIV

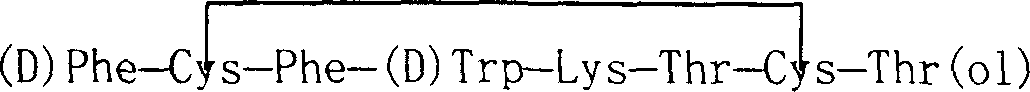

Preparation method of synthesizing octriotide from solid phase polypeptide

ActiveCN1923849AConvenient sourceReduce usagePeptidesBulk chemical productionHydrogen fluorideSide chain

The invention discloses an aoqu-peptide preparing method of solid-phase polypeptide, which comprises the following steps: adopting 2-chloride-trityl resin, 4-methyl trityl resin or 4-methoxyl trityl resin as raw material; connecting amino acid with protective group according to solid-phase synthetic method; obtaining protected octapeptide resin; removing Fmoc-protective group sequently; stripping side-chain protective group; cutting peptide to obtain reduced aoqu-peptide; oxidizing through air under pH 7-11 condition; separating and purifying rought product through C18 (C8) column to produce exquisite.

Owner:SHANGHAI SOHO YIMING PHARMA

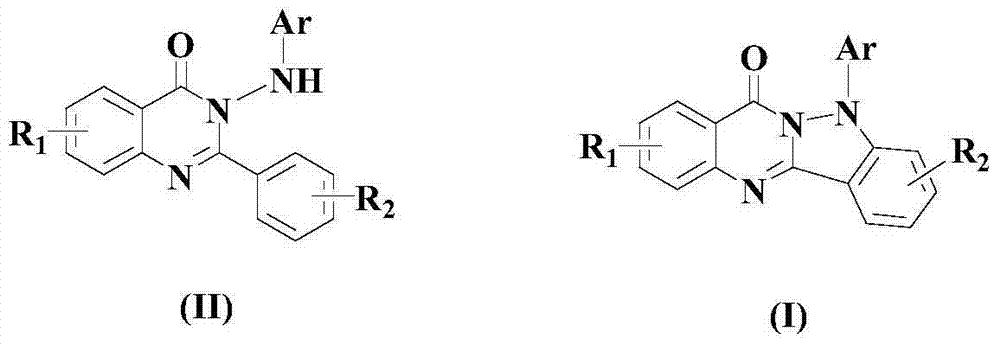

Method for synthesizing quinazolino indazole derivatives

The invention relates to a method for synthesizing quinazolino indazole derivatives. The method comprises the following steps: using a palladium compound as a catalyst, and producing an intramolecular dehydrogenation coupling reaction of 2-aryl-3-aryl amino quinazolinone derivatives in an oxygen atmosphere in the presence of alkali and a molecular sieve so as to obtain the quinazolino indazole derivatives with diversified structures. The method overcomes the defect that a halogenated compound has to be used as a reaction substrate in the prior art under the synergistic effect of the catalyst, alkali and the molecular sieve, achieves a reaction for efficiently synthesizing the quinazolino indazole derivatives by a one-pot method, has the advantages of high efficiency, environmental friendliness, high yield and purity and the like, expands the application range of the transition metal catalytic dehydrogenation coupling reaction, enriches synthetic methods and paths of the quinazolino indazole derivatives, and has very high theoretical research and application values.

Owner:WENZHOU UNIVERSITY

Method for preparing 2-P-octyl-phenenl-2-amino-propanediol hydrochloride

InactiveCN1814583AEasy to manufactureEfficient manufacturingOrganic compound preparationAmino-hyroxy compound preparationSilanesPropanediol

The invention offers 2-amphi capryl phenethyl-2-amino group propylene glycol hydrochloride preparation method. It includes the following steps: doing Friedel-Crafts reaction for styrene and capryl chloride to produce amphi capryl styrene; doing Michael addition reaction with kharophen diethyl malonate under alkali action to produce 2-amphi capryl phenethyl-2-kharophen diethyl malonate; reacting with triethyl silane to produce 2-amphi capryl phenethyl-2-kharophen diethyl malonate; reducing and hydrolyzing to produce 2-amphi capryl phenethyl-2-amino group propylene glycol; acidifying with hydrochloric acid to produce salt. It has the advantages of simple line, low cost, short period, little pollution, and high yield. It also offers the intermediate compound preparation method.

Owner:NANJING YOKO PHARMA GRP CO LTD

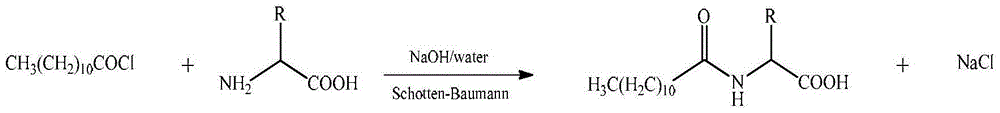

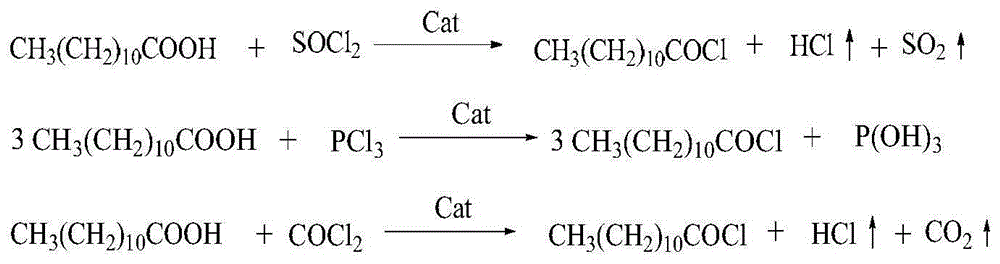

Method for synthesizing laurel acyl amino acid sodium

ActiveCN105152957AHigh catalytic activityReduce solubilityOrganic compound preparationCarboxylic acid amides preparationAmino acid synthesisFatty amine

The invention discloses a method for synthesizing laurel acyl amino acid sodium. The method comprises the steps that lauric acid and phosgene react by being catalyzed by organic aryl amide, and lauroyl chloride is prepared; lauroyl chloride and amino acid react in an alkaline solution, and lauroyl amino acid salt is prepared; extraction separation is carried out, a catalyst is recycled from an organic phase, a water phase is sequentially subjected to acidification, filter separation, sodium hydroxide neutralizing and cooling crystallization, and laurel acyl amino acid sodium is obtained. According to the method, organic aryl amide is mainly adopted as the catalyst for the reaction of lauric acid and phosgene, the lauric acid acylation reaction is thorough, no residue exists, acyl chloride products do not need layering, distilling and other purifying processes can be directly used for synthesizing laurel acyl amino acid sodium, and especially the catalyst can be recycled and cyclically utilized through a simple method. Compared with use of existing DMF and other fatty amine catalysts, the process steps are greatly simplified, the yield and quality of the product are improved, production cost is reduced, environmental protection is facilitated, and the requirements of industrial production are met.

Owner:CHANGSHA PUJI BIOTECH

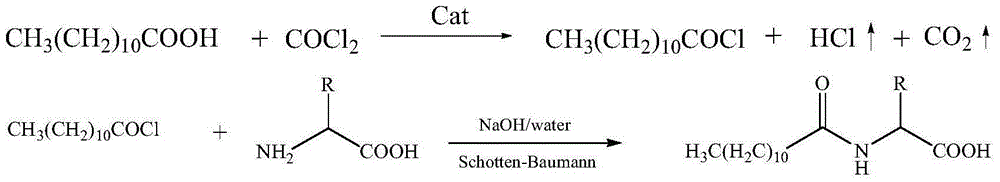

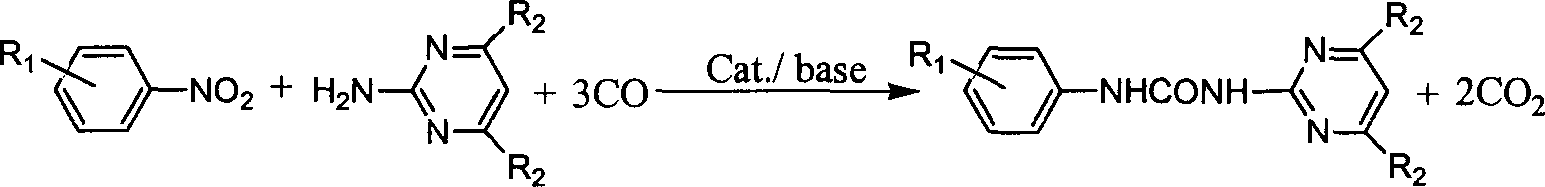

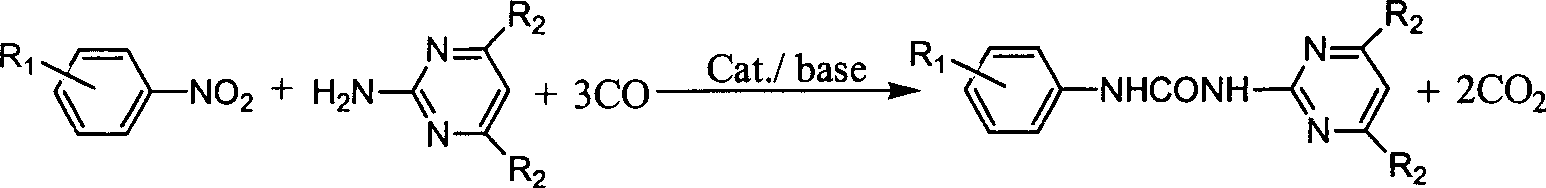

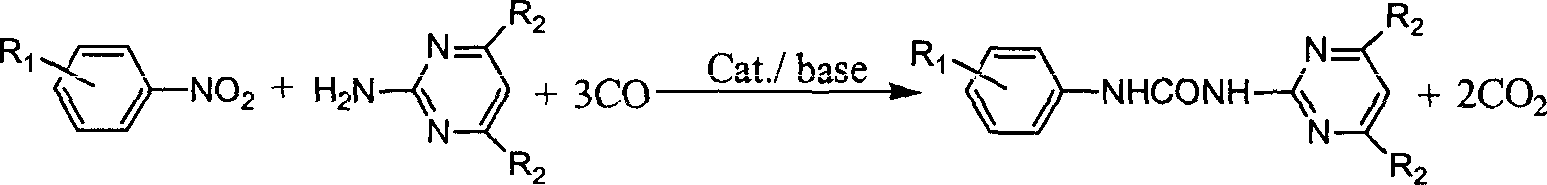

N-phenyl-N'-pyrimidinyl-substituted urea derivative synthesizing method

The method for synthesizing N-phenyl-N'-pyrimidyl substituted urea derivative is characterized by that in the presence of CO it uses substituted aminopyrimidine derivative and substituted nitrobenzene compound as raw material, uses selenium dioxide as catalyst, and uses organic alkali of triethylamine as catalyst promotor and makes them implement reaction in organic solvent in a slosed high-pressure still. The substituent R1 on the nitrobenzene can be one or several kinds of electron-donating and / or electron-attacting groups or be hydrogen atoms, and the substitutent R2 on the aminopyrimidine derivative can be one or several kinds of inert groups or hydrogen atoms. The mole dose of selenium dioxide is 0.1-20% of substrate, its reaction time is 2-20 hr., reaction temp. is 50-200 deg.C, and CD reaction pressure is 1-10.0 MPa (gauge pressure).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

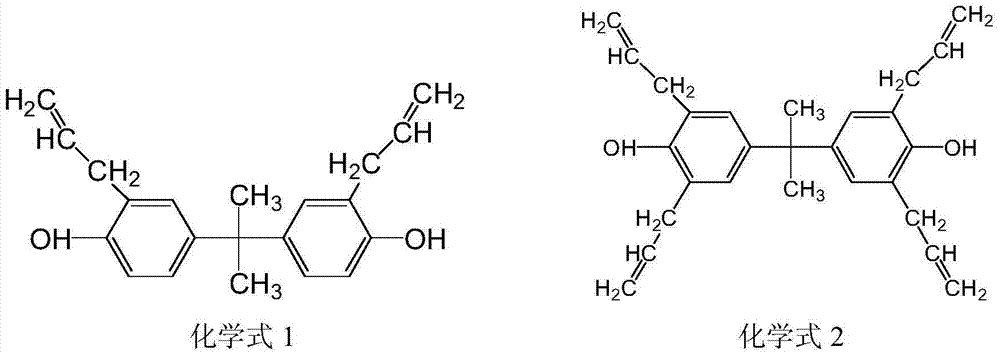

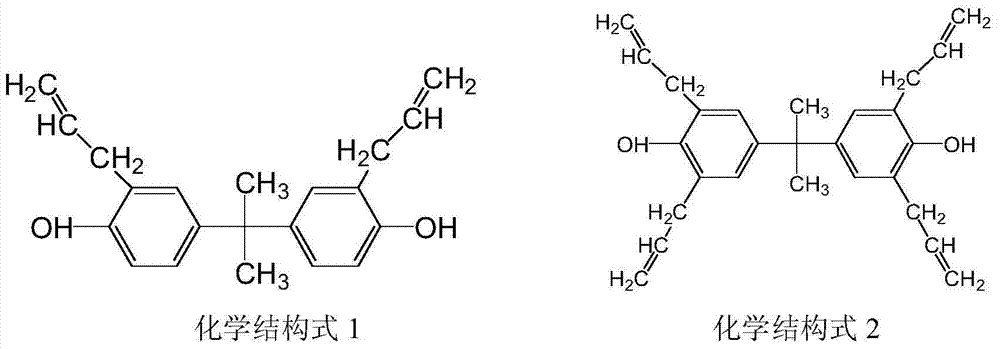

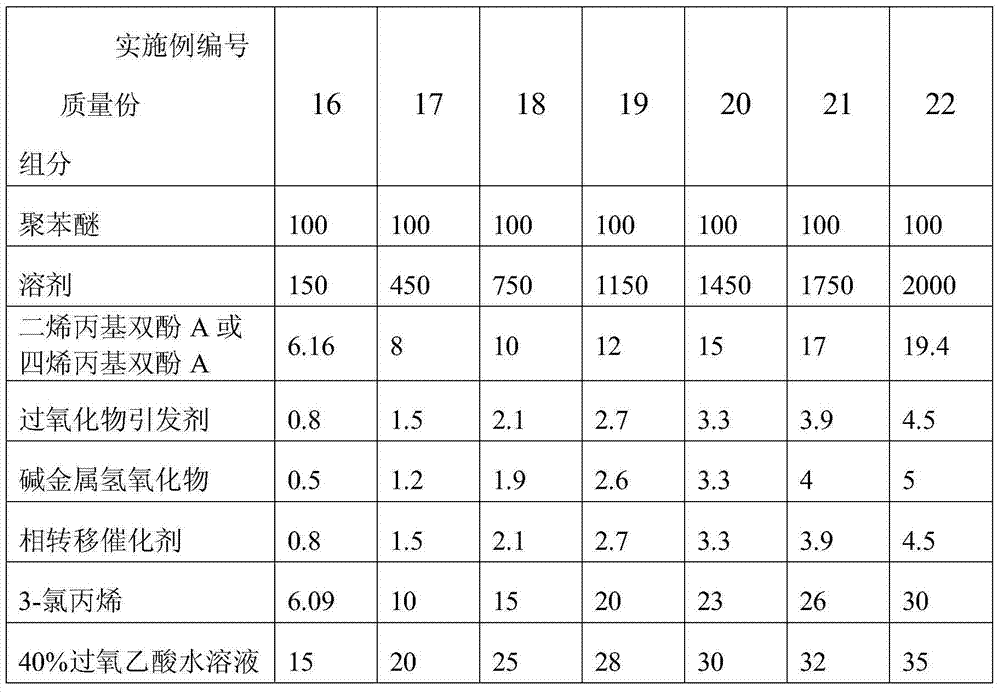

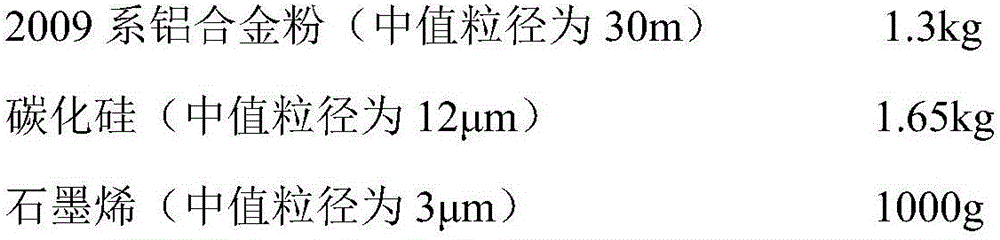

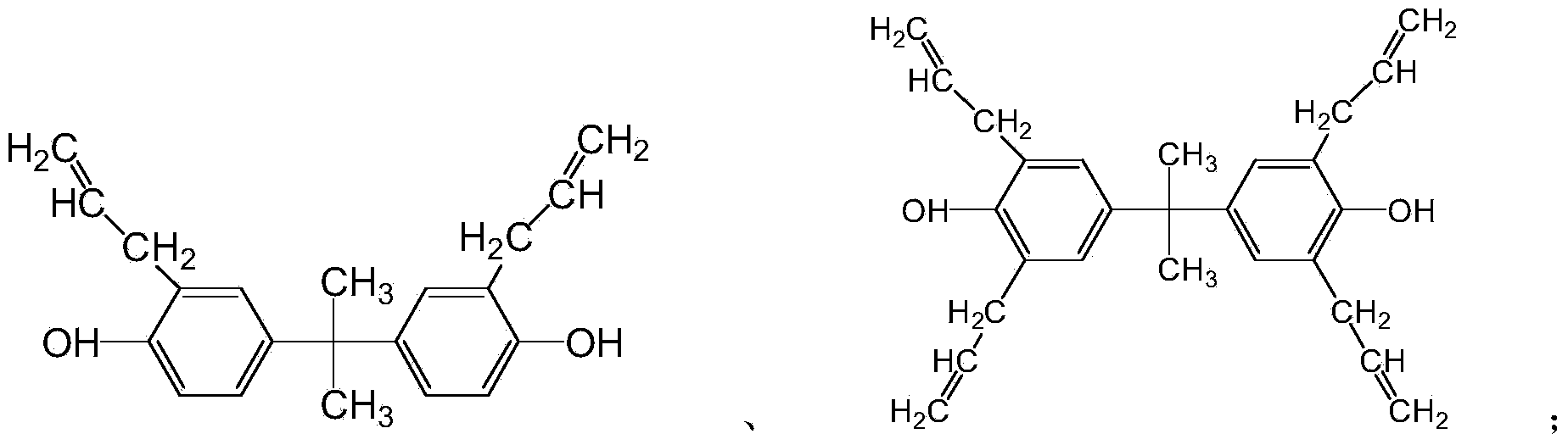

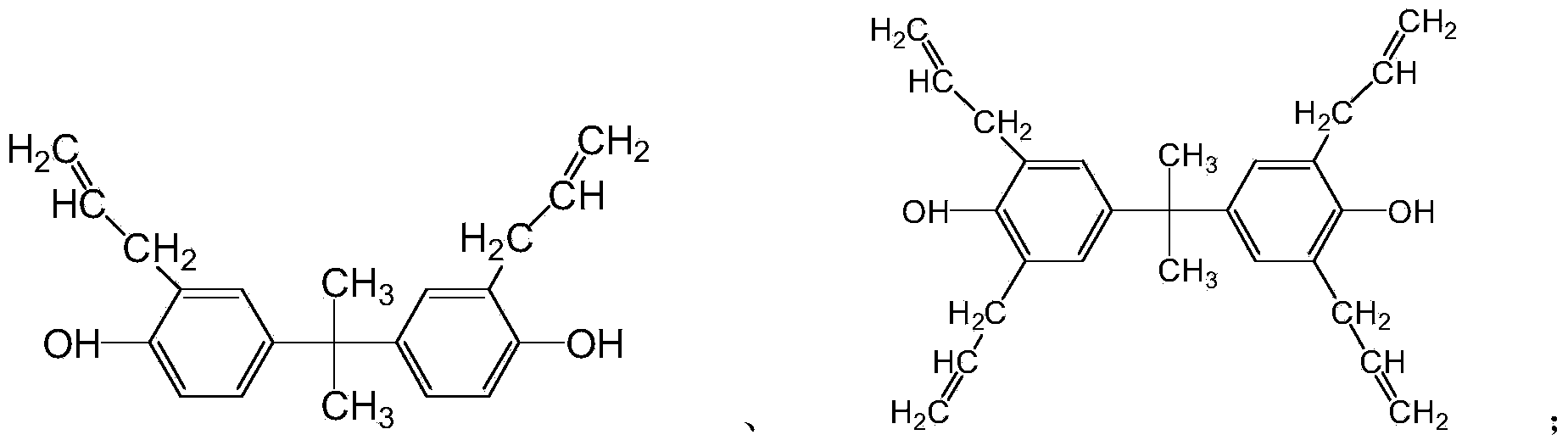

Polyfunctional group polyphenylene ether resin and preparation method thereof

The invention discloses polyfunctional group polyphenylene ether resin and a preparation method thereof. The method is characterized by comprising the following steps: in a reactor, adding polyphenyl ether, a solvent and diallyl bisphenol A or tetraallyl bisphenol A, and adding a peroxide initiator for reaction for 1-10h at 30-90 DEG C; adding alkali metal hydroxides and a phase transfer catalyst, and dropwise adding 3-allyl chloride for reaction for 6-24h at 30-50 DEG C; distilling a reaction solution, recovering fraction below 50 DEG C, and then adding 40% peracetic acid for reaction for 5-15h at 20-60 DEG C; extracting the reaction solution with deionized water for three times, distilling off most of the solvent from the extraction liquid, then dropwise adding the residual solution in methanol for precipitation and filtration, and finally washing solids with methanol and drying to obtain the polyfunctional group polyphenylene ether resin. The polyphenylene ether resin and other resins can form a composition with multiple uses, and the polyphenylene ether resin can be used for manufacturing films or copper coated substrates of printed circuit boards and other fiber cloth laminated boards.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

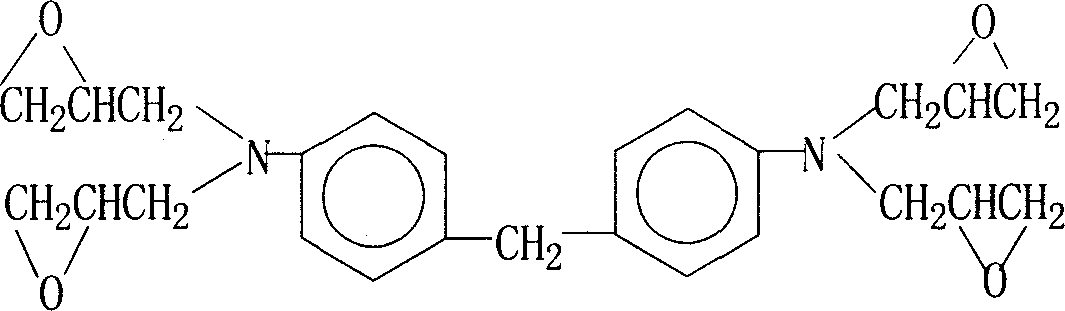

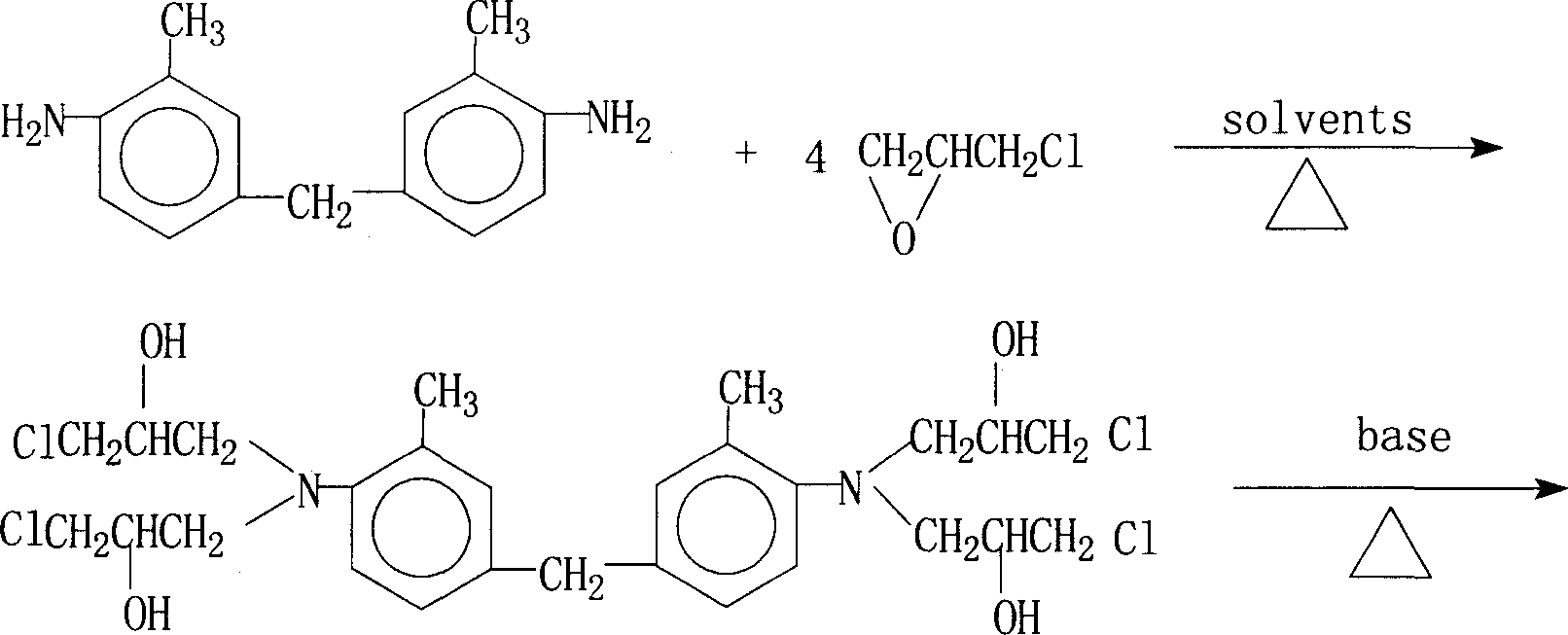

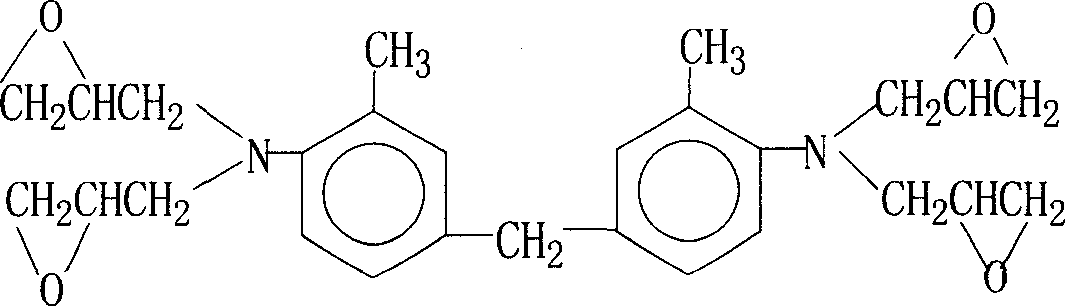

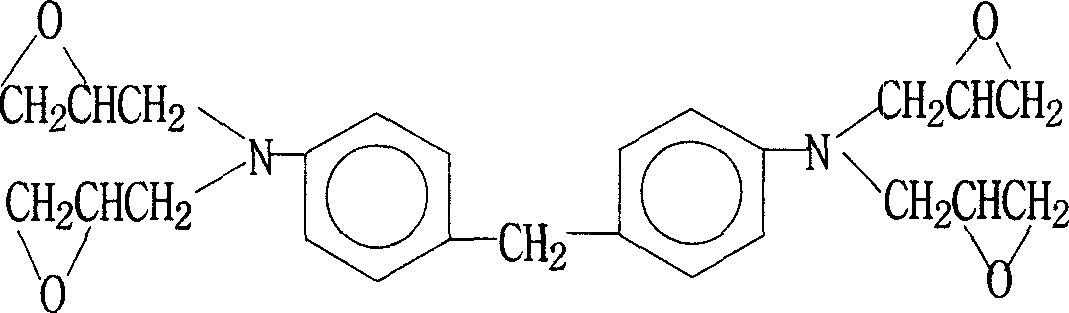

Process for preparing glycidic amine type polyfunctional epoxy resin

InactiveCN1900135AEasy to recycleConvenient sourceOrganic chemistryChemical recyclingMethylanilineEpoxy

The process of preparing glycidic amine type polyfunctional epoxy resin includes the following steps: 1. reaction between 4, 4'-methylene di-o-methylaniline and chloroepoxy propane in the molar ratio of 1 to 4-20 in water-alcohol solvent at 40-90 deg.c for 3-10 hr; and 2. dropping water solution of alkali metal hydroxide in the concentration of 20 % at 60 deg.c to produce desalting ring-closing reaction at 60-80 deg.c, extracting with extractant, water washing, separating, and vacuum volatizing to obtain N, N, N', N'-tetraglycidyl-4, 4'-methylene di-o-methylaniline. The present invention is one industrial process with simple operation, low cost, high product quality, high yield and less three wastes.

Owner:DONGHUA UNIV +1

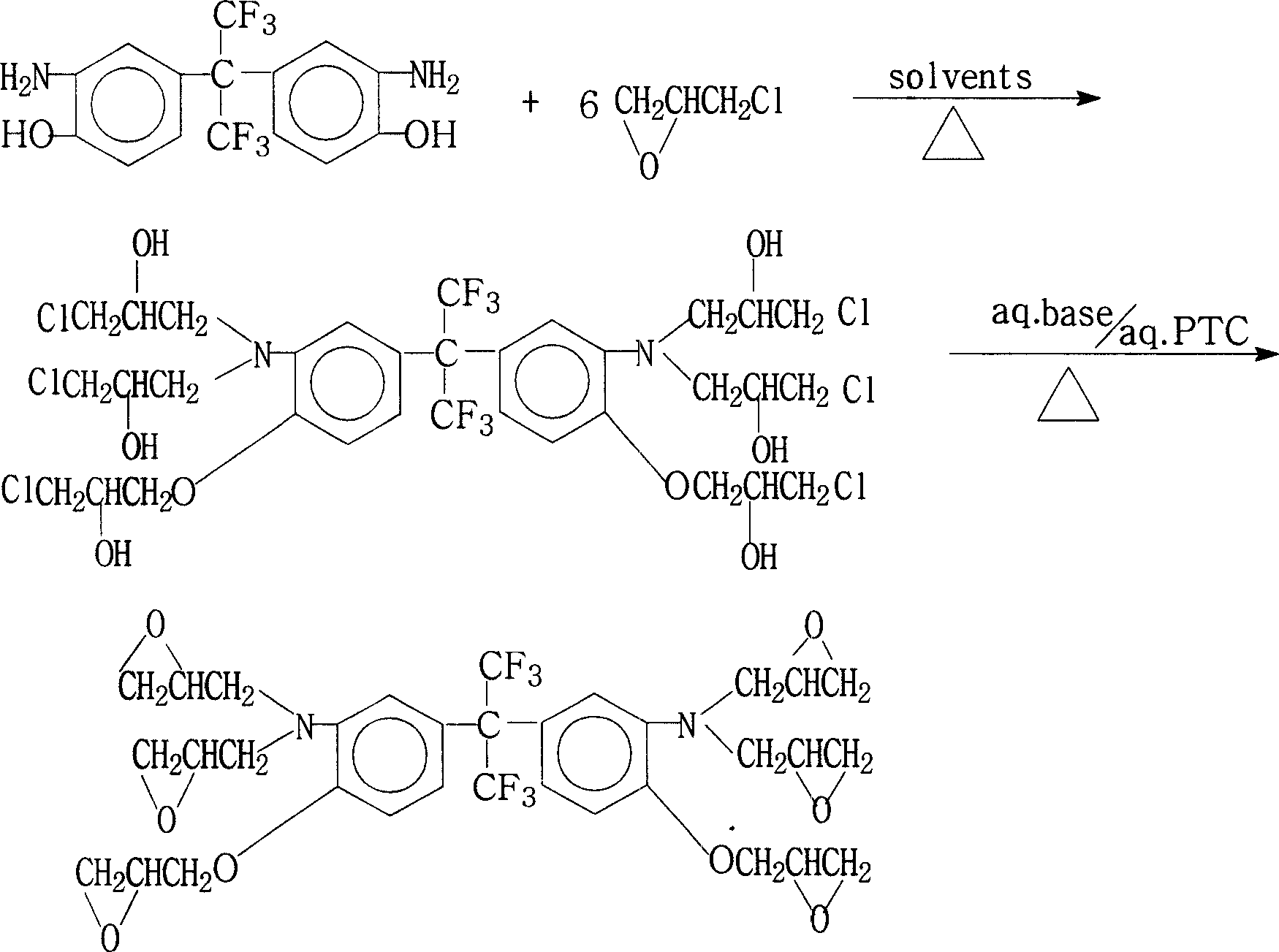

Method for preparing fluorine-contained multi-function epoxy resin

The invention discloses a manufacture method for multi-functional epoxy resin containing fluorine that includes the following steps: 2, 2-double (3- amino group-4 - hydroxy benzenes)-1, 1, 1, 3, 3, 3-BAHPFP and ECH reacting for 3-12 hours at 40-90 degree centigrade in water and organic solvent; cooling to 70 degree centigrade, adding PTC solution and alkali material solution, reacting for 2-10 hours at 40-70 degree centigrade, heating to 1-5 hours at 80-90 degree centigrade, adding wate and organic solvent, whisking and laying to gain organic layer, washing, separating to gain N, N, N', N', 0, 0'- hexa-glycidyl group- 2, 2- double (3- amino group-4- hydroxy benzenes)- 1, 1, 1, 3, 3, 3-HGBAHPFP. The invention has the advantages of easy to operate, good quality, high yield, little waste, etc.

Owner:DONGHUA UNIV

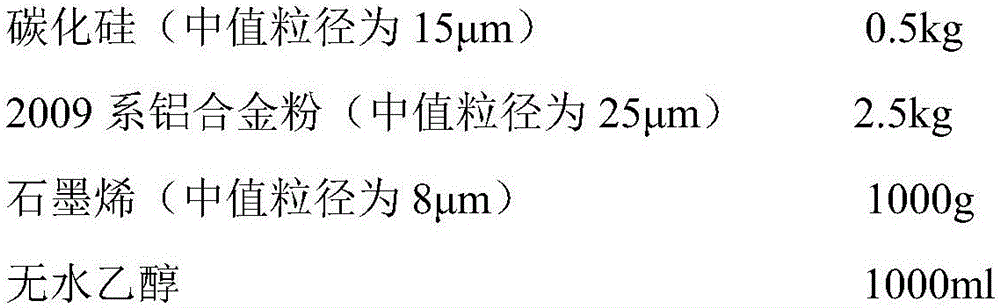

Graphene, aluminum and silicon carbide composite material and preparation method and application thereof

The invention relates to a graphene, aluminum and silicon carbide composite material and a preparation method thereof. The composite material is prepared from of constituents of 10-40 vol% of silicon carbide, 0.5-2 wt% of graphene, and the balance aluminum alloy. The composite material is prepared through a powder metallurgic method and can be obtained through proportioning, powder mixing, packaging, vacuum degassing and hot isostatic forming. The composite material has the advantages of low density, low weight, high hardness, high tensile strength and the like, the strength, fatigue resistance and toughness of the material are remarkably improved through addition of a proper amount of graphene, and thus the composite material has broader application prospects in the field of structural pieces.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

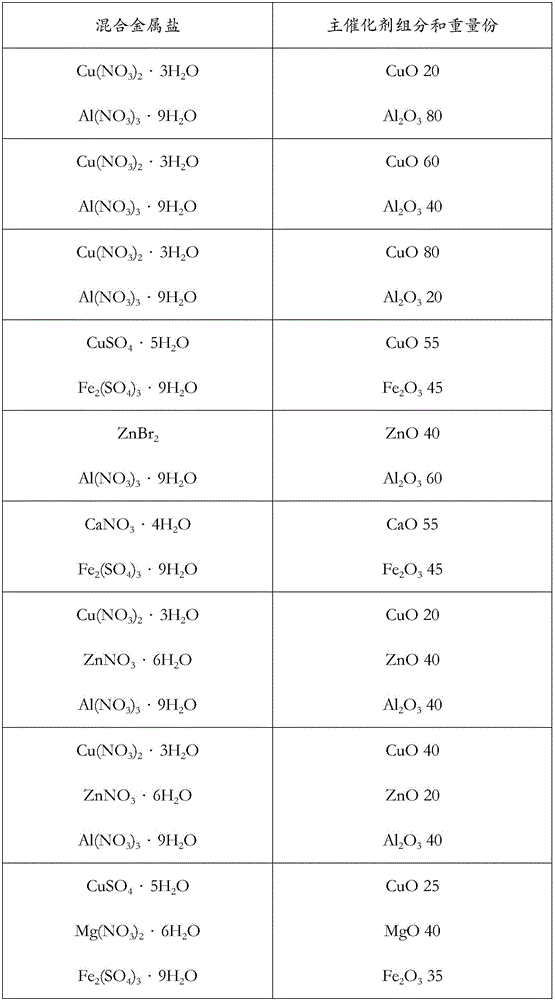

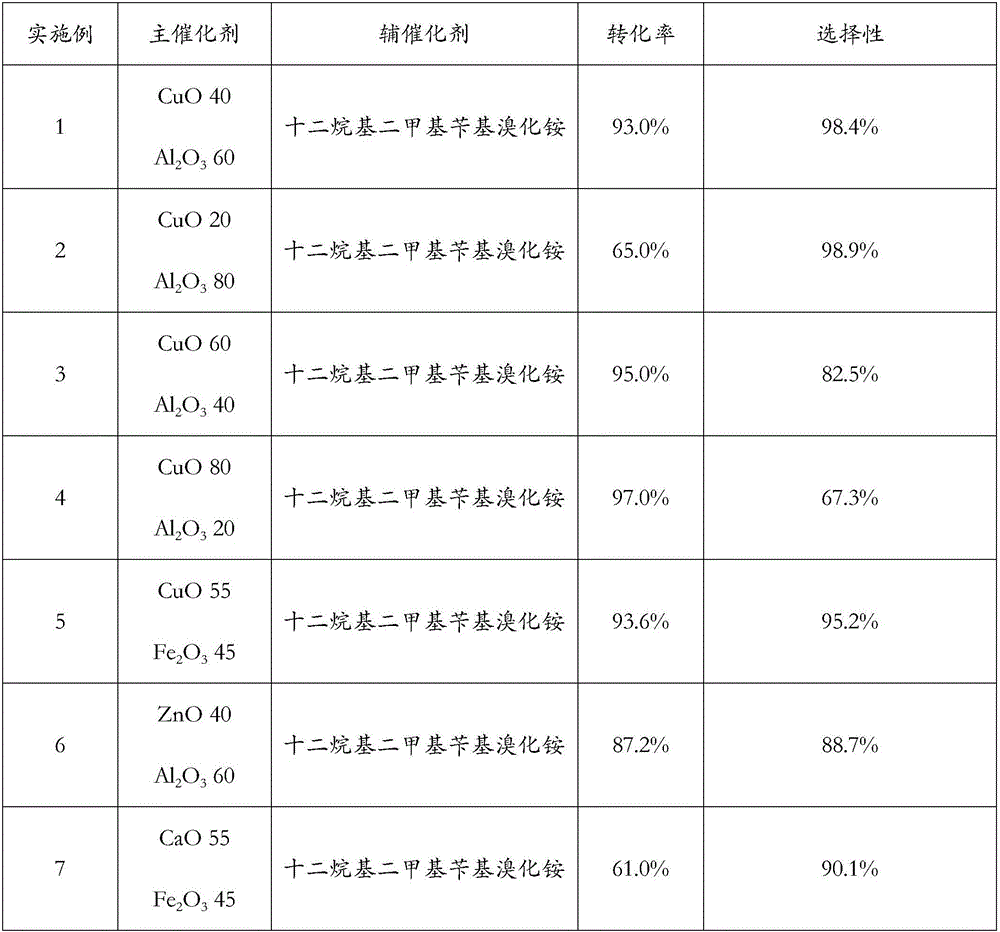

Ethylene sulfate preparation method and catalyst thereof

InactiveCN106831701ASimple process routeThree wastes lessOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAmmoniumMetal

The invention discloses a process for preparing ethylene sulfate from sulfur trioxide and ethylene oxide and catalyst preparation and mainly solves problems of high quantity of waste gas, waste water and industrial residues and difficulty in product purification of an existing process route. Catalysts include a main catalyst and an auxiliary catalyst; the main catalyst is metal mixed oxide MaOb / NcOd, wherein M is selected from at least one of Cu, Mg, Zn, Ca, Co or Ni, and N is selected from at least one of Al, Fe, Cr or Zr; the auxiliary catalyst is quaternary ammonium salt R1R2R3R4N+X.

Owner:盐城利庞新型材料科技有限公司 +1

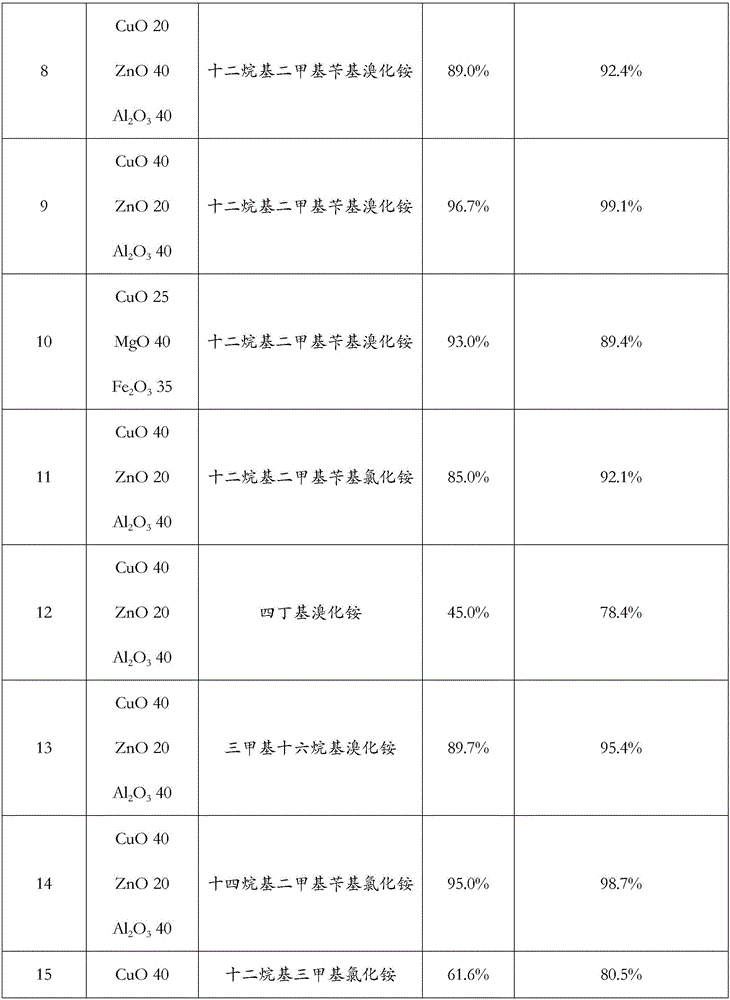

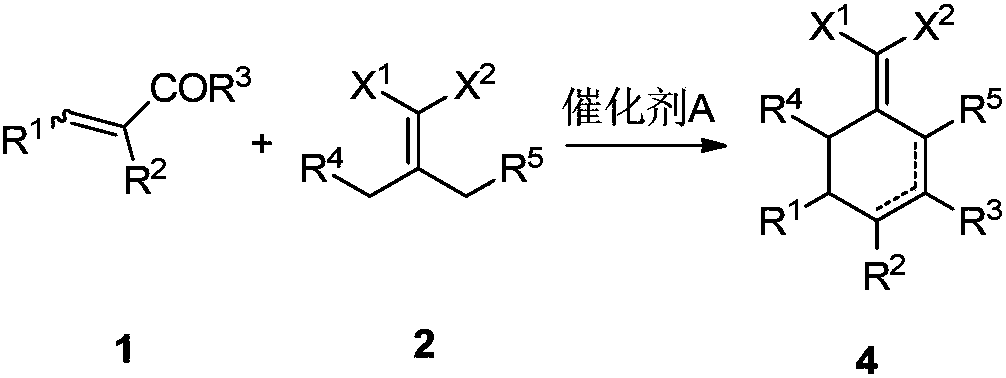

Preparation method for 2-(cyclohexenyl) malonic acid derivative and application thereof

ActiveCN108264469AEfficient synthesisHigh reaction yieldBiocideOrganic compound preparationArylMalonic acid

The invention provides a preparation method for a 2-(cyclohexenyl) malonic acid derivative and application thereof. The method takes polylefin and a 2-substituted malonic acid derivative as raw materials, the two materials are subjected to a cyclization reaction in the presence of catalyzer, and the 2-(cyclohexenyl) malonic acid derivative is obtained. Compared with the prior art, the preparationmethod adopts a completely different strategy and has the special functions that (1) a 2-(2, 6-disubstituted cyclohexenyl) malonic acid derivative can be more efficiently synthesized; (2) the reactionyield is high, the reaction conditions are mild, the three wastes are less, and the method is beneficial to industrial production. More importantly, the method expands the application of the 2-(cyclohexenyl) malonic acid derivative in organic synthesis, especially the synthesis of a 2-aryl malonic acid derivative and corresponding pesticides such as a herbicide of pinoxaden.

Owner:ORIENTAL LUZHOU AGROCHEM

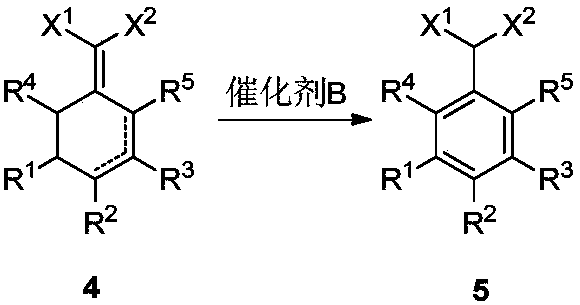

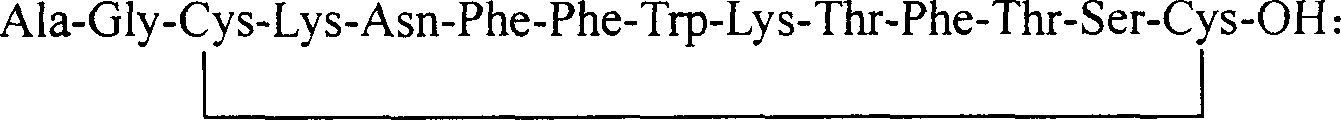

Preparation method of synthesizing growth chalone from solid phase polypeptide

InactiveCN1923851AConvenient sourceReduce usageSomatostatinsPeptide preparation methodsHydrogen fluorideSomatomedin

The invention discloses a chalone preparing method of solid-phase polypeptide, which comprises the following steps: adopting 2-chloride-trityl resin, 4-methyl trityl resin or 4-methoxyl trityl resin as raw material; connecting amino acid with protective group according to solid-phase synthetic method; obtaining protected octapeptide resin; removing Fmoc-protective group sequently; stripping side-chain protective group; cutting peptide to obtain reduced aoqu-peptide; oxidizing through air under pH 7-11 condition; separating and purifying rought product through C18 (C8) column to produce exquisite.

Owner:SHANGHAI SOHO YIMING PHARMA +1

Preparation method of macroporous absorption resin

InactiveCN101693750AReduce pollutionReduce dosageOther chemical processesBenzoyl peroxideWater vapor

The invention relates to a preparation method of macroporous absorption resin, which comprises the following steps of adding framework raw materials, a pore-forming agent, an initiating agent and a dispersing agent into deionized water, fully stirring and mixing; sequentially raising the temperature of a liquid mixture for suspension polymerization by four stages to gradually cure the liquid mixture to oyster white 20-60mu spherical particles, wherein the framework raw materials are divinylbenzene with the weight percentage concentration of 80 percent, the pore-forming agent is one of isooctane and n-pentane, the initializing agent is benzoyl peroxide, and the dispersing agent is polyvinyl alcohol; transferring the oyster white spherical particles into an elution column, introducing vapour with temperature of 130-150 DEG C as an eluting agent, eluting the pore-forming agent remained in the oyster white spherical particles; and sieving the obtained oyster white spherical particles to obtain the 20-60mu macroporous absorption resin with specific surface area more than 800m2 / g. The method has little pollution and low production cost; and the prepared macroporous absorption resin has better property.

Owner:崔建

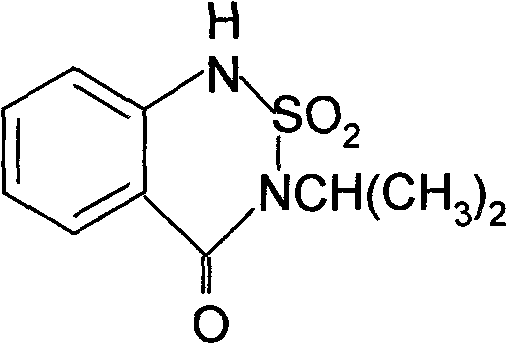

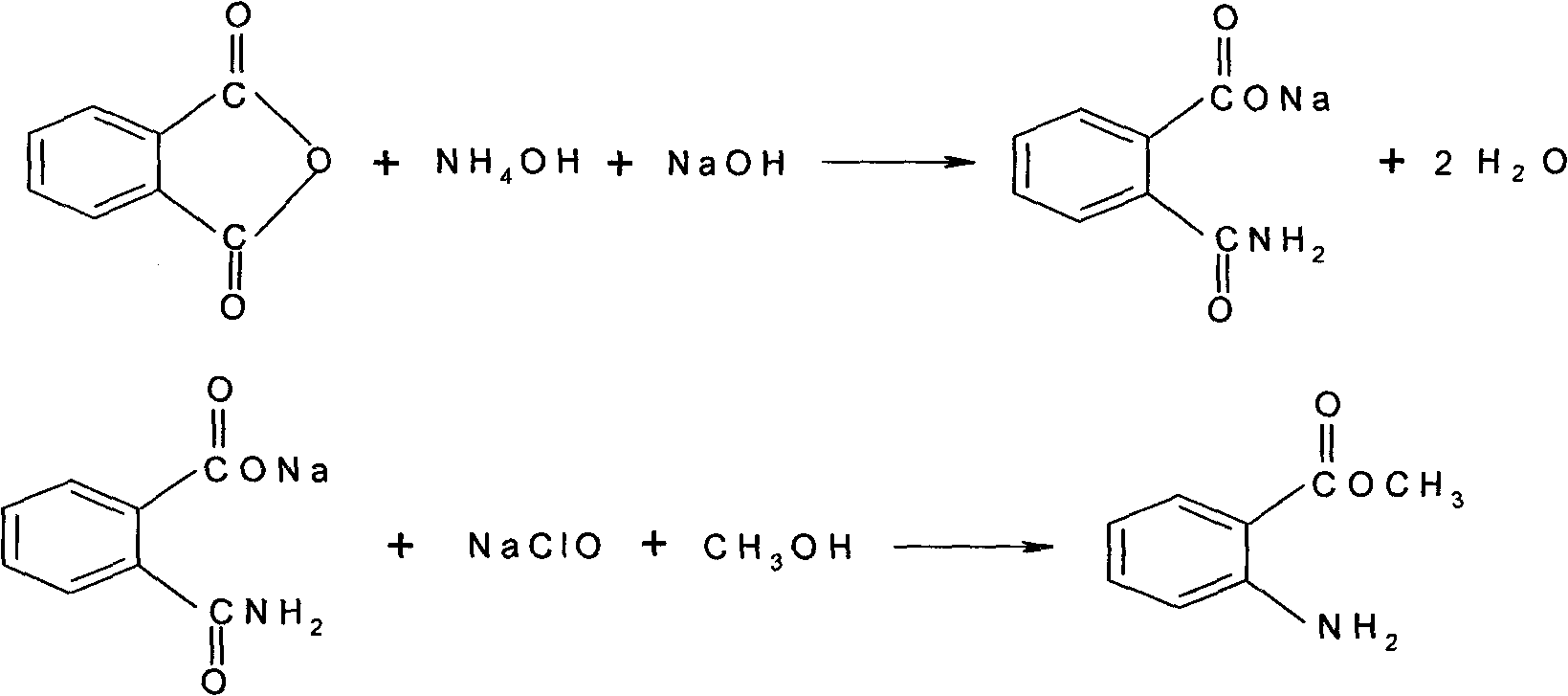

Synthetic method of bentazone

InactiveCN101863858ALow priceIncreased cyclization yieldOrganic chemistrySulfonyl chlorideMethyl anthranilate

The invention discloses a synthetic method of bentazone, comprising the following steps: taking phthalic anhydride as a main raw material; aminating, degrading and esterifying the phthalic anhydride to obtain methyl anthranilate; taking the methyl anthranilate, chlorosulfonic acid, isopropyl amine and phosphorus oxychloride as raw materials and triethylamine as an acid binding agent to prepare o-isopropylamide sulfonamido-methyl benzoate by a one-pot method; and finally carrying out cyclization and acidizing reaction on the o-isopropylamide sulfonamido-methyl benzoate by utilizing sodium alkoxide to synthesize the bentazone. In the method, the phthalic anhydride with cheap price and wide source is taken as the raw material instead of isopropylamide sulfonyl chloride, the o-isopropylamide sulfonamido-methyl benzoate is directly synthesized by a one-step method and meanwhile a catalyst is added to improve the cyclization yield; the synthetic method has the characteristics of easy operation, less three wastes, high yield, low cost and the like; and the final bentazone product has the yield up to over 85% and the purity up to over 98%.

Owner:江苏绿利来股份有限公司 +1

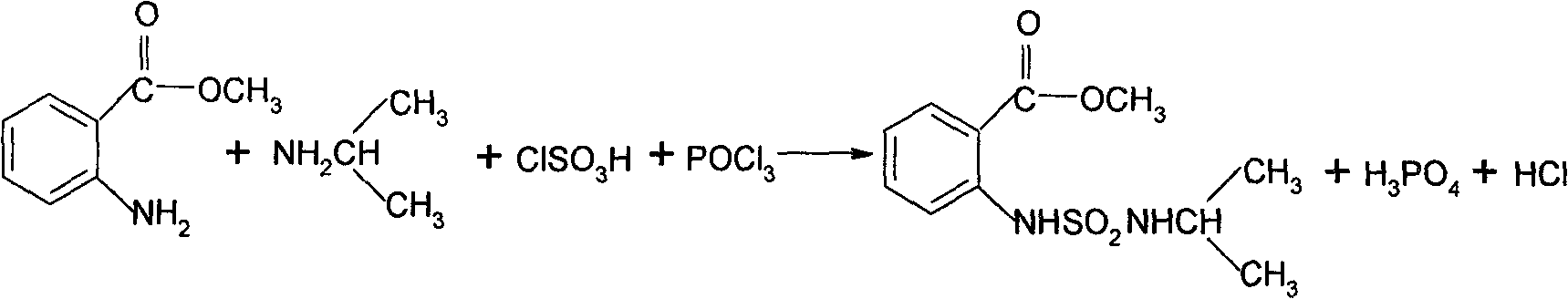

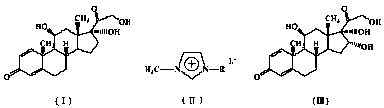

Synthetic method of 16alpha-hydroxy prednisonlone

InactiveCN101875681ALow costSuitable for industrial productionSteroidsReaction temperatureDouble bond

The invention discloses a synthetic method of 16alpha-hydroxy prednisonlone as shown in formula (III), comprising the following steps: taking the prednisonlone as shown in formula (I) as a raw material; carrying out dehydration reaction to generate a double bond in acidic ionic liquid as shown in formula (II); adding hydrogen peroxide aqueous solution to react; and adding water for further hydrolyzation after full reaction to finally obtain the 16alpha-hydroxy prednisonlone. The synthetic method of the invention adopts the property of the acidic ionic liquid as a reaction medium as well as a catalyst and changes technological conditions such as reaction time, reaction temperature and the like, thus achieving the purpose of reduced cost, energy conservation and emission reduction, and being applicable to industrial production.

Owner:无棣鑫岳化工集团有限公司

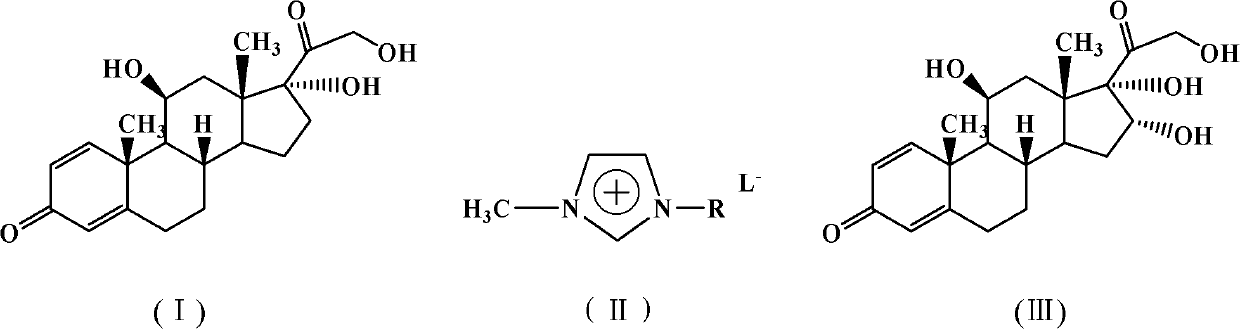

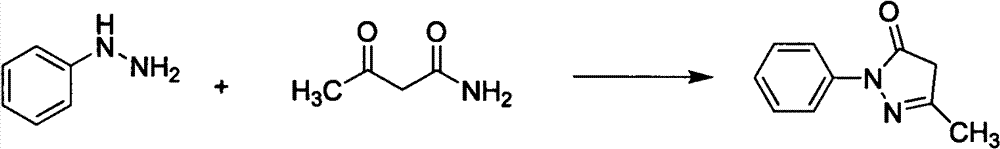

Preparation method for edaravone

The invention discloses a preparation method for edaravone. The preparation method comprises a step of subjecting hydrazinobenzene and ethyl acetoacetate to a cyclization reaction under a solvent-free condition and action of an acid so as to prepare edaravone, wherein the usage amount of the acid is 0.02 to 10 equivalent of the molar weight of hydrazinobenzene. The preparation method provided by the invention has the advantages of mild conditions, fast reaction, safety, reliability, easy and convenient operation, low cost, almost quantitative completion of the reaction, capacity of obtaining a high purity (greater than 98%) crude product which accords with medicinal standards after simple recrystallization, and suitability for industrial production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

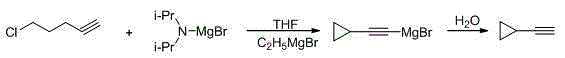

Method for efficiently preparing cylopropyl ethylnen

InactiveCN105152846AHigh yieldAtom utilization is highHydrocarbon from halogen organic compoundsOrganic solventDistillation

The invention discloses a method for effectively preparing cylopropyl ethylnen as shown in the formula (I). The method comprises the steps that firstly, cylopropyl methyl ketone shown in the formula (II) is taken as a raw material and fully reacts in an organic solvent under the effect of phosphorus pentachloride and a catalyst, a reaction solution is subjected to reduced pressure distillation to obtain 1,1-dichloro-1-cylopropyl ethane as shown in the formula (III), an elimination reaction is then carried out under the effect of alkali, and a reaction solution is subjected to rectification and purification to obtain the product cylopropyl ethylnen. The method for effectively preparing the cylopropyl ethylnen has the advantages of being mild in reaction condition, high in yield, low in cost, little in three-waste and the like, and is suitable for industrial production.

Owner:JIUJIANG ZHONGTIAN PHARMA +1

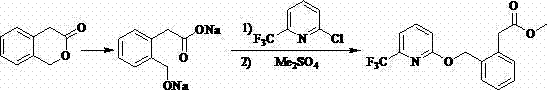

A synthetic process of a green efficient agricultural fungicide

ActiveCN104262239AShort reaction pathSimple and safe operationOrganic chemistryMeth-Agricultural engineering

A synthetic process of a green efficient agricultural fungicide is disclosed. The synthetic process includes: preparing 4-(methoxymethene)-3-isobenzofuranone by adopting 3-isochromanone as an initial raw material; preparing methyl (E)-2-(2-halomethylphenyl)-3-methoxy acrylate from the 4-(methoxymethene)-3-isobenzofuranone in methanol, a third inert solvent and a halogenating agent; and reacting the methyl (E)-2-(2-halomethylphenyl)-3-methoxy acrylate and 2-hydroxy-6-(trifluoromethyl)pyridine or 6-trifluoromethyl-2-pyridinol salt to obtain picoxystrobin. The synthetic process has characteristics of short reaction steps, mild reaction conditions, simple, convenient and feasible post-treatment, little three-waste, low cost, high yield, and suitability for industrial production. A product is good in appearance, and has external standard purity higher than 98%.

Owner:ZHEJIANG TIDE CROP TECH

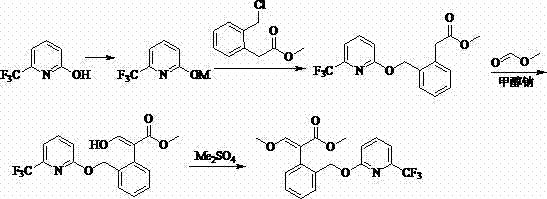

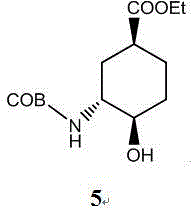

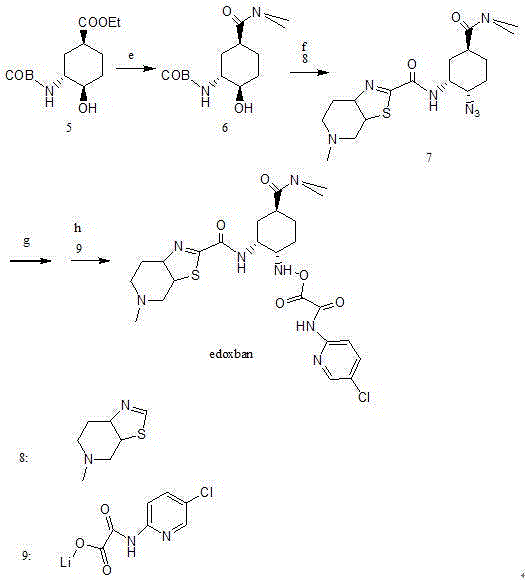

Edoxaban intermediate and preparation method thereof

InactiveCN105198776AStable and reliable quantityHigh yieldCarbamic acid derivatives preparationOrganic compound preparationPtru catalystFormic acid ethyl ester

The invention relates to an edoxaban intermediate and a preparation method thereof. The preparation method of the edoxaban intermediate comprises steps as follows: (a), (1s)-3- cyclohexene-1-formic acid is taken as a raw material, and a compound 2 is generated in the presence of a catalyst, a halogen and a weak base; (b), the compound 2 generates a compound 3 under the action of strong base in an absolute ethanol solution; (c), the compound 3 generates a compound 4 in an ammonia and ethanol solution; (d), the compound 4 reacts with a protecting group of amino under the action of a catalyst, and a compound 5, (1S,3R,4R)-3-[(t-butyloxycarboryl)amino]-4-hydroxycyclohexyl ethyl formate, is generated. Raw materials and reagents required in the synthesis method of the edoxaban intermediate are easy to obtain, the yield is high, the cost is low, reaction conditions are mild, three wastes are relatively fewer, and the quality of the product is stable and reliable.

Owner:天津药物研究院药业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method 2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method](https://images-eureka.patsnap.com/patent_img/272a8674-ad69-4d90-a5f1-6a96e0f2479a/A2005100957660002C1.PNG)

![2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method 2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method](https://images-eureka.patsnap.com/patent_img/272a8674-ad69-4d90-a5f1-6a96e0f2479a/A2005100957660002C2.PNG)

![2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method 2-amido-2-[2-(4-alkylphenyl)ethyl]-1,3-methyl glycol preparation method](https://images-eureka.patsnap.com/patent_img/272a8674-ad69-4d90-a5f1-6a96e0f2479a/A2005100957660002C3.PNG)

![Process for producing 2,2-bis[3-amido-4-(4-aminophenoxy)phenyl] hexafluoropropane Process for producing 2,2-bis[3-amido-4-(4-aminophenoxy)phenyl] hexafluoropropane](https://images-eureka.patsnap.com/patent_img/58e7e5b4-1e2e-4d41-908c-4cca25cc8d76/s2008100349765e00011.PNG)

![Process for producing 2,2-bis[3-amido-4-(4-aminophenoxy)phenyl] hexafluoropropane Process for producing 2,2-bis[3-amido-4-(4-aminophenoxy)phenyl] hexafluoropropane](https://images-eureka.patsnap.com/patent_img/58e7e5b4-1e2e-4d41-908c-4cca25cc8d76/s2008100349765d00021.PNG)