Patents

Literature

79results about How to "High separation yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

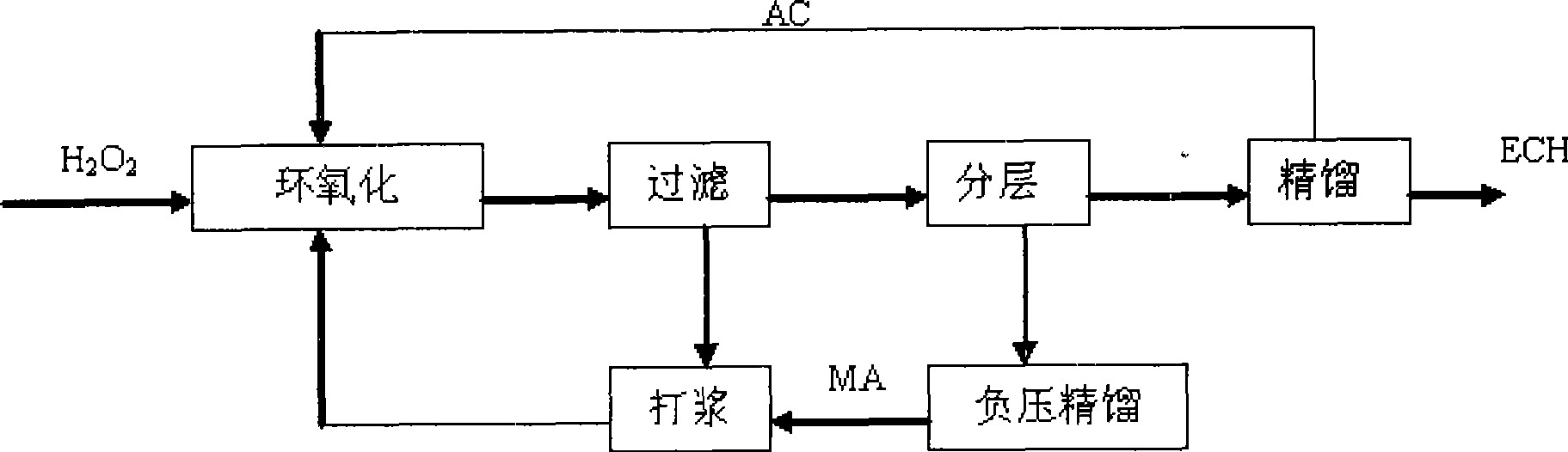

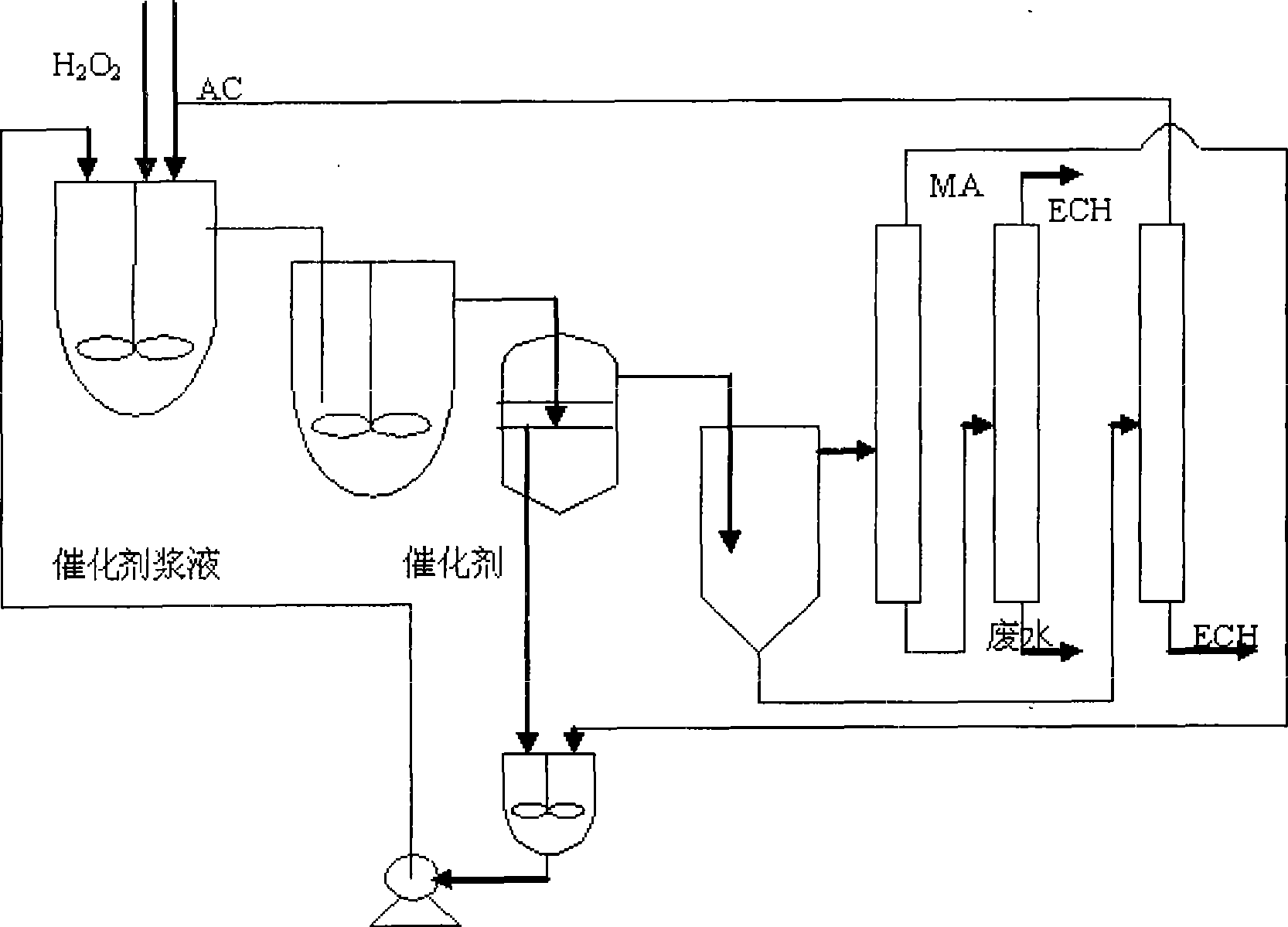

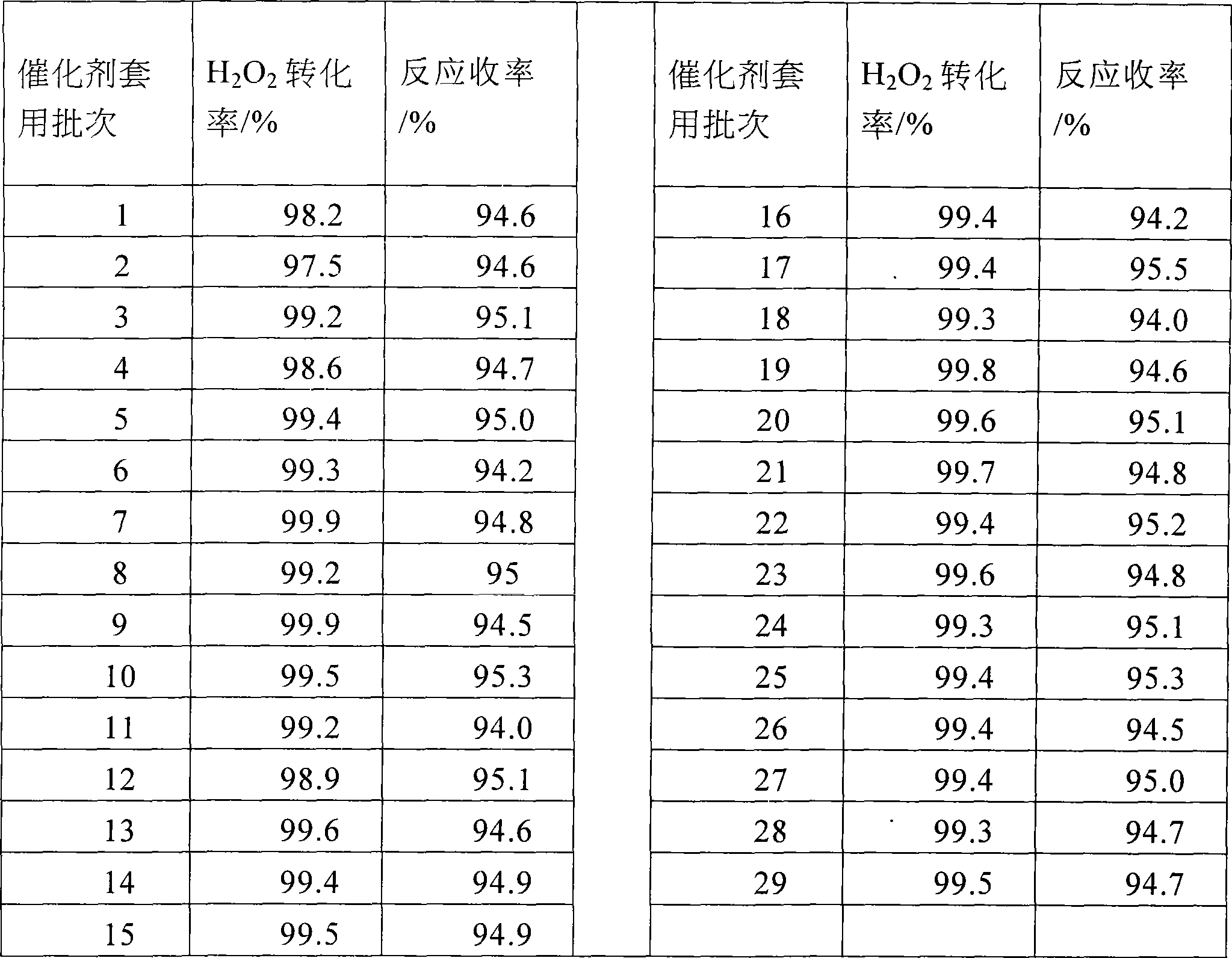

Continuous production method of epoxy chloropropane by hydrogen peroxide process

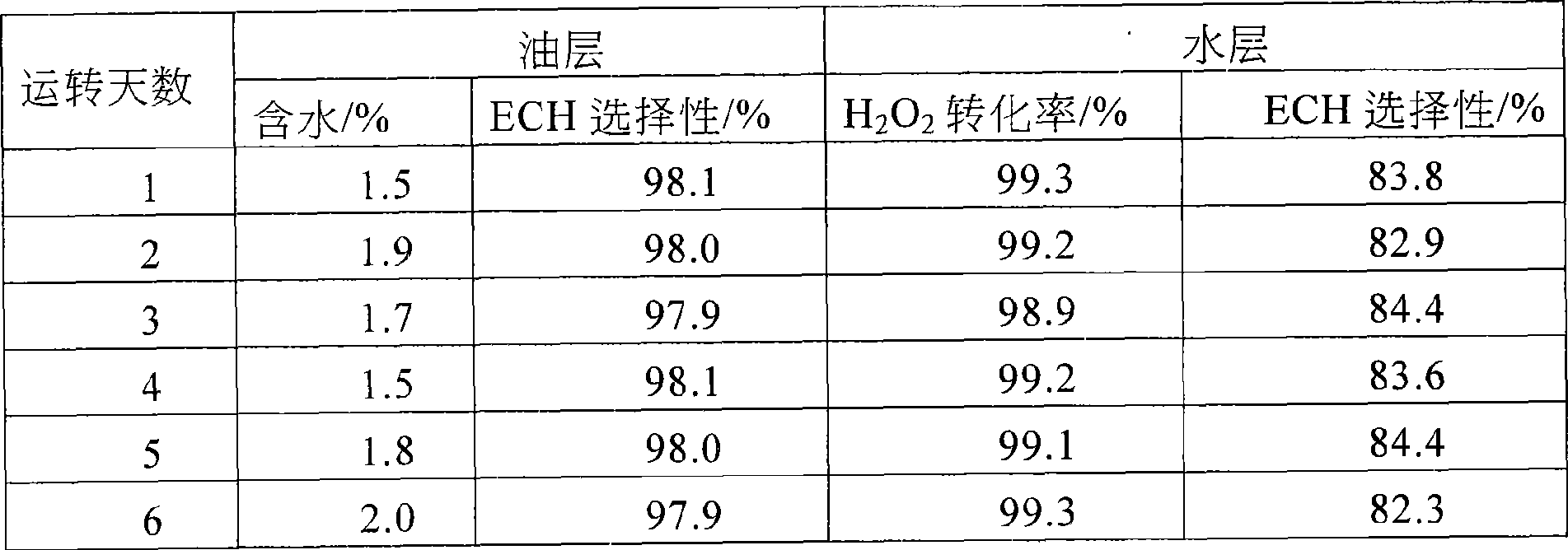

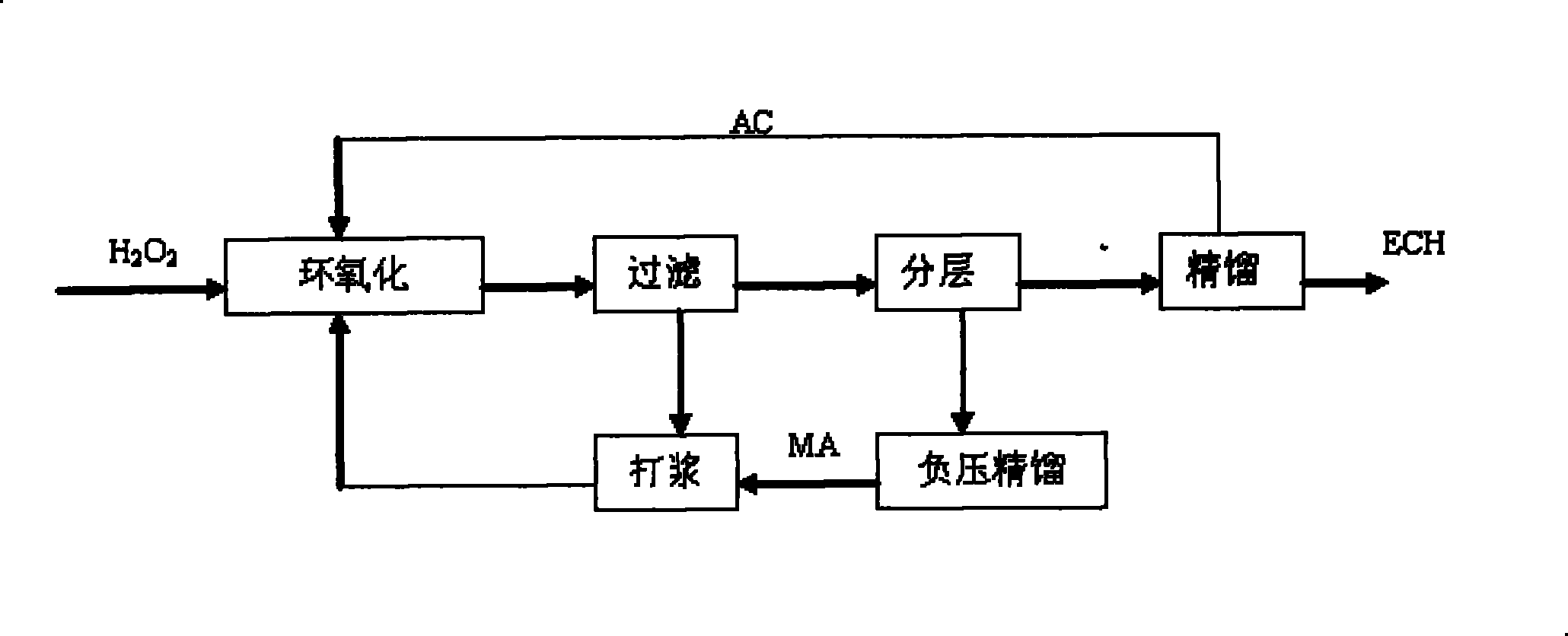

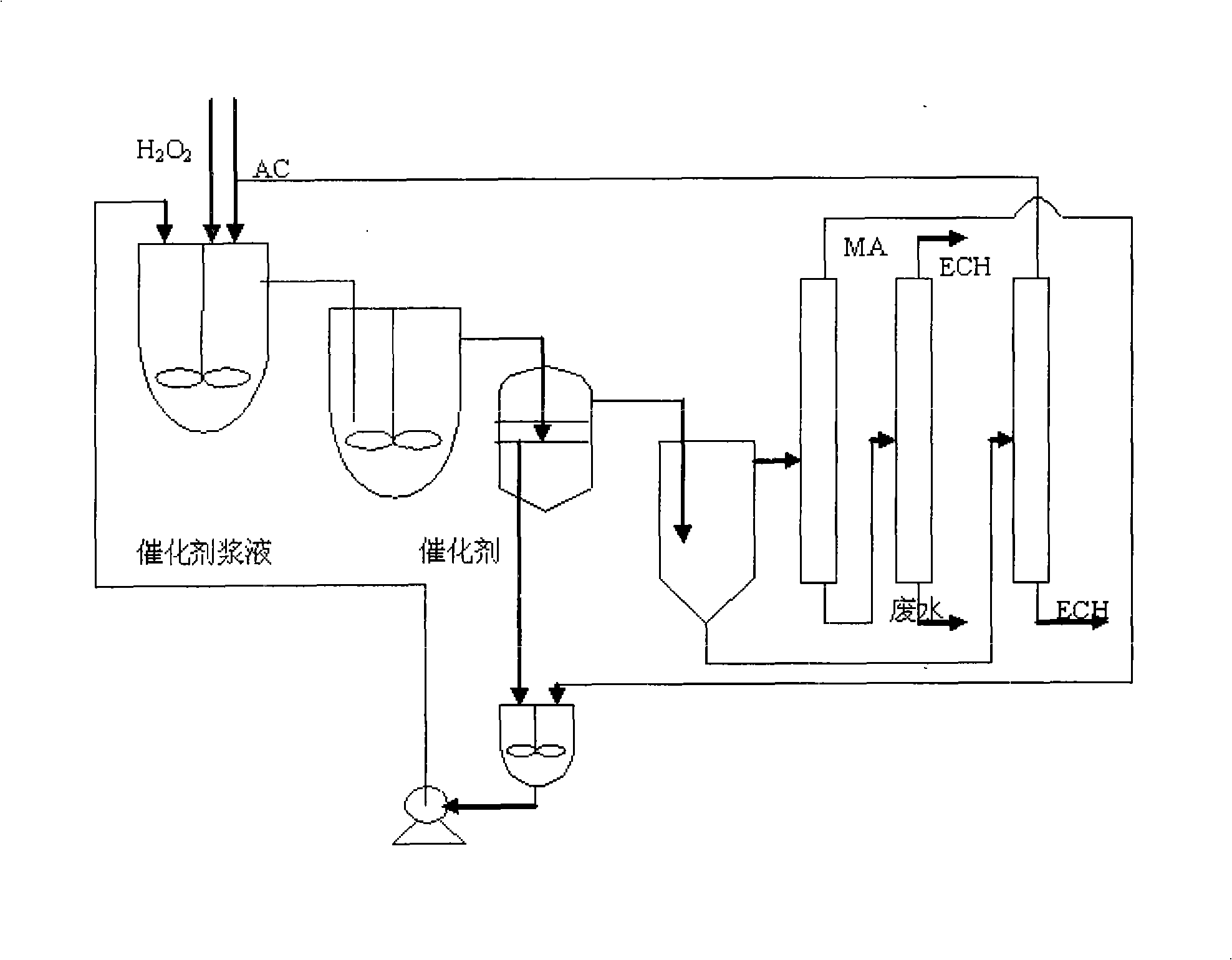

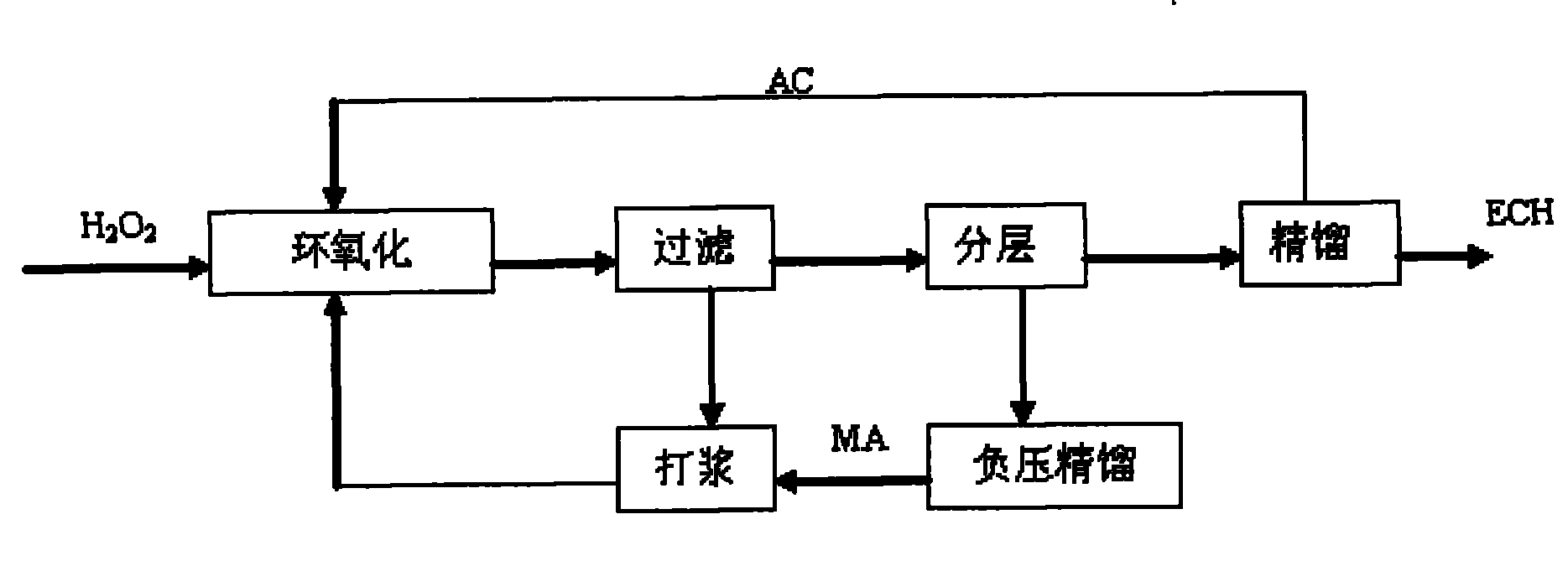

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for preparing 2,5-diformyl furan by catalyzing 5-hydroxy methyl furfural

ActiveCN101619050AHigh separation yieldLess catalystOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFuranNitrite

The invention provides a method for preparing 2,5-diformyl furan by catalytic oxidation of 5-hydroxy methyl furfural. The method comprises the following steps: taking air or oxygen as an oxygen source, taking a mixture of inorganic vanadium oxides, 2,2,6,6-4-pipecolate-oxygen radicals and derivatives and nitrites of the 2,2,6,6-4-pipecolate-oxygen radicals as a compound catalyst system, and oxidizing the 5-hydroxy methyl furfural into the 2,5-diformyl furan at a temperature of between 50 and 120 DEG C. The method has the advantages of high oxidizing efficiency, few byproducts, mild reaction conditions, easy separation and purification of products and quite high practicability.

Owner:中科化物(大连)科技实业有限公司

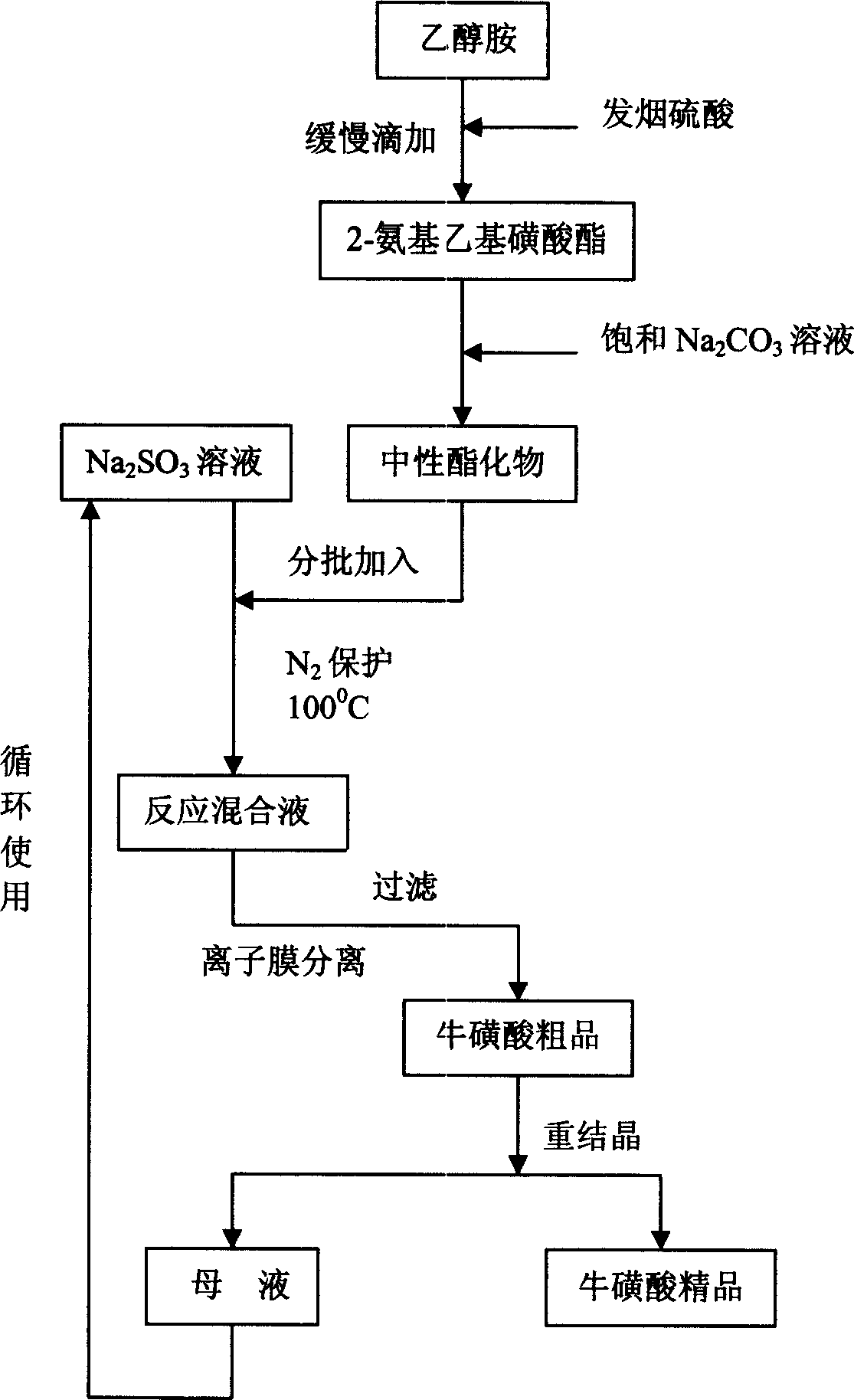

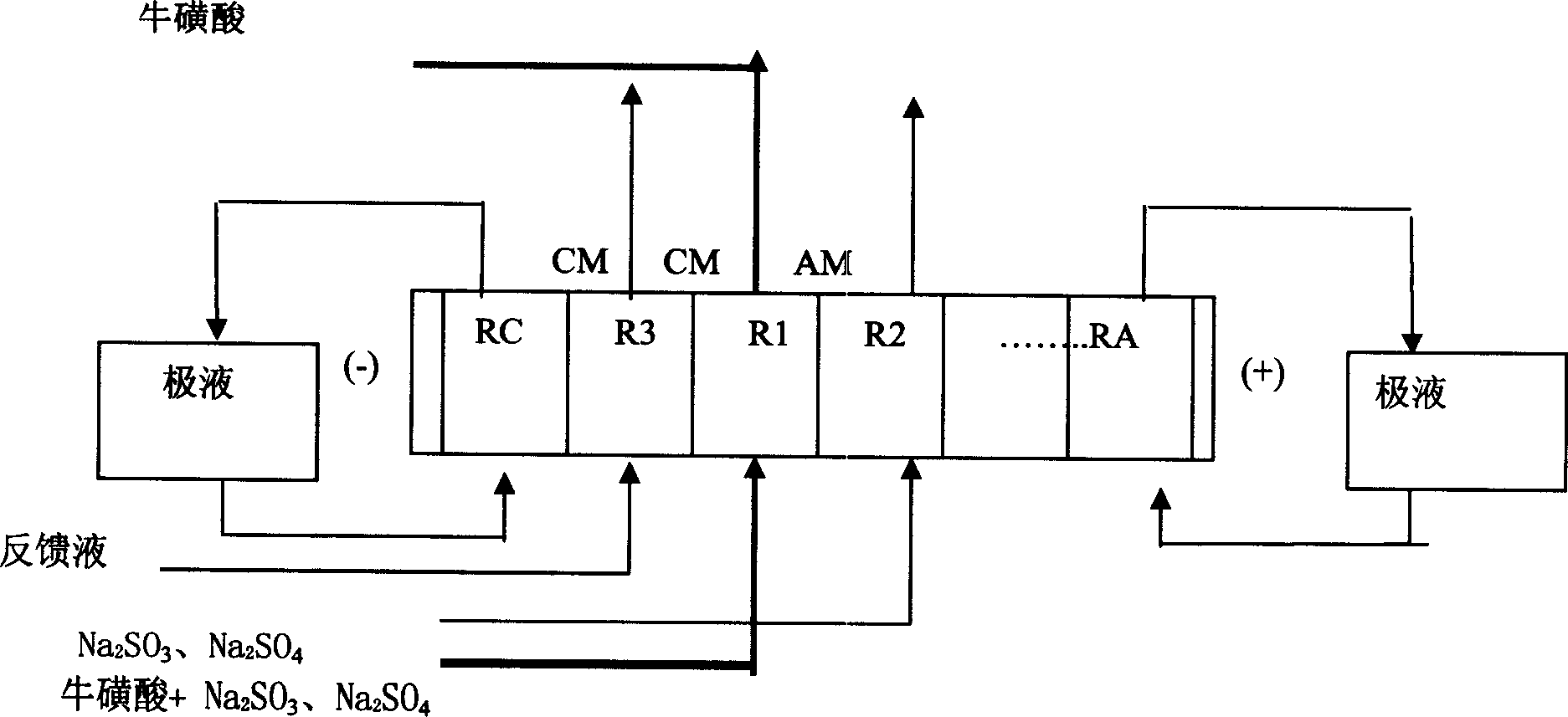

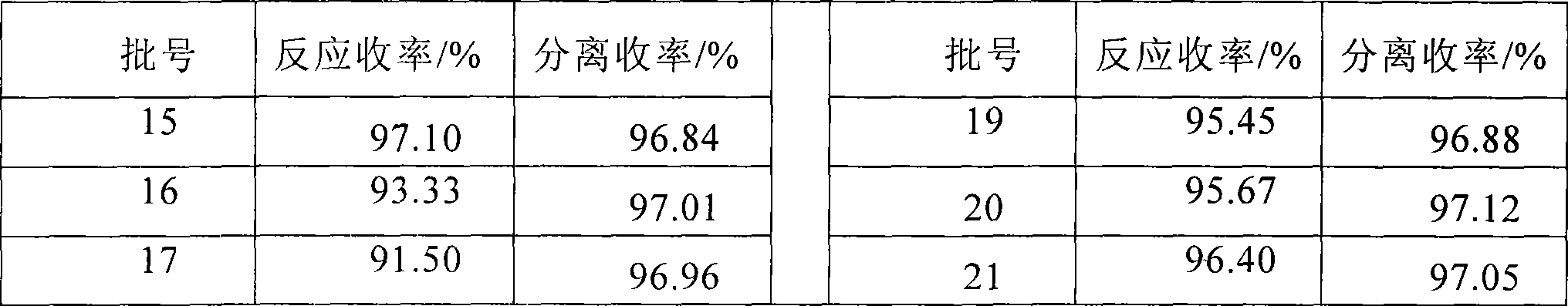

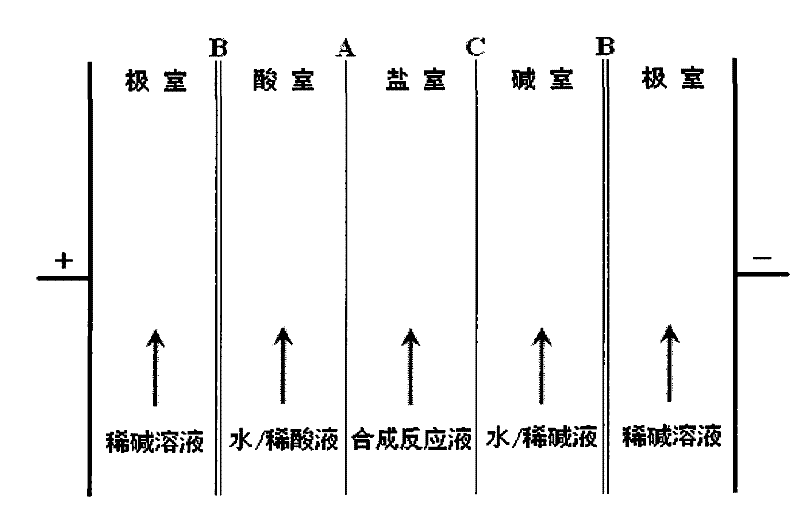

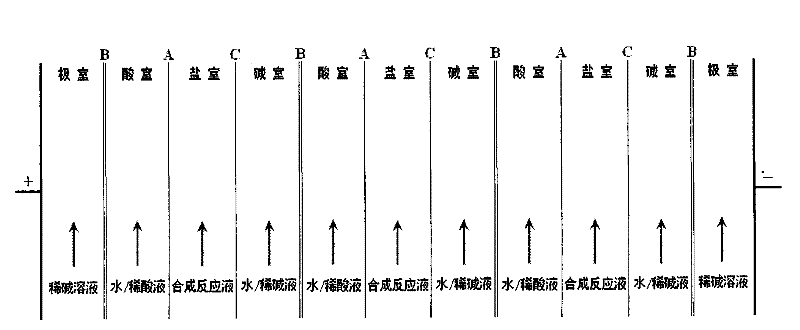

Technique of ion membrane process for preparing taurine

InactiveCN1626511ACaused byExtended service lifeOrganic compound preparationSulfonic acid preparationTaurine synthesisInorganic salts

A process for preparing taurine includes preparing the mixture containing taurine from ethanolamine by cyclc method, separating out inorganic salt by feedback type elecric dialysis with ion membrane, crystallizing taurine in solution, and using the residual mother liquid for next reduction reaction. Its advantages are high output rate and high current efficiency.

Owner:ZHEJIANG UNIV

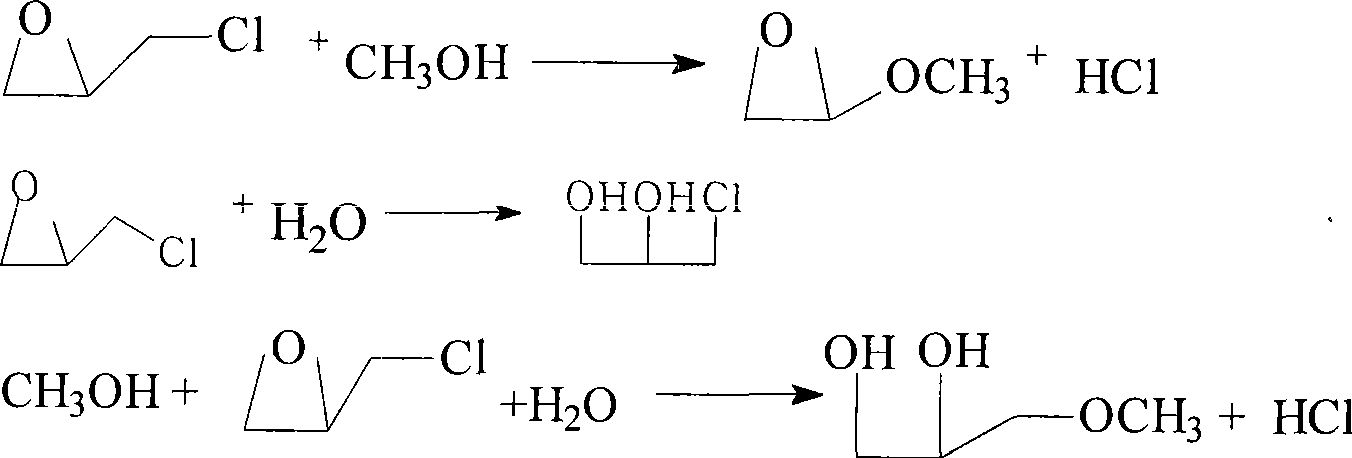

Production method of epoxy chloropropane by hydrogen peroxide method

The invention discloses a method for preparing epoxy chloropropane with the oxidation of chloropropene. The chloropropene, a solvent and fine particles of titanium silicate molecular sieve catalyst are put into a reaction pot and a hydrogen dioxide solution is added at 10 DEG C to 80 DEG C. The method is characterized in that a reaction is carried out under a subacidity condition and after the reaction, materials pass through an intermediate tank for oil-water dissociation to be divided into oil phase and water phase; the oil phase is sent into a rectifying tower for separating the chloropropene and ECH. After the water phase is filtered, a catalyst filter cake is washed by the solvent, regenerated or applied to an epoxidation reaction after being directly beat with the solvent. The ECH is extracted from an aqueous layer after filtration by the chloropropene. An extracted oil layer and an oil layer obtained from the separation of a reaction solution are combined and rectified, or the extracted oil layer is applied to the epoxidation reaction; water left from the extraction is rectified for recycling methanol and applied to the preparation of catalysts; and the method has simple procedures, small consumption amount of solvents, high separation yield of reaction products and easy realization of industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

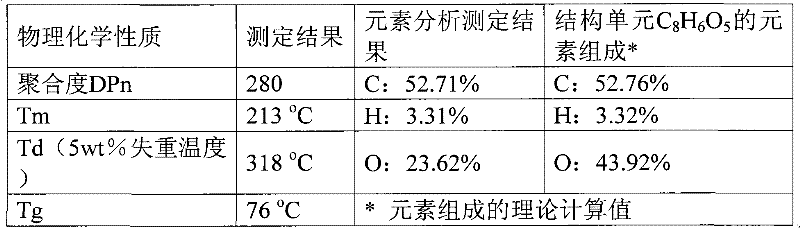

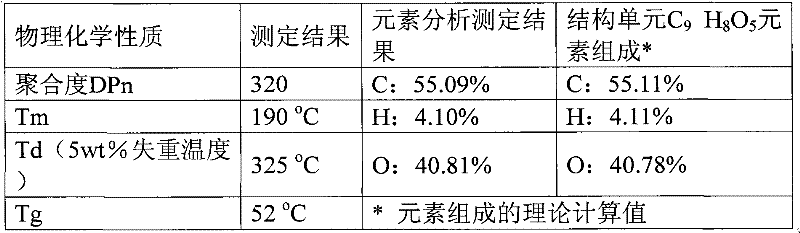

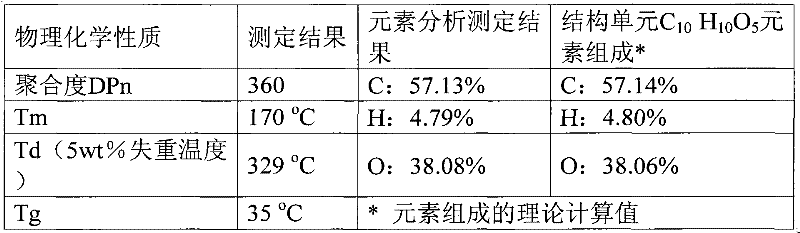

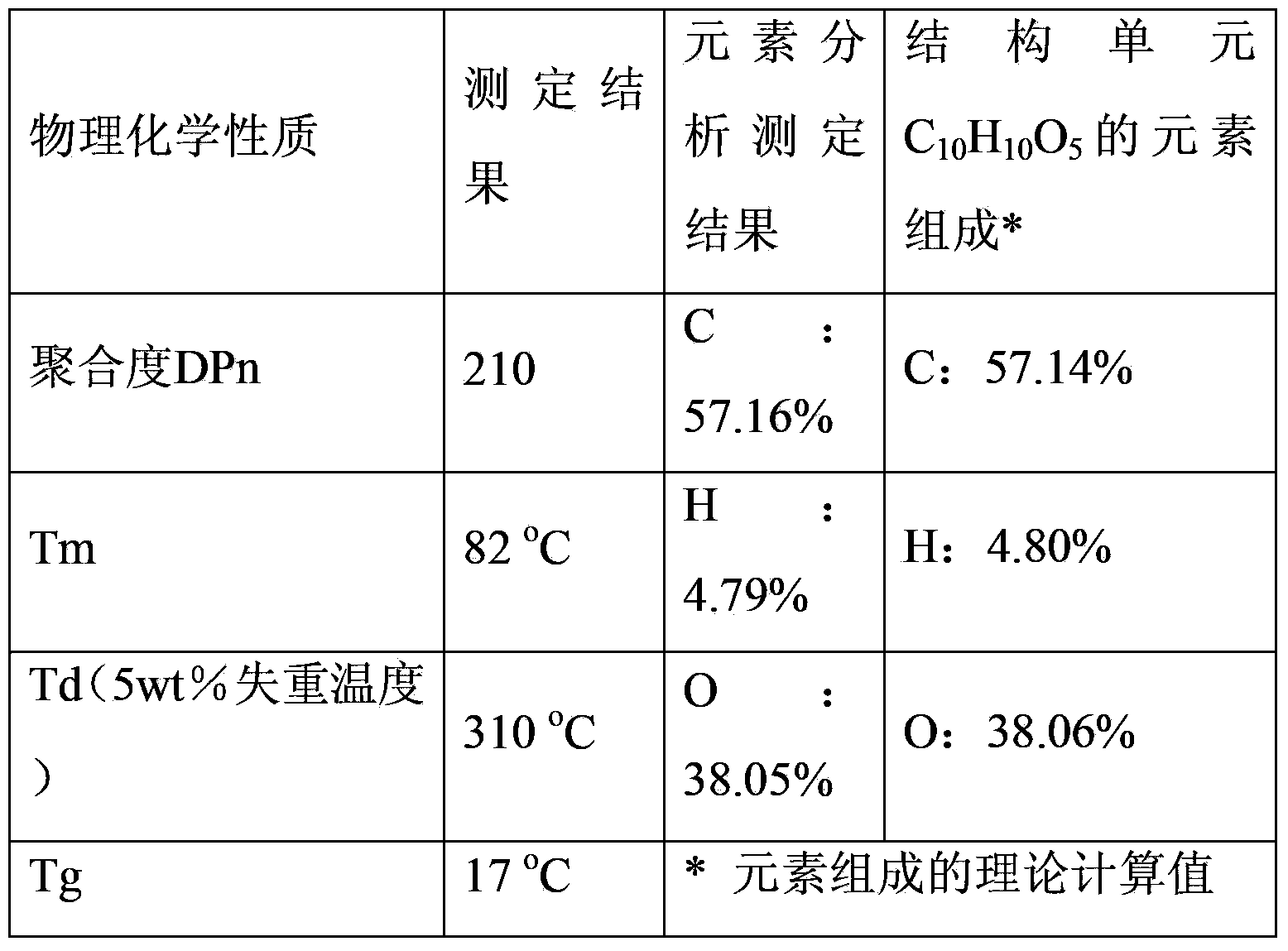

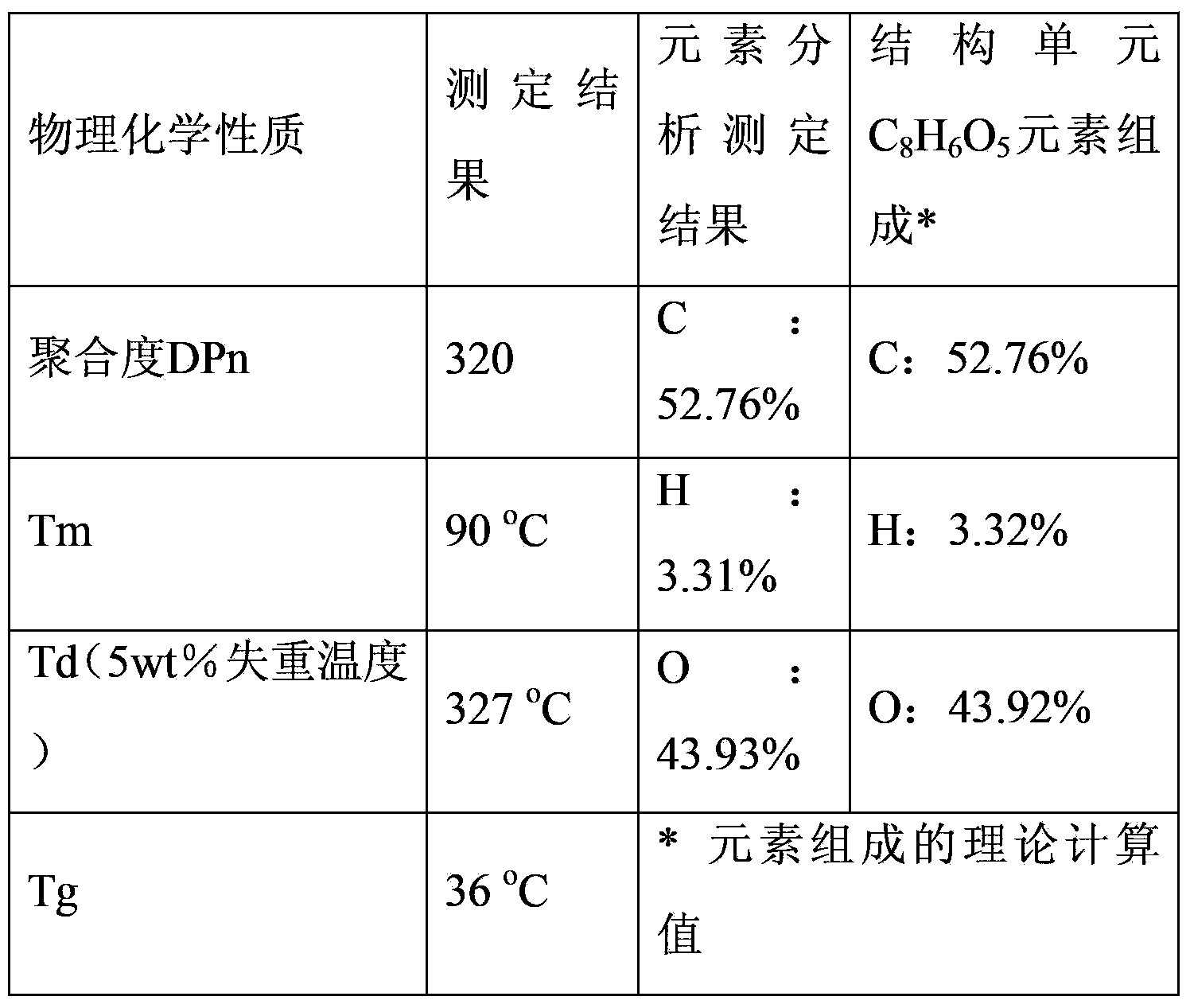

Method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing

The invention discloses a method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing. The method is characterized by comprising the following steps of: under the action of a compound catalyst, undergoing esterification and polymerization reactions on 2,5-furan dioctyl phthalate and low-carbon diatomic alcohol serving as raw materials at the temperature of 130-280 DEG C under the pressure of 2-15 mmHg for 1.5-16 hours; removing excessive low-carbon diatomic alcohol and other impurities by using a vacuum distillation or azeotropic distillation method; and purifying a polymer product with a dissolving-precipitating technology to obtain a high-quality oligofuran dioctyl phthalate ester product. The method has the advantages of high product yield, easinessin separating the product and good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing aromatic aldehyde ketone by utilizing air as oxidant in hydro solvent system

InactiveCN1789225AHigh separation yieldSelectiveCarbonyl compound preparation by oxidationKetoneAromatic alcohol

A methid for preparing aromatic keto-aldehyde in water dissolvent system employing air as oxidation agent, employing 2,2,6,6-tetramethylpiperidine-oxygen free radical (TEMPO), 1,3-dibromo-5,5-dimethylhydantoin and sodium nitrite as catalyst, water as dissolvent, air with pressure lower than 1.2 Mpa as oxidation agent, oxidating the serial aromatic alcohol and hetero-aromatic alcohol under temperature of lower than 160 Deg C to relative aromatic aldehyde and ketone.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

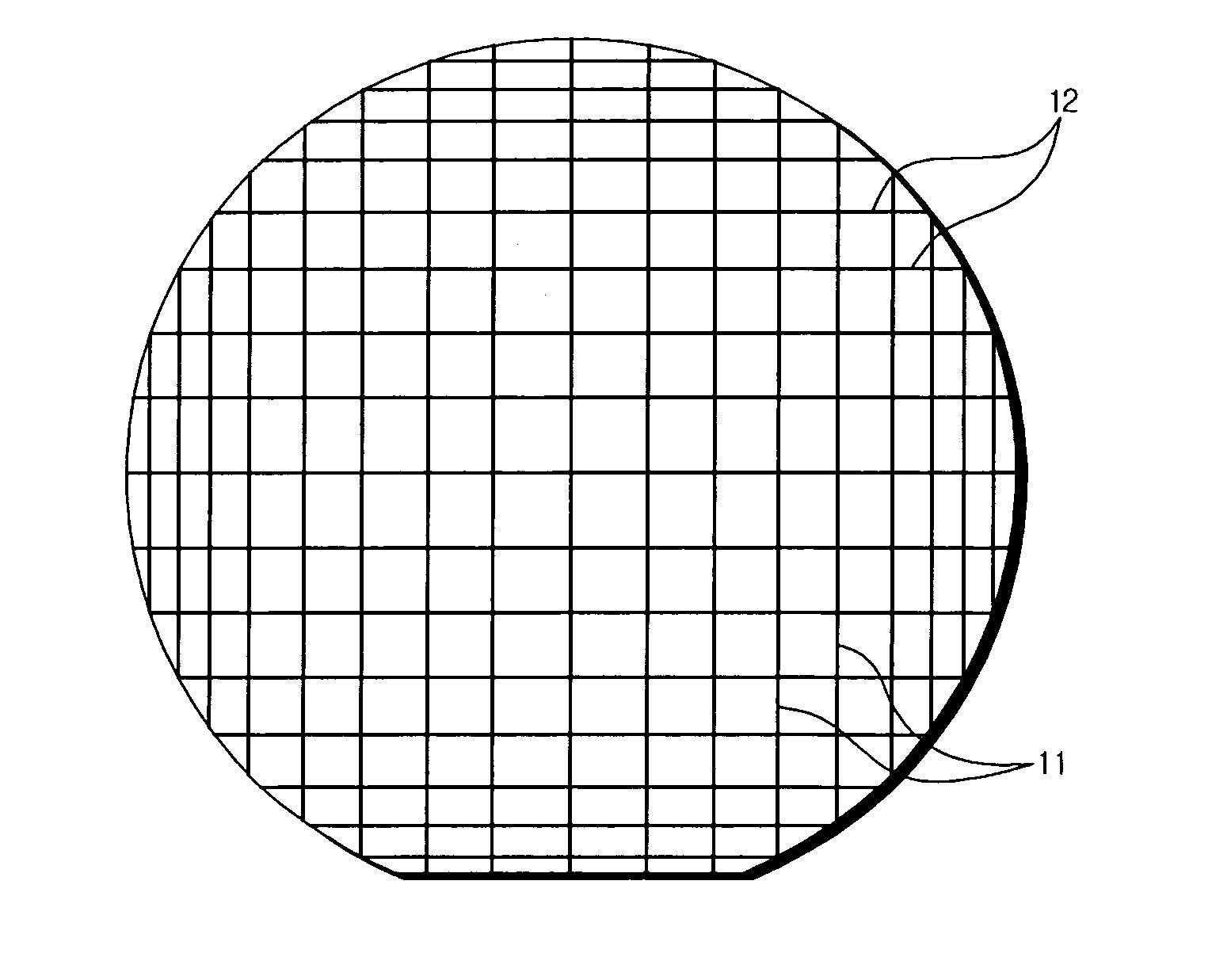

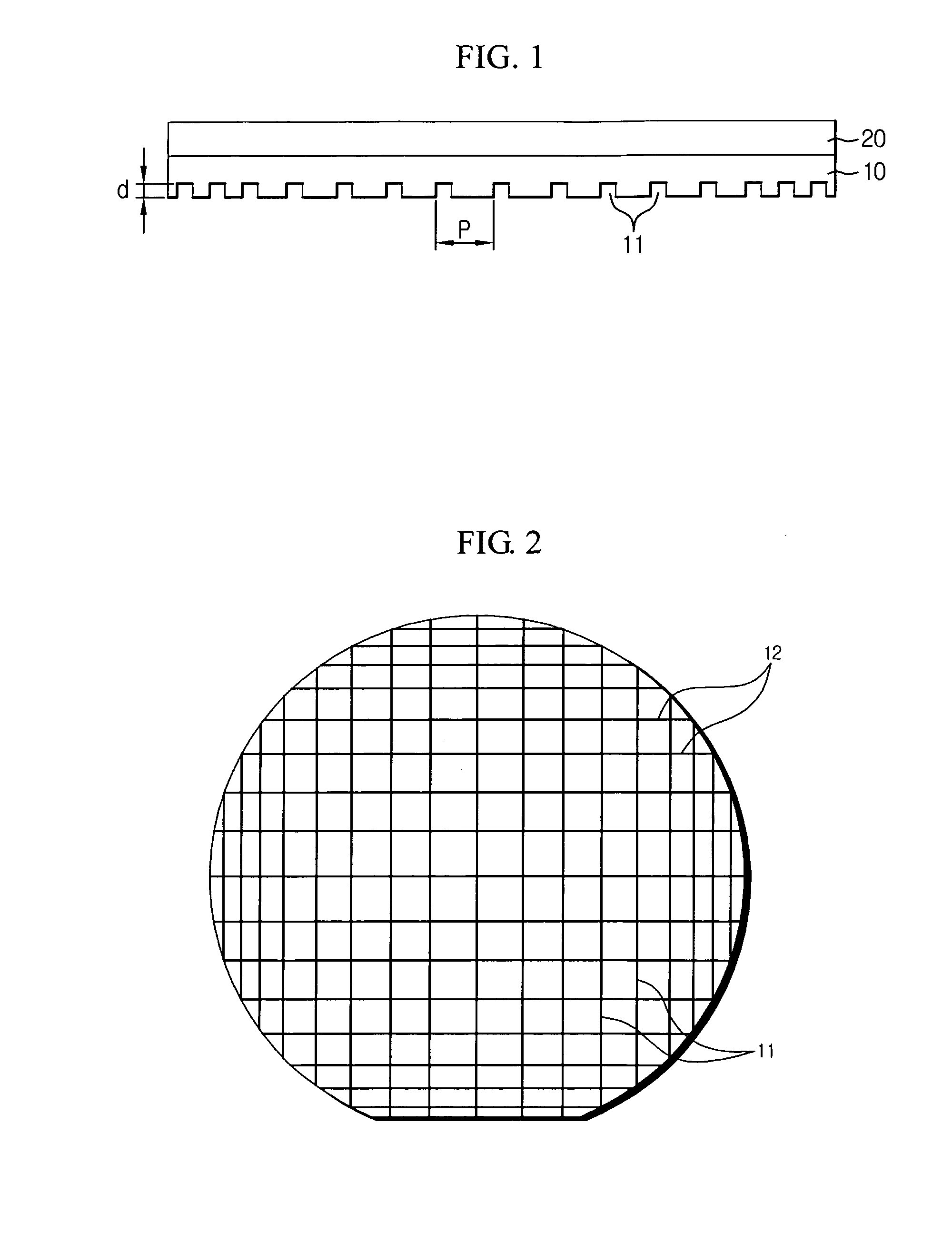

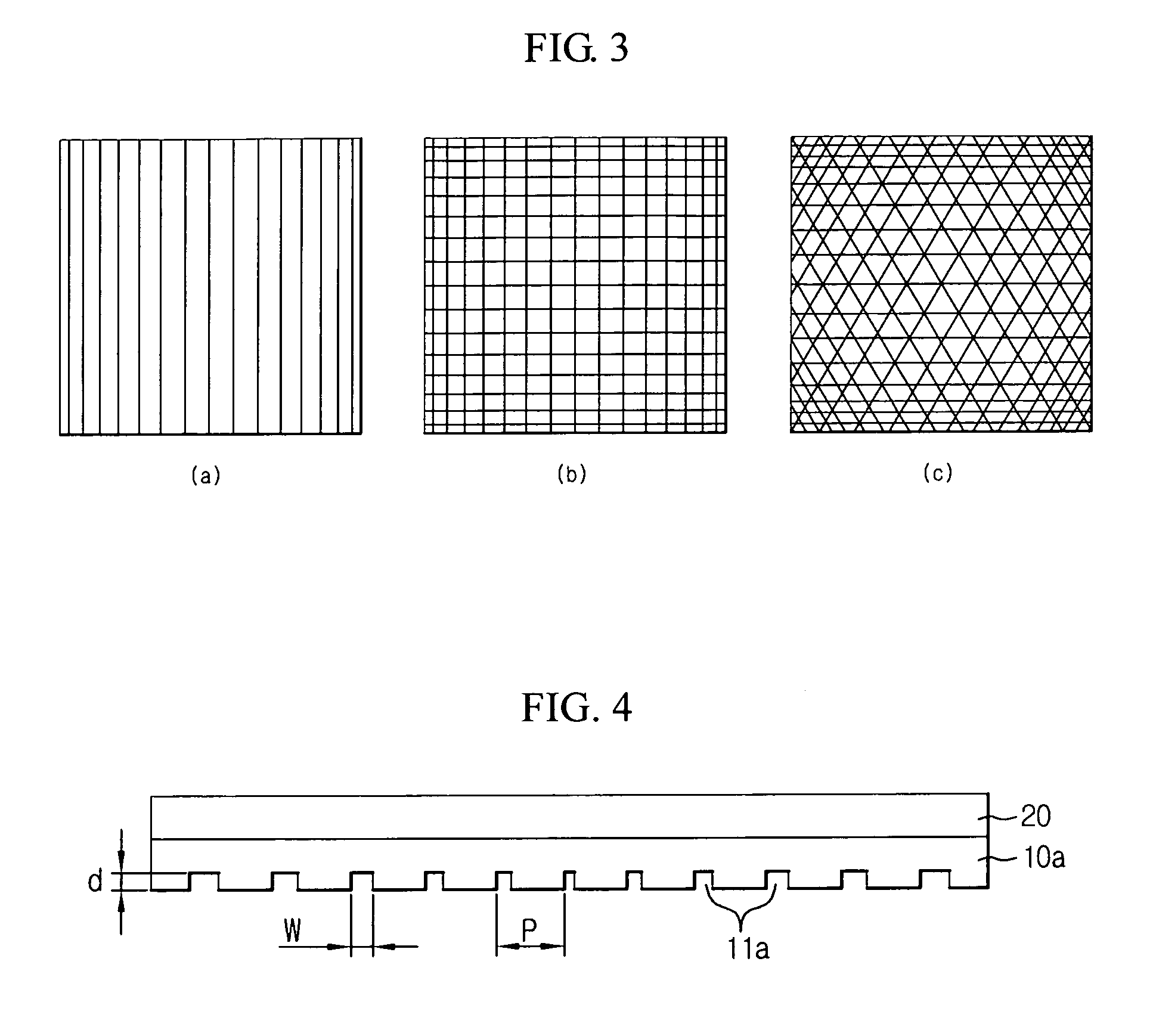

Nitride semiconductor substrate and manufacturing method thereof

InactiveUS20080142846A1Relieve pressureQuality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideNitride semiconductors

The present invention relates to a nitride semiconductor substrate such as gallium nitride substrate and a method for manufacturing the same. The present invention forms a plurality of trenches on a lower surface of a base substrate that are configured to absorb or reduce stresses applied larger when growing a nitride semiconductor film on the base substrate from a central portion of the base substrate towards a peripheral portion. That is, the present invention forms the trenches on the lower surface of the base substrate such that pitches get smaller or widths or depths get larger from the central portion of the base substrate towards the peripheral portion.

Owner:LG SILTRON

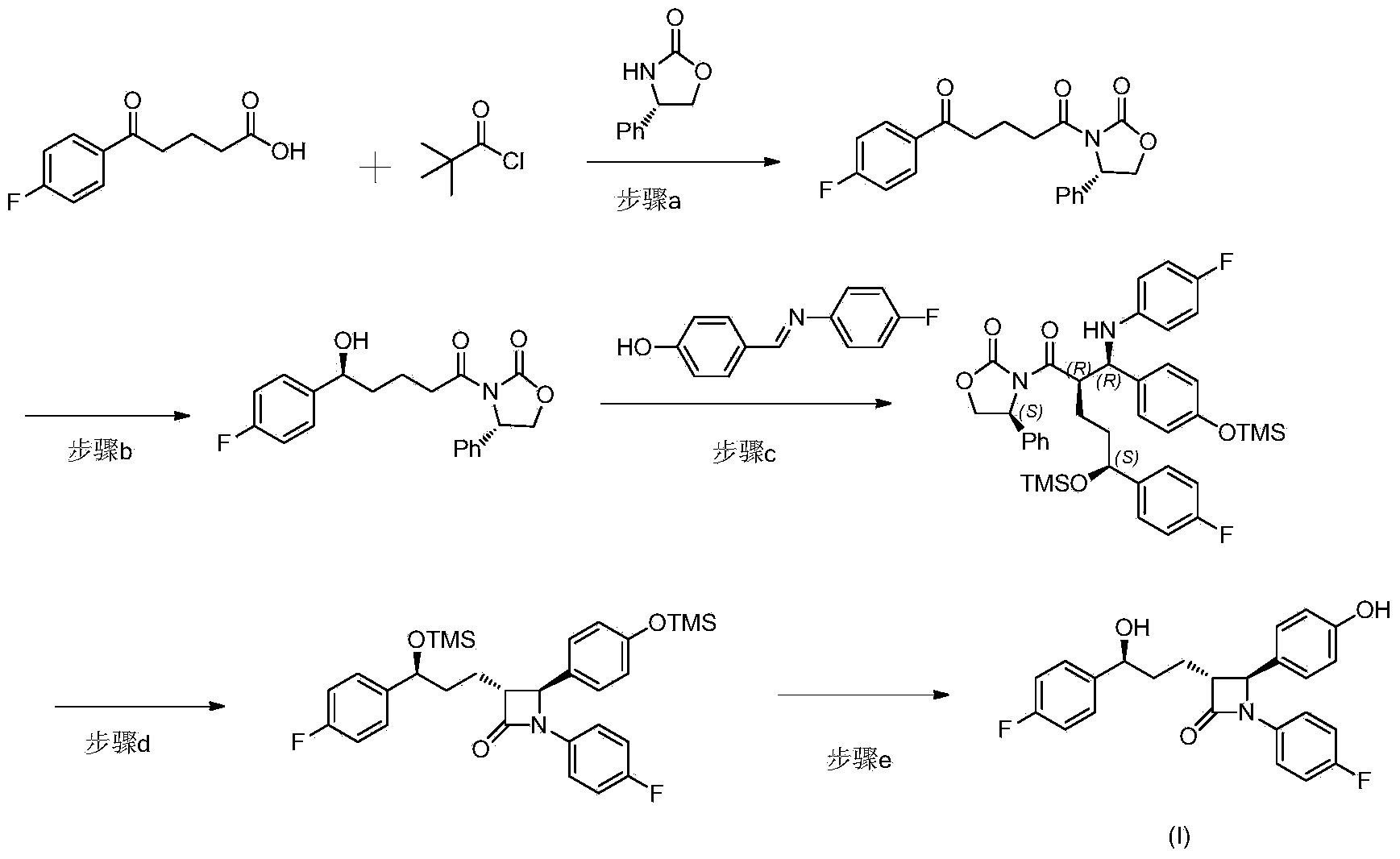

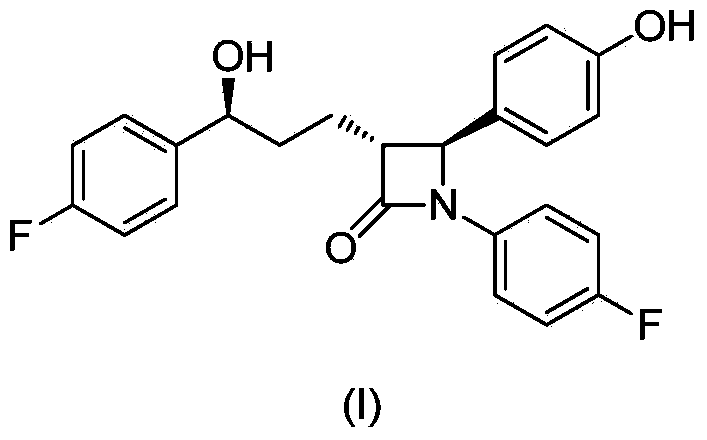

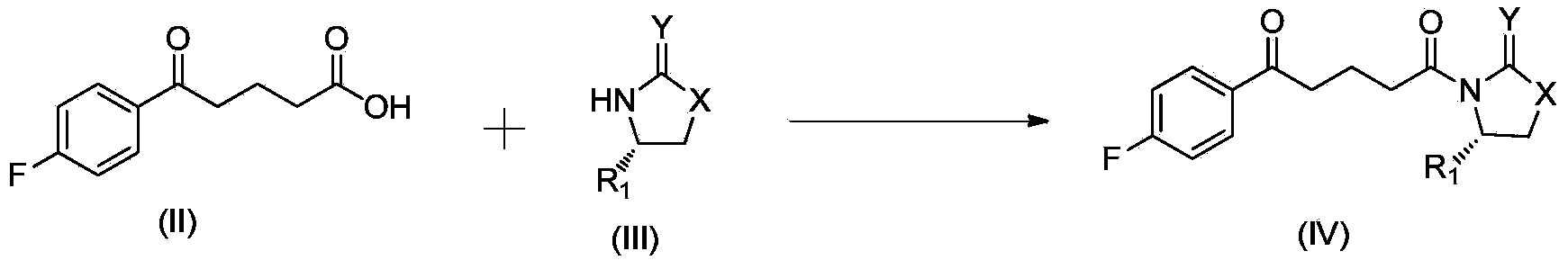

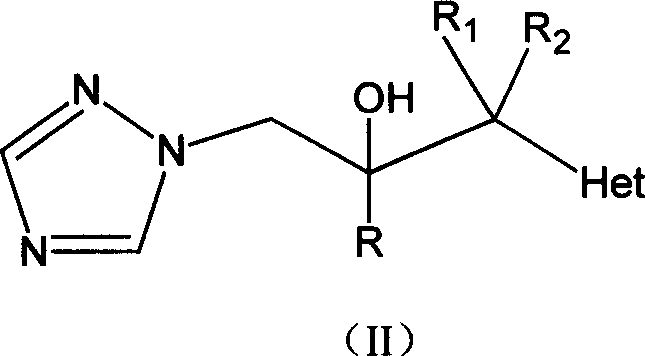

Stereselective synthesis method for lipid-lowering drug ezetimibe

ActiveCN103965089AHigh chemical purityHigh optical purityOrganic chemistryBulk chemical productionLipid lowering drugSynthesis methods

The invention provides a stereselective synthesis method for a lipid-lowering drug ezetimibe shown in formula I. The method comprises the following steps: a, P-fluorobenzoyl butyric acid shown in formula II reacts with a chiral auxiliary shown in formula III to obtain ketone shown in formula IV; b, under the existence of a chiral catalyst, the ketone shown in formula IV is reduced to chiral alcohol shown in formula V; c, chiral alcohol shown in formula V reacts with a silicyl protective agent to obtain a protected compound shown in formula VI, and then the compound shown in formula VI and imine shown in formula VII are subjected to addition and protecting groups are removed, so that a compound shown in formula VIII and a diastereomer thereof shown in formula IX are obtained, and through recrystallization with an appropriate solvent, an optically pure compound shown in formula VIII is obtained; d, the compound shown in formula VIII is protected with an acylation reagent, so that a compound shown in formula X is obtained, and amide shown in formula X is cyclized with a fluorinion catalyst, so that protected lactam shown in formula XI is obtained; then protecting groups are removed, and the ezetimibe shown in formula I is obtained.

Owner:SHANGHAI FANGNAN PHARMA

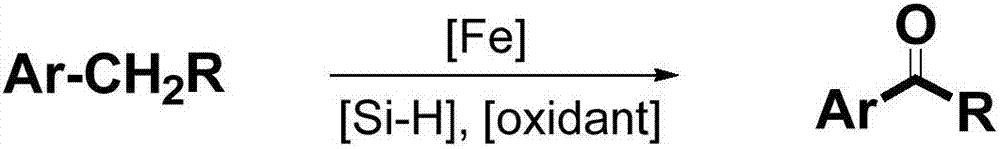

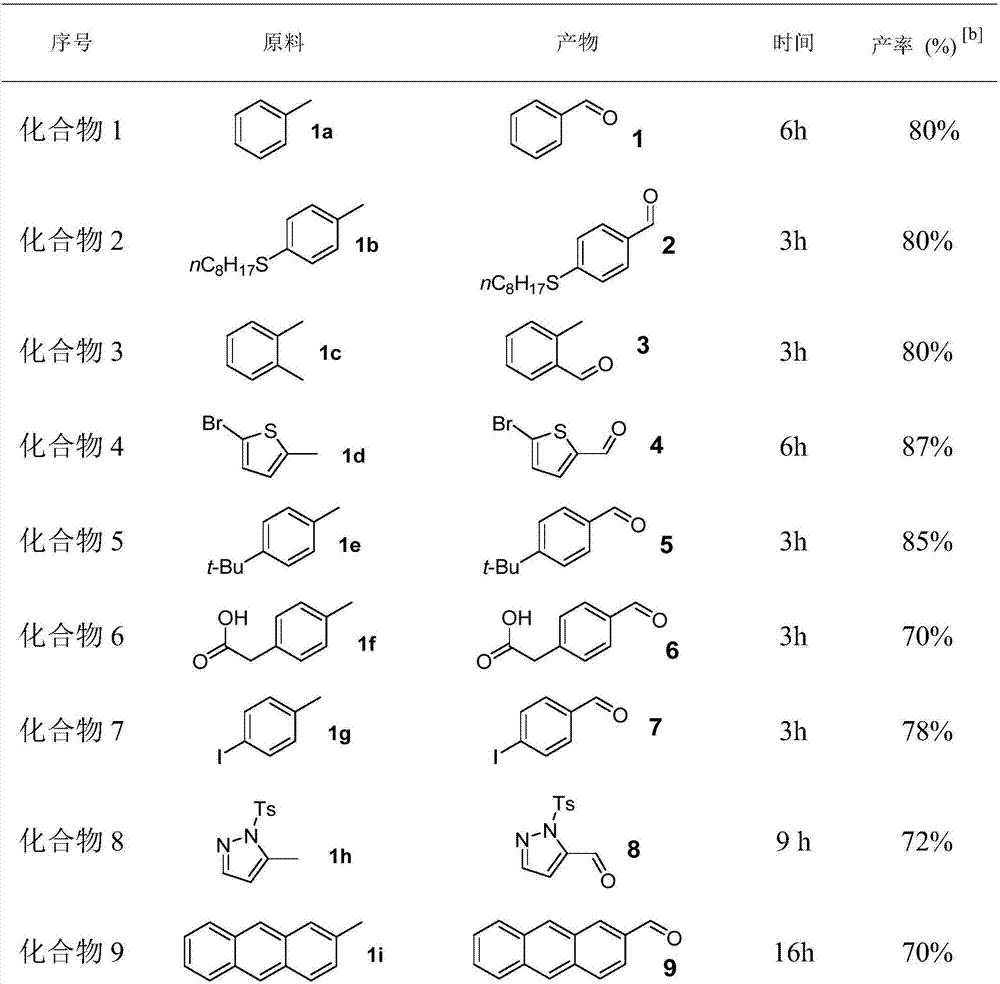

Method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing alkyl aromatic compound by iron

ActiveCN107216242ABroad compatibilityGood compatibilitySugar derivativesOrganic compound preparationSide chainCatalytic oxidation

The invention discloses a method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing an alkyl aromatic compound by iron, and belongs to the technical field of catalytic synthesis. According to the method, a low-cost and environment-friendly iron catalyst is used under a normal pressure; under the action of hydrogen and silicon reagents serving as an accelerant and an oxidant, a side chain of an aromatic hydrocarbon is oxidized into a carbonyl group for generating the corresponding aromatic aldehyde, aromatic ketone and aromatic ester. The method for preparing the aromatic aldehyde, the aromatic ketone and the aromatic ester through a catalytic oxidation reaction, which is provided by the invention, has numerous advantages that a catalyst, reaction raw materials, the oxidant and a silicon reagent are wide in sources and good in stability and is low-cost and environment-friendly; the alkyl aromatic compound is metered to participate in a reaction; the reaction condition is mild; the compatibility of functional groups is good; the scope of application is wide; the reaction selectivity is good; in an optimized reaction condition, the separation yield of a target product can be up to approximately 95 percent.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing furan derivatives through biomass catalytic conversion

The invention relates to a method for preparing furan derivatives through biomass catalytic conversion. The method is characterized in that glucose, sucrose, cellobiose, cellulose, hemicellulose, lignocellulose, and the like are adopted as raw materials; under the effect of a catalyst, the raw materials are subjected to hydrolysis, isomerization, and dehydration reactions in a polar organic solvent, such that furan derivatives such as 5-hydroxymethylfurfural, 5-alkoxymethylfurfural, and furan acetals are obtained. The method has high raw material utilization rate. The system has the advantages of easy separation and easy purification.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

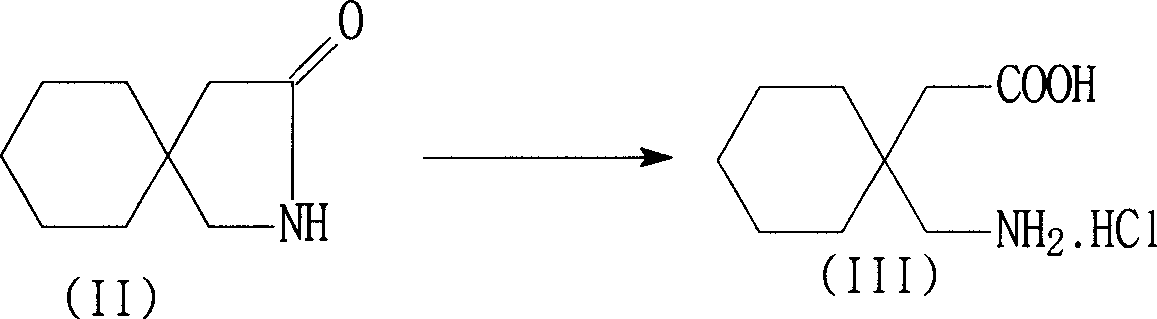

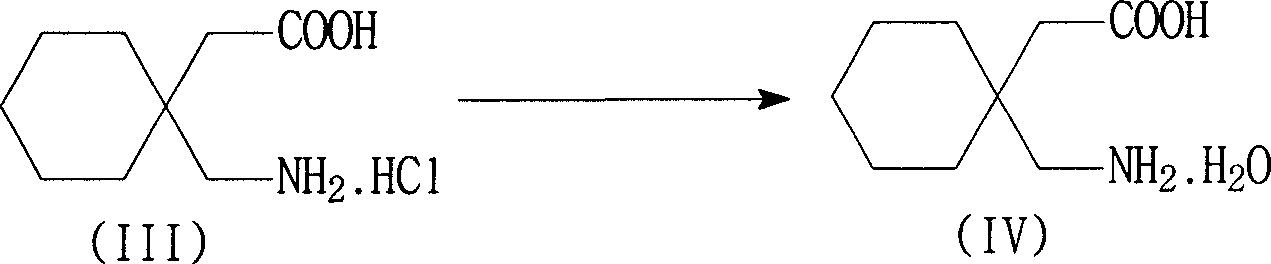

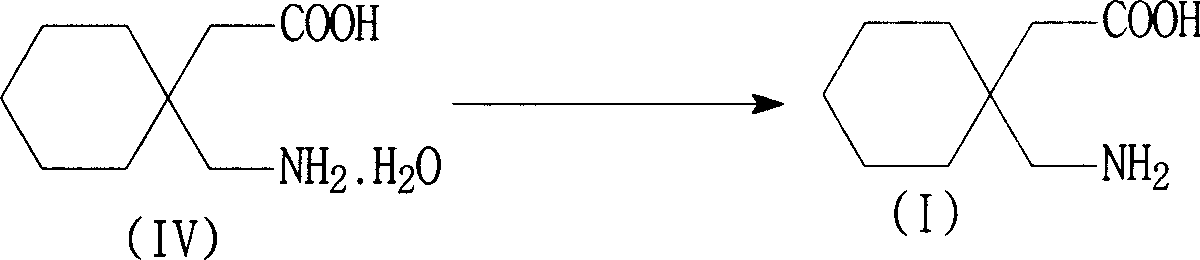

Production of gabapendin

ActiveCN1896050AAvoid distillationReduce energy consumptionOrganic compound preparationAmino-carboxyl compound preparationAlcoholSolvent

Production of gabapentin is carried out by 3,3-pentylidene butyrolactam as initial raw material, hydrolyzing to obtain gabapentin salt, converting it into gabapentin hydrate and elutriating out gabapentin from alcohol solvent, neutralizing while adsorbing and decoluring residual hydrate by active carbon and siliceous earth, controlling pH to 8-8.5 and recovering mother-liquid. It is safe and convenient, has short period, less consumption and higher recovery rate. It can be used for industrial production.

Owner:ZHEJIANG CHIRAL MEDICINE CHEM

Method for preparing furan derivatives by catalytic conversion of fructose-based biomass

A method for preparing furan derivatives by catalytic conversion of fructose-based biomass is characterized by: taking biomass such as fructose, cane sugar, inulin and the like as raw materials, taking low-boiling-point alcohols comprising aliphatic alcohols or alicyclic alcohols all with six or less than six carbon atoms as a solvent, and under the effect of a catalyst, performing reactions comprising hydrolysis, dehydration, etherfication and the like for coupling so as to obtain furan derivatives such as 5-alkoxymethyl furfural, levulinate esters, 5-hydroxymethylfurfural and the like. The method has the advantages of high raw material utilization rate, high in-situ coupling efficiency in the dehydration and etherfication reactions, and easily separated and purified system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

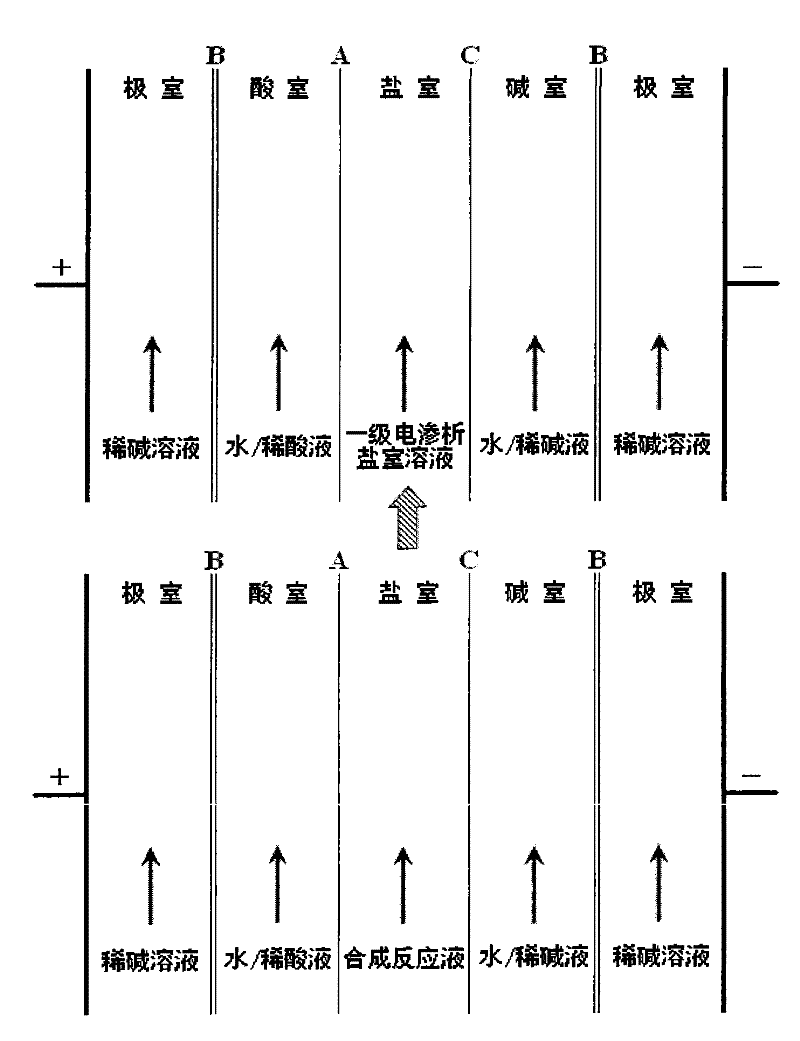

Method for extracting ascorbyl-2-phosphate through bipolar membrane electrodialysis

InactiveCN101747376AShorten the separation processHigh separation yieldGroup 5/15 element organic compoundsElectrodialysisPhosphoric Acid EstersPhosphate ion

The invention discloses a method for separating high-purity AMP through the bipolar membrane electrodialysis technology. Cl- in AMP reaction liquid is effectively removed by using the obvious difference between the migration speed of 5, 6-O-isopropyl ascorbyl phosphate in electrodialysis membrane modulus and the migration speed of Cl-in the electrodialysis membrane modulus. Alkali metal positive ions and negative ions in the AMP reaction liquid are separated by using the resolving function of the bipolar membrane electrodialysis to positive ions and negative ions, so acidic deprotected AMP is obtained and alkali metal is recovered and is cyclically used for AMP synthetic reaction. The acidic deprotected AMP and alkali-earth metal oxides form AMP alkaline-earth metal salts through salt formation. Moreover, phosphate ions which are not removed from solution can be removed through sedimentation. Finally, high-purity AMP alkaline-earth metal salts are obtained through concentration, decolorization, crystallization and drying.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for caprolactone

The invention discloses a preparation method for caprolactone. The method comprises the following steps: with supersaturated aliphatic acid and cyclohexanone as reaction raw materials, carrying out a reaction at 40 to 50 DEG C for 1 to 2 h so as to obtain a crude caprolactone solution; then carrying out negative pressure distillation so as to remove a solvent and incompletely reacted raw materials; and cooling the residual solution and carrying out crystallization, filtering and separation so as to obtain caprolactone. The method has the advantages of simple operation, high separation yield of caprolactone, small loss, capacity of realizing continuous feeding in the whole separation process from the crude caprolactone solution to the caprolactone product and applicability to industrial production.

Owner:NANJING RED SUN NEW MATERIAL

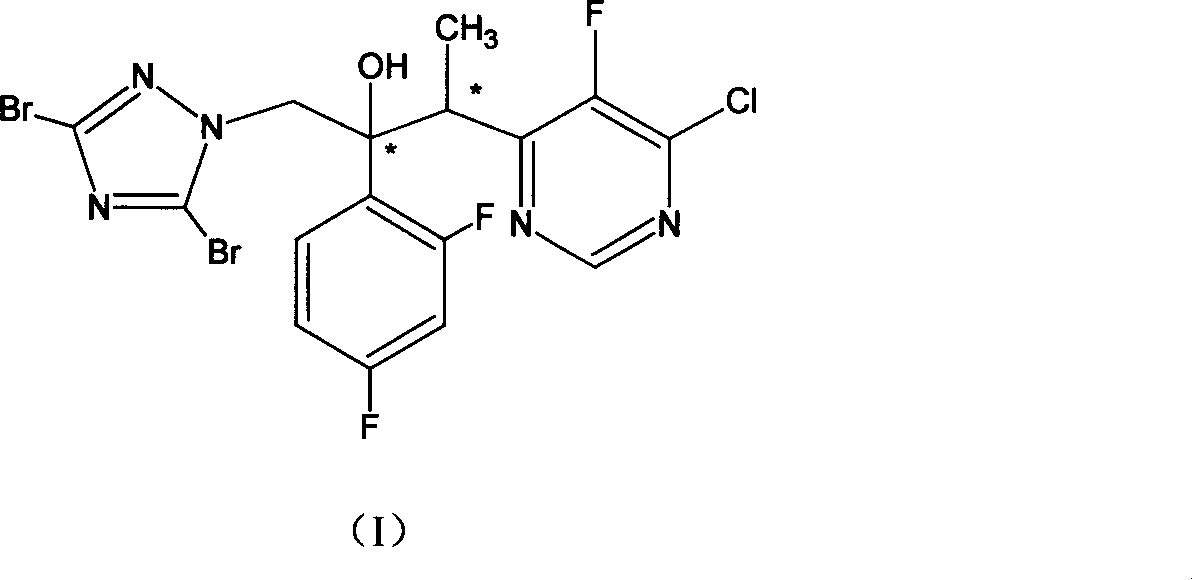

Prepn process and intermediate for voriconazole

The present invention relates to 3-(4-chloro-5-fluoropyrimidyl-6-yl)-2-(2ú¼4-diflurophenyl)-1-(3ú¼5-dibromo-1H-[1ú¼2ú¼4]-triazolyl-1-yl)butyl-2-alcohol, as the intermediate for voriconazole, ad its preparation process and the voriconazole preparing process therewith.

Owner:JIANGSU HANSOH PHARMA CO LTD

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for preparing imino ether by virtue of catalytic conversion of aromatic aldehyde

The invention provides a method for preparing imino ether by virtue of catalytic conversion of aromatic aldehyde. The method is characterized in that one or two of oxygen gas and air is / are taken as an oxygen source, one or two of ammonia water, ammonia gas, urea and ammonium salt is / are taken as a nitrogen source, and alcohol with low boiling point is taken as a solvent, so that aromatic aldehyde is subjected to an ammoxidation reaction in the presence of a catalyst, and nitrile which is generated in situ and alcohol are subjected to an addition reaction so as to obtain imino ether. The method has the advantages that the raw material utilization ratio is high, the catalyst is easy to recover and recycle, and the separation, purification and derivative conversion of target products are easy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

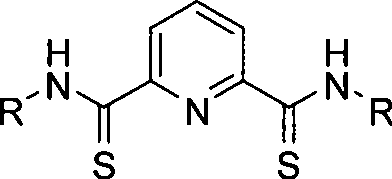

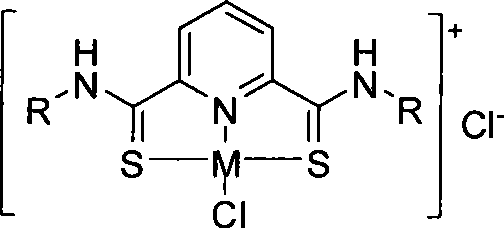

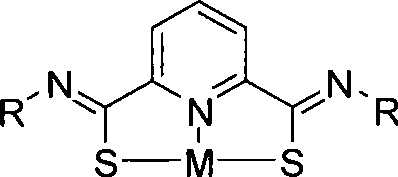

Forcipate thioacid amide ligand, complex compound and application of sulfo-2, 6-pyridine diformamide framework

InactiveCN101445481AHigh selectivityHigh separation yieldOrganic-compounds/hydrides/coordination-complexes catalystsNickel organic compoundsHeck reactionAlkoxy group

The invention relates to forcipate thioacid amide ligand of sulfo-2, 6-pyridine diformamide framework and a complex compound thereof, the constitutional formula thereof is as above, wherein, R in the formula is C2 to C8 alkyl, and phenyl-substituted alkyl or phenyl-substituted by alkoxy; and M is nickel, palladium or platinum. The ligand provided by the invention is non-phospine ligand and keeps stable against air and water, and lone pair electrons on nitrogen in the thioacid amide can adjust the electric property of sulfur, substitutional group on nitrogen can adjust the electron and the spatial configuration of the whole ligand; the ligand has the advantages of convenient compound, high total yield, and numerous compound. The complex compound provided by the invention has the advantages of high stability owing to the special forcipate structure, high catalytic activity during the catalytic reaction, wide application range, good selectivity and mild reaction condition, and is widely applicable to the cross coupled reaction of the transition metal catalyze, such as the Heck reaction and the like.

Owner:WUHAN UNIV

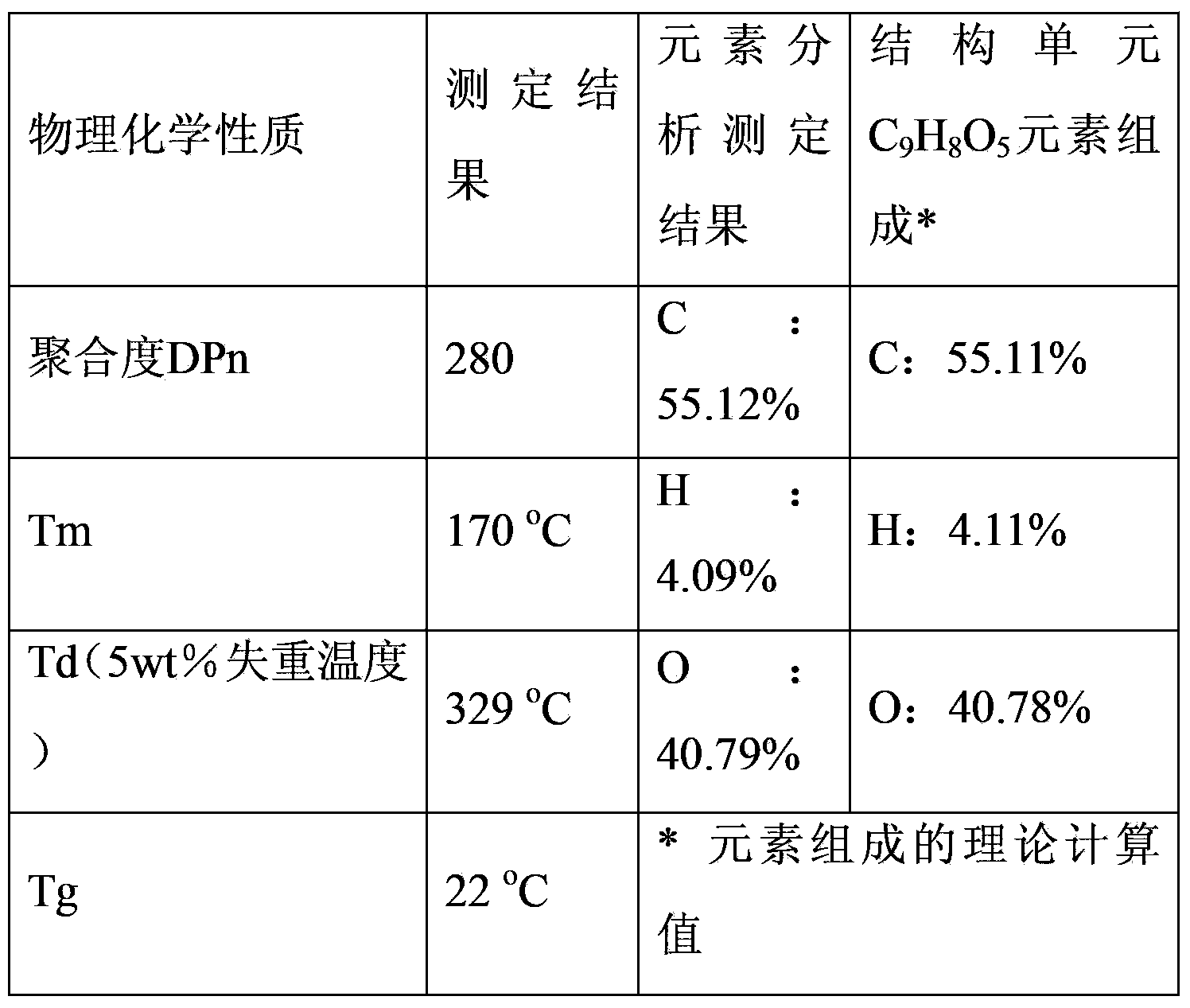

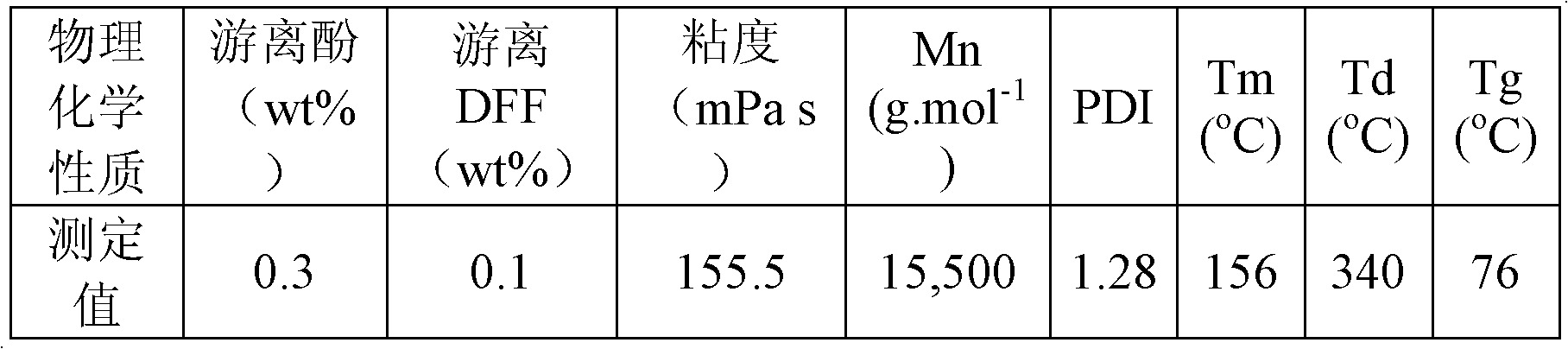

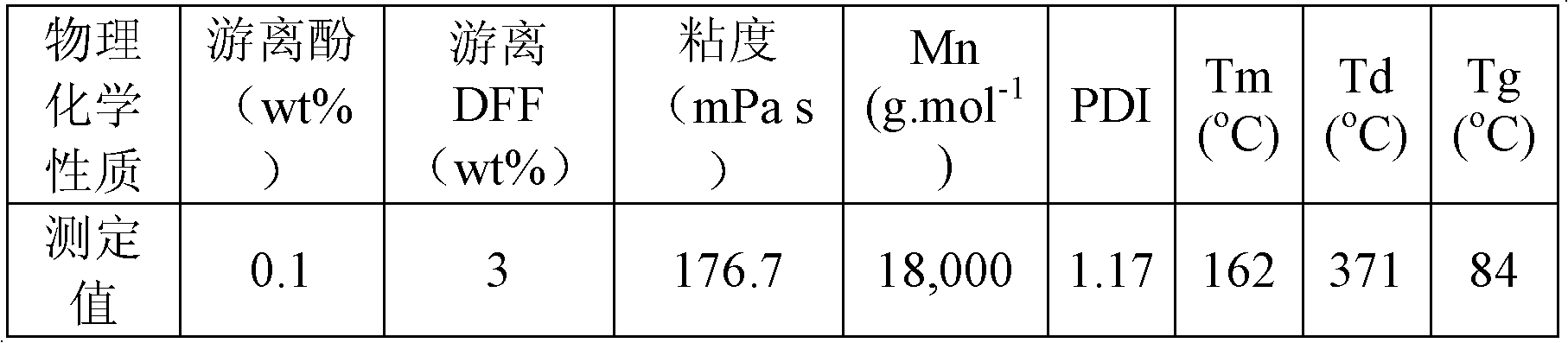

Biomass based polyester preparation method

A biomass based polyester preparation method is as follows: biomass based monomer 2, 5-dihydroxy methyl furan and a dibasic acid are used as raw materials for esterification prepolymerization for reaction for 0.5-10h in the presence of a catalyst at 90-300 DEG C under the protection of nitrogen; ester exchange condensation is performed at 150-350 DEG C under the condition of 1-10mmHg vacuum, and the reaction is performed for 0.1-15h; a dissolution-precipitation method is used for purification and removing of impurities and unreacted monomers and oligomers to obtain the biomass based polyester product. The biomass based polyester product prepared by the preparation method is high in yield, easy in product separation, and environmental friendly, and has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

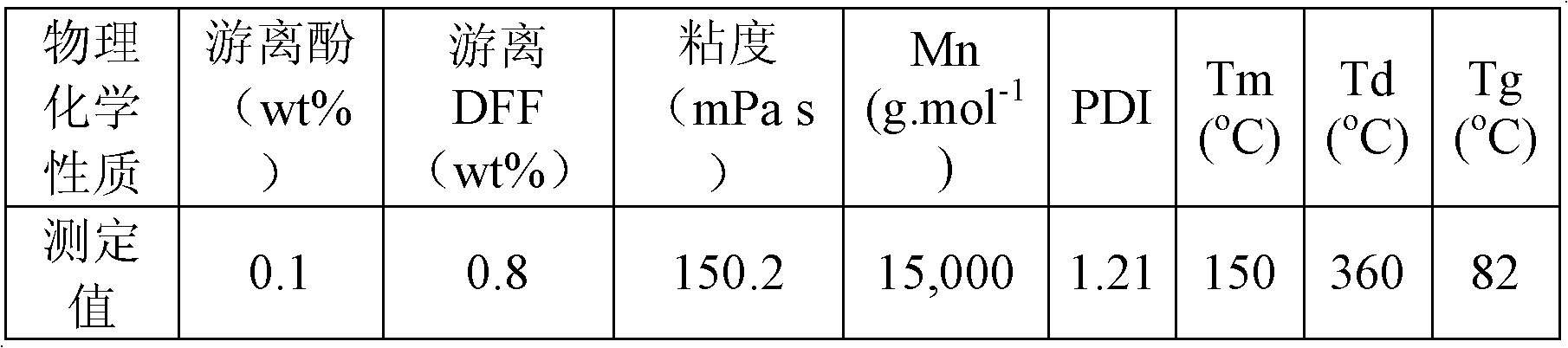

Biomass-based phenolic resin and preparation method thereof

The invention relates to a preparation method of a biomass-based phenolic resin. According to the invention, a biomass monomer 2,5-diformyl furan and phenol are adopted as raw materials; under the catalyzing of alkali, a temperature of 30-200 DEG C, and nitrogen gas protection, the raw materials are subjected to a addition and condensation reactions for 1-10h; and water and other impurities in the reaction system are removed with a vacuum distillation method, such that a novel phenolic resin high-quality product with 2,5-diformyl furan for substituting formaldehyde is obtained. With the method, the prepared product has the advantages of high yield, easy separation, and environment-friendliness. The method has good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

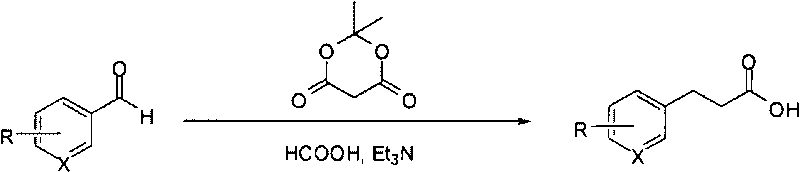

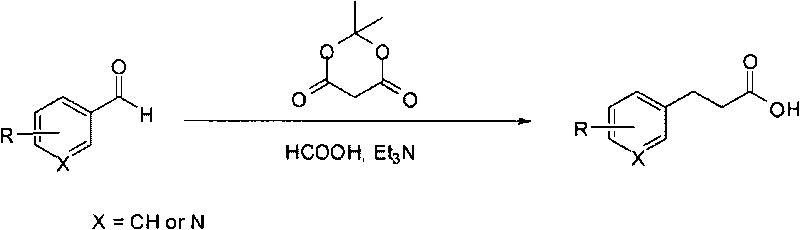

Method for fast synthesizing 3-substituted aromatic acid

InactiveCN101747171AThe synthesis process is simplePurification and separation method is simpleOrganic compound preparationCarboxylic acid esters preparationHalogenFatty amine

The invention relates to a practical method for synthesizing 3-substituted aromatic acid, which not only solves the problems of the conventional method which has high cost, long reaction time, complicate aftertreatment and inconvenience for application operation, but also solves the problem that the conventional method is not applicable to a method for preparing 3-substituted aromatic acid by using aldehyde, the benzene rings of which have groups of nitryl, halogen and the like as raw materials. In the technical scheme, aromatic formaldehyde, dimethyl ethidine malonic ester are used as raw materials, reflux reaction is carried out in a mixed solvent of formic acid and saturated fatty amine, and then extraction by alkalization and acidification is performed for purification to directly obtain high-purification 3-substituted aromatic acid.

Owner:上海药明康德新药开发有限公司

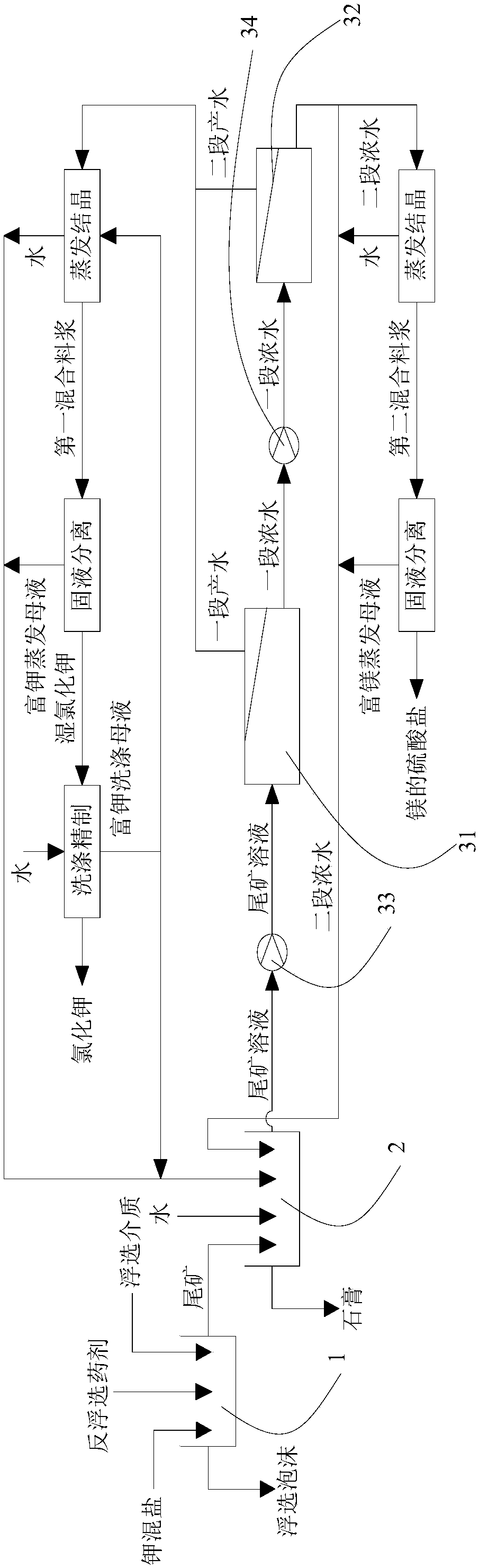

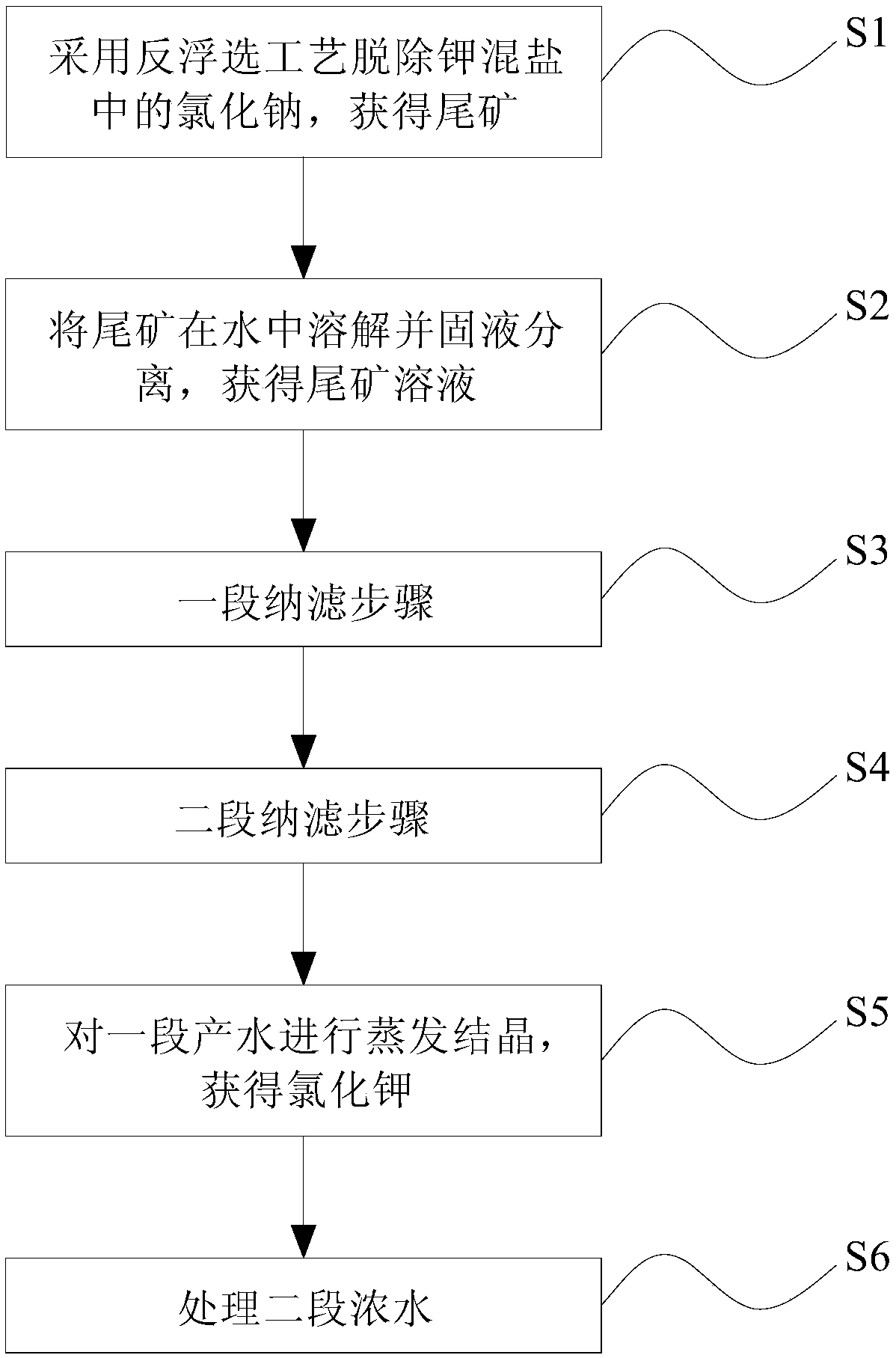

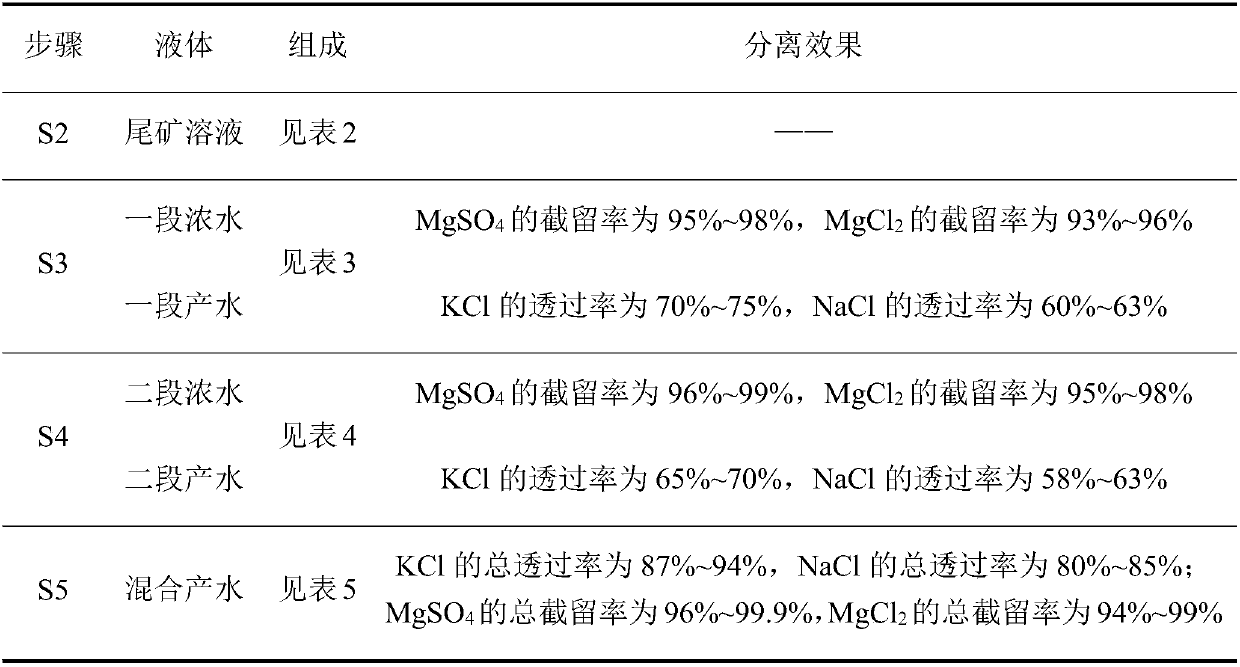

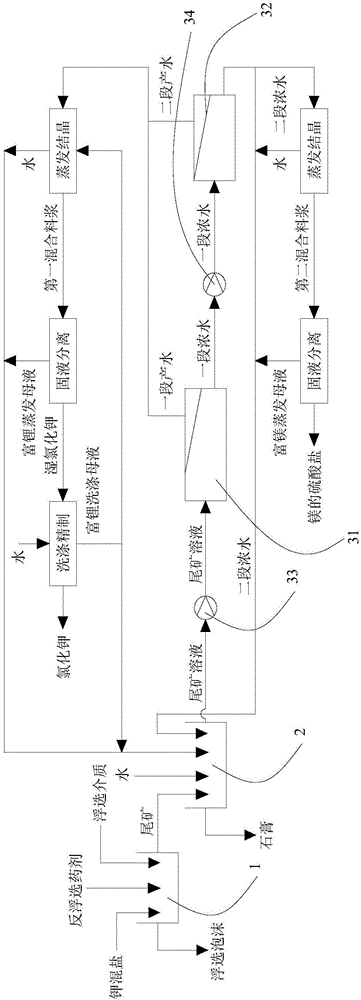

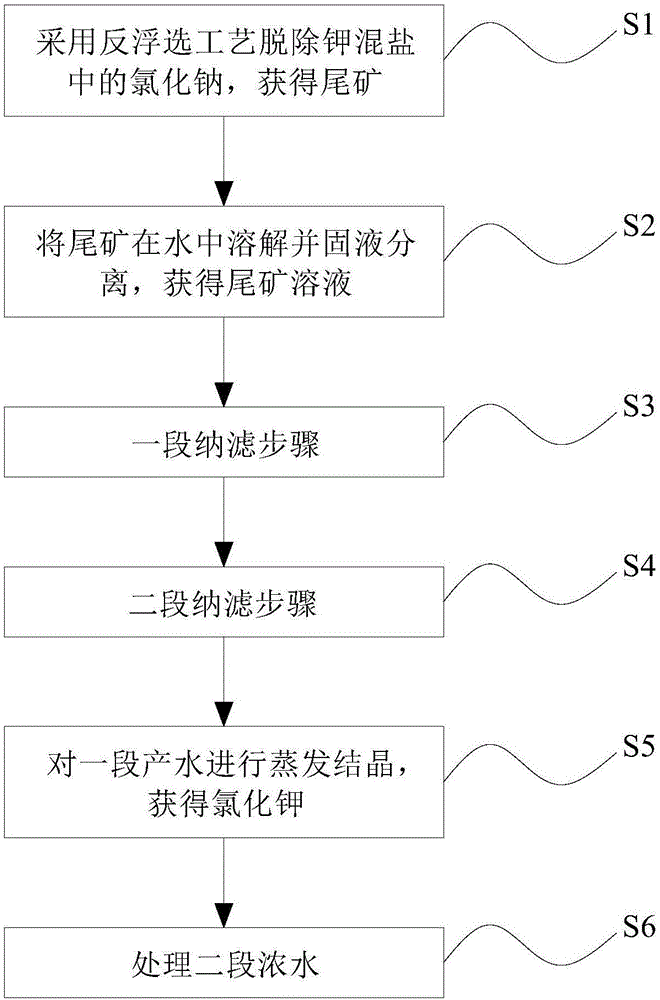

Utilize potassium mixed salt to prepare the method for potassium chloride

ActiveCN106430248BGuaranteed yieldEasy to separateReverse osmosisAlkali metal chloridesNanofiltrationMethods preparation

The invention discloses a method for preparing potassium chloride by utilizing potassium mixed salt. The method comprises the steps that a reverse flotation process is adopted to remove sodium chloride in the potassium mixed salt, and a tailing is obtained; the tailing is dissolved in water, and solid-liquid separation is performed to obtain a tailing solution; a section of nanofiltration step is executed, wherein a nanofiltration membrane system is adopted to conduct a section of nanofiltration treatment on the tailing solution to obtain a section of concentrated water and a section of produced water and comprises a first nanofiltration membrane module and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module, the section of concentrated water is stored in the first concentrated water tank, and the section of produced water is stored in the first produced water tank; evaporative crystallization is conducted on the section of produced water to obtain the potassium chloride. The invention provides a novel method for producing potassium chloride by using potassium mixed salt as a raw material. The method has the advantages of being simple in process, high in product purity and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

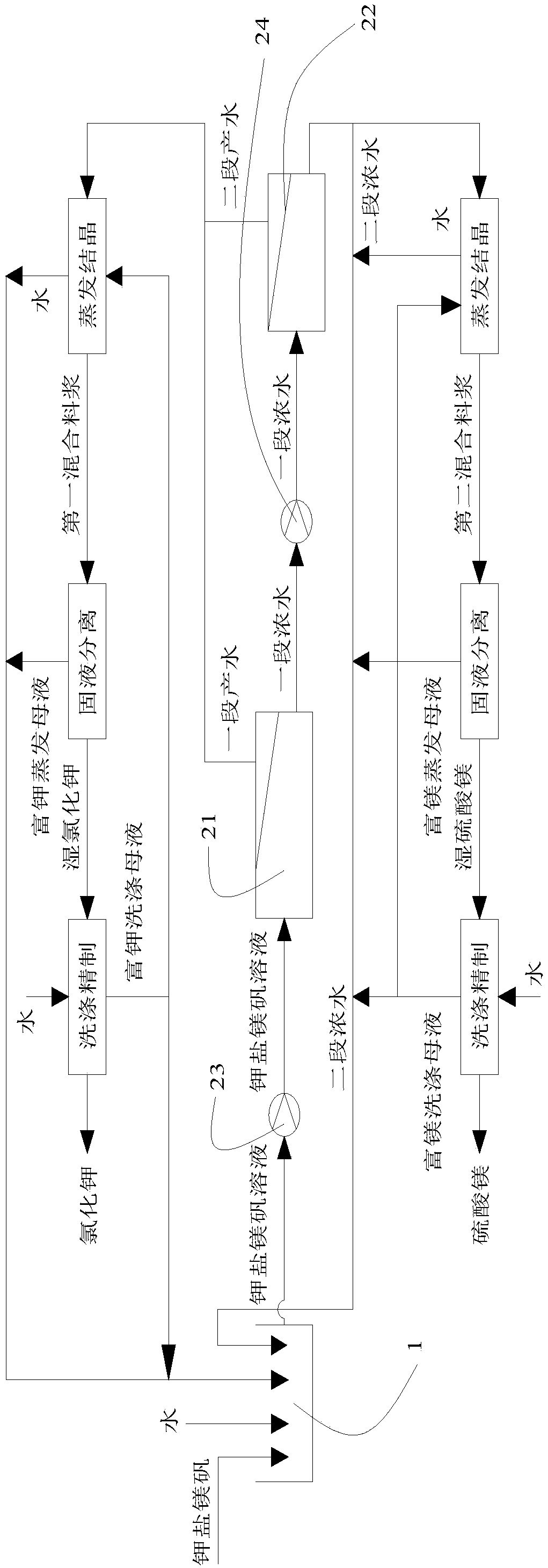

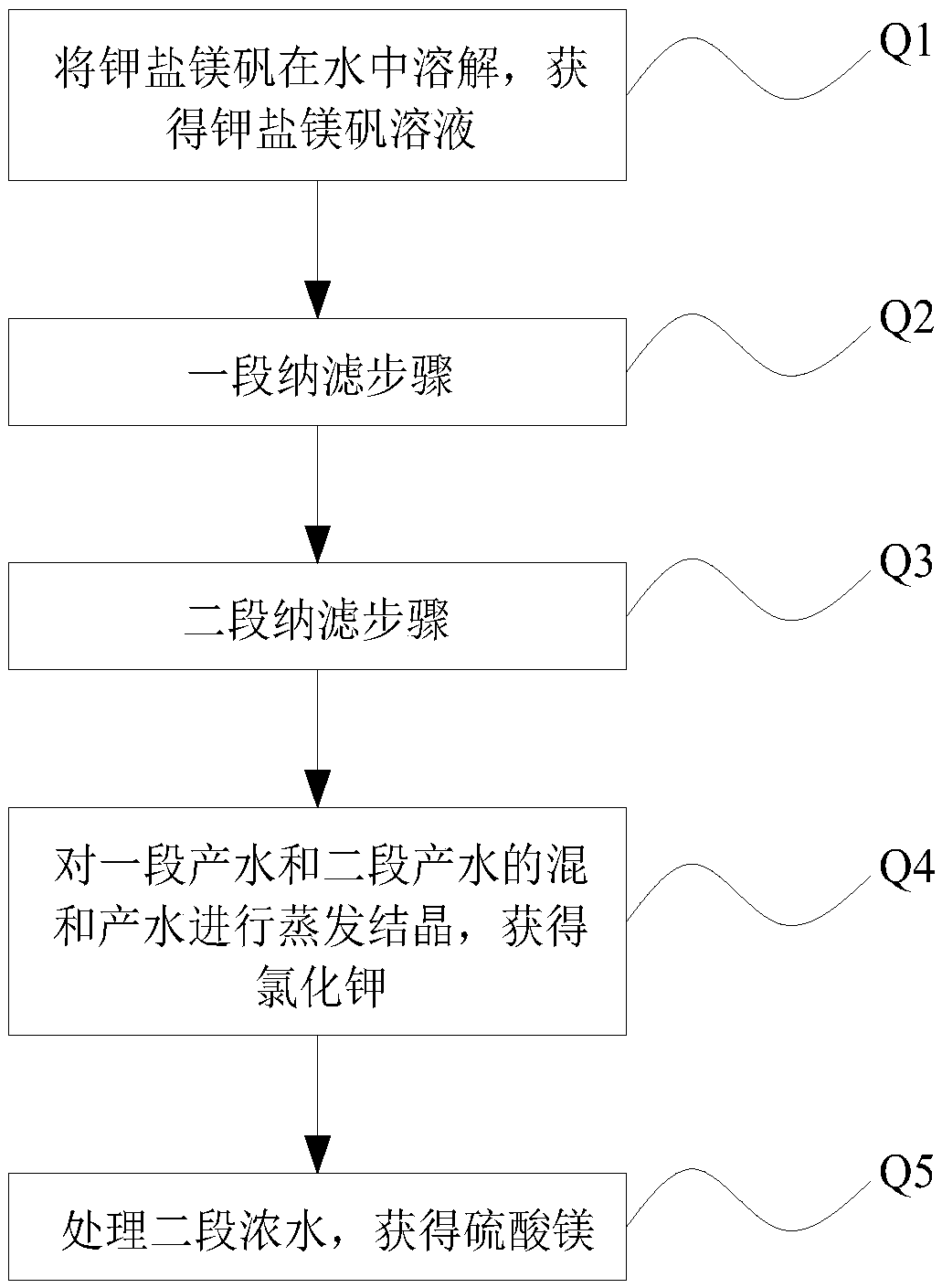

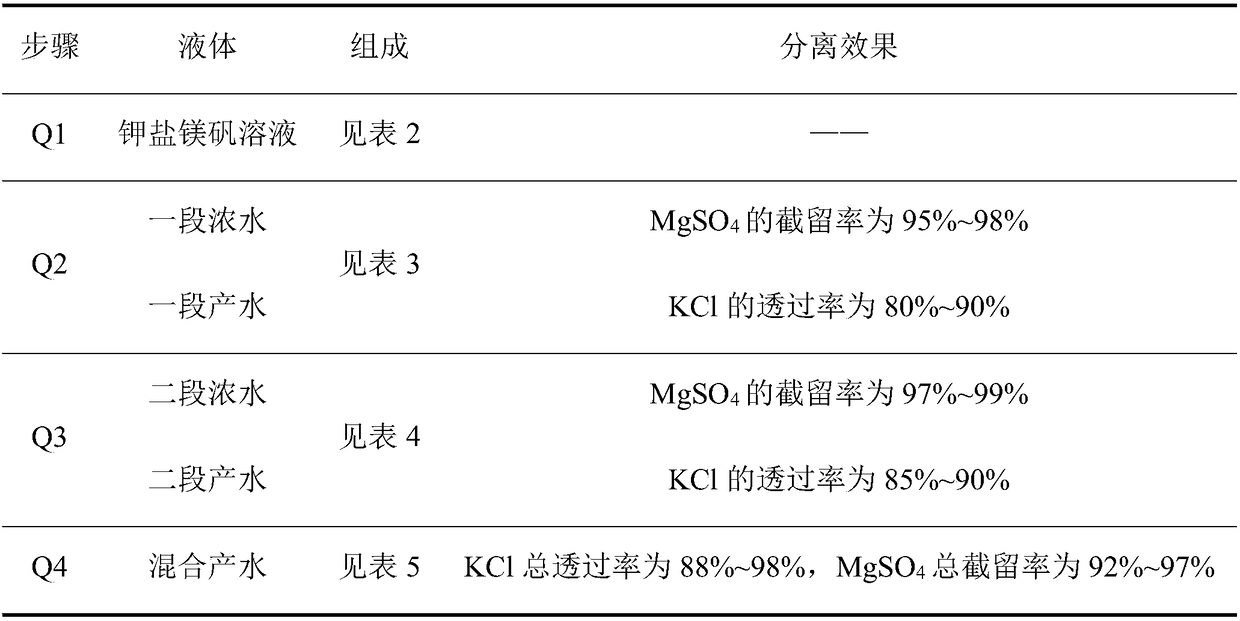

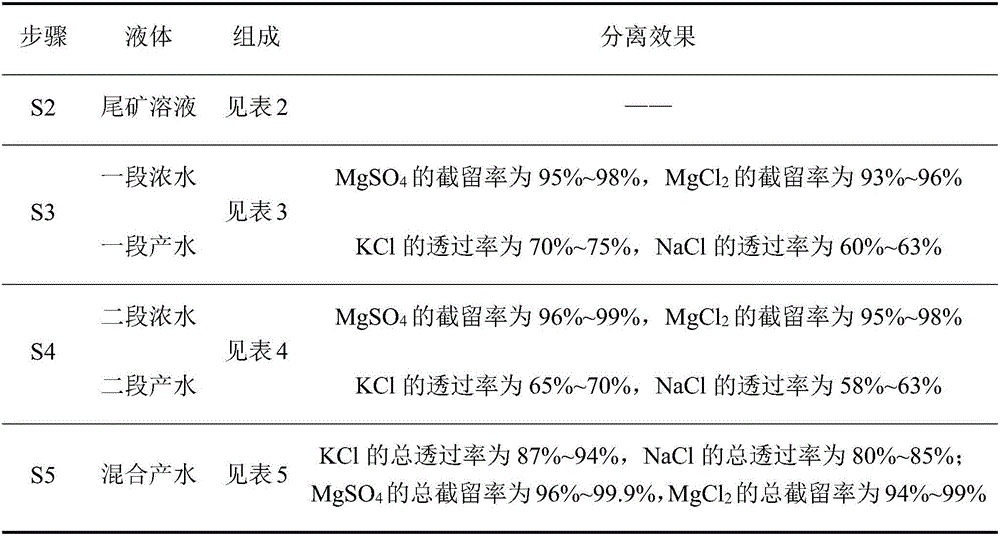

The method for preparing potassium chloride and magnesium sulfate by using kainite

ActiveCN106517250BAvoid excessive consumptionHigh separation yieldMagnesium sulfatesAlkali metal chloridesStrontiumChloride

The invention discloses a method for preparing potassium chloride and magnesium sulfate from kainite. The method comprises the following steps: dissolving the kainite in water to obtain a kainite solution, and performing primary nanofiltration: performing primary nanofiltration treatment on the kainite solution by adopting a nanofiltration membrane system to obtain primary concentrated water and primary producing water, wherein the nanofiltration membrane system comprises a first nanofiltration membrane assembly and a first concentrated water tank and a first producing water tank which are connected to the first nanofiltration membrane assembly, the primary concentrated water is stored in the first primary concentrated water tank, and the primary producing water is stored in the first producing water tank; performing evaporative crystallization on the primary producing water to obtain potassium chloride; performing evaporative crystallization on the primary concentrated water to obtain magnesium sulfate, or performing secondary nanofiltration to obtain secondary concentrated water, and performing evaporative crystallization on the secondary concentrated water to obtain the magnesium sulfate. The invention provides a novel method for producing the potassium chloride and the magnesium sulfate from the kainite serving as a raw material; and furthermore, the method has the advantages of simple process, high product purity and high yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

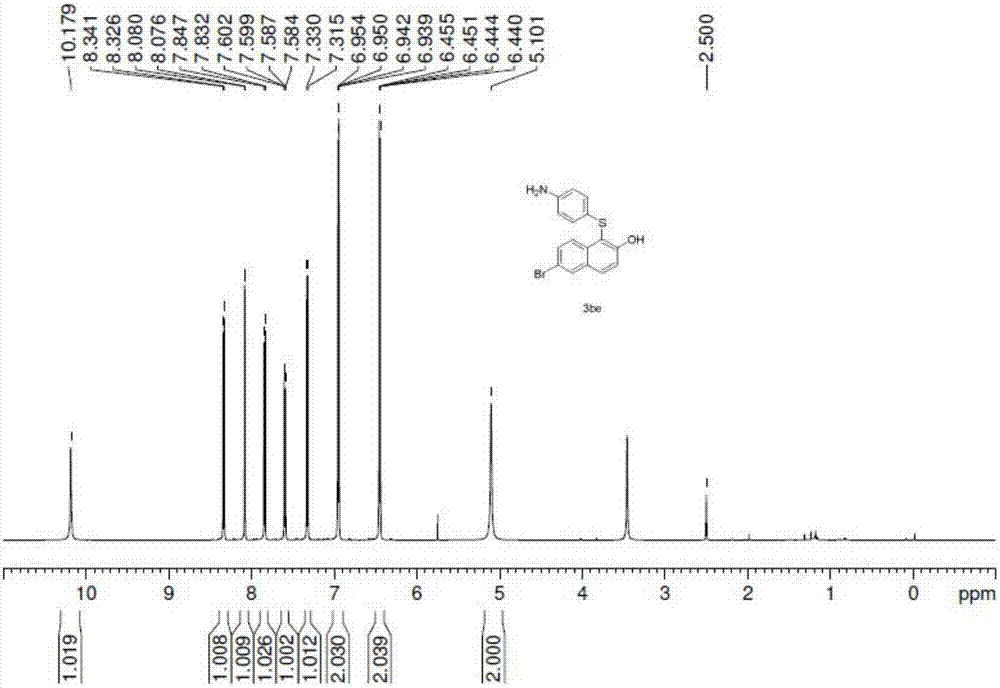

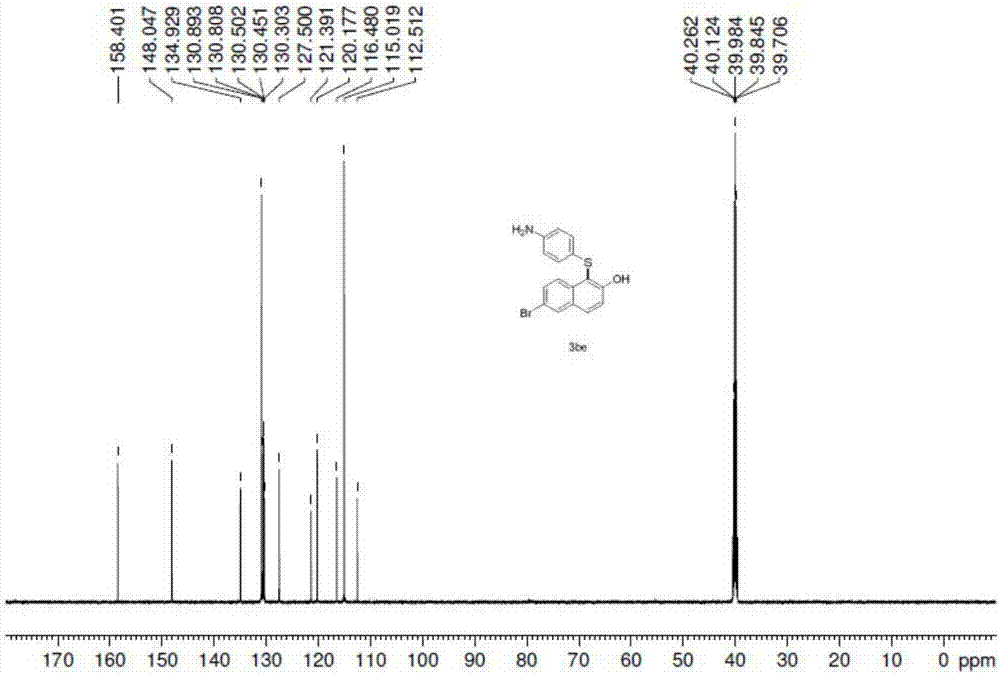

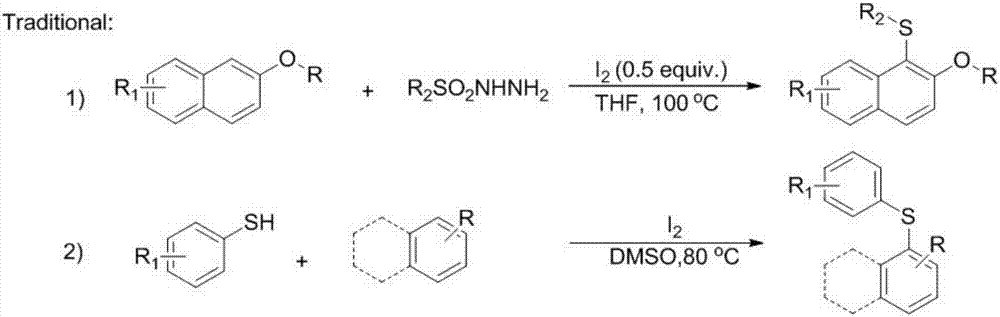

Synthetic method for aryl thioether compounds

ActiveCN106966933AAchieve green synthesisHigh separation yieldSulfide preparationThio-Phthalocyanine

The invention provides a synthetic method for aryl thioether compounds. The synthetic method comprises the following steps: adding phenolic compounds or aminated compounds, thio-alcohol compounds, a transition-metal catalyst and water into a reaction bottle, sealing the reaction bottle, introducing oxygen into the reaction bottle, carrying out heating and a stirring reaction and then successively carrying out extraction, drying, concentration and purifying so as to obtain the aryl thioether compounds. According to the invention, the phthalocyanine transition-metal catalyst is employed for catalysis of the oxidation coupling reaction of phenol or aminated compounds with thio-alcohol compounds so as to prepare the aryl thioether compounds; the synthetic method is simple in steps, easy and practicable in operation and high in product yield, as high as 80% or above and provides a novel approach for synthesis of the aryl thioether compounds; and compared with conventional methods, the method has the advantages that raw materials are cheap and easily available, water is used as a solvent (the catalyst can be dissolved in water), aryl thioether compounds with high separation yield can be obtained under heterogeneous conditions, and reaction efficiency and the atom economy of reaction can be improved.

Owner:ZHENGZHOU UNIV

Method for preparing 2,5-diformyl furan by catalyzing 5-hydroxy methyl furfural

ActiveCN101619050BHigh separation yieldHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFuranNitrite

The invention provides a method for preparing 2,5-diformyl furan by catalytic oxidation of 5-hydroxy methyl furfural. The method comprises the following steps: taking air or oxygen as an oxygen source, taking a mixture of inorganic vanadium oxides, 2,2,6,6-4-pipecolate-oxygen radicals and derivatives and nitrites of the 2,2,6,6-4-pipecolate-oxygen radicals as a compound catalyst system, and oxidizing the 5-hydroxy methyl furfural into the 2,5-diformyl furan at a temperature of between 50 and 120 DEG C. The method has the advantages of high oxidizing efficiency, few byproducts, mild reaction conditions, easy separation and purification of products and quite high practicability.

Owner:中科化物(大连)科技实业有限公司

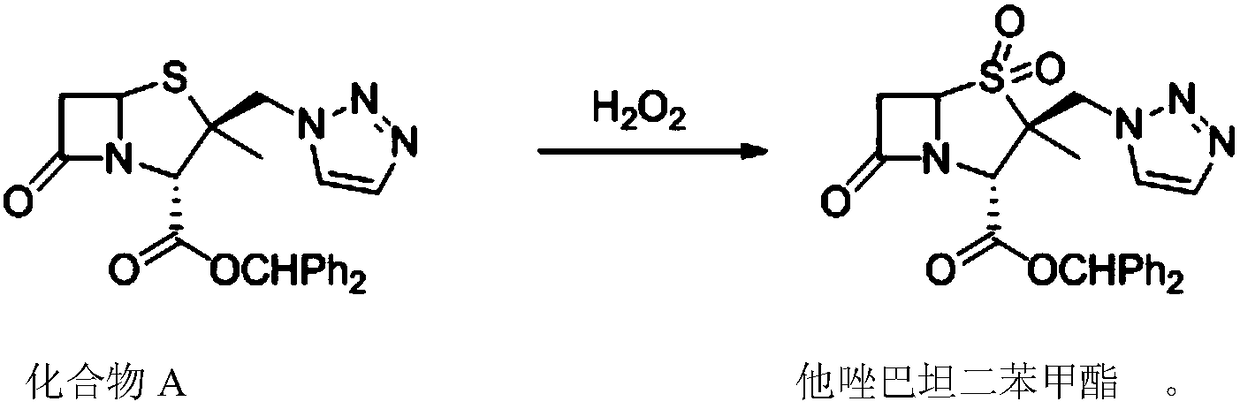

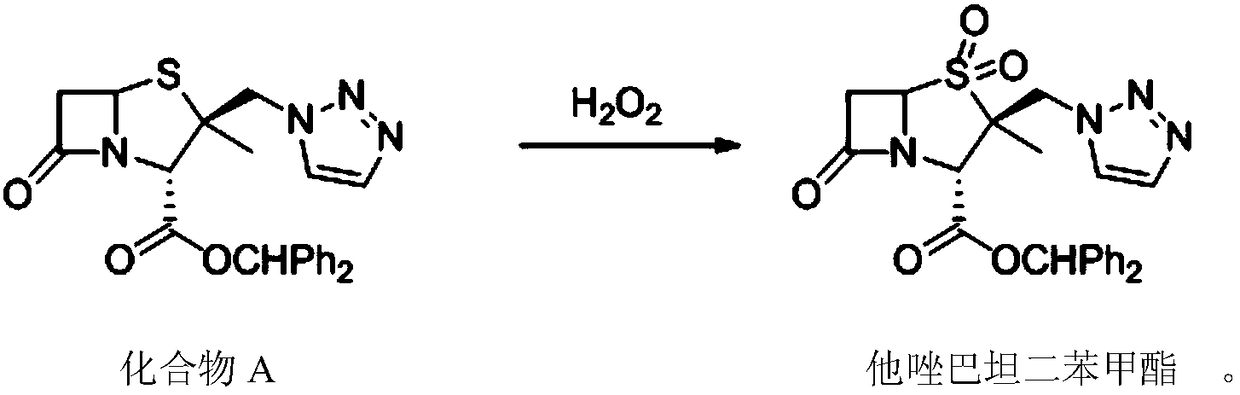

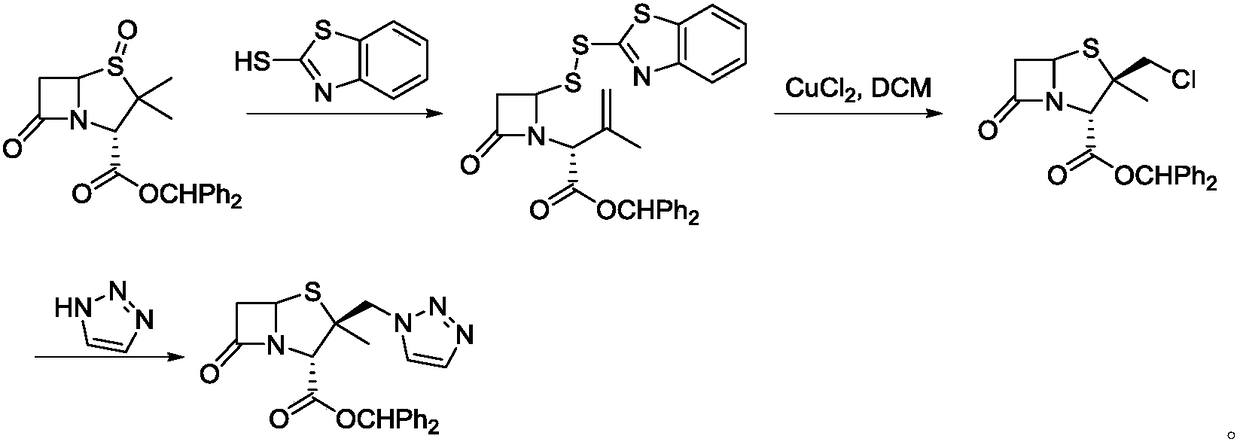

Synthetic method of tazobactam diphenylmethyl ester

InactiveCN109053767AReduce the generation of waste solidsLess wasteOrganic chemistryBy-productHydrogen peroxide

The invention provides a synthetic method of tazobactam diphenylmethyl ester. The synthetic method comprises the following step: under the action of a catalyst, a compound A and hydrogen peroxide aresubjected to an oxidation reaction to obtain the tazobactam diphenylmethyl ester (the synthetic route is as follows). In the synthetic method provided by the application, the hydrogen peroxide is usedas an oxidant, and the only by-product is water, so that on the one hand, the generation of waste solids can be greatly reduced, the amount of three wastes is greatly reduced, and the environment-friendly performance of the process is improved, and on the other hand, since the reaction by-product is only water, the synthetic method is adopted to facilitate improvement of the purity of a tazobactam diphenylmethyl ester product. Besides, the synthetic method has the advantages that the purity of the product can reach 98%, the post-treatment operation is simple, the separation yield is as high as 95.7%, and amplified production is easy.

Owner:ASYMCHEM LAB TIANJIN

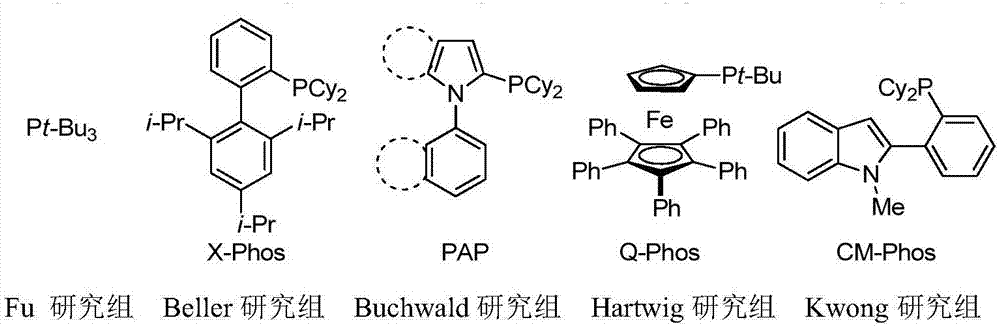

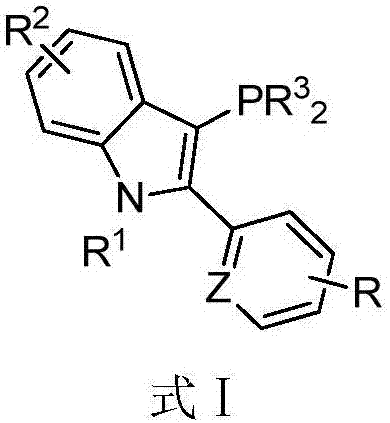

Phosphine ligand for indole skeleton as well as preparation method and application of phosphine ligand

InactiveCN107445991AHigh catalytic activityGood choiceCarboxylic acid nitrile preparationOrganic compound preparationArylNitrogen

The invention provides a phosphine ligand for a 3-(disubstituted phosphino)-1-alkyl-2-substituted phenyl-indole skeleton as well as a preparation method and application of the phosphine ligand. The structure of the phosphine ligand for the 3-(disubstituted phosphino)-1-alkyl-2-substituted phenyl-indole skeleton is shown as the following formula I: (shown in the description), wherein Z is carbon or nitrogen, R is alkyl, substituted alkyl, olefin, aryl or fluorine, R1 is alkyl, substituted alkyl or aryl, R2 is alkyl, substituted alkyl or fluorine, and R3 is alkyl, substituted alkyl or aryl.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

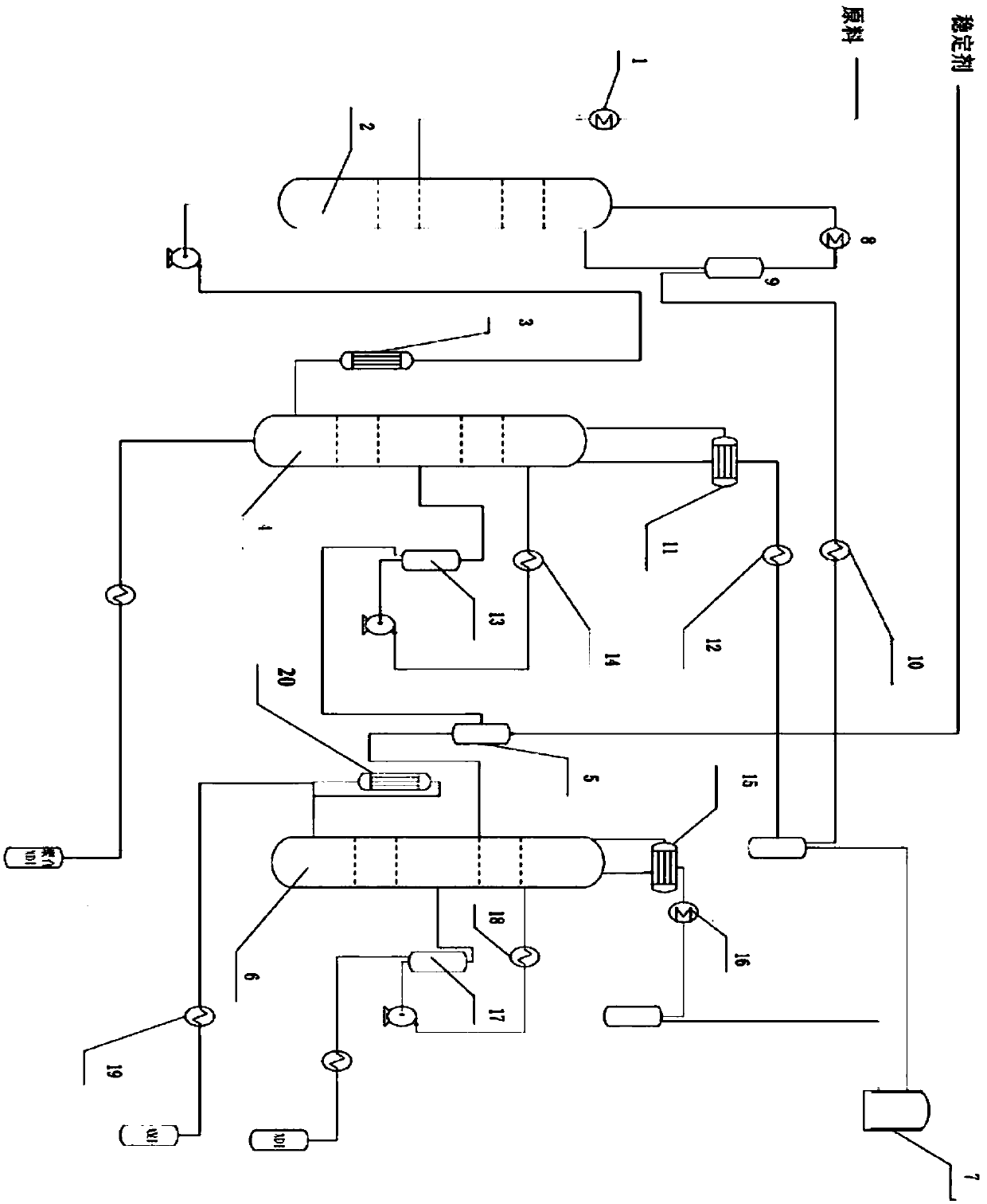

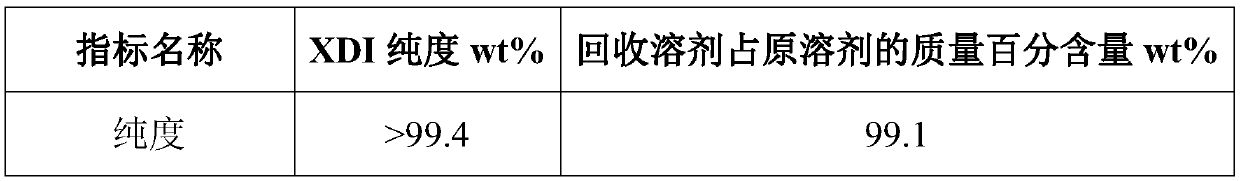

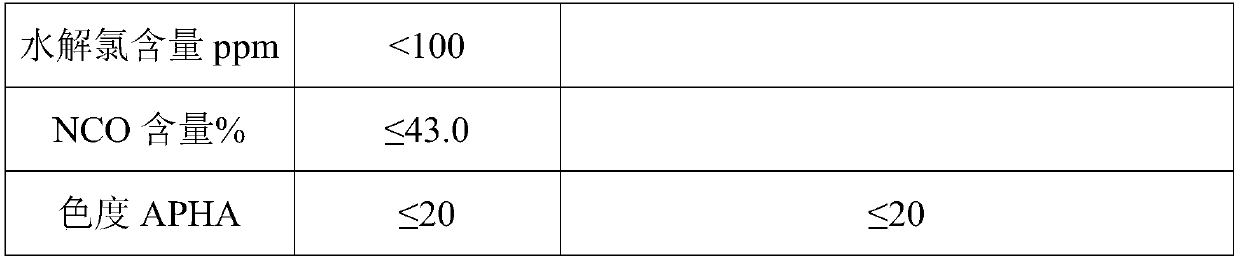

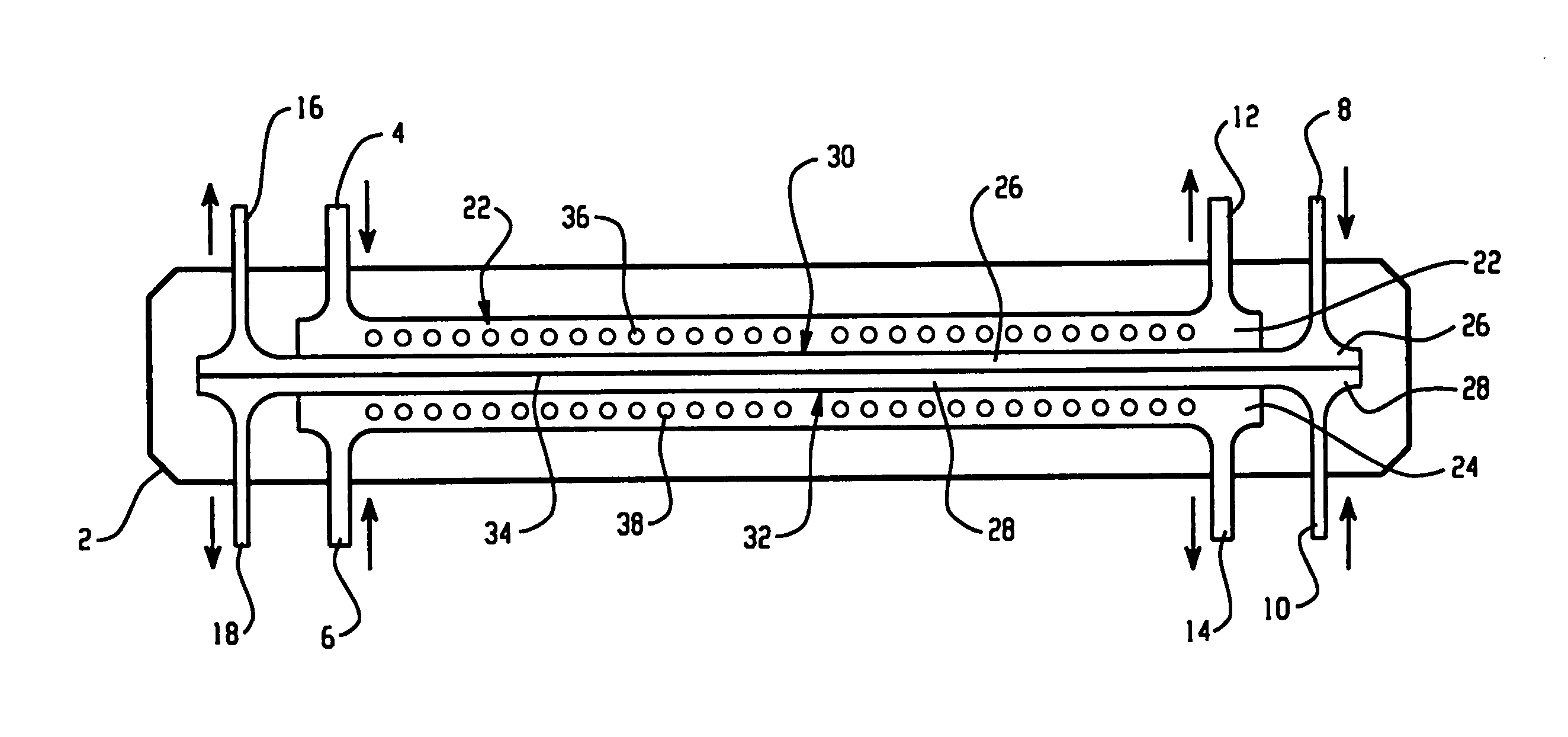

System and method for separating and refining xylylene diisocyanate product

ActiveCN110483337ASmall amount of aggregationSimple methodIsocyanic acid derivatives purification/separationSolventProcess engineering

The invention provides a system and method for separating and refining a xylylene diisocyanate product. The system comprises a desolventizing column, a de-heavy column, a stabilizer mixing device anda product refining column, wherein a to-be-treated raw material enters the desolventizing column through a feeding port of the desolventizing column; a column bottom material outlet of the desolventizing column is connected with a material inlet of the de-heavy column; a middle material outlet of the de-heavy column is connected with a feeding port of the stabilizer mixing device; a material outlet of the stabilizer mixing device is connected with the product refining column; and a material outlet is formed in the middle of the product refining column. The system and method are scientific in design, reasonable in structure, energy-saving, low in production cost, reliable in production quality, simple in process, easy to operate, high in safety, low in energy consumption, high in extractedproduct purity, high in product separation yield and less in XDI polymerization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

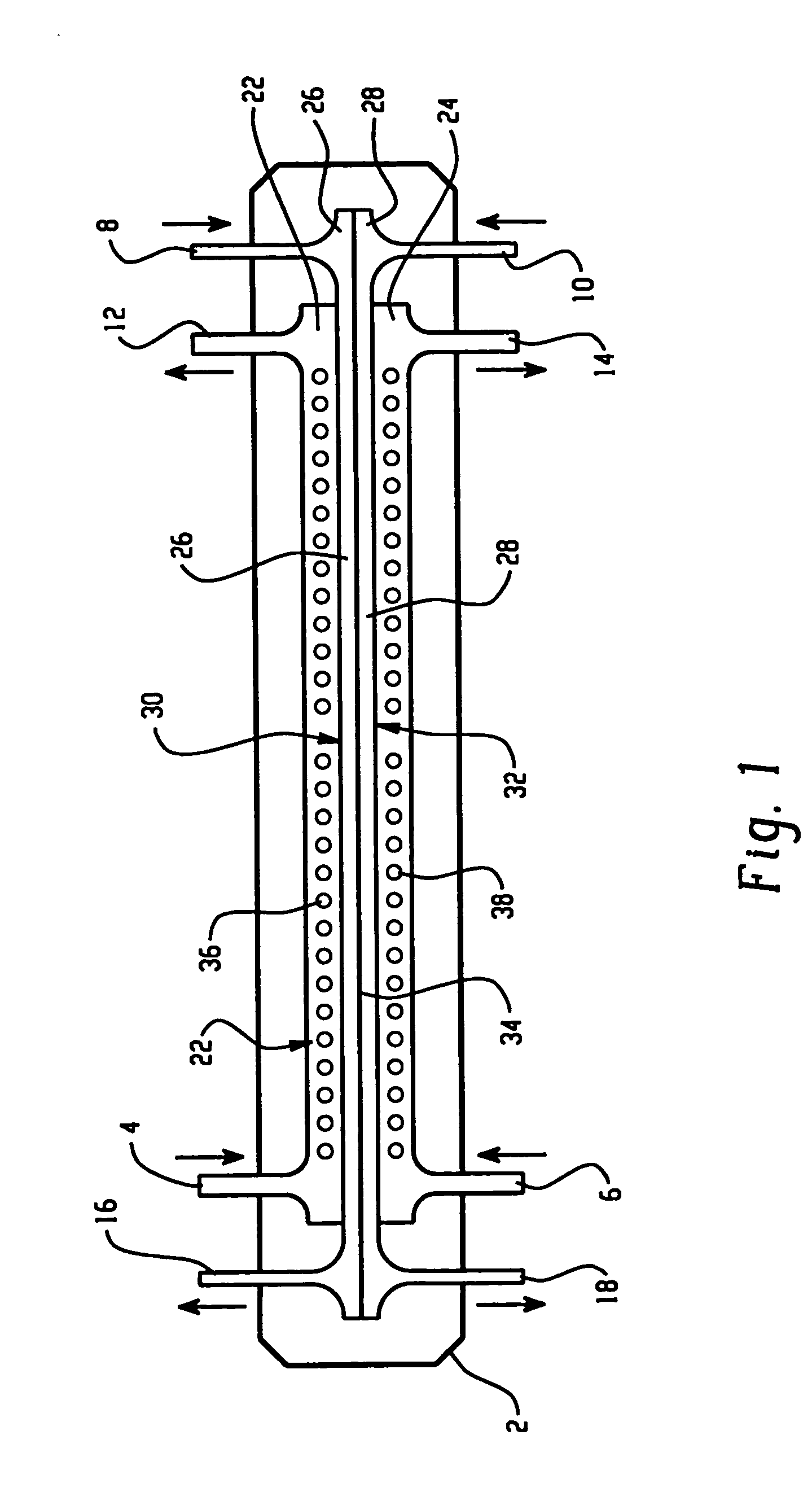

Electrophoresis apparatus and method

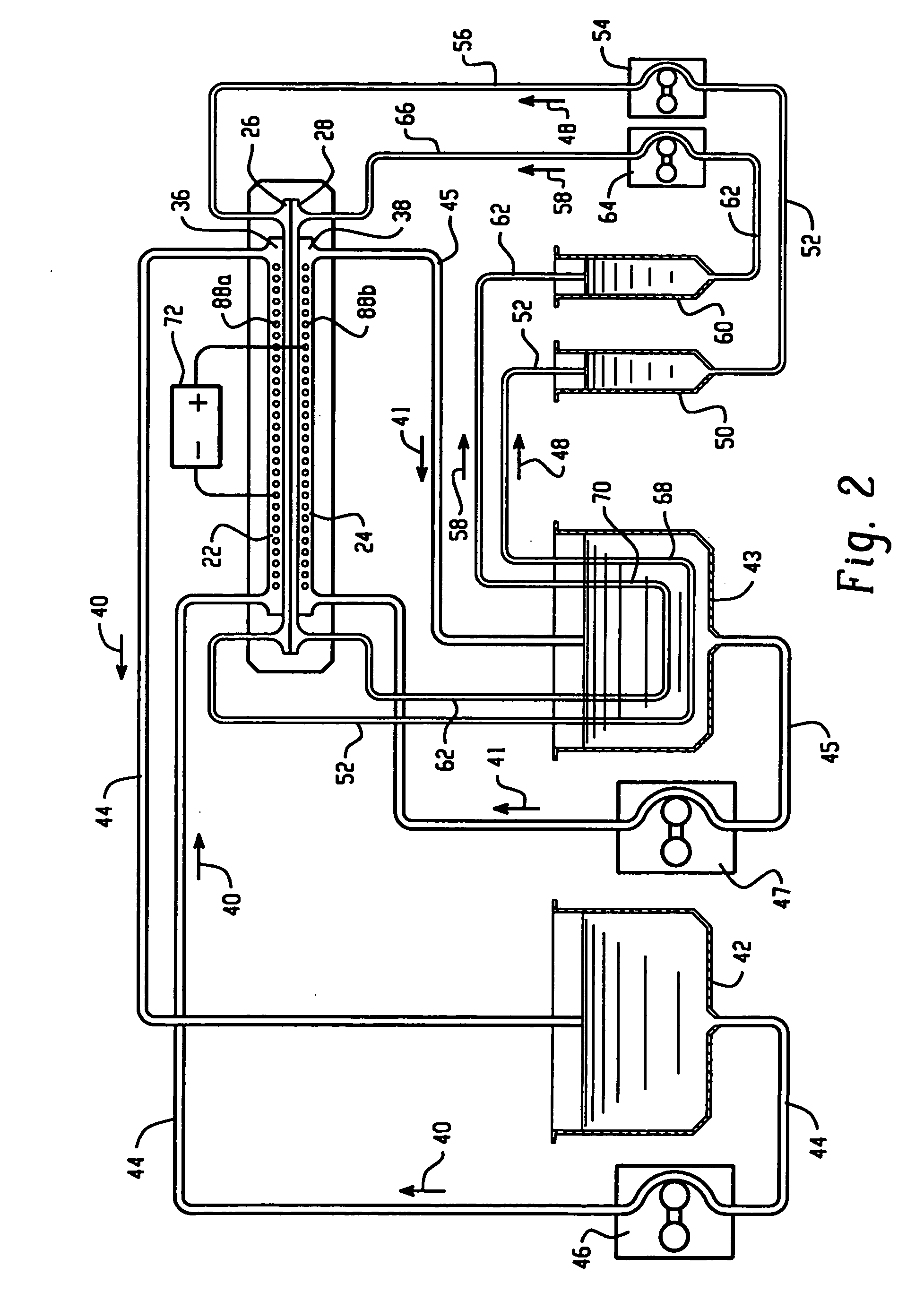

InactiveUS20050167270A1Increase separation speedReduce operating costsSludge treatmentElectrostatic separationElectrolysisElectrophoresis

An electrophoretic apparatus comprising: a first electrolyte chamber containing a first electrode; a second electrolyte chamber containing a second electrode; a first sample chamber disposed between the first and second electrolyte chambers and proximate to the first electrolyte chamber; a second sample chamber disposed between the first sample chamber and the second electrolyte; three ion-permeable barriers separating the first electrolyte chamber, the first sample chamber, the second sample chamber, and the second electrolyte chamber, respectively, wherein the ion-permeable barriers impede convective mixing of the contents in each of the respective chambers; a first electrolyte reservoir and a second electrolyte reservoir in fluid communication with the first and second electrolyte chambers, respectively; a first sample reservoir and a second sample reservoir in fluid communication with the first and second sample chambers, respectively; means adapted for communicating a first electrolyte and a second electrolyte between the respective electrolyte chambers and reservoirs; means adapted for communicating a first fluid and a second fluid between the respective sample chambers and reservoirs, wherein at least one of the first and second fluid contains at least a sample, wherein application of an electric potential causes migration of at least one component through at least one of the ion-permeable barriers.

Owner:GRADIPORE +1

Method for preparing potassium chloride by utilizing potassium mixed salt

ActiveCN106430248AGuaranteed yieldEasy to separateReverse osmosisAlkali metal chloridesReverse flotationNanofiltration

The invention discloses a method for preparing potassium chloride by utilizing potassium mixed salt. The method comprises the steps that a reverse flotation process is adopted to remove sodium chloride in the potassium mixed salt, and a tailing is obtained; the tailing is dissolved in water, and solid-liquid separation is performed to obtain a tailing solution; a section of nanofiltration step is executed, wherein a nanofiltration membrane system is adopted to conduct a section of nanofiltration treatment on the tailing solution to obtain a section of concentrated water and a section of produced water and comprises a first nanofiltration membrane module and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module, the section of concentrated water is stored in the first concentrated water tank, and the section of produced water is stored in the first produced water tank; evaporative crystallization is conducted on the section of produced water to obtain the potassium chloride. The invention provides a novel method for producing potassium chloride by using potassium mixed salt as a raw material. The method has the advantages of being simple in process, high in product purity and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com