Technique of ion membrane process for preparing taurine

The invention relates to a preparation process, the technique of the ion membrane method, which is applied in the ion membrane method taurine preparation process. In the field of heating and cooling, it can solve the problems of many heating and cooling steps, complicated separation steps, and decomposition of taurine, and achieve the effects of long service life, good insulation and corrosion resistance, and high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

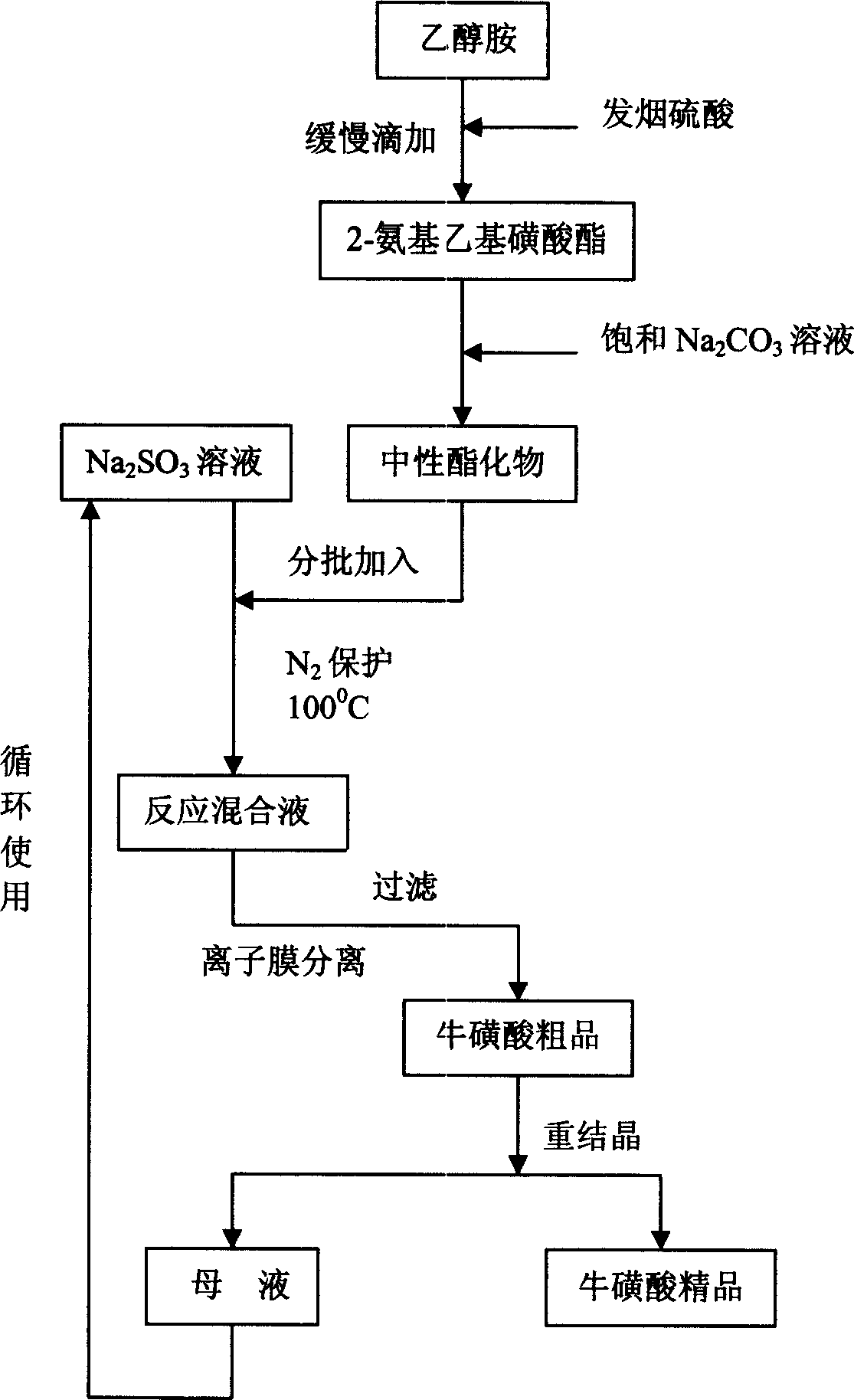

[0015] see figure 1 ,

Embodiment approach

[0017] Esterification reaction: Measure 400ml of ethanolamine in a three-necked flask, slowly add 224ml of oleum dropwise under stirring, control the temperature below 20°C, and then stir for another 2hr after the dropwise addition. It was dehydrated under reduced pressure and neutralized to pH 7 with saturated sodium carbonate solution.

[0018] Reduction reaction: Dissolve 356g of anhydrous sodium sulfite in a three-necked flask with 1000ml of water, vacuumize, fill with nitrogen, heat to 100°C, add the esterified product into the three-necked flask within 3 hours, and then filter while it is hot.

[0019] Membrane separation: put the above filtrate into the feedback ion membrane electrodialysis separation device for ion membrane electrodialysis separation. After migration and separation of inorganic salts in the mixed solution, the taurine solution crystallizes out the taurine product. This is the first cycle.

[0020] The second cycle: the above remaining mother liquor ca...

Embodiment 2

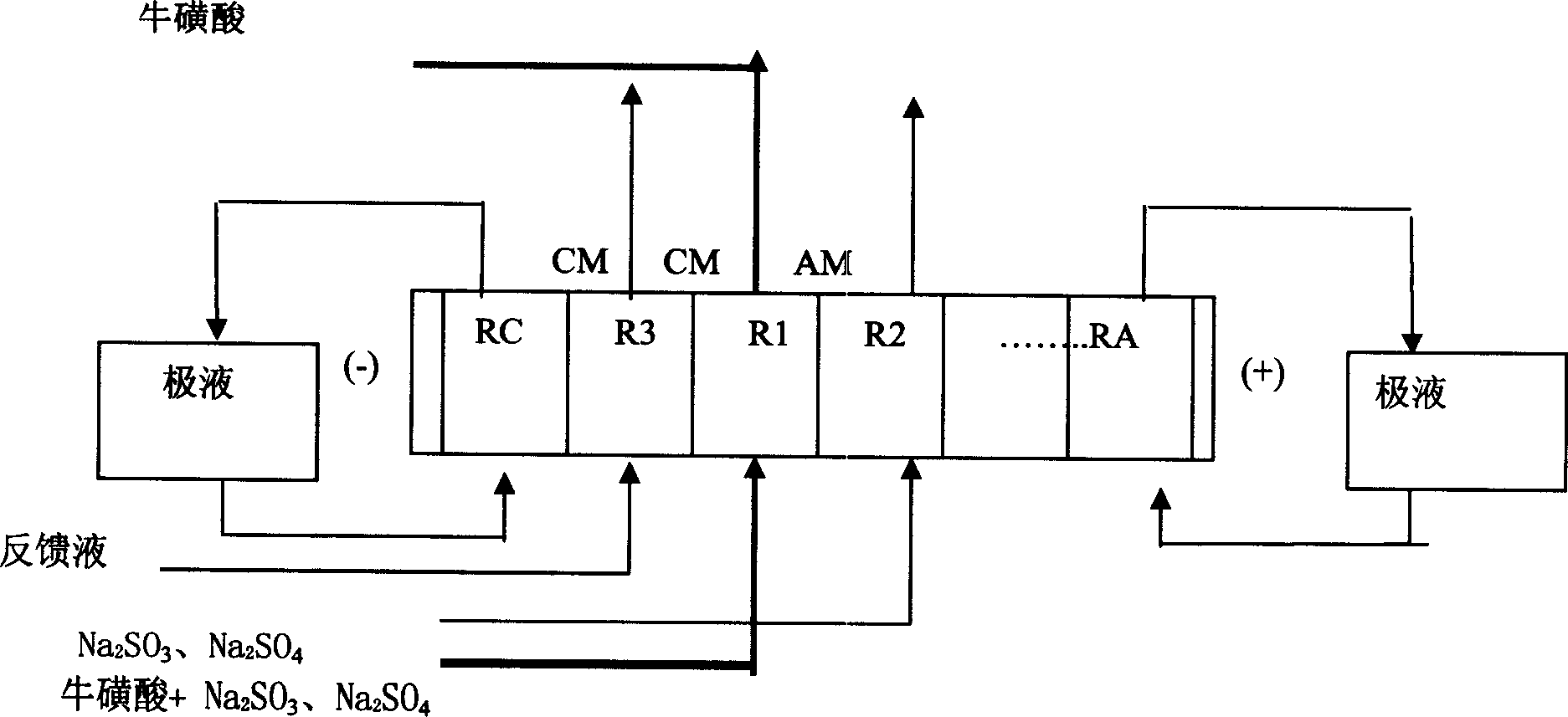

[0023] see figure 2 , using a 3-chamber ion membrane electrodialysis separation device, according to the arrangement order of cation exchange membrane, cation exchange membrane and anion exchange membrane, an ion membrane electrodialysis separation device with 3 chambers repeatedly arranged, composed of cation and cation exchange membrane The chamber is the amino acid feedback chamber, the chamber composed of cation and anion exchange membranes is the mixed solution chamber, the introduced taurine and Na 2 SO 3 、Na 2 SO 4The mixture, the anion exchange membrane and the lower group of cation exchange membranes are composed of a salt chamber. The amino acid feedback chamber is near the cathode, and the salt chamber is near the anode. The size of the ion exchange membrane is 200mm×400mm, and the three-chamber structure is arranged in 200 groups. During operation, taurine and Na 2 SO 3 、Na 2 SO 4 Water mixed solution for circulating membrane separation, operating current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com